Page 1

Sly Fox

FOX-HUNT

TRANSMITTER KIT

Ramsey Electronics Model No. FHT-1

Get involved in the fox hunting fun! This kit combines a

crystal locked true FM transmitter with a microprocessor

for reliable operation. Multiple transmission “modes”

assure a “sly fox” that will challenge any fox hunter.

• Selectable high (5W) or low power (800 mW) operation - unit can

even be programmed to change power levels during use!

• Delay times from one minute to one hour !

• Stable crystal operation with a 146.52 crystal included.

• Sixteen modes of operation available. Can even generate a 1 KHZ

tone to “fool” Doppler type direction finders!

• Fully microprocessor controlled for easy use, no diodes to add.

Easy and fun to use!

• Smartkey CW ID input - just key your call in and it remembers!

• Runs on 12 - 14 Volts DC at less than 1 amp.

• Built in test points for tune up. Align with any digital multimeter -

tuning tool included, too!

• Add optional electronic VOICE ID CIRCUIT for harassment

messages - up to 20 seconds, “Ha, ha you can’t find me!”

• Informative manual answers questions on theory, hookups and

uses - enhances resale value, too!

FHT-1 • 1

Page 2

RAMSEY TRANSMITTER KITS

• FM-10, FM-25 FM Stereo Transmitters

• FM-1,2,4 FM Wireless Microphones

• PB-1 Telephone Transmitter

RAMSEY RECEIVER KITS

• FR-1 FM Broadcast Receiver

• AR-1 Aircraft Band Receiver

• SR-1 Shortwave Receiver

• AA-7 Active Antenna

• SC-1 Shortwave Converter

RAMSEY HOBBY KITS

• SG-7 Personal Speed Radar

• SS-70 Speech Scrambler

• TT-1 Telephone Recorder

• SP-1 Speakerphone

• MD-3 Microwave Motion Detector

• PH-10 Peak hold Meter

• LC-1 Inductance-Capacitance Meter

RAMSEY AMATEUR RADIO KITS

• FX Series VHF and UHF Transceivers

• HR Series HF All Mode Receivers

• QRP Series HF CW Transmitters

• CW-7 CW Keyer

• PA Series VHF and UHF Power Amplifiers

• Packet Computer Interfaces

• QRP Power Amplifiers

RAMSEY MINI-KITS

Many other kits are available for hobby, school, Scouts and just plain FUN.

New kits are always under development. Write or call for our free Ramsey

catalog.

FHT-1 FOX-HUNT TRANSMITTER KIT INSTRUCTION MANUAL

Ramsey Electronics publication No. MFHT-1 Revision 1.1

First printing: October 1993

COPYRIGHT 1993 by Ramsey Electronics, Inc. 793 Canning Parkway, Victor, New York

14564. All rights reserved. No portion of this publication may be copied or duplicated without the

written permission of Ramsey Electronics, Inc. Printed in the United States of America.

FHT-1 • 2

Page 3

Ramsey Publication No. FHT-1

KIT ASSEMBLY

AND INSTRUCTION MANUAL FOR

SlyFox FOX HUNT

TRANSMITTER KIT

TABLE OF CONTENTS

Introduction to the FHT-1 .............. 4

How it works .................................. 5

Parts list ........................................ 6

FHT-1 Assembly instructions ........ 8

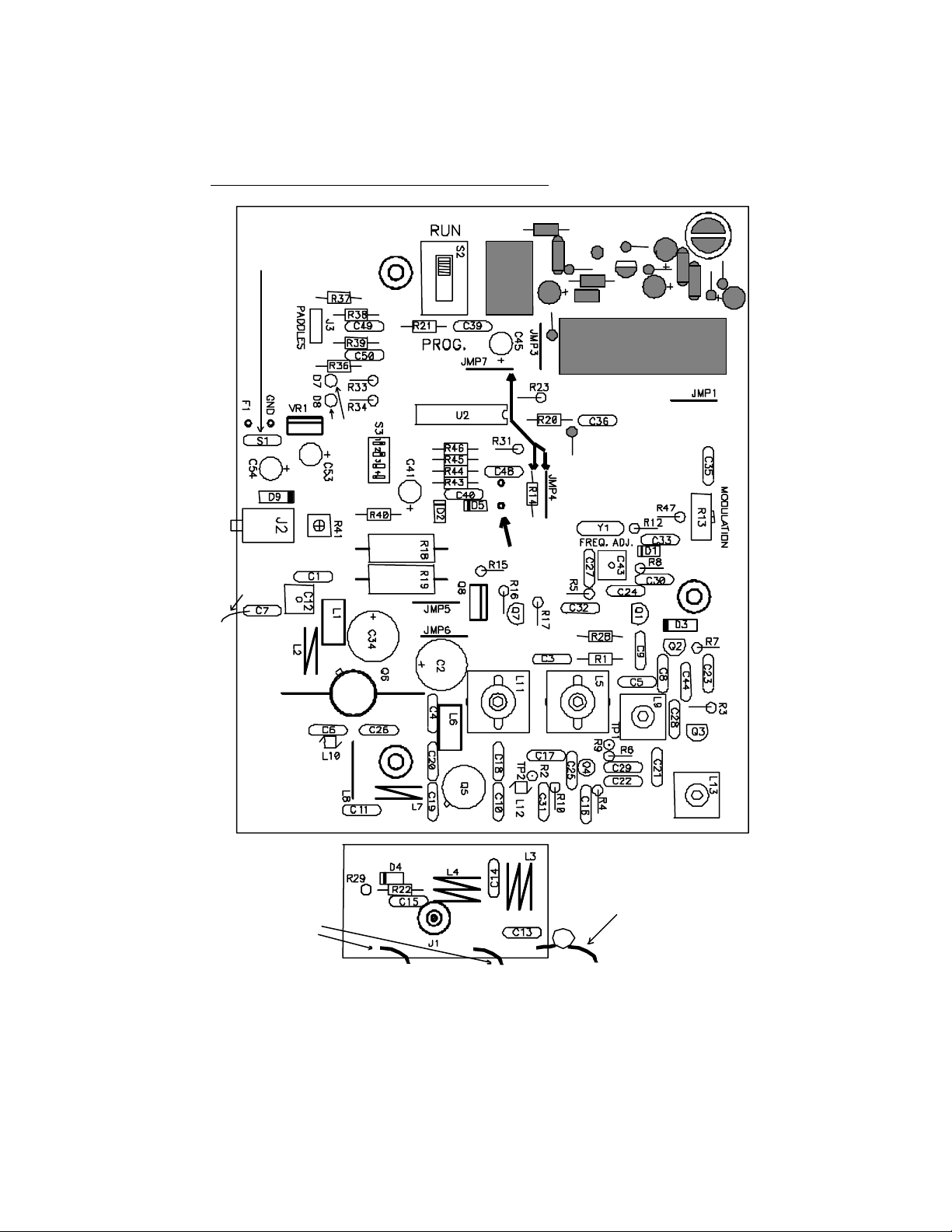

Parts Layout diagram .................... 9

Schematic diagram ..................... 18

Initial testing ................................ 21

Programming ............................... 24

Troubleshooting ........................... 28

Ramsey kit warranty ................... 31

Price $5.00

FHT-1 • 3

RAMSEY ELECTRONICS, INC.

793 Canning Parkway

Victor, New York 14564

Phone (716) 924-4560

Fax (716) 924-4555

Page 4

INTRODUCTION

Finding a small, hidden radio transmitter may seem fairly easy at first, but

with a sly transmitter the hunt can be made very challenging! With the

interest in radio foxhunting on the rise, the need arose for a low cost

transmitter to be used as the radio “fox” for the hunt! The problem is trying to

configure a HT or converted commercial band transmitter to key at different

times, ID itself, and perhaps leave a brief message. By the time all these

components are assembled together, a small fortune is usually invested in

radios, timers, and ID’ers with a good deal of interconnection necessary.

What’s really needed is an inexpensive portable transmitter with all these

options built in, and that's why the FHT Fox Hunt Transmitter was created.

Also, building your own rig is one of the most satisfying and rewarding

experiences you can have - and that's what ham radio is all about! This little,

easy to understand two meter FM transmitter is our attempt to provide the

ham community with a simple, fun to build kit that you'll enjoy operating at a

fox hunt, especially when you tell the other operators that the fox rig is a

home-brew.

