Page 1

280-F

Manufactured By

Frozen Fry Dispenser

Equipment Manual

English (Rev H)

Automated Equipment LLC

5140 Moundview Drive

Red Wing, MN 55066 U.S.A.

For Warranty Service & Technical Support:

US & Canada call: 1 (800) 248-2724

International call: 1 (651) 385-2273

Sales Fax: 1 (651) 385-2166

Service Fax: 1 (651) 385-2172

http://www.autoequipllc.com

Business Hours:

Monday – Friday: 8:00 AM to 5:00 PM CST

(excluding. holidays)

P/N 293511

After hours, your call will be handled by a voice mail

paging service. The on-call technician will be paged and

will return your call.

Table of Contents

Introduction.............................................................................................................................................1

Unpacking & Installation........................................................................................................................1

Intended Use ...........................................................................................................................................1

Specifications..........................................................................................................................................1

Warranty ..................................................................................................................................................2

Service Information ................................................................................................................................3

Equipment Safety.................................................................................................................................... 4

Dispenser Assembly (Models prior to s/n 28FR0802B0249)...............................................................6

Dispenser Assembly (Models after and including s/n 28FR0802B0249)...........................................9

Disassembly, Defrost & Cleaning........................................................................................................12

Dispenser Startup.................................................................................................................................13

Operation...............................................................................................................................................14

Daily Opening and Closing ..................................................................................................................15

User Function Menu Structure ............................................................................................................18

Manager Function Menu Structure......................................................................................................19

Diagnostic Function Menu Structure..................................................................................................20

Error Detection......................................................................................................................................23

Troubleshooting....................................................................................................................................24

Calibrations and Adjustments.............................................................................................................27

Part Identification..................................................................................................................................30

Refrigeration System............................................................................................................................40

Electrical Diagram – Two Temperature Probe Configuration...........................................................44

Electrical Diagram – Single Temperature Probe Configuration .......................................................45

Copyright © 2011 Automated Equipment LLC All rights reserved.

Page 2

The information in this manual is subject to change without notice.

IN NO EVENT WILL AUTOMATED EQUIPMENT LLC BE LIABLE FOR TECHNICAL OR

EDITORIAL OMISSIONS MADE HEREIN, NOR FOR DIRECT, SPECIAL, INCIDENTAL, OR

CONSEQUENTIAL DAMAGES RESULTING FROM THE FURNISHING, PERFORMANCE,

OR USE OF THIS MATERIAL.

This manual is copyrighted with all rights reserved. Under the copyright laws, this manual may

not be copied, in whole or part, without the written consent of Automated Equipment LLC.

Product names mentioned herein are for identification purposes only, and may be trademarks

and/or registered trademarks of their respective companies.

Copyright © 2011 Automated Equipment LLC All rights reserved.

Page 3

RAM™ 280-F Frozen Fry Dispenser

Introduction

This manual contains important information on

the proper installation, operation, and care of

the RAM 280-F Frozen Fry Dispenser.

Following the instructions and procedures in

this document will ensure that your dispenser

provides years of reliable service. If any

problems with the dispenser arise, this manual

will also provide troubleshooting tips and

service information.

Unpacking & Installation

Remove all packing material from Dispenser.

Open Cabinet Door. Disassemble, clean,

sanitize and dry the Hopper and Accumulator

assemblies. Clean, sanitize and dry Fry

Baskets. (see pages 6-12

for assembly,

disassembly & cleaning). Reassemble all

components (see pages 13-17

for startup and

operation).

Intended Use

The Frozen Fry Dispenser is intended to

maintain and dispense frozen fries from two

independent hoppers. Each is capable of

dispensing different volumes of fries.

All product should be removed daily for

cleaning and maintenance of the dispenser.

The performance of the system requires that

recommended procedures for storage and use

of the dispensed product be followed closely.

HAZARD COMMUNICATION STANDARD:

Hazard Communication Standard (HCS)

Procedures in this manual may include the use

of chemical products. These chemical products

will be highlighted with boldface letters followed

by the abbreviation (HCS) in the text of the

procedure. See the HCS Manual for the

appropriate Material Safety Data Sheets

(MSDS).

Specifications

Electrical Requirements:

Domestic:

• 120 Volts a.c., 60 Hertz, 8 Amps, 1Φ

International:

• 220 - 240 Volts a.c., 50 Hertz,

3.3 Amps, 1Φ (Revisions A, B, C)

• 220 - 240 Volts a.c., 50 Hertz,

3.7 Amps, 1Φ (Revision D)

Internal Circuit Breaker:

Dimensions:

• 28" wide, 29" deep, 75" high

(712 mm x 737mm x 1905mm)

Recommended Operating Dimensions:

• 30” wide, 31” deep, 79” high

(762 mm x 788mm x1930mm)

Weight: 440 lbs (200 kg)

Hopper Capacity:

• 60 lbs(27.3 kg) fries, 30Lbs(13.6 kg) per

Hopper, weight may vary with product.

Operating Temperature:

• -2°F to 10°F (-19°C to -12°C)

(Recommended Ambient Operating

Temperature of 75°F (24°C))

• ST (Sub Tropical)

Refrigeration:

Domestic:

• R-404A: 14.75 oz,

International:

• R-404A: 420 g -1250-2640 kPa

Maximum Operating Altitude & Safe Tilt:

• Maximum Altitude: 7000 ft (2,134

meters), Maximum Tilt = 10 degrees

Noise Emissions: < 70 dB (A)

15 Amps

SERIAL NUMBER:

The information on the

serial number identification label is as

follows:

Examples:

Model 28F LON

Manufacturing

Facility

Year 07 08

Month 11 03

Revision Level A C

Sequence

Number

28FR0711A00183 LONR0803C00294

R R

00183 00294

Copyright © 2011 Automated Equipment LLC All rights reserved.

FCC STATEMENT

WARNING: This equipment generates, uses,

and can radiate radio frequency energy and,

if not installed and used in accordance with

the instruction manual, may cause

interference to radio communications.

1

Page 4

RAM™ 280-F Frozen Fry Dispenser

Warranty

The terms "we", “us”, “our” or “factory” hereinafter refer to Automated Equipment LLC. We warrant the

purchased product to be free from manufacturing defects in material and workmanship under normal

use and conditions for the period and component specified below. Warranty is part only unless

otherwise specified.

Components Covered Term is located on dispenser

Electronic Circuit Board Assemblies See Serial # / Warranty Label

Electrical and Mechanical Moving Parts See Serial # / Warranty Label

Structural frame work or enclosures

Refrigeration Compressor

Crew removable components:

Baskets

Basket Rack and Guides

Drip Tray

Power Cord

Hoppers, Fry Diverters & Drums

Flap Doors

Accumulator Doors & Housings

See Serial # / Warranty Label

See Serial # / Warranty Label

(no labor, part only)

90 days

90 days

90 days

90 days

90 days

90 days

90 days

The Warranty period commences on the date of shipment of the RAM 280-F Frozen Fry

Dispenser (hereinafter “Product”) from our manufacturing facility.

EXCEPT AS OTHERWISE PROVIDED HEREIN WE MAKE NO OTHER WARRANTIES, EXPRESSED

OR IMPLIED AND SPECIFICALLY DISCLAIM ANY WARRANTY OF MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE.

We shall not be liable for any direct, indirect, consequential damages (including damages for loss of

business profits, business interruption, loss of business information and the like) arising out of the use

of or inability to use the Product.

THIS WARRANTY IS VOID IF THE PRODUCT IS NOT FUNCTIONING CORRECTLY DUE TO

ABUSE OR NEGLECT BY THE PURCHASER, ITS EMPLOYEES, AGENTS, OR OTHER

REPRESENTATIVES EITHER BY BREAKING, BENDING, MISUSE, ABUSE, DROPPING,

ALTERATION, IMPROPER MAINTENANCE OR ANY OTHER FORM OF NEGLECT OR IMPROPER

USAGE. THIS WARRANTY DOES NOT COVER DAMAGE TO THE PRODUCT CAUSED BY

NATURAL CAUSES SUCH AS LIGHTNING, ELECTRICAL CURRENT FLUCTUATIONS, FLOOD,

FIRE, TORNADOES, OR OTHER ACTS OF GOD. WE WILL INVOICE PURCHASER FOR REPAIRS

MADE NECESSARY BY THE HEREIN LISTED CAUSES.

This warranty is governed by the substantive laws of Minnesota, U.S.A., without giving effect to the

conflict of law provisions.

This warranty is non-transferable and applies only to the original Purchaser.

2

Copyright © 2011 Automated Equipment LLC All rights reserved.

Page 5

RAM™ 280-F Frozen Fry Dispenser

Service Information

Warranty Service

Warranty service must be initiated by calling our Technical Support Hotline at 1-800-248-2724

(U.S./Canada) or 651-385-2273 to establish all warranty requests.

Our Technical Support personnel will determine the cause of failure and provide appropriate resolution.

Any required replacement parts will be provided by us or by an authorized Service Support

Center/Parts Distributor.

Our Technical Support personnel will make all reasonable efforts to perform such repairs during normal

business hours, and will not be responsible for any after-hours or holiday charges.

Non-Warranty Service

Service is normally conducted by customer appointed personnel, or by contracting a local service

agent. The service person must be licensed in refrigeration to troubleshoot, open, or repair refrigeration

and related systems.

Service fees are in accordance with industry standards.

Replacement parts are available through local Service Support Center/Parts Distributors or direct from

us by calling 1-800-248-2724 (U.S./Canada) or 651-385-2273 in the event a local distributor is not

available.

Our Technical Support Hot Line is available for telephone assistance providing product technical

support, parts and parts information, and service agent referral.

Contact our Technical Support Hotline at 1-800-248-2724 (U.S./Canada) or 651-385-2273.

Record the following information for your records:

Date of Installation

Service Agency Telephone

Serial Number

When repairing this unit, use only replacement parts supplied by us, or supplied by our Factory

Authorized Parts Distributor. Use of replacement parts other than those supplied by us or by our

Factory Authorized Parts Distributor will void the warranty.

All shipping charges are F.O.B. factory, and are subject to change without notice. Prices will be those in

effect at the time of shipment.

Automated Equipment LLC. reserves the right to make suitable substitutions in materials, depending

upon their availability.

Copyright © 2011 Automated Equipment LLC All rights reserved.

3

Page 6

RAM™ 280-F Frozen Fry Dispenser

Equipment Safety

• Turn the Power Switch off and disconnect the Dispenser Power Cord from the wall outlet

before cleaning, moving or servicing the Dispenser.

• Inspect the Dispenser on a regular basis to identify potential problems before they occur.

• Keep the Dispenser clean.

• Keep hands away from the Accumulator Doors and Dispenser Drums while the Dispenser is

operating.

• Fry Baskets may be hot. Pick them up by the handles only.

• Do NOT roll the Dispenser to the back sink for cleaning, this will cause unnecessary wear on

the Dispenser.

• If the Power Cord is damaged it must be replaced by the manufacturer or its service agent or

a similarly qualified person in order to avoid a hazard.

• Use only the Power Cord that came with the Dispenser. Do NOT use an extension cord.

• Do NOT modify the Power Cord

• In a safety emergency, immediately disconnect the Dispenser Power Cord from the wall

outlet.

• Do NOT obstruct access to the wall outlet or place pressure on the Power Cord.

• Only trained and/or qualified personnel should service the electrical system.

• DO NOT SPRAY THE DISPENSER WITH LIQUID OR SOLVENTS.

It is not sealed against jetting fluids and contamination may get into sensitive components.

Spraying the dispenser may void the warranty.

• Use caution when handling heavy parts such as back and top panels.

• Always reinstall service panels when maintenance is complete.

