Page 1

Features

• Smart Card Interface

– Compliance with ISO 7816, EMV2000, GIE-CB, GSM and WHQL Standards

Card Clock Stop High or Low for Card Power-down Modes

Support Synchronous Cards with C4 and C8 Contacts

Card Detection and Automatic de-activation Sequence

Programmable Activation Sequence

– Direct Connection to the Smart Card

Logic Level Shifters

Short Circuit Current Limitation (see electrical characteristics)

8kV+ ESD Protection (MIL/STD 883 Class 3)

– Programmable Voltage

5V ±5% at 65 mA (Class A)

3V ±0.2V at 65 mA (Class B)

1.8V ±0.14V at 40 mA

– Low Ripple Noise: < 200 mV

• Versatile Host Interface

– ICAM (Conditional Access) Compatible

– Two Wire Interface (TWI) Link

Programmable Address Allow up to 8 Devices

– Programmable Interrupt Output

– Automatic Level Shifter (1.6V to VCC)

• Reset Output Includes

– Power-On Reset (POR)

– Power-Fail Detector (PFD)

• High-efficiency Step-up Converter: 80 to 98% Efficiency

• Extended Voltage Operation: 3V to 5.5V

• Low Power Consumption

– 180 mA Maximum In-rush Current

– 30 μA Typical Power-down Current (without Smart Card)

• 4 to 48 MHz Clock Input, 7 MHz Min for Step-up Converter (for AT83C24)

• 18 to 48MHz Clock input (for AT83C24NDS)

• Industrial Temperature Range: -40 to +85°C

• Packages: SO28 and QFN28

Smart Card

Reader

Interface with

Power

Management

AT83C24B

AT83C24NDS

Description

The AT83C24 is a smart card reader interface IC for smart card reader/writer applications such as EFT/POS terminals and set top boxes. It enables the management of

any type of smart card from any kind of host. Up to 8 AT83C24 can be connected in

parallel using the programmable TWI address.

Its high efficiency DC/DC converter, low quiescent current in standby mode makes it

particularly suited to low power and portable applications. The reduced bill of material

allows reducing significantly the system cost. A sophisticated protection system guar

antees timely and controlled shutdown upon error conditions.

The AT83C24NDS is a dedicated version approved by NDS for use with NDS VideoGuard conditional access software in set-top boxes. All AT83C24 datasheet is

applicable to AT83C24NDS. The main differences between AT83C24 and

AT83C24NDS are listed below:

1/ CLASS A card supplied with CVCC = 4.75 to 5.25V for AT83C24NDS,

CLASS A card supplied with CVCC = 4.6 to 5.25V for AT83C24

2/ 18MHz minimum on input clock for AT83C24NDS

3/ Up to 10µF for capacitor connected on CVCC pin for AT83C24,

3.3µF mandatory for AT83C24NDS

-

4234F–SCR–10/05

Page 2

Acronyms TWI: Two-wire Interface

POR: Power On Reset

PFD: Power Fail Detect

ART: Automatic Reset Transition

ATR: Answer To Reset

MSB: Most Significant Bit

LSB: Least Significant bit

SCIB: Smart Card Interface Bus

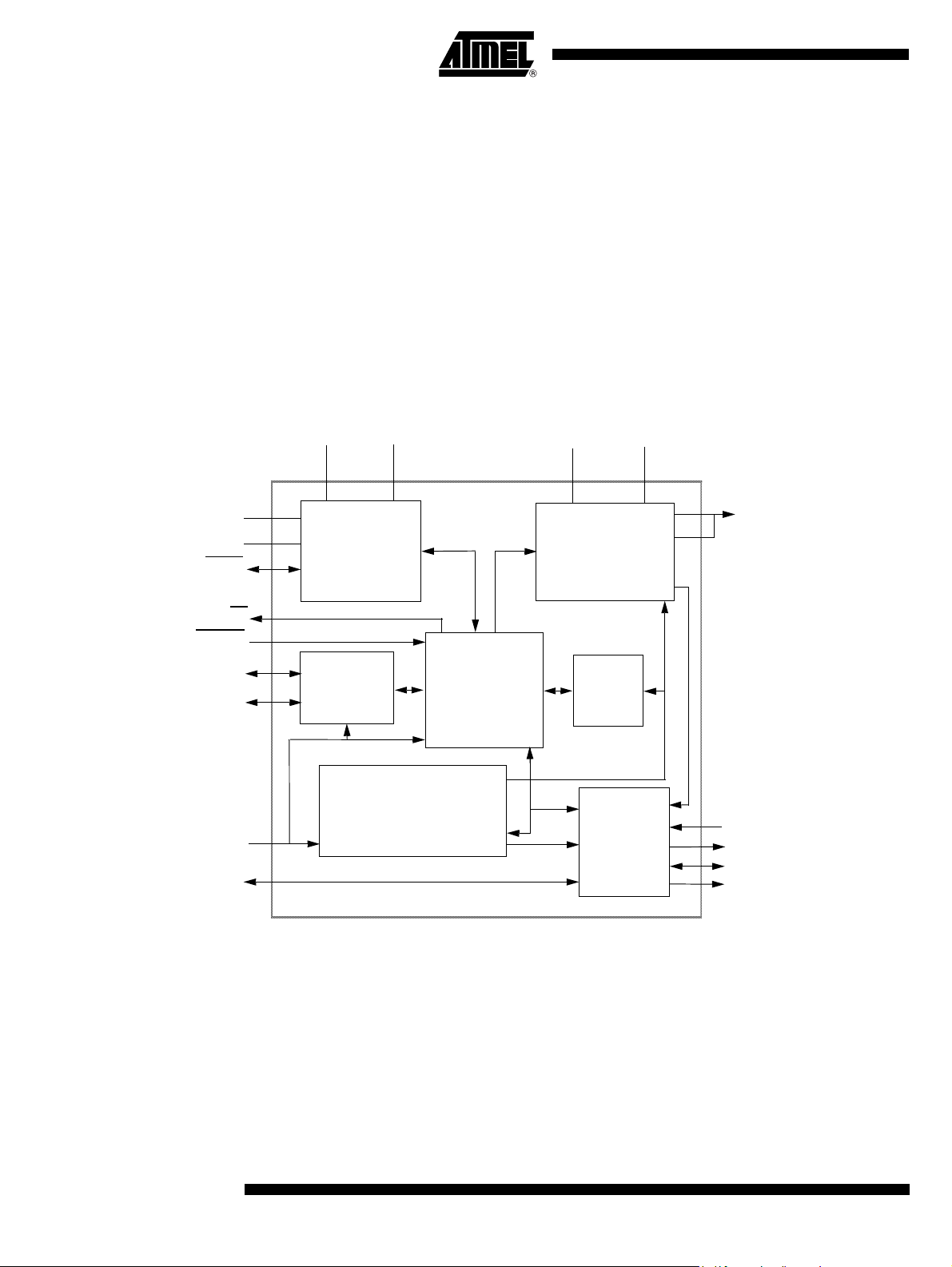

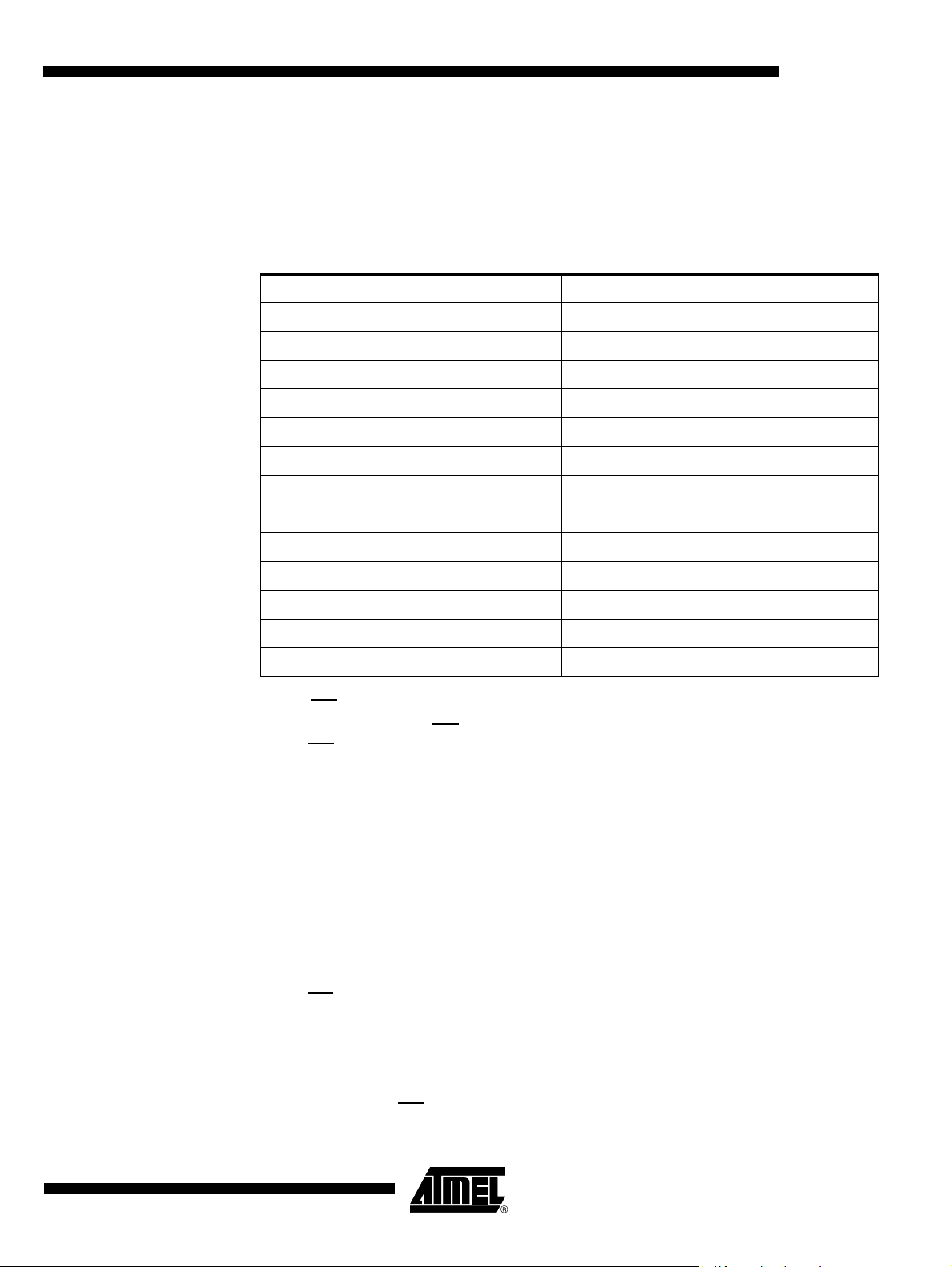

Block Diagram

DVCC

EVCC

RESET

PRES/ INT

A2/CK, A1/RST, A0/3V, CMDVCC

SCL

SDA

CLK

I/O, C4, C8

VCC

Voltage

supervisor

POR/PFD

TWI

Controller

Clocks Controller

VSS

Main

Control

& Logic Unit

LI

DC/DC

Converter

Timer

16 Bits

Analog

Drivers

CVSS

CVCC

CVCCIN

CPRES

CRST

CIO, CC4, CC8

CCLK

2

AT83C24

4234F–SCR–10/05

Page 3

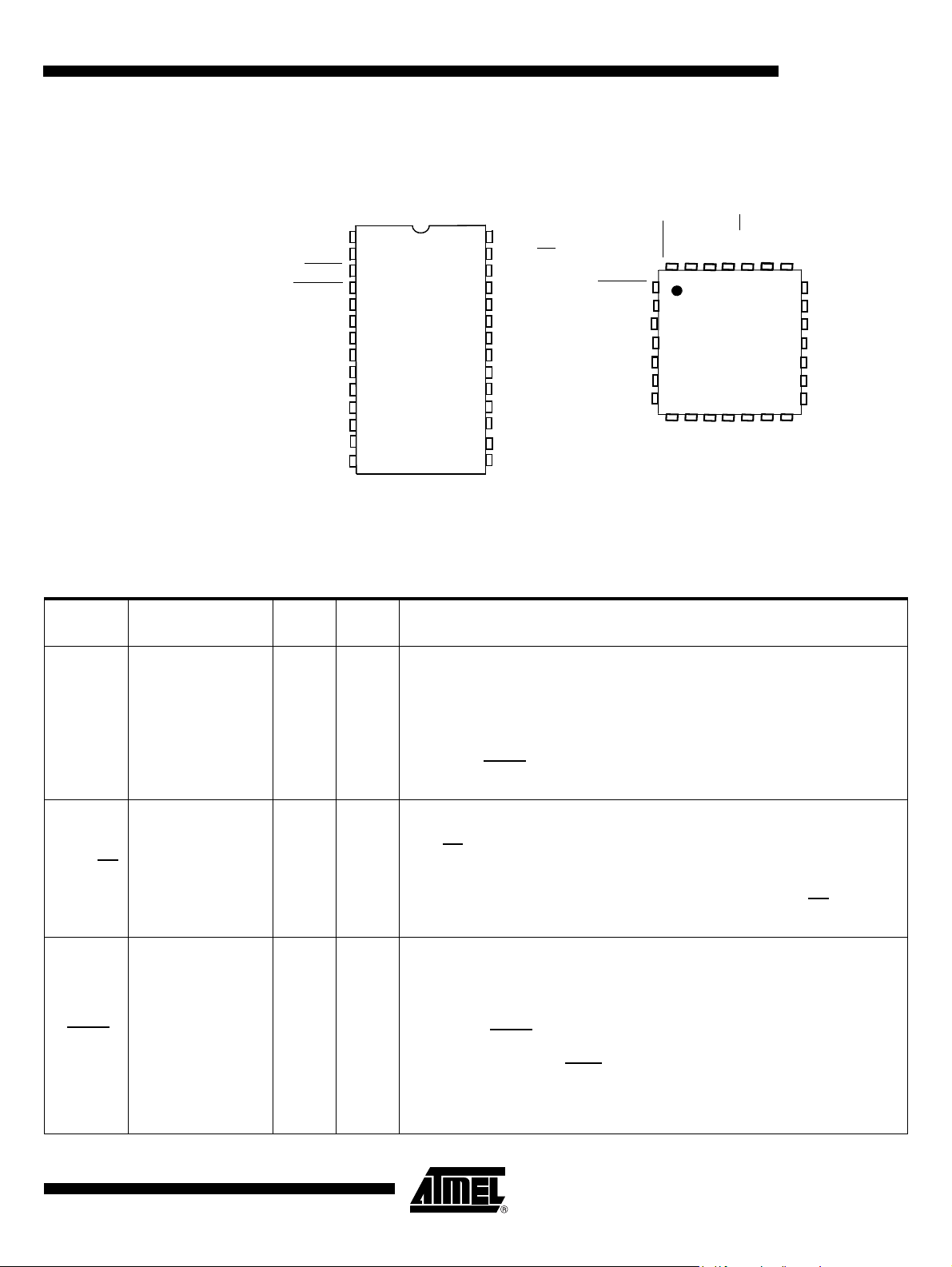

Pin Description

Pinouts (Top View) 28-pin SOIC Pinout QFN28 pinout

AT83C24

Signals

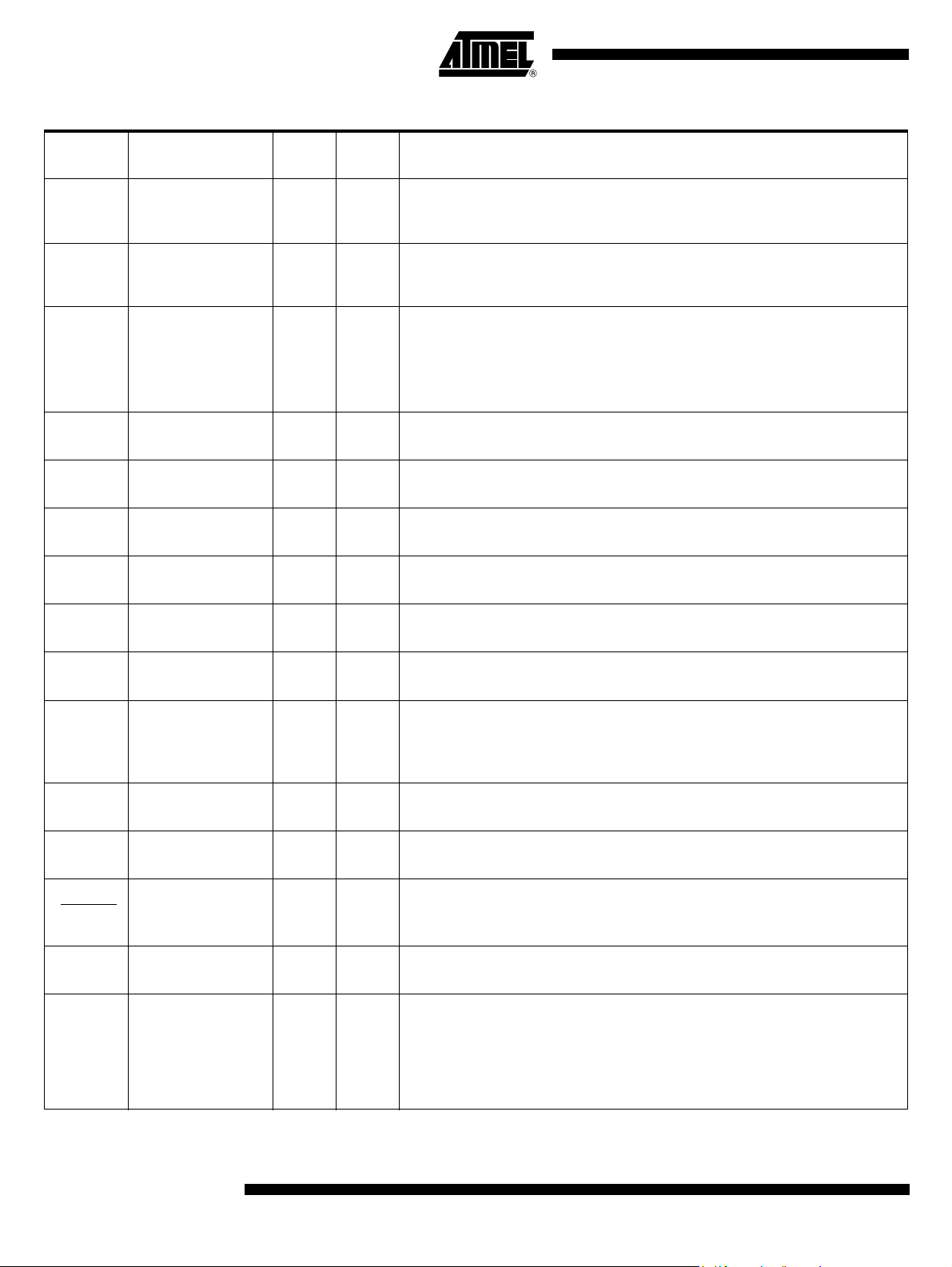

Table 1. Ports Description

Pad Name Pad Internal

Power Supply

A2/CK-

A1/RST-

A0/3V

EVCC 3 kV I

C8

1

DVCC

VSS

VCC

CVSS

CVCC

CRST

CCLK

NC

CC4

2

3

4

5

6

7

8

LI

9

10

11

12

13

14

RESET

CMDVCC

CVCCin

Note: 1. NC = Not Connected

2. SOIC and QFN packages are available for AT83C24 and for AT83C24NDS

ESD

Limits

Pad

Type

Description

Microcontroller Interface Function:

TWI bus slave address selection input.

A2/CK and A1/RST pins are respectively connected to CCLK and CRST signals in

“transparent mode” (see

A0/3V is used for hardware activation to select CVCC voltage (3V or 5V).

The slave address of the device is based on the value present on A2, A1, A0 on the

rising edge of

CLK rising edge.

CLK

28

RESET

DVCC

C8

27

26

28

1

2

V

CC

3

4

LI

5

6

7

8

9

CRST

QFN 28

TOP VIEW

101112

NC

CCLK

CLK

25

CC4

C4

PRES/INT

24

23

13

CC8

CPRES

I/O

22

EVCC

21

20

A2

/CK

19

A1

/RST

18

/3V

A0

17

SCL

16

SDA

15

NC

14

CIO

19

17

15

27

26

25

24

23

22

21

20

18

16

PRES/INT

C4

I/O

EVCC

/CK

A2

/RST

A1

/3V

A0

SCL

SDA

NC

CIO

CC8

CPRES

CMDVCC

VSS

CVSS

CVCC

CVCCin

page 17 ).

RESET pin (see Table 2). In fact, the address is taken internally at the 11th

PRES/INT EVCC

RESET VCC

4234F–SCR–10/05

3 kV

3 kV

O

open-

drain

I/O

open-

drain

Microcontroller Interface Function:

Depending on IT_SEL value (see CONFIG4 register),

PRES/INT outputs card presence status or interruptions (page 9)

An internal Pull-up (typ 330kΩ,see Table 18)to EVCC can be activated in the pad if

necessary using INT_PULLUP bit (CONFIG4 register).

Remark: during power up and before registers configuration, the PRES/INT signal must

be ignored.

Microcontroller Interface Function:

• Power-on reset

• A low level on this pin keeps the AT83C24 under reset even if applied on power-on.

It also resets the AT83C24 if applied when the AT83C24 is running (see Power

monitoring §).

• Asserting RESET when the chip is in Shut-down mode returns the chip to normal

operation.

• AT83C24 is driving the Reset pin Low on power-on-reset or if power fail on VCC or

DVCC (see POWERMON bit in CONFIG4 register), this can be used to reset or

interrupt other devices. After reset, AT83C24 needs to be reconfigured before

starting a new card session.

3

Page 4

Table 1. Ports Description (Continued)

Pad Name Pad Internal

Power Supply

ESD

Limits

Pad

Type Description

SDA VCC

SCL VCC

I/O EVCC

C4 EVCC

C8 EVCC

CLK EVCC

CIO CVCC 8 kV+

CC4 CVCC 8 kV+

3 kV

3 kV

3 kV

3 kV I/O

3 kV I/O

3 kV

I/O

open-

drain

I/O

open-

drain

I/O

(pull-up)

(pull-up)

I

I/O

(pull-up)

I/O

(pull-up)

Microcontroller Interface Function

TWI serial data

Microcontroller Interface Function

TWI serial clock

Microcontroller Interface Function

Copy of CIO pin and high level reference for EVCC.

An external pull up to EVCC is needed on IO pin.

I/O is the reference level for EVCC if EVCC is connected to a capacitor.

This feature is unused if EVCC is connected to VCC.

Microcontroller Interface Function

Copy of Card CC4.

Microcontroller Interface Function

Copy of Card CC8.

Microcontroller Interface Function

Master Clock

Smart card interface function

Card I/O

Smart card interface function

Card C4

CC8 CVCC 8 kV+

CPRES VCC 8 kV+

CCLK CVCC 8 kV+ O

CRST CVCC 8 kV+ O

CMDVCC EVCC

VCC 3 kV+ PWR

LI 3 kV+ PWR

3 kV+

I/O

(pull-up)

I

(pull-up)

I

(pull-up)

Smart card interface function

Card C8

Smart card interface function

Card presence

An internal Pull-up to VCC can be activated in the pad if necessary using PULLUP bit

(CONFIG1 register).

Smart card interface function

Card clock

Smart card interface function

Card reset

Microcontroller Interface Function:

Activation/Shutdown of the smart card Interface.

Supply Voltage

VCC is used to power the internal voltage regulators and I/O buffers.

DC/DC Input

LI must be tied to VCC pin through an external coil (typically 4.7 μH) and provides the

current for the charge pump of the DC/DC converter.

It may be directly connected to VCC if the step-up converter is not used (see STEPREG

bit in CONFIG4 register and see minimum VCC values in

Table 21 (class B)).

Table 20 (class A) and

4

AT83C24

4234F–SCR–10/05

Page 5

Table 1. Ports Description (Continued)

Pad Name Pad Internal

Power Supply

CVCC 8 kV+ PWR

ESD

Limits

AT83C24

Pad

Type Description

Card Supply Voltage

CVCC is the programmable voltage output for the Card interface.

It must be connected to external decoupling capacitors (see page 34 and page 36).

CVCCin 8 kV+ PWR

DVCC 3 kV+ PWR

EVCC 3 kV+ PWR

CVSS 8 kV+ GND

VSS GND Ground

Card Supply Voltage

This pin must be connected to CVCC.

Digital Supply Voltage

Is internally generated and used to supply the digital core.

This pin has to be connected to an external capacitor of 100 nF and should not be

connected to other devices.

Extra Supply Voltage (Microcontroller power supply)

EVCC is used to supply the internal level shifters of host interface pins.

EVCC voltage can be supplied from the external EVCC pin connected to the host power

supply.

If EVCC cannot be connected to the host power supply, it must be tied to an external

capacitor. EVCC voltage can be generated internally by an automatic follow up of the

logic high level on the I/O pin. In this configuration, connect a 100 nF + 100kOhms in

parallel between EVCC pin and VSS pin.

DC/DC Ground

CVSS is used to sink high shunt currents from the external coil.

Note: ESD Test conditions: 3 positive and 3 negative pulses on each pin versus GND. Pulses generated

according to Mil/STD 883 Class3. Recommended capacitors soldered on CVCC and VCC pins.

4234F–SCR–10/05

5

Page 6

Operational Modes

TWI Bus Control The Atmel Two-wire Interface (TWI) interconnects componen ts on a uniq ue two-wire bu s, made

up of one clock line and one data line with speeds of up to 400 Kbits per second, based on a

byte-oriented transfer format.

The TWI-bus interface can be used:

– To configure the AT83C24

– To select the operating mode of the card: 1.8V, 3V or 5V

– To configure the automatic activation sequence

– To start or stop sessions (activation and de-activation sequences)

– To initiate a warm reset

– To control the clock to the card in active mode

– To control the clock to the card in stand-by mode (stop LOW, stop HIGH or running)

– To enter or leave the card stand-by or power-down modes

– To select the interface ( connection to the host I/O / C4/ C8)

– To request the status (card present or not, over-current and out of range supply

voltage occurrence)

– To drive and monitor the card contacts by software

– To accurately measure the ATR delay when automatic activation is used

TWI Commands

Frame Structure The structure of the TWI bus data frames is made of one or a series of write and read com-

mands completed by STOP.

Write commands to the AT83C24 have the structure:

ADDRESS BYTE + COMMAND BYTE + DATA BYTE(S)

Read commands to the AT83C24 have the structure:

ADDRESS BYTE + DATA BYTE(S)

The ADDRESS BYTE is sampled on A2/CK, A1/RST, A0/3V after each reset (hard/soft/general

call) but A2/CK, A1/RST, A0/3V can be used for transparent mode after the reset.

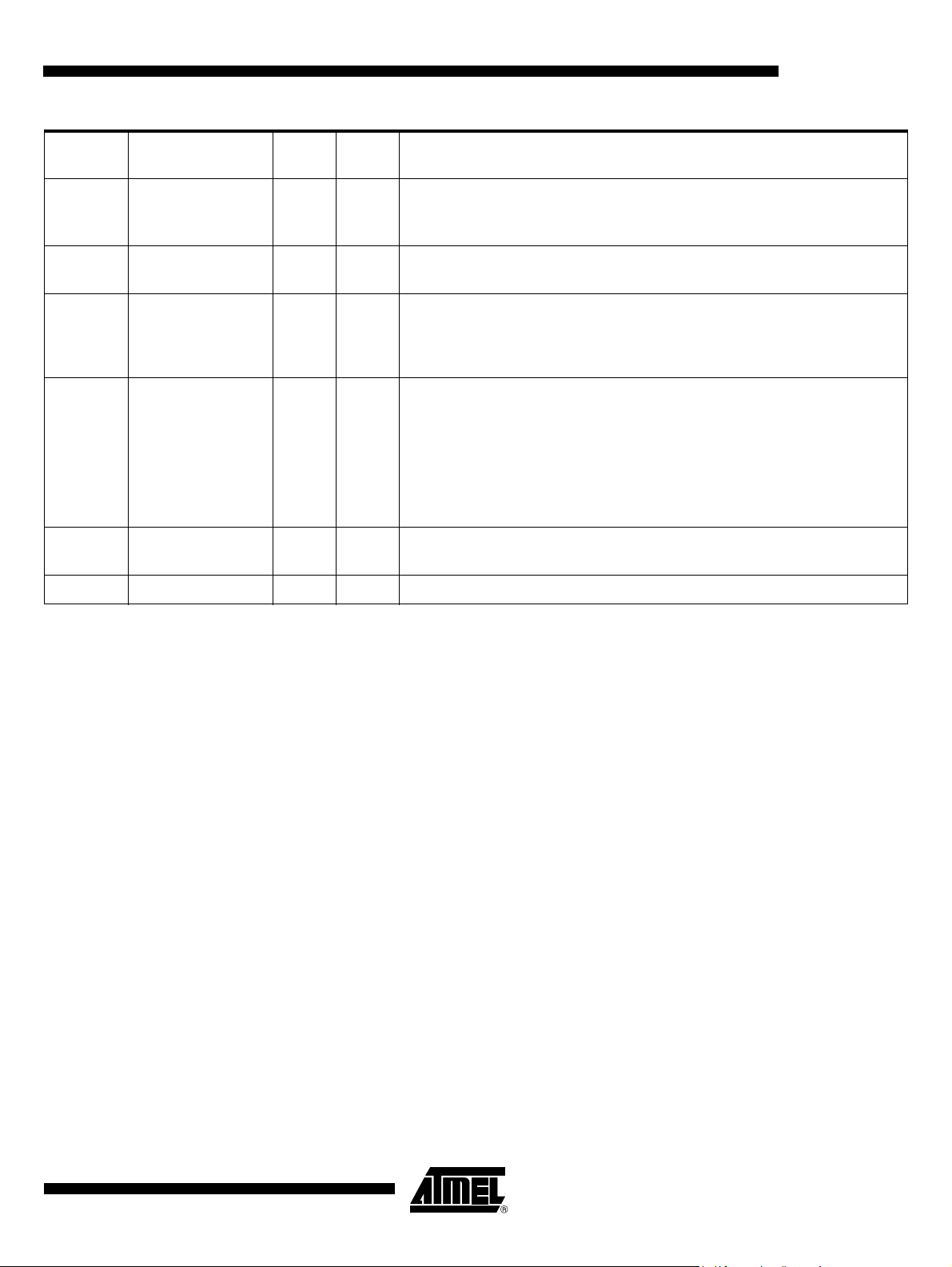

Figure 1. Data transfer on TWI bus

acknowledgement

SDA

SCL

Adresse byte

123456

from slave

78

command

and/or data

9

start condition

6

AT83C24

stop condition

4234F–SCR–10/05

Page 7

AT83C24

Address Byte The first byte to send to the device is the address byte. The device controls if the hardware

address (A2/CK, A1/RST, A0/3V pins on reset) corresponds to the address given in the

address byte (A2, A1, A0 bits).

