Rain Bird ESP-6LX+, ESP-8LX+, ESP-20LX+, ESP-24LX+, ESP-8LXi+ Installation, Programming, And Operation Manual

...Page 1

1

ESP-LX+ & LXi+ Installation, Programming, & Operation Guide

Rain Bird Sales, Inc. - Turf Products

970 W. Sierra Madre, Azusa, CA 91702

www.rainbird.com

P/N 634415-B

Installation, Programming, & Operation Guide

ESP-LX+ and ESP-LXi+

Indoor Models

ESP-8LXi+

ESP-12LXi+

ESP-16LXi+

Indoor / Outdoor Models

ESP-6LX+ ESP-16LX+

ESP-8LX+ ESP-20LX+

ESP-12LX+ ESP-24LX+

Page 2

Special Upgrade Oer

Save an extra 15% o new sprinkler timers and

irrigation controllers at the Rain Bird Online Store.*

Still struggling with your old sprinkler

timer? Having a hard time complying

with local watering restrictions?

Upgrading to a new Rain Bird sprinkler

timer is easier than you might think.

New timers are easier to program than

ever before, with powerful features to

help save you time and water while

keeping your yard healthy and vibrant.

There are lots of models to meet your

needs, including indoor and outdoor

versions, exible modular timers and

even smart controllers that

automatically adjust themselves

based on the weather.

Shop Now at store.rainbird.com and

enjoy exclusive upgrade savings!

UPGRADE15

at checkout to save an extra 15% o*

* Additional discount not valid on clearance items, bundles or store specials.

Discount applies to controller products only. Cannot be combined with

other store discount codes. Valid at the Rain Bird Online Store only.

Enter discount code:

Subject to change without notice.

® Registered trademark of Rain Bird Corporation.

Page 3

2

ESP-LX+ & LXi+ Installation, Programming, & Operation Guide

TABLE OF CONTENTS

Introduction ....................................................................................... 2

LX+ and LXi+ Series Controllers.................................................. 2

Controller Stations ................................................................... 2

Station Layout .......................................................................... 3

Controls, Switches, and Indicators ................................................ 4

Programming the Controller ............................................................... 6

Definitions ..................................................................................... 6

Programming Under Battery Power ............................................. 6

Programming Checklist ................................................................ 7

Fill Out Programming Chart .......................................................... 8

Clear All Program Information ..................................................... 10

Set Time...................................................................................... 11

Set Date ...................................................................................... 12

Select Program........................................................................... 13

Set Watering Day Cycle............................................................... 14

Custom .................................................................................. 14

Cyclical .................................................................................. 16

Odd/Even Cycle .................................................................... 18

Set Station Watering Times .......................................................... 19

Set Program Start Times ............................................................. 21

Set Water Budget........................................................................ 23

Set Station Delays ....................................................................... 24

Set MV / Pump Starts ................................................................. 26

Set Rain Delay............................................................................. 28

Set Calendar Days OFF .............................................................. 29

Set Sensor System and Bypass Switch ...................................... 31

Operating the Controller ................................................................... 33

Operate Controller Automatically ................................................ 33

Run Program(s) Manually ........................................................... 34

Run Station(s) Manually .............................................................. 35

Run Test Program ....................................................................... 36

Rapid Station Test Routine RASTER........................................... 37

Introduction ................................................................................ 37

RASTER Operation ..................................................................... 38

Running a RASTER (Rapid Station Test Routine) ......................... 38

Valve Testing ............................................................................... 40

Troubleshooting Open and Shorted Valve Circuits ...................... 43

Open Circuits ......................................................................... 43

Short Circuits ......................................................................... 44

Installing the Controller .................................................................... 45

Installation Checklist .................................................................... 45

Select Location ........................................................................... 46

Remove Door and Face Panel.................................................... 48

Mount Controller on Wall ............................................................. 50

Connect Field Wires .................................................................... 52

