Page 1

Features

• PWM and Direction-controlled Driving of Four Externally-powered NMOS Transistors

• A Programmable Dead Time Is Included to Avoid Peak Currents Within the H-bridge

• Integrated Charge Pump to Provide Gate Voltages for High-side Drivers and to Supply

the Gate of the External Battery Reverse Protection NMOS

• 5V/3.3V Regulator and Current Limitation Function

• Reset Derived From 5V/3.3V Regulator Output Voltage

• Sleep Mode With Supply Current of Typically < 45 µA, Wake-up by Signal on Pins EN2

or on LIN Interface

• A Programmable Window Watchdog

• Battery Overvoltage Protection and Battery Undervoltage Management

• Overtemperature Warning and Protection (Shutdown)

• LIN 2.0 Compliant

• 3.3V/5V Regulator with Trimmed Band Gap

• QFN32 Package

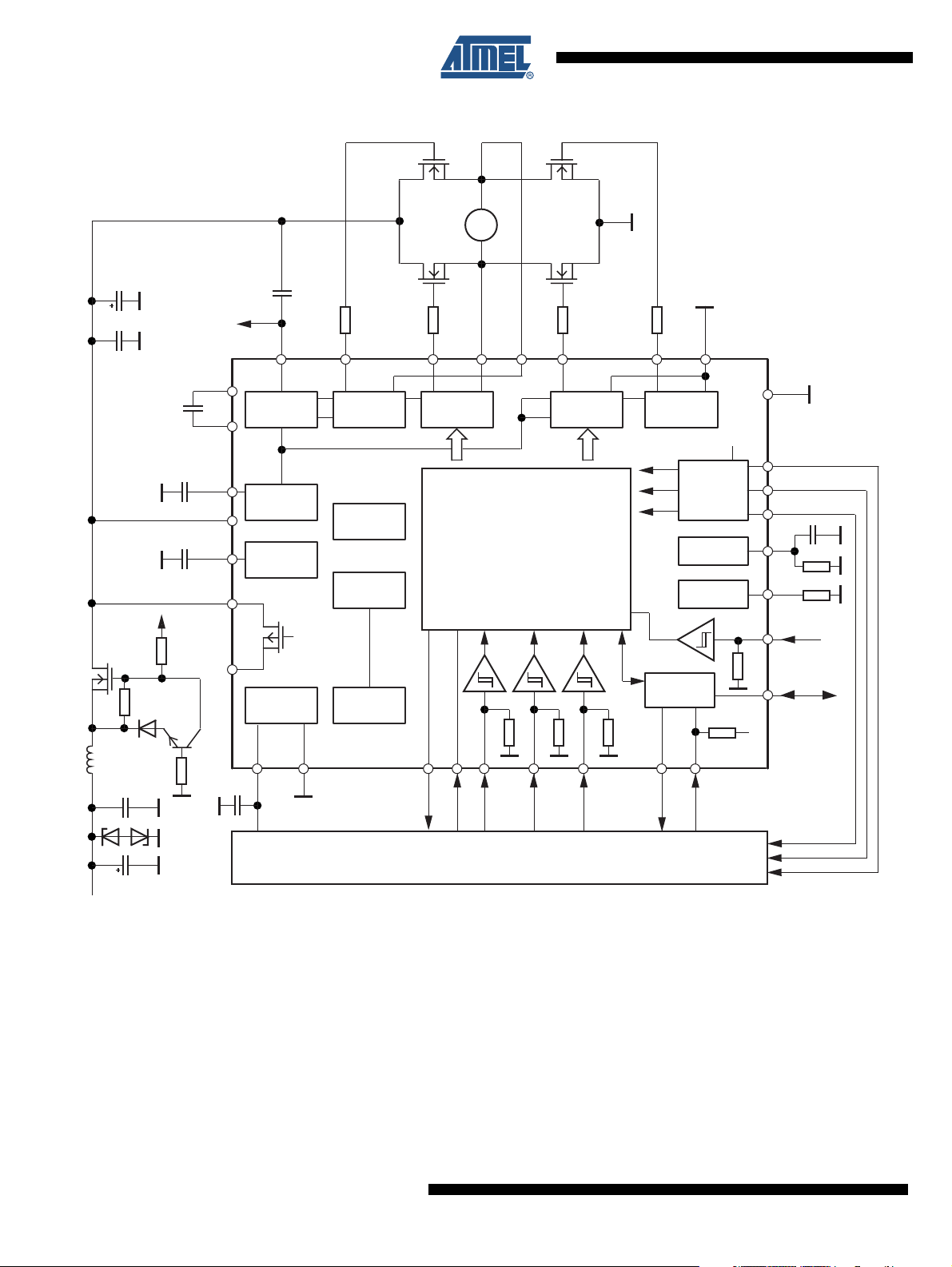

1. Description

The ATA6823 is designed for several body and powertrain applications. The IC is

used to drive a continuous current motor in a full H-bridge configuration. An external

microcontroller controls the driving function of the IC by providing a PWM signal and a

direction signal and allows the use of the IC in a motor-control application. The PWM

control is performed by the low-side switch; the high-side switch is permanently on in

the driving phase. The VMODE configuration pin can be set to 5V or 3.3V mode (for

regulator and interface high level). The window watchdog has a programmable time,

programmable by choosing a certain value of the external watchdog resistor RWD,

internally trimmed to an accuracy of 10%. For communication a LIN transceiver 2.0 is

integrated.

H-bridge Motor

Driver

ATA6823

Preliminary

4856E–AUTO–07/07

Page 2

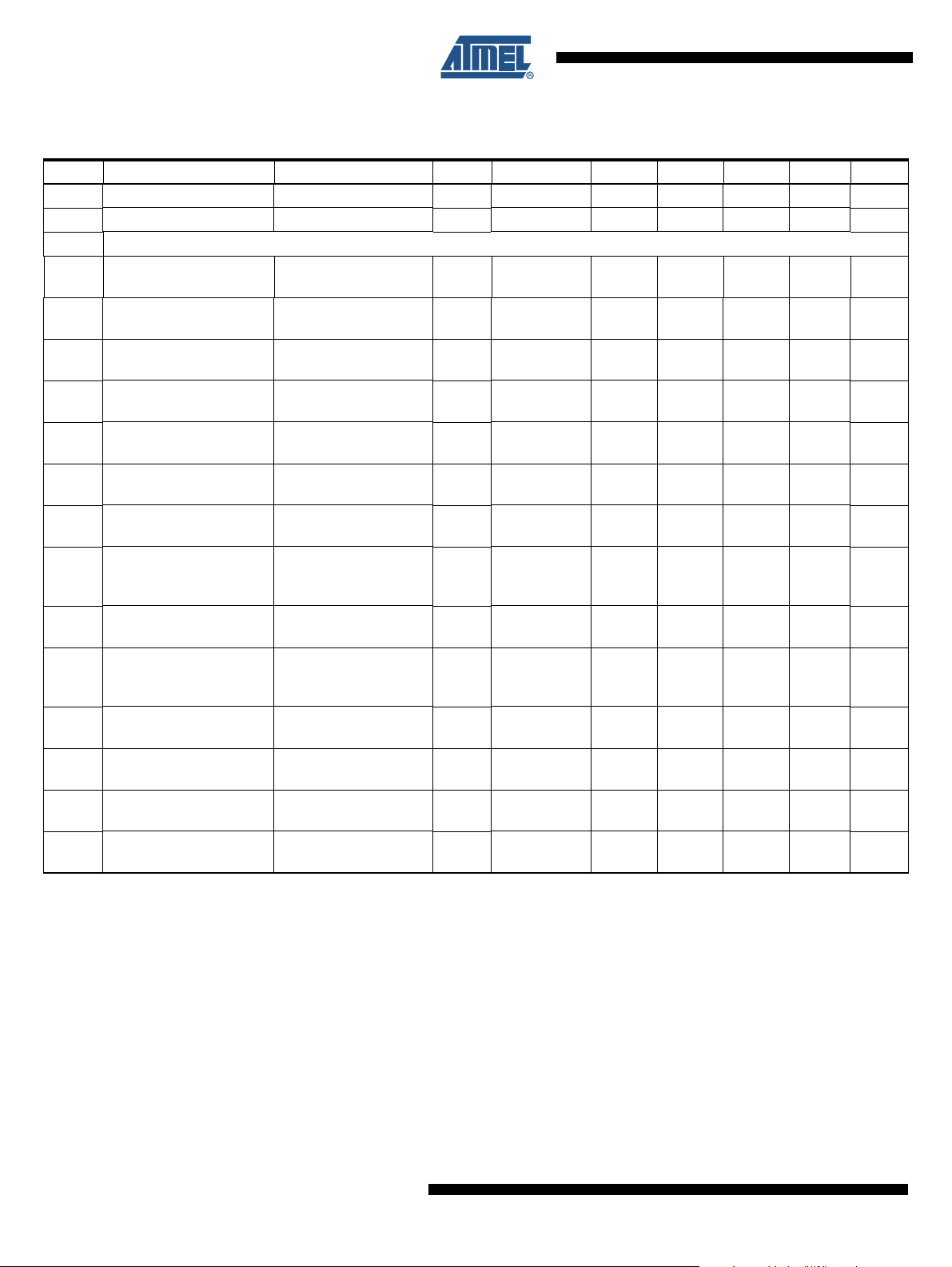

Figure 1-1. Block Diagram

M

CP

VRES H2

CPLO

Charge

Pump

CPIH

VG

PBAT

VBAT

CP

VINT

VBAT

VBATSW

12V

Regulator

Vint 5V

Regulator

VCC 5V

Regulator

VCC

R

GATE

HS Driver 2

OTP

12 bit

Oscillator

VBG

Bandgap

VMODE /RESET

R

GATE

H1

HS Driver 1

Logic Control

EN1

WD

S1 S2 L2

DIR

R

GATE

LS Driver 1

PWM

R

GATE

LS Driver 2

OT

UV

Supervisor

OV

CC timer

WD timer

LIN

TXRX

PGNDL1

VBAT

VCC

GND

DG3

DG2

DG1

CC

EN2

LIN

Microcontroller

Battery

2

ATA6823 [Preliminary]

