Page 1

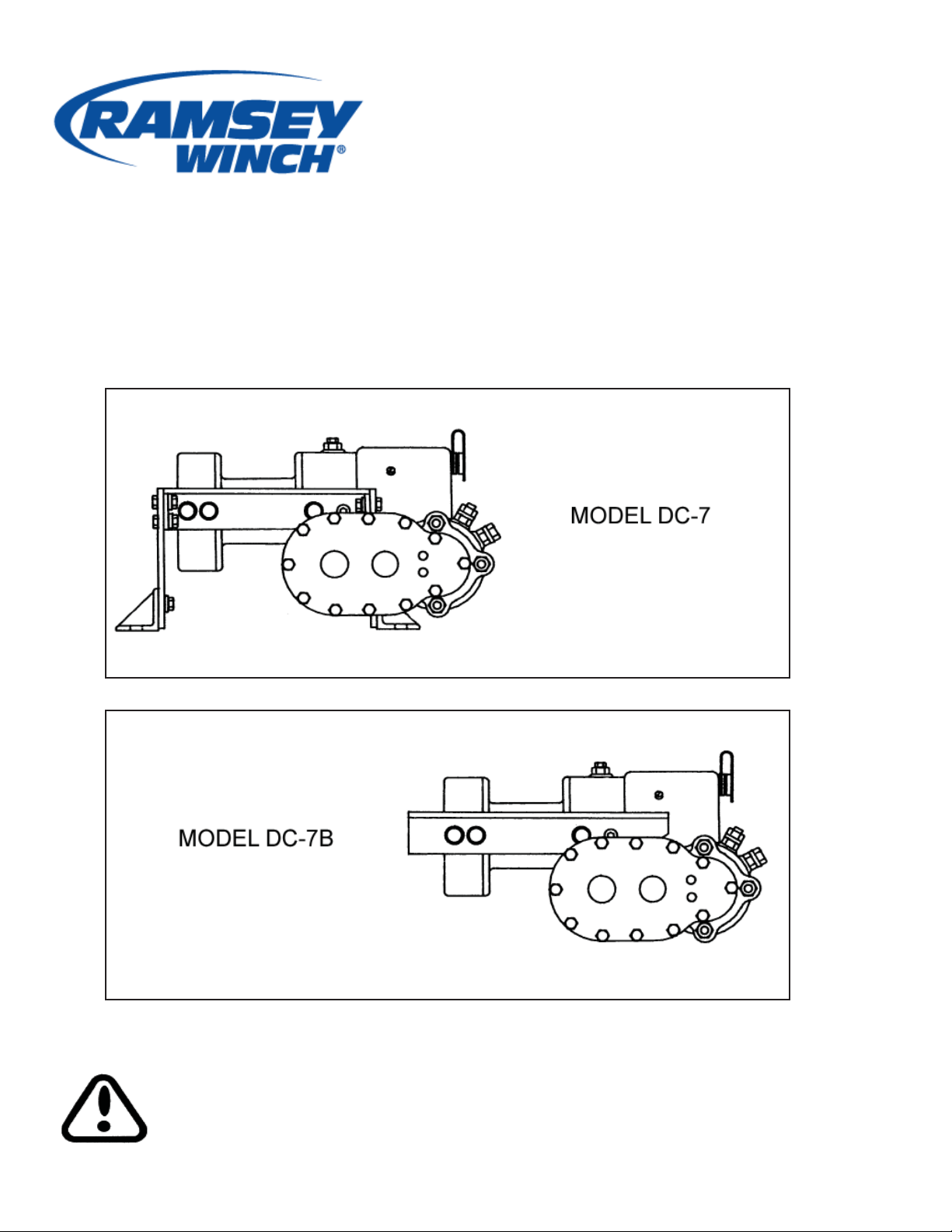

OPERATING,SERVICE,

AND MAINTENANCE

MANUAL

MODELS DC•7/DC•7B SERIES

INDUSTRIAL LOW-MOUNT WINCHES

CAUTION: READ AND UNDERSTAND THIS MANUAL BEFORE

INSTALLATION AND OPERATION OF WINCH.

SEE SAFEGUARDS AND WARNING!

Page 2

TABLE OF CONTENTS

INTRODUCTION ....................................................... 1

WARRANTY INFORMATION

SPECIFICATION

T ECHNIQ UES OF O PERATIO N

....................................................... 1

....................................................... 1

....................................................... 2

WARNINGS ....................................................... 2

WINCH MAINT ENANCE

WINCH MOUNTING

ELECT RICAL CON NECTIO NS

CABLE INSTALLATION

TROUBLE SHOOTING GU IDE

....................................................... 3

....................................................... 4

....................................................... 4

....................................................... 4

....................................................... 4-5

INSTRUCTI ONS FOR OVERHAUL OF

RAMSEY M ODEL DC-7/DC-7B SERIES WINCHES

DISASSEMBLY

REASSEMBLY

DIMENSIONAL DRAWING

PAR TS LIST AND PARTS DRAWING

SOL ENOID AND SW ITCH ASSEM BL Y PARTS LIST

T EST PROCEDUR E FOR SO L ENOID

T EST PROCEDUR E FOR M OTO R

MOTOR ASSEM BLY PARTS L IST

....................................................... 6-9

....................................................... 9-11

....................................................... 12-13

....................................................... 14-17

....................................................... 18

....................................................... 19

....................................................... 20

....................................................... 21

LIMITED WARRANTY ....................................................... 22

Page 3

S

RAMSEY ELECTRICAL WINCH MODEL DC-7 SERIES

PLEASE READ THIS MANUAL CAREFULLY

This manual contains useful ideas in obtaining the most effi cient operation from your Ramsey

Winch, and safety procedures one needs to know before operating a Ramsey Winch.

WARRANTY INFORMATION

Ramsey Winches are designed and built to exacting specifi cations. Great care and skill go into

every winch we make. If the need should arise, warranty procedure is outlined on the back of

your self-addressed postage paid warranty card.

Please read and fi ll out the enclosed warranty card and send it to Ramsey Winch Company. If

you have any problems with your winch, please follow instructions for prompt service on all warranty claims. Refer to back page for limited warranty.

