Page 1

INSTALLATION INSTRUCTIONS FOR SIERRA

GRILLE GUARD KIT # 295946 AND

WRAPAROUND KIT #295947

ON 1999-2007 FORD F250-550

SUPERDUTY AND 2002-2005 EXCURSION

Notice

Ramsey kits are designed for use with Ramsey Winches only.

Use or sale of kits for other winches or applications voids warranty.

Warning

Ramsey offers mounting kits and winches for various vehicles. In crash tests on a limited number of automotive

manufacturer’s vehicles, winches/mounting kits, which have been properly mounted, have not interfered with air bag

operation.

The user/customer, or their installer, must verify that the mounting kit does not interfere with the factory air bag sensors, which must not be relocated or modified in any way.

The user/customer should follow the vehicle manufacturer’s recommendations and those of a qualified mechanic to

determine if the winching/mounting kit might interfere with the air bag operation. The user/customer should then

determine the suitability of a winch/mounting kit on a particular vehicle.

PLEASE BE ADVISED THAT THE VEHICLE’S AIR BAG SYSTEM MAY NOT OPERATE PROPERLY IF THE

WINCH/MOUNTING KIT IS NOT MOUNTED IN COMPLIANCE WITH THE VEHICLE MANUFACTURER’S RECOMMENDATIONS.

DO NOT ATTACH TOW HOOK TO ANY PART OF MOUNTING KIT UNLESS INSTRUCTED TO DO SO.

DO NOT SUBSTITUTE ATTACHING HARDWARE ITEMS (BOLTS, NUTS, OR WASHERS).

READ AND UNDERSTAND WINCH OWNER’S MANUAL BEFORE INSTALLATION AND OPERATION OF THE WINCH.

SEE WARNINGS AND CAUTIONS IN WINCH OWNER’S MANUAL.

IMPORTANT NOTES!