4856E–AUTO–07/07

Page 3

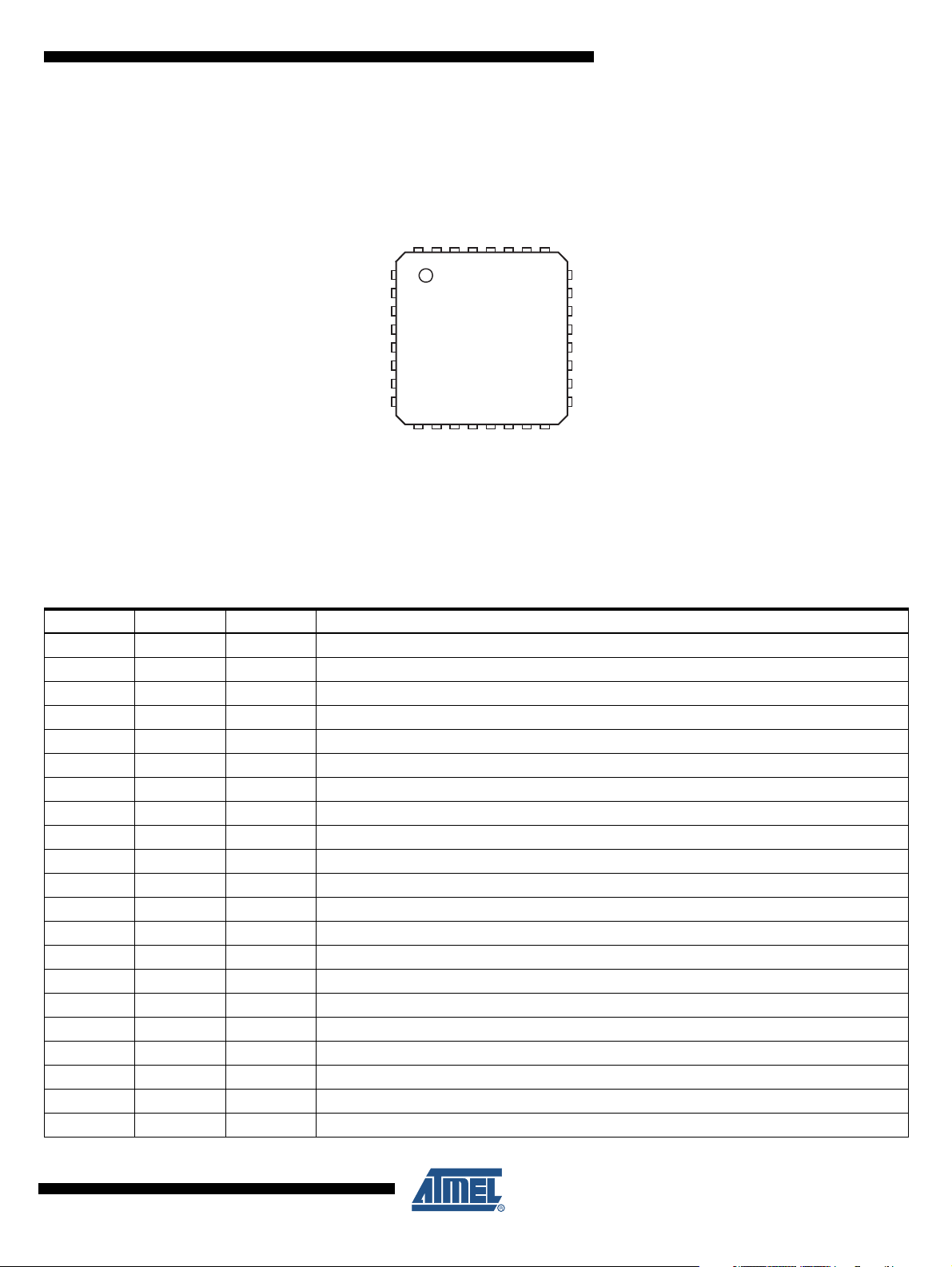

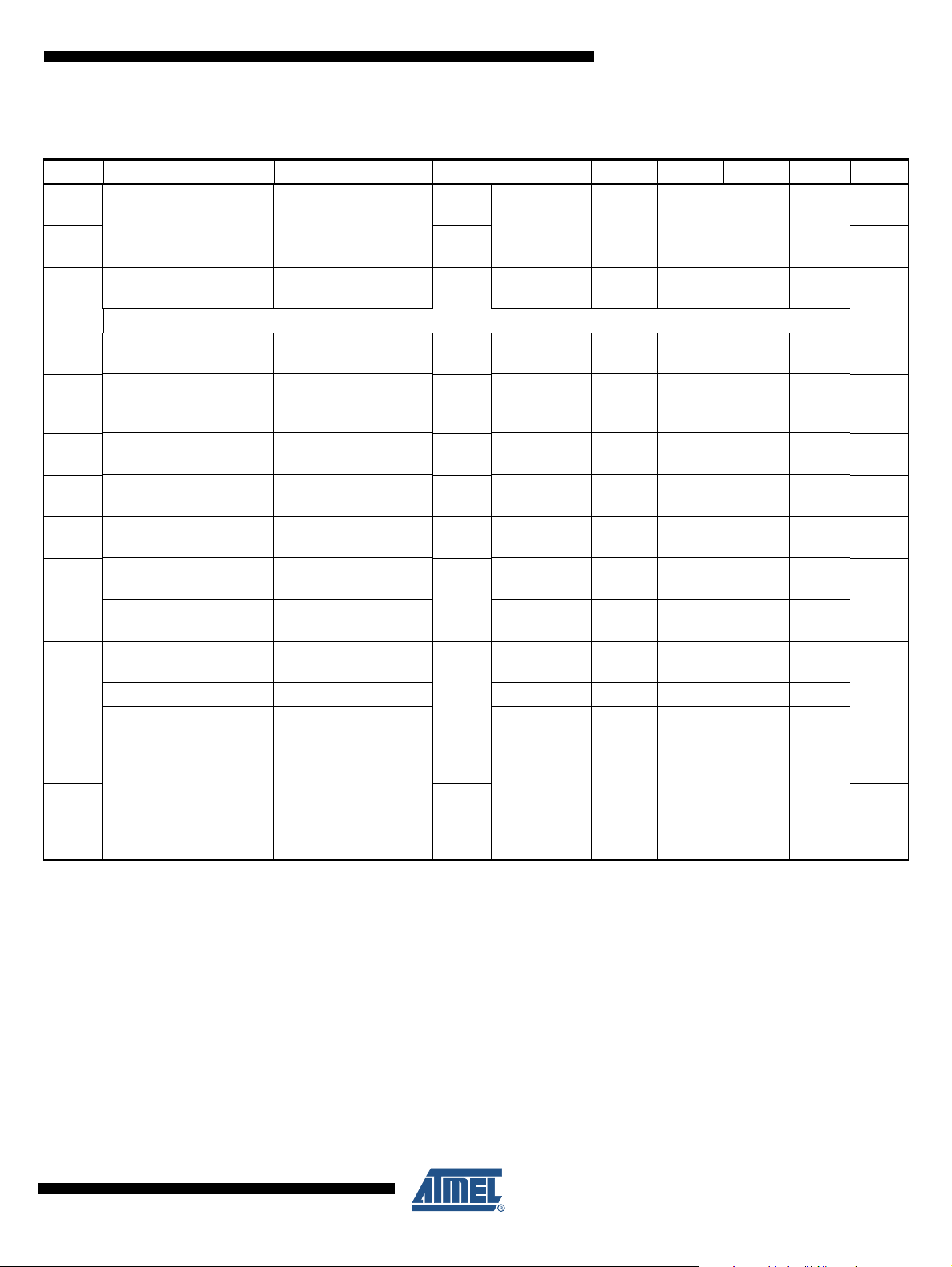

2. Pin Configuration

/

Figure 2-1. Pinning QFN32

VMODE

VINT

RWD

CC

RESET

WD

GND

LIN

EN2

VBATSW

VBAT

VCC

PGNDL1L2

32 31 30 29 28 27 26 25

1

2

3

Atmel YWW

4

5

6

7

8

ATA6823

ZZZZZ-AL

9 10 11 12 13 14 15 16

PBAT

24

23

22

21

20

19

18

17

ATA6823 [Preliminary]

VG

CPLO

CPHI

VRES

H2

S2

H1

S1

Table 2-1. Pin Description

Pin Symbol I/O Function

1 VMODE I Selector for V

2 VINT I/O Blocking capacitor 220 nF/10V/X7R

3 RWD I Resistor defining the watchdog interval

4 CC I/O RC combination to adjust cross conduction time

5 /RESET O Reset signal for microcontroller

6 WD I Watchdog trigger signal

7 GND I Ground for chip core

8 LIN I/O LIN-bus terminal

9 TX I Transmit signal to LIN bus from microcontroller

10 DIR I Defines the rotation direction for the motor

11 PWM I PWM input controls motor speed

12 EN1 I Microcontroller output to keep the chip in Active mode

13 RX O Receive signal from LIN bus for microcontroller

14 DG3 O Diagnostic output 3

15 DG2 O Diagnostic output 2

16 DG1 O Diagnostic output 1

17 S1 I/O Source voltage H-bridge, high-side 1

18 H1 O Gate voltage H-bridge, high-side 1

19 S2 I/O Source voltage H-bridge, high-side 2

20 H2 O Gate voltage H-bridge, high-side 2

21 VRES I/O Gate voltage for reverse protection NMOS, blocking capacitor 470 nF/25V/X7R

TX

DIR

EN1

PWM

RX

DG3

DG2

DG1

Note: YWW Date code (Y = Year - above 2000, WW = week number)

ATA6823 Product name

ZZZZZ Wafer lot number

AL Assembly sub-lot number

and interface logic voltage level

CC

4856E–AUTO–07/07

3

Page 4

Table 2-1. Pin Description (Continued)

Pin Symbol I/O Function

22 CPHI I

23 CPLO O

24 VG I/O Blocking capacitor 470 nF/25V/X7R

25 PBAT I Power supply (after reverse protection) for charge pump and H-bridge

26 L2 O Gate voltage H-bridge, low-side 2

27 L1 O Gate voltage H-bridge, low-side 1

28 PGND I Power ground for H-bridge and charge pump

29 VCC O 5V/100 mA supply for microcontroller, blocking capacitor 2.2 µF/10V/X7R

30 VBAT I Supply voltage for IC core (after reverse protection)

31 VBATSW O 100Ω PMOS switch from V

32 EN2 I Enable input

Charge pump capacitor 220 nF/25V/X7R

BAT

3. General Statement and Conventions

• Parameter values given without tolerances are indicative only and not to be tested in

production

• Parameters given with tolerances but without a parameter number in the first column of

parameter table are “guaranteed by design” (mainly covered by measurement of other

specified parameters). These parameters are not to be tested in production. The tolerances

are given if the knowledge of the parameter tolerances is important for the application

• The lowest power supply voltage is named GND

• All voltage specifications are referred to GND if not otherwise stated

• Sinking current means that the current is flowing into the pin (value is positive)

• Sourcing current means that the current is flowing out of the pin (value is negative)

3.1 Related Documents

• Qualification of integrated circuits according to Atmel® HNO procedure based on AEC-Q100

• AEC-Q100-004 and JESD78 (Latch-up)

• ESD STM 5.1-1998

• CEI 801-2 (only for information regarding ESD requirements of the PCB)

4

ATA6823 [Preliminary]

4856E–AUTO–07/07

Page 5

4. Application

4.1 General Remark

This chapter describes the principal application for which the ATA6823 was designed. Because

Atmel cannot be considered to understand fully all aspects of the system, application and environment, no warranties of fitness for a particular purpose are given.

