Page 1

Features

• Utilizes the AVR

• AVR – High-performance and Low-power RISC Architecture

– 118 Powerful Instructions – Most Single Clock Cycle Execution

– 32 x 8 General-purpose Working Registers

– Up to 1.5 MIPS Throughput at 1.5 MHz

• Data and Nonvolatile Program Memory

– 8K Bytes Flash Program Memory

Endurance: 1,000 Write/Erase Cycles

– 256 Bytes Internal SRAM

– 512 Bytes EEPROM

Endurance: 100,000 Write/Erase Cycles

– Programming Lock for Flash Program and EEPROM Data Security

• Peripheral Features

– One 8-bit Timer/Counter with Separate Prescaler

– One 16-bit Timer/Counter with Separate Prescaler

• Special Microcontroller Features

– Low-power Idle and Power-down Modes

– External and Internal Interrupt Sources

– 6-channel, 10-bit ADC

• Specifications

– Low-power, High-speed CMOS Process Technology

– Fully Static Operation

• Power Consumption at 1.5 MHz, 3.6V, 25°C

– Active: 1.2 mA

– Idle Mode: 0.2 mA

– Power-down Mode: <10 µA

• I/O and Packages

– Seven General Output Lines

– Two External Interrupt Lines

– 48-lead LQFP/VQFP Package

• Operating Voltage

– 3.3 - 6.0V

• Speed Grade

– 0 - 1.5 MHz

®

RISC Architecture

8-bit

Microcontroller

with 8K Bytes

Programmable

Flash

AT90C8534

Preliminary

Description

The AT90C8534 is a low-power CMOS 8-bit microcontroller based on the AVR RISC

architecture. By executing powerful instructions in a single clock cycle, the

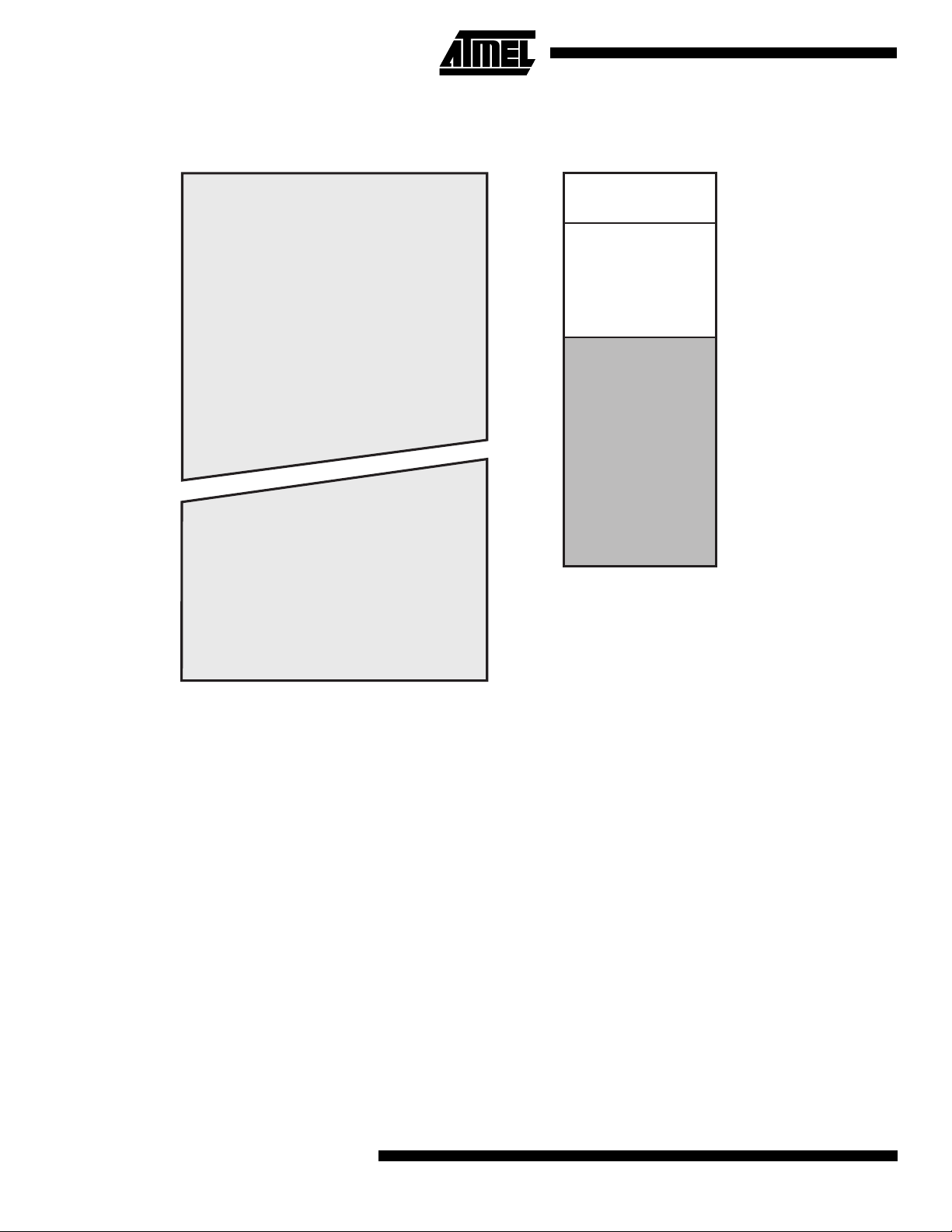

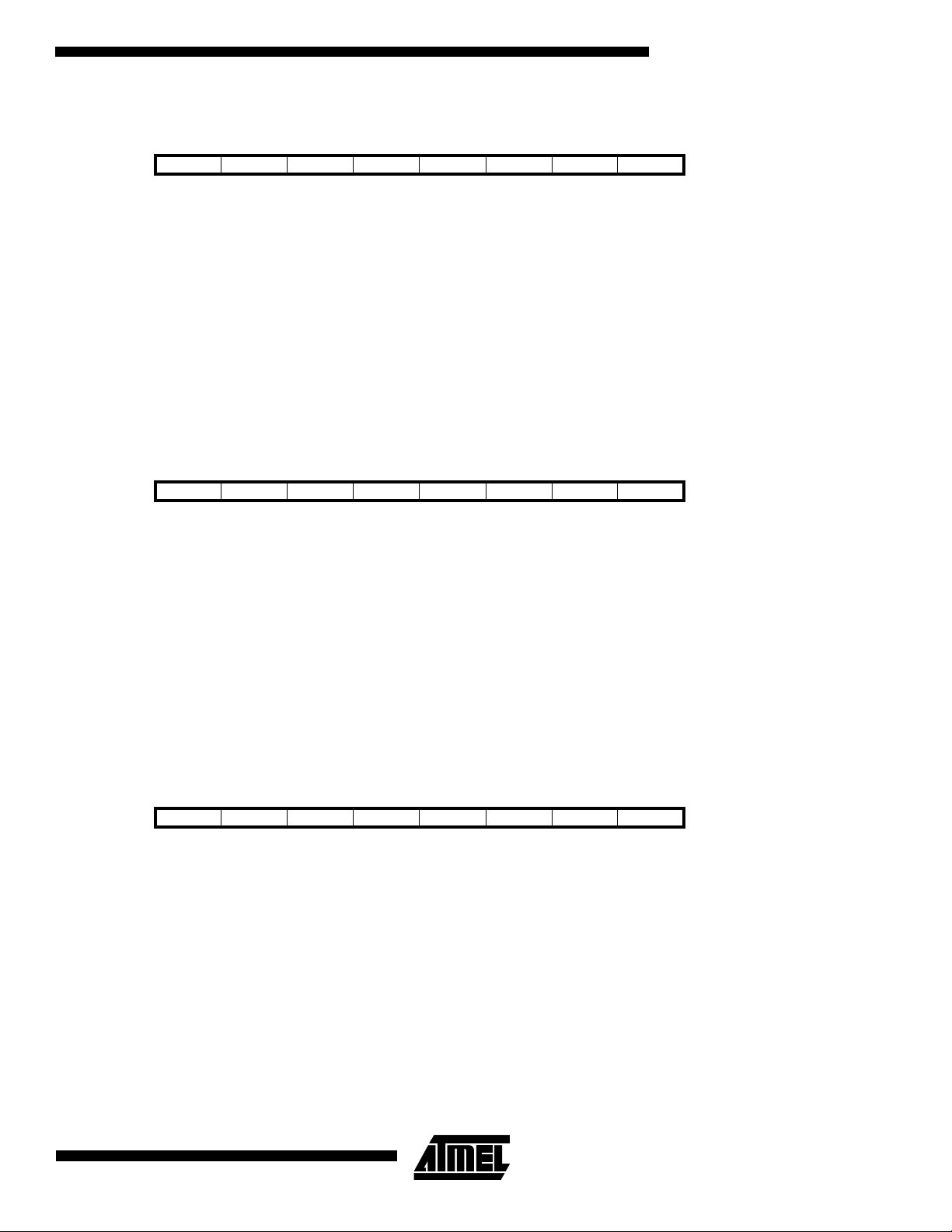

Pin Configuration

ADIN0

NC

NC

NC

NC

NC

NC

NC

NC

NC

AGND

NC

NC

PA0

PA1

PA2

PA3NCNCNCNC

4847464544434241403938

1

2

3

4

5

6

7

8

9

10

11

12

1314151617181920212223

ADIN3

ADIN4

AVCC

ADIN5

ADIN1

ADIN2

NC

NC

RESET

PA4

VCC

PA5

NC

37

24

XTAL2

XTAL1

36

NC

35

INT0

34

INT1

33

PA6

32

NC

31

GND

30

NC

29

NC

28

NC

27

NC

26

NC

25

NC

(continued)

Rev. 1229B–11/00

1

Page 2

AT90C8534 achieves throughputs approaching 1 MIPS per MHz allowing the system designer to optimize power consumption versus processing speed.

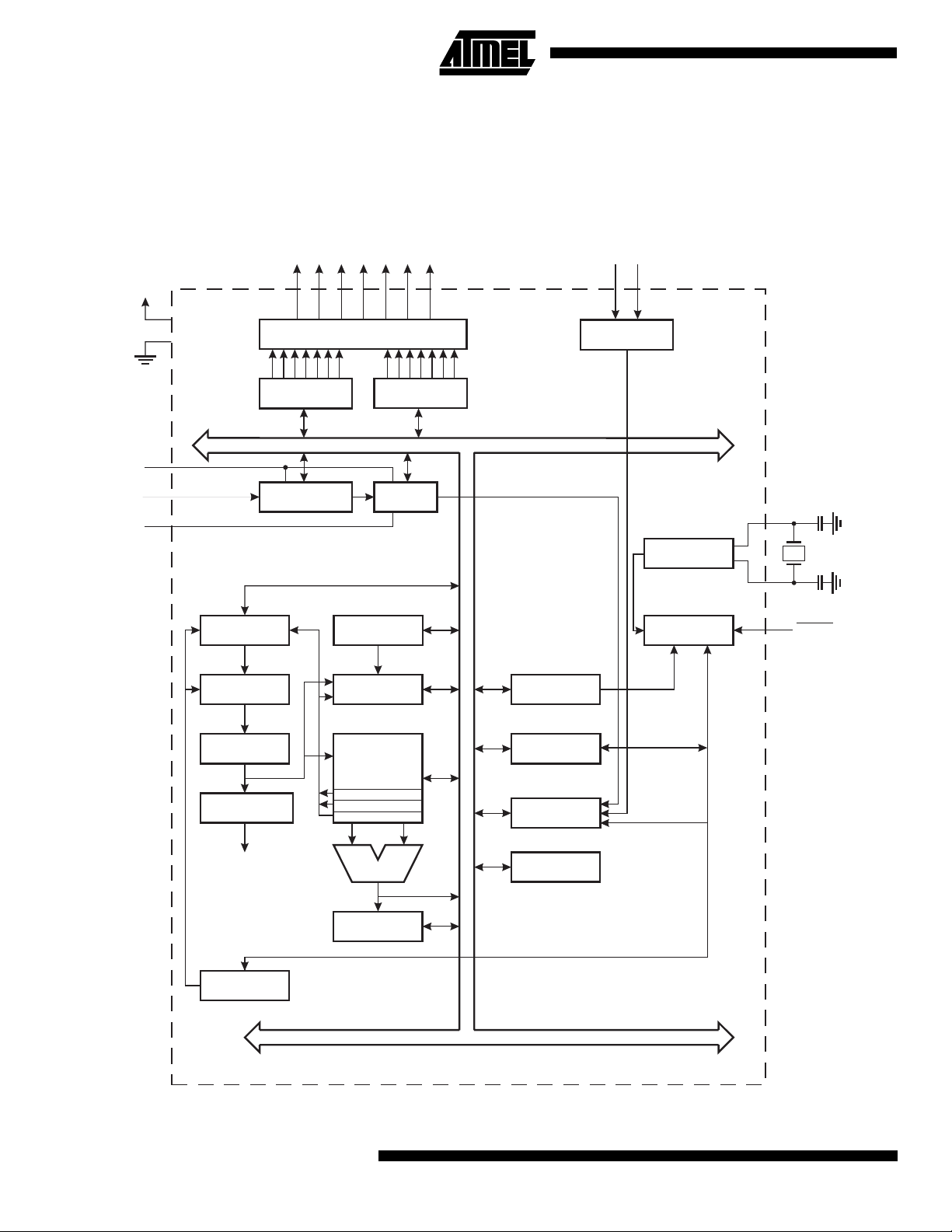

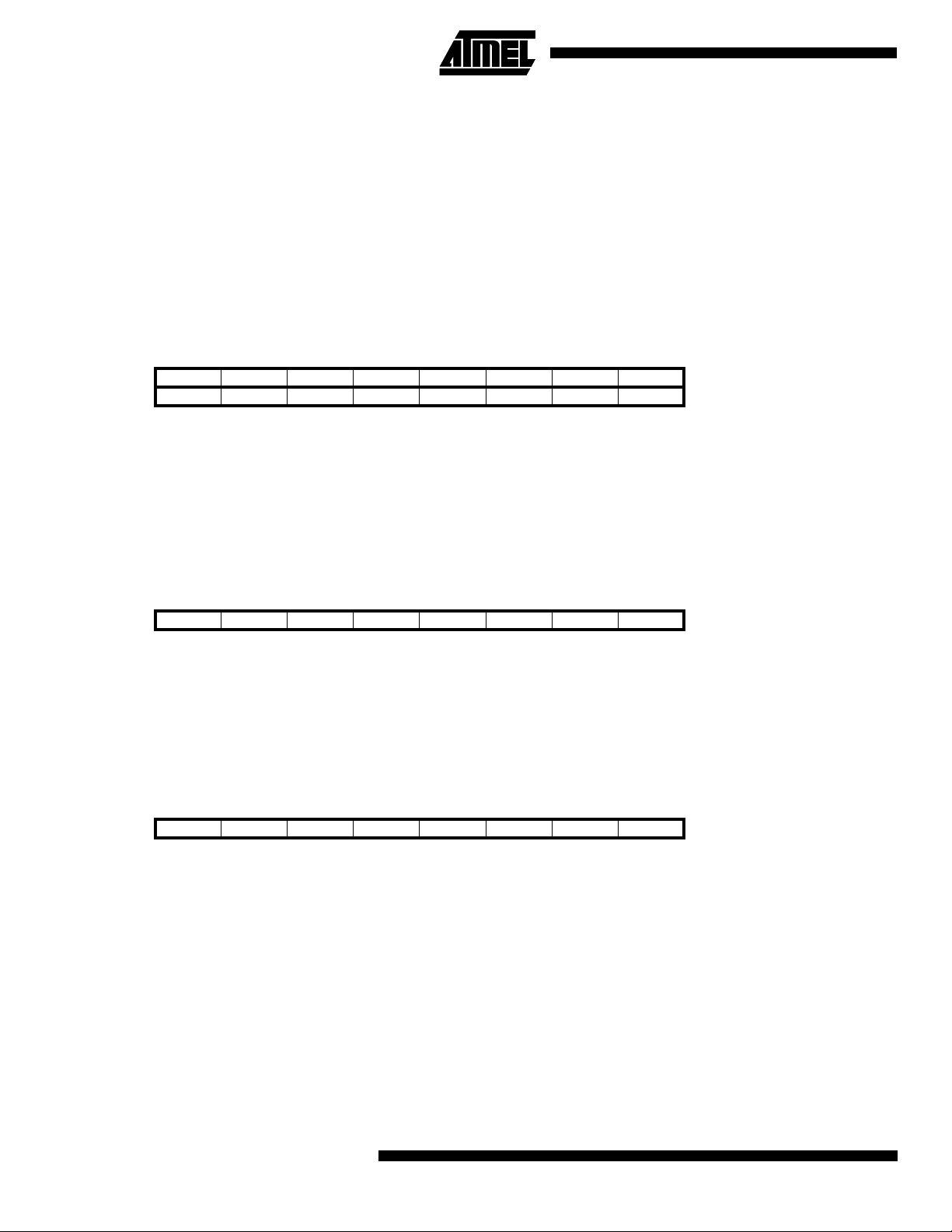

Block Diagram

Figure 1. The AT90C8534 Block Diagram

VCC

GND

AVCC

ADIN5..0

AGND

PROGRAM

COUNTER

PROGRAM

FLASH

PA0 - PA6

PORTA DRIVERS

DATA REGISTER

PORTA

ANALOG MUX ADC

REG. PORTA

STACK

POINTER

SRAM

DATA DIR.

