2013

OWNER’S MANUAL

2013

3500/4500/5500

CHASSIS CAB

OWNER’S MANUAL

2013

3500/4500/5500

CHASSIS CAB

OWNER’S MANUAL

RAM TRUCK

DIESEL SUPPLEMENT

VEHICLES SOLD IN CANADA

With respect to any Vehicles Sold in Canada, the name

Chrysler Group LLC shall be deemed to be deleted and the

name Chrysler Canada Inc. used in substitution therefore.

DRIVING AND ALCOHOL

Drunken driving is one of the most frequent causes of

accidents.

Your driving ability can be seriously impaired with blood

alcohol levels far below the legal minimum. If you are

drinking, don’t drive. Ride with a designated non-drinking

driver, call a cab, a friend, or use public transportation.

WARNING!

Driving after drinking can lead to an accident. Your

perceptions are less sharp, your reflexes are slower,

and your judgment is impaired when you have been

drinking. Never drink and then drive.

This manual illustrates and describes the operation of

features and equipment that are either standard or optional

on this vehicle. This manual may also include a description

of features and equipment that are no longer available or

were not ordered on this vehicle. Please disregard any

features and equipment described in this manual that are

not on this vehicle.

Chrysler Group LLC reserves the right to make changes in

design and specifications, and/or make additions to or

improvements to its products without imposing any obligation upon itself to install them on products previously

manufactured.

Copyright © 2012 Chrysler Group LLC

INSTALLATION OF RADIO TRANSMITTING EQUIPMENT

Special design considerations are incorporated into this

vehicle’s electronic system to provide immunity to radio

frequency signals. Mobile two-way radios and telephone

equipment must be installed properly by trained personnel.

The following must be observed during installation.

The positive power connection should be made directly to

the battery and fused as close to the battery as possible.

The negative power connection should be made to body

sheet metal adjacent to the negative battery connection.

This connection should not be fused.

Antennas for two-way radios should be mounted on the roof

or the rear area of the vehicle. Care should be used in

mounting antennas with magnet bases. Magnets may affect

the accuracy or operation of the compass on vehicles so

equipped.

The antenna cable should be as short as practical and

routed away from the vehicle wiring when possible. Use

only fully shielded coaxial cable.

Carefully match the antenna and cable to the radio to

ensure a low Standing Wave Ratio (SWR).

Mobile radio equipment with output power greater than

normal may require special precautions.

All installations should be checked for possible interfer-

ence between the communications equipment and the

vehicle’s electronic systems.

SECTION PAGE

TABLE OF CONTENTS

1

INTRODUCTION .............................................................3

2

THINGS TO KNOW BEFORE STARTING YOUR VEHICLE .............................5

3

UNDERSTANDING YOUR INSTRUMENT PANEL ...................................11

4

STARTING AND OPERATING ..................................................31

5

WHAT TO DO IN EMERGENCIES ...............................................95

6

MAINTAINING YOUR VEHICLE ...............................................101

7

MAINTENANCE SCHEDULE ..................................................147

8

INDEX ....................................................................173

1

2

3

4

5

6

7

8

INTRODUCTION

CONTENTS

䡵 A MESSAGE FROM CHRYSLER GROUP LLC ....4

1

4 INTRODUCTION

A MESSAGE FROM CHRYSLER GROUP LLC

Chrysler Group LLC and Cummins® welcome you as a

Cummins® turbocharged diesel-powered truck owner.

Your diesel truck will sound, feel, drive, and operate

differently from a gasoline-powered truck. It is important

that you read and understand this manual.

Almost 100% of the heavy duty trucks in the United

States and Canada are diesel-powered because of the fuel

economy, rugged durability, and high torque which permits pulling heavy loads. Cummins® engines power well

over half of these trucks. Now this same technology and

proven performance is yours in your truck equipped

with the Cummins® turbocharged diesel engine.

You may find that some of the starting, operating, and

maintenance procedures are different. However, they are

simple to follow and careful adherence to them will

ensure that you take full advantage of the features of this

engine.

NOTE: Some aftermarket products may cause severe

engine/transmission and/or exhaust system damage.

Your vehicle’s Powertrain Control Systems can detect

and store information about vehicle modifications that

increase horsepower and torque output such as whether

or not performance-enhancing powertrain components,

commonly referred to as downloaders, power boxes, or

performance chips have been used.

This information cannot be erased and will stay in the

system’s memory even if the modification is removed. This

information can be retrieved by Chrysler Group LLC, and

service and repair facilities, when servicing your vehicle.

This information may be used to determine if repair will be

covered by the New Vehicle Limited Warranty.

There is a probability that the use of a “performance chip”

will prohibit the engine from starting. In this instance, the

vehicle will need to be serviced by a authorized dealer in

order to return the vehicle to it’s factory settings.

THINGS TO KNOW BEFORE STARTING YOUR VEHICLE

CONTENTS

䡵

REMOTE STARTING SYSTEM — IF EQUIPPED . . .6

▫ How To Use Remote Start .................6

2

䡵 ENGINE BREAK-IN RECOMMENDATIONS ....10

6 THINGS TO KNOW BEFORE STARTING YOUR VEHICLE

REMOTE STARTING SYSTEM — IF EQUIPPED

This system uses the Remote Keyless Entry

(RKE) transmitter to start the engine conveniently from outside the vehicle while still

maintaining security. The system has a range of

approximately 300 ft (91 m).

How To Use Remote Start

All of the following conditions must be met before the

engine will remote start:

• Shift lever in PARK

• Doors closed

NOTE:

• The vehicle must be equipped with an automatic

transmission to be equipped with Remote Start.

• The remote start system will wait for the “Wait To

Start” telltale to extinguish before cranking the engine.

This allows time for the intake heater to pre-heat the

incoming air, and is normal operation in cold weather.

Refer to “Electronic Vehicle Information Center/EVIC

Warning Lights” in “Understanding Your Instrument

Panel” for further information on and “Wait To Start”

telltale and pre-heat cycle.

• Hood closed

• HAZARD switch off

• BRAKE switch inactive (brake pedal not pressed)

• Ignition key removed from ignition switch

• Battery at an acceptable charge level

• RKE PANIC button not pressed

• Fuel meets minimum requirement

• Water In Fuel Indicator Light is not illuminated

• Wait To Start Light is not illuminated

WARNING!

• Do not start or run an engine in a closed garage or

confined area. Exhaust gas contains Carbon Monoxide (CO) which is odorless and colorless. Carbon

Monoxide is poisonous and can cause serious injury or death when inhaled.

• Keep Remote Keyless Entry (RKE) transmitters

away from children. Operation of the Remote Start

System, windows, door locks or other controls

could cause serious injury or death.

THINGS TO KNOW BEFORE STARTING YOUR VEHICLE 7

Remote Start Abort Message On Electronic Vehicle Information Center (EVIC) – If Equipped

The following messages will display in the EVIC if the

vehicle fails to remote start or exits remote start prematurely:

• Remote Start Aborted - Door Ajar

• Remote Start Aborted - Hood Ajar

• Remote Start Aborted - Fuel Low

• Remote Start Aborted - System Fault

The EVIC message stays active until the ignition is turned

to the ON/RUN position.

2

8 THINGS TO KNOW BEFORE STARTING YOUR VEHICLE

To Enter Remote Start Mode

Press and release the REMOTE START button on

the RKE transmitter twice, within five seconds.

The parking lights will flash and the horn will

chirp twice (if programmed). In cold ambient

temperature conditions, the diesel vehicle may delay crank

up to 30 seconds for the fuel and grid heater. Once the

vehicle has started, the engine will run for 15 minutes.

NOTE:

• The engine can be started two consecutive times (two

15-minute cycles) with the RKE transmitter. However,

the ignition switch must be cycled to the ON position

before you can repeat the start sequence for a third

cycle.

To Exit Remote Start Mode Without Driving The Vehicle

Press and release the REMOTE START button one time or

allow the engine to run for the entire 15-minute cycle.

• The park lamps will turn on and remain on during

Remote Start mode.

• For security, power window and power sunroof operation (if equipped) are disabled when the vehicle is

in the Remote Start mode.

NOTE: To avoid unintentional shut downs, the system

will disable the one time press of the REMOTE START

button for two seconds after receiving a valid Remote

Start request.

To Exit Remote Start Mode And Drive The Vehicle

To exit Remote start Mode and Drive the vehicle Before the

end of the 15-minute cycle, press and release the unlock

button on the RKE transmitter to unlock the door and

disarm the Vehicle Security Alarm System (if equipped).

Then prior to the end of the 15 minute cycle, insert the Key

Fob (if equipped) and rotate to RUN.

NOTE:

• The ignition switch must be in the ON/RUN position

in order to drive the vehicle.