Most Ramsey Electronics kits can be classified as "Skill Level 1" if we use

the old Heathkit

guidelines for ease of assembly. That means that our kits

are intended to be successful for first-time kit builders. This FHT-1 Fox-hunt

Transmitter is best regarded as a "Skill Level 2" project, and should not be

taken lightly, even by experienced, licensed radio amateurs. Still, this stepby-step manual is written with the beginner in mind, because we are well

aware of the fascination fox hunting holds, which means this could be your

very first kit project. To be honest, we'd like to see first-time builders start out

with an easier kit such as the Ramsey HR-40 forty meter all-mode receiver

before assembling the FHT-1, but we are confident that you can construct

the FHT-1 successfully if you follow this manual carefully and patiently.

Before beginning the project or even studying the circuit description, it’s

worthwhile to develop some prior respect for how much transmitter is packed

onto the circuit board. The dozen semiconductor devices (diodes, transistors

and IC chip) give the equivalent of about 130 or more transistors and diodes.

And, in addition to 13 inductors, a crystal and the various plugs and jacks,

there are over 60 capacitors and resistors. Surely, all that should result in a

decent transmitter! You could easily spend twice the money plus hours of

time trying to gather the equivalent parts from catalogs and still need to make

your own circuit board.

FHT-1 • 4

Page 5

FHT-1 CIRCUIT DESCRIPTION

Basic overview: The FHT-1 is a crystal controlled FM transmitter that uses a

varactor modulated crystal oscillator followed by a 9 times frequency

multiplier and power amplifier. Test points are built-in for easy alignment. The

“brains” of the unit is a Motorola microcontroller programmed to remember

your CW ID and to control transmit power and timing.

Detailed description: Transistor Q1 functions as a Colpitts crystal oscillator

whose frequency is determined by Y1 and varactor diode D1. Transistor Q2

functions as a buffer amplifier to isolate the crystal oscillator from other

portions of the circuit. The crystal oscillator frequency is multiplied by 3

(tripled) in transistor Q3. Frequency multipliers are nothing more than

amplifiers that produce lots of distortion! In this case we're interested in

having enough distortion so that the third harmonic is fairly strong. We "pickoff" or filter the third harmonic with a band pass filter, comprised of L9,13 and

capacitors C28,21,22,16. This allows transistor Q4 to be driven only by the

third harmonic of the crystal frequency - in this case, around 48 MHz. Q4 is

another tripler, multiplying up the 48 MHz to 144 MHz. Inductors L5,11 and

capacitors C25,17,18,10 form a band pass filter for the three times output

frequency.

From here on out, we're working at the actual carrier frequency and use a

couple of transistors to amplify the signal up to a 4 to 6 watt level. Transistor

Q5 boosts the signal to the 250 mW range and Q6 then produces the full

power output. Impedances must be matched between stages to allow for

maximum power transfer, and that's the function of a couple of coils that are

hand wound. A low pass filter follows the final amplifier to limit out of band

signals (remember those multiplier stages?). Modulation is accomplished by

varying the capacitance of varactor diode, D1. This varying capacitance shifts

the frequency of the crystal ever so slightly causing a frequency shift, which

is FM or Frequency Modulation. And yes - this frequency shift does get

multiplied as it travels through the multiplier stages. The signal used to vary

the varactor diode is our desired audio modulation. There is no need to

control the voltage to any other transistors since they all operate class "C". A

class C amplifier draws no current unless it is driven, so there is no need to

switch the later stages on and off.

The microcontroller U2 contains the programming to control the transmitter’s

functions . When in programming mode, the chip is enabled to remember the

CW ID that is “sent” to it via the Paddles input. The four DIP switches can be

set to run one of sixteen different programs controlling on and off times and

power levels, including one user-programmable mode.

FHT-1 • 5

Page 6

FHT-1 FOX-HUNT TRANSMITTER KIT PARTS LIST

Resistors and potentiometers:

1 2 ohm resistor (red-black-gold) [R6]

2 47 ohm resistors (yellow-violet-black) [R18,19]

1 51 ohm resistor (green-brown-black) [R10]

2 100 ohm resistor (brown-black-brown) [R28,40]

1 270 ohm resistor (red-violet-brown) [R8]

2 390 ohm resistors (orange-white-brown) [R33,34]

3 470 ohm resistors (yellow-violet-brown) [R7,16,20]

9 1K ohm resistors (brown-black-red) [R1,2,4,9,12,21,22,29,31]

1 2.2K ohm resistor (red-red-red) [R15]

1 4.7K ohm resistor (yellow-violet-red) [R47]

11 10K ohm resistors (brown-black-orange)

[R14,17,23,36,37,38,39,43,44,45,46]

2 47K ohm resistors (yellow-violet-orange) [R3,5]

1 200 ohm potentiometer (marked 201) [R41]

1 5K potentiometer (marked 502) [R13]

Capacitors

1 2 or 2.2 pf disc capacitor (marked 2 or 2.2 or 2K or 2.2K) [C17]

1 4.7 or 5 pf disc capacitor (marked 4.7 or 5 or 4.7K or 5K) [C21]

2 10 pf disc capacitor (marked 10 or 10K) [C19,20]

1 12 pf disc capacitor (marked 12 or 12K) [C25]

1 15 pf disc capacitor (marked 15 or 15K) [C27]

1 22 pf disc capacitor (marked 22 or 22K) [C18]

3 39 pf disc capacitor (marked 39 or 39K) [C13,15,28]

2 47 pf disc capacitor (marked 47 or 47K) [C10,22]

1 56 pf disc capacitor (marked 56 or 56K) [C14]

6 100 pf disc capacitor (marked 100 or 101 ) [C6,11,16,24,26,29]

1 150 pf disc capacitor (marked 150 or 151) [C48]

1 470 pf disc capacitor (marked 470 or 471) [C30]

6 .001 uf disc capacitor (marked .001 or 1000 or 102)

[C7,8,23,31,32,44]

9 .01 uf disc capacitor (marked .01 or 10 nf or 103)

[C1,3,4,5,33,39,40,49,50]

3 .1 uf disc capacitor (marked .1 or 104) [C9,35,36]

4 10 uf electrolytic capacitor [C41,45,53,54]

2 100 to 220 uf electrolytic capacitor [C2,34]

2 Trimmer capacitor, 35 pf [C12,43]

Inductors and ferrite cores

2 Shielded can tunable inductor (marked 007007) [L9,13]

2 Tunable inductor (pink plastic body) [L5,11]

2 6 hole ferrite bead core [L1,6]

FHT-1 • 6

Page 7

2 Small ferrite bead core [L10,12]

2 Aluminum coil shield cans [for L5,11]

Semiconductor devices

1 1N4002 style black epoxy diode [D9]

3 1N4148 style signal diode (glass body with black band) [D2,4,5]

1 FS4059 varactor diode (black body with yellow color band) [D1]

1 Zener diode, 6.2 volt (gray body with black band) [D3]

3 2N3904 NPN transistor (marked 2N3904) [Q1,2,7]

1 2SC2498 or 2570 VHF/UHF NPN transistor [Q3]

1 NE021 flat pack NPN transistor (marked 021) [Q4]

1 2N3866 metal can NPN transistor [Q5]

1 SD1127 metal can RF power transistor [Q6]

1 2N5193 PNP transistor (marked 2N5193) [Q8]

1 7805 voltage regulator IC (marked 7805) [VR1]

1 68HC705K1 microcontroller IC (marked FHT1)

2 LED Light emitting diode [D7,8]

Special components

1 Crystal 16.280 MHz (for 146.520 MHz output) [Y1]

1 2.5MM sub-miniature phono jack [J2]

1 Push-on aluminum heat sink

1 5/16" x 20 bolt (to wind coils on)

1 ½ foot enameled magnet wire (#28)

1 ½ foot tinned buss wire (#20)

1 FHT epoxy printed circuit board

1 Low Pass Filter printed circuit board

1 SPDT Slide switch [S2]

1 4 pin DIP switch[S3]

1 16 pin IC socket

1 SO 239 chassis mount connector

2 #4-40 screws, 1/2” - 5/8” in length

4 #4-40 nuts

1’ black jacketed wire (#18)

1 1’ red jacketed wire with fuseholder

Required, not supplied

12 volt DC power source at 1 amp minimum

Dummy load or suitable antenna

Enclosure such as the Ramsey CFHT

FHT-1 • 7

Page 8

RAMSEY Learn-As-You-Build KIT ASSEMBLY

There are over 200 solder connections on the FHT-1 printed circuit board.

