Page 1

OPERATING, SERVICE AND

MAINTENANCE MANUAL

WILDCAT SERIES 60,000 LB

INDUSTRIAL

CAUTION

WINCH. SEE WARNINGS!

: READ AND UNDERSTAND THIS MANUAL BEFORE INSTALLATION AND OPERATION OF

WINCH

Page 2

TABLE OF CONTENTS

WARRANTY INFORMATION ........................................................................................................................... 2

SPECIFICATIONS.......................................................................................................................................... 2

WARNINGS................................................................................................................................................... 2

HYDRAULIC SYSTEM REQUIREMENTS........................................................................................................... 3

PERFORMANCE CHARTS .............................................................................................................................. 3

CABLE INSTALLATION .................................................................................................................................. 4

CLUTCH OPERATION .................................................................................................................................... 5

WINCH OPERATION...................................................................................................................................... 5

MAINTENANCE............................................................................................................................................. 5

LUBRICATION TABLE.................................................................................................................................... 6

TROUBLE SHOOTING GUIDE.......................................................................................................................... 6

INSTRUCTIONS FOR WINCH DISASSEMBLY..............................................................................................7-14

DISASSEMBLY OF INPUT CARRIER ............................................................................................................. 15

ASSEMBLY OF INPUT CARRIER................................................................................................................... 16

DISASSEMBLY OF INTERMEDIATE CARRIER................................................................................................ 17

ASSEMBLY OF INTERMEDIATE CARRIER..................................................................................................... 18

DISASSEMBLY OF OUTPUT CARRIER .......................................................................................................... 19

ASSEMBLY OF OUTPUT CARRIER................................................................................................................ 20

WILDCAT HOSE HOOKUP ............................................................................................................................ 21

PARTS DRAWING........................................................................................................................................ 23

PARTS LIST................................................................................................................................................ 24

AIR CYLINDER PARTS LIST ......................................................................................................................... 25

DIMENSIONAL DRAWING ............................................................................................................................ 26

LIMITED WARRANTY .................................................................................................................................. 27

1 OM-914214-0609-D

Page 3

Lb

31 9

37 11

43 13

49 15

RAMSEY HYDRAULIC PLANETARY WINCH MODEL WILDCAT 60K

PLEASE READ THIS MANUAL CAREFULLY

This manual contains useful ideas in obtaining the most efficient operation from your Ramsey Winch, and safety

procedures one needs to know before operating a Ramsey Winch. Do not operate this winch until you have carefully

read and understand the "WARNINGS" and "OPERATION" sections of this manual.

WARRANTY INFORMATION

Ramsey Winches are designed and built to exacting specifications. Great care and skill go into every winch we make.

If the need should arise, warranty procedure is outlined on the back of your self-addressed postage paid warranty card.

Please read and fill out the enclosed warranty card and send it to Ramsey Winch Company. If you have any problems

with your winch, please follow instructions for prompt service on all warranty claims. Refer to back page for limited

warranty.

SPECIFICATIONS*

APPROXIMATE WEIGHT: 1400 LBS

WORKING PRESSURE: 2600 PSI

CABLE DIAMETER: 1 INCH

MAX FLOW: 60 GPM

LAYER

OF

CABLE

1 50 20 60000 27100

2 110 43 50000 22600

3 180 71 42800 19300

4 260 102 37500 16900

* These specifications are based on recommended wire rope of 1” Extra Improved Plow Steel Cable and a 7.7

cu. in. / Rev. motor.

NOTE: The rated line pulls shown are for the winch only. Consult the wire rope manufacturer for wire rope ratings.

CAPACITY

Ft m Lb Kg

LINE PULL

LOW SPEED

LINE SPEED

fpm mpm

LINE PULL LINE SPEED

22500

18700

16000

14000

HIGH SPEED CABLE

Kg fpm mpm

10200 75 23

8500 90 27

7200 105 32

6300 120 37

WARNINGS:

CLUTCH MUST BE FULLY ENGAGED BEFORE STARTING THE WINCHING OPERATION.

DO NOT START WINCH MOTOR BEFORE ENGAGING CLUTCH.

DO NOT DISENGAGE CLUTCH UNDER LOAD.

STAY OUT FROM UNDER AND AWAY FROM RAISED LOADS.

STAND CLEAR OF CABLE WHILE PULLING. DO NOT TRY TO GUIDE CABLE.

DO NOT EXCEED MAXIMUM LINE PULL RATINGS SHOWN IN TABLE.

DO NOT USE WINCH TO LIFT, SUPPORT, OR OTHERWISE TRANSPORT PEOPLE.

A MINIMUM OF 5 WRAPS OF CABLE AROUND THE DRUM BARREL IS NECESSARY TO HOLD THE LOAD.

CABLE ANCHOR IS NOT DESIGNED TO HOLD LOAD.

