Page 1

Features

• Dual ADC with 8-bit Resolution

• 1 Gsps Sampling Rate per Channel, 2 Gsps in Interlaced Mode

• Single or 1:2 Demultiplexed Output

• LVDS Output Format (100Ω)

• 500 mVpp Analog Input (Differential Only)

• Differential or Single-ended 50Ω PECL/LVDS Compatible Clock Inputs

• Power Supply: 3.3V (Analog), 3.3V (Digital), 2.25V (Output)

• LQFP144 Package

• Temperature Range:

– 0°C < TA < 70°C (Commercial Grade)

– -40°C < TA < 85°C (Industrial Grade)

• 3-wire Serial Interface

– 16-bit Data, 3-bit Address

– 1:2 or 1:1 Output Demultiplexer Ratio Selection

– Full or Partial Standby Mode

– Analog Gain (±1.5 dB) Digital Control

– Input Clock Selection

– Analog Input Switch Selection

– Binary or Gray Logical Outputs

– Synchronous Data Ready Reset

– Data Ready Delay Adjustable on Both Channels

– Interlacing Functions:

Offset and Gain (Channel to Channel) Calibration

Digital Fine SDA (Fine Sampling Delay Adjust) on One Channel

– Internal Static or Dynamic Built-In Test (BIT)

Dual 8-bit

1 Gsps ADC

AT84AD001B

Smart ADC

™

Performance

• Low Power Consumption: 0.7W Per Channel

• Power Consumption in Standby Mode: 120 mW

• 1.5 GHz Full Power Input Bandwidth (-3 dB)

• SNR = 42 dB Typ (6.8 ENOB), THD = -51 dBc, SFDR = -54 dBc at Fs = 1 Gsps

Fin = 500 MHz

• 2-tone IMD3: -54 dBc (499 MHz, 501 MHz) at 1 Gsps

• DNL = 0.25 LSB, INL = 0.5 LSB

• Channel to Channel Input Offset Error: 0.5 LSB Max (After Calibration)

• Gain Matching (Channel to Channel): 0.5 LSB Max (After Calibration)

• Low Bit Error Rate (10

-13

) at 1 Gsps

Application

• Instrumentation

• Satellite Receivers

• Direct RF Down Conversion

• WLAN

2153C–BDC–04/04

1

Page 2

Description The AT84AD001B is a monolithic dual 8-bit analog-to-digital converter, offering low

1.4W power consumption and excellent digitizing accuracy. It integrates dual on-chip

track/holds that provide an enhanced dynamic performance with a sampling rate of up to

1 Gsps and an input frequency bandwidth of over 1.5 GHz. The dual concept, the integrated demultiplexer and the easy interleaving mode make this device user-friendly for

all dual channel applications, such as direct RF conversion or data acquisition. The

smart function of the 3-wire serial interface eliminates the need for external components, which are usually necessary for gain and offset tuning and setting of other

parameters, leading to space and power reduction as well as system flexibility.

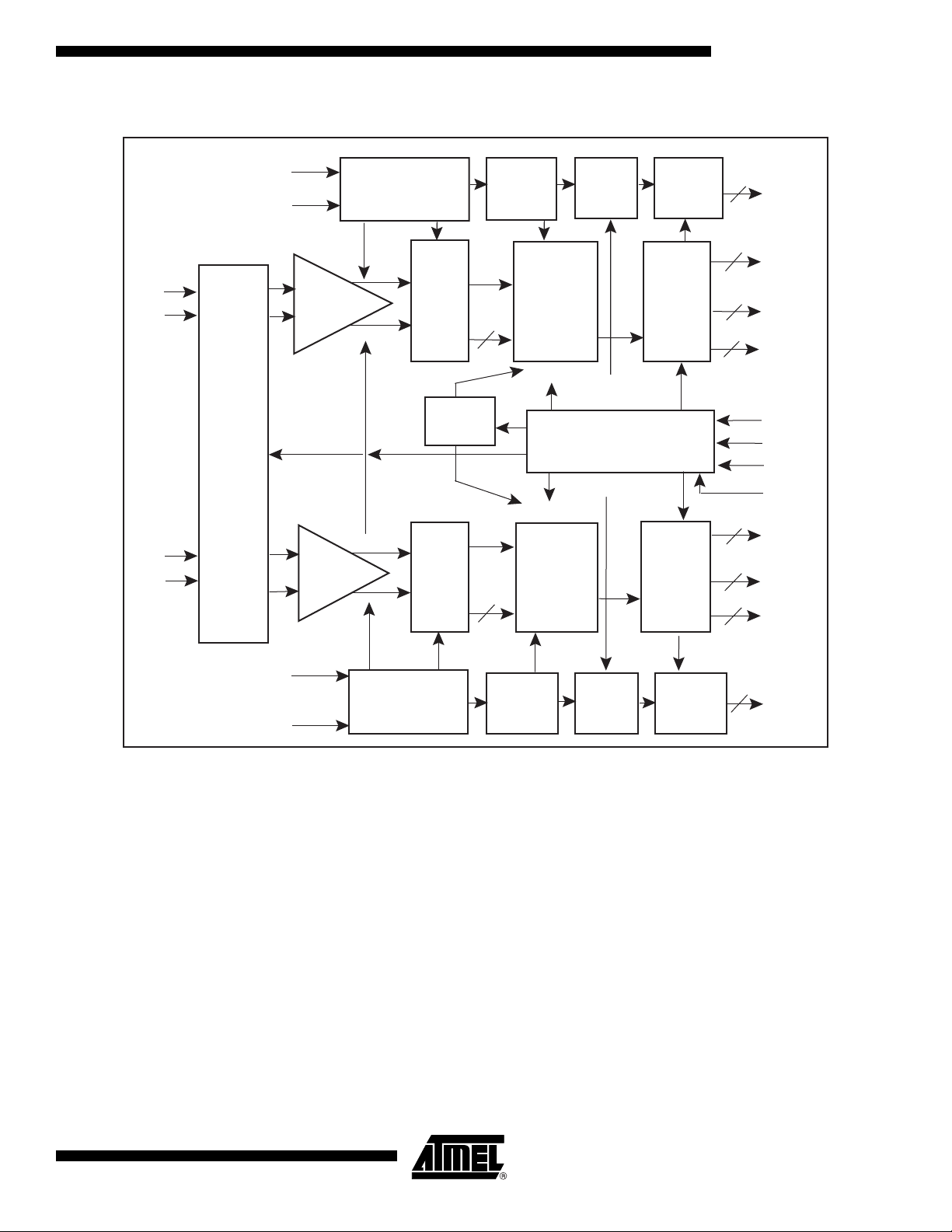

Functional Description

The AT84AD001B is a dual 8-bit 1 Gsps ADC based on advanced high-speed

BiCMOS technology.

Each ADC includes a front-end analog multiplexer followed by a Sample and Hold (S/H),

and an 8-bit flash-like architecture core analog-to-digital converter. The output data is

followed by a switchable 1:1 or 1:2 demultiplexer and LVDS output buffers (100Ω).

Two over-range bits are provided for adjustment of the external gain control on each

channel.

A 3-wire serial interface (3-bit address and 16-bit data) is included to provide several

adjustments:

• Analog input range adjustment (±1.5 dB) with 8-bit data control using a 3-wire bus

interface (steps of 0.18 dB)

• Analog input switch: both ADCs can convert the same analog input signal I or Q

• Gray or binary encoder output. Output format: DMUX 1:1 or 1:2 with control of the

output frequency on the data ready output signal

• Partial or full standby on channel I or channel Q

• Clock selection:

– Two independent clocks: CLKI and CLKQ

– One master clock (CLKI) with the same phase for channel I and channel Q

– One master clock but with two phases (CLKI for channel I and CLKIB for

channel Q)

• ISA: Internal Settling Adjustment on channel I and channel Q

• FiSDA: Fine Sampling Delay Adjustment on channel Q

• Adjustable Data Ready Output Delay on both channels

• Test mode: decimation mode (by 16), Built-In Test.

A calibration phase is provided to set the two DC offsets of channel I and channel Q

close to code 127.5 and calibrate the two gains to achieve a maximum difference of

0.5 LSB. The offset and gain error can also be set externally via the 3-wire serial

interface.

The AD84AD001B operates in fully differential mode from the analog inputs up to the

digital outputs. The AD84AD001B features a full-power input bandwidth of 1.5 GHz.

2

AT84AD001B

2153C–BDC–04/04

Page 3

Figure 1. Simplified Block Diagram

AT84AD001B

Vini

Vinib

Vinq

Vinqb

INPUT

MUX

CLKI

DDRB

Gain control I

Calibration

Gain/offset

ISA I

Gain control Q

Calibration

Gain/offset

ISA Q & FiSDA

+

S/H

-

Input switch

+

S/H

-

Clock Buffer

ADC

ADC

8bit

8bit

Q

Divider

2 to16

DoirI

I

8

BIT

DoirQ

8

DMUX

DMUX

DRDA

I

1:2

or

1:1

I

DMUX control

3-wire Serial Interface

3WSI

DMUX control

1: 2

or

1: 1

Q

LVDS

Clock

Buffer

LVDS

Buffer

I

LVDS

buffer

Q

16

16

16

16

2

CLKIO

DOAI

DOAIN

DOBI

DOBIN

2

DOIRI

DOIRIN

Data

Clock

Ldn

Mode

2

DOIRQ

DOIRQN

DOAQ

DOAQN

DOBQ

DOBQN

CLKQ

DDRB

Clock Buffer

Divider

2 to 16

DRDA

Q

LVDS

Clock

Buffer

2

CLKQO

2153C–BDC–04/04

3

Page 4

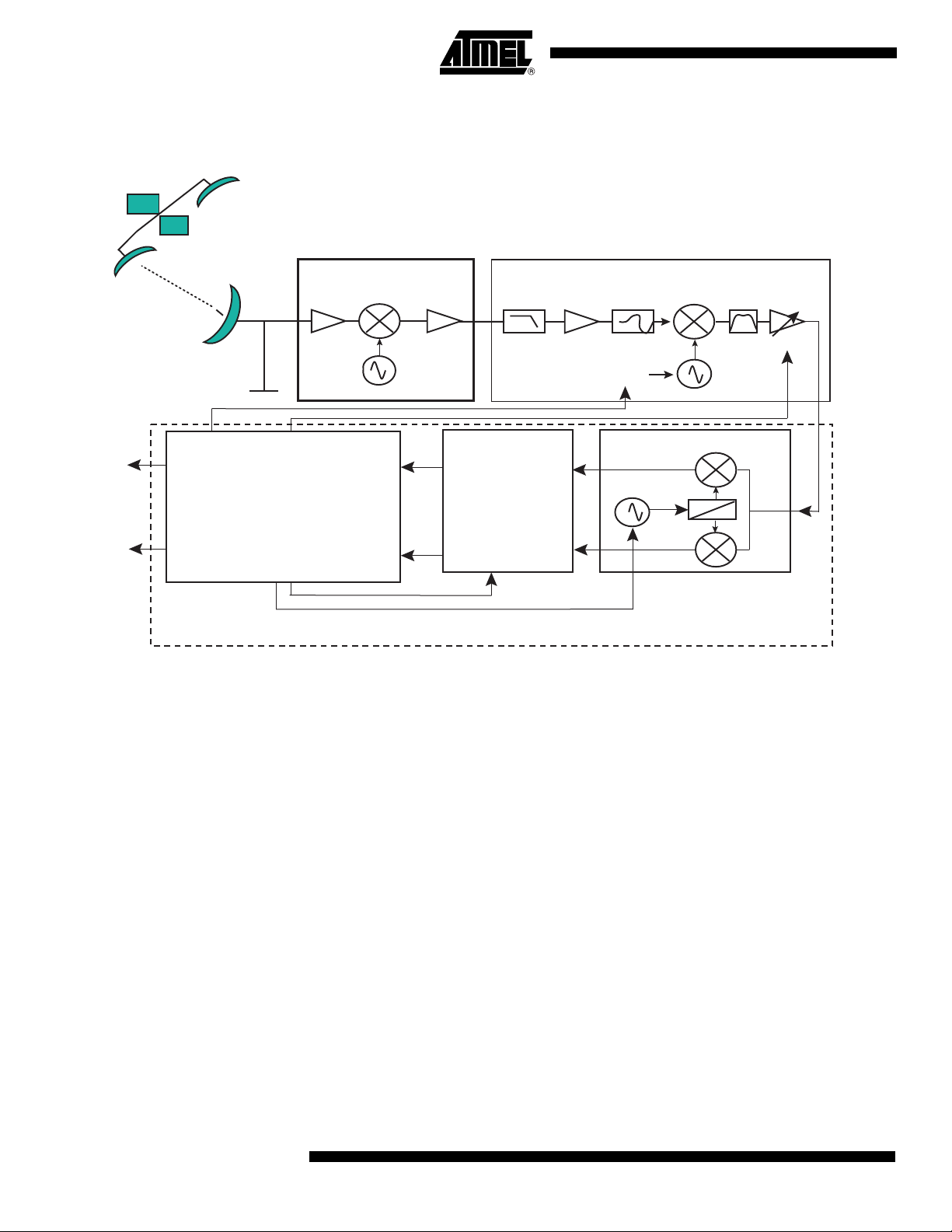

Typical Applications

Figure 2. Satellite Receiver Application

Satellite

Dish

I

Control Functions:

Clock and Carrier

Recovery...

Q

Low Noise Converter

(Connected to the Dish)

