Page 1

OPERATING, SERVICE

AND MAINTENANCE

MANUAL

MODEL DC-300 SERIES RAM-LOK®

EQUIPPED INDUSTRIAL LOW-

MOUNT WINCHES

INCLUDES: DC-300/DC-346, DC-24-300/DC-24-346.

DCY-300/DCY-346, DCY-24-300/DCY-24-346

AND MODELS EQUIPPED WITH OPTIONAL ADJUST-

ABLE, AUTOMATIC OIL COOLED SAFETY BRAKE:

DCG-300, DCYG-300 SERIES WINCHES.

CAUTION: READ AND UNDERSTAND THIS MANUAL BEFORE INSTALLATION AND

OPERATION OF WINCH. SEE SAFEGUARDS AND WARNINGS!

Page 2

TABLE OF CONTENTS

INTRODUCTION..................................................................................1

WARRANTY

INFORMATION

................................................................1

SPECIFICATION

TECHNIQUES OF

.......... .. .. .... .. .. .... .. .. .. .... .. .. ..... . .. .... .. .. .... .. .. .. .... .. .. .... .. .. 1

OPERATION........................................................ .. 2

WARNING........................................................................................... 2

WINCH

WINCH

ELECTRICAL

CABLE

ADJUSTING THE OIL COOLED SAFETY

SERVICING OF THE OIL COOLED SAFETY

RE-ASSEMBLING AND CHECKING THE

TEST FOR PROPER BRAKE

INSTRUCTIONS FOR CHECKING

ARRANGEMENT AND SETTING OF WORM

TROUBLE SHOOTING

MAINTENANCE...................................................................... 3

MOUNTING............ ............................................................... . 4

CONNECTIONS........................................................... 4

INSTALLATION................ ...................................................... 4

BRAKE.............................. 4

BRAKE.........................

BRAKE............................... 6

ASSEMBLY......................................... 6

ASSEMBLY

BRAKE........................ 7

GUIDE......................................................... 8-9

INSTRUCTIONS FOR OVERHAUL OF

RAMSEY MODEL DC-300 SERIES LEVER

WINCHES

5

DISASSEMBLY.....................................................................

REASSEMBLY......................................................................

DIMENSIONAL

PARTS LIST AND PARTS

SOLENOID ASSEMBLY PARTS

TEST PROCEDURE FOR

TEST PROCEDURE FOR

MOTOR ASSEMBLY PARTS

LIMITED

WARRANTY ........................................................................ 25

DRAWING................................................................ 17

DRAWING ..... .... ...... .... ... ....... ... .... ..... .

LIST .

...............................................21

SOLENOI D............................................... 22

MOTOR .................................................... 23

LIST ................................................... .. 24

10-13

13-16

18-20

Page 3

RAMSEY ELECTRICAL WINCH MODEL DC-300 SERIES

PLEASE READ THIS MANUAL CAREFULLY

This manual contains useful ideas in obtaining the most effi cient operation from your Ramsey

Winch, and safety procedures one needs to know before operating a Ramsey Winch.

WARRANTY INFORMATION

Ramsey Winches are designed and built to exacting specifi cations. Great care and skill go into

every winch we make. If the need should arise, warranty procedure is outlined on the back of your

self-addressed postage paid warranty card. Please read and fi ll out the enclosed warranty card and

send it to Ramsey Winch Company. If you have any problems with your winch, please follow instructions for prompt service on all warranty claims. Refer to back page for limited warranty.

SPECI F ICATIONS: Conform s to SAE J706

Rated Line Pull 1 st Laye r (lb .) 9 ,0 0 0

(kgs.) 4,070

Tot al G ear Reduction:

Weight: OC-300/0C-346 (long drum) 116 lb. (52.6 Kgs.)

DCY-300/DCY-346 (short drum) 105 lb. (47.6 Kgs.)

MAXI M UM GEAR BOX O IL TEMPERAT U RE SHOU LD N O T EXCEED 250°F

Layer of Cabl e 1

Rated Line Pul l lb. 9,000 7,500 6,400 5,600

per layer

*Lon g Drum Cable

capacity per layer M. 7 18 28 42

*Short "Y" Drum

cable capacity Ft.

per layer

LINE SPEED

DC-300/DCY-300

DC-24-300/DCY-24-300

DC-346/DCY-346

DC-24-346/DCY-24-346

* These specifi cations are based on recommended cable of 3/8” (9.5mm)

EIPS cable.

Winch only conforms to SAE J706. For SAE qualifi cation of mounting

angles, if applicable, consult Ramsey Engineering.

DC-300 470

DC-346 360

234

kgs. 4,070 3,390 2,890 2,530

Ft.

M. 4 9 16 22

VOLTS FPM FPM FPM FPM

12 14 65 7 110 5 180 2.5 310

24 (4.3) 30 (2.1) 50 (1.5) 90 (0.7) 155

12 16.5 70 8.5 140 5.5 200 2.5 360

24 (5) 35 (2.5) 70 (1.5) 100 (0.7) 180

25 60 95

15 30 55 75

NO LOAD 2000# LOAD 4000# LOAD 9000# LOAD

(MPM) AMPS (MPM) AMPS (MPM) AMPS (MPM) AMPS

140

NOTE:The rated line pulls shown are for the winch only. Consult the wire rope manufacturer for

wire rope ratings.

DUTY CYCLE

Winch duty cycles are shown below:

6

5

4

3

MINUTES

2

1

0

180

270 360

AMPS

12 V

5

4

3

2

MINUTES

1

0

90 120 160 190

AMPS

24 V

1

Page 4

TECHNIQUES OF OPERATION

The best way to get acquainted with how your winch operates is to make test runs before you actually

use it. Plan your test in advance. Remember, you hear your winch as well as see it operate. Get to

recognize the sounds of a light steady pull, a heavy pull, and sounds caused by load jerking or shifting. Gain confi dence in operating your winch and its use will become second nature with you.

The uneven spooling of cable, while pulling a load, is not a problem. unless there is a cable pile

up on

one end of drum. If this happens, reverse the winch to relieve the load and move your anchor point

further to the center of the vehicle. After the job is done you can unspool and rewind for a neat lay of

the cable.

When pulling a load where there is even a remote chance of cable failure. place a blanket, jacket

or tarpaulin over the cable about six feet behind the hook. This will slow the snap back of a broken

cable and could prevent serious injury. Check oil level of winch every six months. Replace oil annually or more often if winch is used frequently. Use 3/4 pint of all purpose E. P. 140 oil in the worm

gear housing and 1/2 pint SAE 20 for spur gear box. If the oil is contaminated with metallic particles,

inspect winch for cause of abnormal wear.

Periodically check all electrical connections and mounting bolts. Tighten hardware if necessary.

The minimum ampere-hour rating of vehicle battery should be 70, and used with at least a 40

amp alternator. An Auxiliary battery is recommended to supply additional battery power. Inspect the

cable frequently. If the cable becomes frayed with broken strands, replace immediately. Cable and

hook assembly may be purchased from a Ramsey distributor.

