Page 1

Features

• Secure battery authentication

• Superior SHA-256 Hash Algorithm

• Best in class 256 bit key length

• Guaranteed Unique 48 bit Serial Number

• High speed single wire interface

• Supply Voltage: 2.5 – 5.5V

• <100nA Sleep Current

• 4KV ESD protection

• Green compliant (exceeds RoHS) 3 pin SOT-23 package

CryptoAuthentication™

Applications

• Cell Phones

• PDA and Smart Phones

• Portable Media Players

• Digital Cameras & Camcorders

• Cordless Tools

• Handheld Devices

1. Introduction

The AT88SA100S is a small authentication chip that can be used to

validate battery packs and other replaceable items that contain a

power source. It uses the industry leading SHA-256 hash algorithm

to provide the ultimate level of security.

An industry leading key length of 256 bits prevents exhaustive

attacks while multiple physical security features prevent

unauthorized disclosure of the secret key stored within the chip.

This key is automatically erased when power is removed from the

device.

It is shipped with a guaranteed unique 48 bit serial number that is

used in combination with an input challenge and the stored secret

key to generate a response that is unique for every individual

device.

The chip also includes 80 one-time fuses that can be used to

configure the system and/or retain permanent status. The values in

these fuses can also be locked to prevent modification.

AT88SA100S

Battery Authentication

Chip

Preliminary

8558A–SMEM–03/09

Page 2

1.1. Memory Resources

Sram 256 bits of SRAM that are used for storage of a key. The LoadSram command provides a

mechanism to securely initialize this block during personalization. This memory will retain its value

when the chip is put/goes to sleep, so long as a supply voltage in excess of V

the chip.

MemValid A single bit that tells whether or not Sram contains valid data. It’s cleared when power is lost and set

when the SRAM is loaded with a secret key.

Fuse Block of 128 fuse bits that can be read and written through the 1 wire interface. The first 8 bits are

lock bits that control burn ability on 16 bit words of the array. Fuse[88-95] are manufacturing ID

values fixed by Atmel. Fuse[96-127] are programmed by Atmel with a serial number that (in

combination with MaskSN) is guaranteed to be unique and which includes lot/wafer info.

ROM Metal mask programmed memory. Unrestricted reads are permitted on the first 64 bits of this array.

The physical ROM will be larger and will contain other information that cannot be read.

ROM MfrID 2 bytes of ROM that, when combined with Fuse[88:95] specifies the 24 bit manufacturing

ID code (MfrID). This value is assigned by Atmel and is always the same for all chips of a

particular model number. For the AT88SA100S, this value is 0xFF FF FF. The MfrID can

be read by accessing ROM bytes 0 & 1 of Address 0. The 24 bit MfrID value can always

be read by the system and is always included in the message digested by the MAC

command.

ROM SN 2 bytes of ROM that can be used to identify chips among others on the wafer. These bits

reduce the number of fuses necessary to construct a unique serial number. The ROM SN

is read by accessing ROM bytes 2 & 3 of Address 0. The complete serial number is

extended with an additional 32 fuses to form the 48 bit serial number. The serial number

can always be read by the system and is optionally included in the message digested by

the MAC command.

RevNum 4 bytes of ROM that are used by Atmel to identify the design revision of the AT88SA100S

chip. These bytes can be freely read as the four bytes returned from ROM address 1,

however system code should not depend on this value as it may change from time to time.

is still supplied to

RETAIN

1.2. Fuse Map

The AT88SA100S chip incorporates 128 one-time fuses within the chip. Once burned, there is no way to reset the

value of a fuse. Fuses, with the exception of the manufacturing ID and serial number bits, initialized by Atmel, have a

value of 1 when shipped from the Atmel factory and transition to a 0 when they are burned.

Table 1. The 128 fuses in the AT88SA100S chip are arranged in the following manner:

Fuse # Name Description

0 – 7 Fuse Lock Bits Each bit locks the current value of the corresponding 16 bit block of the fuse array,

see below for more details.

8 Æ 87 Status Fuses These fuses can be written with the BurnFuse command and can always be read

with the Read command.

88 Æ 95 MfrID See Section 1.1. Set by Atmel, can’t be modified in the field

96 Æ 127 Serial Number See Section 1.1. Set by Atmel, can’t be modified in the field

Fuse Lock Bits These 8 fuses can be used to prevent further writing of the status fuses. Bit 0, when burned, locks

Fuse[0-15] from being modified, Bit[1] locks Fuse[16-31] and so on up through bit 5, which locks

Fuse[80-87]. Fuse[88-127] can never be modified with the BurnFuse command. Note that burning bit

0 has the effect of preventing any changes to the current value of the lock bits.

2 AT88SA100S [Preliminary]

8558A–SMEM–03/09

Page 3

AT88SA100S [ Preliminary]

Status Fuses These fuses can be used to store various information which is not secret. Their value can always be

determined using the Read command. They can be individually burned using the BurnFuse

command. Two common usage models for these fuses are:

1. Consumption logging, i.e. burn one bit after every n uses, the host system keeps track of the

number of uses so far for this serial number since the last fuse burn.

2. Model number information. In this situation, the bits are written at the factory and their value is

locked to prevent modifications in the field. This method can also be used for feature enabling.

1.3. SHA-256 Computation

This chip performs only one cryptographic calculation – a keyed digest of an input challenge using the SHA-256

algorithm, documented here:

http://csrc.nist.gov/publications/fips/fips180-2/fips180-2.pdf

1.3.1. SHA Computation Example

In order to ensure that there is no ambiguity, the following example vector is provided in addition to the sample vectors

in the NIST document. In this example, all values are listed in hex. For all but the key, bytes are listed in the order that

they appear on the bus – first on the left. Key is listed in the same order, so the 01 at the left of the key string is the first

byte passed to SHA-256.

Key 01030507090B0D0F11131517191B1D1F21232527292B2D2F31333537393B3D3F

Challenge 020406080A0C0E10121416181A1C1E20222426282A2C2E30323436383A3C3E40

Opcode 01

Mode 40 (include serial number in message)

Param2 0000

MfrID Fuses 77

S/N Fuses 8899AABB

MfrID ROM CCDD

MaskSN ROM EEFF

The 88 bytes over which the digest is calculated are 0103…3D3F0204…3E4001400000…EEFF

Digest: 7D38245733717A488575B9F794F7BCAFE033A3848D39430DA25141FDEBEAA1C2

A Read command executed on address 0 of the ROM (MfrID ROM, MaskSN ROM) would return CC DD EE FF, with

CC being the first byte on the bus and FF being the last.

