Page 1

Features

5

6

7

8

9

10

11

12

13

29

28

27

26

25

24

23

22

21

A7

A6

A5

A4

A3

A2

A1

A0

I/O0

A14

A13

A8

A9

A11

OE

A10

CE

I/O7

432

1

323130

14151617181920

I/O1

I/O2

GND

I/O3

I/O4

I/O5

I/O6

A12

A15

A16

RESET *

VCCWEA17

• Single-voltage Operation

–5V Read

– 5V Reprogramming

• Fast Read Access Time - 55 ns

• Internal Program Control and Timer

• Sector Architecture

– One 16K Byte Boot Block with Programming Lockout

– Two 8K Byte Parameter Blocks

– Two Main Memory Blocks (96K, 128K Bytes)

• Fast Erase Cycle Time - 10 seconds

• Byte-by-byte Programming - 10 µs/Byte Typical

• Hardware Data Protection

• DAT A Polling for End of Program Detection

• Low Power Dissipation

– 50 mA Active Current

– 100 µA CMOS Standby Current

• Typical 10,000 Write Cycles

Description

The AT49F002(N)(T) is a 5-volt only in-system reprogrammable Flash memory. Its 2

megabits of memory is orga nized as 262,144 words by 8 bits. Manufactured with

Atmel’s advanced nonvolatile CMOS technology, the device offers access times to 55

ns with power dissipation of just 275 mW over the commercial temperature range.

(continued)

2-megabit

(256K x 8)

