Page 1

OPERATING, SERVICE

AND MAINTENANCE

MANUAL

MODEL H-930 SERIES

®

DOW-LOK

EQUIPPED

INDUSTRIAL LOW-MOUNT WINCHES

CAUTION: READ AND UNDERSTAND THIS MANUAL BEFORE INSTALLATION

AND OPERATION OF WINCH. SEE SAFEGUARDS AND WARNING!

Page 2

TABLE OF CONTENTS

INTRODUCTION ................................................................................................................1

WARRANTY INFORMATION ..............................................................................................1

SPECIFICATIONS..............................................................................................................1

TECHNIQUES OF OPERATION...........................................................................................2

WARNINGS.......................................................................................................................2

WINCH MAINTENANCE.....................................................................................................3

WINCH MOUNTING ..........................................................................................................3

CABLE INSTALLATION......................................................................................................3

HYDRAULIC SYSTEMS/PERFORMANCE CHARTS ............................................................4

HYDRAULIC SCHEMATIC..................................................................................................4

TROUBLESHOOTING.........................................................................................................5

INSTRUCTIONS FOR OVERHAUL OF 930/H-930 SERIES

DISASSEMBLY ........................................................................................................ 6-9

RE-ASSEMBLY ...................................................................................................... 9-12

AIR SHIFTER OVERHAUL ...............................................................................................13

DIMENSIONAL DRAWINGS.............................................................................................14

PARTS LIST AND PARTS DRAWING ......................................................................... 16-17

LIMITED WARRANTY.....................................................................................BACK COVER

Page 3

RAMSEY WINCH MODEL H-930 DOW-LOK

PLEASE READ THIS MANUAL CAREFULLY

This manual contains useful ideas in obtaining the most efficient operation from your Ramsey

Winch, and safety procedures one needs to know before operating a Ramsey Winch.

WARRANTY INFORMATION

Ramsey Winches are designed and built to exacting specifications. Great care and skill go into every

winch we make. If the need should arise, warranty procedure is outlined on the back of your selfaddressed postage paid warranty card. Please read and fill out the enclosed warranty card and send

it to Ramsey Winch Company. If you have any problems with your winch, please follow instructions

for prompt service on all warranty claims. Refer to back page for limited warranty.