8-BIT DATA BUS

MCU CONTROL

REGISTER

INT1,0

EXTERNAL

INTERRUPTS

OSCILLATOR

TIMING AND

CONTROL

XTAL1

XTAL2

RESET

INSTRUCTION

REGISTER

INSTRUCTION

DECODER

CONTROL

LINES

PROGRAMMING

LOGIC

2

AT90C8534

GENERAL

PURPOSE

REGISTERS

X

Y

Z

ALU

STATUS

REGISTER

TIMER/

COUNTERS

INTERRUPT

UNIT

EEPROM

Page 3

AT90C8534

The AVR core combines a rich instruction set with 32 general-purpose working registers. All the 32 registers are directly

connected to the Arithmetic Logic Unit (ALU), allowing two independent registers to be accessed in one single instruction

executed in one clock cycle. The resulting architecture is more code efficient while achieving throughputs up to ten times

faster than conventional CISC microcontrollers.

The AT90C8534 provides the following features: 8K bytes of programmable Flash, 512 bytes EEPROM, 256 bytes SRAM,

7 general output lines, 2 external interrupt lines, 32 general-purpose working registers, 2 flexible timer/counters, internal

and external interrupts, 6-channel, 10-bit ADC, and 2 software-selectable power saving modes. The Idle mode stops the

CPU while allowing the ADC, timer/counters and interrupt system to continue functioning. The Power-down mode saves

the SRAM and register contents but freezes the oscillator, disabling all other chip functions until the next interrupt or hardware reset.

The device is manufactured using Atmel’s high-density nonvolatile memory technology. The on-chip programmable Flash

allows the program memory to be reprogrammed by a conventional nonvolatile memory programmer. By combining an

8-bit RISC CPU with programmable Flash on a monolithic chip, the Atmel AT90C8534 is a powerful microcontroller that

provides a highly flexible and cost-effective solution to many embedded control applications.

The AT90C8534 AVR is supported with a full suite of program and system development tools including: C compilers, macro

assemblers, program debugger/simulators, in-circuit emulators and evaluation kits.

Pin Descriptions

VCC

Digital supply voltage

GND

Digital ground

Port A (PA6..PA0)

Port A is a 7-bit output port with tri-state mode. The Port A output buffers can sink 20 mA and can drive LED displays

directly. The port pins are tri-stated when a reset condition becomes active, even if the clock is not running.

INT1, 0

External interrupt input pins. A falling or rising edge on either of these pins will generate an interrupt request. Interrupt

pulses longer than 40 ns will generate an interrupt, even if the clock is not running.

ADIN5..0

ADC input pins. Any of these pins can be selected as the input to the ADC.

RESET

Reset input. An external reset is generated by a low level on the RESET pin. Reset pulses longer than 100 ns will generate

a reset, even if the clock is not running. Shorter pulses are not guaranteed to generate a reset.

XTAL1

Input to the inverting oscillator amplifier and input to the internal clock operating circuit.

XTAL2

Output from the inverting oscillator amplifier

AVCC

This is the supply voltage pin for the A/D Converter. If the ADC is not used, the pin must be connected to V

used, the pin should be connected to VCC via a low-pass filter. See page 30 for details on operation of the ADC.

AGND

Analog ground. If the board has a separate analog ground plane, this pin should be connected to this ground plane.

Otherwise, connect to GND.

. If the ADC is

CC

3

Page 4

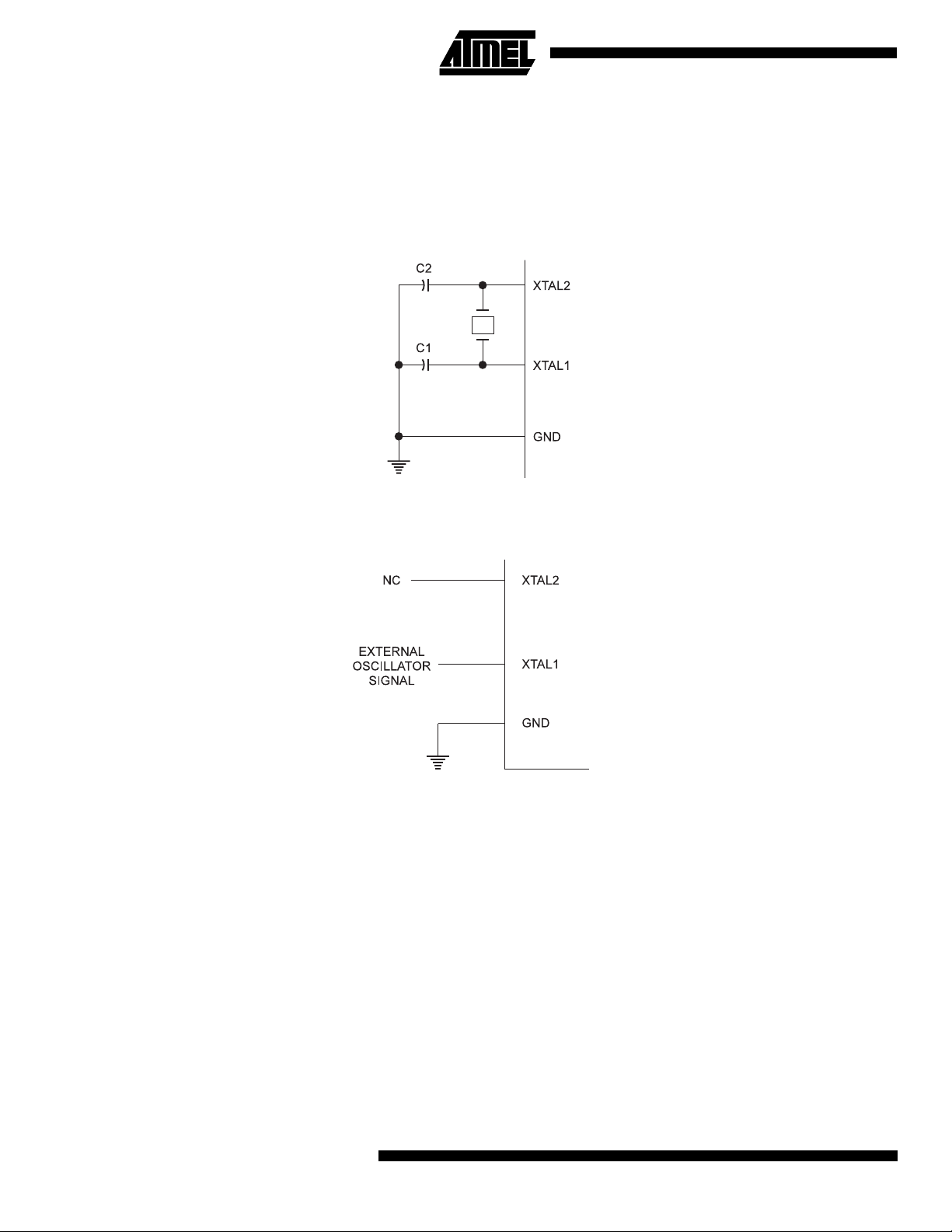

Crystal Oscillators

XTAL1 and XTAL2 are input and output, respectively, of an inverting amplifier that can be configured for use as an on-chip

oscillator, as shown in Figure 2. Either a quartz crystal or a ceramic resonator may be used. To drive the device from an

external clock source, XTAL2 should be left unconnected while XTAL1 is driven as shown in Figure 3. Note that XTAL2

should not be used to drive other components.

Figure 2. Oscillator Connections

Figure 3. External Clock Drive Configuration

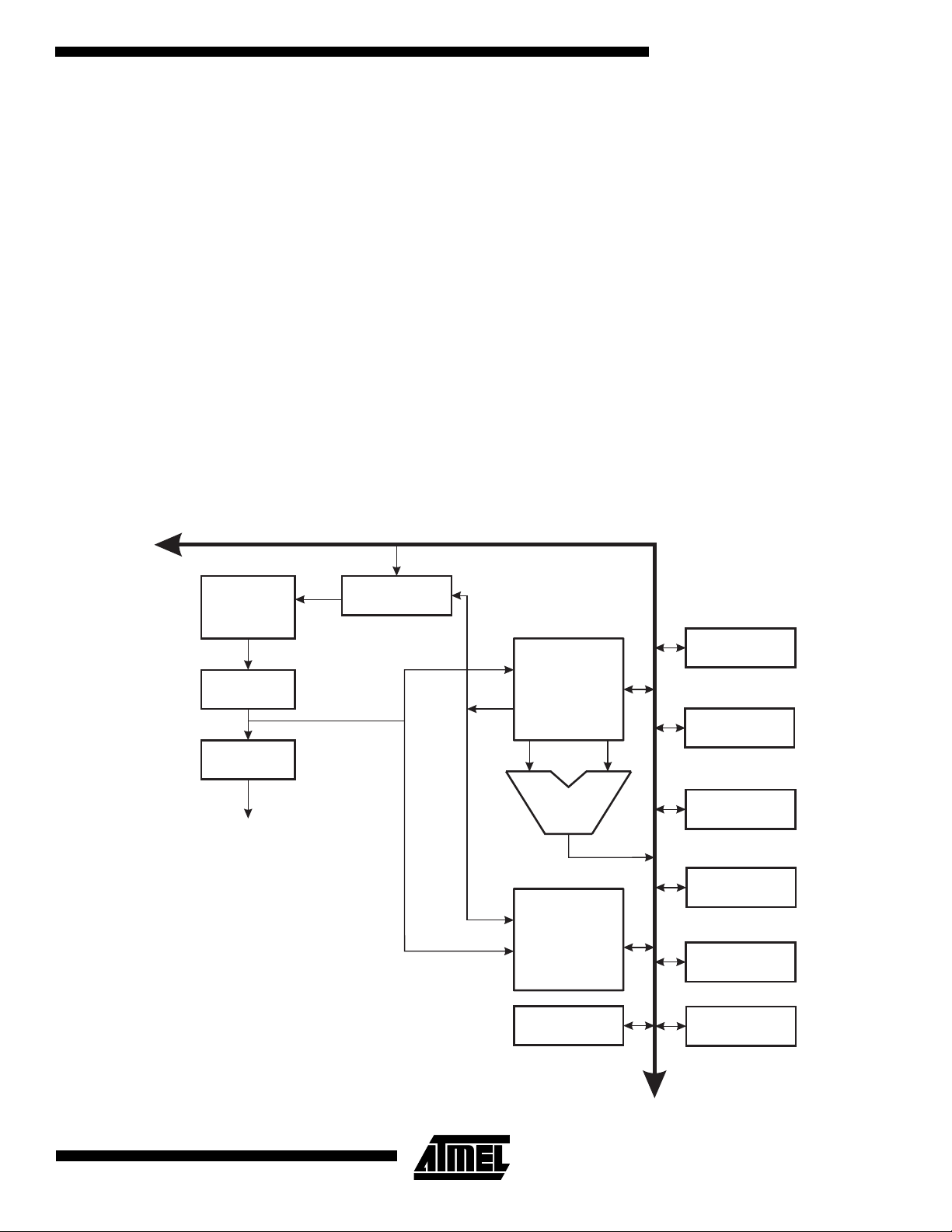

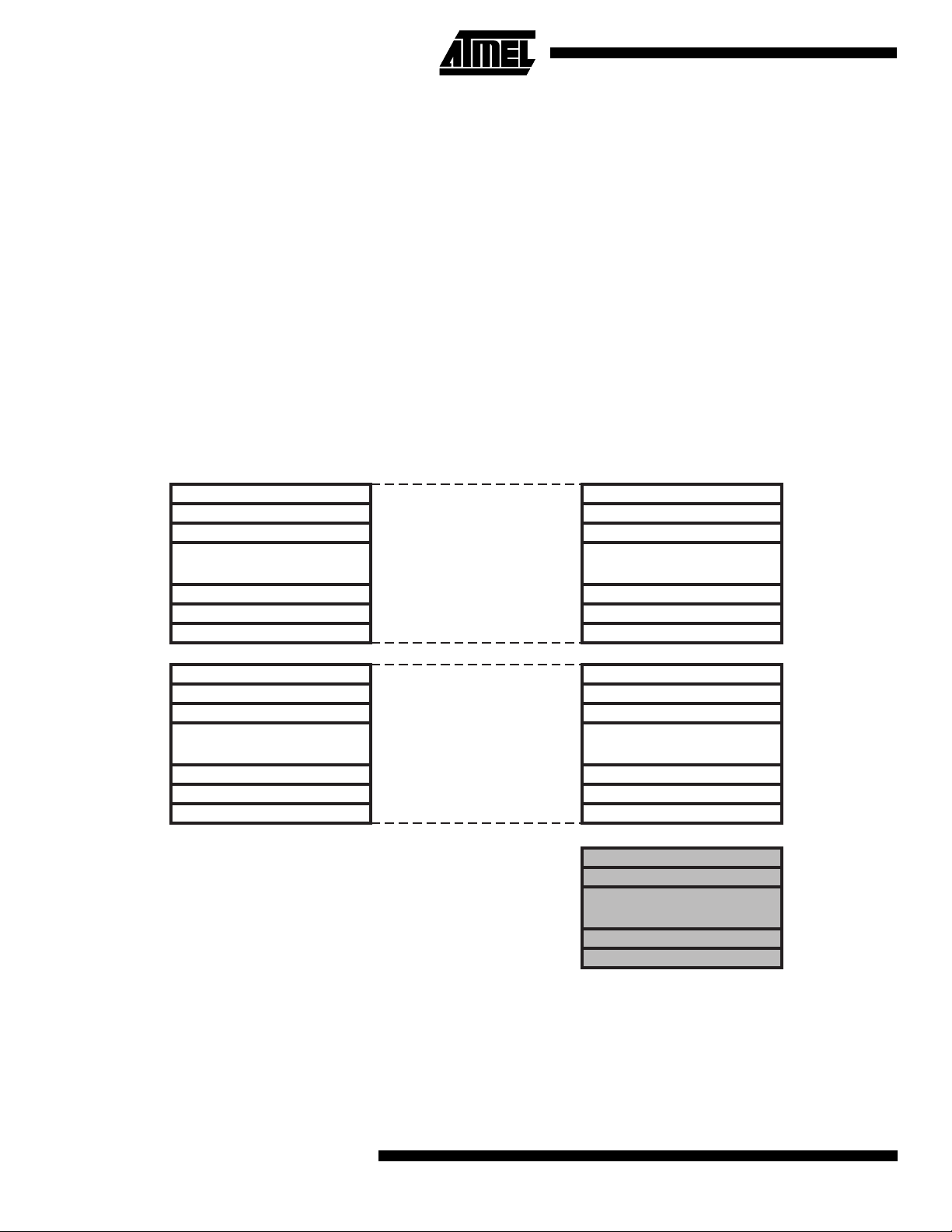

Architectural Overview

The fast-access register file concept contains 32 x 8-bit general-purpose working registers with a single clock cycle access

time. This means that during one single clock cycle, one ALU (Arithmetic Logic Unit) operation is executed. Two operands

are output from the register file, the operation is executed and the result is stored back in the register file – in one clock

cycle.

Six of the 32 registers can be used as three 16-bit indirect address register pointers for Data Space addressing, enabling

efficient address calculations. One of the three address pointers is also used as the address pointer for the constant table

look-up function. These added function registers are the 16-bit X-register, Y-register and Z-register.

The ALU supports arithmetic and logic functions between registers or between a constant and a register. Single register

operations are also executed in the ALU. Figure 4 shows the AT90C8534 AVR RISC microcontroller architecture.

In addition to the register operation, the conventional memory addressing modes can be used on the register file as well.

This is enabled by the fact that the register file is assigned the 32 lowermost Data Space addresses ($00 - $1F), allowing

them to be accessed as though they were ordinary memory locations.

4

AT90C8534

Page 5

AT90C8534

The I/O memory space contains 64 addresses for CPU peripheral functions such as Control Registers, Timer/Counters,

A/D converters and other I/O functions. The I/O memory can be accessed directly or as the Data Space locations

following those of the register file, $20 - $5F.

The AVR uses a Harvard architecture concept – with separate memories and buses for program and data. The program

memory is executed with a single-level pipelining. While one instruction is being executed, the next instruction is

pre-fetched from the program memory. This concept enables instructions to be executed in every clock cycle. The program

memory is programmable Flash memory.

With the relative jump and call instructions, the whole 4K word (8K bytes) address space is directly accessed. Most AVR

instructions have a single 16-bit word format. Every program memory address contains a 16- or 32-bit instruction.

During interrupts and subroutine calls, the return address program counter (PC) is stored on the stack. The stack is effectively allocated in the general data SRAM and, consequently, the stack size is only limited by the total SRAM size and the

usage of the SRAM. All user programs must initialize the stack pointer (SP) in the reset routine (before subroutines or

interrupts are executed). The 9-bit stack pointer is read/write accessible in the I/O space.

The 256 bytes data SRAM can be easily accessed through the five different addressing modes supported in the AVR

architecture.

