Page 1

Features

• High-density, High-performance, Electrically-erasable Complex

Programmable Logic Device

– 128 Macrocells

– 5 Product Terms per Macrocell, Expandable up to 40 per Macrocell

– 84, 100, 160 Pins

– 7.5 ns Maximum Pin-to-pin Delay

– Registered Operation up to 125 MHz

– Enhanced Routing Resources

• Flexible Logic Macrocell

– D/T/Latch Configured Flip-flops

– Global and Individual Register Control Signals

– Global and Individual Output Enable

– Programmable Output Slew Rate

– Programmable Output Open Collector Option

– Maximum Logic Utilization by Burying a Register within a COM Output

• Advanced Power Management Features

– Automatic 10 µA Standby for “L” Version

– Pin-controlled 1 mA Standby Mode

– Programmable Pin-keeper Inputs and I/Os

– Reduced-power Feature per Macrocell

• Available in Commercial and Industrial Temperature Ranges

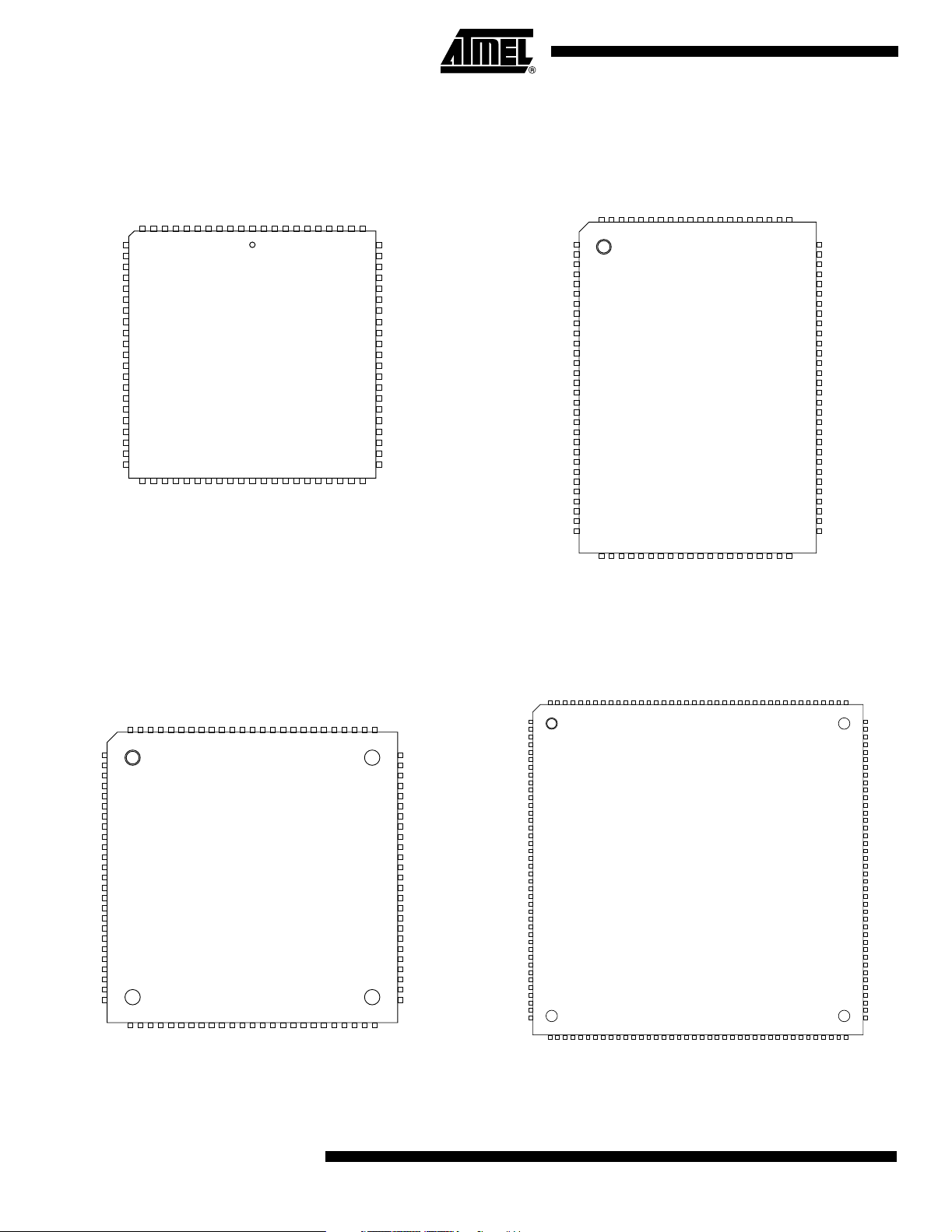

• Available in 84-lead PLCC, 100-lead PQFP, 100-lead TQFP and 160-lead PQFP Packages

• Advanced EE Technology

– 100% Tested

– Completely Reprogrammable

– 10,000 Program/Erase Cycles

– 20-year Data Retention

– 2000V ESD Protection

– 200 mA Latch-up Immunity

• JTAG Boundary-scan Testing to IEEE Std. 1149.1-1990 and 1149.1a-1993 Supported

• Fast In-System Programmability (ISP) via JTAG

• PCI-compliant

• 3.3 or 5.0V I/O Pins

• Security Fuse Feature

Highperformance

EE PLD

ATF1508AS

ATF1508ASL

Enhanced Features

• Improved Connectivity (Additional Feedback Routing, Alternate Input Routing)

• Output Enable Product Terms

• Transparent-latch Mode

• Combinatorial Output with Registered Feedback within Any Macrocell

• Three Global Clock Pins

• ITD (Input Transition Detection) Circuits on Global Clocks, Inputs and I/O

• Fast Registered Input from Product Term

• Programmable “Pin-keeper” Option

• V

Power-up Reset Option

CC

• Pull-up Option on JTAG Pins TMS and TDI

• Advanced Power Management Features

– Edge-controlled Power-down “L”

