Page 1

Features

• ARM7TDMI

• One 16-bit Fixed-point OakDSPCore

• Dual Ethernet 10/100 Mbps MAC Interface with Voice Priority

• Multi-layer AMBA

• 256 x 32-bit Boot ROM

• 88K bytes of Integrated Fast RAM

• Flexible External Bus Interface with Programmable Chip Selects

• Codec Interface

• Multi-level Priority, Individually-maskable, Vectored Interrupt Controller

• Three 16-bit Timer/Counters

• Additional Watchdog Timer

• Two USARTs with FIFO and Modem Control Lines

• Industry-standard Serial Peripheral Interface (SPI)

• Up to 24 General-purpose I/O Pins

• On-chip SDRAM Controller for Embedded ARM7TDMI and OakDSPCore

• JTAG Debug Interface

• Software Development Tools Available for ARM7TDMI and OakDSPCore

• Supported by a Wide Range of Ready-to-use Application Software,

including Multi-tasking Operating System, Networking

and Voice-processing Functions

• Available in a 208-lead PQFP Package

™

ARM® Thumb™ Processor Core

™

Architecture

®

Smart Internet

Appliance

Processor

(SIAP™)

AT75C220 –

Description

The AT75C220, Atmel’s latest device in the family of smart internet appliance processors (SIAP), is a high-performance processor designed for professional internet

appliance applications such as the Ethernet IP phone. The AT75C220 is built around

an ARM7TDMI microcontroller core running at 40 MIPS with an OakDSPCore co-processor running at 60 MIPS and a dual Ethernet 10/100 Mbps MAC interface.

In a typical standalone IP phone, the DSP handles the voice processing functions

(voice compression, acoustic echo cancellation, etc.) while the dual-port Ethernet

10/100 Mbps MAC interface establishes the connection to the Ethernet physical layer

(PHY) that links the network and the PC. In such an application, the power of the

ARM7TDMI allows it to run a VoIP protocol stack as well as all the system control

tasks.

Atmel provides the AT75C220 with three levels of software modules:

• a special port of the Linux kernel as the proposed operating system

• a comprehensive set of tunable DSP algorithms for voice processing, tailored to be

run by the DSP subsystem

• a broad range of application-level software modules such as H323 telephony or

POP-3/SMTP E-mail services

CPU

Peripherals

Rev. 1396A–05/01

1

Page 2

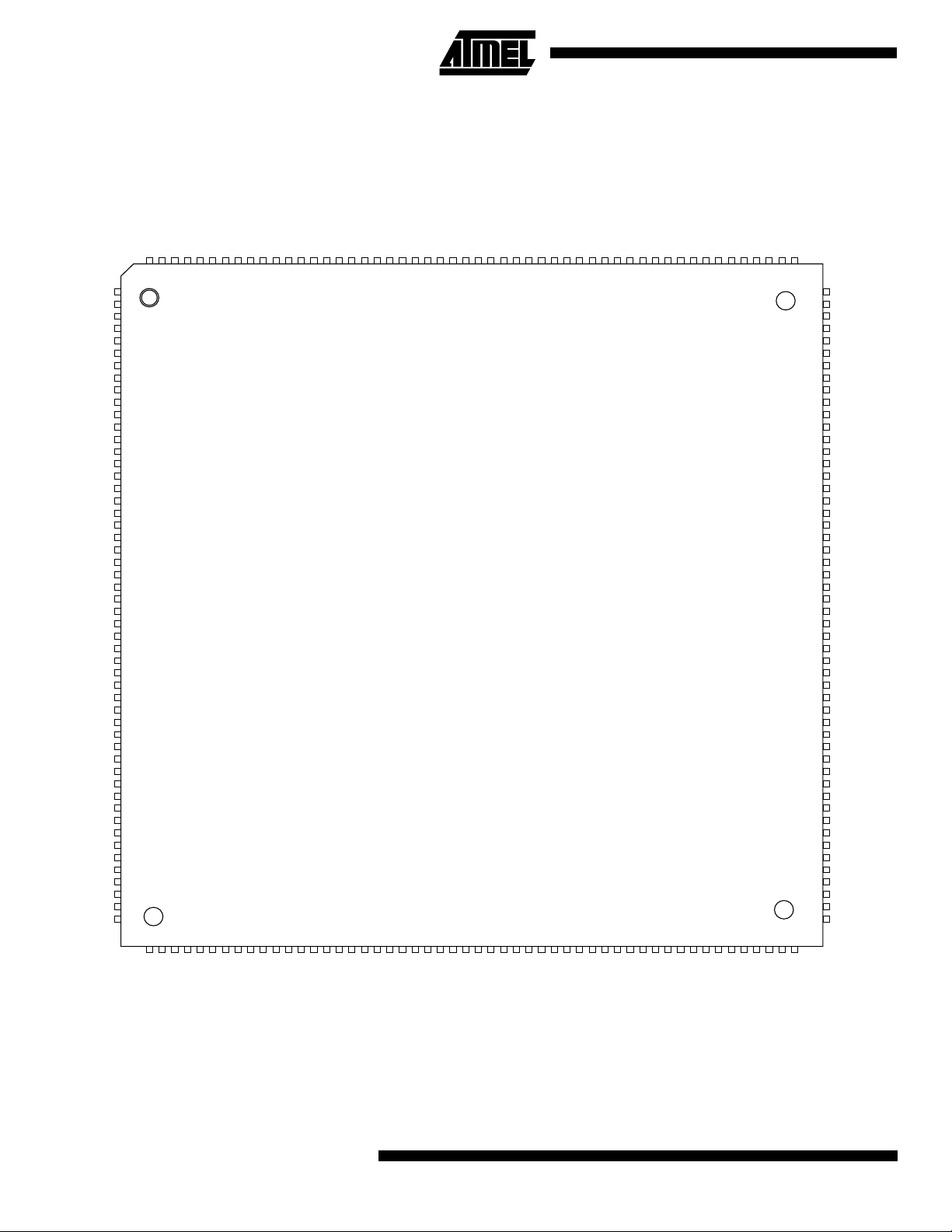

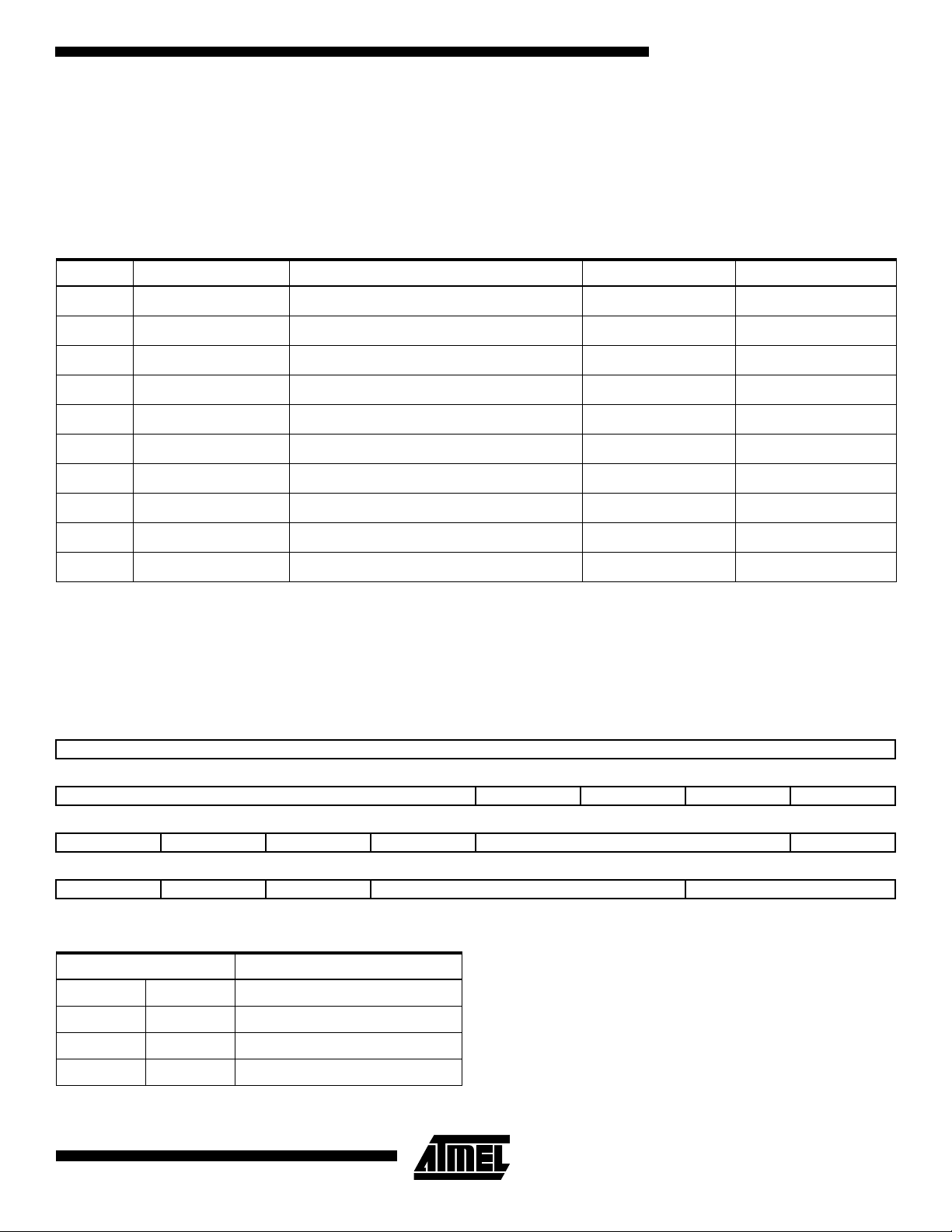

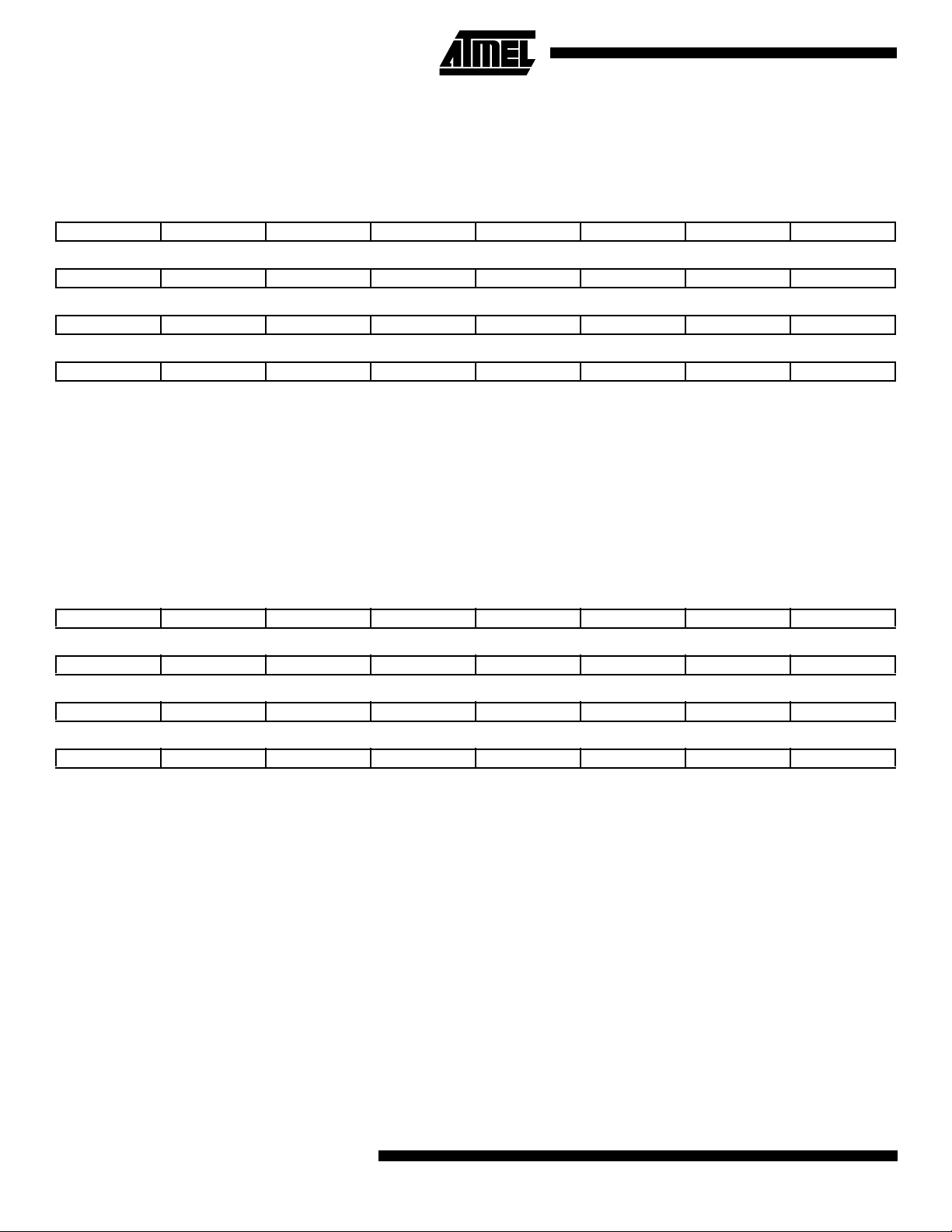

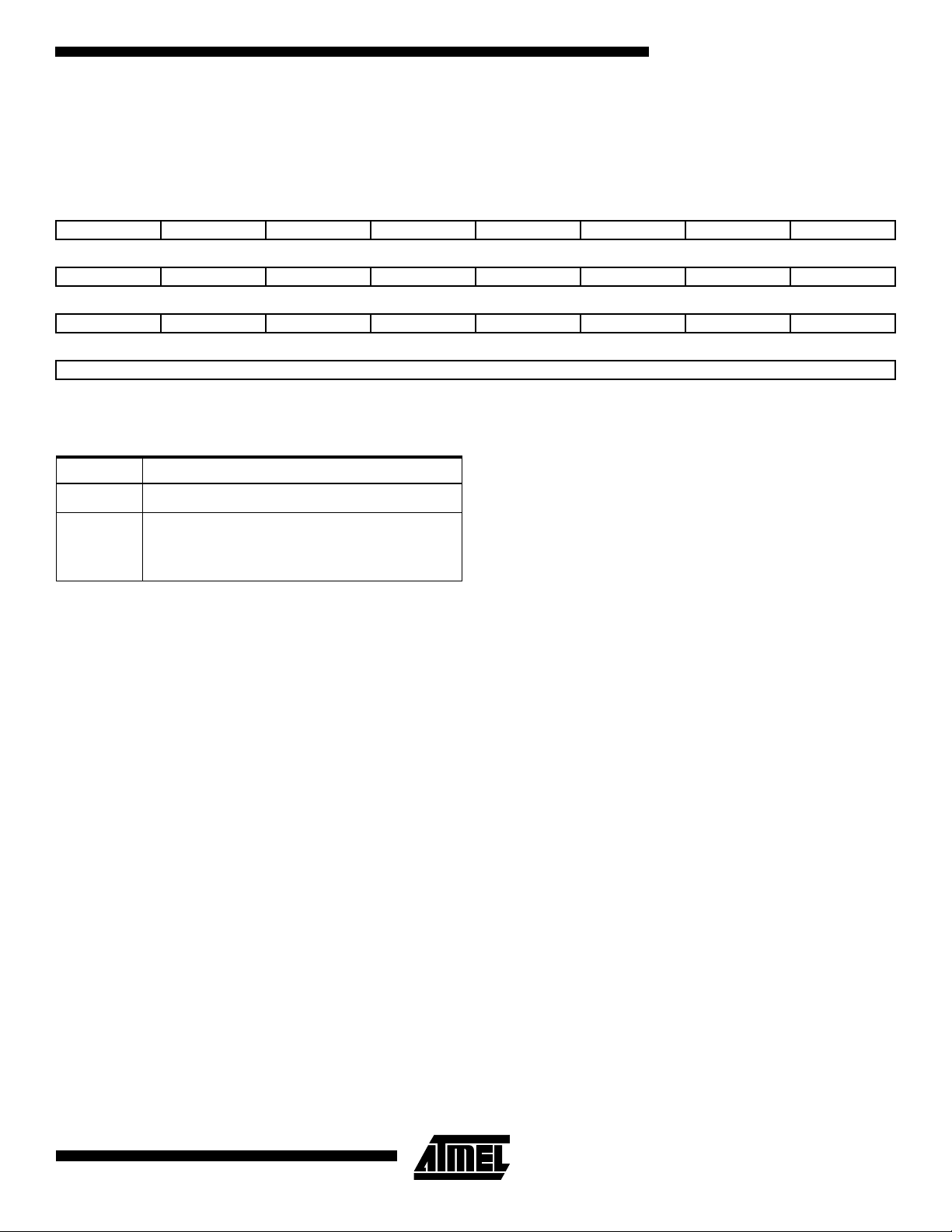

AT75C220 Pin Configuration

Figure 1. AT75C220 Pinout in 208-lead PQFP Package

VDD3V3

B0256

GND

DBW32

VDD3V3

PB9

PB8/NCE2

PB7/NCE1

PB6/NWDOVF

PB5/NRIA

PB4

PB3/NCTSA

PB2/TIOB1

PB1/TIOA1

PB0/TCLK1

GND

TXDB

RXDB

NDCDA

NDSRA

NDTRA

NCTSA

NRTSA

208

207

206

205

204

203

202

201

200

199

198

197

196

195

194

193

192

191

190

189

188

187

GND

SCLKA

VDDV3

FSA

STXA

SRXA

NTRST

MA_COL

MA_CRS

MA_TXER

MA_TXD0

MA_TXD1

MA_TXD2

MA_TXD3

MA_TXEN

XVDDV3

MA_TXCLK

GND

MA_RXD0

MA_RXD1

MA_RXD2

MA_RXD3

MA_RXER

MA_RXCLK

GND

VDD2V5

MA_RXDV

MA_MDC

MA_MDIO

MA_LINK

MB_COL

MB_CRS

GND

VDD2V5

VDD3V3

MB_TXER

MB_TXD0

MB_TXD1

MB_TXD2

GND

MB_TXD3

MB_TXEN

MB_TXCLK

MB_RXD0

MB_RXD1

MB_RXD2

MB_RXD3

MB_RXER

MB_RXCLK

MB_RXDV

MB_MDC

VDDV3

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

5354555657585960616263646566676869707172737475767778798081828384858687888990919293949596979899