• Do NOT drill or otherwise puncture cabinet walls or top.

• Keep unit upright at all times.

CAUTION!

Only trained and/or qualified personnel should perform service on this

equipment.

Only trained and/or qualified personnel, licensed in refrigeration, should

perform service on the refrigeration systems of this equipment.

Service functions described in this manual could cause irreversible damage to

the equipment and/or injury to personnel if performed improperly.

If the power cord is damaged, it must be replaced by the manufacturer, or its

service agent, or a similarly qualified person in order to avoid a hazard.

4

Copyright © 2011 Automated Equipment LLC All rights reserved.

Page 7

Equipment Safety Cont.

RAM™ 280-F Frozen Fry Dispenser

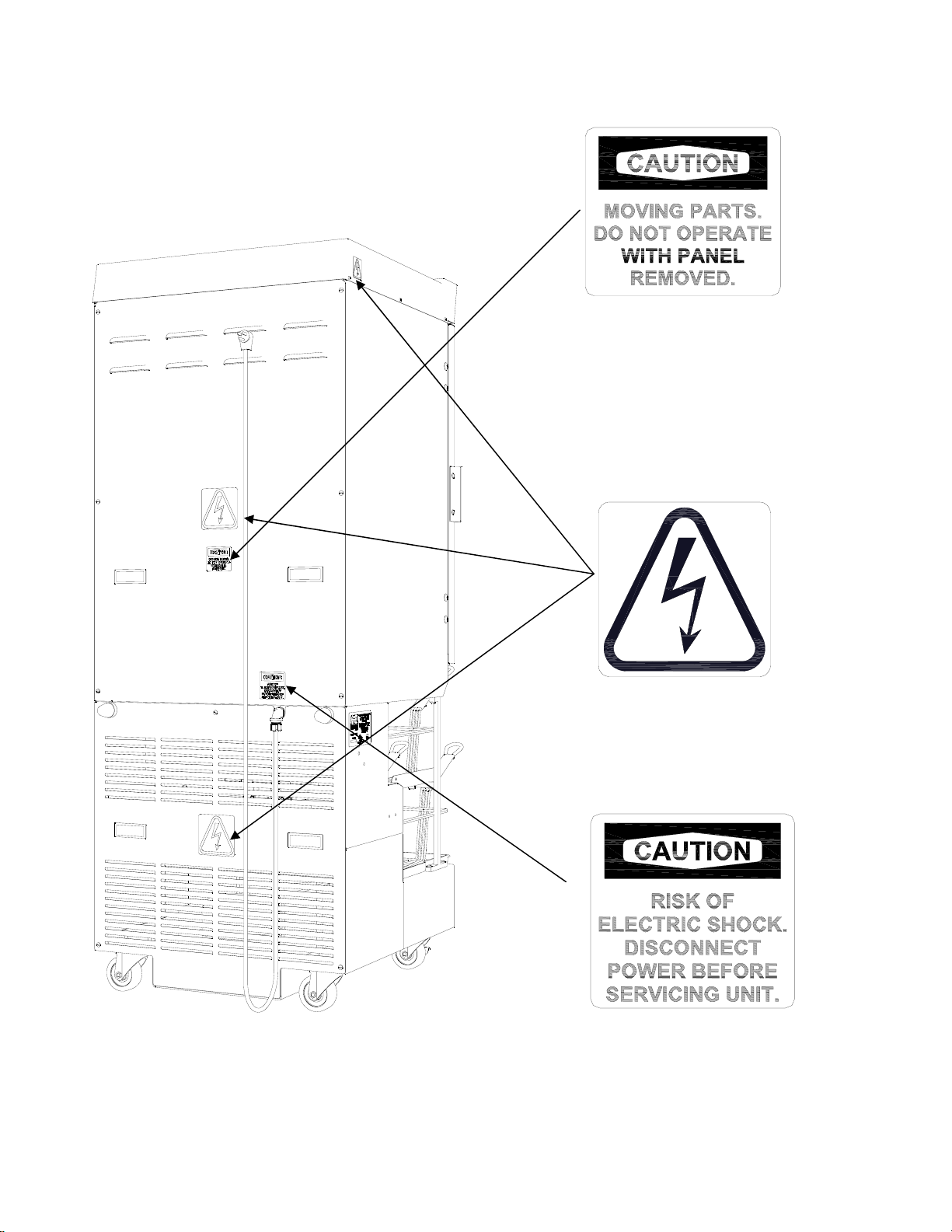

Label is located on the rear access panel and

applies to each of the drum motor and

accumulator assemblies within the enclosure.

CAUTION, MOVING PARTS.

DO NOT OPERATE WITH PANEL

REMOVED

Label is located on Top Cover and Rear Access

Panels.

INDICATES HAZARDOUS VOLTAGE

WITHIN

Label is located near Power Cord inlet.

CAUTION, RISK OF ELECTRIC SHOCK.

DISCONNECT POWER BEFORE

SERVICING UNIT.

Copyright © 2011 Automated Equipment LLC All rights reserved.

5

Page 8

RAM™ 280-F Frozen Fry Dispenser

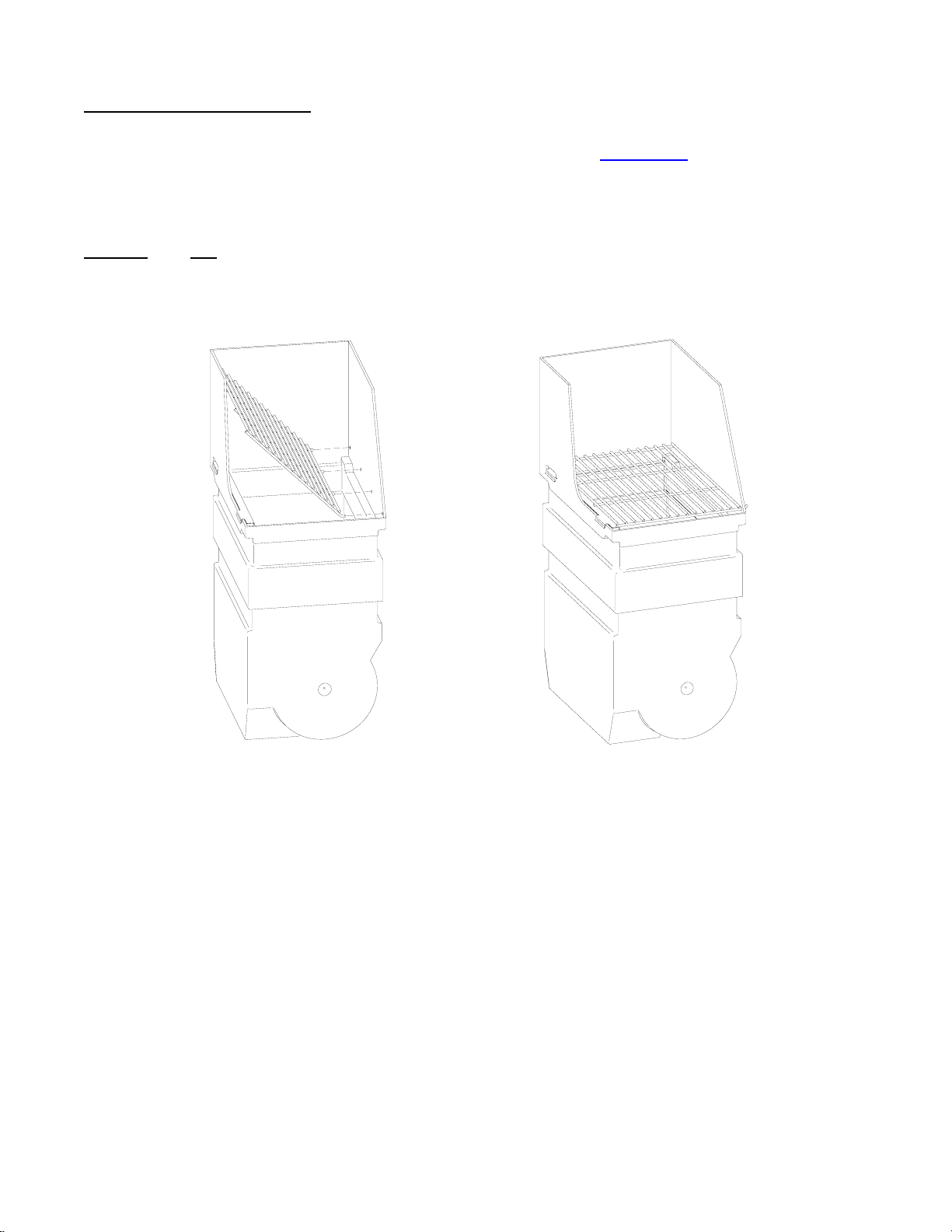

Dispenser Assembly (Models prior to s/n 28FR0802B0249)

Note: Before assembling the Dispenser it is recommended that all parts be cleaned, sanitized,

dry, and handled in a sanitary manner. Refer to the Cleaning Procedures (Page 12

information.

) for more

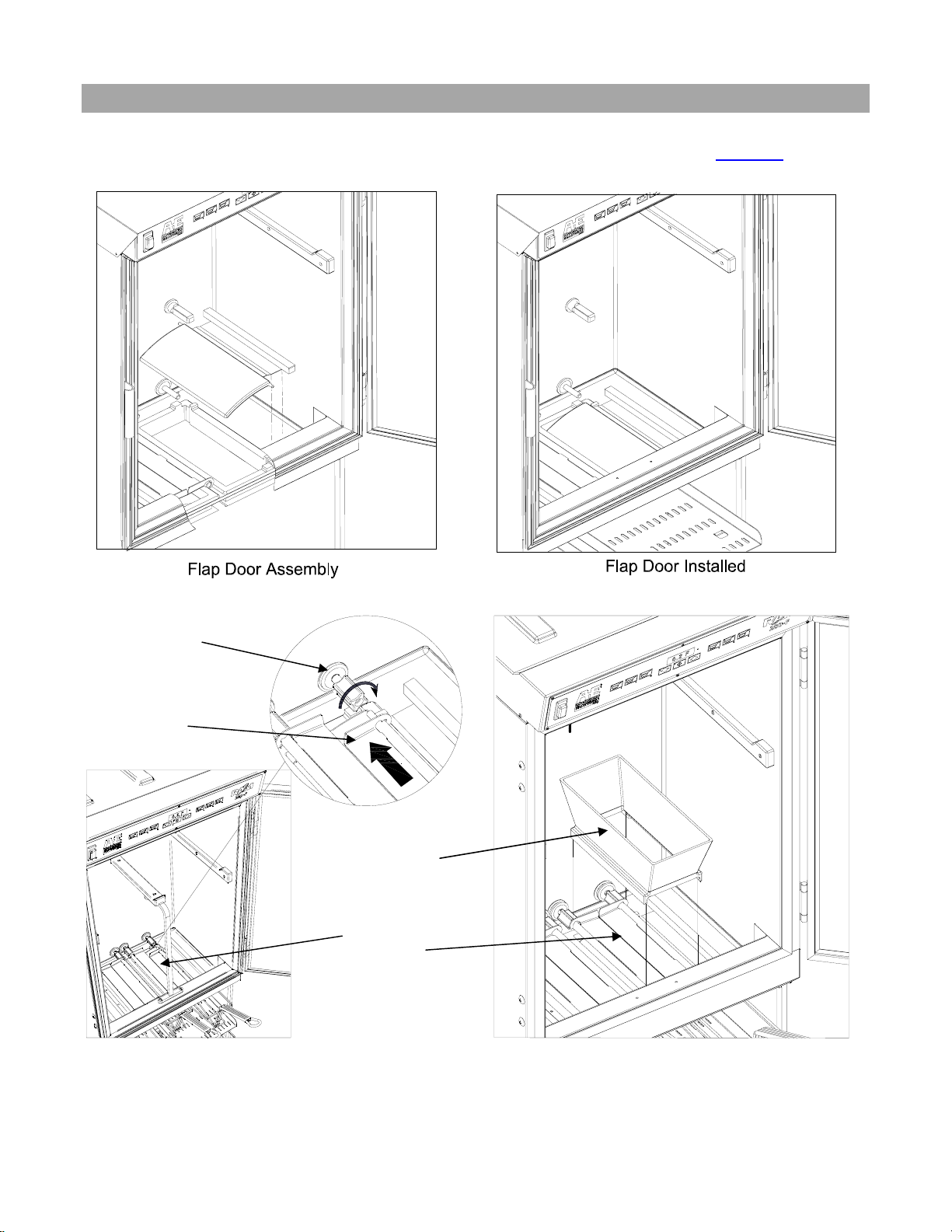

Open the cabinet door. Install the left and right flap door assemblies as shown above.

