Page 1

OPERATING, SERVICE AND

MAINTENANCE MANUAL

MODEL HD-P50,000

INDUSTRIAL PLANETARY WINCH

WITH AIR TENSIONER AND 2 SPEED MOTOR

CAUTION: READ AND UNDERSTAND THIS MANUAL BEFORE INSTALLATION

AND OPERATION OF WINCH. SEE WARNINGS!

Page 2

TABLE OF CONTENTS

INTRODUCTION ............................................................................................................ 1

WARRANTY INFORMATION ......................................................................................... 1

SPECIFICATIONS .......................................................................................................... 1

WARNINGS .................................................................................................................... 1

HYDRAULIC SYSTEM REQUIREMENTS ...................................................................... 2

PERFORMANCE CHARTS ............................................................................................ 2

WINCH OPERATION ..................................................................................................... 3

CLUTCH OPERATION ................................................................................................... 3

CABLE INSTALLATION ................................................................................................. 3

MAINTENANCE ............................................................................................................. 4

TROUBLE SHOOTING GUIDE ...................................................................................... 4

INSTRUCTIONS FOR OVERHAUL ............................................................................. 5-9

MOUNTING CONFIGURATIONS ..................................................................................10

DIMENSIONAL DRAWING ............................................................................................11

PARTS LIST AND PART DRAWING ....................................................................... 12-15

LIMITED WARRANTY ..................................................................................... Back cover

Page 3

RAMSEY HYDRAULIC PLANETARY WINCH MODEL HD-P50,000

PLEASE READ THIS MANUAL CAREFULLY

This manual contains useful ideas in obtaining the most efficient operation from your Ramsey Winch, and

safety procedures one needs to know before operating a Ramsey Winch. Do not operate this winch until

you have carefully read and understand the "WARNINGS" and "OPERATION" sections of this manual.

WARRANTY INFORMATION

Ramsey Winches are designed and built to exacting specifications. Great care and skill go into every winch

we make. If the need should arise, warranty procedure is outlined on the back of your self-addressed postage paid warranty card. Please read and fill out the enclosed warranty card and send it to Ramsey Winch

Company. If you have any problems with our winch, please follow instructions for prompt service on all warranty claims. Refer to back page for limited warranty.

