Page 1

OPERATING, SERVICE AND

MAINTENANCE MANUAL

English . . . . . . . . . . . . . . . . . . . . .1

Français . . . . . . . . . . . . . . . . . . .17

Deutsch . . . . . . . . . . . . . . . . . . .33

Español . . . . . . . . . . . . . . . . . . .49

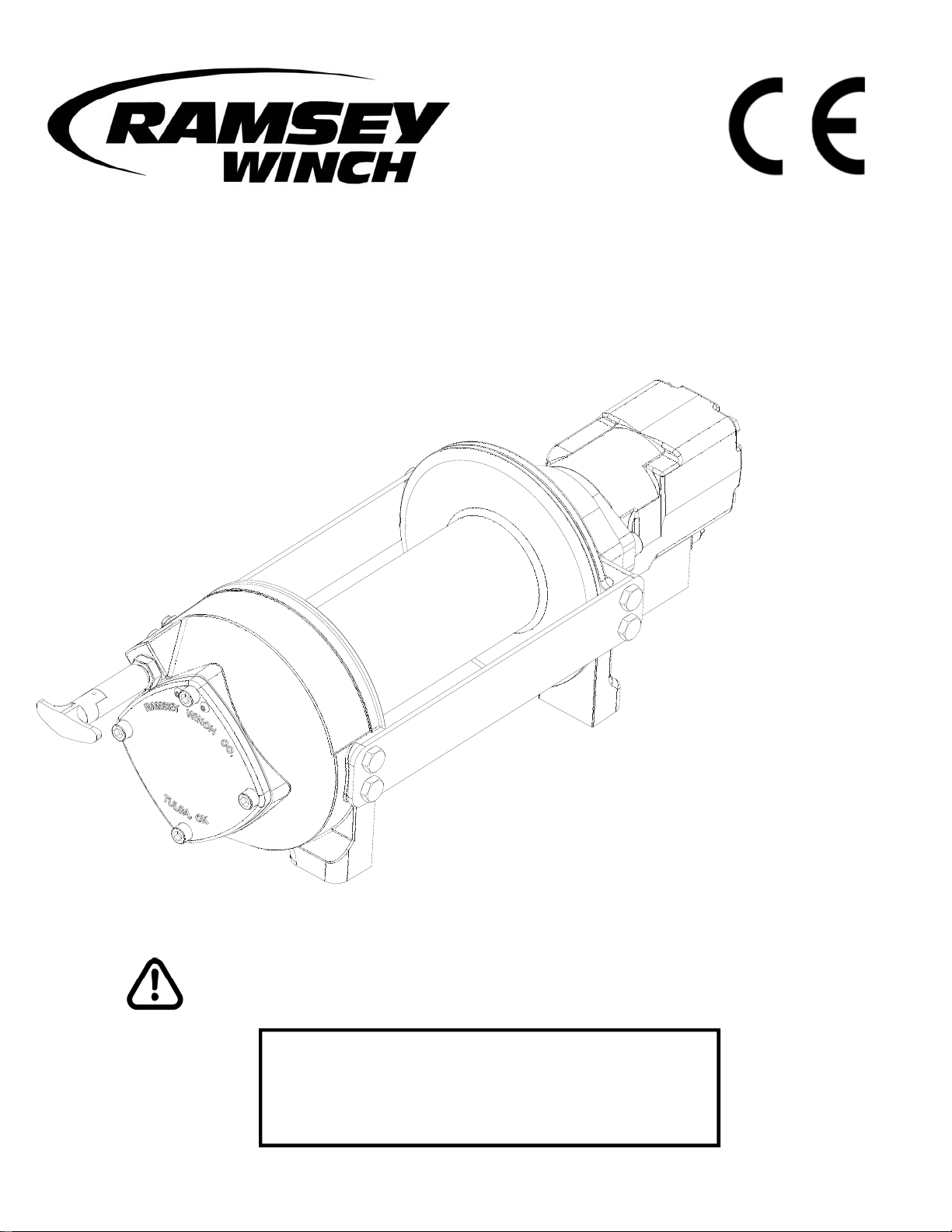

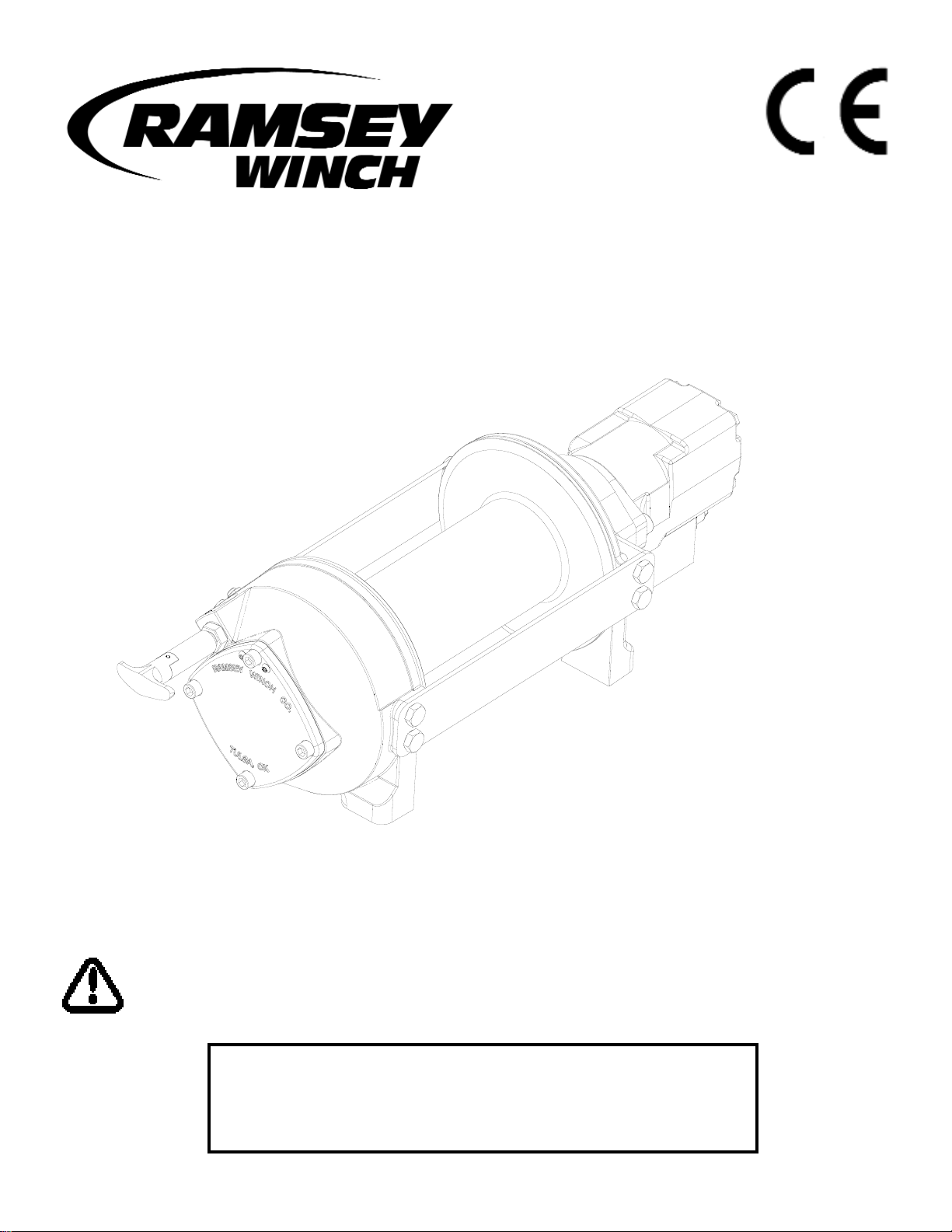

MODEL HD-P10000 PLANETARY WINCH

CAUTION: READ AND UNDERSTAND THIS MANUAL BEFO RE INSTALLATION AND

OPERATION OF WINCH. SEE WARNINGS!

Ramsey Winch Company

P.O. Box 581510 - Tulsa, OK 74158-1510 USA

Phone: (918) 438-2760 - Fax (918) 438-6688

Visit us at http://www.ramsey.com

OM-914186-0309-D

Page 2

TABLE OF CONTENTS

I

NTRODUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

WARRANTY INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

WARNINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

WINCH MOUNTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

CABLE INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

HYDRAULIC SYSTEM REQUIREMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

TYPICAL LAYOUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

PERFORMANCE CHARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

TROUBLE SHOOTING GUIDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

OVERHAUL INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-10

DIMENSIONAL DRAWINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-2

PARTS LIST AND PARTS DRAWINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-16

LIMITED WARRANTY

RAMSEY WINCH warrants each new RAMSEY Winch to be free from defects in material and workmanship for a period of one (1) year

from date of purchase.

The obligation under this warranty, statutory or otherwise, is limited to the replacement or repair at the Manufacturer's factory, or at a point

designated by the Manufacturer, of such part that shall appear to the Manufacturer, upon inspection of such part, to have been defective in

material or workmanship.

This warranty does not obligate RAMSEY WINCH to bear the cost of labor or transportation charges in connection with the replacement or

repair of defective parts, nor shall it apply to a product upon which repair or alterations have been made, unless authorized by

Manufacturer, or for equipment misused, neglected or which has not been installed correctly.

RAMSEY WINCH shall in no event be liable for special or consequential damages. RAMSEY WINCH makes no warranty in respect to

accessories such as being subject to the warranties of their respective manufacturers.

RAMSEY WINCH, whose policy is one of continuous improvement, reserves the right to improve its products through changes in design or

materials, as it may deem desirable without being obligated to incorporate such changes in products of prior manufacture.

If field service at the request of the Buyer is rendered and the fault is found not to be with RAMSEY WINCH's product, the Buyer shall pay

the time and expense to the field representative. Bills for service, labor or other expenses that have been incurred by the Buyer without

approval or authorization by RAMSEY WINCH will not be accepted.

See warranty card for details.

Page 3

PLEASE READ THIS MANUAL CAREFULLY

This manual contains useful ideas for obtaining the most efficient operation from your Ramsey Winch, and safety procedures

one needs to know before operating a Ramsey Winch. Do not operate this winch until you have carefully read and understand

the "WARNING" and "OPERATION" sections of this manual.

WARRANTY INFORMATION

Ramsey Winches are designed and built to exacting specifications. Great care and skill go into every winch we make. If the

need should arise, warranty procedure is outlined on the back of your self-addressed postage paid warranty card. Please read

and fill out the enclosed warranty card and send it to Ramsey Winch Company. If you have any problems with your winch,

please follow instructions for prompt service on all warranty claims. Refer to back page for limited warranty.

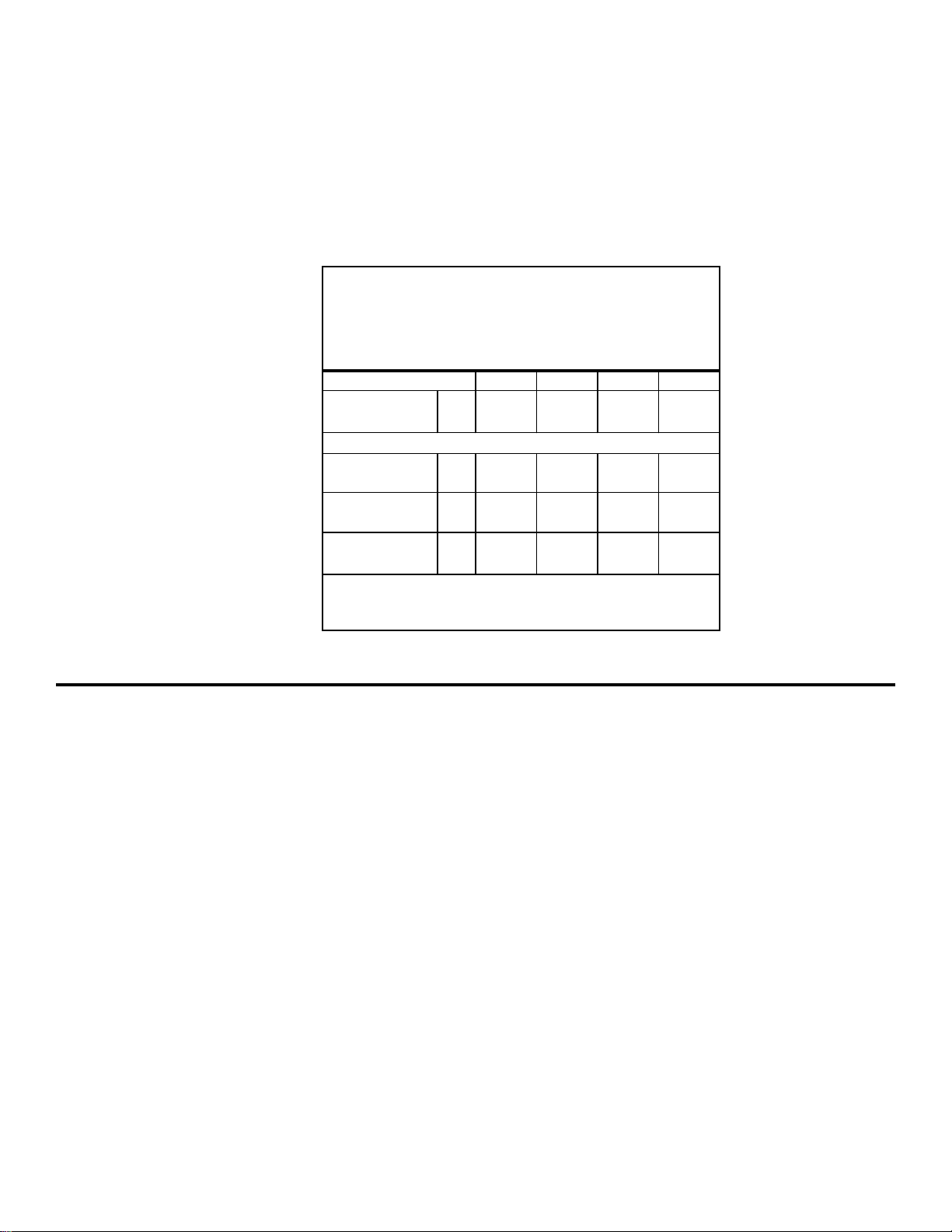

SPECIFICATIONS*

NOTE: The rated line pulls shown are for the winch only. Consult the wire rope manufacturer for wire rope ratings.

WARNINGS:

A MOTOR SPOOL (OPEN CENTER) DIRECTIONAL CONTROL VALVE IS REQUIRED FOR BRAKE OPERATION.

CLUTCH MUST BE FULLY ENGAGED BEFORE STARTING THE WINCH.

DO NOT DISENGAGE CLUTCH UNDER LOAD.

DO NOT LEAVE CLUTCH ENGAGED WHEN WINCH IS NOT IN USE.

STAY OUT FROM UNDER AND AWAY FROM RAISED LOADS.

STAND CLEAR OF CABLE WHILE PULLING. DO NOT TRY TO GUIDE CABLE.

DO NOT EXCEED MAXIMUM LINE PULL RATINGS SHOWN IN TABLE.

DO NOT USE WINCH TO LIFT, SUPPORT, OR OTHERWISE TRANSPORT PERSONNEL.

A MINIMUM OF 5 WRAPS OF CABLE AROUND THE DRUM BARREL IS NECESSARY TO HOLD THE LOAD. CABLE CLAMP

(SETSCREW) IS NOT DESIGNED TO HOLD LOAD.

IN CAR CARRIER APPLICATIONS, AFTER PULLING VEHICLE ON CARRIER, BE SURE TO SECURE VEHICLE TO CARRIER

BED. DO NOT MAINTAIN LOAD ON WINCH CABLE WHILE TRANSPORTING VEHICLE. DO NOT USE WINCH AS A TIEDOWN.

WHEN PULLING A HEAVY LOAD PLACE A BLANKET, JACKET, OR TARPAULIN OVER THE CABLE FIVE OR SIX FEET FROM

THE HOOK.

AVOID CONDITIONS WHERE LOAD SHIFTS OR JERKS OCCUR, AS THEY MAY INDICATE A DANGEROUS SITUATION.

3

Rated Line Pull (lbs.)

………………………………………

10,000

(Kg.)

………………………………………

4,545

Gear Reduction 5.1:1

HD-P10000 STD. …….. 87 lbs. (39.5 Kg)

HD-P10000 "Y" ……….. 82 lbs. (37.2 Kg)

1234

lbs. 10,000 8,300 7,100 6,200

Kg. 4,530 3,760 3,220 2,810

ft. 205080115

m 6 15 24 35

ft. 15305575

m491622

FPM32384451

MPM 9.8 11.6 13.4 15.5

………………………………………………

Weight (without cable)

* These specifications are based on recommended wire rope of

7/16" (11mm) EIPS cable and a 24.9 cu.in./Rev. motor.

