Page 1

Features

• Contactless Power Supply

• Contactless Read/Write Data Transmission

• Radio Frequency f

• 128-bit EEPROM User Memory: 16 Bytes (8 Bits Each)

• 8-bit Configuration Memory

• High Q-antenna Tolerance Due to Built-in Options

• Applications

– Access Control

• Standard Unique Format (Manchester, RF/64)

• 40-bitData Memory

• 14-bit Parity Memory

• 9-bit Header Memory

• On-chip Trimmed Antenna Capacitor

– 330 pF ±3%

– 250 pF ±3%

• Mega Pads 200 µm × 400 µm

• Mega Pads 200 µm × 400 µm with 25 µm Gold Bumps for Direct Coil Bonding

• Other Options:

– Direct Access Mode

– OTP Functionality

from 100 kHz to 150 kHz

RF

1. Description

The ATA5575 is a contactless read/write identification IC (IDIC®) for applications in

the 100-kHz to 150-kHz frequency band. A single coil connected to the chip serves as

the IC’s power supply and bi-directional communication interface. The antenna and

chip together form a transponder or tag.

Read/Write

LF RFID IDIC

100 kHz to

150 kHz

ATA5575M1

Summary

Preliminary

The on-chip 128-bit user EEPROM (16 bytes with 8 bits each) can be read and written

byte-wise from a base station (reader). Data is transmitted from the IDIC (uplink) using

load modulation. This is achieved by damping the RF field with a resistive load

between the two terminals Coil 1 and Coil 2. The IC receives and decodes serial base

station commands (downlink), which are encoded as 100% amplitude modulated

(OOK) pulse-interval-encoded bit streams.

The ATA5575 is an EEPROM-based circuit. It is optimized for maximum read range.

Programming is also possible, but the write range is limited.

The chip has to be locked after loading the application-specific data into the device.

Until the enable bits are set properly, the ATA5575M1 transmits all digits “0” in unique

format. Typical applications run at 125 kHz.

NOTE: This is a summary document.

The complete document is available.

For more information, please contact

your local Atmel sales office.