Field Wire Entrances .............................................................. 52

Station Valve Wiring ............................................................... 53

Master Valve Wiring ............................................................... 53

Sensor System Wiring ........................................................... 54

Pump Start Relay Wiring ............................................................. 55

Connect Main Power Wires ......................................................... 56

ESP-LX+ (Outdoor / Indoor Controller)................................. 56

ESP-LXi+ (Indoor only Controller) ......................................... 60

Install Battery .............................................................................. 62

Diagnostic Circuit Breaker .......................................................... 64

Troubleshooting ............................................................................... 65

Page 4

1ESP-LX+ & LXi+ Installation, Programming, & Operation Guide

ATTENTION: UN DISJONCTEUR OU UN INTERRUPTEUR DOIT ETRE

INSTALLE SUR LE PRIMAIRE POUR ISOLER LE PROGRAMMATEUR.

LA MEMOIRE EST MAINTENUE GRACE A UNE BATTERIE RE-

CHARGEABLE A DISPOSER SELON LA REGLEMENTATION

LOCALE.

Léclair avec le symbole de la flèche, placé dans les

limites dun triangle èquilatéral est prévu pour avertir

lutilisateur de la présence de tension dangereuse

non isolé dans lenceinte du produit qui pourrait ëtre

dune importance suffisante pour présenter un risque

dèlectrocution aux personnes.

Le point dexclamation dans un triangle èquilatéral est

prévu pour avertir lutilisateur de la présence

dinstructions importantes pour les opérations et

lentretien (service) dans les manuels fournis avec

lappareil.

WARNING: A CIRCUIT BREAKER OR CUTOFF SWITCH IS TO BE

PROVIDED IN THE FIXED WIRING TO ISOLATE THE CONTROL-

LER.

MEMORY IS RETAINED BY A BATTERY, WHICH IS TO BE DIS-

POSED OF IN ACCORDANCE WITH LOCAL REGULATIONS.