BAND BRAKE IS NOT TO BE USED TO HOLD LOAD

2 OM-914214-0609-D

Page 4

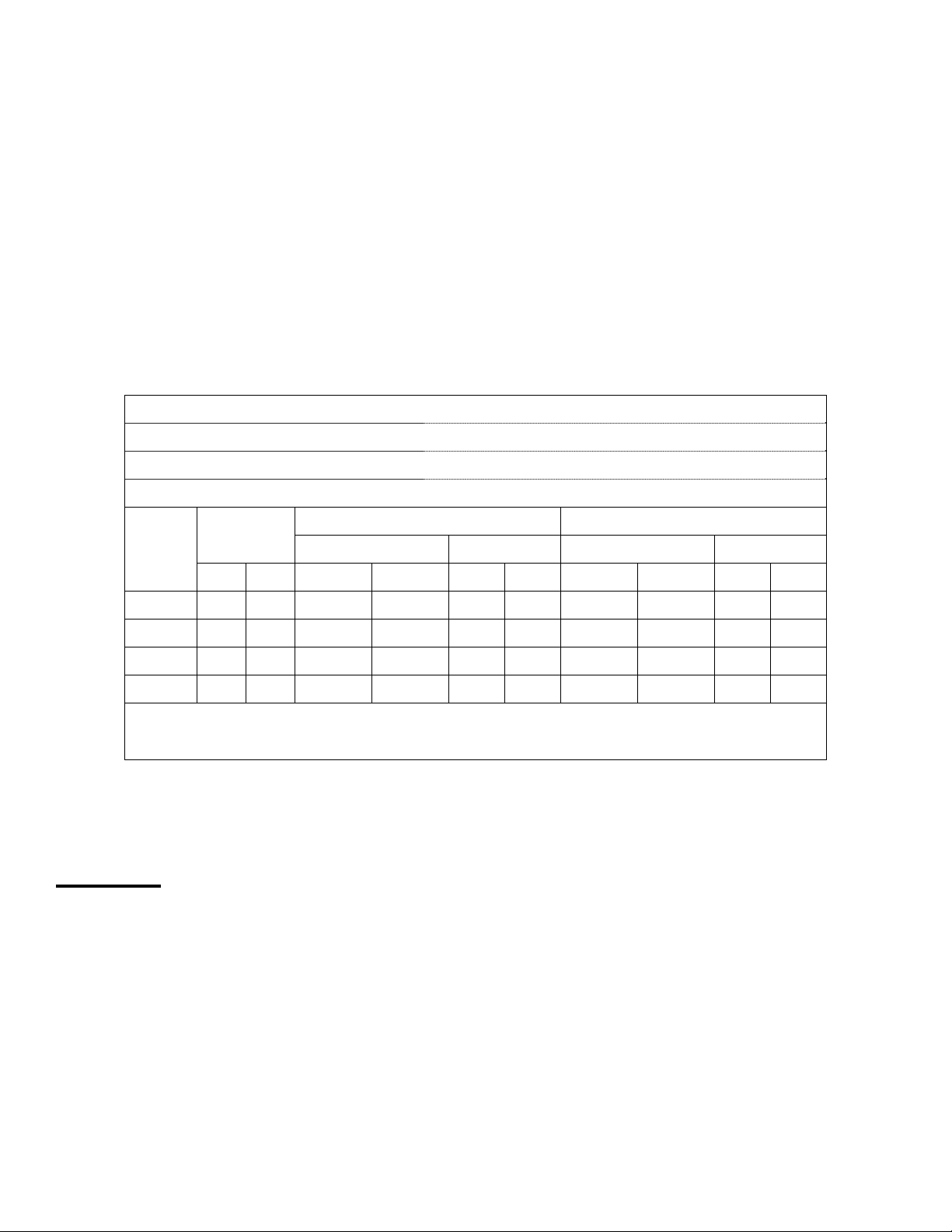

HYDRAULIC SYSTEM REQUIREMENTS

Refer to the performance charts, below, to properly match your hydraulic system to winch performance.

The charts consist of:

(1) Line pull (lb.) first layer vs. working pressure (PSI) and (2) line speed, first layer (FPM) vs. gallons per

minute (GPM). Performance based on a motor displacement of 7.7 cubic inches/rev with 60 GPM

maximum flow rate. Motor has (2) 1”-12 SAE straight thread o-ring ports.

Note: A motor spool (open center) directional control valve is required for brake operation.

MOTOR CASE DRAIN

MOTOR 2 SPEED

SAE -16

1" TUBING SIZE

12 VDC

PORT #5

SHIFT SOLENOID

COUNTER BALANCE

VALVE

COUNTER BALANCE/SPEED SELECTOR BLOCK

LOW PRESSURE LINE

BRAKE

PORT #1

PORT#3

SAE -16

1" TUBING SIZE

60K AIR CONNECTIONS

HIGH PRESSURE LINE

CLUTCH

DIRECT LINE TO TANK

PAYOUT

PAYIN

BAND BRAKE

3 POSITION

4 WAY VALVE

SYSTEM

RELIEF

PUMP

CUSTOMER

SUPPLIED

PERFORMANCE CHARTS

BASED ON 7.7 CU IN/REV MOTOR

3 OM-914214-0609-D

60000

60

40000

20000

First Layer

Line Pull (Lbs.)

0

0 500 1000 1500 2000 2500 3000

Pressure (PSI)

50

40

30

First Layer

20

Line Speed (Ft/Min)

10

0

0102030405060

Flow (GPM)

Page 5

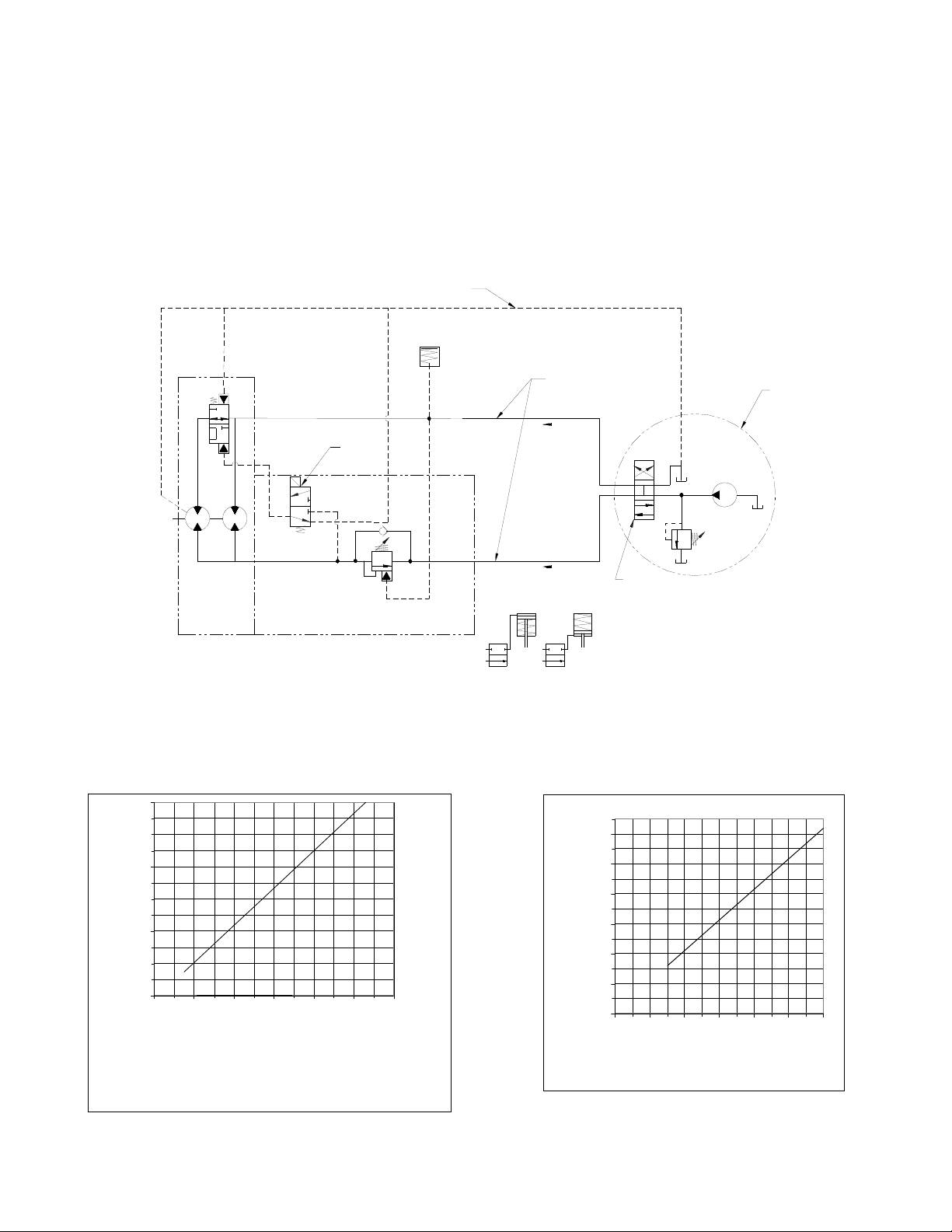

CABLE INSTALLATION

1. Unwind cable by rolling it out along the ground to prevent kinking. Securely wrap end of wire

rope, opposite hook, with plastic or similar tape to prevent fraying.