SPECIFICATIONS: Conforms to SAE J706

Rated Line Pull 1st Layer (Lbs.)................................................................................................3,000

Total Gear Reduction: All Models...........................................................................................298:1

Weight: DC-7 ......................................................................................................70 Lbs.(32 Kgs.)

DCX-7 ....................................................................................................75 Lbs. ( 34 K g

DC-78 ....................................................................................................60 Lbs. (27 Kgs.)

DCX-78 ..................................................................................................65 Lbs. (29 Kgs.)

MAXIMUM GEAR BOX OIL TEMPERATURE SHOULD NOT EXCEED................................................................2500F.

Layer of Cable 2 3 4 5**

Rated Line P u ll Lbs. 2,600 2,300 2,000 1,800

per layer Kgs. 1,170 990 900 810

*DC-7/78 Drum Cable Ft 20 35 50 70

capacity per layer M 6 10 15 21

*DCX-7/78 Drum Cable

capacit y p e r layer M 12 19 28 38

LIN E SPEED FPM FPM FPM FPM

ALL MODELS 24

(Kgs.)................................................................................................1,360

1

3,000

1,350

10

Ft

VOLTS (MPM) AMPS (MPM)

12 17 80 12 110 8 150 7 180

3

15

4

NO LOAD 1000# LOA D 2000# LOA D 3000# LOAD

.

40 (3.7).60 (2.4).75 (2.0)

(5.2)

40 65 95 125

(MPM) AMPS (MPM) AMPS

AMP

.

90

s.)

*These specifi cations are based on recommended 1/4” diameter

extra improved plow steel wire rope.

**5th Layer does not conform to SAE J706

NOTE: The rated line pulls shown are for the winch only. Consult the wire rope manufacturer for wire

rope ratings.

DUTY CYCLE

Winch duty cycles are shown below:

6

5

4

3

MINUTES

2

1

0

180

270 360

AMPS

12 V 24 V

5

4

3

2

MINUTES

1

0

90 120 160 190

AMPS

1

Page 4

TECHNIQUES OF OPERATION

The best way to get acquainted with how your winch operates is to make test runs before you

actually use it. Plan your test in advance. Remember, you hear your winch, as well as see it

operate. Get to recognize the sounds of a light steady pull, a heavy pull, and sounds caused by

load jerking or shifting. Gain confi dence in operating your winch and its use will become second

nature with you.

The uneven spooling of cable, while pulling a load, is not a problem, unless there is a cable pile

up on one end of drum. If this happens, reverse the winch to relieve the load and move your anchor point further to the center of the vehicle. After the job is done you can unspool and rewind

for a neat lay of the cable.

When pulling a load where there is even a remote chance of cable failure, place a blanket,

jacket or tarpaulin over the cable about six feet behind the hook. This will slow the snap back of

a broken cable and could prevent serious injury.

Check oil level of winch every six months. Replace oil annually or more often if winch is used

frequently. Use 3/4 pint of all purpose E. P. 140 oil in the worm gear housing and 1/2 pint SAE

20 for spur gear box. If the oil is contaminated with metallic particles, inspect winch for cause

of abnormal wear. Periodically check all electrical connections and mounting bolts. Tighten

hardware if necessary.

The minimum ampere-hour rating of vehicle battery should be 70, and used with at least a 40

amp alternator. An Auxiliary battery is recommended to supply additional battery power.

Inspect the cable frequently. If the cable becomes frayed with broken strands, replace immediately. Cable and hook assembly may be purchased from a Ramsey distributor.

WARNINGS:

STAY OUT FROM UNDER AND AWAY FROM RAISED LOADS.

STAND CLEAR OF CABLE WHILE PULLING. DO NOT TRY TO GUIDE CABLE. DO NOT

EXCEED MAXIMUM LINE PULL RATINGS SHOWN IN TABLE.

DO NOT USE WINCH TO LIFT, SUPPORT, OR OTHERWISE TRANSPORT PERSONNEL.

A MINIMUM OF 5 WRAPS OF CABLE AROUND THE DRUM BARREL IS NECESSARY

TO HOLD THE LOAD. CABLE CLAMP IS NOT DESIGNED TO HOLD LOAD.

DISCONNECT THE REMOTE CONTROL SWITCH FROM WINCH WHEN NOT IN USE. A

RAMSEY PART NO. 282053 SAFETY ON-OFF SWITCH IN YOUR VEHICLE IS RECOMMENDED.

2

Page 5

WINCH MAINTENANCE

Adhering to the following maintenance schedule will keep your winch in top condition and performing as it should with a minimum of repair.

A. WEEKLY

1. Check the oil level and maintain it to the oil level plug. If oil is leaking out, determine loca tion and repair.

2. Check the pressure relief plug in top of the gear housing. Be sure that it is in good operat ing condition so that hot oil gasses may escape.

3. Lubricate cable with light oil.

B. MONTHLY

1. Lubricate the various grease fi ttings located in the cable drum, end bearing, clutch housing

or clutch operating linkage. Any good grade of moly-disulfi de containing grease is accept-

able.

2. Check the winch mounting bolts. If any are missing, replace them and securely tighten any

that are loose. Make sure to use only grade 5 bolts or better.

3. Check the torque setting of the oil cooled worm brake. Make any adjustments required, fol lowing the procedure described in ADJUSTING THE OIL COOLED WORM BRAKE in the

Owner’s Manual.

4. Check alignment of chain and sprockets and adjust as required to minimize wear.

5. Inspect the cable. If the cable has become frayed with broken strands, replace immediately.

C. ANNUALL Y

1. Drain the oil from the winch annually or more often if winch is used frequently.

2. Fill the winch to the oil level plug with clean kerosene. Run the winch a few minutes with

no load in the reel in direction. Drain the kerosene from the winch.

3. Refi ll the winch to the oil level plug with all purpose E.P. 140 gear oil.

4. Inspect frame and surrounding structure for cracks or deformation.

5. Gear wear can be estimated by rocking the drum back and forth and if necessary drain oil

and remove cover for closer inspection.

3

Page 6

WINCH MOUNTING

WINCH MOUNTING

It is most important that this winch be mounted securely so that the three major sections (the

clutch housing end, the cable drum and the gear housing end) are properly aligned.