• For vehicles equipped with the Electronic Vehicle

Information Center (EVIC), the message “Insert Key/

Turn To On” will flash in the EVIC until you insert the

Key Fob into the ignition swich. Once inserted, the

message “Turn To On” will flash in the EVIC until you

turn the ignition switch to the ON/RUN position.

THINGS TO KNOW BEFORE STARTING YOUR VEHICLE 9

Remote Start Comfort Systems – If Equipped

When remote start is activated, the heated steering

wheel, and driver heated seat features will automatically

turn on in cold weather. In warm weather, the driver

vented seat feature will automatically turn on when the

remote start is activated. These features will stay on

through the duration of remote start or until the ignition

switch is turned to the ON position.

The Remote Start Comfort System can be activated and

deactivated through the Electronic Vehicle Information

Center (EVIC). For more information on Remote Start

Comfort System operation refer to “Electronic Vehicle

Information Center (EVIC)/Customer-Programmable

Features (System Setup)” in “Understanding Your Instrument Panel”.

2

10 THINGS TO KNOW BEFORE STARTING YOUR VEHICLE

ENGINE BREAK-IN RECOMMENDATIONS

The Cummins® turbocharged diesel engine does not

require a break-in period due to its construction. Normal

operation is allowed, providing the following recommendations are followed:

• Warm up the engine before placing it under load.

Do not operate the engine at idle for prolonged periods.

•

• Use the appropriate transmission gear to prevent

engine lugging.

• Observe vehicle oil pressure and temperature indicators.

• Check the coolant and oil levels frequently.

• Vary throttle position at highway speeds when carry-

ing or towing significant weight.

NOTE: Light duty operation such as light trailer towing

or no load operation will extend the time before the

engine is at full efficiency. Reduced fuel economy and

power may be seen at this time.

For additional vehicle break-in requirements, refer to

“Trailer Towing” in “Starting and Operating” of the

Owners Manual.

Because of the construction of the Cummins® turbocharged diesel engine, engine run-in is enhanced by

loaded operating conditions which allow the engine

parts to achieve final finish and fit during the first

6,000 miles (10 000 km).

UNDERSTANDING YOUR INSTRUMENT PANEL

CONTENTS

䡵 INSTRUMENT CLUSTER .................12

䡵 INSTRUMENT CLUSTER DESCRIPTIONS .....13

䡵 ELECTRONIC VEHICLE INFORMATION

CENTER (EVIC) ........................23

▫ Electronic Vehicle Information Center (EVIC)

Displays .............................23

▫ Vehicle Information (Customer Information

Features) ............................29

3

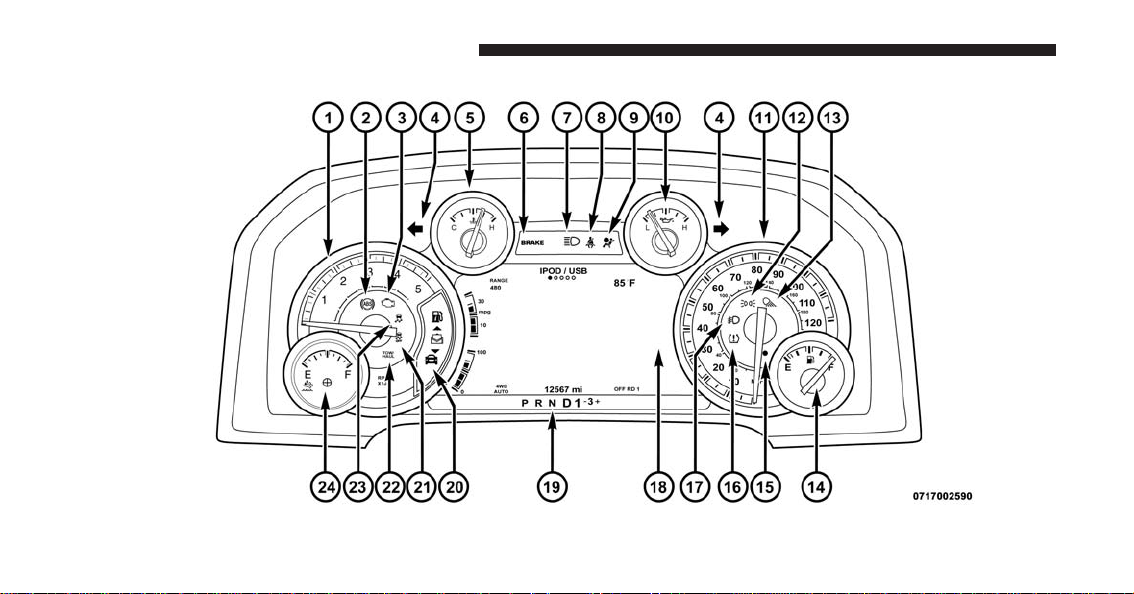

12 UNDERSTANDING YOUR INSTRUMENT PANEL

INSTRUMENT CLUSTER

INSTRUMENT CLUSTER DESCRIPTIONS

1. Tachometer

The tachometer indicates engine speed in Revolutions

Per Minute (RPM x 1000).

CAUTION!

Do not operate the engine with the tachometer

pointer at high RPM for extended periods. Engine

operation over 3200 RPM (Redline) can result in

significant damage that will not be covered under

warranty.

2. Anti-Lock Brake (ABS) Light

This light monitors the Anti-lock Brake System

(ABS). The light will turn on when the ignition

switch is turned to the ON/RUN position and

may stay on for as long as four seconds.

UNDERSTANDING YOUR INSTRUMENT PANEL 13

If the ABS light remains on or turns on while driving, it

indicates that the anti-lock portion of the brake system is

not functioning and that service is required. However,

the conventional brake system will continue to operate

normally if the BRAKE warning light is not on.

If the ABS light is on, the brake system should be serviced

as soon as possible to restore the benefits of anti-lock

brakes. If the ABS light does not turn on when the

ignition switch is turned to the ON/RUN position, have

the light inspected by an authorized dealer.

3. Malfunction Indicator Light (MIL)

The Malfunction Indicator Light (MIL) is part of

an onboard diagnostic (OBDII) system which

monitors the emissions and engine control system. If the vehicle is ready for emissions testing, the light

will come on when the ignition is first turned on and

remain on, as a bulb check, until the engine is started.

3

14 UNDERSTANDING YOUR INSTRUMENT PANEL

If the vehicle is not ready for emissions testing the light

will come on when the ignition is first turned on and

remain on for 15 seconds, then blink for 5 seconds, and

remain on until the vehicle is started. If the bulb does not

come on during starting, have the condition investigated

promptly.

If this light comes on and remains on while driving, it

suggests a potential engine control problem and the need

for system service.

Although your vehicle will usually be drivable and not

need towing, see your authorized dealer for service as

soon as possible.

CAUTION!

Prolonged driving with the Malfunction Indicator

Light (MIL) on could cause damage to the engine

(Continued)

CAUTION! (Continued)

control system. It also could affect fuel economy and

drivability. If the MIL is flashing, severe catalytic

converter damage and power loss will soon occur.

Immediate service is required.

WARNING!

A malfunctioning catalytic converter, as referenced

above, can reach higher temperatures than in normal

operating conditions. This can cause a fire if you

drive slowly or park over flammable substances such

as dry plants, wood, cardboard, etc. This could result

in death or serious injury to the driver, occupants or

others.

4. Turn Signal Indicators

The arrow will flash with the exterior turn signal

when the turn signal lever is operated.

NOTE:

A continuous chime will sound if the vehicle is driven

more than 1 mile (1.6 km) with either turn signal on.

Check for an inoperative outside light bulb if either

indicator remains on and does not flash, or flashes at a

rapid rate.

5. Engine Coolant Temperature

This gauge shows the engine coolant temperature. The

gauge pointer will likely show higher temperatures when

driving in hot weather, up mountain grades, or in heavy

stop and go traffic. If the red Warning Light turns on

while driving, safely bring the vehicle to a stop, and turn

off the engine. DO NOT operate the vehicle until the

cause is corrected.

UNDERSTANDING YOUR INSTRUMENT PANEL 15

CAUTION!

Driving with a hot engine cooling system could

damage your vehicle. If the temperature gauge reads

“H” pull over and stop the vehicle. Idle the vehicle

with the air conditioner turned off until the pointer

drops back into the normal range. If the pointer

remains on the “H” and you hear continuous chimes,

turn the engine off immediately and call an authorized dealer for service.

WARNING!

A hot engine cooling system is dangerous. You or

others could be badly burned by steam or boiling

coolant. You may want to call an authorized dealer

for service if your vehicle overheats. If you decide to

(Continued)

3

16 UNDERSTANDING YOUR INSTRUMENT PANEL

WARNING! (Continued)

look under the hood yourself, see “Maintaining Your

Vehicle.” Follow the warnings under the “Cooling

System Pressure Cap” paragraph.

