Page 1

7

8

9

10

11

12

13

14

15

16

17

39

38

37

36

35

34

33

32

31

30

29

I/O

I/O

I/O

GND

I/O

I/O

I/O

I/O

VCC

I/O

I/O

I/O

I/O

I/O

I/O

VCC

I/O

I/O

I/O

I/O

GND

I/O

65432

1

4443424140

1819202122232425262728

I/O

I/O

I/O

I/O

GND

VCC

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O/PD

VCC

OE2/I

GCLR/I

OE1/I

CLK/I

GND

I/O

I/O

Features

• High-density, High-performance Electrically-erasable Complex

Programmable Logic Device

– 44-pin, 32 I/O CPLD

– 7.5 ns Maximum Pin-to-pin Delay

– Registered Operation Up To 125 MHz

– Fully Connected Input and Feedback Logic Array

– Backward Compatibility with ATF1500/L Software and Hardware

• Flexible Logic Macrocell

– D/T/Latch Configurable Flip Flops

– Global and Individual Register Control Signals

– Global and Individual Output Enable

– Programmable Output Slew Rate

• Advanced Power Management Features

– Automatic 3 mA Stand-By (ATF1500AL)

– Pin-controlled 10 mA Standby Mode

– Programmable Pin-Keeper Inputs and I/Os

• Available in Commercial and Industrial Temperature Ranges

• Available in 44-pin PLCC and TQFP Packages

• Advanced Flash Technology

– 100% Tested

– Completely Reprogrammable

– 100 Program/Erase Cycles

– 20 Year Data Retention

– 2000V ESD Protection

– 200 mA Latch-up Immunity

• Supported By Popular 3rd Party Tools

• Security Fuse Feature

• Pin-compatible with the Most Commonly Used Devices

Highperformance

EPLD

ATF1500A

ATF1500AL

Description

The ATF1500A is a hig h-performance, hi gh-density complex PLD. Built on an

advanced Flash technol ogy, it has maxi mum pin to pin delay s of 7.5 ns and supports

sequential logic operati on at spee ds u p to 1 25 MHz . With 32 logic macro cell s and u p

to 36 inputs, it easily integrates logic from several TTL, SS I, MSI and classic PLDs.

The ATF1500A’s global input and feedback architecture simplifies logic placement

and eliminates pinout changes due to design changes.

