Page 1

Features

• Incorporates the ARM926EJ-S

– DSP Instruction Extensions, ARM Jazelle

– 16 Kbyte Data Cache, 16 Kbyte Instruction Cache, Write Buffer

– 220 MIPS at 200 MHz

– Memory Management Unit

– EmbeddedICE

™

In-circuit Emulation, Debug Communication Channel Support

• Additional Embedded Memories

– One 32 Kbyte Internal ROM, Single-cycle Access at Maximum Matrix Speed

– One 32 Kbyte Internal SRAM, Single-cycle Access at Maximum Matrix Speed

• External Bus Interface (EBI)

– EBI Supports Mobile DDR, SDRAM, Low Power SDRAM, Static Memory,

Synchronous CellularRAM, ECC-enabled NAND Flash and CompactFlash

• Metal Programmable (MP) Block

– 500,000 Gates/250,000 Gates Metal Programmable Logic (through 5 Metal Layers)

for AT91CAP9S500A/AT91CAP9S250A Respectively

– Ten 512 x 36-bit Dual Port RAMs

– Eight 512 x 72-bit Single Port RAMs

– High Connectivity for Up to Three AHB Masters and Four AHB Slaves

– Up to Seven AIC Interrupt Inputs

– Up to Four DMA Hardware Handshake Interfaces

– Delay Lines for Double Data Rate Interface

– UTMI+ Full Connection

– Up to 77 Dedicated I/Os

• LCD Controller

– Supports Passive or Active Displays

– Up to 24 Bits per Pixel in TFT Mode, Up to 16 Bits per Pixel in STN Color Mode

– Up to 16M Colors in TFT Mode, Resolution Up to 2048x2048, Supports Wider

Screen Buffers

• Image Sensor Interface

– ITU-R BT. 601/656 External Interface, Programmable Frame Capture Rate

– 12-bit Data Interface for Support of High Sensibility Sensors

– SAV and EAV Synchronization, Preview Path with Scaler, YCbCr Format

• USB 2.0 Full Speed (12 Mbits per second) OHCI Host Double Port

– Dual On-chip Transceivers

– Integrated FIFOs and Dedicated DMA Channels

• USB 2.0 High Speed (480 Mbits per second) Device Port

– On-chip Transceiver, 4 Kbyte Configurable Integrated DPRAM

– Integrated FIFOs and Dedicated DMA Channels

– Integrated UTMI+ Physical Interface

• Ethernet MAC 10/100 Base T

– Media Independent Interface (MII) or Reduced Media Independent Interface (RMII)

– 28-byte FIFOs and Dedicated DMA Channels for Receive and Transmit

• Multi-Layer Bus Matrix

– Twelve 32-bit-layer Matrix, Allowing a Maximum of 38.4 Gbps of On-chip Bus

Bandwidth at Maximum 100 MHz System Clock Speed

– Boot Mode Select Option, Remap Command

• Fully-featured System Controller, Including

– Reset Controller, Shutdown Controller

™

ARM® Thumb® Processor

®

Technology for Java® Acceleration

Customizable

Microcontroller

™

Processor

AT91CAP9S500A

AT91CAP9S250A

Preliminary

6264A–CAP–21-May-07

Page 2

– Four 32-bit Battery Backup Registers for a Total of 16 Bytes

– Clock Generator and Power Management Controller

– Advanced Interrupt Controller and Debug Unit

– Periodic Interval Timer, Watchdog Timer and Real-Time Timer

• Reset Controller (RSTC)

– Based on Two Power-on Reset Cells, Reset Source Identification and Reset Output Control

• Shutdown Controller (SHDC)

– Programmable Shutdown Pin Control and Wake-up Circuitry

• Clock Generator (CKGR)

– 32,768 Hz Low-power Oscillator on Battery Backup Power Supply, Providing a Permanent

Slow Clock

– 8 to 16 MHz On-chip Oscillator

– Two PLLs up to 240 MHz

– One USB 480 MHz PLL

• Power Management Controller (PMC)

– Very Slow Clock Operating Mode, Software Programmable Power Optimization Capabilities

– Four Programmable External Clock Signals

• Advanced Interrupt Controller (AIC)

– Individually Maskable, Eight-level Priority, Vectored Interrupt Sources

– Two External Interrupt Sources and One Fast Interrupt Source, Spurious Interrupt Protected

• Debug Unit (DBGU)

– 2-wire UART and Support for Debug Communication Channel, Programmable ICE Access

Prevention

• Periodic Interval Timer (PIT)

– 20-bit Interval Timer plus 12-bit Interval Counter

• Watchdog Timer (WDT)

– Key-protected, Programmable Only Once, Windowed 16-bit Counter Running at Slow Clock

• Real-Time Timer (RTT)

– 32-bit Free-running Backup Counter Running at Slow Clock with 16-bit Prescaler

• Four 32-bit Parallel Input/Output Controllers (PIOA, PIOB, PIOC and PIOE)

– 128 Programmable I/O Lines Multiplexed with up to Two Peripheral I/Os

– Input Change Interrupt Capability on Each I/O Line

– Individually Programmable Open-drain, Pull-up Resistor and Synchronous Output

• DMA Controller (DMAC)

– Acts as one Bus Matrix Master

– Embeds 4 Unidirectional Channels with Programmable Priority, Address Generation, Channel

Buffering and Control

– Supports Four External DMA Requests and Four Internal DMA Requests from the Metal

Programmable Block (MPBlock)

• Twenty-two Peripheral DMA Controller Channels (PDC)

• One 2.0A and 2.0B Compliant CAN Controller

– 16 Fully-programmable Message Object Mailboxes, 16-bit Time Stamp Counter

• Two Multimedia Card Interfaces (MCI)

™

– SDCard/SDIO and MultiMedia

– Automatic Protocol Control and Fast Automatic Data Transfers with PDC

Card 3.31 Compliant

• Two Synchronous Serial Controllers (SSC)

– Independent Clock and Frame Sync Signals for Each Receiver and Transmitter

– I²S Analog Interface Support, Time Division Multiplex Support

– High-speed Continuous Data Stream Capabilities with 32-bit Data Transfer

2

AT91CAP9S500A/AT91CAP9S250A

6264A–CAP–21-May-07

Page 3

AT91CAP9S500A/AT91CAP9S250A

• One AC97 Controller (AC97C)

– 6-channel Single AC97 Analog Front End Interface, Slot Assigner

• Three Universal Synchronous/Asynchronous Receiver Transmitters (USART)

– Individual Baud Rate Generator, IrDA

Encoding/Decoding

– Support for ISO7816 T0/T1 Smart Card, Hardware Handshaking, RS485 Support

• Two Master/Slave Serial Peripheral Interface (SPI)

– 8- to 16-bit Programmable Data Length, Four External Peripheral Chip Selects

– Synchronous Communications at Up to 90 Mbits/sec

• One Three-channel 16-bit Timer/Counters (TC)

– Three External Clock Inputs, Two Multi-purpose I/O Pins per Channel

– Double PWM Generation, Capture/Waveform Mode, Up/Down Capability

• One Four-channel 16-bit PWM Controller (PWMC)

• One Two-wire Interface (TWI)

– Master and Slave Mode Support, All Two-wire Atmel EEPROMs Supported

®

• IEEE

1149.1 JTAG Boundary Scan on All Digital Pins

• Required Power Supplies:

– 1.08V to 1.32V for VDDCORE and VDDBU

– 3.0V to 3.6V for VDDOSC, VDDPLL and VDDIOP0 (Peripheral I/Os)

– Programmable 1.65V to 1.95V or 3.0V to 3.6V for VDDIOP1 (Peripheral I/Os) and for VDDIOM

(Memory I/Os) and VDDIOMPP/VDDIOMP (MP Block I/Os)

• Available in 324- and 400-ball LFBGA RoHS-compliant Packages

®

Infrared Modulation/Demodulation, Manchester

1. Description

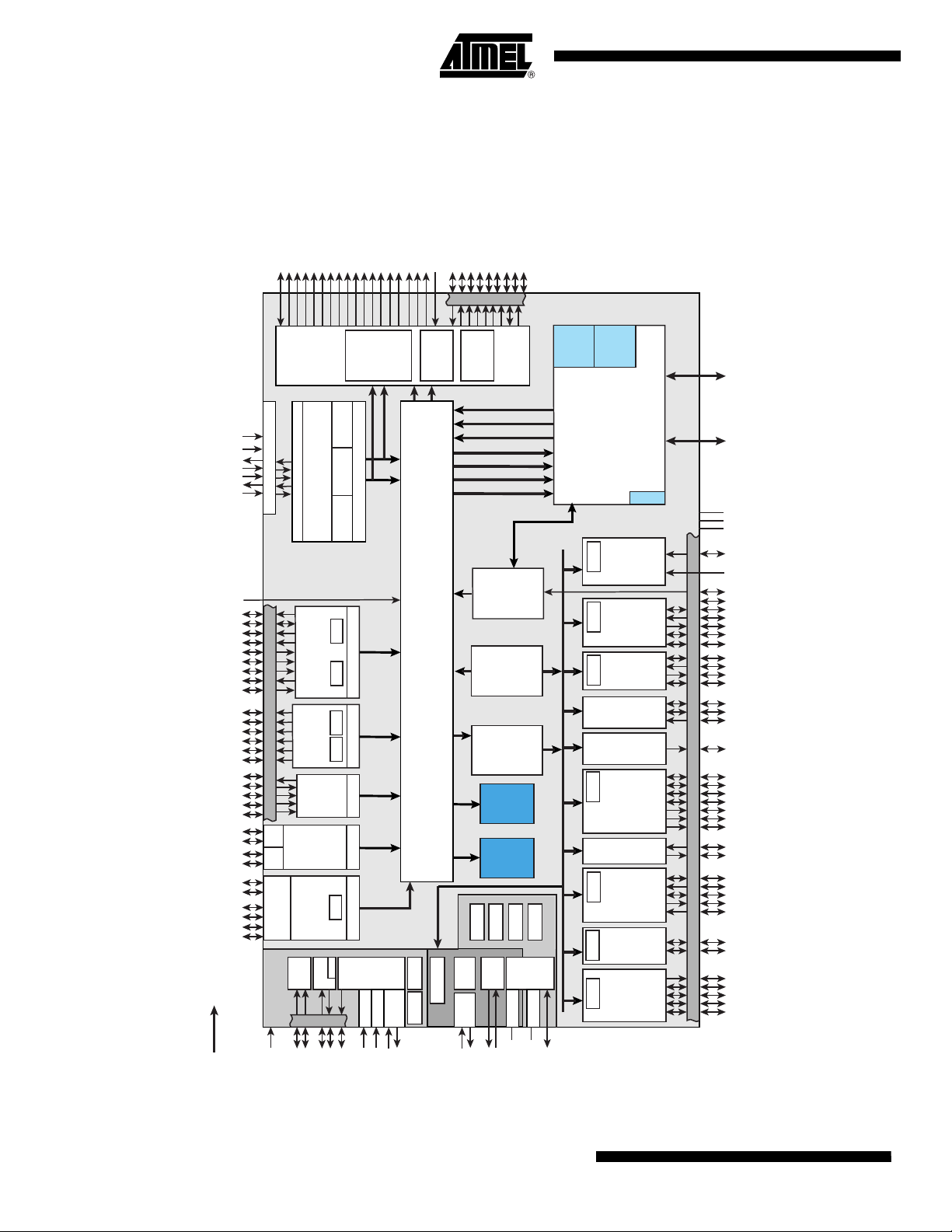

The AT91CAP9S500A/AT91CAP9S250A family is based on the integration of an ARM926EJ-S

processor with fast ROM and SRAM memories, and a wide range of peripherals. By providing up

to 500K gates of metal programmable logic, AT91CAP9S500A/AT91CAP9S250A is the ideal

platform for creating custom designs.

The AT91CAP9S500A/AT91CAP9S250A embeds a USB High-speed Device, a 2-port USB

OHCI Host, an LCD Controller, a 4-channel DMA Controller, and one Image Sensor Interface. It

also integrates several standard peripherals, such as USART, SPI, TWI, Timer Counters, PWM

generators, Multimedia Card interface, and one CAN Controller.

The AT91CAP9S500A/AT91CAP9S250A is architectured on a 12-layer matrix, allowing a maximum internal bandwidth of twelve 32-bit buses. It also features one external memory bus (EBI)

capable of interfacing with a wide range of memory devices.

The initial release of the AT91CAP9S500A/AT91CAP9S250A is packaged in a 400-ball LFBGA

RoHS-compliant package. A future release will also be available in a 324-ball LFBGA RoHScompliant package.

