Page 1

OPERATING, SERVICE AND

MAINTENANCE MANUAL

English (Original Instructions) .......................................... 1

Français

Deutsch

Español

(Traduction des instructions originales) ...... 17

(Übersetzung der Originalanleitung) ............ 35

(Traducción de las instrucciones originales) 53

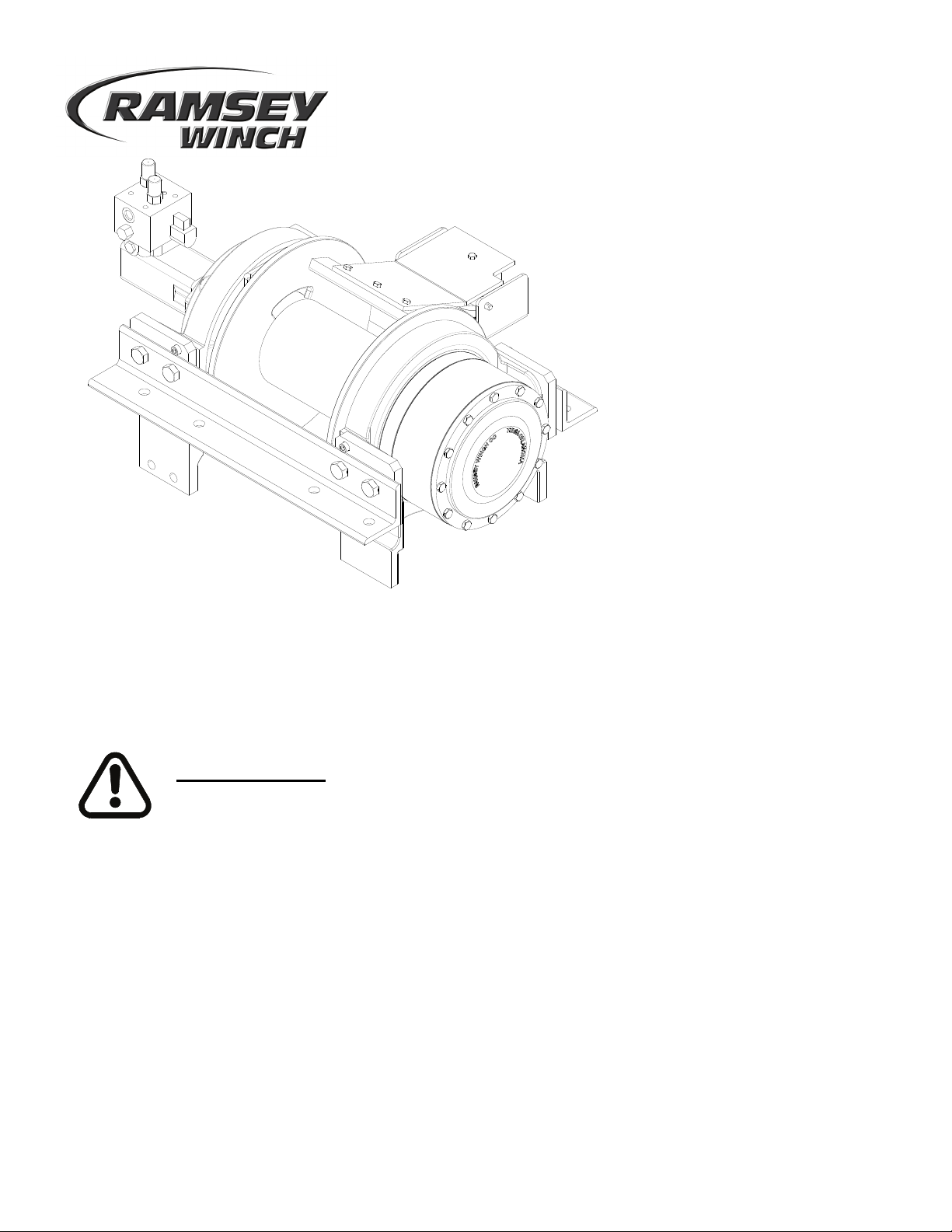

MODEL HD-P 177,9

INDUSTRIAL PLANETARY WINCH

Intended Purpose: Vehicle recovery and pulling loads

Ramsey Authorized Representative in the Community:

(Please contact for regulatory inquiries only.)

Alura Group BV

P.O. Box 18626

2502 EP The Hague

The Netherlands

Tel: (31) (0) 70 362-4896

Fax: (31) (0) 70 346-7299

CAUTION: READ AND UNDERSTAND THIS MANUAL BEFORE INSTALLATION

AND OPERATION OF WINCH. SEE WARNINGS!

RAMSEY WINCH COMPANY

Post Office Box 581510 Tulsa, Oklahoma 74158-1510 USA

Phone: (918) 438-2760 Fax: (918) 438-6688

Visit us at http://www.ramsey.com

OM-914249-1012-B

Page 2

05/03/11

Page 3

TABLE OF CONTENTS

SPECIFICATIONS ............................................................................................................ 1

WARNINGS ...................................................................................................................... 1

USER’S RESPONSIBILITY FOR CE COMPLIANCE ....................................................... 1

HYDRAULIC SYSTEM REQUIREMENTS ........................................................................ 2

PERFORMANCE CHARTS .............................................................................................. 2

WINCH OPERATION ........................................................................................................ 3

CLUTCH OPERATION ..................................................................................................... 3

CABLE INSTALLATION .................................................................................................... 3

MAINTENANCE ................................................................................................................ 4

TROUBLE SHOOTING GUIDE ......................................................................................... 4

INSTRUCTIONS FOR OVERHAUL ............................................................................... 5-9

MOUNTING CONFIGURATIONS ................................................................................... 10

DIMENSIONAL DRAWING ........................................................................................ 11-12

PARTS LIST AND PART DRAWING ......................................................................... 13-16

Page 4

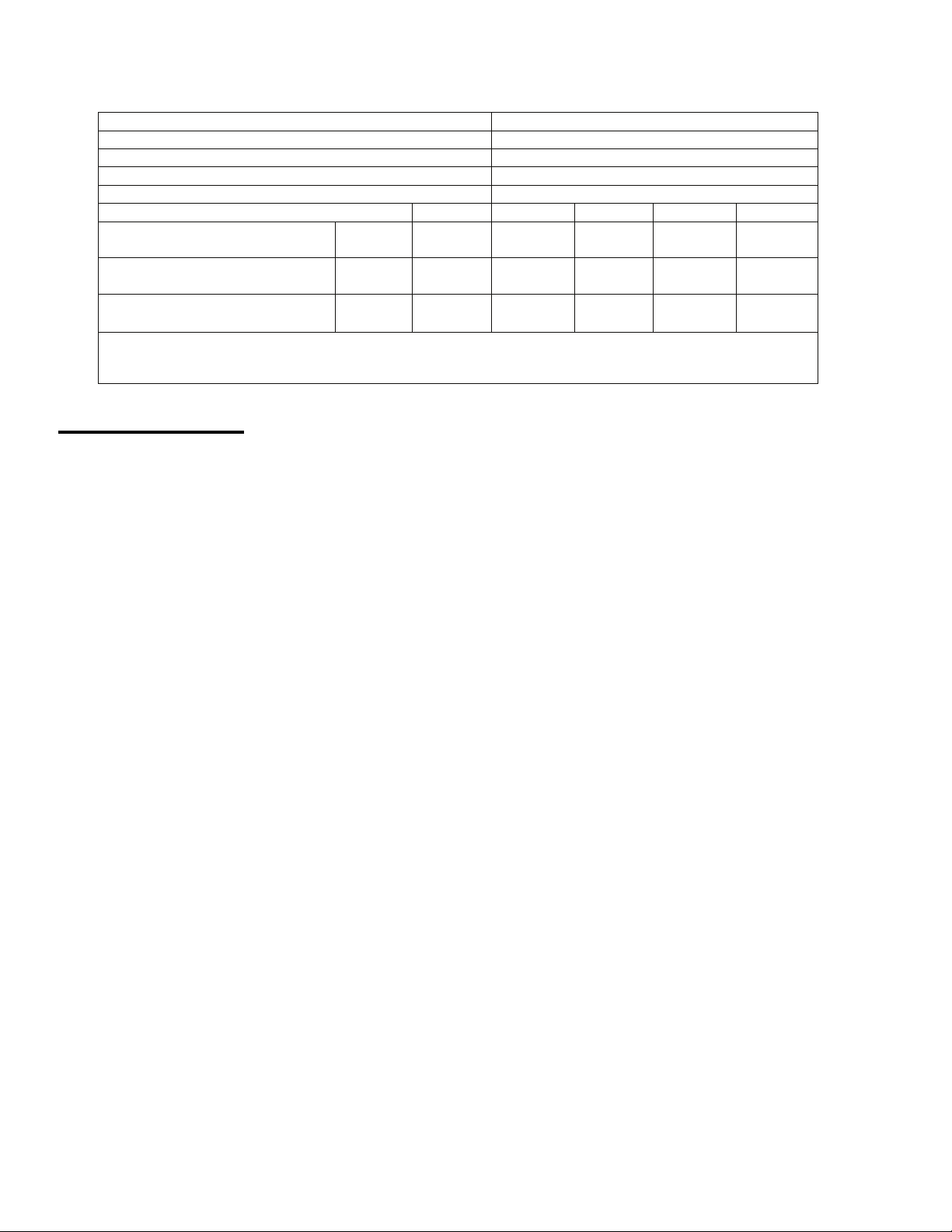

SPECIFICATIONS*

Rated Line Pull (lbs.) 177,9 kN (40,000 lb)

Noise Level 76db

Ambient Tempereature Range -28C to 60C (-20F to 140F)

Gear Reduction 51.35:1

Weight (without rope) 365 kg (804 lb)

*Rated line pull

per layer

*Rope capacity

per Layer

*Line speed

at 64,3 LPM

(at 17 GPM)

* These specifications are based on recommended 20mm (.787") Bridon Dyform

34LR/PI/MAX 1960 grade wire rope or equivilant with minimum breaking strength

of 355,8 kN (80,000 lb) and a 195 cc (11.9 cu in /rev)

kN

Lbs.

M.

Ft.

MPM

FPM

12LAYER OF ROPE

177,9

40,000

9

30

4,2

13.8

149,5

33,600

19

65

5,0

16.3

345

128,5

28,900

33

110

5,7

18.8

113,0

25,400

48

160

6,5

21.3

100,1

22,700

65

215

7,3

23.8

WARNINGS:

THE USER SHALL ENSURE THAT THE OPERATING PERSONNEL ARE GIVEN THE NECESSARY TRAINING.

THE OPERATOR SHALL ALWAYS WORK IN COMPLIANCE WITH THE OPERATING INSTRUCTIONS.

A MOTOR SPOOL (OPEN CENTER) DIRECTIONAL CONTROL VALVE IS REQUIRED FOR BRAKE OPERATION.

CLUTCH MUST BE TOTALLY ENGAGED BEFORE STARTING THE WINCHING.

DO NOT START WINCH MOTOR BEFORE ENGAGING CLUTCH.

DO NOT DISENGAGE CLUTCH UNDER LOAD.

STAY OUT FROM UNDER AND AWAY FROM RAISED LOADS.

STAND CLEAR OF CABLE WHILE PULLING. DO NOT TRY TO GUIDE CABLE.

DO NOT EXCEED MAXIMUM LINE PULL RATINGS SHOWN IN TABLE.

DO NOT USE WINCH TO LIFT, SUPPORT, OR OTHERWISE TRANSPORT PEOPLE.

A MINIMUM OF 2 WRAPS OF CABLE AROUND THE DRUM BARREL IS NECESSARY TO HOLD THE LOAD.

AVOID CONDITIONS WHERE LOAD SHIFTS OR JERKS OCCUR. EXCESSIVE “INCHING” SHALL BE AVOIDED.

USER’S RESPOSIBILITY FOR CE COMPLIANCE

1. Use only a motor spool (open center) control valve per Hydraulic System Requirements.

2. If a remote-operated winch control valve is used, refer to Hydraulic System Requirements for Emergency Stop

components to be installed.

3. Adjust system relief pressure per Hydraulic System Requirements.

4. Mount winch per Winch Mounting Instructions.

5. Install 20mm (.787 inch), grade 1960 wire rope with minimum breaking strength of 355,8kN (80,000 lb). Maximum rope length of 65 m (215 ft) for five layers maximum. Attach rope per Rope Installation Instructions. Hook

must have a safety latch and a minimum breaking strength of 445 kN.

1

Page 5

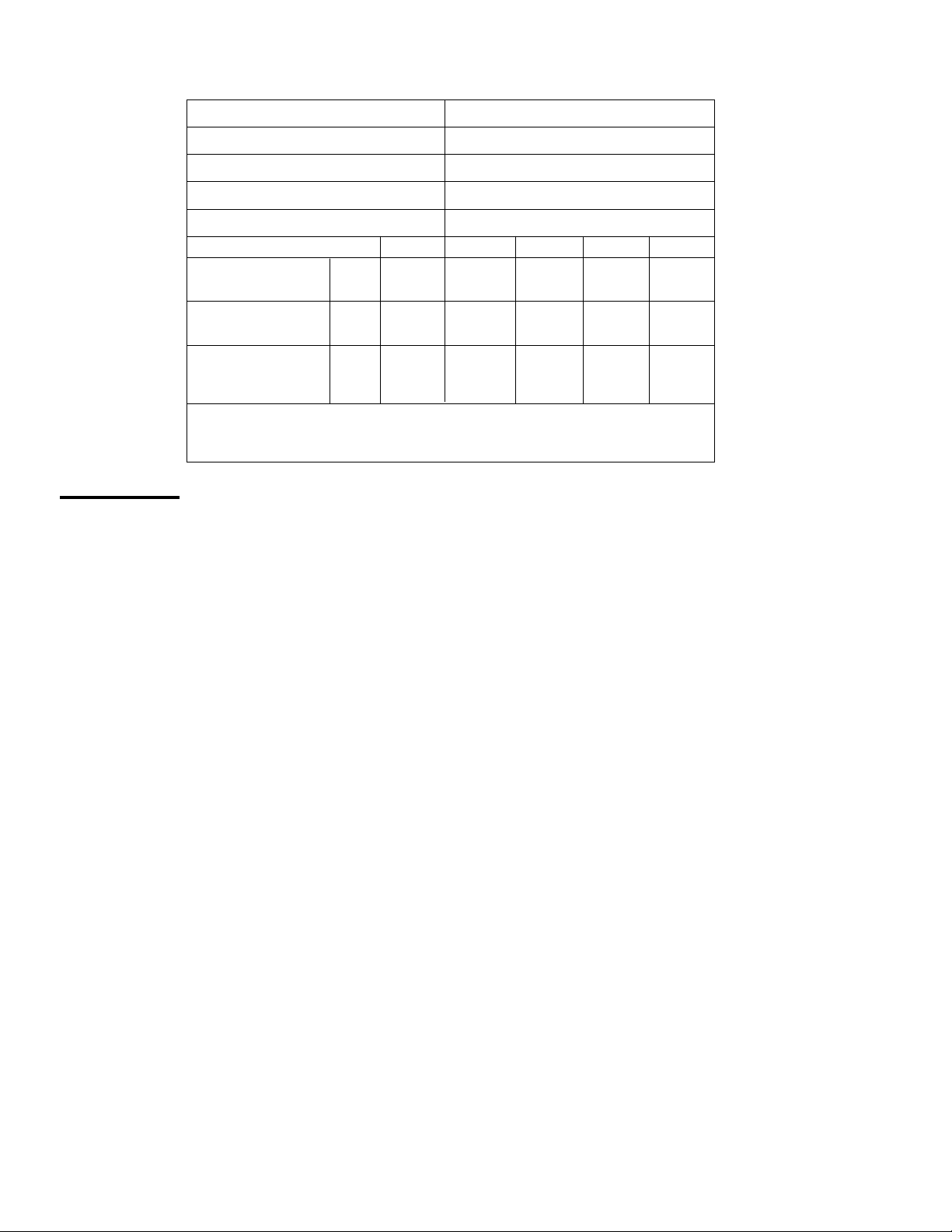

Refer to the performance charts below to properly match your hydraulic system to the winch performance. The

charts consist of: (1) Line Pull first layer kN (lb) vs. Working Pressure (PSI). (2) Line Speed, first layer MPM

(FPM) vs. flow LPM (GPM).

HYDRAULIC SYSTEM REQUIREMENTS

1. Motor spool (open center) control valve.

2. Emergency Stop:

A. If winch is controlled by a direct-operated manual valve, that valve serves as the E-stop.

B. If a remote operated control valve is used, a solenoid-operated hydraulic dump valve, normally open to

tank, and an emergency stop switch (to open the dump valve) is required. The E-stop switch is to be

normally closed and have a red, resettable push button actuator with yellow background. The E-stop

switch must be easily accessible to the operator.

3. Relief valve set at 193 bar (2800 psi) which is the rated capacity limiter.

4. Flow rate of 64,3 LPM (17 GPM) maximum. Do not exceed 75,7 LPM (20 GPM) or motor and winch may be

damaged.

5. Hydraulic fluid with a viscosity between 20-43 cSt (100-200 SUS). Maximum operating temperature 85C

(180F). Cleanliness level of ISO 17-14 or better.

DUAL-A & B PORT CONTROL

WITH BRAKE RELEASE SHUTTLE

TYPICAL LAYOUT

MOTOR

BRAKE

PORT

HIGH PRESSURE LINE

12,7 mm (.50 in)

I.D. MINIMUM

PROVIDED BY USER

LOW PRESSURE LINE

19 mm (.75 in) I.D. MINIMUM

DUMP VALVE

*

PUMP

MAX. FLOW &

PRESSURE AT

RATED LOAD:

64,3 LPM (17 GPM)

193 bar (2800 PSI)

PERFORMANCE CHARTS

10,6 (35)

9,1 (30)

7,6 (25)

6,1 (20)

4,6 (15)

3,1 (10)

1,5 (5)

0

LINE SPEED-FIRST LAYER MPM (FPM)

0 18,9 37,9 56,7

(0) (5) (10) (15)

FLOW LPM (GPM)

BASED ON 195 cc (11.9 cu in) MOTOR

64,3

(17)

3 POSITION

4 WAY VALVE

(MOTOR SPOOL)

REQUIRED ONLY IF REMOTE-OPERATED CONTROL VALVE IS USED. SEE 2B

*

IN HYDRAULIC SYSTEMS REQUIREMENTS. NOT REQUIRED FOR A

DIRECT-OPERATED MANUAL VALVE.

