Page 1

OWNER'S MANUAL

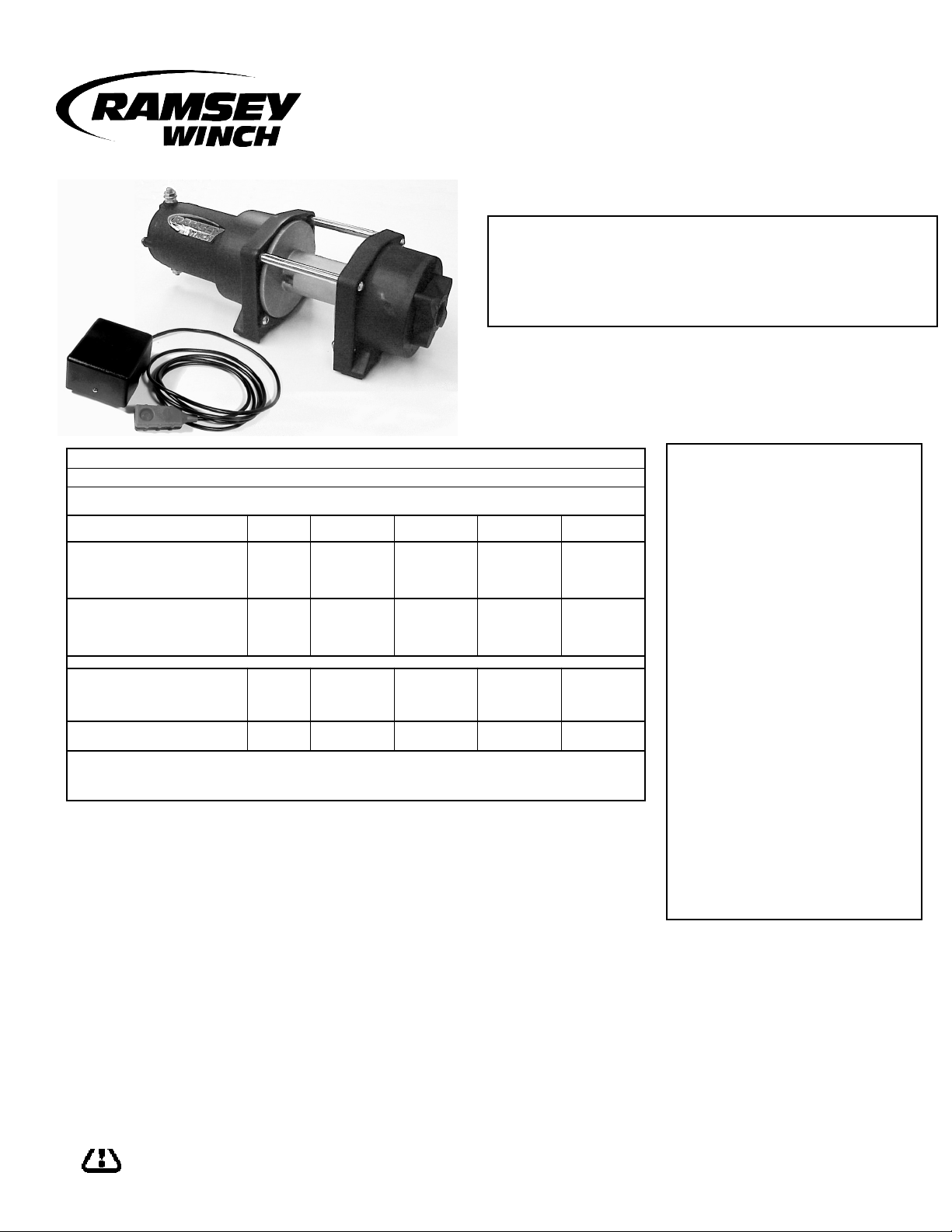

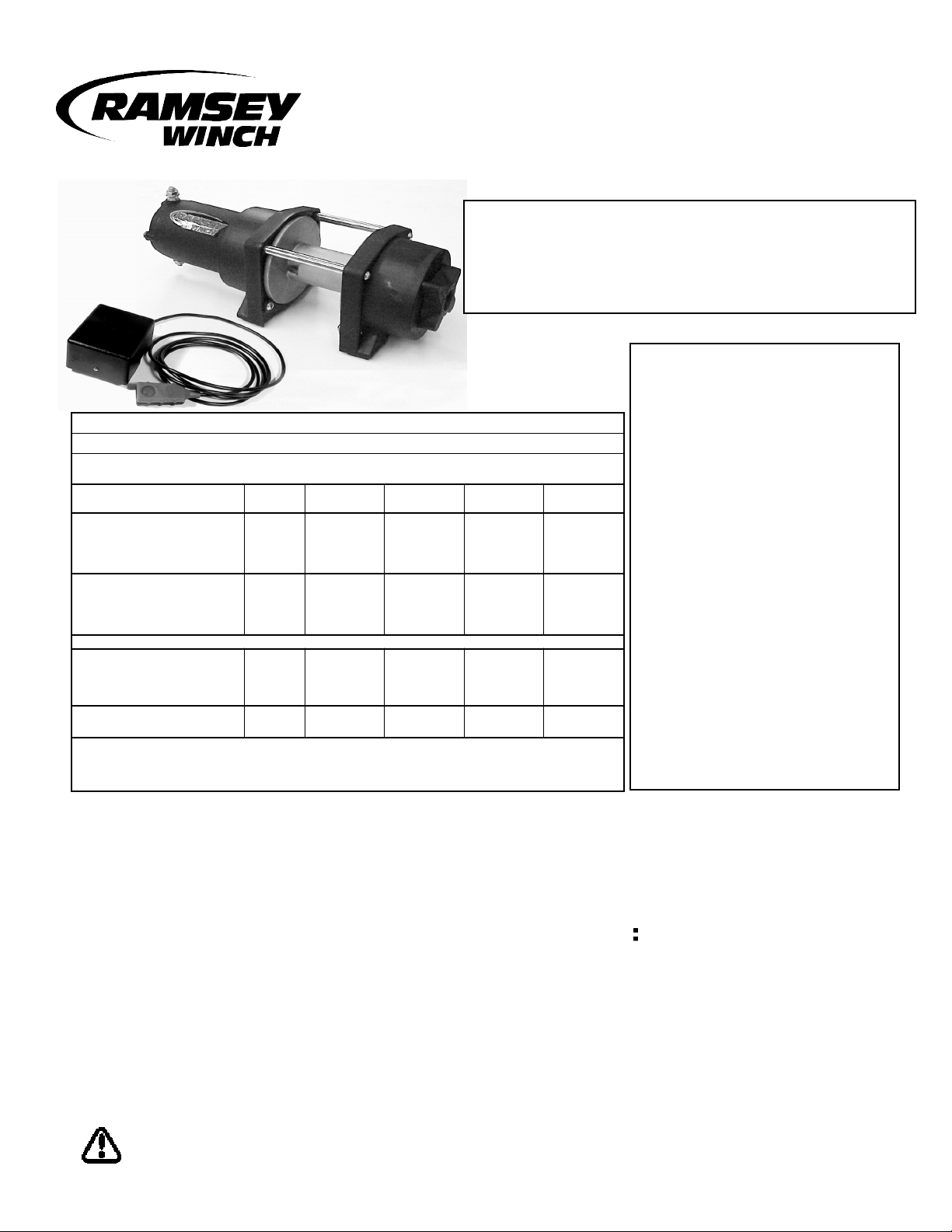

Electric Winch Model ATV 8

with Push Button Remote Control Switch

English (Original Instructions) . . . . . . . . . . . . . . . 1

Français (Traduction des instructions originales) . . 10

Deutsch (Übersetzung der Originalanleitung) . . . . . 18

Español (Traducción de las instrucciones originales) 28

First Layer Line Pull 8kN (1800 lb)

Noise Level 81 db

Ambient Temperature Range -28 to 60 C (-20F to 140F)

YER OF ROPE

LA

Rated Line Pull Per Layer

Cumulative Rope Capacity

Per Layer

Line Pull First Layer

Amp Draw 12V 31 72 101

* These specifications are based on recommended 5 mm (.196") 1960 grade wire rope

kN 8 6,6 5,3 4,8

lb 1,800 1,400 1,200 1,100

m 1,5 4,5 6 10,6

ft 5 15 20 37

kN No 2,6 5,3

lb Load 600 1,200 1800

1 2 3 4

Intended Purpose: Self recovery of vehicles and pulling of loads.

RAMSEY WINCH COMPANY

Post Office Box 581510 Tulsa, Oklahoma 74158-1510 USA

Phone: (918) 438-2760 Fax: (918) 438-6688

Visit us at http://ww.ramsey.com

6,6

135

WARNINGS:

THE USER SHALL ENSURE THAT THE

OPERATING PERSONNEL ARE GIVEN

THE NECESSARY TRAINING.

THE OPERATOR SHALL ALWAYS WORK

IN COMPLIANCE WITH THE OPERATING INSTRUCTIONS.

CLUTCH MUST BE FULLY ENGAGED

BEFORE STARTING THE WINCH.

DO NOT DISENGAGE CLUTCH UNDER

LOAD.

STAY OUT FROM UNDER AND AWAY

FROM RAISED LOADS.

STAND CLEAR OF ROPE WHILE

PULLING. DO NOT TRY TO GUIDE

ROPE.

DO NOT USE WINCH TO LIFT, SUPPORT, OR OTHERWISE TRANSPORT

PERSONNEL.

A MINIMUM OF 2 WRAPS OF ROPE

AROUND THE DRUM BARREL IS NECESSARY TO HOLD THE LOAD.

AVOID CONDITIONS WHERE LOAD

SHIFTS OR JERKS OCCUR. EXCESSIVE

“INCHING” SHALL BE AVOIDED.

Ramsey Authorized Representative in the Community:

(Please contact for regulatory inquiries only.)

Alura Group BV

P.O. Box 18626

2502 EP The Hague

The Netherlands

Tel: (31) (0) 70 362-4896

Fax: (31) (0) 70 346-7299

CAUTION: Read and understand this manual before installation and operation of winch. See Safety Precautions.

OM-914220-1012-B

Page 2

4707 N. Mingo Tulsa, Oklahoma 74117 (918) 438-2760

EC DECLARATION OF CONFORMITY

as defined by Machinery Directive 2006/42/EC

Here with we declare that winch model ATV 8 complies

with the following directive provided that the USER complies with all responsibilities described in the Owner’s

Manual:

2006/42/EC

Applied harmonized standards:

EN 14492-1:2006

Power-Driven Winches

ISO 9001:2000

Quality Management Systems

Requirements

EC-KONFORMITÄTSERKLÄRUNG

gemäß Maschinenrichtlinie 2006/42/EC

Hiermit erklären wir, dass das Windenmodell ATV 8 der

folgenden Richtlinie entspricht, sofern der BENUTZER

alle Anweisungen im Benutzerhandbuch befolgt:

2006/42/EC

Angewandte harmonisierte Normen:

EN 14492-1:2006

Kraftgetriebene Winden

ISO 9001:2000 Qualitätsmanagementsysteme Anforderungen

Ramsey Authorized Representative in the Community / Ramsey Représentant autorisé dans la comuauté /

Ramsey Bevollmächtigter in der Europäischen Union / Ramsey Representante autorizado en la comunidad.

DÉCLARATION DE CONFORMITÉ EC

aux termes de la directive Machines 2006/42/EC

Nous déclarons par la présente que le modèle de treuil ATV 8

est conforme à la directive suivante, sous réserve que

l’UTILISATEUR ait assumé toutes les responsabilités figurant

dans le manuel de l’utilisateur :

2006/42/EC

Normes harmonisées appliquées :

EN 14492-1:2006

Treuils motorisés

ISO 9001:2000

Systèmes de gestion de la qualité - Exigences

DECLARACIÓN EC DE CONFORMIDAD

según se define en la directiva de máquinas 2006/42/EC

Con la presente declaramos que el modelo de cabestrante

ATV 8 se halla en conformidad con la siguiente directiva

siempre que el USUARIO cumpla todas las responsabilidades descritas en el Manual del propietario:

2006/42/EC

Normas armonizadas aplicadas:

EN 14492-1:2006

Cabestrantes accionados mecánicamente

ISO 9001:2000

Requisitos de los Sistema de gestión de la calidad

(Please contact for regulatory inquiries only. / Veuillez prendre contact uniquement pour des questions réglementaires.)

(Bitte nur bei Regulierungsfragen kontaktieren. / Póngase en contacto sólo por cuestiones de reglamentación.)

Alura Group BV

P.O. Box 18626

2502 EP The Hague

The Netherlands

Tel: (31) (0) 70 362-4896

Fax: (31) (0) 70 346-7299

Serial Number / Numéro de série/ Seriennummer/ Número de Serie:_____________________

Signature / Signature / Unterschrift / Firma:

Todd Brady

Engineering Manager / Directeur technique/ Technischer Leiter/ Director de ingeniería

Date / Date / Datum / Fecha:

04-29-11

2

Page 3

Contents

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . .cover

User’s Responsibility for CE Compliance . . . . . . . . .2

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . .2

Winch Installation . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Rope Installation . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Electrical Connections . . . . . . . . . . . . . . . . . . . . . . .4

End of Service Measures . . . . . . . . . . . . . . . . . . . . .4

Electrical Schematics . . . . . . . . . . . . . . . . . . . . . . . .5

Winch Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Trouble Shooting Guide . . . . . . . . . . . . . . . . . . . . . .7

Winch Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . .8

CE Declaration of Conformity . . . . . . . . . . . . . . . . . .9

H. To respool correctly, it is necessary to keep a slight

load on the rope. Do not allow the rope to slip

through your hand and do not approach the winch too

closely.