Throughout this document, the complete message processed by the SA100S chip is documented. According to the

above specification, this always includes a single bit of ‘1’ pad after the message, followed by a 64 bit value

representing the total number of bits being hashed (less pad and length). If the length is less than 447 (512-64-1) then

the necessary number of ‘0’ bits are included between the ‘1’ pad and ‘length’ to stretch the last message block out to

512 bits.

When using standard libraries to calculate the SHA-256 digest, these pad and length bits should probably not be

passed to the library as most standard software implementations of the algorithm add them in automatically.

3

8558A–SMEM–03/09

Page 4

1.4. Security Features

This chip incorporates a number of physical security features designed to protect the key from unauthorized release.

These include an active shield over the entire surface of the internal memory encryption, internal clock generation,

glitch protection, voltage tamper detection and other physical design features.

Both the clock and logic supply voltage are internally generated, preventing any direct attack via the pins on these two

signals.

2. IO Protocol

Communications to and from this chip take place over a single asynchronously timed wire using a pulse count scheme.

The overall communications structure is a hierarchy:

Table 2. IO Hierarchy

Tokens

Flags

Blocks

Packets

2.1. IO Tokens

There are a number of IO tokens that may be transmitted along the bus:

Input: (To device)

Wake Wake device up from sleep (low power) state

Zero Send a single bit from system to the device with a value of 0

One Send a single bit from system to the device with a value of 1

Output: (From the device)

ZeroOut Send a single bit from the device to the system with a value of 0

OneOut Send a single bit from the device to the system with a value of 1

The waveforms are the same in either direction, however there are some differences in timing based on the expectation

that the host has a very accurate and consistent clock while the device has significant variation in its internal clock

generator due to normal manufacturing and environmental fluctuations.

The bit timings are designed to permit a standard UART running at 230.4K baud to transmit and receive the tokens

efficiently. Each byte transmitted or received by the UART corresponds to a single bit received or transmitted by the

device. Refer to Applications Notes on Atmel’s website for more details describing how the UART should be controlled.

Implement a single data bit transmitted on the bus, or the wake-up event.

Comprised of eight tokens (bits) which convey the direction and meaning of the next group of bits (if any)

which may be transmitted.

of data follow the command and transmit flags. They incorporate both a byte count and a checksum to

ensure proper data transmission

of bytes form the core of the block without the count and CRC. They are either the input or output

parameters of a AT88SA100S chip command or status information from the AT88SA100S chip

4 AT88SA100S [Preliminary]

8558A–SMEM–03/09

Page 5

AT88SA100S [ Preliminary]