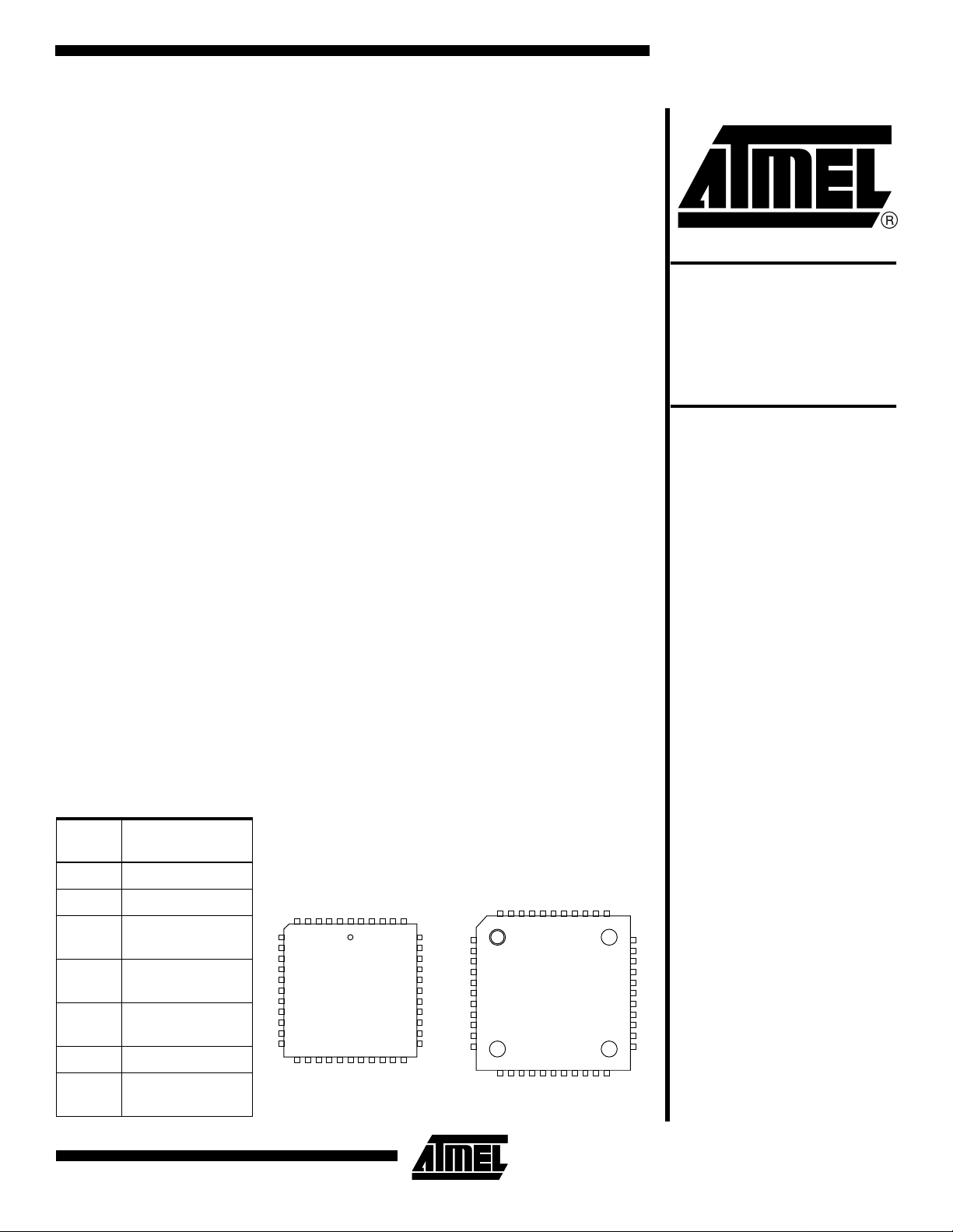

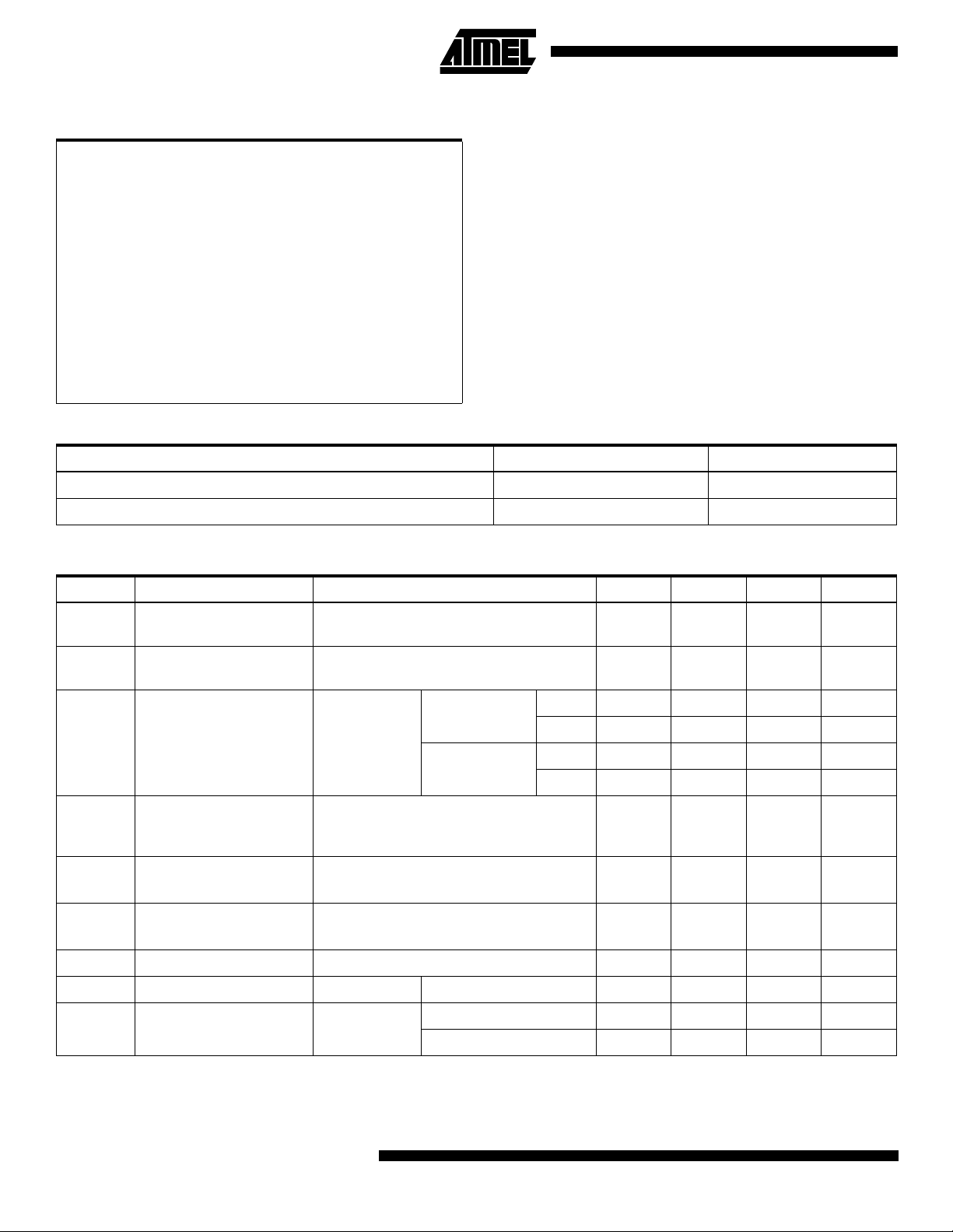

Pin Configurations

Pin

Name Function

CLK Clock

I Logic Inputs

I/O

GCLR

OE1,

OE2

VCC +5V Supply

PD

Bidirectional

Buffers

Register Reset

(active low)

Output Enable

(active low)

Power Down

(active high)

PLCC

Top View

GND

VCC

I/O

I/O

4443424140393837363534

1

I/O

2

I/O

3

I/O

4

5

I/O

6

I/O

7

I/O

8

I/O

9

10

I/O

11

I/O

1213141516171819202122

I/O

I/O

(continued)