LAYER OF CABLE

*Rated line pull

per layer

HD-P10000

(STD. DRUM)

* Line Speed (at

15 GPM)

HD-P10000 ("Y"

DRUM)

* Cable Capacity per Layer

Page 4

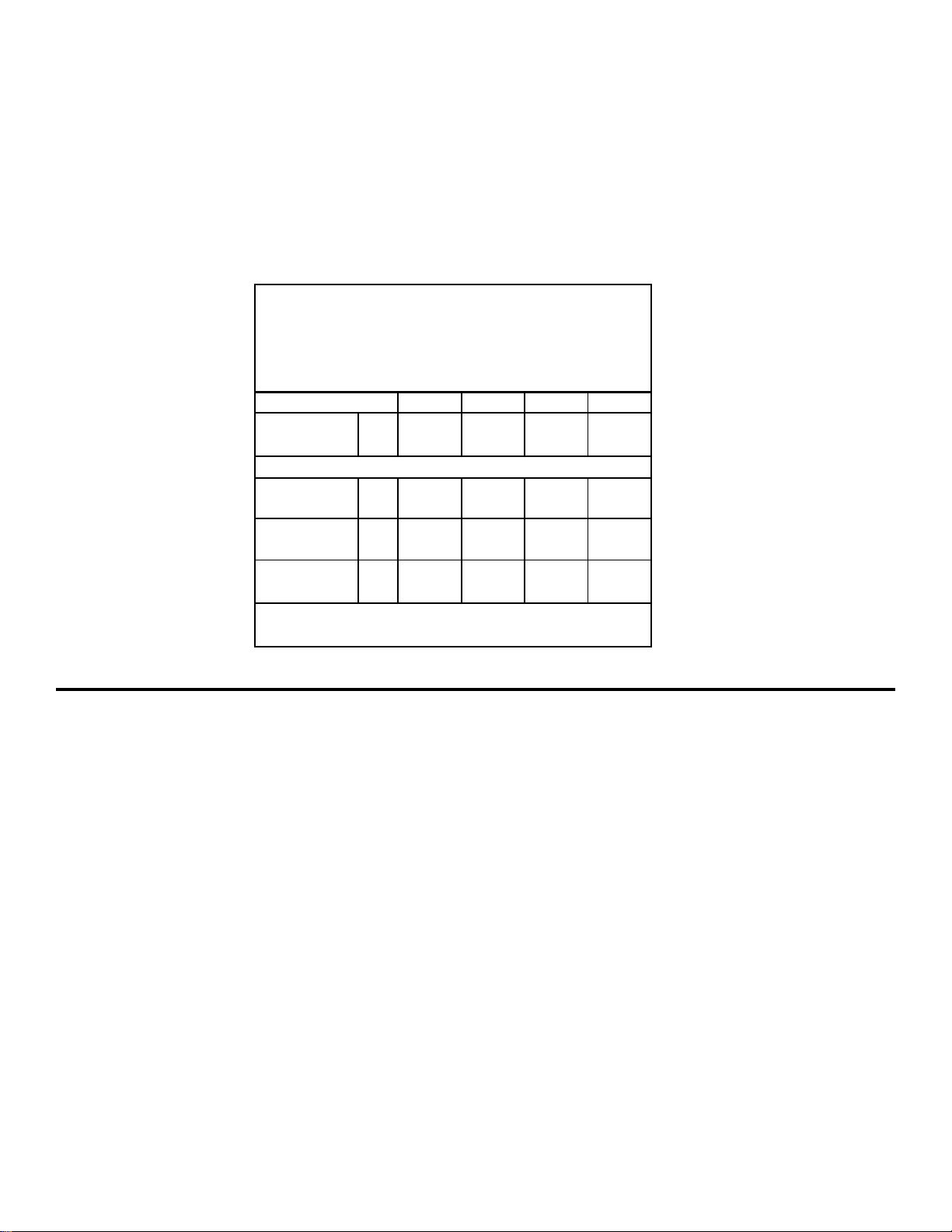

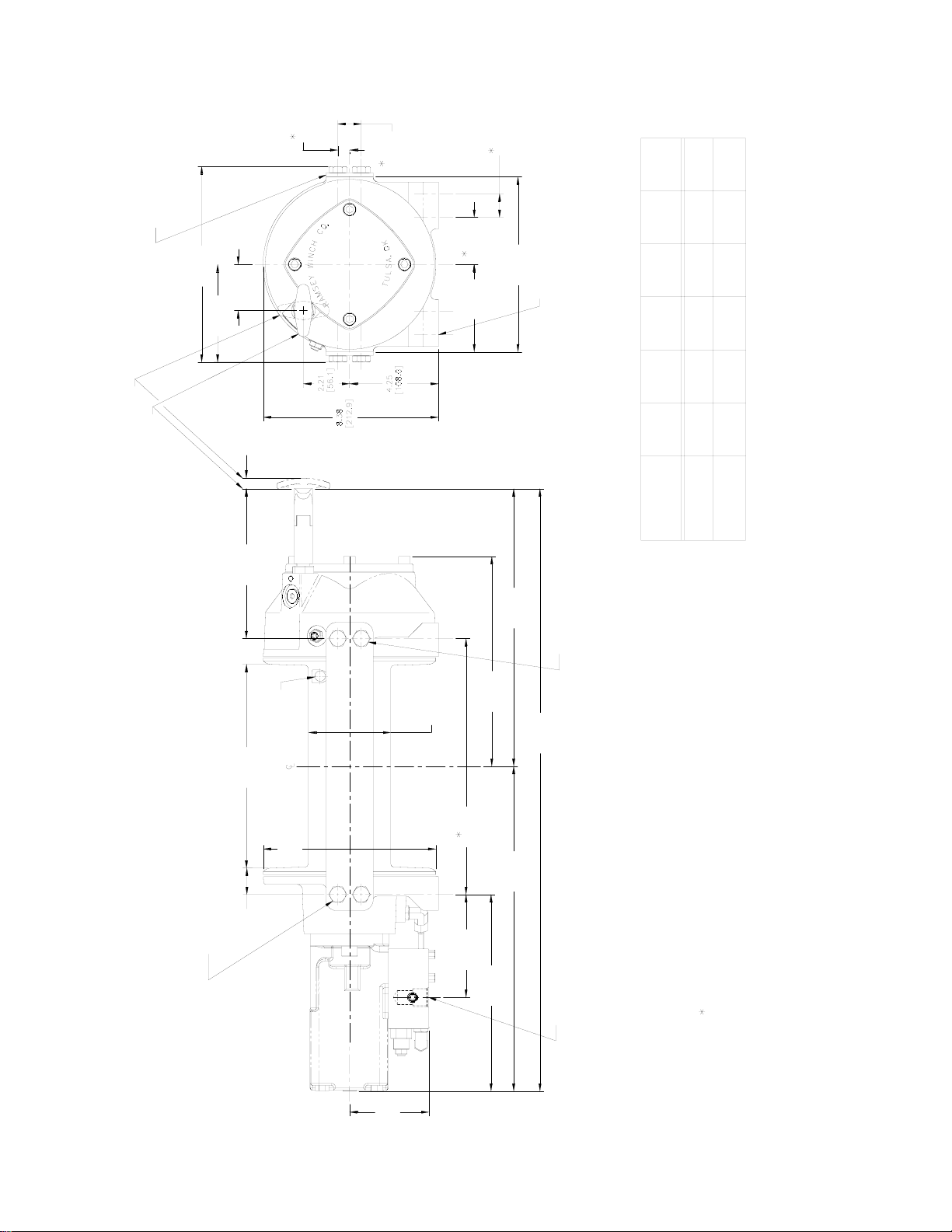

WINCH MOUNTING

ESSENTIAL MOUNTING INSTRUCTIONS TO MAINTAIN ALIGNMENT OF PLANETARY WINCH COMPONENTS:

I

t is most important that this winch be mounted securely so

that the three major sections (the motor end, the cable drum,

and the gear housing end) are properly aligned. Excessive

bushing wear and difficulty in freespooling are usually symptoms of misalignment.

In the as-installed condition, if the winch is mid-mounted,

then at least one tie-plate must be attached to the mounting

feet at the bottom of the winch to maintain alignment. If the

winch is foot mounted then at least one tie-plate must remain

mounted at midpoint of winch to maintain alignment. It is

always preferred to used BOTH tie-plates in the final installed

configuration.

Angle Mounting Kit, P/N 251006 (for Std. Drum) or 251007

(for “Y” drum), is recommended for maximum ease in

mounting the winch. The angle kit will allow the winch to be

mounted in upright or midmount applications and will meet

the criteria of serving as a solid and true mounting surface.

When mounting the winch with other than the recommended

Ramsey Angle Kit, the mounting hole patterns described in

the Dimensional drawings on pages 14-15 should be used.

The mounting surface must be flat within .015 inch and sufficiently stiff to resist flexing. If a steel plate is used for foot

mounting, it should be .750 inch thick. For this mounting application eight (8) 1/2-13NC x 1-1/2” long grade 5 capscrews with lockwashers

will be needed to mount winch. Capscrews should be tightened to 85 ft-lb (115 Nm) torque.

NOTE: If angles or a steel plate are used in mounting winch, tie-plates provided with winch are to be attached to the remaining mounting

pads, whether they be side or foot.

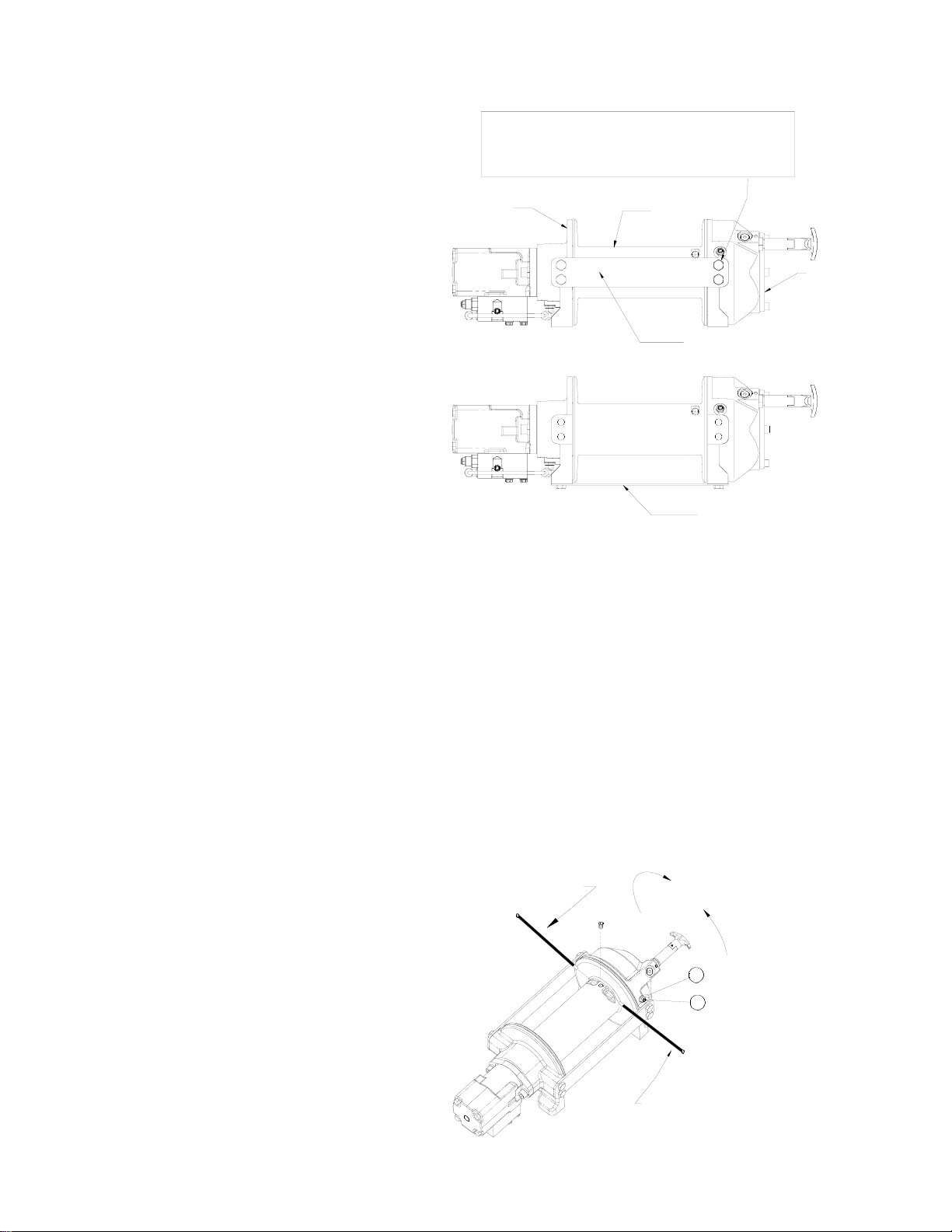

CABLE INSTALLATION

An “A” or “B” decal on the clutch end bearing indicates the spooling direction of the cable. Also, a letter “A” or “B” is stamped in the end

bearing on the clutch end indicating rotation direction. If the decal is damaged or unreadable, contact Customer Service for additional

instructions to determine proper direction. To reverse the rotation direction, exchange positions of the cartridge and plug shown at

right.

1. Unwind cable by rolling it out along the

ground to prevent kinking. Securely wrap

end of cable, opposite hook, with plastic

or similar tape to prevent fraying.

2. Place taped end of cable into hole in cable

drum as shown below. Use the 3/8-16NC

x 1/2” long hex socket drive setscrew

(included with drum assembly item #1) to

secure cable to drum.

3. Carefully run winch in the "reel-in" direc-

tion. Keeping tension on end of cable,

spool all the cable onto the cable drum,

taking care to form neatly wrapped layers.

After installing cable, check freespool operation. Disengage clutch and pull on cable at a

walking speed. If cable “birdnests”, loosen

jam nut (item #20) and turn nylon setscrew

(item #17) clockwise to increase drag on

drum. If cable pull is excessive, loosen nylon

setscrew by turning counterclockwise. Tighten jam nut when proper setting is obtained.

CAUTION: OVER-TIGHTENING OF JAM NUT MAY STRIP NYLON SETSCREW.

MOTOR END CABLE DRUM

GEAR HOUSING END

TIEPLATE AT SIDE LOCATION

TIEPLATE AT FOOT (BASE) LOCATION

FOOT MOUNT

MID MOUNT

CAUTION:

If longer bolts (minimum grade 5) are substituted to mount winch or to

mount a roller guide at the side mount pads, bolt length must be such as to allow a

minimum of .50 inch thread length engagement in the tapped holes in side of each

end bearing. Use of excessive length bolts will damage the winch and prevent

freespool of the drum. Torque bolts to 55 ft-lbs. (75 Nm).

SETSCREW

"A" ROTATION

DIRECTION

"B" ROTATION

DIRECTION

INSERT CABLE AS SHOWN FOR "B" ROTATION

OVERWOUND APPLICATION.

(UNDERWOUND APPLICATION REQUIRES CABLE TO

COME UNDER DRUM FROM OPPOSITE DIRECTION

AND INSERTED IN THIS SAME CABLE POCKET.)

INSERT CABLE AS SHOWN FOR "A" ROTATION

OVERWOUND APPLICATION.

(UNDERWOUND APPLICATION REQUIRES CABLE TO

COME UNDER DRUM FROM OPPOSITE DIRECTION

AND INSERTED IN THIS SAME CABLE POCKET.)

20

17

4

Page 5

5

MAINTENANCE

1. Inspect the cable for damage and lubricate frequently. If the cable becomes frayed with broken strands, replace immediately. Cable and

hook assembly (100’ long cable) P/N 524118 (“Y” drum) or (150’ long cable) P/N 524119 (STD drum) may be purchased from a

Ramsey distributor.

2. Check that the clutch is fully engaging. See OPERATION instructions, above, for the appropriate clutch shifter. FOR MANUAL CLUTCH

ONLY: Monthly, disengage clutch, put several drops of oil on the clutch handle shaft and work clutch handle IN and OUT several times

to lubricate inside the shifter assembly.

3. Check to see that the drum cable does not overrun (“birdnest”) when freespooling. Refer to page 4 if it does.

4. Replace drum bushings and seals if seals begin to seep grease. Refer to the Overhaul Instructions, pages 8-10. Add additional lubricant, Mobilith SHC 007, to gears and drum bearings if required.

OPERATION

The best way to get acquainted with how your winch operates is to make test runs before you actually use it. Plan your test in advance.

Remember, you hear your winch as well as see it operate. Get to recognize the sounds of a light steady pull, a heavy pull, and sounds

caused by load jerking or shifting. Avoid conditions where load shifts or jerks occur, as they may indicate a dangerous situation.

The uneven spooling of cable, while pulling the load, is not a problem, unless there is a cable pileup on one end of the drum. If this happens,

reverse the winch to relieve the load, and move your anchor point further to the center of the vehicle. After the job is done you can unspool

and rewind for a neat lay of the cable.

When pulling a heavy load, place a blanket, jacket, and tarpaulin over the cable about five or six feet behind the hook. In the event of a broken cable, this will slow the snap back of the cable and could prevent serious injury.

The winch clutch allows rapid unspooling of the cable, from the cable drum, for hooking onto the load. The clutch is operated by the clutch

shifter lever or air shifter.

WARNING: DO NOT DISENGAGE CLUTCH UNDER LOAD!

MANUAL CLUTCH SHIFTER (Refer to dimensional drawing page 11):

TO DISENGAGE CLUTCH: Run the winch in the reverse (reel out) direction until the load is off the cable. Pull handle out and rotate 90°. With

handle in the “DISENGAGED” position, cable may now be free-spooled from the drum.

