Page 1

ESP-LXIVM Controller

Troubleshooting Guide

Page 2

For product manuals, instructional videos and FAQs,

please visit: www.rainbird.com/esplxivm

For free professional support for programming and

troubleshooting, please call: 1-866-544-1406

Local Rain Bird Contact Information

Distributor Mgr:

Email:

Phone:

Area Specification Mgr

Public Agency Manager:

Email:

Phone:

Contractor Account Mgr:

Email:

Phone:

Water Conservation Mgr:

Email:

Phone:

2 ESP-LXIVM Controller Troubleshooting Guide

Table of

Contents

Page 3

Contents

Local Rain Bird Contact Information ..................................... 2

Tools ..................................................................... 4

Recommended ............................................................................. 4

Useful ............................................................................................... 5

LX-IVM Compatible Valves .................................5

Controller Features ............................................. 6

Front Panel .....................................................................................6

2-Wire Settings .............................................................................7

Diagnostics .................................................................................... 7

Cabinet Components ................................................................. 8

Basic Programming ............................................9

Troubleshooting Flow Charts .............................10

Getting Started ...........................................................................10

2-Wire Mapping .........................................................................11

No Water Days, No Run Times, … ........................................13

Shorted Paths ..............................................................................14

Shorted Path (Manual Method) .........................................15

Duplicate Address .....................................................................19

Flow Alarm ...................................................................................20

Ping Valve / Sensor (Ping Test) ..............................................22

Field Wiring Diagnostics ...................................23

Tools and Equipment ...............................................................23

Total System Milliamp Draw ..................................................23

3 ESP-LXIVM Controller Troubleshooting Guide

Table of

Contents

Page 4

Field Wiring Issues .....................................................................23

Broken Wire (Open Circuit) List Not Responding .........24

Short Circuit ..............................................................................25

Ground Fault .............................................................................26

Relay Wiring .................................................................................27

IVM Power Filter Connection .................................................29

Controller Diagnostics ...................................... 30

IVM Interface Module ....................................... 37

LED Indicators .............................................................................37

LED Status ....................................................................................38

Module Status ..........................................................................38

2-Wire Path Status ...................................................................38

Individual Path Status ............................................................38

Tools

Recommended

• MAXI Cable 2-Wire communications cable.

• Rain Bird WC20 splice kits for ALL electrical wiring connections.

• Rain Bird genuine Wire Stripper

For video showing proper wire splice instructions and other

installation tips, please visit:

www.rainbird.com/esplxivm

NOTE: If installing or repairing

communications wiring for

IQ Software, do not install

the communications

cables in the same conduit

as the 2-Wire path wiring.

Rain Bird

Wire Stripper

4 ESP-LXIVM Controller Troubleshooting Guide

Table of

Contents

Page 5

Useful

• Milliamp Meter

Recommended Model: Armada Pro 93

• As-Built Drawing

If you don’t have it, make it using a cable locator

• LX-IVM Troubleshooting Tools

A list of ESP-LXIVM Controller Troubleshooting Videos

can be found here:

https://www.rainbird.com/esplxivm

LX-IVM Compatible Valves

Videos for ESP-LXIVM compatible valves ,connecting and troubleshooting

can be found here:

• PGA Series

https://www.rainbird.com/products/pga-series

• PEB Series

https://www.rainbird.com/products/pebpesb-series

• EFB-CP Series

https://www.rainbird.com/products/efb-cp-series

• BPE Series

https://www.rainbird.com/products/300-bpes

NOTE: Rain Bird HV, DV, and JTV Series residential valves are not

compatible with IVM-SOL. Use only Rain Bird commercial series

valves for ESP-LXIVM installations:

NOTE: Physical intereference on any valves can be addressed

through “clocking” to avoid being “in-line” with IVM-SOL or

removing the component (e.g. Flow Control).