186

TXDA

185

RXDA

184

GND

183

PA0/OAKAIN0

PA1/OAKAIN1

PA2/OAKAOUT0

PA3/OAKAOUT1

182

181

180

179

PA4

PA5NCVDD3V3

178

177

176

175

PA6

174

PA7

PA8/TCLK0

173

172

PA9/TIOA0

PA10/TIOB0

PA11/SCKA

171

170

169

VDD3V3

GND

168

167

PA12/NPCS1

GND

VDD2V5

PA19/ACLK

166

165

164

163

TCK

162

TMS

161

100

TDI

160

101

TDO

159

102

VDD3V3

GND

158

157

156

155

154

153

152

151

150

149

148

147

146

145

144

143

142

141

140

139

138

137

136

135

134

133

132

131

130

129

128

127

126

125

124

123

122

121

120

119

118

117

116

115

114

113

112

111

110

109

108

107

106

105

103

104

VDD3V3

NC

VDD2V5

GND

TST

IRQ0

FIQ

RESET

GND

VDD3V3

NPCSS

SPCK

MOSI

MISO

NWAIT

VDD2V5

GND

NSOE

NWR

NWE3

GND

VDD3V3

NWE2

NWE1

NWE0

NCE3

VDD3V3

NCE2

NCE1

NCE0

VDD2V5

XTALIN

XTALOUT

GND

PLL_GND

XREF240

PLL_VDD2V5

GND

VDD2V5

NC

GND

NC

DQM1

DQM0

WE

NC

CAS

RAS

CS1

CS0

DCLK

GND

A0A1A2A3A4A5A6A7A8

GND

MB_LINK

MB_MDIO

2

AT75C220

A9

A10

A11

A12

A13

A14

A15

A16

A17

GND

A18

VDD3V3

A19

A20

A21

D0D1D2

D3

D4

GND

D5D6D7D8D9

VDD3V3

D10

D11

D12

D13

D14

GND

VDD2V5

D15

GND

VDD3V3

NGNT

NREQ

VDD3V3

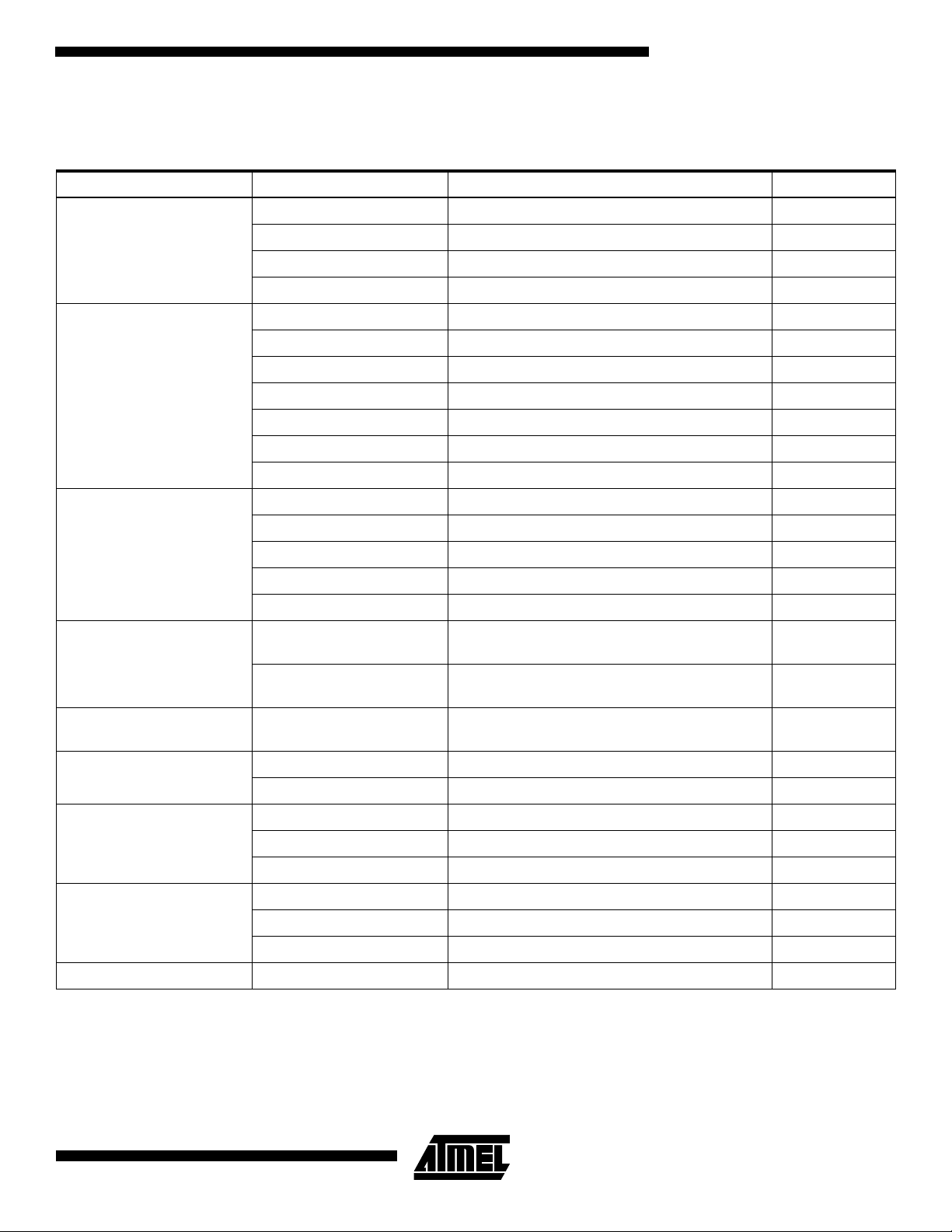

Page 3

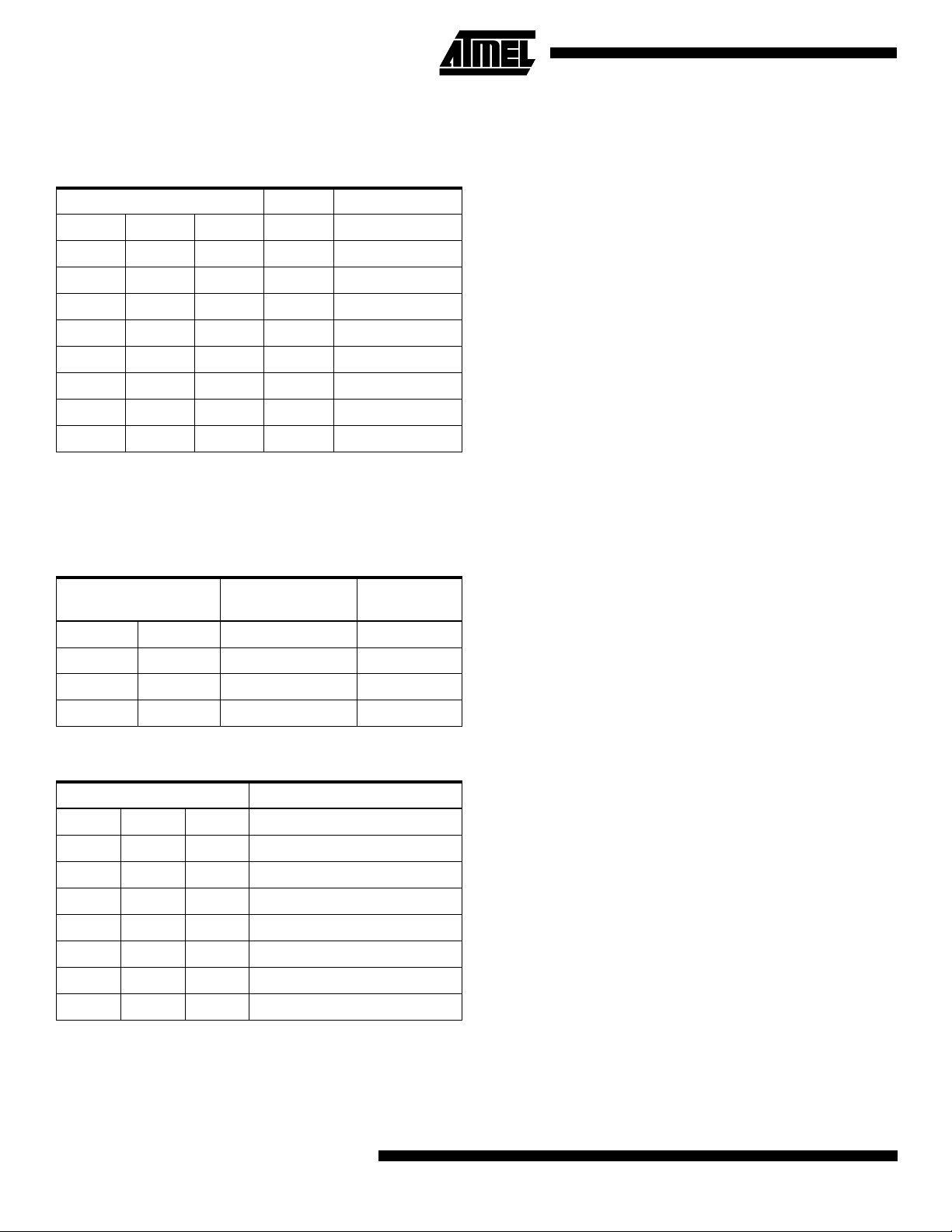

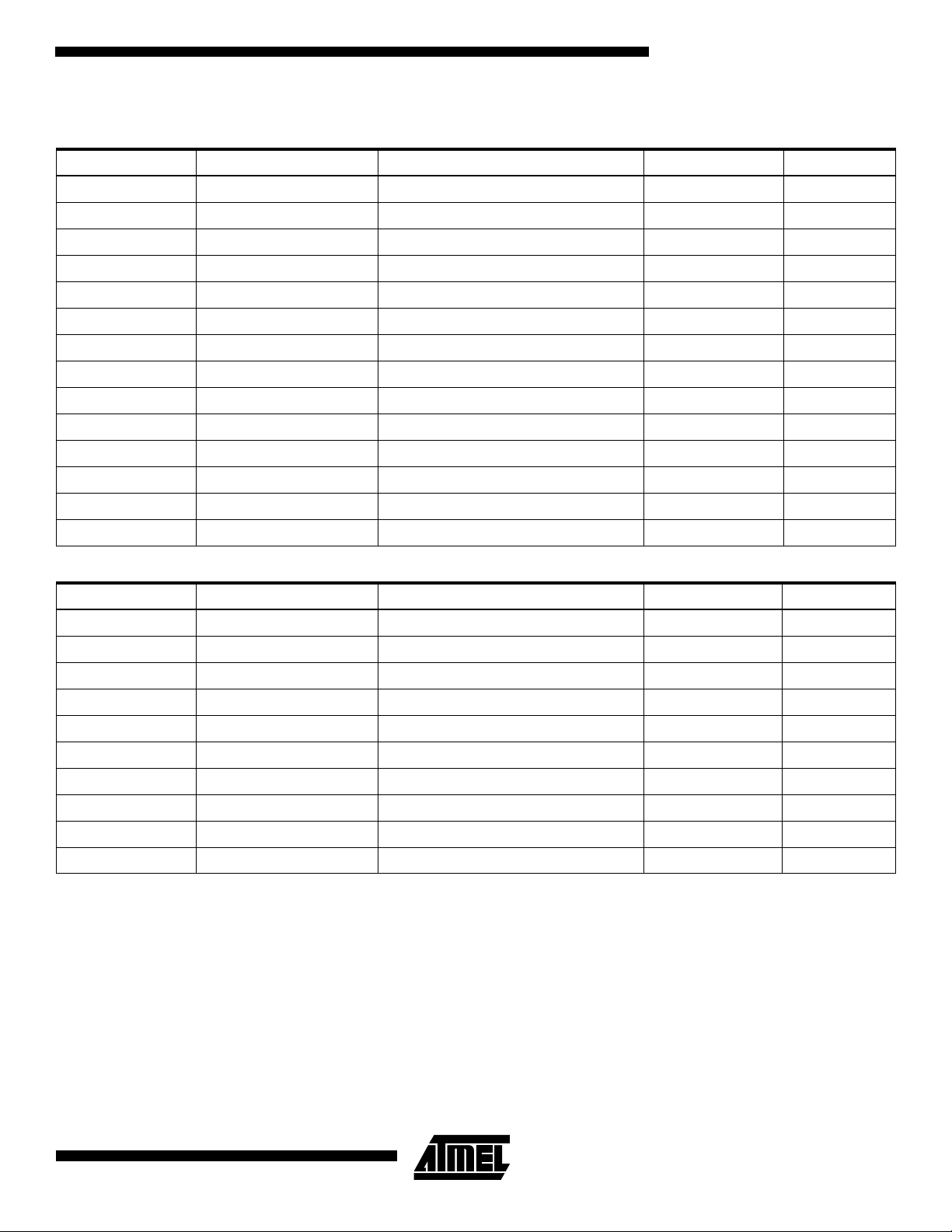

AT75C220

Pin Description

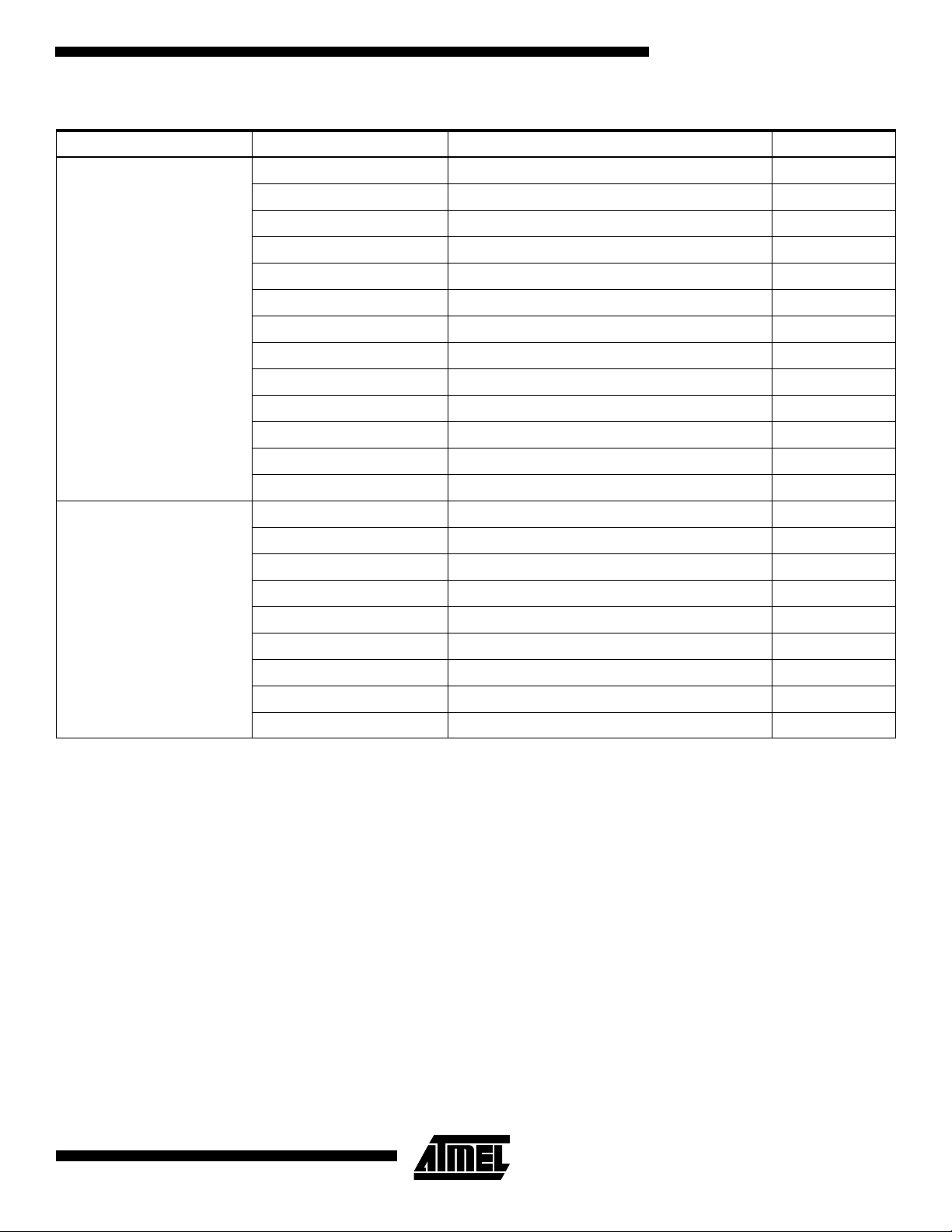

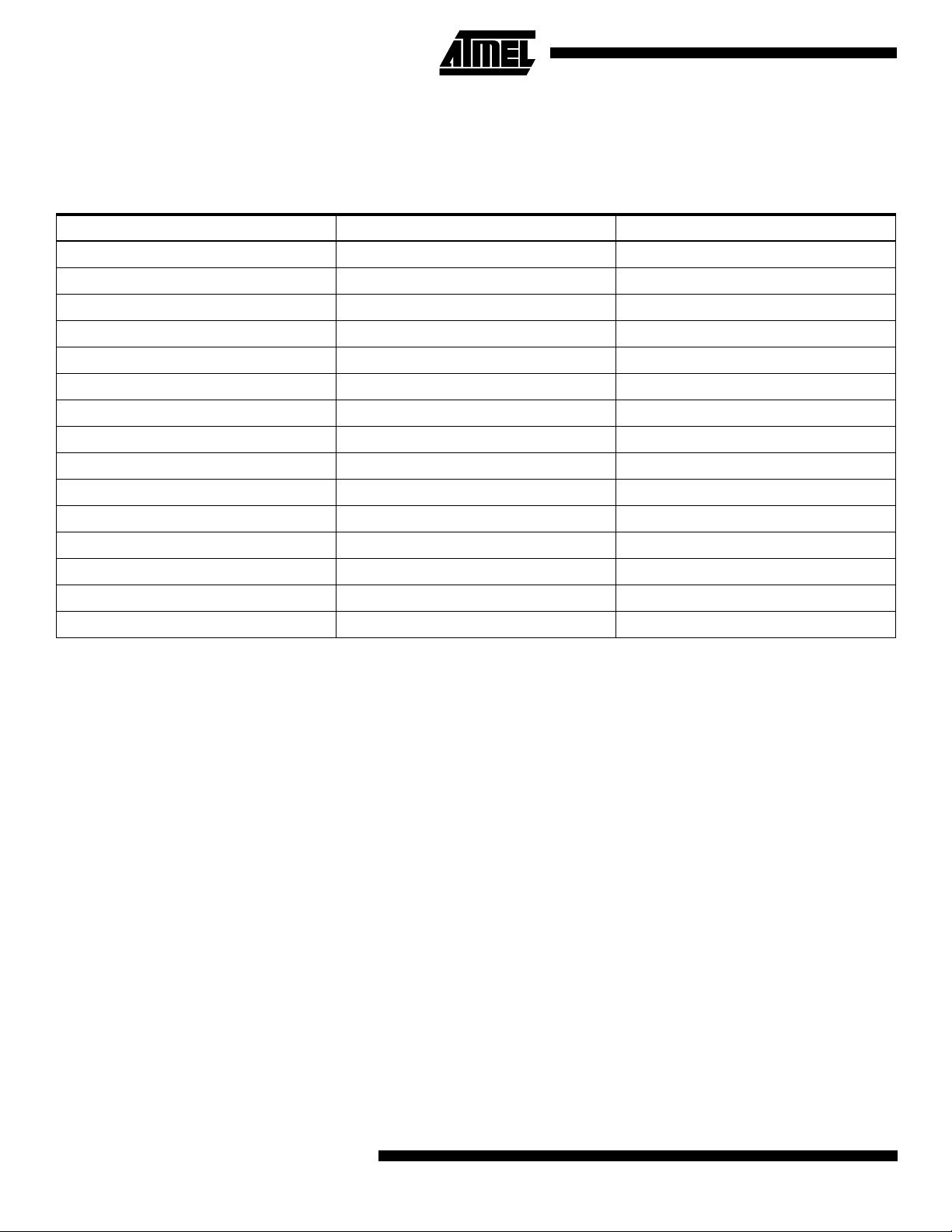

Table 1. AT75C220 Pin Description List

Block Pin Name Function Type

Common Bus A[21:0] Address Bus Output

D[15:0] Data Bus Input/Output

NREQ Bus Request Input

NGNT Bus Grant Output

Synchronous Dynamic

Memory Controller

Static Memory Controller NCE0, NCE3 Chip Selects Output

I/O Port A PA[12:0] General-purpose I/O lines. Multiplexed with

I/O Port B PB[9:0] General-purpose I/O lines. Multiplexed with

DSP Subsystem OAKAIN[1:0] OakDSPCore User Input Input

DCLK SDRAM Clock Output

DQM[1:0] SDRAM Byte Masks Output

CS0 SDRAM Chip Select 0 Output

CS1 SDRAM Chip Select 1 Output

RAS Row Address Strobes Output

CAS Column Address Strobes Output

WE SDRAM Write Enable Output

NWE[1:0] Byte Select/Write Enable Output

NSOE Output Enable Output

NWR Memory Block Write Enable Output

NWAIT Enable Wait States Input

Input/Output

peripheral I/Os.

PA[19] General-purpose I/O line. Multiplexed with

peripheral I/Os.

peripheral I/Os.

Input/Output

Input/Output

OAKAOUT[1:0] OakDSPCore User Output Output

Timer/Counter 0 TCLK0 Timer 0 External Clock Input

TIOA0 Timer 0 Signal A Input/Output

TIOB0 Timer 0 Signal B Input/Output

Timer/Counter 1 TCLK1 Timer 1 External Clock Input

TIOA1 Timer 1 Signal A Input/Output

TIOB1 Timer 1 Signal B Input/Output

Watchdog NWDOVF Watchdog Overflow Output

3

Page 4

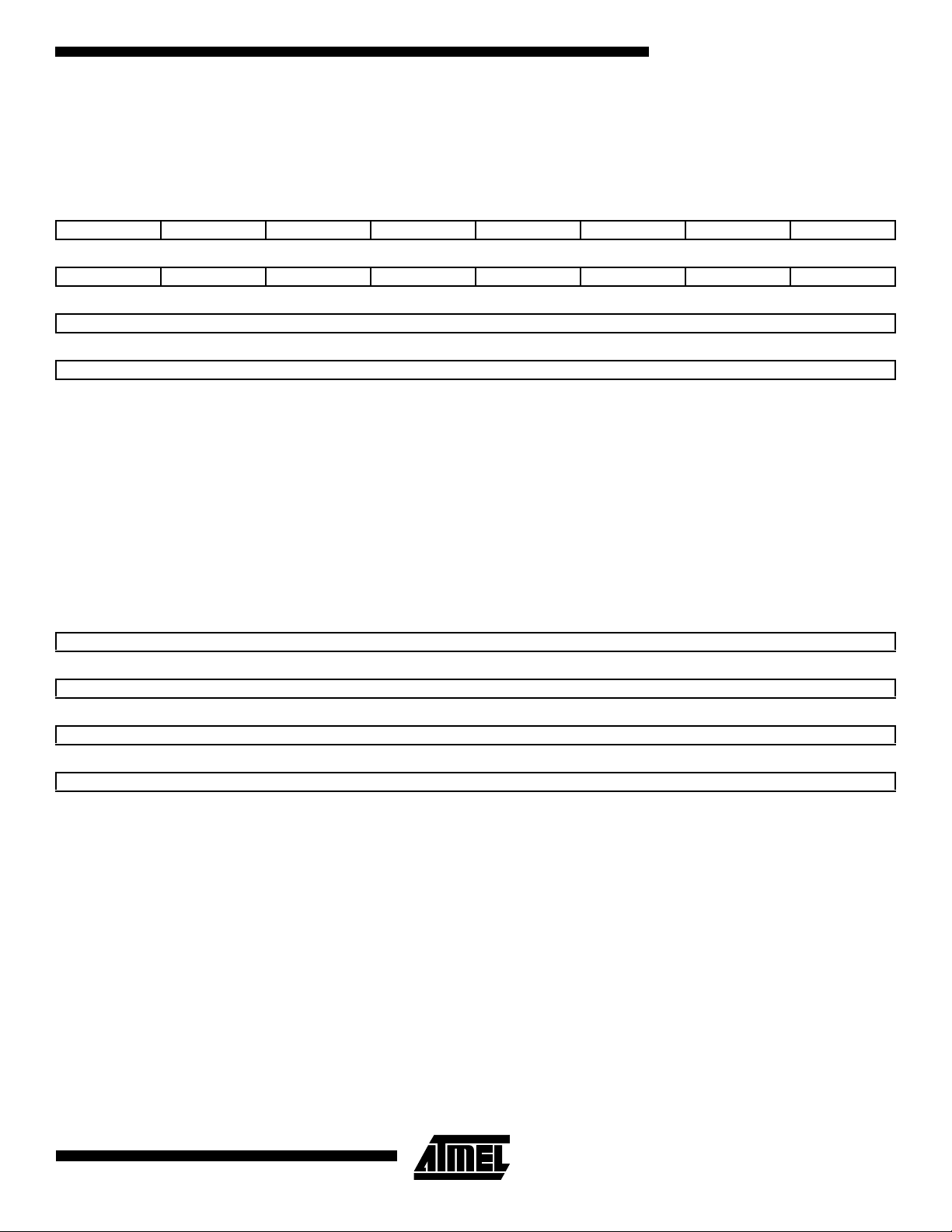

Table 1. AT75C220 Pin Description List (Continued)

