Page 1

Features

• ATA6833 Temperature Range T

• ATA6834 Extended Temperature Range T

• Direct Driving of 6 External NMOS Transistors with a Maximum Switching Frequency of

50 kHz

• Integrated Charge Pump to Provide Gate Voltages for High-side Drivers and to Supply

the Gate of the External Battery Reverse Protection NMOS

• Built-in 5V/3.3V Voltage Regulator with Current Limitation

• Reset Signal for the Microcontroller

• Sleep Mode with Supply Current of typically < 45 µA

• Wake-up via LIN Bus or High Voltage Input

• Programmable Window Watchdog

• Battery Overvoltage Protection and Battery Undervoltage Management

• Overtemperature Warning and Protection (Shutdown)

• 200 mA Peak Current for Each Output Driver

• LIN Transceiver Conformal to LIN 2.1 and SAEJ2602-2 with Outstanding EMC and ESD

Performance

• QFN48 Package 7 mm × 7 mm

= 125°C, TJ = 150°C

A

= 150°C, TJ = 200°C

A

BLDC Motor

Driver and LIN

System Basis

Chip

ATA6833

1. Description

The ATA6833 and ATA6834 are system basis chips for three-phase brushless DC

motor controllers designed in Atmel

SMART-I.S.

FETs, the system basis chip forms a BLDC motor control unit for automotive

applications. In addition, the circuits provide a 3.3V/5V linear regulator and a window

watchdog.

The circuit includes various control and protection functions like overvoltage and overtemperature protection, short circuit detection, and undervoltage management.

Thanks to these function blocks, the driver fulfils a maximum of safety requirements

and offers a high integration level to save cost and space in various applications. The

target applications are most suitable for the automotive market due to the robust technology and the high qualification level. ATA6834, in particular, is designed for

applications in a high-temperature environment.

™

1. In combination with a microcontroller and six discrete power MOS-

®

’s state-of-the-art 0.8 µm SOI technology

ATA6834

Preliminary

9122B–AUTO–10/08

Page 2

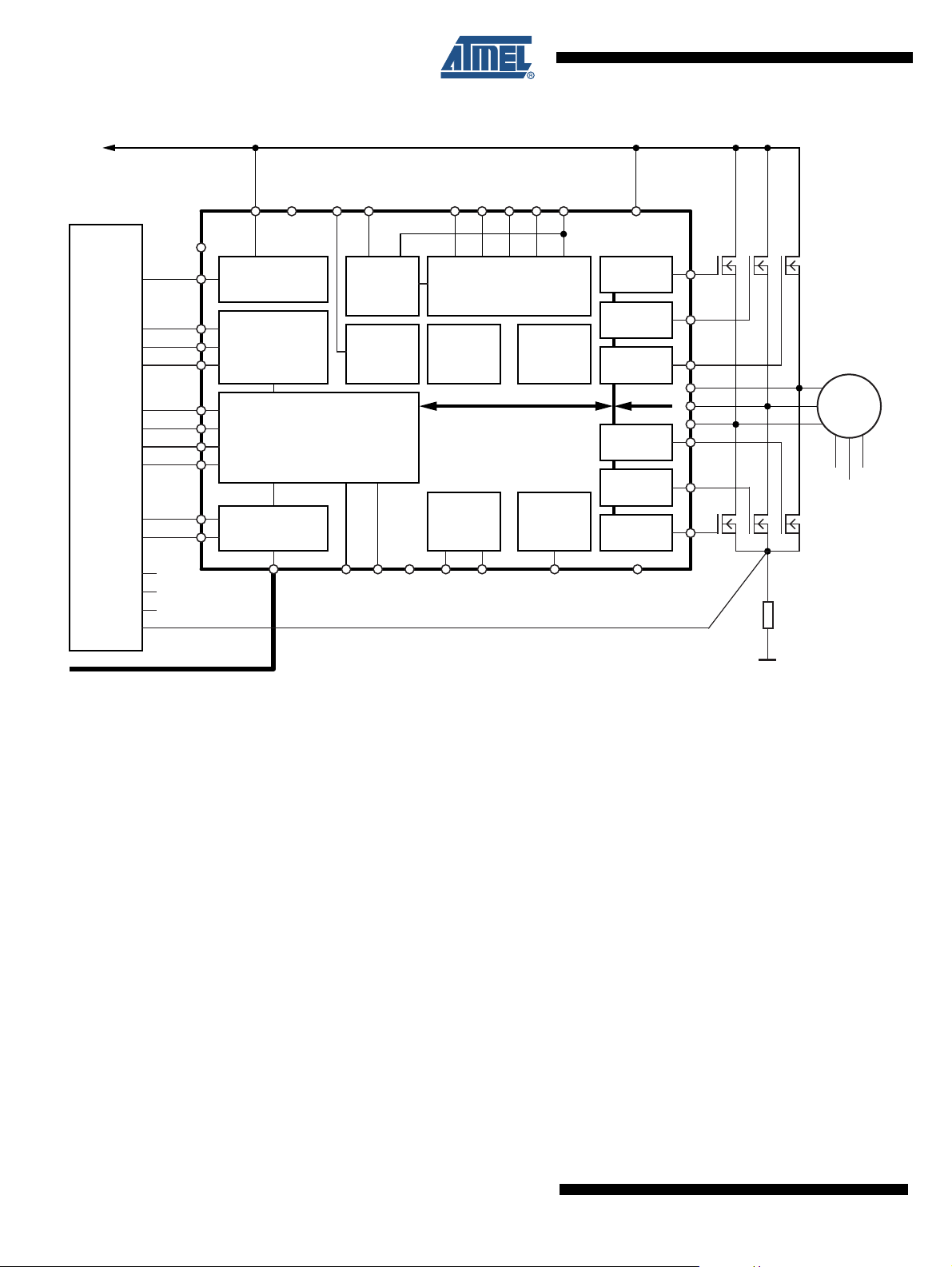

Figure 1-1. Block Diagram

Supervisor:

Short Circuit

Overtemperature

Undervoltage

CP

VBATSW VINTVBAT

VBAT

PBAT

VG

LIN EN1

CPLO2CPLO1

CPOUTCPHI2CPHI1

CC

Timer

WD

Timer

VBG

LIN

Hall A

Hall B

Hall C

ATA6833/34

Logic Control

Oscillator

VINT 5V

Regulator

13V

Regulator

Microcontroller

High-side

Driver 1

High-side

Driver 2

High-side

Driver 3

3.3/5V VCC

Regulator

Low-side

Driver 3

Low-side

Driver 2

Low-side

Driver 1

L2

L1

L3

VMODE

H2

H3

DG3

/RESET

DG2

DG1

WD

IH1-3

IL1-3

TX

RX

VCC

H1

S2

S3

S1

RWD WDDGNDEN2 PGND

M

Hall A

Hall C

Hall B

CC

2

ATA6833/ATA6834 [Preliminary]