That means your work could be 99% perfect and you could still have 2 or 3

cold solder points or solder bridges. Since this circuit is more sophisticated

than a direct-conversion HF receiver or a CW HF transmitter, a beginner or

casual amateur could have a harder time tracing a problem due to a poor

solder connection. Therefore, PLEASE take us seriously when we say that

good soldering is essential to the proper operation of your transmitter!

• Use a 25-watt soldering pencil with a clean, sharp tip.

• Use only rosin-core solder intended for electronics use.

• Use bright lighting, a magnifying lamp or bench-style

magnifier may be helpful.

• Do your work in stages, taking breaks to check your work.

Carefully brush away wire cuttings so they don't lodge

between solder connections.

We have a two-fold "strategy" for the order of the following kit assembly

steps. First, we install parts in physical relationship to each other, so there's

minimal chance of inserting wires into wrong holes. Second, whenever

possible, we install in an order that fits our "Learn-As-You-Build" Kit building

philosophy.

For each part, our word "Install" always means these steps:

1. Pick the correct part value to start with.

2. Insert it into the correct PC board location.

3. Orient it correctly, follow the PC board drawing and the written

directions for all parts - especially when there's a right way

and a wrong way to solder it in. (Diode bands, electrolytic

capacitor polarity, transistor shapes, dotted or notched ends

of IC's, and so forth.)

4. Solder all connections unless directed otherwise. Use enough

heat and solder flow for clean, shiny, completed connections.

Don't be afraid of any pen-style soldering iron having enough

heat to damage a component.

5. Trim or "nip" the excess component lead wire after soldering.

NOTE: Save some of the longer wire scraps nipped from resistors and

capacitors. These will be used to form wire jumpers (JMP1, etc.) to be

soldered in just like parts during these construction steps.

Now, let's start building!

FHT-1 • 8

Page 9

FHT-1 PC Board component placement diagram

Shaded Parts used in Voice ID option

External Switch

S1

connections

(opt)

To

Low

Pass

LED 1

LED 2

Board Filter

short

leads

TEST

Connection

s

-

+

Micro

Battery

Backu p

Ground

Jumpers

TP3

FHT-1 • 9

Long Lead

for

mounting

C7

Page 10

1. Install J2, the subminiature phone jack.. Gently push the solder tabs

through the PC board being careful not to bend or strain them. Solder all

three tabs.

2. Install R41, 200 ohm trimmer pot (marked 201). This is the audio

output or volume control.

3. Install R40, 100 ohm (brown-black-brown). This completes your

earphone monitor output for the transmitter.

4. Install diode D9, the 1N4002 type (black body with a silver band). Be

sure to observe the correct polarity! See the parts placement diagram for

correct orientation.

5. Install C54, 10 uf electrolytic capacitor. Electrolytic capacitors are

polarized with a (+) and a (-) lead and must be installed in the correct

orientation. Ordinarily, only the negative side is marked on the capacitor

body with a dark band and the (-) sign clearly shown, while PC boards

will usually show the (+) hole location. Use care to ensure proper

polarity.

6. In the same manner, install another 10uF electrolytic capacitor in the

C53 position. See the parts placement diagram for correct orientation.

7. Install voltage regulator VR1, marked 7805. Observe the correct

placement of the metal tab. Mount it so that the lettering on the device

faces toward capacitor C53 and jack J2. This IC provides a stable

source of 5 volts for the digital sections of the circuit.

8. Install the LED’s (light emitting diodes) D8 and D7. Being diodes,

these components are polarized and must be installed with regard to

their polarity. Identify the cathode (or - lead) side lead which is the

shorter of the two component leads, and is usually marked with a “flat”

notch on the plastic body of the LED. These leads should face toward

the outside of the PC board as shown in the parts placement diagram.

9. Install R34, 390 ohm (orange-white-brown). Notice that this resistor

is “standing up” on the circuit board.

10. Install R33, 390 ohm (orange-white-brown) in the same manner.

11. Install R36, 10K ohm (brown-black-orange).

12. Install C50, .01 uF disc capacitor ( marked .01 or 103 or 10nF).

13. Install R39, 10K ohm (brown-black- orange).

14. Install C49, .01 uF (marked .01 or 103 or 10nF).

15. Install R38, another 10K (brown-black-orange).

16. Install R37, yet another 10 K (what colors were those?!) (brown-

FHT-1 • 10

Page 11

black-orange).

17. Install R21, 1K ohm (brown-black-red).

18. Install C39, .01uF disc cap (marked .01 or 103 or 10nF).

19. Next we’ll install switch S2 (the run - program switch for the

microprocessor). Gently slide the six solder pins through the PC board

for connection. Solder all six connections. Use enough heat to “flow” the

connections, especially on the ground “plane” connections.

20. Install C45, 10 uF electrolytic. Be sure to observe the correct polarity.

See the parts placement diagram for correct orientation.

21. Install JMP7, jumper wire. Use a piece of wire clipped from a

previously installed component bent into a small "U" or wire staple

shape. Jumpers act as electronic "bridges" carrying signals over PC

board traces underneath.

22. Install another wire jumper, JMP3.

23. Install resistor R23, a 10K ohm (marked brown-black-orange). Note

that this is a “stand up” component, so follow the parts placement

diagram.

24. Install R20, 470 ohm (yellow-violet-brown).

25. Install C36, 0.1 uF disc cap (marked .1 or 104).

26. Form and install jumper JMP1. This completes the audio path from

the microcontroller IC to the FM transmitter section of the unit. If you

have purchased the voice ID option, the accompanying FHID-1 manual

will direct you in the proper steps to take concerning JMP1 and

associated components.

27. Now that your soldering skills have been warmed up, we’ll install the

16 pin IC socket in the U2 position. We provide this socket because

many people feel it is easier to install a socket than to risk damaging the

IC chip while installing it. However, please be aware that we have seen

more service problems with improper socket insertion than from

soldering in ICs. Make sure that the IC socket is perfectly flat against the

PC board before soldering, and pay extra attention to not “bridge” or

splash solder between pads or traces while installing this socket. Do not

install the microcontroller yet, we’ll do that while we’re testing!

28. Next, install resistors R43,R44, R45, and R46 which are all 10K ohm

(brown-black-orange). These are “pull down” resistors, that is, they “pull”

the corresponding pins of U2 to ground potential unless one of the

switches contained in S3 is turned on. These resistors insure a good

logic zero or one condition for the microcontroller.

29. Install the DIP switch, S3. This “switch” looks like an eight pin IC - it

FHT-1 • 11

Page 12

uses the same pin configuration as one. When installing be careful not to

bend the solder pins, and make sure to push the switch flat to the board.

30. Install C41, 10 uF electrolytic. Watch that polarity!

31. Install R31, 1K ohm (brown-black-red). Notice that this is another

“stand up” resistor.

32. Install C48, 150 pF disc capacitor (marked 150 or 151).

33. Install C40, .01 disc capacitor (marked .01 or 103 or 10nF).

34. Install small signal diode D5, 1N4148 (opaque orange/red with black

band). Diodes are polarized, so be sure to orient the part correctly! See

the parts layout diagram for correct placement.

35. In the same manner install diode D2 - remember that polarity!

Whew! Time to take a breather. We’ve just completed the entire

microcontroller section of the transmitter. Now is a good time to recheck your

work paying careful attention to parts orientation, Also, look over the solder

side of the PC board for any solder bridges or splashes. “Touch up“ any

connections which are less than perfect.

Now we’re going to begin building the 144 MHz transmitter section of the

unit. While you shouldn't be afraid of this, please try to remember that at

VHF frequencies component lead length can be the difference between a

working unit and a marginally performing one. Follow the instructions

carefully and your unit will perform admirably with no trouble. Be sure to fit all

components as close as mechanically possible to the PC board for best

results.

36. Install R14, 10K ohm (brown-black-orange).

37. Form and install jumper JMP4.

38. Install C35, .1 uf (marked .1 or 104).

39. Install R13, 5K stand up trimmer pot. This is the modulation

adjustment control.

40. Install R47, 4.7K (yellow-violet-red).

41. Install R12, 1K ohm (brown-black-red).

42. Install Y1, crystal. This is the "heart" of the FM transmitter,

producing the initial signal which is multiplied and amplified up to the

final transmitted signal.

43. Install D1, FS4059 varactor diode (small black body with yellow

band). Varactor diodes act as voltage variable capacitors. In this case,

D1's capacitance is varied by the amplified voltage from the

FHT-1 • 12

Page 13

microcontroller, causing the crystal oscillator's frequency to change - in

exact step with your CW ID. Voila, FM or Frequency Modulation!

