Page 1

1. Introduction

The development board for the ATA6621/22/24 (ATA6621-EK, ATA6622-EK,

ATA6624-EK) is designed to give designers a quick start with the ICs and for prototyping and testing of new LIN designs.

The ATA6621, ATA6622 and ATA6624 are system basis chips (SBCs) with fully integrated LIN transceiver according to the LIN specification 2.0, window watchdog with

adjustable trigger times and low-drop voltage regulator providing 5V/50 mA

(3.3V/50 mA for the ATA6622). The output current of the regulator can be boosted by

using an external NPN transistor.

The ATA6622 and the ATA6624 are totally pin- and function-compatible, the only difference between these circuits is the regulator’s output voltage.

ATA6621/22/24

Development

The ATA6621 differs in a few more ways—an initial overview of these differences

starts with the different pins listed in Table 1-1:

Table 1-1. Overview of Pin Differences

Pin No. ATA6621 ATA6622 ATA6624

2 PTRIG GND GND

6 Not connected GND GND

8 Not connected GND GND

10 Not connected INH INH

16 GND KL_15 KL_15

17 TEMP GND GND

Figure 1-1. ATA6621/22/24 Development Board

Board

Application Note

4970A–AUTO–01/07

Page 2

Another difference is unequal watchdog timing (see Section 2.3 on page 4).

The combination of the features included in the ATA6621/22/24 makes it possible to develop

simple, but powerful and cheap, slave nodes in LIN-bus systems.

The ICs are designed to handle the low-speed data communication in vehicles, for example, in

convenience electronics. Improved slope control at the LIN driver ensures secure data communication up to 20 Kbaud.

Sleep Mode and Silent Mode guarantee a very low current consumption.

This document has been developed to give the user an easy start with the development board

of the ATA6621/22/24. For more detailed information about the use of these devices themselves, refer to the corresponding datasheets.

1.1 Development Board Features

The development board for the ATA6621/22/24 supports the following features:

• All necessary components to put the ATA6621/22/24 in operation are included

• Placeholders for some optional components for extended functions included

• All pins easily accessible

• Easily adaptable watchdog times by replacing a resistor

• Possibility to place an external NPN transistor for boosting up the output current of the

voltage regulator (jumper J1)

• Possibility of selecting between master or slave operation (mounting D3 and R4)

1.2 Quick Start

The development board for the ATA6621/22/24 is shipped with all necessary components and

a default jumper setting to start with the development of a LIN slave node immediately.

After connecting an external 12V DC power supply between the terminals VB and GND, the

circuit is in the Pre-normal mode (Fail Safe mode) and a 5V (3.3V) DC voltage provided by the

internal voltage regulator can be measured between VCC and GND. (The Pre-normal mode is

called Fail Safe mode in the datasheets of the devices ATA6622 and ATA6624.) Furthermore,

the following voltages or states can be measured at the pins WD_OSC, TEMP, INH, RXD and

LIN:

Table 1-2. ATA6621

Mode VCC WD_OSC TEMP INH RXD LIN Transceiver

Pre-normal mode 5V 2.5V ~2V - 5V Recessive Off

Normal mode 5V 2.5V ~2V - 5V Recessive On

Table 1-3. ATA6622

Mode VCC WD_OSC TEMP INH RXD LIN Transceiver

Fail Safe mode 3.3V 1.23V - On 3.3V Recessive Off

Normal mode 3.3V 1.23V - On 3.3V Recessive On

2

ATA6621/22/24 Development Board

4970A–AUTO–01/07

Page 3

ATA6621/22/24 Development Board

Table 1-4. ATA6624

Mode VCC WD_OSC TEMP INH RXD LIN Transceiver

Fail Safe mode 5V 1.23V - On 5V Recessive Off

Normal mode 5V 1.23V - On 5V Recessive On

As the window watchdog of the ATA6621/22/24 is already active in the Pre-normal mode (Fail

Safe mode), a periodic reset signal will be generated at the pin NRES as long as no trigger

signal can be received at the watchdog trigger input. Normally the connected microcontroller

will be monitored by the watchdog, so it has to generate the required trigger signal as

described in Section 2.3 on page 4 and in more detail in the datasheet of the corresponding

device. For the quick start it is sufficient to generate a square-wave signal with V

f = 75Hz at pin NTRIG or PTRIG for the ATA6621 or with f = 50Hz at pin NTRIG for the

ATA6622 and ATA6624 (this is recommended only for testing purposes). In order to check

that the watchdog is triggered in the expected way, the reset pin NRES can be monitored until

a continuous high level is available.

Please note that the communication is still inactive in Pre-normal mode (Fail Safe mode).

In order to communicate via the LIN bus interface you have to switch to normal mode by

applying the VCC voltage (5V or 3.3V, as appropriate) at pin EN.

= VCC and

PP

2. Hardware Description

In the following sections only the normal operating conditions will be described. For further

information concerning one of the mentioned features, refer to the corresponding datasheet.

2.1 Power Supply (VB and GND)

In order to get the development board running, an external 5.7V to 18V DC power supply is

required between the terminals VB and GND. The input circuit is protected against

inverse-polarity with the protection diode D1, so that there is normally a difference between

the VB and VS level of approximately 0.7V.