TQFP

Top View

I/O/PD

VCC

OE2/I

GCLR/I

OE1/I

I/O

I/O

I/O

VCC

GND

CLK/I

I/O

GND

I/O

I/O

I/O

33

I/O

32

I/O

31

I/O

30

I/O

29

VCC

28

I/O

27

I/O

26

I/O

25

I/O

24

GND

23

I/O

I/O

I/O

Rev. 0759E–06/99

1

Page 2

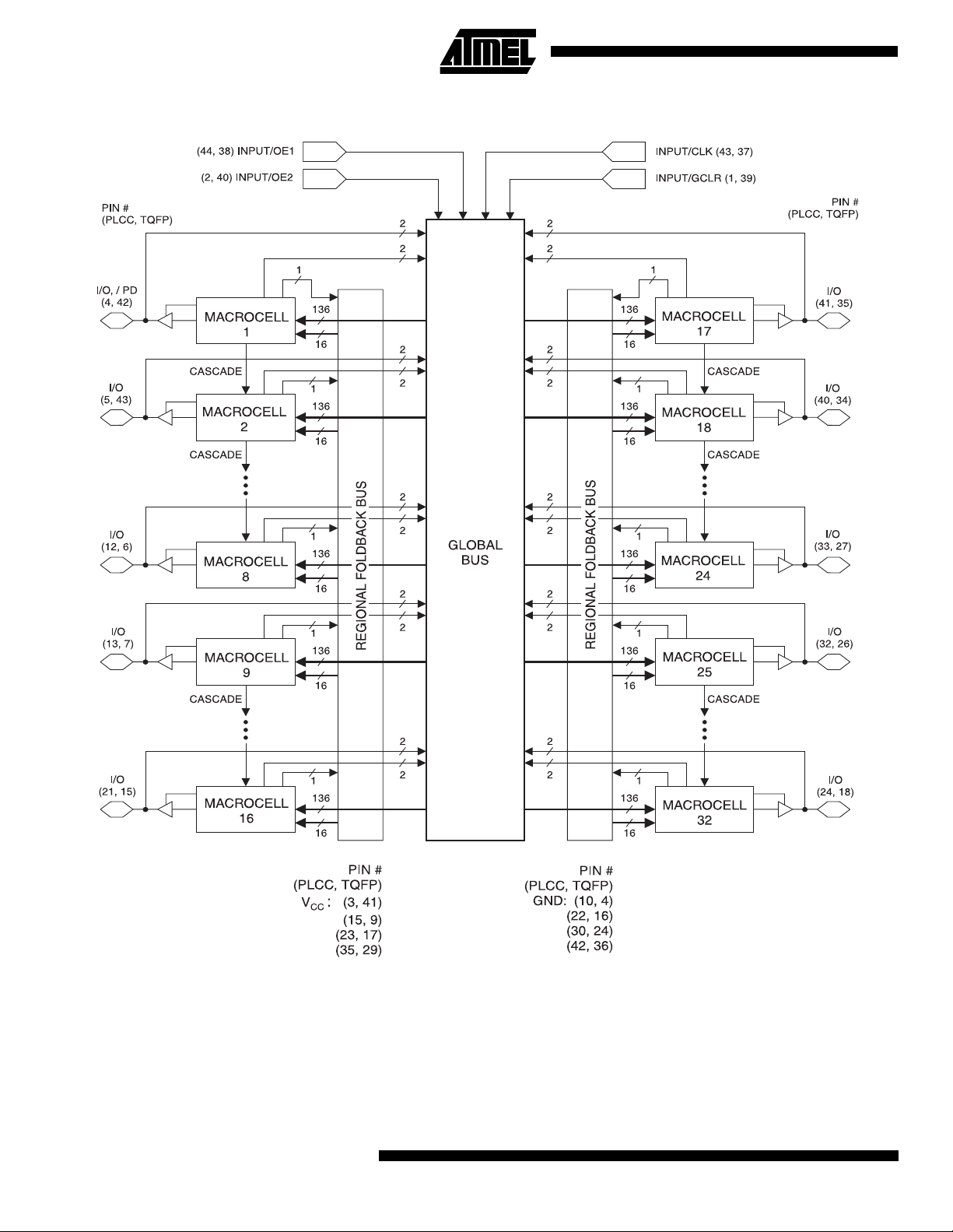

Functional Logic Diagram

(1)

Note: 1. Arrows connecting macrocells indicate direction and groupings of CASIN/CASOUT data flow.

The ATF1500A has 32 bi-directional I/O pins and 4 dedicated input pins. Eac h dedicate d input pin c an also serve

as a global control signal: register clock, register reset or

output enable. Each of these control signals can be

selected for use individually within each macrocell.

2

ATF1500A(L)

Each of the 32 logic macrocells generates a buried feedback, which goes to th e global bu s. Each inp ut and I/O pin

also feeds into the global bus. Because of this global bussing, each of these signals is always available to all 32

macrocells in the device.

Page 3

ATF1500A(L)

Each macrocell also generates a foldback logic term, which

goes to a regional bu s. Al l s ign al s wi thin a reg ion al bus are

connected to all 16 macrocells within the region.

Cascade logic between macrocells in the ATF1500A allows

fast, efficient generation of complex logic functions. Th e

ATF1500A co ntains 4 s uch lo gic ch ains, each capabl e of

creating sum term logic with a fa n in of up to 40 product

terms.