I. Observe spooling of rope onto drum. Side pulls can

cause rope to pileup at one end of the drum. To

correct uneven stacking, spool out that section of the

rope and move it to the other end of the drum and

continue winching. Uneven spooling which causes

rope pileup can interfere with the winch tie rods

causing damage to the winch.

J. Neat, tight spooling avoids rope binding which is

caused when a load is applied and the rope is pinched

between two other wraps of rope. If this happens,

alternately power the winch in and out a few inches.

Do not attempt to work a bound rope under load, free

by hand.

User’s Responsibility for CE Compliance

1. Mount winch per Winch Installation Instructions.

2. Install the emergency stop switch per Installation

Instructions included with the Emergency Stop Switch Kit.

3. Install 5 mm (.196 inch) grade 1960 wire rope. Maximum

rope length of 10,6 M (37 ft) for four layers maximum.

4. Attach rope to the drum per Rope Installation Instructions.

5. Use a hook which includes a safety latch and has a

minimum breaking strength of 20 kN.

Safety Precautions

A. Keep yourself and others a safe distance to the side of

the rope when pulling under load.

B. Do not step over a rope, or near a rope under load.

C. Use a heavy rag or gloves to protect hands from burrs

when handling winch rope.

D. Modification, alteration, or deviation to the winch

should only be made by Ramsey Winch Company.

E. Keep the duration of your pulls as short as possible.

If the motor becomes uncomfortably hot to the touch,

stop and let it cool for a few minutes. Do not pull

more than one minute at or near the rated load. Do

not maintain power to the winch if the motor stalls.

Electric winches are for intermittent usage and should

not be used in constant duty applications.

F. Disconnect the remote control switch from the winch

when not in use.

G. Do not use winch in hoisting applications due to

required hoist safety factors and features.

Winch Installation

1. Tighten mounting bolts to 21,6 Nm (16 ft lb) torque.

2. Do not attach motor and battery leads until instructed

to do so.

3. It is very important that the winch be mounted on

a flat surface, with the rope underwound as

shown in the dimensional drawing on page 6.

CAUTION: Supplied 22,6 mm (.88 in) long

mounting bolts with lockwashers are for a

recommended winch mounting plate ness of

4,7 mm (.18 in). If a different mounting plate

thickness is used, the bolt length must be

adjusted accordingly or damage to winch

may occur. Replacement bolts must be SAE

Grade 5 or equivalent.

3

Page 4

Operation

Rope Installation

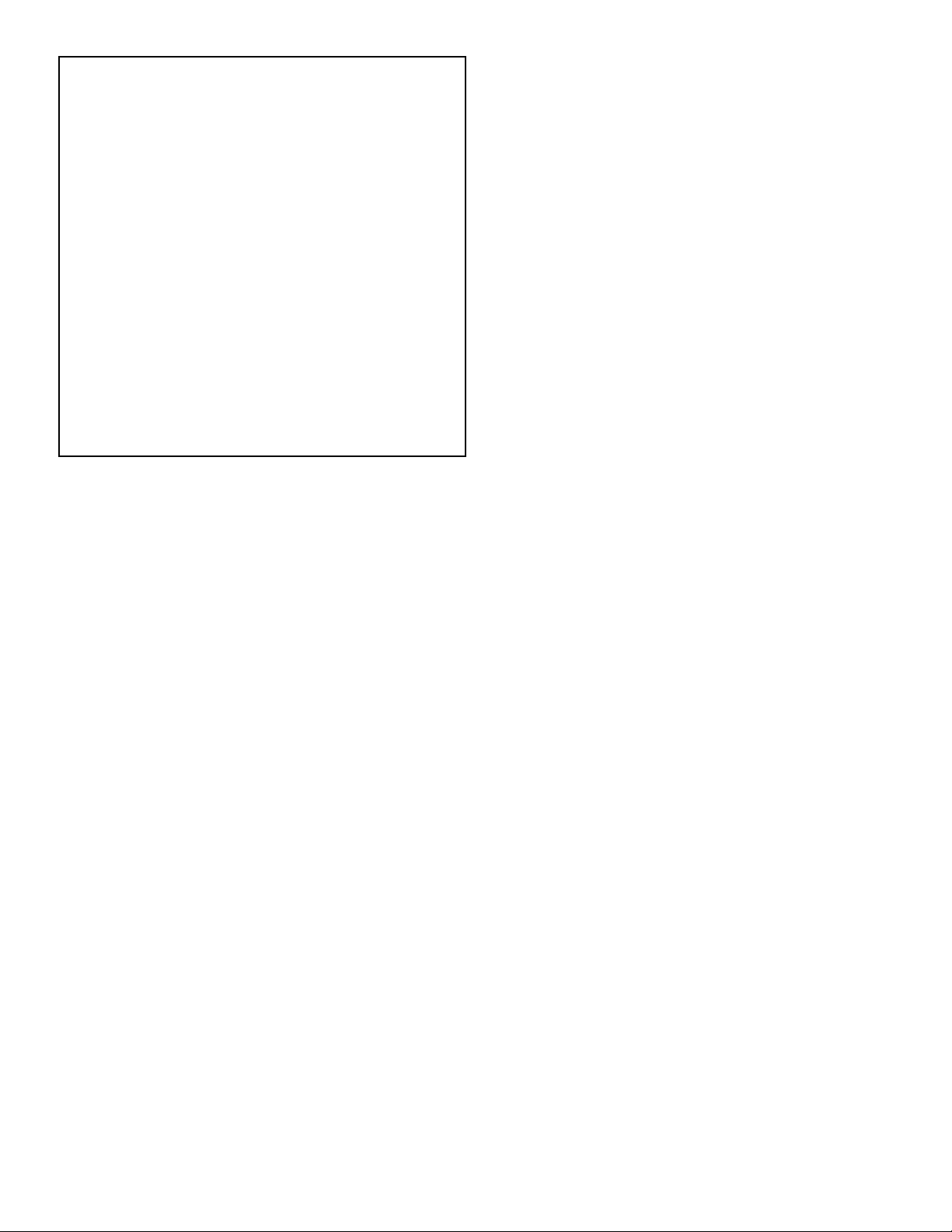

The winch clutch allows rapid unspooling of the wire

rope for hooking onto the load or anchor point. The

clutch is operated by the shifter located on the end of the

winch as follows:

1. To disengage the clutch,

turn the clutch shifter to

the "FREESPOOL" position. When the clutch is

in FREESPOOL, the

arrow on the clutch knob

will point to FREESPOOL

on the decal on the

winch. Wire rope may

now be freespooled off

the drum.

2. To engage the clutch, turn the clutch shifter to the

"ENGAGED" position. When the clutch is in ENGAGED

position, the arrow on the clutch knob will point to

ENGAGED on the decal on the winch. The winch is

now ready for pulling.

Note: Rope must be installed so that it feeds from

the bottom of the drum.

Unwind the new rope by rolling it out along the ground to

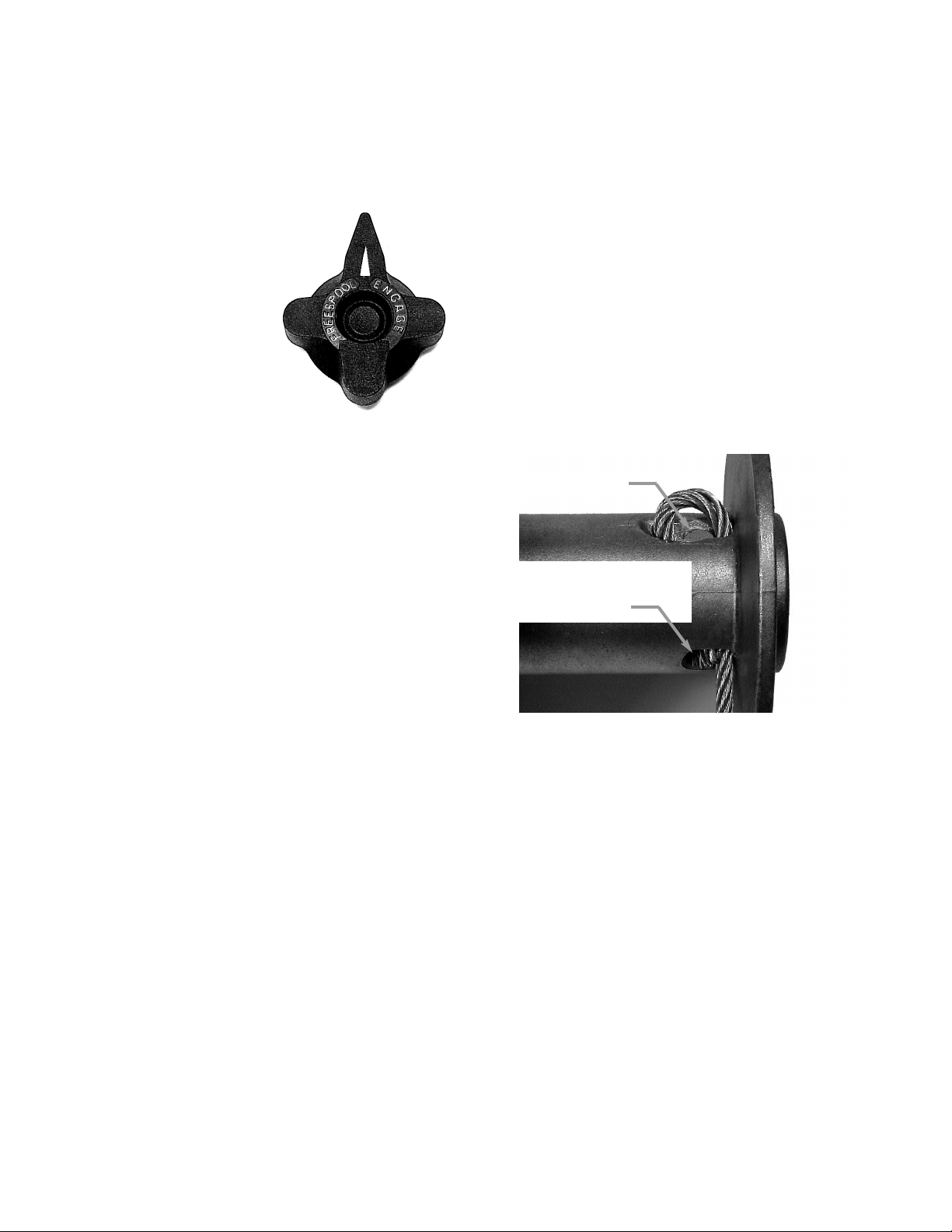

prevent kinking. Remove old rope and observe the manner in which it is attached to the rope drum flange,

watching carefully for the rope anchor puck.

Before installing the new rope assembly, securely wrap

the end of the rope with tape to prevent fraying.

Slide the rope through narrow end of the pocket against

drum flange and wrap the rope around the anchor puck.

Pull the rope and anchor back into the wide end of the

pocket leaving approximately 1/8” beyond edge of pocket as shown. Use a hammer and drift punch to drive the

back side of the wire rope, firmly seating the wire rope

and anchor into the pocket.

Anchor Puck

Your battery must be kept in good condition. A fully

charged battery and proper connections are essential.

Run the vehicle engine during winching operations to

keep battery charged.

Maintenance

Corrosion on electrical connections will reduce performance or may cause a short. Clean all connections. In

salty environments use a silicone sealer to protect from

corrosion.

All moving parts in the winch are permanently lubricated

with broad temperature range lithium based grease.

Lubricate rope periodically using light penetrating oil.

Inspect for broken strands and replace if necessary. If

the rope becomes worn or damaged, it must be

replaced.

The short end of the cable should

extend approximately 1/8” beyond

the top edge of pocket.

Wind on the rope by pulling in a light load to keep the

tension constant. Allow the rope to swivel by using a

length of chain or a swivel block between the rope hook

and the load.

4

Page 5

Electrical Connections

End of Service Measures

For normal self-recovery work, your existing electrical

system is adequate. Your battery should be kept in good

condition. A fully charged battery and proper connections are essential.

The solenoid assembly reverses the direction of rope

drum rotation.

CAUTION: BE SURE BATTERY CABLES ARE NOT

DRAWN TAUT ACROSS ANY SURFACES WHICH

COULD POSSIBLY DAMAGE THEM.

1. As shown on the schematic on the next page, con-

nect the red battery lead #13 and red lead from

winch control solenoid to the E-stop solenoid.

2. Install emergency stop switch, solenoid, and rocker

switch per kit # 282067.

2. Connect the black battery lead to the negative (-) ter-

minal of the battery.

3. Connect the black motor lead to the #2 pole of the

motor.

When winch reaches the end of it’s serviceable life,

dispose of per local environmental regulations.

4. Connect the black with yellow stripe motor lead to

the #1 pole of the motor.

5. The remote switch plugs into the receptacle on the

solenoid.

The remote control switch is waterproof. It has push button stations on either side. It is designed this way to prevent quick winch reversals which can lead to solenoid

failure. Make sure the motor has stopped fully before

reversing. To actuate winch, plug remote control switch

into the receptacle in the solenoid cover. Run winch forward and reverse to check connection and determine

winch operating directions. Snap appropriate “IN” and

“OUT” disc into proper thumb cavity. The switch is also

color coded to aid you in not having to guess which

direction your winch will run in. DO NOT LEAVE

SWITCH PLUGGED IN WHEN WINCH IS NOT IN USE.