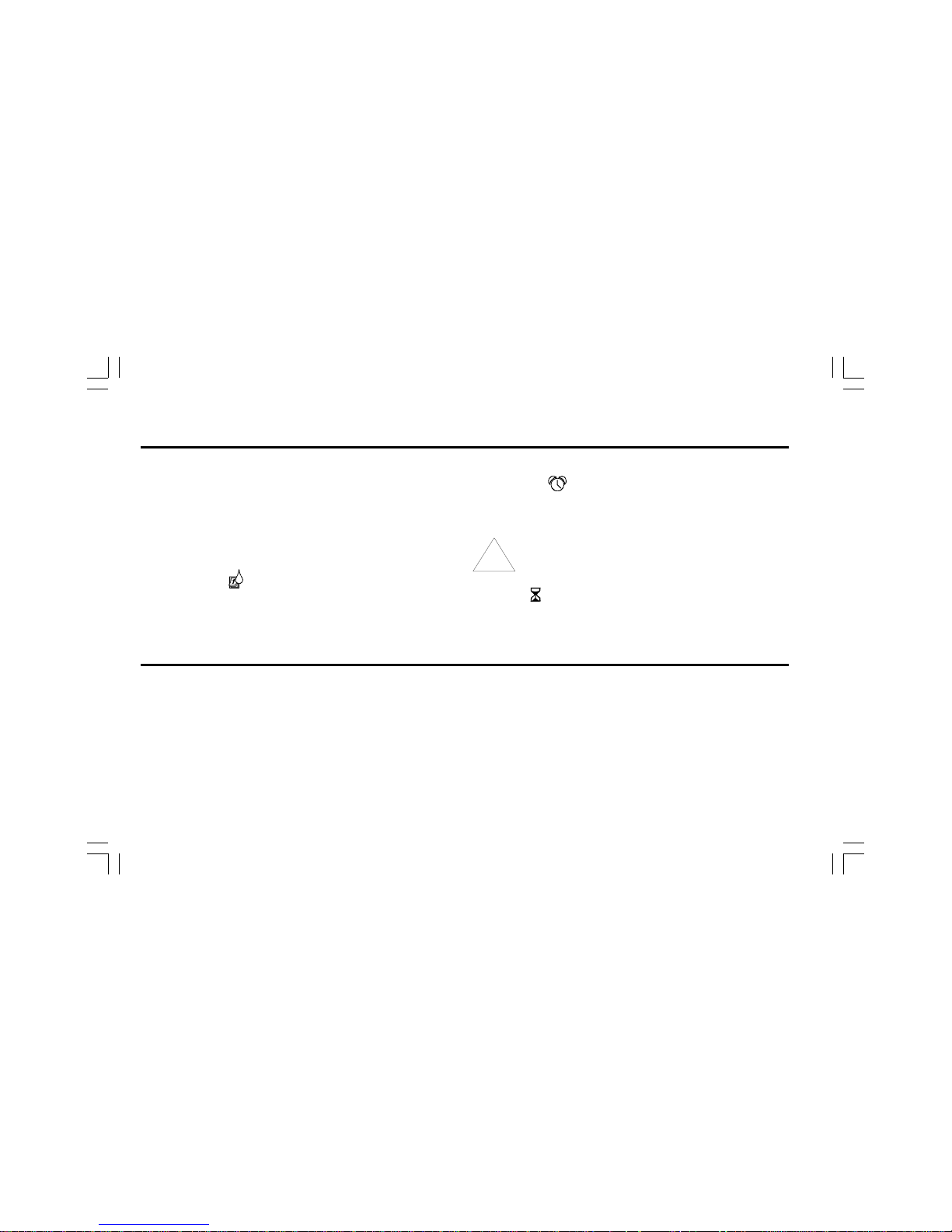

CAUTION ICONS

The lightning flash with arrowhead symbol, within an

equilateral triangle, is intended to alert the user to the

presence of uninsulated dangerous voltage within

the products enclosure that may be of sufficient

magnitude to constitute a risk of electronic shock to

persons.

The exclamation point within an equilateral triangle is

intended to alert the user to the presence of important

operating and maintenance (servicing) instructions in

the literature accompanying the product.

Page 5

2 ESP-LX+ & LXi+ Installation, Programming, & Operation Guide

INTRODUCTION

LX+ and LXi+ Series Controllers

The ESP (Extra Simple Programming) -LX+, -LXi+ Series

controller is an irrigation timing system for residential and light

commercial use.

The ESP-LX+ comes in 6-, 8-, 12-, 16-, 20-, or 24-station

models, designed for either indoor or outdoor use. The

ESP-LXi+ comes in 8-, 12-, or 16-station models, for indoor use

only.

ESP-LX+ and ESP-LXi+ controllers bearing the

remote ready icon (shown at right) can be

connected to Rain Birds Radio Frequency (RF)

receivers (RM-1R & RMX-1R).

For example, the illustration on page 3 shows that station 1 is

currently watering. When station 1 is finished, the controller

will shut it off and start station 2. In the same way, station 3 will

begin watering when station 2 is finished.

NOTE: ESP-LX+ and -LXi+ controllers let you set a

delay between stations. For example, if you set a oneminute delay, station 1 will run until finished, followed

by a one-minute delay. Then station 2 will operate,

followed by a one-minute delay.