9122B–AUTO–10/08

Page 3

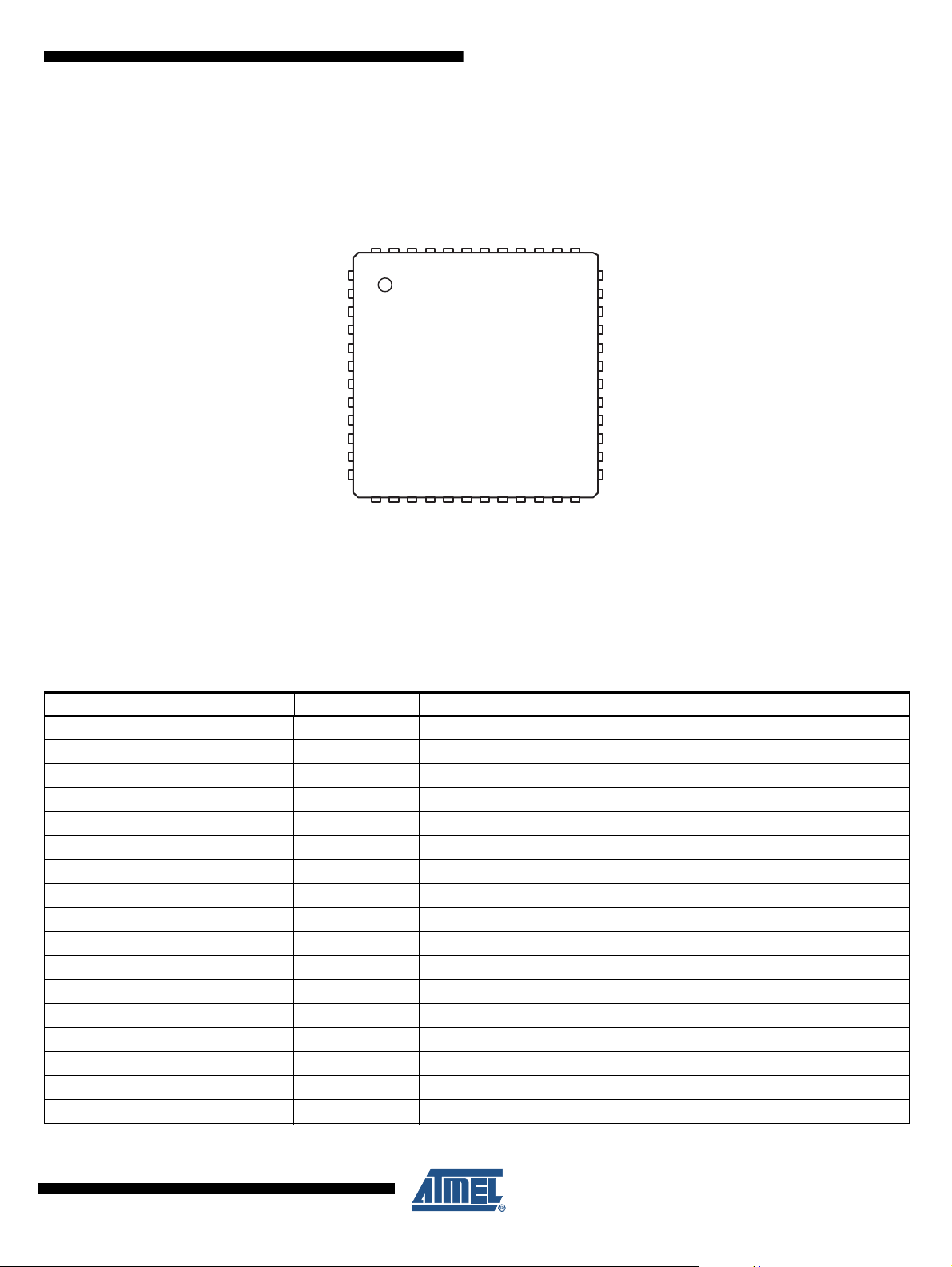

2. Pin Configuration

Figure 2-1. Pinning QFN48

VMODE

VINT

RWD

CC

/RESET

WD

WDD

EN1

NC

NC

GND

NC

ATA6833/ATA6834 [Preliminary]

VG

L1

L2

L3

VBAT

EN2

VBATSW

48 47 46 45 44 43 42 41 40 39 38 37

1

2

3

4

5

6

ATA6833/ATA6834

7

8

9

10

11

12

13 14 15 16 17 18 19 20 21 22 23 24

NC

LIN

TXD

PGND

NC

VCC

Atmel YWW

ZZZZZ-AL

IL2

IL3

IH3

IH2

IL1

IH1

RXD

NC

PBAT

36

35

34

33

32

31

30

29

28

27

26

25

DG1

CPLO1

CPHI1

CPLO2

CPHI2

CPOUT

S1

H1

S2

H2

S3

H3

DG3

DG2

Note: YWW Date code (Y = Year - above 2000, WW = week number)

ATA683x Product name

ZZZZZ Wafer lot number

AL Assembly sub-lot number

Table 2-1. Pin Description

Pin Symbol I/O Function

1 VMODE I Selector for V

2 VINT I/O Blocking capacitor

3 RWD I Resistor defining the watchdog interval

4 CC I/O RC combination to adjust cross conduction time

5 /RESET O Reset signal for microcontroller

6 WD I Watchdog trigger signal

7 WDD I Enable and disable the watchdog

8 EN1 I Microcontroller output to switch system in Sleep Mode

9 N.C. Connect to GND

10 N.C. Connect to GND

11 GND I Ground

12 NC Connect to GND

13 LIN I/O LIN-bus terminal

14 NC Connect to GND

15 TXD I Transmit signal to LIN bus from microcontroller

16 IL3 I Control Input for output L3

17 IH3 I Control Input for output H3

and interface logic voltage level

CC

9122B–AUTO–10/08

3

Page 4

Table 2-1. Pin Description

Pin Symbol I/O Function

18 IL2 I Control Input for output L2

19 IH2 I Control Input for output H2

20 IL1 I Control Input for output L1

21 IH1 I Control Input for output H1

22 RXD O Receive signal from LIN bus for microcontroller

23 DG1 O Diagnostic output 1

24 DG2 O Diagnostic output 2

25 DG3 O Diagnostic output 3

26 H3 O Gate voltage high-side 3

27 S3 I/O Voltage at half bridge 3

28 H2 O Gate voltage high-side 2

29 S2 I/O Voltage at half bridge 2

30 H1 O Gate voltage high-side 1

31 S1 I/O Voltage at half bridge 1

32 CPOUT I/O Charge pump output capacitor

33 CPHI2 I Charge pump capacitor 2

34 CPLO2 O Charge pump capacitor 2

35 CPHI1 I Charge pump capacitor 1

36 CPLO1 O Charge pump capacitor 1

37 NC Connect to GND

38 PBAT I Power supply (after reverse protection) for charge pump and gate drivers

39 VG I/O Blocking capacitor

40 L1 O Gate voltage H-bridge, low-side 1

41 L2 O Gate voltage H-bridge, low-side 2

42 L3 O Gate voltage H-bridge, low-side 3

43 PGND I Power ground for H-bridge and charge pump

44 VCC O 5V/100 mA supply for microcontroller

45 NC Connect to GND

46 VBAT I Supply voltage for IC core (after reverse protection)

47 EN2 I High voltage enable input

48 VBATSW O 100Ω PMOS switch from V

BAT

4

ATA6833/ATA6834 [Preliminary]

9122B–AUTO–10/08

Page 5

ATA6833/ATA6834 [Preliminary]

3. Functional Description

3.1 Power Supply Unit with Supervisor Functions

3.1.1 Power Supply

The IC has to be supplied by a reverse-protected battery voltage. To prevent damage to the IC,

proper external protection circuitry has to be added. It is recommended to use at least one

capacitor combination of storage and RF capacitors behind the reverse protection circuitry,

which is connected close to the VBAT and GND pins of the IC.

A fully integrated low-power and low-drop regulator (VINT regulator), stabilized by an external

blocking capacitor, provides the necessary low-voltage supply needed for the wake-up process.

A trimmed low-power band gap is used as reference for the VINT regulator as well as for the

VCC regulator. All internal blocks are supplied by VINT regulator. VINT regulator must not be

used for any external supply purposes.

Nothing inside the IC except the logic interface to the external microcontroller is supplied by the

5V/3.3V VCC regulator.

Both voltage regulators are checked by a “power-good comparator”, which keeps the whole chip

in reset as long as the internal supply voltage (VINT regulator output) is too low and generates a

reset for the external microcontroller if the output voltage of the VCC regulator is not sufficient.

3.1.2 VBatt Switch

This high-voltage switch provides the battery voltage at pin VBATSW for various purposes. It is

switched ON after power on reset when the IC transits to Active Mode and it will only turn OFF

when the IC changes to Sleep Mode. Watchdog resets do not have an effect on the switch. The

switch can be used for measuring purposes as well as to switch on external voltage regulators.

3.1.3 Voltage Supervisor

This function is implemented to protect the IC and the external power MOS transistors from

damage due to overvoltage on PBAT input. In the event of overvoltage (V

(V

), the external NMOS motor driver transistors will be switched off. The failure state will be

THUV

flagged on DG2 pin. It is recommended to block PBAT with an external RF capacitor to suppress

high frequency disturbances.

3.1.4 Temperature Supervisor

An integrated temperature sensor prevents the IC from overheating. If the temperature is above

the overtemperature pre-warning threshold T

HIGH to signal this event to the external microcontroller. The microcontroller should take actions

to reduce the power dissipation in the IC. If the temperature rises above the overtemperature

shutdown threshold T

transceiver will be switched OFF immediately and the /RESET signal will go LOW. Both thresholds have a built-in hysteresis to avoid oscillations. The IC will return to normal operation (Active

Mode) when it has cooled down below the shutdown threshold. When the junction temperature

drops below the pre-warning threshold, bit DG3 will be switched LOW.

J switch off

) or undervoltage

THOV

, the diagnostic pin DG3 will be switched to

JPW set

, the VCC regulator and all output drivers together with the LIN

9122B–AUTO–10/08

5

Page 6

3.2 Active Mode and Sleep Mode

Sleep Mode

LIN

VCC

EN1

Active ModeActive Mode

T

bus

= 90 µs Regulator Wake-up Time = 4 × T

OSC

T

gotosleep

= 10 µs

T

debounce

The IC has two modes: Sleep Mode and Active Mode. Switching between the modes is

described below. By default the IC starts in Active Mode (which means normal operation) after

power-on. A Go to Sleep procedure switches the IC from Active Mode to Sleep Mode (standby).

A Go to Active procedure brings the IC back from Sleep Mode to Active Mode. When in Sleep

Mode the internal 5V supply (VINT regulator), the EN2 pin input structure, and a certain part of

the LIN receiver remain active to ensure a proper startup of the system. The VCC regulator is

turned off.

The Go to Sleep and Go to Active procedures are implemented as follows:

Go to Sleep:

Pin EN1 is a low-voltage input supplied by the VCC regulator. It is ESD protected by diodes

against VCC and GND. Thus the input voltage at pin EN1 must not go below GND or exceed the

output voltage of the VCC regulator. A transition from HIGH to LOW followed by a permanent

LOW signal for a minimum time period t

Sleep Mode as the EN1 is edge triggered. V

to keep EN1 LOW during normal operation.

Go to Active Using Pin EN2:

Pin EN2 is a high-voltage input for external wake-up signals. Its input structure consists of a

comparator with a built-in hysteresis. It is ESD-protected by diodes against GND and V

and for this reason the applied input voltage must not go below GND or exceed V

EN2 up to V

Go to Active Using the LIN Interface:

switches the IC to Active Mode. EN2 is debounced and edge triggered.

