Page 1

Operations Guide

ESP-MC, ESP-SAT, ESP-SITE-Satellite and Maxicom2Interface Board (MIB) Kit

P/N 634593 REV F

Page 2

Safety Information

ii

Warning!

Important safety information and warning messages appear throughout this manual. To ensure correct operation

and to avoid additional expense, read this manual thoroughly before you begin installation.

“WARNING: A CIRCUIT BREAKER OR CUTOFF

SWITCH IS TO BE PROVIDED IN THE FIXED WIRING

TO ISOLATE THE CONTROLLER”

“MEMORY IS RETAINED BY A BATTERY WHICH IS

TO BE DISPOSED OF IN ACCORDANCE WITH

LOCAL REGULATIONS”

Caution icons

The lightening flash with arrowhead

symbol, within an equilateral triangle, is

intended to alert the user to the

presence of uninsulated “dangerous

voltage” within the product’s enclosure

that may be of sufficient magnitude to

constitute a risk of electric shock to

persons.

The exclamation point within an

equilateral triangle is intended to alert

the user to the presence of important

operating and maintenance (servicing)

instructions in the literature

accompanying the product.

“ATTENTION: UN DISJONCTEUR OU UN

IMTERRUPTEUR DOIT ETRE INSTALLE SUR LE

PRIMAIRE POUR ISOLER LE PROGRAMMATEUR”

“LA MEMOIRE EST MAINTENUE GRACE A UNE

BATTERIE RECHARGEABLE A DISPOSER SELON LA

REGLEMENTATION LOCALE”

L’éclair avec is symbole de la flèche,

placé dans les limites d’un triangle

équilatéral est prévu pour avertir

l’utilisateur de la présence de “tension

dangereuse” non isolée dans l’enceinte

du produit qui pourrait ëtre d’une

importance suffisante pour présenter un

risque d’électrocution aux personnes.

Le point d’exclamation dans un triangle

équilatéral est prévu pour avertir

l’utilisateur de la présence d’instructions

importantes pour les opérations et

l’entretien (service) dans les manuels

fournis avec l’appareil.

Page 3

Contents

iii

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Welcome to Rain Bird . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

The ESP-MC Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

The ESP-SAT Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

The Maxicom

2

Interface Board (MIB) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

The ESP-SITE-Satellite Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Special Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

*For installation instructions see poster included in controller box

Looking at the Controller’s Faceplate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Rain Bird RASTER

TM

(Rapid Station Test Routine) . . . . . . . . . . . . . . . . . . . . . . .7

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

RASTER

TM

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Beginning the RASTER

TM

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Station Valve Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Troubleshooting Open and Shorted Valve Circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Open Circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Short Circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Troubleshooting Opens and Shorts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Programming the Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Preparing to Program the Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Setting the Time and Date . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Setting up a Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Step 1: Selecting a Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Step 2: Selecting the Cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Step 3: Setting the Length of a Station’s Watering Time . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Step 4: Setting Watering Start Times . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Step 5: Setting Programs to Stack or Overlap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Step 6: Setting the MV/PUMP Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Setting Rain Delay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Setting Cycle + Soak

TM

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Setting the Water Budget . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Setting Event Day Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Page 4

Contents, continued

iv

Setting a Delay between Stations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Clearing All Programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Operating the Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Operating Automatically . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Operating Manually . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Operating a Program or Programs Manually . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Operating a Station or Stations Manually . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Using the Test Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Using the Sensor Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Fuse Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Using the Diagnostic Circuit Breaker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Replacing the Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

General Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Maxicom

2

-specific Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Appendix A: Scheduling Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

ESP-MC and ESP-SAT Controllers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Appendix B: Maxicom2Central Control System Overview . . . . . . . . . . . . . . .34

ESP-SITE-Satellite Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Appendix C: Setting the Channel Number . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Appendix D: ESP-MC Controller Spare Parts List . . . . . . . . . . . . . . . . . . . . . .39

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Service Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

inside back cover

Page 5

Introduction

1

Welcome to Rain Bird

Thank you for purchasing your new, state-of-the-art Rain Bird controller. For more than six decades, Rain Bird has

led the irrigation industry in meeting all of your water management needs by providing the highest quality

products and services available. Your new Rain Bird controller is designed to give you a lifetime of on-site watering

control.

The ESP-MC Controller

The ESP-MC series controller is a stand-alone controller appropriate for residential or commercial use. Thin easy-touse built-in computers offer four programs for up to 40 watering stations. It can also be upgraded to function as a

satellite controller that is part of the Maxicom2irrigation system. For more information about using your

controller with the Maxicom2system, see Appendix B, on page 34.

The ESP-SAT Controller

The ESP-SAT series controller is ready to be used in conjunction with the Maxicom2irrigation system or as a

stand-alone unit. It is appropriate for residential or commercial use and its easy-to-use, built-in computer offers

four programs for up to 40 watering stations.

The Maxicom2Interface Board (MIB)

The Maxicom2Interface Board (MIB) kit for the ESP-MC controller converts the stand-alone ESP-MC to an ESP-SAT

controller that can be linked to the Maxicom2system.

The ESP-SITE-Satellite Controller

The ESP-SITE-Satellite controller is ready to be used in conjunction with the Maxicom2irrigation system. It is

appropriate for residential or commercial use and its easy-to-use, built-in computer offers four programs for up to

40 watering stations. For information specific to the ESP-SITE-Satellite controller, see Appendix B, page 36 and the

ESP-SITE-Satellite Installation Guide that came with your controller.

The ESP-SITE-Satellite Upgrade Kit for ESP-MC or ESP-SAT controllers converts these controllers to ESP-SITE-Satellite

controllers.

Page 6

Introduction, continued

2

Special Features

The ESP-MC, ESP-SAT and ESP-SITE-Satellite controllers are available as metal wall-mount (WM)

or stainless steel pedestal-mount (SS) models, with 8-, 12-, 16-, 24-, 28, 32, 36- or 40-station capability.

All configurations have the following special features:

• Anti-rust, corrosion-resistant design

• Four independent programs

• Cycle + Soak

TM

feature for water conservation and erosion control

• Programs and time are retained, even during power outages

• Diagnostic circuit breaker that identifies a station with a short circuit

• Convenient Test Program

• Rain Delay from 1 to 99 days

• 365-day calendar with various scheduling options for watering cycles

• Option to set any day of the month as a non-watering day

• Cycle and fault indicator lights

• Easy-to-read liquid crystal display

• Optional sensors that suspend watering when the soil is wet

• Universal remote-ready connections

• True independent day cycles by program

• Programmable program overlap

• Station timing from one minute to 12 hours

Note: For installation instructions see poster included in controller box.

Page 7

Looking at the Controller’s Faceplate

3

Before beginning to program or operate your controller, take a moment to become familiar with the controller’s

faceplate. The following pages contain a short description of each of the keys and indicators. Specific instructions for

all of the operations you can perform begin on page 7.

Page 8

Looking at the Controller’s Faceplate, continued

4

WATERING SUSPENDED BY SENSOR

This light is on when watering has been suspended by a sensor or the sensor jumper wire has been removed and

the sensor switch is in the ACTIVE position.

SENSOR OFF/ACTIVE

If you want to activate the sensor, set the switch to ACTIVE. If you wish to override the sensor or there is no sensor

connected to the controller, set the switch to OFF. When no sensor is connected, be certain that the jumper cable

connecting the SENSOR terminals on the controller’s circuit board is installed. If you set the SENSOR switch to

ACTIVE without a sensor or jumper cable connected, the controller cannot operate the valves and no watering

will occur.

▲/ON

Press to turn a setting on or to advance the setting in the display.

▼/OFF

Press to turn a setting off or to decrease the setting in the display.

PGM

Press to change the program displayed on the screen. When the PGM key is pressed, the indicator on the left side

of the screen cycles through programs A, B, C and D.

MAN START/ADV.

Press to advance to the next setting in the display or to manually start an operation.

FAULT RESET

Press to clear the fault reading from the display. Press this key after you have fixed the short circuit indicated by

the diagnostic fault indicator in the display.

PUMP/MV STATUS

This light is on when the Master Valve 1 (MV1) circuit is enabled for the active station.

STATION STATUS

This light is on when a valve is active.

LINKED TO Maxicom2(ESP-SAT and ESP-SITE-Satellite versions only)

This light is on when the STAND ALONE/MAXICOM switch is in the MAXICOM position and the controller is

physically linked to the Maxicom2system.

EVEN DAY CYCLE

This light is on when the controller’s active program is set to water on even days of the month.

Page 9

Looking at the Controller’s Faceplate, continued

5

ODD DAY CYCLE

This light is on when the controller’s active program is set to water on odd days of the month.

CYCLICAL DAY CYCLE

This light is on when the controller’s active program is set to water in a cycle with a specified number of days.

CUSTOM DAY CYCLE

This light is on when the controller’s active program is set to water on specific days of the week.

AUTO

Set the dial here to have the controller automatically run the programs you set.

STATION WATERING TIME

Set the dial here to set the length of an individual station’s watering time.

WATERING START TIME

Set the dial here to set a program’s watering start times. Eight start times are available for each program.

MV PUMP START

Set the dial here to enable or disable Master Valve 1 (MV1) for a particular station.

PROGRAM OVERLAP

Set the dial here to set programs to either stack or overlap. The default for all programs is stack.

TIME/CALENDAR

Set the dial here to set the time and date.

EVENT DAY OFF

Set the dial here to set optional day(s) off within the month.

RAIN DELAY

Set the dial here to delay watering for a specified number of days.

MON — SUN

Set the dial to the day of the week to turn that day off or on when setting a custom program cycle.

CUSTOM

Set the dial here to set a program cycle to water on specific days of the week.

CYCLICAL

Set the dial here to set a program cycle to water at specific intervals, such as every day, every second day, every

third day, etc.

Page 10

Looking at the Controller’s Faceplate, continued

6

ODD DAYS

Set the dial here to set a program cycle that waters on odd days of the month.

EVEN DAYS

Set the dial here to set a program cycle that waters on even days of the month.

WATER BUDGET

Set the dial here to set the water budget percentage for a program. The default is 100%.

CYCLE + SOAK

TM

Set the dial here to break a station’s watering time into intervals to conserve water and prevent erosion.

TEST PROGRAM/STATION DELAY

Set the dial here to set and start a test program cycle for all stations. Also, access the Station Delay feature by

placing the dial in this position and holding down the ▲/ON and ▼/OFF keys simultaneously.

MANUAL WATERING

Set the dial here to water a station manually.

OFF/PROGRAM RESET

Set the dial here to shut the controller and its valves down, such as during the winter months. Also reset all

programs by placing the dial in this position and holding down the ▲/ON and MAN START/ADV keys for 10

seconds.

STAND ALONE/MAXICOM (located on the back of the front panel)

If you want your controller to function as a stand-alone unit, set this switch to STAND ALONE. If you want it to function

as a satellite connected to the Maxicom2system, set this switch to MAXICOM (ESP-SAT and ESP-SITE-Satellite versions

only). If the controller is not connected to Maxicom2, the position of this switch will have no effect on watering.

Page 11

Rain Bird RASTERTM(Rapid Station Test Routine)

7

Introduction

Rain Bird’s new RApid Station TEst Routine (RASTERTM) lets you diagnose field wiring and solenoid problems

quickly and easily.

The RASTERTMsends an electronic signal to each valve on the controller and then displays the valve’s current

operating condition in the easy-to-read digital display.

The RASTERTMtests and displays two different valve operating conditions:

• Open — Indicates an open circuit between the controller and the valve.

• Short — Indicates a short circuit between the controller and the valve.

The RASTER

TM

is a fast and easy way to make sure the controller’s master valves and all station valves are operating

properly.

The new RASTERTMfeature is available on the Rain Bird ESP-MC, ESP-SAT, ESP-SITE-SAT and ESP-LX+ controllers.

Page 12

Rain Bird RASTERTM(Rapid Station Test Routine), continued

8

RASTERTMOperation

Use the following procedure to perform the

RASTERTMon the master valves and all other

controller station valves.