5-volt Only

Flash Memory

AT49F002

AT49F002N

AT49F002T

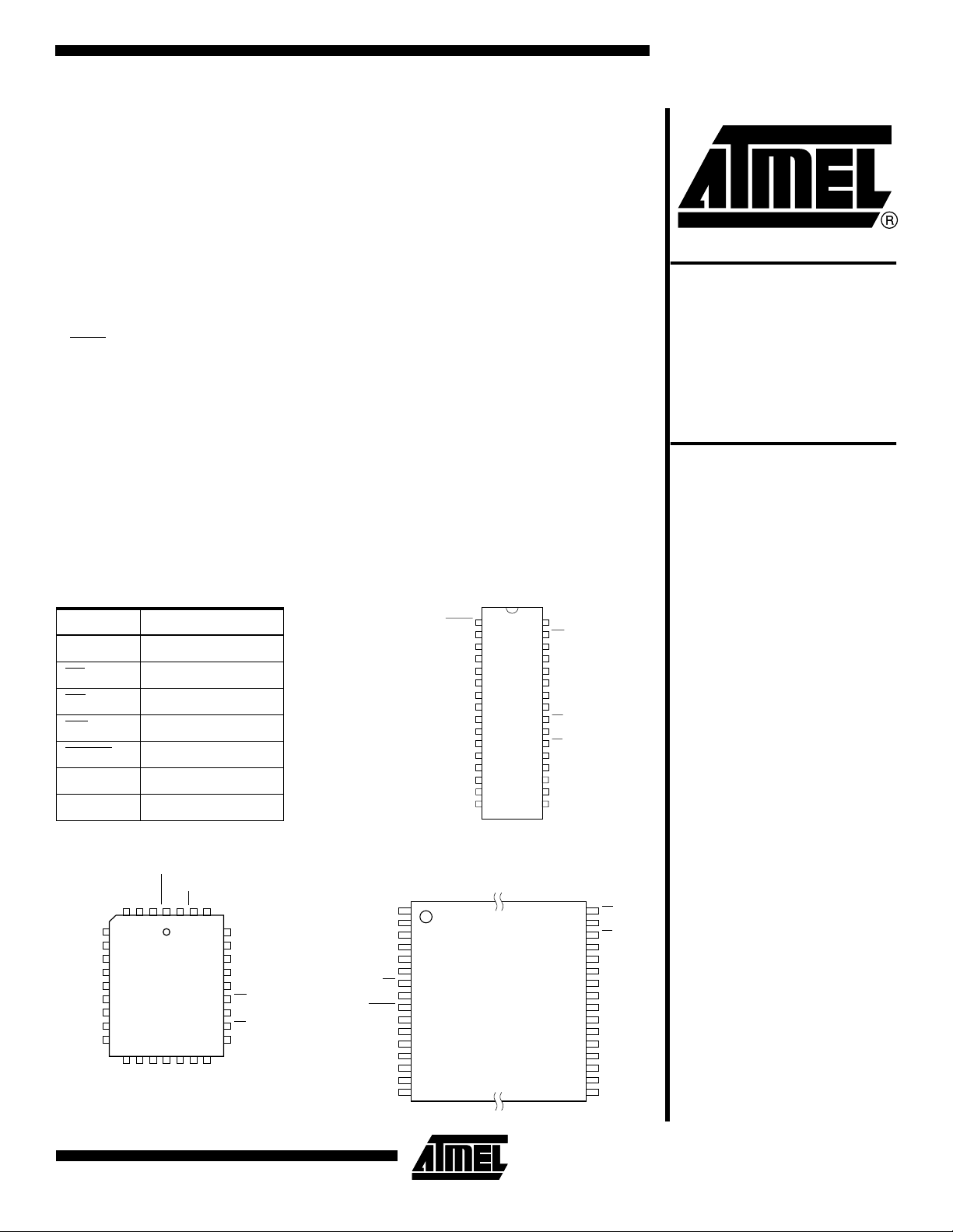

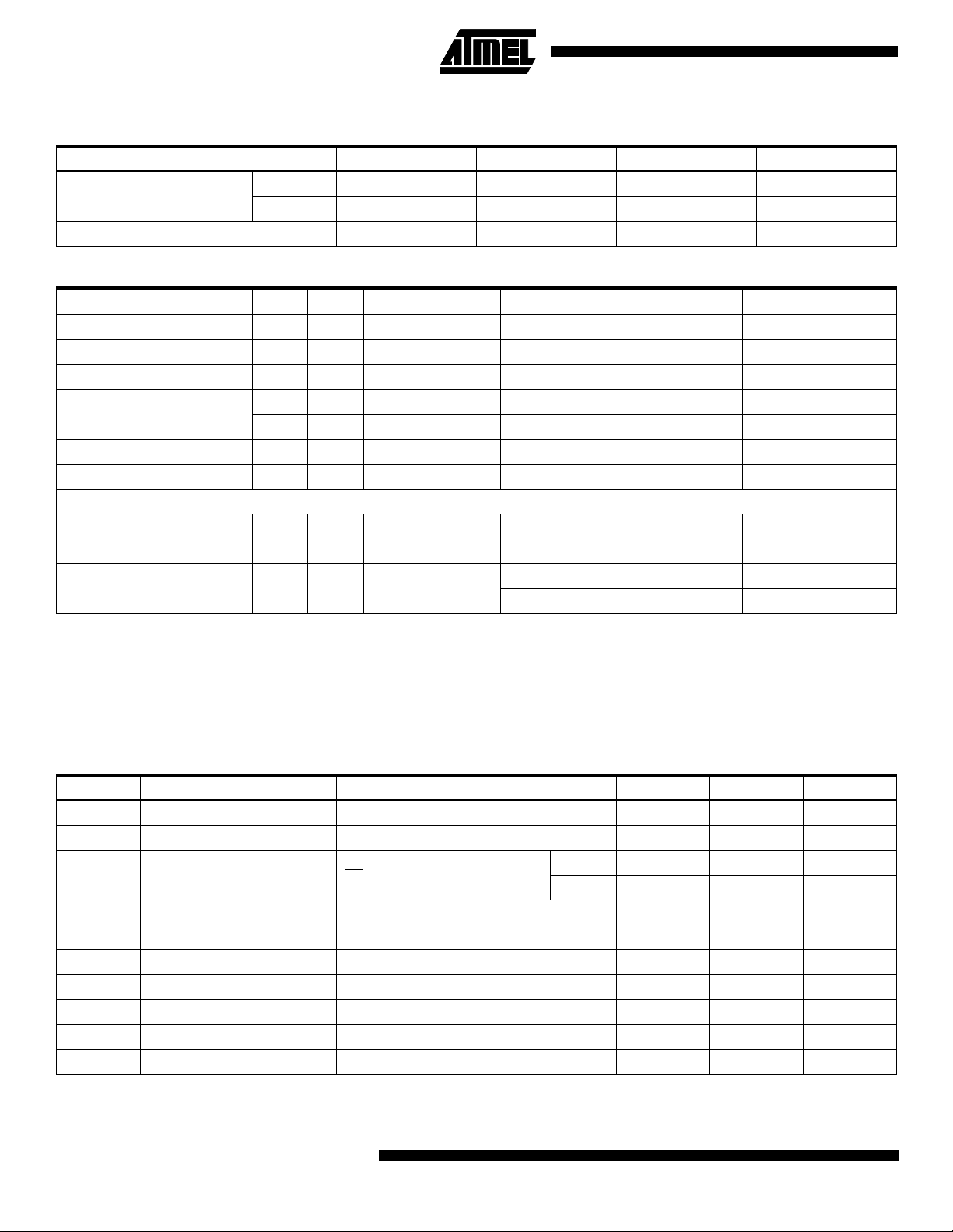

Pin Configurations

Pin Name Function

A0 - A17 Addresses

CE

OE

WE Write Enable

RESET

I/O0 - I/O7 Data Inputs/Outputs

DC Don’t Connect

*Note: This pin is a DC on the AT49F002(N)(T).

Chip Enable

Output Enable

RESET

PLCC Top View

DIP Top View

1

* RESET

2

A16

3

A15

4

A12

5

A7

6

A6

7

A5

8

A4

9

A3

10

A2

11

A1

12

A0

13

I/O0

14

I/O1

15

I/O2

16

GND

VSOP Top View (8 x 14 mm) or

TSOP Top View (8 x 20 mm)

Type 1

1

A11

2

A9

3

A8

4

A13

5

A14

6

A17

7

WE

8

VCC

A16

A15

A12

9

10

11

12

13

A7

14

A6

15

A5

16

A4

* RESET

AT49F002NT

VCC

32

WE

31

A17

30

A14

29

A13

28

A8

27

A9

26

A11

25

OE

24

A10

23

CE

22

I/O7

21

I/O6

20

I/O5

19

I/O4

18

I/O3

17

OE

32

A10

31

CE

30

I/O7

29

I/O6

28

I/O5

27

I/O4

26

I/O3

25

GND

24

I/O2

23

I/O1

22

I/O0

21

A0

20

A1

19

A2

18

A3

17

Rev. 1017D–10/99

1

Page 2

When the device is dese lecte d, the CMO S stan dby cu rrent

is less than 100 µA. For the AT49F002N(T) pin 1 for the

DIP and PLCC packages and pin 9 for the TSOP package

are don’t connect pins.

To allow for simple in-system reprogrammability, the

AT49F002(N)(T) does not require high input voltages for

programming. Five-volt-only commands determine the read

and programming operation o f the device. Readin g data

out of the device is similar to reading from an EPROM; it

has standard CE

, OE, and WE inputs to avoid bu s conten tion. Reprogramming the AT49F002(N)(T) is performed by

erasing a block of data and then programming on a byte by

byte basis. The byte pr ogram ming time is a fast 50 µs. The

end of a program cycle can be optionally detected by the

polling feature. Once the end of a byte program

DATA

cycle has been detected, a new access for a read or program can begin. The typical nu mber of pr ogram a nd erase

cycles is in excess of 10,000 cycles.

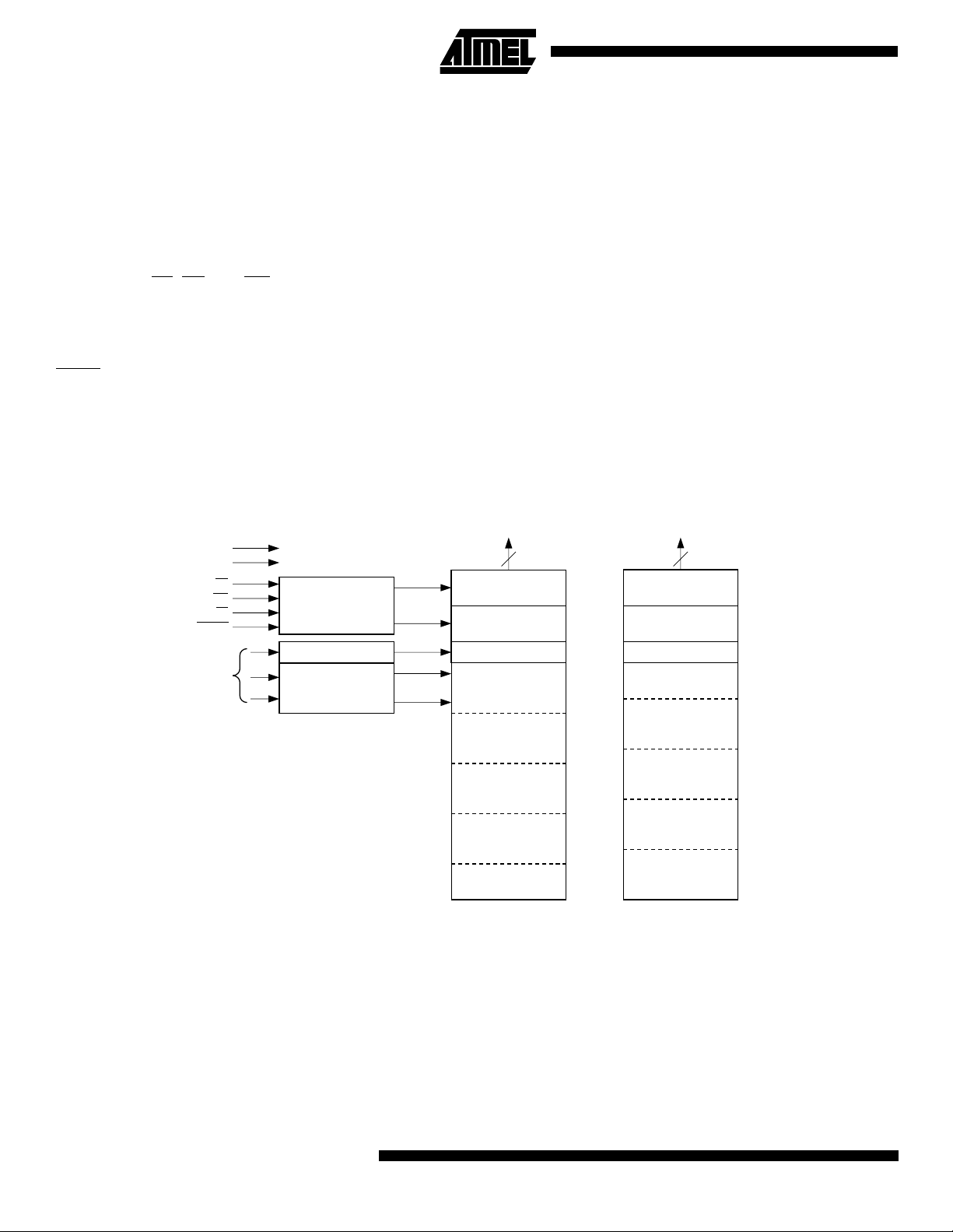

Block Diagram

VCC

GND

OE

WE

CE

RESET

ADDRESS

INPUTS

CONTROL

LOGIC

Y DECODER

X DECODER

The device is erased by executing the er ase command

sequence; the device internally controls the erase operations. There are two 8K byte para meter bloc k sectio ns and

two main memory blocks.