LOW SPEED

HIGH SPEED

177,9 (40,000)

155,6 (35,000)

133,4 (30,000)

111,2 (25,000)

89,0 (20,000)

66,7 (15,000)

LINE PULL-FIRST LAYER kN (lb)

44,5 (10,000)

0

WORKING PRESSURE bar (PSI) AT 64,3 LPM (17 GPM)

SYSTEM RELIEF

193 BAR (2800 PSI)

(RATED CAPACITY LIMITER)

0137,9

68,9

(0) (2000)

(1000)

E-STOP SWITCH

*

(3000)

206,8

2

Page 6

WINCH FRAME MOUNTING

Use (8) 7/8 inch diameter grade 5 or better bolts to attach mounting frame to wrecker.

ROPE INSTALLATION

1. Unwind rope by rolling it out along the ground to prevent kinking. Securely wrap end of wire rope, op-

posite hook, with plastic or similar tape to prevent fraying.

2. Insert the end of rope into the slot on the inside of the drum flange. Pull the wire rope through the

pocket on the outside of the drum flange and loop back into pocket around the anchor “puck”. Use a

soft hammer to drive the back side of the wire rope, firmly seating the wire rope and anchor into the

pocket.

3. Carefully run the winch in the “reel-in” direction. Keeping tension on end of rope, spool all the rope on-

to the rope drum, taking care to form neatly wrapped layers.

INSERT WIRE ROPE

INTO SLOT IN

DRUM FLANGE

AS SHOWN

ANCHOR

PUCK

PULL WIRE ROPE

THRU POCKET AND

LOOP BACK INTO POCKET

AS SHOWN

CLUTCH OPERATION

To engage clutch:

1. Move the clutch control valve to the “clutch engaged” position.

2. Anytime the temperature is below freezing, run the motor in the “rope out” direction only until the drum

starts to turn. In extreme cold temperatures (below 0˚ F/-18˚ C), pull out on the rope by hand only

until the drum starts to turn.

3. Wait at least 3 seconds for the clutch to fully engage, after which the winch is ready to winch in the

rope.

WARNING: Do not attempt to engage the clutch by first running the winch motor and then moving the

clutch control valve to the "clutch-engaged" position while the motor is running. Do not start picking up

the load at the same time the clutch is being engaged.

To disengage clutch:

1. Run the winch in the "rope out" direction until the load is off the rope.

2. Move the clutch control valve to the "clutch-disengaged" position.

3. The rope may now be pulled off by hand.

WINCH OPERATION

The best way to get acquainted with how your winch operates is to make test runs before you use it. Plan

your test in advance. Remember, you hear your winch, as well as see it operate. Learn to recognize the

sounds of a light steady pull, a heavy pull, and sounds caused by load jerking or shifting. Gain confidence in

operating your winch and its use will become second nature with you.

The uneven spooling of rope, while pulling a load, is not a problem, unless there is a rope pileup on one end

of drum. If this happens, reverse the winch to relieve the load and move your anchor point further to the center of the vehicle. After the job is done you can unspool and rewind for a neat lay of the rope.

3

Page 7

MAINTENANCE

Adhering to the following maintenance schedule will keep your winch in top condition and performing as it should with a minimum of repair.

A. WEEKLY

1.

Check the oil level and maintain it to the oil level plug. If oil is leaking out, determine location and

repair.

2. Check the pressure relief plug in the gear housing cover. Be sure that it is not plugged.

3. Lubricate cable with light oil.

B. MONTHLY

1. Check the winch mounting bolts. If any are missing, replace them and securely tighten any that are

loose. Use grade 5 or better bolts.

Inspect the cable. If the cable has become frayed with broken strands, replace immediately.

2.

C. ANNUALLY

1.

Drain the oil from the winch annually or more often if winch is used frequently.

2. Fill the winch to the oil level plug with clean kerosene. Run the winch a few seconds with no load in

the reel in direction. Drain the kerosene from the winch.

3. Refill the winch to the oil level plug with all-purpose SAE 75W-90 synthetic gear oil.

4. Inspect frame and surrounding structure for cracks or deformation.

END OF SERVICE MEASURES

When winch reaches the end of it’s serviceable life, dispose of per local environmental regulations.

TROUBLESHOOTING GUIDE

CONDITIONS POSSIBLE CAUSE CORRECTION

OIL LEAKS

FROM WINCH

1. Seals damaged or

worn.

2. Too much oil. 2. Drain excess oil. Refer to OPERATION.

1. Replace seal.

3. Damaged gaskets. 3. Replace gaskets.

1. Low flow rate 1. Check flow rate. Refer to HYDRAULIC

WINCH RUNS

TOO SLOW

2. Hydraulic motor

SYSTEMS performance chart page 2.

2. Replace motor.

worn out.

CABLE DRUM

WILL NOT

FREESPOOL

1. Clutch not disengaged

1. Check air pressure to clutch cylinder: 100

PSI Minimum required. Refer to page 10 for

port location.

BRAKE WLL NOT

RELEASE

1. Brake line disconnected or blocked.

1. Check brake function.

4

Page 8

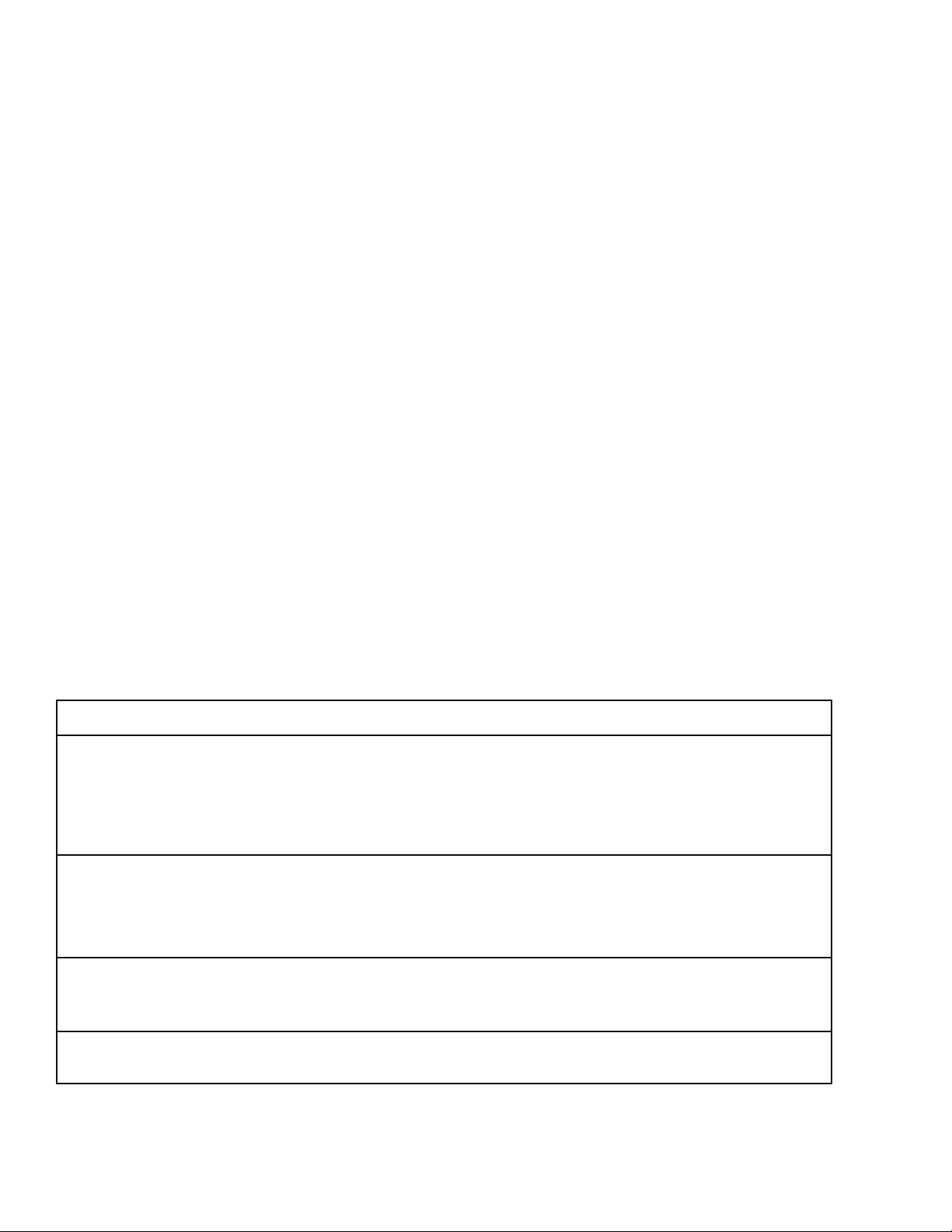

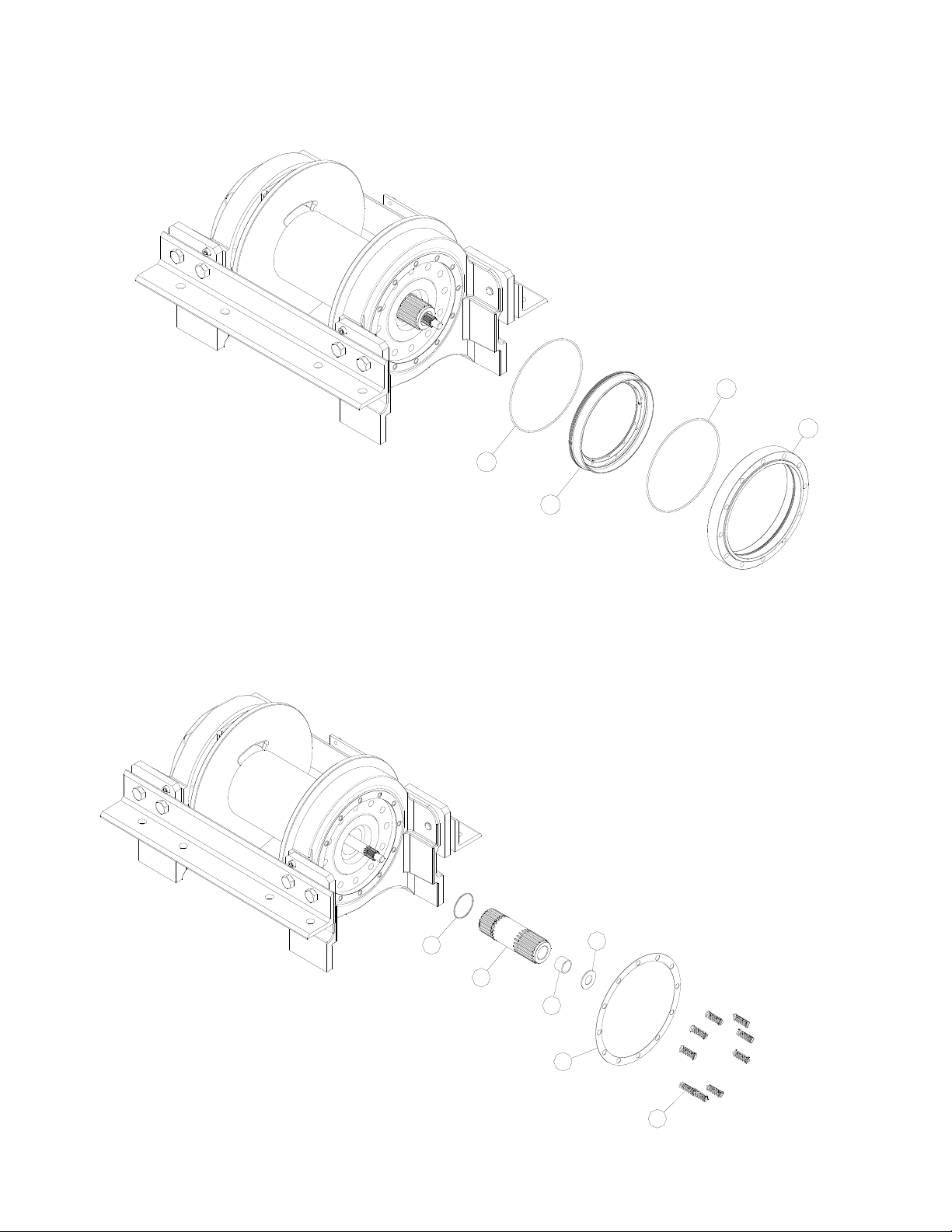

INSTRUCTIONS FOR OVERHAUL

DIS-ASSEMBLY

1. Drain oil from gear housing cover by removing pipe plug #37 and relief fitting #32. Remove tensioner assembly.

32

37

Disconnect tube #40 from elbow #43 on valve #41 and fitting #29 on brake #30b. Remove motor #33 and gasket

2.

#30a by removing (2) capscrews #22. Remove valve #41, if needed, from motor by loosening (4) capscrews #16.

16

43

41

22

33

30a

40

5

Page 9

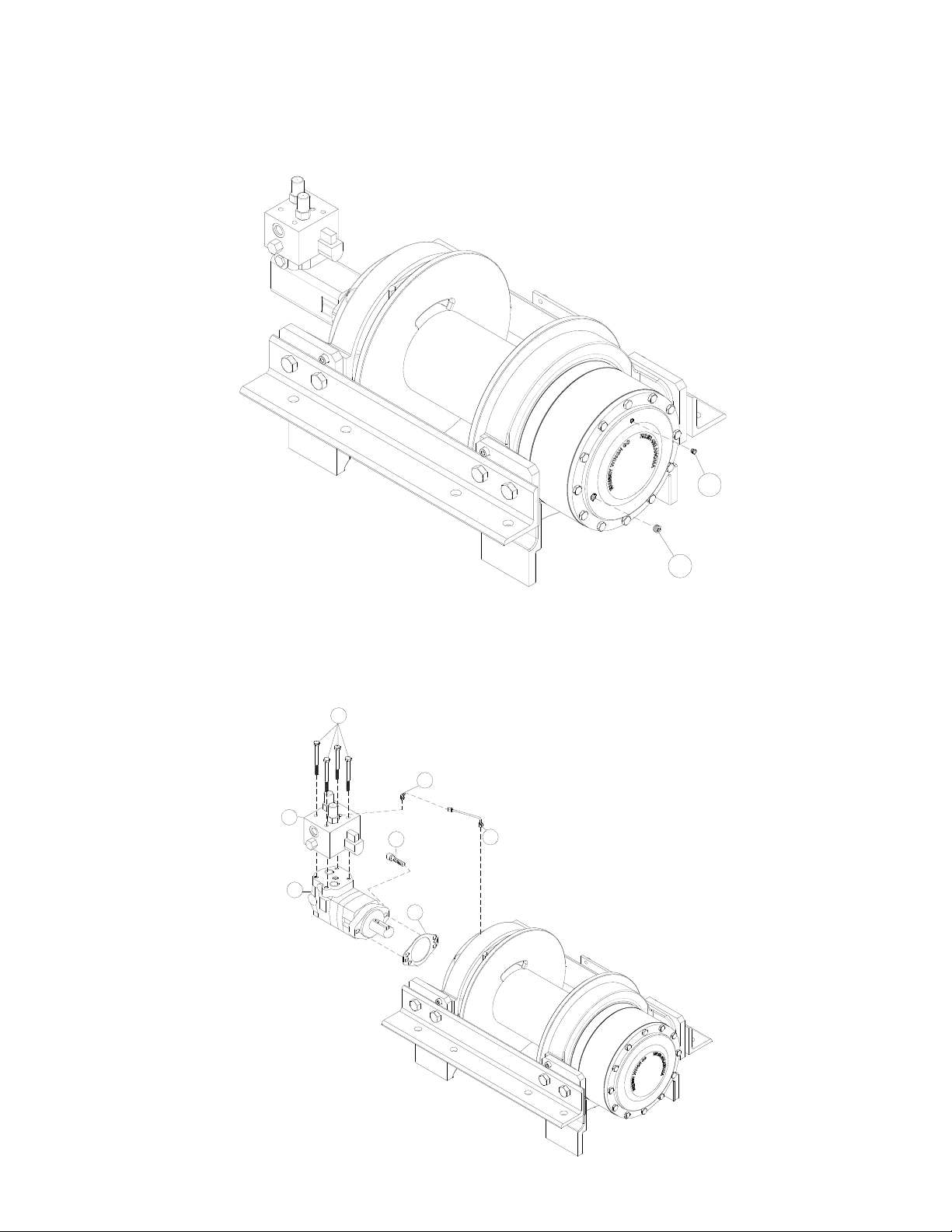

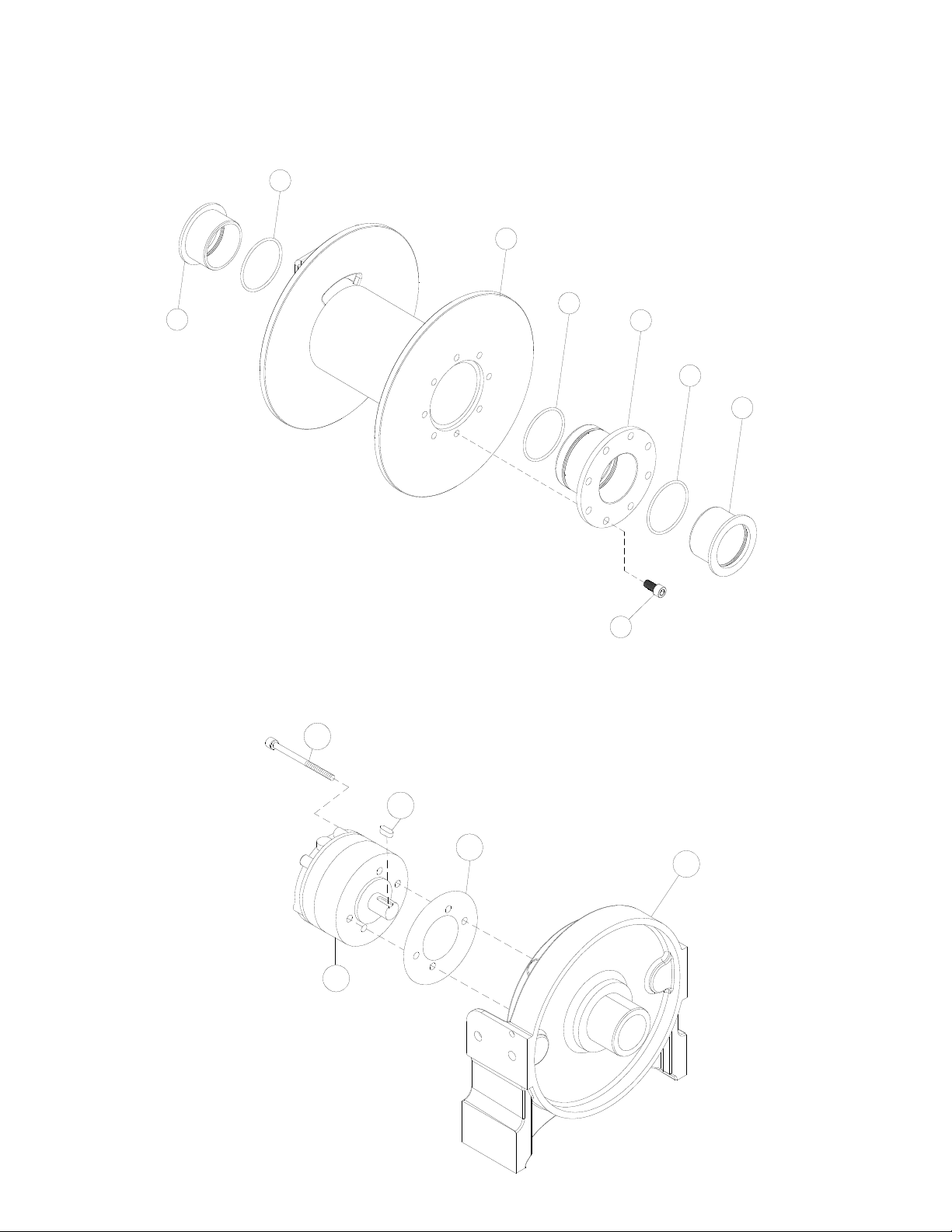

3. Remove (12) capscrews #18 to remove gear housing cover and gasket from ring gear. Remove input thrust washer,

sun gear and input carrier assembly from inside ring gear. Remove ring gear and gasket. Remove output carrier assembly. Inspect gear housing cover bushing #15 for damage or wear. Replace if damaged or excessive wear.

