Page 1

Page 2

.

Page 3

TABLE OF CONTENTS

INTRODUCTION................................................................................. 1

WARRANTY INFORMATION............................................................ 1

SPECIFICATION.................................................................................. 1

TECHNIQUES OF OPERATION........................................................ 2

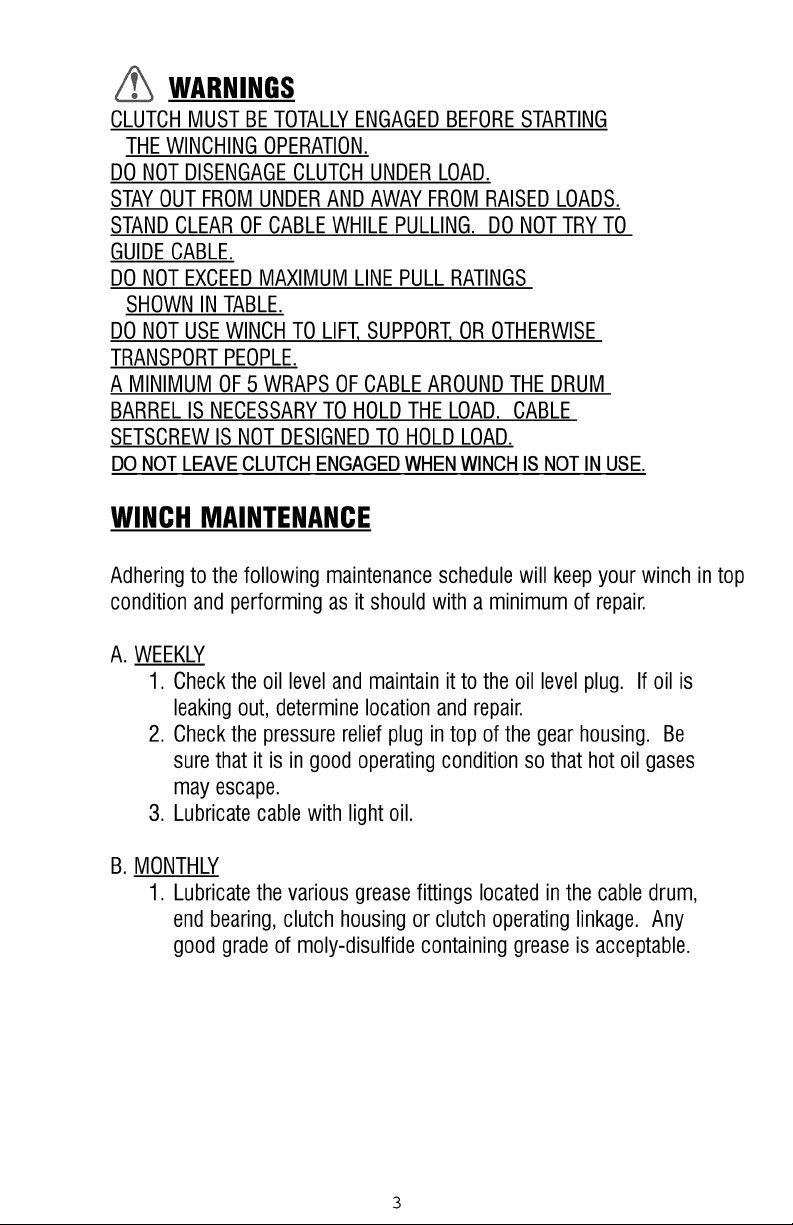

WARNINGS.......................................................................................... 3

WINCH MAINTENANCE................................................................... 3

CABLE INSTALLATION..................................................................... 4

HYDRAULIC SYSTEMS/PERFORMANCE CHARTS..................... 5

TYPICAL LAYOUT/HYD. SYSTEM DIAGRAM.............................. 5

TROUBLE SHOOTING GUIDE.......................................................... 6

INSTRUCTIONS FOR OVERHAUL OF

RAMSEY MODEL HD-200 RAM-LOK® WINCH

DIS-ASSEMBLY.........................................................................7-10

RE-ASSEMBLY........................................................................10-12

DIMENSIONAL DRAWING.............................................................. 13

PARTS LIST AND PARTS DRAWING........................................ 14-15

LIMITED WARRANTY...................................................................... 16

Page 4

RAMSEY WINCH MODEL HD-200 RAM-LOK ®

PLEASE READ THIS MANU

This manual contains useful ideas in obtaining the most efficient operation

from your Ramsey Winch, and safety procedures one needs to know before

operating a Ramsey Winch.

W

ARRANTY INFORMATION

Ramsey Winches are designed and built to exacting specifications. Great

care and skill go into every winch we make. If the need should arise,

warranty procedure is outlined on the back of your self-addressed postage

paid warranty card. Please read and fill out the enclosed warranty card and

send it to Ramsey Winch Company. If you have any problems with your

winch, please follow instructions for prompt service on all warranty claims.

