Page 1

Features

• ARM7TDMI

• Two 16-bit Fixed-point OakDSPCore

• 256 x 32-bit Boot ROM

• 88K Bytes of Integrated Fast RAM for Each DSP

• Flexible External Bus Interface with Programmable Chip Selects

• Dual Codec Interface

• Multi-level Priority, Individually Maskable, Vectored Interrupt Controller

• Three 16-bit Timer/Counters

• Additional Watchdog Timer

• Two USARTs with FIFO and Modem Control Lines

• Industry-standard Serial Peripheral Interface

• Up to 23 General-purpose I/O Pins

• On-chip DRAM Controller

• JTAG Debug Interface

• Software Development Tools Available for ARM7TDMI and OakDSPCore

• Supported by a Wide Range of Ready-to-use Application Software, including

Multitasking Operating System, Networking, Modems and Voice-processing Functions

• Available in a 160-lead PQFP Package

• 3.3V Power Supply

™

ARM® Thumb® Processor Core

®

Cores

Description

The Atmel AT75C310 Smart Internet Appliance Processor (SIAP™) is a high-performance processor designed for internet appliance applications such as Internet Telephony (Voice over Internet Protocol – VoIP). The AT75C310 is built around an

ARM7TDMI microcontroller core running at 20 MIPS with two DSP co-processors running at 40 MIPS each. All three processors deliver unmatched performance for low

power consumption.

In a typical standalone VoIP phone, one DSP handles the voice-processing functions

(voice compression, acoustic echo cancellation, etc.) while the other deals with the

telephony functions such as dialing, line echo cancellation, caller ID detection, highspeed modem, etc. In such an application, the power of the ARM7TDMI allows it to

run the VoIP protocol stack as well as all the system control tasks.

Atmel provides the AT75C310 with three levels of software modules:

• A special port of the Linux kernel as the proposed operating system

• A comprehensive set of tunable DSP algorithms for modems and voice processing,

tailored to be run by the DSP subsystems

• A broad range of application-level software modules such as H323 telephony or

POP-3/SMTP e-mail services

Smart Internet

Appliance

Processor

(SIAP™)

