Page 1

Features

• RF Frequency Range of 264–456 MHz

• 6 dBm RF Output into Matched Antenna

• RF Output Power Adjustable over 36 dB with 1 dB Resolution

• Phase-locked Loop (PLL) Based Frequency Synthesizer

• Supports OOK Modulation

• Data Bandwidth of Up to 10 Kbps Manchester

• 2-volt Operation

• 8-bit AVR

• Minimal External Components

• Space-saving 20-lead TSSOP

• 2 KB (1K x 16) of Flash Program Memory

• 128 Bytes of EEPROM

• 128 Bytes of SRAM

• In-system Programmable Data and Program Memory

• Six I/Os (Serial I/F, LED Drive Outputs, Button Input Interrupts)

• Low Battery Detect and Brown-out Protection

• Software Fine-tuning of VCO Tank Circuit

â

RISC Microcontroller Core

Smart RF

™

Wireless Data

Microtransmitter

Applications

• Remote Keyless Entry (RKE) Transmitters

• Wireless Security Systems

• Home Appliance Control (Lighting Control, Ceiling Fans)

• Radio Remote Control (Hobby, Toys)

• Garage Door Openers

• Wireless PC Peripherals (Keyboard, Mouse)

• Telemetry (Tire Pressure, Utility Meter, Asset Tracking)

Description

The Atmel AT86RF401 Smart RF™Microtransmitter is a highly integrated, low-cost RF

transmitter, combined with an AVR

single LiMnO

coin cell (CR2032 or similar), three capacitors, an inductor and a tuned-

2

loop antenna to implement a complete on-off keyed (OOK) wireless RF data

transmitter.

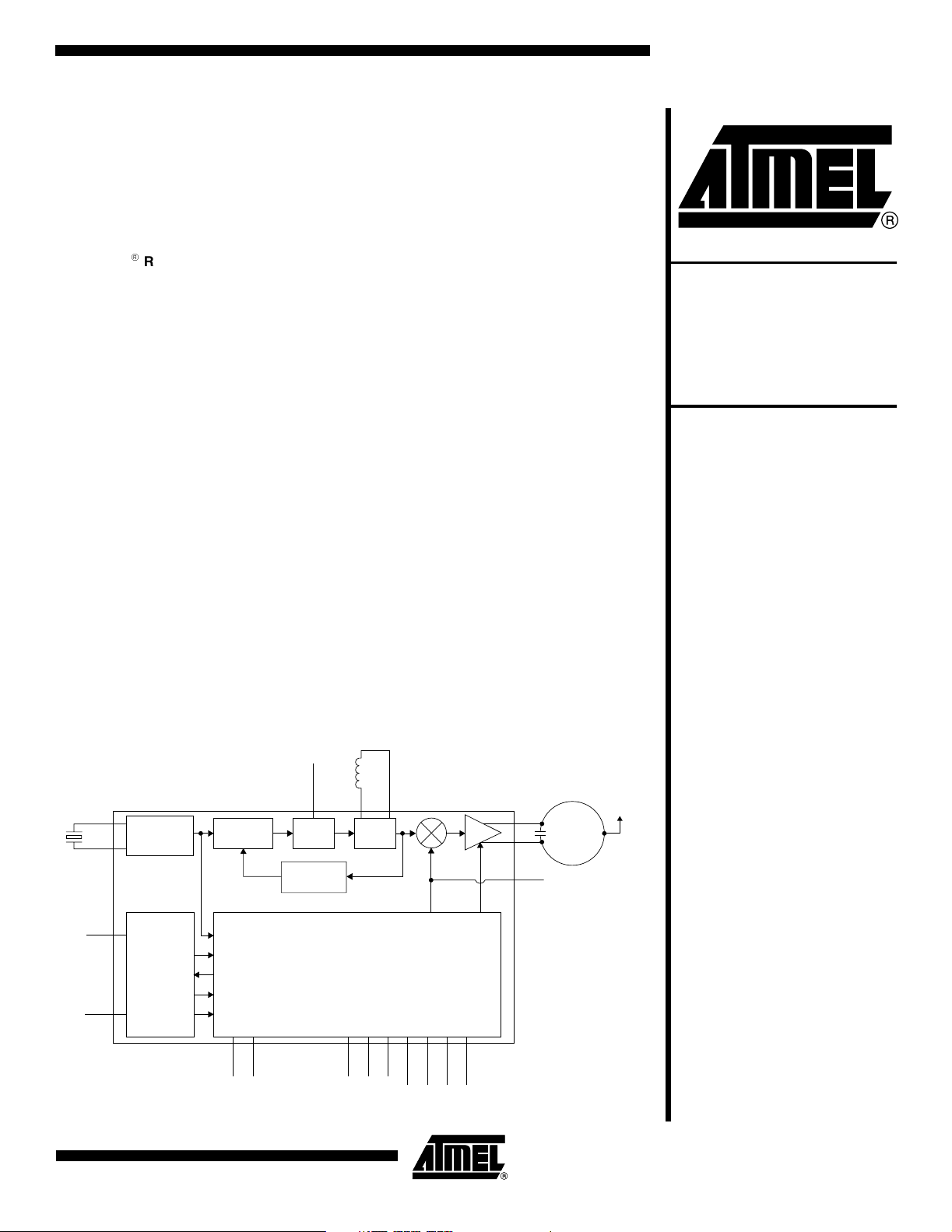

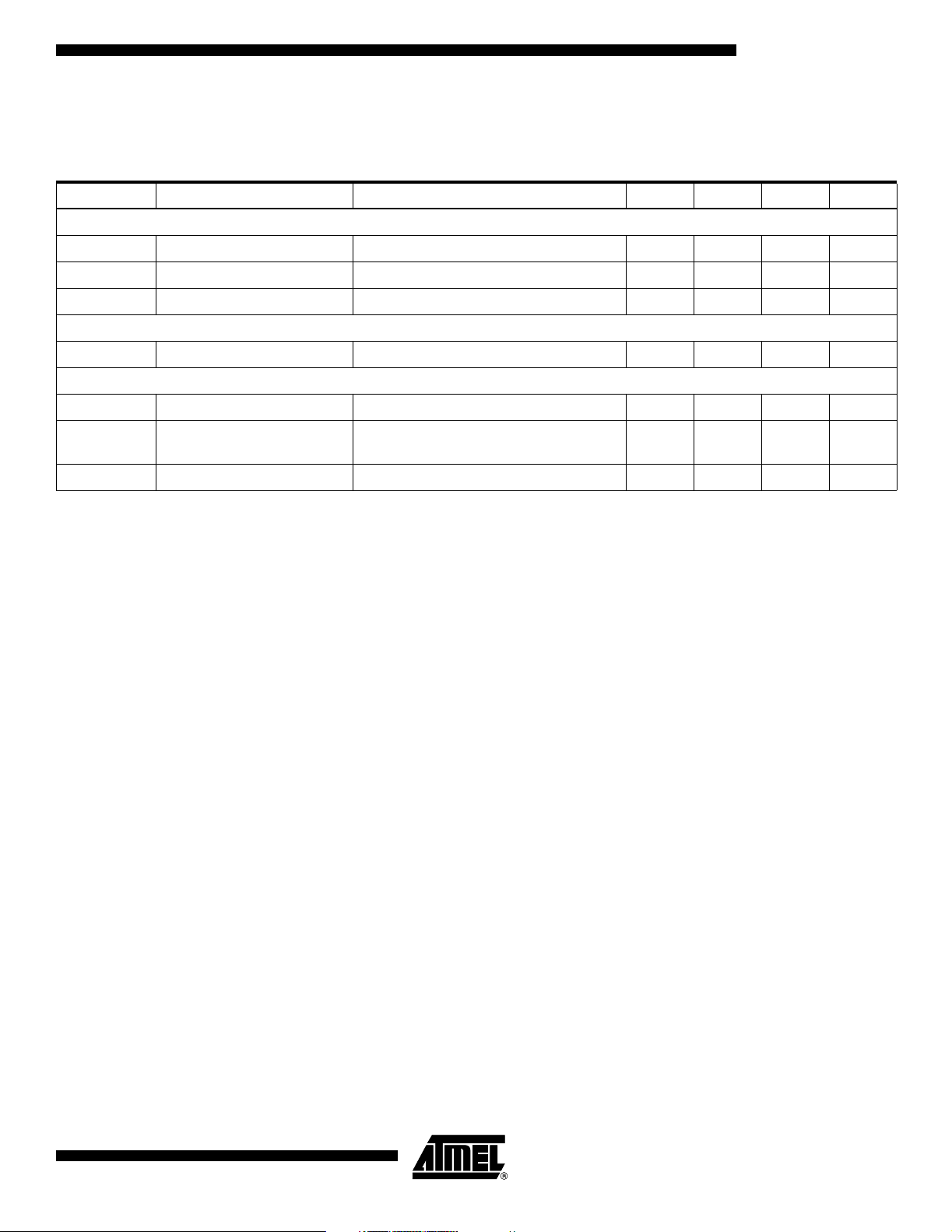

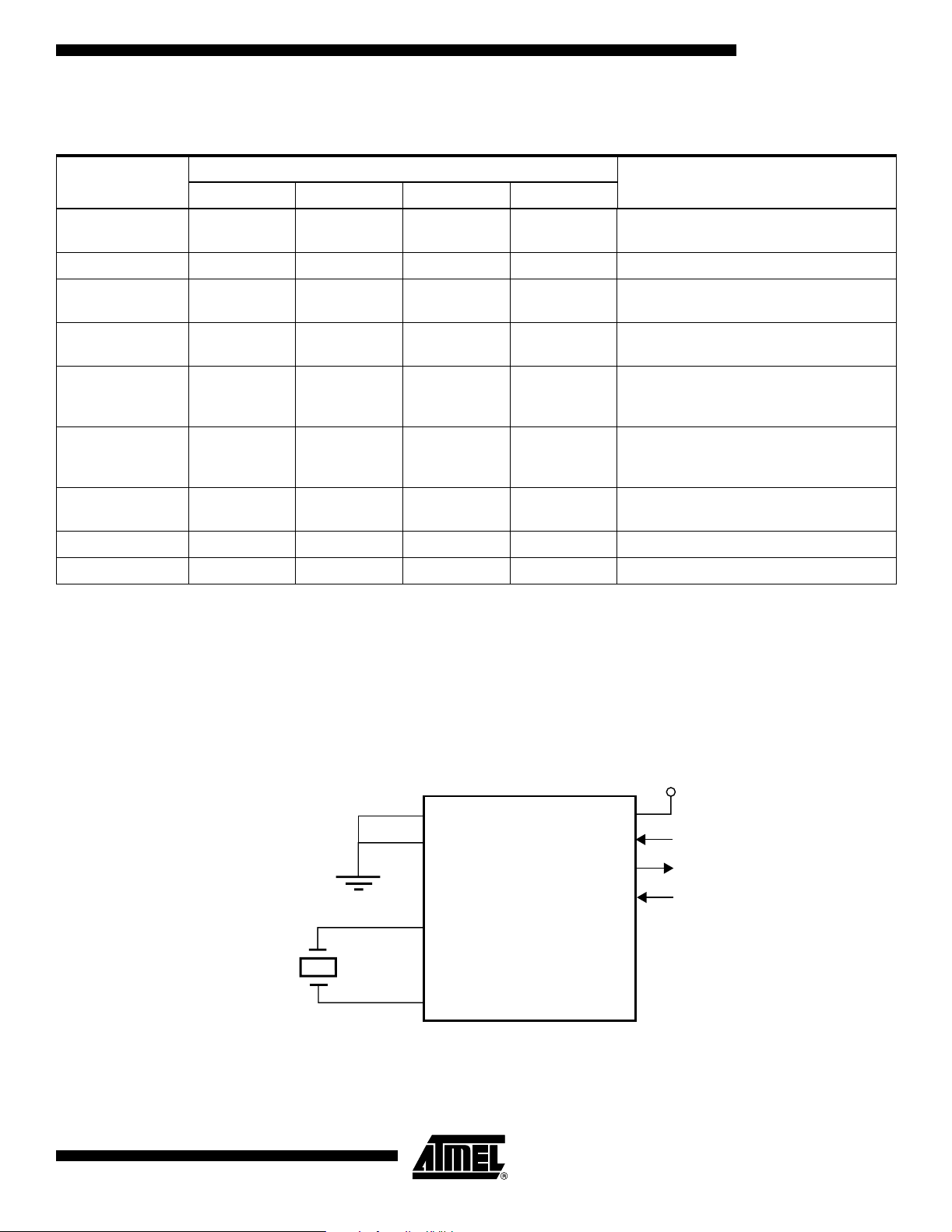

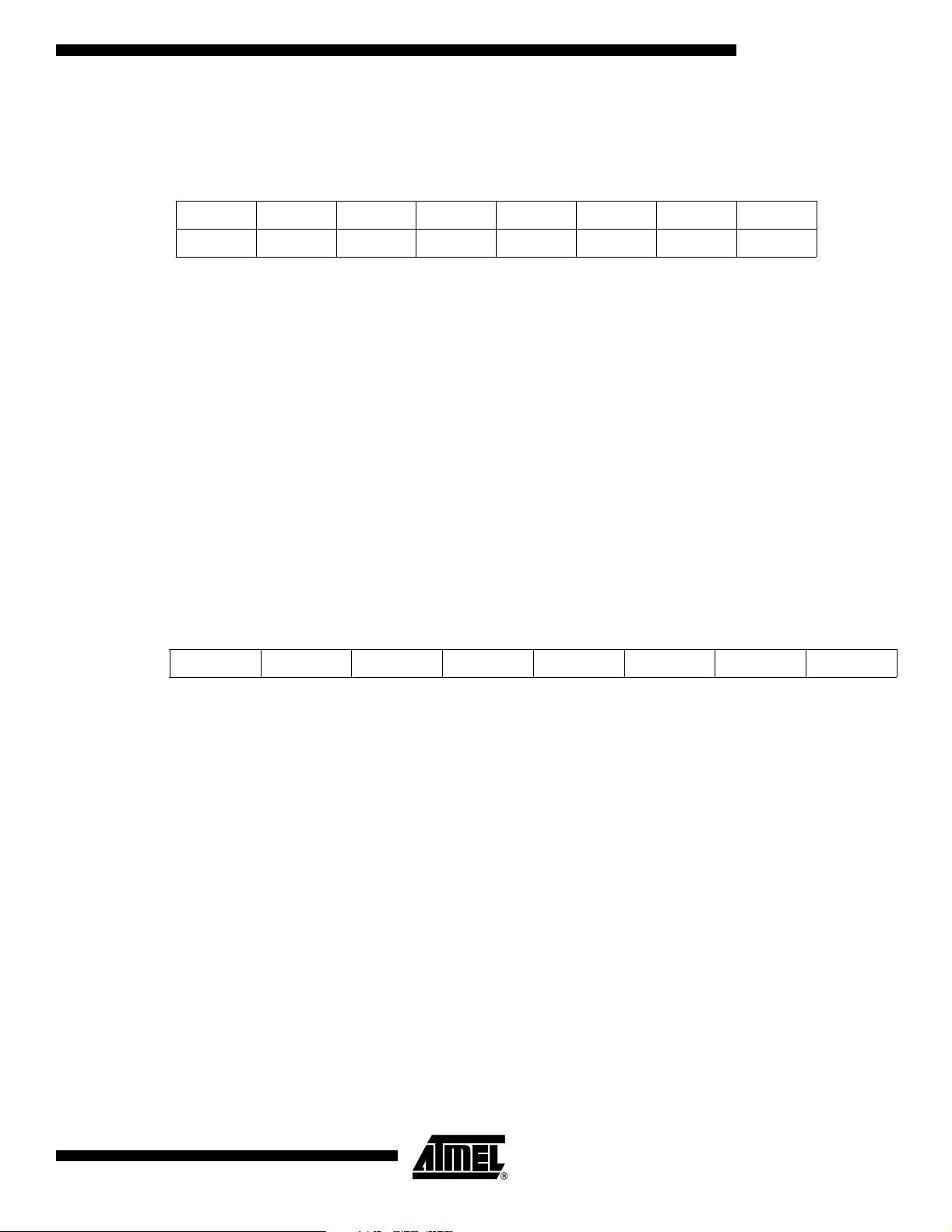

Figure 1. Block Diagram

XTAL/CLK

XTALB

OSCILLATOR

PHASE

DETECTOR

RISC microcontroller. It requires only a crystal, a

L1

VCO

L2

ANT

RF

AMP

ANTB

CFIL

LOOP FIL

LOOP

FILTER

PRESCALER

÷

24

B+

AT86RF401

Preliminary

AVDD

AGND

POWER

SUPPLY

SUPERVISOR

CLOCK

RESET

WATCHDOG

LOW-VOLTAGE DETECT

BROWN-OUT PROTECT

DVDD

DGND

DATA

AVR RISC µC

2 KB Flash Program Memory

128 Bytes EEPROM Data Memory

IO5

IO4

IO3

SDI/IO0

SCK/IO2

SDO/IO1

GAIN

TRIM

RESETB

1424D–RKE–09/02

1

Page 2

In-system programmable, nonvolatile Flash program memory and EEPROM data storage make possible rapid time-to-market and lower inventory costs.