Accumulator

Motor shaft

with Chuck

Accumulator

Door

Accumulator

Housing

Accumulator

Accumulator Door Assembly Accumulator Housing Assembly

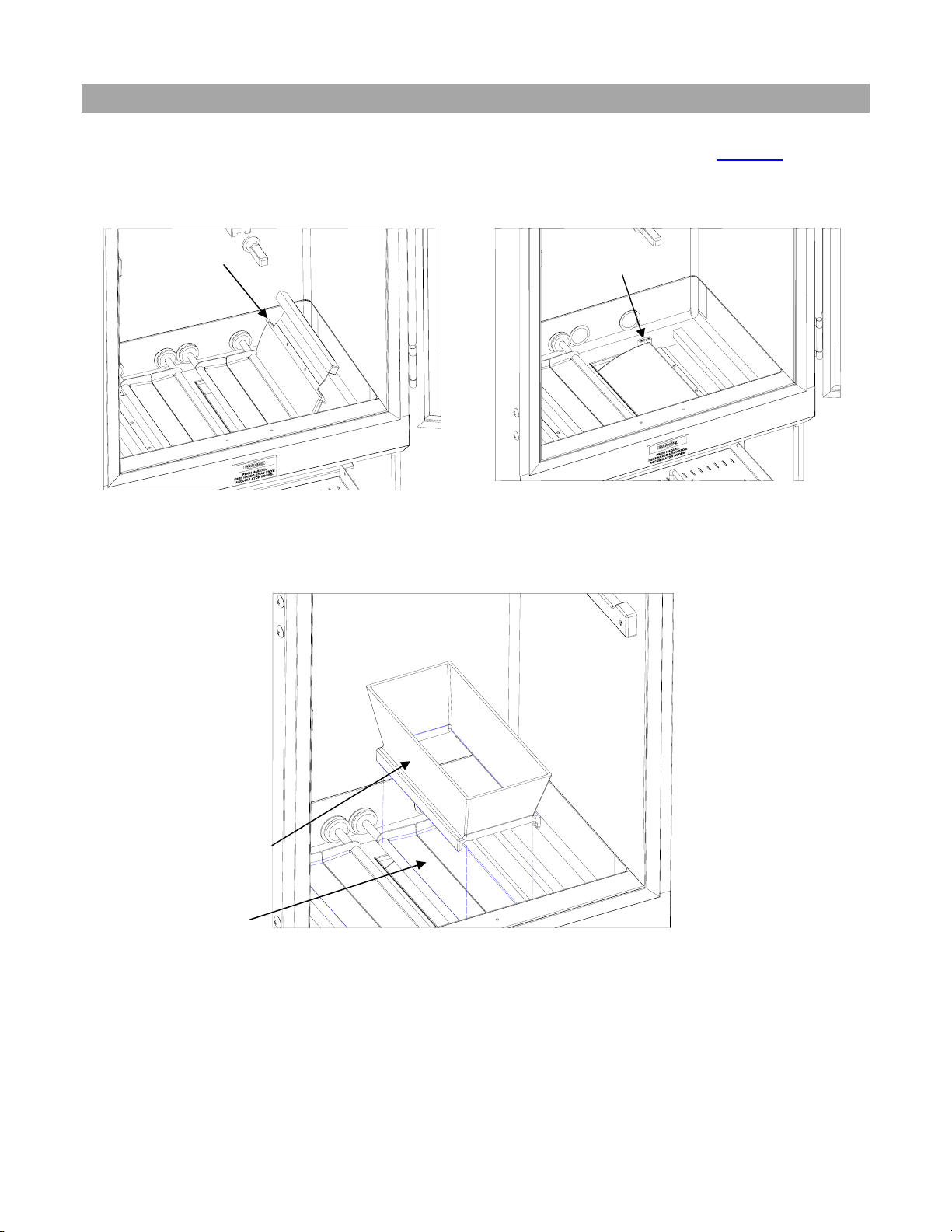

Install the left and right Accumulator Doors by first inserting the rear of the doors onto the Accumulator

Motor Shafts, then slide the Chucks forward and rotate the chucks clockwise until finger-tight. Install

the left and right Accumulator Housings over the Accumulator Doors.

6

Copyright © 2011 Automated Equipment LLC All rights reserved.

Page 9

RAM™ 280-F Frozen Fry Dispenser

Dispenser Assembly Cont.

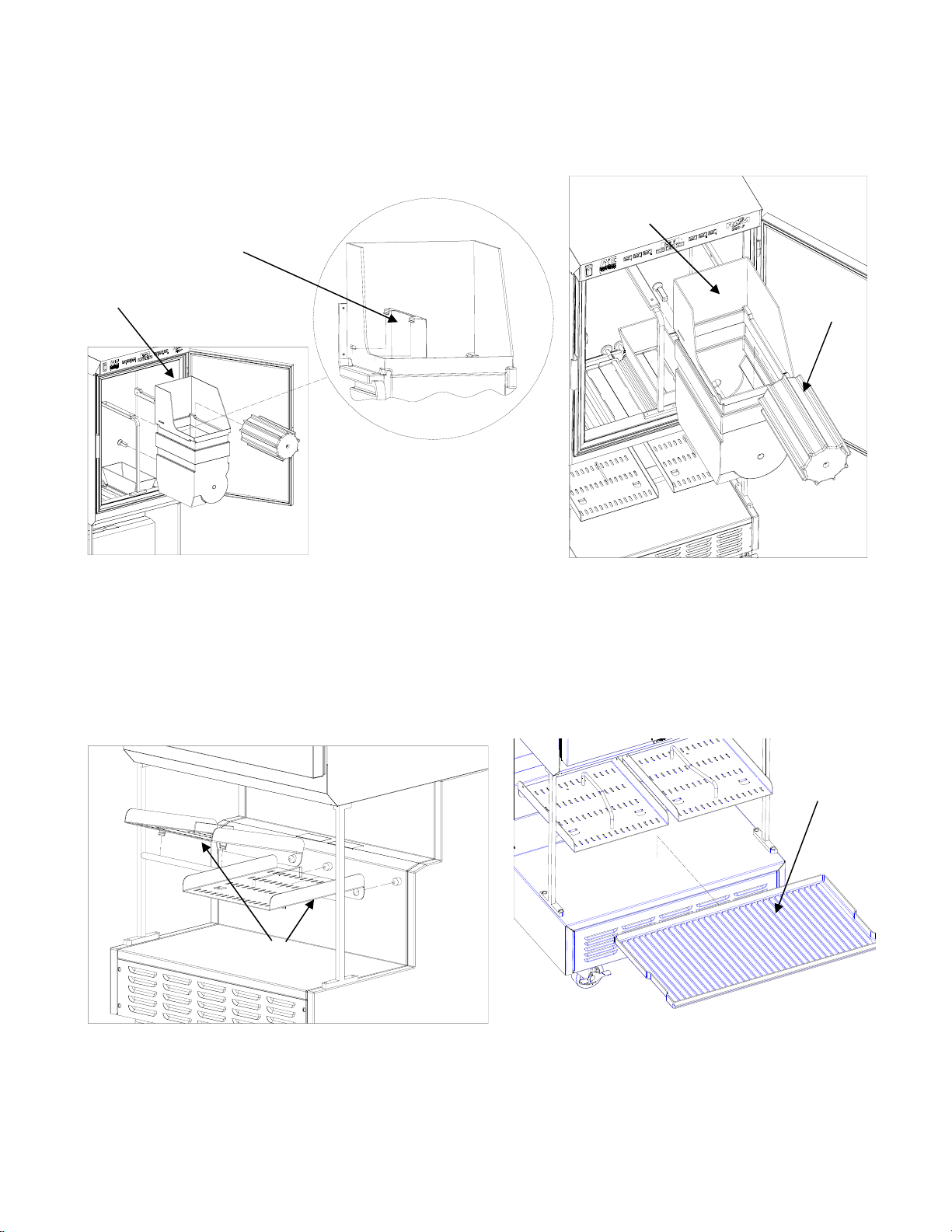

Note: Accumulator Housings, Drums, and Fry Diverters are universal to left, and right, positions

within the cabinet. The Hoppers are NOT universal to the left, and right, positions within the

cabinet.

Fry

Hopper

Diverter

Hopper

Drum

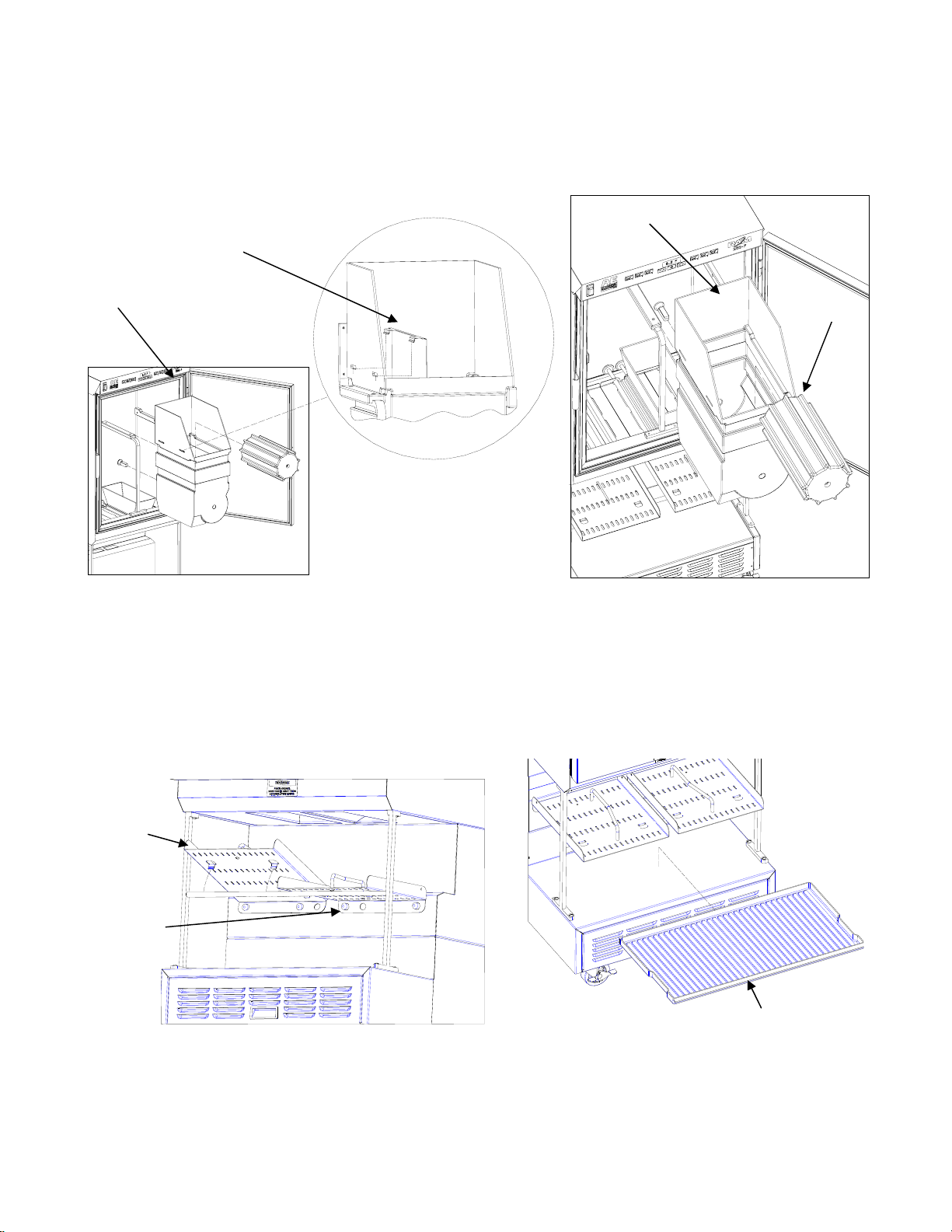

Fry Diverter Assembly Drum and Hopper Assembly

Install the Fry Diverters in the Hoppers by sliding the Fry Diverters into the slot located on the inside

