Page 1

English (Original Instructions) . . . . . . . . . . . . . . . 1

CE

OPERATING, SERVICE AND

MAINTENANCE MANUAL

Français (Traduction des instructions originales) . . 19

Deutsch (Übersetzung der Originalanleitung) . . . . . 35

Español(Traducción de las instrucciones originales).53

MODEL H 49,8 SERIES LEVER EQUIPPED

INDUSTRIAL LOW-MOUNT WINCHES

INTENDED USE: VEHICLE RECOVERY AND PULLING OF LOADS

CAUTION: READ AND UNDERSTAND THIS MANUAL BEFORE INSTALLATION

AND OPERATION OF WINCH. SEE WARNINGS!

Ramsey Winch Company

P.O. Box 581510 - Tulsa, OK 74158-1510 USA

Phone: (918) 438-2760 - Fax (918) 438-6688

Visit us at http://www.ramsey.com

Ramsey Authorized Representative in the Community

Please contact for regulatory inquiries only.

Alura Group BV

P.O. Box 18626

2502 EP The Hague

The Netherlands

Tel: (31) (0) 70 362-4896

Fax: (31) (0) 70 346-7299

OM-914216-1012-D

Page 2

4707 N. Mingo Tulsa, Oklahoma 74117 (918) 438-2760

EC DECLARATION OF CONFORMITY

as defined by Machinery Directive 2006/42/EC

Here with we declare that winch model H49,8 complies

with the following directive provided that the USER

complies with all responsibilities described in the Owner’s

Manual:

2006/42/EC

Applied harmonized standards:

EN 14492-1:2006

Power-Driven Winches

ISO 9001:2000

Quality Management Systems

Requirements

DÉCLARATION DE CONFORMITÉ EC

aux termes de la directive Machines 2006/42/EC

Nous déclarons par la présente que le modèle de treuil H49,8

est conforme à la directive suivante, sous réserve que

l’UTILISATEUR ait assumé toutes les responsabilités figurant

dans le manuel de l’utilisateur :

2006/42/EC

Normes harmonisées appliquées :

EN 14492-1:2006

Treuils motorisés

ISO 9001:2000

Systèmes de gestion de la qualité - Exigences

EC-KONFORMITÄTSERKLÄRUNG

gemäß Maschinenrichtlinie 2006/42/EC

Hiermit erklären wir, dass das Windenmodell H49,8 der

folgenden Richtlinie entspricht, sofern der BENUTZER

alle Anweisungen im Benutzerhandbuch befolgt:

2006/42/EC

Angewandte harmonisierte Normen:

EN 14492-1:2006

Kraftgetriebene Winden

ISO 9001:2000 Qualitätsmanagementsysteme Anforderungen

DECLARACIÓN EC DE CONFORMIDAD

según se define en la directiva de máquinas 2006/42/EC

Con la presente declaramos que el modelo de cabestrante

H49,8 se halla en conformidad con la siguiente directiva

siempre que el USUARIO cumpla todas las

responsabilidades descritas en el Manual del propietario:

2006/42/EC

Normas armonizadas aplicadas:

EN 14492-1:2006

Cabestrantes accionados mecánicamente

ISO 9001:2000

Requisitos de los Sistema de gestión de la calidad

Ramsey Authorized Representative in the Community / Ramsey Représentant autorisé dans la comuauté /

Ramsey Bevollmächtigter in der Europäischen Union / Ramsey Representante autorizado en la comunidad.

(Please contact for regulatory inquiries only. / Veuillez prendre contact uniquement pour des questions réglementaires.)

(Bitte nur bei Regulierungsfragen kontaktieren. / Póngase en contacto sólo por cuestiones de reglamentación.)

Alura Group BV

P.O. Box 18626

2502 EP The Hague

The Netherlands

Tel: (31) (0) 70 362-4896

Fax: (31) (0) 70 346-7299

Serial Number / Numéro de série/ Seriennummer/ Número de Serie:_____________________

Signature / Signature / Unterschrift / Firma:

Todd Brady

Engineering Manager / Directeur technique/ Technischer Leiter/ Director de ingeniería

Date / Date / Datum / Fecha:

05/03/2011

Page 3

Page 4

TABLE OF CONTENTS

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

WARNINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

USER’S RESPONSIBILITY FOR CE COMPLIANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