2.2 Voltage Regulator (PVCC and VCC)

The internal 5V/3.3V voltage regulator is capable of driving loads with up to 50 mA current

consumption so the SBCs are able to supply a microcontroller, sensors and/or other ICs. The

voltage regulator is protected against overloads by means of current limitation and overtemperature shutdown. To boost the maximum load current, an external NPN transistor may be

used, with its base being connected to the VCC pin and its emitter connected to PVCC. If this

is done, the regulated output voltage of 5V or 3.3V is available at pin PVCC. For this reason,

the pin PVCC and not the pin VCC is led to the connector available off the board.

But in normal operation, the pins PVCC and VCC have to be connected directly. This is done

by setting jumper J1.

4970A–AUTO–01/07

3

Page 4

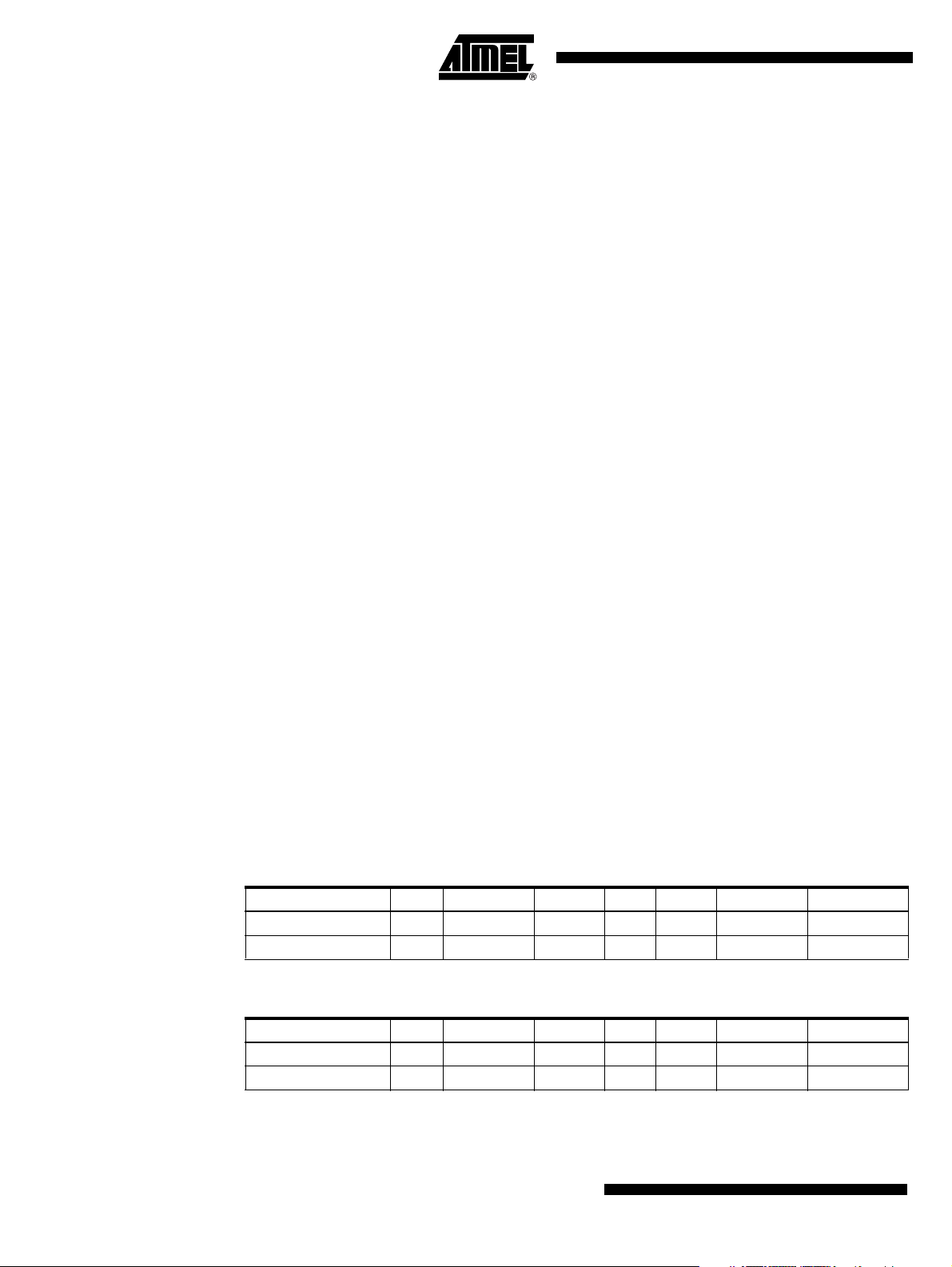

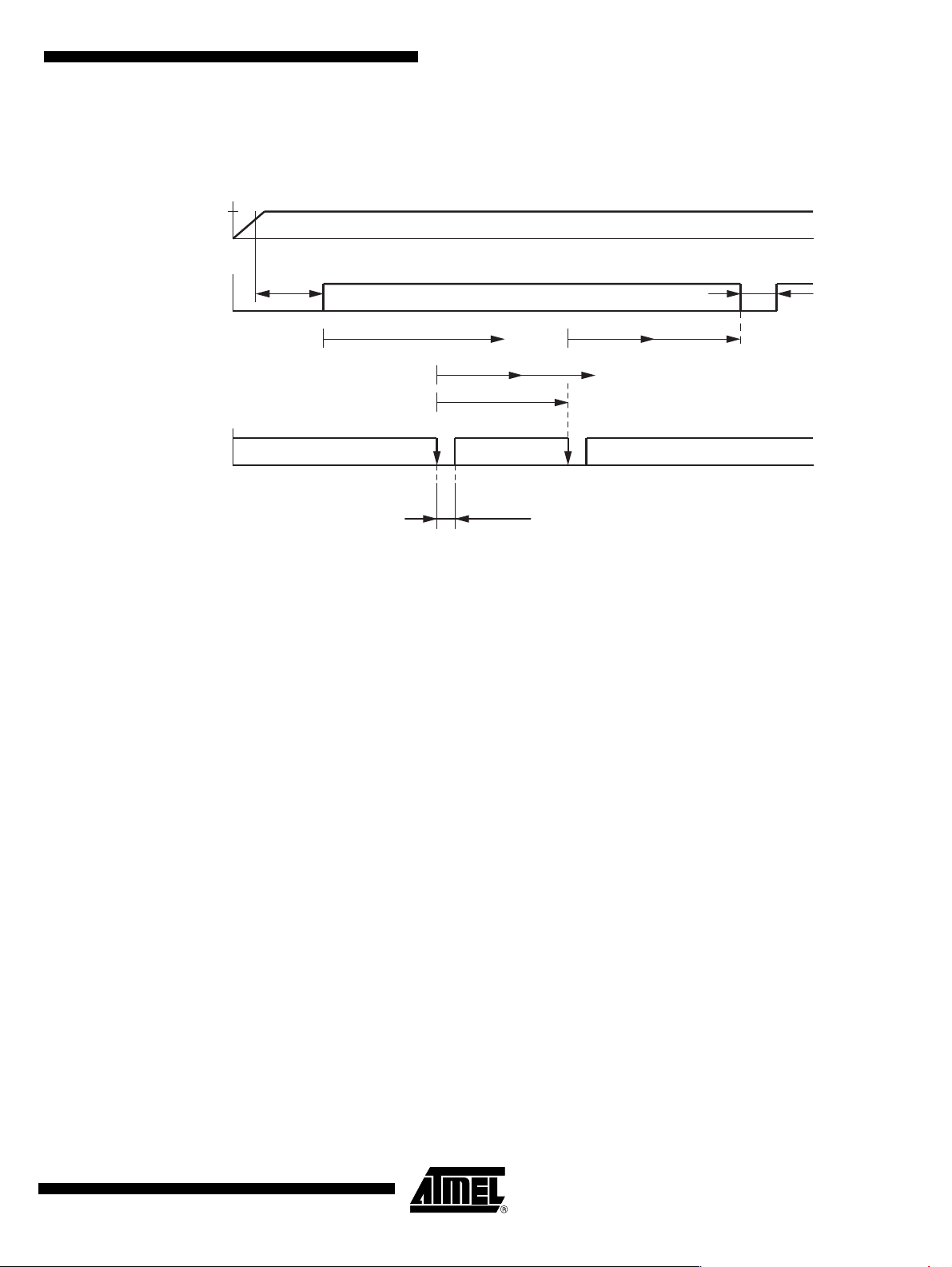

2.3 The Window Watchdog (PTRIG, NTRIG and NRES)

s

The watchdog anticipates a trigger signal from the microcontroller at the NTRIG input (negative edge) within a defined time window. The ATA6621 has an additional PTRIG input, so it is

also possible to trigger the watchdog with a positive edge. If no correct trigger signal is

received, a reset signal will be generated at the NRES output. During Silent or Sleep Mode the

watchdog is switched off to reduce current consumption.

The minimum time for the first watchdog pulse is required after the undervoltage reset at the

NRES pin disappears and is defined as lead time t

The timing basis of the watchdog is provided by the internal oscillator, whose time period t

is adjustable via the external resistor R3 at the pin WD_OSC. For the ATA6621, the voltage at

this pin is 2.5V, for the ATA6622 and ATA6624 it is 1.23V (see Table 1-2 on page 2 through

Table 1-4 on page 3). Due to these different voltages at the devices, the resulting timings are

also different. There is a resistor R3 with a value of 51 kΩ mounted on the development board,

which results in the following timing sequence for the ATA6621:

Figure 2-1. Timing Sequence with R3 = 51 kΩ at the ATA6621

= 5V

V

CC

Undervoltage Reset Watchdog Reset

= 10 ms

t

NRES

reset

.