Hopper walls. Install Drums into the Hoppers making sure the square opening in the drum is pointed to

the rear of the Hopper. Repeat assembly for left and right hopper. Install the hopper assemblies into

the cabinet by sliding them onto the hopper supports. DO NOT force the drum on to the shaft. Rotate

the drum in the hopper until the square opening meshes with the drum motor shaft, then slide the

hopper assembly back until it drops into place.

Drip Tray

Basket

Trays

Basket Tray Assembly Drip Tray assembly

Once the Accumulator Housings and Hopper Assemblies are in place, close the Cabinet Door.

Assemble Basket Tray and Drip Tray to lower dispensing area. Basket Trays are not universal to the

left and right positions.

Copyright © 2011 Automated Equipment LLC All rights reserved.

7

Page 10

RAM™ 280-F Frozen Fry Dispenser

Using the Hash-brown Rack

The RAM 280-F cabinet can be used to store frozen hash-browns while serving breakfast. To use the

cabinet for hash-brown storage, properly assemble the dispenser (pages 6-11

), then install the hashbrown rack accessory as shown in the diagram below. The rack will serve as a shelf inside the

refrigerated cabinet for hash-brown storage.

Note: The hash-brown racks should be removed during normal operation.

Caution

: Do not store hash-browns on the drum below the rack, this can damage the dispenser.

Insert the four rods of the hash-brown rack into the holes in the side of the hopper then lower the rack

onto the fry diverter.

Hash-brown rack

PN: 293966

(shown with

Hopper PN:

293139)

Hash-brown rack installation

8

Copyright © 2011 Automated Equipment LLC All rights reserved.

Page 11

RAM™ 280-F Frozen Fry Dispenser

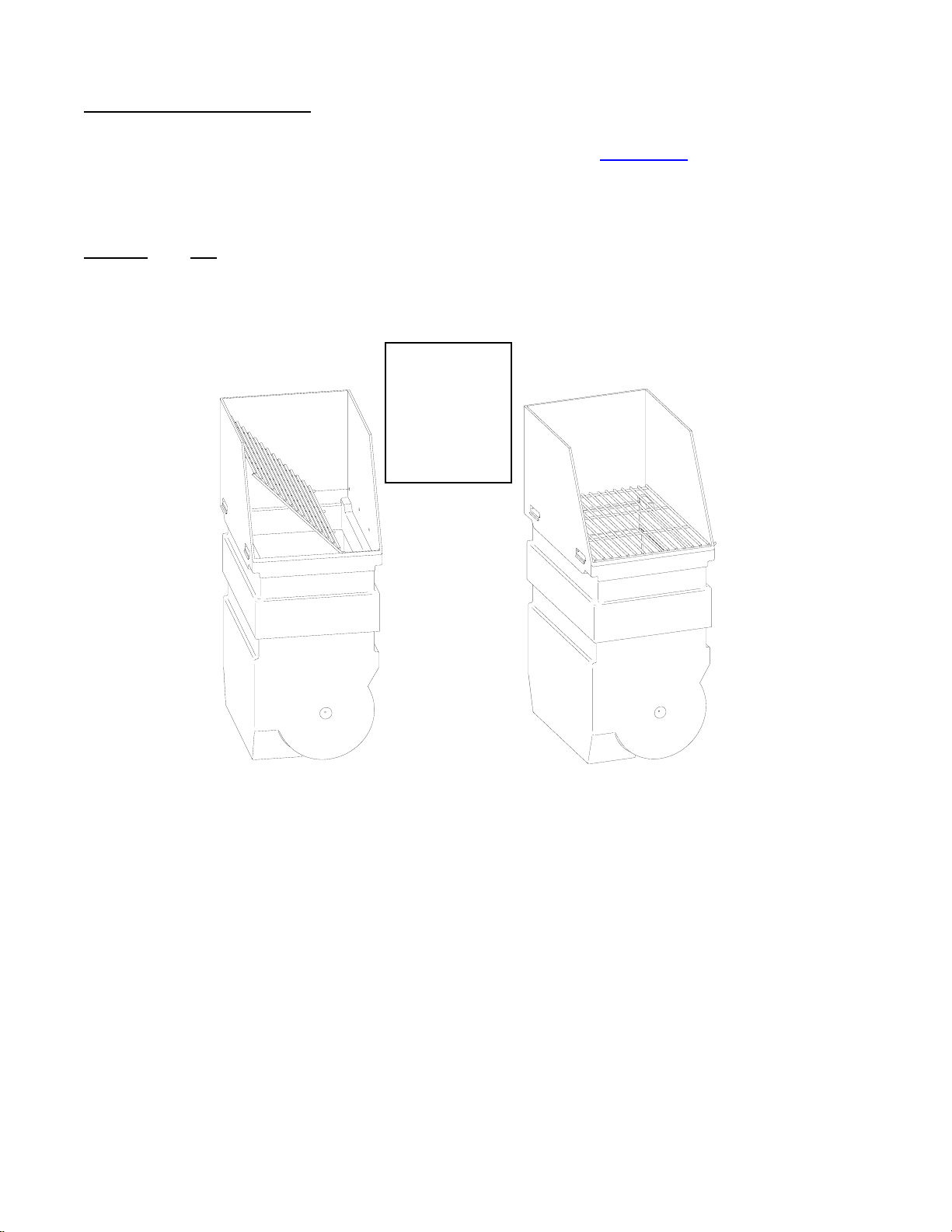

Dispenser Assembly (Models after and including s/n 28FR0802B0249)

Note: Before assembling the Dispenser it is recommended that all parts be cleaned, sanitized,

dry, and handled in a sanitary manner. Refer to the Cleaning Procedures (page 12

information.

Pivot Block

) for more

Open the cabinet door. Accumulator doors are pre-installed. Install the left and right flap doors by

slipping them under the accumulator doors and seating the pivot pin into the plastic pivot blocks, as

shown above. (Accumulator Doors are hidden for clarity in Right Hand view).

Accumulator Housing Assembly

Install the left and right Accumulator Housings over the Accumulator Doors.

Copyright © 2011 Automated Equipment LLC All rights reserved.

9

Page 12

RAM™ 280-F Frozen Fry Dispenser

Dispenser Assembly Cont.

Note: Accumulator Housings, Drums, and Fry Diverters are universal to left, and right, positions

within the cabinet. The Hoppers and Basket trays are NOT universal to the left, and right,

positions of the cabinet.

]

Fry

Hopper

Diverter

Hopper

Drum

Fry Diverter Assembly Drum and Hopper Assembly

Install the Fry Diverters in the Hoppers by sliding the Fry Diverter tabs into the slots located on the

inside Hopper walls. Install Drums into the Hoppers making sure the square opening in the drum is

pointed toward the rear of the Hopper. Repeat assembly for left and right hoppers. Install the hopper

assemblies into the cabinet by sliding them onto the hopper supports. DO NOT force the drum on to the

shaft. Rotate the drum in the hopper until the square opening meshes with the drum motor shaft, then

slide the hopper assembly backward until it drops into place.

Left

Basket

Tray

Right

Basket

Tray

Drip Tray

Basket Tray Assembly Drip Tray assembly

Once the Accumulator Housings and Hopper Assemblies are in place, close the Cabinet Door.

Assemble Basket Tray and Drip Tray to lower dispensing area. Basket Trays are not universal to the

left and right positions.

10

Copyright © 2011 Automated Equipment LLC All rights reserved.

Page 13

RAM™ 280-F Frozen Fry Dispenser

Using the Hash-brown Rack

The RAM 280-F cabinet can be used to store frozen hash-browns while serving breakfast. To use the

cabinet for hash-brown storage, properly assemble the dispenser (pages 9-11

), then install the hashbrown rack accessory as shown in the diagram below. The rack will serve as a shelf inside the

refrigerated cabinet for hash-brown storage.

Note: The hash-brown racks should be removed during fry dispensing.

Caution

: Do not store hash-browns on the drum below the rack, this can damage the dispenser.

Insert the four rods of the hash-brown rack into the holes in the side of the hopper then lower the rack

onto the fry diverter.

Hash-brown

rack

PN: 293966

(shown with

Hopper p/n

294396)

Hash-brown rack installation

Copyright © 2011 Automated Equipment LLC All rights reserved.

11

Page 14

RAM™ 280-F Frozen Fry Dispenser

Disassembly, Defrost & Cleaning

IMPORTANT! These cleaning instructions

are intended as a guide. Refer to your local,

state, and federal regulations for any

additional instructions and for cleaning

frequency requirements.

Remove all Baskets from the dispense area.

Open the Cabinet Door and remove the left and

right Hopper Assemblies by lifting the front of

the Hopper up slightly and pulling forward on

assembly.

Remove any unused product from the Hoppers

and Accumulator Housings by emptying the

product into an approved storage container.

Place the storage container immediately into a

freezer to maintain frozen product.

Defrost

Because the dispenser employs a cold wall

design, it will be necessary to manually defrost

the cabinet daily. After removing the product,

using the On/Off Switch turn the power OFF

and unplug the dispenser power cord. Open

the Cabinet Door and allow 1 hour to defrost.

Note: Failure to turn the dispenser power off

prior to defrosting the cabinet may result in a

cabinet over-temperature error. (Error -5-).

Caution: Never use a sharp object to remove

frost build-up. Never drill or otherwise

puncture cabinet walls or top.

Lift and remove the Accumulator Housings.

For dispensers with removable accumulator

doors: remove the Accumulator Doors by

rotating the chucks Counter-Clockwise until

unlocked, then pull the accumulator doors

forward.

Take the removable components from the

Dispenser to the washing area. Wash them

with a hot solution of detergent and water.

Rinse each component with clear water and

sanitize (wash/rinse/sanitize) (HCS). Allow

components to air dry,.

NOTE: The removable components are NOT

dishwasher safe.

Move the Dispenser out from the wall to clean

behind and underneath it.

Do NOT roll the dispenser to the back sink for

cleaning, this will cause unnecessary wear on

the dispenser.

Once the cabinet is free of frost, wipe down the

internal and external cabinet with a hot solution

of detergent and water. Rinse with clear water

and repeat wipe down with sanitizing solution

(HCS) and allow to air dry.