2. Place taped end of cable around the drum and into the track on drum flange. Secure using

supplied u-bolt #62 and (2) washers #64 and (2) nuts #65.

3. Carefully run the winc h in the “reel-in” direction. Keeping tensio n on end of cable, spool all the

cable onto the cable drum, taking care to form neatly wrapped layers.

4. After installing cable, band brake is used to prevent bird nesting while pulling out cable, when

clutch is disengaged.

65

64

INSERT CABLE AS SHOWN

62

4 OM-914214-0609-D

Page 6

CLUTCH OPERATION

WARNING: CLUTCH MUST BE FULLY ENGAGED BEFORE STARTING THE WINCHING OPERATION.

To engage clutch:

1. Move clutch control to engage the clutch.

2. Run the motor in the cable out direction until the drum begins to turn.

WARNING: DO NOT DISENGAGE CLUTCH UNDER LOAD.

To disengage clutch:

1. Run the winch in the "cable out" direction until the load is off the cable.

2. Move the clutch control to disengage the clutch. The cable may now be spooled off.

WINCH OPERATION

The best way to get acquainted with how your winch operates is to make test runs before you use

it. Plan your test in advance. Remember, you hear your winch, as well as see it operate; learn to

recognize the sounds of a light steady pull, a heavy pull, and sounds caused by load jerking or

shifting. Gain confidence in operating your winch and its use will become second nature with you.

The uneven spooling of cable while pulling a load is not a problem, unless there is a cable pileup

on one end of drum. If this happens reverse the winch to relieve the load and move your anchor

point further to the center of the vehicle. After the job is done you can unspool and rewind for a

neat lay of the cable.

MAINTENANCE

Adhering to the following maintenance schedule will keep your winch in top condition and performing

as it should with a minimum of repair.

A. WEEKLY

1. Check the oil level and maintain it to the oil level plug. If oil is leaking out, determine location and

repair.

2. Check the pressure relief plug on the gear housing cover and the brake housing cover. Be sure they

are not plugged.

3.

Lubricate cable with light oil.

4. Lubricate drum bushings with grease. It is necessary to remove cable to expose the grease zerks on

drum. Use high quality lithium grease for best results.

5. Apply a high quality lithium grease to clutch spline. Apply band brake to control drum. Declutch drum

and apply grease to spline between clutch and drum.

B. MONTHLY

1.

Check the winch mounting bolts. If any are missing, replace them and securely tighten any that are

loose. Use grade 5 or better bolts.

2. Inspect the cable. If the cable has become frayed with broken strands, replace immediately.

C. ANNUALLY

Drain the oil from the winch annually or more often if winch is used frequently.

1.

2. Refill the winch to the oil level plug with all purpose GL-5 oil, (see page 6) or gear lube compatible with

your climate.

3. Inspect winch for damage and wear.

5 OM-914214-0609-D

Page 7

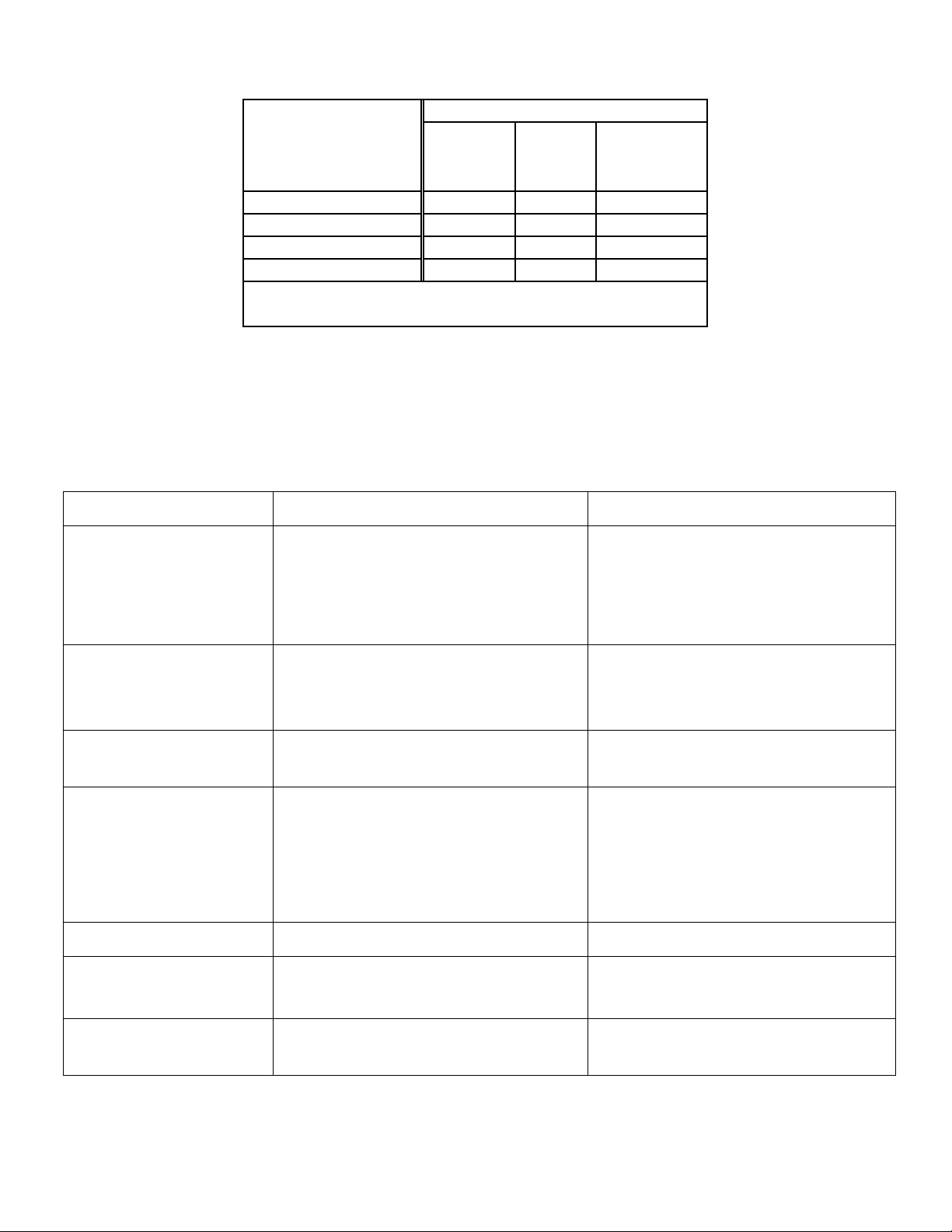

LUBRICATION TABLE

TempRangeF(C)