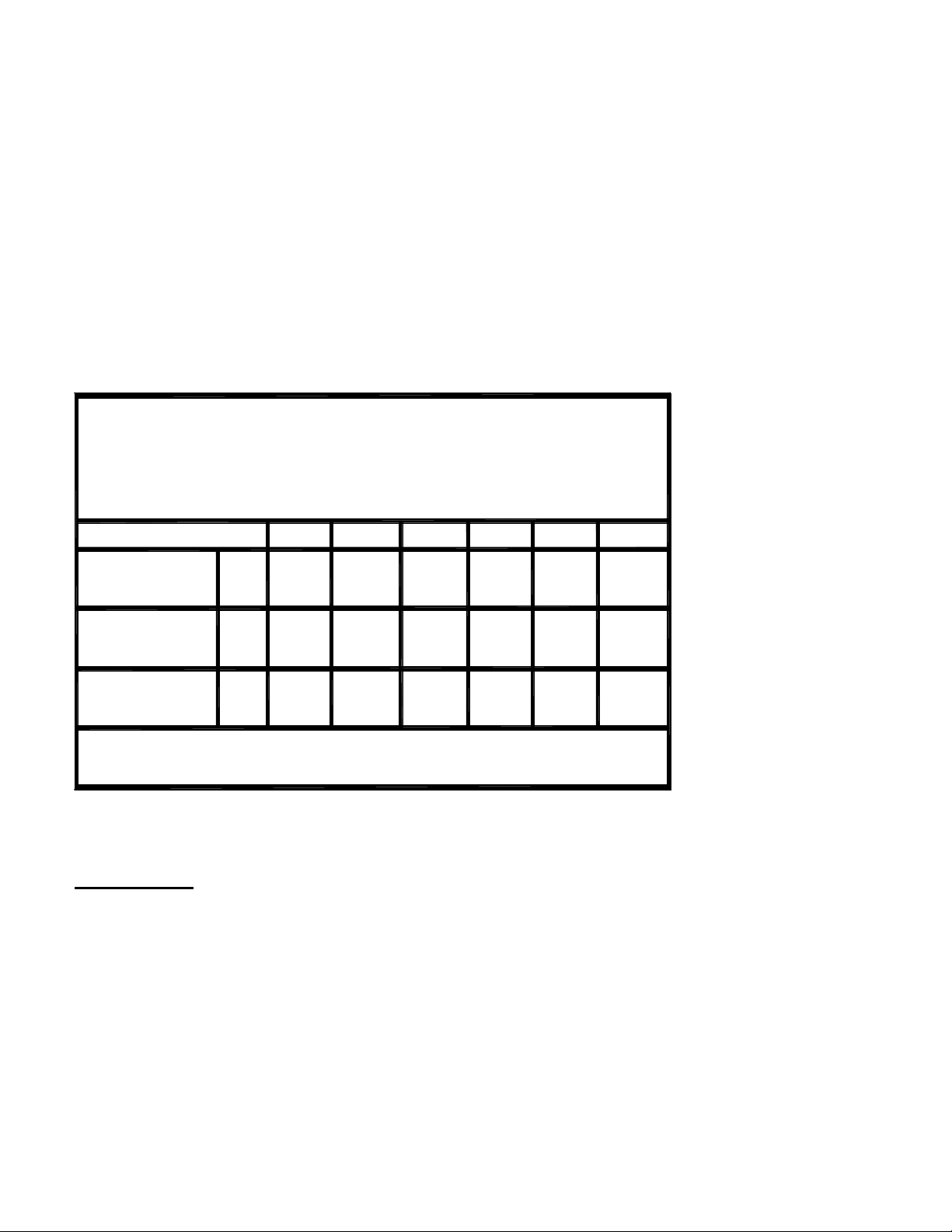

SPECIFICATIONS* (LOW SPEED MODE)

Rated Line Pull (lbs.).........................................................................50,000

(Kgs.)..............................................................................22,670

Gear Reduction................................................................................51.35:1

Weight (without cable)...............................................742 lb. (337.27 Kgs.)

*Rated line pull

per layer

*Cable capacity

*Line speed

(at 25 GPM)

Lbs.

Kg.

Ft.

M.

FPM

MPM

1 2LAYER OF CABLE

50,000

22,680

25

7

20 22

5.6

41,800

18,960

55

16

6.6

3 4 5 6

36,000

16,320

95

28

25

7.6

31,600

14,330

135

41

28

8.6

28,100

12,740

185

56

31

9.5

25,400

11,520

235

71

35

10.5

* These specifications are based on recommended wire rope of .75 inch

dia. EIPS cable and 11.9 cu.in./Rev. motor.

NOTE: The rated line pulls shown are for the winch only. Consult the wire rope manufacturer for wire rope

ratings.

WARNINGS:

CLUTCH MUST BE TOTALLY ENGAGED BEFORE STARTING THE WINCHING OPERATION.

DO NOT START WINCH MOTOR BEFORE ENGAGING CLUTCH.

DO NOT DISENGAGE CLUTCH UNDER LOAD.

STAY OUT FROM UNDER AND AWAY FROM RAISED LOADS.

STAND CLEAR OF CABLE WHILE PULLING. DO NOT TRY TO GUIDE CABLE.

DO NOT EXCEED MAXIMUM LINE PULL RATINGS SHOWN IN TABLE.

DO NOT USE WINCH TO LIFT, SUPPORT, OR OTHERWISE TRANSPORT PEOPLE.

A MINIMUM OF 5 WRAPS OF CABLE AROUND THE DRUM BARREL IS NECESSARY TO HOLD THE LOAD.

CABLE ANCHOR IS NOT DESIGNED TO HOLD LOAD.