Static current consumption is kept to a minimum with an ultra-low current shutdown

mode. Normal operation resumes when a button is pressed. This activates the crystal

oscillator circuit that serves as the clock for the AVR microcontroller.

The RF carrier is synthesized utilizing an on-board Voltage Controlled Oscillator (VCO).

Optimal tuning of the VCO is maintained over component tolerance through the use of a

software-controlled switched capacitor array. Its accuracy is maintained with a PLL

detector that compares the crystal oscillator to a frequency-scaled version (divided by

24) of the RF carrier. The resulting error signal adjusts the VCO to produce a very stable

RF carrier.

An interrupt-based bit-timer structure, integral to the AVR microcontroller, simplifies the

implementation of user-specific, data-bit encoding routines, such as PWM or Manchester, for modulating the RF carrier. Thirty-six dB of RF power output control is available to

the user in 1 dB steps and is addressable in software. The RF signal output is placed

differentially on a tuned-loop antenna, which may be realized as a counterspread copper trace on a PCB.

The AT86RF401 is fabricated in Atmel’s 0.6 µm Mixed Signal CMOS + EEPROM process, enabling true system-level integration (SLI).

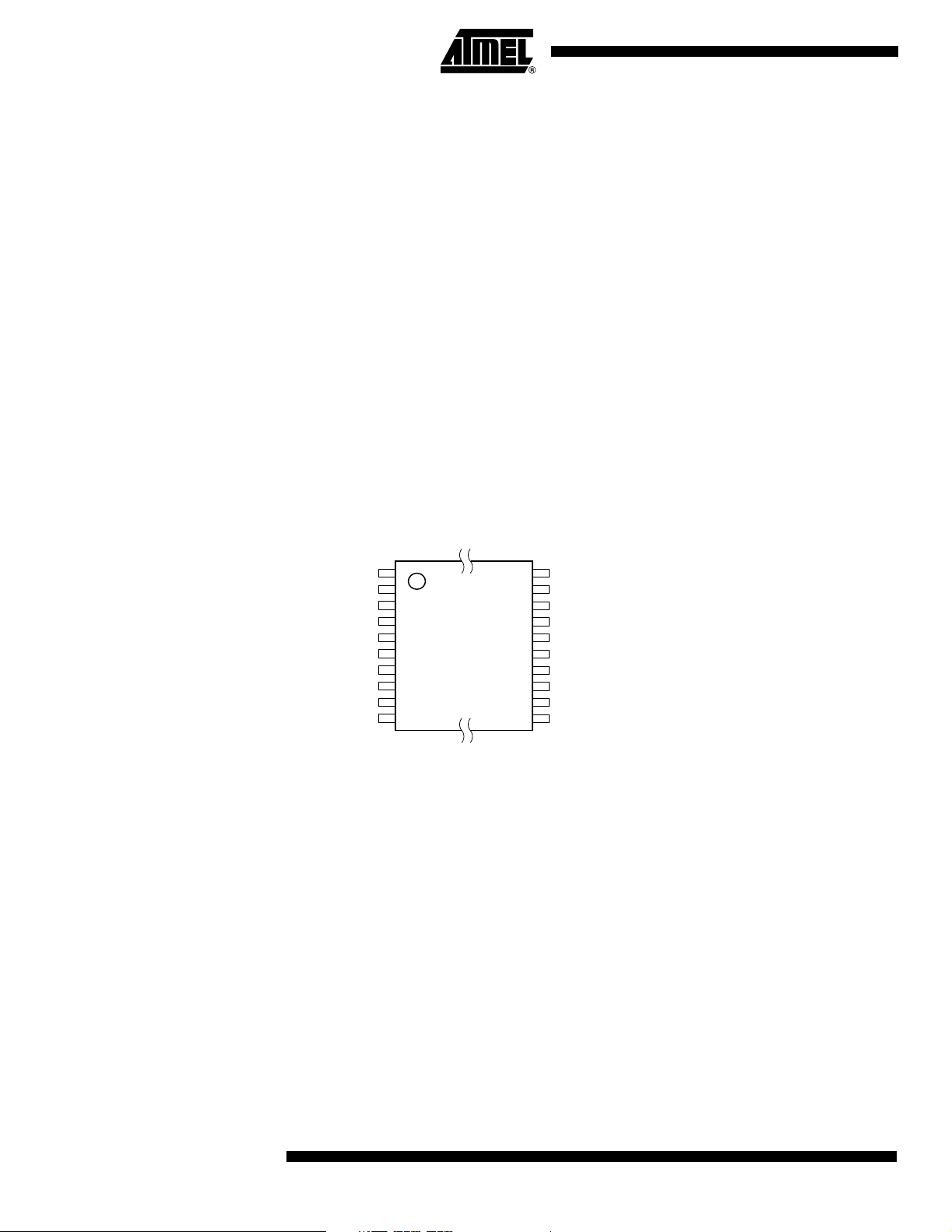

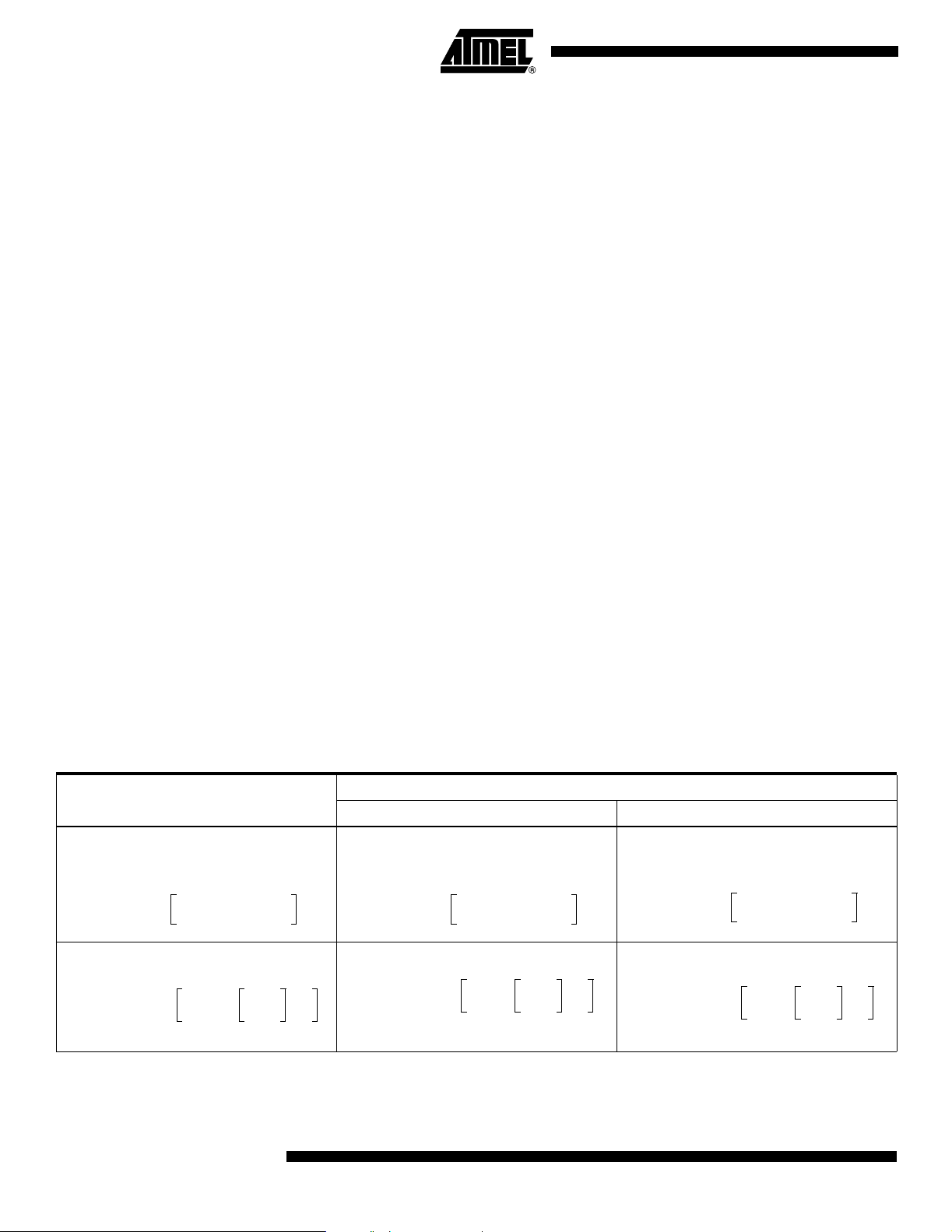

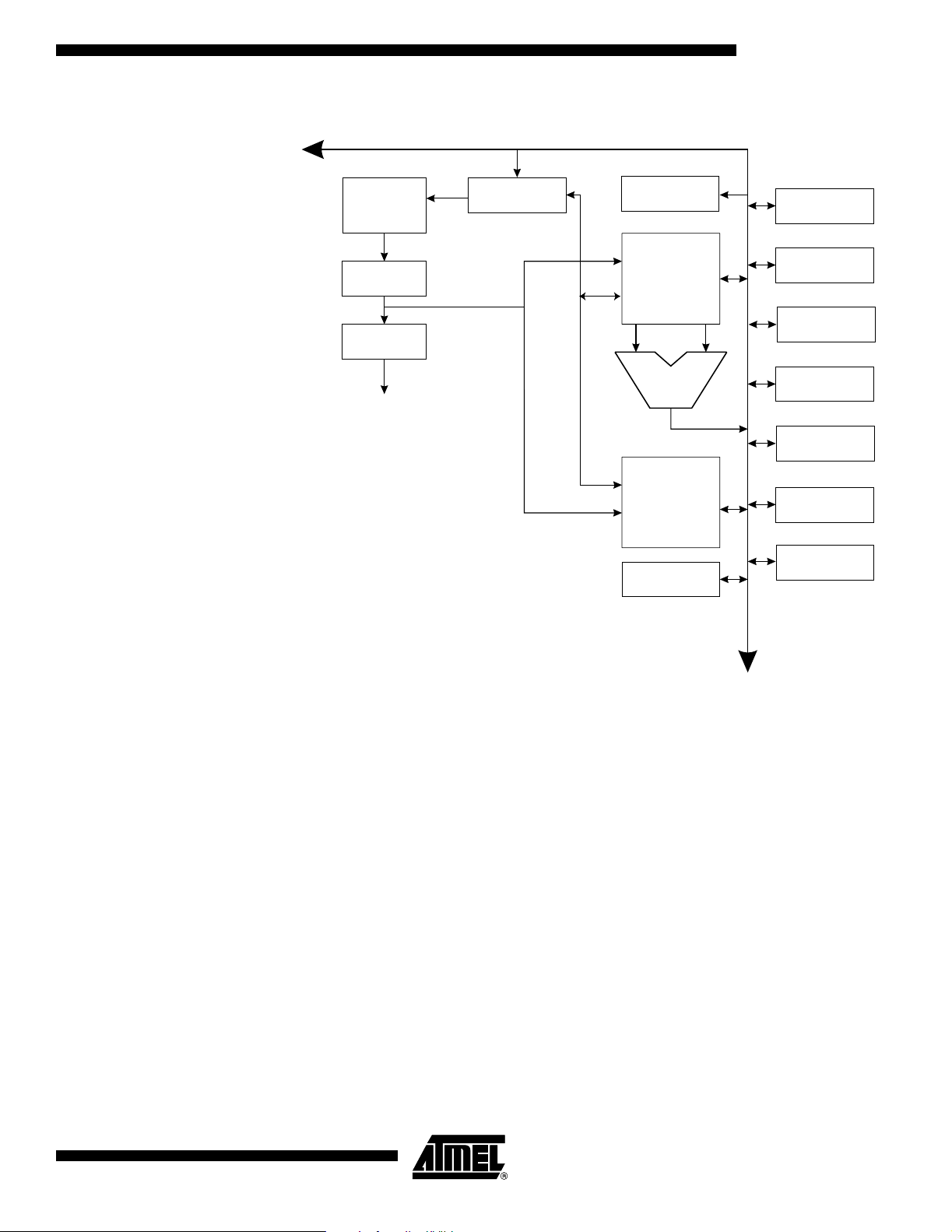

Figure 2. 20-lead TSSOP

ANTB

LOOPFIL

RESETB

N/C

I/O0 (SDI)

I/O1 (SDO)

I/O2 (SCK)