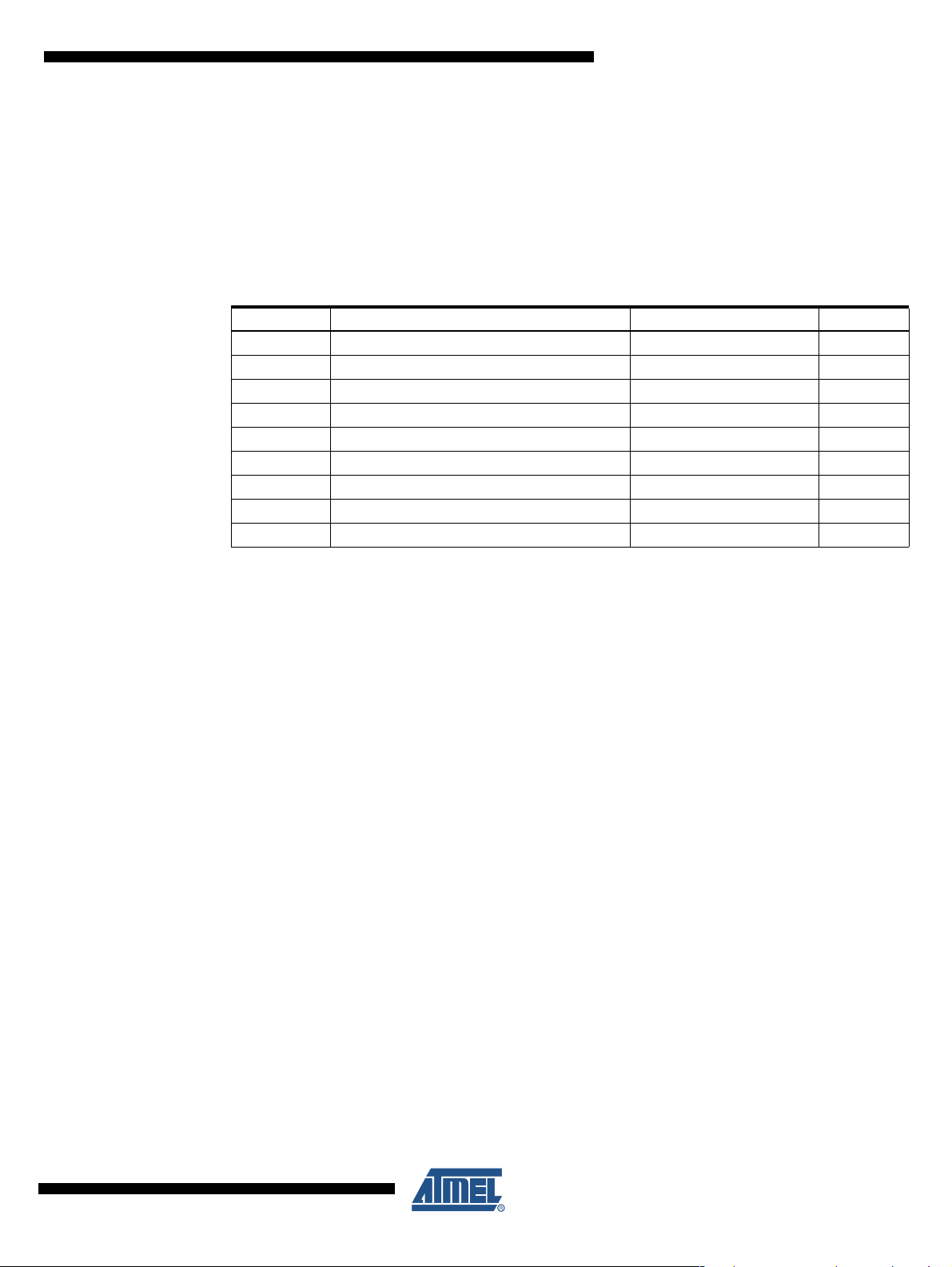

Table 4-1. Typical External Components

ATA6823 [Preliminary]

Component Function Value Tolerance

C

C

C

R

C

C

C

R

C

VINT

VCC

CC

CC

VG

CP

VRES

RWD

LIN

Blocking capacitor at VINT 220 nF, 10V, X7R 10%

Blocking capacitor at VCC 2.2 µF, 10V, X7R 10%

Cross conduction time definition capacitor Typical 330 pF, 100V, COG

Cross conduction time definition resistor Typical 10 kΩ

Blocking capacitor at VG 470 nF, 25V, X7R 10%

Charge pump capacitor 220 nF, 25V, X7R 10%

Reservoir capacitor 470 nF, 25V, X7R 10%

Watchdog time definition resistor Typical 51 kΩ 1%

Filter capacitor for LIN bus Typical 220 pF, 100V 10%

5. Functional Description

5.1 Power Supply Unit with Supervisor Functions

5.1.1 Power Supply

The IC is supplied by a reverse-protected battery voltage. To prevent it from destruction, proper

external protection circuitry has to be added. It is recommended to use at least a capacitor combination of storage and HF caps behind the reverse protection circuitry and closed to the VBAT

pin of the IC (see Figure 1-1 on page 2).

A fully-internal low-power and low-drop regulator, stabilized by an external blocking capacitor

provides the necessary low-voltage supply needed for the wake-up process. The low-power

band gap reference is trimmed and is used for the bigger VCC regulator, too. All internal blocks

are supplied by the internal regulator.

Note: The internal supply voltage V

Nothing inside the IC except the logic interface to the microcontroller is supplied by the 5V/3.3V

VCC regulator.

A power-good comparator checks the output voltage of the V

chip in reset as long as the voltage is too low.

There is a high-voltage switch which brings out the battery voltage to the pin VBATSW for measurement purposes. This switch is switched ON for VCC = HIGH and stays ON in case of a

watchdog reset going to sleep mode, VBATSW turns OFF. The signal can be used to switch on

external voltage regulators, etc.

must not be used for any other supply purpose!

INT

regulator and keeps the whole

INT

4856E–AUTO–07/07

5

Page 6

5.1.2 Voltage Supervisor

This block is intended to protect the IC and the external power MOS transistors against overvoltage on battery level and to manage undervoltage on it.

Function: in case of both overvoltage alarm (V

nal NMOS motor bridge transistors will be switched off. The failure state will be flagged via DG2.

No other actions will be carried out. The voltage supervision block is connected to VBAT and filtered by a first-order low pass with a corner frequency of typical 15 kHz.

5.1.3 Temperature Supervisor

There is a temperature sensor integrated on-chip to prevent the IC from overheating due to a

failure in the external circuitry and to protect the external NMOSFET transistors.

In case of detected overtemperature (150°C), the diagnostic pin DG3 will be switched to “H” to

signalize this event to the microcontroller. It should undertake actions to reduce the power dissipation in the IC. In case of detected overtemperature (165°C), the V

including the LIN transceiver will be switched OFF immediately and /RESET will go LOW.

Both temperature thresholds are correlated. The absolute tolerance is ±10°C and there is a

built-in hysteresis of about 10°C to avoid fast oscillations. After cooling down below the 155°C

threshold; the IC will go into Active mode.

The LIN interface has a separate thermal shutdown with disabled the low-side driver at typically

165°C.

5.2 Sleep Mode

To be able to guarantee the low quiescent current of the inactive IC, a Sleep mode is established. In Sleep mode it is possible to wake-up the IC by using the pins EN2 or LIN. In Sleep

mode, the following blocks are active:

) and of undervoltage alarm (V

THOV

CC

) the exter-

THUV

regulator and all drivers

• Band gap

• Internal 5V regulator (VINT) with external blocking capacitor of 220 nF

• Input structure for detecting the EN2 pins threshold

• Wake-up block of the LIN receive part

5.3 Wake-up and Sleep Mode Strategy

The IC has two modes: Sleep and Active. The change between the modes is described below.

The default state after power-on is Active mode.

The wake-up procedure brings the IC from a standby mode (Sleep) to an active mode (Active).

The internal 5V supply VINT, the EN2 pin input structure and a certain part of the LIN receiver

are permanently active to ensure a proper startup of the system.

The Go to Active and Go to Sleep procedures are implemented as follows:

• Go to Active by activating pin EN2

The input EN2 is intended as a switch-on pin from an external signal. Its input structure consists

of a comparator with built-in hysteresis. It is ESD-protected by diodes against GND and V

this reason the input voltage level must be positive and not higher than V

BAT

; for

BAT

.

6

ATA6823 [Preliminary]

4856E–AUTO–07/07

Page 7

ATA6823 [Preliminary]

Pulling the EN2 pin up to the V

level will drive the IC into Active mode. EN2 is debounced with

BAT

a time constant of 20 µs, based on a 100 kHz clock.

• Go to Active using the LIN interface

The second possibility for wake-up can be performed using the LIN transceiver. In Sleep mode,

the LIN receiver is partially active.

The wake-up by LIN requires 2 steps:

1. If the voltage on pin LIN is below a value of V

/DATwake

(about V

– 2V) the receive part

VBAT

of the LIN interface is active (not to be confused with Active mode of the whole IC). The

active receive part is able to detect a valid LOW on the LIN pin.

2. If LIN = LOW during a filter time t

(typically 70 µs) the IC will change to Active

wakeLIN

mode. A short change back to HIGH during the filter time will reset the filter. This information is stored in a latch after entering Active mode

If the change to Active mode was caused by LIN, the EN1 or EN2 pins may remain LOW without

disturbing the Active mode.

• Stay in Active via EN1

The input EN1 is intended to keep the IC in Active Mode via a signal from the microcontroller.

The input is ESD-protected by diodes against GND and VCC. Therefore, the input voltage must

be positive and not higher than V

the VCC regulator is off in the Sleep mode and V

. EN1 cannot be used to switch from Sleep to Active because

CC

will be zero.

CC

• Go to Sleep

A HIGH to LOW transition at pin EN1 and a following permanent LOW for the time t

gotosleep

(typically 20 µs) switches the IC to Sleep mode.

