Page 1

OPERATING, SERVICE

AND MAINTENANCE

MANUAL

MODEL DCS-200

ELECTRIC INDUSTRIAL SPEED

REDUCER EZ ANCHOR

CAUTION: READ AND UNDERSTAND THIS MANUAL BEFORE

INSTALLATION AND OPERATION OF WINCH.

SEE WARNINGS!

Page 2

…

…

…

…

…

…

…

…

…

…

…

TABLE OF CONTENTS

INTRODUCTION ………………………………………

WARRANTY INFORMATION ………………………………………

SPECIFIC ATION ………………………………………

WARNINGS ………………………………………

MAINTENANCE ………………………………………

TR O U BLE SHOO TI NG GU IDE ………………………………………

INSTRUCTIONS FOR OVERHAUL OF RAMSEY MODEL DC-S200 SERIES

DISASSEMBLY & REASSEM BLY

………………………………………

DIM ENSIONAL DRAWIN G ………………………………………

PARTS LIST AND PART DR AWING ………………………………………

SOLENOID ………………………………………

LI M ITED WARRANTY ………………………………………

1

1

1

1

2

3-4

5-9

10

11-12

13

LA ST PAGE

2

Page 3

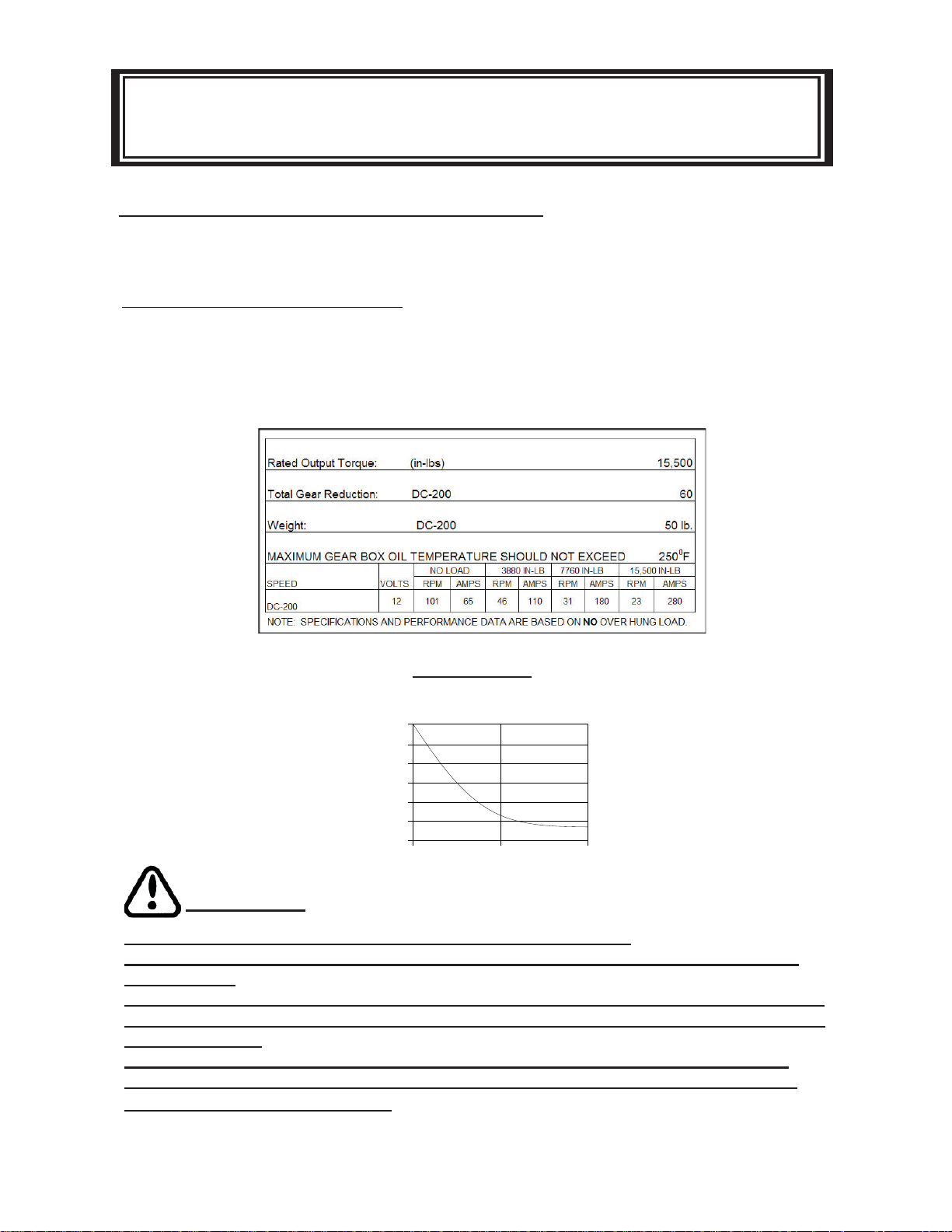

RAMSEY ELECTRIC SPEED REDUCER MODEL DCS-200 SERIES

PLEASE READ THIS MANUAL CAREFULLY

This manual contains useful ideas in obtaining the most effi cient operation from your

Ramsey Speed Reducer, and safety procedures one needs to know before operation.

WARRANTY INFORMATION

Ramsey Speed Reducers are designed and built to exacting specifi cations. Great

care and skill go into every speed reducer we make. If the need should arise, warranty procedure is outlined on the back of this manual. If you have any problems

with your speed reducer, please follow instructions for prompt service on all warranty

claims. Refer to back page for limited warranty.

DUTY CYCLE

Speed reducer duty cycles is shown below:

6

5

4

3

MINUTES

2

1

0

180

270 360

AMPS

12V

WARNINGS