WINCH MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

ROPE INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

WINCH MOUNTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

TROUBLE SHOOTING GUIDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

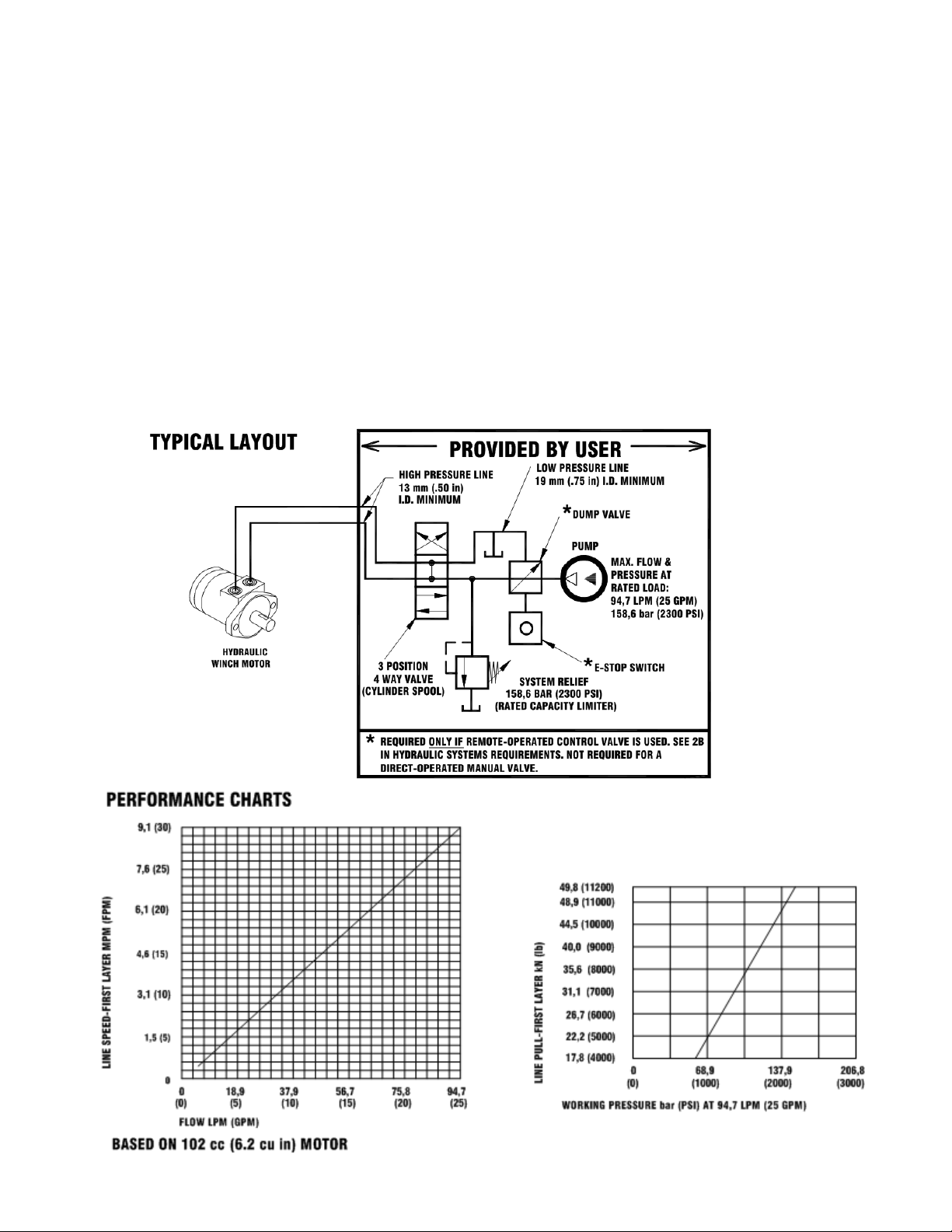

HYDRAULIC SYSTEM REQUIREMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

PERFORMANCE CHARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

END OF SERVICE MEASURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

INSTRUCTIONS FOR OVERHAUL

DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-12

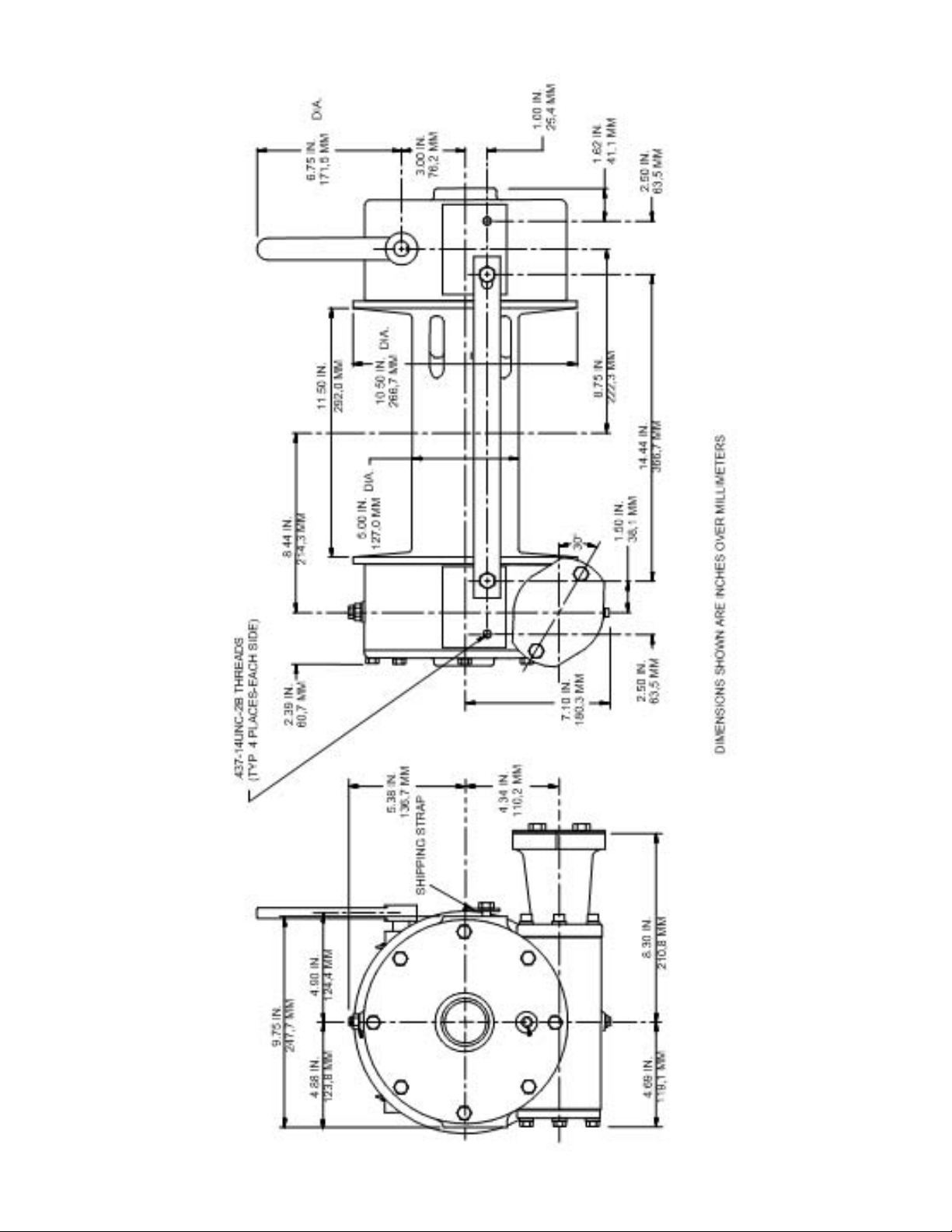

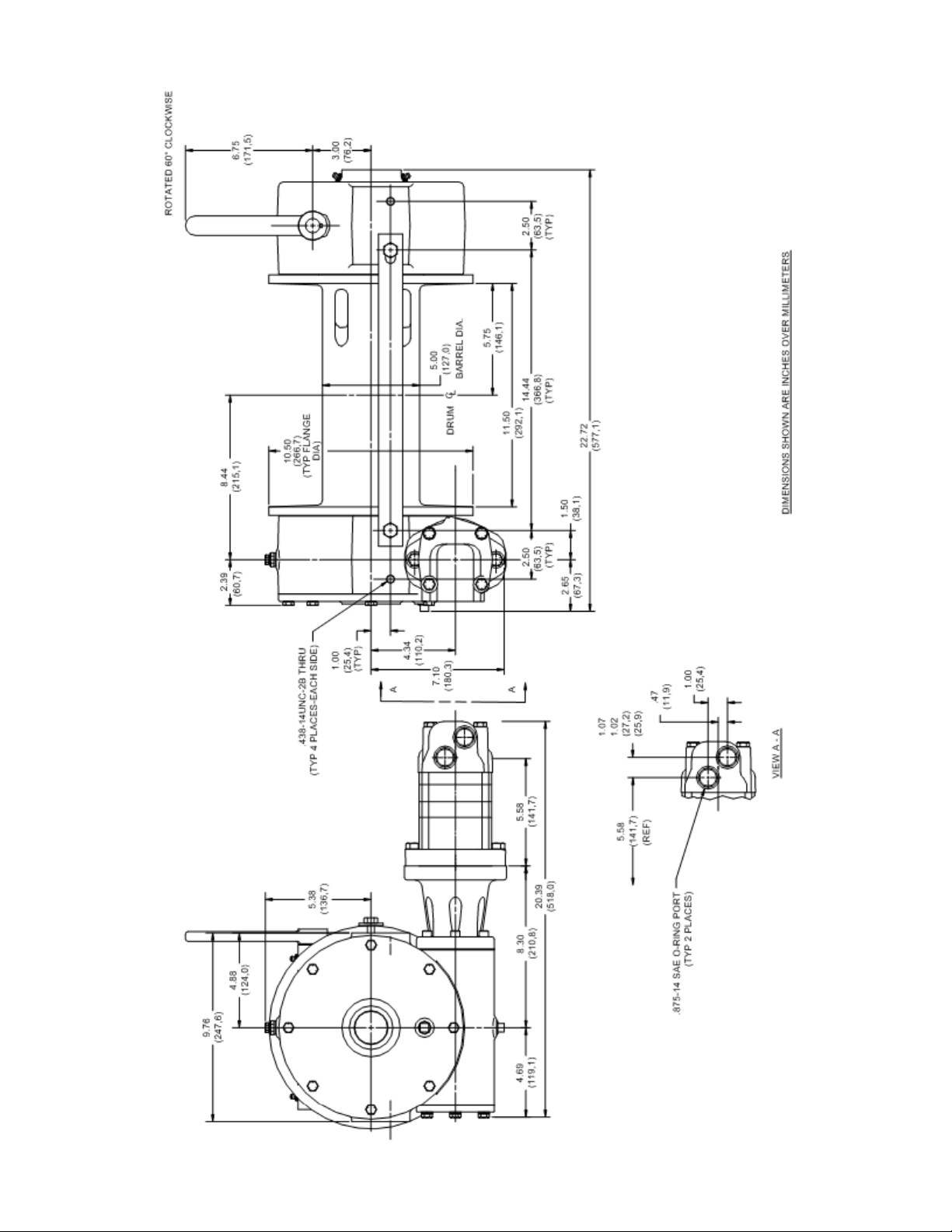

DIMENSIONAL DRAWINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-14

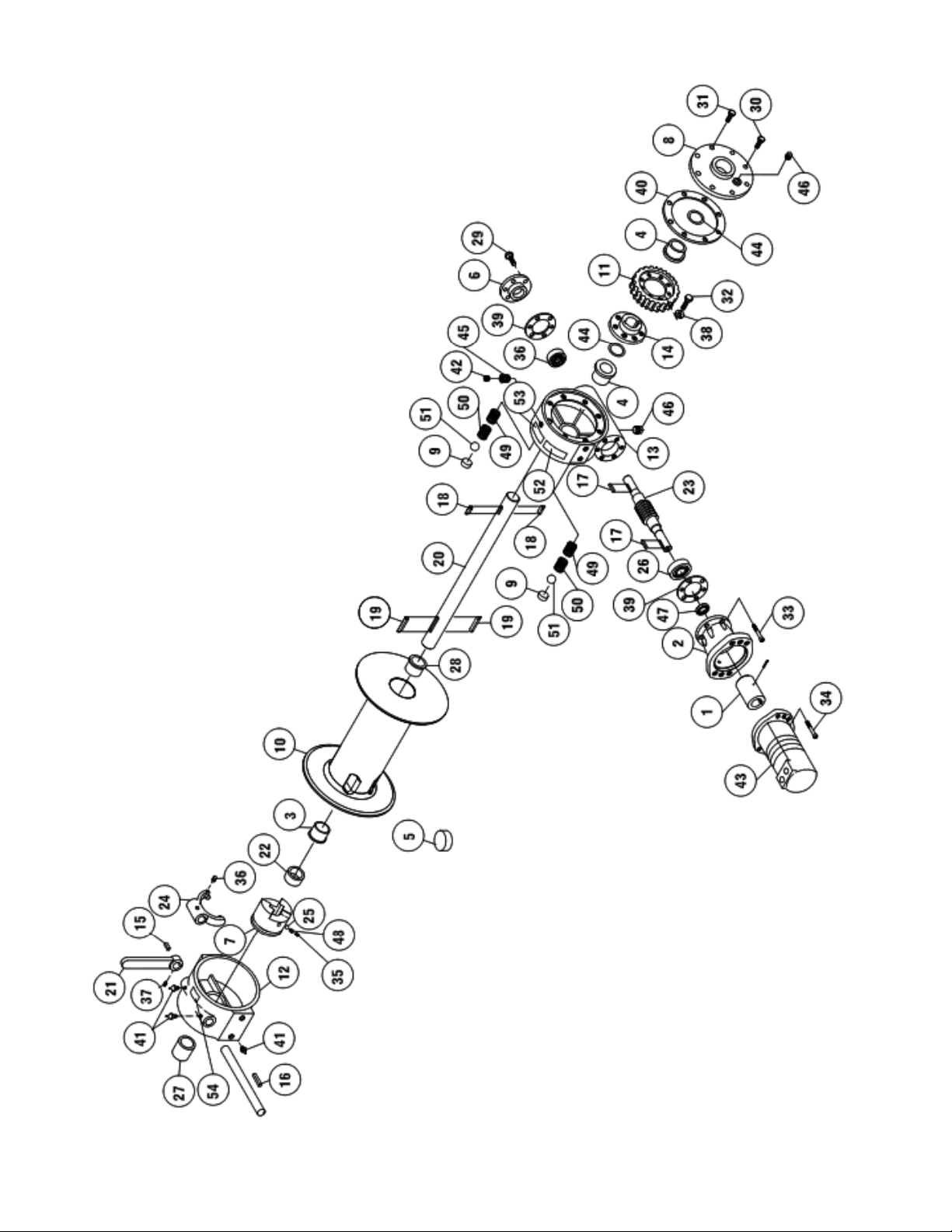

PARTS LIST AND PARTS DRAWING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15-16

CE DECLARATION OF CONFORMITY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Page 5

5

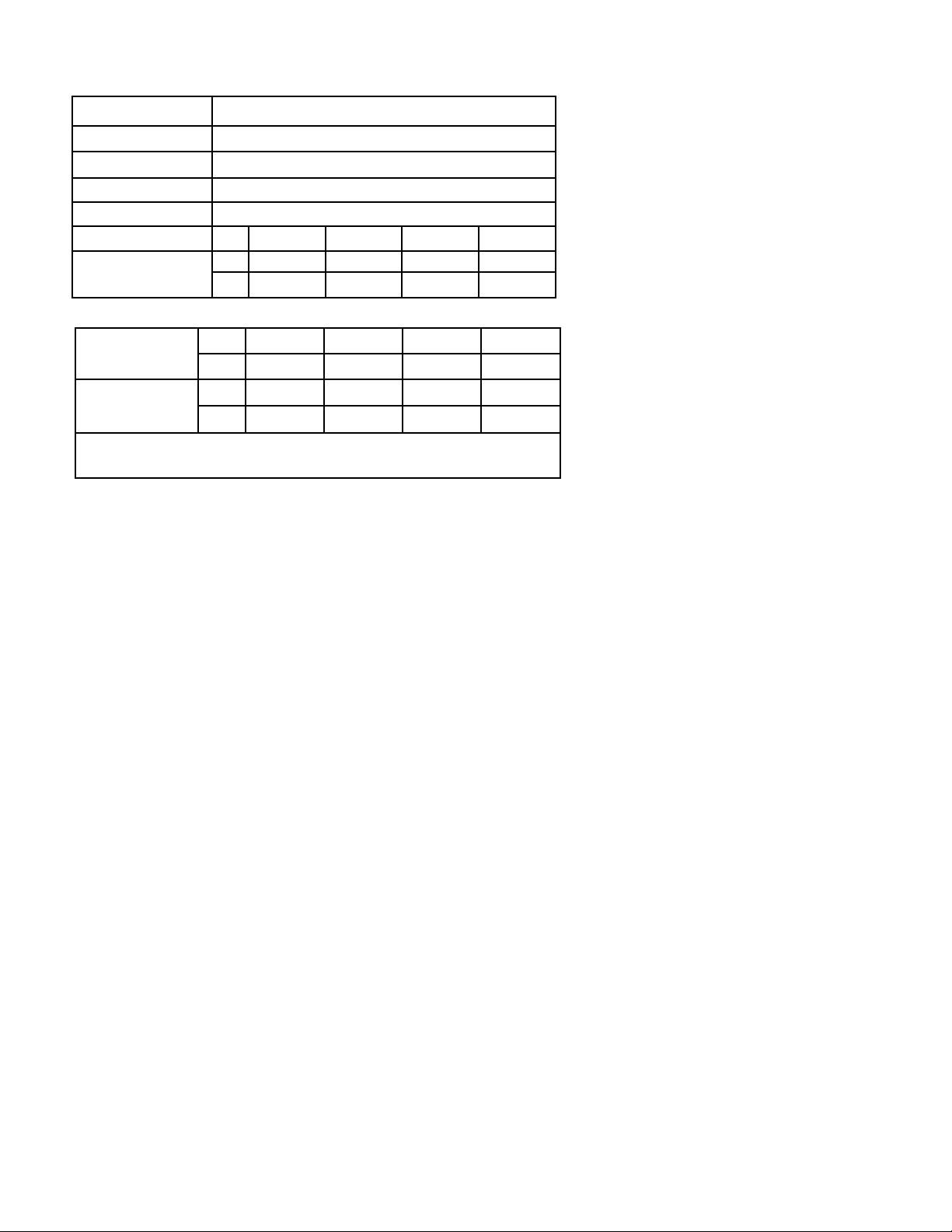

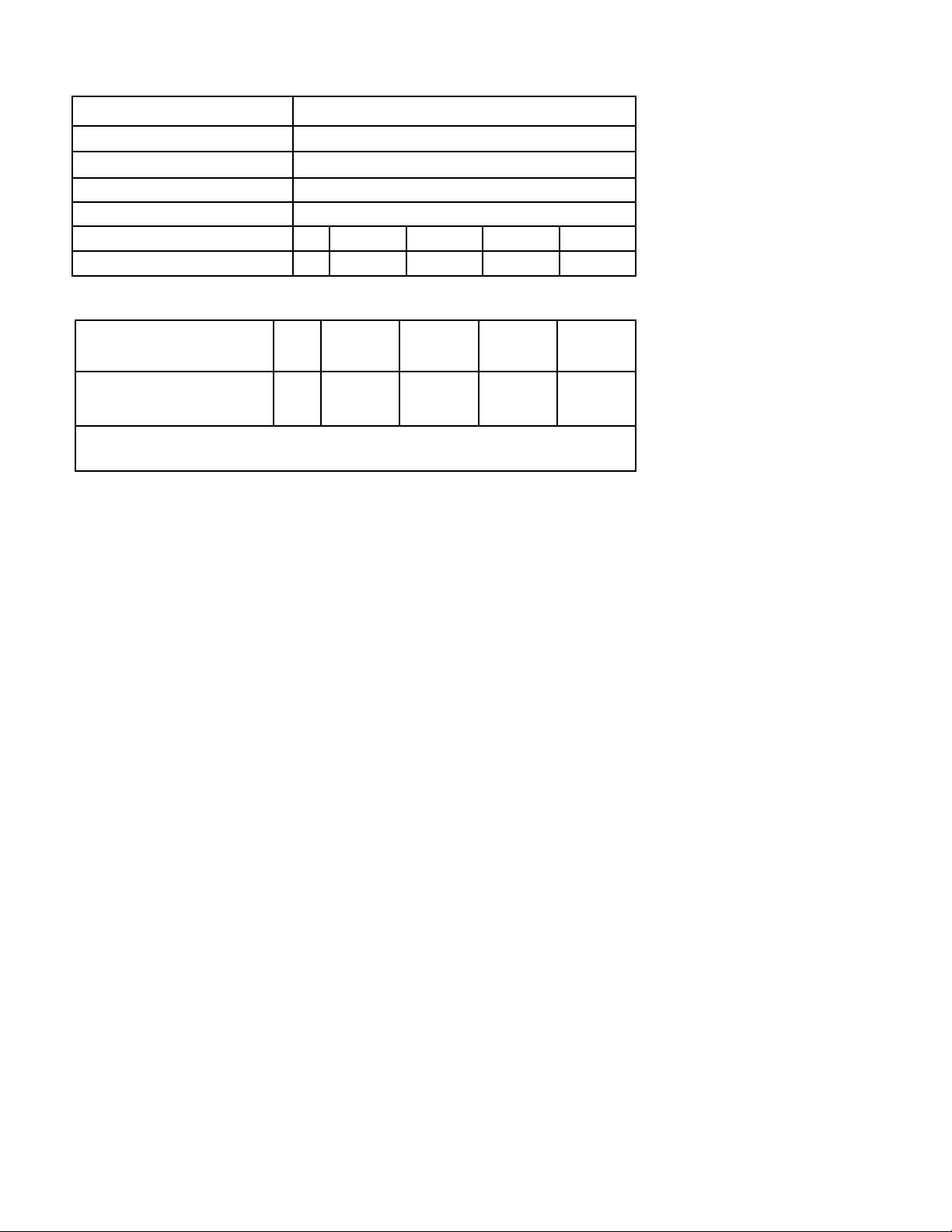

SPECIFICATIONS*

* Rope Capacity Per Layer

WARNINGS:

THE USER SHALL ENSURE THAT THE OPERATING PERSONNEL ARE GIVEN THE NECESSARY TRAINING.

THE OPERATOR SHALL ALWAYS WORK IN COMPLIANCE WITH THE OPERATING INSTRUCTIONS.

CLUTCH MUST BE FULLY ENGAGED BEFORE STARTING THE WINCH.

DO NOT DISENGAGE CLUTCH UNDER LOAD.

STAY OUT FROM UNDER AND AWAY FROM RAISED LOADS.

STAND CLEAR OF ROPE WHILE PULLING. DO NOT TRY TO GUIDE ROPE.

DO NOT USE WINCH TO LIFT, SUPPORT, OR OTHERWISE TRANSPORT PERSONNEL.

A MINIMUM OF 2 WRAPS OF ROPE AROUND THE DRUM BARREL IS NECESSARY TO HOLD THE LOAD.

AVOID CONDITIONS WHERE LOAD SHIFTS OR JERKS OCCUR. EXCESSIVE “INCHING” SHALL BE AVOIDED.

USER’S RESPONSIBILITY FOR CE COMPLIANCE

1. Use only a cylinder spool (closed center) control valve per Hydraulic System Requirements.

2. If a remote-operated winch control valve is used, refer to Hydraulic System Requirements for Emergency Stop

components to be installed.

3. Adjust system relief pressure per Hydraulic System Requirements

4. Mount winch per Winch Mounting Instructions.

5. Install 12 mm (.472 inch), grade 1960 wire rope. Maximum rope length of 47 M (155 ft) for four layers maximum.

Attach rope to the drum per Rope Installation Instructions. Hook must have a safety latch and a minimum breaking

strength of 125 kN.

First Layer Line Pull

49,8 kN (11,200 lb)

Noise Level

81 db

Ambient Temp. Range -28C to 60C (-20F to 140F)

Gear Reduction 40:1

Weight (without rope) 91Kg (200 lb)

LAYER OF ROPE 1234

Line pull per layer

kN 49 ,8 42,4 37,0 32,8

lb 11,200 9,500 8,300 7,300

*Rope Capacity

Per Layer

m 9 19 33 47

ft 30 65 110 155

* Line Speed at

56,7 LPM (15

GPM)

MPM 9,1 10,3 11,8 13,0

FPM 30 34 39 43

* These specifications are based on recommended wire rope of 12 mm (.472") 1960

grade wire rope and a 102 cc (6.2 cu in) /Rev. motor.

Page 6

WINCH MAINTENANCE

Adhering to the following maintenance schedule will keep your winch in top condition and performing as it should with a minimum of repair.

A. WEEKLY

1. Check the oil level and maintain it to the oil level plug. If oil is leaking out, determine location and repair.

2. Check the pressure relief plug in top of the gear housing. Be sure that it is in good operating condition so that hot oil gasses may escape.

3. Lubricate rope with light oil.

B. MONTHLY

1. Lubricate the various grease fittings located in the rope drum, end bearing, clutch housing or clutch operating linkage. Any good grade of

moly-disulfide containing grease is acceptable.

2. Check the action of the sliding clutch, making sure it is fully engaging and disengaging with the rope drum. Remove the plastic plug in

top of the housing and observe if the clutch is fully engaging. If clutch is not fully engaging, inspect clutch shifter assembly parts, check

for damage or excessive wear and replace as necessary. Observe the jaws on both the clutch and rope drum, checking for rounding of

the driving faces. If rounding has occurred they should be replaced immediately.

3. Check the winch mounting bolts. If any are missing, replace them and securely tighten any that are loose. Make sure to use only grade

5 bolts or better.

4.. Inspect the rope. If the rope has become frayed with broken strands, replace immediately.

C. ANNUALLY

1. Drain the oil from the winch annually or more often if winch is used frequently.

2. Fill the winch to the oil level plug with clean kerosene. Run the winch a few minutes with no load in the reel in direction. Drain the

kerosene from the winch.

3. Refill the winch to the oil level plug with all purpose E.P. 140 gear oil.

4. Inspect frame and surrounding structure for cracks or deformation.

5. Gear wear can be estimated by rocking the drum back and forth and if necessary drain oil and remove cover for closer inspection.