Warning: Do not spray the Dispenser with

Liquid or Solvents. The Dispenser does not

provide a water tight seal. Contaminants

and moisture may get into sensitive

components.

Dry all components and reassemble the

Dispenser (page 6-11

). Move Dispenser back

into place.

Notice: The dispenser must be accessible

from all sides for routine cleaning and

maintenance. A minimum of 0.5” (13 mm)

clearance on both sides and 2” (50 mm)

behind the dispenser is recommended.

Lift and remove left and right Flap door

assemblies.

Remove left and right Basket Guide assemblies

from the Dispenser by lifting up on the front of

the guide until it unlatches, then pull outward

and upward. Remove Drip Tray by lifting, tilting

and sliding forward.

12

Copyright © 2011 Automated Equipment LLC All rights reserved.

Page 15

RAM™ 280-F Frozen Fry Dispenser

Dispenser Startup

Make sure Power Switch, located on the left portion of the operator panel, is turned off. Assemble the

Dispenser (Pages 6-11

Note: Turn Dispenser on a minimum of 90 minutes (depending on ambient temperature

conditions) before loading frozen product into the Dispenser. Once the temperature display has

dropped to 10°F (-12°C) load frozen product into Dispenser and use the Dispenser.

). Plug the Power Cord into an approved outlet and turn the Dispenser on.

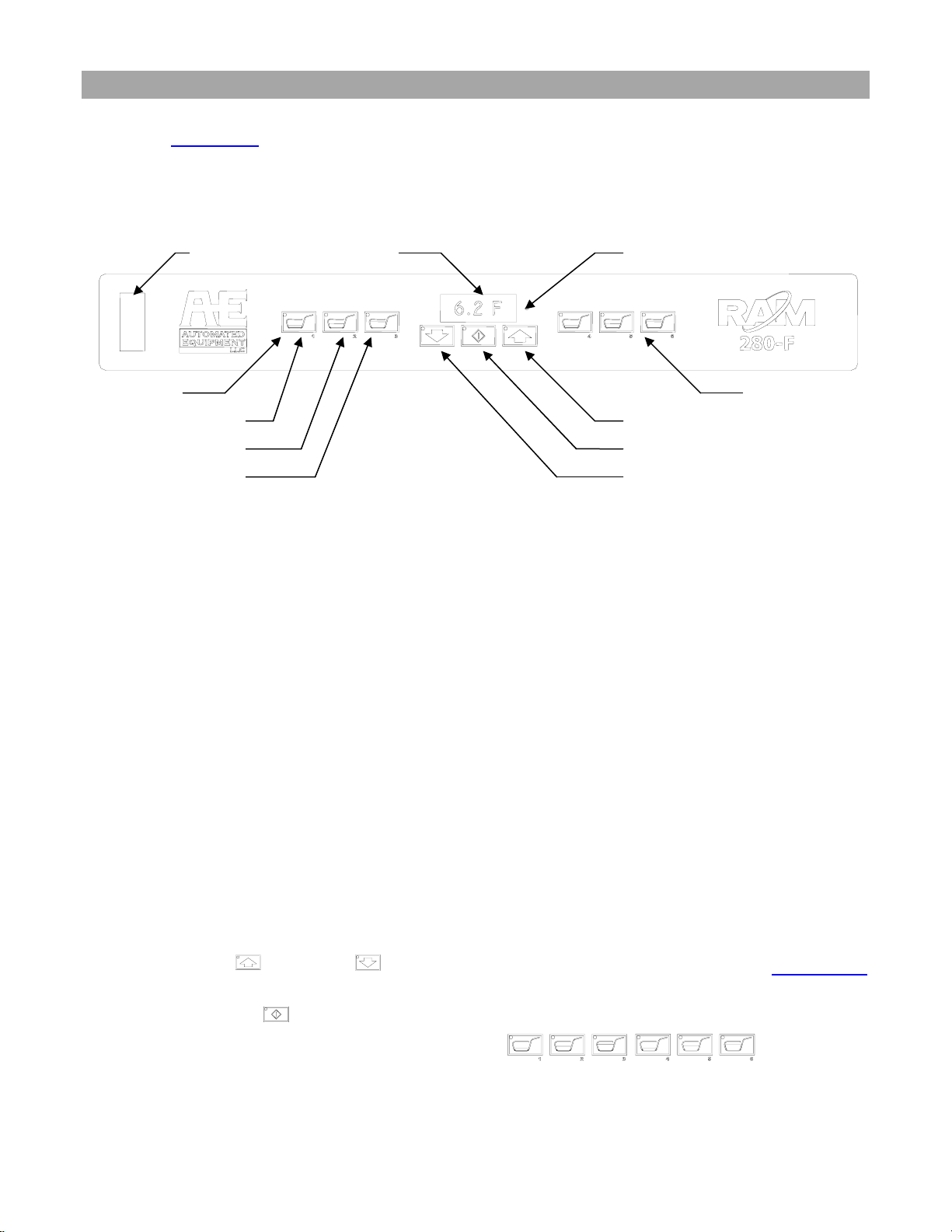

Power Light

Up Button

Enter Button

Down Button

Basket Size

Buttons

Basket Size

Buttons

Medium loads

Power Switch

Small loads

Large loads

Display

The Operator Panel consists of a Power Switch and three groups of controls: the Left Hopper controls,

center System controls with Data Display, and the Right Hopper controls. Each Hopper is controlled as

if it were an independent dispenser.

On power up, the display will very briefly show the Software Name, Software Version, Copyright Notice,

and then the Main Screen (typically the dispenser temperature). The Dispenser will NOT respond to

keypad selections before the Main Screen is displayed.

The Main Screen will appear as shown above. The number displayed in the center represents the

interior cabinet temperature.

The operator panel is used to make basket load size selections and to access controller functions.

Note: The Managers Menu and Diagnostic Menu may require a manager’s password to

access the Functions. By Default these Passwords are disabled.

• Use the Up

and Down Arrow Buttons to access a desired function. (See pages 18-22

for a complete list of functions and their descriptions.)

• Press the Enter

• Basket Size Buttons also function as numbers:

Button to select the desired function.

(e.g. Left Small=1, Left Medium=2, Left Large=3, Right Small=4, Right Medium=5, Right Large=6)

Copyright © 2011 Automated Equipment LLC All rights reserved.

13

Page 16

RAM™ 280-F Frozen Fry Dispenser

Operation

Note: This machine is to be used only for dispensing frozen fries or other approved product.

Any other use may cause injury to personnel or damage to the machine.

The Frozen Fry Dispenser is intended to maintain and dispense frozen fries on demand from two

independent hoppers eliminating the need for staging full baskets of fries. Dispensing and cooking fries

direct from the freezer results in improved fry quality, consistency and yield.

Do not stage full baskets of fries on the bottom tray. The lower tray area should be used for

empty fry basket storage only.

Loading the Hoppers

Note: To achieve optimum fry yield and the

most consistent basket loads, it is important

to use the following technique for loading

frozen fries into the Hopper.

The dispenser will accept 60 lbs (27.3kg) of

French fries, 30 lbs (13.6kg) per hopper

(approximately 5 bags per hopper) Hopper

capacity may vary depending on the product.

Warning: Pinch Hazard

. Personnel should

take care not to place hands or fingers near

the Drum inside the Hoppers while this

machine is in operation. Hands or fingers

could be pinched between the Drum and the

Hopper as the Drum turns.

Note: Do NOT shake or drop fries from the

bag or box into the Hopper, this will result in

unnecessary fry breakage.

For each bag or box of fries:

1. Remove the bag of fries from the case. Be

careful not to crush the fries.

2. Open the top of the bag or box completely.

(A partially open bag may retain fries.)

3. Hold the opened end of the bag closed with

your hand and lay it in the Hopper with the

opening toward the side opposite of the

Diverter.

4. Release the opened end of the bag or box.

5. Empty the bag into the Hopper by pulling it

evenly toward the diverter. When adding

multiple bags of fries, alternate the

placement of the bag in the Hopper

opposite of the previous bag. The second

bag of fries should be emptied into the

Hopper with the opening toward the

Diverter, and pulling it evenly toward the

Hopper wall opposite the Diverter.

6. This crisscross loading method assures an

even distribution of fry lengths in the Hopper

and the Baskets.

14

7. Repeat until each hopper is full.

Copyright © 2011 Automated Equipment LLC All rights reserved.

Page 17

RAM™ 280-F Frozen Fry Dispenser

Daily Opening and Closing

Setup and Operation

1. Fill one or both hoppers with product.

Note: DO NOT SHAKE OR DROP the fries

into the Hopper(s) (refer to “Loading the

Hoppers”, page 14

).

2. Select a Basket Size Button for left and/or

right Hopper to dispense desired load.

3. Default settings are:

• Small load = 0.50 LBS(225 gr)

• Medium load = 1.0 LBS(450 gr)

• Large load = 1.5 LBS(700 gr)

A LED light will illuminate next to the

basket load size that is currently selected.

4. The drum motor for one/both sides will turn

until the selected target weights are

achieved. If there is insufficient product in

the hopper a low fry warning will flash for

the effected side. (blinking ‘o’).

5. Place a basket under the Accumulator

Outlet for the selected side(s). Lift the front

of the basket slightly and slide the basket

forward over the basket sensor. The

Accumulator Doors will open and close,

discharging product into the waiting basket.

6. Remove the basket.

7. The dispenser will repeat step 4, preparing

the next basket. The dispenser will

automatically dispense as soon as the next

basket is present.

8. Automatic Load Size “Downshift”

Note: For dispensers with serial

numbers after LONR1001D01242 or

dispensers with upgraded software.

When in the large load size setting, the

machine will automatically shift the weight

selection down to the medium setting if a

basket has not been dispensed within 4

minutes. The weight selection will remain in

the medium setting until the operator elects

to change it.

Daily Closing

Select ‘Last Basket/Cancel Selections’ from

the operator panel to cancel all currently

selected basket loads: Using the Operator

Panel, press the Up Arrow

Button until

“U1” is displayed then press the Enter

Button.

Both sides will stop automatically refilling the

accumulator housing. Dispense any fries

present in the accumulator housing into a

basket. The dispenser will NOT refill the

housing.

Empty the dispenser. Dispose of any unused

product or place into an approved storage

container. Place container immediately into

freezer to maintain frozen product.

Take the removable components from the

Dispenser to the washing area. Wash them with

a hot solution of detergent and water. Rinse

with clear water and sanitize (HCS). Allow to air

dry. (See ‘Disassembly & Cleaning’ instructions,

page 12

Defrost Cabinet Daily:

.)

Turn the power switch off then open the

Cabinet Door to allow the Dispenser to

defrost for one hour or until free of frost.

Caution: Never use a sharp object to remove

frost build-up.

Once the cabinet is free of frost, wipe down the

internal and external cabinet with a hot solution

of detergent and water. Rinse with clear water

and repeat wipe down with sanitizing solution

(HCS) and allow to air dry.

Reassemble the Dispenser (pages 6-11

Dispenser back into place.

Note: Failure to turn the dispenser power off

prior to defrosting the cabinet may result in a

cabinet over-temperature error (Err 5).

). Move

Copyright © 2011 Automated Equipment LLC All rights reserved.

15

Page 18

RAM™ 280-F Frozen Fry Dispenser

Last Basket/Cancel Selections

Before cleaning the dispenser or if it becomes

necessary to stop automatic dispensing, the

operator is able to cancel all selected basket

loads. Both Drums will stop turning and any

currently selected basket load lights will turn off

for both sides of the dispenser. Any fries

present in the accumulator housing will

dispense automatically if a basket is presented.

The dispenser will NOT refill the housing.