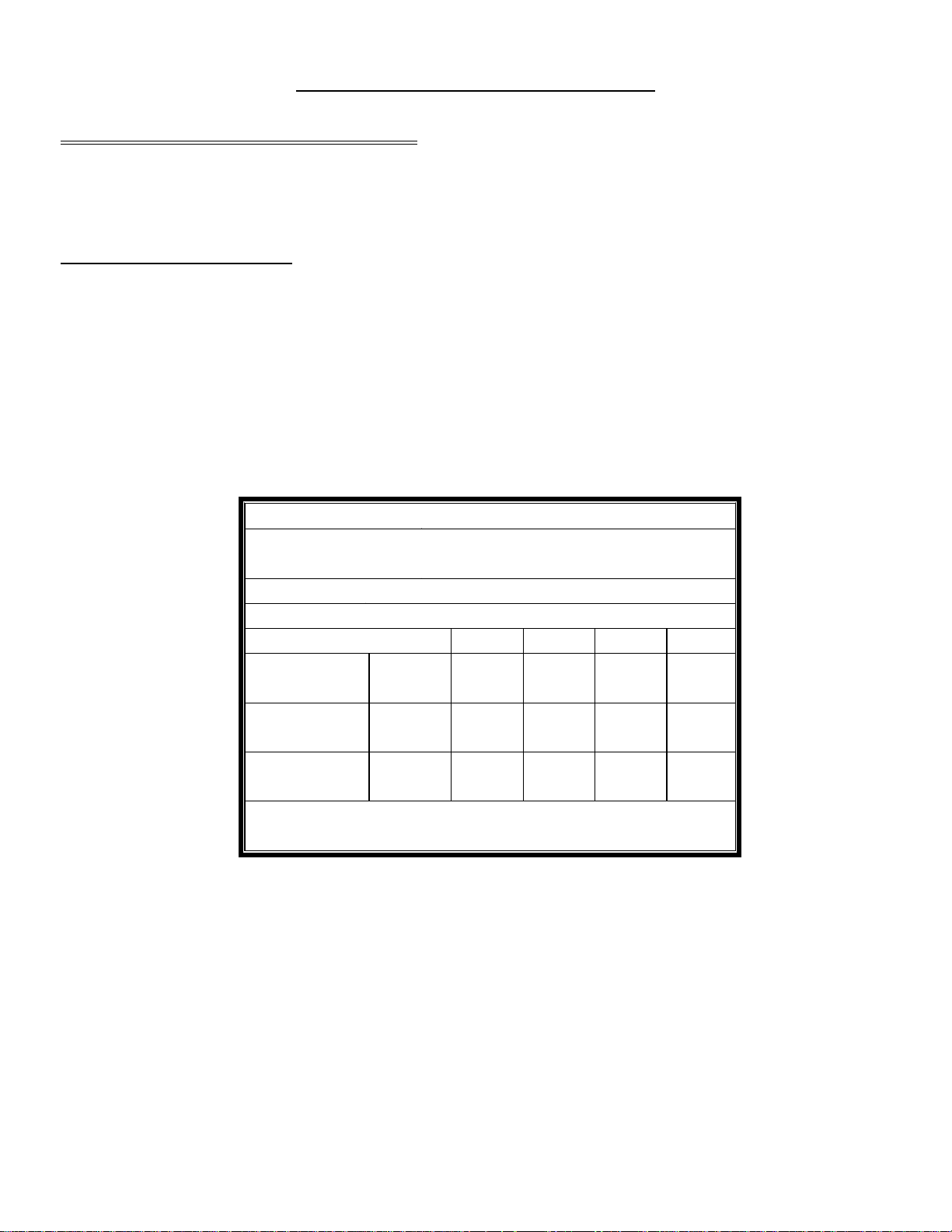

SPECIFICATIONS: CONFORMS TO SAE J706

Rated Line Pull 1st Layer

Gear Reduction: .................................................................................. 41:1

Shipping Weight H-930 .............................................. 515 lbs. (238 kgs)

Layer of Cable 1 2 3 4

Rated Line Pull lbs 30,000 24,500 20,700 18,000

All Models kgs 13,590 11,090 9,370 8,150

*Cable capacity ft 25 65 105 155

All Models m 7 19 31 47

Line Speed

*These specifications are based on recommended cable of 3/4"

(19mm) 6x19 extra improved plow steel cable.

(lbs) .................................................... 30,000

(kgs) ................................................... 13,590

FPM 13 17.6 20 24

MPM 3.9 5.3 6 7.2

NOTE: The rated line pulls shown are for the winch only. Consult the wire rope manufacturer for wire rope ratings.

1

Page 4

TECHNIQUES OF OPERATION

The best way to get acquainted with how your winch operates is to make test runs before you actually use it. Plan

your test in advance. Remember, you hear your winch, as well as see it operate. Get to recognize the sounds of a

light steady pull, a heavy pull, and sounds caused by load jerking or shifting. Gain confidence in operating your

winch and its use will become second nature with you.

The uneven spooling of cable, while pulling a load, is not a problem, unless there is a cable pileup on one end of the

drum. If this happens reverse the winch to relieve the load and move your anchor point further to the center of the

vehicle. After the job is done, you can unspool and rewind for a neat lay of the cable.

The Dow-lok® clutch provides freespooling and clutch engagement with the cable drum. With the clutch disengaged, the cable can be freespooled off the drum. For winching in the load, the clutch must be fully engaged with the

drum.

Notches on the shifter shaft engage the bracket to positively latch the Dow-lok® clutch in the engaged, “IN” position

or disengaged, “OUT” position.

TO DISENGAGE CLUTCH raise handle so notch clears bracket. Pull handle out and latch the shaft notch onto bracket.

DO NOT ATTEMPT TO DISENGAGE WITH A LOAD ON THE WINCH.

TO ENGAGE CLUTCH raise handle so notch clears bracket. and push handle in as far as it will go. The clutch will

automatically spring into engagement and latch when the clutch aligns with the drum shaft. In order to attain full engagement, internal elements of the clutch MUST be aligned. This alignment will take place when cable drum or cable

drum shaft turns a maximum of 1/4 revolution.

DO NOT ATTEMPT TO LIFT A LOAD UNLESS NOTCH IN SHIFTER SHAFT IS SECURELY LATCHED. KEEP CLEAR OF

SPRING LOADED HANDLE DURING AUTOMATIC ENGAGEMENT.

The air-shifter clutch allows rapid unspooling of the cable, from cable drum, for hooking onto load. The air shifter

requires a separate, regulated air supply of 60-90 PSI. The clutch is operated by an air-cylinder as follows:

TO DISENGAGE CLUTCH run the winch in the reverse “OUT” direction until the load is off the cable. Apply 70-90 PSI

to inlet port fitting of air cylinder.

TO ENGAGE CLUTCH remove air pressure from air cylinder. Run the winch in reverse “OUT” direction until the cable

drum starts turning. After the clutch is fully engaged, the winch is ready for winching in the cable.

WARNINGS

• CLUTCH MUST BE TOTALLY ENGAGED BEFORE STARTING THE WINCHING OPERATION.

• DO NOT DISENGAGE THE CLUTCH UNDER LOAD.

• DO NOT LEAVE CLUTCH ENGAGED WHEN WINCH IS NOT IN USE.

• STAY OUT FROM UNDER AND AWAY FROM RAISED LOADS.

• STAND CLEAR OF CABLE WHILE PULLING. DO NOT TRY TO GUIDE CABLE.