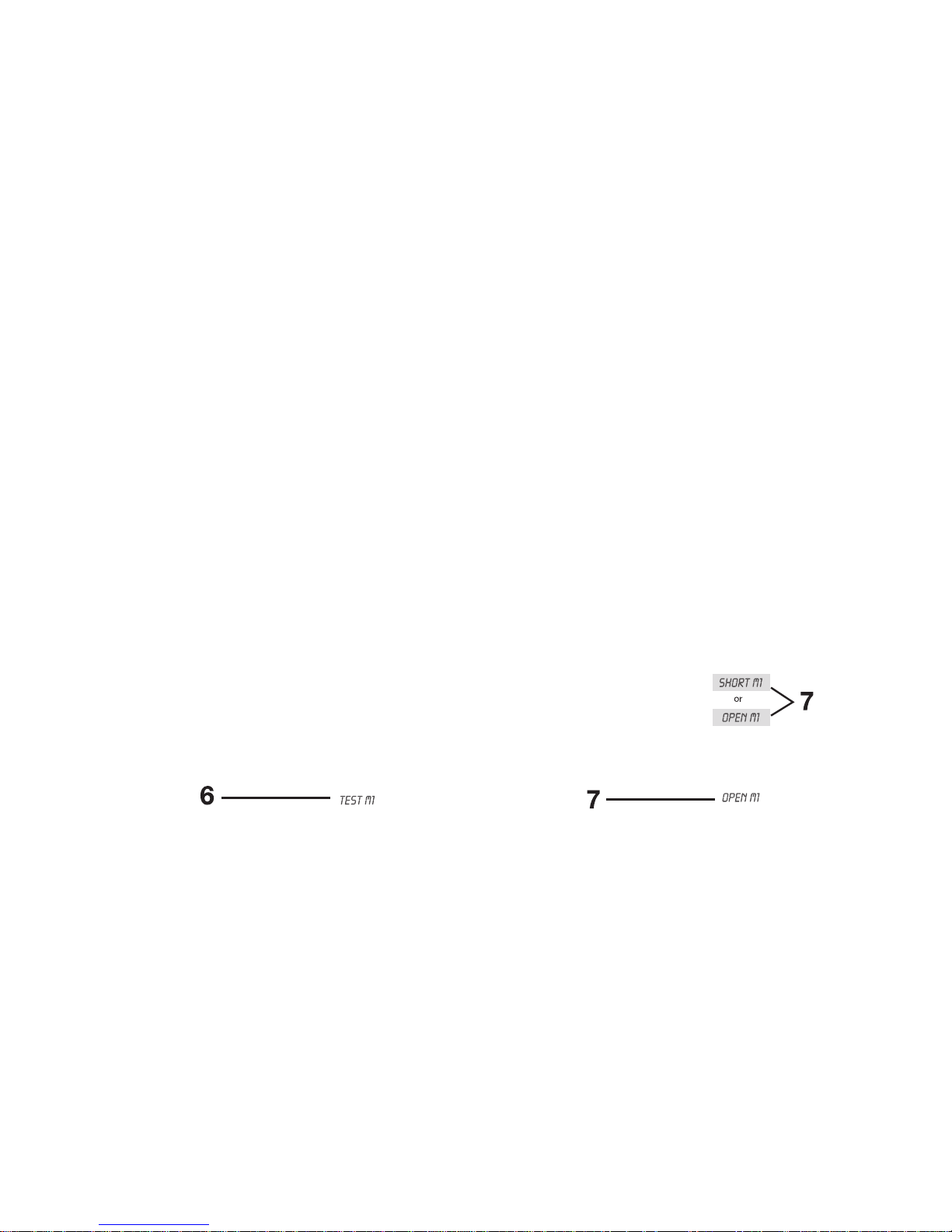

Beginning the RASTER

TM

1. Turn the Programming Dial to “OFF.”

2. Press and release the

▲/ON and ▼/OFF

at the same time.

3. The display will look like the illustration below.

4. Press the “MAN START/ADV” to begin the

RASTER

TM

.

5. The display shows “TEST IO” and the indicator

lights on the front panel flash once as the

RASTER

TM

confirms the proper operation of the

controller’s front panel lights.

NOTE: If the front panel is not connected to the

output board or the controller is disconnected

from the main power the display will show the

message “

NO OUT.”

The RASTERTMthen automatically begins the test

on the controller’s master valves and each station

valve, beginning with the master valve 1.

Page 13

Rain Bird RASTERTM(Rapid Station Test Routine), continued

9

6. The display shows “TEST M1” and “TEST M2” as

the RASTERTMbegins to check the operation of the

master valves (an automatic valve installed on the

mainline pipe upstream from the station valves).

7. If the display shows “SHORT M1” or “OPEN M1”

or “SHORT M2” or “OPEN M2” there may be a

faulty circuit between the controller and the

master valve. (On irrigation systems not equipped

with a master valve, the “OPEN M1” or “OPEN

M2” indicator is normal and requires no service.)

See “Troubleshooting Open and Shorted Valve

Circuits” on page 11 for more information.

Page 14

Rain Bird RASTERTM(Rapid Station Test Routine), continued

10

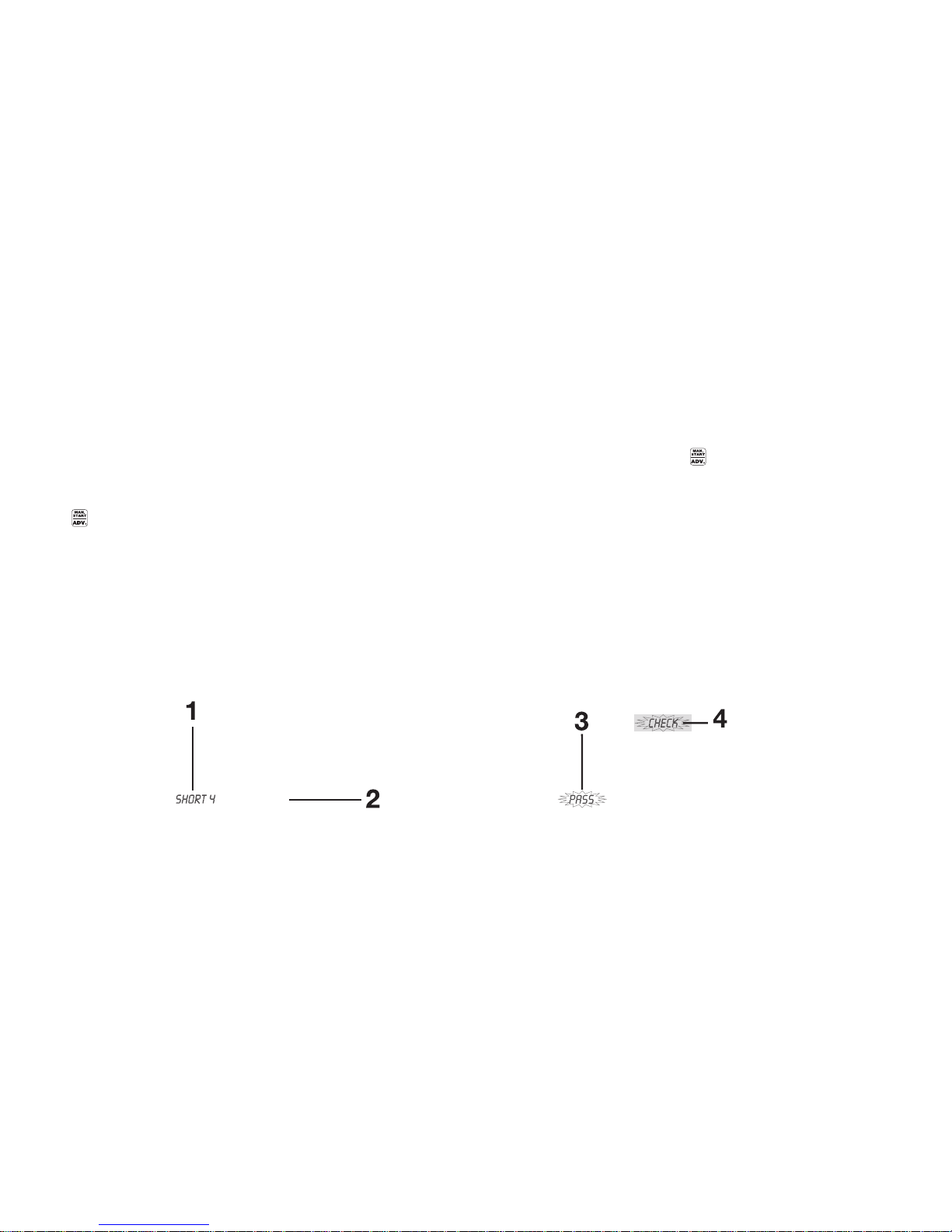

Station Valve Testing

After testing the master valves, the RASTER

TM

automatically tests each valve station, in numerical

order, from lowest to highest.

1. The display shows the valve’s operating condition

(OPEN or SHORT), followed by the station

number (up to 40 stations, depending on

controller model). This sample display indicates

there is a short on valve station number 4.

2. The RASTERTMdisplays the condition of each valve

being tested for 10 seconds, and then moves to

the next valve. You can press “MAN/START/ADV”

(or any other magenta button) at any time to

advance to the next station to be tested.

NOTE: Any controller station that does not have a

valve connected to it will display an OPEN signal.

For example, if you have a 12-station controller and

only have stations 1 through 10 connected to valves,

stations 11 and 12 will show “OPEN” on the

RASTER

TM

. This is normal and does not indicate any

problem with the controller or system valves.

3. If the master valves and all station valves pass the

RASTERTM, the display flashes “PASS” for 10

seconds.

4. If the RASTERTMdetected a problem on the master

valves or any station valve, the display flashes

“CHECK” for three seconds and then displays the

valve’s problem condition (OPEN or SHORT) and

station number or master valve.

Each problem valve will flash in the display for

five seconds. Press “MAN START/ADV” at any

time to display the next problem valve detected.

Any valve displaying “OPEN” or “SHORT” should

be checked for field wiring or other circuit

problems. See “Troubleshooting Open and

Shorted Valve Circuits” on page 11 for more

information.

Page 15

Rain Bird RASTERTM(Rapid Station Test Routine), continued

11

5. Turn the Programming Dial from “OFF” to

“AUTO” (or any other dial position) at any time to

exit RASTERTMmode.

6. The controller returns to normal operation.

Troubleshooting Open and

Shorted Valve Circuits

Open Circuits

When the RASTERTMshows an “OPEN” valve circuit,

it indicates a complete break in the current flow

between the controller and the valve.

NOTE: The RASTERTMwill display an “OPEN”

indicator if no valve solenoid is connected to the

controller station. This is normal and the system

does

not need service.

These are the most common causes of open circuits:

• A malfunctioning valve solenoid

• Field wires that have been cut or pulled loose

• Loose wire connections on the controller’s

terminal strip or at the valve solenoid

• A damaged component on the controller’s

internal circuit board

Page 16

Rain Bird RASTERTM(Rapid Station Test Routine), continued

12

Short Circuits

When the RASTERTMshows a “SHORT” test result, it

indicates an unintended re-routing of the current

flow somewhere between the controller and the

valve.

These are some of the most common causes of

short circuits:

• A shorted valve solenoid

• Nicked or “skinned” field wires

• Loose or corroded wire connections on the

controller’s terminal strip or at the valve solenoid

• A malfunctioning component on the controller’s

internal circuit board.

Troubleshooting Opens and Shorts

Use the following procedure to troubleshoot any

valve identified as “OPEN” or “SHORT.”

1. Make sure the problem valve’s station wires are

securely connected on the controller’s terminal

strip.

2. If the wires were securely connected, move the

problem station’s wires to a station that passed

the RASTERTMand re-start the test.

3. If the “OPEN” or “SHORT” moves to the new

station, check the problem valve’s solenoid and

field wiring.