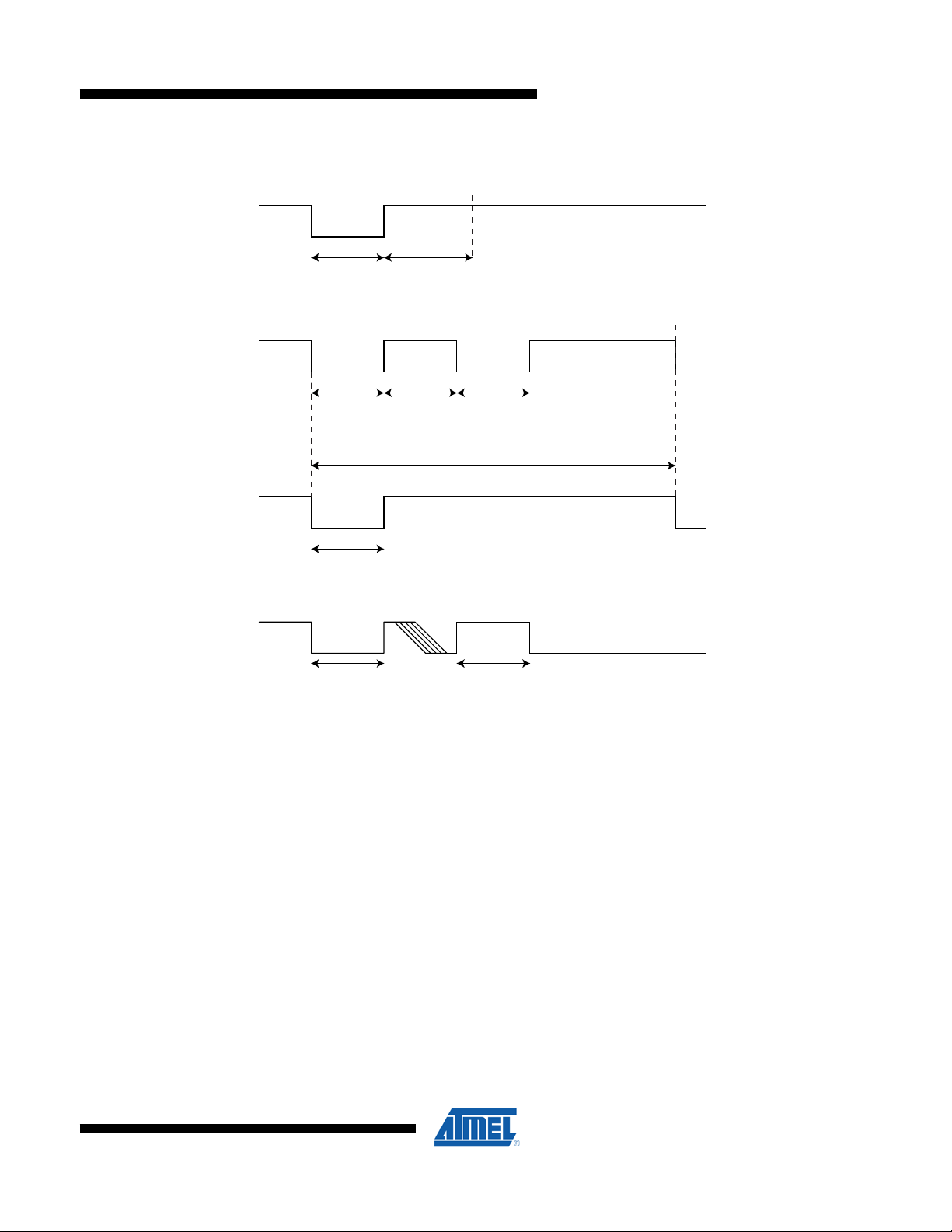

2.2. AC Parameters

Figure 1. AC Parameters

data commWAKE

LOGIC Ø

LOGIC 1

NOISE

SUPPRESION

t

WLO

t

START

t

START

t

LIGNORE

t

WHI

t

ZHI

t

ZLO

t

BIT

t

HIGNORE

8558A–SMEM–03/09

5

Page 6

μ

μ

μ

μ

μ

μ

μ

μ

μ

μ

μ

μ

μ

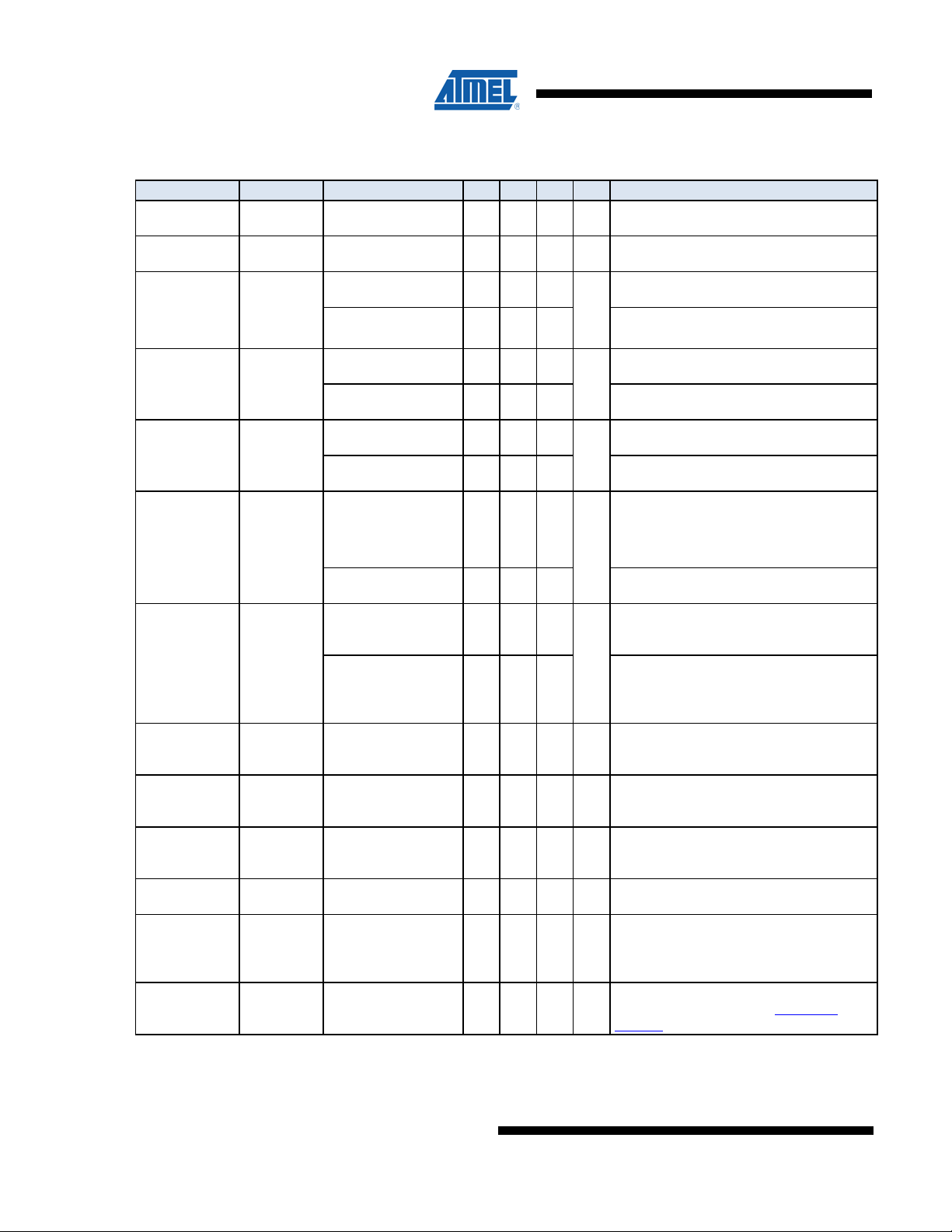

Table 3. AC Parameters

Parameter Symbol Direction Min Typ Max Unit Notes

Wake Low

Duration

Wake Delay to

Data Comm.

Start pulse

duration

Zero

transmission

t

WLO

t

WHI

t

START

t

ZHI

high pulse

Zero

transmission

t

ZLO

low pulse

(1)

Bit time

Turn around

delay

High side

glitch filter @

t

BIT

t

TURNAROUND

t

HIGNORE_A

active

Low side glitch

filter @ active

High side

glitch filter @

t

LIGNORE_A

t

HIGNORE_S

sleep

Low side glitch

filter @ sleep

IO Timeout

Watchdog

reset

t

LIGNORE_S

t

TIMEOUT

t

WATCHDOG

Note 1: START, ZLO, ZHI & BIT are designed to be compatible with a standard UART running at 230.4K baud for both

transmit and receive.