• DO NOT EXCEED MAXIMUM LINE PULL RATINGS SHOWN IN TABLE.

• DO NOT USE WINCH TO LIFT, SUPPORT, OR OTHERWISE TRANSPORT PEOPLE.

• A MINIMUM OF 5 WRAPS OF CABLE AROUND THE DRUM BARREL IS NECESSARY TO HOLD THE LOAD. CA-

BLE ANCHOR IS NOT DESIGNED TO HOLD LOAD.

2

Page 5

WINCH MAINTENANCE

Adhering to the following maintenance schedule will keep your winch in top condition and performing as it should

with a minimum of repair.

A. WEEKLY

1. Check the oil level and maintain it to the oil level plug. If oil is leaking out, determine location and repair.

2. Check the pressure relief plug in top of the gear housing. Be sure that it is in good operating condition so

that hot oil gasses may escape.

3. Lubricate cable with light oil.

B. MONTHLY

1. Lubricate the various grease fittings located in the cable drum, end bearing, clutch housing or clutch operating linkage. Any good grade of moly-disulfide containing grease is acceptable.

2. On the Dow-Lok clutch, check the action of the locking ring. Make sure it is spring loaded and free to

move fully against the cable drum in the engaged position and that it is pulled full away from the cable

drum and latched when disengaged.

3. Check the winch mounting bolts. If any are missing, replace them and securely tighten any that are loose.

Make sure to use only grade 5 bolts or better.

4. Inspect the cable. If the cable has become frayed with broken strands, replace immediately.

C. ANNUALLY

1. Drain the oil from the winch annually or more often if winch is used frequently.

2. Fill the winch to the oil level plug with clean kerosene. Run the winch a few minutes with no load in the

reel in direction. Drain the kerosene from the winch.

3. Refill the winch to the oil level plug with all purpose E.P. 140 gear oil.

4. Inspect frame and surrounding structure for cracks or deformation.

5. Gear wear can be estimated by rocking the drum back and forth and if necessary drain oil and remove

cover for closer inspection.

WINCH MOUNTING

It is most important that this winch be mounted securely so that the three major sections (the clutch housing end, the

cable drum, and the gear housing end) are properly aligned.

All standard model 930/H-930 series winches are furnished with recommended mounting angles. Angle size is

1/2x4x4 high strength steel angle.

CABLE INSTALLATION

1. Unwind cable by rolling it out along the ground to prevent kinking. Securely wrap end of wire rope, opposite hook,

with plastic or similar tape to prevent fraying.

2. Insert end of cable, opposite hook end, into the hole in drum barrel. Secure cable to drum barrel, using setscrew

furnished with winch, TIGHTEN SETSCREW SECURELY.

3. Carefully run the winch in the “reel-in” direction. Keeping tension on end of cable, spool all the cable onto the cable drum, taking care to form neatly wrapped layers.