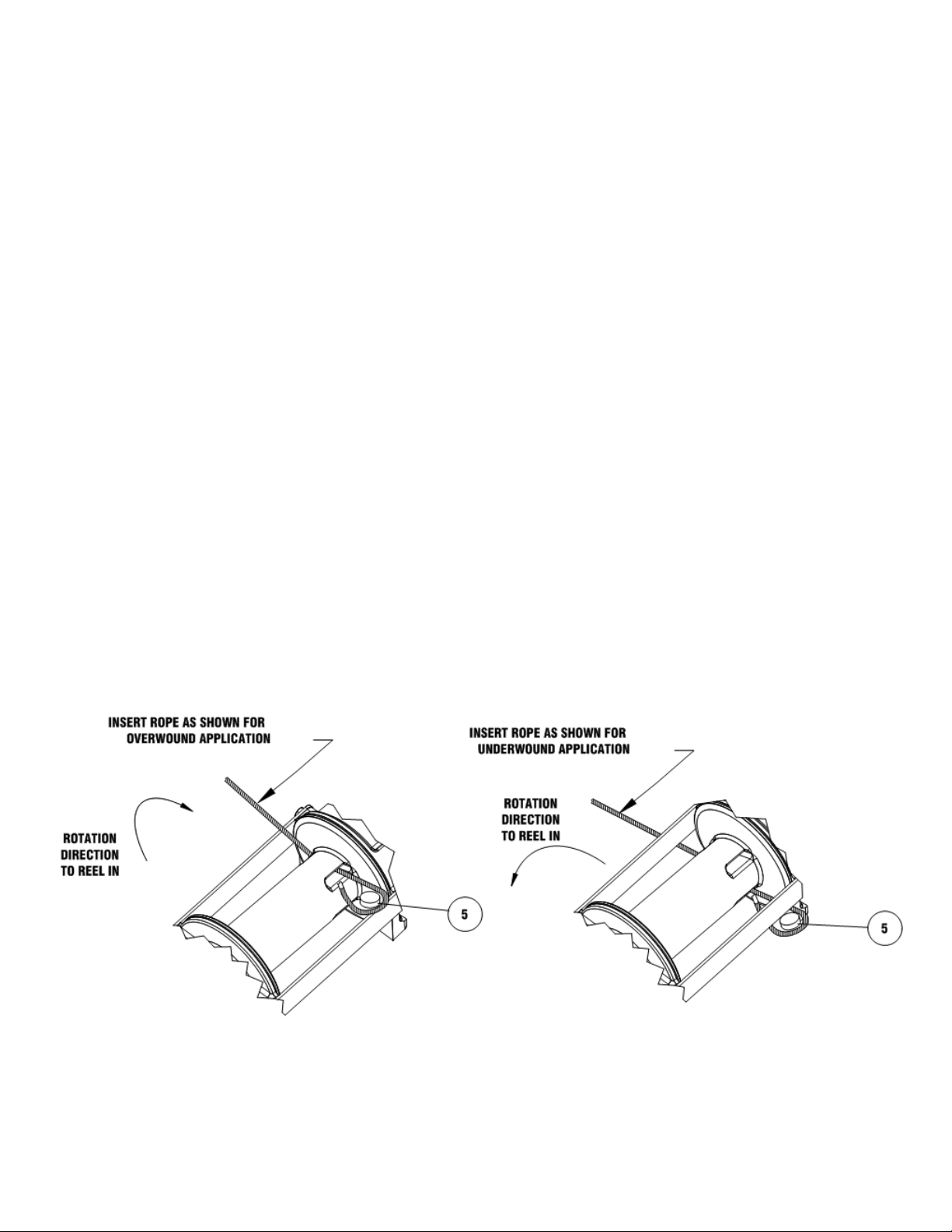

ROPE INSTALLATION

1.

Unwind rope by rolling it out along the ground to prevent kinking. Securely wrap end of rope, opposite hook, with plastic or similar tape to prevent fraying.

2. Slide the wire rope through narrow end of the pocket against the drum flange. Wrap the wire rope around on the anchor “puck” (item #5) and pull the

wire rope and anchor back into the wide end of the pocket. Use a soft hammer to drive the back side of the wire rope, firmly seating the wire rope and

anchor into the pocket.

3. Carefully run winch in the "reel-in" direction. Keeping tension on end of rope, spool all the rope onto the rope drum, taking care to form neatly

wrapped layers.

6

Page 7

7

TROUBLESHOOTING GUIDE

CONDITION POSSIBLE CAUSE CORRECTION

CLUTCH INOPERATIVE OR BINDS

UP.

1. Dry or rusted shaft. 1. Clean and lubricate.

2. Bent yoke or linkage. 2. Replace yoke or shaft assembly.

3. Clutch jaws are in contact. 3. See TECHNIQUES OF OPERATION.

OIL LEAKS FROM HOUSING. 1. Seal damaged or worn. 1. Replace seal.

2. Too much oil. 2. Drain excess oil. Refer to TECHNIQUES OF

OPERATION.

3. Damaged gasket. 3. Replace gasket.

WINCH RUNS TOO SLOW 1. Hydraulic motor worn out. 1. Replace motor.

2. Low flow rate. 2. Check flow rate. Refer to WINCH MOUNTING

above.

ROPE DRUM WILL NOT FREE

SPOOL.

1. Winch not mounted squarely,

causing end bearings to bind

drum.

1. Check mounting. Refer to WINCH MOUNTING

above.

ROPE BIRDNESTS WHEN CLUTCH

IS DISENGAGED.

1. Drag brake disc worn. 1. Replace discs.

HYDRAULIC FLUID LEAKS OUT

HOLE IN MOTOR ADAPTER.

1. Hydraulic motor shaft seal

damaged.

1. Replace seal.

WINCH MOUNTING

It is most important that this winch be mounted securely so that the three major sections (the clutch housing end, the rope drum and

the gear housing end) are properly aligned. If mounting angles are used, 13mm (.50 in) thick spacers must be used to provide

clearance between the drum flange and mounting angles. The spacers (4) must be installed between the clutch and gear housing

ends and the mounting angles. Recommended mounting angles are: 10 X 65 X 65mm (3/8 x 2-1/2 x 3") Lg. high strength 248 GPa

(36,000 PSI) yield steel angle.

Page 8

Refer to the performance charts below to properly match your hydraulic system to the winch performance.

The charts consist of: (1) Line Pull first layer kN (lb) vs. Working Pressure bar (PSI). (2) Line Speed, first layer MPM

(FPM) vs. flow LPM.

HYDRAULIC SYSTEM REQUIREMENTS

1.

Cylinder spool (closed center) control valve

2. Emergency Stop:

A. If winch is controlled by a direct-operated manual valve, that valve serves as the E-stop.

B. If a remote operated control valve is used, a solenoid-operated hydraulic dump valve, normally open to

tank, and an emergency stop switch (to open the dump valve) is required. The E-stop switch is to be

normally closed and have a red, resettable push button actuator with a yellow background. The E-stop

switch must be easily accessible to the operator.

3. Relief valve set to 158,6 bar (2300 psi) which is the rated capacity limiter.

4. Flow rate of 94,7 LPM (25 GPM) maximum.

5. Hydraulic fluid with a viscosity between 20-43 cSt (100-200 SUS). Maximum operating temperature 85C (180F).

Cleanliness level of ISO 17-14 or better.

8

Page 9

9

END OF SERVICE MEASURES

When winch reaches the end of it’s serviceable life, dispose of per local environmental regulations.

INSTRUCTIONS FOR OVERHAUL OF RAMSEY

MODEL H 49,8

DIS-ASSEMBLY

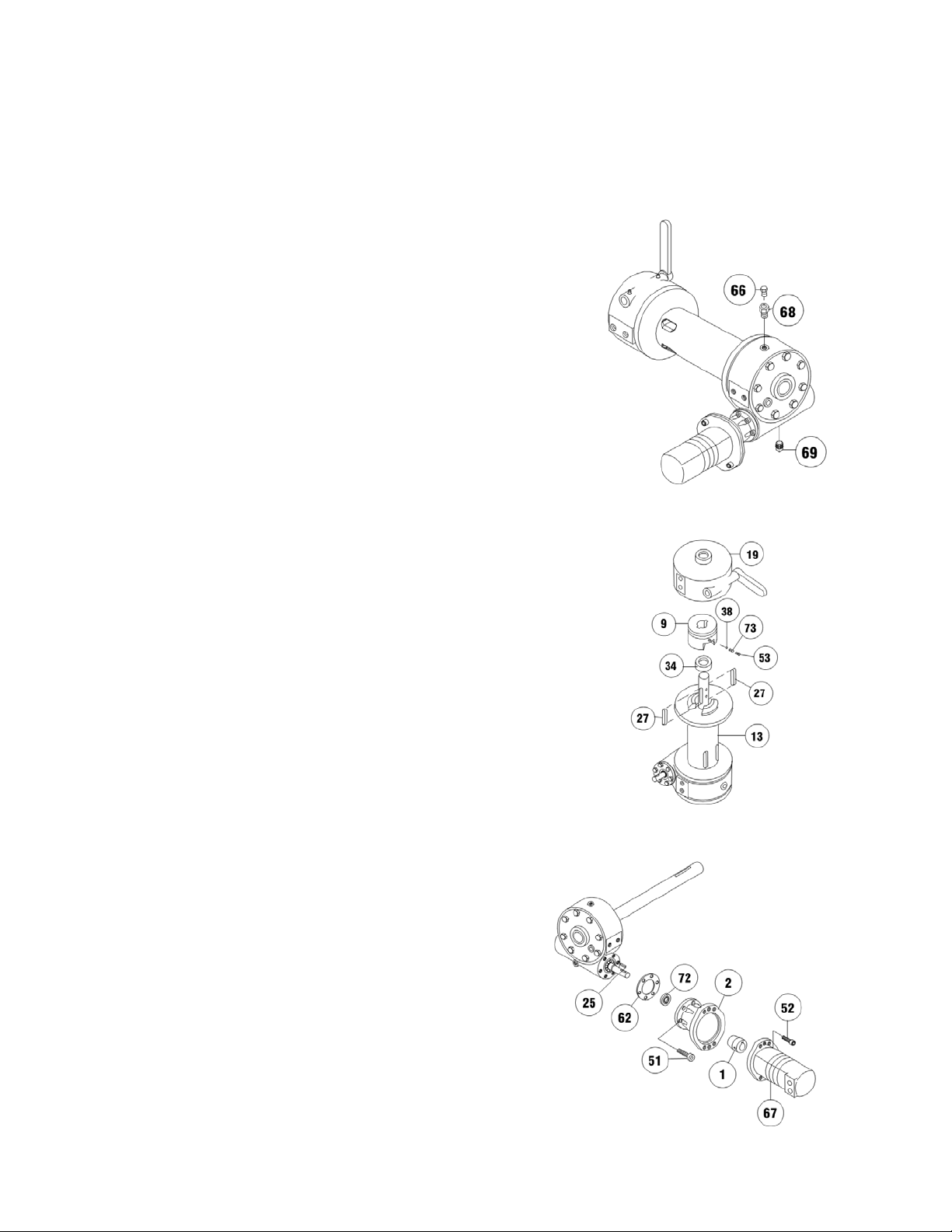

FIGURE 1

Drain oil from gear housing by removing pipe

plug #69 from bottom of gear housing.

Remove relief fittings #66 and reducer #68 from top

of gear housing.

FIGURE 2

Slide clutch housing #19 from end of drum shaft.

Remove setscrew #53, spring #73 and poppet ball

#38 from jaw clutch #9. Slide jaw clutch from end of

drum shaft.

Remove two keys #27 from keyways. Once keys

have been removed, drum #13 and drum spacer #34

can be removed from drum shaft.

FIGURE 3

Remove motor #67 and coupling assembly #1 from

adapter #2 by unscrewing two capscrews #52.

Remove key #25 from worm shaft. Unscrew six

capscrews #51 and remove adapter from gear

housing. Replace adapter seal #72 and gasket #62.

FIGURE 1

FIGURE 2

FIGURE 3

Page 10

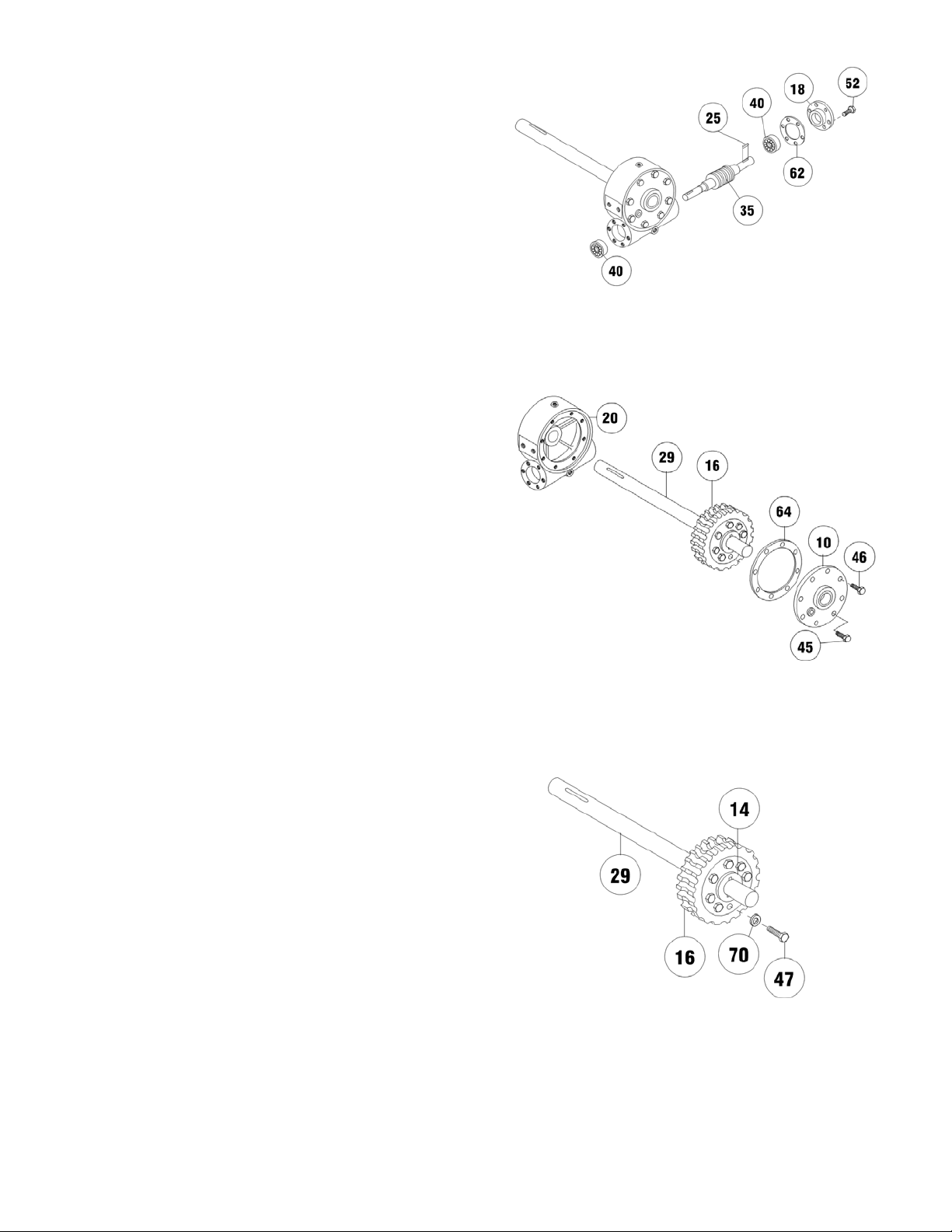

FIGURE 4

Remove bearing cap #18 from gear housing by

unscrewing six capscrews #52.

Remove worm #35 and bearings #40 from gear

housing. Use a soft hammer to gently tap input end

of worm and drive worm and bearing from gear

housing. Once worm has been removed from

housing, bearing can be pressed from end of worm.

Check for signs of wear or damage to worm #35 and

bearing #40. Replace if necessary.

FIGURE 5

Remove gear housing cover #10 from gear housing

#20 by unscrewing capscrews #46 & 45. Thread

two of the capscrews into the tapped holes of th

cover and tighten. This will pull the cover loose from

the gear housing.

Remove cover gasket #64 and pull shaft #29, with

gear attached, from gear housing.

FIGURE 6

Check for signs of wear on gear teeth. If necessary,

replace gear by removing six capscrews #47.

Place new gear #16 onto gear hub #14. Align holes

in gear with holes in hub. Press gear onto hub.

Be sure gear is seated all the way on the hub.

Use six capscrews #47 and lockwashers #59 to

secure gear to hub. Torque to 61 Nm (45 ft lb) each.