The device has the capability to protect the data in the boot

block; this feature is enabled by a command sequence.

The 16K-byte boot block section includes a reprogramming

lock out feature to prov ide data in tegr i ty. The boot sector is

designed to contai n user secur e code, and when the feature is enabled, the boot sector is protected from being

reprogrammed.

In the AT49F002(N)(T), once the boot block programming

lockout feature is enabled, the contents of the boot block

are permanent and cannot be changed. In the

AT49F002(T), once the boot block programm ing lockout

feature is enabled, the contents of the boot block cannot be

changed with input voltage levels of 5.5 volts or less.

AT49F002(N)

DATA INPUTS/OUTPUTS

I/O7 - I/O0

8

INPUT/OUTPUT

BUFFERS

PROGRAM

DATA LATCHES

Y-GATING

MAIN MEMORY

BLOCK 2

(128K BYTES)

MAIN MEMORY

BLOCK 1

(96K BYTES)

PARAMETER

BLOCK 2

(8K BYTES)

PARAMETER

BLOCK 1

(8K BYTES)

BOOT BLOCK

(16K BYTES)

3FFFF

20000

1FFFF

08000

07FFF

06000

05FFF

04000

03FFF

00000

AT49F002(N)T

DATA INPUTS/OUTPUTS

I/O7 - I/O0

8

INPUT/OUTPUT

BUFFERS

PROGRAM

DATA LATCHES

Y-GATING

BOOT BLOCK

(16K BYTES)

PARAMETER

BLOCK 1

(8K BYTES)

PARAMETER

BLOCK 2

(8K BYTES)

MAIN MEMORY

BLOCK 1

(96K BYTES)

MAIN MEMORY

BLOCK 2

(128K BYTES)

3FFFF

3C000

3BFFF

3A000

39FFF

38000

37FFF

20000

1FFFF

00000

2

AT49F002(N)(T)

Page 3

Device Operation

READ: The AT49F002(N)(T) is accessed like an EPROM.

When CE

at the memory location determined by the address pins is

asserted on the outputs. The outputs are put in the high

impedance state whenever CE

control gives designers flexibility in preventing bus contention.

COMMAND SEQUENCES: When th e device is first p owered on it will be reset to the read or standby mode

depending upon the state of the control line inputs. In order

to perform other device functions, a series of command

sequences are entered into the device. The command

sequences are shown in the Command Definitions table.

The command sequences are written by applying a low

pulse on the WE

tively) and OE

edge of CE

latched by the first rising edge of CE

microprocessor write timings are used. The address locations used in the command sequences are not affected by

entering the command sequences.

RESET: A RESET

tem application s. When RE SET

device is in its standa rd oper at ing mod e. A low l evel on th e

RESET

the outputs of the device in a high impedance state. If the

RESET

or erase operation, the operation may not be successfully

completed and the op eratio n will have to be repeate d after

a high level is applied to the RESET

is reasserted on the RESET

read or standby mode, depending upon the state of the

control inputs. By ap plyi ng a 12 V

RESET

even if the boot block loc kout feature has be en enabled

(see Boot Bloc k Prog ramming Locko ut Over ride s ection) .

The RESET feature is not available for the AT49F002N(T).

ERASURE: Before a byte can be repr ogramme d, the main

memory block or parameter block which contains the byte

must be erased. The erased state of the memor y bits is a

logical “1”. The entire devic e can be eras ed at one tim e by

using a 6-byte soft ware code. T he software chip erase

code consists of 6-byte load commands to specific address

locations with a specific data pattern (please refer to the

Chip Erase Cycle Waveforms).

After the software c hi p e ra se has been initiate d, the d evi ce

will internally time the er ase operation so that no e xternal

clocks are required. The maximum time needed to erase

the whole chip is t

been enabled, the data in the boot sector will not be

erased.

and OE are low and WE is high, the data stored

or OE is high. This dual-line

or CE input with CE or WE low (respec-

high. The address is latched on the falling

or WE, whichever occurs last. The data is

or WE. Standard

input pin is provi ded to eas e some s ys-

is at a logic high level, the

input halts the prese nt device oper ation and puts

pin makes a high to low transition during a program

pin. When a high level

pin, the device returns to the

± 0.5V input signa l to th e

pin, the boot block array can be reprogrammed

. If the boot block lockout feature has

EC

AT49F002(N)(T)

CHIP ERASE: If the boot block lockout has been enabled,

the Chip Erase function will erase Parameter Block 1,

Parameter Block 2, M ain Me mory B lock 1, a nd Mai n Memory Block 2 but not the boot block. If the Boot Block Lockout

has not been enabled, the Chip Erase function will erase

the entire chip. After the full chip erase the device will

return back to read mode. Any c omm and dur ing chip er as e

will be ignored.

SECTOR ERASE: As an alternative to a full chip erase, the

device is organized into sectors that can be individually

erased. There are two 8K-byte parameter block sections

and two main memory blocks. The 8K-byte parameter

block sections can be independently erased and reprogrammed. The two main memory sections are designed to

be used as alternative memory sectors. That is, whenever

one of the blocks has bee n er as ed and repr og ramme d, the

other block should be erased and r eprogrammed be fore

the first block i s ag ain e ra se d. The Se ctor Erase comman d

is a six bus cycle operation. The sector address is latched

on the falling WE

input command is latched at the ri sing edge of WE

sector erase starts after the rising edge of WE

cycle. The erase op eration is in ternally contr olled; it will

automatically time to completion.

BYTE PROGRAMMING: Once the memory array is

erased, the device is programmed (to a logical “0”) on a

byte-by-byte bas is. Please not e that a data “0” cannot b e

programmed ba ck to a “1”; only erase operations can convert “0”s to “1”s. Programming is ac complished via the

internal device command register and is a 4 bus cycle

operation (please refer to the Command Definitions table).

The device will automatic al ly generate the required interna l

program pulses.

The program cyc le has addres ses latched on the falling

edge of WE

latched on the rising edge of WE

first. Programming is completed after the specified t

time. The DATA

the end of a program cycle.

BOOT BLOCK PROGRAMMING LOCKOUT: The device

has one designated block that has a programming lockout

feature. This feature prevents programming of data in th e

designated block once the feature has been enabled. The

size of the block is 16K bytes. This block, referred to as the

boot block, can contain secure code that is used to bring up

the system. Enablin g the l ockou t featur e wil l allow the boot

code to stay in the device while data in the rest of the

device is updated. This feature does not have to be activated; the boot block’s usage as a write protec ted reg io n is

optional to the user. The address range of the boot block is

00000 to 03FFF for the AT49F002(N) while the address

edge of the sixth cycle while the 30H data

. The

of the sixth

or CE, whichever occurs last, and the data

or CE, whichever occurs

cycle

polling feature may also be used to indicate

BP

3

Page 4

range of the boot block is 3C000 to 3F FFF for the

AT49F002(N)T.