Refer to back page for limited warranty.

AL CAREFULLY.

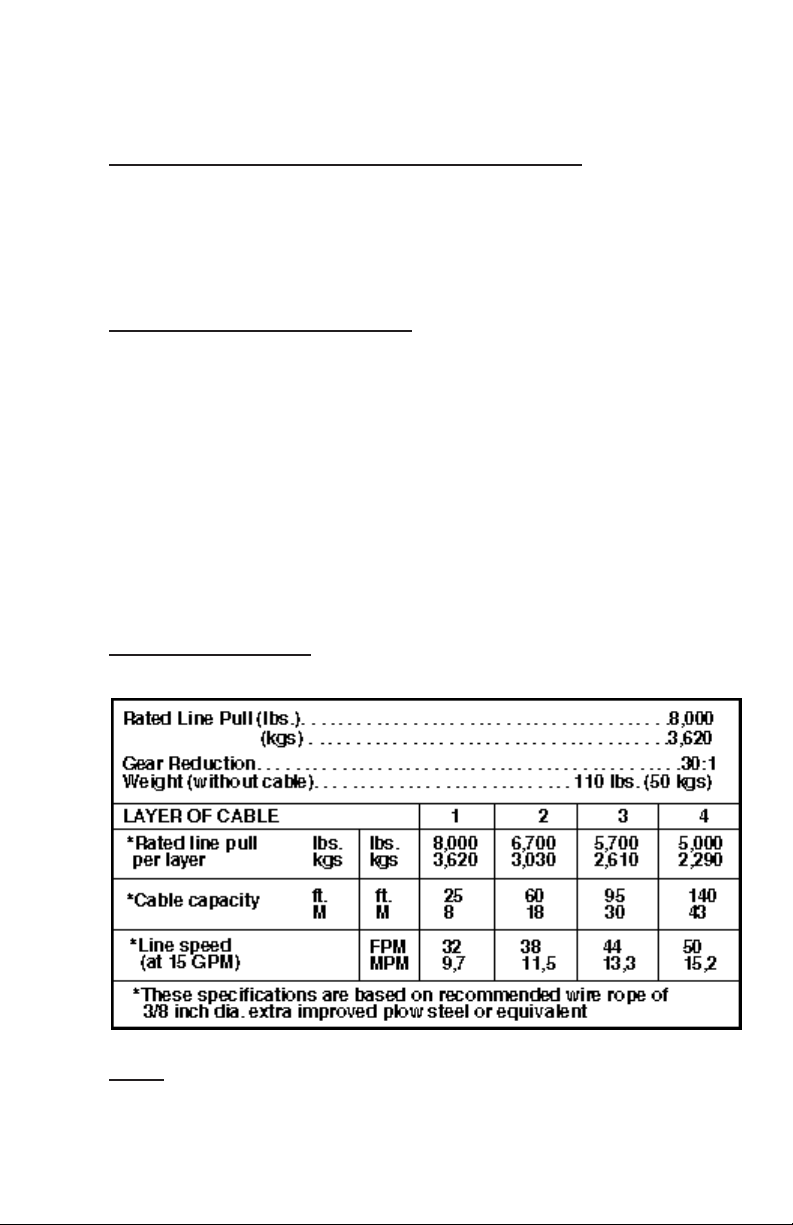

SPECIFICATIONS: CONFORMS TO SAE J706

NOTE: The rated line pulls shown are for the winch only. Consult the wire

rope manufacturer for wire rope ratings.

1

Page 5

TECHNIQUES OF OPERATION

The best way to get acquainted with how your winch operates is to make

test runs before you actually use it. Plan your test in advance. Remember,

you hear your winch, as well as see it operate. Get to recognize the sounds

of a light steady pull, a heavy pull, and sounds caused by load jerking or

shifting. Gain confidence in operating your winch and its use will become

second nature with you.

The uneven spooling of cable, while pulling a load, is not a problem, unless

there is a cable pileup on one end of drum. If this happens reverse the

winch to relieve the load and move your anchor point further to the center

of the vehicle. After the job is done you can unspool and rewind for a neat

lay of the cable.

When pulling a load where there is even a remote chance of cable failure,

place a blanket, jacket or tarpaulin over the cable about six feet behind the

hook. This will slow the snap back of a broken cable and could prevent

serious injury.

NOTE:

respooling unloaded cable onto the drum.

The Ram-Lok®semi-automatic clutch allows rapid unspooling of the cable,

from cable drum, for hooking onto the load. The clutch on the winch is

operated as follows:

1. TO DISENGAGE CL

direction until the load is off the cable. Lift up knob and pull out, lock in

place. See warning label located by shifter knob. The clutch is now locked

out and the cable may be pulled off by hand.