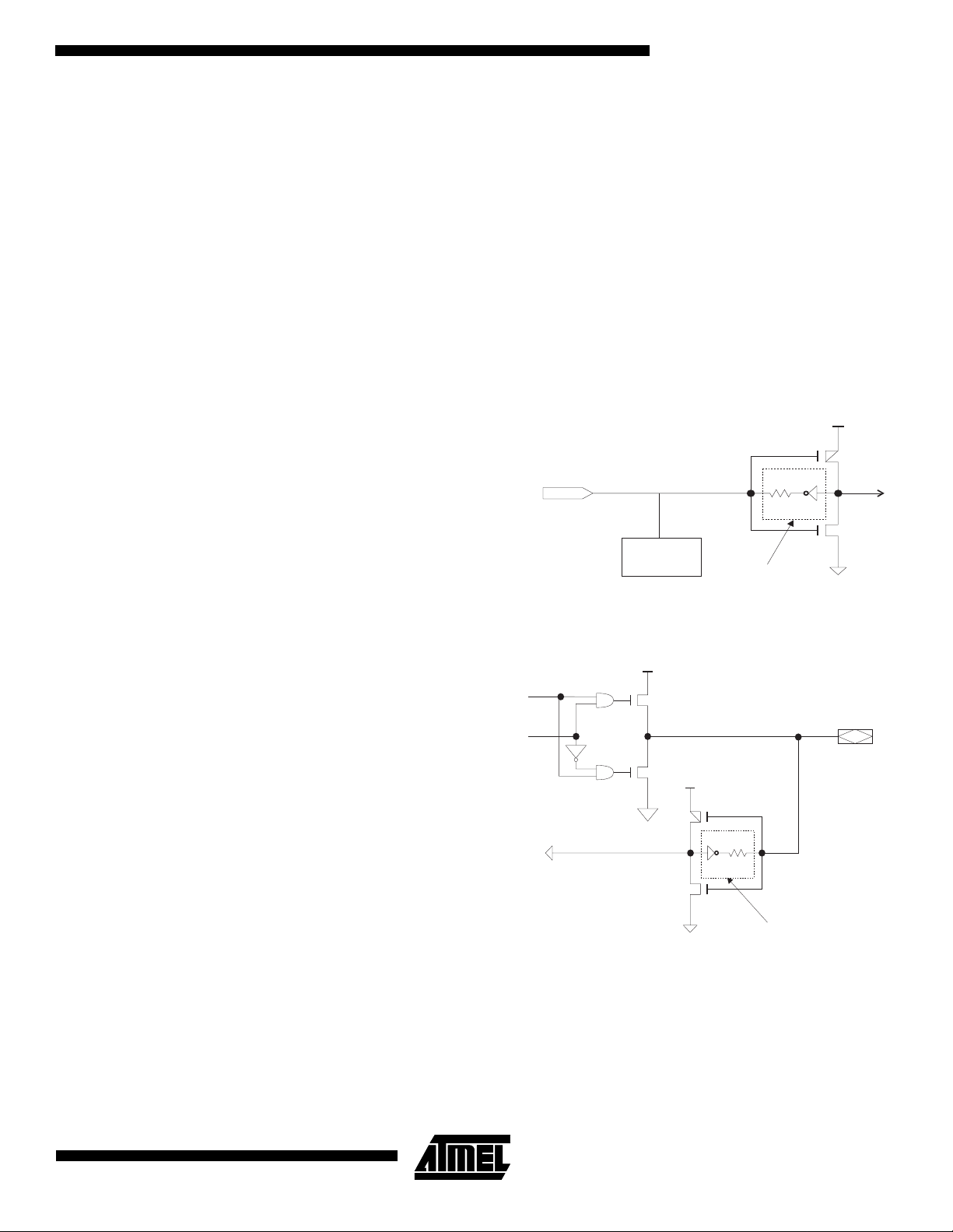

Bus Friendly Pin-Keeper Input and I/O’s

All Input and I/O pins on the ATF1500A have programma-

ble “pin keeper” circuits. If activated, when any pin is driven

high or low and then subsequently left floating, it will stay at

that previous high or low level.

This circuitry prevents unus ed Input and I/O lines from

floating to intermedi ate volta ge levels , which caus e unnecessary power consumption and system noise. The keeper

circuits eliminate the need for external pull-up resistors and

eliminate their DC power consumption.

Pin-keeper cir cuits can be disab led. Progr amming i s controlled in the logic design file. Once the pin-keeper circuits

are disabled, normal termination pr ocedures are r equired

for unused inputs and I/Os.

Speed/Power Management

The ATF1500A has seve ral built-i n spe ed and power m anagement features. The ATF1500A co ntains circuitry that

automatically puts the device into a low power stand-by

mode when no logic transitions are oc cu rrin g. Thi s not only

reduces power consumptio n during inactiv e periods, but

also provides a proportional power savings for most applications running at system speeds below 10 MHz.

All ATF1500As also have an optional pin-controlled power

down mode. In this mode, current drops to below 10 mA.

When the power down option is selected, the PD pin is

used to power down the part. The power down o ption is

selected in the desi gn source file. Whe n enabled, the

device goes into power down when the PD pin is high. In

the power down mode, all inter nal logi c si gnals ar e latche d

and held, as ar e any en abl ed out put s. Al l pin t rans itio ns ar e

ignored until the PD is brought low. When the power down

feature is enabled, the PD cannot be used as a logic input

or output. However, the PD pin's macrocell may still be

used to generate buried foldback and cascade logic s ignals.

Each output also has in divi dual sl ew rate contr ol. This may

be used to reduce system noise by slowing down o utputs

that do not need to operate at maximum speed. Outputs

default to slow switching, and may be specified as fas t

switching in the design file.

Design Software Support

ATF1500A designs are supported by several 3rd party

tools. Automated fitters allow logic synthesis using a variety

of high level description languages and formats.