44. Install C33, .01 uF disc (marked .01 or 103 or 10nF).

45. Install R8, 270 ohm (red-violet-brown). Make sure you stand this part

up.

46. Install trimmer capacitor, C43 (black body with orange top). This

trimmer is used for setting the FHT-1 exactly on frequency.

47. Install C27, 15 pf disc capacitor (marked 15 or 15K).

48. Install R5, 47K ohm (yellow-violet-orange).

49. Install C30, 470 pf disc capacitor (marked 470 or 471).

50. Install C24, 100 pf disc capacitor (marked 100 or 101).

51. Install C32, .001 disc capacitor (marked .001 or 102).

52. Identify Q1, a 2N3904 NPN transistor (marked 2N3904). Install Q1,

observe correct placement of the flat side. Press the transistor snugly

into the PC board so that only a minimum amount of wire lead is

exposed above the board. In soldering, do not be afraid of using enough

heat to make a good solid connection.

53. Install D3, zener diode (gray body with black band). A zener diode

functions as a voltage regulator since it has the property of holding the

voltage across it constant. In this case we wish to hold the voltage to the

crystal oscillator steady to keep us on frequency, even with a poorly

regulated power supply.

54. Identify Q2, another 2N3904 NPN transistor (marked 2N3904).

Install Q2, observe correct placement of the flat side.

55. Install C9, .1 uf disc capacitor (marked .1 or 104).

56. Install C8, .001 uf disc capacitor (marked .001 or 1000 or 102).

57. Install R7, 470 ohm (yellow-violet-brown).

58. Install C23, .001 uf disc capacitor (marked .001 or 1000 or 102).

The oscillator and the first buffer stage of the transmitter is finished. Take a

break and look over component placement and soldering. Are all the

components (except the stand up resistors) flat to the board? If not, be sure

to “walk” them to the PC board by heating one solder pad at a time and

pushing that end of the component flat to the board while the solder is still

molten, kind of a strike while the iron is hot technique. If this technique is

used, be especially careful not to lift the printed circuit pads or traces away

from the board material.

59. Install C44, .001 uF disc cap (marked .001 or 102).

FHT-1 • 13

Page 14

60. Install C5, .01 uf disc capacitor (marked .01 or 10 nf or 103).

5

61. Install R3, 47K ohm (yellow-violet-orange).

62. Install C28, 39 pf disc capacitor (marked 39 or 39K).

63. Install Q3, 2SC2498 NPN

VHF transistor (marked C2498).

Position the flat side as shown on

the parts layout. Be advised that

this transistor has a different

“pinout” than the 2N3904 that was

previously installed so please

trust us when we say to follow the parts layout diagram. Make sure that

you push this transistor as close to the board as possible.

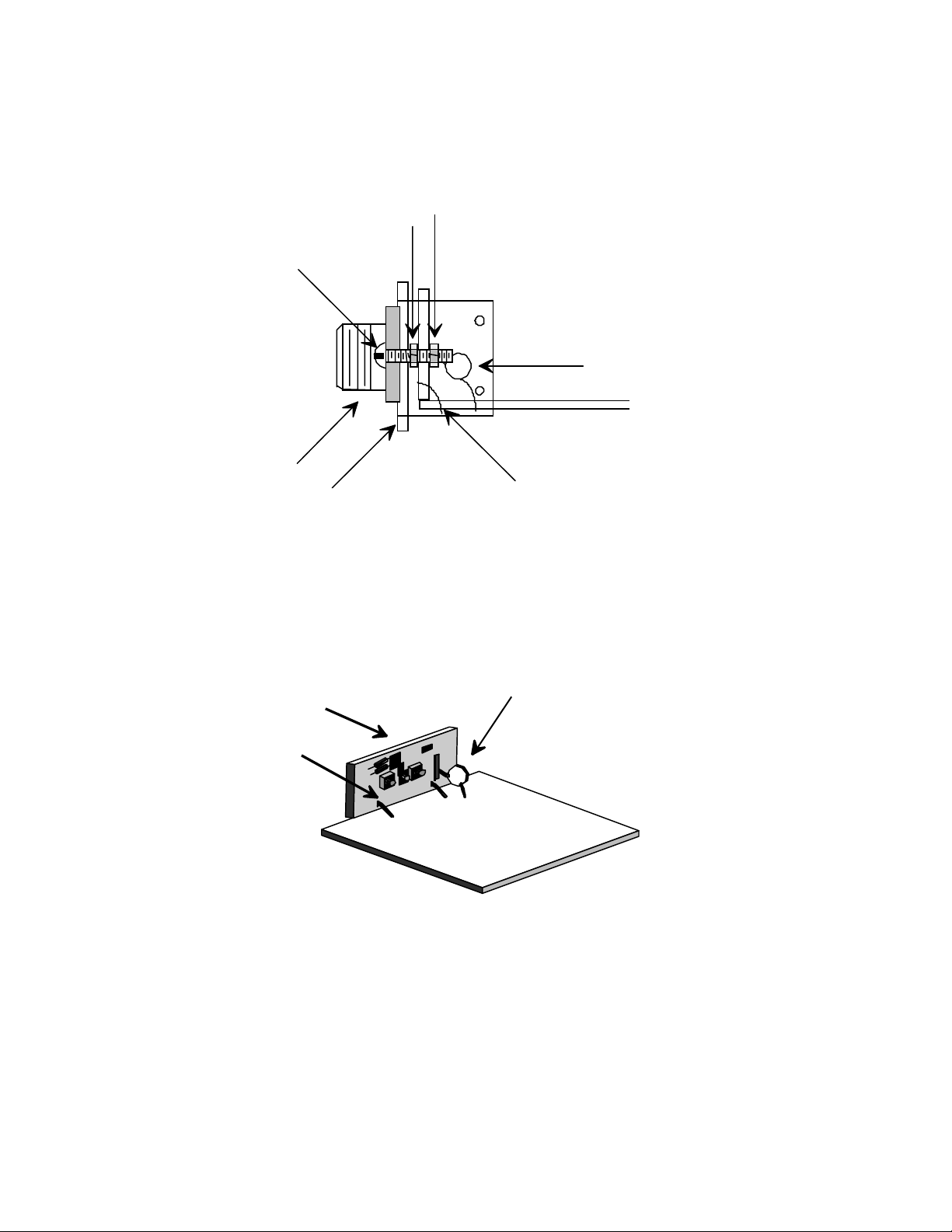

Resistor

Test point loop

PC board

64. Install L9, slug tuned shielded coil (marked 007007). This coil is part

of the first tripler section. It is tuned to the third harmonic of the crystal

oscillator.

Markings on

this side

FHT-1 • 14

This lead tow ard L

Long lead

collector

Page 15

65. Install L13, another slug tuned shielded coil (marked 007007). This

coil is also part of the first tripler section.

66. Install C21, 4.7 or 5 pf disc capacitor (marked 4.7 or 5 or 4.7K or

5K).

67. Install TP1. Select a 1K resistor, R9 (brown-black-red). Trim back

one lead wire to a length of a quarter inch. Bend this wire into a small

loop as shown. This loop will act as a convenient point to connect a test

probe for tuning up your transmitter. Insert the resistor into the PC board

and hold it carefully while you solder it to the board.

68. Install R6, 2 ohm resistor (red-black-gold).

69. Install C29, 100 pf disc capacitor (marked 100 or 101).

70. Install C22, 47 pf disc capacitor (marked 47 or 47K).

71. Install R4, 1 K ohm (brown-black-red).

72. Locate Q4, NE021, the tiny black

transistor disc stuck to a piece of

paper (marked 021). Carefully remove

it from its protective paper and bend

all three leads down 90 degrees from

its body. Notice how one lead is

longer than the others, that lead (the

collector) must be installed exactly as

shown in the drawing - pointing

towards L5. Set Q4 into the PC board

making sure that its body is snugly

against the PC board and positioned correctly. You should be able to

read the printed markings on the part, if you cannot, then you have the

transistor flipped over. Solder and trim all three leads.

6 hole ferrite core

enameled wire

tin ends

73. Install L5, pink color

slug tuned inductor.

Make sure you place the

coil body right up against

the PC board snugly.

3 turns through center

74. Install aluminum coil

shield can cover over L5.

75. Install R1, 1K ohm

(brown-black-red).

enameled wire

tin ends

76. Install R28, 100 ohm (brown-black-brown).

77. Install C3, .01 uF (marked .01 or 103 or 10nF).

78 Install C16, 100 pf disc capacitor (marked 100 or 101).

FHT-1 • 15

Page 16

79. Install C25, 12 pf disc capacitor

(marked 12 or 12K).