10

FIGURE 4

FIGURE 5

FIGURE 6

Page 11

11

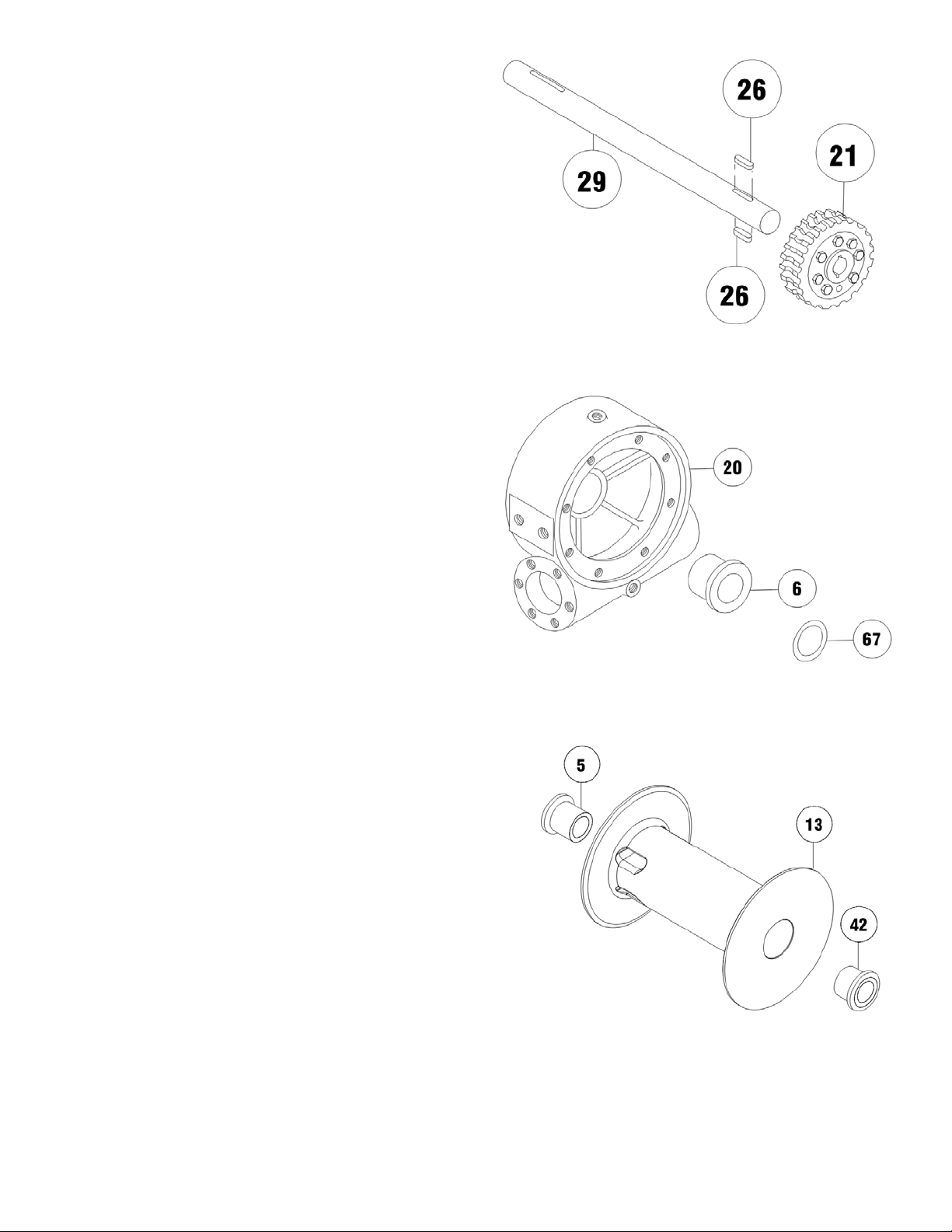

FIGURE 7

If shaft and/or hub is damaged, replace as follows:

a. Tap keys #26 into short keyways of drum shaft

#29.

b. Press shaft #29 and keys through gear hub #21

until end of keys on long end of shaft are flush

with hub.

c. Secure gear to hub using six #47 capscrews

with lockwashers #59. Torque to 61 Nm (45 ft lb)

each.

FIGURE 8

Check gear housing bushing #6 and quad ring #67

for signs of wear. Replace if necessary by pressing

old bushing from gear housing #20. Press new

bushing into place and insert new quad ring #67 into

groove inside of bushing.

FIGURE 9

Check drum bushings #5 & #42 for signs of wear.

Replace if necessary by pressing old bushings from

drum #13. Press new ones into place. The drum

assembly is also available with new bushings

pressed into place.

FIGURE 7

FIGURE 8

FIGURE 9

Page 12

12

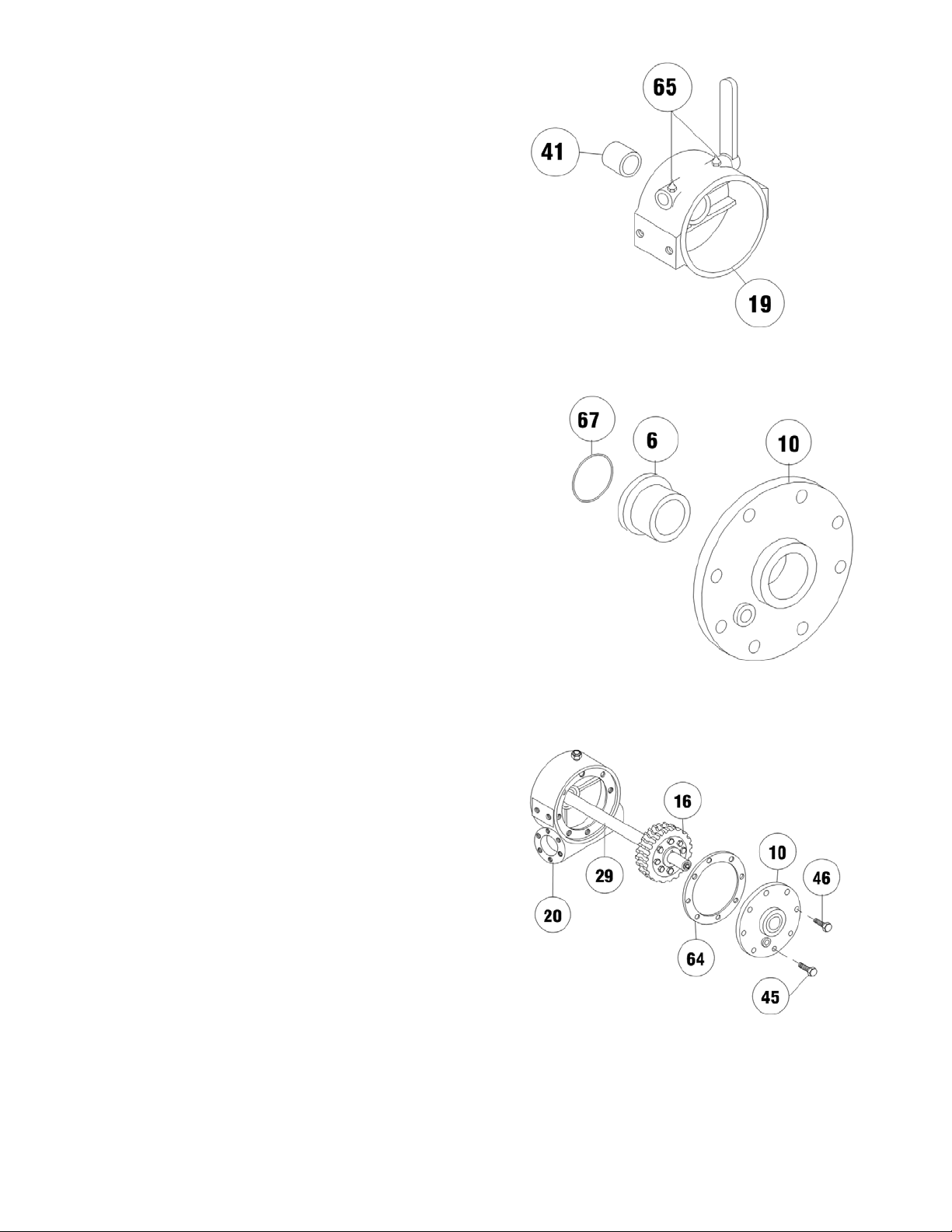

FIGURE 10

Check clutch housing bushing #41 for wear. If necessary, remove old bushing and press new bushing

into place. Apply grease to lube fittings #65 to lubricate clutch shifter shaft.

FIGURE 11

Check cover bushing #6 and quad ring #67 for

signs of wear. Replace if necessary by pressing old

bushing from gear housing cover #10. Press new

bushing into place and insert new quad ring #67

into groove inside of bushing.

FIGURE 12

Apply grease to end of shaft #29, opposite gear #16.

Apply grease to bushing in gear housing #20. Place

greased end of shaft through bushing in gear housing #20. Place gasket #64 onto gear housing cover

#10. Apply grease to gear end of shaft and cover

bushing. Place cover onto shaft and secure to housing with seven #46 and one #45 capscrews. Tighten

capscrews to 16.1 Nm (12 ft lb) each.

FIGURE 10

FIGURE 11

FIGURE 12

Page 13

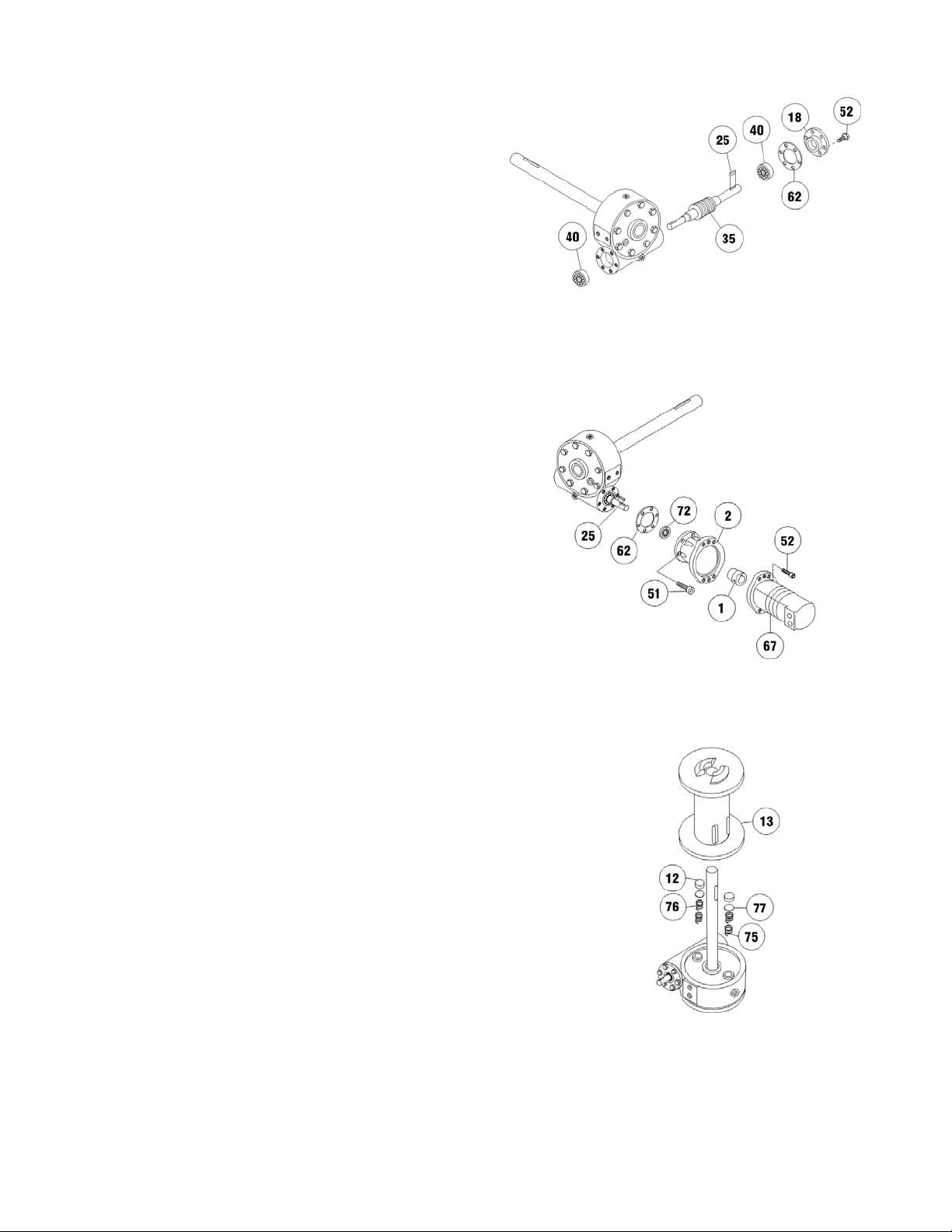

FIGURE 13

Press bearing #40 onto worm #35. NOTE: Be sure

that thick shoulder of bearings outer race (side with

manufacturer's name and part number) is out, away

from worm threads. Press bearing and worm into

gear housing. Slip gasket #62 onto bearing cap #18.

Use six capscrews #52 to secure bearing cap to

gear housing. Tighten capscrews to 16.1 Nm (12 ft

lb) each. Place key #25 into keyway of worm #35.

FIGURE 14

Attach adapter #2 to gear housing using six

capscrews #51. Tighten capscrews to 16.1 Nm

(12 ft lb) each. Insert key #25 into keyway of worm

shaft. Slide tapered end of coupling #1 over end of

worm shaft.

Place motor shaft, with key in keyway, into coupling.

Secure motor #67 to adapter, using two capscrews

#52. Tighten capscrews to 53 Nm (39 ft lb) each.

FIGURE 15

Place winch with gear housing cover down on work

bench. Drum shaft should be in vertical position.

Set springs #75 & #76 into pockets of gear housing

with drag brakes #12 on top of disc #77and springs.

Apply grease to shaft and drum bushings. Slide

drum assembly #13 onto drum shaft with drum jaws

upward as shown.

13

FIGURE 13

FIGURE 14

FIGURE 15

Page 14

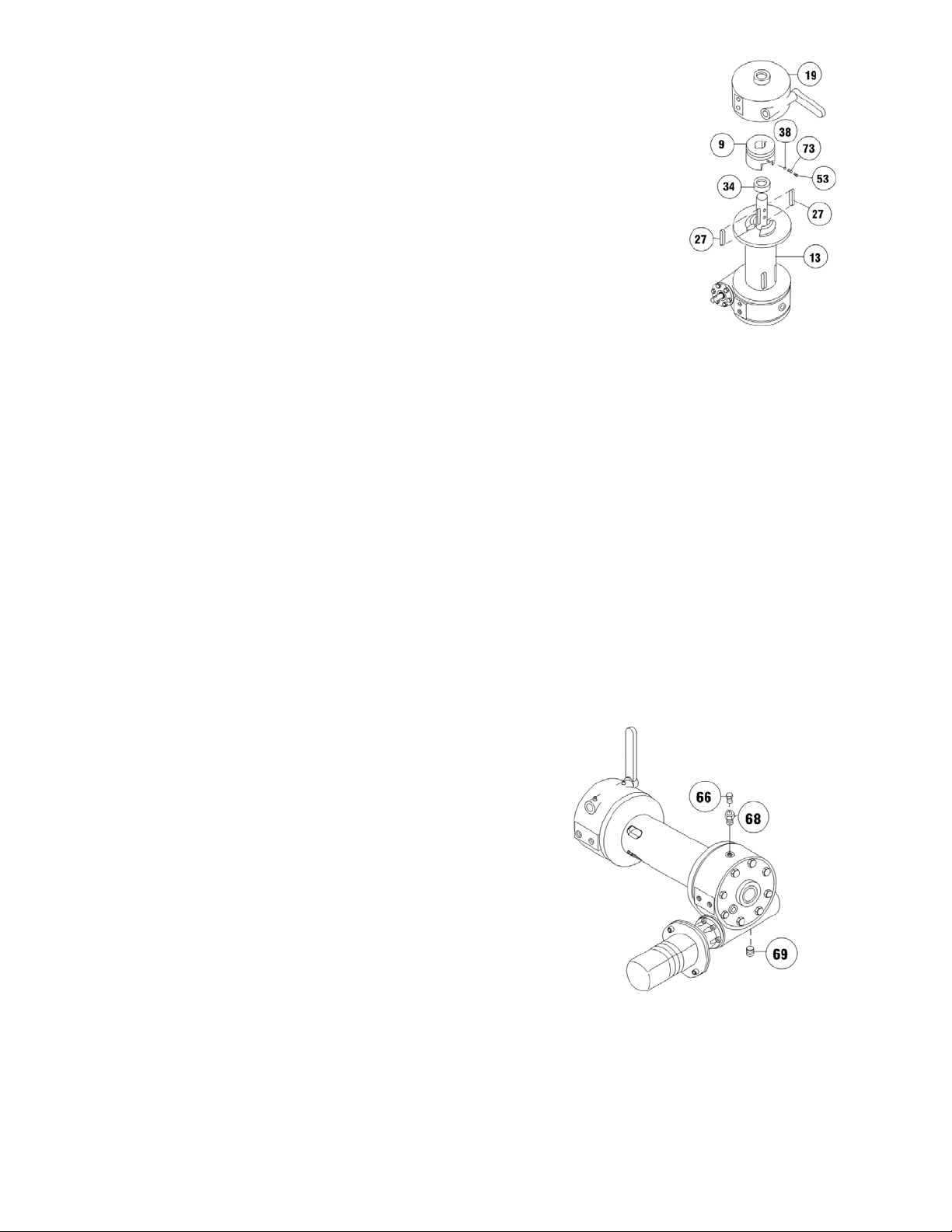

FIGURE 16

Slide spacer #34 over end of drum shaft. Press

drum downward to compress drag brake springs in

gear housing. Insert keys #27 into keyways. A rubber or brass mallet will be needed to gently tap keys

into position.