DO NOT EXCEED MAXIMUM RATINGS SHOWN IN THE TABLE.

DO NOT USE SPEED REDUCER TO LIFT, SUPPORT, OR OTHERWISE TRANSPORT

PERSONNEL.

DISCONNECT THE REMOTE CONTROL SWITCH FROM SPEED REDUCER WHEN NOT

IN USE. A RAMSEY PART NO. 282053 SAFETY ON-OFF SWITCH IN YOUR VEHICLE IS

RECOMMENDED.

IF A CABLE DRUM IS ADDED, A MINIMUM OF 5 WRAPS OF CABLE AROUND THE

DRUM IS NECESSARY TO SUPPORT THE RATED LOAD. A CABLE CLAMP IS NOT

DESIGNED TO HOLD THE LOAD.

Page 4

WINCH MAINTENANCE

Adhering to the following maintenance schedule will keep your speed reducer in top

condition and performing as it should with a minimum of repair.

A. WEEKLY

1. Check the oil level and maintain it to the oil level plug. If oil is leaking out,

determine location and repair.

2. Check the pressure relief plug in top of the gear housing. Be sure that it is

in good operating condition so that hot oil gasses may escape.

B. MONTHLY

1. Check the speed reducer bolts. If any are missing, replace them and secure ly tighten any that are loose. Make sure to use only grade 5 bolts or better.

C. ANNUALLY

1. Drain the oil from the speed reducer annually or more often if used

frequently.

2. Fill the speed reducer to the oil level plug with clean kerosene. Run the

speed reducer a few minutes with no load in the reel in direction. Drain the

kerosene from speed reducer.

3. Refi ll the speed reducer to the oil level plug with all purpose EP 140 gear

oil.

4. Inspect frame and surrounding structure for cracks or deformation.

5. Gear wear can be estimated by rocking the drum back and forth and if

necessary drain oil and remove cover for closer inspection.