The memory spaces in the AVR architecture are all linear and regular memory maps.

Figure 4. The AT90C8534 AVR RISC Architecture

AVR

4K X 16

Program

Memory

Instruction

Register

Instruction

Decoder

Control Lines

AT90C8534 Architecture

Program

Counter

32 x 8

General

Purpose

Registrers

Direct Addressing

Indirect Addressing

256 x 8

SRAM

Data Bus 8-bit

ALU

Data

Interrupt

Unit

Status

and Control

8-bit

Timer/Counter

16-bit

Timer/Counter

Analog to Digital

Converter

512 x 8

EEPROM

7

Output Lines

5

Page 6

Figure 5. Memory Maps

Data MemoryProgram Memory

Program Flash

(4K x 16)

$000

32 Gen. Purpose

Working Registers

64 I/O Registers

Internal SRAM

(256 x 8)

$0000

$001F

$0020

$005F

$0060

$015F

$FFF

A flexible interrupt module has its control registers in the I/O space with an additional global interrupt enable bit in the status

register. All the different interrupts have a separate interrupt vector in the interrupt vector table at the beginning of the

program memory. The different interrupts have priority in accordance with their interrupt vector position. The lower the

interrupt vector address, the higher the priority.

6

AT90C8534

Page 7

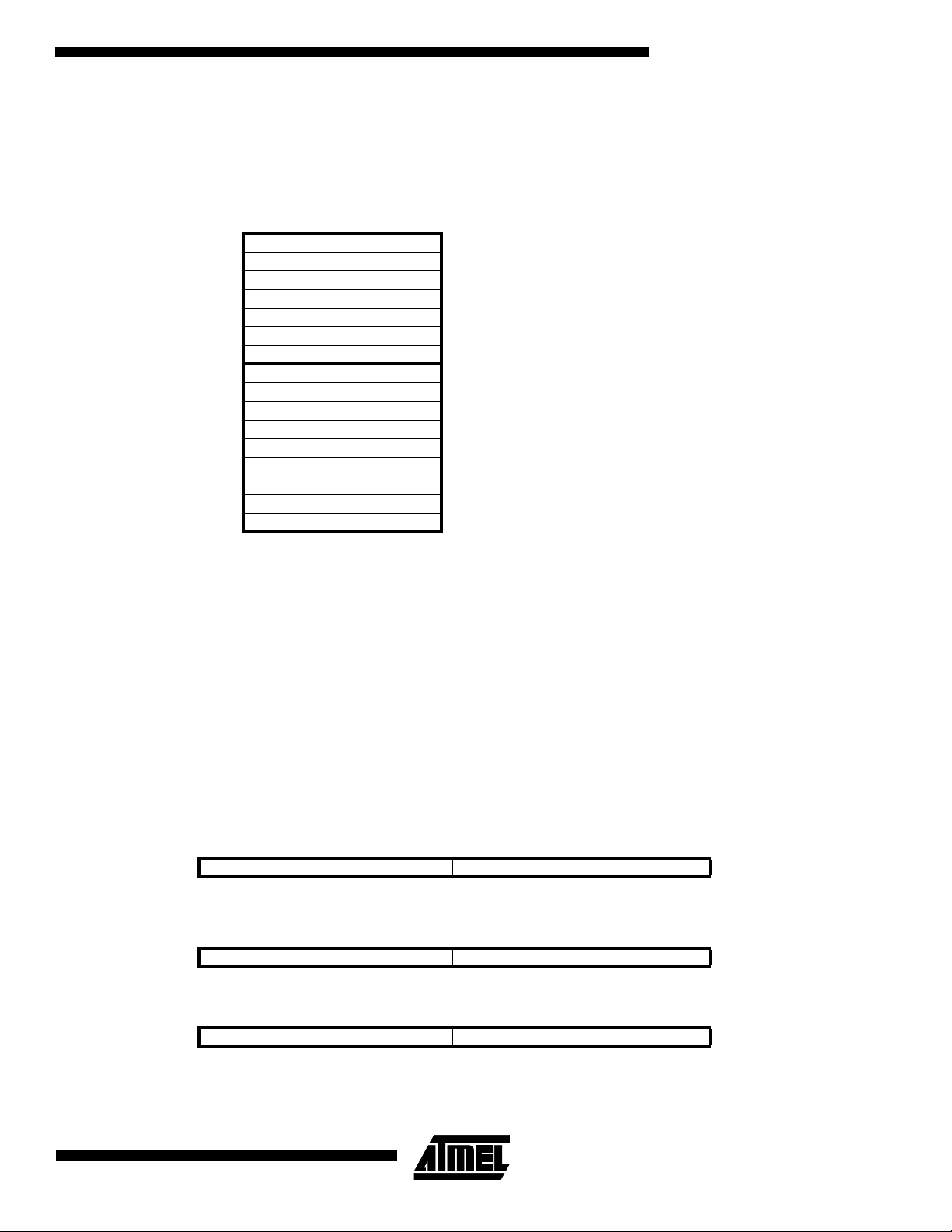

General-purpose Register File

Figure 6 shows the structure of the 32 general-purpose working registers in the CPU.

Figure 6. AVR CPU General-purpose Working Registers

70Addr.

R0 $00

R1 $01

R2 $02

…

R13 $0D

General R14 $0E

Purpose R15 $0F

Working R16 $10

Registers R17 $11

…

R26 $1A X-register low byte

R27 $1B X-register high byte

R28 $1C Y-register low byte

R29 $1D Y-register high byte

R30 $1E Z-register low byte

R31 $1F Z-register high byte

AT90C8534

All the register operating instructions in the instruction set have direct and single-cycle access to all registers. The only

exception are the five constant arithmetic and logic instructions SBCI, SUBI, CPI, ANDI and ORI between a constant and a

register and the LDI instruction for load immediate constant data. These instructions apply to the second half of the

registers in the register file – R16..R31. The general SBC, SUB, CP, AND and OR and all other operations between two

registers or on a single register apply to the entire register file.

As shown in Figure 6, each register is also assigned a data memory address, mapping them directly into the first 32 locations of the user Data Space. Although not being physically implemented as SRAM locations, this memory organization

provides great flexibility in access of the registers, as the X-, Y- and Z-registers can be set to index any register in the file.

X-register, Y-register and Z-register

The registers R26..R31 have some added functions to their general-purpose usage. These registers are address pointers

for indirect addressing of the Data Space. The three indirect address registers X, Y and Z are defined as:

Figure 7. X-, Y- and Z-registers

15 0

X-register 7 0 7 0

R27 ($1B) R26 ($1A)

15 0

Y-register 7 0 7 0

R29 ($1D) R28 ($1C)

15 0

Z-register 7 0 7 0

R31 ($1F) R30 ($1E)

In the different addressing modes these address registers have functions as fixed displacement, automatic increment and

decrement (see the descriptions for the different instructions).

7

Page 8

ALU – Arithmetic Logic Unit

The high-performance AVR ALU operates in direct connection with all the 32 general-purpose working registers. Within a

single clock cycle, ALU operations between registers in the register file are executed. The ALU operations are divided into

three main categories: arithmetic, logical and bit functions.

Programmable Flash Program Memory

The AT90C8534 contains 8K bytes of on-chip programmable Flash memory for program storage. Since all instructions are

16- or 32-bit words, the Flash is organized as 4K x 16. The Flash memory has an endurance of at least 1000 write/erase

cycles. The AT90C8534 program counter (PC) is 12 bits wide, thus addressing the 4096 program memory addresses.

Constant tables must be allocated within the address 0 - 4K (see the LPM – Load Program Memory instruction description).

See page 9 for the different program memory addressing modes.

SRAM Data Memory

The following figure shows how the AT90C8534 SRAM memory is organized.

Figure 8. SRAM Organization

Register File

R0

R1

R2

...

R29

R30

R31

I/O Registers

$00

$01

$02

...

$3D

$3E

$3F

Data Address Space

$0000

$0001

$0002

...

$001D

$001E

$001F

$0020

$0021

$0022

...

$005D

$005E

$005F

Internal SRAM

$0060

$0061

...

$015E

$015F

The lower 352 data memory locations address the register file, the I/O memory and the internal data SRAM. The first

96 locations address the register file + I/O memory, and the next 256 locations address the internal data SRAM.

The five different addressing modes for the data memory cover: Direct, Indirect with Displacement, Indirect, Indirect with

Pre-decrement and Indirect with Post-increment. In the register file, registers R26 to R31 feature the indirect addressing

pointer registers.

The direct addressing reaches the entire data space.

8

AT90C8534

Page 9

AT90C8534

The Indirect with Displacement mode features 63 address locations reached from the base address given by the Y- or

Z-register.

When using register indirect addressing modes with automatic pre-decrement and post-increment, the address registers X,

Y and Z are decremented and incremented.

The 32 general-purpose working registers, 64 I/O registers and the 256 bytes of internal data SRAM in the AT90C8534 are

all accessible through all these addressing modes.

See the next section for a detailed description of the different addressing modes.

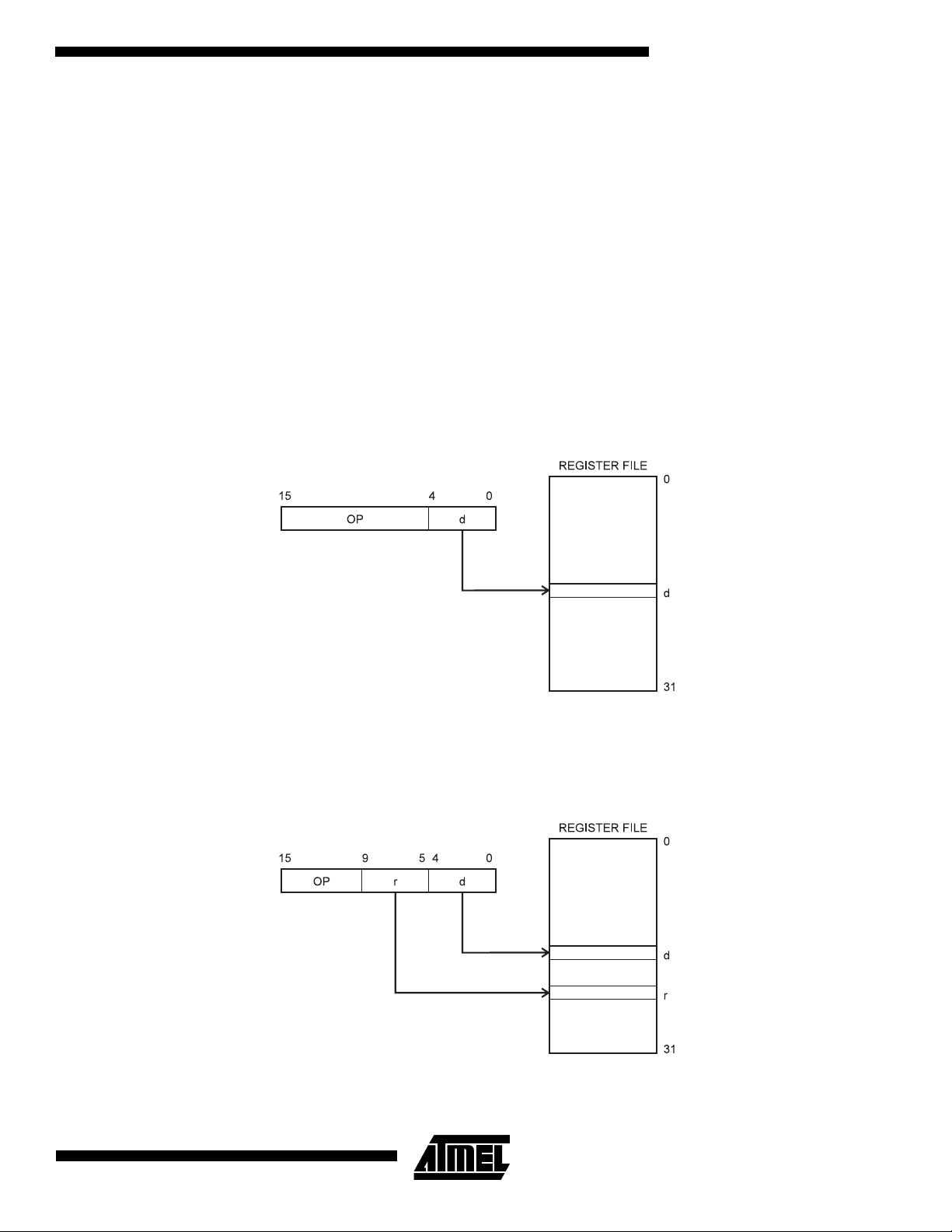

Program and Data Addressing Modes

The AT90C8534 AVR RISC microcontroller supports powerful and efficient addressing modes for access to the program

memory (Flash) and data memory (SRAM, Register file and I/O memory). This section describes the different addressing

modes supported by the AVR architecture. In the figures, OP means the operation code part of the instruction word. To

simplify, not all figures show the exact location of the addressing bits.

Register Direct, Single Register Rd

Figure 9. Direct Single Register Addressing

The operand is contained in register d (Rd).

Register Direct, Two Registers Rd And Rr

Figure 10. Direct Register Addressing, Two Registers

Operands are contained in register r (Rr) and d (Rd). The result is stored in register d (Rd).

9

Page 10

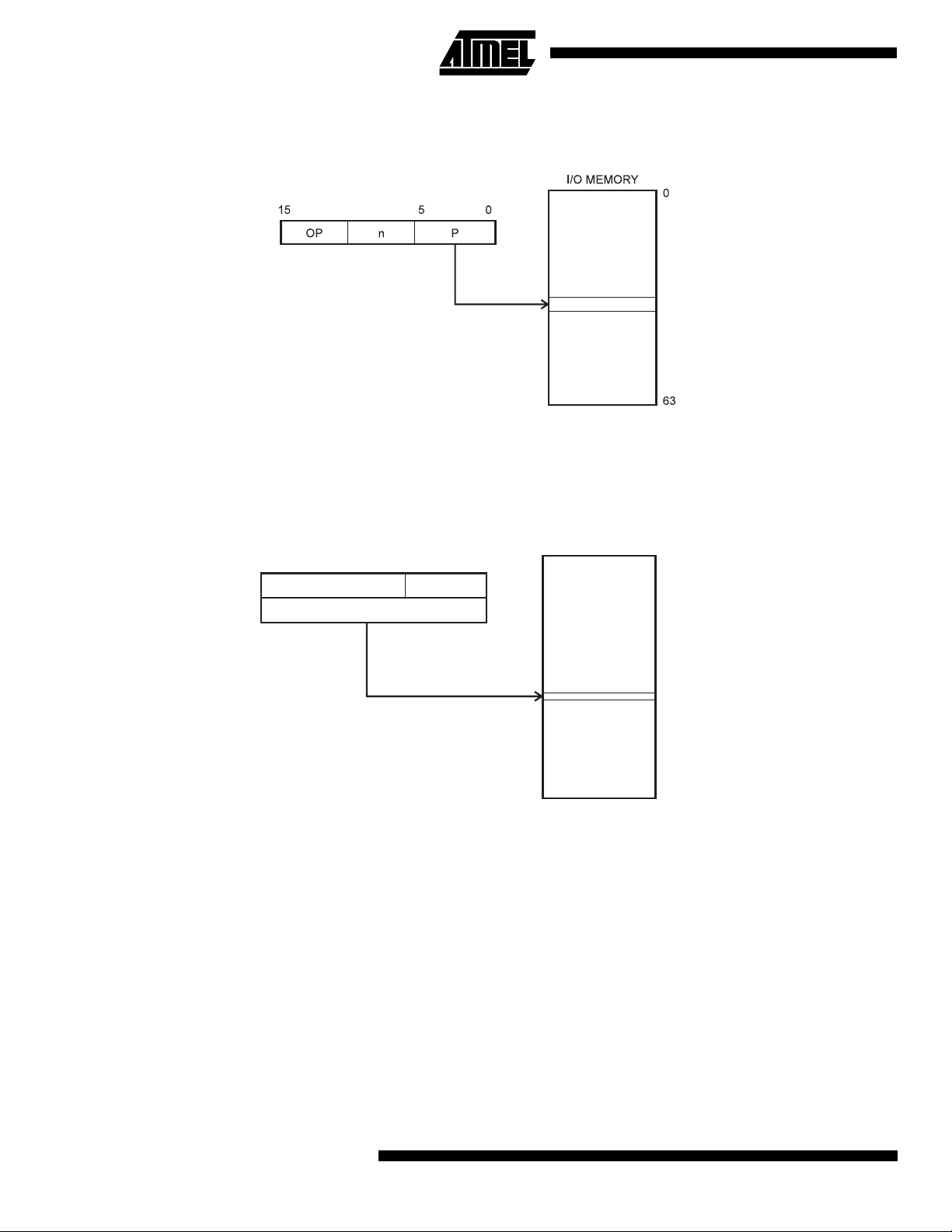

I/O Direct

Figure 11. I/O Direct Addressing

Operand address is contained in six bits of the instruction word. n is the destination or source register address.

Data Direct

Figure 12. Direct Data Addressing

Data Space

31

OP Rr/Rd

15 0

20 19

16 LSBs

16

$0000

$015F

A 16-bit data address is contained in the 16 LSBs of a 2-word instruction. Rd/Rr specify the destination or source register.