The RAM-LOK® semi-automatic clutch allows rapid unspooling of the cable, from cable drum, for

hooking onto a load. The clutch is operated by the "T-handle". located on the end of the winch, as

follows:

1. TO DISENGAGE CLUTCH, run the winch in the reverse (reel out) direction until the load is

off the cable. Pull outward on the clutch handle, rotate it counter-clockwise 90

0

and release.

The clutch is now locked out and the cable may be pulled off by hand.

2. TO ENGAGE CLUTCH, pull outward on the handle, rotate it clockwise 900 and release.

Run the winch in reverse until the clutch handle snaps fully in or until the cable drum starts

turning. At this point make sure the clutch handle is all the way in. The plastic plug in top of

clutch housing may be removed, for inspection of clutch to assure total engagement. After

the clutch is fully engaged, the winch is ready for winching in the cable.

WARNINGS

CLUTCH MUST BE TOTALLY ENGAGED BEFORE STARTING THE WINCHING OPERATION.

DO NOT DISENGAGE CLUTCH UNDER LOAD.

DO NOT LEAVE CLUTCH ENGAGED WHEN WINCH IS NOT IN USE.

STAY OUT FROM UNDER AND AWAY FROM RAISED LOADS.

STAND CLEAR OF CABLE WHILE PULLING. DO NOT TRY TO GUIDE CABLE.

DO NOT EXCEED MAXIMUM LINE PULL RATINGS SHOWN IN TABLE.

DO NOT USE WINCH TO LIFT,SUPPORT,OR OTHERWISE TRANSPORT PERSONNEL.

A MINIMUM OF 5 WRAPS OF CABLE AROUND THE DRUM BARREL IS NECESSARY TO HOLD THE

LOAD. CABLE CLAMP IS NOT DESIGNED TO HOLD LOAD.

DISCONNECT THE REMOTE CONTROL SWITCH FROM WINCH WHEN NOT IN USE. A RAMSEY PART

NO. 282053 SAFETY ON-OFF SWITCH IN YOUR VEHICLE IS RECOMMENDED.

2

Page 5

WINCH MAINTENANCE

Adhering to the following maintenance schedule will keep your winch in top condition and

performing as it should with a minimum of repair.

A. WEEKLY

1. Check the oil level and maintain it to the oil level plug. If oil is leaking out, determine

location and repair.

2. Check the pressure relief plug in top of the gear housing. Be sure that it is in good

operating condition so that hot oil gasses may escape.

3. Lubricate cable with light oil.

B. MONTHLY

1. Lubricate the various grease fi ttings located in the cable drum, end bearing, clutch housing

or clutch operating linkage. Any good grade of moly-disulfi de containing grease is

acceptable.

2. Check the action of the sliding clutch, making sure it is fully engaging and disengaging with

the cable drum. Remove the plastic plug in top of the housing and observe if the clutch is

fully engaging. If clutch is not fully engaging, inspect clutch shifter assembly parts, check

for damage or excessive wear and replace as necessary. Observe the jaws on both the

clutch and cable drum, checking for rounding of the driving faces. If rounding has occurred

they should be replaced immediately.

3. Check the winch mounting bolts. If any are missing, replace them and securely tighten any

that are loose. Make sure to use only grade 5 bolts or better.

4. Check the torque setting of the oil cooled worm brake. Make any adjustments required,

following the procedure described in ADJUSTING THE OIL COOLED WORM BRAKE in the

Owner's Manual.

5. Check alignment of chain and sprockets and adjust as required to minimize wear.

6. Inspect the cable. If the cable has become frayed with broken strands, replace immediately.

C. ANNUALLY

1. Drain the oil from the winch annually or more often if winch is used frequently.

2. Fill the winch to the oil level plug with clean kerosene. Run the winch a few minutes with

no load in the reel in direction. Drain the kerosene from the winch.

3. Refi ll the winch to the oil level plug with all purpose E.P. 140 gear oil.

4. Inspect frame and surrounding structure for cracks or deformation.

5. Gear wear can be estimated by rocking the drum back and forth and if necessary drain oil

and remove cover for closer inspection.

3

Page 6

WINCH MOUNTING

It is most important that this winch be mounted securely so that the three major sections (the clutch housing end, the cable drum and the gear housing end) are properly aligned. All standard model DC-300 Series

Winches are furnished with recommended mounting angles. Angle size is

1/4 x 2-1/2 x 2-1/2 x 36" Lg. high strength (50,000 PSI yield) steel angle.

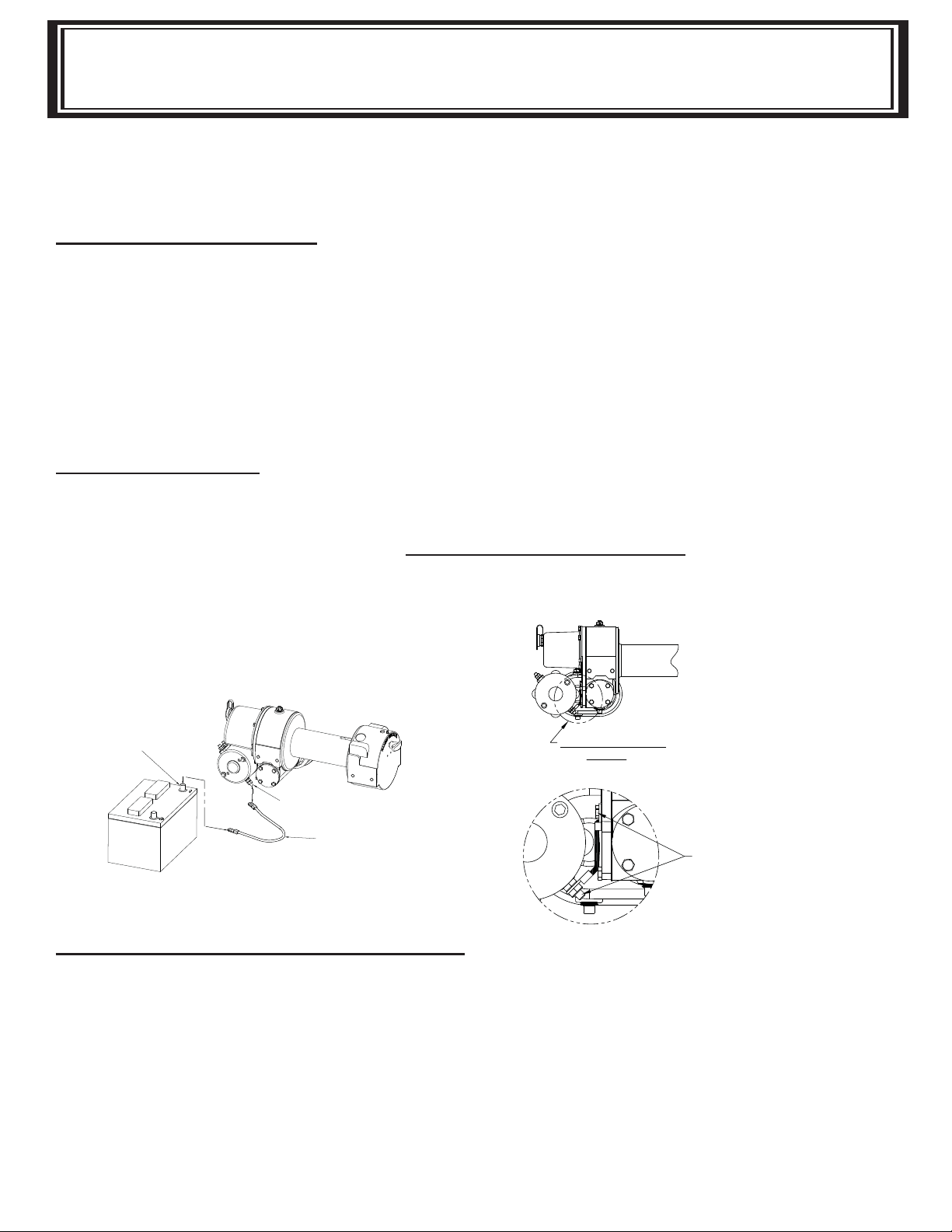

ELECTRICAL CONNECTIONS

See dimensional drawing on page 17. Using a power cable with appropriate end terminals, connect the