Apply grease to keys and end of shaft. Place jaw

clutch #9 over end of shaft and slide jaw clutch over

keys.

Note: Be sure that tapped hole on side of jaw clutch

is on same side of shaft as the two ball detents.

Insert ball poppet #38, spring #73, and setscrew #53 into tapped hole of jaw clutch.

If jaw clutch and/or drum shaft have been replaced two new detents MUST be drilled as follows:

Slide jaw clutch over end of shaft. Engage jaws of clutch with jaws of drum. Use a 10 mm (3/8")

dia. drill, using hole in jaw clutch as a guide to drill a 3 mm (1/8") deep detent (as measured to the

center of the drill point) in shaft. Slide jaw clutch upward 24 mm (15/16") and drill 2nd detent.

If only the clutch is replaced, the new detents are to be drilled on the side of the shaft opposite the

old detents. Apply grease to bushing in clutch housing assembly #19. Set clutch housing onto end

of drum shaft. Pull jaw clutch upward, toward clutch housing, enough to allow yoke in clutch housing

to fit properly in groove around jaw clutch. Slide clutch housing assembly and jaw clutch downward

into place.

The setscrew should be tightened enough to allow ball, when placed in ball detents, to sufficiently

hold jaw clutch "IN" and "OUT".

FIGURE 17

Insert plug #69 into bottom of gear housing.

Permatex may be applied to threads to help

prevent leakage.

Pour 2 pints of EP 140 gear oil into housing through

hole in top of housing. Insert relief fitting #66 into

reducer #68. Reducer should then be placed into

hole on top of gear housing. Tighten fittings and

reducer securely.

14

FIGURE 16

FIGURE 17

Page 15

15

H 49,8 DIMENSIONAL - NO MOTOR

Page 16

16

H 49,8 DIMENSIONAL WITH MOTOR

Page 17

17

H 49,8 PARTS DRAWING

Page 18

Page 19

TREUILS INDUSTRIELS

CE

English (Original Instructions) . . . . . . . . . . . . . . . 1

Français (Traduction des instructions originales) . . 19

MANUEL D’EXPLOITATION,

DE DÉPANNAGE ET

D’ENTRETIEN

Deutsch (Übersetzung der Originalanleitung) . . . . . 35

Español(Traducción de las instrucciones originales).52

BAS ÉQUIPÉS D’UN LEVIER,

MODÈLES DE LA GAMME H 49,8

UTILISATION PRÉVUE : DÉPANNAGE DE VÉHICULE ET TRACTION DE CHARGES

MISE EN GARDE : ASSUREZ-VOUS DE LIRE ET DE COMPRENDRE CE MANUEL

AVANT D’INSTALLER ET D’UTILISER LE TREUIL. LISEZ LES AVERTISSEMENTS !

Ramsey Winch Company

P.O. Box 581510 - Tulsa, OK 74158-1510 USA

Téléphone : +1 (918) 438-2760 – Télécopieur : +1 (918) 438-6688

Nous visiter à http://www.ramsey.com

Ramsey Représentant autorisé dans la comuauté:

Veuillez prendre contact uniquement pour des questions réglementaires.

Alura Group BV

P.O. Box 18626

2502 EP The Hague

The Netherlands

Tel: (31) (0) 70 362-4896

Fax: (31) (0) 70 346-7299

OM-914216-1012-D

Page 20

TABLE DES MATIÈRES

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

CARACTÉRISTIQUES TECHNIQUES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

AVERTISSEMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

RESPONSABILITÉ DE L’UTILISATEUR POUR CONFORMITÉ AUX NORMES CE . . . . . . . . . . . . . . . . . . . . . . . . .20

ENTRETIEN DU TREUIL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

POSE DU CÂBLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

FIXATION DU TREUIL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

GUIDE DE DÉPANNAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

CARACTÉRISTIQUES DU SYSTÈME HYDRAULIQUE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

DIAGRAMMES DE PERFORMANCES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

FIN DE LA PROCÉDURE D’ENTRETIEN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

INSTRUCTIONS DE RÉVISION

DÉPOSE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24-29

PLANS COTÉS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30-31

LISTE ET SCHÉMA DES PIÈCES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32-33

DÉCLARATION DE CONFORMITÉ CE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Page 21

20

CARACTÉRISTIQUES TECHNIQUES*

* Capacité du câble par couche

AVERTISSEMENTS :

L’UTILISATEUR DOIT VEILLER À CE QUE TOUT OPÉRATEUR REÇOIVE LA FORMATION NÉCESSAIRE.

L’OPÉRATEUR DOIT TOUJOURS TRAVAILLER EN CONFORMITÉ AVEC LES INSTRUCTIONS D’UTILISATION.

L’EMBRAYAGE DOIT ÊTRE COMPLÈTEMENT ENCLENCHÉ AVANT DE DÉMARRER LE TREUIL.

NE RELÂCHEZ JAMAIS L’EMBRAYAGE EN PRÉSENCE D’UNE CHARGE.

NE VOUS PLACEZ JAMAIS SOUS UNE CHARGE SOULEVÉE NI À PROXIMITÉ.

RESTEZ À L’ÉCART DU CÂBLE LORS DU TREUILLAGE. N’ESSAYEZ PAS DE GUIDER LE CÂBLE.

N’UTILISEZ PAS LE TREUIL POUR SOULEVER, MAINTENIR OU TRANSPORTER DES PERSONNES.

IL CONVIENT DE CONSERVER AU MINIMUM DEUX TOURS DE CÂBLE AUTOUR DU TAMBOUR POUR

MAINTENIR LA CHARGE.

ÉVITEZ TOUTE SITUATION DE GLISSEMENT DE LA CHARGE OU D’À-COUPS. ÉVITEZ LES

MOUVEMENTS SACCADÉS.

RESPONSABILITÉ DE L’UTILISATEUR POUR CONFORMITÉ AUX NORMES CE

1. Utilisez uniquement un distributeur à tiroir cylindrique (centre fermé), conformément aux indications fournies sous

la rubrique Caractéristiques du système hydraulique.

2. En cas d’utilisation d’un distributeur de treuil commandé à distance, consultez la rubrique Caractéristiques du système

hydraulique pour déterminer les composants à installer pour le dispositif d’arrêt d’urgence.

3. Réglez la pression de décharge du système conformément aux instructions de la rubrique Caractéristiques du

système hydraulique.

4. Montez le treuil conformément aux instructions fournies sous la rubrique Installation du treuil.

5. Installez un câble métallique de 12 mm de diamètre, de classe de résistance 1960. Longueur de câble maximale

de 47 m pour quatre couches maximum. Attachez le câble au tambour comme indiqué dans les Instructions de pose du

câble. Le crochet doit être équipé d’un verrou de sécurité et doit avoir une résistance à la rupture minimale de 125 kN.

Traction du câble, première couche

49,8 kN

Niveau sonore

81 dB

Plage de température ambiante De -28 ºC à 60 ºC

Démultiplication 40:1

Poids (sans le câble) 91 kg

COUCHE DE CÂBLE 1234

Traction du câble par couche kN 49,8 42,4 37,0 32,8

*Capacité du câble

par couche

m 9 19 33 47

*Vitesse du

câble à 56,7 l/min

m/min 9,1 10,3 11,8 13,0

*Ces caractéristiques se fondent sur l’utilisation d’un câble en acier recommandé de 12 mm de

diamètre et de calibre 1960, et d’un moteur de 102 cm

3

/tr.

Page 22

ENTRETIEN DU TREUIL

L’observation du calendrier de maintenance suivant vous permettra de maintenir votre treuil en bon état et garantira un fonctionnement avec

un minimum de réparations.

A. HEBDOMADAIRE

1. Vérifiez le niveau d’huile et maintenez-le au niveau du bouchon. En cas de fuite d’huile, déterminez l’emplacement de la fuite et réparez.

2. Vérifiez le bouchon d’échappement en haut de la boîte d’engrenages. Assurez-vous qu’il fonctionne bien afin que les gaz issus de l’huile

chaude puissent être évacués.

3. Lubrifiez le câble avec de l’huile légère.

B. MENSUEL

1. Lubrifiez les divers graisseurs situés dans le tambour du câble, le roulement d’extrémité, le carter d’embrayage ou la tringlerie

d'embrayage. Vous pouvez utiliser toute graisse de bonne qualité contenant du bisulfure de molybdène.

2. Vérifiez l’action du crabot baladeur et assurez-vous qu’il s’enclenche sur le tambour du câble et s'en dégage complètement.

Retirez le bouchon en plastique du haut du carter et vérifiez si l’embrayage s’enclenche bien. S'il ne s'enclenche pas à fond, examinez

les pièces de l'embrayeur afin de déceler toute trace de détérioration ou d’usure excessive, et procédez aux remplacements

éventuellement nécessaires. Observez les mâchoires de l’embrayage et du tambour afin de déceler tout arrondissement des surfaces.

Si elles se sont arrondies, changez immédiatement les pièces.

3. Vérifiez les boulons de fixation du treuil. Remplacez tout boulon manquant et serrez fermement les autres. Veillez à utiliser uniquement

des boulons de classe 5 ou supérieure.

4. Examinez le câble. Tout câble dénudé ou effiloché doit être remplacé immédiatement.

C. ANNUEL

1. Le treuil doit être vidangé une fois par an ou plus souvent en cas d’usage fréquent.

2. Remplissez le treuil de kérosène propre jusqu’au niveau du bouchon de niveau d’huile. Faites fonctionner le treuil quelques minutes sans

charge dans le sens de l’enroulement. Éliminez le kérosène du treuil.

3. Remplissez le treuil d’huile pour engrenages E.P. 140 polyvalente jusqu’au bouchon de niveau d’huile.

4. Examinez le châssis et l’armature qui l’entoure afin de déceler toute déformation ou fissure éventuelle.

5. Pour évaluer l’usure des engrenages, secouez le tambour d’un mouvement de va-et-vient et, si nécessaire, vidangez l'huile et déposez

le capot pour un examen plus approfondi.

POSE DU CÂBLE

1. Déroulez le câble sur le sol pour éviter qu'il ne se torde. Recouvrez bien l’extrémité du câble opposée au crochet avec un ruban adhésif plastique ou

de type équivalent pour éviter qu’il ne s’effiloche.

2. Insérez le câble dans la partie étroite du logement, contre la collerette du tambour. Enroulez le câble autour du galet d’ancrage (pièce nº 5) et rentrez

les deux dans l’extrémité large du logement. Utilisez un marteau-caoutchouc pour acheminer l’arrière du câble, en le plaçant fermement avec le galet

d’ancrage dans le logement.

3. Faites tourner avec précaution le treuil dans le sens de l’enroulement. Maintenez une tension sur l’extrémité du câble et enroulez tout le câble sur

le tambour en veillant à former des couches régulières.

21

Page 23

22

GUIDE DE DÉPANNAGE

ANOMALIE CAUSE PROBABLE CORRECTIF

L'EMBRAYAGE NE FONCTIONNE

PAS OU SE GRIPPE.

1. Arbre sec ou rouillé.

2. Fourchette ou tringlerie courbée.

3. Les griffes de l’embrayage sont

en contact.

1. Nettoyez et lubrifiez.

2. Remplacez la fourchette ou la tringlerie.

3. Reportez-vous aux TECHNIQUES D’UTILISATION.

FUITE D’HUILE AU NIVEAU

DU CARTER.

1. Joint d’étanchéité endommagé

ou usé.

2. Trop d’huile.

3. Joint statique endommagé.

1. Remplacez le joint d’étanchéité.

2. Vidangez l’excédent d’huile. Reportez-vous aux

TECHNIQUES D’UTILISATION.

3. Remplacez le joint statique.

LE TREUIL FONCTIONNE

TROP LENTEMENT.

1. Moteur hydraulique usé.

2. Débit faible.

1. Remplacez le moteur.

2. Vérifiez le débit. Reportez-vous à la rubrique

FIXATION DU TREUIL ci-dessus.

LE TAMBOUR NE RELÂCHE PAS

LE REMBOBINAGE.

1. Treuil mal monté, ce qui entraîne

un grippage du tambour par les

paliers d’extrémité.

1. Vérifiez le montage. Reportez-vous à la rubrique

FIXATION DU TREUIL ci-dessus.

LE CÂBLE SE DÉTEND ET FORME

DE LARGES BOUCLES LORSQUE

L’EMBRAYAGE EST

DÉSENCLENCHÉ.

1. Disque du sabot d’appui usé. 1. Remplacez les disques.

LE FLUIDE HYDRAULIQUE FUIT

AU NIVEAU DU TROU DE

L’ADAPTATEUR DU MOTEUR.

1. Joint de l’arbre du moteur

hydraulique endommagé.

1. Remplacez le joint d’étanchéité.

FIXATION DU TREUIL

Ce treuil doit absolument être monté correctement afin que les trois principales parties soient alignées (l’extrémité du carter

d’embrayage, le tambour du câble et l’extrémité de la boîte d'engrenages). Si on utilise des cornières de montage, il faut placer des

entretoises de 13 mm d’épaisseur pour créer le dégagement requis entre la collerette du tambour et les cornières. Les entretoises (4)

doivent être installées entre les extrémités du carter d’embrayage et de la boîte d’engrenages. Les caractéristiques recommandées

pour les cornières sont les suivantes : cornières en acier haute résistance (248 GPa) mesurant 10 x 65 x 65 mm de long.

Page 24

Reportez-vous aux diagrammes de performances ci-dessous pour établir une correspondance entre votre système hydraulique

et le fonctionnement de votre treuil. Ces diagrammes sont constitués des éléments suivants : (1) Traction du câble, première

couche, exprimée en kN, en fonction de la pression de service, exprimée en bars (2) Vitesse du câble, première couche,

exprimée en m/min, en fonction du débit, exprimé en l/min.

CARACTÉRISTIQUES DU SYSTÈME HYDRAULIQUE

1. Distributeur à tiroir cylindrique de moteur (centre fermé).

2. Arrêt d’urgence :

A. Si un treuil est commandé par un distributeur à commande directe, ce distributeur sert de dispositif d’arrêt d’urgence.

B. En cas d’utilisation d’un distributeur commandé à distance, une soupape de décharge hydraulique commandée par

solénoïde, normalement ouvrant sur le réservoir, et un interrupteur d’arrêt d’urgence (pour l’ouverture de la soupape

de décharge) sont requis. L’interrupteur d’arrêt d’urgence doit être normalement fermé et doit être doté d’un boutonpoussoir d’activation rouge, avec réinitialisation, sur fond jaune. L’interrupteur d’arrêt d’urgence doit être facilement

accessible à l’opérateur.