4. If the “OPEN” or “SHORT” reoccurs on the

original station, the controller’s internal circuitry

may need service.

Page 17

Programming the Controller

13

Using the keys and dial on the controller's faceplate, you can set up the controller to operate automatically. You

can also run the controller manually without making changes in the programs you have set.

This chapter will guide you through the use of the controller's keys and dial and will give you step-by-step

instructions for setting up the four programs to suit your needs.

Preparing to Program the Controller

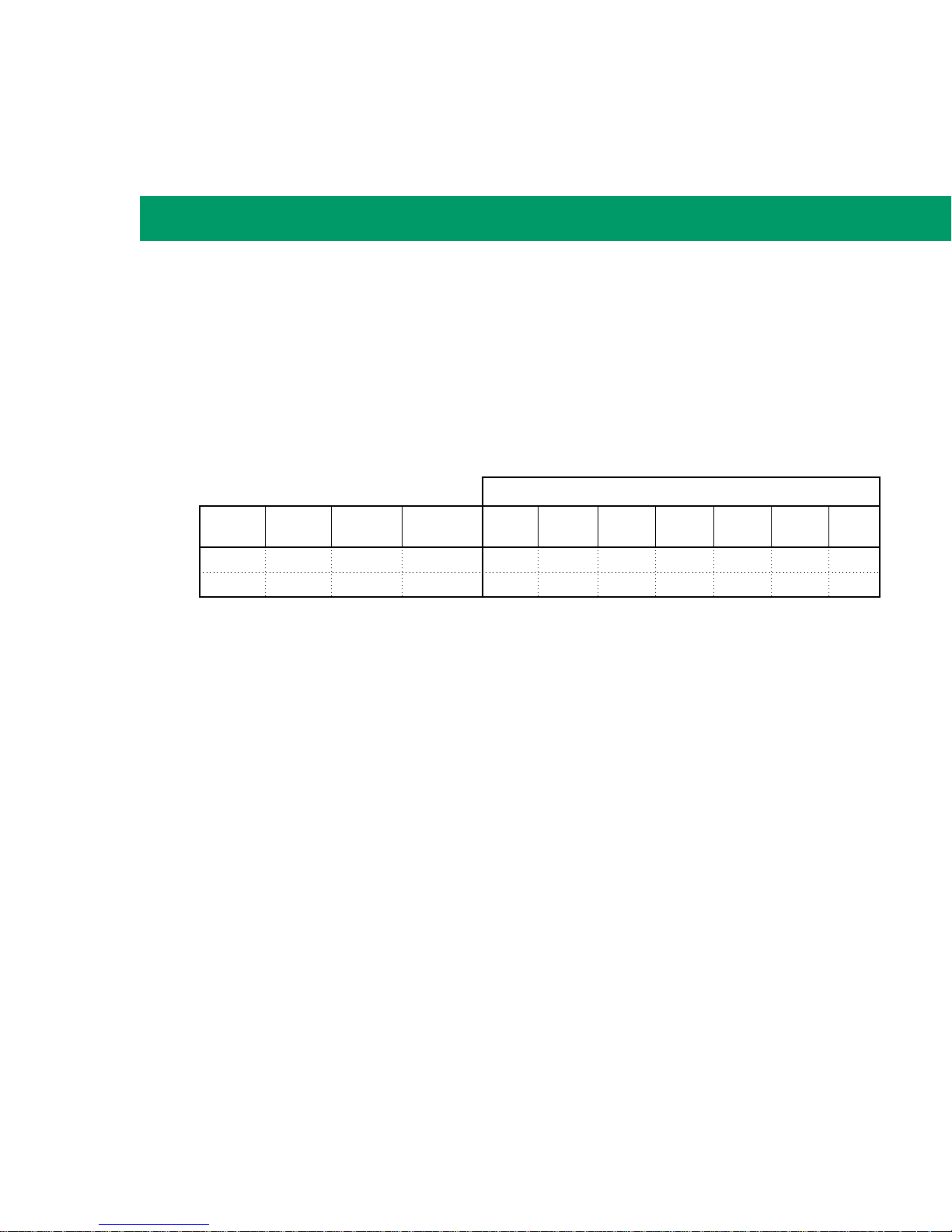

The controller comes from the factory without a pre-set default program. The following table presents a summary

of the controller’s default program settings:

Before you begin programming, it is a good idea to chart your watering schedule on a piece of paper, taking into

account the schedule for all stations and how often you want to repeat the schedule. A blank schedule is provided

for you on pages 32-33.

Custom Cycle

Progr.

Station#Water

Time

Start

Time

A All 0 Min 8:00A on on on on on on on

1

(MON)2(TUES)3(WED)4(THU)5(FRI)6(SAT)7(SUN)

Page 18

Programming the Controller, continued

14

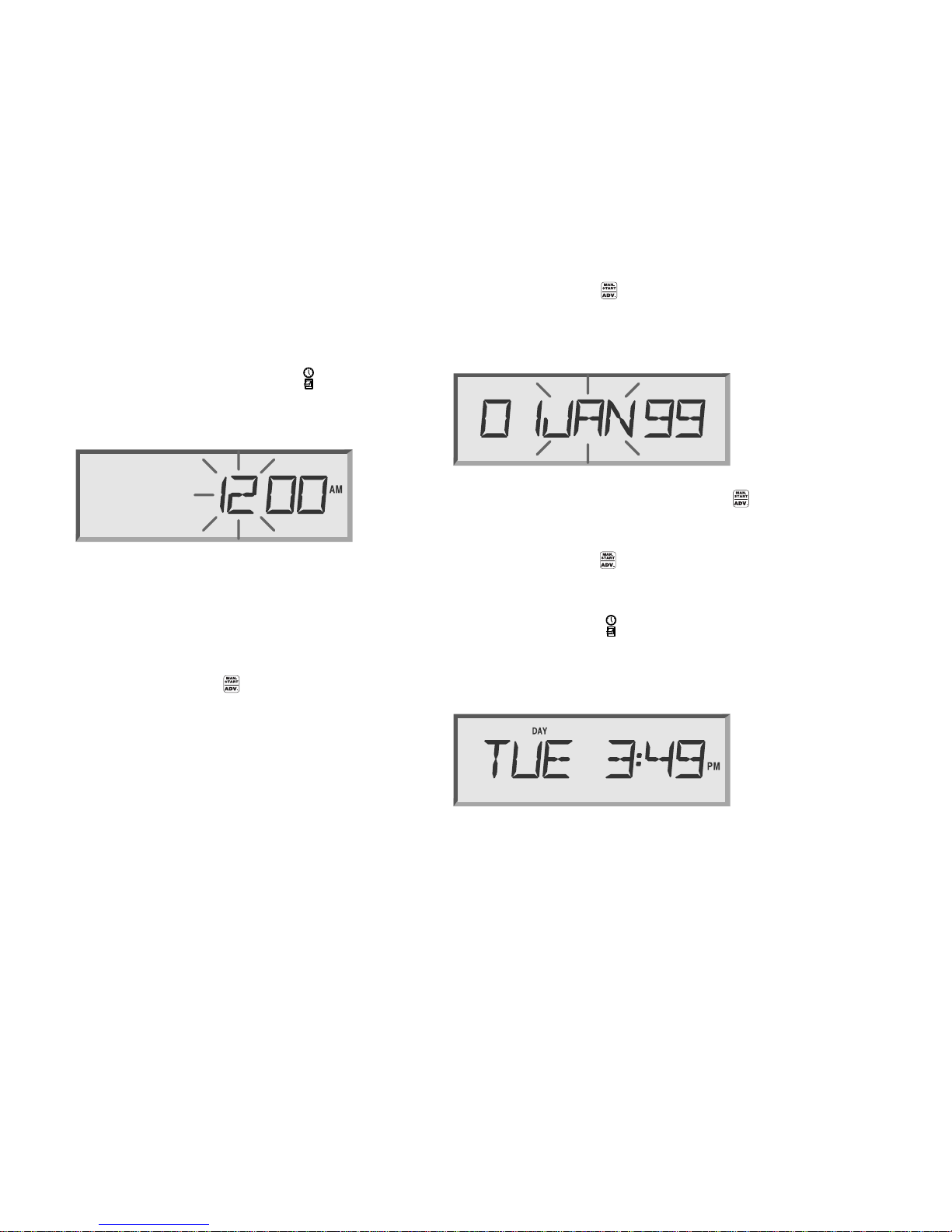

Setting the Time and Date

The first step in programming the controller is

setting the controller’s internal clock and calendar.

To do so,

1. Rotate the dial to TIME/CALENDAR.

The hour digits in the display flash, indicating

that they are ready to be set.

2. Use the arrow keys to set the hour.

If you have a 60 Hz model, as you pass 12:00 the

am/pm designation changes.

Note: The 60 Hz model displays time in the

12-hour am/pm mode. The 50 Hz model displays

time in the 24-hour mode.

3. Press MAN START/ADV.

The minute digits flash, indicating that they are

ready to be set.

4. Use the arrow keys to set the minutes to the

current time.

5. Press MAN START/ADV.

A new display appears with the day, month and

year. The month flashes, indicating that it is ready

to be set.

6. Use the arrow keys and the MAN START/ADV

key to set the month, day and year the same way

you set the hour and minutes.

7. Press MAN START/ADV twice to return to the

time of day display.

The hour continues to flash as long as the dial is

left at TIME/CALENDAR .

8. Return the dial to AUTO.

The display shows the day of the week and time

of day.

Page 19

Programming the Controller, continued

15

Setting up a Program

There are four independent programs available with

the controller: A, B, C, and D. You can set each

program to operate according to your specifications.

When you set up a program, you:

• select the program

• choose a cycle setting for the program

• assign stations and set the station’s watering

durations and start times

It is easier to select a program and program it

completely. Jumping from program to program can

be confusing.

Step 1: Selecting a Program

To select the program you want to set up,

Press PGM to cycle through the available

programs.

The program indicator on the far left side of the

display changes.

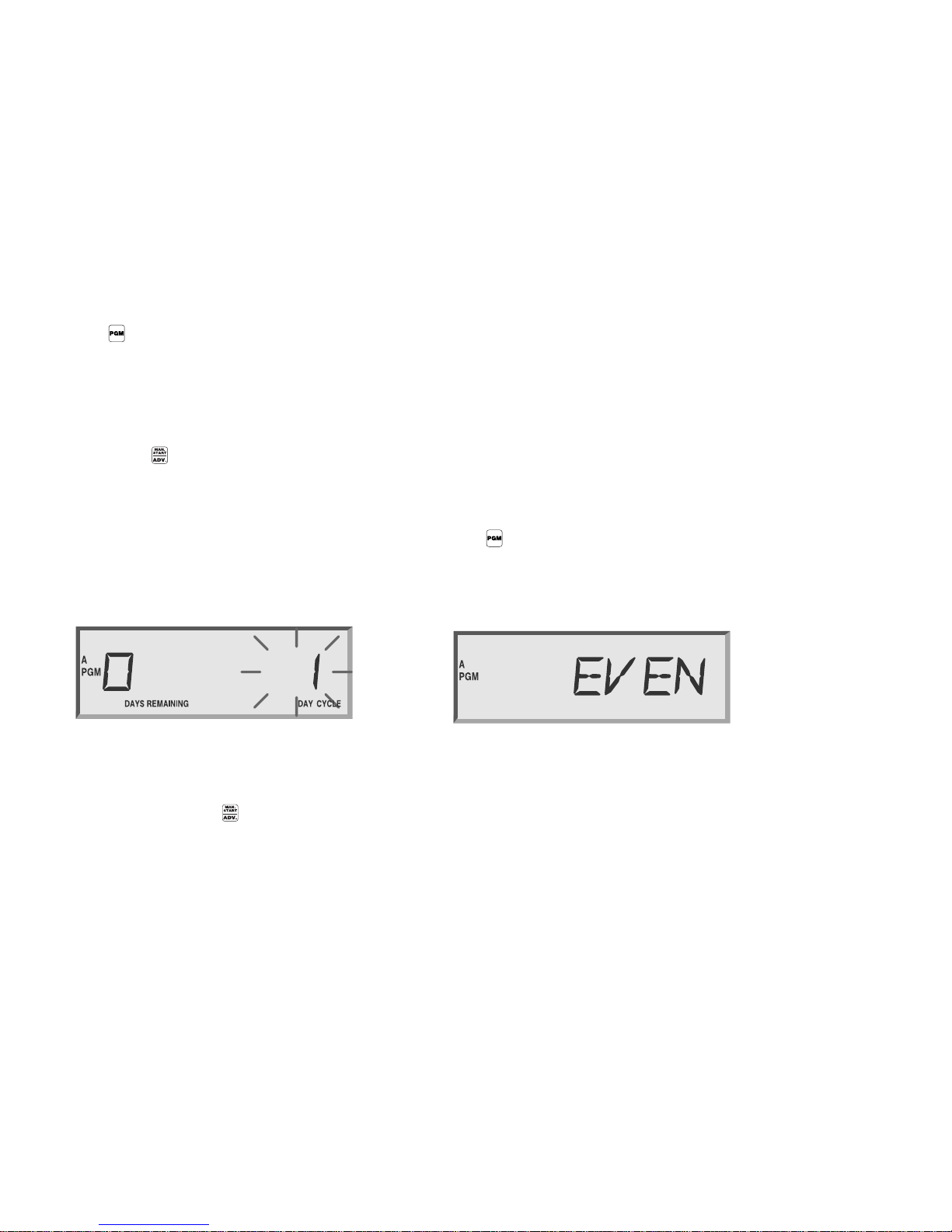

Step 2: Selecting the Cycle

Each program can operate in one of four cycle modes:

• CUSTOM waters on the days of the week you select.