9167AS–RFID–11/09

Page 2

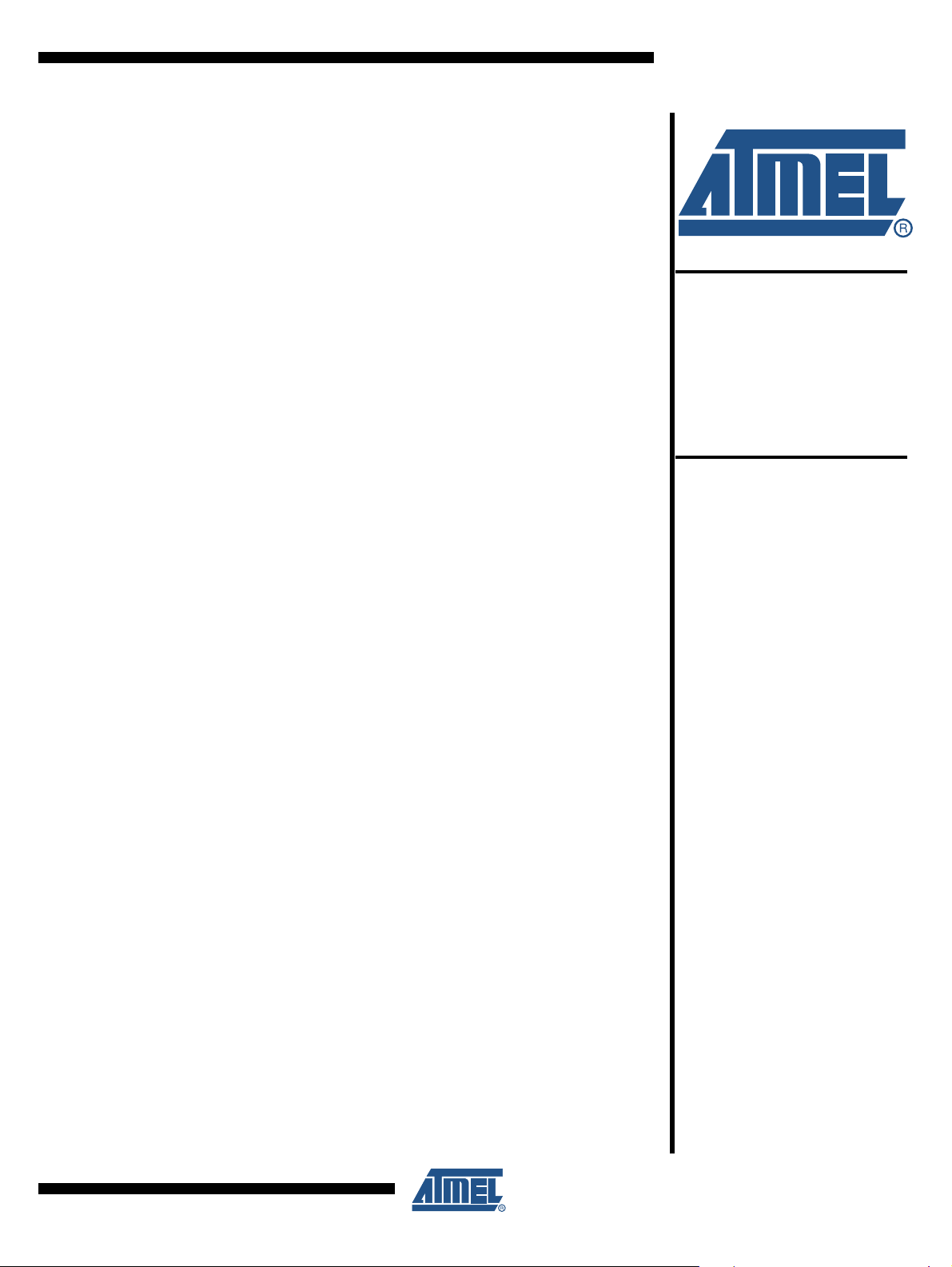

2. System Block Diagram

Data

Reader

or

Base station

ATA5575

Power

Tr ansponder

Coil interface

Controller

Memory

Memory

(136-bit EEPROM)