31

42

31

15

5

18

4. Remove (8) capscrews #20 to remove clutch retainer plate #10 from clutch piston. Remove clutch #9.

9

10

20

6

Page 10

5. Remove clutch housing #27 with piston #28 inside. To remove piston from clutch housing apply air to 1/8” port. Remove orings #28 and #35 and inspect for damage or wear.

35

27

36

28

6. Remove (9) springs #39, thrust washer #26, gasket #31, output shaft #12 and spacer #13 from gear end bearing. Inspect output shaft bushing #14 for damage or wear. Replace if damaged or excessive wear.

13

12

26

14

31

39

7

Page 11

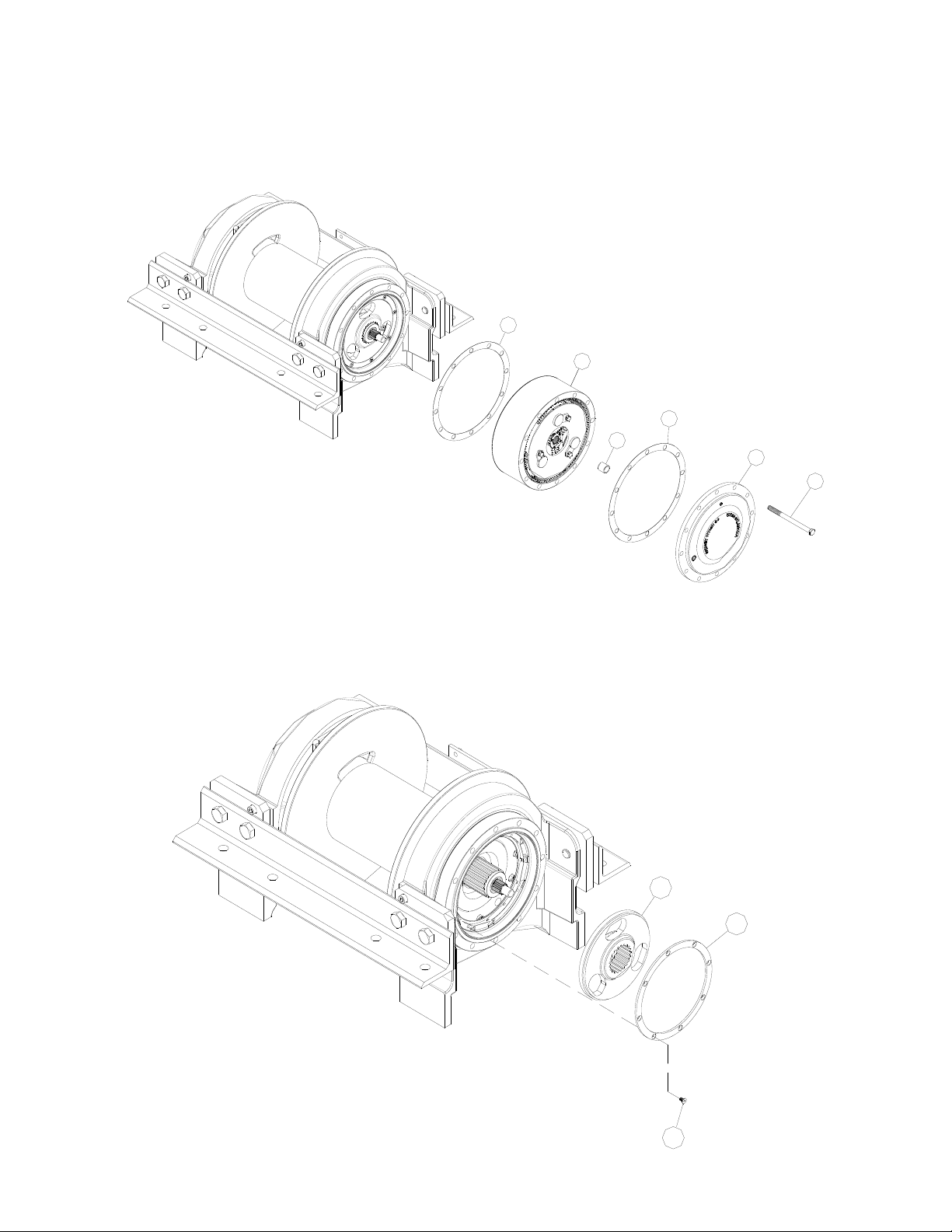

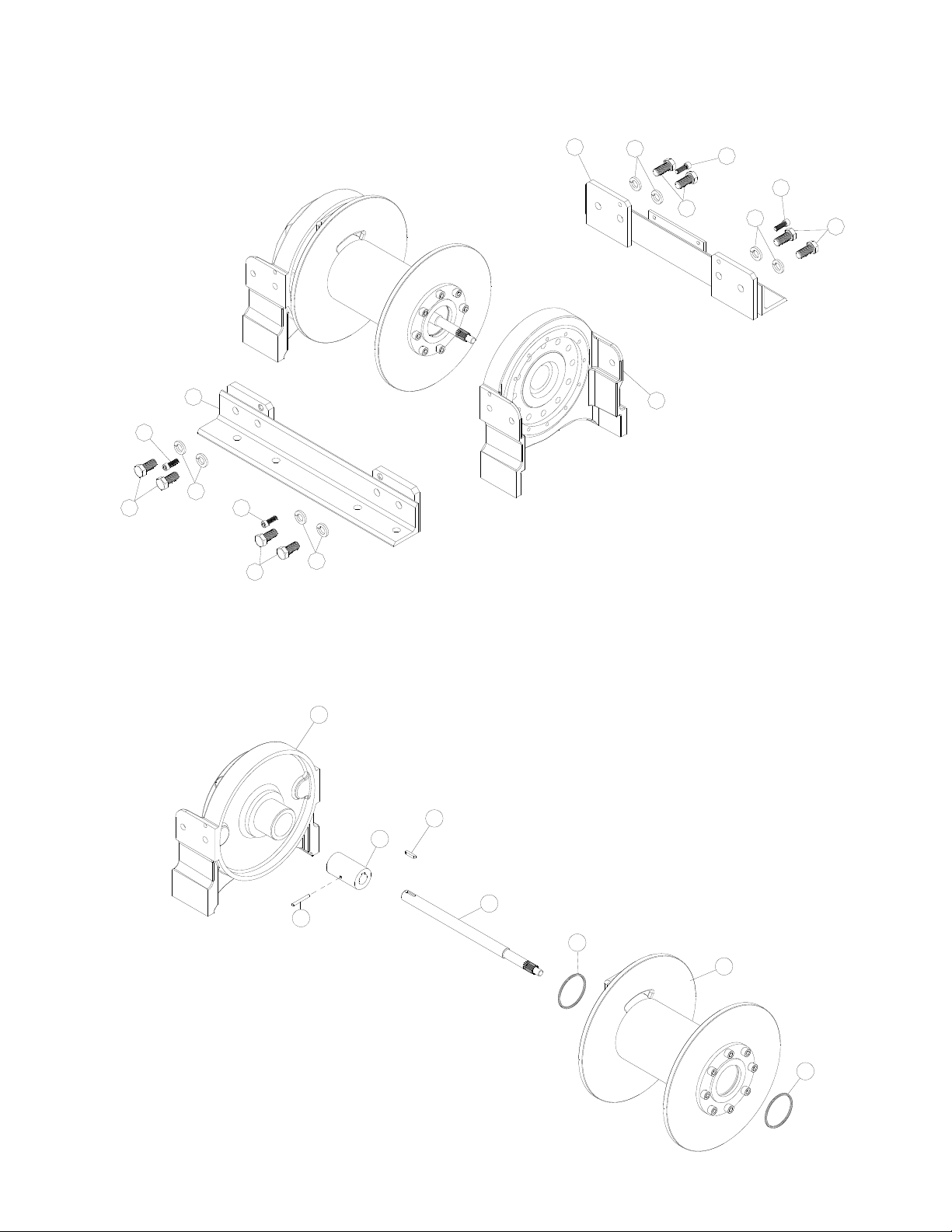

7. Remove winch tie bars #2 and #3 by removing (8) capscrews #19, (8) lock washers # 24, and (4) shoulder bolts

#25. Pull gear end bearing #7 from drum assembly #1.

2

3

25

24

19

25

19

24

24

7

25

25

19

24

19

8. Pull drum assembly #1 from end bearing #6. Remove quad-rings #34 from grooves in drum bushings. Remove input

shaft #11 from end bearing. Examine splined ends of input shaft for signs of wear, replace if damaged. Examine drum

assembly #1 for signs of wear.

6

8

4

11

38

34

1

34

8

Page 12

If splines inside drum driver #102 are damaged, drum driver must be replaced. Remove drum driver by unscrewing (8)

9.

capscrews #105. If bushings show signs of wear, replace by pressing old bushings from drum #101 and removing orings from grooves in drum and drum driver. Place well oiled o-rings #106 into driver and drum. Place well oiled o-ring

#107 on outside of driver. Press bushings #104 into drum driver until flange is flush and #103 is flush against drum

106

101

107

103

102

106

104

.

105

10.

Remove brake assembly screws #17 from brake #36a attaching brake to end bearing #6. Remove coupling #4 and

gasket #36e from end bearing. Take note of mounting configuration for proper mounting of parts during re-assembly.