5

Page 6

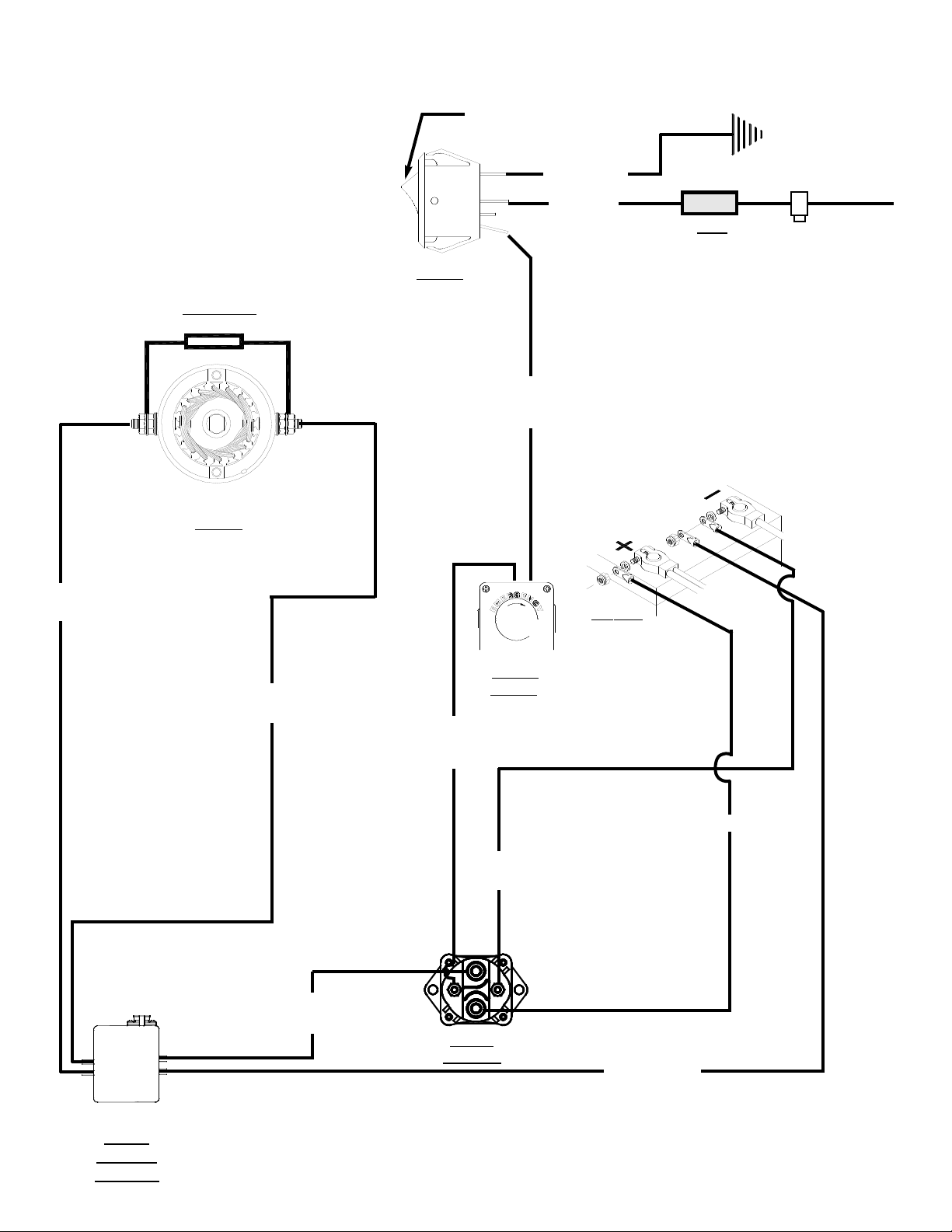

ELECTRICAL SCHEMATICS

3

2

1

#2

CAPACITOR

MOTOR

#1

SWITCH

Rocker switch

in OFF position

YELLOW

(FROM E-STOP

SWITCH)

BLACK

RED

5 amp

FUSE

GROUND

WIRE SPLICE

TO VEHICLE

IGNITION

BLACK MOTOR

LEAD

BLACK W/ YELLOW

STRIPE MOTOR LEAD

RED

LEAD

YELLOW

(FROM E-STOP

SWITCH)

(GROUND)

E-STOP

SOLENOID

BATTERY

E-STOP

SWITCH

RED (#13)

BLACK

BLACK

BATTERY LEAD

WINCH

CONTROL

SOLENOID

6

Page 7

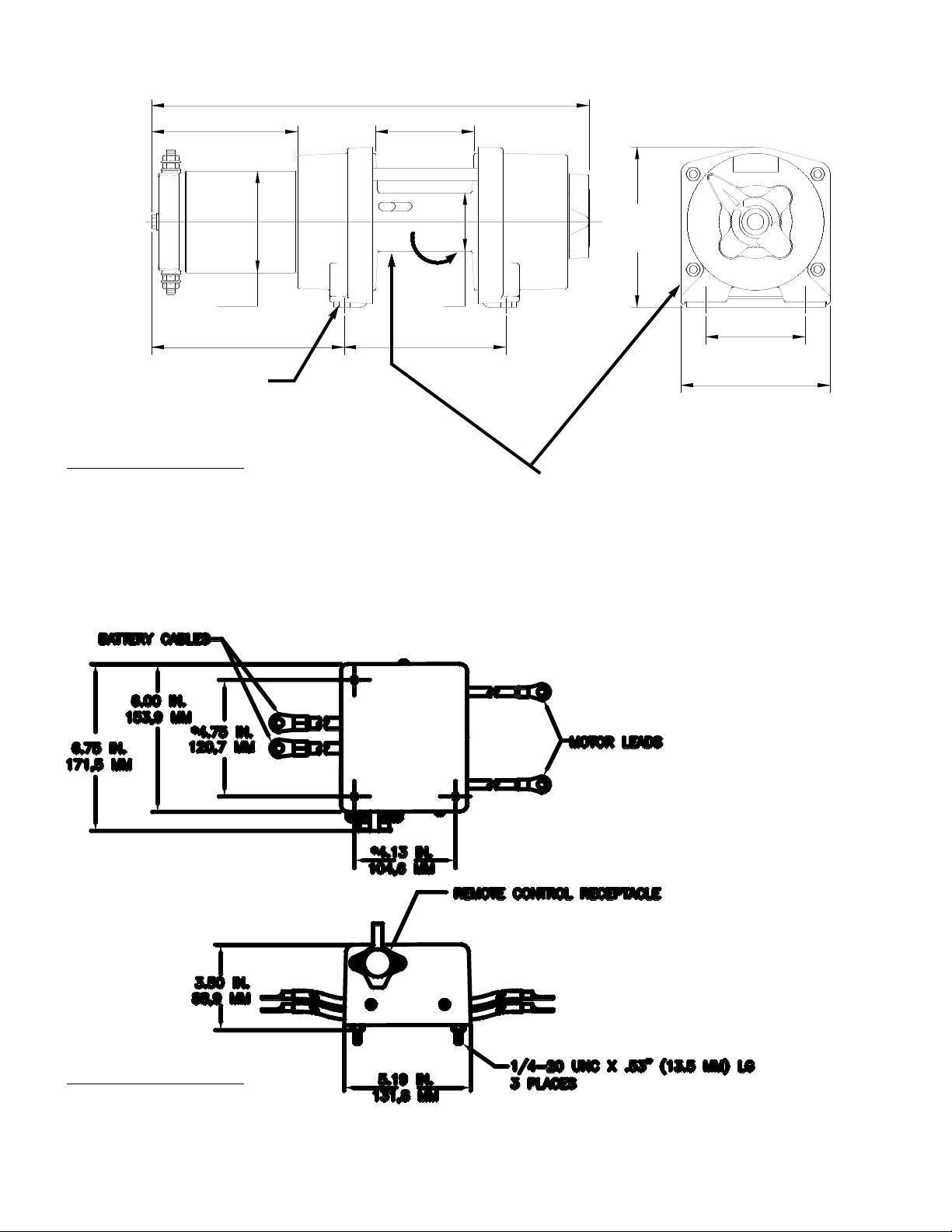

Winch Mounting

*

WARNING

LINE UNDER TENSION

CLUTCH WITH WINCH

DO NOT DISENGAGE

4.83

122,7

3.00

76,2

4.50

114,3

E

L

O

O

P

S

E

E

R

F

D

E

G

A

G

N

Ø3.00

76,2

5.80

147,4

4.88

124,0

DRUM

CABLE SPOOLS

"IN" UNDER DRUM

4.40

111,8

13.19

335,0

2.97

75,4

Ø1.75

44,4

*

5/16-18 NC

4 Places

*Mounting Hole P

attern

Four 11/32” (8,6 mm) diameter

holes on 4.88” (124 mm) x 3.00”

(76,2 mm) pattern

Solenoid Mounting

Cable must exit

under the drum

*Mounting Hole P

attern

Three 9/32” (7,1 mm) diameter

holes on 4.75” (120,7 mm) x

4.13” (104,9 mm) pattern

Note: Allow sufficient clearance

next to receptacle to plug remote

switch into.

7

Page 8

TROUBLESHOOTING

Defective remote switch plug

MOTOR RUNS IN ONLY

ONE DIRECTION

Defective solenoid or stuck sole

noid

MOTOR RUNS EXTREMELY HOT Long period of operation Cooling-off periods are essential to pre-

Insufficient battery.

MOTOR RUNS, BUT WITH

INSUFFICIENT POWER OR

WITH LOW LINE SPEED

Bad connection

Insufficient charging system

Disengage winch clutch, remove remote

control switch from the socket and jump

pins at 8 and 4 o'clock. Motor should

run. Jump pins at 8 and 10 o'clock.

Motor should run.

Jar solenoid assembly to free contacts.

Check each solenoid by applying +12

volts to coil-terminal (it should make an

audible click when energized).

vent overheating.

Test for faulty vehicle battery

Check battery cable for corrosion; clean

and grease.

Replace with larger capacity charging

system.

MOTOR RUNS, BUT DRUM

DOES NOT TURN

MOTOR WILL NOT OPERATE

MOTOR WATER DAMAGED

Clutch not engaged if clutch engaged but symptoms still

exist, it will be necessary to disassemble

winch to determine cause and repair.

Defective solenoid or stuck

solenoid.

Defective remote switch plug.

Defective motor.

Loose connections

Submerged in water or water from

high pressure car wash.

Jar solenoid assembly to free contacts.

Check each solenoid by applying +12

volts to coil-terminal (it should make an

audible click when energized).

Disengage winch clutch, remove remote

control switch from the socket and jump

pins at 8 and 4 o'clock. Motor should

run.

If solenoids operate, check for voltage at

armature post; replace motor.

Check all electrical connections from the

battery to the motor.

Allow to drain and dry thoroughly, then

run motor without load in short bursts to

dry windings.

8

Page 9

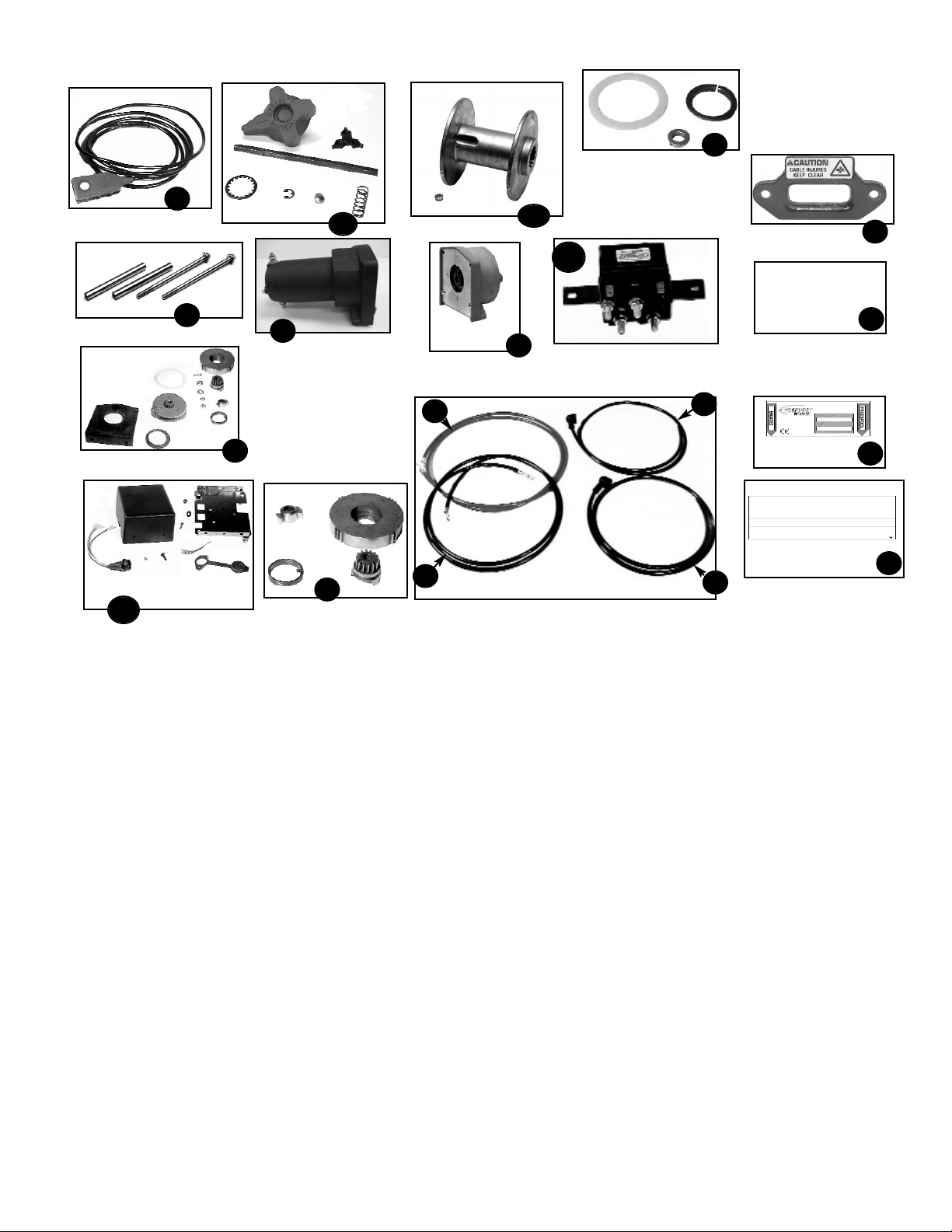

ATV 8 PARTS

INTENDED PURPOSE: VEHICLE RECOVERY AND PULLING OF LOADS.