Once the feature is enabled, the data in th e boot blo ck ca n

no longer be erased or prog ramme d with inpu t vol tage le vels of 5.5V or less. Data in the ma in memory blo ck ca n still

be changed through the regular programming method. To

activate the lockout feature, a seri es of six progr am commands to specific addresses with specific data must be

performed. Please refer to the Command Definitions table.

BOOT BLOCK LOCKOUT DETECTION: A software

method is available to determine if programming of the boot

block section is locked out. When the device is in the software product i dentifica tion mode (see Sof tware Pr oduct

Identification Entry and Exit sections) a read from address

location 00002H will s how if progr ammin g the boot bl ock is

locked out for the AT49F002(N), and a read from address

location 3C002H will show if programming the boot block is

locked out for AT49F002(N)T. If the data on I/O0 is low, the

boot block can be program med; if the da ta on I/O0 i s high,

the program loc kout feature has been activa ted and the

block cannot be programm ed. The softw are product id entification exit code should be used to return to standard

operation.

BOOT BLOCK PROGRAMMING LOCKOUT OVERRIDE:

The user can override th e boot block programm ing lock out

by taking the RESET

tected boot block data can be altered through a chip erase,

sector erase or word programming. When the RESET

brought back to TTL levels the boot block programming

lockout feature is again a ctive. Thi s feat ure is n ot ava ilabl e

on the AT49F002N(T).

pin to 12 volts. By doing th is, pro-

pin is

PRODUCT IDENTIFICATION: The product identification

mode identifies the device and manufacturer as Atmel. It

may be accessed by hardware or software operation. The

hardware operation mode can be used by an external programmer to identify the correct programming algorithm for

the Atmel product.

For details, see Oper ating Mo des (for hardw are ope ratio n)

or Software Product Identification. The manufacturer and

device code is the same for both modes.

DATA POLLING: The AT49F002(N)(T) features DATA

ing to indicate the end of a program cycle. During a program cycle an attempted read of the last byte loaded will

result in the complement of the loaded data on I/O7. Once

the program cycle has been completed, true data is valid

on all outputs and the next cy cle may begin. DATA

may begin at any time during the program cycle.

TOGGLE BIT: In addition to DATA

AT49F002(N)(T) provides another method for determining

the end of a program or erase cycle. During a program or

erase operation, success ive atte mpt s to read data fr om the

device will result in I/O6 toggling between one and zero.

Once the program cycle has completed, I/O6 will stop toggling and valid data will be read. Exami ning the to ggle bit

may begin at any time during a program cycle.

HARDWARE DATA PROTECTION: Hardware features

protect against inadvertent programs to the

AT49F002(N)(T) in the following ways: (a) V

is below 3.8V (typical), the program function is inhib-

V

CC

ited. (b) Program inhi bit: holding a ny one of OE

high or WE high inhibits program cyc les. (c) Noise filter :

pulses of less than 15 ns (typical) on the WE

will not initiate a program cycle.

polling the

CC

or CE inputs

poll-

polling

sense: if

low, CE

4

AT49F002(N)(T)

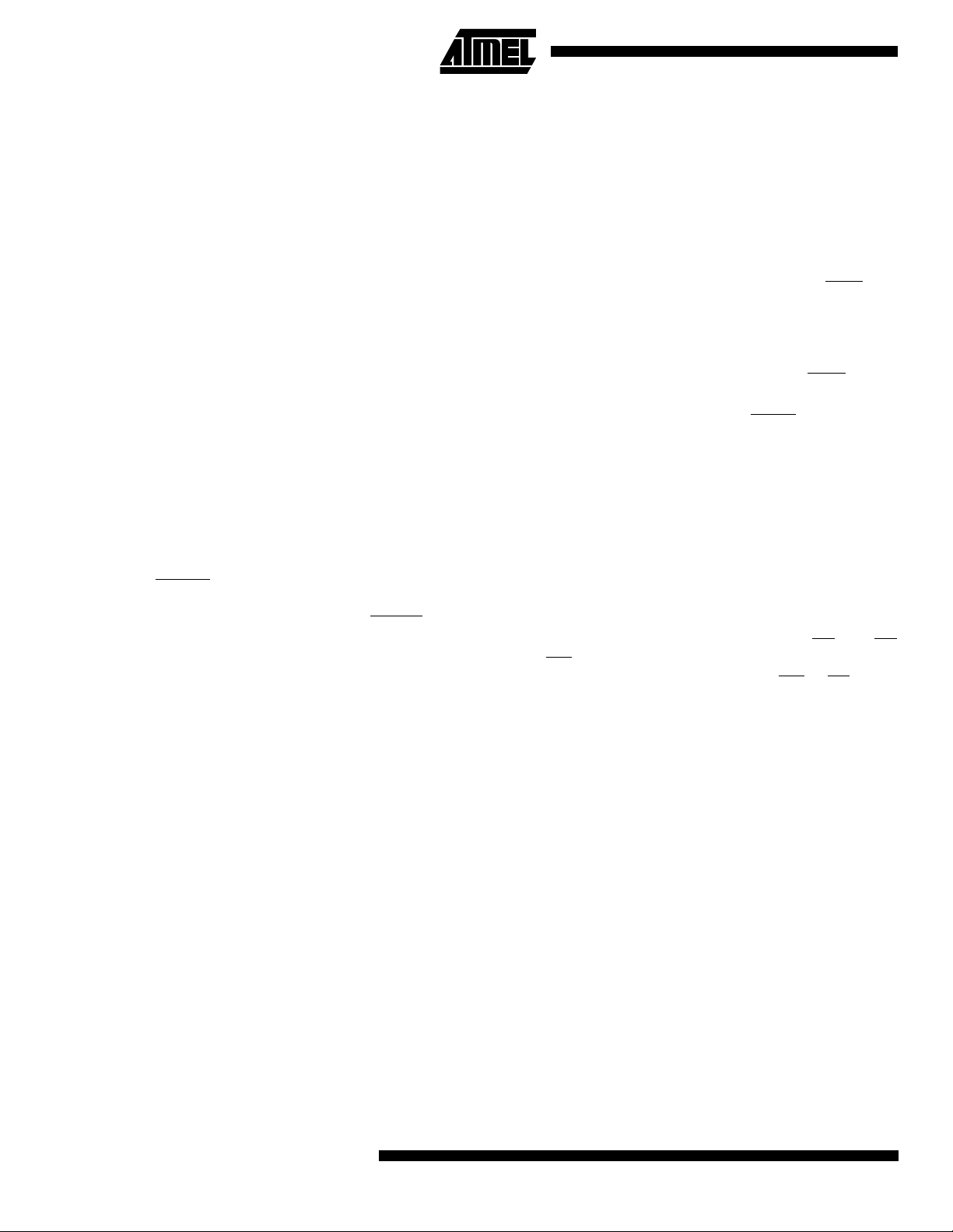

Page 5

AT49F002(N)(T)

Cycle

(1)

OUT

2nd Bus

Cycle

3rd Bus

Cycle

4th Bus

Cycle

5th Bus

Cycle

IN

6th Bus

Cycle

(4)

Command Definition (in Hex)