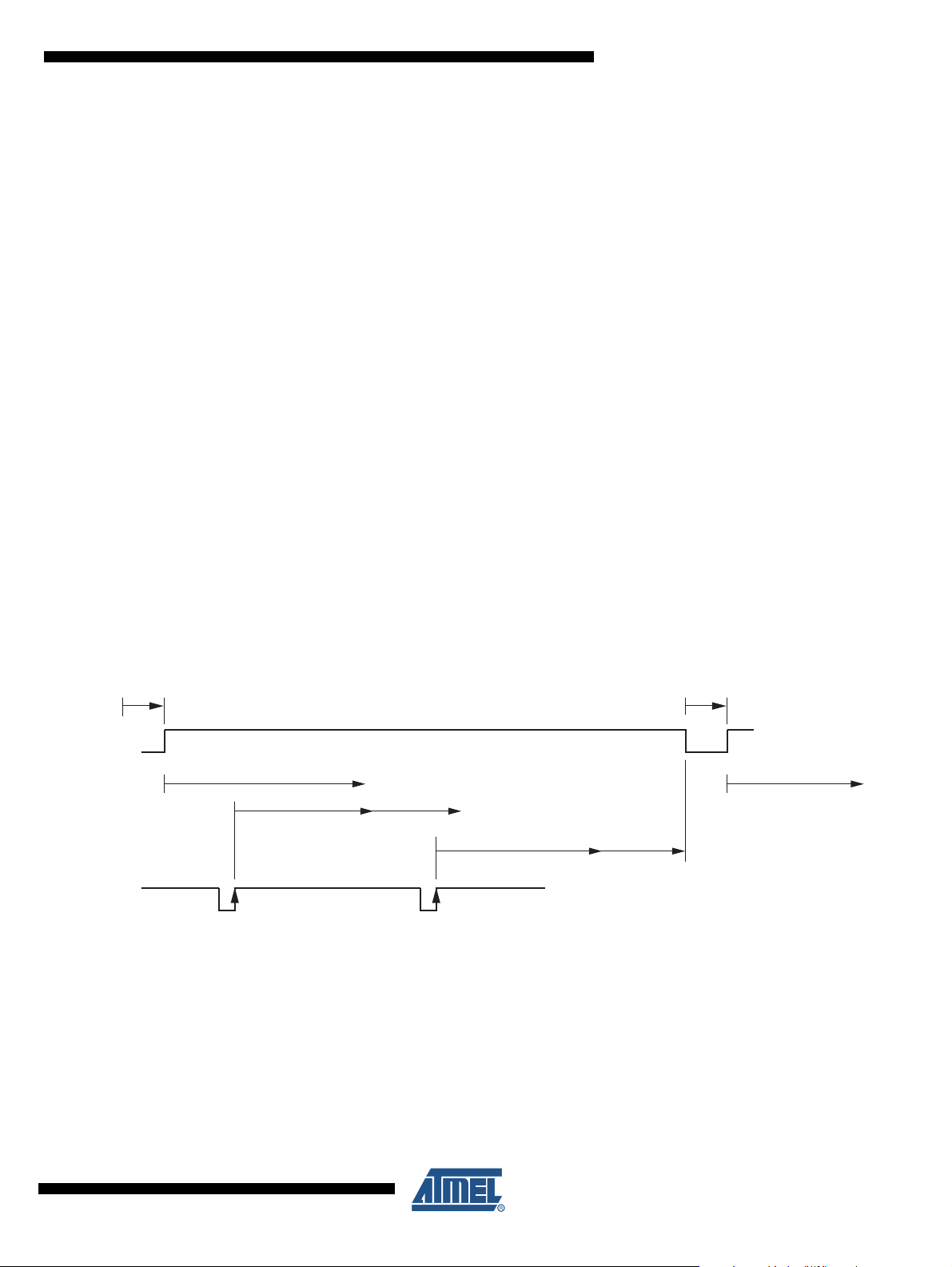

Figure 5-1 illustrates the wake-up by LIN. The status PREWAKE is characterized by the acti-

vated receive block of the LIN interface. After going to Active mode, the V

regulator starts

CC

working.

Go to Sleep is possible with a valid HIGH to LOW transition at pin EN1 (permanent LOW for

longer than t

) if EN1 was in a valid HIGH state (HIGH for longer than tdb) before.

db

4856E–AUTO–07/07

7

Page 8

Figure 5-1. Wake-up by pin LIN

LIN

VBAT

EN1

RX

t < t

wake LIN

45% VBAT

t

wake LIN

VBAT - 1.5V

activating

55% VBAT

"PREWAKE"

t

t

db

t

STATUS

ACTIVE

SLEEP

t

t

db

t

8

ATA6823 [Preliminary]

4856E–AUTO–07/07

Page 9

5.4 5V/3.3V VCC Regulator

/

The 5V/3.3V regulator is fully integrated on-chip. It requires only a 2.2 µF ceramic capacitor for

stability and has 100 mA current capability. Using the VMODE pin, the output voltage can be

selected to either 5V or 3.3V. Switching of the output voltage during operation is not intended to

be supported. The VMODE pin must be hard-wired to either VINT for 5V or to GND for 3.3V. The

logic HIGH level of the microcontroller interface will be adapted to the VCC regulator voltage.

ATA6823 [Preliminary]

The output voltage accuracy is in general < ±3%; in the 5V mode with V

<5%.

To prevent destruction of the IC, the current delivered by the regulator is limited to maximum

160 mA to 320 mA. The delivered voltage will break down and a reset may occur.

Please note that this regulator is the main heat source on the chip. The maximum output current

at maximum battery voltage and high ambient temperature can only guaranteed if the IC is

mounted on an efficient heat sink.

A power-good comparator checks the output voltage of the VCC regulator and keeps the external microcontroller in reset as long as the voltage is too low.

5.5 Reset and Watchdog Management

The timing basis of the watchdog is provided by the trimmed internal oscillator. Its period T

adjustable via the external resistor R

The watchdog expects a triggering signal (a rising edge) from the microcontroller at the WD

input within a period time window of T

switched off during Sleep mode.

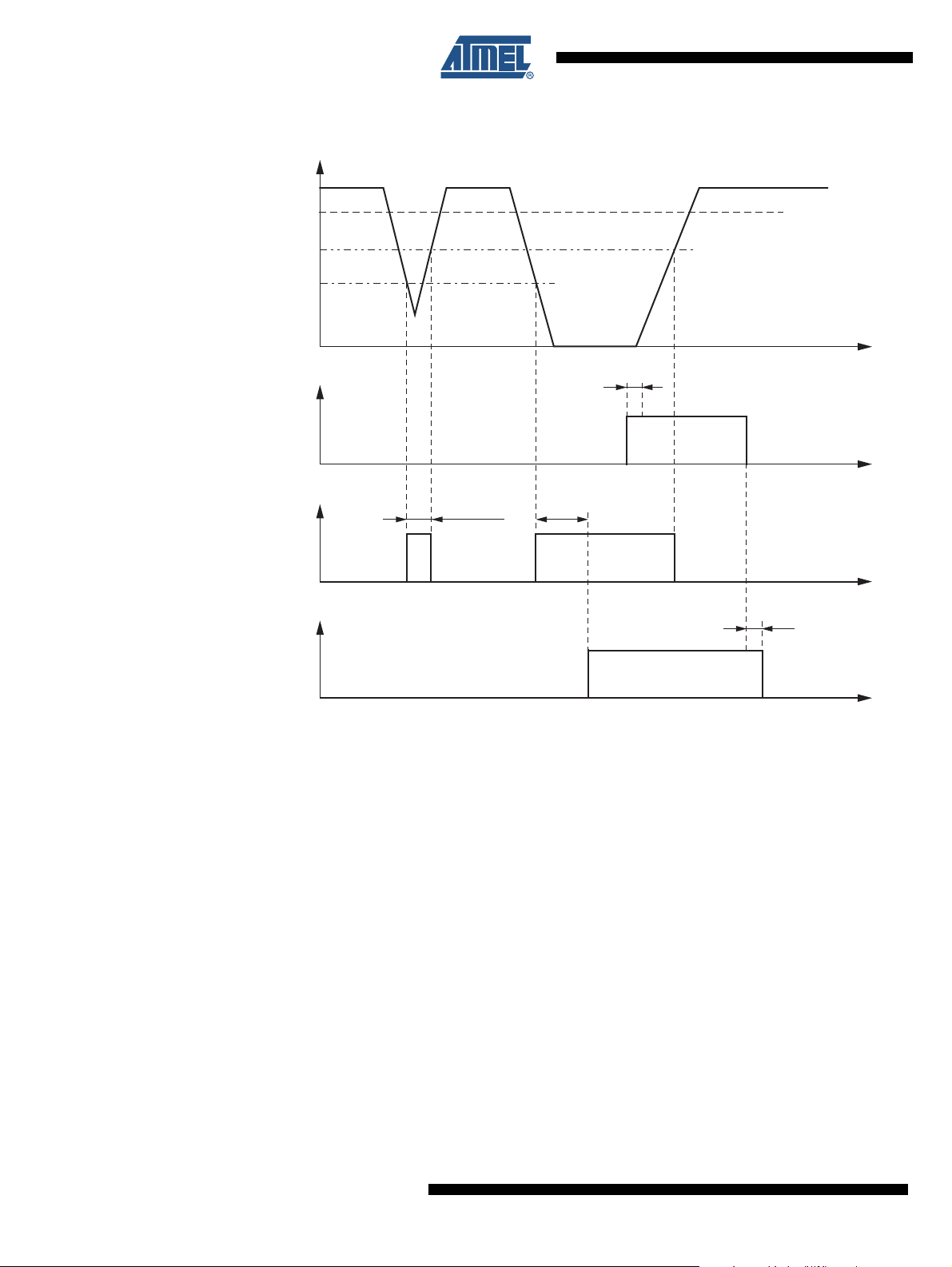

Figure 5-2. Timing Diagram of the Watchdog Function

res

< 8V it is limited to

VBAT

.

WD

. In order to save current consumption, the watchdog is

WD

t

resshortt

OSC

is

RESET

WD

5.5.1 Timing Sequence

4856E–AUTO–07/07

t

d

t

1

t

2

For example, with an external resistor R

of the watchdog.

T

= 12.32 µs, t1= 12.1 ms, t2= 9.61 ms, TWD= 16.88 ms ±10%

OSC

The times t

= 68 ms and td= 68 ms are fixed values with a tolerance of 10%.

res

t

d

t

1

=33kΩ ±1% we get the following typical parameters

WD

t

2

9

Page 10

After ramp-up of the battery voltage (power-on reset), the VCC regulator is switched on. The

0

reset output, /RESET, stays low for the time t

initial lead time t

(typically 68 ms for setups in the controller) the watchdog waits for a rising

d

(typically 68 ms), then switches to high. For an

res

edge on WD to start its normal window watchdog sequence. If no rising edge is detected, the

watchdog will reset the microcontroller for t

Times t

(close window) and t2 (open window) form the window watchdog sequence. To avoid

1

and wait td for the rising edge on WD.

res

receiving a reset from the watchdog, the triggering signal from the microcontroller must hit the

timeframe of t

= 9.61 ms. The trigger event will restart the watchdog sequence.