• CYCLICAL waters according to a cycle with a

specified number of days.

• ODD waters only on odd days of the month.

• EVEN waters only on even days of the month.

Note: All programs default to the custom cycle.

To set a custom cycle,

1. Rotate the dial to CUSTOM.

The display shows the program and CUSTOM.

The display shows USED if the program is active

and using a different cycle mode. If desired, you

can override the previous setting.

2. If the program you want is not displayed, press

PGM until it is.

3. Press ON.

The display shows CUSTOM and the custom

light on the faceplate illuminates.

4. Rotate the dial to the first day of the week and use

the ON and OFF keys to turn the day on or off.

The display shows the day and the ON/OFF

setting.

5. Repeat step 4 for all the days of the week you

want to change.

6. Return the dial to AUTO.

The controller returns to the time of day display

and waters on the days you have specified.

Page 20

Programming the Controller, continued

16

To set a cyclical cycle,

1. If the program you want is not displayed, press

PGM until it is.

2. Rotate the dial to CYCLICAL.

The display shows the number of days remaining

and the number of days in the cycle. The number

of days in the cycle is flashing, indicating that it is

ready to be set. If it is not flashing, press MAN

START/ADV until the number of days in the

cycle is flashing.

The display shows USED if the program is active

and using a different cycle mode. If this is the

case, you can override the previous setting.

3. Press ON.

The cyclical display appears and the cyclical light

on the faceplate illuminates.

4. Use the arrow keys to set the number of days in

the cycle.

For example, if you set a 3-day cycle, the controller

skips two days and waters on the third.

5. Press MAN START/ADV to toggle to the left

side of the display.

The number of days remaining in the cycle

flashes, indicating that it is ready to be set.

6. Use the arrow keys to set the number of days

remaining before the next watering day. This tells

the controller where today is in the cycle you

have just set. For example, if DAYS REMAINING

is set to “0,” watering will occur today. If DAYS

REMAINING is set to “1,” watering will occur

tomorrow.

7. Return the dial to AUTO.

The controller returns to the time of day display

and waters on the days you have specified.

To set an

odd or even cycle,

1. If the program you want is not displayed, press

PGM until it is.

2. Rotate the dial to ODD DAYS or EVEN DAYS.

The display shows the program and ODD or

EVEN.

The display shows USED if the program is active

and using a different cycle mode. If this is the

case, you can override the previous setting.

3. Press ON.

The display shows either ODD or EVEN and the

corresponding light on the faceplate illuminates.

4. Return the dial to AUTO.

The controller returns to the time of day display

and waters on the days you have specified.

Note: The 31st day of the month defaults to ON, so

if you do not want to water on the 31st, you must set

that day to OFF. See page 21 for more information

.

Page 21

Programming the Controller, continued

17

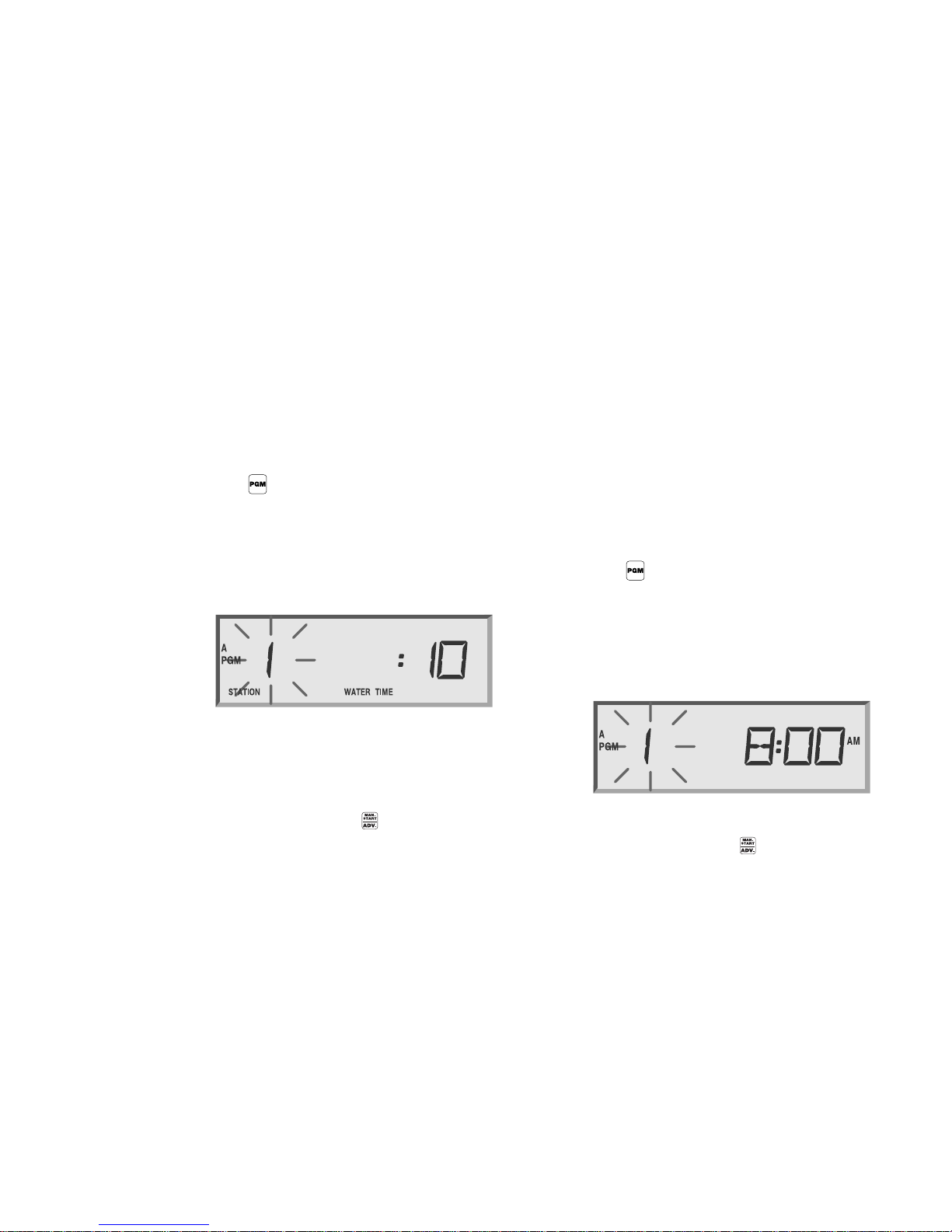

Step 3: Setting the Length of

a Station’s Watering Time

Within the program you are setting, you can set the

length of a station’s watering time from 0 minutes to

12 hours. Set the time in one-minute increments for

up to two hours; set it in 10-minute increments

from two hours to 12 hours.

To set the length of a station’s watering time,

1. If the program you want is not displayed, press

PGM until it is.

2. Rotate the dial to STATION WATERING TIME.

The display shows the program, the station

number and the length of watering time. The

station number is flashing, indicating that it is

ready to be set.

If the station is included in any other program,

the controller will let you know by replacing the

length of watering time with USED.

3. Use the arrow keys to display the station number

you wish to set.

4. Press MAN START/ADV to toggle to the right

side of the display.

The length of watering time flashes, indicating

that it is ready to be set.

5. Use the arrow keys to set the length of time.

If USED is displayed, you can still set the length

of time. (You can include the same station in

different programs and give that station different

lengths of watering time.)

6. Return the dial to AUTO.

The controller returns to the time of day display.

Step 4: Setting Watering Start Times

For each program, you may assign up to eight start

times per day, available on the quarter hour.

To assign start times,

1. If the program you want is not displayed, press

PGM until it is.

2. Rotate the dial to WATERING START TIME.

The display shows the program, the number of the

start time and the start time. The number of the

start time is flashing, indicating that it is ready to

be set.

3. Use the arrow keys to select one of the eight start

times.

4. Press MAN START/ADV to toggle to the right

side of the display.

The start time flashes, indicating that it is ready

to be set.

Page 22

Programming the Controller, continued

18

5. Use the arrow keys to select a start time. Start

times are available in 15 minute intervals, with an

OFF setting available between the 11:45 pm and

12:00 am options on the 60 Hz model (and

between 23:45 and 24:00 on the 50 Hz model).

Note: Start times are displayed in chronological

order. If a start time is deleted by setting it to OFF,

all later start times are automatically moved down

one start time number. When a start time is added

to any start time number, the controller automatically

reorganizes the times so that times appear in

chronological order. This reorganization only occurs

after the dial has been moved off the WATERING

START TIMES position.

6.

If you want to set additional start times, press MAN

START/ADV to toggle back to the left side of the

display and the next available start time number. Set

the next start time in the same fashion as the first.

7. Return the dial to AUTO.

The controller returns to the time of day display.