1. RIGHT AND LEFT HAND DIRECTIONS AS IF SEATED BEHIND STEERING WHEEL.

2. ALL FASTENING HARDWARE MUST BE LOOSELY ASSEMBLED UNTIL DIRECTED TO TIGHTEN.

RAMSEY WINCH COMPANY

P.O. BOX 581510

TULSA, OKLAHOMA 74158

PHONE: (918) 438-2760 • FAX: (918) 438-6888

http://www.ramsey.com

913398-0307-B

Page 2

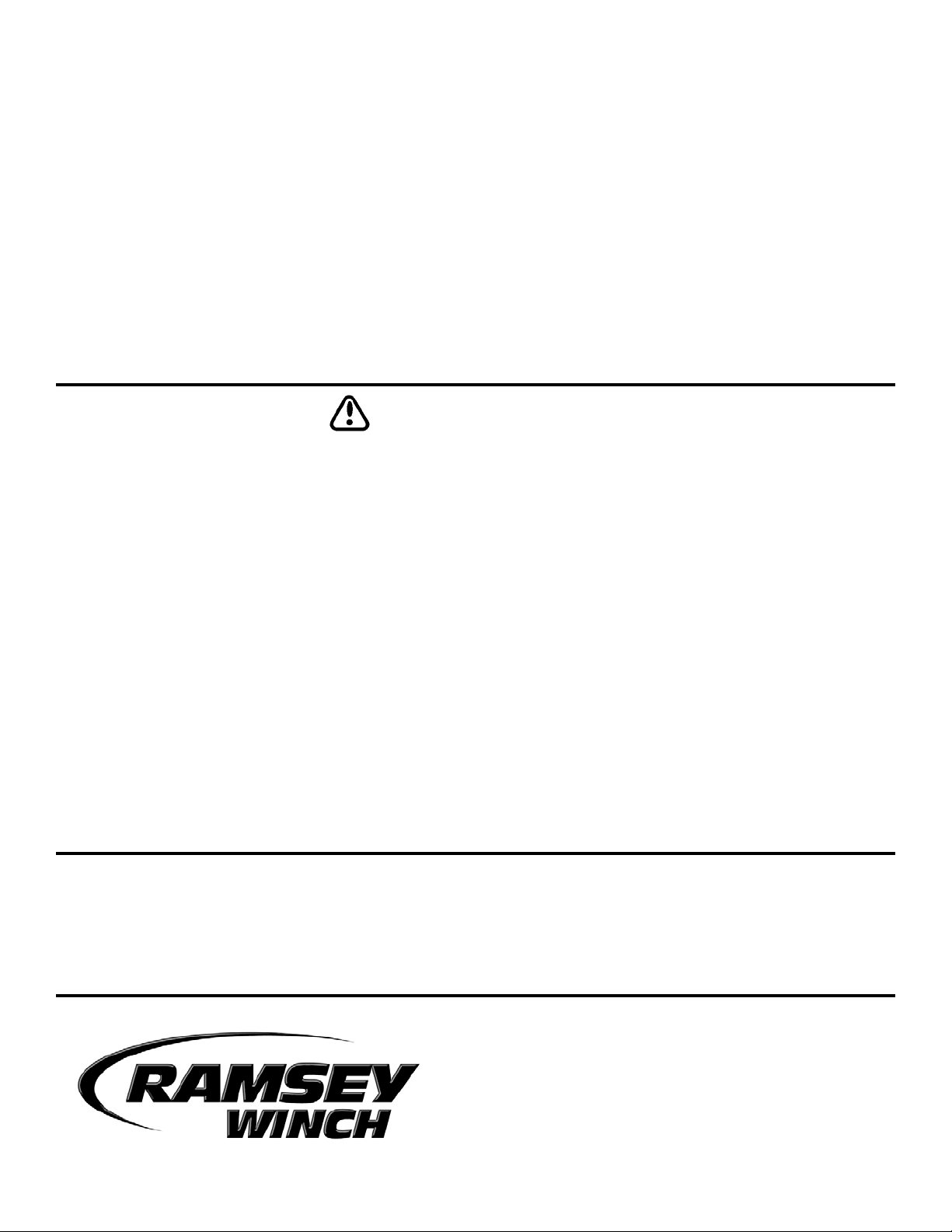

1. Remove vehicle bumper in order to access

tow hooks and frame.

2. Remove tow hooks by removing (3) 12mm factory bolts.

3. Remove the three nuts on the underside of the blocker bar as

shown at lower right. Remove blocker bar.

On some models, to remove the blocker bar, remove the four

bolts that hold the blocker bar to the bracket as shown

below.