17

30c

30e

6

30b

9

Page 13

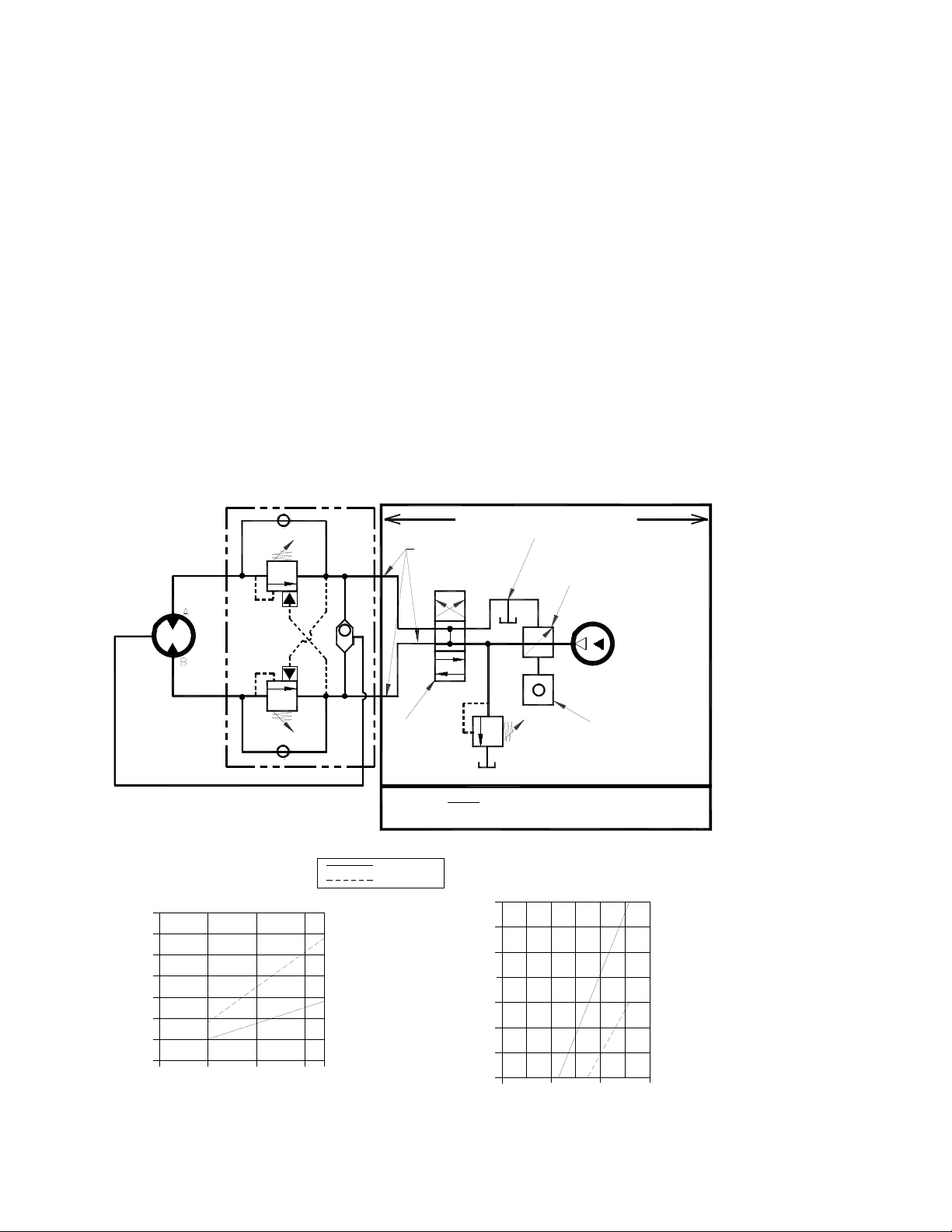

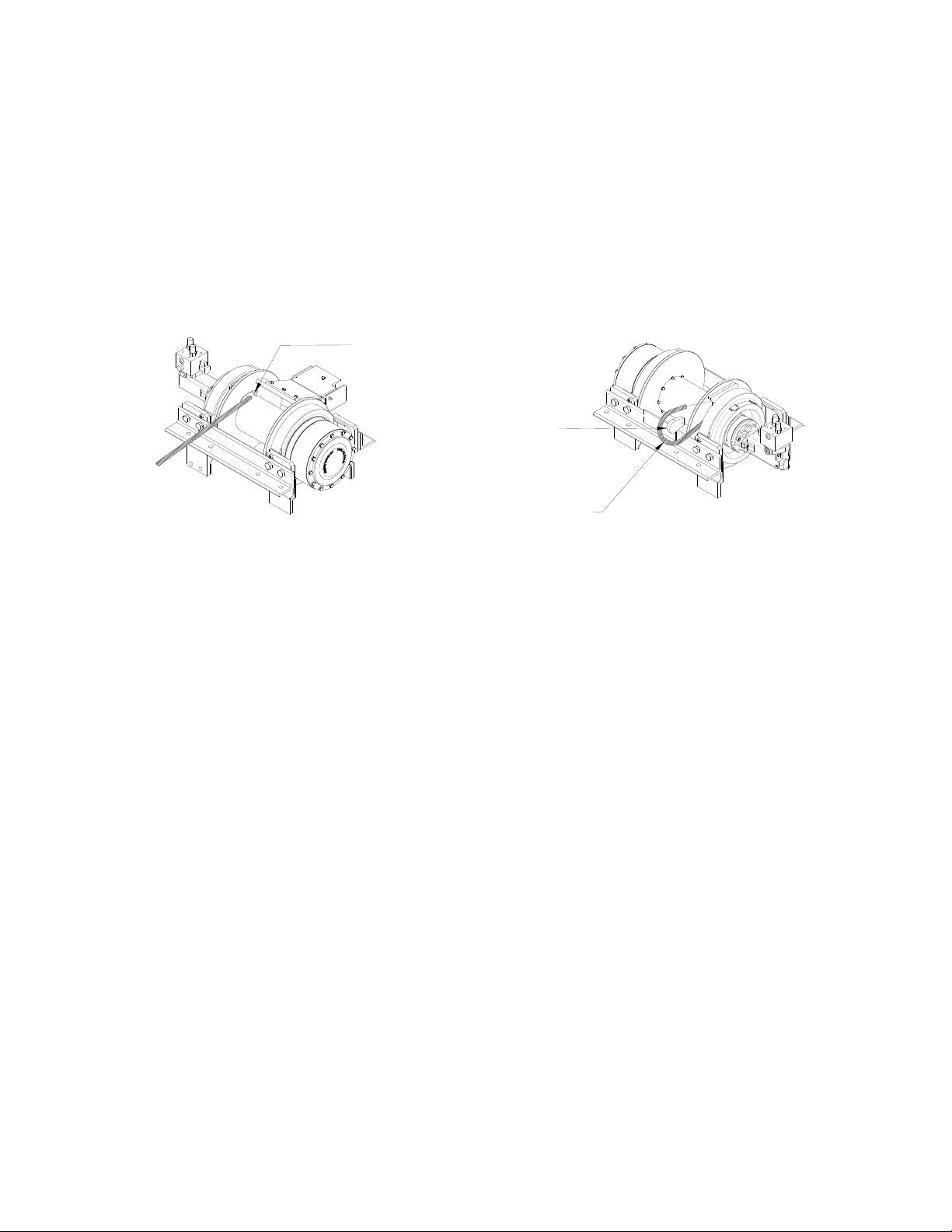

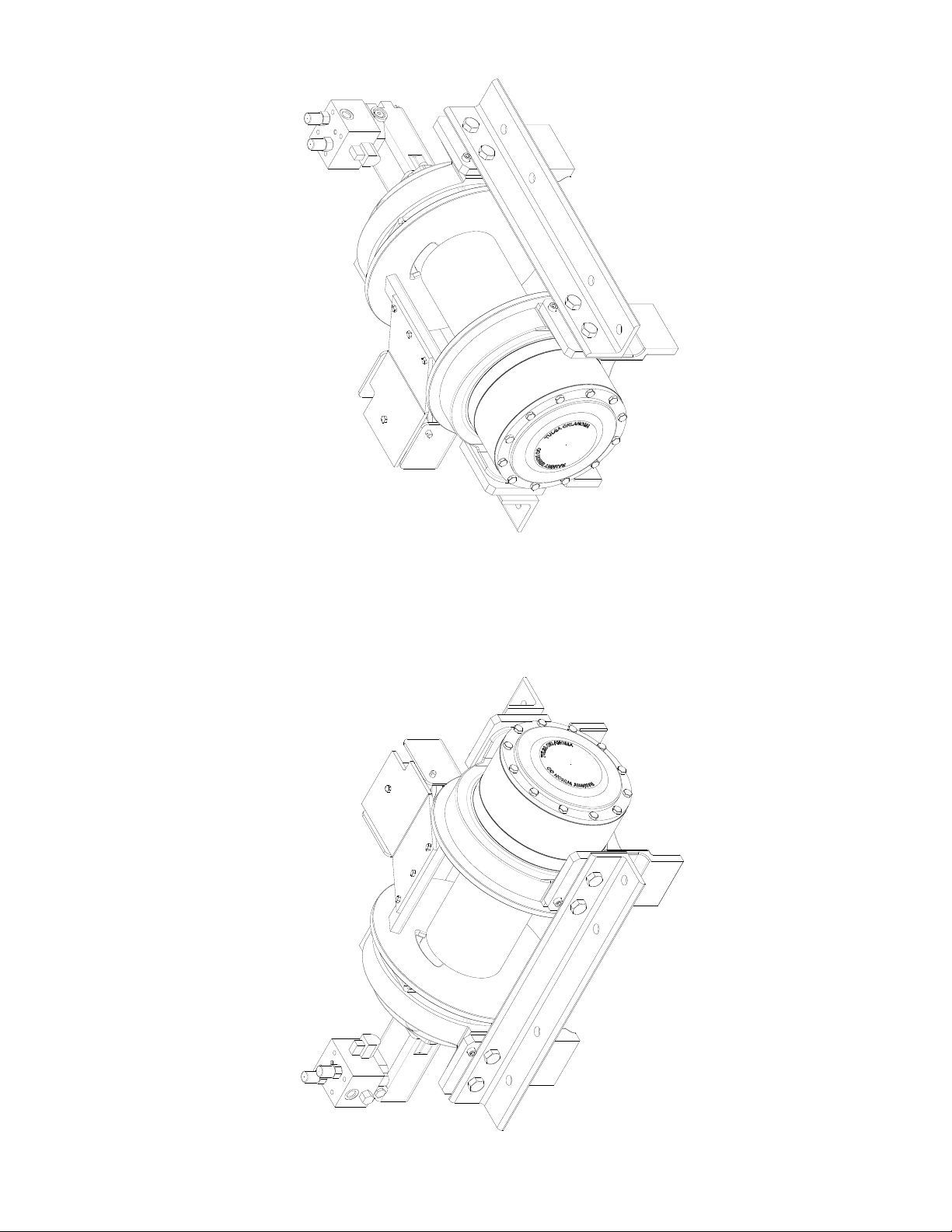

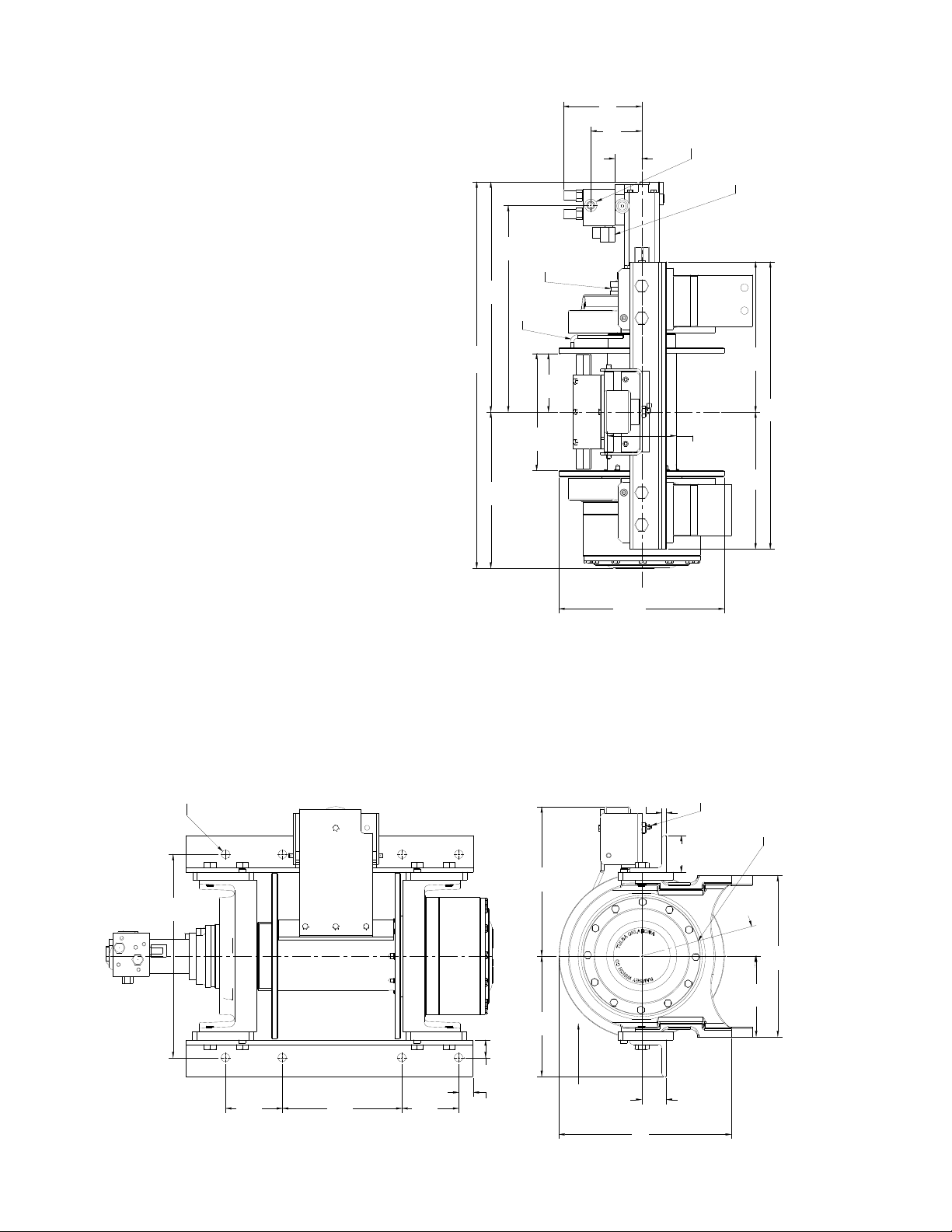

R.H. MOUNTING

CONFIGURATION

WINCH MOUNTING CONFIGURATION

10

L.H. MOUNTING

CONFIGURATION

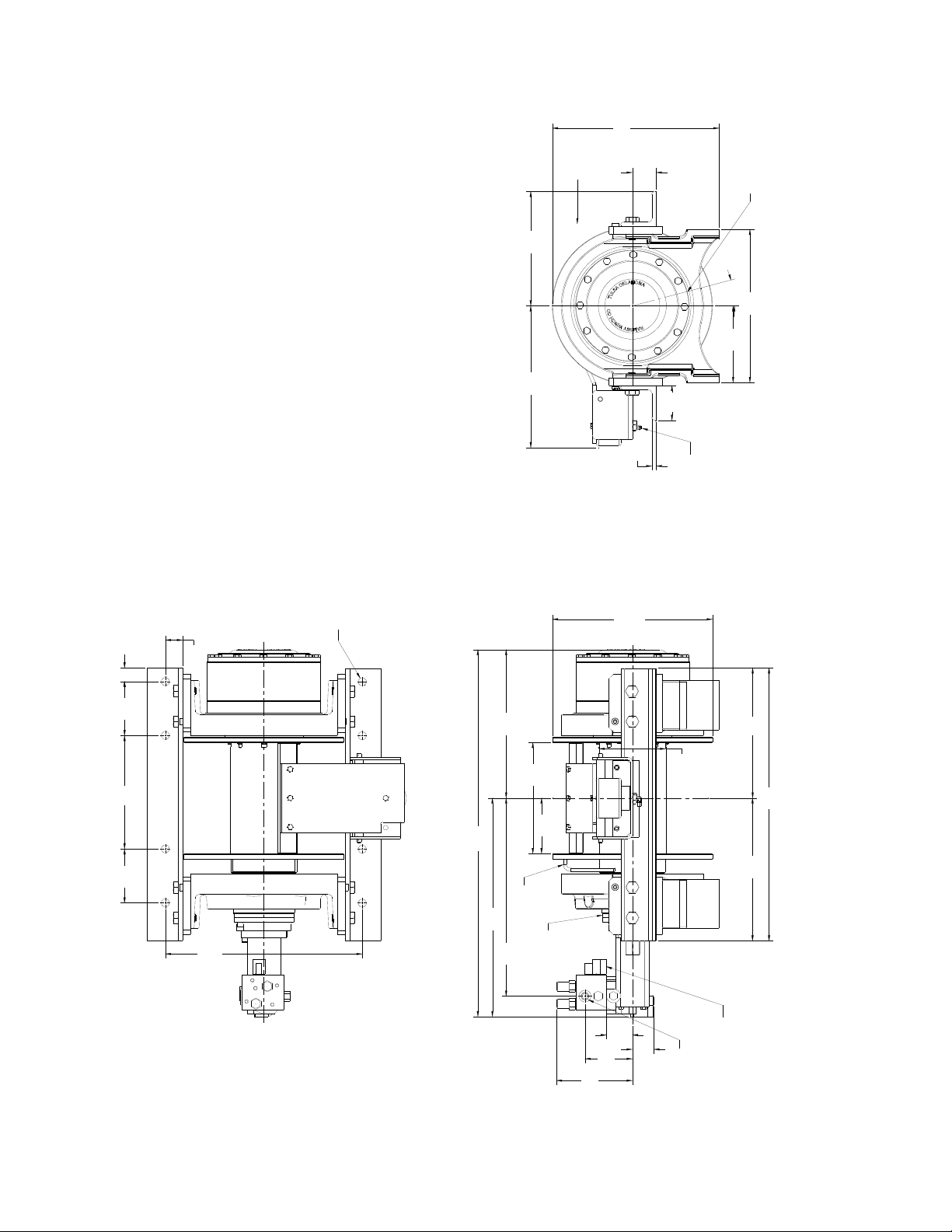

Page 14

8.54

216,91

5.54

140,71

2.91

73,91

22.50

571,50

STATIC LOAD

HOLDING BRAKE

25.06

636,52

WEDGE POCKET

CABLE ANCHOR

THREAD O-RING PORT

2-PLACES OPPOSITE SIDES

7/8-14 SAE STRAIGHT

FOR HIGH SPEED/LOW TORQUE

1/4" SPADE, 24V

42.07

1068,58

6.38

162,05

12.75

323,85

Ø7.50

DRUM

190,50

BARREL

17.02

432,30

Winch Model HD-P 177,9

L.H. Configuration shown

DRUM

452,20

Ø18.00

FLANGE

Ø.91

X8

23,01

0.50

12,7

(TYP)

BRASS COMPRESSION FITTING

16.36

415,54

L

31.28

794,51

DRUM C

56,54

14.92

AIR PRESSURE FOR TENSIONER

WITH TAPPERED SLEEVE FOR

(50 PSI MIN, 90 PSI MAX)

1/4" DIAMETER TUBING

ORIENT AS SHOWN

(CLUTCH IS SPRING ENGAGED)

PORT (100 TO 120 PSI )

FOR DISENGAGING CLUTCH

1/8-27NPT PRESSURE

4.00

101,6

(TYP)

16.25

412,75

22.13

(TYP)

561,98

15°

17.56

446,02

8.78

223,01

13.13

333,50

1.94

49,28

(TYP)

2.68

68,07

6.19

(TYP)

157,17

330,2

13.00

(TYP)

6.19

157,17

1.56

(TYP)

39,62

(TYP)

CABLE IN

ROTATION

(TYP)

18.75

476,25

11

Page 15

R.H. Configuration shown

Winch Model HD-P 177,9

18.75

476,25

CABLE IN

ROTATION

13.13

333,50

16.25

476,25

2.68

68,07

(TYP)

4.00

101,6

(TYP)

.50

12,7

(TYP)

1/4" DIAMETER TUBING

(50 PSI MIN, 90 PSI MAX)

WITH TAPPERED SLEEVE FOR

BRASS COMPRESSION FI TTING

AIR PRESSURE FOR TENSIONER

(CLUTCH IS SPRING ENGAGED)

ORIENT AS SHOWN

PORT (100 TO 120 PSI)

FOR DISENGAGING CLUTCH

1/8-27NPT PRESSURE

15°

17.56

446,02

8.78

223,01

Ø.91

X8

23,01

1.56

39,62

(TYP)

6.19

(TYP)

157,17

330,2

13.00

(TYP)

6.19

(TYP)

157,17

1.94

49,28

(TYP)

17.02

432,30

12.75

323,85

6.38

42.07

1068,58

25.06

636,52

22.13

(TYP)

561,98

162,05

CABLE ANCHOR

WEDGE POCKET

22.72

577,08

STATIC LOAD

HOLDING BRAKE

8.54

DRUM

452,20

Ø18.00

FLANGE

56,54

14.92

Ø7.50

DRUM

190,50

BARREL

L

31.28

794,51

DRUM C

16.36

415,54

2.91

73,91

2.41

62,21

5.32

158,49

216,91

1/4" SPADE, 24V

7/8-14 SAE STRAIGHT

FOR HIGH SPEED/LOW TORQ UE

THREAD O-RING PORT

2-PLACES OPPOSITE SIDES

12

Page 16

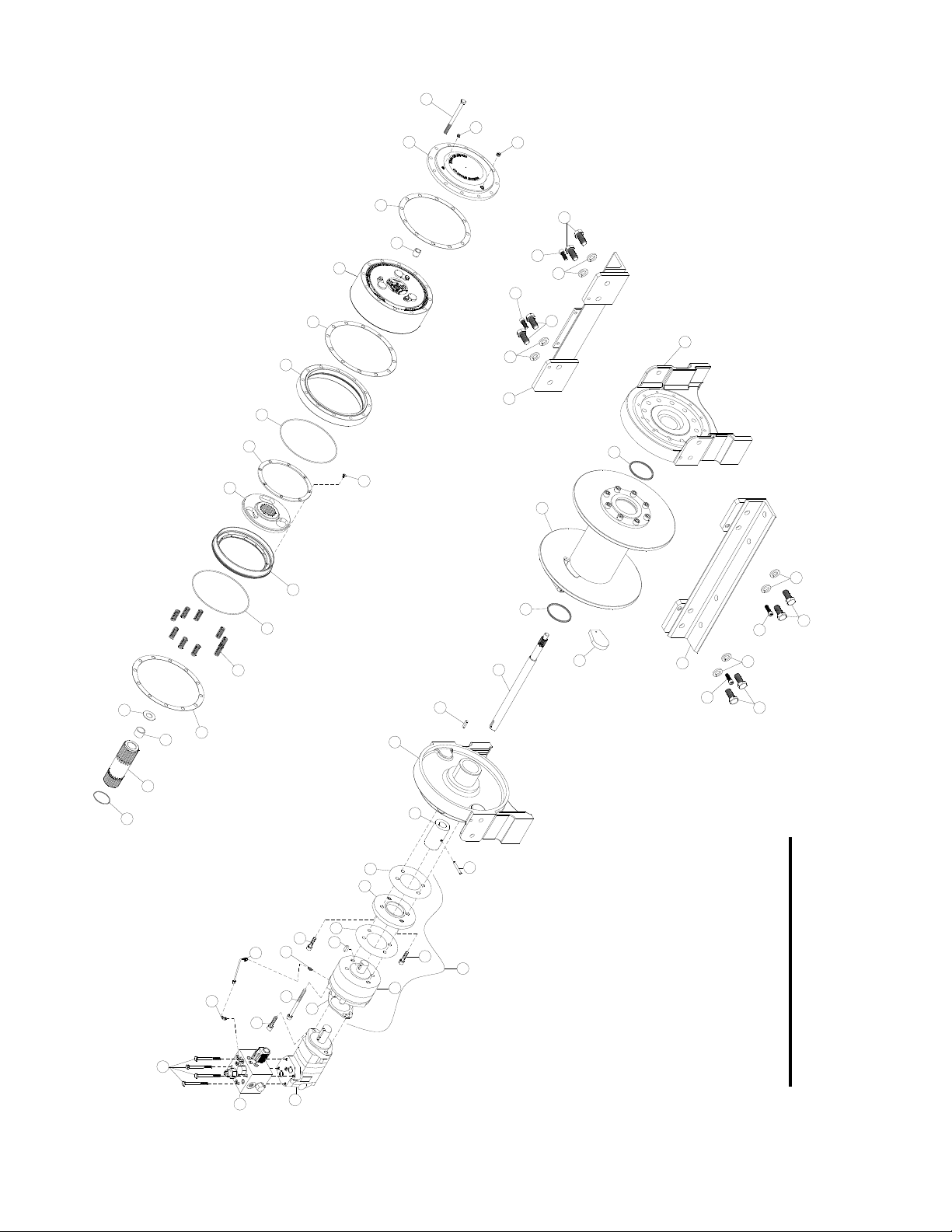

18

5

31

15

42

31

27

35

10

9

28

36

20

32

37

19

25

24

25

19

7

24

2

34

1

24

34

19

25

39

26

31

14

12

13

30e

30d

30e

21

29

40

43

16

17

22

30c

30a

8

6

4

21

30b

11

38

30

23

3

24

25

19

HDP 177,9 WINCH

41

33

13

Page 17

PARTS LIST - HDP 177,9

1 1 234241 DRUM ASSEMBLY 26 1 418520 WASHER-THRUST

2 1 243071 MOUNTING ANGLE 27 1 426059 CYLINDER

3 1 243072 MOUNTING ANGLE 28 1 426060 PISTON

4 1 324284 MOTOR COUPLING 29 1 432023 FITTING

Item No. Qty Part No. Description Item No. Qty Part No. Description

5 1 328180 GEAR HOUSING COVER 30 1 438037 BRAKE ASSEMBLY

6 1 338419 MOTOR END BEARING 30a 1 MOTOR END GASKET

7 1 338417 GEAR END BEARING 30b 1 BRAKE

8 1 342081 KEY 30c 1 KEY

9 1 342517 CLUTCH 30d 1 ADAPTER PLATE

10 1 352035 CLUTCH RETAINING RING 30e 2 ADAPTER PLATE GASKET

11 1 357549 INPUT SHAFT 31 3 442210 GASKET

12 1 357543 OUTPUT COUPLING 32 1 456008 RELIEF FITTING

13 1 362327 SPACER 33 1 458126 MOTOR

14 1 412044 BUSHING 34 2 462040 QUAD RING

15 1 412105 BUSHING 35 1 462103 ORING 2-274

16 4 414400 CAPSCREW-3/8-24NF X4LG,HXHD,GR-5 36 1 462104 ORING 2-275

17 2 414595 CAPSCREW-1/2-13NC X 3-1/2 LG, SOC HD 37 1 468040 PIPE PLUG

18 12 414612 CAPSCREW 1/2-13NC X 7 LG HEX HD 38 1 470075 PIN

19 8 414788 CAPSCREW 7/8-9NC X 2.5 LG HEX HD 39 9 494140 SPRING

20 8 414819 CAPSCREW 1/4-20NC X 1/2 LG FLAT HD 40 1 509125 TUBE ASSEMBLY

21 2 414947 CAPSCREW-1/2-13NC X 1 LG,HEX SOC HD 41 1 516065 VALVE-CONTROL (DUAL ROTATION)