Bandpass

Amplifier

11..12 GHz

Local oscillator

Bandpass

Amplifier

I

Q

Demodulation

1..2 GHz

Low Pass

Filter

AT84AD001B

Clock

Satellite Tuner

Tunable

Band Filter

Synthesizer

1.5 … 2.5 GHz

I

Local Oscillator

Q

Q

Band Filter

0

90

Quadrature

IF

AGC

4

AT84AD001B

2153C–BDC–04/04

Page 5

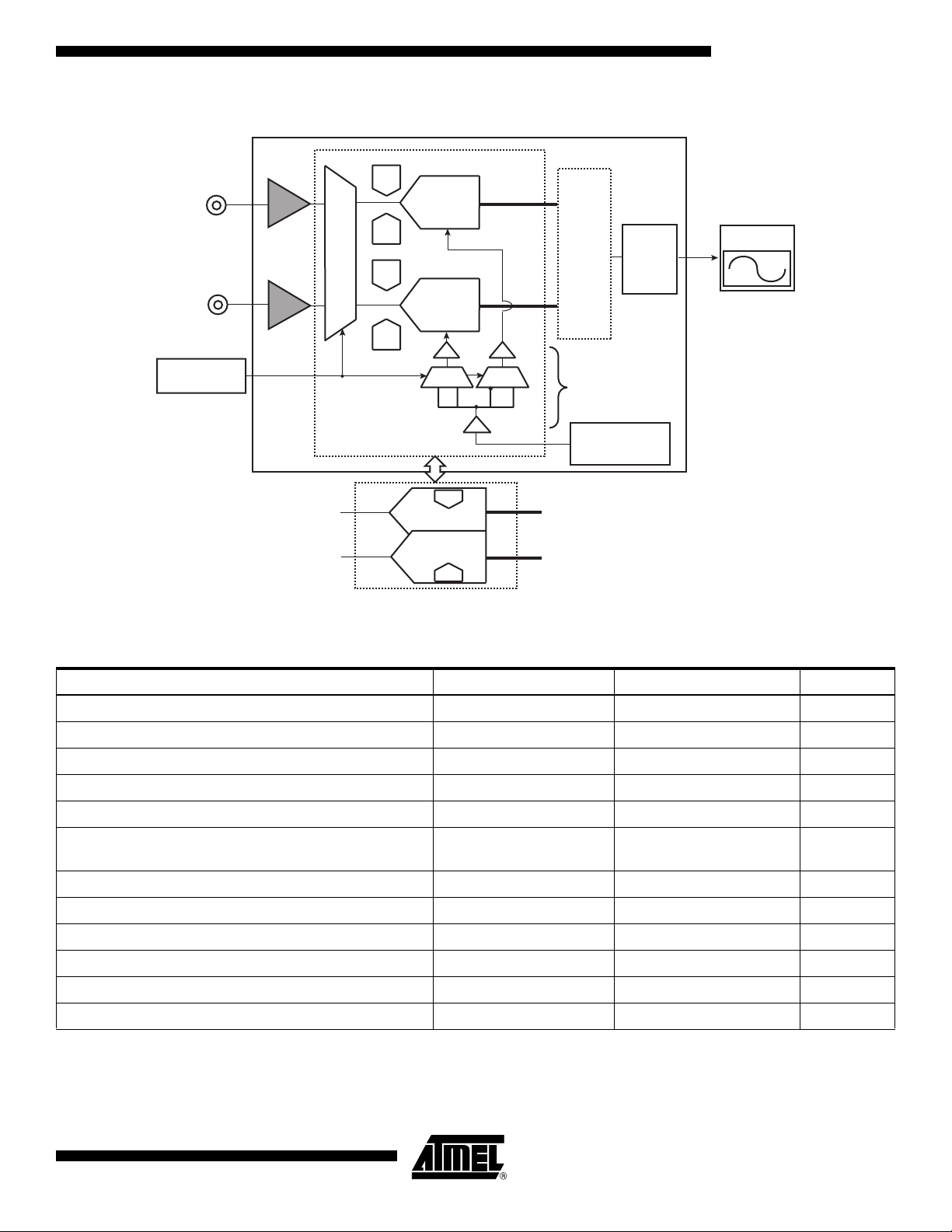

Figure 3. Dual Channel Digital Oscilloscope Application

DAC

Channel B

A

Channel A

A

Gain

ADC B

DAC

Offset

DAC

Offset

Analog switch

DAC

Gain

ADC A

FISO

RAM

AT84AD001B

Display

µP

Channel Mode

Selection

Clock

selection

Timing

circuit

DACs

Smart dual

ADC

DACs

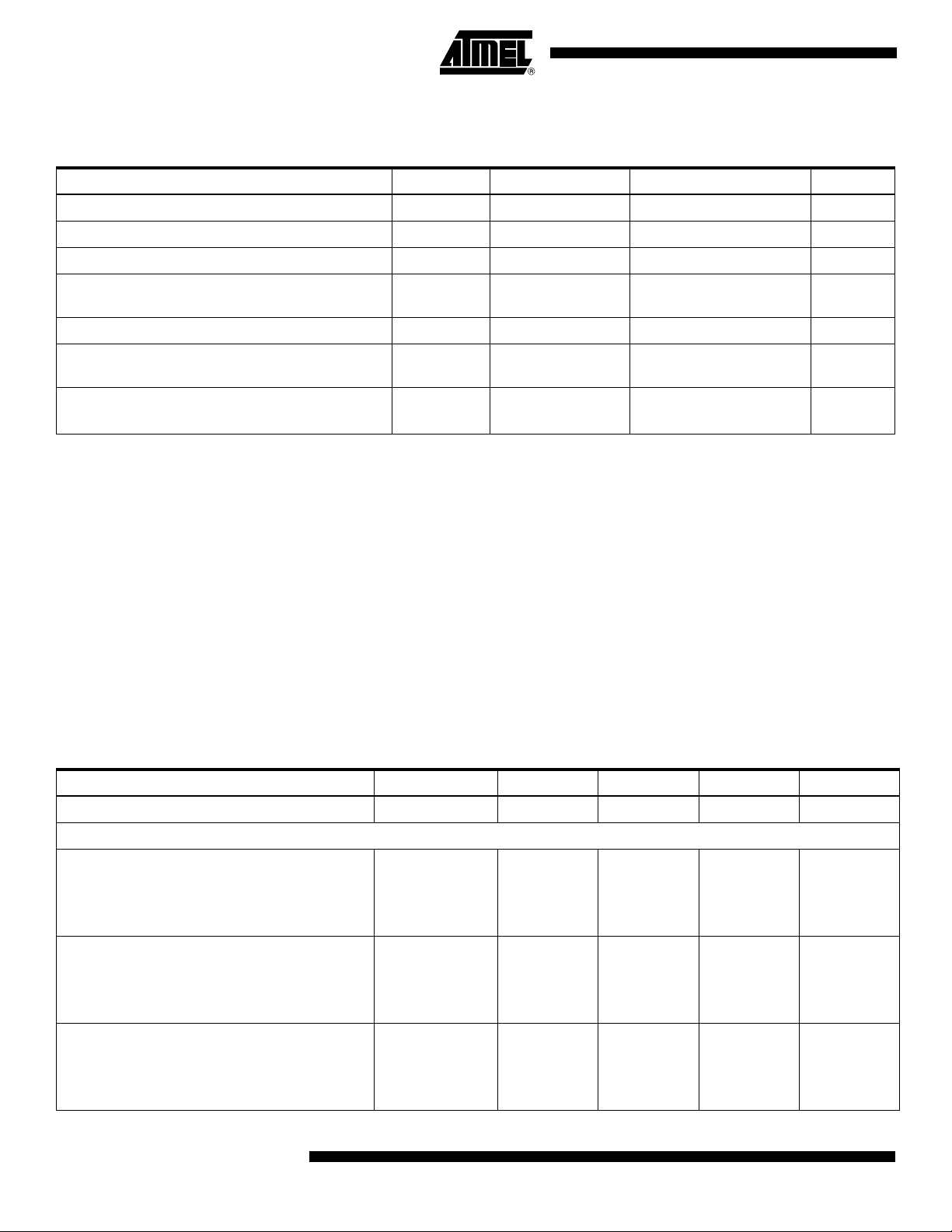

Table 1. Absolute Maximum Ratings

Parameter Symbol Value Unit

Analog positive supply voltage V

Digital positive supply voltage V

Output supply voltage V

Maximum difference between V

Minimum V

CCO

Analog input voltage

CCA

and V

CCD

V

CCA

V

V

or V

INI

V

or V

INQ

Digital input voltage V

Clock input voltage V

Maximum difference between V

CLK

and V

CLKB

CLK

V

or VC

CLK

Maximum junction temperature T

Storage temperature T

Lead temperature (soldering 10s) T

CCA

CCD

CCO

to V

CCO

D

- V

J

stg

leads

CCD

INIB

INQB

LKB

CLKB

3.6 V

3.6 V

3.6 V

± 0.8 V

1.6 V

1/-1 V

-0.3 to V

-0.3 to V

+ 0.3 V

CCD

+ 0.3 V

CCD

-2 to 2 V

125 °C

-65 to 150 °C

300 °C

Note: Absolute maximum ratings are limiting values (referenced to GND = 0V), to be applied individually, while other parameters are

within specified operating conditions. Long exposure to maximum ratings may affect device reliability.

5

2153C–BDC–04/04

Page 6

Table 2. Recommended Conditions of Use

Parameter Symbol Comments Recommended Value Unit

Analog supply voltage V

Digital supply voltage V

Output supply voltage V

V

Differential analog input voltage (full-scale)

INi

V

INQ

-V

CCA

CCD

CCO

-V

IniB

or

INQB

3.3 V

3.3 V

2.25 V

500 mVpp

Differential clock input level Vinclk 600 mVpp

Internal Settling Adjustment (ISA) with a 3-wire

serial interface for channel I and channel Q

Operating temperature range T

ISA -50 ps

Ambient

Commercial grade

Industrial grade

< 70

0 < T

A

-40 < TA < 85

Electrical Operating Characteristics

Unless otherwise specified:

•V

•V

• LVDS digital outputs (100Ω)

•T

• Full temperature range: 0° C < T

= 3.3V; V

CCA

- V

INI

INB

(typical) = 25° C

A

or V

CCD

INQ

(industrial grade)

= 3.3V; V

- V

INQB

= 2.25V

CCO

= 500 mVpp full-scale differential input

< 70° C (commercial grade) or -40°C < TA < 85° C

A

°C

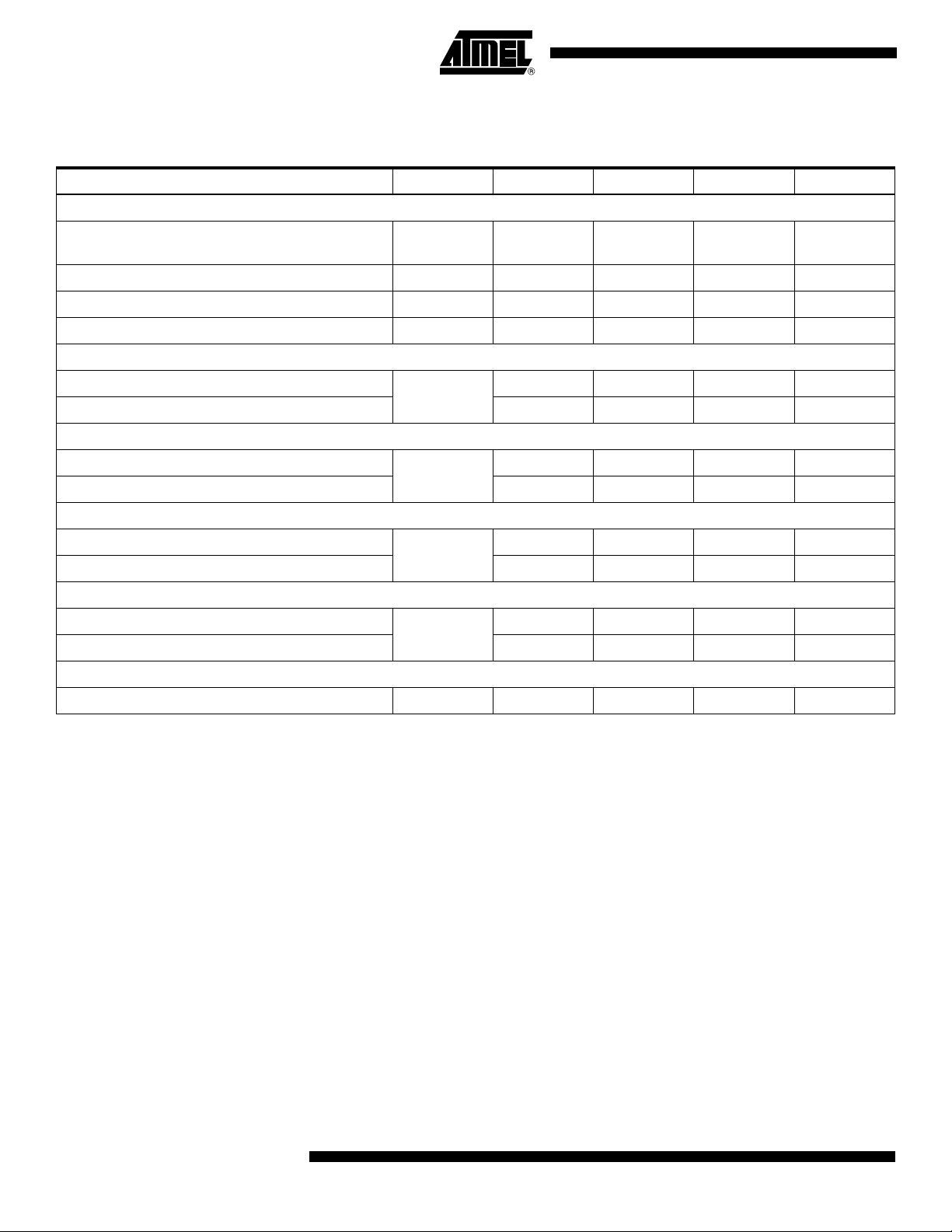

Table 3. Electrical Operating Characteristics in Nominal Conditions

Parameter Symbol Min Typ Max Unit

Resolution 8Bits

Power Requirements

Positive supply voltage

- Analog

- Digital

Output digital (LVDS) and serial interface

Supply current (typical conditions)

- Analog

- Digital

- Output

Supply current (1:2 DMUX mode)

- Analog

- Digital

- Output

6

AT84AD001B

V

V

V

I

CCA

I

CCD

I

CCO

I

CCA

I

CCD

I

CCO

CCA

CCD

CCO

3.15

3.15

2.0

3.3

3.3

2.25

150

230

100

150

260

175

3.45

3.45

2.5

180

275

120

180

310

210

V

V

V

mA

mA

mA

mA

mA

2153C–BDC–04/04

Page 7

AT84AD001B

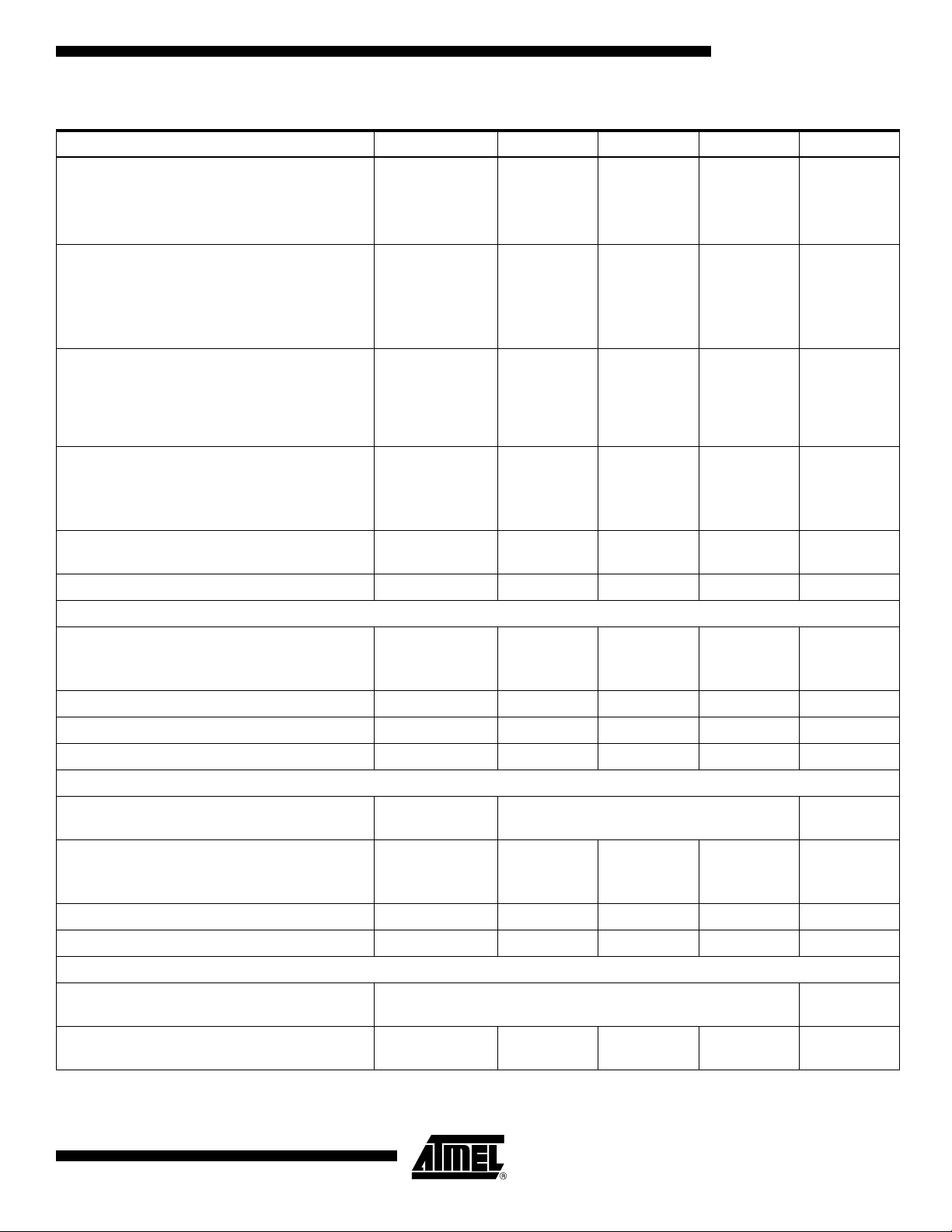

Table 3. Electrical Operating Characteristics in Nominal Conditions (Continued)

Parameter Symbol Min Typ Max Unit

Supply current (2 input clocks, 1:2 DMUX mode)

- Analog

- Digital

- Output

Supply current

(1 channel only, 1:1 DMUX mode)

- Analog

- Digital

- Output

Supply current

(1 channel only, 1:2 DMUX mode)

- Analog

- Digital

- Output

I

CCA

I

CCD

I

CCO

I

CCA

I

CCD

I

CCO

I

CCA

I

CCD

I

CCO

150

290

180

80

160

55

80

170

90

180

350

215

95

190

65

95

205

110

mA

mA

mA

mA

mA

mA

mA

Supply current (full standby mode)

- Analog

- Digital

- Output

Nominal dissipation

(1 clock, 1:1 DMUX mode, 2 channels)

I

CCA

I

CCD

I

CCO

P

12

24

3

D

1.4 1.7 W

17

34

5

mA

mA

mA

Nominal dissipation (full standby mode) stbpd 120 mW

Analog Inputs

- V

or

- V

IN

IniB

INQB

mV

450 500 550

mV

2pF

V

INi

Full-scale differential analog input voltage

V

INQ

Analog input capacitance I and Q C

Full power input bandwidth (-3 dB) FPBW 1.5 GHz

Gain flatness (-0.5 dB) 500 MHz

Clock Input

Logic compatibility for clock inputs and DDRB

Reset (pins 124,125,126,127,128,129)

PECL/ECL/LVDS

PECL/LVDS clock inputs voltages

(V

CLKI/IN

or V

CLKQ/QN

)

- V

V

IL

IH

600 mV

Differential logical level

Clock input power level -9 0 6 dBm

Clock input capacitance 2 pF

Digital Outputs

Logic compatibility for digital outputs

(depending on the value of V

CCO

)

Differential output voltage swings

(assuming V

2153C–BDC–04/04

= 2.25V)