Modulator

Analog front end

Data-rate

generator

Write

decoder

POR

Coil 2

Coil 1

Controller

Te st logic HV generator

Input register

Mode register

Figure 2-1. RFID System Using ATA5575 Tag

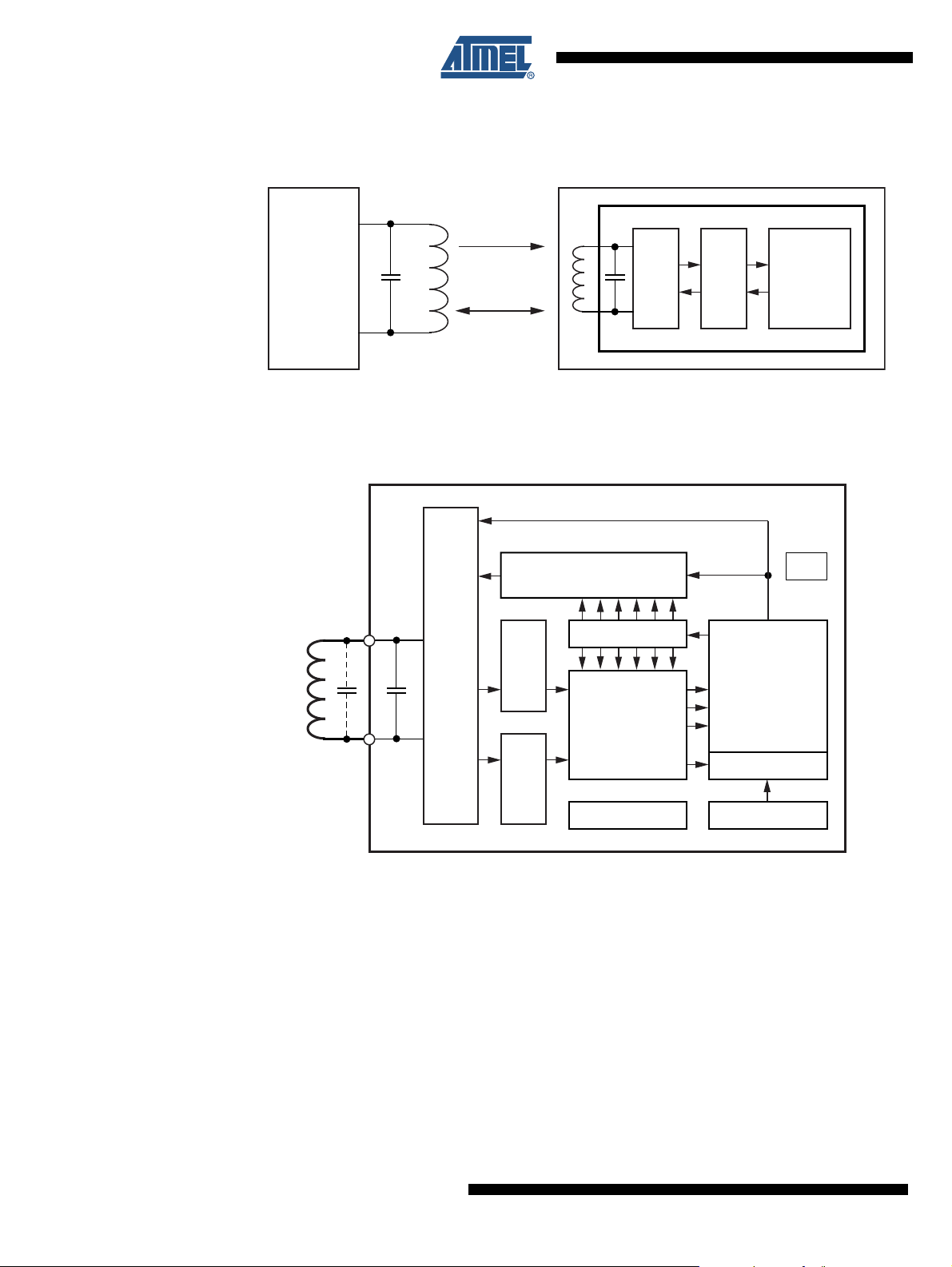

3. ATA5575 - Functional Blocks

Figure 3-1. Block Diagram

2

ATA5575M1 [Preliminary]

9167AS–RFID–11/09

Page 3

4. Analog Front End (AFE)

The AFE includes all circuits which are directly connected to the coil terminals, it generates the

IC’s power supply and handles the bi-directional data communication with the reader. The

AFE consists of the following blocks:

• Rectifier to generate a DC supply voltage from the AC coil voltage

• Clock extractor

• Switchable load between Coil 1 and Coil 2 for data transmission from tag to the reader

• Field-gap detector for data transmission from the base station to the tag

• ESD protection circuitry

4.1 Data Rate Generator

The data rate is fixed to RF/64.

4.2 Write Decoder

The write decoder detects the write gaps and verifies the validity of the data stream according

to the Atmel

ATA5575M1 [Preliminary]

®

downlink protocol (pulse interval encoding).

4.3 HV Generator

This on-chip charge pump circuit generates the high voltage required for programming the

EEPROM.

4.4 DC Supply

Power is externally supplied to the IDIC via the two coil connections. The IC rectifies and regulates this RF source and uses it to generate its supply voltage.

4.5 Power-On Reset (POR)

The power-on reset circuit blocks the voltage supply to the IDIC until an acceptable voltage

threshold has been reached. This, in turn, triggers the default initialization delay sequence.

During this configuration period of 98 field clocks, the ATA5575 is initialized with the configuration data stored in EEPROM byte 16.

4.6 Clock Extraction

The clock extraction circuit uses the external RF signal as its internal clock source.

4.7 Controller

The control logic module executes the following functions:

• Load mode register with configuration data from EEPROM byte 16 after power-on and

during reading

• Controls each EEPROM memory read/write access and handles the data protection

• Handle the downlink command decoding, detecting protocol violations and error conditions

9167AS–RFID–11/09

3

Page 4

4.8 Mode Register

4.9 Modulator

4.10 Memory

The mode register maintains a readable shadow copy of the configuration data held in byte 16

of the EEPROM. It is continually refreshed during read mode and (re-)loaded after every POR

event or reset command. Depending on the version, the configuration data is pre-programmed

when leaving Atmel’s production.