5 ESP-LXIVM Controller Troubleshooting Guide

Milliamp

Meter

Table of

Contents

Page 6

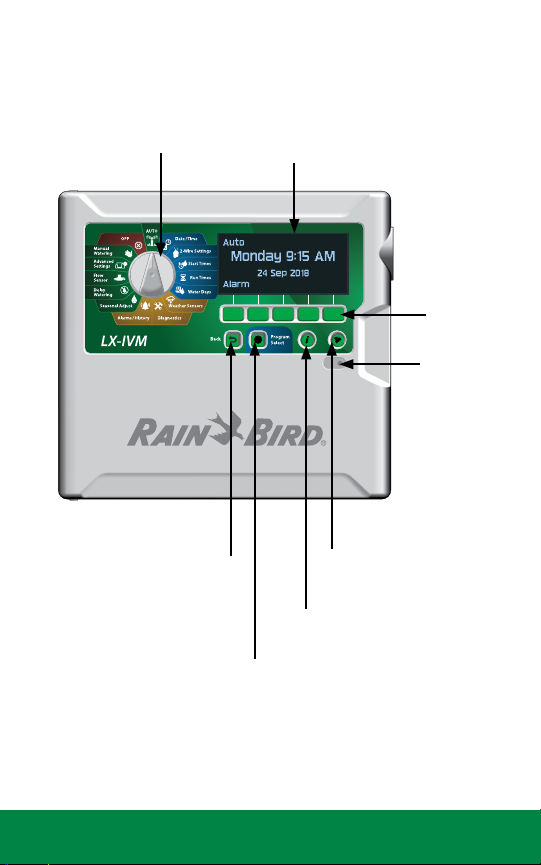

Controller Features

Front Panel

PROGRAMMING

DIAL

BACK BUTTON

PROGRAM

SELECT BUTTON

DISPLAY

PROGRAMMING

KEYS

ALARM

LIGHT

LANGUAGE

SELECT BUTTON

INFORMATION

BUTTON

6 ESP-LXIVM Controller Troubleshooting Guide

Table of

Contents

Page 7

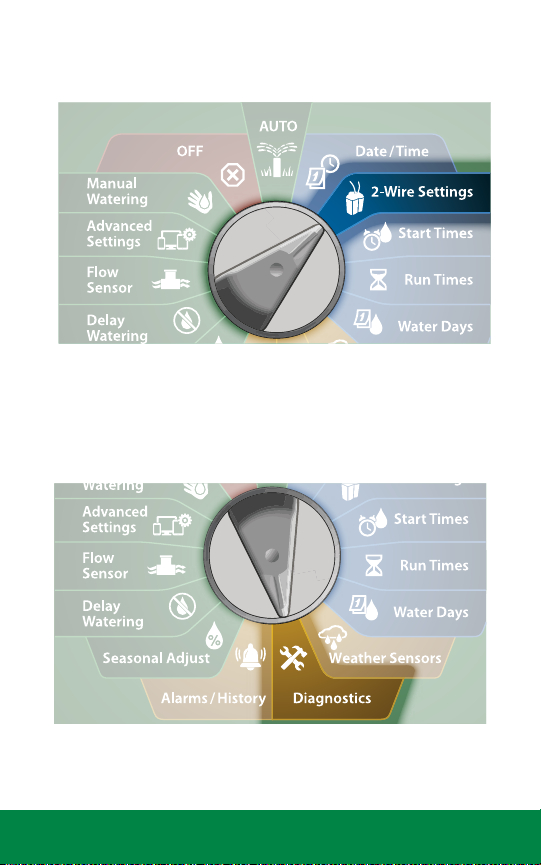

2-Wire Settings

Diagnostics

7 ESP-LXIVM Controller Troubleshooting Guide

Table of

Contents

Page 8

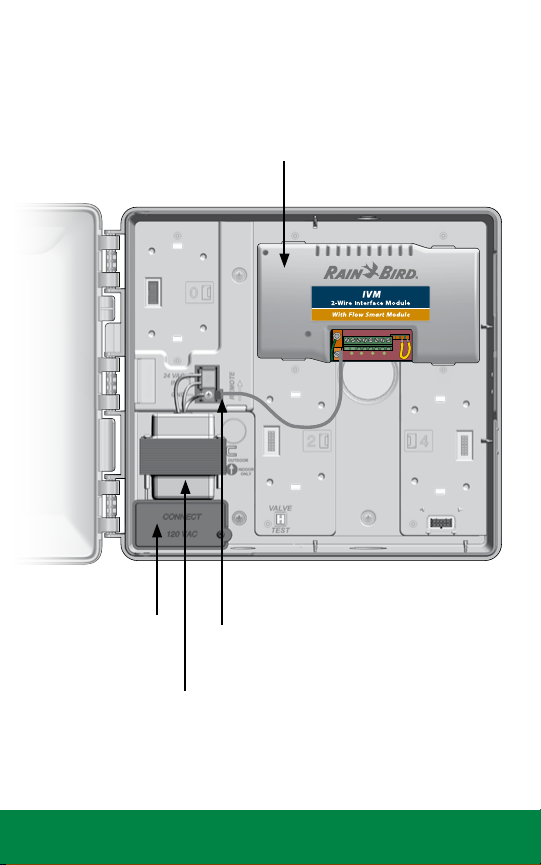

Cabinet Components

IVM 2WIRE INTERFACE MODULE

JUNCTION

BOX

TRANSFORMER

8 ESP-LXIVM Controller Troubleshooting Guide

CONNECTOR

Table of

Contents

Page 9

Basic Programming

The ESP-LXIVM Controller has 2-Wire Settings to help get you started

and guide you through each step of the installation and hardware

setup process.

It’s most effective to use the 2-Wire Settings in the order they appear in the

2-Wire Settings menu, as follows:

1. Master Valves

2. Weather Sensors (if present)

3. Station Setup

4. Flow Sensors (if present)

Installation, Programming & Operation Guide

For more information see the LX-IVM Field Device Installation Guide that

came with the LX-IVM Controller.

Or download the LX-IVM User Manual at:

www.rainbird.com/esplxivm

9 ESP-LXIVM Controller Troubleshooting Guide

Table of

Contents

Page 10

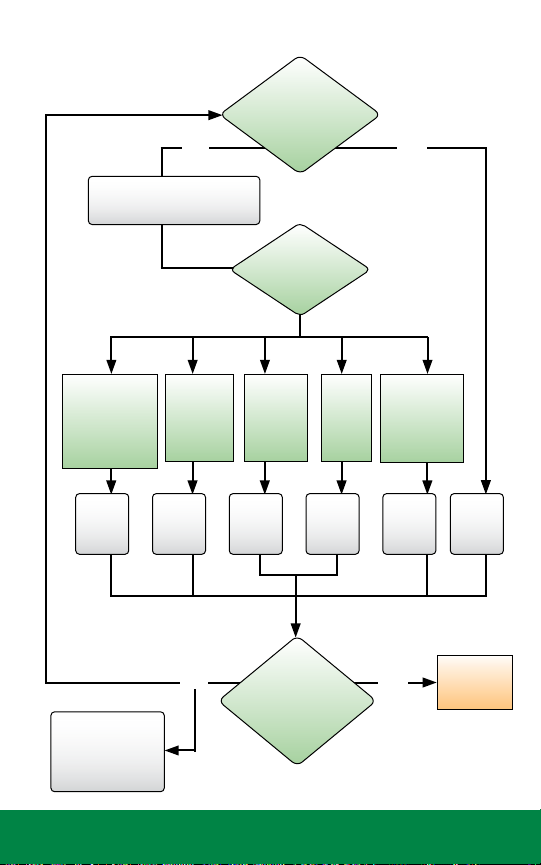

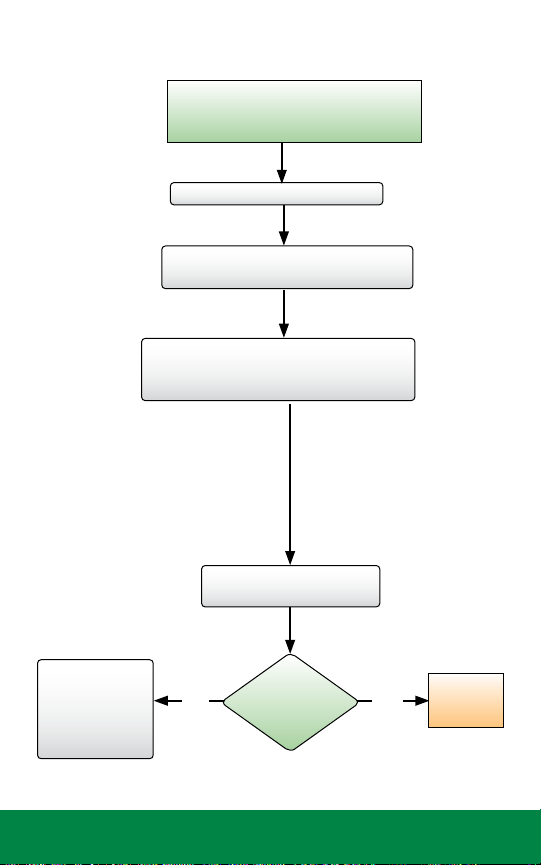

Troubleshooting Flow Charts

What does

the screen

display?

Is the LX-IVM

front panel

Alarm Light on?

Is the LX-IVM

front panel

Alarm Light

still on?

Getting Started

YES NO

Turn the dial to AUTO and

press the Alarm button

No Water Days

No Run Times

No Start Times

No PGM will...