CCO

V

OD

LV DS

220 270 350 mV

7

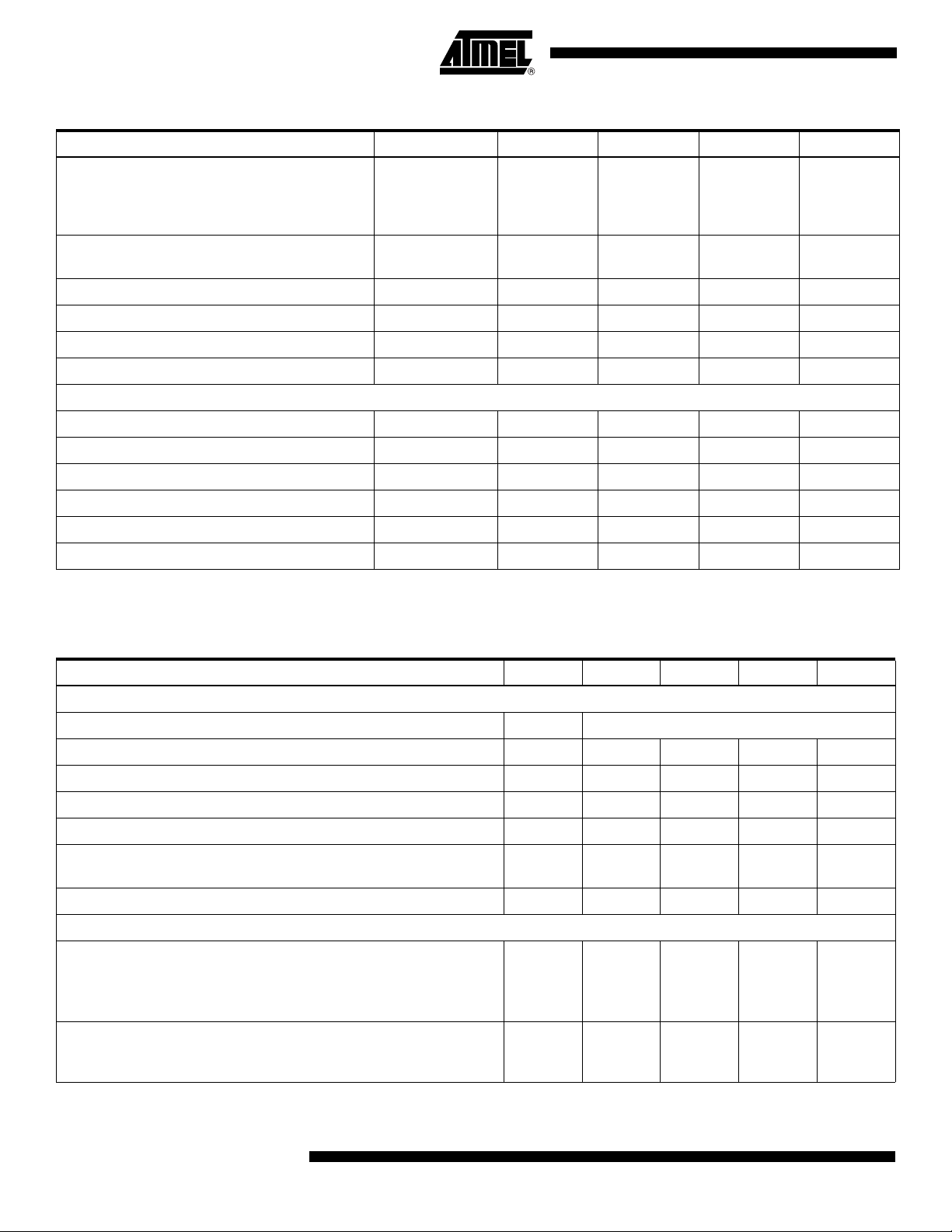

Page 8

Table 3. Electrical Operating Characteristics in Nominal Conditions (Continued)

Parameter Symbol Min Typ Max Unit

Output levels (assuming V

100Ω differentially terminated

Logic 0 voltage

Logic 1 voltage

Output offset voltage (assuming V

100Ω differentially terminated

Output impedance R

Output current (shorted output) 12 mA

Output current (grounded output) 30 mA

Output level drift with temperature 1.3 mV/°C

Digital Input (Serial Interface)

Maximum clock frequency (input clk) Fclk 50 MHz

Input logical level 0 (clk, mode, data, ldn) -0.4 0 0.4 V

= 2.25V)

CCO

= 2.25V)

CCO

V

OL

V

OH

V

OS

O

1.0

1.25

1125 1250 1325 mV

1.1

1.35

1.2

1.45

50 W

V

V

Input logical level 1 (clk, mode, data, ldn) V

- 0.4 V

CCO

- 0.4 V

CCO

+ 0.4 V

CCO

Output logical level 0 (cal) -0.4 0 0.4 V

Output logical level 1 (cal) V

- 0.4 V

CCO

CCO

V

+ 0.4 V

CCO

Maximum output load (cal) 15 pF

Note: The gain setting is 0 dB, one clock input, no standby mode [full power mode], 1:1 DMUX, calibration off.

Table 4. Electrical Operating Characteristics

Parameter Symbol Min Typ Max Unit

DC Accuracy

No missing code Guaranteed over specified temperature range

Differential non-linearity DNL 0.25 0.6 LSB

Integral non-linearity INL 0.5 1 LSB

Gain error (single channel I or Q) with calibration -0.5 0 0.5 LSB

Input offset matching (single channel I or Q) with calibration -0.5 0 0.5 LSB

Gain error drift against temperature

Gain error drift against V

CCA

0.062

0.064

Mean output offset code with calibration 127 127.5 128 LSB

Transient Performance

LSB/°C

LSB/mV

Bit Error Rate

Fs = 1 Gsps

BER 10

-13

Fin = 250 MHz

ADC settling time channel I or Q

(between 10% - 90% of output response)

V

-V

= 500 mVpp

Ini

iniB

TS 170 ps

Note: Gain setting is 0 dB, two clock inputs, no standby mode [full power mode], 1:2 DMUX, calibration on.

8

AT84AD001B

-10

10

2153C–BDC–04/04

Error/

sample

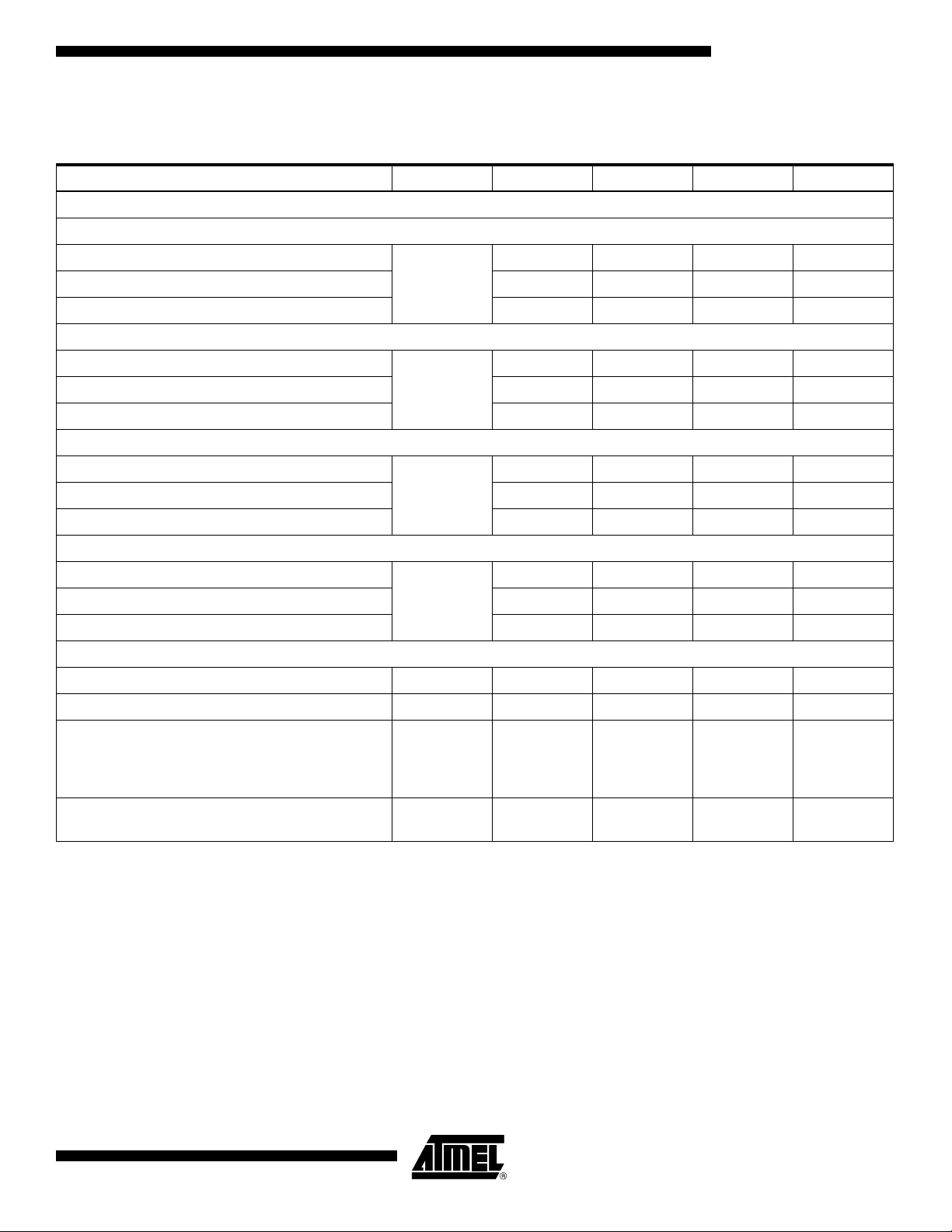

Page 9

AT84AD001B

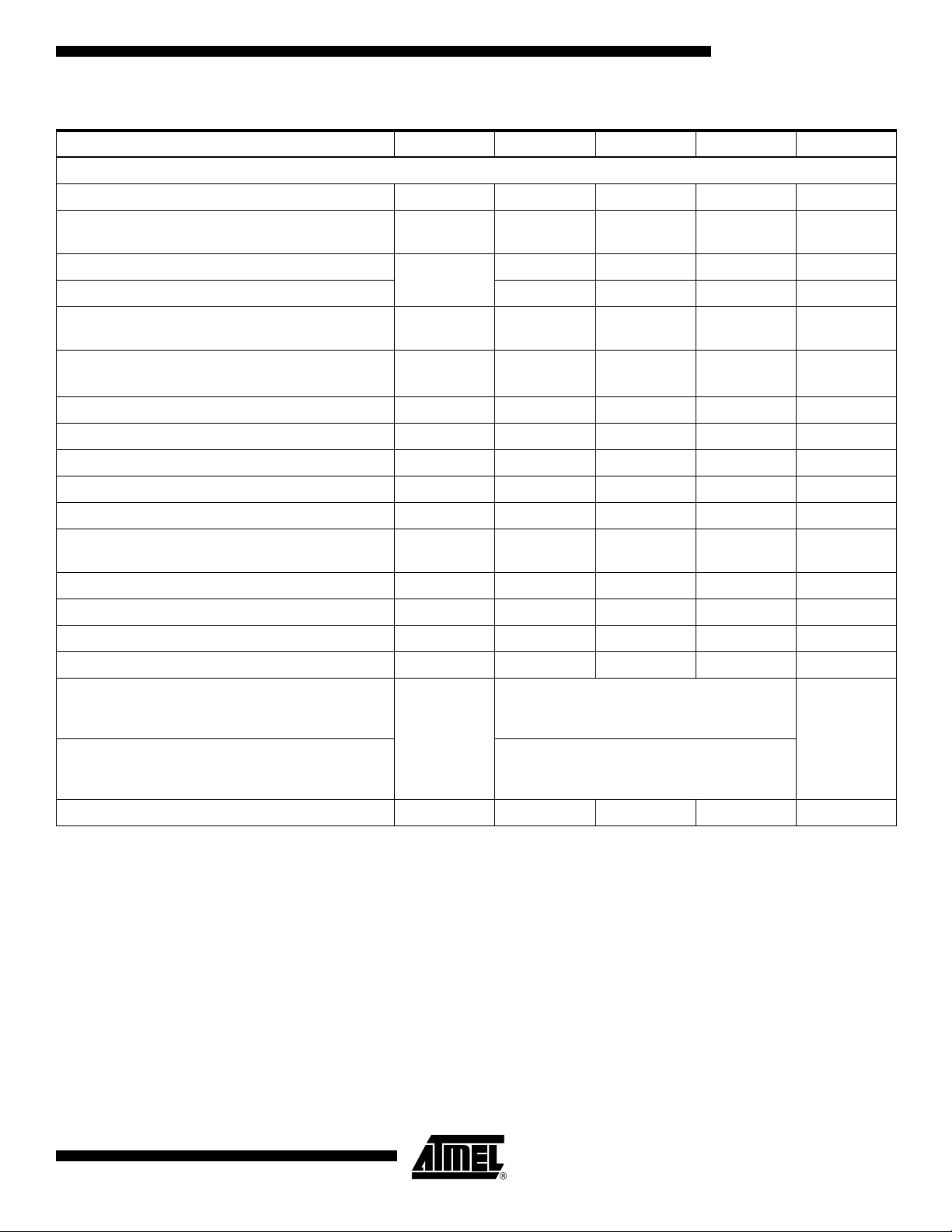

Table 5. AC Performances

Parameter Symbol Min Typ Max Unit

AC Performance

Signal-to-noise Ratio

Fs = 1 Gsps Fin = 20 MHz

Fs = 1 Gsps Fin = 500 MHz 40 42 dBc

Fs = 1 Gsps Fin = 1 GHz 41 dBc

Effective Number of Bits

Fs = 1 Gsps Fin = 20 MHz

Fs = 1 Gsps Fin = 500 MHz 6.5 6.8 Bits

Fs = 1 Gsps Fin = 1 GHz 6.2 Bits

Total Harmonic Distortion (First 9 Harmonics)

Fs = 1 Gsps Fin = 20 MHz

Fs = 1 Gsps Fin = 500 MHz 45 51 dBc

Fs = 1 Gsps Fin = 1 GHz 42 dBc

Spurious Free Dynamic Range

Fs = 1 Gsps Fin = 20 MHz

Fs = 1 Gsps Fin = 500 MHz 48 54 dBc

Fs = 1 Gsps Fin = 1 GHz 43 dBc

Two-tone Inter-modulation Distortion (Single Channel)

= 499 MHz , F

F

IN1

Band flatness from DC up to 600 MHz ±0.5 dB

= 501 MHz at Fs = 1 Gsps IMD -54 dBc

IN2

SNR

ENOB

|THD|

|SFDR|

42 44 dBc

77.2 Bits

48 54 dBc

50 56 dBc

Phase matching using auto-calibration and FiSDA

in interlace mode (channel I and Q)

Fin = 250 MHz

Fs = 1 Gsps

Crosstalk channel I versus channel Q

Fin = 250 MHz, Fs = 1 Gsps

Notes: 1. Differential input [-1 dBFS analog input level], gain setting is 0 dB, two input clock signals, no standby mode,

1:1 DMUX, ISA = -50 ps.

2. Measured on the AT84AD001TD-EB Evaluation Board.

2153C–BDC–04/04

(2)

dϕ -0.7 0 0.7 °

Cr -55 dB

9

Page 10

Table 6. AC Performances in Interlace Mode

Parameter Symbol Min Typ Max Unit

Interlace Mode

Maximum equivalent clock frequency Fint = 2 x Fs

Where Fs = external clock frequency

Minimum clock frequency F

F

int

int

2Gsps

20 Msps

Differential non-linearity in interlace mode intDNL 0.25 LSB

Integral non-linearity in interlace mode intINL 0.5 LSB

Signal-to-noise Ratio in Interlace Mode

Fint = 2 Gsps Fin = 20 MHz

42 dBc

iSNR

Fint = 2 Gsps Fin = 250 MHz 40 dBc

Effective Number of Bits in Interlace Mode

Fint = 2 Gsps Fin = 20 MHz

7.1 Bits

iENOB

Fint = 2 Gsps Fin = 250 MHz 6.8 Bits

Total Harmonic Distortion in Interlace Mode

Fint = 2 Gsps Fin = 20 MHz

52 dBc

|iTHD|

Fint = 2 Gsps Fin = 250 MHz 49 dBc

Spurious Free Dynamic Range in Interlace Mode

Fint = 2 Gsps Fin = 20 MHz

|iSFDR|

54 dBc

Fint = 2 Gsps Fin = 250 MHz 52 dBc

Two-tone Inter-modulation Distortion (Single Channel) in Interlace Mode

= 249 MHz , F

F

IN1

= 251 MHz at F

IN2

= 2 Gsps iIMD -54 dBc

int

Note: One analog input on both cores, clock I samples the analog input on the rising and falling edges. The calibration

phase is necessary. The gain setting is 0 dB, one input clock I, no standby mode, 1:1 DMUX, FiSDA adjustment.

10

AT84AD001B

2153C–BDC–04/04

Page 11

AT84AD001B

Table 7. Switching Performances

Parameter Symbol Min Typ Max Unit

Switching Performance and Characteristics - See “Timing Diagrams” on page 12.