– Individual Macrocell Power Option

– Disable ITD on Global Clocks, Inputs and I/O for “Z” Parts

Rev. 0784O–PLD–09/02

1

Page 2

I/O/PD1

VCCIO

I/O/TDI

GND

I/O/TMS

VCCIO

GND

84-lead PLCC

Top View

I/O

I/O

I/O

I/O

GND

I/O

I/O

I/O

VCCINT

INPUT/OE2/GCLK2

INPUT/GCLR

INPUT/OE1

INPUT/GCLK1

987654321

11

10

12

13

14

15

I/O

16

I/O

17

I/O

18

I/O

19

20

I/O

21

I/O

22

I/O

23

24

I/O

25

I/O

26

27

I/O

28

I/O

29

I/O

30

I/O

31

I/O

32

333435363738394041424344454647484950515253

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

VCCIO

GND

848382818079787776

I/O

I/O

GND

I/O/PD2

VCCINT

I/O/GCLK3

I/O

I/O

I/O

I/O

GND

VCCIO

I/O

I/O

I/O

I/O

I/O

I/O

75

74

73

72

71

70

69

68

67

66

65

64

63

62

61

60

59

58

57

56

55

54

VCCIO

I/O

I/O

GND

I/O/TDO

I/O

I/O

I/O

I/O

VCCIO

I/O

I/O

I/O

I/O/TCK

I/O

I/O

GND

I/O

I/O

I/O

I/O

I/O

I/O/PD1

VCCIO

I/O/TDI

GND

I/O/TMS

VCCIO

GND

100-lead PQFP

Top View

I/O

I/O

I/O

GND

I/O

I/O

I/O

VCCINT

INPUT/OE2/GCLK2

INPUT/GCLR

99989796959493929190898887868584838281

100

1

I/O

2

I/O

3

4

I/O

5

6

7

I/O

8

I/O

9

I/O

10

I/O

11

I/O

12

I/O

13

14

I/O

15

I/O

16

I/O

17

18

I/O

19

I/O

20

21

I/O

22

I/O

23

I/O

24

I/O

25

I/O

26

I/O

27

I/O

28

29

I/O

30

I/O

31323334353637383940414243444546474849

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

GND

VCCIO

INPUT/OE1

INPUT/GCLK1

GND

I/O

I/O/PD2

VCCINT

I/O/GCLK3

I/O

I/O

I/O

I/O

GND

VCCIO

I/O

I/O

I/O

I/O

80

I/O

79

I/O

78

I/O

77

I/O

76

GND

75

I/O/TDO

74

I/O

73

I/O

72

I/O

71

I/O

70

I/O

69

I/O

68

VCCIO

67

I/O

66

I/O

65

I/O

64

I/O/TCK

63

I/O

62

I/O

61

GND

60

I/O

59

I/O

58

I/O

57

I/O

56

I/O

55

I/O

54

I/O

53

VCCIO

52

I/O

51

I/O

50

I/O

I/O

I/O

I/O/PD1

VCCIO

I/O/TDI

GND

I/O/TMS

VCCIO

100-lead TQFP

Top View

I/O

I/O

I/O

I/O

I/O

GND

I/O

I/O

I/O

VCCINT

INPUT/OE2/GCLK2

INPUT/GCLR

INPUT/OE1

INPUT/GCLK1

GND

I/O/GCLK3

9998979695949392919089888786858483828180797877

100

1

2

I/O

3

4

5

I/O

6

I/O

7

I/O

8

I/O

9

I/O

10

I/O

11

12

I/O

13

I/O

14

I/O

15

16

I/O

17

I/O

18

19

I/O

20

I/O

21

I/O

22

I/O

23

I/O

24

I/O

25

I/O

26272829303132333435363738394041424344454647484950

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

GND

VCCIO

GND

I/O

VCCINT

I/O/PD2

160-lead PQFP

Top View

I/O

I/O/PD2

I/O

N/C

N/C

N/C

N/C

I/O

I/O

I/O

I/O

I/O

GND

I/O

I/O

I/O

I/O

VCCINT

INPUT/OE2/GCLK2

INPUT/GCLR

INPUT/OE1

INPUT/GCLK1

GND

I/O/GCLK3

I/O

I/O

I/O

VCCIO

I/O

I/O

I/O

I/O

I/O

N/C

N/C

N/C

N/C

I/O

I/O

I/O

160

159

158

157

156

155

154

153

152

151

150

149

148

147

146

145

144

143

142

141

140

139

138

137

136

135

134

133

132

131

130

129

128

127

126

125

124

123

122

121

120

1

I/O

I/O

VCCIO

I/O

I/O

I/O

I/O

I/O

I/O

76

75

I/O

74

GND

73

I/O/TDO

72

I/O

71

I/O

70

I/O

69

I/O

68

I/O

67

I/O

66

VCCIO

65

I/O

64

I/O

63

I/O

62

I/O/TCK

61

I/O

60

I/O

59

GND

58

I/O

57

I/O

56

I/O

55

I/O

54

I/O

53

I/O

52

I/O

51

VCCIO

I/O

I/O

I/O

I/O

I/O

I/O

I/O

GND

I/O

N/C

2

N/C

3

N/C

4

N/C

5

N/C

6

N/C

7

N/C

8

VCCIO

9

I/O/TDI

10

I/O

11

I/O

12

I/O

13

I/O

14

I/O

15

I/O

16

I/O

17

GND

18

I/O

19

I/O

20

I/O

21

I/O

22

I/O/TMS

23

I/O

24

I/O

25

I/O

26

VCCIO

27

I/O

28

I/O

29

I/O

30

I/O

31

I/O

32

I/O

33

I/O

34

N/C

35

N/C

36

N/C

37

N/C

38

N/C

39

N/C

40

N/C

414243444546474849505152535455565758596061626364656667686970717273747576777879

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

N/C

N/C

N/C

N/C

GND

VCCIO

GND

VCCINT

I/O/PD1

I/O

GND

I/O

I/O

I/O

I/O

I/O

I/O

I/O

N/C

N/C

N/C

N/C

119

N/C

118

N/C

117

N/C

116

N/C

115

N/C

114

N/C

113

GND

112

I/O/TDO

111

I/O

110

I/O

109

I/O

108

I/O

107

I/O

106

I/O

105

I/O

104

VCCIO

103

I/O

102

I/O

101

I/O

100

I/O

99

I/O/TCK

98

I/O

97

I/O

96

I/O

95

GND

94

I/O

93

I/O

92

I/O

91

I/O

90

I/O

89

I/O

88

I/O

87

N/C

86

N/C

85

N/C

84

N/C

83

N/C

82

N/C

81

N/C

80

I/O

I/O

N/C

VCCIO

2

ATF1508AS(L)

0784O–PLD–09/02

Page 3

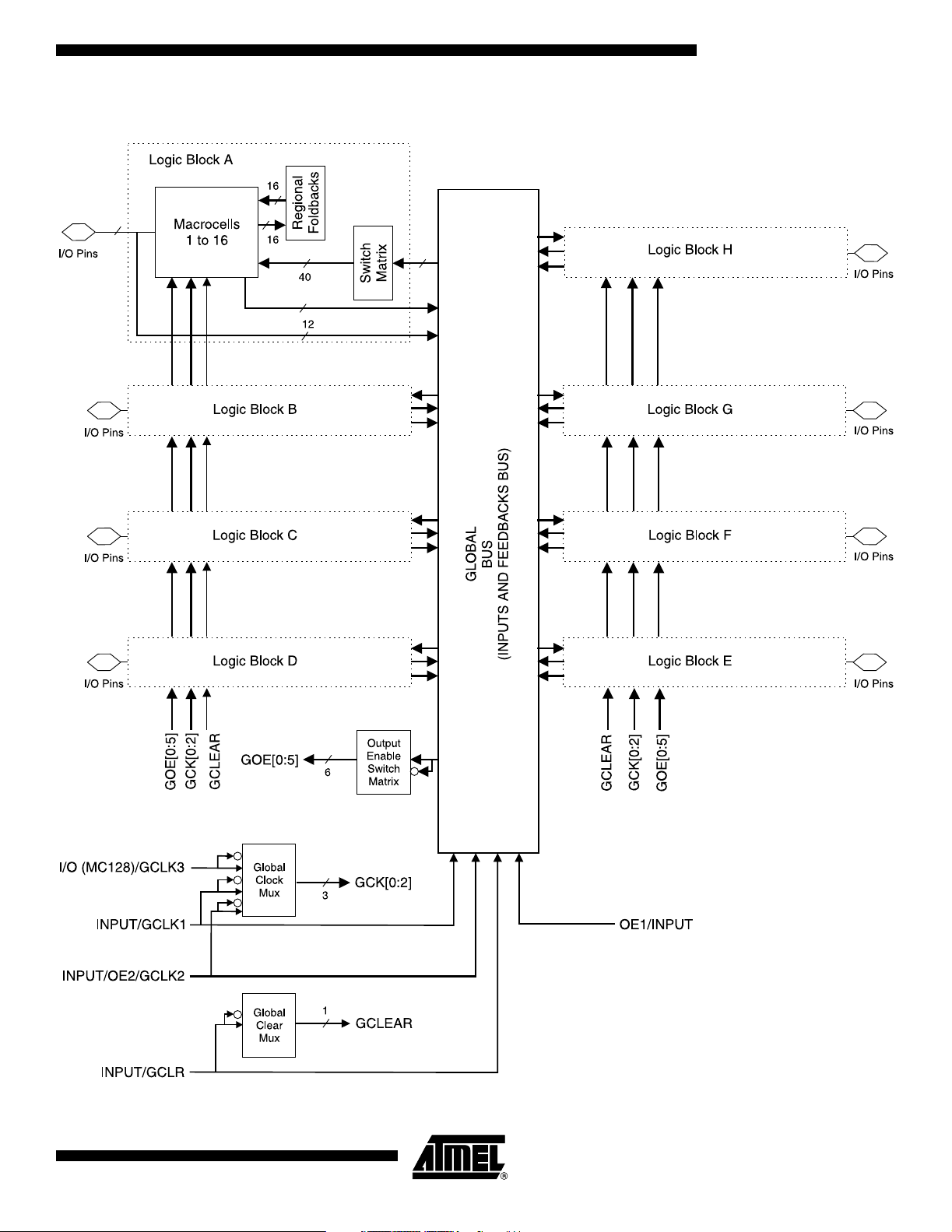

Block Diagram

8to12

ATF1508AS(L)

16

0784O–PLD–09/02

3

Page 4

Description The ATF1508AS is a high-performance, high-density complex programmable logic device

(CPLD) that utilizes Atmel’s proven electrically-erasable technology. With 128 logic macrocells

and up to 100 inputs, it easily integrates logic from several TTL, SSI, MSI, LSI and classic

PLDs. The ATF1508AS’s enhanced routing switch matrices increase usable gate count and

increase odds of successful pin-locked design modifications.

The ATF1508AS has up to 96 bi-directional I/O pins and four dedicated input pins, depending

on the type of device package selected. Each dedicated pin can also serve as a global control

signal, register clock, register reset or output enable. Each of these control signals can be

selected for use individually within each macrocell.

Each of the 128 macrocells generates a buried feedback that goes to the global bus. Each

input and I/O pin also feeds into the global bus. The switch matrix in each logic block then

selects 40 individual signals from the global bus. Each macrocell also generates a foldback

logic term that goes to a regional bus. Cascade logic between macrocells in the ATF1508AS

allows fast, efficient generation of complex logic functions. The ATF1508AS contains eight

suchlogicchains,eachcapableofcreatingsumtermlogicwithafan-inofupto40product

terms.