More Exit

Shorted

Paths

Duplicate

Address

Flow

Alarm

Device Not

Responding

Go to

page

13

Call the ESP-LX

SeriesHOTLINE at

+1-866-5441406

10 ESP-LXIVM Controller Troubleshooting Guide

Go to

page

14

Go to

page

19

YES NO

Go to

page

20

Go to

page

22

Go to

page

23

END - Job

Well Done!

Table of

Contents

Page 11

2-Wire Mapping

Next

Next

Next

Start

2-Wire Mapping “maps” or records information on the wire-path of any

connected IVM devices. A total of 4 wire paths are available in a LX-IVM

Controller.

NOTE: While this information is helpful for diagnostics, not doing

2-wire mapping WILL NOT affect irrigation functions. But if 2-wire

mapping is NOT done, it will raise an alarm at the controller.

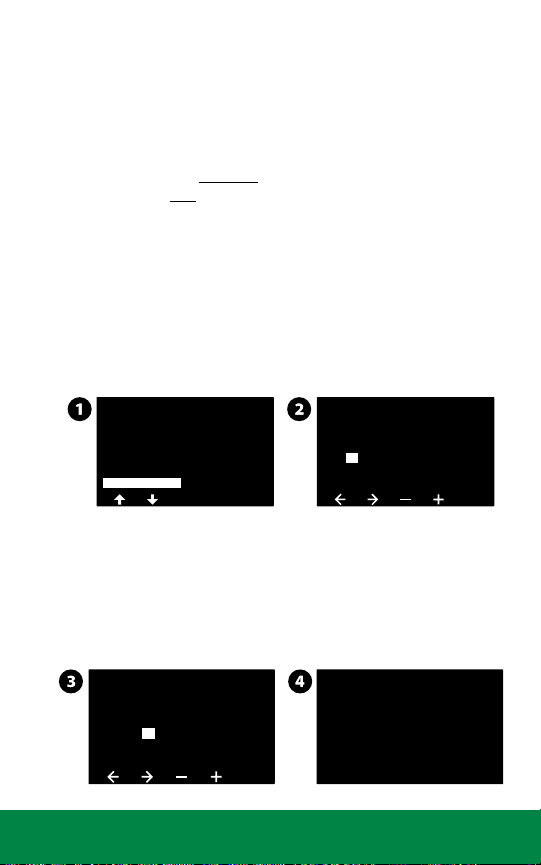

To initiate 2-wire mapping, follow the steps below:

Turn the Dial to 2-Wire Settings

1. At the Advanced Station Settings screen, press the Down Arrow

key to select 2-Wire Mapping, then press Next.

2. At the 2-Wire Device Mapping screen, press the + and – keys to

set the desired hour (from 0 to 23), then press the Right Arrow

key.

Advanced Station Settings

Cycle & Soak

Inter-Station Delay

SimulStations

Station Sequencing

2-Wire Mapping

2-Wire Device Mapping

Start Device Mapping In

00 00:

HH:MM

3. Press the + and – keys to set the desired minute (from 1 to 59),

then press Next.

4. At the confirmation screen, press Start to begin Device

Mapping.

NOTE: All irrigation is disrupted during the mapping process.

2-Wire Device Mapping

Start Device Mapping In

01

05:

HH:MM

11 ESP-LXIVM Controller Troubleshooting Guide

Attention

Device Mapping will

interrupt all irrigation

and could take several

minutes

Table of

Contents

Page 12

5. A confirmation screen shows the process is set to run.

Done

Cancel

Ping

Ping

Mapping

Mapping will begin

In 1 Hrs and 5

Mins.

The following pictures show the List Not responding screen without

and with 2-wire mapping done.

Without 2-wire mapping With 2-wire mapping

LIST NOT RESPONDING

AT 01/01/18

Type

STA

STA

STA008 --STA010 ---

002

004#---

12 : 00 PM

Path

---

LIST NOT RESPONDING

AT 01/01/18

Type

STA

STA

STA008 2

STA010 2

002

004#2

12 : 00 PM

Path

2

12 ESP-LXIVM Controller Troubleshooting Guide

Table of

Contents

Page 13

No Water Days, No Run Times, …

Is the

LX-IVM system

working?

Turn the dial to Date/Time and

ensure time and date are correct

Turn the dial to Start Times,

Run Times and Water Days

and follow programming

directions in the User Manual

Test LX-IVM system using

Manual Watering or Auto

Check the display

for Alarms, see

page 10

Troubleshooting

NO

YES

END - Job

Well Done!

13 ESP-LXIVM Controller Troubleshooting Guide

Table of

Contents

Page 14

Shorted Paths

The controller has automatically entered Short Finding

Mode to protect itself against a short on the 2-wire path

Turn the dial to Diagnostics and select

Diagnostics from the menu, then press Next

Press the Down Arrow button to select

Test Shorted Paths, then press Next

Press the Down Arrow button to select

the Path (1-4) to test, then press Next

Trouble Shoot in the Field using a milliamp meter.

A sharp increase in current should be observed

right before the Short Condition in 2-wire Path.

NOTE: Shorted Path will

display “Fault”.

Press and hold the Yes button

to energize the selected path

Note: Irrigation will be disabled

If issue cannot be resolved using the Shorted Paths Test, refer

to the Shorted Path (Manual Method) on the next page.

Next Page

14 ESP-LXIVM Controller Troubleshooting Guide

Table of

Contents

Page 15

Shorted Path (Manual Method)

Did the

controller exit Short

Finding Mode and are

both Indicator Lights

illuminated?

Open the front panel and check

the two indicator lights on the

IVM 2-Wire Interface Module.

The top indicator light should

be green and the bottom

indicator light should be

dark. This indicates that the

controller put the module in

Short Finding Mode

If there are more than one 2-wire paths

connected, disconnect the first 2-wire path

Disconnect the second/

third/fourth 2-wire path

NO YES

NOTE: In “looped”

systems, cut the loop in

the middle to create two

independent paths.

Reconnect the Maxi-Cable to verify the

controller goes back into Short Finding Mode

15 ESP-LXIVM Controller Troubleshooting Guide

Next Page

Table of

Contents

Page 16

Wires

damaged, or found

repairs of the

Maxi-Cable?

What does

the display

show?

Shorted Path (Manual Method) cont.

Repair damaged

Maxi-Cable

using Maxi

Cable and DRB/Y

connectors

YES

Go to an IVM device approx.

50% the length of the 2-wire

path. Disconnect the IVM device

2-wire splice to disconnect the

second half of the 2-wire path.

Reconnect the

Maxi-Cable to verify

the controller goes

back into Short

Finding Mode

Walk the length of

the 2-wire path and

look for signs of recent

constructions (trenching,

new fence, sign, tree, etc.)