3. La soupape de décharge doit être réglée pour 158,6 bar, qui est la limite de capacité nominale.

4. Débit maximal de 94,7 l/min.

5. Fluide hydraulique ayant une viscosité comprise entre 20 et 43 cSt. Température de service maximale de 85 ºC. Propreté

de niveau ISO 17-14 ou supérieur.

23

Page 25

24

FIN DE LA PROCÉDURE D’ENTRETIEN

Quand le treuil arrive à la fin de sa durée de vie, débarrassez-vous en en respectant les règlements locaux de protection

de l’environnement.

INSTRUCTIONS DE RÉVISION DES TREUILS RAMSEY

Modèle H 49,8

DÉPOSE

FIGURE 1

Retirez le bouchon cylindrique (pièce nº 69) du bas

de la boîte d’engrenages afin d’en vidanger l’huile.

Retirez le raccord de dégagement (pièce nº 66)

et le réducteur (pièces nº 68) du haut de la boîte.

FIGURE 2

Faites glisser le carter d’embrayage (pièce nº 19)

de l’extrémité de l’arbre du tambour. Retirez la vis

de pression (pièce nº 53), le ressort (pièce nº 73) et

la bille de verrouillage (pièce nº 38) de l’embrayage

à griffes (pièce nº 9). Faites glisser l’embrayage

à griffes de l’extrémité de l’arbre du tambour.

Retirez les deux clavettes (pièce nº 27) de leur

rainure. Lorsque les clavettes ont été retirées,

le tambour (pièce nº 13) et son entretoise

(pièce nº 34) peuvent être retirés de l’axe

du tambour.

FIGURE 3

Dévissez les deux vis d’assemblage (pièce nº 52)

pour retirer le moteur (pièce nº 67) et le

raccordement (pièce nº 1) de l’adaptateur

(pièce nº 2).

Retirez la clavette (pièce nº 25) de l’arbre à vis

sans fin. Dévissez les six vis d’assemblage

(pièce nº 51) et retirez l’adaptateur de la boîte

d’engrenages. Remplacez le joint d'étanchéité

(pièce nº 72) et le joint statique (pièce nº 62)

de l’adaptateur.

FIGURE 1

FIGURE 2

FIGURE 3

Page 26

FIGURE 4

Retirez les six vis d’assemblage (pièce nº 52)

pour sortir le chapeau de palier (nº 18) de la boîte

d'engrenages.

Retirez la vis sans fin (pièce nº 35) et les roulements

(pièce nº 40) de la boîte d'engrenages. Utilisez un

marteau-caoutchouc pour tapoter l’extrémité d’entrée

de la vis sans fin et sortir cette dernière ainsi que

le roulement de la boîte d’engrenages. Une fois

la vis sans fin retirée de la boîte, le roulement peut

se dégager du bout de la vis sans fin.

Examinez la vis sans fin (pièce nº 35) et les

roulements (pièce nº 40) afin de vous assurer qu’ils

ne sont ni usés ni endommagés, et remplacez-les

le cas échéant.

FIGURE 5

Retirez le couvercle (pièce nº 10) de la boîte

d’engrenages (pièce nº 20) en dévissant les

vis d'assemblage (pièces nº 46 et no 45).

Enfilez deux de ces vis dans les deux trous taraudés

du couvercle et serrez-les. Ceci désolidarisera

le couvercle de la boîte d'engrenages.

Retirez le joint statique (pièce nº 64) du couvercle

et tirez l’arbre (pièce nº 29) avec la roue de la boîte

d’engrenages.

FIGURE 6

Vérifiez si les dents de la roue ne présentent pas

de trace d’usure. Si nécessaire, remplacez la roue

en enlevant les six vis d’assemblage (pièce nº 47)

Placez la nouvelle roue (pièce nº 16) sur le moyeu

de la roue (pièce nº 14). Alignez les trous de la roue

sur les trous du moyeu. Enfilez la roue sur le moyeu.

Veillez à ce que la roue soit logée en butée contre

le moyeu. Utilisez les six vis d’assemblage

(pièce nº 47) et rondelles de sécurité (pièce nº 59)

pour fixer la roue sur le moyeu. Serrez chaque vis

à un couple de 61 Nm.

25

FIGURE 4

FIGURE 5

FIGURE 6

Page 27

26

FIGURE 7

Si l’arbre et/ou le moyeu d’engrenage sont

endommagés, remplacez-les comme indiqué

ci-dessous :

a. Tapotez sur les clavettes (pièce nº 26) afin

de les placer dans les rainures courtes

de l’arbre du tambour (pièce nº 29).

b. Enfoncez l’arbre (pièce nº 29) et les clavettes

dans le moyeu d’engrenage (pièce nº 21)

jusqu’à ce que l’extrémité des clavettes

de la longue extrémité de l'arbre soit au même

niveau que le moyeu.

c. À l’aide des six vis d’assemblage (pièce nº 47)

et rondelles de sécurité (pièce nº 59), fixez

la roue sur le moyeu. Serrez chaque vis à un

couple de 61 Nm.

FIGURE 8

Vérifiez que la bague de la boîte d’engrenages

(pièce nº 6) et le joint d’étanchéité quatre lobes

(pièce nº 67) ne sont pas usés. Si nécessaire,

remplacez-les en appuyant sur la bague usagée

pour la sortir de la boîte d'engrenages (pièce nº 20).

Appuyez sur la bague neuve pour la mettre en

place et insérez un joint d’étanchéité quatre lobes

neuf (pièce nº 67) dans la rainure à l’intérieur

de la bague.

FIGURE 9

Vérifiez les bagues du tambour (pièces nº 5 et nº 42)

pour déceler les signes d’usure. Le cas échéant,

remplacez-les en sortant les anciennes bagues du

tambour (pièce nº 13) et appuyez sur les bagues

neuves pour les mettre en place. L’ensemble du

tambour est également disponible avec des bagues

neuves en place.

FIGURE 7

FIGURE 8

FIGURE 9

Page 28

27

FIGURE 10

Vérifiez que la bague de la boîte d’engrenages

(pièce nº 41) n’est pas usée. Le cas échéant, retirez

la bague usagée et remplacez-la par une neuve.

Appliquez de la graisse au raccord de graissage

(pièce nº 65) pour lubrifier l’arbre de l’embrayeur.

FIGURE 11

Vérifiez que la bague (pièce nº 6) et le joint

d’étanchéité quatre lobes (pièce nº 67) ne sont pas

usés. Si nécessaire, remplacez-les en appuyant sur

la bague usagée pour la sortir de la boîte

d'engrenages (pièce nº 10). Appuyez sur la bague

neuve pour la mettre en place et insérez un joint

d’étanchéité quatre lobes neuf (pièce nº 67) dans

la rainure à l’intérieur de la bague.

FIGURE 12

Appliquez de la graisse à l’extrémité de l'arbre

(pièce nº 29), à l'opposé de l'engrenage

(pièce nº 16). Appliquez de la graisse sur

la bague de la boîte d’engrenages (pièce nº 20).

Placez l’extrémité graissée de l’arbre dans

la bague de la boîte d’engrenages (pièce nº 20).

Placez le joint statique (pièce nº 64) sur le

couvercle de la boîte d’engrenages (pièce nº 10).

Appliquez de la graisse sur l’extrémité engrenages

de l'arbre et sur la bague. Placez le couvercle sur

l’arbre et fixez-le à la boîte au moyen des sept

vis d'assemblage (pièce nº 46) et de la vis

(pièce nº 45). Serrez chaque vis à un couple

de 16,1 Nm.

FIGURE 10

FIGURE 11

FIGURE 12

Page 29

FIGURE 13

Placez le roulement (pièce nº 40) sur la vis sans

fin (nº 35). REMARQUE : assurez-vous que

l'épaulement épais du chemin de roulement du palier

(côté avec le nom du fabricant et le numéro de

référence) n'est pas vers les filets de la vis sans fin.

Appuyez sur le roulement et sur la vis sans fin pour

les placer dans la boîte d'engrenages. Faites glisser

le joint statique (pièce nº 62) sur le chapeau de

palier (pièce nº 18). Utilisez six vis d’assemblage

(pièce nº 52) pour fixer le chapeau sur la boîte

d’engrenages. Serrez chaque vis à un couple

de 16,1 Nm. Insérez la clavette (pièce nº 25) dans

la rainure de la tige à vis sans fin (pièce nº 35).

FIGURE 14

Utilisez les six vis d’assemblage (pièce nº 51)

pour fixer l’adaptateur (pièce nº 2) à la boîte

d'engrenages. Serrez chaque vis à un couple

de 16,1 Nm. Insérez la clavette (pièce nº 25)

dans la rainure de la tige à vis sans fin. Faites

glisser l’extrémité conique du raccordement

(pièce nº 1) sur l’extrémité de la vis sans fin.

Placez l’arbre du moteur, avec la clavette dans

sa rainure, dans le raccordement. Utilisez deux vis

d’assemblage (pièce nº 52) pour fixer le moteur

(pièce nº 67) à l’adaptateur. Serrez chaque vis

à un couple de 53 Nm.

FIGURE 15

Placez le treuil sur l’établi avec le couvercle

de la boîte d’engrenages tourné vers le bas.

L’arbre du tambour doit être en position verticale.

Placez les ressorts (pièces nº 75 et nº 76) dans les

logements correspondants de la boîte d’engrenages

avec les sabots d'appui (pièce nº 12) sur le disque

(pièce nº 77) et sur les ressorts. Appliquez

de la graisse sur l’arbre et sur les bagues du

tambour. Faites glisser le tambour (pièce nº 13)

sur son arbre, les mâchoires tournées vers le haut.

28

FIGURE 13

FIGURE 14

FIGURE 15

Page 30

FIGURE 16

Faites glisser la bague d’espacement (pièce nº 34) sur

l’extrémité de l’arbre du tambour. Appuyez sur le tambour vers

le bas pour comprimer les ressorts dans la boîte d’engrenages.

Insérez les clavettes (pièce nº 27) dans leur rainure. Utilisez un

maillet en caoutchouc ou un marteau en laiton pour tapoter

délicatement les clavettes afin de les mettre en place.

Appliquez de la graisse sur les clavettes et sur l'extrémité

de l'arbre. Placez l’embrayage à griffes (pièce nº 9) sur

l’extrémité de l’arbre et faites-le glisser par-dessus les clavettes.

Remarque : Veillez à ce que le trou taraudé sur le côté

de l’embrayage à griffes se trouve du même côté de l’arbre que

les deux butées à bille.Insérez la bille de verrouillage (pièce

nº 38), le ressort (pièce nº 73 et la vis d’assemblage (pièce nº 53) dans le trou taraudé de l’embrayage à griffes.

Si l’embrayage à griffes et/ou le tambour ont été remplacés, deux nouvelles butées à bille DOIVENT être

percées de la manière suivante :

Faites glisser l’embrayage à griffes sur l’extrémité de l’arbre. Enclenchez les mâchoires de l’embrayage sur

celles du tambour. En utilisant comme guide le trou dans l’embrayage à griffes, utilisez une perceuse de 10 mm

de diamètre pour percer dans l’arbre une butée de 3 mm de profondeur (mesurée à partir du centre du point

de percée). Faites glisser l’embrayage à griffes de 24 mm vers le haut et percez une deuxième butée.

Si vous ne remplacez que l’embrayage, percez les nouvelles butées du côté de l’arbre opposé à celui des

anciennes butées. Appliquez de la graisse sur la bague du carter d’engrenages (pièce nº 19). Placez le carter

d’embrayage sur l’extrémité de l’arbre du tambour. Tirez l’embrayage à griffes vers le haut, vers le carter

d'embrayage, assez pour permettre à la fourchette du carter de rentrer correctement dans la rainure autour

de l'embrayage. Faites glisser vers le bas le carter d’embrayage et l’embrayage à griffes pour les remettre

en place.

La vis de pression doit être suffisamment serrée pour permettre à la bille, lorsqu’elle est placée dans une des

butées de retenir l’embrayage à griffe dans la position embrayée ou débrayée.

FIGURE 17

Insérez le bouchon (pièce nº 69) dans la partie inférieure

de la boîte d’engrenages. On peut appliquer du Permatex

sur les filets afin de mieux éviter les fuites.

Versez 1 litre d’huile pour engrenages 140 E.P.

dans le carter par l’orifice supérieur. Insérez le raccord

de dégagement (pièce nº 66) dans le réducteur

(pièce nº 68). Placez ensuite ce dernier dans le trou

situé sur le dessus de la boîte d'engrenages.

Serrez fermement le raccord et le réducteur.

29

FIGURE 16

FIGURE 17

Page 31

30

PLAN COTÉ DU TREUIL H 49,8 – SANS MOTEUR

Page 32

31

PLAN COTÉ DU TREUIL H 49,8 – AVEC MOTEUR

Page 33

Page 34

33

SCHÉMA DES PIÈCES DU TREUIL H 49,8

Page 35

English (Original Instructions) . . . . . . . . . . . . . . . 1

CE

Français (Traduction des instructions originales) . . 19

BETRIEBS-, INSTANDHALTUNGSUND WARTUNGSHANDBUCH

Deutsch (Übersetzung der Originalanleitung) . . . . . 35

Español(Traducción de las instrucciones originales).52

MODELLREIHE H 49,8 TIEF GESETZTE WINDEN FÜR

DEN KOMMERZIELLEN EINSATZ MIT HEBEL

VERWENDUNGSZWECK: BERGEN VON FAHRZEUGEN UND

ZIEHEN VON LASTEN

ACHTUNG: VOR DER MONTAGE UND INBETRIEBNAHME DER WINDE MUSS DIESES

HANDBUCH GELESEN UND VERSTANDEN WERDEN. SIEHE WARNHINWEISE!

Ramsey Winch Company

P.O. Box 581510 - Tulsa, OK 74158-1510 USA

Telefon: +1 918-438-2760 - Fax +1 918-438-6688

Besuchen Sie uns: http://www.ramsey.com

Ramsey Bevollmächtigter in der Europäischen Union:

(Bitte nur bei Regulierungsfragen kontaktieren.)

Alura Group BV

P.O. Box 18626

2502 EP The Hague

The Netherlands

Tel: (31) (0) 70 362-4896

Fax: (31) (0) 70 346-7299

OM-914216-1012-D

Page 36

INHALTSVERZEICHNIS

EINFÜHRUNG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

TECHNISCHE DATEN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

WARNHINWEISE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

VERANTWORTUNG DES BENUTZERS BEZÜGLICH CE-COMPLIANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

WARTUNG DER WINDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

AUFLEGEN DES SEILS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

MONTAGE DER WINDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

FEHLERSUCHE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

HYDRAULIKANFORDERUNGEN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

LEISTUNGSDIAGRAMME . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

AUSSERBETRIEBSETZUNG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

ANLEITUNG ZUM ÜBERHOLEN

DEMONTAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41-46

MASSZEICHNUNGEN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47-48

TEILELISTE UND TEILEZEICHNUNG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49-50

EG-KONFORMITÄTSERKLÄRUNG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

Page 37

37

TECHNISCHE DATEN*

* Seilkapazität pro Lager

WARNHINWEISE:

DER BENUTZER MUSS SICHERSTELLEN, DASS DAS BEDIENPERSONAL DIE ERFORDERLICHE

SCHULUNG ERHÄLT.

DER BEDIENER MUSS BEIM BETRIEB STETS DIE BEDIENUNGSANWEISUNGEN BEFOLGEN.

VOR BEGINN DES WINDENBETRIEBS MUSS SICHERGESTELLT WERDEN, DASS DIE KUPPLUNG VOLLSTÄNDIG

EINGERÜCKT IST.

DIE KUPPLUNG NICHT UNTER LAST AUSRÜCKEN.

NIEMALS UNTER ODER NEBEN ANGEHOBENEN LASTEN STEHEN.