2

Page 3

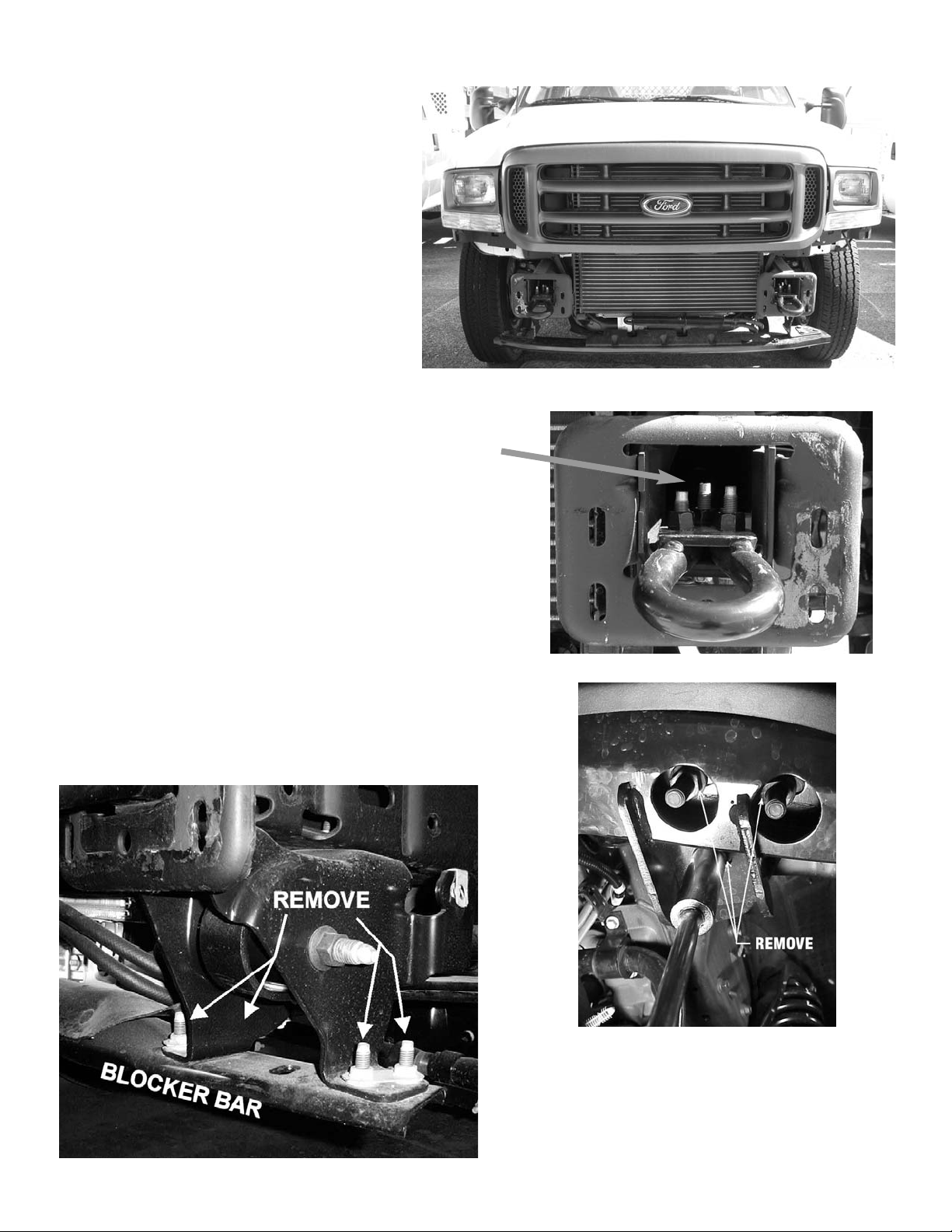

FOR 1999-2004 MODELS:

4. Fasten upper support brackets (item #5 & #6) to vehicle bumper bracket as shown at right using factory hardware.

FOR 2005 MODELS:

4a. Take (1) 1/2” bolt with rod (item #17) and place (1) 1/2”

flat washer (item #18) on bolt and hold in place using

(1) plastic gasket (item #23), threaded onto bolt.

The following views are looking up from underside of

vehicle with orientation to front of vehicle as indicated.

Driver side shown.

4b. Locate slotted holes in bottom of frame and on outside of

frame rail as shown at right.