d

OSC

t

= 1.9 m

nres

NTRIG

PTRIG

td = 49 ms

= 10 ms

t

1

t

trigg

t

t

wd

> 3 µs

= 10.5 ms

2

t

1

t

2

4

ATA6621/22/24 Development Board

4970A–AUTO–01/07

Page 5

ATA6621/22/24 Development Board

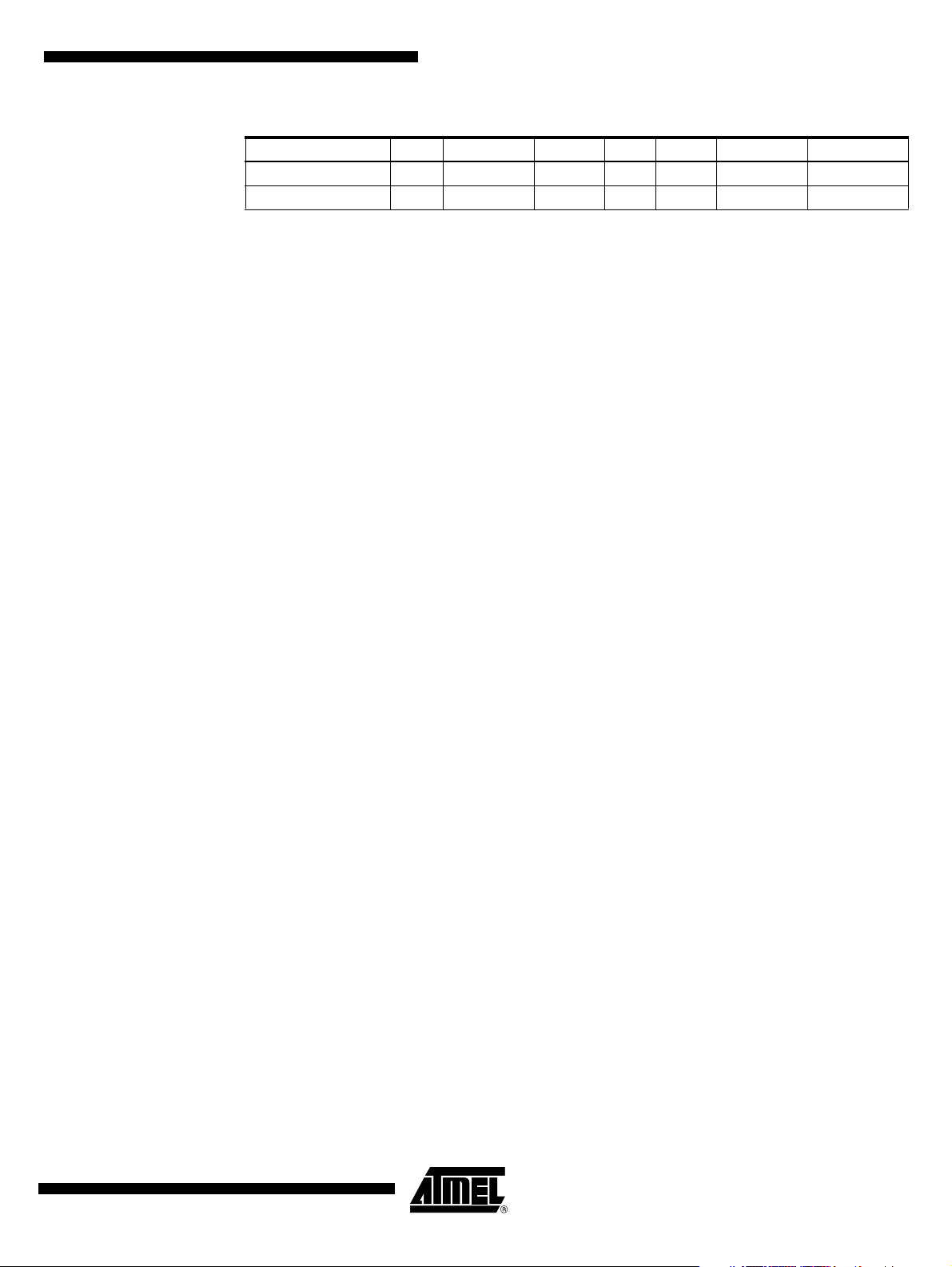

t

For the ATA6622 and ATA6624 the resistor R3 at pin WD_OSC with the same value of 51 kΩ

results in the different timing sequence shown in Figure 2-2:

Figure 2-2. Timing Sequence with R3 = 51 kΩ at the ATA6622 and ATA6624

= 3.3V/5V

V

CC

Undervoltage Reset Watchdog Rese

t

= 4 ms

NRES

reset

t

nres

= 4 ms

td = 150 ms

NTRIG

If you want to change the watchdog times mentioned above it is only necessary to change the

value of the external resistor R3 (refer to the corresponding datasheet).

2.4 LIN Interface (LIN, TXD and RXD)

2.4.1 Bus Pin (LIN)

A low-side driver with internal current limitation and thermal shutdown as well as an internal

pull-up resistor in compliance with the LIN specification 2.0 is implemented. LIN receiver

thresholds are compatible with the LIN protocol specification.

At the LIN pin there is a 220-pF capacitor to ground on the board. Additionally, when using the

development board for a LIN master application, there is the opportunity to mount the two necessary extra components diode D2 (LL4148) in series with resistor R1 (1kΩ) on the board at

their designated placeholders.

= 20 ms

t

1

t

trigg

= 21 ms

t

2

t

wd

> 200 ns

t

1

t

2

2.4.2 Input Pin (TXD)

2.4.3 Output Pin (RXD)

4970A–AUTO–01/07

This pin is the microcontroller interface to control the state of the LIN output. TXD must be

pulled to ground in order to have the LIN bus low. If TXD is high, the LIN output transistor is

turned off and the bus is in the recessive state, pulled up by the internal resistor. If TXD is low,

the LIN output transistor is turned on and the bus is in the dominant state. An internal timer

prevents the bus line from being driven permanently in the dominant state. If TXD is forced to

low longer than t

> 20 ms, the LIN bus driver is switched to the recessive state.