TO ENGAGE CLUTCH: Pull handle out, rotate 90° and release handle. Run the winch in reverse until the clutch handle snaps fully into the

“ENGAGED” position. DO NOT attempt to pull a load unless the handle is fully at the “ENGAGED” position. If manual shift indicator light is

present, the green light is lit when clutch is fully “ENGAGED”. DO NOT attempt to pull a load unless the green light is lit. To install light to the

vehicle electrical system refer to the Electrical Schematic on page 12.

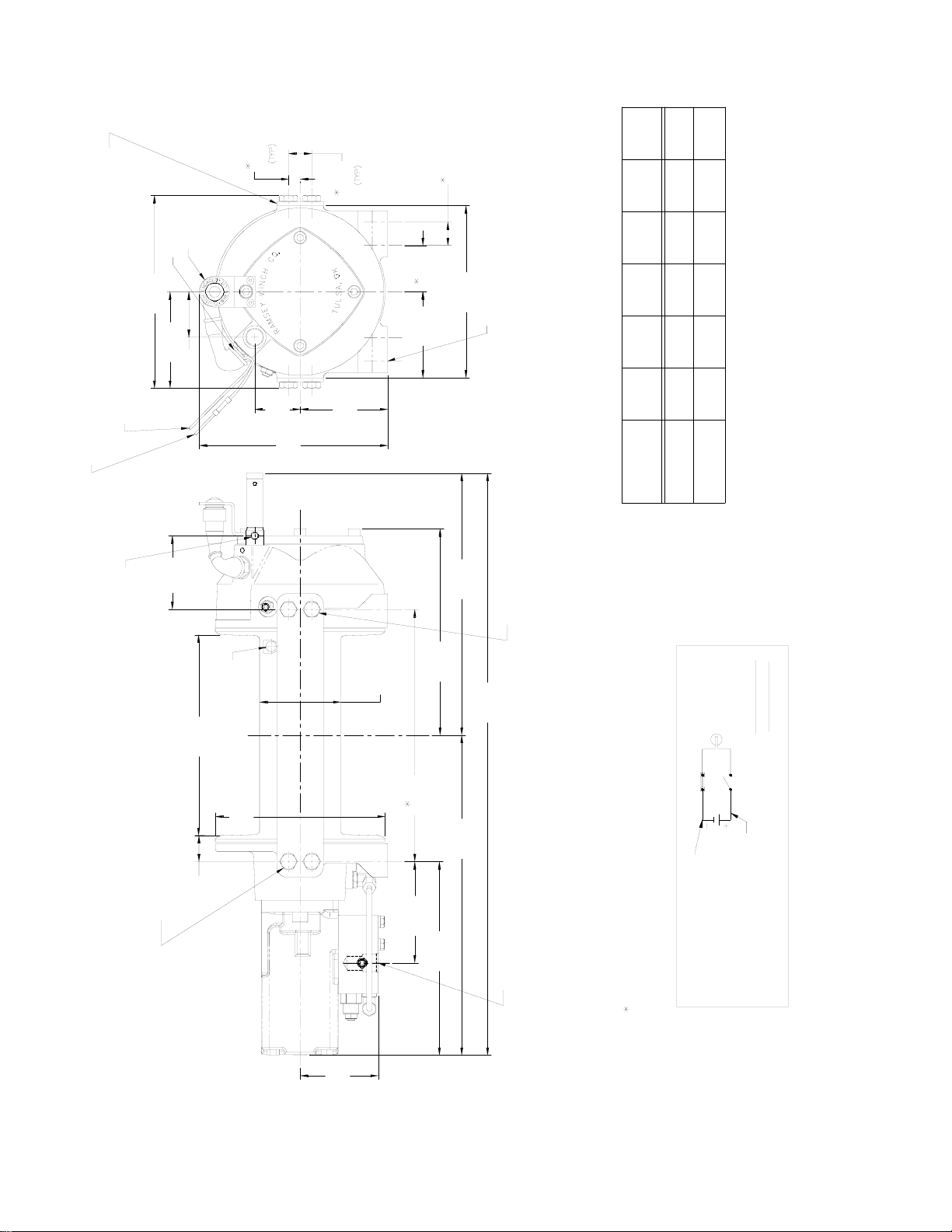

AIR CYLINDER CLUTCH SHIFTER (Refer to the dimensional drawing page 12):

TO DISENGAGE CLUTCH: Run the winch in the reverse (reel out) direction until load is off the cable. Apply air pressure to the .125-27 NPT

port: 80 PSI (min.)-150 PSI (max.). CAUTION: PRESSURE MUST NOT EXCEED 150 PSI.

TO ENGAGE CLUTCH: Remove air pressure from the cylinder (a return spring engages the plunger). Run winch in reverse until the clutch

engagement indicator light (green light) is lit. To install light to the vehicle electrical system refer to the Electrical Schematic on page 12.

(REEL IN) RAISE INLET

"A" ROTATION

"B" ROTATION

CABLE DRUM

ROTATION DIRECTION

CABLE DRUM

ROTATION DIRECTION

CARTRIDGE

POSITION

CARTRIDGE

POSITION

PLUG

POSITION

Page 6

HYDRAULIC SYSTEM REQUIREMENTS

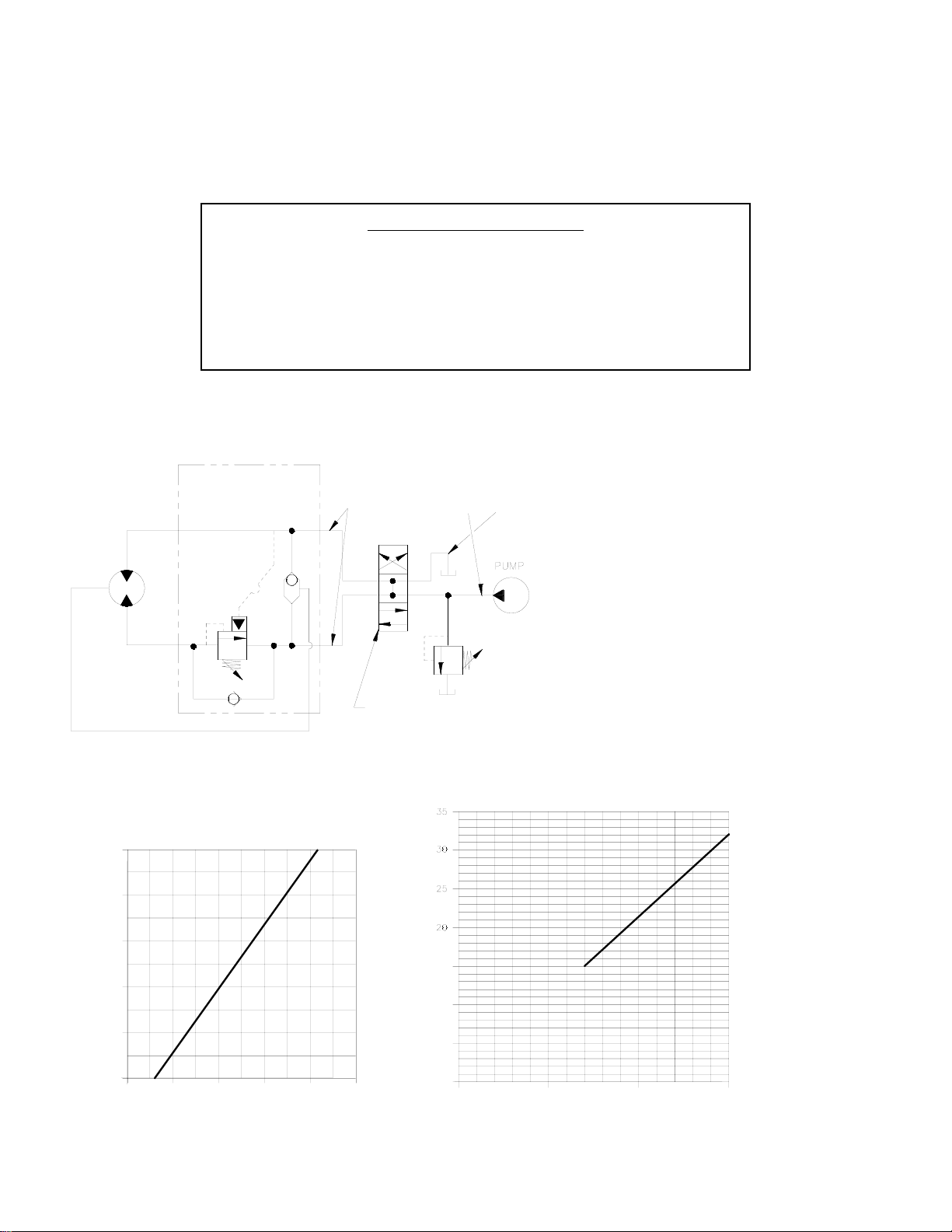

Refer to the performance charts below to properly match your hydraulic system to the winch performance. The

charts consist of:

(1) Line Pull first layer (lb.) vs. Working Pressure (PSI)

(2) Line Speed, first layer (FPM) vs. flow (GPM)

SYSTEM REQUIREMENTS

MOTOR SPOOL (OPEN CENTER) CONTROL VALVE REQUIRED

2100 PSI RELIEF VALVE SETTING

15 GPM FLOW RATE

DO NOT EXCEED 20 GPM--MOTOR AND WINCH MAY BE DAMAGED

10 MICRON NOMINAL FILTRATION

SYSTEM

RELIEF

3 POSITION

4 WAY VALVE

(MOTOR SPOOL)

MAX. FLOW &

PRESSURE AT

RATED LOAD:

15 GPM

2100 PSI

HIGH PRESSURE LINE

(.50 I.D. MINIMUM)

LOW PRESSURE LINE

(.75 I.D. MINIMUM)

PORT CONTROL

B

TYPICAL LAYOUT

WITH BRAKE RELEASE SHUTTLE

MOTOR

BRAKE

PORT

A

WORKING PRESSURE (PSI) AT 15 GPM

FLOW (GPM)

LINE PULL-FIRST LAYER (LB)

LINE SPEED-FIRST LAYER (FPM)

051015

0

5

10

15

0

0

1000

2000

3000

4000

5000

6000

7000

8000

1000 2000 2500

BASED ON 24.9 CU. IN. MOTOR

1500500

PERFORMANCE CHARTS

9000

10000

6

Page 7

TROUBLESHOOTING GUIDE

CONDITIONS POSSIBLE CAUSE CORRECTION/ACTION

DRUM WILL NOT ROTATE

AT NO LOAD

Winch not mounted squarely, causing end bearing

to bind up

Check mounting. Refer to Winch Mounting, page 2.

Gears damaged Inspect and replace damaged gears

DRUM WILL NOT ROTATE

UNDER LOAD

Winch not mounted squarely, causing end bearing

to bind up

Check mounting. Refer to Winch Mounting, page 2.

Load greater than rated capacity of winch Refer to Specifications page 1 for line pull rating.

Low hydraulic system pressure Check pressure. Refer to Hydraulic Systems per-

formance charts page 4.

WINCH RUNS TOO SLOW Low hydraulic system flow rate Check flow rate. Refer to Systerm Requirements and

Typical Layout page 4.

Motor worn out Replace motor

DRUM WILL NOT

FREESPOOL

Clutch not disengaged. Check Adjustment of Manual

Shifter, page 10.

Check Operation, page 5.

Winch not mounted squarely, causing end bearing

to bind up

Check mounting. Refer to Winch Mounting, page 2.

Side mounted bolts too long, causing binding of ring

gear (Item #15, page 16).

Check bolt length. Bolt thread MUST NOT engage

threaded holes in sides of end bearing more than the

.50 inch thread depth in the end bearing.

BRAKE WILL NOT HOLD Incorrect directional control valve (cylinder spool-

closed center)

Use only a motor spool (open center) control valve.

LOAD DRIFTS Excessive Backpressure (100 PSI Max.) Check for restrictions in hydraulic system. Refer to

System Requirements and Typical Layout page 4.

CABLE BIRDNESTS WHEN

CLUTCH IS DISENGAGED

Drag screw improperly adjusted Adjust nylon drag screw. Refer to Cable Installation,

page 3.

EXCESSIVE NOISE Hydraulic system flow too high Check flow rate. Refer to Typical Layout page 4.

Drum in bind, winch not mounted squarely Check mounting. Refer to Winch Mounting, page 2.

DRUM CHATTERS IN

“REEL IN” DIRECTION

Low hydraulic system flow rate Check flow rate. Refer to Typical Layout page 4.

Low hydraulic system relief pressure setting Check relief valve setting.

OIL LEAKS FROM

BREATHER VENT UNDER

MOTOR END BEARING

Damaged brake o-rings, backup rings, or sealing

surfaces

Disassemble brake and inspect. See Overhaul

Instructions, pg. 8.