LubricantDescription*

Min

Ambient&

Operating

Max

Ambient

MaxOperating

80W140Synthetic ‐25(‐32) 125(52) 225(107)

75W90Synthetic ‐40(‐40) 115(46) 215(102)

80W90Conventional ‐20(‐29) 100(38) 180(82)

85W140Conventional 20(6) 120(50) 200(93)

*UseAPIGL‐5orEPlubricants.

TROUBLE SHOOTING GUIDE

CONDITIONS POSSIBLE CAUSE CORRECTION

OIL LEAKS FROM WINCH

WINCH RUNS TOO SLOW

CABLE DRUM WILL NOT

FREESPOOL

BRAKE WLL NOT HOLD

BRAKE WILL NOT RELEASE

WINCH WILL NOT OPERATE

AT HIGH SPEED

1. Seals damaged or worn.

2. Too much oil.

3. Damaged o-rings.

4. Case drain not connected.

1. Low flow rate.

2. Hydraulic motor worn out.

1. Clutch not disengaged 1. Check operation, refer to Clutch

1. Incorrect directional control valve

(cylinder spool, closed center).

2. Excessive hydraulic system back

pressure.

3. Sprag clutch worn out.

1. Brake line disconnected or blocked 1. Repair brake line.

1. Shift solenoid not working. 1. Verify shift spool is energized.

1. Replace seal

2. Drain excess oil. Refer to page 7.

3. Replace o-rings.

4. Connect case drain.

1. Check flow rate. Refer to Hydraulic

Systems Performance Chart, page 3.

2. Replace motor.

Operation, page 5.

1. Use only a motor spool (open center)

directional control valve.

2. Reduce system back pressure to less

than 100 psi.

3. Replace sprag clutch mechanism.

WINCH OPERATES

ERRATICALLY ON INHAUL

1. Sprag hub is reversed. 1. Install sprag hub correctly.

6 OM-914214-0609-D

Page 8

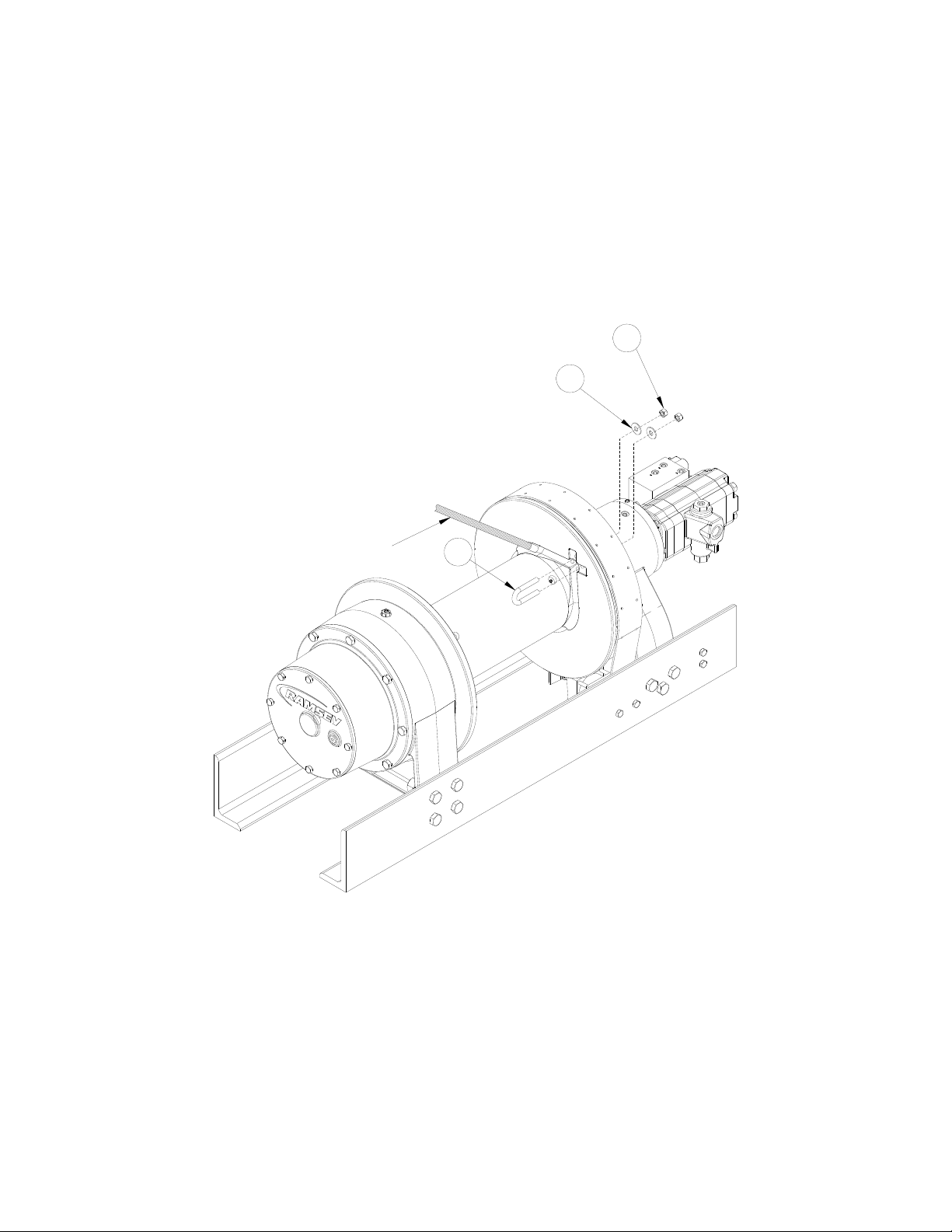

INSTRUCTIONS FOR DISASSEMBLY

1. Remove wire rope from drum.

2. Drain oil from winch by removing (2) plugs #54, removing the lower plug first.

3. When replacing lubricant, use 160 oz of applicable lube for your climate from table on page 6

adding 4 oz at #44 and the remaining at # 55.