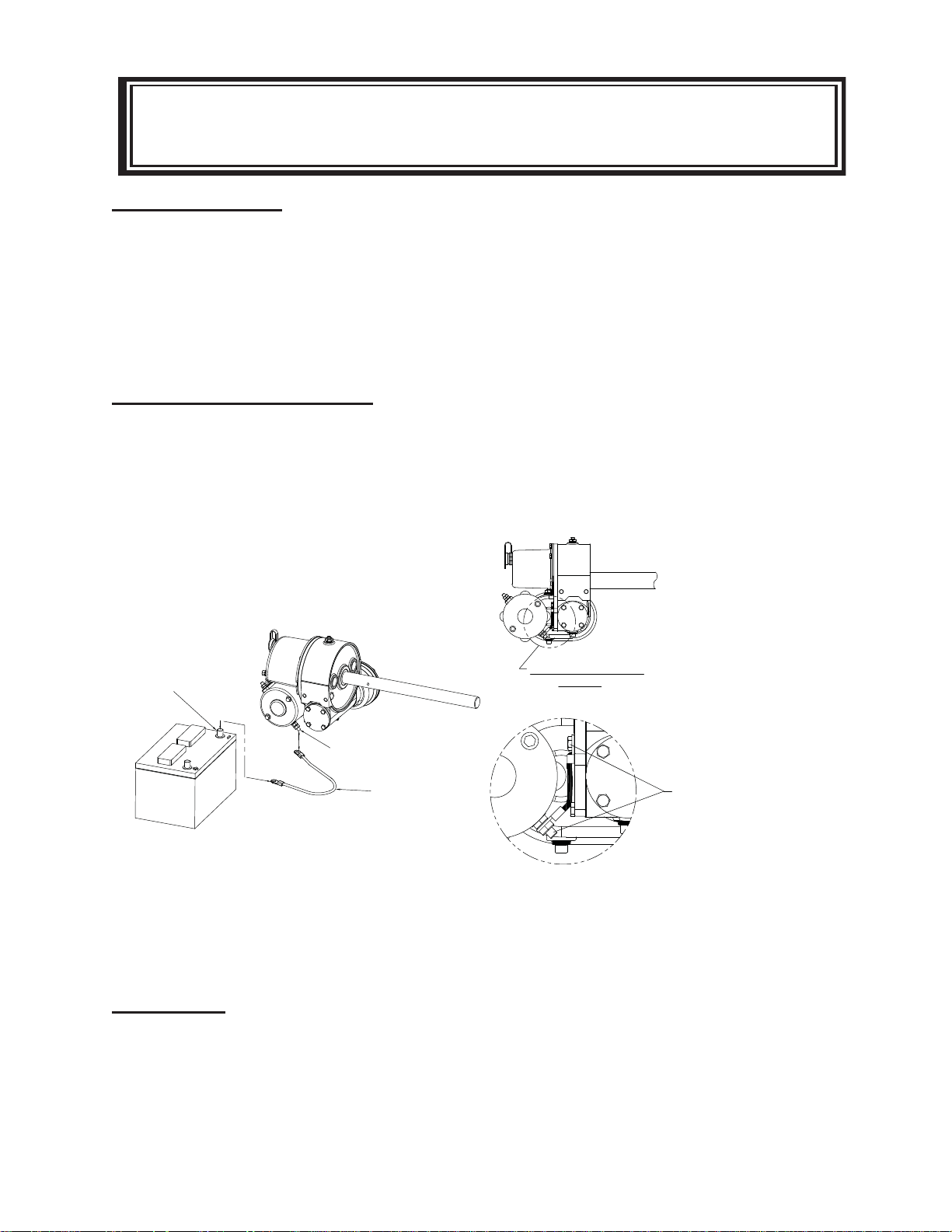

ELECTRICAL CONNECTIONS

See dimensional drawing on page 10. Using a power cable with appropriate end

terminals, connect the positive (+) battery terminal to the 5/16” dia. stud on the plastic

solenoid cover on the winch.

IMPORTANT: Hold inner nut on stud with a wrench while tightening outer nut. Using

a ground cable with appropriate end terminals, connect the negative (-) battery terminal to the 3/8” dia. bolt at motor. For distances up to 15 feet from battery to winch,

use #2 Ga. Wire for the above connections. For distances greater than 15 feet, use

wire larger than #2 Ga.

4

Page 5

WINCH MOUNTING

WINCH MOUNTING

It is most important that this winch be mounted securely so that the three major sections (the clutch housing end, the cable drum and the gear housing end) are properly

aligned.

All standard model DC-200 Series Winches are furnished with recommended mounting angles. Angle size is 1/4 x 2-1/2 x 2-1/2 x 36” Lg. high strength (50,000 PSI yield)

steel angle.

ELECTRICAL CONNECTIONS

See dimensional drawing on page 18. Using a power cable with appropriate end

terminals, connect the positive (+) battery terminal to the 5/16” dia. stud on the plastic

solenoid cover on the winch. In applications where the chassis is non-grounded, a

jumper wire (#440315) will be required between the winch and the motor ground. This

ground is required to insure a suffi cient ground to operate the solenoid assembly (see

diagram below).

WINCH WILL NOT OPERATE UNLESS

GROUND CABLE IS INSTALLED FROM THE

ISOLATED GROUND TERMINAL T O THE

NEGATIVE BATTERY POST.