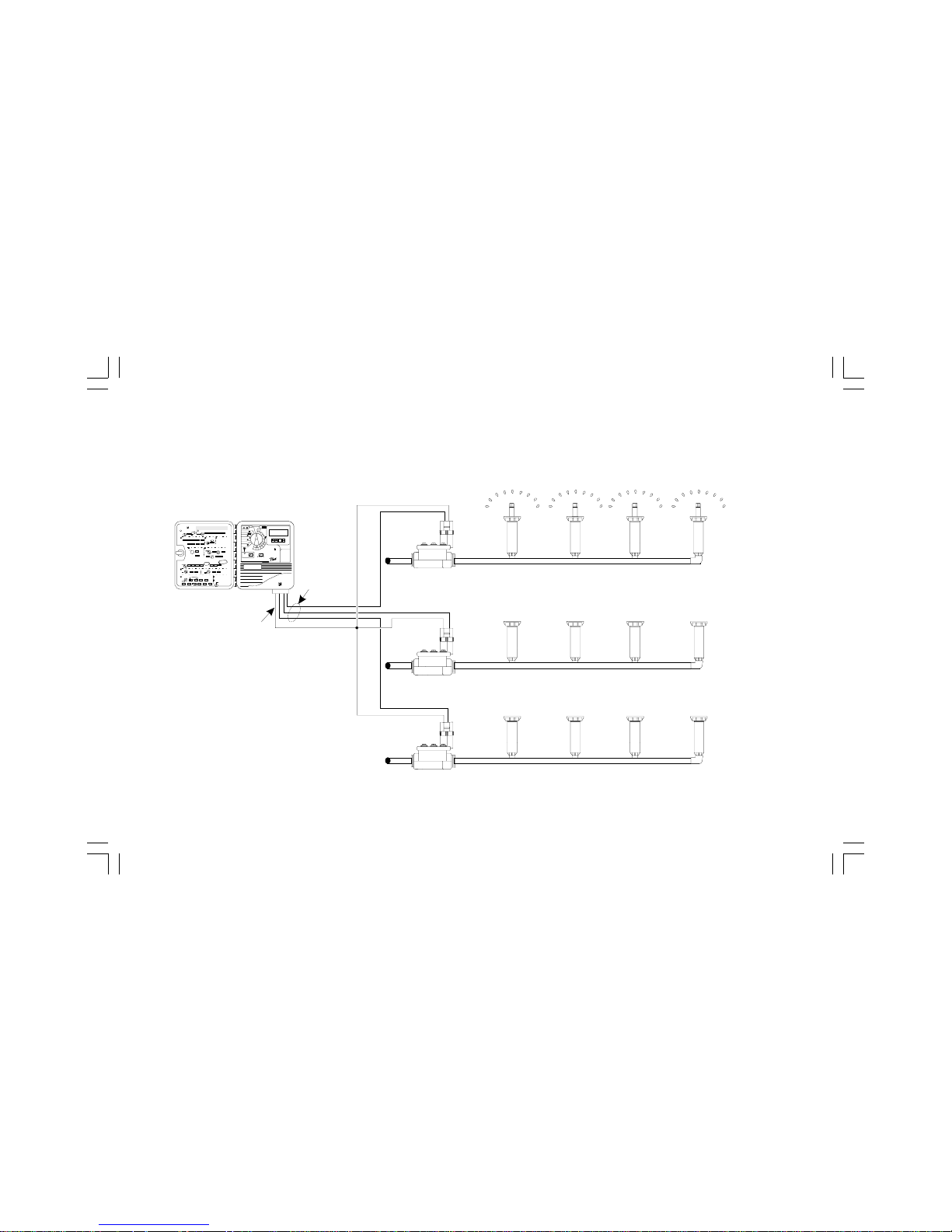

Controller Stations

Your ESP-LX+ or LXi+ Series controller is an electronic clock

that controls when your sprinkler system turns on, and how

long the sprinklers run. The controller has several sprinkler

stations connected to it, as shown in the illustration on the

following page. Each station is connected to a remote control

sprinkler valve.

The valve opens when it receives power from the controller,

and the sprinklers connected to that valve turn on. When these

sprinklers have run for their programmed time, the controller

shuts off the valve and opens the next valve in sequence.