positive (+) battery terminal to the 5/16" dia. stud on the plastic solenoid cover on the winch. IMPORTANT:

hold inner nut on stud with a wrench while tightening outer nut. Using a ground cable with appropriate end

terminals, connect the negative (-) battery terminal to motor isolated ground terminal. For distances up to

15 feet from battery to winch, use #2 Ga.

wire (#440315) will be required between the winch and the motor ground. This ground is required to

insure a suffi cient ground to operate the solenoid assembly (see diagram below). For distances up to

15 feet from battery to winch, use #2 Ga. wire for the above connections. For distances greater than 15 feet,

use wire larger than #2 Ga.

CABLE INSTALLATION

1. Unwind cable by rolling it out along the ground to prevent kinking. Securely wrap end of cable, opposite

hook, with plastic or similar tape to prevent fraying.

2. Insert the end of cable, opposite hook end, into the 7/16" dia. hole in drum barrel. Secure cable to drum

barrel, using setscrew furnished with winch. TIGHTEN SETSCREW SECURELY.

3. Carefully run winch in the "reel-in" direction. Keeping tension on end of cable, spool all the cable onto the

cable drum, taking care to form neatly wrapped layers.

In applications where the chassis is non-grounded, a jumper

WINCH WILL NOT OPERATE UNLESS

GROUND CABLE IS INSTALLED FROM THE

ISOLATED GROUND TERMINAL TO THE

NEGATIVE BAT TERY POST.

(SEE DIAGRAM BELOW)

NEGATIVE BATTERY POST

ISOLATED GROUND

TERMINAL

GROUND CABLE

SEE ILLUSTRATION

BELOW

JUMPER CABLE (#440315) MUST BE

INSTALLED ON WINCH FROM MOTOR

ISOLATED GROUND STUD TO GEAR

HOUSING COVER BOLT AS SHOWN

FOR NON GROUNDED CHASSIS

APPLICATIONS.

ADJUSTING THE OIL COOLED WORM BRAKE

The oil-cooled, fully adjustable, automatic safety brake operates in the worm housing lubricant, all parts being

submerged in oil. When the brake wears to the point that the load begins to rift, the brake can be adjusted as

follows:

1. Loosen the lock nut on the adjusting screw.2. Tighten the brake by turning the adjusting screw clockwise.

CAUTION: Only 1/4 turn is usually required to adjust the brake.

Over-tightening can cause overheating, and damage to the brake

parts. Tighten the lock nut after adjustment is completed.

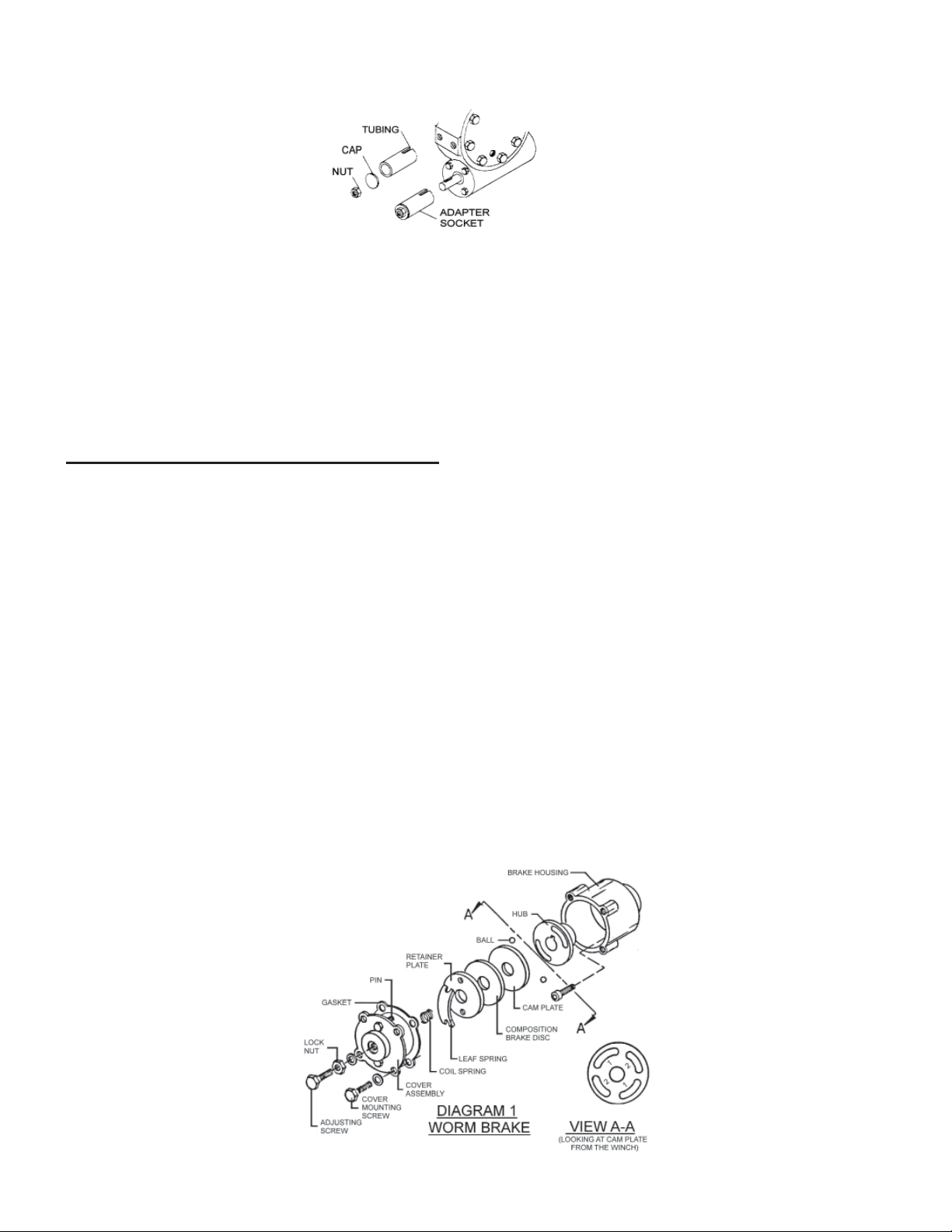

If the brake does not respond to adjustment then a new leaf spring and brake disc is needed. A torque wrench

can be equipped with a special adapter to fi t the input shaft (worm) of the winch. The adapter can be made by

welding a nut to the end of a piece of tubing as shown in the following fi gure.