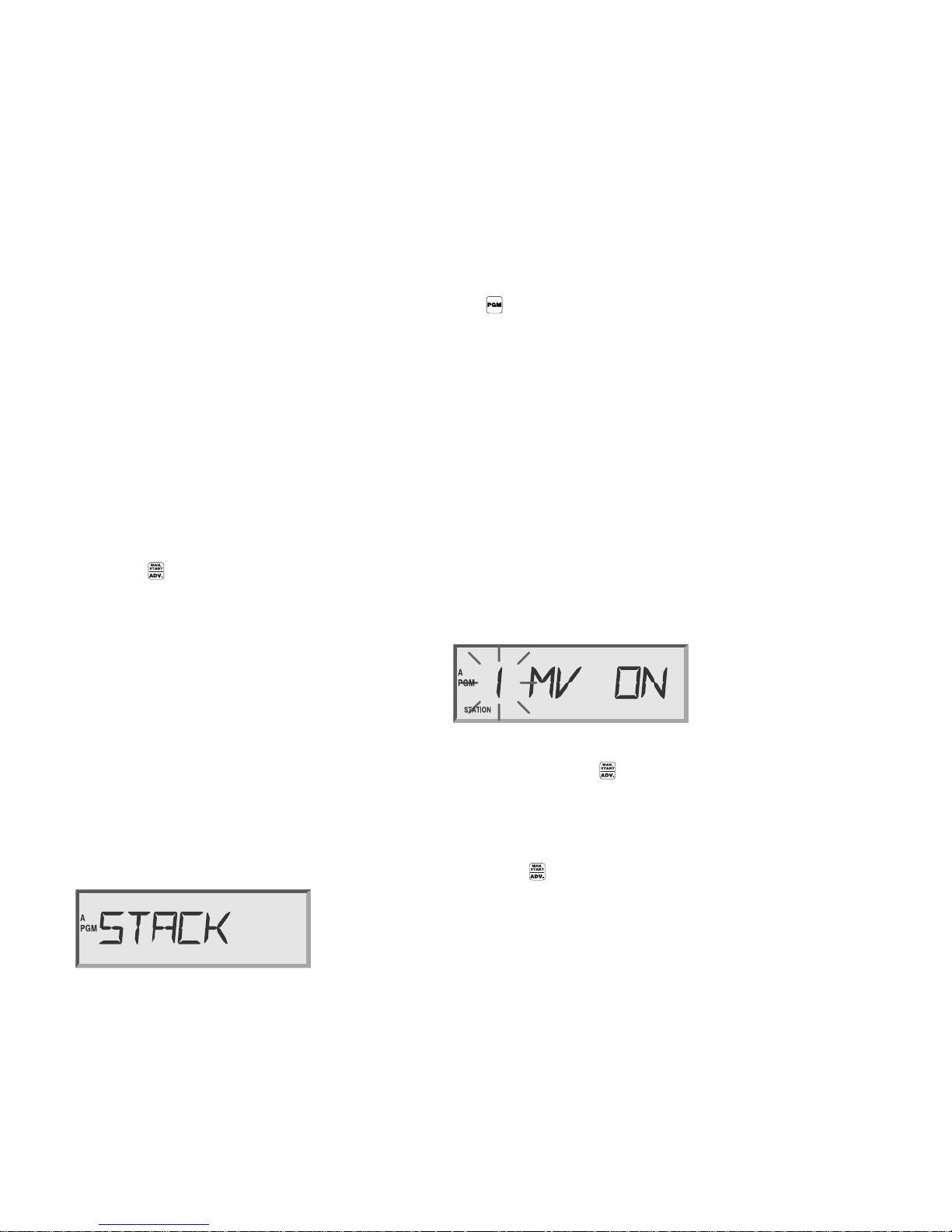

Step 5: Setting Programs to Stack or Overlap

You can set a program to stack (run one at a time) or

overlap (run simultaneously). The controller can run

up to nine valves simultaneously. The default setting

is to stack all programs.

To set programs to stack or overlap,

1. Rotate the dial to PROGRAM OVERLAP.

The display shows the program and STACK or

OVERLAP.

2. If the program you want is not displayed, press

PGM until it is.

3. Use the arrow keys to set the program to either

STACK or OVERLAP.

4. Return the dial to AUTO.

The controller returns to the time of day display.

Step 6: Setting the MV/PUMP Start

The controller has two master valve terminals on its

circuit board. MV2 (master valve 2) is enabled when

any station operates. MV1 (master valve 1) can be

enabled or disabled for each individual station.

To set MV1 for a station,

1. Rotate the dial to MV PUMP START.

The display shows the station number and MV

ON or OFF. The station number is flashing,

indicating that it is ready to be set.

2. Use the arrow keys to select the station number.

3. Press MAN START/ADV to toggle to the right

side of the display. The ON or OFF flashes,

indicating that it is ready to be set.

4. Press either the ON or OFF key.

5. If you want to set another station, press MAN

START/ADV to toggle back to the left side of

the display to continue setting stations.

6. When you are finished setting stations, return the

dial to AUTO.

The controller returns to the time of day display.

Page 23

Programming the Controller, continued

19

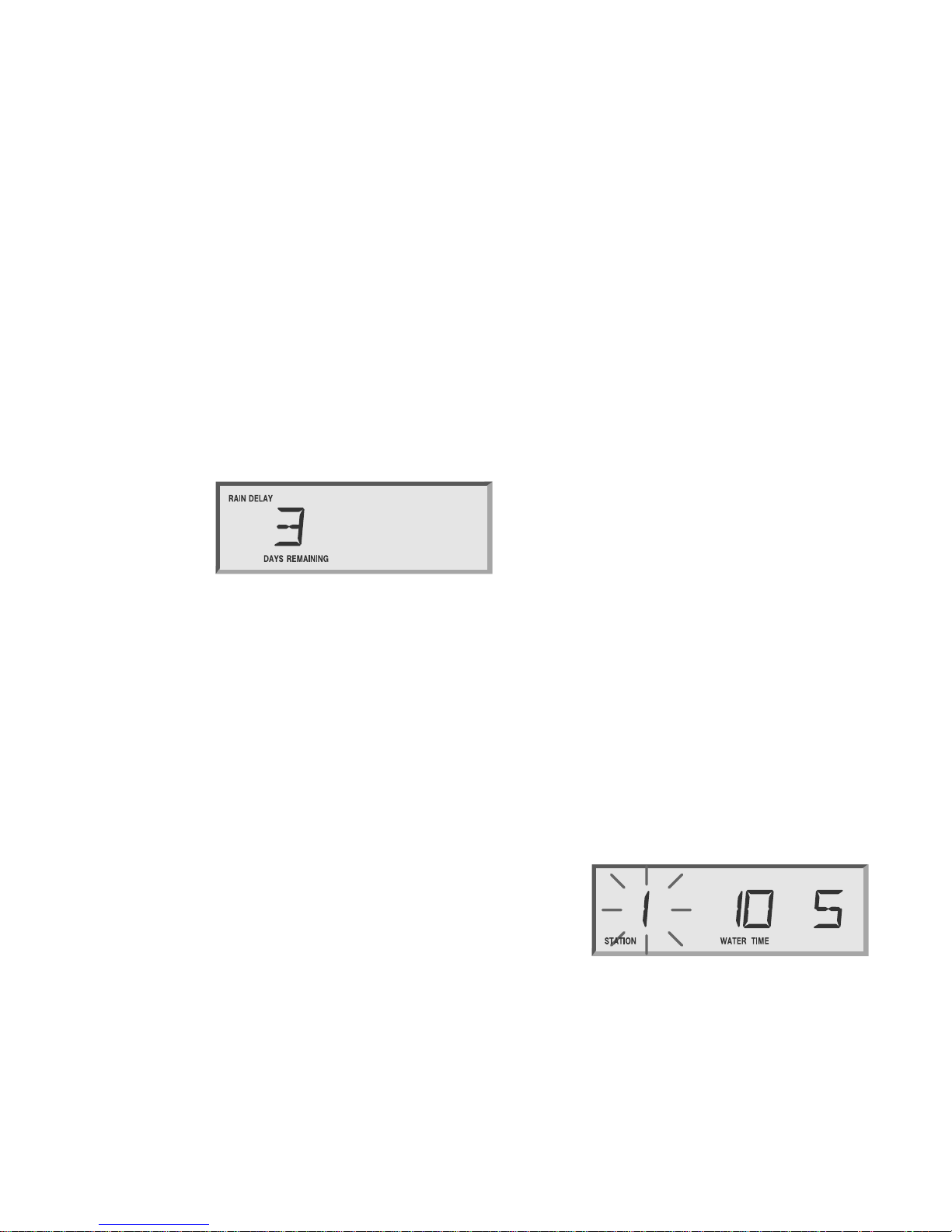

Setting Rain Delay

The controller allows you to delay watering for a

specified number of days up to a maximum of 99

days. The Rain Delay setting affects all programs.

To set a Rain Delay,

1. Rotate the dial to RAIN DELAY.

The display shows RAIN DELAY and the number

of days until watering will resume.

2. Use the arrow keys to set the number of days to

begin watering.

3. Return the dial to AUTO.

The controller returns to the time of day display

and will delay watering for the number of days

you have specified.

Note: To cancel a Rain Delay, reset the number of

days to 0.

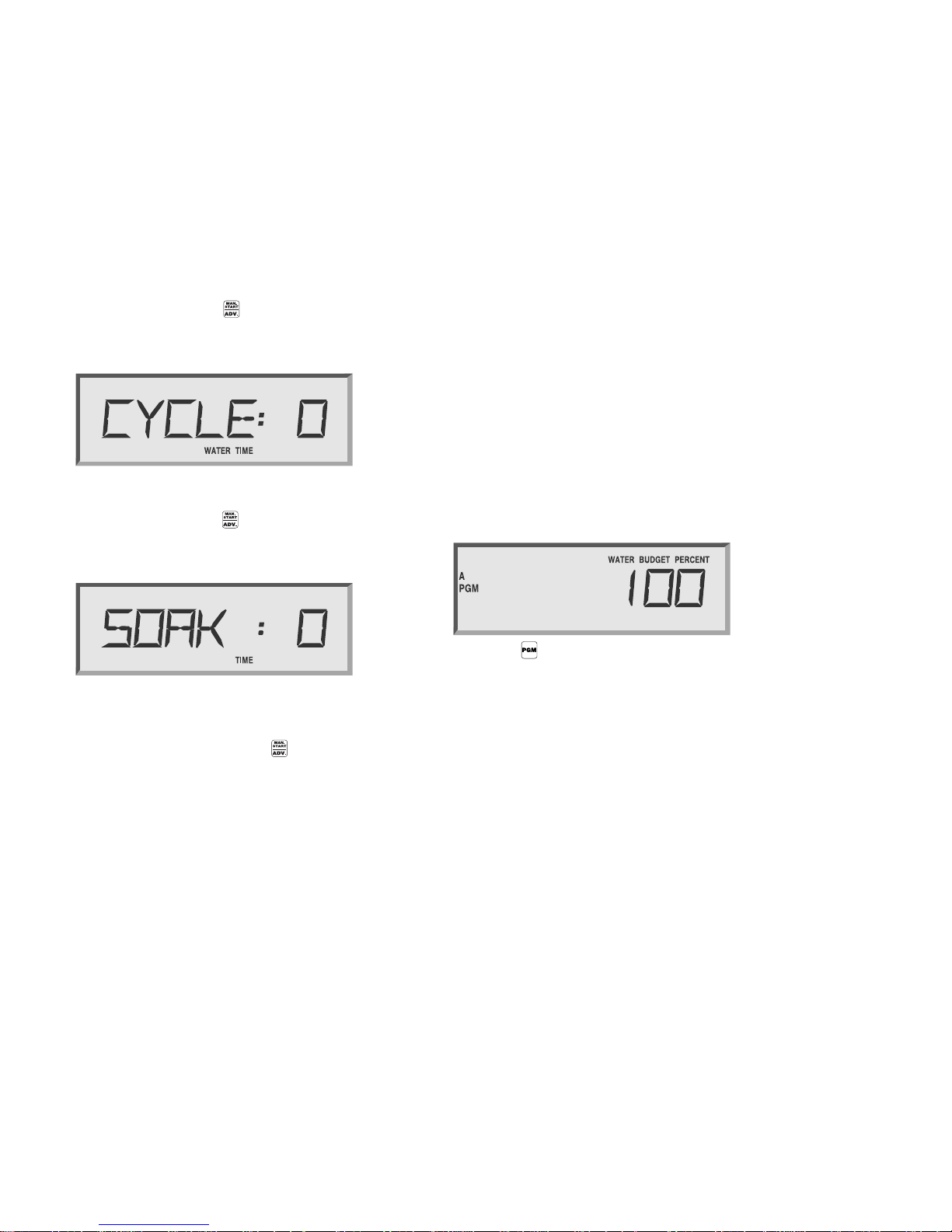

Setting Cycle + Soak

TM

The Cycle + SoakTMfeature is designed to conserve

water that might puddle in tight soils, such as clay,

or end up as runoff on slopes. Cycle + SoakTMlets

you break up the total watering time of a station

into shorter cycles with a soak time between cycles.

You set the maximum watering time length and the

minimum soak time. This setting affects all

programs in which the station is included.

For example, if you want to water a station for a 20

minutes, but runoff occurs after five minutes, you

can set the station for five-minute maximum cycles

and a minimum of 25 minutes between cycles.

While the station is in soak mode, the controller

operates other stations in the program.