NO

Connect all

2-wire paths at

NO

the controller

and observe

screen

Go back to

Troubleshooting,

page 10

NOTE: Instead of

physically disconnecting

the 2-wire path, you

could instead use

a clamp meter. See

page 18.

16 ESP-LXIVM Controller Troubleshooting Guide

Next Page

Table of

Contents

Page 17

Check the

controller display to

see if it has exited

Short Finding

Mode

Shorted Path (Manual Method) cont.

YES NO

The problem is downstream

between this point and the

end of the 2-wire path

Re-connect the 2-wire path

and go to an IVM device

approx. 50% between this

point and the end of the

2-wire path. Disconnect the

2-wire splice to disconnect the

second half of the 2-wire path.

NOTE: Once a small section 2-wire path is identified as having an

issue, use “Energize Path for Testing” and Milliamp Meter to track

for a sharp increase in test current before the location of the short.

For video instructions on Automatic Short

Finding Mode, please visit:

www.rainbird.com/esplxivm

17 ESP-LXIVM Controller Troubleshooting Guide

The problem is

upstream between this

point and the controller

Re-connect the 2-wire path

and go to an IVM device

approx. 50% between this

point and the controller.

Disconnect the 2-wire splice

to disconnect the second

half of the 2-wire path.

Next Page

Table of

Contents

Page 18

Shorted Path (Manual Method) cont.

Alternatively you can measure current draw in your system using

Diagnostics/ Diagnostics/Controller Output:

NOTE: Before measuring the amperage, calculate the approximate

current that the 2-wire path is consuming.

System Amperage Calculation

Quantity of IVM-SOL X 0.67 mA

Quantity of IVM-OUT X 0.67 mA

+

Quantity of other IVM-SEN X 6 mA

+

Approximate total system amperage in mA

=

If there is a mismatch, follow a process similar to page 10 to disconnect

50% of devices and redo calculation above. Continue todisconnect 50% of

devices until you identify section of 2-wire Path with issues.

NOTE: Self-healing: Note that IVM Controller tracks the health

of the 2-wire Path to see if shorts are resolved and then

automatically resumes irrigation. You do not need go back to the

Controller to reset or restart.

For video instructions on Locating a Short

on the Two-Wire Path, please visit:

www.rainbird.com/esplxivm

18 ESP-LXIVM Controller Troubleshooting Guide

Table of

Contents

Page 19

Duplicate Address

Is the

LX-IVM system

working?

The controller will Alarm if duplicate

device addresses are entered for one or

more of IVM-SOL, IVM-SEN and IVM-OUT.

Turn the dial to 2-Wire Settings

Press the Down Arrow button to

select Station Setup, then press Next

Use the + and - buttons to cycle through all

the stations. Verify that all 2-wire addresses

are correct and there are no duplicates.

NOTE: Only the first two

duplicates will be shown,

so you may need to repeat

this process until all of

the duplicates have been

addressed.

Test LX-IVM system using

Manual Run or Auto Run

Check the display

for Alarms,

see page 10

Trouble-

shooting

19 ESP-LXIVM Controller Troubleshooting Guide

NO YES

END - Job

Well Done!

Table of

Contents

Page 20

Flow Alarm

Go Back and select FloZone Flow Alarms

Alarms are issued when flow conditions

exceed your High or Low Flow settings.

Turn the dial to Alarms/History

Press the Down Arrow button to

select Flow Alarms, then press Next

Press the Down Arrow button to select

Station Flow Alarms, then press Next

Troubleshoot and fix any

station that shows an alarm

CONTINUED

FROM NEXT

PAGE (21)

Troubleshoot and fix any

FloZone that shows an alarm

Next Page

20 ESP-LXIVM Controller Troubleshooting Guide

Table of

Contents

Page 21

Flow Alarms cont.

Alarm is

cleared on

the display

After fixing any station or FloZone issues,

go Back and select Clear Flow Alarms

Run all zones manually

Check the Alarms screen to see if previous alarm cleared

NO YES

GO BACK

TO PREVIOUS

PAGE (20)

21 ESP-LXIVM Controller Troubleshooting Guide

END - Job

Well Done!

Table of

Contents

Page 22

Ping Valve / Sensor (Ping Test)

Assumption: A valve or sensor may not be working

Turn the dial to Diagnostics

Press the Down Arrow button to select

Ping Valve/Sensor then press Next

Press the + and - buttons to select the type of device to test

(Station, Master Valve, Flow Sensor, Weather Sensor, etc.)

Press the <> button to select the number

of the device to test, then press Ping

The controller will ping the selected device and

report a voltage reading if the device responds

Interpreting Ping Results

If the device does not respond verify the address and check the wire

splices. The voltage reading is a measurement of the charge of the

device capacitors.

If the voltage is low, wait a minute then ping again.

If the voltage is still low (below 23 volts), disconnect the device

from the 2-wire path and connect directly to an unused wire path at

Controller and repeat Ping Test. If the voltage is fine, the issue is with

2-wire path / splicing. If the voltage is still bad, replace the device.

22 ESP-LXIVM Controller Troubleshooting Guide

Table of

Contents

Page 23

Field Wiring Diagnostics

The ESP-LXIVM Controller includes multiple diagnostic functions to help

you determine the cause of a field wiring issue.

Tools and Equipment

• An accurate “as-built” showing wire path and 2-wire device locations,

the number and type of the 2-wire devices on each wire path, and

2-wire addresses

• Filled out LX-IVM Controller Programming Guide with 2-wire

addresses and station/MV/sensor assignments

• A Volt/Ohm Meter (multi-meter) capable of reading 0 to 50 volts AC/

DC and resistance from 0 to 1,000,000 Ohms

• A Clamp Meter for measuring AC current with a precision of 1.0 mA

(milliamp)

• Wire tracing and fault finding equipment

• Spare system components and tools including: spare IVM-SOL, IVMSEN device, WC20 Splice Kits and wire strippers

Total System Milliamp Draw

Before troubleshooting a field wiring issue, calculate the expected total

system draw in milliamp (mA). This value can be compared to actual

readings during troubleshooting.

• Each IVM-SOL, IVM-OUT draws 0.67mA

• IVM-SEN draws 6 mA

• Add up the total devices of each type for each wire path and

calculate the wire path mA draw

• Add the mA for each wire path together for the total system mA

draw

Field Wiring Issues

Field wiring issues are typically caused by a broken wire, a short circuit or a

ground fault in the 2-wire path. Refer to the section that best describes the

observed symptoms to troubleshoot.