3

Page 4

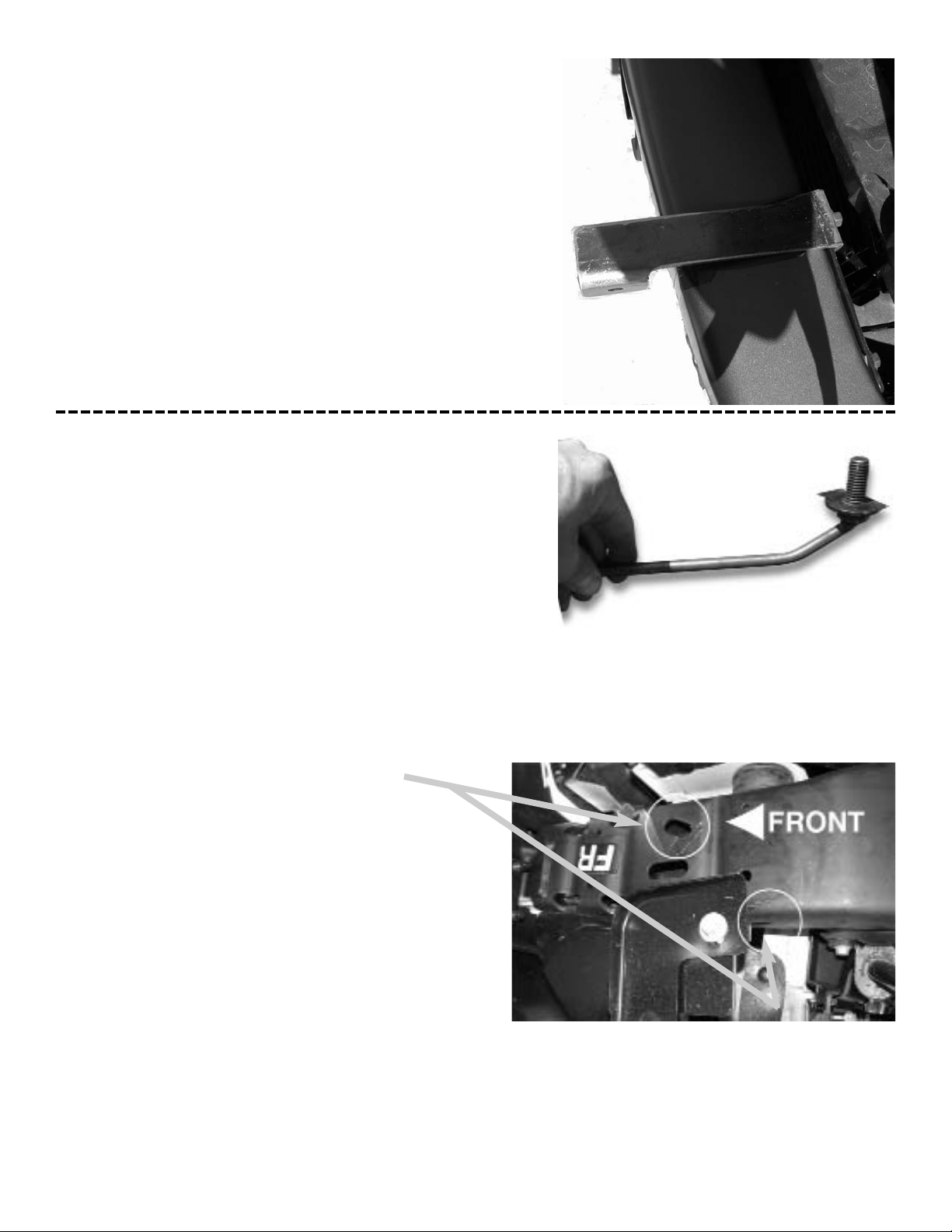

4c. Insert 1/2” bolt with extension through hole in bottom of

frame and position it so that threads extend out of frame

through slotted hole near top of frame.

Use rod extension to maneuver bolt. Bolt threads should

extend out of frame rail as shown at lower right.

4d. With bolt in place, insert upper support bracket (item

#8) on top of frame so that small tab extends out past

vehicle grille and large tab with slotted hole rests over

threads.

4e. Fasten upper support bracket to frame rail using 1/2”

flat washer (item #18) and locknut (item #16). Tighten

until snug.

4f. Repeat for passenger side.

4

Page 5

When properly installed, upper support bracket will protrude from vehicle between the vehicle grille and the top

of the front bumper. Small tab will mount to sideplate of

grille guard.

Note: The outer edges of the upper brackets should

be 32 1/4” or slightly less apart and the inner edges

of the lower brackets should be 32 7/8” or slightly

more apart in order to attach the center unit to them.

Because the mounting hardware for these brackets

need to be tightened prior to attaching the center unit

to them, make sure the spacing is correct before you

tighten the mounting hardware. Once the bumper is

re-installed, it will not be possible to adjust the

mounting hardware for these brackets.

10. Install lower mounting brackets (Item #3 & #4) to

frame rails at tow hook holes. Use (3) 12mm x 40 mm

capscrews (item #11), (3) 1/2” lockwashers (item

#19), and (3) 12mm hex nuts (item #15) per side.

Tighten hardware for upper and lower mounting brackets before bumper is re-installed. Refer to Torque Value

Chart for proper torque.

11. Re-install bumper. Bumper should slip over lower

mounting brackets.

12. Re-install blocker bar.

5

Page 6

13. Install winch channel to center unit using (2) 3/8” x 1 capscrews (item #10), (2) 3/8” locknuts (item #14), and channel gasket (item #20) on each side. Attach loosely.

14. Install center unit to upper brackets using (1) 3/8” X 1 capscrew (item #10), (1) 3/8” locknut (item #14), and upper

mounting bracket gasket (item #22) on each side. Attach

loosely.

15. Install center unit to lower brackets using (2) 1/2” x 1-1/2

capscrews (item #12), (2) 1/2” locknuts (item #16), and

lower mounting bracket gasket (item #21) on each side.

Attach loosely.

6

HOLES FOR

WRAPAROUND

UNIT

HOLES FOR

LITE TUBES

If installing Grille Guard only, skip steps 16-

18.

16. Remove 3/8” capscrew that attaches Center Unit to

Upper Mounting Bracket.

17. Install Wrap Around Right and Left units (Items #27

and #28) to side plates of center unit using (2 per

side) 1/4” capscrews (Item #32) and lock nuts

(Item #33) with wraparound shim (Item #31) and

(2 per hole) washers (Item #34). See previous page

for location of mounting holes. Re-install 3/8” capscrew and locknut through Upper Mounting Bracket,

side plate of Center Section Assembly, and Wrap

Around units.

18. Install Headlight Grille Right and Left units (Item #29

and #30) to Wrap Around units and side plates of

Center unit using (2) 1/4” x 1-1/4” capscrews (Item

#32), and lock nuts (Item #33) with washers (Item

#34). Far end of Headlight Grille units will snap into

Wrap Around units.

Page 7

7

19. Install tow hooks to tapped holes in lower mounting

brackets using (3) 12mm x 50 mm capscrews (item

#13) on each side.