1st Bus

Command

Sequence

Read 1 Addr D

Chip Erase 6 5555 AA 2AAA 55 5555 80 5555 AA 2AAA 55 5555 10

Sector Erase 6 5555 AA 2AAA 55 5555 80 5555 AA 2AAA 55 SA

Byte Program 4 5555 AA 2AAA 55 5555 A0 Addr D

Boot Block Lockout

Product ID Entry 3 5555 AA 2AAA 55 5555 90

Product ID Exit

Product ID Exit

Notes: 1. The DATA FORMAT in each bus cycle is as follows: I/O7 - I/O0 (Hex)

(3)

(3)

2. The 16K byte boot sector has the address range 00000H to 03FFFH for the AT49F002(N) and 3C000H to 3FFFFH for the

AT49F002(N)T

3. Either one of the Product ID Exit commands can be used.

4. SA = sector addresses:

For the AT49F002(N):

SA = 00000 to 03FFF for BOOT BLOCK

Nothing will happen and the device goes back to the read mode in 100 ns

SA = 04000 to 05FFF for PARAMETER BLOCK 1

SA = 06000 to 07FFF for PARAMETER BLOCK 2

SA = 08000 to 1FFFF for MAIN MEMORY ARRAY BLOCK 1

This command will erase - PB1, PB2 and MMB1

SA = 20000 to 3FFFF for MAIN MEMORY ARRAY BLOCK 2

Bus

Cycles

(2)

6 5555 AA 2AAA 55 5555 80 5555 AA 2AAA 55 5555 40

3 5555 AA 2AAA 55 5555 F0

1 XXXX F0

Addr Data Addr Data Addr Data Addr Data Addr Data Addr Data

30

For the AT49F002(N)T:

SA = 3C000 to 3FFFF for BOOT BLOCK

Nothing will happen and the device goes back to the read mode in 100 ns

SA = 3A000 to 3BFFF for PARAMETER BLOCK 1

SA = 38000 to 39FFF for PARAMETER BLOCK 2

SA = 20000 to 37FFF for MAIN MEMORY ARRAY BLOCK 1

This command will erase - PB1, PB2 and MMB1

SA = 00000 to IFFFF for MAIN MEMORY ARRAY BLOCK 2

Absolute Maximum Ratings*

Temperature Under Bias................................ -55°C to +125°C

Storage Temperature.....................................-65°C to +150°C

All Input Voltages

(including NC Pins)

with Respect to Ground...................................-0.6V to +6.25V

All Output Voltages

with Respect to Ground.............................-0.6V to V

Voltage on OE

with Respect to Ground...................................-0.6V to +13.5V

+ 0.6V

CC

*NOTICE: Stresses beyo nd thos e lis ted under “Absolute Maxi-

mum Ratings” may cause permanent damage to the

device. This is a stress rating only and functional

operation of the device at these or any other conditions beyond those indicated in the operational sections of this specification is not implied. Exposure to

absolute maximum rating cond itions for extended

periods may affect device reliability.

5

Page 6

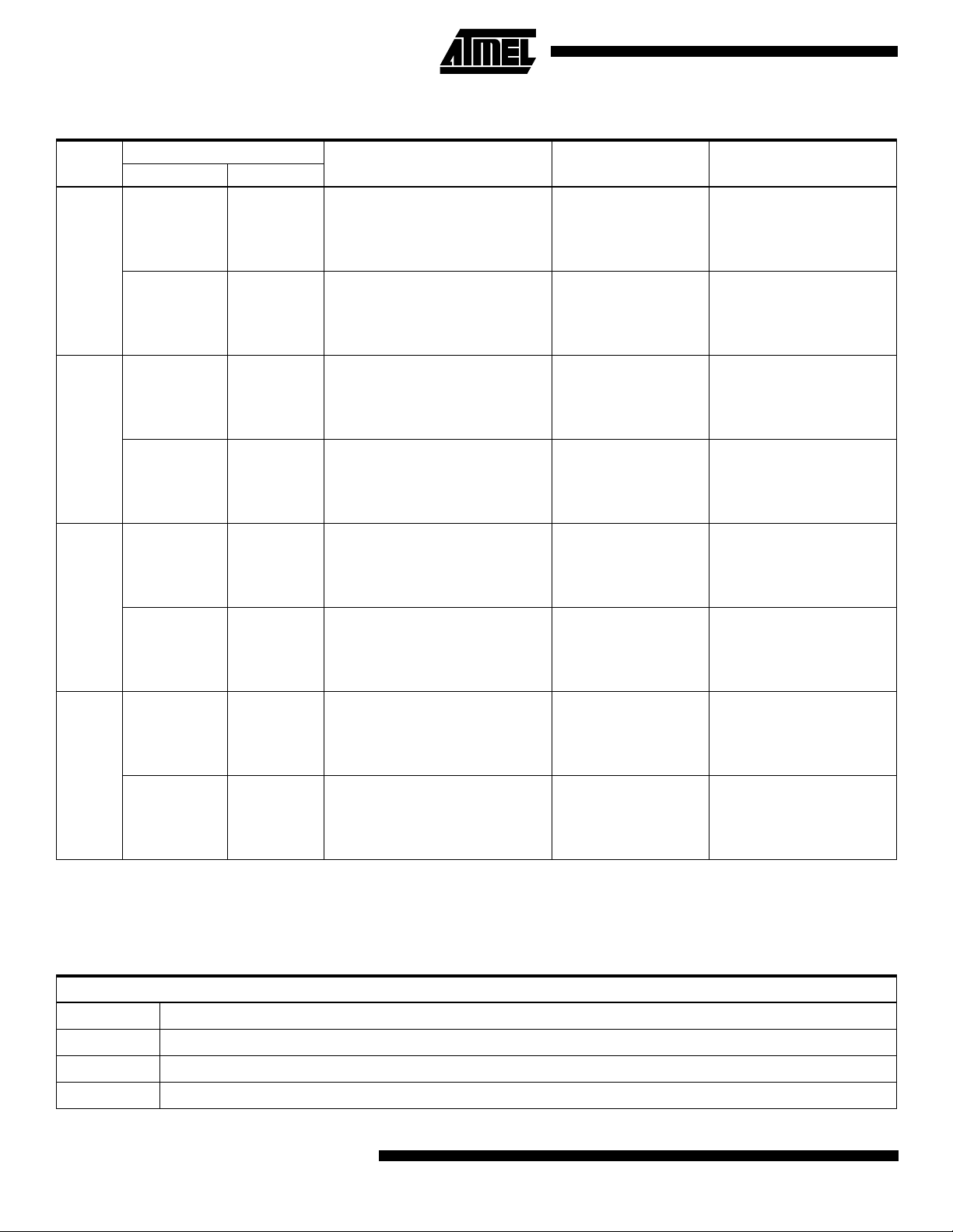

DC and AC Operating Range

AT49F002(N)(T)-55 AT49F002(N)(T)-70 AT49F002(N)(T)-90 AT49F002(N)(T)-12

Operating

Temperature (Case)

Power Supply 5V ± 10% 5V ± 10% 5V ± 10% 5V ± 10%

V

CC

Com. 0

Ind. -40

°C - 70°C0°C - 70°C0°C - 70°C0°C - 70°C

°C - 85°C-40°C - 85°C-40°C - 85°C-40°C - 85°C

Operating Modes

Mode CE OE WE RESET

Read V

Program/Erase

(2)

Standby/Write Inhibit V

IL

V

IL

IH

XXV

Program Inhibit

XVILXV

Output Disable X V

V

IL

V

IH

(1)

X

IH

V

IH

V

IL

XV

IH

XV

Reset XXX V

(6)

V

IH

V

IH

IH

V

IH

IH

IH

IL

Product Identification

Hardware V

Software

(5)

Notes: 1. X can be VIL or V

IH.