(SEE DIAGRAM BELOW)

SEE ILLUSTRATION

NEGATIVE BATTERY POST

Isolated Motor Ground

ISOLATED GROUND

TERMINAL

GROUND CABLE

For non-grounded chassis applications

BELOW

JUMPER CABLE (#440315) MUST BE

INSTALLED ON WINCH FROM MOTOR

ISOLATED GROUND STUD TO GEAR

HOUSING COVER BOLT AS SHOWN

FOR NON GROUNDED CHASSIS

APPLICATIONS.

a jumper wire (#440315) is required to

ground the solenoid assembly.

IMPORTANT: hold inner nut on stud with a wrench while tightening outer nut. Using a

ground cable with appropriate end terminals, connect the negative(-) battery terminal

to the motor isolated ground terminal.

5

Page 6

TROUBLE SHOOTING GUIDE

CONDITION CORRECTIONPOSSIBLE CAUSE

OIL LEAKS FROM HOUSING

MOTOR RUNS IN ONE

DIRECTION

1. Seal damaged or worn.

2. Too much oil

3. Damaged gasket

1. Inoperative solenoid or

stuck solenoid.

2. Inoperative switch.

3. Broken wire or bad connection.

1. Replace seal.

2. Drain excess oil. Refer to

TECHNIQUES OF OPERATION.

3. Replace gasket.

1. Jar solenoid to free contacts.

Check by applying 12 volts to

coil terminal (it should make an

audible click when energized).

2. Disengage speed reducer

clutch or remove armature

lead. Remove switch plug

from hood. Raise connector cover on hood and with

a screw driver, short the

bottom two pins. Solenoid

should click. Short the two left

hand pins. The other solenoid should operate. If both

solenoids operate check for a

broken wire in switch cable.

3. Check for loose connection on

switch and switch connector.

MOTOR RUNS, BUT OUTPUT SHAFT DOES NOT

TURN.

1. Sheared drum shaft

key.

2. Stripped bronze

gear.

3. Parted shaft.

6

1-3. It will be necessary to

disassemble speed reducer

to determine cause and

repair.

Page 7

CONDITION CORRECTIONPOSSIBLE CAUSE

MOTOR RUNS EXTREMELY

HOT.

MOTOR RUNS, BUT WITH

INSUFFICIENT POWER, OR

WITH LOW RPM.

1. MOTOR WILL NOT OPER-

ATE.

1. Long period of operation.

2. Insuffi cient battery .

3. Electrical cables from

battery to speed reducer

too small.

4. Bad electrical connections.

5. Insuffi cient charging system.

1. Inoperative solenoid or

stuck solenoid

2. Inoperative switch.

3. Inoperative motor.

4. Loose connections.

1. Cooling-off periods are essen tial to prevent over-heating.

2. Check battery terminal volt

age under load. If 10 volts or

less, replace or parallel another

battery to it at motor terminal.

3. Must be #2 Ga. Wire for

distances up to 15 feet from

battery to speed reducer. Use

larger than #2 Ga. For

distances greater than 15 feet.

4. Check all connections for

looseness or corrosion;

Tighten, clean and grease.

5. Insuffi cient charging system.

1. Jar solenoid to free contacts.

Check by applying 12 volts to coil

terminal (it should make an

audible click when energized)

2. Disengage speed reducer clutch

or remove armature lead.

Remove switch plug from hood.

Raise connector cover on hood

and with a screw driver, short the

bottom two pins. Solenoid should

click. Short the two left hand pins.

Solenoid should click. Short the

two left pins. The other solenoid

should operate. If both solenoids

operate check for a broken wire in

switch cable.

3. If solenoids operate, check for

voltage at armature post; replace

motor.

4. Tighten connections on bottom

side of hood and on motor.

7

Page 8

INSTRUCTIONS FOR OVERHAUL OF RAMSEY

DCS-200 SPEED REDUCER

1. Drain oil from worm gear housing by

removing (item #35) plug from bottom

of gear housing. Remove relief fi tting

and reducer (items #32 & #34) from

top of gear housing. Remove Speed

Reducer from mounting.

2. Drain oil spur gear housing by removing

(item #35) plug. Remove cover and gasket

(items #5 & #29) from spur gear housing by

unscrewing twelve cap screws (item #20).

Slide gear (item #7) from end of worm shaft

(item#15) with gears attached. Check bearings (item#16) and thrust washers (item#44)

for signs of wear, replace if necessary.