• Broken Wire (Open Circuit)

• Short Circuit

• Ground Fault

Next Page

23 ESP-LXIVM Controller Troubleshooting Guide

Table of

Contents

Page 24

NOTE: A majority of field wiring issues are caused by poor wire

splices. Use only WC20 Splice Kits. All splices should be made in

splice boxes.

NOTE: If the 2-wire path is Looped, disconnect the loop half way

out before troubleshooting.

Broken Wire (Open Circuit) List Not Responding

If there is a broken wire causing an open circuit in the 2-wire path, you

will notice one or more stations are not running even though they are

programmed to operate. If the system is using flow sensing, you will

receive a low (zero) flow alarm for each disconnected 2-wire station.

Controller Diagnostics

1. Turn the dial to Test All Stations / Check System. Select 2-Wire

Diagnostics.

2. Select the List Not Responding. The results will indicate that

one or more devices have an open circuit and you will be

prompted to Check Wiring. Go to the location of the 2-wire

devices that are not responding and check all wire splices.

2-Wire Path Diagnostics

1. Note the “List Not Responding” displays and corresponding

wire paths. If you notice that all the 2-wire devices that are not

responding are in a single leg of the 2-wire path, the open

circuit exists between the last working 2-wire device and

the first non-working 2-wire device. Check the splices at that

location first. Also look for signs of recent construction/digging

between the working and non-working 2-wire devices.

NOTE: If 2-Wire mapping is not done, the wire path column will

not include any information.

2. Turn the controller dial to 2-Wire Diagnostics; Select Short

Finding; Turn Short Finding Mode On. Use a Clamp Meter to

measure the Amp Draw of the 2-wire path cable conductors at

the last working device and the first non-working device. Note

any discrepancies in the readings. You must know the number

and type of each device downstream to know what the mA

reading up should be reading (see the Total System Milliamp

Draw section for more information).

24 ESP-LXIVM Controller Troubleshooting Guide

Table of

Contents

Page 25

Short Circuit

If there is a short circuit (can be caused by crossed red and black wires)

in the 2-wire path, the controller Alarm light will be illuminated and the

alarm will inform you the controller has switched to Short Finding Mode.

You must fix the short circuit before the controller will switch back to

normal irrigation mode.

2-Wire Path Diagnostics

1. Disconnect each 2-wire path cable one at a time from the

controller IVM 2-Wire Interface Module until the controller exits

Short Finding Mode. Reconnect that 2-wire path cable, and if

the Short Finding Mode returns you know the short is on that

leg of the 2-Wire path.

2. Refer to the as-built to see the location of the 2-wire path. Walk

the route of the 2-wire path cable and check for signs of recent

construction/digging.

3. Find a device location about half-way down the 2-wire path

cable. Disconnect the splices. See if the controller is still in

Short Finding Mode. If the Short Finding Mode has cleared, the

problem is downstream of this location. If the controller is still

in Short Finding Mode, the problem is between this location

and the controller. Keep disconnecting segments of the 2-wire

path until you isolate the problem.

4. Use a Clamp Meter to measure the Amp Draw of the 2-wire

path cable conductors at the last working device and the first

non-working device. Note any discrepancy in the readings. You

must know the number and type of each device downstream to

know what the mA reading up should be reading (see the Total

System Milliamp Draw section for more information).

5. The problem may be caused by a device that was damaged by

a lightning power surge. The controller will exit Short Finding

Mode when the damaged device is disconnected from the

2-wire path.

25 ESP-LXIVM Controller Troubleshooting Guide

Table of

Contents

Page 26

Ground Fault

A ground (earth) fault can be caused when a 2-wire path conductor

is leaking to ground, possibly due to a bad wire splice, or a nicked or

damaged cable. This issue may come and go depending on the soil

moisture level. When the soil is very wet the problem will be worse than

when the soil is dry.

Controller Diagnostics

1. Turn dial to Diagnostics / Diagnostics / Control Output.

2. Select Controller. Note the Milliamp (mA) reading. The mA

reading will be higher than normal when current is leaking

to ground. You must know the number and type of each

device in the system to know what the mA reading should be

reading (see the Total System Milliamp Draw section for more

information).

3. Disconnect each 2-wire path cable one at a time from the

controller IVM 2-Wire Interface Module. Recheck the Control

Output to isolate which segment of the 2-wire path has the

ground fault.

4. Find a device location about half-way down the 2-wire path

cable. Disconnect the splices.

5. Check the Control Output to see if the ground fault has been

isolated. If the Control Output is normal, the problem is

downstream of this location. If the Control Output still shows

the ground fault, the problem is between this location and the

controller. Keep disconnecting segments of the 2-wire path

until you isolate the problem.

2-Wire Path Diagnostics

1. Turn the controller dial to Diagnostics / Diagnostics / Test

Shorted Path.

2. Use a Clamp Meter to measure the Amp Draw of the 2-wire

path cable conductors at various splice locations. Note any

discrepancy in the readings. You must know the number and

type of each device downstream to know what the mA reading

up should be reading (see the Total System Milliamp Draw

section for more information).

26 ESP-LXIVM Controller Troubleshooting Guide

Table of

Contents

Page 27

Relay Wiring

For valves without compatible latching solenoids.

IVM-SOL device can be used to connect any Rain Bird Commercial Valve

to the LX-IVM Controller. For Non-Rain Bird Valve, use IVM-OUT device in

conjunction with a compatible DC latching solenoid to connect to a LX-IVM

controller. In the event, a compatible DC latching solenoid is not available,

you can use the Rain Bird Pump Start Relay with following modifications to

power the AC Solenoid.

1. Connect 110V relay to the + or - 24VAC terminals at the

controller’s IVM 2-wire Interface Module.

NOTE: Do not connect 2-wire path to the 110V relay terminals.

2. Unplug PSR relay coil wires and output to AC Solenoid.

NOTE: Feed the solenoid wires through bottom of the PSR

enclosure.

27 ESP-LXIVM Controller Troubleshooting Guide

Table of

Contents

Page 28

3. Connect the red and white IVM-OUT wire to the red wire of the

DC Latching Relay. Connect the black and white IVM-OUT wire to

the black wire of the DC Latching Relay.

4. Connect the red IVM-OUT wire to the red wire on the 2-Wire

path. Then connect the black IVM-OUT wire to the black wire on

the 2-Wire path.

Input Power

from 24VAC

Out Terminal

at Controller

IVM-OUT

AC Solenoid

Model Nos.

PSR110-IVM

and PSR220-IVM

Allow 3 ft. (1 m)

Extra Cable

Length

28 ESP-LXIVM Controller Troubleshooting Guide

AC Solenoid

Table of

Contents

Page 29

IVM Power Filter Connection

Electrical Noise in the input power can cause undesirable behavior of the

LXIVM Controllers. Sources of Electrical Noise include VFD Pump and other

Electrical Equipment.