Note: If there is nothing left for the controller to do

but wait until a soak time elapses, the display shows

SK.

Note: The test program does not respond to Cycle +

Soak

TM

settings.

To set Cycle + SoakTM,

1. Rotate the dial to CYCLE + SOAK

TM

.

The display shows the station number, the

maximum length of time to water and the

minimum soak time. The station number flashes,

indicating that it is ready to be set.

Page 24

Programming the Controller, continued

20

2. Use the arrow keys to select the station.

3. Press MAN START/ADV.

The length of time to water flashes, indicating

that it is ready to be set.

4. Use the arrow keys to set the maximum watering

time from 1 to 99 minutes.

5. Press MAN START/ADV .

The length of time to soak flashes, indicating that

it is ready to be set.

6. Use the arrow keys to set the minimum soak time

from 1 to 99 minutes.

7. If you want to set Cycle + Soak

TM

for another

station, press MAN START/ADV again.

8. When you have finished setting Cycle + Soak

TM

,

return the dial to AUTO.

The controller returns to the time of day display.

Setting the Water Budget

The water budget feature allows you to increase or

decrease a program’s watering time in increments of

1% without having to reset the timing for each

station in the program. You can set the budget for

0% to 300%. You can use the 0% setting to shut a

program down temporarily.

To set the water budget,

1. Rotate the dial to WATER BUDGET.

The display shows the program and the water

budget percentage.

2. Press PGM until the program you want is

displayed.

3. Use the arrow keys to set the percentage.

4. Return the dial to AUTO.

The controller returns to the time of day display.

The default percentage for all programs is 100%.

When the water budget for a program is set to

other than 100%, WATER BUDGET will show in

the display whenever that program is selected.

Note: The maximum watering time with WATER

BUDGET is 16 hours.

Page 25

Programming the Controller, continued

21

Setting Event Day Off

The Event Day Off feature allows you to omit

temporarily a calendar day or days from the

watering cycle. After a calendar day passes, that day

returns to the default setting. The default for all days

is ON. If the 31st is set to OFF, it remains off until it is

set to ON. This is to accommodate odd day watering

cycles which do not allow watering on the 31st.

To set a day off,

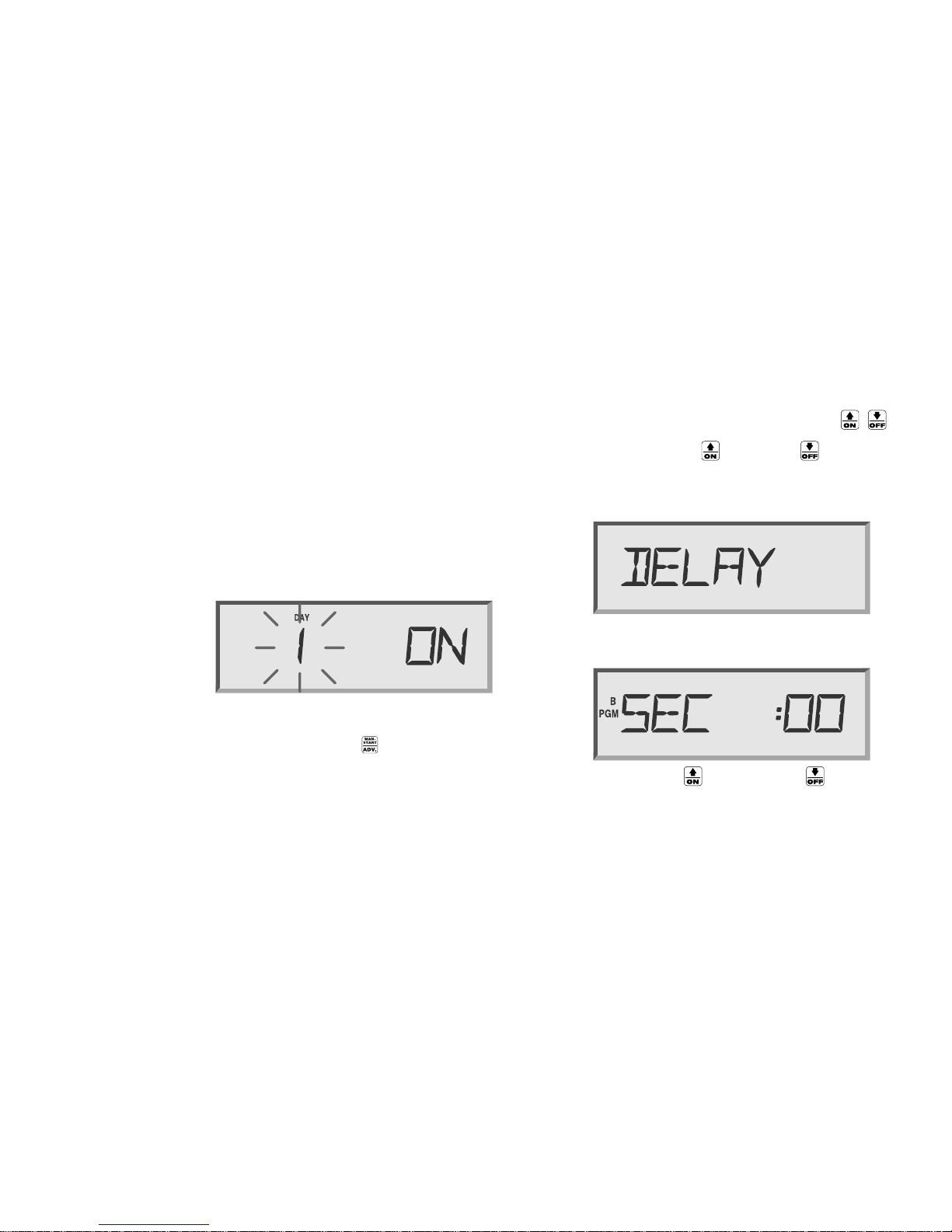

1. Rotate the dial to EVENT DAY OFF.

The display shows the day of the month on the

left and the ON or OFF setting on the right. The

day of the month is flashing, indicating that it is

ready to be set.

2. Use the arrow keys to set the day of the month

you wish to change.

3. Press MAN START/ADV to toggle to the right

side of the display.

The ON/OFF setting flashes, indicating that it is

ready to be set.

4. If you are setting the day to on, press ON; if you

are setting the day to off, press OFF.

5. Return the dial to AUTO.

When a day off arrives, the display shows NON

(for non-watering day) and the controller does

not allow watering.

Setting a Delay between Stations

The controller allows you to set a delay between

stations for each program. The delay can be from 0

seconds (default) to nine hours.

To set a delay between stations,

1. Rotate the dial to TEST/STATION DELAY .

2. Press both

▲/ON and ▼/OFF keys

simultaneously.

The display shows DELAY.

3. Press the PGM key to select the program to which

the delay is to be applied.

4. Use the

▲/ON and the ▼/OFF keys to

select the delay time you desire. The delay time

can be set in:

•

one-second increments, between one second

and five minutes

• one-minute

increments, between five min-

utes and nine

hours

Page 26

Programming the Controller, continued

22

Clearing All Programs

The controller allows you to clear all programs. This

function erases all settings and programs previously

set, allowing you to completely reprogram the

controller.

To clear all programs from the controller,

1. Rotate the dial to OFF.

2. Hold down the

▲/ON and MAN START/ADV

keys for 10 seconds.

The display cycles through various items on the

screen as the controller clears the registers.

When the screen returns to Thu 12:00 am, all

programs have been cleared and you may begin

programming the controller.

Page 27

Operating the Controller

23

Once you have programmed the controller, operating it is easy. You may choose to operate it completely

automatically or to operate it manually from time to time. When you operate the controller manually, you do not

disturb any of the programmed instructions.

Page 28

Operating the Controller, continued

24

Operating Automatically

To operate the controller automatically,

Rotate the dial to AUTO.

The controller runs each of the programs as you

have specified.

Note: The controller will operate automatically in any

position except for OFF. However, there will be no

display of the day, time or program status. When the

controller is in the OFF position, the controller will

not operate.

Operating Manually

There are a number of functions you can perform

manually. Each one is described in this section.

Operating a Program or

Programs Manually

You can select, start and manually advance

programs for semi-automatic operation.

To do so,

1. Rotate the dial to AUTO.

The display shows the day of the week and the

time of day.

2. Press PGM until the program you wish to

operate is displayed.

3. Press MAN START/ADV to start the selected

program.

4. If you want to operate more than one program,

press PGM to select another program and

press MAN START/ADV again.

The second program runs when the first is

complete. You can stack all four programs in this

way.

Page 29

Operating the Controller, continued

25

Operating a Station or Stations Manually

You can initiate one-time operation of a single

station or a combination of stations. If you run more

than one station, they will run in the order in which

they were selected.

To operate one station or multiple stations,

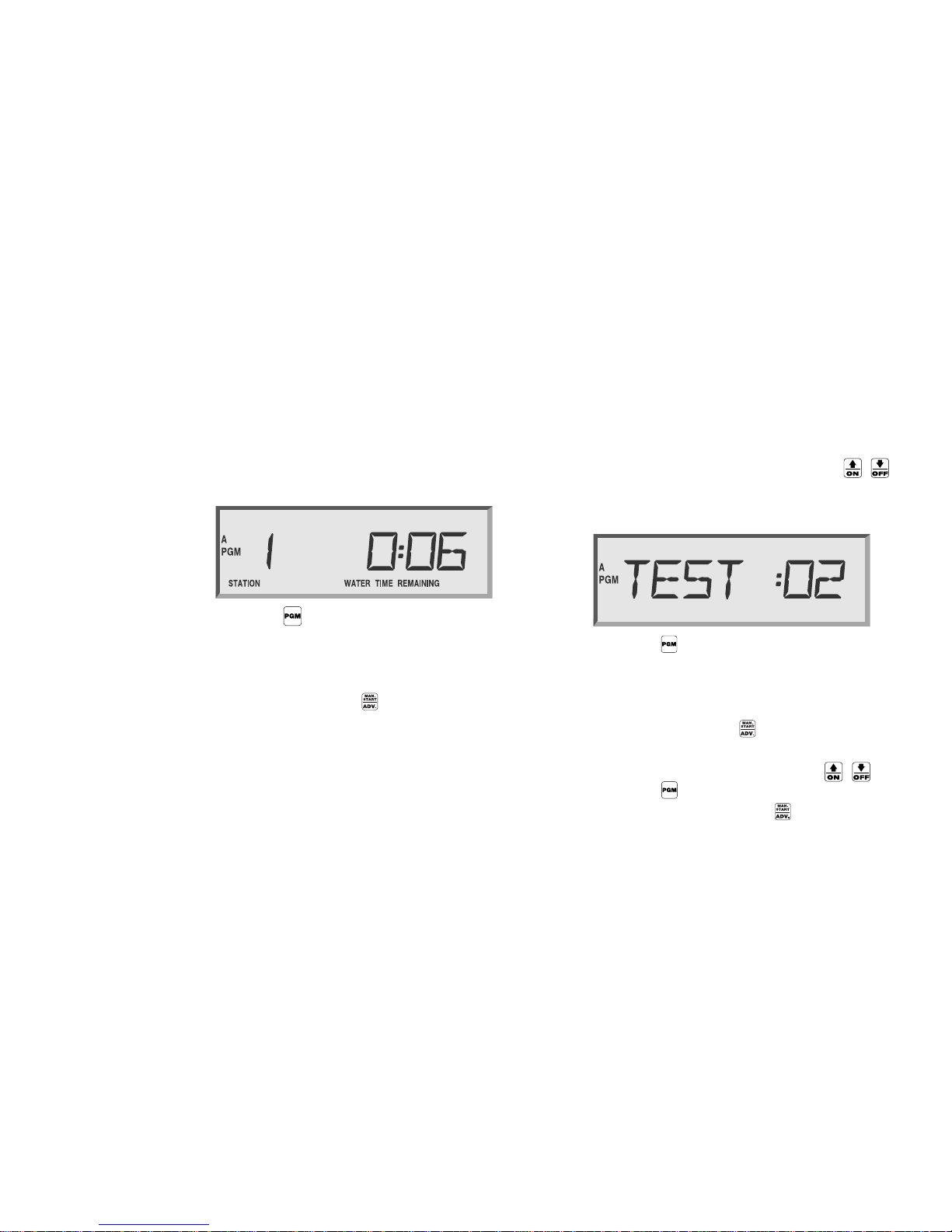

1. Rotate the dial to MANUAL WATERING.

The display shows the program, the station

number and any watering time remaining on that

station.