6. Brake Warning Light

This light monitors various brake functions,

including brake fluid level and parking brake

application. If the brake light turns on it may

indicate that the parking brake is applied, that

the brake fluid level is low, or that there is a problem with

the Anti-lock Brake System reservoir.

If the light remains on when the parking brake has been

disengaged, and the fluid level is at the full mark on the

master cylinder reservoir, it indicates a possible brake

hydraulic system malfunction or that a problem with the

Brake Booster has been detected by the Anti-Lock Brake

System (ABS) / Electronic Stability Control (ESC) system.

In this case, the light will remain on until the condition

has been corrected. If the problem is related to the brake

booster, the ABS pump will run when applying the brake

and a brake pedal pulsation may be felt during each stop.

The dual brake system provides a reserve braking capacity in the event of a failure to a portion of the hydraulic

system. A leak in either half of the dual brake system is

indicated by the Brake Warning Light, which will turn on

when the brake fluid level in the master cylinder has

dropped below a specified level.

The light will remain on until the cause is corrected.

NOTE: The light may flash momentarily during sharp

cornering maneuvers, which change fluid level conditions. The vehicle should have service performed, and

the brake fluid level checked.

If brake failure is indicated, immediate repair is necessary.

WARNING!

Driving a vehicle with the red brake light on is

dangerous. Part of the brake system may have failed.

It will take longer to stop the vehicle. You could have

a collision. Have the vehicle checked immediately.

Vehicles equipped with the ABS, are also equipped with

Electronic Brake Force Distribution (EBD). In the event of

an EBD failure, the Brake Warning Light will turn on

along with the ABS Light. Immediate repair to the ABS

system is required.

Operation of the Brake Warning Light can be checked by

turning the ignition switch from the OFF position to the

ON/RUN position. The light should illuminate for approximately two seconds. The light should then turn off

unless the parking brake is applied or a brake fault is

detected. If the light does not illuminate, have the light

inspected by an authorized dealer.

UNDERSTANDING YOUR INSTRUMENT PANEL 17

The light also will turn on when the parking brake is

applied with the ignition switch in the ON/RUN position.

NOTE: This light shows only that the parking brake is

applied. It does not show the degree of brake application.

7. High Beam Indicator

This indicator shows that headlights are on high

beam. Push the multifunction lever forward to

switch the headlights to high beam, and pull toward

yourself (normal position) to return to low beam.

8. Seat Belt Reminder Light

When the ignition switch is first turned to ON/

RUN, this light will turn on for four to eight

seconds as a bulb check. During the bulb check, if

the driver’s seat belt is unbuckled, a chime will sound.

After the bulb check or when driving, if the driver’s seat

belt remains unbuckled, the seat belt reminder light will

3

18 UNDERSTANDING YOUR INSTRUMENT PANEL

flash or remain on continuously. Refer to “Occupant

Restraints” in “Things To Know Before Starting Your

Vehicle” for further information.

9. Air Bag Warning Light

If the gauge pointer moves to either extreme of the gauge,

the Check Gauges indicator will illuminate and a single

chime will sound.

11. Speedometer

This light will turn on for four to eight seconds

as a bulb check when the ignition switch is first

turned to ON/RUN. If the light is either not

on during starting, stays on, or turns on while

driving, have the system inspected at an authorized

dealer as soon as possible. Refer to “Occupant Restraints”

in “Things To Know Before Starting Your Vehicle” for

further information.

10. Engine Oil Pressure

The pointer should always indicate some oil pressure

when the engine is running. A continuous high or low

reading under normal driving conditions may indicate

a lubrication system malfunction. Immediate service

should be obtained from an authorized dealer.

The speedometer shows the vehicle speed in miles per

hour and/or kilometers per hour (mph/km/h).

12. Park/Headlight ON Indicator — If Equipped

This indicator will illuminate when the park

lights or headlights are turned on.

13. Cargo Light

The cargo light will illuminate when the cargo

light is activated by pressing the cargo light

button on the headlight switch.

14. Fuel Gauge

Shows level of fuel in tank when ignition switch is in the

ON/RUN position.

15. Vehicle Security Light — If Equipped

This light will flash at a fast rate for approxi-

mately 15 seconds, when the vehicle security

alarm is arming, and then will flash slowly

until the vehicle is disarmed.

16. Tire Pressure Monitoring Telltale Light

Each tire, including the spare (if provided),

should be checked monthly when cold and in-

flated to the inflation pressure recommended by

the vehicle manufacturer on the vehicle placard

or tire inflation pressure label. (If your vehicle has tires of

a different size than the size indicated on the vehicle

placard or tire inflation pressure label, you should determine the proper tire inflation pressure for those tires.)

UNDERSTANDING YOUR INSTRUMENT PANEL 19

As an added safety feature, your vehicle has been

equipped with a Tire Pressure Monitoring System

(TPMS) that illuminates a low tire pressure telltale when

one or more of your tires is significantly under-inflated.

Accordingly, when the low tire pressure telltale illuminates, you should stop and check your tires as soon as

possible, and inflate them to the proper pressure. Driving

on a significantly under-inflated tire causes the tire to

overheat and can lead to tire failure. Under-inflation also

reduces fuel efficiency and tire tread life, and may affect

the vehicle’s handling and stopping ability.

Please note that the TPMS is not a substitute for proper

tire maintenance, and it is the driver’s responsibility to

maintain correct tire pressure, even if under-inflation has

not reached the level to trigger illumination of the TPMS

low tire pressure telltale.

3

20 UNDERSTANDING YOUR INSTRUMENT PANEL

Your vehicle has also been equipped with a TPMS

malfunction indicator to indicate when the system is not

operating properly. The TPMS malfunction indicator is

combined with the low tire pressure telltale. When the

system detects a malfunction, the telltale will flash for

approximately one minute and then remain continuously

illuminated. This sequence will continue upon subsequent vehicle start-ups as long as the malfunction exists.

When the malfunction indicator is illuminated, the system may not be able to detect or signal low tire pressure

as intended. TPMS malfunctions may occur for a variety

of reasons, including the installation of replacement or

alternate tires or wheels on the vehicle that prevent the

TPMS from functioning properly. Always check the

TPMS malfunction telltale after replacing one or more

tires or wheels on your vehicle, to ensure that the

replacement or alternate tires and wheels allow the TPMS

to continue to function properly.

CAUTION!

The TPMS has been optimized for the original

equipment tires and wheels. TPMS pressures and

warning have been established for the tire size

equipped on your vehicle. Undesirable system operation or sensor damage may result when using replacement equipment that is not of the same size,

type, and/or style. Aftermarket wheels can cause

sensor damage. Do not use tire sealant from a can or

balance beads if your vehicle is equipped with a

TPMS, as damage to the sensors may result.

NOTE: The TPMS telltale is also accompanied by a “Low

Tire” message in the odometer (Base Cluster), or in the

Electronic Vehicle Information Center (EVIC) screen indicating “Low Tire” for EVIC enabled clusters.

17. Front Fog Light Indicator — If Equipped

This indicator will illuminate when the front fog

lights are on.

18. Electronic Vehicle Information Center (EVIC)

The Electronic Vehicle Information Center (EVIC) features a driver-interactive display that is located in the

instrument cluster. For further information, refer to

“Electronic Vehicle Information Center (EVIC)”.

19. Transmission Gear Position Indicator

The Transmission Gear Position Indicator is selfcontained within the instrument cluster. It displays the

gear range of the automatic transmission.

UNDERSTANDING YOUR INSTRUMENT PANEL 21

on the shift lever to activate ERS. Refer to “Automatic

Transmission” in “Starting And Operating” for further

information.

20. Electronic Vehicle Information Center (EVIC) Menu

The Electronic Vehicle Information Center (EVIC) features a driver-interactive display that is located in the

instrument cluster. For further information, refer to

“Electronic Vehicle Information Center (EVIC)”.

21. Electronic Stability Control (ESC) OFF Indicator

Light — If Equipped

This light indicates that the Electronic Stability

Control (ESC) is in Partial Off or Full Off mode.

3

NOTE: The highest available transmission gear is displayed in the lower right corner of the Electronic Vehicle

Information Center (EVIC) whenever the Electronic

Range Select (ERS) feature is active. Use the +/- selector

22. TOW/HAUL

The TOW HAUL button is located on the center

stack upper switch bank. This light will illuminate when TOW HAUL mode is selected.

22 UNDERSTANDING YOUR INSTRUMENT PANEL

23. Electronic Stability Control (ESC) Activation/

Malfunction Indicator Light — If Equipped

Each time the ignition is turned to ON/RUN, the ESC

system will be ON, even if it was turned off previously.