Rain Bird recommends the GSP-IVM Filter to filter the noise from the input

power and ensure normal operation of the Controller. Symptoms can include

inconsistent operation of the stations (stations not running as programmed)

and inability read flow from a compatible flow sensor.

Rain Bird recommends the following modification to the controller to “filter

out” the noise and ensuring normal operations of the Controller.

Choke: Schaffner

P/N: RD5122-6-9M6

Terminal Block

on LX-IVM

ORANGE

YELLOW

ORANGE

YELLOW

GREEN or GREEN YEL.

(not connected)

(24VAC IN)

BLUE

BROWN

GROUND

LX-IVM Transformer

(26.5VAC Out)

NOTE: IVM Filter Kit can be sourced from Rain Bird GSP via the

online services store (link below).

https://servicesstore.rainbird.com/ivm-filter.html

29 ESP-LXIVM Controller Troubleshooting Guide

Capacitor, Kemet P/N:

C274ACF5100SA0J

Table of

Contents

Page 30

Controller Diagnostics

Use this table to troubleshoot issues using the built-in diagnostic features

of the ESP-LXIVM controller.

Category Issue Potential Cause Solution

Controller

Alarms

Red alarm

light on the

controller

front panel is

illuminated.

Controller

alarm; No

2-Wire Module.

Controller

alarm; 2-Wire

path Off.

Controller

alarm;

Duplicate

Device Address.

Controller

alarm; Short

Finding Mode.

Controller

alarm; No

Device

Addresses.

The controller is

reporting an alarm

condition.

The IVM 2-Wire

Interface Module

is not properly

attached to the

controller module

slots.

Someone has

manually turned the

2-wire path Off.

Duplicate Device

addresses have been

entered.

2-wire path is

shorted and the

controller has

automatically

switched to the

Short Finding Mode.

The lower left

status light on the

controller is dark.

Device addresses

have not been

entered for any

stations.

Turn dial to Auto, press the Alarm button,

review the alarm conditions, and address

the issue(s).

Check the upper status light on the IVM

2-Wire Interface Module. It should be solid

green if it is properly connected to the

controller. Remove and reinstall the module

making sure it is fully seated in the module

slots.

Turn dial to Off, press the 2-Wire Path button,

and turn the 2-wire path On.

Note the duplicate Device Addresses posted

in the alarm screen, verify and enter the

correct Device addresses.

Disconnect the 2-wire cables from the IVM

2-Wire Interface Module one at a time until

the alarm condition clears. The lower left

status light on the controller will alternate

between red and green when the wire path

with the short is removed.

Trace the path of this 2-wire cable and look

for source of issue (disturbed soil, new tree or

fence post, etc).

Disconnect the 2-wire cable halfway between

the controller and end of cable and check to

see if the alarm clears to help identify short

location on the cable.

Use a volt/ohm and clamp meter to identify

which devices are receiving power.

Fix the short and check that the alarm is

cleared.

Turn dial to 2-Wire Settings / Station Setup.

Enter the address (see label on each Device)

for each station. Addresses are also required

for Master Valves, Weather Sensors and Flow

Sensor.

30 ESP-LXIVM Controller Troubleshooting Guide

Table of

Contents

Page 31

Category Issue Potential Cause Solution

Controller

Alarms

Controller

alarm; Zero

Learned

Flow.

Controller

alarm; Flow

Alarm.

The Learn Flow

Utility has recorded

a zero (0) flow rate

for one or more

station.

FloWatch (flow

sensing utility) has

detected a high or

low flow condition.

Turn dial to Flow Sensor / Set Flow Rates /

View Flow Rates / View Station Rates. Check for

stations that have a 0 flow rate and are labeled

Learned.

• If all stations have learned a 0 flow check flow

sensor/ input connections, Flow Sensor configuration, FloZone assignments, etc.

• If only one or a few stations have learned a

0 flow rate check the valve operation (flow

control stem position, solenoid, wiring, etc.).

• If just small flow rate valves/stations (like drip

zones) have learned a 0 flow rate the flow

sensor may be too large for the lower flow

rates. Check the product technical specs for the

minimum flow rate of the flow sensor.

Turn dial to Alarms / History / Flow Alarms,

and review the posted Station and/or FloZone

(mainline) flow alarms. Note the station(s) or

FloZone(s) that were identified. If you configured

FloWatch to Diagnose & Eliminate or Alarm &

Shut Down, the problem station(s) or FloZone(s)

will be quarantined. Clear the Flow Alarms and

test the system.

• Station flow alarms – Manually turn on the

station. Turn dial to Flow Sensor / View Current

Flow. The current and expected flow rates

will be listed. Check the valve & sprinklers to

identify the issue and correct it. If sprinklers or

nozzles have been replaced, relearn the station

flow rate.

• FloZone alarms - Manually start a program.

Turn dial to Flow Sensor, View Current Flow. The

current and expected flow rates will be listed.

Check the water source(s) and mainline to

identify the issues and correct it.

• If FloZone high flow alarms are being triggered

by manual watering (QCV, manually bleeding

valves, etc.) consider using the MV Water

Window located under the Manual Watering

dial position. Configure window open and

close times, days of the week, MV(s) you want

open, and the

expected additional flow rate to allow for the

manual watering.

31 ESP-LXIVM Controller Troubleshooting Guide

Table of

Contents

Page 32

Category Issue Potential Cause Solution

Controller

Alarms

2-Wire Path

Issues

Controller alarm;

Invalid Module

Config.

Controller alarm;

No PGM will Auto

Run.

Controller

Alarm; No

Power – Irrigation

Functions are

Disabled.

Communication

with 2-wire

devices is

intermittent.

Controller loses

connection to

2-wire devices

after a heavy

irrigation or

rainfall event.

A non-compatible

module has been

inserted into one

of the controller

module slots.

Incomplete

programming.

No primary power

to the controller

transformer

Front panel

ribbon cable is

disconnected

2-wire cable

or splices are

leaking to ground

or between

conductors.

Communication

signal and power

leaks to ground.

Remove any recently added modules, one at a

time, until the alarm condition clears.

• ESP-LXME/-LXMEF Controller 4-, 8-, &

12-Station Modules, FSM Flow Smart

Modules, M50 and SM75 Modules are not

compatible.

Turn dial to Diagnostics / Confirm Programs

/ Program Summary. Missing programming

parameters are identified by an N. For

programs to automatically run you need to

program Start Days, Start Times, and Station

Run Times.

Check the power input to the controller

transformer. The display is being powered by

the 9v backup battery.

Check both ends of the ribbon cable to make

sure it is firmly connected to the backplane

and front panel.