2. TO ENGAGE CL

located by shifter knob. Run the winch in reverse until the shifter knob

snaps fully in or until the cable drum starts turning. At this point make sure

the shifter knob is all the way in. The plastic plug in top of clutch housing

may be removed, for inspection of clutch to assure total engagement. After

the clutch is fully engaged, the winch is ready for winching in the cable.

The Ramsey level winder is an available accessory for tightly

UTCH, run the winch in the reverse (reel out)

UTCH, lift up knob then release. See warning label

2

Page 6

Page 7

2. Check the action of the sliding clutch, making sure it is fully engaging and

disengaging with the cable drum. Remove the plastic plug in top of the

housing and observe if the clutch is fully engaging. If clutch is not fully

engaging, inspect clutch shifter assembly parts, check for damage or

excessive wear and replace as necessary. Observe the jaws on both the

clutch and cable drum, checking for rounding of the driving faces. If

rounding has occurred they should be replaced immediately.

3. Check the winch mounting bolts. If any are missing, replace them and

securely tighten any that are loose. Make sure to use only grade 5 bolts

or better.

4. Check alignment of chain and sprockets and adjust as required to

minimize wear.

5. Inspect the cable. If the cable has become frayed with broken strands,

replace immediately.

C. ANNU

ALLY

1. Drain the oil from the winch annually or more often if winch is used

frequently.

2. Fill the winch to the oil level plug with clean kerosene. Run the winch a

few minutes with no load in the reel in direction. Drain the kerosene from

the winch.

3. Refill the winch to the oil level plug with all purpose E.P. 140 gear oil.

4. Inspect frame and surrounding structure for cracks or deformation.

5. Gear wear can be estimated by rocking the drum back and forth and if

necessary drain oil and remove cover for closer inspection.

CABLE INST

ALLATION

1. Unwind cable by rolling it out along the ground to prevent kinking.

Securely wrap end of cable, opposite hook, with plastic or similar tape to

prevent fraying.

2. Insert the end of cable, opposite hook end, into the 7/16" dia. hole in

drum barrel. Secure cable to drum barrel, using setscrew furnished with

winch. TIGHTEN SETSCREW SECUREL

Y.

3. Carefully run winch in the "reel-in" direction. Keeping tension on end of

cable, spool all the cable onto the cable drum, taking care to form neatly

wrapped layers.

4

Page 8

HYDRAULIC SYSTEMS

FLOW (GPM)

5

0

10

15

7,000

6,000

8,000

20

25

30

35

LINE PULL-FIRST LAYER (LB.)

LINE SPEED-FIRST LAYER (FPM)

STATIC

DYNAMIC

WORKING PRESSURE, PSI

0

0

1,000

1,000

3,000

2,000

5,000

4,000

10

3,0002,000

5

15

HD-200 PERFORMANCE

8,000 LB. DUTY RATING

30:1 GEAR RATIO

(.50 I.D. MINIMUM)

HIGH PRESSURE LINES

LOW PRESSURE LINES

(.75 I.D. MINIMUM)

HYDRAULIC

WINCH MOTOR

CYLINDER SPOOL

3 POSITION 4 WAY

(SUCTION)

PUMP INLET LINE

EMERGENCY STOP

CONTROL VALVE

RELIEF VALVE

FLUID FILTER

FLUID

RESERVOIR

LOW PRESSURE LINES

PUMP

Refer to performance charts, below, to properly match your hydraulic system to the

HD-200 winch performance. The charts consist of:

1. Line pull (lbs.) first layer vs. working pressure (P.S.I.). STATIC (solid line)

refers to hoisting a suspended load from rest; DYNAMIC (dashed line) refers

to maintaining the motion of a moving load.

2. Line speed, first layer (F.P.M.) vs. gallons per minute (G.P.M.).

Performance based on a motor displacement of 3.6 cubic inches with 15 GPM maximum flow rate.

5

Page 9

Page 10

INSTRUCTIONS FOR OVERHAUL OF RAMSEY

MODEL HD-200 RAM-LOK®

DIS-ASSEMBL

1. Drain oil from gear

housing by removing

(item #36) plug from

bottom of gear

housing. Remove

plugs (items #34 &

#35) from top of gear

housing. Remove

adapter rod (item

#26) by driving pin

(item #37) from

shifter shaft of

winch. Remove

mounting frame

(item #1) from winch

by removing hardware

shown.

Y

2. Remove clutch housing (item

#9) and clutch (item #5) from

winch assembly.

Remove two keys (item #31)

from keyways. A screwdriver

can be used, at notch, to aid in

the removal of keys. Once keys

have been removed, drum (item

#7) and thrust washer (item

#46) can be removed from

drum shaft.