Block Pin Name Function Type

Serial Peripheral Interface MISO Master In/Slave Out Input/Output

MOSI Master Out/Slave In Input/Output

SPCK Serial Clock Input/Output

NPCSS Chip Select/Slave Select Input/Output

NPCS1 Optional SPI Chip Select 1 Output

USART A RXDA Receive Data Input

TXDA Transmit Data Output

NRTSA Ready to Send Output

NCTSA Clear to Send Input

NDTRA Data Terminal Ready Output

NDSRA/BOOTN Data Set Ready Input

NDCDA Data Carrier Detect Input

USART B RXDB Receive Data Input

TXDB Transmit Data Output

JTAG Interface NTRST Test Reset Input

TCK Test Clock Input

TMS Test Mode Select Input

TDI Test Data Input Input

TDO Test Data Output Output

Codec Interface SCLKA Serial Clock Input/Output

FSA Frame Pulse Input/Output

STXA Transmit Data to Codec Input

SRXA Receive Data to Codec Output

MAC A Interface MA_COL MAC A Collision Detect Input

MA_CRS MAC A Carrier Sense Input

MA_TXER MAC A Transmit Error Output

MA_TXD[3:0] MAC A Transmit Data Bus Output

MA_TXEN MAC A Transmit Enable Output

MA_TXCLK MAC A Transmit Clock Input

MA_RXD[3:0] MAC A Receive Data Bus Input

MA_RXER MAC A Receive Error Input

MA_RXCLK MAC A Receive Clock Input

MA_RXDV MAC A Receive Data Valid Output

MA_MDC MAC A Management Data Clock Output

MA_MDIO MAC A Management Data Bus Input/Output

MA_LINK MAC A Link Interrupt Input

4

AT75C220

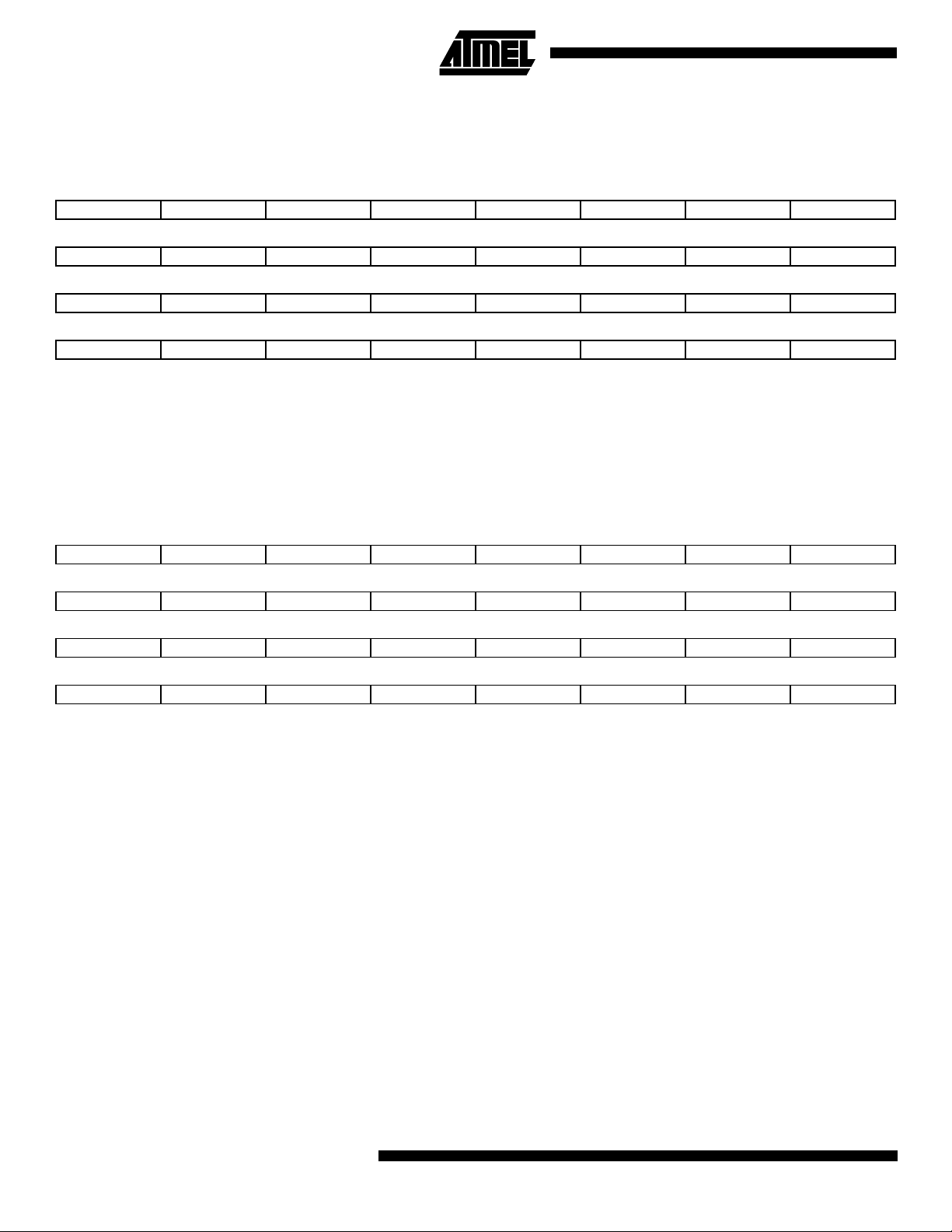

Page 5

AT75C220

Table 1. AT75C220 Pin Description List (Continued)

Block Pin Name Function Type

MAC B Interface MB_COL MAC B Collision Detect Input

MB_CRS MAC B Carrier Sense Input

MB_TXER MAC B Transmit Error Output

MB_TXD[3:0] MAC B Transmit Data Bus Output

MB_TXEN MAC B Transmit Enable Output

MB_TXCLK MAC B Transmit Clock Input

MB_RXD[3:0] MAC B Receive Data Bus Input

MB_RXER MAC B Receive Error Input

MB_RXCLK MAC B Receive Clock Input

MB_RXDV MAC B Receive Data Valid Output

MB_MDC MAC B Management Data Clock Output

MB_MDIO MAC B Management Data Bus Input/Output

MB_LINK MAC B Link Interrupt Input

Miscellaneous RESET Power on Reset Input

FIQ/LOWP Fast Interrupt/Low Power Input

IRQ0 External Interrupt Requests Input

XREF240 External 240 MHz PLL Reference Input

XTALIN External Crystal Input Input

XTALOUT External Crystal Ouptut Output

TST Test Mode Input

B0256 Package Size Option (1 = 256 pins) Input

DBW32 External Data Bus Width for CS0 (1 = 32 bits) Input

5

Page 6

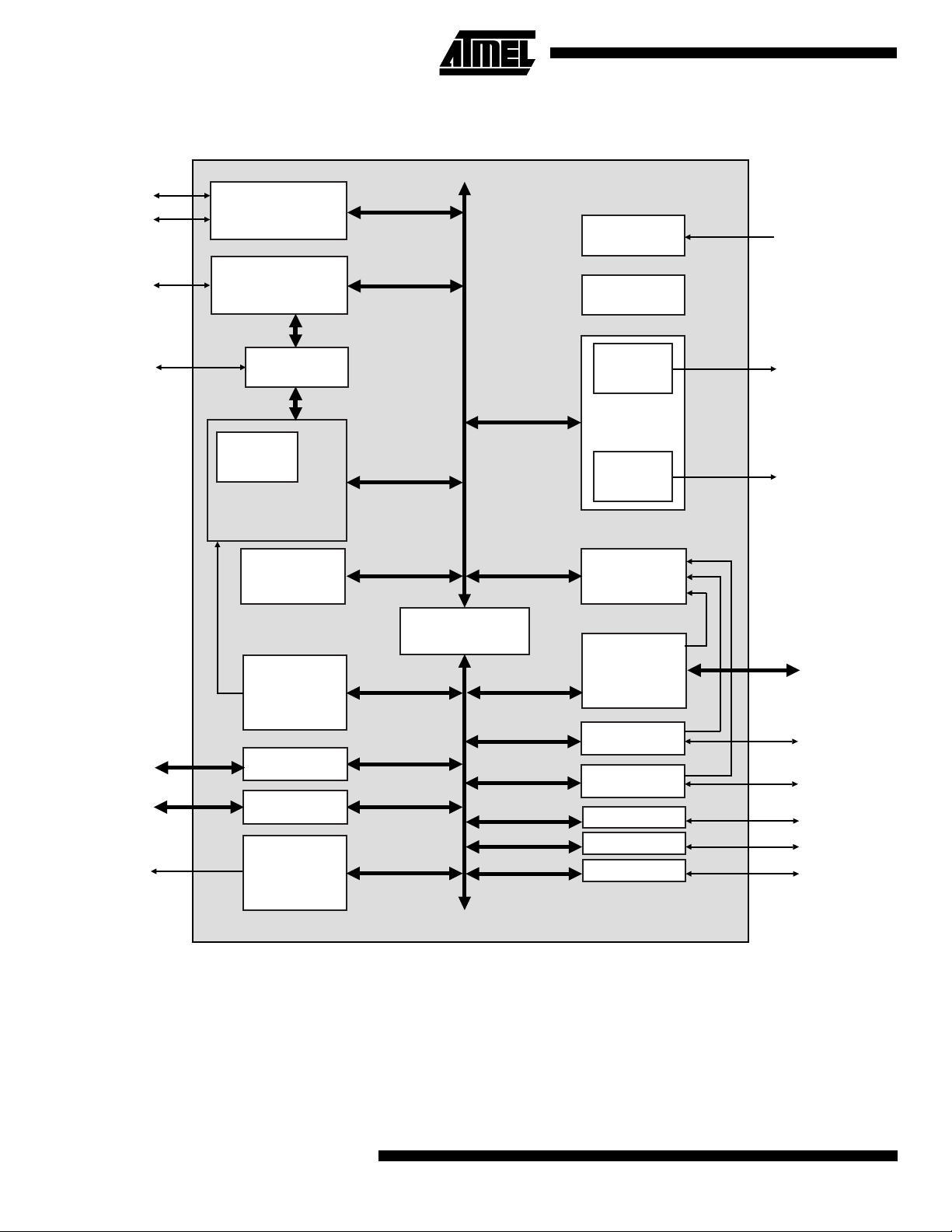

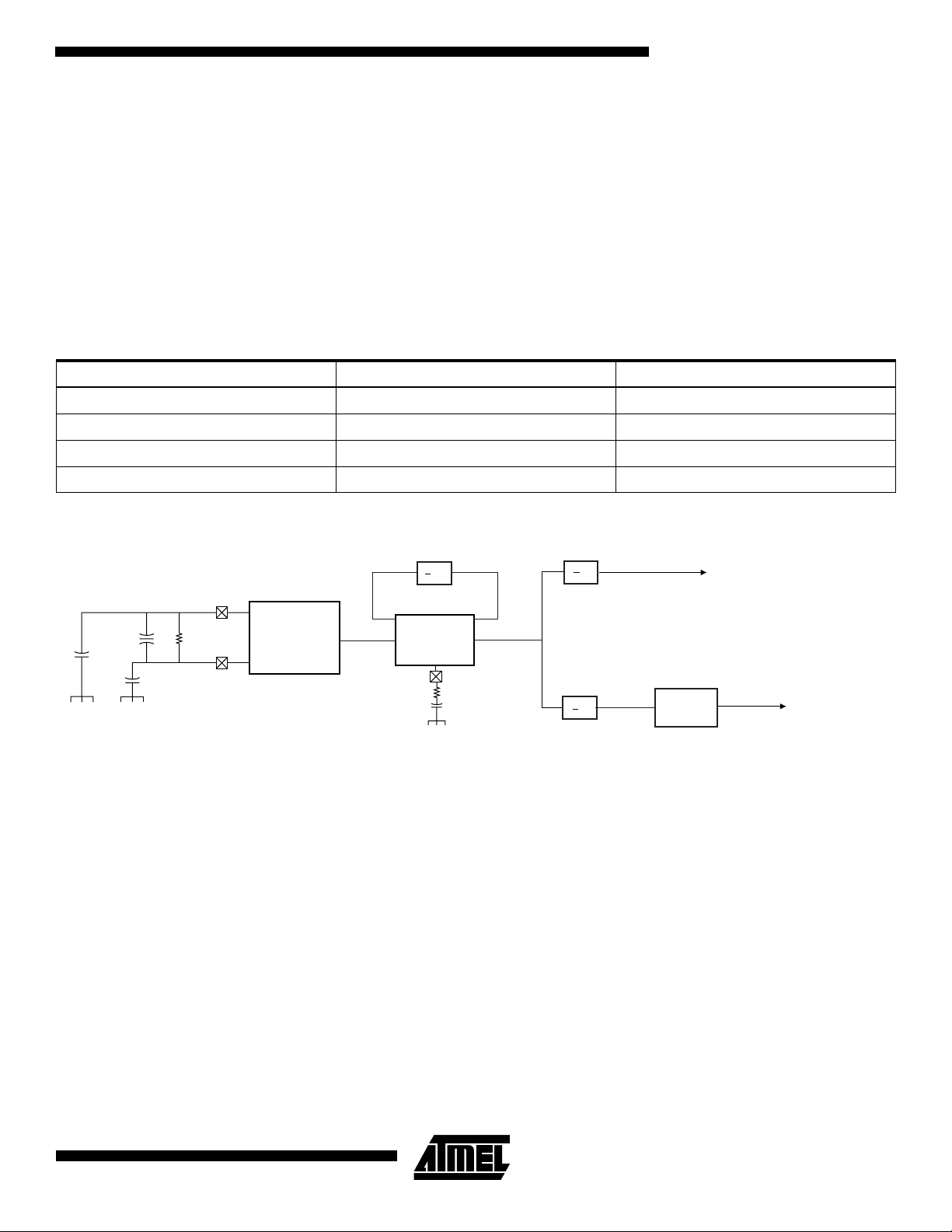

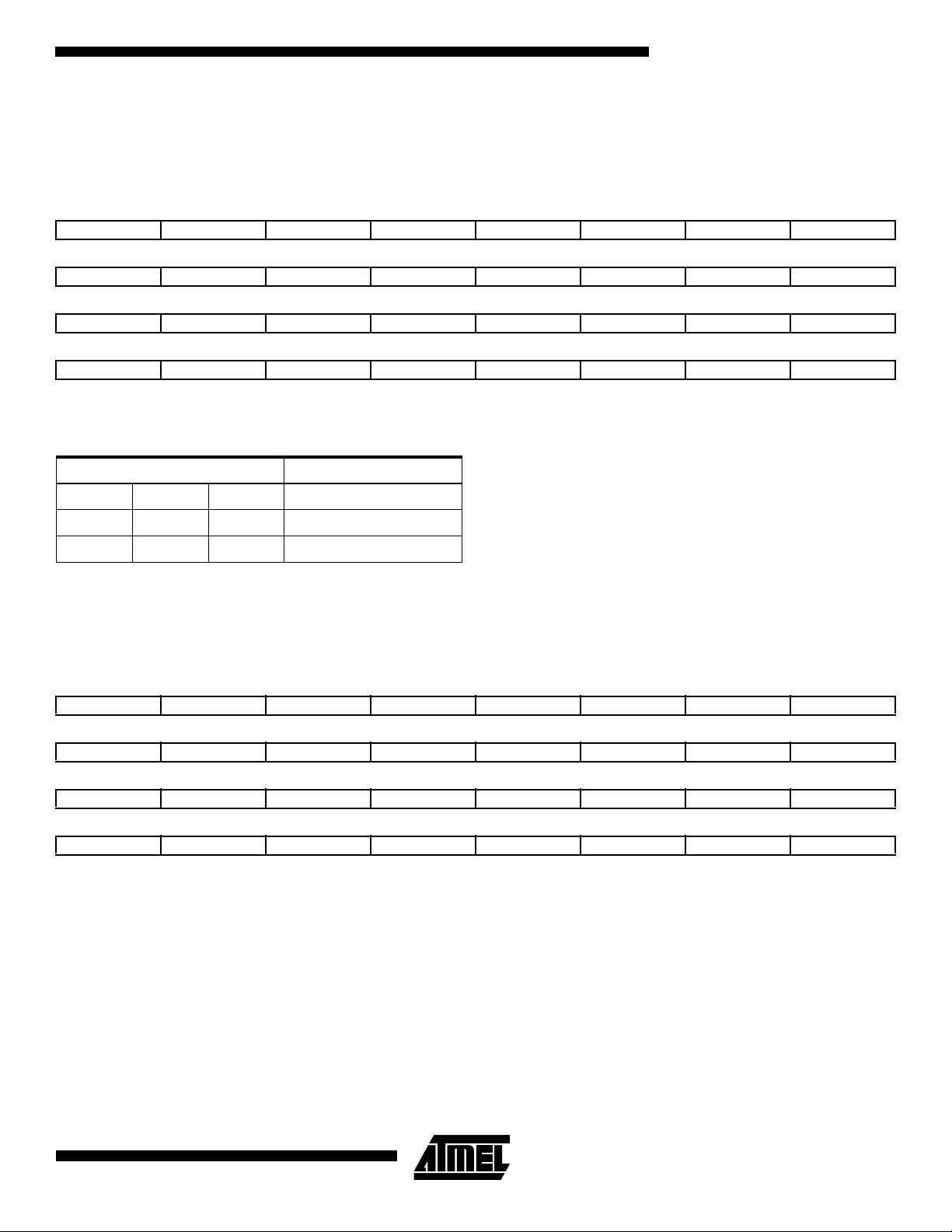

Figure 2. AT75C220 Block Diagram

Dual Ethernet

10/100 Mbps

MAC Interface

OakDSPCore

DSP Subsystem

ASB

Reset

Clocks

JTAG

Embedded

ICE

ARM7TDMI Core

Boot ROM

IRQ

Controller

PIO A

PIO B

Watchdog

Timer

SDRAM

Controller

External Bus

Interface

SRAM

Controller

Peripheral Data

Controller

AMBA Bridge

SPI

USART A

USART B

Timer/Counter 0

Timer/Counter 1

Timer/Counter 2

APB

6

AT75C220

Page 7

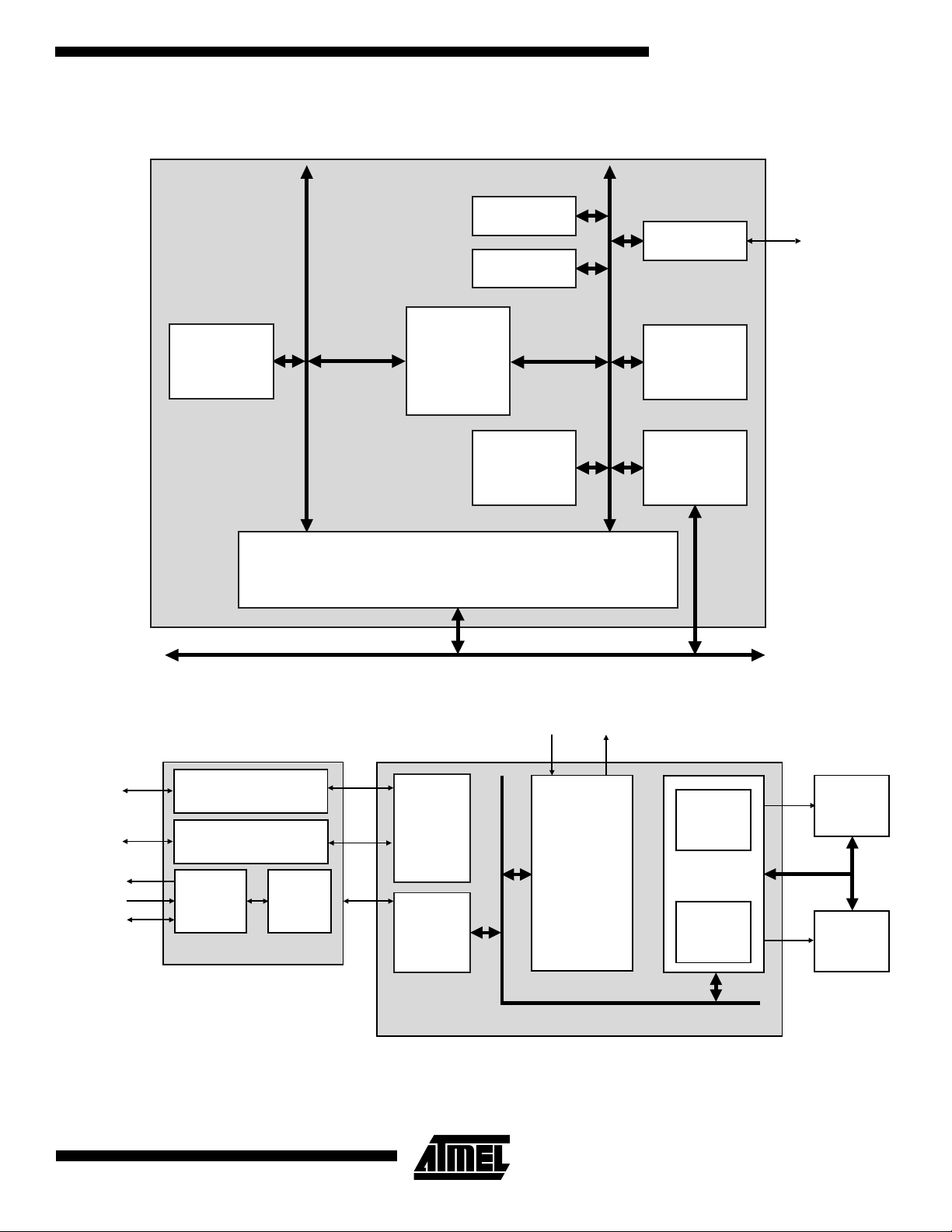

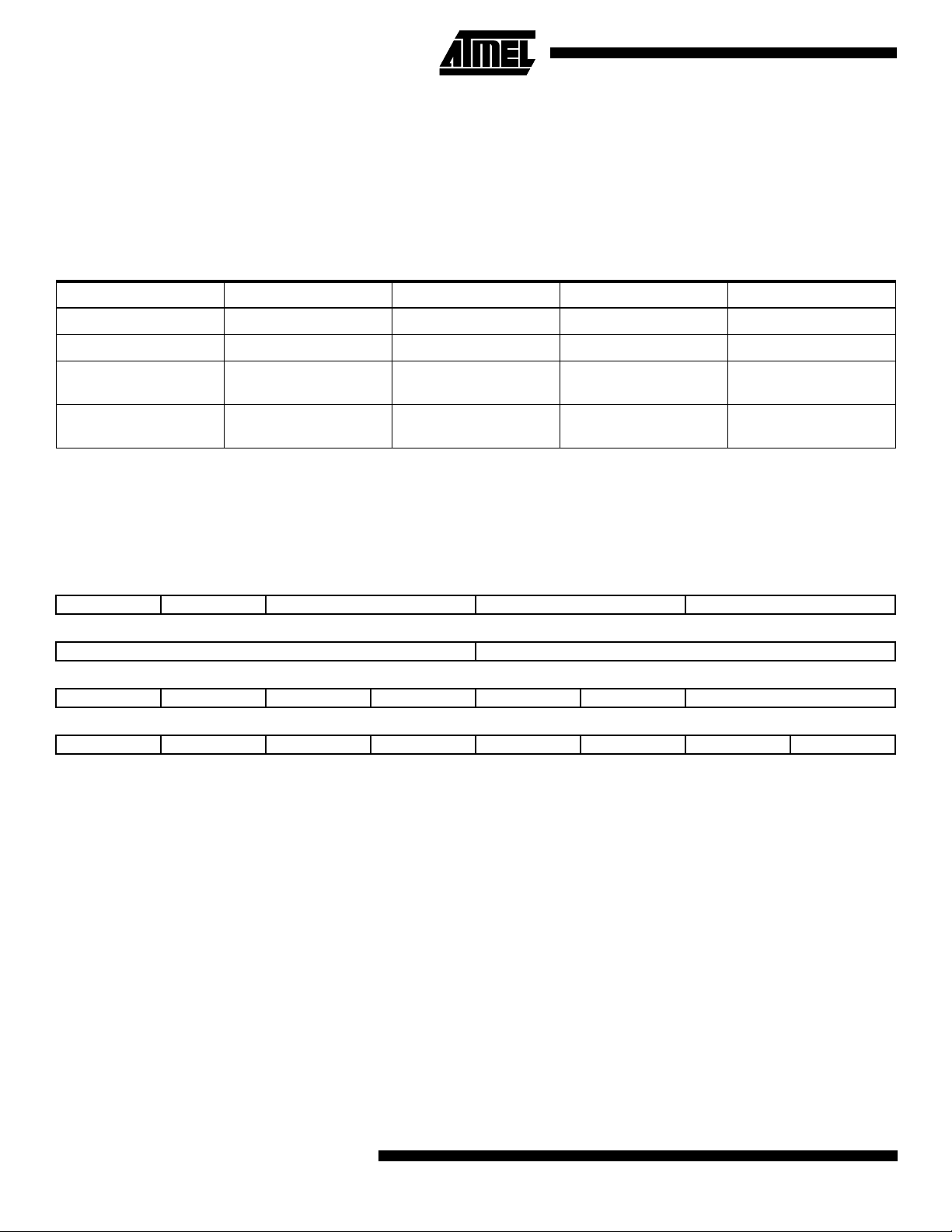

Figure 3. DSP Subsystem Block Diagram

Oak Program Bus Oak Data Bus

AT75C220

2K x 16 X-RAM

Codec Interface

2K x 16 Y-RAM

24K x 16

Program RAM

OakDSPCore

Emulation

Bus Interface Unit

DSP Subsystem

ASB

Figure 4. Application Example – Standalone Ethernet Telephone

Network

PC

Speaker

Microphone

Handset

Ethernet

10/100 Mbps PHY

Ethernet

10/100 Mbps PHY

Speaker

Phone

Interface

Analog Front End

Voice

Codec

Dual-port

Ethernet

10/100 Mbps

MAC

Interface

Voice

Processing

DSP Subsystem

On-chip

Module

Keyboard Screen

Protocol

ARM7TDMI Core

VolP

Stack

16K x 16

General-

purpose RAM

256 x 16

Dual-port

Mailbox

SDRAM

Controller

External Bus

Interface

SRAM

Controller

SDRAM

Flash

AT75C220

7

Page 8

Architectural Overview

The AT75C220 integrates an embedded ARM7TDMI processor. External SDRAM and SRAM/Flash interfaces are

provided so that processor code and data may be stored

off-chip.