2

Figure 5-3. T

versus RWD

WD

60

50

40

30

TWD (ms)

20

10

max

min

0

10 20 30 40 50 60 70 80 90 10

RWD (kΩ)

typ

If triggering fails, /RESET will be pulled to ground for a shortened reset time of typically 2 ms.

The watchdog start sequence is similar to the power-on reset.

The internal oscillator is trimmed to a tolerance of < ±10%. This means that t

and t2 can also

1

vary by ±10%. The following calculation shows the worst case calculation of the watchdog

period T

t

= 0.90 × t1 = 10.87 ms, t

1min

t

= 0.90 × t2 = 8.65ms, t

2min

T

wdmax

T

wdmin

T

= 16.42 ms ±3.15 ms (±19.1%)

wd

Figure 5-3 above shows the typical watchdog period T

resistor R

A reset will be active for V

which the microcontroller has to provide.

wd

= 1.10 × t1 = 13.28 ms

1max

= 1.10 × t2 = 10.57 ms

2max

= t

+ t

= 10.87 ms + 8.65 ms = 19.52 ms

2min

= 13.28 ms

.

CC

< V

tHRESx

; the level V

= t

1min

1max

OSC

depending on the value of the external

WD

is realized with a hysteresis (HYS

tHRESx

RESth

).

5.6 LIN Transceiver

10

ATA6823 [Preliminary]

A bi-directional bus interface is implemented for data transfer between the LIN bus and the local

LIN protocol controller.

The transceiver consists of a low side driver (1.2V at 40 mA) with slew rate control, wave shaping, current limitation, and a high-voltage comparator followed by a debouncing unit in the

receiver.

4856E–AUTO–07/07

Page 11

5.6.1 Transmit Mode

During transmission, the data at the pin TX will be transferred to the bus driver to generate a bus

signal on pin LIN.

To minimize the electromagnetic emission of the bus line, the bus driver has an integrated slew

rate control and wave-shaping unit. Transmission will be interrupted in the following cases:

• Thermal shutdown active or overtemperature LIN active

• Sleep mode

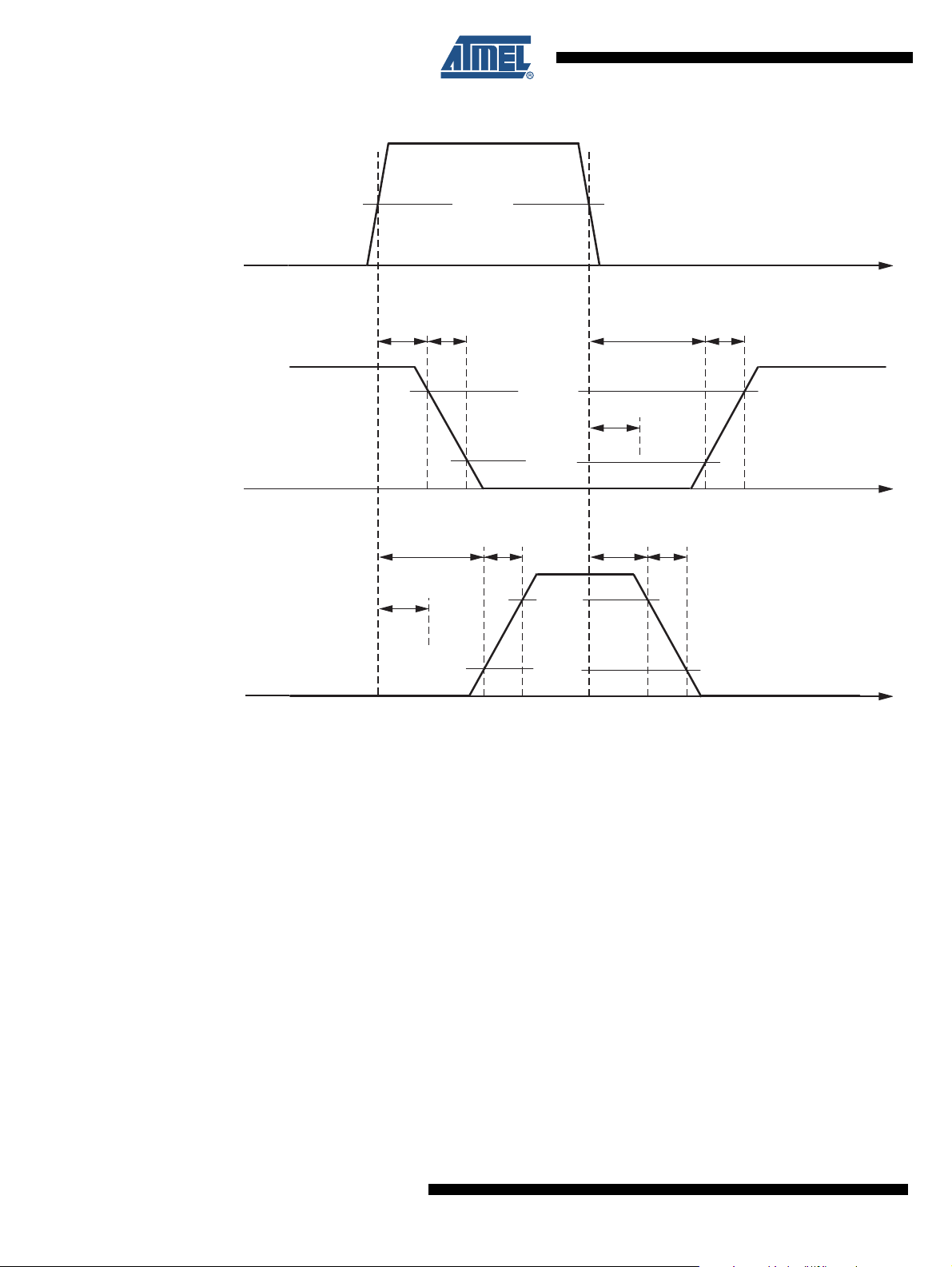

Figure 5-4. Definition of Bus Timing Parameters

ATA6823 [Preliminary]

TXD

(input to transmitting Node)

TH

Rec(max)

V

S

(Transceiver

supply

of transmitting

node)

TH

TH

TH

Dom(max)

Rec(min)

Dom(min)

RXD

(output of receiving Node 1)

RXD

(output of receiving Node 2)

t

Bit

LIN Bus Signal

t

rx_pdf(1)

t

Bus_dom(max)

t

Bus_dom(min)

t

Bit

t

Bus_rec(min)

t

Bit

Thresholds of

receiving node 1

Thresholds of

receiving node 2

t

Bus_rec(max)

t

rx_pdr(1)

t

rx_pdr(2)

t

rx_pdf(2)

The recessive BUS level is generated from the integrated 30 kΩ pull-up resistor in series with an

active diode. This diode prevents the reverse current of VBUS during differential voltage

between VSUP and BUS (V

No additional termination resistor is necessary to use the ATA6823 in LIN slave nodes. If this IC

is used for LIN master nodes, it is necessary that the BUS pin be terminated via an external 1 kΩ

resistor in series with a diode to VBAT.

5.6.2 TXD Dominant Time-out Function

The TXD input has an internal pull-down resistor. An internal timer prevents the bus line from

being driven permanently in dominant state. If TXD is forced low longer than t

pin LIN will be switched off to recessive mode. To reset this mode switch TXD to high (> 10 µs)

before switching LIN to dominant again.

4856E–AUTO–07/07

BUS>VSUP

).

> 18.4 ms, the

dom

11

Page 12

5.7 Control Inputs EN1, EN2, DIR, PWM

5.7.1 Pins EN1, EN2

Any of the enable pins may be used to activate the IC with a HIGH. EN1 is a low level input, EN2

has to withstand a voltage up to 40V. Internal pull-down resistors are included.

5.7.2 Pin DIR

Logical input to control the direction of the external motor to be controlled by the IC. An internal

pull-down resistor is included.

5.7.3 Pin PWM

Logical input for PWM information delivered by external microcontroller. Duty cycle and frequency at this pin are passed through to the H-bridge. An internal pull-down resistor is included.

Table 5-1. Status of the IC Depending on Control Inputs and Detected Failures

Control Inputs Driver Stage for External Power MOS Comments

ON DIR PWM H1 L1 H2 L2

0 X X OFF OFF OFF OFF Standby mode

1 0 PWM ON OFF /PWM PWM Motor PWM forward

1 1 PWM /PWM PWM ON OFF Motor PWM reverse

The internal signal ON is high when

• At least one valid trigger has been accepted (SYNC = 1)

•V

is inside the specified range (UV = 0 and nOV = 1)

BAT

• The charge pump has reached its minimum voltage (CPOK = 1) and

• The device is not overheated (OT2 = 0)

In case of a short circuit, the appropriate transistor is switched off after a debounce time of about

10 µs. In order to avoid cross current through the bridge, a cross conduction timer is implemented. Its time constant is programmable by means of an RC combination.

Table 5-2. Status of the Diagnostic Outputs

Device Status Diagnostic Outputs Comments

CPOK OT1 OV UV SC DG1 DG2 DG3

0 X X X X – 1 – Charge pump failure

X 1 X X X – – 1 Overtemperature warning

X X 1 X X – 1 – Overvoltage

X X X 1 X – 1 – Undervoltage

X X X X 1 1 – – Short circuit

Note: X represents: don't care – no effect)

OT1: Overtemperature warning

OV: Overvoltage of VBAT

UV: Undervoltage of VBAT

SC: Short circuit

CPOK: Charge pump OK

12

In order to be able to distinguish between a wake-up from LIN or from EN2, the source of

wake-up is flagged in DG1 until the first valid trigger (LIN = 0, EN2 = 1).

ATA6823 [Preliminary]

4856E–AUTO–07/07

Page 13

5.8 VG Regulator

The VG regulator is used to generate the gate voltage for the low-side driver. Its output voltage

will be used as one input for the charge pump, which generates the gate voltage for the

high-side driver. The purpose of the regulator is to limit the gate voltage for the external power

MOS transistors to 12V. It needs a ceramic capacitor of 470 nF for stability. The output voltage

is reduced if the supply voltage at VBAT falls below 12V.

5.9 Charge Pump

The integrated charge pump is needed to supply the gates of the external power MOS transistors. It needs a shuffle capacitor of 220 nF and a reservoir capacitor of 470 nF. Without load, the

output voltage on the reservoir capacitor is V

dedicated internal oscillator of 100 KHz. The charge pump is designed to reach a good EMC

level.

5.10 Thermal Shutdown

There is a thermal shutdown block implemented. With rising junction temperature, a first warning

level will be reached at 150°C. At this point the IC stays fully functional and a warning will be

sent to the microcontroller. At junction temperature 165°C the VCC regulator will be switched off

and a reset occurs.