3

Page 6

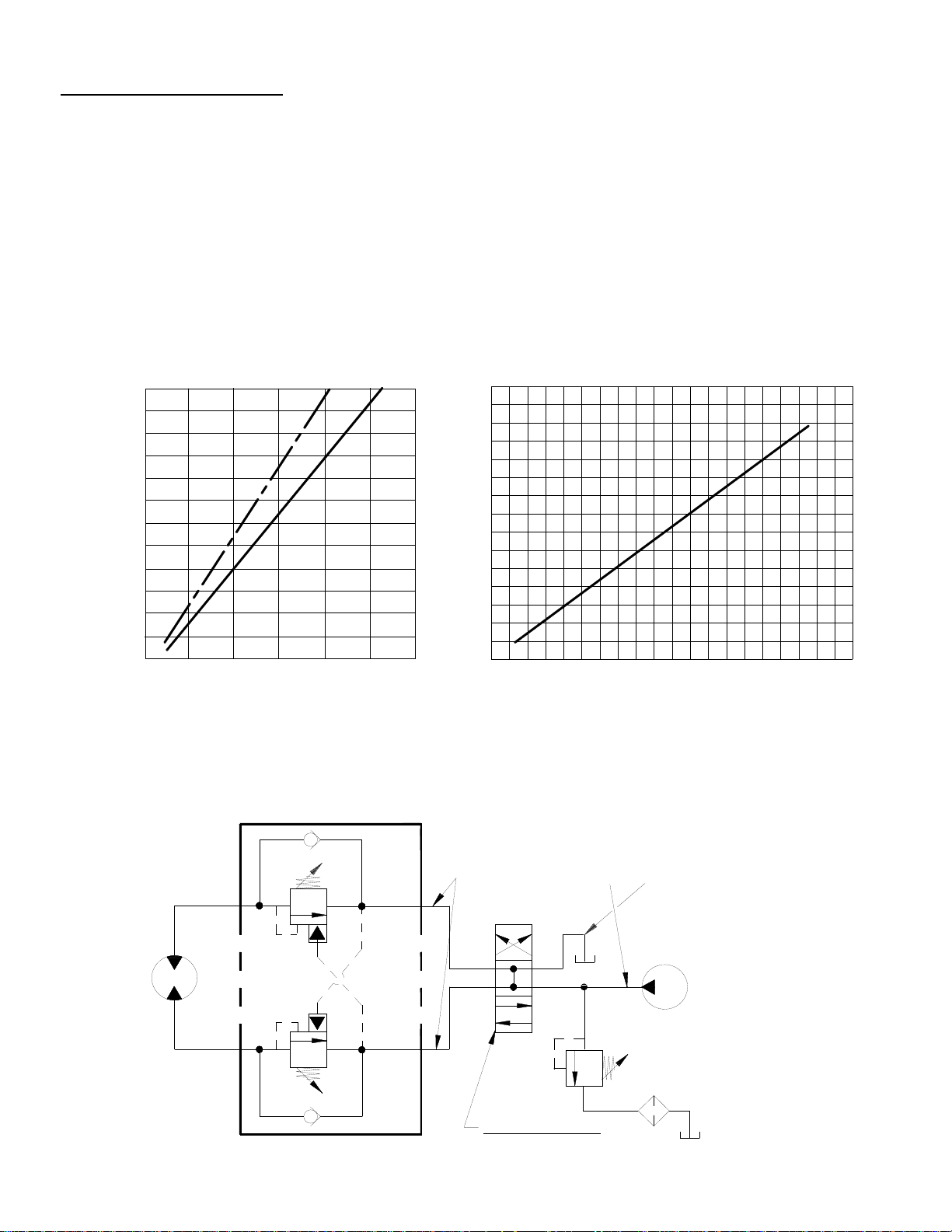

HYDRAULIC SYSTEMS

Refer to the performance charts, below, to properly match your hydraulic system to the H930 Series Winch performance. The charts consist of: (1) Line speed, first layer (F.P.M.) vs. gallons per minute (G.P.M.) and (2) Line pull

(lbs.) first layer vs. working pressure (P.S.I). STATIC (solid line) refers to hoisting a suspended load from rest; DYNAMIC (dotted line) refers to maintaining the motion of a moving load.

Performance based on a motor displacement of 24 cubic inches with 35 GPM maximum flow rate. See page 14 for

motor port size.

H930 Performance

30,000 Lb. Duty Rating

41:1 Gear Ratio

30,000

25,000

20,000

15,000

10,000

5,000

LINE PULL, LBS., FIRST LAYER

C

I

C

I

M

T

A

A

T

YN

S

D

0

0

WORKING PRESSURE, P.S.I.

2,0001,000 0

TYPICAL LAYOUT

DUAL-A & B PORT CONTROL

3,000

15

10

5

LINE SPEED, FPM, FIRST LAYER

0

10

GALLONS PER MINUTE

20

30 35

MOTOR

HIGH PRESSURE LINE

A

B

CONTROL VALVE

3 POSITION, 4 WAY VALVE

(MOTOR OR CYLINDER SPOOL)

4

LOW PRESSURE LINE

PUMP

Page 7

TROUBLESHOOTING GUIDE

CONDITION POSSIBLE CAUSE CORRECTION

Dry or rusted shaft. Clean and lubricate.

Bent yoke or linkage Replace yoke or shaft assembly

CLUTCH INOPERATIVE OR BINDS UP

OIL LEAKS FROM HOUSING

WINCH RUNS TOO SLOW

CABLE DRUM WILL NOT FREE SPOOL

CABLE BIRDNESTS WHEN CLUTCH IS

DISENGAGED

HYDRAULIC FLUID LEAKS FROM HOLE

IN MOTOR ADAPTER

Debris in clutch Clean and lubricate.

Clutch not disengaging, drum

does not freespool

Seal damaged or worn Replace seal.

Too much oil. Drain excess oil. Refer to Techniques of Operation.

Damaged gasket Replace gasket

Hydraulic motor worn out. Replace motor.

Low flow rate.

Winch not mounted squarely,

causing end bearings to bind

drum.

Clutch not disengaged.

Drag brake disc worn. Replace discs.

Damaged motor shaft seal. Replace seal.

Adjust clutch air shifter. See page 14.

Check flow rate. Refer to Hydraulic Systems

Performance Chart, page 2.

Check mounting. Refer to Winch Mounting section.

Check air pressure to clutch cylinder--70 psi minimum

required.

5

Page 8

INSTRUCTIONS FOR OVERHAUL FOR MODEL H930 “DOW-LOK” WINCH

DISASSEMBLY

Refer to parts list and parts drawing pages for actual item

4

64

49

4

75

48

64

(2)

Remove two capscrews (item #49) from clutch housing (item

#20). Remove the clutch shifter cover (item #37) by removing

four capscrews (item #40). Remove the shifter lever assembly

(item #1) by removing cotter pin and clevis pin (items #65 &

#66).