Maximum operating clock frequency F

Maximum operating clock frequency in BIT and

decimation modes

(BIT, DEC)

S

F

S

1 Gsps

750 Msps

Minimum clock frequency (no transparent mode)

Minimum clock frequency (with transparent mode) 1 Ksps

Minimum clock pulse width [high]

(No transparent mode)

Minimum clock pulse width [low]

(No transparent mode)

Aperture delay: nominal mode with ISA & FiSDA TA 1 ns

Aperture uncertainty Jitter 0.4 ps (rms)

Data output delay between input clock and data TDO 3.8 ns

Data Ready Output Delay TDR 3 ns

Data Ready Reset to Data Ready TRDR 2 ns

Data Output Delay with Data Ready TD2

Data Ready (CLKO) Delay Adjust (140 ps steps) Tdrda range -560 to 420 ps

Output skew 50 100 ps

Output rise/fall time for DATA (20% - 80%) TR/TF 300 350 500 ps

Output rise/fall time for DATA READY (20% - 80%) TR/TF 300 350 500 ps

Data pipeline delay (nominal mode)

Data pipeline delay (nominal mode) in S/H

transparent mode

F

S

TC1 0.4 0.5 50 ns

TC2 0.4 0.5 50 ns

3.5 (port A, 1:1 DMUX mode)

TPD

4 (port A, 1:2 DMUX mode)

3 (port A, 1:1 DMUX mode)

3.5 (port A, 1:2 DMUX mode)

10 Msps

1/2 Fs

+Tdrda

3 (port B)

2.5 (port B)

ps

Clock cycles

DDRB recommended pulse width 1 ns

2153C–BDC–04/04

11

Page 12

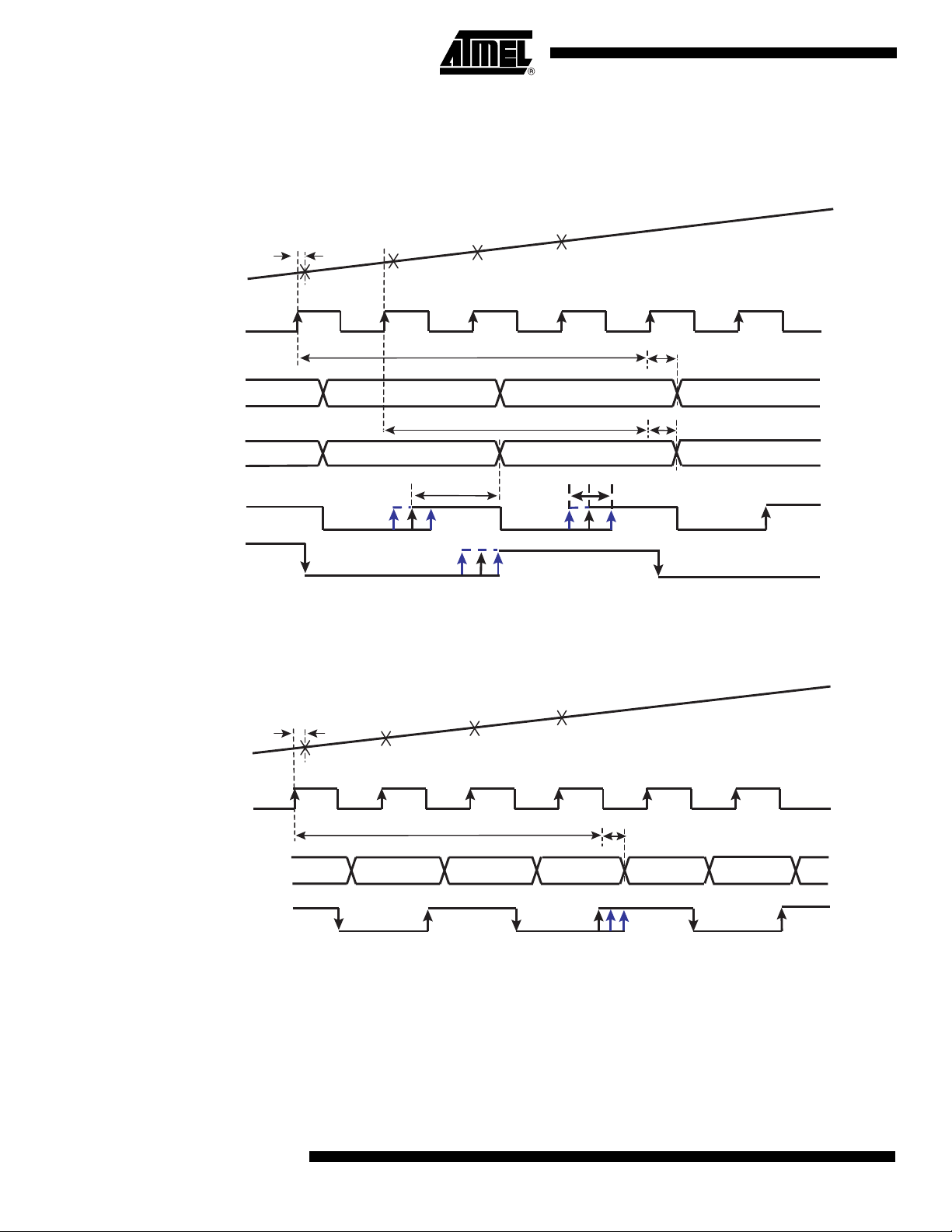

Timing Diagrams

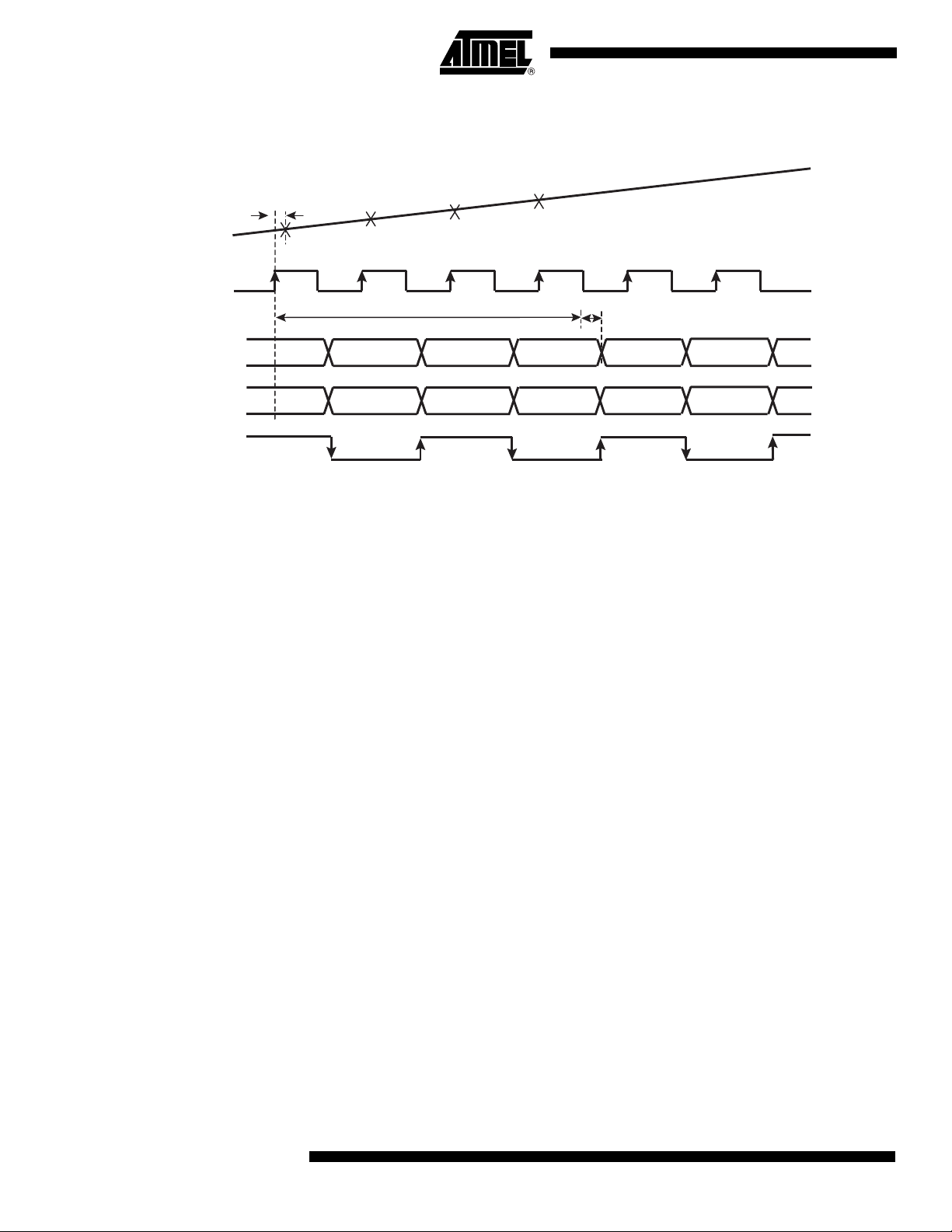

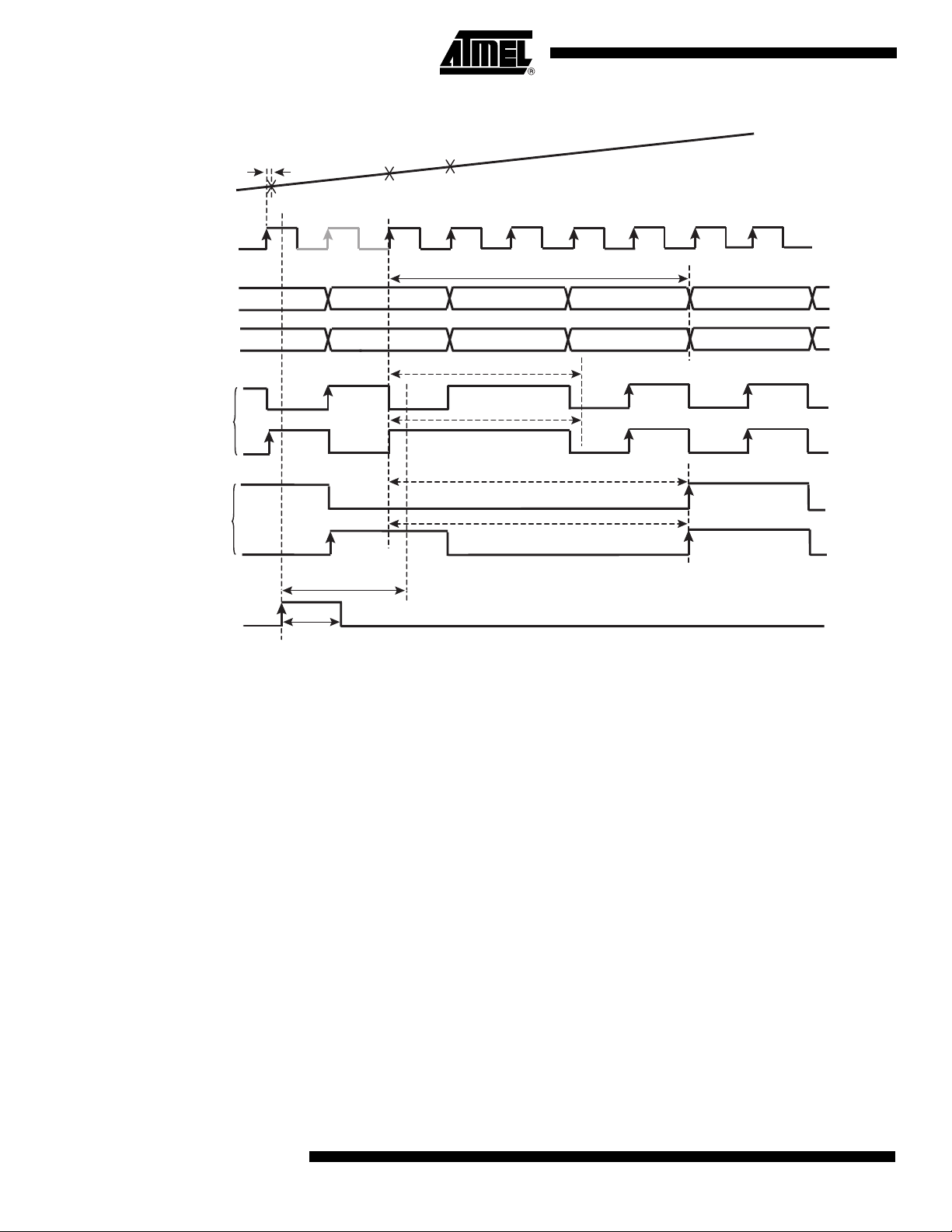

Figure 4. Timing Diagram, ADC I or ADC Q, 1:2 DMUX Mode, Clock I for ADC I, Clock Q for ADC Q

Address: D7 D6 D5 D4 D3 D2 D1 D0

1 1 X X 1 X 0 0

TA

VIN

N + 1

N

N + 2

CLKI or CLKQ

Pipeline delay = 4 clock cycles

DOIA[0:7]

or DOQA[0:7]

DOIB[0:7]

or DOQB[0:7]

N - 4

Pipeline delay = 3 clock cycles

N - 3 N - 1 N +1

TD2

CLKOI or CLKOQ

(= CLKI/2)

CLKOI or CLKOQ

(= CLKI/4)

Figure 5. 1:1 DMUX Mode, Clock I = ADC I, Clock Q = ADC Q

Address: D7 D6 D5 D4 D3 D2 D1 D0

1 1 X X 0 X 0 0

N + 3

N - 2

Programmable delay

TDO

N

TDO

12

TA

VIN

N

N + 1

CLKI or CLKQ

Pipeline delay = 3.5 clock cycles

DOIA[0:7]

or DOQA[0:7]