10

AT90C8534

Page 11

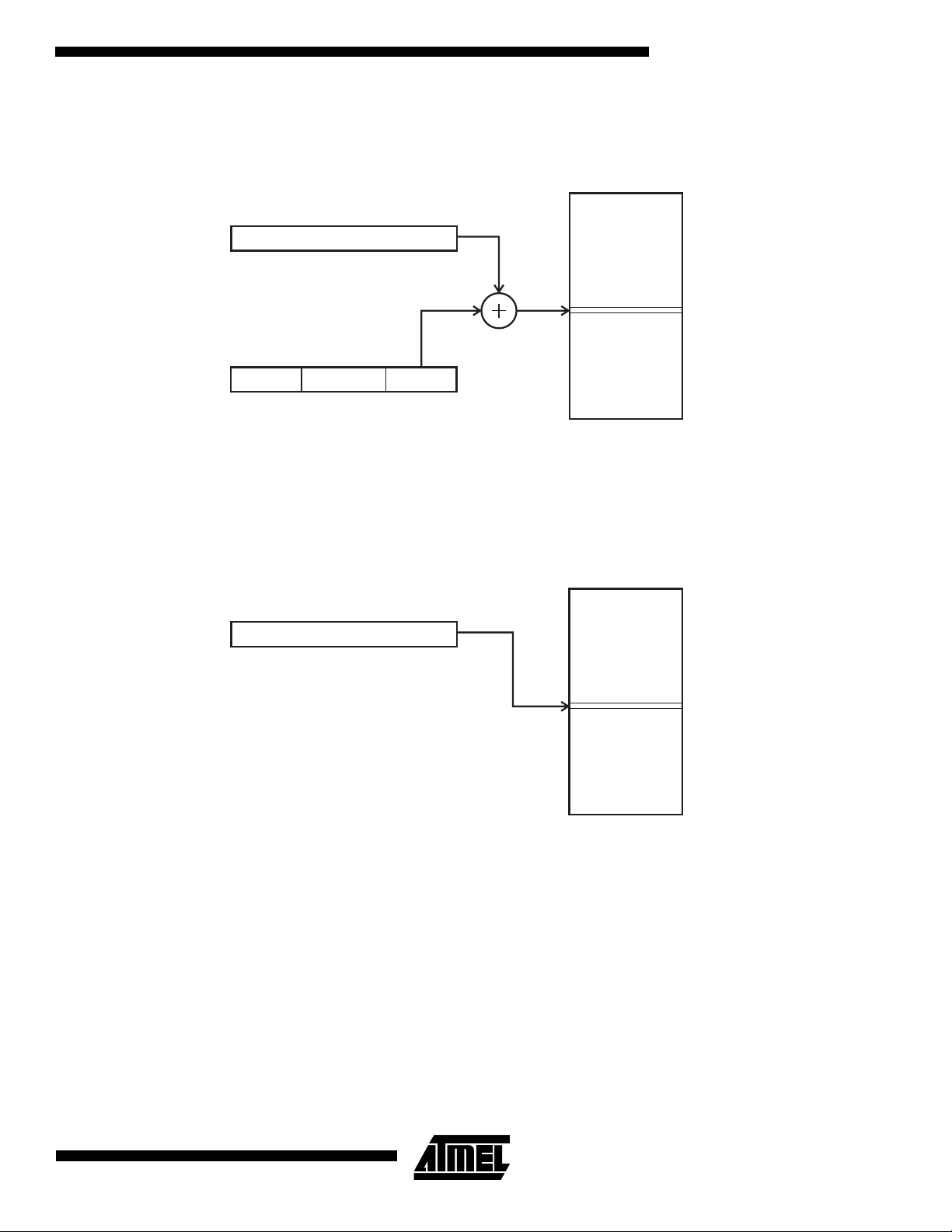

Data Indirect with Displacement

Figure 13. Data Indirect with Displacement

AT90C8534

15

Y OR Z - REGISTER

15

OP an

Data Space

0

05610

$0000

$015F

Operand address is the result of the Y- or Z-register contents added to the address contained in six bits of the instruction

word.

Data Indirect

Figure 14. Data Indirect Addressing

Data Space

015

X, Y OR Z - REGISTER

$0000

Operand address is the contents of the X-, Y- or the Z-register.

$015F

11

Page 12

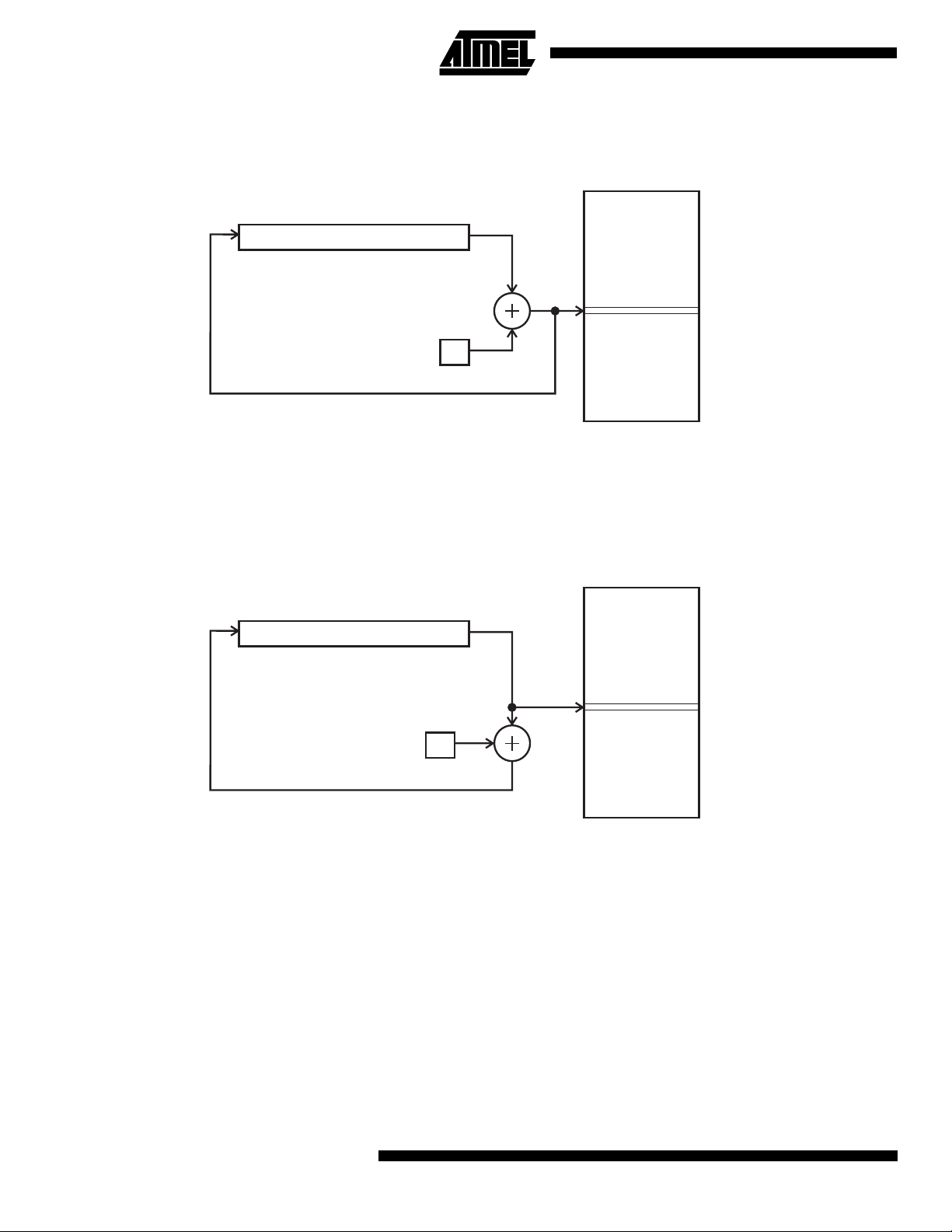

Data Indirect with Pre-decrement

Figure 15. Data Indirect Addressing with Pre-decrement

Data Space

015

X, Y OR Z - REGISTER

-1

$0000

$015F

The X-, Y- or the Z-register is decremented before the operation. Operand address is the decremented contents of the X-,

Y- or the Z-register.

Data Indirect with Post-increment

Figure 16. Data Indirect Addressing with Post-increment

Data Space

015

X, Y OR Z - REGISTER

$0000

1

$015F

The X-, Y- or the Z-register is incremented after the operation. Operand address is the content of the X-, Y- or the Z-register

prior to incrementing.

12

AT90C8534

Page 13

AT90C8534

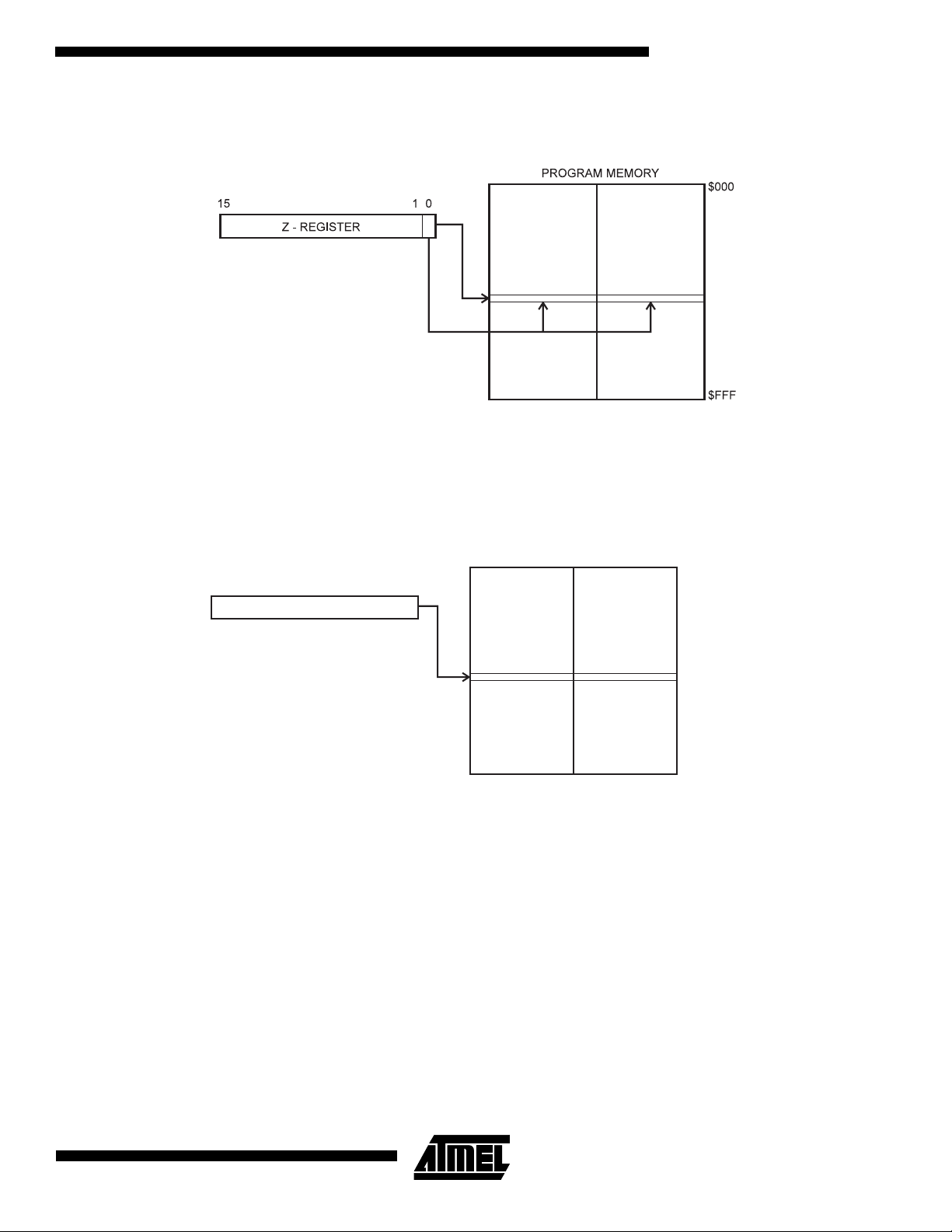

Constant Addressing Using the LPM Instruction

Figure 17. Code Memory Constant Addressing

Constant byte address is specified by the Z-register contents. The 15 MSBs select word address (0 - 4K), the LSB selects

low byte if cleared (LSB = 0) or high byte if set (LSB = 1).

Indirect Program Addressing, IJMP and ICALL

Figure 18. Indirect Program Memory Addressing

PROGRAM MEMORY

$000

15 0

Z-REGISTER

$7FF/$FFF

Program execution continues at address contained by the Z-register (i.e., the PC is loaded with the contents of the

Z-register).

13

Page 14

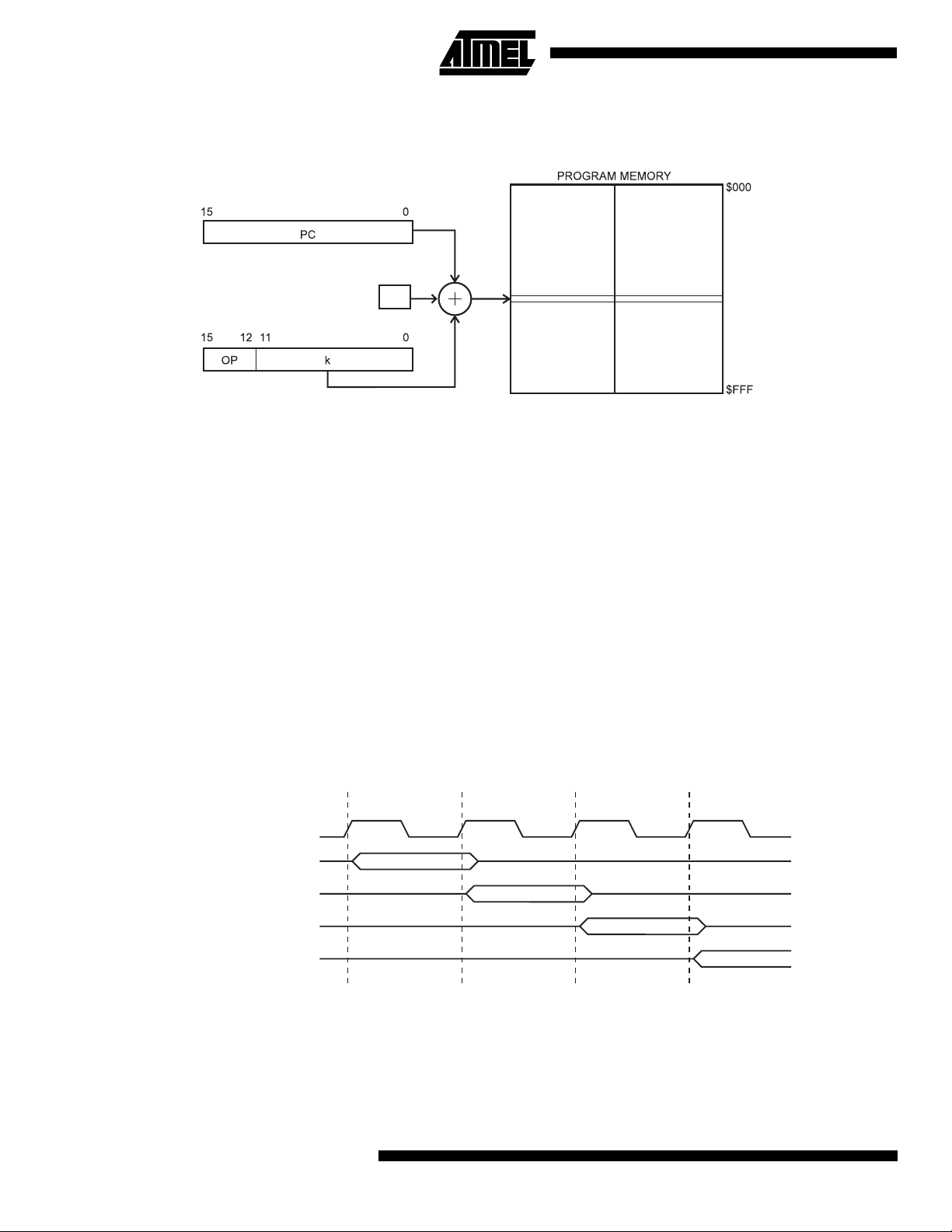

Relative Program Addressing, RJMP And RCALL

Figure 19. Relative Program Memory Addressing

+1

Program execution continues at address PC + k + 1. The relative address k is from -2048 to 2047.

EEPROM Data Memory

The AT90C8534 contains 512 bytes of data EEPROM memory. It is organized as a separate data space, in which single

bytes can be read and written. The EEPROM has an endurance of at least 100,000 write/erase cycles. The access

between the EEPROM and the CPU is described on page 28, specifying the EEPROM Address Registers, the EEPROM

Data Register, and the EEPROM Control Register.

Memory Access Times and Instruction Execution Timing

This section describes the general access timing concepts for instruction execution and internal memory access.

The AVR CPU is driven by the System Clock Ø, directly generated from the external clock crystal for the chip. No internal

clock division is used.