NOTE

: The shifter lever assembly (item #1) and bracket (item

#34) will remain together. If it is necessary to separate them,

you must loosen the large jam nut and screw the clevis and nut

off the shifter shaft. If necessary, remove the flat springs (item

#86) by removing the two capscrews, lockwashers and nuts

(items #55, #59 & #56).

numbers and corresponding parts numbers.

(1)

Drain oil from gear housing by removing pipe plug (item

#75) from gear housing.

Shift clutch into the engaged “IN” position. Remove frame

angles (item #4) from winch by unscrewing (items #48 &

#49) capscrews with lockwashers (item #64)

59

55

1

71

19

47

40

37

86

65

56

34

20

66

30

52

57

Remove clutch housing from end of drum shaft along with yoke

(item #30). NOTE: It will be necessary to pull the yoke upward

inside the clutch housing as far as it will go in order to clear the

locking ring attached to drum. Press in on retainer plate (item

#79) to relieve the spring tension and remove the retainer ring

(item #82).

Remove four capscrews (item #38), retainer plate, springs

(item #85) and spacer (item #28).

44

9

77

10

32

77

15

38

28

79

NOTE: For overhaul of air shifter, refer to page 13.

(3)

Slide the locking ring (item #10) from the clutch.

NOTE

: The locking ring cannot be removed unless

the clutch is engaged, with dowel pins (item #77)

seated in the shaft keyways.

Rotate the drum so the eight balls (item #32) and

four dowel pins (item #77) can be removed.

If necessary, the clutch (item #9) may be disassembled from the drum by removing eight capscrews (item #44). Slide drum (item #15) from

drum shaft.

6

Page 9

(5)

54

72

50

14

53

84

25

67

2

89

(4)

Remove motor (item #72) from adapter plate (item

#25) by removing capscrews (item #54) . Remove

adapter plate and coupling (item #2) from adapter

(item #3) by unscrewing eight capscrews (item #50).

Remove key (item #23) from worm shaft. Unscrew

23

six capscrews (item #53) and remove adapter from

gear housing. Replace adapter seal (item #80) and

gasket (item #67).

Drag brake disc (item #14), spacer (item #89) and

80

3

spring (item #84) should be examined and replaced if

necessary.

Remove bearing cap (item #17) from gear housing by unscrewing six (item #51) capscrews. Remove worm (item

#29) and bearings (item #33) from gear housing. Use a

soft hammer to gently tap input end of worm and drive

worm and bearing from gear housing. Once worm has been

removed from housing, bearing can be pressed from end of

worm.

Check for signs of wear or damage to worm (item #29)

and bearings (item #33). Replace if necessary.

18

(6)

Remove gear housing cover (item #12) from gear housing

16

69

(item #18) by unscrewing eight capscrews (item #42).

Thread two of the capscrews into the two tapped holed of

cover and tighten. This will pull the cover loose from gear

27

12

42

housing.

Remove cover gasket (item #69) and pull shaft (item

#27), with gear (item #16) attached, from gear housing.

33

29

67

51

17

33

7

Page 10

21

27

16

46

63

(8)

If shaft and/or hub is damaged, replace as follows:

1. Tap keys (item #24) into short keyways of drum shaft

(item #27).

2. Press shaft (item #27) and keys through gear hub

(item #21) until end of keys on long end of shaft are

flush with hub.

3. Secure gear to hub using ten (item #46) capscrews

with lockwashers (item #63). Torque to 121 ft. lbs.

(164 Nm.) each.

(7)

Check for signs of wear on gear teeth. If necessary, replace gear by removing eight capscrews (item #46) and

lockwashers (item #63).

Place new gear (item #16) onto gear hub (item #21).

Align holes in gear with holes in hub. Press gear onto hub.

Be sure gear is seated all the way on the hub. Use ten capscrews (item #46) and lockwashers (item #63) to secure

gear to hub. Torque to 121 ft. lbs. (164 Nm.) each.

24

21

27

16

24

46

63

6

18

73

(10)

Check drum bushings (items #35 $) for signs of

wear. Replace if necessary by pressing old bushings from

drum (item #15). Press bushing (item #35) into bore in

drum until it's flange is seated against bottom of counterbore. Press bushing (item #36) into opposite bore on

drum until end of bushing extends .50" from end of drum.

(9)

Check gear housing bushing (item #6) and o-ring (item

#73) for signs of wear. Replace if necessary by pressing

old bushing from gear housing (item #18). Press new

bushing into place and insert new o-ring (item #73) into

groove inside of bushing.

15

36

35

8

Page 11

19

36

(12)

Check cover bushing (item #6) and o-ring (item

#73) for signs of wear. Replace if necessary by

pressing old bushing from gear housing cover (item

#12). Press new bushing into place and insert new

o-ring (item #73) into groove inside of bushing.