WÄHREND DES ZIEHENS EINEN SICHEREN ABSTAND ZUM SEIL EINHALTEN. NICHT VERSUCHEN, DAS SEIL

ZU LENKEN.

DIE WINDE NICHT ZUM HEBEN, TRAGEN ODER ANDERWEITIGEN TRANSPORT VON PERSONEN VERWENDEN.

ZUM HALTEN DER LAST SIND MINDESTENS 2 SEILWICKLUNGEN UM DIE SEILTROMMEL NOTWENDIG.

BEDINGUNGEN VERMEIDEN, BEI DENEN SICH DIE LAST VERSCHIEBT ODER RUCKARTIGE BEWEGUNGEN

VORKOMMEN. ÜBERMÄSSIGEN „TIPPBETRIEB“ VERMEIDEN.

VERANTWORTUNG DES BENUTZERS BEZÜGLICH CE-COMPLIANCE

1. Nur einen Steuerschieber (Zylinderwicklung, geschlossenes Zentrum) gemäß den Hydraulikanforderungen verwenden.

2. Wenn ein fernbedienter Windensteuerschieber verwendet wird, siehe die Hydraulikanforderungen für zu installierende

Notstoppkomponenten.

3. Hydrauliküberdruck gemäß den Hydraulikanforderungen anpassen.

4. Die Winde gemäß den Windeninstallationsanweisungen montieren.

5. Drahtseil (12 mm Drahtstärke, Sorte 1960) installieren. Es gilt eine maximale Seillänge von 47 m für maximal 4 Lagen.

Das Seil gemäß den Seilinstallationsanweisungen an der Trommel befestigen. Der Haken muss eine Sicherheitssperre

und eine minimale Abreißfestigkeit von 125 kN aufweisen.

Seilzugkraft, erste Lage

49,8 kN

Lärmpegel

81 db

Umgebungstemperaturbereich 28 ºC bis 60 ºC

Getriebeuntersetzung 40:1

Gewicht (ohne Seil) 91 kg

SEILLAGE 1234

Seilzugkraft pro Lage kN 49 ,8 42,4 37,0 32,8

* Seilkapazität

pro Lage

m 9 19 33 47

* Seilgeschwindigkeit

bei 56,7 l/min

mpm 9,1 10,3 11,8 13,0

* Diese technischen Daten basieren auf dem empfohlenen Drahtseil (12 mm Drahtstärke,

Sorte 1960) und einem 102 cm

3

/R Motor.

Page 38

WARTUNG DER WINDE

Bei Einhaltung der folgenden Wartungsintervalle bleibt die Winde stets in optimalem Zustand und sollte mit minimalem Reparaturaufwand

ordnungsgemäß funktionieren.

A. WÖCHENTLICH

1. Ölstand prüfen und ggf. bis zur Ölstandsschraube auffüllen. Bei einem Ölleck dessen Lage ausfindig machen und reparieren.

2. Das Überdruckventil an der Oberseite des Getriebekastens überprüfen. Stets in gutem Zustand halten, damit die heißen Ölgase

entweichen können.

3. Das Seil mit einem leichten Öl schmieren.

B. MONATLICH

1. Die verschiedenen Schmiernippel in der Seiltrommel, im Endlager, Kupplungsgehäuse oder Kupplungsgestänge schmieren.

Ein molybdändisulfidhaltiges Schmierfett guter Qualität verwenden.

2. Die Funktion der Rutschkupplung prüfen und sicherstellen, dass sie die Seiltrommel vollständig ein- und ausrückt. Zur Prüfung der

vollständigen Einrückung der Kupplung kann der Kunststoffstopfen auf dem Gehäuse entfernt werden. Wenn die Kupplung nicht

vollständig einrückt, die Teile der Kupplungshebel-Baugruppe überprüfen und auf Beschädigungen oder starken Verschleiß untersuchen.

Die entsprechenden Teile bei Bedarf ersetzen. Die Backen an der Kupplung und an der Seiltrommel auf Rundungen (Abnutzung) der

Antriebsflächen untersuchen. Falls auf diesen Flächen Rundungen gefunden werden, ist ein sofortiger Ersatz notwendig.

3. Die Befestigungsschrauben der Winde überprüfen. Fehlende Schrauben ersetzen und lockere Schrauben festziehen. Nur Schrauben der

Sorte 5 oder besser verwenden.

4. Das Seil inspizieren. Ein ausgefranstes oder beschädigtes Seil muss sofort ersetzt werden.

C. JÄHRLICH

1. Das Öl mindestens jährlich wechseln, öfter bei häufigem Einsatz.

2. Die Winde bis zur Ölstandsschraube mit sauberem Kerosin auffüllen. Die Winde einige Minuten lang ohne Last in Aufwickelrichtung laufen

lassen. Das Kerosin aus der Winde ablassen.

3. Die Winde bis zur Ölstandsschraube mit Allzweckgetriebeöl E.P. 140 auffüllen.

4. Den Rahmen und das den Rahmen umgebende Gefüge auf Risse und Verformungen überprüfen.

5. Der Zahnradverschleiß kann durch Hin- und Herbewegen der Trommel geschätzt werden. Falls notwendig, das Öl ablassen, den Deckel

abnehmen und genauer inspizieren.

AUFLEGEN DES SEILS

1. Zum Abwickeln das Seil auf dem Boden entlang auslegen, um ein Knicken zu vermeiden. Das dem Haken entgegengesetzte Seilende mit Plastik- oder

ähnlichem Klebeband umwickeln, um ein Ausfransen zu verhindern.

2. Das Drahtseil durch das schmale Ende der Tasche bis gegen den Trommelflansch einführen. Das Drahtseil um den Anker-Puck (Nr. 5) wickeln und dann

das Drahtseil mit dem Anker in das weite Ende der Tasche zurückziehen. Mit einem Gummihammer auf die Rückseite des Drahtseils klopfen, bis das

Drahtseil und der Anker fest in der Tasche sitzen.

3. Die Winde langsam in Aufwickelrichtung in Bewegung setzen. Das Seilende gespannt halten und das Seil vollständig auf die Seiltrommel aufwickeln.

Darauf achten, dass sauber gewickelte Lagen entstehen.

Page 39

39

FEHLERSUCHE

ZUSTAND MÖGLICHE URSACHE ABHILFE

KUPPLUNG FUNKTIONIERT NICHT

ODER HÄNGT FEST.

1. Trockene oder verrostete Welle.

2. Gabelkopf oder Gestänge

verbogen.

3. Kupplungsbacken berühren sich.

1. Reinigen und schmieren.

2. Gabelkopf oder Wellenbaugruppe ersetzen.

3. Siehe HINWEISE ZUM BETRIEB.

ÖL LECKT AUS DEM GEHÄUSE. 1. Dichtung beschädigt oder

verschlissen.

2. Zu viel Öl.

3. Beschädigter Dichtring.

1. Dichtung ersetzen.

2. Überschüssiges Öl ablassen. Siehe HINWEISE

ZUM BETRIEB.

3. Dichtring ersetzen.

DIE WINDE LÄUFT ZU LANGSAM. 1. Hydraulikmotor ist abgenutzt.

2. Niedrige Förderrate.

1. Motor ersetzen.

2. Förderrate überprüfen. Siehe MONTAGE DER

WINDE oben.

KEIN FREILAUF AN DER

SEILTROMMEL.

1. Winde nicht gerade montiert,

wodurch die Trommel durch die

Endlager eingeklemmt wird.

1. Zusammenbau überprüfen. Siehe MONTAGE DER

WINDE oben.

SEIL VERWICKELT SICH BEI

AUSGERÜCKTER KUPPLUNG.

1. Trommelbremsscheibe

verschlissen.

1. Scheiben ersetzen.

HYDRAULIKÖL LECKT AUS DEM

LOCH IM MOTORADAPTER.

1. Wellendichtung des

Hydraulikmotors beschädigt.

1. Dichtung ersetzen.

MONTAGE DER WINDE

Es ist sehr wichtig, dass diese Winde sicher befestigt wird, damit die drei Hauptsegmente (Kupplungsgehäuse, Seiltrommel und

Getriebekasten) richtig ausgerichtet sind. Falls Montagewinkel verwendet werden, müssen 13 mm breite Abstandshalter für einen

Spalt zwischen dem Trommelflansch und den Montagewinkeln verwendet werden. Die Abstandshalter (4) müssen zwischen

Kupplungsgehäuse und Getriebekasten und den Montagewinkeln installiert werden. Die folgenden Montagewinkel werden empfohlen:

Montagewinkel aus hochfestem Stahl (248 GPa) mit einer Größe von 10 X 65 X 65 mm.

Page 40

Zur richtigen Wahl der Hydraulik für die Leistung der Winde ist auf die folgenden Leistungsdiagramme Bezug zu nehmen.

Die Diagramme zeigen: (1) Seilzugkraft, erste Lage (kN) im Vergleich zum Arbeitsdruck (bar). (2) Seilgeschwindigkeit,

erste Lage (m/min) im Vergleich zur Förderrate (l/min).

HYDRAULIKANFORDERUNGEN

1. Steuerschieber (Zylinderwicklung, geschlossenes Zentrum).

2. Notstopp:

A. Falls die Winde durch einen direktbedienten Handschieber gesteuert wird, funktioniert dieser Schieber als Notstopp.

B. Wenn ein fernbedienter Steuerschieber verwendet wird, sind ein magnetgesteuerter hydraulischer

Entleerungsschieber (normalerweise gegen den Tank geöffnet) und ein Notstoppschalter (zum Öffnen des

Entleerungsschiebers) erforderlich. Der Notstoppschalter ist ein Öffnerkontakt und hat einen roten, rücksetzbaren

Druckknopfschalter mit gelbem Hintergrund. Der Notstoppschalter muss für den Bediener einfach zugänglich sein.

3. Überdruckventil auf 158,6 bar eingestellt, entspricht dem Nennkapazitätsbegrenzer.

4. Maximale Förderrate von 94,7 l/min.

5. Hydrauliköl mit einer Viskosität zwischen 20 und 43 cSt. Maximale Betriebstemperatur 85 °C. Sauberkeitsstufe

ISO 17-14 oder besser.

40

Page 41

41

AUSSERBETRIEBSETZUNG

Die Winde am Ende ihrer Brauchbarkeitszeit gemäß örtlichen Umweltvorschriften entsorgen.

ÜBERHOLUNGSANWEISUNGEN FÜR RAMSEY

MODELL H 49,8

DEMONTAGE

ABBILDUNG 1

Das Öl aus dem Getriebekasten ablassen.

Dazu den Rohrstopfen (Nr. 69) an der

Getriebeunterseite entfernen.

Überdruckventile (Nr. 66) und Reduzierstück (Nr. 68)

von der Oberseite des Getriebekastens entfernen.

ABBILDUNG 2

Das Kupplungsgehäuse (Nr. 19) vom Ende der

Trommelwelle herunterziehen. Stellschraube

(Nr. 53), Feder (Nr. 73) und Ventilkugel (Nr. 38)

von der Klauenkupplung (Nr. 9) entfernen.

Die Klauenkupplung vom Ende der Trommelwelle

herunterziehen.

Die zwei Keile (Nr. 27) von den Keilnuten abziehen.

Nachdem die Keile entfernt wurden, können die

Trommel (Nr. 13) und der Trommelabstandshalter

(Nr. 34) von der Trommelwelle entfernt werden.

ABBILDUNG 3

Den Motor (Nr. 67) und die Kupplungsbaugruppe

(Nr. 1) aus dem Adapter (Nr. 2) ausbauen.

Dazu die zwei Kopfschrauben (Nr. 52) entfernen.

Den Keil (Nr. 25) von der Schneckenantriebswelle

abziehen. Sechs Kopfschrauben (Nr. 51) entfernen

und den Adapter vom Getriebekasten abnehmen.

Die Adapterdichtung (Nr. 72) und den Dichtring

(Nr. 62) einbauen.

ABBILDUNG 1

ABBILDUNG 2

ABBILDUNG 3

Page 42

ABBILDUNG 4

Durch Entfernen von sechs Kopfschrauben (Nr. 52)

den Lagerdeckel (Nr. 18) vom Getriebekasten

abnehmen.

Die Schnecke (Nr. 35) und das Lager (Nr. 40) aus

dem Getriebekasten ausbauen. Mit einem

Gummihammer sanft auf das Antriebsende der

Schnecke klopfen und die Schnecke mit dem Lager

aus dem Getriebekasten treiben. Nachdem die

Schnecke aus dem Getriebekasten entfernt wurde,

kann das Lager aus dem Ende der Schnecke

herausgestemmt werden.

Schnecke (Nr. 35) und Lager (Nr. 40) auf Anzeichen

von Verschleiß oder Beschädigungen überprüfen.

Bei Bedarf ersetzen.

ABBILDUNG 5

Den Deckel (Nr. 10) vom Getriebekasten (Nr. 20)

abnehmen. Dazu die Kopfschrauben (Nr. 46 und

Nr. 45) entfernen. Zwei Kopfschrauben in die

Gewindebohrungen des Deckels einsetzen und

festziehen. Dadurch wird der Deckel vom

Getriebekasten abgestemmt.

Den Dichtring (Nr. 64) vom Deckel abnehmen

und die Welle (Nr. 29) mit befestigtem Zahnrad

aus dem Getriebekasten ausbauen.

ABBILDUNG 6

Die Zahnradzähne auf Verschleißanzeichen

überprüfen. Das Zahnrad bei Bedarf ersetzen.

Dazu die sechs Kopfschrauben (Nr. 47) entfernen.

Das neue Zahnrad (Nr. 16) auf der Zahnradnabe

(Nr. 14) anbringen. Die Löcher im Zahnrad mit den

Löchern in der Nabe ausrichten. Zahnrad auf die

Nabe drücken. Sicherstellen, dass das Zahnrad

ordnungsgemäß auf der Nabe sitzt. Zum Befestigen

des Zahnrads auf der Nabe sechs Kopfschrauben

(Nr. 47) und Sicherungsscheiben (Nr. 59)

verwenden. Jeweils auf 61 Nm festziehen.

42

ABBILDUNG 4

ABBILDUNG 5

ABBILDUNG 6

Page 43

43

ABBILDUNG 7

Falls die Welle und/oder Nabe beschädigt ist,

wie folgt ersetzen:

a. Die Keile (Nr. 26) in die kurzen Keilnuten der

Trommelwelle (Nr. 29) klopfen.

b. Die Welle (Nr. 29) und die Keile durch die

Zahnradnabe (Nr. 21) pressen, bis die Keilenden

am langen Ende der Welle oberflächenbündig

mit der Nabe abschließen.

c. Das Zahnrad mit sechs Kopfschrauben (Nr. 47)

und Sicherungsscheiben (Nr. 59) an der Nabe

befestigen. Jeweils auf 61 Nm festziehen.

ABBILDUNG 8

Die Getriebekastenbuchse (Nr. 6) und die

Vierlippendichtung (Nr. 67) auf Anzeichen von

Verschleiß überprüfen. Bei Bedarf die alte Buchse

aus dem Getriebekasten (Nr. 20) stemmen und

eine neue Buchse einpressen. Die neue Buchse

einpressen und eine neue Vierlippendichtung

(Nr. 67) in die Rille in der Buchse einsetzen.

ABBILDUNG 9

Die Seiltrommelbuchsen (Nr. 5 und Nr. 42)

auf Anzeichen von Verschleiß überprüfen.

Bei Bedarf die alten Buchsen aus der Trommel

(Nr. 13) stemmen und neue einpressen.

Die Trommelbaugruppe ist ebenfalls mit

eingepressten neuen Buchsen erhältlich.

ABBILDUNG 7

ABBILDUNG 8

ABBILDUNG 9

Page 44

44

ABBILDUNG 10

Die Kupplungsgehäusebuchse (Nr. 41) auf

Anzeichen von Verschleiß überprüfen. Bei Bedarf

die alte Buchse herausstemmen und eine neue

Buchse einpressen. Zum Schmieren der

Kupplungshebelwelle Schmierfett auf die

Schmiernippel (Nr. 65) auftragen.