To cancel currently selected basket loads,

using the Operator Panel, press the Up Arrow

Button until “U1” is displayed then press

the Enter

Button. Both sides will stop

automatically refilling the accumulator housing.

To return to normal operation for one or both

sides select a Basket Size

Button for the

effected side(s)

Error Conditions

The dispenser’s controller can detect an error

or abnormal condition. When an error condition

is detected the display will flash and state the

error that has occurred. (i.e. "Err 4")

Empty Hopper Warnings

If one or both of the hoppers runs empty, or the

Dispenser is otherwise unable to dispense, the

Empty Hopper Light for the effected side will

flash,(‘□’ flashing in the display) and the

unselected Basket Size Button LED lights for

the effected side will flash. The dispense cycle

will stop.

The blinking ’□’ for the effected side indicates

the dispenser was unable to achieve the target

weight on the accumulator doors. It may also

indicate a scale obstruction, calibration

problem, or bridged fries in the hopper.

If the Empty Hopper lights are flashing, check

and/or fill the Hopper and press the currently

selected Basket Load Button to restart the

cycle.

Note: The Dispenser will also retry the

weigh cycle every 90 seconds.

Resetting Errors: When an error does occur,

it is normally reset by pushing the Enter

Button.

In the event the error is only effecting one side

of the dispenser, the unselected basket size

lights will also flash for the effected side and

this side will be disabled until the error is reset.

The unaffected side will continue to function

normally.

Note: Errors 5, 6 & 7 relating to the

refrigeration systems, while requiring

corrective action, will not disable the fry

dispensing portion of the equipment.

If the error condition persists, turn the Power

Switch off and unplug the Power Cord from the

wall outlet. Check the Power Cord for any

obvious defect. Open the Cabinet Door to make

sure the dispenser is properly assembled (page

6-11) and the product is loaded properly.

See pages 23-26

for a complete list of errors

and for a troubleshooting guide to aid in

resolving the error conditions.

Normal Operation

Empty Hopper Warning

Door Ajar Warning

In Revision C and D dispensers equipped with

a door switch, the controller is capable of

detecting an open cabinet door. The

temperature on the main display will flash

alerting the operator that the door is ajar. The

warning will automatically clear once the door is

no longer open. If the door ajar condition

persists for more than 15 minutes the

refrigeration compressor will shut off until the

door is closed again. Neither condition will

effect the operation of the dispensing portion of

the machine but is intended to alert the operator

of an open door condition and avoiding

unnecessary wear on the refrigeration systems

of the RAM 280-F Frozen Fry Dispenser.

16

Copyright © 2011 Automated Equipment LLC All rights reserved.

Page 19

Bypass Mode of Operation

RAM™ 280-F Frozen Fry Dispenser

Bypass mode will allow the one or both sides of

the dispenser to remain operational in the event

that a basket sensor fails. Bypass Mode is

intended to be a temporary condition until a

replacement basket sensor can be installed.

Note: Bypass Mode is a volatile condition

and will return to normal operation if the

power is turned off and back on again.

While in Bypass Mode the effected sides basket

sensor is disabled and will not dispense fries

automatically into a basket when presented.

To dispense the fries into a basket, press the

selected Basket Size

Button after placing

an empty basket under the accumulator door

opening. The accumulator doors will cycle

each time the Basket Size

Button is

depressed.

While in Bypass Mode the dispenser will

otherwise appear to operate normally, refilling

the accumulator housings automatically after

each dispense cycle with the selected load of

fries.

Note: Engaging Bypass Mode (D11) is

performed from the Diagnostic Functions

Menu (pages 20-22

) using the Operator

Panel on the front of the Dispenser and may

require a manager’s password to access the

menu.

To access the Diagnostics Menu, on the

Operator Panel, press the Up Arrow

until "U4" is displayed then press the Enter

button

button. The display will change to "-----" Enter

the managers password (if set) using the

basket size buttons. Then press the Enter

button.

The display will change to "d01". Press the Up

Arrow

press the Enter

button until "d11” is displayed then

button to access the

Bypass Basket Sensor Function.

The display will read “[bYP]” with alternating

flashing brackets. Use the Left or Right Basket

Size

Buttons to select the side to be

bypassed.

The display will default to the current sensor

condition.

Use the Up Arrow

Button to select bypass

mode for the effected side. The display will

read “[YES” if the left side is selected, (“ YES]”

if the right side is selected.) Press the Enter

Button to execute bypass mode and exit to

“d01”. Press Enter

again to exit the

diagnostics menu and enter bypass mode of

operation.

To deselect bypass mode for the effected side:

Press the Down Arrow

Button. The display

will read “[ no” if the left side is selected (“ no]”

if the right side is selected). Press the Enter

Button to exit the function and return to

“d01”. Press the Enter

Button again to

return to the main screen, or to return to normal

operation turn the power off for 15 seconds

then turn the power back on.

Note: The Basket Size Buttons also function

as number buttons:

(e.g. the left medium basket button is

number 2, and the right large basket button

is number 6.)

Copyright © 2011 Automated Equipment LLC All rights reserved.

17

Page 20

RAM™ 280-F Frozen Fry Dispenser

User Function Menu Structure

User

Functions

Main

Screen

U1

U2

U3

U4

U5

Function Name Description

Main Screen Default condition of the display. Live temperature, error

display, and hopper status (full/empty)

Last Basket/ Cancel

Selections

Halts weighing in process.

Turns off all size button lights.

Immediate return to Main screen.

1. Request side to calibrate. Display reads: “[CAL]” with

alternating flashing brackets. Use Basket size button to

select side.

2. Waits for a basket to be placed for the side to be

calibrated then empties the accumulator doors into the

basket. The Display will read “[ -- “ (“ -- ]”) until a basket

is presented.

Calibrate Scales

3. Remove hopper for side to be calibrated. NOTE: Leave

the housing in place on the accumulator doors.

Note: See procedure

on page 27

4. Tares automatically. Display reads “[ 0.0 “ (“ 0.0 ]”)

5. Waits for 1.0 lb reference. Display reads “[ 1.0 “ (“ 1.0 ]”)

Place 1.0 lb (450 gr) weight on the accumulator doors.

6. Waits for 2.0 lb reference. Display reads “[ 2.0 “ (“ 2.0 ]”)

Place 2.0 lb (900 gr) weight on the accumulator doors.

7. Waits for weight removal. Display will read “ --- “ Remove

weight(s) from the accumulator doors.

8. Reinstall hopper.

9. The dispenser will return to normal operation with no

basket size selected on effected side.

Request password (if set) to enter manager functions.*

Display shows dashes only if a password is set.

Goes straight to “F1” if no password is set. (page 19)

Enter Manager

Functions*

Use basket size buttons to enter five-digit password†.

Press the Enter Button to execute and close function.

If the password was successfully entered, “F1” will be

displayed. You are now in the Manager Menu. (page 19)

Request password, set or not, to enter diagnostic menu.

Display shows dashes only.

Use basket size buttons to enter five-digit password.

Enter Diagnostic

Functions*

Note: Password can be bypassed if not set. (press enter)

Enter button executes and closes function.

If the password was successfully entered, “d01” will be

displayed. You are now in the Diagnostics Menu. (page 20)

Display shows current software version number. (i.e. “ 1.0 “

Software version

Enter button closes function.

• Use the Up and Down Arrow Buttons to find the desired function.

• Press the Enter

• Basket Size Buttons also function as numbers:

Button to select the desired function.

(Left Small=1, Left Medium=2, Left Large=3, Right Small=4, Right Medium=5, Right Large=6)

*Service Password to access both the Manager Menu and Diagnostic Menu: 22463†

†Note: Using the Service Password to access the Manager Function menu will erase the

manager’s password (if set) and restore it to default (no password).

18

Copyright © 2011 Automated Equipment LLC All rights reserved.

Page 21

RAM™ 280-F Frozen Fry Dispenser

Manager Function Menu Structure

Manager

Functions

F1

F2

F3

F4

F5

F6

Function Name Description

Exit Manager

Immediate return to the Main Screen.

Functions

Allows the basket load targets to be customized for each

basket load size. 0.25 lb to 2.0 lb (100gr-1000gr)

Display reads currently selected target load.

Set Basket Load

Target weights

Size buttons select basket load size to change.

Up button increases target in 0.05 lb steps (25gr).

Down button decreases target in 0.05 lb steps (25gr).

Enter button stores new settings and closes function.

Allows the cabinet target temperature to be changed. The

default is 0°F (-18°C). Display reads the current target

temperature.

Up button will increase the target temperature in 1°

Set Target

Temperature

increments.

Down button will decrease the target temperature in

1° increments.

Enter button stores the new setting, closes the

function, and exits to F1.

Sets the temperature difference that activates the

refrigeration compressor. For example: if the target

temperature is 5°F with a 6° differential, the compressor will

Set Differential

cycle on at 11°F and off at 5°F. Default is 5°F (3°C) for one

probe and 6°F (3°C) for two probe controlled dispensers.

Setting is adjustable from 4°F to 15°F (2°C to 8°C).

Display reads “dF. 5F”

Changes from English to Metric units. Display will default to

currently selected unit.

Up button sets metric units. Display reads “gr”.

Set Metric or English

Down button sets English units. Display reads “Lb”

Enter button saves setting and closes function.

Note: Must Recalibrate Scales. See procedure on page 27.

Allows a password to be set to access both manager and

diagnostic functions. (default is no password)

Display shows dashes

Set Password

Use Size buttons to enter a 5 digit password then

press the enter button to save the password and exit.

Note: Password must be entered twice. (double entry)

Entering “11111” twice will clear any passwords.

• Use the Up and Down Arrow Buttons to find the desired function.

• Press the Enter

• Basket Size Buttons also function as numbers:

Button to select the desired function.

(Left Small=1, Left Medium=2, Left Large=3, Right Small=4, Right Medium=5, Right Large=6)

Service Password to access both the Manager Menu and Diagnostic Menu: 22463

Note: Using the Service Password to access the Manager Function menu will erase the

manager’s password (if set) and restore it to default (no password).

Copyright © 2011 Automated Equipment LLC All rights reserved.

19

Page 22

RAM™ 280-F Frozen Fry Dispenser

Diagnostic Function Menu Structure

Diagnostic

Functions

D01

D02

D03

D04

D05

Function Name Description

Exit Diagnostics

Immediate Return to Main screen.

Displays the last 10 recorded errors in reverse order starting

with the last error recorded.

Display Last Error

Up button shows next error.

Down button shows previous error.

Enter button closes function.

Displays the number of occurrences of each error.

Display shows Error number and Number of Occurrences.

(i.e.: “05 02” means Error 5 has occurred 2 times since the

Error Log

error log was last cleared.)

Up button shows next error.

Down button shows previous error.

Enter button closes function and returns to D01.

Clears the error log. Display will read “Cl Err”. Press enter

to continue. Display will Read “Cl. No”.

Up arrow will select ‘clear errors’.

Display will read “Cl.YES”

Press enter to clear error log and exit the function and

Clear Errors

return to D1 or:

Down arrow will deselect ‘clear errors’.

Display will read “Cl. No”

Press the Enter button to execute selected option, exit the

function and return to D01.

Caution: Read procedure on page 29 before continuing.

Displays the cabinet temperature probe reading in tenths of a

Calibrate Temperature

Probe.

Note: See procedure

on page 29.

degree i.e.”-1.5°F”

Allows the cabinet temperature probe to be corrected.

Up arrow will increase temperature in 0.1° increments.

Down arrow will decrease the temperature in 0.1°

increments.

Enter button will save the new setting and exit to D01.

20

D06

D07

Read Control Probe*

*Used only with two

probe systems.

Control Probe Offset

Copyright © 2011 Automated Equipment LLC All rights reserved.