XTAL/CLK

L1

L2

1

2

3

4

5

6

7

8

9

10

20

19

18

17

16

15

14

13

12

11

ANT

CFIL

AVDD

DVDD

AGND

DGND

I/O5

I/O4

I/O3

XTALB

2

AT86RF401

1424D–RKE–09/02

Page 3

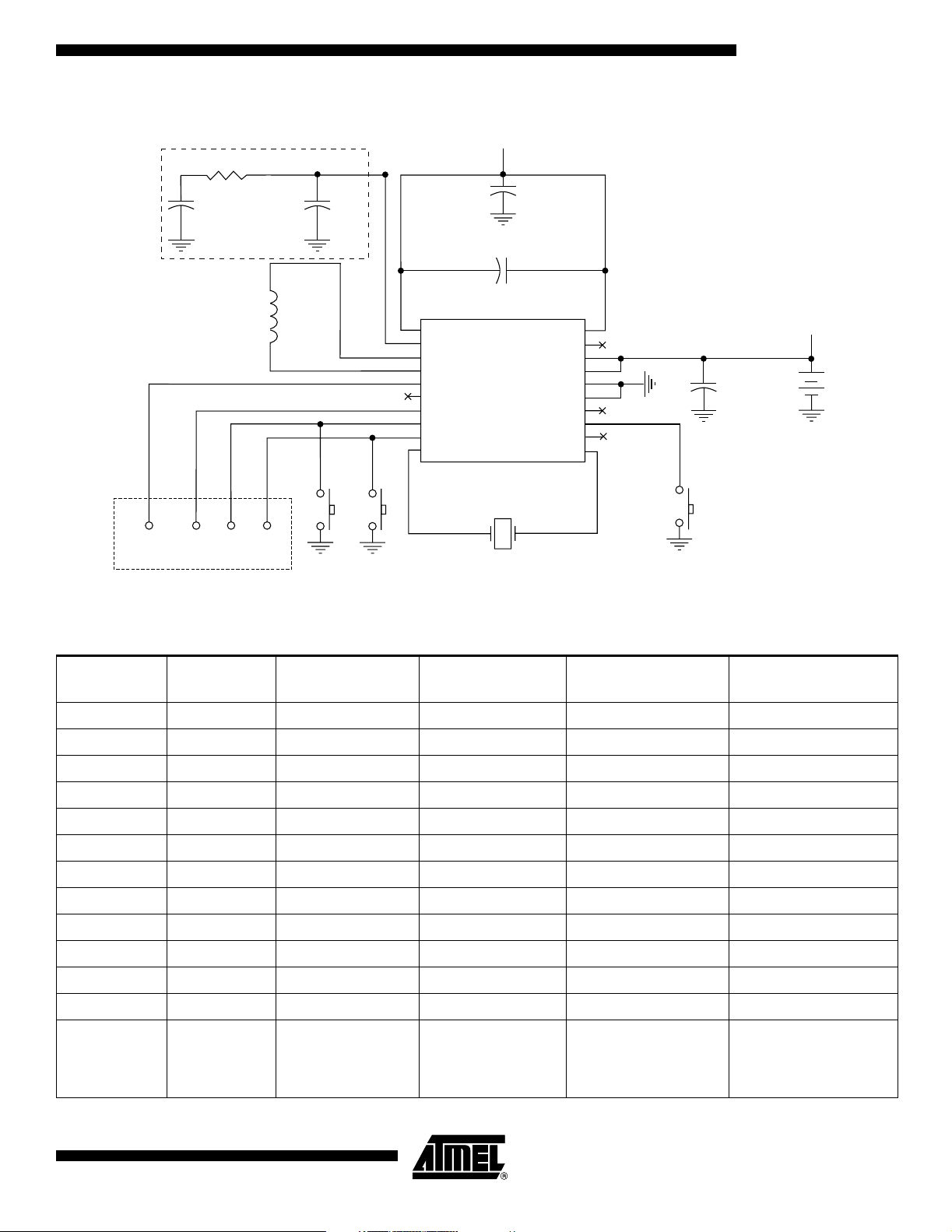

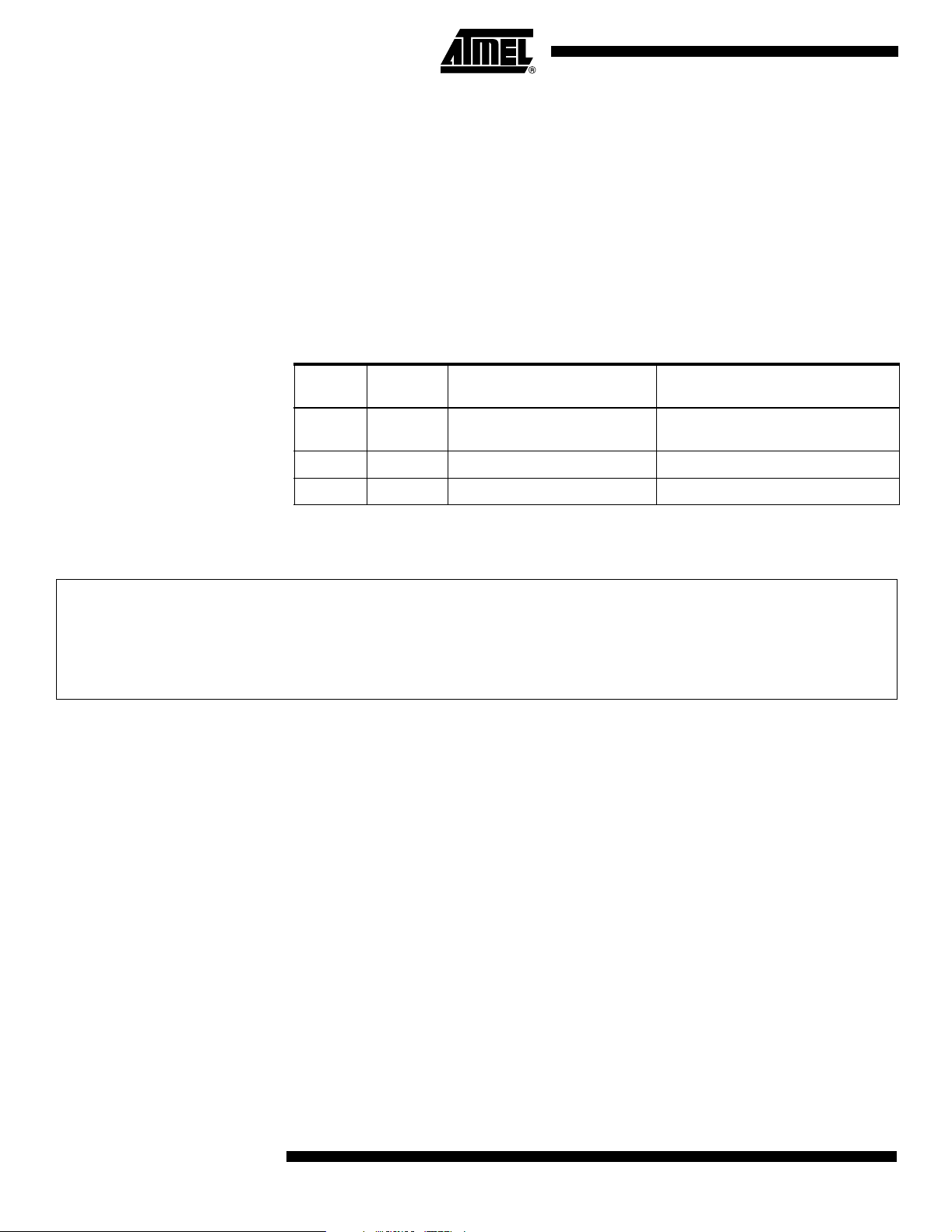

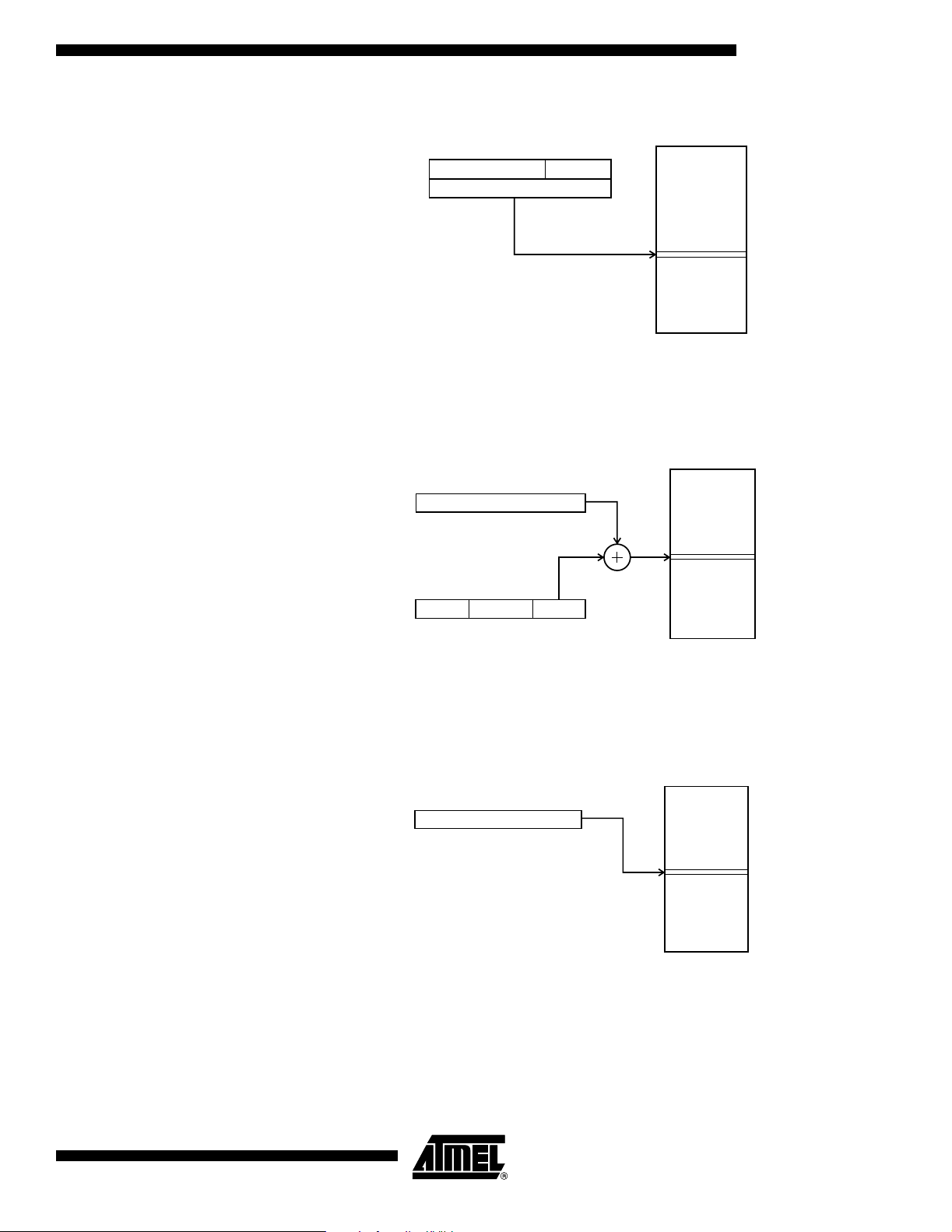

Figure 3. Sample Circuit

EXTERNAL LOOP FILTER (OPTIONAL)

AT86RF401

V+

R1

C4

L1

RESET SDO

SDI

SCLK

SPI Programming Interface

S1

C3

U1

Y1

C2

ANT

CFIL

AVDD

DVDD

AGND

DGND

IO5

IO4

IO3

XTALB

20

19

18

17

16

15

14

13

12

11

C5

1

ANTB

2

LOOPFIL

3

L1

4

L2

5

RESETB

6

NC

7

IO0/SDI

8

IO1/SDO

9

IO2/SCLK

10

XTAL/CLK

S2 S

V+

C1 B1

3

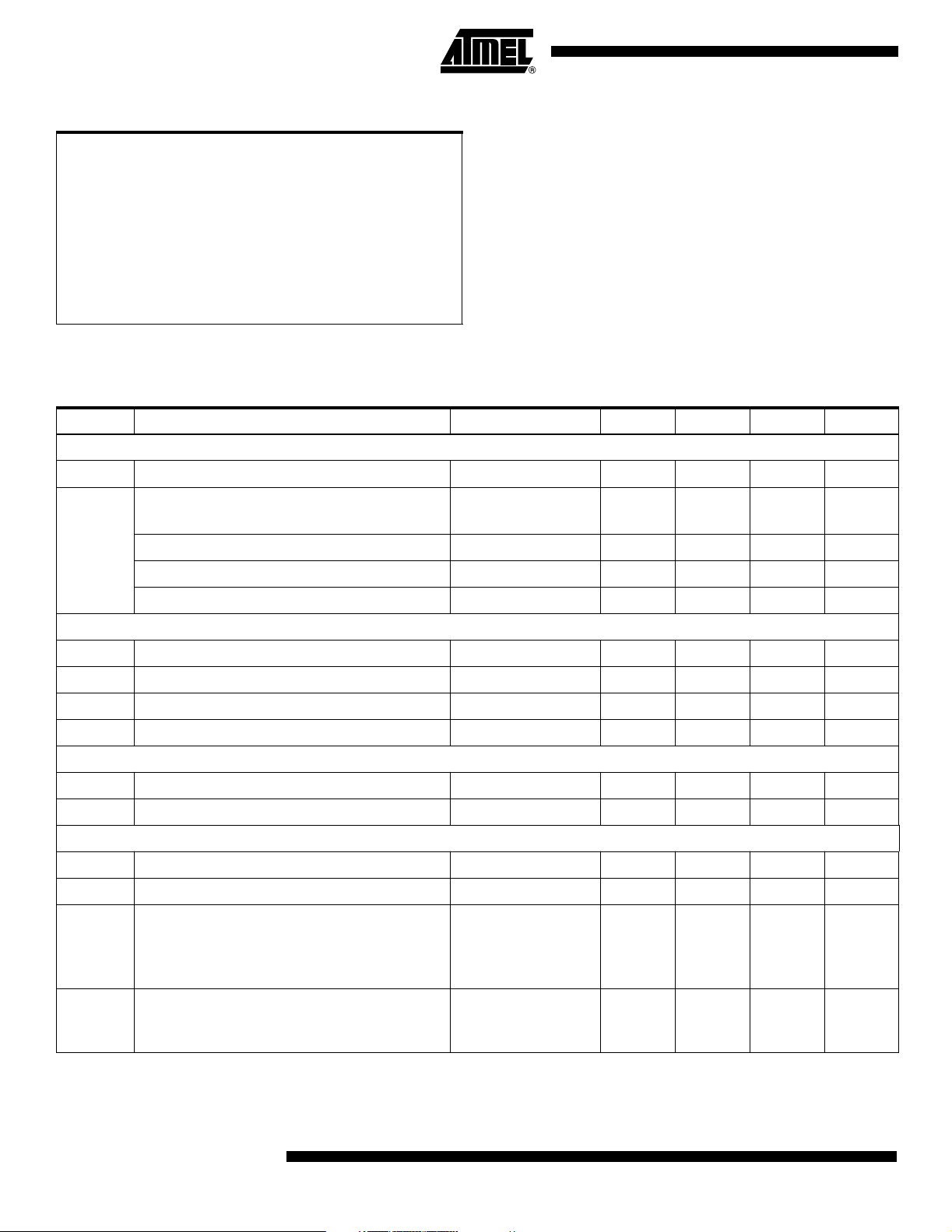

Table 1. Recommended Parts List

Value

Part Number

B1 3.6V CR2032, Li Battery

C1 0.01 µF 0603, X7R, ± 10%

C2 100 pF 0603, COG, ± 5%

C3 Antenna Dependent Antenna Dependent Antenna Dependent 0603, COG, ± 0.1 pF

C4 Not req’d Not req’d Frequency Dependent 0603, COG, ± 5%

C5 Not req’d Not req’d Frequency Dependent 0603, COG, ± 0.25 pF

L1 82 nH 39 nH Frequency Dependent 1608, ± 5%

R1 Not req’d Not req’d Frequency Dependent 0603, ± 5%

S1 Switch SPST

S2 Switch SPST

S3 Switch SPST

U1 AT86RF401 20-lead TSSOP

Y1 13.125 MHz 18.08 MHz Frequency Dependent

(Common)

Value

(315 MHz)

Value

(433.92 MHz)