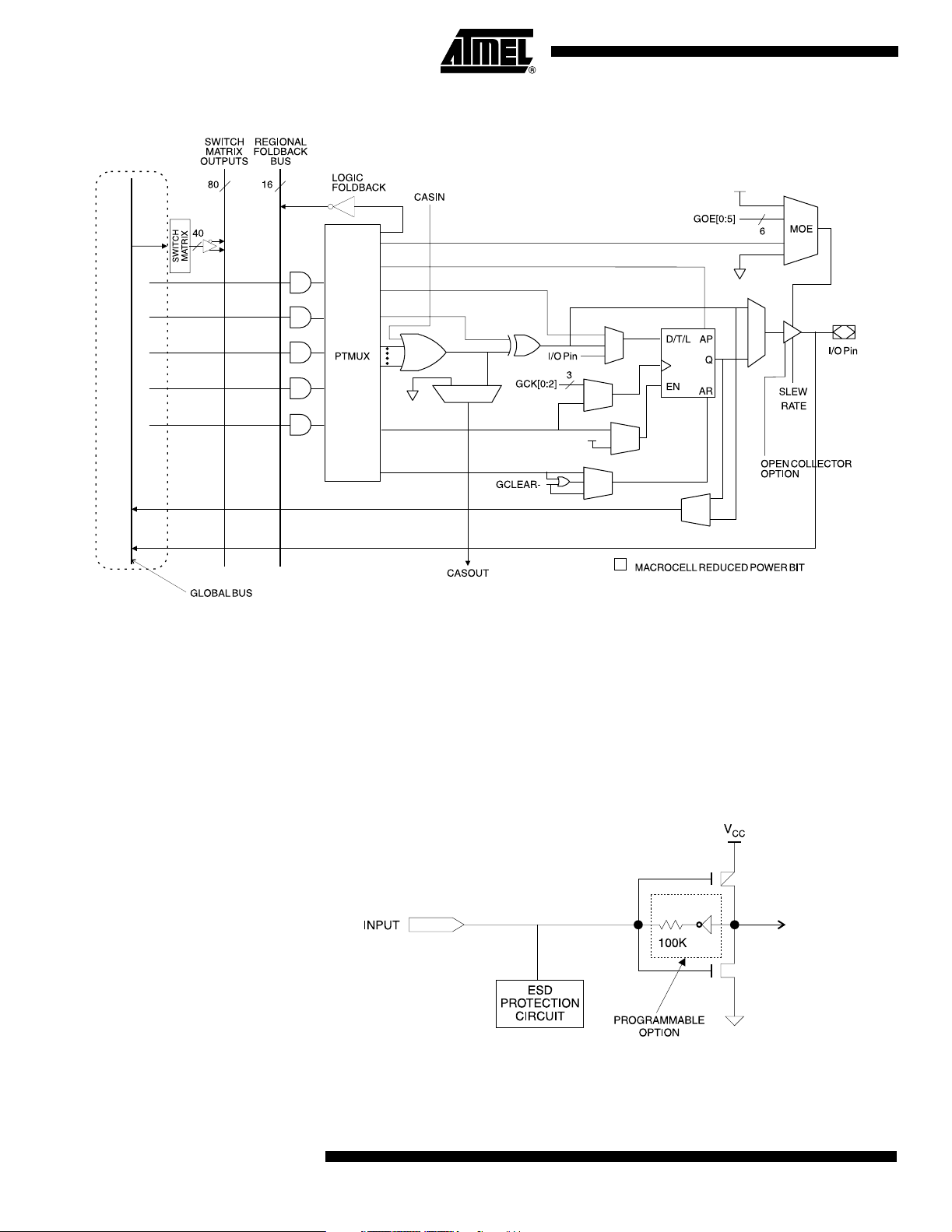

The ATF1508AS macrocell, shown in Figure 1, is flexible enough to support highly-complex

logic functions operating at high speed. The macrocell consists of five sections: product terms

and product term select multiplexer; OR/XOR/CASCADE logic, a flip-flop, output select and

enable, and logic array inputs.

Unused macrocells are automatically disabled by the compiler to decrease power consumption. A security fuse, when programmed, protects the contents of the ATF1508AS. Two bytes

(16 bits) of User Signature are accessible to the user for purposes such as storing project

name, part number, revision or date. The User Signature is accessible regardless of the state

of the security fuse.

Product Terms and Select Mux

OR/XOR/ CASCADE Logic

The ATF1508AS device is an in-system programmable (ISP) device. It uses the industry-standard 4-pin JTAG interface (IEEE Std. 1149.1), and is fully compliant with JTAG’s Boundaryscan Description Language (BSDL). ISP allows the device to be programmed without removing it from the printed circuit board. In addition to simplifying the manufacturing flow, ISP also

allows design modifications to be made in the field via software.

Each ATF1508AS macrocell has five product terms. Each product term receives as its inputs

all signals from both the global bus and regional bus.

The product term select multiplexer (PTMUX) allocates the five product terms as needed to

the macrocell logic gates and control signals. The PTMUX programming is determined by the

design compiler, which selects the optimum macrocell configuration.

The ATF1508AS’s logic structure is designed to efficiently support all types of logic. Within a

single macrocell, all the product terms can be routed to the OR gate, creating a 5-input

AND/OR sum term. With the addition of the CASIN from neighboring macrocells, this can be

expanded to as many as 40 product terms with a little small additional delay.

The macrocell’s XOR gate allows efficient implementation of compare and arithmetic functions. One input to the XOR comes from the OR sum term. The other XOR input can be a

product term or a fixed high- or low-level. For combinatorial outputs, the fixed level input

allows polarity selection. For registered functions, the fixed levels allow DeMorgan minimization of product terms. The XOR gate is also used to emulate T- and JK-type flip-flops.

4

ATF1508AS(L)

0784O–PLD–09/02

Page 5

ATF1508AS(L)

Flip-flop The ATF1508AS’s flip-flop has very flexible data and control functions. The data input can

come from either the XOR gate, from a separate product term or directly from the I/O pin.

Selecting the separate product term allows creation of a buried registered feedback within a

combinatorial output macrocell. (This feature is automatically implemented by the fitter software). In addition to D, T, JK and SR operation, the flip-flop can also be configured as a flowthrough latch. In this mode, data passes through when the clock is high and is latched when

the clock is low.

The clock itself can be either the Global CLK Signal (GCK) or an individual product term. The

flip-flop changes state on the clock’s rising edge. When the GCK signal is used as the clock,

one of the macrocell product terms can be selected as a clock enable. When the clock enable

function is active and the enable signal (product term) is low, all clock edges are ignored. The

flip-flop’s asynchronous reset signal (AR) can be either the Global Clear (GCLEAR), a product

term, or always off. AR can also be a logic OR of GCLEAR with a product term. The asynchronous preset (AP) can be a product term or always off.

Extra Feedback The ATF15xxSE Family macrocell output can be selected as registered or combinatorial. The

extra buried feedback signal can be either combinatorial or a registered signal regardless of

whether the output is combinatorial or registered. (This enhancement function is automatically

implemented by the fitter software.) Feedback of a buried combinatorial output allows the creation of a second latch within a macrocell.

I/O Control The output enable multiplexer (MOE) controls the output enable signal. Each I/O can be indi-

vidually configured as an input, output or for bi-directional operation. The output enable for

each macrocell can be selected from the true or compliment of the two output enable pins, a

subset of the I/O pins, or a subset of the I/O macrocells. This selection is automatically done

by the fitter software when the I/O is configured as an input, all macrocell resources are still

available, including the buried feedback, expander and cascade logic.

Global Bus/Switch Matrix

The global bus contains all input and I/O pin signals as well as the buried feedback signal from

all 128 macrocells. The switch matrix in each logic block receives as its inputs all signals from

the global bus. Under software control, up to 40 of these signals can be selected as inputs to

the logic block.

Foldback Bus Each macrocell also generates a foldback product term. This signal goes to the regional bus

and is available to 16 macrocells. The foldback is an inverse polarity of one of the macrocell’s

product terms. The 16 foldback terms in each region allows generation of high fan-in sum

terms (up to 21 product terms) with a little additional delay.

3.3V or 5.0V I/O Operation

Open-collector Output Option

The ATF1508AS device has two sets of VCCpins viz, V

always be connected to a 5.0V power supply. V

patible” with both 3.3V and 5.0V inputs. V

connected for 3.3/5.0V power supply.

This option enables the device output to provide control signals such as an interrupt that can

be asserted by any of the several devices.