All standard model DC-7/DC-78 Series Winches are furnished with recommended mounting

angles. Model DC-7 Winch is furnished with 1/4 x 2 x 2 high strength steel angles. Model DC78 Winch is furnished with 3/16 x 1-1/2 x 2 high strength steel angle.

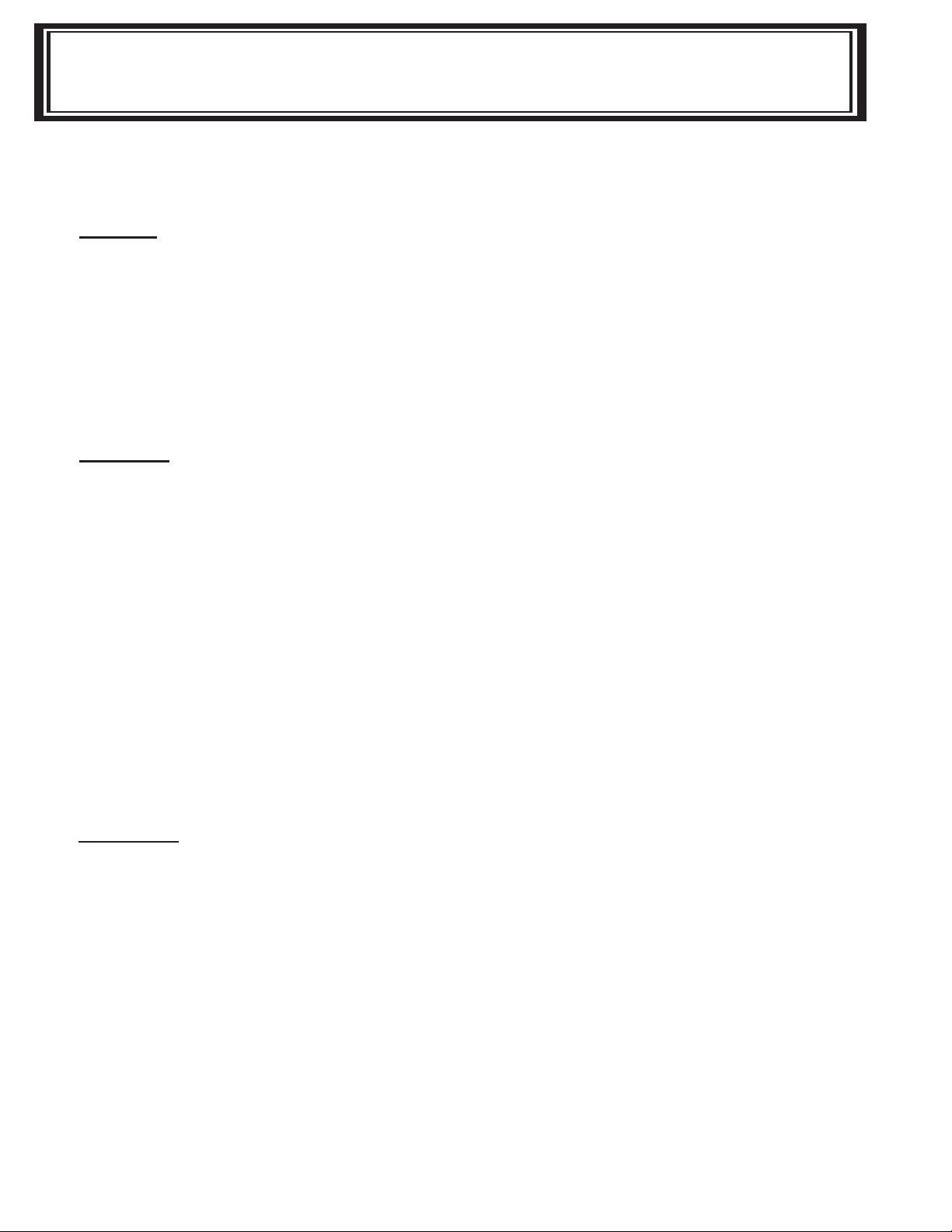

ELECTRICAL CONNECTIONS

See dimensional drawings on pages 12 & 13. Using a power cable with appropriate end terminals, connect the positive (+) battery terminal to the 5/16” dia. stud on the plastic solenoid cover

on the winch. IMPORTANT: hold inner nut on stud with a wrench while tightening outer nut.

Using a ground cable with appropriate end terminals, connect the negative (-) battery terminal to the motor isolated ground terminal. In applications where the chassis is non-grounded,

a jumper wire (#440315) will be required between the winch and the motor isolated ground

terminal. This ground is required to insure a suffi cient ground to operate the solenoid assembly

(see diagram below). For distances up to 15 feet from battery to winch, use #2 Ga. wire for the

above connections. For distances greater than 15 feet, use wire larger than #2 Ga.

WINCH WILL NOT OPERATE UNLESS

GROUND CABLE IS INSTALLED FROM THE

ISOLATED GROUND TERMINAL TO THE

NEGATIVE BAT TERY POST.

(SEE DIAGRAM BELOW)

SEE ILLUSTRATION

BELOW

NEGATIVE BATTERY POST

ISOLATED GROUND

TERMINAL

GROUND CABLE

JUMPER WIRE(#440315) MUST BE

INSTALLED ON WINCH FROM MOTOR

ISOLATED GROUND STUD TO GEAR

HOUSING COVER BOLT AS SHOWN

FOR NON GROUNDED CHASSIS

APPLICATIONS.

For non-grounded chassis applica-

Isolated Motor Ground

tions a jumper wire (#440315) is required to ground the solenoid

assembly.

CABLE INSTALLATION

1. Unwind cable by rolling it out along the ground to prevent kinking. Securely wrap end of

cable, opposite hook, with plastic or similar tape to prevent fraying.

2. Insert the end of cable, opposite hook end, into the 21/64” dia. hole in drum barrel. Secure

cable to drum barrel, using setscrew furnished with winch. TIGHTEN SETSCREW

SECURELY.

3. Carefully run winch in the “reel-in” direction. Keeping tension on end of cable, spool all the

cable onto the cable drum, taking care to form neatly wrapped layers.