Input Diagram

V

CC

INPUT

ESD

PROTECTION

CIRCUIT

100K

PROGRAMMABLE

OPTION

I/O Diagram

V

CC

OE

DATA

V

CC

100K

PROGRAMMABLE

OPTION

I/O

3

Page 4

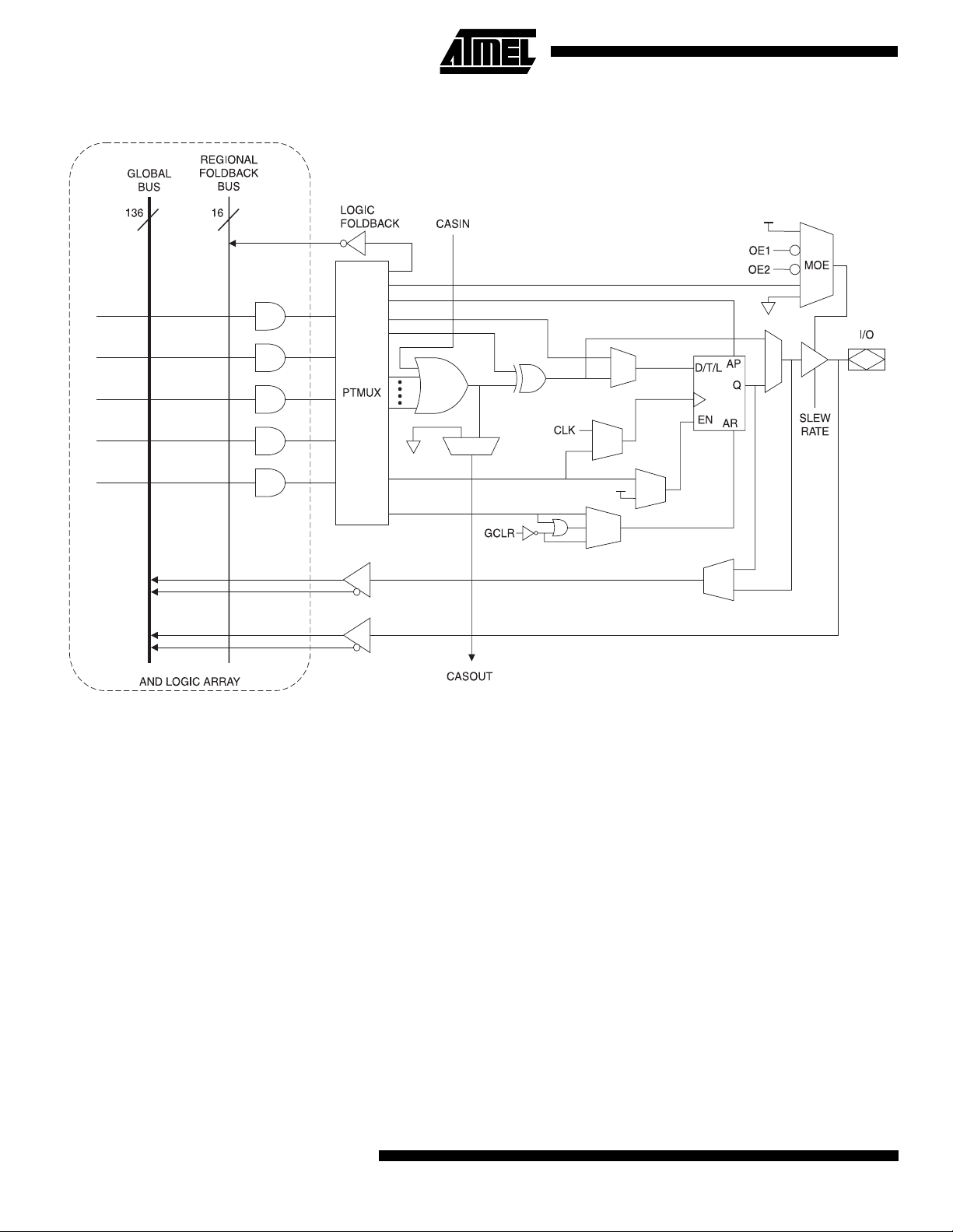

ATF1500A(L) Macrocell

ATF1500A Macrocell

The ATF1500A macr ocell is flexible enou gh to support

highly complex logic functions operating at high speed. The

macrocell consists of five sections: product terms and product term select multiplexer; OR/XOR/CASCADE logic; a flip

flop; output select and enable; and logic array inputs.

Product Terms and Select Mux

Each ATF1500A macrocell has five pr oduct terms. Each

product term recei ve s a s its inp u ts al l s ig nal s f ro m bo th th e

global bus and regional bus.

The product term select multip lexer ( PTMUX ) alloc ates th e

five product terms as needed to the macrocell logic gates

and control signals. The PTMUX programming is determined by the design c ompiler, which se lects the opt imum

macrocell configuration.

OR/XOR/CASCADE Logic

The ATF1500A macrocell’s OR/XOR/CASCADE logic

structure is design ed to effi c ien tly su pport al l ty pes of log ic .

Within a single mac rocell, all the product term s can be

4

ATF1500A(L)

routed to the OR g ate, cr eating a fi ve input AND/OR sum

term. With the addition of the CASIN from neighboring

macrocells, this can be expanded to as many as 40 product

terms with a very small addition al del ay.

The macrocell’s XOR gate allows efficient implementation

of compare and arithmetic fun ctions. O ne input to the XOR

comes from the OR sum term. The other XOR input can be

a product term or a fixed high or low level. For combinatorial outputs, the fixed level input allows output polarity

selection. F or re gist ere d func tio ns, th e fix ed leve ls al low De

Morgan minimization of the product terms. The XOR gate is

also used to emulate T-type flip flops.

Flip Flop

The ATF1500A’s flip flop has very fle xible dat a and contro l

functions. The data input can come from either the XOR

gate or from a separate product term. Selecting the separate product term allows creation of a buried registered

feedback within a combinatorial output macrocell.

Page 5

ATF1500A(L)

In addition to D, T, JK and SR operation, the flip flop can

also be configured as a flow-through latch. In this mode,

data passes through when the clock is high and is latched

when the clock is low.

The clock itself can be e ither the global CLK pi n or an ind ividual product term. The flip flop changes state on the

clock’s rising edge. When the CLK pin is used as the clock,

one of the macrocell product terms can be selected as a

clock enable. When the cloc k enable func tion is active an d

the enable signal (produc t term) is low , all clo ck edges are

ignored.

The flip flop’s asynchronous reset signal (AR) can be either

the pin global clear (GCLR), a product term, or always off.

AR can also be a logic OR of GCLR with a product term.

The asynchronous preset (AP) can be a product term or

always off.

Output Select and Enable

The ATF1500A macro cell ou tput can be s elect ed as regi stered or combinatorial. When the outpu t is registered, the

same registered signal is fed back inte rnally to the g lobal

bus. When the output is combi nato rial , the buri ed fee dba ck

can be either the same combinatorial signal or it can be the

register output if the separate product term is chosen as

the flip flop input.

The output enable multiplexer (MOE) controls the output

enable signals . Any buffer ca n be perman ently enab led for

simple output operation. Buffers ca n also be permanently

disabled to allow use of the pin as an i nput. In this confi guration all the ma croce ll res our ces are still ava ilab le, i ncl uding the buried feedback, expander and CASCADE logic.

The output enable for each m acroce ll ca n als o be se lecte d

as either of the two OE pins or as an individual product

term.

Global/Regional Busses

The global bus contains all Input and I/O pin signals as well

as the buried feed back signal from a ll 32 macrocells.

Together with the complement of each signal, this provides

a 68 bit bus as input to every product term. Having the

entire global bus available to each macrocell eliminates

any potential routing proble ms. With this arc hitecture

designs can be modified without requiring pinout changes.

Each macrocell a lso generate s a foldbac k product ter m.

This signal goes to the regi onal bu s, and is av ailab le to 16

macrocells. The foldback is an inverse polarity of one of the

macrocell’s product terms. The 16 foldba ck terms in each

region allow generation of high fan-in sum terms (up to 21

product terms) with a small additional delay.

5

Page 6

Absolute Maximum Ratings*

Temperature Under Bias.................................. -40°C to +85°C

Storage Temperature..................................... -65°C to +150°C

Voltage on Any Pin with

Respect to Ground .........................................-2.0V to +7.0V

Voltage on Input Pins

with Respect to Ground

During Programming.....................................-2.0V to +14.0V

Programming Voltage with

Respect to Ground .......................................-2.0V to +14.0V

(1)

(1)

(1)

*NOTICE: Stresses beyond those listed under “Absolute

Maximum Ratings” may cause permanent da mage to the device . This is a st ress rating only and

functional operatio n of the dev ice at th ese or an y

other conditions beyond those indicated in the

operational sections of this specification is not

implied. Exposure to absolute maximum rating

conditions for exten ded periods may af fect device

reliability .

Note: 1. Minimum voltage is -0.6V DC, which may under-

shoot to -2.0V for pulses of less than 20 ns. Maximum output pin voltage is V

+ 0.75V DC,

CC

which may overshoot to 5.25V for pulses of less

than 20 ns.