CCIO

pins are for input buffers and are “com-

CCINT

pins are for I/O output drives and can be

CCINT

and V

CCIO.VCCINT

pins must

0784O–PLD–09/02

5

Page 6

Figure 1. ATF1508AS Macrocell

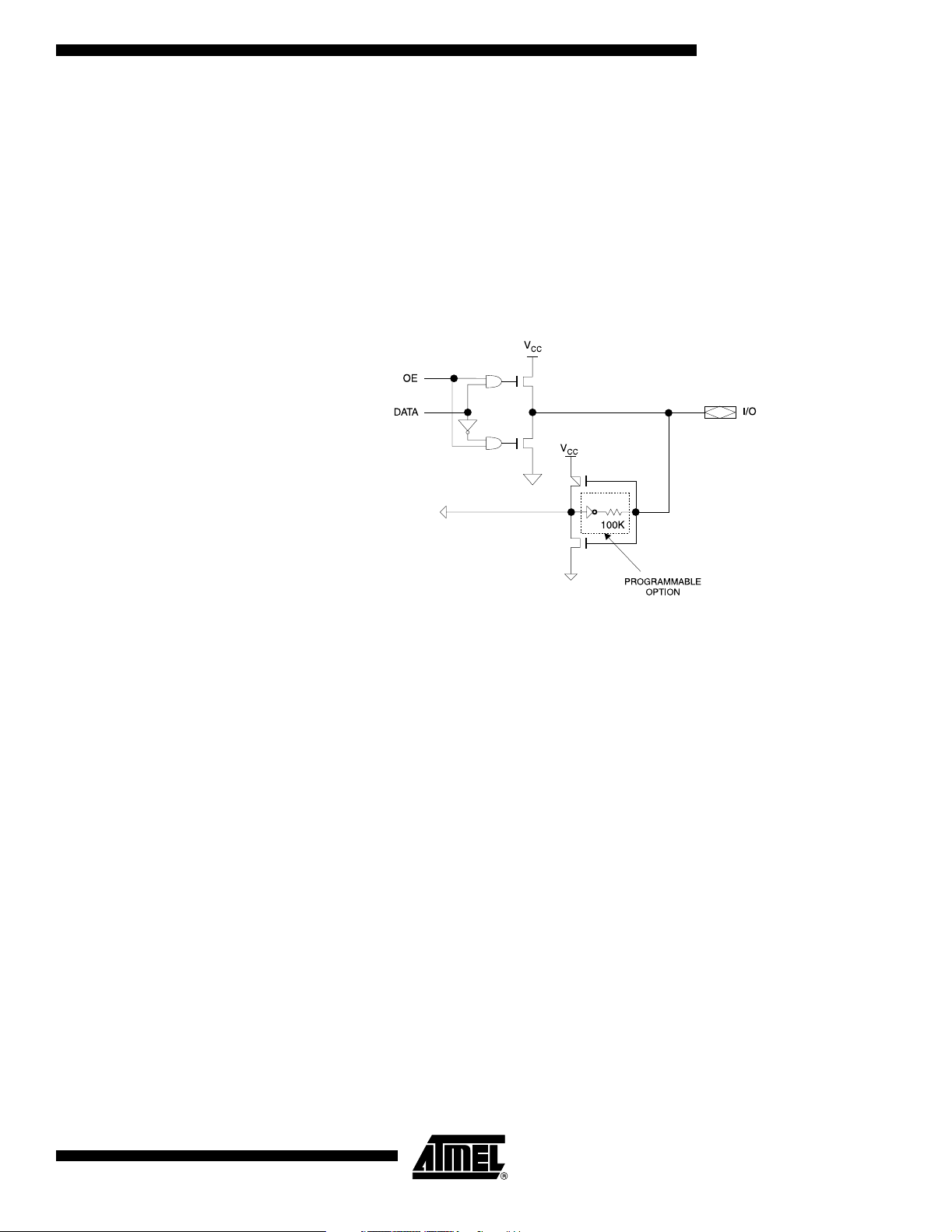

Programmable Pin-keeper Option for Inputs and I/Os

Input Diagram

The ATF1508AS offers the option of programming all input and I/O pins so that “pin-keeper”

circuits can be utilized. When any pin is driven high or low and then subsequently left floating,

it will stay at that previous high- or low-level. This circuitry prevents unused input and I/O lines

from floating to intermediate voltage levels, which causes unnecessary power consumption

and system noise. The keeper circuits eliminate the need for external pull-up resistors and

eliminate their DC power consumption.

6

ATF1508AS(L)

0784O–PLD–09/02

Page 7

ATF1508AS(L)

Speed/Power Management

I/O Diagram

The ATF1508AS has several built-in speed and power management features. The

ATF1508AS contains circuitry that automatically puts the device into a low-power stand-by

mode when no logic transitions are occurring. This not only reduces power consumption during inactive periods, but also provides proportional power-savings for most applications

running at system speeds below 5 MHz.

To further reduce power, each ATF1508AS macrocell has a Reduced-power bit feature. This

feature allows individual macrocells to be configured for maximum power savings. This feature

may be selected as a design option.

All ATF1508 also have an optional power-down mode. In this mode, current drops to below 10

mA. When the power-down option is selected, either PD1 or PD2 pins (or both) can be used to

power down the part. The power-down option is selected in the design source file. When

enabled, the device goes into power-down when either PD1 or PD2 is high. In the power-down

mode, all internal logic signals are latched and held, as are any enabled outputs.

All pin transitions are ignored until the PD pin is brought low. When the power-down feature is

enabled, the PD1 or PD2 pin cannot be used as a logic input or output. However, the pin’s

macrocell may still be used to generate buried foldback and cascade logic signals.

All power-down AC characteristic parameters are computed from external input or I/O pins,

with Reduced-power Bit turned on. For macrocells in reduced-power mode (Reduced-power

bit turned on), the reduced-power adder, tRPA, must be added to the AC parameters, which

include the data paths t

Each output also has individual slew rate control. This may be used to reduce system noise by

slowing down outputs that do not need to operate at maximum speed. Outputs default to slow

switching, and may be specified as fast switching in the design file.

LAD,tLAC,tIC,tACL,tACH

and t

SEXP

.

0784O–PLD–09/02

7

Page 8

Design

Software

ATF1508AS designs are supported by several third-party tools. Automated fitters allow logic

synthesis using a variety of high level description languages and formats.

Support

Power-up Reset The ATF1508AS is designed with a power-up reset, a feature critical for state machine initial-

ization. At a point delayed slightly from V

the state of each output will depend on the polarity of its buffer. However, due to the asynchronous nature of reset and uncertainty of how V

conditions are required:

1. The V

2. After reset occurs, all input and feedback setup times must be met before driving the

clock pin high, and,

3. The clock must remain stable during T

The ATF1508AS has two options for the hysteresis about the reset level, V

Large. During the fitting process users may configure the device with the Power-up Reset hysteresis set to Large or Small. Atmel POF2JED users may select the Large option by including

the flag “-power_reset” on the command line after “filename.POF”. To allow the registers to be

properly reinitialized with the Large hysteresis option selected, the following condition is

added:

4. If V

When the Large hysteresis option is active, I

well.

rise must be monotonic,

CC

falls below 2.0V, it must shut off completely before the device is turned on again.

CC

crossing V

CC

actually rises in the system, the following

CC

.

D

is reduced by several hundred microamps as

CC

, all registers will be initialized, and

RST

RST

, Small and

Security Fuse Usage

A single fuse is provided to prevent unauthorized copying of the ATF1508AS fuse patterns.

Once programmed, fuse verify is inhibited. However, User Signature and device ID remains

accessible.

Programming ATF1508AS devices are in-system programmable (ISP) devices utilizing the 4-pin JTAG pro-

tocol. This capability eliminates package handling normally required for programming and

facilitates rapid design iterations and field changes.

Atmel provides ISP hardware and software to allow programming of the ATF1508AS via the

PC. ISP is performed by using either a download cable or a comparable board tester or a simple microprocessor interface.

To allow ISP programming support by the Automated Test Equipment (ATE) vendors, Serial

Vector Format (SVF) files can be created by the Atmel ISP Software. Conversion to other ATE

tester format beside SVF is also possible

ATF1508AS devices can also be programmed using standard third-party programmers. With

third-party programmer, the JTAG ISP port can be disabled thereby allowing four additional

I/Opinstobeusedforlogic.

Contact your local Atmel representatives or Atmel PLD applications for details.

8

ATF1508AS(L)

0784O–PLD–09/02

Page 9

ATF1508AS(L)

ISP Programming Protection

JTAG-BST Overview

The ATF1508AS has a special feature that locks the device and prevents the inputs and I/O

from driving if the programming process is interrupted for any reason. The inputs and I/O

default to high-Z state during such a condition. In addition the pin-keeper option preserves the

former state during device programming.

All ATF1508AS devices are initially shipped in the erased state thereby making them ready to

use for ISP.

Note: For more information refer to the “Designing for In-System Programmability with Atmel CPLDs”

application note.

The JTAG boundary-scan testing is controlled by the Test Access Port (TAP) controller in the

ATF1508AS. The boundary-scan technique involves the inclusion of a shift-register stage

(contained in a boundary-scan cell) adjacent to each component so that signals at component

boundaries can be controlled and observed using scan testing principles. Each input pin and

I/O pin has its own boundary-scan cell (BSC) in order to support boundary-scan testing. The

ATF1508AS does not currently include a Test Reset (TRST) input pin because the TAP controller is automatically reset at power-up. The six JTAG BST modes supported include:

SAMPLE/PRELOAD, EXTEST, BYPASS and IDCODE. BST on the ATF1508AS is implemented using the Boundary-scan Definition Language (BSDL) described in the JTAG

specification (IEEE Standard 1149.1). Any third-party tool that supports the BSDL format can

be used to perform BST on the ATF1508AS.

The ATF1508AS also has the option of using four JTAG-standard I/O pins for In-System programming (ISP). The ATF1508AS is programmable through the four JTAG pins using

programming compatible with the IEEE JTAG Standard 1149.1. Programming is performed by

using 5V TTL-level programming signals from the JTAG ISP interface. The JTAG feature is a

programmable option. If JTAG (BST or ISP) is not needed, then the four JTAG control pins are

available as I/O pins.

JTAG Boundary-scan Cell (BSC) Testing

The ATF1508AS contains up to 96 I/O pins and four input pins, depending on the device type

and package type selected. Each input pin and I/O pin has its own boundary-scan cell (BSC)

in order to support boundary-scan testing as described in detail by IEEE Standard 1149.1. A

typical BSC consists of three capture registers or scan registers and up to two update registers. There are two types of BSCs, one for input or I/O pin, and one for the macrocells. The

BSCs in the device are chained together through the (BST) capture registers. Input to the capture register chain is fed in from the TDI pin while the output is directed to the TDO pin.

Capture registers are used to capture active device data signals, to shift data in and out of the

device and to load data into the update registers. Control signals are generated internally by

the JTAG TAP controller. The BSC configuration for the input and I/O pins and macrocells are

shown below.