80. Install C17, 2 or 2.2 pf disc capacitor

(marked 2 or 2.2).

81. Install another resistor test point,

TP2. Select a 1K resistor, R2 (brownblack-red). Trim back one lead wire to a

length of one quarter inch. Bend this

wire into a small loop as shown. Insert

the resistor into the PC board and hold it

carefully while you solder it to the board.

Nine parts need handmade preparation

before installation in the transmitter RF

stages of your transmitter. We recommend

that you get them ready for installation before

assembling the Driver and Final stages. If

you prefer to proceed with those stages,

winding coils as you go, that's fine too, as

long as you realize that all coil making details are provided

in this section. The wire used for L1, 6, 10, and 12 is the

smaller gauge enameled wire supplied with your kit. We give you plenty but if

you mess up, you can get a whole 50' spool of it from Radio Shack (278-

1341).

1/4 in.

L2,7

1/4 in.

L 3,4

82. Winding L1 and L6 RF chokes (two identical units ): Examine the

two cylindrical ferrite cores provided in the kit. Notice that there are six

holes at either end of these cylinder shaped units, arranged in two

groups of three. Cut 6" of enameled wire and following the drawing,

thread the wire, pulling each turn gently tight. Tin each end with solder

by holding your soldering iron and solder on the wire ends until the

enamel insulation melts away and the copper wire underneath coats

nicely with solder. Tin all the way up to the ferrite core body. Your

finished RF chokes should look like the diagram. Do not install either

part yet.

83. Winding L10 and L12: Locate the two small black ferrite beads

provided in the kit. Cut 2" of enameled wire and following the drawing,

thread 3 turns through the bead hole, pulling each turn "gently tight." Tin

each end with solder. Tin all the way up to the ferrite core body. Your

finished bead chokes should look like the diagram. Do not install either

part yet.

FHT-1 • 16

Page 17

84. Winding L2 and L7: Use the heavy gauge

tinned bus wire in your kit for these coils.

Wind these coils on the threads of the

provided 5/16"X20 bolt to assure perfect

forming of the coils. (You wondered what that

big bolt was for - didn't you!) Both coils are

1½ turns. They appear to be 2 turns if viewed

from the top. They will fit neatly into the PC

board without any excessive bending or

stretching.

2N5193

E C B

This is the

front side and

faces toward

JMP5 and

R19.

85. Winding L3 and L4: Use the same wire and procedure as used

above for these coils. Each coil is 2½ turns and will appear to be 3 turns

if viewed from the top.

The "legs" or leads for inserting L2, L7, L3 and L4 should be about 1/4” long.

These coils should sit about 1/8" maximum above the PC board when

soldered.

86. Install R10, 51 ohm (green-brown-black). Notice that this resistor

stands up.

87. Install C31, .001 uF disc cap (marked .001 or 102).

88. Install L12, one of the small 3 turn ferrite bead RF chokes you

wound. Pull it up snug against the PC board and solder.

89. Install C10, 47 pf disc capacitor (marked 47 or 47K).

90. Install C18, 22 pf disc capacitor (marked 22 or 22K).

91. Install Q5, 2N3866 metal can RF transistor. Be sure you press the

transistor case flush against the PC board and solder securely.

92. Install L6, a 6 hole ferrite bead choke wound previously.

93. Install C4, .01 uf disc capacitor (marked .01 or 10 nf or 103).

94. Install L11, pink slug tuned coil.

95. Install aluminum shield can cover over L11.

96. Install C2, 100 to 220 uf electrolytic capacitor. Be sure to observe

polarity - especially with this part since it is directly across the power

supply and if reversed, could overheat so fast, so much, that it could

explode!

97. Form and install jumper JMP6. Be sure to keep the following jumpers

as short as possible due to their proximity to the RF amplifier transistors.

98. In the same way install jumper JMP5.

99. Next we’ll install Q8, the 2N5193 power PNP transistor. Notice that

FHT-1 • 17

Page 18

the side with the markings faces towards the jumpers that you just

installed(JMP5 and JMP6). See the parts placement diagram for correct

orientation.

100. Install R15, 2.2K (red-red-red). Notice that this part “stands up”. See

the parts layout diagram for correct placement.

101. Install R16, 470 ohm (yellow-violet-brown). This part also “stands

up”.

102. Identify and install the last 2N3904 transistor, Q7. Be sure to install

with the flat side oriented correctly. See the parts diagram for correct

placement.

103. Install R17, 10K (brown-black-orange).

104. Install R18 and R19,the two large 47 ohm resistors (yellow-violet-

black).These resistors function by limiting the current to the RF “final”

amplifier. This in turn lowers the power output of the transmitter.

Lets “pick apart” the switching network consisting of Q7, Q8 and associated

components. Have a look at the schematic diagram and follow along. When

voltage is applied to the base of Q7 (from the microcontroller U2) transistor

Q7 is turned “on”. This causes current to flow through Q7’s collector and

Component side of

board

Transistor

can

Solder side of

board

Solder can to PC

creates a voltage drop across resistors R15 and R16. This “voltage divider”

is tied to the base of Q8, the power PNP transistor, forward biasing Q8 and

supplying 12VDC to the final transistor, Q6. This is the “high power” mode.

Conversely, when there is no voltage applied to Q7, both Q7 and Q8 are

turned “off”, and the current must flow through resistors R18 and R19. The

voltage drop across these resistors causes less potential to be applied at the

collector of Q6, lowering the output power.

Note to more experienced kit-builders

The “low power” setting can be adjusted by changing the values of R18 and

R19. Please keep both values the same (for equal power dissipation), The

higher the total value - remember that these resistors are in parallel - the

lower the RF output power will become. Please use at least one watt

resistors for this modification.

FHT-1 • 18

Page 19

Also there is a provision to adjust the “high power” output. Notice that jumper

J5 connects the collector of Q8 to the final transistor Q6. by removing this

jumper and installing a suitable resistor (remember to calculate the power

dissipation) the high power output can be lowered from its full 5 watt value.

Heavy buss

wire jumper

(not a scrap component lead)

Wire sits flat

against board

1/2 inch

Please understand that these modifications should not be attempted unless

you are experienced enough to calculate the current and power yourself and

they are not recommended until after the entire unit has been fully tested.

The testing instructions are intended for the existing unmodified kit.

As long as we’re stopped already, now would be a good time to recheck your

work, focusing on parts placement and soldering. Are all the components

snug to the PC board? Resolder any connections that are less than perfect,

and trim all the leads to a reasonable length.

105. Install C1, .01 uF disc (marked .01 or 103 or 10nF).

106. Install L1, a 6 hole ferrite bead wound previously.

107. Install C34, 100 to 220 uF electrolytic capacitor. Remember that this

capacitor is polarized, so be sure to orient it correctly. See the parts

layout diagram for correct placement.

108.Install L2, 1½ turn coil wound previously. Ensure it sits 1/8 inch

above the PC board, as shown in the diagram.

109. Install C12, trimmer capacitor (black body with orange top).

110. Locate Q6, SD1127 RF power transistor. This transistor mounts

somewhat differently from all the other parts. Turn over the PC board

and set the transistor snugly into the large hole and bend the leads over

and into the indicated holes. The leads should be as short as possible

without shorting against the transistor case. Solder the three transistor

leads. See the drawing below.

111. Now we call for something unusual - soldering the transistor case

to the PC board. Run a neat "flow" of solder around the gold transistor

PC board

FHT-1 • 19

Page 20

case to the PC board ground plane. The SD1127 power transistor is

designed by the manufacturer to be soldered directly to a PC board

ground plane for heat sinking and proper VHF performance. This part is

different from other metal can transistors in that the case is connected

internally to the emitter rather than the collector. This provides much

higher gain at VHF frequencies.

112. Install C19, 10 pf disc capacitor (marked 10 or 10K).

113. Install C6, 100 pf disc capacitor (marked 100 or 101).

114. Install L10, small ferrite bead RF choke you wound earlier.

115. Install C26, 100 pf disc capacitor (marked 100 or 101).

116. Prepare an ½ inch long wire jumper from the heavy tinned bus

wire used for winding coils previously. Install this jumper in the L8

location on the PC board. This wire must sit flat against the PC board

and not up above. Believe it or not, this wire is actually an inductor

providing impedance matching into Q6.