Displays the refrigeration temperature controller probe

reading in tenths of a degree i.e.”-8.5°F” . Displays “---“ on

single probe dispensers.

Note: When two temperature probes are present, one is

mounted to an insulated block near the top wall of the cabinet

compartment in the upper right. This probe measures cabinet

temperature and is the temperature displayed on the front of

the operator panel. The other probe is below the block and

mounted against the back wall near the refrigeration

accumulator. This probe controls the refrigeration system.

Enter button will exit to D01.

Allows the temperature control probe to be offset to adjust for

any deviation from actual temperature and to allow for fine

tuning of the refrigeration cycle. Default is 0°F (0°C) for

single probe dispensers. Display will read “oF. 0F”. [Default

is 3°F (2°C) for two probe dispensers.] Adjustable from -5°F

to 15°F(-3°C to 8°C).

Up arrow will increase in 1° increments.

Down arrow will decrease in 1° increments.

Enter button will save the new setting and exit to D01

Page 23

D08

D09

Reset Refrigeration

Errors # 5, #6 & #7

Actuate Outputs

Note: Basket Size

Buttons also function

as numbers

Note: The

refrigeration circuit

contains anti-shortcycle protection.

RAM™ 280-F Frozen Fry Dispenser

Clears and resets any active refrigeration errors (errors 5, 6 &

7)

Display defaults to “Er. no”

Press up arrow, display will read “Er.YES”

Down button will return to “Er. no”

Press enter button to execute and return to D01.

Allows outputs to be turned on and off to aid in diagnosing

problems.

Display shows selected motor and command. (i.e. “d2 on”

indicates the right drum motor’s output is on.)

Use Basket Size Buttons to select an output:

1. Left Drum motor (d1)--Left Small Basket

2. Left Accumulator motor (A1)--Left Medium Basket

4. Right Drum motor (d2)--Right Small Basket

5. Right Accumulator motor (A2)--Right Medium Basket

6. Refrigeration compressor (rF)--Right Large Basket

Up arrow turns output on,

Down arrow turns output off.

Enter button closes function.

The display flashing “rF OFF” indicates the refrigeration

compressor cannot be restarted until the 2 minute short cycle

delay is met.

D10

D11

D12

Diagnostics Display

Note: See page 26

Bypass Basket

Sensors

Note: Volatile setting.

(will reset each time

power is cycled)

Bypass Weighing

Note: Volatile Setting

All outputs will turn off and return to normal operation when

exiting the function.

Shows status of all controller Inputs and Outputs while the

dispenser continues normal operation.

Display shows all activated Inputs and Outputs.(see page 26)

Size and Enter buttons function just as in main screen

during normal operation.

Up Arrow Button does nothing.

Down Arrow button will exit the function.

Allows the dispenser to be used when a basket sensor has

failed.

Display will read “[bYP]” with alternating flashing brackets.

Use Basket Size buttons to select the side to be

bypassed.

Display will default to the current sensor condition.

Up arrow sets bypass mode. “[ YES” ( “YES]”)

Down arrow clears it. “[ no” (“ no]”)

Enter button executes selection, exits function and

returns to D01

Disable the scale to allow other diagnostics to be performed

without wasting product.

Display will read “[SCL]” with alternating flashing brackets.

Use Size Keys to select the side to be bypassed.

Display will default to current scale status.

Up arrow turns the scale on for selected side.

“[ on” (“ on ]”)

Down arrow turns off the scale for selected side.

“[ OFF” (“ OFF ]”)

Enter button executes selection, exits function and

returns to D01

Copyright © 2011 Automated Equipment LLC All rights reserved.

21

Page 24

D13

D14

D15

D16

D17

D18

Bypass Refrigeration

Note: Volatile Setting

Display Scale Weight

Display Scale Volts

Exercise Mode

Note: Volatile Setting

Caution: Ensure the

hopper is empty before

using Exercise Mode

Restore Defaults

Power Volts

RAM™ 280-F Frozen Fry Dispenser

Allows the refrigeration system to be disabled.

Display will read the current status of the refrigeration system

(rF on or rF OFF).

Up arrow enables the refrigeration system.

Down arrow disables the refrigeration system.

Enter button saves the setting, exits the function and

return to D1.

Note: The refrigeration circuit contains anti-short-cycle

protection. The refrigeration compressor cannot be restarted

until the 2 minute short cycle delay is met.

Displays the current calibrated weight on the scale.

Display will read “[SCL]” with alternating flashing brackets.

Use Size Buttons to select the side to be displayed.

Enter Button exits function and returns to D01

Displays the current uncalibrated input from the scale.

Display will read “[SCL]” with alternating flashing brackets.

Use Size Buttons to select the side to be displayed.

Enter Button exits function and returns to D01

Exercise mode is designed to “break in” a replaced

component. When the dispenser is in exercise mode, the

selected side(s) will continuously cycle.

Display will read “[-E-]” with alternating flashing brackets.

Use Size Buttons to select the side to be exercised.

Up arrow selects exercise mode:

Display reads “[ on” (“ on]”)

Down arrow clears exercise mode.

Display reads “[ OFF” (“ OFF]”)

Enter button executes selection and exits to D01

Restores all settings to factory defaults

Display defaults to “rd. no”

Up arrow will select restore defaults:

Display reads “rd.YES”

Down arrow will deselect restore defaults.

Display will read “rd. no”

Enter button will execute selection and exits to D01

Caution: This function will erase scale calibrations,

temperature probe calibrations, changes to target

weights, temperature setpoint, alarm setpoint, and will

reset passwords to defaults.

Displays the current power supply voltage.

Enter Button exits the function and returns to D01

• Use the Up and Down Arrow Buttons to find the desired function.

• Press the Enter

• Basket Size Buttons also function as numbers:

Button to select the desired function.

(Left Small=1, Left Medium=2, Left Large=3, Right Small=4, Right Medium=5, Right Large=6)

Service Password to access both the Manager Menu and Diagnostic Menu: 22463

Note: Using the Service Password to access the Manager Function menu will erase the

manager’s password (if set) and restore it to default (no password).

22

Copyright © 2011 Automated Equipment LLC All rights reserved.

Page 25

RAM™ 280-F Frozen Fry Dispenser

Error Detection

The main display and Basket Size Button LED lights will flash with the detection of an error condition for

the effected side. The display will state the error that has occurred. (i.e. “Err 4”)

If an error does occur, it is normally reset by pushing the Enter

the Power Switch off and unplug the Power Cord from the wall outlet. Check the Power Cord for any

obvious defect. Open the Cabinet Door to make sure the dispenser is properly assembled (pages 6-11

and the product is loaded properly.

See pages 24-26

for troubleshooting an error condition.

Button. If the failure continues, turn

Error Codes

Error Description

01

02

03

Timeout error on left accumulator.

Timeout error on right accumulator.

Left Tare weight has shifted excessively.

)

04

05

06

07

08

09

10

Note: Errors 5, 6 & 7 are refrigeration errors. These errors, while requiring corrective action, will not

disable the fry dispensing portions of the equipment. In order to safeguard the refrigeration system

these are hard errors and may not reset by pushing the Enter

the Diagnostic Menu using Diagnostic Function D08.

Right Tare weight has shifted excessively.

Refrigeration progress too slow. (>25°F for 1.75 Hr)

Refrigeration High Pressure Switch has tripped.

Error on refrigeration relay drive.

Temperature Probe input out of range.

Invalid data in Configuration (normal first time)

Internal System Error

Button. These errors are reset from

Call our Technical Support Hot Line for assistance with these errors.

Copyright © 2011 Automated Equipment LLC All rights reserved.

23

Page 26

RAM™ 280-F Frozen Fry Dispenser

Troubleshooting

The following is a list of errors that may occur, probable causes, and corrective action that may

eliminate the problem. If, after performing the corrective action, the problem persists, call our Technical

Support Hotline for assistance.

Our Technical Support Hotline is available for telephone assistance providing product technical support,

parts and parts information, and service agent referral.

Technical Support Hot Line: 1-800-248-2724 (U.S./Canada) or 651-385-2273.

Error 1 The controller has detected a TIMEOUT ERROR FOR THE LEFT ACCUMULATOR

MOTOR HOME SENSOR. The accumulator home encoder sensor sends an input to the

controller each time the accumulator doors cycle. It lets the controller know that the doors

opened and closed in an acceptable time. A timeout error will occur if the following

conditions are not detected. Accumulator home switch timeouts:

• If it starts in the home area, it must leave it within 0.5 seconds.

• Once it is clear, it will make a half turn, then pause.

• When it has resumed from the pause, it must find the home area within 2.0 seconds.

A Timeout Error could be caused by an accumulator motor fault, broken accumulator

linkage, a disconnected or faulty accumulator encoder or a damaged encoder vane. Verify

the accumulator encoder wiring at both the board and at the encoder is secure and the vane

is in place and undamaged. Check accumulator linkage to ensure it is undamaged.

Error 2 The controller has detected a TIMEOUT ERROR FOR THE RIGHT ACCUMULATOR

MOTOR HOME SENSOR. The accumulator home encoder sensor sends an input to the

controller each time the accumulator doors cycle. It lets the controller know that the doors

opened and closed in an acceptable time. A timeout error will occur if the following

conditions are not detected. Accumulator home switch timeouts:

• If it starts in the home area, it must leave it within 0.5 seconds.

• Once it is clear, it will make a half turn, then pause.

• When it has resumed from the pause, it must find the home area within 2.0 seconds.

A Timeout Error could be caused by an accumulator motor fault, broken accumulator

linkage, a disconnected or faulty accumulator encoder or a damaged encoder vane. Verify

the accumulator encoder wiring at both the board and at the encoder is secure and the vane

is in place and undamaged. Check accumulator linkage to ensure it is undamaged.

Error 3 The controller has detected a LARGE SHIFT IN THE TARE (EMPTY) READING FOR THE

LEFT SIDE’S SCALE INPUT. Could be caused by an obstruction of the scale or lose of

calibration. Verify the accumulator housings and flap doors are properly assembled. Check

accumulator doors to ensure there are no obstructions (i.e. fries jammed underneath).

Verify the shaft collars are not rubbing the back wall of the cabinet. If no obstruction is found

calibrate the scale. (Page 27

)

Error 4 The controller has detected a LARGE SHIFT IN THE TARE (EMPTY) READING FOR THE

RIGHT SIDE’S SCALE INPUT. Could be caused by an obstruction of the scale or lose of

calibration. Verify the accumulator housings and flap doors are properly assembled. Check

accumulator doors to ensure there are no obstructions (i.e. fries jammed underneath).

Verify the shaft collars are not rubbing the back wall of the cabinet. If no obstruction is found

calibrate the scale. (Page 27

)

24

Copyright © 2011 Automated Equipment LLC All rights reserved.

Page 27

RAM™ 280-F Frozen Fry Dispenser

Troubleshooting cont.

Error 5 The controller has detected that the CABINET TEMPERATURE IS NOT COOLING AS

EXPECTED. Likely causes are leaving the cabinet door open for extended periods of time

during operation or the power was left on while defrosting the cabinet. Other possible

causes are a restriction to the air flow across the condensing unit such as might occur with a

dirty or plugged condenser filter and/or coil, an improperly positioned temperature probe or a

malfunction of the refrigeration compressor. Check for obstructions near the condensing

unit inlet grill and inspect and clean the condenser filter and/or coil if needed. (page 40

)

Verify the temperature probes are in place and properly secured to their mounting brackets.

CALL OUR TECHNICAL SUPPORT HOTLINE FOR ASSISTANCE. † (see note below to

reset error)

Errors 6 The HIGH PRESSURE SWITCH FOR THE REFRIGERATION SYSTEM HAS TRIPPED.