Turn dial to Diagnostics / Control Output. The

controller voltage output and 2-wire path

milliamp draw will be displayed.

• If there are no issues you will see Current

Limit OK, Current Overload OK.

• If the 2-wire cable leaks are drawing a high

amount of current you will see Current

Limit Not OK, Current Overload OK. Use the

troubleshooting tips above to find and fix

the 2-wire cable/splice issues.

• If the 2-wire cable leaks are drawing a high

amount of current you will see Current

Limit Not OK, Current Overload Not OK.

The controller will have automatically

switched to Fault Finding Mode. Use the

troubleshooting tips above to find and fix

the 2-wire cable/splice issues.

• Single-jacketed cable and/or incorrect

wires splices were used. When incorrect

cable/splices become submerged it can

create leakage to ground. Double- jacketed

14-2UF Maxi 2-Wire Cable and WC20 Splice

Kits are required.

32 ESP-LXIVM Controller Troubleshooting Guide

Table of

Contents

Page 33

Category Issue Potential

IVM-SEN/

Sensor

Programs Programs

Station

Sequencing

The controller

is not getting

data from

a flow or

weather

sensor

connected to

a IVM-SEN/

Sensor on the

2-wire path.

are running

at random

times.

Stations are

not running

in station

number

sequence

Cause

Sensor wiring

polarity is

reversed.

Flow sensor

output pulse rate

is not compatible

with the LX-IVM

Controller.

Weather sensor

type is not

compatible.

Multiple start

times have been

programmed

unintentionally.

Water Windows

have been

configured so

programs are

paused and

resume later.

Station

Sequencing set

to Sequence by

Station Priority

Solution

Many sensor including flow sensors require wires

to be connected with correct polarity (+ / -). If

the sensor has colored or labeled wires, connect

as follows:

• Sensor red (+) wire to the IVM-SEN Sensor

red wire.

• Sensor black (-) wire to the IVM-SEN Sensor

black wire.

The LX

-IVM Controller requires a minimum input

of 2 pulses per 10 seconds for the smallest station

flow rate. Pulse rates of less than 2 pulses per

10 seconds will not be registered.

compatible flow sensor.

The LX-IVM Controller is not compatible with 4-20

mA or 0-5V weather sensors (discrete switched

sensors only).

Turn dial to Diagnostics / Confirm Programs /

Review Program. Review each program using the

Program Button to select the program. Check for

multiple start times on an individual program. In

some cases users’ mix-up start times and stations

and can inadvertently program the system to

start multiple times per day.

Turn dial to Delay Watering / Water Window. Use

the Programs Button to select a program 1 - 40.

Water Windows control the hours of the day

a program is allowed to operate. If a program

starts outside a Water Window it is paused until

the window opens. If the program is still running

when the Water Window closes the program is

paused and will automatically start the next time

the window opens. Adjust the Water Window

open and close times to allow the program to

complete.

The LX-IVM offers 2 station sequencing modes:

• Sequence by Station Numbers (default) – Sta-

tion selection criteria: a) Non-Irrigation Priority;

b) Station number low to high; c) Program

assignment 1 - 40.

• Sequence by Station Priority (automatically

used if FloManager is On) – Station selection

criteria: a) Station Priority Non-Irrigation, High,

Medium, Low; b) Station Run Time longest

to shortest; c) Station number low to high; d)

Program Assignment 1 - 40.

To change Station Sequencing mode turn dial to

2-Wire Settings / Advanced / Station Sequencing.

Use the +/- softkeys to change the selection.

Change to a

33 ESP-LXIVM Controller Troubleshooting Guide

Table of

Contents

Page 34

Category Issue Potential Cause S olution

Station

Valves

Station

Valves

Master

Valves

A station

valve is not

operating.

A station

valve is not

operating.

The Master

Valve will not

open when

stations are

operating.

Valve is manually

closed or solenoid

is damaged.

Station does not

have run time for a

program with start

days and a start

time.

IVM-SOL or valve

wires are not

spliced correctly.

Incorrect address. Check the address of the station (label on the IVM

Incorrect Valve

Type

2-wire path from

the controller is

not connected to

this area.

MV is assigned to

a different FloZone

than the stations.

MV is Normally

Open but has been

configured as a

Normally Closed

MV.

Station not

configured to open

Master Valve.

MV Address is

incorrect.

Turn dial to Manual Watering / Start Station. Select

the station making sure it has a run time and press

run. Check to see if the valve is operating and if it

isn’t, address the valve issue.

Turn dial to

Run Time. Note which programs the station has run

times programmed. Use Program Summary to make

sure that program has start days and start times.

Turn dial to Diagnostics / Diagnostics / Ping List not

Responding. If the ping test fails check the device

and valve wire splices and repeat the ping test.

device that is connected to the valve) and verify

the address is entered correctly. Turn dial to 2-wire

Setting / Station Setup to access Station Address.

Turn Dial to 2-wire Setting / Station Setup / Valve

Types. Valve types configure the decoder inrush

amps and duration for opening a valve solenoid.

The LX-IVM Valve Types are preconfigured for

Rain Bird commercial valve models. Information

for configuring Valve Types to work with other

valves can be found in the controller manual. Note:

Rain Bird residential valves (DV, JTV, HV) are not

compatible with the LX-IVM system or IVM-SOL.

Ping other valves on the same 2-wire path leg.

If these pings are also unsuccessful, check for an

open wire connections on the 2-wire path.

Turn dial to 2-Wire Settings / Master Valves. Press

Next to advance to FloZone (FZ) Setup screen. MV

needs to be assigned to the same FloZone as the

stations that receive water from this water source.

If the MV valve is Normally Open (powered to close)

it needs to be configured as Normally Open. Turn

dial to 2Wire Settings / MV Setup. Change MV from

Normally Closed (default) to Normally Open.

Go to 2-Wire Settings / Station Setup to make sure

the station is configured as requiring a Master

Valve.

Check the address of the MV (label on the IVM

device that is connected to the MV) and verify the

address is entered correctly. Turn dial to Setup

Wizards / Master Valves to access MV Address.

Diagnostics / Confirm Program

/ Station

34 ESP-LXIVM Controller Troubleshooting Guide

Table of

Contents

Page 35

Category Issue Potential Cause Solution

Master

Valves

IVM 2-Wire

Interface

Module

Pump Start

Relays

Controller

LCD Display

The Master

Valve will not

open when

stations are

operating.

No output

from the

module.

The controller

cannot close

the pump

start relay that

is connected

to a IVM-OUT.

The controller

display is either

too light or too

dark.

Controller

display is

blank.

2-wire device or

valve wires are not

spliced correctly.

IVM-Device is not

functioning or

damaged.