READ OPERATING INSTRUCTIONS BEFORE USE FOR WARNINGS,

INSTALLATION AND OPERATING INSTRUCTIONS.

434577

MODEL: ATV 8

WIRE ROPE MIN. BREAKING STRENGTH: 16 kN

MAX. ROPE DIA: 5 mm

MAX LAYERS: 4 (10 M OF 5 mm ROPE)

1

4

2

3

16

8

NOT

SHOWN

5

7

6

17

12

9

13

11

10

ATV 8 PARTS LIST

ITEM NO. QTY. PART NO. DESCRIPTION

1 1 251110 REMOTE SWITCH ASSY

2 1 251191 CLUTCH KIT

3 1 251192 CABLE DRUM KIT

4 1 251195 BUSHING KIT

5 1 251196 TIE BAR KIT

6 1 251213 CLUTCH END GEAR KIT

7 1 251286 MOTOR KIT

8 1 251234 SOLENOID ASSEMBLY

9 1 251287 MOTOR END GEAR SET

10 1 251248 SOLENOID MOUNTING KIT

11 1 256116 BRAKE KIT

12 1 289197 72" BLACK BATTERY LEAD

13 1 289199 72" RED BATTERY LEAD

14 1 289203 48" BLACK MOTOR LEAD

15 1 289204 48" BLACK W/ YELLOW STRIPE MOTOR LEAD

16 1 422023 HAWSE FAIRLEAD

17 1 282067 E-STOP SWITCH KIT (NOT SHOWN)

18 1 434574 NAME AND DATA TAG

19 1 434577 WARNING TAG

14

18

19

15

9

Page 10

GUIDE DE L'UTILISATEUR

Treuil électrique modèle ATV 8 avec commutateur

de commande à distance à bouton-poussoir

English (Original Instructions) . . . . . . . . . . . . . . . 1

Français (Traduction des instructions originales) . . 10

Deutsch (Übersetzung der Originalanleitung) . . . . . 18

Español (Traducción de las instrucciones originales) 28

Traction du câble, première couche 8 kN (816,47 kg)

Niveau sonore 81 dB

Plage de température ambiante -28 à 60 °C

COUCHE DE CÂBLE 1 2 3 4

Traction nominale par

couche de câble

Capacité cumulative de

câble par couche

Traction du câble,

première couche

Intensité du moteur 12V 31 72 101

* Ces caractéristiques sont basées sur l'utilisation du câble métallique recommandé de 5

mm de calibre 1960

kN 8 6,6 5,3 4,8

lb 1,800 1,400 1,200 1,100

m 1,5 4,5 6 10,6

ft 5 15 20 37

kN À 2,6 5,3

lb vide 600 1,200 1800

6,6

135

AVERTISSEMENTS :

L'UTILISATEUR DOIT VEILLER À CE QUE TOUT

OPÉRATEUR REÇOIVE LA FORMATION

NÉCESSAIRE.

L'OPÉRATEUR DOIT TOUJOURS TRAVAILLER

EN CONFORMITÉ AVEC LES INSTRUCTIONS

D'UTILISATION.

L'EMBRAYAGE DOIT ÊTRE COMPLÈTEMENT

ENCLENCHÉ AVANT DE DÉMARRER LE

TREUIL.

NE JAMAIS RELÂCHER L'EMBRAYAGE EN

PRÉSENCE D'UNE CHARGE.

NE JAMAIS SE PLACER SOUS UNE CHARGE

SOULEVÉE NI À PROXIMITÉ.

RESTER À L'ÉCART DU CÂBLE LORS DU

TREUILLAGE. NE PAS ESSAYER DE GUIDER LE

CÂBLE.

NE PAS UTILISER LE TREUIL POUR

SOULEVER, MAINTENIR OU TRANSPORTER

DES PERSONNES.

IL CONVIENT DE CONSERVER AU MINIMUM

DEUX TOURS DE CÂBLE AUTOUR DU

TAMBOUR POUR MAINTENIR LA CHARGE.

ÉVITER TOUTE SITUATION DE DÉPLACEMENT

DE LA CHARGE OU D'À-COUPS. ÉVITER LES

MOUVEMENTS SACCADÉS.

Utilisation prévue : autodépannage de véhicules et traction de charges.

RAMSEY WINCH COMPANY

Post Office Box 581510 Tulsa, Oklahoma 74158-1510 USA

Phone: (918) 438-2760 Fax: (918) 438-6688

Visit us at http://ww.ramsey.com

Ramsey Représentant autorisé dans la comuauté

(Veuillez prendre contact uniquement pour des questions réglementaires.)

Alura Group BV

P.O. Box 18626

2502 EP The Hague

The Netherlands

Tel: (31) (0) 70 362-4896

Fax: (31) (0) 70 346-7299

MISE EN GARDE : S'ASSURER DE LIRE ET DE COMPRENDRE CE MANUEL AVANT D'INSTALLER ET D'UTILISER LE

TREUIL. PRENDRE CONNAISSANCE DES CONSIGNES DE SÉCURITÉ.

:

OM-914220-1012-B

Page 11

4707 N. Mingo Tulsa, Oklahoma 74117 (918) 438-2760

EC DECLARATION OF CONFORMITY

as defined by Machinery Directive 2006/42/EC

Here with we declare that winch model ATV 8 complies

with the following directive provided that the USER

complies with all responsibilities described in the

Owner’s Manual:

2006/42/EC

Applied harmonized standards:

EN 14492-1:2006

Power-Driven Winches

ISO 9001:2000

Quality Management Systems

Requirements

EC-KONFORMITÄTSERKLÄRUNG

gemäß Maschinenrichtlinie 2006/42/EC

Hiermit erklären wir, dass das Windenmodell ATV 8 der

folgenden Richtlinie entspricht, sofern der BENUTZER

alle Anweisungen im Benutzerhandbuch befolgt:

2006/42/EC

Angewandte harmonisierte Normen:

EN 14492-1:2006

Kraftgetriebene Winden

ISO 9001:2000 Qualitätsmanagementsysteme Anforderungen

DÉCLARATION DE CONFORMITÉ EC

aux termes de la directive Machines 2006/42/EC

Nous déclarons par la présente que le modèle de treuil ATV 8

est conforme à la directive suivante, sous réserve que

l’UTILISATEUR ait assumé toutes les responsabilités figurant

dans le manuel de l’utilisateur :

2006/42/EC

Normes harmonisées appliquées :

EN 14492-1:2006

Treuils motorisés

ISO 9001:2000

Systèmes de gestion de la qualité - Exigences

DECLARACIÓN EC DE CONFORMIDAD

según se define en la directiva de máquinas 2006/42/EC

Con la presente declaramos que el modelo de cabestrante

ATV 8 se halla en conformidad con la siguiente directiva

siempre que el USUARIO cumpla todas las

responsabilidades descritas en el Manual del propietario:

2006/42/EC

Normas armonizadas aplicadas:

EN 14492-1:2006

Cabestrantes accionados mecánicamente

ISO 9001:2000

Requisitos de los Sistema de gestión de la calidad

Ramsey Authorized Representative in the Community / Ramsey Représentant autorisé dans la comuauté /

Ramsey Bevollmächtigter in der Europäischen Union / Ramsey Representante autorizado en la comunidad:

(Veuillez prendre contact uniquement pour des questions réglementaires.)

Alura Group BV

P.O. Box 18626

2502 EP The Hague

The Netherlands

Tel: (31) (0) 70 362-4896

Fax: (31) (0) 70 346-7299

Serial Number / Numéro de série/ Seriennummer/ Número de Serie:_____________________

Signature / Signature / Unterschrift / Firma:

Todd Brady

Engineering Manager / Directeur technique/ Technischer Leiter/ Director de ingeniería

Date / Date / Datum / Fecha:

04-29-11

11

Page 12

Table des matières

Caractéristiques . . . . . . . . . . . . . . . . . . . . .couverture

Responsabilité de l'utilisateur pour la

conformité CE . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Consignes de sécurité . . . . . . . . . . . . . . . . . . . . . .11

Installation du treuil . . . . . . . . . . . . . . . . . . . . . . . .11

Fonctionnement . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Entretien . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Installation du câble . . . . . . . . . . . . . . . . . . . . . . . .12

Branchements électriques . . . . . . . . . . . . . . . . . . .13

Mesures de mise hors service . . . . . . . . . . . . . . . .13

Schéma de câblage . . . . . . . . . . . . . . . . . . . . . . . .14

Pose du treuil . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Guide de dépannage . . . . . . . . . . . . . . . . . . . . . . .16

Nomenclature des pièces . . . . . . . . . . . . . . . . . . .17

Déclaration de conformité CE . . . . . . . . . . . . . . . . .19

Responsabilité de l'utilisateur pour la

conformité CE

1. Monter le treuil conformément aux instructions d'installation

du treuil.

2. Installer le commutateur d'arrêt d'urgence conformément

aux instructions d'installation fournies avec le coffret du

commutateur d'arrêt d'urgence.

3. Installer le câble métallique de 5 mm de calibre 1960.

Longueur de câble maximale de 10,6 m pour quatre

couches maximum.

4. Fixer le câble au tambour conformément aux instructions

d'installation du câble.

5. Utiliser un crochet équipé d'un verrou de sécurité et doté

d'une résistance à la rupture de 20 kN minimum.

F. Déconnecter la télécommande du treuil lorsqu'il

est en repos.

G. Ne pas utiliser le treuil pour le grutage : n'étant pas

fabriqué dans ce but, il n'est pas conforme aux normes

de sécurité pour les levages.

H. Le câble doit être un peu tendu pour bien se

rembobiner. Ne pas tenir le câble et le laisser glisser

sur la main ; ne pas s'approcher trop près du treuil.

I. Examiner l'enroulement du câble sur le tambour. Les

tensions latérales peuvent causer l'empilement du

câble sur un côté du tambour. Pour corriger cette

anomalie, dérouler la section empilée et la déplacer

vers l'autre côté du tambour, puis continuer le

treuillage. Un enroulement irrégulier, provoquant un

empilement du câble, peut nuire à l'action des tirants

du treuil et endommager ce dernier.

J. Un enroulement uniforme et serré empêche le blocage

du câble. Une tension « lâche » peut en effet

provoquer un pincement du câble et le coincer. Si le

câble se coince, sortir puis rentrer à quelques reprises

le câble de quelques centimètres à l'aide du treuil.

Ne jamais essayer de décoincer un câble tendu avec

les mains.

Installation du treuil

1. Serrer les boulons à un couple de 21,6 Nm.

2. Ne pas fixer le moteur ni les câbles de batterie avant

d'en avoir reçu la consigne.

3. Il est très important de fixer le treuil sur une

surface plane ; le câble doit sortir par la partie

inférieure du tambour (voir le dessin des

dimensions à la page 15).

Consignes de sécurité

A. Se tenir à une distance latérale de sécurité pendant

le treuillage.

B. Ne pas enjamber le câble sous charge, ni s'en

approcher.

C. Protéger les mains des ébarbures avec un chiffon

épais ou des gants lors de la manipulation du câble.

D. Toute manipulation du treuil dans le but de le modifier

doit être confiée à la société Ramsey Winch Company.

E. La durée des tractions doit être aussi courte que

possible. Si le moteur devient trop chaud au toucher,

arrêter et le laisser refroidir quelques minutes. Ne pas

tirer pendant plus d'une minute à la capacité nominale

de traction du treuil (ou proche de celle-ci). Couper

l'alimentation du treuil si le moteur cale. Les treuils

électriques sont étudiés pour un usage intermittent et

ne doivent pas rester en service continu.

MISE EN GARDE : Les boulons de fixation de

22,6 mm fournis avec des rondelles sont

prévus pour une plaque de fixation du treuil

d'épaisseur recommandée de 4,7 mm. Si une

plaque de fixation d'épaisseur différente est

utilisée, les boulons devront alors être à la

longueur appropriée, sinon le treuil pourrait

subir des dommages. Ces nouveaux boulons

doivent être SAE 5 ou équivalent.