6264A–CAP–21-May-07

3

Page 4

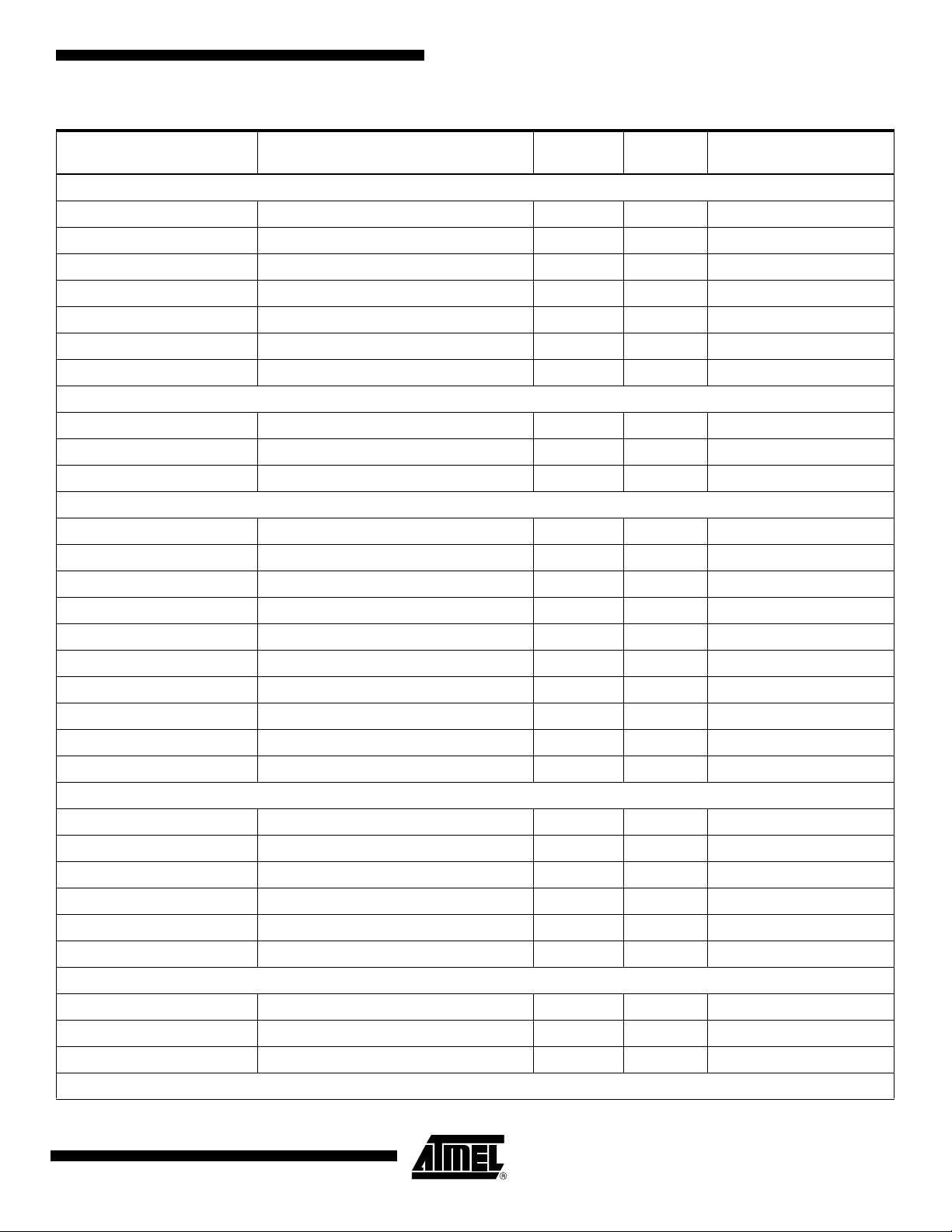

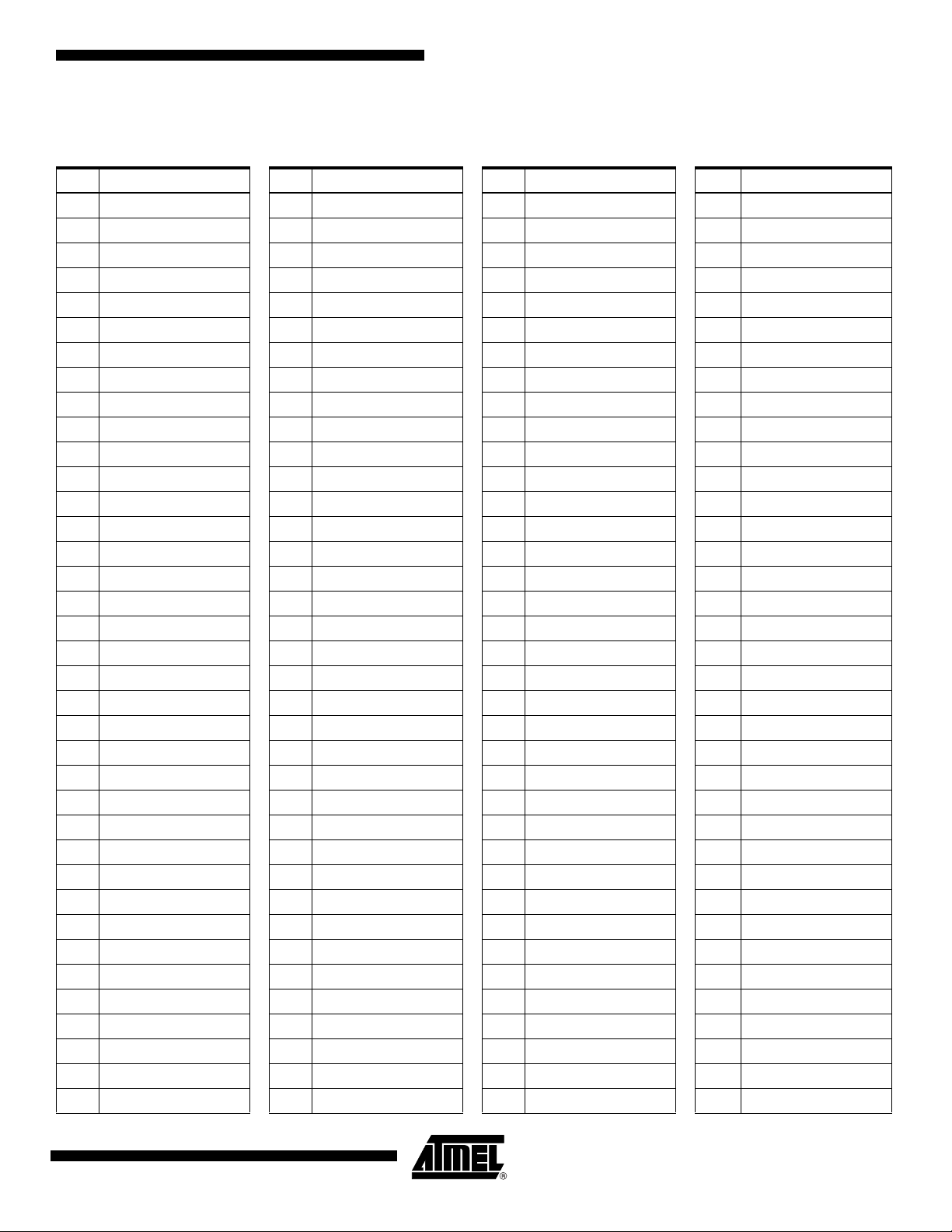

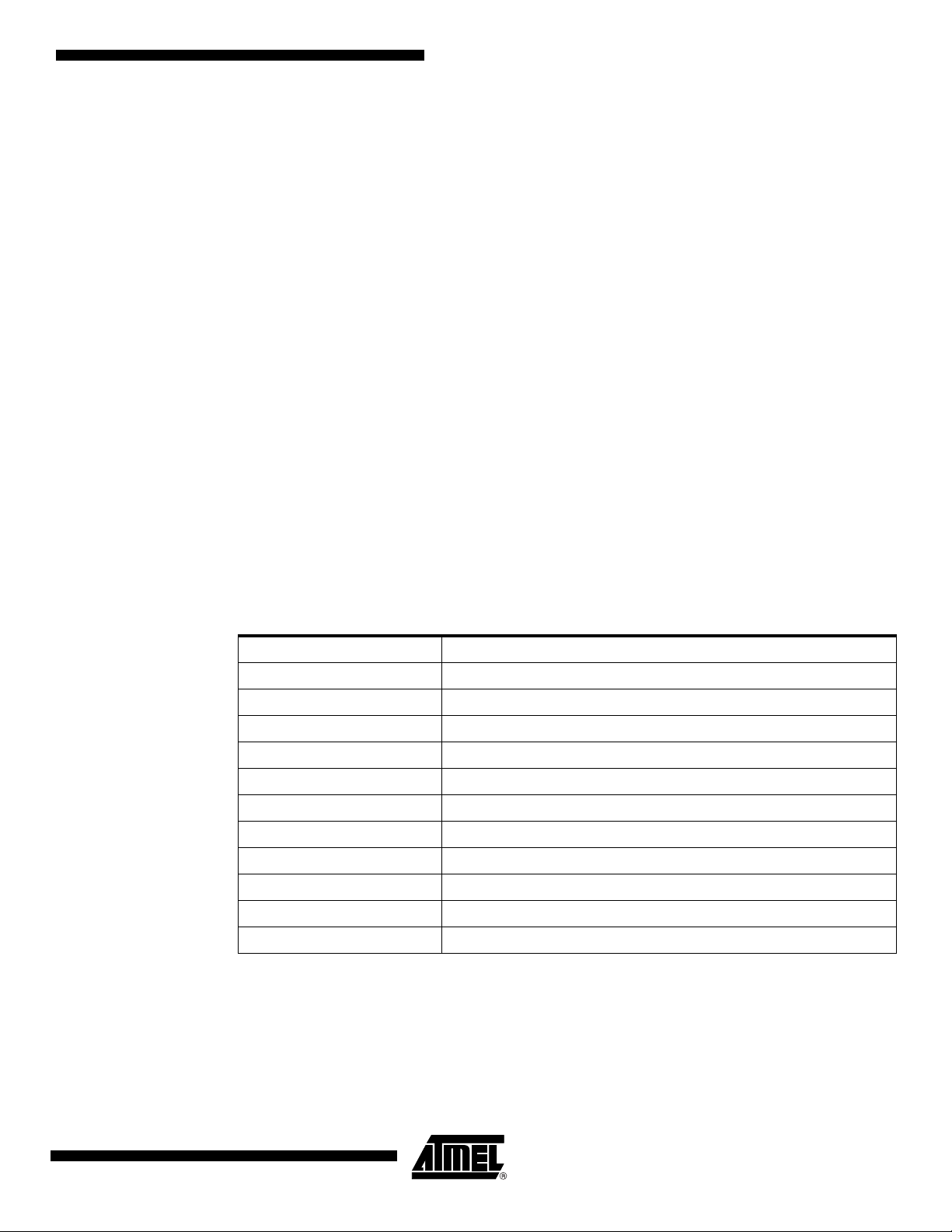

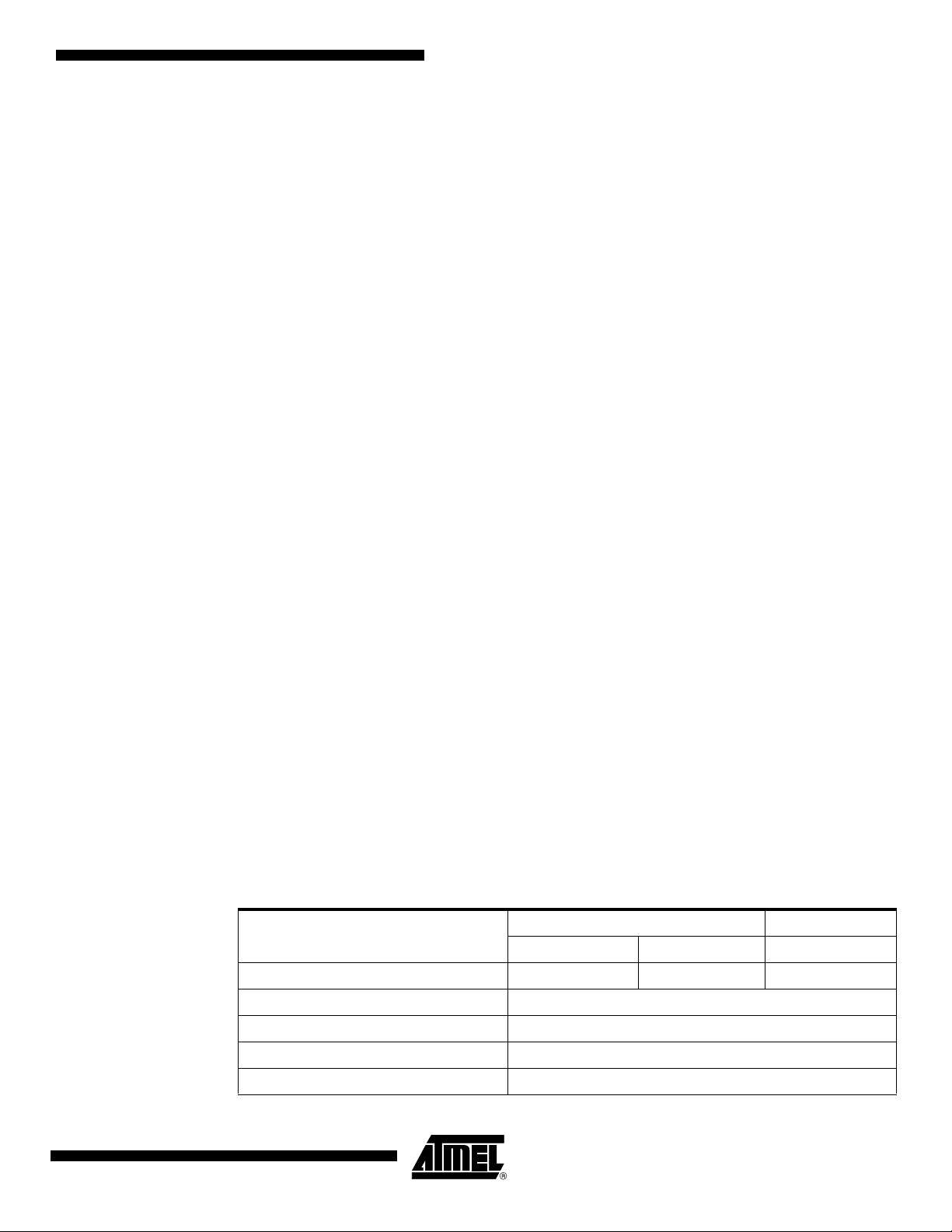

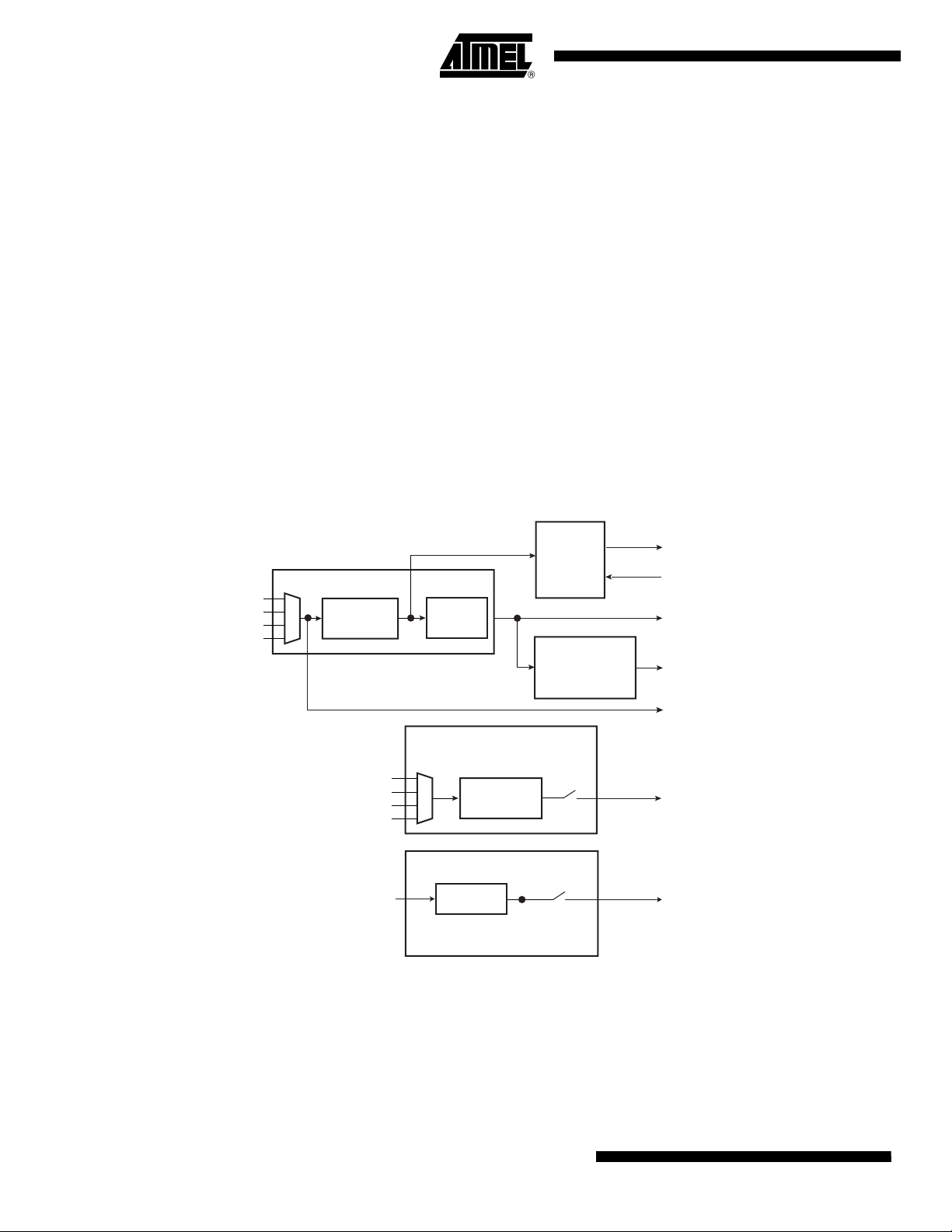

2. AT91CAP9S500A/AT91CAP9S250A Block Diagram

Figure 2-1. AT91CAP9S500A/AT91CAP9S250A Block Diagram

D0-D15

A0/NBS0

A2-A15, A18-A22

A16/BA0

A17/BA1

NCS0

NCS1/BCCS

NRD

NWR0/NWE

NWR1/NBS1

NWR3/NBS3

SDCK, SDCKN

RAS/BCADV, CAS/BCOE

DQS0, DQS1

DDRSDR

Controller

D

I

OSC

PLLB

SDWE/BCWE, SDA10

NANDOE, NANDWE

SDCKE/BCCRE

BCOWAIT

Memory

Burst Cellular

12-layer Matrix

PITWDT

4 GPREG

A23-A24

NWAIT

Static

Controller

RTT

OSC

NCS5/CFCS1

A25/CFRNW

NCS4/CFCS0

NCS2

NCS3/NANDCS

Memory

Controller

4-channel

Peripheral

23-channel

Bridge

Peripheral

SRAM

32Kbytes

ROM

32Kbytes

PIOA

PIOB

SHDC

D16-D31

CFCE1-CFCE2

DMA

DMA

PIOD

PIOC

RSTC

POR

POR

APB

10x

DPR

512x36

PDC

PDC

PDC

PDC

PDC

PDC

PDC

JTAGSEL

NTRST

RTCK

TCK

TMS

TDO

TDI

JTAG Boundary Scan

BMS

EF100

EMDIO

EMDC

ETX0-ETX3

ERX0-ERX3

ERXER-ERXDV

ECRS-ECOL

ETXEN-ETXER

ERXCK-ETXCK/EREFCK

LCDCC

LCDDEN

LCDDOTCK

LCDHSYNC

LCDVSYNC

LCDD0-LCDD23

ISI_MCK

ISI_VSYNC

ISI_HSYNC

ISI_DO-ISI_D11

ISI_PCK

HDMB

HDPB

HDMA

HDPA

FSDM

FSDP

HSDM

HSDP

PLLRC

VBG

SLAVEMASTER

System

Transc.

Transc.

UTMI+

Transc.

Controller

EBI

A1/NBS2/NWR2

& ECC

NAND Flash

CompactFlash

DCache

MMU

In-Circuit Emulator

ICache

ARM926EJ-S Processor

FIFO

MAC

FIFO

10/100 Ethernet

FIFO

LCD

Controller

LUT

Image

Sensor

Interface

USB

OHCI

FIFO

USB

Device

High-Speed

PDC

AIC

DBGU

16K bytes

Bus Interface

16K bytes

DMA

DMA

DMA

DMA

DMA

PMC

PLLA

8x

SPR

512x72

500K Gates (CAP9500)

250K Gates (CAP9250)

Metal Programable Block

L

L

D

ADC

10-bit

8-channel

SSC0

SSC1

AC97C

TC0

TC1

TC2

PWMC

SPI0

SPI1

CAN

USART0

USART1

USART2

TWI

MCI0

MCI1

TWD

CK

CDA

CDB

GNDANA

VDDANA

ADVREF

ADTRIG

AD0-AD7

RK0-RK1

RF0-RF1

RD0-RD1

TD0-TD1

TF0-TF1

TK0-TK1

AC97TX

AC97RX

AC97FS

AC97CK

MISO

MOSI

SPCK

NPCS0

NPCS1

NPCS2

NPCS3

CANRX

CANTX

TWCK

DA0-DA3

DB0-DB3

MPIOB0-MPIOB44

MPIOA0-MPIOA31

DMARQ0-DMARQ3

TIOB0-TIOB2

TIOA0-TIOA2

TCLK0-TCLK2

PWM0-PWM3

SPI0_, SPI1_

TXD0-TXD2

RDX0-RDX2

SCK0-SCK2

RTS0-RTS2

CTS0-CTS2

MCI0_, MCI_1

FIQ

TST

4

AT91CAP9S500A/AT91CAP9S250A

DTXD

DRXD

IRQ0-IRQ1

PCK0-PCK3

PLLRCB

PLLRCA

XIN

XOUT

XIN32

XOUT32

SHDN

WKUP

VDDBU

NRST

VDDCORE

6264A–CAP–21-May-07

Page 5

AT91CAP9S500A/AT91CAP9S250A

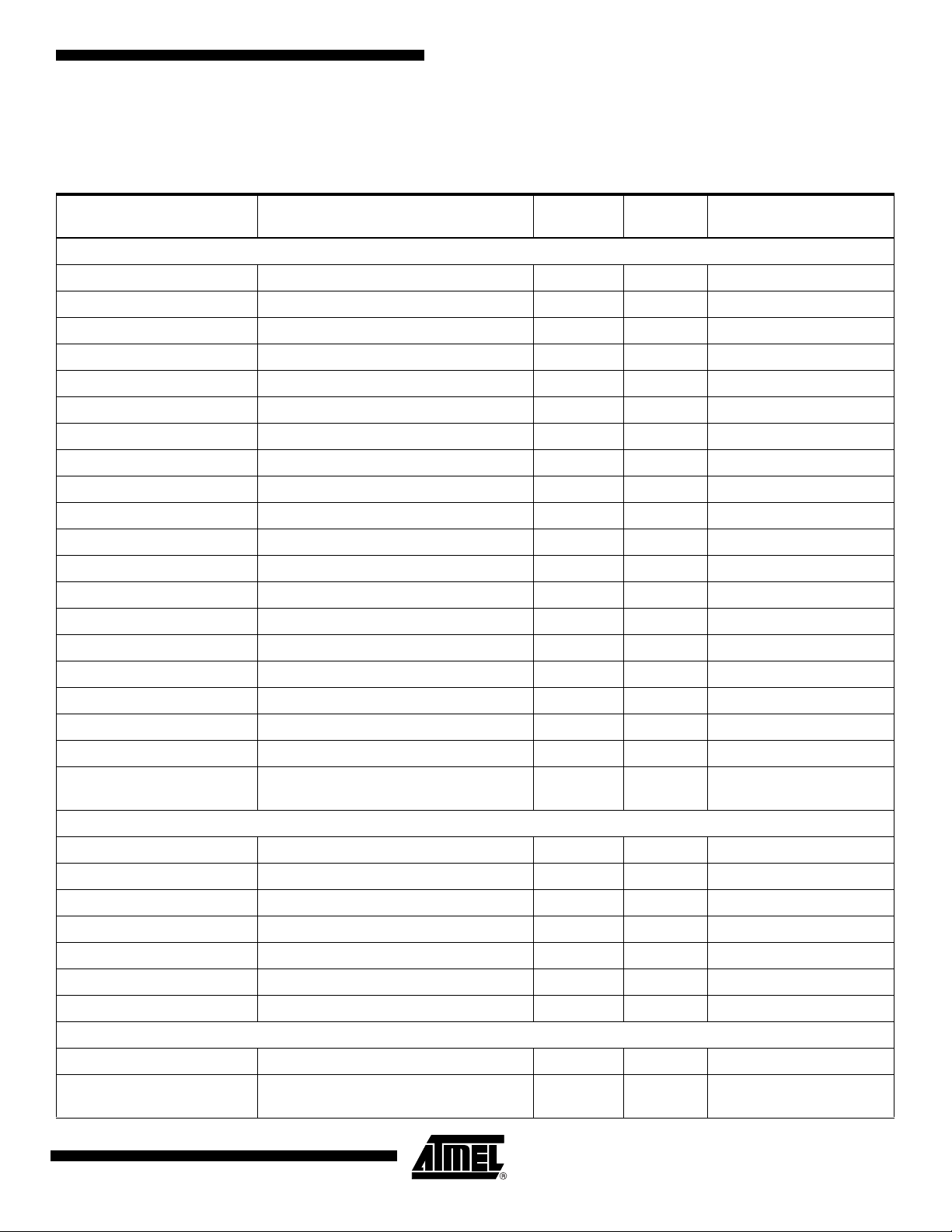

3. Signal Description

Table 3-1 gives details on the signal name classified by peripheral.