22 2 414948 CAPSCREW-1/2-13NCX1 1/4LG,SOCKET HD 42 1 530173 GEARBOX

23 1 408431 CABLE WEDGE 43 1 432018 FITTING – HYD. 7/16-20 90° ELBOW

24 8 418261 LOCKWASHER 7/8 MED SECTION

25 4 418452 SHOULDER BOLT

14

Page 18

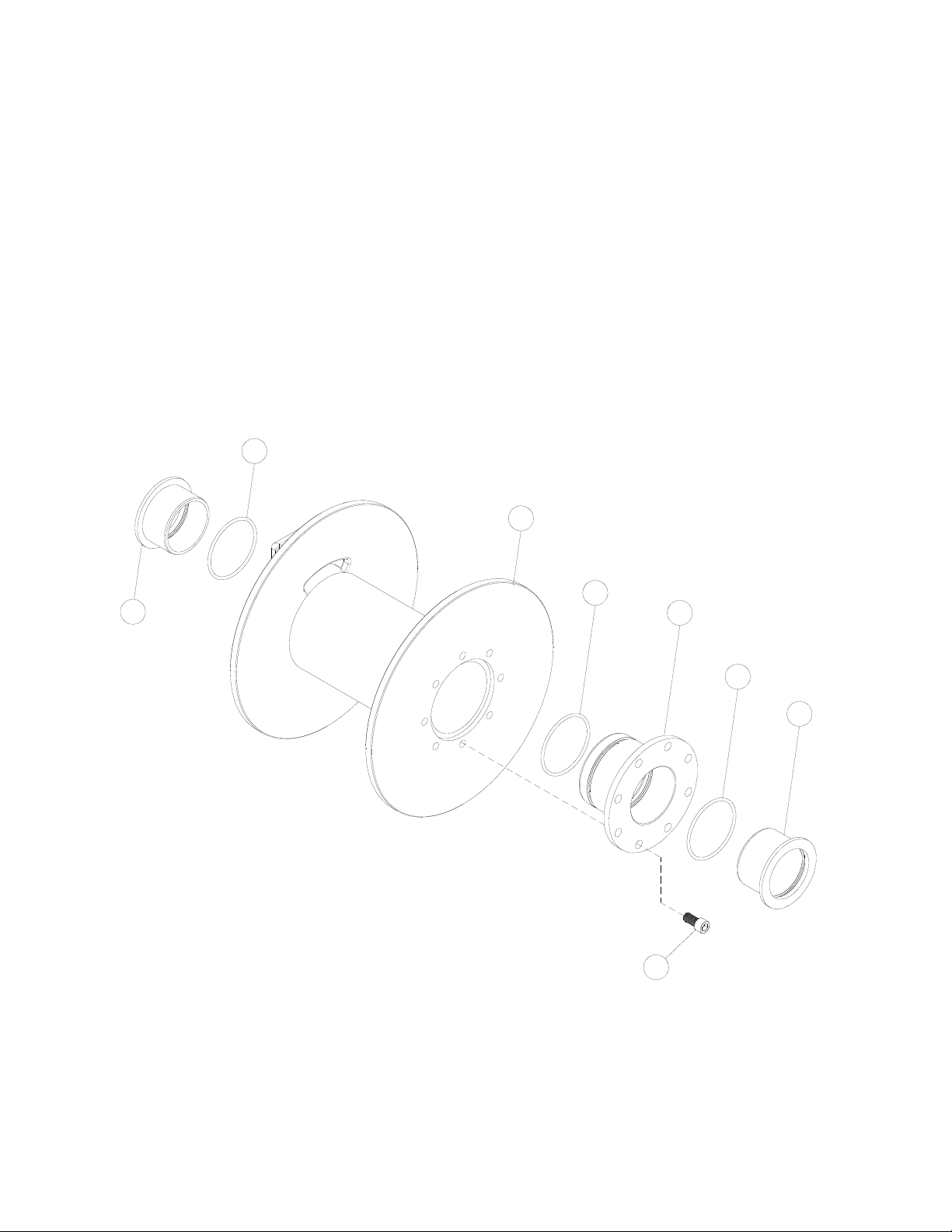

DRUM ASSEMBLY - 234241

Item No. Part No. Quantity Description

101 332272 1 DRUM‐CABLE

102 332226 1 DRIVER‐DRUM

103 412078 1 BUSHING‐DRUM

104 412079 1 BUSHING‐DRUM

105 414978 8 CAPSCREW‐5/8‐18NCX11/4LG,SOCHD

106 462043 2 O‐ RING‐AS‐568‐348,3/16X43/4X43/8

107 462075 1 O‐ RING‐AS‐568‐354,3/16X51/2X51/8

106

101

103

107

102

106

104

105

15

Page 19

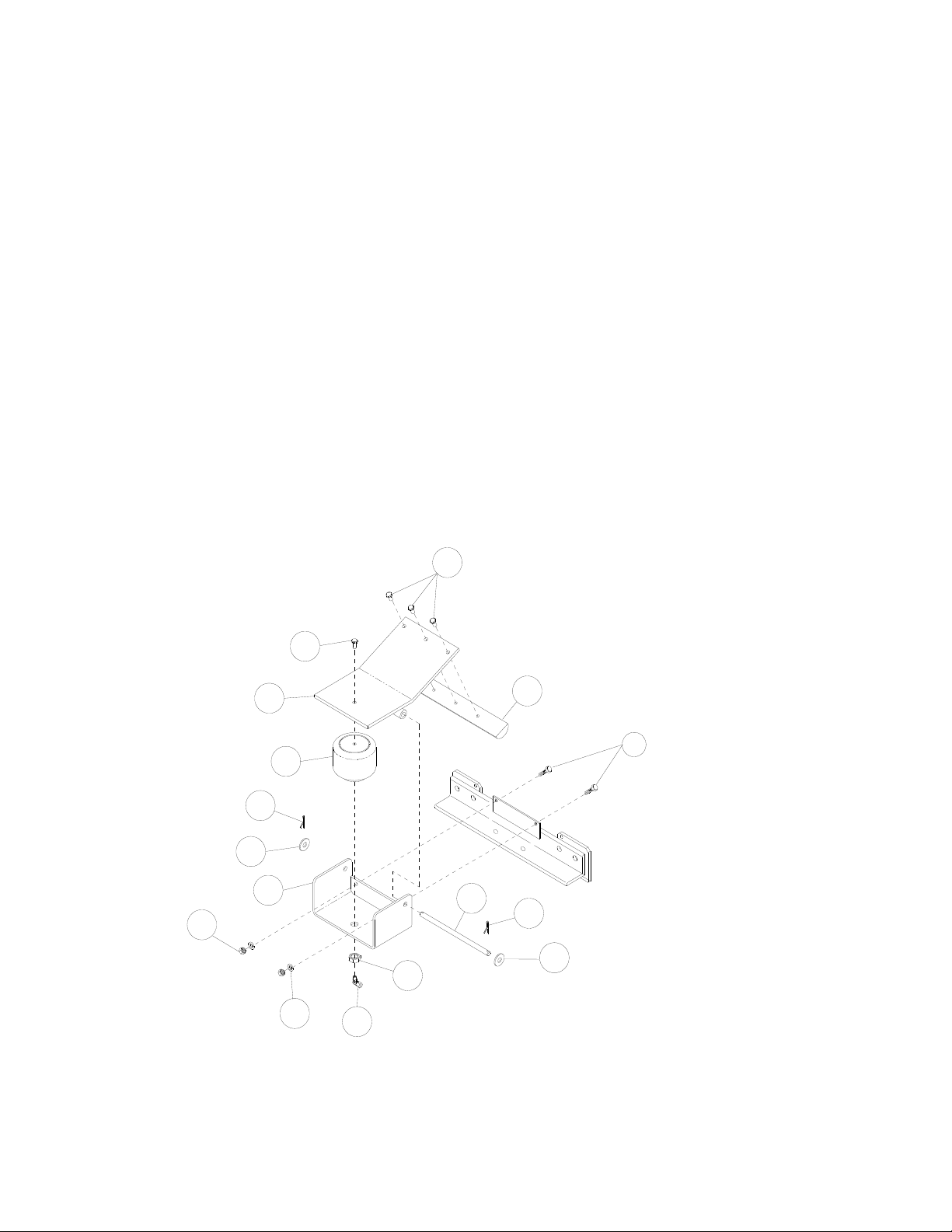

CABLE TENSIONER (OVERWOUND) - 299756

Item No. Part No. Quantity Description

201 265102 1 LEVER ARM

202 304189 1 BAR

203 346046 1 PIVOT PIN

205 408362 1 BRACKET

205 414278 4 CAPSCREW-3/8-16NCX3/4LG,HXHD,GR.5, ZINC PLATED

206 414316 2 CAPSCREW-3/8-16NCX1 1/4,HXHD,GR.5, ZINC PLATED

207 418045 2 NUT-3/8-16NC HEX REG GR.5, ZINC PLATED

208 418098 1 NUT-3/4-16NF HEX JAM

209 418177 2 LOCKWASHER-3/8 MED SECT,ZINC PLATED

210 418223 2 WASHER-1/2 USS FLAT,ZINC PLATED

211 424005 2 COTTER PIN

212 432033 1 FITTING-ELBOW

213 433029 1 ACTUATOR

207

211

210

201

204

213

209

205

205

202

206

203

211

210

208

212

16

Page 20

MANUEL D'UTILISATION, DE DÉPANNAGE ET D’ENTRETIEN

English (Original Instructions) ...........................................1

Français

Deutsch

Español

(Traduction des instructions originales) ...... 17

(Übersetzung der Originalanleitung) ............ 35

(Traducción de las instrucciones originales) . 53

TREUIL PLANÉTAIRE

INDUSTRIEL MODÈLE HD-P 177,9

Utilisation prévue : Dépannage de véhicule et traction de charges

(Veuillez prendre contact uniquement pour des questions réglementaires.)

MISE EN GARDE : ASSUREZ-VOUS DE LIRE ET DE COMPRENDRE CE MANUEL

AVANT D’INSTALLER ET D’UTILISER LE TREUIL. LISEZ LES AVERTISSEMENTS !

RAMSEY WINCH COMPANY

Post Office Box 581510 Tulsa, Oklahoma 74158-1510 États-Unis

Téléphone : (918) 438-2760 Fax : (918) 438-6688

Visitez-nous à l'adresse http://www.ramsey.com

Ramsey Représentant autorisé dans la comuauté:

Alura Group BV

P.O. Box 18626

2502 EP The Hague

The Netherlands

Tel: (31) (0) 70 362-4896

Fax: (31) (0) 70 346-7299

OM-914249-1012-B

Page 21

TABLE DES MATIÈRES

CARACTÉRISTIQUES TECHNIQUES ........................................................................... 19

AVERTISSEMENTS ........................................................................................................ 19

RESPONSABILITÉ DE L’UTILISATEUR POUR

CONFORMITÉ AUX NORMES CE ................................................................................. 19

CARACTÉRISTIQUES DU SYSTÈME HYDRAULIQUE ................................................. 20

TABLEAUX DES PERFORMANCES .............................................................................. 20

FONCTIONNEMENT DU TREUIL ................................................................................... 21

FONCTIONNEMENT DE L’EMBRAYAGE ...................................................................... 21

INSTALLATION DU CÂBLE ............................................................................................ 21

ENTRETIEN .................................................................................................................... 22

GUIDE DE DÉPANNAGE................................................................................................ 22

INSTRUCTIONS DE RÉVISION ................................................................................ 23-27

CONFIGURATIONS DE MONTAGE ............................................................................... 28

PLAN DIMENSIONNEL .............................................................................................. 29-30

LISTE ET SCHÉMA DES PIÈCES ............................................................................. 31-34

Page 22

CARACTÉRISTIQUES TECHNIQUES*

Traction nominale du câble (lb) 177,9 kN (18 143,69 kg)

Niveau sonore 76 dB

Plage de température ambiante -28 °C à 60 °C (-20 °F à 140 °F)

Démultiplication 51.35:1

Poids (sans le câble) 365 kg (804 lb)

COUCHE DE CÂBLE 1 2 3 4 5

*Traction nominale par couche

de câble

*Capacité du câble par couche m

*Vitesse du câble à 64,3 l/min

(17 g/min)

*Ces caractéristiques se fondent sur un câble en acier recommandé de 20 mm (0,787 po), Bridon Dyform 34LR/PI/MAX de

calibre 1960 ou équivalent avec une force de rupture minimum de 355,8 kN (80 000 lb) et un moteur de 195 cm

kN

lb

pi

m/min

pi/min

177,9

40,000

9

30

4,2

13.8

149,5

33,600

19

65

5,0

16.3

128,5

28,900

33

110

5,7

18.8

113,0

25,400

48

160

6,5

21.3

100,1

22,700

65

215

7,3

23.8

3

(11,9 po3)/tr.

AVERTISSEMENTS :

L’UTILISATEUR DOIT VEILLER À CE QUE TOUT OPÉRATEUR REÇOIVE LA FORMATION NÉCESSAIRE.

L’OPÉRATEUR DOIT TOUJOURS TRAVAILLER EN CONFORMITÉ AVEC LES INSTRUCTIONS D’UTILISATION.

UN DISTRIBUTEUR À TIROIR CYLINDRIQUE DE MOTEUR (CENTRE OUVERT) EST OBLIGATOIRE POUR LE

FONCTIONNEMENT DU FREIN.

L’EMBRAYAGE DOIT ÊTRE ENTIÈREMENT ENCLENCHÉ AVANT DE COMMENCER TOUT TREUILLAGE.

NE PAS METTRE LE MOTEUR DU TREUIL EN MARCHE AVANT D’AVOIR ENCLENCHÉ L’EMBRAYAGE.

NE RELÂCHEZ JAMAIS L’EMBRAYAGE EN PRÉSENCE D’UNE CHARGE.

NE VOUS PLACEZ JAMAIS SOUS UNE CHARGE SOULEVÉE NI À PROXIMITÉ.

RESTEZ À L’ÉCART DU CÂBLE LORS DU TREUILLAGE. N’ESSAYEZ PAS DE GUIDER LE CÂBLE.

NE DÉPASSEZ PAS LES CARACTÉRISTIQUES DE TRACTION NOMINALES MAXIMALES INDIQUÉES DANS

LE TABLEAU.

N’UTILISEZ PAS LE TREUIL POUR SOULEVER, MAINTENIR OU TRANSPORTER DES PERSONNES.

IL CONVIENT DE CONSERVER AU MINIMUM DEUX TOURS DE CÂBLE AUTOUR DU TAMBOUR POUR

MAINTENIR LA CHARGE.

RESPONSABILITÉ DE L’UTILISATEUR POUR LA CONFORMITÉ AUX NORMES CE

1. Utilisez uniquement un distributeur à tiroir cylindrique de moteur (centre ouvert), conformément aux indications

fournies sous la rubrique Caractéristiques du système hydraulique.

2. En cas d’utilisation d’un distributeur de treuil commandé à distance, consultez la rubrique Caractéristiques du

système hydraulique pour déterminer les composants à installer pour le dispositif d’arrêt d’urgence.

3. Réglez la pression de décharge du système conformément aux instructions de la rubrique Caractéristiques du

système hydraulique.

4. Montez le treuil conformément aux instructions fournies sous la rubrique Installation du treuil.

5. Installez un câble en acier de 20 mm (0,787 po) de calibre 1960 avec une force de rupture minimale de 355,8 kN

(80 000 lb). La longueur de câble maximale est de 65 m (215 pi) pour cinq couches maximum. Attachez le câble

conformément aux instructions d'installation.

19

Page 23

Reportez-vous aux diagrammes de performances ci-dessous pour établir une correspondance entre votre

Â

È

système hydraulique et le fonctionnement de votre treuil. Ces diagrammes sont constitués des éléments

suivants : (1) Traction du câble, première couche kN (lb) vs. Pression de service, bar (PSI) (2) Vitesse du

câble, première couche, exprimée en m/min, en fonction du débit, exprimé en l/min (gal./min)

CARACTÉRISTIQUES DU SYSTÈME HYDRAULIQUE

1. Distributeur à tiroir cylindrique de moteur (centre ouvert).

2. Arrêt d’urgence :

A. Si le treuil est commandé par un distributeur à commande directe, ce distributeur sert de dispositif d’arrêt

d’urgence.

B. En cas d’utilisation d’un distributeur commandé à distance, une soupape de décharge hydraulique commandée

par solénoïde, normalement ouvrant sur le réservoir, et un interrupteur d’arrêt d’urgence (pour l’ouverture de la

soupape de décharge) sont requis. L’interrupteur d’arrêt d’urgence doit être normalement fermé et doit être doté

d’un bouton-poussoir d’activation rouge, avec réinitialisation, sur fond jaune. L’interrupteur d’arrêt d’urgence doit

être facilement accessible à l’opérateur.

3. La soupape de décharge doit être réglée à 193 bar (2800 psi), qui est la limite de capacité nominale.

4. Débit maximal de 64,3 l/min (17 gal./min). Ne doit pas dépasser 75,7 l/min (20 gal/min) pour ne pas endommager le

moteur ou le treuil.

5. Fluide hydraulique ayant une viscosité comprise entre 20 et 43 cSt. Température de service maximale de 85 ºC.

Propreté de niveau ISO 17-14 ou supérieur.