7

Page 8

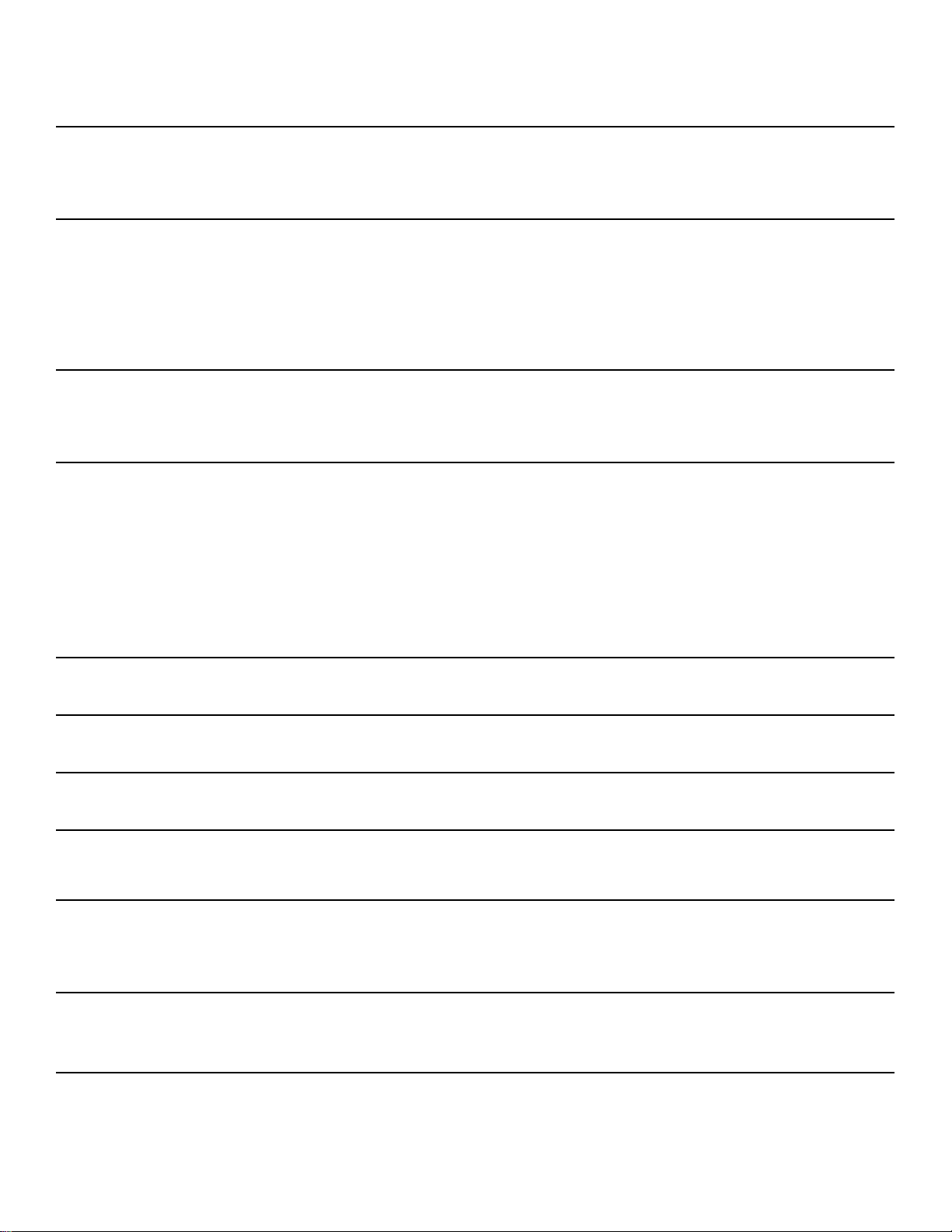

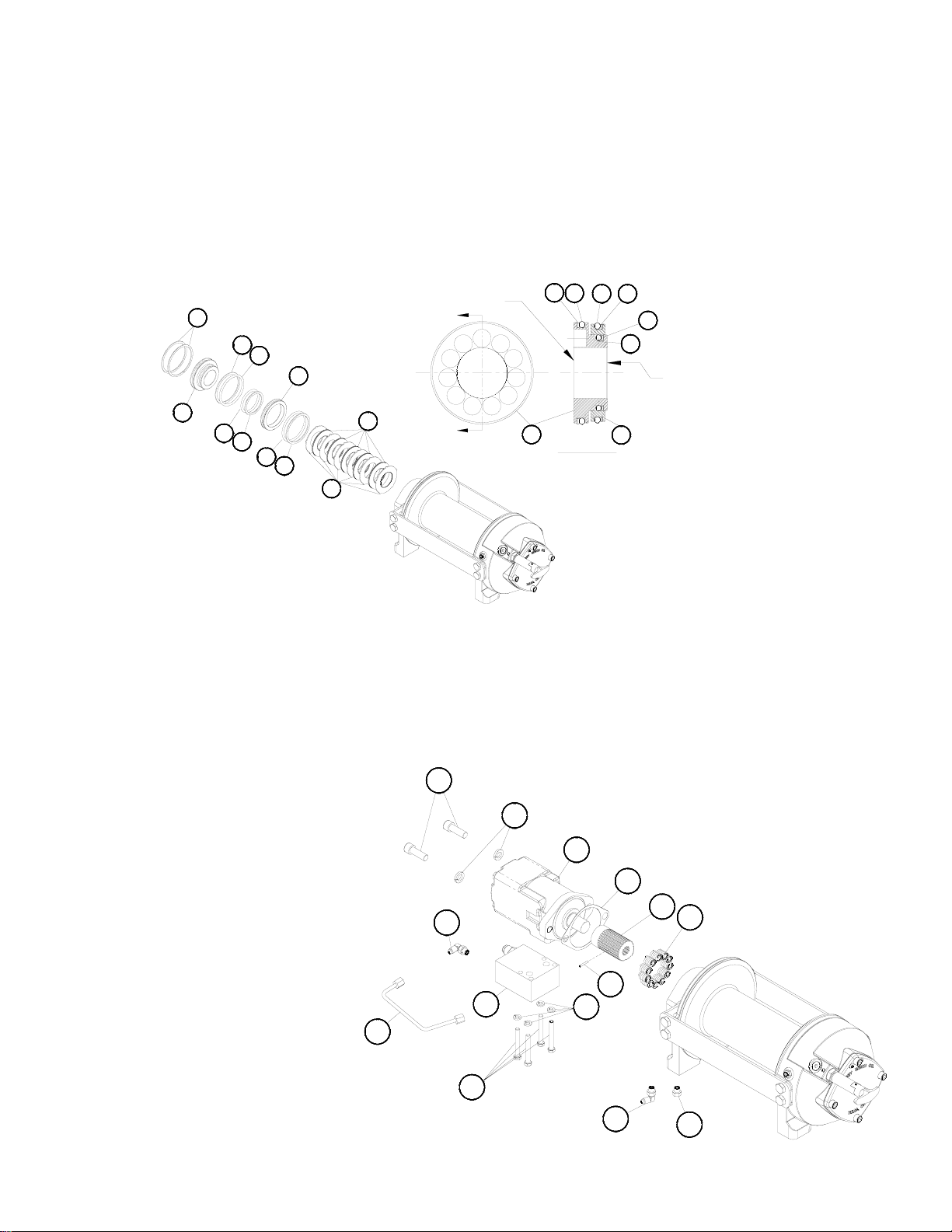

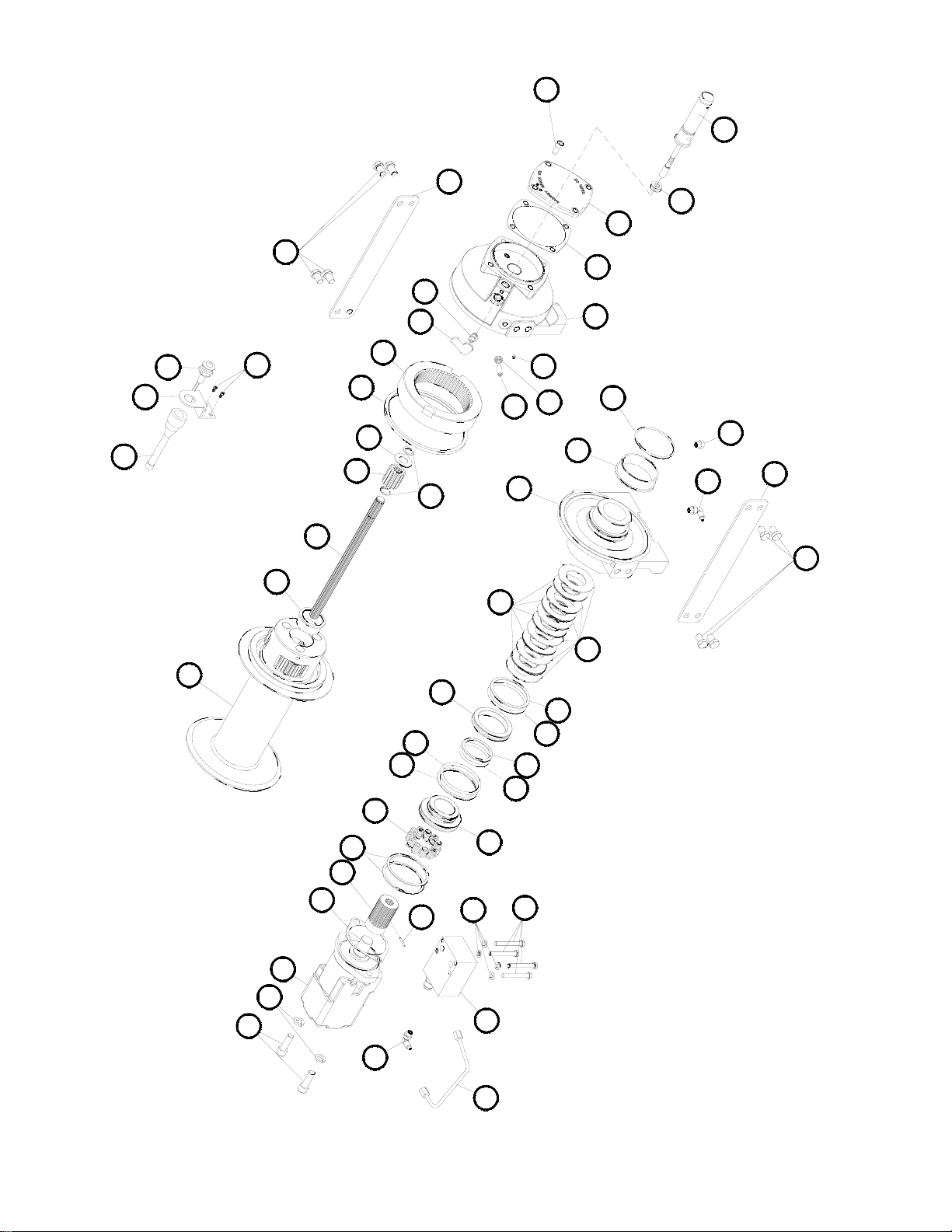

INSTRUCTIONS FOR OVERHAUL HD-P10000 SERIES WINCH

Take note of mounting configurations for proper mounting of parts during re-assembly. Replace all gaskets, o-rings,

and seals during re-assembly.

Disconnect tube (item #44) from elbow fittings (items

#26) on bottom of end bearing and counterbalance valve

(item #45). Remove motor (item #30) from end bearing

by slowly unscrewing capscrews (items #19). CAUTION:

MOTOR IS UNDER SPRING PRESSURE.

Check breather vent (item #48). Make sure it is not

clogged. If oil is leaking from vent, check brake o-rings,

backup rings, and sealing surfaces (see page 8).

Remove springs (items #43) from pockets and inspect for

damage.

Replace gasket (item #28).

Remove coupling (item #25) from end bearing. Examine

coupling for signs of wear, replace if necessary. If necessary, remove counterbalance valve from motor by removing capscrews (items #15).

Remove retaining rings (items #42) with screwdriver.

Remove brake parts from end bearing. NOTE POSITION OF

O-RINGS AND BACKUP RINGS BEFORE REMOVAL. Examine

brake discs (items #5) and stators (items #4) for signs of

wear, and replace if necessary.

Examine o-rings (items #31 and 32) and backup rings

(items #34 and 36) in brake piston (item #6), as well as oring (item #33) and backup ring (item #35) in backup brake

piston (item #7) for signs of wear. Remove o-rings and

backup rings from grooves in brake piston or backup brake

piston and replace if necessary.

Remove tie plates (items #12) from end bearings by

unscrewing capscrews (items #16). Slide motor end

bearing (item #10) and drum (item #1) from gear housing end bearing.

Remove input shaft (item #11) from end bearing. Inspect

shaft and and output sun gear (item #8) for damage and

replace if necessary. To remove the output sun gear,

remove the snap rings (items #41) and thrust washer

(item #47) and pull off the end of the shaft.

Remove bushing (item #14) and o-ring (item #37) from

motor end bearing. Place new, well-oiled o-ring into

groove inside of end bearing and press new bushing onto

end bearing.

43

44

26

45

23

15

26

25

28

30

24

19

48

8

5

4

35

33

7

31

36

32

34

6

42

14

37

10

41

47

8

11

1

12

16

12

16

Page 9

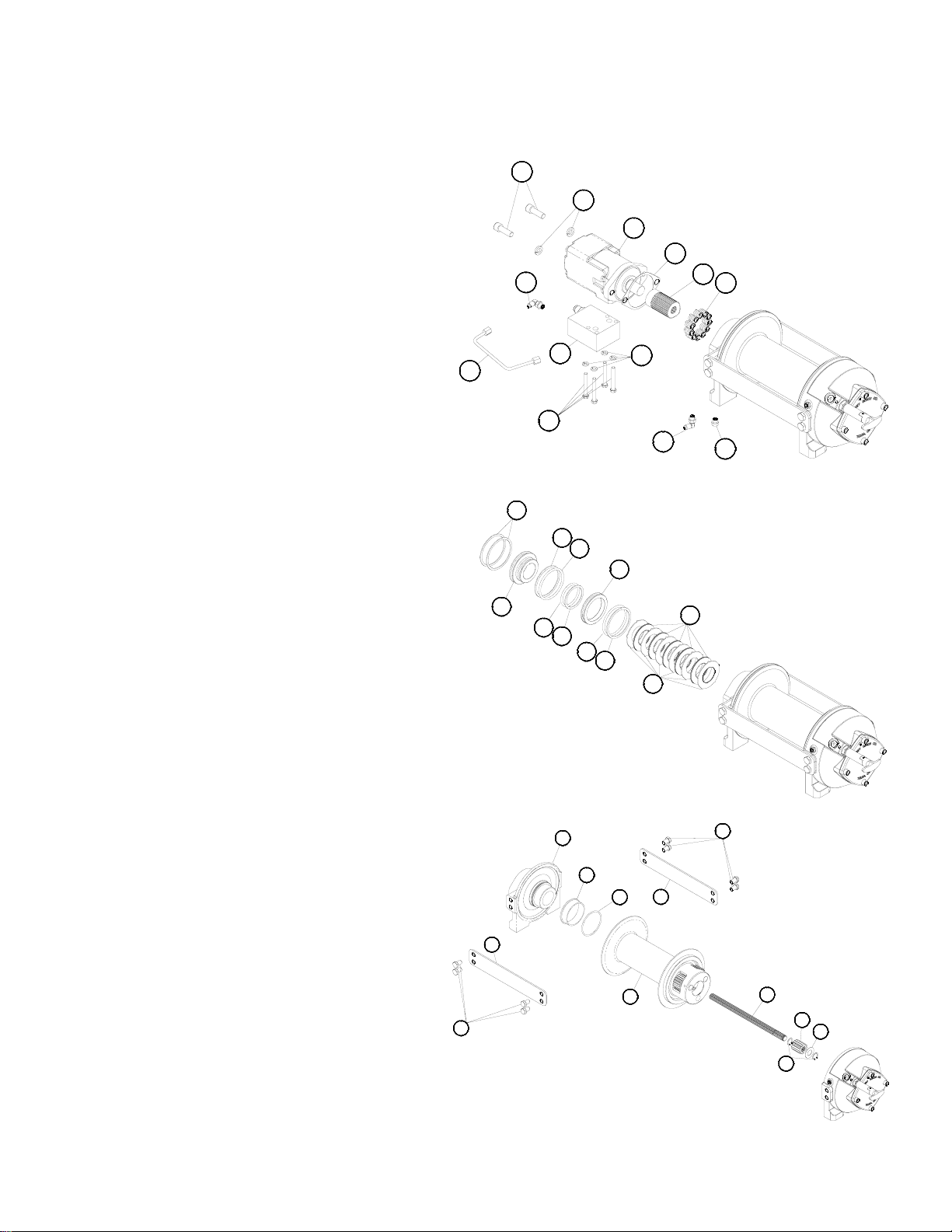

Remove seal (item #40) from gear housing end bearing (item #9).

Loosen nut (item #22) and remove nylon setscrew (item #18). Remove

ring gear from gear housing end bearing, if necessary. Remove bushing

(item #13) from end bearing.

Press new bushing into end bearing. Install ring gear, then nylon setscrew

and nut. Ring gear must be fully seated in end bearing and slot in ring

gear MUST NOT be aligned with clutch shifter hole. Install new seal in end

bearing, with sharp edge of seal outward.

Generously apply grease (MOBILITH SHC 007) to teeth of ring gear (item

#29), teeth of planet gears in drum (item #1), and to bushing (item

#13) in gear housing end bearing. Apply a small amount of grease to

base of bushing (item #14) on motor end bearing. Apply grease to teeth

of output sun gear (item #8) and input shaft (item #11).

Place end of shaft with output sun gear on it into drum. Rotate shaft to

engage planet gears with output sun gear. Place Gear End Bearing on Drum and engage planet gears with ring gear.

Assemble motor end bearing (item #10) to drum assembly and use tie plates (items #12) and capscrews (items #16) to hold

both end bearings together. Tighten capscrews to 55 ft-lbs (75 Nm).

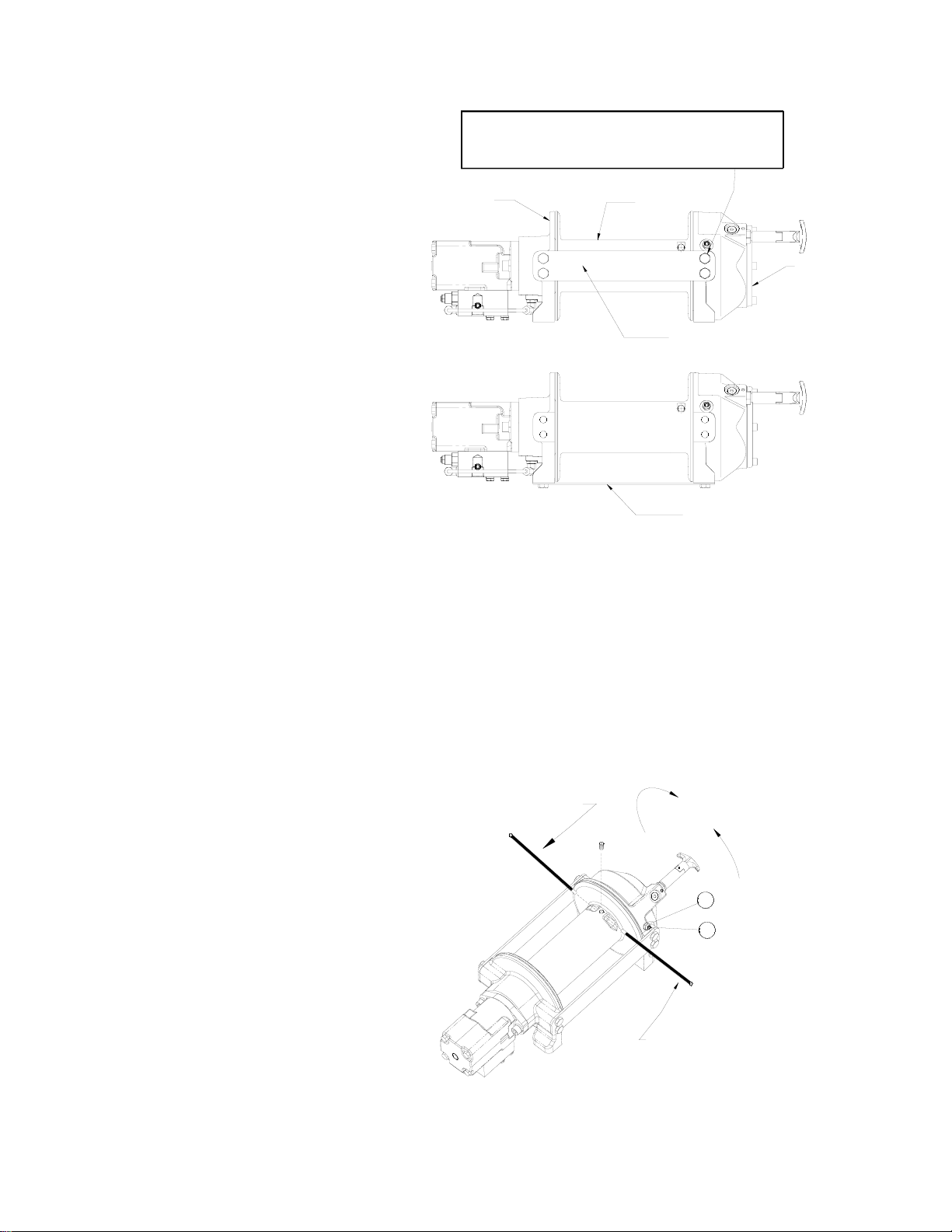

If necessary, remove and replace the shifter assembly (manual, item #2, or air-cylinder, item #3), as follows:

MANUAL CLUTCH SHIFTER ASSEMBLY

Loosen setscrew (item #20) and jam nut on shifter assembly, then unscrew shifter assembly (item #2). Be sure slot in ring

gear is not aligned with clutch shifter hole. Rotate drum, if necessary, to ensure hole and slot are not aligned.