4

Page 7

g

g

TROUBLE SHOOTING GUIDE

CONDITION POSSIBLE CAUSE CORRECTION

OIL LEAKS FROM HOUSING. 1. Seal damaged or worn. 1. Replace seal.

2. Too much oil. 2. Drain excess oil. Refer to

TECHNIQU ES OF OPERATION

3. Damaged gasket. 3. Replace gasket.

MOTOR RU NS IN ONE DIRECTION 1. Inoperative solenoid or stuck solenoid. 1. Jar solenoid to free contacts. Check by applying

ONLY. volts to coil terminal (it should make an audib l e

click when

2. Remove switch plug from hood.

2. Inoperative switch. Raise connector cover on hood and with screw

driver, short the bottom two pins. Solenoid

should click. Short the two left hand pins. The other

solenoid should operate. If both solenoids operate

check for a broken wire in switch cable.

energized). (See Page 19)

3. Broken wire or bad connection 3. Check for loose connection on s

connector.

MOTOR RU NS, BUT DRUM DOES 1. Sheared drum shaft key. 1-3. Dis-assemble winch to

NOT TURN. determine cause and repair.

2. Stripped bronze gear.

3. Parted shaft.

MOTOR RU NS EXTREMELY HOT. 1. Long period of operation.

M OTOR RUNS, BU T WITH

INSUFFI CIENT POWER, OR WITH

LOW LINE SPEED.

MOTOR WILL NOT OPERATE. 1. Inoperative solenoid or stuck solenoid.

2. In sufficient battery .

3. Electrical cables from battery to winch too small.

4. Bad electrical

5. Insufficient charging system 5. Replace with larger system.

1. Cooling-off periods are essential to prevent over

heating.

2. Check battery terminal voltage under load. If 10 volts or

less, replace or parallel another battery to it at motor

terminal.

3. Must be #2 Ga. wire for batte ry to winch too small.

attery to winch. Use larger than #2 Ga. for distances

greater than 15 feet

4. Check all connections for looseness or corrosion;

Ti

hten, clean and grease.

1. Jar solenoid to free contacts. Check by applying 12

volts to coil terminal (it should make an audible click

when ener

ized).

witch and switch

2. Inoperative switch.

3. In o p e rati ve motor.

4. Loose connections.

2. Re-move switch plug from hood. Raise connector

cover on hood and with a screw driver, short the bottom

two pins. Solenoid should click. Short the two left pins.

The other solenoid should operate. If both solenoids

operate, check for a broken wire in switch cable.

3. If solenoids operate, check for voltage at armature post;

replace motor. (See Page 20)

4. Tighten connections on bottom side of hood and on

motor.

5

Page 8

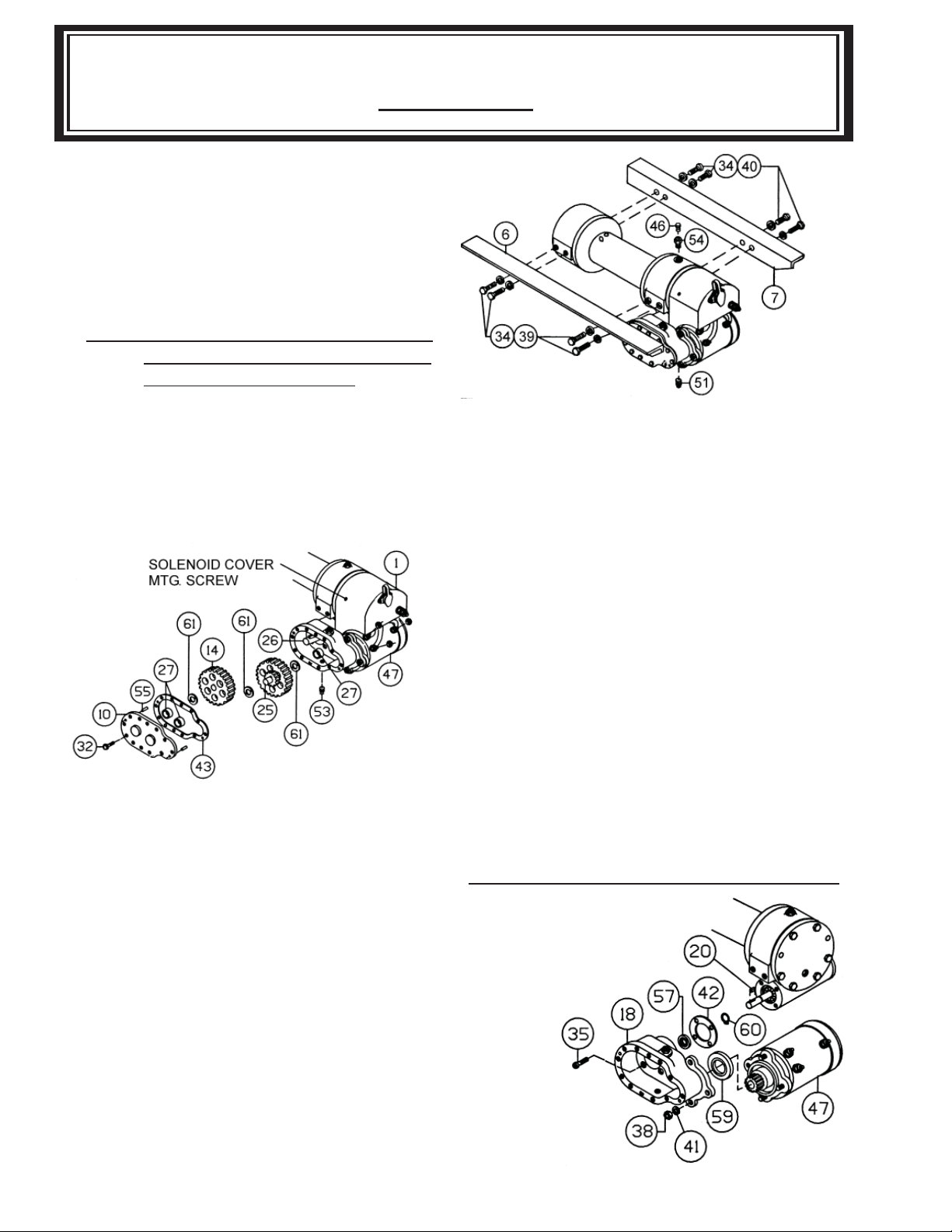

INSTRUCTIONS FOR OVERHAUL OF RAMSEY

MODEL DC-7/DC-7B SERIES WINCHES

DISASSEMBLY

1. Drain oil from worm gear housing by

removing (item #51) plug from bottom of

gear housing. Remove relief fi tting and

reducer (items #46 & #54) from top of

gear housing. Remove winch from mount ing angles (items #6 & #7) by removing

hardware shown (items #34 & #40).