IL

V

IL

V

IH

2. Refer to AC Programming Waveforms.

= 12.0V ± 0.5V.

3. V

H

4. Manufacturer Code: 1FH, Device Code: 07H - AT49F002(N), 08H - AT49F002(N)T

5. See details under Software Product Identification Entry/Exit.

6. This pin is not ava ila ble on the AT49F002N(T).

A1 - A17 = VIL, A9 = VH,

A1 - A17 = VIL, A9 = V

A0 = VIL, A1 - A17=V

A0 = VIH, A1 - A17=V

Ai

Ai D

Ai D

I/O

OUT

IN

X High Z

High Z

X High Z

(3)

H,

A0 = V

(3)

A0 = V

IL

IL

Manufacturer Code

IL

Device Code

IH

Manufacturer Code

Device Code

(4)

(4)

(4)

(4)

DC Characteristics

Symbol Parameter Condition Min Max Units

I

I

I

I

I

V

V

V

V

V

LI

LO

SB1

SB2

CC

(1)

IL

IH

OL

OH1

OH2

Input Load Current VIN = 0V to V

Output Leakage Current V

VCC Standby Current CMOS CE = V

VCC Standby Current TTL CE = 2.0V to V

V

Active Current f = 5 MHz; I

CC

Input Low V oltage 0.8 V

Input High Voltage 2.0 V

Output Low Voltage IOL = 2.1 mA 0.45 V

Output High Voltage IOH = -400 µA 2.4 V

Output High Voltage CMOS IOH = -100 µA; VCC = 4.5V 4.2 V

Note: 1. In the erase mode, ICC is 90 mA.

6

AT49F002(N)(T)

= 0V to V

I/O

CC

CC

- 0.3V to V

CC

OUT

CC

CC

= 0 mA 50 mA

Com. 100 µA

Ind. 300 µA

10 µA

10 µA

3mA

Page 7

AC Read Characteristics

AT49F002(N)(T)

AT49F002(N)(T)

-55-70-90-12

Symbol Parameter

t

ACC

t

CE

t

OE

t

DF

(1)

(2)

(3)(4)

Address to Output Delay 55 70 90 120 ns

CE to Output Delay 55 70 90 120 ns

OE to Output Delay 0 30 0 35 0 40 0 50 ns

CE or OE to Output Float 0 25 0 25 0 25 0 30 ns

Output Hold from OE, CE

t

OH

or Address, whichever

occurred first

AC Read Waveforms

Min Max Min Max Min Max Min Max

(1)(2)(3)(4)

ADDRESS

OUTPUT

Units

0000ns

ADDRESS VALID

CE

t

CE

t

t

ACC

HIGH Z

OE

t

DF

t

OH

OUTPUT

VALID

OE

Notes: 1. CE may be delayed up to t

2. OE may be delayed up to tCE - t

without impact on t

is specified from OE or CE whichever occurs first (CL = 5 pF).

3. t

DF

ACC

.

- tCE after the address transition without impact on t

ACC

after the falling edge of CE without impact on tCE or by t

OE

ACC

.

- tOE after an address change

ACC

4. This parameter is characterized and is not 100% tested.

Input Test Waveform and Measurement Level

tR, tF < 5 ns

Output Load Test

50 ns

5.0V

1.8K

OUTPUT

PIN

1.3K

30 pF

70/90/120 ns

5.0V

1.8K

OUTPUT

PIN

1.3K

100 pF

Pin Capacitance

f = 1 MHz, T = 25°C

Symbol Typ Max Units Conditions

C

IN

C

OUT

Note: 1. This parameter is characterized and is not 100% tested.

(1)

46pFV

812pFV

IN

OUT

= 0V

= 0V

7

Page 8

AC Byte Load Characteristics

Symbol Parameter Min Max Units

t

, t

AS

t

AH

t

CS

t

CH

t

WP

t

DS

tDH, t

t

WPH

OES

OEH

Address, OE Set-up Time 0 ns

Address Hold Time 50 ns

Chip Select Set-up Time 0 ns

Chip Select Hold Time 0 ns

Write Pulse Width (WE or CE)90ns

Data Set-up Time 50 ns

Data, OE Hold Time 0 ns

Write Pulse Width High 90 ns

AC Byte Load Waveforms

WE Controlled

CE Controlled

OE

ADDRESS

CE

WE

DATA IN

OE

ADDRESS

WE

t

OES

t

t

t

OES

t

AS

CS

AS

t

OEH

t

AH

t

WP

t

DS

t

AH

t

t

OEH

t

CH

CH

t

t

DH

WPH

t

CS

CE

t

WPH

t

WP

t

DS

t

DH

DATA IN

8

AT49F002(N)(T)

Page 9

AT49F002(N)(T)

Program Cycle Characteristics

Symbol Parameter Min Typ Max Units

t

BP

t

AS

t

AH

t

DS

t

DH

t

WP

t

WPH

t

EC

Program Cyc le Waveforms

Byte Programming Time 10 50 µs

Address Set-up Time 0 ns

Address Hold Time 50 ns

Data Set-up Time 50 ns

Data Hold Time 0 ns

Write Pulse Width 90 ns

Write Pulse Width High 90 ns

Erase Cycle Time 10 seconds

Sector or Chip Erase Cycle Waveforms

Notes: 1. OE must be high only when WE and CE are both low.

2. For chip erase, the address should be 5555. For sector erase, the address depends on what sector is to be erased.

(See note 4 under command definitions.)

3. For chip erase, the data should be 10H, and for sector erase, the data should be 30H.

9

Page 10

Data Poll ing Char acteristics

(1)

Symbol Parameter Min Typ Max Units

t

DH

t

OEH

t

OE

t

WR

Data Hold Time 10 ns

OE Hold Time 10 ns

OE to Output Delay

(2)

Write Recovery Time 0 ns

Notes: 1. These parameters are characterized and not 100% tested.

2. See t

spec in AC Read Characteristics.

OE

Data Polling Waveforms

WE

CE

t

OE

I/O7

t

DH

OEH

t

t

OE

HIGH Z

WR

ns

A0-A17

Toggle Bit Characteristics

(1)

An An An An An

Symbol Parameter Min Typ Max Units

t

DH

t

OEH

t

OE

t

OEHP

t

WR

Data Hold Time 10 ns

OE Hold Time 10 ns

OE to Output Delay

(2)

OE High Pulse 150 ns

Write Recovery Time 0 ns

Notes: 1. These parameters are characterized and not 100% tested.

2. See tOE spec in AC Read Characteristics.

Toggle Bit Wa veforms

WE

CE

OE

I/O6

Notes: 1. Toggling either OE or CE or both OE and CE will operate toggle bit. The t

(1)(2)(3)

t

OEH

t

OE

t

DH

t

OEHP

HIGH Z

t

WR

specification must be met by the toggling

OEHP

input(s).

2. Beginning and ending state of I/O6 will vary.

3. Any address location may be used but the address should not vary.

ns

10

AT49F002(N)(T)

Page 11

AT49F002(N)(T)

LOAD DATA AA

TO

ADDRESS 5555

LOAD DATA 55

TO

ADDRESS 2AAA

LOAD DATA 90

TO

ADDRESS 5555

ENTER PRODUCT

IDENTIFICATION

MODE

(2)(3)(5)

LOAD DATA AA

TO

ADDRESS 5555

LOAD DATA 55

TO

ADDRESS 2AAA

LOAD DATA F0

TO

ADDRESS 5555

EXIT PRODUCT

IDENTIFICATION

MODE

(4)

OR

LOAD DATA F0

TO

ANY ADDRESS

EXIT PRODUCT

IDENTIFICATION

MODE

(4)

Software Product Identification Entry

Software Product Identification Exit

Notes for software product identification

1. Data Format: I/O7 - I/O0 (Hex);

Address Format: A14 - A0 (Hex).