CONTRÔLE À DOUBLE ORIFICE A ET B

AVEC NAVETTE DE DESSERRAGE DU FREIN

INSTALLATION TYPE

MOTEUR

ORIFICE

FREIN

FOURNI PAR L’UTILISATEUR

CONDUITE HAUTE PRESSION DE

DIAMÈTRE INTERNE MINIMUM

DE 12,7 mm (0,50 po)

CONDUITE BASSE PRESSION DE

DIAMÈTRE INTERNE MINIMUM

DE 19 mm (0,75 po)

SOUPAPE DE DÉCHARGE

*

POMPE

DÉBIT ET PRESSION MAX.

À CHARGE NOMINALE :

64,3 L/MIN (17 G/MIN)

193 bars (2800 PSI)

VALVE À 3 POSITIONS

ET 4 VOIES

(DISTRIBUTEUR

MOTEUR)

REQUIS SEULEMENT EN CAS D’UTILISATION D’UN DISTRIBUTEUR

*

COMMANDÉ À DISTANCE. VOIR SECTION 2B SOUS LA RUBRIQUE

CARACTÉRISTIQUES DU SYSTÈME HYDRAULIQUE. N’EST PAS

NÉCESSAIRE POUR UN DISTRIBUTEUR COMMANDÉ DIRECTEMENT.

TABLEAUX DES PERFORMANCES

10,6 (35)

9,1 (30)

7,6 (25)

6,1 (20)

RE COUCHE, M/MIN (PI/MIN)

4,6 (15)

3,1 (10)

1,5 (5)

BLE, PREMI

VITESSE DU C

BASÉ SUR UN MOTEUR DE 195 cm3 (11,9 po3)

0

0 18,9 37,9 56,7

(0) (5) (10) (15)

DÉBIT, L/MIN (G/MIN)

64,3

(17)

BASSE VITESSE

HAUTE VITESSE

177,9 (40,000)

155,6 (35,000)

133,4 (30,000)

111,2 (25,000)

TRACTION DU CÂBLE, PREMIÈRE COUCHE, kN (lb)

PRESSION DE SERVICE, bar (PSI) À 64,3 L/MIN (17 G/MIN)

LIMITEUR DE SURPRESSION 193 BAR (2800 PSI)

(LIMITEUR À CAPACITÉ NOMINALE)

89,0 (20,000)

66,7 (15,000)

44,5 (10,000)

0

0 137,9

(0) (2000)

COMMUTATEUR

*

D’ARRÊT D’URGENCE

68,9

(1000)

206,8

(3000)

20

Page 24

MONTAGE DU CADRE DU TREUIL

Utilisez (8) boulons de 7/8 po de diamètre de grade 5 ou plus pour fixer le cadre de montage sur la dépanneuse.

POSE DU CÂBLE

1. Déroulez le câble sur le sol pour éviter qu'il ne se torde. Recouvrez bien l’extrémité du câble opposée

au crochet d’un ruban adhésif plastique ou de type équivalent pour éviter qu’elle ne s’effiloche.

2. Insérez l'extrémité du câble dans la fente à l'intérieur de la collerette du tambour. Tirez le câble par la

poche à l'extérieur de la collerette du tambour et faites le revenir dans la poche autour du galet

d'ancrage. Utilisez un marteau-caoutchouc pour acheminer l’arrière du câble, en le plaçant fermement

avec le galet d’ancrage dans le logement. Faites tourner avec précaution le treuil dans le sens de

l’enroulement. Maintenez une tension sur l’extrémité du câble et enroulez tout le câble sur le tambour

en veillant à former des couches régulières.

INSÉREZ LE CÂBLE

INSERT WIRE ROPE

DANS LA FENTE DE

INTO SLOT IN

LA COLLERETTE DU

DRUM FLANGE

TAMBOUR COMME

AS SHOWN

ILLUSTRÉ

GALET D'ANCRAGE

TIREZ LE CÂBLE PAR LA

POCHE ET FAITES LE

REVENIR DANS LA POCHE

LOOP BACK INTO POCKET

COMME ILLUSTRÉ

PULL WIRE ROPE

THRU POCKET AND

ANCHOR

PUCK

AS SHOWN

FONCTIONNEMENT DE L’EMBRAYAGE

Enclenchement de l’embrayage :

1. Déplacez la commande d'embrayage en position « embrayage enclenché ».

2. S’il gèle, faites uniquement tourner le moteur dans le sens de déroulement du câble jusqu’à

ce que le tambour commence à tourner. S’il fait extrêmement froid (au-dessous de -18 ºC),

tirez le câble à la main jusqu’à ce que le tambour commence à tourner.

3. Attendez au moins trois secondes pour que l’embrayage s'enclenche complètement, après

quoi le treuil est prêt à gérer le câble.

AVERTISSEMENT : n'essayez pas d'enclencher l'embrayage en commençant par faire tourner le moteur du treuil

puis en enclenchant la commande d’embrayage pendant le fonctionnement du moteur. Ne commencez pas à

treuiller pendant l’enclenchement de l’embrayage.

Désenclenchement de l’embrayage :

1. Faites fonctionner le treuil dans le sens de déroulement jusqu'à ce que le câble ne tracte

plus la charge.

2. Déplacez la commande de l'embrayage en position « embrayage désenclenché ».

3. Il est désormais possible de tirer le câble à la main.

FONCTIONNEMENT DU TREUIL

Pour vous familiariser avec votre treuil, il est vivement conseillé de l’essayer avant de vraiment l’utiliser.

Préparez l'essai. N’oubliez pas que vous entendez votre treuil autant que vous le voyez fonctionner.

Apprenez à reconnaître le son d'une traction légère et régulière, celui d'une lourde charge ou encore celui

provoqué par des à-coups ou une déviation de la charge. Prenez l’habitude de faire fonctionner votre treuil et

tout deviendra automatique.

L’enroulement irrégulier du câble lors de la traction d’une charge ne présente pas de problème sauf en cas

d’accumulation du câble sur un côté du tambour. Dans ce cas, inversez le fonctionnement du treuil afin de

soulager la charge et déplacez votre point d’attache vers le centre du véhicule. Une fois le travail terminé,

vous pouvez dérouler le câble et l’enrouler à nouveau d’une manière régulière.

21

Page 25

ENTRETIEN

L’observation du calendrier de maintenance suivant vous permettra de maintenir votre treuil en bon

état et garantira un fonctionnement avec un minimum de réparations.

A. HEBDOMADAIRE

1. Vérifiez le niveau d’huile et maintenez-le au niveau du bouchon. En cas de fuite d’huile,

déterminez l’emplacement de la fuite et réparez.

2. Vérifiez le bouchon d'échappement dans le couvercle de la boîte d'engrenages. Assurez-vous

qu’il n’est pas bouché.

3. Lubrifiez le câble avec de l’huile légère.

B. MENSUEL

1. Vérifiez les boulons de fixation du treuil. Remplacez tout boulon manquant et serrez

fermement les autres. Utilisez des boulons de grade 5 ou de qualité supérieure.

2. Examinez le câble. Tout câble dénudé ou effiloché doit être remplacé immédiatement.

C. ANNUEL

1. Le treuil doit être vidangé une fois par an ou plus souvent en cas d’usage fréquent.

2. Remplissez le treuil de kérosène propre jusqu’au niveau du bouchon de niveau d’huile.

Faites fonctionner le treuil quelques secondes sans charge dans le sens de l’enroulement.

Éliminez le kérosène du treuil.

3. Remplissez le treuil d’huile pour engrenages synthétique SAE 75W-90 polyvalente jusqu’au

bouchon de niveau d’huile.

4. Examinez le châssis et l’armature qui l’entoure afin de déceler toute déformation ou fissure

éventuelle.

FIN DE LA PROCÉDURE D’ENTRETIEN

Quand le treuil arrive à la fin de sa durée de vie, débarrassez-vous en en respectant les règlements

locaux de protection de l’environnement.

GUIDE DE RÉSOLUTION DES PROBLÈMES

PROBLÈME CAUSE PROBABLE CORRECTIF

1. Joints d’étanchéité

1. Remplacez le joint d’étanchéité.

endommagés ou usés.

L’HUILE FUIT AU

NIVEAU DU TREUIL.

2. Trop d’huile. 2. Vidangez l’excédent d’huile. Consultez

FONCTIONNEMENT.

3. Joints statiques

3. Remplacez les joints statiques.

endommagés.

1. Débit faible 1. Vérifiez le débit. Reportez-vous aux

LE TREUIL

FONCTIONNE TROP

diagrammes des performances du

SYSTÈME HYDRAULIQUE de la page 2.

LENTEMENT.

2. Moteur hydraulique usé. 2. Remplacez le moteur.

LE TAMBOUR DU

CÂBLE NE TOURNE

PAS EN ROUE LIBRE.

1. Embrayage non

désenclenchée.

1. Vérifiez la pression d’air au cylindre

d’embrayage : 100 psi minimum requis.

Consultez la page 10 pour l’emplacement

de l’orifice.

LE FREIN NE SE

DESSERRE PAS.

1. Câble de frein

déconnecté ou bloqué.

1. Vérifiez le fonctionnement du frein.

22

Page 26

INSTRUCTIONS DE RÉVISION

DÉPOSE

1. Vidangez l’huile du couvercle de la boîte d’engrenages en retirant le bouchon cylindrique n° 37 et le raccord de

dégagement n° 32. Retirez le tendeur

.

32

37

2. Débranchez le tube n° 40 du coude n° 43 sur la valve n° 41 et le raccord n° 29 du frein n° 30b. Pour retirer le moteur nº 33

et le joint statique nº 30a, enlevez les deux vis d’assemblage nº 22. Le cas échéant, retirez la valve nº 41 du moteur en

desserrant les quatre vis d'assemblage nº 16.

16

41

33

43

22

30a

40

23

Page 27

3. Retirez les douze vis d'assemblage n° 18 pour retirer le couvercle de la boîte d'engrenages et le joint de la couronne.

Retirez la rondelle de butée d'entrée, le planétaire et le porte-planétaire d'entrée de l'intérieur de la couronne. Retirez la

couronne et le joint. Retirez le porte-planétaire d'entrée. Inspectez la bague n° 15 du couvercle de la boîte

d'engrenages pour vérifier qu'elle n'est ni endommagée ni usée.

31

42

31

15

5

18

4. Retirez huit vis n° 20 pour retirer la plaque de retenue de l'embrayage n° 10 du piston d'embrayage. Retirez

l'embrayage n° 9.

9

10

24

20

Page 28

5. Retirez le carter d’embrayage n° 27 avec le piston n° 28 à l’intérieur. Pour retirer le piston du carter d'embrayage, appliquez de

l'air dans l'orifice de 1/8 po. Retirez les joints toriques n° 28 et n° 35 et inspectez-les pour détecter l'usure ou les dommages.

35

27

36

28

6. Retirez neufs ressorts n° 39, la rondelle de butée n° 26, le joint n° 31, l'arbre de sortie n° 12 et l'entretoise n° 13 du palier

d'extrémité de la boîte d'engrenages. Inspectez la bague n° 14 de l'arbre de sortie pour détecter l'usure ou les dommages.

Remplacez en cas de dommages ou d'usure excessive.

13

12

26

14

31

25

39

Page 29

7. Retirez les barres de fixation n° 2 et n° 3 en retirant les 8 vis d'assemblage n° 19, les 8 rondelles de blocage n° 24 et les

quatre vis à épaulement n° 25. Tirez le palier d'extrémité d'engrenages n° 7 du tambour n° 1.

2

3

25

24

19

25

19

24

24

7

25

25

19

24

19

8. Tirez le tambour n° 1 du palier d'extrémité n° 6. Retirez les joints quad-ring n° 34 des rainures des bagues du tambour.

Retirez l’arbre d’entrée nº 11 du palier d’extrémité. Examinez l’état des extrémités cannelées de l'arbre et remplacez-le

si nécessaire.

6

8

4

11

38

34

1

34

26

Page 30

Si les cannelures à l’intérieur de l’entraînement du tambour n° 102 sont endommagées, il convient alors de le remplacer.

9.

Retirez l'entraînement du tambour en dévissant les 8 vis n° 105. Si les bagues présentent des signes d'usure, remplacezles en appuyant sur les vieilles bagues pour les retirer du tambour n° 101 et en retirant les joints toriques des rainures du

tambour et de l'entraînement du tambour. Placez des joints toriques n° 106 bien huilés dans l'entraînement et le tambour.

Placez des joints toriques n° 107 bien huilés à l'extérieur de l'entraînement. Appuyez les bagues n° 104 dans

l'entraînement dui tambour jusqu'à ce que la bride et le n° 103 soient tout contre le tambour.

106

101

107

103

102

106

104

105

10.

Retirez les vis n° 17 du frein n° 30b fixant le frein au palier d'extrémité n° 6. Retirez l'accouplement n° 4 et le joint n° 30e du

palier d'extrémité. Prenez note de l’aspect du montage pour assembler correctement les pièces lors du remontage.

17

30c

30e

6

30b

27

Page 31

MONTAGE À

DROITE

CONFIGURATION DE MONTAGE DU TREUIL

28

MONTAGE À

GAUCHE

Page 32

8.54

216,91

5.54

140,71

2.91

73,91

22.50

571,50

STATIQUE

DE CHARGE

FREIN DE MAINTIEN

25.06

636,52

ANCRE DE CÂBLE

À POCHE EN COIN

TORIQUE À FILETAGE DROIT

2 ENDROITS CÔTÉS OPPOSÉS

OUVERTURE 7/8-14 SAE DE JOINT

BROCHE DE 0,6 c m (1/4 po), 24 V

POUR HAUTE VITESSE/FAIBLE COUPLE

42.07

1068,58

6.38

162,05

12.75

323,85

17.02

432,30

Treuil modèle HD-P 177,9

Configuration gauche illustrée

452,20

Ø18.00

Ø.91

X8

23,01

16.25

412,75

22.13

(TYP)

561,98

BRIDE DE

Ø7.50

190,50

CYLINDRE DU

TAMBOUR

0.50

12,7

(TYP)

4.00

101,6

(TYP)

16.36

415,54

L

31.28

794,51

TAMBOUR C

TAMBOUR

56,54

14.92

LAITON AVEC MANCHON CONIQUE

POUR TUBE DE 0,6 CM (1/4 PO) DE DIA.

PRESSION D’AIR POUR TENDEUR

(50 PSI MIN., 90 PSI MAX.)

RACCORD DE COMPRESSION EN

ORIFICE DE PRESSION 1/8-27 NPT (100 À 120 psi)

(L’EMBRAYAGE EST ENCLENCHÉ PAR RESSORT)

ORIENTEZ COMME ILLUSTRÉ

POUR DESENCLENCHER L'EMBRAYAGE

15°

17.56

446,02

8.78

223,01

13.13

333,50

1.94

49,28

(TYP)

2.68

68,07

6.19

(TYP)

157,17

330,2

13.00

(TYP)

6.19

157,17

1.56

(TYP)

39,62

(TYP)

CÂBLE EN

ROTATION

(TYP)

18.75

476,25

29

Page 33

18.75

476,25

CÂBLE EN

Configuration droite illustrée

Treuil modèle HD-P 177,9

ROTATION

13.13

333,50

16.25

476,25

2.68

68,07

(TYP)

4.00

101,6

(TYP)

.50

12,7

(TYP)

RACCORD DE COMPRESSI ON EN

LAITON AVEC MANCHON CONIQUE

ORIFICE DE PRESSION 1/8-27 NPT (100 À 120 psi)

ORIENTEZ COMME ILLUSTRÉ

(L’EMBRAYAGE EST ENCLENCHÉ PAR RESSORT)

POUR DESENCLENCHER L'EMBRAYAGE

15°

17.56

446,02

8.78

223,01

(50 PSI MIN., 91 PSI MAX.)

PRESSION D'AIR POUR TENDEUR

POUR TUBE DE 0,6 CM (1/4 PO) DE DIA.

Ø.91

X8

23,01

1.56

39,62

(TYP)

1.94

49,28

(TYP)

6.19

(TYP)

157,17

330,2

13.00

(TYP)

6.19

(TYP)

157,17

22.13

(TYP)

561,98

17.02

432,30

12.75

323,85

6.38

42.07

1068,58

25.06

162,05

636,52

POCHE EN COIN

ANCRE DE CÂBLE À

22.72

577,08

CHARGE STATIQUE

FREIN DE MAINTIEN DE

452,20

Ø18.00

BRIDE DE

TAMBOUR

56,54

14.92

Ø7.50

190,50

TAMBOUR

CYLINDRE DU

L

31.28

794,51

TAMBOUR C

16.36

415,54

2.91

73,91

2.41

62,21

5.32

158,49

8.54

216,91

HAUTE VITESSE/FAIBLE COUPLE

BROCHE DE 0,6 cm (1/ 4 po), 24 V POUR

TORIQUE À FILETAGE DROIT

2 ENDROITS C ÔTÉS OPPOSÉS

OUVERTURE 7/8-14 SAE DE JOINT

12

30

Page 34

18

5

31

15

42

31

27

35

10

9

28

36

20

32

37

19

25

24

25

19

7

24

2

34

1

24

34

25

19

39

26

31

14

12

13

30e

21

29

40

43

16

17

22

30c

30a

6

30e

30d

30b

8

4

21

11

38

30

23

3

24

25

19

TREUIL HDP 177,9

41

33

31

Page 35

LISTE DES PIÈCES – HDP

1 1 234241 TAMBOUR 26 1 418520 RONDELLE DE BUTÉE

2 1 243071 ANGLE DE MONTAGE 27 1 426059 CYLINDRE

3 1 243072 ANGLE DE MONTAGE 28 1 426060 PISTON

4 1 324284 ACCOUPLEMENT MOTEUR 29 1 432023 RACCORD

5 1 328180 COUVERCLE DE LA BOÎTE D’ENGRENAGES 30 1 438037 FREIN

6 1 338419 PALIER D’EXTRÉMITÉ MOTEUR 30a 1 JOINT D'EXTRÉMITÉ MOTEUR

Nº Qté Nº réf. Description Nº Qté Nº réf. Description

7 1 338417 PALIER D’EXTRÉMITÉ ENGRENAGES 30b 1 FREIN

8 1 342081 CLAVETTE 30c 1 CLAVETTE

9 1 342517 EMBRAYAGE 30d 1 PLAQUE ADAPTATRICE

10 1 352035 BAGUE DE RETENUE D'EMBRAYAGE 30e 2 JOINT DE PLAQUE ADAPTATRICE

11 1 357549 ARBRE D'ENTRÉE 31 3 442210 JOINT STATIQUE

12 1 357543 RACCORDEMENT DE SORTIE 32 1 456008 RACCORD DE DÉGAGEMENT

13 1 362327 ENTRETOISE 33 1 458126 MOTEUR

14 1 412044 BAGUE 34 2 462040 JOINT QUATRE LOBES

15 1 412105 BAGUE 35 1 462103 JOINT TORIQUE 2-274

32

16 4 414400 VIS D'ASSEMBLAGE-3/8-24NF X4LG, HXHD, GR-5 36 1 462104 JOINT TORIQUE 2-275

17 2 414595 VIS D’ASSEMBLAGE-1/2-13 NC X 3-1/2 LONG, TÊTE CREUSE 37 1 468040 BOUCHON CYLINDRIQUE

18 12 414612 VIS D’ASSEMBLAGE 1/2-13NC X 7 LONG TÊTE HEXAGONALE 38 1 470075 GOUPILLE

19 8 414788 VIS D’ASSEMBLAGE 7/8-9NC X 2,5 LONG TÊTE HEXAGONALE 39 9 494140 RESSORT

20 8 414819 VIS D’ASSEMBLAGE 1/4-20NC X 1/2 LONG TÊTE PLATE 40 1 509125 TUBE

21 2 414947 VIS D'ASSEMBLAGE -1/2-13NC X 1 LONG TÊTE CREUSE HEXAGONALE 41 1 516065 DISTRIBUTEUR (ROTATION DOUBLE)

22 2 414948 VIS-1/2-13NCX1 1/4LONG, TÊTE CREUSE 42 1 530173 BOÎTE D'ENGRENAGES

23 1 408431 COIN DE CÂBLE 43 1 432018 RACCORD HYDRAULIQUE COUDÉ 7/16-20 90°

25 4 418452 VIS À ÉPAULEMENT

24 8 418261 RONDELLE DE SÉCURITÉ 7/8 SECTION MOY.