ABBILDUNG 11

Die Abdeckungsbuchse (Nr. 6) und die

Vierlippendichtung (Nr. 67) auf Anzeichen von

Verschleiß überprüfen. Bei Bedarf die alte

Buchse aus der Getriebekastenabdeckung

(Nr. 10) stemmen und eine neue Buchse

einpressen. Die neue Buchse einpressen und

eine neue Vierlippendichtung (Nr. 67) in die Rille

in der Buchse einsetzen.

ABBILDUNG 12

Auf das dem Zahnrad (Nr. 16) gegenüber liegende

Wellenende (Nr. 29) Schmierfett auftragen. Auf die

Buchse im Getriebekasten (Nr. 20) Schmierfett

auftragen. Das geschmierte Wellenende durch die

Buchse im Getriebekasten (Nr. 20) schieben.

Den Dichtring (Nr. 64) auf dem Getriebekasten

(Nr. 10) anbringen. Auf das zahnradseitige Ende

der Welle und auf die Abdeckungsbuchse

Schmierfett auftragen. Den Deckel auf die Welle

schieben und mit sieben Kopfschrauben (Nr. 46)

und einer Kopfschraube (Nr. 45) auf dem

Getriebekasten befestigen. Die Kopfschrauben

auf jeweils 16,1 Nm festziehen.

ABBILDUNG 10

ABBILDUNG 11

ABBILDUNG 12

Page 45

ABBILDUNG 13

Das Lager (Nr. 40) auf die Schnecke (Nr. 35)

pressen. ANMERKUNG: Darauf achten, dass die

dicke Schulter des Außenlaufrings des Lagers

(die Seite mit dem aufgedruckten Herstellernamen

und der Teilenummer) nach außen, vom

Schneckengewinde weg gerichtet ist. Das Lager und

die Schnecke in den Getriebekasten pressen.

Den Dichtring (Nr. 62) auf den Lagerdeckel (Nr. 18)

schieben. Den Lagerdeckel mit sechs

Kopfschrauben (Nr. 52) am Getriebekasten

befestigen. Die Kopfschrauben auf jeweils 16,1 Nm

festziehen. Den Keil (Nr. 25) in die Keilnut der

Schnecke (Nr. 35) einsetzen.

ABBILDUNG 14

Den Adapter (Nr. 2) mit sechs Kopfschrauben

(Nr. 51) am Getriebekasten befestigen.

Die Kopfschrauben auf jeweils 16,1 Nm festziehen.

Den Keil (Nr. 25) in die Keilnut der

Schneckengetriebewelle stecken. Das konische

Ende der Kupplung (Nr. 1) auf die

Schneckenwelle schieben.

Die Motorwelle mit in der Keilnut eingestecktem Keil

in die Kupplung schieben. Den Motor (Nr. 67) mit

zwei Kopfschrauben (Nr. 52) am Adapter befestigen.

Die Kopfschrauben auf jeweils 53 Nm festziehen.

ABBILDUNG 15

Die Winde mit dem Getriebekastendeckel nach

unten auf eine Werkbank legen. Die Trommelwelle

muss vertikal stehen. Die Federn (Nr. 75 und Nr. 76)

in die Taschen des Getriebekastens stecken, sodass

die Trommelbremse (Nr. 12) auf der Scheibe (Nr. 77)

und den Federn gelagert ist. Auf die Welle und

Trommelbuchsen Schmierfett auftragen.

Die Trommelbaugruppe (Nr. 13) wie gezeigt mit

nach oben gerichteten Trommelbacken auf die

Trommelwelle schieben.

45

ABBILDUNG 13

ABBILDUNG 14

ABBILDUNG 15

Page 46

ABBILDUNG 16

Den Abstandshalter (Nr. 34) auf die Trommelwelle

schieben. Die Trommel nach unten drücken, um die

Trommelbremsenfedern im Getriebekasten

zusammenzudrücken. Die Keile (Nr. 27) in die Keilnuten

einsetzen. Die Keile mit einem Gummi- oder

Messinghammer sanft einklopfen.

Auf die Keile und das Wellenende Schmierfett auftragen.

Die Klauenkupplung (Nr. 9) auf die Welle und über die

Keile schieben.

Anmerkung: Sicherstellen, dass sich das Schraubenloch

an der Seite der Klauenkupplung auf derselben Seite der

Welle wie die beiden Kugelarretierungen befindet. Vsentilkugel (Nr. 38), Feder (Nr. 73) und Stellschraube

(Nr. 53) in das Schraubenloch der Klauenkupplung einsetzen.

Falls die Klauenkupplung und/oder Trommelwelle ersetzt wurden, MÜSSEN zwei neue Arretierungen wie folgt

gebohrt werden:

Die Klauenkupplung auf das Wellenende schieben. Die Klauen der Kupplung in die Klauen der Trommel

einrasten. Mit einem Bohrer (Durchmesser von 10 mm) und dem Loch in der Klauenkupplung als Richtlinie

eine 3 mm tiefe Arretierung (gemessen zur Mitte des Bohrlochs) in die Welle bohren. Die Klauenkupplung

24 mm nach oben schieben und die zweite Arretierung bohren.

Falls nur die Kupplung ersetzt wurde, müssen die neuen Arretierungen an der den alten Arretierungen

gegenüber liegenden Seite der Welle gebohrt werden. Auf die Buchse in der Kupplungsgehäuse-Baugruppe

(Nr. 19) Schmierfett auftragen. Das Kupplungsgehäuse auf die Trommelwelle setzen. Die Klauenkupplung so

gegen das Kupplungsgehäuse nach oben ziehen, dass der Gabelkopf im Kupplungsgehäuse richtig in die

Rille auf dem Außenumfang der Klauenkupplung passt. Die Kupplungsgehäuse-Baugruppe und

Klauenkupplung nach unten einschieben.

Die Stellschraube eben so festdrehen, dass die Kugel in den Kugelarretierungen die Klauenkupplung

ausreichend eingerückt („IN“) und ausgerückt („OUT“) halten kann.

ABBILDUNG 17

Die Verschlussschraube (Nr. 69) in den Boden des

Getriebekastens einsetzen. Auf das Gewinde kann

Permatex aufgetragen werden, um Öllecks zu verhindern.

Durch die Öffnung oben im Gehäuse 1 l Getriebeöl EP

140 in das Gehäuse füllen. Das Überdruckventil (Nr. 66)

in das Reduzierstück (Nr. 68) einsetzen. Anschließend

das Reduzierstück in das Loch oben auf dem

Getriebekasten einsetzen. Ventil und Reduzierstück

gut festziehen.

46

ABBILDUNG 16

ABBILDUNG 17

Page 47

47

H 49,8 MASSZEICHNUNG - OHNE MOTOR

Page 48

48

H 49,8 MASSZEICHNUNG - MIT MOTOR

Page 49

49

H 49,8 TEILEZEICHNUNG

Page 50

50

TEILELISTE Modell H 49,8

Page 51

Ramsey Winch Company

1600 North Garnett Road

Tulsa, OK 74116

EG-KONFORMITÄTSERKLÄRUNG

gemäß Maschinenrichtlinie 98/37/EG

Hiermit erklären wir, dass das Windenmodell H49,8 der folgenden Richtlinie entspricht,

sofern der BENUTZER alle Anweisungen im Benutzerhandbuch befolgt:

98/37/EG

Angewandte harmonisierte Normen:

EN 14492-1:2006 Kraftgetriebene Winden

ISO 9001:2000 Qualitätsmanagementsysteme - Anforderungen

Datum 19. August 2008 Unterschrift______________________________

Todd Brady

Engineering Manager

1600 N. Garnett Road Tulsa, Oklahoma 74116 (918) 438-2760

51

Page 52

English (Original Instructions) . . . . . . . . . . . . . . . 1

CE

MANUAL DE FUNCIONAMIENTO,

REPARACIÓN Y MANTENIMIENTO

Français (Traduction des instructions originales) . . 19

Deutsch (Übersetzung der Originalanleitung) . . . . . 35

Español(Traducción de las instrucciones originales).52

CABESTRANTES INDUSTRIALES MONTADOS A PEQUEÑA

ALTURA EQUIPADOS CON PALANCA, MODELO H 49,8

USO PRETENDIDO PARA: RECUPERACIÓN DE VEHÍCULOS Y

ARRASTRE DE CARGAS

PRECAUCIÓN: LEER Y ENTENDER ESTE MANUAL ANTES DE INSTALAR

Y UTILIZAR EL CABESTRANTE. OBSERVAR LAS ADVERTENCIAS.

Ramsey Winch Company

P.O. Box 581510 - Tulsa, OK 74158-1510 USA

Teléfono: + 1 918 438-2760 - Fax: +1 918 438-6688

Visítenos en http://www.ramsey.com

Ramsey Representante autorizado en la comunidad:

(Póngase en contacto sólo por cuestiones de reglamentación.)

Alura Group BV

P.O. Box 18626

2502 EP The Hague

The Netherlands

Tel: (31) (0) 70 362-4896

Fax: (31) (0) 70 346-7299

OM-914216-1012-D

Page 53

CONTENIDO

INTRODUCCIÓN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

ESPECIFICACIONES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

ADVERTENCIAS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

RESPONSABILIDAD DEL USUARIO PARA EL CUMPLIMIENTO CON LAS DISPOSICIONES CE . . . . . . . . . . . . . .54

MANTENIMIENTO DEL CABESTRANTE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

INSTALACIÓN DEL CABLE METÁLICO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

MONTAJE DEL CABESTRANTE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

GUÍA DE SOLUCIÓN DE PROBLEMAS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

REQUISITOS DEL SISTEMA HIDRÁULICO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

GRÁFICOS DE FUNCIONAMIENTO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

MEDIDAS CUANDO TERMINA LA VIDA ÚTIL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

INSTRUCCIONES PARA VERIFICAR EL CABESTRANTE

DESMONTAJE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58-63

DIBUJOS ACOTADOS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64-65

LISTA DE PIEZAS Y DIBUJO DE PIEZAS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66-67

DECLARACIÓN CE DE CONFORMIDAD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

Page 54

54

ESPECIFICACIONES*

* Capacidad del cable por capa

ADVERTENCIAS:

EL USUARIO DEBERÁ GARANTIZAR QUE EL PERSONAL QUE USE EL EQUIPO HAYA RECIBIDO

LA FORMACIÓN NECESARIA.

EL OPERADOR DEBERÁ TRABAJAR SIEMPRE SIGUIENDO LAS INSTRUCCIONES DE FUNCIONAMIENTO.

EL EMBRAGUE DEBE ESTAR TOTALMENTE ENGRANADO ANTES DE COMENZAR A MANEJAR

EL CABESTRANTE.

NO DESENGRANAR EL EMBRAGUE BAJO CARGA.

NO ACERCARSE A LAS CARGAS ELEVADAS.

NO ACERCARSE AL CABLE METÁLICO CUANDO ESTÉ TIRANDO. NO INTENTAR GUIAR EL CABLE METÁLICO.

NO UTILIZAR EL CABESTRANTE PARA LEVANTAR, SUJETAR O TRANSPORTAR PERSONAS.

PARA SUJETAR LA CARGA SE NECESITA UN MÍNIMO DE 2 VUELTAS DE CABLE METÁLICO ALREDEDOR

DEL CUERPO DEL TAMBOR.

EVITAR LAS CONDICIONES EN LAS QUE SE PUEDA PRODUCIR LA SACUDIDA O EL DESPLAZAMIENTO

DE LA CARGA. DEBERÁ EVITARSE EL BALANCEO EXCESIVO.

RESPONSABILIDAD DEL USUARIO PARA EL CUMPLIMIENTO CON LAS DISPOSICIONES CE

1. Emplear solamente una válvula de control (con el centro cerrado) de la bobina del cilindro que sea conforme a los

requisitos del sistema hidráulico.

2. Si se usa una válvula de control del cabestrante accionada de forma remota, consultar la sección de requisitos del

sistema hidráulico para conocer los componentes de parada de emergencia que es necesario instalar.

3. Ajustar la presión de alivio del sistema conforme a lo descrito en la sección de requisitos del sistema hidráulico.

4. Montar el cabestrante según las instrucciones de montaje del cabestrante.

5. Instalar el cable metálico de 12 mm de clase 1960. La longitud máxima del cable debe ser de 47 m para un máximo

de cuatro capas. Conectar el cable al tambor según las instrucciones de instalación del cable. El gancho debe tener un

cierre de seguridad y una resistencia mínima a la ruptura de 125 kN.

Tracción del cable de la primera capa

49,8 kN

Nivel sonoro

81 db

Temperatura ambiente De -28 ºC a 60 ºC

Reducción de engranajes 40:1

Peso (sin cable) 91 kg

CAPA DE CABLE 1234

Tracción de cable por capa kN 49 ,8 42,4 37,0 32,8

*Capacidad del

cable por capa

m 9 19 33 47

* Velocidad del

cable a 56,7 LPM

mpm 9,1 10,3 11,8 13,0

* Estas especificaciones se basan en un cable metálico recomendado de 12 mm de clase 1960 y

en un motor de 102 cc/Rev.

Page 55

MANTENIMIENTO DEL CABESTRANTE

El adherirse al siguiente calendario de mantenimiento hará que el cabestrante esté en excelentes condiciones de funcionamiento y con el

mínimo de reparaciones.

A. SEMANAL

1. Comprobar el nivel de aceite y mantenerlo hasta el tapón del nivel del aceite. Si existe una fuga de aceite, determinar la ubicación

y reparar.

2. Comprobar el regulador de descompresión en la parte superior de la caja de engranajes. Asegurarse de que esté en buenas condiciones

de funcionamiento para que los gases del aceite caliente puedan escapar.

3. Lubricar el cable con aceite ligero.

B. MENSUAL

1. Lubricar los diferentes conectores de engrase ubicados en el tambor del cable, soporte final, cárter del embrague o acoplamiento

de accionamiento del embrague. Es aceptable cualquier grasa de buena calidad o que contenga bisulfuro de molibdeno.

2. Comprobar el funcionamiento del embrague y asegurarse de que se engrana y desengrana totalmente con el tambor del cable.

Retirar el tapón de plástico de la parte superior del cárter y observar si el embrague está totalmente engranado. Si el embrague no está

totalmente engranado, inspeccionar las piezas del conjunto del cambiador del embrague para comprobar si están excesivamente

dañadas o desgastadas y, si es necesario, cambiarlas. Observar las mordazas del embrague y del tambor del cable para comprobar

si las caras activas presentan redondeces. Si tienen redondeces, deben reemplazarse inmediatamente.

3. Comprobar los pernos de montaje del cabestrante. Si falta alguno, ponerlos y apretar firmemente los que estén flojos.

Asegurarse de utilizar solamente pernos de clase 5 o mejores.

4. Inspeccionar el cable. Si el cable está deshilachado y tiene hilos rotos, cambiarlo inmediatamente.

C. ANUAL

1. Purgar el aceite del cabestrante anualmente o más a menudo si se utiliza con frecuencia.

2. Llenar con keroseno limpio el cabestrante hasta el tapón del nivel de aceite. Hacer funcionar el cabestrante durante unos minutos sin

carga en la dirección de enrollado. Purgar el keroseno del cabestrante.

3. Volver a llenar el cabestrante hasta el tapón del nivel de aceite con aceite para engranajes universal E.P. 140.

4. Inspeccionar el bastidor y la estructura circundante en busca de grietas o deformaciones.

5. Se puede calcular el desgaste del engranaje moviendo el tambor de un lado a otro y, si es necesario, se puede purgar el aceite y retirar

la tapa para inspeccionarlo de cerca.

INSTALACIÓN DEL CABLE METÁLICO

1. Desenrollar el cable extendiéndolo sobre el suelo para evitar que se retuerza. Envolver firmemente el extremo del cable, opuesto al gancho, con cinta

plástica o similar para evitar que se deshilache.

2. Deslizar el cable metálico a través del extremo estrecho del receptáculo junto al reborde del tambor. Enrollar el cable metálico alrededor del retenedor