Value

(Ext. Loop Filter) Specification

13.125 MHz:

Crystek

™

P/N 016757

18.080 MHz:

Crystek P/N 016758

1424D–RKE–09/02

3

Page 4

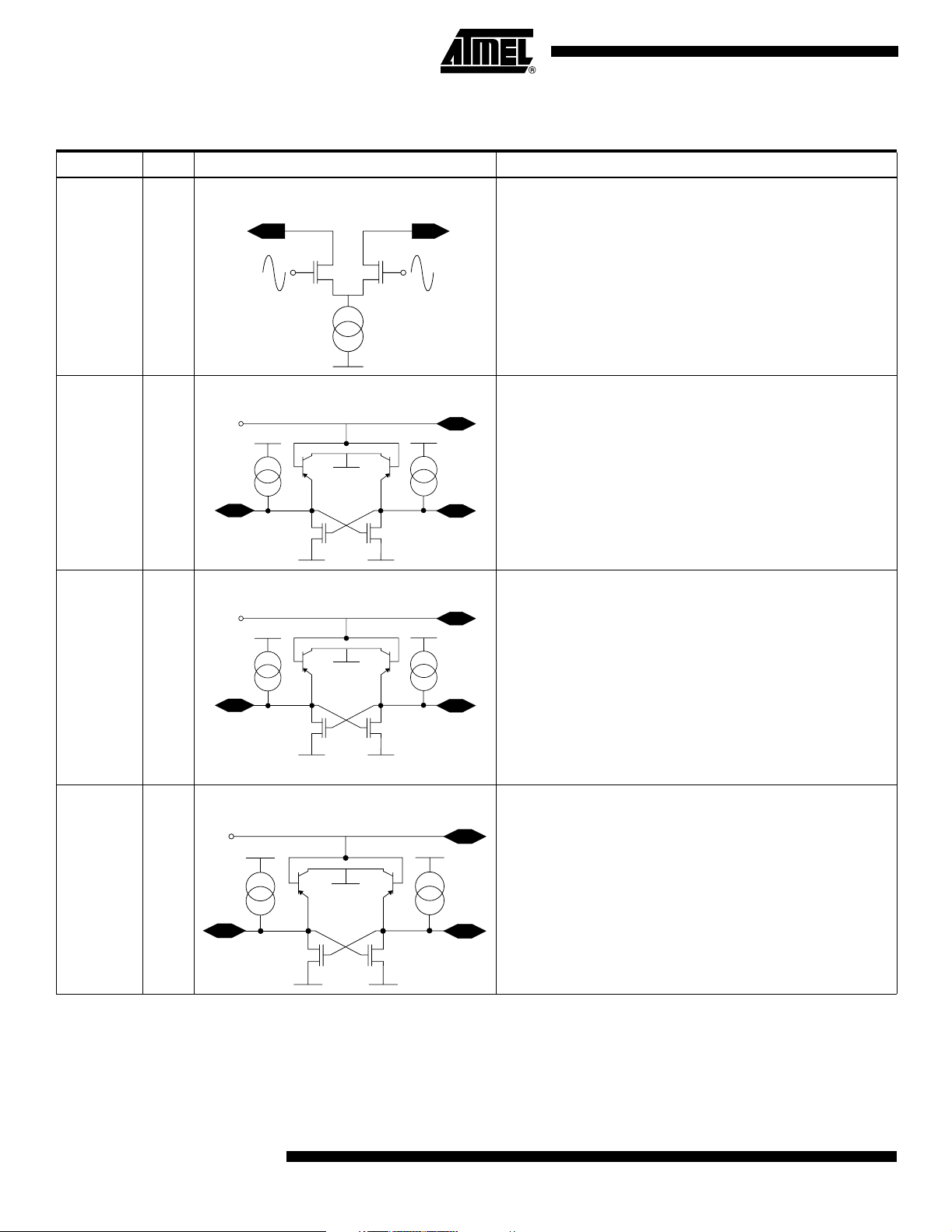

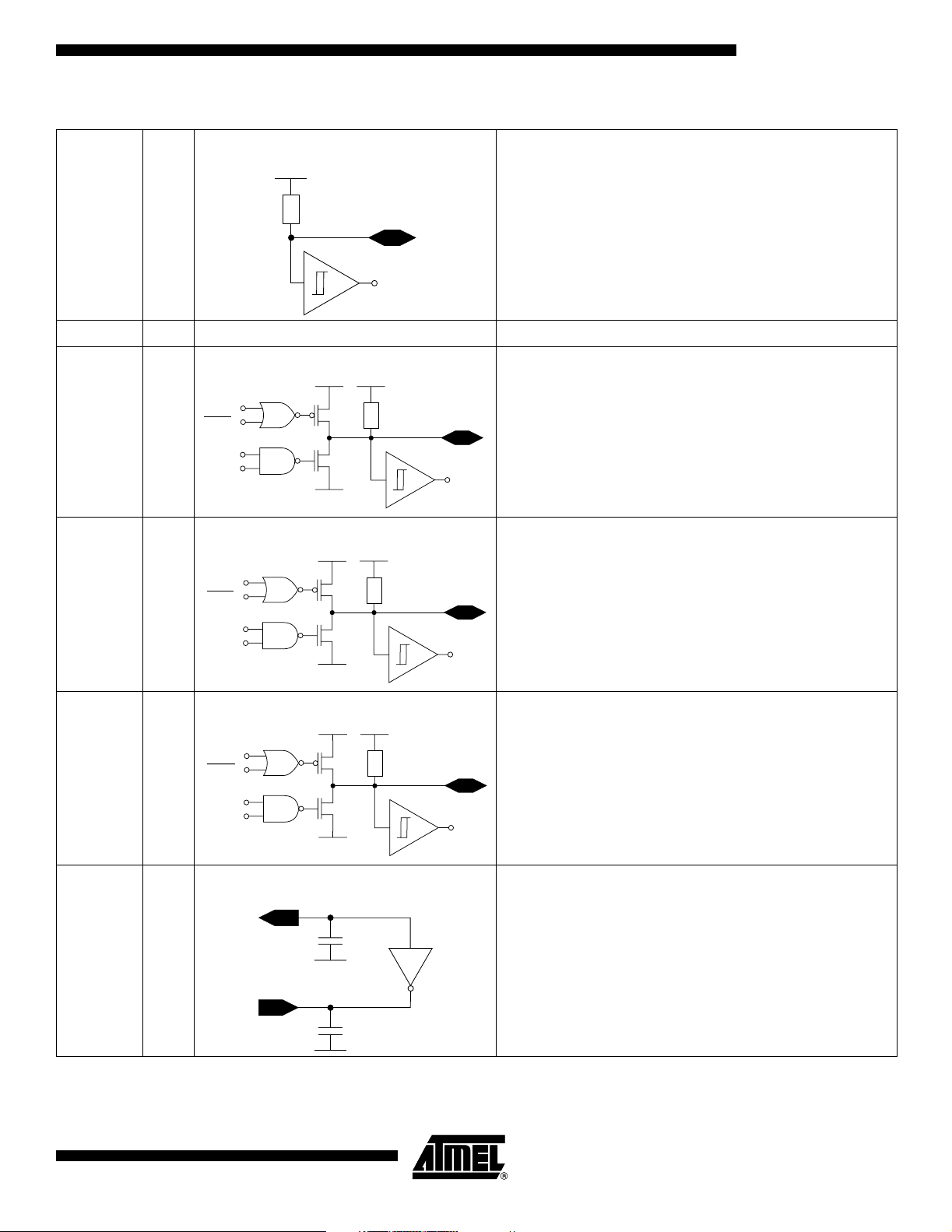

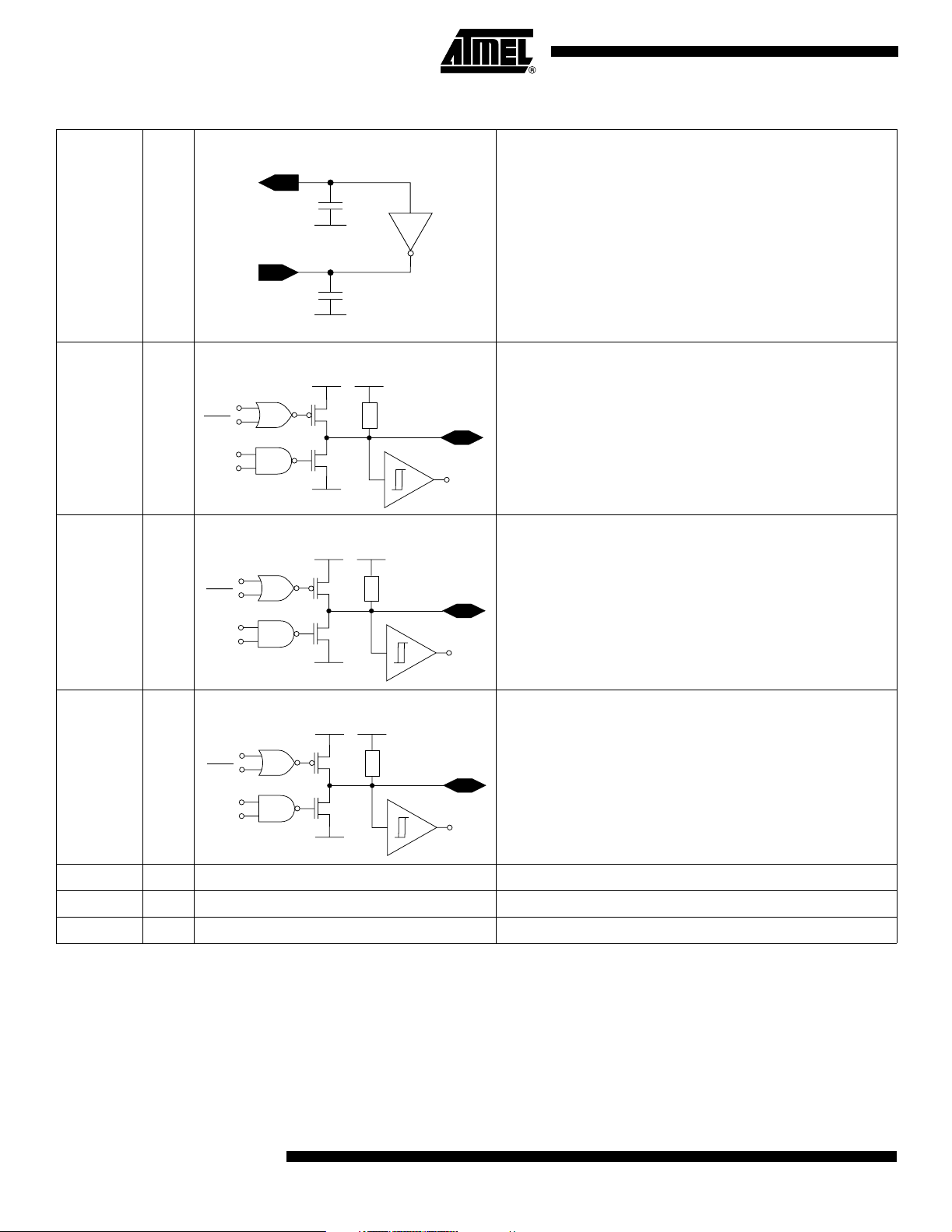

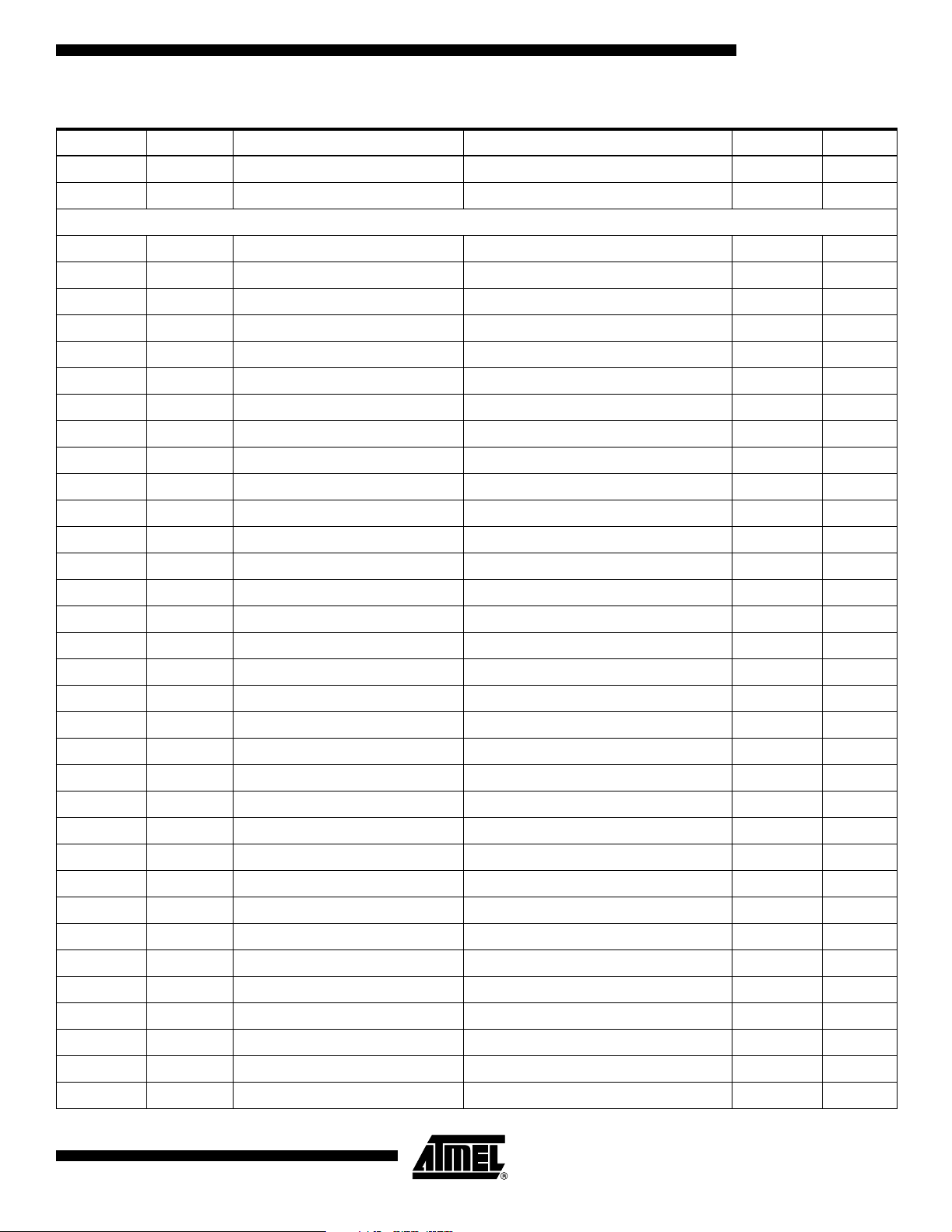

Table 2. Pin Descriptions – 20-lead TSSOP

Symbol Pin Description

120

ANTB 1 Differential Antenna Output

10 mA

LOOPFIL 2

L1 3

V

VCO

V

DD

2

V

DD

External VCO Loop-filter Connection.

V

is the VCO control voltage.

3

V

VCO

V

DD

4

2

V

DD

VCO

External VCO Inductor Connection.

V

is the VCO control voltage.

3

V

VDD

V

DD

4

2

V

DD

VCO

L2 4

4

AT86RF401

External VCO Inductor Connection.

V

is the VCO control voltage.

3

4

VCO

1424D–RKE–09/02

Page 5

Table 2. Pin Descriptions – 20-lead TSSOP (Continued)

V

DD

AT86RF401

SPI Reset Input: A “low” on this pin resets the device and puts

the part into SPI mode. A logic-high on this pin causes the

device to execute its program if the V

RESETB 5

35 k Ω

5

out voltage level.

To AV R

NC 6 No Connect. Float Pin.

V

DDVDD

I/O0 (SDI) 7

I/O1 (SDO)

Data

nable−

Data

Enable

V

DD

Data

Enable−

8

Data

Enable

35 k Ω

7

SPI Data In/Input/Output 0: General-purpose I/O and button

input. In SPI mode, this pin serves as SDI (Serial Data Input).

To AV R

V

DD

35 k Ω

SPI Data Out/Input/Output 1: General-purpose I/O and button

8

input. In SPI mode, this pin serves as SDO (Serial Data

Output).

To AV R

is above the brown-

DD

I/O2 (SCK)

XTAL/CLK 10

1424D–RKE–09/02

V

V

DD

DD

Data

Enable−

9

Data

Enable

10

40 pF

35 k Ω

9

To AV R

SPI Clock/Input/Output 2: General-purpose I/O and button

input. In SPI mode, this pin serves as SCK (SPI Clock Input).

Crystal/Clock Input: Input to the inverting oscillator amplifier

and input to the internal clock operating circuit. This pin may

be driven externally for test purposes.

11

40 pF

5

Page 6

Table 2. Pin Descriptions – 20-lead TSSOP (Continued)

10

40 pF

XTALB 11 Crystal Output: Output from the inverting oscillator amplifier

11

40 pF

V

V

DD

DD

Data

IO3 12 Input/Output 3: General-purpose I/O and button input

IO4 13 Input/Output 4: General-purpose I/O and button input

Enable

Data

Enable

Data

Enable

Data

Enable

V

DD

35 k Ω

V

DD

35 k Ω

12

To AV R

13

To AV R

V

V

DD

DD

Data

IO5 14 Input/Output 5: General-purpose I/O and button input

Enable

Data

Enable

35 k Ω

14

To AV R

DGND 15 Digital Ground

AGND 16 Analog Ground

DVDD 17 Digital Voltage Supply

6

AT86RF401

1424D–RKE–09/02

Page 7

Table 2. Pin Descriptions – 20-lead TSSOP (Continued)

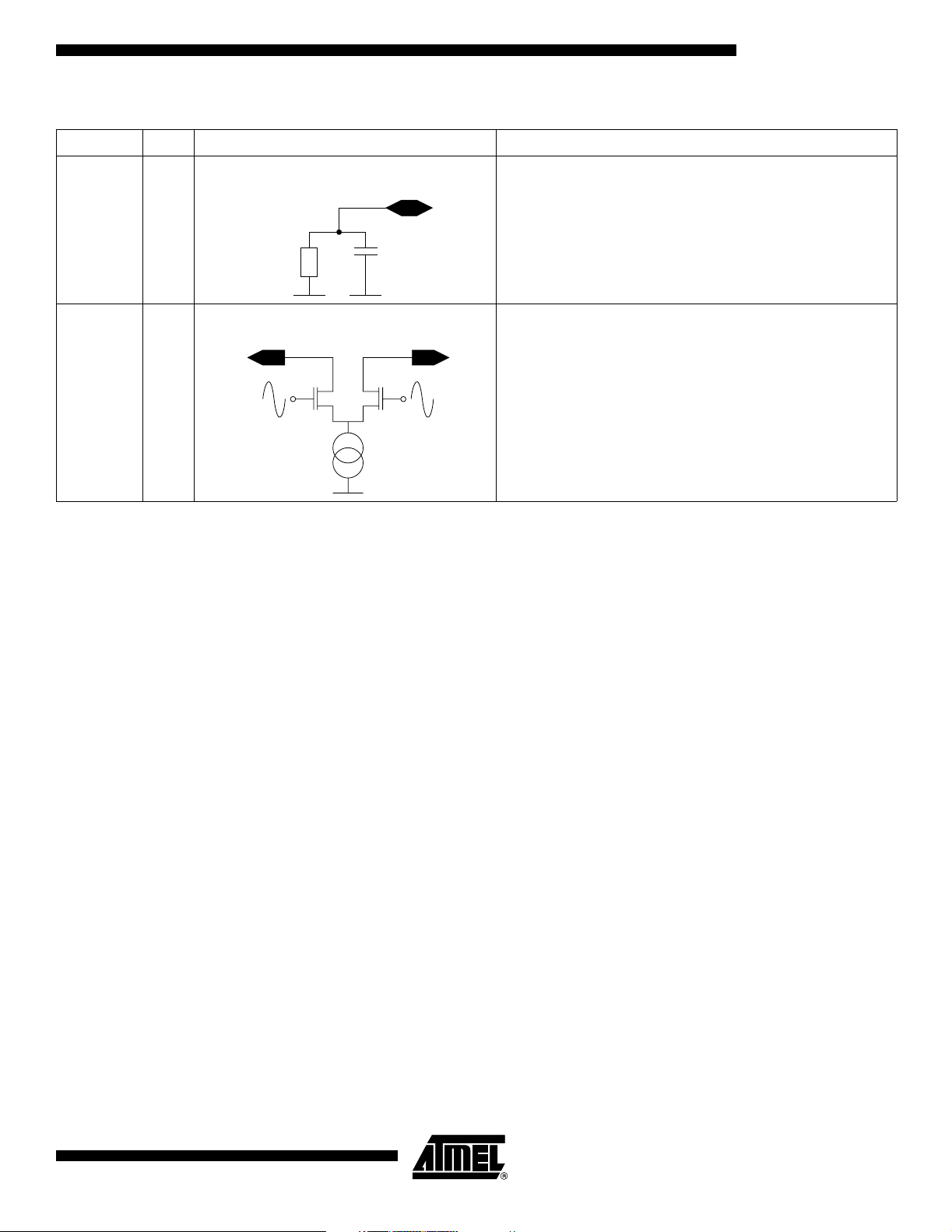

AVDD 18 Analog Voltage Supply

19

CFIL 19 External Data Rate Filter

420 KΩ

120

ANT 20 Differential Antenna Output

1.06 pF

10 mA

AT86RF401

1424D–RKE–09/02

7

Page 8

Absolute Maximum Ratings*

Antenna Voltage (Pins 1, 20)...................................... −1V to 10V

Operating Temperature ........................................−40°Cto+85°C

Storage Temperature (without bias) ................−55°Cto+125°C

Voltage on V

Voltage on Pins 2–19 (TSSOP 20) ................ −0.1 to V

with respect to ground ............................. 6.0V

DD

DD

+0.3V

*NOTICE: Stresses beyond those listed under “Absolute

Maximum Ratings” may cause permanent damage to the device. This is a stress rating only;

functional operation of the device at these or

other conditions beyond those indicated in the

operational sections of this specification is not

implied. Exposure to absolute maximum rating

conditions for extended periods may affect device

reliability.

DC Characteristics

VDD=3.3V;f

Symbol Parameter Conditions Min Typ Max Unit

Supply

V

DD

I

DD

= 13.125 MHz; f

XTAL

AVR=fXTAL

÷ 16; TA=25°C unless otherwise specified.