(11 )

Check end bearing bushing (item #36) for signs of

wear. If necessary, remove old bushing and press new

bushing into place.

6

12

73

RE-ASSEMBLY

18

16

69

27

12

42

(14 )

Press bearing (item #33) onto worm (item #29).

NOTE: Be sure that thick shoulder of bearings outer

race (side with manufacturer1s name and part number) is out, away from worm threads. Press bearing

and worm into gear housing. Slip gasket (item #67)

onto bearing cap (item #17). Use six capscrews (item

#51) to secure brake housing to gear housing. Tighten

capscrews to 45 ft. lbs. (61 Nm.) each.

(13)

Apply grease to end of shaft (item #27), opposite gear

(item #16). Apply grease to bushing in gear housing

(item #18). Place greased end of shaft through bushing

in gear housing (item #18). Place gasket (item #69)

onto gear housing cover (item #12). Apply grease to

gear end of shaft and cover bushing. Place cover onto

shaft and secure to housing with eight (item #42) capscrews. Tighten capscrews to 39 ft. lbs. (52 Nm.) each.

67

29

33

51

17

9

Page 12

(15)

Press bearing (item #33) onto worm and

into housing. NOTE: Be sure that thick

shoulder of bearings outer race (side with

manufacturer's name and part number) is

out, away from worm threads. Attach

adapter (item #3) to gear housing using

six capscrews (item #53). Tighten capscrews to 45 ft. lbs. (61 Nm.) each. Insert

key (item #23) into keyway of worm shaft.

Slide coupling (item #2) over end of worm

shaft. Attach adapter plate (item #25) to

adapter using eight capscrews (item #50).

Tighten capscrews to 21 ft. lbs. (28 Nm.)

each.

Place motor shaft, with key in keyway, into

coupling. Secure motor (item #72) to

adapter, using two capscrews (item #54).

Tighten capscrews to 102 ft. lbs. (138

Nm.) each.

54

72

50

23

67

2

33

80

3

53

25

14

84

15

89

(16)

Place winch with gear housing cover down on work

bench. Drum shaft should be in vertical position. Set

springs (item #84) into pockets of gear housing with

drag brakes (item #14) on top of disc (item #89) and

springs. Slide drum assembly (item #15) onto drum

shaft as shown.

10

Page 13

44

(17 )

Place clutch (item #9) over end of drum shaft. Align the clutch over

9

77

the pilot bushing in drum. Install the eight capscrews (item #44)

and torque the capscrews to 103 ft. lbs. (139 Nm.) to securely seat

the clutch to the drum.

10

15

32

Rotate the drum to align the clutch slots with the shaft keyways.

Lightly grease four dowel pins, (item #77) and eight balls (item #32)

with molybdenum disulfide or graphite bearing grease. Insert the four

77

dowel pins and eight balls. In the engaged position the balls are nearly

flush with the clutch.

Lightly grease the internal and external groove and bore in locking ring

(item #10) and clutch (item #9).

Slide locking ring onto the clutch. When fully engaged, the locking

ring touches the clutch flange and there is .71 to .73 inches between

the end of the locking ring and the end of the clutch.

(18)

Lightly grease the four springs (item #85) and place over four

roll pins on retainer plate (item #76).

78

76

NOTE: If roll pins (items #76 N) are damaged, remove

pins from plate and install new pins as follows:

Insert four roll pins (item #76) into same retainer plate holes.

Drive pins into plate until pins extend 5/16" thru, the clutch

housing side, of retainer plate. Drive roll pins (item #78) into

ends of (item #76) pins, extending 5/16" beyond retainer plate,

until ends of roll pins are flush. Check to make sure that roll

pins still extend 5/16" through retainer plate.

Install spacer (item #28), retainer plate, with springs, and secure to clutch using four capscrews (item #38). Torque capscrews to 9.7 ft./lbs. (13 Nm.) each. Firmly seat the retainer

ring (item #82) into drum shaft groove.

64

48

52

57

30

64

19

47

4

49

4

38

28

79

(19)

Set the yoke (item #30) so that the screw heads

(item #52) engage the external groove in the

locking ring. Push the clutch housing (item #19)

onto the drum shaft and latch the shifter assembly in the engaged "IN" position. Insert the two

capscrews (item #47) and securely tighten.

Attach mounting angles (item #4) to winch assembly using four capscrews (item #48), at

clutch housing, and four capscrews (item #49),

at gear housing, with lockwasher (item #64).

Torque capscrews to 500 ft. lbs. (678 Nm.) each.

11

Page 14

(20)

The shift linkage on top of the clutch housing is adjusted at the

factory to provide reliable shifting of the "Dow-Lok" clutch.