Reinstall shifter assembly with plunger, jam nut, and handle positioned in gear housing as shown below. Thread assembly (with

handle engaged in cylinder slot) into the gear housing. Pull drum toward the gear end bearing housing to remove play. Hold

drum in position and continue threading the shifter assembly in until the gap between the end of the handle and cylinder is

7/16

+0

-1/16

inch and handle is in the horizontal position (see below). Note: This gap will vary with drum endplay. With the

drum pulled against the motor end housing, the gap should be 3/8 inch.

Lightly tighten jam nut. Rotate drum until handle snaps fully into the engaged position. Pull handle out and rotate 90°. Verify that

drum can be rotated freely (at least one full revolution) with clutch shifter at the DISENGAGED position. Securely tighten jam nut

while holding the handle. Tighten setscrew (item #20) securely. Re-check clutch operation as described on page 5.

AIR CYLINDER SHIFTER ASSEMBLY

Loosen set screw (item #20) to remove shifter assembly (item

#3). To reinstall, place 1 or 2 shims (items #44) over plunger

and thread shifter assembly into gear end housing. Add or

remove shims to orient ports for pneumatic connections. Ports

should point down (below horizontal). Tighten setscrew. Check

for clutch operation as described on page 5.

If the light assembly (item #2) or light switch (item #48)

needs to be replaced, refer to the schematic on page 15 for

electrical connections and disassemble and reassemble as

shown below.

29

40

22

18

13

9

9

20

9

42

48

LIGHT SWITCH

LIGHT ASSEMBLY

CYLINDER

23

4

41

2

3

44

21

2

JAM NUT

PLUNGER

AIR-CYLINDER

CLUTCH SHIFTER

MANUAL CLUTCH

SHIFTER

MANUAL CLUTCH ADJUSTMENT

HANDLE (HORIZONTAL)

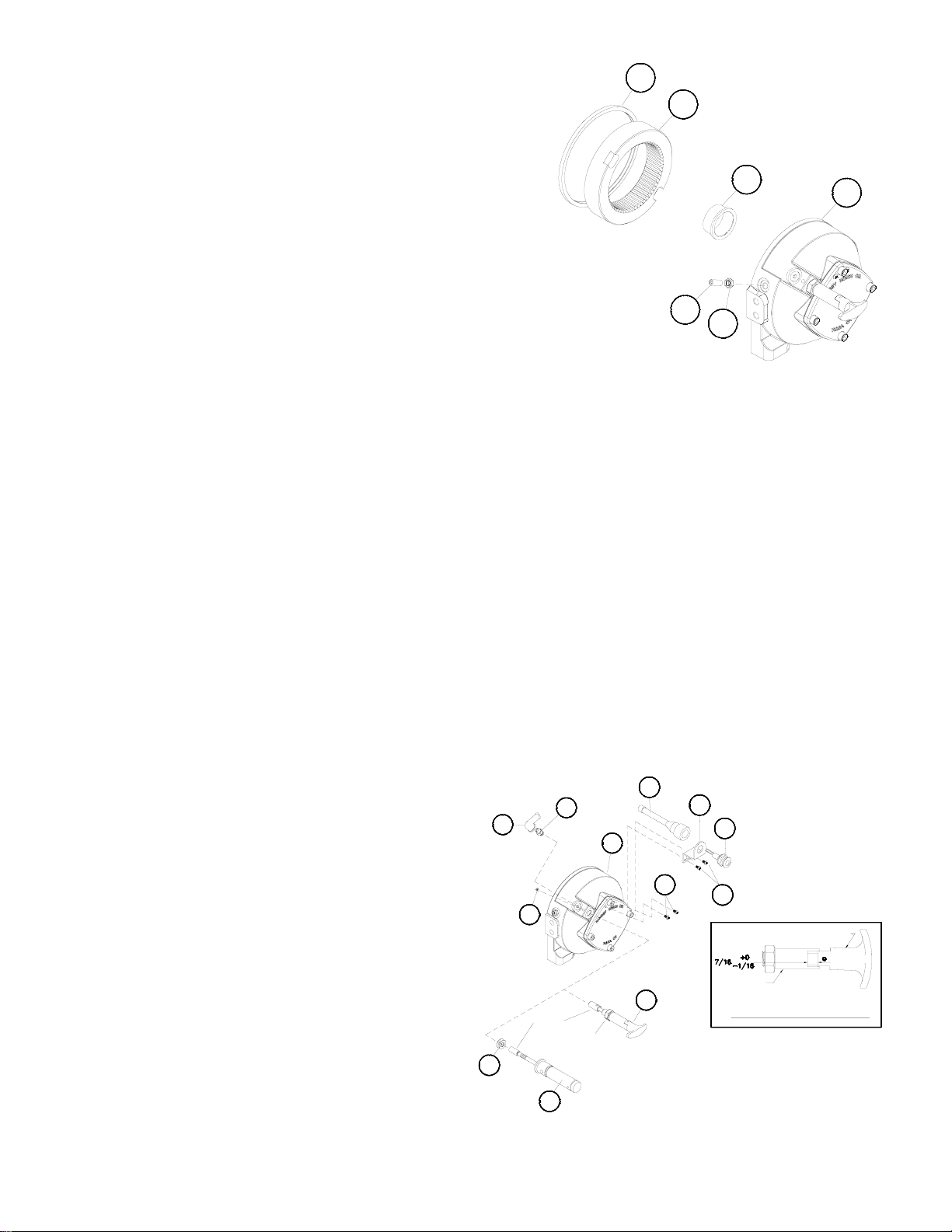

Page 10

Set winch with gear housing end down on work surface.

Install well-oiled o-rings and backup rings into grooves on outside of brake piston and backup brake piston as shown in cross-

section A-A below.

Piston, backup piston, brake discs and stators must be clean and free of grease and oil.

Insert brake discs (item #5) and stators (item #4) into gear end alternating, with stators first and last.

Insert backup brake piston (item #7) into motor end and insert brake piston (item #6) into it. Apply even pressure on piston

when installing.

Install retaining rings (item #42) into grooves in motor end housing.

Insert springs (item #43) into pockets in back of brake piston.

Install roll pin (item #38) into new motor coupling below bottom of spline teeth. Insert motor coupling (item #25),

engaging it with the discs and the input shaft.

Place gasket (item #28) on mounting surface of motor (item #30). Slide motor shaft into coupling. Attach motor to motor end

bearing housing using (2) capscrews (item #19) and (2) lockwashers (item #24). Evenly tighten to 49 ft-lbs. (66 Nm) torque.

Install the counterbalance valve (item #45) to the motor using (4) capscrews (item #15) and (4) lockwashers (item #23).

Tighten to 17 ft-lbs (23 Nm).

Securely connect fittings (item #26) to motor

end housing and counterbalance valve, and

connect tube assembly (item #44) to fittings.

Apply at least 550 PSI hydraulic system pressure to brake and verify that brake releases

(winch drum will rotate).

SECTION A-A

A

A

5

4

35

33

7

31

36

32

34

6

42

DRUM SIDE

MOTOR SIDE

36

31

3533

32

34

7

6

10

26

26

44

48

43

45

23

15

25

28

30

24

19

38

Page 11

BARREL

CLUTCH ENGAGED POSITION

CLUTCH DISENGAGED POSITION

1/2-13UNC X .75 (INCHES) DEEP TAPPED HOLE

(2-PLACES EACH SIDE OF MOTOR END BEARING)

7/8-14 SAE PORT

(2-PLACES)

(2-PLACES EACH SIDE OF GEAR HOUSING END BEARING)

1/2-13UNC X .50 (INCHES) DEEP TAPPED HOLE

NOTES:

1. DIMENSIONS SHOWN ARE INCHES OVER MILLIMETERS.

2. WINCH MOUNTING CAPSCREWS MUST MEET OR EXCEED SAE GRADE 5 SPECIFICATION.

3. THESE HOLE LOCATIONS MUST BE HELD WITHIN ±.03 (0.8mm)

OF TRUE POSITION. RECOMMENDED MOUNTING HOLE DIAMETER IS .53 (13.5mm).

FLANGE

1.25

[31.8]

7.17

[182.1]

Ø3.94

[100.0]

DRUM

(TYP)

1.12

[28.4]

(TYP)

(TYP)

1.12

[28.4]

4.68

[118.9]

9.36

[237.7]

MOVE TIE PLATES TO FEET

FOR SIDE MOUNT INSTALLATIONS,

1/2-13UNC X .75 (INCHES) DEEP TAPPED HOLE

(4-PLACES EACH END BEARING)

CABLE ANCHOR

MM

INCHES

F

28.84

732,4

25.59

649,9

"Y" DRUM

STD. DRUM

296,2

11.66

337,4

13.28

353,7

13.93

395,0

15.55

E

INCHES

MM

D

INCHES

MM

WINCH

MODEL

HD-P10000

HD-P10000

INCHES

MM

A

MM

INCHES

B

MM

INCHES

C

9.75

247,7

6.50

165,1

12.25

311,2

9.00

228,6

10.04

255,0

8.41

213,7

A

B

C

D E

F

2.21

[56.1]

.56

[14.3]

2.25

[57.2]

4.19

[106.4]

8.38

[212.7]

.50

[12.7]

Ø8.25

[209.6]

Ø.50

[Ø12.7]

9.41

[239.1]

4.92

[125.0]

3.79

[96.3]

HD-P10000 MANUAL SHIFT

11

Page 12

(TYP)

1.12

[28.4]

1.12

[28.4]

4.68

[118.9]

9.36

[237.7]

MOVE TIE PLATES TO FEET

FOR SIDE MOUNT INSTALLATIONS,

1/2-13UNC X .75 (INCHES) DEEP TAPPED HOLE

(4-PLACES EACH END BEARING)

CABLE ANCHOR

2.21

[56.1]

12V BATTERY

INDICATOR LIGHT

(ON WHEN CLUTCH

IS ENGAGED)

SWITCH

BUTT

CONNECTOR

ATTACH TO GROUND (16 GA.

WIRE SUPPLIED BY CUSTOMER)

ELECTRICAL

SCHEMATIC

ATTACH TO PTO INDICATOR SWITCH TO

RECEIVE 12V DC WHEN PTO IS ENGAGED.

NOTE: LIGHT SHOULD BE "ON" WHEN CLUTCH IS

ENGAGED AND "OFF" WHEN CLUTCH IS DISENGAGED.

ATTACH TO 12V DC (+)

(SEE ELECTRICAL SCHEMATIC)

ATTACH TO GROUND (-)

(SEE ELECTRICAL SCHEMATIC)

1/8-27NPT PORT

(CONNECT 80 TO 150 PSI**

PRESSURE LINE TO DISENGAGE CLUTCH)

INDICATOR

LIGHT

SWITCH

B

4.92

[125.0]

9.41

[239.1]

3.79

[96.3]

F

Ø8.25

[209.6]

A

D E

C

2.21

[56.1]

4.25

[108.0]

8.38

[212.7]

4.19

[106.4]

2.25

[57.2]

.56

[14.3]

3.59

[91.1]

9.15

[232.4]

Ø.50

[Ø12.7]

BARREL

1/2-13UNC X .75 (INCHES) DEEP TAPPED HOLE

(2-PLACES EACH SIDE OF MOTOR END BEARING)

7/8-14 SAE PORT

(2-PLACES)

(2-PLACES EACH SIDE OF GEAR HOUSING END BEARING)

1/2-13UNC X .50 (INCHES) DEEP TAPPED HOLE

NOTES:

1. DIMENSIONS SHOWN ARE INCHES OVER MILLIMETERS.

2. WINCH MOUNTING CAPSCREWS MUST MEET OR EXCEED SAE GRADE 5 SPECIFICATION.

3. THESE HOLE LOCATIONS MUST BE HELD WITHIN ±.03 (0.8mm)

OF TRUE POSITION. RECOMMENDED MOUNTING HOLE DIAMETER IS .53 (13.5mm).

FLANGE

1.25

[31.8]

Ø3.94

[100.0]

DRUM

C

L

MM

INCHES

F

28.28

718,3

24.99

634,7

"Y" DRUM

STD. DRUM

240,5

9.47

323,1

12.72

353,8

13.93

394,9

15.55

E

INCHES

MM

D

INCHES

MM

WINCH

MODEL

HD-P10000

HD-P10000

INCHES

MM

A

MM

INCHES

B

MM

INCHES

C

9.75

247,7

6.50

165,1

12.25

311,2

9.00

228,6

10.04

255,0

8.41

213,6

HD-P10000 AIR SHIFT

12

Page 13

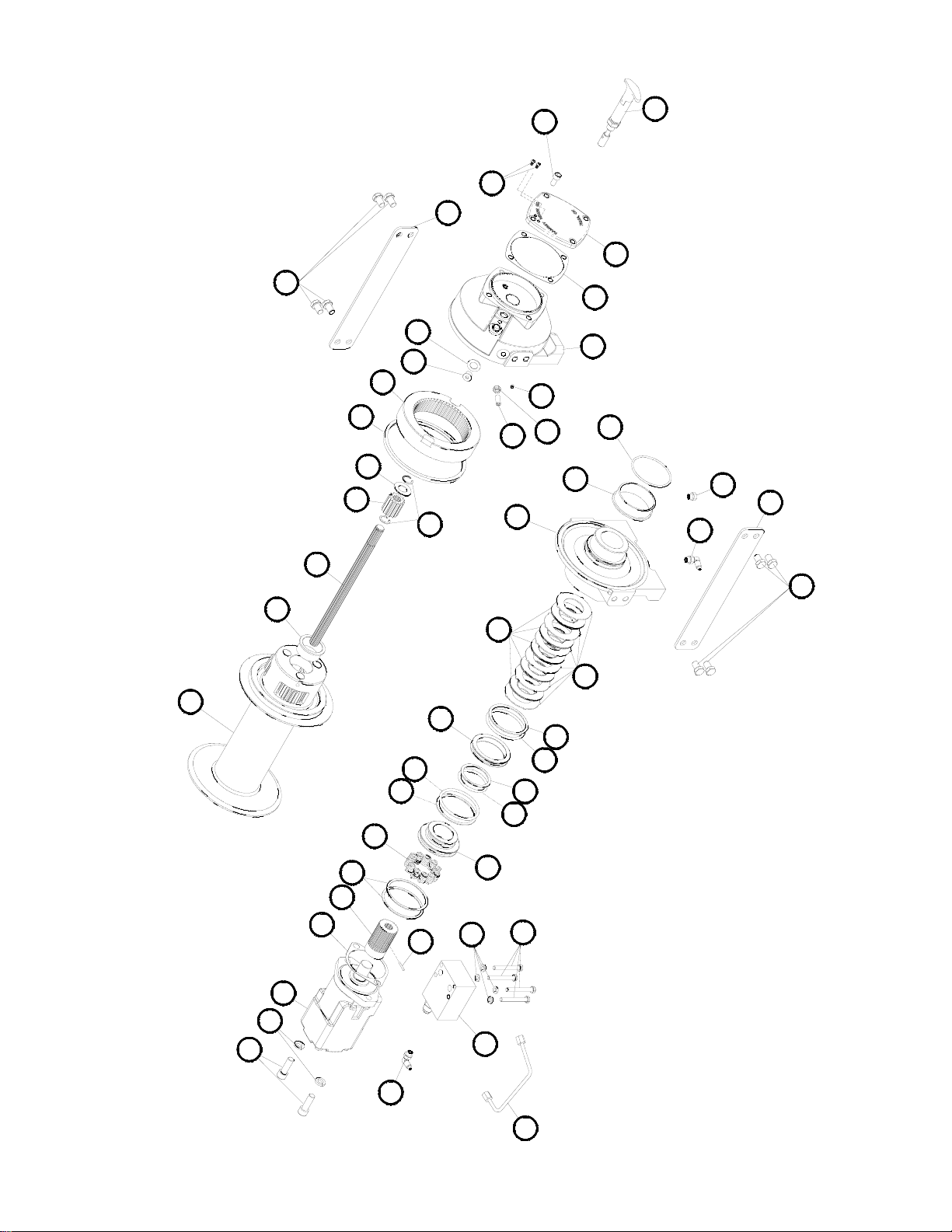

9

10

15

23

45

26

44

19

24

30

38

28

25

42

43

6

34

32

36

31

7

33

35

4

5

37

14

26

12

16

18

22

20

2

39

46

12

16

40

29

8

41

47

11

13

1

27

3

21

17

48

13

Page 14

Item No. Quantity Part No. Description Item No. Quantity Part No. Description

1 1 234207 DRUM ASSY STD 24 2 418218 LOCKWASHER-1/2 ID MED SECT, ZINC

1 234208 DRUM ASSY "Y" 25 1 431020 COUPLING-MOTOR

2 1 276048 SHIFTER ASSY 26 2 432018 FITTING

3 1 328164 COVER-GEAR HOUSING 27 1 442212 GASKET-GEAR HOUSING COVER

4 6 330011 STATOR-BRAKE 28 1 442223 GASKET-MOTOR FLANGE

5 5 330012 DISC-BRAKE 29 1 444084 GEAR-RING

6 1 330013 PISTON-BRAKE 30 1 458079 MOTOR-HYD.