To

CryptoAuthentication

To

CryptoAuthentication

To

CryptoAuthentication

From

CryptoAuthentication

To

CryptoAuthentication

From

CryptoAuthentication

To

CryptoAuthentication

From

CryptoAuthentication

To

CryptoAuthentication

From

CryptoAuthentication

From

CryptoAuthentication

To

CryptoAuthentication

To

CryptoAuthentication

To

CryptoAuthentication

To

CryptoAuthentication

To

CryptoAuthentication

To

CryptoAuthentication

To

CryptoAuthentication

60 -

1 - ms Signal should be stable high for this

4.1 4.34 4.56

4.62 6.0 8.6

4.1 4.34 4.56

4.62 6.0 8.6

4.1 4.34 4.56

4.62 6.0 8.6

37.1 39 -

46.2 60 86

46.2 60 86

46.2 60 86

45 ns Pulses shorter than this in width will be

45 ns Pulses shorter than this in width will be

2

2

7 10 13 ms Starting as soon as 7ms up to 13ms after

374 500 650 ms Max. time from wake until chip is forced

Signal can be stable in either high or low

s

levels during extended sleep intervals.

entire duration.

s

s

s

s

s

s

s

If the bit time exceeds t

TIMEOUT

then

CryptoAuthentication will enter sleep

mode and the wake token must be

resent.

s

CryptoAuthentication will initiate the first

s

low going transition after this time interval

following the end of the Transmit flag

After CryptoAuthentication transmits the

s

last bit of a block, system must wait this

interval before sending the first bit of a

flag

ignored by the chip, regardless of its

state when active

ignored by the chip, regardless of its

state when active

Pulses shorter than this in width will be

s

ignored by the chip when in sleep mode

Pulses shorter than this in width will be

s

ignored by the chip when in sleep mode

the initial signal transition of a token chip

will enter sleep if no complete and valid

token is received.

into sleep mode. Refer to Watchdog

Failsafe Section 3.4

6 AT88SA100S [Preliminary]

8558A–SMEM–03/09

Page 7

AT88SA100S [ Preliminary]

3. DC Parameters

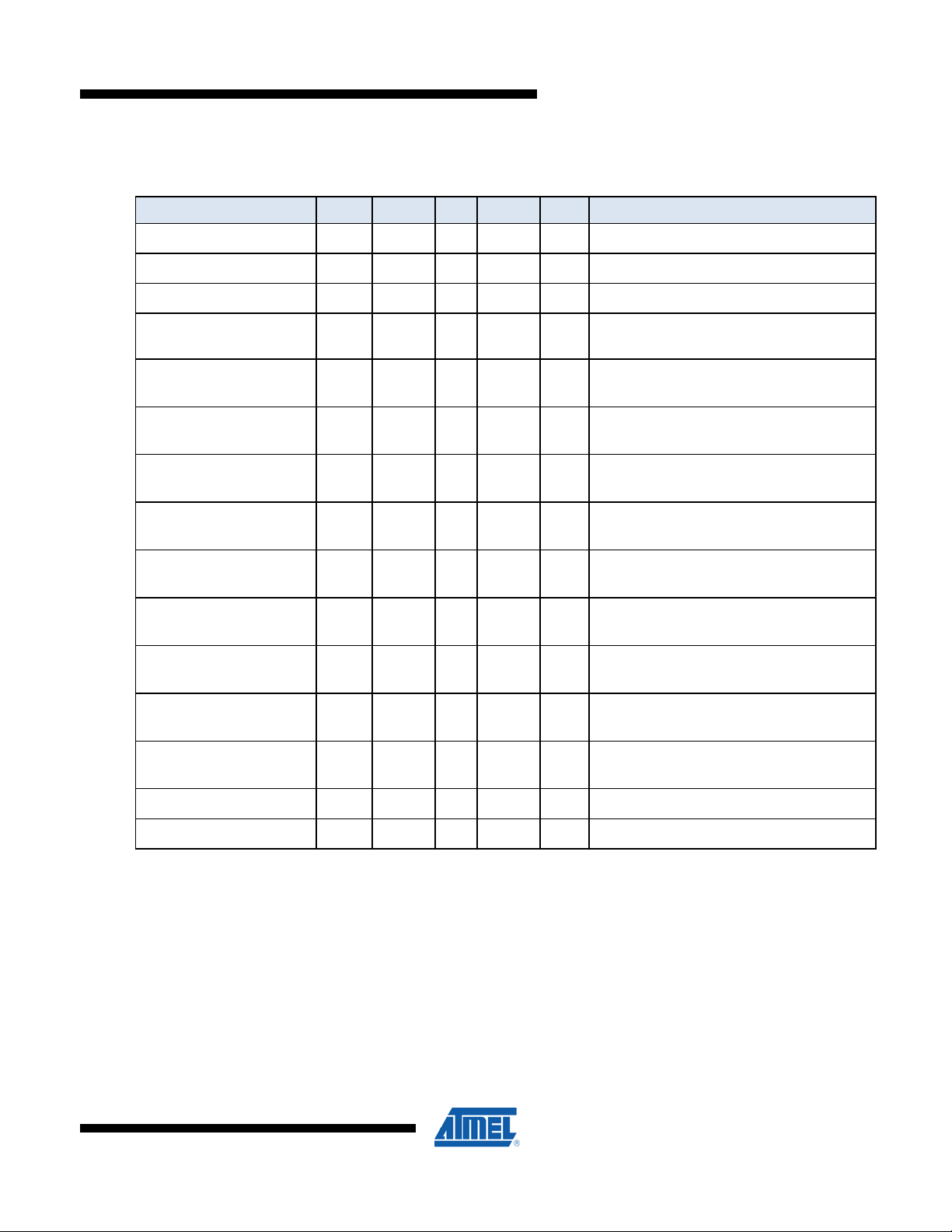

Table 4. DC Parameters

Parameter

Symbol

Min

Typ

Max Unit Notes

Operating temperature

Power Supply Voltage

Fuse Burning Voltage

Active Power Supply

Current

Sleep Power Supply

Current

Input Low Voltage @

V

= 5.5V

cc

Input Low Voltage @

V

= 2.5V

cc

Input High Voltage @

V

= 5.5V

cc

Input High Voltage @

= 2.5V

V

cc

Input Low Voltage when

Active

Input High Voltage when

Active

Output Low voltage

Output Low current

Maximum Input Voltage

ESD

T

A

V

cc

V

BURN

I

CC

I

SLEEP

V

IL

V

IL

V

IH

V

IH

V

IL

V

IH

V

OL

I

OL

V

MAX

V

ESD

-40 85 °C

2.5 5.5 V

3.8 5.5 V

Voltage is applied to Vcc pin

- 10 mA

100 nA

-0.5

.25 * V

cc

-0.5 0.5 V

.25 * V

6.0 V

cc

1.0 3.0 V

-0.5 0.8 V

1.2 6.0 V

0.4 V

4 mA

Vcc + 0.5

4 KV

When chip is in sleep mode,

Vsig = 0.0V, V

Voltage levels for wake token when chip is in

V

sleep mode

= 3.7V.