When reassembling, it may be necessary to readjust it as follows. Attach the bracket (item #34) to the clutch housing with

the capscrews (item #40). Attach the shifter lever assembly to

the yoke using the clevis pin and cotter pin (items #65

B). With the clutch in the engaged "IN" position, the notch

in the shifter shaft should be latched onto the bracket with a

minimum of shaft end play so that the clutch is securely

latched "IN". If adjustment is needed, loosen the large jam nut

and screw the shaft into or out of the clevis as needed. Securely tighten the jam nut.

Lift up on the handle and pull it toward you as far as it will go

until the other notch in the shaft latches onto the bracket, Thus

securing the clutch in the disengaged "OUT" position. You

should now be able to turn the cable drum freely by hand. After

turning the cable drum by hand, lift up on the handle and push

in as far as it will go. Turn the cable drum by hand a maximum

of 1/4 revolution and the handle will spring to the "IN" position

latching the clutch into engagement. Attach the cover (item

#37) to the clutch housing and check the action of the clutch

several times.

1

19

55

37

59

40

65

66

86

56

34

70

74

(21)

Insert plug (item #75) into bottom of gear housing.

Remove plug (items #70 J) from top of gear housing.

Pour 4 pints of E.P. 140 worm gear oil into hole and replace

plugs.

75

12

Page 15

AIR SHIFTER OVERHAUL

DISASSEMBLY

If the air cylinder needs to be removed, remove (4)

capscrews (item #40) that hold the cover (item

#37) and bracket (item #34) onto the clutch housing (item #19). Remove cotter pin (item #65) and

clevis pin (item #66) that hold clevis (item #27) to

yoke. Loosen jam nuts (item #57) and unscrew

stud (item #88) from clevis and air cylinder (item

#67).

To remove air cylinder from bracket, remove (4)

capscrews and lockwashers (items #55 and #59).

RE-ASSEMBLY

59

67

37

55

19

40

34

88

57

27

65

66

Install bracket (Item #34) using (2) capscrews (item

#40), reserving the other (2) capscrews to install

the cover later. Tighten to 18 ft-lbs torque. Install the

air cylinder (item #67) using (4) capscrews and

lockwashers (items #55 and #59). Tighten these

screws to 45 in-lbs.

Apply Loc-tite #262 to stud (item #88). Install (2)

jam nuts (item #57) onto stud, then attach stud to

air cylinder shaft. Screw clevis (item #27) to other

end of stud and adjust stud until back of clevis is 11/8” from bracket (item #34), as shown at right.

Pull yoke to fully engaged position, and attach clevis

to shifter using pin (item #66) securing with cotter

pin (item #65). Confirm that clevis pin is not in a

bind when shifter is in engaged position. Adjust stud

slightly if it is. Tighten jam nuts to keep stud in correct position.

Connect air pressure (70-90 PSI) to inlet port of air

cylinder and disengage clutch. Confirm that clutch is

fully disengaged and freespool winch. Release air

pressure and confirm that travel of air cylinder shaft

is 1/8 to 3/16”. Continue to freespool winch and

confirm that winch shifts to full engagement.

67

37

5559

40

1-1/8"

34

88

57

27

65

66

27

Install cover (item #37) using (2) capscrews (item

#40). Tighten to 18 ft-lbs. torque.

34

13

Page 16

14 15

Page 17

NOTES

Page 18

42

12

73

75

51

17

33

24

14

29

87

75

18

13

60

39

84

89

67

23

70

74

84

89

49

64

48

64

4

77

35

15

14

24

27

77

69

46

16

21

33

67

2

63

73

6

80

3

53

72

88

6

25

50

54

43

71

9

44

76

57

52

66

65

86

37

40

59

55

56

34

1

78

30

19

47

71

28

38

36

36

32

10

79

8

4

64

64

49

48

Model H-930 Dow-Lok

16

Page 19

Y

Y

X

/

Y

Y

HD ALL-THRD C.P.

1/2-20NF X 2 LG HX HD GR.8

1/2-13NC X 2-1/2 LG H

Description

2 414619 CAPSCREW -

®

10 414606 CAPSCREW -

PARTS LIST

Model H930 Dow-Lok

7/8-9NC X 2 LG HX HD GR.5

7/8-9NC X 2 LG HX HD NYLOK H.P.

5/16-18NC X 1-1/4 LG SOC HD LOK-WEL

4 414784 CAPSCREW -

4 414786 CAPSCREW -

8 414871 CAPSCREW -

2-13NC X 1-3/4 LG SOC HD LOK-WEL

CLEVIS

NOT USED

NOT USED

NOT USED

6 414897 CAPSCREW 3/8-16NC X 1 LG SOC. HD.

2 414905 CAPSCREW 3/8-16NC X 1-1/4 LG SOC. HD.

6 414909 CAPSCREW 3/8-16NC X 1-3/4 LG SOC HD LOK-WEL

2 414950 CAPSCREW 1

2 416236 SCREW - #10-24NC X 1/2 HX HD CP

2 418004 NUT #10-24NC HX REG CP

2 418035 NUT 3/8-16NC HX REG C.P.