7 1 330014 PISTON-BACKUP BRAKE 31 1 462067 O-RING PISTON-SM.

8 1 334174 GEAR-OUTPUT, SUN 32 1 462068 O-RING PISTON-LG.

9 1 338327 END BEARING-GEAR HOUSING 33 1 462069 O-RING BACKUP PISTON

10 1 338358 END BEARING-MOTOR 34 1 462070 RING-BACKUP PISTON-LG

11 1 357177 SHAFT-INPUT STD DRUM 35 1 462071 RING-BACKUP BACKUP PISTON

1 357176 SHAFT-INPUT "Y" DRUM 36 1 462072 RING-BACKUP PISTON-SM

12 2 395427 PLATE-TIE STD DRUM 37 1 462073 O-RING

2 395426 PLATE-TIE "Y" DRUM 38 1 470033 SPIROL PIN

13 1 412085 BUSHING-DRUM 39 1 472052 PLUG

14 1 412109 BUSHING-DRUM, MOTOR END 40 1 486080 SEAL

15 4 414159 CAPSCREW-5/16-18UNC X 2 1/2", HEX HEAD, ZINC, GR5 41 2 490003 SNAP RING

16 8 414581 CAPSCREW-1/2-13NC X 3/4", HEX HEAD, ZINC, GR5 42 2 490049 RING-INTERNAL RETAINING

17 4 414901 CAPSCREW-3/8-16NC X 3/4", HEX SOCKET HEAD 43 11 494124 SPRING-BRAKE

18 1 414926 SETSCREW-3/8-16NC X 1", SOCKET HEAD, NYLON 44 1 509132 TUBE-BRAKE RELEASE (PORTS DOWN)

19 2 414952 CAPSCREW-1/2-13NC X 1 1/2", SOCKET HEAD, ZINC 1 509131 TUBE-BRAKE RELEASE (PORTS UP)

20 1 416016 SETSCREW-1/4-20NC X 1/4", HEX SOCKET HEAD CUP 45 1 516041 VALVE-MOTOR CONTROL (A ROTATION)

21 2 416239 SCREW-#10-24NC X 3/8", HEX SOCKET BUTTON HEAD 1 516042 VALVE-MOTOR CONTROL (B ROTATION)

22 1 418036 NUT-3/8-16 NC, HEX JAM, ZINC 46 1 518037 THRUST WASHER

23 4 418163 LOCKWASHER-5/16 MED SECT, ZINC 47 1 518047 THRUST WASHER

48 1 456038 BREATHER VENT

PARTS LIST - MANUAL SHIFT

14

Page 15

6

7

39

16

28

14

18

20

24

22

14

18

43

31

10

45

51

13

15

1

11

12

17

25

50

28

49

21

26

32

40

30

27

46

47

8

36

34

38

33

9

35

37

44

48

42

23

4

2

41

52

29

5

19

3

15

Page 16

Item No. Quantity Part No. Description Item No. Quantity Part No. Description

1 1 234207 DRUM ASSY STD 26 2 418218 LOCKWASHER-1/2 ID MED SECT, ZINC

1 234208 DRUM ASSY "Y" 27 1 431020 COUPLING-MOTOR

2 1 236020 LIGHT ASSY 28 2 432018 FITTING

3 1 276058 SHIFTER ASSY 29 1 442212 GASKET-GEAR HOUSING COVER

4 1 312569 BRACKET - LIGHT ASSY 30 1 442223 GASKET-MOTOR FLANGE

5 1 328164 COVER-GEAR HOUSING 31 1 444084 GEAR-RING

6 6 330011 STATOR-BRAKE 32 1 458079 MOTOR-HYD.

7 5 330012 DISC-BRAKE 33 1 462067 O-RING PISTON-SM.

8 1 330013 PISTON-BRAKE 34 1 462068 O-RING PISTON-LG

9 1 330014 PISTON-BACKUP BRAKE 35 1 462069 O-RING BACKUP PISTON

10 1 334174 GEAR-OUTPUT, SUN 36 1 462070 RING-BACKUP PISTON-LG

11 1 338327 END BEARING-GEAR HOUSING 37 1 462071 RING-BACKUP BACKUP PISTON

12 1 338358 END BEARING-MOTOR 38 1 462072 RING-BACKUP PISTON-SM

13 1 357177 SHAFT-INPUT STD DRUM 39 1 462073 O-RING

1 357176 SHAFT-INPUT "Y" DRUM 40 1 470033 SPIROL PIN

14 2 395427 PLATE-TIE STD DRUM 41 1 482013 RUBBER BOOT

2 395426 PLATE-TIE "Y" DRUM 42 1 482045 RUBBER BOOT

15 1 412085 BUSHING-DRUM 43 1 486080 SEAL

16 1 412109 BUSHING-DRUM, MOTOR END 44 2 488007 SHIM

17 4 414159 CAPSCREW-5/16-18UNC X 2 1/2", HEX HEAD, ZINC, GR5 45 2 490003 SNAP RING

18 8 414581 CAPSCREW-1/2-13NC X 3/4", HEX HEAD, ZINC, GR5 46 2 490049 RING-INTERNAL RETAINING

19 4 414901 CAPSCREW-3/8-16NC X 3/4", HEX SOCKET HEAD 47 11 494124 SPRING-BRAKE

20 1 414926 SETSCREW-3/8-16NC X 1", SOCKET HEAD, NYLON 48 1 504021 SWITCH

21 2 414952 CAPSCREW-1/2-13NC X 1 1/2", SOCKET HEAD, ZINC 49 1 509132 TUBE-BRAKE RELEASE (PORTS DOWN)

22 1 416016 SETSCREW-1/4-20NC X 1/4" HEX SOCKET HEAD CUP 1 509131 TUBE-BRAKE RELEASE (PORTS UP)

23 2 416239 SCREW-#10-24NC X 3/8", HEX SOCKET BUTTON HEAD 50 1 516041 VALVE-MOTOR CONTROL A ROTATION

24 1 418036 NUT-3/8-16 NC, HEX JAM, ZINC 1 516042 VALVE-MOTOR CONTROL B ROTATION

25 4 418163 LOCKWASHER-5/16 MED SECT, ZINC 51 1 518047 THRUST WASHER

52 1 456038 BREATHER VENT

PARTS LIST - AIR SHIFT

16

Page 17

MANUEL D’UTILISATION,

DE DÉPANNAGE

ET D’ENTRETIEN

TREUIL À PLANÉTAIRE MODÈLE HD-P10000

MISE EN GARDE : ASSUREZ-VOUS DE LIRE ET DE COMPRENDRE CE MANUEL AVANT D’INSTALLER

ET D’UTILISER LE TREUIL. N’OUBLIEZ PAS LES AVERTISSEMENTS ET MISES EN GARDE.

Ramsey Winch Company

P.O. Box 581510 - Tulsa, OK 74158-1510 USA

Phone: (918) 438-2760 - Fax (918) 438-6688

Visit us at http://www.ramsey.com

Page 18

TABLE OF CONTENTS

INTRODUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

INFORMATIONS DE GARANTIE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

CARACTÉRISTIQUES TECHNIQUES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

AVERTISSEMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

FIXATION DU TREUIL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

INSTALLATION DU CÂBLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

ENTRETIEN DU TREUIL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

TECHNIQUES D’UTILISATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

SYSTÈMES HYDRAULIQUES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

DISPOSITION TYPE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

GRAPHIQUES DE PERFORMANCES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

GUIDE DE RÉSOLUTION DES PROBLÈMES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

INSTRUCTIONS DE RÉVISION DES TREUILS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24-26

PLAN COTÉ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27-28

LISTE ET SCHÉMA DES PIÈCES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29-32

GARANTIE LIMITÉE

RAMSEY WINCH garantit chaque treuil RAMSEY neuf contre tout défaut de matériau et de fabrication pendant une période d’un (1) an à

partir de la date d’achat. L'obligation aux termes de cette garantie, statutaire ou autre, est limitée au remplacement ou à la réparation à l’usine du fabricant, ou à un endroit désigné par le fabricant, de la pièce qui semblera présenter un défaut de fabrication ou de matériau, suite

à l'inspection effectuée par le fabricant.

Cette garantie n’oblige pas RAMSEY WINCH à s’acquitter des frais de main-d'ouvre ou de transport liés au remplacement ou à la réparation des pièces défectueuses, et ne s'applique pas à un produit ayant subi des réparations ou des modifications (sauf si elles ont été

autorisées par le fabricant), ou en cas de mauvaise utilisation de l’équipement, de négligence ou de matériel mal installé.

RAMSEY WINCH ne pourra en aucun cas être tenue responsable des dommages particuliers et indirects. RAMSEY WINCH n’émet aucune

garantie au sujet des accessoires et portant par exemple sur les garanties de leurs fabricants respectifs. RAMSEY WINCH s’efforce de

poursuivre une politique d’amélioration constante et se réserve par conséquent le droit d'améliorer ses produits par le biais de modifications de leur conception ou des matériaux employés, selon les besoins, et sans être obligée d'incorporer ces modifications aux produits

fabriqués précédemment.

En cas d’intervention sur le terrain à la demande de l’acquéreur, et si la défaillance s’avère ne pas provenir du produit RAMSEY WINCH,

l’acquéreur s’engage à s’acquitter auprès du représentant des frais correspondant au temps et aux dépenses.

Les factures d'entretien, de main-d’ouvre et autres frais engagés par l’acquéreur sans l'accord ou l'autorisation de RAMSEY WINCH ne

seront pas acceptées.

Reportez-vous à la carte de garantie pour les détails.

Page 19

VEUILLEZ LIRE ATTENTIVEMENT CE MANUEL.

Ce manuel contient des conseils utiles pour l'utilisation efficace de votre treuil Ramsey ; il aborde aussi les procédures de sécurité à connaître absolument avant l’utilisation d’un tel équipement.

INFORMATIONS DE GARANTIE

Les treuils Ramsey sont conçus et fabriqués selon des spécifications rigoureuses. Ils font tous l’objet d’un travail soigné et

compétent. En cas de besoin, la procédure de recours en garantie est détaillée au verso de votre carte de garantie préadressée

à port payé. Veuillez lire et remplir la carte de garantie ci-jointe, et l'envoyer à Ramsey Winch Company. En cas de problème

avec votre treuil, suivez les instructions fournies afin d’obtenir un service rapide de recours en garantie.

*CARACTÉRISTIQUES TECHNIQUES

Remarque : les tractions nominales indiquées sont uniquement pour le treuil. Consultez le fabricant du câble pour les caractéristiques nomi-

nales de ce dernier.

AVERTISSEMENTS :

UN DISTRIBUTEUR À TIROIR CYLINDRIQUE DE MOTEUR (CENTRE OUVERT) EST NÉCESSAIRE POUR LE FONCTIONNEMENT DU FREIN.

L’EMBRAYAGE DOIT ÊTRE ENTIÈREMENT ENCLENCHÉ AVANT DE COMMENCER TOUT TREUILLAGE.

NE RELÂCHEZ JAMAIS L’EMBRAYAGE EN PRÉSENCE D’UNE CHARGE.

NE LAISSEZ PAS L’EMBRAYAGE ENCLENCHÉ LORSQUE LE TREUIL N’EST PAS UTILISÉ.

NE VOUS PLACEZ JAMAIS SOUS UNE CHARGE SOULEVÉE NI À PROXIMITÉ.

RESTEZ À L’ÉCART DU CÂBLE LORS DU TREUILLAGE. N’ESSAYEZ PAS DE GUIDER LE CÂBLE.

NE DÉPASSEZ PAS LES CARACTÉRISTIQUES DE TRACTION NOMINALES MAXIMALES INDIQUÉES DANS LE TABLEAU.

N’UTILISEZ PAS LE TREUIL POUR SOULEVER, MAINTENIR OU TRANSPORTER DES PERSONNES.

IL CONVIENT DE CONSERVER AU MINIMUM CINQ TOURS DE CÂBLE AUTOUR DU TAMBOUR POUR MAINTENIR LA

CHARGE. L’ATTACHE DU CÂBLE N’EST PAS CONÇUE POUR ASSURER LE MAINTIEN D’UNE CHARGE.

DANS LES APPLICATIONS DE TRANSPORT D’AUTOMOBILES, VEILLEZ À BIEN FIXER LE VÉHICULE SUR LE PORTE-

VOITURES. LA CHARGE IMPOSÉE AU CÂBLE DU TREUIL NE DOIT PAS ÊTRE MAINTENUE PENDANT LE TRANSPORT. N’UTILISEZ PAS LE TREUIL COMME DISPOSITIF D’ATTACHE.

LORSQUE VOUS TREUILLEZ UNE LOURDE CHARGE, PLACEZ UNE COUVERTURE, UNE VESTE OU UNE BÂCHE SUR LE

CÂBLE À ENVIRON 1,8 m DU CROCHET.

ÉVITEZ TOUS RISQUES DE GLISSEMENT DE LA CHARGE OU D’À-COUPS À SON NIVEAU, CAR ILS POURRAIENT

S’AVÉRER DANGEREUX.

19

(lbs.)

………………………………………

10,000

(Kg.)

………………………………………

4,545

Démultiplication 5.1:1

HD-P10000 STD. …….. 87 lbs. (39.5 Kg)

HD-P10000 "Y" ……….. 82 lbs. (37.2 Kg)

1234

lbs. 10,000 8,300 7,100 6,200

Kg. 4,530 3,760 3,220 2,810

ft. 205080115

m 6 15 24 35

ft. 15305575

m491622

FPM32384451

MPM 9.8 11.6 13.4 15.5

Traction du câble

nominale

………………………………………………

Poids (sans le câble)

*Ces caractéristiques techniques sont basées sur un câble d’aéronef

galvanisé de 11 mm ou sur un câble en acier de charrue amélioré et

sur un moteur de 408 cm³/tr.

Couche de câble

*Traction Nominale

Par Couche De Câble

HD-P10000 (STD.

DRUM)

* Vitesse du câble

(à 56 l/min)

HD-P10000 ("Y"

DRUM)

* Capacité De Câble Par Couche

Page 20

FIXATION DU TREUIL

INSTRUCTIONS DE MONTAGE IMPORTANTES POUR MAINTENIR L’ALIGNEMENT DES ÉLÉMENTS DU TREUIL À PLANÉTAIRE :

Ce treuil doit absolument être monté correctement afin que les

trois principales parties soient alignées (l’extrémité du carter

d’embrayage, le tambour du câble et l’extrémité de la boîte d'engrenages).

À des fins de conformité, s’il s’agit d’un montage de treuil intermédiaire, il convient de fixer au moins une plaque de serrage aux

pieds de fixation au bas du treuil pour maintenir l’alignement.

REMARQUE : si le treuil est installé sur pieds, au moins une

plaque de serrage doit être placée au point intermédiaire pour

maintenir l’alignement. Il est toujours souhaitable d’utiliser les

deux plaques de serrage pour l’installation finale.

Il est conseillé d’utiliser le coffret de montage sur cornières, nº

251006 (pour tambour « Standard ») et nº 251007 (pour tambour « Y ») pour faciliter l’installation du treuil. Ce coffret permet

de s’adapter aux installations verticales ou intermédiaires, et

constitue une surface de montage droite et solide.

Si vous installez le treuil sans le coffret de cornières Ramsey

recommandé, il convient alors d’utiliser les trous de fixation

décrits en page 14. La surface de fixation doit être plane, à 0,38

mm près, et suffisamment rigide pour ne pas fléchir. Si une

plaque d’acier est employée pour l’installation sur pied, elle doit

mesurer 19 mm d’épaisseur. Pour ce type de montage, vous

aurez besoin de huit vis d’assemblage 1/2-13 NC x 1,5 po de long, grade 5, avec leurs rondelles de sécurité. Ces vis devront être serrées à

un couple de 115 Nm.

REMARQUE : si des cornières ou une plaque d’acier sont utilisées pour l’installation du treuil, les plaques de serrage fournies doivent être

fixées aux cales de montage restantes, qu’elles soient latérales ou inférieures.

INSTALLATION DU CÂBLE

Un autocollant placé sur le dessus du palier d’extrémité indique le sens de l’enroulement du câble. Les lettres « A » ou « B » figurent aussi

sur le palier d’extrémité, côté frein, pour indiquer le sens de rotation. Si cet autocollant est détérioré ou illisible, contactez le service clientèle

pour savoir comment déterminer le sens de rotation correct.

1. Déroulez le câble sur le sol pour éviter qu'il ne se torde. Recouvrez bien l’extrémité du câble opposée au crochet d’un ruban adhésif plastique ou de type équivalent pour éviter qu’il ne s’effiloche.