BAT

gotosleep

(typical 10 µs) at pin EN1 switches the IC to

is switched off in Sleep Mode. It is recommended

CC

BAT

, B,

BAT

. Pulling

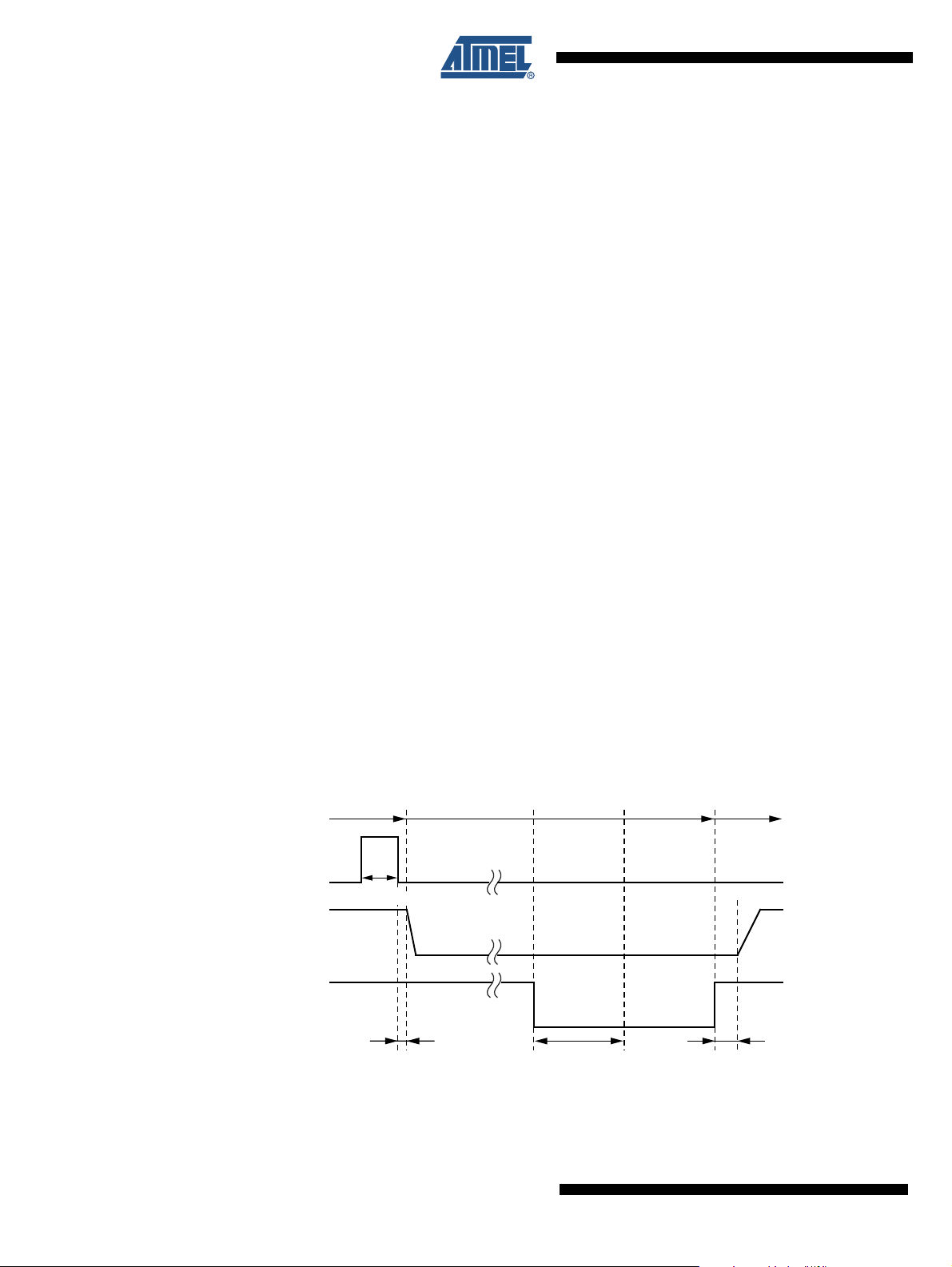

Using the LIN interface provides a second possibility to wake-up the IC (see Figure 3-1). A falling edge at pin LIN followed by a dominant bus level maintained for a minimum time period

(T

) and ending with a rising edge leads to a remote wake-up request. The device switches

bus

from Sleep Mode to Active Mode. The VCC regulator is activated and the internal LIN slave termination resistor is switched on.

Figure 3-1. Wake-up Using the LIN Interface

6

ATA6833/ATA6834 [Preliminary]

9122B–AUTO–10/08

Page 7

ATA6833/ATA6834 [Preliminary]

0

5

10

15

20

25

30

35

40

0255075100125150

Load Current (mA)

ESR (Ω)

ESR versus Load Current at Pin VCC

ESR

min

(C

VCC

= 2.2 µF)

ESR

max

(C

VCC

= 2.2 µF)

0

5

10

15

20

25

0255075100125150

ESR (Ω)

Load Current (mA)

ESR versus Load Current at Pin VCC

ESR

max

(C

VCC

= 10 µF)

ESR

min

(C

VCC

= 10 µF)

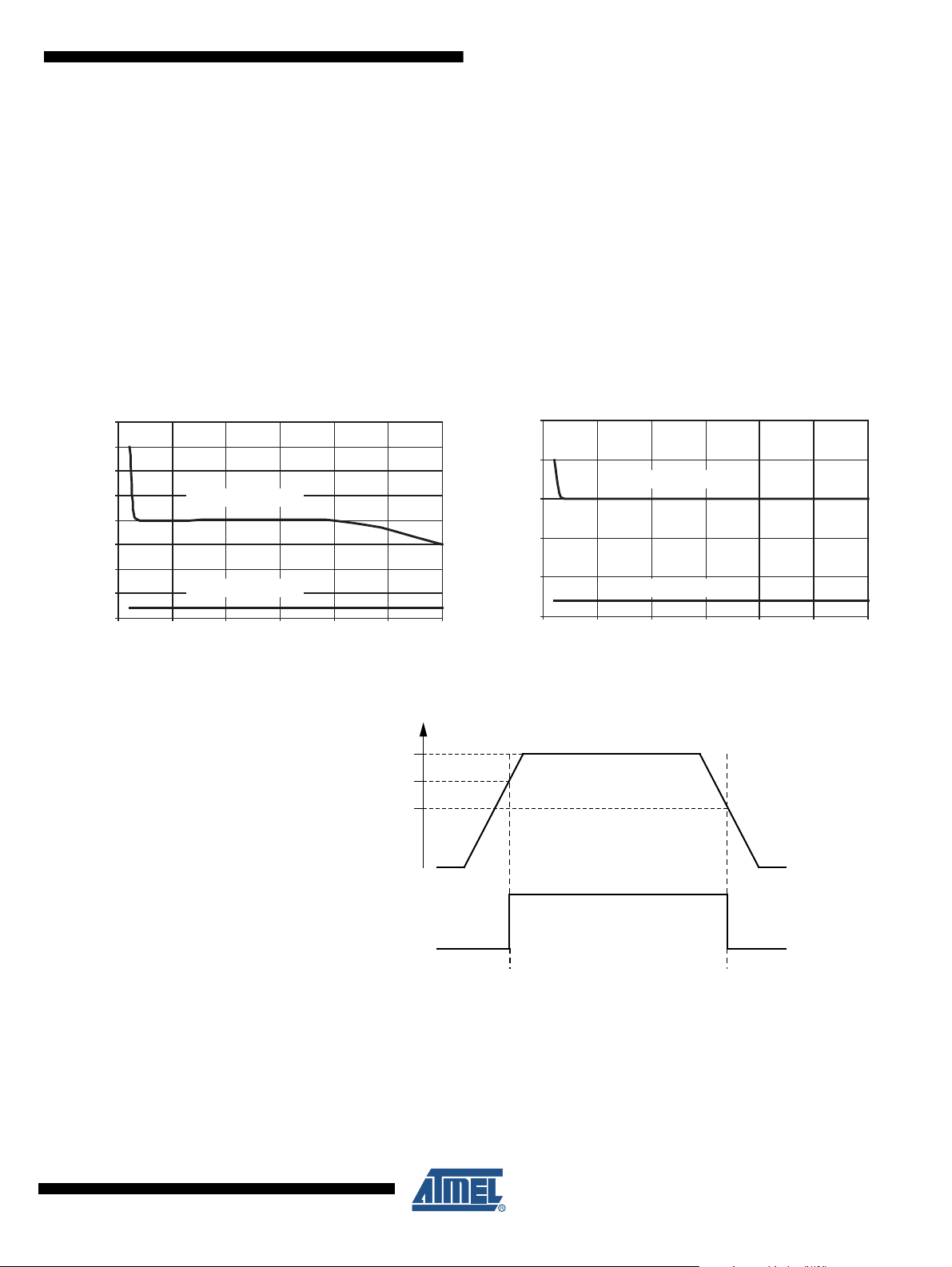

3.3 5V/3.3V VCC Regulator

The 5V/3.3V regulator is fully integrated. It requires an external electrolytic capacitor in the range

of 2.2 µF up to 10 µF and with an ESR in the range from 2Ω to 15Ω for stability (see Figure 3-2).

The output voltage can be configured as either 5V or 3.3V by connecting pin VMODE to either

pin VINT or GND. Since the regulator is not designed to be switched between both output voltages during operation, it is advisable to hard-wire VMODE pin. The logic levels of the

microcontroller interface are adapted to the VCC regulator output voltage. The maximum output

current (I

80 mA. The VCC regulator has a built-in short circuit protection. A comparator checks the output

voltage of the VCC regulator and keeps the external microcontroller in reset as long as the voltage is below the lower operation minimum (shown in Figure 3-33).