ATA6823 [Preliminary]

plus VG. The charge pump is clocked with a

BAT

5.11 H-bridge Driver

The IC includes two push-pull drivers for control of two external power NMOS used as high-side

drivers and two push-pull drivers for control of two external power NMOS used as low-side drivers. The drivers are able to be used with standard and logic-level power NMOS.

The drivers for the high-side control use the charge pump voltage to supply the gates with a voltage of VG above the battery voltage level. The low-side drivers are supplied by VG directly. It is

possible to control the external load (motor) in the forward and reverse direction (see Table 5-1

on page 12). The duty cycle of the PMW controls the speed. A duty cycle of 100% is possible in

both directions.

5.11.1 Cross Conduction Time

To prevent high peak currents in the H-bridge, a non-overlapping phase for switching the external power NMOS is realized. An external RC combination defines the cross conduction time in

the following way:

t

(µs) = 0.41 × RCC (kΩ) × CCC (nF) (tolerance: ±5% ±0.15 µs)

CC

The RC combination is charged to 5V and the switching level of the internal comparator is 67%

of the start level.

The resistor R

value has to be ≤ 5 nF. Use of COG capacitor material is recommended.

The time measurement is triggered by the PWM or DIR signal crossing the 50% level.

must be greater than 5 kΩ and should be as close as possible to 10 kΩ, the C

CC

CC

4856E–AUTO–07/07

13

Page 14

Figure 5-5. Timing of the Drivers

PWM or

DIR

Lx

Hx

t

LxHLtLxf

t

HxLH

t

CC

50%

t

Hxr

80%

20%

80%

t

LxLH

t

CC

t

HxHLtHxf

t

t

Lxr

t

The delays t

5.12 Short Circuit Detection

To detect a short in H-bridge circuitry, internal comparators detect the voltage difference

between source and drain of the external power NMOS. If the transistors are switched ON and

the source-drain voltage difference is higher than the value V

>t

(typically 10 µs) the signal SC (short circuit) will be set and the drivers will be switched off

SC

immediately. The diagnostic pin DG1 will be set to “H”. With the next transition on pin PWM, the

bit will be cleared and the corresponding drivers, depending on the DIR pin, will be switched on

again.

There is a PBAT supervision block implemented to detect the possible voltage drop on PBAT

during a short circuit. If the voltage at PBAT falls under V

>t

the drivers will be switched off immediately and DG1 will be set to “H”. It will be cleared as

SC

above.

HxLH

and t

20%

include the cross conduction time tCC.

LxLH

(4V with tolerances) for a time

SC

(5.6V with tolerances) for a time

SCPB

t

14

ATA6823 [Preliminary]

4856E–AUTO–07/07

Page 15

ATA6823 [Preliminary]

6. Absolute Maximum Ratings

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. This is a stress rating

only and functional operation of the device at these or any other conditions beyond those indicated in the operational sections of this

specification is not implied. Exposure to absolute maximum rating conditions for extended periods may affect device reliability.

Pin Description Pin Name Min Max Unit

Ground GND 0 0 V

Power ground PGND –0.3 +0.3 V

Reverse protected battery voltage VBAT –0.3 +40 V

Reverse protected battery voltage PBAT –0.3 +40 V

Digital output /RESET –0.3 V

Digital output DG1, DG2, DG3 –0.3 V

4.9V output, external blocking capacitor VINT –0.3 +5.5 V

Cross conduction time capacitor/resistor

combination

CC –0.3 V

Digital input coming from microcontroller WD –0.3 V

Watchdog timing resistor RWD –0.3 V

Digital input direction control DIR –0.3 V

Digital input PWM control + Test mode PWM –0.3 V

Digital input for enable control EN1 –0.3 V

Digital input for enable control EN2 –0.3 V

5V regulator output VCC –0.3 +5.5 V

Digital input VMODE –0.3 V

12V output, external blocking capacitor VG –0.3 +16 V

Digital output RX –0.3 V

Digital input TX –0.3 V

LIN data pin LIN –27

(1)

Source external high-side NMOS S1, S2 –2 +30 V

Gates external low-side NMOS L1, L2 V

Gates of external high-side NMOS H1, H2 V

– 0.3 V

PGND

– 1 VS + 16 V

S

Charge pump CPLO –0.3 V

Charge pump CPHI –0.3 V

Charge pump output VRES –0.3 +30 V

Switched VBAT VBATSW –0.3 V

Power dissipation P

Storage temperature ϑ

Soldering temperature (10s) ϑ

Notes: 1. For V

VBAT

≤ 13.5V

tot

STORE

SOLDERING

–40 +150 °C

2. May be additionally limited by external thermal resistance

+ 0.3 V

VCC

+ 0.3 V

VCC

+ 0.3 V

VINT

+ 0.3 V

VINT

+ 0.3 V

VCC

+ 0.3 V

VCC

+ 0.3 V

VCC

+ 0.3 V

VCC

+ 0.3 V

VBAT

+ 0.3 V

VINT

+ 0.3 V

VCC

+ 0.3 V

VCC

V

+ 2 V

VBAT

+ 0.3 V

VG

+ 0.3 V

PBAT

+ 0.3 V

VRES

+ 0.3 V

VBAT

(2)

1.4

240 °C

W

4856E–AUTO–07/07

15

Page 16

7. Thermal Resistance

Parameters Symbol Value Unit

Thermal resistance junction to heat slug R

Thermal resistance junction to ambient when heat

slug is soldered to PCB

thjc

R

thja

<5 K/W

25 K/W

8. Operating Range

The operating conditions define the limits for functional operation and parametric characteristics of the device. Functionality outside these

limits is not implied unless otherwise stated explicitly.

Parameters Symbol Min Max Unit

Operating supply voltage

Operating supply voltage

Operating supply voltage

Operating supply voltage

Operating supply voltage

(1)

(2)

(3)

(4)

(5)

Ambient temperature range under bias T

Normal functionality T

Normal functionality, overtemperature warning T

Drivers for H1, H2, L1, L2, and LIN are switched

OFF, VCC regulator is OFF

Note: 1. Full functionality

2. H-bridge drivers may be switched off (undervoltage detection)

3. H-bridge drivers are switched off, 5V/3.3V regulator with reduced parameters, RESET works correctly

4. H-bridge drivers are switched off, 5V regulator not working, RESET not correct

5. H-bridge drivers are switched off

V

V

V

V

V

VBAT1

VBAT2

VBAT3

VBAT4

VBAT5

a

a

a

T

a

718V

6< 7V

3< 6V

0< 3V

> 20 40 V

–40 +125 °C

–40 +125 °C

150 165 °C

165 180 °C

16

ATA6823 [Preliminary]

4856E–AUTO–07/07

Page 17

ATA6823 [Preliminary]

9. Electrical Characteristics

All parameters given are valid for 7V ≤ VBAT ≤ 18V and for –40°C ≤ϑambient ≤ 125°C unless stated otherwise.

No. Parameters Test Conditions Pin Symbol Min Typ Max Unit Type*

1 Power Supply and Supervisor Functions

VBAT

VBAT

(1)

<40V

≤ 9V

25, 30 I

30 V

30 V

30 V

30 V

29 V

29 V

regulation

regulation

VBAT1

VBAT2

INT

BG

THOV

TOVhys

THUV

TUVhys

ON_VBATSW

CC1

CC2

DC line

DC load

OS1

4.84.945.1 V A

1.225 1.235 1.245 V A

19.8 22.3 V A

11.5VA

6.5 7 V A

0.2 0.4 V A

4.85

(3.2)

4.75

(3.2)

<1 50 mV A

<10 50 mV A

100 300 mA C

7mAA

50 µA A

100 Ω A

5.15

(3.4)

5.25

(3.4)

VA

VA

29 ESL 1 20 nH D

29 ESR 0 0.5 Ω D

29 C

VCC

1.5 3.0 µF D

sc

1.1 Current consumption V

Current consumption V

1.2

in Standby mode

BATVVBAT

BAT

= 13.5V

=13.5V 25, 30 I

V

VBAT

1.3 Internal power supply 2 V

1.4 Band gap voltage V

Overvoltage threshold

1.5

V

BAT

Overvoltage threshold

1.6

hysteresis V

Undervoltage threshold

1.7

V

BAT

Undervoltage threshold

1.8

hysteresis V

On resistance of V

1.9

switch

BAT

BAT

BAT

Measured during

qualification only

Measured during

qualification only

V

VBAT

= 13.5V 31 R

2 5V/3.3V Regulator

VCC

VCC

9V < V

= 0 mA to 100 mA

I

load

6V < V

I

= 0 mA to 100 mA

load

= 0 mA to 100 mA 29

load

= 0 mA to 100 mA 29

load

> 6V 29 I

VBAT

(2), (3)

2.1 Regulated output voltage

2.2 Regulated output voltage

2.3 Line regulation I

2.4 Load regulation I

2.5 Output current limitation V

Serial inductance to C

2.6

including PCB

Serial resistance to C

2.7

including PCB

2.8 Blocking cap at VCC

* Type: A = 100% tested, B = 100% correlation tested, C = Characterized on samples, D = Design parameter

Notes: 1. EN, DIR, PWM = high

2. The use of X7R material is recommended

3. For higher values, stability at zero load is not guaranteed

4. Tested during qualification only

5. Value depends on T

; function tested with digital test pattern

OSC

6. Tested during characterization only

7. Supplied by charge pump

8. See section “Cross Conduction Time”

9. Voltage between source-drain of external switching transistors in active case

10. The short-circuit message will never be generated for switch-on time < t

4856E–AUTO–07/07

17

Page 18

9. Electrical Characteristics (Continued)

All parameters given are valid for 7V ≤ VBAT ≤ 18V and for –40°C ≤ϑambient ≤ 125°C unless stated otherwise.