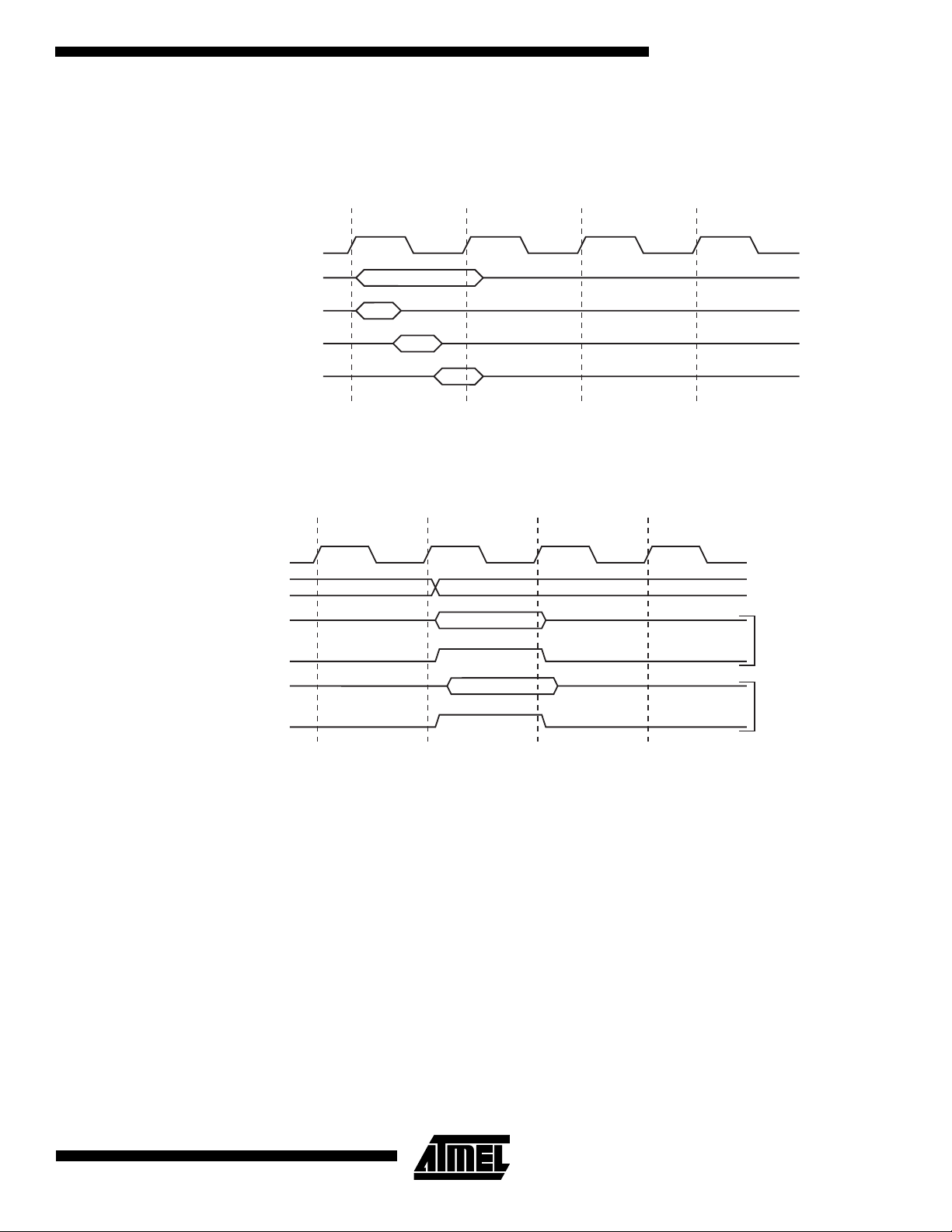

Figure 20 shows the parallel instruction fetches and instruction executions enabled by the Harvard architecture and the

fast-access register file concept. This is the basic pipelining concept to obtain up to 1 MIPS per MHz with the corresponding

unique results for functions per cost, functions per clocks and functions per power unit.

Figure 20. The Parallel Instruction Fetches and Instruction Executions

T1 T2 T3 T4

System Clock Ø

1st Instruction Fetch

1st Instruction Execute

2nd Instruction Fetch

2nd Instruction Execute

3rd Instruction Fetch

3rd Instruction Execute

4th Instruction Fetch

14

AT90C8534

Page 15

AT90C8534

Figure 21 shows the internal timing concept for the register file. In a single clock cycle an ALU operation using two register

operands is executed and the result is stored back to the destination register.

Figure 21. Single Cycle ALU Operation

T1 T2 T3 T4

System Clock Ø

Total Execution Time

Register Operands Fetch

ALU Operation Execute

Result Write Back

The internal data SRAM access is performed in two System Clock cycles as described in Figure 22.

Figure 22. On-Chip Data SRAM Access Cycles

T1 T2 T3 T4

System Clock Ø

Address

Data

WR

Data

RD

Prev. Address

Address

Write

Read

15

Page 16

I/O Memory

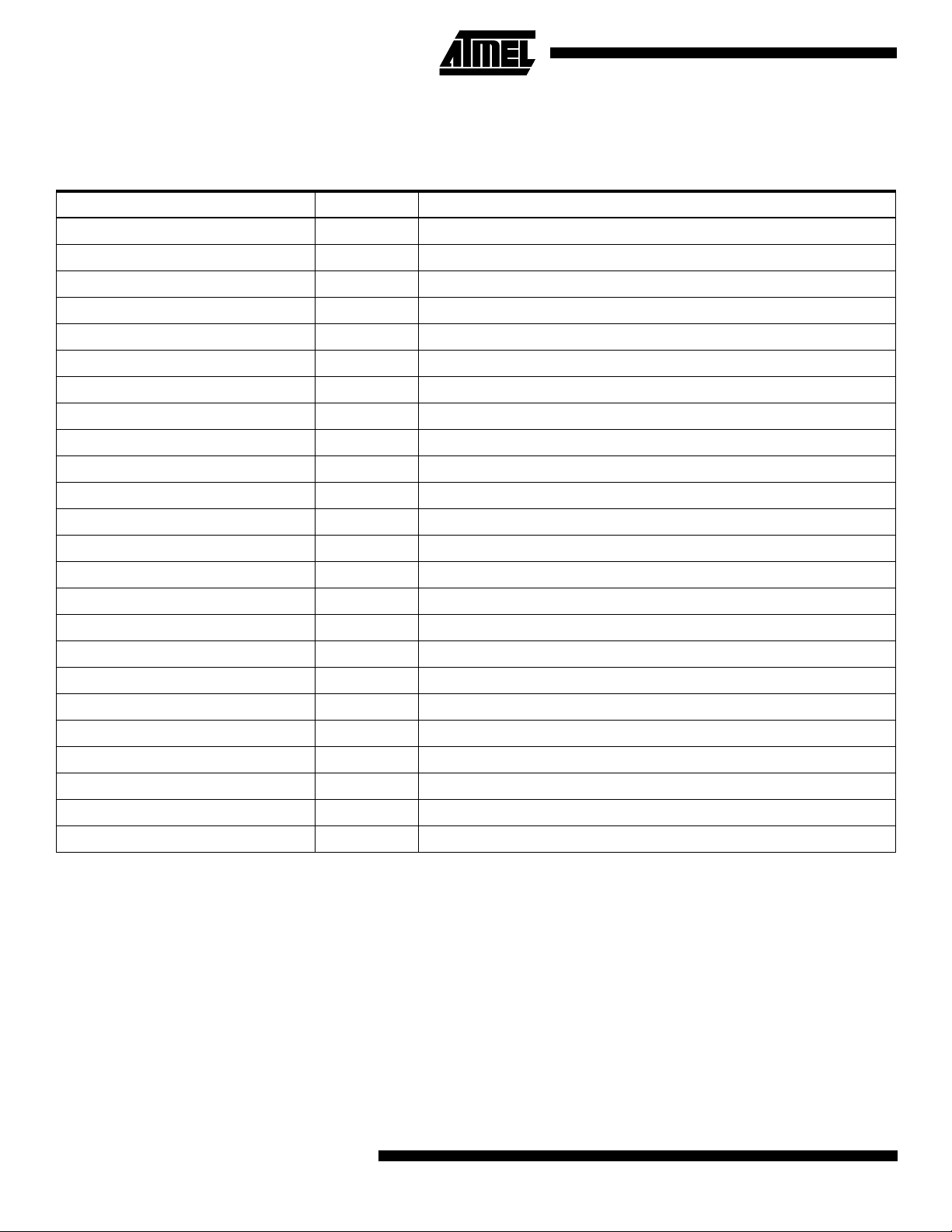

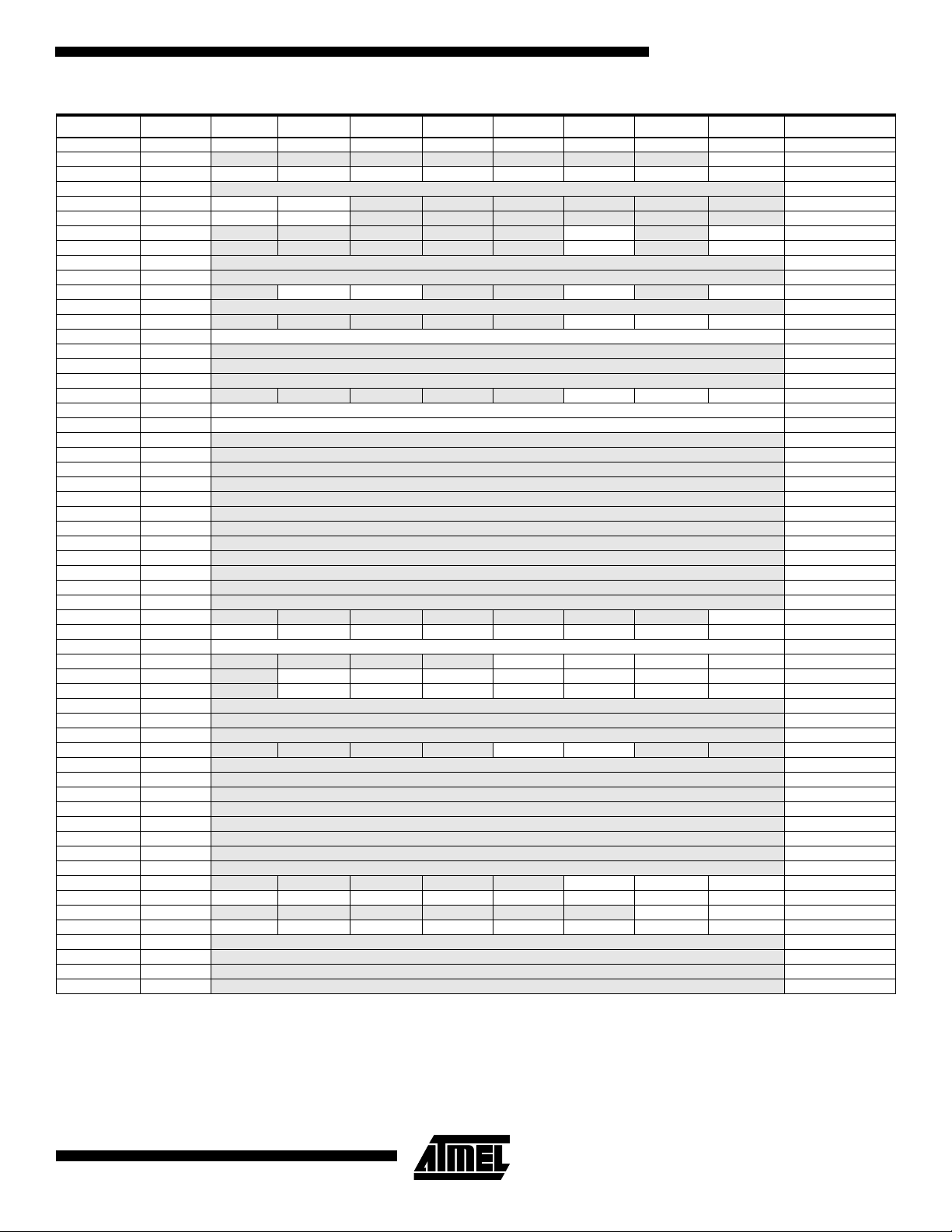

The I/O space definition of the AT90C8534 is shown in Table 1.

Table 1. AT90C8534 I/O Space

I/O Address (SRAM Address) Name Function

$3F ($5F) SREG Status REGister

$3E ($5E) SPH Stack Pointer High

$3D ($5D) SPL Stack Pointer Low

$3B ($5B) GIMSK General Interrupt MaSK register

$3A ($5A) GIFR General Interrupt Flag Register

$39 ($59) TIMSK Timer/Counter Interrupt MaSK register

$38 ($58) TIFR Timer/Counter Interrupt Flag register

$35 ($55) MCUCR MCU general Control Register

$33 ($53) TCCR0 Timer/Counter0 Control Register

$32 ($52) TCNT0 Timer/Counter0 (8-bit)

$2E ($4E) TCCR1 Timer/Counter1 Control Register

$2D ($4D) TCNT1H Timer/Counter1 High Byte

$2C ($4C) TCNT1L Timer/Counter1 Low Byte

$1F ($3E) EEARH EEPROM Address Register High Byte

$1E ($3E) EEARL EEPROM Address Register Low Byte

$1D ($3D) EEDR EEPROM Data Register

$1C ($3C) EECR EEPROM Control Register

$1B ($3B) PORTA Data Register, Port A

$1A ($3A) DDRA Data Direction Register, Port A

$10 ($30) GIPR General Interrupt Pin Register

$07 ($27) ADMUX ADC Multiplexer Select Register

$06 ($26) ADCSR ADC Control and Status Register

$05 ($25) ADCH ADC Data Register High

$04 ($24) ADCL ADC Data Register Low

Note: Reserved and unused locations are not shown in the table.

The AT90C8534 I/Os and peripherals are placed in the I/O space. The I/O locations are accessed by the IN and OUT

instructions transferring data between the 32 general-purpose working registers and the I/O space. I/O registers within the

address range $00 - $1F are directly bit-accessible using the SBI and CBI instructions. In these registers, the value of

single bits can be checked by using the SBIS and SBIC instructions. Refer to the instruction set section for more details.

When using the I/O specific commands, IN and OUT, the I/O addresses $00 - $3F must be used. When addressing I/O registers as SRAM, $20 must be added to this address. All I/O register addresses throughout this document are shown with

the SRAM address in parentheses.

For compatibility with future devices, reserved bits should be written to zero if accessed. Reserved I/O memory addresses

should never be written.

The I/O and peripherals control registers are explained in the following sections.

16

AT90C8534

Page 17

AT90C8534

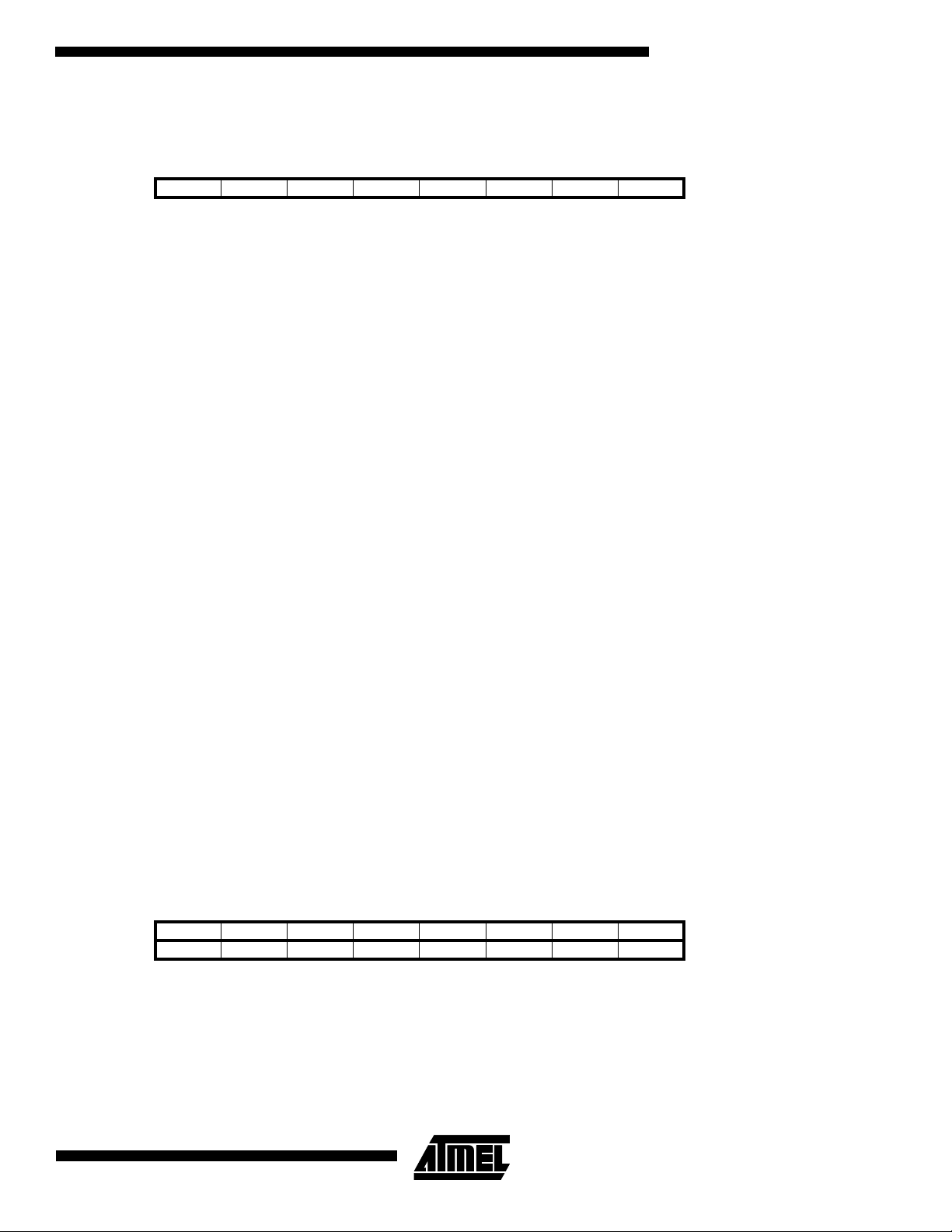

Status Register – SREG

The AVR status register (SREG) at I/O space location $3F ($5F) is defined as:

Bit 76543210

$3F ($5F) I T H S V N Z C SREG

Read/Write R/W R/W R/W R/W R/W R/W R/W R/W

Initial value 0 0 0 0 0 0 0 0

Bit 7 – I: Global Interrupt Enable

•

The global interrupt enable bit must be set (one) for the interrupts to be enabled. The individual interrupt enable control is

then performed in separate control registers. If the global interrupt enable bit is cleared (zero), none of the interrupts are

enabled independent of the individual interrupt enable settings. The I-bit is cleared by hardware when an interrupt routine is

entered and is set by the RETI instruction to enable subsequent interrupts.