Supply Voltage 2.0 3.3 5.0 V

=3.3V

V

Standby Current (off)

DD

= 25°C

T

A

– 0.1 0.5 µA

AVR Active – 3.4 – mA

Frequency Synthesizer + AVR Active – 14.3 – mA

Transmit (FS, AVR and Power Amp active) CW modulation – 23.2 – mA

Digital Inputs (SDI, SCK, RESETB, IOx)

V

IH

V

IL

I

IH

I

IL

High-level Input Voltage 0.8* V

Low-level Input Voltage 0 – 0.2* V

High-level Input Current VIH=V

Low-level Input Current VIL=0V, VDD=5.0V −140 ––µA

Digital Outputs (SDO, IOx)

V

OH

V

OL

High-level Output Voltage IOH= −500 µA VDD−0.4 ––V

Low-level Output Voltage IOL=2mA ––0.4 V

Microcontroller/System

t

TX

f

AVR

EE

EE

LIFE

CYCLES

Time from Button Wake-up to RF Outputs Active – 0.5 1.0 ms

AVR Clock Frequency ––1.25 MHz

EEPROM Retention

EEPROM Write/Erase Endurance

, V

DD

=5.0V ––1µA

DD

Initial programming

conditions:

V

=3.3V±10%

DD

Te mp = 25 °C±10%

2.0V ≤ V

DD

≤ 5.0V

−40°C ≤ Te m p ≤

85°C

DD

– V

DD

DD

V

V

––10 years

––100,000 cycles

8

AT86RF401

1424D–RKE–09/02

Page 9

Analog/RF Specs

AT86RF401

VDD=3.3V;f

Symbol Parameter Conditions Min Typ Max Unit

RF Amplifier

I

PA

P

CTLRANGE

P

CTLRES

Crystal Oscillator

f

OSC

Frequency Synthesizer/PLL

F

OUT

1

P

HARM

f

MOD

Note: 1. Characterized but not guaranteed by test due to dependency on PCB trace antenna

Functional

= 13.125 MHz; f

XTAL

Power Amp Output Current Transmitting (RF “ON”), 0 dB Attenuation – 8.6 – mA

Power Control Range – 36 – dB

Power Control Resolution – 1 – dB

Oscillation Frequency Range 11 – 19 MHz

Output Frequency Range 264 – 456 MHz

Harmonics

OOK Modulation Data Rate Using Manchester Data Bit Encoding ––10 Kbps

AVR=fXTAL

÷ 16; TA=25°C unless otherwise specified.

I/O Pins Static during RF Transmission

Using PCB Trace Antenna

– −60 – dBc

The complete circuit consists of the following functional blocks.

Description

Transmitter

Crystal Oscillator The crystal oscillator circuit is designed to work with crystals with fundamental frequen-

cies between 11 and 19 MHz. Forty pF of internal capacitance is connected between

each of the crystal input pins and (chip) ground. Alternatively, an external clock can be

used for these functions.

This circuit provides the master clock for the entire chip. A programmable divider is used

to provide the AVR system clock.

Radio Frequency Power Amplifier

Frequency Synthesizer The frequency synthesizer utilizes a PLL, which consists of a phase detector, a ÷24

Lock Detector The lock detection block provides an indication of the state of the phase lock loop (PLL).

The RF power amplifier generates a differential output suitable for driving an off-chip

tuned-loop antenna from the PLL output. The PLL output signal is gated using on-off

keyed (OOK) modulation before transmission. It is used as the RF carrier frequency for

the transmitted data stream. The amplifier can be configured via software to reduce the

power output by 36 dB (with 1 dB resolution).

prescaler, an on-chip loop filter and an integrated VCO. The VCO output is buffered

prior to the output amplifier. The output frequency is 24 times the crystal frequency. To

offset component tolerance, a switched capacitor array is connected between pins 3

and 4 of the VCO. Thirty-two discrete steps of capacitance are available to tune the

VCO control voltage. An internal window comparator monitors the magnitude of the tuning voltage and is used by the AVR core to determine the optimal tuning configuration.

Lock condition is determined by counting the number of cycle slips in a given time

1424D–RKE–09/02

9

Page 10

period. A number of registers are available to adjust the performance of the lock detector. These include lock delay and unlock delay timers as well as a cycle slip counter.

Bandgap Reference The device uses a 1.2V (nominal) bandgap reference generator to provide consistent

performance over a wide range of input supply voltages. This reference voltage is used

throughout the device.

Brown-out Protection/Low Battery Detection

Brown-out Protection

Low Battery Detection

The brown-out protection and low battery detection functions consist of a voltage reference, a sampling block and an autozero comparator. The circuit’s primary operating

mode is brown-out protection.

The brown-out protection circuit detects when the level of VDDdrops below the minimum

voltage that guarantees proper operation. The brown-out voltage for this device is typically 1.8 volts.

If a brown-out occurs, the device enters a reset state. It stays in this state until either of

the following occurs:

• The level of VDDincreases ~0.1–0.2 volts above the brown-out voltage. This causes

the device to enter a warm reboot state.

• The level of V

drops to ~0 volts, then increases above the POR level. This places

DD

thedeviceintothe“cold start” mode of operation, identical to battery insertion.

The low battery detection feature allows the programmer to select a value for VDDat

which a warning is issued to the user. This warning may be utilized to activate an I/O

port, for example.

If low battery detection occurs, Bit 7 of register BL_CONFIG is set. Bit 6 of register

BL_CONFIG is used to indicate that Bit 7 is valid. It is left to the programmer to poll both

bits to ensure the potential warning is valid.

Bits 5–0 of register BL_CONFIG are used to program the low battery detect level. This

warning level is programmable between ~1.5–2.7 volts.

Note: The warning level can be set below the brown-out voltage level.

The formula for calculating the low battery detection threshold is located in Table 3.

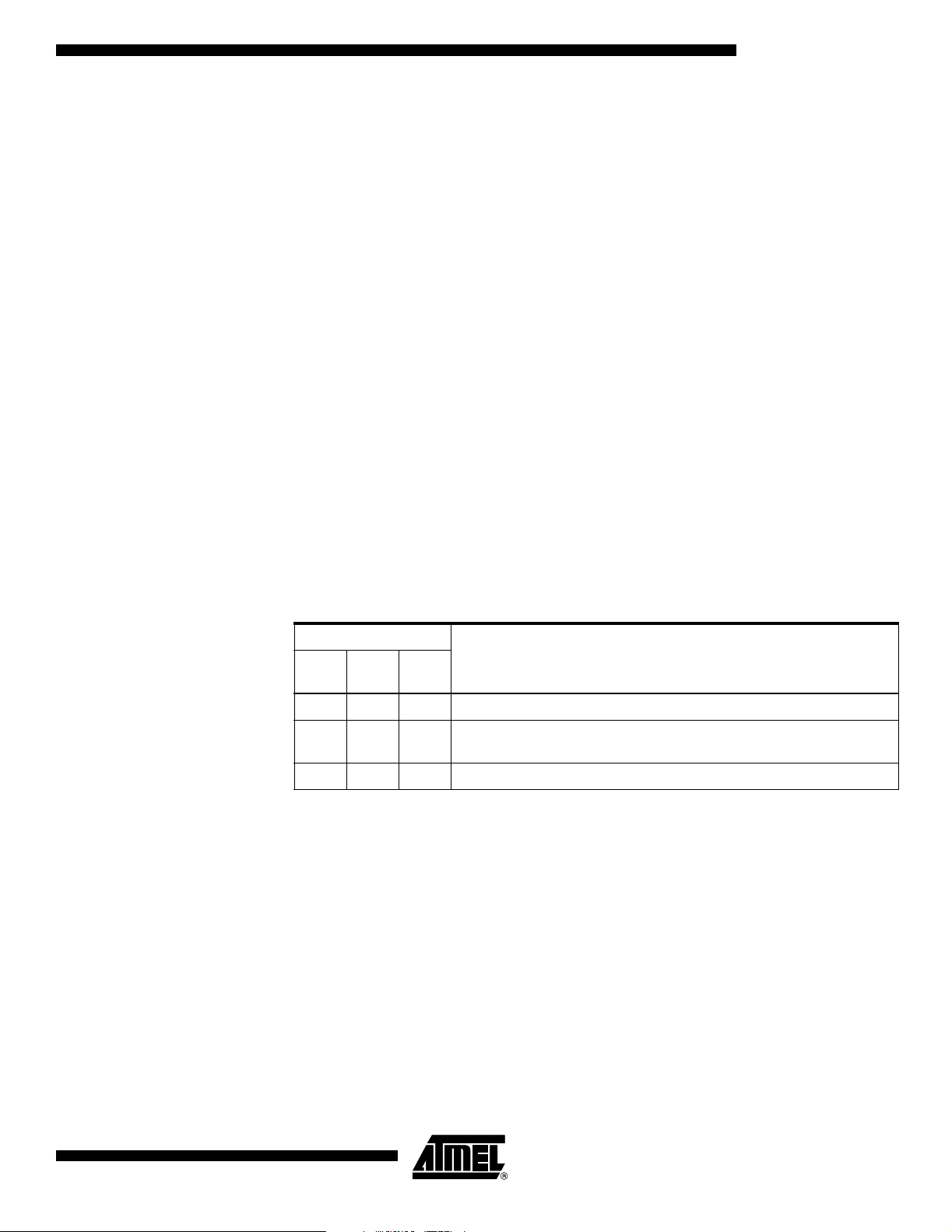

Table 3. Low Battery Detection Threshold Formulas (V

VDDFalling

VDD

-----------------------------------------------------------=

1

3.887 V

0.887

---------------

BL[5:0] 71 3.887

10

AT86RF401

63

×

REF

× BL[5:0]+

V

REF

-------------

V

1–××=

DD

bo_hyst = 1 (large hysteresis) bo_hyst = 0 (small hysteresis)

VDD

BL[5:0] 71 4.05

is approximately 0.7 volts)

REF

4.05 V

×

× BL[5:0]+

REF

V

REF

-------------

V

DD

-----------------------------------------------------------=

0.887

---------------

1

63

1–××=

V

Rising

DD

VDD

BL[5:0] 71 4.22

-----------------------------------------------------------=

1

4.22 V

×

0.887

---------------

63

REF

× BL[5:0]+

V

REF

-------------

V

DD

1424D–RKE–09/02

1–××=

Page 11

AT86RF401

Bit Timer A hardware assist has been included in the AT 86 R F4 01 to make transmission of data

easier. Keying of the transmitter is timed by this logic, and interrupts are generated

when data is needed by the timer or when transmission is complete. The timer also supports code that uses polling instead of interrupts. Using polling instead of interrupts may

facilitate higher bit rates. Additionally, this timer may be used to time pulses arriving at

the I/O3 pin. This enables the AT86RF401 to be used to decode the signal detected by

an external receiver chip.

Transmit Mode Bit Coding and Timing

Interrupts There are two interrupts associated with transmit mode:

Bit Timer in Receive Mode When put into receive mode, the bit timer times pulses arriving at the I/O3 pin. When

Bit coding is done by the AVR before data is sent to the bit timer. Bit timing is controlled

by the count value in the Bit Timer Count (BTCNT) register and the two most significant

bits in the Bit Timer Control Register (BTCR). Generally the time of each bit is:

P

P countval 1+()×=

xx

where

P

istheperiodofeachtimeslotand

and BTCR registers.

countval

1. Transmit Buffer Empty Interrupt: This vectors to address 0x04. Flag 0 is set, and,

2. TXDONE Interrupt: This vectors to address 0x02. Flag 2 is set, and, if enabled,

enabled, the counter counts up from zero and places that value in the BTCNT register

when an edge occurs. If the edge is rising, the DATA bit in the BTCR is set. If the edge

is falling, the DATA bit in the BTCR is reset. This mode may be used to decode signals

from a receiver chip easily.

xx

= {BTCR[7:6], BTCNT[7:0]}.

if enabled, this interrupt is generated when the timer removes the value from the

DATA bit in the BTCR. This interrupt service routine should load the next bit into

the DATA bit in the BTCR.

an interrupt is generated when the counter has counted down to zero and the

buffer is empty. This indicates that the transmission is complete. This interrupt

service routine should turn off the transmitter and turn off the bit timer using the

mode bits.

P

is the AVR clock period that is set in the PWR_CTL register.

countval

is the counter value in the BTCNT

Bit Timer Operation as a Generic Timer/Counter

1424D–RKE–09/02

The Bit Timer may be used as a generic timer by not allowing it to key off the transmitter.

An interrupt is generated after the amount of time dictated by the count value.

11

Page 12

Watchdog Timer When enabling the watchdog timer, the status of the watchdog time is unknown. The

user is advised to execute a WDR instruction before enabling the watchdog. Otherwise,

the device might get reset before the first WDR after enabling is reached. To prevent the

unintentional disabling of the watchdog, a special turn-off procedure must be followed

when the watchdog is disabled. Refer to the description of the Watchdog Timer Control

Register on page 38 for details (see Register $22 in I/O Memory). The watchdog timer

prescaler determines the number of system clocks that occur before the watchdog reset

is asserted. The system clock is determined by Bits[7:5] of the AVR_CONFIG register.

Reset and Interrupt Handling

The AT86RF401 Reset and Interrupt vectors are defined in Table 4. The I-bit in the status register must be set to enable the interrupts.

Table 4. Reset and Interrupt Vectors

Vector

Number

1 $000 RESETB, Watchdog, Buttons Hardware Pin or Watchdog or

2 $002 Transmission Done (TXDONE) Bit Timer Flag 2 Interrupt

4 $004 Transmit Buffer Empty Bit Timer Flag 0 Interrupt

Program

Address Source Interrupt Definition

The most typical and general program setup for the Reset and Interrupt Vector

Addresses are:

Address Labels Code Comments

$000 jmp RESET ; Reset handler

$002 jmp BT_F2_ISR ; Bit timer flag 2 interrupt service routine

$004 jmp BT_F0_ISR ; Bit timer flag 0 interrupt service routine

$006 MAIN: <instr> xxx ; Main program start

…… ……

Reset Sources The AT86RF401 has several sources of reset:

• Power-on Reset: The device is reset when the supply voltage is applied between the

VDD and GND pins. There are 10

occurring and the part becoming active. This is to ensure that the power is stable.

• External Reset: The device is reset when a logic low level is present on the RESETB

pin. This resets all I/O Registers and puts the part into SPI mode. The I/O Registers

may be read and written by the SPI interface after two AVR System Clocks.

• Watchdog Reset: This is similar to power-on reset but is caused by the watchdog

timer and does not have a 10

• Brown-out Reset: This is caused by the battery voltage dropping below the Brownout Threshold voltage trip point.

• Button Reset (software reset): The part is placed into a special reset state by

software. The part is released from reset when a properly configured button is

activated, and the part is not in external reset or brown-out reset. In the button reset

state, most I/O registers are not reset.

6

cycles of delay between Power-on Reset

6

cycle delay prior to becoming active.

Button Reset

12

AT86RF401

1424D–RKE–09/02

Page 13

AT86RF401

During power-on reset and watchdog reset, all I/O registers are set to their initial values,

and the program starts execution from address $000.

Note: The instruction placed in address $000 must be an RJMP (relative jump) instruction or a

JMP (absolute jump) to the reset handling routine. If an RJMP or JMP instruction is not

present at address $000, the part is placed into a “no program” resetstate.Thisistopro-

tect the part from fetching instructions when no program is present.

Interrupt Response Time The interrupt execution response for all the enabled AVR interrupts is a minimum of four

clock cycles. After the four clock cycles, the program vector address for the actual interrupt handling routine is executed. During this four clock cycle period, the Program

Counter is pushed onto the stack. The vector is a jump to the interrupt routine, and this

jump takes two clock cycles. If an interrupt occurs during execution of a multi-cycle

instruction, this instruction is completed before the interrupt is served.

A return from an interrupt handling routine takes four clock cycles. During these four

clock cycles, the Program Counter is popped back from the stack. When AVR exits from

an interrupt, it will always return to the main program and execute one more instruction

before any pending interrupt is served.

Note: The Status Register (SREG) is not saved by the AVR hardware. This must be performed

by user software when required.

Memory Programming

Program Memory Lock Bits

In-system Flash and EEPROM

SPI Interface Both the program and data memory arrays can be programmed using the serial SPI bus

The AT86RF401 microtransmitter provides two lock bits that can be left unprogrammed

(“1”) or can be programmed (“0”) to obtain the additional features listed in Table 5.

Table 5. Lock Bit Protection Modes

Program Lock Bits

ModeLB1 LB2

Protection Type

1 1 1 No program lock features

201

3 0 0 Same as mode 2, but Verify is also disabled

Note: The lock bits can only be erased with the Chip Erase operation.

The AT86RF401 offers 2 Kbytes (1K x 16) of in-system reprogrammable Flash program

memory and 128 bytes of EEPROM data memory. This memory can be programmed

serially via the SPI interface.

while RESETB is pulled to GND. The serial interface consists of pins SCK, SDI (input)

and SDO (output).

Further programming of the EEPROM is disabled (both program and

data memory).

1424D–RKE–09/02

When programming, an auto-erase cycle is built into the self-timed programming operation, and there is no need to first execute the Chip Erase instruction. The Chip Erase

operation sets every memory location in the EEPROM array to $FF.