AT75C310 –

CPU

Peripherals

Rev. 1369A–01/01

1

Page 2

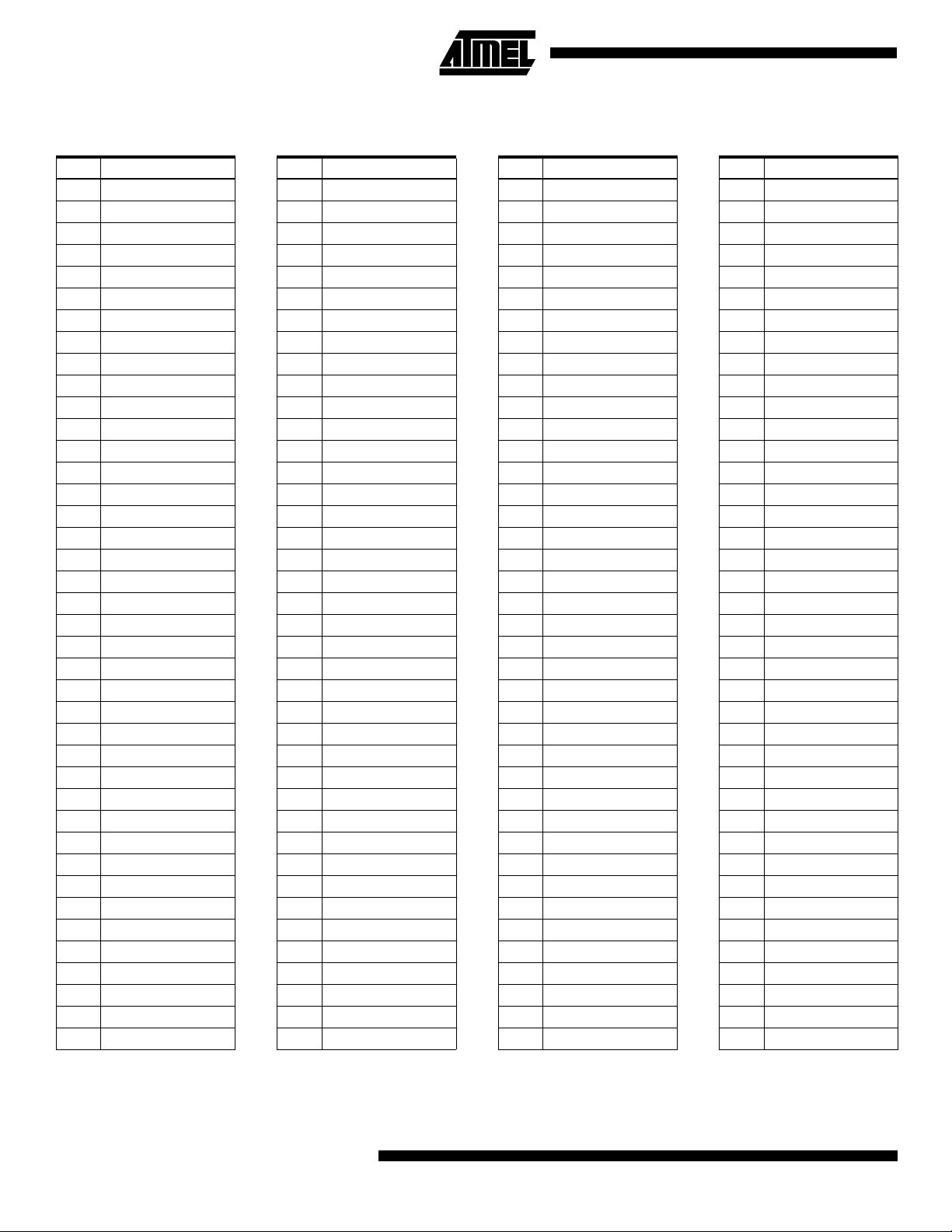

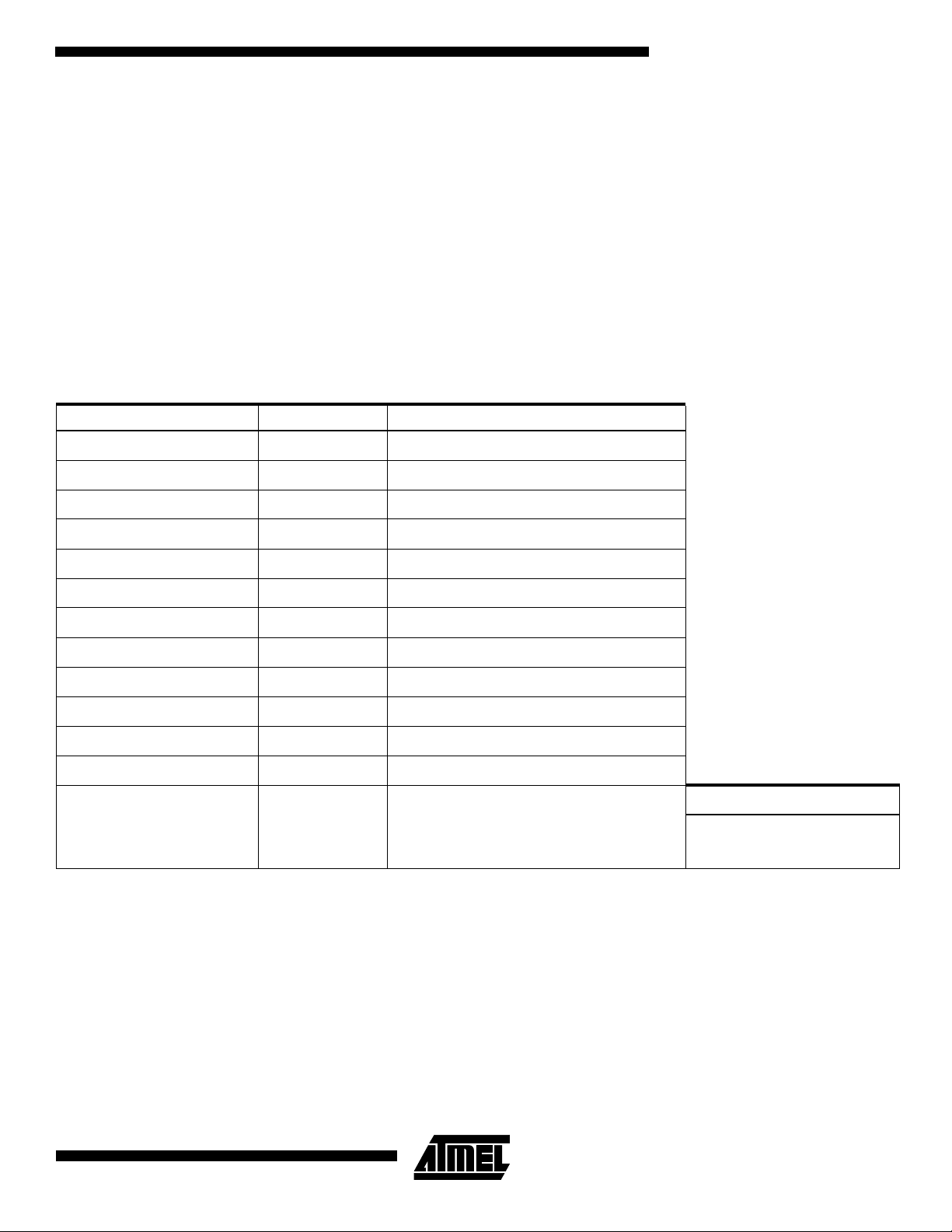

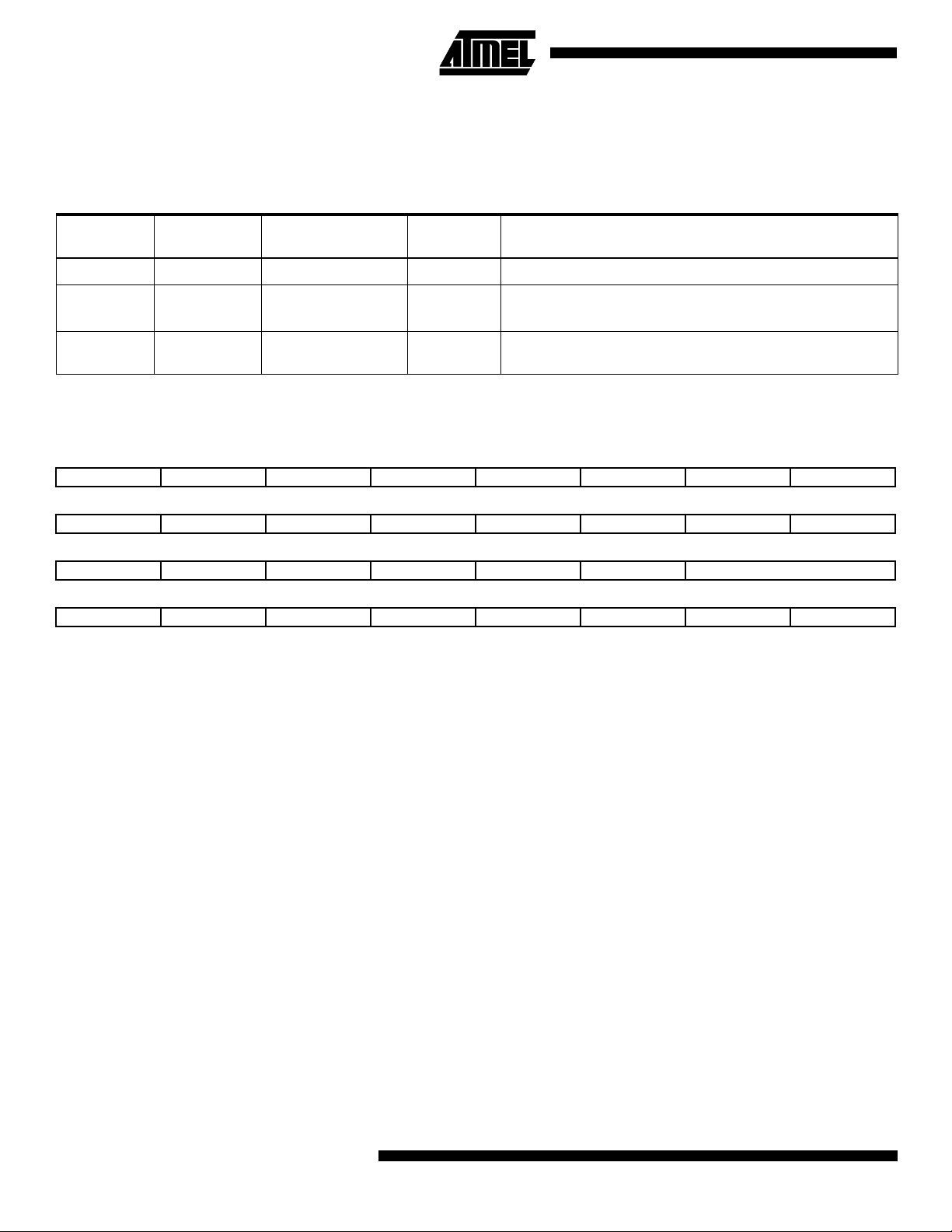

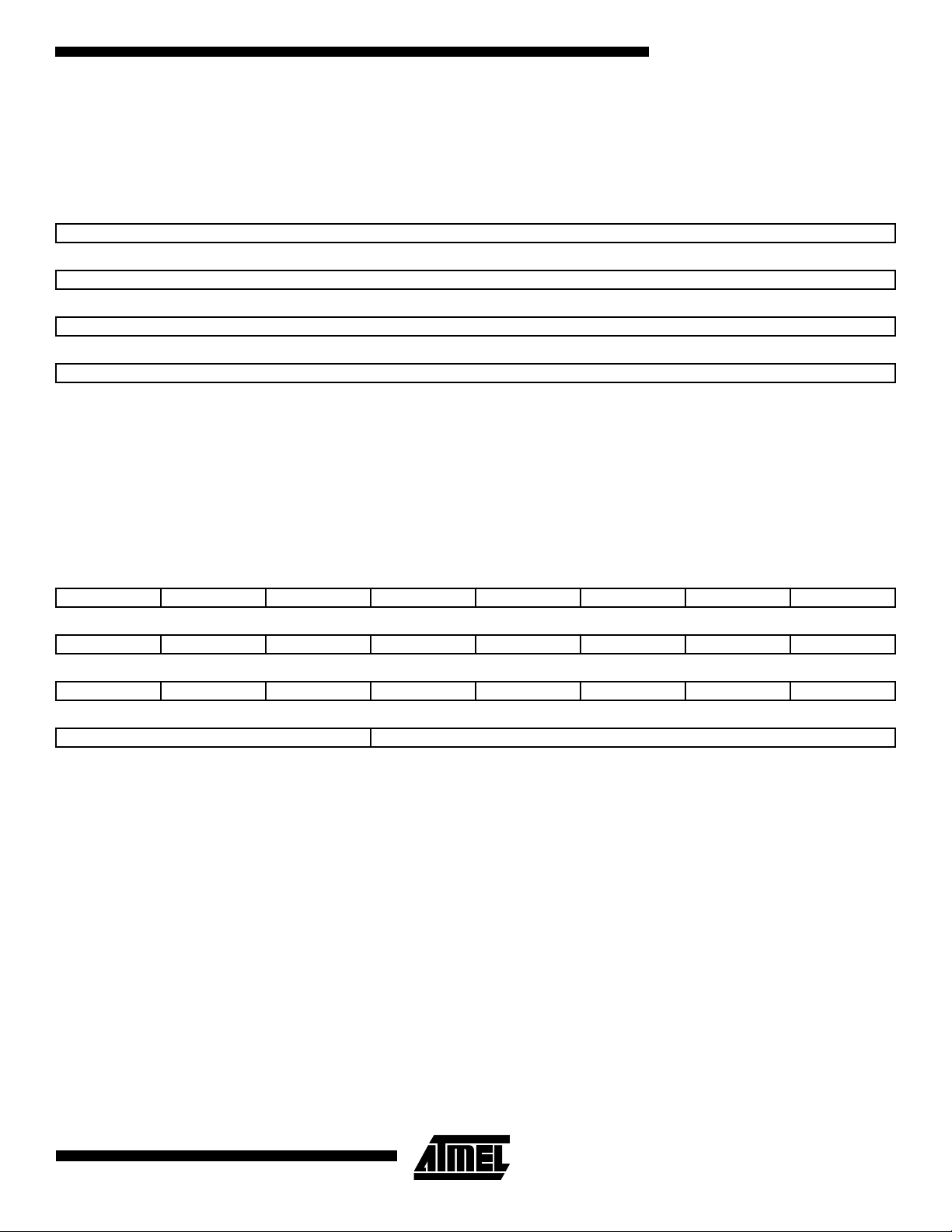

AT75C310 Pin Configuration

Table 1. AT75C310 Pinout in 160-lead PQFP Package

Pin Signal Name Pin Signal Name Pin Signal Name Pin Signal Name

VDD

1

D11

2

NCE3

3

VSS

4

NDOE

5

D12

6

D13

7

NWE0

8

D14

9

VSS

10

VDD

11

NWE1

12

D15

13

NDWE

14

VDD

15

VDD

16

VSS

17

VSS

18

VDD

19

MOSI

20

MISO

21

SPCK

22

NPCSS

23

RXDA

24

TXDA

25

VSS

26

VDD

27

NRTSA

28

NCTSA

29

NDTRA

30

NDSRA/BOOTN

31

VSS

32

VDD

33

NDCDA

34

TXDB

35

RXDB

36

VDD

37

PB7/NCE1

38

VSS

39

VSS

40

VSS

41

PB6/NWDOVF

42

PB5/NRIA

43

PB4

44

VSS

45

VDD

46

PB3

47

RESET

48

VDD

49

IRQ0

50

PB2/TIOB1

51

PB9

52

PB1/TIOA1

53

PB8/NCE2

54

PB0/TCLK1

55

VDD

56

XREF80

57

VSS

58

XTALIN

59

XTALOUT

60

VSS

61

XREF96

62

VDD

63

TST

64

NTRST

65

TCK

66

TMS

67

TDI

68

TDO

69

VSS

70

PA0/OakAIN0

71

PA1/OakAIN1

72

PA2/OakAOUT0

73

PA3/OakAOUT1

74

VSS

75

VDD

76

PA4/OakBIN0

77

PA5/OakBIN1

78

PA6/OakBOUT0

79

PA7/OakBOUT1

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

101

102

103

104

105

106

107

108

109

110

111

112

113

114

115

116

117

118

119

120

VDD

PA8/TCLK0

PA 9 /T I O A 0

VSS

PA10/TIOB0

PA11/SCLKA

VSS

PA12/NPCS1

VDD

VSS

VDD

NREQ

FIQ

NGNT

VSS

VDD

SCLKA

FSA

STXA

SRXA

A0

A1

A2

A3

VDD

A4

A5

A6

A7

VDD

VSS

A8

A9

A10

A11

A12

A13

A14

A15

VSS

121

122

123

124

125

126

127

128

129

130

131

132

133

134

135

136

137

138

139

140

141

142

143

144

145

146

147

148

149

150

151

152

153

154

155

156

157

158

159

160

VSS

A16

A17

VDD

VSS

A18

A19

A20

A21

VDD

VSS

D0

NCAS0

D1

D2

NCAS1

D3

VSS

NRAS0

D4

NRAS1

VSS

VDD

D5

SRXB

STXB

D6

FSB

VDD

VSS

D7

SCLKB

D8

NSOE

VDD

VSS

NCE0

D9

D10

VDD

2

AT75C310

Page 3

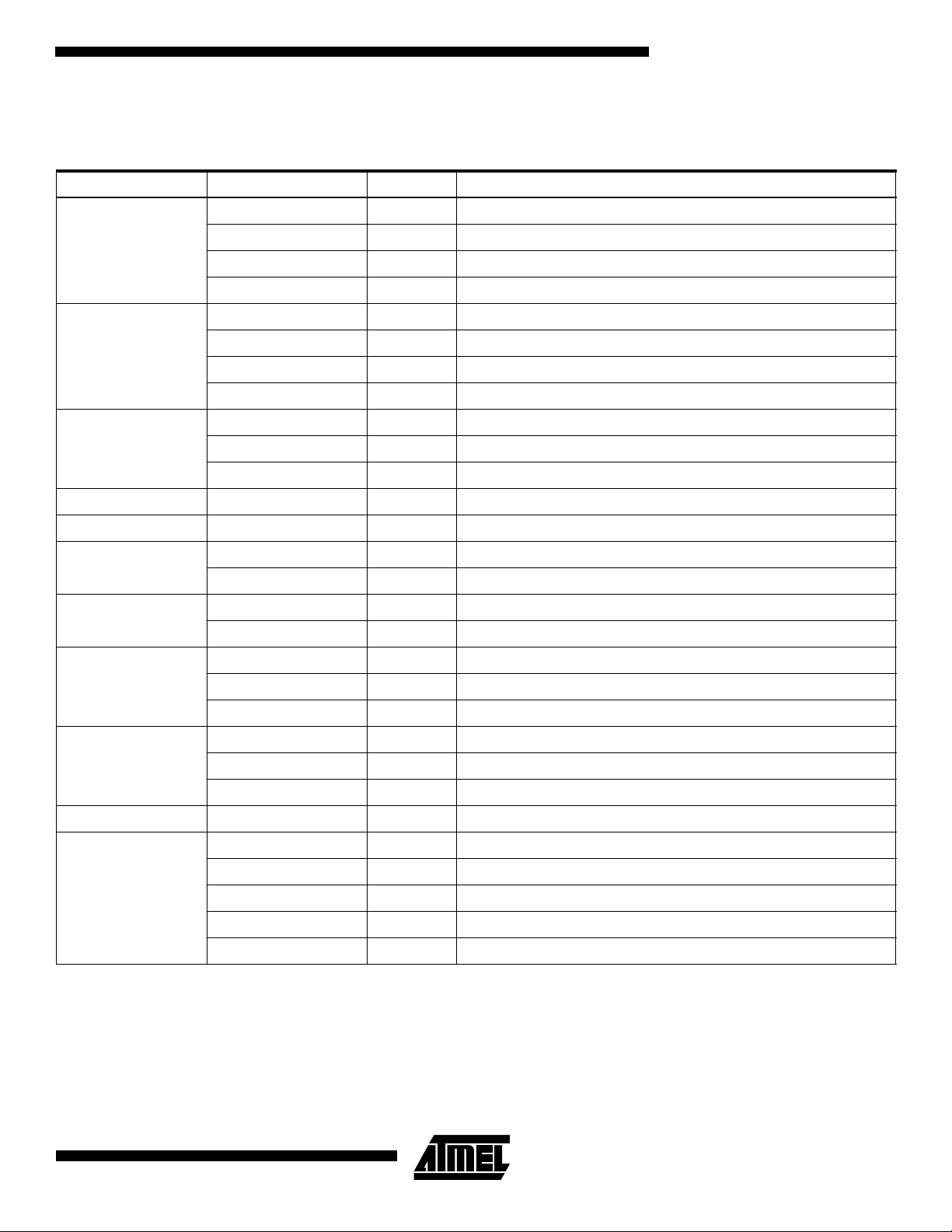

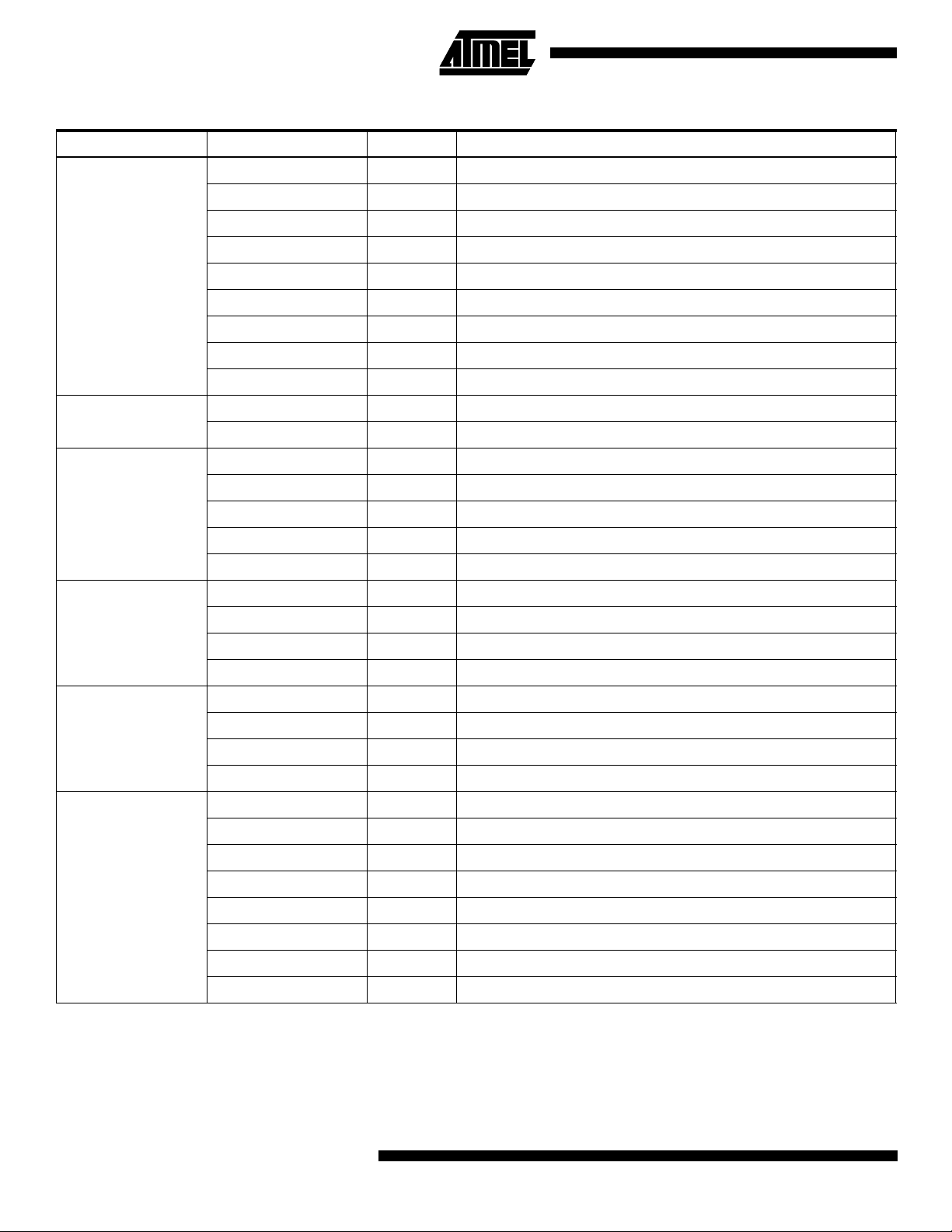

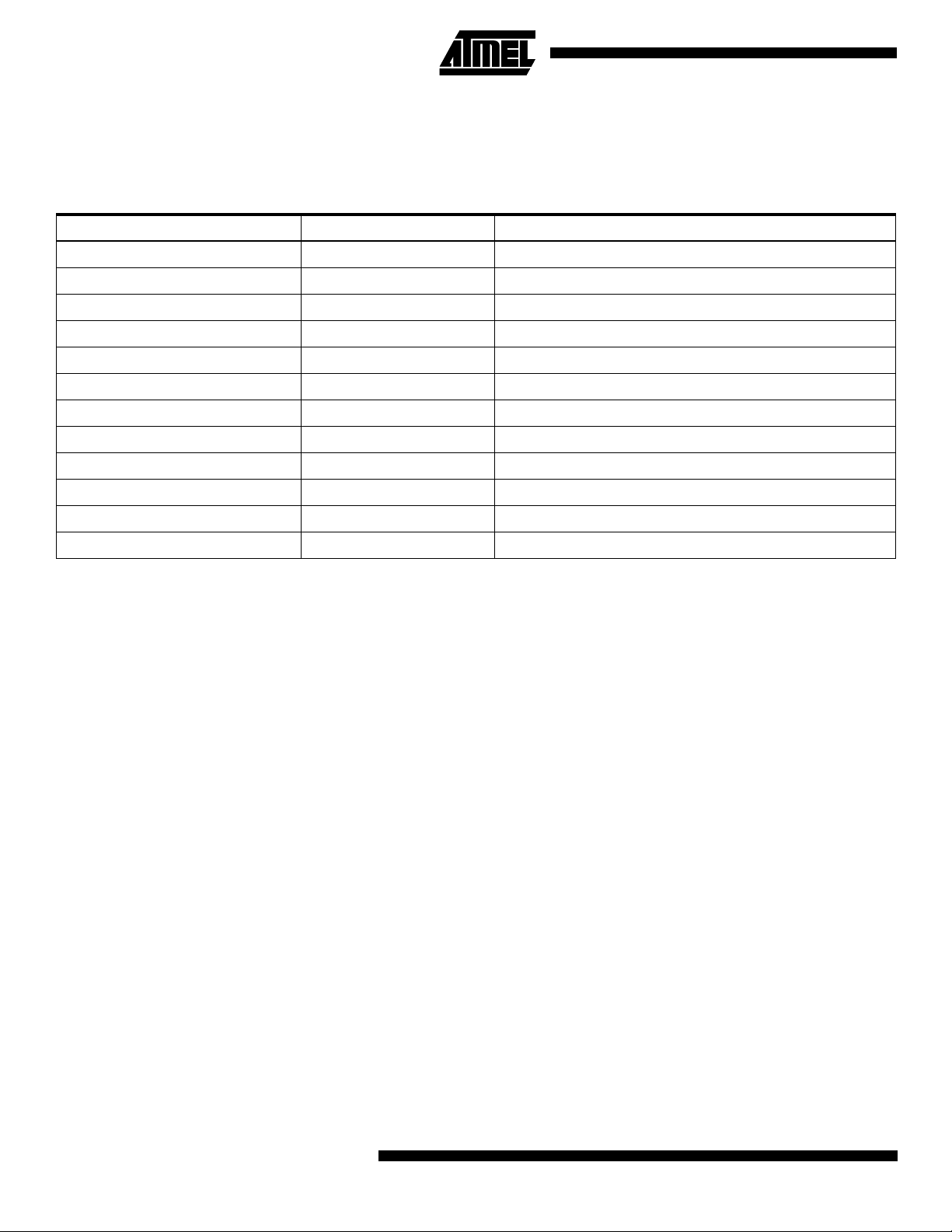

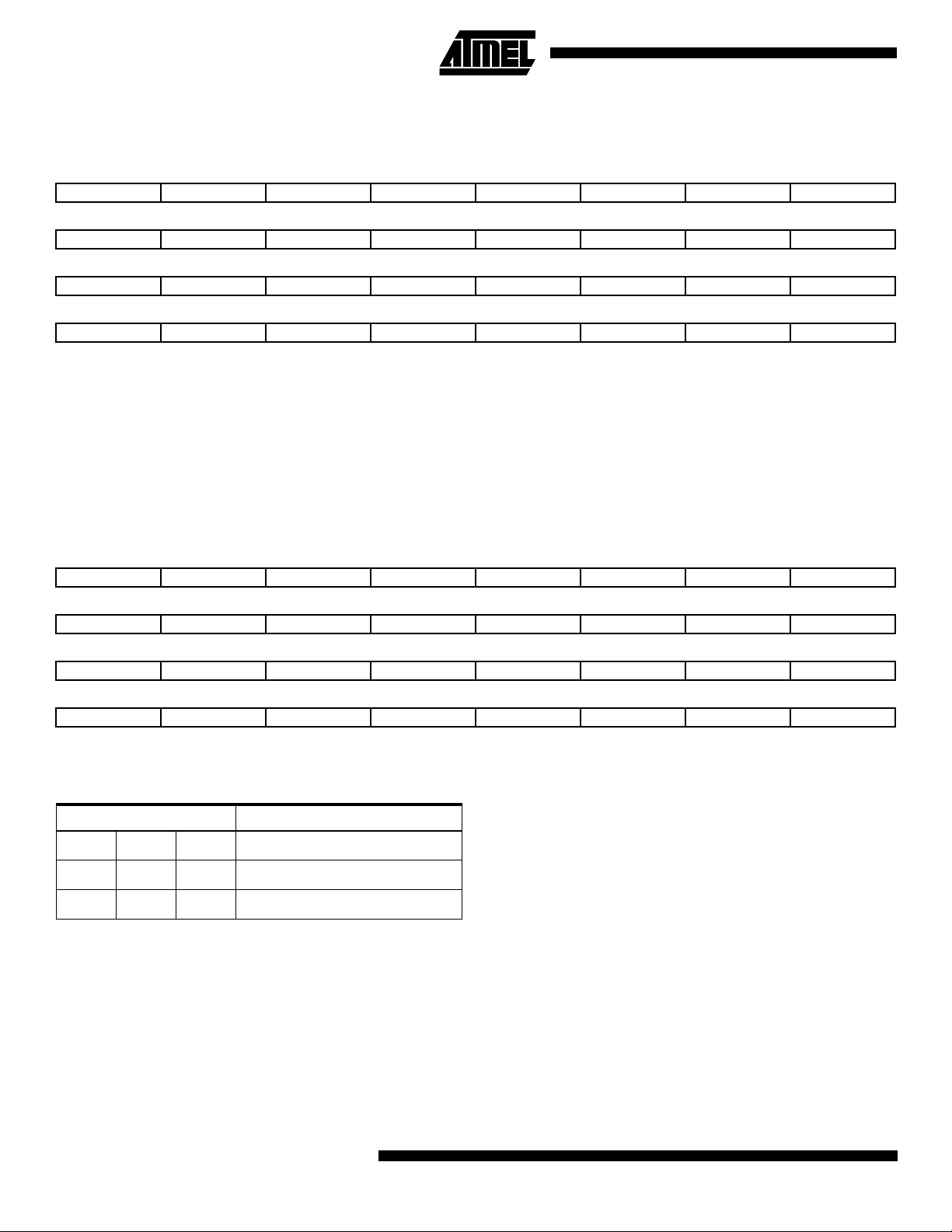

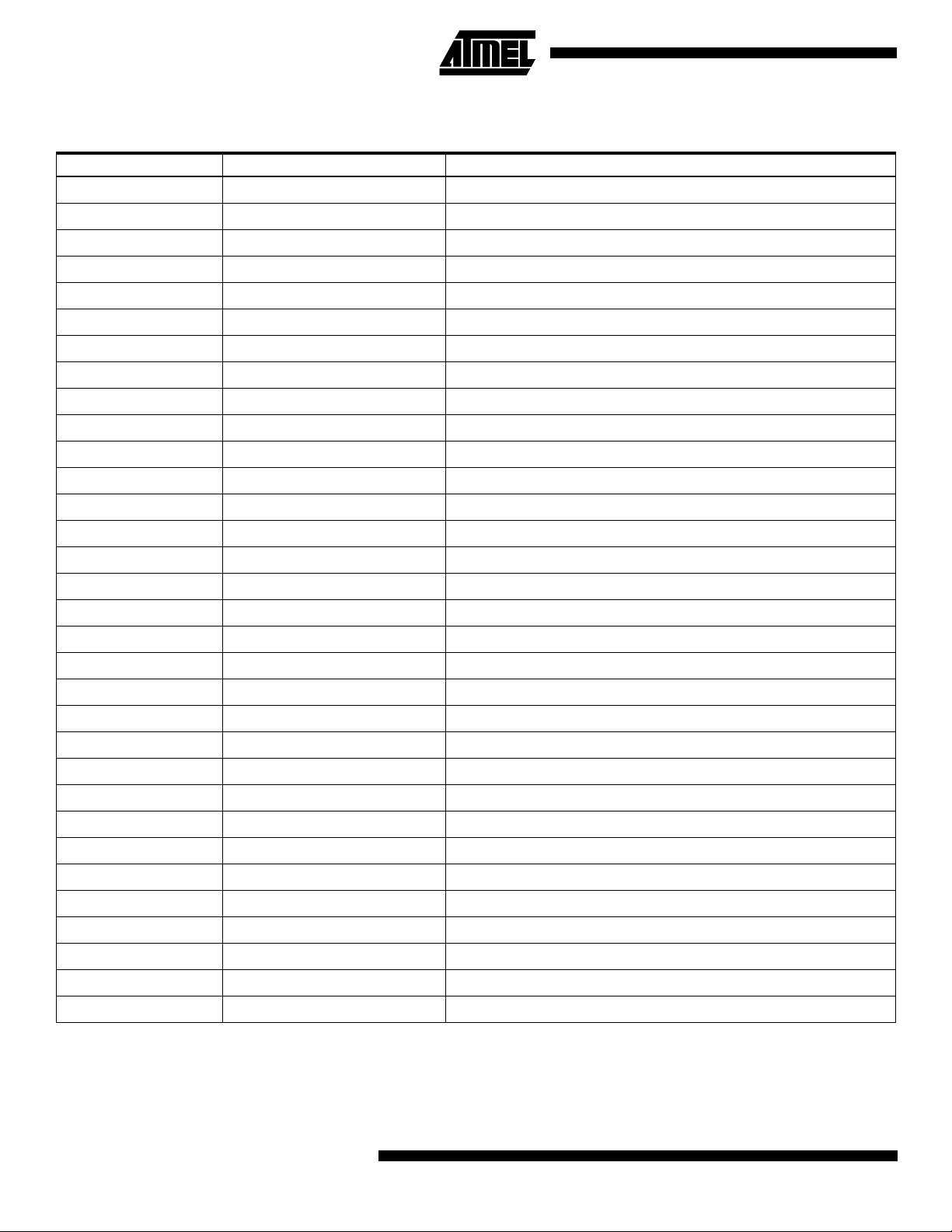

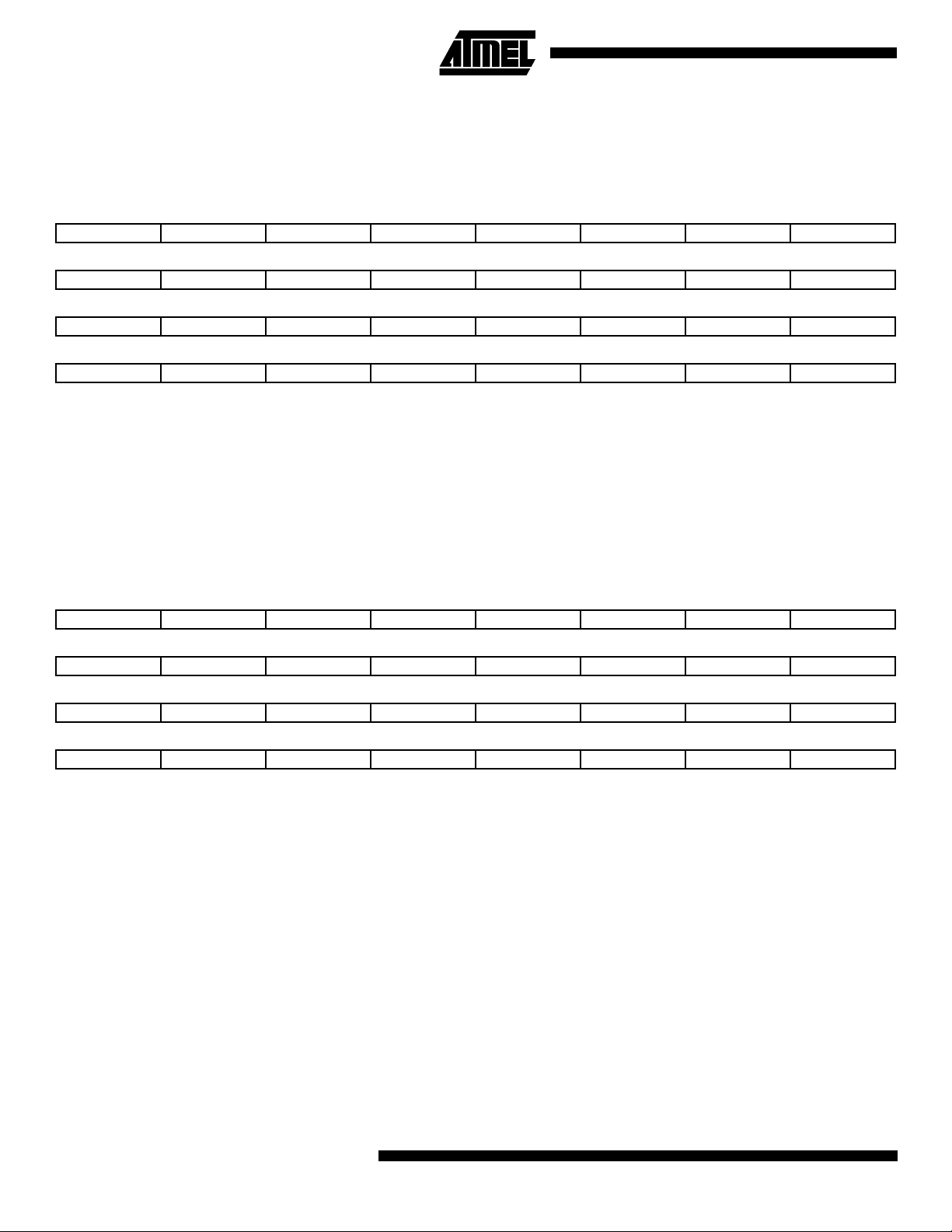

AT75C310 Pin Description

Table 2. AT75C310 Pin Description

Block Pin Name Type Function

A[21:0] O Address Bus

AT75C310

Common Bus

Dynamic Memory

Controller

Static Memory

Controller

I/O Port A PA[12:0] I/O General Purpose I/O Lines. Multiplexed with peripheral I/Os