12

Page 13

Fonctionnement

Installation du câble

L'embrayage favorise le déroulement rapide du câble

pour l'accrocher à la charge ou au point d'ancrage. Il est

commandé par un bouton qui se trouve à l'extrémité

du treuil :

1. Pour débrayer le

tambour, tourner le

bouton à la position

« FREESPOOL »

(roue libre). Lorsque

l'embrayage est en

position « FREESPOOL »,

la flèche sur le bouton

d'embrayage est orientée

vers « FREESPOOL » sur

l'autocollant du treuil.

Le câble peut être alors

déroulé librement du tambour.

2. Pour embrayer le tambour, tourner le bouton à la

position « ENGAGED » (embrayé). Lorsque

l'embrayage est en position « ENGAGED », la flèche

sur le bouton d'embrayage est orientée vers

« ENGAGED » sur l'autocollant du treuil. Le treuil est

maintenant prêt à tirer.

Remarque : installer le câble de façon à ce qu'il

sorte par le bas du tambour.

Dérouler le câble neuf sur le sol pour éviter qu'il se torde.

Déposer le câble usé en vérifiant comment il est fixé

au tambour (examiner en particulier le galet d'ancrage

du câble).

Avant de placer le nouveau câble, protéger l'extrémité

opposée au crochet en l'enveloppant avec du ruban

bien serré.

Insérer le câble dans la partie étroite du logement

(tout contre la joue du tambour) puis l'enrouler sur le

galet d'ancrage. Enfiler à nouveau le câble, cette fois

dans la partie large du logement, et le faire sortir

d'environ 3 mm. Avec un marteau et un chasse-goupille,

acheminer l'arrière du câble pour le fixer solidement avec

l'ancrage dans le logement.

Galet d'ancrage

Le câble doit ressortir d'environ

3 mm du logement.

La batterie doit être maintenue en bon état (une batterie

complètement chargée et des branchements corrects

sont essentiels). Laisser tourner le moteur du véhicule

pendant les treuillages afin de conserver la charge de

la batterie.

Entretien

La corrosion des connexions électriques compromet

le rendement du treuil ou risque de provoquer un courtcircuit. Nettoyer toutes les connexions. En milieux salins,

appliquer une pâte à base de silicone comme protection

anticorrosion.

Toutes les pièces mobiles du treuil ont été lubrifiées de

façon permanente avec de la graisse au lithium

(plage de températures étendue).

Le câble doit être lubrifié régulièrement avec de l'huile

légère pénétrante. Inspecter le câble et le remplacer s'il

est éraillé. Un câble usé ou endommagé doit être

immédiatement remplacé.

Enrouler le câble en tirant une charge légère pour qu'il

reste tendu. Permettre au câble de pivoter en plaçant une

chaîne ou une poulie à émerillon entre le crochet et la

charge.

13

Page 14

Branchements électriques

Mesures de mise hors service

Le système électrique existant est adéquat pour tout

travail d'autodépannage normal. La batterie doit être

maintenue en bon état (une batterie complètement

chargée et des branchements corrects sont essentiels).

Le solénoïde inverse le sens de rotation du tambour.

MISE EN GARDE : VÉRIFIER QUE LES CÂBLES DE

BATTERIE NE SONT PAS TROP TENDUS EN TRAVERS

D'UNE SURFACE QUI RISQUERAIT DE LES

ENDOMMAGER.

1. Comme le montre le schéma de la page suivante,

brancher le câble rouge de la batterie n° 13 et le

câble rouge du solénoïde de commande du treuil sur

le solénoïde d'arrêt E.

2. Installer le commutateur d'arrêt d'urgence, le

solénoïde et l'interrupteur à bascule conformément

au coffret n° 282067.

3. Brancher le câble noir de la batterie sur la borne

négative (-) de la batterie.

Lorsque le treuil arrive en fin de vie, le mettre au

rebut conformément à la règlementation

environnementale locale.

4. Brancher le câble noir moteur sur la borne n° 2

du moteur.

5. Brancher le câble noir moteur strié de jaune sur la

borne n° 1 du moteur.

6. La télécommande est branchée sur la prise

du solénoïde.

La télécommande est étanche. Elle comporte un

dispositif de commande de chaque côté. Ces dispositifs

sont destinés à éviter les inversions rapides de sens de

fonctionnement du treuil, pouvant causer une défaillance

du solénoïde. S'assurer que le moteur du treuil est

entièrement arrêté avant toute inversion. Pour mettre en

service le treuil, brancher la télécommande sur la prise

du couvercle du solénoïde. Faire fonctionner le treuil en

avant et en arrière pour vérifier les branchements et

déterminer les sens de fonctionnement. Enclencher les

disques IN (Enroulement) et OUT (Déroulement) dans les

cavités appropriées. Ce commutateur comporte

également un code couleur afin de vous aider à ne pas

avoir à deviner le sens de fonctionnement de votre treuil.

NE PAS LAISSER LE COMMUTATEUR BRANCHÉ

LORSQUE LE TREUIL N'EST PAS UTILISÉ.

14

Page 15

SCHÉMA DE CÂBLAGE

3

2

1

#2

CONDENSATEUR

MOTEUR

#1

Interrupteur à bascule

en position « OFF »

COMMUTATEUR

(DU COMMUTATEUR

JAUNE

D'ARRÊT E)

NOIR

ROUGE

5 A

FUSIBLE

MISE À LA TERRE

JONCTION DE CÂBLE

VERS

L'ALLUMAGE

DU VÉHICULE

CÂBLE NOIR

MOTEUR

CÂBLE NOIR MOTEUR

STRIÉ DE JAUNE

CÂBLE

ROUGE

COMMUTATEUR

D'ARRÊT E

JAUNE

(DU COMMUTATEUR

D'ARRÊT E)

(MISE À LA TERRE)

SOLÉNOÏDE

D'ARRÊT E

BATTERIE

ROUGE (n° 13)

NOIR

CÂBLE

NOIR BATTERIE

SOLÉNOÏDE

DE

COMMANDE

DU TREUIL

15

Page 16

Pose du treuil

*

AVERTISSEMENTNE

4.83

122,7

3.00

76,2

4.50

114,3

E

L

O

O

P

S

E

E

R

F

D

E

G

A

G

N

Ø3.00

76,2

5.80

147,4

4.88

124,0

TAMBOUR

ENROULEMENTS DU

CÂBLE SOUS LE TAMBOUR

4.40

111,8

13.19

335,0

2.97

75,4

Ø1.75

44,4

*

RELÂCHEZ JAMAIS L'EMBRAYAGE

AVEC SI LE CABLE DU TREUIL

EST SOUS TENSION

CÂBLES DE BATTERIE

CÂBLES DE MOTEUR

PRISE DE TÉLÉCOMMANDE

6.00 IN.

153,9 MM

6.75 IN.

3 EMPLACEMENTS

171,5 MM

*4.75 IN.

120,7 MM

*4.13 IN.

104,6 MM

3.50 IN.

88,9 MM

5.19 IN.

131,8 MM

1/4-20 UNC X 13,5 MM LONG.

5/16-18 NC

4 emplacements

*Agencement des trous de montage

Quatre trous, diamètre 8,6 mm sur un

agencement de 124 mm x 76,2 mm

Pose du solénoïde

Le câble doit sortir par

le bas du tambour

*Agencement des trous de montage

Trois trous, diamètre 7,1 mm sur un

agencement de 120,7 mm x 104,9 mm

16

Remarque : prévoir un dégagement

suffisant à côté de la prise pour y

brancher la télécommande.

Page 17

GUIDE DE DÉPANNAGE

LE MOTEUR TOURNE DANS UN

SEUL SENS.

LE MOTEUR SURCHAUFFE.

LE MOTEUR TOURNE, MAIS AVEC UNE

PUISSANCE INSUFFISANTE OU UNE FAIBLE

VITESSE DE TRACTION.

Prise de télécommande défectueuse.

Solénoïde bloqué ou défectueux.

Trop longue utilisation.

Tension de batterie insuffisante.

Mauvaise connexion.

Système de charge insuffisant.

Débrayer le tambour, débrancher la

télécommande, puis établir un pont entre les

broches à 8 et à 4 heures. Le moteur devrait

tourner. Établir un pont entre les broches à 8 et

à 10 heures. Le moteur devrait tourner.

Secouer le solénoïde pour libérer les contacts.

Vérifier si la borne de la bobine émet un déclic

lorsque l'on y applique une tension de 12 volts.

Il est indispensable d'observer des périodes de

refroidissement pour éviter la surchauffe.

Vérifier l'état de la batterie du véhicule.

Vérifier les câbles de batterie (corrosion), et

nettoyer ou graisser au besoin.

Remplacer par un système de charge

plus puissant.

LE MOTEUR TOURNE, MAIS PAS LE

TAMBOUR.

LE MOTEUR REFUSE DE TOURNER.

MOTEUR IMMERGÉ.

Le tambour n'est pas embrayé. Si le tambour est embrayé, mais refuse de

tourner, le treuil doit alors être démonté pour

déterminer la cause de l'anomalie et faire la

réparation.

Solénoïde bloqué ou défectueux.

Prise de télécommande défectueuse.

Moteur défectueux.

Connexions lâches.

Le moteur a été plongé dans l'eau ou

a traversé un poste de lavage

haute pression.

Secouer le solénoïde pour libérer les contacts.

Vérifier si la borne de la bobine émet un déclic

lorsque l'on y applique une tension de 12 volts.

Débrayer le tambour, débrancher la

télécommande, puis établir un pont entre

les broches à 8 et à 4 heures. Le moteur

devrait tourner.

Si le solénoïde fonctionne, vérifier la tension à la

borne de l'induit ; remplacer le moteur.

Vérifier les connexions électriques entre la

batterie et le moteur.

Laisser s'égoutter et sécher complètement, puis

faire tourner à vide le moteur par à-coups pour

faire sécher l'armature.

17

Page 18

PIÈCES DE L'ATV 8

INTENDED PURPOSE: VEHICLE RECOVERY AND PULLING OF LOADS.

READ OPERATING INSTRUCTIONS BEFORE USE FOR WARNINGS,

INSTALLATION AND OPERATING INSTRUCTIONS.

434577

MODEL: ATV 8

WIRE ROPE MIN. BREAKING STRENGTH: 16 kN

MAX. ROPE DIA: 5 mm

MAX LAYERS: 4 (10 M OF 5 mm ROPE)

1

5

4

2

3

16

8

NON

ILLUSTRÉ

7

6

17

12

9

13

11

10

14

15

NOMENCLATURE DE L'ATV 8

Nº PIÈCE QTÉ RÉFÉRENCE DESCRIPTION

1 1 251110 TÉLÉCOMMANDE

2 1 251191 EMBRAYAGE

3 1 251192 TAMBOUR

4 1 251195 JEU DE BAGUES

5 1 251196 JEU DE TIRANTS

6 1 251213 RÉDUCTEUR

7 1 251286 MOTEUR

8 1 251234 SOLÉNOÏDE

9 1 251287 TRAIN D'ENGRENAGE DU MOTEUR

10 1 251248 LOT DE MONTAGE DU SOLÉNOÏDE

11 1 256116 FREIN

12 1 289197 CÂBLE NOIR BATTERIE 1,8 M

13 1 289199 CÂBLE ROUGE BATTERIE 1,8 M

14 1 289203 CÂBLE NOIR MOTEUR 1,2 M

15 1 289204 CÂBLE NOIR MOTEUR STRIÉ DE JAUNE 1,2 M

16 1 422023 GUIDE-CÂBLE À ÉCUBIER

17 1 282067 COFFRET DU COMMUTATEUR D'ARRÊT E (NON ILLUSTRÉ)

18 1 434574 ÉTIQUETTE SIGNALÉTIQUE

19 1 434577 ÉTIQUETTE D'AVERTISSEMENT

18

19

18

Page 19

BENUTZERHANDBUCH

Elektrische Winde Modell ATV 8

mit Drucktasten-Fernbedienungsschalter

English (Original Instructions) . . . . . . . . . . . . . . . 1

Français (Traduction des instructions originales) . . 10

Deutsch (Übersetzung der Originalanleitung) . . . . . 18

Español (Traducción de las instrucciones originales) 28

Seilzugkraft, erste Lage 8 Kn (816,47 kg)

Lärmpegel 81 db

Umgebungstemperaturbereich -28 bis 60 °C

SEILLAGE 1 2 3 4

kN 8 6,6 5,3 4,8

Nominale Zugkraft pro Lage

lb 1,800 1,400 1,200 1,100

Kumulative Seilaufnahme pro

Lage

Seilzugkraft, erste Lage

Stromaufnahme 12V 31 72 101

* Diese technischen Daten basieren auf dem empfohlenen Drahtseil (5 mm Drahtstärke, Sorte

1960).

m 1,5 4,5 6 10,6

ft 5 15 20 37

kN Ohne 2,6 5,3

lb Last 600 1,200 1800

6,6

135

WARNHINWEISE:

DER BENUTZER MUSS SICHERSTELLEN,

DASS DAS BEDIENPERSONAL DIE

ERFORDERLICHE SCHULUNG ERHÄLT.

DER BEDIENER MUSS BEIM BETRIEB STETS

DIE BEDIENUNGSANWEISUNGEN BEFOLGEN.