1

OM 914244-0511-D

Page 4

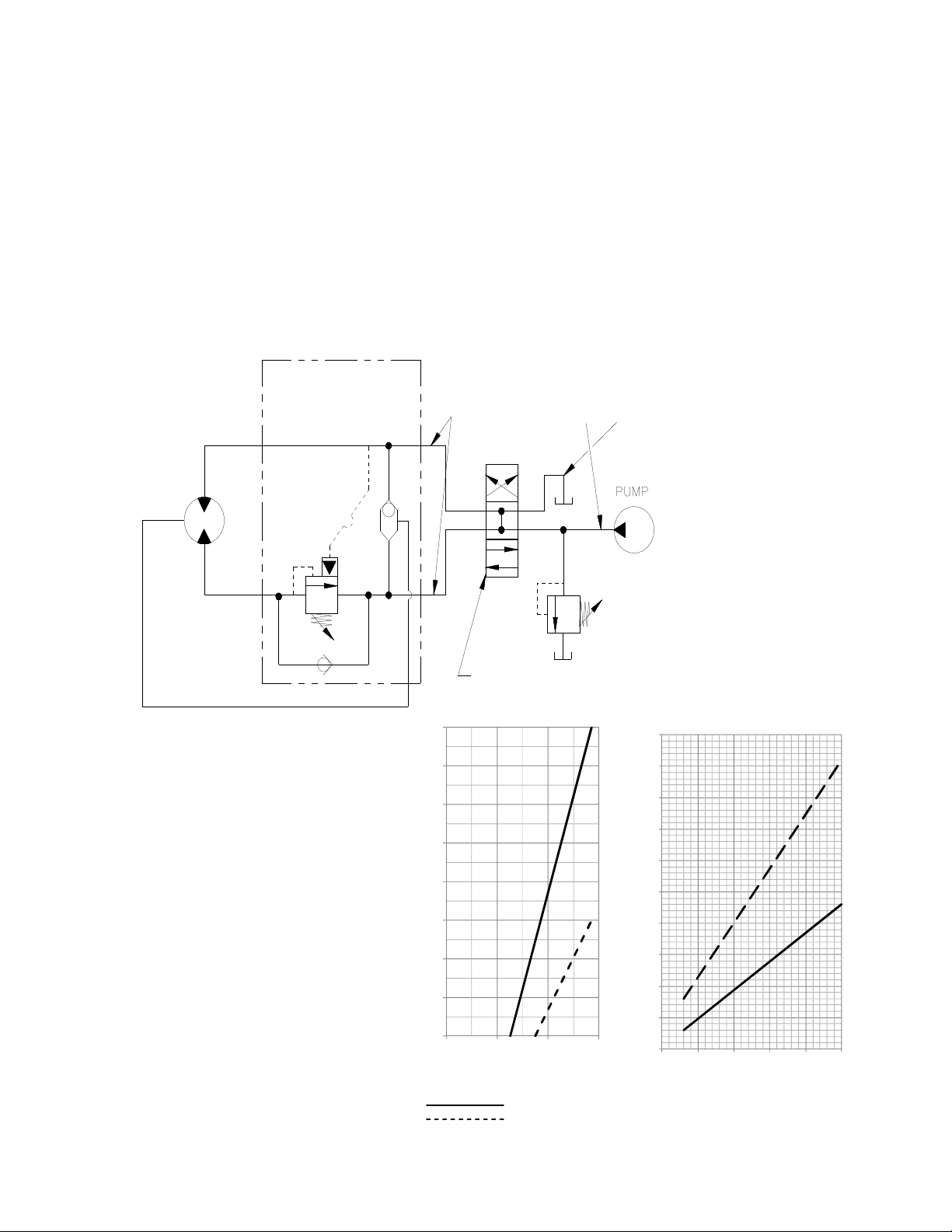

HYDRAULIC SYSTEM REQUIREMENTS

Refer to the performance charts to properly match your hydraulic system to HDP-50000 winch performance.

The charts consist of:

(1) Line pull (lb.) first layer vs. working pressure (PSI) and (2) Line speed (FPM) first layer vs. flow (GPM).

Performance is based on a motor displacement of 11.9 cubic inches with 25 GPM maximum flow rate.