I/O Port B PB[9:0] I/O General Purpose I/O Lines. Multiplexed with peripheral I/Os

DSP Subsystem A

DSP Subsystem B

Timer/Counter 0

D[15:0] I/O Data Bus

NREQ I Bus Request

NGNT O Bus Grant

NRAS[1:0] O Row Address Strobe

NCAS[1:0] O Column Address Strobe

NDWE O DRAM Write Enable

NDOE O DRAM Output Enable

NCE[3:0] O Chip Selects

NWE[1:0] O Byte Select/Write Enable

NSOE O SRAM Output Enable

OakAIN[1:0] I OakDSPCore A User Inputs

OakAOUT[1:0] O OakDSPCore A User Outputs

OakBIN[1:0] I OakDSPCore B User Inputs

OakBOUT[1:0] O OakDSPCore B User Outputs

TCLK0 I Timer 0 External Clock

TIOA0 I/O Timer 0 Signal A

TIOB0 I/O Timer 0 Signal B

TCLK1 I Timer 1 External Clock

Timer/Counter 1

Watchdog NWDOVF O Watchdog Overflow

Serial Peripheral

Interface

TIOA1 I/O Timer 1 Signal A

TIOB1 I/O Timer 1 Signal B

MISO I/O Master In/Slave Out

MOSI I/O Master Out/Slave In

SPCK I/O Serial Clock

NPCSS I/O Chip Select/Slave Select

NPSC1 O Optional SPI Chip Select 1

3

Page 4

Table 2. AT75C310 Pin Description (Continued)

Block Pin Name Type Function

RXDA I Receive Data

TXDA O Transmit Data

NRTSA O Ready to Send

NCTSA I Clear To Send

USART A

NDTRA O Data Terminal Ready

NDSRA/BOOTN I Data Set Ready

NDCDA I Data Carrier Detect

NRIA I Ring Indicator

SCLKA I/O Serial Clock

USART B

JTAG Interface

Codec Interface A

Codec Interface B

RXDB I Receive Data

TXDB O Transmit Data

NTRST I JTAG Test Reset

TCK I JTAG Test Clock

TMS I JTAG Test Mode Select

TDI I JTAG Test Data Input

TDO O JTAG Test Data Output

SCLKA I/O Codec Serial Clock

FSA I/O Frame Sync Pulse

STXA O Transmit Data to Codec

SRXA I Receive Data from Codec

SCLKB I/O Codec Serial Clock

FSB I/O Frame Sync Pulse

STXB O Transmit Data to Codec

SRXB I Receive Data from Codec

RESET I Master Reset

FIQ/LOWP I Fast Interrupt/Low Power

IRQ0 I External Interrupt request

Miscellaneous

4

XREF96 I External 96 MHz PLL Reference

XREF80 I External 80 MHZ PLL Reference

XTALIN I External Crystal Input

XTALOUT O External Crystal Output

TST I Test Mode

AT75C310

Page 5

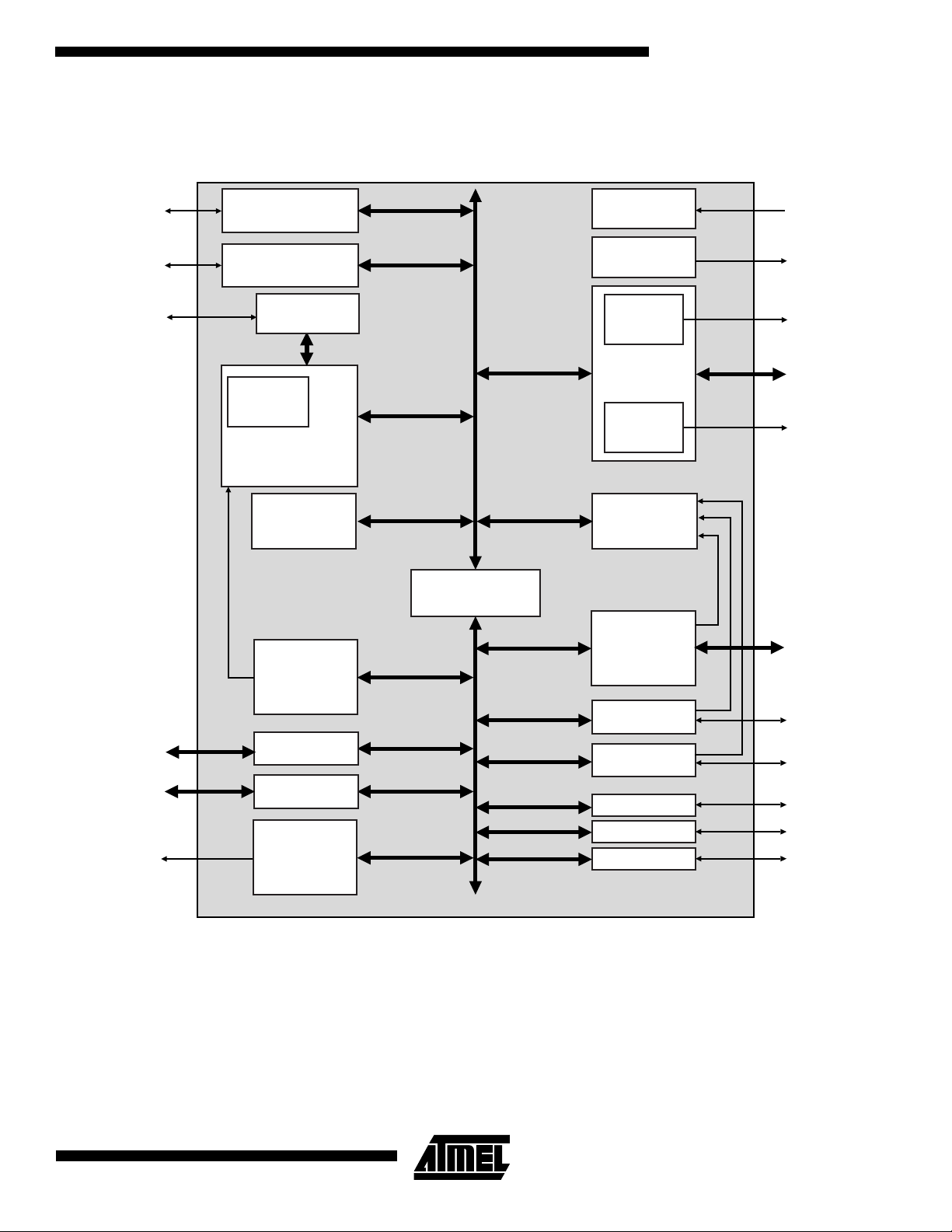

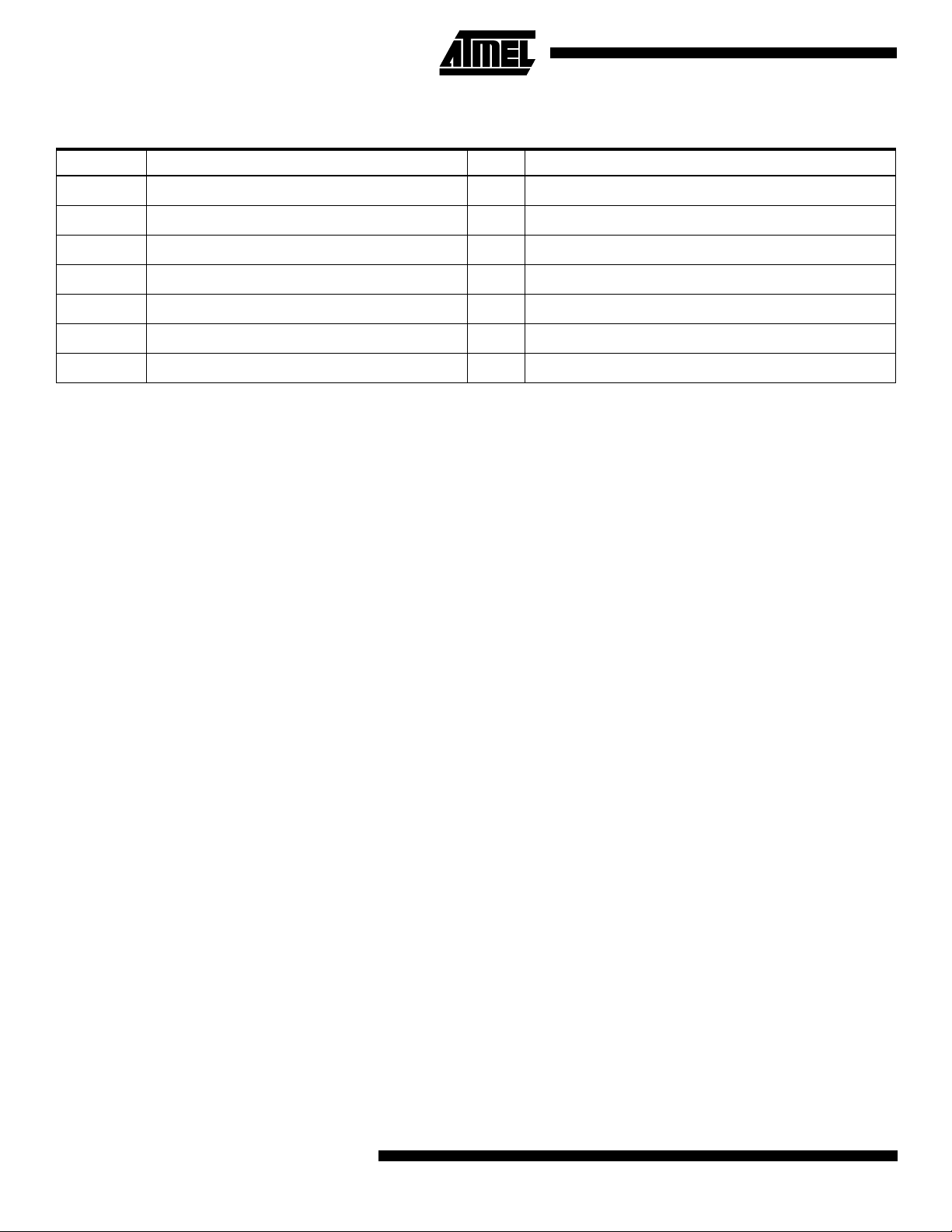

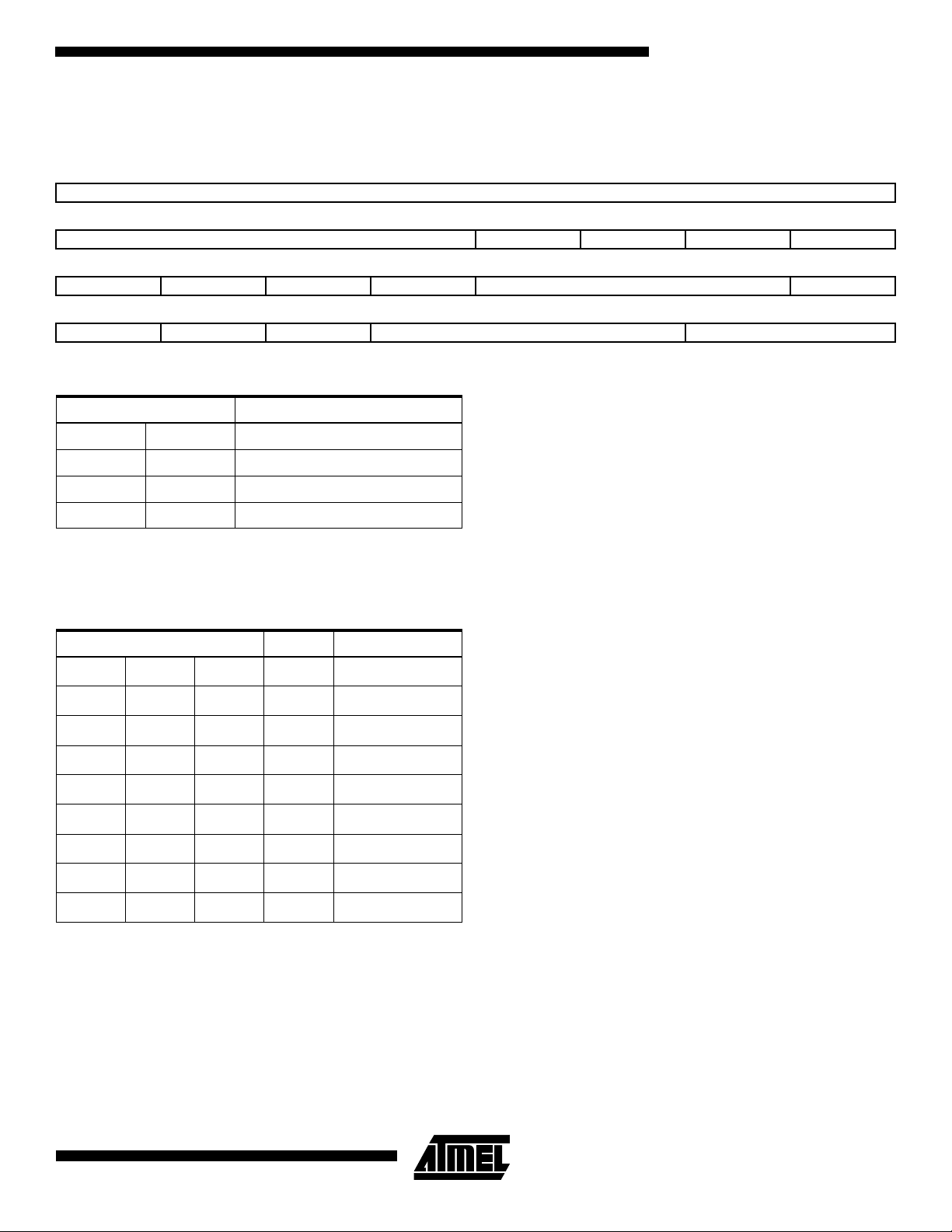

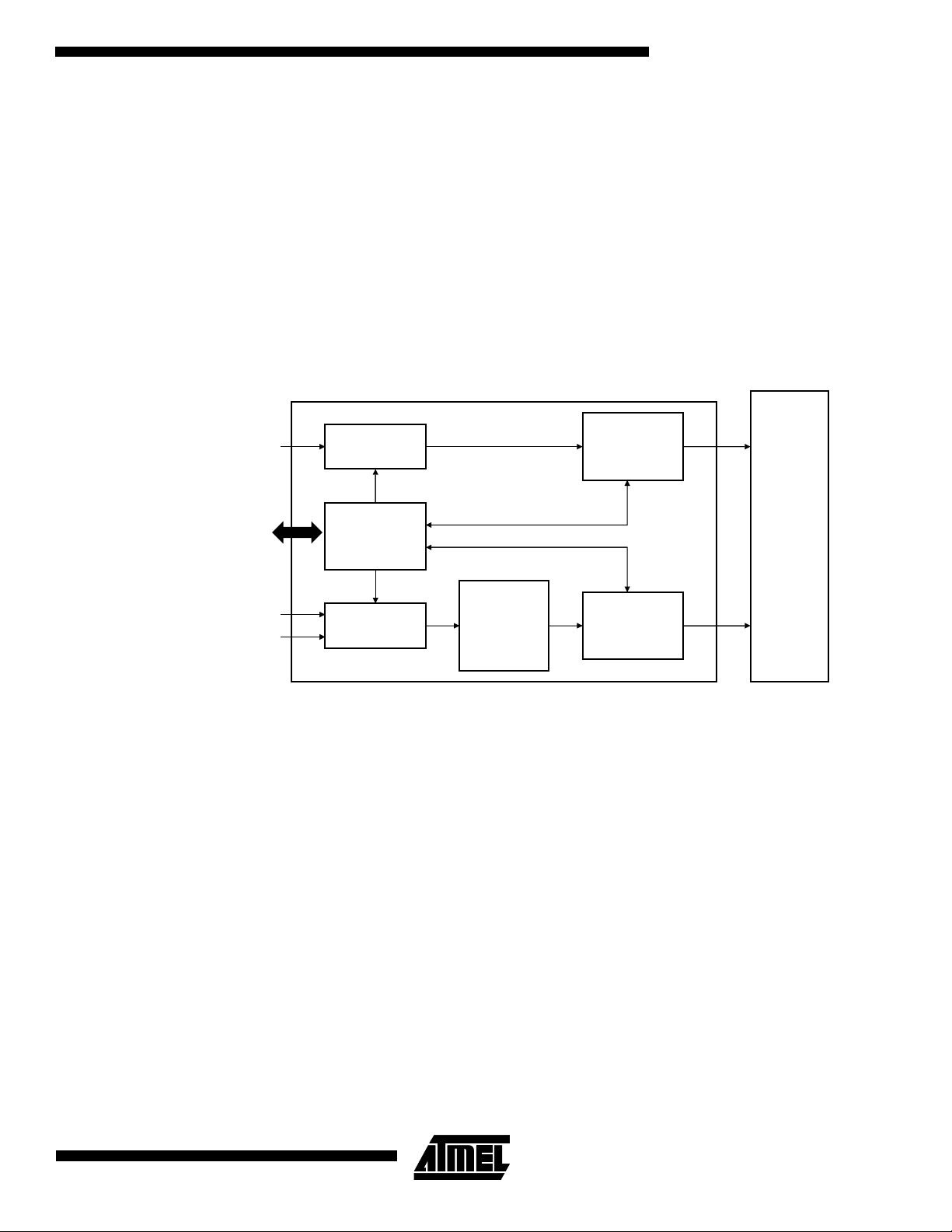

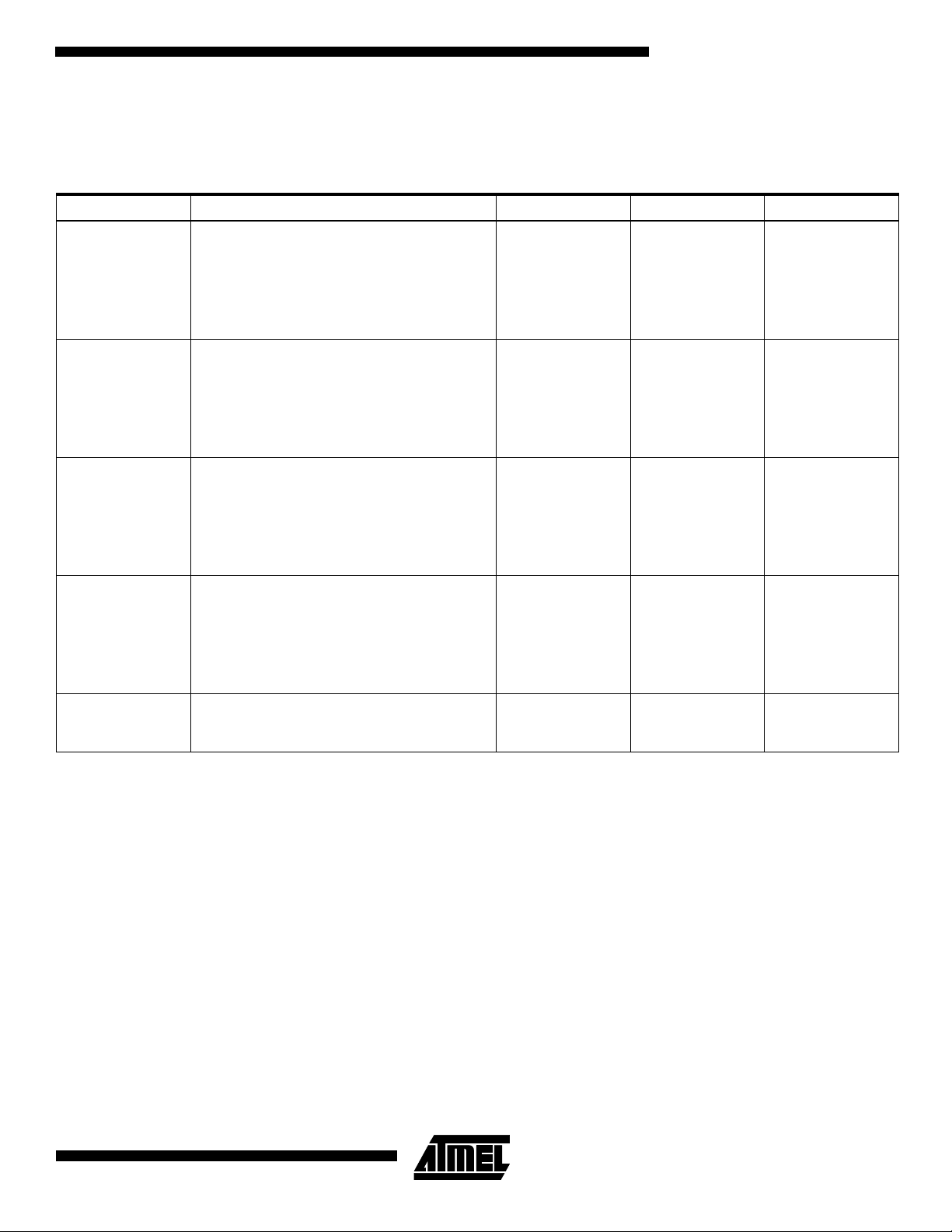

Block Diagram

Figure 1. AT75C310 Block Diagram

AT75C310

OakDSPCore 0

DSP Subsystem

OakDSPCore 1

DSP Subsystem

JTAG

Embedded

ICE

ARM7TDMI Core

Boot ROM

IRQ

Controller

AMBA

TM

ASB

Bridge

Reset

Clocks

DRAM

Controller

External Bus

Interface

SRAM

Controller

Peripheral Data

Controller

SPI

PIO 0

PIO 1

Watchdog

Timer

USART 0

USART 1

Timer/Counter 0

Timer/Counter 1

Timer/Counter 2

APB

5

Page 6

Architectural Overview

The AT75C310 architecture consists of two main buses,

the Advanced System Bus (ASB) and the Advanced

Peripheral Bus (APB).