2. A1 - A17 = V

Manufacture Code is read for A0 = V

Device Code is read for A0 = V

3. The device does not remain in identification mode if

powered down.

4. The device returns to standard operation mode.

5. Manufacturer Code: 1FH

Device Code: 07H - AT49F002(N)

.

IL

08H - AT49F002(N)T

;

IL

.

IH

(1)

(1)

Boot Block Lockout Feature Enabl e

Algorithm

Notes for boot block lockout feature enable:

1. Data Format: I/O7 - I/O0 (Hex);

Address Format: A14 - A0 (Hex).

2. Boot block lockout feature enabled.

(1)

LOAD DATA AA

TO

ADDRESS 5555

LOAD DATA 55

TO

ADDRESS 2AAA

LOAD DATA 80

TO

ADDRESS 5555

LOAD DATA AA

TO

ADDRESS 5555

LOAD DATA 55

TO

ADDRESS 2AAA

LOAD DATA 40

TO

ADDRESS 5555

PAUSE 1 second

(2)

11

Page 12

AT49F002 Ordering Information

I

(mA)

t

ACC

(ns)

55 50 0.1 AT49F002-55JC

70 50 0.1 AT49F002-70JC

90 50 0.1 AT49F002-90JC

120 50 0.1 AT49F002-12JC

CC

Ordering Code Package Operation RangeActive Standby

AT49F002-55PC

AT49F002-55TC

AT49F002-55VC

50 0.3 AT49F002-55JI

AT49F002-55PI

AT49F002-55TI

AT49F002-55VI

AT49F002-70PC

AT49F002-70TC

AT49F002-70VC

50 0.3 AT49F002-70JI

AT49F002-70PI

AT49F002-70TI

AT49F002-70VI

AT49F002-90PC

AT49F002-90TC

AT49F002-90VC

50 0.3 AT49F002-90JI

AT49F002-90PI

AT49F002-90TI

AT49F002-90VI

AT49F002-12PC

AT49F002-12TC

AT49F002-12VC

50 0.3 AT49F002-12JI

AT49F002-12PI

AT49F002-12TI

AT49F002-12VI

32J

32P6

32T

32V

32J

32P6

32T

32V

32J

32P6

32T

32V

32J

32P6

32T

32V

32J

32P6

32T

32V

32J

32P6

32T

32V

32J

32P6

32T

32V

32J

32P6

32T

32V

Commercial

(0° to 70°C)

Industrial

(-40° to 85°C)

Commercial

(0° to 70°C)

Industrial

(-40° to 85°C)

Commercial

(0° to 70°C)

Industrial

(-40° to 85°C)

Commercial

(0° to 70°C)

Industrial

(-40° to 85°C)

Package Type

32J 32-lead, Plastic J-leaded Chip Carrier Package (PLCC)

32P6 32-pin, 0.600" Wide, Plastic Dual Inline Package (PDIP)

32T 32-lead, Plastic Thin Small Outline Package (TSOP) (8 x 20 mm)

32V 32-lead, Plastic Thin Small Outline Package (VSOP) (8 x 14 mm)

12

AT49F002(N)(T)

Page 13

AT49F002N Ordering Information

I

(mA)

t

ACC

(ns)

55 50 0.1 AT49F002N-55JC

70 50 0.1 AT49F002N-70JC

90 50 0.1 AT49F002N-90JC

120 50 0.1 AT49F002N-12JC

CC

Ordering Code Package Operation RangeActive Standby

AT49F002N-55PC

AT49F002N-55TC

AT49F002N-55VC

50 0.3 AT49F002N-55JI

AT49F002N-55PI

AT49F002N-55TI

AT49F002N-55VI

AT49F002N-70PC

AT49F002N-70TC

AT49F002N-70VC

50 0.3 AT49F002N-70JI

AT49F002N-70PI

AT49F002N-70TI

AT49F002N-70VI

AT49F002N-90PC

AT49F002N-90TC

AT49F002N-90VC

50 0.3 AT49F002N-90JI

AT49F002N-90PI

AT49F002N-90TI

AT49F002N-90VI

AT49F002N-12PC

AT49F002N-12TC

AT49F002N-12VC

50 0.3 AT49F002N-12JI

AT49F002N-12PI

AT49F002N-12TI

AT49F002N-12VI

32J

32P6

32T

32V

32J

32P6

32T

32V

32J

32P6

32T

32V

32J

32P6

32T

32V

32J

32P6

32T

32V

32J

32P6

32T

32V

32J

32P6

32T

32V

32J

32P6

32T

32V

AT49F002(N)(T)

Commercial

(0° to 70°C)

Industrial

(-40° to 85°C)

Commercial

(0° to 70°C)

Industrial

(-40° to 85°C)

Commercial

(0° to 70°C)

Industrial

(-40° to 85°C)

Commercial

(0° to 70°C)

Industrial

(-40° to 85°C)

Package Type

32J 32-lead, Plastic J-leaded Chip Carrier Package (PLCC)

32P6 32-pin, 0.600" Wide, Plastic Dual Inline Package (PDIP)

32T 32-lead, Plastic Thin Small Outline Package (TSOP) (8 x 20 mm)

32V 32-lead, Plastic Thin Small Outline Package (VSOP) (8 x 14 mm)

13

Page 14

AT49F002T Ordering Information

I

(mA)

t

ACC

(ns)

55 50 0.1 AT49F002T-55JC

70 50 0.1 AT49F002T-70JC

90 50 0.1 AT49F002T-90JC

120 50 0.1 AT49F002T-12JC

CC

Ordering Code Package Operation RangeActive Standby

AT49F002T-55PC

AT49F002T-55TC

AT49F002T-55VC

50 0.3 AT49F002T-55JI

AT49F002T-55PI

AT49F002T-55TI

AT49F002T-55VI

AT49F002T-70PC

AT49F002T-70TC

AT49F002T-70VC

50 0.3 AT49F002T-70JI

AT49F002T-70PI

AT49F002T-70TI

AT49F002T-70VI

AT49F002T-90PC

AT49F002T-90TC

AT49F002T-90VC

50 0.3 AT49F002T-90JI

AT49F002T-90PI

AT49F002T-90TI

AT49F002T-90VI

AT49F002T-12PC

AT49F002T-12TC

AT49F002T-12VC

50 0.3 AT49F002T-12JI

AT49F002T-12PI

AT49F002T-12TI

AT49F002T-12VI

32J

32P6

32T

32V

32J

32P6

32T

32V

32J

32P6

32T

32V

32J

32P6

32T

32V

32J

32P6

32T

32V

32J

32P6

32T

32V

32J

32P6

32T

32V

32J

32P6

32T

32V

Commercial

(0° to 70°C)

Industrial

(-40° to 85°C)

Commercial

(0° to 70°C)

Industrial

(-40° to 85°C)

Commercial

(0° to 70°C)

Industrial

(-40° to 85°C)

Commercial

(0° to 70°C)

Industrial

(-40° to 85°C)

Package Type

32J 32-lead, Plastic J-leaded Chip Carrier Package (PLCC)