The AT75C220 architecture consists of two main buses,

the Advanced System Bus (ASB) and the Advanced

Peripheral Bus (APB).

The ASB is designed for maximum performance. It interfaces the processor with the on-chip DSP subsystem and

the external memories and devices by the means of the

external bus interface (EBI).

The APB is designed for access to on-chip peripherals and

is optimized for low power consumption. The AMBA bridge

provides an interface between the ASB and APB.

The AT75C220 uses a multi-layer AMBA bus:

• It integrates two independent AMBA ASB buses. The two

buses are connected by a bridge that is not visible to the

other devices on the bus.

• The primary bus (ARM bus) is the main processor bus to

which most peripherals are connected.

• The secondary bus (MAC bus) is used exclusively for

Ethernet traffic.

The ARM7TDMI, USART DMA and ASB-ASB bridge

devices are masters on the ARM ASB bus, the MAC DMA

and ASB-ASB Bridge are masters on the MAC ASB bus

and the Flash/SRAM and SDRAM interfaces are ASB

slaves. For more details on bus arbitration, see “Arbitration

Using Multi-layer AMBA” on page 31.

All the peripherals are accessed by means of the APB bus.

An on-chip peripheral data controller (PDC) transfers data

between the on-chip USARTs and the memories without

processor intervention. Most importantly, the PDC removes

the processor input-handling overhead and significantly

reduces the number of clocks required for data transfer. It

can transfer up to 64K contiguous bytes without reprogramming the starting address. As a result, the performance of

the microcontroller is increased and power consumption

reduced.

The AT75C220 peripherals are designed to be programmed with a minimum number of instructions. Each

peripheral has 16K bytes of address space allocated in the

upper part of the address space. The peripheral register set

is composed of control, mode, data, status and interrupt

registers.

To maximize the efficiency of bit manipulation, frequentlywritten registers are mapped into three memory locations.

The first address is used to set the individual register bits,

the second resets the bit and the third address reads the

value stored in the register. A bit can be set or reset by writing a one to the corresponding position at the appropriate

address. Writing a zero has no effect. Individual bits can

thus be modified without having to use costly read-modifywrite and complex bit-manipulation instructions and without

having to store-disable-restore the interrupt state.

All of the external signals of the on-chip peripherals are

under the control of the parallel I/O controllers. The PIO

controllers can be programmed to insert an input filter on

each pin or generate an interrupt on a signal change. After

reset, the user must carefully program the PIO controllers

in order to define which peripherals are connected with offchip logic.

The ARM7TDMI processor operates in little-endian mode

in the AT75C220. The processor's internal architecture and

the ARM and Thumb instruction sets are described in the

ARM7TDMI datasheet, literature number 0673. The memory map and the on-chip peripherals are described in this

datasheet.

Peripheral Data Controller

The AT75C220 has a four-channel peripheral data controller (PDC) dedicated to the two on-chip USARTs. One PDC

channel is connected to the receiving channel and one to

the transmitting channel of each USART.

The user interface of a PDC channel is integrated in the

memory space of each USART channel. It contains a 32-bit

address pointer register and a 16-bit count register. When

the programmed number of bytes is transferred, an end-oftransfer interrupt is generated by the corresponding

USART. For more details on PDC operation and programming, see the section describing the USART on page 74 .

8

AT75C220

Page 9

Memory Map

AT75C220

The memory map is divided into regions of 256 megabytes.

The top memory region (0xF000_0000) is reserved and

subdivided for internal memory blocks or peripherals within

the AT75C220. The device can define up to six other active

external memory regions by means of the static memory

controller and SDRAM memory controller. See Table 2.

The memory map is divided between the two ASB buses.

All regions except the 16 megabytes between

0xFB00_0000 and 0xFBFF_FFFF are located on the ARM

ASB bus. Accesses to locations between 0xFB00_0000

and 0xFBFF_FFFF are routed to the MAC ASB bus.

The memory map assumes default values on reset. External memory regions can be reprogrammed to other base

addresses. For details, see “SMC: Static Memory Controller” on page 16 and “SDMC: SDRAM Controller” on page

24. Note that the internal memory regions have fixed locations that cannot be reprogrammed.

There are no hardware locks to prevent incorrect programming of the regions. Programming two or more regions to

have the same base address results in undefined behavior.

The ARM reset vector with address 0x00000000 is mapped

to internal ROM or external memory depending on the signal pin NDSRA/BOOTN. After booting, the ROM region can

be disabled and some external memory such as SDRAM or

Flash can be mapped to the bottom of the memory map by

programming SMC_CS0 or DMC_MR0.

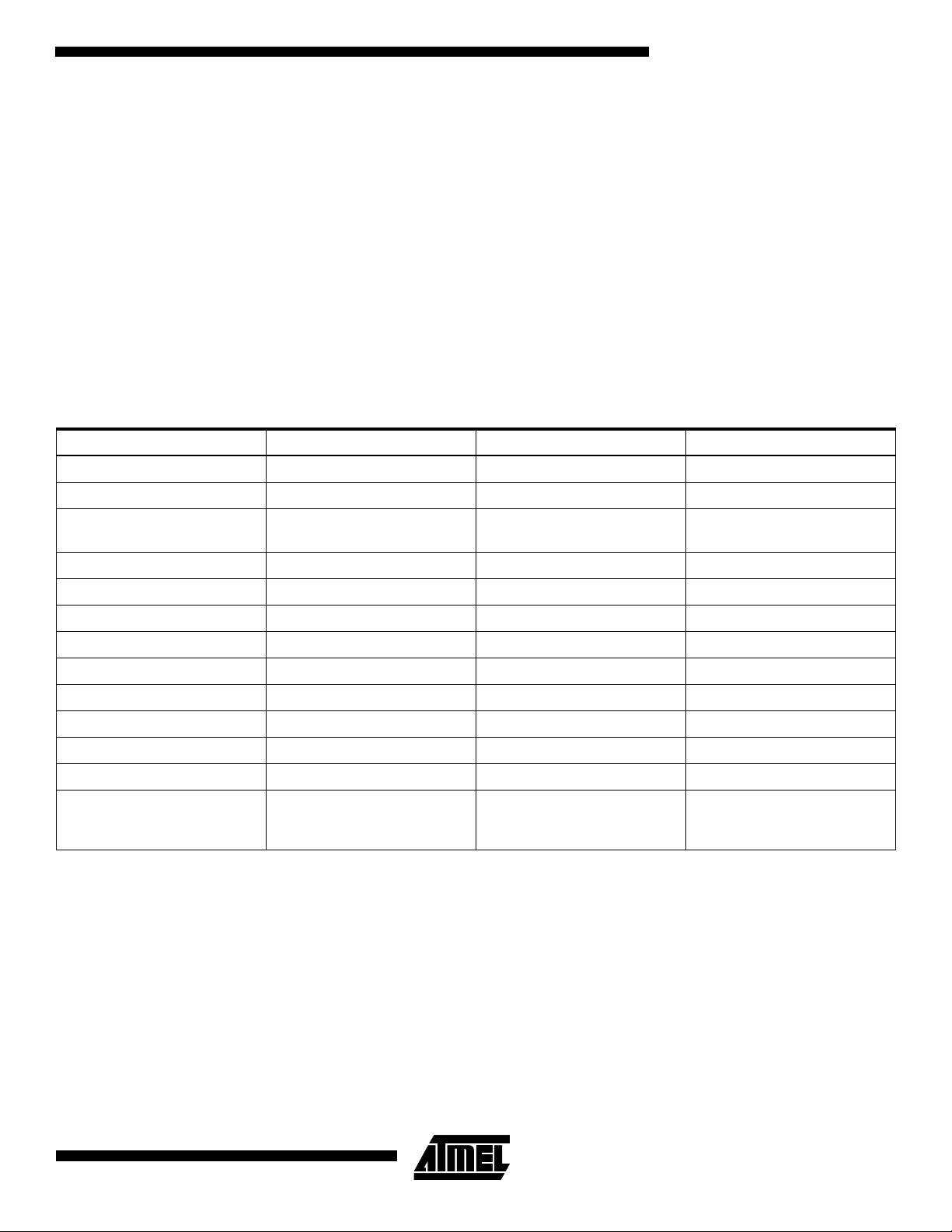

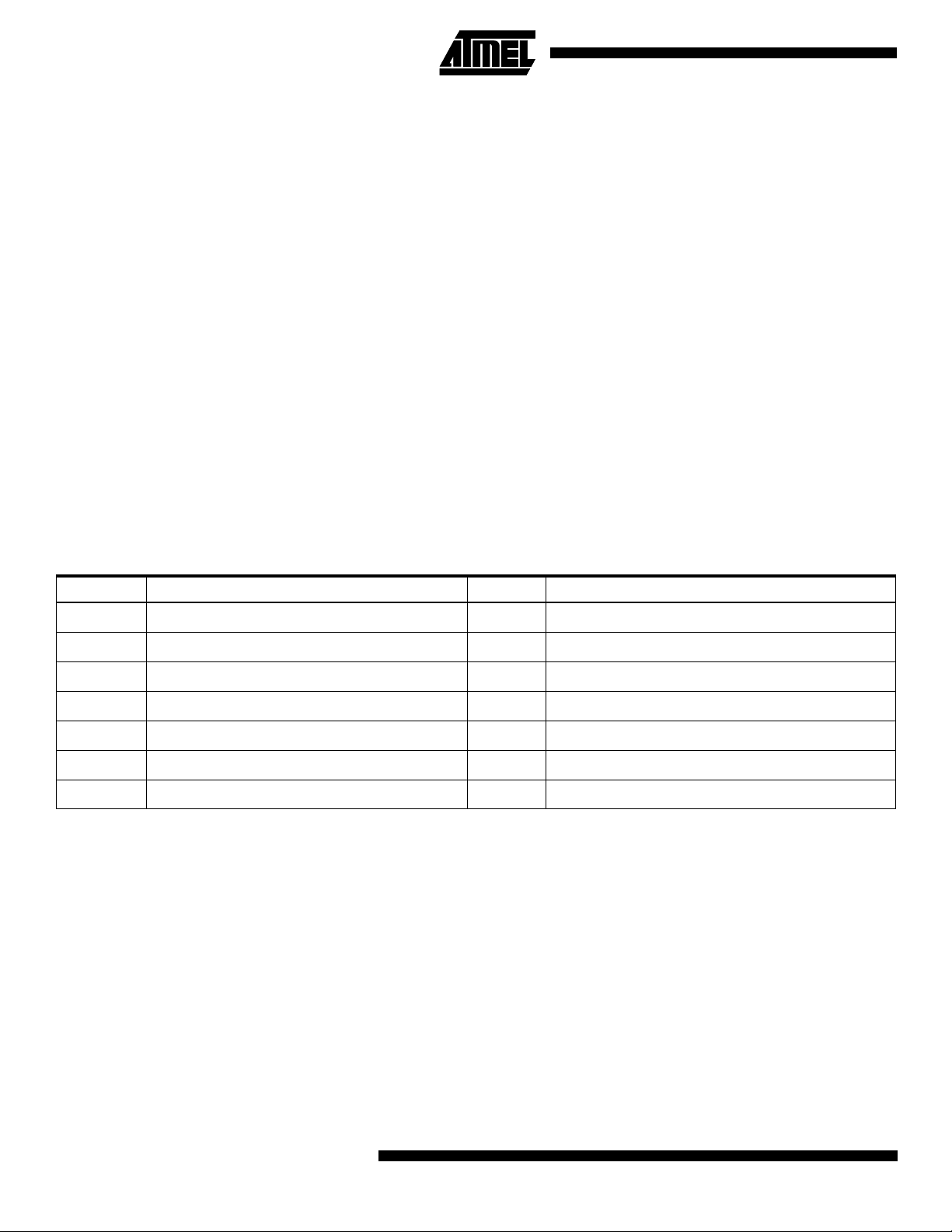

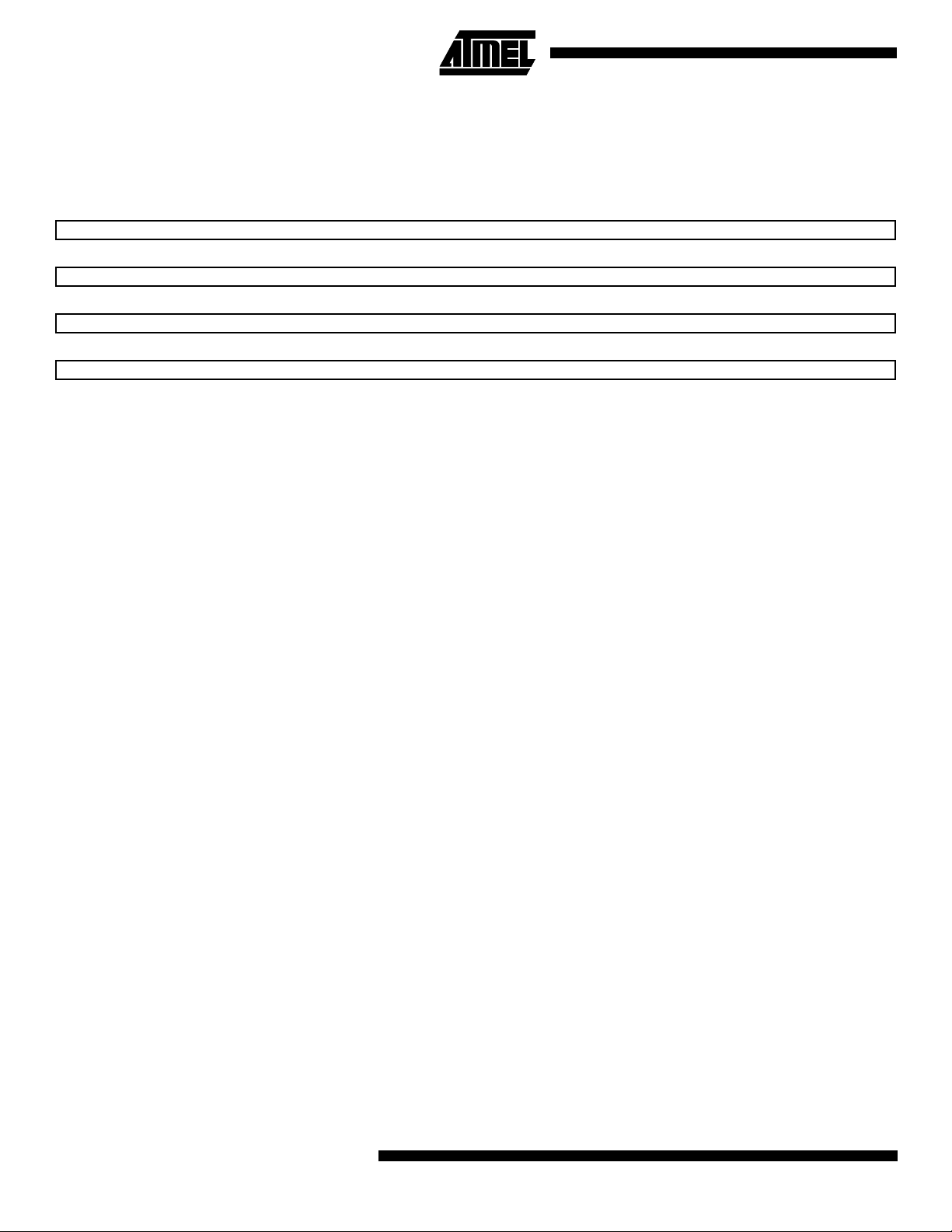

Table 2. AT75C220 Memory Map

Default Base Address Region Type Normal Mode Boot Mode

0xFF000000 Internal APB Bridge

0xFE000000 Internal Reserved

0xFD000000 Internal Oak A Program RAM

(24K x 16 bits)

0xFC000000 Frame Buffer (16K x 16 bits)

0xFB000000 Internal Reserved (MAC ASB Bus)

0xFA000000 Internal Oak A DPMB (256 x 16 bits)

0xF9000000 Internal Boot ROM (1 KB)

0x50000000 External SDMC_CS1

0x40000000 External SDMC_CS0

0x30000000 External SMC_CS3

0x20000000 External SMC_CS2

0x10000000 External SMC_CS1

0x00000000 External/Internal SMC_CS0 Boot ROM

0x000003FF

0x00000000

9

Page 10

Peripheral Memory Map

The register maps for each peripheral are described in the corresponding section of this datasheet. The peripheral memory

map has 16K bytes reserved for each peripheral.

Table 3. AT75C220 Peripheral Memory Map

Base Address (Normal Mode) Peripheral Description

0xFF000000 MODE AT75C220 Mode Controller

0xFF004000 SMC Static Memory Controller

0xFF008000 SDMC SDRAM Controller

0xFF00C000 PIOA Programmable I/O

0xFF010000 PIO B Keypad PIO

0xFF014000 TC Timer/Counter Channels

0xFF018000 USARTA USART

0xFF01C000 USARTB USART

0xFF020000 SPI Serial Peripheral Interface

0xFF024000 Reserved

0xFF028000 WDT Watchdog Timer

0xFF030000 AIC Interrupt Controller

0xFF034000 MACA MAC Ethernet

0xFF038000 MACB MAC Ethernet

0xFFFFF000 AIC (alias) Interrupt Controller

Initialization

Reset initializes the user interface registers to their default

states as defined in the peripheral sections of this

datasheet and forces the ARM7TDMI to perform the next

instruction fetch from address zero. Except for the program

counter, the ARM core registers do not have defined reset

states. When reset is active, the inputs of the AT75C220

must be held at valid logic levels.

There are three ways in which the AT75C220 can enter

reset:

1. Hardware reset. Caused by asserting the RESET

pin, e.g., at power-up.

2. Watchdog timer reset. The WD timer can be pro-

grammed so that if timed out, a pulse is generated

that forces a chip reset.

3. Software reset. There are two software resets which

are asserted by writing to bits [11:10] of the SIAP

mode register. SIAP_MD[11] forces a software reset

with RM set low and SIAP_MD[10] forces a reset

with RM set high.

Reset Pin

The reset pin should be asserted for a minimum of 10 clock

cycles. However, if external DRAM is fitted, then reset

should be applied for the time interval specified by the

SDRAM datasheet, typically 200 µs. The OakDSPCores

are only released from reset by the ARM program control.

When reset is released, the pin NDSRA/BOOTN is sampled to determine if the ARM should boot from internal

ROM or from external memory connected to NCS0. The

details of this boot operation are described in the section

“Boot Mode” on page 11.

Processor Synchronization

The ARM and the OakDSPCore processors have their own

PLLs and at power-on each processor has its own indeterminate lock period. To guarantee proper synchronization of

inter-processor communication through the mailboxes, a

specific reset sequence should be followed.

Once the ARM core is out of reset, it should set and clear

the reset line of the OakDSPCore three times. This guarantees message synchronization between the ARM and the

OakDSPCore.

10

AT75C220

Page 11

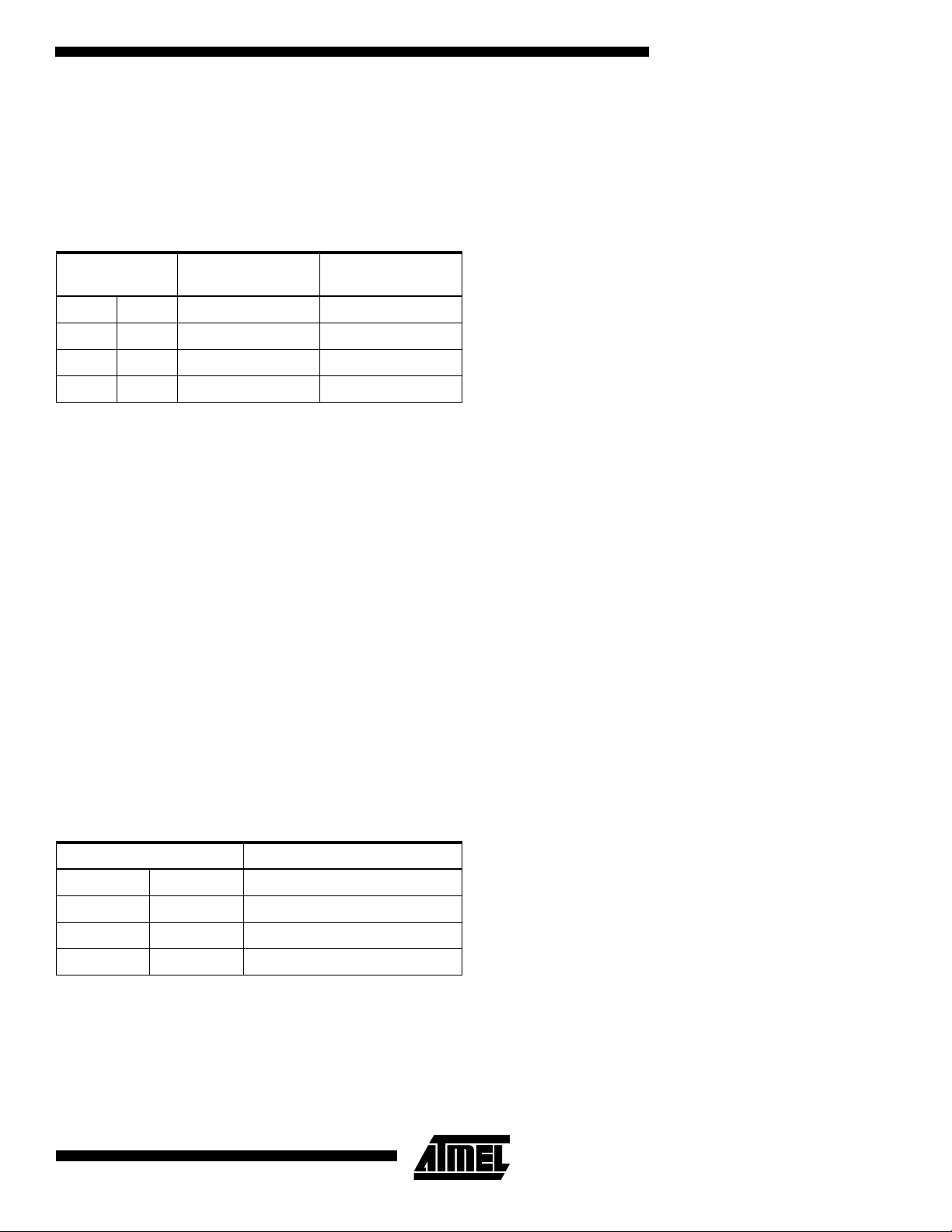

Clocking

AT75C220

The AT75C220 mode register controls clock generation.

Oscillator and PLL

The AT75C220 uses an external 16 MHz crystal (XCLK)

and an on-chip PLL to generate the internal clocks. The

PLL generates a 240 MHz clock that is divided down to produce the ARM clock and Oak clock.

Oak System Clock

The Oak subsystem runs at 60MHz.

Other Clocks

The codec interfaces run from 800 kHz that is seperate

from the Oak clock.

The USARTs and timers operate from divided ARM clocks.

ARM System Clock

The ARM subsystem runs at 40 MHz.

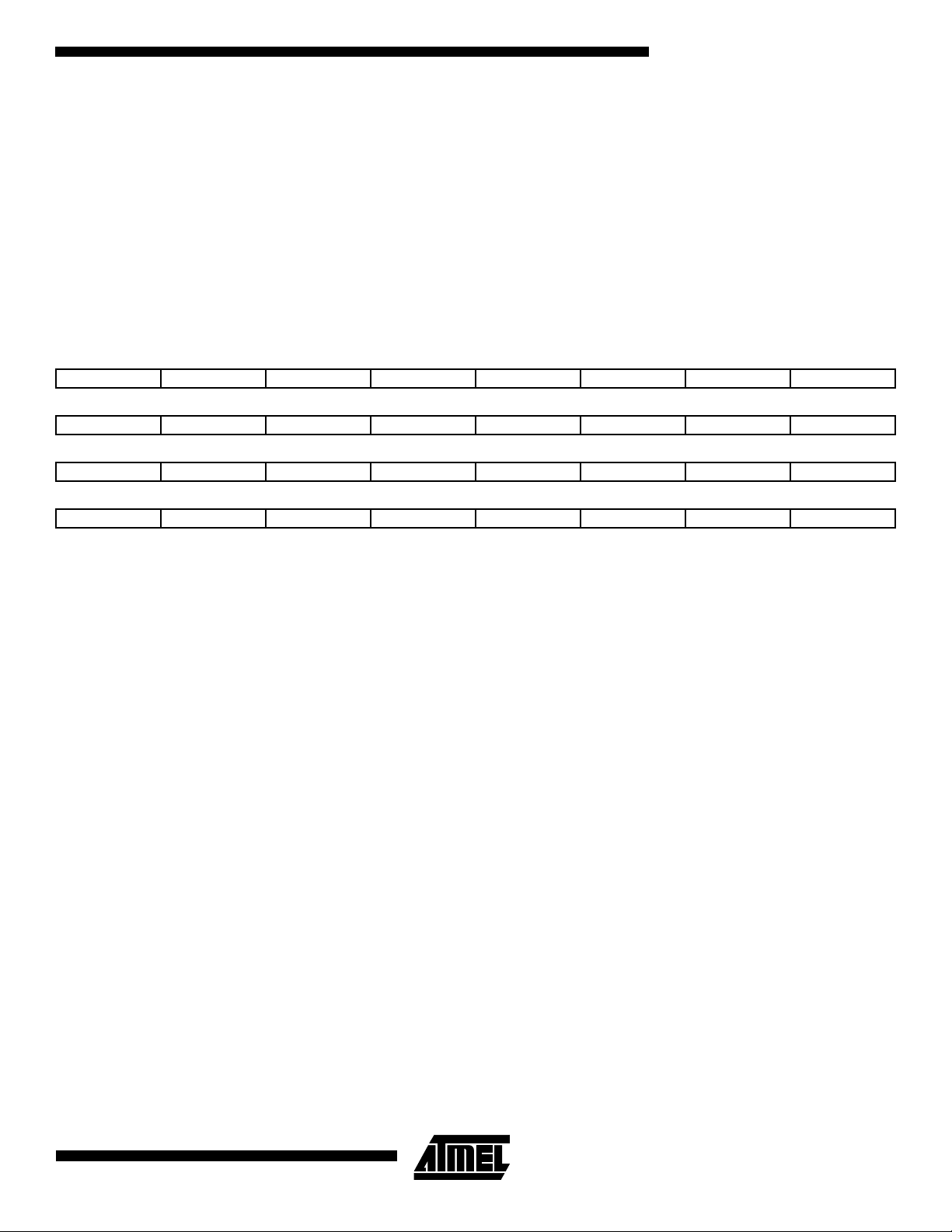

Table 4. Clock Source and Frequency

Source Frequency Comment

Crystal 16 MHz External crystal

PLL Output 240 MHz Crystal multiplied by 15

ARM Clock 40 MHz PLL divided by 6

Oak Clock 60 MHz PLL divided by 4

Figure 5. AT75C220 Clocking

16 MHz

XTAL

XTALIN

.

.

15

.

.

6

40 MHz

ARM Core

Clock

10 pF

10 pF

1 MΩ

XTALOUT

Oscillator

16 MHz

PLL

XREF 240F

100 Ω

10 nF

Boot Mode

The AT75C220 has an integrated 1-Kbyte ROM to support

the boot software. When the device is released from reset,

the ARM starts fetching from address 0x00000000. If the

RM flag in the SIAP-E mode register (SIAP_MD on page

12) is low, the internal boot ROM is mapped to the bottom

1K byte of the memory map. If RM is high, the bottom 16M

bytes of memory address will default to external memory

region 0.

If NDSRA/BOOTN is asserted on reset, the internal boot

ROM program is executed. The boot program reads data

from USART A and writes it to the Oak Program RAM (in

the ARM memory map whereas the Oak is in reset). The

downloaded software can then configure the various con-

240 MHz

.

.

4

60 MHz

Phase

Generator

40 MHz

DSP Subsystem

Clock

trol registers in the AT75C220 and its peripherals so as to

perform external memory accesses. This allows the Flash

to be written.

The boot ROM code:

• sets CTS active

• waits for approximately three seconds for the start of a

Flash download sequence from the USART.

If the special header is not received, the AT75C220 boots

normally, i.e., from external memory at 0x00000000.

If the special header is received, the boot ROM enters the

code download process.

11

Page 12

AT75C220 Mode Controller

The ARM configures the mode of the AT75C220 by means

of the SIAP-E mode controller.

The SIAP-E mode controller is a memory-mapped peripheral that sits on the APB bus.

Register Map

Base Address: 0xFF000000

Table 5. AT75C220 Register Map

Register Address Register Name Description Access Reset Value

0x0 SIAP_MD SIAP-E Mode Register Read/write 0x00B0340

0x4 SIAP_ID SIAP-E ID Register Read-only 0x0000220

0x8 SIAP_RST SIAP-E Reset Status

Register

0xC SIAP_CLKF SIAP-E Clock Status

Register

Note: 1. If the PKG flag is set, the reset value is 0x00010220 since the AT75C220 is bonded in large bond-out mode.

Read/write 0x0000001

Read-only 0x0000001

SIAP-E Mode Register

Register Name: SIAP_MD

Access: Read/write

Reset Value: 0x00B0342

31 30 29 28 27 26 25 24

–– JCIDBG OUTDIV INDIV

(1)

23 22 21 20 19 18 17 16

ICP IPOLTST

15 14 13 12 11 10 9 8

– CRA – DBA SW2 SW1 LPCS

76543210

SA LP ––IA – RA RM

• RM: Remap

On reset being released this flag is set to the value of NDSRA/BOOTN. When RM is active low the Boot ROM is

mapped to location 0x00000000. Subsequently, this flag can be set high by software so that the ROM mapping is disabled and another memory controller region (e.g. FLASH) is mapped to location 0x00000000.

• RA: OAKA Reset

This flag resets to active low so that the OAKA is held in reset. The OAKA is be released from reset by asserting this

flag high.

• IA: Inhibit OAKA Clock

This flag resets to active low so that the OAKA clock is enabled. The OAKA clock is be inhibited by asserting this flag

high.

• LP: Low Power Mode

On reset this field is high. When written high the PLL is disabled and the ARM and OAK cores and logic are clocked at

the low power clock frequency. Note, in this mode the ARM and OAK are clocked at the same frequency determined by

the LPCS field. When LP is written low the PLL is enabled and once it has locked the clock is switched over to the normal operating frequency.

12

AT75C220

Page 13

AT75C220

• SA: Slow ARM Mode

On reset this field is low. In normal operating mode, if bit SA is set. The ARM clock is 34Mhz (i.e. the PLL value is

divided by 7). IF SA is not set the ARM clock is 40MHz (i..e the PLL divisor is 6). SA can be switched during low power

mode but should not be changed when LP is low.

• LPCS: Low Power Clock Select

This field is used to select a slower clock frequency for the ARM system clock as per the table below.

Oscillator Clock

LPCS

00 1 8 MHz

0 1 16 1 MHz

1 0 64 250 kHz

1 1 512 32 kHz

Divisor

ARM and Oak

System Clock

• SW1: Software Reset 1

Writing a 1 to this bit forces the SIAP into reset with RM set to 0.

• SW2: Software Reset 2

Writing a 1 to this bit forces the SIAP into reset with RM set to 1.

• DBA: OAKA Debug Mode

This flag resets low. To enter OAKA debug mode (specific pins are multiplexed out on functional pins), this bit should

be set.

• CRA: CODECA Reset

This flag resets to active low so that the CODECA is held in reset. The CODECA is released from reset by asserting

this flag high.

• IPOLTST: PLL Bias Adjustment

This can be used to tune the PLL if the bias current is not correct after manufacture.

Bias Factor 15 IPOLTST–()4⁄=

• ICP: PLL Charge Pump Current

This can be used to tune the PLL if it does not function with the default current of 2.5 µA.

IICP

( 1 )+ 2.5µA×=

• INDIV

Input frequency range of PLL.

INDIV PLL Input Frequency Range

0 0 5 kHz to 40 MHz

0 1 40 MHz to 80 MHz

1 0 80 MHz to 160 MHz

1 1 160 MHz to 250 MHz

13

Page 14

• OUTDIV

Output frequency range of PLL.

OUTDIV PLL Output Frequency Range

0 0 40 MHz to 250 MHz

0 1 20 MHz to 40 MHz

1 0 10 MHz to 20 MHz

1 1 5 MHz to 10 MHz

• JCIDBG

This field controls the mode of the JCI. The Oak subsystem has its own JTAG port. This port is used to communicate

serially with the Oak OCEM module.

SIAP-E ID Register

Register Name: SIAP_ID

Access: Read-only

Reset Value: 0x00000220 in small bond-out mode

0x0001220 in large bond-out mode

31 30 29 28 27 26 25 24

––––––––

23 22 21 20 19 18 17 16

–––––––PKG

15 14 13 12 11 10 9 8

76543210

IDENT

IDENT

• IDENT: Identifier

This field indicates the device identifier 0x0220.

• PKG: Package

This bit reflects the state of the data bus width signal DBW and indicates the SIAP package size.

14

AT75C220

Page 15

AT75C220

SIAP-E Reset Status Register

Register Name: SIAP_RST

Access: Read/write

Reset Value: 0x00000001

31 30 29 28 27 26 25 24

––––––––

23 22 21 20 19 18 17 16

––––––––

15 14 13 12 11 10 9 8

––––––––

76543210

–––––RST RST RST

• RST[2:0]: Reset

These bits indicate the cause of the last reset.

RST Reset Event

0 0 1 Hardware

0 1 0 Watchdog Timer

100 Software

SIAP-E Clock Status Register

Register Name: SIAP_CLKF

Access: Read-only

Reset Value: 0x00000001

31 30 29 28 27 26 25 24

––––––––

23 22 21 20 19 18 17 16

––––––––

15 14 13 12 11 10 9 8

––––––––

76543210

–––––––CLK

• CLK: Clock Status

This bit indicates which clock is in use by the system. When set, the low power clock is in use. When cleared, the PLL

is locked and the high power clock is in use. This can be used by software to determine when the power mode has

changed after the LP bit has been written.

15

Page 16

External Bus Interface

The external bus interface (EBI) generates the signals

which control access to external memories or peripheral

devices.

SMC: Static Memory Controller

The static memory controller (SMC) is used by the

AT75C220 to access external static memory devices.

Static memory devices include external Flash, SRAM or

peripherals.

The SMC provides a glueless memory interface to external

memory using the common address and data bus and

some dedicated control signals. The SMC is highly programmable and has up to 24 bits of address bus, a 32- or

16-bit data bus and up to four chip select lines. The SMC

supports different access protocols allowing single clockcycle accesses. The SMC is programmed as an internal

peripheral that has a standard APB bus interface and a set

of memory-mapped registers. The SMC shares the external address and data buses with the DMC and any external

bus master.

Table 6. Signal Interface

FPDRAM Description Type Notes

External Memory Mapping

The memory map associates the internal 32-bit address

space with the external 24-bit address bus. The memory

map is defined by programming the base address and

page size of the external memories. Note that A[2:23] is

only significant for 32-bit memory and A[1:23] for 16-bit

memory.

If the physical memory-mapped device is smaller than the

programmed page size, it wraps around and appears to be

repeated within the page. The SMC correctly handles any

valid access to the memory device within the page.

In the event of an access request to an address outside

any programmed page, an abort signal is generated by the

internal decoder. Two types of abort are possible: instruction prefetch abort and data abort. The corresponding

exception vector addresses are 0x0000000C and

0x00000010. It is up to the system programmer to program

the exception handling routine used in case of an abort.

If the AT75C220 is in internal boot mode, any chip select

configured with a base address of zero will be disabled as

the internal ROM is mapped to address zero.

A[23:0] Address bus Output

D[31:0] Data bus I/O

NCE[3:0] Active low chip enables Output

NWE[3:0] Active low byte select/write strobe signals Output

NWR Active low write strobe signals Output

NSOE Active low read enable signal Output

NWAIT Active low wait signal Input

Data Bus Width

A data bus width of 32 or 16 bits can be selected for each

chip select. This option is controlled by the DBW field in the

Chip Select Register (SMC_CSR) of the corresponding

chip select.

The AT75C220 always boots up with a data bus width of 16

bits set in SMC_CSR0.

Byte-write or Byte-select Mode

Each chip select with a 32-/16-bit data bus operates with

one or two different types of write mode:

1. Byte-write mode supports four (32-bit bus) or two

2. Byte-select mode selects the appropriate byte(s)

This option is controlled by the BAT field in SMC_CSR for

the corresponding chip select.

Byte-write access can be used to connect four 8-bit devices

as a 32-bit memory page or two 8-bit devices as a 16-bit

memory page.

D[15:0] used when data bus width is 16

NCE[3] can be configured for LCD interface mode

(16-bit bus) byte writes and a single read signal.

using four (32-bit bus) or two (16-bit bus) byte-select

lines and separate read and write signals.

16

AT75C220

Page 17

AT75C220

For a 32-bit bus:

• The signal NWE0 is used as the write enable signal for

byte 0.

• The signal NWE1 is used as the write enable signal for

byte 1.

• The signal NWE2 is used as the write enable signal for

byte 2.

• The signal NWE3 is used as the write enable signal for

byte 3.

• The signal NSOE enables memory reads to all memory

blocks.

For a 16-bit bus:

• The signal NWE0 is used as the write enable signal for

byte 0.

• The signal NWE1 is used as the write enable signal for

byte 1.

• The signal NSOE enables memory reads to all memory

blocks.

Byte-select mode can be used to connect one 32-bit device

or two 16-bit devices in a 32-bit memory page or one 16-bit

device in a 16-bit memory page.

For a 32-bit bus:

• The signal NWE0 is used to select byte 0 for read and

write operations.

• The signal NWE1 is used to select byte 1 for read and

write operations.

• The signal NWE2 is used to select byte 2 for read and

write operations.

• The signal NWE3 is used to select byte 3 for read and

write operations.

• The signal NWR is used as the write enable signal for

the memory block.

• The signal NSOE enables memory reads to the memory

block.

For a 16-bit bus:

• The signal NWE0 is used to select byte 0 for read and

write operations.

• The signal NWE1 is used to select byte 1 for read and

write operations.

• The signal NWR is used as the write enable signal for

the memory block.

• The signal NSOE enables memory reads to the memory

block.

During boot, the number of external devices (number of

active chip selects) and their configurations must be programmed as required. The chip select addresses that are

programmed take effect immediately. Wait states also take

effect immediately when they are programmed to optimize

boot program execution.

Read Protocols

The SMC provides two alternative protocols for external

memory read access: standard and early read. The difference between the two protocols lies in the timing of the

NSOE (read cycle) waveform.

The protocol is selected by the DRP field in the Memory

Control Register (SMC_MCR) and is valid for all memory

devices. Standard read protocol is the default protocol after

reset.

• Standard Read Protocol

Standard read protocol implements a read cycle in which

NSOE and the write strobes are similar. Both are active

during the second half of the clock cycle. The first half of

the clock cycle allows time to ensure completion of the previous access, as well as the output of address and NCE

before the read cycle begins.

During a standard read protocol external memory access,

NCE is set low and ADDR is valid at the beginning of the

access, whereas NSOE goes low only in the second half of

the master clock cycle to avoid bus conflict. The write

strobes are the same in both protocols. The write strobes

always go low in the second half of the master clock cycle.

• Early Read Protocol

Early read protocol provides more time for a read access

from the memory by asserting NSOE at the beginning of

the clock cycle. In the case of successive read cycles in the

same memory, NSOE remains active continuously. Since a

read cycle normally limits the speed of operation of the

external memory system, early read protocol allows a

faster clock frequency to be used. However, an extra wait

state is required in some cases to avoid contention on the

external bus.

In early read protocol, an early read wait state is automatically inserted when an external write cycle is followed by a

read cycle to allow time for the write cycle to end before the

subsequent read cycle begins. This wait state is generated

in addition to any other programmed wait states (i.e., data

float wait). No wait state is added when a read cycle is followed by a write cycle, between consecutive accesses of

the same type or between external and internal memory

accesses. Early read wait states affect the external bus

only. They do not affect internal bus timing.

Write Protocol

During a write cycle, the data becomes valid after the falling edge of the write strobe signal and remains valid after

the rising edge of the write strobe. The external write strobe

waveform on the appropriate write strobe pin is used to

control the output data timing to guarantee this operation.

Thus, it is necessary to avoid excessive loading of the write

strobe pins, which could delay the write signal too long and

cause a contention with a subsequent read cycle in standard protocol. In early read protocol, the data can remain

17

Page 18

valid longer than in standard read protocol due to the additional wait cycle that follows a write access.

Wait States

The SMC can automatically insert wait states. The different

types of wait states are:

• standard wait states

• data float wait states

• external wait states

• chip select change wait states

• early read wait states (see “Read Protocols” on page 17

for details)

• standard wait states

Each chip select can be programmed to insert one or more

wait states during an access on the corresponding device.

This is done by setting the WSE field in the corresponding

SMC_CSR. The number of cycles to insert is programmed

in the NWS field in the same register. The correspondence

between the number of standard wait states programmed

and the number of cycles during which the write strobe

pulse is held low is found in Table 7. For each additional

wait state programmed, an additional cycle is added.

Table 7. Correspondence Wait States/Number of Cycles

Wait States Cycles

01/2

SMC_CSR register for the corresponding chip select. The

value (0 - 7 clock cycles) indicates the number of data float

waits to be inserted and represents the time allowed for the

data output to go high impedance after the memory is disabled.

The SMC keeps track of the programmed external data

float time even when it makes internal accesses to ensure

that the external memory system is not accessed while it is

still busy.

Internal memory accesses and consecutive accesses to

the same external memory do not have added data float

wait states.

When data float wait states are being used, the SMC prevents the DMC or external master from accessing the

external data bus.

• External Wait

The NWAIT input can be used to add wait states at any

time NWAIT is active low and is detected on the rising edge

of the clock. If NWAIT is low at the rising edge of the clock,

the SMC adds a wait state and does not change the output

signals.

• Chip Select Change Wait States

A chip select wait state is automatically inserted when consecutive accesses are made to two different external memories (if no wait states have already been inserted). If any

wait states have already been inserted (e.g., data float

wait), then none are added.

11

• Data Float Wait State

Some memory devices are slow to release the external

bus. For such devices it is necessary to add wait states

(data float waits) after a read access before starting a write

access or a read access to a different external memory.

The Data Float Output Time (TDF) for each external memory device is programmed in the TDF field of the

LCD Interface Mode

NCE3 can be configured for use with an external LCD controller by setting the LCD bit in the SMC_CSR3 register.

Additionally, WSE must be set and NWS programmed with

a value of one or more.

In LCD mode, NCE3 is shortened by one-half clock cycle at

the leading and trailing edges, providing positive address

setup and hold. For read cycles, the data is latched in the

SMC as NCE3 is raised at the end of the access.

18

AT75C220

Page 19

AT75C220

SMC Register Map

The SMC is programmed using the registers listed in the

Table 8. The memory control register (SMC_MCR) is used

to program the number of active chip selects and data read

protocol. Four chip select registers (SMC_CSR0 to

SMC_CSR3) are used to program the parameters for the

Table 8. SMC Register Map

Offset Register Name Description Access Reset Value

0x00

SMC_CSR0

Chip Select Register

individual external memories. Each SMC_CSR must be

programmed with a different base address, even for

unused chip selects. The AT75C220 resets such that

SMC_CSR0 is configured as having a 16-bit data bus.

Read/write 0x0000203D

0x04

0x08

0x0C

0x10

0x14

0x18

0x1C

0x20

0x24

SMC_CSR1

SMC_CSR2

SMC_CSR3

–

–

–

–

–

SMC_MCR

Chip Select Register

Chip Select Register

Chip Select Register

Reserved

Reserved

Reserved

Reserved

Reserved

Memory Control Register

Read/write 0x10000000

Read/write 0x20000000

Read/write 0x30000000

––

––

––

––

––

Read/ write 0

SMC Chip Select Register

Register Name:SMC_CSR0..SMC_CSR3

Access: Read/write

Reset Value:

31 30 29 28 27 26 25 24

BA

23 22 21 20 19 18 17 16

BA –––LCD

15 14 13 12 11 10 9 8

––CSEN BAT TDF PAGES

76543210

PAGES MWS WSE NWS DBW

• DBW: Data Bus Width

DBW Data Bus Width

00Reserved

0 1 16-bit external bus

1 0 32-bit external bus

11Reserved

19

Page 20

• NWS: Number of Wait States

This field is valid only if WSE is set.