The modulator encodes the serialized EEPROM data for transmission to a tag reader or a

base station. Modulation available: Manchester.

Figure 4-1. Memory Map

1………………....…………….8

Configuration Data Byte 16

User Data Byte 15

User Data Byte 14

User Data Byte 13

User Data Byte 12

User Data Byte 11

User Data Byte 10

User Data Byte 9

User Data Byte 8

User Data Byte 7

User Data Byte 6

User Data Byte 5

User Data Byte 4

User Data Byte 3

User Data Byte 2

User Data Byte 1

User Data Byte 0

8 bits

Not transmitted

The memory is a 136-bit EEPROM, which is arranged in 17 bytes of 8 bits each. Programming

is carried out byte-wise, so a complete byte will be programmed with a single command.

Byte 16 contains the mode/configuration data, which is not transmitted during regular read

operations.

A special bit combination in byte 16 will lock the entire memory. Once locked, the memory

(including byte 16 itself) can not be re-programmed once more via the RF field.

4

ATA5575M1 [Preliminary]

9167AS–RFID–11/09

Page 5

ATA5575M1 [Preliminary]

5. Absolute Maximum Ratings

Stresses beyond those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. This is a stress rating

only and functional operation of the device at these or any other conditions beyond those indicated in the operational sections of this

specification is not implied. Exposure to absolute maximum rating conditions for extended periods may affect device reliability.

Parameters Symbol Value Unit

Maximum DC current into Coil1/Coil2 I

Maximum AC current into Coil1/Coil2

f = 125 kHz

Power dissipation (dice) (free-air condition, time of

application: 1s)

Electrostatic discharge maximum to ANSI/ESD-STM5.1-2001

standard (HBM)

Operating ambient temperature range T

Storage temperature range (data retention reduced) T

I

coil p

P

V

coil

tot

max

amb

stg

t

6. Electrical Characteristics

T

= +25°C; f

amb

No. Parameters Test Conditions Symbol Min. Typ. Max. Unit Type*

1 RF frequency range f

Supply current

(without current

2.1

consumed by the external

LC tank circuit)

2.2

2.3

3.1

Coil voltage (AC supply)

3.2 Program EEPROM

4 Start-up time V

5.1

Clamp

5.2 20 mA current into Coil1/2 V

6.1

Modulation parameters

6.2

6.3 Thermal stability V

*) Type means: T: directly or indirectly tested during production; Q: guaranteed based on initial product qualification data

Notes: 1. I

2. Current into Coil1/Coil2 is limited to 10 mA.

3. Since the EEPROM performance is influenced by assembly processes, Atmel can not confirm the parameters for -DDW

= 125 kHz; unless otherwise specified

coil

100 125 150 kHz

T

amb

= 25°C

RF

(1)

I

DD

Read – full temperature

range

Programming – full

temperature range

Read mode and write

command

coil pp

3 mA current into Coil1/2 V

3 mA current into Coil1/2

and modulation ON

20 mA current into Coil1/2

and modulation ON

measurement setup: EEPROM programmed to 00 ... 000 (erase all); chip in modulation defeat.

DD

(2)

(2)

= 6V t

mod lo /Tamb

V

coil pp

startup

V

V

pp

pp

pp

pp

6V

16 V

TBD 17 TBD V T

TBD 20 TBD V T

TBD 7 TBD V Q

TBD 9 TBD V T

(tested die on unsawn wafer) delivery.

TBD mA

TBD mA

TBD mW

TBD V

–40 to +85 °C

–40 to +150 °C

1.5 3 µA T

25µAQ

25 µA Q

clamp

clamp

VQ

VQ

1.1 ms Q

–1 mV/°C Q

9167AS–RFID–11/09

5

Page 6

6. Electrical Characteristics (Continued)

T

= +25°C; f

amb

No. Parameters Test Conditions Symbol Min. Typ. Max. Unit Type*

7.1 Clock detection level V

7.2 Gap detection level V

8 Programming time

9 Endurance Erase all / write all

10.1

10.2 Top = 150°C

Data retention

10.3 Top = 250°C

11.1

Resonance capacitor

11.2 TBD 250 TBD

*) Type means: T: directly or indirectly tested during production; Q: guaranteed based on initial product qualification data