2. Placez l’extrémité effilée du câble dans le trou du tambour, comme indiqué ci-dessous. Utilisez une vis de pression à tête creuse hexagonale 3/8-16 NC x ½ po de long (sur le tambour « Y » 234165 et sur le tambour « Standard » 234166) pour fixer le câble au tambour.

3. Faites tourner avec précaution le treuil dans le sens de l’enroulement. Conservez une tension sur l’extrémité du câble et enroulez tout le

câble sur le tambour en veillant à former

des couches régulières.

Une fois le câble installé, vérifiez que le tambour tourne librement. Désenclenchez l’embrayage et tirez sur le câble en marchant. Si

le câble se détend et forme des boucles

autour du tambour, desserrez le contre-écrou

(pièce nº 27) et tournez la vis en Nylon (pièce

nº 22) dans le sens des aiguilles d’une montre pour augmenter le frottement sur le tambour. Si le frottement est trop important,

desserrez cette vis en la tournant dans le

sens inverse des aiguilles d’une montre.

Serrez le contre-écrou une fois le réglage correct obtenu.

MISE EN GARDE : tout serrage excessif du

contre-écrou pourrait fausser le filet de la vis

de pression en Nylon.

EXTRÉMITÉ

MOTEUR

TAMBOUR DU CÂBLE

EXTRÉMITÉ BOÎTE

D'ENGRENAGES

PLAQUE DE SERRAGE LATÉRALE

PLAQUE DE SERRAGE AU PIED (BASE)

MONTAGE SUR PIED

MONTAGE INTERMÉDIAIRE

MISE EN GARDE : en cas d'utilisation de boulons plus longs (grade 5 minimum)

pour la fixation du treuil ou d'un guide à galets au niveau des cales de fixation

latérales, la longueur des boulons ne doit pas permettre un engagement des filets

de plus de 12 mm dans les trous taraudés sur les côtés de chaque palier d'extrémité

(cf. page 15). Des boulons trop longs endommageraient le treuil et empêcheraient le

tambour de tourner librement. Serrez les boulons à un couple de 75 Nm.

20

Vis de pression

Sens de

rotation « A »

Sens de

rotation « B »

INSÉREZ LE CÂBLE COMME INDIQUÉ POUR

L'ENROULEMENT PAR LE DESSUS, ROTATION « B ».

(POUR L'ENROULEMENT PAR LE DESSOUS, LE CÂBLE

DOIT VENIR DU SENS OPPOSÉ, PASSER SOUS LE

TAMBOUR ET ÊTRE INSÉRÉ DANS CE MÊME LOGEMENT.)

INSÉREZ LE CÂBLE COMME INDIQUÉ POUR

L'ENROULEMENT PAR LE DESSUS, ROTATION « A ».

(POUR L'ENROULEMENT PAR LE DESSOUS, LE CÂBLE

DOIT VENIR DU SENS OPPOSÉ, PASSER SOUS LE

TAMBOUR ET ÊTRE INSÉRÉ DANS CE MÊME LOGEMENT.)

20

17

Page 21

21

ENTRETIEN

1. Examinez l’état du câble et lubrifiez-le fréquemment. Tout câble effiloché ou comportant des brins brisés doit être remplacé immédiate-

ment. Il est possible de se procurer un ensemble câble-crochet (câble de 30 mètres) nº réf. 524118 (tambour « Y ») ou (câble de 45

mètres) nº réf. 524119 (tambour « Standard ») auprès d’un distributeur Ramsey.

2. Assurez-vous que l’embrayage est complètement enclenché. Reportez-vous aux instructions de la rubrique FONCTIONNEMENT, ci-

dessus, selon le type d’embrayage. POUR LES EMBRAYAGES MANUELS UNIQUEMENT : tous les mois, désenclenchez l'embrayage,

placez plusieurs gouttes d'huile sur l'arbre et manipulez plusieurs fois l'embrayage pour lubrifier l’intérieur du cylindre.

3. Assurez-vous que le câble ne se détend pas pour former de larges boucles lors du déroulement libre. Reportez-vous à la page 20.

4. Remplacez les bagues du tambour ainsi que les joints lorsqu'ils commencent à perdre de la graisse. Reportez-vous aux INSTRUC-

TIONS DE RÉVISIONS en page 24-26. Le cas échéant, ajoutez du lubrifiant, Mobilith SHC 007, aux engrenages.

FONCTIONNEMENT

Pour vous familiariser avec votre treuil, il est vivement conseillé de l’essayer avant de vraiment l’utiliser. Préparez votre essai à l’avance.

N’oubliez pas que vous entendez votre treuil autant que vous le voyez fonctionner. Apprenez à reconnaître le son d'une traction légère et

régulière, celui d'une lourde charge ou encore celui provoqué par des à-coups ou une déviation de la charge. Évitez tous risques de glissements de la charge ou d’à-coups à son niveau, car ils pourraient représenter de dangereuses conditions.

L’embrayage du treuil permet un déroulement rapide du câble, à partir du tambour, afin de le fixer à une charge. L’embrayage est actionné au

moyen de sa manette ou du cylindre pneumatique.

AVERTISSEMENT : NE RELÂCHEZ JAMAIS L’EMBRAYAGE EN PRÉSENCE D’UNE CHARGE!

EMBRAYEUR MANUEL (cf. page 27)

POUR DÉSENCLENCHER L’EMBRAYAGE – Faites fonctionner le treuil dans le sens de déroulement jusqu'à ce que le câble ne tracte plus la

charge. Tirez sur la poignée et tournez-la de 90º. Avec la poignée en position « DÉSENCLENCHÉE », le tambour peut désormais tourner

librement.

POUR ENCLENCHER L’EMBRAYAGE – Tirez sur la poignée, faites-la tourner de 90º, puis relâchez-la. Faites fonctionner le treuil dans le sens

inverse jusqu’à ce que la poignée s’enclenche en position « ENCLENCHÉE ». N’essayez PAS de treuiller une charge si la poignée n'est pas

complètement « ENCLENCHÉE ». Si le témoin lumineux d’embrayage manuel est présent, la lumière verte s’allume lorsque l’embrayage est «

ENCLENCHÉ ». N’essayez PAS de treuiller une charge si le témoin vert n’est pas allumé. Pour brancher ce voyant sur le système électrique

du véhicule, reportez-vous au schéma de câblage de la page 28.

EMBRAYEUR À CYLINDRE PNEUMATIQUE (cf. page 28)

POUR DÉSENCLENCHER L’EMBRAYAGE – Faites fonctionner le treuil dans le sens de déroulement jusqu'à ce que le câble ne tracte plus la

charge. Appliquez une pression pneumatique à l’orifice de 0,125-27 NPT de 550 kPa (minimum) à 1 030 kPa (maximum). MISE EN GARDE :

la pression ne doit pas dépasser 1 030 kPa.

POUR ENCLENCHER L’EMBRAYAGE – Retirez la pression pneumatique du cylindre (un ressort de rappel enclenche le piston plongeur). Faites

fonctionner le treuil dans le sens inverse jusqu'à ce que le témoin lumineux d'enclenchement de l'embrayage (voyant vert) s’allume.

N’essayez PAS de treuiller une charge si le témoin vert n’est pas allumé. Pour brancher ce voyant sur le système électrique du véhicule,

reportez-vous au schéma de câblage en page 28.

ENTRÉE CORRESPONDANT

À L'ENROULEMENT

SENS DE ROTATION « A »

SENS DE ROTATION « B »

SENS DE ROTATION

DU TAMBOUR

SENS DE ROTATION

DU TAMBOUR

POSITION DE

LA CARTOUCHE

POSITION DE

LA CARTOUCHE

POSITION

DE LA FICHE

Page 22

CARACTÉRISTIQUES DU SYSTÈME HYDRAULIQUE

Reportez-vous aux diagrammes de performances ci-dessous pour établir une correspondance entre votre système

hydraulique et le fonctionnement de votre treuil. Ces diagrammes sont constitués des éléments suivants :

(1) Traction du câble, première couche (lb) / Pression de fonctionnement (PSI)

(2) Vitesse du câble, première couche en pieds par minute (FPM) / débit en gallons par minute (GPM)

CARACTÉRISTIQUES DU SYSTÈME

UN DISTRIBUTEUR À TIROIR CYLINDRIQUE DE MOTEUR (CENTRE OUVERT) EST NÉCESSAIRE.

SOUPAPE DE SURPRESSION SUR 14 400 kPa (2 100 PSI)

DÉBIT DE 56 L/MIN

NE DOIT PAS DÉPASSER 75 L/MIN - RISQUE D’ENDOMMAGEMENT DU MOTEUR ET DU TREUIL

FILTRATION NOMINALE DE 10 MICRONS

B

Disposition Type

Avec Navette De Desserrage Du Frein

Moteur

Entrée

Frein

A

Échappement

Du Système

Valve À 3

Positions Et 4 Voies

(Distributeur Moteur)

Débit Et Pression

Maximum À Charge

Nominale :

56 L/Min

14 400 Kpa (2 100 PSI)

Conduite Haute Pression

(Diamètre Interne

Conduite Basse Pression

(Diamètre Interne Minimum De 19 mm)

Pompe

Contrôle D’entrée

Minimum De 12 mm)

0 5 10 15

0

5

10

15

0

0

1000

2000

3000

4000

5000

6000

7000

8000

1000 2000 2500

1500500

9000

10000

Diagrammes De Performances

Pression De Fonctionnement À 56 L/Min (PSI)

Débit (GPM)

Traction Du Câble, Première Couche (LB)

Vitesse Du Câble, Première Couche (FPM)

Basé Sur Un Moteur De 254 Cm³

22

Page 23

23

PROBLÈME CAUSE POSSIBLE SOLUTION

LE TAMBOUR NE TOURNE

PAS EN L’ABSENCE DE

CHARGE.

Treuil mal monté, ce qui entraîne un grippage du

tambour par les roulements de l’extrémité.

Vérifiez le montage. Reportez-vous à la rubrique

Fixation du treuil de la page 20.

Pignons endommagés. Examinez les pignons endommagés et remplacez-

les.

LE TAMBOUR NE TOURNE

PAS EN PRÉSENCE D’UNE

CHARGE.

Treuil mal monté, ce qui entraîne un grippage du

tambour par les roulements de l’extrémité.

Vérifiez le montage. Reportez-vous à la rubrique

Fixation du treuil de la page 20.

Charge dont le poids dépasse la capacité nominale

du treuil.

Consultez les caractéristiques nominales de traction

à la rubrique Caractéristiques, page 19.

Pression du système hydraulique faible. Vérifiez la pression. Reportez-vous aux diagrammes

des performances des systèmes hydrauliques de la

page 22.

LE TREUIL FONCTIONNE

TROP LENTEMENT.

Débit faible. Vérifiez le débit. Reportez-vous aux diagrammes des

SYSTÈMES HYDRAULIQUES.

Moteur hydraulique usé. Remplacez le moteur.

LE TAMBOUR NE

RELÂCHE PAS LE REMBOBINAGE.

Embrayage non désenclenché. Vérifiez le RÉGLAGE.

Reportez-vous à la page 25.

Vérifiez le fonctionnement, page 21.

Treuil mal monté, ce qui entraîne un grippage du

tambour par les roulements de l’extrémité.

Vérifiez le montage. Reportez-vous à la

rubrique FIXATION DU TREUIL.

Boulons de fixation latérale (pièce nº 15, page 30)

trop longs qui provoquent un grippage de la

couronne.

Vérifiez la longueur des boulons. Le filet de boulon

NE DOIT PAS s’engager dans les trous filetés sur les

côtés du palier d’extrémité sur plus des 12 mm de

profondeur.

LE FREIN NE TIENT PAS. Distributeur inadapté (distributeur à tiroir cylindrique,

centre fermé)

Utilisez uniquement un distributeur à tiroir cylindrique

de moteur (centre ouvert).

LA CHARGE GLISSE. Contre-pression trop importante (100 PSI max.) Assurez-vous de l'absence de restrictions au niveau

du système hydraulique. Reportez-vous aux caractéristiques du système et à la disposition type en

page 22.

LE CÂBLE SE DÉTEND

LORSQUE L’EMBRAYAGE

EST RELÂCHÉ.

Vis de rappel mal réglée. Réglez la vis de rappel en Nylon. Reportez-vous à la

rubrique Installation du câble en page 20.

BRUIT EXCESSIF Débit du système hydraulique trop élevé. Vérifiez le débit. Reportez-vous à la rubrique

Disposition type en page 22.

Grippage du tambour, treuil mal monté. Vérifiez le montage. Reportez-vous à la rubrique

Fixation du treuil de la page 20.

LE TAMBOUR BROUTE

DANS LE SENS DE L’ENROULEMENT.

Débit du système hydraulique faible. Vérifiez le débit. Reportez-vous à la rubrique

Disposition type en page 22.

Réglage de pression d’échappement du système

hydraulique faible.

Vérifiez le réglage de la soupape de surpression.

FUITE D’HUILE AU NIVEAU

DU RENIFLARD

Joints toriques de frein, bagues d’appui ou surfaces

d'étanchéité endommagés

Démontez le frein et vérifiez. Reportez-vous aux

instructions de révision, page 24.

GUIDE DE RÉSOLUTION DES PROBLÈMES

Page 24

INSTRUCTIONS DE RÉVISION DES TREUILS DE LA GAMME HD-P10000

Prenez note des configurations de montage pour l’assemblage correct des pièces lors du remontage. Remplacez

tous les joints statiques, les joints toriques et les joints d’étanchéité lors du remontage.

Débranchez le tube (pièce nº 44) des raccords coudés

(pièce nº 26) au bas du palier d’extrémité et de la valve de

contre-pression (pièce nº 45). Retirez le moteur (pièce nº

30) du palier d’extrémité en dévissant lentement les vis

d’assemblage (pièce nº 19). MISE EN GARDE : LE

MOTEUR EST SOUS LA PRESSION DES RESSORTS.

Vérifiez le reniflard (pièce nº 48). Assurez-vous qu’il n’est

pas bouché. Si de l’huile fuit à ce niveau, vérifiez les joints

toriques des freins, les bagues d’appui et les surfaces d’étanchéité (cf. page 24).

Retirez les ressorts (pièce nº 43) de leurs logements et

vérifiez leur état.

Remplacez le joint statique (pièce nº 28).

Retirez le raccordement (pièce nº 25) du palier d’extrémité.

Examinez-le afin de déceler toute trace d'usure et remplacez-le si nécessaire. Le cas échéant, retirez la valve de contre-pression

du moteur en retirant les vis d’assemblage (pièce nº 15).

Retirez les bagues de retenue (pièce nº 42) avec un

tournevis. Retirez les pièces du frein du palier d’extrémité.

NOTEZ LA POSITION DES JOINTS TORIQUES ET DES

BAGUES D’APPUI AVANT LA DÉPOSE. Vérifiez l’état des disques de frein (pièce nº 5) et des stators (pièce nº 4), et

procédez aux remplacements éventuellement nécessaires.

Examinez les joints toriques (pièces nº 31 et 32) et les

bagues d’appui (pièces nº 34 et 36) du piston de frein (pièce

nº 6), ainsi que le joint torique (pièce nº 33) et la bague

d’appui (pièce nº 35) du piston auxiliaire de frein (pièce nº 7)

afin de déceler tout signe d’usure. Retirez les joints toriques

et les bagues d’appui des rainures du piston de frein ou du

piston de frein auxiliaire, et remplacez-les si nécessaire.

Retirez les plaques de serrage (pièce nº 12) des paliers

d’extrémité en dévissant les vis d’assemblage (pièce nº

16). Faites glisser le palier d’extrémité du moteur (pièce nº

10) et le tambour (pièce nº 1) du palier d’extrémité de la

boîte d’engrenages.

Retirez l’arbre d’entrée (pièce nº 11) du palier d’extrémité.

Inspectez l’état de l’arbre et du planétaire de sortie (pièce

nº 8), et remplacez-les si nécessaire. Pour retirer le planétaire de sortie, enlevez les circlips (pièce nº 41) et la rondelle de butée (pièce nº 47), et tirez le bout de l’arbre.

Retirez la bague (pièce nº 14) et le joint torique (pièce nº

37) du palier d’extrémité du moteur. Placez le joint torique

neuf et bien huilé dans la rainure, à l'intérieur du palier

d'extrémité et pressez la bague neuve sur le palier.

43

44

26

45

23

15

26

25

28

30

24

19

48

24

5

4

35

33

7

31

36

32

34

6

42

14

37

10

41

47

8

11

1

12

16

12

16

Page 25

Retirez le joint d’étanchéité (pièce nº 40) du palier d’extrémité de la boîte d'engrenages (pièce nº 9). Desserrez l’écrou (pièce nº 22) et retirez la vis de pression

en Nylon (pièce nº 18). Si nécessaire, retirez la couronne du palier d’extrémité de

la boîte d'engrenages. Retirez la bague (pièce nº 13) du palier d’extrémité.

Placez une bague neuve sur le palier. Réinstallez la couronne, puis la vis de pression en Nylon et l'écrou. La couronne doit être bien en place sur le palier d'extrémité, et sa fente NE DOIT PAS être alignée sur le trou de l'embrayeur. Placez un

joint d’étanchéité neuf sur le palier d’extrémité, avec le bord effilé tourné vers l’extérieur.