The “ESC Activation/Malfunction Indicator

Light” in the instrument cluster will come on

when the ignition switch is turned to the

ON/RUN position. It should go out with the

engine running. If the “ESC Activation/Malfunction Indicator Light” comes on continuously with the engine

running, a malfunction has been detected in the ESC

system. If this light remains on after several ignition

cycles, and the vehicle has been driven several miles

(kilometers) at speeds greater than 30 mph (48 km/h), see

your authorized dealer as soon as possible to have the

problem diagnosed and corrected.

NOTE:

The “ESC Off Indicator Light” and the “ESC Activation/

Malfunction Indicator Light” come on momentarily each

time the ignition switch is turned to ON/RUN.

The ESC system will make buzzing or clicking sounds

when it is active. This is normal; the sounds will stop

when ESC becomes inactive following the maneuver that

caused the ESC activation.

24. DEF Gauge

The DEF Gauge displays the actual level of Diesel

Exhaust Fluid in the DEF tank. Diesel Exhaust Fluid

(DEF) is required to maintain normal vehicle operation

and emissions compliance. More information is available

in the Electronic Vehicle Information (EVIC) section

under the heading of Diesel Exhaust Fluid (DEF) Warning Messages.

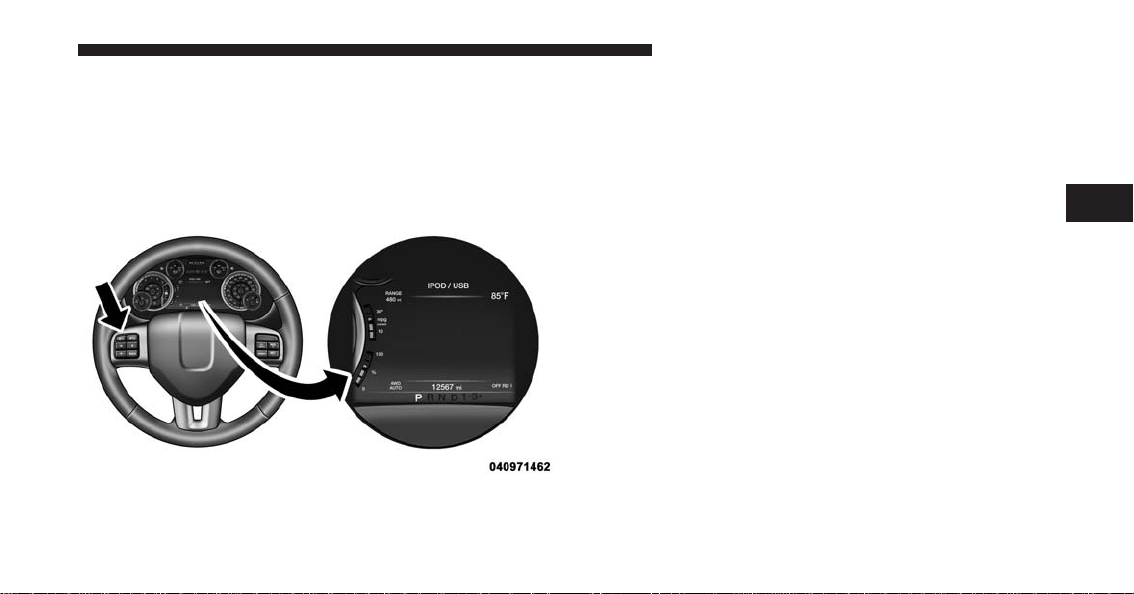

ELECTRONIC VEHICLE INFORMATION CENTER (EVIC)

The Electronic Vehicle Information Center (EVIC) features a driver-interactive display that is located in the

instrument cluster.

UNDERSTANDING YOUR INSTRUMENT PANEL 23

This system conveniently allows the driver to select a

variety of useful information by pressing the switches

mounted on the steering wheel.

Refer to “Electronic Vehicle Information Center – If

Equipped” in the Owner’s Manual for further information.

Electronic Vehicle Information Center (EVIC) Displays

When the appropriate conditions exist, the Electronic

Vehicle Information Center (EVIC) Displays the following messages:

• System Setup Unavailable – Vehicle Not in Park

• System Setup Unavailable – Vehicle in Motion

• Service Air Filter

3

Electronic Vehicle Information Center (EVIC)

• Perform Service

24 UNDERSTANDING YOUR INSTRUMENT PANEL

• Exhaust Filter XX% Full Safely Drive at Highway

Speeds To Remedy

• Exhaust Filter Full – Power Reduced See Dealer

• Exhaust Service Required – See Dealer Now

• 5 MPH Max Speed Refill DEF

• Service DEF System See Dealer

• 5 MPH Max Speed in XXX mi Service DEF System See

Dealer

• Exhaust System – Filter XX% Full Service Required See

Dealer

• Exhaust System – Regeneration In Process Exhaust

Filter XX% Full

• Exhaust System – Regeneration Completed

• DEF Low Refill Soon

• Speed Limited to 5 MPH in XXX mi Refill DEF

• 5 MPH Max Speed on Restart, Long Idle or Refuel

Refill DEF

• 5 MPH Max Speed on Restart, Long Idle or Refuel

Service DEF See Dealer

• 5 MPH Max Speed Service DEF System See Dealer

• Coolant Low

• Engine Power Reduced During Warmup

• Engine Power Reduced up to 30-sec During Warmup

• Engine Power Reduced up to 2-min During Warmup

• Active Airbox Service Required See Dealer

EVIC Warning Lights

Water In Fuel Indicator Light

The “Water In Fuel Indicator Light” will illuminate when there is water detected in the fuel

filters. If this light remains on, DO NOT start the

vehicle before you drain the water from the fuel

filters to prevent engine damage. Refer to “Maintenance

Procedures/ Draining Fuel/Water Separator Filters” in

“Maintaining Your Vehicle” for further information.

Wait To Start Light

The “Wait To Start Light” will illuminate when the

ignition is turned to the RUN position and the

intake manifold temperature is below 66°F (19°C). Wait

until the “Wait To Start Light” turns OFF, then start the

vehicle. Refer to “Starting Procedures” in “Starting and

Operating” for further information.

UNDERSTANDING YOUR INSTRUMENT PANEL 25

NOTE: The “Wait To Start Light” may not illuminate if

the intake manifold temperature is warm enough.

Low Coolant Level Indicator

This telltale will turn on to indicate the vehicle

coolant level is low.

Cold Ambient Derate Mode Messages

The vehicle will display messages when a derate (engine

power reduction) is activated to protect the turbocharger

during engine start up in cold ambient temperatures.

• Engine Power Reduced During Warmup -

sage will display during start up when the ambient

temperature is between 10° F (-12° C) and -10° F (-23° C).

•

Engine Power Reduced Up To 30 Sec (Seconds) During

Warmup

when the ambient temperature is between -10° F

(-23° C) and -25 F (-32° C).

- This message will display during start up

This mes-

3

26 UNDERSTANDING YOUR INSTRUMENT PANEL

•

Engine Power Reduced Up To 2 Min (Minutes) During

Warmup

- This message will display during start up

when the ambient temperature is -25° F (-32° C) and

below.

• Coolant Low - This telltale will turn on to indicate the

vehicle coolant level is low. See “Adding Coolant”

under the section “Maintaining Your Vehicle” for more

information.

Diesel Exhaust Fluid (DEF) Warning Messages

Your vehicle will begin displaying warning messages

when the DEF level reaches a driving range of approximately 350 miles (563 km). If the following warning

message sequence is ignored, your vehicle may be limited to a maximum speed of 5 MPH (8 km/H) unless DEF

is added.

• DEF Low Refill Soon – This message will display

when the low level is reached, during vehicle start up,

and with increased frequency during vehicle operation. It will be accompanied by a single chime. Approximately 5 gallons (19 Liters) of DEF is required to

refill the tank when this message is initially displayed.

on pickup applications, and approximately 7 gallons

(28 Liters) are required on chassis-cab applications.

• Speed Limited to 5 MPH in XXX mi Refill DEF – This

message will continuously display if the “DEF Low

Refill Soon” message is ignored, and the frequency of

occurance of the chime will increase unless up to

2 gallons (7.5 Liters) of DEF is added to the tank.

• 5 MPH Max Speed on Restart, Long Idle or Refuel

Refill DEF – This message will continuously display

when the counter reaches zero, and will be accompanied by a periodic chime.

• The vehicle will only be capable of a maximum speed

of 5 MPH upon the first of the following conditions to

occur:

• If the vehicle is shutoff and restarted.

• If the vehicle is idled for an extended period of time,

approximately one hour or greater.

• If the system detects that the level of fuel in the tank

has increased.

• Add a minimum of 2 gallons (9.5 Liters) of DEF to the

tank in order to avoid vehicle operation at a maximum

speed of 5 MPH (8 km/H).

• 5 MPH Max Speed Refill DEF – The vehicle will only

be capable of a maximum speed of 5 MPH (8 km/H)

when this message is displayed. Add up to 2.5 gallons

(9.5 Liters) of DEF to the tank to restore normal vehicle

operation.