N - 3

CLKOI or CLKOQ

DOIB[0:7] and DOQB[0:7] are high impedance

AT84AD001B

N + 2

N - 2

N + 3

N - 1

TDO

N

N + 1

2153C–BDC–04/04

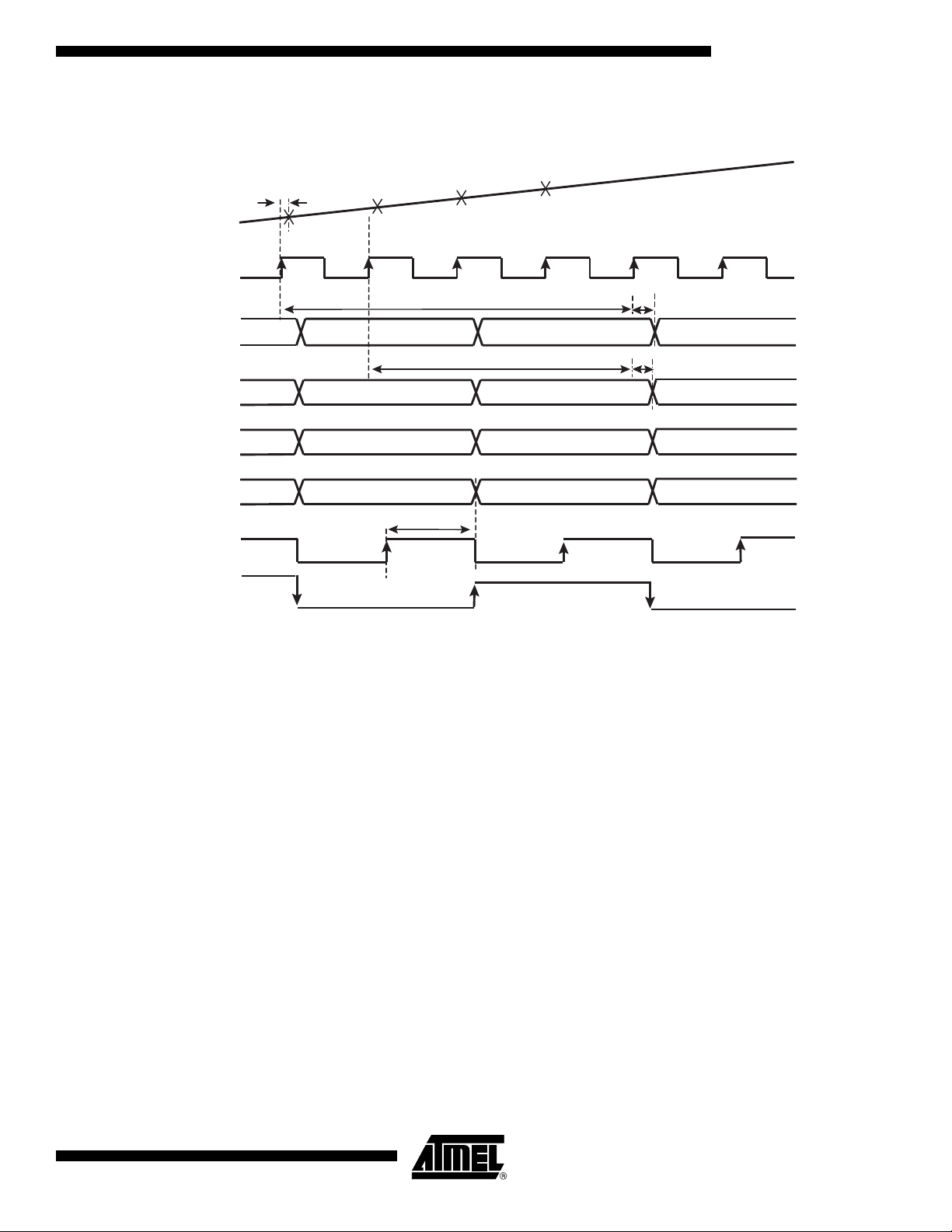

Page 13

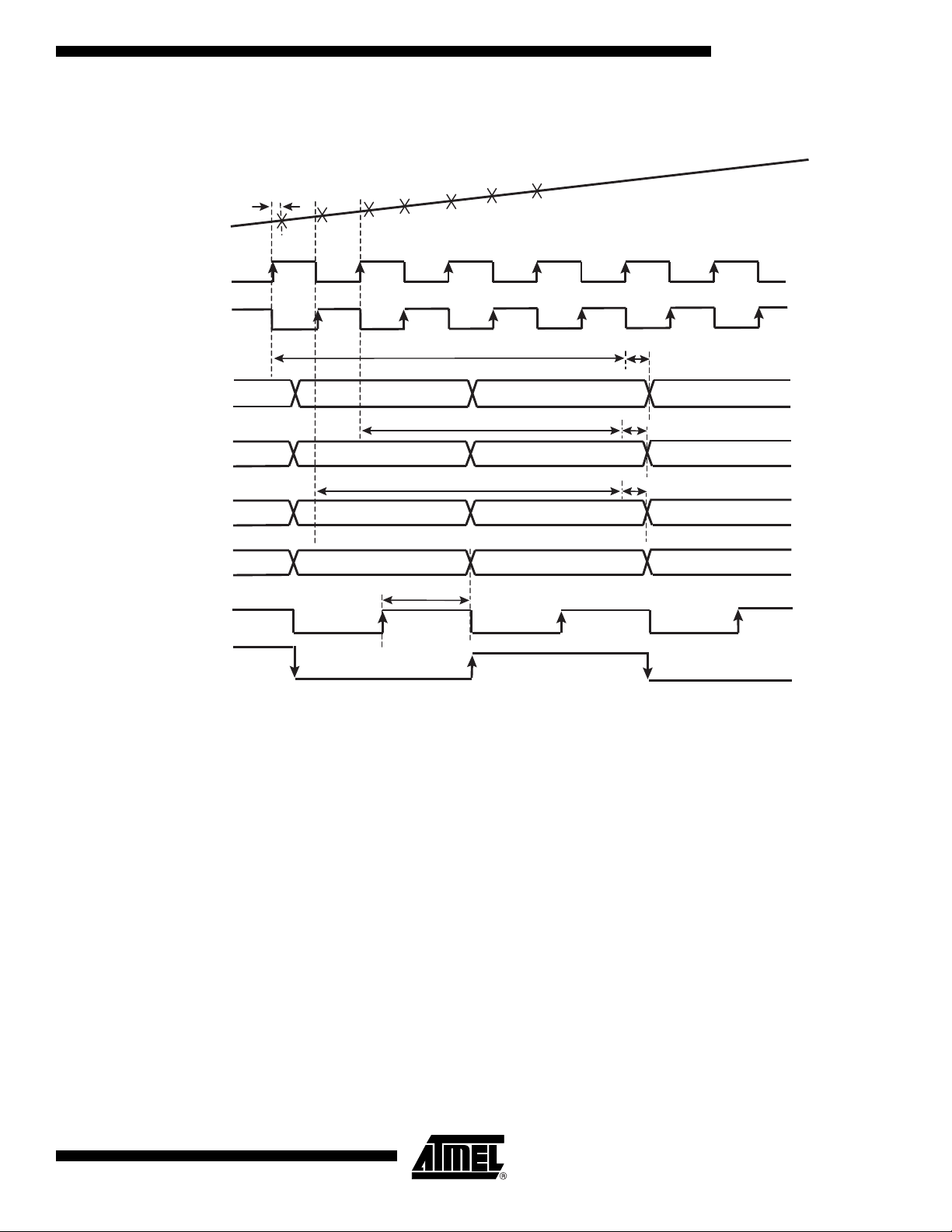

Figure 6. 1:2 DMUX Mode, Clock I = ADC I, Clock I = ADC Q

Address: D7 D6 D5 D4 D3 D2 D1 D0

1 0 X X 1 X 0 0

AT84AD001B

TA

VIN

N

CLKI

DOIA[0:7]

DOIB[0:7]

DOQA[0:7]

DOQB[0:7]

CLKOI

(= CLKI/2)

CLKOI

(= CLKI/4)

CLKOQ is high impedance

N + 1

Pipeline delay = 4 clock cycles

NI - 4

Pipeline delay = 3 clock cycles

NI - 3 NI - 1 NI +1

NQ - 4 NQ - 2 NQ

NQ - 3 NQ - 1 NQ +1

N + 2

TD2

N + 3

NI - 2

TDO

NI

TDO

2153C–BDC–04/04

13

Page 14

Figure 7. 1:1 DMUX Mode, Clock I = ADC I, Clock I = ADC Q

Address: D7 D6 D5 D4 D3 D2 D1 D0

1 0 X X 0 X 0 0

TA

VIN

N

N + 1

CLKI

Pipeline delay = 3.5 clock cycles

DOIA[0:7]

DOQA[0:7]

N - 3

N - 3

CLKOI

DOIB[0:7] and DOQB[0:7] are high impedance

CLKOQ is high impedance

N + 2

N - 2

N - 2

N + 3

N - 1

N - 1

TDO

N

N

N + 1

N + 1

14

AT84AD001B

2153C–BDC–04/04

Page 15

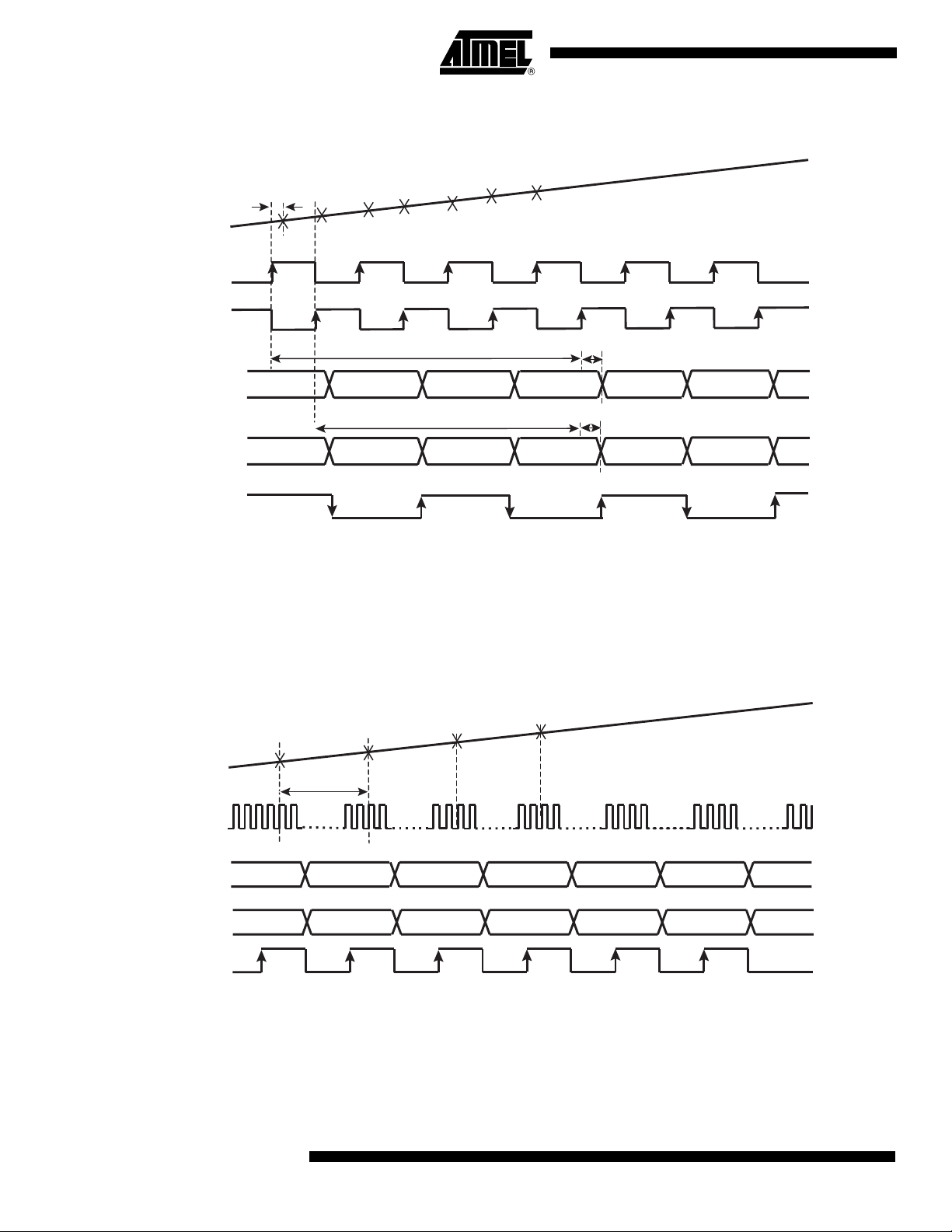

Figure 8. 1:2 DMUX Mode, Clock I = ADC I, Clock IN = ADC Q

Address: D7 D6 D5 D4 D3 D2 D1 D0

0 X X X 1 X 0 0

N + 4

N + 5

VIN

CLKI

CLKIN

TA

N + 2

N + 1

N

N + 3

AT84AD001B

N + 6

DOQA[0:7]

DOQB[0:7]

DOIA[0:7]

DOIB[0:7]

CLKOI

(= CLKI/2)

CLKOI

(= CLKI/4)

CLKOQ is high impedance

Pipeline delay = 4 clock cycles

N - 8

Pipeline delay = 3 clock cycles

N - 6 N - 2 N + 2

Pipeline delay = 3.5 clock cycles

N - 7 N - 3 N + 1

N - 5 N - 1 N + 3

TD2

N - 4

TDO

N

TDO

TDO

2153C–BDC–04/04

15

Page 16

Figure 9. 1:1 DMUX Mode, Clock I = ADC I, Clock IN = ADC Q

Address: D7 D6 D5 D4 D3 D2 D1 D0

0 X X X 0 X 0 0

N + 4

N + 5

VIN

CLKI

CLKIN

TA

N + 2

N + 1

N

N + 3

N + 6

Pipeline delay = 3.5 clock cycles

DOQA[0:7]

DOIA[0:7]

N - 6

Pipeline delay = 3 clock cycles

N - 5

N - 4

N - 3

CLKOI

(= CLKI/2)

DOIB[0:7] and DOQB[0:7] are high impedance

CLKOQ is high impedance

Figure 10. 1:1 DMUX Mode, Decimation Mode Test (1:16 Factor)

Address: D7 D6 D5 D4 D3 D2 D1 D0

1 0 X X 0 X 0 0

N + 16

VIN

N - 16

16 clock cycles

N

N - 2

N - 1

N + 32

TDO

TDO

N

N + 1

N + 2

N + 3

CLKI

DOIA[0:7]

DOQA[0:7]

N - 16

N - 16

N

N

N + 16 N + 32 N + 48

N + 16 N + 32 N + 48

CLKOI

DOIB[0:7] and DOQB[0:7] are high impedance

CLKOQ is high impedance

Notes: 1. The maximum clock input frequency in decimation mode is 750 Msps.

2. Frequency(CLKOI) = Frequency(Data) = Frequency(CLKI)/16.

16

AT84AD001B

2153C–BDC–04/04

Page 17

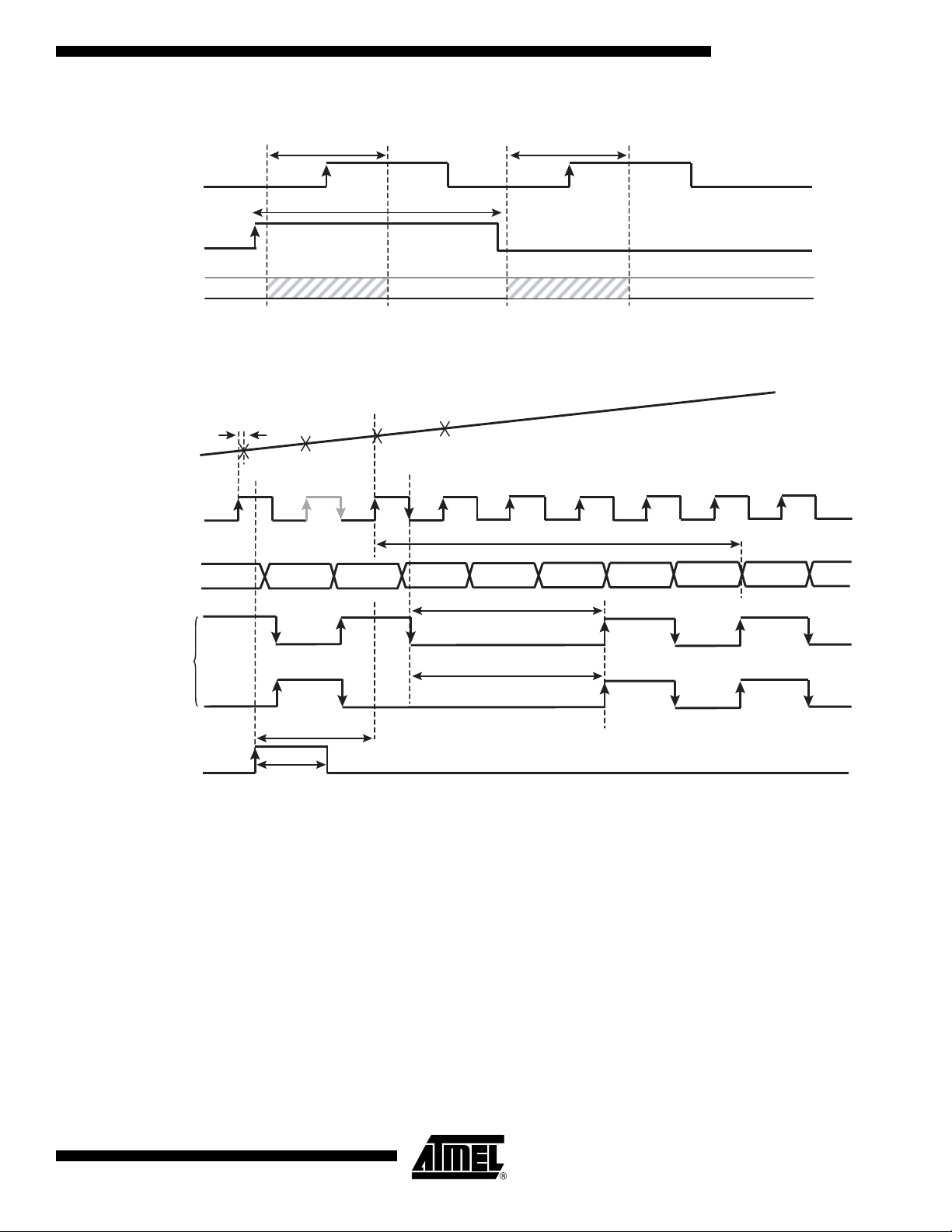

Figure 11. Data Ready Reset

AT84AD001B

500 ps

CLKI or

CLKQ

1 ns min

DDRB

Figure 12. Data Ready Reset 1:1 DMUX Mode

TA

VIN

Clock in

Reset

CLKI or

CLKQ

DOIA[0:7] or

DOQA[0:7]

N

ALLOWED

N + 1

500 ps

FORBIDDENFORBIDDEN

ALLOWED

Pipeline Delay + TDO

N

TDR

CLKOI or

CLKOQ

2 ns

TDR

DDRB

1 ns min

Note: The Data Ready Reset is taken into account only 2 ns after it is asserted. The output clock first completes its cycle (if the reset

occurs when it is high, it goes low only when its half cycle is complete; if the reset occurs when it is low, it remains low) and then

only, remains in reset state (frozen to a low level in 1:1 DMUX mode). The next falling edge of the input clock after reset makes

the output clock return to normal mode (after TDR).

2153C–BDC–04/04

17

Page 18

Figure 13. Data Ready Reset 1:2 DMUX Mode

TA

VIN

CLKI or

CLKQ

DOIA[0:7] or

DOQA[0:7]

Clock in

Reset

N

N + 1

Pipeline Delay + TDO

N

DOIB[0:7] or

DOQB[0:7]

CLKOI or CLKOQ

(= CLKI/2)

CLKOI or CLKOQ

(= CLKI/4)

DDRB

Notes: 1. In 1:2 DMUX, Fs/2 mode:

The Data Ready Reset is taken into account only 2 ns after it is asserted. The output clock first completes its cycle (if the

reset occurs when it is low, it goes high only when its half cycle is complete; if the reset occurs when it is high, it remains

high) and then only, remains in reset state (frozen to a high level in 1:2 DMUX Fs/2 mode). The next rising edge of the input

clock after reset makes the output clock return to normal mode (after TDR).

2. In 1:2 DMUX, Fs/4 mode:

The Data Ready Reset is taken into account only 2 ns after it is asserted. The output clock first completes its cycle (if the

reset occurs when it is high, it goes low only when its half cycle is complete; if the reset occurs when it is low, it remains low)

and then only, remains in reset state (frozen to a low level in 1:2 DMUX Fs/4 mode). The next rising edge of the input clock

after reset makes the output clock return to normal mode (after TDR).

