Ramsey PATRIOT 15000 W User Manual

PATRIOT 15000

LAYER OF CABLE

RATED LINE PULL

PER LAYER

CUMULATIVE CABLE

CAPACITY PER LAYER

* DEPENDS ON 7/16” (11mm) DIA. CABLE BEING

UNIFORMLY WOUND ONTO DRUM

LINE PULL FIRST LAYER

LINE SPEED

FIRST LAYER (24V)

AMP DRAW

(LBS) 15,000 12,200 10,300 9,000

(KGS) 6,800 5,530 4,670 4,080

(FT)* 15 35 60 90

(M)* 4.5 10.5 18 27

(LBS)

(KGS)

MPM 7.6 4.6 3.3 2.7 2.2 1.8 1.6 1.2

FPM 23.7 16.2 11.6 9.9 8.2 7.1 6.1 4.4

MPM 7.2 4.9 3.5 3 2.5 2.2 1.9 1.3

24V 40 70 100 120 145 170 195 250

1 2 3 4

NO

LOAD

Ramsey Winch Company

OWNERS MANUAL

FRONT MOUNT ELECTRIC WINCH

Model Patriot 15000 24V

With Motor Thermal Protection

2,000 4,000 6,000 8,000 10,000 12,000 15,000

900 1,810 2,720 3,620 4,530 5,440 6,800

Congratulations

You have purchased the finest winch available in its service

class. It features a highly efficient 3 stage planetary gear set

which transmits torque from a series wound D.C. motor. A safe

positive clutch allows free spooling for quick cable deployment.

An automatic load holding brake is designed to hold the full rated

capacity of the winch. It was designed and manufactured to

provide you with the utmost in utility. As with any device that

combines power and movement in its use, there are dangers if

improperly used. At the same time, there are easier and faster

ways for getting the job done if certain precautions are taken first.

Please read this manual carefully. It contains useful ideas in

obtaining the most efficient operation from your Ramsey Winch

and safety procedures you need to know before beginning use.

When you follow our guidlines for operation, your Ramsey Winch

will give you many years of satisfying service. Thank you for

choosing Ramsey. You will be glad you have one working for

you.

Contents

Performance Specifications........................................ Front Cover

Safety Precautions ...................................................................... 2

Tips for Safe Operation ............................................................... 2

Techniques of Operation .............................................................3

Installation ...................................................................................4

Operating Instructions ................................................................. 6

Electrical Connections and Operation.......................................... 6

Maintenance................................................................................6

Trouble Shooting Guide............................................................... 7

Winch Parts List......................................................................8-10

Warranty .....................................................................Back Cover

Please Note:

mount vehicle use. The winches are not designed for and should not

be used in industrial applications (car haulers/carriers, wreckers,

hoisting, etc.), and Ramsey does not warrant them to be suitable for

such use. Ramsey makes a separate, complete line of winches for

industrial/commercial use. Please contact the factory for further

information.

Ramsey Patriot 15000™ winches are designed for front

CAUTION: Read and understand this manual before installation and operation of winch. See Safety Precautions.

Safety Precautions To Guard

Against Possible Injury.....

Tips for Safe Operation

A minimum of five wraps of cable around

the drum barrel is necessary to hold the

rated load. Cable clamp is not designed to

hold the load.

A. Keep yourself and others a safe distance to the side

of the cable when pulling under load.

B. Do not step over a cable, or near a cable under load.

C. Use supplied hook strap when handling hook for

spooling wire rope.

D. Do not move the vehicle to pull a load on the winch

cable. This could result in cable breakage and/or

winch damage

E. Use a heavy rag or gloves to protect hands from

burrs when handling winch cable.

F. Apply blocks to wheels when vehicle is on an incline.

G. Winch clutch should be disengaged when winch is

not in use and fully engaged when in use.

H. Modification, alteration, or deviation to the winch

should only be made by Ramsey Winch Company.

I. Keep the duration of your pulls as short as possible.

If the motor becomes uncomfortably hot to the touch,

stop and let it cool for a few minutes. Do not pull

more than one minute at or near the rated load. Do

not maintain power to the winch if the motor stalls.

Electric winches are for intermittent usage and

should not be used in constant duty applications.

J. Disconnect the remote control switch from the winch

when not in use. A Ramsey Part No. 282053 safety

on-off switch in your vehicle is recommended.

K. Do Not use winch in hoisting applications due to

required hoist safety factors and features.

L. Do not exceed maximum line pull ratings shown in

tables. Shock loads must not exceed these ratings.