2. Press PGM until the program using the

desired station is displayed.

3. Use the arrow keys to select the station you want

to operate.

4. Press MAN START/ADV to start the selected

station.

5. If you want to operate more than one station,

repeat steps 2 through 4.

6. Return the dial to AUTO.

The stations operate in the sequence they were

selected. After the stations finish watering, the

controller returns to the automatic mode.

Note: If you are operating a station manually, you

cannot change the amount of time the station will

water. The controller will water the programmed

amount.

Using the Test Program

This program allows you to run a test cycle for all

the stations on a particular program. You may select

how long the test will last.

To set and then start a test program,

1. Rotate the dial to OFF for 3 seconds, to cancel any

pending work. Otherwise the test program will be

executed after the automatic mode work finishes.

2. Rotate the dial to TEST/STATION DELAY .

The display shows the program, TEST and the

length of time to test.

3. Press PGM until the program you want to test

is displayed.

4. Use the arrow keys to set the length of time to test

each station, from one to 99 minutes.

5. Press MAN START/ADV to start the test.

6. If you want to add other programs to the test, with

the dial set to TEST/STATION DELAY ,

press PGM to select the program.

Then press MAN START/ ADV to stack the new

program after the first one. You can stack four

programs.

Note: To cancel the test on all programs, rotate the

dial to OFF.

Page 30

Operating the controller, continued

26

Using the Sensor Option

The controller allows you to connect a sensor that

can disable watering. When a sensor is connected to

the controller and it suspends watering, the sensor

light on the front panel illuminates.

To enable the sensor,

Set the sensor switch to ACTIVE.

The controller operates as usual until the sensor

suspends watering and the SUSPENDED BY

SENSOR light is on.

Note: When no sensor is attached, the jumper cable

supplied with each controller must be in place,

connecting the SENSOR terminals on the controller

circuit board. If you set the SENSOR switch to

ACTIVE with neither a sensor nor the jumper cable

connected, the controller cannot operate the valves

and no watering will occur.

Fuse Detection

The controller display will show FUSE if a fuse is

missing or blown.

Using the Diagnostic Circuit Breaker

The controller is equipped with a circuit overload

protection system. This system causes the controller

to skip over a station that has an electrical short

circuit, rather than blow a fuse which would shut

down the entire system. When the controller tries to

start a station that has a short circuit, the electronic

circuit breaker senses the short circuit and skips that

station. The controller skips to the next station, but

flashes the skipped station number and FAULT in

the display.

Once you have corrected the problem, push the

FAULT RESET key to clear the flashing fault

indicator.

Note: The diagnostic circuit breaker allows detection

on all stations, as well as the master valve.

Replacing the Battery

1. Open the cabinet door.

2. Release the latch by sliding it to the left and swing

the panel open.

3. Open the battery cover on the back of the

faceplate. Remove the 9-volt battery.

4. Install a new rechargeable 9-volt battery and

close the cover.

5. Close the faceplate.

IMPORTANT! Use only rechargeable batteries in

your controller. Non-rechargeable batteries could

damage the controller or be a fire hazard.

Page 31

Troubleshooting

27

The following pages contain possible problems you may encounter and some solutions. Before calling

Rain Bird, check this list. If you cannot solve the problem yourself, call our Technical Service Hotline at

1-800-247-3782 (1-800-BIRD-SVC) and we will be glad to help you.

General Troubleshooting

Problem

The display is flashing.

Solution

There may be a power outage. Or, check the battery; it may be dead or improperly connected.

Problem

Parts are missing or damaged.

Solutions

Try one of the following solutions:

• Damage occurred during shipping. Return the controller.

•

Lightning has damaged the controller. If the controller is installed, replace the piece that is

damaged (front panel, output board, transformer, cabinet, etc.).

Problem

The controller is dead; the display is blank and there is no station output.

Solutions

Try one of the following solutions:

• There is no power to the controller. Check that the main power source is on.

• The transformer is not connected properly. Check that the 5-wire cable from the transformer is

properly connected to J7 on the controller output board.

• The transformer is bad. Check if there are 24 V AC between the “24VAC” and “COM” terminals.

Page 32

Troubleshooting, continued

28

Problem

The display and programming operate normally, but stations and master valves will not activate.

Solutions

Try one of the following solutions:

• Watering has been suspended by a sensor. Check if the sensor LED on the front panel is lit. If so,

then watering has been suspended by your sensor. If watering is required immediately, move the

Sensor Bypass switch to OFF.

• No sensor is installed. The Sensor Bypass switch is in the ACTIVE position and the jumper wire

across the sensor inputs has been removed. Place the Sensor Bypass switch in the OFF position

and add a wire jumper across the two Sensor terminals on the output board.

• The sensor is malfunctioning. Remove the sensor and place the Sensor Bypass switch in the OFF

position and attempt to activate the valves. If this works, place the Sensor Bypass switch in the

ACTIVE position and attempt to activate the valves. If the display indicates that valves are active,

but they are not coming on and the WATERING SUSPENDED BY SENSOR LED is on, then the

sensor input is not working properly. Repair or replace the sensor.

• The main fuse is blown. If the word FUSE appears in the display, replace the 2.5 A fuse located on

the output board.

Problem

The controller will not execute the programmed schedule.

Solutions

Try one of the following solutions:

• The controller dial is in the OFF position. Place the dial in the AUTO position.

• The Rain Delay feature has been activated. When the Rain Delay feature is active, the words RAIN

DELAY appear in the upper left corner of the controller display. There is also a number indicating

the number of days remaining before the controller will start running its schedule. To eliminate

the Rain Delay, turn the dial to the RAIN DELAY position and use the ▼/Off key to set the

number of days remaining to zero.

• There is no start time programmed for one or more programs. Place the dial in the WATERING

START TIMES position and select the desired program with the PGM key. Check to see if an

appropriate start time is entered for each program.

• Today has been programmed as a Non-Watering Day. If this is a Non-Watering Day, the word

NON will appear in the display. If you would like to water today, move the dial to the EVENT DAY

OFF position, select the appropriate day of the month and set it to ON.

Page 33

Troubleshooting, continued

29

• The fuse is blown and the battery is still charged. Replace the fuse.

• There is no power to the controller and the battery is still charged. Check the input power source.

Problem

A station will not activate.

Solutions

Try one of the following solutions:

• No run time has been programmed. Place the dial in the STATION WATERING TIME position, select

the desired program, select the station you would like to water and set the desired watering time.

• There is no start time for the program containing the desired station. Place the dial in the

WATERING START TIMES position and select the desired program with the PGM key. Check

to see if the appropriate start times are entered.

• There is a short circuit in the valve wiring or solenoid. In this case, the message FAULT XX will

flash in the display. Check station wiring and the solenoid. After the short circuit is repaired, press

the FAULT RESET key on the controller front panel.

• The MOV or Triac failed. Remove the output board and take it to your local Rain Bird distributor

for repair or warranty replacement.

Problem

The controller activates stations at unexpected times.

Solutions

Try one of the following solutions:

• The MAN START/ADV. key is stuck, causing a program to start unexpectedly. Press the MAN

START/ADV. key and make sure that it releases when you remove your finger.

• Additional program times have been entered accidentally. Check the program start times for all

four programs. Delete any that should not be there.

• The controller’s panel is temporally scrambled due to power fluctuations and surges. Shut off the

power to the controller by removing the main power AND removing the battery. Let the controller

sit for about five minutes, then restore the power to the controller. If this does not work, reset the

controller by holding down the ▲/ON. and MAN START/ADV. keys until words in the

display begin to change. When the display shows “12:00,” reprogram the controller.

• Stations may be wired to the wrong terminal locations. Check which station wires lead to which zone

by connecting the wiring (one station at a time) to the 24 V AC terminal on the controller. When you

confirm that the wiring turns on the desired zone, reconnect the wires to the corresponding station.

Page 34

Troubleshooting, continued

30

Problem

The actual watering time is different from the time programmed.

The Water Budget feature is active. Check the Water Budget for the program containing the station(s)

exhibiting the problem.

Problem

The display is blank, partial or displays something which is not readable.

Solution

A surge caused the display to scramble. Turn off the main power to the controller, remove the

rechargeable battery and let the controller sit for about five minutes. Reconnect the power and reattach

the rechargeable battery. If there has been no permanent damage, the controller will operate normally.

Maxicom2-specific Troubleshooting

Problem

The controller is not operating under Maxicom2control.

Solution

Try one of the following solutions:

• Check the MAXICOM...STAND ALONE switch on the back of the controller front panel. It should

be in the MAXICOM position.

• Contact the Rain Bird Technical Service Hotline for assistance.

Problem

The controller does not water, but the Maxicom2system reports normal operation.

Solution

The SENSOR switch is in the incorrect position. Move the SENSOR switch to OFF.

Problem

A Maxicom2feature appears to operate correctly at the computer, but will not function when it is

sent to the controller.

Solution

Verify that the channel assignment on the controller matches the CCU channel assignment. The

controller has a maximum of 28 channel assignments, depending on the type of CCU the controller

is connected to. ESP-SITE-Satellite controllers must be set to channel 1.

Page 35

Appendix A: Scheduling Chart

31

Before you begin programming, it is a good idea to chart your watering schedule, taking into account the schedule

for all stations and how often you want to repeat the schedule. For specific programming instructions, see page 13.

A sample schedule appears below. A blank schedule that you can copy and fill in appears on the following pages.

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

PROGRAMMING CHART

For ESP-MC Controllers

Rain Bird Technical Services: 800-247-3782

Station Description

MV/Pump

Relay 1

Station Delay

Water Budget

Program

Start Times

Watering

Days

STK OVR STK OVR STK OVRSTK OVR

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

Run Time Run Time Run Time Run TimeCycle Soak

*

%

%

%

%

Back turf #2

Back turf #1

Front shrubs

Back shrubs

Side shrubs

Front turf #4

Front turf #3

Front turf #2

Front turf #1

4

10

10

20

20

5

10

10

20

20

20

100% 100%

120%

43%

3

8:00

7:00

8:45

6:00

7:00

9:00

11:00

2:00

4:00

8:00

10:00

11:45

9:00

3:00

Page 36

32

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

Rain Bird Technical Services: 800-247-3782

Station Description

MV/Pump

Relay 1

Station Delay

Water Budget

Program

Start Times

Watering

Days

STK OVR STK OVR STK OVRSTK OVR

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

Run Time Run Time Run Time Run TimeCycle Soak

*

%

%

%

%

Page 37

33

24

23

22

21

20

19

18

17

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

Notes:

Days Off:

*

MV/Pump Relay #2 is always on whenever any station operates.

Page 38

Appendix B: Maxicom2Central Control System Overview

34

ESP-MC and ESP-SAT Controllers

The controller is one part of Rain Bird’s Maxicom2Central Control System. (See the illustration on the next page.)

The satellite controllers receive commands from the Cluster Control Unit (CCU) and operate stations according to

schedules programmed at the central computer.