7

Page 11

3. Remove motor and coupling (item

#27) from (item #3) adapter by

unscrewing two (item #23)

capscrews with lockwasher.

Remove key (item #11) from

worm shaft. Unscrew four

capscrews (item #19) and remove

adapter from gear housing.

Replace adapter seal (item #41)

and gasket (item #29).

4. Remove bearing cap (item #4) from gear housing by unscrewing

four capscrews (item #19). Remove worm (item #13) and bearings

(item #14) from gear housing. Use soft hammer to gently tap input

end of worm and drive worm and bearing from gear housing. Once

worm has been removed from housing, bearing can be pressed from

end of worm.

Check for signs of

wear or damage to

worm (item #13) and

bearing (item #14).

Replace if necessary.

5. Remove gear housing cover

(item #6) from gear housing

(item #10) by unscrewing

capscrews (item #18). Thread

two of the capscrews into the

two tapped holes of cover and

tighten. This will pull the cover

loose from gear housing.

Remove cover gasket (item

#30) and pull shaft (item #12),

with gear attached, and thrust

washer (item #45) from gear

housing.

8

Page 12

Page 13

10. Check cover bushing (item

#15) for signs of wear. If

necessary remove old bushing

and press bushing into place.

RE-ASSEMBLY

11. Apply grease to end of shaft, opposite gear. Apply grease to

bushing in gear housing (item #10). Place greased end of shaft

through thrust washer (item #46) and bushing in gear housing

(item #10). Place gasket (item #30) onto gear housing

cover (item #6). Apply

grease to gear end of shaft

and cover bushing. Place

cover onto shaft and secure

to housing with ten

(item #18) capscrews.

Tighten capscrews to

8 ft. lbs. (10.8 Nm.) each.

12. Press bearing (item #14) onto worm (item #13). NOTE: Be sure

that thick shoulder of bearings outer race (side with

manufacturer's name and part number) is out, away from worm

threads. Press bearing and worm into gear housing. Slip gasket

(item #29) onto bearing cap (item #4). Use four capscrews (item

#19) to secure cap to gear housing. TIGHTEN CAPSCREWS

TO 8 FT. LBS. (10.8 Nm.) EACH.

10

Page 14

13. Press bearing (item #14) onto worm and into housing. NOTE: Be

sure that thick shoulder of bearings outer race (side with

manufacturer's name and part number) is out, away from worm

threads. Place gasket (item #29) onto adapter (item #3). Attach

adapter to gear housing using four (4)

capscrews (item #22). TIGHTEN

CAPSCREWS TO 12 FT. LBS. (16.3 Nm.)

EACH. Insert key (item #11) into keyway

of worm shaft. Slide tapered end

of coupling (item #27) over end

of worm shaft. Be sure roll

pin (item #38) is in coupling.

Place motor shaft, with

key in keyway, into coupling.

Secure motor to adapter, using

two (2) capscrews (item #23)

and lockwashers. TIGHTEN

CAPSCREWS TO 75 FT. LBS.

(102 Nm.) EACH.

14. Place winch with gear housing cover down on work bench. Drum

shaft should be in vertical position. Slide thrust washer (item #45)

over drum shaft and slide downward until washer rests on gear

housing. Set springs (item #43) into pockets of gear housing with

drag brakes (item #28) on top of springs. Slide drum assembly

(item #7) onto drum shaft with drum jaws upward.

11

Page 15

15. Place thrust washer (item #46) over end of

drum shaft and slide downward until spacer

rests on drum. Press drum downward to

compress springs in gear housing.

Insert keys (item #31) into keyways with

sharp edge of keys pointing outward and

notched end of keys upward. A rubber or

brass mallet will be needed to gently

tap keys into position.

Apply grease to keys and end of shaft.

Place jaw clutch (item #5) over

end of shaft and slide jaw clutch

over keys.

Set clutch housing (item #9) over end of drum shaft. Pull jaw

clutch (item #5) upward, toward clutch housing, enough to allow

yoke, in clutch housing, to fit properly in groove around

jaw clutch.

16. Attach frame assembly

(item #1) using six

capscrews (item #21)

with lockwashers and

two capscrews (item #20)

with lockwasher. Torque

capscrews to 34 ft. lbs.

(46 Nm.) each. Insert plug

(item #36) into bottom of

gear housing. Permatex may

be applied to threads to help

prevent leakage.

Attach adapter rod (item #26) to clutch shaft using pin (item #37).

Pour 3/4 pint of SAE 140 EP gear oil into housing through hole in

top of housing. Insert relief fitting (item #34) into reducer (item

#35). Reducer should then be placed into hole on top of gear

housing. Tighten fitting and reducer securely.

12

Page 16

13

Model HD-200 Ram-Lok

®

Page 17

Page 18

Page 19

Page 20

Loading...

Loading...