UNDERSTANDING YOUR INSTRUMENT PANEL 27

NOTE: A minimum of 2 gallons (9.5 Liters) may be

required to restore normal vehicle operation. Although

the vehicle will start normally and can be placed in gear

after this message has been initially displayed, extreme

caution should be utilized since the vehicle will only be

capable of maneuvering at a maximum speed of 5 MPH

(8 km/H).

Diesel Exhaust Fluid (DEF) Fault Warning Messages

There are four different messages which are displayed if

the vehicle detects that the DEF system has been filled

with a fluid other than DEF, has experienced component

failures, or when tampering has been detected. The

vehicle may be limited to a maximum speed of 5 MPH

(8 km/H) if the DEF system is not serviced within less

than 250 miles (402 km) of the fault being detected.

3

28 UNDERSTANDING YOUR INSTRUMENT PANEL

When the DEF system needs to be serviced the following

warnings will display:

• Service DEF System – See Dealer —

This message will

display when the fault is initially detected, each time the

vehicle is started, and periodically during driving. The

message will be accompanied by a single chime. We

recommend you drive to your nearest authorized dealer

and have your vehicle serviced as soon as possible.

• 5 MPH Max Speed in 200 mi Service DEF System See

Dealer —

This message will display if the DEF system

has not been serviced after the “Service DEF System –

See Dealer” message is displayed. This message will

continuously display until the mileage counter reaches

zero, and will be accompanied by a periodic chime. The

message will continue to countdown until it reaches zero

unless the vehicle is serviced. We recommend you drive

to your nearest authorized dealer and have your vehicle

serviced immediately.

NOTE: Under some circumstances this mileage counter

may start with a value of less than 200 miles (322 km). For

example, if recurring faults are detected in a time interval

of less than 40 hours, the counter may restart at the value

where it stopped when a previous fault was temporarily

remedied, or at a minimum of 50 miles (80 km).

• 5 MPH Max Speed on Restart, Long Idle or Refuel

Service DEF See Dealer — This message will continu-

ously display when the mileage counter reaches zero,

and will be accompanied by a periodic chime.

• The vehicle will only be capable of a maximum speed

of 5 MPH upon the first of the following conditions to

occur:

• If the vehicle is shutoff and restarted.

• If the vehicle is idled for an extended period of time,

approximately one hour or greater.

• If the system detects that the level of fuel in the tank

has increased.

• 5 MPH Max Speed Service DEF System See Dealer —

This message will continuously display, and will be

accompanied by a periodic chime. Although the vehicle can be started and placed in gear, the vehicle will

only operate at a maximum speed of 5 MPH. Your

vehicle will require towing, see your authorized dealer

for service.

NOTE: When this message is displayed, the engine can

still be started. However, the vehicle will only operate at

a maximum speed of 5 MPH.

RAM Active Air System

Your vehicle is equipped with an advanced Ram Active

Air system that provides enhanced performance,

especially when towing under demanding hot or high

altitude conditions. If the EVIC displays the message

“Active Airbox Service Required See Dealer”, vehicle

performance may be reduced until service is performed

by an authorized RAM dealer.

UNDERSTANDING YOUR INSTRUMENT PANEL 29

Vehicle Information (Customer Information Features)

Press and release the UP or DOWN button until “Vehicle

Info” displays in the EVIC and press the SELECT button.

Press the UP and DOWN button to scroll through the

available information displays, then press SELECT to

display anyone of the following choices.

• Battery Voltage

Displays the actual battery voltage.

NOTE: The battery voltage may show a fluctuation at

various engine temperatures. This cycling operation is

caused by the post-heat cycle of the intake manifold

heater system. The number of cycles and the length of the

cycling operation is controlled by the engine control

module. Post-heat operation can run for several minutes,

and then the electrical system and voltmeter needle will

stabilize.

3

30 UNDERSTANDING YOUR INSTRUMENT PANEL

• Coolant Temp

• Fuel Filter Life

Displays the actual coolant temperature.

• Oil Pressure

Displays the actual oil pressure.

• Trans Temperature

Displays the actual automatic transmission sump temperature.

• Engine Hours

Displays the total hours of engine operation, and the

hours in drive and at idle.

• Oil Filter Life

Displays the percentage of oil filter life remaining, and

the miles since the last reset.

Displays the percentage of fuel filter life remaining, and

the miles since the last reset.

• Exhaust Brake

Displays actual exhaust brake power.

• Turbo Boost

Displays actual turbo boost value.

• Tire Pressure Monitor System

Displays the actual tire pressure

STARTING AND OPERATING

CONTENTS

䡵 STARTING PROCEDURES .................34

▫ Starting Fluids ........................45

▫ Manual Transmission – If Equipped .........34

▫ Automatic Transmission – If Equipped .......35

▫ Keyless Enter-N-Go™ ...................35

▫ Extreme Cold Weather ...................40

▫ Normal Starting Procedure – Engine Manifold

Air Temperature Above 66° F (19° C) ........40

▫ Starting Procedure – Engine Manifold Air

Temperature 0°F To 66°F (–18°C to 19°C) ......41

▫ Starting Procedure – Engine Manifold Air

Temperature Below 0°F (-18°C) .............43

䡵 NORMAL OPERATION – DIESEL ENGINE .....46

▫ Cold Weather Precautions ................46

▫ Engine Idling .........................49

▫ Stopping The Engine ....................50

▫ Idle Shutdown ........................51

▫ Programmable Maximum Vehicle Speed

(Chassis Cab Only) .....................51

▫ Operating Precautions ...................52

Cooling System Tips – Automatic Transmission . .52

▫

4

32 STARTING AND OPERATING

䡵 ENGINE BLOCK HEATER — IF EQUIPPED ....54

▫ Block Heater Usage .....................54

䡵 DIESEL EXHAUST BRAKE

(ENGINE BRAKING) ....................55

䡵 POWER TAKE OFF OPERATION —

IF EQUIPPED (CHASSIS CAB ONLY) .........75

▫ Stationary Mode .......................76

▫ Mobile Mode .........................77

䡵 AUTOMATIC TRANSMISSION —

IF EQUIPPED ..........................57

▫ Key Ignition Park Interlock ...............59

▫ Brake/Transmission Shift Interlock System ....59

▫ Six-Speed Automatic Transmission –

If Equipped ..........................59

䡵 MANUAL TRANSMISSION — IF EQUIPPED . . .71

▫ Shifting .............................71

▫ Downshifting .........................73

▫ Reverse Shifting .......................74

▫ Power Take Off – Aftermarket Installation .....78

䡵 ENGINE RUNAWAY .....................78

䡵 FUEL REQUIREMENTS ...................79

▫ Fuel Specifications .....................80

▫ Bio-Diesel Fuel Requirements ..............81

䡵 ADDING FUEL – 2500/3500 DIESEL MODELS . .84

䡵 ADDING FUEL – CHASSIS CAB MODELS .....87

▫ Fuel Filler Cap ........................88

▫ Avoid Using Contaminated Fuel ............88

▫ Bulk Fuel Storage – Diesel Fuel ............88

STARTING AND OPERATING 33

䡵 DIESEL EXHAUST FLUID .................93

▫ Diesel Exhaust Fluid Storage ..............89

▫ Adding Diesel Exhaust Fluid ..............90

▫ System Overview ......................93

4

34 STARTING AND OPERATING

STARTING PROCEDURES

Before starting your vehicle, adjust your seat, adjust both

inside and outside mirrors, and fasten your seat belts.

The starter should not be operated for more than 15-second

intervals. Waiting a few minutes between such intervals

will protect the starter from overheating.

WARNING!

• Do not leave children or animals inside parked

vehicles in hot weather. Interior heat build up may

cause serious injury or death.

• When leaving the vehicle, always remove the key

fob and lock your vehicle.

(Continued)

WARNING! (Continued)

• Never leave children alone in a vehicle, or with

access to an unlocked vehicle. Allowing children

to be in a vehicle unattended is dangerous for a

number of reasons. A child or others could be

seriously or fatally injured. Children should be

warned not to touch the parking brake, brake pedal

or the shift lever. Do not leave the key fob in or

near the vehicle (or in a location accessible to

children), A child could operate power windows,

other controls, or move the vehicle.

Manual Transmission – If Equipped

Apply the parking brake, place the shift lever in NEUTRAL and press the clutch pedal to the floor before

starting the vehicle. This vehicle is equipped with a

clutch interlocking ignition system. It will not start unless

the clutch is fully pressed.

Automatic Transmission – If Equipped

Start the engine with the transmission in the NEUTRAL

or PARK position. Apply the brake before shifting to any

driving range.

Tip Start Feature

Do not press the accelerator. Turn the ignition switch

briefly to the START position and release it. The starter

motor will continue to run but will automatically disengage when the engine is running.