The Maxicom2Central Control System for ESP-MC and ESP-SAT controllers chiefly consists of seven parts:

1. Central Computer uses the Maxicom2software program to control the entire irrigation system

2. Computer Data Path transfers information from the central computer to the CCU by phone

communication or by radio/direct communication

3. Cluster Control Unit operates field devices by executing commands received from the central

computer

4. Satellite Data Path transfers information from the cluster control unit to the field devices by a

two-wire path (TW) or by MAXILink radio communication

5. Field Devices includes either satellite controllers or decoders:

Satellite controllers — send a 24 VAC power signal to each station

Decoders — control and monitor system functions

6. Stations consist of irrigation valves, sensors or switch-operated devices

7. Weather Station interprets weather conditions and sends information to the central computer

Page 39

Appendix B, continued

35

Central Computer

Phone

Point-to-point

Radio

Link

Trunk

Radio

Cellular

Telephone

Satellite

Controller

Decoder

Satellite

Controller

Valve

Sensor

Hardwire/

Short-haul

Modem

Two-wire Path (TW) MAXILink Radio (LINK/R)

Weather Station

Sensor

Switch

or

CCU

at site

CCU

at site

Valve Valve

Valve

1. Central

Computer

2. Computer

Data Path

Options

3. CCU

4. Satellite Data

Path Options

5. Field Devices

6. Stations

7. Weather

Station

Phone (PH) Version Radio/Direct Version

Page 40

Appendix B, continued

36

ESP-SITE-Satellite Controller

The controller is one part of Rain Bird’s Maxicom2Central Control System. (See the illustration on the next page).

The satellite controllers receive commands from the central computer and operate stations according to

schedules programmed at the central computer.

The Maxicom2Central Control System for ESP-SITE-Satellite controllers chiefly consists of five parts:

1. Central Computer uses the Maxicom2software program to control the entire irrigation system

2. Computer Data Path transfers information from the central computer to the ESP-SITE-Satellite by

phone communication or by radio/direct communication

3. Controller operates stations by executing commands received from the central

computer

4. Stations consist of irrigation valves, sensors or switch-operated devices

5. Weather Station interprets weather conditions and sends information to the central computer

Page 41

Appendix B, continued

37

Central Computer

Phone

Point-to-point

Radio

Link

Trunk

Radio

Cellular

Telephone

Hardwire/

Short-haul

Modem

Weather Station

Switch

or

ESP-SITE-Satellite

Controller

ESP-SITE-Satellite

Controller

Fiber Optic

Cable

Valve Valve

Sensor

Valve Valve

Sensor

1. Central Computer

2. Computer Data

Path Options

3. ESP-SITE-Satellite

Controller

4. Stations

5. Weather Station

Phone (PH) Version Radio/Direct Version

Page 42

Appendix C: Setting the Channel Number

38

If you are using an ESP-SAT or ESP-SITE-Satellite

controller, each Maxicom2satellite on a CCU must

have a channel number for successful

communication.

To set the channel number,

1. Turn the dial on the controller’s faceplate to the

TIME/CALENDAR position.

2. Press the MAN. START/ADV. key on the

faceplate until the number “1” and the word

“CHAN” appear in the display.

3. Use the

▲/ON and ▼/OFF keys to select

the channel number you desire.

Note: If the satellite is a 32- or 40-station model,

the controller will operate the first 24 stations on

the channel number you select and the remaining

stations on the next number in the sequence. For

example, if you select channel 5 on a 40-station

satellite, stations 1-24 will operate on channel 5,

and stations 25-40 will operate on channel 6.

Warning! Never select channel 28 (on a CCU-28)

or channel 6 (on a CCU-6) for a 32- or 40-station

satellite. There are no channels higher than 28 for

the CCU-28 and no channels higher than 6 for the

CCU-6. Stations will not operate when assigned to

channels higher than 28 (CCU-28) or 6 (CCU-6).

Note: ESP-SITE Satellite controllers must be set

to channel 1.

Page 43

Appendix D: ESP-MC Controller Spare Parts

39

Part Description

ESP-8MC Front Panel

ESP-12MC Front Panel

ESP-16MC Front Panel

ESP-24MC Front Panel

ESP-28MC Front Panel

ESP-32MC Front Panel

ESP-36MC Front Panel

ESP-40MC Front Panel

Cabinet

PED-DD16 Terminal Board, 1-24 Stations

PED-DD16 Terminal Board, 25-40 Stations

ESP-8MC Output Board

ESP-12MC Output Board

ESP-16MC Output Board

ESP-24MC Output Board

ESP-28MC Output Board

ESP-32MC Output Board

ESP-36MC Output Board

ESP-40MC Output Board

120V Transformer

230V Transformer

Manual — English and Spanish

Fuse (2.5 Amp)

Rechargeable Battery

Door Lock

Appendix D: ESP-MC Controller Spare Parts List

Page 44

Glossary

40

circuit board

One of the etched, copper clad sheets of insulating material onto which electronic components and terminals are

assembled. Controllers contain circuit boards.

controller

A device that activates the field solenoid valves.

CPU board

The central processing unit (CPU) circuit board inside the controller.

Cycle + Soak

TM

A feature that allows you to conserve water that might puddle in tight soils (such as clay) or end up as runoff on

slopes. Cycle + SoakTMlets you break up the total watering time of a station into shorter cycles with a soak time

between cycles.

default setting

The start-up settings for the controller. The default settings cannot be changed.

ESP-MC

An 8-, 12-, 16-, 24-, 28-, 32-, 36-, or 40-independent station controller that is a stand-alone unit, but is upgradable

to a satellite controller linked to Maxicom2.

ESP-SAT and ESP-SITE-Satellite

A controller that can operate as a stand-alone unit or as a satellite controller linked to Maxicom2.

GPM

Gallons per minute.

hardwire

Communication cable used to transmit data between devices.

liquid crystal display (LCD)

The illuminated display used on the faceplate of most controllers.

manual

Requires user input, rather than being automatically performed by the PC program.

Page 45

Glossary, continued

41

master valve (MV)

An electrically operated valve located on a system’s main line that controls the flow of water to all other electric

and manual valves downstream of it.

master valve circuit

An electrical circuit located on many controllers used to control a master valve. If the master valve circuit is not

programmable, regardless of what station is on at the controller, the master valve circuit produces voltage to

control the master valve. When all of the stations on the controller are off, the master valve circuit turns off. If,

however, the master valve circuit is programmable, then it can be set to operate only when certain stations are

active.

MIB

Maxicom2Interface Board (MIB). Allows for satellite controller operation. The MIB is preinstalled in ESP-SAT

controllers, but can also be installed in ESP-MC controllers to add satellite capability.

monitor

To observe conditions in and around the irrigation system and send the information to the different components

in the system for appropriate action.

program

A single station or group of stations operating with the same scheduling parameters. All stations in a given

program operate the same day cycle, start times and water budget.

satellite

A controller in the field capable of communicating with the Cluster Control Unit (CCU).

satellite controller

Same as satellite.

sensor system

An optional addition to the controller that disables watering. An example is the Rain Bird Rain Check.

site

A single, remote irrigated area controlled by a CCU. For example, one park is a site in a city-wide park system.

Page 46

Glossary, continued

42

soil infiltration rate

The rate at which soils accept water.

solenoid

A portion of a field valve that receives a 24 V AC electrical current from the controller.

station schedule

The watering schedule for one of the stations controlled by the controller.

valve

A manual or electrically operated device used to control flow of water in an irrigation system.

water budget

A feature available in some controllers and central control systems allowing adjustment of water application times

without reprogramming each station or irrigation schedule.

watering cycle

The complete cycle of watering for all stations controlled by the controller.

Page 47

Page 48

Service Information

44

In the unlikely event this equipment should malfunction, all repairs should be performed by an

authorized Rain Bird Maxicom2Authorized Service Center.

For information on Maxicom2Authorized Service Centers, contact Rain Bird at:

Rain Bird Corporation

Turf Products

6991 East Southpoint Rd.

Tucson, AZ 85706

Phone: (520)

741-6100

Fax: (520)

741-6522

Rain Bird Technical Service Hotline

1-800-247-3782 (1-800-BIRD-SVC)

Rain Bird Specifications Hotline

1-800-458-3005

www.rainbird.com

Page 49

Warranty

45

This product is covered by Rain Bird’s Three-year Trade Warranty. For details, see the Rain Bird

Landscape Irrigation Products Catalog.

Page 50

Notes

Page 51

Guía de Operación

Controladores ESP-MC, ESP-SAT, controlador de satélite ESP-SITE

y conjunto de tarjeta de interface Maxicom2(MIB)

P/N 634593 REV F

Page 52

“ADVERTENCIA: ES NECESARIO INSTALAR UN

INTERRUPTOR AUTOMÁTICO O DE DESCONEXIÓN

EN EL CABLEADO FIJO PARA AISLAR AL

CONTROLADOR”

“LA MEMORIA ES MANTENIDA POR UNA BATERÍA

LA CUAL DEBE DESCARTARSE SEGÚN LAS

REGULACIONES LOCALES”

Iconos de precaución

El símbolo de relámpago con punta en

forma de flecha, dentro de un triángulo

equilátero, está diseñado para alertar al

usuario de la presencia de “voltaje

peligroso” sin aislamiento dentro del

envolvente del producto que puede ser

de una magnitud suficiente como para

constituir un riesgo de choque eléctrico

para las personas.

El signo de exclamación dentro de un

triángulo equilátero está diseñado para

alertar al usuario de la existencia de

instrucciones importantes de

funcionamiento y mantenimiento

(servicio) en la literatura que acompaña

al producto.

“WARNING: A CIRCUIT BREAKER OR CUTOFF

SWITCH IS TO BE PROVIDED IN THE FIXED WIRING

TO ISOLATE THE CONTROLLER”

“MEMORY IS RETAINED BY A BATTERY WHICH IS

TO BE DISPOSED OF IN ACCORDANCE WITH

LOCAL REGULATIONS”

Caution icons

The lightening flash with arrowhead

symbol, within an equilateral triangle, is

intended to alert the user to the

presence of uninsulated “dangerous

voltage” within the product’s enclosure

that may be of sufficient magnitude to

constitute a risk of electric shock to

persons.

The exclamation point within an

equilateral triangle is intended to alert

the user to the presence of important

operating and maintenance (servicing)

instructions in the literature

accompanying the product.

Información sobre medidas de seguridad

ii

¡Advertencia!

En este manual figuran importantes advertencias y medidas de seguridad. Para garantizar el manejo adecuado y

evitar gastos adicionales, lea bien este manual antes de comenzar a instalar el aparato.

Page 53

Introducción . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Bienvenidos a Rain Bird . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

El controlador ESP-MC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

El controlador ESP-SAT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

La tarjeta de interface Maxicom

2

(MIB) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

El controlador de satélite ESP-SITE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Características especiales . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

*Para instrucciones de instalación ver poster incluído en la caja del controlador

Familiarícese con la placa frontal del controlador . . . . . . . . . . . . . . . . . . . . . . .3

Rutina de Prueba de Estaciones Rápida — RASTER

TM

. . . . . . . . . . . . . . . . . . .7

Introducción . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Operación del RASTER

TM

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Iniciar el RASTER

TM

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Prueba de Válvulas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Solución de Problemas de Cortos y Circuitos Abiertos en las Válvulas . . . . . . . . . . . . . . . . . .12

Circuitos Abiertos . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Corto Circuitos . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Resolver Cortos y Circuitos Abiertos . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Programación del controlador . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Antes de programar el controlador . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Programación del reloj y el calendario . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Configuración de un programa . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Primer paso: Selección del programa . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Segundo paso: Selección del ciclo . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Tercer paso: Programación de la duración del riego de una estación . . . . . . . . . . . . . . .18

Cuarto paso: Programación de las horas de inicio del riego . . . . . . . . . . . . . . . . . . . . . . .19

Quinto paso: Configuración de programas para apilarlos o sobreponerlos . . . . . . . . .20

Sexto paso: Configuración del arranque de la bomba de la válvula principal . . . . . . . .20

Programación del ajuste Rain Delay (Demora por lluvia) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Programación del ajuste Cycle + Soak

TM

(Ciclo y remojo) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Programación del ajuste Water Budget (Ahorro de agua) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Programación del ajuste Event Day Off (Apagado en días especiales) . . . . . . . . . . . . . . . . . .23

Contenido

iii

Page 54

Programación del ajuste de demora entre estaciones . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Función para borrar todos los programas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Operación del controlador . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25