Appliquez une quantité généreuse de graisse (MOBILITH SHC 007) sur les dents

de la couronne (pièce nº 29) et des roues planétaires du tambour (pièce nº 1),

ainsi que sur la bague (pièce nº 13) du palier d’extrémité de la boîte d'engrenages. Appliquez une petite quantité de graisse à la base de la bague (pièce nº

14) du palier d’extrémité du moteur. Appliquez de la graisse sur les dents du

planétaire de sortie (pièce nº 8) et sur l’arbre d’entrée (pièce nº 11).

Placez l’extrémité de l’arbre avec le planétaire de sortie dans le palier d’extrémité de la boîte d’engrenages. Placez le tambour par-dessus

l’arbre et faites tourner le tambour pour enclencher les roues planétaires sur le planétaire de sortie et sur la couronne.

Fixez le palier d’extrémité du moteur (pièce nº 10) sur le tambour et utilisez les plaques de serrage (pièce nº 12) et les vis d’assemblage

(pièce nº 16) pour maintenir les deux paliers d’extrémité ensemble. Serrez les vis d’assemblage à un couple de 75 Nm.

Si nécessaire, retirez et remplacez l’embrayeur (manuel, pièce nº 2, ou cylindre pneumatique, pièce nº 3) comme indiqué ci-dessous.

EMBRAYEUR MANUEL

Desserrez la vis de pression (pièce nº 20) et le contre-écrou, puis dévissez l’embrayeur (pièce nº 2). Assurez-vous que la fente de la

couronne n’est pas alignée sur le trou de l’embrayeur. Faites tourner le tambour, si nécessaire, pour vous assurer que le trou et la fente ne

sont pas alignés.

Réinstallez l’embrayeur avec le piston plongeur, le contre-écrou et la poignée dans la boîte d’engrenages, comme indiqué ci-dessous. Enfilez

l’ensemble (avec la poignée insérée dans la fente du cylindre) dans la boîte d’engrenages. Tirez le tambour vers le palier d’extrémité du

moteur afin d’éliminer le jeu. Maintenez le tambour en place et continuez d’enfiler l’ensemble de l’embrayeur jusqu’à ce que l’espace entre le

bout de la poignée et le cylindre soit de 11

+0

-1,5

mm et que la poignée soit en position horizontale (cf. ci-dessous). Remarque : cet

espace varie en fonction du jeu axial du tambour. Lorsque le tambour est tiré contre la boîte d’engrenages, l’espace doit être de 9 mm.

Serrez légèrement le contre-écrou. Faites tourner le tambour jusqu’à ce que la poignée s’enclenche complètement. Tirez sur la poignée et

tournez-la de 90º. Assurez-vous que le tambour peut tourner librement (au moins un tour complet) avec l’embrayeur en position

DÉSENCLENCHÉE. Serrez fermement le contre-écrou tout en maintenant la poignée. Serrez fermement la vis de pression (pièce nº 20).

Revérifiez le fonctionnement de l’embrayage comme indiqué en page

21.

EMBRAYEUR À CYLINDRE PNEUMATIQUE

Desserrez la vis de pression (pièce nº 20) pour retirer l’embrayeur

(pièce nº 3). Pour la réinstallation, placez une ou deux cales (pièce nº

44) sur le piston plongeur et enfilez l’ensemble de l’embrayeur dans

la boîte côté engrenages. Ajoutez ou retirez des cales afin d’orienter

les ouvertures pour les connexions pneumatiques. Ces ouvertures

doivent être dirigées vers le bas (sous l’horizontale). Serrez la vis de

pression. Vérifiez le fonctionnement de l’embrayage, comme indiqué

en page 21.

Si la lampe (pièce nº 2) ou son commutateur (pièce nº 48) doit être

remplacé(e), reportez-vous au schéma de la page 28 pour les

branchements électriques, et déposez puis remontez comme indiqué

ci-dessous.

29

40

22

18

13

9

25

Contre-Écrou

23

4

41

2

3

44

21

2

20

9

42

48

Commutateur

De La Lampe

Lampe

Cylindre

Poignée (Horizontale)

Réglage Boîte Manuelle

Embrayeur Boîte

Manuelle

Embrayeur À Cylindre

Pneumatique

Plongeur

Piston

Page 26

Placez le treuil sur l’établi avec l’extrémité de la boîte d’engrenages tournée vers le bas.

Placez des joints toriques et des bagues d'appui bien huilés dans les rainures, sur l’extérieur du piston de frein et du piston de frein auxiliaire,

comme indiqué sur la coupe A-A ci-dessous.

Le piston, le piston auxiliaire, les disques de frein et les stators doivent être propres et exempts de graisse et d’huile.

Insérez les disques de frein (pièce nº 5) et les stators (pièce nº 4) en les alternant, avec les stators en premier et en dernier.

Insérez le piston de frein auxiliaire (pièce nº 7) dans l'extrémité moteur et placez le piston de frein (pièce nº 6) dedans. Appliquez une pres-

sion uniforme sur le piston lors du montage.

Installez les bagues de retenue (pièce nº 42) dans les rainures du carter côté moteur.

Insérez les ressorts (pièce nº 40) dans les logements à l’arrière du piston de frein.

Installez une goupille cylindrique (pièce nº 38) dans le raccordement neuf du moteur, sous le bas des dentelures.

Insérez le raccordement du moteur (pièce nº 25) en l’enclenchant sur les disques et l’arbre d’entrée. Placez le joint statique (pièce nº 28) sur

la surface de montage du moteur (pièce nº 30). Faites glisser l’arbre du moteur dans le raccordement. Fixez le moteur au carter du palier

d’extrémité moteur au moyen de deux vis d’assemblage (pièce nº 19) et de deux rondelles de sécurité (pièce nº 24). Serrez uniformément à

un couple de 66 Nm.

Installez la valve de contre-pression (pièce nº 45)

sur le moteur au moyen de quatre vis d’assemblage (pièce nº 15) et de quatre rondelles de sécurité (pièce nº 23). Serrez à un couple de 23 Nm.

Connectez bien les raccords (pièce nº 26) à la

boîte côté moteur et à la valve de contre-pression,

et connectez le tube (pièce nº 44) aux raccords.

Appliquez au frein une pression d’au moins 3 780

kPa (550 PSI) du système hydraulique et assurezvous que le frein se relâche (que le tambour du

treuil tourne

5

4

35

33

7

31

36

32

34

6

42

A

A

CÔTÉ MOTEUR

CÔTÉ

TAMBOUR

VUE TRANSVERSALE A-A

36

31

3533

32

34

7

6

26

26

26

44

48

43

45

23

15

25

28

30

24

19

38

Page 27

(TYP)

1.12

[28.4]

(TYP)

(TYP)

1.12

[28.4]

4.68

[118.9]

9.36

[237.7]

CABLE ANCHOR

MM

POUCES

F

28.84

732,4

25.59

649,9

"Y" DRUM

STD. DRUM

296,2

11.66

337,4

13.28

353,7

13.93

395,0

15.55

E

POUCES

MM

D

POUCES

MM

Modèle de

La Treuil

HD-P10000

HD-P10000

POUCES

MM

A

MM

POUCES

B

MM

POUCES

C

9.75

247,7

6.50

165,1

12.25

311,2

9.00

228,6

10.04

255,0

8.41

213,7

A

B

C

D E

F

2.21

[56.1]

.56

[14.3]

2.25

[57.2]

4.19

[106.4]

8.38

[212.7]

.50

[12.7]

Ø8.25

[209.6]

Ø.50

[Ø12.7]

9.41

[239.1]

4.92

[125.0]

3.79

[96.3]

REMARQUES :

1. LES DIMENSIONS SONT INDIQUÉES EN POUCES PUIS EN MILLIMÈTRES.

2. LES VIS D'ASSEMBLAGE DU TREUIL DOIVENT AU MOINS RÉPONDRE AUX

SPÉCIFICATIONS SAE, GRADE 5.

3. L'EMPLACEMENT DE CES TROUS DO

IT SE TROUVER À ± 0,8 MM DE LA

POSITION EXACTE. LE DIAMÈTRE RECOMMANDÉ POUR LES TROUS DE

FIXATION EST DE 13,5 MM.

EMBRAYAGE EN POSITION DÉSENCLENCHÉE

EMBRAYAGE EN POSITION ENCLENCHÉE

POUR LES INSTALLATIONS LATÉRALES,

DÉPLACEZ LES PLAQUES DE SERRAGE AUX PIEDS

TROU TARAUDÉ DE 1/2-13 UNC X 0,75 PO DE PROFONDEUR

(2 ENDROITS DE CHAQUE CÔTÉ DU PALIER D’EXTRÉMITÉ)

TROU TARAUDÉ DE 1/2-13 UNC

X 0,75 PO DE PROFONDEUR

(4 ENDROITS, CHAQUE PALIER D'EXTRÉMITÉ)

TROU TARAUDÉ DE 1/2-13 UNC

X 0,50 PO DE PROFONDEUR

D’EXTRÉMITÉ DE LA BOÎTE D’ENGRENAGES)

BARREL

(2-PLACES EACH SIDE OF GEAR HOUSING END BEARING)

FLANGE

1.25

[31.8]

7.17

[182.1]

Ø3.94

[100.0]

DRUM

Ouverture de 7/8-14 SAE

(2 ENDROITS )

HD-P10000 Boîte Manuelle

27

Page 28

B

4.92

[125.0]

9.41

[239.1]

3.79

[96.3]

F

Ø8.25

[209.6]

A

D E

C

2.21

[56.1]

4.25

[108.0]

8.38

[212.7]

4.19

[106.4]

2.25

[57.2]

.56

[14.3]

3.59

[91.1]

9.15

[232.4]

Ø.50

[Ø12.7]

MM

F

28.28

718,3

24.99

634,7

"Y" DRUM

STD. DRUM

240,5

9.47

323,1

12.72

353,8

(TYP)

1.12

[28.4]

1.12

[28.4]

4.68

[118.9]

9.36

[237.7]

CABLE ANCHOR

2.21

[56.1]

BARREL

FLANGE

1.25

[31.8]

Ø3.94

[100.0]

DRUM

C

L

13.93

394,9

15.55

E

MM

D

MM

HD-P10000

HD-P10000

MM

A

MM

B

MM

C

9.75

247,7

6.50

165,1

12.25

311,2

9.00

228,6

10.04

255,0

8.41

213,6

Ouverture de 1/8-27 NPT**

Pression min. de 550 KPa

Pression max. de 1033 KPa

Pour désenclencher l'embrayage

Embrayage enclenché par ressort

TROU TARAUDÉ DE 1/2-13 UNC X 0,75 PO DE PROFONDEUR

(2 ENDROITS DE CHAQUE CÔTÉ DU PALIER D’EXTRÉMITÉ)

À RELIER À LA TERRE (-)

(CF. SCHÉMA DE CÂBLAGE)

À RELIER AU 12 V C.C. (+)

(CF. SCHÉMA DE CÂBLAGE)

POUR LES INSTALLATIONS LATÉRALES,

DÉPLACEZ LES PLAQUES

DE SERRAGE AUX PIEDS

COMMUTATEUR

TÉMOIN

LUMINEUX

TROU TARAUDÉ DE 1/2-13 UNC X 0,75 PO DE PROFONDEUR

(4 ENDROITS, CHAQUE PALIER D'EXTRÉMITÉ)

TROU TARAUDÉ DE 1/2-13 UNC X 0,50 PO DE PROFONDEUR

(2 ENDROITS DE CHAQUE CÔTÉ DU PALIER D’EXTRÉMITÉ

DE LA BOÎTE D’ENGRENAGES)

Ouverture de 7/8-14 SAE

(2 ENDROITS )

NOTES:

1. LES DIMENSIONS SONT INDIQUÉES EN POUCES PUIS EN MILLIMÈTRES.

2. LES VIS D'ASSEMBLAGE DU TREUIL DOIVENT AU MOINS RÉPONDRE AUX

SPÉCIFICATIONS SAE, GRADE 5.

3. L'EMPLACEMENT DE CES TROUS DOIT SE TROUVER À ± 0,8 MM DE LA

POSITION EXACTE. LE DIAMÈTRE RECOMMANDÉ POUR LES TROUS DE

FIXATION EST DE 13,5 MM.

Modèle de

La Treuil

POUCES

POUCES

POUCES

POUCES

POUCES

POUCES

BATTERIE

ENCLENCHÉ)

12 V C.C.

TÉMOIN LUMINEUX

(ALLUMÉ LORSQUE

L’EMBRAYAGE EST

COMMUTATEUR

CONNECTEUR

D’EXTRÉMITÉ

À RELIER À LA TERRE (FIL DE

CALIBRE 16 FOURNI PAR LE CLIENT)

SCHÉMA

DE CÂBLAGE

À RELIER AU C OMMUTATEUR DE L’IND ICATEUR DE PRISE DE FORCE POUR

RECEVOIR DU 12 V C.C. LORSQUE LA PRISE DE FOR CE EST ENCLENCHÉE.

REMARQUE : LA LUMIÈRE DOIT S’ALLUMER LORSQUE L'EMBRAYAGE EST

ENCLENCHÉ ET S’ÉTEINDRE LORSQU’IL EST DÉSENCLENCHÉ.

HD-P10000 Avec Embrayeur Pneumatique

28

Page 29

9

10

15

23

45

26

44

19

24

30

38

28

25

42

43

6

34

32

36

31

7

33

35

4

5

37

14

26

12

16

18

22

20

2

39

46

12

16

40

29

8

41

47

11

13

1

27

3

21

17

48

29

Page 30

Nº pièce Qté Nº réf. Description Nº pièce Qté Nº réf. Description

1 1 234207 TAMBOUR (standard) 24 2 418218 Rondelle de sécurité - 1/2 po sect. moy. ZINC

1 234208 TAMBOUR (« Y ») 25 1 431020 RACCORDEMENT MOTEUR

2 1 276048 EMBRAYEUR 26 2 432018 RACCORD

3 1 328164 Boîte - Engrenage 27 1 442212 JOINT STATIQUE

4 6 330011 STATOR - FREIN 28 1 442223 JOINT STATIQUE - BRIDE MOTEUR

5 5 330012 DISQUE - FREIN 29 1 444084 COURONNE

6 1 330013 PISTON - FREIN 30 1 458079 MOTEUR - Hydraulique

7 1 330014 PISTON - FREIN AUX. 31 1 462067 PISTON - JOINT TORIQUE - petit

8 1 334174 PLANÉTAIRE - SORTIE 32 1 462068 PISTON - JOINT TORIQUE - grand

9 1 338327 PALIER D’EXTRÉMITÉ - BOÎTE D’ENGRENAGES 33 1 462069 JOINT TORIQUE - PISTON AUX.

10 1 338358 PALIER D’EXTRÉMITÉ - MOTEUR 34 1 462070 BAGUE - PISTON AUX. - grand

11 1 357177 ARBRE - ENTRÉE, TAMBOUR « Standard » 35 1 462071 BAGUE D’APPUI - PISTON AUX.

1 357176 ARBRE - ENTRÉE, TAMBOUR « Y » 36 1 462072 BAGUE - PISTON AUX. - petit

12 2 395427 PLAQUE DE SERRAGE, TAMBOUR « Standard » 37 1 462073 JOINT TORIQUE

2 395426 PLAQUE DE SERRAGE, TAMBOUR « Y » 38 1 470033 GOUPILLE SPIROL

13 1 412085 BAGUE - TAMBOUR 39 1 472052 FICHE

14 1 412109 BAGUE - TAMBOUR, EXTRÉMITÉ MOTEUR 40 1 486080 JOINT D’ÉTANCHÉITÉ

15 4 414159 VIS D'ASSEMBLAGE - 5/16-18 UNC x 2,5 po, TÊTE HEX., ZINC, GR. 5 41 2 490003 CIRCLIP

16 8 414581 VIS D’ASSEMBLAGE - 1/2-13 NC x 3/4 po, TÊTE HEX., ZINC, GR. 5 42 2 490049 BAGUE RETENUE - INTERNE

17 4 414901 VIS - 1/4-20 NC x 1/2 po, TÊTE RONDE, FENDUE, ZINC 43 11 494124 RESSORT - FREIN

18 1 414926 VIS DE PRESSION - 3/8-16 NC x 1 po, TÊTE CREUSE, NYLON 44 1 509132 TUBE - RELÂCHEMENT FREIN (ENTRÉE BAS)

19 2 414952 VIS D’ASSEMBLAGE - 1/2-13 NC x 1,5 po, TÊTE CREUSE, ZINC 1 509131 TUBE - RELÂCHEMENT FREIN (ENTRÉE HAUT)

20 1 416016 VIS DE PRESSION - 1/4-20 NC x 1/4 po, TÊTE CREUSE HEX. 45 1 516041 DISTRIBUTEUR - MOTEUR (ROTATION A)

21 2 416239 VIS-#10-24NC X 3/8", TÊTE CREUSE 1 516042 DISTRIBUTEUR - MOTEUR (ROTATION B)

22 1 418036 CONTRE-ÉCROU - 3/8-16 NC, HEX., ZINC 46 1 518037 RONDELLE DE BUTÉE

23 4 418163 Rondelle de sécurité - 5/16 po sect. moy. ZINC 47 1 518047 RONDELLE DE BUTÉE

48 1 456038 RENIFLARD