DOM

This pin reports the state of the LIN bus to the microcontroller. LIN high (recessive state) is

reported by a high level at RXD, LIN low (dominant state) is reported by a low level at RXD.

The output has an internal pull-up structure with typ. 5 kΩ to VCC.

The output is short-circuit protected.

5

Page 6

2.5 Temp Pin (TEMP) (ATA6621 Only)

Besides the internal temperature monitoring of the voltage regulator, an additional sensor

measures the junction temperature and provides a linearized voltage at the TEMP pin.

Together with the analog functions of the microcontroller (for example, the analog comparator

and/or the analog-to-digital converter), this enables the application to detect overload conditions. Further actions in order to prevent the IC from damage can be implemented.

2.6 Mode and TM Input Pins (MODE and TM)

The TM input is only used for Atmel® internal-testing purposes and therefore connected

directly to GND. The Mode input is pulled to GND by the 4.7-kΩ resistor R1 and therefore the

watchdog is active in the normal operation mode. Especially during the early development

phase it can be helpful to have the possibility to deactivate the watchdog in order to debug the

application program without disturbing RESETS caused by the watchdog. Therefore the

watchdog can be switched off by connecting the MODE pin to VCC externally.

2.7 Reset Output (NRES)

After ramping up the battery voltage or after a wake-up from Sleep mode, the 5V regulator is

switched on and the VCC voltage exceeds the undervoltage threshold. The implemented undervoltage delay keeps the NRES output at low level for approximately 10 ms after VCC

reaches its nominal value. Then it switches to high and the watchdog waits for the trigger

sequence from the microcontroller.

The NRES pin switches to low if the watchdog is not triggered correctly (see Section 2.3 on

page 4).

In the ATA6621 the Reset output is a push-pull state supplied by the VCC voltage.

In the ATA6622 and ATA6624, the Reset output is an open drain output implemented with a

single MOS transistor which is switched on in case of a VCC undervoltage or if the watchdog

is not triggered correctly. In order to pull up the NRES output of the ATA6622/24 an external

resistor connected to VCC

opment board.

If a reset occurs (NRES is Low), the circuit switches to Pre-normal mode (Fail Safe mode).

is necessary. This resistor (R9) is taken into account on the devel-

2.8 KL_15 Input (KL_15) (ATA6622/24 Only)

This pin is a high voltage input used to wake up the device from Sleep or Silent mode. It is an

edge sensitive pin (rising edge). It is usually connected to the ignition in order to generate a

local wake-up in the application if the ignition is switched on. To protect the pin against voltage

transients, a series resistor R12 and a 100-nF ceramic capacitor C8 have to be used. If this

pin is not needed, it must be connected to GND.

2.9 Inhibit Output (INH) (ATA6622/24 Only)

This pin is a high-side switch and it is normally used to switch on an external voltage regulator

during Normal mode or Fail Safe mode. In Sleep mode or Silent mode the INH output is

switched off.

For master node applications it is possible to switch off the external master resistor (R4) by the

INH pin.

6

ATA6621/22/24 Development Board

4970A–AUTO–01/07

Page 7

3. Boosting the Voltage Regulator

For some applications there is a need for a higher current than the internal voltage regulator

can deliver (50 mA). So it is possible to boost the maximum current by using an external NPN

transistor. On the development board there is already a placeholder for this part, into which

would fit, for example, the MJD31C in a D-PAK package. In addition to the transistor itself

there are two more components to be placed on the development board, the resistor R7 (3.3Ω)

and the electrolytic capacitor C4 (2.2 µF). The jumper J1 has to be removed in this case.

Note that the output voltage is no longer short-circuit protected when boosting the output current with an external NPN transistor.

The limiting parameter for the output current is the maximum power dissipation of the external

NPN transistor. In the version at this stage the thermal resistance of the MJD31C soldered on

the minimum pad size is 80 K/W, meaning the maximum possible output current in the case of

V

= 12V is approximately 230 mA at room temperature. It is not recommended to exceed this

S

limit, because the transistor could be damaged as a result of overtemperature. If a higher output current is required, additional cooling of the external transistor has to be ensured (see

Figure 3-2, Figure 3-3 and Figure 3-4 on page 8).

Figure 3-1. Boosting the Voltage Regulator

ATA6621/22/24 Development Board

Place T1, R7 and C4 and remove jumper J1 when boosting the output current

4970A–AUTO–01/07

7

Page 8

Figure 3-2, Figure 3-3 and Figure 3-4 show the maximum output current (I

regulator as a function of the supply voltage (V

(R

) of the external NPN transistor T1.

thJA

) at different coolings or thermal resistances

S

) of the voltage

max

Figure 3-2. I

Figure 3-3. I

versus VS at R

max

350

300

250

200

(mA)

150

max

I

100

50

0

versus VS at R

max

600

500

400

300

(mA)

max

200

I

= 80 K/W (No Additional Cooling)

thJA

Ta = 25˚C

T

= 85˚C

a

T

= 125˚C

a

10 12 14 16 18 20

VS (V)

= 50 K/W (Additional Cooling)

thJA

= 25˚C

T

a

T

= 85˚C

a

Figure 3-4. I

100

versus VS at R

max

1400

1200

1000

800

(mA)

600

max

I

400

200

T

= 125˚C

0

10 12 14 16 18 20

a

VS (V)