Remove old bearings and press new bearings into place. Remove solenoid assembly

(item #1) by unscrewing cap screws (items

#22 and #24). Disconnect solenoid cables

from motor (item #33). Make note of which

terminals cables are attached to.

3. Remove key (item #11) and snap

ring (item #43) from worm shaft.

Remove motor (item #33) from

spur gear housing (item #9) by

removing (3) nuts and lock wash ers (items #25 and #27). Un-

screw (4) cap screws (item #23) to

remove spur gear box (item #9)

and gasket (item #28) from gear

housing. Replace lip seals (items

#40 & #42) by pressing old seals

from spur gear housing and press ing new seals into place.

8

Page 9

4. Remove bearing cap (item #3)

from gear housing by unscrewing

four cap screws (item #21).

Remove worm (item #15) and

bearing (item #17) from gear

housing. Use a soft hammer to

gently tap input end of worm

and drive worm and bearing from

gear housing. Once worm has

been removed from housing,

bearing can be pressed from end

of worm.

Check for signs of wear to worm

(item #15) and bearings (item

#17). Replace if necessary.

5. Remove gear housing cover (item #4)

from gear housing (item #10) by

unscrewing fi ve remaining cap screws

(item #21). Place cap screw into two

tapped holes of cover and tighten. This

will pull the cover loose from the gear

housing.

6. Check for signs of wear on gear

teeth. If replacement of gear is

necessary, gear must be replaced

as follows:

a. Press gear (item #8) from shaft

(item #14).

b. Examine shaft keys and key

ways. If distortion of keys and/

or keyways are evident, shaft

and keys should be replaced.

c. Use a soft hammer to gently

tap keys (item #31) into key

ways. Press gear (item #8) over

shaft and keys. Gear must be

centered over keys.

Remove cover gasket (item#30) and

pull shaft (item#14), with gear attached,

and thrust washer (item #46) from gear

housing.

9

Page 10

7. Remove seal (item #41) from back of

gear housing (item #10). Check bush ing (item #19) for signs of wear. Press

bushing (item #19) from gear housing

and replace if necessary. Press new

bushing and seal back into place.

8. Check cover bushing (item #18) for

signs of wear. Replace if necessary

by removing old bushing and pressing

new bushing into place.

13

12

7

9. Check gears of spur gear shaft assembly

for signs of wear, replace if necessary.

Press old gears from shaft (item #13). Tap

key (item #12) into keyway of shaft (item

#13). Press shaft through gears (item #7)

so that gears are centered on shaft and key.

7

10. Apply grease to end of shaft op posite gear. Apply grease to bush ing in gear housing (item #10).

Place greased end of shaft through

thrust washer (item #45) and bush ing in gear housing (item #10).

Place gasket (item #30) onto gear

housing cover (item #4). Apply

grease to gear end of shaft and

bushing in cover. Place thrust

washer (item #46) on gear end of

shaft. Place cover onto shaft and

secure to housing with fi ve (item

#21) cap screws at the fi ve lower

most holes.

10

Page 11

10. Press bearing (item #17) onto worm.

(item #15). NOTE: Be sure thick shoulder

of bearings outer race (side with

manufacturer’s name and part number) is

out, away from worm threads. Press

bearing and worm into gear housing. Slip

gasket (item #28) onto bearing cap (item

#3). Use four cap screws (item #21) to

secure cap to gear housing. Torque cap

screws to 7 ft-lbs (9.4 Nm) each.

Attach solenoid assembly (item #1) to

gear housing. Use two (item #24) cap

screws and three (item #22) cap screws

with three fl at washers (item #26).

Tighten cap screws to 7 ft-lbs. (9.4 Nm)

each. Insert plug (item #37) into tapped

hole of cover. Permatex may be applied

to threads to help prevent oil leakage.

TIGHTEN plug securely.

11. Press bearing (item #17) onto worm

and into worm gear housing. NOTE:

Be sure thick shoulder of bearings

outer race (side with manufacturer’s

name and number) is out, away

from worm threads. Place gasket (item

#28) onto spur gear housing (item #9).

Secure spur gear housing to worm gear

housing using four cap screws (item

#23). Torque cap screws to 7 ft-lbs (9.4

Nm) each.

Mount motor (item #33) to spur gear

housing (item #9) using three lock

washers and nuts (items #25 and #27).

Attach solenoid cables to motor

terminals. Tighten all nuts securely.