4

Page 7

After welding the cap and nut to the tubing, slot the tubing as shown. This will allow the special

adapter to slide over the keyway and will then act as a large socket. A torque wrench can then be

used to apply the proper torque. Turn the torque wrench so that the drum turns in the spool out

direction or lowering direction. The torque rating for the Model 300/346 should be 9 to 15 ft. lbs.

If the torque wrench does not show the proper value as it turns, then the worm brake adjusting bolt should be turned clockwise 1/4 turn. Each time the adjusting bolt is turned, check the

torque reading. Continue this procedure until the proper torque reading is achieved. Then tighten

the lock nut.

SERVICING OIL COOLED SAFETY BRAKE

1. Remove the drain plug and drain the worm gear oil from the worm housing.

2. Back off the lock nut, then the adjusting screw, both two turns or more by turning them counter

clockwise.

3. Remove the cover mounting screws.

4. Remove the cover along with coil spring and leaf spring.

5. Remove the retainer plate, composition brake disc, cam plate and balls. Note slots balls are in.

6. Inspect parts as follows:

a). Composition brake discs are 1/8” thick when new. Replace if thinner than 0.080” or if

surfaces are glazed or burnt.

b). Inspect the fl at, ground surface of the cam plate and retainer plate for glazing, warpage, or

other damage. Glazing can be removed by scraping carefully.

c). Inspect the leaf spring. It should be bowed 1/8”.

5

Page 8

BRAKE - CHECKING / RE-ASSEMBLY AND TESTING

RE-ASSEMBLING AND CHECKING THE BRAKE

1. Press brake hub into place over worm shaft and key.

2. Assemble ball into appropriate slots of cam. (Refer to diagram 1, page 5 ), Use stiff grease to hold

balls into place and slide cam over end of worm. Be sure that balls are secure, between cam slots

and hub slots. Refer to Page 7 to determine proper ball slot setting.

3. Install brake disc.

4. Install retainer plate, smooth side ward brake disc.

5. Install the gasket on the cover with a small amount of grease or sealer.

6. The coil spring goes over the adjusting screw on the inside of the cover.

7. Install the notches of the leaf spring on the pins protruding through the cover.

The hollow side of the leaf spring goes toward the brake.

8. Install brake housing cover, making sure the protruding pins go through the leaf spring and into the

holes in the retainer plate.

9. Bolt cover into place with the mounting screws. Install drain plug and add 1 pint all purpose

E.P. 140 oil.

10. Turn winch in the hoisting direction at least one turn of the input shaft.

11. Turn the adjusting screw in until it is fi nger tight.

TEST FOR PROPER BRAKE ASSEMBLY

After the brake has been adjusted to the proper torque setting disengage clutch. Start vehicle engine

and run winch in the reel in (hoisting direction). Allow winch to run in this direction for one minute.

Place your hand on the safety brake housing. If housing is not hot to the touch then run winch in the

reverse direction (cable out) for one minute. Brake housing should begin to heat.

When these conditions exist, proper installation has been made. If heating becomes noticeable when

running the winch in forward rotation (hoisting direction), the brake should be again disassembled.

When disassembled, place the brake balls in the alternate set of slots in the cam plate, then carefully

follow the instructions for re-assembling and checking the brake.

6

Page 9

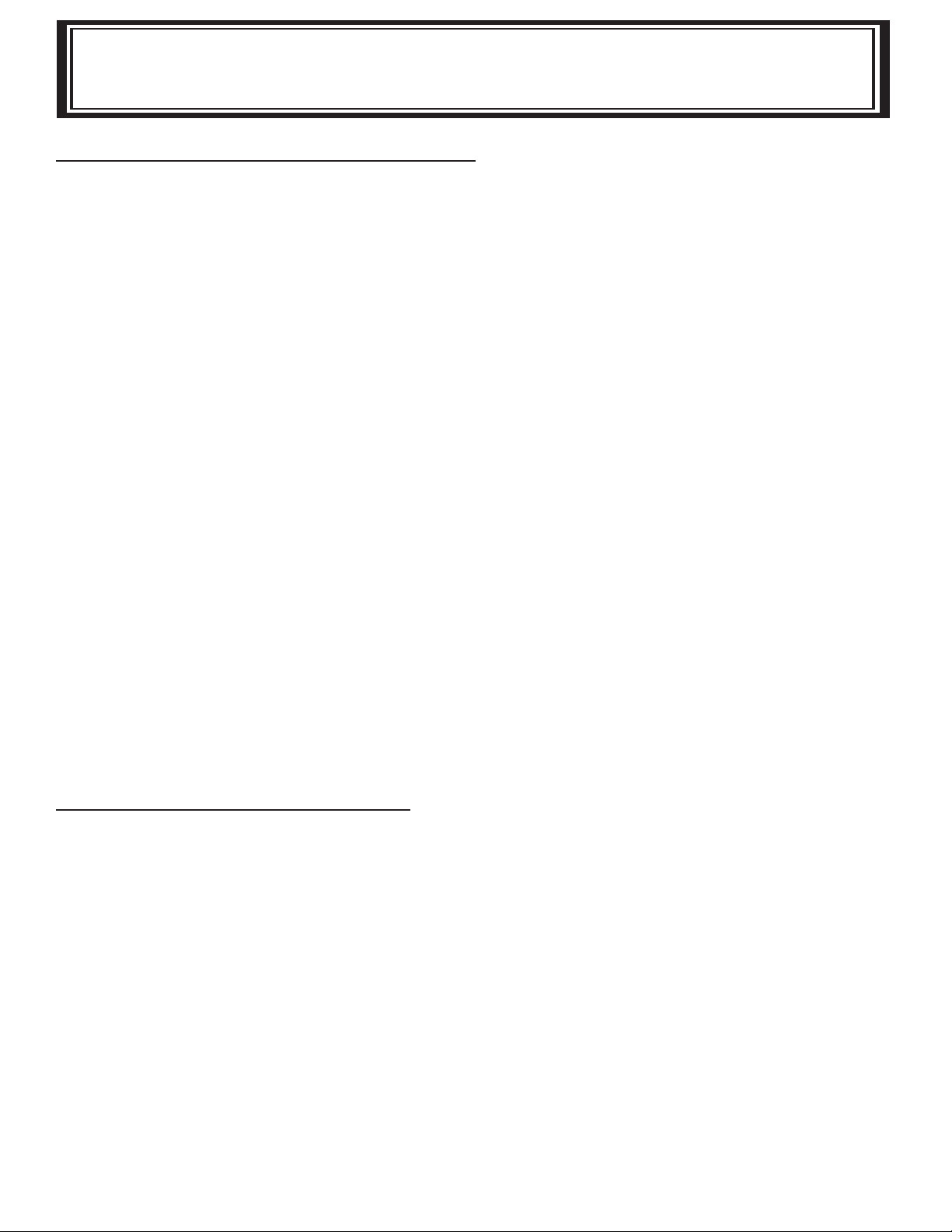

INSTRUCTIONS FOR CHECKING ASSEMBLY ARRANGEMENT

AND

SETTING OF WORM BRAKE

When the worm brake is assembled the brake must be set with the balls in the #1 or the #2 set of

cam slots. (View A-A, page 5). It is indicated on the name plate whether the balls were installed in

the #1 or the #2 slots at the factory.