No. Parameters Test Conditions Pin Symbol Min Typ Max Unit Type*

2.9 HIGH threshold VMODE 1 VMODE H 4.0 V A

2.10 LOW threshold VMODE 1 VMODE L 0.7 V A

3 Reset and Watchdog

VCC threshold voltage

3.1

level for /RESET

threshold voltage

V

3.2

3.3

3.4

3.5

3.6

3.7

CC

level for /RESET

Hysteresis of /RESET

level

Length of pulse at

/RESET pin

Length of short pulse at

/RESET pin

Wait for the first WD

trigger

Time for VCC < V

tHRESL

before activating /RESET

Resistor defining internal

3.8

bias currents for

watchdog oscillator

Watchdog oscillator

3.9

period

Watchdog oscillator

3.10

period with internal

resistor

Watchdog input

3.11

low-voltage threshold

Watchdog input

3.12

high-voltage threshold

Hysteresis of watchdog

3.13

input voltage threshold

3.14 Close window

* Type: A = 100% tested, B = 100% correlation tested, C = Characterized on samples, D = Design parameter

Notes: 1. EN, DIR, PWM = high

2. The use of X7R material is recommended

3. For higher values, stability at zero load is not guaranteed

4. Tested during qualification only

5. Value depends on T

6. Tested during characterization only

7. Supplied by charge pump

8. See section “Cross Conduction Time”

9. Voltage between source-drain of external switching transistors in active case

10. The short-circuit message will never be generated for switch-on time < t

VMODE = “H”

(VMODE = “L”)

VMODE = “H”

(VMODE = “L”)

(4)

(5)

(5)

(5)

(4)

29 V

29 V

29 HYS

5t

5t

5t

29 t

3R

R

= 33 kΩ 3T

RWD

6V

6V

6V

(5)

; function tested with digital test pattern

OSC

tHRESH

tHRESL

RESth

res

resshort

d

delayRESL

RWD

OSC

T

OSC_start

ILWD

IHWD

hysWD

t1

4.6

(3.05)

VA

4.1 (2.7) V A

0.2 V A

6800 T

200 T

6800 T

100

100

100

0.5 2 µs C

10 91 kΩ D

11.09 13.55 µs A

16 24 µs A

0.7 ×

V

VCC

0.3 ×

V

VCC

VA

VA

1VA

980 ×

T

OSC

sc

A

A

A

A

18

ATA6823 [Preliminary]

4856E–AUTO–07/07

Page 19

ATA6823 [Preliminary]

9. Electrical Characteristics (Continued)

All parameters given are valid for 7V ≤ VBAT ≤ 18V and for –40°C ≤ϑambient ≤ 125°C unless stated otherwise.

No. Parameters Test Conditions Pin Symbol Min Typ Max Unit Type*

3.15 Open window

Output low-voltage of

3.16

/RESET

Internal pull-up resistor at

3.17

pin /RESET

(5)

At I

= 1 mA 5 V

OLRES

t2

OLRES

5R

PURES

5 10 15 kΩ D

4 Lin Transceiver

4.1 Low-level output current

Normal mode;

V

=0V, VRX=0.4V

LIN

13 IL

RX

4mAD

Normal mode;

4.2 High-level output current

V

LIN=VBAT

13 IH

RX

4mAD

VRX=VCC–0.4V

Driver recessive output

4.3

voltage

Driver dominant voltage

4.4

V

BUSdom_DRV_LoSUP

Driver dominant voltage

4.5

V

BUSdom_DRV_HiSUP

Driver dominant voltage

4.6

V

BUSdom_DRV_LoSUP

Driver dominant voltage

4.7

V

BUSdom_DRV_HiSUP

4.8 Pull up resistor to VS

4.9 Current limitation V

Input leakage current at

the receiver including

4.10

pull-up resistor as

specified

V

TXD

V

VAT

R

load

V

VAT

R

load

V

VAT

R

load

V

VAT

R

load

= 0V; I

= 7.3V

= 500Ω

= 18V

= 500Ω

= 7.3V

= 1000Ω

= 18V

= 1000Ω

= 0 mA 8 V

LIN

The serial diode is

mandatory

= V

BUS

BAT_max

Input leakage current

driver off

= 0V

V

BUS

= 12V

V

BAT

BUSrec

8V

8V

8V

8V

8R

8I

8I

_LoSUP

_HiSUP

_LoSUP_1k

_HiSUP_1k_

LIN

BUS_LIM

BUS_PAS_dom

0.9 ×

VBAT

0.6 V

0.8 V

20 30 60 kΩ D

50 200 mA

–1 mA

Driver off

Leakage current LIN

4.11

recessive

8V < V

8V < V

V

BUS

≥ V

BAT

BUS

< 18V

< 18V

BAT

8I

BUS_PAS_rec

* Type: A = 100% tested, B = 100% correlation tested, C = Characterized on samples, D = Design parameter

Notes: 1. EN, DIR, PWM = high

2. The use of X7R material is recommended

3. For higher values, stability at zero load is not guaranteed

4. Tested during qualification only

5. Value depends on T

; function tested with digital test pattern

OSC

6. Tested during characterization only

7. Supplied by charge pump

8. See section “Cross Conduction Time”

9. Voltage between source-drain of external switching transistors in active case

10. The short-circuit message will never be generated for switch-on time < t

sc

780 ×

T

OSC

0.4 V A

V

1.2 V

2V

20 µA

A

4856E–AUTO–07/07

19

Page 20

9. Electrical Characteristics (Continued)

All parameters given are valid for 7V ≤ VBAT ≤ 18V and for –40°C ≤ϑambient ≤ 125°C unless stated otherwise.

No. Parameters Test Conditions Pin Symbol Min Typ Max Unit Type*

Leakage current at

ground loss

Control unit disconnected

4.12

from ground

Loss of local ground must

GND

V

BAT

0V < V

not affect communication

in the residual network

Node has to sustain the

current that can flow

4.13

under this condition. Bus

must remain operational

V

BAT

V

SUP_Device

0V < V

under this condition

Center of receiver

4.14

threshold

4.15 Receiver dominant state V

4.16 Receiver recessive state V

4.17 Receiver input hysteresis V

Dominant time for

4.18

wake-up via LIN-bus

V

BUS_CNT

(V

EN

EN

HYS

V

LIN

5 Control Inputs EN1, DIR, PWM, WD, TX

Input low-voltage

5.1

threshold

Input high-voltage

5.2

threshold

5.3 Hysteresis

(6)

5.4 Pull-down resistor EN1, DIR, PWN, WD R

5.5 Pull-up resistor TX R

5.6 Rise/fall time t

5.7 Debounce time EN1

(6)

6Charge Pump

6.1 Charge pump voltage Load = 0A 21 VCP

6.2 Charge pump voltage

Load = 3 mA,

C

CP

* Type: A = 100% tested, B = 100% correlation tested, C = Characterized on samples, D = Design parameter

Notes: 1. EN, DIR, PWM = high

2. The use of X7R material is recommended

3. For higher values, stability at zero load is not guaranteed

4. Tested during qualification only

5. Value depends on T

; function tested with digital test pattern

OSC

6. Tested during characterization only

7. Supplied by charge pump

8. See section “Cross Conduction Time”

9. Voltage between source-drain of external switching transistors in active case

10. The short-circuit message will never be generated for switch-on time < t

= VS

Device

=12V

BUS

< 18V

8I

disconnected

= GND

< 18V

BUS

=

th_dom+Vth_rec

)/2

8I

8V

= 5V 8 V

= 5V 8 V

= V

th_rec

– V

th_dom

8V

= 0V 8 T

= 100 nF

21 VCP

BUS_NO_gnd

BUS

BUS_CNT

BUSdom

BUSrec

BUShys

BUS

V

IL

V

IH

–1 1 mA

100 µA

0.475 VS 0.5 VS 0.525 VS V

0.4 VS V

0.6 VS V

0.1 VS 0.175 VS V

30 90 150 µs D

0.7 ×

V

VCC

0.3 ×

V

VCC

VA

VA

HYS 0.7 A

PD

PU

rf

t

db

25 50 100 kΩ D

25 50 100 kΩ D

100 ns D

sc

2 × T

V

+ V

VBAT

VG

100

– 1

3 × T

V

VBAT

+ V

100

VG

µs D

VA

VA

20

ATA6823 [Preliminary]

4856E–AUTO–07/07

Page 21

ATA6823 [Preliminary]

9. Electrical Characteristics (Continued)

All parameters given are valid for 7V ≤ VBAT ≤ 18V and for –40°C ≤ϑambient ≤ 125°C unless stated otherwise.

No. Parameters Test Conditions Pin Symbol Min Typ Max Unit Type*

Period charge pump

6.3

oscillator

CP load current in VG

6.4

without CP load

CP load current in VG

6.5

with CP load

Load = 0A I

Load = 3 mA,

= 100 nF

C

CP

7H-bridge Driver

Low-side driver HIGH

7.1

output voltage

ON-resistance of sink

7.2

stage of pins L1, L2

ON-resistance of source

7.3

stage of pins L1, L2

Output peak current at

7.4

pins L1, L2, switched to

= 3V

V

Lx

LOW

Output peak current at

7.5

pins L1, L2, switched to

V

= 3V

Lx

HIGH

Pull-down resistance at

7.6

pins L1, L2

ON-resistance of sink

7.7

stage of pins H1, H2

ON-resistance of source

7.8

stage of pins H1, H2

Output peak current at

7.9

pins Hx, switched to LOW

Output peak current at

7.10

pins Hx, switched to

HIGH

Static high-side switch

7.11

output low-voltage pins

Hx

V

V

V

V

V

V

V

V

V

I

Hx

Sx

Sx

VBAT

Sx

Hx

VBAT

Sx

Hx

Sx

= 0

= V

VBAT

= 13.5V

= V

VBAT

= V

VBAT

= 13.5V

= V

VBAT

= V

VBAT

= 0V

= 1 mA

+ 3V

+ 3V

* Type: A = 100% tested, B = 100% correlation tested, C = Characterized on samples, D = Design parameter

Notes: 1. EN, DIR, PWM = high

2. The use of X7R material is recommended

3. For higher values, stability at zero load is not guaranteed

4. Tested during qualification only

5. Value depends on T

; function tested with digital test pattern

OSC

6. Tested during characterization only

7. Supplied by charge pump

8. See section “Cross Conduction Time”

9. Voltage between source-drain of external switching transistors in active case

10. The short-circuit message will never be generated for switch-on time < t

T

100

VGCPz

I

VGCP

V

LxH

R

DSON_LxL,

x = 1, 2

R

DSON_LxH,

x = 1, 2

I

LxL,

x = 1, 2

I

LxH,

x = 1, 2

R

PDLx

x = 1, 2

R

DSON_HxL,

x = 1, 2

R

DSON_HxH,

x = 1, 2

I

HxL,

x = 1, 2

I

HxH,

x = 1, 2

V

HxL

x = 1, 2

911µsA

100 µA D

3.3 mA A

V

VG

VD

20 Ω A

20 Ω A

100 mA D

–100 mA D

30 100 kΩ A

20 Ω A

20 Ω A

100 mA D

–100 mA D

,

sc

0.3 V

4856E–AUTO–07/07

21

Page 22

9. Electrical Characteristics (Continued)

All parameters given are valid for 7V ≤ VBAT ≤ 18V and for –40°C ≤ϑambient ≤ 125°C unless stated otherwise.