Table 3-1. Signal Description List

Active

Signal Name Function Type

Power Supplies

VDDIOM EBI I/O Lines Power Supply Power 1.65V to 3.6V

VDDIOP0 Peripherals I/O Lines Power Supply Power 3.0V to 3.6V

VDDIOP1 Peripherals I/O Lines Power Supply Power 1.65V to 3.6V

VDDIOMPA MP Block I/O A Lines Power Supply Power 1.65V to 3.6V

VDDIOMPB MP Block I/O B Lines Power Supply Power 1.65V to 3.6V

VDDBU Backup I/O Lines Power Supply Power 1.08V to 1.32V

VDDPLL PLL Power Supply Power 3.0V to 3.6V

VDDUTMII USB UTMI+ Interface Power Supply Power 3.0V to 3.6V

VDDUTMIC USB UTMI+ Core Power Supply Power 1.08V to 1.32V

VDDUPLL USB UTMI+ PLL Power Supply Power 1.08V to 1.32V

Level Comments

VDDANA ADC Analog Power Supply Power 3.0V to 3.6V

VDDCORE Core Chip Power Supply Power 1.08V to 1.32V

GND Ground Ground

GNDPLL PLL Ground Ground

GNDUTMII USB UTMI+ Interface Ground Ground

GNDUTMIC USB UTMI+ Core Ground Ground

GNDUPLL USB UTMI+ PLL Ground Ground

GNDANA ADC Analog Ground Ground

GNDBU Backup Ground Ground

GNDTHERMAL Thermal Ground Ball Ground

Clocks, Oscillators and PLLs

XIN Main Oscillator Input Input

XOUT Main Oscillator Output Output

XIN32 Slow Clock Oscillator Input Input

XOUT32 Slow Clock Oscillator Output Output

PLLRCA PLL A Filter Input

PLLRCB PLL B Filter Input

Thermally coupled with

package substrate

PCK0 - PCK3 Programmable Clock Output Output

Shutdown, Wakeup Logic

SHDN Shutdown Control Output Do not tie over VDDBU

WKUP Wake-Up Input Input

6264A–CAP–21-May-07

Accept between 0V and

VDDBU

5

Page 6

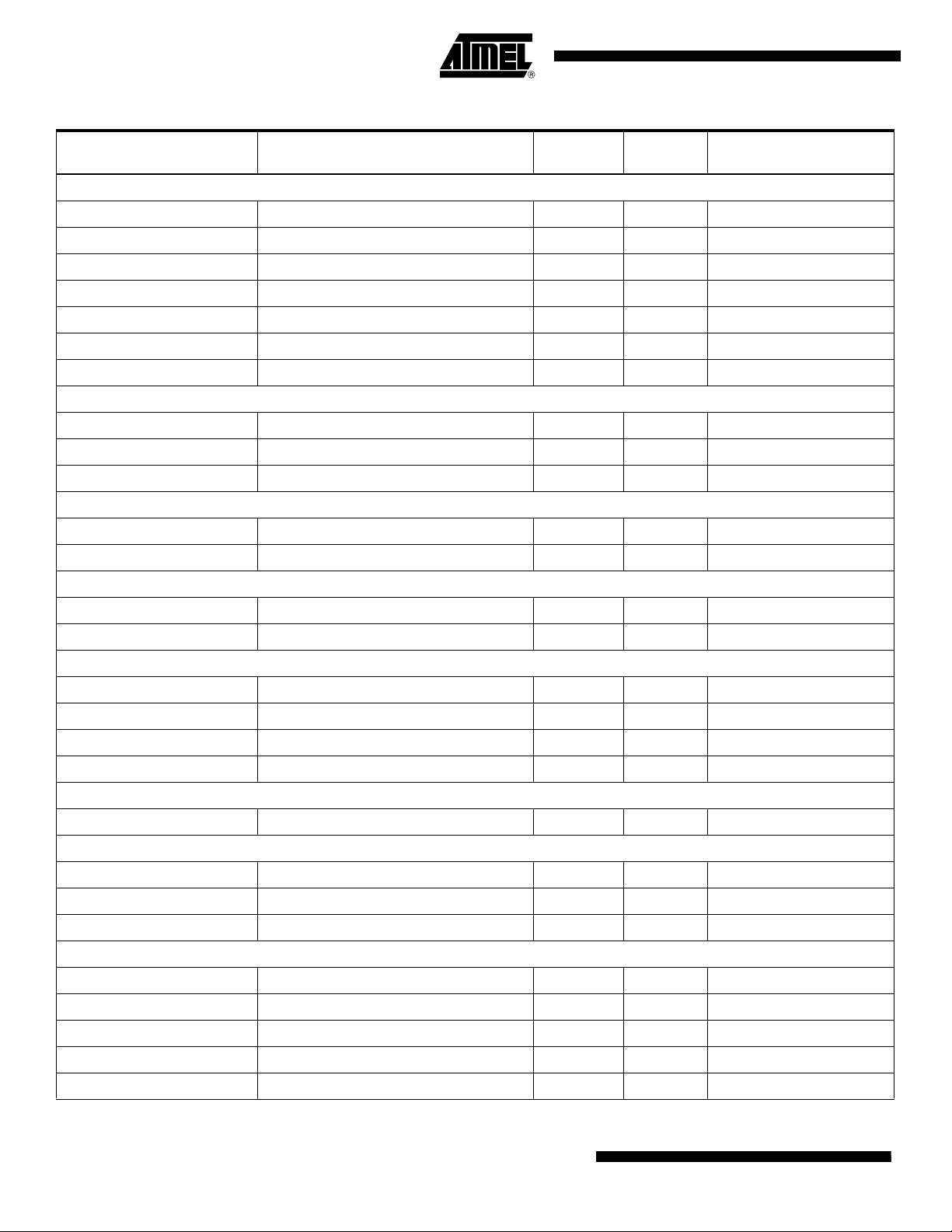

Table 3-1. Signal Description List (Continued)

Active

Signal Name Function Type

ICE and JTAG

NTRST Test Reset Signal Input Low No pull-up resistor

TCK Test Clock Input No pull-up resistor

TDI Test Data In Input No pull-up resistor

TDO Test Data Out Output

TMS Test Mode Select Input No pull-up resistor

JTAGSEL JTAG Selection Input Pull-down resistor

RTCK Return Test Clock Output

Reset/Test

NRST Microcontroller Reset I/O Low Pull-up resistor

TST Test Mode Select Input Pull-down resistor

BMS Boot Mode Select Input Pull-up resistor

Debug Unit - DBGU

DRXD Debug Receive Data Input

DTXD Debug Transmit Data Output

Level Comments

Advanced Interrupt Controller - AIC

IRQ0 - IRQ1 External Interrupt Inputs Input

FIQ Fast Interrupt Input Input

PIO Controller - PIOA - PIOB - PIOC - PIOD

PA0 - PA31 Parallel IO Controller A I/O Pulled-up input at reset

PB0 - PB31 Parallel IO Controller B I/O Pulled-up input at reset

PC0 - PC31 Parallel IO Controller C I/O Pulled-up input at reset

PD0 - PD31 Parallel IO Controller D I/O Pulled-up input at reset

Direct Memory Access Controller - DMA

DMARQ0-DMARQ3 DMA Requests Input

External Bus Interface - EBI

D0 - D31 Data Bus I/O Pulled-up input at reset

A0 - A25 Address Bus Output 0 at reset

NWAIT External Wait Signal Input Low

Static Memory Controller - SMC

NCS0 - NCS5 Chip Select Lines Output Low

NWR0 - NWR3 Write Signal Output Low

NRD Read Signal Output Low

NWE Write Enable Output Low

NBS0 - NBS3 Byte Mask Signal Output Low

6

AT91CAP9S500A/AT91CAP9S250A

6264A–CAP–21-May-07

Page 7

AT91CAP9S500A/AT91CAP9S250A

Table 3-1. Signal Description List (Continued)

Active

Signal Name Function Type

CompactFlash Support

CFCE1 - CFCE2 CompactFlash Chip Enable Output Low

CFOE CompactFlash Output Enable Output Low

CFWE CompactFlash Write Enable Output Low

CFIOR CompactFlash IO Read Output Low

CFIOW CompactFlash IO Write Output Low

CFRNW CompactFlash Read Not Write Output

CFCS0 - CFCS1 CompactFlash Chip Select Lines Output Low

NAND Flash Support

NANDCS NAND Flash Chip Select Output Low

NANDOE NAND Flash Output Enable Output Low

NANDWE NAND Flash Write Enable Output Low

DDR/SDRAM Controller

SDCK DDR/SDRAM Clock Output

SDCKN DDR Inverted Clock Output

Level Comments

DQS0 DDR Data Qualifier Strobe 0 I/O

DQS1 DDR Data Qualifier Strobe 1 I/O

SDCKE SDRAM Clock Enable Output High

SDCS SDRAM Controller Chip Select Output Low

BA0 - BA1 Bank Select Output

SDWE SDRAM Write Enable Output Low

RAS - CAS Row and Column Signal Output Low

SDA10 SDRAM Address 10 Line Output

Burst CellularRAM Controller

BCCK Burst CellularRAM Clock Output

BCCRE Burst CellularRAM Enable Output

BCADV Burst CellularRAM Burst Advance Signal Output

BCWE Burst CellularRAM Write Enable Output

BCOE Burst CellularRAM Output Enable Output

BCOWAIT Burst CellularRAM Output Wait Input

Multimedia Card Interface MCI

MCIx_CK Multimedia Card Clock Output

MCIx_CD Multimedia Card Command I/O

MCIx_D0 - D3 Multimedia Card Data I/O

Universal Synchronous Asynchronous Receiver Transmitter USART

6264A–CAP–21-May-07

7

Page 8

Table 3-1. Signal Description List (Continued)

Signal Name Function Type

SCKx USARTx Serial Clock I/O

TXDx USARTx Transmit Data I/O

RXDx USARTx Receive Data Input

RTSx USARTx Request To Send Output

CTSx USARTx Clear To Send Input

Synchronous Serial Controller - SSC

TDx SSCx Transmit Data Output

RDx SSCx Receive Data Input

TKx SSCx Transmit Clock I/O

RKx SSCx Receive Clock I/O

TFx SSCx Transmit Frame Sync I/O

RFx SSCx Receive Frame Sync I/O

AC97 Controller - AC97C

AC97RX AC97 Receive Signal Input

AC97TX AC97 Transmit Signal Output

Active

Level Comments

AC97FS AC97 Frame Synchronization Signal Output

AC97CK AC97 Clock signal Input

Timer/Counter - TC

TCLKx TC Channel x External Clock Input Input

TIOAx TC Channel x I/O Line A I/O

TIOBx TC Channel x I/O Line B I/O

Pulse Width Modulation Controller- PWMC

PMWx Pulse Width Modulation Output Output

Serial Peripheral Interface - SPI

SPIx_MISO Master In Slave Out I/O

SPIx_MOSI Master Out Slave In I/O

SPIx_SPCK SPI Serial Clock I/O

SPIx_NPCS0 SPI Peripheral Chip Select 0 I/O Low

SPIx_NPCS1 - SPIx_NPCS3 SPI Peripheral Chip Select Output Low

Two-Wire Interface

TWD Two-wire Serial Data I/O

TWCK Two-wire Serial Clock I/O

CAN Controller

CANRX CAN input Input

CANTX CAN output Output

8

AT91CAP9S500A/AT91CAP9S250A

6264A–CAP–21-May-07

Page 9

AT91CAP9S500A/AT91CAP9S250A

Table 3-1. Signal Description List (Continued)

Active

Signal Name Function Type

LCD Controller - LCDC

LCDD0 - LCDD23 LCD Data Bus Input

LCDVSYNC LCD Vertical Synchronization Output

LCDHSYNC LCD Horizontal Synchronization Output

LCDDOTCK LCD Dot Clock Output

LCDDEN LCD Data Enable Output

LCDCC LCD Contrast Control Output

Ethernet 10/100 E

ETXCK/EREFCK Transmit Clock or Reference Clock Input MII only, REFCK in RMII

ERXCK Receive Clock Input MII only

ETXEN Transmit Enable Output

ETX0-ETX3 Transmit Data Output ETX0-ETX1 only in RMII

ETXER Transmit Coding Error Output MII only

ERXDV Receive Data Valid Input

Level Comments

RXDV in MII, CRSDV in

RMII

ERX0-ERX3 Receive Data Input ERX0-ERX1 only in RMII

ERXER Receive Error Input

ECRS Carrier Sense and Data Valid Input MII only

ECOL Collision Detect Input MII only

EMDC Management Data Clock Output

EMDIO Management Data Input/Output I/O

EF100 Force 100Mbit/sec. Output High RMII only

USB High Speed Device

FSDM USB Full Speed Data - Analog

FSDP USB Full Speed Data + Analog

HSDM USB High Speed Data - Analog

HSDP USB High Speed Data + Analog

VBG Bias Voltage Reference Analog

PLLRCU USB PLL Test Pad Analog

OHCI USB Host Port

HDPA USB Host Port A Data + Analog

HDMA USB Host Port A Data - Analog

HDPB USB Host Port B Data + Analog

HDMB USB Host Port B Data - Analog

ADC

AD0-AD7 Analog Inputs Analog

6264A–CAP–21-May-07

9

Page 10

Table 3-1. Signal Description List (Continued)

Signal Name Function Type

ADVREF ADC Voltage Reference Analog

ADTRIG ADC Trigger Input

Image Sensor Interface - ISI

ISI_D0-ISI_D11 Image Sensor Data Input

ISI_MCK Image Sensor Reference Clock Output

ISI_HSYNC Image Sensor Horizontal Synchro Input

ISI_VSYNC Image Sensor Vertical Synchro Input

ISI_PCK Image Sensor Data Clock Input

MPBLOCK - MPB

MPIOA0-MPIOA31 MPBlock I/Os A I/O

MPIOB0-MPIOB44 MPBlock I/Os B I/O

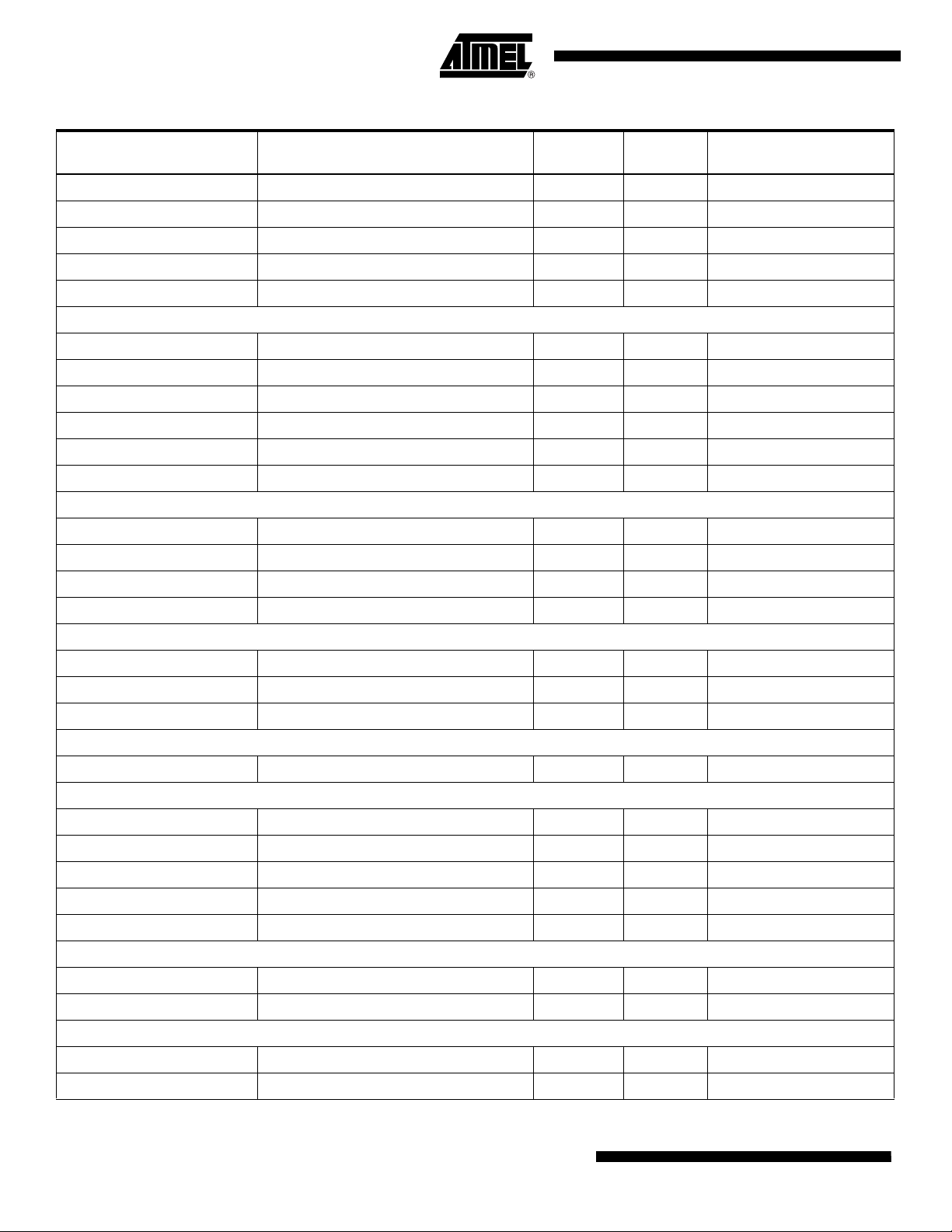

4. Package and Pinout

The AT91CAP9S500A/AT91CAP9S250A is available in a 400-ball RoHS-compliant BGA package, 17 x 17 mm, 0.8mm ball pitch.

Active

Level Comments

4.1 400-ball BGA Package Outline

Figure 4-1 shows the orientation of the 400-ball BGA Package.

A detailed mechanical description is given in the section “AT91CAP9S500A/AT91CAP9S250A

Mechanical Characteristics” of the product datasheet.

Figure 4-1. 400-ball BGA Package Outline (Top View)