11

Page 12

12. Place snap ring (item #43) over

end of worm shaft (item #15) and set

into snap ring groove. Insert key

(item #11) into key way of worm

shaft. Place thrust washer (item

#44) over each end of spur gear

shaft (item #13). Set spur gear shaft

assembly into bearing of spur gear

housing. Slide gear (item #7) and

(item #44) thrust washer (item #44)

over end of worm shaft (item #15).

Insert pins (item #38) into cover (item

#5). Place gasket (item #29) onto

cover. Attach cover and gasket to spur

gear housing using twelve cap screws

(item #20).

Torque cap screws to 8 ft. lb. (10.8 Nm.) each. Insert plug (item #35) into bottom

of spur gear housing. Permatex may be applied to threads to help prevent oil

leakage. Remove reducer and fi tting (items #32 & #34) from top of spur gear

housing. Pour 1/2 pint of SAE 20 weight motor oil into spur gear box. Replace reducer and fi tting into top of spur gear housing. Tighten reducer and fi tting securely .

13. When mounting the speed reducer

torque to 34 ft. Lb. (46 Nm) each.

Insert plug (item #35) into bottom of

gear housing. Permatex may be

applied to threads to help prevent

leakage. Pour 3/4 pint of EP 140

gear oil into housing thru hole in top

of housing. Insert relief fi tting (item

#32) into reducer (item #34).

Reducer should then be placed into

hole on top of gear housing. Tighten

fi tting and reducer securely.

12

Page 13

NOTES

13

Page 14

273,6

10.77

7.44

188.9

3.72

94,4

DIMENSIONAL DRAWING

DCS-200

7.05

92,1

3.63

271,3

10.68

10.77

179,1

273,6

FROM NEGATIVE

BATTER Y TERMINAL TO

MOTOR GROUND STUD

CONNECT GROUND CABLE

6.85

173,9

CONNECT POWER CABLE

FROM POSITIVE

BATTER Y TERMINAL HERE

A

2.50

63,5

C

MM

INCHES

34,9

4.00

101,6

B

1.25

1.13

28,7

1.37

DIMENSIONS SHOWN ARE INCHES OVER MILLIMETERS

C

B

INCHES

A

INCHES

WINCH

MM

MM

MODEL

17.55

445,7

260,1

10.24

8.50

215,9

160417

20.05

12.74

11.00

160418

509,3

21.55

14.24

12.50

279,4 323,6

25.49

547,4

18.18

361,7

317,5

16.44

160419

647,4

417,6 461,8

160420

14

Page 15

MODEL DCS - 200 12V

EXPLODED VIEW

39

1

22

26

37

24

COMPONENT BREAKDOWN

SEE PAGE 18 FOR

21

3

28

17

15

11

43

10

32

34

31

14

41

31

17

28

4

30

45

19

40

34

32

9

18

46

8

35

23

33

42

27

25

35

44

13

12

16

6

21

2

47

7

7

44

16

15

44

16

29

38

5

38

36

20

Page 16

PARTS LIST

MODEL DCS-200

442185 GASKET

1PIN

M O DEL DC- S200 SPEED REDUCER ®

NO QTY. PART NO. DESCRIPTION

ITEM

1 357556 SHAFT 1 1/4 X 15.894 38 2 47000

1 357555 SHAFT 1 1/4 X 14.394 37 1 468018 PIP E P LUG SOC. HD

1 357557 SHAFT 1 1/4 X 19.832 39 1 482013 RUBBER BOOT

9 1 338203 HOUSI NG SPUR GEA R 31 4 450016 KEY (BA RTH)