Either an external system clock is supplied at pin XTAL/CLK or a crystal needs to be

connected across pins XTAL/CLK and XTALB. The minimum low and high periods for

the serial clock (SCK) input are defined as follows:

Low:

4 XTAL Clock Cycles

High:

16 XTAL Clock Cycles

13

Page 14

Serial Programming Algorithm

Refer to Figure 4 (page 15), Figure 5 (page 16) and Figure 6 (page 17). To program and

verify the AT86RF401 in the serial programming mode, the following sequence is

recommended.

Power-up Sequence:

1. Apply power between VDD and GND while RESETB and SCK are set to “0”.Ifa

crystal is not connected across pins XTAL and XTALB, apply a clock signal to the

XTAL pin. If the programmer can not guarantee that SCK is held low during

power-up, RESETB must be given a positive pulse after SCK has been set to “0”.

2. Wait for at least 20 ms and enable serial programming by sending the Programming Enable instruction to pin SDI. This must occur prior to any program/erase

operations.

3. If a chip erase is performed, wait 4 ms, give RESETB a positive pulse and start

over again from Step 2.

4. The array is programmed one byte at a time by supplying the address and data

together with the appropriate Write instruction. The memory location is first automatically erased before new data is written. The next byte can be written after

4ms.

5. Any memory location can be verified by using the Read instruction, which

returns the content at the selected address at serial output SDO.

6. At the end of the programming session, RESETB must be set high to commence

normal operation.

14

AT86RF401

1424D–RKE–09/02

Page 15

Data EEPROM Access from the AVR

Table 6. AT86RF401 Serial Programming Instruction Set

Instruction Format

AT86RF401

Instruction

Programming

Enable

Chip Erase

Read Program

Memory

Write Program

Memory

1010 1100 0101 0011 xxxx xxxx xxxx xxxx

1010 1100 100x xxxx xxxx xxxx xxxx xxxx

0010 H000 0000 00aa bbbb bbbb oooo oooo

0100 H000 0000 00aa bbbb bbbb iiii iiii

Read

EEPROM

1010 0000 0000 0000 xbbb bbbb oooo oooo

Memory

Write

EEPROM

1100 0000 0000 0000 xbbb bbbb iiii iiii

Memory

Write Lock Bits

I/O Read

I/O Write

1010 1100 111x x21x xxxx xxxx xxxx xxxx

10110000 0000 0000 00bbbbbb oooo oooo

11010000 0000 0000 00bbbbbb iiii iiii

Note: a = address high bits

b = address low bits

H =0:Lowbyte,1:Highbyte

o = data out

i = data in

x = don’tcare

1=lockbit1

2=lockbit2

OperationByte 1 Byte 2 Byte 3 Byte 4

Enable Serial Programming after

RESETB goes low.

Chip erase EEPROM

Read H (high or low) data o from Program

memory at word address a:b

Write H (highorlow)datai to Program

memory at word address a:b

Read data o from EEPROM memory at

address b

Write data i to EEPROM memory at

address b

Write lock bits. Set bits 21 = “0” to

program lock bits.

Read data 0 from I/O memory address b

Write data i to I/O memory address b

1424D–RKE–09/02

Figure 4. Serial Programming and Verify

AT86RF401

RESETB

GND

6 to 20 MHz

Notes: 1. When

2. When

explanation.

XTALB

XTAL

writing

,dataisclockedonthe

reading

, data is clocked on the

BAT

SCK

SDO

SDI

rising

falling

2.0–3.5V

CLOCK IN

DATA OUT

INSTR. IN, DATA IN

edge of CLK.

edge of CLK. See Figure 5 for an

15

Page 16

Figure 5. Serial Programming Waveforms

SERIAL DATA INPUT (SDI)

SERIAL DATA OUTPUT (SDO)

SERIAL CLOCK INPUT (SCK)

Note: This device includes an integrated 128-byte EEPROM, which is accessed by three registers located in the I/O memory space.

These are the DEECR, DEEDR and DEEAR registers. For more information, refer to I/O Register Description.

MSB

MSB LSB

LSB

AVR Core

Architectural Overview The fast-access register file concept contains 32 x 8-bit general-purpose working regis-

ters with a single clock cycle access time. This means that during one single clock cycle,

one Arithmetic Logic Unit (ALU) operation is executed. Two operands are output from

the register file, the operation is executed, and the result is stored back in the register

file in one clock cycle.

Six of the 32 registers can be used as three 16-bit indirect address register pointers for

Data Space addressing, enabling efficient address calculations. One of the three

address pointers is also used as the address pointer for look-up tables in Flash program

memory. These added function registers are the 16-bit X-register, Y-register and Zregister.

The ALU supports arithmetic and logic operations between registers or between a constant and a register. Single register operations are also executed in the ALU. Figure 6

shows the AT86RF401 AVR architecture.

In addition to the register operation, the conventional memory addressing modes can be

used on the register file as well. This is enabled by the fact that the register file is

assigned the 32 lowest data space addresses ($00–$1F), allowing them to be accessed

as though they were ordinary memory locations.

The I/O memory space contains 64 addresses for CPU peripheral functions as Control

Registers, Timer/Counters, A/D converters and other I/O functions. The I/O Memory can

be accessed directly or as the Data Space locations following those of the register file,

$20–$5F.

16

AT86RF401

1424D–RKE–09/02

Page 17

Figure 6. AVR Core Architecture

AT86RF401

Data Bus 8-bit

1K x 16

Program

Memory

Instruction

Register

Instruction

Decoder

Control Lines

Program

Counter

Direct Addressing

Status

and Control

32 x 8

General

Purpose

Registers

ALU

Indirect Addressing

128 x 8

Data

SRAM

128 x 8

EEPROM

Bit Timer

SPI Unit

RF

Transmitter

Brown-out/Low

Battery Detector

Programmable

Clock Divider

6

I/O Lines

Watchdog

Timer

The AVR uses a Harvard architecture concept, with separate memories and buses for

program and data. The program memory is executed with a two-stage pipeline. While

one instruction is being executed, the next instruction is prefetched from the program

memory. This concept enables instructions to be executed in every clock cycle. The program memory is in-system, reprogrammable Flash memory.

With the jump and call instructions, the whole 1K word address space is directly

accessed. Most AVR instructions have a single 16-bit word format. Every program

memory address contains a 16- or 32-bit instruction.

During interrupts and subroutine calls, the return address program counter (PC) is

stored on the stack. The stack is effectively allocated in the general data SRAM, and

consequently the stack size is only limited by the total SRAM size and the usage of the

SRAM. All user programs must initialize the SP in the reset routine (before subroutines

or interrupts are executed). The 7-bit stack pointer SP is read/write accessible in the I/O

space.

The 128-byte data SRAM can be easily accessed through the five different addressing

modes supported in the AVR architecture.

The memory spaces in the AVR architecture are all linear and regular memory maps.

1424D–RKE–09/02

17

Page 18

A flexible interrupt module has its control registers in the I/O space with an additional

global interrupt enable bit in the status register. All interrupts have a separate interrupt

vector in the interrupt vector table at the beginning of the program memory. The interrupts have priority in accordance with their interrupt vector position; the lower the

interrupt vector address, the higher the priority.

Figure 7. Memory Maps

Program Memory

$000

Application Flash Section

$3FF

18

AT86RF401

1424D–RKE–09/02

Page 19

AT86RF401

General-purpose Register File

Figure 8 shows the structure of the 32 general-purpose working registers in the CPU.

Figure 8. AVR CPU General-purpose Working Registers

70Addr.

R0 $00

R1 $01

R2 $02

…

R13 $0D

R14 $0E

R15 $0F

R16 $10

R17 $11

…

R26 $1A X-register low byte

R27 $1B X-register high byte

R28 $1C Y-register low byte

R29 $1D Y-register high byte

R30 $1E Z-register low byte

R31 $1F Z-register high byte

All the register operating instructions in the instruction set have direct and single cycle

access to all registers. The only exception is the five constant arithmetic and logic

instructions (SBCI, SUBI, CPI, ANDI and ORI) between a constant and a register, and

the LDI instruction for load immediate constant data. These instructions apply to the

second half of the registers in the register file, R16...R31. The general SBC, SUB, CP,

AND and OR and all other operations between two registers or on a single register apply

to the entire register file.

As shown in Figure 9, each register is also assigned a data memory address, mapping

the registers directly into the first 32 locations of the user data space. Although not being

physically implemented as SRAM locations, this memory organization provides great

flexibility in access of the registers, as the X, Y and Z registers can be set to index any

register in the file.

1424D–RKE–09/02

19

Page 20

TheX,YandZRegisters The registers R26...R31 have some added functions to their general-purpose usage.

These registers are address pointers for indirect addressing of the data space. The

three indirect address registers X, Y and Z are defined as shown in Figure 9.

Figure 9. The X, Y and Z Registers

15 XH XL 0

XRegister 70 0 7 0

R27 ($1B) R26 ($1A)

15 YH YL 0

YRegister 70070

R29 ($1D) R28 ($1C)

15 ZH ZL 0

ZRegister 70 0 7 0

R30 ($1F) R31 ($1E)

In the different addressing modes, these address registers have functions as fixed displacement, automatic increment and decrement (see the descriptions for the different

instructions).

Arithmetic Logic Unit (ALU)

In-system Selfprogrammable Flash

Program Memory

The high-performance AVR ALU operates in direct connection with all the 32 generalpurpose working registers. Within a single clock cycle, ALU operations between registers in the register file are executed. The ALU operations are divided into three main

categories: arithmetic, logical and bit-functions. The multiplier is not present in this version of the core. Therefore, the MUL instruction is not supported.

The AT86RF401 contains 2 Kbytes of on-chip Flash memory for program storage. Since

all instructions are 16- or 32-bit words, the Flash is organized as 1K x 16.

The Flash memory has an endurance of at least 1000 write/erase cycles. The PC is 10

bits wide, thus addressing the 1024 program memory locations. See the Memory Programming section (page 13) for a detailed description on Flash data serial downloading.

Constant tables can be allocated within the entire program memory address space (see

Table 10, Instruction Set, page 44).

20

AT86RF401

1424D–RKE–09/02

Page 21

AT86RF401

SRAM Data Memory Figure 10 shows how the AT86RF401 SRAM memory is organized.

Figure 10. SRAM Organization

Register File

R0

R1

R2

...

R29

R30

R31

I/O Registers

$00

$01

$02

...

$3D

$3E

$3F

Data Address Space

$0000

$0001

$0002

...

$001D

$001E

$001F

$0020

$0021

$0022

...

$005D

$005E

$005F

Internal SRAM

$0060

$0061

...

$00DE

$00DF

Program and Data Addressing Modes

The lower 224 Data Memory locations address the Register File, the I/O Memory and

the internal data SRAM. The first 96 locations address the Register File + I/O Memory,

and the next 128 locations address the internal data SRAM.

The five different addressing modes for the data memory cover: Direct, Indirect with Displacement, Indirect, Indirect with Pre-decrement, and Indirect with Post-increment. In

the register file, registers R26 to R31 feature the indirect addressing pointer registers.

The direct addressing reaches the entire data space.

The Indirect with Displacement mode features a 63 address locations reach from the

base address given by the Y or Z register.

When using register indirect addressing modes with automatic pre-decrement and postincrement, the address registers X, Y and Z are decremented and incremented.

The 32 general-purpose working registers, 64 I/O registers and the 128 bytes of internal

data SRAM in the AT86RF401 are all accessible through all these addressing modes.

The AT86RF401 AVR Enhanced RISC microcontroller supports powerful and efficient

addressing modes for access to the program memory (Flash) and data memory (SRAM,

Register File and I/O Memory). This section describes the different addressing modes

supported by the AVR architecture. In the figures, OP means the operation code part of

the instruction word. To simplify, not all figures show the exact location of the addressing bits.

1424D–RKE–09/02

21

Page 22

Register Direct, Single Register Rd

Figure 11. Direct Single Register Addressing

The operand is contained in register d (Rd).

Register Direct, Two Registers Rd and Rr

I/O Direct Figure 13. I/O Direct Addressing

Figure 12. Direct Register Addressing, Two Registers

Operands are contained in register r (Rr) and d (Rd). The result is stored in register d

(Rd).

22

Operand address is contained in 6 bits of the instruction word. “n” is the destination or

source register address.

AT86RF401

1424D–RKE–09/02

Page 23

Data Direct Figure 14. Direct Data Addressing

31

OP Rr/Rd

16 LSBs

15 0

A 16-bit Data Address is contained in the 16 LSBs of a two-word instruction. Rd/Rr

specify the destination or source register.

20 19

AT86RF401

Data Space

16

$00

$DF

Data Indirect with

Figure 15. Data Indirect with Displacement

Displacement

15

Y OR Z - REGISTER

15

OP an

Operand address is the result of the Y or Z register contents added to the address contained in 6 bits of the instruction word.

Data Indirect Figure 16. Data Indirect Addressing

X, Y OR Z - REGISTER

Data Space

0

05610

Data Space

015

$00

$DF

$0000

1424D–RKE–09/02

$DF

Operand address is the contents of the X, Y or Z register.

23

Page 24

Data Indirect with Pre-decrement

Figure 17. Data Indirect Addressing with Pre-decrement

Data Space

015

X, Y OR Z - REGISTER

-1

$0000

$DF

The X, Y or Z register is decremented before the operation. Operand address is the

decremented contents of the X, Y or Z register.

Data Indirect with

Figure 18. Data Indirect Addressing with Post-increment

Post-increment

The X, Y or Z register is incremented after the operation. Operand address is the content of the X, Y or Z register prior to incrementing.

Constant Addressing Using the LPM Instruction

Figure 19. Code Memory Constant Addressing

X, Y OR Z - REGISTER

Data Space

015

1

$0000

$DF

24

$3FF

Constant byte address is specified by the Z register contents. The 10 MSBs select word

address (0–1K). For LPM, the LSB selects low byte if cleared (LSB = 0) or high byte if

set (LSB = 1).

AT86RF401

1424D–RKE–09/02

Page 25

AT86RF401

Indirect Program Addressing, IJMP and ICALL

Relative Program Addressing, RJMP and RCALL

Figure 20. Indirect Program Memory Addressing

$3FF

Program execution continues at address contained by the Z register (i.e., the PC is

loaded with the contents of the Z register).

Figure 21. Relative Program Memory Addressing

1

$3FF

Program execution continues at address PC + k + 1. The relative address k is from −

2048 to 2047.

1424D–RKE–09/02

25

Page 26

EEPROM Data Memory The AT86RF401 contains 128 bytes of data EEPROM memory. It is organized as a sep-

arate data space in which single bytes can be read and written. The access between the

EEPROM and the CPU is described in the Memory Programming section (page 13).

Memory Access Times and Instruction Execution Timing

This section describes the general access timing concepts for instruction execution and

internal memory access.

The AVR CPU is driven by the System Clock Ø generated from the main oscillator for

the chip. A programmable clock divider generates this clock from the crystal oscillator

input.

Figure 22 shows the parallel instruction fetches and instruction executions enabled by

the Harvard architecture and the fast-access register file concept. This is the basic pipelining concept to obtain up to 1 MIPS per MHz with the corresponding unique results for

functions per cost, functions per clocks and functions per power unit.