Page 36

TAMBOUR - 234241

Nº Nº réf. Quantité Description

101 332272 1 TAMBOUR‐CÂBLE

102 332226 1 ENTRAÎNEMENT‐TAMBOUR

103 412078 1 BAGUE‐TAMBOUR

104 412079 1 BAGUE‐TAMBOUR

105 414978 8 VISD’ASSEMBLAGE,5/16‐18NCx11/4poTÊTECREUSE

106 462043 2 JOINTTORIQUE‐AS‐568‐348,3/16X43/4X43/8PO

107 462075 1 JOINTTORIQUE‐AS‐568‐354,3/16X51/2X51/8PO

106

101

103

107

102

106

104

105

33

Page 37

TENDEUR DE CÂBLE (ENROULEMENT PAR LE DESSUS) - 299744

Nº Nº réf. Quantité Description

201 265102 1 BRAS DE LEVIER

202 304174 1 BARRE

203 346046 1 BROCHE DE PIVOT

205 408362 1 SUPPORT

205 414278 4 VIS-3/8-16NCX3/4LONG,TÊTE HEX., GR.5, PLAQUÉ ZINC

206 414316 2 VIS D’ASSEMBLAGE-3/8-16 NCX1 1/4,TÊTE

HEX., GR.5, PLAQUÉ ZINC

207 418045 2 ÉCROU-3/8-16NC HEX NORMAL GR.5, PLAQUÉ ZINC

208 418098 1 ÉCROU-3/4-16NF CONTRE-ÉCROU HEX.

209 418177 2 RONDELLE DE BLOCAGE-3/8 SECT. MOY., PLAQUÉ ZINC

210 418223 2 RONDELLE-1/2 USS PLATE, PLAQUÉ ZINC

211 424005 2 GOUPILLE FENDUE

212 432033 1 RACCORD COUDÉ

213 433029 1 ACTIONNEUR

207

211

210

201

204

213

209

205

205

202

206

203

211

210

208

212

34

Page 38

BETRIEBS-, INSTANDHALTUNGS- UND

WARTUNGSHANDBUCH

English (Original Instructions) .......................................... 1

Français

Deutsch

Español

(Traduction des instructions originales) ...... 17

(Übersetzung der Originalanleitung) ............ 35

(Traducción de las instrucciones originales) . 53

MODELL HD-P 177,9 INDUSTRIELLE

HYDRAULISCHE SEILWINDE MIT PLANETENGETRIEBE

Verwendungszweck: Fahrzeug-Abschlepp-/Bergungsarbeiten und Ziehen von Lasten

Ramsey Bevollmächtigter in der Europäischen Union:

(Bitte nur bei Regulierungsfragen kontaktieren.)

Alura Group BV

P.O. Box 18626

2502 EP The Hague

The Netherlands

Tel: (31) (0) 70 362-4896

Fax: (31) (0) 70 346-7299

ACHTUNG: VOR DER MONTAGE UND INBETRIEBNAHME DER WINDE MUSS DIESES

HANDBUCH GELESEN UND VERSTANDEN WERDEN. SIEHE WARNHINWEISE!

RAMSEY WINCH COMPANY

P.O. Box 581510, Tulsa, Oklahoma 74158-1510, USA

Telefon: +1 (918) 438-2760 Fax: +1 (918) 438-6688

Besuchen Sie uns: http://www.ramsey.com

OM-914249-1012-B

Page 39

INHALTSVERZEICHNIS

TECHNISCHE DATEN .................................................................................................... 37

WARNHINWEISE ............................................................................................................ 37

VERANTWORTUNG DES BENUTZERS BEZÜGLICH CE-COMPLIANCE ................... 37

HYDRAULIKANFORDERUNGEN ................................................................................... 38

LEISTUNGSDIAGRAMME .............................................................................................. 38

WINDENBETRIEB .......................................................................................................... 39

KUPPLUNGSBETRIEB ................................................................................................... 39

INSTALLATION DES WINDENSEILS ............................................................................. 39

WARTUNG ...................................................................................................................... 40

FEHLERSUCHE .............................................................................................................. 40

ANLEITUNG ZUM ÜBERHOLEN ............................................................................... 41-45

MONTAGEKONFIGURATIONEN ................................................................................... 46

MASSZEICHNUNG .................................................................................................... 47-48

TEILELISTE UND TEILEZEICHNUNG ...................................................................... 49-52

Page 40

TECHNISCHE DATEN*

Nominale Zugkraft (kN)

177,9 kN

Lärmpegel

Umgebungstemperaturbereich

Getriebeuntersetzung

Gewicht (ohne Seil)

SEILLAGE 1 2 3 4 5

*Nominale Zugkraft pro Lage kN 177,9 149,5 128,5 113,0 100,1

*Seilkapazität pro Lage m 9 19 33 48 65

*Seilgeschwindigkeit bei

64,3 l/min

* Diese technischen Daten basieren auf dem empfohlenen Drahtseil (20 mm Drahtstärke, Sorte 1960)

Bridon Dyform 34LR/PI/MAX oder äquivalent mit einer Mindestbruchlast von 355,8 kN und einem

3

195 cm

/R Motor.

m/min 4,2 5,0 5,7 6,5 7,3

-28 bis 60 °C

76 db

51.35:1

365 kg

WARNHINWEISE:

DER BENUTZER MUSS SICHERSTELLEN, DASS DAS BEDIENPERSONAL DIE ERFORDERLICHE

SCHULUNG ERHÄLT.

DER BEDIENER MUSS BEIM BETRIEB STETS DIE BEDIENUNGSANWEISUNGEN BEFOLGEN.

FÜR DIE BREMSE IST EIN WEGE-VENTIL (MOTORWICKLUNGS-DURCHFLUSSSYSTEM) ERFORDERLICH.

VOR BEGINN DES WINDENBETRIEBS MUSS SICHERGESTELLT WERDEN, DASS DIE KUPPLUNG VOLLSTÄNDIG

EINGERÜCKT IST.

DIE KUPPLUNG MUSS VOR DEM START DES WINDENMOTORS EINGERÜCKT SEIN.

DIE KUPPLUNG NICHT UNTER LAST AUSRÜCKEN.

NIEMALS UNTER ODER NEBEN ANGEHOBENEN LASTEN STEHEN.

WÄHREND DES ZIEHENS EINEN SICHEREN ABSTAND ZUM SEIL EINHALTEN. NICHT VERSUCHEN, DAS SEIL

ZU LENKEN.

DIE IN DER TABELLE ANGEFÜHRTE MAXIMALE ZUGKRAFT NICHT ÜBERSCHREITEN.

DIE WINDE NICHT ZUM HEBEN, TRAGEN ODER ANDERWEITIGEN TRANSPORT VON PERSONEN VERWENDEN.

ZUM HALTEN DER LAST SIND MINDESTENS 2 SEILWICKLUNGEN UM DEN TROMMELZYLINDER NOTWENDIG.

VERANTWORTUNG DES BENUTZERS BEZÜGLICH CE-COMPLIANCE

1. Nur ein Durchfluss-Wegeventil (Motorwicklung) gemäß den Hydraulikanforderungen verwenden.

2. Wenn ein fernbedienter Windensteuerschieber verwendet wird, siehe die Hydraulikanforderungen für zu

installierende Notstoppkomponenten.

3. Hydrauliküberdruck gemäß den Hydraulikanforderungen anpassen.

4. Die Winde gemäß den Windeninstallationsanweisungen montieren.

5. Drahtseil (20 mm Drahtstärke, Sorte 1960) mit einer Mindestbruchlast von 355,8 kN installieren. Die maximale

Seillänge für maximal fünf Lagen beträgt 65 m. Das Seil gemäß den Seilinstallationsanweisungen befestigen.

37

Page 41

Zur richtigen Wahl der Hydraulik für die Leistung der Winde ist auf die folgenden Leistungsdiagramme Bezug

zu nehmen. Die Diagramme zeigen: (1) Seilzugkraft (kN), erste Lage im Vergleich zum Arbeitsdruck (bar).

(2) Seilgeschwindigkeit, erste Lage (m/min) im Vergleich zur Förderrate (l/min).

HYDRAULIKANFORDERUNGEN

1. Wegeventil (Motor-Durchflusssystem).

2. Notstopp:

A. Falls Winde durch einen direktbedienten Handschieber gesteuert wird, funktioniert dieser Schieber

als Notstopp.

B. Wenn ein fernbedienter Steuerschieber verwendet wird, sind ein magnetgesteuerter hydraulischer

Entleerungsschieber (normalerweise gegen den Tank geöffnet) und ein Notstoppschalter (zum

Öffnen des Entleerungsschiebers) erforderlich. Der Notstoppschalter ist ein Öffnerkontakt und hat

einen roten, rücksetzbaren Druckknopfschalter mit gelbem Hintergrund. Der Notstoppschalter muss

für den Bediener einfach zugänglich sein.

3. Überdruckventil auf 193 bar eingestellt, entspricht dem Nennkapazitätsbegrenzer.

4. Maximale Förderrate von 64,3 l/min. 75,7 l/min nicht überschreiten, das ansonsten Motor und Winde

beschädigt werden können.

5. Hydrauliköl mit einer Viskosität zwischen 20 und 43 cSt (100-200 SUS). Maximale Betriebstemperatur

85 °C. Sauberkeitsstufe ISO 17-14 oder besser.

DOPPELANSCHLUSSREGLER (A UND B)

MIT BREMSENFREIGABEVENTIL

TYPISCHE ANORDNUNG

MOTOR

BREMSENANSCHLUSS

VOM BENUTZER BEREITGESTELLT

HOCHDRUCKLEITUNG

(MIND. 12,7 mm

INNENDURCHMESSER)

NIEDERDRUCKLEITUNG (MIND.

19 mm INNENDURCHMESSER)

*

ENTLEERUNGSSCHIEBER

PUMPE

MAXIMALE

FÖRDERRATE UND

DRUCK BEI NENNLAST:

64,3 l/min, 193 bar

LEISTUNGSDIAGRAMME

10,6 (35)

9,1 (30)

7,6 (25)

6,1 (20)

4,6 (15)

3,1 (10)

1,5 (5)

0

0 18,9 37,9 56,7

SEILGESCHWINDIGKEIT, ERSTE LAGE (m/min)

(0) (5) (10) (15)

FÖRDERRATE (l/min)

BASIEREND AUF EINEM 195 CM3 MOTOR

64,3

(17)

*

4-WEGEVENTIL

MIT 3 STELLUNGEN

(MOTORWICKLUNG)

NUR ERFORDERLICH, FALLS FERNBEDIENTER STEUERSCHIEBER

*

VERWENDET WIRD. SIEHE 2B IN HYDRAULIKANFORDERUNGEN. NICHT

ERFORDERLICH BEI DIREKTBEDIENTEM HANDSCHIEBER.

LANGSAME GESCHWINDIGKEIT

HOHE GESCHWINDIGKEIT

SEILZUGKRAFT, ERSTE LAGE (kN)

ÜBERDRUCKVENTIL 193 BAR

(NENNKAPAZITÄTSBEGRENZER)

177,9 (40,000)

155,6 (35,000)

133,4 (30,000)

111,2 (25,000)

89,0 (20,000)

66,7 (15,000)

44,5 (10,000)

0

0 137,9

(0) (2000)

ARBEITSDRUCK (bar) BEI 64,3 l/min

NOTSTOPPSCHALTER

68,9

(1000)

38

206,8

(3000)

Page 42

MONTAGE DES WINDEN-ANBAURAHMENS

Für die Befestigung des Anbaurahmens am Bergungsfahrzeug müssen acht (8) Schrauben der Sorte 5 mit

einem Mindestdurchmesser von 22 mm (7/8-Zoll) verwendet werden.

AUFLEGEN DES SEILS

1. Zum Abwickeln das Seil auf dem Boden entlang auslegen, um ein Knicken zu vermeiden. Das dem

Haken gegenüberliegende Seilende mit Plastik- oder ähnlichem Klebeband umwickeln, um ein

Ausfransen zu verhindern.

2. Das Seilende in den Schlitz an der Innenseite des Trommelflansches einführen. Das Drahtseil durch

ie Tasche an der Außenseite des Trommelflansches ziehen und schleifenförmig zurück in die Tasche

um den Anker-Puck wickeln. Mit einem Gummihammer auf die Rückseite des Drahtseils klopfen, bis

das Drahtseil und der Anker fest in der Tasche sitzen.

3. Die Winde langsam in Aufwickelrichtung in Bewegung setzen. Das Seilende gespannt halten und das

Seil vollständig auf die Seiltrommel aufwickeln. Darauf achten, dass sauber gewickelte Lagen entstehen.

DRAHTSEIL WIE

INSERT WIRE ROPE

GEZEIGT IN DEN

INTO SLOT IN

SCHLITZ IM

DRUM FLANGE

TROMMELFLANSCH

AS SHOWN

EINFÜHREN

ANKER-PUCK

ANCHOR

PUCK

DRAHTSEIL WIE GEZEIGT

DURCH DIE TASCHE UND

LOOP BACK INTO POCKET

SCHLEIFENFÖRMIG ZURÜCK

PULL WIRE ROPE

THRU POCKET AND

IN DIE TASCHE ZIEHEN

AS SHOWN

KUPPLUNGSBETRIEB

Einrücken der Kupplung:

1. Den Kupplungssteuerschieber in die eingerückte Position stellen.

2. Bei Temperaturen unter null Grad immer zuerst der Motor in Seilabrollrichtung laufen lassen, bis sich

die Trommel zu drehen beginnt. Bei extrem niedrigen Temperaturen (unter -18 ºC) das Seil nur von

Hand herausziehen, bis sich die Trommel zu drehen beginnt.

3. Mindestens 3 Sekunden warten, bis die Kupplung vollständig eingerückt ist. Danach ist die Winde

zum Aufrollen des Seils bereit.

WARNUNG: Nicht versuchen, zum Einrücken der Kupplung zuerst den Windenmotor in Betrieb zu setzen und

dann den Kupplungssteuerschieber bei laufendem Motor in die Einrückstellung zu stellen. Niemals gleichzeitig

mit dem Einrücken der Kupplung das Aufnehmen der Last beginnen.

Ausrücken der Kupplung:

1. Die Winde in Abwickelrichtung laufen lassen, bis das Seil von der Last befreit ist.

2. Den Kupplungssteuerschieber in die ausgerückte Position stellen.

3. Anschließend kann das Seil von Hand abgezogen werden.

WINDENBETRIEB

Um mit der Funktion der Winde vertraut zu werden, sollte vor der tatsächlichen Verwendung ein Probelauf

durchgeführt werden. Die Probeläufe im Voraus planen. Beim Betrieb hören und sehen Sie die Winde.

Werden Sie mit den Geräuschen vertraut, die bei einem leichten konstanten Zug, schweren Zug und bei

ruckartigen Bewegungen oder Verschiebung der Last zu hören sind. Nachdem Sie sich mit allen Funktionen

der Winde vertraut gemacht haben, ist deren Bedienung sehr einfach.

Ein ungleichmäßiges Spulen des Seils beim Ziehen einer Last stellt kein Problem dar, außer wenn sich das

Seil an einem Trommelende aufstaut. In diesem Fall das Seil abspulen, um die Last vom Seil zu nehmen,

und den Ankerpunkt weiter zur Fahrzeugmitte verschieben. Nach Gebrauch kann die Winde abgespult und

das Seil in sauberen Lagen aufgewickelt werden.

39

Page 43

WARTUNG

Bei Einhaltung der folgenden Wartungsintervalle bleibt die Winde stets in optimalem Zustand und sollte mit

minimalem Reparaturaufwand ordnungsgemäß funktionieren.

A. WÖCHENTLICH

1. Ölstand prüfen und ggf. bis zur Ölstandsschraube auffüllen. Bei einem Ölleck dessen Lage ausfin dig

machen und reparieren.

2. Das Überdruckventil im Getriebekastendeckel überprüfen. Sicherstellen, dass es nicht verstopft ist.

3. Das Seil mit einem leichten Öl schmieren.

B. MONATLICH

1. Die Befestigungsschrauben der Winde überprüfen. Fehlende Schrauben ersetzen und lockere

Schrauben festziehen. Nur Schrauben der Sorte 5 oder besser verwenden.

2. Das Windenseil inspizieren. Ein ausgefranstes oder beschädigtes Seil muss sofort ersetzt werden.

C. JÄHRLICH

1. Das Öl mindestens jährlich wechseln, öfter bei häufigem Einsatz.

2. Die Winde bis zur Ölstandsschraube mit sauberem Kerosin auffüllen. Die Winde einige Sekunden

lang ohne Last in Aufwickelrichtung laufen lassen. Das Kerosin aus der Winde ablassen.

3. Die Winde bis zur Ölstandsschraube mit synthetischem Allzweckgetriebeöl SAE 75W-90 auffüllen.

4. Den Rahmen und das den Rahmen umgebende Gefüge auf Risse und Verformungen überprüfen.

AUSSERBETRIEBSETZUNG

Die Winde am Ende ihrer Brauchbarkeitszeit gemäß örtlichen Umweltvorschriften entsorgen.