= 20 K/W (Additional Cooling)

thJA

= 25˚C

T

a

= 85˚C

T

a

= 125˚C

T

0

10 12 14 16 18 20

a

VS (V)

8

ATA6621/22/24 Development Board

4970A–AUTO–01/07

Page 9

ATA6621/22/24 Development Board

Figure 3-5 to Figure 3-10 on page 11 show some typical operating characteristics measured at

the ATA6621. The supply voltage V

(reverse battery protection). The external circuitry is shown in Figure 4-1 on page 12.

is approximately a diode forward voltage lower than V

S

bat

Figure 3-5. Output Voltage PV

ATA6621 with External Boosttransistor MJD31C

6

5

4

(V)

3

CC

PV

2

1

0

024681012

Figure 3-6. Output Voltage PV

5.020

5.0 15

5.0 10

(V)

CC

5.005

PV

5.000

4.995

versus Battery Voltage V

CC

I

= 0

OUT

I

= 20 mA

OUT

V

(V)

bat

versus Battery Voltage V

CC

at Startup

bat

at Different Output Currents

bat

ATA6621 with External Boosttransistor MJD31C

= 0

I

OUT

I

= 20 mA

OUT

I

= 100 mA

OUT

4970A–AUTO–01/07

4.990

01020304050

V

(V)

bat

9

Page 10

Figure 3-7. Load- transient Response Ch1: I

, Ch2: PV

OUT

CC

Figure 3-8. Startup Response Ch1: VS, Ch2: PV

CC

10

ATA6621/22/24 Development Board

4970A–AUTO–01/07

Page 11

ATA6621/22/24 Development Board

Figure 3-9. Switching from Silent to Normal Mode Ch1: NRES, Ch2: PV

CC

Figure 3-10. Output Voltage PVCC versus Temperature at Different Load Currents

5,05

5,04

5,03

5,02

(V)

CC

5,01

PV

5,00

4,99

4,98

-40-200 20406080100120

I

= 100 mA

OUT

I

OUT

= 20 mA

Temperature (˚C)