The ASB is designed for maximum performance. It interfaces the processor with the on-chip DSP subsystems and

the external memories and devices by means of the External Bus Interface (EBI).

The APB is designed for accesses to on-chip peripherals

and is optimized for low power consumption. The AMBA

Bridge provides an interface between the ASB and the

APB.

An on-chip Peripheral Data Controller (PDC) transfers data

between the on-chip USARTs and the memories without

processor intervention. Most importantly, the PDC removes

the processor interrupt handling overhead and significantly

reduces the number of clock cycles required for a data

transfer. It can transfer up to 64K contiguous bytes without

reprogramming the starting address. As a result, microcontroller performance is increased and power consumption

reduced.

The AT75C310 peripherals are designed to be programmed with a minimum number of instructions. Each

peripheral has a 16 KB address space allocated in the

upper part of the address space. The peripheral register set

is composed of control, mode, data, status and interrupt

registers.

To maximize the efficiency of bit manipulation, frequentlywritten registers are mapped into three memory locations.

The first address is used to set the individual register bits,

the second resets the bits and the third address reads the

value stored in the register. A bit can be set or reset by writing a one to the corresponding position at the appropriate

address. Writing a zero has no effect. Individual bits can

™

thus be modified without having to use costly read-modifywrite and complex bit-manipulation instructions, and without having to store-disable-restore the interrupt state.

All external signals of the on-chip peripherals are controlled

by the parallel I/O controllers. The PIO controllers can be

programmed to insert an input filter on each pin or to generate an interrupt on a signal change. After reset, the user

must carefully program the PIO controllers in order to

define which peripheral signals are connected with off-chip

logic.

The ARM7TDMI processor operates in little-endian mode

in the AT75C310. The processor’s internal architecture and

the ARM and Thumb instruction sets are described in theAtmel ARM7TDMI datasheet, literature number 0673. The

memory map and the on-chip peripherals are described in

this datasheet. The DSP subsystems are described in the

datasheet entitled “AT75C310 DSP Subsystem”, literature

number 1368. Electrical characteristics are documented in

a separate datasheet entitled “AT75C310 Electrical and

Mechanical Characteristics”, literature number 1370.

PDC: Peripheral Data Controller

The AT75C310 has a four-channel PDC dedicated to the

two on-chip USARTs. One PDC channel is connected to

the receiving channel and one to the transmitting channel

of each USART.

The user interface of a PDC channel is integrated in the

memory space of each USART channel. It contains a 32-bit

address pointer register and a 16-bit count register. When

the programmed number of bytes is transferred, an end of

transfer interrupt is generated by the corresponding

USART. For more details on PDC operation and programming, see the section “USART: Universal Synchronous/Asynchronous Receiver/Transmitter” on page 53.

6

AT75C310

Page 7

Memory Map

The memory map is divided into memory regions of 64

megabytes. The top seven memory regions are reserved

and subdivided for internal memory blocks or peripherals

within the AT75C310. The AT75C310 can define up to six

other active external memory regions by means of the

static memory controller and DRAM memory controller.

The memory map assumes default values on reset. External memory regions can be reprogrammed to other base

addresses. For details, see the sections “SMC: Static

Memory Controller” on page 15 and “DMC: Dynamic Memory Controller” on page 24. It should be noted that the internal memory regions have fixed locations that cannot be

reprogrammed.

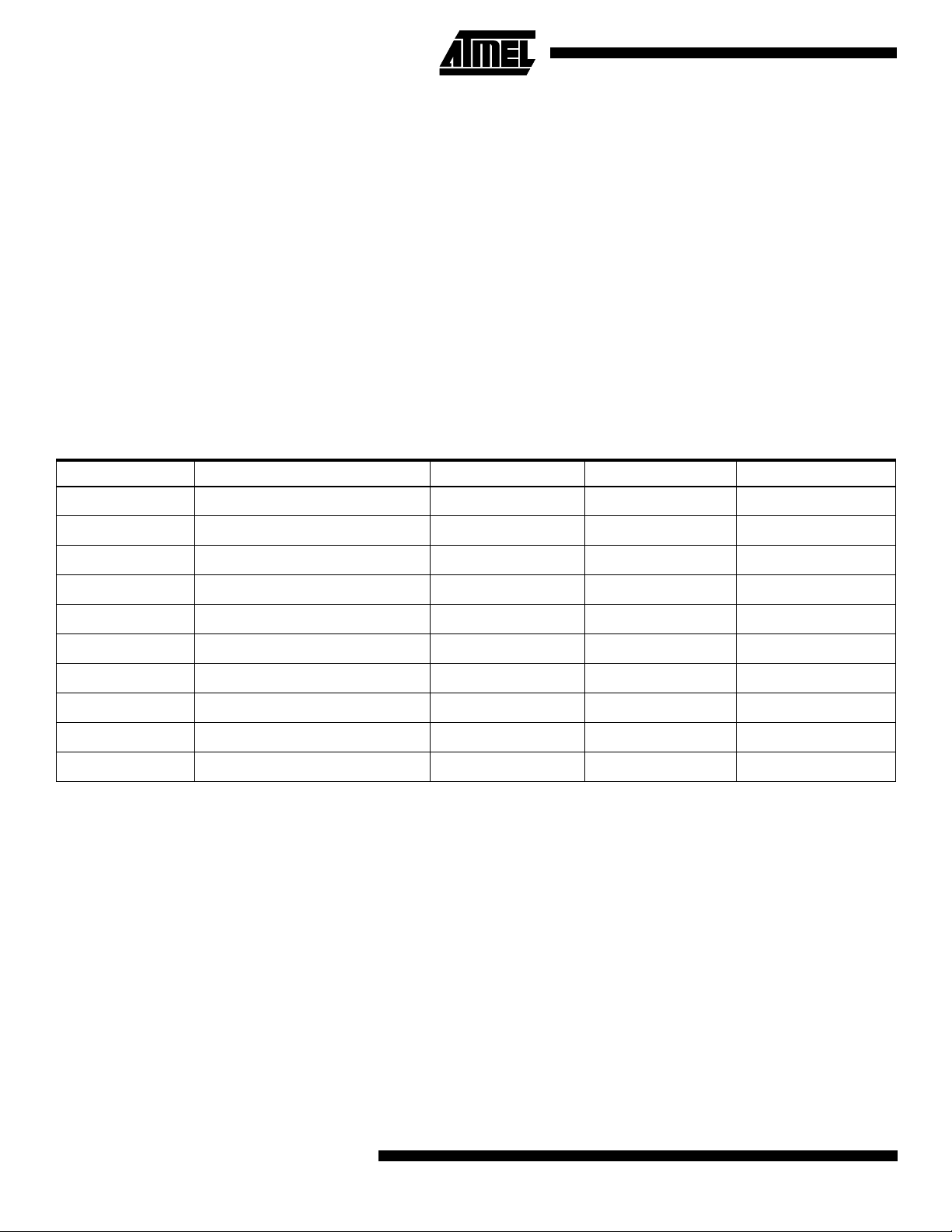

Table 3. Memory Map

Default Base Address Region Type Normal Mode

There are no hardware locks to prevent incorrect programming of the regions. Programming two or more regions to

have the same base address results in undefined behavior.

The ARM reset vector with address 0x00000000 is mapped

to internal ROM or external memory depending on the signal pin NDSRA/BOOTN. After booting, the ROM region can

be disabled and some external memory such as DRAM or

Flash can be mapped to the bottom of the memory map by

programming SMC_CS0 or DMC_MR0.

AT75C310

0xFF000000

0xFE000000

0xFD000000

0xFC000000

0xFB000000

0xFA000000

0xF9000000

0x50000000

0x40000000

0x30000000

0x20000000

0x10000000

0x00000000

Internal Peripherals

Internal OAK B (24K x 16 Program SRAM)

Internal OAK A (24K x 16 Program SRAM)

Internal Reserved

Internal Dual-port Mailbox for Oak B (2K x 16)

Internal Dual-port Mailbox for Oak A (2K x 16)

Internal Boot ROM (1K x 16)

External DMC_MR1

External DMC_MR0

External SMC_CS3

External SMC_CS2

External SMC_CS1

External/Internal SMC_CS0

Boot Mode

0x000003FF

Boot ROM

0x00000000

7

Page 8

Peripheral Memory Map

The register maps for each peripheral are described in the corresponding sections of this datasheet. The peripheral memory map has 16KB reserved for each peripheral.

Table 4. Peripheral Memory Map

Base Address Peripheral Description

0xFF000000 MODE Mode Controller

0xFF004000 SMC Static Memory Controller

0xFF008000 DMC DRAM Memory Controller

0xFF00C000 PIO A Programmable I/O

0xFF010000 PIO B Keypad PIO

0xFF014000 TC Timer/Counter Channels

0xFF018000 USART A USART

0xFF01C000 USART B USART

0xFF020000 SPI Serial Peripheral Interface

0xFF024000 Reserved

0xFF028000 WDT Watchdog Timer

0xFF030000 AIC Advanced Interrupt Controller

8

AT75C310

Page 9

Initialization

Reset initializes the user interface registers to their default

states as defined in the peripheral sections of this

datasheet and forces the ARM7TDMI to perform the next

instruction fetch from address zero. Except for the program

counter, the ARM core registers do not have defined reset

states. When reset is active, the inputs of the AT75C310

must be held at valid logic levels.

There are three ways in which the AT75C310 can enter

reset:

1. Hardware reset. Caused by asserting the RESET

pin, e.g., at power-up.

2. Watchdog timer reset. The watchdog timer can be

programmed so that if it is timed out, a pulse is generated that forces a chip reset.

3. Software reset. There are two software resets which

are asserted by writing to bits [11:10] of the

AT75C310 mode register. SIAP_MD[11] forces a

software reset with RM set low and SIAP_MD[10]

forces a reset with RM set high.

AT75C310

Reset Pin

The reset pin should be asserted for a minimum of 10 clock

cycles. However, if external DRAM is fitted, reset should be

applied for the time interval specified by the DRAM

datasheet, typically 200 µs. The OakDSPCores are only

released from reset by ARM program control.

When reset is released, the pin NDSRA/BOOTN is sampled to determine if the ARM should boot from internal

ROM or from external memory connected to NCS0. The

details of this boot operation are described in the section

“Boot Mode” on page 11.

Processor Synchronization

The ARM and the OakDSPCore processors have their own

PLLs and at power-on each processor has its own indeterminate lock period. To guarantee proper synchronization of

inter-processor communication through the mailboxes, a

specific reset sequence should be followed.

Once the ARM core is out of reset, it should set and clear

the reset line of each OakDSPCore three times. This guarantees message synchronization between the ARM and

the OakDSPCores.

9

Page 10

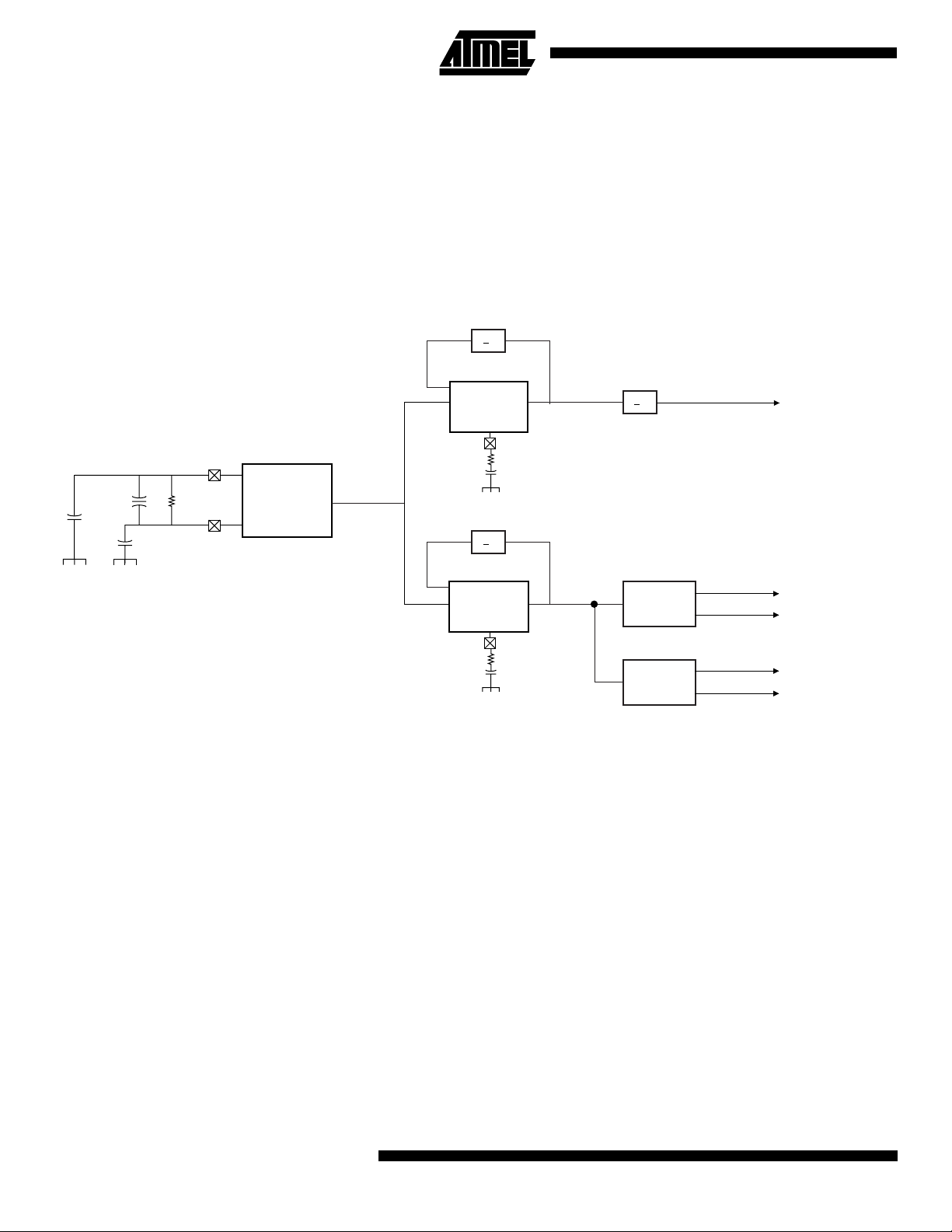

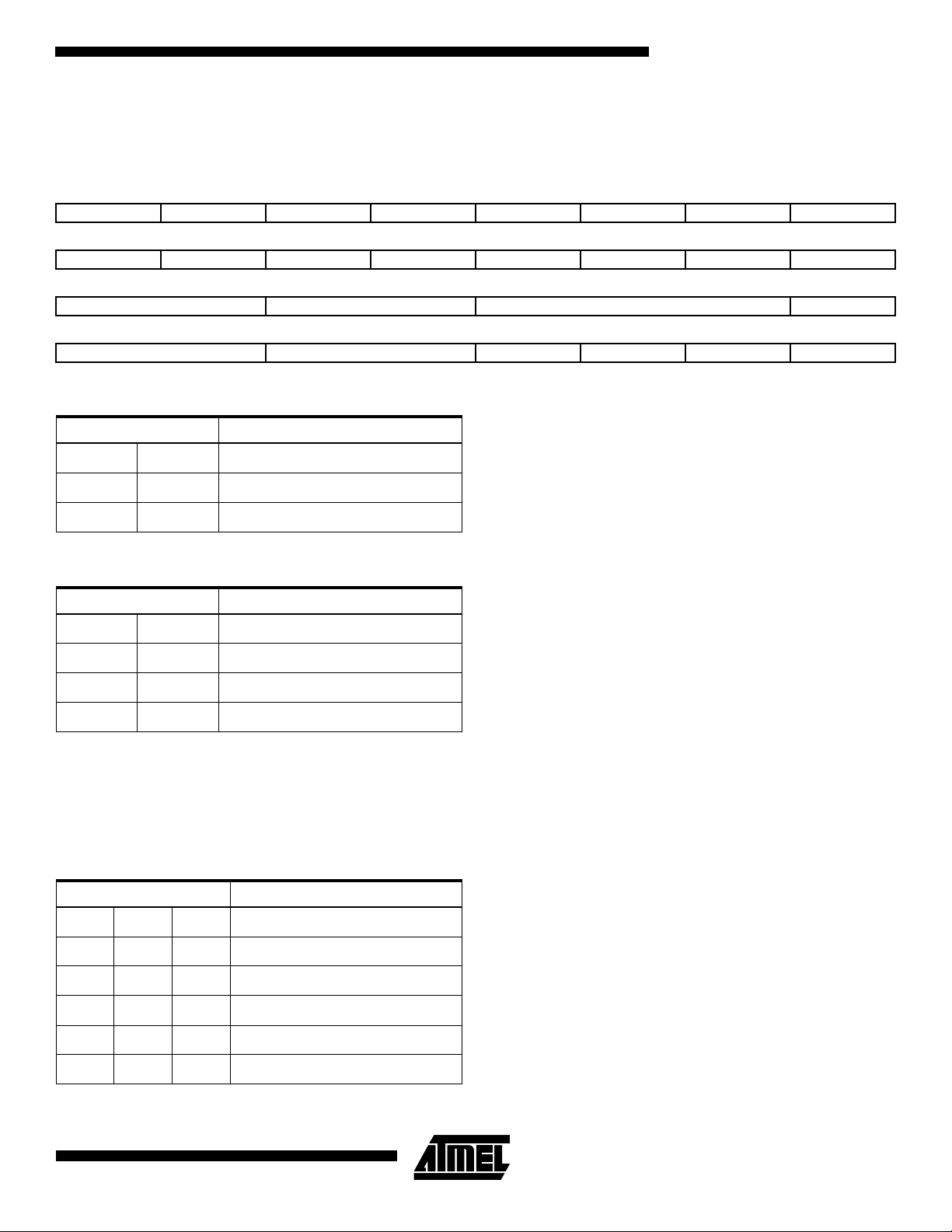

Clocking

The AT75C310 uses an external 16 MHz crystal (XCLK)

and two on-chip PLLs to generate the internal clocks. One

PLL generates a 96 MHz clock that is divided down to produce the ARM clocks and the other produces an 80 MHz

clock used to generate the Oak and Codec interface

clocks.

The ARM core runs at 24 MHz whereas the DSP subsystems run at 40 MHz.

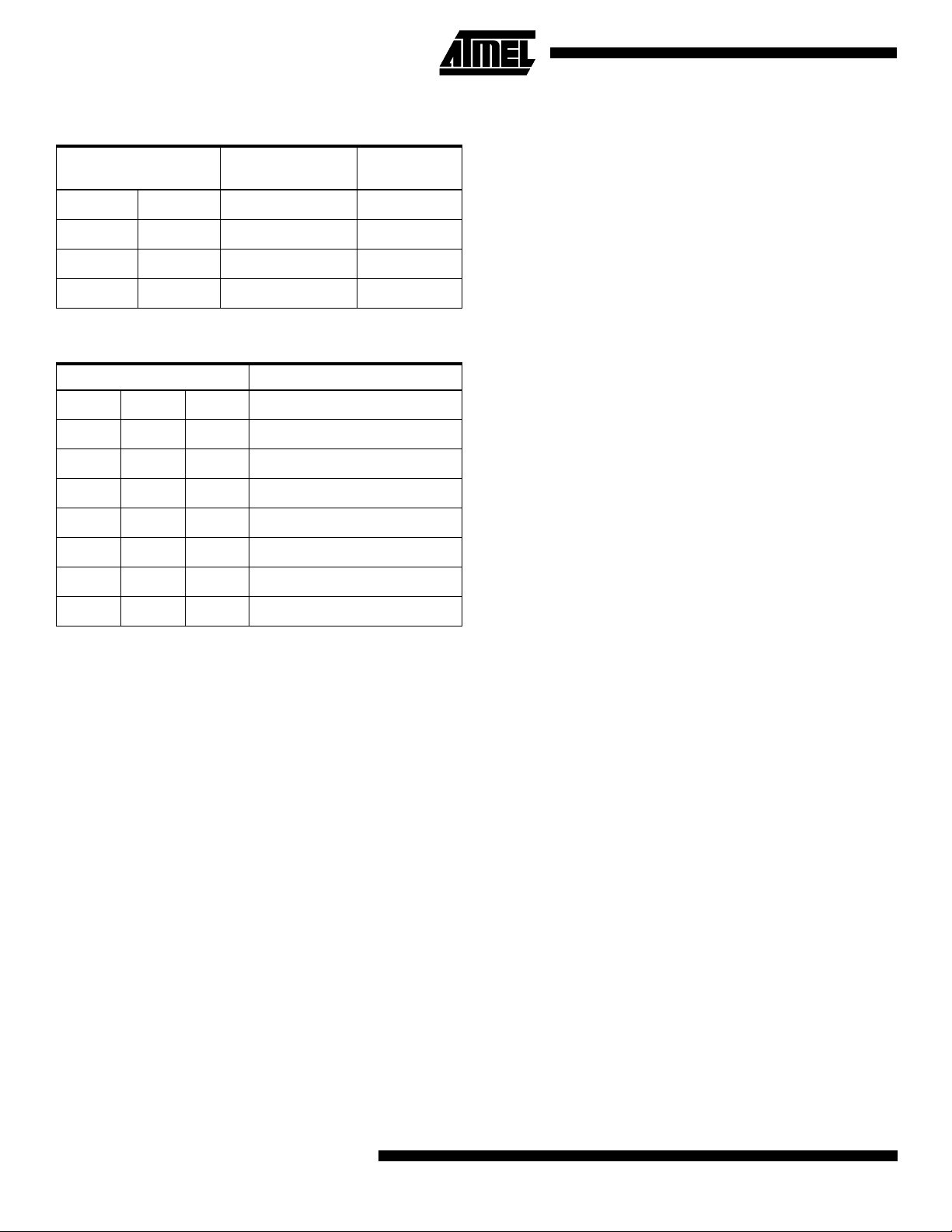

Figure 2. AT75C310 Clock Circuitry Diagram

Note that there is a common synchronous mode where the

ARM and OAK systems both run from the Oak PLL. This

results in the ARM running at 20 MHz and the Oak at

40 MHz.

A block diagram of the clock circuitry can be seen below in

Figure 2.

.

.

6

10 pF

10 pF

16 MHz

XTAL

XTALIN

1 MΩ

XTALOUT

Oscillator

16 MHz

100 Ω

10 nF

100 Ω

10 nF

PLL

.

.

PLL

XREF 96

5

XREF 80

96 MHz

80 MHz

.

.

4

Phase

Generator

Phase

Generator

24 MHz

40 MHz

40 MHz

40 MHz

40 MHz

ARM Clock

Core

DSP Subsystem A

Clocks

DSP Subsystem B

Clocks

10

AT75C310

Page 11

Boot Mode

When the reset pin is deasserted, i.e., when the AT75C310

exits from reset state, the NDSRA/BOOTN pin is sampled.

If NDSRA/BOOTN is high, the ARM starts fetching from

address 0x00000000, which corresponds to the external

memory. In a typical application, the external memory

located at 0x00000000 is a nonvolatile memory containing

the application.

If NDSRA/BOOTN is low, the internal boot ROM is

remapped to 0x00000000 and the internal boot program is

executed.

The boot program configures the USART A, waits for a

sync pattern, undertakes handshake processes and copies

all the incoming serial data into the Oak A internal program

AT75C310

memory. Note that this memory is in the ARM memory

space whereas the Oak A memory is in reset. Following

download, the ARM executes a jump and starts to fetch out

of the Oak A program memory. The downloaded routine is

typically more complex and faster and is able to program a

true application into the Flash memory.

If the initial handshake process fails, the AT75C310 falls

back into the normal boot mode, i.e., out of the external

memory.

The assembly source code of the boot program is given in

section “Assembly Source Code – Boot Program” on page

126.

11

Page 12

AT75C310 Mode Controller

The mode controller is a memory-mapped peripheral which sits on the APB. It is used to configure the mode in which the

AT75C310 operates.

Table 5. Mode Controller Registers Map

Register

Address

0x0 SIAP_MD Mode Register Read/write 0x00000001 if NDSRA/BOOTN is 1; else0x00000000

0x4 SIAP_ID ID Register Read 0x00010001 for 240-lead package;

0x8 SIAP_RST Reset Status

Register

Name Description Access Reset Value

0x00000001 for 160-lead package

Read/write 0x00000001 after hard reset

Register

Mode Register

Register Name: SIAP_MD

31 30 29 28 27 26 25 24

––––––––

23 22 21 20 19 18 17 16

––––––––

15 14 13 12 11 10 9 8

CRB CRA DBB DBA SW2 SW1 LPCS

76543210

– LP CS IB IA RB RA RM

• RM: Remap

When reset is released, this flag is set to the value of NDSRA/BOOTN. When RM is active low, the Boot ROM is

mapped to 0x00000000. Subsequently, this flag can be set high by software so that the ROM mapping is disabled and

another memory controller region (e.g., Flash) is mapped to location 0x00000000.

• RA: OAKA Reset

This flag resets to active low so that the Oak A is held in reset. The Oak A is released from reset by asserting this flag

high and then low three times. This generates the required reset sequence to the Oaks of 010101.

• RB: OAKB Reset

This flag resets to active low so that Oak B is held in reset. The Oak B is released from reset by asserting this flag high

and then low three times. This generates the required reset sequence to the Oaks of 010101.

• IA: Inhibit Oak A Clock

This flag resets to active low so that the Oak A clock is enabled. The Oak A clock is inhibited by asserting this flag high.

• IB: Inhibit Oak B Clock

This flag resets to active low so that the Oak B clock is enabled. The Oak B clock is inhibited by setting this flag high.

• CS: Synchronous Clock Mode

When high, the ARM, Oak A and Oak B run from the OakDSPCore clock, thus the ARM runs at 20 MHz and the

OakDSPCores at 40 MHz. When low, the ARM and OakDSPCores run from asynchronous clocks.

12

AT75C310

Page 13

AT75C310

• LP: Low Power Mode

When high, the ARM is clocked at the low-power frequency. The DMC clock is disabled so the DRAM refresh is also

disabled. This field can only be set to high. Writing a zero to this field has no effect. Low-power mode can only be

exited by a reset. See the section “Clocking” on page 10 for more details.

• LPCS: Low Power Clock Select

This field is used to select a slower clock frequency for the ARM system clock. This field is sampled when the LP flag is

changed from low to high. When the LP flag is low, this field is ignored. Once the LP flag has been set high, further

changes to this field have no effect. See the section “Clocking” on page 10 for more details.

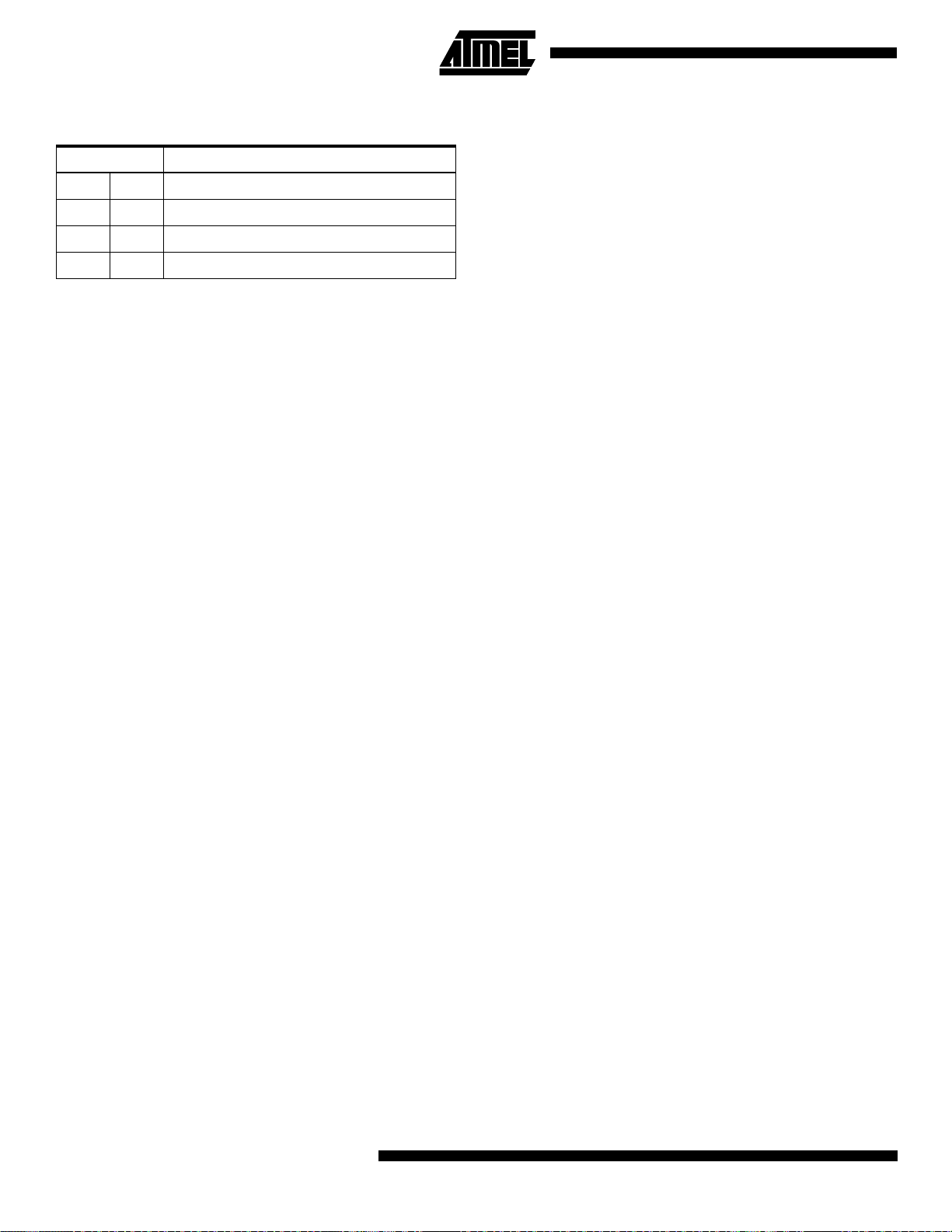

LPCS Divisor ACLK Frequency

0

01 8 MHz

0

132 500 kHz

1

0 128 125 kHz

1

11024 16 kHz

• DBA: Oak A Debug Mode

This flag resets low. This bit should be set to enter Oak A debug mode (test-specific pins are multiplexed out on functional pins).

• DBB: Oak B Debug Mode

This flag resets low. This bit should be set to enter Oak B debug mode (test-specific pins are multiplexed out on functional pins).

• CRA: Codec A Reset

This flag resets to active low so that the Codec A is held in reset. The Codec A is released from reset by asserting this

flag high.

• CRB: Codec B Reset

This flag resets to active low so that the Codec A is held in reset. The Codec A is released from reset by asserting this

flag high.

• SW1: Software Reset 1

Writing a one to this bit forces the AT75C310 into reset with RM set to zero.

• SW2: Software Reset 2

Writing a one to this bit forces the AT75C310 into reset with RM set to one.

13

Page 14

ID Register

Register Name: SIAP_ID

31 30 29 28 27 26 25 24

––––––––

23 22 21 20 19 18 17 16

––––––––

15 14 13 12 11 10 9 8

PKG –––––––

76543210

–––––VERS VERS VERS

• PKG: Package

This bit reflects the state of the data bus width signal DBW and indicates the AT75C310 package size, 1 for the 240lead PQFP option and 0 for the 160-lead PQFP option. The signal DBW is bonded to either power or ground depending

on the package used during manufacturing.

• VERS[2:0]: Version

This flag indicates the version number of the AT75C310. This field is reset to 0 x 1.

Reset Register

Register Name: SIAP_RST

31 30 29 28 27 26 25 24

––––––––

23 22 21 20 19 18 17 16

––––––––

15 14 13 12 11 10 9 8

––––––––

76543210

–––––RST RST RST

• RST[2:0]: Reset

These bits indicate the cause of the last reset.

RST Reset Event

0

0

1

0 1 Hardware

1 0 Watchdog Timer

0 0 Software

14

AT75C310

Page 15

EBI: External Bus Interface

The EBI generates the signals which control access to the

external memory or peripheral devices. The EBI is fully programmable and can address up to 64 megabytes. Its main

characteristic is to allow the connection of both static and

dynamic memories on the same bus. The address and data

lines are shared between static and dynamic devices

whereas the control lines are distinct. The control lines are

driven by two separate subsystems: the SMC (static memory controller) and the DMC (dynamic memory controller).

The static devices include regular static memories and

memory-mapped peripherals. The supported dynamic

devices are mainly EDO RAMs.

SMC: Static Memory Controller

The static memory controller (SMC) is used by the

AT75C310 to access external static memory devices.

Static memory devices include external Flash, SRAM or

peripherals.

The SMC provides a glueless memory interface to external

memory using the common address and data bus and

some dedicated control signals. The SMC is highly programmable and has up to 24 bits of address bus, a 32- or

16-bit data bus and up to four chip select lines. The SMC

supports different access protocols allowing single clockcycle accesses. The SMC is programmed as an internal

peripheral that has a standard APB bus interface and a set

AT75C310

of memory-mapped registers. The SMC shares the external address and data buses with the DMC and any external

bus master.

External Memory Mapping

The memory map associates the internal 32-bit address

space with the external 24-bit address bus. The memory

map is defined by programming the base address and

page size of the external memories. Note that A2 - A23 is

only significant for 32-bit memory and A1 - A23 for 16-bit

memory.

If the physical memory-mapped device is smaller than the

programmed page size, it wraps around and appears to be

repeated within the page. The SMC correctly handles any

valid access to the memory device within the page.

In the event of an access request to an address outside

any programmed page, an abort signal is generated by the

internal decoder. Two types of abort are possible: instruction prefetch abort and data abort. The corresponding

exception vector addresses are 0x0000000C and

0x00000010. It is up to the system programmer to program

the exception handling routine used in case of an abort.

If the AT75C310 is in internal boot mode, any chip select

configured with a base address of zero will be disabled as

the internal ROM is mapped to address zero.

15

Page 16

Signal Interface Table 6. Signal Interface

FPDRAM Description Type Notes

A[23:0] Address bus O

D[31:0] Data bus I/O

NCE[3:0] Active low chip enables O

NWE[3:0] Active low byte select/write strobe signals O

NWR Active low write strobe signals O

NSOE Active low read enable signal O

NWAIT Active low wait signal I

Data Bus Width

A data bus width of 32 or 16 bits can be selected for each

chip select. This option is controlled by the DBW field in the

Chip Select Register (SMC_CSR) of the corresponding

chip select.

The AT75C310 always boots up with a data bus width of 16

bits set in SMC_CSR0.

Byte-write or Byte-select Mode

Each chip select with a 32-/16-bit data bus operates with

one or two different types of write mode:

1. Byte-write mode supports four (32-bit bus) or two

(16-bit bus) byte writes and a single read signal.

2. Byte-select mode selects the appropriate byte(s)

using four (32-bit bus) or two (16-bit bus) byte-select

lines and separate read and write signals.

This option is controlled by the BAT field in SMC_CSR for

the corresponding chip select.

Byte-write access can be used to connect four 8-bit devices

as a 32-bit memory page or two 8-bit devices as a 16-bit

memory page.

For a 32-bit bus:

• The signal NWE0 is used as the write enable signal for

byte 0.

• The signal NWE1 is used as the write enable signal for

byte 1.

• The signal NWE2 is used as the write enable signal for

byte 2.

• The signal NWE3 is used as the write enable signal for

byte 3.

• The signal NSOE enables memory reads to all memory

blocks.

For a 16-bit bus:

• The signal NWE0 is used as the write enable signal for

byte 0.

D[15:0] used when Data Bus Width is 16

NCE[3] can be configured for LCD interface mode

• The signal NWE1 is used as the write enable signal for

byte 1.

• The signal NSOE enables memory reads to all memory

blocks.

Byte-select mode can be used to connect one 32-bit device

or two 16-bit devices in a 32-bit memory page or one 16-bit

device in a 16-bit memory page.

For a 32-bit bus:

• The signal NWE0 is used to select byte 0 for read and

write operations.

• The signal NWE1 is used to select byte 1 for read and

write operations.

• The signal NWE2 is used to select byte 2 for read and

write operations.

• The signal NWE3 is used to select byte 3 for read and

write operations.

• The signal NWR is used as the write enable signal for

the memory block.

• The signal NSOE enables memory reads to the memory

block.

For a 16-bit bus:

• The signal NWE0 is used to select byte 0 for read and

write operations.

• The signal NWE1 is used to select byte 1 for read and

write operations.

• The signal NWR is used as the write enable signal for

the memory block.

• The signal NSOE enables memory reads to the memory

block.

During boot, the number of external devices (number of

active chip selects) and their configurations must be programmed as required. The chip select addresses that are

programmed take effect immediately. Wait states also take

effect immediately when they are programmed to optimize

boot program execution.

16

AT75C310

Page 17

AT75C310

Read Protocols

The SMC provides two alternative protocols for external

memory read access: standard and early read. The difference between the two protocols lies in the timing of the

NSOE (read cycle) waveform.

The protocol is selected by the DRP field in the memory

control register (SMC_MCR) and is valid for all memory

devices. Standard read protocol is the default protocol after

reset.

• Standard Read Protocol

Standard read protocol implements a read cycle in which

NSOE and the write strobes are similar. Both are active

during the second half of the clock cycle. The first half of

the clock cycle allows time to ensure completion of the previous access, as well as the output of address and NCE

before the read cycle begins.

During a standard read protocol external memory access,

NCE is set low and ADDR is valid at the beginning of the

access, whereas NSOE goes low only in the second half of

the master clock cycle to avoid bus conflict. The write

strobes are the same in both protocols. The write strobes

always go low in the second half of the master clock cycle.

• Early Read Protocol

Early read protocol provides more time for a read access

from the memory by asserting NSOE at the beginning of

the clock cycle. In the case of successive read cycles in the

same memory, NSOE remains active continuously. Since a

read cycle normally limits the speed of operation of the

external memory system, early read protocol allows a

faster clock frequency to be used. However, an extra wait

state is required in some cases to avoid contention on the

external bus.

In early read protocol, an early read wait state is automatically inserted when an external write cycle is followed by a

read cycle to allow time for the write cycle to end before the

subsequent read cycle begins. This wait state is generated

in addition to any other programmed wait states (i.e., data

float wait). No wait state is added when a read cycle is followed by a write cycle, between consecutive accesses of

the same type or between external and internal memory

accesses. Early read wait states affect the external bus

only. They do not affect internal bus timing.

Write Protocol

During a write cycle, the data becomes valid after the falling edge of the write strobe signal and remains valid after

the rising edge of the write strobe. The external write strobe

waveform (on the appropriate write strobe pin) is used to

control the output data timing to guarantee this operation.

Thus, it is necessary to avoid excessive loading of the write

strobe pins, which could delay the write signal too long and

cause a contention with a subsequent read cycle in standard protocol. In early read protocol, the data can remain

valid longer than in standard read protocol due to the additional wait cycle that follows a write access.

Wait States

The SMC can automatically insert wait states. The different

types of wait states are:

• Standard wait states

• Data float wait states

• External wait states

• Chip select change wait states

• Early read wait states (see “Read Protocols” on page 17

for details)

• Standard wait states

Each chip select can be programmed to insert one or more

wait states during an access on the corresponding device.

This is done by setting the WSE field in the corresponding

SMC_CSR. The number of cycles to insert is programmed

in the NWS field in the same register. The correspondence

between the number of standard wait states programmed

and the number of cycles during which the write strobe

pulse is held low is found in Table 7. For each additional

wait state programmed, an additional cycle is added.

Table 7. Correspondence Wait States/Number of Cycles

Wait States Cycles

01/2

11

• Data Float Wait State

Some memory devices are slow to release the external

bus. For such devices, it is necessary to add wait states

(data float waits) after a read access before starting a write

access or a read access to a different external memory.

The data float output time (TDF) for each external memory

device is programmed in the TDF field of the SMC_CSR

register for the corresponding chip select. The value (0 - 7

clock cycles) indicates the number of data float waits to be

inserted and represents the time allowed for the data output to go high-impedance after the memory is disabled.

The SMC keeps track of the programmed external data

float time even when making internal accesses, thus ensuring that the external memory system is not accessed while

it is still busy.

Internal memory accesses and consecutive accesses to

the same external memory do not have added data float

wait states.

When data float wait states are being used, the SMC prevents the DMC or external master from accessing the

external data bus.

17

Page 18

• External Wait

The NWAIT input can be used to add wait states at any

time NWAIT is active low and is detected on the rising edge

of the clock. If NWAIT is low at the rising edge of the clock,

the SMC adds a wait state and does not change the output

signals.

• Chip Select Change Wait States

A chip select wait state is automatically inserted when consecutive accesses are made to two different external memories and no wait states have been inserted. If wait states

have been inserted (e.g., data float wait), then none are

added.

LCD Interface Mode

NCE3 can be configured for use with an external LCD controller by setting the LCD bit in the SMC_CSR3 register.

Table 8. SMC Register Map

Offset Register Description Register Name Access Reset State

Additionally, WSE must be set and NWS programmed with

a value of 1 or more.

In LCD mode, NCE3 is shortened by one-half clock cycle at

the leading and trailing edges, providing positive address

setup and hold. For read cycles, the data is latched in the

SMC as NCE3 is raised at the end of the access.

SMC Register Map

The SMC is programmed using the registers listed in Table

8. The memory control register (SMC_MCR) is used to program the number of active chip selects and data read protocol. Four chip select registers (SMC_CSR0 to

SMC_CSR3) are used to program the parameters for the

individual external memories. Each SMC_CSR must be

programmed with a different base address even for unused

chip selects. The AT75C310 resets such that SMC_CSR0

is configured as having a 16-bit data bus.

0x00

0x04

0x08

0x0C

0x10

0x14

0x18

0x1C

0x20

0x24

Chip Select Register

Chip Select Register

Chip Select Register

Chip Select Register

Reserved

Reserved

Reserved

Reserved

Reserved

Memory Control Register

SMC_CSR0 Read/write 0x0000203D

SMC_CSR1 Read/write 0x10000000

SMC_CSR2 Read/write 0x20000000

SMC_CSR3 Read/write 0x30000000

–– –

–– –

–– –

–– –

–– –

SMC_MCR Read/write 0

18

AT75C310

Page 19

AT75C310

SMC Chip Select Register

Register Name: SMC_CSR0..SMC_CSR3

31 30 29 28 27 26 25 24

BA

23 22 21 20 19 18 17 16

BA –––LCD

15 14 13 12 11 10 9 8

––CSEN BAT TDF PAGES

76543210

PA GE S – WSE NWS DBW

• DBW: Data Bus Width

DBW Data Bus Width

00Reserved

0 1 16-bit external bus

1 0 32-bit external bus

11Reserved

• WSE: Wait State Enable

• NWS: Number of Wait States

This field is valid only if WSE is set.

NWS WSE Wait States

X

0

0

0

0

1

1

1

1

XX

00

01

10

11

00

01

10

11

00

11

12

13

14

15

16

17

18

19

Page 20

• PAGES: Page Size

PAGES Page Size

0 0 1 MB BA[31 - 20]

0 1 4 MB BA[31 - 22]

1 0 16 MB BA[31 - 24]

11 Reserved –

• TDF: Data Float Output Time

TDF Cycles after Transfer

00 0 0

00 1 1

01 0 2

01 1 3

10 0 4

10 1 5

Base

Address

11 0 6

11 1 7

• BAT: Byte Access Mode

0 = Byte-write Mode

1 = Byte-select Mode

• CSEN: Chip Select Enable

Active high

• LCD: LCD Mode Enable

Active high. SMC_CSR3 only.

• BA: Base Address

This field contains the high-order bits of the base address. If the page size is larger than 1 MB, then the unused bits of

the base address are ignored by the SMC decoder.

20

AT75C310

Page 21

SMC Memory Control Register

Register Name: SMC_MCR

31 30 29 28 27 26 25 24

––––––––

23 22 21 20 19 18 17 16

––––––––

15 14 13 12 11 10 9 8

––––––––

76543210

–––DRP ––––

• DRP: Data Read Protocol

0 = Standard Read Mode

1 = Early Read Mode

AT75C310

21

Page 22

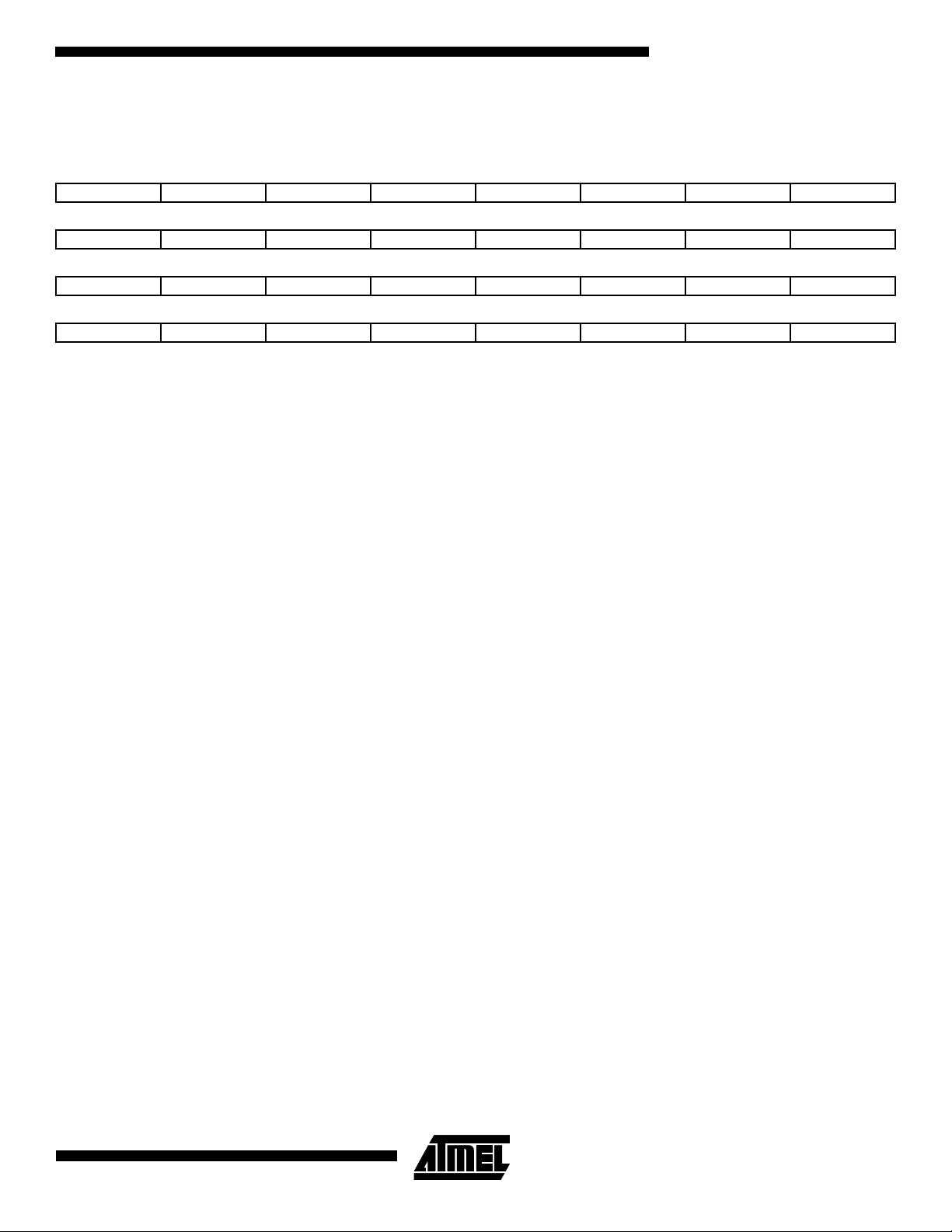

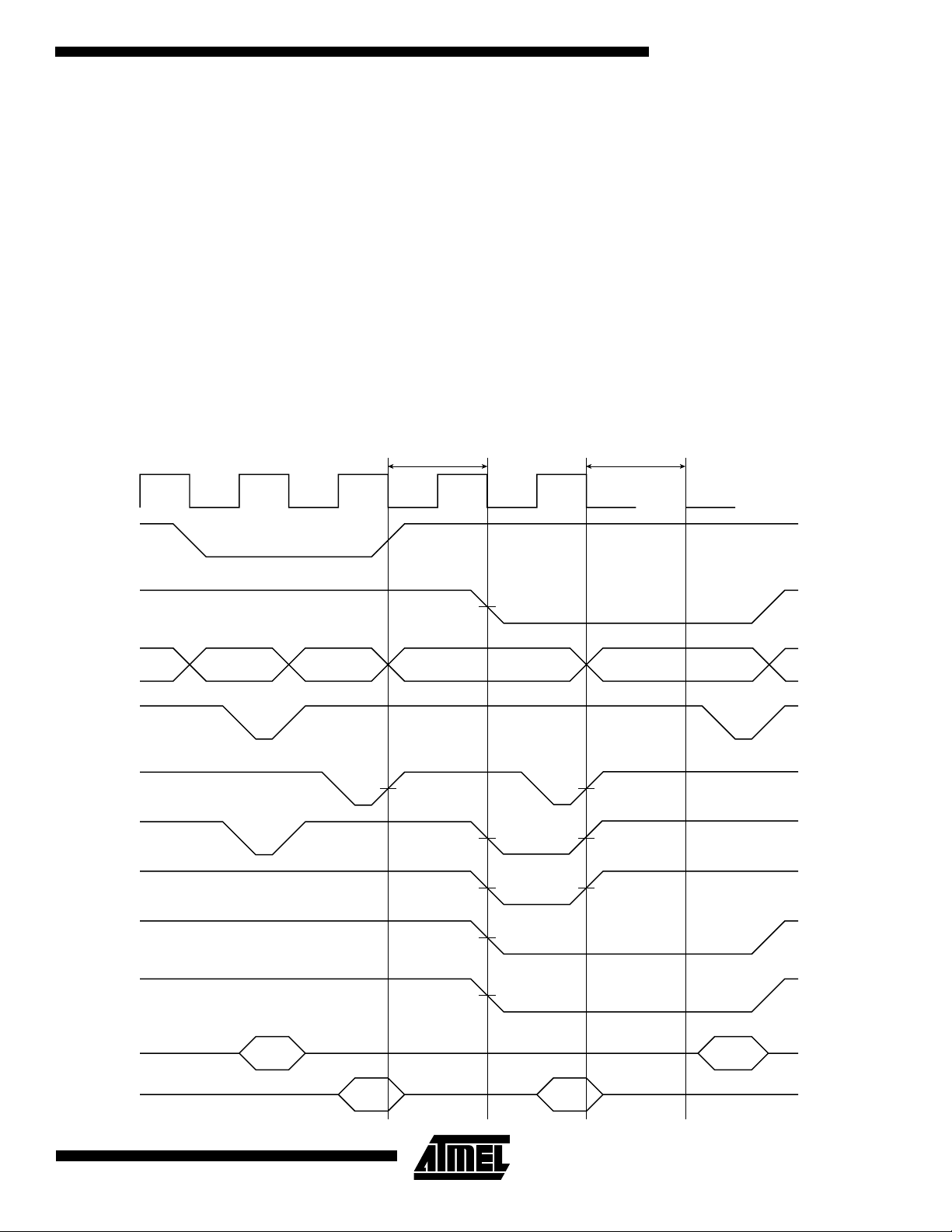

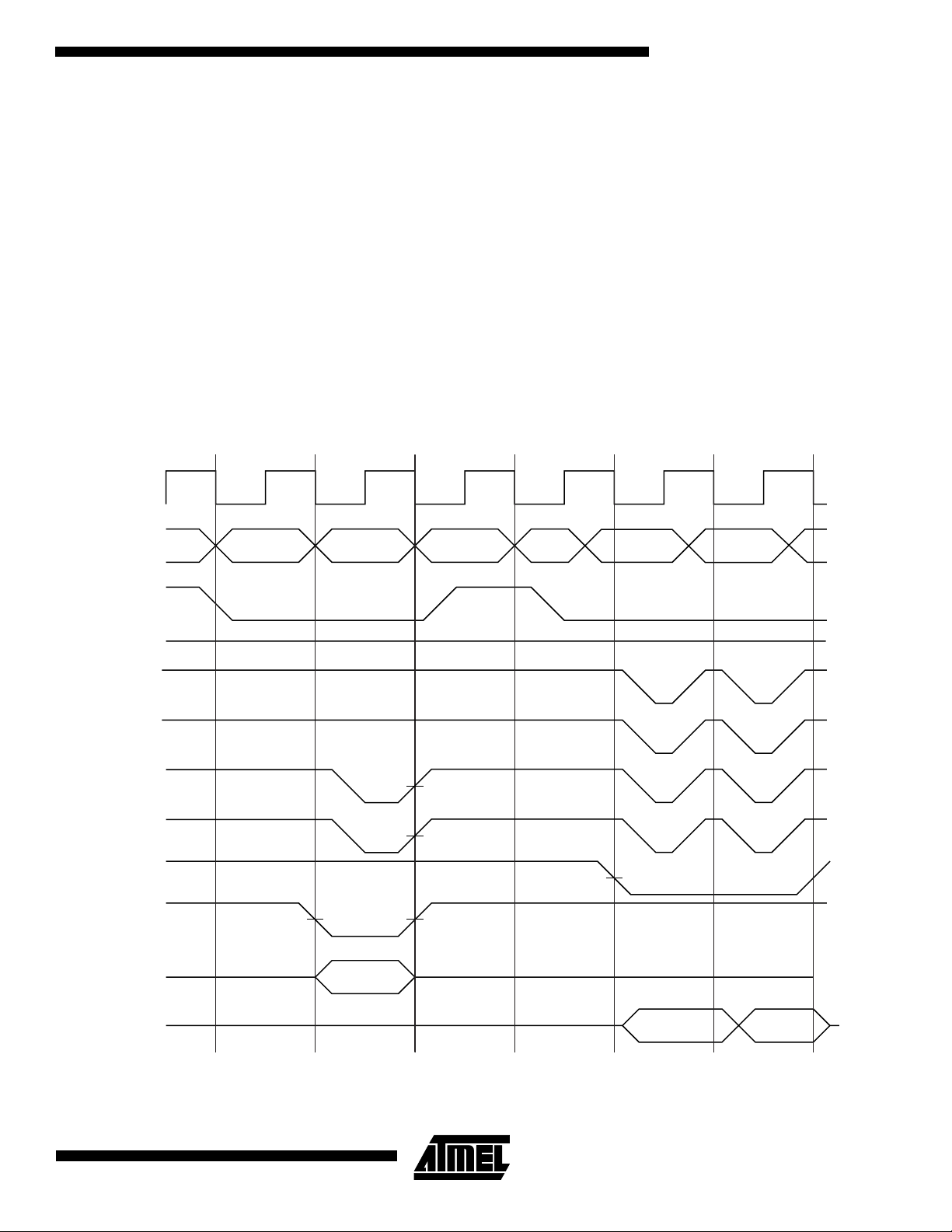

Switching Waveforms

Figure 3 shows a write to memory 0, followed by a write

and a read to memory 1. SMC_CSR0 is programmed for

one wait state with BAT = 0 and DFT = 0. SMC_CSR1 is

programmed for zero wait states with BAT = 1 and

DFT = 0. SMC_MCR is programmed for early reads from

all memories.

The write to memory 0 is a 32-bit word access and, therefore, all four NWE strobes are active. As BAT = 0, they are

configured as write strobes and have the same timing as

NWR. As the access employs a single wait state, the write

strobe pulse is one clock cycle long.

There is a chip select change wait state between the memory 0 write and the memory 1 write. The new address is

output at the end of the memory 0 access but the strobes

are delayed for one clock cycle.

The write to memory 1 is a half-word (16-bit) access to an

odd half-word address and, therefore, NWE2 and NWE3

are active. As BAT = 1 they are configured as byte-select

Figure 3. Write to Memory 0, Write and Read to Memory 1

BCLK

signals and have the same timing as NCE. As the access

has no internal wait states, the write strobe pulse is onehalf clock cycle long. Data and address are driven until the

write strobe rising edge is sensed at the SIAP pin to guarantee positive hold times.

There is an early read wait state between the memory 1

write and the memory 1 read to provide time for the

AT75C310 to disable the output data before the memory is

read. If the read was normal mode, i.e., not early, the

NSOE strobe would not fall until the rising edge of BCLK

and no wait state would be inserted. If the write and early

read were to different memories, then the early read wait

state is not required as a chip select wait state will be

implemented.

The read from memory 1 is a byte access to an address

with a byte offset of two and, therefore, only NWE2 is

active.

NCE0

NCE1

NWR

NSOE

NWE0

NWE1

NWE2

NWE3

A

22

D (SIAP)

D (MEM)

AT75C310

Page 23

AT75C310

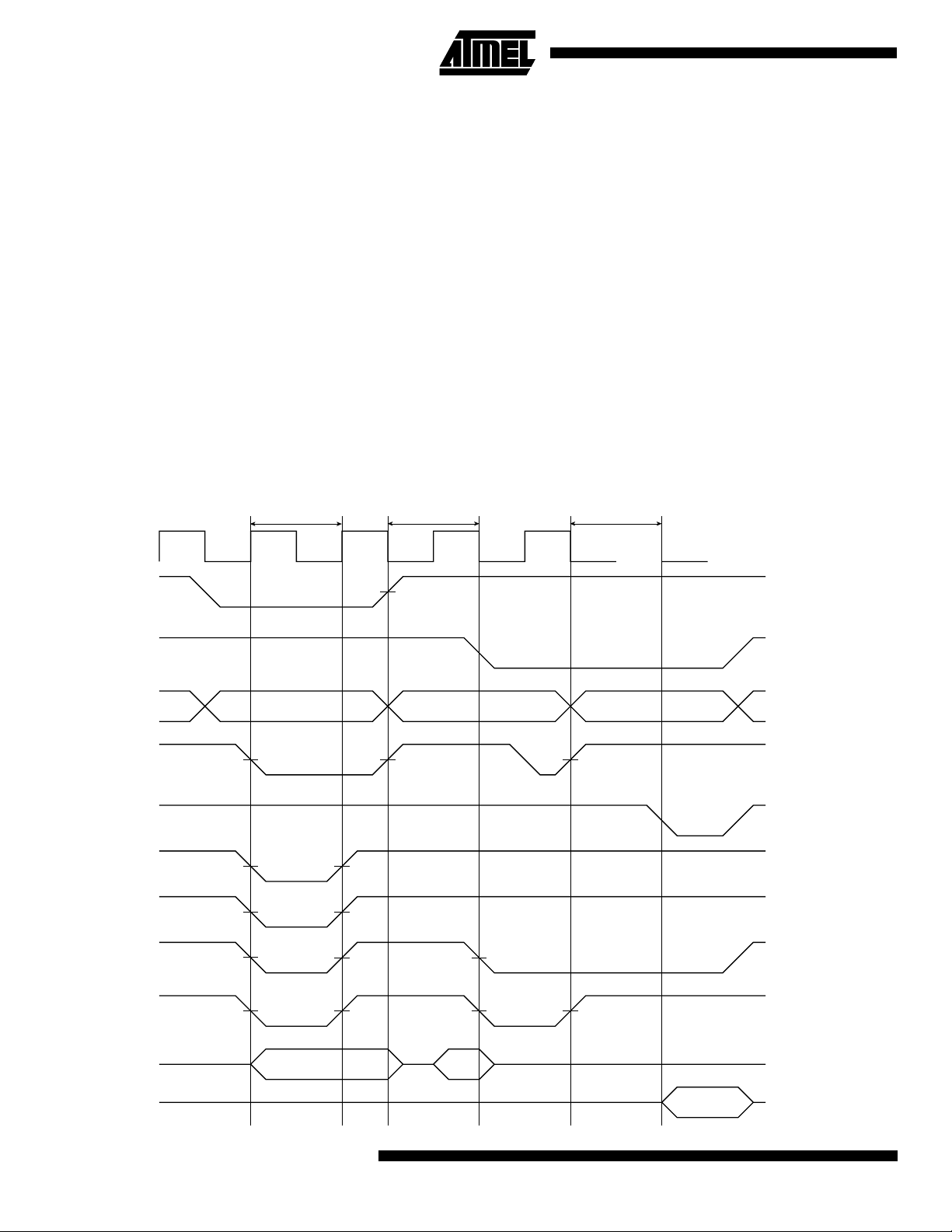

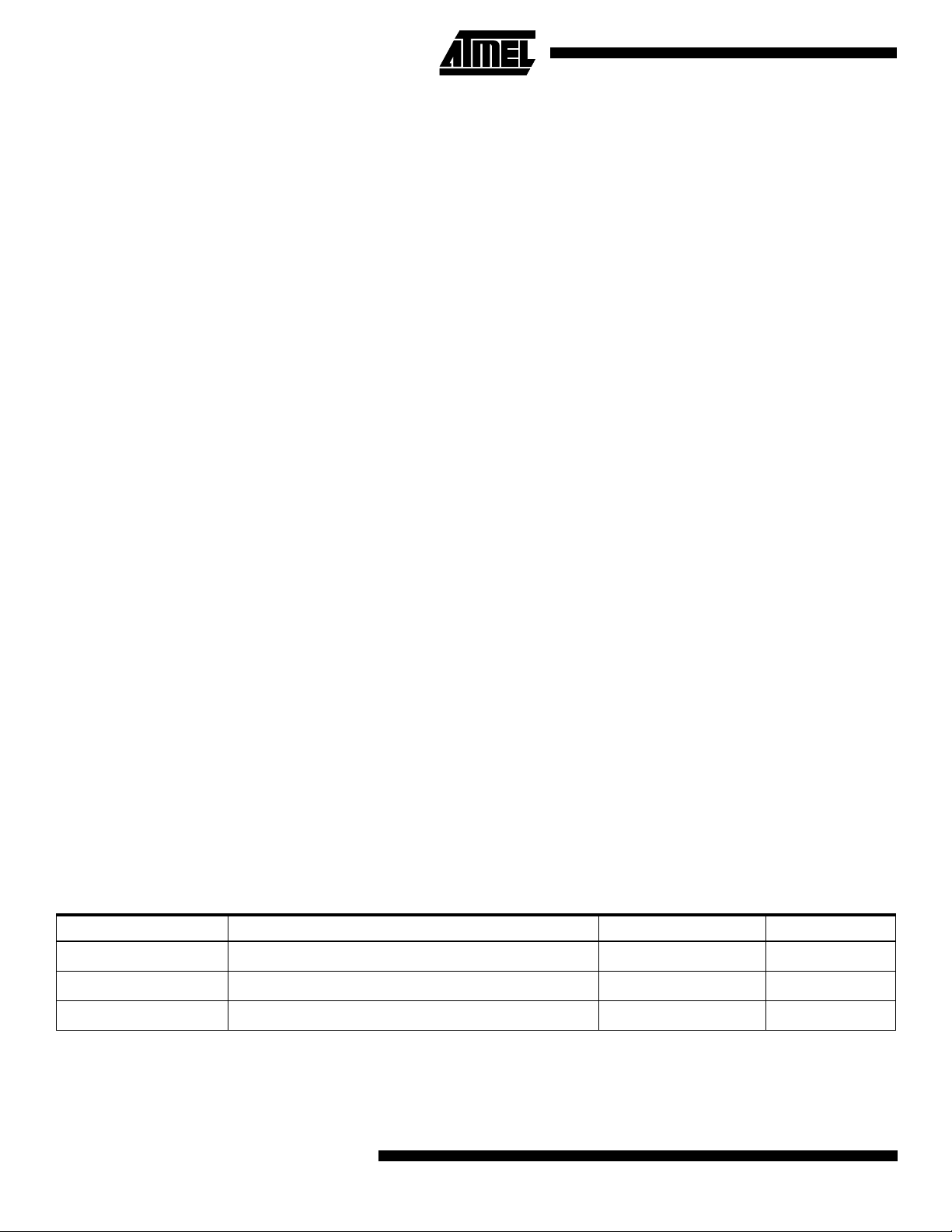

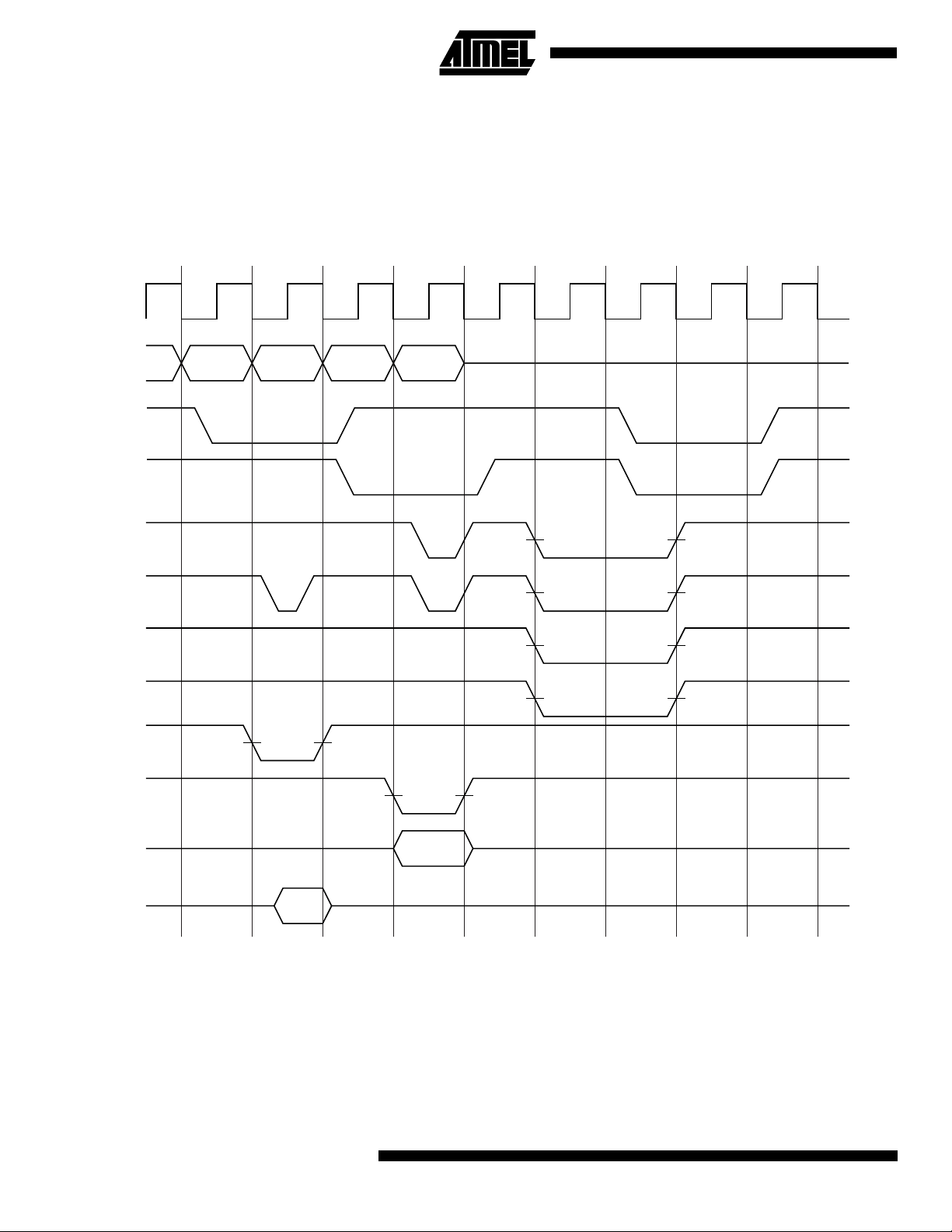

Figure 4 shows a write and a read to memory 0, followed

by a read and a write to memory 1. SMC_CSR0 is programmed for zero wait states with BAT = 0 and DFT = 0.

SMC_CSR1 is programmed for zero wait states with

BAT = 1 and DFT = 1. SMC_MCR is programmed for normal reads from all memories

The write to memory 0 is a byte access and, therefore, only

one NWE strobe is active. As BAT = 0, they are configured

as write strobes and have the same timing as NWR.

The memory 0 read immediately follows the write as early

reads are not configured and an early read wait state is not

required. As early reads are not configured, the read strobe

pulse is one-half clock cycle long.

output at the end of the memory 0 access but the strobes

are delayed for one clock cycle.

The write to memory 1 is a half-word (16-bit) access to an

even half-word address and, therefore, NWE0 and NWE1

are active. As BAT = 1, they are configured as byte select

signals and have the same timing as NCE.

As DFT = 1 for memory 1, a wait state is implemented

between the read and write to provide time for the memory

to stop driving the data bus. DFT wait states are only implemented at the end of read accesses.

The read from memory 1 is a byte access to an address

with a byte offset of two and, therefore, only NWE2 is

active.

There is a chip select change wait state between the memory 0 write and the memory 1 read. The new address is

Figure 4. Write and Read to Memory 0, Read and Write to Memory 1

Chip Select

Wait State

BCLK

NCE0

Data Float

Wait State

NCE1

NWR

NSOE

NWE0

NWE1

NWE2

NWE3

D (SIAP)

A

D (MEM)

23

Page 24

DMC: Dynamic Memory Controller

The ARM can access external DRAM by means of the

DRAM memory controller. The DMC sits on the ASB bus

and provides a glueless memory interface to external EDO

DRAM using the common address and data buses.

The AT75C310 supports two DRAM memory regions, each

with its own RAS signal. Both DRAM regions share the

same CAS, OE, WE, address and data signals.

The DRAM controller is programmed as an internal peripheral that has a standard APB bus interface and a set of

memory-mapped registers.

The DMC is designed to operate with extended data-out

(EDO) DRAM. It supports two 16-MByte address spaces

and a programmable 16- or 32-bit data bus. The controller

multiplexes the processor address to form DRAM row and

column addresses. The row and column addresses can be

configured to support various combinations of DRAM memory size, page size and data bus width.

The DMC supports:

• One or two DRAM memory regions

• DRAM memory region size of 2, 4, 8 or 16 megabytes

• DRAM page size of 256, 512, 1024 or 2048 columns

• Up to 15 row- and 11 column-address bits

• Asymmetric row and column addressing

• 16- or 32-bit DRAM data bus

• Automatic page breaking of burst accesses

• Automatic CAS-before-RAS refresh on timer trigger

• Automatic power-up initialization sequence

DMC Operation

The DMC multiplexes the ASB address to DRAM row and

column addresses. The column address must be between

eight and eleven bits. The row address is the required number of higher-order bits to support all combinations of permitted page- and memory-region sizes and both data bus

widths.

The DMC automatically inserts precharge and RAS cycles

and supplies an updated row address to the DRAM when a

sequential burst access from an ASB bus master crosses a

DRAM page boundary. The necessary number of wait

states is inserted to hold the bus master during the pre-

charge and RAS cycles.

The DMC performs a CAS-before-RAS refresh cycle on

both DRAM memory regions on the rising edge of a trigger

signal from the AT75C310 on-chip timer. If the DMC is per-

forming a DRAM access when the trigger occurs, the

access will finish before the refresh operation is performed.

In the case of a burst access, the refresh is not performed

until the end of the burst.

The DMC is capable of limiting the length of a burst access

if a refresh trigger has been received. If the feature is

enabled, the DMC performs the refresh operation once it

has been pending for 32 accesses in a burst sequence.

The DMC includes the functionality to interface the 32-bit

ASB data bus with a 16-bit DRAM data bus. It automatically

performs two accesses to the DRAM to service a 32-bit

access from the ASB.

Initialization Sequence

The DMC performs eight CAS-before-RAS refresh opera-

tions to both DRAM banks at the end of the AT75C310

reset pulse. The processor is not required to perform any

DRAM initialization operations. However, it is required to

initialize the DMC.

Data Alignment

The DMC only supports accesses to the appropriate data

boundary, i.e., word accesses must be word-aligned and

half-word accesses must be half-word-aligned. Misaligned

accesses will be ignored by the DMC, and the AMBA

decoder will therefore flag an abort to the appropriate ASB

bus master.

The ARM processor does not guarantee the level of the

bottom two address bits for an instruction access in ARM

state or the bottom address bit for an instruction fetch in

Thumb state. Therefore, the DMC will service misaligned

instruction fetches and force alignment, e.g., a 16-bit

instruction fetch from address 0x00000003 is performed as

a 16-bit read of address 0x00000002.

Table 9. DMC Register Map

Register Offset Register Description Register Name Access

0x0

0x4

0x8

24

DRAM Region 0 Configuration Register

DRAM Region 1 Configuration Register

DRAM Common Configuration Register

AT75C310

DMC_MR0 Read/write

DMC_MR1 Read/write

DMC_CR Read/write

Page 25

AT75C310

DRAM Memory Region Configuration Register

For each of the two DRAM memory regions there is a memory-mapped register.

Register Name: DMC_MR0..DMC_MR1

Reset value of DMC_MR0 is 0x40000000; reset value of DMC_MR1 is 0x50000000

31 30 29 28 27 26 25 24

BA

23 22 21 20 19 18 17 16

BA –––––

15 14 13 12 11 10 9 8

––––––––

76543210

––– SZ PS EMR

• EMR: Enable Memory Region

When low, the memory region is not enabled; any access to this region will generate an abort.

• PS: Page Size

This field should be set to the number of column address lines that are required by the external DRAM. It also indicates

the number of columns per page. The controller breaks sequential bursts on page boundaries.

PS Columns No. Column Address LInes

00

01

10

1 1

256 8

512 9

1024 10

2048 11

• SZ: Size

This field indicates the size of the memory region.

SZ Size of Memory Region

00 2 MB

01 4 MB

10 8 MB

1 1 16 MB

• BA: Base Address

This field indicates the base address of the memory region. It should be programmed with the top 11 bits of the

required base address. The number of bits used for address decoding is dependent on the SZ field.

SZ BA Bits Used

2 MB BA[31:21]

4 MB BA[31:22]

8 MB BA[31:23]

16 MB BA[31:24]

25

Page 26

DRAM Common Configuration Register (DMC_CR)

The Common Configuration Register defines parameters which are common to the two DRAM regions.

Register Name: DMC_CR

Reset Value is 0x00000000

31 30 29 28 27 26 25 24

––––––––

23 22 21 20 19 18 17 16

––––––––

15 14 13 12 11 10 9 8

––––––––

76543210

–––––ROR BBR DBW

• DBW: Data Bus Width

When high, the DRAM data bus is 32 bits wide. When low, the DRAM data bus is only 16 bits wide. The DMC splits 32bit transfers into two 16-bit transfers which are transparent to the ASB.

• BBR: Break Burst for Refresh

When this flag is high, the controller breaks long burst accesses every 32 CAS cycles if a refresh cycle is pending in

order to allow the refresh cycle to be performed. This prevents excessively long bursts from delaying refresh cycles.

• ROR: RAS-only Refresh

When high, the CAS signal is held inactive (high) during normal DRAM accesses, thereby generating a RAS-only

Refresh cycle. This feature allows software to generate the row address and initiate the refresh cycle. When low, memory operations behave as normal and CAS is not inhibited.

DRAM Interface

Table 10. DRAM Interface

FPDRAM Description Type Notes

NRAS[1:0]

NCAS[3:0]

NWE

NOE

A[14:0]

D[31:0]

Row Address Strobe O

Column Address

Strobe

Write Enable O

Output Enable O

Address Bus O

Data Bus I/O

O

One strobe per DRAM region. Common to four bytes in each region

One strobe per byte. Common to both DRAM regions. Only NCAS[1:0] used

when Data Bus Width is 16

Common to both regions

Common to both regions

Multiplexed row and column addresses

D[15:0] used when Data Bus Width is 16

26

AT75C310

Page 27

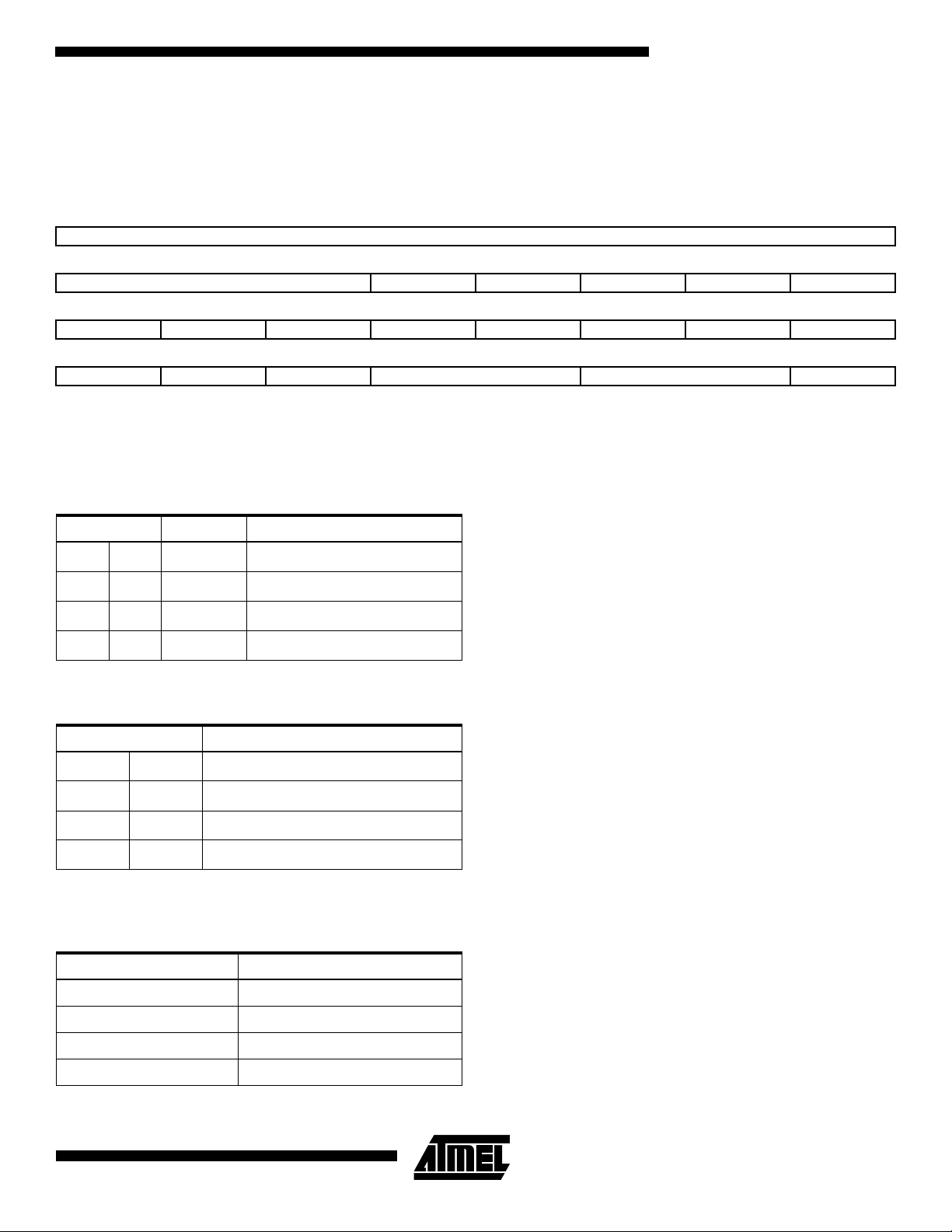

Dynamic Memory Accesses

Figure 5 and Figure 6 describe the different bus operations

that can be performed by DMC.

Write Access Followed by Burst Read Access

Figure 5 shows a write to DRAM0 followed by a burst of

two reads from the same device.

The write access takes two clock cycles. During the first

cycle, the row address is output and the RAS strobe is

asserted. In the next cycle, the column address is output

and the CAS strobes are asserted. The read is a half-word

(16-bit) access to an odd half-word address so only CAS2

and CAS3 are active.

Figure 5. Write to DRAM0 Waveform

BCLK

AT75C310

The read access is not sequential to the write access

(regardless of the addresses) and the RAS strobe is there-

fore raised for a precharge cycle between the accesses.

The read accesses take two clock cycles to read the first

word of data and one additional clock cycle for the second

word. The row address and RAS are asserted in the same

manner as for the read access. The column address and

CAS strobes are asserted earlier for a read access than for

a write access in order to provide time for the data to read

the processor core. The read accesses shown are word

(32-bit) accesses and all four CAS strobes are therefore

active.

The DMC asserts BWAIT to the ARM during the row

address and precharge cycles.

RAS0

RAS1

CAS0

CAS1

CAS2

CAS3

NDOE

NDWE

D (SIAP)

A

D (MEM)

27

Page 28

Read and Write Accesses Followed by CAS before RAS Refresh

Figure 6 shows a read access followed by a write. As the

accesses are to different devices, there is no need for a

precharge cycle.

Figure 6. Read Access Followed by a Write

BCLK

A

RAS0

RAS1

CAS0

The read is a byte access (one CAS strobe is active) and

the write is a half-word access (two CAS strobes are

active).

The CAS before RAS refresh cycle refreshes all DRAM

devices controlled by the DMC. All RAS and CAS strobes

are therefore active.

CAS1

CAS2

CAS3

NDOE

NDWE

D (SIAP)

D (MEM)

28

AT75C310

Page 29

AIC: Advanced Interrupt Controller

The AT75C310 has an eight-level priority, individually

maskable interrupt controller. This feature substantially

reduces the software and real-time overhead in handling

internal and external interrupts.

The interrupt controller is connected to the NFIQ (fast interrupt request) and the NIRQ (standard interrupt request)

inputs of the ARM7TDMI processor. The processor’s NFIQ

line can only be asserted by the external fast interrupt

request input FIQ. The NIRQ line can be asserted by the

interrupts generated by the on-chip peripherals and the

external interrupt request lines IRQ0 and FIQ.

Figure 7. Interrupt Controller Block Diagram

AT75C310

The eight-level priority encoder allows the customer to

define the priority between the different NIRQ interrupt

sources.

Internal sources are programmed to be level-sensitive or

edge-triggered. External sources can be programmed to be

positive- or negative-edge triggered or high- or low-level

sensitive.

The interrupt sources are listed in Table 11 and the AIC

programmable registers in Table 12.

FIQ Source

Advanced Peripheral

Bus (APB)

Internal Interrupt Sources

External Interrupt Sources

Note: After a hardware reset, the AIC pins are controlled by the PIO controller. They must be configured to be controlled by the periph-

eral before being used.

Memorization

Control

Logic

Memorization

Prioritization

Controller

NFIQ

Manager

NIRQ

Manager

NFIQ

ARM7TDMI

Core

NIRQ

29

Page 30

Table 11. AIC Interrupt Sources

Interrupt Source Interrupt Name Interrupt Description

0 FIQ/LOWP

1 WDIRQ

2SWIRQ

3UAIRQ

4TC0IRQ

5TC1IRQ

6TC2IRQ

7PIOAIRQ

8 LCDIRQ

9 SPIIRQ

10 IRQ0

11 –

12 OAKIRQ

13 OAKBIRQ

14 UBIRQ

15 PIOBIRQ

16 –

17 –

18 –

19 –

20 –

21 –

22 –

23 –

24 –

25 –

26 –

27 –

28 –

29 –

30 –

31 –

Fast interrupt (external), low-power

Watchdog

Software (Generated by AIC)

USART A

Timer/Counter0

Timer/Counter1

Timer/Counter2

PIO A

LCD Controller

SPI

External 0

Reserved

OAK A Semaphore

OAK B Semaphore

USART B

PIO B

Reserved

Reserved

Reserved

Reserved

Reserved

Reserved

Reserved

Reserved

Reserved

Reserved

Reserved

Reserved

Reserved

Reserved

Reserved

Reserved

30

AT75C310

Page 31

AT75C310

Priority Controller

The NIRQ line is controlled by an eight-level priority

encoder. Each source has a programmable priority level of

7 to 0. Level 7 is the highest priority and level 0 the lowest.

When the AIC receives more than one unmasked interrupt

at a time, the interrupt with the highest priority is serviced

first. If both interrupts have equal priority, the interrupt with

the lowest interrupt source number is serviced first. Interrupt source numbers are given in Table 11.

The current priority level is defined as the priority level of

the current interrupt at the time the register AIC_IVR is

read (the interrupt which will be serviced).

If a higher priority unmasked interrupt occurs and an interrupt already exists, there are two possible outcomes

depending on whether the AIC_IVR has been read.

1. If the NIRQ line has been asserted but the AIC_IVR

has not been read, then the processor will read the

new higher priority interrupt handler address in the

AIC_IVR register and the current interrupt level is

updated.

2. If the processor has already read the AIC_IVR, then

the NIRQ line is reasserted. When the processor

has authorized nested interrupts to occur and reads

the AIC_IVR again, it reads the new, higher-priority

interrupt handler address. At the same time, the

current priority value is pushed onto a first-in lastout stack and the current priority is updated to the

higher priority.

When the End of Interrupt Command Register

(AIC_EOICR) is written, the current interrupt level is

updated with the last stored interrupt level from the stack (if

any). Hence, at the end of a higher priority interrupt, the

AIC returns to the previous state corresponding to the preceding lower priority interrupt which had been interrupted.

Interrupt Handling

The interrupt handler must read the AIC_IVR as soon as

possible. This de-asserts the NIRQ request to the processor and clears the interrupt in case it is programmed to be

edge-triggered. This permits the AIC to assert the NIRQ

line again when a higher-priority unmasked interrupt

occurs.

At the end of the interrupt service routine, the End of Interrupt Command Register (AIC_EOICR) must be written.

This allows pending interrupts to be serviced.

Interrupt Masking

Each interrupt source, including FIQ, can be enabled or

disabled using the command registers AIC_IECR and

AIC_IDCR. The interrupt mask can be read in the read-only

register AIC_IMR. A disabled interrupt does not affect the

servicing of other interrupts.

Interrupt Clearing and Setting

All interrupt sources which are programmed to be edge-

triggered (including FIQ) can be individually set or cleared

by writing to the registers AIC_ISCR and AIC_ICCR,

respectively. This function of the interrupt controller is avail-

able for auto-test or software debug purposes.

Fast Interrupt Request

The external FIQ line is the only source which can raise a

fast interrupt request to the processor. Therefore, it has no

priority controller.

The external FIQ line can be programmed to be positive- or

negative-edge triggered or high- or low-level sensitive in

the AIC_SMR0 register.

The interrupt handler can be stored starting from address

0x0000001C as described in the Atmel ARM7TDMI

datasheet, literature number 0673.

Software Interrupt

Interrupt source 1 of the AIC is a software interrupt. It must

be programmed to be edge-triggered in order to set or clear

it by writing to the AIC_ISCR and AIC_ICCR.

This is independent of the SWI instruction of the

ARM7TDMI processor.

Standard Interrupt Sequence

The following conditions are assumed:

• The AIC has been programmed and interrupts are

enabled.

• The instruction at address 0x18 (IRQ exception vector

address) jumps into a default handler which reads

AIC_IVR and then jumps to the specific service routine

for the read interrupt number.

When NIRQ is asserted, if the bit “I” of CPSR is 0, the

sequence is:

1. The CPSR is stored in SPSR_irq, the current value

of the Program Counter is loaded in the IRQ link

register (R14_irq) and the Program Counter (R15)

is loaded with 0x18. In the following cycle during

fetch at address 0x1C, the ARM core adjusts

R14_irq, decrementing it by 4.

2. The ARM core enters IRQ mode if it is not already.

3. When the instruction at 0x18 is executed, the Program Counter is loaded with the start address of the

default interrupt handler.

4. The previous interrupt priority level is stored onto a

stack. Note that if no interrupt was active, the previous interrupt priority will be zero.

5. The AIC_IVR register is read causing the IRQ

request to be cancelled and the current interrupt priority is updated. Any registers that may be used can

be stored onto the stack at this point if required. The

31

Page 32

code then checks the interrupt number and

branches to the required service routine.

6. The service routine should start by saving the Link

Register (R14_irq) and the SPSR (SPSR_irq). Note

that the Link Register must be decremented by four

when it is saved if it is to be restored directly into the

Program Counter at the end of the interrupt. Alternatively, this can be done at the start of the default

handler.

7. Further interrupts can then be unmasked by clearing the “I” bit in the CPSR, allowing re-assertion of

the NIRQ to be taken into account by the core. This

occurs if an interrupt with a higher priority than the

current one occurs.

8. The Interrupt Handler then proceeds as required,

saving the registers which will be used and restoring them at the end. During this phase, an interrupt

of priority higher than the current level restarts the

sequence from step 1. Note that if the interrupt is

programmed to be level sensitive, the source of the

interrupt must be cleared during this phase.

9. The “I” bit in the CPSR must be set in order to mask

interrupts before exiting to ensure that the interrupt

is completed in an orderly manner.

10. The service routine should then branch to the common exit routine.

11. The stored priority level is fetched (from a stack)

and witten to the End Of Interrupt Command Register (AIC_EOICR) in order to indicate to the AIC that

the current interrupt is finished. This restores the

previous current level if one existed. If another interrupt is pending with lower or equal priority than the

old current level but with higher priority than the new

current level, the NIRQ line is re-asserted. The

interrupt sequence does not immediately start

because the “I” bit is set in the core.

12. The SPSR (SPSR_irq) is restored. Finally, the

saved value of the Link Register is restored directly

into the PC. This has the effect of returning from the

interrupt to whatever was being executed before

and of loading the CPSR with the stored SPSR,

masking or unmasking the interrupts depending on

the state saved in the SPSR (the previous state of

the ARM core).

Note that the “I” bit in the SPSR is significant. If it is set, it

indicates that the ARM core was just about to mask IRQ

interrupts when the mask instruction was interrupted.

Hence, when the SPSR is restored, the mask instruction is

completed (IRQ is masked).

Fast Interrupt Sequence

It is assumed that:

• The AIC has been programmed and the fast interrupt is

enabled.

• The instruction at address 0x1C (FIQ exception vector

address) is a branch to an FIQ service routine or the first

instruction of the FIQ routine

Nested fast interrupts are not needed by the user.

When NFIQ is asserted, if the bit “F” of CPSR is 0, the

sequence is:

1. The CPSR is stored in SPSR_fiq, the current value

of the Program Counter is loaded in the FIQ link

register (R14_fiq) and the Program Counter (R15) is

loaded with 0x1C. In the following cycle, during

fetch at address 0x20, the ARM core adjusts

R14_fiq, decrementing it by four.

2. The ARM core enters FIQ mode and starts execut-

ing the instruction at address 0x1c, which may be a

branch or the first service routine instruction.

3. The AIC_FVR register is read. This results in the

cancellation of the FIQ request and returns 0x0.

4. The previous step has the effect of branching to the

corresponding interrupt service routine. It is not

necessary to save the Link Register (R14_fiq) and

the SPSR (SPSR_fiq) if nested fast interrupts are

not needed.

5. The Interrupt Handler then proceeds as required. It

is not necessary to save registers R8 to R13

because FIQ mode has its own dedicated registers

and the user R8 to R13 are banked. The other registers, R0 to R7, must be saved before being used,

and restored at the end (before the next step). Note

that if the fast interrupt is programmed to be level

sensitive, the source of the interrupt must be

cleared during this phase in order to de-assert the

NFIQ line.

6. Finally, the Link Register (R14_fiq) is restored into

the PC after decrementing it by 4 (with instruction

sub pc, lr, #4 for example). This has the effect of

returning from the interrupt to whatever was being

executed before, and of loading the CPSR with the

SPSR, masking or unmasking the fast interrupt

depending on the state saved in the SPSR.

Note that the “F” bit in the SPSR is significant. If it is set, it

indicates that the ARM core was just about to mask FIQ

interrupts when the mask instruction was interrupted.

Hence, when the SPSR is restored, the interrupted instruction is completed (FIQ is masked).

32

AT75C310

Page 33

AT75C310

AIC User Interface

Base Address: 0xFF030000

Table 12. AIC Memory Map

Offset Register Description Register Name Access Reset State

0x000

0x004

–––Read/write 0

0x07C

0x080

0x084

–

0x0FC

0x100

0x104

0x108

0x10C

0x110

0x114

0x118

0x11C

Source Mode Register 0

Source Mode Register 1

Source Mode Register 31

Reserved

Reserved

Reserved

Reserved

IRQ Vector Register

FIQ Vector Register

Interrupt Status Register

Interrupt Pending Register

Interrupt Mask Register

Core Interrupt Status Register

Reserved

Reserved

AIC_SMR0 Read/write 0

AIC_SMR1 Read/write 0

AIC_SMR31 Read/write 0

–––

–––

–––

–––

AIC_IVR Read-only 0

AIC_FVR Read-only 0

AIC_ISR Read-only 0

AIC_IPR Read-only (see Note 1)

AIC_IMR Read-only 0

AIC_CISR Read-only 0

–––

–––

0x120

0x124

0x128

0x12C

0x130

Note: 1. The reset value of this register depends on the level of the external IRQ lines. All other sources are cleared at reset.

Interrupt Enable Command Register

Interrupt Disable Command Register

Interrupt Clear Command Register

Interrupt Set Command Register

End of Interrupt Command Register

AIC_IECR Write-only –

AIC_IDCR Write-only –

AIC_ICCR Write-only –

AIC_ISCR Write-only –

AIC_EOICR Write-only –

33

Page 34

AIC Source Mode Register

Register Name: AIC_SMR0..AIC_SMR31

Access Type: Read/write

Reset Value: 0

31 30 29 28 27 26 25 24

––––––––

23 22 21 20 19 18 17 16

––––––––

15 14 13 12 11 10 9 8

––––––––

76543210

– SRCTYPE –– PRIOR

• PRIOR: Priority Level

Programs the priority level for all sources except source 0 (FIQ).

The priority level can be between 0 (lowest) and 7 (highest).

The priority level is not used for the FIQ in the SMR0.

• SRCTYPE: Interrupt Source Type

Programs the input to be positive- or negative-edge triggered or positive- or negative-level sensitive.

The active level or edge is not programmable for the internal sources.

SRCTYPE Internal Sources External Sources

00

01

10

11

Level-sensitive Low-level sensitive

Edge-triggered Negative-edge triggered

Level-sensitive High-level sensitive

Edge-triggered Positive-edge triggered

AIC Interrupt Vector Register

Register Name: AIC_IVR

Access Type: Read-only

Reset Value: 0

31 30 29 28 27 26 25 24

––––––––

23 22 21 20 19 18 17 16

––––––––

15 14 13 12 11 10 9 8

––––––––

76543210

PRIOR IRQID

• PRIOR

Interrupt priority

• IRQID

Active interrupt number. Used to select required service routine.

34

AT75C310

Page 35

AIC FIQ Vector Register

Register Name: AIC_FVR

Access Type: Read-only

Reset Value: 0

31 30 29 28 27 26 25 24

23 22 21 20 19 18 17 16

15 14 13 12 11 10 9 8

76543210

• FIQV: FIQ Vector Register

FIQ = 0x00000000 if FIQ active

FIQ = 0xFFFFFFFF otherwise

AIC Interrupt Status Register

Register Name: AIC_ISR

Access Type: Read-only

Reset Value: 0

AT75C310

FIQV

FIQV

FIQV

FIQV

31 30 29 28 27 26 25 24

––––––––

23 22 21 20 19 18 17 16

––––––––

15 14 13 12 11 10 9 8

––––––––

76543210

PRIOR IRQID

• PRIOR

Interrupt priority

• IRQID

Active interrupt number. Used to select required service routine.

35

Page 36

AIC Interrupt Pending Register

Register Name: AIC_IPR

Access Type: Read-only

Reset Value: Undefined

31 30 29 28 27 26 25 24

––––––––

23 22 21 20 19 18 17 16

––––––––

15 14 13 12 11 10 9 8

PIOBIRQ UBIRQ OAKBIRQ OAKAIRQ – IRQ0 SPIIRQ LCDIRQ

76543210

PIOAIRQ TC2IRQ TC1IRQ TC0IRQ UAIRQ SWIRQ WDIRQ FIQ

• Interrupt Pending

0 = Corresponding interrupt is inactive

1 = Corresponding interrupt is pending

AIC Interrupt Mask Register

Register Name: AIC_IMR

Access Type: Read-only

Reset Value: 0

31 30 29 28 27 26 25 24

––––––––

23 22 21 20 19 18 17 16

––––––––

15 14 13 12 11 10 9 8

PIOBIRQ UBIRQ OAKBIRQ OAKAIRQ – IRQ0 SPIIRQ LCDIRQ

76543210

PIOAIRQ TC2IRQ TC1IRQ TC0IRQ UAIRQ SWIRQ WDIRQ FIQ

• Interrupt Mask

0 = Corresponding interrupt is disabled

1 = Corresponding interrupt is enabled

36

AT75C310

Page 37

AIC Core Interrupt Status Register

Register Name: AIC_CISR

Access Type: Read-only

Reset Value: 0

31 30 29 28 27 26 25 24

––––––––

23 22 21 20 19 18 17 16

––––––––

15 14 13 12 11 10 9 8

––––––––

76543210

––––––NIRQ NFIQ

• NFIQ: NFIQ Status

0 = NFIQ line inactive

1 = NFIQ line active

• NIRQ: NIRQ Status

0 = NIRQ line inactive

1 = NIRQ line active

AT75C310

AIC Interrupt Enable Command Register

Register Name: AIC_IECR

Access Type: Write-only

31 30 29 28 27 26 25 24

––––––––

23 22 21 20 19 18 17 16

––––––––

15 14 13 12 11 10 9 8

––––––––

76543210

––––––NIRQ NFIQ

• NFIQ: NFIQ Status

0 = NFIQ line inactive

1 = NFIQ line active

• NIRQ: NIRQ Status

0 = NIRQ line inactive

1 = NIRQ line active

37

Page 38

AIC Interrupt Disable Command Register

Register Name: AIC_IDCR

Access Type: Write-only

31 30 29 28 27 26 25 24

––––––––

23 22 21 20 19 18 17 16

––––––––

15 14 13 12 11 10 9 8

––––––––

76543210

––––––NIRQ NFIQ

• NFIQ: NFIQ Status

0 = NFIQ line inactive

1 = NFIQ line active

• NIRQ: NIRQ Status

0 = NIRQ line inactive

1 = NIRQ line active

AIC Interrupt Clear Command Register

Register Name: AIC_ICCR

Access Type: Write-only

31 30 29 28 27 26 25 24

––––––––

23 22 21 20 19 18 17 16

––––––––

15 14 13 12 11 10 9 8

––––––––

76543210

––––––NIRQ NFIQ

• NFIQ: NFIQ Status

0 = NFIQ line inactive

1 = NFIQ line active

• NIRQ: NIRQ Status

0 = NIRQ line inactive

1 = NIRQ line active

38

AT75C310

Page 39

AIC Interrupt Set Command Register

Register Name: AIC_ISCR

Access Type: Write-only

31 30 29 28 27 26 25 24

––––––––

23 22 21 20 19 18 17 16

––––––––

15 14 13 12 11 10 9 8

––––––––

76543210

––––––NIRQ NFIQ

• NFIQ: NFIQ Status

0 = NFIQ line inactive

1 = NFIQ line active

• NIRQ: NIRQ Status

0 = NIRQ line inactive

1 = NIRQ line active

AT75C310

AIC End of Interrupt Command Register

Register Name: AIC_EOICR

Access Type: Write-only

31 30 29 28 27 26 25 24

––––––––

23 22 21 20 19 18 17 16

––––––––

15 14 13 12 11 10 9 8

––––––––

76543210

––––––––

The End of Interrupt Command Register is used by the interrupt routine to indicate that the interrupt handling is complete.

Any value can be written because it is only necessary to make a write to this register location to signal the end of interrupt

handling. The value written is taken by the AIC and used as the new interrupt priority level, i.e., if no interrupt was active

when the current routine was entered, zero is written. If an interrupt was active and interrupt nesting is enabled, the value

written should be the priority and interrupt number of the previous interrupt.

39

Page 40

PIO: Parallel I/O Controller

The AT75C310 has 23 programmable I/O lines. Three pins

on the AT75C310 are dedicated as general-purpose I/O

pins. Other I/O lines are multiplexed with an external signal

of a peripheral to optimize the use of available package

pins. Refer to Table 13 and Table 14 on page 42. These

lines are controlled by two separate and identical PIO controllers, PIO A and PIO B. Each PIO controller also provides an internal interrupt signal to the AIC.

Multiplexed I/O Lines

Most I/O lines are multiplexed with an I/O signal of a

peripheral. After reset, the pin is controlled by the PIO controller and is in input mode.

When a peripheral signal is not used in an application, the

corresponding pin can be used as a parallel I/O. Each parallel I/O line is bi-directional, whether the peripheral defines

the signal as input or output. Figure 8 shows the multiplexing of the peripheral signals with parallel I/O signals.

If a pin is multiplexed between the PIO controller and a

peripheral, the pin is controlled by the registers PIO_PER

(PIO Enable) and PIO_PDR (PIO Disable). The register

PIO_PSR (PIO Status) indicates whether the pin is controlled by the corresponding peripheral or by the PIO controller.