Figure 3-2. ESR versus Load Current for External Capacitors with Different Values

) of the regulator is 100 mA. For TJ> 150°C the I

OS1

of ATA6834 is reduced to

OS1

Figure 3-3. /RESET as Function of the VCC Output Voltage

100% VCC

9122B–AUTO–10/08

VCC

88% VCC

80% VCC

/RESET

0V

7

Page 8

3.4 Reset and Watchdog Management

Watchdog

trigger edge

Reset and lead

time, no trigger

Watchdog cycle,

no trigger

Watchdog cycle, trigger

during t

2

window

Reset and lead time,

trigger during lead time

t

resshort

t

1

t

2

t

1

t

d

t

res

t

d

t

1

t

res

t

2

Watchdog trigger

in t

2

window

88% VCC

VCC

WD

/RESET

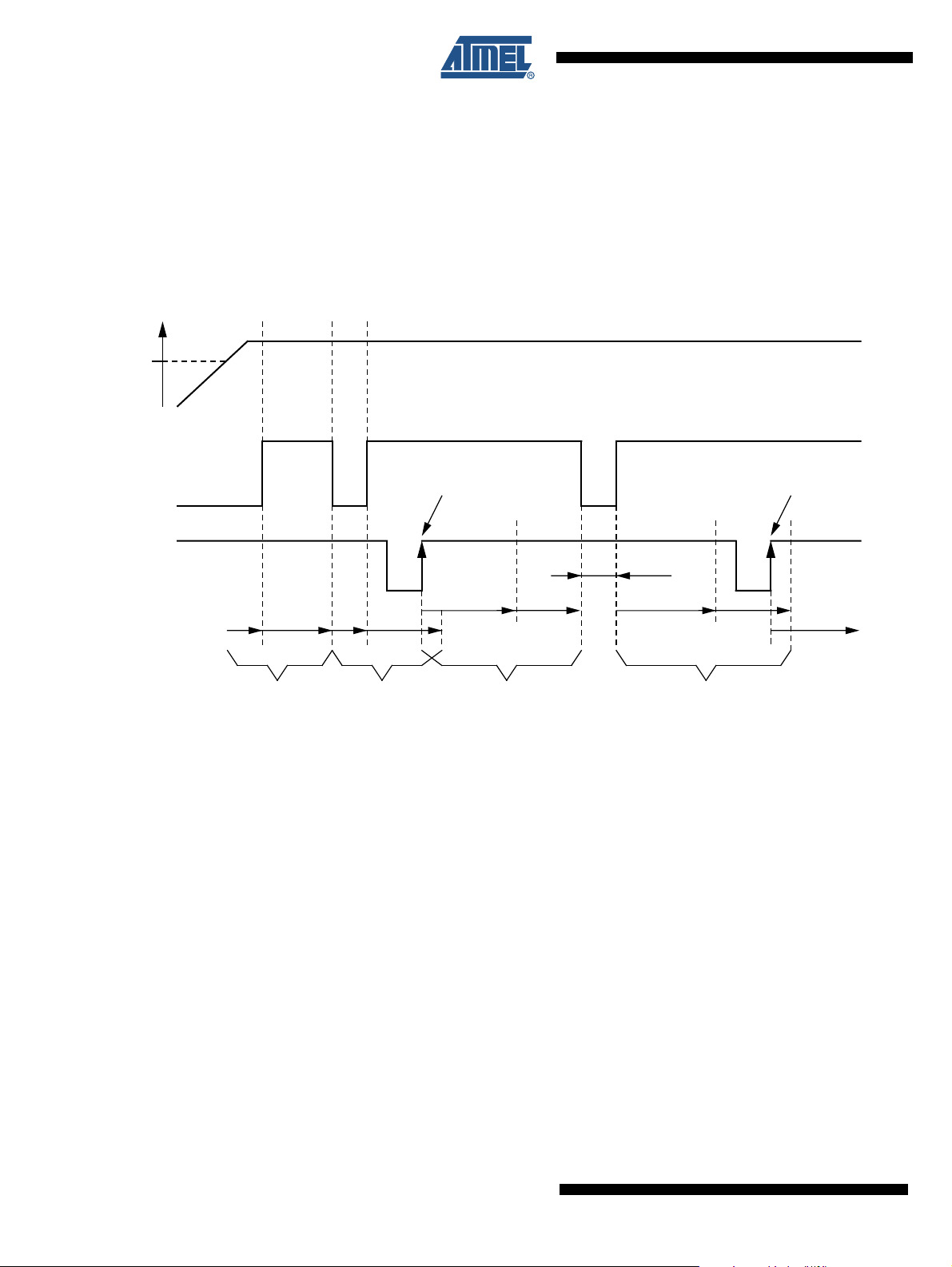

The watchdog timing is based on the trimmed internal watchdog oscillator. Its period time T

is determined by the external resistor RWD. A HIGH signal on WDD pin enables the watchdog

function; a LOW signal disables it. Since WDD pin is equipped with an internal pull-up resistor

the watchdog is enabled by default. In order to keep the current consumption as low as possible

the watchdog is switched off during Sleep Mode.

The timing diagram in Figure 3-4 shows the watchdog and external reset timing.

Figure 3-4. Timing Diagram of the Watchdog in Conjunction with the /RESET Signal

OSC

8

After power-up of the VCC regulator (VCC output exceeds 88% of its nominal value) /RESET

output stays LOW for the timeout period t

res

switches to HIGH. During the following time t

expected otherwise another external reset will be triggered.

When the watchdog has been correctly triggered for the first time, normal watch-dog operation

begins. A normal watchdog cycle consists of two time sections t

for the time t

edges on WD pin during t

at /RESET if no valid trigger has been applied at pin WD during t2. Rising

resshort

also cause a short pulse on /RESET. Start for such a cycle is always

1

the time of the last rising edge either on WD pin or on /RESET pin.

If the watchdog is disabled (WDD = LOW), only the initial reset for the time t

will be generated.

Additional resets will be generated if the VCC output voltage drops below 80% of its nominal

value.

The following example demonstrates how to calculate the timing scheme for valid watchdog trigger pulses, which the external microcontroller has to provide in order to prevent undesired

resets.

ATA6833/ATA6834 [Preliminary]

(typical 10 ms). Subsequently /RESET output

(typical 500 ms) a rising edge at the input WD is

d

and t2 followed by a short pulse

1

after power-up

res

9122B–AUTO–10/08

Page 9

Example:

)

ATA6833/ATA6834 [Preliminary]

Using an external resistor R

T

= 12.32 µs

OSC

t

=980 × T

1

t

=780 × T

2

t

+ t2 = 21.68 ms ±10%

1

= 12.07 ms ±10%

OSC

= 9.609 ms ±10%

OSC

=33kΩ ±1% results in typical parameters as follows:

WD

Hence, the minimum time the external microcontroller has to wait before pin WD can be triggered is in worst case t

WD pin is t

t

max–tmin

=0.9× (t1+t2) = 19.51 ms. Thus watchdog trigger input must remain within

max

= 6.23 ms.

Other values can be set up by picking a different resistor value for R

=1.1× t1= 13.28 ms. The maximum time for the watchdog trigger on

min

. The dependency of T

WD

OSC

on the value of RWD is shown in Figure 3-5.

Figure 3-5. T

versus R

OSC

(µs)

OSC

T

WD

45

40

35

30

25

20

15

10

5

0

10 20 30 40 50 60 70 80 90 100

T

(µs)

OSCmax

RWD (kΩ)

T

OSCmin

(µs)

T

(µs

OSC

3.5 Charge Pump

9122B–AUTO–10/08

A charge pump has been implemented in order to provide sufficient voltage to operate the external high-side power-NMOS transistors and the VG regulator, which drives the low-side

Power-NMOS transistors. The charge pump output voltage at CPOUT pin is controlled to settle

typically about 15V above the voltage at pin PBAT. A built-in supervisor circuit checks if the output voltage is sufficient to operate the VG regulator and external Power-NMOS transistors. The

output voltage is accepted as good when it rises above VCP

CPGOOD

. A charge pump failure is

flagged at DG2 if this minimum can not be reached or if the output voltage drops below the lower

threshold of VCP

CPGOOD

due to overloading.

The two shuffle capacitors should have the same value. The value of the reservoir capacitor

should be at least twice the value of one shuffle capacitor. Two external shuffle capacitors and

an external reservoir capacitor have to be provided. The typical values for the two shuffle capacitor is 100F, and for the reservoir capacitor is 470 nF. All capacitors should be ceramic. It is

advisable to pick a reservoir capacitor with twice or three-times the size of the two equally-sized

shuffle capacitors. The greater the capacitors, the greater the output current capability.

9

Page 10

3.6 VG Regulator

The VG regulator provides a stable voltage to supply the low-side gate drivers and to deliver sufficient voltage for the external low-side Power-NMOS transistors. Typically the output voltage is

12V. In order to guarantee reliable operation even with a low battery voltage, the VG regulator is

supplied by the charge pump output. For stability, an external ceramic capacitor of typically

470 nF has to be provided. There is no internal supervision of the VG output voltage.