If the level is not stable on A2/CK pin (or A1/RST pin, or A0/3V pin) at reset, the user has to send

the commands to the possible address taken by the device.

If A2/CK to A0/3V are tied to the host microcontroller and their reset values are unknown, a general call on the TWI bus allows to reset all the AT83C24 devices and set their address after

A2/CK to A0/3V are fixed.

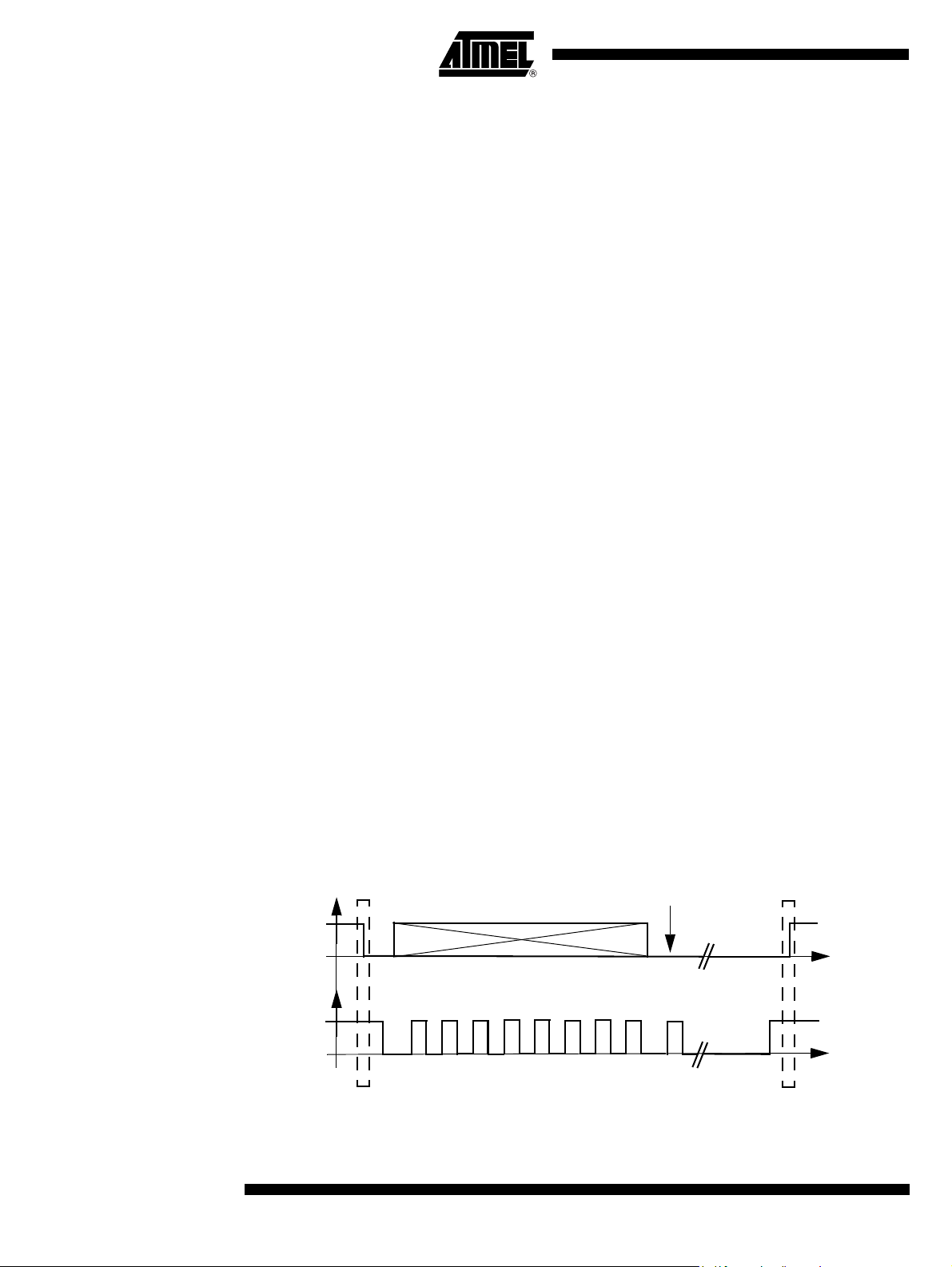

Figure 2. Address Byte

b7 b6 b5

1

0

Slave Address on 7 Bits

0

b4

b3 b2 b1

0

A2

A1

1 for READ Command

0 for WRITE Command

A0

b0

R/W

Up to 8 devices can be connected on the sam e TWI bus. Each device is configured with a differ ent combination on A2/CK, A1/RST, A0/3V pins. The corresponding address byte values for

read/write operations are listed below.

Table 2. Address Byte Values

A2

(A2/CK pin)

0 0 0 0x41 0x40

0 0 1 0x43 0x42

0 1 0 0x45 0x44

0 1 1 0x47 0x46

1 0 0 0x49 0x48

A1

(A1/RST pin)

A0

(A0/3V pin)

Address Byte

for

Read

Command

Address Byte

for

Write

Command

4234F–SCR–10/05

1 0 1 0x4B 0x4A

1 1 0 0x4D 0x4C

1 1 1 0x4F 0x4E

7

Page 8

Write Commands The write commands are:

1. Reset:

Initializes all the logic and the TWI interface as after a power-up or power-fail reset. If a

smart card is active when RESET falls, a deactivation sequence is performed. This is a onebyte command.

2. Write Config:

Configures the device according to the last six bits in the CONFIG0 register and to the fol-

lowing four bytes in CONFIG1, CONFIG2, CONFIG3 then CONFIG4 registers. This is a

five bytes command.

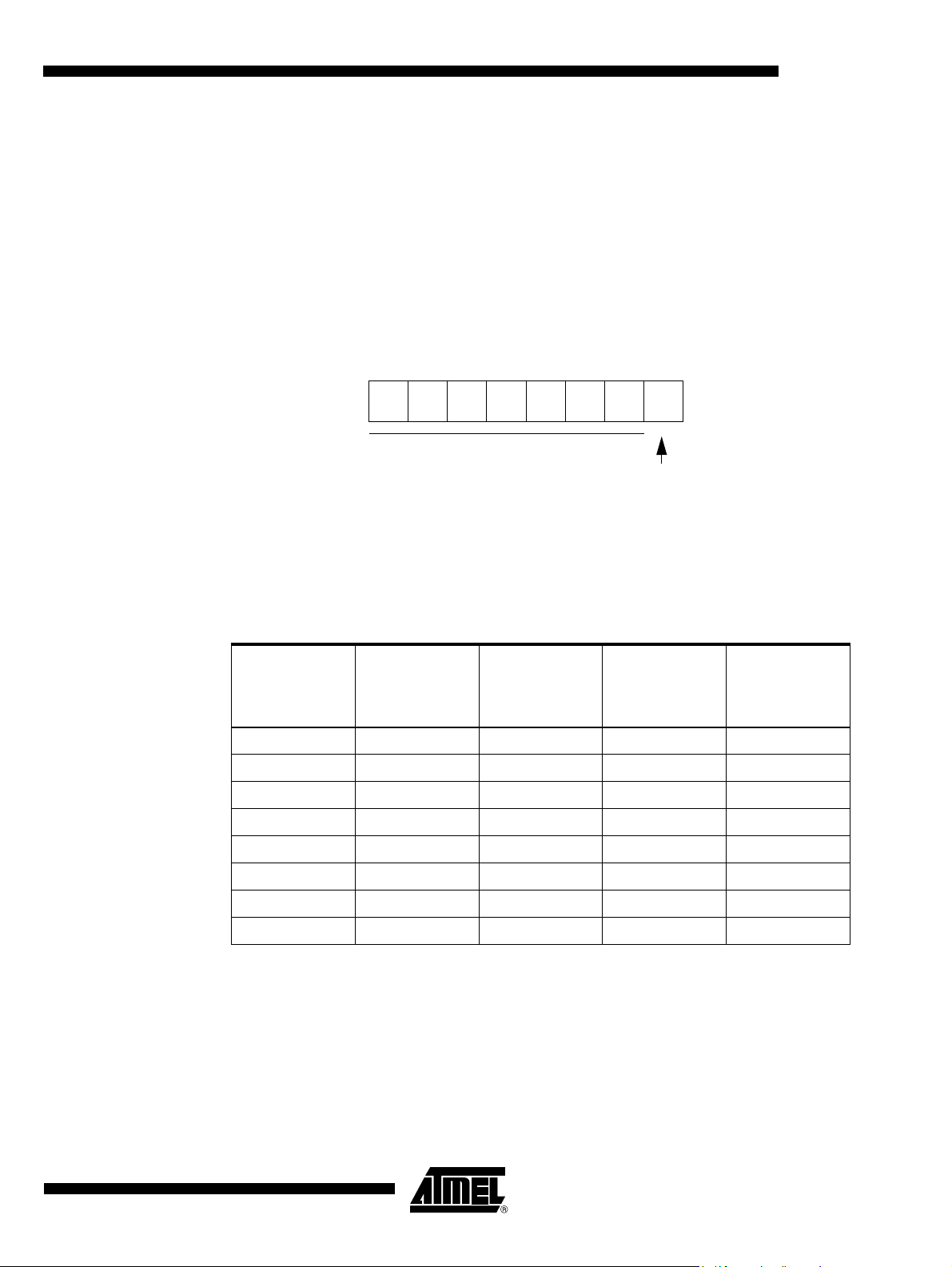

Figure 3. Command byte format for Write CONFIG0 command

b7 b6 b5 b4 b3 b2 b1

0

1

X

X

CONFIG0 on 6 Bits

X

X

b0

X

X

3. Write Timer:

Program the 16-bit automatic reset transition timer with the following two bytes. This is a

three bytes command.

4. Write Interface:

Program the interface. This is a one-byte command. The MSB of the command byte is fixed

at 0.

5. General Call Reset:

A general call followed by the value 06h has the same effect as a Reset command.

Table 3. Write Commands Description

Address Byte

(See Table 2) Command Byte

Data Byte 1Data Byte 2Data Byte 3Data Byte

4

1. Reset 0100 A2A1A00 1111 1111

2. Write config

3. Write Timer 0100 A2A1A00 1111 1100 TIMER1 TIMER0

4. Write Interface

5. General Call

Reset

8

AT83C24

0100 A2A1A00

0100 A2A1A00

0000 0000 0000 0110

(10 + CONFIG0 6

bits)

(0+INTERFACE 7

bits)

CONFIG1 CONFIG2 CONFIG3 CONFIG4

4234F–SCR–10/05

Page 9

AT83C24

Read Command After the slave address has been configured, the read command allows to read one or several

bytes in the following order:

• ST A TUS, CONFIG0, CONFIG1, CONFIG2, CONFIG3, INTERF ACE, TIMER1, TIMER0,

CAPTURE1, CAPTURE0

• FFh is completing the transfer if the microcontroller attempts to read beyond the last byte.

Note: Flags are only reset after the corresponding byte read has been acknowledged by the master.

Table 4. Read Command Description

Byte Description Byte Value

Address byte 0100 A2A1A01

Data byte 1 STATUS

Data byte 2 CONFIG0

Data byte 3 CONFIG1

Data byte 4 CONFIG2

Data byte 5 CONFIG3

Data byte 6 CONFIG4

Data byte 7 INTERFACE

Data byte 8 TIMER 1 (MSB)

Data byte 9 TIMER 0 (LSB)

Data byte 10 CAPTURE 1 (MSB)

Data byte 11 CAPTURE 0 (LSB)

Data byte 12 0xFF

Interrupts The PRES/INT behavior depends on IT_SEL bit value (see CONFIG4 register).

• If IT_SEL= 0, the PRES/INT output is High by default (on chip pull up or open drain).

PRES/

INT is driven Low by any of the following event:

– INSERT bit set in CONFIG0 register (card insertion/extraction or bit set by software )

– VCARD_INT bit set in STATUS register (the DC/DC output voltage has settled)

– over-current detection on CVCC

– VCARDERR bit set in CONFIG0 register (out of range vol t age on CVCC or bit set b y

software)

– ATRERR bit set in CONFIG0 register (no ATR before the card clock counter

overflows or bit set by software).This control of ATR timing is only available if ART bit

=1.

If IT_SEL=0, a read command of STATUS register and of CONFIG0 register will release

PRES/

INT pin to high level.

Several AT83C24 devices can share the same interrupt and the microcontroller can identify

the interrupt sources by polling the status of the AT83C24 devices using TWI commands.

4234F–SCR–10/05

• If IT_SEL= 1 (mandatory for NDS applications and for software compatibility with existing

devices) the PRES/

INT output is High to indicate a card is present and none of the following

event has occured:

9

Page 10

Card Presence Detection

The card presence is provided by the CPRES pin. The polarity of card presence contact is

selected with the CARDDET bit (see CONFIG1 register). A programmable filtering is controlled

with the CDS[2-0] bits (see CONFIG1 register).

An internal pull-up on the CPRES pin can be disconnected in order to reduce the consumption,

an external pull-up must then be connected to VCC. The PULLUP bit (see CONFIG1 register)

controls this feature.

The card presence switch is usually connected to Vss ( card present if CPRES=1). The CARDDET bit must be set. The internal pull up can be connected.

If the card presence contact is connected to Vcc (card present if CPRES=0), the internal pull-up

must be disconnected (see PULLUP bit) and an external pull-down must be connected to the

CPRES pin.

An interrupt can be generated if a card is inserted or extracted (see interrupts §).