FEHLERSUCHE

ZUSTAND MÖGLICHE URSACHE ABHILFE

1. Dichtungen

1. Dichtung ersetzen.

beschädigt oder

ÖL LECKT AUS

DER WINDE.

verschlissen.

2. Zu viel Öl. 2. Überschüssiges Öl ablassen. Siehe BETRIEB.

3. Beschädigter 3. Dichtringe ersetzen.

1. Niedrige Förderrate. 1. Förderrate überprüfen. Siehe HYDRAULIK-

DIE WINDE LÄUFT

ZU LANGSAM.

2. Hydraulikmotor ist

LEISTUNGSDIAGRAMM auf Seite 2.

2. Motor ersetzen.

abgenutzt.

KEIN FREILAUF

AN DER

SEILTROMMEL.

1. Kupplung nicht

ausgerückt.

1. Luftdruck zum Kupplungszylinder überprüfen:

Mindestens 6,9 bar sind erforderlich. Siehe

Seite 10 für die Lage des Anschlusses.

BREMSE KANN

NICHT GELÖST

WERDEN.

1. Bremsleitung

abgetrennt oder

blockiert.

1. Bremsenfunktion überprüfen.

40

Page 44

ANLEITUNG ZUM ÜBERHOLEN

DEMONTAGE

1. Das Öl aus dem Getriebekastendeckel ablassen. Dazu den Rohrstopfen (Nr. 37) und das Überdruckventil (Nr. 32)

entfernen. Spannerbaugruppe entfernen.

32

37

2. Rohr (Nr. 40) vom Kniestück (Nr. 43) bei Schieber (Nr. 41) und Fitting (Nr. 29) bei Bremse (Nr. 30b) trennen. Den Motor

(Nr. 33) und den Dichtring (Nr. 30a) durch Entfernen der zwei (2) Kopfschrauben (Nr. 22) ausbauen. Das Ventil (Nr. 41),

falls notwendig, durch Lösen der vier (4) Kopfschrauben (Nr. 16) vom Motor abnehmen.

16

43

41

22

33

30a

40

41

Page 45

3. Zwölf (12) Kopfschrauben (Nr. 18) abnehmen und den Getriebekastendeckel und Dichtring aus dem Hohlrad ziehen.

Die antriebsseitige Anlaufscheibe, das Sonnenrad und die antriebsseitige Trägerbaugruppe aus der Innenseite des

Hohlrads entfernen. Hohlrad und Dichtring entfernen. Die abtriebsseitige Trägerbaugruppe entfernen.

Getriebekastendeckelbuchse (Nr. 15) auf Beschädigungen oder Verschleiß überprüfen.

31

42

31

15

5

18

4. Acht (8) Kopfschrauben (Nr. 20) entfernen, um die Kupplungsrückhalteplatte (Nr. 10) vom Kupplungskolben zu

entfernen. Kupplung (Nr. 9) entfernen.

9

10

42

20

Page 46

5. Kupplungsgehäuse (Nr. 27) mit Kolben (Nr. 28) entfernen. Zum Entfernen des Kolbens vom Kupplungsgehäuse Druckluft am

1/8-Zoll-Anschluss anwenden. O-Ringe (Nr. 28 und Nr. 35) entfernen und auf Beschädigungen oder Verschleiß überprüfen.

35

27

36

28

6. Neun (9) Federn (Nr. 39), Anlaufscheibe (Nr. 26), Dichtring (Nr. 31), Abtriebswelle (Nr. 12) und Abstandhalter (Nr. 13) vom

Getriebeendlager entfernen. Abtriebswellenbuchse (Nr. 14) auf Beschädigungen oder Verschleiß überprüfen. Bei Beschädigungen oder übermäßigem Verschleiß ersetzen.

13

12

26

14

31

43

39

Page 47

7. Die Windenverbindungsstangen (Nr. 2 und Nr. 3) entfernen. Hierzu die acht (8) Kopfschrauben (Nr. 19), acht (8)

Sicherungsscheiben (Nr. 24) und vier (4) Schulterschrauben (Nr. 25) entfernen. Getriebeendlager (Nr. 7) von

Trommelbaugruppe (Nr. 1) ziehen.

2

3

25

24

19

25

19

24

24

7

25

25

19

24

19

8. Trommelbaugruppe (Nr. 1) vom Endlager (Nr. 6) ziehen. Die Vierlippendichtungen (Nr. 34) aus den Rillen in den

Seiltrommelbuchsen entfernen. Die Antriebswelle (Nr. 11) aus dem Endlager entfernen. Die Keile der

Antriebswelle auf Anzeichen von Verschleiß untersuchen und bei Bedarf ersetzen.

6

8

4

38

11

34

1

34

44

Page 48

9. Wenn die Keile im Seiltrommelantrieb (Nr. 102) beschädigt sind, muss der Seiltrommelantrieb ersetzt werden.

Zum Ausbauen des Seiltrommelantriebs die acht (8) Kopfschrauben (Nr. 105) entfernen. Falls die Buchsen

Anzeichen von Verschleiß zeigen, die alten Buchsen aus der Trommel (Nr. 101) stemmen und ersetzen und die

O-Ringe aus den Rillen der Seiltrommel und des Trommelantriebs herausnehmen. Gut geölte O-Ringe (Nr. 106)

in den Antrieb und die Seiltrommel einsetzen. Einen gut geölten O-Ring (Nr. 107) außen im Antrieb einsetzen.

Die Buchsen (Nr. 104) in den Seiltrommelantrieb drücken, bis der Flansch bündig ist und Nr. 103 bündig mit der

Trommel ist.

106

101

107

103

102

106

104

105

10. Bremsbaugruppenschrauben (Nr. 17) von der Bremse (Nr. 30b) entfernen und die Bremse am Endlager (Nr. 6)

befestigen. Kupplung (Nr. 4) und Dichtring (Nr. 30e) vom Endlager ausbauen. Auf die Zusammensetzung der Teile

achten, damit diese wieder richtig zusammengebaut werden.

17

30c

30e

6

30b

45

Page 49

RECHTSSEITIGE MONTAGE

MONTAGEKONFIGURATION FÜR WINDE

LINKSSEITIGE MONTAGE

46

Page 50

8.54

216,91

5.54

140,71

2.91

73,91

22.50

571,50

STATISCHE LAST

BREMSENHALT

25.06

636,52

TASCHENSEILANKER

KONISCHER

7/8-14 SAE O-RING-BOHRUNG, GERADE

(2 STELLEN ENTGEGENGESETZTE SEITEN )

0,6 CM GREIFER, 24 V

NIEDRIGES DREHMOMENT

FÜR HOHE GESCHWINDIGKEIT /

42.07

1068,58

6.38

162,05

12.75

323,85

17.02

432,30

Windenmodell HD-P 177,9

Linksseitige Konfiguration abgebildet

Ø.91

X8

23,01

16.25

412,75

22.13

(TYP)

561,98

452,20

Ø18.00

Ø7.50

190,50

LANSCH

TROMMELF

0.50

12,7

(TYP)

4.00

101,6

(TYP)

16.36

415,54

L

C

31.28

794,51

TROMMEL

ZYLINDER

TROMMEL

56,54

14.92

MESSINGVERSCHRAUBUNG MIT

KONISCHER MUFFE FÜR

DRUCKLUFTROHR DURCHM. 0,6 CM

FÜR SPANNER (MI N. 3,4 bar, MAX. 6,2 bar)

WIE GEZEIGT AUSRICHTEN

(KUPPLUNG IST FEDERBETÄTIGT)

FÜR AUSRÜCKENDE KUPPLUNG

1/8-27NPT DRUCKANSCHLUSS (6,9-8,3 bar)

15°

17.56

446,02

8.78

223,01

13.13

333,50

1.94

49,28

(TYP)

2.68

68,07

6.19

(TYP)

157,17

330,2

13.00

(TYP)

6.19

1.56

39,62

(TYP)

157,17

(TYP)

CABLE IN

ROTATION

(TYP)

18.75

476,25

47

Page 51

18.75

476,25

SEIL IN

Windenmodell HD-P 177,9

Rechtsseitige Konfiguration abgebildet

DREHUNG

13.13

333,50

16.25

476,25

2.68

68,07

(TYP)

4.00

101,6

(TYP)

.50

12,7

(TYP)

KONISCHER MUFFE FÜR

MESSINGVERSCHRAUBUNG MIT

DRUCKLUFTROHR DURCHM. 0,6 cm

FÜR SPANNER (MI N. 3,4 bar, MAX. 6,2 bar)

WIE GEZEIGT AUSRICHTEN

(KUPPLUNG IST FEDERBETÄTIGT)

FÜR AUSRÜCKENDE KUPPLUNG

1/8-27NPT DRUCKANSCHLUSS (6,9-8,3 bar)

15°

17.56

446,02

8.78

223,01

Ø.91

X8

23,01

1.56

39,62

(TYP)

6.19

(TYP)

157,17

330,2

13.00

(TYP)

6.19

(TYP)

157,17

1.94

49,28

(TYP)

17.02

432,30

12.75

323,85

6.38

42.07

1068,58

25.06

636,52

22.13

(TYP)

561,98

162,05

KONISCHER

TASCHENSEILANKER

22.72

577,08

BREMSENHALT

STATISCHE LAST

452,20

Ø18.00

FLANSCH

TROMMEL

56,54

14.92

Ø7.50

190,50

TROMMEL

ZYLINDERL

L

31.28

794,51

TROMMEL C

16.36

415,54

2.91

73,91

2.41

62,21

5.32

158,49

8.54

216,91

NIEDRIGES DREHMOMENT

FÜR HOHE GESCHWINDIGKEIT /

0,6 CM (1/4-ZOLL) GREIFER, 24 V

48

7/8-14 SAE O-RING-B OHRUNG, GERADE

(2 STELLEN ENTGEGENGESETZTE SEITEN)

Page 52

18

5

31

15

42

31

27

35

10

9

28

36

20

32

37

19

25

24

25

19

7

24

2

34

1

24

34

25

19

39

26

31

14

12

13

30e

21

29

40

43

16

17

22

30c

30a

6

30e

30d

30b

8

4

21

11

38

30

23

3

24

25

19

HDP 177,9 WINDE

41

33

49

Page 53

TEILELISTE - HDP

1 1 234241 TROMMELBAUGRUPPE 26 1 418520 ANLAUFSCHEIBE

2 1 243071 MONTAGEWINKEL 27 1 426059 ZYLINDER

3 1 243072 MONTAGEWINKEL 28 1 426060 KOLBEN

4 1 324284 MOTORKUPPLUNG 29 1 432023 FITTING

5 1 328180 GETRIEBEKASTENDECKEL 30 1 438037 BREMSENBAUGRUPPE

Lfd. Nr. Anz. Teile-Nr. Beschreibung Lfd. Nr. Anz. Teile-Nr. Beschreibung

6 1 338419 MOTORENDLAGER 30a 1 MOTORSEITIGER DICHTRING

7 1 338417 GETRIEBEENDLAGER 30b 1 BREMSE

8 1 342081 KEIL 30c 1 KEIL

9 1 342517 KUPPLUNG 30d 1 ADAPTERPLATTE

10 1 352035 KUPPLUNGSSICHERUNGSRING 30e 2 ADAPTERPLATTE - SICHERUNGSRING

11 1 357549 ANTRIEBSWELLE 31 3 442210 DICHTRING

12 1 357543 ABTRIEBSKUPPLUNG 32 1 456008 ÜBERDRUCKVENTIL

13 1 362327 ABSTANDHALTER 33 1 458126 MOTOR

14 1 412044 BUCHSE 34 2 462040 VIERLIPPENDICHTUNG

15 1 412105 BUCHSE 35 1 462103 O-RING 2-274

16 4 414400 KOPFSCHRAUBE 3/8-24NF X 4 LG, SECHSKANT, SORTE 5 36 1 462104 O-RING 2-275

17 2 414595 KOPFSCHRAUBE 1/2-13NC X 3-1/2 LG, INBUS 37 1 468040 ROHRSTOPFEN

18 12 414612 KOPFSCHRAUBE 1/2-13NC X 7 LG SECHSKANT 38 1 470075 STIFT

19 8 414788 KOPFSCHRAUBE 7/8-9NC X 2.5 LG SECHSKANT 39 9 494140 FEDER

20 8 414819 KOPFSCHRAUBE 1/4-20NC X 1/2 LG FLACHKOPF 40 1 509125 ROHR, KOMPLETT

21 2 414947 KOPFSCHRAUBE 1/2-13NC X 1 LG, INNENSECHSKANT 41 1 516065 SCHIEBER - STEUERUNG (DOPPELTE DREHUNG)

22 2 414948 KOPFSCHRAUBE 1/2-13NCX1 1/4LG, INBUS 42 1 530173 GETRIEBE

25 4 418452 SCHULTERSCHRAUBE

23 1 408431 SEILKONUS 43 1 432018 FITTING - HYDR. 7/16-20 90° KNIESTÜCK

24 8 418261 SICHERUNGSSCHEIBE, 7/8, GETEILT

50

Page 54

TROMMELBAUGRUPPE - 234241

Lfd. Nr. Teile-Nr. Menge Beschreibung

101 332272 1 TROMMEL - SEIL

102 332226 1 ANTRIEB - TROMMEL

103 412078 1 BUCHSE - TROMMEL

104 412079 1 BUCHSE - TROMMEL

105 414978 8 KOPFSCHRAUBE 5/818NC X 1 1/4LG, INBUS

106 462043 2 ORING AS568348, 3/16 X 4 3/4 X 4 3/8

107 462075 1 ORING AS568354, 3/16 X 5 1/2 X 5 1/8

106

101

103

107

102

106

104

105

51

Page 55

SEILSPANNVORRICHTUNG (AUFWICKLUNG ÜBER DIE TROMMEL) - 299744

Lfd. Nr. Teile-Nr. Menge Beschreibung

201 265102 1 HEBELARM

202 304174 1 BAR

203 346046 1 DREHZAPFENSTIFT

205 408362 1 HALTERUNG

205 414278 4 KOPFSCHRAUBE 3/8-16NCX3/4LG, SECHSKANT, SORTE 5, VERZINKT

206 414316 2 KOPFSCHRAUBE 3/8-16NCX1 1/4, SECHSKANT, SORTE 5, VERZINKT

207 418045 2 MUTTER 3/8-16NC SECHSKANT REG SORTE 5 VERZINKT

208 418098 1 MUTTER 3/4-16NF SECHSKANT KONTERMUTTER

209 418177 2 SICHERUNGSSCHEIBE 3/8, GETEILT, VERZINKT

210 418223 2 UNTERLEGSCHEIBE 1/2 USS FLACHKOPF, VERZINKT

211 424005 2 SPLINT

212 432033 1 FITTING - KNIESTÜCK

213 433029 1 STELLGLIED

207

211

210

201

204

213

209

205

205

202

206

203

211

210

208

212

52

Page 56

MANUAL DE FUNCIONAMIENTO, REPARA-

CIÓN Y MANTENIMIENTO

English (Original Instructions). . . . . . . . . . . . . . . . . . . . . .1

Français (Traduction des instructions originales). . . . . 17

Deutsch (Übersetzung der Originalanleitung) . . . . . . . . 35

Español (Traducción de las instrucciones originales) . 53

CABESTRANTE PLANETARIO

INDUSTRIAL MODELO HD-P 177,9

Uso pretendido para: recuperación de vehículos y arrastre de cargas

PRECAUCIÓN: LEER Y ENTENDER ESTE MANUAL ANTES DE INSTALAR Y

Ramsey Representante autorizado en la comunidad:

UTILIZAR EL CABESTRANTE. OBSERVAR LAS ADVERTENCIAS.

RAMSEY WINCH COMPANY

Post Office Box 581510 Tulsa, Oklahoma 74158-1510 EE.UU.

Teléfono: + 1 918 438-2760 Fax: +1 918 438-6688

Visítenos en http://www.ramsey.com

(Póngase en contacto sólo por cuestiones de reglamentación.)

Alura Group BV

P.O. Box 18626

2502 EP The Hague

The Netherlands

Tel: (31) (0) 70 362-4896

Fax: (31) (0) 70 346-7299

OM-914249-1012-B

Page 57

ÍNDICE

ESPECIFICACIONES ..................................................................................................... 55

ADVERTENCIAS ............................................................................................................ 55

RESPONSABILIDAD DEL USUARIO PARA

EL CUMPLIMIENTO CON LAS DISPOSICIONES CE ................................................... 55

REQUISITOS DEL SISTEMA HIDRÁULICO .................................................................. 56

GRÁFICOS DE FUNCIONAMIENTO .............................................................................. 56

FUNCIONAMIENTO DEL CABESTRANTE .................................................................... 57

FUNCIONAMIENTO DEL EMBRAGUE .......................................................................... 57

INSTALACIÓN DEL CABLE ............................................................................................ 57

MANTENIMIENTO .......................................................................................................... 58

GUÍA DE SOLUCIÓN DE PROBLEMAS ......................................................................... 58

INSTRUCCIONES PARA VERIFICAR EL CABESTRANTE ...................................... 59-63

CONFIGURACIONES DE MONTAJE ............................................................................. 64

DIBUJO ACOTADO ................................................................................................... 65-66

LISTA DE PIEZAS Y DIBUJO DE PIEZAS ................................................................ 67-70

Page 58

ESPECIFICACIONES*

Tracción de cable nominal (libras) 177,9 kN (40.000 libras)

Nivel sonoro 76 db

Temperatura ambiente De -28º C a 60º C (de -20º F a 140º F)

Reducción de engranajes 51,35:1

Peso (sin cable) 365 kg (804 libras)

CAPA DE CABLE 1 2 3 4 5

*Tracción de cable

nominal por capa

kN

Libras

177,9

40.000

149,5

33.600

128,5

28.900

113,0

25.400

100,1

22.700

*Capacidad del

cable por capa

*Velocidad del

cable a 64,3 LPM

(17 GPM)

* Estas especificaciones se basan en un cable metálico recomendado de 20 mm (0,787 pulgadas)

Bridon Dyform 34LR/PI/MAX de clase 1960 o equivalente con una resistencia mínima a la ruptura de

355,8 kN (80.000 libras) y en un motor de 195 cc (11,9 pulgadas cúbicas)/Rev.

M

Pies

MPM

PPM

9

30

4,2

13,8

19

65

5,0

16,3

33

110

5,7

18,8

48

160

6,5

21,3

65

215

7,3

23,8

ADVERTENCIAS:

EL USUARIO DEBERÁ GARANTIZAR QUE EL PERSONAL QUE USE EL EQUIPO HAYA RECIBIDO

LA FORMACIÓN NECESARIA.