117. Install L7, a 1½ turn coil wound previously. Ensure that the coil is

seated flush against the PC board and not mounted with long leads up

in the air - which would add undesired additional inductance.

118. Install C11, 100 pF disc capacitor (marked 100 or 101).

119. Install C20, a 10 pF disc capacitor (marked 10 or 10K).

Wow! You’ve completed most of the RF output section of the Sly Fox

transmitter. Give your eyes a well deserved rest now - only ten parts to go

before the entire unit is ready for testing. After your break have a good hard

look at your creation for solder bridges and misplaced components - these

can be costly errors especially in the RF output section - those components

are expensive! Touch up any questionable connections.

Lastly we’ll assemble the low-pass filter section of the transmitter output and

the power detector section of the transmitter. Please pay particular attention

to component lead lengths while constructing this section, as long leads will

add unwanted inductance to your circuit. To optimize this filtering it has been

placed on a separate circuit board which we’ll build first and then install.

IMPORTANT NOTE

When constructing the Low Pass Filter PC board it is important to

understand that the components will be installed on the “solder” side of

the circuit board, or the side containing the printed circuit traces.

Solder the components on the same side, and then clip the leads as the

FHT-1 • 20

Page 21

#4-40 Screw

#4-40 nuts

Spacer nut

SO-239 Fema le

Case Panel

1

02

Ground Jumper

C7

pass through the “component “ side of the circuit board. Pay particular

attention to the disc capacitors to ensure that there is a good solder “flow”

between the component lead and the PC traces. Be sure to lead enough lead

exposed on the “solder” side to accomplish a good connection.

121. Install TP3, the last test point. Select a 1K resistor, R29 (brown-

black-red), and install as before.

Filter PC board

Gr o un d Jum pe r s

C 7

102

MAIN BOARD

122. Install D4, 1N4148 style signal diode (glass body with black band).

Observe correct orientation of the banded end.

123. Install R22, 1K ohm (brown-black-red).

FHT-1 • 21

Page 22

124. Install C15, 39 pf disc capacitor (marked 39 or 39K).

125. Install L4, 2½ turn coil wound previously. Make sure it seats as

close as possible without touching the PC board.

126. Install C14, 56 pf disc capacitor (marked 56 or 56K).

• bridged over solder joints,

• misplaced components,

• transistors or diodes placed wrong,

• electrolytic capacitors installed wrong.

127. Install L3, another 2½ turn coil. Be sure it sits flush against the PC

board.

128. Install C13, 39 pf disc capacitor (marked 39 or 39K).

129. Install C7, .001 uf disc capacitor (marked .001 or 1000 or 102).

solder only one end of the disc capacitor to the filter PC board. This

component will “connect” the two circuit boards so be sure not to trim the

component lead that will connect to the main PC board. See the parts

diagram for correct placement.

130. Using scrap leads, install the two ground connection wires to the

filter PC board to “mate” the ground between the main board and the

filter board.

131. Now we’ll install the RF output connector (SO239). Please note that

this will be described in conjunction with the FHT case set - if you did not

purchase this with your kit you may need to install an extra “spacer” #440 bolt to ensure that the connector does not touch the low pass filter PC

board .

132. First, insert the two #4-40 mounting screws through the mounting

L9: 2 turns

L13: 3 turns

L5: 8 turns

holes on the chassis mount connector. Then slide the screws through the

case set panel hole marked “Antenna”. Using the #4-40 nuts provided,

tighten the nuts to the screw securing the connector to the panel. When

FHT-1 • 22

Page 23

this is accomplished, proceed to slide the screws through the holes in the

filter PC board, and finish up by installing the last two #4-40 nuts.

133. Now position the filter circuit board assembly at a right angle to the

main circuit board. Carefully solder the two ground connections and

capacitor C7 from the filter circuit board to the main board. Follow the

diagram below for PC board placement.

134. Now solder the center pin of the SO239 connector to the filter circuit

board assembly.

135. Locate the aluminum press on heatsink and slip it on Q6.

131. Install the 12” piece of black wire to the GND hole on the main PC

board.

136. Install the red wire (with the fuse inline) to the F1 hole on the PC

board.

137. If you intend to add your own external switch, wire the contacts in

the S1 holes - if not - install a jumper wire in that location.

FHT-1 • 23

Page 24

CONGRATULATIONS

This completes our assembly of the FHT-1 Sly Fox transmitter, now's a

good time to give your masterpiece a good going over, being especially alert

for any:

TESTING, ALIGNMENT AND ADJUSTMENT

To prepare your FHT-1 for testing, you'll need the following items:

1. The hexagonal, non-metallic alignment tool included with your kit.

2. A suitable 50 ohm dummy load.

3. Proper cable to connect from FHT-1 transmitter (SO239) to dummy

load.

4. A 12 volt DC power source of at least 1 amp.

5. A digital multimeter.

With all the above set-up and handy, let's get testing!

1. Using your hex head tuning tool, back out the coil slugs in L9, L13,

L5, L11 even with the top of their plastic coil form. If a slug binds, gently

rock it back and forth till it loosens up, be very careful not to crack the

slug as they are brittle. Slowly rotate each slug clockwise into the coil

form the indicated number of turns:

2. Rotate modulation control R13 fully counter-clockwise.

3. Notice that we have not yet installed the microcontroller, U2. In order

to first test the transmitter section, we’ll need to “fool” the transmitter into

thinking that the micro is telling it to transmit on high power. This is

accomplished by tying the P(ush) T(o) T(alk) line and

control line to the +5V DC supply. A clip-lead or jumper wire must be

attached from jumper JMP7 to jumper JMP4 and

R14 as shown in the parts placement diagram. Without these

connections the unit will not operate.

the high power

one side of resistor

4. Apply 12 volts to the FHT-1 transmitter board. It’s a good idea to

fuse the power to the FHT-1, 1 to 2 amps will do.

5. Connect a proper 50 ohm dummy load to antenna connector J1. In

a pinch, a light bulb may be used - see the section "Verifying

Transmitter RF Power Output".

6. Hook your multimeter to TP1 and set the meter to the 200 mVDC,

(0.2 VDC range).

FHT-1 • 24

Page 25

7. Adjust L9 and L13 for maximum indication on TP1. No more than a

turn or two is needed. You will have to go back and forth between these

coils as they interact. You should get a reading of at least 50 mV.

8. Move your meter probe over to TP2 and adjust L5 and L11 for

maximum negative reading. Once again, go back and forth between the

two coils. You should get a reading of at least -90 mV. It is very

important to tune for the best peak as this will ensure proper transmitter

operation.

9. You should now be able to see RF power at the output antenna

jack, J1. Adjust capacitor C12 for maximum RF power output. Connect

your voltmeter to TP 3 and peak for maximum DC voltage.

10. Slightly spread or compress coils L3 and L7 to maximize output

power. Power should be at least 4 watts with a 12 volt power source.

11. Next, power down the unit, remove the jumper from jumper JMP7 to

resistor R14. this will disable the high power mode and enable low power

operation. When power is re-applied to the unit, the transmitter should

be at approximately 1 W RF output.

12. If a frequency counter or service monitor is available, adjust

capacitor C43 for exactly 146.520 MHz. If you do not have such

equipment, use a receiver with a center tune meter.

13. Disconnect the power source from unit to continue with assembly.

See Installation and Programming of the Microcontroller on the following

pages.

This completes the transmitter alignment of your FHT-1. Now it is time to

remove the clip lead or jumper connections from jumper JMP7 to JMP4, the

PTT enable.

FHT-1 • 25

Page 26

VERIFYING TRANSMITTER RF OUTPUT

The most important thing to know is whether your transmitter is delivering

some measurable and reassuring level of RF power to the antenna. The

sound of the transmitter keying in a receiver is of some help, but even the

simplest crystal oscillator can send a fine signal into your neighbor's

receiver. Ideally, you have a small RF wattmeter, already inserted in the

antenna line, capable of accurately measuring low output power in watts.

And it cost you less than what you paid for the transmitter kit. Right? In the

words of Wayne from "Wayne's World"... Not! So here are a few other ideas

for you to try.

Saying the same thing another way, we

assume you know that accurate, commercially

built RF wattmeters cost much more than

what you paid for this Ramsey transmitter kit.