3.7 Output Drivers and Control Inputs IL1-IL3, IH1-IH3

This IC offers six push-pull output drivers for the external low-side and high-side power-NMOS

transistors. To guarantee reliable operation, the low-side drivers are supplied by the VG regulator while the high-side drivers are supplied directly by the charge pump. All drivers are designed

to operate at switching frequencies in the range of DC up to 50 kHz. The maximum gate charge

that can be delivered to each external Power-NMOS transistor at 50 kHz is 100 nC.

The output drivers are directly controlled by the digital input pins IL1 to IL3 and IH1 to IH3 (see

Table 3-1). All pins are equipped with an internal pull-down resistor. To operate the output driv-

ers properly the following requirements have to be fulfilled:

1. Device is in Active Mode.

2. In case of watchdog is enabled, at least one valid watchdog trigger has been accepted.

3. The voltage at pin PBAT lies within its operation range. Neither undervoltage nor overvoltage is present.

4. The charge pump output voltage has been accepted as good, thus it exceeded

VCP

CPGOOD

5. No overtemperature shutdown has occurred.

If a short circuit is detected by one of the sense inputs S1 to S3, the output drivers will be

switched off after a debounce time of 6 µs and the output DG1 will be flagged (see also Section

3.8 “Short Circuit Detection” on page 11). The output drivers will be enabled again and DG1 will

be cleared with a rising edge at one of the control inputs (IL1 to IL3, IH1 to IH3).

.

10

Additional logic prevents short circuits due to switching on one power-NMOS transistor while the

opposite one in the same branch is switched on already.

Table 3-1. Status of the Output Drivers Depending on the Control Inputs

Control

Inputs

Mode

Sleep X X OFF Sleep Mode

Active 0 0 OFF

Active 1 0 L[1..3] ON, H[1..3] OFF

Active 0 1 H[1..3] ON, L[1..3] OFF

Active 1 1 OFF Shoot-through protection

IL[1..3]

Control

Inputs

IH[1..3]

Driver Stage for External

ATA6833/ATA6834 [Preliminary]

Power MOS

L[1..3], H[1..3] Comments

9122B–AUTO–10/08

Page 11

3.8 Short Circuit Detection

Short circuits in the motor bridge circuitry are sensed by S1 to S3 inputs. Internal comparators

monitor the voltage differences between the drain and the source terminals of the external

power-NMOS transistors. If one transistor switches on and the voltage drop from its drain to

source stays higher than the threshold V

a short circuit in this branch is detected. In this case, all output drivers are switched off immediately and DG1 pin will be set to HIGH. With a rising edge at any of the pins IL1 to IL3 or IH1 to

IH3, the diagnostic output DG1will be reset and the drivers can be switched on again.

3.9 Cross Conduction Timer

In order to prevent damage of the motor bridge due to peak currents a non-overlapping phase

for switching the power-NMOS transistors is mandatory. Therefore, a cross conduction timer has

been implemented to prevent switching on any output driver for a time t

has been switched off. This also accounts for toggling any other driver after a short circuit was

detected. An external RC parallel combination defines the value for t

follows:

t

= KCC × RCC [kΩ] × CCC [nF], KCC is specified in Section 8. “Electrical Characteristics” on

CC

page 15.

ATA6833/ATA6834 [Preliminary]

(typical 4V) for a longer time than tSC (typically 6 µs),

SC

after any other driver

CC

and can be estimated as

CC

The RC combination is connected between CC and GND pins. When one of the drivers has

been switched off the RC combination is charged to 5V (VINT) and discharged with its time constant. Any low to high transition at the control inputs will be masked out at the driver outputs until

the voltage at CC pin drops below 67% of its initial value (VINT). The timer will be re-triggered at

any time by any falling edge at the control inputs. This is shown in the following figure.

Figure 3-6. Timing Scheme of the Cross Conduction Timer

IL1

L1

IH1

H1

IL3

L3

V

= V

CC

VINT

CC

V

= 67% V

CC

VINT

t

cc

t

cc

t

cc

9122B–AUTO–10/08

At least 5 kΩ minimum and 5 nF at maximum should be used as values for the RC combination.

10 kΩ is recommended. If the non-overlapping phase is controlled by the external microcon-

troller, it is possible to do without the external capacitor. The minimum time t

is defined by the

CC

parasitic capacitance at CC pin.

11

Page 12

3.10 Diagnostic Outputs D1 - D3

As mentioned in the sections above, the diagnostic outputs DG1 to DG3 are used to signal failures. This is summarized in the following table.

Table 3-2. Status of the Diagnostic Outputs (Normal Operation)

Device Status Diagnostic Outputs Comments

CPOK OT1 OV UV SC DG1 DG2 DG3

0 X X X X – 1 – Charge pump failure

X 1 X X X – – 1 Overtemperature prewarning

X X 1 X X – 1 – Overvoltage

X X X 1 X – 1 – Undervoltage

X X X X 1 1 – – Short circuit

Note: X represents: no effect)

OT1: overtemperature warning

OV: overvoltage of PBAT

UV: undervoltage of PBAT

SC: short circuit

CPOK: charge pump OK

In order to differentiate between LIN and EN2 wake-up, DG1 output will be set to LOW or HIGH

respectively. LOW indicates wake-up by LIN, HIGH indicates wake-up by EN2. DG1 output will

be cleared by the first valid watchdog trigger after wake-up or by the first rising edge at one of

the control inputs (IL1 to IL3 and IH1 toIH3) if the watchdog is disabled.

3.11 LIN Transceiver

Table 3-3. Indicating Wake-up Source

Diagnostic Outputs

Wake-up SourceDG1 DG2 DG3

1–– EN2

0–– LIN

ATA6833 and ATA6834 include a fully integrated LIN transceiver complying with LIN specification 2.1 and SAEJ2602 2. The transceiver consists of a low-side driver with slew rate control,

wave shaping, current limiting, and a high voltage comparator followed by a debouncing unit in

the receiver.

During transmission, the data applied at pin TXD will be transferred to the bus driver to generate

a bus signal on LIN pin. TXD input has an internal pull-up resistor.

To minimize the electromagnetic emission of the bus line, the bus driver has a built-in slew rate

control and wave-shaping unit. The transmission will be aborted by a thermal shutdown or by a

transition to Sleep Mode.

12

ATA6833/ATA6834 [Preliminary]

9122B–AUTO–10/08

Page 13

Figure 3-7. Definition of Bus Timing Parameters

ATA6833/ATA6834 [Preliminary]

(Input to transmitting node)

TXD

VS

(Transceiver supply

of transmitting node)

RXD

(Output of receiving node1)

TH

TH

TH

TH

Rec(max)

Dom(max)

Rec(min)

Dom(min)

t

rx_pdf(1)

t

Bit

t

Bus_dom(max)

LIN Bus Signal

t

Bus_dom(min)

t

Bit

t

Bus_rec(min)

t

Bit

Thresholds of

receiving node1

Thresholds of

receiving node2

t

Bus_rec(max)

t

rx_pdr(1)

(Output of receiving node2)

RXD

The recessive BUS level is generated from the integrated 30 kΩ pull-up resistor in series with an

active diode. This diode protects against reverse currents on the bus line in case of a voltage difference between the bus line and VSUP (V

necessary to use the IC as a LIN slave. If this IC is used as a LIN master, the LIN pin is terminated by an external 1 kΩ resistor in series with a diode to VBAT.

As PWM communication directly over the LIN transceiver in both directions is possible, there is

no TXD timeout feature implemented in the LIN transceiver.

t

rx_pdr(2)

BUS

> V

t

rx_pdf(2)

). No additional termination resistor is

SUP

9122B–AUTO–10/08

13

Page 14

4. Absolute Maximum Ratings

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. This is a stress rating

only and functional operation of the device at these or any other conditions beyond those indicated in the operational sections of this

specification is not implied. Exposure to absolute maximum rating conditions for extended periods may affect device reliability.

All voltages are referenced to pin GND. [xxx] Values for the ATA6834.

Parameters Pin Symbol Min. Max. Unit

Input voltage PGND V

PGND

Negative input current VBAT IVBAT TBD TBD mA

Negative input current PBAT IPBAT TBD TBD mA

Supply voltage VBAT V

Supply voltage PBAT V

Logic output voltage

Logic input voltage

/RESET, DG1,

DG2, DG3, RXD

IL1-3, IH1-3, WD,

WDD, EN1, TXD

V

V

Output voltage VINT, VCC V

Analog input voltage RWD, CC V

Digital input voltage EN2 V

Digital input voltage VMODE V

Output voltage VG V

Input voltage LIN V

Output voltage S1, S2, S3 V

Output voltage L1, L2, L3 V

Output voltage H1, H2, L3 V

Charge pump CPLO1, 2 V

Charge pump CPHI1, 2 V

Output voltage CPOUT V

Output voltage VBATSW V

Storage temperature T

/RESET

V

IL1-3

V

S1

L1

H1

CPLO1

CPHO1

VBAT

PBAT

, V

DG1

, V

DG3

, V

IH1-3

, V

EN1

, V

INT

RWD

EN2

VMODE

VG

VLIN

, VS2, V

, VL2, V

, VH2, V

, V

, V

CPOUT

VBATSW

Storage

, V

RXD

, VWD,

TXD

VVCC

CPLO2

CPHO2

S3

L3

H3

DG2

,

–0.3 +0.3 V

–0.3 +40 (500 ms) V

–0.3 +40 (500 ms) V

–0.3 V

–0.3 V

+ 0.3 V

VCC

+ 0.3 V

VCC

–0.3 +5.5 V

–0.3 V

–0.3 V

–0.3 V

+ 0.3 V

VCC

+ 0.3 V

VBAT

+ 0.3 V

VINT

–0.3 +16 V

–27 V

+ 2 V

VBAT

–6 +30 V

V

– 0.3 V

PGND

V

– 1 V

S1, 2, 3

–0.3 V

–0.3 V

+ 0.3 V

VG

+ 16 V

S1, 2, 3

+ 0.3 V

PBAT

+ 0.3 V

CPOUT

–0.3 +40 V

–0.3 V

+ 0.3 V

VBAT

–55 +150 °C

5. Thermal Resistance

Parameters Symbol Value Unit

Thermal resistance junction to heat slug R

Thermal resistance junction to ambient when heat slug

is soldered to PCB

14

ATA6833/ATA6834 [Preliminary]

thjc

R

thja

<5 K/W

25 K/W

9122B–AUTO–10/08

Page 15

ATA6833/ATA6834 [Preliminary]