4. Remove (2) nuts #408b from air cylinder #408a. Air cylinder may now be removed. If needed,

mounting bracket #401 may be removed by removing pin #404 from pin #405 and then sliding

pin out of mounting bracket. Brake band #5 may be expanded over drum flange to barrel for

easiest removal.

44

55

54

54

14

66

5

NOTE:

BRAKE BAND FITS

OVER DRUM FLANGE

408b

401

404

405

408a

7 OM-914214-0609-D

Page 9

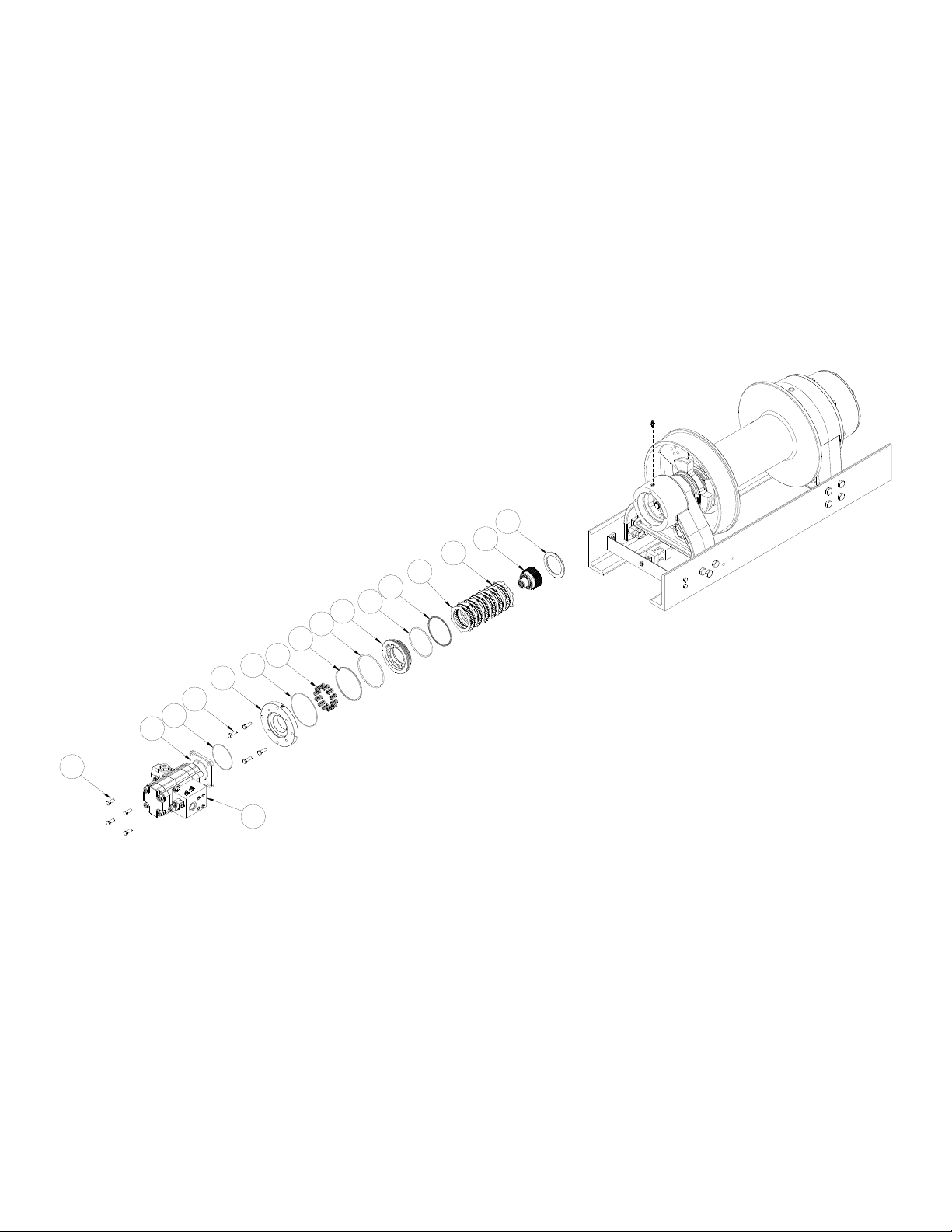

5. Remove motor #45 from winch by first disconnecting hydraulic lines (see page 21), solenoid

wires, and then remove (4) bolts #37. O-ring #72 may now be removed.

6. Remove brake cover #42 by removing (4) bolts #66. The cover is spring loaded, use care

when removing. Remove o-ring #46 then springs #61 may be removed; residual oil may be

present in the brake housing.

7. Remove piston #11 including o-rings and backup rings #47, #48, #49, and #50 by using a

momentary puff of compressed air into the brake port located on top of the end bearing.

Capture the piston by placing a shop rag over the opening prior to using air.

8. Remove the sprag brake hub assembly #40, (7) stator plates #12, (6) disc brakes #13, and the

spacer #28. The sprag brake hub assembly #40 is not a serviceable part, if damaged a

replacement assembly should be ordered.

28

40

13

12

48

47

11

49

50

61

46

42

66

72

45

37

63

8 OM-914214-0609-D

Page 10

9. Remove (8) cover bolts #36; cover #10, and o-ring #51.

10. Remove snap ring #58, and sun gear #17.

11. The planetary carrier assembly #4 may now be removed along with (2) spacers #24.

12. Remove second snap ring #58 and intermediate sun gear #16.

13. Planetary carrier assembly #3 may now be removed.

3

24

4

24

51

10

36

17

58

16

58

9 OM-914214-0609-D

Page 11

14. Using a nylon strap, support ring gear #20 from a hoist or boom, this ring gear is heavy.

Remove (8) bolts #37 leaving the top most bolt for last. Remove the final bolt while supporting

ring gear. Set ring gear aside. Remove the o-ring #52.

15. Remove output sun gear #15.

16. Using a large pair of snap ring pliers remove the snap ring #60 from the shaft located inside

the planetary carrier assembly #2.

17. Using a nylon strap and hoist slide the output planetary carrier #2 from the ring gear housing.

The output planetary carrier is heavy.

18. Remove the spacer #27.

2

60

52

20

37

15

27

10 OM-914214-0609-D

Page 12

19. Remove the clutch cylinder #1 by removing the (2) cotter keys #404 and (2) pins #406 from

either end of the air cylinder #407.

20. The clutch cylinder support angle #8 can be removed by removing the four bolts #38 and nuts

#65 attaching it to the mounting angles.