Three factors determine which slots the balls should be in:

1. Direction cable winds on the drum. It normally WINDS OVER THE TOP of the drum barrel.

2. The side of the winch that the input shaft is on. The INPUT SHAFT IS NORMALLY TOWARD

THE CAB. Whether the winch has the gear box on the right or on the left side of the winch does

not affect the brake setting.

EXAMPLE: When cable winds over the top of the drum, winch has a right cut gear and input shaft

is toward the cab (diagram 2) , then the balls need to be in the #2 cam slots.

If any one of these three factors differ from those stated above, the balls need to be in the #1 slots in

the cam. A second change in these factors requires the original arrangement,and if all three factors

are different, the balls need to be in the #1 slots. (See page 5 and 6 for disassembly and assembly

instructions).

DIAGRAM 2

Input side of winch

toward cab

Cable winds

over top

7

Page 10

TROUBLE SHOOTING GUIDE

CONDITION POSSIBLE CAUSE CORRECTION

CLUTCH INOPERATIVE OR BINDS 1. Dry or rusted shaft. 1. Clean and

UP. 2. Bent yoke or linkage. 2. Replace yoke or

.

OIL LEAKS FROM HOUSING. 1. Seal damaged or worn. 1. Replace

LOAD DRIFTS DOWN. 1. Safety brak e has 1. Replace brake disc.

CABLE DRUM WILL NOT FREE 1. Winch not mounted 1. Check mounting. Refer to

SPOOL. squarely, causing end WINCH MOUNTING Page

CABLE BIR DNESTS WHEN CLUTCH 1. Drag brake disc worn. 1. Replace

IS

DISENGAGED.

MOTOR RUNS IN ONE DIRECTION 1. Inoperative solenoid 1. Jar solenoid to

ONLY. or stuck sol

MOTOR RUNS, BUT DRUM DOES 1. Clutch not engaged. 1-4. If clutch engaged

NOT TURN. symptom still exists, it will

3. Clutch jaws are in 3. See TECHNIQUES OF

contact.

2. Too much oil. 2. Drain excess oil. Refer to

3. Damaged gasket. 3. Replace

become worn. Page 5, Diagram 1).

2. Safety brake out of 2. Turn adjusting bolt

adjustment. wise 1/4 turn or

bearings to bind

enoid. contacts. Check by

2. Inoperative switch. 2. Disengage winch clutch

3. Broken wire or bad 3. Check for loose

connection. on switch and

2. Sheared drum shaft

3. Stripped bronze

4.

Parted

shaft.

drum.

gear.

key.

assembly

OPERATION.

TECHNIQUES OF

load does not

12 volts to coil terminal

should make an

click when

remove armature

Remove switch plug

hood. Raise connector

on hood and with a

driver, short the

two pins. Solenoid

click. Short the two

hand pins. The

solenoid should

If both solenoids

check for a broken wire

switch

connector.

necessary to diswinch to determine

and

repair.

lubricate.

.

seal.

gasket.

discs.

energized).

cable.

shaft

OPERATION.

clock-

until

drift.

free

applying

audible

lead.

screw

bottom

should

left

other

operate.

operate

connection

switch

but

assemble

cause

(

See

from

4.

(

it

or

cover

in

be

8

Page 11

TROUBLE SHOOTING GUIDE

CONDITION

MOTOR RUNS EXTREMELY HOT. 1. Long period of operation. 1. Cooling-off periods

MOTOR RUNS, BUT WITH 2. Insufficient battery. 2. Check battery

INSUFFICIENT

LOW LINE SPEED. volts or less,replace

MOTOR WILL NOT OPERATE. 1. Inoperative solenoid 1. Jar solenoid to

POWER, OR WITH voltage under load. If

POSSIBLE CAUSE CORRECT

to prevent

another

terminal.

3. Electrical cables from 3. Must be #2 Ga. wire

winch too small distances up to 15 feet

battery to winch. Use

Ga. for

feet.

4. Bad electrical 4. Check all connections

connections. looseness or

Tighten, clean and

5. Insufficient charging 5. Replace with

capacity charging

or stuck solenoid. contacts. Check by

12 volts to coil

(it should make an

when

2. Inoperative switch. 2. Disengage winch clutchorremove

armature lead.

plug from

cover

driver, short the

Solenoid

two

should operate. If

operate,

in

ION

battery

distances

energized).

on

hood and with a

should

left

pins. The other

check

switch

cable.

over-

terminal

corrosion;

larger

terminal

hood.

are

essential

heating.

10

or

parallel

to it at motor

for

battery to

from

larger

than #2

greater than 15

for

grease.

system.

system.

free

applying

audible

Re-

Raise connector

bottom

click. Short the

both

for a broken wire

click

move switch

screw

two pins.

solenoid

solenoids

3. Inoperative motor. 3. If solenoids

for voltage

replace

4. Loose connections. 4. Tighten connections

of hood and

operate,

at

armature post;

motor.

on

motor.

check

on

bottom side

9

Page 12

INSTRUCTIONS FOR OVERHAUL OF RAMSEY

MODEL DC-300 SERIES RAM-LOK

1. Drain oil from worm gear housing by removing

(item #54) plug from bottom of gear housing .

Remove relief fi tting and reducer (items #50 & #53)

from top of gear housing. Remove mounting

angles (items #4 & #5) from winch by removing

hardware shown.

2 Drain oil from spur gear housing by removing (item#

54) plug. Remove cover and gasket (items #9 & 44)

from spur gear housing by unscrewing twelve cap-

screws (item #28 ). Slide gear (item#12)from end of

worm shaft (item #23).

Remove spur gear shaft (item #21 ), with gears

attached. Check bearings (item #24 ) and thrust

washers (item #68 ) for signs of wear, replace if

necessary.

Remove old bearings and press new bearings into

place.

Remove solenoid assembly (item #2) by unscrew ing capscrews (items #30 & #34). Disconnect so-

lenoid cables from motor (item #51) . Make note of

which terminals cables are attached to.

3. Remove key (item# 19) and snap ring (item

#65) from worm shaft. Remove motor (item

#51) from spur gear housing (item #16) by

removing (3) nuts and lockwashers (items

#39 & #41). Unscrew (4) capscrews (item

#33) to remove spur gear box (item #16)

and gasket (item #43) from gear hous ing. Replace lip seals (items #62 & #64) by

pressing old seals from spur gear housing

and pressing new seals into place.

10

Page 13

4. Slide clutch housing (item #17) from end of drum

shaft. Slide jaw clutch (item #7) from end of drum

shaft .

Remove (2) keys (item #47) from keyways. A

screw driver can be used, at notch, to aid in re moval of keys. Once keys have been removed,

drum (item #10) and thrust washer (item #70) can

be removed from drum shaft. Parts under drum,

thrust washer (item #69), spring and disc (items

#66 & #42) should also be removed.