VOR BEGINN DES WINDENBETRIEBS MUSS

SICHERGESTELLT WERDEN, DASS DIE

KUPPLUNG VOLLSTÄNDIG EINGERÜCKT IST.

DIE KUPPLUNG NICHT UNTER LAST

AUSRÜCKEN.

NIEMALS UNTER ODER NEBEN

ANGEHOBENEN LASTEN STEHEN.

WÄHREND DES ZIEHENS EINEN SICHEREN

ABSTAND ZUM SEIL EINHALTEN. NICHT

VERSUCHEN, DAS SEIL ZU LENKEN.

DIE WINDE NICHT ZUM HEBEN, TRAGEN

ODER ANDERWEITIGEN TRANSPORT VON

PERSONEN VERWENDEN.

ZUM HALTEN DER LAST SIND MINDESTENS 2

SEILWICKLUNGEN UM DEN

TROMMELZYLINDER NOTWENDIG.

BEDINGUNGEN VERMEIDEN, BEI DENEN SICH

DIE LAST VERSCHIEBT ODER RUCKARTIGE

BEWEGUNGEN VORKOMMEN.

ÜBERMÄSSIGEN „TIPPBETRIEB“

VERMEIDEN

.

RAMSEY WINCH COMPANY

Post Office Box 581510 Tulsa, Oklahoma 74158-1510 USA

Phone: (918) 438-2760 Fax: (918) 438-6688

Visit us at http://ww.ramsey.com

Ramsey Bevollmächtigter in der Europäischen Union

(Bitte nur bei Regulierungsfragen kontaktieren.)

Alura Group BV

P.O. Box 18626

2502 EP The Hague

The Netherlands

Tel: (31) (0) 70 362-4896

Fax: (31) (0) 70 346-7299

ACHTUNG: VOR DER INSTALLATION UND INBETRIEBNAHME DER WINDE MUSS DIESES HANDBUCH GELESEN UND

VERSTANDEN WERDEN. SIEHE VORSICHTSMASSNAHMEN.

:

OM-914220-1012-B

Page 20

4707 N. Mingo Tulsa, Oklahoma 74117 (918) 438-2760

EC DECLARATION OF CONFORMITY

as defined by Machinery Directive 2006/42/EC

Here with we declare that winch model ATV 8 complies

with the following directive provided that the USER

complies with all responsibilities described in the Owner’s

Manual:

2006/42/EC

Applied harmonized standards:

EN 14492-1:2006

Power-Driven Winches

ISO 9001:2000

Quality Management Systems

Requirements

EC-KONFORMITÄTSERKLÄRUNG

gemäß Maschinenrichtlinie 2006/42/EC

Hiermit erklären wir, dass das Windenmodell ATV 8 der

folgenden Richtlinie entspricht, sofern der BENUTZER

alle Anweisungen im Benutzerhandbuch befolgt:

2006/42/EC

Angewandte harmonisierte Normen:

EN 14492-1:2006

Kraftgetriebene Winden

ISO 9001:2000 Qualitätsmanagementsysteme Anforderungen

DÉCLARATION DE CONFORMITÉ EC

aux termes de la directive Machines 2006/42/EC

Nous déclarons par la présente que le modèle de treuil ATV 8

est conforme à la directive suivante, sous réserve que

l’UTILISATEUR ait assumé toutes les responsabilités figurant

dans le manuel de l’utilisateur :

2006/42/EC

Normes harmonisées appliquées :

EN 14492-1:2006

Treuils motorisés

ISO 9001:2000

Systèmes de gestion de la qualité - Exigences

DECLARACIÓN EC DE CONFORMIDAD

según se define en la directiva de máquinas 2006/42/EC

Con la presente declaramos que el modelo de cabestrante

ATV 8 se halla en conformidad con la siguiente directiva

siempre que el USUARIO cumpla todas las

responsabilidades descritas en el Manual del propietario:

2006/42/EC

Normas armonizadas aplicadas:

EN 14492-1:2006

Cabestrantes accionados mecánicamente

ISO 9001:2000

Requisitos de los Sistema de gestión de la calidad

Ramsey Authorized Representative in the Community / Ramsey Représentant autorisé dans la comuauté /

Ramsey Bevollmächtigter in der Europäischen Union / Ramsey Representante autorizado en la comunidad:

(Bitte nur bei Regulierungsfragen kontaktieren.)

Alura Group BV

P.O. Box 18626

2502 EP The Hague

The Netherlands

Tel: (31) (0) 70 362-4896

Fax: (31) (0) 70 346-7299

Serial Number / Numéro de série/ Seriennummer/ Número de Serie:_____________________

Signature / Signature / Unterschrift / Firma:

Todd Brady

Engineering Manager / Directeur technique/ Technischer Leiter/ Director de ingeniería

Date / Date / Datum / Fecha:

04-29-11

20

Page 21

Inhaltsverzeichnis

Technische Daten . . . . . . . . . . . . . . . . . . . . .Titelseite

Benutzerverantwortung für CE-Compliance . . . . . . .20

Vorsichtsmaßnahmen . . . . . . . . . . . . . . . . . . . . . . .20

Windeninstallation . . . . . . . . . . . . . . . . . . . . . . . . .20

Betrieb . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Wartung . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Installation des Seils . . . . . . . . . . . . . . . . . . . . . . .21

Elektrische Anschlüsse . . . . . . . . . . . . . . . . . . . . . .22

Außerbetriebssetzung . . . . . . . . . . . . . . . . . . . . . . .22

Elektroschaltpläne . . . . . . . . . . . . . . . . . . . . . . . . .23

Installation der Winde . . . . . . . . . . . . . . . . . . . . . . .24

Fehlersuche . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Teileliste (Winde) . . . . . . . . . . . . . . . . . . . . . . . . . .26

CE-Konformitätserklärung . . . . . . . . . . . . . . . . . . .27

Benutzerverantwortung für EG-Compliance

1. Die Winde gemäß den Windeninstallationsanweisungen

montieren.

2. Den Notstoppschalter gemäß den mit dem

Notstoppschalter-Anbausatz gelieferten

Installationsanweisungen installieren.

3. Drahtseil (5 mm Drahtstärke, Sorte 1960) installieren.

Es gilt eine maximale Seillänge von 10,6 m für maximal

4 Lagen.

4. Das Seil gemäß den Seilinstallationsanweisungen an der

Trommel befestigen.

5. Einen Haken verwenden, der einer Sicherheitssperre und

eine minimale Abreißfestigkeit von 20 kN aufweist.

F. Bei Nichtgebrauch den Fernbedienungsschalter von der

Winde trennen.

G. Die Winde aufgrund erforderlicher Hubsicherheitsfaktoren

und -eigenschaften nicht in Hubanwendungen

verwenden.

H. Für korrektes Aufspulen muss eine geringe Last am

Drahtseil unterhalten werden. Das Drahtseil nicht durch

die Hand gleiten lassen und nicht zu nahe an die

Winde treten.

I. Aufspulen des Seils auf Trommel beobachten. Seitlicher

Zug kann Seilstau am Ende der Trommel bewirken. Um

ungleichmäßige Stapelung zu korrigieren, den betroffenen

Abschnitt des Seils abspulen und auf die andere Seite der

Trommel verlegen und dann weiterwinden.

Ungleichmäßiges Spulen kann zu Seilstau führen, der

die Zugstangen der Winde und die Winde selbst

beschädigen kann.

J. Ordentliches, sattes Aufspulen vermeidet

Seilverklemmung, was auftritt, wenn eine Last angelegt

wird und das Seil zwischen zwei früheren Wicklungen

von Seil eingeklemmt wird. Falls dies passiert, die Winde

abwechslungsweise ein paar Zentimeter ein- und

auswinden lassen. Niemals versuchen, ein

eingeklemmtes, unter Last stehendes Seil von Hand zu

befreien.

Windeninstallation

1. Die Befestigungsschrauben auf 21,6 Nm festziehen.

2. Die Motor- und Batterieklemmen erst nach

entsprechender Anweisung anbringen.

Vorsichtsmaßnahmen

A. Man muss sich und andere müssen sich beim

Ziehen unter Last seitlich des Seils in sicherer

Entfernung aufhalten.

B. Nicht in die Nähe eines Drahtseils unter Last treten bzw.

ein solches übersteigen.

C. Zum Schutz der Hände vor Graten beim Handhaben des

Windenseils einen schweren Lappen oder Handschuhe

verwenden.

D. Modifikation, Abänderung oder Anpassung der Winde

sollte ausschließlich durch Ramsey Winch Company

durchgeführt werden.

E. Die Dauer der Ziehvorgänge möglichst kurz halten. Falls

sich der Motor beunruhigend heiß anfühlt, den Vorgang

stoppen und den Motor ein paar Minuten abkühlen

lassen. Nicht mehr als eine Minute lang im Bereich der

Nennlast der Winde ziehen. Bei Absterben des Motors die

Stromversorgung zur Winde unterbrechen. Elektrische

Winden eignen sich für kurzzeitige Einsätze und nicht für

Anwendungen mit Dauerbetrieb.

3. Es ist sehr wichtig, dass die Winde an eine ebene

Oberfläche angebaut wird, wobei das Drahtseil

gemäß der Maßzeichnung auf Seite 24 unten

durchgeführt wird.

ACHTUNG: Die gelieferten 22,6 mm

Befestigungsschrauben mit Sicherungsscheiben

sind für eine Winden-Anbauplatte mit einer

Stärke von 4,7 mm empfohlen. Falls eine

Anbauplatte mit einer anderen Stärke

verwendet wird, muss die Schraubenlänge

entsprechend angepasst werden, da ansonsten

die Winde beschädigt werden kann.

Ersatzschrauben müssen die SAE-Spezifikation

für Sorte 5 erfüllen oder übertreffen

21

Page 22

Betrieb

Installation des Seils

Die Windenkupplung ermöglicht schnelles Abspulen des

Drahtseils zum Einhaken an der Last oder am

Verankerungspunkt. Die Kupplung wird durch den Hebel

am Ende der Winde wie folgt betätigt:

1. Um die Kupplung

auszurücken, den

Kupplungshebel in die

Position FREESPOOL

(Freilauf) drehen. Wenn

sich die Kupplung im

FREILAUF befindet, zeigt

der Pfeil am

Kupplungsknopf auf

FREESPOOL (Aufkleber

an der Winde).

Das Drahtseil kann jetzt

frei von der Trommel abgespult werden.

2. Um die Kupplung einzurücken, den Kupplungshebel in

die Position ENGAGED (Eingerückt) drehen. Wenn die

Kupplung EINGERÜCKT ist, zeigt der Pfeil am

Kupplungsknopf auf ENGAGED (Aufkleber an der

Winde). Die Winde ist jetzt zum Ziehen bereit.

Anmerkung: Das Drahtseil muss so installiert

werden, dass es an der Unterseite der Trommel

beginnt.

Zum Abwickeln das neue Drahtseil am Boden entlang

auslegen, um Knicken zu vermeiden. Das alte Drahtseil

entfernen und beachten, wie es am Trommelflansch

befestigt ist, und insbesondere auf die

Drahtseilverankerung achten.

Vor Installation einer neuen Drahtseilbaugruppe zur

Vermeidung von Ausfransen das Ende des Drahtseils fest

mit Band umwickeln.

Das Drahtseil durch das schmale Ende der Öffnung

gegen den Trommelflansch einführen und das Drahtseil

um die Seilverankerung wickeln. Das Drahtseil und die

Verankerung in das weite Ende der Öffnung zurückziehen,

sodass das Seil wie abgebildet ungefähr 3 mm über den

Rand der Öffnung vorsteht. Mit einem Hammer die

Rückseite des Drahtseils durchtreiben, bis das Drahtseil

und die Verankerung fest in der Öffnung sitzen.

Seilverankerung

Die Batterie muss in gutem Zustand gehalten werden.

Es ist sehr wichtig, dass die Batterie vollständig

aufgeladen ist und die Anschlüsse korrekt

vorgenommen wurden. Den Fahrzeugmotor während

des Windenbetriebs laufen lassen, damit die Batterie

aufgeladen bleibt.

Wartung

Bei Korrosion an den elektrischen Anschlüssen kann die

Leistung beeinträchtigt und ein Kurzschluss verursacht

werden. Alle Anschlüsse reinigen. Bei salzhaltigen

Umfeldbedingungen sollte zum Schutz vor Korrosion ein

Silikondichtmittel verwendet werden.

Alle beweglichen Teile in der Winde werden mit

temperatur-tolerantem lithiumbasiertem Schmiermittel

ständig geschmiert.

Das Drahtseil regelmäßig mit einem leichten Penetrieröl

schmieren. Auf gebrochene Litzen überprüfen und

nötigenfalls ersetzen. Ein abgenutztes oder beschädigtes

Drahtseil muss ersetzt werden.

Das kurze Ende des Kabels sollte

ungefähr 3 mm über den oberen

Rand der Öffnung vorstehen.

Das Drahtseil durch Einziehen einer leichten Last für

gleichmäßige Spannung aufwickeln. Das Drahtseil

hin- und herschwenken lassen; dazu ein Kettenglied oder

einen Wirbelblock zwischen dem Drahtseil und der Last

verwenden.

22

Page 23

Elektrische Anschlüsse

Außerbetriebssetzung

Das elektrische System Ihres Fahrzeuges ist für normale

Abschlepp-/Bergungsarbeiten ausreichend. Die Batterie

muss in gutem Zustand gehalten werden. Es ist sehr

wichtig, dass die Batterie vollständig aufgeladen ist und

die Anschlüsse korrekt vorgenommen wurden.