cc

Voltage levels for wake token when chip is in

sleep mode

Voltage levels for wake token when chip is in

sleep mode

Voltage levels for wake token when chip is in

sleep mode

When chip is in active mode,

V

= 2.5 – 5.5V

cc

When chip is in active mode,

V

= 2.5 – 5.5V

cc

When chip is in active mode,

V

= 2.5 – 5.5V

cc

When chip is in active mode,

V

= 2.5 – 5.5V, V

cc

= 0.4V

OL

V

Human Body Model, Sig & V

pins.

cc

8558A–SMEM–03/09

7

Page 8

3.1. IO Flags

The host system is always the bus master, so before any IO transaction, the system must first send an 8 bit flag to the

chip to indicate the IO operation that is to be performed, as follows:

Value Name Meaning

0x77 Command

0x88 Transmit

0xCC Sleep

All other values are reserved and will be ignored.

3.1.1. Command Timing

After a command flag is transmitted, a command block should be sent to the chip. During parsing of the parameters

and subsequent execution of a properly received command, the chip will be busy and not respond to transitions on the

signal pin. The delays for these operations are listed in the table below:

After this flag, the system starts sending a command block to the chip. The first bit of the

block can follow immediately after the last bit of the flag.

After a turn-around delay, the chip will start transmitting the response for a previously

transmitted command block.

Upon receipt of a sleep flag, the chip will enter a low power mode until the next wake token

is received.

Table 5. Command Timing

Parameter Symbol

ParsingDelay

MemoryDelay

FuseDelay

MacDelay

PersonalizeDelay

t

PARSE

t

EXEC_MEM

t

EXEC_FUSE

t

EXEC_MAC

t

PERSON

In this document, t

is used as shorthand for the delay corresponding to whatever command has been sent to the

EXEC

chip.

Mi

Max Unit Notes

n

0 50

50 100

150 300

15 30 ms Delay to execute MAC command

Delay to check CRC and parse opcode and parameters

μs

before an error indication will be available

Delay to execute Read, Write and/or SramLock commands

μs

Delay to execute BurnFuse commands

μs

7 15 ms Delay to execute GenPersonalizationKey or LoadSram

8 AT88SA100S [Preliminary]

8558A–SMEM–03/09

Page 9

AT88SA100S [ Preliminary]

3.1.2. Transmit Flag

The transmit flag is used to turn around the signal so that the device can send data back to the system, depending on

its current state. The bytes that the device returns to the system, depending on its current state as follows:

Table 6. Return Codes

State Description Error/Status Description

After wake, but prior to first

command

After successful command

execution

Execution error 0x0F Command was properly received but could not be executed by the

After CRC or other parsing

error

The device always transmits complete blocks to the system, so in the above table the status/error bytes result in 4

bytes going to the system – count, error, CRC x 2.

After receipt of a command block, the device will parse the command for errors, a process which takes t

(Refer to 3.1.1). After this interval the system can send a transmit token to the device – if there was an error then the

device will respond with an error code. If there is no error then the device internally transitions automatically from t

and will not respond to any transmit tokens until both delays are complete.

to t

EXEC

0x11 Indication that a proper wake token has been received by the device.

Return bytes per “Output Parameters” in Command section of this

–

0xFF Command was NOT properly received by the device and should be

document. In some cases this is a single byte with a value of 0x00

indicating success. The transmit flag can be resent to the device

repeatedly if a re-read of the output is necessary.

AT88SA100S chip. Changes in the AT88SA100S chip state or the

value of the command bits must happen before it is re-attempted.

re-issued by the system.

PARSE

PARSE

3.1.3. Sleep Flag

The sleep flag is used to transition the device to the low power state, which causes a complete reset of the device’s

internal command engine and input/output buffer. It can be sent to the device at any time when the device will accept a

flag.

To achieve the specified I

achieve I

avoid additional leakage on the input circuit of the chip.

if the sleep state of the input pin is high, the voltage on the input signal should be within 0.5V of VCC to

SLEEP

Atmel recommends that the input signal be brought below VIL when the chip is asleep. To

SLEEP

3.1.4. Pause State

The pause state is entered via the PauseLong command and can be exited only when the watchdog timer has expired

and the chip transitions to a sleep state. When in the pause state, the chip ignores all transitions on the signal pin but

does not enter a low power consumption mode.

The pause state provides a mechanism for multiple AT88SA100S chips on the same wire to be selected and to

exchange data with the host microprocessor. The PauseLong command includes an optional address field which is

compared to the values in Fuses 84-87. If the two match, then the chip enters the pause state, otherwise it continues to

monitor the bus for subsequent commands. The host would selectively put all but one AT88SA100S in the pause state

before executing the MAC command on the active chip. After the end of the watchdog interval all the chips will have

entered the sleep state and the selection process can be started with a wake token (which will then be honored by all

chips) and selection of a subsequent chip.

9

8558A–SMEM–03/09

Page 10

3.2. IO Blocks

Commands are sent to the chip, and responses received from the chip, within a block that is constructed in the

following way:

Byte

Number

0 Count Number of bytes to be transferred to the chip in the block, including count, packet and

1 to (N-2) Packet Command, parameters and data, or response. Refer to Section 4 for more details.

N-1, N Checksum CRC-16 verification of the count and packet bytes. The CRC polynomial is 0x8005, the

3.3. IO Flow

The general IO flow for a MAC command is as follows:

3. System sends wake token.

4. System sends Transmit Flag.

5. Receive 0x11 value from the device to verify proper wakeup synchronization.

6. System sends Command Flag.

7. System sends command block.

8. System waits t

9. System sends Transmit Flag. If command format is OK, the device ignores this flag because the computation

10. System waits t

11. System sends Transmit Flag.

12. Receive output block from the device, system checks CRC.

13. If CRC from the device is incorrect, indication transmission error, system resends Transmit flag.

14. System sends sleep flag to the device.

All commands other than MAC have a short execution delay. In these cases the system should omit steps 6, 7 & 8 and

replace this with a wait of duration t

Name Meaning

checksum, so this byte should always have a value of (N+1). The maximum size block is

39 and the minimum size block is 4. Values outside this range will cause unpredictable

operation.

initial register value should be 0 and after the last bit of the count and packet have been

transmitted the internal CRC register should have a value that matches that in the block.