Possible causes include a restriction to the air flow across the condensing unit such as

might occur with a dirty or plugged condenser filter and/or coil. Check for obstructions near

the condensing unit inlet grill. Inspect and clean the condenser filter and/or coil if needed

(page 40

). A failed refrigeration over pressure switch, or a loose wire to the over pressure

switch could cause this error. A failed feedback relay or a loose wire to the feedback relay

can cause this error. Finally a very short duration power outage can case this error. CALL

OUR TECHNICAL SUPPORT HOTLINE FOR ASSISTANCE. (WARNING: HIGH

VOLTAGE. Unplug the dispenser before attempting to repair the wiring for the high

pressure switch.) † (see note below to reset error)

Errors 7 The controller has detected an ERROR ON THE REFRIGERATION RELAY DRIVE

indicating the compressor feedback relay did not turn off when the controller turned off

refrigeration. This could be caused by a stuck refrigeration relay, the feedback relay stuck

shut, a short circuit, or controller output failure. Verify there is no foreign material or loose

connections around the relay output. † (see note below to reset error)

Error 8 The controller has determined an INPUT FROM THE CABINET OR REFRIGERATION

CONTROL TEMPERATURE PROBE IS OUT OF RANGE HIGH OR LOW. The most likely

cause is a failed or disconnected temperature probe. Verify the temperature probes wires

are properly secured at the controller board.

Error 9 NVRAM CHECKSUM ERROR. The controller has detected invalid or corrupt data. It is

normal to get this error the first time a dispenser is powered on after a new processor

has been installed or replaced. The data may be invalid for several reasons. The

processor writes the permanent data (error logs, configuration, and operating parameters)

along with extra data that it uses to verify the data is valid. If the error persists it likely

indicates a failure of the NVRAM. CALL OUR TECHNICAL SUPPORT HOTLINE FOR

ASSISTANCE.

Error 10 An INTERNAL SYSTEM ERROR HAS OCCURRED. This error could occur for various

reasons including electrical interference, an error in the dispensers software or a fault in the

processor. CALL OUR TECHNICAL SUPPORT HOTLINE FOR ASSISTANCE.

†Note: Errors 5, 6 & 7 are refrigeration errors. These errors, while requiring corrective action, will not disable

the fry dispensing portions of the equipment. In order to safeguard the refrigeration system these are hard errors

and may not reset by pushing the Enter

Errors 5, 6 & 7. These errors are reset from the Diagnostic Menu using Diagnostic Function D08.

For Warranty Service & Technical Support call: US & Canada: 1 (800) 248-2724

International: 1 (651) 385-2273

After hours, your call will be handled by a voice mail paging service. The on call technician will be paged and will

return your call.

Copyright © 2011 Automated Equipment LLC All rights reserved.

Button. Call our Technical Support Hot Line for assistance with

25

Page 28

Troubleshooting cont.

RAM™ 280-F Frozen Fry Dispenser

Using the Diagnostic Display (D10):

Function D10 allows the user to see the status of all controller inputs and outputs on the main screen

while continuing to use the dispenser. As inputs and outputs turn on and off their corresponding

segment will also turn on and off. The diagram below identifies which segment on the display will light

for each input and output.

The user can continue to use both sides of the dispenser while in this function. If an error condition

occurs while in the function it can still be reset by pressing the Enter Button on the operator panel.

This function is especially useful for checking basket sensor and accumulator home switch status. It

will also allow a technician to determine when the dispenser is calling for each side’s drum and

accumulator motors to run and when the refrigeration compressor should be running.

L Drum Motor lit: The controller is calling for the left drum motor to run.

L Basket Sensor lit: The left basket sensor has detected a basket.

L Acc Motor lit: The controller is calling for the left accumulator motor to run.

L Home Sensor lit: The left accumulator encoder sensor has detected the home position.

Refrigeration lit: The controller is calling for the refrigeration compressor to run.

Power lit: The controller is turned on. Mainly used as a reference light.

Compressor lit: The refrigeration compressor is running.

R Acc Motor lit: The controller is calling for the right accumulator motor to run.

R Home Sensor lit: The right accumulator encoder sensor has detected the home position.

R Drum Motor lit: The controller is calling for the right drum motor to run.

R Basket Sensor lit: The right basket sensor has detected a basket.

The example displayed left indicates the

following inputs/outputs are on:

Left Drum Motor

Left Home Sensor

Refrigeration

Power

Compressor

Example

Right Acc Motor

Right Basket Sensor

26

Copyright © 2011 Automated Equipment LLC All rights reserved.

Page 29

RAM™ 280-F Frozen Fry Dispenser

Calibrations and Adjustments

Scale Calibration

The RAM 280-F Frozen Fry Dispenser will

maintain and dispense fries from two hoppers.

Each side has a scale which weighs and

dispenses frozen fries independent of one

another. These scales may require calibration

periodically.

1) Open the cabinet door and remove the

hopper from the dispenser for the side to be

calibrated.

Note: The accumulator housing(s) should

remain in place on the accumulator doors.

Calibration of the scales is performed using the

operator panel on the front of the Dispenser.

2) Press the Up Arrow

displayed then press the Enter

Button until "U2" is

Button. The

display will change to "[CAL]" (“[---]” metric)

with flashing brackets alternating from left to

right.

3) Select the side to be calibrated by pressing

a Basket Size

Button on the side to be

calibrated. The display will change to "[ --" if

the left side’s scale is selected or "-- ]" if the

right side’s scale is selected.

4) Place an empty fry basket under the

accumulator doors for the side to be calibrated.

Lift the front of the basket slightly and slide the

basket forward over the window for the basket

sensor. The accumulator doors will open and

close to dispense any contents into the basket

to ensure the Accumulator Housing is empty

before zeroing the scale.

5) The display will change to "0.0". The scale

now tares (zeros) itself automatically.

6) After it achieves a stable tare the display will

change to "1.0" or “450” in metric. Place a 1 lb

(450 g) reference weight on the accumulator

doors for the side to be calibrated. (Note: Four

frozen ¼ lb patties can be used in place of a 1

lb reference weight.)

7) Once the scale stabilizes the display will

change to "2.0" or “900” in metric. Place a 2 lb

(900 g) reference weight (an additional 1 lb

(450 g)) on the accumulator doors for the side

to be calibrated.

8) After the scale stabilizes the display will

change to "---". Remove the reference weight(s)

from the accumulator doors and reinstall the

hopper for the side that was calibrated.

9) Close the cabinet door.

The dispenser will return to normal operation

with no basket size selected for the side that

was calibrated.

10) Repeat for the opposite side’s scale if

required

Set Manager Password

A password can be set to restrict unauthorized

access to both the Manager and Diagnostic

Function Menus. Once set, the password will

need to be entered to gain access to restricted

menus. Take care to remember your password

or write it down and keep it in a safe location.

A manager password is set and/or changed

from the Manager Function Menu (page 19

)

using the operator panel on the front of the

dispenser and requires the current manager’s

password (if set) to access the menu.

To access the Manager Function Menu and set

or change the manager password, press the Up

Arrow

press the Enter

Button until "U3" is displayed then

Button.

If a password is required the display will change

to "

" Enter the managers password (if set)

-----

using the basket size buttons. Then press the

Enter

button.

Note: The Basket Size Buttons also function as

number buttons:

(e.g. the left medium basket button is number 2,

and the right large basket button is number 6.)

The display will change to "F1". Press the Up

Arrow

press the Enter

change to "

Button until "F6" is displayed then

Button. The display will

" Enter a manager password

-----

using the basket size buttons. As the

password is entered the dashes in the display

will move from the bottom segments to the

middle segments, i.e. "---

" Press the Enter

--

button to save the password.

Note: The password must be entered twice

(double entry).

If successful the display will change to "F1".

Press the Enter

Button to exit to the Main

Screen and return to normal operation.

Copyright © 2011 Automated Equipment LLC All rights reserved.

27

Page 30

Target Weight Adjustment

RAM™ 280-F Frozen Fry Dispenser

Each Basket Size Button’s Target Weight can

be individually customized.

Default settings are:

• Small load = 0.50 LBS(225 gr)

• Medium load = 1.0 LBS(450 gr)

• Large load = 1.5 LBS(700 gr)

Note: Adjustments to the target weight for

basket size buttons are performed from the

Manager Function Menu (page 19

) using the

operator panel on the front of the dispenser and

may require a manager’s password to access

the menu.

To access the Manager Function Menu and

customize the Target Weights for the Basket

Size Buttons press the Up Arrow

Button

until "U3" is displayed then press the Enter

Button.

If a password is required the display will change

to "-----" Enter the managers password (if set)

using the basket size buttons. Then press the

Enter

button.

Note: The Basket Size Buttons also function as

number buttons:

The display will change to "F1". Press the Up

Arrow

press the Enter

Button until "F2" is displayed then

Button.

The display will default to the Left Small Basket

Button’s current Target Weight. (i.e. "0.50Lb").

Select and press the Basket Size Button to be

customized.

An LED light will illuminate next to the currently

selected Basket Size Button and the display will

read the current target weight assigned for the

button.

To change the target weight for the currently

selected Basket Size Button, press the Up

Arrow

Button to increase the target weight

in 0.05 LB increments (25gr), or the Down

Arrow

Button to decrease the target weight.

Repeat until all adjustments have been made.

Press the Enter

Button to store the new

settings and close the function.

The display will read "d01". To exit to the Main

Screen and return to normal operation press

the Enter

Button.

(e.g. the left medium basket button is number 2,

and the right large basket button is number 6.)

28

Copyright © 2011 Automated Equipment LLC All rights reserved.

Page 31

RAM™ 280-F Frozen Fry Dispenser

Temperature Probe Calibration

The RAM 280-F Frozen Fry Dispenser has

used two different temperature control

configurations, one using a single probe and

the other a two probe configuration. The single

probe configuration, serial number

LONR0903C00692 and going forward, uses a

single temperature probe mounted to an

insulated block on the top wall of the cabinet

compartment in the upper right. It is the

temperature displayed on the control panel and

also used to control the refrigeration system.

The two probe configuration, serial numbers

LONR0903C00691 and earlier, has one probe

mounted to an insulated block on the top wall of

the cabinet compartment in the upper right. This

probe measures cabinet temperature and is the

temperature displayed on the front of the

operator panel. The other probe is below the

block and mounted against the back wall near

the refrigeration accumulator. This probe

controls the refrigeration system.

The temperature control is factory set. Unless

the controller or the temperature probe(s) are

replaced, it will not be necessary to change

these values. In addition, raising or lowering

the set point temperature can compensate for

small discrepancies between the probe

temperature and actual temperature. However,

differences of greater than 2º should be

corrected. The method for adjusting the

temperature probe is simple, but requires an

accurate thermometer (preferably certified) to

measure the probes deviation from the actual

temperature:

Place the thermometer into the freezer

compartment as close to the cabinet

temperature probe as practical. The machine

should be operating at or near normal operating

temperature, -2°F to 10°F (-19°C to -12°C). If

the thermometer has a sensing probe, make

certain that it is not touching any metal in the

compartment, otherwise it may give a false

reading.

If the difference between the display and the

thermometer is greater than 2º, an adjustment

should be made.

Note: Calibration of the temperature probe is

performed from the Diagnostic Functions Menu

using the Operator Panel on the front of the

Dispenser and may require a manager’s

password to access the menu.

To access the Diagnostics Menu, on the

Operator Panel, press the Up Arrow

Button until "U4" is displayed then press the

Enter

The display will change to "

button.

" Enter the

-----

managers password (if set) using the basket

size buttons. Then press the Enter

button.

Note: The Basket Size Buttons also function as

number buttons: