Page 1

1. Features

• Sensitive Layer Over a 0.35 µm CMOS Array

• Image Zone: 0.4 x 14 mm = 0.02" x 0.55"

• Image Array: 8 x 280 = 2240 pixels

• Pixel Pitch: 50 µm x 50 µm = 500 dpi

• Pixel Clock: up to 2 MHz Enabling up to 1780 Frames per Second

• Die Size: 1.64 x 17.46 mm

• Operating Voltage: 3V to 3.6V

• Naturally Protected Against ESD: > 16 kV Air Discharge

• Power Consumption: 16 mW at 3.3V, 1 MHz, 25°C

• Operating Temperature Range: -40°C to +85°C

• Chip-on-Board (COB), Chip-on-Board (COB) with Connector

• Complies With the European Directive for Restriction of Hazardous Substances

(RoHS Directive)

2. Applications

• PDA (Access Control, Data Protection)

• Notebook, PC-add on (Access Control, e-business)

• PIN Code Replacement

• Automated Teller Machines, POS

• Building Access

• Electronic Keys (Cars, Home)

• Portable Fingerprint Imaging for Law Enforcement

• TV Access

Thermal

Fingerprint

Sensor with

0.4 mm x 14 mm

(0.02" x 0.55")

Sensing Area

and

Digital Output

(On-chip ADC)

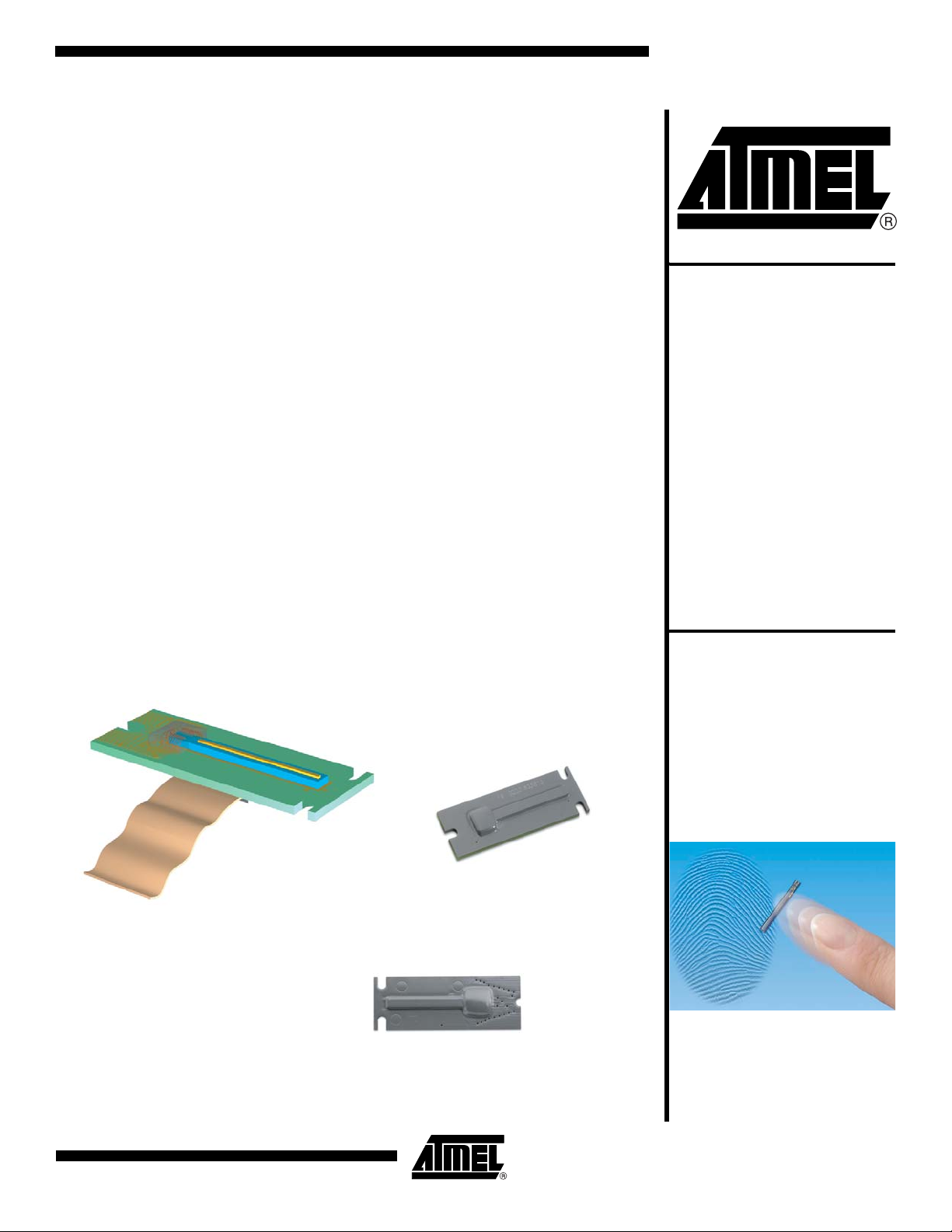

Figure 2-1. FingerChip® Packages

Chip-on-board Package

with Connector

Chip-on-board Package

Actual size

AT77C102B

FingerChip®

(COB)

Rev. 5364A–BIOM–09/05

Page 2

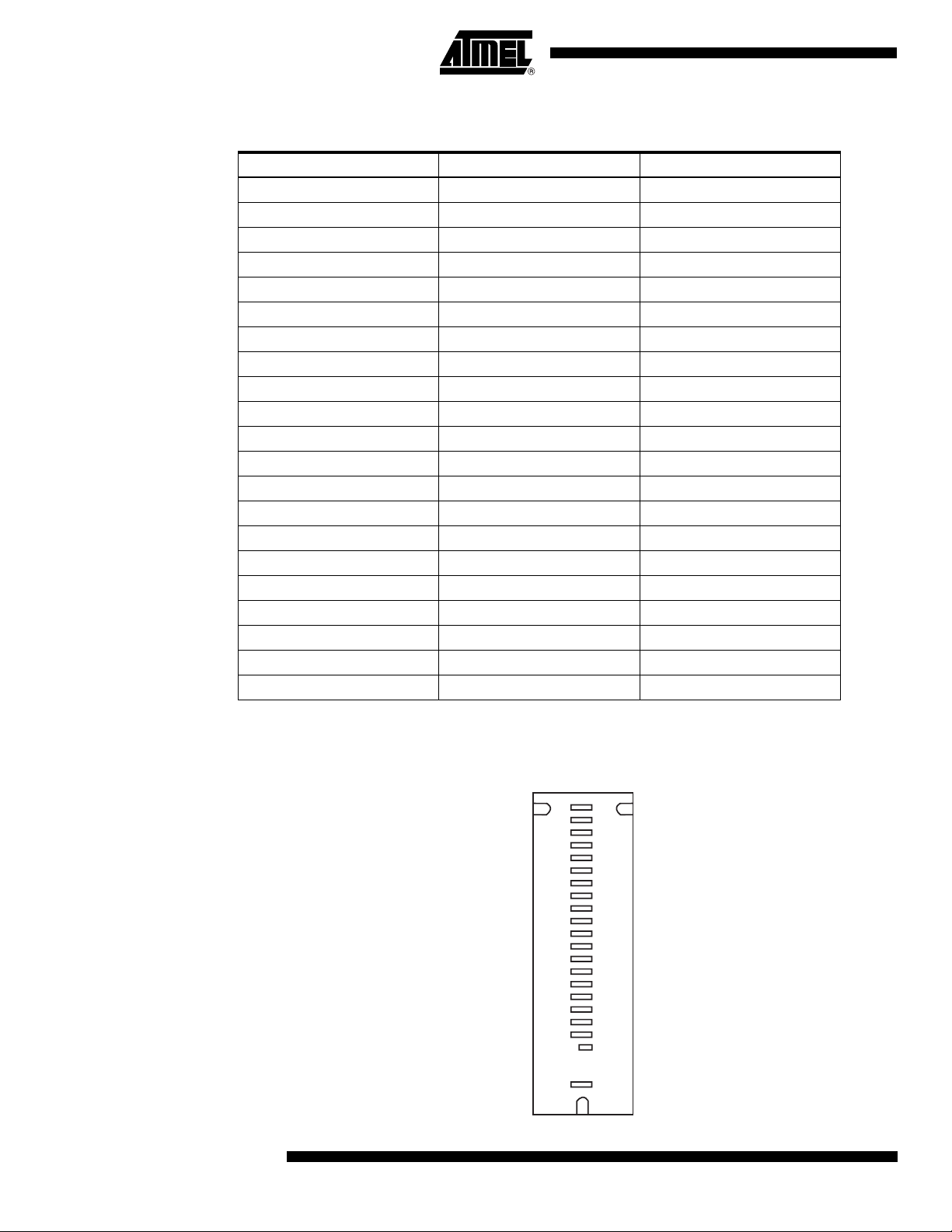

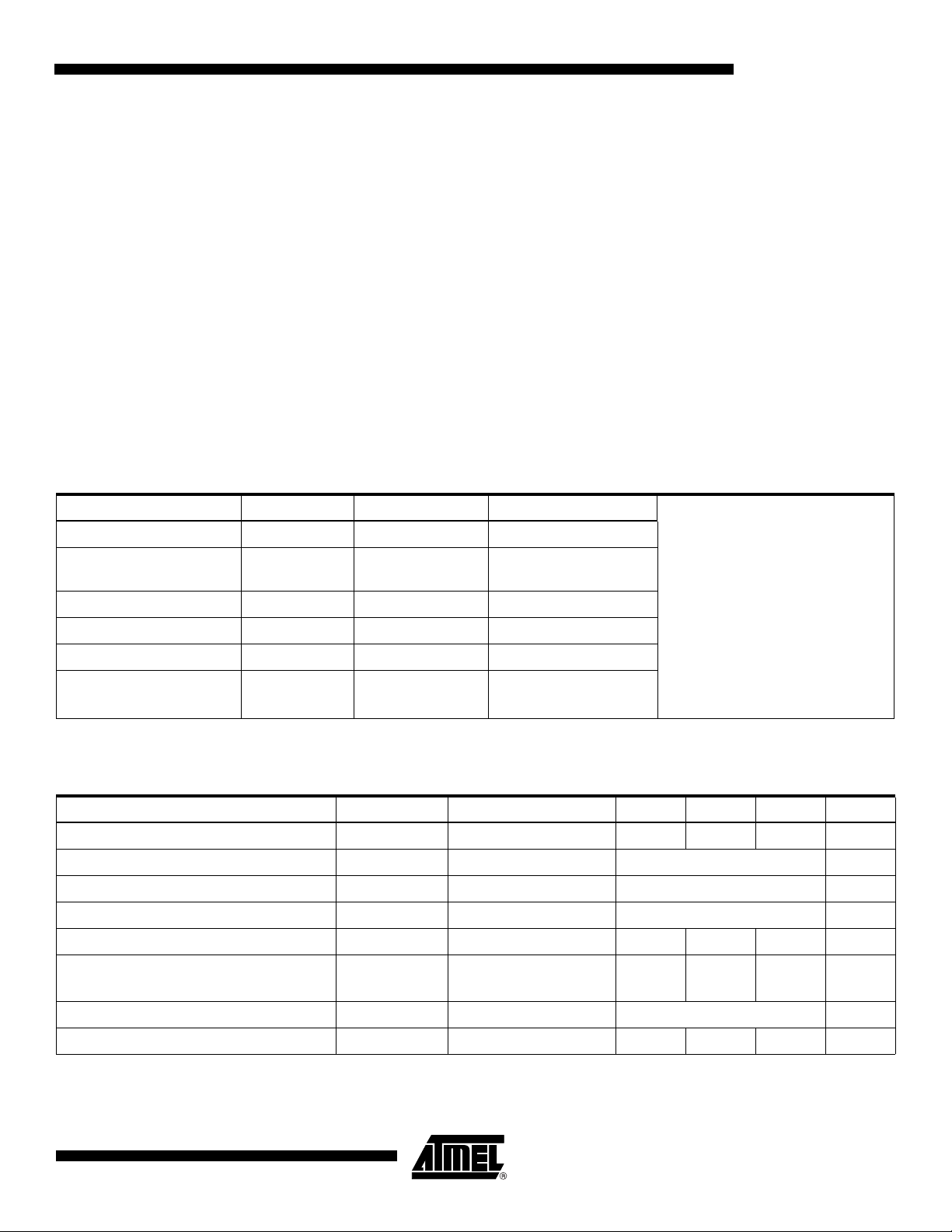

Table 2-1. Pin Description for Chip-on-Board Package: AT77C102B-CB01YV

Pin Number Name Type

1GNDGND

2 AVE Analog output

3 AVO Analog output

4TPPPower

5 TPE Digital input

6VCCPower

7GNDGND

8 RST Digital input

9 PCLK Digital input

10 OE Digital input

11 ACKN Digital output

12 De0 Digital output

13 Do0 Digital output

14 De1 Digital output

15 Do1 Digital output

16 De2 Digital output

17 Do2 Digital output

18 De3 Digital output

19 Do3 Digital output

20 FPL GND

21 GND GND

The die attach is connected to pins 1, 7 and 21, and must be grounded. The FPL pin must be

grounded.

GND

AVE

AVO

TPP

TPE

VCC

GND

RST

PCLK

OE

ACKN

De0

Do0

De1

Do1

De2

Do2

De3

Do3

FPL

GND

2

AT77C102B

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

5364A–BIOM–09/05

Page 3

AT77C102B

Table 2-2. Pin Description for COB with Connector Package: AT77C102B-CB02YV

Pin Number Name Type

1FPLGND

2 Not connected

3 Not connected

4 DE3 Digital output

5 DO3 Digital output

6 DE2 Digital output

7 DO2 Digital output

8 DE1 Digital output

9 DO1 Digital output

10 DE0 Digital output

11 DO0 Digital output

12 AVE Analog output

13 AVO Analog output

14 TPP Power

15 TPE Digital input

16 VCC Power

17 GND GND

(1)

18 RST Digital input

19 PCLK Digital input

20 OE Digital input

21 ACKN Digital output

Note: 1. Ref. Connector: FH18-21S-0.3SHW (HIROSE).

5364A–BIOM–09/05

3

Page 4

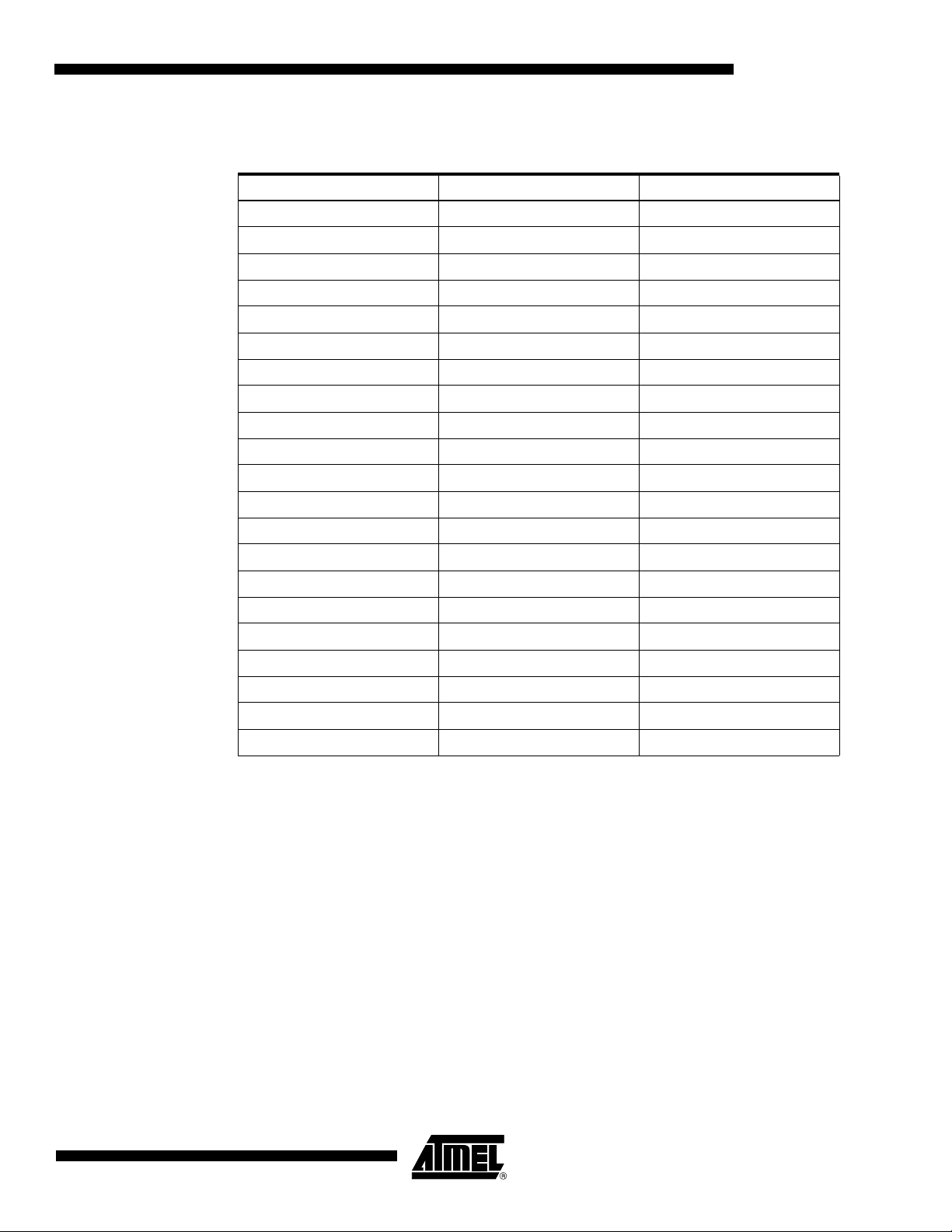

Figure 2-2. COB with Flex

(1)

Flex with metallizations up

Flex with metallizations down

Figure 2-3. Flex Output Side

1

3

Note: 1. Flex is not provided by Atmel.

(FingerChip Connector Side)

Flex Output

Metallizations Up

2

4

AT77C102B

5364A–BIOM–09/05

Page 5

3. Description

AT77C102B

The AT77C102B is part of the Atmel FingerChip monolithic fingerprint sensor family for which no

optics, no prism and no light source are required.

The AT77C102B is a single-chip, high-performance, low-cost sensor based on temperature

physical effects for fingerprint sensing.

The AT77C102B has a linear shape, which captures a fingerprint image by sweeping the finger

across the sensing area. After capturing several images, Atmel proprietary software can reconstruct a full 8-bit fingerprint image.

The AT77C102B has a small surface combined with CMOS technology, and a Chip-on-Board

package assembly. These facts contribute to a low-cost device.

The device delivers a programmable number of images per second, while an integrated analogto-digital converter delivers a digital signal adapted to interfaces such as an EPP parallel port, a

USB microcontroller or directly to microprocessors. No frame grabber or glue interface is therefore necessary to send the frames. These facts make AT77C102B an easy device to include in

any system for identification or verification applications.

Table 3-1. Absolute Maximum Ratings

()

Parameter Symbol Comments Value

Positive supply voltage V

Temperature stabilization

power

CC

TPP GND to 4.6

Front plane FPL GND to V

Digital input voltage RST PCLK GND to V

Storage temperature T

Lead temperature

(soldering, 10 seconds)

T

stg

leads

Do not solder Forbidden

GND to 4.6 Note: Stresses beyond those listed

under “Absolute Maximum Ratings”

may cause permanent damage to the

device. These are stress ratings only

CC

CC

-50 to +95

+0.5

+0.5

and functional operation of the device at

these or any other conditions beyond

those indicated in the operational

sections of this specification is not

implied. Exposure to absolute

maximum rating conditions for extended

periods may affect device reliability.

Table 3-2. Recommended Conditions Of Use

Parameter Symbol Comments Min Typ Max Unit

Positive supply voltage V

CC

Front plane FPL Must be grounded GND V

Digital input voltage CMOS levels V

Digital output voltage CMOS levels V

Digital load C

Analog load

Operating temperature range T

C

R

amb

L

A

A

Not connected

V grade -40°C to +85°C°C

Maximum current on TPP ITPP 0 100 mA

3V 3.3V 3.6V V

50 pF

pF

kΩ

5364A–BIOM–09/05

5

Page 6

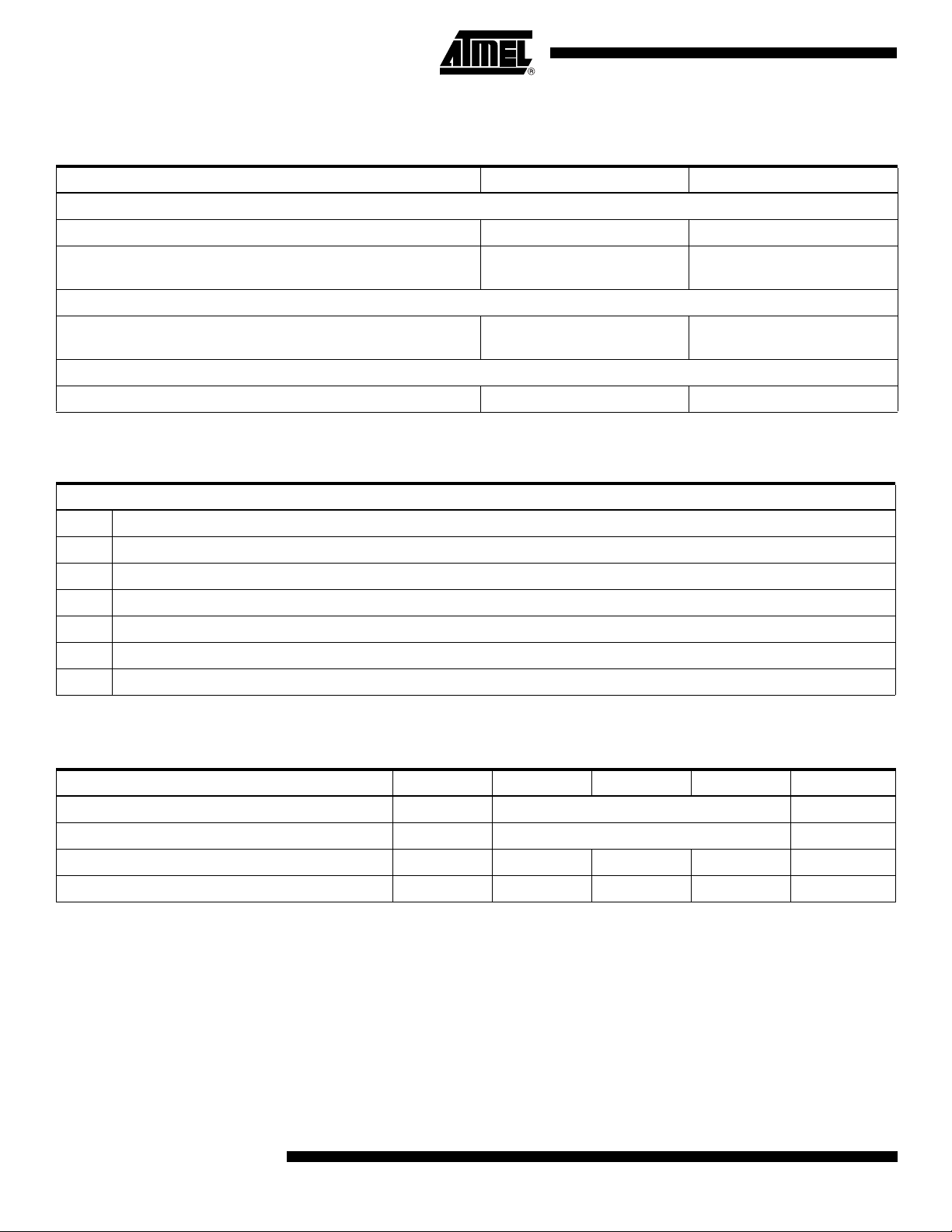

Table 3-3. Resistance

Parameter Min Value Standard Method

ESD

On pins. HBM (Human Body Model) CMOS I/O 2 kV MIL-STD-883 - method 3015.7

On die surface (Zapgun)

Air discharge

Mechanical Abrasion

Number of cycles without lubricant multiply by an estimated factor

of 20 for correlation with a real finger

Chemical Resistance

Cleaning agent, acid, grease, alcohol, diluted acetone 4 hours Internal method

±16 kV

200 000 MIL E 12397B

NF EN 6100-4-2

Table 3-4. Specifications

Explanation Of Test Levels

I 100% production tested at +25°C

II 100% production tested at +25°C, and sample tested at specified temperatures (AC testing done on sample)

III Sample tested only

IV Parameter is guaranteed by design and/or characterization testing

V Parameter is a typical value only

VI 100% production tested at temperature extremes

D 100% probe tested on wafer at T

= +25°C

amb

Table 3-5. Physical Parameter

Parameter Test Level Min Typ Max Unit

Resolution IV 50 µm

Size IV 8 x 280 Pixel

Yield: number of bad pixels I 5 Bad pixels

Equivalent resistance on TPP pin I 20 30 47 Ω

6

AT77C102B

5364A–BIOM–09/05

Page 7

AT77C102B

.

Table 3-6. 3.3V Power supply

The following characteristics are applicable to the operating temperature -40°C ≤ Ta ≤ +85°C

Typical conditions are: V

C

120 pF on digital outputs, analog outputs disconnected unless otherwise specified

load

Parameter Symbol Test Level Min Typ Max Unit

Power Requirements

= +3.3 V; T

CC

= 25°C; F

amb

= 1 MHz; Duty cycle = 50%

PCLK

Positive supply voltage V

Active current on V

Current on V

CC

Power dissipation on V

= 0

C

load

Current on V

CC

pin, 1 MHz

CC

pin, in static mode C

CC

load

= 0 pF

in NAP mode I

CCNAP

CC

I

CC

P

CC

I

IV

I

IV

I10µA

3.0 3.3 3.6 V

5

4

16

13

Analog Output

Voltage range V

AVx

IV 0 2.9 V

Digital Inputs

Logic compatibility CMOS

Logic “0” voltage V

Logic “1” voltage V

Logic “0” current I

Logic “1”current I

TPE logic “0” voltage I

TPE logic “1” voltage I

IL

IH

IL

IH

IL

IH

TPE 1 -10 0 µA

TPE 1 0 300 µA

I0 0.8V

I2.3 VCCV

I-10 0µA

I 0 10 µA

Digital Outputs

Logic compatibility CMOS

Logic “0” voltage

Logic “1” voltage

(1)

(1)

V

OL

V

OH

I0.6V

I2.4 V

25

18

7

5

mA

mA

mW

mW

Note: 1. With IOL = 1 mA and IOH = -1 mA

5364A–BIOM–09/05

7

Page 8

Table 3-7. Switching Performances

.

The following characteristics are applicable to the operating temperature -40°C ≤ Ta ≤ +85°C

Typical conditions are: nominal voltage; T

C

120 pF on digital and analog outputs unless otherwise specified

load

Parameter Symbol Test Level Min Typ Max Unit

= 25°C; F

amb

= 1 MHz; Duty cycle = 50%

PCLK

Clock frequency f

Clock pulse width (high) t

Clock pulse width (low) t

Clock setup time (high)/reset falling edge t

No data change t

Reset pulse width high t

PCLK

HCLK

LCLK

Setup

NOOE

HRST

I0.512MHz

I 250 ns

I 250 ns

I0ns

IV 100 ns

IV 50 ns

Table 3-8. 3.3V ±10% Power Supply

Parameter Symbol Test Level Min Typ Max Unit

Output delay from PCLK to ACKN rising edge t

Output delay from PCLK to ACKN falling edge t

Output delay from PCLK to data output Dxi t

Output delay from PCLK to analog output AVx t

Output delay from OE to data high-Z t

Output delay from OE to data output t

PLHACKN

PHLACKN

PDATA

PAV I D EO

DATA Z

ZDATA

I 145 ns

I 145 ns

I 120 ns

I 250 ns

IV 34 ns

IV 47 ns

Figure 3-1. Reset

8

Reset RST

Clock PCLK

AT77C102B

t

HRST

t

SETUP

5364A–BIOM–09/05

Page 9

Figure 3-2. Read One Byte/Two Pixels

f

PCLK

AT77C102B

Clock

PCLK

Acknowledge

ACKN

Data output

Do0-3, De0-3

Video analog output

AVO, AVE

Figure 3-3. Output Enable

t

HCLK

t

PLHACKN

Data #N

Data #N-1

t

PAVIDEO

t

LCLK

t

PHLACKN

Data #N

Data #N+1

t

PDATA

Data #N+1

Data #N+2

Output enable

OE

Data output

Do0-3, De0 -3

t

ZDATA

Hi-Z

Data output

t

DATAZ

Hi-Z

5364A–BIOM–09/05

9

Page 10

Figure 3-4. No Data Change

t

PCLK

OE

NOOE

Note: OE must not change during TNOOE after the PCLK falls. This is to ensure that the output drivers of the data are not driving cur-

rent, so as to reduce the noise level on the power supply.

Figure 3-5. AT77C102B Block Diagram

PCLK

RST

Column selection

1

8 lines of 280 columns of pixels

8

Chip temperature

stabilizati

TPP

3.1 Functional Description

The circuit is divided into two main sections: sensor and data conversion. One particular column

among 280 plus one is selected in the sensor array (1), then each pixel of the selected column

sends its electrical information to the amplifiers (2) [one per line], then two lines at a time are

selected (odd and even) so that two particular pixels send their information to the input of two 4bit analog-to-digital converters (3), so two pixels can be read for each clock pulse (4).

on

Clock

Reset

1 dummy colum

n

2240

temperature

8

Chip

sensor

Line sel

Amp

Ev

en

Odd

Analog

output

4-bit

ADC

4-bit

ADC

ACKN

4

8

Latches

4

Output

enable

OEAVE AVOTPE

De0-3

Do0-3

10

AT77C102B

5364A–BIOM–09/05

Page 11

Figure 3-6. Functional Description

AT77C102B

1 2 3 4

Column selection Line sel

8 lines of 280 columns of pixels

1 dummy colum

Amp

8

n

Chip

temperature

sensor

Ev

en

Odd

4-bit

ADC

4-bit

ADC

4

8

latches

4

3.2 Sensor

Each pixel is a sensor in itself. The sensor detects a temperature difference between the beginning of an acquisition and the reading of the information: this is the integration time. The

integration time begins with a reset of the pixel to a predefined initial state. Note that the integration time reset has nothing to do with the reset of the digital section.

Then, at a rate depending on the sensitivity of the pyroelectric layer, on the temperature variation between the reset and the end of the integration time, and for the duration of the integration

time, electrical charges are generated at the pixel level.

3.3 Analog-to-digital Converter/ Reconstructing an 8-bit Fingerprint Image

An analog-to-digital converter (ADC) is used to convert the analog signal coming from the pixel

into digital data that can be used by a processor.

De0-3

Do0-3

As the data rate for the parallel port and the USB is in the range of 1 MB per second, and at least

a rate of 500 frames per second is needed to reconstruct the image with a fair sweeping speed

of the finger, two 4-bit ADCs have been used to output two pixels at a time on one byte.

3.4 Start Sequence

A reset is not necessary between each frame acquisition.

The start sequence must consist in:

1. Setting the RST pin to high.

2. Setting the RST pin to low.

3. Sending 4 clock pulses (due to pipe-line).

4. Sending clock pulses to skip the first frame.

Note that after a reset it is recommended to skip the first 200 slices to stabilize the acquisition.

Figure 3-7. Start Sequence

Reset RS

Clock PCLK

T 4 + 1124 clock pulses to skip the first frame

1431 2 11124

5364A–BIOM–09/05

11

Page 12

3.5 Reading the Frames

A frame consists of 280 true columns plus one dummy column of eight pixels. As two pixels are

output at a time, a system must send 281 x 4 = 1124 clock pulses to read one frame.

Reset must be low when reading the frames.

3.6 Read One Byte/Output Enable

The clock is taken into account on its falling edge and data is output on its rising edge.

For each clock pulse, after the start sequence, a new byte is output on the Do0-3 and De0-3

pins. This byte contains two pixels: 4-bit on Do0-3 (odd pixels), 4-bit on De0-3 (even pixels).

To output the data, the output enable (OE) pin must be low. When OE is high, the Do0-3 and

De0-3 pins are in high-impedance state. This facilitates an easy connection to a microprocessor

bus without additional circuitry since the data output can be enabled using a chip select signal.

Note that the AT77C102B always sends data: there is no data exchange to switch to read/write

mode.

3.7 Power Supply Noise

IMPORTANT: When a falling edge is applied on OE (that is when the Output Enable becomes

active), then some current is drained from the power supply to drive the eight outputs, producing

some noise. It is important to avoid such noise just after the PCLK clock’s falling edge, when the

pixels’ information is evaluated: the timing diagram (Figure 3-2) and time T

val time when the power supply must be as quiet as possible.

define the inter-

NOOE

3.8 Video Output

3.9 Pixel Order

Figure 3-8. Pixel Order

Pixel #1 (1,1)

Pixel #8 (1,8)

An analog signal is also available on pins AVE and AVO. Note that video output is available one

clock pulse before the corresponding digital output (one clock pipe-line delay for the analog to

digital conversion).

After a reset, pixel 1 is located on the upper left corner, looking at the chip with bond pads to the

right. For each column of eight pixels, pixels 1, 3, 5 and 7 are output on odd data Do0-3 pins,

and pixels 2, 4, 6 and 8 are output on even data De0-3 pins. The Most Significant Bit (MSB) is bit

3, and the Least Significant Bit is bit 0.

Pixel #2233 (280,1)

ads

p

B ond

Pixel #2240 (280,8)

12

AT77C102B

5364A–BIOM–09/05

Page 13

3.10 Synchronization: The Dummy Column

A dummy column has been added to the sensor to act as a specific pattern to detect the first

pixel. Therefore, 280 true columns plus one dummy column are read for each frame.

The four bytes of the dummy column contain a fixed pattern on the first two bytes, and temperature information on the last two bytes.

Table 1. Dummy Column Description

Dummy Byte Odd Even

Dummy Byte 1 DB1: 111X 0000

Dummy Byte 2 DB2: 111X 0000

Dummy Byte 3 DB3: rrrr nnnn

Dummy Byte 4 DB4: tttt pppp

Note: x represents 0 or 1

The sequence 111X0000 111X0000 appears on every frame (exactly every 1124 clock pulses),

so it is an easy pattern to recognize for synchronization purposes.

3.11 Thermometer

The dummy bytes DB3 and DB4 contain some internal temperature information.

AT77C102B

The even nibble nnnn in DB3 can be used to measure an increase or decrease of the chip’s temperature, using the difference between two measures of the same physical device. The following

table gives values in Kelvin.

Table 1. Temperature Table

nnnn

Decimal

15 1111

14 1110

13 1101

12 1100

11 1011

10 1010

9 1001

8 1000

7 0111

6 0110

5 0101

4 0100

3 0011

2 0010

1 0001

0 0000

nnnn

Binary

Temperature differential with code 8

in Kelvin

> 11.2

8.4

7

5.6

4.2

2.8

1.4

0

-1.4

-2.8

-4.2

-5.6

-7

-8.4

-11.2

< -16.8

5364A–BIOM–09/05

13

Page 14

For code 0 and 15, the absolute value is a minimum (saturation).

When the image contrast becomes faint because of a low temperature difference between the

finger and the sensor, it is recommended to use the temperature stabilization circuitry to

increase the temperature by two codes (that is from 8 to 10), so as to obtain a sensor increase of

at least >1.4 Kelvin. This enables enough contrast to obtain a proper fingerprint reconstruction.

3.12 Integration Time and Clock Jitter

The AT77C102B is not very sensitive to clock jitters (clock variations). The most important

requirement is a regular integration time that ensures the frame reading rate is also as regular as

possible, so as to obtain consistent fingerprint slices.

If the integration time is not regular, the contrast can vary from one frame to another.

Note that it is possible to introduce some waiting time between each set of 1124 clock pulses,

but the overall time of one frame read must be regular. This waiting time is generally the time

needed by the processor to perform some calculation over the frame (to detect the finger, for

instance).

Figure 3-9. Read One Frame

Reset RST is lo

Clock PCLK

w

123456 112411231122112111201119

Column 1 Column 2 Column 280 Dummy Column 281

Pixels 1 & 2 3 & 4 5 & 6 7 & 8 1 & 2 3 & 4 7 & 8 DB1 DB2 DB3 DB

Figure 3-10. Regular Integration Time

Frame n

Clock PCLK

1124 pulses

3.13 Power Management

3.14 Nap Mode

Several strategies are possible to reduce power consumption when the device is not in use.

The simplest and most efficient is to cut the power supply using external means.

A nap mode is also implemented in the AT77C102B. To activate this nap mode, you must:

1. Set the reset RST pin to high. By doing this, all analog sections of the device are internally powered down.

2. Set the clock PCLK pin to high (or low), thus stopping the entire digital section.

3. Set the TPE pin to low to stop the temperature stabilization feature.

4. Set the Output Enable OE pin to high, so that the output is forced in HiZ.

REGULAR INTEGRATION TIME

Frame n+1

1124 pulses

Frame n+2

1124 pulses

Frame n+3

1124 pulse

4

s

14

AT77C102B

5364A–BIOM–09/05

Page 15

Figure 3-11. Nap Mode

AT77C102B

Nap mode

Reset RS

Clock PCLK

T

Nap

In nap mode, all internal transistors are in shut mode. Only leakage current is drained in the

power supply, generally less than the tested value.

3.15 Static Current Consumption

When the clock is stopped (set to 1) and the reset is low (set to 0), the device’s analog sections

drain some current, whereas, if the outputs are connected to a standard CMOS input, the digital

section does not consume any current (no current is drained in the I/O). In this case the typical

current value is 5 mA. This current does not depend on the voltage (it is almost the same from 3

to 3.6V).

3.16 Dynamic Current Consumption

When the clock is running, the digital sections, and particularly the outputs if they are heavily

loaded, consume current. In any case, the current should be less than the testing machine (120

pF load on each I/O), and a maximum of 50 pF is recommended.

The AT77C102B, running at about 1 MHz, consumes less than 7 mA on the V

3.17 Temperature Stabilization Power Consumption (TPP Pin)

When the TPE pin is set to 1, current is drained via the TPP pin. The current is limited by the

internal equivalent resistance given in Table 3-4 on page 6 and a possible external resistor.

CC

pin.

Most of the time, TPE is set to 0 and no current is drained in TPP. When the image contrast

becomes low because of a low temperature differential (less than 1 Kelvin), then it is recommended to set TPE to 1 for a short time so that the dissipated power in the chip elevates the

temperature, allowing contrast recovery. The necessary time to increase the chip’s temperature

by one Kelvin depends on the dissipated power, the thermal capacity of the silicon sensor and

the thermal resistance between the sensor and its surroundings. As a rule of thumb, dissipating

300 mW in the chip elevates the temperature by 1 Kelvin in one second. With the 30Ω typical

value, 300 mW is 3V applied on TPP. If the power supply is 3.6V, an external resistor must be

added in the application to limit the current under 100 mA.

5364A–BIOM–09/05

15

Page 16

4. Packaging: Mechanical Data

Figure 4-1. Product Reference: AT77C102B-CB01YV

TOP VIEW

SCALE 10/1

SIDE VIEW

SCALE 10/1

A

0.2 A

0.89 ±0.3

2.33 ±0.5

1.64

0.74 ±0.06

+0.07

At 0.4 heigh from B ref.

-0.01

0.32

Top View (all dimensions in mm)

1

4

min

0.2

26.6 ±0.3

0.2

max

max

5.20

Dam and Fill

5.90

max

1.5

max.

2.95 ±0.50

9 ±0.3

0.82 ±0.50

B

0.82 ±0.18

Figure 4-2. Product Reference: AT77C102B-CB01YV

Bottom View (All dimensions in mm)

+

_

0.08

+0.08

-0.12

(x3)

(x3)

1

+

_

0.08

0.5

6.30

+

_

0.15

1.15

+

_

2.15 0.15

+

_

0.1

+0.33

0.75

- 0.25

RO. 75

+0.15

1.5

- 0.23

23.85

+

_

0.08

3.5

+

_

0.15

1

+

_

0.08

1.5

+

_

0.08

2

+

_

0.15

2

+

_

0.1

16

AT77C102B

5364A–BIOM–09/05

Page 17

Figure 4-3. Product Reference: AT77C102B-CB02YV

All Dimensions in mm

9.85 ±0.3

5.9 max

5.2 max

14.32

AT77C102B

+0.04

-0.01

FLEX OUTPUT

2.9±0.5

1.5 MAX

0.2 min

4.1 Package Information

Scale 4/1

1.9±0.4

4.1 ±0.2

0.18

±

0.82

)

3

(x

+0.15

-0.23

1.5

A

1.64

+0.07

-0.01

8.9 ±0.5

8.8 ±0.2

1.25 ±0.5

26.6 ±0.3

FLEX OUTPUT

0.75

+0.33

-0.25

2.39 ±0.5

R0.75

0.08

+

-0.12

(x 3)

+

_

0.74 0.06

±0.5

4.1

(x 2)

6.3 ±0.1

1.78 ±0.5

A

4.1.1 Electrical Disturbances

When looking at the fingerchip device from the top with the glob top to the right, the right edge

must never be in contact with customer casing or any component to avoid electrical

disturbances.

Figure 4-4. Epoxy Overflow

Maximum epoxy overflow width: 0.55 mm on the die edge.

Maximum epoxy overflow thickness: 0.33 mm.

Note: Refer to Figure 4-1 on page 16.

5364A–BIOM–09/05

AA Section

Fingerchip

0.55

0.33

Epoxy Glue Overflow

17

Page 18

5. Ordering Information

5.1 Package Device

Atmel prefix

FingerChip family

Device type

Package

CB01: Chip On Board (COB)

CB02: COB with connector

AT77C 102B- —

CBXX

VY

Quality level:

— : standard

Temperature range

o

V: -40

C to +85o C

RoHS compliant

18

AT77C102B

5364A–BIOM–09/05

Page 19

Atmel Corporation Atmel Operations

2325 Orchard Parkway

San Jose, CA 95131, USA

Tel: 1(408) 441-0311

Fax: 1(408) 487-2600

Regional Headquarters

Europe

Atmel Sarl

Route des Arsenaux 41

Case Postale 80

CH-1705 Fribourg

Switzerland

Tel: (41) 26-426-5555

Fax: (41) 26-426-5500

Asia

Room 1219

Chinachem Golden Plaza

77 Mody Road Tsimshatsui

East Kowloon

Hong Kong

Tel: (852) 2721-9778

Fax: (852) 2722-1369

Japan

9F, Tonetsu Shinkawa Bldg.

1-24-8 Shinkawa

Chuo-ku, Tokyo 104-0033

Japan

Tel: (81) 3-3523-3551

Fax: (81) 3-3523-7581

Memory

2325 Orchard Parkway

San Jose, CA 95131, USA

Tel: 1(408) 441-0311

Fax: 1(408) 436-4314

Microcontrollers

2325 Orchard Parkway

San Jose, CA 95131, USA

Tel: 1(408) 441-0311

Fax: 1(408) 436-4314

La Chantrerie

BP 70602

44306 Nantes Cedex 3, France

Tel: (33) 2-40-18-18-18

Fax: (33) 2-40-18-19-60

ASIC/ASSP/Smart Cards

Zone Industrielle

13106 Rousset Cedex, France

Tel: (33) 4-42-53-60-00

Fax: (33) 4-42-53-60-01

1150 East Cheyenne Mtn. Blvd.

Colorado Springs, CO 80906, USA

Tel: 1(719) 576-3300

Fax: 1(719) 540-1759

Scottish Enterprise Technology Park

Maxwell Building

East Kilbride G75 0QR, Scotland

Tel: (44) 1355-803-000

Fax: (44) 1355-242-743

RF/Automotive

Theresienstrasse 2

Postfach 3535

74025 Heilbronn, Germany

Tel: (49) 71-31-67-0

Fax: (49) 71-31-67-2340

1150 East Cheyenne Mtn. Blvd.

Colorado Springs, CO 80906, USA

Tel: 1(719) 576-3300

Fax: 1(719) 540-1759

Biometrics/Imaging/Hi-Rel MPU/

High Speed Converters/RF Datacom

Avenue de Rochepleine

BP 123

38521 Saint-Egreve Cedex, France

Tel: (33) 4-76-58-30-00

Fax: (33) 4-76-58-34-80

Literature Requests

www.atmel.com/literature

DDisclaimer: The information in this document is provided in connection with Atmel products. No license, express or implied, by estoppel or otherwise, to any

intellectual property right is granted by this document or in connection with the sale of Atmel products. EXCEPT AS SET FORTH IN ATMEL’S TERMS AND CONDI-

TIONS OF SALE LOCATED ON ATMEL’S WEB SITE, ATMEL ASSUMES NO LIABILITY WHATSOEVER AND DISCLAIMS ANY EXPRESS, IMPLIED OR STATUTORY

WARRANTY RELATING TO ITS PRODUCTS INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTY OF MERCHANTABILITY, FITNESS FOR A PARTICULAR

PURPOSE, OR NON-INFRINGEMENT. IN NO EVENT SHALL ATMEL BE LIABLE FOR ANY DIRECT, INDIRECT, CONSEQUENTIAL, PUNITIVE, SPECIAL OR INCIDENTAL DAMAGES (INCLUDING, WITHOUT LIMITATION, DAMAGES FOR LOSS OF PROFITS, BUSINESS INTERRUPTION, OR LOSS OF INFORMATION) ARISING OUT

OF THE USE OR INABILITY TO USE THIS DOCUMENT, EVEN IF ATMEL HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES. Atmel makes no

representations or warranties with respect to the accuracy or completeness of the contents of this document and reserves the right to make changes to specifications

and product descriptions at any time without notice. Atmel does not make any commitment to update the information contained herein. Unless specifically provided

otherwise, Atmel products are not suitable for, and shall not be used in, automotive applications. Atmel’s products are not intended, authorized, or warranted for use

as components in applications intended to support or sustain life.

© Atmel Corporation 2005. All rights reserved. Atmel®, logo and combinations thereof, Everywhere You Are®, FingerChp® and others, are

registered trademarks or trademarks of Atmel Corporation or its subsidiaries. Other terms and product names may be trademarks of others.

Printed on recycled paper.

5364A–BIOM–09/05

Loading...

Loading...