Notes: 1. I

2. Current into Coil1/Coil2 is limited to 10 mA.

3. Since the EEPROM performance is influenced by assembly processes, Atmel can not confirm the parameters for -DDW

= 125 kHz; unless otherwise specified

coil

= 8V V

coil pp

= 8V V

coil pp

clkdet

gapdet med

TBD 550 TBD mV T

TBD 550 TBD mV T

From last command gap

to re-enter read mode

T

prog

55.76msT

(64 + 648 internal clocks)

(3)

Top = 55°C

Mask option

V

coil pp

measurement setup: EEPROM programmed to 00 ... 000 (erase all); chip in modulation defeat.

DD

(3)

(3)

(3)

(4)

= 1V

n

cycle

t

retention

t

retention

t

retention

C

100000 Cycles Q

10 20 50 Years Q

96 hrs T

24 hrs Q

TBD 330 TBD

r

(tested die on unsawn wafer) delivery.

pF T

6

ATA5575M1 [Preliminary]

9167AS–RFID–11/09

Page 7

Headquarters International

Atmel Corporation

2325 Orchard Parkway

San Jose, CA 95131

USA

Tel: 1(408) 441-0311

Fax: 1(408) 487-2600

Atmel Asia

Unit 1-5 & 16, 19/F

BEA Tower, Millennium City 5

418 Kwun Tong Road

Kwun Tong, Kowloon

Hong Kong

Tel: (852) 2245-6100

Fax: (852) 2722-1369

Product Contact

Web Site

www.atmel.com

Literature Requests

www.atmel.com/literature

Atmel Europe

Le Krebs

8, Rue Jean-Pierre Timbaud

BP 309

78054

Saint-Quentin-en-Yvelines Cedex

France

Tel: (33) 1-30-60-70-00

Fax: (33) 1-30-60-71-11

Technical Support

rfid@atmel.com

Atmel Japan

9F, Tonetsu Shinkawa Bldg.

1-24-8 Shinkawa

Chuo-ku, Tokyo 104-0033

Japan

Tel: (81) 3-3523-3551

Fax: (81) 3-3523-7581

Sales Contact

www.atmel.com/contacts

Disclaimer: The information in this document is provided in connection with Atmel products. No license, express or implied, by estoppel or otherwise, to any

intellectual property right is granted by this document or in connection with the sale of Atmel products. EXCEPT AS SET FORTH IN ATMEL’S TERMS AND CONDI-

TIONS OF SALE LOCATED ON ATMEL’S WEB SITE, ATMEL ASSUMES NO LIABILITY WHATSOEVER AND DISCLAIMS ANY EXPRESS, IMPLIED OR STATUTORY

WARRANTY RELATING TO ITS PRODUCTS INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTY OF MERCHANTABILITY, FITNESS FOR A PARTICULAR

PURPOSE, OR NON-INFRINGEMENT. IN NO EVENT SHALL ATMEL BE LIABLE FOR ANY DIRECT, INDIRECT, CONSEQUENTIAL, PUNITIVE, SPECIAL OR INCIDENTAL DAMAGES (INCLUDING, WITHOUT LIMITATION, DAMAGES FOR LOSS OF PROFITS, BUSINESS INTERRUPTION, OR LOSS OF INFORMATION) ARISING OUT OF

THE USE OR INABILITY TO USE THIS DOCUMENT, EVEN IF ATMEL HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES. Atmel makes no

representations or warranties with respect to the accuracy or completeness of the contents of this document and reserves the right to make changes to specifications

and product descriptions at any time without notice. Atmel does not make any commitment to update the information contained herein. Unless specifically provided

otherwise, Atmel products are not suitable for, and shall not be used in, automotive applications. Atmel’s products are not intended, authorized, or warranted for use

as components in applications intended to support or sustain life.

© 2009 Atmel Corporation. All rights reserved. Atmel®, logo and combinations thereof, IDIC® and others are registered trademarks or trade-

marks of Atmel Corporation or its subsidiaries. Other terms and product names may be trademarks of others.

9167AS–RFID–11/09

Loading...

Loading...