Bit 6 – T: Bit Copy Storage

•

The bit copy instructions BLD (Bit LoaD) and BST (Bit STore) use the T-bit as source and destination for the operated bit. A

bit from a register in the register file can be copied into T by the BST instruction and a bit in T can be copied into a bit in a

register in the register file by the BLD instruction.

Bit 5 – H: Half-carry Flag

•

The half-carry flag H indicates a half-carry in some arithmetical operations. See the Instruction Set description for detailed

information.

Bit 4 – S: Sign Bit, S = N⊄⊕ V

•

The S-bit is always an exclusive or between the negative flag N and the two’s complement overflow flag V. See the Instruction Set description for detailed information.

•

Bit 3 – V: Two’s Complement Overflow Flag

The two’s complement overflow flag V supports two’s complement arithmetics. See the Instruction Set description for

detailed information.

Bit 2 – N: Negative Flag

•

The negative flag N indicates a negative result from an arithmetical or logical operations. See the Instruction Set description for detailed information.

Bit 1 – Z: Zero Flag

•

The zero flag Z indicates a zero result from an arithmetical or logical operations. See the Instruction Set description for

detailed information.

•

Bit 0 – C: Carry Flag

The carry flag C indicates a carry in an arithmetical or logic operation. See the Instruction Set description for detailed

information.

Note that the status register is not automatically stored when entering an interrupt routine or restored when returning from

an interrupt routine. This must be handled by software.

Stack Pointer – SP

The AT90C8534 Stack Pointer is implemented as two 8-bit registers in the I/O space locations $3E ($5E) and $3D ($5D).

As the AT90C8534 data memory has $15F locations, nine bits are used.

Bit 151413121110 9 8

$3E ($5E) –––––––SP8 SPH

$3D ($5D) SP7 SP6 SP5 SP4 SP3 SP2 SP1 SP0 SPL

76543210

Read/Write RRRRRRRR/W

R/W R/W R/W R/W R/W R/W R/W R/W

Initial value 0 0 0 0 0 0 0 0

00000000

The Stack Pointer points to the data SRAM stack area where the Subroutine and Interrupt Stacks are located. This stack

space in the data SRAM must be defined by the program before any subroutine calls are executed or interrupts are

enabled. The Stack Pointer is decremented by 1 when data is pushed onto the stack with the PUSH instruction and it is

17

Page 18

decremented by 2 when data is pushed onto the stack with subroutine RCALL and interrupt. The Stack Pointer is incremented by 1 when data is popped from the stack with the POP instruction and it is incremented by 2 when data is popped

from the stack with return from subroutine RET or return from interrupt RETI.

Reset and Interrupt Handling

The AT90C8534 provides six different interrupt sources. These interrupts and the separate reset vector each have a

separate program vector in the program memory space. All interrupts are assigned individual enable bits that must be set

(one) together with the I-bit in the status register in order to enable the interrupt.

The lowest addresses in the program memory space are automatically defined as the Reset and Interrupt vectors. The

complete list of vectors is shown in Table 2. The list also determines the priority levels of the different interrupts. The lower

the address, the higher the priority level. RESET has the highest priority and next is INT0 (the External Interrupt Request

0), etc.

Table 2. Reset and Interrupt Vectors

Vector No. Program Address Source Interrupt Definition

1 $000 RESET Hardware Pin

2 $001 INT0 External Interrupt Request 0

3 $002 INT1 External Interrupt Request 1

4 $003 TIMER1 OVF Timer/Counter1 Overflow

5 $004 TIMER0 OVF Timer/Counter0 Overflow

6 $005 ADC ADC Conversion Complete

7 $006 EE_RDY EEPROM Ready

The most typical program setup for the Reset and Interrupt vector addresses are:

Address Labels Code Comments

$000 rjmp RESET ; Reset Handler

$001 rjmp EXT_INT0 ; IRQ0 Handler

$002 rjmp EXT_INT1 ; IRQ1 Handler

$003 rjmp TIM1_OVF ; Timer1 Overflow Handler

$004 rjmp TIM0_OVF ; Timer0 Overflow Handler

$005 rjmp ADC ; ADC Conversion Complete Interrupt Handler

$006 rjmp EE_RDY ; EEPROM Ready Handler

;

$007 MAIN: ldi r16, high(RAMEND); Main program start

out SPH, r16

ldi r16, low(RAMEND)

out SPL, r16

<instr> xxx

…………

18

AT90C8534

Page 19

AT90C8534

Reset

During reset, all I/O registers are set to their initial values and the program counter is set to address $000. When reset is

released, the program starts execution from this address. The instruction placed in address $000 must be an RJMP (relative jump) instruction to the reset handling routine. If the program never enables an interrupt source, the interrupt vectors

are not used and regular program code can be placed at these locations. The circuit diagram in Figure 23 shows the reset

logic. Table 3 defines the timing and electrical parameters of the reset circuitry

Figure 23. Reset Logic

CLOCK

Table 3. Reset Characteristics (V

Symbol Parameter Min Typ Max Units

V

RST

t

TOUT

RESET Pin Threshold Voltage 0.6 V

Reset Delay Time-out Period - 1026 - clocks

= 5.0V)

CC

CC

V

External reset

The AT90C8534 has one source of reset: the external reset pin. The external reset is used for three purposes:

1. Power-on Reset. During power-on, the external reset must be held active (low) until 100 ns after V

has reached

CC

the minimum operation voltage.

2. Brown-out Reset. If V

active immediately, and must be held active until 100 ns after V

drops below the minimum operation voltage during operation, the external reset must go

CC

rises to the minimum operation voltage.

CC

3. Normal Operation Reset. During normal operation, reset is generated by holding the external reset active for at

least 100 ns.

When the external reset is released, an internal timer that is clocked from the external clock input is started, holding the

internal reset active until the external clock source has toggled a certain number of times (see Table 3). This is illustrated in

Figure 24 and Figure 25.

19

Page 20

Figure 24. External Reset on Start-up

V

VCC

RESET

TIME-OUT

INTERNAL

RESET

POT

Figure 25. External Reset during Operation

V

RST

t

TOUT

Interrupt Handling

The AT90C8534 has two 8-bit Interrupt Mask control registers; GIMSK (General Interrupt Mask register) and TIMSK

(Timer/Counter Interrupt Mask register).

When an interrupt occurs, the Global Interrupt Enable I-bit is cleared (zero) and all interrupts are disabled. The user software can set (one) the I-bit to enable nested interrupts. The I-bit is set (one) when a Return from Interrupt instruction (RETI)

is executed.

When the Program Counter is vectored to the actual interrupt vector in order to execute the interrupt handling routine, hardware clears the corresponding flag that generated the interrupt. Some of the interrupt flags can also be cleared by writing a

logical “1” to the flag bit position(s) to be cleared.

If an interrupt condition occurs when the corresponding interrupt enable bit is cleared (zero), the interrupt flag will be set

and remembered until the interrupt is enabled or the flag is cleared by software.

If one or more interrupt conditions occur when the global interrupt enable bit is cleared (zero), the corresponding interrupt

flag(s) will be set and remembered until the global interrupt enable bit is set (one), and will be executed by order of priority.

Note that the status register is not automatically stored when entering an interrupt routine and restored when returning from

an interrupt routine. This must be handled by software.

20

AT90C8534

Page 21

AT90C8534

General Interrupt Mask Register – GIMSK

Bit 76543210

$3B ($5B) INT1 INT0 ––––––GIMSK

Read/Write R/W R/W R R R R R R

Initial value 00000000

Bit 7 – INT1: External Interrupt Request 1 Enable

•

When the INT1 bit is set (one) and the I-bit in the Status Register (SREG) is set (one), the external pin interrupt is enabled.

The external interrupt is activated on falling or rising edge of the INT1 pin. The corresponding interrupt of External Interrupt

Request 1 is executed from program memory address $002. See also “External Interrupts”.

Bit 6 – INT0: External Interrupt Request 0 Enable

•

When the INT0 bit is set (one) and the I-bit in the Status Register (SREG) is set (one), the external pin interrupt is enabled.

The external interrupt is activated on falling or rising edge of the INT0 pin. The corresponding interrupt of External Interrupt

Request 0 is executed from program memory address $001. See also “External Interrupts”.

Bits 5..0 – Res: Reserved Bits

•

These bits are reserved bits in the AT90C8534 and always read as zero.

General Interrupt Flag Register – GIFR

Bit 76543 210

$3A ($5A) INTF1 INTF0 ––––––GIFR

Read/Write R/W R/W R R R R R R

Initial value 00000000

Bit 7 – INTF1: External Interrupt Flag 1

•

When an event on the INT1 pin triggers an interrupt request, INTF1 becomes set (one). If the I-bit in SREG and the INT1 bit

in GIMSK are set (one), the MCU will jump to the interrupt vector at address $002. The flag is cleared when fetching the

interrupt vector. Alternatively, the flag can be cleared by writing a logical “1” to it.

Bit 6 – INTF0: External Interrupt Flag 0

•

When an event on the INT0 pin triggers an interrupt request, INTF0 becomes set (one). If the I-bit in SREG and the INT0 bit

in GIMSK are set (one), the MCU will jump to the interrupt vector at address $001. The flag is cleared when fetching the

interrupt vector. Alternatively, the flag can be cleared by writing a logical “1” to it.

Bits 5..0 – Res: Reserved Bits

•

These bits are reserved bits in the AT90C8534 and always read as zero.

General Interrupt Pin Register – GIPR

Bit 76543210

$10 ($30) ––––IPIN1 IPIN0 ––GIPR

Read/Write RRRRRRRR

Initial value 0 0 0 0 x x 0 0

Bits 7..4 – Res: Reserved Bits

•

These bits are reserved bits in the AT90C8534 and always read as zero.

•

Bit 3 – IPIN1: External Interrupt Pin 1

Reading this bit returns the logical value present on input pin INT1 (after synchronization latches).

Bit 2 – IPIN0: External Interrupt Pin 0

•

Reading this bit returns the logical value present on input pin INT0 (after synchronization latches).

Bits 1..0 – Res: Reserved Bits

•

These bits are reserved bits in the AT90C8534 and always read as zero.

21

Page 22

Timer/Counter Interrupt Mask Register – TIMSK

Bit 76543210

$39 ($59) –––––TOIE1 – TOIE0 TIMSK

Read/Write RRRRRR/WRR/W

Initial value 00000000

Bits 7..3 – Res: Reserved Bits

•

These bits are reserved bits in the AT90C8534 and always read as zero.

•

Bit 2 – TOIE1: Timer/Counter1 Overflow Interrupt Enable

When the TOIE1 bit is set (one) and the I-bit in the Status Register is set (one), the Timer/Counter1 Overflow interrupt is

enabled. The corresponding interrupt (at vector $003) is executed if an overflow in Timer/Counter1 occurs, i.e., when the

Overflow Flag (Timer/Counter1) is set (one) in the Timer/Counter Interrupt Flag Register (TIFR).

Bit 1 – Res: Reserved Bit

•

This bit is a reserved bit in the AT90C8534 and always reads as zero.

•

Bit 0 – TOIE0: Timer/Counter0 Overflow Interrupt Enable

When the TOIE0 bit is set (one) and the I-bit in the Status Register is set (one), the Timer/Counter0 Overflow interrupt is

enabled. The corresponding interrupt (at vector $004) is executed if an overflow in Timer/Counter0 occurs, i.e., when the

Overflow Flag (Timer0) is set (one) in the Timer/Counter Interrupt Flag Register (TIFR).

Timer/Counter Interrupt Flag Register – TIFR

Bit 76543210

$38 ($58) –––––TOV1 – TOV0 TIFR

Read/Write RRRRRR/WRR/W

Initial value 00000000

Bits 7..3 – Res: Reserved Bits

•

These bits are reserved bits in the AT90C8534 and always read as zero.

Bit 2 – TOV1: Timer/Counter1 Overflow Flag

•

The TOV1 is set (one) when an overflow occurs in Timer/Counter1. TOV1 is cleared when fetching the interrupt vector.

Alternatively, TOV1 is cleared by writing a logical “1” to the flag. When the I-bit in SREG and TOIE1 (Timer/Counter1

Overflow Interrupt Enable) and TOV1 are set (one), the Timer/Counter1 Overflow Interrupt is executed.

Bit 1 – Res: Reserved Bit

•

This bit is a reserved bit in the AT90C8534 and always reads as zero.

•

Bit 0 – TOV0: Timer/Counter0 Overflow Flag

The bit TOV0 is set (one) when an overflow occurs in Timer/Counter0. TOV0 is cleared when fetching the interrupt vector.

Alternatively, TOV0 is cleared by writing a logical “1” to the flag. When the SREG I-bit and TOIE0 (Timer/Counter0 Overflow Interrupt Enable) and TOV0 are set (one), the Timer/Counter0 Overflow interrupt is executed.

External Interrupts

The external interrupts are triggered by the INT1 and INT0 pins. The external interrupts can be triggered by a falling or

rising edge.

Interrupt Response Time

The interrupt execution response for all the enabled AVR interrupts is four clock cycles minimum. Four clock cycles after

the interrupt flag has been set, the program vector address for the actual interrupt handling routine is executed. During this

4-clock-cycle period, the Program Counter (2 bytes) is pushed onto the stack and the Stack Pointer is decremented by 2.

The vector is normally a relative jump to the interrupt routine, and this jump takes two clock cycles. If an interrupt occurs

during execution of a multi-cycle instruction, this instruction is completed before the interrupt is served.

A return from an interrupt handling routine (same as for a subroutine call routine) takes four clock cycles. During these four

clock cycles, the Program Counter (2 bytes) is popped back from the stack, the Stack Pointer is incremented by 2 and the

I-flag in SREG is set. When the AVR exits from an interrupt, it will always return to the main program and execute one more

instruction before any pending interrupt is served.

22

AT90C8534

Page 23

AT90C8534

MCU Control Register – MCUCR

The MCU Control Register contains control bits for general MCU functions.

Bit 76543210

$35 ($55) – SE SM ––ISC1 – ISC0 MCUCR

Read/Write R R/W R/W R R R/W R R/W

Initial value 0 0 0 0 0 0 0 0

Bit 7 – Res: Reserved Bit

•

This bit is reserved bits in the AT90C8534 and always reads as zero.

•

Bit 6 – SE: Sleep Enable

The SE bit must be set (one) to make the MCU enter the sleep mode when the SLEEP instruction is executed. To avoid the

MCU entering the sleep mode, unless it is the programmer’s purpose, it is recommended to set the Sleep Enable (SE) bit

just before the execution of the SLEEP instruction.

Bit 5 – SM: Sleep Mode

•

This bit selects between the two available sleep modes. When SM is cleared (zero), Idle Mode is selected as Sleep Mode.

When SM is set (one), Power-down Mode is selected as Sleep Mode. For details, refer to the section “Sleep Modes”.

Bit 4..3 – Res: Reserved Bits

•

These bits are reserved bits in the AT90C8534 and always read as zero.

•

Bit 2 – ISC1: Interrupt Sense Control 1

The external interrupt 1 is activated by the external pin INT1 if the SREG I-flag and the corresponding interrupt mask in the

GIMSK are set. If ISC1 is cleared (zero) a falling edge on INT1 activates the interrupt. If ISC1 is set (one), a rising edge on

INT1 activates the interrupt. Edges on INT2 are registered asynchronously. Pulses on INT1 wider than 40 ns will generate

an interrupt. Shorter pulses are not guaranteed to generate an interrupt.