6. Operating Range

The operating conditions define the limits for functional operation and parametric characteristics of the device. Functionality outside these

limits is not implied unless otherwise stated explicitly. [xxx] Values for the ATA6834

Parameters Symbol Min Max Unit

Operating supply voltage

Operating supply voltage

Operating supply voltage

(1)

(2)

(3)

(t = 500 ms) V

Ambient temperature range T

Junction temperature range T

V

V

VBAT

VBAT

VBAT

A

J

5.5 V

4.3 5.5 V

(4)

V

THOV

–40 +150 °C

–40 +150 (200) °C

Notes: 1. Full functionality

2. Output drivers are switched off, extended range for parameters for voltage regulators

3. Output drivers and charge pump are switched off

4. Voltages higher V

for maximum 500 ms

THOV

7. Noise and Surge Immunity

Parameters Standard and Test Conditions Value

Conducted interferences ISO 7637-1 Level 4

Conducted disturbances CISP25 Level 5

ESD (Human Body Model) ESD S 5.1 ±2 kV

ESD (Human Body Model) DIN EN61000-4-2, Pin LIN, VBAT, PBAT to GND ±6 kV

Latch-up immunity JESD78, AEL-Q100 (004) Class II, level A

Note: 1. Test pulse 5: V

bat max

= 40V

(4)

THOV

40 V

(1)

V

8. Electrical Characteristics

All parameters given are valid for 5.5V ≤V

GND. [xxx] Values for the ATA6834.

No. Parameters Test Conditions Pin Symbol Min. Typ. Max. Unit Type*

1 Power Supply and Supervisor Functions

1.1 Current consumption V

Current consumption V

1.3

in Standby Mode

Current consumption V

1.4

in Standby Mode

1.5 Internal power supply V

VBATVVBAT

VBAT

V

VBAT

VBAT

V

PBAT

VBAT

1.6 Overvoltage threshold PBAT V

Overvoltage threshold

1.7

hysteresis

1.8 Undervoltage threshold PBAT V

Undervoltage threshold

1.9

hysteresis

V

1.10 R

VBAT-Switch switch

DSON

VBAT

I

VBATSW

*) Type means: A = 100% tested, B = 100% correlation tested, C = Characterized on samples, D = Design parameter

≤ 18V and for –40°C ≤ TJ ≤ 150°C (200°C) unless stated otherwise. All values refer to PIN

VBAT

= 13.5V

= 13.5V VBAT I

= 13.5V PBAT I

> 7V VINT V

= 13.5V,

(1)

= –15 mA

VBAT I

PBAT V

PBAT V

VBATSW R

VBAT

VBAT

VPBAT

VINT

THOV

TOVhys

THUV

TUVhys

ON_VBATSW

7mAA

65 µA A

TBD µA A

4.7 5.0 5.3 V A

19.8 22.3 V A

11.5VA

5.0 5.5 V A

0.2 0.4 V A

100 Ω A

9122B–AUTO–10/08

15

Page 16

8. Electrical Characteristics (Continued)

All parameters given are valid for 5.5V ≤V

GND. [xxx] Values for the ATA6834.

No. Parameters Test Conditions Pin Symbol Min. Typ. Max. Unit Type*

1.11 Thermal prewarning set T

1.12 Thermal prewarning reset T

Thermal prewarning

1.13

hysteresis

1.14 Thermal shutdown off T

1.15 Thermal shutdown on T

Thermal shutdown

1.16

hysteresis

Ratio thermal shutdown

1.17

off/thermal prewarning set

Ratio thermal shutdown

1.18

on/thermal prewarning

reset

2 5V/3.3V Regulator

V

MODE=VINT

2.1 Regulated output voltage

2.2 Regulated output voltage

V

MODE

I

Load

V

MODE=VINT

V

MODE

I

Load

150°C < TJ<200°C

V

2.3 Regulated output voltage

2.4 Regulated output voltage

MODE=VINT

V

MODE

I

Load

V

MODE=VINT

V

MODE

I

Load

150°C < T

V

2.5 Line regulation

2.6 Load regulation

MODE=VINT

V

MODE

I

Load

V

MODE=VINT

V

MODE

I

Load

I

Load

150°C < T

V

2.7 Output current limit

MODE=VINT

V

MODE

I

Load

*) Type means: A = 100% tested, B = 100% correlation tested, C = Characterized on samples, D = Design parameter

≤ 18V and for –40°C ≤ TJ ≤ 150°C (200°C) unless stated otherwise. All values refer to PIN

VBAT

, 7V < V

BAT

= GND, 5.5V < V

< 40V

<40V

BAT

JPW set

JPW reset

ΔT

J switch off

J switch on

ΔT

J switch off

T

J switch off

T

JPW set

T

J switch on

T

JPW reset

JPW

120

(170)

105

(155)

150

(200)

135

(185)

/

1.05 1.15 B

/

1.05 1.15 B

4.85

V

CC

V

VCC

3.20

145

(195)

130

(180)

170

(220)

155

(205)

15 °C B

175

(225)

160

(210)

200

(250)

185

(235)

15 °C B

5.15

3.40 V A

= 0 to 100 mA

, 7V < V

= GND, 5.5V < V

=0to80mA

, 5.5V < V

=GND, 5V<V

BAT

BAT

BAT

< 40V

<40V

BAT

<7V

<5.5V

4.85

V

CC

V

VCC

3.20

4.50

V

CC

V

VCC

2.97

5.15

3.40

5.15

3.40 V A

=0to60mA

, 5.5V < V

=GND, 5V<V

=0to50mA

<200°C

J

, 7V < V

= GND, 5.5V < V

BAT

BAT

BAT

<7V

<5.5V

< 40V

<40V

BAT

4.50

V

CC

V

VCC

2.97

5.15

3.40

50

V

CC

50 mV A

= 50 mA, –40°C < TJ< 150°C

, V

=GND, V

BAT

BAT

= 0 to 100 mA

>7V

>5.5V

V

CC

50

50

=0to80mA,

<200°C

J

, V

=GND, V

BAT

BAT

>7V

>5.5V

V

CC

I

OS1

100

100

320

320 mA C

@ RESET

°C B

°C B

°C B

°C B

VA

VA

mV A

16

ATA6833/ATA6834 [Preliminary]

9122B–AUTO–10/08

Page 17

ATA6833/ATA6834 [Preliminary]

8. Electrical Characteristics (Continued)

All parameters given are valid for 5.5V ≤V

GND. [xxx] Values for the ATA6834.

No. Parameters Test Conditions Pin Symbol Min. Typ. Max. Unit Type*

V

MODE=VINT

V

2.8 Output current limit

I

Load

MODE

150°C < TJ<200°C

2.12 HIGH threshold VMODE V

2.13 LOW threshold VMODE V

3 Reset and Watchdog

3.1

threshold voltage level

V

CC

for /RESET

VMODE = VINT

(VMODE = GND)

3.2 Hysteresis of /RESET level HYS

3.3 Length of pulse at /RESET t

Length of short pulse at

3.4

/RESET

3.5 Wait for the first WD trigger t

Time for VCC < V

3.6

before activating /RESET

3.8 Watchdog oscillator period R

tHRESL

RWD

3.12 Close window t1

3.13 Open window t2

Output low-level at pin

3.14

/RESET

Internal pull-up resistor at

3.15

pin /RESET

I

OLRES

4 LIN Transceiver

4.1 Low-level output current

4.2 High-level output current

Driver recessive output

4.3

voltage

Driver dominant voltage

4.4

V

BUSdom_DRV_LoSUP

Driver dominant voltage

4.5

V

BUSdom_DRV_HiSUP

Driver dominant voltage

4.6

V

BUSdom_DRV_LoSUP

Driver dominant voltage

4.7

V

BUSdom_DRV_HiSUP

Normal mode;

V

LIN

Normal mode; V

V

RXD=VCC

V

TXD=VCC

V

VBAT

R

load

V

VBAT

R

load

V

VBAT

R

load

V

VBAT

R

load

4.8 Pull up resistor to VS serial diode required R

4.9 Current limitation V

BUS

*) Type means: A = 100% tested, B = 100% correlation tested, C = Characterized on samples, D = Design parameter

≤ 18V and for –40°C ≤ TJ ≤ 150°C (200°C) unless stated otherwise. All values refer to PIN

VBAT

, V

>7V

=GND, V

@ RESET,

BAT

BAT

>5.5V

VCC I

= 33 kΩ T

OS1

VMODE H

VMODE L

V

tHRESH

RESth

res

t

resshort

d

t

delayRESL

OSC

70

70

320

320

4.0 V A

0.7 V A

4.1

(2.7)

4.7

(3.0)

0.2 V A

812msA

1.8 2.2 ms A

400 600 ms A

2 µsC

11.09 13.55 µs A

980 ×

T

OSC

780 ×

T

OSC

= 1 mA V

=0V, V

RXD

=0.4V

LIN=VBAT

–0.4V

; I

=0mA V

LIN

= 7.3V

= 500Ω

= 18V

= 500Ω

= 7.3V

= 1000Ω

= 18V

= 1000Ω

= V

BAT_max

OLRES

R

PURES

IL

RXD

IH

RXD

BUSrec

V

_LoSUP

V

_HiSUP

V

_LoSUP_1k

V

_HiSUP_1k_

LIN

I

BUS_LIM

5 10 15 kΩ D

2mAD

0.9 ×

VBAT

0.6 V A

0.8 V A

20 47 kΩ A

50 200 mA A

0.4 V A

–2 mA D

1.2 V A

2VA

mA C

VA

VA

A

A

9122B–AUTO–10/08

17

Page 18

8. Electrical Characteristics (Continued)

All parameters given are valid for 5.5V ≤V

GND. [xxx] Values for the ATA6834.