Table 9. NWS, WSE Values

NWS WSE Wait States

XX X 0 0

0001 1

0011 2

0101 3

0111 4

1001 5

1011 6

1101 7

1111 8

• WSE: Wait State Enable

• MWS: Multiply Wait States

See Table 9, where

WS NWS 1+()81+×=

• PAGES: Page Size

PAGES Page Size

0 0 1M byte BA[31 - 20]

0 1 4M bytes BA[31 - 22]

1 0 16M bytes BA[31 - 24]

11 Reserved –

• TDF: Data Float Output Time

TDF Cycles after Transfer

00 0 0

00 1 1

01 0 2

01 1 3

10 0 4

10 1 5

11 0 6

11 1 7

Base

Address

• BAT: Byte Access Mode

0 = Byte Write Mode

1 = Byte Select Mode

20

AT75C220

Page 21

AT75C220

• CSEN: Chip Select Enable

Active high.

• LCD: LCD Mode Enable

Active high. SMC_CSR3 only.

• BA: Base Address

This field contains the high-order bits of the base address. If the page size is larger than 1M byte, then the unused bits

of the base address are ignored by the SMC decoder.

SMC Memory Control Register

Register Name:SMC_MCR

31 30 29 28 27 26 25 24

––––––––

23 22 21 20 19 18 17 16

––––––––

15 14 13 12 11 10 9 8

––––––––

76543210

–––DRP ––––

• DRP: Data Read Protocol

0 = Standard Read Mode

1 = Early Read Mode

21

Page 22

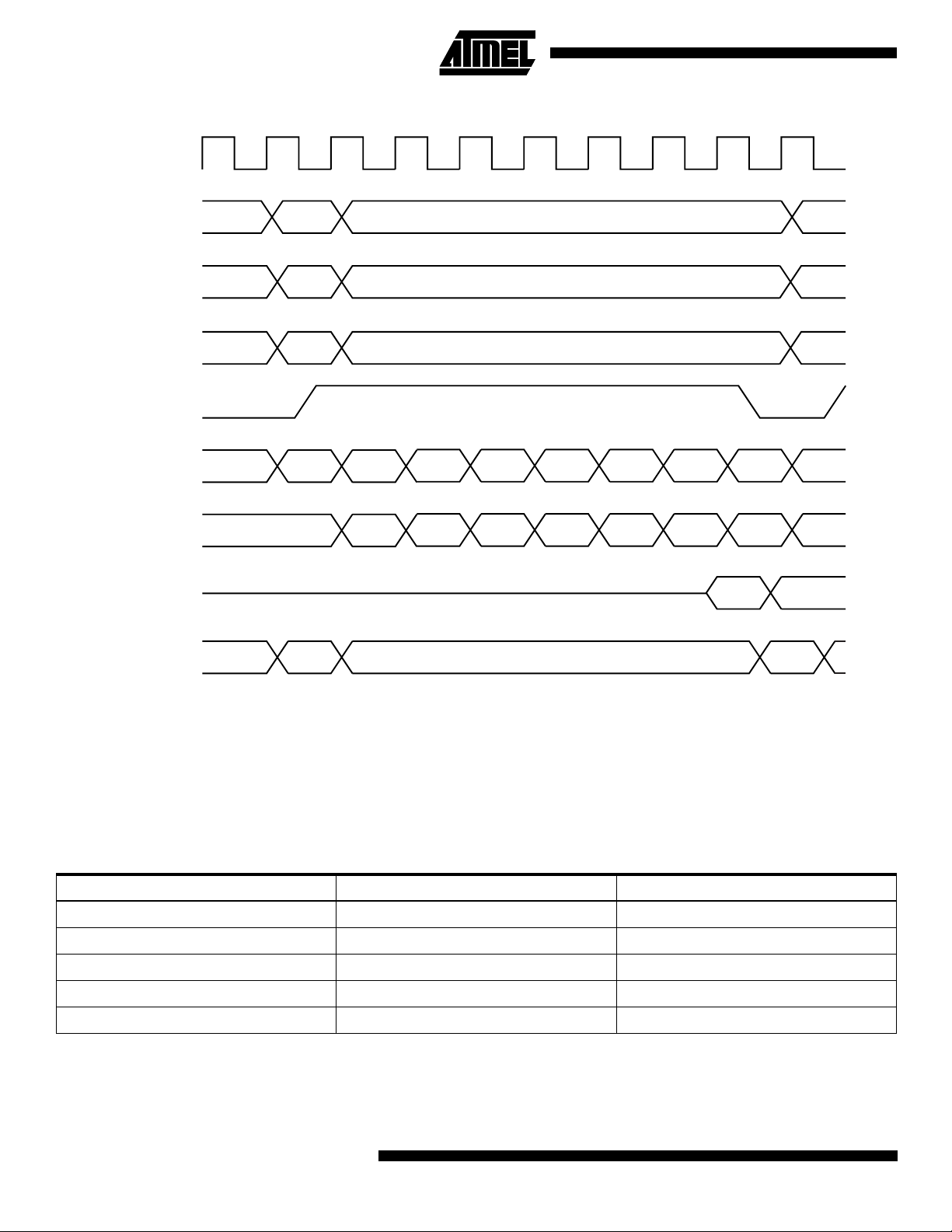

Switching Waveforms

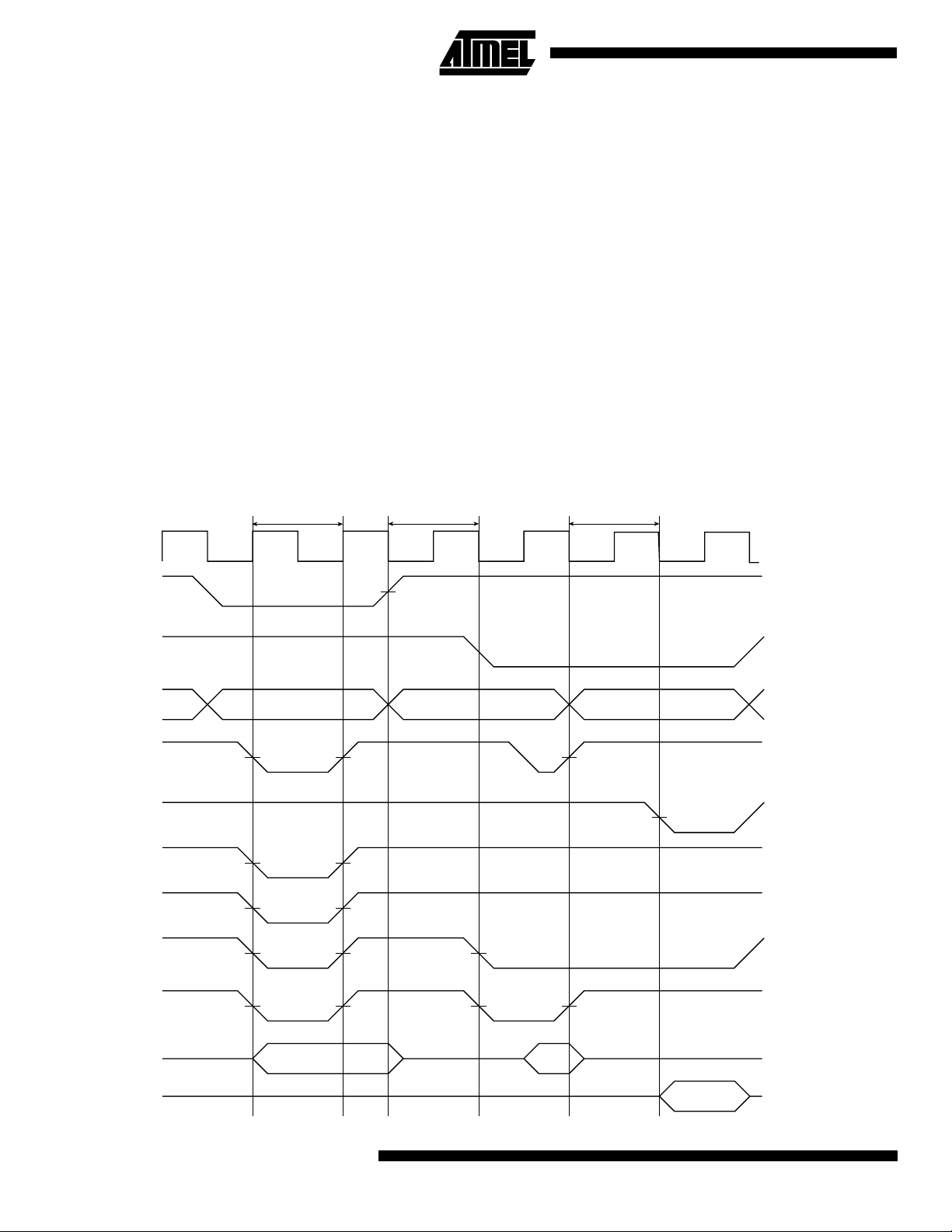

Figure 6 shows a write to memory 0 followed by a write and

a read to memory 1. SMC_CSR0 is programmed for one

wait state with BAT = 0 and DFT = 0. SMC_CSR1 is programmed for zero wait states with BAT = 1 and DFT = 0.

SMC_MCR is programmed for early reads from all

memories.

The write to memory 0 is a word access and therefore all

four NWE strobes are active. As BAT = 0, they are configured as write strobes and have the same timing as NWR.

As the access employs a single wait state, the write strobe

pulse is one clock cycle long.

There is a chip select change wait state between the memory 0 write and the memory 1 write. The new address is

output at the end of the memory 0 access, but the strobes

are delayed for one clock cycle.

The write to memory 1 is a half-word access to an odd halfword address and, therefore, NWE2 and NWE3 are active.

Figure 6. Write to Memory 0, Write and Read to Memory 1

Internal Wait State Chip Select Wait State Early Read Wait State

BCLK

As BAT = 1, they are configured as byte select signals and

have the same timing as NCE. As the access has no internal wait states, the write strobe pulse is one- half clock

cycle long. Data and address are driven until the write

strobe rising edge is sensed at the SIAP pin to guarantee

positive hold times.

There is an early read wait state between memory 1 write

and memory 1 read to provide time for the AT75C220 to

disable the output data before the memory is read. If the

read was normal mode, i.e., not early, the NSOE strobe

would not fall until the rising edge of BCLK and no wait

state would be inserted. If the write and early read were to

different memories, then the early read wait state is not

required as a chip select wait state will be implemented.

The read from memory 1 is a byte access to an address

with a byte offset of 2 and therefore only NWE2 is active.

NCE0

NCE1

NWR

NSOE

NWE0

NWE1

NWE2

NWE3

A

22

D (SIAP)

D (MEM)

AT75C220

Page 23

AT75C220

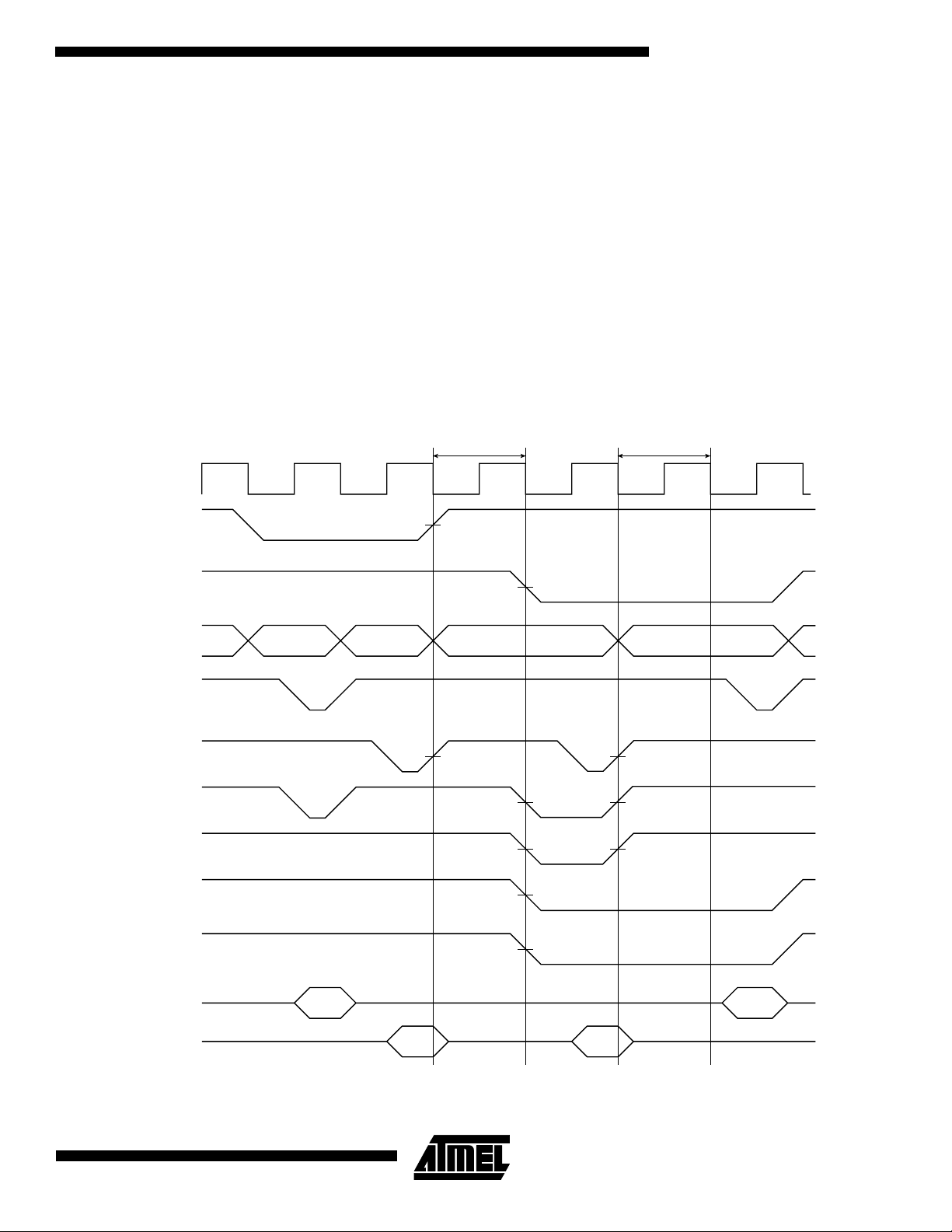

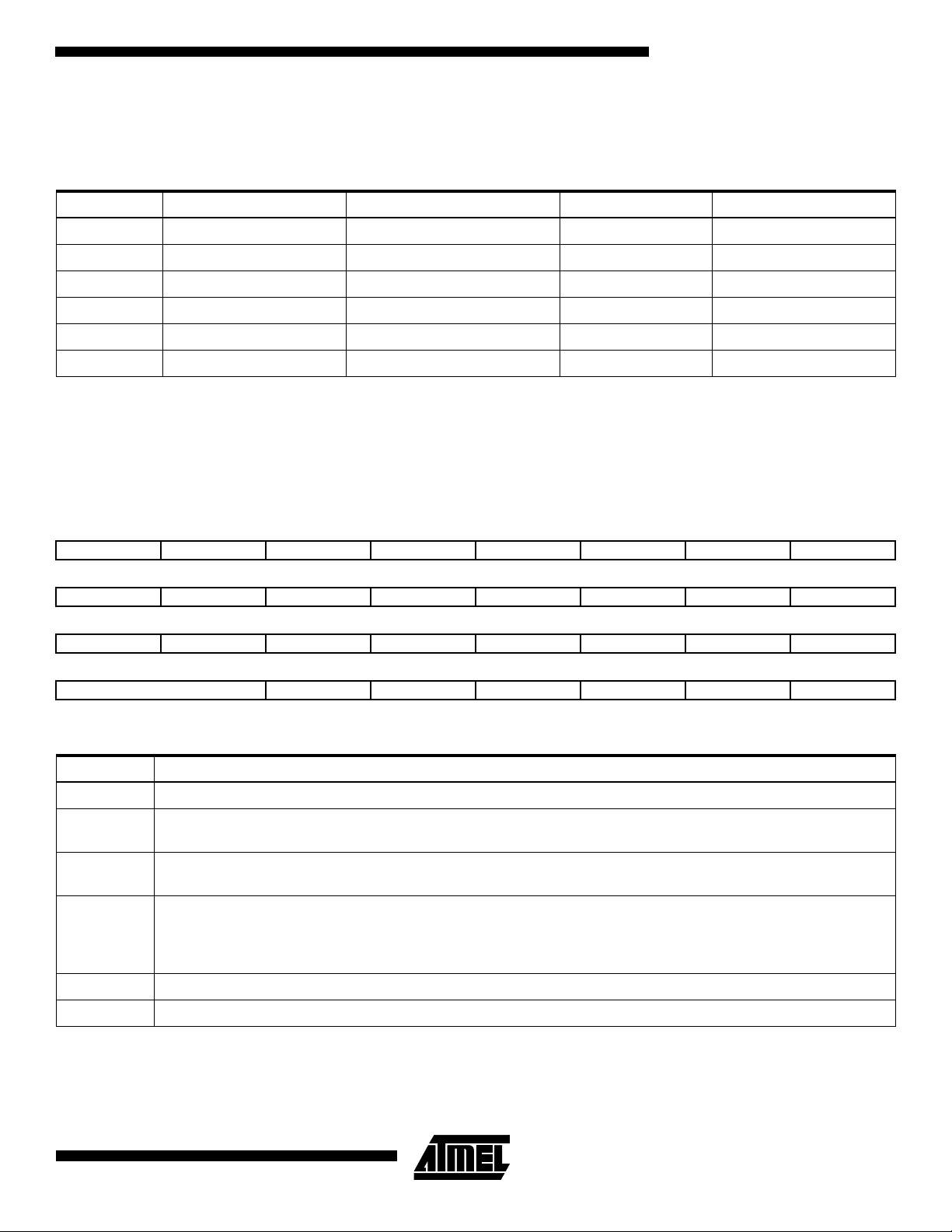

Figure 7 shows a write and a read to memory 0 followed by

a read and a write to memory 1. SMC_CSR0 is programmed for zero wait states with BAT = 0 and DFT = 0.

SMC_CSR1 is programmed for zero wait states with BAT =

1 and DFT = 1. SMC_MCR is programmed for normal

reads from all memories

The write to memory 0 is a byte access and, therefore, only

one NWE strobe is active. As BAT = 0, they are configured

as write strobes and have the same timing as NWR.

The memory 0 read immediately follows the write as early

reads are not configured and an early read wait state is not

required. As early reads are not configured, the read strobe

pulse is one-half clock cycle long.

There is a chip select change wait state between the memory 0 write and the memory 1 read. The new address is

output at the end of the memory 0 access but the strobes

are delayed for one clock cycle.

The write to memory 1 is a half-word access to an odd halfword address and, therefore, NWE2 and NWE3 are active.

As BAT = 1, they are configured as byte select signals and

have the same timing as NCE.

As DFT = 1 for memory 1, a wait state is implemented

between the read and write to provide time for the memory

to stop driving the data bus. DFT wait states are only implemented at the end of read accesses.

The read from memory 1 is a byte access to an address

with a byte offset of 2 and, therefore, only NWE2 is active.

Figure 7. Write and Read to Memory 0, Read and Write to Memory 1

Chip Select

Wait State

BCLK

NCE0

Data Float

Wait State

NCE1

NWR

NSOE

NWE0

NWE1

NWE2

NWE3

D (SIAP)

A

D (MEM)

23

Page 24

SDMC: SDRAM Controller

The AT75C220 integrates an SDRAM controller (SDMC).

The ARM accesses external SDRAM by means of the

SDRAM memory controller.

The SDMC shares the same address and data pins as the

static memory controller but has separate control signals.

The SDMC interface is a memory-mapped APB slave.

For very low frequency selection in low power mode, the

SDRAM should be refreshed frequently.

Table 10. External Memory Interface

Signal Name Type Description

DCLK Output SDRAM Clock

A[21:0] Output Memory address (Shared with SMC)

D[15:0] Input Memory data input (Shared with SMC)

DQM[1:0] Output SDRAM byte masks

CS0 Output SDRAM chip select, active low

CS1 Output SDRAM chip select, active high

Main features of the SDMC are:

• External memory mapping

• Up to 4 chip select lines

• 32- or 16-bit data bus

• Byte write or byte select lines

• Two different read protocols

• Programmable wait state generation

• External wait request

• Programmable data float time

• Programmable burst mode

WE Output SDRAM write enable, active low

RAS Output Row Address Select, active low

CAS Output Column Address Select, active low

The signals RAS, CAS, WE, A[21:0], and D[15:0] have

functions similar to those of a conventional DRAM.

DCLK is the free-running, normally continuous clock to

which all other signals are synchronized; CKE is an enable

signal that gates the other control inputs. Note that CKE is

not bonded out since it is always active high.

APB Interface

The SDMC interface is a memory-mapped APB slave.

ASB Interface

The SDMC is also an ASB slave and has a reserved memory region in the ASB memory map.