21. Remove the clutch yoke #29 by removing center pivot bolt #21 and nut #65.

NOTE:

VIEW SHOWN LESS DRUM AND ANGLE CUT AWAY FOR CLARITY

21

65

66

29*

1

* CLUTCH YOKE #29 SHOWN REMOVED

AND PARTIALLY INSTALLED

FOR CLARITY

406

404

404

29*

407

406

409

66

402

8

65

11 OM-914214-0609-D

Page 13

22. By removing snap ring #58 and ball bearing #31, the input shaft #22 may be removed.

23. To remove the motor end bearing #18, support drum #14 with a nylon strap or chain and hoist.

Lift on the drum to tension the strap. Remove (6) bolts #67 and (6) nuts #68 attaching the end

bearing to the mounting angles #6 and #7. The motor end bearing #18 will be supported on the

output shaft end and may be slid off using a nylon strap and hoist to lift it.

14

67

7

56

6

18

67

22

68

31

58

12 OM-914214-0609-D

Page 14

24. While continuing to support the drum #14, remove the clutch #9, snap ring #60 and spacer

#25.

25. The output shaft #23 may be slid from the drum assembly.

26. The drum #14 is now supported only by the nylon strap and maybe removed as needed.

27. The (2) bushings #34 may be pressed from the drum if replacement is necessary.

14

34

23

25

60

9

34

13 OM-914214-0609-D

Page 15

28. To remove gear end bearing #18, from mounting angles #6 and #7, first remove (4) 7/8-9NC

bolts #67 and (4) nuts #68 from each angle. Shaft oil seal #56 and end bearing bushing #33

can be removed and replaced at this time, if necessary.

67

7

33

56

6

19

68

67

68

14 OM-914214-0609-D

Page 16

DISASSEMBLY OF INPUT CARRIER

Carrier assemblies may be purchased as a complete assembly (see pg. 23) or parts may be

purchased individually (see parts list below). If purchasing individual parts, it will be necessary to

disassemble the input gear carrier as outlined below.

1. Carefully drive roll pin #104 into carrier pin #103 so that it is captured within carrier pin #103

but not touching the opposite side of the input carrier #106.

2. Tap carrier pin #103 to remove it from the input carrier #106.

3. Slide the planet gear #101and the (2) thrust washers #102 from the carrier assembly #106.

Bearings #105 may then be pressed out.

4. Remove the roll pin #104 from the carrier pin #106.

5. Repeat this process for the two remaining gears in the carrier.

106

INPUT CARRIER

102

104

ITEM # QTY PART # DESCRIPTION

101 3 334221 GEA R-PLANET

102 6 51807 0 THRU ST WASHER

103 3 470124 PI N-CARRI ER

104 3 47004 0 ROLL PIN 1/4 DIA X 1 1/4 LG

105 3 40214 0 BEARING-DRAWN CUP NEEDL E ROLLER

106 1 317023 CARRIER-INPUT

103

101

105

102

15 OM-914214-0609-D

Page 17

ASSEMBLY OF INPUT CARRIER

Note: Item Numbers refer to Carrier parts list on page 15

1. Place carrier #106 on flat clean surface.

2. Place the gear #101 on a flat thin clean metal plate; Align the bearing with the chamfer facing

toward the gear. Using a press, press the bearing flush to the gear surface.

3. Place thrust washer #102 on top of gear #101. Insert carrier pin #103 into carrier #106,

aligning roll pin #104 with the matching hole on the carrier #106.

4. Insert a thrust washer between gear #101 and carrier #106. Completely insert carrier pin #103

into carrier #106 using care to align the roll pin hole in carrier pin #103 with the roll pin hole in

the carrier #106.

5. Drive roll pin #104 into carrier #106 until roll pin #104 is ¼” past flush with surface of the carrier

#106.

6. Repeat this process to install the two remaining gears into the carrier.

16 OM-914214-0609-D

Page 18

DISASSEMBLY OF INTERMEDIATE CARRIER

Carrier assemblies may be purchased as a complete assembly (see pg. 23) or parts may be

purchased individually (see parts list below). If purchasing individual parts, it will be necessary to

disassemble the intermediate gear carrier as outlined below.

1. Carefully drive roll pin #204 into carrier pin #205 so that it is captured within carrier pin #205

but not touching the opposite side of the intermediate carrier #201.

2. Tap carrier pin #205 to remove it from the intermediate carrier #201.

3. Slide the planet gear #202and the (2) thrust washers #203 from the carrier assembly #201.

Bearings #206 may then be pressed out.

4. Remove the roll pin #204 from the carrier pin #205.

5. Repeat this process for the two remaining gears in the carrier.

201

INTERMEDIATE CARRIER

203

206

204

ITEM # QTY PART # DESCRIPTION

201 1 31702 2 INTERMEDIA TE CA RRIER

202 3 334219 PL ANE T GEAR

203 6 51807 5 THRU ST WASHER

204 3 47004 0 ROLL PIN 1/4 DIA X 5 /8 L G

205 3 47012 5 CA RRIER PI N

206 6 40214 0 BEARING-DRAWN CUP NEEDL E ROLLER

205

202

206

203

17 OM-914214-0609-D

Page 19

ASSEMBLY OF INTERMEDIATE CARRIER

Note: Item Numbers refer to Carrier parts list on page 17

1. Place carrier #201 on flat clean surface.

2. Place the gear #202 on a flat thin clean metal plate; Align the bearing with the chamfer facing

of the gear. Using a press, press the bearing flush to the gear surface.

3. Repeat Step 2 for other side of gear #202.

4. Place thrust washer #203 on top of gear #202. Insert carrier pin #205 into carrier #201,

aligning roll pin #204 with the matching hole on the carrier #201.

5. Insert a thrust washer #203 between gear #202 and carrier #201. Completely insert carrier pin

#205 into carrier #201 using care to align the roll pin hole in carrier pin #205 with the roll pin

hole in the carrier #201.

6. Drive roll pin #204 into carrier #206 until roll pin #204 is ¼” past flush with surface of the carrier

#206.

7. Repeat this process to install the two remaining gears into the carrier.

18 OM-914214-0609-D

Page 20

DISASSEMBLY OF OUTPUT CARRIER

Carrier assemblies may be purchased as a complete assembly (see pg. 23) or parts may be

purchased individually (see below). If purchasing individual parts, it will be necessary to

disassemble the gear carrier as outlined below.

1. Carefully drive roll pin #305 into carrier pin #304 so that it is captured within carrier pin #304

but not touching the opposite side of the output carrier #301.

2. Tap carrier pin #304 to remove it from the output carrier #301.

3. Place a plastic pail in a position to catch bearings #306, spacer #307 and thrust washers #303,

then slide the gear #302 from the carrier #301.