NOTE: DC-7B WINCH SHOWN. See Pg.

14 & 15 for mounting brackets and

hardware for DC-7 winch.

2. Drain oil from spur gear box by removing

(item #53) plug,from bottom of spur gear

box. Remove cover and gasket (items #10 &

#43) from spur gear housing by unscrew ing

twelve cap screws (item #32). Slide gear

(item #14) from end of worm shaft (item

#26). Remove spur gear shaft (item #25),

with gears attached. Check bearings (item

#27) and thrust washers (item #61) for signs

of wear, replace if necessary. Remove old

bearings and press new bearings into place.

Remove solenoid assembly (item #1) from

winch as follows: Disconnect solenoid ca bles from motor (item #47). Make note of

which terminals cables are attached to. Re move solenoid cover from solenoid mounting

bracket by unscrewing two solenoid cover

mounting screws. Solenoid mounting bracket

may then be removed from winch by un screwing two soc. hd. screws attaching

solenoid bracket to gear housing of winch.

SEE SOLENOID ASS’Y. PARTS LIST, Pg.18

3. Remove key (item #20) and snap ring (item #60)

from worm shaft. Remove motor (item #47) from

spur gear housing (item #18) by removing three

nuts and lockwashers (items #38 & #41). Uns crew four capscrews (item #35) to remove spur

gear box (item #18) and gasket (item #42) from

gear housing. Replace lip seals (items #57 &

#59) by pressing old seals from spur gear hous ing and pressing new seals into place.

6

Page 9

4. Slide end bearing (item #17) and drum (item

#11) from drum shaft. Remove two keys (item

#22) from drum shaft.

5. Remove bearing cap (item #8) and gasket (item

#42) from gear housing by unscrewing four cap screws (item #33). Remove worm (item #26) and

bearing (item #28) from gear housing. Use a soft

hammer to gently tap input end of worm and

drive worm and bearing from gear housing.

Once worm has been removed from housing,

bearing can be pressed from end of worm.

Check for signs of wear to worm (item #26) and

bearings (item #28). Replace if necessary.

6. Remove gear housing cover (item #9) from

gear housing (item #19) by unscrewing six

remaining capscrews (item #64).

Remove cover gasket (item #44) and pull

shaft (item #23),with gear (item #15)

attached, and thrust washer (item #62) from

gear housing.

7

Page 10

7. Check for signs of wear on gear teeth. If replacement of

gear is necessary gear must be replaced as follows:

a) Press gear (item #15) from shaft (item #23).

b) Examine shaft keys (item #22) and keyways. If dis tortion of keys and/or keyways is evident, shaft

and keys should be replaced.

c) Tap keys (item #22) fi rmly into shaft keyways.

Press shaft and keys through gear keyways until

end of keys, on long end of shaft are fl ush with

gear.

8. Remove seal (item #58) from back of gear housing

(item#19). Press bushing (item #31) from gear hous ing. Press new bushing and seal back into place.

9. ON DCX-7 & DCX-7B ONLY. Check drum bushing

(item #29) for signs of wear. Replace if necessary

by pressing old bushing from drum and pressing

new one into place.

10. Check end bearing bushing (item #29) for signs of

wear. If necessary, remove old bushing and press

new bushing into place.

8

Page 11

11.Check cover bushing (item #30)for signs of wear. Replace if

necessary by removing old bushing and pressing new bush ing into place.

12. Check motor for signs of wear. If necessary replace

motor (item #47)

13. Check gears (items #13 & #14) of spur gear shaft as sembly for signs of wear, replace if necessary. Press

old gears from shaft (item #25). Tap key (item #21)

into keyway of shaft (item #25). Press shaft through

gears so that gears are centered on shaft and key.

14. Apply grease to end of shaft, opposite gear.

Apply grease to bushing in gear housing

(item #19). Place greased end of shaft

through thrust washer (item #62) and bush ing in gear housing. Place gasket (item

#44) onto gear housing cover (item #9). Ap ply grease to gear end of shaft and bushing

in cover. Place cover onto shaft and secure

to housing with six (item #64) capscrews.

9

Page 12

15. Place winch, with gear housing cover down,

onto work bench. Drum shaft should be in

vertical position. Place keys (item #22) into

keyways of shaft. A rubber or brass mallet

will be needed to gently tap keys into posi tion. Apply grease to keys and end of shaft.

Slide keyway end of drum (item #11) over

drum shaft and keys.

Apply grease to bushing in end bearing

(item #17) and end of drum shaft. Slide end

bearing over end of drum shaft.

16. Press bearing (item #28) onto worm (item

#26). NOTE: Be sure thick shoulder of bear ings outer race (side with manufacturer’s name

and part number) is out, away from worm

threads. Press bearing and worm into gear

housing. Slip gasket (item #42) onto bearing

cap (item #8). Use four capscrews (item #33) to

secure cap to gear housing. Torque capscrews

to 8ft. lbs. (10.8 Nm.) each.

Attach solenoid assembly to winch as follows:

Place fl atwashers (item #74) between gear housing cover

and solenoid bracket. Use two (item #36) capscrews to

fasten solenoid bracket to gear housing. Tighten all

cover mounting capscrews to 8ft. lbs. (10.8 Nm) each.

Secure solenoid cover to solenoid bracket using two

solenoid cover mounting screws.

SEE SOLENOID ASSEMBLY PARTS LIST

PAGE 18

17. Press bearing (item #28) onto worm and

into worm gear housing. NOTE: Be sure

thick shoulder of bearings outer race (side

with manufacturer’s name and number) is

out, away from worm threads. Place gasket

(item #42) onto spur gear housing (item

#18). Secure spur gear housing to worm

gear housing using four capscrews (item

#35). Torque capscrews to 8ft. lbs. (10.8

Nm.) each. Mount motor (item #47) to spur

gear housing (item #18) using three lock

washers and nuts (items #41 & #38). Attach

solenoid cables to motor terminals. Tighten

all nuts securely.