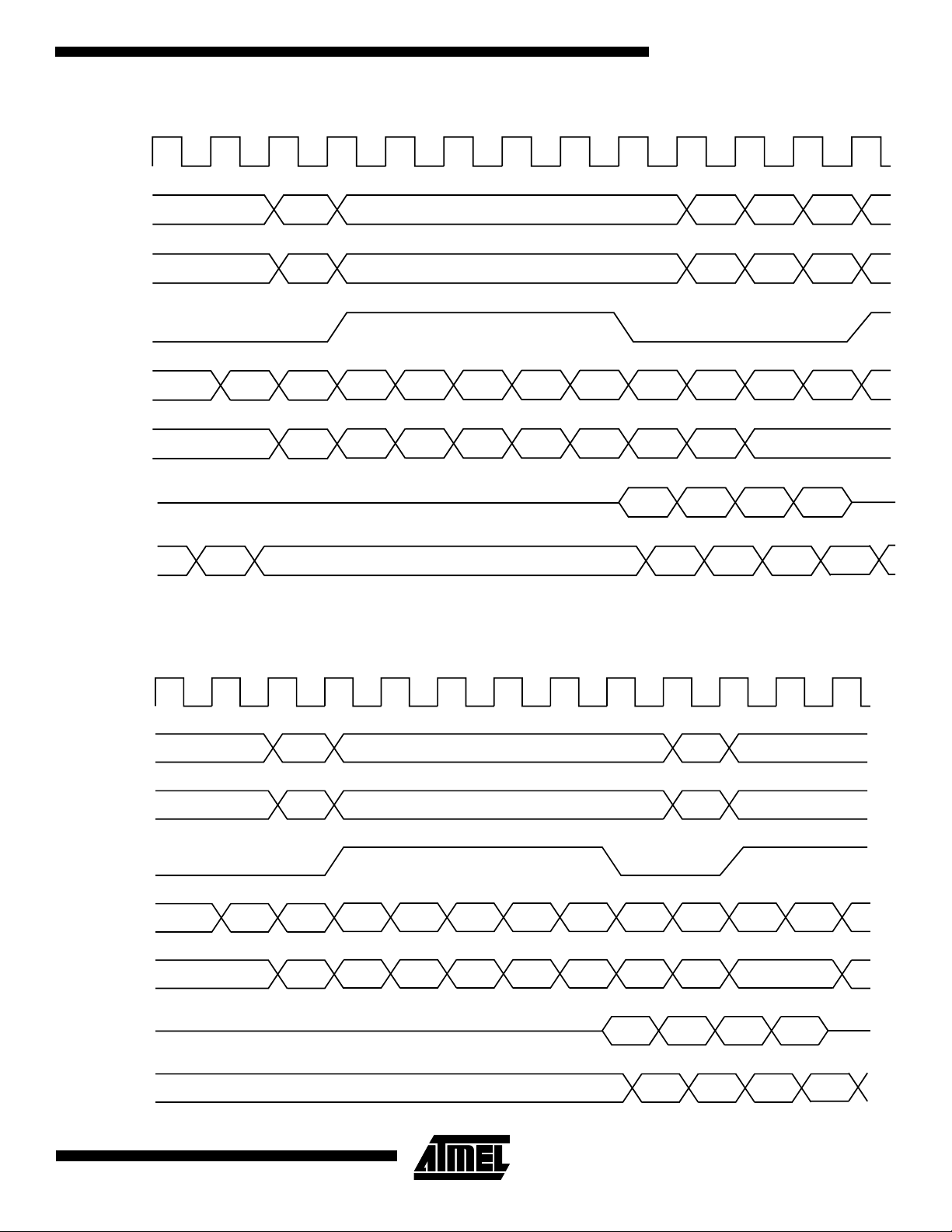

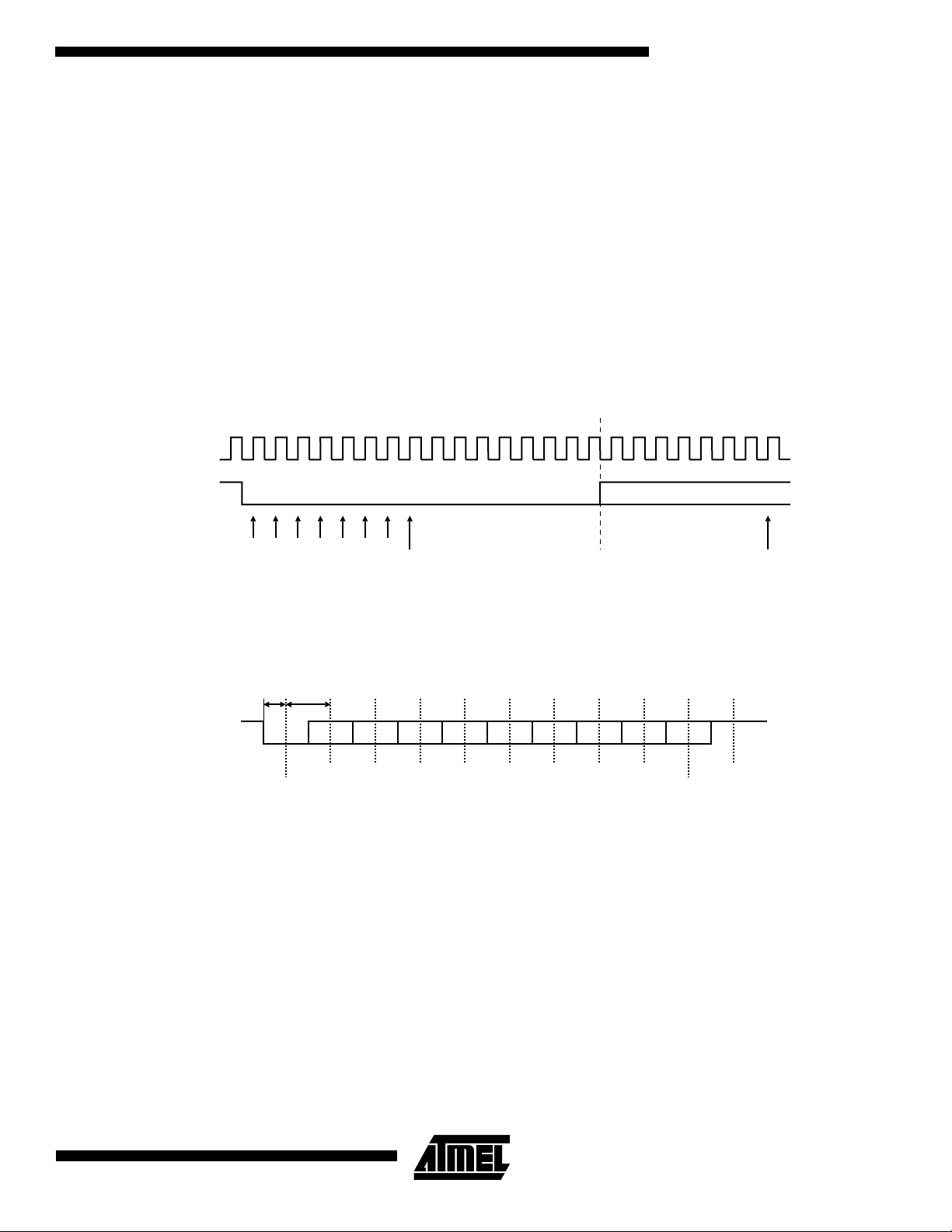

Read and Write Bursts

The SDMC has been modified so read accesses are performed in bursts of four for accesses to 32-bit memory or

bursts of eight for 32-bit access to 16-bit memory. Read

accesses are performed as shown in Figure 8, Figure 9

and Figure 10. Note that read bursts are terminated if a

non-sequential access is detected. However, pipelined

commands from the SDRAM may be still be executed but

the resultant read data is ignored.

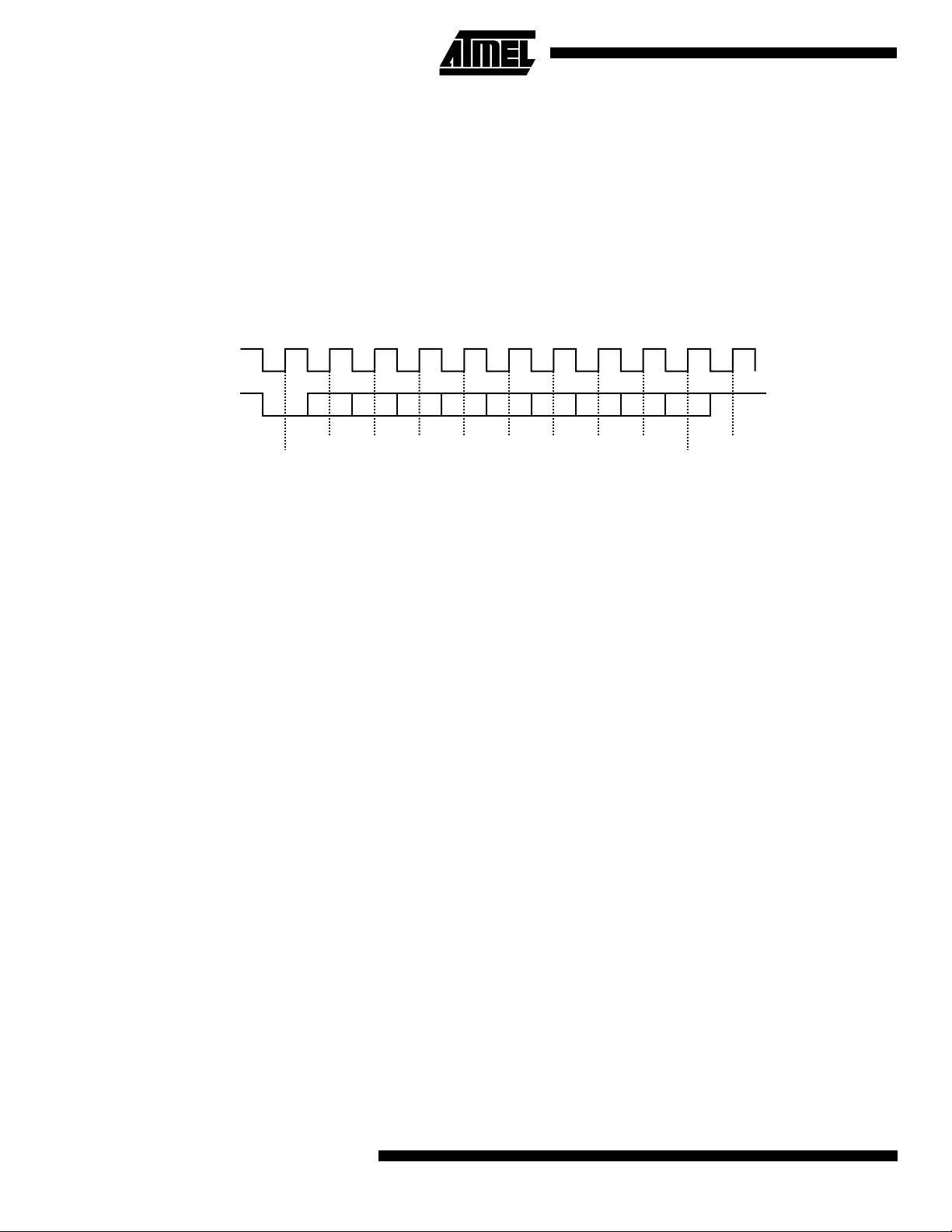

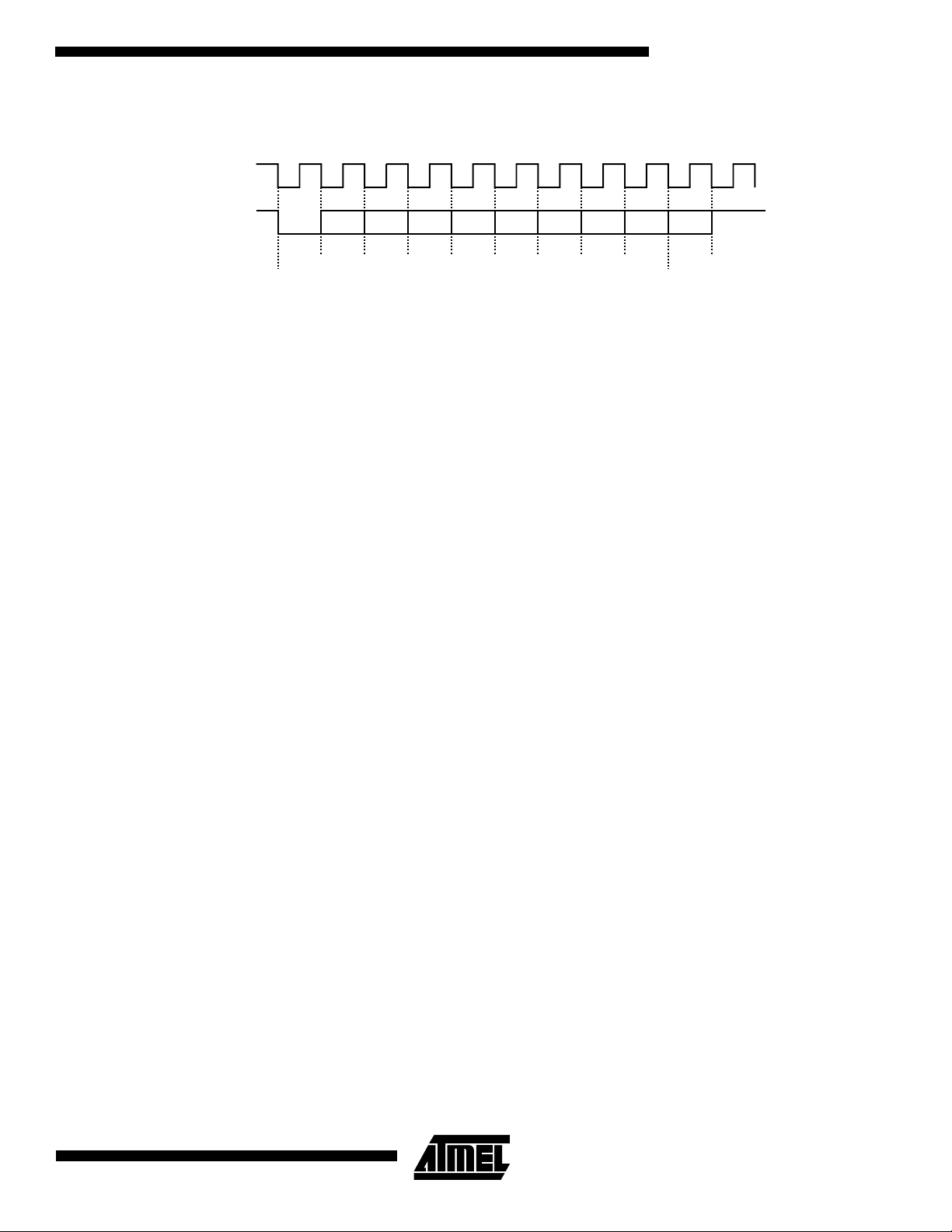

Three separate read accesses are shown in Figure 8, Figure 9 and Figure 10. In Figure 8, the data from all four

reads is used, in Figure 9 the data from the last two reads

is discarded. Figure 10 shows a single non-sequential

access to a new row.

24

AT75C220

Page 25

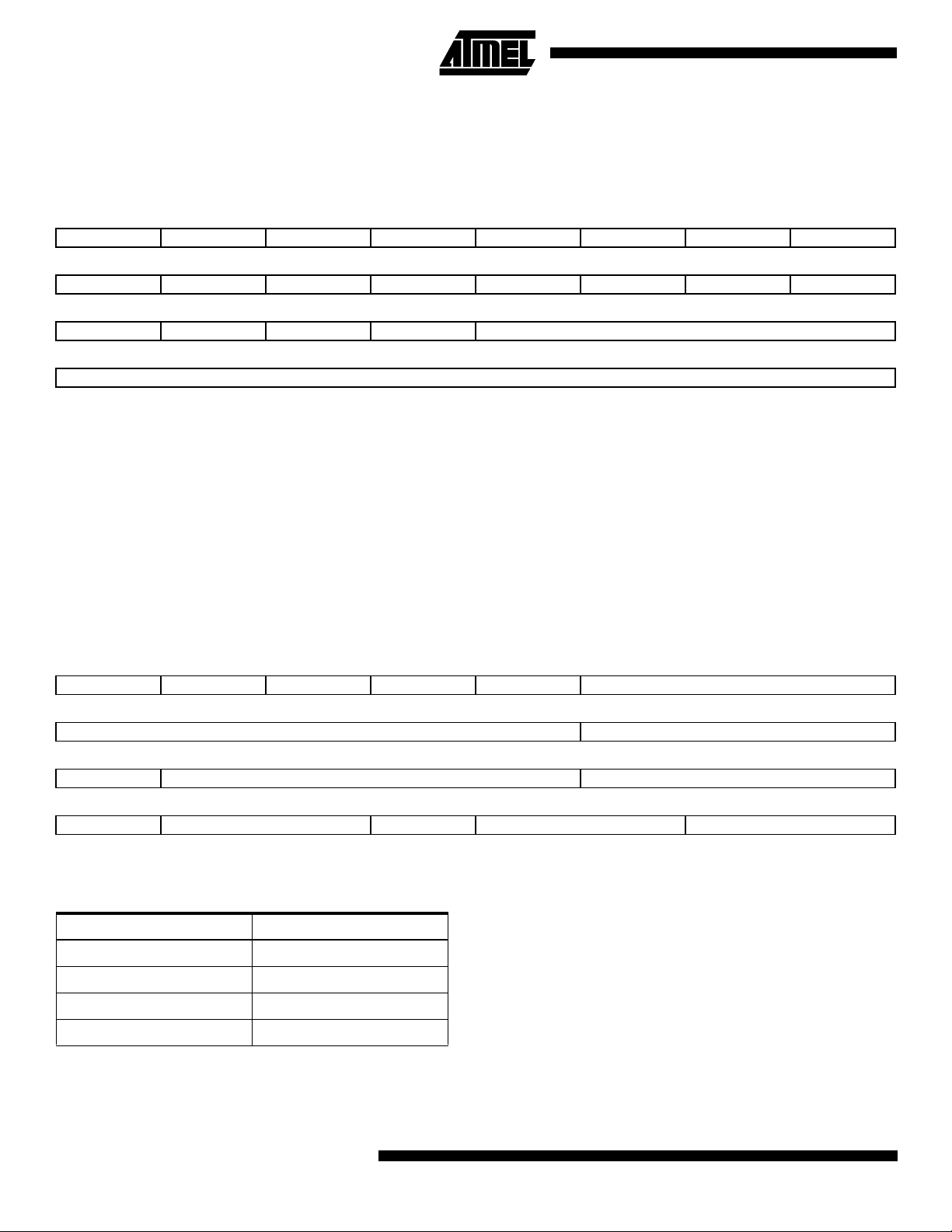

Figure 8. Read with Burst Length of 4 and CAS Latency of 2

P

BCLK

AT75C220

BA

BTRAN

BWAIT

SDRAM CMD

addr

sdmc_data

BD

NOP PRE NOP ACT NOP READ READ READ READ NOP NOP NO

A0 A2 A3A1

NSEQ SEQ SEQ SEQ NSEQ

BANK ROW COL0 COL1 COL2 COL3

Figure 9. Read with Burst Length of 2 and CAS Latency of 2

D0 D1 D2 D3

D0 D1 D2 D3

BCLK

BA

BTRAN

BWAIT

SDRAM CMD

Addr

sdmc_data

BD

A0 A2 A3A1

NSEQ SEQ SEQ SEQ

NOP PRE NOP ACT NOP READ READ READ READ NOP NOP PRE

BANK ROW COL0 COL1 COL2 COL3

D0 D1 D2 D3

D0 D1 x x

BANK

25

Page 26

Figure 10. Read Showing a Single Access for a Non-sequential Read to a New Row

BCLK

BA

BTRAN

hburst_h

BWAIT

SDRAM CMD

Addr

sdmc_data

BD

A0 A1

NSEQ NSEQ

INCR INCR

NOP PRE NOP ACT NOP READ NOP NOP

BANK ROW COL0 COL1

NOP

D0

D0

Writes can burst continuously until any of the following conditions are achieved:

1. The following access is a read.

2. The following access is to a new row.

3. The following access is non-sequential.

When any of these conditions occur, the write burst is broken and SDMC goes inactive.

Table 11. SDRAM Refresh Rates

Clock Speed (MHz) Tick (us) Counter Needed

40 0.25 62.5

81.2512.5

1 10 1.5625

0.025 400 0.0390625

0.0032 3125 0.005

SDRAM Refresh

Table 11 shows the counter values needed for a refresh

rate of 15.625 µs in the SDMC. As can be seen, at clock

speeds of 1 MHz and below it is unfeasible to maintain data

integrity in the SDRAM. Note that in low power modes it is

not a requirement to maintain data in the SDRAM.

26

AT75C220

Page 27

AT75C220

SDMC Register Map

Base Address: 0xFF008000

Table 12. SDMC Register Map

Offset Register Name Description Access Reset Value

0x0000 SDRAM_MODE Mode Register Read/write 0x00000000

0x0004 SDRAM_TIMER Timer Register Read/write 0x00000000

0x0008 SDRAM_CFG Configuration Register Read/write 0x00000000

0x000C SDRAM_16BIT Selects 16-/32-bit modes Read/write 0x00000001

0x0010 SDRAM_CS0_ADDR Base address for CS0 Read/write 0x00000040

0x0014 SDRAM_CS1_ADDR Base address for CS1 Read/write 0x00000050

SDRAM_MODE Register

Register Name: SDRAM_MODE

Access Type: Read/write

Reset Value: 0x0

31 30 29 28 27 26 25 24

––––––––

23 22 21 20 19 18 17 16

––––––––

15 14 13 12 11 10 9 8

–––––––MODE

76543210

MODE ––––––

• MODE

MODE Description

000 Normal mode. Any access to the SDRAM will be decoded normally.

001 The NOP command is issued to the SDRAM when the host accesses the SDRAM memory area, regardless of the

cycle.

010 The all banks precharge command is issued to the SDRAM when the host accesses the SDRAM memory area,

regardless of the cycle.

011 The load mode register command is issued to the SDRAM when the host accesses the SDRAM memory area,

regardless of the cycle. The address offset with respect to the SDRAM memory base address is used to program the

mode register. For example, when this mode is activated, an access to the “SDRAM_BASE + offset” generates a load

mode register command with the value offset written to the mode register of the SDRAM.

100 A refresh command is issued to the SDRAM. An all banks precharge command must precede.

others Reserved

27

Page 28

SDRAM_TIMER Register

Register Name: SDRAM_TIMER

Access Type: Read/write

Reset Value: 0x0

31 30 29 28 27 26 25 24

––––––––

23 22 21 20 19 18 17 16

––––––––

15 14 13 12 11 10 9 8

–––– CNT

76543210

CNT

• CNT

This 12-bit field is loaded into a timer which generates the refresh pulse. Each time the refresh pulse is generated, a

refresh burst is initiated. The length of this refresh burst (number of rows refreshed) can be adjusted at compile time by

modifying the value RFSH_LEN. The refresh commands will begin when the timer is loaded for the first time. The value

to be loaded depends on the clock frequency used in the SDMC configuration module, the refresh rate of the SDRAM

and the refresh burst length where 15.6 microseconds is a typical value for a burst of length one.

SDRAM_CFG Register

Register Name: SDRAM_CFG

Access Type: Read/write

Reset Value: 0x0

31 30 29 28 27 26 25 24

––––– TRAS

23 22 21 20 19 18 17 16

15 14 13 12 11 10 9 8

TRP TRC TWR

76543210

TWR CAS NB NR NC

TRCD TRP

• NC

Sets the number of column bits. Default is eight column bits.

NC Column Bits

00 8

01 9

10 10

11 11

28

AT75C220

Page 29

AT75C220

• NR

Sets the number of row bits. Default is 11 row bits.

NR Row Bits

00 11

01 12

10 13

11 Reserved

• NB

Sets the number of banks. Default is two banks.

NB Number of Banks

02

14

• CAS

Sets the CAS latency. The SDMC has been modified so that it only supports a CAS latency of two. Writing to this register will have no effect.

• TWR

Sets the value of TWR expressed in number of cycles. Default is two cycles.

• TRC

Sets the value of TRC expressed in number of cycles. Default is eight cycles.

• TRP

Sets the value of TRP expressed in number of cycles. Default is three cycles.

• TRCD

Sets the value of TRCD expressed in number of cycles. Default is three cycles.