Keyless Enter-N-Go™

This feature allows the driver to operate the ignition switch with the push

of a button, as long as the Remote

Start/Keyless Enter-N-Go™ Key Fob

is in the passenger compartment.

STARTING AND OPERATING 35

Normal Starting

Using The ENGINE START/STOP Button

1. The transmission must be in PARK or NEUTRAL.

2. Press and hold the brake pedal while pressing the

ENGINE START/STOP button once.

3. The system takes over and attempts to start the

vehicle. If the vehicle fails to start, the starter will

disengage automatically after 10 seconds.

4. If you wish to stop the cranking of the engine prior to

the engine starting, remove your foot from the brake

pedal and press the button again.

NOTE:

is obtained without pumping or pressing the accelerator

pedal.

Normal starting of either a cold or a warm engine

4

36 STARTING AND OPERATING

NOTE: Under cold weather conditions, the engine may

not immediately crank if the ⬙Wait To Start⬙ telltale is

illuminated. This is normal operation. For vehicles

equipped with the optional remote start package the

vehicle will automatically crank when the ⬙Wait To Start⬙

time has elapsed. See the section ⬙Starting Procedure

Engine Manifold Air Temperature 0°F to 66°F (18° C to

19°C)⬙ for more information.

To Turn Off The Engine Using ENGINE START/STOP

Button

1. Place the shift lever/shift selector in PARK, then press

and release the ENGINE START/STOP button.

2. The ignition switch will return to the OFF position.

3. If the shift lever/shift selector is not in PARK, the

ENGINE START/STOP button must be held for two

seconds and vehicle speed must be above 5 mph

(8 km/h) before the engine will shut off. The ignition

switch position will remain in the ACC position until

the shift lever/shift selector is in PARK and the button

is pressed twice to the OFF position. If the shift

lever/shift selector is not in PARK and the ENGINE

START/STOP button is pressed once, the EVIC (if

equipped) will display a “Vehicle Not In Park” message and the engine will remain running. Never leave

a vehicle out of the PARK position, or it could roll.

NOTE: If the ignition switch is left in the ACC or RUN

(engine not running) position and the transmission is

in PARK, the system will automatically time out after

30 minutes of inactivity and the ignition will switch to the

OFF position.

ENGINE START/STOP Button Functions –

With Driver’s Foot OFF The Brake Pedal

(In PARK Or NEUTRAL Position)

The ENGINE START/STOP button operates similar to an

ignition switch. It has four positions, OFF, ACC, RUN

and START. To change the ignition switch positions

without starting the vehicle and use the accessories

follow these steps.

1. Starting with the ignition switch in the OFF position:

2. Press the ENGINE START/STOP button once to

change the ignition switch to the ACC position (EVIC

displays “ACC”),

3. Press the ENGINE START/STOP button a second time

to change the ignition switch to the RUN position

(EVIC displays “RUN”),

STARTING AND OPERATING 37

4. Press the ENGINE START/STOP button a third time

to return the ignition switch to the OFF position (EVIC

displays “OFF”).

Keyless Enter-N-Go™ Starting Procedure – Engine Manifold Air Temperature 0° F To 66° F (–18° C to 19° C)

NOTE: The temperature displayed in the Electronic

Vehicle Information Center (EVIC) does not necessarily

reflect the engine manifold air temperature. Refer to

“Electronic Vehicle Information Center (EVIC)” in “Understanding Your Instrument Panel” for further information. When engine temperatures fall below 66°F (19°C)

the “Wait To Start Light” will remain on indicating the

intake manifold heater system is active.

4

38 STARTING AND OPERATING

Follow the steps in the “Normal Starting” procedure

except:

1. Pushing the engine start button with the driver’s foot

on the brake will move the ignition from OFF or ACC

to RUN, and will illuminate the ⬙Wait To Start⬙ telltale.

The engine will not immediately crank, this is normal

operation.

The “Wait To Start⬙ telltale will remain on for a period of

2.

time that varies depending on the engine temperature.

3. While the ⬙Wait to Start⬙ telltale is on, the EVIC will

additionally display a gauge or bar whose initial

length represents the full ⬙Wait to Start⬙ time period.

Its length will decrease until it disappears when the

⬙Wait to Start⬙ time has elapsed.

CAUTION!

If the “Water in Fuel Indicator Light” remains on,

DO NOT START engine before you drain the water

from the fuel filters to avoid engine damage. Refer to

“Maintenance Procedures/Draining Fuel/Water Separator Filter” in “Maintaining Your Vehicle” for further information.

4. After engine “Wait To Start” telletale goes off, the

engine will automatically crank on vehicles equipped

with the optional remote start package.

CAUTION!

The engine may automatically crank when the ‘‘Wait

To Start’’ time has elapsed. To abort the automatic

starting process, ensure the driver’s foot is fully

removed from the brake pedal prior to pushing the

START/STOP button to cycle the ignition off.

5. After engine start-up, check to see that there is oil

pressure.

6. Allow the engine to idle about three minutes until the

manifold heaters have completed the post-heat cycle.

7. Release the parking brake and drive.

STARTING AND OPERATING 39

NOTE:

• Engine idle speed will automatically increase to

1,000 RPM and engage the Variable Geometry Turbocharger at low coolant temperatures to improve engine

warm-up.

• If the engine stalls, or if the ignition switch is left ON

for more than two minutes after the “Wait To Start

Light” goes out, reset the grid heaters by turning the

ignition switch to the OFF position for at least five

seconds and then back ON. Repeat steps 1 through 7 of

“Keyless Enter-N-Go Starting Procedure – Engine

Manifold Air Temperature Below 66° F (19° C).”

4

40 STARTING AND OPERATING

Extreme Cold Weather

The Cummins® diesel engine is equipped with several

features designed to assist cold weather starting and

operation:

• The engine block heater is a resistance heater installed

in the water jacket of the engine just above and behind

the oil filter. It requires a 110–115 Volt AC electrical

outlet with a grounded, three-wire extension cord.

NOTE:

The engine block heater cord is a factory installed

option. If your vehicle is not equipped, heater cords are

available from your authorized MOPAR® dealer.

• A 12 Volt heater built into the fuel filter housings aid in

preventing fuel gelling. It is controlled by a built-in

thermostat.

A heated intake air system both improves engine start-

•

ing and reduces the amount of white smoke generated

by a warming engine.

Normal Starting Procedure – Engine Manifold Air Temperature Above 66° F (19° C)

Observe the instrument panel cluster lights when starting

the engine.

1. Always apply the parking brake.

2. Shift into PARK for an automatic transmission. For

vehicles equipped with a manual transmission, fully

press and hold the clutch pedal and shift into NEUTRAL.

3. Turn the ignition switch to the ON position and watch

the instrument panel cluster lights.

CAUTION!

If the “Water in Fuel Indicator Light” remains on, DO

NOT START the engine before you drain the water

(Continued)

CAUTION! (Continued)

from the fuel filters to avoid engine damage. Refer to

“Maintenance Procedures/Draining Fuel/Water Separator Filter” in “Maintaining Your Vehicle” for further information.

4. Turn the ignition switch to the START position and

crank the engine. Do not press the accelerator during

starting.

CAUTION!

Do not crank engine for more than 15 seconds at a

time or starter motor damage may result. Turn the

ignition switch to the OFF position and wait at least

two minutes for the starter to cool before repeating

start procedure.

STARTING AND OPERATING 41

5. When the engine starts, release the key fob.

6. Check that the oil pressure warning light has turned

off.

7. Release the parking brake.

Starting Procedure – Engine Manifold Air Temperature 0°F To 66°F (–18°C to 19°C)

4

NOTE: The temperature displayed in the Electronic Vehicle Information Center (EVIC) does not necessarily

reflect the engine manifold air temperature. Refer to

“Electronic Vehicle Information Center (EVIC)” in “Understanding Your Instrument Panel” for further information. When engine temperatures fall below 66°F (19°C)

the “Wait To Start Light” will remain on indicating the

intake manifold heater system is active.

42 STARTING AND OPERATING

Follow the steps in the “Normal Starting” procedure

except:

The “Wait To Start” telltale will remain on for a period of

1.

time that varies depending on the engine temperature.

2. While the ⬙Wait To Start” telltale is on, the EVIC will

additionally display a gauge or bar whose initial

length represents the full ⬙Wait To Start⬙ time period.

Its length will decrease until it disappears when the

⬙Wait To Start⬙ time has elapsed.

CAUTION!

If the “Water in Fuel Indicator Light” remains on, DO

NOT START engine before you drain the water from

the fuel filters to avoid engine damage. Refer to

“Maintenance Procedures/Draining Fuel/Water Separator Filter” in “Maintaining Your Vehicle” for further information.

3. After the “Wait To Start” telltale goes off, turn the

ignition switch to the START position. Do not press the

accelerator during starting.