M. To respool correctly, it is necessary to keep a slight

load on the cable. This is accomplished by (wearing

gloves) holding the cable with one hand and the

remote control with the other, starting as far back and

in the center as you can, walking up keeping load on

the cable as the winch is powered in. Do not allow

the cable to slip through your hand and do not

approach the winch too closely. Turn off the winch

and repeat the procedure until all the cable except a

few feet is in. Disconnect the remote control switch

and finish spooling in cable by rotating the drum by

hand with clutch disengaged. On hidden winches,

spool in cable under power using supplied hook

strap.

Don’t underestimate the potential danger in winching

operations. Neither should you fear them. Do learn the

basic dangers and avoid them.

Observe spooling of cable onto drum. Side pulls can

cause cable to pileup at one end of the drum. To correct

uneven stacking, spool out that section of the cable and

move it to the other end of the drum and continue

winching. Uneven spooling which causes cable pileup

can interfere with the tie bars causing damage to the

winch.

Store the remote control switch inside your vehicle where

it will not become damaged. Inspect it before you plug it

in.

When ready to begin spooling in, plug in remote control

switch with clutch disengaged. Do not engage clutch

with motor running.

Never connect the hook back to the cable. This causes

cable damage. Always use a sling or chain of suitable

strength, as shown in the illustration.

Observe your winch while winching, if possible, while

standing at a safe distance. If you use vehicle drive to

assist, stop and get out every few feet to assure the cable

is not piling up in one corner. Jamming cable can break

your winch.

Do not attach tow hooks to winch mounting apparatus.

They must attach to vehicle frame.

When double lining during stationary winching, the winch

hook should be attached to the chassis of the vehicle.

Since the greatest pulling power is achieved on the

innermost layer of your winch, it is desirable to pull off as

much line as you can for heavy pulls. If this is not

practical, use a snatch block and double line

arrangement (see illustration). Remember, a minimum of

5 wraps of cable around the drum barrel is necessary to

hold the rated load.

Neat, tight spooling avoids cable binding which is caused

when a load is applied and the cable is pinched betwen

two others. If this happens, alternately power the winch

in and out a few inches. Do not attempt to work a bound

cable under load, free by hand.