1 1 278027 SOLENOID ASSEMBLY - 12V 23 4 414845 CAP SCREW 1/4 - 20NC X 1 LG. SOC. HD. NYLOK

2 1 282001 SWTICH ASSEMBLY 24 2 420012 CAPSCREW-1/4-20NCX3/4LG,HXSOCHD, SS

3 1 316083 CAP BEARING 25 3 418528 NUT-3/8- 24N F HEX REG, STAINLESS STEEL

4 1 328134 COVER WORM GEAR HSG 26 3 418529 WASHER- 1/4 FLAT STAIN LESS STEEL

NO QTY. PART NO. DESCRIPTION

ITEM

5 1 328106 COVER SP UR GEAR HSG 27 3 428530 LOCKWASHER-3/8 MED SECT, STA INLESS STEEL

8 1 334161 GEA R R. H. - 60:1 30 1 442205 GASKET

7 2 334003 GEA R 29 1

6 1 334239 GEA R 28 2 442184 GASKET

11 1 342023 KEY SQUARE 33 1 262037 MOTOR 12V

10 1 338273 HOUSING GEAR 32 2 456008 RELIEF FITTING

16

14 1 357554 SHAFT 1 1/4 X 11.894 36 2 468017 PIPE PLUG SOC. HD

13 1 356901 SHAFT SPUR 35 2 468011 PIPE PLUG SQ. HD

12 1 342033 KEY SQUARE 34 2 468002 REDUCER

16 3 402001 BEA RIN G N EEDLE 41 1 486017 OIL SEAL

17 2 402002 BEA RIN G BALL 42 1 486023 OIL SEAL

15 1 368001 WORM RH 60:1 40 1 486009 OIL SEAL

20 12 420009 CA PSCREW-1/4-20NCX3/4,HXHD, SS 45 1 518015 THRUST WASHER

19 1 412045 BUSHING 44 3 518002 THRUST WASHER

18 1 412044 BUSHING 43 1 490003 SN AP RING

21 9 420010 CAPSCREW-1/4-20NCX7/8 LG. HEX HD, SS 46 1 518040 THRUST WASHER

22 3 420011 CA PSCREW-1/4-20NCX1LG, HXHD, SS 47 4 418535 FLANGE NUT

Page 17

SOLENOID ASSEMBLY P ARTS

ITEM NO. QTY. PART NO DESCRIPTION

1 1 280009 CABLE - BOLT ASS 'Y

2 3 289077 WIRE ASS'Y

3 1 289091 WIRE ASS'Y

4 2 364001 STRAP

5 2 364002 STRAP

6 1 408035 SOLENOID BRA CKET

7 2 416283 SCREW-#10-24UN C SS

8 2 416277 SCREW-#10-24UN C

9 2 418536 NUT-HEX #10-24NC REG., SS

10 2 418531 NUT-5/16- 18NC HEX REG., SS

11 2 418140 WASHER-#10 FLAT ZI NC P LT

12 1 418532 LOCKWASHER-5/16 SS

13 1 418533 WASHER-5/16, S/P, SS

14 1 418534 WASHER-5/16 S/P, SS

15 1 430013 FEMA LE CONN E

CTOR

16 2 440071 TERMINAL TAB

17 2 440110 SOLEN OID-12V

18 1 472071 COVER

19 1 482029 COVER- CONNECTOR

8

8

20 4 530106 COVER- TERMINA L

278204—12V

16

20

12

9

19

7

11

To Yellow

17

18

7

11

4

2

To Red

10

13

10

To Green

14

15

17

6

5

3

1

21

9

4

18

5

3

3

21

17

21

21

Page 18

LIMITED WARRANTY

RAMSEY WINCH warrants each new RAMSEY Winch to be free from defects in material and

workmanship for a period of one (1) year from date of purchase.

e obligation under this warranty, statutory or otherwise, is limited to the replacement or repair

at the Manufacturer’s factory, or at a point designated by the Manufacturer, of such part that

shall appear to the Manufacturer, upon inspection of such part, to have been defective in material or workmanship.

is warranty does not obligate RAMSEY WINCH to bear the cost of labor or transportation

charges in connection with the replacement or repair of defective parts, nor shall it

apply to a product upon which repair or alterations have been made, unless authorized by Manufacturer, or for equipment misused, neglected or which has not been installed correctly.

RAMSEY WINCH shall in no event be liable for special or consequential damages. RAMSEY

WINCH makes no warranty in respect to accessories such as being subject to the warranties of

their respective manufacturers.

RAMSEY WINCH, whose policy is one of continuous improvement, reserves the right to improve its products through changes in design or materials as it may deem desirable without being

obligated to incorporate such changes in products of prior manufacture.

If eld service at the request of the Buyer is rendered and the fault is found not to be with

RAMSEY WINCH’s product, the Buyer shall pay the time and expense to the eld representative. Bills for service, labor or other expenses that have been incurred by the Buyer without approval or authorization by RAMSEY WINCH will not be accepted

RAMSEY WINCH COMPANY

Post Offi ce Box 581510 Tulsa, Oklahoma 74158-1510

Telephone: (918) 438-2760 FAX: (918) 438-6688

OM 912712-1013-B

Loading...

Loading...