10

Page 13

18. Place snap ring (item #60) over end of

worm shaft (item #26) and set into snap ring

groove. Insert key (item #20) into keyway of

worm shaft. Place thrust washer (item #61)

over each end of spur gear shaft (item #25).

Set spur gear shaft assembly into bearing

of spur gear housing. Slide gear (item #14)

and thrust washer over end of worm shaft.

Insert pins (item #55) into spur gear housing

(item #18). Attach cover (item #10) and

gasket (item #43) to spur gear housing us ing twelve capscrews (item #32). Torque

capscrews to 8ft. lbs. (10.8 Nm.) each.

Remove reducer and fi tting (items #50 &

#46)from top of spur gear housing. Fill spur

gear box with 1/2 pint of SAE 20 motor oil.

Replace reducer and fi ttings into top of spur

gear housing. Tighten reducer and fi tting

securely.

19. Attach mounting angles (items #6 & #7)

using eight capscrews (item #34) with

lockwashers (item #39 & #40). Torque

capscrews to 12 ft. lbs. (16 Nm.) each.

Insert plug (item #51) into bottom of

gear housing. Permatex may be applied

to threads to help prevent leakage.

Pour 3/4 pint of EP 140 gear oil into

housing thru hole in top of housing. Insert

relief fi tting (item #46) into reducer (item

#54). Reducer should then be placed into

hole on top of gear housing. Tighten fi t-

ting and reducer securely. NOTE: DC-78

winch shown. See pages 14 & 15 for

mounting brackets and hardware for

DC-7 winch.

11

Page 14

DIMENSIONAL DRAWING

DC7 / DCX7

12

Page 15

DIMENSIONAL DRAWING

DC-7B / DCX-7B

13

Page 16

PARTS LIST

MODEL DC-7 & DC-7X 12V & 24V

PART

NO. DESCRIPTION DESCRIPTION

1 1 206007 FOOT BRACE 40 6 414310 CAP S CRE W 3/8-16NCX1 HX HD CP

2 1 206008 FOOT BRACE (MOT OR SIDE) 41 4 414845 CAPSCREW 1/4-20NCX1 LG SOC HD NYLOK

3 1 278035 SOLENOID ASSEMBLY 12V 42 2 414850 CA PSCREW 1/4-20NCX3/ 4 LG SOC HD CP

4 1 278036 SOLENOID ASSEMBLY 24V 43 4 414873 CA PSCREW 5/16-18NCX 3/4 LG SOC HD CP

5 1 282001 SWI T CH A SSEMBLY 44 NOT USED

6 1 299617 ANGLE DC7 45 7 418022 NUT 5/16- 18NC HX REG CP

7 1 299618

8 1 299621 ANGLE DC7X 47 3 418040 NUT 3/8- 24NF HX RE G CP

9 1 299622 ANGLE DC7X 48 8 418163 LOCKW ASHER 5/16 MED S E CT CP

10 1 316083 BE ARING CAP 49 7 418163 LOCKWASHER 5/16 MED SECT CP

11 1 328009 CO VER 50 9 418177 LOCKW ASHER 3/8 MED S E CT CP

12 1 328106 COVER 51 2 442184 GASKET

13 1 332051 DRUMDC7 52 1 442185 GASKET

14 1 332053 DRUM DC7X 53 1 442186 GASKET

15 1 334001 G E AR IDLER 54 NOT USED

16 2 334003 GEAR 55 2 456008 RE

17 1 334007 GEAR 56 1 262037 MOTO R 12V

18 NOT USED 57 1 262036 MOT O R 24V

19 1 338053 END B E ARING 58 NOT USED

20 1 338203 SP UR GEA R HOUSING 59 1 468002 REDUCE R

21 1 338238 G E AR HOUS ING 60 2 468010 PIPE P LUG

22 1 342023 KE Y 61 2 468017 PIPE P LUG

23 1 342033 KE Y 62 1 468018 PIPE P LUG

24 4 342075 KEY 63 1 468024 REDUCER

25 1 350331 END P LATE ( MOT OR END) 64 2 470001 DOWE LL P IN

26 1 350332 END PLATE (O PP. MOTOR END) 65 1 482013 RUBBER BOOT

27 1 357446 DRUM SHAFT DC7 66 1 48

28 1 357447 DRUM SHAFT DC7X 67 1 486017 OIL S E AL

29 1 356901 SHAFT 68 1 486023 O IL SEAL

30 1 368132 W ORM 69 1 490003 S NAP RING

31 3 402001 BE ARING 70 3 518002 THRUST WAS HE R

32 2 402002 BE ARING 71 1 518015 THRUST WAS HE R

33 1 412003 BUS HING 72 NOT USED

34 2 412046 BUS HING DC7X 73 6 414020 CAP S CRE W 1/4-20NCX3/4 LG HX HDGR5

35 1 412046 BUS HING 74 2 418153 FLAT WAS HE R 1/4

36 12 414038 CAPSCREW 1/4-20NCX3/4 LG HX HD

37 4 414045 CAPSCREW 1/4-20NCX7/8 LG HX HD GR5

38 4 414137 CAPSCREW 5/16-18NCX3/4 LG HX HD CP

39 7 414071 CAPSCREW 5/16-18NCX1 LG HX HD GR5

QTY. QTY.QTY.

ANGLE DC7 46 6 418035 NUT 3/8- 16NC HX REG CP

1 412046 BUSHING DC7 HVY PATCH

GR5

ITEM

NO.

PART

NO.