5. Remove bearing cap (item #6) from gear housing

by unscrewing four capscrews (item #29). Remove

worm (item #23) and bearing (item #25) from gear

housing . Use a soft hammer to gently tap input

end of worm and drive worm and bearing from

gear housing. Once worm has been removed

from housing, bearing can be pressed from end of

worm.

6. Remove gear housing cover (item #8)

from gear housing (item #18) by un screwing fi ve remaining capscrews

(item#29). Place capscrew into two

tapped holes of cover and tighten. This

will pull the cover loose from gear

housing .

Remove cover gasket (item #45) and

pull shaft (item #22), with gear at-

tached, and thrust washer (item #70)

from gear housing.

Check for signs of wear to worm (item #23) and

bearings (item #25). Replace if necessary. For

models with optional worm brake refer to page 5,

SERVICING OF THE OIL COOLED SAFETY

BRAKE,for disassembly and page 6, for

re -assembly instructions .

11

Page 14

7. Check for signs of wear on gear teeth. If replacement

of gear is necessary, gear must be replaced as follows:

a. Press gear ( item #14) from shaft (item #22).

b. Examine shaft keys and keyways. If distortion of

keys and/or keyways are evident, shaft and keys

should be replaced.

c. Use a soft hammer to gently tap keys (item #48)

into keyways. Press gear (item #14) over shaft and

keys. Gear must be centered over keys.

8. Remove seal (item #63) from back of gear housing

(item # 18). Check bushing (item #27) for signs of

wear. Press bushing (item #27) from gear housing

and replace if necessary. Press new bushing and

seal back into place.

9. Check drum bushings (item #26) for signs of wear.

Replace if necessary by pressing old bushings from drum

(item #10) and pressing new ones into place.

10. Examine shifter assembly (item #1) for damage to yoke.

Yoke should be fi rmly attached to shaft, yet, able to swivel

freely around shaft. Replace if necessary by removing pin

(item #58) from handle (item #15). Remove rubber plug

(item #59) from housing. Unscrew setscrew enough to allow

shifter assembly to be removed from housing.

Check clutch housing bushing (item #26) for signs of wear.

Remove if necessary by pressing old bushing from housing

(item #17) and pressing new one into place. Install new

shifter assembly (item #1) by placing end of shaft, opposite

yoke, through spring (item #67) and into housing (item #17).

Attach (item #15) handle to shaft using roll pin (item #58).

Tighten setscrew, in housing, enough to allow shifter

assembly

12

Page 15

11. Check cover bushing (item #8) for signs of wear. Replace

if necessary by removing old bushing and pressing new

bushing into place.

12. Check pinion gear on motor for signs of wear. If neces-

sary replace motor (item #51).

13. Check gears of spur gear shaft assembly for signs

of wear, replace if necessary. Press old gears from

shaft (item #21). Tap key (item #20) into keyway of

shaft (item # 21). Press shaft through gears so that

gears are centered on shaft and key.

RE-ASSEMBLY

14. Apply grease to end of shaft, opposite gear. Apply

grease to bushing in gear housing (item #18). Place

greased end of shaft through thrust washer (item #70)

and bushing in gear housing (item #18). Place gasket

(item #45) onto gear housing cover (item #8). Apply

grease to gear end of shaft and bushing in cover.

Place cover onto shaft and secure to housing with

fi ve (item #29) capscrews at the fi ve lower most

holes.

13

Page 16

15. Place winch, with gear housing

cover down, on work bench.

Drum shaft should be in vertical

position. Slide thrust washer (item

#69) over drum shaft and slide

downwards until washer rests on

gear housing. Set springs (item

#66) and drag brake disc (item

#42) into pockets of gear hous ing. Grease bushings in drum

(item #10). Slide drum assembly

onto drum shaft with drum jaws

upward.

16. Place thrust washer (item #70) over end of drum

shaft and slide downward until spacer rests on

drum. Press drum (item#10) downward to compress

springs in gear housing.

Insert keys (item #47) into keyways with sharp edge

of keys pointing outward notched end of keys upward.

A rubber or brass mallet will be needed to gently tap

keys into position.

Apply grease to keys and end of shaft. Place jaw

clutch (item #7) over end of shaft and slide jaw clutch

over keys.

Set clutch housing (item #17) over end of drum shaft.

Pull jaw clutch (item #7) upward, toward clutch hous ing, enough to allow yoke, in clutch housing, to fi t

properly in groove around jaw clutch.

14

Page 17

17. Press bearing (item #24) onto worm (item #23)

NOTE: Be sure thick shoulder of bearings outer

race (side with manufacturer’s name and part

number) is out, away from worm threads. Press

bearing and worm into gear housing. Slip gas ket (item #43) onto bearing cap (item #6).

Use four capscrews (item #29) to secure cap to

gear housing. Torque capscrews to 8 ft. lb. (10.8

Nm .) each.

Attach solenoid assembly ( item #2) to gear

housing. Use two (item #34) capscrews and

three (item #30) capscrews with three fl atwash-

ers (item #40). Tighten capscrews to 8 ft. lb.

(10.8 Nm ) each. Insert plug (item #56) into

tapped hole of cover. Permatex may be applied

to threads to help prevent oil leakage.

TIGHTEN plug securely.

18. Press bearing ( Item #24) onto worm and into

worm gear housing. NOTE: Be sure thick shoul der of bearings outer race (side with manufac turer’s name and number) is out, away from

worm threads. Place gasket (item #43) onto

spur gear housing (item #16). Secure spur gear

housing to worm gear housing using four cap screws (item #33). Torque capscrews to 8 ft. lb.

(10 .8 Nm.) each.

Mount motor (item #51) to spur gear housing

(item #16) using three lockwashers and nuts

(items #39 & #41). Attach solenoid cables to

motor terminals. Tighten all nuts securely.

15

Page 18

19. Place snap ring(item #65) over end of worm

shaft (item #23) and set into snap ring groove.

Insert key (item #19) into keyway of worm shaft.

Place thrust washer (item #68) over each end

of spur gear shaft (item #21). Set spur gear

shaft assembly into bearing of spur ear hous ing. Slide gear (item #12) and (item #68) thrust washer over end of worm shaft (item #23).

Insert pins (item #57) into cover (item#9). Place

gasket (item #44) onto cover. Attach cover and

gasket to spur gear housing using twelve cap screws (item #28). Torque capscrews to 8 ft. lb.

(10.8 Nm) each.

Insert plug (item #54)into bottom of spur gear

housing. Permatex may be applied to threads

to help prevent oil leakage.

Remove reducer and fi tting (items #50 & #53)

from top of spur gear housing. Pour 1/ 2 pint

of SAE 20 weight motor oil into spur gear box.

Replace reducer and fi tting into top of spur

gear housing. Tighten reducer and fi tting

securely.

20. Attach mounting angles (items #4 & #5) using

six capscrews (item #32) with lockwashers

and capscrews (items #35 & #31). Torque

capscrews to 34 ft. lb. (46 Nm.) each. Insert

plug (item #54) into bottom of gear housing.