Figure 4. Card Presence Input

VCC

– over-current detection on CVCC

– VCARDERR bit set in CONFIG0 register (out of range vol t age on CVCC or bit set b y

software)

VSS

VCC

VSS

External

Pull-up

Card

Contact

Presence

Card

Contact

Presence

External

Pull-down

CPRES

PRES/INT

VCC

(See Table 18)

Internal

Pull-up

EVCC

= 1 Closed

= 0 Open

INT_PULLUP Bit

PULLUP Bit CARDDET Bit

= 1 Closed

= 0 Open

IT_SEL Bit

IT Controller

= 1 No Card if CPRES = 0

= 0 No Card if CPRES = 1

FILTERING

CDS[2-0]

CARDIN bit

= 1 Card Inserted

= 0 No Card

10

AT83C24

4234F–SCR–10/05

Page 11

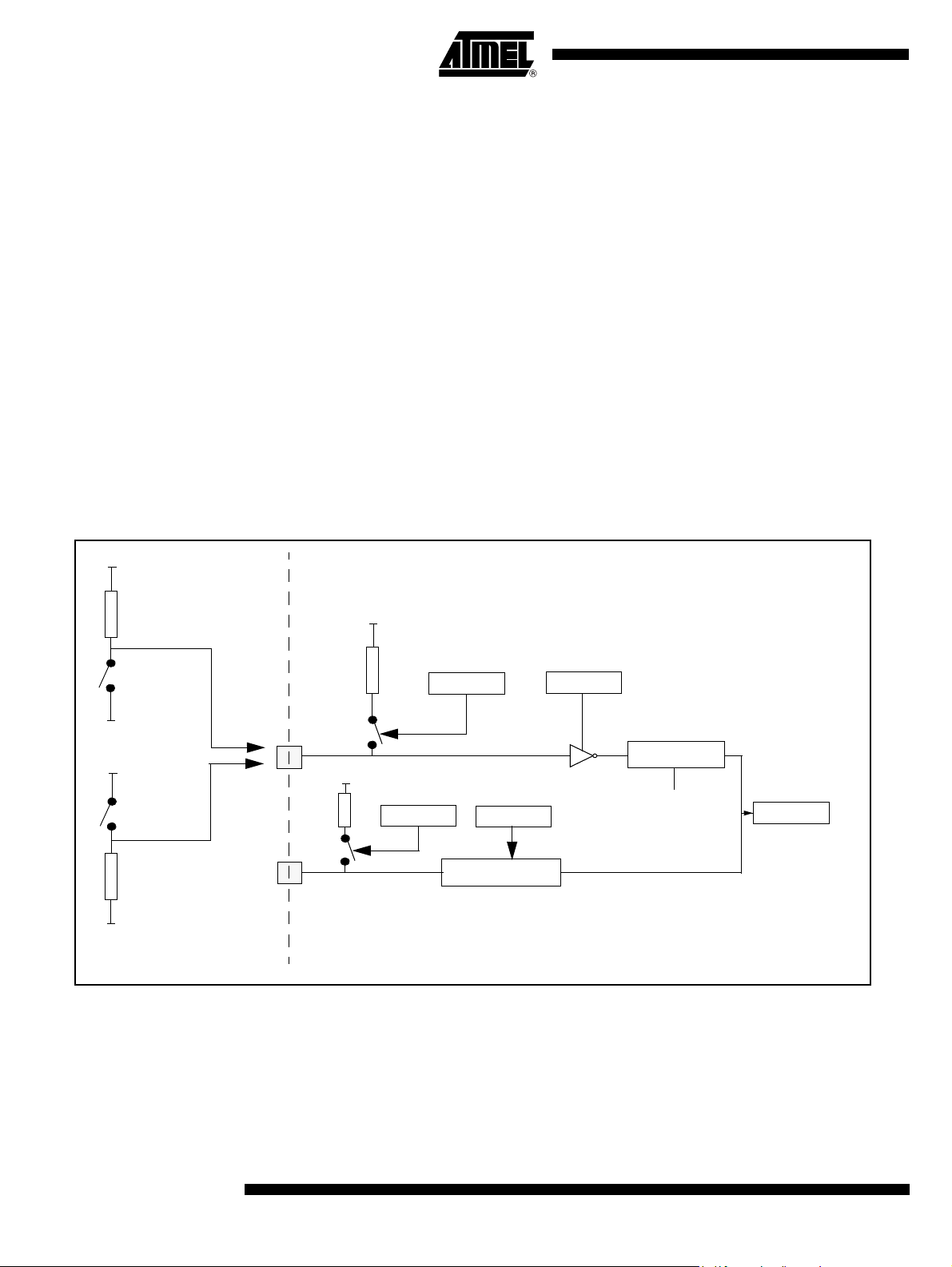

CIO, CC4, CC8 Controller

The CIO, CC4, CC8 output pins are driven re spectively by CARDIO, CARDC4, CARDC8 bits

values or by I/O, C4, C8 signal pins. This selection depends of the IODIS bit value. If IODIS is

reset, data are bidirectional between respectively I/O, C4, C8 pins and CIO, CC4, CC8 pins.

Figure 5. CIO, CC4, CC8 Block Diagram

I/O

AT83C24

CVCC

0

CIO

EVCC

C4

EVCC

C8

IO and CIO pins are linked together thro ugh the on chip level shifters if IODIS bit=0 in INTERFACE register. This is done automatically during an hardware activation.

Their iddle level are 1. With IO high, CIO is pulled up.

The same behavior is applicable on C4/ CC4 and C8/ CC8 pins.

The maximum frequency on those lines depends on CLK frequency (3 clock rising edges to

transfer). With CLK=27MHz, the maximum fre q uen cy on this lin e is 1.5MHz.

Due to the minimum transfer delay allowed for NDS applications, the CLK minimum frequ ency is

18MHz.

CARDIO bit

CARDC4 bit

CARDC8 bit

1

CVCC

0

1

CVCC

0

1

IODIS bit

CC4

CC8

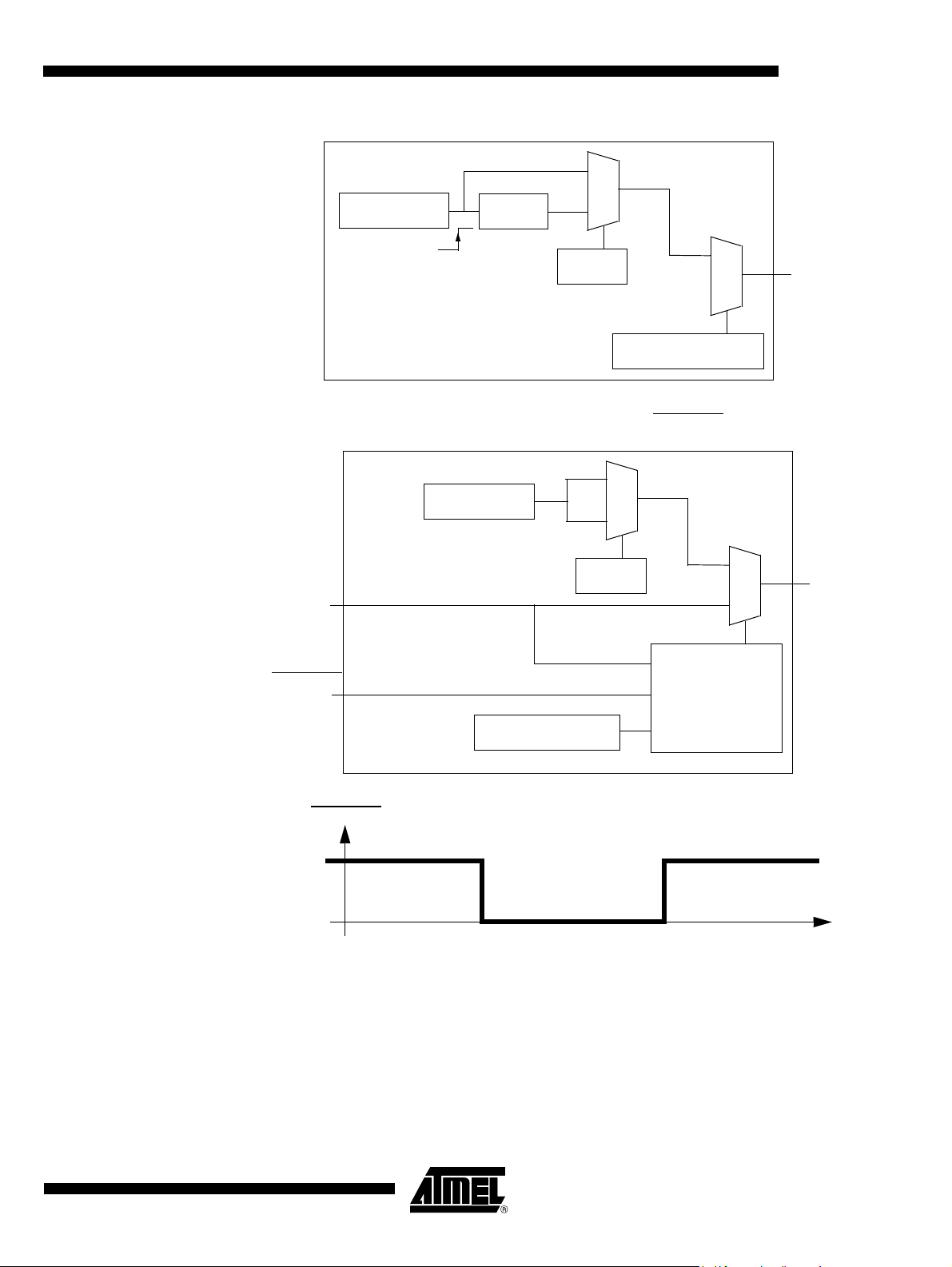

Clock Controller The clock controller generates two clocks (as shown in Figure 6 and Figure 7):

1. a clock for the CCLK: Four different sources can be used: CLK pin, DCCLK signal,

CARDCK bit or A2/CK pin (in transparent mode).

2. a clock for DC/DC converter.

4234F–SCR–10/05

11

Page 12

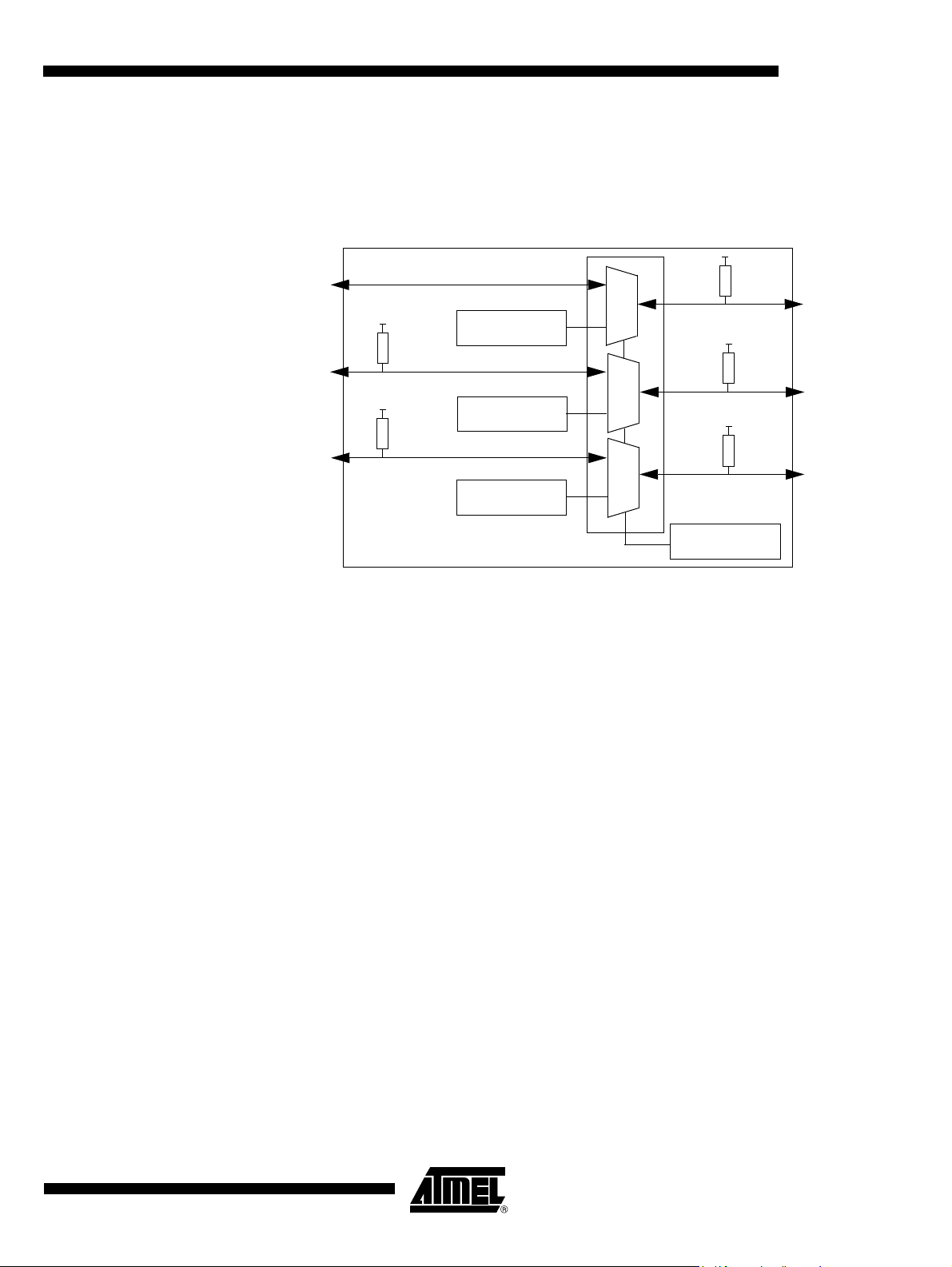

Figure 6. Clock Block Diagram with Software Activation (see page 14)

CLK

A2/CK

Figure 7. Clock Block Diagram with Hardware Activation (see page 14)

CLK

DCK[2:0]

CKS[2:0]

DCK[2:0]

DCCLK

CARDCK bit

DCCLK

DC/DC

0

1

CKSTOP bit

DC/DC

CCLK

A2/CK

CMDVCC

A1/RST

CRST_SEL bit

CKS[2:0]

CARDCK bit

Hardware

activation

CKSTOP bit

0

1

CCLK

CRST Controller The CRST output pin is driven by the A1 /RST pin signal pin or by the CARDRST bit value. This

selection depends of the CRST_SEL bit value (see CONFIG4 register).

If the CRST pin signal is driven by the CARDRST bit value, two modes are available:

• If the ART bit is reset, CRST pin is driven by CARDRST bit.

• If the ART bit is set, CRST pin is controlled and follows the “Automatic Reset Transition”

(

page 15).

12

AT83C24

4234F–SCR–10/05

Page 13

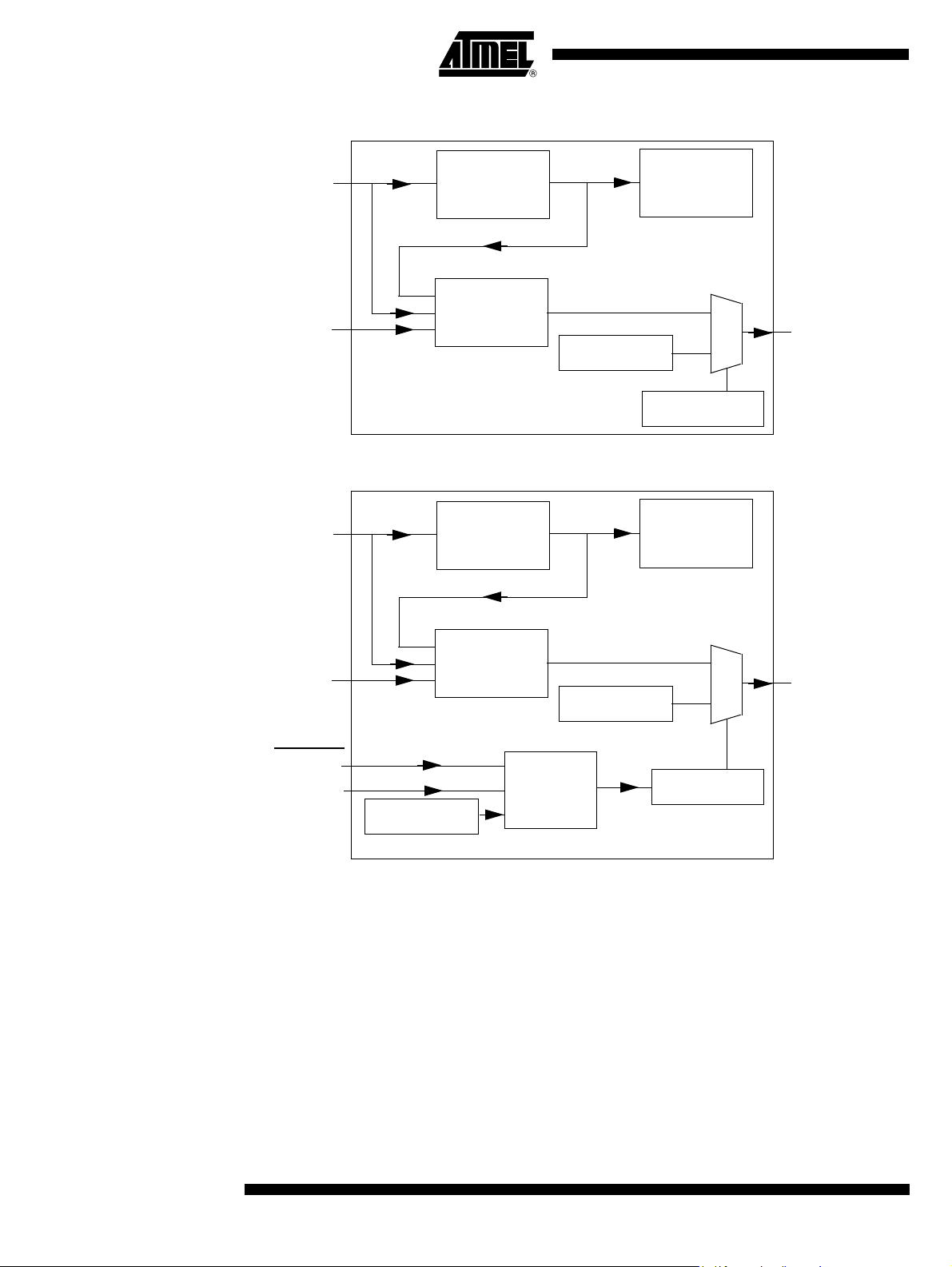

Figure 8. CRST Block Diagram with soft activation

AT83C24

0

CARDRST bit

Figure 9. CRST Block Diagram with Hardware Activation (CMDVCC pin used)

CARDRST bit

A1/RST

tb delay

see Fig 12

1

ART bit

ART bit

0

1

CRST_SEL bit = 0

0

1

CRST

0

1

CRST

CMDVCC

CMDVCC

Hardware

activation

CRST_SEL bit = 1

deactivation

activation

4234F–SCR–10/05

13

Page 14

Activation Sequence

Hardware Activation (DC/DC started with CMDVCC)

Initial conditions:

CARDDET bit must be configured in accordance to the smart card connector polarity.

IT_SEL bit, CRST_SEL bit (see CONFIG4 register) must be set and CARDRST bit (see INTER-

FACE register) must be cleared. A smart card must be detected to enable to start the DC/DC

(CVCC= 3V or 5V).

The hardware activation sequence is started by hard ware with CMDVCC pin going high to low. It

follows this automatic sequence:

• CIO / CC4 / CC8 and IO / C4 / C8 are respectively linked together (IODIS bit is cleared).

• The DC/DC is started and CVCC is set according to the A0/3V pin: 5V (Class A) if A0/3V is

High and 3V (Class B) is A0/3V is Low.

• CCLK signal is enabled (CKSTOP bit cleared) when CVCC has settled to the programmed

voltage (see Electrical Characteristics) and the level on A1/RST is 0. The CCLK so ur ce can

be DCCLK signal, CLK signal , A2/CK signals or CARDCK bit (see Figures 5).

• CRST signal is linked with A1/RST pin as soon as A1/RST pin level is 0. A rising edge on

A1/RST pin set the CRST pin.

Note: 1. The card must be deactivated to change the voltage.

Figure 10. Activation sequence with CMDVCC

CMDVCC

A1/RST

CCLK

CVCC

CRST

CIO

14

Note: For NDS applications, the host usually starts activation with A1/RST = 0.

AT83C24

4234F–SCR–10/05

Page 15

Software Activation (DC/DC Started With Writing in VCARD[1:0] bits) and ART bit = 1

Initial conditions: CARDRST bit = 0, CKSTOP bit =1, IODIS bit = 1.

The following sequence can be applied:

1. Card Voltage is set by software to the required value (VCARD[1:0] bits in CONFIG0

register). This writing starts the DC/DC.

2. Wait the end of the DC/DC init with a polling on VCARDOK bit (STATUS register) or

wait for PRES/

INT to go Low if enabled (if IT_SEL bit = 0 in CONFIG4 register).

When VCARDOK bit is set (by hardware), CARDIO bit should be set by software.

3. CKSTOP, IODIS are programmed by software. CKSTOP bit is reset to have the

clock running. IODIS is reset to drive the I/O, C4, C8 pins and the CIO,CC4, CC8

pins according to each other.

4. CARDRST bit (see INTERFACE register) is set by software.

Automatic Reset Transition description:

A 16-bit counter starts when CARDRST bit is set. It counts card clock cycles. The CRST signal

is set when the counter reaches the TIMER[1-0] value which corresponds to the “tb” time (

11).The counter is reseted when the CRST pin is released and it is stopped at the first start bit of

the Answer To Request (ATR) on CIO pin.

The CIO pin is not checked during the first 200 clock cycles (ta on Figure 11). If the ATR arrives

before the counter reaches Timer[1-0] value, the activation sequence fails, the CRST signal is

not set and the Capture[1-0] register contains the value of the counter at the arrival of the ATR.

AT83C24

Figure

If the ATR arrives after the rising edge on CRST pin and before the card clock counter overflows

(65535 clock cycles), the activation sequence completes. The Cap ture[1-0] register contain s the

value of the counter at the arrival of the ATR (tc time on

Figure 11).

Figure 11. Software activation with ART bit = 1

CARDRST bit set

CVCC

4

3

1

CRST

CCLK

CIO

ta

2

tb

tc

4234F–SCR–10/05

15

Page 16

ISO 7816 constraints: ta = 200 card clock cycles

400 card clock cycles< = tb

400 card clock cycles< = tc < = 40000 card clock cycles

Note: Timer[1-0] reset value is 400.

Software Activation (DC/DC Started by Writing in VCARD[1:0] bits) and ART bit = 0

The activation sequence is controlled by software using TWI commands, depending on the

cards to support. For ISO 7816 cards, the following sequence can be applied:

1. Card Voltage is set by software to the required value (VCARD[1:0] bits in CONFIG0

register). This writing starts the DC/DC.

2. Wait of the end of the DC/DC init with a polling on VCARDOK bit (STATUS register)

or wait for PRES/

INT to go Low if enabled (if IT_SEL bit = 0 in CONFIG4 register).

When VCARDOK bit is set (by hardware), CARDIO bit should be set by software.

3. CKSTOP, IODIS are programmed by software. CKSTOP bit is reset to have the

clock running. IODIS is reset to drive the I/O, C4, C8 pins and the CIO,CC4, CC8

pins according to each other.

4. CRST pin is controlled by software using CARDRST bit (see INTERFACE register).

Figure 12. Software activation without automatic control (ART bit = 0)

CVCC

CRST

CCLK

CIO

1

3

4

ATR

2

Note: It is assumed that initially VCARD[1:0], CARDCK, CARDIO and CARDRST bits are cleared,

CKSTOP and IODIS are set (those bits are further explained in the registers description)

Note: The user should check the AT83C24 status and possibly resume the activation sequence if one

TWI transfer is not acknowledged during the activation sequence.

Deactivation Sequence

The card automatic deactivation is triggered when one the following condition occurs:

• ICARDERR bit is set by hardware

16

AT83C24

4234F–SCR–10/05

Page 17

AT83C24

• VCARDERR bit is set by hardware (or by software)

• INSERT is set and CARDIN is cleared (card extraction)

• SHUTDOWN is set by software

• CMDVCC goes from Low to High

• Power fail on VCC (see POWERMON bit in CONFIG4 register)

• Reset pin going low

It is a self-timed sequence which cannot be interrupted when started (see Figure 13). Each step

is separated by a delay based on Td equal to 8 periods of the DC/DC clock, typically 2 µs:

1. T0: CARDRST is cleared, SHUTDOWN bit set.

2. T0 + 5 x Td:CARDCK is cleared, CKSTOP, CARDIO and IODIS are set.

3. T0 + 6 x Td: CARDIO is cleared.

4. T0 + 7 x Td: VCARD[1-0] = 00.

Figure 13. Deactivation Sequence

CVCC

CRST

CCLK

CIO,

CC4,

CC8

t1

Notes: 1. Setting ICARDERR by software does not trigger a deactivation. VCARDERR can be used to

deactivate the card by software.

2. t1=5 to 5.5*Td, and t2=0.5*Td to Td.

t2

Td

T ransparent Mode If the microcontroller outputs ISO 7816 signals, a transparent m ode a llows to con nect RST/CL K

and I/O/C4/C8 signals after an electrical level control. The AT83C24 level shifters adapt the ca rd

signals to the smart card voltage selection.

The CRST and CCLK microcontroller signals can be respectively connected to the A1/RST and

A2/CK pins.

4234F–SCR–10/05

The CRST_SEL bit (in CONFIG4 register) selects standard or transparent configuration for the

CRST pin. CKS in CONFIG2 allows to select standard or transparent configuration for the CCLK

pin. So CCLK and CRST are independent. A2/CK to A0/3V inputs always give the TWI address

at reset. The A0/3V pin can be used for TWI addressing and easily connect two AT83C24

devices on the same TWI bus.

17

Page 18

Figure 14. Transparent Mode Description

Microcontroller

AT83C24

CCLK

CRST

CIO

CC4

CC8

A2/CK

A1/RST

I/O

C4

C8

CCLK

CRST

CIO

CC4

CC8

SMART CARD

Power Modes Two power-down modes are available to reduce the AT83C24 power consumption (see STUT-

DOWN bit in CONFIG1 register and LP bits in CONFIG3 register).

To enter in the mode number 4 (see Table 5), the sequence is the following:

– First select the Low-power mode by setting the LP bit

– The activation of the SHUTDOWN bit can then be done.

The AT83C24 exits Power-down if a software/hardware reset is done or if SHUTDOWN bit is

cleared. The AT83C24 is then active immediately.

Either a hardware reset or a TWI command clearing the SHUTDOWN bit can cause an exit from

Power-down. The internal registers retain their value during the shutdown mode.

In Power-down mode, the device is sleeping and waiting for a wake up condition.

To reduce power consumption, the User should stop the clock on the CLK input after setting the

SHUTDOWN bit. The clock can be enabled again just before exiting SHUTDOWN (at least 10

µs before a START bit on SDA).

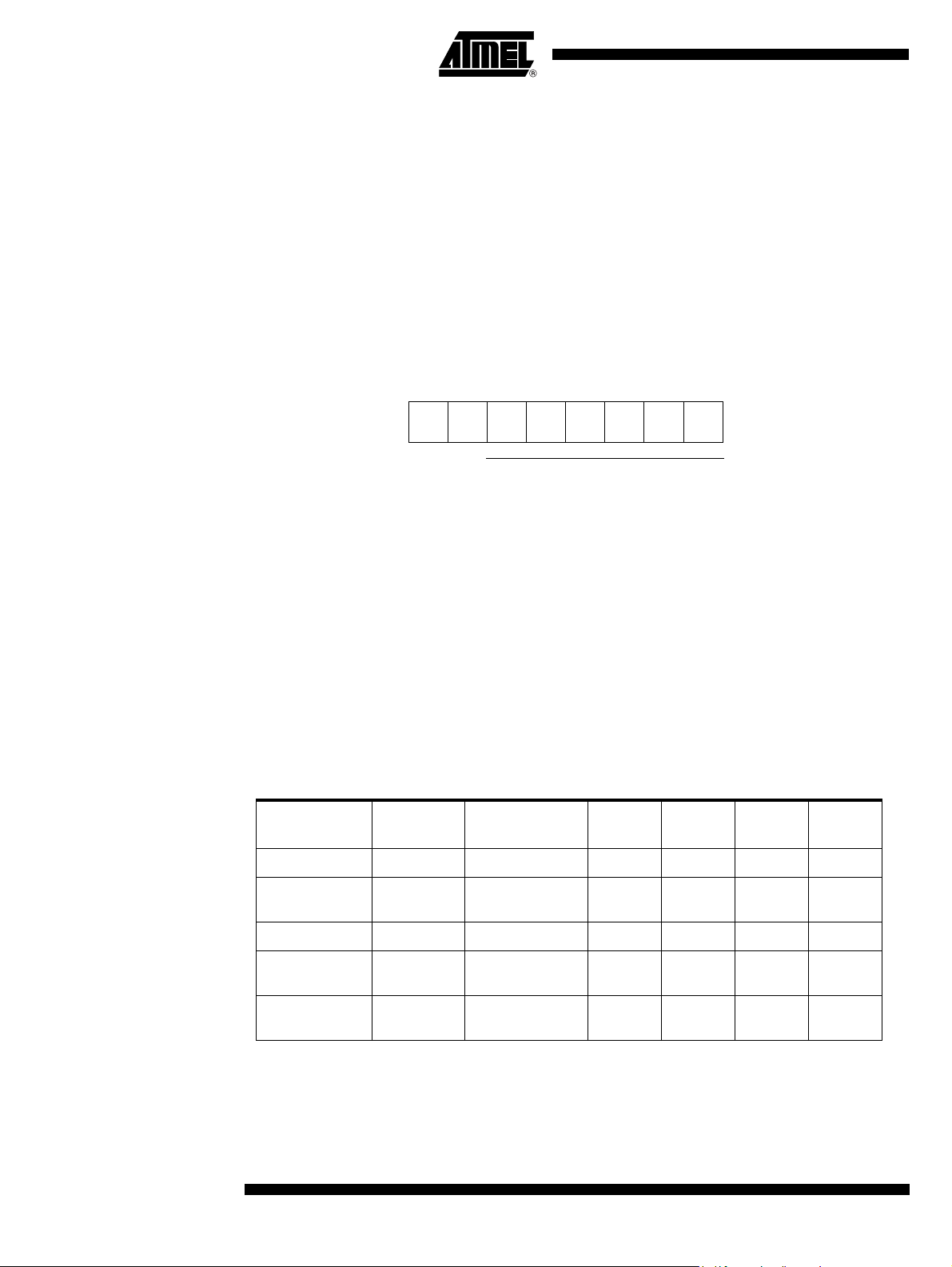

Table 5. Power Modes Description

Typical

Mode

Number

Shutdown

Bit

1 0 X 0 11

2 0 X 1 11 70 mA Regulator mode: VCC = 5.25V, CVCC = 5V,

3 0 X X 00 3 mA DC/DC off, CLK = 10MHz, VCC=3V to 5V

4 1 0 X 00 90 µA The TWI interface of the AT83C24 is active

5 1 1 X 00 30 µA Pulsed mode of the internal 3V logic regulator

LP

STEPREG VCARD[1:0]

Bit

Supply

Current

160 mA

30 mA

Description

Step up mod e : VC C = 3V, CVCC = 5V,

Icard = 65mA

Icard = 0

Icvcc = 65mA

but its analog blocs are switched off to reduce

the consumption

18

AT83C24

4234F–SCR–10/05

Page 19

Power Monitoring The AT83C24 needs only one power supply to run: VCC.

If the microcontroller outputs signals with a different electrical level, the host positive supply is

connected to EVCC.

EVCC and VCC pins can be connected together if they have the same voltage.

• If EVCC and VCC have different electrical levels:

The EVCC pin and RESET pin should be connected with a resistor bridge. RESET pin high

level must be higher than VIH (see Table 19). When EVCC drops, RESET pin level drops

too. A deactivation sequence starts if a card was active.

Then the AT83C24 resets if RESET pin stays low.

• If EVCC and VCC have the same value, then they should be connected:

The AT83C24 integrates an internal 3V r egulato r to feed its logic from th e VCC supp ly. The

bit powermon allows the user to select if the internal PFD monitors VCC or the internal regulated 3V. If the PFD monitors VCC (POWERMON bit=0), a deactivation is performed if VCC

falls below VPFDP (see VPFDP value in the datasheet). Same deactivation is performed if

the internal 3V falls below VPFDP and POWERMON bit = 1.

AT83C24

4234F–SCR–10/05

19

Page 20

Registers

Table 6. CONFIG0 (Config Byte 0)

7 6 5 4 3 2 1 0

1 0 ATRERR INSERT ICARDERR VCARDERR VCARD1 VCARD0

Bit

Number

7-6 1-0 These bits cannot be programmed and are read as 1-0.

Bit Mnemonic Description

5 ATRERR

4 INSERT

3 ICARDERR

Answer to Reset Interrupt

This bit is set when the card clock counter overflows (no falling edge on CIO

is received before the overflow of the card clock counter).

This bit is cleared by hardware when this register is read. It can be set by

software for test purpose. The reset value is 0.

Card Insertion Interrupt

This bit is set when a card is inserted or extracted: a change in CARDIN value

filtered according to CDS[2-0]. After power up, if the level on CPRES pin is 0,

then INSERT bit is set.

It can be set by software for test purpose.

This bit is cleared by hardware when this register is read. It cannot be cleared

by software.

The reset value is 0.

Card Over Current Interrupt

This bit is set when an over current is detected on CVCC. It can be set by

software for test purpose (no card deactivation is performed, no IT is

performed).

This bit is cleared by hardware when this register is read. It cannot be cleared

by software.

The reset value is 0.

2 VCARDERR

1-0 VCARD[1:0]

Card Out of Range Voltage Interrupt

This bit is set when the output voltage goes out of the voltage range specified

by VCARD field. It can be set by software for test purpose and deactivate the

card.

This bit is cleared by hardware when this register is read. It cannot be cleared

by software.

The reset value is 0.

Card Voltage Selection

VCARD[1:0] = 00: 0V

VCARD[1:0] = 01: 1.8V (see STEPREG bit)

VCARD[1:0] = 10: 3V

VCARD[1:0] = 11: 5V

VCARD[1:0] writing to 1.8V, 3V, 5V starts the DC/DC if a card is detected.

VCARD[1:0] writing to 0 stops the DC/DC.

No card deactivation is performed when the voltage is changed between

1.8V, 3V or 5V. The microcontroller should deactivate the card before

changing the voltage.

The reset value is 00.

20

AT83C24

4234F–SCR–10/05

Page 21

Table 7. CONFIG 1 (Config Byte 1)

7 6 5 4 3 2 1 0

X ART SHUTDOWN CARDDET PULLUP CDS2 CDS1 CDS0

AT83C24

Bit

Number

7 X This bit should not be set.

6 ART

5

4 CARDDET

3 PULLUP

Bit

Mnemonic

SHUTDOWN

Description

Automatic Reset Transition

Set this bit to have the CRST pin changed according to activation sequence.

Clear this bit to have the CRST pin immediately following the value programmed

in CARDRST.

The reset value is 0.

Shutdown

Set this bit to reduce the power consumption. An automatic de-activation

sequence will be done.

Clear this bit to enable VCARD[1:0] selection.

The reset value is 0.

Card Presence Detection Polarity

Set this bit to indicate the card presence detector is closed when no card is

inserted (CPRES is low).

Clear this bit to indicate the card presence detector is open when no card is

inserted (CPRES is high).Changing CARDDET will set INSERT bit (see

CONFIG0) even if no card is inserted or extracted.

The reset value is 0.

Pull-up Enable

Set this bit to enable the internal pull-up on the CPRES pin. This allows to

minimize the number of external components.

Clear this bit to disable the internal pull-up and minimize the power consumption

when the card detection contact is on. Then an external pull-up must be

connected to V

The reset value is 1.

CC

(typically a 1 MΩ resistor).

4234F–SCR–10/05

2-0 CDS[2:0]

Card Detection filtering

CPRES is sampled by the master clock provided on CLK input. A change on

CPRES is detected after:

CDS[2-0] = 0: 0 sample

CDS[2-0] = 1: 4 identical samples

CDS [2-0] = 2: 8 identical samples (reset value)

CDS[2-0] = 3: 16 identical samples

CDS[2-0] = 4: 32 identical samples

CDS[2-0] = 5: 64 identical samples

CDS[2-0] = 6: 128 identical samples

CDS[2-0] = 7: 256 identical samples

The reset value is 2.

(1)

Note: W hen CDS[2-0] = 0 and IT_ SEL = 0, PRES/ INT = 1 when no

card is present and PRES/INT = 0 when a card is inserted

even if CLK is STOPPED. This can be used to wake up the

external microcontroller and restart CLK when a card is

inserted in the AT83C24.

If CDS[2-0] = 0, IT_SEL = 1 and CLK is stop ped, a card insertion or

extraction has no effect on PRES/

INT pin.

21

Page 22

Table 8. CONFIG2 (Config Byte 2)

7 6 5 4 3 2 1 0

X DCK2 DCK1 DCK0 X CKS2 CKS1 CKS0

Bit

Number

7 X This bit should not be set.

6-4 DCK[2:0]

3 X This bit should not be set.

2-0 CKS[2:0]

Bit

Mnemonic

Description

DC/DC Clock prescaler factor

DCCLK is the DC/DC clock. It is the division of CLK input by DCK prescaler.

DCK = 0: prescaler factor equals 1 (CLK = 4 to 4.61MHz)

DCK [2:0] = 1: prescaler factor equals 2 (CLK = 7 to 9.25MHz)

DCK [2:0] = 2: prescaler factor equals 4 (CLK = 14 to 18.5 MHz)

DCK [2:0] = 3: prescaler factor equals 6 (CLK = 21 to 27.6 MHz)

DCK [2:0] = 4: prescaler factor equals 8 (CLK = 28 to 34.8 MHz)

DCK [2:0] = 5: prescaler factor equals 10 (CLK = 35 to 43 MHz)

DCK [2:0] = 6: prescaler factor equals 12 (CLK = 43.1 to 48 MHz)

DCK [2:0] = 7: reserved

The reset value is 1.

DCCLK must be as close as possible to 4 MHz with a duty cycle of 50%.

DCK must be programmed before starting the DC/DC.

The other values of CLK are not allowed.

DCK has to be properly configured before resetting the STEPREG bit.

Card Clock prescaler factor

CKS [2:0] = 0: CCLK = CLK (then the maximum frequency on CLK is 24 MHz)

CKS [2:0] = 1: CCLK = DCCLK (DC/DC clock)

CKS [2:0] = 2: CCLK = DCCLK / 2

CKS [2:0] = 3: CCLK = DCCLK / 4

CKS [2:0] = 4: CCLK = A2

CKS [2:0] = 5: CCLK = A2 / 2

CKS [2:0] = 6: CCLK = CLK / 2

CKS [2:0] = 7: CCLK = CLK / 4

The reset value is 0.

22

Notes: 1. When this register is changed, a special logic insures no glitch occurs on the CCLK pi n and

actual configuration changes can be delayed by half a period to two periods of CCLK.

2. CCLK must be stopped with CKSTOP bit before switching from CKS = (0, 1, 2, 3, 6, 7) to CKS

= (4, 5) or vice versa.

3. When DCK = 0, only CKS=4 and CKS=5 are allowed.

4. The user can’t directly select A2 or A2/2 after a reset or when switching from CKS = (0, 1, 2, 3,

6, 7) to CKS = (4, 5). To select A2, the user should select A2/2 first and after A2. To select

A2/2, the user should select A2 first and after A2/2.

AT83C24

4234F–SCR–10/05

Page 23

Table 9. CONFIG3 (Config Byte 3)

7 6 5 4 3 2 1 0

EAUTO VEXT1 VEXT0 ICCADJ LP X X X

AT83C24

Bit

Number

7-5

4 ICCADJ

3 LP

Bit

Mnemonic

EAUTO

VEXT1

VEXT0

Description

EVCC voltage configuration:

EAUTO VEXT1 VEXT0

0 0 0 EVCC = 0 the regulator is switched off.

0 0 1EVCC = 2.3V

0 1 0 EVCC = 1.8V

0 1 1 EVCC = 2.7V

1 X X EVCC voltage is the level detected on I/O input pin.

if EVCC is supplied from the external EVCC pin, the user can switch off the

internal EVCC regulator to decrease the consumption.

If EVCC is switched off, and no external EVCC is supplied, the AT83C24 is

inactive until a hardware reset is done.

The reset value is 100.

CICC overflow adjust

This bit controls the DC/DC sensitivity to any overflow current .

Set this bit to decrease the DC/DC sensitivity (CI

20%, see Electrical Characteristics). The start of the DC/DC with a high current

load is easier.

Clear this bit to have a normal configuration.

The reset value is 0.

Low-power Mode

Set this bit to enable low-power mode during shutdown mode (pulsed mode

activated).

Clear this bit to disable low-power mode during shutdown mode.

The activation reference is the following:

• First select the Low-power mode by setting LP bit.

• The activation of SHUTDOWN bit can then be done.

This bit as no effect when SHUTDOWN bit is cleared.

The reset value is 0.

is increased by about

CC_ovf

4234F–SCR–10/05

2 X This bit should not be set.

1

0 X This bit should not be set.

X

This bit should not be set.

23

Page 24

Table 10. CONFIG4 (Config Byte 4)

7 6 5 4 3 2 1 0

X X X STEPREG INT_PULLUP POWERMON IT_SEL CRST_SEL

Bit Number Bit Mnemonic Description

7-5 X-X-X These bits should not be set.

Step Regulator mode

Clear this bit to enable the automatic step-up converter (CVCC is stable even if VCC is not higher than CVCC).

Set this bit to permanently disable the step-up converter (CVCC is stable only if VCC is sufficiently higher than

4 STEPREG

3 INT_PULLUP

2 POWERMON

CVCC).

This bit must be set before activating the DC/DC converter if no external coil is present.

The reset value is 0.

This bit must always be set if no external coil is used

Internal pull-up

Set this bit to activate the internal pull-up (connected internally to EVCC) on PRES/INT pin.

Clear this bit to deactivate the internal pull-up.

PRES/INT is an open drain output with a programmable internal pull up.

The reset value is 0.

Power monitor

Set this bit to monitor any glitch on the Digital Supply Voltage (DVCC) of the AT83C24.

Clear this bit to monitor any glitch on VCC.

The reset value is 0.

1 IT_SEL

0 CRST_SEL

Interrupt Select

Set this bit to disable INSERT and VCARD_INT interrupts. Then PRES/INT is pulled up when a card is present

and no error is detected.

Clear this bit to have all the interrupt sources enabled and active Low.

IT_SEL must be set to enable a hardware activation with CMDVCC.

The reset value is 0.

Card Reset Selection

Set this bit to have the CRST pin driven by hardware through the A1 pin (only with hardware activation).

Clear this bit to have the CRST pin driven by software through the CARDRST bit.

CRST_SEL must be set when CMDVCC is used (hardware activation).

The reset value is 0.

24

AT83C24

4234F–SCR–10/05

Page 25

Table 11. INTERFACE (Interface Byte)

7 6 5 4 3 2 1 0

0 IODIS CKSTOP CARDRST CARDC8 CARDC4 CARDCK CARDIO

Bit Number Bit Mnemonic Description

7 0 This bit should not be set.

Card I/O isolation

Set this bit to drive the CIO, CC4, CC8 pins according to CARDIO, CARDC4, CARDC8 respectively and to put

I/O, C4, C8 in Hi-Z. This can be used to have the I/O, and C4 and C8 pins of the host communicating with

6 IODIS

5 CKSTOP

another AT83C24 interface, while CIO, CC4 and CC8 are driven by software (or if the card is in standby or

power-down modes).

Clear this bit to drive the I/O/CIO, C4/CC4 and C8/CC8 pins according to each other. This can be used to activate

asynchronous cards.

The reset value is 1.

CARD Clock Stop

Set this bit to stop CCLK according to CARDCK. This can be used to set asynchronous cards in power-down

mode (GSM) or to drive CCLK by software.

Clear this bit to have CCLK running according to CKS. This can be used to activate asynchronous cards.

Note: 1. When this bit is changed a special logi c ensures that no glitch oc curs on the CCLK pin

AT83C24

and actual configuration changes can be delayed by half a period to two periods of

CCLK.

2. CKSTOP must be set before switching on the DC/DC with VCARD[1:0].

4 CARDRST

3 CARDC8

2 CARDC4

1 CARDCK

0 CARDIO

The reset value is 1.

Card Reset

Set this bit to enter a reset sequence according to ART bit value.

Clear this bit to drive a low level on the CRST pin.

The reset value is 0.

Card C8

Set this bit to drive the CC8 pin High with the on-chip pull-up (according to IODIS bit value). The pin can then be

an input (read in STATUS register).

Clear this bit to drive a low level on the CC8 pin (according to IODIS bit value).

The reset value is 0.

Card C4

Set this bit to drive the CC4 pin High with the on-chip pull-up (according to IODIS bit value). The pin can then be

an input (read in STATUS register).

Clear this bit to drive a low level on the CC4 pin (according to IODIS bit value).

The reset value is 0.

Card Clock

Set this bit to set a high level on the CCLK pin (according to CKSTOP bit value).

Clear this bit to drive a low level on the CCLK pin.

The reset value is 0.

Card I/O

Set this bit to drive the CIO pin High with the on-chip pull-up (according to IODIS bit value). The pin can then be

an input (read in STATUS register).

Clear this bit to drive a low level on the CIO pin (according to IODIS bit value).

The reset value is 0.

4234F–SCR–10/05

25

Page 26

Table 12. STATUS (Status Byte)

7 6 5 4 3 2 1 0

CC8 CC4 CARDIN VCARDOK X VCARD_INT CRST CIO

Bit Number Bit Mnemonic Description

7 CC8

6 CC4

5 CARDIN

4 VCARD_OK

3 X This bit should not be set.

2 VCARD_INT

Card CC8

This bit provides the actual level on the CC8 pin when read.

The reset value is 0.

Card CC4

This bit provides the actual level on the CC4 pin when read.

The reset value is 0.

Card Presence Status

This bit is set when a card is detected.

It is cleared otherwise.

Card Voltage Status

This bit is set by the DCDC when the output voltage remains within the

voltage range specified by VCARD[1:0] bits.

It is cleared otherwise.

The reset value is 0.

Card voltage interrupt

This bit is set when VCARD_OK bit is set.

This bit is cleared when read by the microcontroller.

The reset value is 0.

1 CRST

0 CIO

Table 13. TIMER 1 (Timer MSB)

7 6 5 4 3 2 1 0

Bit 15 Bit 14 Bit 13 Bit 12 Bit 11 Bit 10 Bit 9 Bit 8

Bit

Number

7 - 0 Bits 15 - 8 Timer MSB (bits 15 to 8)

Bit

Mnemonic

Description

Reset value = 0x00000001

Card RST

This bit provides the actual level on the CRST pin when read.

The reset value is 0.

Card I/O

This bit provides the actual level on the CIO pin when read.

The reset value is 0.

26

AT83C24

4234F–SCR–10/05

Page 27

Table 14. TIMER 0 (Timer LSB)

7 6 5 4 3 2 1 0

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

AT83C24

Bit

Number

7 - 0 bits 7 - 0 Timer LSB (bits 7to 0)

Bit

Mnemonic

Description

Reset value = 0x10010000

Table 15. CAPTURE 1 (Capture MSB)

7 6 5 4 3 2 1 0

bit 15 bit 14 bit 13 bit 12 bit 11 bit 10 bit 9 bit 8

Bit

Number

7 - 0 bits 15 - 8 See “software activation with ART = 1”, page 15.

Bit

Mnemonic

Description

Reset value = 0x00000000

Table 16. CAPTURE 0 (Capture LSB)

7 6 5 4 3 2 1 0

bit 7 bit 6 bit 5 bit 4 bit 3 bit 2 bit 1 bit 0

Bit

Number

Bit

Mnemonic

Description

4234F–SCR–10/05

7 - 0 bits 7 - 0 See “software activation with ART = 1”, page 15.

Reset value = 0x00000000

27

Page 28

Electrical Characteristics

Absolute Maximum Ratings

Ambient Temperatu r e Under Bias: .....................-40°C to 85°C

Storage Temperature:................................... -65°C to +150°C

Voltage on VCC: ........................................V

Voltage on SCIB pins (***):.........CVSS -0.5V to CVCC + 0.5V

*

*NOTICE: S tresses at or above those listed under “Absolute

Maximum Ratings” may cause permanent damage to the device. This is a stress rating only and

functional operation of the device at these or any

-0.5V to +6.0V

SS

other conditions above those indicated in the

operational sections of this specification is not

implied. Exposure to absolute maximum rating

conditions may affect device reliability.

Voltage on host interface pins:.......VSS -0.5V to EVCC + 0.5V

Voltage on other pins:......................VSS -0.5V to VCC + 0.5V

Power Dissipation value is based on the maximum allowable die temperature and the thermal

resistance of the package.

Power Dissipation: .......................................................... 1.5W

Thermal resistor of QFN pack-

age..(**)............................35°C/W

Thermal resistor of SO package.................................48°C/W

(**) Exposed die attached pad must be soldered to ground

Thermal resistor are measured on multilayer PCB with 0 m/s air flow.

(***) including shortages between any groups of smart card pins.

AC/DC Parameters EVCC connected to host power supply: from 1.6V to 5.5V.

TA = -40°C to +85°C; VSS = 0V; VCC = 3V to 5.5V.

CLASS A card supplied with CVCC = 4.75 to 5.25V for AT83C24NDS

CLASS A card supplied with CVCC = 4.6 to 5.25V for AT83C24

CLASS B card supplied with CVCC = 2.8V to 3.2V

CLASS C card supplied with CVCC = 1.68V to 1.92V

Table 17. Core (VCC)

Symbol Parameter Min Typ Max Unit Test Conditions

V

PFDP

V

PFDM

t

rise, tfallVDD

Power fail high level threshold 2.4 2.5 2.6 V

Power fail low level threshold 2.25 2.35 2.45 V

rise and fall time 1 μs 600s Not tested.

Table 18. Host Interface (I/O, C4, C8, CLK, A2, A1, A0, CMDVCC, PRES/INT)

Symbol Parameter Min Typ Max Unit Test Conditions

V

V

Input Low-voltage -0.5

IL

Input High Voltage 0.7 x EVCC EVCC + 0.5 V

IH

0.3 x EVCC

0.25 x EVCC

EVCC from 2.7V to VCC

V

EVCC from 1.6 to 2.7V

EAUTO=0

EAUTO=1

EVCC from 1.6V to VCC

28

AT83C24

4234F–SCR–10/05

Page 29

AT83C24

Table 18. Host Interface (I/O, C4, C8, CLK, A2, A1, A0, CMDVCC, PRES/INT) (Continued)

Symbol Parameter Min Typ Max Unit Test Conditions

V

V

EI

R

PRES/INT

Output Low-voltage (I/O, C4, C8, PRES/INT)

OL

Output High Voltage (C4, C8, PRES/INT)

OH

V

on I/O depends on external pull up value

OH

Extra Supply Current +3 mA CL = 100 nF

CC

0.8 x EVCC EVCC V

PRES/INT weak pull-up output current 300 330 360 κΩ

0.05

0.4

EVCC EVCC pin not connected to a power supply Vpeak - 10 mV Vpeak Vpeak + 25 mV V

EVCC EVCC pin connected to a power supply

Vpeak -

200mV

CLK Clock signal for AT83C24 4 48 MHz

VVIOL = -100 μA

I

-1.2 mA

OL =

EVCC from 1.6V to VCC

IOH = 100 μA

Short to VSS

INT_PULLUP = 0: Internal

pull-up active.

CL = 100 nF, EIcc = +3

mA

Vpeak on I/O from 1.6V to

VCC

EAUTO = 1:

min duration 1µs,

min frequency 0.1Hz,

spikes <50ns are filtered.

EAUTO = 1

If DCK[2:0] =0

(CLK=4MHz to 4.61MHz),

a duty cycle of 50% is

needed.

CLK Clock signal for AT83C24NDS 18 48 MHz

no constrainst on duty

cycle

Table 19. Host Interface (SCL, SDA, RESET)

Symbol Parameter Min Typ Max Unit Test Conditions

V

V

V

V

Input Low-voltage -0.5

IL

Input High Voltage

IH

Output Low-voltage 0.4 V IOL = -3 mA

OL

Input trigger hysteresis 0.1 x VCC

HIST

3

0.7 x VCC

1.9

0.3 x VCC

VCC + 0.5 V

VCC > 4.5V

V

VCC <= 4.5V

VCC > 4.5V

VCC <= 4.5V

Table 20. Smart Card Class A

Symbol Parameter Min Typ Max Unit Test Conditions

VCC=3V to 5.5V,

STEPREG=0

VCC > 5.35V, STEPREG = 1

CI

CC

CICC_ovf

Card Supply Current Capability 65

65

Card Supply Current Overflow:

ICCADJ = 0 (reset value)

ICCADJ = 1

66

66

120

130

130

150

mA

mA VCC from 3 to 5.5V

4234F–SCR–10/05

29

Page 30

Table 20. Smart Card Class A

Symbol Parameter Min Typ Max Unit Test Conditions

0 < Icard < 60mA CL =10µF

Ripple on CVCC

Spikes on CVCC 4.6 5.3 V

Vcardok up Vcardok high level threshold 4.8 4.9 V

60

150

200

350

for AT83C24

mV

0 < Icard < 65mA CL = 3.3µF

for AT83C24NDS

Max. charge 40 nA.s

Max. duration 400 ns

Max. Icard variation 200 mA

Vcardok down Vcardok low level threshold

T

VHL

T

VLH

CVCC valid to 0

CVCC 0 to Valid

4.6

4.75

4.8

4.8

180

500

180

110

240

170

250

750

250

250

300

250

AT83C24

V

AT83C24NDS

Icard = 0, VCC > V

CL = 3.3 μF Icard = 0

μs

CL = 10 μF Icard = 0

(see note 1)

VCC = 3V, CL = 3.3µF

Icard = 65mA

Icard = 0mA

μs

VCC = 3V, CL = 10µF

Icard = 65mA

Icard = 0mA

Notes: 1. Capacitor: X7R type or X5R type, max ESR value is 30mΩ (100kHz-100MHz),

Replacing 3.3µF by 2.2µF in parrallel with 1µF is better for ESR and noise reduction.

Table 21. Smart Card Class B

Symbol Parameter Min Typ Max Unit Test Conditions

CI

CC

CICC_ovf

Card Supply Current Capability

Card Supply Current Overflow:

ICCADJ = 0 (reset value)

ICCADJ = 1

65

65

66

66

130

140

140

150

VCC=3V to 5.5V, STEPREG=0

mA

VCC > 5.35V, STEPREG = 1

mA VCC from 3.0 to 5.5V

PFDP

Ripple on CVCC 60

Spikes on CVCC 2.76 3.24 V

Vcardok up Vcardok high level threshold 2.8 3 V

Vcardok

down

T

30

Vcardok low level threshold 2.76 2.9 V

VHL

CVCC valid to 0

130

400

AT83C24

200

350

250

500

0 < Icard < 65mA CL =10µF

mV

0 < Icard < 65mA CL = 3.3µF

Maxi. charge 40 nA.s

Max. duration 400 ns

Max. variation Icard 200mA

Icard = 0, VCC > V

CL = 3.3 μF Icard = 0

μs

(see note 1)

CL = 10 μF Icard = 0

PFDP

4234F–SCR–10/05

Page 31

AT83C24

Table 21. Smart Card Class B

Symbol Parameter Min Typ Max Unit Test Conditions

VCC = 3V, CL = 3.3µF

140

110

T

VLH

CVCC 0 to Valid

130

100

Notes: 1. Capacitor: X7R type or X5R type, max ESR value is 30mΩ (100kHz-100MHz),

Replacing 3.3µF by 2.2µF in parrallel with 1µF is better for ESR and noise reduction.

Table 22. Smart Card Class C

Symbol Parameter Min Typ Max Unit Test Conditions

250

250

250

250

Icard = 65mA

Icard = 0mA

μs

VCC = 3V, CL = 10µF

Icard = 60mA

Icard = 0mA

CI

Card Supply Current Capability 40 mA VCC = 3V

CC

Card Supply Current Overflow:

CICC_ovf

ICCADJ = 0 (reset value)

45 mA

ICCADJ = 1

Spikes on CVCC 1.68 1.92 V

Vcardok up Vcardok high level threshold 1.75 1.8 V

Vcardok

down

T

T

Vcardok low level threshold 1.7 1.75 V

CVCC valid to 0 180 300 μs

VHL

200

100

VLH

CVCC 0 to valid

50

60

300

150

80

100

Icard = 0, CL = 10 μF

CVCC = 1.8V to 0.4V

Icard = 40mA, CL = 10 μF

Icard = 0, CL = 10 μF

μs

Icard = 40mA, CL = 3.3 μF

Icard = 0, CL = 3.3 μF

CVCC = 0.4 to VCARDOK

Notes: 1. Capacitor: X7R type or X5R type, max ESR value is 30mΩ (100kHz-100MHz),

Replacing 3.3µF by 2.2µF in parrallel with 1µF is better for ESR and noise reduction.

Table 23. Smart Card Clock (CCLK pin)

Symbol Parameter Min Typ Max Unit Test Conditions

(1)

(1)

(1)

(1)

(1)

V

V

tR t

4234F–SCR–10/05

Output Low-voltage 0 0.4 V

OL

Output High Voltage

OH

I

Short Circuit Current -30 30 mA Short to GND or CVCC

OS

Rise and Fall time

F

CVCC - 0.45

0.7CVCC

CVCC

CVCC

16

22.5

50

IOL = -200 μA CLASS

A&B&C

IOH = +200 μA CLASS

A&B

V

CLASS C

C

30 pF CLASS A

L =

C

30 pF CLASS B

ns

L =

C

30 pF CLASS C

L =

measurement between

10% and 90% of CVCC

31

Page 32

Table 23. Smart Card Clock (CCLK pin) (Continued)

Symbol Parameter Min Typ M ax Unit Test Conditions

0.2

CLASS A

CCLK from 0.5 to 4.2V

Rise and Fall Slew rate

0.12 V/ns

CLASS B

CCLK from 0.5 to 0.85 x

CVCC

Low level voltage stability

(taking into account PCB design)

High level voltage stability

(taking into account PCB design)

-0.25 0.5 V CLASS A&B&C

4.2

2.35

CVCC-0.4

CVCC+0.25

CVCC+0.25

CVCC+0.25

CVCC = CLASS A

V

CVCC = CLASS B

CLASS C

CCLK Smart card clock frequency 24 MHz CL = 30pF, CLK=48MHz

Table 24. Smart Card I/O (CIO, CC4, CC8 pins)

Symbol Parameter Min Typ Max Unit Test Conditions

V

V

V

Input Low-voltage -0.3V 0.8 V IIL = 500 µA

IL

I

Input Low Current 700 µA CVCC = CLASS A&B&C

IL

Input High Voltage

IH

I

Input High Current -20 +20 μA

IH

Output Low-voltage 0

OL

0.6 x CVCC

0.7 x CVCC

CVCC

CVCC

0.45

0.3

0.3

CVCC = CLASS A

V

CVCC = CLASS B & C

IOL = -1 mA CLASS A

V

IOL = -1 mA CLASS B

IOL = -1 mA CLASS C

V

I

tR t

tR t

Output High Voltage

OH

Output Short Circuit Current -15 +15 mA Short to GND or CVCC

OS

Low level voltage stability

(taking into account PCB design)

High level voltage stability

(taking into account PCB design)

0.75 x CVCC

0.9 x CVCC

-0.25

-0.25

-0.25

CVCC-0.5 CVCC+0.25 V CVCC = CLASS A&B&C

CVCC

CVCC

0.6

0.4

0.4

IOH = 40 μA CLASS

A&B&C

V

IOH = 0μA, CLASS A&B

CLASS A

V

CLASS B

CLASS C

CL = 65 pF

CLASS A:

Output rise and fall time

F

0.1 μs

measurement between

0.6V and 70% of CVCC

CLASS B & C:

measurement between

0.4V and 70% of CVCC

Input rise and fall time 1 μs CL = 65 pF

F

32

AT83C24

4234F–SCR–10/05

Page 33

AT83C24

Table 25. Smart Card RST (CRST pin)

Symbol Parameter Min Typ Max Unit Test Conditions

0.12 x CVCC

V

Output Low-voltage

OL

0

0

0.4

0.2

IOL = -20 µA CLASS

A&B&C

V

IOL = -200 µA CLASS A

IOL = -200 µA CLASS

B&C

V

I

Output High Voltage 0.9*CVCC CVCC V

OH

Output High Current -15 +15 mA Short to GND or CVCC

OS

IOH = 200 µA

CLASS A&B&C

CL = 30pF

tR t

Rise and Fall time 0.1 µs

F

measurement between

10% and 90% of CVCC

Low level voltage stability

(taking into account PCB design)

High level voltage stability

(taking into account PCB design)

-0.25

4.2

2.35

CVCC-0.4

0.50V

0.30V

0.30V

CVCC+0.25 V

V

CLASS A

CLASS B

CLASS C

CLASS A

CLASS B

CLASS C

Table 26. Card Presence

Symbol Parameter Min Typ Max Unit Test Conditions

Short to VSS

R

CPRES

CPRES weak pull-up output current 300 330 360 κΩ

PULLUP = 1:

Internal pull-up active

Table 27. TWI (SDA, SCL pins)

Symbol Parameter Min Typ Max Unit Test Conditions

t

SU;DAT

t

HD;DAT

t

Data set-up time 20 10 ns Not tested

Data hold time 10 0 ns Not tested

Fall time on SDA signal 50 ns Not tested

fDA

4234F–SCR–10/05

33

Page 34

Typical Application

Figure 1. Typical Standard Mode Application Diagram for 3 AT83C24 (up to 8 AT83C24 if needed)

EVCC

VCC

TWI

RST

INT0

Px.y

Host

MICROCONTROLLER

VSS

XTAL2

4 to 48 MHz

VSS

XTAL1

See note

for

I/O

pull up

SDA,

SCL

pullups

V

Reset

pullup

CC

A2/CK

A1/RST

A0/3V

V

CC

SCL

SDA

RESET

PRES/INT

I/O, C4, C8

EVCC

V

CC

A2/CK

A1/RST

A0/3V

VSS

SCL

SDA

RESET

PRES/INT

I/O, C4, C8

CLK

EVCC

V

CC

A2/CK

A1/RST

A0/3V

VSS

SCL

SDA

RESET

PRES/INT

I/O, C4, C8

CLK

EVCC

EVCC

CLK

EVCC

VSS

VCC

VSS

VCC

100nF

C13

VSS

VCC

VSS

AT83C24

100nF

C14

VSS

CVSS

AT83C24

100nF

C15

VSS

CVSS

AT83C24

L1

4.7µH

LI

CVSS

CIO, CC4, CC8

CPRES

CVCCin

DVCC

L2

4.7µH

LI

CIO, CC4, CC8

CRST

CPRES

CCLK

CVCC,

CVCCin

DVCC

L3

4.7µH

LI

CIO, CC4, CC8

CRST

CPRES

CCLK

CVCC,

CVCCin

DVCC

CRST

CCLK

CVCC,

C4

C5

C1

CVSS

VSS

CVSS

VSS

CVSS

VSS

100nF

C2

2.2µF

100nF

C5

2.2µF

100nF

C8

V

CC

2.2µF

Card 1

2.2uF

C3

CVSS

VSS

V

CC

Card 2

2.2uF

C6

CVSS

100nF

VSS

V

CC

Card 3

2.2uF

C9

CVSS

100nF

VSS

1uF

C10

CVSS

100nF

1uF

C11

CVSS

1uF

C12

CVSS

Note: 1. The external resistor on I/O can be removed if the host pin has an internal resistor.

34

AT83C24

4234F–SCR–10/05

Page 35

Page 36

Typical NDS Application

Figure 2. Typical NDS Standard Mode Application Diagram for 1 AT83C24NDS.

EVCC

See note 2

V

VCC

TWI

RST

See note1

for

I/O

pull up

SDA,

SCL

pullups

CC

Reset

pullup

EVCC

SCL

SDA

RESET

VSS

CC

V

100nF

C13

L1

4.7µH

LI

VSS

CVSS

CRST

CIO, CC4, CC8

CCLK

C1

VSS

V

CC

2.2µF

Smart

Card 1

Host

MICROCONTROLLER

VSS

XTAL2

VSS

Note: 1. The external resistor on I/O can be removed if the host pin has an internal resistor.

XTAL1

18.432 or 27MHz

INT0

Px.y

Px.y

Px.y

Px.y

PRES/INT

I/O, C4, C8

CLK

A2/CLK

A1/RST

A0/3V

CVCCin

CVCC

CVSS

1uF

C2

CVSS

2.2uF

C3

100nF

C10

CVSS

AT83C24NDS

DVCC

100nF

VSS

2. The internal pull up on PRES/INT is disabled during reset (recommended external 20kOhms

pull up).

3. Refer to application note for AT83C24NDS software configuration.

CPRES

card

present

VSS

36

AT83C24

4234F–SCR–10/05

Page 37

Ordering Information

Part Number Supply Voltage Temperature Range Package Packing

AT83C24B-PRTIL

AT83C24B-PRRIL

AT83C24B-PRTIM

AT83C24B-PRRIM

AT83C24B-TISIL 3V to 5.5V Industrial SO28 Stick

AT83C24B-TIRIL 3V to 5.5V Industrial SO28 Tape&Reel

AT83C24B-TISIM 4.00V to 5.5V Industrial SO28 Stick

AT 83C24B-TIRIM 4.00V to 5.5V Industrial SO28 Tape&Reel

AT83C24

(2)

(2)

(2)

(2)

3V to 5.5V Industrial QFN28 Tray

3V to 5.5V Industrial QFN28 Tape&Reel

4.00V to 5.5V Industrial QFN28 Tray

4.00V to 5.5V Industrial QFN28 Tape&Reel

AT83C24NDS-PRTIL

AT 83C24NDS-PRRIL

AT 83C24NDS-PRTIM

AT83C24NDS-PRRIM

AT83C24NDS-TISIL

AT83C24NDS-TIRIL

AT83C24NDS-TISIM

AT 83C24NDS-TIRIM

AT83C24B-PRTUL

AT 83C24B-PRRUL

AT83C24B-PRTUM

AT83C24B-PRRUM

(1)(2)

(1)(2)

(1)(2)

(1)(2)

(1)

(1)

(1)

(1)

(2)

(2)

(2)

(2)

3V to 5.5V Industrial QFN28 Tray

3V to 5.5V Industrial QFN28 Tape&Reel

4.00V to 5.5V Industrial QFN28 Tray

4.00V to 5.5V Industrial QFN28 Tape&Reel

3V to 5.5V Industrial SO28 Stick

3V to 5.5V Industrial SO28 Tape&Reel

4.00V to 5.5V Industrial SO28 Stick

4.00V to 5.5V Industrial SO28 Tape&Reel

3V to 5.5V Industrial & Green QFN28 Tray

3V to 5.5V Industrial & Green QFN28 Tape&Reel

4.00V to 5.5V Industrial & Green QFN28 Tray

4.00V to 5.5V Industrial & Green QFN28 Tape&Reel

AT83C24B-TISUL 3V to 5.5V Industrial & Gree n SO28 Stick

AT83C24B-TIRUL 3V to 5.5V Industrial & Green SO28 Tape&Reel

4234F–SCR–10/05

AT83C24B-TISUM 4.00V to 5.5V Industrial & Green SO28 Stick

AT83C24B-TIRUM 4.00V to 5.5V Industrial & Green SO28 Tape&Reel

AT83C24NDS-PRTUL

AT83C24NDS-PRRUL

AT83C24NDS-PRTUM

AT 83C24NDS-PRRUM

(1)(2)

(1)(2)

(1)(2)

(1)(2)

3V to 5.5V Industrial & Green QFN28 Tray

3V to 5.5V Industrial & Green QFN28 Tape&Reel

4.00V to 5.5V Industrial & Green QFN28 Tray

4.00V to 5.5V Industrial & Green QFN28 Tape&Reel

37

Page 38

Part Number Supply Voltage Temperature Range Package Packing

AT83C24NDS-TISUL

AT83C24NDS-TIRUL

AT83C24NDS-TISUM

AT83C24NDS-TIRUM

(1)

(1)

(1)

(1)

3V to 5.5V Industrial & Green SO28 Stick

3V to 5.5V Industrial & Green SO28 Tape&Reel

4.00V to 5.5V Industrial & Green SO28 Stick

4.00V to 5.5V Industrial & Green SO28 Tape&Reel

Note: 1. Enhanced AC/DC parameters, see first page for differences between AT83C24 and AT83C24NDS.

2. Refer to index mark for proper placement.

38

AT83C24

4234F–SCR–10/05

Page 39

Package Drawings

QFN28

AT83C24

4234F–SCR–10/05

39

Page 40

SO28

Page 41

Datasheet Change Log

AT83C24

Changes from 4234A-05/03 to 4234B-02/04

Changes from 4234B-02/04 to 4234C - 04/04

Changes from 4234C-04/04 to 4234D - 07/04

Changes from 4234D-04/04 to 4234E - 09/04

1. Addition of CRST, CIO, CCLK controllers descriptions, page 10.

2. Update of Hardware\Software activation description, page 14.

3. Suppression of low voltage regulator mode for power down modes, page 18.

4. Modification of clock values in CONFIG2 regsiter, page 22.

5. Addition of a point on QFN pinout view, page2.

6. Update of electrical characteristics, page 28.

1. Addition of references in ordering information

2. Update of EVCC description

3. Update of CARDDET bit and INSERT bit description

1. Update for Rev 4 silicon version (index 4 on component).

2. Software workaround for A2 or A2/2 selection in CKS register.

3. Max speed on IO/CIO transfer

4. New conditions for hardware activation (see IT_SEL).

5. SO28 drawing package (error with SO32).

6. Adjusted electrical parameters for NDS compliance, pages 28, 29, 30.

1. QFN28 new package drawing.

2. Clock input parameters for AT83C24 and AT83C24NDS.

Changes from 4234E - 09/04 to 4234F - 10/05

1. Updated green product ordering information.

4234F–SCR–10/05

41

Page 42

Atmel Corporation Atmel Operations

2325 Orchard Parkway

San Jose, CA 95131, USA

Tel: 1(408) 441-0311

Fax: 1(408) 487-2600

Regional Headquarters

Europe

Atmel Sarl

Route des Arsenaux 41

Case Postale 80

CH-1705 Fribourg

Switzerland

Tel: (41) 26-426-5555

Fax: (41) 26-426-5500

Asia

Room 1219

Chinachem Golden Plaza

77 Mody Road Tsimshatsui

East Kowloon

Hong Kong

Tel: (852) 2721-9778

Fax: (852) 2722-1369

Japan

9F, Tonetsu Shinkawa Bldg.

1-24-8 Shinkawa

Chuo-ku, Tokyo 104-0033

Japan

Tel: (81) 3-3523-3551

Fax: (81) 3-3523-7581

Memory

2325 Orchard Parkway

San Jose, CA 95131, USA

Tel: 1(408) 441-0311

Fax: 1(408) 436-4314

Microcontrollers

2325 Orchard Parkway

San Jose, CA 95131, USA

Tel: 1(408) 441-0311

Fax: 1(408) 436-4314

La Chantrerie

BP 70602

44306 Nantes Cedex 3, France

Tel: (33) 2-40-18-18-18

Fax: (33) 2-40-18-19-60

ASIC/ASSP/Smart Cards

Zone Industrielle

13106 Rousset Cedex, France

Tel: (33) 4-42-53-60-00

Fax: (33) 4-42-53-60-01

1150 East Cheyenne Mtn. Blvd.

Colorado Springs, CO 80906, USA

Tel: 1(719) 576-3300

Fax: 1(719) 540-1759

Scottish Enterprise Technology Park

Maxwell Building

East Kilbride G75 0QR, Scotland

Tel: (44) 1355-803-000

Fax: (44) 1355-242-743

RF/Automotive

Theresienstrasse 2

Postfach 3535

74025 Heilbronn, Germany

Tel: (49) 71-31-67-0

Fax: (49) 71-31-67-2340

1150 East Cheyenne Mtn. Blvd.

Colorado Springs, CO 80906, USA

Tel: 1(719) 576-3300

Fax: 1(719) 540-1759

Biometrics/Imaging/Hi-Rel MPU/

High Speed Converters/RF Datacom

Avenue de Rochepleine

BP 123

38521 Saint-Egreve Cedex, France

Tel: (33) 4-76-58-30-00

Fax: (33) 4-76-58-34-80

Literature Requests

www.atmel.com/literature

Disclaimer: The information in this docume nt is pro vided in connection with Atmel products. No license, express o r implie d, by estoppel or other wise,to anyintellectualproperty right is granted by this document or in connection with the sale of Atmel products. EXC EPT AS SET FORTH IN ATMEL’S TERMS AND CONDI-TIONS OF

SALE LOCATED ON ATMEL’S WEB SITE, ATMEL ASSUMES NO LIABILITY WHATSOEVER AND DISCLAIMS ANY EXPRESS, IMPLIED OR STATUTORYWARRANTY RELATING TO ITS PRODUCTS INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTY OF MERCHANTABILITY, FITNESS FOR A PARTICULARPURPOSE, OR NON-INFRINGEMENT. IN NO EVENT SHALL ATMEL BE LIABLE FOR ANY DIRECT, INDIRECT, CONSEQUENTIAL, PUNITIVE, SPECIAL

OR INCIDEN-TAL DAMAGES (INCLUDING, W ITHOUT LIMITATION, DAMAGES FOR LOSS OF PROFITS, BUSINESS INTERRUPTION, OR LOSS OF INFORMATION) ARISING OUTOF THE USE OR INABILITY TO USE THIS DOCUMENT, EVEN IF ATMEL HAS B EEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES. Atmel makes norepresentationsor warrantie s with respect to the accuracy or completeness of the conten ts of this document and reserves the right to make

changes to specificationsand product descriptions at any time without notice. Atmel does not make any commitment to update the informati on contained herein.

Unless specifically provided otherwise, Atmel products are not suitable for, and shall not be used in, automotive applications. Atmel’s products are not intended,

authorized, or warranted for useas components in applications intended to sup port or sustainlife.

© Atmel Corporation 200 5. All rights reserved. Atmel®, logo and combinations thereof, are registered trademarks, and Everywhere You Are

are the trademarks of Atmel Corporation or its subsidiaries. Other terms and product names may be trademarks of others.

Printed on recycled paper.

4234F–SCR–10/05

SM

Loading...

Loading...