2

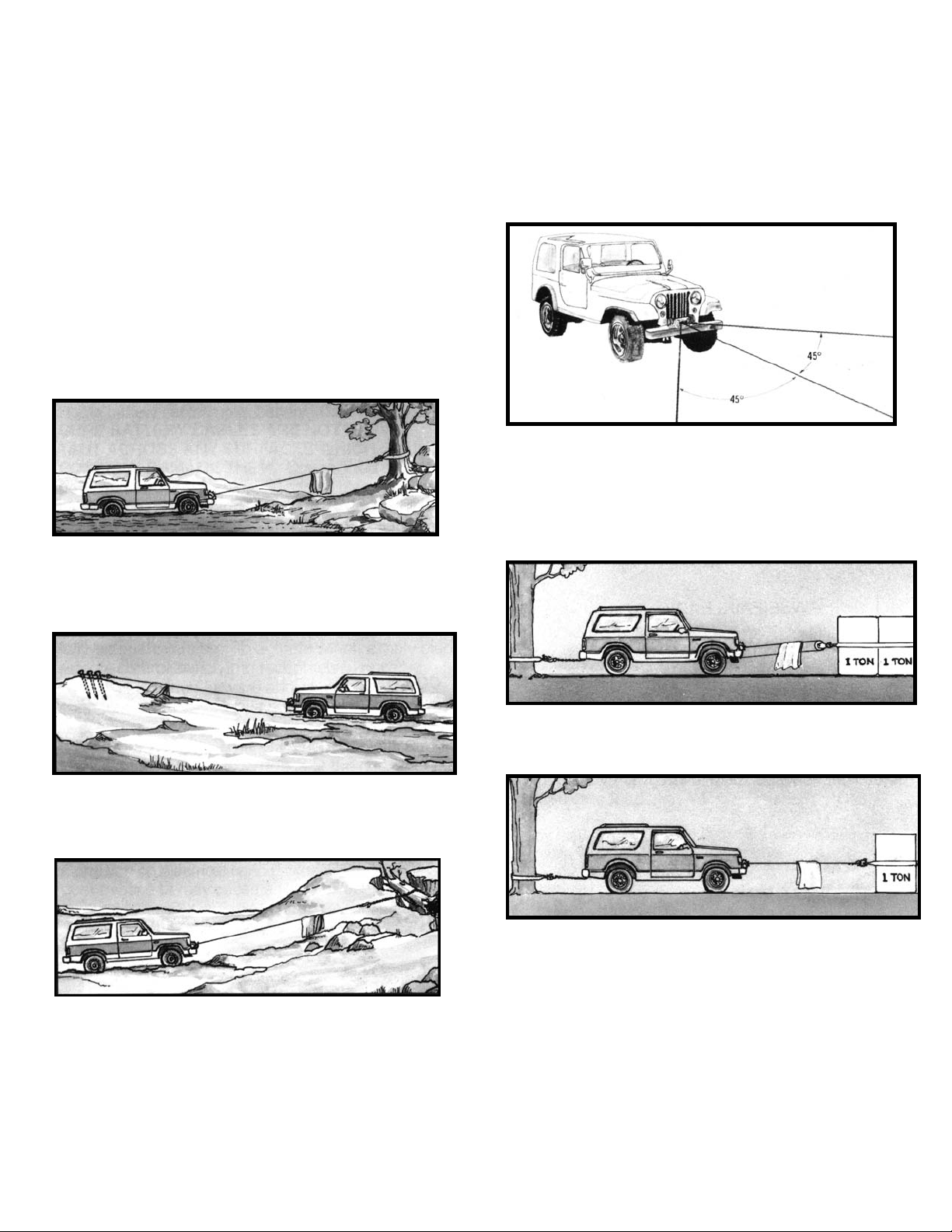

Techniques of Operation

The best way to get acquainted with how your winch

operates is to make a few test runs before you actually

need to use it. Plan your test in advance. Remember

you hear your winch as well as see it operate. Get to

recognize the sound of a light steady pull, a heavy pull,

and sounds caused by load jerking or shifting. The

winch may make more noise when running in the

‘out’ direction under load. This noise should

decrease with use and is not detrimental to the winch

operation. Soon you will gain confidence in operating

your winch and its use will become second nature with

you.

Your winch will not only pull your vehicle up or ease your

vehicle down a steep grade, it will also pull another

vehicle or a load while your vehicle is anchored in a

stationary position. The sketches on this page show you

a few techniques.

For basic self-recovery, anchor to a tree or heavy rock.

When anchoring to a tree, always use a tree trunk

protector.

When pulling a heavy load, place a blanket, jacket or

tarpaulin over the cable five or six feet from the hook. It

will slow the snap back in the event of a broken cable.

Also, open the vehicle hood for additional protection.

Use the vehicle wheel power to help the winch, but don’t

overtake the winch line. Plan your pull. You can’t always

hook up and pull out in one step. Examine all the areas

for anchoring possibilities as well as leverage situations,

direction, and goal.

Winches equipped with cable guide fairleads can pull

from several directions. Pull from an angle only to

straighten up the vehicle-otherwise you can damage

structural members or other parts of your vehicle and

cause excess cable buildup on one end of the winch

drum.

Stakes driven in solid earth and chained together make a

good anchor point for self-recovery when no solid anchor

point is available.

For a solid anchor, bury a log with earth or sand or place

it in a deep ravine.

For a direct pull of 2000 lbs., hitch truck to a tree or solid

anchor, and take out of gear.

To double the pull, use 2-part line and tie off to chassis.

Take out of gear.