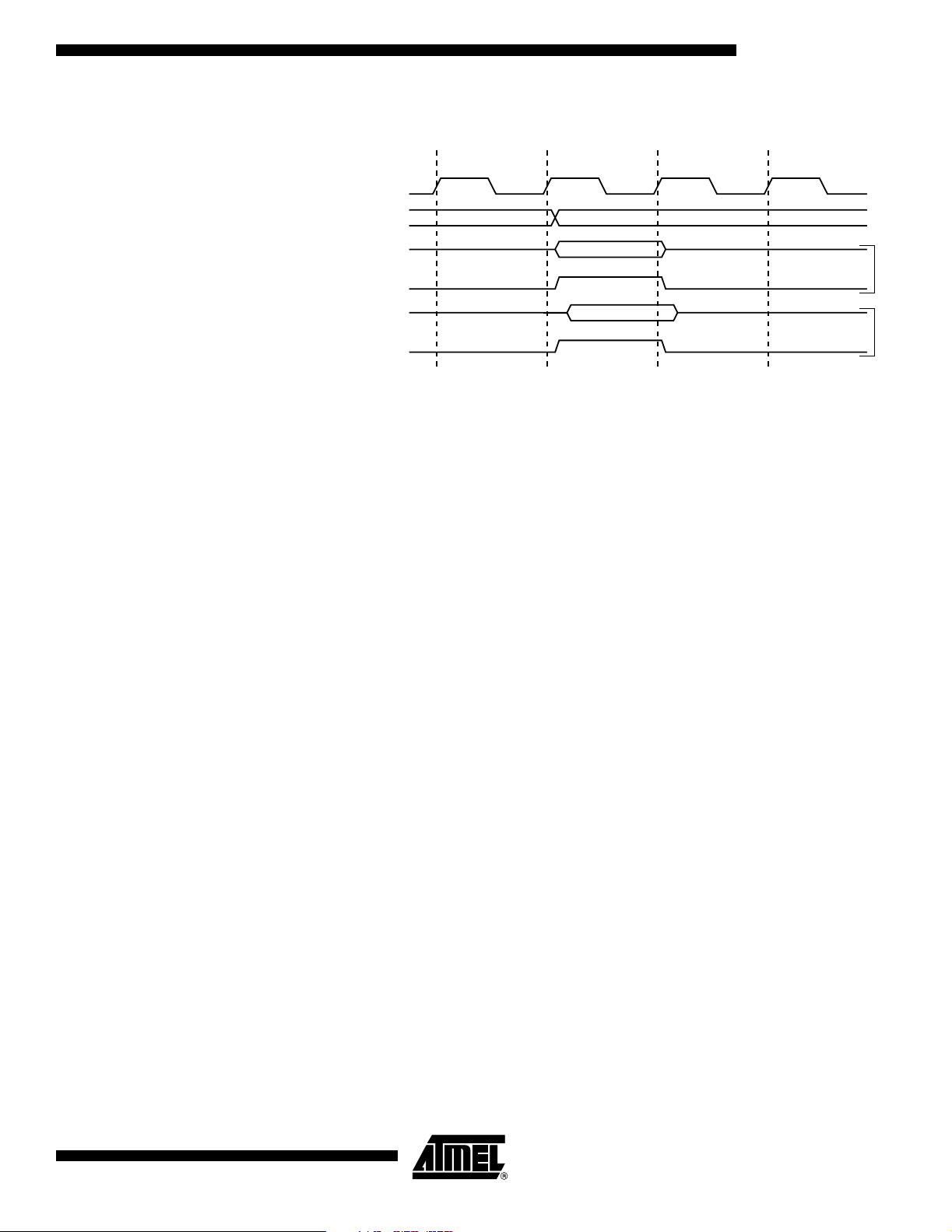

Figure 22. The Parallel Instruction Fetches and Instruction Executions

T1 T2 T3 T4

System Clock Ø

1st Instruction Fetch

1st Instruction Execute

2nd Instruction Fetch

2nd Instruction Execute

3rd Instruction Fetch

3rd Instruction Execute

4th Instruction Fetch

Figure 23 shows the internal timing concept for the register file. In a single clock cycle,

an ALU operation using two register operands is executed, and the result is stored back

to the destination register.

Figure 23. Single Cycle ALU Operation

T1 T2 T3 T4

System Clock Ø

Total Execution Time

Register Operands Fetch

ALU Operation Execute

Result Write Back

The internal data SRAM access is performed in two System Clock cycles as described

in Figure 24.

26

AT86RF401

1424D–RKE–09/02

Page 27

Figure 24. On-chip Data SRAM Access Cycles

T1 T2 T3 T4

System Clock Ø

AT86RF401

Address

Data

Write

Data

Read

Prev. Address

Address

All I/Os and peripherals are placed in the I/O space. The I/O locations are accessed by

the IN and OUT instructions, transferring data between the 32 general-purpose working

registers and the I/O space. I/O registers within the address range $00–$1F are directly

bit-accessible using the SBI and CBI instructions. In these registers, the value of single

bits can be checked by using the SBIS and SBIC instructions. Refer to Table 10,

“Instruction Set Manual,” on page 44 for more details. When using the I/O specific commands IN and OUT, the I/O addresses $00–$3F must be used. When addressing I/O

registers as SRAM, $20 must be added to these addresses.

For compatibility with future devices, reserved bits should be written to “0” if accessed.

Reserved I/O memory addresses should never be written.

Some of the status flags are cleared by writing a logical “1” to them. Note that the CBI

and SBI instructions will operate on all bits in the I/O register, writing a “1” back into any

flag read as set, thus clearing the flag. The CBI and SBI instructions work with registers

$00 to $1F only.

The I/O and peripherals control registers are explained in the following sections.

Write

Read

1424D–RKE–09/02

27

Page 28

I/O Memory

The I/O space definition of the AT86RF401 is shown in Table 7 below.

Table 7. AT86RF401 I/O Space Definitions

Address Hex Name Function

$3F SREG Status Register

$3E SPH Stack Pointer High Register (program to 0 x 00)

$3D SPL Stack Pointer Low Register

$35 BL_CONFIG Battery Low Configuration Register

$34 B_DET Button Detect Register

$33 AVR_CONFIG AVR Configuration Register

$32 IO_DATIN I/O DATA IN Register

$31 IO_DATOUT I/O DATA OUT Register

$30 IO_ENAB I/O Enable Register

$22 WDTCR Watchdog Timer Control Register

$21 BTCR Bit Timer Control Register

$20 BTCNT Bit Timer Count Register

$1E DEEAR Data EEPROM Address Register

$1D DEEDR Data EEPROM Data Register

$1C DEECR Data EEPROM Control Register

$17 LOCKDET2 Lock Detector Configuration Register 2

$16 VCOTUNE VCO Tuning Register

$14 PWR_ATTEN Power Attenuation Control Register

$12 TX_CNTL Transmitter Control Register

$10 LOCKDET1 Lock Detector Configuration Register 1

Note: Reserved and unused locations are not shown in the table.

28

AT86RF401

1424D–RKE–09/02

Page 29

AT86RF401

I/O and Control Registers

The AT86RF401 I/Os and peripherals are placed in the I/O space. The various I/O locations are accessed by the IN and OUT instructions transferring data between the 32

general-purpose working registers and the I/O space. I/O registers within the address

range $00–$1F are directly bit-accessible using the SBI and CBI instructions. In these

registers, the value of single bits can be checked by using the SBIS and SBIC instructions. Refer to Table 10 on page 44 for more details. The different I/O and peripherals

control registers are explained in the following sections.

Transmitter Control Register Descriptions

Lock Detector Configuration Register 1 – LOCKDET1

Bit 76543210

$10 –––UPOK ENKO BOD CS1 CS0

Read/Write R/W R/W R/W R/W R/W R/W R/W R/W

Initial Value 00000000

• Bits[7:5]

Reserved.

• Bit[4]: UPOK

If set high, this bit resets the unlock counter. The bit is level sensitive, and the unlock

counter will not count unless this bit is set to “0”. Leaving this bit high essentially disables the unlock detector.

• Bit[3]: ENKO (Enable Key on Bit)

If set to “1”, the rising edge of TXK starts the blackout period, during which any cycle

slips are ignored and do not affect the unlock circuit.

• Bit[2]: BOD (Black Out Disable)

When set high, cycle slips are counted immediately but only if LOCK is asserted high

(TX_CNTL b[2]).

• Bits[1:0] CS[1:0]: Cycle Slip Counter

These two bits determine how many cycle slips are allowed before the LOCKDETECT

signal is set low. The cycle slips are not counted unless the blackout logic is either disabled or the blackout window has passed.

CS[1:0] Functionality

00 1 cycle slip causes unlock condition

01 2 cycle slips cause unlock condition

10 3 cycle slips cause unlock condition

11 4 cycle slips cause unlock condition

1424D–RKE–09/02

29

Page 30

Transmit Control Register – TX_CNTL

Bit 76543210

$12 ––TXE TXK – LOC ––

Read/Write R/W R/W R/W R/W R/W R/W R/W R/W

Initial Value 00000000

• Bit[7:6]

Reserved.

• Bit[5]: TXE, Transmitter Enable

This bit turns on the transmitter.

• Bit[4]: TXK, Transmitter Key

ThisbitisORedwiththeoutputfromthebittimer.Ifthebittimerisusedtokeythetransmitter, the TXK bit should be programmed to “0”. If the bit timer is not used, this bit may

be used to manually key the transmitter.

Figure 25. Modulation Control Logic

Bit Timer

TXK

PLL

RF

IN

POWER

AMP

RF

OUT

ON/OFF

• Bit[3]

Reserved.

• Bit[2]: LOC, PLL Lock

This bit is set when the frequency synthesizer in the transmitter is locked. Usually this bit

should be set before transmitting.

Power Attenuation Control Register – PWR_ATTEN

Bit 76543210

$14 ––PCC2 PCC1 PCC0 PCF2 PCF1 PCF0

Read/Write R/W R/W R/W R/W R/W R/W R/W R/W

Initial Value 00000000

This register is used to select the power attenuation level. The total power attenuation is

the sum of the coarse attenuation and fine attenuation. As an example, to obtain 15 dB

of attenuation, the coarse setting of 12 dB and fine setting of 3 dB would be selected. To

obtain 12 dB coarse attenuation, Bits[5:3] would be set to [010]. To obtain 3 dB of fine

attentuation would require Bits[2:0] to be set to [011].

• Bits[7:6]

Reserved

30

AT86RF401

1424D–RKE–09/02

Page 31

• Bits[5:3]: PCC, Power Control (coarse)

Attenuates the output power in 6 dB steps.

PCC[5:3] Output Attenuation

000 0 dB

001 6 dB

010 12 dB

011 18 dB

100 24 dB

101 30 dB

110 Invalid

111 Invalid

• Bits[2:0]: PCF, Power Control (fine)

Attenuates the output power in 1 dB steps.

PCF[2:0] Output Attenuation

AT86RF401

000 0 dB

001 1 dB

010 2 dB

011 3 dB

100 4 dB

101 5 dB

110 Invalid

111 Invalid

VCO Tuning Register 6 – VCOTUNE

Bit 76543210

VCOVDET[1] VCOVDET[0] – VCOTUNE[4] VCOTUNE[3] VCOTUNE[2] VCOTUNE[1] VCOTUNE[0]

$16

Read/Write R R R/W R/W R/W R/W R/W R/W

Initial Value **000000

Note: * These values are unknown at initial startup.

• Bits[4:0]: VCO Tuning Capacitor Array

This device requires the use of an external inductor to tune the VCO. Tolerance of the

inductor, coupled with process variation of the device, can lead to variations in the tuning point of the VCO. A switched array of tuning capacitors has been added internally to

thedeviceinorderto“fine tune” the VCO. This capacitance is switched across pins 3

1424D–RKE–09/02

31

Page 32

and 4 (L1 and L2) of the device. The capacitor array is set by VCOTUNE[4:0] and is

comprised of the following switched capacitance levels:

VCOTUNE[4:0] Capacitance (pF)

00000 0

00001 0.03

00010 0.06

00011 0.09

00100 0.12

00101 0.15

00110 0.18

00111 0.21

01000 0.24

01001 0.27

01010 0.30

01011 0.33

01100 0.36

01101 0.39

01110 0.42

01111 0.45

10000 0.48

10001 0.51

10010 0.54

10011 0.57

10100 0.60

10101 0.63

10110 0.66

10111 0.69

11000 0.72

11001 0.75

11010 0.78

11011 0.81

11100 0.84

11101 0.87

11110 0.90

11111 0.93

32

AT86RF401

1424D–RKE–09/02

Page 33

AT86RF401

• Bits[7:6]: VCO Voltage Detector

The VCO Voltage Detector circuit monitors the level of the VCO control voltage. This circuit, along with the VCO Switch Caps and the Lock Detect circuit, is intended for use

with a software algorithm to tune the VCO such that the VCO control voltage is centered

approximately at 1.1V.

The Voltage Detector circuit consists of two comparators with fixed reference voltages

of V1 (lower reference voltage) and V2 (upper reference voltage). The VCO Control

Voltage is compared to these two reference voltages and generates the state table

listed in Table 8. The state of these comparators is output to Bits 7 and 6 (Vcodet[1:0])

of the VCOTUNE register.

Table 8. VCO Window Comparator States

VCOvdet[1:0] VCO Control Voltage

00

01

10

11 Not a valid state.

Above lower comparator threshold and below upper comparator

threshold. Control Voltage is within the valid window of operation.

Below both thresholds. Control Voltage is outside the recommended

window of operation.

Above both thresholds. Control Voltage is outside the recommended

window of operation.

Lock Detector Configuration Register 2 – LOCKDET2

Bit 76543210

$17 EUD LAT ULC[2] ULC[1] ULC[0] LC[2] LC[1] LC[0]

Read/Write R/W R/W R/W R/W R/W R/W R/W R/W

Initial Value 00000000

• Bit[7]: EUD

A “1” enables the unlock detect logic.

• Bit[6]: LAT (Lock Always True)

Forces the lockdetect signal to “1” at the output of the lock detect circuitry. This may be

useful if the lock detect signal is not going high for some reason, and a power amp interlock has been implemented, and the user wishes to enable the power amp output stage.

1424D–RKE–09/02

33

Page 34

• Bit[5:3]: ULC[2:0]

The unlock count (ULC) bits count a certain number of reference clocks, after which the

unlock detect circuit looks for a number of cycle slips determined by CS[1:0] before

making the loc detect signal go low. The ULC bits essentially control the blackout period

of the unlock detect circuit. The unlock counter is reset by the KEY signal rising (if

ENKO is asserted), or by the LOC rising edge, or by the UPOK signal being set high.

Number of REF

ULC[2:0]

000 8

001 16

010 32

011 64

100 128

101 256

110 512

111 1024

Clocks of Delay

• Bits[2:0]: LC[2:0]

The Lock Count (LC) bits control a counter that, after a number of reference clocks,

cause lock detect to go high. This counter will reset if a cycle slip or a reset signal occurs

(which happens if TXE goes low), if an out-of-lock condition occurs, if the crystal oscillator frequency is too low, or if the VCO feedback frequency is too low.

LC[2:0] Number of REF Clocks of Delay

000 8

001 16

010 32

011 64

100 128

101 256

110 512

111 1024

34

AT86RF401

1424D–RKE–09/02

Page 35

EEPROM Control Register Descriptions

Data EEPROM Control Register – DEECR

Bit 76543210

$1C ––––BSY EEU EEL EER

Read/Write R/W R/W R/W R/W R R/W R/W R/W

Initial Value 0 00000000

• Bits[7:4]

Reserved. These bits should be “ 0 ” when written; otherwise, results will be

unpredictable.

• Bit[3]: EEPROM Busy Bit

Initially set to “0”. This bit will be set high during writes to the EEPROM.

• Bit[2]: EEPROM Unlock Bit

Set this bit to “1” before writing the EEPROM. Reset this bit to “0” after the write is complete. This bit should be left in the zero state when the EEPROM is not being used,

which will protect the EEPROM data during power transients.

AT86RF401

• Bit[1]: EEPROM Load Bit

To write the EEPROM, use the following procedure:

Note: Because of noise and power considerations, the EEPROM should not be written while

the transmitter is enabled.

1. Set the unlock bit.

2. Write the address of the first byte to the DEEAR.

3. Set the load bit. This locks the page address in the DEEAR. Keep the unlock bit

set.

4. Write the desired data to the DEEDR register. This byte is loaded into the

EEPROM and will be written when the load bit is later deasserted.

5. If it is desired to write another byte in the same page, write the new address to

the DEEAR register, and a new byte to the DEEDR register. Continue until all

bytes that are to be written are loaded into the EEPROM. Bytes may only be

loaded to an address once. There are eight bytes per page.

6. Deassert the load bit. This starts the write operation. Some time after load is

deasserted, the busy bit will go high. Another read or write operation may not be

started until the busy bit has returned to “0”. Writes take approximately 4 ms to

complete. Again, the unlock bit must still be set when deasserting the load bit.

7. After all writes are complete, write “0” to the unlock bit.

• Bit[0]: EEPROM Read Bit

To read the EEPROM use the following procedure:

1. Write the address to the DEEAR.

2. Set the read bit.

3. Read the data register. The read bit will reset itself.

4. If another read needs to be done, repeat steps 1–3 again.

1424D–RKE–09/02

35

Page 36

Data EEPROM Data Register – DEEDR

Bit 76543210

$1D ED7 ED6 ED5 ED4 ED3 ED2 ED1 ED0

Read/Write R/W R/W R/W R/W R/W R/W R/W R/W

Initial Value 0 00000000

• Bits[7:0]

This register contains the byte to be written to EEPROM. If a read operation has been

done, this register contains that last byte read from the data EEPROM.

Data EEPROM Address Register – DEEAR

Bit 76543210

$1E – PA6 PA5 PA4 PA3 BA2 BA1 BA0

Read/Write R/W R/W R/W R/W R/W R/W R/W R/W

Initial Value 0 00000000

• Bit[7]

Reserved.

• Bits[6:3]: Data EEPROM Page Address

These bits select the page in the EEPROM that is to be accessed. These bits are write

locked and cannot be altered when the load bit is set.

• Bits[2:0]: Data EEPROM Byte Address

These bits select the byte in the page that is to be accessed. During a page write operation, these bits are used in combination with the DEEDR register to write bytes into a

page.

36

AT86RF401

1424D–RKE–09/02

Page 37

Bit Timer Register Descriptions

Bit Timer Count Register – BTCNT

Bit 76543210

$20 C7 C6 C5 C4 C3 C2 C1 C0

Read/Write R/W R/W R/W R/W R/W R/W R/W R/W

Initial Value 00000000

• Bit [7:0]

Lowest 8 bits of

determines a counter value that sets the width of a mark or a space that is sent to the

transmitter. The width of the mark or space is:

P

XX=PAVR

P

where

that is determined by the ACS bits of the AVR configuration register, AVR_CONFIG.

Bit Timer Control Register – BTCR

XX

countval

*

(countval

. When combined with bits [7:6] of the BTCR register,

+1)

is the period of the mark or space, and

AT86RF401

P

is the period of the AVR clock

AVR

countval

Bit 76543210

$21 C9 C8 M1 M0 IE F2 DATA F0

Read/Write R/W R/W R/W R/W R/W R R/W R

Initial Value 00000000

• Bit[7:6]

Count_val[9:8]. MSB of BTCNT counter value bits.