= 0

I

OUT

4970A–AUTO–01/07

11

Page 12

4. Schematic and Layout of the Development Board for the ATA6621/22/24

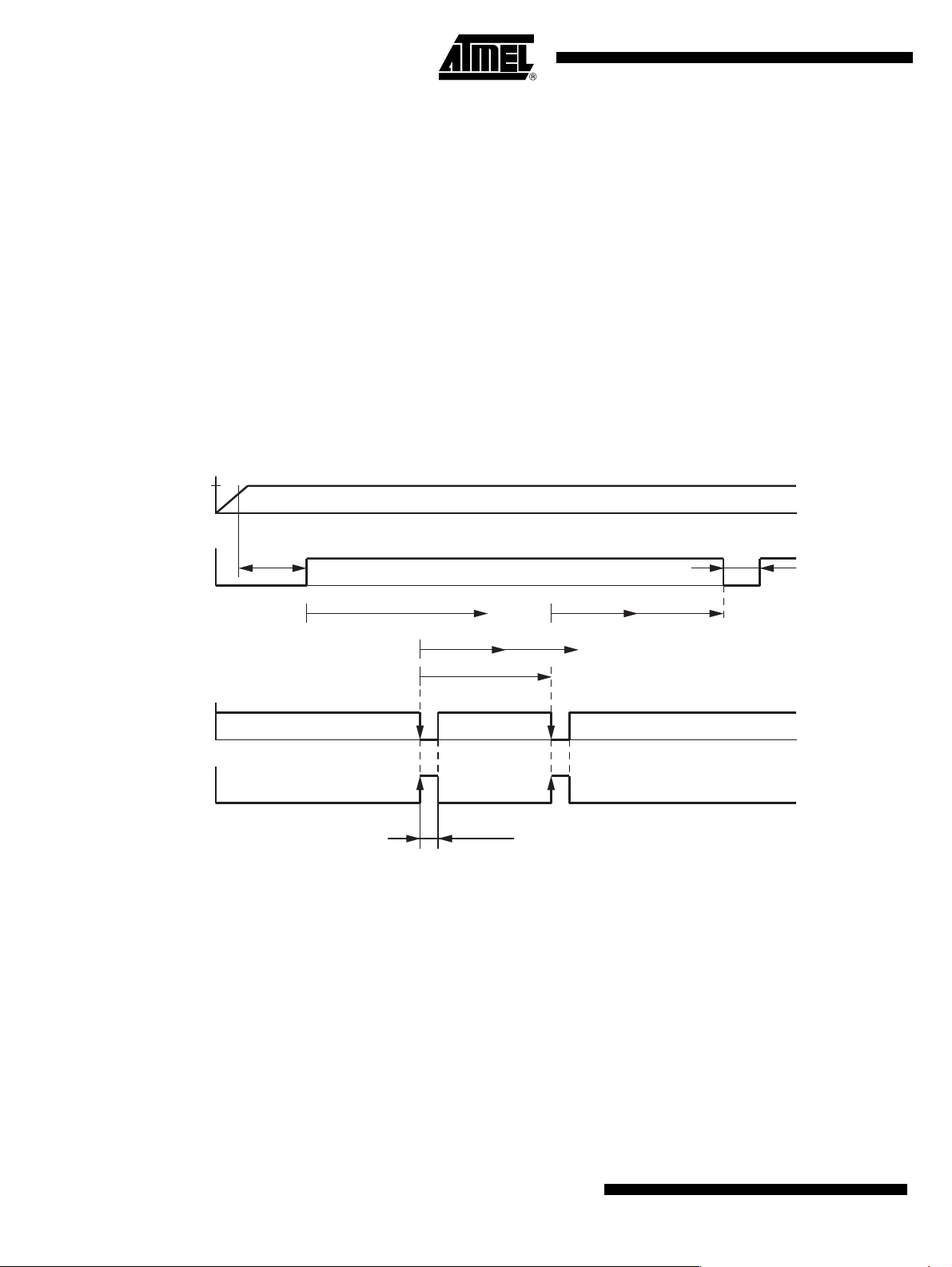

Figure 4-1. Schematic of the Development Board for the ATA6621/22/24

PVCC

VBAT

D1

LL4148

V1

R8

100Ω/1W

R8b

0

VS

R10

10Ω/2W

R10b

0

GND

TEMP

EN

PTRIG

NTRIG

WAKE

LIN

RXD

TXD

TEMP

D2

BZG04-33

+

+

C3

10 µF

C2

22 µF/50V

C1

100 nF

C5

100 nF

R6

10 kΩ

R13

S1

Wake

J1

VCC

0

R5

33 kΩ

R7

3.3Ω

EN

PTRIG

NTRIG

WAKE

GND

+

C4

2.2 µF

VS

20 19 18

1

2

3

4

5

67 8 109

NC

VCC

GND

GND

LIN

T1

MJD31C

PVCC

17

ATA6621/

ATA6622/

ATA6624

GND

NC

TEMP

GND

RXD

GND

16

KL15INH

NC

TEMP

15

14

13

12

11

R11

47 kΩ

C7

1 nF

MODE

TM

WD_OSC

NRES

TXD

(ATA6622/24)

R12

47 kΩ

MODE

R3

51 kΩ

KL_15

LL4148

C8

100 nF

R1

4.7 kΩ

R9

PVCC

10 kΩ

INH

(ATA6622/24)

220 pF

D3

R4

1 kΩ

LIN

C6

NRES

MODE

KL_15

12

MODE

KL_15

X1

Notes: 1. D3 and R4 are only necessary for a master node.

2. R9 and R13 are only needed for ATA6622 and ATA6624.

3. Pin KL_15 and the corresponding external circuitry are only available at the ATA6622/24.

4. Pin INH and the corresponding external circuitry are only available at the ATA6622/24.

5. Pin 17 has to be connected to GND by replacing C7 with a 0Ω resistor at ATA6622 or

ATA6624.

6. ATA6621: Pin 10 has to be connected to GND via R11 = 0. Pin 16 has to be connected to

GND by replacing C8 by a 0Ω resistor.

ATA6621/22/24 Development Board

ATA6621-EK

ATA6622-EK

ATA6624-EK

Revision 2.0

4970A–AUTO–01/07

Page 13

ATA6621/22/24 Development Board

Figure 4-2. ATA6621/22/24 Board Component Placement; Top Side, Top View

Figure 4-3. ATA6621/22/24 Development Board; Top Side, Top View

4970A–AUTO–01/07

13

Page 14

Figure 4-4. ATA6621/22/24 Development Board; Bottom Side, Top View (as if PCB Were

Transparent)

14

ATA6621/22/24 Development Board

4970A–AUTO–01/07

Page 15

ATA6621/22/24 Development Board

5. The Development Board in a Simple Application

To show just how easy it is to develop a LIN-based application with the development board for

the ATA6621/22/24, here is a little example for a complete LIN slave node consisting of the

ATA6621 and the microcontroller ATmega88, a flasher controlled via the LIN bus.

The LIN interface of the slave is implemented with the ATA6621 and the control of the flasher

as well as the protocol handling is done by the ATmega88 microcontroller. In the schematic of

this slave node it is obvious that there are almost no other external components needed to fulfill the requirements of this application, other than the development board of the

ATA6621/22/24 and the ATmega88.

Figure 5-1. Simple Application Using the Development Board for the ATA6621/22/24 (Schematic)

X4

X5

X6

X7

NRES

X1

VS

TEMP

EN

NTRIG

LIN

RXD

TXD

VS

LIN

XISP1

ISP

JP1

S1

JP2

Development board

ATA6621/6622/6624

330Ω

PVCCPB4

PB3PB5

PVCC

NRES

R1

LED1

PVCC

330Ω

LEDLED

D2D1

R2

LED2

PVCC

100 nF

C1

PD3

PD4

GND (3)

VCC (4)

GND (5)

VCC (6)

PB6

PB7

Flasher

TXD

PD2

PD1

32 31 30 28

1

2

3

4

5

91011 1312

LED2

PC5

PD0

PC6/NRST

29

U1

ATMEGA88

MLF 5 mm × 5 mm

0.5 mm pitch

32 lead

PB1

NTRIGRXD

PC4

PC3

1427152616

ENLED1NRES

PC2

25

XL1

XL2

R5

1 kΩ

24

23

22

21

20

196

187

178

VS

+

100 µF

T1

BC817-40

PC1

PC0

ADC7

GND (21)

AREF

ADC6

AVC C

PB5

GND (33)

C8

100 nF

C6

C4

100 nF

PB5

TEMP

C7

10 µF

PVCC

C5

100 nF

+

4970A–AUTO–01/07

PD5

PD6

PD7

PB1

PB0

PB1 PB4PB3

PB2

PB3

PB4

15

Page 16

For testing purposes two jumpers (JP1 and JP2) have been added to the LIN part of this application in order to have the opportunity to easily change some parameters at the pins NRES

and VCC/PVCC. Additionally, the switch S1 has been included to generate a wake pulse.