See page 10 for motor port size.

TYPICAL LAYOUT

PORT CONTROL

WITH BRAKE RELEASE SHUTTLE

MOTOR

BRAKE

A

PORT

B

PERFORMANCE CHARTS

(BASED ON 11.9 CU. IN./REV MOTOR)

HIGH PRESSURE LINE

(.50 I.D. MINIMUM)

3 POSITION

4 WAY VALVE

(MOTOR SPOOL)

5000 0

4500 0

4000 0

3500 0

3000 0

LOW PRESSURE LINE

(.75 I.D. MINIMUM)

MAX. FLOW &

PRESSURE AT

RATED LOAD:

15 GPM

2500 PSI

SYSTEM

RELIEF

50

45

40

35

30

25

2500 0

LIN E PULL (LB), FIRST L AYER

2000 0

1500 0

1000 0

0 1000 2000 3000

PRESSURE (PSI)

LOW SPEED

HIGH SPEED

2

20

15

10

5

LINE SPEED (FPM), FIRST LA YER

0

0 5 10 15 20 25

FLOW RATE (GPM)

OM 914244-0712-E

Page 5

WINCH OPERATION

The best way to get acquainted with how your winch operates is to make test runs before you use it. Plan

your test in advance. Remember, you hear your winch, as well as see it operate. Learn to recognize the

sounds of a light steady pull, a heavy pull, and sounds caused by load jerking or shifting. Gain confidence in

operating your winch and its use will become second nature with you.

The uneven spooling of cable, while pulling a load, is not a problem, unless there is a cable pileup on one end

of drum. If this happens, reverse the winch to relieve the load and move your anchor point further to the center of the vehicle. After the job is done you can unspool and rewind for a neat lay of the cable.

CLUTCH OPERATION

To engage clutch:

1. Move the clutch control valve to the “clutch engaged” position.

2. Anytime the temperature is below freezing, run the motor in the “cable out” direction only until the

drum starts to turn. In extreme cold temperatures (below 0˚ F/-18˚ C), pull out on the cable by hand

only until the drum starts to turn.

3. Wait at least 3 seconds for the clutch to fully engage, after which the winch is ready to winch in the

cable.

WARNING: Do not attempt to engage the clutch by first running the winch motor and then moving the

clutch control valve to the "clutch-engaged" position while the motor is running. Do not start picking up

the load at the same time the clutch is being engaged.

To disengage clutch:

1. Run the winch in the "cable out" direction until the load is off the cable.

2. Move the clutch control valve to the "clutch-disengaged" position.

3. The cable may now be pulled off by hand.

CABLE INSTALLATION

1. Unwind cable by rolling it out along the ground to prevent kinking. Securely wrap end of wire rope, opposite hook, with plastic or similar tape to prevent fraying.

2. Insert the end of cable, opposite hook end, into the hole in drum barrel. Secure cable to drum barrel,

using setscrew furnished with winch. TIGHTEN SETSCREW SECURELY.

3. Carefully run the winch in the “reel-in” direction. Keeping tension on end of cable, spool all the cable

onto the cable drum, taking care to form neatly wrapped layers.

3

OM 914244-0712-E

Page 6

MAINTENANCE

Adhering to the following maintenance schedule will keep your winch in top condition and performing as it should with a minimum of repair.

A. WEEKLY

1.

Check the oil level and maintain it to the oil level plug. If oil is leaking out, determine location and

repair.

2.

Check the pressure relief plug in the gear housing cover. Be sure that it is not plugged.

3.

Lubricate cable with light oil.

B. MONTHLY

1.

Check the winch mounting bolts. If any are missing, replace them and securely tighten any that are

loose. Use grade 5 or better bolts.

2.

Inspect the cable. If the cable has become frayed with broken strands, replace immediately.

C. ANNUALLY

1.

Drain the oil from the winch annually or more often if winch is used frequently.

2.

Fill the winch to the oil level plug with clean kerosene. Run the winch a few seconds with no load in

the reel in direction. Drain the kerosene from the winch.