No. Parameters Test Conditions Pin Symbol Min Typ Max Unit Type*

Static high-side switch

7.12

output high-voltage pins

H1, H2

= –10 µA

I

Lx

(PWM = static)

V

HxHstat1

V

V

VBAT

VG

+

– 1

(7)

Sink resistance between

7.13

Hx and ground in Sleep

R

Hxsleep

310kΩ

mode

Dynamic Parameters

Dynamic high-side switch

7.14

output high-voltage pins

H1, H2

Propagation delay time,

7.15

low-side driver from high

to low

= 5 nF

C

Hx

C

= 100 nF

CB

= 20 kHz

f

PWM

Figure 5-5 on page 14

= 13.5V

V

VBAT

V

HxHdyn1

t

LxHL

V

VBAT

VVG – 1

+

Propagation delay time,

7.16

low-side driver from low to

t

LxLH

high

= 13.5V

V

7.17 Fall time low-side driver

VBAT

CGx=5 nF

7.18 Rise time low-side driver t

Propagation delay time,

7.19

high-side driver from high

to low

Figure 5-5 on page 14

V

= 13.5V

VBAT

t

Lxr

t

HxHL

Lxf

Propagation delay time,

7.20

high-side driver from low

t

HxLH

to high

= 13.5V,

V

7.21 Fall time high-side driver

C

VBAT

Gx

= 5 nF

7.22 Rise time high-side driver t

7.23 Cross conduction time

(8)

7.24 External resistor R

7.25 External capacitor C

of tCC switching

R

7.26

ON

transistor

R

t

Hxf

Hxr

t

CC

CC

CC

ONCC

5kΩ

* Type: A = 100% tested, B = 100% correlation tested, C = Characterized on samples, D = Design parameter

Notes: 1. EN, DIR, PWM = high

2. The use of X7R material is recommended

3. For higher values, stability at zero load is not guaranteed

4. Tested during qualification only

5. Value depends on T

; function tested with digital test pattern

OSC

6. Tested during characterization only

7. Supplied by charge pump

8. See section “Cross Conduction Time”

9. Voltage between source-drain of external switching transistors in active case

10. The short-circuit message will never be generated for switch-on time < t

sc

V

+

V

VBAT

V

VBAT

V

VG

+

VG

V

V

0.5 µs

0.5 + t

CC

µs

0.5 µs

0.5 µs

0.5 µs

0.5 + t

CC

µs

0.5 µs

0.5 µs

10 µs

5nF

100 Ω

22

ATA6823 [Preliminary]

4856E–AUTO–07/07

Page 23

ATA6823 [Preliminary]

9. Electrical Characteristics (Continued)

All parameters given are valid for 7V ≤ VBAT ≤ 18V and for –40°C ≤ϑambient ≤ 125°C unless stated otherwise.

No. Parameters Test Conditions Pin Symbol Min Typ Max Unit Type*

Switching level of t

7.27

comparator

Short circuit detection

7.28

voltage

Short circuit detection

7.29

time

8 Input EN2

Input low-voltage

8.1

threshold

Input high-voltage

8.2

threshold

8.3 Hysteresis

8.4 Pull-down resistor R

8.5 Rise/fall time t

8.6 Debounce time

9 Diagnostic Outputs DG1, DG2, DG3

9.1 Low level output current V

9.2 High level output current V

* Type: A = 100% tested, B = 100% correlation tested, C = Characterized on samples, D = Design parameter

Notes: 1. EN, DIR, PWM = high

2. The use of X7R material is recommended

3. For higher values, stability at zero load is not guaranteed

4. Tested during qualification only

5. Value depends on T

6. Tested during characterization only

7. Supplied by charge pump

8. See section “Cross Conduction Time”

9. Voltage between source-drain of external switching transistors in active case

10. The short-circuit message will never be generated for switch-on time < t

CC

(9)

(10)

(6)

(6)

(6)

= 0.4V

DG

= VCC – 0.4V

DG

; function tested with digital test pattern

OSC

(6)

V

swtcc

V

SC

t

SC

V

V

0.653 ×

V

3.544.5V

IL

IH

2.3 3.6 V

2.8 4.0 V

VCC

0.667 ×

V

VCC

0.68 ×

V

VCC

51015ms

HYS 0.47 V

PD

rf

t

db

50 100 200 kΩ

100 ns

2 × T

100

3 × T

100

IL 4 mA

IH 4 mA

sc

V

µs

4856E–AUTO–07/07

23

Page 24

10. Schaffner and Electromagnetic Compatibility

10.1 Transients on Power-supply Rail (Battery)

The application (including IC and external protection circuitry, see Figure 1-1 on page 2) has to

withstand the test pulses in Table 10-1.

Table 10-1. Test Pulses

Test

Pulse No.

1 –100V 10 min R

2 150V 10 min R

3a –200V 10 min R

3b 200V 10 min R

4 4V/5.5V 15 ms/2s R

540V

Test

Level

Duration or Number

of Pulses Specs

5 pulses, 1 minute

recurrence period

Acceptance

= 10Ω A

i

= 10Ω A

i

= 50Ω A

i

= 50Ω A

i

= 0.01Ω A

i

R

= 0.5Ω, td = 400 ms, tr = 5 ms B

i

level

Figure 10-1. Pulse 1 (R

V

12V

-100V

Figure 10-2. Pulse 2 (R

150V

= 10Ω)

i

90%

= 10Ω)

i

V

200 ms

< 100 µs

t10%

1 µs

1 ms

5s

200 ms

50 µs

2 µs

90%

24

12V

ATA6823 [Preliminary]

10%

50 µs

t

4856E–AUTO–07/07

Page 25

Figure 10-3. Pulse 3a (Ri = 50Ω)

V

12V

-200V

10 ms

100 µs

90 ms

ATA6823 [Preliminary]

100 ns

5 ns

t

10%

90%

Figure 10-4. Pulse 3b (R

V

200V

12V

100 µs

Figure 10-5. Pulse 4 (R

12V

= 50Ω)

i

= 0.01Ω)

i

90%

10%

90 ms10 ms

t

5 ns

100 ns

4856E–AUTO–07/07

5.5V

4.0V

0V

t

15 ms 2000 ms50 ms 100 ms< 5 ms

25

Page 26

10.2 Transients on Pin LIN

Transients to these pins are coupled capacitively to the IC and are valid for the application with

external circuitry concerning figure 6.

Values: Pulse 3a, Pulse 3b (see Figure 10-3 and Figure 10-4 on page 25) coupled via 1 nF to

LIN, R

Acceptance level A

=50Ω

i

10.3 Conducted Emissions, Radiated Emissions and Susceptibility

The application using the IC described in this specification has to fulfill the demands of the following specifications:

• GM GMW3100 (2001-08)

• TL82166 (1998-02)

• TL82366 (2002-03)

• TL965 (1999-10)

It is the responsibility of both the deliverer and the user of the described IC to meet the mentioned specifications.

11. ESD and Latch-up Requirements

The device withstands pulses when tested according to ESD STM 5.1-1998:

• Constant voltage 2 kV

• R = 1.5 kΩ

• C = 100 pF

1 pulse per polarity and per pin

3 samples, 0 failures

Electrical post stress testing at room temperature

Static latch-up tested according to AEC-Q100-004 and JESD78.

• 3 to 6 samples, 0 failures

• Electrical post stress testing at room temperature

In test, the voltage at the pins VBAT, LIN, CP, VBATSW, Hx, and Sx must not exceed 45V when

not able to drive the specified current.

26

ATA6823 [Preliminary]

4856E–AUTO–07/07

Page 27

ATA6823 [Preliminary]

12. Ordering Information

Extended Type Number Package Remarks

ATA6823-PHQY QFN32 Pb-free

13. Package Information

Package: QFN 32 - 7 x 7

Exposed pad 4.7 x 4.7

Dimensions in mm

Not indicated tolerances ± 0.05

32

1

8

Drawing-No.: 6.543-5097.01-4

Issue: 1; 24.02.03

14. Revision History

0.9±0.1

+0

0.05-0.05

0.3

0.6

24

17

7

4.7

3225

1

technical drawings

according to DIN

specifications

8

916

0.65 nom.

4.55

4856E–AUTO–07/07

Please note that the following page numbers referred to in this section refer to the specific revision

mentioned, not to this document.

Revision No. History

4856E-AUTO-07/07 • Put datasheet in a new template

27

Page 28

Headquarters International

Atmel Corporation

2325 Orchard Parkway

San Jose, CA 95131

USA

Tel: 1(408) 441-0311

Fax: 1(408) 487-2600

Atmel Asia

Room 1219

Chinachem Golden Plaza

77 Mody Road Tsimshatsui

East Kowloon

Hong Kong

Tel: (852) 2721-9778

Fax: (852) 2722-1369

Product Contact

Web Site

www.atmel.com

Literature Requests

www.atmel.com/literature

Atmel Europe

Le Krebs

8, Rue Jean-Pierre Timbaud

BP 309

78054

Saint-Quentin-en-Yvelines Cedex

France

Tel: (33) 1-30-60-70-00

Fax: (33) 1-30-60-71-11

Technical Support

auto_control@atmel.com

Atmel Japan

9F, Tonetsu Shinkawa Bldg.

1-24-8 Shinkawa

Chuo-ku, Tokyo 104-0033

Japan

Tel: (81) 3-3523-3551

Fax: (81) 3-3523-7581

Sales Contact

www.atmel.com/contacts

Disclaimer: The information in this document is provided in connection with Atmel products. No license, express or implied, by estoppel or otherwise, to any

intellectual property right is granted by this document or in connection with the sale of Atmel products. EXCEPT AS SET FORTH IN ATMEL’S TERMS AND CONDI-

TIONS OF SALE LOCATED ON ATMEL’S WEB SITE, ATMEL ASSUMES NO LIABILITY WHATSOEVER AND DISCLAIMS ANY EXPRESS, IMPLIED OR STATUTORY

WARRANTY RELATING TO ITS PRODUCTS INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTY OF MERCHANTABILITY, FITNESS FOR A PARTICULAR

PURPOSE, OR NON-INFRINGEMENT. IN NO EVENT SHALL ATMEL BE LIABLE FOR ANY DIRECT, INDIRECT, CONSEQUENTIAL, PUNITIVE, SPECIAL OR INCIDENTAL DAMAGES (INCLUDING, WITHOUT LIMITATION, DAMAGES FOR LOSS OF PROFITS, BUSINESS INTERRUPTION, OR LOSS OF INFORMATION) ARISING OUT OF

THE USE OR INABILITY TO USE THIS DOCUMENT, EVEN IF ATMEL HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES. Atmel makes no

representations or warranties with respect to the accuracy or completeness of the contents of this document and reserves the right to make changes to specifications

and product descriptions at any time without notice. Atmel does not make any commitment to update the information contained herein. Unless specifically provided

otherwise, Atmel products are not suitable for, and shall not be used in, automotive applications. Atmel’s products are not intended, authorized, or warranted for use

as components in applications intended to support or sustain life.

© 2007 Atmel Corporation. All rights reserved. Atmel®, logo and combinations thereof, and others are registered trademarks or trademarks of

Atmel Corporation or its subsidiaries. Other terms and product names may be trademarks of others.

4856E–AUTO–07/07

Loading...

Loading...