CAUTION!

Do not crank engine for more than 15 seconds at a

time or starter motor damage may result. Turn the

ignition switch to the OFF position and wait at least

two minutes for the starter to cool before repeating

start procedure.

4. After engine start-up, check that the oil pressure

warning light has turned off.

5. Allow the engine to idle about three minutes until the

manifold heaters have completed the post-heat cycle.

6. Release the parking brake and drive.

NOTE:

• Engine idle speed will automatically increase to

1,000 RPM and engage the Variable Geometry Turbocharger at low coolant temperatures to improve engine

warm-up.

• Automatic equipped vehicles with optional Keyless

Enter-N-Go™ – If the start button is pushed once

while in park with the ignition off and driver’s foot on

the brake pedal, the vehicle will automatically crank

and start after the Wait to Start time has elapsed. If it is

desired to abort the start process before it completes,

the driver’s foot should be fully removed from the

brake pedal prior to pushing the start button again in

order for the ignition to move directly to off.

STARTING AND OPERATING 43

• If the engine stalls, or if the ignition switch is left ON

for more than two minutes after the “Wait To Start”

telltale goes out, reset the grid heaters by turning the

ignition switch to the OFF position for at least five

seconds and then back ON. Repeat steps 1 through 5 of

“Starting Procedure – Engine Manifold Air Temperature Below 66°F (19°C).”

Starting Procedure – Engine Manifold Air Temperature Below 0°F (-18°C)

In extremely cold weather below 0°F (-18°C) it may be

beneficial to cycle the manifold heaters twice before

attempting to start the engine. This can be accomplished

by turning the ignition OFF for at least five seconds and

then back ON after the “Wait To Start” telltale has turned

off, but before the engine is started. However, excessive

cycling of the manifold heaters will result in damage to

the heater elements or reduced battery voltage.

4

44 STARTING AND OPERATING

NOTE: If multiple pre-heat cycles are used before

starting, additional engine run time may be required to

maintain battery state of charge at a satisfactory level.

1. If the engine stalls after the initial start, the ignition

must be turned to the OFF position for at least five

seconds and then to the ON position to recycle the

manifold heaters.

NOTE: Excessive white smoke and poor engine performance will result if manifold heaters are not recycled.

2. Heat generated by the manifold heaters dissipates

rapidly in a cold engine. If more than two minutes

pass between the time the “Wait To Start” telltale turns

off and the engine is started, recycle the manifold

heaters by turning the ignition switch to the OFF

position for at least five seconds and then back ON.

3. If the vehicle is driven and vehicle speed exceeds

19 mph (31 km/h) before the manifold heater postheat (after start) cycle is complete, the manifold heaters will shut off.

4. If the engine is started before the “Wait To Start”

telltale turns off, the preheat cycle will turn off.

5. If the engine is cranked for more than 10 seconds, the

post-heat cycle will turn off.

NOTE:

• Engine idle speed will automatically increase to

1,000 RPM and engage the Variable Geometry Turbocharger at low coolant temperatures to improve engine

warm-up.

• When a diesel engine is allowed to run out of fuel or

the fuel gels at low temperatures, air is pulled into the

fuel system. If your engine has run out of fuel, refer to

“Maintenance Procedures/Priming If The Engine Has

Run Out Of Fuel” in “Maintaining Your Vehicle” for

further information.

Starting Fluids

STARTING AND OPERATING 45

WARNING!

WARNING!

Starting fluids or flammable liquids must never be

used in the Cummins® diesel engine (see Warning

label). Never pour diesel fuel, flammable liquid,

starting fluids (ether) into the air cleaner canister, air

intake piping, or turbocharger inlet in an attempt to

start the vehicle. This could result in a flash fire and

explosion causing serious personal injury and engine

damage.

The engine is equipped with an automatic electric air

preheating system. If the instructions in this manual are

followed, the engine should start in all conditions.

• Do not leave children or animals inside parked

vehicles in hot weather. Interior heat build up may

cause serious injury or death.

• When leaving the vehicle, always remove the key

fob and lock your vehicle.

• Never leave children alone in a vehicle, or with

access to an unlocked vehicle. Allowing children

to be in a vehicle unattended is dangerous for a

number of reasons. A child or others could be

seriously or fatally injured. Children should be

warned not to touch the parking brake, brake pedal

or the shift lever. Do not leave the key fob in or

near the vehicle (or in a location accessible to

children), A child could operate power windows,

other controls, or move the vehicle.

4

46 STARTING AND OPERATING

NORMAL OPERATION – DIESEL ENGINE

Observe the following when the engine is operating.

• All message center lights are off.

• Malfunction Indicator Light (MIL) is off.

• Engine oil pressure is above 10 psi (69 kPa) at idle.

• Voltmeter operation:

The voltmeter may show a gauge fluctuation at various

engine temperatures. This cycling operation is caused by

the post-heat cycle of the intake manifold heater system.

The number of cycles and the length of the cycling

operation is controlled by the engine control module.

Post-heat operation can run for several minutes, and then

the electrical system and voltmeter needle will stabilize.

Cold Weather Precautions

Operation in ambient temperature below 32°F (0°C) may

require special considerations. The following charts suggest these options:

Fuel Operating Range

NOTE: Use “Ultra Low Sulfur Diesel Fuels” ONLY.

The cycling action will cause temporary dimming of the

headlamps, interior lamps, and also a noticeable reduction in blower motor speed.

*No. 1 Ultra Low Sulfur Diesel Fuel should only be used

where extended arctic conditions (-10°F/-23°C) exist.

NOTE:

• Use of Climatized Ultra Low Sulfur Diesel Fuel or

Number 1 Ultra Low Sulfur Diesel Fuel results in a

noticeable decrease in fuel economy.

• Climatized Ultra Low Sulfur Diesel Fuel is a blend of

Number 2 Ultra Low Sulfur and Number 1 Ultra Low

Sulfur Diesel Fuels which reduces the temperature at

which wax crystals form in fuel.

• The fuel grade should be clearly marked on the pump

at the fuel station

• The engine requires the use of “Ultra Low Sulfur

Diesel Fuel”. Use of incorrect fuel could result in

engine and exhaust system damage. Refer to “Fuel

Requirements” in “Starting and Operating” for further

information.

Engine Oil Usage

Refer to “Maintenance Procedures” in “Maintaining Your

Vehicle” for the correct engine oil viscosity.

STARTING AND OPERATING 47

Winter Front Usage

A winter front or cold weather cover is to be used in

ambient temperatures below -10°C, especially during

extended idle conditions to reduce condensation

build-up within engine crankcase. If a winter front or

cold weather cover is to be used, a percentage of the total

grille opening area must be left uncovered to provide

sufficient air flow to the charge air cooler and automatic

transmission oil cooler. The percentage of opening must

be increased with the increasing ambient air temperature

and/or engine load. If the cooling fan can be heard

cycling frequently, increase the size of the opening in the

winter front. A suitable cold weather cover is available

from your MOPAR® dealer.

Battery Blanket Usage

A battery loses 60% of its cranking power as the battery

temperature decreases to 0°F (-18°C). For the same decrease in temperature, the engine requires twice as much

4

48 STARTING AND OPERATING

power to crank at the same RPM. The use of 120 VAC

powered battery blankets will greatly increase starting

capability at low temperatures. Suitable battery blankets

are available from your authorized MOPAR® dealer.

Engine Warm-Up

Avoid full throttle operation when the engine is cold.

When starting a cold engine, bring the engine up to

operating speed slowly to allow the oil pressure to

stabilize as the engine warms up.

NOTE: High-speed, no-load running of a cold engine

can result in excessive white smoke and poor engine

performance. No-load engine speeds should be kept

under 1,200 RPM during the warm-up period, especially

in cold ambient temperature conditions.

Your vehicle is equipped with a turbo speed limiter, this

feature limits the engine speed to 1,200 RPM when

engine coolant temperatures are below 70°F (21°C). This

feature is designed to protect the turbocharger from

damage and will only operate in PARK or NEUTRAL.

If temperatures are below 32°F (0°C), operate the engine

at moderate speeds for five minutes before full loads are

applied.

NOTE:

• If ambient temperatures are low and the coolant

temperature is below 180°F (82°C), the engine idle

speed will slowly increase to 1,000 RPM after two

minutes of idle, if the following conditions are met:

• foot is off brake pedal and throttle pedal

• automatic transmission is in PARK

• vehicle speed is zero

• Applying the throttle will cancel fast idle

• Operating the exhaust brake at idle will greatly im-

prove warm up rate and will help keep the engine

close to operating temperature during extended idle.

Engine Idling

Avoid prolonged idling, long periods of idling may be

harmful to your engine because combustion chamber

temperatures can drop so low that the fuel may not burn

completely. Incomplete combustion allows carbon and

varnish to form on piston rings, engine valves, and

injector nozzles. Also, the unburned fuel can enter the

crankcase, diluting the oil and causing rapid wear to the

engine.