No. Parameters Test Conditions Pin Symbol Min. Typ. Max. Unit Type*

Input leakage current at the

4.10

receiver including pull-up

resistor as specified

Input leakage current

driver off

V

BUS

V

BAT

Driver off

Leakage current LIN

4.11

recessive

8V < V

8V < V

V

BUS

Leakage current at ground

loss

Control unit disconnected

4.12

from ground

Loss of local ground must

GND

V

BAT

0V < V

not affect communication in

the residual network

Node has to sustain the

current that can flow under

4.13

this condition. Bus must

remain operational under

V

BAT

V

SUP_Device

0V < V

this condition

V

4.14 Center of receiver threshold

4.15 Receiver dominant state V

4.16 Receiver recessive state V

4.17 Receiver input hysteresis V

BUS_CNT

(V

th_dom+Vth_rec

EN

EN

HYS

7V < V

TH

rec(max)

TH

Dom(max)

t

4.18 Duty cycle 1

= 50 µs

Bit

D1 = t

Load1: 1 nF + 1 kΩ

Load2: 10 nF + 500Ω

7V < V

TH

rec(min)

TH

4.19 Duty cycle 2

Dom(min)

t

= 50 µs

Bit

D2 = t

Load1: 1 nF + 1 kΩ

Load2: 10 nF + 500Ω

4.20 Receiver propagation delay

Symmetry of receiver

4.21

propagation delay rising

edge minus falling edge

7V < V

t

rec_pd

7V < V

t

rx_sym

*) Type means: A = 100% tested, B = 100% correlation tested, C = Characterized on samples, D = Design parameter

≤ 18V and for –40°C ≤ TJ ≤ 150°C (200°C) unless stated otherwise. All values refer to PIN

VBAT

= 0V

I

BUS_PAS_dom

–1 mA A

= 12V

< 18V

BAT

BUS

= V

BAT

Device

= 12V

BUS

< 18V

= VS

< 18V

I

BUS_PAS_rec

I

BUS_NO_gnd

20 µA A

–1 +1 mA A

disconnected

= GND

< 18V

BUS

=

)/2

= 5V V

= 5V V

= V

– V

th_rec

< 18V

VBAT

=0.744× V

=0.581× V

th_dom

VBAT

VBAT

I

BUS

V

BUS_CNT

BUSdom

BUSrec

V

BUShys

0.475 ×

V

VBAT

0.6 ×

V

VBAT

0.5 ×

V

VBAT

100 µA A

0.525 ×

V

VBAT

0.4 ×

V

VBAT

0.175 ×

V

VBAT

D1 0.396 A

Bus_rec(min)

< 18V

VBAT

=0.422× V

=0.284× V

/(2 × t

Bit

VBAT

VBAT

)

D2 0.581 A

/(2×t

, t

rx_pdf

Bit

rx_pdf

)

t

)

rx_pd

t

rx_sym

–2 +2 µs

6µsA

Bus_rec(max)

< 18V

VBAT

= max(t

rx_pdr

< 18V

VBAT

= t

– t

rx_pdr

VA

VA

VA

VA

18

ATA6833/ATA6834 [Preliminary]

9122B–AUTO–10/08

Page 19

ATA6833/ATA6834 [Preliminary]

8. Electrical Characteristics (Continued)

All parameters given are valid for 5.5V ≤V

GND. [xxx] Values for the ATA6834.

No. Parameters Test Conditions Pin Symbol Min. Typ. Max. Unit Type*

Dominant time for wake-up

4.22

via LIN-bus

V

LIN

5 Control Inputs EN1, IL1-3, IH1-3, WD, TX, WDD

5.1 Input low-level threshold V

5.2 Input high-level threshold V

5.3 Hysteresis HYS 0.3 C

5.4 Pull-down resistor EN1, IL1-3, IH1-3, WD R

5.5 Pull-up resistor TXD, WDD R

5.7 Debounce time EN1 t

6Charge Pump

V

VBAT

I

6.1 Charge pump voltage

6.2 Charge pump voltage

Period charge pump

6.3

oscillator

Charge pump output

6.4

voltage for active drivers

LoadCPOUT

I

LoadVG

C

CP1,2

C

CPOUT

V

VBAT

I

LoadCPOUT

I

LoadVG

C

CP1,2

C

CPOUT

7 VG Regulator

V

VG Regulator Output

7.1

Voltage

VG Regulator Line

7.2

Regulation

VG Regulator Load

7.3

Regulation

BAT

V

CPOUT

I

LoadVG

V

BAT

V

CPOUT1

I

LoadVG

V

BAT

V

CPOUT

I

LoadVG1

8 H-bridge Driver

Low-side driver HIGH

8.1

output voltage

ON-resistance of sink stage

8.2

of pins Lx

ON-resistance of source

8.3

stage of pins Lx

ILX = 100 mA R

ILX = 100 mA R

*) Type means: A = 100% tested, B = 100% correlation tested, C = Characterized on samples, D = Design parameter

≤ 18V and for –40°C ≤ TJ ≤ 150°C (200°C) unless stated otherwise. All values refer to PIN

VBAT

= 0V T

gotosleep

BUS

IL

IH

PD

PU

30 90 150 µs A

0.3 ×

V

VCC

0.7 ×

V

VCC

25 50 100 kΩ A

25 50 100 kΩ A

91011 µsA

> 7V

= 0A

= 0A

= 47 nF

CPOUT V

CPOUT

V

VBAT

+ 11V

V

VBAT

+ 18

= 220 nF

> 7V

= 7.5 mA,

= 0A

= 47 nF

CPOUT V

CPOUT

V

VBAT

+10V

= 220 nF

2.5 µs B

CPOUT VCP

T

CP

CPGOOD

TBD 7.5 TBD V A

= 13.5V

= 20V

VG V

VG

11 12.5 14 V A

= 7.5 mA

= 13.5V

= 20V, V

CPOUT2

= 35V

VG ΔV

VG_Line

100 mV A

= 7.5 mA

= 13.5V

= 25V

=1mA, I

LoadVG2

=60mA

VG ΔV

VG_Load

V

LxH

DSON_LxL

DSON_LxH

100 mV A

V

VG

20 Ω A

20 Ω A

VA

VA

VA

VA

VD

9122B–AUTO–10/08

19

Page 20

8. Electrical Characteristics (Continued)

All parameters given are valid for 5.5V ≤V

GND. [xxx] Values for the ATA6834.

No. Parameters Test Conditions Pin Symbol Min. Typ. Max. Unit Type*

Output peak current at pins

8.4

Lx switched to LOW

Output peak current at pins

8.5

Lx switched to HIGH

Sink resistance between Lx

8.6

and GND

ON-resistance of sink stage

8.7

of pins Hx

ON-resistance of source

8.8

stage of pins Hx

Output peak current at pins

8.9

Hx (switched from low to

high

Output peak current at pins

8.10

Hx (switched from high to

low)

Output peak current at pins

8.11

Hx (switched from low to

high

Output peak current at pins

8.12

Hx (switched from high to

low)

Output voltage low level

8.13

pins Hx

Output voltage high level

8.14

pins Hx

Sink resistance between Hx

8.15

and Sx

Sink resistance between Sx

8.16

and GND

V

= 3V I

Lx

= 3V I

V

Lx

V

= 0V R

Sx

= V

V

Sx

IHx = 100 mA

VHx – VSx = 0V;

V

VBAT

C = 10 nF

R = 1Ω

V

Hx

V

VBAT

C = 10 nF

R = 1Ω

V

= 0V;

Lx

V

VBAT

C = 10 nF

R = 1Ω

V

LX

V

VBAT

C = 10 nF

R = 1Ω

V

Sx

= 1 mA

I

Hx

= –100 µA V

I

Hx

Dynamic Parameters

Propagation delay time,

8.17

low-side driver from high to

low

Propagation delay time,

8.18

low-side driver from low to

high

V

8.19 Fall time low-side driver

8.20 Rise time low-side driver

VBAT

CGx = 5 nF

V

VBAT

CGx = 5 nF

*) Type means: A = 100% tested, B = 100% correlation tested, C = Characterized on samples, D = Design parameter

≤ 18V and for –40°C ≤ TJ ≤ 150°C (200°C) unless stated otherwise. All values refer to PIN

VBAT

–100 mA D

100 mA D

45 75 115 kΩ A

20 Ω A

20 Ω A

–200 mA C

VBAT

= 7V – 20V

Lx to

GND

LxL

LxH

R

Lxsink

DSON_HxL

R

DSON_HxH

I

HxH,

– VSx = 10V;

= 7 – 20V

= 7 – 20V

I

I

LxH,

HxL

200 mA C

–200 mA C

= 10V;

= 7 – 20V

= 0V

= 13.5V

= 13.5V

Sx to

GND

I

LxL

V

HxHstat

R

Hxsink

R

Sxsink

t

LxHL

t

LxLH

t

t

HxL

Lxf

Lxr

200 mA C

0.3 V A

V

VCPOUT

– 1V

V

VCPOUT

45 75 115 kΩ A

1MΩ D

0.9 µs A

0.9 µs A

TBD µs A

TBD µs A

VA

20

ATA6833/ATA6834 [Preliminary]

9122B–AUTO–10/08

Page 21

ATA6833/ATA6834 [Preliminary]

8. Electrical Characteristics (Continued)

All parameters given are valid for 5.5V ≤V

GND. [xxx] Values for the ATA6834.