Die Magnetschalterbaugruppe reversiert die Drehrichtung

der Drahtseiltrommel.

ACHTUNG: DARAUF ACHTEN, DASS DIE

BATTERIEKABEL NICHT STRAFF ÜBER EINE FLÄCHE

GESPANNT SIND. SIE KÖNNTEN DADURCH

BESCHÄDIGT WERDEN.

1. Wie auf dem Schaltplan auf der nächsten Seite die

rote Batterieklemme Nr. 13 und die rote Klemme vom

Windenmagnetschalter mit dem

Notstoppmagnetschalter verbinden.

2. Notstoppschalter, Magnetschalter und Wippschalter

gemäß Anbausatz 282067 anbauen.

3. Die schwarze Batterieklemme mit dem Minuspol (-)

der Batterie verbinden.

Wenn das Ende der Lebensdauer der Winde erreicht ist,

die Winde gemäß den vor Ort geltenden

Umweltvorschriften entsorgen.

4. Die schwarze Motorklemme mit dem Pol Nr. 2 des

Motors verbinden.

5. Die schwarze Motorklemme mit dem gelben Streifen

mit dem Pol Nr. 1 des Motors verbinden.

6. Der Fernbedienungsschalter wird am Anschluss am

Magnetschalter eingesteckt.

Der Fernbedienungsschalter ist wasserdicht. Er ist an

beiden Seiten mit Drucktasten versehen. Dadurch soll ein

schnelles Wechseln der Wickelrichtung der Winde, was

zu einem Ausfall des Magnetschalters führen kann,

verhindert werden. Darauf achten, dass der Motor

vollständig zum Stillstand kommt, bevor die

Wickelrichtung geändert wird. Um die Winde in Betrieb

zu setzen, den Fernbedienungsschalter in den Anschluss

in der Magnetschalterabdeckung einstecken. Die Winde

im Vor- und Rücklauf betreiben, um die Anschlüsse zu

prüfen und die Betriebslaufrichtung der Winde zu

bestimmen. Die entsprechende Ein- und

Ausgangsscheibe (IN / OUT) in die entsprechende

Daumenmulde drücken. Der Schalter ist farbkodiert zur

einfachen Bestimmung der Wickelrichtung der Winde.

DEN SCHALTER NICHT EINGESTECKT LASSEN, WENN

DIE WINDE NICHT GEBRAUCHT WIRD.

23

Page 24

ELEKTROSCHALTPLÄNE

3

2

1

#2

KONDENSATOR

MOTOR

#1

SCHALTER

Wippschalter in

Position OFF (Aus)

SCHWARZ

ROT

GELB

(VOM

NOTSTOPPSCH

ALTER)

MASSE

SPLEISS

5 A

SICHERUNG

ZU FAHRZEUGZÜNDUNG

SCHWARZE

MOTORKLEMME

SCHWARZE MOTORKLEMME

MIT GELBEM STREIFEN

ROTE KLEMME

NOTSTOPPS

CHAL

GELB

(VOM NOTSTOPPSCHALTER)

SCHWARZE

(MASSE)

NOTSTOPPMAGNETSCHALTER

BATTERIE

TER

ROT (NR. 13)

WINDENM

AGNETSC

HALTER

SCHWARZE

BATTERIEKLEMME

24

Page 25

Installation der Winde

*

WARNHINWEISE

UNTER SPANNUNG IST.

AUSRÜCKEN, WENN DIE WINDE

DIE KUPPLUNG NICHT

4.83

122,7

3.00

76,2

4.50

114,3

E

L

O

O

P

S

E

E

R

F

D

E

G

A

G

N

Ø3.00

76,2

5.80

147,4

4.88

124,0

TROMMEL

SEIL SPULT UNTER

DER TROMMEL AUF

4.40

111,8

13.19

335,0

2.97

75,4

Ø1.75

44,4

*

BATTERIEKABEL

MOTORKLEMMEN

FERNBEDIENUNGSANSCHLUSS

6.00 IN.

153,9 MM

6.75 IN.

3 Stellen

171,5 MM

*4.75 IN.

120,7 MM

*4.13 IN.

104,6 MM

3.50 IN.

88,9 MM

5.19 IN.

131,8 MM

1/4-20 UNC X 13,5 MM LANG

5/16 18 NC,

4 Stellen

*Bohrlochmuster

Vier Löcher, 8,6 mm Durchm.,

124 mm x 76,2 mm Muster

Installation des Magnetschalters

Seil muss unter

Trommel austreten

*Bohrlochmuster

Drei Löcher, 7,1 mm Durchm.,

120,7 mm x 104,9 mm Muster

25

Anmerkung: Neben dem Anschluss

ausreichend Freiraum zum Einstecken des

Fernbedienungsschalters belassen.

Page 26

FEHLERSUCHE

MOTOR DREHT SICH NUR IN

EINE RICHTUNG.

MOTOR WIRD EXTREM HEISS.

MOTOR LÄUFT, JEDOCH MIT

UNGENÜGENDER LEISTUNG ODER

LANGSAMER SEILGESCHWINDIGKEIT.

Defekter FernbedienungsschalterAnschluss.

Magnetschalter ist defekt oder klemmt.

Dauerbetrieb. Zur Vermeidung einer Überhitzung müssen

Schwache Batterie.

Defekte Verbindung/Anschlüsse.

Zu schwache Lichtmaschine.

Windenkupplung ausrücken,

Fernbedienungsschalter aus Anschluss entfernen

und die Stifte in der 8- und 4-Uhr-Position

überbrücken. Der Motor sollte laufen. Die Stifte in

der 8- und 10-Uhr-Position überbrücken. Der

Motor sollte laufen.

Magnetschalter-Baugruppe etwas rütteln, um die

Kontakte zu lösen. Durch Anlegen von +12 Volt

an die Spulenklemme alle Magnetschalter

prüfen (bei der Aktivierung sollte ein Klicken

hörbar sein).

Abkühlperioden eingeräumt werden.

Auf fehlerhafte Fahrzeugbatterie prüfen.

Batteriekabel auf Korrosion prüfen, reinigen

und schmieren.

Stärkere Lichtmaschine einbauen.

MOTOR DREHT SICH, ABER TROMMEL

DREHT SICH NICHT.

MOTOR FUNKTIONIERT NICHT.

WASSERSCHADEN AM MOTOR.

Kupplung nicht eingerückt. Wenn die Symptome nach dem Einrücken weiter

bestehen, muss die Winde auseinander gebaut,

die Ursache gefunden und behoben werden.

Magnetschalter ist defekt oder klemmt.

Defekter Fernbedienungs-schalterAnschluss.

Defekter Motor.

Lose Anschlüsse.

In Wasser eingetaucht oder

Hochdruckwasser einer Waschanlage.

Magnetschalter-Baugruppe etwas rütteln, um die

Kontakte zu lösen. Durch Anlegen von +12 Volt

an die Spulenklemme alle Magnetschalter

prüfen (bei der Aktivierung sollte ein Klicken

hörbar sein).

Windenkupplung ausrücken,

Fernbedienungsschalter aus Anschluss entfernen

und die Stifte in der 8- und 4-Uhr-Position

überbrücken. Der Motor sollte laufen.

Wenn die Magnetschalter i. O. sind, auf

Spannung am Ankerpol prüfen; Motor ersetzen.

Alle elektrischen Verbindungen/Anschlüsse von

der Batterie zum Motor prüfen.

Wasser ablaufen lassen und Motor gründlich

trocknen, dann Motor ohne Last wiederholt

kurze Zeit laufen lassen, um die Windungen

zu trocknen.

26

Page 27

ATV 8 TEILE

INTENDED PURPOSE: VEHICLE RECOVERY AND PULLING OF LOADS.

READ OPERATING INSTRUCTIONS BEFORE USE FOR WARNINGS,

INSTALLATION AND OPERATING INSTRUCTIONS.

434577

MODEL: ATV 8

WIRE ROPE MIN. BREAKING STRENGTH: 16 kN

MAX. ROPE DIA: 5 mm

MAX LAYERS: 4 (10 M OF 5 mm ROPE)

4

1

2

3

16

8

NICHT

ABGEBILDET

5

7

6

17

12

9

13

11

10

14

15

ATV 8 TEILELISTE

ARTIKEL-

NR.

1 1 251110 FERNBEDIENUNGSSCHALTER-BAUGRUPPE

2 1 251191 KUPPLUNGS-SATZ

3 1 251192 SEILTROMMEL-SATZ

4 1 251195 BUCHSEN-SATZ

5 1 251196 VERBINDUNGSSTANGEN-SATZ

6 1 251213 KUPPLUNGSSEITIGER GETRIEBE-SATZ

7 1 251286 MOTOR-SATZ

8 1 251234 MAGNETSCHALTERBAUGRUPPE

9 1 251287 MOTORSEITIGER GETRIEBE-SATZ

10 1 251248 MAGNETSCHALTER-ANBAUSATZ

11 1 256116 BREMS-SATZ

12 1 289197 SCHWARZE BATTERIEKLEMME (1,8 m)

13 1 289199 ROTE BATTERIEKLEMME (1,8 m)

14 1 289203 SCHWARZE MOTORKLEMME (1,2 m)

15 1 289204 SCHWARZE MOTORKLEMME MIT GELBEM STREIFEN (1,2 m)

16 1 422023 SEILMAUL

17 1 282067 NOTSTOPPSCHALTER-SATZ (NICHT ABGEBILDET)

18 1 434574 TYPEN- UND DATENSCHILD

19 1 434577 WARNSCHILD

ANZ. TEILE-NR. BESCHREIBUNG

18

19

27

Page 28

MANUAL DEL PROPIETARIO

Cabestrante eléctrico modelo ATV 8

con teleinterruptor de botón

English (Original Instructions) . . . . . . . . . . . . . . . 1

Français (Traduction des instructions originales) . . 10

Deutsch (Übersetzung der Originalanleitung) . . . . . 18

Español (Traducción de las instrucciones originales) 28

Tracción del cable de la primera capa 8 kN (816,47 kg)

Nivel sonoro 81 dB

Temperatura ambiente De -28º C a 60º C

CAPA DE CABLE 1 2 3 4

Tracción de cable nominal

por capa

Capacidad acumulativa

del cable por capa

Tracción del cable de la

primera capa

Consumo en amperaje 12V 31 72 101

* Estas especificaciones se basan en un cable metálico recomendado de 5 mm de clase

1960

kN 8 6,6 5,3 4,8

lb 1,800 1,400 1,200 1,100

m 1,5 4,5 6 10,6

ft 5 15 20 37

kN Sin 2,6 5,3

lb carga 600 1,200 1800

6,6

135

ADVERTENCIAS:

EL USUARIO DEBERÁ GARANTIZAR QUE EL

PERSONAL QUE USE EL EQUIPO HAYA

RECIBIDO LA FORMACIÓN NECESARIA.

EL OPERADOR DEBERÁ TRABAJAR SIEMPRE

SIGUIENDO LAS INSTRUCCIONES DE

FUNCIONAMIENTO.

EL EMBRAGUE DEBE ESTAR TOTALMENTE

ENGRANADO ANTES DE COMENZAR A

MANEJAR EL CABESTRANTE.

NO DESENGRANAR EL EMBRAGUE BAJO

CARGA.

NO ACERCARSE A LAS CARGAS ELEVADAS.

NO ACERCARSE AL CABLE METÁLICO

CUANDO ESTÉ TIRANDO. NO INTENTAR

GUIAR EL CABLE METÁLICO.

NO UTILIZAR EL CABESTRANTE PARA

LEVANTAR, SUJETAR O TRANSPORTAR

PERSONAS.

PARA SUJETAR LA CARGA SE NECESITA UN

MÍNIMO DE 2 VUELTAS DE CABLE METÁLICO

ALREDEDOR DEL CUERPO DEL TAMBOR.

EVITAR LAS CONDICIONES EN LAS QUE SE

PUEDA PRODUCIR LA SACUDIDA O EL

DESPLAZAMIENTO DE LA CARGA. DEBERÁ

SE EL BALANCEO EXCESIVO.

Uso pretendido para: autorrecuperación de vehículos y arrastre de cargas.

RAMSEY WINCH COMPANY

Post Office Box 581510 Tulsa, Oklahoma 74158-1510 USA

Phone: (918) 438-2760 Fax: (918) 438-6688

Visit us at http://ww.ramsey.com

Ramsey Representante autorizado en la comunidad

(Póngase en contacto sólo por cuestiones de reglamentación.)

Alura Group BV

P.O. Box 18626

2502 EP The Hague

The Netherlands

Tel: (31) (0) 70 362-4896

PRECAUCIÓN: leer y entender este manual antes de instalar y utilizar el cabestrante. consultar la sección

precauciones de seguridad.