• TRAS

Sets the value of TRAS expressed in number of cycles. Default is five cycles.

SDRAM_16bit Register

Register Name: SDRAM_16BIT

Access Type: Read/write

Reset Value: 0x1

31 30 29 28 27 26 25 24

––––––––

23 22 21 20 19 18 17 16

––––––––

15 14 13 12 11 10 9 8

––––––––

76543210

–––––––16BIT

• 16BIT

This bit is used to set the width of the external memory. If this field is set, the address is assumed to be 16 bits wide. If

not set, the memory bus is assumed to be 32 bits wide.

29

Page 30

SDRAM_CS0_ADDR Register

Register Name: SDRAM_CS0_ADDR

Access Type: Read/write

Reset Value: 0x40

31 30 29 28 27 26 25 24

––––––––

23 22 21 20 19 18 17 16

––––––––

15 14 13 12 11 10 9 8

–––––––CS0_ADDR

76543210

CS0_ADDR

• CS0_ADDR

This bit is used to set the eight most significant bits of the address of CS0.

SDRAM_CS1_ADDR Register

Register Name: SDRAM_CS1_ADDR

Access Type: Read/write

Reset Value: 0x50

31 30 29 28 27 26 25 24

––––––––

23 22 21 20 19 18 17 16

––––––––

15 14 13 12 11 10 9 8

–––––––CS1_ADDR

76543210

• CS1_ADDR

This bit is used to set the eight most significant bits of the address of CS1.

CS1_ADDR

30

AT75C220

Page 31

Arbitration Using Multi-layer AMBA

AT75C220

The AT75C220 has two separate ASB (multi-layer AMBA)

buses that can be decoupled during most normal operations. The ability to couple the two ASB buses is provided

to allow the ARM to receive and transmit Ethernet frames

via the two Ethernet MACs.

The ARM bus is the main processor bus to which most

peripherals are connected.

The MAC bus is used exclusively for Ethernet traffic.

An ASB-ASB bridge that is transparent to the other devices

on the bus connects the two ASB buses. Figure 11 shows

the connection between the two buses.

Figure 11. ASB - ASB Bridge

ASB (ARM)

MAC

Arbiter

ASB - ASB Bridge

Slave

Master

Master

Slave

ASB (MAC)

ARM

Arbiter

The ASB-ASB bridge consists of two channels: the first is a

master on the MAC bus and a slave on the ARM bus. The

second channel is a master on the ARM bus and a slave on

the MAC bus.

The ARM7TDMI is the default master and always requests

the bus. It is always granted the bus in absence of a

request from another master.

The MAC ASB has two priority levels, the two MACs share

low priority access and the bridge has high priority. The

MACs do not burst more than four words per access and

release the bus request between accesses so the MACs

can share a priority level with a simple round-robin arbitration scheme.

The ARM is likely to be the only master accessing the MAC

bus via the bridge and should not perform more than a couple of cycles before releasing the MAC bus. Care should be

taken to prevent other masters on the ARM bus holding the

MAC bus for more than a few cycles. Otherwise, the MACs

drop frames due to FIFO overflow or underflow.

Coupled Bus Operation

When a master on one bus accesses a slave on the other

bus, the following operations occur:

• The master arbitrates for the local ASB bus if it does not

already have access to the bus.

• When the local bus arbiter grants the master the local

bus, the master initiates a cycle with an address

corresponding to a slave on the remote bus.

• The bridge is selected as the slave on the local bus and

responds by inserting wait cycles. The bridge also

requests the remote bus from the remote bus arbiter.

• When the bridge is granted the remote bus, the two ASB

buses are coupled and the transfer completes.

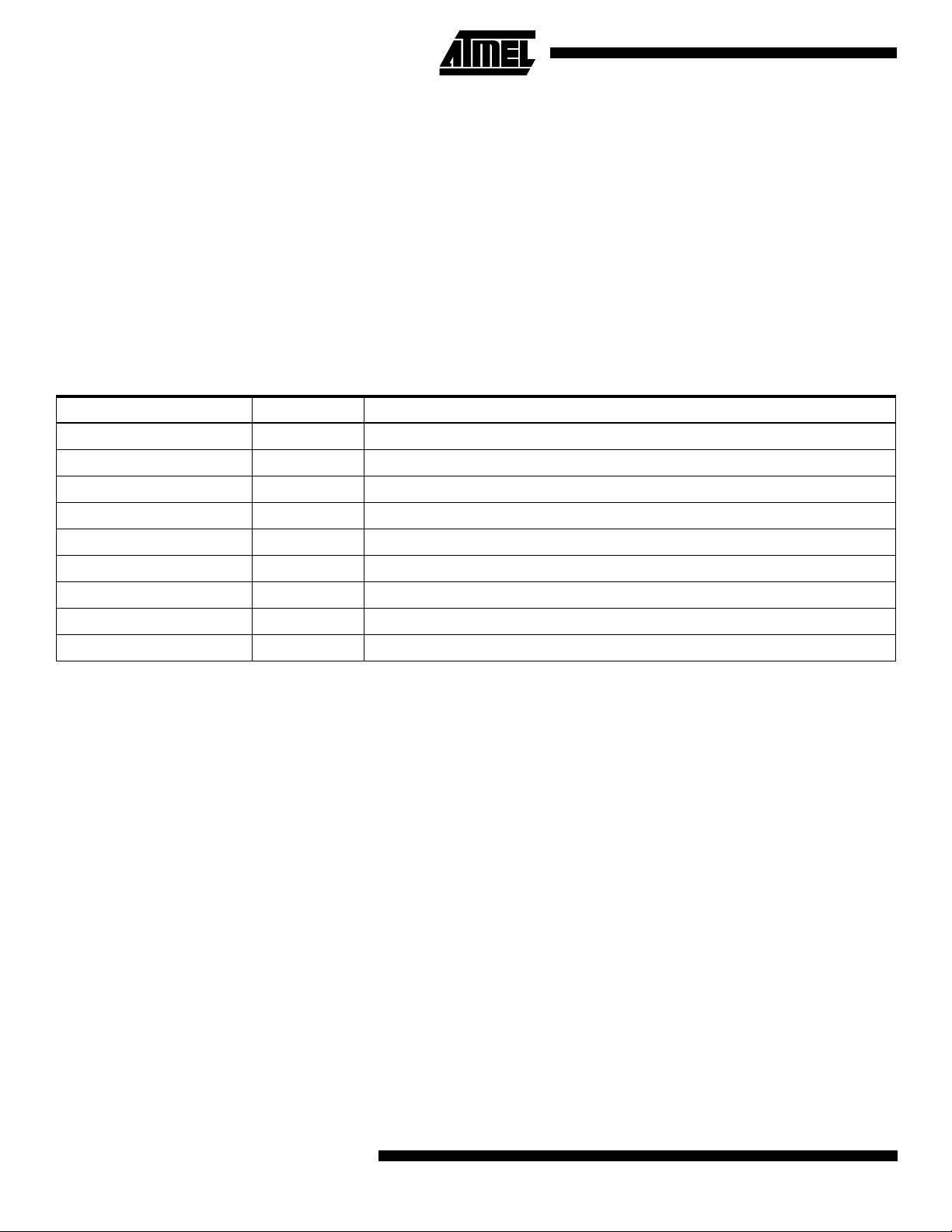

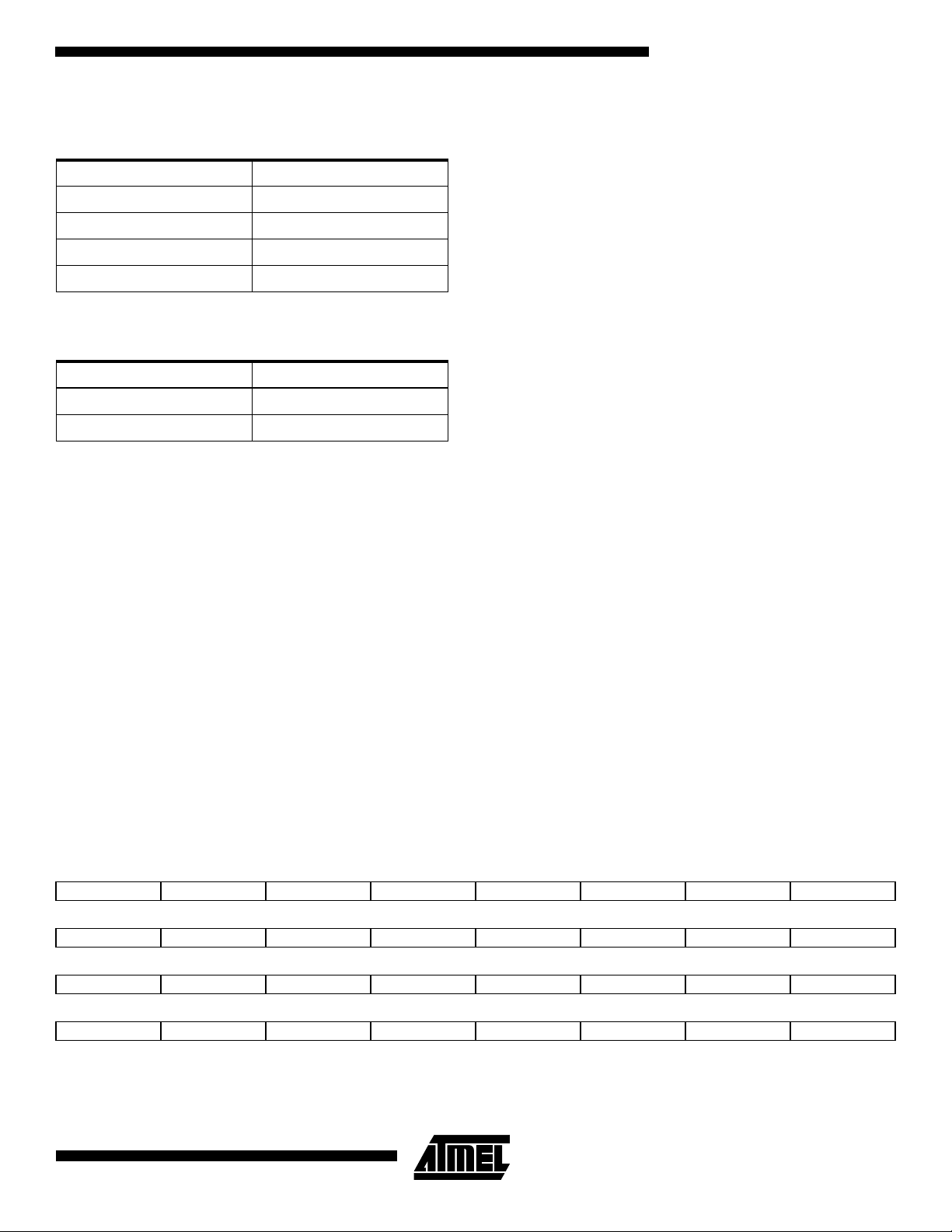

ASB-ASB Bridge Timing

The AMBA ASB performs pipelined arbitration. The bridge

can only request the bus when the address of the slave is

available. For this reason, the bridge must insert a wait

cycle during the arbitration cycle on the remote bus

because it cannot request the bus early. Figure 12 shows a

write cycle from a master on the ARM bus to a slave on the

MAC bus. The slave does not add wait states. All cycles

operate in the same way as the write cycle until the buses

are coupled when the operation becomes slavedependent.

Deadlock

Deadlock is avoided by forcing the ARM processor to

release the bus if both the ARM and one of the MACs

request the bridge at the same time. The bridge responds

to the ARM with a signal to force the ARM to retry the operation later. The MAC can complete its access and release

the bus in the normal way.

Deadlock can still occur if a master that does not support

retract attempts to access the MAC bus at the same time

as one of the MACs is requesting the ARM bus. This situation is avoided if only the ARM is used to access the MAC

bus.

31

Page 32

Figure 12. ASB-to-ASB Bridge Write Timing

BCLK

ARM Bus Signals

BTRAN

BA/BWRITE

DSEL

BWAIT

BD

MAC Bus Signals

BREQ

BGNT

BTRAN

BA/BWRITE

DSEL

BWAIT

BD

32

AT75C220

Page 33

Ethernet MAC

AT75C220

The AT75C220 integrates two identical Ethernet MACs,

known as MAC A and MAC B.

The Ethernet MAC is described more fully in the IEEE standard 802.3. It is a programmable device on the APB bus by

means of 56 configuration and status registers. The Ethernet MAC is an ASB master.

The main features of the Ethernet MAC are:

• Compatibility with IEEE standard 802.3

• 10 and 100 Mbit/s operation

• Full-and half-duplex operation

• MII interface to the physical layer

• Register interface to address, status and control

registers

Table 13. External Interface

Signal Name Description Type

COL Collision detect from the PHY Input

CRS Carrier sense from the PHY Input

TXER Transmit error signal to the PHY. Asserted if the DMA block fails to fetch data

from memory during frame transmission.

TXD[3:0] Transmit data to the PHY Output

• DMA interface

• Interrupt generation to signal receive and transmit

completion

• 28-byte transmit and 28-byte receive FIFOs

• Automatic pad and CRC generation on transmitted

frames

• Address checking logic to recognize four 48-bit

addresses

• Supports promiscuous mode where all valid frames are

copied to memory

• Supports physical layer management through MDIO

interface

Output

TXEN Transmit enable to the PHY Output

TXCLK Transmit clock from the PHY Input

RXD[3:0] Receive data from the PHY Input

RXER Receive error signal from the PHY Input

RXCLK Receive clock from the PHY Input

RXDV Receive data valid signal from the PHY Input

MDC Management data clock Output

MDIO Management data I/O Input/Output

DMA Operation

Frame data is transferred to and from the Ethernet MAC via

the DMA interface. All transfers are 32-bit words and may

be single accesses or bursts of two, three or four words.

Burst accesses do not cross 16-byte boundaries.

The DMA controller performs four types of operations on

the ASB bus. In order of priority, they are receive buffer

manager write, receive buffer manager read, transmit data

DMA read and receive data DMA write.

Transmitter Mode

Transmit frame data needs to be stored in contiguous

memory locations and need not be word-aligned.

The transmit address register is written with the address of

the first byte to be transmitted. Transmit is initiated by writ-

ing the number of bytes to transfer (length) to the transmit

control register. The transmit channel then reads data from

memory 32 bits at a time and places them in the transmit

FIFO.

The transmit block starts frame transmission once three

words have been loaded into the FIFO.

The transmit address register must be written before the

transmit control register. While a frame is being transmitted, it is possible to set up one other frame for transmission

by writing new values to the transmit address and control

registers. Reading the transmit address register returns the

address of the buffer currently being accessed by the transmit FIFO. Reading the transmit control register returns the

total number of bytes to be transmitted. The buffer not

queued bit in the transmit status register indicates whether

33

Page 34

another buffer can be safely queued. An interrupt is generated whenever this bit is set.

Frame assembly starts by adding preamble and the start

frame delimiter. Data is taken from the transmit FIFO wordby-word. If necessary, padding is added to make the frame

length 60 bytes. The CRC is calculated as a 32-bit polynomial. This is inverted and appended to the end of the frame,

making the frame length a minimum of 64 bytes. The CRC

is not appended if the NCRC bit is set in the transmit control register.

In full duplex mode frames are transmitted immediately.

Back-to-back frames are transmitted at least 96 bit times

apart to guarantee the interframe gap.

In half-duplex mode the transmitter checks carrier sense. If

asserted, it waits for it to de-assert and then starts transmission after the interframe gap of 96 bit times.

If the collision signal is asserted during transmission, the

transmitter will transmit a jam sequence of 32 bits taken

from the data register and then retry transmission after the

backoff time has elapsed. An error is indicated and any further attempts aborted if 16 attempts cause collisions.

If transmit DMA underruns, bad CRC is automatically

appended using the same mechanism as jam insertion.

Underrun also causes TXER to be asserted.

Receiver Mode

When a packet is received, it is checked for valid preamble,

CRC, alignment, length and address. If all these criteria are

met, the packet is stored successfully in a receive buffer. If

at the end of reception the CRC is bad, then the received

buffer is recovered.

Each received frame including CRC is written to a single

receive buffer.

Receive buffers are word-aligned and are capable of containing 1518 bytes of data (the maximum length of an

Ethernet frame).

The start location for each received frame is stored in

memory in a list of receive buffer descriptors at a location

pointed to by the receive buffer queue pointer register.

Each entry in the list consists of two words. The first word is

the address of the received buffer; the second is the

receive status. Table 14 defines an entry in the received

buffer descriptor list.

To receive frames, the buffer queue must be initialized by

writing an appropriate address to bits [31:2] in the first word

of each list entry. Bit zero must be written with zero. After a

frame is received, bit zero becomes set and the second

word indicates what caused the frame to be copied to

memory.

The start location of the received buffer descriptor list

should be written to the received buffer queue pointer register before receive is enabled (by setting the receive

enable bit in the network control register). As soon as the

received block starts writing received frame data to the

receive FIFO, the received buffer manager reads the first

receive buffer location pointed to by the received buffer

queue pointer register. If the filter block is active, the frame

should be copied to memory; the receive data DMA operation starts writing data into the receive buffer. If an error

occurs, the buffer is recovered. If the frame is received

without error, the queue entry is updated. The buffer

pointer is rewritten to memory with its low-order bit set to

indicate successful frame reception and a used buffer. The

next word is written with the length of the frame and how

the destination address was recognized.

The next receive buffer location is then read from the following word or, if the current buffer pointer had its wrap bit

set, the beginning of the table. The maximum number of

buffer pointers before a wrap bit is seen is 1024. If a wrap

bit is not seen by then, a wrap bit is assumed in that entry.

The received buffer queue pointer register must be written

with zero in its lower-order bit positions to enable the wrap

function to work correctly.

If bit zero is set when the receive buffer manager reads the

location of the receive buffer, then the buffer has already

been used and cannot be used again until software has

processed the frame and cleared bit zero. In this case, the

DMA block will set the buffer’s unavailable bit in the

received status register and trigger an interrupt. The frame

will be discarded and the queue entry will be reread on

reception of the next frame to see if the buffer is now available. Each discarded frame increments a statistics register

that is cleared on being read.

When there is network congestion, it is possible for the

MAC to be programmed to apply backpressure. This is

when half-duplex mode collisions are forced on all received

frames by transmitting 64 bits of data (a default pattern).

Reading the received buffer queue register returns the

location of the queue entry currently being accessed. The

queue wraps around to the start after either 1024 entries

(i.e., 2048 words) or when the wrap bit is found to be set in

bit 1 of the first word of an entry.

34

AT75C220

Page 35

AT75C220

Table 14. Received Buffer Descriptor List

Bit Function

Word 0

31:2 Address of beginning of buffer

1 Wrap bit. If this bit is set, the counter that is ORed with the received buffer queue pointer register to give the

pointer to entries in this table will be cleared after the buffer is used.

0 Ownership bit. 1 indicates software owns the pointer, 0 indicates that the DMA owns the buffer. If this bit is not

zero when the entry is read by the receiver, the buffer’s unavailable bit is set in the received status register and

the receiver goes inactive.

Word 1

31 Global all ones broadcast address detected

30 Multicast hash match

29 Unicast hash match

28 External address (optional)

27 Unknown source address (reserved for future use)

26 Local address match (Specific address 4 match)

25 Local address match (Specific address 3 match)

24 Local address match (Specific address 2 match)

23 Local address match (Specific address 1 match)

22:11 Reserved written to 0.

10:0 Length of frame including FCS

Address Checking

Whether or not a frame is stored depends on what is

enabled in the network configuration register, the contents

of the specific address and hash registers and the frame's

destination address. In this implementation of the MAC the

frame’s source address is not checked.

A frame will not be copied to memory if the MAC is transmitting in half-duplex mode at the time a destination

address is received.

The hash register is 64 bits long and takes up two locations

in the memory map.

There are four 48-bit specific address registers, each taking up two memory locations. The first location contains the

first four bytes of the address; the second location contains

the last two bytes of the address stored in its least significant byte positions. The addresses stored can be specific,

group, local or universal.

Ethernet frames are transmitted a byte at a time, LSB first.

The first bit (i.e., the LSB of the first byte) of the destination

address is the group/individual bit and is set one for multicast addresses and zero for unicast. This bit corresponds

to bit 24 of the first word of the specific address register.

The MSB of the first byte of the destination address corresponds to bit 31 of the specific address register.

The specific address registers are compared to the destination address of received frames once they have been

activated. Addresses are deactivated at reset or when the

first byte [47:40] is written and activated or when the last

byte [7:0] is written. If a receive frame address matches an

active address, the local match signal is set and the store

frame pulse signal is sent to the DMA block via the HCLK

synchronization block.

A frame can also be copied if a unicast or multicast hash

match occurs, it has the broadcast address of all ones, or

the copy all frames bit in the network configuration register

is set.

The broadcast address of 0xFFFFFFFF is recognized if the

no broadcast bit in the network configuration register is

zero. This sets the broadcast match signal and triggers the

store frame signal.

The unicast hash enable and the multicast hash enable bits

in the network configuration register enable the reception of

35

Page 36

hash matched frames. So all multicast frames can be

received by setting all bits in the hash register.

The CRC algorithm reduces the destination address to a 6bit index into a 64-bit hash register. If the equivalent bit in

the register is set, the frame will be matched depending on

whether the frame is multicast or unicast and the appropriate match signals will be sent to the DMA block

If the copy all frames bit is set in the network configuration

register, the store frame pulse will always be sent to the

DMA block as soon as any destination address is received.

Register Map

Base Address MAC A: 0xFF034000

Base Address MAC B: 0xFF038000

Table 15. Ethernet MAC Register Map

Offset Register Name Description Access Reset Value

0x00 ETH_CTL Network Control Register Read/write 0x0

0x04 ETH_CFG Network Configuration Register Read/write 0x800

0x08 ETH_SR Network Status Register Read-only 0x4

0x0C ETH_TAR Transmit Address Register Read/write 0x0

0x10 ETH_TCR Transmit Control Register Read/write 0x0

0x14 ETH_TSR Transmit Status Register Read/write 0x18

0x18 ETH_RBQP Receive buffer queue pointer Read/write 0x0

0x1C – Reserved Read-only 0x0

0x20 ETH_RSR Receive Status Register Read/write 0x0

0x24 ETH_ISR Interrupt Status Register Read/write 0x0

0x28 ETH_IER Interrupt Enable Register Write-only –

0x2C ETH_IDR Interrupt Disable Register Write-only –

0x30 ETH_IMR Interrupt Mask Register Read-only 0xFFFF

0x34 ETH_MAN PHY Maintenance Register Read/write 0x0

Statistics Registers

0x40 ETH_FRA Frames transmitted OK Read/write 0x0

0x44 ETH_SCOL Single collision frames Read/write 0x0

0x48 ETH_MCOL Multiple collision frames Read/write 0x0

0x4C ETH_OK Frames received OK Read/write 0x0

0x50 ETH_SEQE Frame check sequence errors Read/write 0x0

0x54 ETH_ALE Alignment errors Read/write 0x0