Permatex may be applied to threads to help

prevent leakage.

Pour 3/4 pint of EP 140 gear oil into housing

thru hole in top of housing. Insert relief fi tting

(item #50) into reducer (item #53). Reducer

should then be placed into hole on top of

gear housing. Tighten fi tting and reducer

securely.

16

Page 19

DIMENSIONAL DRAWING

6,4

3.72

CONNECT POWER CABLE

BATTERY TERMINAL HERE

FROM POSITIVE (+)

6.22

.25

94,4

157,9

1.12

28,6

3.47

7.03

88,2

178,6

CONNECT GROUND CABLE

GROUND TERMINAL TO

BATTERY TERMINAL.

NEGATIVE

FROM MOTOR ISOLATED

D

MM

INCHES

C

MM

INCHES

MM

INCHES

AB

MM

INCHES

WINCH

MODEL

333,3

13.12

8.94

227,0

287,3

11.31

7.78

197,6

DC-200

8.12

11.44

6.31

5.28

DCY-200

206,3

290,5

160,3

134,1

2.50

6.75

63,5

171,4

A

B

4.56

115,8

2.50

63,5

3.62

92,0

3.50

DIA.

6.41

88,9

162,8

7.25

DIA.

184,2

1.37

34,9

2.50

63,5

D

36.00

914,4

2.12

53,9

POSITION

CLUTCH AT

DIS-ENGAGED

17

2.19

55,6

DIMENSIONS SHOWN ARE INCHES OVER MILLIMETERS

2.50

63,5

.69

17,5

C

Page 20

DC-300 SERIES

EXPLODED VIEW

2

30

40

8

56

34

29

43

31

32

41

5

32

41

26

10

38

1

67

60

37

59

49

58

17

15

26

70

7

26

42

48

22

47

6

25

23

19

18

53

50

66

63

69

48

42

47

4

41

41

32

45

26

14

65

70

27

54

25

64

43

62

50

53

16

66

35

32

68

24

21

33

12

12

29

61

41

39

54

20

11

24

57

9

51

68

SEE PAGE 21 FOR

COMPONENT BREAKDOWN

3

44

57

55

28

SEE PAGE 20 FOR OPTIONAL WORM BRAKE PARTS LIST

18

Page 21

DC-300 SERIES

PARTS LIST

ITEM

NO.

1 1 276028 SHIFTER ASSEMBLY

2 1 278027 SOLENOID ASSEMBLY-12V

3 1 282001 SWITCH ASSEMBLY

4 1 302808 ANGLE (S TD)

5 1 302809 ANGLE (S TD)

6 1 316083 CAP-BEARING

7 1 324160 JAW CLUTCH

8 1 328143 COVER-W O RM G E A R HOUS ING

9 1 328106 COVER-SPUR GEAR HOUSING

10 1 332007 DRUM-MOD. Y

11 1 334001 IDLER GEAR

12 2 334003 GEAR

13 1 334129 PINION

14 1 334161 GEAR R. H. -60: 1

15 1 336010 HANDLE

16 1 338203 HOUSING-SPUR GEAR

17 1 338208 HOUSING-CLUTCH

18 1 338273 HOUSING-GEAR

19 1 342023 KEY-SQUARE

20 1 342033 KEY-SQUARE

21 1 356901 SHAFT-SPUR

22 1 357487 SHAFT-DRUM-STD.

23 1 368001 WORM-R.H.-60:1

24 3 402001 BEARING-NEEDLE

25 2 402002 BEARING-BALL

26 4 412003 BUSHING

27 1 412045 BUSHING

28 12 414038 CAPSCREW 1/4-20NCX3/4 LG HX HD Z/P GR5

29 9 414045 CAPS CREW 1/4-20NCX7/8 LG HX HD GR5

30 3 414059 CAPSCREW 1/ 4 -20NCX1 LG HX HD Z/P

31 1 414279 CAPS CREW 3/8-16NCX3/4 LG HX HD GR5

32 6 414282 CAPS CREW 3/8-16NCX1-1/4 LG HX HD Z/P GR5

33 4 414845 CAPSCREW 1/ 4 -20NCX1 LG SO C HD NYLOK

34 2 414856 CAPSCREW 1/ 4 -20NCX3/4 LG SOC HD Z/P

35 1 414912 CAPSCREW 3/ 8 -16NCX5/8 LG SOC HD

36 1 416029 SETSCREW 1/4-20NCX5/16 LG SOC HD

37 1 416030 SETSCREW 1/4-20NCX3/8 LG SOC HD (DOG PT)

38 1 416059 SETSCREW 3/8-16NCX1/2 LG SOC HD

39 3 418040 NUT 3/8-24NF HX REG Z/P

40 3 418154 WA S HE R 1/ 4 F LAT ALUM.

41 10 418177 LOCKWAS HE R-3/ 8 M E D S ECT Z/P

42 2 438014 DRAG BRAKE

43 2 442184 GASKET

44 1 442185 GASKET

45 1 442205 GASKET

46 1 450001 KEY

47 2 450006 KEY (BARTH)

48 4 450016 KEY (BARTH)

49 1 456001 LUB FITTING

50 2 456008 RELIEF FITTING

51 1

52 1 462015 O-RING

53 2 468002 REDUCER

54 2 468011 PIPE PLUG SQ. HD.

55 2 468017 PIPE PLUG SOC. HD.

56 1 468018 PIPE PLUG SOC. HD.

57 2 470001 PIN

58 1 470033 SPIROL PIN

59 1 472012 PLUG

60 1 472013 PLUG

61 1 482013 RUBBER BOOT

62 1 486009 OIL SEAL

63 1 486017 OIL SEAL

64 1 486023 OIL SEAL

65 1 490003 SNAP RING

66 2 494002 SPRING

67 1 494053 SPRING

68 3 518002 THRUST WASHER

69 1 518014 THRUST WASHER

70 2 518015 THRUST WASHER

71 1 518018 FIBER W ASHER

QTY PART NO. DESCRIPTI ON

1 278028 SOLENOID ASSEMBLY-24V

1 302811 ANGLE (MOD. Y)

1 302810 ANGLE (MOD. Y)

1 332105 DRUM-STD.

1 334163 GEAR R.H. -46:1

1 357488 SHAFT-DRUM-MOD. Y

1 368019 WORM-R.H.-46:1

1 262036 MOTOR-24V

262037

MOTOR-12V

FOR GASKET KIT & SEAL KIT

ORDER #246039

19

Page 22

H

PARTS LIST

MODEL DC-300 SERIES RAM-LOK

DESCRIPTION

101 1 306034 SPRING-FLAT

102 1 314008 CAM PLATE

103 1 328128 COVER

104 1 338007 HOUSING-BRAKE

105 1 340002 HUB

106 1 342027 KEY

107 1 352022 RETAIN ER PLATE

109 1 358022 WORM - R.H. 45:1 RATION

ITEM NO QTY PART NO.

108 1 35802l WORM - R.H. 50:1 RATION

112 4 414039 CAPSCREW 1/4 20NCx 1 LG. HX.HD. GR.S

113 1 414228 CA PSCREW 3/8-lSNCx 1-l/2 LG. HX.HO. ALL-THRO.