3.

Refill the winch to the oil level plug with all-purpose SAE 75W-90 synthetic gear oil.

4.

Inspect frame and surrounding structure for cracks or deformation.

TROUBLESHOOTING GUIDE

CONDITIONS POSSIBLE CAUSE CORRECTION

1. Seals damaged or

1. Replace seal.

worn.

OIL LEAKS FROM

WINCH

2. Too much oil. 2. Drain excess oil. Refer to OPERATION.

3. Damaged gaskets. 3. Replace gaskets.

1. Low flow rate 1. Check flow rate. Refer to HYDRAULIC SYS-

WINCH RUNS

TOO SLOW

2. Hydraulic motor

TEMS performance chart page 2.

2. Replace motor.

worn out.

CABLE DRUM

WILL NOT

FREESPOOL

1. Clutch not disengaged

1. Check air pressure to clutch cylinder: 100 PSI

Minimum required. Refer to page 10 for port

location.

BRAKE WLL NOT

RELEASE

1. Brake line disconnected or blocked.

4

1. Check brake function.

OM 914244-0712-E

Page 7

INSTRUCTIONS FOR OVERHAUL

DIS-ASSEMBLY

1.

Drain oil from gear housing cover by removing pipe plug #37 and relief fitting #32. Remove tensioner assembly

.

2.

Disconnect tube #40 from elbow #43 on valve #41 and fitting #29 on brake #30b. Remove motor #33 and gasket

#30a by removing (2) capscrews #22. Remove valve #41, if needed, from motor by loosening (4) capscrews #16.

16

43

41

22

33

30a

40

5

OM 914244-0712-E

Page 8

3. Remove (12) capscrews #18 to remove gear housing cover and gasket from ring gear. Remove input thrust washer,

sun gear and input carrier assembly from inside ring gear. Remove ring gear and gasket. Remove output carrier assembly. Inspect gear housing cover bushing #15 for damage or wear. Replace if damaged or excessive wear.

31

42

31

15

5

18

4. Remove (8) capscrews #20 to remove clutch retainer plate #10 from clutch piston. Remove clutch #9.

9

10

20

6

OM 914244-0712-E

Page 9

5. Remove clutch housing #27 with piston #28 inside. To remove piston from clutch housing apply air to 1/8” port. Remove orings #28 and #35 and inspect for damage or wear.

35

27

36

28

6. Remove (9) springs #39, thrust washer #26, gasket #31, output shaft #12 and spacer #13 from gear end bearing. Inspect output shaft bushing #14 for damage or wear. Replace if damaged or excessive wear.

13

12

14

26

31

39

7

OM 914244-0712-E

Page 10

7. Remove winch tie bars #2 and #3 by removing (8) capscrews #19, (8) lock washers # 24, and (4) shoulder bolts

#25. Pull gear end bearing #7 from drum assembly #1.

2

3

25

24

19

25

19

24

24

7

25

25

19

24

19

8.

Pull drum assembly #1 from end bearing #6. Remove quad-rings #34 from grooves in drum bushings. Remove input

shaft #11 from end bearing. Examine splined ends of input shaft for signs of wear, replace if damaged. Examine drum

assembly #1 for signs of wear.

6

8

4

38

11

23

34

1

34

8

OM 914244-0712-E

Page 11

9.

If splines inside drum driver #102 are damaged, drum driver must be replaced. Remove drum driver by unscrewing (8)

capscrews #105. If bushings show signs of wear, replace by pressing old bushings from drum #101 and removing orings from grooves in drum and drum driver. Place well oiled o-rings #106 into driver and drum. Place well oiled o-ring

#107 on outside of driver. Press bushings #104 into drum driver until flange is flush and #103 is flush against drum

106

101

.

107

103

10.

Remove brake assembly screws #17 attaching brake #30b to end bearing #6. Remove coupling #4 and gasket #30e

from end bearing. Take note of mounting configuration for proper mounting of parts during re-assembly.