0784O–PLD–09/02

9

Page 10

BSC

Configuration

Pins and

Macrocells

(Except JTAG

TAP Pin s

)

BSC Configuration for Macrocell

Note: The ATF1508AS has a pull-up option on TMS and TDI pins. This feature is selected as a design

option.

TDO

OEJ

OUTJ

0

DQ

1

0

DQ

1

DQ

DQ

0

1

0

1

Pin

Boundary Scan Definition Language (BSDL) Models for the ATF1508

10

ATF1508AS(L)

Capture

DR

TDI

Shift

Macrocell BSC

Update

DR

Mode

Clock

These are now available in all package types via the Atmel Web Site. These models can be

used for Boundary-scan Test Operation in the ATF1508AS and have been scheduled to conform to the IEEE 1149.1 standard.

0784O–PLD–09/02

Page 11

ATF1508AS(L)

PCI Compliance The ATF1508AS also supports the growing need in the industry to support the new Peripheral

Component Interconnect (PCI) interface standard in PCI-based designs and specifications.

The PCI interface calls for high current drivers, which are much larger than the traditional TTL

drivers.

PCI Voltage-tocurrent Curves

for +5V

Signaling in

Pull-up Mode

PCI Voltage-tocurrent Curves

for +5V

Signaling in

Pull-down Mode

VCC

2.4

1.4

VCC

2.2

Voltage

-2

AC drive

Voltage

DC

drive point

AC drive

point

point

Pull Up

-44

Pull Down

Current (mA)

Test Point

-178

0784O–PLD–09/02

0.55

DC

drive point

3,6

95

Test Point

Current (mA)

380

11

Page 12

PCI DC Characteristics

Symbol Parameter Conditions Min Max Units

V

V

V

I

IH

I

IL

V

V

C

C

C

L

CC

IH

IL

OH

OL

IN

CLK

IDSEL

PIN

Supply Voltage 4.75 5.25 V

Input High Voltage 2.0 VCC+0.5 V

Input Low Voltage -0.5 0.8 V

Input High Leakage Current

Input Low Leakage Current

Output High Voltage I

Output Low Voltage I

(1)

(1)

VIN=2.7V 70 µA

VIN= 0.5V -70 µA

=-2mA 2.4 V

OUT

=3mA,6mA 0.55 V

OUT

Input Pin Capacitance 10 pF

CLK Pin Capacitance 12 pF

IDSEL Pin Capacitance 8pF

Pin Inductance 20 nH

Note: 1. Leakage current is without pin-keeper off.

PCI AC Characteristics

Symbol Parameter Conditions Min Max Units

I

OH(AC)

Switching 0 < V

Current High 1.4 < V

(Test High) V

I

OL(AC)

Switching V

Current Low 2.2 > V

(Test Point) V

I

CL

SLEW

SLEW

R

F

Low Clamp Current -5 < VIN≤ -1 -25+(VIN+1)/0.015 mA

Output Rise Slew Rate 0.4V to 2.4V load 0.5 3.0 V/ns

Output Fall Slew Rate 2.4V to 0.4V load 0.5 3.0 V/ns

Notes: 1. Equation A: I

2. Equation B: I

=11.9(V

OH

= 78.5 * V

OL

- 5.25) * (V

OUT

*(4.4-V

OUT

3.1 < V

0.1 > V

OUT

)for0V<V

OUT

≤ 1.4 -44 mA

OUT

< 2.4 -44+(V

OUT

OUT<VCC

=3.1V -142 µA

OUT

> 2.2V 95 mA

OUT

>0 V

OUT

> 0 Equation B

OUT

= 0.71 206 mA

OUT

+ 2.45) for VCC>V

< 0.71V.

OUT

OUT

>3.1V.

- 1.4)/0.024 mA

OUT

Equation A

/0.023 mA

OUT

(1)

(2)

mA

mA

12

ATF1508AS(L)

0784O–PLD–09/02

Page 13

ATF1508AS(L)

Power-down Mode

The ATF1508AS includes two pins for optional pin-controlled power-down feature. When this

mode is enabled, the PD pin acts as the power-down pin. When the PD1 and PD2 pin is high,

the device supply current is reduced to less than 10 mA. During power-down, all output data

and internal logic states are latched and held. Therefore, all registered and combinatorial output data remain valid. Any outputs that were in a high-Z state at the onset will remain at highZ. During power-down, all input signals except the power-down pin are blocked. Input and I/O

hold latches remain active to ensure that pins do not float to indeterminate levels, further

reducing system power. The power-down pin feature is enabled in the logic design file.

Designs using either power-down pin may not use the PD pin logic array input. However, buried logic resources in this macrocell may still be used.

Power-down AC Characteristics

Symbol Parameter

t

IVDH

t

GVDH

t

CVDH

t

DHIX

t

DHGX

t

DHCX

t

DLIV

t

DLGV

t

DLCV

t

DLOV

Notes: 1. For slow slew outputs, add t

Valid I, I/O before PD High 7 10 15 20 25 ns

Valid OE

Valid Clock

(2)

before PD High 7 10 15 20 25 ns

(2)

before PD High 7 10 15 20 25 ns

I, I/O Don’t Care after PD High 12 15 25 30 35 ns

(2)

OE

Don’t Care after PD High 12 15 25 30 35 ns

(2)

Clock

Don’t Care after PD High 12 15 25 30 35 ns

PD Low to Valid I, I/O 1 1 1 1 1 µs

PD Low to Valid OE (Pin or Term) 1 1 1 1 1 µs

PD Low to Valid Clock (Pin or Term) 1 1 1 1 1 µs

PD Low to Valid Output 1 1 1 1 1 µs

.

SSO

2. Pin or product term.

(1)(2)

-7 -10 -15 -20 -25

UnitsMin Max Min Max Min Max Min Max Min Max

Absolute Maximum Ratings*

Temperature Under Bias .................................. -40°C to +85°C

Storage Temperature ..................................... -65°C to +150°C

Voltage on Any Pin with

Respect to Ground .........................................-2.0V to +7.0V

Voltage on Input Pins

with Respect to Ground

During Programming.....................................-2.0V to +14.0V

Programming Voltage with

Respect to Ground .......................................-2.0V to +14.0V

0784O–PLD–09/02

*NOTICE: Stresses beyond those listed under “Absolute

Maximum Ratings” may cause permanent damage to the device. This is a stress rating only and

functional operation of the device at these or any

(1)

other conditions beyond those indicated in the

operational sections of this specification is not

implied. Exposure to absolute maximum rating

conditions for extended periods may affect device

(1)

Note: 1. Minimum voltage is -0.6V DC, which may under-

reliability.

shoot to -2.0V for pulses of less than 20 ns.

(1)

which may overshoot to 7.0V for pulses of less

Maximum output pin voltage is V

+ 0.75V DC,

CC

than 20 ns.

13

Page 14

DC and AC Operating Conditions

Commercial Industrial

Operating Temperature (Ambient) 0°C - 70°C -40°C - 85°C

V

or V

CCINT

V

(3.3V) Power Supply 2.7V - 3.6V 2.7V - 3.6V

CCIO

(5V) Power Supply 5V ± 5% 5V ± 10%

CCIO

DC Characteristics

(1)

Symbol Parameter Condition Min Typ Max Units

I

IL

Input or I/O Low

VIN=V

CC

-2 -10 µA

Leakage Current

I

IH

Input or I/O High

210µA

Leakage Current

I

OZ

Tri-state Output

VO=VCCor GND -40 40 µA

Off-state Current

I

CC1

Power Supply

Current, Standby

VCC=Max

V

=0,V

IN

Std Mode Com. 160 mA

CC

Ind. 180 mA

“L” Mode Com. 10 µA

Ind. 10 µA

I

I

V

V

V

V

V

V

CC2

CC3

CCIO

CCIO

IL

IH

OL

OH

Power Supply Current,

Power-down Mode

(2)

Reduced-power Mode

Supply Current

Supply Voltage

Supply Voltage 3.3V Device Output 3.0 3.6 V

Input Low Voltage -0.3 0.8 V

Input High Voltage 2.0 V

Output Low Voltage (TTL)

Output Low Voltage (CMOS)

Output High Voltage (TTL)

VCC=Max

V

=0,V

IN

V

=Max

CC

V

=0,V

IN

“PD” Mode 1 10 mA

CC

Std Mode Com. 65 mA

CC

Ind. 85 mA

5.0V Device Output Com. 4.75 5.25 V

Ind. 4.5 5.5 V

+0.3 V

CCIO

V

IN=VIH

V

CCIO

V

IN=VIH

VCC=MIN,IOL=0.1mA

V

IN=VIH

V

CCIO

or V

IL

=MIN,IOL=12mA

or V

IL

or V

IL

=MIN,IOH=-4.0mA

Com. 0.45 V

Ind. 0.45 V

Com. 0.2 V

Ind. 0.2 V

2.4 V

Notes: 1. Not more than one output at a time should be shorted. Duration of short circuit test should not exceed 30 sec.

2. I

refers to the current in the reduced-power mode when macrocell reduced-power is turned ON.

CC3

14

ATF1508AS(L)

0784O–PLD–09/02

Page 15

ATF1508AS(L)

Pin Capacitance

C

IN

C

I/O

Note: 1. Typical values for nominal supply voltage. This parameter is only sampled and is not 100% tested. The OGI pin (high-voltage

pin during programming) has a maximum capacitance of 12 pF.