2 418141 LOCKWASHER - #10 MED

4 418149 LOCKWASHER 1/4 MED SECT CP

10 418217 LOCKWASHER 1/2 MED SECT

8 418258 LOCKWASHER 7/8 MED SECT

1 424005 COTTER PIN

1 424205 PIN -

NOT USED

2 442192 GASKET

1 442195 GASKET

1 456008 FITTING - RELIEF

2 456031 FITTING- LUBE

1 458165 MOTOR-HYD.

2 462013 QUAD RING

1 468002 REDUCER

ROLL

2 468011 PIPE PLUG

4 470042 PIN -

DOWEL

ROLL

NOT USED

NOT USED

4 470044 PIN -

4 470056 PIN -

1 474030 PLATE - RETAINER

1 486068 SEAL - OIL

1 490025 RING - RETAINER

2 494002 SPRING - DISC

4 494069 SPRING

2 494078 SPRING - FLAT

1 518016 THRUST WASHER

1 516056 MOTOR VALVE

2 530094 SPACER - BRAKE

84

87

89

47

46

68

69

1 1 276040 SHIFTER ASSEMBL

2 1 299733 COUPLING ASSEMBL

3 1 300048 ADAPTER 48

4 2 302902 ANGLE 49

5 NOT USED 50

6 2 308083 BUSHING 51

7 NOT USED 52

8 1 416059 SETSCREW - 3/8-16NC X 1/2 LG CUT POINT 53

9 1 324151 CLUTCH 54

1 NOT USED 56

10 1 324321 LOCKING RING 55

12 1 328122 COVER - GEAR HSG. 57

13 2 328127 COVER - DRAG BRAKE 58

14 2 330010 SHOE - DRAG BRAKE 59

15 1 332132 DRUM 60

16 1 334150 GEAR - R.H. 61

17 1 316021 BEARING CAP 62

18 1 338253 HOUSING - GEAR 63

19 1 338254 HOUSING - CLUTCH 64

20 NOT USED 65

21 1 340068 HUB - GEAR 66

22 NOT USED 67

23 1 342083 KE

24 2 342153 KE

25 1 350535 PLATE - ADAPTER 70

26 NOT USED 71

27 1 357457 SHAFT - DRUM 72

28 1 362224 SPACER 73

29 1 368212 WORM - R.H. 74

30 1 370052 YOKE 75

31 NOT USED 76

32 8 400011 BALL - CLUTCH 77

33 2 402045 BEARING - BALL 78

34 1 408112 BRACKET - CLUTCH SHIFTER 79

35 1 412051 BUSHING 80

36 2 412052 BUSHING 81

37 1 413028 COVER - SHIFTER 82

38 4 414038 CAPSCREW - 1/4-20NC X 3/4 LG HX HD GR.5 83

39 4 414055 CAPSCREW - 1/4-20NC X 1/2 LG HX HD C.P.

40 4 414069 CAPSCREW - 5/16-18NC X 3/4 HX HD 85

41 NOT USED 86

42 8 414277 CAPSCREW - 3/8-16NC X 1 LG HX HD NYLOK H.P.

43 3 414305 CAPSCREW - 3/8-16NC X 3 1/4, HXHD, Z/P, G5 88

44 8 414571 CAPSCREW - 1/2-20NF X 1 LG HX HG GR.5

Item No. Qty. Part No. Description Item No. Qty. Part No.

45 NOT USED

17

Page 20

LIMITED WARRANTY

RAMSEY WINCH warrants each new RAMSEY Winch to be free

from defects in material and workmanship for a period of one (1)

year from date of purchase.

The obligation under this warranty, statutory or otherwise, is limited to the replacement or repair at the Manufacturer’s factory, or

at a point designated by the Manufacturer, of such part that shall

appear to the Manufacturer, upon inspection of such part, to have

been defective in material or workmanship.

This warranty does not obligate RAMSEY WINCH to bear the cost

of labor or transportation charges in connection with the replacement or repair of defective parts, nor shall it apply to a product

upon which repairs or alterations have been made, unless authorized by the Manufacturer, or for equipment misused, neglected or

which has not been installed correctly.

RAMSEY WINCH, whose policy is one of continuous improvement, reserves the right to improve its products through changes

in design or materials as it may deem desirable without being obligated to incorporate such changes in products of prior manufacture.

If field service at the request of the Buyer is rendered and the fault

is found not to be with Ramsey Winch’s product, the Buyer shall

pay the time and expense of the field representative. Bills for service, labor or other expenses that have been incurred by the

Buyer without approval or authorization by Ramsey Winch will not

be accepted.

Ramsey Winch Company

Post Office Box 581510 ● Tulsa, Oklahoma 74158

Telephone: (918) 438-2760 ● www.ramsey.com

FAX: (918) 438-6688

914226-0109-A

Loading...

Loading...