LIEF FITTING

6009 OIL S E AL

FOR GASKET AND SEA L ORDER

PART NO 246033

14

Page 17

MODEL DC-7 AND DCX-7 12 V & 24 V

EXPLODED VIEW

15

Page 18

PARTS LIST

MODEL DC-7B & DC-7BX 12V & 24V

PART

NO. DE SCR IPTION DESCR IPTION

1 1 206007 F OOT BRACE 40 6 414310 CAPSCREW 3/8-16NCX 1 HX HD CP

2 1 206008 F OOT BRACE (MOTOR SIDE ) 41 4 414845 CAPSCRE W 1/4-20NCX1 LG SO C HD NYLOK

3 1 278035 SOLENOID ASSE MBLY 12V 42 2 414850 CAPSCREW 1/4-20NCX3/4 LG S OC HD CP

4 1 278036 SOLENOID ASSE MBLY 24V 43 4 414873 CAPSCREW 5/16-18NCX3/4 LG S OC HD CP

5 1 282001 SWITCH ASSEMBLY 44 NOT USED

6 1 299617 ANGLE DC7 45 7 418022 NUT 5/16-18NC HX REG CP

7 1 299618

8 1 299621 ANGLE DC7X 47 3 418040 NUT 3/8-24NF HX REG CP

9 1 299622 ANGLE DC7X 48 8 418163 LO CK WASHE R 5/16 ME D S E CT CP

10 1 316083 BEARING CAP 49 7 418163 LOCK WAS HE R 5/16 ME D S E CT CP

11 1 328009 COVER 50 9 418177 LOCKWASHER 3/8 MED SE CT CP

12 1 328106 COVER 51 2 442184 GASKET

13 1 332051 DRUMDC7 52 1 442185 GASKET

14 1 332053 DRUM DC7X 53 1 442186 GAS K E T

15 1 334001 GEAR IDLE R 54 NOT US E D

16 2 334003 GEAR 55 2 456008 RE

17 1 334007 GEAR 56 1 262 0 3 7 M OTOR 12V

18 NOT USED 57 1 2620 3 6 M OTOR 24V

19 1 338053 END BEARING 58 NOT USED

20 1 338203 SPUR G E AR HOUS ING 59 1 468002 RE DUCE R

21 1 338238 GEAR HOUS ING 60 2 468010 P IPE PLUG

22 1 342023 KEY 61 2 468017 P IPE PLUG

23 1 342033 KEY 62 1 468018 P IPE PLUG

24 4 342075 KEY 63 1 468024 REDUCER

25 1 350331 END PLATE ( MOTOR END) 64 2 470001 DOWELL PIN

26 1 350332 END PLATE ( OPP. MOT OR END) 65 1 482013 RUB B E R B OOT

27 1 357446 DRUM S HAFT DC7 66 1 48

28 1 357447 DRUM S HAFT DC7X 67 1 486017 OIL SEAL

29 1 356901 SHAFT 68 1 486023 OIL SEAL

30 1 368132 WO RM 69 1 490003 S NAP RI NG

31 3 402001 BEARING 70 3 518002 THRUST W ASHER

32 2 402002 BEARING 71 1 518015 THRUST W ASHER

33 1 412003 BUSHI NG 72 NOT USED

34 2 412046 BUSHI NG DC7X 73 6 414020 CAPSCREW 1/4-20NCX 3/4 LG HX HDGR5

35 1 412046 BUSHI NG 74 2 418153 FLAT WA S HE R 1/4

36 12 414038 CA P S CRE W 1/4-20NCX3/4 LG HX HD

37 4 414045 CA P S CRE W 1/4-20NCX7/8 LG HX HD GR5

38 4 414137 CA P S CRE W 5/16-18NCX3/4 LG HX HD CP

39 7 414071 CA P S CRE W 5/16-18NCX1 LG HX HD GR5

QTY. QTY.QTY.

ANGLE DC7 46 6 418035 NUT 3/8-16NC HX RE G CP

1 412046 BUSHI NG DC7 HVY P ATCH

GR5

ITEM

NO.

PART

NO.

LIEF FITTING

6009 OIL SEAL

FOR GA S K E T AND S E AL ORDE R

PART NO 246033

16

Page 19

MODEL DC-7B AND DCX-7B 12 V & 24 V

EXPLODED VIEW

17

Page 20

E

M

A

D

G

/

T

A

P

Z

O

S

A

SOLENOID ASSEMBLY PARTS

ITEM NO. QTY. PART NO. DESCRIPTION

1 1 280009 CA BLE&BOLT ASSY-W/A LL 12&24V SOL

2 1 289077 WIRE ASSY-4.5LG,#6GA GPT BLK,2-TER

3 1 289091 WIRE ASSY-EXT,FEM CONN TO SOL,PL

4 1 328104 COVER-SOLEN ,DC7&8,INJ/MOLD,PURC

5 2 364001 STRAP-COPPER,MAKE FROM FINISH ED

6 2 364002 STRAP-COPPER ,MAKE FROM FINISH E

7 1 408038 BRACKET-SOL MTG,DC7,8,FOLDED,16

8 2 416199 MACHSCREW8-32NCX1/2LG.RD HD SLO

9 4 416216 SCREW-#10-24NCX1/2LG,RDHD,SLOT,Z

10 2 418004 NUT-HEX #10-24NC REG.,ZINC PLATED

11 2 418022 NUT-5/16-18NC HEX REG,ZINC PLATED

12 2 418140 WASHER-#10 FLAT STEEL,SA E,ZIN C PL

13 2 418142 WASHER-#8,FLAT,ALUMINUM

14 1 418163

15 1 418164 WASHER-5/16 SHAKE PRF,INT TEETH,Z/

16 1 418165 WASHER-5/16 SHAKE PRF,EXT TEETH,

17 1 430013 CONNECTOR-FEMALE RECEPTACLE,M

18 1 440114 SOLENOID - 24 VOLT

18 1 440110 SOLENOID 12 VOLT

19 2 440071

20 1 482029 COVER-FEMALE RECEPTA CLE,URETH

278035 - 12 V

278036 - 24 V

LOCKWASHER-5/1 6 MED SECT,ZINC PL

TERMIN AL TA B-MALE,AMP#61499-1,BRA

18

Page 21

TEST PROCEDURE FOR SOLENOIDS

Steps to follow when testing current fl ow through DC solenoids.

It should be noted that when testing a 12 volt or 24 volt solenoid, the DC motor and battery

must be of the same voltage.

To test the solenoids: (See Figure 1).