(1)

Typ Max Units Conditions

810 pF V

810 pF V

=0V;f=1.0MHz

IN

=0V;f=1.0MHz

OUT

Timing Model

U

Input Test Waveforms and Measurement Levels

rR,tF= 1.5 ns typical

Output AC Test Loads

(3.0V)*

(703 )*

(8060 )*

Note: *Numbers in parenthesis refer to 3.0V operating conditions (preliminary).

0784O–PLD–09/02

15

Page 16

SUPPLY CURRENT VS. FREQUENCY

SUPPLY CURRENT V S. SUP PLY VOLT AGE

= 25°C, F = 0)

(T

250.0

200.0

(mA)

150.0

CC

I

100.0

STANDARD POWER

A

REDUCED POWER MODE

200.0

150.0

(mA)

100.0

CC

I

50.0

LOW-POWER ("L") VERSION

(T

STANDARD POWER

= 25°C)

A

REDUCED POWER MODE

50.0

4.50 4.75 5.00 5.25 5.50

V

(V)

CC

SUPPLY CURRENT V S. SUP PLY VOLTAGE

LOW-POWER ("L") VERSION

(T

= 25°C, F = 0)

30.0

20.0

A)

µ

µ

µ

µ

(

CC

I

10.0

0.0

4.50 4.75 5.00 5.25 5.50

A

V

(V)

CC

SUPPLY CURRENT VS. FREQUENCY

STANDARD POWER

(T

= 25°C, F = 0)

300.0

250.0

200.0

A)

µ

µ

µ

µ

(

150.0

CC

I

100.0

50.0

STANDARD POWER

0.0

0.00 2 0.00 40.00 60.00 80.00 100.00

A

REDUCED POWER MODE

FREQUENCY (MHz)

0.0

0.00 5.00 10.00 15.00 20.00

FREQUE NCY (MHz)

OUTPUT SOURCE CURRENT

VS. S UPPLY VOL TAGE (VOH = 2.4V, T

0

-10

-20

-30

IOH (mA)

-40

-50

-60

4.50 4.75 5.00 5.25 5.50

SUPP LY VOLT AGE (V)

= 25°C)

A

INPUT CLAMP CURRENT

VS. INPUT VOLTAGE (V

0

-20

-40

-60

-80

-100

INPUT CURRENT (mA)

-120

-140

-160

-1.4 -1.2 -1.0 -0 .8 -0.6 -0 .4 -0.2 0.0

INPUT VOL TAGE (V)

=5V,TA= 25°C)

CC

16

SUPPLY CURRENT VS. SUPPLY VOLTAGE

PIN-CONTROLLED POWER-DOWN MODE

(T

= 25°C, F = 0)

1100.0

A)

µ

µ

µ

µ

(

CC

I

1000.0

STANDARD POWER

900.0

800.0

700.0

4.50 4.75 5.00 5.25 5.50

A

REDUCED POWER MODE

V

(V)

CC

ATF1508AS(L)

OUTPUT SINK CURRENT

VS. SUPPLY VOLTAGE ( VOL = 0.5V, T

43

42

41

40

39

IOL (mA)

38

37

36

4.50 4.75 5 .00 5.25 5.50

SUPPLY VOLTAGE (V)

= 25°C)

A

0784O–PLD–09/02

Page 17

ATF1508AS(L)

OUTPUT SOURCE CURRENT

VS. SUPPLY V OLTAGE ( V

-10

-30

-50

IOH (mA)

-70

-90

-110

0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0

OUTPU T VOLTA GE (V)

=5V,TA= 25°C)

CC

INPUT CURRENT

40

30

A)

µ

µ

µ

µ

20

10

0

-10

INPUT CURRENT (

-20

-30

VS. INPUT VOLTAGE (V

0.00.51.01.52.02.53.03.54.04.55.0

INPU T VOLTA GE (V)

=5V,TA= 25°C)

CC

NORMALIZED TCO

1.20

1.10

1.00

NORMALIZ ED TPD

0.90

0.80

4.50 4.75 5.00 5.25 5.50

VS. SUPPLY VOLTAGE ( T

SUPPLY VOLTAGE (V)

= 25°C)

A

NORMALIZED TSU

1.20

1.10

1.00

NORMALIZ ED TSU

0.90

0.80

4.50 4.75 5.00 5.25 5.50

VS. SUPPLY VOLTAGE ( T

SUPPLYVOLTAGE (V)

= 25°C)

A

OUTPUT SINK CURRENT

140

120

100

IOL (mA)

VS. OUTPUT VOLTAGE (V

80

60

40

20

0

0.0 0.5 1.0 1.5 2.0 2 .5 3.0 3.5 4.0 4.5 5.0

OUTPUT VOLTAGE(V)

=5V,TA= 25°C)

CC

NORMALIZED TPD

1.20

VS. SUPPLY VOLTAGE (T

1.10

1.00

NORMALIZ ED TPD

0.90

0.80

4.50 4.75 5.00 5.25 5.50

SUPP LY VOLTAGE (V)

= 25°C)

A

NORMALIZED TPD

1.20

1.10

1.00

NORMALIZ ED TPD

0.90

0.80

-40 0 25 75

VS. TEMPERATURE (V

TEMPERATURE (C)

CC

=5.0V)

NORMALIZED TCO

1.20

1.10

1.00

NORMALIZ ED TCO

0.90

0.80

-40 0 25 75

VS. TEMPERATURE (V

TEMPERATURE (C)

CC

=5.0V)

0784O–PLD–09/02

17

Page 18

NORMALIZED TSU

1.20

1.10

1.00

NORMALIZ ED TSU

0.90

0.80

-40 0 25 75

VS. TEMPERATURE (V

TEMPERATURE (C)

CC

=5.0V)

18

ATF1508AS(L)

0784O–PLD–09/02

Page 19

ATF1508AS(L)

AC Characteristics

Symbol Parameter

t

PD1

t

PD2

t

SU

t

H

t

FSU

t

FH

t

COP

t

CH

t

CL

t

ASU

t

AH

t

ACOP

t

ACH

t

ACL

t

CNT

f

CNT

Input or Feedback to

Non-registered Output

I/O Input or Feedback to

Non-registered Feedback

Global Clock Setup Time 6 7 11 16 20 ns

Global Clock Hold Time 0 0 0 0 0 ns

Global Clock Setup Time of

Fast Input

Global Clock Hold Time of

Fast Input

Global Clock to Output Delay 4.5 5 8 10 13 ns

Global Clock High Time 3 4 5 6 7 ns

Global Clock Low Time 3 4 5 6 7 ns

Array Clock Setup Time 3 3 4 4 5 ns

Array Clock Hold Time 2 3 4 5 6 ns

Array Clock Output Delay 7.5 10 15 20 25 ns

Array Clock High Time 3 4 6 8 10 ns

Array Clock Low Time 3 4 6 8 10 ns

Minimum Clock Global Period 8 10 13 17 22 ns

Maximum Internal Global

Clock Frequency

(1)

-7 -10 -15 -20 -25

UnitsMin Max Min Max Min Max Min Max Min Max

7.5 10 3 15 20 25 ns

793121620ns

33333ns

0.5 0.5 1.0 1.5 2 MHz

125 100 76.9 66 50 MHz

t

ACNT

f

ACNT

f

MAX

t

IN

t

IO

t

FIN

t

SEXP

t

PEXP

t

LAD

t

LAC

t

IOE

t

OD1

0784O–PLD–09/02

Minimum Array Clock Period 8 10 13 17 22 ns

Maximum Internal Array

125 100 76.9 66 50 MHz

Clock Frequency

Maximum Clock Frequency 166.7 125 100 41.7 33.3 MHz

Input Pad and Buffer Delay 0.5 0.5 2 2 2 ns

I/O Input Pad and Buffer Delay 0.5 0.5 2 2 2 ns

FastInputDelay 11222ns

Foldback Term Delay 4 5 8 10 12 ns

Cascade Logic Delay 0.8 0.8 1 1 1.2 ns

Logic Array Delay 3 5678ns

Logic Control Delay 3 5678ns

InternalOutputEnableDelay 22334ns

Output Buffer and Pad Delay

21.5456ns

(Slow slew rate = OFF;

V

=5V;CL=35pF)

CCIO

19

Page 20

AC Characteristics (Continued)

Symbol Parameter

(1)

-7 -10 -15 -20 -25

UnitsMin Max Min Max Min Max Min Max Min Max

t

OD2

t

OD3

t

ZX1

t

ZX2

t

ZX3

t

XZ

t

SU

t

H

t

FSU

t

FH

Output Buffer and Pad Delay

2.52.0567ns

(Slow slew rate = OFF;

V

=3.3V;CL=35pF)

CCIO

Output Buffer and Pad Delay

55.5 8 10 12ns

(Slow slew rate = ON;

V

=5Vor3.3V;CL=35pF)

CCIO

Output Buffer Enable Delay

4.0 5.0 7 9 10 ns

(Slow slew rate = OFF;

V

=5.0V;CL=35pF)

CCIO

Output Buffer Enable Delay

4.5 5.5 7 9 10 ns

(Slow slew rate = OFF;

V

=3.3V;CL=35pF)

CCIO

Output Buffer Enable Delay

9 9 10 11 12 ns

(Slow slew rate = ON;

V

= 5.0V/3.3V; CL=35pF)

CCIO

Output Buffer Disable Delay

(C

=5pF)

L

45678ns

Register Setup Time 3 2 4 5 6 ns

Register Hold Time 2 3 4 5 6 ns

Register Setup Time of Fast

33223ns

Input

Register Hold Time of Fast

0.5 0.5 2 2 2.5 ns

Input

t

RD

t

COMB

t

IC

t

EN

t

GLOB

t

PRE

t

CLR

t

UIM

t

RPA

RegisterDelay 12122ns

CombinatorialDelay 12122ns

ArrayClockDelay 35678ns

RegisterEnableTime 35678ns

GlobalControlDelay 11111ns

RegisterPresetTime 23456ns

RegisterClearTime 23456ns

SwitchMatrixDelay 11222ns

Reduced-power Adder

(2)

10 11 13 14 15 ns

Notes: 1. See ordering information for valid part numbers.