No. Parameters Test Conditions Pin Symbol Min. Typ. Max. Unit Type*

Propagation delay time,

8.21

high-side driver from high

to low

Propagation delay time,

8.22

high-side driver from low to

high

V

8.23 Fall time high-side driver

8.24 Rise time high-side driver

Short circuit detection

8.25

voltage

C

V

C

VBAT

Gx

VBAT

Gx

8.26 Short circuit detection time t

Cross Conduction Timer

Cross conduction time

8.27

constant

9 Input EN2

9.1 Input low level threshold V

9.2 Input high level threshold V

9.3 Hysteresis HYS 0.47 V C

9.4 Pull-down resistor R

9.5 Debounce time t

10 Diagnostic Outputs DG1, DG2, DG3

10.1 Low level output current V

10.2 High level output current V

DG

DG

*) Type means: A = 100% tested, B = 100% correlation tested, C = Characterized on samples, D = Design parameter

≤ 18V and for –40°C ≤ TJ ≤ 150°C (200°C) unless stated otherwise. All values refer to PIN

VBAT

= 13.5V,

= 5 nF

= 13.5V,

= 5 nF

t

HxHL

t

HxLH

t

t

V

K

Hxf

Hxr

SC

db

SC

CC

IH

PD

3.5 4 4.5 V A

5.4 6 6.6 µs A

TBD 0.41 TBD B

IL

2.3 3.6 V A

2.8 4.0 V A

50 100 200 kΩ A

10 20 25 µs A

0.9 µs A

0.9 µs A

TBD µs A

TBD µs A

= 0.4V IL 2 mA A

= VCC – 0.4V IH –2 mA A

9122B–AUTO–10/08

21

Page 22

9. Application

This section describes the principal application for which the ATA6833/ATA6834 was designed.

Figure 9-1. Typical Application

Battery

+

C

CPOUT

ADC

C

VCC

VMODE

/RESET

IH1-3

IL1-3

Microcontroller

VCC

DG1

DG2

DG3

WD

EN1

RX

TX

C

VBAT

3.3/5V VCC

Regulator

Supervisor:

Short Circuit

Overtemperature

Undervoltage

Logic Control

LIN

LIN

VINT

VBATSW

VINT

C

VG

VG

13V

Regulator

VINT 5V

Regulator

EN2

GND

C

CP1

CPHI1

CPLO1

VBG

ATA6833/34

WD

Timer

RWD

WDD

CPLO2

CP

C

CP2

CPHI2

CPOUT

Oscillator

CC

Timer

CC

PBAT

High-side

Driver 3

High-side

Driver 2

High-side

Driver 1

Low-side

Driver 1

Low-side

Driver 2

Low-side

Driver 3

PGND

H3

H2

H1

S1

S2

S3

L1

L2

L3

22

Hall C

Hall B

Hall A

LIN

KL 15

R

WD

R

CC

ATA6833/ATA6834 [Preliminary]

C

CC

9122B–AUTO–10/08

Page 23

ATA6833/ATA6834 [Preliminary]

Table 9-1. Typical External Components

Component Function Min. Typical Max.

CVINT Blocking capacitor at VINT 100 nF 220 nF/10V 470 nF

C

VCC

ESL (C

VCC

ESR (C

VCC

CVG Blocking capacitor at VG 220 nF 470 nF, 25V 1 µF

CCP1 Charge pump shuffle capacitor 47 nF 220 nF/25V 470 nF

CCP2 Charge pump shuffle capacitor 47 nF 220 nF/25V 470 nF

CCPOUT Charge pump reservoir capacitor 220 nF 470 nF, 25V 1 µF

RRWD

RCC

CCC

Blocking capacitor at VCC 1.5 µF 10 µF

Serial inductance to C

)

PCB

Serial resistance to C

)

PCB

Resistor defining internal bias currents

for watchdog oscillator

Cross conduction time definition

resistor

Cross conduction time definition

capacitor

including

VCC

including

VCC

1nH 20nH

2Ω 15Ω

10 kΩ 33 kΩ 91 kΩ

5kΩ 10 kΩ

330 pF 5 nF

9122B–AUTO–10/08

23

Page 24

10. Ordering Information

specifications

according to DIN

technical drawings

Issue: 1; 19.10.06

Drawing-No.: 6.543-5137.01-4

0.5 nom.

5.5

24 13

37 48

36

25

1

12

Z

4.5

±0.15

Bottom

7

48

1

12

Pin 1 identification

Top

Package: VQFN_7 x 7_48L

Exposed pad 4.5 x 4.5

Dimensions in mm

Not indicated tolerances ±0.05

0.2

0.9

±0.1

0.4±0.1

Z 10:1

0.23

±0.07

Extended Type Number Package Remarks

ATA6833-PLQW QFN48

ATA6834-PLQW QFN48

11. Package Information

12. Revision History

24

ATA6833/ATA6834 [Preliminary]

Please note that the following page numbers referred to in this section refer to the specific revision

mentioned, not to this document.

Revision No. History

9122B-AUTO-10/08

• Put datasheet in the latest template

• Section 8 “Electrical Characteristics” on pages 15 to 21 changed

9122B–AUTO–10/08

Page 25

Headquarters International

Atmel Corporation

2325 Orchard Parkway

San Jose, CA 95131

USA

Tel: 1(408) 441-0311

Fax: 1(408) 487-2600

Atmel Asia

Room 1219

Chinachem Golden Plaza

77 Mody Road Tsimshatsui

East Kowloon

Hong Kong

Tel: (852) 2721-9778

Fax: (852) 2722-1369

Product Contact

Web Site

www.atmel.com

Literature Requests

www.atmel.com/literature

Atmel Europe

Le Krebs

8, Rue Jean-Pierre Timbaud

BP 309

78054

Saint-Quentin-en-Yvelines Cedex

France

Tel: (33) 1-30-60-70-00

Fax: (33) 1-30-60-71-11

Technical Support

auto_control@atmel.com

Atmel Japan

9F, Tonetsu Shinkawa Bldg.

1-24-8 Shinkawa

Chuo-ku, Tokyo 104-0033

Japan

Tel: (81) 3-3523-3551

Fax: (81) 3-3523-7581

Sales Contact

www.atmel.com/contacts

Disclaimer: The information in this document is provided in connection with Atmel products. No license, express or implied, by estoppel or otherwise, to any

intellectual property right is granted by this document or in connection with the sale of Atmel products. EXCEPT AS SET FORTH IN ATMEL’S TERMS AND CONDI-

TIONS OF SALE LOCATED ON ATMEL’S WEB SITE, ATMEL ASSUMES NO LIABILITY WHATSOEVER AND DISCLAIMS ANY EXPRESS, IMPLIED OR STATUTORY

WARRANTY RELATING TO ITS PRODUCTS INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTY OF MERCHANTABILITY, FITNESS FOR A PARTICULAR

PURPOSE, OR NON-INFRINGEMENT. IN NO EVENT SHALL ATMEL BE LIABLE FOR ANY DIRECT, INDIRECT, CONSEQUENTIAL, PUNITIVE, SPECIAL OR INCIDENTAL DAMAGES (INCLUDING, WITHOUT LIMITATION, DAMAGES FOR LOSS OF PROFITS, BUSINESS INTERRUPTION, OR LOSS OF INFORMATION) ARISING OUT OF

THE USE OR INABILITY TO USE THIS DOCUMENT, EVEN IF ATMEL HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES. Atmel makes no

representations or warranties with respect to the accuracy or completeness of the contents of this document and reserves the right to make changes to specifications

and product descriptions at any time without notice. Atmel does not make any commitment to update the information contained herein. Unless specifically provided

otherwise, Atmel products are not suitable for, and shall not be used in, automotive applications. Atmel’s products are not intended, authorized, or warranted for use

as components in applications intended to support or sustain life.

© 2008 Atmel Corporation. All rights reserved. Atmel®, Atmel logo and combinations thereof, and others are registered trademarks,

SMART-I.S.

™

and others are trademarks of Atmel Corporation or its subsidiaries. Other terms and product names may be trademarks of others.

9122B–AUTO–10/08

Loading...

Loading...