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

ABCDE FGHJ KL MNPRT UV

BALL A1

YW

10

AT91CAP9S500A/AT91CAP9S250A

6264A–CAP–21-May-07

Page 11

AT91CAP9S500A/AT91CAP9S250A

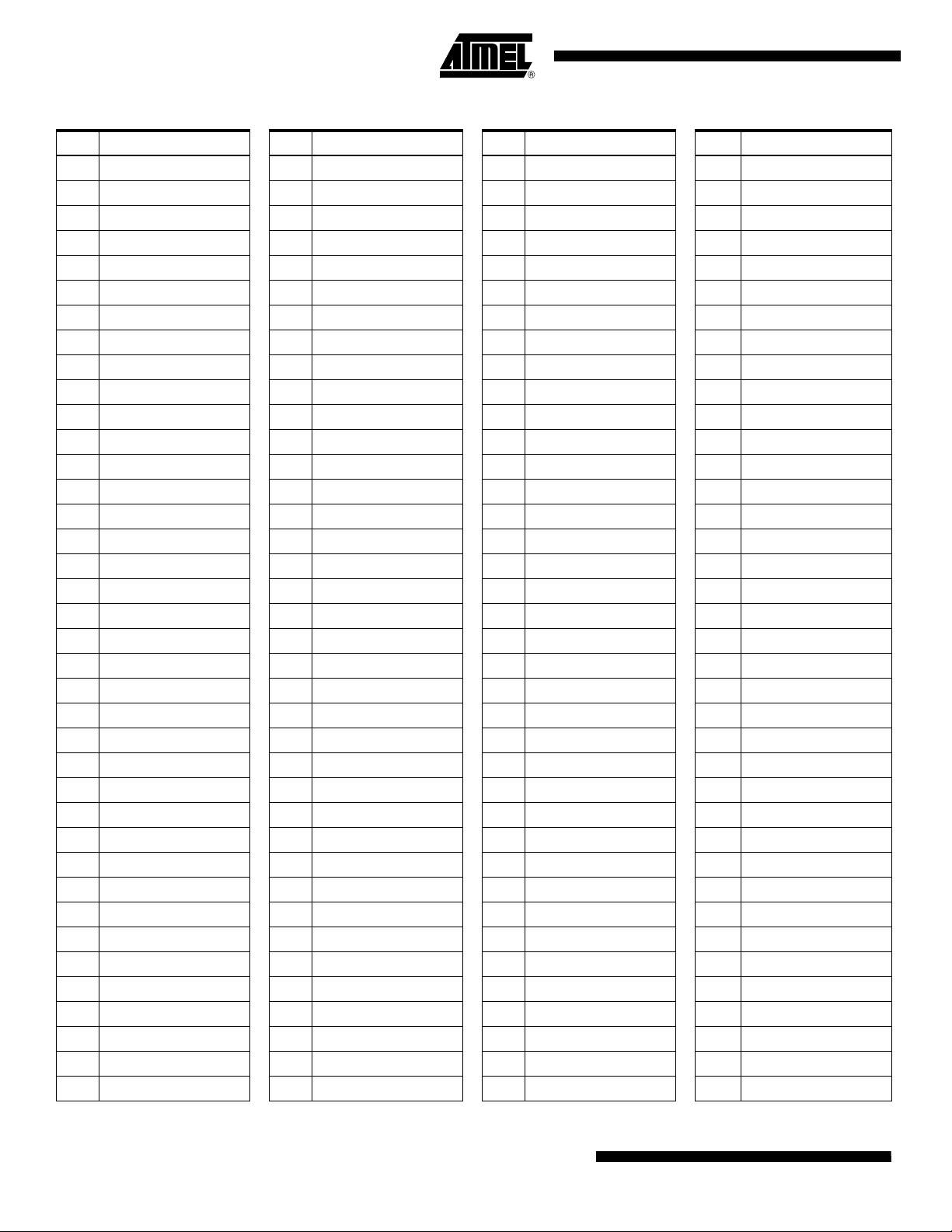

4.2 400-ball BGA Package Pinout

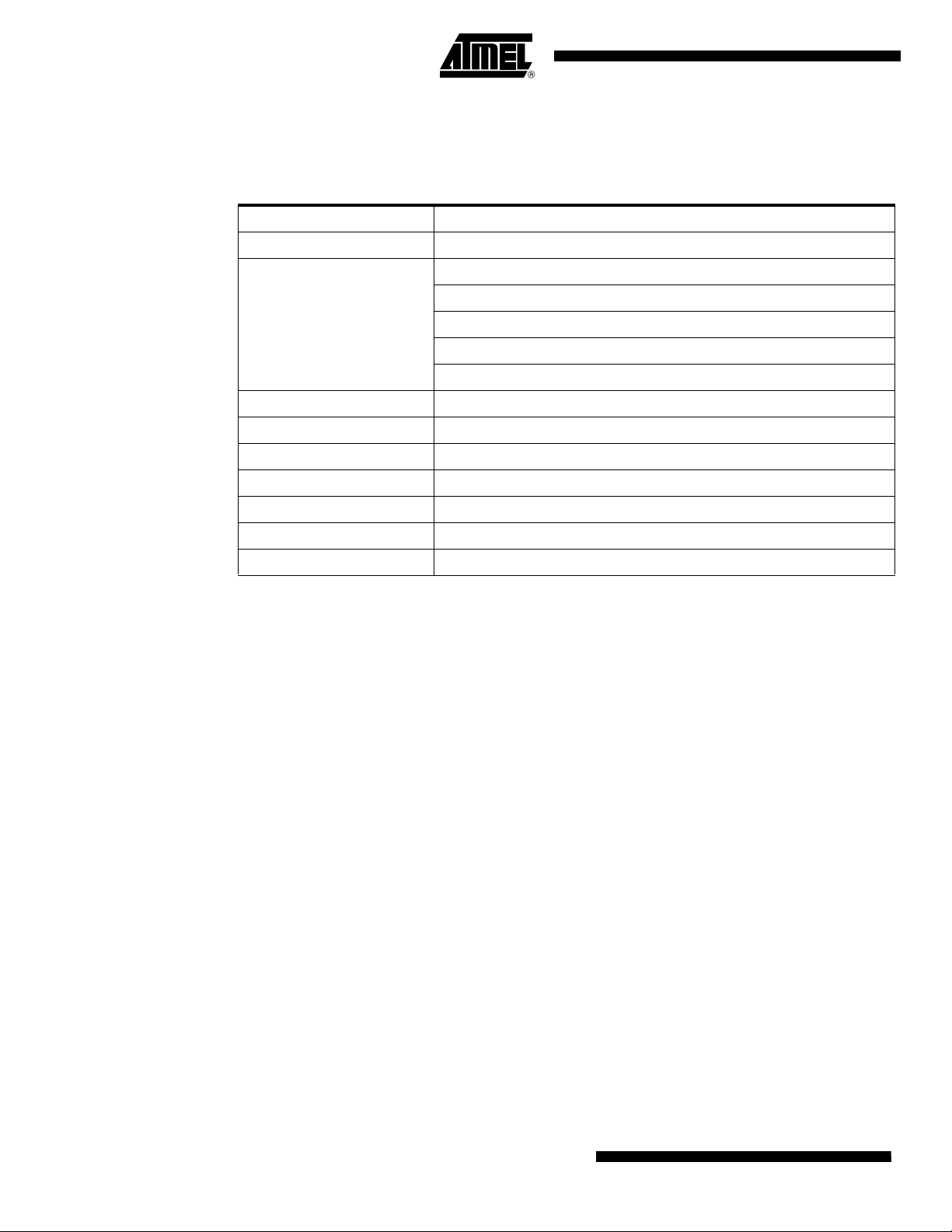

Table 4-1. AT91CAP9S500A/AT91CAP9S250A Pinout for 400-ball BGA Package

Pin Signal Name Pin Signal Name Pin Signal Name Pin Signal Name

A1 PC5 F1 PA3 L1 PA22 T1 PD22

A2 PC3 F2 PA4 L2 PA25 T2 PD23

A3 PC2 F3 PA8 L3 PA29 T3 PD30

A4 PC1 F4 PA5 L4 PA31 T4 VDDCORE

A5 PC0 F5 PA6 L5 PD6 T5 SDDRCS

A6 BMS F6 VDDIOM L6 GNDIO T6 DQS0

A7 NRST F7 VDDIOP0 L7 GNDCORE T7 D4

A8 GNDCORE F8 PC24 L8 PA18 T8 D11

A9 PB18 F9 NC L9 GNDTHERMAL T9 D14

A10 PB17 F10 VDDCORE L10 GNDTHERMAL T10 SDA10

A11 PB14 F11 GNDIO L11 GNDTHERMAL T11 VDDCORE

A12 PB15 F12 PB23 L12 GNDTHERMAL T12 MPIOA0

A13 GNDANA F13 PB6 L13 GNDCORE T13 MPIOA9

A14 PB26 F14 NC L14 GNDIO T14 GNDIO

A15 VDDIOP0 F15 NC L15 VDDCORE T15 MPIOA25

A16 GNDIO F16 NC L16 MPIOB28 T16 MPIOA24

A17 FSDP F17 GNDPLL L17 MPIOB32 T17 MPIOA29

A18 FSDM F18 WKUP0 L18 MPIOB34 T18 MPIOB3

A19 HSDP F19 SHDW L19 MPIOB31 T19 MPIOB17

A20 HSDM F20 PLLRCA L20 MPIOB29 T20 MPIOB18

B1 PC17 G1 PA7 M1 PA26 U1 PD25

B2 PC16 G2 PA10 M2 PA30 U2 PD31

B3 PC14 G3 PA11 M3 PD11 U3 BCCLK

B4 PC11 G4 PA9 M4 PD12 U4 A0

B5 PC10 G5 PA12 M5 PD13 U5 D0

B6 PC9 G6 PD10 M6 PD15 U6 D1

B7 TDO G7 GNDIO M7 GNDCORE U7 NWR1

B8 TCK G8 GNDCORE M8 PA28 U8 DQS1

B9 PB20 G9 VDDIOP0 M9 GNDTHERMAL U9 A7

B10 PB19 G10 PC8 M10 GNDTHERMAL U10 A13

B11 PB13 G11 PB25 M11 GNDTHERMAL U11 A20

B12 ADVREF G12 PB21 M12 GNDTHERMAL U12 GNDIO

B13 PB16 G13 PB8 M13 NRD U13 MPIOA4

B14 PB27 G14 PB0 M14 MPIOB26 U14 MPIOA11

B15 PB24 G15 PB2 M15 GNDIO U15 MPIOA16

B16 HDMA G16 NC M16 MPIOB16 U16 VDDMPIOA

B17 VDDIOP0 G17 VDDPLL M17 GNDCORE U17 MPIOA23

6264A–CAP–21-May-07

11

Page 12

Table 4-1. AT91CAP9S500A/AT91CAP9S250A Pinout for 400-ball BGA Package (Continued)

Pin Signal Name Pin Signal Name Pin Signal Name Pin Signal Name

B18 GNDIO G18 GNDCORE M18 MPIOB27 U18 MPIOA28

B19 VDDUTMII G19 TST M19 MPIOB25 U19 MPIOB6

B20 GNDUTMII G20 PLLRCB M20 MPIOB24 U20 MPIOB9

C1 PC23 H1 PA13 N1 PD7 V1 PD26

C2 PC22 H2 PA14 N2 PD8 V2 RAS

C3 PC21 H3 PD0 N3 PD16 V3 SDCKE

C4 PC20 H4 PA15 N4 PD19 V4 D3

C5 PC18 H5 PD1 N5 PD20 V5 VDDIOM

C6 PC15 H6 VDDIOP1 N6 PD29 V6 D5

C7 PC12 H7 VDDCORE N7 GNDIO V7 D9

C8 PC6 H8 GNDIO N8 VDDIOM V8 D15

C9 NTRST H9 GNDIO N9 NCS1 V9 A11

C10 TDI H10 PB10 N10 VDDCORE V10 GNDCORE

C11 VDDANA H11 PB4 N11 A3 V11 A22

C12 PB12 H12 VDDMPIOB N12 A6 V12 MPIOA1

C13 PB29 H13 JTAGSEL N13 VDDCORE V13 MPIOA6

C14 PB9 H14 GNDCORE N14 MPIOB11 V14 MPIOA10

C15 PB7 H15 GNDPLL N15 MPIOB13 V15 MPIOA13

C16 HDPA H16 NC N16 MPIOB12 V16 MPIOA17

C17 HDPB H17 VDDCORE N17 MPIOB14 V17 MPIOA20

C18 VDDUPLL H18 MPIOB44 N18 MPIOB15 V18 MPIOA27

C19 VDDUTMIC H19 XOUT32 N19 MPIOB22 V19 MPIOB5

C20 VBG H20 XIN32 N20 MPIOB23 V20 VDDMPIOB

D1 PC29 J1 PD3 P1 PD9 W1 SDWE

D2 PC28 J2 PD2 P2 PD14 W2 OWAIT

D3 PC27 J3 PD5 P3 PD18 W3 NANDWE

D4 PC26 J4 PA17 P4 PD27 W4 GNDIO

D5 PC25 J5 PA19 P5 PD28 W5 D6

D6 PC19 J6 VDDIOP0 P6 VDDIOM W6 A2

D7 NANDOE J7 PA16 P7 NWR3 W7 A5

D8 PC7 J8 GNDCORE P8 D8 W8 A14

D9 GNDIO J9 GNDTHERMAL P9 D10 W9 A17

D10 TMS J10 GNDTHERMAL P10 GNDIO W10 A19

D11 NC J11 GNDTHERMAL P11 A9 W11 NWR0

D12 PB31 J12 GNDTHERMAL P12 A12 W12 MPIOA2

D13 PB22 J13 GNDIO P13 NC W13 MPIOA5

D14 VDDCORE J14 GNDBU P14 MPIOB8 W14 MPIOA8

D15 PB3 J15 GNDBU P15 MPIOB0 W15 MPIOA12

12

AT91CAP9S500A/AT91CAP9S250A

6264A–CAP–21-May-07

Page 13

AT91CAP9S500A/AT91CAP9S250A

Table 4-1. AT91CAP9S500A/AT91CAP9S250A Pinout for 400-ball BGA Package (Continued)

Pin Signal Name Pin Signal Name Pin Signal Name Pin Signal Name

D16 PB1 J16 MPIOB42 P16 MPIOB1 W16 MPIOA15

D17 HDMB J17 MPIOB39 P17 MPIOB7 W17 MPIOA21

D18 PLLRCU J18 MPIOB43 P18 MPIOB10 W18 MPIOA22

D19 GNDUTMIC J19 MPIOB41 P19 MPIOB21 W19 GNDIO

D20 GNDUPLL J20 GNDIO P20 VDDMPIOB W20 VDDCORE

E1 PC30 K1 PD4 R1 PD21 Y1 SDCK

E2 PA2 K2 PA21 R2 PD17 Y2 SDCKN

E3 PA1 K3 PA24 R3 PD24 Y3 A1

E4 PA0 K4 PA27 R4 CAS Y4 GNDCORE

E5 PC31 K5 PA23 R5 VDDCORE Y5 A4

E6GNDIOK6GNDIOR6D2 Y6A8

E7 VDDCORE K7 PA20 R7 D7 Y7 A10

E8 PC13 K8 VDDCORE R8 VDDIOM Y8 A15

E9 PC4 K9 GNDTHERMAL R9 D13 Y9 A18

E10 RTCK K10 GNDTHERMAL R10 D12 Y10 A21

E11 VDDIOP0 K11 GNDTHERMAL R11 VDDIOM Y11 NCS0

E12 PB30 K12 GNDTHERMAL R12 A16 Y12 MPIOA3

E13 PB28 K13 GNDCORE R13 VDDIOM Y13 MPIOA7

E14 PB11 K14 MPIOB33 R14 NC Y14 VDDMPIOA

E15 PB5 K15 MPIOB30 R15 NC Y15 MPIOA14

E16 NC K16 MPIOB35 R16 NC Y16 MPIOA18

E17 VDDPLL K17 MPIOB38 R17 MPIOB2 Y17 MPIOA19

E18 VDDBU K18 MPIOB40 R18 MPIOB4 Y18 MPIOA26

E19 XIN K19 MPIOB37 R19 MPIOB19 Y19 MPIOA30

E20 XOUT K20 MPIOB36 R20 MPIOB20 Y20 MPIOA31

5. Power Considerations

5.1 Power Supplies

The AT91CAP9S500A/AT91CAP9S250A has several types of power supply pins:

• VDDCORE pins: Power the core, including the processor, the embedded memories and the

peripherals; voltage range between1.08V and 1.32V, 1.2V nominal.

• VDDIOM pins: Power the External Bus Interface; voltage ranges between 1.65V and 1.95V

(1.8V nominal) or between 3.0V and 3.6V (3.3V nominal).

• VDDIOP0 pins: Power the Peripherals I/O lines and the USB transceivers; voltage range

between 3.0V and 3.6V, 3.3V nominal.

• VDDIOP1 pins: Power the Peripherals I/O lines involving the Image Sensor Interface; voltage

ranges from 1.65V to 3.6V, 1.8V, 2.5V, 3V or 3.3V nominal.

6264A–CAP–21-May-07

13

Page 14

• VDDIOMPA pins: Power the MP Block I/O A lines; voltage ranges from 1.65V to 3.6V, 1.8V,

2.5V, 3V or 3.3V nominal.

• VDDIOMPB pins: Power the dedicated MP Block I/O B lines; voltage ranges from 1.65V to

3.6V, 1.8V, 2.5V, 3V or 3.3V nominal.

• VDDBU pin: Powers the Slow Clock oscillator and a part of the System Controller; voltage

range between1.08V and 1.32V, 1.2V nominal.

• VDDPLL pin: Powers the PLL cells; voltage ranges between 3.0V to 3.6V, 3.3V nominal.

• VDDUTMII pin: Powers the UTMI+ interface; voltage ranges from 3.0V to 3.6V, 3.3V nominal.

• VDDUTMIC pin: Powers the UTMI+ core; voltage ranges between 1.08V and 1.32V, 1.2V

nominal.

• VDDUPLL pin: Powers the USB PLL cell; voltage ranges between 1.08V and 1.32V, 1.2V

nominal.

• VDDANA pin: Powers the ADC cell; voltage ranges between 3.0V and 3.6V, 3.3V nominal.

The power supplies VDDIOM, VDDIOP0 and VDDIOP1 are identified in the pinout table and the

multiplexing tables. These supplies enable the user to power the device differently for interfacing

with memories and for interfacing with peripherals.

Ground pins GNDIO are common to VDDIOM, VDDIOP0, VDDIOP1, VDDIOMPA and VDDIOMPB pin power supplies. Separated ground pins are provided for VDDCORE, VDDBU,

VDDPLL, VDDUTMII, VDDUTMIC, VDDUPLL and VDDANA. These ground pins are, respectively, GNDBU, GNDOSC, GNDPLL, GNDUTMII, GNDUTMIC, GNDUPLL and GNDANA.

Special GNDTHERMAL ground balls are thermally coupled with package substrate.

5.2 Power Consumption

The AT91CAP9S500A/AT91CAP9S250A consumes about 700 µA (TBC) of static current on

VDDCORE at 25°C. This static current may go up to 7 mA (TBC) if the temperature increases to

85°C.

On VDDBU, the current does not exceed 3 µA(TBC) @25°C, but can rise at up to 20 µA(TBC)

@85°C.

For dynamic power consumption, the AT91CAP9S500A/AT91CAP9S250A consumes a maximum of 90 mA (TBC) on VDDCORE at typical conditions (1.2V, 25°C, processor running fullperformance algorithm).

5.3 Programmable I/O Lines Power Supplies

The power supply pins VDDIOM, VDDMPIOA and VDDMPIOB accept two voltage ranges. This

allows the device to reach its maximum speed either out of 1.8V or 3.3V external memories.

The target maximum speed is 100 MHz on the pin DDR/SDR and MPIOA or MPIOB pins loaded

with 30 pF for power supply at 1.8V and 50 pF for power supply at 3.3V. The other signals (control, address and data signals) do not go over 50 MHz.

The voltage ranges are determined by programming registers in the Chip Configuration registers

located in the Matrix User Interface.

14

At reset, the selected voltage defaults to 3.3V nominal and power supply pins can accept either

1.8V or 3.3V. Obviously, the device cannot reach its maximum speed if the voltage supplied to

the pins is 1.8V only. The user must make sure to program the EBI voltage range before getting

the device out of its Slow Clock Mode.

AT91CAP9S500A/AT91CAP9S250A

6264A–CAP–21-May-07

Page 15

6. I/O Line Considerations

6.1 JTAG Port Pins

TMS, TDI and TCK are Schmitt trigger inputs and have no pull-up resistors.

TDO and RTCK are outputs, driven at up to VDDIOP0, and have no pull-up resistors.

The JTAGSEL pin is used to select the JTAG boundary scan when asserted at a high level. It

integrates a permanent pull-down resistor of about 15 kΩ to GNDBU so that it can be left uncon-

nected for normal operations.

The NTRST signal is described in Section 6.3 ”Reset Pins” on page 15.

All the JTAG signals are supplied with VDDIOP0.

6.2 Test Pin

The TST pin is used for manufacturing test purposes when asserted high. It integrates a permanent pull-down resistor of about 15 kΩ to GNDBU so that it can be left unconnected for normal

operations. Driving this line at a high level leads to unpredictable results.

This pin is supplied with VDDBU.

AT91CAP9S500A/AT91CAP9S250A

6.3 Reset Pins

NRST is an open-drain output integrating a non-programmable pull-up resistor. It can be driven

with voltage at up to VDDIOP0.

NTRST is an input which allows reset of the JTAG Test Access port. It has no action on the

processor.

As the product integrates power-on reset cells that manage the processor and the JTAG reset,

the NRST and NTRST pins can be left unconnected.

The NRST and NTRST pins both integrate a permanent pull-up resistor of 90 kΩ minimum to

VDDIOP0.

The NRST signal is inserted in the Boundary Scan.

6.4 PIO Controllers

All the I/O lines which are managed by the PIO Controllers integrate a programmable pull-up

resistor of 90 kΩ minimum. Programming of this pull-up resistor is performed independently for

each I/O line through the PIO Controllers.

After reset, all the I/O lines default as inputs with pull-up resistors enabled, except those multiplexed with the External Bus Interface signals that must be enabled as Peripheral at reset. This

is indicated in the column “Reset State” of the PIO Controller multiplexing tables.

6.5 Shutdown Logic Pins

The SHDN pin is an output only, which is driven by the Shutdown Controller only at low level. It

can be tied high with an external pull-up resistor at VDDBU only.

6264A–CAP–21-May-07

The pin WKUP is an input-only. It can accept voltages only between 0V and VDDBU.

15

Page 16

7. Processor and Architecture

7.1 ARM926EJ-S Processor

• RISC Processor based on ARM v5TEJ Architecture with Jazelle technology for Java

acceleration

• Two Instruction Sets

– ARM High-performance 32-bit Instruction Set

– Thumb High Code Density 16-bit Instruction Set

• DSP Instruction Extensions

• 5-Stage Pipeline Architecture:

– Instruction Fetch (F)

– Instruction

– Execute (E)

– Data Memory (M)

– Register Write (W)

• 16-Kbyte Data Cache, 16-Kbyte Instruction Cache

– Virtually-addressed 4-way Associative Cache

– Eight words per line

– Write-through and Write-back Operation

– Pseudo-random or Round-robin Replacement

• Write Buffer

– Main Write Buffer with 16-word Data Buffer and 4-address Buffer

– DCache Write-back Buffer with 8-word Entries and a Single Address Entry

– Software Control Drain

• Standard ARM v4 and v5 Memory Management Unit (MMU)

– Access Permission for Sections

– Access Permission for large pages and small pages can be specified separately for

each quarter of the page

– 16 embedded domains

• Bus Interface Unit (BIU)

– Arbitrates and Schedules AHB Requests

– Separate Masters for both instruction and data access providing complete Matrix

system flexibility

– Separate Address and Data Buses for both the 32-bit instruction interface and the

32-bit data interface

– On Address and Data Buses, data can be 8-bit (Bytes), 16-bit (Half-words) or 32-bit

(Words)

Decode (D)

7.2 Bus Matrix

16

AT91CAP9S500A/AT91CAP9S250A

• 12-layer Matrix, handling requests from 12 masters

• Programmable Arbitration strategy

– Fixed-priority Arbitration

6264A–CAP–21-May-07

Page 17

7.3 Matrix Masters

AT91CAP9S500A/AT91CAP9S250A

– Round-Robin Arbitration, either with no default master, last accessed default master

or fixed default master

• Burst Management

– Breaking with Slot Cycle Limit Support

– Undefined Burst Length Support

• One Address Decoder provided per Master

– Three different slaves may be assigned to each decoded memory area: one for

internal boot, one for external boot, one after remap

• Boot Mode Select

– Non-volatile Boot Memory can be internal or external

– Selection is made by BMS pin sampled at reset

• Remap Command

– Allows Remapping of an Internal SRAM in Place of the Boot Non-Volatile Memory

– Allows Handling of Dynamic Exception Vectors

The Bus Matrix of the AT91CAP9S500A/AT91CAP9S250A manages twelve Masters and thus

each master can perform an access concurrently with the others, assuming that the slave it

accesses is available.