2. The t

parameter must be added to the t

RPA

LAD,tLAC,tTIC,tACL

power mode.

,andt

parameters for macrocells running in the reduced-

SEXP

20

ATF1508AS(L)

0784O–PLD–09/02

Page 21

ATF1508AS(L)

ATF1508AS Dedicated Pinouts

Dedicated Pin 84-lead J-lead 100-lead PQFP 100-lead TQFP 160-lead PQFP

INPUT/OE2/GCLK2 2 92 90 142

INPUT/GCLR 1 91 89 141

INPUT/OE1 84 90 88 140

INPUT/GCLK1 83 89 87 139

I/O /GCLK3 81 87 85 137

I/O / PD (1, 2) 12,45 3,43 1,41 63,159

I/O / TDI(JTAG) 14 6 4 9

I/O / TMS(JTAG) 23 17 15 22

I/O / TCK(JTAG) 62 64 62 99

I/O / TDO(JTAG) 71 75 73 112

GND 7,19,32,42,

47,59,72,82

VCCINT 3,43 41,93 39,91 61,143

VCCIO 13,26,38,

53,66,78

N/C – – – 1,2,3,4,5,6,7,34,35,36,

#ofSIGNALPINS 68 84 84 100

# USER I/O PINS 64 80 80 96

13,28,40,45,

61,76,88,97

5,20,36,53,68,84 3,18,34,51,66,82 8,26,55,79,104,133

11,26,38,43,

59,74,86,95

17,42,60,66,95,

113,138,148

37,38,39,40,44,45,46,

47,74,75,76,77,81,82,

83,84,85,86,87,114,

115,116,117,118,119,

120,124,125,126,127,

154,155,156,157

OE (1, 2) Global OE Pins

GCLR Global Clear Pin

GCLK (1, 2, 3) Global Clock Pins

PD (1, 2) Power-down pins

TDI, TMS, TCK, TDO JTAG pins used for boundary scan testing or in-system programming

GND Ground Pins

VCCINT VCC pins for the device (+5V - Internal)

VCCIO VCC pins for output drivers (for I/O pins) (+5V or 3.3V - I/Os)

0784O–PLD–09/02

21

Page 22

ATF1508AS I/O Pinouts

84-lead

MC PLB

1 A – 4 2 160 33 C – 27 25 41

2A––––34C––––

3

4 A – – – 158 36 C – – – 32

5 A 11 2 100 153 37 C 30 25 23 31

6 A 10 1 99 152 38 C 29 24 22 30

7A––––39C––––

8 A 9 100 98 151 40 C 28 23 21 29

9 A – 99 97 150 41 C – 22 20 28

10A––––42C––––

11 A 8 98 96 149 43 C 27 21 19 27

12 A – – – 147 44 C – – – 25

13 A 6 96 94 146 45 C 25 19 17 24

14 A 5 95 93 145 46 C 24 18 16 23

15A––––47C––––

A/

PD1

J-lead

12 3 1 159 35 C 31 26 24 33

100-lead

PQFP

100-lead

TQFP

160-lead

PQFP MC PLB

84-lead

J-lead

100-lead

PQFP

100-lead

TQFP

160-lead

PQFP

16 A 4 94 92 144 48

17 B 22 16 14 21 49 D 41 39 37 59

18B––––50D––––

19 B 21 15 13 20 51 D 40 38 36 58

20 B – – – 19 52 D – – – 57

21 B 20 14 12 18 53 D 39 37 35 56

22 B – 12 10 16 54 D – 35 33 54

23B––––55D––––

24 B 18 11 9 15 56 D 37 34 32 53

25 B 17 10 8 14 57 D 36 33 31 52

26B––––58D––––

27 B 16 9 7 13 59 D 35 32 30 51

28 B – – – 12 60 D – – – 50

29 B 15 8 6 11 61 D 34 31 29 49

30 B – 7 5 10 62 D – 30 28 48

31B––––63D––––

32

B/

TDI

14 6 4 9 64 D 33 29 27 43

C/

TMS

23 17 15 22

65 E 44 42 40 62 97 G 63 65 63 100

22

ATF1508AS(L)

0784O–PLD–09/02

Page 23

ATF1508AS I/O Pinouts (Continued)

ATF1508AS(L)

84-lead

MC PLB

66E––––98G––––

67

68 E – – – 64 100 G – – – 102

69E46444265101G656765103

70 E – 46 44 67 102 G – 69 67 105

71E––––103G––––

72E48474568104G677068106

73E49484669105G687169107

74E––––106G––––

75E50494770107G697270108

76 E – – – 71 108 G – – – 109

77E51504872109G707371110

78 E – 51 49 73 110 G – 74 72 111

79E––––111G––––

80E52525078112

81 F – 54 52 80 113 H – 77 75 121

E/

PD2

J-lead

45 43 41 63 99 G 64 66 64 101

100-lead

PQFP

100-lead

TQFP

160-lead

PQFP MC PLB

G/

TDO

84-lead

J-lead

71 75 73 112

100-lead

PQFP

100-lead

TQFP

160-lead

PQFP

82F––––114H––––

83F54555388115H 737876122

84 F – – – 89 116 H – – – 123

85F55565490117H 747977128

86F56575591118H 758078129

87F––––119H––––

88F57585692120H 768179130

89 F – 59 57 93 121 H – 82 80 131

90F––––122H––––

91F58605894123H 778381132

92 F – – – 96 124 H – – – 134

93F60626097125H 798583135

94F61636198126H 808684136

95F––––127H––––

96

F/

TCK

62 64 62 99 128

H/

GCLK3

81 87 85 137

0784O–PLD–09/02

23

Page 24

ATF1508AS Ordering Information

t

PD

(ns)

7.5 4.5 166.7 ATF1508AS-7 JC84

10 5 125 ATF1508AS-10 JC84

10 5 125 ATF1508AS-10 Jl84

15 5 100 ATF1508AS-15 JC84

15 8 100 ATF1508AS-15 JI84

t

CO1

(ns)

f

MAX

(MHz)

Ordering Code Package

ATF1508AS-7 QC100

ATF1508AS-7 AC100

ATF1508AS-7 QC160

ATF1508AS-10 QC100

ATF1508AS-10 AC100

ATF1508AS-10 QC160

ATF1508AS-10 Ql100

ATF1508AS-10 Al100

ATF1508AS-10 Ql160

ATF1508AS-15 QC100

ATF1508AS-15 AC100

ATF1508AS-15 QC160

ATF1508AS-15 QI100

ATF1508AS-15 AI100

ATF1508AS-15 QI160

84J

100Q1

100A

160Q1

84J

100Q1

100A

160Q1

84J

100Q1

100A

160Q1

84J

100Q1

100A

160Q1

84J

100Q1

100A

160Q1

Operation Range

Commercial

(0°Cto70°C)

Commercial

(0°Cto70°C)

Industrial

(-40°Cto+85°C)

Commercial

(0°Cto70°C)

Industrial

(-40°Cto+85°C)

Using “C” Product for Industrial

To use commercial product for Industrial temperature ranges, down-grade one speed grade from the “I” to the “C” device

(7 ns “C” = 10 ns “I”) and de-rate power by 30%.

Package Type

84J 84-lead, Plastic J-leaded Chip Carrier (PLCC)

100Q1 100-lead, Plastic Quad Pin Flat Package (PQFP)

100A 100-lead, Very Thin Plastic Gull Wing Quad Flat Package (TQFP)

160Q1 160-lead, Plastic Quad Pin Flat Package (PQFP)

24

ATF1508AS(L)

0784O–PLD–09/02

Page 25

ATF1508AS(L)

ATF1508ASL Ordering Information

t

PD

(ns)

20 12 83.3 ATF1508ASL-20 JC84

25 15 70 ATF1508ASL-25 JC84

25 15 70 ATF1508ASL-25 JI84

Using “C” Product for Industrial

To use commercial product for Industrial temperature ranges, down-grade one speed grade from the “I” to the “C” device

(7 ns “C” = 10 ns “I”) and de-rate power by 30%.

t

CO1

(ns)

f

MAX

(MHz)

Ordering Code Package

84J

ATF1508ASL-20 QC100

ATF1508ASL-20 AC100

ATF1508ASL-20 QC160

ATF1508ASL-25 QC100

ATF1508ASL-25 AC100

ATF1508ASL-25 QC160

ATF1508ASL-25 QI100

ATF1508ASL-25 AI100

ATF1508ASL-25 QI160

100Q1

100A

160Q1

84J

100Q1

100A

160Q1

84J

100Q1

100A

160Q1

Operation Range

Commercial

(0°Cto70°C)

Commercial

(0°Cto70°C)

Industrial

(-40°Cto+85°C)

Package Type

84J 84-lead, Plastic J-leaded Chip Carrier (PLCC)

100Q1 100-lead, Plastic Quad Pin Flat Package (PQFP)

100A 100-lead, Very Thin Plastic Gull Wing Quad Flat Package (TQFP)

160Q1 160-lead, Plastic Quad Pin Flat Package (PQFP)

0784O–PLD–09/02

25

Page 26

Package Information

84J–PLCC

1.14(0.045) X 45°

B

e

0.51(0.020)MAX

45° MAX (3X)

Notes: 1. This package conforms to JEDEC reference MS-018, Variation AF.