When changing the ISC1 bit, an interrupt can occur. Therefore, it is recommended to first disable INT1 by clearing its interrupt Enable bit in the GIMSK register. Then ISC1 bit can be changed. Finally, the INT1 interrupt flag should be cleared by

writing a logical “1” to its interrupt Flag bit in the GIFR register before the interrupt is re-enabled.

Bit 1 – Res: Reserved Bit

•

This bit is reserved bits in the AT90C8534 and always reads as zero.

Bit 0 – ISC0: Interrupt Sense Control 0

•

The external interrupt 0 is activated by the external pin INT0 if the SREG I-flag and the corresponding interrupt mask in the

GIMSK are set. If ISC0 is cleared (zero), a falling edge on INT0 activates the interrupt. If ISC0 is set (one), a rising edge on

INT0 activates the interrupt. Pulses on INT0 wider than 40 ns will generate an interrupt. Shorter pulses are not guaranteed

to generate an interrupt.

When changing the ISC0 bit, an interrupt can occur. Therefore, it is recommended to first disable INT0 by clearing its interrupt Enable bit in the GIMSK register. Then ISC0 bit can be changed. Finally, the INT0 interrupt flag should be cleared by

writing a logical “1” to its interrupt Flag bit in the GIFR register before the interrupt is re-enabled.

Sleep Modes

To enter any of the two sleep modes, the SE bit in MCUCR must be set (one) and a SLEEP instruction must be executed.

The SM bit in the MCUCR register selects which sleep mode, Idle or Power-down, is activated by the SLEEP instruction.

If an enabled interrupt occurs while the MCU is in a sleep mode, the MCU awakes. The CPU is then halted for four cycles,

executes the interrupt routine and resumes execution from the instruction following SLEEP. The contents of the register

file, SRAM and I/O memory are unaltered. If a reset occurs during sleep mode, the MCU wakes up and executes from the

Reset vector.

Idle Mode

When the SM bit is cleared (zero), the SLEEP instruction forces the MCU into the Idle Mode, stopping the CPU but allowing

Timer/Counters, ADC and the interrupt system to continue operating. This enables the MCU to wake up from external

triggered interrupts as well as internal ones like the Timer Overflow and ADC interrupts.

23

Page 24

Power-down Mode

When the SM bit is set (one), the SLEEP instruction makes the MCU enter the Power-down Mode. In this mode, the

external oscillator is stopped, while the external interrupts continue operating. Only an external reset or an external edge

interrupt on INT0 or INT1 can wake up the MCU.

Note that if INT0 or INT1 is used for wake-up from Power-down Mode, the edge is remembered until the MCU wakes up.

When waking up from Power-down Mode, a delay from the wake-up condition occurs until the wake-up becomes effective.

This allows the clock to restart and become stable after having been stopped. The wake-up period is equal to the reset

delay time-out period t

TOUT

.

Timer/Counters

The AT90C8534 provides two general-purpose Timer/Counters – one 8-bit T/C and one 16-bit T/C. Timer/Counters 0 and

1 have individual prescaling selection from the same 10-bit prescaling timer.

Timer/Counter Prescaler

Figure 26. Prescaler for Timer/Counter0 and 1

For Timer/Counters 0 and 1, the five different prescaled selections are: CK, CK/8, CK/64, CK/256 and CK/1024, where CK

is the oscillator clock. In addition, the Timer/Counters can be stopped.

8-bit Timer/Counter0

Figure 27 shows the block diagram for Timer/Counter0.

The 8-bit Timer/Counter0 can select clock source from CK or prescaled CK. In addition, it can be stopped as described in

the specification for the Timer/Counter0 Control Register – TCCR0. The overflow status flag is found in the Timer/Counter

Interrupt Flag Register – TIFR. Control signals are found in the Timer/Counter0 Control Register – TCCR0. The interrupt

enable/disable setting for Timer/Counter0 is found in the Timer/Counter Interrupt Mask Register – TIMSK.

The 8-bit Timer/Counter0 features both a high resolution and a high accuracy usage with the lower prescaling opportunities. Similarly, the high prescaling opportunities make the Timer/Counter0 useful for lower speed functions or exact timing

functions with infrequent actions.

24

AT90C8534

Page 25

Figure 27. Timer/Counter0 Block Diagram

TA BUS

TIMER INT. MASK

REGISTER (TIMSK)

TOIE1

TOIE0

T/C0 OVER-

FLOW IRQ

TIMER INT. FLAG

REGISTER (TIFR)

AT90C8534

T/C0 CONTROL

REGISTER (TCCR0)

8-BIT DA

TIMER/COUNTER0

(TCNT0)

TOV0

TOV1

07

T/C CLK SOURCE

CONTROL

LOGIC

CS02

Timer/Counter0 Control Register – TCCR0

Bit 7 6 5 4 3 2 1 0

$33 ($53) –– – – –CS02 CS01 CS00 TCCR0

Read/Write R R R R R R/W R/W R/W

Initial value 0 0 0 0 0 0 0 0

Bits 7..3 – Res: Reserved Bits

•

These bits are reserved bits in the AT90C8534 and always read zero.

•

Bits 2, 1, 0 – CS02, CS01, CS00: Clock Select0, Bits 2, 1 and 0

The Clock Select0 bits 2, 1 and 0 define the prescaling source of Timer/Counter0.

Table 4. Clock 0 Prescale Select

CS02 CS01 CS00 Description

0 0 0 Stop, Timer/Counter0 is stopped.

CS01

CS00

CK

00 1CK

01 0CK/8

01 1CK/64

10 0CK/256

1 0 1 CK/1024

1 1 0 Reserved

1 1 1 Reserved

The Stop condition provides a Timer Enable/Disable function. The prescaled CK modes are scaled directly from the CK

oscillator clock.

25

Page 26

Timer Counter0 – TCNT0

Bit 76543210

$32 ($52) MSB LSB TCNT0

Read/Write R/W R/W R/W R/W R/W R/W R/W R/W

Initial value 0 0 0 0 0 0 0 0

The Timer/Counter0 is realized as an up-counter with read and write access. If the Timer/Counter0 is written and a clock

source is selected, the Timer/Counter0 continues counting in the timer clock cycle following the write operation.

16-bit Timer/Counter1

Figure 28 shows the block diagram for Timer/Counter1.

The 16-bit Timer/Counter1 can select clock source from CK or prescaled CK. In addition, it can be stopped as described in

the specification for the Timer/Counter1 Control Register – TCCR1. The overflow status flag is found in the Timer/Counter

Interrupt Flag Register – TIFR. Control signals are found in the Timer/Counter1 Control Register – TCCR1. The interrupt

enable/disable setting for Timer/Counter1 is found in the Timer/Counter Interrupt Mask Register – TIMSK.

The 16-bit Timer/Counter1 features both a high resolution and a high accuracy usage with the lower prescaling opportunities. Similarly, the high prescaling opportunities make the Timer/Counter1 useful for lower speed functions or exact timing

functions with infrequent actions.

Figure 28. Timer/Counter1 Block Diagram

T/C1 OVER-

FLOW IRQ

TOIE0

TA BUS

8-BIT DA

TIMER INT. MASK

REGISTER (TIMSK)

TIMER/COUNTER1

(TCNT1)

TOIE1

TIMER INT. FLAG

REGISTER (TIFR)

TOV0

TOV1

015

T/C CLK SOURCE

T/C1 CONTROL

REGISTER (TCCR1)

CONTROL

LOGIC

Timer/Counter1 Control Register – TCCR1

Bit 7 6 5 4 3 2 1 0

$2E ($4E) –– – – –CS12 CS11 CS10 TCCR1

Read/Write R R R R R R/W R/W R/W

Initial value 0 0 0 0 0 0 0 0

Bits 7..3 – Res: Reserved Bits

•

These bits are reserved bits in the AT90C8534 and always read zero.

CS12

CS11

CS10

CK

26

AT90C8534

Page 27

AT90C8534

Bits 2, 1, 0 – CS12, CS11, CS10: Clock Select1, Bits 2, 1 and 0

•

The Clock Select1 bits 2, 1 and 0 define the prescaling source of Timer/Counter1.

Table 5. Clock 1 Prescale Select

CS12 CS11 CS10 Description

0 0 0 Stop, Timer/Counter1 is stopped.

00 1CK

01 0CK/8

01 1CK/64

10 0CK/256

1 0 1 CK/1024

1 1 0 Reserved

1 1 1 Reserved

The Stop condition provides a Timer Enable/Disable function. The prescaled CK modes are scaled directly from the CK

oscillator clock.

Timer/Counter1 – TCNT1H AND TCNT1L

Bit 151413121110 9 8

$2D ($4D) MSB TCNT1H

$2C ($4C) LSB TCNT1L

76543210

Read/Write R/W R/W R/W R/W R/W R/W R/W R/W

R/W R/W R/W R/W R/W R/W R/W R/W

Initial value 0 0 0 0 0 0 0 0

00000000

This 16-bit register contains the prescaled value of the 16-bit Timer/Counter1. To ensure that both the high and low bytes

are read and written simultaneously when the CPU accesses these registers, the access is performed using an 8-bit

temporary register (TEMP). If the main program and interrupt routines perform access using TEMP, interrupts must be disabled during access from the main program.

TCNT1 Timer/Counter1 Write:

When the CPU writes to the high byte TCNT1H, the written data is placed in the TEMP register. Next, when the CPU

writes the low byte TCNT1L, this byte of data is combined with the byte data in the TEMP register, and all 16 bits are

written to the TCNT1 Timer/Counter1 register simultaneously. Consequently, the high byte TCNT1H must be accessed

first for a full 16-bit register write operation.

TCNT1 Timer/Counter1 Read:

When the CPU reads the low byte TCNT1L, the data of the low byte TCNT1L is sent to the CPU and the data of the

high byte TCNT1H is placed in the TEMP register. When the CPU reads the data in the high byte TCNT1H, the CPU

receives the data in the TEMP register. Consequently, the low byte TCNT1L must be accessed first for a full 16-bit register read operation.

The Timer/Counter1 is realized as an up-counter with read and write access. If Timer/Counter1 is written to and a clock

source is selected, the Timer/Counter1 continues counting in the timer clock cycle after it is preset with the written value.

27

Page 28

EEPROM Read/Write Access

The EEPROM access registers are accessible in the I/O space.

The write access time is in the range of 2.5 - 35 ms, depending on the V

ware detect when the next byte can be written. A special EEPROM Ready interrupt can be set to trigger when the

EEPROM is ready to accept new data.

In order to prevent unintentional EEPROM writes, a specific write procedure must be followed. Refer to the description of

the EEPROM Control Register for details on this.

When the EEPROM is written, the CPU is halted for two clock cycles before the next instruction is executed. When the

EEPROM is read, the CPU is halted for four clock cycles before the next instruction is executed.

EEPROM Address Register – EEARH and EEARL

Bit 151413121110 9 8

$1F ($3F) –––––––EEAR9 EEARH

$1E ($3E) EEAR7 EEAR6 EEAR5 EEAR4 EEAR3 EEAR2 EEAR1 EEAR0 EEARL

76543210

Read/Write R/W R/W R/W R/W R/W R/W R/W R/W

R/W R/W R/W R/W R/W R/W R/W R/W

Initial value 0 0 0 0 0 0 0 x

xxxxxxxx

The EEPROM Address Registers (EEARH and EEARL) specify the EEPROM address in the 512 bytes EEPROM space.

The EEPROM data bytes are addressed linearly between 0 and 511.

voltages. A self-timing function lets the user soft-

CC

EEPROM Data Register – EEDR

Bit 76543210

$1D ($3D) MSB LSB EEDR

Read/Write R/W R/W R/W R/W R/W R/W R/W R/W

Initial value 0 0 0 0 0 0 0 0

Bits 7..0 – EEDR7.0: EEPROM Data

•

For the EEPROM write operation, the EEDR register contains the data to be written to the EEPROM in the address given

by the EEAR register. For the EEPROM read operation, the EEDR contains the data read out from the EEPROM at the

address given by EEAR.

EEPROM Control Register – EECR

Bit 76543210

$1C ($3C) ––––EERIE EEMWE EEWE EERE EECR

Read/Write R R R R R/W R/W R/W R/W

Initial value 0 0 0 0 0 0 0 0

Bits 7..4 – Res: Reserved Bits

•

These bits are reserved bits in the AT90S8535 and will always read as zero.

Bit 3 – EERIE: EEPROM Ready Interrupt Enable

•

When the I bit in SREG and EERIE are set (one), the EEPROM Ready Interrupt is enabled. When cleared (zero), the

interrupt is disabled. The EEPROM Ready interrupt generates a constant interrupt when EEWE is cleared (zero).

•

Bit 2 – EEMWE: EEPROM Master Write Enable

The EEMWE bit determines whether setting EEWE to one causes the EEPROM to be written. When EEMWE is set (one),

setting EEWE will write data to the EEPROM at the selected address. If EEMWE is zero, setting EEWE will have no effect.

When EEMWE has been set (one) by software, hardware clears the bit to zero after four clock cycles. See the description

of the EEWE bit for a EEPROM write procedure.

28

AT90C8534

Page 29

AT90C8534

Bit 1 – EEWE: EEPROM Write Enable

•

The EEPROM Write Enable Signal EEWE is the write strobe to the EEPROM. When address and data are correctly set up,

the EEWE bit must be set to write the value into the EEPROM. The EEMWE bit must be set when the logical “1” is written

to EEWE, otherwise no EEPROM write takes place. The following procedure should be followed when writing the

EEPROM (the order of steps 2 and 3 is unessential):

1. Wait until EEWE becomes zero.

2. Write new EEPROM address to EEARL and EEARH (optional).

3. Write new EEPROM data to EEDR (optional).

4. Write a logical “1” to the EEMWE bit in EECR (to be able to write a logical “1” to the EEMWE bit, the EEWE bit must

be written to zero in the same cycle).

5. Within four clock cycles after setting EEMWE, write a logical “1” to EEWE.

Caution: An interrupt between step 4 and step 5 will make the write cycle fail, since the EEPROM Master Write Enable

will time-out. If an interrupt routine accessing the EEPROM is interrupting another EEPROM access, the EEAR or EEDR

register will be modified, causing the interrupted EEPROM access to fail. It is recommended to have the global interrupt

flag cleared during steps 2 to 5 to avoid these problems.

When the write access time (typically 2.5 ms at V

(zero) by hardware. The user software should poll this bit and wait for a zero before writing the next byte. When EEWE has

been set, the CPU is halted for two cycles before the next instruction is executed.

Bit 0 – EERE: EEPROM Read Enable

•

The EEPROM Read Enable Signal EERE is the read strobe to the EEPROM. When the correct address is set up in the

EEAR register, the EERE bit must be set. When the EERE bit is cleared (zero) by hardware, requested data is found in the

EEDR register. The EEPROM read access takes one instruction and there is no need to poll the EERE bit. When EERE

has been set, the CPU is halted for four cycles before the next instruction is executed.

The user should poll the EEWE bit before starting the read operation. Writing of any EEPROM I/O register is blocked when

a write operation is in progress (except the EERIE bit, which can be written). Hence, if a read access is attempted during a

write access, the address cannot be modified and read access will not be performed. The write operation will complete

undisturbed.

= 5V or 4 ms at VCC = 2.7V) has elapsed, the EEWE bit is cleared

CC

Prevent EEPROM Corruption

During periods of low VCC, the EEPROM data can be corrupted because the supply voltage is too low for the CPU and the

EEPROM to operate properly. These issues are the same as for board-level systems using the EEPROM, and the same

design solutions should be applied.

An EEPROM data corruption can be caused by two situations when the voltage is too low. First, a regular write sequence

to the EEPROM requires a minimum voltage to operate correctly. Secondly, the CPU itself can execute instructions

incorrectly if the supply voltage for executing instructions is too low.

EEPROM data corruption can easily be avoided by following these design recommendations (one is sufficient):

1. Keep the AVR RESET active (low) during periods of insufficient power supply voltage. This is best done by an

external low V

tion note AVR 180 for design considerations regarding power-on reset and low-voltage detection.

2. Keep the AVR core in Power-down Sleep Mode during periods of low V

to decode and execute instructions, effectively protecting the EEPROM registers from unintentional writes.

3. Store constants in Flash memory if the ability to change memory contents from software is not required. Flash

memory cannot be updated by the CPU and will not be subject to corruption.

Reset Protection circuit, often referred to as a Brown-out Detector (BOD). Please refer to applica-

CC

. This will prevent the CPU from attempting

CC

29

Page 30

Analog-to-digital Converter

Feature list:

• 10-bit Resolution

• ± 2 LSB Accuracy (AVcc = 3.3 - 6.0V)

• 76 - 175

• Up to 13 kSPS

• 6 Multiplexed Input Channels

• Rail-to-rail Input Range

• Free Run or Single Conversion Mode

• Interrupt on ADC Conversion Complete

• Sleep Mode Noise Canceler

The AT90C8534 features a 10-bit successive approximation ADC. The ADC is connected to a 6-channel Analog Multiplexer, which allows each of the pins ADIN5..0 to be used as an input for the ADC. The ADC contains a Sample and Hold

Amplifier that ensures that the input voltage to the ADC is held at a constant level during conversion. A block diagram of the

ADC is shown in Figure 29.