• Bits[5:4]

Bit Timer Mode.

Mode[1:0] Bit Timer Function

00 Bit Timer Disabled

01 Transmit Mode, Transmitter Not Keyed

10 Receive Mode

11 Transmit Mode, Transmitter Keyed

• Bit[3]: Interrupts Enabled

If this bit is set, the Flag2 and Flag0 will generate their respective interrupts when they

are set. Flag0 interrupt vector is located at 0 x 04. Flag2 interrupt vector is located at

0 x 02. Typically, a JMP instruction resides at these vector locations to pass control to

an interrupt handler. For Flag0 only, slightly faster execution can be achieved if the JMP

instruction is eliminated, and the interrupt service routine is located beginning at 0 x 04.

1424D–RKE–09/02

37

Page 38

• Bit[2]: Flag2

In transmit mode, this flag indicates the Transmit Done condition that occurs when the

buffer is empty and the counter has counted down to “0”. In receive mode, this flag indicates that an edge has occurred, and the AVR should process the count value in the

BTCR and BTCNT registers. This bit is cleared upon read, e.g., IN R16, BTCR.

Mode[1:0] Flag2 Function

00 Disabled

01

10 An edge has been detected at the IO3 pin.

11

Indicates Transmit Done condition; buffer is empty and the

counter has expired.

Indicates Transmit Done condition; buffer is empty and the

counter has expired.

• Bit[1]: Data Bit

In transmit mode, this is a one-bit buffer that the AVR writes data to and the bit timer

extracts data from. When the bit timer removes the value from this register, the Flag0 bit

is set, and if enabled, an interrupt (INT2) is generated. If the interrupt is used, the ISR

should load a new bit into the buffer. If the interrupt is not enabled, then a polling method

should be used to detect Flag0 being set. Because of overhead associated with interrupt

handling, it may be slightly faster to use polling.

In receive mode, the value in this register indicates whether the edge at the IO3 pin was

rising or falling. A “1” indicates a rising edge occurred, and a “0” indicates that a falling

edge was detected. The number of AVR clock cycles since the last edge is held in the

C[9:0] (

countval

) bits (that is, unless an overflow condition has occurred).

• Bit[0]: Flag0

In transmit mode, this flag indicates the buffer is empty and the AVR should load new

data into it. In receive mode, this indicates a counter overflow condition has occurred.

The AVR should increment its software counter if this condition has occurred. This bit is

cleared upon read, e.g., IN R16, BTCR.

Watchdog Timer Control Register – WDTCR

Bit 76543210

$22 –––WDTOE WDE WDP2 WDP1 WDP0 WDTCR

Read/Write R R R R/W R/W R/W R/W R/W

Initial Value 00000000

• Bits[7:5]

Reserved. These bits will always read as “0”.

• Bit[4]: WDTOE, Watchdog Turn-off Enable

This bit must be set (“1”) when the WDE bit is cleared. Otherwise, the watchdog will not

be disabled. Once set, hardware will clear this bit to “0” after four clock cycles. Refer to

the description of the WDE bit for a watchdog disable procedure.

• Bit[3]: WDE, Watchdog Enable

When the WDE is set (“1”), the Watchdog Timer is enabled, and if the WDE is cleared

(“0”), the Watchdog Timer function is disabled. WDE can only be cleared if the WDTOE

38

AT86RF401

1424D–RKE–09/02

Page 39

AT86RF401

bit is set (“1”). To disable an enabled Watchdog Timer, the following procedure must be

followed: In the same operation, write a logical “1” to WDTOE and WDE. A logical “1”

must be written to WDE even though it is set to “1” before the disable operation starts.

Within the next four clock cycles, write a logical “0” to WDE. This disables the watchdog.

• Bits[2:0]: WDP2, WDP1, WDP0, Watchdog Timer Prescaler 2, 1 and 0

The WDP2, WDP1 and WDP0 bits determine the Watchdog Timer prescaling when the

Watchdog Timer is enabled. The different prescaling values and their corresponding

time-out periods are shown in Table 9.

Table 9. Watchdog Timer Prescale Select

WDP2 WDP1 WDP0 Number of System Clock Cycles

0 0 0 2,048 cycles

0 0 1 4,096 cycles

0 1 0 8,192 cycles

0 1 1 16,384 cycles

1 0 0 32,768 cycles

1 0 1 65,536 cycles

I/O Enable Register – IO_ENAB

Bit 76543210

$30 – BOHYST IOE5 IOE4 IOE3 IOE2 IOE1 IOE0

Read/Write R/W R/W R/W R/W R/W R/W R/W R/W

Initial Value 00000000

1 1 0 131,072 cycles

1 1 1 262,144 cycles

Note:

T

wdt

XTALB

period

ACS

div

WDT

××=

div

Example:

If the crystal period is 50 ns and the system clock divider is set to 32 (Bits[7:5] in the

PWR_CTL register are set to 010) and the WDT prescaler is set to 32K, then:

Watchdog Timeout = 50 ns × 32 × 32768 = 52 ms

• Bit[7]

Reserved.

• Bit[6]

If set to “1”, additional hysteresis is added to the battery low and brown-out logic. See

BL_CONFIG register description and Table 3 (page 10) for more details.

1424D–RKE–09/02

39

Page 40

• Bits[5:0]

If set to “1”, the corresponding bit (pin) IO[5:0] is configured as an output. Data may then

be written to that output by writing to the IO_DATA register. If set to “0”, the corresponding bit (pin) may be either a button input (refer to the Button Detect Register, $34) used

to wake the part up or a normal digital input.

I/O Data Out Register – IO_DATOUT

Bit 76543210

$31 ––IOO5 IOO4 IOO3 IOO2 IOO1 IOO0

Read/Write R R R/W R/W R/W R/W R/W R/W

Initial Value 00000000

• Bits[7:6]: Reserved

These bits read “0”.

IO_ENAB[n] IO_DATOUT[n] IO[n]

0 0 Normal Input

0 1 Button Input

1 0 Output Driven Low

1 1 Output Driven High

• Bits[5.0]

If enabled in the IO_ENAB register and not in test mode, the data in Bits[5:0] goes to the

corresponding general-purpose output IO [5:0].

I/O Data In Register – IO_DATIN

Bit 76543210

$32 ––IOI5 IOI4 IOI3 IOI2 IOI1 IOI0

Read/Write R/WR/WRRRRRR

Initial Value 00

• Bits[7:6]: Reserved

This bit reads “0”.

• Bits[5:0]

These bits directly read the data from the I/O pins IO[5:0]. Writes to these bits have no

effect.

AVR Configuration Register – AVR_CONFIG

Bit 76543210

$33 – ACS1 ACS0 TM BD BLI SLEEP BBM

Read/Write R/W R/W R/W R/W R R W R/W

Initial Value 00000000

40

AT86RF401

1424D–RKE–09/02

Page 41

AT86RF401

• Bits[6:5]: AVR System Clock Select

These bits select the divide value of the XTALB input that is used to produce the AVR

System Clock.

ACS[1:0] AVR System Clock

11 XTALB/16

10 XTALB/32

01 XTALB/64

00 XTALB/128

This clock select value may be programmed on the fly by either the AVR processor in

normal operation or by an I/O write SPI command during SPI mode. Note that during

SPI mode, the I/O and serial programming logic runs at XTALB/16 frequency.

• Bit[4]: Test Mode

When this bit is set to “1”, the part enters test mode. The I/O pins, if enabled, assume

the following functionality:

I/O5 I/O4 I/O3 I/O2 I/O1 I/O0

Normal Mode

(RESETB = 1)

SPI Mode

(RESETB = 0)

Notes: 1. IO_ENAB register is NOT used for SPI pins.

2. In SPI mode, the I/O registers may be directly accessed via the SPI interface. Txkey, lockdetect may be output using this

mode.

txkey

(Output)

txkey

(Output)

lockdetect

(Output)

lockdetect

(Output)

• Bit[3]: Battery Dead

Indicates battery is dead. Only readable by SPI interface.

• Bit[2]: Battery Low Indicator

This bit is identical to Bit[7] of Battery Low Configuration Register ($35). When Bit[6] of

Battery Low Configuration Register ($35) is set (Battery Low Valid), a set bit in this location indicates that the battery voltage is lower than the voltage level that is determined

by Bits[5:0] of Battery Low Configuration Register ($35).

• Bit [1]: Sleep Bit

When set, this bit stops the crystal oscillator. This stops the AVR processor with the program counter frozen at the current instruction. Sleep will also stop the Watchdog Timer.

The Watchdog Timer is only restarted if the part wakes up. If an I/O pin is configured as

a button, a button press will start the oscillator and check the battery level. If the battery

level is greater than the Battery Dead level, the AVR system clock is started and normal

program execution continues. If the battery level is below the Battery Dead level, the

crystal oscillator is turned off, putting the part back to sleep until a button is pressed

again (care should be taken not to put the part to sleep unless a button is configured and

enabled).

txenable

(Output)

txenable

(Output)

RFU RFU RFU

SPI_CLK SDO SDI

1424D–RKE–09/02

• Bit[0]: Button Boot Mode (BBM)

If the BBM bit is set and the part is brought out of sleep mode by a button input activation, the part will enter the button reset state. In this state, the part will reboot and begin

code execution at the reset location. This bit is reset at POR and when exiting the button

reset state. All other registers remain unchanged.

41

Page 42

Button Detect Register – B_DET

Bit 76543210

$34 ––BD5 BD4 BD3 BD2 BD1 BD0

Read/Write R R R/W R/W R/W R/W R/W R/W

Initial Value 00000000

• Bits[7:6]

Reserved. These bits read “0”.

• Bits[5:0]

When an I/O pin is configured as a button using the IO_ENAB and IO_DATOUT registers and a logic low is detected on that pin, the button detect logic is activated. If the part

is in sleep mode, the part responds as described in the Power Control Register description. If a good battery is present, the appropriate bit is set in this register. A bit in this

register is cleared by writing a “0” to it.

Battery Low Configuration Register – BL_CONFIG

Bit 76543210

$35 BL BLV BL5 BL4 BL3 BL2 BL1 BL0

Read/Write R R R/W R/W R/W R/W R/W R/W

Initial Value 00000000

• Bit[7]: Battery Low

When Bit 6 in this register is set (Battery Low Valid), the BL (Battery Low) bit indicates

that the battery voltage is lower than the voltage level that is determined by Bits [5:0] of

this register.

• Bit[6]: Battery Low Valid

When the Battery Low Configuration Register is written, this bit is set to “0”. When the

battery voltage has been sampled and compared to the voltage determined by the BLx

bits, this bit is set to “1” indicating that the data in Bit 7 (Battery Low) is valid. This can

take up to 3100 XTAL cycles to complete.

• Bit[5:0]: Battery Low Detection Level

This value is sent to the battery monitor. The threshold is calculated using the formulas

shown in Table 3 (page 10).

42

AT86RF401

1424D–RKE–09/02

Page 43

AT86RF401

The Stack Pointer – SP The Stack Pointer is implemented as two 8-bit registers in the I/O space locations $3E

($5E) and $3D ($5D). Caution: As the data memory has 224 locations, only 8 bits are

used and the SPH register must be programmed to 0 x 00.

Bit 15 14 13 12 11 10 9 8

$3E –––––SP10 SP9 SP8 SPH

$3D SP7 SP6 SP5 SP4 SP3 SP2 SP1 SP0 SPL

76543210

Read/Write RRRRRR/WR/WR/W

R/W R/W R/W R/W R/W R/W R/W R/W

Initial Value 00000000

00000000

The Stack Pointer points to the data SRAM stack area where the Subroutine and Interrupt Stacks are located. This stack space in the data SRAM must be defined by the

program before any subroutine calls are executed or interrupts are enabled. The Stack

Pointer must be set to point above $60. The Stack Pointer is decremented by one when

data is pushed onto the stack with the PUSH instruction, and it is decremented by two

when the return address is pushed onto the stack with subroutine call and interrupt. The

Stack Pointer is incremented by one when data is popped from the stack with the POP

instruction, and it is incremented by two when data is popped from the stack with Return

from Subroutine (RET) or Return from Interrupt (RETI).

The Status Register – SREG The AVR status register – SREG – at I/O space location $3F is defined as:

Bit 76543210

$3F ITHSVNZC

Read/Write R/W R/W R/W R/W R/W R/W R/W R/W

Initial Value 00000000

• Bit[7] – I: Global Interrupt Enable

The global interrupt enable bit must be set (“1”) for the interrupts to be enabled. The

individual interrupt enable control is then performed in the interrupt mask registers

(GIMSK/TIMSK). If the global interrupt enable register is cleared (“0”), none of the interrupts are enabled, independent of the GIMSK/TIMSK values. The I-bit is cleared by

hardware after an interrupt has occurred and is set by the RETI instruction to enable

subsequent interrupts.

• Bit[6] – T: Bit Copy Storage

The bit copy instructions BLD (Bit LoaD) and BST (Bit STore) use the T-bit as source

and destination for the operated bit. A bit from a register in the register file can be copied

into T by the BST instruction, and a bit in T can be copied into a bit in a register in the

register file by the BLD instruction.

• Bit[5] – H: Half Carry Flag

The half carry flag H indicates a half carry in some arithmetic operations. See Table 10,

“SRAM Organization,” on page 21 for detailed information.

1424D–RKE–09/02

43

Page 44

Table 10. Instruction Set

• Bit[4] – S: Sign Bit, S = N⊕V

The S-bit is always an exclusive or between the negative flag N and the two’s complement overflow flag V. See Table 10 for detailed information.

• Bit[3] – V: Two’s Complement Overflow Flag

The two’s complement overflow flag V supports two’s complement arithmetics. See

Table 10 below for detailed information.

• Bit[2] – N: Negative Flag

The negative flag N indicates a negative result after the different arithmetic and logic

operations. See Table 10 below for detailed information.

• Bit[1] – Z: Zero Flag

The zero flag Z indicates a zero result after the different arithmetic and logic operations.

See Table 10 below for detailed information.

• Bit[0] – C: Carry Flag

The carry flag C indicates a carry in an arithmetic or logic operation. See Table 10 for

detailed information.

Mnemonics

Arithmetic and Logic Instructions

ADD Rd, Rr Add Two Registers Rd ← Rd + Rr Z,C,N,V,H

ADC Rd, Rr Add with Carry Two Registers Rd ← Rd + Rr + C Z,C,N,V,H 1

ADIW Rdl,K Add Immediate to Word Rdh:Rdl ← Rdh:Rdl + K Z,C,N,V,S 1

SUB Rd, Rr Subtract Two Registers Rd ← Rd - Rr Z,C,N,V,H 2

SUBI Rd, K Subtract Constant from Register Rd ← Rd - K Z,C,N,V,H 1

SBC Rd, Rr Subtract with Carry Two Registers Rd ← Rd-Rr-C Z,C,N,V,H 1

SBCI Rd, K Subtract with Carry Constant from

SBIW Rdl,K Subtract Immediate from Word Rdh:Rdl ← Rdh:Rdl - K Z,C,N,V,S 1

AND Rd, Rr Logical AND Registers Rd ← Rd • Rr Z,N,V 2

ANDI Rd, K Logical AND Register and

OR Rd, Rr Logical OR Registers Rd ← Rd v Rr Z,N,V 1

ORI Rd, K Logical OR Register and Constant Rd ← Rd v K Z,N,V 1

EOR Rd, Rr Exclusive OR Registers Rd ← Rd ⊕ Rr Z,N,V 1

COM Rd One’s Complement Rd ← $FF − Rd Z,C,N,V 1

Operands Description Operation Flags #Clocks

Rd ← Rd-K-C Z,C,N,V,H 1

Register

Rd ← Rd • KZ,N,V1

Constant

NEG Rd Two’s Complement Rd ← $00 − Rd Z,C,N,V,H 1

SBR Rd,K Set Bit(s) in Register Rd ← Rd v K Z,N,V 1

CBR Rd,K Clear Bit(s) in Register Rd ← Rd • ($FF - K) Z,N,V 1

INC Rd Increment Rd ← Rd + 1 Z,N,V 1

DEC Rd Decrement Rd ← Rd − 1Z,N,V1

TST Rd Test for Zero or Minus Rd ← Rd • Rd Z,N,V 1

44

AT86RF401

1424D–RKE–09/02

Page 45

Table 10. Instruction Set (Continued)

AT86RF401

Mnemonics

CLR Rd Clear Register Rd ← Rd ⊕ Rd Z,N,V 1

SER Rd Set Register Rd ← $FF None 1

Branch Instructions

RJMP k Relative Jump PC ← PC+k+1 None 1

IJMP Indirect Jump to (Z) PC ← Z None 2

JMP k Direct Jump PC ← k None 2

RCALL k Relative Subroutine Call PC ← PC+k+1 None 3

ICALL Indirect Call to (Z) PC ← Z None 3

CALL k Direct Subroutine Call PC ← k None 3

RET Subroutine Return PC ← STACK None 4

RETI Interrupt Return PC ← STACK I 4