N + 1

TDR

TDR

TDR + 2 cycles

TDR + 2 cycles

2 ns

1 ns min

18

AT84AD001B

2153C–BDC–04/04

Page 19

Functions Description

Table 8. Description of Functions

Name Function

V

CCA

V

CCD

V

CCO

GNDA Analog ground

GNDD Digital ground

GNDO Output ground

V

, V

INI

INIB

V

, V

INQ

INQB

CLKOI, CLKOIN, CLKOQ,

CLKOQN

CLKI, CLKIN, CLKQ, CLKQN Differential clock inputs I and Q

DDRB, DDRBN

Mode

Clk

Data Input data for 3-wire bus

Ldn

<D0AI0:DOAI7>

<D0AI0N:DOAI7N>

<D0BI0:DOBI7>

<D0BI0N:DOBI7N>

Positive analog power supply

Positive digital power supply

Positive output power supply

Differential analog inputs I

Differential analog inputs Q

Differential output data ready I

and Q

Synchronous data ready reset

I and Q

Bit selection for 3-wire bus or

nominal setting

Input clock for 3-wire bus

interface

Beginning and end of register

line for 3-wire bus interface

Differential output data port

channel I

VCCA = 3.3V

VINI

VINIB

VINQ

VINQB

CLKI

CLKIB

CLKQ

CLKQB

GNDA

VCCD = 3.3V VCCO = 2.25V

AT84AD001B

GNDD

GNDO

DOIRI, DOIRIN DOIRQ,

DOIRQN

VtestQ

VtestI

mode dataclk ldn

AT84AD001B

D0AI0 DOAI7

D0AI0N DOAI7N

32

D0BI0

DOBI7

D0BI0N

DOBI7N

D0AQ0 DOAQ7

32

D0AQ0 DOAQ7

DOBQ0

DOQBQ7

DOBQ0N

DOQBQ7N

4

DOIRI, DOIRIN

DOIRQ, DOIRQN

4

CLOCKOI, CLOCKOIB

CLOCKOQ, CLOCKOQB

2

VtestI

VtestQ

Vdiode

Differential output IN range

data I and Q

Test voltage output for ADC Q

(to be left open)

Test voltage output for ADC I

(to be left open)

<D0AQ0:DOAQ7>

<D0AQ0N:DOAQ7N>

<D0BQ0:DOBQ7>

<D0BQ0N:DOBQ7N>

2153C–BDC–04/04

Differential output data port

channel Q

Vdiode

Cal

Output bit status internal

calibration

Test diode voltage for Tj

measurement

19

Page 20

Digital Output Coding (Nominal Settings)

Table 9. Digital Output Coding (Nominal Setting)

Differential

Analog Input

Volt a g e Leve l

Digital Output

I or Q (Binary Coding)

Out-of-range Bit

> 250 mV > Positive full-scale + 1/2 LSB 1 1 1 1 1 1 1 1 1

250 mV

248 mV

1 mV

-1 mV

-248 mV

-250 mV

Positive full-scale + 1/2 LSB

Positive full-scale - 1/2 LSB

Bipolar zero + 1/2 LSB

Bipolar zero - 1/2 LSB

Negative full-scale + 1/2 LSB

Negative full-scale - 1/2 LSB

1 1 1 1 1 1 1 1

1 1 1 1 1 1 1 0

1 0 0 0 0 0 0 0

0 1 1 1 1 1 1 1

0 0 0 0 0 0 0 1

0 0 0 0 0 0 0 0

< -250 mV < Negative full-scale - 1/2 LSB 0 0 0 0 0 0 0 0 1

Pin Description

Table 10. AT84AD001B LQFP 144 Pin Description

Symbol Pin number Function

GNDA, GNDD, GNDO

V

CCA

V

CCD

V

CCO

V

INI

V

INIB

V

INQ

10, 12, 22, 24, 36, 38, 40, 42, 44, 46, 51,

54, 59, 61, 63, 65, 67, 69, 85, 87, 97, 99,

109, 111, 130, 142, 144

41, 43, 45, 60, 62, 64 Analog positive supply: 3.3V typical

9, 21, 37, 39, 66, 68, 88, 100, 112, 123,

141

11, 23, 86, 98, 110, 143

57, 58

55, 56

47, 48

Ground pins. To be connected to external

ground plane

3.3V digital supply

2.25V output and 3-wire serial interface

supply

In-phase (+) analog input signal of the

sample & hold differential preamplifier

channel I

Inverted phase (-) of analog input signal

)

(V

INI

In-phase (+) analog input signal of the

sample & hold differential preamplifier

channel Q

0

0

0

0

0

0

V

INQB

49, 50

Inverted phase (-) of analog input signal

(V

)

INQ

CLKI 124 In-phase (+) clock input signal

CLKIN 125

Inverted phase (-) clock input signal

(CLKI)

CLKQ 129 In-phase (+) clock input signal

20

AT84AD001B

2153C–BDC–04/04

Page 21

AT84AD001B

Table 10. AT84AD001B LQFP 144 Pin Description (Continued)

Symbol Pin number Function

CLKQN 128

DDRB 126 Synchronous data ready reset I and Q

DDRBN 127 Inverted phase (-) of input signal (DDRB)

Inverted phase (-) clock input signal

(CLKQ)

DOAI0, DOAI1, DOAI2, DOAI3, DOAI4,

DOAI5, DOAI6, DOAI7

DOAI0N, DOAI1N, DOAI2N, DOAI3N,

DOAI4N, DOAI5N, DOAI6N, DOAI7N,

DOBI0, DOBI1, DOBI2, DOBI3, DOBI4,

DOBI5, DOBI6, DOBI7

DOBI0N, DOBI1N, DOBI2N, DOBI3N,

DOBI4N, DOBI5N, DOBI6N, DOBI7N

DOAQ0, DOAQ1, DOAQ2, DOAQ3,

DOAQ4, DOAQ5, DOAQ6, DOAQ7

DOAQ0N, DOAQ1N, DOAQ2N, DOAQ3N,

DOAQ4N, DOAQ5N, DOAQ6N, DOAQ7N

DOBQ0, DOBQ1, DOBQ2, DOBQ3,

DOBQ4, DOBQ5, DOBQ6, DOBQ7

DOBQ0N, DOBQ1N, DOBQ2N,

DOBQ3N, DOBQ4N, DOBQ5N,

DOBQ6N, DOBQ7N

117, 113, 105, 101, 93, 89, 81, 77

118, 114, 106, 102, 94, 90, 82, 78

119, 115, 107, 103, 95, 91, 83, 79

120, 116, 108, 104, 96, 92, 84, 80

136, 140, 4, 8, 16, 20, 28, 32

135, 139, 3, 7, 15, 19, 27, 31

134, 138, 2, 6, 14, 18, 26, 30

133, 137, 1 ,5, 13, 17, 25, 29

In-phase (+) digital outputs first phase

demultiplexer (channel I) DOAI0 is the

LSB. D0AI7 is the MSB

Inverted phase (-) digital outputs first

phase demultiplexer (channel I) DOAI0N

is the LSB. D0AI7N is the MSB

In-phase (+) digital outputs second phase

demultiplexer (channel I) DOBI0 is the

LSB. D0BI7 is the MSB

Inverted phase (-) digital outputs second

phase demultiplexer (channel I) DOBI0N

is the LSB. D0BI7N is the MSB

In-phase (+) digital outputs first phase

demultiplexer (channel Q) DOAI0 is the

LSB. D0AQ7 is the MSB

Inverted phase (-) digital outputs first

phase demultiplexer (channel Q) DOAI0N

is the LSB. D0AQ7N is the MSB

In-phase (+) digital outputs second phase

demultiplexer (channel Q) DOBQ0 is the

LSB. D0BQ7 is the MSB

Inverted phase (-) digital outputs second

phase demultiplexer (channel Q)

DOBQ0N is the LSB. D0BQ7N is the MSB

In-phase (+) out-of-range bit input

DOIRI 75

DOIRIN 76 Inverted phase of output signal DOIRI

DOIRQ 34

DOIRQN 33 Inverted phase of output signal DOIRQ

MODE 74

CLK 73 Input clock for 3-wire bus interface

DATA 72 Input data for 3-wire bus

LND 71

CLKOI 121 Output clock in-phase (+) channel I

2153C–BDC–04/04

(I phase) combined demultiplexer

out-of-range is high on the leading edge of

code 0 and code 256

In-phase (+) out-of-range bit input

(Q phase) combined demultiplexer

out-of-range is high on the leading edge of

code 0 and code 256

Bit selection for 3-wire bus interface or

nominal setting

Beginning and end of register line for

3- wire bus interface

21

Page 22

Table 10. AT84AD001B LQFP 144 Pin Description (Continued)

Symbol Pin number Function

CLKOIN 122 Inverted phase (-) output clock channel I

CLKOQ 132

CLKOQN 131 Inverted phase (-) output clock channel Q

VtestQ, VtestI 52, 53 Pins for internal test (to be left open)

Cal 70 Calibration output bit status

Vdiode 35

Figure 14. AT84AD001B Pinout (Top View)

Output clock in-phase (+) channel Q,

1/2 input clock frequency

Positive node of diode used for die

junction temperature measurements

LQFP 144

20 by 20 by 1.4 mm

Atmel - Dual 8-bit

22

AT84AD001B

2153C–BDC–04/04

Page 23

Typical Characterization Results

Nominal conditions (unless otherwise specified):

•V

•V

• LVDS digital outputs (100Ω)

• TA (typical) = 25° C

• Full temperature range: 0

= 3.3V; V

CCA

- V

INI

INB

< TA < 85° C (industrial grade)

or V

= 3.3V; V

CCD

to V

INQ

AT84AD001B

= 2.25V

CCO

= 500 mVpp full-scale differential input

INQB

°C < TA < 70°C (commercial grade) or -40°C

Typical Full Power Input Bandwidth

• Fs = 500 Msps

• Pclock = 0 dBm

•Pin = -1 dBFS

• Gain flatness (±0.5 dB) from DC to > 500 MHz

• Full power input bandwidth at -3 dB > 1.5 GHz

Figure 15. Full Power Input Bandwidth

0

-1

-2

-3

-4

-5

dBFS

-6

-7

-8

-9

-10

-11

100 300 500 700 900 1100 1300 1500 1700 1900 2100 2300 2500 2700 2900

Fin (MHz)

-3 dB Bandwidth

2153C–BDC–04/04

23

Page 24

Typical Crosstalk Figure 16. Crosstalk (Fs = 500 Msps)

80

70

60

50

40

dBc

30

20

10

0

0 100 200 300 400 500 600 700 800 900 1000

Note: Measured on the AT84AD001TD-EB Evaluation Board.

Fin (MHz)

Typical DC, INL and DNL Patterns

1:2 DMUX mode, Fs/4 DR type

Figure 17. Typical INL (Fs = 50 Msps, Fin = 1 MHz, Saturated Input)

0,6

0,4

0,2

0

INL (Lsb )

-0,2

-0,4

-0,6

1 16 31 46 61 76 91 106 121 136 151 166 181 196 211 226 241 256

Codes

24

AT84AD001B

2153C–BDC–04/04

Page 25

Figure 18. Typical DNL (Fs = 50 Msps, Fin = 1 MHz, Saturated Input)

0,3

0,2

0,1

0

DNL (Lsb)

-0,1

-0,2

-0,3

1 16 31 46 61 76 91 106 121 136 151 166 181 196 211 226 241 256

Typical Step Response Figure 19. Step Response

250

200

AT84AD001B

Codes

150

Codes

100

50

0

2.4E-12 1.3E-09 2.5E-09 3.8E-09 5.0E-09 6.3E-09 7.5E-09 8.8E-09

• Fs = 1 Gsps

• Pclock = 0 dBm

• Fin = 100 MHz

•Pin = -1 dBFS

Channel IA Channel QA

Time (s)

2153C–BDC–04/04

25

Page 26

Figure 20. Step Response (Zoom)

250

200

150

Codes

100

50

0

4.9E-09 6.1E-09 7.4E-09

• Fs = 1 Gsps

• Pclock = 0 dBm

• Fin = 500 MHz

•Pin = -1 dBFS

Figure 21. Step Response

250

200

90%

Tr = 160 ps

10%

Channel IA Channel QA

Time (s)

150

Codes

100

50

0

4.9E-13 2.5E-10 5.0E-10 7.5E-10 1.0E-09 1.3E-09 1.5E-09 1.8E-09

Channel IA Channel QA

Time (s)

26

AT84AD001B

2153C–BDC–04/04

Page 27

Figure 22. Step Response (Zoom)

)

250

AT84AD001B

Typical Dynamic Performances Versus Sampling Frequency

200

150

odes

100

50

9.8E-10

10%

0

1.2E-09 1.5E-09

Channel IA Channel QA

90%

Tr = 170 ps

ime (s

Figure 23. ENOB Versus Sampling Frequency in Nyquist Conditions (Fin = Fs/2)

7.6

7.4

7.2

7.0

6.8

ENOB (Bit)

6.6

6.4

6.2

6.0

100 200 300 400 500 600 700 800 900 1000 1100

Fs (Msps)

Figure 24. SFDR Versus Sampling Frequency in Nyquist Conditions (Fin = Fs/2)

-50

-53

-56

-59

SFDR (dBc)

-62

-65

100 300 500 700 900 1100

Fs (Msps)

2153C–BDC–04/04

27

Page 28

Figure 25. THD Versus Sampling Frequency in Nyquist Conditions (Fin = Fs/2)

-48

-50

-52

-54

THD (dBc)

-56

-58

-60

100 300 500 700 900 1100

Fs (Msps)

Figure 26. SNR Versus Sampling Frequency in Nyquist Conditions (Fin = Fs/2)

45

44

Typical Dynamic Performances Versus Input Frequency

43

SNR (dBc)

42

41

40

100 300 500 700 900 1100

Fs (Msps)

Figure 27. ENOB Versus Input Frequency (Fs = 1 Gsps)

8.0

7.5

7.0

6.5

ENOB (Bit)

6.0

5.5

28

5.0

0 200 400 600 800 1000

Fin (MHz)

AT84AD001B

2153C–BDC–04/04

Page 29

Figure 28. SFDR Versus Input Frequency (Fs = 1 Gsps)

-35

-40

-45

-50

SFDR (dBc)

-55

-60

-65

0 200 400 600 800 1000

Fin (MHz)

Figure 29. THD Versus Input Frequency (Fs = 1 Gsps)

-35

AT84AD001B

-40

-45

-50

THD (dBc)

-55

-60

-65

0 200 400 600 800 1000

Fin (MHz)

Figure 30. SNR Versus Input Frequency (Fs = 1 Gsps)

50

48

46

44

42

40

SNR (dBc)

38

36

34

32

30

0 200 400 600 800 1000

Fin (MHz)

2153C–BDC–04/04

29

Page 30

Typical Reconstructed

0

50

100

150

200

250

1 513 1025 1537 2049 2561 3073 3585

Signals and Signal

Spectrum

Figure 31. Fs = 1 Gsps and Fin = 20 MHz (1:2 DMUX, Fs/2 DR Type, FiSDA = -15 ps, ISA = -50 ps)

250

200

150

Codes

100

50

0

1 513 1025 1537 2049 2561 3073 3585

Samples

Ch IA

Ch QA

20

0

-20

-40

dBc

-60

-80

-100

-120

0 31 62 93 125 156 187 218 249

F (Msps)

Figure 32. Fs = 1 Gsps and Fin = 500 MHz (1:2 DMUX, Fs/2 DR Type, FiSDA = -15 ps, ISA = -50 ps)

20

0

-20

-40

Codes

Ch IA

Ch QA

Samples

dBc

-60

-80

-100

-120

0 31 62 93 125 156 187 218 249

F (Msps)

Ch IA

Ch QA

Ch IA

Ch QA

Figure 33. Fs = 1 Gsps and Fin = 1 GHz (1:2 DMUX, Fs/2 DR Type, FiSDA = -15 ps, ISA = -50 ps)

250

200

150

Codes

100

50

0

1 513 1025 1537 2049 2561 3073 3585

Samples

Ch IA

Ch QA

Note: The spectra are given with respect to the output clock frequency observed by the acquisition system (Figures 31 to 33).