7.4 Matrix Slaves

Each Master has its own decoder, which is defined specifically for each master. In order to simplify the addressing, all the masters have the same decoding.

Table 7-1. List of Bus Matrix Masters

Master 0 ARM926™ Instruction

Master 1 ARM926 Data

Master 2 Peripheral DMA Controller

Master 3 LCD Controller

Master 4 USB High Speed Device Controller

Master 5 Image Sensor Interface

Master 6 DMA Controller

Master 7 Ethernet MAC

Master 8 OHCI USB Host Controller

Master 9 MP Block Master 0

Master 10 MP Block Master 1

Master 11 MP Block Master 2

The Bus Matrix of the AT91CAP9S500A/AT91CAP9S250A manages ten Slaves. Each Slave

has its own arbiter, thus permitting a different arbitration per Slave to be programmed.

6264A–CAP–21-May-07

17

Page 18

The LCD Controller, the DMA Controller, the USB Host and the USB OTG have a user interface

mapped as a Slave of the Matrix. They share the same layer, as programming them does not

require a high bandwidth.

Table 7-2. List of Bus Matrix Slaves

Slave 0 Internal SRAM 32 Kbytes

Slave 1 MP Block Slave 0 (MP Block Internal Memories)

Internal ROM

LCD Controller User Interface

Slave 2

Slave 3 MP Block Slave 1 (MP Block Internal Memories)

Slave 4 External Bus Interface

Slave 5 DDR Controller Port 2

Slave 6 DDR Controller Port 3

Slave 7 MP Block Slave 2 (MP Block External Chip Selects)

Slave 8 MP Block Slave 3 (MP Block Internal Peripherals)

Slave 9 Internal Peripherals for AT91CAP9

DMA Controller User Interface

USB High Speed Device Interface

OHCI USB Host Interface

7.5 Master-to-Slave Access

All the Masters can normally access all the Slaves. However, some paths do not make sense,

such as allowing access from the Ethernet MAC to the Internal Peripherals. Thus, these paths

are forbidden or simply not wired, and shown “-” in Table 7-3,

“AT91CAP9S500A/AT91CAP9S250A Masters to Slaves Access,” on page 19.

18

AT91CAP9S500A/AT91CAP9S250A

6264A–CAP–21-May-07

Page 19

AT91CAP9S500A/AT91CAP9S250A

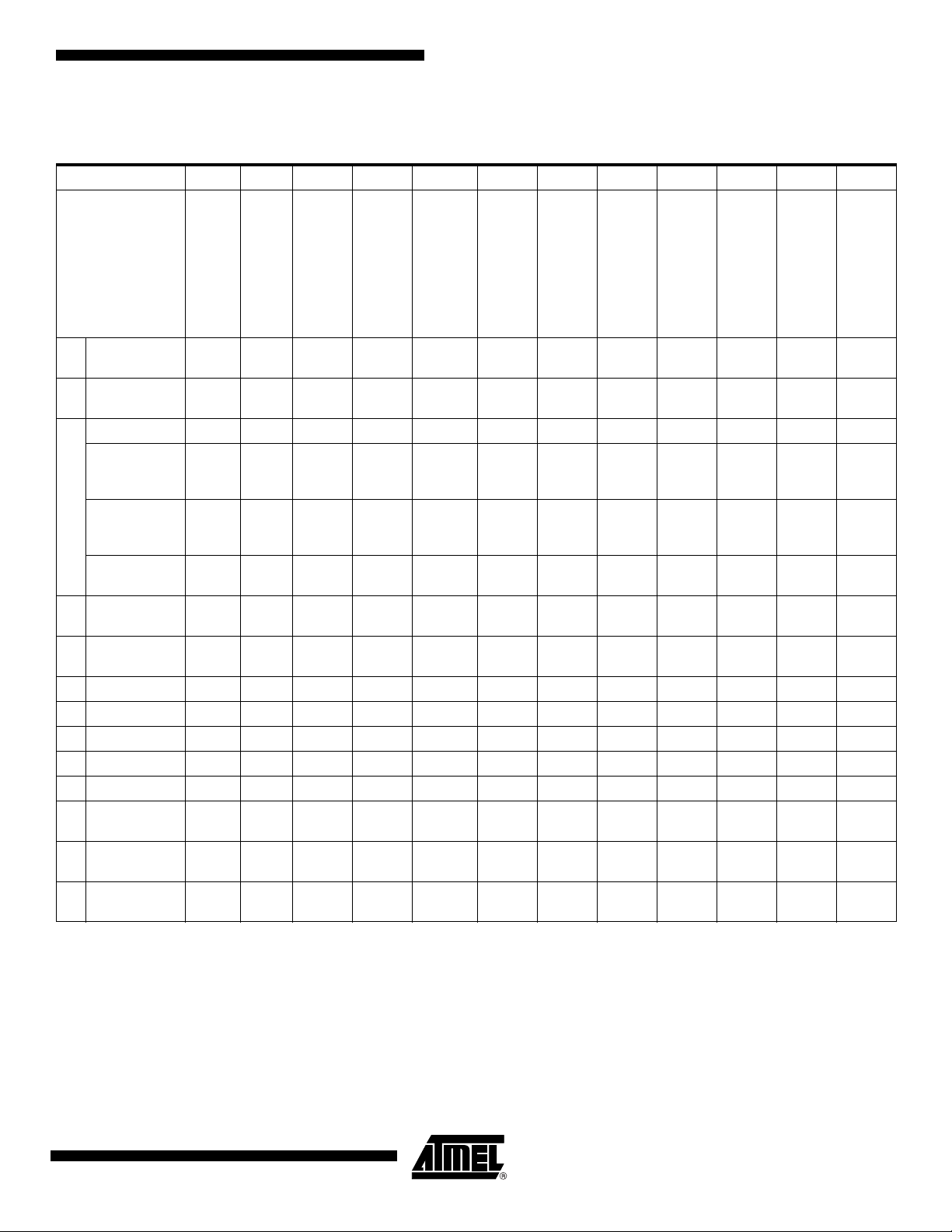

Table 7-3. AT91CAP9S500A/AT91CAP9S250A Masters to Slaves Access

Master 0 1 2 3 4 5 6 7 8 9 10 11

Slave

ARM926 Instruction

LCDCtrl

ARM926 Data

Peripheral DMA Ctrl

Device Ctrl

USB High Speed

Image Sensor Interface

DMA Ctrl

Ethernet MAC

OHCI USB Host Ctrl

MP Block Master 0

MP Block Master 1

MP Block Master 2

Internal SRAM

0

32 Kbytes

MP Block

1

Slave 0

XXXX X XXXXXXX

XXXX X XXXXXXX

Internal ROM X X X X X X X X X X X X

LCD

Controller

XX-- - ----XXX

User Interface

2

USB High

Speed Device

XX - - - - X - - X X X

Interface

OHCI USB

Host Interface

MPBlock

3

Slave 1

External Bus

4

Interface

XX-- - ----XXX

XXXX X XXXXXXX

XXXX X XXXXXXX

-

- DDR Port 0 X - - - - - - - - - - -

5 DDR Port 1 - X - - - - - - - - - -

6 DDR Port 2 X

DDR Port 3 X

7

8

9

MPBlock

Slave 2

MPBlock

Slave 3

Internal

Peripherals

XXXX X XXXXXXX

XXXX X XXXXXXX

XX X - - - X - - X X X

(1)

(1)

(1)

X

(1)

X

(1)

X

(1)

X

(1)

X

(1)

X

(1)

X

(1)

X

(1)

X

(1)

X

(1)

X

(1)

X

(1)

X

(1)

X

(1)

X

(1)

X

(1)

X

(1)

X

Note: 1. DDR Port 2 or Port 3 is selectable for each master through the Matrix Remap Control Register.

6264A–CAP–21-May-07

19

Page 20

7.6 Peripheral DMA Controller

• Acting as one Matrix Master

• Allows data transfers from/to peripheral to/from any memory space without any intervention

of the processor.

• Next Pointer Support, forbids strong real-time constraints on buffer management.

• Twenty-two Channels

– Two for each USART

– Two for the Debug Unit

– One for the TWI

– One for the ADC Controller

– Two for the AC97 Controller

– Two for each Serial Synchronous Controller

– Two for each Serial Peripheral Interface

– One for the each Multimedia Card Interface

The Peripheral DMA Controller handles transfer requests from the channel according to the following priorities (Low to High priorities):

– DBGU Transmit Channel

– USART2 Transmit Channel

– USART1 Transmit Channel

– USART0 Transmit Channel

– AC97 Transmit Channel

– SPI1 Transmit Channel

– SPI0 Transmit Channel

– SSC1 Transmit Channel

– SSC0 Transmit Channel

– DBGU Receive Channel

– TWI Transmit/Receive Channel

– ADC Receive Channel

– USART2 Receive Channel

– USART1 Receive Channel

– USART0 Receive Channel

– AC97 Receive Channel

– SPI1 Receive Channel

– SPI0 Receive Channel

– SSC1 Receive Channel

– SSC0 Receive Channel

– MCI1 Transmit/Receive Channel

– MCI0 Transmit/Receive Channel

7.7 DMA Controller

20

AT91CAP9S500A/AT91CAP9S250A

• Acting as one Matrix Master

6264A–CAP–21-May-07

Page 21

AT91CAP9S500A/AT91CAP9S250A

• Embeds 4 unidirectional channels with programmable priority

• Address Generation

– Source / destination address programming

– Address increment, decrement or no change

– DMA chaining support for multiple non-contiguous data blocks through use of linked

lists

– Scatter support for placing fields into a system memory area from a contiguous

transfer. Writing a stream of data into non-contiguous fields in system memory

– Gather support for extracting fields from a system memory area into a contiguous

transfer

– User enabled auto-reloading of source, destination and control registers from initially

programmed values at the end of a block transfer

– Auto-loading of source, destination and control registers from system memory at end

of block transfer in block chaining mode

– Unaligned system address to data transfer width supported in hardware

• Channel Buffering

– 8-word FIFO

– Automatic packing/unpacking of data to fit FIFO width

• Channel Control

– Programmable multiple transaction size for each channel

– Support for cleanly disabling a channel without data loss

– Suspend DMA operation

– Programmable DMA lock transfer support

• Transfer Initiation

– Support four External DMA Requests and four Internal DMA request from the MP

Block

– Support for Software handshaking interface. Memory mapped registers can be used

to control the flow of a DMA transfer in place of a hardware handshaking interface