1. Securely clamp a motor to a bench or work surface.

2. Attach a #6 gauge jumper wire from”A” terminal on the motor to one of the fi eld termi-

nals on the motor, (F-2).

3. Attach the other motor fi eld terminal (F-1) to one of the side terminals of the solenoid.

4. Ground the solenoid to the motor with a wire as shown.

5. Attach positive (+) battery wire to the opposite side terminal of solenoid.

Ground the negative (-) battery wire to the motor isolated ground terminal.

6. Touch “hot” wire, from the positive battery terminal, to small terminal of the solenoid.

7. The motor should now be running if the solenoid is good. If not, make sure the motor

will run directly from the battery. (See motor test procedure page 20).

8. To test the upper contacts use the same hookup except use the top terminals.

(See Figure 2). When hooked up as shown in Figure 2, motor should start running.

When the “hot” wire is touched to the small terminal the motor will stop operating.

The top terminals are normally closed; ie: connected, and the side terminals open, or

not connected. When the solenoid operates, the top terminals are disconnected

and the side terminals are connected.

Take care not to bring hot wires into contact with ground in order to prevent electrical

arcing.

BATTERY

(TOP TERMINALS)

SIDE SIDE

(SMALL)

SOLENOID

GROUND WIRE(-) FROM

SOLENOID TO MOTOR

FIGURE-1

F2

ISOLATED GROUND

TERMINAL

MOTOR

BATTERY

A

F1

(TOP TERMINALS)

(SMALL)

SOLENOID

GROUND WIRE(-) FROM

SOLENOID TO MOTOR

FIGURE-2

SIDESIDE

ISOLATED GROUND

F2

TERMINAL

MOTOR

A

F1

19

Page 22

TEST PROCEDURE FOR MOTOR

The Ramsey Winch motor is a (4 pole-4 coil) series wound 12 volt or 24 volt DC motor. The 4

pole, 4 coil feature provides high torque at low speeds. To test the motor to determine if it is

functioning properly, fi rst securely fasten the motor to a bench or work surface so it will not jump

or move around during test procedure (the starting torque of motor is high).

1. Connect a jumper wire (at least a number 6 wire) from F-1 to “A” motor terminals

(See Figure 1).

2. Attach a wire (at least a number 6 wire) from positive ( + ) battery terminal to F-2

motor terminal. Ground negative(-) battery terminal to motor isolated ground terminal.

(See Figure 1). Motor should now run.

To reverse the direction of rotation:

1. Attach jumper wire from F-2 to•• motor terminals (See Figure 2).

2. Attach wire from positive (+)battery terminal to F-1 motor terminal. Ground negative(-)

battery terminal to motor isolated ground terminal (See Figure 2).

NOTE: Always attach battery wire solidly to motor terminals. Make and break the connection of

negative (-) battery terminal at the motor isolated ground terminal. This avoids burning the motor terminals.

CAUTION: Do not run the motor for a long period of time in fashion mentioned above, because

the motor could become damaged.

The motor running idle on the bench will draw 55 amperes and must run free and easy. If the

ampere draw is more than 60 amps and the motor runs rough or has a strange sound, it should

be replaced. With the motor attached in place on a winch (less cable on arum) the ampere draw

should be approximately 65 to 70 amps.

If after following the procedure outlined, the test on the winch signifi cantly exceeds 70 amperes

refer to your Owners Manual for trouble shooting suggestions on the mechanical portion of the

winch. See Figure 3 for the solenoids connection to the motor and the battery

CW

BATTERY

SOLENOIDS TO MOTOR CONNECTIONS

THE DASHED LINES ARE CURRENT'S PATH IN FORWARD ROTATION.

SOLID LINES ARE CURRENT'S PATH AT ALL TIMES.

NOTE:

DIRECTION OF MOTOR ROTATION DEPENDS ON WHICH SMALL

TERMINAL OF EITHER SOLENOID IS CONNECTED TO BATTERY'S

POSITVE TERMINAL.

BATTERY

A

F2

F1

ISOLATED GROUND

TERMINAL

A

F2

F1

ISOLATED

GROUND

F2

F1

A

FIGURE-1

MOTOR-CLOCKWISE ROTATION

CCW

F2

BATTERY

ISOLATED

GROUND

F1

A

FIGURE-2

MOTOR-COUNTER CLOCKWISE ROTATION

BATTERY

20

SOLENOIDS TO MOTOR CONNECTIONS

THE DASHED LINES ARE CURRENT'S PATH IN REVERSE

ROTATION. SOLID LINES ARE CURRENT'S PATH AT ALL TIMES.

FIGURE-3

ISOLATED GROUND

TERMINAL

Page 23

NOTES

21

Page 24

LIMITED WARRANTY

RAMSEY WINCH warrants each new RAMSEY Winch to be free from defects in material and

workmanship for a period of one (1) year from date of purchase.

The obligation under this warranty, statutory or otherwise, is limited to the replacement or repair

at the Manufacturer’s factory, or at a point designated by the Manufacturer, of such part that

shall appear to the Manufacturer, upon inspection of such part, to have been defective in material or workmanship.

This warranty does not obligate RAMSEY WINCH to bear the cost of labor or transportation

charges in connection with the replacement or repair of defective parts, nor shall it

apply to a product upon which repair or alterations have been made, unless authorized by

Manufacturer, or for equipment misused, neglected or which has not been installed correctly.

RAMSEY WINCH shall in no event be liable for special or consequential damages. RAMSEY

WINCH makes no warranty in respect to accessories such as being subject to the warranties of

their respective manufacturers.

RAMSEY WINCH, whose policy is one of continuous improvement, reserves the right to im-

prove its products through changes in design or materials as it may deem desirable without being obligated to incorporate such changes in products of prior manufacture.

If fi eld service at the request of the Buyer is rendered and the fault is found not to be with

RAMSEY WINCH’s product, the Buyer shall pay the time and expense to the fi eld representa-

tive. Bills for service, labor or other expenses that have been incurred by the Buyer without approval or authorization by RAMSEY WINCH will not be accepted

RAMSEY WINCH COMPANY

Post Offi ce Box 581510 Tulsa, Oklahoma 74158-1510

Telephone: (918) 438-2760 FAX: (918) 438-6688

OM-912403-L-1013

Loading...

Loading...