3

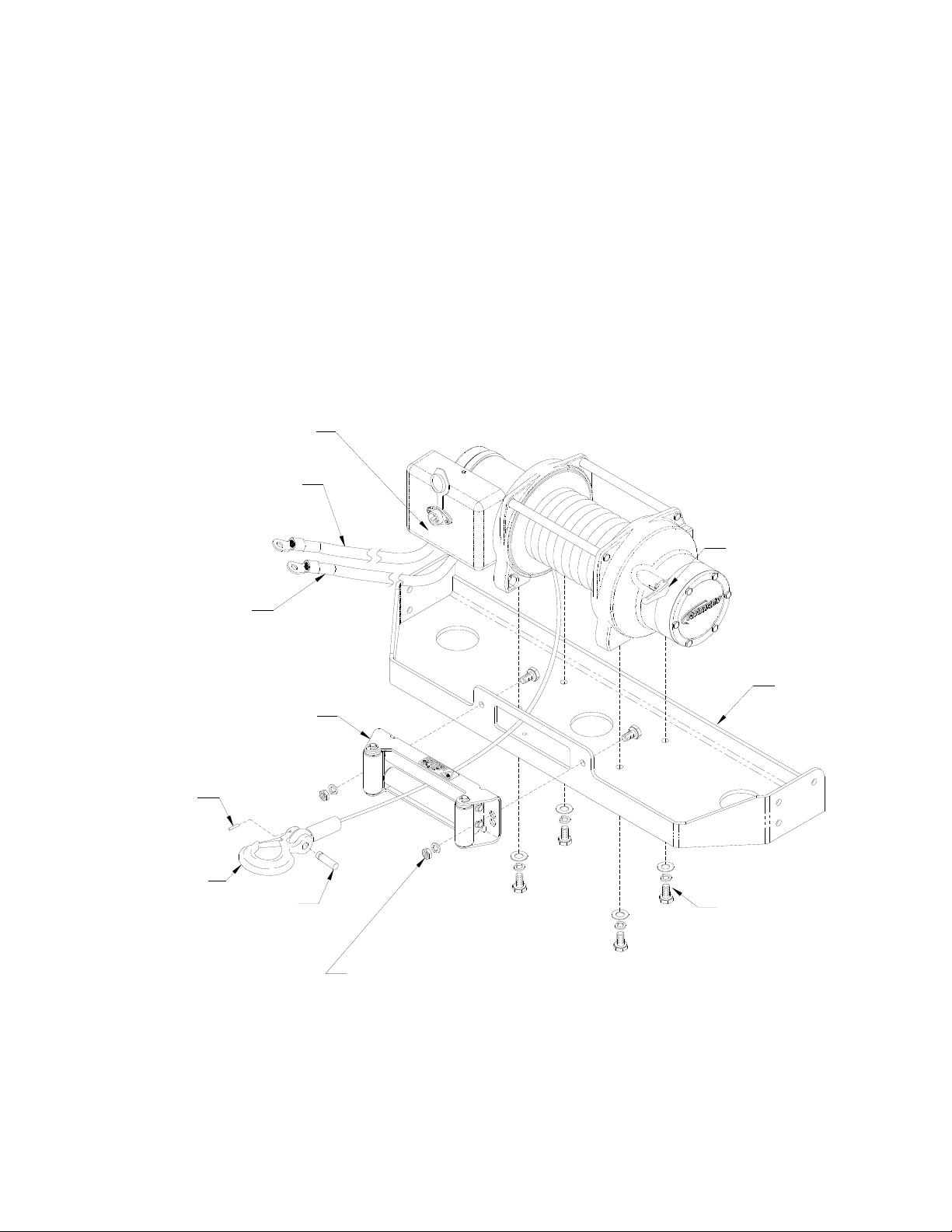

Installation

E

O

The winch shown in this owners manual is solely and

exclusively designed for vehicle mounted, non-industrial

applications. All other applications will void warranty.

It is very important that the winch be mounted on a flat

surface so that the three major sections (the motor end,

the cable drum, and the gear housing end) are properly

aligned. It is recommended that Ramsey kits be used to

mount the winch. They are designed to align the winch

and distribute up to the full rated load evenly, to avoid

possible damage to the winch or vehicle.

NOTE: If recommended mounting is not used, a kit of

equal design must be used.

CONTROL SWITCH

RECEPTACLE

CONNECT BLACK GROUND CABLE

TO NEGATIVE (-) TERMINAL

OF VEHICLE BATTERY.

Attach fairlead to channel using hardware furnished with

winch.

NOTE: To ensure proper alignment of roller fairlead to

winch, position larger (1/2”) holes at top.

Attach winch to channel. Thread capscrews with

lockwashers through mounting holes in channel and into

winch feet (see FIGURE 1).

CLUTCH HANDLE

CONNECT RED CABLE

TO POSITIVE (+) TERMINAL

OF VEHICLE BATTERY.

ROLLER FAIRLEAD

(CAUTION DECAL ON TOP)

ROLL PIN

CABLE HOOK

CLEVIS PIN

WINCH MOUNTING HARDWAR

FOUR 7/16-14NC X 1.00 LG. B

FOUR 7/16 LOCK WASHERS

FAIRLEAD MOUNTING HARDWARE

FOUR 7/16 FLAT WASHERS

TWO 7/16-14NC X 1.25 LG BOLTS

TWO 7/16 LOCK WASHERS & TWO 7/16-14NC NUTS

IN THE TOP 1/2" DIA. HOLES OF FAIRLEAD

MOUNTING CHANNEL

FIGURE 1

4

Loading...

Loading...