The ADC has two separate analog supply voltage pins, AVCC and AGND. AGND must be connected to GND, and the

voltage on AVCC must not differ more than ± 0.3V from V

to connect these pins.

Figure 29. Analog-to-digital Converter Block Schematic

µs Conversion Time

. See “ADC Noise Canceling Techniques” on page 36 for how

CC

ADC CONVERSION

COMPLETE IRQ

External

8-BIT DATA BUS

Reference

Voltage

Analog

Inputs

6-

CHANNEL

MUX

ADC MULTIPLEXER

SELECT (ADMUX)

-

+

SAMPLE & HOLD

COMPARATOR

MUX2

MUX1

MUX0

ADC CTRL. & STATUS

REGISTER (ADCSR)

ADES

ADBSY

ADFR

ADIF

ADIF

ADIE

ADIE

ADPS1

ADPS2

CONVERSION LOGIC10-BIT DAC

90

ADC DATA REGISTER

(ADCH/ADCL)

ADPS0

Operation

The ADC can operate in two modes – Single Conversion and Free Run. In Single Conversion Mode, each conversion will

have to be initiated by the user. In Free Run Mode the ADC is constantly sampling and updating the ADC Data Register.

The ADFR bit in ADCSR selects between the two available modes.

The ADC is enabled by writing a logical “1” to the ADC Enable bit, ADEN in ADCSR. The first conversion that is started

after enabling the ADC will be preceded by a dummy conversion to initialize the ADC. To the user, the only difference will

be that this conversion takes 12 more ADC clock pulses than a normal conversion.

30

AT90C8534

Page 31

AT90C8534

A conversion is started by writing a logical “1” to the ADC Start Conversion bit, ADSC. This bit stays high as long as the

conversion is in progress and will be set to zero by hardware when the conversion is completed. If a different data channel

is selected while a conversion is in progress, the ADC will finish the current conversion before performing the channel

change.

As the ADC generates a 10-bit result, two data registers, ADCH and ADCL, must be read to get the result when the conversion is complete. Special data protection logic is used to ensure that the contents of the data registers belong to the same

conversion when they are read. This mechanism works as follows:

When reading data, ADCL must be read first. Once ADCL is read, ADC access to data registers is blocked. This means

that if ADCL has been read, and a conversion completes before ADCH is read, none of the registers are updated and the

result from the conversion is lost. When ADCH is read, ADC access to the ADCH and ADCL registers is re-enabled.

The ADC has its own interrupt, ADIF, which can be triggered when a conversion completes. When ADC access to the data

registers is prohibited between reading of ADCH and ADCL, the interrupt will trigger even if the result gets lost.

Prescaling

Figure 30. ADC Prescaler

ADEN

CK

ADPS0

ADPS1

ADPS2

Reset

7-BIT ADC PRESCALER

CK/2

CK/4

ADC CLOCK SOURCE

CK/8

CK/16

CK/32

CK/64

CK/128

The ADC contains a prescaler, which divides the system clock to an acceptable ADC clock frequency. The ADC accepts

input clock frequencies in the range of 80 - 170 kHz.

The ADPS0 - ADPS2 bits in ADCSR are used to generate a proper ADC clock input frequency from any XTAL frequency

above 160 kHz. The prescaler starts counting from the moment the ADC is switched on by setting the ADEN bit in ADCSR.

The prescaler keeps running for as long as the ADEN bit is set, and is continuously reset when ADEN is low.

When initiating a conversion by setting the ADSC bit in ADCSR, the conversion starts at the following rising edge of the

ADC clock cycle. The actual sample-and-hold takes place 1.5 ADC clock cycles after the start of the conversion. The result

is ready and written to the ADC Result Register after 13 cycles. In Single Conversion Mode, the ADC needs one more

clock cycle before a new conversion can be started (see Figure 32). If ADSC is set high in this period, the ADC will start the

new conversion immediately. In Free Run Mode, a new conversion will be started immediately after the result is written to

the ADC Result Register. Using Free Run Mode and an ADC clock frequency of 170 kHz gives the lowest conversion time,

76 µs, equivalent to 13 kSPS. For a summary of conversion times, see Table 6.

31

Page 32

Figure 31. ADC Timing Diagram, First Conversion (Single Conversion Mode)

13

Cycle number

ADC clock

ADEN

ADSC

Hold strobe

ADIF

ADCH

ADCL

1 212

Dummy Conversion Actual Conversion

14 15

Figure 32. ADC Timing Diagram, Single Conversion

2 3 4 5 6 7 8

Cycle number

ADC clock

1

16 17

18

19 20 21 22 23

10 11 12 13

9

24 25 26 1

MSB of result

LSB of result

Second

Conversion

14

12

2

ADSC

Hold strobe

ADIF

ADCH

ADCL

MSB of result

LSB of result

One Conversion Next Conversion

32

AT90C8534

Page 33

Figure 33. ADC Timing Diagram, Free Run Conversion

AT90C8534

Cycle number

ADC clock

ADSC

Hold strobe

ADIF

ADCH

ADCL

11 12 13

12

MSB of result

LSB of result

One Conversion Next

Conversion

Table 6. ADC Conversion Time

Sample Cycle

Condition

1st Conversion, Free Run 14 25 25 147 - 313

1st Conversion, Single 14 25 26 153 - 325

Free Run Conversion 2 13 13 76 - 163

Single Conversion 2 13 14 82 - 175

Number

Result Ready

(Cycle Number)

Total Conversion

Time (Cycles)

Total Conversion

Time (µs)

ADC Noise Canceler Function

The ADC features a noise canceler that enables conversion during idle mode to reduce noise induced from the CPU core.

To make use of this feature, the following procedure should be used.

1. Make sure that the ADC is enabled and is not busy converting. Single Conversion Mode must be selected and the

ADC conversion complete interrupt must be enabled. Thus:

ADEN = 1

ADSC = 0

ADFR = 0

ADIE = 1

2. Enter idle mode. The ADC will start a conversion once the CPU has been halted.

3. If no other interrupts occur before the ADC conversion completes, the ADC interrupt will wake up the MCU and

execute the ADC conversion complete interrupt routine.

33

Page 34

ADC Multiplexer Select Register – ADMUX

Bit 76543210

$07 ($27) –––––MUX2 MUX1 MUX0 ADMUX

Read/Write R R R R R R/W R/W R/W

Initial value 0 0 0 0 0 0 0 0

Bits 7..3 – Res: Reserved Bits

•

These bits are reserved bits in the AT90C8534 and always read as zero.

•

Bits 2..0 – MUX2..MUX0: Analog Channel Select Bits 2 - 0

The value of these three bits selects which analog input 5 - 0 is connected to the ADC. Selections 110 and 111 are

reserved and should not be used.

Table 7. ADC Channel Selections

MUX2 MUX1 MUX0 Channel

000 ADIN0

001 ADIN1

010 ADIN2

011 ADIN3

100 ADIN4

101 ADIN5

110 reserved

111 reserved

ADC Control and Status Register – ADCSR

Bit 76543210

$06 ($26) ADEN ADSC ADFR ADIF ADIE ADPS2 ADPS1 ADPS0 ADCSR

Read/Write R/W R/W R/W R/W R/W R/W R/W R/W

Initial value00000000

•

Bit 7 – ADEN: ADC Enable

Writing a logical “1” to this bit enables the ADC. By clearing this bit to zero, the ADC is turned off. Turning the ADC off while

a conversion is in progress will terminate this conversion.

•

Bit 6 – ADSC: ADC Start Conversion

In Single Conversion Mode, a logical “1” must be written to this bit to start each conversion. In Free Run Mode, a logical “1”

must be written to this bit to start the first conversion. The first time ADSC has been written after the ADC has been

enabled, or if ADSC is written at the same time as the ADC is enabled, a dummy conversion will precede the initiated conversion. This dummy conversion performs initialization of the ADC.

ADSC remains high during the conversion. ADSC goes low after the actual conversion is finished, but before the result is

written to the ADC Data Registers. This allows a new conversion to be initiated before the current conversion is complete.

The new conversion will then start immediately after the current conversion completes. When a dummy conversion

precedes a real conversion, ADSC will stay high until the real conversion is finished.

Writing a 0 to this bit has no effect.

Bit 5 – ADFR: ADC Free Run Select

•

When this bit is set (one), the ADC operates in Free Run Mode. In this mode, the ADC samples and updates the data

registers continuously. Clearing this bit (zero) will terminate Free Run Mode.

Bit 4 – ADIF: ADC Interrupt Flag

•

This bit is set (one) when an ADC conversion completes and the data registers are updated. The ADC Conversion Complete Interrupt is executed if the ADIE bit and the I-bit in SREG are set (one). ADIF is cleared by hardware when executing

34

AT90C8534

Page 35

AT90C8534

the corresponding interrupt handling vector. Alternatively, ADIF is cleared by writing a logical “1” to the flag. Beware that if

doing a read-modify-write on ADCSR, a pending interrupt can be disabled. This also applies if the SBI or CBI instructions

are used.

Bit 3 – ADIE: ADC Interrupt Enable

•

When this bit is set (one) and the I-bit in SREG is set (one), the ADC Conversion Complete Interrupt is activated.

•

Bits 2..0 – ADPS2..ADPS0: ADC Prescaler Select Bits

These bits determine the division factor between the XTAL frequency and the input clock to the ADC.

Table 8. ADC Prescaler Selections

ADPS2 ADPS1 ADPS0 Division Factor

000 2

001 2

010 4

011 8

100 16

101 32

110 64

111 128

ADC Data Register – ADCL AND ADCH

Bit 151413121110 9 8

$05 ($25) ––––––ADC9 ADC8 ADCH

$04 ($24) ADC7 ADC6 ADC5 ADC4 ADC3 ADC2 ADC1 ADC0 ADCL

76543210

Read/Write RRRRRRRR

RRRRRRRR

Initial value 8 0 0 0 0 0 0 0

80000000

When an ADC conversion is complete, the result is found in these two registers. In Free Run Mode, it is essential that both

registers are read, and that ADCL is read before ADCH.

Scanning Multiple Channels

Since change of analog channel always is delayed until a conversion is finished, the Free Run Mode can be used to scan

multiple channels without interrupting the converter. Typically, the ADC Conversion Complete interrupt will be used to

perform the channel shift. However, the user should take the following fact into consideration:

The interrupt triggers once the result is ready to be read. In Free Run Mode, the next conversion will start immediately

when the interrupt triggers. If ADMUX is changed after the interrupt triggers, the next conversion has already started and

the old setting is used.

35

Page 36

ADC Noise Canceling Techniques

Digital circuitry inside and outside the AT90C8534 generates EMI, which might affect the accuracy of analog measurements. If conversion accuracy is critical, the noise level can be reduced by applying the following techniques:

1. The analog part of the AT90C8534 and all analog components in the application should have a separate analog

ground plane on the PCB. This ground plane is connected to the digital ground plane via a single point on the PCB.

2. Keep analog signal paths as short as possible. Make sure analog tracks run over the analog ground plane, and

keep them well away from high-speed switching digital tracks.

3. The AVCC pin on the AT90C8534 should be connected to the digital VCC supply voltage as shown in Figure 34.

4. Use the ADC noise canceler function to reduce induced noise from the CPU.

Figure 34. ADC Power Connections

GND

VCC

AT90VC8534

NOTE: PIN PLACEMENT IS AN ILLUSTRATION ONLY

ADIN0

ADIN1

ADIN2

ADIN3

ADIN4

ADIN5

AGND

AVCC

Analog Ground Plane

10nF

36

AT90C8534

Page 37

AT90C8534

ADC Characteristics

TA = -40°C to 85°C

Symbol Parameter Condition Min Typ Max Units

Resolution 10 Bits

Absolute Accuracy AV

= 3.3 - 6.0V 2 LSB

CC

INL Integral Nonlinearity AVCC = 3.3 - 6.0V 1 LSB

DNL Differential Nonlinearity AV

Zero Error (Offset) AV

= 3.3 - 6.0V 2 LSB

CC

= 3.3 - 6.0V 0.5 LSB

CC

Conversion Time 76 175 µs

Clock Frequency 80 170 kHz

AV

R

R

CC

REF

AIN

Analog Supply Voltage VCC - 0.3

(1)

VCC + 0.3

Reference Input Resistance 6 10 13 KΩ

Analog Input Resistance 100 MΩ

(1)

V

Note: 1. AVCC must not go below 3.3V or above 6.0V.

Output Port A

Port A is a 7-bit general output port with tri-state mode.

The port has true read-modify-write functionality. This means that one port pin can be tri-stated without unintentionally

tri-stating any other pin with the SBI and CBI instructions. The same applies for changing drive value.

Two I/O memory address locations are allocated for Port A, one each for the Data Register – PORTA, $1B($3B) and Data

Direction Register – DDRA, $1A($3A). Both locations are read/write.

The Port A output buffers can sink 20 mA and thus drive LED displays directly.

Port A Data Register – PORTA

Bit 76543210

$1B ($3B) – PORTA6 PORTA5 PORTA4 PORTA3 PORTA2 PORTA1 PORTA0 PORTA

Read/Write R R/W R/W R/W R/W R/W R/W R/W

Initial value 0 0 0 0 0 0 0 0

Port A Data Direction Register – DDRA

Bit 76543210

$1A ($3A) – DDA6 DDA5 DDA4 DDA3 DDA2 DDA1 DDA0 DDRA

Read/Write R R/W R/W R/W R/W R/W R/W R/W

Initial value 0 0 0 0 0 0 0 0

All seven pins in Port A have equal functionality.

PAn, General Output pin: The DDAn bit in the DDRA register selects tri-state mode of this pin. If DDAn is set (one), PAn is

configured to drive out the value in PORTAn. If DDAn is cleared (zero), PAn is configured as a tri-state pin.

37

Page 38

Table 9. DDAn Effects on Port A Pins

DDAn PORTAn Comment

0 0 Tri-state (high-Z)

0 1 Tri-state (high-Z)

1 0 Push-pull Zero Output

1 1 Push-pull One Output

Note: n: 6, 5, …, 0, pin number.

Memory Programming

Program and Data Memory Lock Bits

The AT90C8534 MCU provides two Lock bits that can be left unprogrammed (“1”) or can be programmed (“0”) to obtain the

additional features listed in Table 10.

Table 10. Lock Bit Protection Modes

Memory Lock Bits

Protection TypeMode LB1 LB2

1 1 1 No memory lock features enabled.

2 0 1 Further programming of the Flash and EEPROM is disabled.

3 0 0 Same as mode 2 and verify is also disabled.

Note: The Lock bits can only be erased with the Chip Erase command.

Signature Bytes

All Atmel microcontrollers have a 3-byte signature code that identifies the device. The three bytes reside in a separate

address space.

For the AT90C8534 they are:

1. $00: $1E (indicates manufactured by Atmel)

2. $01: $93 (indicates 8 KB Flash memory)

3. $02: $04 (indicates AT90C8534 device when $01 is $93)

Programming the Flash and EEPROM

Atmel’s AT90C8534 offers 8K bytes of Flash program memory and 512 bytes of EEPROM data memory.

The AT90C8534 is shipped with the on-chip Flash program and EEPROM data memory arrays in the erased state

(i.e., contents = $FF) and ready to be programmed. This device supports a parallel programming mode, enabled by the

pin.

PEN

The program and data memory arrays on the AT90C8534 are programmed byte-by-byte.

Parallel Programming

This section describes how to parallel program and verify Flash program memory, EEPROM data memory and memory

Lock bits in the AT90C8534.

38

AT90C8534

Page 39

AT90C8534

Signal Names

In this section, some pins of the AT90C8534 are referenced by signal names describing their function during parallel programming. See Figure 35 and Table 11. Pins not described in Table 11 are referenced by pin names.

The XA1/XA0 pins determines the action executed when the XTAL1 pin is given a positive pulse. The coding is shown in

Table 12.

When pulsing WR

bits are assigned functions as shown in Table 13.

Figure 35. Parallel Programming

or OE, the command loaded determines the action executed. The command is a byte where the different

AT90VC8534

+5V

RDY/BSY

OE

WR

BS

XA0

XA1

RESET

INT1

ADIN1

ADIN2

ADIN3

ADIN4

ADIN5

RESET

PEN

XTAL1

GND

Table 11. Pin Name Mapping

Signal Name in

Programming Mode Pin Name I/O Function

VCC

INT0,PA6-0

DATA

RDY/BSY

OE ADIN1 I Output Enable (active low)

WR

BS ADIN3 I Byte Select (“0” selects low byte, “1” selects high byte)

XA0 ADIN4 I XTAL1 Action Bit 0

XA1 ADIN5 I XTAL1 Action Bit 1

DATA INT0, PA6-0 I/O Bi-directional Data Bus (output when OE

INT1 O “0”: Device is busy programming, “1”: Device is ready for new command

ADIN2 I Write Pulse (active low)

is low)

39

Page 40

.

Table 12. XA1 and XA0 Coding

XA1 XA0 Action when XTAL1 is Pulsed

0 0 Load Flash/EEPROM/Signature Byte Address (high or low address byte for Flash/EEPROM determined by BS)