The first byte transmitted (N-1) is the least significant byte of the CRC value so the last

byte of the block is the most significant byte of the CRC.

for the device to check for command formation errors.

PARSE

engine is busy. If there was an error, the device responds with an error code.

, Refer to 3.1.1.

EXEC

+ t

PARSE

EXEC

.

3.4. Synchronization

Because the communications protocol is half duplex, there is the possibility that the system and the device will fall out

of synchronization with each other. In order to speed recovery, the device implements a timeout that forces the device

to sleep. See Section 2.6.1.

10 AT88SA100S [Preliminary]

8558A–SMEM–03/09

Page 11

AT88SA100S [ Preliminary]

3.4.1. IO Timeout

After a leading transition for any data token has been received, the device will expect another token to be transmitted

within a t

assumes that the synchronization with the host is lost and transitions to a sleep state.

After the device receives the last bit of a command block, this timeout circuitry is disabled. If the command is properly

formatted, then the timeout counter is re-enabled with the first transmit token that occurs after t

an error in the command, then it is re-enabled with the first transmit token that occurs after t

In order to limit the active current if the device is inadvertently awakened, the IO timeout is also enabled when the

device wakes up. If the first token does not come within the t

performing any operations.

3.4.2. Synchronization Procedures

When the system and the device fall out of synchronization, the system will ultimately end up sending a transmit flag

which will not generate a response from the device. The system should implement its own timeout which waits for

t

during which time the device should go to sleep automatically. At this point, the system should send a Wake

TIMEOUT

token and after t

It may be possible that the system does not get the 0x11 code from the device for one of the following reasons:

1. The system did not wait a full t

Wake token and Transmit flag as a data bits. Recommended resolution is to wait twice the t

issue the Wake token.

2. The device went into the sleep mode for some reason while the system was transmitting data. In this case, the

device will interpret the next data bit as a wake token, but ignore some of the subsequently transmitted bits during

its wake-up delay. If any bytes are transmitted after the wake-up delay, they may be interpreted as a legal flag,

though the following bytes would not be interpreted as a legal command due to an incorrect count or the lack of a

correct CRC. Recommended resolution is to wait the t

3. There is some internal error condition within the device which will be automatically reset after a t

see below. There is no way to externally reset the device – the system should leave the IO pin idle for this interval

and issue the Wake token.

interval. If the leading edge of the next token is not received within this period of time, the device

TIMEOUT

+ t

WLO

PARSE

.

PARSE

interval, then the device will go back to sleep without

TIMEOUT

+ t

, a Transmit token. The 0x11 status indicates that the resynchronization was successful.

WHI

delay with the IO signal idle in which case the device may have interpreted the

TIMEOUT

delay and re-issue the Wake token.

TIMEOUT

EXEC

delay and re-

TIMEOUT

WATCHDOG

. If there is

interval,

3.5. Watchdog Failsafe

After the Wake token has been received by the device, a watchdog counter is started within the chip. After t

chip will enter sleep mode, regardless of whether it is in the middle of execution of a command and/or whether some IO

transmission is in progress. There is no way to reset the counter other than to put the chip to sleep and wake it up

again.

This is implemented as a fail-safe so that no matter what happens on either the system side or inside the various state

machines of the device including any IO synchronization issue, power consumption will fall to the low sleep level

automatically.

3.6. Byte and Bit Ordering

The device is a little-endian chip:

• All multi-byte aggregate elements within this spec are treated as arrays of bytes and are processed in the order

received.

• Data is transferred to/from the device least significant bit first on the bus.

• In this document, the most significant bit appears towards the left hand side of the page.

8558A–SMEM–03/09

WATCHDOG

, the

11

Page 12

4. Commands

The command packet is broken down in the following way:

Byte Name Meaning

0 Opcode The Command code

1 Param1 The first parameter – always present

2-3 Param2 The second parameter – always present

4 + Data Optional remaining input data

If a command fails because the CRC within the block is incorrect, the opcode is invalid or one of the parameters is

illegal, then immediately after t

packet. The value of that byte will be either 0x0F or 0xFF depending on the source of the error. See Section 2.3.2.

If a command is received successfully then after the appropriate execution delay the system will be able to retrieve the

output block as described in the individual command descriptions below.

In the individual command description tables below, the Size column describes the number of bytes in the parameter

documented in each particular row. The total size of the block for each of the commands is fixed, though that value is

different for each command. If the block size for a particular command is incorrect, the chip will not attempt the

command execution and return an error.

the system will be able to retrieve an error response block containing a single byte

PARSE

12 AT88SA100S [Preliminary]

8558A–SMEM–03/09

Page 13

AT88SA100S [ Preliminary]

4.1. MAC

Computes a SHA-256 digest of the key, challenge and other fixed information on the chip to generate an output

response. If MemValid is not set, indicating that no valid key is stored in the SRAM, then this command will return an

error. The hashed message includes the following bytes, concatenated in this order:

256 bits Key (Stored in Sram)

256 bits Challenge

8 bits Opcode (always 0x01)

8 bits Mode input

16 bits Param2 input

88 bits All 0’s

8 bits MfrID Fuse[88-95]

32 bits SerialNum Fuse[96-127], or 0’s

16 bits ROM MfrID

16 bits ROM SN), or 0’s

1 bit 1’s – SHA-256 padding

255 bits 0’s – SHA-256 padding

64 bits Length (704) per SHA-256

Table 7. Input Parameters

Name Size Notes

Opcode MAC 1 0x08

Param2 Zero 2 Must be 0x00 00

Data Challenge 32 Input portion of message to be digested

Table 8. Output Parameters

Name Size Notes

Response 32 SHA-256 digest

Table 9. Mode Encoding

Bit Notes

6 If set, then the 4 bytes of Serial Number Fuses and the two bytes of ROM SN will be included in the

message, otherwise these bits will be set to 0 in the message.

0-5, 7 Ignored, must be all 0.