Since this solid-state transmitter does not

require lots of critical tuning or adjustments, a

periodic power output check-up should

suffice. If you do not own or have access to a

low-level RF power meter, use a trick that is

decades old, the common flashlight or panel

Dash Input

Dot Input

Ground

bulb. All you need to know is the basic

differences between bright, superbright, dim,

unlit and burned out! Using a light bulb to

check power output is also a satisfying way to put Ohm's Law to work. Your

Radio Shack catalog specifies operating voltage and current in milliamperes

for a variety of small replacement lamps. It may be worth your while to make

up a simple plug-in "output tester" for your transmitter, a male PL259 plug

connected to a socket for the bulb of your choice or even soldered directly to

the bulb.

RF voltage levels in this transmitter can vary from 2 to 25 volts RMS

depending on various factors. Typically, 1 watt power levels are achieved in

5 to 7 volts RMS volts range, and 5 watts at 15 to 20 volts. A good test bulb

for this level is the PR-4 flange-style flashlight bulb or the type 243 bulb with

screw-in body. Both are rated to give normal brilliance at 2.33 volts, drawing

270 milliamps of current. Using Ohm's law, P=IE, we see that normal

brilliance requires 2.33 volts x .270 amperes for .62 watts of DC power

consumption. We can conclude that even a watt or so of RF should light this

bulb reasonably well. A type PR-12 bulb is suitable for checking RF outputs

in the 1-3 watt range. Try it out!

Please remember, though, that a flashlight bulb does NOT present the

proper load impedance to the transmitter output, so theoretical calculations

based on the bulb`s rating can only be approximate. For example, the PR-4

FHT-1 • 26

Page 27

at full brilliance presents only an 8.2 ohm load to the transmitter. Because of

this, the transmitter may act "flaky" when tuning up into a light bulb, and by

all means you should not consider a light bulb an accurate indicator of the

FHT-1's performance! If ANY flashlight bulb lights up when connected to the

antenna jack of this transmitter, you can be satisfied that you have RF output

power at least equal to the DC power rating of the bulb you are using. If you

burn out your bulb, rejoice and put your rig on the air!

FHT-1 • 27

Page 28

Amateur radio magazines and handbooks provide a variety of circuits for RF

wattmeters and relative field-strength indicators, including methods of using

your VOM as an indicating device. CQ magazine for March 1990 offers an

article by KB4ZGC on how to make a highly accurate yet inexpensive

dummy load and wattmeter capable of showing 1/10-watt differences in RF

power. If you use a wattmeter characterized for the HF frequency region, it

will not give accurate results at the much higher two meter frequencies,

although it will be quite adequate for go/no-go testing.

YOUR POWER SUPPLY AND RF OUTPUT POWER

For optimum performance, one or two volts of extra DC supply power can

make quite a difference in any transmitter. For example, two lantern batteries

in series, or 8 "D cells" will obviously provide "about 12 volts" with sufficient

current capability for casual operating. For maximum RF output power, use a

supply of 13 to 14 volts DC. The easiest method is to place two fresh "D

Mode DIP Switch

(1=on)

Time

OFF

Power

out

Toggle

Power

45 sec.

Timer ON

0 0 0 0 0 user user user user user

1 0 0 0 1 0 High N N N

2 0 0 1 0 0 High N Y Y

3 0 0 1 1 4 High N Y Y

4 0 1 0 0 4 Low N Y Y

5 0 1 0 1 4 High Y Y Y

6 0 1 1 0 4 High Y Y N

7 0 1 1 1 4 High Y N N

8 1 0 0 0 8 High N Y Y

9 1 0 0 1 8 Low N Y Y

10 1 0 1 0 8 High Y Y Y

11 1 0 1 1 12 High Y Y N

12 1 1 0 0 12 High Y N N

13 1 1 0 1 24 High Y Y Y

14 1 1 1 0 60 High N Y Y

Tone

ON

15 1 1 1 1 60 High Y N N

FHT-1 • 28

Page 29

cells" in series with your power source, if a full 13.6-15 volts DC is not

Ramsey FHT-1 Processor Flow Chart

available. A word of caution concerning wall plug style AC adapter power

supplies: They are not suitable for operation of your transmitter due to their

Initial

Setup

Read Mode

Switch

Check

program

switch

Record

CW ID

Program

Mode Info

Program OFF

time info

Program Tone

Frequency

Program

Run

Set power

Send ID

Time

ON

bit set

Tone

ON

bit set

Enable Tone

output

No

Yes

No

Yes

Check

Program

Switch

Program

Run

45 sec

ON timer

OFF timer

FHT-1 • 29

Page 30

poor regulation, AC ripple content and RFI susceptibility. If your supply voltage

is in the 11-12 volt range, you can expect a 600 to 800 ma current flow and

about 4 watts of the RF output power. With a solid 13 to 14 volt supply, you

can expect about 1 amp current draw and up to 5 or 6 watts of RF output

power.

IMPORTANT NOTE: If you are experimenting with this transmitter and see a

sudden and massive increase in power output and DC current, you have not

reached the promised land or created a 25 watt transmitter! Sudden surges

like that are a sure sign of amplifier self-oscillation. Kill the DC power supply

immediately, because your Q6 RF power transistor is heading to selfdestruction while probably interfering with every TV set in the neighborhood! A

poorly matched antenna along with higher supply voltages is usually

responsible for this occurring. Any prolonged "parasitic" emissions may also

overheat and destroy other components in the amplifier stages.

INSTALLATION AND PROGRAMMING OF THE MICROCONTROLLER

The following instructions are for programming the Ramsey FHT-1

Fox Hunt Transmitter. If you intend only to use a CW ID then these directions

will be all that are necessary for complete operation. When using the unit in

CW ID modes it is strongly recommended that a battery backup power supply

be added to the microcontroller. This is due to the fact that if for any reason

power is interrupted during or after programming, all the programmed

information will be lost. This voltage should be between 3 - 5V DC and can be

connected to the circuit board as shown in the parts layout diagram. The IC

draws negligible current, so 3 standard “AA” or “AAA” cells connected in series

or a surplus 3.9V lithium will work quite well. Under NO circumstances should

more than 5V DC be applied to the microcontroller.

NOTE: If you have the optional voice ID kit you’ll still need to complete the

testing instructions for CW use, but battery backup is not required.

1. Install the 16 pin microcontroller IC labeled FHT into the U2 socket.

Notice that the IC is marked with a notch, band or dot denoting pin one of

the device. Be sure to orient this component as shown in the parts layout

diagram. Be careful not to bend any of the pins underneath the body of the

component while inserting. Also,check to make sure that the IC is pushed

snug into the IC socket.

2. Now connect your keyer paddles or keying device to the three holes at

J3 marked (surprisingly enough) “paddles”. See the diagram for correct

placement.

Before you use the FHT-1 you must first program the CW ID.

Failure to properly identify a transmission is against the FCC rules.

FHT-1 • 30

Page 31

MODE 0 PROGRAMMING:

The FHT-1 has 16 different modes of operation of increasing

difficulty. The mode is selected by setting the DIP switch S3. By setting

the mode you control; how long the transmitter is on the air, if a tone is

present, power level, and the time until the next transmission. Mode 0 is the

user programmable mode. You must program this mode first to enter your

ID.

1. Turn off the FHT-1.

2. Connect a small monitor earphone to J2.

3. Center the earphone adjustment pot, R41, to mid-range. You can re-

adjust this trimmer while you are sending code into your FHT-1 to a

more comfortable level.

3. Switch S2 to Program.

4. Turn on the power.

The FHT-1 is now waiting for you to send your callsign or ID. Simply send as

you would with your keyer. The FHT-1 remembers the letters and spaces

that you send. The ID will be about 15 seconds long, or about 10 to 15

characters.

If you make a mistake simply turn off the power wait 10 seconds and turn it

back on to start over.

5. When the memory is full LED 1 will light.

6. Set the DIP switch for the desired mode:

S3-1 enables the tone.

S3-2 enables the 45 second ON time.

S3-3 sets the output to high power.

S3-4 enables the output power high/low toggle.

7. When the switches are set as desired close either the dot or dash

paddle to enter the value.

8. LED 1 will go out and LED 2 will light.

9. Set the DIP switch for the desired OFF time. The time is set in 4

minute increments so all switches off equals 0 OFF time.

S3-1 on equals 4 minutes OFF time.

All switches on equals 15 times 4 minutes = 60 minutes OFF time.

10. Close either the dot or dash paddle to enter the OFF time value.

11. LED 2 and LED 1 will light.

12. Set the DIP switches for the desired tone frequency.

All switches off equals the lowest tone frequency.

FHT-1 • 31

Page 32

All switches on equals the highest tone frequency.

For a frequency of 1000 Hz set S3-4 and S3-1 on.