20. If needed, install License Plate Bracket (item #26)

to underside of Winch Channel using (2) 1/4” capscrews (Item # 9).

21. Align and tighten all bolts to proper torque before

installing winch. See Torque Value Chart below.

22. Install the fairlead using hardware furnished with the

winch. Note that the top holes in the Channel

Assembly align with the bottom holes on the roller

fairlead.

23. Install the winch in the Winch Channel according to

mounting instructions in the Winch owner’s manual,

using supplied hardware.

24. Refer to Winch owner’s manual for instructions on

electrical connections. Be sure battery cables are

not drawn taut across any surfaces which could

possibly damage them.

25. Push battery cable into loom (Item #24) and slide

loom up cables as close as possible to mounting

frame assembly. Secure using cable ties (item #25)

at each end of loom. To improve appearance, wrap

ends of loom with electrical tape.

26. Plug remote switch into receptacle on top of solenoid. Run winch forward and reverse to check connections. Snap appropriate “IN” and “OUT” disk into

proper thumb cavity, after determining winch operating direction. Do not leave switch plugged in when

not in use.

27. Place end of wire rope through fairlead and attach

clevis hook. Use clevis pin and cotter pin (furnished

with winch).

Bolt Torque, Torque,

Size ft-lbs. Nm

1/4-20 5 ft-lbs 7 Nm

3/8-16 34 ft-lbs 46 Nm

1/2-13 87 ft-lbs 118 Nm

12mm 60 ft-lbs 90 Nm

Torque Value Chart

Page 8

8

Page 9

9

Parts List

4

22

24

1

2

25

5

6

23

3

19

7

10

8

12

28

14

11

29

21

20

9

30

15

16

17

18

27

13

ITEM

NO.

PART NO. QTY DESCRIPTION

1 R-CHANNEL321 1 WINCH CHANNEL

2 R-P295940 1 CENTER UNIT

3 R-LM940R 1 LOWER MOUNT RIGHT

4 R-0M940L 1 LOWER MOUNT LEFT

5 R-US293R 1 UPPER SUPPORT RIGHT (99-04 MODELS)

6 R-US293L 1 UPPER SUPPORT LEFT (99-04 MODELS)

7 R-US946R 1 UPPER SUPPORT RIGHT (05 MODELS)

8 R-US946L 1 UPPER SUPPORT LEFT (O5 MODELS)

9 HCS1/4-20X1 2 HEX CAPSCREW 1/4NC-20 X 1” LG

10 HCS3/8X1 6 HEX CAPSCREW 3/8NC-16 X 1” LG

11

HCS12mmX40mm

6 HEX CAPSCREW 12mm X 40mm LG

12 HCS1/2X1.5 4 HEX CAPSCREW 1/2NC-13 X 1 1/2” LG

13 HCS12mmX50 6 HEX CAPSCREW 12mm X 50mm COARSE

14 LNUT3/8-16 6 3/8NC-16 LOCKNUT

15 HEXNUT 12mm 6 12mm HEX NUT

16 LNUT1/2-13 6 1/2NC-13 LOCKNUT

17

HCS1/2w/EXTENSION

2 HEX CAPSCREW 1/2 W/EXTENSION ROD

18 WASHERFLAT1/2 4 1/2 FLAT WASHER

19 LOCKWASHER1/2 6 1/2 LOCKWASHER

20 R-GASKETCHAN 2 CHANNEL GASKET (2 HOLES)

21 R-GASKET940LN 2 LOWER BRACKET GASKET (2 HOLES)

22 GASKETUS 2 UPPER BRACKET GASKET (1 HOLE)

23 GASKET1/2 2 GASKET FOR 1/2” BOLT W/EXTENSION ROD

24 R-LOOM 1 LOOM

25 R-CABLETIE 1 CABLE TIE

26 R-408127 1 LICENSE PLATE ASSEMBLY

ADDITIONAL PARTS FOR WRAPAROUND KIT #295947

27 R-W941R 1 WRAPAROUND RIGHT

28 R-W941L 1 WRAPAROUND LEFT

29 R-G293R 1 HEADLIGHT GRILL RIGHT

30 R-G293L 1 HEADLIGHT GRILL LEFT

31 R-GASKET294W 2 WRAP SHIM

32 HCS1/4X1 10 HEX CAPSCREW 1/4NC-20 X 1” LG

33 LNUT1/4 10 1/4NC-20 LOCKNUT

34 WASHFLAT1/4 20 1/4 FLAT WASHERS

31

33

34

26

Loading...

Loading...