114 4 414821 CA PSCREW 1/4-20NCx18LG. BUTTON HO.

115 1 418035 NUT 3/8-lSNC HX.JA M

116 6 418154 WASHER- FLAT 1/4 ALUM.

117 1 442189 G ASKET

110 2 400003 BALL

111 2 414021 CAPSCREW 1/4 -20NCx 1 LG. HX.HD. GR.S NY-LOK HVY.PATC

118 1 474001 PLA TE-THRUST

119 1 485069 THREAD SEAL

120 1 494007 SPRIN G

20

Page 23

SOLENOID ASSEMBLY PARTS

21

Page 24

TEST PROCEDURE FOR SOLENOIDS

Steps to follow when testing current fl ow through DC solenoids. It should be noted that when test-

ing a 12 volt or 24 volt solenoid, the DC motor and battery must of the same voltage.

To test the solenoids: (See Figure 1).

1. Securely clamp a motor to a bench or work surface.

2. Attach a #6 gauge jumper wire from “A” terminal on the motor to one of the fi eld terminals on

the motor, (F-2).

3. Attach the other motor fi eld terminal (F-1)to one of the side terminals of the solenoid.

4. Ground the solenoid to the motor with a wire as shown.

5. Attach positive (+) battery wire to the opposite side terminal of solenoid.

Ground the negative (-) battery wire to the motor isolated ground terminal.

6. Touch “hotwire”, from the positive battery terminal, to small terminal of the solenoid.

7. The motor should now be running if the solenoid is good. If not, make sure the motor will

run directly from the battery. (See motor test procedure page 23).

8. To test the upper contacts use the same hookup except use the top terminals. (See

Figure 2). When hooked up as shown in Figure 2, motor should start running. When the

“hotwire” is touched to the small terminal the motor will stop operating.

The top terminals are normally closed; ie: connected, and the side terminals open, or not

connected. When the solenoid operates, the top terminals are disconnected and the side

terminals are connected.

Take care not to bring hot wires into contact with ground in order to prevent electrical arcing.

BATTERY

(TOP TERMINALS)

SIDE SIDE

(SMALL)

SOLENOID

GROUND WIRE(-) FROM

SOLENOID TO MOTOR

FIGURE-1

F2

ISOLATED GROUND

TERMINAL

MOTOR

BATTERY

A

F1

(TOP TERMINALS)

(SMALL)

SOLENOID

GROUND WIRE(-) FROM

SOLENOID TO MOTOR

FIGURE-2

SIDESIDE

ISOLATED GROUND

TERMINAL

F2

MOTOR

A

F1

22

Page 25

TEST PROCEDURE FOR MOTOR

The Ramsey Winch motor is a (4 pole-4 coil)series wound 12 volt or 24 volt DC motor.

The 4 pole, 4

coil feature provides high torque at low speeds. To test the motor to determine if it is functioning

properly, fi rst securely fasten the motor to a bench or work surface so it will not jump or move around

during test procedure (the starting torque of motor is high).

1. Connect a jumper wire (at least a number 6 wire) from F-1 to “A” motor terminals (See Figure 1).

2. Attach a wire (at least a number 6 wire)from positive (+) battery terminal to F-2 motor terminal.

Ground negative (-)battery terminal to motor

isolated ground terminal (See Figure 1). Motor

should now run.

To reverse the direction of rotation:

1. Attach jumper wire from F-2 to “A” motor terminals (See Figure 2).

2. Attach wire from positive (+) battery terminal to F-1 motor terminal. Ground negative (-) battery

terminal to motor

isolated ground terminal.(See Figure 2).

NOTE: Always attach battery wire solidly to motor terminals. Make and break the connection of the

negative (-) battery terminal at the motor isolated ground terminal. This avoids burning the motor

terminals. CAUTION: Do not run the motor for a long period of time in fashion mentioned above,

because the motor could become damaged.

With the motor running idle on the bench will draw 55 amperes and must run free and easy. If the

ampere draw is more than 60 amps and the motor runs rough or has a strange sound, it should be

replaced.

With the motor attached in place on a winch (less cable on drum} the ampere draw should be approximately 65 to 70 amps.

If after following the procedure outlined, the test on the winch signifi cantly exceeds 70 amperes refer

to your Owners Manual for trouble shooting suggestions on the mechanical portion of the winch.

See Figure 3 for the solenoids connection to the motor and the battery.

CW

BATTERY

SOLENOIDS TO MOTOR CONNECTIONS

THE DASHED LINES ARE CURRENT'S PATH IN FORWARD ROTATION.

SOLID LINES ARE CURRENT'S PATH AT ALL TIMES.

NOTE:

DIRECTION OF MOTOR ROTATION DEPENDS ON WHICH SMALL

TERMINAL OF EITHER SOLENOID IS CONNECTED TO BATTERY'S

POSITVE TERMINAL.

BATTERY

A

F2

F1

ISOLATED GROUND

TERMINAL

A

F2

F1

ISOLATED

GROUND

F2

F1

A

FIGURE-1

MOTOR-CLOCKWISE ROTATION

CCW

F2

BATTERY

ISOLATED

GROUND

F1

A

FIGURE-2

MOTOR-COUNTER CLOCKWISE ROTATION

BATTERY

SOLENOIDS TO MOTOR CONNECTIONS

THE DASHED LINES ARE CURRENT'S PATH IN REVERSE

ROTATION. SOLID LINES ARE CURRENT'S PATH AT ALL TIMES.

23

FIGURE-3

ISOLATED GROUND

TERMINAL

Page 26

LIMITED WARRANTY

RAMSEY WINCH warrants each new RAMSEY Winch to be free from defects in material and

workmanship for a period of one (1) year from date of purchase.

The obligation under this warranty, statutory or otherwise, is limited to the replacement or repair at

the Manufacturer’s factory, or at a point designated by the Manufacturer, of such part that shall

appear to the Manufacturer, upon inspection of such part, to have been defective in material or

workmanship.

This warranty does not obligate RAMSEY WINCH to bear the cost of labor or transportation

charges in connection with the replacement or repair of defective parts, nor shall it

apply to a product upon which repair or alterations have been made, unless authorized by Manufacturer, or for equipment misused, neglected or which has not been installed correctly.

RAMSEY WINCH shall in no event be liable for special or consequential damages. RAMSEY

WINCH makes no warranty in respect to accessories such as being subject to the warranties of

their respective manufacturers.

RAMSEY WINCH, whose policy is one of continuous improvement, reserves the right to improve

its products through changes in design or materials as it may deem desirable without being obligated to incorporate such changes in products of prior manufacture.

If fi eld service at the request of the Buyer is rendered and the fault is found not to be with

RAMSEY WINCH’s product, the Buyer shall pay the time and expense to the fi eld representative.

Bills for service, labor or other expenses that have been incurred by the Buyer without approval or

authorization by RAMSEY WINCH will not be accepted

RAMSEY WINCH COMPANY

Post Offi ce Box 581510 Tulsa, Oklahoma 74158-1510

Telephone: (918) 438-2760 FAX: (918) 438-6688

OM-912448-1013-K

Loading...

Loading...