Fuses in the module

have blown due to

short or secondary

power connected to

the 2-wire path.

Module is in

Automatic Short

Finding Mode due to

short or secondary

power connected to

the 2-wire path.

Amp draw of the

pump start relay

is more than the

Device can provide.

The display contrast

needs to be

adjusted.

Controller LCD

display is damaged.

Primary power to

the controller has

been lost or turned

off.

Controller ribbon

cable is not

connected or

damaged.

Turn dial to Diagnostics / Diagnostics /

MV and ping the MV address. If the ping

Ping

test fails

check the decoder and valve wire splices and

repeat the ping test.

Turn dial to

Valve or Sensor, then ping the MV address. If the

ping test fails swap the device, enter the new

address and repeat the ping test.

Find the source of the short or power

connected to the 2-wire path and address

the problem. A replacement 2-wire Module is

available for purchase.

Find the source of the short or power

connected to the 2-wire path and address

the problem.

Use a Rain Bird PSR-Series Pump Start Relay

that incorporates an ice-cube relay, double

relay system. You can also add an ice -cube

relay to the existing pump start relay. Contact

Rain Bird Technical Services or Global Support

Plan for relay model and wiring diagram.

Turn dial to Off, press Contrast +/- buttons to

adjust display contrast.

Plug in a 9V battery into the battery slot

on the back of the controller front panel. If

information is now visible on the display it

is not damaged and working correctly. See

other potential causes. If no information is

displayed, remove the 2-wire module. If the

alarm light on the front panel turns on after 1

minute but no information is in the display, the

LCD is damaged and the front panel should

be replaced. A replacement panel is available

for purchase.

This can be verified by checking the status

lights on the 2-wire module. If both status

lights on the module are dark the primary

power is likely off. Find primary power source

to the controller and turn it on. If the power

breaker is tripped or fuse is blown, find source

of problem, fix the issue, and turn the power

back on.

Check to make sure the ribbon cable is securely

connected to both the controller backplane and

the front panel. If the cable has broken wires or

connectors, replace it.

Diagnostics / Diagnostics /

Select

Ping

35 ESP-LXIVM Controller Troubleshooting Guide

Table of

Contents

Page 36

Category Issue Potential

Simul

Stations

(Simultaneous

Station

Operation)

Weather

Sensors

Controller

Knockouts

Too many

or too few

stations are

operating

simultaneously

when

program(s)

operate.

Weather

sensor is not

preventing

controller

manual

operation.

Wireless

weather

sensor is not

providing

input to the

controller.

I am having

trouble

removing the

knock-outs

on the

ESP-LX Series

Controller

plastic cabinet.

Cause

LX-IVM

(Controller)

SimulStations

are configured

incorrectly.

PGM (Program)

SimulStations

are configured

incorrectly.

This is by

design.

Sensor receiver

is not wired to

the controller

module

correctly.

Unlike knockouts on a metal

enclosure,

these plastic

knock-outs are

designed to be

removed by

applying force

to the center at

the dimple.

Solution

Turn dial to 2-wire Setting / Advanced /

SimulStations. Select LX-IVM SimulStations

and adjust the maximum number of

simultaneous irrigation stations you want to

allow to operate across all programs at any

time. Non- Irrigation SimulStations control

stations with Non-Irr Priority.

Turn dial to 2-wire Setting / Advanced

SimulStations. Select PGM SimulStations

and adjust the maximum number of

simultaneous irrigation stations you want

to allow to operate simultaneously within

the currently selected program. Move

the Program Button to select the other

programs 1 - 40.

Manual station, program or test program

operation (from the front panel or a remote)

is allowed regardless of the weather sensor

state. To see the current state of a weather

sensor, turn the dial to Weather Sensors. The

status of each sensor is displayed.

The IVM 2-Wire Interface Module includes

4 terminals for wireless weather sensor

connections. Wiring connections should be

made as follows:

• Sensor receiver power wires to + and –

terminals.

• Sensor receiver sensor wires to Sen and

C terminals.

Prior to installing the cabinet, place on a flat

surface with the knock-out facing up. Locate

the dimple in the center of the knock-out

you wish to remove. Place the tip of a large

Phillips screwdriver in the dimple. Use a

rubber or wooden mallet to firmly strike

the top of the screwdriver. The knock-out

should pop out in a single piece. If it breaks,

use pliers to remove the pieces. Do not use a

flat-bladed screwdriver around the outside

of the knock-out as this could crack the case.

36 ESP-LXIVM Controller Troubleshooting Guide

Table of

Contents

Page 37

IVM Interface Module

This section explains the LED Status indicators on the IVM 2-Wire Interface

Module.

LED Indicators

MODULE STATUS

2WIRE PATH

STATUS

1

2 3 4

INDIVIDUAL PATHS

37 ESP-LXIVM Controller Troubleshooting Guide

Table of

Contents

Page 38

LED Status

Module Status

Module State Description LED Light

POWER OFF Power off or module is held in reset. Dark

POWER UP During initial power up or after reset Briefly lights GREEN

ENUMERATION or ERROR Waiting for enumeration. Flashing RED

CONFIGURATION After enumeration, while receiving

NORMAL After configuration download is

SHORT ADDRESS

CONFIGURATION

device addresses and configuration from

the front panel

complete (from front panel and setting

all IVM-SEN to either flow or weather).

This is the Normal up and running state.

During the Normal state, there are

devices in the field that have not yet

been programmed with short addresses.

All other normal communication to field

devices still function while in this state.

2-Wire Path Status

Module State Description LED Light

POWER OFF Power off or module is held in reset. Dark

2-wire ON Normal state with 2-Wire path powered

2-wire OFF 2-Wire path powered down. Dark

on.

Individual Path Status

to indicate power

applied

Flashing ORANGE

Solid GREEN

Flashing GREEN

Blinking GREEN

Module State Description LED Light

POWER OFF Power off or module is held in reset. Dark

Individual path enabled Path connected (2-Wire path may be

Individual path disabled Path disconnected (2-wire path may be

on or off).

on or off).

Solid GREEN

Solid RED

38 ESP-LXIVM Controller Troubleshooting Guide

Table of

Contents

Page 39

Rain Bird Corporation

6991 E. Southpoint Road

Tucson, AZ 85756

Phone: (520) 741-6100

Questions?

Call the Rain Bird Professional Support Line at

+1-866-544-1406

or else visit our web site at

www.rainbird.com/esplxseries

Rain Bird Rewards:

www.rainbird.com/rewards

Phone - 1-888-370-1814

Global Service Plan:

www.rainbird.com/gsp

Phone: 866-GSP-XPRT (477-9778)

Registered trademark of Rain Bird Corporation

2020 Rain Bird Corporation 23DE20

Loading...

Loading...