4. Remove the roll pin #305 from the carrier pin #304.

5. Repeat this process for the two remaining gears in the carrier.

301

OUTPUT CARRIER

303

305

ITEM # QTY PART # DESCRIPTION

301 1 317021 OUTPUT CA RRIE R

302 3 33421 8 PLANE T GEAR

303 6 518074 THRU ST WASHER

304 3 470126 CARRI ER PIN

305 3 470036 ROLL PIN 1/4 DIA X 1 1/4 LG

306 204 40 213 6 BEARI NG-NE EDLE ROLLER

307 3 362315 S PACER

306

304

302

307

306

303

19 OM-914214-0609-D

Page 21

ASSEMBLY OF OUTPUT CARRIER

Note: Item Numbers refer to Carrier parts list on page 19

1. Place output carrier #301 on flat clean surface.

2. A tool the width of the gear #302 and the diameter of the carrier pin #304 is helpful to install

needle bearings #306.

3. Place the output gear #302 on a flat thin clean metal plate; metal plate should not be thicker

than thrust washer #303 and should be able to slide into gear pocket of output carrier #301.

Grease the inside of gear #302 and insert the greased tool described above into gear #302.

4. Place one row of needle bearings #306 into gear #302 carefully sliding them down the gap

between the tool and the gear so they stand vertically.

5. Install spacer #307, and the next row of needle bearings #306 as detailed in step 4 above.

6. With tool remaining in place slide the gear #302 (resting on the thin plate) into position in the

output carrier #301.

7. Place thrust washer #303 on top of gear #302. Insert carrier pin #304 into carrier #301

8. Turn output carrier #301 on its side so that the gear #302 is on top. Remove the thin plate.

Remove tool by pushing carrier pin #304 into output carrier #301 until planet pin is at least half

way past the last row of bearings #306. The tool may now be removed completely.

9. Insert a thrust washer between gear #302 and output carrier #301. Completely insert carrier

pin #304 into carrier #301 using care to align the roll pin hole in carrier pin #304 with the roll

pin hole in the output carrier #301.

10. Drive roll pin #305 into output carrier #301 until roll pin #305 is ¼” past flush with surface of the

output carrier #301.

11. Repeat this process to install the two remaining gears into the output carrier.

20 OM-914214-0609-D

Page 22

HOSE HOOKUP

71

41

30

71

41

41

69

53

32

39

59

71

41

32

70

21 OM-914214-0609-D

Page 23

NOTES

22 OM-914214-0609-D

Page 24

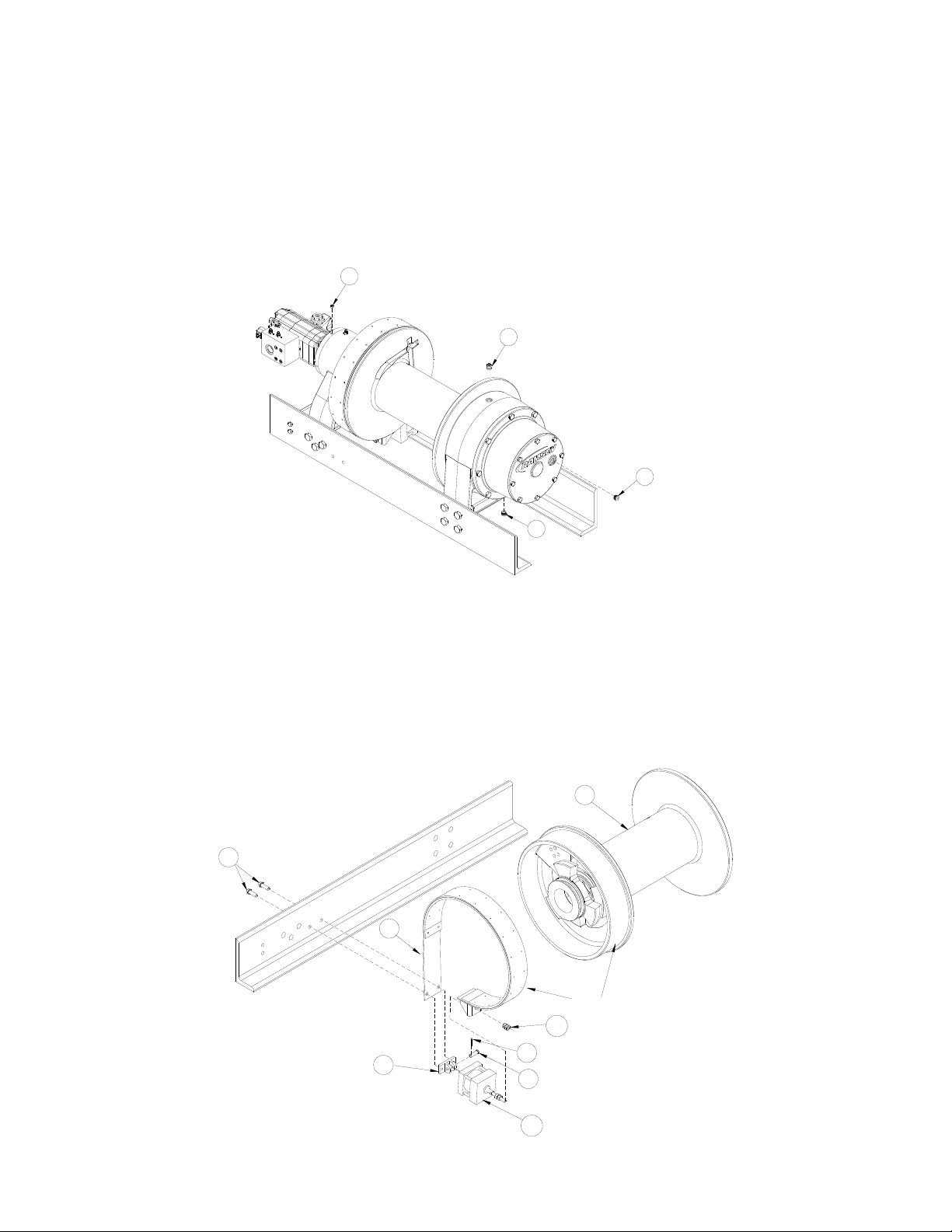

PARTS DRAWING

36 54 10

55

44

19

27

2601552

2037316

54 68

24

4581758

24

51

65 34 23

64

33

6

56 5

1

67

18

35

8

44

25 60

68

57

29

21

22

9

12

28

58

31

65

65

1

74

6111

474813

7 66

67

37

63

37

45

72

66

42

46

50

49

NOTES:

1. ITEM 1 - AIRCYLINDER KIT CONTAINS FASTENERS AND

CYLINDERS FOR CLUTCH AND BAND BRAKE.