DC and AC Operating Conditions

Commercial Industrial

Operating Temperature (ambient) 0°C - 70°C-40°C - 85°C

V

Power Supply 5V ± 5% 5V ± 10%

CC

DC Characteristics

Symbol Parameter Condition Min Typ Max Units

I

IL

I

IH

Input or I/O

Low Leakage Current

Input or I/O

High Leakage Current

≤ VIL (Max) -10 µA

0 ≤ V

IN

V

, Min ≤ VIN ≤ V

IH

CC

10 µA

Com. 70 mA

ATF1500A

I

CC1

(1)

Power Supply Current,

Standby

VCC = Max,

V

= 0, V

IN

CC

Ind. 100 mA

Com. 3 mA

ATF1500AL

Ind. 5 mA

I

I

V

V

V

V

CC2

OS

IL

IH

OL

OH

Power Supply Current,

Pin-Controlled Power

Down Mode

Output Short Circuit

Current

Input Low Voltage

Input High Voltage 2.0 VCC + 1 V

Output Low Voltage VCC = Min IOL = 12 mA 0.45 V

Output High Voltage VCC = Min

V

= Max,

CC

V

= 0, V

IN

V

OUT

VCC, Min < VCC

< VCC, Max

CC

= 0.5V -130 mA

-0.5 0.8 V

I

= -4 mA 2.4 V

OH

I

= -0.2 mA VCC - 0.2 V

OH

210mA

Note: 1. All ICC parameters measured with outputs open, and a 16-bit loadable, up/down counter programmed into each region.

6

ATF1500A(L)

Page 7

AC Waveforms

Register AC Characteristics, Input Pin Clock

-7 -10 -12 -15 -20 -25

Symbol Parameter

(1)

t

t

t

t

COS

CFS

SIS

SFS

Clock to Output 4.52526282929ns

Clock to Feedback 2 2 2 2 2 2 ns

I, I/O Setup Time 6 8 10 11 14 16 ns

Feedback Setup

Time

6 8 10 11 12 13 ns

ATF1500A(L)

UnitsMin Max Min Max Min Max Min Max Min Max Min Max

t

HS

t

PS

t

WS

Input, I/O, Feedback

Hold Time

Clock Period 6 8 9 10 11 12 ns

Clock Width3 44.555.56 ns

0 00000ns

External Feedback

+ t

+ t

COS

CFS

)

)

) 166.7 125 111 100 91 83 MHz

PS

2 33455ns

6 9 10 12 13 14 ns

F

MAXS

t

RPRS

t

RTRS

1/(t

SIS

Internal Feedback

1/(t

SFS

No Feedback 1/(t

Reset Pin Recovery

Time

Reset Term

Recovery Time

Note: 1. For slow slew outputs, add t

95 76.9 62.5 52.6 43 40 MHz

125 100 83.3 76.9 71 66 MHz

.

SSO

7

Page 8

Register AC Characteristics, Product Term Clock

-7 -10 -12 -15 -20 -25

Symbol Parameter

(1)

t

t

t

t

t

COA

CFA

SIA

SFA

HA

Clock to Output 7.5 10 12 15 18 20 ns

Clock to Feedback 5 7 7 9 12 15 ns

I, I/O Setup Time 3 3 4 4 8 10 ns

Feedback Setup

Time

Input, I/O, Feedback

Hold Time

3 3 4 4 12 15 ns

2 34455ns

UnitsMin Max Min Max Min Max Min Max Min Max Min Max

t

PA

t

WA

Clock Period 6 8 10 12 24 30 ns

Clock Width 3 4 5 6 12 15 ns

External Feedback

+ t

+ t

COA

CFA

)

)

) 166.7 125 100 83.3 41.7 33.3 MHz

PA

0000 00ns

4566 78ns

F

MAXA

t

RPRA

t

RTRA

1/(t

SIA

Internal Feedback

1/(t

SFA

No Feedback 1/(t

Reset Pin Recovery

Time

Reset Term

Recovery Time

Note: 1. For slow slew outputs, add t

95.2 76.9 62.5 52.6 38 33.3 MHz

125 100 90.9 76.9 41.7 33.3 MHz

.

SSO

8

ATF1500A(L)

Page 9

AC Characteristics

Symbol Parameter

ATF1500A(L)

-7 -10 -12 -15 -20 -25

UnitsMin Max Min Max Min Max Min Max Min Max Min Max

t

t

t

t

t

t

t

t

t

t

t

PD

PD2

PD3

PD4

EA

ER

PZX

PXZ

PF

PO

RPF

(1)

I, I/O or FB to

Non-Registered

27.5310312315320325 ns

Output

I, I/O to Feedback 5 7 8 9 12 14 ns

Feedback to

(1)

Non-Registered

27.5310312315320325 ns

Output

Feedback to

Feedback

(1)

OE Term to Output

Enable

OE Term to Output

Disable

OE Pin to Output

(1)

Enable

OE Pin to Output

Disable

1.5 5.5 1..5 7 1.5 8 1.5 9 1.5 10 1.5 11 ns

5 7 8 9 12 14 ns

27.5310312315320325 ns

27.5210212215220225 ns

25.52 7 2 8 2 9210211 ns

Preset to Feedback 6 9 9 12 18 20 ns

(1)

Preset to Registered

Output

Reset Pin to

Feedback

8.51214202325ns

34355.56ns

Reset Pin to

(1)

t

t

t

t

t

t

RPO

RTF

RTO

CAS

SSO

FLD

Registered Output

Reset Term to

Feedback

Reset Term to

(1)

Registered Output

Cascade Logic Delay 0.8 0.8 1 1 1.5 1.5 ns

Slow Slew Output

Adder

Foldback Term Delay 4 5 7 8 10 12 ns

Note: 1. For slow slew outputs, add t

5.5 7 8 11 13 15 ns

6 9 9 121520ns

8.51214202325ns

333444ns

.