30

AT84AD001B

20

0

-20

-40

dBc

-60

-80

-100

-120

0 31 62 93 125 156 187 218 249

F (Msps)

Ch IA

Ch QA

Fout/2

2153C–BDC–04/04

Page 31

AT84AD001B

Figure 34. Fs = 1 Gsps and Fin = 20 MHz (Interleaving Mode Fint = 2 Gsps, Fs/4 DR Type, FiSDA = -15 ps, ISA = -50 ps)

250

200

150

Codes

100

50

0

1 2048 4095 6142 8189 10236 12283 14330 16377

Samples

20

0

-20

-40

dBc

-60

-80

-100

-120

0 125 250 375 500 624 749 874 999

Fs (MHz)

Fs/2

Figure 35. Fs = 1 Gsps and Fin = 250 MHz (Interleaving Mode Fint = 2 Gsps, Fs/4 DR Type, FiSDA = -15 ps, ISA = -50 ps)

250

200

150

Codes

100

50

0

1 2048 4095 6142 8189 10236 12283 14330 16377

Samples

20

0

-20

-40

dBc

-60

-80

-100

-120

0 125 250 375 500 624 749 874 999

Fs (MHz)

Fs/2

2153C–BDC–04/04

31

Page 32

Typical Performance Sensitivity Versus Power Supplies and Temperature

Figure 36. ENOB Versus V

Fs/4 DR Type, ISA = -50 ps)

7.4

7.2

7.0

6.8

ENOB (Bit)

6.6

6.4

6.2

6.0

3.1 3.15 3.2 3.25 3.3 3.35 3.4 3.45 3.5

CCA

= V

(Fs = 1 Gsps, Fin = 500 MHz, 1:2 DMUX,

CCD

Vcca = Vccd (V)

Figure 37. SFDR Versus V

Fs/4 DR Type, ISA = -50 ps)

-40

-45

-50

SFDR (dBc)

-55

-60

3.1 3.15 3.2 3.25 3.3 3.35 3.4 3.45 3.5

CCA

= V

(Fs = 1 Gsps, Fin = 500 MHz, 1:2 DMUX,

CCD

Vcca = Vccd (V)

32

AT84AD001B

2153C–BDC–04/04

Page 33

AT84AD001B

Figure 38. THD Versus V

Fs/4 DR Type, ISA = -50 ps)

-40

-45

-50

THD (dBc)

-55

-60

3.1 3.15 3.2 3.25 3.3 3.35 3.4 3.45 3.5

Figure 39. SNR Versus V

Fs/4 DR Type, ISA = -50 ps)

45.0

CCA

CCA

= V

= V

(Fs = 1 Gsps, Fin = 500 MHz, 1:2 DMUX,

CCD

Vcca = Vccd (V)

(Fs = 1 Gsps, Fin = 500 MHz, 1:2 DMUX,

CCD

44.0

43.0

SNR (dBc)

42.0

41.0

40.0

3.1 3.15 3.2 3.25 3.3 3.35 3.4 3.45 3.5

Vcca = Vccd (V)

2153C–BDC–04/04

33

Page 34

Figure 40. ENOB Versus Junction Temperature (Fs = 1 Gsps, 1:2 DMUX, Fs/4 DR

Type, ISA = -50 ps)

8.0

7.5

7.0

6.5

ENOB (Bit)

6.0

5.5

5.0

-50 -25 0 25 50 75 100

Tj (˚C)

1 Gsps 20 MHz

1 Gsps 502 MHz

1 Gsps 998 MHz

Figure 41. SFDR Versus Junction Temperature (Fs = 1 Gsps, 1:2 DMUX, Fs/4 DR

Type, ISA = -50 ps)

-35

1 Gsps 998 MHz

-40

-45

-50

SFDR (dBc)

-55

1 Gsps 502 MHz

1 Gsps 20 MHz

34

-60

-65

-50 -25 0 25 50 75 100

Tj (˚C)

AT84AD001B

2153C–BDC–04/04

Page 35

AT84AD001B

Figure 42. THD Versus Junction Temperature (Fs = 1 Gsps, 1:2 DMUX, Fs/4 DR

Type, ISA = -50 ps)

-35

1 Gsps 998 MHz

-40

-45

THD (dBc)

-50

-55

-60

-50 -25 0 25 50 75 100

Tj (˚C)

1 Gsps 502 MHz

1 Gsps 20 MHz

Figure 43. SNR Versus Junction Temperature (Fs = 1 Gsps, 1:2 DMUX, Fs/4 DR

Type, ISA = -50 ps)

45.0

44.0

43.0

SNR (dBc)

42.0

41.0

1 Gsps 20 MHz

1 Gsps 502 MHz

2153C–BDC–04/04

40.0

1 Gsps 998 MHz

-50 -25 0 25 50 75 100

Tj (˚C)

35

Page 36

Test and Control Features

3-wire Serial Interface Control Setting

Table 11. 3-wire Serial Interface Control Settings

Mode Characteristics

Mode = 1 (2.25V) 3-wire serial bus interface activated

3-wire serial bus interface deactivated

Nominal setting:

Dual channel I and Q activated

One clock I

0 dB gain

DMUX mode 1:1

Mode = 0 (0V)

DRDA I & Q = 0 ps

ISA I & Q = 0 ps

FiSDA Q = 0 ps

Binary output

Decimation test mode OFF

Calibration setting OFF

Data Ready = Fs /2

36

AT84AD001B

2153C–BDC–04/04

Page 37

AT84AD001B

3-wire Serial Interface and Data Description

The 3-wire bus is activated with the control bit mode set to 1. The length of the word is

19 bits: 16 for the data and 3 for the address. The maximum clock frequency is

50 MHz.

Table 12. 3-wire Serial Interface Address Setting Description

Address Setting

Standby

Gray/binary mode

1:1 or 1:2 DMUX mode

000

001

010

011

100

Analog input MUX

Clock selection

Auto-calibration

Decimation test mode

Data Ready Delay Adjust

Analog gain adjustment

Data7 to Data0: gain channel I

Data15 to Data8: gain channel Q

Code 00000000: -1.5 dB

Code 10000000: 0 dB

Code 11111111: 1.5 dB

Steps: 0.011 dB

Offset compensation

Data7 to Data0: offset channel I

Data15 to Data8: offset channel Q

Data7 and Data15: sign bits

Code 11111111b: 31.75 LSB

Code 10000000b: 0 LSB

Code 00000000b: 0 LSB

Code 01111111b: -31.75 LSB

Steps: 0.25 LSB

Maximum correction: ±31.75 LSB

Gain compensation

Data6 to Data0: channel I/Q (Q is matched to I)

Code 11111111b: -0.315 dB

Code 10000000b: 0 dB

Code 0000000b: 0 dB

Code 0111111b: 0.315 dB

Steps: 0.005 dB

Data6: sign bit

Internal Settling Adjustment (ISA)

Data2 to Data0: channel I

Data5 to Data3: channel Q

Data15 to Data6: 1000010000

2153C–BDC–04/04

37

Page 38

Table 12. 3-wire Serial Interface Address Setting Description (Continued)

Address Setting

Testability

Data3 to Data0 = 0000

101

110

111

Mode S/H transparent OFF: Data4 = 0 ON: Data4 = 1

Data7 = 0

Data8 = 0

Built-In Test (BIT)

Data0 = 0 BIT Inactive Data0 = 1 BIT Active

Data1 = 0 Static BIT Data1 = 1 Dynamic BIT

If Data1 = 1, then Ports BI & BQ = Rising Ramp

Ports AI & AQ = Decreasing Ramp

If Data1 = 0, then Data2 to Data9 = Static Data for BIT

Ports BI & BQ = Data2 to Data9

Ports AI & AQ = NOT (Data2 to Data9)

Data Ready Delay Adjust (DRDA)

Data2 to Data0: clock I

Data5 to Data3: clock Q

Steps: 140 ps

000: -560 ps

100: 0 ps

111: 420 ps

Fine Sampling Delay Adjustment (FiSDA) on channel Q

Data10 to Data6: channel Q

Steps: 5 ps

Data4: sign bit

Code 11111: -75 ps

Code 10000: 0 ps

Code 00000: 0 ps

Code 01111: 75 ps

Notes: 1. The Internal Settling Adjustment could change independently of the two analog sampling times (TA channels I and Q) of the

sample/hold (with a fixed digital sampling time) with steps of ±50 ps:

Nominal mode will be given by Data2…Data0 = 100 or Data5…Data3 = 100.

Data5…Data3 = 000 or Data2…Data0 = 000: sampling time is -200 ps compared to nominal.

Data2…Data0 = 111 or Data5…Data3 = 111: sampling time is 150 ps compared to nominal.

We recommend setting the ISA to -50 ps to optimize the ADC’s dynamic performances.

2. The Fine Sampling Delay Adjustment enables you to change the sampling time (steps of ±5 ps) on channel Q more precisely, particularly in the interleaved mode.

3. A Built-In Test (BIT) function is available to rapidly test the device’s I/O by either applying a defined static pattern to the dual

ADC or by generating a dynamic ramp at the output of the dual ADC. This function is controlled via the 3-wire bus interface

at the address 110. The maximum clock frequency in dynamic BIT mode is 750 Msps.

Please refer to “Built-In Test (BIT)” on page 43 for more information about this function.

4. The decimation mode enables you to lower the output bit rate (including the output clock rate) by a factor of 16, while the

internal clock frequency remains unchanged. The maximum clock frequency in decimation mode is 750 Msps.

5. The “S/H transparent” mode (address 101, Data4) enables bypassing of the ADC’s track/hold. This function optimizes the

ADC’s performances at very low input frequencies (Fin < 50 MHz).

6. In the Gray mode, when the input signal is overflow (that is, the differential analog input is greater than 250 mV), the output

data must be corrected using the output DOIR:

If DOIR = 1: Data7 unchanged

Data6 = 0, Data5 = 0, Data4 = 0, Data3 = 0, Data2 = 0, Data1 = 0, Data0 = 0.

In 1:2 DMUX mode, only one out-of-range bit is provided for both A and B ports.

38

AT84AD001B

2153C–BDC–04/04

Page 39

Table 13. 3-wire Serial Interface Data Setting Description

AT84AD001B

Setting for Address:

000 D15 D14 D13 D12 D11 D10 D9

Full standby mode XXXXXX 0 XXXXXXX11

Standby channel I

Standby channel Q

No standby mode XXXXXX 0 XXXXXXX00

Binary output mode XXXXXX 0 XXXXXX1XX

Gray output mode XXXXXX 0 XXXXXX0XX

DMUX 1:2 mode XXXXXX 0 XXXXX1XXX

DMUX 1:1 mode XXXXXX 0 XXXXX0XXX

Analog selection mode

→ ADC I

Input I

Input Q → ADC Q

Analog selection mode

Input I

→ ADC I

Input I → ADC Q

Analog selection mode

Input Q

Input Q → ADC Q

→ ADC I

(2)

(3)

XXXXXX 0 XXXXXXX01

XXXXXX 0 XXXXXXX10

XXXXXX 0 XXX11XXXX

XXXXXX 0 XXX10XXXX

XXXXXX 0 XXX0XXXXX

(1)

D8 D7 D6 D5 D4 D3 D2 D1 D0

Clock Selection mode

CLKI

→ ADC I

CLKQ → ADC Q

Clock selection mode

CLKI

→ ADC I

CLKI → ADC Q

Clock selection mode

CLKI

→ ADC I

CLKIN → ADC Q

Decimation OFF modeXXXXXX 0 0XXXXXXXX

Decimation ON mode XXXXXX 0 1XXXXXXXX

Keep last calibration

calculated value

No calibration phase

No calibration phase

No calibration value

Start a new calibration

phase

(4)

(5)

XXXXXX 0 X11XXXXXX

XXXXXX 0 X10XXXXXX

XXXXXX 0 X0XXXXXXX

XXXX0 1 0 XXXXXXXXX

XXXX0 0 0 XXXXXXXXX

XXXX1 1 0 XXXXXXXXX

2153C–BDC–04/04

39

Page 40

Table 13. 3-wire Serial Interface Data Setting Description (Continued)

Setting for Address:

000 D15 D14 D13 D12 D11 D10 D9

Control wait bit

calibration

In 1:2 DMUX

FDataReady

I & Q = Fs/2

In 1:2 DMUX

FDataReady

I & Q = Fs/4

Notes: 1. D9 must be set to “0”

(6)

2. Mode standby channel I: use analog input I Vini, Vinib and Clocki.

3. Mode standby channel Q: use analog input Q Vinq, Vinqb and Clockq.

4. Keep last calibration calculated value - no calibration phase: D11 = 0 and D10 = 1. No new calibration is required. The values taken into account for the gain and offset are either from the last calibration phase or are default values (reset values).

5. No calibration phase - no calibration value: D11 = 0 and D10 = 0. No new calibration phase is required. The gain and offset

compensation functions can be accessed externally by writing in the registers at address 010 for the offset compensation

and at address 011 for the gain compensation.

6. The control wait bit gives the possibility to change the internal setting for the auto-calibration phase:

For high clock rates (> 500 Msps) use a = b = 1.

For clock rates > 250 Msps and < 500 Msps use a = 1 and b = 0.

For clock rates > 125 Msps and < 250 Msps use a = 0 and b = 1.

For low clock rates < 125 Msps use a = 0 and b = 0.

X X a b X X 0 XXXXXXXXX

X 0 X X X X 0 XXXXXXXXX

X 1 X X X X 0 XXXXXXXXX

(1)

D8 D7 D6 D5 D4 D3 D2 D1 D0

3-wire Serial Interface Timing Description

The 3-wire serial interface is a synchronous write-only serial interface made of three

wires:

• sclk: serial clock input

• sldn: serial load enable input

• sdata: serial data input

The 3-wire serial interface gives write-only access to as many as 8 different internal registers of up to 16 bits each. The input format is always fixed with 3 bits of register

address followed by 16 bits of data. The data and address are entered with the Most

Significant Bit (MSB) first.

The write procedure is fully synchronous with the rising clock edge of “sclk” and

described in the write chronogram (Figure 44 on page 41).

• “sldn” and “sdata” are sampled on each rising clock edge of “sclk” (clock cycle).

• “sldn” must be set to 1 when no write procedure is performed.

• A minimum of one rising clock edge (clock cycle) with “sldn” at 1 is required for a

correct start of the write procedure.

• A write starts on the first clock cycle with “sldn” at 0. “sldn” must stay at 0 during the

complete write procedure.

• During the first 3 clock cycles with “sldn” at 0, 3 bits of the register address from

MSB (a[2]) to LSB (a[0]) are entered.

• During the next 16 clock cycles with “sldn” at 0, 16 bits of data from MSB (d[15]) to

LSB (d[0]) are entered.

• An additional clock cycle with “sldn” at 0 is required for parallel transfer of the serial

data d[15:0] into the addressed register with address a[2:0]. This yields 20 clock

cycles with “sldn” at 0 for a normal write procedure.

40

AT84AD001B

2153C–BDC–04/04

Page 41

Figure 44. Write Chronogram

AT84AD001B

• A minimum of one clock cycle with “sldn” returned at 1 is requested to close the

write procedure and make the interface ready for a new write procedure. Any clock

cycle where “sldn” is at 1 before the write procedure is completed interrupts this

procedure and no further data transfer to the internal registers is performed.

• Additional clock cycles with “sldn” at 0 after the parallel data transfer to the register

(done at the 20th consecutive clock cycle with “sldn” at 0) do not affect the write

procedure and are ignored.

It is possible to have only one clock cycle with “sldn” at 1 between two following write

procedures.

• 16 bits of data must always be entered even if the internal addressed register has

less than 16 bits. Unused bits (usually MSBs) are ignored. Bit signification and bit

positions for the internal registers are detailed in Table 12 on page 37.

To reset the registers, the Pin mode can be used as a reset pin for chip initialization,

even when the 3-wire serial interface is used.

Mode

sclk

sldn

sdata

Internal register

value

Reset setting

Reset

12 345 1314151617181920

a[2] a[1]

a[0] d[15]

d[8]

d[7]

d[6]

d[5]

d[4]

d[3]

d[2]

d[1]

d[0]

New d

Write procedure

Figure 45. Timing Definition

Mode

sclk

sldn

Twlmode

Tdmode

Tssldn

Thsldn

Tsclk

Twsclk

Tdmode

2153C–BDC–04/04

sdata

Tssdata

Thsdata

41

Page 42

Table 14. Timing Description

Name Parameter

Tsclk Sclk period 20 ns

Twsclk High or low time of sclk 5 ns

Tssldn Setup time of sldn before rising edge of sclk 4 ns

Thsldn Hold time of sldn after rising edge of sclk 2 ns

Tssdata Setup time of sdata before rising edge of sclk 4 ns

Thsdata Hold time of sdata after rising edge of sclk 2 ns

Twlmode Minimum low pulse width of mode 5 ns

Tdmode

Minimum delay between an edge of mode and the

rising edge of sclk

Min Typ Max

10 ns

Val ue

Unit

Calibration Description The AT84AD001B offers the possibility of reducing offset and gain matching between

the two ADC cores. An internal digital calibration may start right after the 3-wire serial

interface has been loaded (using data D12 of the 3-wire serial interface with address

000).

The beginning of calibration disables the two ADCs and a standard data acquisition is

performed. The output bit CAL goes to a high level during the entire calibration phase.

When this bit returns to a low level, the two ADCs are calibrated with offset and gain and

can be used again for a standard data acquisition.

If only one channel is selected (I or Q) the offset calibration duration is divided by two

and no gain calibration between the two channels is necessary.

Figure 46. Internal Timing Calibration

3-wire Serial Interface

LDN

CAL

Tcal

The Tcal duration is a multiple of the clock frequency ClockI (master clock). Even if a

dual clock scheme is used during calibration, ClockQ will not be used.

The control wait bits (D13 and D14) give the possibility of changing the calibration’s setting depending on the clock’s frequency:

• For high clock rates (> 500 Msps) use a = b = 1, Tcal = 10112 clock I periods.

• For clock rates > 250 Msps and < 500 Msps use a = 1, b = 0, Tcal = 6016 clock I

periods.

• For clock rates > 125 Msps and < 250 Msps use a = 0, b = 1 ,Tcal = 3968 clock I

periods.

• For low clock rates (< 125 Msps) use a = 0, b = 0 , Tcal = 2944 clock I periods.