2. ITEM 63 CONTAINS FASTENERS FOR BRAKE VALVE.

3. HOSE KIT CONTAINS FITTINGS AND HOSE.

34

14 43

62

40

23 OM-914214-0609-D

Page 25

PARTS LIST

ITEM QTY PART NO DESCRIPTION ITEM QTY PART NO DESCRIPTION

1 1 256131 AIR CYLINDER 38 NOT USED

2 1 296691 OUTPUT CARRIER ASSEMBLY 39 1 432018 FITTING JIC O-RING EL

3 1 296690 INTERMEDIATE CARRIER ASSEMBLY 40 1 296952 SPRAG BRAKE HUB ASSEMBLY

4 1 296689 INPUT CARRIER ASSEMBLY 41 4 432023 FITTING JIC O-RING NIPPLE

5 1 299749 BAND BRAKE 42 1 438043 BRAKE COVER

6 1 303146 LH MOUNTING ANGLE 43 2 456001 FITTING-LUBE, 3/16 DRIVE FIT, SHORT

7 1 303147 RH MOUNTING ANGLE 44 2 456008 FITTING-RELIEF1/8-27NPTF, 15 PSI MAX

8 1 312574 CLUTCH CYLINDER SUPPORT BRACKET 45 1 458148 MOTOR-HYD

9 1 324509 CLUTCH 46 1 462063 O-RING 2-165

10 1 328172 GEAR HOUSING COVER 47 1 462082 O-RING 2-358

11 1 330016 BRAKE PISTON 48 1 462083 BACK UP RING

12 7 330017 STATOR PLATE 49 1 462084 O-RING 2-362

13 6 330018 DISC-BRAKE 50 1 462085 BACK UP RING

14 1 332238 DRUM 51 1 462090 O-RING 2-270

15 1 334217 GEAR-SUN OUTPUT 52 1 462089 O-RING 2-279

16 1 334220 GEAR-SUN INTERMEDIATE 53 1 432053 FITTING JIC O-RING NIPPLE

17 1 334222 GEAR-SUN INPUT 54 2 468041 PLUG, -8 SAE, 3/4"-16 UNF

18 1 338378 END BEARING-MOTOR SIDE 55 1 468042 REDUCER-3/4-16 SAE O-RING X 1/8NPTF

19 1 338389 END BEARING-GEAR SIDE 56 1 486094 SEAL-OIL-SHAFT

20 1 338390 HOUSING-GEAR 57 1 486095 SEAL-OIL-SHAFT

21 1 414543 CAPSCREW-1/2-13NCX3LG,HXHD, GR 5 58 3 490006 SNAP RING 5100-125

22 1 357186 INPUT SHAFT 59 1 432054 FITTING JIC SWIVEL EL

23 1 357187 SHAFT-OUTPUT 60 2 490062 SNAP RING 5100-375

24 2 362301 SPACER 61 12 494129 SPRING-BRAKE

25 1 362311 SPACER-SHAFT 62 1 514021 U-BOLT

26 NOT USED 63 1 516048 COUNTER BALANCE BLOCK

27 1 362312 SPACER 64 2 418223 FLATWASHER 1/2

28 1 362305 SPACER 65 7 418069 NUT-1/2-13NC HEX REG,Z/P

29 1 370062 YOKE-SHIFTER 66 8 414556 CAPSCREW-1/2-13NCX1 3/4 HXHD GR.5

30 1 432048 FITTING JIC SWIVEL TEE 67 14 414790 BOLT-7/8-9NC X 3.25 LG,HXHD,GR8,PLATED

31 1 402132 BALL BEARING 68 14 418108 NUT-7/8-9NC HEX REG Z/P

32 2 432049 FITTING JIC BRANCH TEE 69 1 509137 HOSE

33 1 412135 END BEARING BUSHING 70 2 509140 HOSE

34 2 412137 DRUM BUSHING 71 3 509141 HOSE

35 1 412136 END BEARING BUSHING 72 1 462081 ORING 2-159

36 8 414277 CAPSCREW-3/8-16NCX1LG HXHD GR 5 73 NOT USED

37 14 414578 CAPSCREW-1/2-13NCX1 1/4,HXHD,GR5,ZP 74 1 468016 PIPE PLUG 1/8-27NPTF

24 OM-914214-0609-D

Page 26

AIR CYLINDER KIT #256131 PARTS LIST

402

402

409

403

403

404

406

404

401

405

404

406

408

407

ITEM QTY PART NO DESCRIPTION

401 1 408422 MOUNTING BRACKET

402 2 418067 NUT-1/2-20NF HEX JAM

403 2 418223 WASHER-1/2 USS FLAT

404 3 424005 COTTER PIN- 1/8 DIA X 1 LG

405 1 424027 CLEVIS PIN-1/2 SHAFT DIA X 1 1/2 LG

406 2 424205 CLEVIS PIN-1/2 SHAFT DIA X 1 23/64 LG

407 1 433031 AIR CYLINDER

408 1 433032 AIR CYLINDER

409 1 448108 EYE BOLT

25 OM-914214-0609-D

Page 27

DIMENSIONAL DRAWING

Bolt Size

(inches)

7/16 14 54 78

1/2 13 78 119

5/8 11 154 230

3/4 10 257 380

7/8 9 382 600

1 8 587 700

Thd s Per

Inch

Bolt Torque (ft-lb)

SAE Grade 5 SAE Grade 8

26 OM-914214-0609-D

Page 28

Limited Warranty

RAMSEY WINCH warrants each new RAMSEY WINCH to be free from defects in

material and workmanship for a period of one (1) year from date of purchase.

The obligation under this warranty, statutory or otherwise, is limited to the

replacement or repair at the Manufacturer's factory, or at a point designated by the

Manufacturer, of such part that shall appear to the Manufacturer, upon inspection of

such part, to have been defective in material or workmanship.

This warranty does not obligate RAMSEY WINCH to bear the cost of labor or

transportation charges in connection with the replacement or repair of defective

parts, nor shall it apply to a product upon which repair or alterations have been

made, unless authorized by Manufacturer, or for equipment misused, neglected or

which has not been installed correctly.

RAMSEY WINCH shall in no event be liable for special or consequential damages.

RAMSEY WINCH makes no warranty in respect to accessories such as being

subject to the warranties of their respective manufacturers.

RAMSEY WINCH, whose policy is one of continuous improvement, reserves the

right to improve its products through changes in design or materials as it may deem

desirable without being obligated to incorporate such changes in products of prior

manufacture.

If field service at the request of the Buyer is rendered and the fault is found not to

be with RAMSEY WINCH's product, the Buyer shall pay the time and expense to

the field representative. Bills for service, labor or other expenses that have been

incurred by the Buyer without approval or authorization by RAMSEY WINCH will not

be accepted.

See warranty card for details.

Ramsey Winch Company

Post Office Box 581510

Tulsa, Oklahoma 74158-1510

Telephone: (#918) 438-2760 FAX: (#918) 438-6688

27

OM-914214-0609-D

Loading...

Loading...