SSO

9

Page 10

Power Down AC Characteristics

-7 -10 -12 -15 -20 -25

Symbol Parameter

UnitsMinMaxMinMaxMinMaxMinMaxMinMaxMinMax

t

IVDH

t

GVDH

t

CVDH

t

DHIX

t

DHGX

t

DHCX

t

DLIV

t

DLGV

t

DLCV

t

DLOV

(1)

Valid I, I/O Before

PD High

Valid OE

(2)

Before PD High

Valid Clock

(2)

Before PD High

Input Don’t Care

After PD High

OE Don’t Care

After PD High

Clock Don’t Care

After PD High

PD Low to Valid I,

I/O

PD Low to Valid

(2)

OE

PD Low to Valid

(2)

Clock

PD Low to Valid

Output

Notes: 1. For slow slew outputs, add t

2. Pin or Product Term.

7 1012152025 ns

7 1012152025 ns

7 1012152025 ns

15 20 22 25 30 35 ns

15 20 22 25 30 35 ns

15 20 22 25 30 35 ns

111111µs

111111µs

111111µs

111111µs

.

SSO

Input Test Waveforms and

Output Test Load

Measurement Levels

AC

DRIVING

LEVELS

3.0V

0.0V

1.5V

t

, tf 1.5 ns

r

AC

MEASUREMENT

LEVEL

Pin Capacitance

f = 1 MHz, T = 25°C

C

IN

C

OUT

Note: 1. Typical values for nominal supply voltage. This parameter is only sampled and is not 100% tested.

10

(1)

Typ Max Units Conditions

4.5 5.5 pF VIN = 0V

3.5 4.5 pF V

ATF1500A(L)

OUT

= 0V

Page 11

ATF1500A(L)

Power Up Reset

The ATF1500A’s registers are designed to reset during

power up. At a point delayed slightly from V

, all registers will be re set to th e low st ate. As a r esult,

V

RST

crossing

CC

the registered output state will always be low on power-up.

This feature is critical for state machine initialization. How-

ever, due to the asynchronous nature of reset and the

uncertainty of h ow V

actually rises in the sys tem, the fo l-

CC

lowing conditions are required:

1. The V

rise must be monotonic, from below 0.7 volt,

CC

2. After reset occurs, all input and feedback setup times

must be met before driving the clock signal high, and

3. Signals from which clocks are derived must remain stable during t

PR

.

Power Down Mode

The ATF1500A includes an optional pin controlled power

down feature. When this mod e is enab led, the P D pin acts

as the power down pin. When the PD pin is high, the device

supply current is reduced to less than 10 mA. During power

down, all output data and internal logic states are latched

and held. Therefore, all registered and combinatorial output

data remain valid. Any outputs which were in a HI-Z state at

the onset of power down will r emain at HI-Z. During power

down, all input signals except the power down pin are

blocked. Input an d I/O hol d latche s rema in activ e to insur e

that pins do not fl oat to inde termina te leve ls, f urther reducing system power. The power down pin feature is enabled

in the logic design file. Designs using the power down pin

may not use the PD pin logic array input. However, all other

PD pin macrocell resources may still be used, including the

buried feedback and foldback product term array inputs.

preload mode i s enab led by r aising an inp ut pin to a h igh

voltage level. Contact Atmel PLD Applications for PRELOAD pin assignments, timing and voltage requirements.

Parameter Description Typ Max Units

t

PR

V

RST

Power-Up

Reset Time

Power-Up

Reset

Voltage

210 µs

3.8 4.5 V

Output Slew Rate Control

Each ATF1500A macrocell contains a configuration bit for

each I/O to control its output slew rate. This allows selected

data paths to operate at ma ximu m th roughput while redu cing system noise from outputs that are not speed-critical.

Outputs default to slow edges, and may be individually set

to fast in the design file. O utput transitio n times for outp uts

configured as “slow” have a t

delay adder.

SSO

Register Preload

The ATF1500A’s registers are provided with circuitry to

allow loading of each register with either a high or a low.

This feature will simplify testing since an y state can be

forced into the registers to control test sequencing. A

JEDEC file with preload is generated whe n a source fil e

with preload vectors is compiled. Once downloaded, the

JEDEC file preload sequence will be done automatica lly

when vectors are run by any approved programmers. The

Security Fuse Usage

A single fuse is provided to prevent unauthoriz ed copying

of the ATF1500A fuse patterns. Once programmed, fuse

verify and preload are prohibited. However, the 160-bit

User Signature remains accessible.

The security fuse should be programmed last, as its effect

is immediate.

11

Page 12

NORMALIZED SUPPLY CURRENT

vs. INPUT FREQUENCY

(V

ATF1500A

I

CC

= 5V, TA = 25˚C)

cc

I

mA

CC

SUPPLY CURRENT

vs. FREQUENCY

ATF1500AL (V

= 5V, TA = 25˚C)

CC

NORMALIZED SUPPLY CURRENT

vs. SUPPLY VOLTAGE

ATF1500 (TA = 25˚C)

I

CC

OUTPUT SOURCE CURRENT

vs. SUPPLY VOLTAGE (V

I

OH

= 2.4V, TA = 25˚C)

OH

ICC mA

I

mA

OL

NORMALIZED SUPPLY CURRENT

vs. AMBIENT TEMPERATURE

ATF1500 (V

CC

= 5V)

OUTPUT SINK SURRENT

vs. SUPPLY VOLTAGE (TA = 25˚C, V

= 0.45V)

OL

12

vs. OUTPUT VOLTAGE (V

IOH mA

ATF1500A(L)

OUTPUT SOURCE CURRENT

= 2.4V, TA = 25˚C)

OH

I

OH

vs. OUTPUT VOLTAGE (V

OUTPUT SOURCE CURRENT

mA

= 5V, TA = 25˚C)

CC

Page 13

ATF1500A(L)

INPUT CURRENT vs. INPUT VOLTAGE

(V

CC

= 5V, TA = 25˚C)

vs. OUTPUT VOLTAGE (V

OUTPUT SINK CURRENT

I

mA

OL

= 5V, TA = 25˚C)

CC

INPUT CLAMP CURRENT

vs. INPUT VOLTAGE

t

t

COS

PD

NORMALIZED t

vs. AMBIENT TEMPERATURE (V

NORMALIZED t

vs. AMBIENT TEMPERATURE (VCC = 5V)

PD

COS

= 5V)