• Interrupt

– Programmable Interrupt generation on DMA Transfer completion Block Transfer

completion, Single/Multiple transaction completion or Error condition

7.8 Debug and Test Features

• ARM926 Real-time In-circuit Emulator

– Two real-time Watchpoint Units

– Two Independent Registers: Debug Control Register and Debug Status Register

– Test Access Port Accessible through JTAG Protocol

– Debug Communications Channel

• Debug Unit

–Two-pin UART

– Debug Communication Channel Interrupt Handling

– Chip ID Register

• IEEE1149.1 JTAG Boundary-scan on All Digital Pins

6264A–CAP–21-May-07

21

Page 22

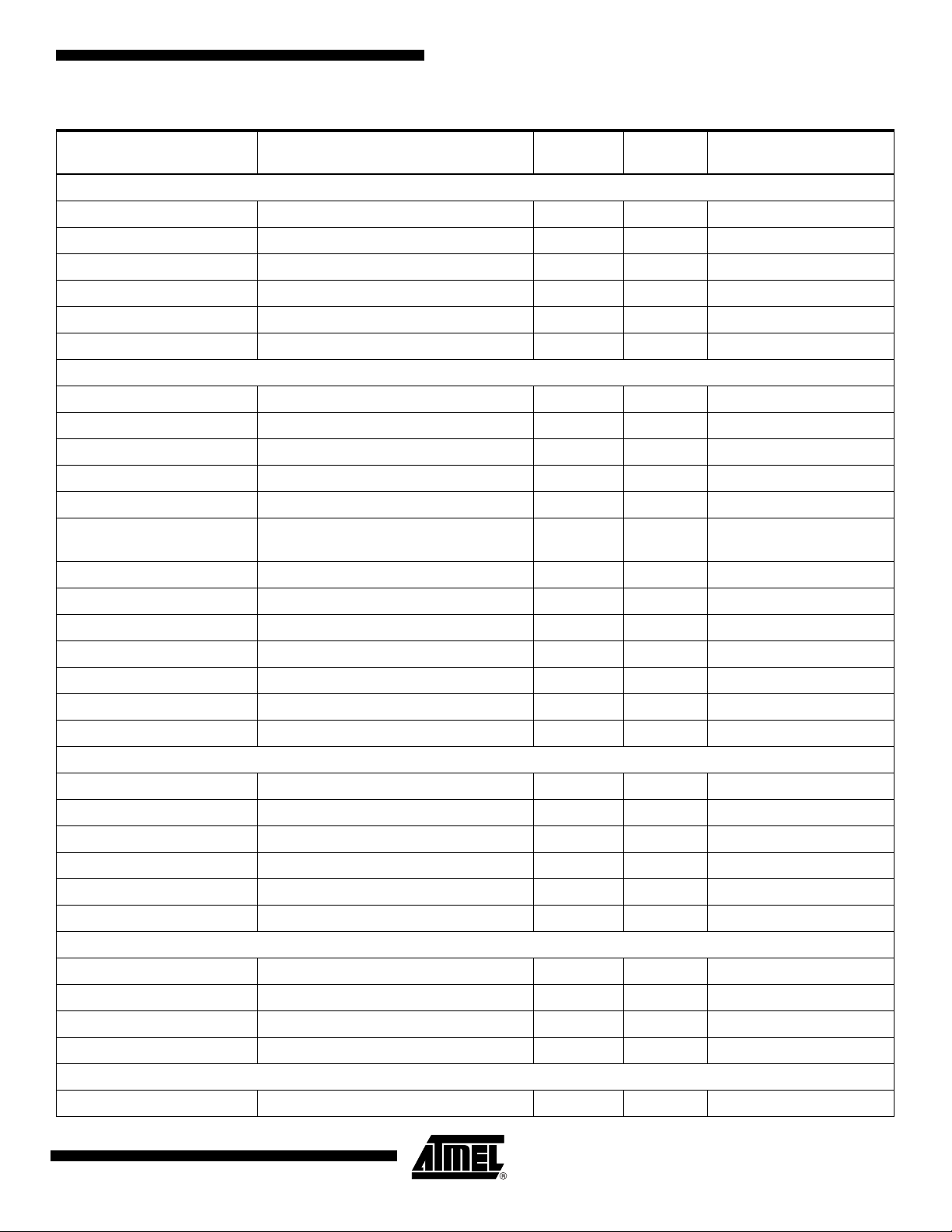

8. Memories

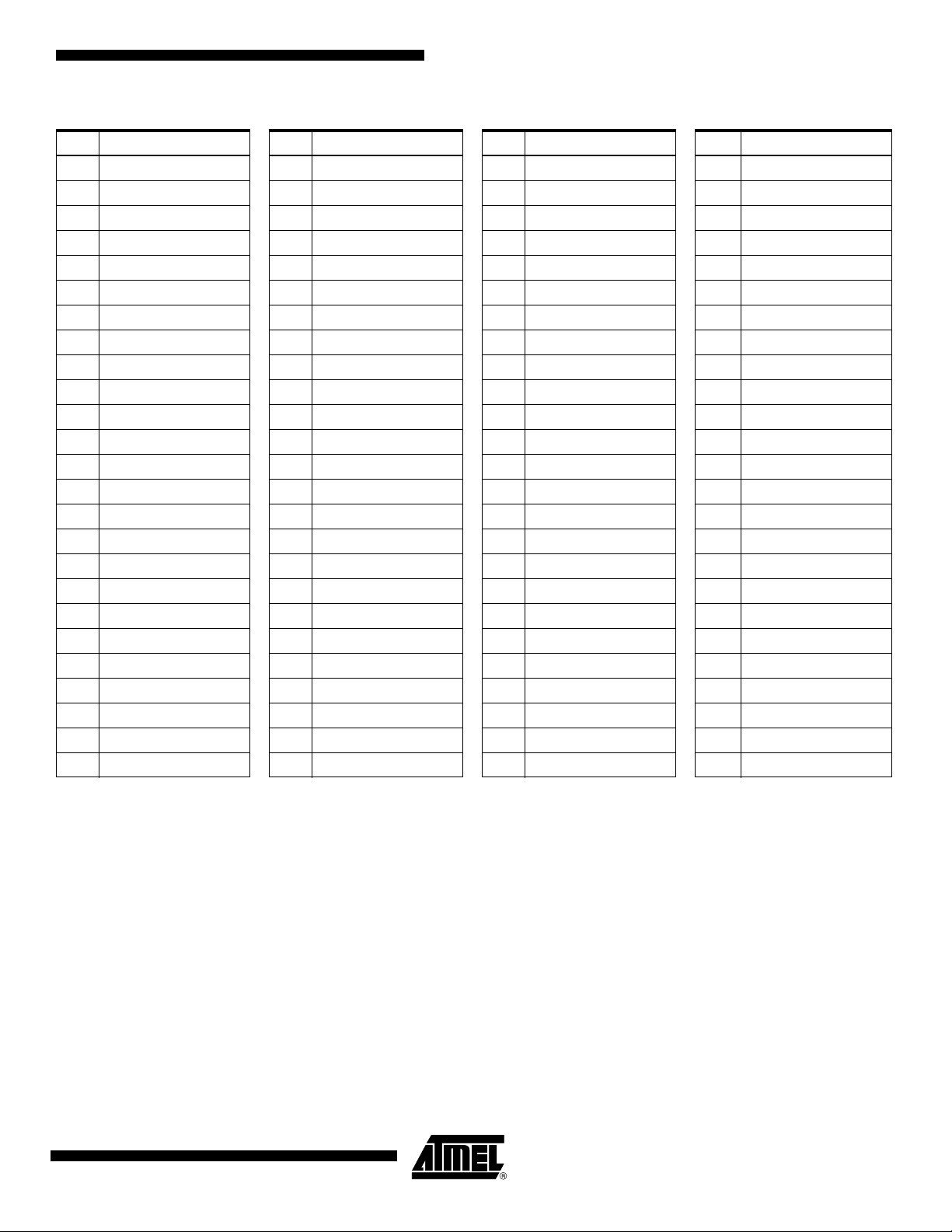

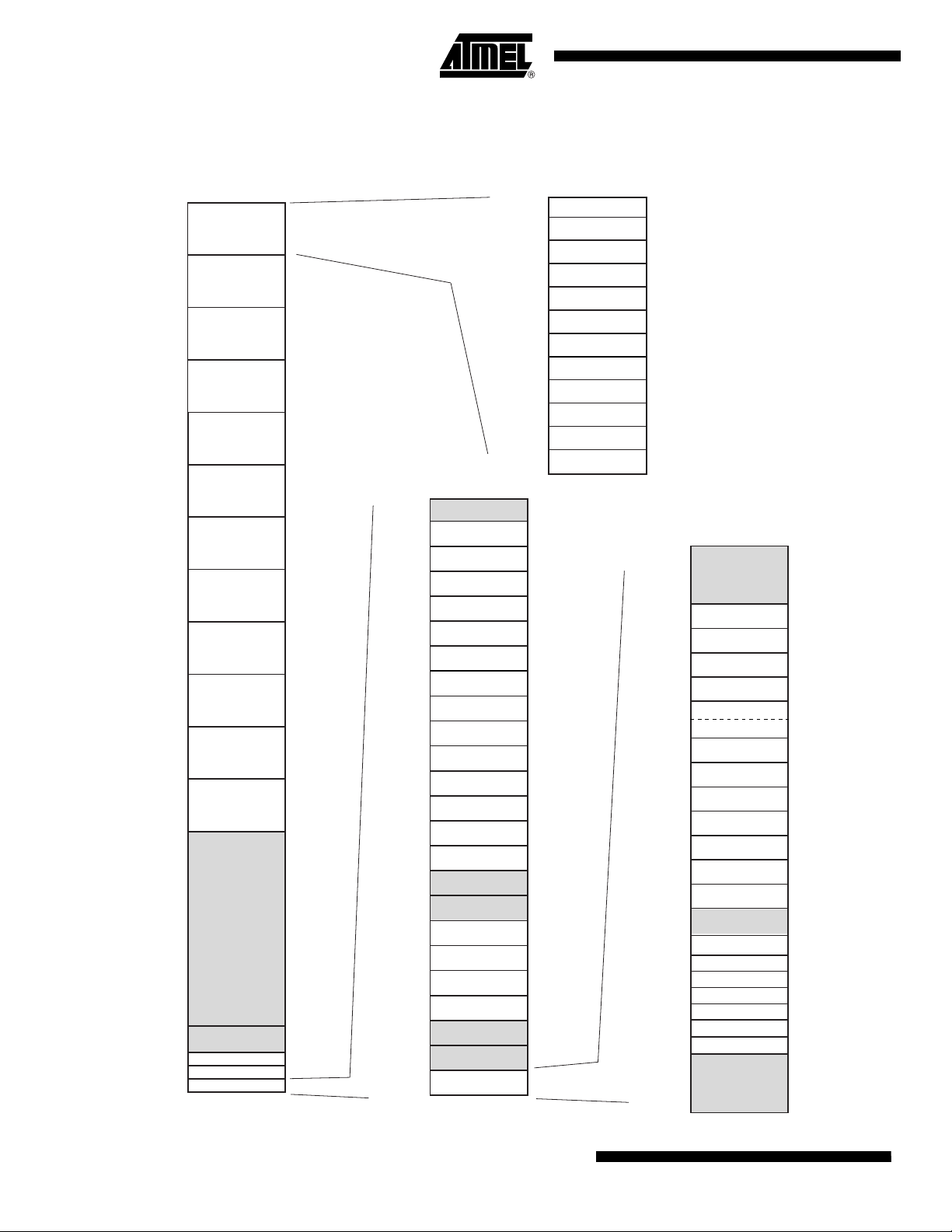

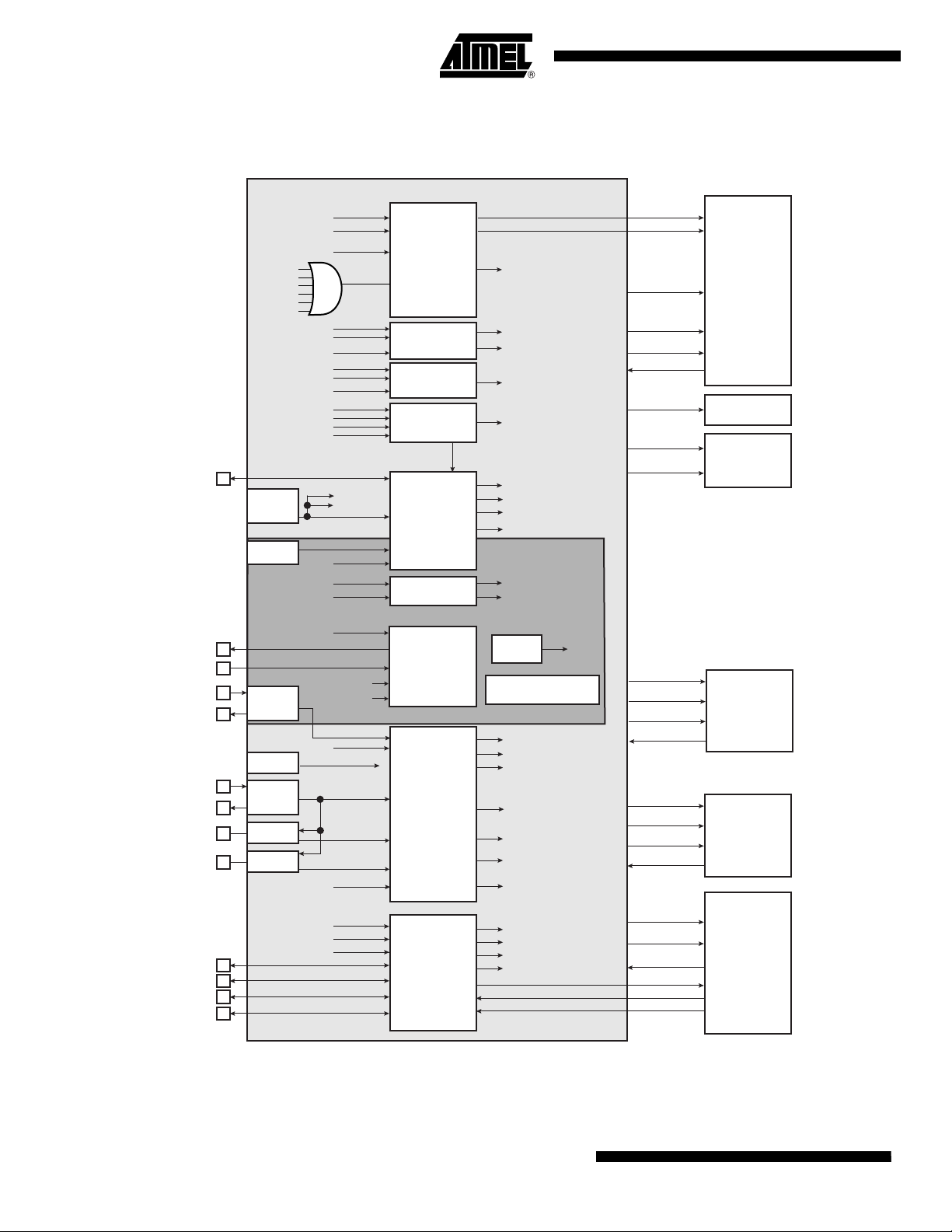

Figure 8-1. AT91CAP9S500A/AT91CAP9S250A Memory Mapping

0x0000 0000

0x0FFF FFFF

0x1000 0000

0x1FFF FFFF

0x2000 0000

0x2FFF FFFF

0x3000 0000

0x3FFF FFFF

0x4000 0000

0x4FFF FFFF

0x5000 0000

0x5FFF FFFF

0x6000 0000

0x6FFF FFFF

0x7000 0000

0x7FFF FFFF

0x8000 0000

0x8FFF FFFF

0x9000 0000

0x9FFF FFFF

0xA000 0000

0xAFFF FFFF

0xB000 0000

0xBFFF FFFF

0xC000 0000

0xEFFF FFFF

0xF000 0000

0xFCFF FFFF

0xFD00 0000

0xFE00 0000

0xFF00 0000

0xFFFF FFFF

Address Memory Space

Internal Memories

EBI

Chip Select 0

EBI

Chip Select 1/

EBI BCRAMC

EBI

Chip Select 2

EBI

Chip Select 3/

NANDFlash

EBI

Chip Select 4/

Compact Flash

Slot 0

EBI

Chip Select 5/

Compact Flash

Slot 1

EBI

DDRSDRC

MPB SLAVE2

Chip Select 0

MPB SLAVE 2

Chip Select 1

MPB SLAVE 2

Chip Select 2

MPB SLAVE 2

Chip Select 3

Undefined

(Abort)

Undefined

(Abort)

MPB SLAVE3

MPB SLAVE3

Internal Peripherals

256M Bytes

256M Bytes

256M Bytes

256M Bytes

256M Bytes

256M Bytes

256M Bytes

256M Bytes

256M Bytes

256M Bytes

256M Bytes

256M Bytes

768M Bytes

208M Bytes

16M Bytes

16M Bytes

16M Bytes

0xFF00 0000

0xFFF7 8000

0xFFF7 C000

0xFFF8 0000

0xFFF8 4000

0xFFF8 8000

0xFFF8 C000

0xFFF9 0000

0xFFF9 4000

0xFFF9 8000

0xFFF9 C000

0xFFFA 0000

0xFFFA 4000

0xFFFA 8000

0xFFFA C000

0xFFFB 0000

0xFFFB 4000

0xFFFB 8000

0xFFFB C000

0xFFFC 0000

0xFFFC 4000

0xFFFC 8000

0xFFFC C000

0xFFFF C000

0xFFFF FFFF

Peripheral Mapping

TCO, TC1, TC2

0x0000 0000

0x0010 0000

0x0020 0000

0x0030 0000

0x0040 0000

0x0050 0000

0x0060 0000

0x0070 0000

0x0080 0000

0x0090 0000

0x00A0 0000

0x00B0 0000

Reserved

UDPHS

MCI0

MCI1

TWI

USART0

USART1

USART2

SSC0

SSC1

AC97C

SPI0

SPI1

CAN0

Reserved

Reserved

PWMC

EMAC

ADCC

ISI

Reserved

Reserved

SYSC

Internal Memory Mapping

Boot Memory (1)

SRAM

MPB SLAVE0

MPB SLAVE0

ROM

LCDC

UDPHS

USB HOST

MPB SLAVE1

MPB SLAVE1

MPB SLAVE1

MPB SLAVE1

16K Bytes

16K Bytes

16K Bytes

16K Bytes

16K Bytes

16K Bytes

16K Bytes

16K Bytes

16K Bytes

16K Bytes

16K Bytes

16K Bytes

16K Bytes

16K Bytes

16K Bytes

16K Bytes

16K Bytes

16K Bytes

16K Bytes

16K Bytes

16K Bytes

16K Bytes

16K Bytes

16K Bytes

0xFFFF C000

0xFFFF E200

0xFFFF E400

0xFFFF E600

0xFFFF E800

0xFFFF EA00

0xFFFF EB10

0xFFFF EC00

0xFFFF EE00

0xFFFF F000

0xFFFF F200

0xFFFF F400

0xFFFF F600

0xFFFF F800

0xFFFF FA00

0xFFFF FC00

0xFFFF FD00

0xFFFF FD10

0xFFFF FD20

0xFFFF FD30

0xFFFF FD40

0xFFFF FD50

0xFFFF FD60

0xFFFF FFFF

Notes :

(1) Can be ROM, EBI_NCS0 or SRAM

depending on BMS and REMAP

System Controller Mapping

Reserved

ECC

BCRAMC

DDRSDRC

SMC

MATRIX

CCFG

DMA

DBGU

AIC

PIOA

PIOB

PIOC

PIOD

Reserved

PMC

RSTC

SHDC

RTT

PIT

WDT

GPBR

Reserved

512 Bytes

512 Bytes

512 bytes

512 Bytes

512 Bytes

512 Bytes

512 Bytes

512 bytes

512 bytes

512 Bytes

512 bytes

512 bytes

512 bytes

256 Bytes

16 Bytes

16 Bytes

16 Bytes

16 Bytes

16 Bytes

16 Bytes

22

AT91CAP9S500A/AT91CAP9S250A

6264A–CAP–21-May-07

Page 23

AT91CAP9S500A/AT91CAP9S250A

A first level of address decoding is performed by the Bus Matrix, i.e., the implementation of the

Advanced High-performance Bus (AHB) for its Master and Slave interfaces with additional

features.

Decoding breaks up the 4G bytes of address space into 16 banks of 256M bytes. The banks 1 to

7 are directed to the EBI that associates these banks to the external chip selects EBI_NCS0 to

EBI_NCS5 and EBI_SDDRCS. The bank 0 is reserved for the addressing of the internal memories, and a second level of decoding provides 1M byte of internal memory area. The banks 8 to

11 are directed to MP Block (Slave 2) and may be used to address external memories. The bank

15 is split into three parts, one reserved for the peripherals that provides access to the Advanced

Peripheral Bus (APB), the two others are directed to MP Block (Slave 3) and may provide

access to the MP Block APB or to other AHB peripherals.

Other areas are unused and performing an access within them provides an abort to the master

requesting such an access.

Each Master has its own bus and its own decoder, thus allowing a different memory mapping

per Master. However, in order to simplify the mappings, all the masters have a similar address

decoding.

Regarding Master 0 and Master 1 (ARM926 Instruction and Data), three different Slaves are

assigned to the memory space decoded at address 0x0: one for internal boot, one for external

boot and one after remap. Refer to Table 8-1, “Internal Memory Mapping,” on page 23 for

details.

8.1 Embedded Memories

• 32 Kbyte ROM

– Single Cycle Access at full matrix speed

• 32 Kbyte Fast SRAM

– Single Cycle Access at full matrix speed

• 20 Kbyte MP Block Fast Dual Port RAM (ten 512x36 DPR instances)

– Used as Dual Port RAM completely managed by MP Block

• 32 Kbyte MP Block Fast Single Port RAM (eight 512x72 SPR instances)

– Used as Single Port RAM completely managed by MP Block

8.1.1 Internal Memory Mapping

Table 8-1 summarizes the Internal Memory Mapping, depending on the Remap status and the

BMS state at reset.

Table 8-1. Internal Memory Mapping

0x0000 0000 ROM EBI_NCS0 SRAM

0x0010 0000 SRAM

0x0020 0000 MP Block Slave 0 (hsel[0])

0x0030 0000 MP Block Slave 0 (hsel[1])

0x0040 0000 ROM

Address

REMAP = 0 REMAP = 1

BMS = 0 BMS = 1

6264A–CAP–21-May-07

23

Page 24

Table 8-1. Internal Memory Mapping (Continued)

0x0050 0000 LCD Controller User Interface

0x0060 0000 USB High Speed Device Interface

0x0070 0000 OHCI USB Host User Interface

0x0080 0000 MP Block Slave 1 (hsel[0])

0x0090 0000 MP Block Slave 1 (hsel[1])

0x00A0 0000 MP Block Slave 1 (hsel[2])

0x00B0 0000 MP Block Slave 1 (hsel[3])

8.1.1.1 Internal 32 Kbyte Fast SRAM

The AT91CAP9S500A/AT91CAP9S250A integrates a 32 Kbyte SRAM, mapped at address

0x0010 0000,which is accessible from the AHB bus. This SRAM is single cycle accessible at full

matrix speed.

8.1.1.2 Boot Memory

The AT91CAP9S500A/AT91CAP9S250A Matrix manages a boot memory which depends on

the level on the pin BMS at reset. The internal memory area mapped between address 0x0 and

0x000F FFFF is reserved at this effect.

If BMS is detected at 1, the boot memory is the memory connected on the Chip Select 0 of the

External Bus Interface. The default configuration for the Static Memory Controller, byte select

mode, 16-bit data bus, Read/Write controlled by Chip Select, allows to boot on a 16-bit non-volatile memory.

If BMS is detected at 0, the boot memory is the embedded ROM.

8.1.2 Boot Program

• Downloads and runs an application from external storage media into internal SRAM

• Downloaded code size depends on embedded SRAM size

• Automatic detection of valid application

• Bootloader on a non-volatile memory

• Boot Uploader in case no valid program is detected in external NVM and supporting several

communication media

The external memories are accessed through the External Bus Interface. Each Chip Select lines

has a 256 Mbyte memory area assigned.

8.2 External Memories

The external memories are accessed through the External Bus Interfaces. Each Chip Select line

has a 256 Mbyte memory area assigned.

Refer to Figure 8-1 on page 22.

– SPI DataFlash

®

connected on NPCS0 of the SPI0

– Serial communication on a DBGU

– USB Bulk Device Port

– External Memories Mapping

24

AT91CAP9S500A/AT91CAP9S250A

6264A–CAP–21-May-07

Page 25

8.2.1 External Bus Interface

The AT91CAP9S500A/AT91CAP9S250A features one External Bus Interface to offer high

bandwidth to the system and to prevent any bottleneck while accessing the external memories.

• Optimized for Application Memory Space support

• Integrates three External Memory Controllers:

– Static Memory Controller

– 4-port DDR/SDRAM Controller

– Burst/CellularRAM Controller

– ECC Controller for NAND Flash

• Additional logic for NAND Flash

• Optional Full 32-bit External Data Bus

• Up to 26-bit Address Bus (up to 64 Mbytes linear per chip select)

• Up to 6 chips selects, Configurable Assignment:

– Static Memory Controller on NCS0

– Burst/CellularRAM Controller or Static Memory Controller on NCS1

– Static Memory Controller on NCS2

– Static Memory Controller on NCS3, Optional NAND Flash support

– Static Memory Controller on NCS4 - NCS5, Optional CompactFlash support

• One dedicated chip select:

– DDR/SDRAM Controller on NCS6

AT91CAP9S500A/AT91CAP9S250A

and CompactFlash

8.2.2 Static Memory Controller

• 8-, 16- or 32-bit Data Bus

• Multiple Access Modes supported

– Byte Write or Byte Select Lines

– Asynchronous read in Page Mode supported (4- up to 32-byte page size)

• Multiple device adaptability

– Compliant with LCD Module

– Control signals programmable setup, pulse and hold time for each Memory Bank

• Multiple Wait State Management

– Programmable Wait State Generation

– External Wait Request

– Programmable Data Float Time

• Slow Clock mode supported

8.2.3 DDR/SDRAM Controller

• Supported devices:

– Standard and Low Power SDRAM (Mobile SDRAM)

– Mobile DDR

• Numerous configurations supported

– 2K, 4K, 8K Row Address Memory Parts

– SDRAM with two or four Internal Banks

6264A–CAP–21-May-07

25

Page 26

– SDRAM with 16- or 32-bit Data Path

– Mobile DDR with four Internal Banks

– Mobile DDR with 16-bit Data Path

• Programming facilities

– Word, half-word, byte access

– Automatic page break when Memory Boundary has been reached

– Multibank Ping-pong Access

– Timing parameters specified by software

– Automatic refresh operation, refresh rate is programmable

– Multiport (4 Ports)

• Energy-saving capabilities

– Self-refresh, power down and deep power down modes supported

• Error detection

– Refresh Error Interrupt

• DDR/SDRAM Power-up Initialization by software

• SDRAM CAS Latency of 1, 2 and 3 supported

• DDR CAS latency of 3 supported

• Auto Precharge Command not used

8.2.4 Burst Cellular RAM Controller

• Supported devices:

– Synchronous Cellular RAM version 1.0, 1.5 and 2.0

• Numerous configurations supported

– 64K, 128K, 256K, 512K Row Address Memory Parts

– Cellular RAM with 16- or 32-bit Data Path

• Programming facilities

– Word, half-word, byte access

– Automatic page break when Memory Boundary has been reached

– Timing parameters specified by software

– Only Continuous read or write burst supported

• Energy-saving capabilities

– Standby and Deep Power Down (DPD) modes supported

– Low Power features (PASR/TCSR) supported

• Cellular RAM Power-up Initialization by hardware

• Cellular RAM CAS latency of 2 and 3 supported (Version 1.0)

• Cellular RAM CAS latency of 2, 3, 4, 5 and 6 supported (Version 1.5 and 2.0)

• Cellular RAM variable or fixed latency supported (Version 1.5 and 2.0)

• Multiplexed address/data bus supported (Version 2.0)

• Asynchronous and Page mode not supported.

26

AT91CAP9S500A/AT91CAP9S250A

6264A–CAP–21-May-07

Page 27

8.2.5 Error Corrected Code Controller

• Tracking the accesses to a NAND Flash device by trigging on the corresponding chip select

• Single bit error correction and 2-bit Random detection.