32P6 32-pin, 0.600" Wide, Plastic Dual Inline Package (PDIP)

32T 32-lead, Plastic Thin Small Outline Package (TSOP) (8 x 20 mm)

32V 32-lead, Plastic Thin Small Outline Package (VSOP) (8 x 14 mm)

14

AT49F002(N)(T)

Page 15

AT49F002NT Ordering Information

I

(mA)

t

ACC

(ns)

55 50 0.1 AT49F002NT-55JC

70 50 0.1 AT49F002NT-70JC

90 50 0.1 AT49F002NT-90JC

120 50 0.1 AT49F002NT-12JC

CC

Ordering Code Package Operation RangeActive Standby

AT49F002NT-55PC

AT49F002NT-55TC

AT49F002NT-55VC

50 0.3 AT49F002NT-55JI

AT49F002NT-55PI

AT49F002NT-55TI

AT49F002NT-55VI

AT49F002NT-70PC

AT49F002NT-70TC

AT49F002NT-70VC

50 0.3 AT49F002NT-70JI

AT49F002NT-70PI

AT49F002NT-70TI

AT49F002NT-70VI

AT49F002NT-90PC

AT49F002NT-90TC

AT49F002NT-90VC

50 0.3 AT49F002NT-90JI

AT49F002NT-90PI

AT49F002NT-90TI

AT49F002NT-90VI

AT49F002NT-12PC

AT49F002NT-12TC

AT49F002NT-12VC

50 0.3 AT49F002NT-12JI

AT49F002NT-12PI

AT49F002NT-12TI

AT49F002NT-12VI

32J

32P6

32T

32V

32J

32P6

32T

32V

32J

32P6

32T

32V

32J

32P6

32T

32V

32J

32P6

32T

32V

32J

32P6

32T

32V

32J

32P6

32T

32V

32J

32P6

32T

32V

AT49F002(N)(T)

Commercial

(0° to 70°C)

Industrial

(-40° to 85°C)

Commercial

(0° to 70°C)

Industrial

(-40° to 85°C)

Commercial

(0° to 70°C)

Industrial

(-40° to 85°C)

Commercial

(0° to 70°C)

Industrial

(-40° to 85°C)

Package Type

32J 32-lead, Plastic J-leaded Chip Carrier Package (PLCC)

32P6 32-pin, 0.600" Wide, Plastic Dual Inline Package (PDIP)

32T 32-lead, Plastic Thin Small Outline Package (TSOP) (8 x 20 mm)

32V 32-lead, Plastic Thin Small Outline Package (VSOP) (8 x 14 mm)

15

Page 16

Pac ka ging Inf ormation

32J, 32-lead, Plastic J-leaded Chip Carrier (PLC C)

Dimensions in Inches and (Millimeters)

JEDEC STANDARD MS-016 AE

.045(1.14) X 45˚

.032(.813)

.026(.660)

.050(1.27) TYP

PIN NO.1

IDENTIFY

.553(14.0)

.547(13.9)

.300(7.62) REF

.430(10.9)

.390(9.90)

.453(11.5)

.447(11.4)

.495(12.6)

.485(12.3)

.025(.635) X 30˚ - 45˚

.595(15.1)

.585(14.9)

AT CONTACT

POINTS

.022(.559) X 45˚ MAX (3X)

.012(.305)

.008(.203)

.530(13.5)

.490(12.4)

.021(.533)

.013(.330)

.030(.762)

.015(.381)

.095(2.41)

.060(1.52)

.140(3.56)

.120(3.05)

32P6, 32-pin, 0.600" Wide,

Plastic Dual Inline Package (PDIP)

Dimensions in Inches and (Millimeters)

1.67(42.4)

.220(5.59)

SEATING

PLANE

MAX

.161(4.09)

.125(3.18)

.110(2.79)

.090(2.29)

.012(.305)

.008(.203)

1.64(41.7)

1.500(38.10) REF

.065(1.65)

.041(1.04)

.630(16.0)

.590(15.0)

.690(17.5)

.610(15.5)

PIN

0

REF

15

1

.566(14.4)

.530(13.5)

.090(2.29)

.005(.127)

.065(1.65)

.015(.381)

.022(.559)

.014(.356)

MAX

MIN

32T, 32-lead, Plastic Thin Small Outline Package

(TSOP)

Dimensions in Millimeters and (Inches)*

INDEX

MARK

0.50(.020)

BSC

0

REF

5

7.50(.295)

REF

8.20(.323)

7.80(.307)

0.15(.006)

0.05(.002)

18.5(.728)

18.3(.720)

0.25(.010)

0.15(.006)

0.70(.028)

0.50(.020)

20.2(.795)

19.8(.780)

1.20(.047) MAX

0.20(.008)

0.10(.004)

*Controlling dimension: millimeters

32V, 32-lead, Plastic Thin Small Outline Package

(TSOP)

Dimensions in Millimeters and (Inches)

INDEX

MARK

0.50(.020)

BSC

0

REF

5

7.50(.295)

REF

8.10(.319)

7.90(.311)

0.15(.006)

0.05(.002)

12.5(.492)

12.3(.484)

0.25(.010)

0.15(.006)

0.70(.028)

0.50(.020)

14.2(.559)

13.8(.543)

1.20(.047) MAX

0.20(.008)

0.10(.004)

16

AT49F002(N)(T)

Page 17

Atmel Headquarters Atmel Operations

Corporate Headquarters

2325 Orchard Parkway

San Jose, CA 95131

TEL (408) 441- 0311

FAX (408) 487-2600

Europe

Atmel U.K., Ltd.

Coliseum Business Centre

Riverside Way

Camberley, Surrey GU15 3YL

England

TEL (44) 1276-686-677

FAX (44) 1276-686-697

Asia

Atmel Asia, Ltd.

Room 1219

Chinachem Golden Plaza

77 Mody Road Tsimhatsui

East Kowloon

Hong Kong

TEL (852) 2721- 9778

FAX (852) 2722-1369

Japan

Atmel Japan K.K.

9F, Tonetsu Shinkawa Bldg.

1-24-8 Shinka wa

Chuo-ku, Tokyo 104-0033

Japan

TEL (81) 3-3523-3551

FAX (81) 3-3523-7581

Atmel Colorado Springs

1150 E. Cheyenne Mtn. Blvd.

Colorado Springs, CO 80906

TEL (719) 576-3300

FAX (719) 540-1759

Atmel Rousset

Zone Indus triel le

13106 Rousset Cedex

France

TEL (33) 4-4253-6000

FAX (33) 4-4253-6001

Fax-on-Demand

North America:

1-(800) 292-8635

International:

1-(408) 441-0732

e-mail

literature@atmel.com

Web Site

http://www.atmel.com

BBS

1-(408) 436-4309

© Atmel Corporation 1999.

Atmel Corporation makes no warranty for the use of its products, other than those expressly contained in the Company’s standard warranty which is detailed in Atmel’s Terms and Conditions located on the Company’s web site. The Company assumes no responsibility for

any errors which may appear in this document, reserves the right to change devices or specifications detailed herein at any time without

notice, and does not make any commitment to update the information contained herein. No licenses to patents or other intellectual property of Atmel are granted by the Company in connection with the sale of Atmel products, expressly or by implication. Atmel’s products are

not authorized for use as critical components in life support devices or systems.

®

Marks b eari ng

Ter ms and product names in this document may be trademarks of others.

and/or ™ are registered trademarks and trademarks of Atmel Corporation.

Printed on recycled paper.

1017D–10/99/xM

Loading...

Loading...