CC

NORMALIZED t

vs. SUPPLY VOLTAGE (TA = 25˚C)

t

COS

COS

t

COA

NORMALIZED t

vs. AMBIENT TEMPERATURE (VCC = 5V)

COA

13

Page 14

t

SIS

vs. SUPPLY VOLTAGE (TA = 25˚C)

NORMALIZED t

SIS

t

SIS

NORMALIZED t

vs. AMBIENT TEMPERATURE (VCC = 5V)

SIS

t

SIA

NORMALIZED t

vs. SUPPLY VOLTAGE (TA = 25˚C)

SIA

t

SIA

NORMALIZED t

vs. AMBIENT TEMPERATURE (VCC = 5V)

SIA

14

ATF1500A(L)

Page 15

Ordering Information

ATF1500A(L)

t

PD

(ns)

7.5 4.5 95 ATF1500A-7AC

10 5 76.9 ATF1500A-10AC

12 6 62.5 ATF1500A-12AC

15 8 52.6 ATF1500A-15AC

20 9 40 ATF1500AL-20AC

t

COS

(ns)

F

MAX

(MHz) Ordering Code Package Operation Range

ATF1500A-7JC

ATF1500A-10JC

ATF1500A-10AI

ATF1500A-10JI

ATF1500A-12JC

ATF1500A-12AI

ATF1500A-12JI

ATF1500A-15JC

ATF1500A-15AI

ATF1500A-15JI

ATF1500AL-20JC

ATF1500AL-20AI

ATF1500AL-20JI

44A

44J

44A

44J

44A

44J

44A

44J

44A

44J

44A

44J

44A

44J

44A

44J

44A

44J

Commercial

(0°C to 70°C)

Commercial

(0°C to 70°C)

Industrial

(-40°C to 85°C)

Commercial

(0°C to 70°C)

Industrial

(-40°C to 85°C)

Commercial

(0°C to 70°C)

Industrial

(-40°C to 85°C)

Commercial

(0°C to 70°C)

Industrial

(-40°C to 85°C)

25 9 43 ATF1500AL-25AC

ATF1500AL-25JC

ATF1500AL-25AI

ATF1500AL-25JI

44A

44J

44A

44J

Commercial

(0°C to 70°C)

Industrial

(-40°C to 85°C)

Using “C” Product for Industrial

To use commercial product for Industrial temperature ranges, down-grade one speed grade from the “I” to the “C” device

(7 ns “C” = 10 ns “I”) and de-rate power by 30%.

Package Type

44A 44-lead, Thin Plastic Gull Wing Quad Flatpack (TQFP)

44J 44-lead, Plastic J-leaded Chip Carrier (PLCC)

15

Page 16

Packaging Information

44A, 44-lead, Thin (1.0 mm)

Plastic Gull Wing Quad Flat Package (TQFP)

Dimensions in Millimeters and (Inches)*

12.21(0.478)

11.75(0.458)

10.10(0.394)

9.90(0.386)

0.15(0.006)

0.05(0.002)

0.80(0.031) BSC

0.20(.008)

0.09(.003)

PIN 1 ID

0

7

0.75(0.030)

0.45(0.018)

SQ

0.45(0.018)

0.30(0.012)

SQ

1.20(0.047) MAX

44J, 44-lead, Plastic J-leaded Chip Carrier (PLCC)

Dimensions in Inches and (Millimeters)

.045(1.14) X 45°

.032(.813)

.026(.660)

.050(1.27) TYP

PIN NO.1

IDENTIFY

.045(1.14) X 30° - 45°

.656(16.7)

SQ

.650(16.5)

.695(17.7)

.685(17.4)

.500(12.7) REF SQ

.022(.559) X 45° MAX (3X)

SQ

.012(.305)

.008(.203)

.630(16.0)

.590(15.0)

.021(.533)

.013(.330)

.043(1.09)

.020(.508)

.120(3.05)

.090(2.29)

.180(4.57)

.165(4.19)

*Controlling dimension: millimeters

16

ATF1500A(L)

Page 17

Atmel Headquarters Atmel Operations

Corporate Headquarters

2325 Orchard Parkway

San Jose, CA 95131

TEL (408) 441- 0311

FAX (408) 487-2600

Europe

Atmel U.K., Ltd.

Coliseum Business Centre

Riverside Way

Camberley, Surrey GU15 3YL

England

TEL (44) 1276-686-677

FAX (44) 1276-686-697

Asia

Atmel Asia, Ltd.

Room 1219

Chinachem Golden Plaza

77 Mody Road Tsimhatsui

East Kowloon

Hong Kong

TEL (852) 2721 -9778

FAX (852) 2722-1369

Japan

Atmel Japan K.K.

9F, Tonetsu Shinkawa Bldg.

1-24-8 Shink awa

Chuo-ku, Tokyo 104-0033

Japan

TEL (81) 3-3523-3551

FAX (81) 3-3523-7581

Atmel Colorado Springs

1150 E. Cheyenne Mtn. Blvd.

Colorado Springs, CO 80906

TEL (719) 576-3300

FAX (719) 540-1759

Atmel Rousset

Zone Indu strie lle

13106 Rousset Cedex

France

TEL (33) 4-4253-6000

FAX (33) 4-4253-6001

Fax-on-Demand

North America:

1-(800) 292-8635

International:

1-(408) 441-0732

e-mail

literature@atmel.com

Web Site

http://www.atmel.com

BBS

1-(408) 436-4309

© Atmel Corporation 1999.

Atmel Corporation makes no warranty for the use of its products, other than those expressly contained in the Company’s standard warranty which is detailed in Atmel’s Terms and Conditions located on the Company’s web site. The Company assumes no responsibility for

any errors which may appear in this document, reserves the right to change devices or specifications detailed herein at any time without

notice, and does not make any commitment to update the information contained herein. No licenses to patents or other intellectual property of Atmel are granted by the Company in connection with the sale of Atmel products, expressly or by implication. Atmel’s products are

not authorized for use as critical components in life support devices or systems.

Marks bearing ® and/or ™ are registered trademarks and trademarks of Atmel Corporation.

Terms and product names in this document may be trademarks of others.

Printed on recycled paper.

0759E–06/99/xM

Loading...

Loading...