13. Close either the dot or dash paddle to enter the tone frequency.

LED 2 and LED 1 will both go out.

14. Set the DIP switch for the desired operating mode.

Mode 0 is the user programmable mode. Or you may select any

other mode.

15. Switch S2 to RUN.

A complete timing cycle of the transmitter begins with the transmission

of the CW ID which takes 15 seconds, followed by a 45 second period in

which the transmitter can be off or on (keyed) with or without a tone

depending on the selected mode. Then follows the off time which can be

any length from none at all , to up over an hour. The cycle then repeats.

16. While the ID and tone are being transmitted it is time to adjust R13,

the modulation level adjustment. Listen on a receiver for best audio

quality. Ideally, a two-way radio service monitor should be used to adjust

this control.

Once the unit is initially programmed, any of the following modes may be

selected. One of these modes should suit your needs. Simply set the DIP

switch as indicated by the chart and turn the unit on.

FHT-1 • 32

Page 33

As you can see mode 1 will send the ID (15sec.) then wait 45sec. and

then start over. This is the beacon mode Identifying once per minute.

Please read carefully BEFORE calling or writing in about your kit. Most problems can be solved

Mode 2 Identifies then sends a tone for 45 sec. so it will be on the air

without contacting the factory.

continuously. These modes will make the Fox easy to find for beginners.

Notice that this is not a "fine print" warranty. We want you to understand your rights and ours too! All

Try modes 3 through 7 for a little more challenge and for the really tough

Ramsey kits will work if assembled properly. The very fact that your kit includes this new manual is your

almost impossible to find fox mode 15 is only on the air 15 seconds every

assurance that a team of knowledgeable people have field-tested several "copies" of this kit straight

hour.

from the Ramsey Inventory. If you need help, please read through your manual carefully, all information

required to properly build and test your kit is contained within the pages!

1. DEFECTIVE PARTS: It's always easy to blame a part for a problem in your kit, Before you conclude

TROUBLESHOOTING HINTS

that a part may be bad, thoroughly check your work. Today's semiconductors and passive components

have reached incredibly high reliability levels, and it’s sad to say that our human construction skills

have not! But on rare occasions a sour component can slip through. All our kit parts carry the Ramsey

The transmitter is very easy to troubleshoot, providing you use some simple

Electronics Warranty that they are free from defects for a full ninety (90) days from the date of

common sense. If you cannot get any readings on the test points or RF

purchase. Defective parts will be replaced promptly at our expense. If you suspect any part to be

power output, check and see if the crystal oscillator is running - how? Well,

defective, please mail it to our factory for testing and replacement. Please send only the defective part

(s), not the entire kit. The part(s) MUST be returned to us in suitable condition for testing. Please be

take a look at the crystal and see the frequency marked on it, it should be

aware that testing can usually determine if the part was truly defective or damaged by assembly or

16.280 MHz (1/9 of 146.52 MHz), right in the middle of the HF shortwave

usage. Don't be afraid of telling us that you 'blew-it', we're all human and in most cases, replacement

broadcast band, easily received on any shortwave radio. You should be able

parts are very reasonably priced.

tto "hear" the oscillator running quite easily. If crystal oscillator operation is

2. MISSING PARTS: Before assuming a part value is incorrect, check the parts listing carefully to see if

confirmed, let's move on a step further. The oscillator is followed by a tripler

it is a critical value such as a specific coil or IC, or whether a RANGE of values is suitable (such as

stage, and 3 times 16.280 MHz is 48.840 MHz. Once again this signal can

"100 to 500 uF"). Often times, common sense will solve a mysterious missing part problem. If you're

missing five 10K ohm resistors and received five extra 1K resistors, you can pretty much be assured

be tuned on a nearby receiver such as a scanner. One more tripler follows

that the '1K ohm' resistors are actually the 'missing' 10 K parts ("Hum-m-m, I guess the 'red' band really

and that moves us up to the final 146.520 MHz output frequency, easily

does look orange!") Ramsey Electronics project kits are packed with pride in the USA. If you believe

tuned on a two meter rig. This procedure will lead us to the final amplifier

we packed an incorrect part or omitted a part clearly indicated in your assembly manual as supplied

with the basic kit by Ramsey, please write or call us with information on the part you need and proof of

stages where we can pretty much do a thorough visual inspection.

kit purchase

Common problems to look for are solder bridges or interchanged

3. FACTORY REPAIR OF ASSEMBLED KITS:

capacitors - "hum-m-m-, that's not a .001 uf where a 100 pf should be is it?"

To qualify for Ramsey Electronics factory repair, kits MUST:

If there is a problem in getting the modulation working, a scope or audio

1. NOT be assembled with acid core solder or flux.

amplifier will allow tracing down any problem in short order. The audio drives

2. NOT be modified in any manner.

3. BE returned in fully-assembled form, not partially assembled.

the varactor diode D1. How about keying of the transmitter? Check to be

4. BE accompanied by the proper repair fee. No repair will be undertaken until we have received the

sure that the PTT line is switching off and on. If you hear a AC hum on the

MINIMUM repair fee (1/2 hour labor) of $18.00, or authorization to charge it to your credit card

transmitted signal, usual causes are RF getting back into the power supply

account.

5. INCLUDE a description of the problem and legible return address. DO NOT send a separate letter;

or a bad VSWR on the antenna.

include all correspondence with the unit. Please do not include your own hardware such as

These short checks in no way detail any and all problems that can rear their

non-Ramsey cabinets, knobs, cables, external battery packs and the like. Ramsey

Electronics, Inc., reserves the right to refuse repair on ANY item in which we find excessive

ugly head, but should get you on the way to solving most errors. We'd like to

problems or damage due to construction methods. To assist customers in such situations,

be able to foresee a problem a builder may encounter, but the sheer number

Ramsey Electronics, Inc., reserves the right to solve their needs on a case-by-case basis.

of parts and the permutations and combinations of installing them makes an

The repair is $36.00 per hour, regardless of the cost of the kit. Please understand that our technicians

list of precise, exact solutions impossible. If you run into a roadblock, gather

are not volunteers and that set-up, testing, diagnosis, repair and repacking and paperwork can take

all your thoughts and information and give a call to the factory for some help.

nearly an hour of paid employee time on even a simple kit. Of course, if we find that a part was

If you elect to enlist the help of a local expert, great - but be sure the expert

defective in manufacture, there will be no charge to repair your kit (But please realize that our

is qualified - no need for having someone lead you down the wrong path!

technicians know the difference between a defective part and parts burned out or damaged through

improper use or assembly).

Remember you may always return the kit for factory service, and there's no

charge if the problem is our fault. See the warranty on the last page of this

4. REFUNDS: You are given ten (10) days to examine our products. If you are not satisfied, you may

manual.

return your unassembled kit with all the parts and instructions and proof of purchase to the factory for a

full refund. The return package should be packed securely. Insurance is recommended. Please do not

cause needless delays, read all information carefully.

OTHER ENCLOSURE RECOMMENDATIONS

The Ramsey Kit Warranty

FHT-1 • 33

Page 34

Fox Hunt Transmitter FHT-1

Quick Reference Page Guide

Introduction to the FHT-1 .............. 4

How it works ................................. 5

Parts list ........................................ 6

FHT-1 Assembly instructions ........ 8

Parts Layout diagram .................... 9

Schematic diagram ..................... 18

Initial testing ................................ 21

Programming ............................... 24

Troubleshooting ........................... 28

Ramsey kit warranty ................... 31

REQUIRED TOOLS

• Soldering Iron (Radio Shack #RS64-2072)

• Thin Rosin Core Solder (RS64-025)

• Needle Nose Pliers (RS64-1844)

• Small Diagonal Cutters (RS64-1845)

• <OR> Complete Soldering Tool Set

(RS64-2801)

ADDITIONAL SUGGESTED ITEMS

• Soldering Iron Holder/Cleaner (RS-64-2078)

TOTAL SOLDER POINTS

373

ESTIMATED ASSEMBLY

TIME

Beginner .............. 11 hrs

Intermediate ......... 6.3 hrs

Advanced ............. 4.7 hrs

Price: $5.00

Ramsey Publication No. MFHT-1

Assembly and Instruction manual for:

RAMSEY MODEL NO. FHT-1 "Sly Fox"

FOX HUNT TRANSMITTER KIT

RAMSEY ELECTRONICS, INC.

793 Canning Parkway

Victor, New York 14564

Phone (716) 924-4560

Fax (716) 924-4555

FHT-1 • 34

Loading...

Loading...