102

106

104

105

17

30b

30c

30e

6

9

OM 914244-0712-E

Page 12

L.H. MOUNTING

CONFIGURATION

WINCH MOUNTING CONFIGURATION

R.H. MOUNTING

CONFIGURATION

10

OM 914244-0712-E

Page 13

11

OM 914244-0712-E

Page 14

12

Page 15

18

5

32

37

31

15

42

25

31

27

35

10

9

28

36

39

26

31

14

20

8

6

24

2

23

11

19

25

24

19

7

34

1

24

34

25

3

24

25

19

19

12

13

30e

29

40

43

16

41

17

22

30c

30a

33

4

38

30b

30

HDP 50,000 WINCH

13

OM 914244-0712-E

Page 16

PARTS LIST - HDP 50,000

14

OM 914244-1012-A

Page 17

DRUM ASSEMBLY - 234191

Item No. Part No. Quantity Description

101 332197 1 DRUM-CABLE

102 332226 1 DRIVER-DRUM

103 412078 1 BUSHING-DRUM

104 412079 1 BUSHING-DRUM

105 414978 8 CAPSCREW-5/8-18NC X 1 1/4LG, SOC HD

106 462043 2 O-RING-AS-568-348, 3/16 X 4 3/4 X 4 3/8

107 462075 1 O-RING-AS-568-354, 3/16 X 5 1/2 X 5 1/8

106

101

103

107

102

106

104

105

15

OM 914244-0712-E

Page 18

CABLE TENSIONER (OVERWOUND) - 299754

Item No. Part No. Quantity Description

201 265112 1 LEVER ARM

202 304174 1 BAR

203 346046 1 PIVOT PIN

204 408428 1 BRACKET

205 414278 4 CAPSCREW-3/8-16NCX3/4LG,HXHD,GR.5, ZINC PLATED

206 414316 2 CAPSCREW-3/8-16NCX1 1/4,HXHD,GR.5, ZINC PLATED

207 418045 2 NUT-3/8-16NC HEX REG GR.5, ZINC PLATED

208 418098 1 NUT-3/4-16NF HEX JAM

209 418177 2 LOCKWASHER-3/8 MED SECT,ZINC PLATED

210 418223 2 WASHER-1/2 USS FLAT,ZINC PLATED

211 424005 2 COTTER PIN

212 432033 1 FITTING-ELBOW

213 433029 1 ACTUATOR

207

201

213

211

204

214

210

210

209

210

214

215

212

205

205

202

206

203

211

210

208

16

OM 914244-1012-A

Page 19

LIMITED WARRANTY

RAMSEY WINCH warrants each new RAMSEY WINCH to be free from defects in material and workmanship for a period of

one (1) year from date of purchase.

The obligation under this warranty, statutory or otherwise, is limited to the replacement or repair at the Manufacturer's factory, or

at a point designated by the Manufacturer, of such part that shall appear to the Manufacturer, upon inspection of such part, to have

been defective in material or workmanship.

This warranty does not obligate RAMSEY WINCH to bear the cost of labor or transportation charges in connection with the re-

placement or repair of defective parts, nor shall it apply to a product upon which repair or alterations have been made, unless authorized by Manufacturer, or for equipment misused, neglected or which has not been installed correctly.

RAMSEY WINCH shall in no event be liable for special or consequential damages. RAMSEY WINCH makes no warranty in

respect to accessories such as being subject to the warranties of their respective manufacturers.

RAMSEY WINCH, whose policy is one of continuous improvement, reserves the right to improve its products through changes in

design or materials as it may deem desirable without being obligated to incorporate such changes in products of prior manufacture.

If field service at the request of the Buyer is rendered and the fault is found not to be with RAMSEY WINCH's product, the Buyer

shall pay the time and expense to the field representative. Bills for service, labor or other expenses that have been incurred by the

Buyer without approval or authorization by RAMSEY WINCH will not be accepted.

See warranty card for details.

RAMSEY WINCH COMPANY

Post Office Box 581510 Tulsa, Oklahoma 74158-1510

Telephone: (918) 438-2760 FAX: (918) 438-6688

OM-914244-0712-E

Loading...

Loading...