:

OM-914220-1012-B

Page 29

4707 N. Mingo Tulsa, Oklahoma 74117 (918) 438-2760

EC DECLARATION OF CONFORMITY

as defined by Machinery Directive 2006/42/EC

Here with we declare that winch model ATV 8 complies

with the following directive provided that the USER

complies with all responsibilities described in the Owner’s

Manual:

2006/42/EC

Applied harmonized standards:

EN 14492-1:2006

Power-Driven Winches

ISO 9001:2000

Quality Management Systems

Requirements

EC-KONFORMITÄTSERKLÄRUNG

gemäß Maschinenrichtlinie 2006/42/EC

Hiermit erklären wir, dass das Windenmodell ATV 8 der

folgenden Richtlinie entspricht, sofern der BENUTZER

alle Anweisungen im Benutzerhandbuch befolgt:

2006/42/EC

Angewandte harmonisierte Normen:

EN 14492-1:2006

Kraftgetriebene Winden

ISO 9001:2000 Qualitätsmanagementsysteme Anforderungen

DÉCLARATION DE CONFORMITÉ EC

aux termes de la directive Machines 2006/42/EC

Nous déclarons par la présente que le modèle de treuil ATV 8

est conforme à la directive suivante, sous réserve que

l’UTILISATEUR ait assumé toutes les responsabilités figurant

dans le manuel de l’utilisateur :

2006/42/EC

Normes harmonisées appliquées :

EN 14492-1:2006

Treuils motorisés

ISO 9001:2000

Systèmes de gestion de la qualité - Exigences

DECLARACIÓN EC DE CONFORMIDAD

según se define en la directiva de máquinas 2006/42/EC

Con la presente declaramos que el modelo de cabestrante

ATV 8 se halla en conformidad con la siguiente directiva

siempre que el USUARIO cumpla todas las

responsabilidades descritas en el Manual del propietario:

2006/42/EC

Normas armonizadas aplicadas:

EN 14492-1:2006

Cabestrantes accionados mecánicamente

ISO 9001:2000

Requisitos de los Sistema de gestión de la calidad

Ramsey Authorized Representative in the Community / Ramsey Représentant autorisé dans la comuauté /

Ramsey Bevollmächtigter in der Europäischen Union / Ramsey Representante autorizado en la comunidad:

(Póngase en contacto sólo por cuestiones de reglamentación.)

Alura Group BV

P.O. Box 18626

2502 EP The Hague

The Netherlands

Tel: (31) (0) 70 362-4896

Fax: (31) (0) 70 346-7299

Serial Number / Numéro de série/ Seriennummer/ Número de Serie:_____________________

Signature / Signature / Unterschrift / Firma:

Todd Brady

Engineering Manager / Directeur technique/ Technischer Leiter/ Director de ingeniería

Date / Date / Datum / Fecha:

04-29-11

29

Page 30

Contenido

Especificaciones . . . . . . . . . . . . . . . . . . . . . .portada

Responsabilidad del usuario para el

cumplimiento con las disposiciones CE . . . . . . . . .29

Precauciones de seguridad . . . . . . . . . . . . . . . . . .29

Instalación del cabestrante . . . . . . . . . . . . . . . . . . .29

Funcionamiento . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Mantenimiento . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Instalación del cable metálico . . . . . . . . . . . . . . . . .30

Conexiones eléctricas . . . . . . . . . . . . . . . . . . . . . .31

Medidas cuando termina la vida útil . . . . . . . . . . . .31

Esquemas eléctricos . . . . . . . . . . . . . . . . . . . . . . .32

Montaje del cabestrante . . . . . . . . . . . . . . . . . . . . .33

Guía de solución de problemas . . . . . . . . . . . . . . .34

Lista de piezas del cabestrante . . . . . . . . . . . . . . . .35

Declaración CE de conformidad . . . . . . . . . . . . . . .36

Responsabilidad del usuario para el

cumplimiento con las disposiciones CE

1. Montar el cabestrante según las instrucciones

de instalación.

2. Instalar el interruptor de parada de emergencia según las

instrucciones de instalación que se incluyen en el kit del

interruptor de parada de emergencia.

3. Instalar el cable metálico de 5 mm de clase 1960.

La longitud máxima del cable debe ser de 10,6 m para

un máximo de cuatro capas.

4. Conectar el cable al tambor según las instrucciones de

instalación del cable.

5. Usar un gancho que incorpore un cierre de seguridad y que

tenga una resistencia mínima a la ruptura de 20 kN.

Precauciones de seguridad

A. Manténgase a sí mismo y a los demás a una distancia

segura de la parte lateral del cable cuando tire de

una carga.

B. No pise ni se acerque a un cable que esté bajo carga.

C. Use un trapo grueso o guantes para protegerse las manos

de las rebabas al manipular el cable del cabestrante.

D. La modificación, alteración o el desvío del cabestrante

deben ser realizados únicamente por la compañía Ramsey

Winch Company.

E. Procure que la duración de los períodos de tracción sea lo

más corta posible. Si el motor se calienta demasiado al

tacto, párelo y deje que se enfríe durante unos minutos.

No aplique tracción al nivel o cerca del nivel nominal de

tracción durante más de un minuto. No mantenga la

alimentación eléctrica al cabestrante en el caso de que el

motor se pare. Los cabestrantes eléctricos están diseñados

para su uso intermitente y no deben utilizarse en

aplicaciones de tareas constantes.

Desconecte el teleinterruptor (interruptor del control

F.

remoto) del cabestrante cuando no se utilice.

G. No utilice el cabestrante en aplicaciones de izado debido a

los factores y las características de seguridad que

requieren este tipo de tareas.

H. Para enrollar correctamente el cable, es necesario

mantenerlo bajo una ligera carga. No deje que el cable

se deslice sobre sus manos, ni se acerque demasiado

al cabestrante.

I. Observe el proceso de enrollado del cable sobre el tambor.

Las fuerzas de tiro laterales pueden hacer que el cable se

acumule en un extremo del tambor. Para corregir la falta de

uniformidad en el enrollado, desenrolle la sección del cable

no uniforme, pásela al otro extremo del tambor y continúe

con el proceso de enrollado. El enrollado no uniforme

causante de las acumulaciones de cable puede interferir

con las barras de acoplamiento del cabestrante y

ocasionar daños.

J. El enrollamiento uniforme y tenso evita los atrapamientos

del cable que se producen cuando se aplica una carga y el

cable está pinzado entre otras dos vueltas de cable. Si esto

ocurre, haga avanzar y retroceder el cable alternativamente

unos cuantos centímetros. No intente deshacer con la

mano un atrapamiento que se haya formado en un

cable bajo carga.

Instalación del cabestrante

1. Apriete los pernos de montaje a un par de 21,6 Nm.

2. No conecte los cables del motor y de la batería hasta

que no se le indique expresamente.

3. Es muy importante que el cabestrante esté

montado sobre una superficie plana, con el cable

de forma que salga por la parte inferior del

tambor, tal y como se muestra en el gráfico de

dimensiones de la página 33.

PRECAUCIÓN: los pernos de montaje de

22,6 mm de largo con arandelas de

seguridad que se proporcionan deben

utilizarse con una placa recomendada para

el montaje del cabestrante con un grosor de

4,7 mm. Si se utiliza una placa de montaje

de un grosor diferente, la longitud de los

pernos debe ser ajustada de forma acorde

para no causar daños en el cabestrante.

Los pernos de reemplazo deben ser de clase

SAE 5 o de una clase equivalente.

30

Page 31

Funcionamiento

Instalación del cable metálico

El embrague del cabestrante permite el desenrollado

rápido del cable para engancharlo en la carga o en un

punto de anclaje. El embrague se acciona con un

cambiador situado en el extremo del cabestrante, de la

siguiente manera:

1. Para desengranar el

embrague, gire el

cambiador del embrague

a la posición

"FREESPOOL"

(enrollado libre).

Cuando el embrague está

en la posición

"FREESPOOL", la flecha

del mando del embrague

apuntará hacia "FREESPOOL"

en la etiqueta del cabestrante. Esto permite

desenrollar el cable libremente del tambor.

2. Para engranar el embrague, gire el cambiador del

embrague a la oposición "ENGAGED" (embragada).

Cuando el embrague está en la posición "ENGAGED",

la flecha del mando del embrague apuntará hacia

"ENGAGED" en la etiqueta del cabestrante.

El cabestrante está listo para la acción de

tiro o tracción.

La batería debe mantenerse en buen estado. Es esencial

que la batería esté totalmente cargada y que las

conexiones se hayan realizado correctamente. Mantenga

el motor del vehículo encendido durante el

funcionamiento del cabestrante para mantener

cargada la batería.

Nota: el cable se debe instalar de forma que salga

por la parte inferior del tambor.

Desenrolle el nuevo cable extendiéndolo sobre el suelo

para evitar el retorcimiento. Retire el cable viejo y fíjese

en la forma en la que está conectado a la brida del

tambor, con especial atención al retenedor de anclaje

del cable.

Antes de instalar el conjunto del cable nuevo, envuelva

el extremo del cable con cinta adhesiva para evitar que

se deshilache.

Pase el cable a través del extremo estrecho del

receptáculo, contra la brida del tambor, y enróllelo en el

retenedor de anclaje. Tire del cable y del retenedor de

anclaje hacia el interior del extremo ancho del

receptáculo, dejando aproximadamente 3 mm

sobresaliendo por el borde del receptáculo, tal y como

se muestra. Use un martillo y un extractor para dirigir el

lado posterior del cable, asentando éste último y el

retenedor de anclaje firmemente en el receptáculo.

Retenedor de anclaje

El extremo corto del cable debe

sobresalir aproximadamente

3 mm en el borde superior

del receptáculo.

Mantenimiento

La corrosión de las conexiones eléctricas reducirá el

rendimiento o puede causar un cortocircuito. Es

necesario limpiar todas las conexiones. En ambientes

salados, usar un sellador de silicona para protegerlas de

la corrosión.

Todas las partes móviles del cabestrante están

permanentemente lubricadas con una grasa de litio

resistente a un amplio rango de temperaturas.

Lubricar el cable periódicamente con un aceite ligero y

penetrante. Comprobar que el cable no tenga hilos

sueltos y reemplazarlo si es necesario. Si el cable se

desgasta o daña, debe ser reemplazado.

Enrolle el cable tirando de una carga ligera para

mantener una tensión constante. Deje que el cable gire,

utilizando un eslabón de cadena o un bloque de giro

entre el gancho del cable y la carga.

31

Page 32

Conexiones eléctricas

Medidas cuando termina la vida útil

Para el trabajo normal de autorrecuperación, el sistema

eléctrico existente es adecuado. La batería debe

mantenerse en buen estado. Es esencial que la batería

esté totalmente cargada y que las conexiones se hayan

realizado correctamente.

El conjunto del solenoide invierte la dirección de rotación

del tambor del cable.

PRECAUCIÓN: ASEGÚRESE DE QUE LOS CABLES DE

LA BATERÍA NO SE ROCEN CONTRA NINGUNA

SUPERFICIE YA QUE PODRÍAN DAÑARSE.

1. Tal y como se muestra en el esquema de la página

siguiente, conecte el cable rojo de la batería

(elemento núm. 13) y el cable rojo del solenoide

de control del cabestrante al solenoide de parada

de emergencia.

2. Instale el interruptor de parada de emergencia, el

solenoide y el conmutador basculante para el

kit núm. 282067.

Cuando el cabestrante llegue al final de su vida

útil, desecharlo según las normativas

medioambientales locales.

3. Conecte el cable negro de la batería al terminal

negativo (-) de la batería.

4. Conecte el cable negro del motor al borne número 2

del motor.

5. Conecte el cable negro con raya amarilla del motor

al borne número 1 del motor.

6. El teleinterruptor se enchufa en el receptáculo

del solenoide.

El teleinterruptor es impermeable. Dispone de teclados

de botones a cada lado y está diseñado de esta forma

para evitar las inversiones repentinas del cabestrante, lo

que podría provocar un fallo del solenoide. Asegúrese de

que el motor se haya detenido totalmente antes de

invertir la dirección del giro. Para activar el cabestrante,

enchufe el teleinterruptor en el receptáculo de la cubierta

del solenoide. Haga funcionar el cabestrante hacia

adelante y hacia atrás para comprobar las conexiones y

determinar las direcciones de funcionamiento del mismo.

Encaje el disco correspondiente "IN" y "OUT" en la

cavidad correspondiente. El interruptor también está

codificado con colores para no tener que adivinar en qué

dirección funcionará el cabestrante. NO DEJE EL

INTERRUPTOR ENCHUFADO CUANDO NO ESTÉ

UTILIZANDO EL CABESTRANTE.

32

Page 33

ESQUEMAS ELÉCTRICOS

3

2

1

#2

CONDENSADOR

MOTOR

#1

Conmutador basculante en la

posición de apagado (OFF)

INTERRUPTOR

AMARILLO

(DESDE EL INTERRUPTOR DE

PARADA DE EMERGENCIA)

NEGRO

ROJO

5 A

FUSIBLE

PUESTA A TIERRA

EMPALME DE HILO

AL ENCENDIDO

DEL VEHÍCULO

CABLE NEGRO DEL

MOTOR

CABLE NEGRO CON RAYA

AMARILLA DEL MOTOR

CABLE

ROJO

INTERRUPTOR DE PARADA

DE EMERGENCIA

AMARILLO

(DESDE EL INTERRUPTOR DE

PARADA DE EMERGENCIA)

NEGRO

(PUESTA A TIERRA)

SOLENOIDE DE PARADA

DE EMERGENCIA

BATERÍA

ROJO (Núm.13)

CABLE

NEGRO DE LA BATERÍA

SOLENOIDE DE

CONTROL DEL

CABESTRANTE

33

Page 34

Montaje del cabestrante

*

ADVERTENCIA

ESTÁ EN TENSIÓN

EMBRAGUE SI EL CABLE

NO DESENGRANAR EL

4.83

122,7

3.00

76,2

4.50

114,3

E

L

O

O

P

S