• Automatic Hamming Code Calculation while writing

– ECC value available in a register

• Automatic Hamming Code Calculation while reading

– Error Report, including error flag, correctable error flag and word address being

detected erroneous

– Support 8- or 16-bit NAND Flash devices with 512-, 1024-, 2048- or 4096-byte

pages

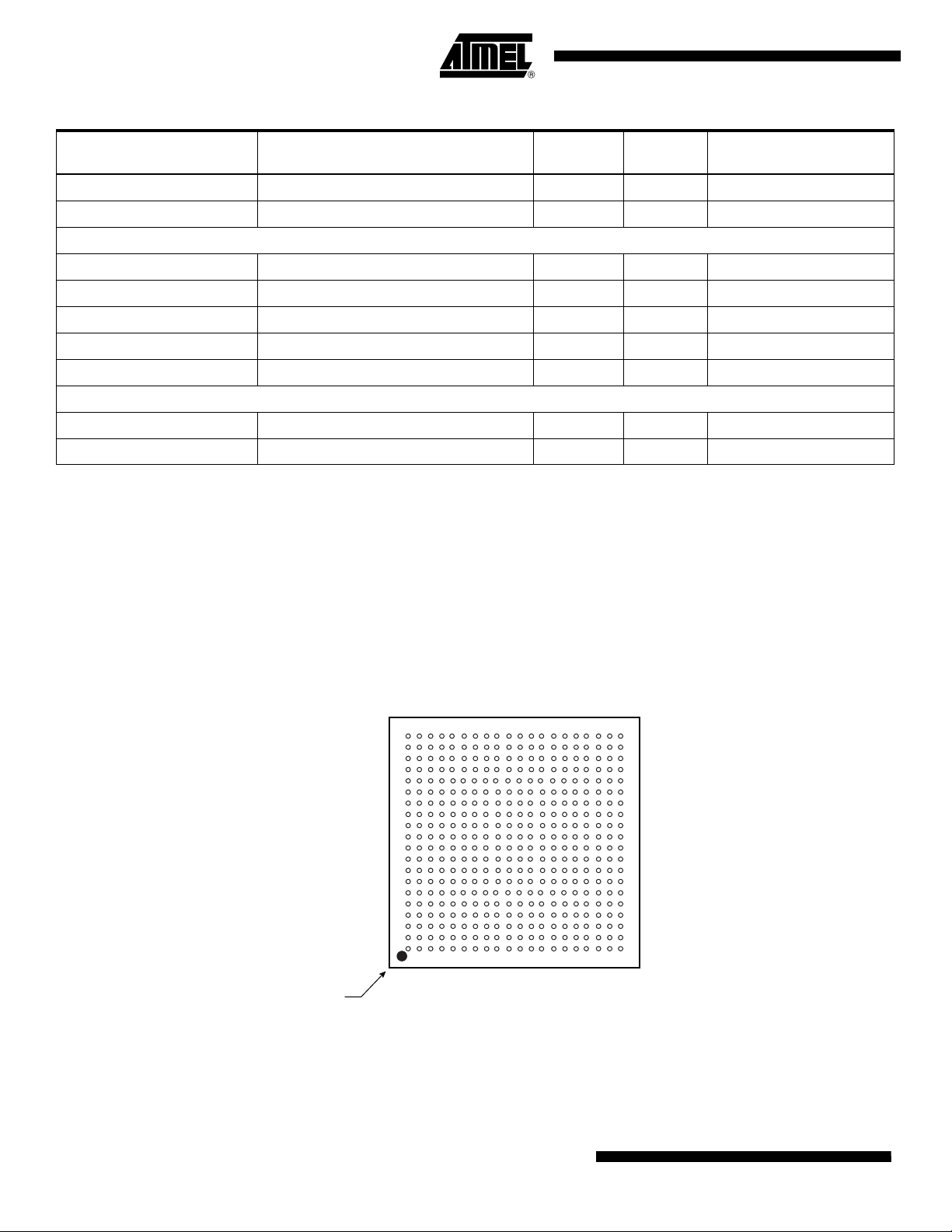

9. System Controller

The System Controller is a set of peripherals, which allow handling of key elements of the system, such as power, resets, clocks, time, interrupts, watchdog, etc.

The System Controller User Interface also embeds the registers that allow configuration of the

Matrix and a set of registers for the chip configuration. The chip configuration registers are used

to configure:

AT91CAP9S500A/AT91CAP9S250A

– EBI chip select assignment and voltage range for external memories

– MP Block

The System Controller peripherals are all mapped within the highest 16 Kbytes of address

space, between addresses 0xFFFF C000 and 0xFFFF FFFF.

However, all the registers of System Controller are mapped on the top of the address space.

This allows all the registers of the System Controller to be addressed from a single pointer by

using the standard ARM instruction set, as the Load/Store instructions have an indexing mode of

± 4 Kbytes.

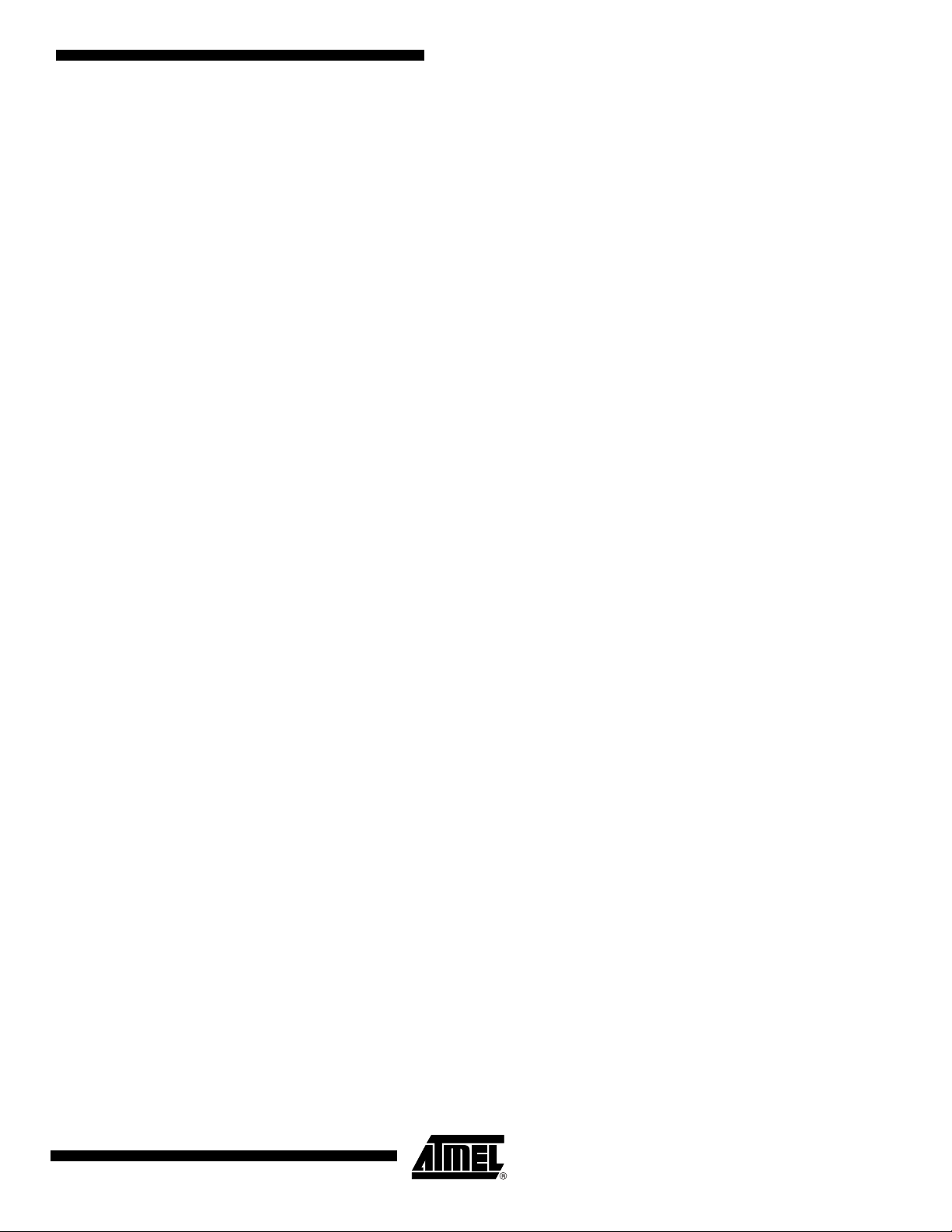

Figure 9-1 on page 28 shows the System Controller block diagram.

Figure 8-1 on page 22 shows the mapping of the User Interfaces of the System Controller

peripherals.

6264A–CAP–21-May-07

27

Page 28

9.1 System Controller Block Diagram

Figure 9-1. AT91CAP9S500A/AT91CAP9S250A System Controller Block Diagram

NRST

SHDN

WKUP

XIN32

XOUT32

XIN

XOUT

PLLRCA

PLLRCB

PA0-PA31

PB0-PB31

PC0-PC31

PD0-PD31

periph_irq[2..29]

pit_irq

rtt_irq

wdt_irq

dbgu_irq

pmc_irq

rstc_irq

periph_nreset

dbgu_rxd

periph_nreset

proc_nreset

VDDCORE

POR

VDDBU

POR

backup_nreset

SLOW

CLOCK

OSC

UTMI PLL

MAIN

OSC

PLLA

PLLB

periph_nreset

periph_nreset

periph_clk[2]

dbgu_rxd

irq0-irq1

fiq

MCK

MCK

debug

SLCK

debug

idle

SLCK

SLCK

SLCK

backup_nreset

SLCK

int

UDPHSCK

por_ntrst

jtag_nreset

rtt_alarm

MAINCK

PLLACK

PLLBCK

System Controller

Advanced

Interrupt

Controller

Debug

Unit

Periodic

Interval

Timer

Watchdog

Timer

wdt_fault

WDRPROC

Reset

Controller

Real-Time

Timer

Shut-Down

Controller

Power

Management

Controller

PIO

Controllers

VDDCORE Powered

int

dbgu_irq

dbgu_txd

pit_irq

wdt_irq

rstc_irq

periph_nreset

proc_nreset

backup_nreset

VDDBU Powered

rtt_irq

rtt_alarm

Voltage

Controller

battery_save

4 General-purpose

Backup Registers

periph_clk[2..31]

pck[0-3]

PCK

UHPCK

MCK

pmc_irq

idle

periph_irq[2]

irq0-irq1

fiq

dbgu_txd

por_ntrst

nirq

nfiq

ntrst

proc_nreset

PCK

debug

jtag_nreset

MCK

periph_nreset

UDPHSCK

periph_clk[28]

periph_nreset

periph_irq[28]

UHPCK

periph_clk[29]

periph_nreset

periph_irq[29]

periph_clk[7..31]

periph_nreset

periph_irq[7..27]

in

out

enable

ARM926EJ-S

Boundary Scan

TAP Controller

Bus Matrix

USB High-speed

Device Port

USB Host

Por t

Embedded

Peripherals

28

AT91CAP9S500A/AT91CAP9S250A

6264A–CAP–21-May-07

Page 29

9.2 Reset Controller

• Based on two Power-on-Reset cells

– One on VDDBU and one on VDDCORE

• Status of the last reset

– Either general reset (VDDBU rising), wake-up reset (VDDCORE rising), software

• Controls the internal resets and the NRST pin output

– Allows shaping a reset signal for the external devices

9.3 Shutdown Controller

• Shutdown and Wake-Up logic

– Software programmable assertion of the SHDN pin

– Deassertion Programmable on a WKUP pin level change or on alarm

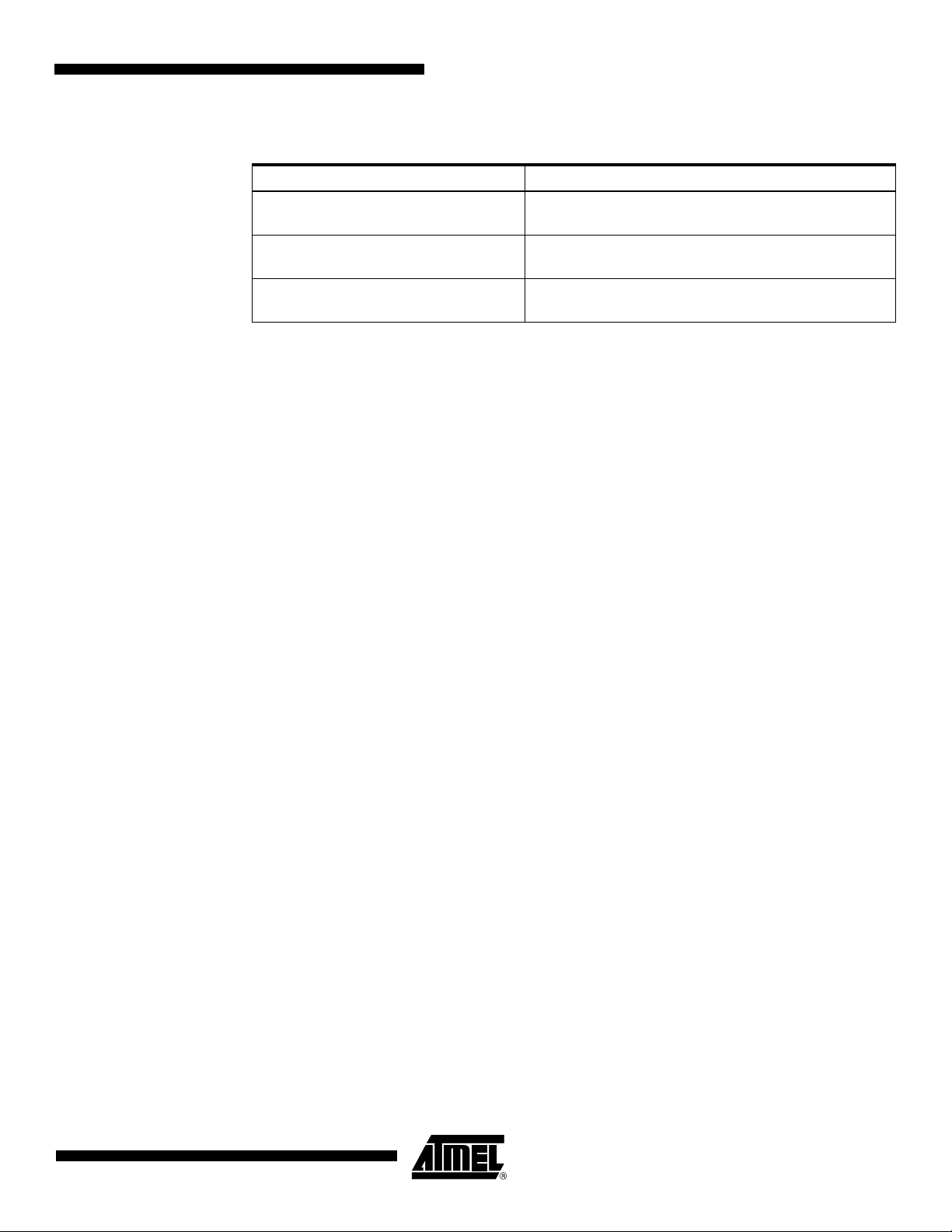

9.4 Clock Generator

• Embeds the low power 32,768 Hz Slow Clock Oscillator

– Provides the permanent Slow Clock SLCK to the system

• Embeds the Main Oscillator

– Oscillator bypass feature

– Supports 8 to 16 MHz crystals

– 12 MHz crystal is required for USB High-Speed Device

• Embeds 2 PLLs

– Output 80 to 200 MHz clocks

– Integrates an input divider to increase output accuracy

– 1 MHz minimum input frequency

AT91CAP9S500A/AT91CAP9S250A

reset, user reset or watchdog reset

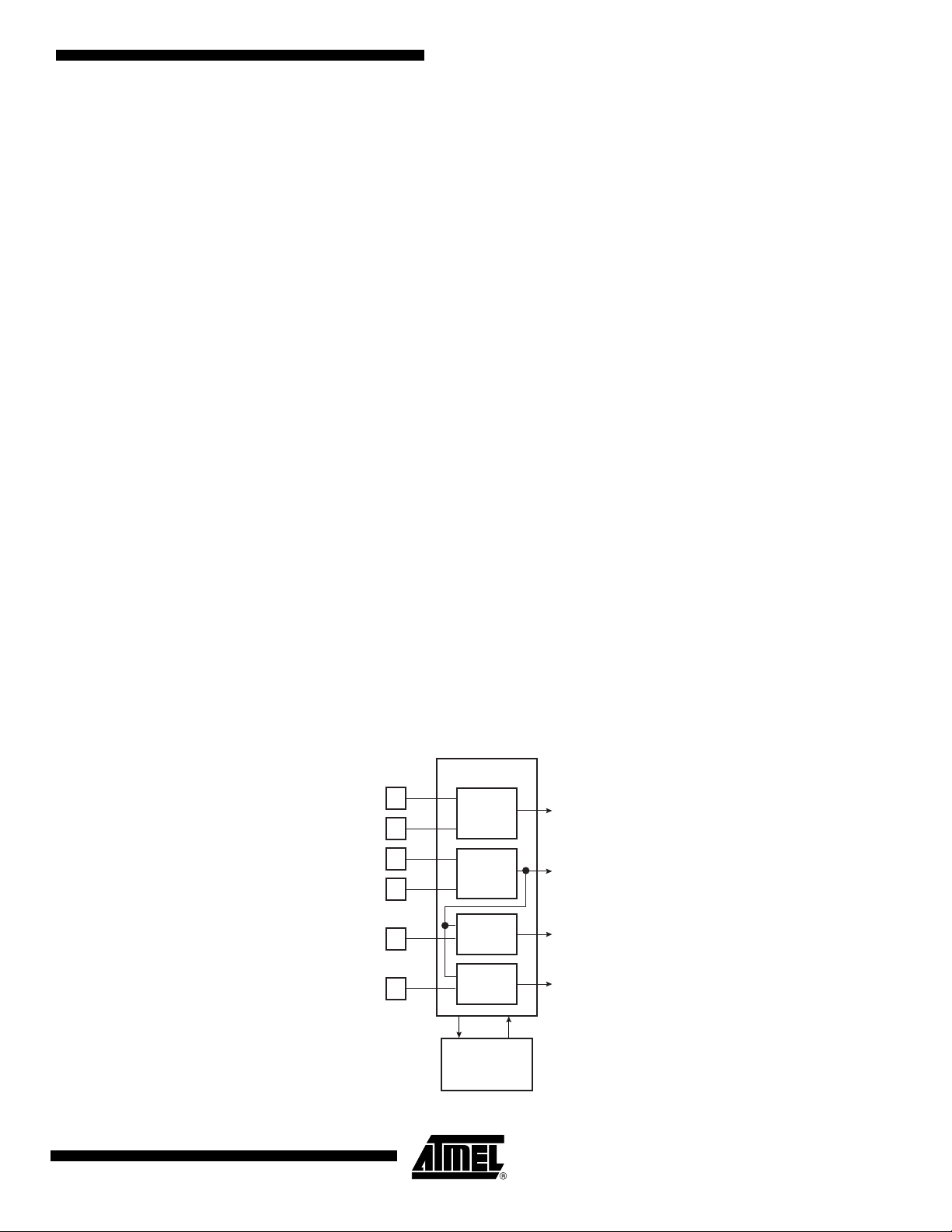

Figure 9-2. Clock Generator Block Diagram

XIN32

XOUT32

XIN

XOUT

PLLRCA

PLLRCB

6264A–CAP–21-May-07

Clock Generator

Slow Clock

Oscillator

Main

Oscillator

PLL and

Divider A

PLL and

Divider B

Power

Management

Controller

Slow Clock

SLCK

Main Clock

MAINCK

PLLA Clock

PLLACK

PLLB Clock

PLLBCK

ControlStatus

29

Page 30

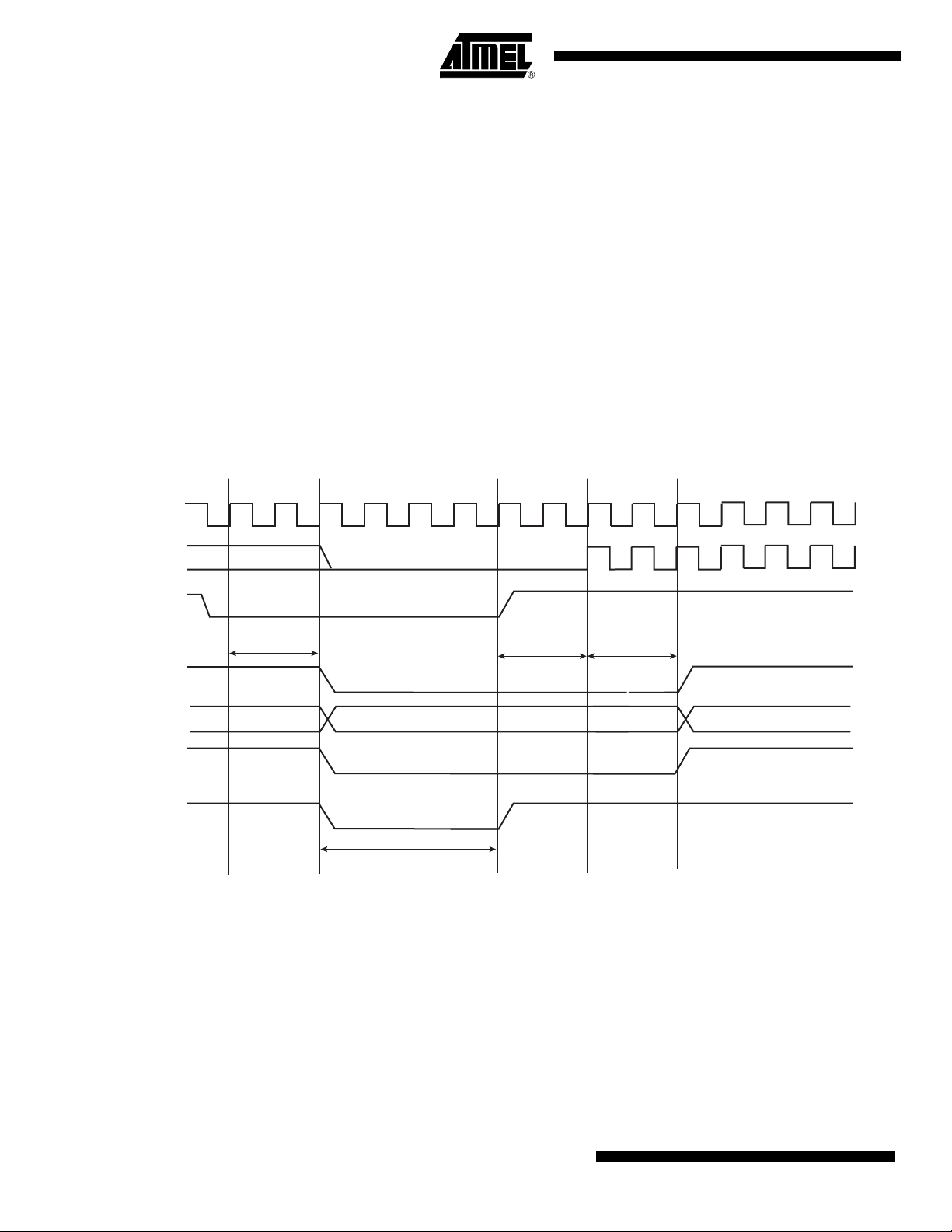

9.5 Power Management Controller

•Provides:

– the Processor Clock PCK

– the Master Clock MCK, in particular to the Matrix and the memory interfaces

– the USB High-speed Device Clock UDPHSCK

– the USB Host Clock UHPCK

– independent peripheral clocks, typically at the frequency of MCK

– four programmable clock outputs: PCK0 to PCK3

• Five flexible operating modes:

– Normal Mode, processor and peripherals running at a programmable frequency

– Idle Mode, processor stopped waiting for an interrupt

– Slow Clock Mode, processor and peripherals running at low frequency

– Standby Mode, mix of Idle and Backup Mode, peripheral running at low frequency,

processor stopped waiting for an interrupt

– Backup Mode, Main Power Supplies off, VDDBU powered by a battery

Figure 9-3. AT91CAP9S500A/AT91CAP9S250A Power Management Controller Block Diagram

Processor

SLCK

MAINCK

PLLACK

PLLBCK

Master Clock Controller

Prescaler

/1,/2,/4,...,/64

Clock

Controller

Idle Mode

Divider

/1,/2,/4

Peripherals

Clock Controller

ON/OFF

Programmable Clock Controller

PCK

int

MCK

periph_clk[..]

DDRCK

9.6 Periodic Interval Timer

• Includes a 20-bit Periodic Counter, with less than 1 µs accuracy

• Includes a 12-bit Interval Overlay Counter

• Real-time OS or Linux/WinCE compliant tick generator

30

AT91CAP9S500A/AT91CAP9S250A

SLCK

MAINCK

PLLACK

PLLBCK

PLLBCK

Prescaler

/1,/2,/4,...,/64

USB Clock Controller

Divider

/1,/2,/4

ON/OFF

ON/OFF

pck[..]

UHPCK

6264A–CAP–21-May-07

Page 31

AT91CAP9S500A/AT91CAP9S250A

9.7 Watchdog Timer

• 16-bit key-protected only-once-Programmable Counter

• Windowed, prevents the processor to be in a dead-lock on the watchdog access

9.8 Real-time Timer

• Two Real-time Timers, allowing backup of time with different accuracies

– 32-bit Free-running back-up Counter

– Integrates a 16-bit programmable prescaler running on the embedded 32,768 Hz

oscillator

– Alarm Register to generate a wake-up of the system through the Shutdown

Controller

9.9 General-Purpose Backed-up Registers

• Four 32-bit backup general-purpose registers

9.10 Advanced Interrupt Controller

• Controls the interrupt lines (nIRQ and nFIQ) of the ARM Processor

• Thirty-two individually maskable and vectored interrupt sources

– Source 0 is reserved for the Fast Interrupt Input (FIQ)

– Source 1 is reserved for system peripherals (PIT, RTT, PMC, DBGU, etc.)

– Programmable Edge-triggered or Level-sensitive Internal Sources

– Programmable Positive/Negative Edge-triggered or High/Low Level-sensitive

• Four External Sources plus the Fast Interrupt signal

• 8-level Priority Controller

– Drives the Normal Interrupt of the processor

– Handles priority of the interrupt sources 1 to 31

– Higher priority interrupts can be served during service of lower priority interrupt

• Vectoring

– Optimizes Interrupt Service Routine Branch and Execution

– One 32-bit Vector Register per interrupt source

– Interrupt Vector Register reads the corresponding current Interrupt Vector

•Protect Mode

– Easy debugging by preventing automatic operations when protect models are

enabled

•Fast Forcing

– Permits redirecting any normal interrupt source on the Fast Interrupt of the

processor

9.11 Debug Unit

6264A–CAP–21-May-07

• Composed of two functions

–Two-pin UART

– Debug Communication Channel (DCC) support

31

Page 32

•Two-pin UART

• Debug Communication Channel Support

9.12 Chip Identification

• Chip ID: 0x039A03A0

• JTAG ID: 0x05B1B03F

• ARM926 TAP ID: 0x0792603F

9.13 PIO Controllers

• 4 PIO Controllers, PIOA to PIOD, controlling a total of 128 I/O Lines

• Each PIO Controller controls up to 32 programmable I/O Lines

• Fully programmable through Set/Clear Registers

• Multiplexing of two peripheral functions per I/O Line

• For each I/O Line (whether assigned to a peripheral or used as general purpose I/O)

• Synchronous output, provides Set and Clear of several I/O lines in a single write

– Implemented features are 100% compatible with the standard Atmel USART

– Independent receiver and transmitter with a common programmable Baud Rate

Generator

– Even, Odd, Mark or Space Parity Generation

– Parity, Framing and Overrun Error Detection

– Automatic Echo, Local Loopback and Remote Loopback Channel Modes

– Support for two PDC channels with connection to receiver and transmitter

– Offers visibility of and interrupt trigger from COMMRX and COMMTX signals from

the ARM Processor’s ICE Interface

– PIOA has 32 I/O Lines

– PIOB has 32 I/O Lines

– PIOC has 32 I/O Lines

– PIOD has 32 I/O Lines

– Input change interrupt

– Glitch filter

– Multi-drive option enables driving in open drain

– Programmable pull up on each I/O line

– Pin data status register, supplies visibility of the level on the pin at any time

32

AT91CAP9S500A/AT91CAP9S250A

6264A–CAP–21-May-07

Page 33

10. Peripherals

10.1 User Interface

10.2 Identifiers

AT91CAP9S500A/AT91CAP9S250A

The peripherals are mapped in the upper 256 Mbytes of the address space between the

addresses 0xFFFA 0000 and 0xFFFC FFFF. Each user peripheral is allocated 16 Kbytes of

address space.

A complete memory map is presented in Figure 8-1 on page 22.

The AT91CAP9S500A/AT91CAP9S250A embeds a wide range of peripherals. Table 10-1

defines the Peripheral Identifiers of the AT91CAP9S500A/AT91CAP9S250A. A peripheral identifier is required for the control of the peripheral interrupt with the Advanced Interrupt Controller

and for the control of the peripheral clock with the Power Management Controller.

Table 10-1. AT91CAP9S500A/AT91CAP9S250A Peripheral Identifiers

Peripheral

ID

0 AIC Advanced Interrupt Controller FIQ

1 SYSC System Controller Interrupt

2 PIOA-D Parallel I/O Controller A to D

3 MPB0 MP Block Peripheral 0

4 MPB1 MP Block Peripheral 1

5 MPB2 MP Block Peripheral 2

6 MPB3 MP Block Peripheral 3

7 MPB4 MP Block Peripheral 4

8 US0 USART 0

9 US1 USART 1

10 US2 USART 2

11 MCI0 Multimedia Card Interface 0

12 MCI1 Multimedia Card Interface 1

13 CAN CAN Controller

14 TWI Two-Wire Interface

15 SPI0 Serial Peripheral Interface 0

Peripheral

Mnemonic Peripheral Name

External

Interrupt

6264A–CAP–21-May-07

16 SPI1 Serial Peripheral Interface 1

17 SSC0 Synchronous Serial Controller 0

18 SSC1 Synchronous Serial Controller 1

19 AC97 AC97 Controller

20 TC0, TC1, TC2 Timer/Counter 0, 1 and 2

21 PWMC Pulse Width Modulation Controller

22 EMAC Ethernet MAC

23 Reserved Reserved

33

Page 34

Table 10-1. AT91CAP9S500A/AT91CAP9S250A Peripheral Identifiers (Continued)

Peripheral

ID

24 ADCC ADC Controller

25 ISI Image Sensor Interface

26 LCDC LCD Controller

27 DMA DMA Controller

28 UDPHS USB High Speed Device Port

29 UHP USB Host Port

30 AIC Advanced Interrupt Controller IRQ0

31 AIC Advanced Interrupt Controller IRQ1

Peripheral

Mnemonic Peripheral Name

10.2.1 Peripheral Interrupts and Clock Control

10.2.1.1 System Interrupt

The System Interrupt in Source 1 is the wired-OR of the interrupt signals coming from:

• the DDR/SDRAM Controller

• the BCRAM Controller

• the Debug Unit

• the Periodic Interval Timer

• the Real-Time Timer

• the Watchdog Timer

• the Reset Controller

• the Power Management Controller

• the MP Block

The clock of these peripherals cannot be deactivated and Peripheral ID 1 can only be used

within the Advanced Interrupt Controller.

External

Interrupt

10.2.1.2 External Interrupts

All external interrupt signals, i.e., the Fast Interrupt signal FIQ or the Interrupt signals IRQ0 to

IRQ1, use a dedicated Peripheral ID. However, there is no clock control associated with these

peripheral IDs.

10.2.1.3 Timer Counter Interrupts

The three Timer Counter channels interrupt signals are OR-wired together to provide the interrupt source 19 of the Advanced Interrupt Controller. This forces the programmer to read all

Timer Counter status registers before branching the right Interrupt Service Routine.

The Timer Counter channels clocks cannot be deactivated independently. Switching off the

clock of the Peripheral 19 disables the clock of the 3 channels.

34

AT91CAP9S500A/AT91CAP9S250A

6264A–CAP–21-May-07

Page 35

AT91CAP9S500A/AT91CAP9S250A

10.3 Peripherals Signals Multiplexing on I/O Lines

The AT91CAP9S500A/AT91CAP9S250A features 4 PIO controllers, PIOA, PIOB, PIOC and

PIOD, that multiplex the I/O lines of the peripheral set.

Each PIO Controller controls up to 32 lines. Each line can be assigned to one of two peripheral

functions, A or B. The multiplexing tables in the following paragraphs define how the I/O lines of

the peripherals A and B are multiplexed on the PIO Controllers. The two columns “Function” and

“Comments” have been inserted in this table for the user’s own comments; they may be used to

track how pins are defined in an application.

Note that some peripheral functions which are output only may be duplicated within both tables.

The column “Reset State” indicates whether the PIO Line resets in I/O mode or in peripheral

mode. If I/O is mentioned, the PIO Line resets in input with the pull-up enabled, so that the

device is maintained in a static state as soon as the reset is released. As a result, the bit corresponding to the PIO Line in the register PIO_PSR (Peripheral Status Register) resets low.

If a signal name is mentioned in the “Reset State” column, the PIO Line is assigned to this function and the corresponding bit in PIO_PSR resets high. This is the case of pins controlling

memories, in particular the address lines, which require the pin to be driven as soon as the reset

is released. Note that the pull-up resistor is also enabled in this case.

6264A–CAP–21-May-07

35

Page 36

10.3.1 PIO Controller A Multiplexing

Table 10-2. Multiplexing on PIO Controller A

PIO Controller A Application Usage

Reset

I/O Line Peripheral A Peripheral B Comments

PA0 MCI0_D0 SPI0_MISO I/O VDDIOP0

PA1 MCI0_CD SPI0_MOSI I/O VDDIOP0

PA2 MCI0_CK SPI0_SPCK I/O VDDIOP0

PA3 MCI0_D1 SPI0_NPCS1 I/O VDDIOP0

PA4 MCI0_D2 SPI0_NPCS2 I/O VDDIOP0

PA5 MCI0_D3 SPI0_NPCS0 I/O VDDIOP0

PA6 AC97FS I/O VDDIOP0

PA7 AC97CK I/O VDDIOP0

PA8 AC97TX I/O VDDIOP0

PA9 AC97RX I/O VDDIOP0

PA10 IRQ0 PWM1 I/O VDDIOP0

PA11 DMARQ0 PWM3 I/O VDDIOP0

PA12 CANTX PCK0 I/O VDDIOP0

PA13 CANRX I/O VDDIOP0

PA14 TCLK2 IRQ1 I/O VDDIOP0

PA15 DMARQ3 PCK2 I/O VDDIOP0

PA16 MCI1_CK ISI_D0 I/O VDDIOP1

PA17 MCI1_CD ISI_D1 I/O VDDIOP1

State

Power

Supply Function Comments

PA18 MCI1_D0 ISI_D2 I/O VDDIOP1

PA19 MCI1_D1 ISI_D3 I/O VDDIOP1

PA20 MCI1_D2 ISI_D4 I/O VDDIOP1

PA21 MCI1_D3 ISI_D5 I/O VDDIOP1

PA22 TXD0 ISI_D6 I/O VDDIOP1

PA23 RXD0 ISI_D7 I/O VDDIOP1

PA24 RTS0 ISI_PCK I/O VDDIOP1

PA25 CTS0 ISI_HSYNC I/O VDDIOP1

PA26 SCK0 ISI_VSYNC I/O VDDIOP1

PA27 PCK1 ISI_MCK I/O VDDIOP1

PA28 SPI0_NPCS3 ISI_D8 I/O VDDIOP1

PA29 TIOA0 ISI_D9 I/O VDDIOP1

PA30 TIOB0 ISI_D10 I/O VDDIOP1

PA31 DMARQ1 ISI_D11 I/O VDDIOP1

36

AT91CAP9S500A/AT91CAP9S250A

6264A–CAP–21-May-07

Page 37

10.3.2 PIO Controller B Multiplexing

Table 10-3. Multiplexing on PIO Controller B

PIO Controller B Application Usage

AT91CAP9S500A/AT91CAP9S250A

Reset

I/O Line Peripheral A Peripheral B Comments

PB0 TF0 I/O VDDIOP0

PB1 TK0 I/O VDDIOP0

PB2 TD0 I/O VDDIOP0

PB3 RD0 I/O VDDIOP0

PB4 RK0 TWD I/O VDDIOP0

PB5 RF0 TWCK I/O VDDIOP0

PB6 TF1 TIOA1 I/O VDDIOP0

PB7 TK1 TIOB1 I/O VDDIOP0

PB8 TD1 PWM2 I/O VDDIOP0

PB9 RD1 LCDCC I/O VDDIOP0

PB10 RK1 PCK1 I/O VDDIOP0

PB11 RF1 I/O VDDIOP0

PB12 SPI1_MISO I/O VDDIOP0

PB13 SPI1_MOSI AD0 I/O VDDIOP0

PB14 SPI1_SPCK AD1 I/O VDDIOP0

PB15 SPI1_NPCS0 AD2 I/O VDDIOP0

PB16 SPI1_NPCS1 AD3 I/O VDDIOP0

PB17 SPI1_NPCS2 AD4 I/O VDDIOP0

State

Power

Supply Function Comments

PB18 SPI1_NPCS3 AD5 I/O VDDIOP0

PB19 PWM0 AD6 I/O VDDIOP0

PB20 PWM1 AD7 I/O VDDIOP0

PB21 ETXCK/EREFCK TIOA2 I/O VDDIOP0

PB22 ERXDV TIOB2 I/O VDDIOP0

PB23 ETX0 PCK3 I/O VDDIOP0

PB24 ETX1 I/O VDDIOP0

PB25 ERX0 I/O VDDIOP0

PB26 ERX1 I/O VDDIOP0

PB27 ERXER I/O VDDIOP0

PB28 ETXEN TCLK0 I/O VDDIOP0

PB29 EMDC PWM3 I/O VDDIOP0

PB30 EMDIO I/O VDDIOP0

PB31 ADTRIG EF100 I/O VDDIOP0

6264A–CAP–21-May-07

37

Page 38

10.3.3 PIO Controller C Multiplexing

Table 10-4. Multiplexing on PIO Controller C

PIO Controller C Application Usage

Reset

I/O Line Peripheral A Peripheral B Comments

PC0 LCDVSYNC I/O VDDIOP0

PC1 LCDHSYNC I/O VDDIOP0

PC2 LCDDOTCK I/O VDDIOP0

PC3 LCDDEN PWM1 I/O VDDIOP0

PC4 LCDD0 LCDD3 I/O VDDIOP0

PC5 LCDD1 LCDD4 I/O VDDIOP0

PC6 LCDD2 LCDD5 I/O VDDIOP0

PC7 LCDD3 LCDD6 I/O VDDIOP0

PC8 LCDD4 LCDD7 I/O VDDIOP0

PC9 LCDD5 LCDD10 I/O VDDIOP0

PC10 LCDD6 LCDD11 I/O VDDIOP0

PC11 LCDD7 LCDD12 I/O VDDIOP0

PC12 LCDD8 LCDD13 I/O VDDIOP0

PC13 LCDD9 LCDD14 I/O VDDIOP0

PC14 LCDD10 LCDD15 I/O VDDIOP0

PC15 LCDD11 LCDD19 I/O VDDIOP0

PC16 LCDD12 LCDD20 I/O VDDIOP0

PC17 LCDD13 LCDD21 I/O VDDIOP0

State

Power

Supply Function Comments

PC18 LCDD14 LCDD22 I/O VDDIOP0

PC19 LCDD15 LCDD23 I/O VDDIOP0

PC20 LCDD16 ETX2 I/O VDDIOP0

PC21 LCDD17 ETX3 I/O VDDIOP0

PC22 LCDD18 ERX2 I/O VDDIOP0

PC23 LCDD19 ERX3 I/O VDDIOP0

PC24 LCDD20 ETXER I/O VDDIOP0

PC25 LCDD21 ECRS I/O VDDIOP0

PC26 LCDD22 ECOL I/O VDDIOP0

PC27 LCDD23 ERXCK I/O VDDIOP0

PC28 PWM0 TCLK1 I/O VDDIOP0

PC29 PCK0 PWM2 I/O VDDIOP0

PC30 DRXD I/O VDDIOP0

PC31 DTXD I/O VDDIOP0

38

AT91CAP9S500A/AT91CAP9S250A

6264A–CAP–21-May-07

Page 39

10.3.4 PIO Controller D Multiplexing

Table 10-5. Multiplexing on PIO Controller D

PIO Controller D Application Usage

AT91CAP9S500A/AT91CAP9S250A

Reset

I/O Line Peripheral A Peripheral B Comments

PD0 TXD1 SPI0_NPCS2 I/O VDDIOP0