8558A–SMEM–03/09

13

Page 14

4.2. Read

Reads 4 bytes from Fuse, ROM or MemValid. Any attempt to present the chip with an illegal Fuse address will result in

an error return.

Table 10. Input Parameters

Name Size Notes

Opcode READ 1 0x02

Param1 Mode 1 Fuse, ROM or MemValid. Refer to 1.1.

Param2 Address 2

Data – 0

Table 11. Output Parameters

Name Size Notes

Contents 4 The contents of the specified memory location.

Table 12. Mode Encoding

Which 4 bytes within array. Bits 2-15 are ignored by the chip

and should be 0’s.

Name Value Notes

ROM 0x00 Reads four bytes from the ROM. Bit 1 of the address parameter must be 0.

Fuse 0x01 Reads the value of 32 fuses. Bit 1 of the address parameter must be 1. The

LSB of the first byte returned contains the fuse numbered address<<5, and

so on.

MemValid 0x03 Returns four bytes. The LSB of the first byte indicates whether or not the

contents of the SRAM are valid. All other bits in all bytes have a value of 0.

The address parameter is ignored.

14 AT88SA100S [Preliminary]

8558A–SMEM–03/09

Page 15

AT88SA100S [ Preliminary]

4.3. BurnFuse

Burns one of the 88 user accessible fuse bits.

The power supply pin must meet the V

actual fuse blow will not be attempted and the chip will return the error code. If the watchdog timer is within t

its expiration, this command will also be aborted and return an error.

The values in fuses #88-127 are reserved for the MfrID and SerialNumber and cannot be blown via this command. All

addresses above 0x4C (87) will result in an error.

Fuses, with the exception of those initialized by Atmel, have a value of 1 on shipment from the Atmel factory and

transition to a 0 when they are burned.

Fuse bits #0 through #7 of the fuse array are word lock bits. Burning one of these has the effect of locking the

corresponding 16 bit word within Fuse. Bit 0 locks fuses 0-15, bit 1 locks fuses 16-31 and so on. If bit 0 is burned, then

the value of the lock bits can no longer be changed. The values of lock bits 6 & 7 are ignored by the chip.

There is a very small interval during t

not be removed during this interval, or the fuse may end up in a state where it reads as un-blown but cannot be burned.

Table 13. Input Parameters

Name Size Notes

Opcode BURNFUSE 1 0x04

Param1 Address 1 Must be 0x00 00

Param2 Zero 2 Should be all 0’s

Data – 0

Table 14. Output Parameters

specification in order to burn fuses reliably. If the voltage is too low then the

BLOW

EXEC_FUSE

EXEC_FUSE

when the fuse element is actually being blown. The power supply must

of

Name Size Notes

Success 1 Upon successful completion, a value of 0 will be returned by the device.

15

8558A–SMEM–03/09

Page 16

4.4. GenPersonalizationKey

This command generates a decryption digest that will be used by the subsequent command (LoadSram) to decrypt the

key value that is to be written into the SRAM. This command must be run immediately prior to LoadSram within the

same watchdog cycle.

This command loads a transport key from an internal secure storage location and then uses that key along with an

input seed to generate a decryption digest using SHA-256. Neither the transport key nor the decryption digest can be

read from the chip. Upon completion, an internal bit is set indicating that the decryption digest has been generated and

is ready to use by LoadSram. This bit is cleared (and the digest lost) when the watchdog timer expires, the chip goes to

sleep or the power is cycled.

Table 15. Input Parameters

Name Size Notes

Opcode GenPers 1 0x20

Param1 Zero 1 Must be 0x00

Param2 KeyID 2 Identification number of the personalization key to be loaded

Data Seed 16

Table 16. Output Parameter

Name Size Notes

Success 1

The SHA-256 message body used to create the decryption digest which is internally stored in the chip consists of the

following 512 bits:

256 bits Stored Key[KeyID]

64 bits All 1’s

127 bits Input seed

1 bit ‘1’ pad

64 bits length of message in bits, fixed at 512

Upon successful execution, a value of 0 will be returned by the AT88SA100S

chip.

Seed for digest generation. The least significant bit of the last

byte is ignored.

16 AT88SA100S [Preliminary]

8558A–SMEM–03/09

Page 17

AT88SA100S [ Preliminary]

4.5. LoadSram

Writes 256 bits into the battery backed SRAM and locks this memory against further modification. The value in the

battery backed SRAM cannot be read, it must be verified via the MAC command. If the SRAM is already valid then this

command will fail with an error response. The only way to unlock the SRAM is to remove power from the device.

The input data is always decrypted using the decryption digest previously generated by GenPersonalizationKey prior to

being written into the battery backed SRAM.

Note: Both the GenPersonalizationKey and LoadSram commands must be run consecutively within a single wake

cycle prior to the expiration of the watchdog timer. If any command is inserted between these two operations

then LoadSram will fail.

Table 17. Input Parameters

Name Size Notes

Opcode LOADSRAM 1 0x10

Param1 Zero1 1 Must be 0x00

Param2 Zero2 2 Must be 0x00 00

Data Map 32 Encrypted value to be written into the SRAM.

Table 18. Output Parameter

Name Size Notes

Success 1

The AT88SA100S chip executes the following sequence on receipt of this command.

1. If the internal flag (indicating that a personalization key has been loaded) is not set, then return error. If the

MemValid flag is set, return error.

2. Successively XOR each byte in the data parameter with the corresponding byte from the personalization key

generated by GenPersonalizationKey.

3. Transfer the bytes to the battery backed SRAM.

4. Set MemValid (internal flag) to 1.

Upon successful execution, a value of 0 will be returned by the AT88SA100S

chip.

8558A–SMEM–03/09

17

Page 18

4.6. PauseLong

Forces the chip into a busy mode until the watchdog timer expires, after which it will automatically enter the sleep state.

During execution of this command the chip will ignore all activity on the IO signal. This command is used to prevent bus

conflicts in a system that also includes a CryptoAuthentication host chip sharing the same signal wire.

Table 19. Input Parameters

Name Size Notes

Opode PAUSELONG 1 0x01

Param1 Selector 1 Which chip to put into the pause state, 0x00 for all chips

Param2 Zero 2 Must be 0x00 00

Data Ignored 0

Table 20. Output Parameter

Name Size Notes

Success 1 If the command indicates that some other chip should go into the pause state, a

value of 0 will be returned by this AT88SA100S chip. If this chip goes into the

pause state no value will be returned.