2. Dimensions D1 and E1 do not include mold protrusion.

Allowable protrusion is .010"(0.254 mm) per side. Dimension D1

and E1 include mold mismatch and are measured at the extreme

material condition at the upper or lower parting line.

3. Lead coplanarity is 0.004" (0.102 mm) maximum.

PIN NO. 1

IDENTIFIER

D1

D

1.14(0.045) X 45°

E1 E

0.318(0.0125)

0.191(0.0075)

NOM

D2/E2

MAX

B1

A2

A1

A

COMMON DIMENSIONS

(Unit of Measure = mm)

SYMBOL

A 4.191 – 4.572

A1 2.286 – 3.048

A2 0.508 – –

D 30.099 – 30.353

D1 29.210 – 29.413 Note 2

E 30.099 – 30.353

E1 29.210 – 29.413 Note 2

D2/E2 27.686 – 28.702

B 0.660 – 0.813

B1 0.330 – 0.533

e 1.270 TYP

MIN

NOTE

26

2325 Orchard Parkway

TITLE

R

San Jose, CA 95131

ATF1508AS(L)

84J, 84-lead, Plastic J-leaded Chip Carrier (PLCC)

DRAWING NO.

84J

0784O–PLD–09/02

10/04/01

REV.

B

Page 27

100Q1 – PQFP

ATF1508AS(L)

C

PIN1ID

PIN 1

e

B

0º~7º

E1

E

D1

D

COMMON DIMENSIONS

A

SYMBOL

L

A1

A – 3.04 3.4

A1 0.25 0.33 0.5

D 23.20 BSC

E 17.20 BSC

E1 14.00 BSC

B 0.22 – 0.40

D1 20 BSC

L 0.73 – 1.03

e 0.65 BSC

(Unit of Measure = mm)

JEDEC STANDARD MS-022, GC-1

MIN

NOM

MAX

NOTE

R

0784O–PLD–09/02

2325 Orchard Parkway

San Jose, CA 95131

TITLE

100Q1, 100-lead, 14 x 20 mm Body, 3.2 mm Footprint, 0.65 mm Pitch,

Plastic Quad Flat Package (PQFP)

09/10/2002

DRAWING NO.

100Q1

REV.

B

27

Page 28

100A – TQFP

PIN 1

B

PIN 1 IDENTIFIER

e

E1 E

D1

D

C

0˚~7˚

A1

L

Notes: 1. This package conforms to JEDEC reference MS-026, Variation AED.

2. Dimensions D1 and E1 do not include mold protrusion. Allowable

protrusion is 0.25 mm per side. Dimensions D1 and E1 are maximum

plastic body size dimensions including mold mismatch.

3. Lead coplanarity is 0.08 mm maximum.

A2 A

SYMBOL

COMMON DIMENSIONS

(Unit of Measure = mm)

MIN

A – – 1.20

A1 0.05 – 0.15

A2 0.95 1.00 1.05

D 15.75 16.00 16.25

D1 13.90 14.00 14.10 Note 2

E 15.75 16.00 16.25

E1 13.90 14.00 14.10 Note 2

B 0.17 – 0.27

C 0.09 – 0.20

L 0.45 – 0.75

e 0.50 TYP

NOM

MAX

NOTE

28

2325 Orchard Parkway

TITLE

R

San Jose, CA 95131

ATF1508AS(L)

100A, 100-lead, 14 x 14 mm Body Size, 1.0 mm Body Thickness,

0.5 mm Lead Pitch, Thin Profile Plastic Quad Flat Package (TQFP)

10/5/2001

DRAWING NO.

100A

0784O–PLD–09/02

REV.

C

Page 29

160Q1 – PQFP

ATF1508AS(L)

D1

E1

Top View

A2

A1

e

b

L1

Side View

Notes: 1. This drawing is for general information only. Refer to JEDEC Drawing

MS-022, Variation DD-1, for additional information.

2. To be determined at seating plane.

3. Regardless of the relative size of the upper and lower body sections,

dimensions D1 and E1 are determined at the largest feature of the body

exclusive of mold Flash and gate burrs, but including any mismatch

between the upper and lower sections of the molded body.

4. Dimension b does not include Dambar protrusion. The Dambar

protrusion(s) shall not cause the lead width to exceed b maximum by more

than 0.08 mm. Dambar cannot be located on the lower radius or the lead

foot.

5. A1 is defined as the distance from the seating plane to the lowest point of

the package body.

D

E

Bottom View

COMMON DIMENSIONS

(Unit of Measure = mm)

SYMBOL

A1 0.25 – 0.50 5

A2 3.20 3.40 3.60

D 31.20 BSC 2

D1 28.00 BSC 3

E 31.20 BSC 2

E1 28.00 BSC 3

e 0.65 BSC

b 0.22 – 0.40 4

L1 1.60 REF

MIN

NOM

MAX

NOTE

R

0784O–PLD–09/02

2325 Orchard Parkway

San Jose, CA 95131

TITLE

160Q1, 160-lead, 28 x 28 mm Body, 3.2 Form Opt.,

Plastic Quad Flat Pack (PQFP)

DRAWING NO.

160Q1

A

3/28/02

REV.

29

Page 30

Atmel Headquarters Atmel Operations

Corporate Headquarters

2325 Orchard Parkway

San Jose, CA 95131

TEL 1(408) 441-0311

FAX 1(408) 487-2600

Europe

Atmel Sarl

Route des Arsenaux 41

Case Postale 80

CH-1705 Fribourg

Switzerland

TEL (41) 26-426-5555

FAX (41) 26-426-5500

Asia

Room 1219

Chinachem Golden Plaza

77 Mody Road Tsimshatsui

East Kowloon

Hong Kong

TEL (852) 2721-9778

FAX (852) 2722-1369

Japan

9F, Tonetsu Shinkawa Bldg.

1-24-8 Shinkawa

Chuo-ku, Tokyo 104-0033

Japan

TEL (81) 3-3523-3551

FAX (81) 3-3523-7581

Memory

2325 Orchard Parkway

San Jose, CA 95131

TEL 1(408) 441-0311

FAX 1(408) 436-4314

Microcontrollers

2325 Orchard Parkway

San Jose, CA 95131

TEL 1(408) 441-0311

FAX 1(408) 436-4314

La Chantrerie

BP 70602

44306 Nantes Cedex 3, France

TEL (33) 2-40-18-18-18

FAX (33) 2-40-18-19-60

ASIC/ASSP/Smart Cards

Zone Industrielle

13106 Rousset Cedex, France

TEL (33) 4-42-53-60-00

FAX (33) 4-42-53-60-01

1150 East Cheyenne Mtn. Blvd.

Colorado Springs, CO 80906

TEL 1(719) 576-3300

FAX 1(719) 540-1759

Scottish Enterprise Technology Park

Maxwell Building

East Kilbride G75 0QR, Scotland

TEL (44) 1355-803-000

FAX (44) 1355-242-743

RF/Automotive

Theresienstrasse 2

Postfach 3535

74025 Heilbronn, Germany

TEL (49) 71-31-67-0

FAX (49) 71-31-67-2340

1150 East Cheyenne Mtn. Blvd.

Colorado Springs, CO 80906

TEL 1(719) 576-3300

FAX 1(719) 540-1759

Biometrics/Imaging/Hi-Rel MPU/

High Speed Converters/RF Datacom

Avenue de Rochepleine

BP 123

38521 Saint-Egreve Cedex, France

TEL (33) 4-76-58-30-00

FAX (33) 4-76-58-34-80

e-mail

literature@atmel.com

Web Site

http://www.atmel.com

© Atmel Corporation 2002.

Atmel Corporation makes no warranty for the use of its products, other than those expressly contained in the Company’s standard warranty

which is detailed in Atmel’s Terms and Conditions located on the Company’s web site. The Company assumes no responsibility for any errors

which may appear in this document, reserves the right to change devices or specifications detailed herein at any time without notice, and does

not make any commitment to update the information contained herein. No licenses to patents or other intellectual property of Atmel are granted

by the Company in connection with the sale of Atmel products, expressly or by implication. Atmel’s products are not authorized for use as critical

components in life support devices or systems.

AT ME L®is the registered trademark of Atmel.

Other terms and product names may be the trademarks of others.

Printed on recycled paper.

0784O–PLD–09/02 xM

Loading...

Loading...