For the microcontroller part of this slave node, only a few blocking capacitors are necessary.

XISP1 is the programming interface and D1, D2, R1 and R2 report the internal status of the

slave node. Because the flasher runs with 12V DC, the transistor T1 is needed to transfer the

5V from the microcontroller to the 12V level. Furthermore, the flasher produces some glitches,

so that there are some capacitors needed in order to block the 12V power supply.

Figure 5-2. A Simple Application Using the Development Board for the ATA6621

(Photograph)

16

ATA6621/22/24 Development Board

4970A–AUTO–01/07

Page 17

Atmel Corporation Atmel Operations

2325 Orchard Parkway

San Jose, CA 95131, USA

Tel: 1(408) 441-0311

Fax: 1(408) 487-2600

Regional Headquarters

Europe

Atmel Sarl

Route des Arsenaux 41

Case Postale 80

CH-1705 Fribourg

Switzerland

Tel: (41) 26-426-5555

Fax: (41) 26-426-5500

Asia

Room 1219

Chinachem Golden Plaza

77 Mody Road Tsimshatsui

East Kowloon

Hong Kong

Tel: (852) 2721-9778

Fax: (852) 2722-1369

Japan

9F, Tonetsu Shinkawa Bldg.

1-24-8 Shinkawa

Chuo-ku, Tokyo 104-0033

Japan

Tel: (81) 3-3523-3551

Fax: (81) 3-3523-7581

Memory

2325 Orchard Parkway

San Jose, CA 95131, USA

Tel: 1(408) 441-0311

Fax: 1(408) 436-4314

Microcontrollers

2325 Orchard Parkway

San Jose, CA 95131, USA

Tel: 1(408) 441-0311

Fax: 1(408) 436-4314

La Chantrerie

BP 70602

44306 Nantes Cedex 3, France

Tel: (33) 2-40-18-18-18

Fax: (33) 2-40-18-19-60

ASIC/ASSP/Smart Cards

Zone Industrielle

13106 Rousset Cedex, France

Tel: (33) 4-42-53-60-00

Fax: (33) 4-42-53-60-01

1150 East Cheyenne Mtn. Blvd.

Colorado Springs, CO 80906, USA

Tel: 1(719) 576-3300

Fax: 1(719) 540-1759

Scottish Enterprise Technology Park

Maxwell Building

East Kilbride G75 0QR, Scotland

Tel: (44) 1355-803-000

Fax: (44) 1355-242-743

RF/Automotive

Theresienstrasse 2

Postfach 3535

74025 Heilbronn, Germany

Tel: (49) 71-31-67-0

Fax: (49) 71-31-67-2340

1150 East Cheyenne Mtn. Blvd.

Colorado Springs, CO 80906, USA

Tel: 1(719) 576-3300

Fax: 1(719) 540-1759

Biometrics

Avenue de Rochepleine

BP 123

38521 Saint-Egreve Cedex, France

Tel: (33) 4-76-58-47-50

Fax: (33) 4-76-58-47-60

Literature Requests

www.atmel.com/literature

Disclaimer: The information in this document is provided in connection with Atmel products. No license, express or implied, by estoppel or otherwise, to any

intellectual property right is granted by this document or in connection with the sale of Atmel products. EXCEPT AS SET FORTH IN ATMEL’S TERMS AND CONDI-

TIONS OF SALE LOCATED ON ATMEL’S WEB SITE, ATMEL ASSUMES NO LIABILITY WHATSOEVER AND DISCLAIMS ANY EXPRESS, IMPLIED OR STATUTORY

WARRANTY RELATING TO ITS PRODUCTS INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTY OF MERCHANTABILITY, FITNESS FOR A PARTICULAR

PURPOSE, OR NON-INFRINGEMENT. IN NO EVENT SHALL ATMEL BE LIABLE FOR ANY DIRECT, INDIRECT, CONSEQUENTIAL, PUNITIVE, SPECIAL OR INCIDENTAL DAMAGES (INCLUDING, WITHOUT LIMITATION, DAMAGES FOR LOSS OF PROFITS, BUSINESS INTERRUPTION, OR LOSS OF INFORMATION) ARISING OUT

OF THE USE OR INABILITY TO USE THIS DOCUMENT, EVEN IF ATMEL HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES. Atmel makes no

representations or warranties with respect to the accuracy or completeness of the contents of this document and reserves the right to make changes to specifications

and product descriptions at any time without notice. Atmel does not make any commitment to update the information contained herein. Unless specifically provided

otherwise, Atmel products are not suitable for, and shall not be used in, automotive applications. Atmel’s products are not intended, authorized, or warranted for use

as components in applications intended to support or sustain life.

© 2007 Atmel Corporation. All rights reserved. Atmel®, logo and combinations thereof, Everywhere You Are® and others are registered trade-

marks or trademarks of Atmel Corporation or its subsidiaries. Other terms and product names may be trademarks of others.

4970A–AUTO–01/07

Loading...

Loading...