If the engine is allowed to idle, under some conditions

the idle speed may increase to 900 RPM then return to

normal idle speed. This is normal operation.

NOTE: For EVIC messages related to the vehicle’s exhaust system, refer to “Maintenance Procedures/

Intervention Regeneration Strategy – EVIC Message Process Flow” in “Maintaining Your Vehicle” for further

information.

STARTING AND OPERATING 49

Idle-Up Feature – Automatic Transmission Only

The driver-controlled high idle speed feature will help

increase cylinder temperatures and provide additional

cab heat, however, excessive idling may still cause the

exhaust aftertreatment system to not properly regenerate.

Extended periods of idle time should be avoided.

The Idle-Up feature uses the speed control switches to

increase engine idle speed and quickly warm the vehicle’s interior.

1. With the transmission in PARK, the parking brake

applied, and the engine running, press the speed

control switch to the ON position, then press the SET

switch.

4

50 STARTING AND OPERATING

2. The engine RPM will go up to 1100 RPM. To increase

the RPM, press and hold the ACCEL/RESUME switch

and the idle speed will increase to approximately

1500 RPM. To decrease the RPM, press and hold the

DECEL switch and the idle speed will decrease to

approximately 1100 RPM.

3. To cancel the Idle–Up feature, either press the CANCEL switch, press the ON/OFF switch, or press the

brake pedal.

Stopping The Engine

Idle the engine a few minutes before routine shutdown.

After full load operation, idle the engine three to

five minutes before shutting it down. This idle period

will allow the lubricating oil and coolant to carry excess

heat away from the combustion chamber, bearings, internal components, and turbocharger. This is especially

important for turbocharged, charge air-cooled engines.

NOTE:

• During engine shut down on vehicles equipped with

manual transmissions, it is normal for the diesel engine to resonate heavily for a moment during engine

shut off. When the engine is connected to a manual

transmission, this resonance causes load gear rattle

from the transmission. This is commonly referred to as

“shut down rattle.” The manufacturer recommends

performing engine shut down with the clutch pedal

pushed to the floor (clutch disengaged). When engine

shut down is performed in this manner the rattle is

reduced (not eliminated).

• Refer to the following chart for proper engine shutdown.

Driving

Condition

Stop and

Go

Stop and

Go

Highway

Speeds

City Traffic Maximum

Highway

Speeds

Uphill

Grade

Load

Empty Cool Less than

Medium One

Medium Warm Two

GCWR

Maximum

GCWR

Maximum

GCWR

Turbo-

charger

Tempera-

ture

Hot Five

Shutdown

Idle Time

(min.)

Before

Engine

One

Three

Four

STARTING AND OPERATING 51

Idle Shutdown

This feature can be enabled so that the truck will automatically shutdown when the truck has been idling for a

set period of time when the engine is at operating

temperature. Idle time can be set in 5 minute increments

between 5 and 60 minutes. See your local authorized

dealer to enable this feature.

Programmable Maximum Vehicle Speed (Chassis Cab Only)

This feature allows the owner to set a maximum vehicle

speed for the vehicle. The 3500 Series maximum vehicle

speed can be set between 40 mph (64 km/h) and 87 mph

(140 km/h). The 4500/5500 Series maximum vehicle

speed can be set between 40 mph (64 km/h) and 85 mph

(136 km/h). See your local authorized dealer to enable

this feature.

NOTE: DO NOT set the maximum vehicle speed to a

value greater than what the vehicle tires are rated for.

4

52 STARTING AND OPERATING

Operating Precautions

Avoid Overheating The Engine

The temperature of the engine coolant (antifreeze) (a

mixture of 50% ethylene-glycol and 50% water) must not

exceed the normal range of the temperature gauge 240°F

(116°C) with a 16 psi (110 kPa) radiator cap.

Usually the engine coolant (antifreeze) temperature indicated during operation will be to the left of center in the

normal range of the gauge.

Avoid Low Coolant Temperature Operation

Continual operation at low engine coolant (antifreeze)

temperature below the normal range on the gauge 140°F

(60°C) can be harmful to the engine. Low engine coolant

(antifreeze) temperature can cause incomplete combustion which allows carbon and varnish to form on piston

rings and injector nozzles. Also, the unburned fuel can

enter the crankcase, diluting the lubricating oil and

causing rapid wear to the engine.

Cooling System Tips – Automatic Transmission

To reduce potential for engine and transmission overheating in high ambient temperature conditions, take the

following actions:

• City Driving —

When stopped, shift the transmission into NEUTRAL

and increase engine idle speed.

• Highway Driving —

Reduce your speed.

• Up Steep Hills —

Select a lower transmission gear.

• Air Conditioning —

Turn it off temporarily.

Do Not Operate The Engine With Low Oil Pressure

When the engine is at normal operating temperature, the

minimum oil pressures required are:

Idle 700 to 800 RPM 10 psi (69 kPa)

Full speed and load 30 psi (207 kPa)

CAUTION!

If oil pressure falls to less than normal readings, shut

the engine off immediately. Failure to do so could

result in immediate and severe engine damage.

STARTING AND OPERATING 53

Do Not Operate The Engine With Failed Parts

All engine failures give some warning before the parts

fail. Be on the alert for changes in performance, sounds,

and visual evidence that the engine requires service.

Some important clues are:

• engine misfiring or vibrating severely

• sudden loss of power

• unusual engine noises

• fuel, oil or coolant leaks

• sudden change, outside the normal operating range, in

the engine operating temperature

• excessive smoke

• oil pressure drop

4

54 STARTING AND OPERATING

ENGINE BLOCK HEATER — IF EQUIPPED

The engine block heater warms engine coolant and

permits quicker starts in cold weather. Connect the heater

cord to a ground-fault interrupter protected 110–115 Volt

AC electrical outlet with a grounded, three-wire extension cord.

The engine block heater cord is routed under the hood to

the right side and can be located just behind the grille

near the headlamp.

NOTE: The engine block heater cord is a factory installed option. If your vehicle is not equipped, heater

cords are available from your authorized MOPAR®

dealer.

The block heater must be plugged in at least one hour to

have an adequate warming effect on the coolant.

WARNING!

Remember to disconnect the cord before driving.

Damage to the 110–115 Volt electrical cord could

cause electrocution.

NOTE: The block heater will require 110 Volts AC and

6.5 Amps to activate the heater element.

Block Heater Usage

For ambient temperatures below 0°F (-18°C), engine

block heater usage is recommended.

For ambient temperatures below –20°F (-29°C), engine

block heater usage is required.

DIESEL EXHAUST BRAKE (ENGINE BRAKING)

The purpose of the exhaust brake (engine braking) feature is to supply negative (braking) torque from the

engine. Typically, the engine braking is used for, but not

limited to, vehicle towing applications where vehicle

braking can be achieved by the internal engine power,

thereby sparing the mechanical brakes of the vehicle.

Benefits of the exhaust brake are:

• vehicle driving control

• reduced brake fade

• longer brake life

• faster cab warm-up.

The exhaust brake feature will only function when the

driver toggles it on by pushing the exhaust brake button

until the ⬙Exhaust Brake Indicator⬙ is illuminated. Normal (Full Strength) exhaust brake mode is indicated by a

yellow ⬙Exhaust Brake Indicator⬙.

STARTING AND OPERATING 55

4

Exhaust Brake Switch

Once the ⬙Exhaust Brake Indicator” is illuminated and

the vehicle is moving faster than 5 mph (8 km/h); the

exhaust brake will automatically operate when the driver

removes pressure from the accelerator pedal. Exhaust

braking is most effective when the engine RPM is higher.

56 STARTING AND OPERATING

The automatic transmission will downshift more aggressively in TOW/HAUL mode when the exhaust brake is

enabled to increase brake performance.

CAUTION!

Use of aftermarket exhaust brakes is not recommended and could lead to engine damage

NOTE: For optimum braking power it is recommended

to use the exhaust brake while in TOW/HAUL mode.

The exhaust brake feature can also be used to reduce the

engine warm up time. To use the exhaust brake as a

warm-up device, the vehicle must be stopped or moving

less than 5 mph (8 km/h), the ⬙Exhaust Brake Indicator⬙

must be on, and the coolant temperature must be below

180°F (82°C) and ambient temperature below 60°F (16°C).

WARNING!

Do not use the exhaust brake feature when driving in

icy or slippery conditions as the increased engine

braking can cause the rear wheels to slide and the

vehicle to swing around with the possible loss of

vehicle control, which may cause an accident possibly resulting in personal injury or death.

Automatic Smart Exhaust Brake

Automatic Exhaust Brake technology delivers smoother,

less aggressive exhaust braking characteristics during