42

AT84AD001B

2153C–BDC–04/04

Page 43

The calibration phase is necessary when using the AT84AD001B in interlace mode,

where one analog input is sampled at both ADC cores on the common input clock’s ris

ing and falling edges. This operation is equivalent to converting the analog signal at

twice the clock frequency

Table 15. Matching Between Channels

AT84AD001B

-

Parameter

Gain error (single channel I or Q) without calibration 0 LSB

Gain error (single channel I or Q) with calibration -0.5 0 0.5 LSB

Offset error (single channel I or Q) without calibration 0 LSB

Offset error (single channel I or Q) with calibration -0.5 0 0.5 LSB

Mean offset code without calibration (single channel I or Q) 127.5

Mean offset code with calibration (single channel I or Q) 127 127.5 128

Val ue

During the ADC’s auto-calibration phase, the dual ADC is set with the following:

• Decimation mode ON

• 1:1 DMUX mode

• Binary mode

Any external action applied to any signal of the ADC’s registers is inhibited during the

calibration phase.

Gain and Offset Compensation Functions

It is also possible for the user to have external access to the ADC’s gain and offset compensation functions:

• Offset compensation between I and Q channels (at address 010)

• Gain compensation between I and Q channels (at address 011)

UnitMin Typ Max

To obtain manual access to these two functions, which are used to set the offset to middle code 127.5 and to match the gain of channel Q with that of channel I (if only one

channel is used, the gain compensation does not apply), it is necessary to set the ADC

to “manual” mode by writing 0 at bits D11 and D10 of address 000.

Built-In Test (BIT) A Built-In Test (BIT) function is available to allow rapid testing of the device’s I/O by

either applying a defined static pattern to the ADC or by generating a dynamic ramp at

the ADC’s output. The dynamic ramp can be used with a clock frequency of up to

750 Msps. This function is controlled via the 3-wire bus interface at address 101.

• The BIT is active when Data0 = 1 at address 110.

• The BIT is inactive when Data0 = 0 at address 110.

• The Data1 bit allows choosing between static mode (Data1 = 0) and dynamic mode

(Data1 = 1).

When the static BIT is selected (Data1 = 0), it is possible to write any 8-bit pattern by

defining the Data9 to Data2 bits. Port B then outputs an 8-bit pattern equal to Data9 ...

Data2, and Port A outputs an 8-bit pattern equal to NOT (Data9 ... Data2).

43

2153C–BDC–04/04

Page 44

Example:

Address = 110

Data =

D15 D14 D13 D12 D11 D10 D9 D8 D7 D6 D5 D4 D3 D2 D1 D0

XXXXXX0101010101

One should then obtain 01010101 on Port B and 10101010 on Port A.

When the dynamic mode is chosen (Data1 = 1) port B outputs a rising ramp while Port A

outputs a decreasing one.

Note: In dynamic mode, use the DRDA function to align the edges of CLKO with the middle of

the data.

Decimation Mode The decimation mode is provided to enable rapid testing of the ADC at a maximum clock

frequency of 750 Msps. In decimation mode, one data out of 16 is output, thus leading to

a maximum output rate of 46.875 Msps.

Note: Frequency (CLKO) = frequency (Data) = Frequency (CLKI)/16.

Die Junction Temperature Monitoring Function

A die junction temperature measurement setting is included on the board for junction

temperature monitoring.

The measurement method forces a 1 mA current into a diode-mounted transistor.

Caution should be given to respecting the polarity of the current.

In any case, one should make sure the maximum voltage compliance of the current

source is limited to a maximum of 1V or use a resistor serial-mounted with the current

source to avoid damaging the transistor device (this may occur if the current source is

reverse-connected).

The measurement setup is illustrated in Figure 47.

Figure 47. Die Junction Temperature Monitoring Setup

VDiode (Pin 35)

1 mA

GNDD

(Pin 36)

Protection

Diodes

44

AT84AD001B

2153C–BDC–04/04

Page 45

AT84AD001B

The VBE diode’s forward voltage in relation to the junction temperature (in steady-state

conditions) is shown in Figure 48.

Figure 48. Diode Characteristics Versus T

860

840

820

800

780

760

740

720

Diode Voltage (mV)

700

680

660

640

620

-20-100 102030405060708090100110120

J

Junction Temperature (˚C)

VtestI, VtestQ VtestI and VtestQ pins are for internal test use only. These two signals must be left

open.

Equivalent Input/Output Schematics

Figure 49. Simplified Input Clock Model

CLK

CLKB

VCCD/2

50Ω

50Ω

VCCD

GNDD

100Ω

100Ω

2153C–BDC–04/04

45

Page 46

Figure 50. Simplified Data Ready Reset Buffer Model

VCCD

DDRB

100Ω

VCCD/2

50Ω

Figure 51. Analog Input Model

DC Coupling

(Common Mode = Ground = 0V)

50Ω

GND

VinI

50Ω

DDRBN

Vinl Reverse

Termination

VinI Double Pad

VinQ Reverse

Termination

ESD

ESD

Vcca

GND

50Ω

Sel Input I

GND – 0.4V

MAX

GNDD

100Ω

Vcca

GND

46

GND

VinQ

AT84AD001B

VinQ

Double

Pad

Sel Input Q

2153C–BDC–04/04

Page 47

Figure 52. Data Output Buffer Model

VCCO

GNDO

AT84AD001B

DOAIO, DOAI7

DOBIO, DOBI7

DOAION, DOAI7N

DOBION, DOBI7N

Definitions of Terms

Table 16. Definitions of Terms

Abbreviation Definition Description

BER Bit Error Rate

DNL

ENOB

FPBW

IMD

INL

JITTER

NPR Noise Power Ratio

Differential

Non-Linearity

Effective Number of

Bits

Full Power Input

Bandwidth

Inter-Modulation

Distortion

Integral

Non-Linearity

Aperture

uncertainty

The probability to exceed a specified error threshold for a sample at a maximum specified

sampling rate. An error code is a code that differs by more than ±4 LSB from the correct code

The differential non-linearity for an output code i is the difference between the measured step

size of code i and the ideal LSB step size. DNL (i) is expressed in LSBs. DNL is the

maximum value of all DNL (i). A DNL error specification of less than 1 LSB guarantees that

there are no missing output codes and that the transfer function is monotonic

ENOB

The analog input frequency at which the fundamental component in the digitally

reconstructed output waveform has fallen by 3 dB with respect to its low frequency value

(determined by FFT analysis) for input at full-scale -1 dB (-1 dBFS)

The two tones intermodulation distortion (IMD) rejection is the ratio of either of the two input

tones to the worst third order intermodulation products

The integral non-linearity for an output code i is the difference between the measured input

voltage at which the transition occurs and the ideal value of this transition. INL (i) is

expressed in LSBs and is the maximum value of all |INL (i)|

The sample-to-sample variation in aperture delay. The voltage error due to jitters depends on

the slew rate of the signal at the sampling point

The NPR is measured to characterize the ADC’s performance in response to broad

bandwidth signals. When applying a notch-filtered broadband white noise signal as the input

to the ADC under test, the Noise Power Ratio is defined as the ratio of the average out-ofnotch to the average in-notch power spectral density magnitudes for the FFT spectrum of the

ADC output sample test

SINAD 1.76– 20

---------------------------------------------------------------------------- -=

6.02

A

-----------

log+

Fs/2

Where A is the actual input amplitude and Fs is

the full scale range of the ADC under test

2153C–BDC–04/04

47

Page 48

Table 16. Definitions of Terms (Continued)

Abbreviation Definition Description

ORT

Overvoltage

Recovery Time

The time to recover a 0.2% accuracy at the output, after a 150% full-scale step applied on

the input is reduced to midscale

PSRR

SFDR

SINAD

SNR

SSBW

TA Aperture delay

TC

TD1

TD2

TDO

TDR

TF Fall Time

Power Supply

Rejection Ratio

Spurious Free

Dynamic Range

Signal to Noise and

Distortion Ratio

Signal to Noise

Ratio

Small Signal Input

Bandwidth

Encoding Clock

period

Time Delay from

Data Transition to

Data Ready

Time Delay from

Data Ready to

Data

Digital Data Output

Delay

Data Ready Output

Delay

The ratio of input offset variation to a change in power supply voltage

The ratio expressed in dB of the RMS signal amplitude, set at 1 dB below full-scale, to the

RMS value of the highest spectral component (peak spurious spectral component). The peak

spurious component may or may not be a harmonic. It may be reported in dB (related to the

converter -1 dB full-scale) or in dBc (related to the input signal level)

The ratio expressed in dB of the RMS signal amplitude, set to 1 dB below full-scale (-1

dBFS) to the RMS sum of all other spectral components including the harmonics, except DC

The ratio expressed in dB of the RMS signal amplitude, set to 1 dB below full-scale, to the

RMS sum of all other spectral components excluding the first 9 harmonics

The analog input frequency at which the fundamental component in the digitally

reconstructed output waveform has fallen by 3 dB with respect to its low frequency value

(determined by FFT analysis) for input at full-scale -10 dB (-10 dBFS)

The delay between the rising edge of the differential clock inputs (CLK, CLKB) [zero crossing

point] and the time at which VIN and VINB are sampled

TC1 = minimum clock pulse width (high)

TC = TC1 + TC2

TC2 = minimum clock pulse width (low)

The general expression is TD1 = TC1 + TDR - TDO with TC = TC1 + TC2 = 1 encoding clock

period

The general expression is TD2 = TC2 + TDR - TDO with TC = TC1 + TC2 = 1 encoding clock

period

The delay from the rising edge of the differential clock inputs (CLK, CLKB) [zero crossing

point] to the next point of change in the differential output data (zero crossing) with a

specified load

The delay from the falling edge of the differential clock inputs (CLK, CLKB) [zero crossing

point] to the next point of change in the differential output data (zero crossing) with a

specified load

The time delay for the output data signals to fall from 20% to 80% of delta between the low

and high levels

THD

TPD Pipeline Delay

TR Rise Time The time delay for the output data signals to rise from 20% to 80% of delta between the low

48

AT84AD001B

Total Harmonic

Distortion

The ratio expressed in dB of the RMS sum of the first 9 harmonic components to the RMS

input signal amplitude, set at 1 dB below full-scale. It may be reported in dB (related to the

converter -1 dB full-scale) or in dBc (related to the input signal level )

The number of clock cycles between the sampling edge of an input data and the associated

output data made available (not taking into account the TDO)

and high levels

2153C–BDC–04/04

Page 49

AT84AD001B

Table 16. Definitions of Terms (Continued)

Abbreviation Definition Description

TRDR Data Ready Reset

Delay

TS Settling Time The time delay to rise from 10% to 90% of the converter output when a full-scale step

The delay between the falling edge of the Data Ready output asynchronous reset signal

(DDRB) and the reset to digital zero transition of the Data Ready output signal (DR)

function is applied to the differential analog input

VSWR Voltage Standing

Wave Ratio

The VSWR corresponds to the ADC input insertion loss due to input power reflection. For

example, a VSWR of 1.2 corresponds to a 20 dB return loss (99% power transmitted and 1%

reflected)

2153C–BDC–04/04

49

Page 50

Using the AT84AD001B Dual 8-bit 1 Gsps ADC

Decoupling, Bypassing and Grounding of Power Supplies

Figure 53. V

Figure 54. V

PC Board 2.25V

and V

CCD

PC Board 3.3V

PC Board GND

Bypassing and Grounding Scheme

CCO

PC Board GND

Bypassing and Grounding Scheme

CCA

The following figures show the recommended bypassing, decoupling and grounding

schemes for the dual 8-bit 1 Gsps ADC power supplies.

L

VCCD

1µF

100 pF

L

VCCA

C

C

L

VCCO

1µF

100 pF

C

Note: L and C values must be chosen in accordance with the operation frequency of the application.

Figure 55. Power Supplies Decoupling Scheme

10 nF

VCCA

GNDA

VCCO

GNDO

100 pF

VCCO

10 nF

GNDO

VCCA

100 pF

GNDA

VCCD

100 pF 10 nF

GNDD

Note: The bypassing capacitors (1 µF and 100 pF) should be placed as close as possible to the board connectors, whereas the

decoupling capacitors (100 pF and 10 nF) should be placed as close as possible to the device.

50

AT84AD001B

2153C–BDC–04/04

Page 51

AT84AD001B

Analog Input Implementation

Figure 56. Termination Method for the ADC Analog Inputs in DC Coupling Mode

Channel I

Channel Q

The analog inputs of the dual ADC have been designed with a double pad implementation as illustrated in Figure 56. The reverse pad for each input should be tied to ground

via a 50Ω resistor.

The analog inputs must be used in differential mode only.

50Ω

50Ω Source

GND

GND

50Ω Source

GND

50Ω

50Ω

GND

50Ω

VinI

VinI

VinIB

VinIB

VinQ

VinQ

VinQB

VinQB

Dual ADC

2153C–BDC–04/04

51

Page 52

Figure 57. Termination Method for the ADC Analog Inputs in AC Coupling Mode

50Ω

50Ω Source

Channel I

GND

GND

50Ω

50Ω

50Ω Source

Channel Q

GND

GND

50Ω

VinI

VinI

VinIB

VinIB

VinQ

VinQ

VinQB

VinQB

Dual ADC

Clock Implementation The ADC features two different clocks (I or Q) that must be implemented as shown in

Figure 58. Each path must be AC coupled with a 100 nF capacitor.

Figure 58. Differential Termination Method for Clock I or Clock Q

ADC Package

100 nF

CLK

50Ω

100 nF

CLKB

Note: When only clock I is used, it is not necessary to add the capacitors on the CLKQ and

CLKQN signal paths; they may be left floating.

VCCD/2

50Ω

Differential Buffer

52

AT84AD001B

2153C–BDC–04/04

Page 53

Figure 59. Single-ended Termination Method for Clock I or Clock Q

AT84AD001B

VCCD

AC coupling capacitor

50Ω

Source

AC coupling capacitor

50Ω

Output Termination in 1:1 Ratio

R1

CLK

50Ω

50Ω

CLKB

VCCD/2

When using the integrated DMUX in 1:1 ratio, the valid port is port A. Port B remains

unused.

Port A functions in LVDS mode and the corresponding outputs (DOAI or DOAQ) have to

be 100Ω differentially terminated as shown in Figure 60 on page 54.

The pins corresponding to Port B (DOBI or DOBQ pins) must be left floating (in high

impedance state).

R2

Figure 60 shows the example of a 1:1 ratio of the integrated DMUX for channel I (the

same applies to channel Q).

2153C–BDC–04/04

53

Page 54

Figure 60. Example of Termination for Channel I Used in DMUX 1:1 Ratio (Port B Unused)

DOBI0 / DOBI0N

DOBI1 / DOBI1N

DOBI2 / DOBI2N

Port B

Port A

DOBI3 / DOBI3N

DOBI4 / DOBI4N

DOBI5 / DOBI5N

DOBI6 / DOBI6N

DOBI7 / DOBI7N

DOAI0 / DOAI0N

DOAI1 / DOAI1N

DOAI2 / DOAI2N

DOAI3 / DOAI3N

DOAI4 / DOAI4N

DOAI5 / DOAI5N

DOAI6 / DOAI6N

DOAI7 / DOAI7N

Floating (High Z)

Dual ADC Package

VCCO

DOAI0

DOAI0N

Z0 = 50Ω

Z0 = 50Ω

LVDS In

100Ω

LVDS In

Note: If the outputs are to be used in single-ended mode, it is recommended that the true and false signals be terminated with a 50Ω

resistor.

Using the Dual ADC With and ASIC/FPGA Load

54

AT84AD001B

Figure 61 on page 55 illustrates the configuration of the dual ADC (1:2 DMUX mode,

independent I and Q clocks) driving an LVDS system (ASIC/FPGA) with potential additional DMUXes used to halve the speed of the dual ADC outputs.

2153C–BDC–04/04

Page 55

Figure 61. Dual ADC and ASIC/FPGA Load Block Diagram

AT84AD001B

Data rate = FsI/2

CLKI/CLKIN @ FsI

CLKQ/CLKQN @ FsQ

Port A

Channel I

Port A

Channel Q

Dual 8-bit 1 Gsps ADC

Port B

Channel I

DEMUX

8:16

Data rate = FsQ/2

DMUX

8:16

DMUX

8:16

Data rate = FsQ/4

ASIC / FPGA

Port B

Channel Q

Note: The demultiplexers may be internal to the ASIC/FPGA system.

2153C–BDC–04/04

DMUX

8:16

55

Page 56

Thermal Characteristics

Simplified Thermal

Model for LQFP 144

The following model has been extracted from the ANSYS FEM simulations.

Assumptions: no air, no convection and no board.

20 x 20 x 1.4 mm

Figure 62. Simplified Thermal Model for LQFP Package

Silicon Junction

355 µm silicon die

25 mm

λ

40 µm Epoxy/Ag glue

λ

Copper paddle

λ

Aluminium paddle

λ

Resin bottom

λ = 0.007W/cm/

2

= 0.95W/cm/˚C

= 0. 02 W / c m/ ˚C

= 2.5W/cm/˚C

= 0. 75W /c m/ ˚C

˚C

0.6˚C/watt

1.4˚C/watt

0.1˚C/watt