The Selector parameter provides a mechanism to select which device will pause if there are multiple devices on the

bus:

• If the Selector parameter is 0x00, then every chip receiving this command will go into the pause state and no chip will

return a success code.

• If any of the bits of the Selector parameter are set, then the chip will read the values of Fuse[84-87] and go to sleep

only if those fuse values match the least significant 4 bits of the Selector parameter. If the chip does NOT go into the

pause state, it returns an error code of 0x0F. Otherwise it goes into the pause state and never returns any code.

5. Pinout

There are three pins on the chip.

Pin # Name Description

1 Signal IO channel to the system, open drain output. It is expected that an external pull-up resistor

will be provided to pull this signal up to V

in use this pin can be pulled to either V

2

3

V

CC

V

SS

Power supply, 2.5 – 5.5V. This pin should be bypassed with a high quality 0.1μF capacitor

close to this pin with a short trace to V

Connect to system ground.

18 AT88SA100S [Preliminary]

8558A–SMEM–03/09

for proper communications. When the chip is not

CC

or V

.

.

Page 19

AT88SA100S [ Preliminary]

6. Package Drawing

3TS1 - Shrink SOT

3

E1

1

e1

2

E

Top View

b

A2

A

SEATING

PLANE

e

D

A1

Side View

Notes: 1. Dimension D does not include mold flash, protrusions or gate burrs.

Mold flash, protrusions or gate burrs shall not exceed 0.25 mm per

end. Dimension E1 does not include interlead flash or protrusion.

Interlead flash or protrusion shall not exceed 0.25 mm per side.

2. The package top may be smaller than the package bottom. Dimensions D and E1 are determined at the outermost extremes of the

plastic body exclusive of mold flash, tie bar burrs, gate burrs and

interlead flash, but including any mismatch between the top and

bottom of the plastic body.

3. These dimensions apply to the flat section of the lead between 0.08

mm and 0.15 mm from the lead tip.

This drawing is for general information only. Refer to JEDEC Drawing

TO-236, Variation AB for additional information.

End View

SYMBOL

A

A1

A2

D

E

E1

L1

e1

b

C

L

L1

COMMON DIMENSIONS

(Unit of Measure = mm)

MIN

0.89

0.01

0.88

2.80

2.10

1.20

NOM

2.90

1.30

MAX

1.12

-

0.10

-

1.02

-

3.04

2.64

-

1.40

0.54 REF

1.90 BSC

0.50

0.30

-

NOTE

1,2

1,2

3

Package Drawing Contact:

R

packagedrawings@atmel.com

TITLE

3TS1, 3-lead, 1.30 mm Body, PlasticThin

Shrink Small OutlinePackage (Shrink SOT)

8558A–SMEM–03/09

11/5/08

DRAWING NO.GPC

3TS1

REV.

ATBG

19

Page 20

7. Revision History

Table 21. Revision History

Doc. Rev. Date Comments

8558A 03/2009 Initial document release

20 AT88SA100S [Preliminary]

8558A–SMEM–03/09

Page 21

Headquarters

Atmel Corporation

2325 Orchard Parkway

San Jose, CA 95131

USA

Tel: 1(408) 441-0311

Fax: 1(408) 487-2600

International

Atmel Asia

Room 1219

Chinachem Golden Plaza

77 Mody Road Tsimshatsui

East Kowloon

Hong Kong

Tel: (852) 2721-9778

Fax: (852) 2722-1369

Product Contact

Web Site

www.atmel.com

Literature Requests

www.atmel.com/literature

Atmel Europe

Le Krebs

8, Rue Jean-Pierre Timbaud

BP 309

78054 Saint-Quentin-enYvelines Cedex

France

Tel: (33) 1-30-60-70-00

Fax: (33) 1-30-60-71-11

Technical Support

securemem@atmel.com

Atmel Japan

9F, Tonetsu Shinkawa Bldg.

1-24-8 Shinkawa

Chuo-ku, Tokyo 104-0033

Japan

Tel: (81) 3-3523-3551

Fax: (81) 3-3523-7581

Sales Contact

www.atmel.com/contacts

Disclaimer: The information in this document is provided in connection with Atmel products. No license, express or implied, by estoppel or otherwise, to any

intellectual property right is granted by this document or in connection with the sale of Atmel products. EXCEPT AS SET FORTH IN ATMEL’S TERMS AND

CONDITIONS OF SALE LOCATED ON ATMEL’S WEB SITE, ATMEL ASSUMES NO LIABILITY WHATSOEVER AND DISCLAIMS ANY EXPRESS, IMPLIED

OR STATUTORY WARRANTY RELATING TO ITS PRODUCTS INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTY OF MERCHANTABILITY,

FITNESS FOR A PARTICULAR PURPOSE, OR NON-INFRINGEMENT. IN NO EVENT SHALL ATMEL BE LIABLE FOR ANY DIRECT, INDIRECT,

CONSEQUENTIAL, PUNITIVE, SPECIAL OR INCIDEN-TAL DAMAGES (INCLUDING, WITHOUT LIMITATION, DAMAGES FOR LOSS OF PROFITS, BUSINESS

INTERRUPTION, OR LOSS OF INFORMATION) ARISING OUT OF THE USE OR INABILITY TO USE THIS DOCUMENT, EVEN IF ATMEL HAS BEEN ADVISED

OF THE POSSIBILITY OF SUCH DAMAGES. Atmel makes no representations or warranties with respect to the accuracy or completeness of the contents of this

document and reserves the right to make changes to specifications and product descriptions at any time without notice. Atmel does not make any commitment to

update the information contained herein. Unless specifically provided otherwise, Atmel products are not suitable for, and shall not be used in, automotive

applications. Atmel’s products are not intended, authorized, or warranted for use as components in applications intended to support or sustain life.

© 2009 Atmel Corporation. All rights reserved. Atmel®, Atmel logo and combinations thereof, and others are registered trademarks, CryptoAuthentication™, and

others, are trademarks of Atmel Corporation or its subsidiaries. Other terms and product names may be trademarks of others.

8558A–SMEM–03/09

Loading...

Loading...