Page 6

3ESP-LX+ & LXi+ Installation, Programming, & Operation Guide

Station Layout

Page 7

4 ESP-LX+ & LXi+ Installation, Programming, & Operation Guide

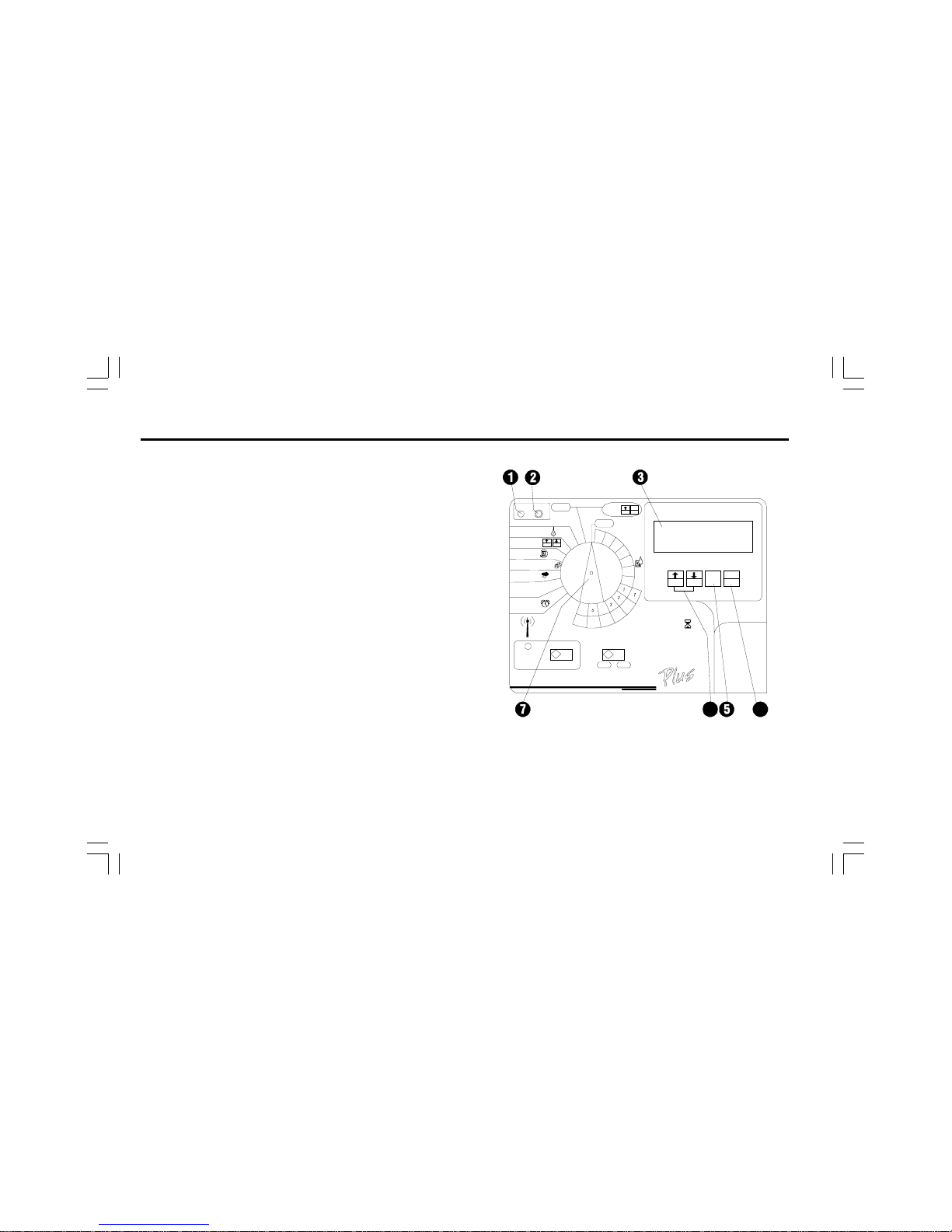

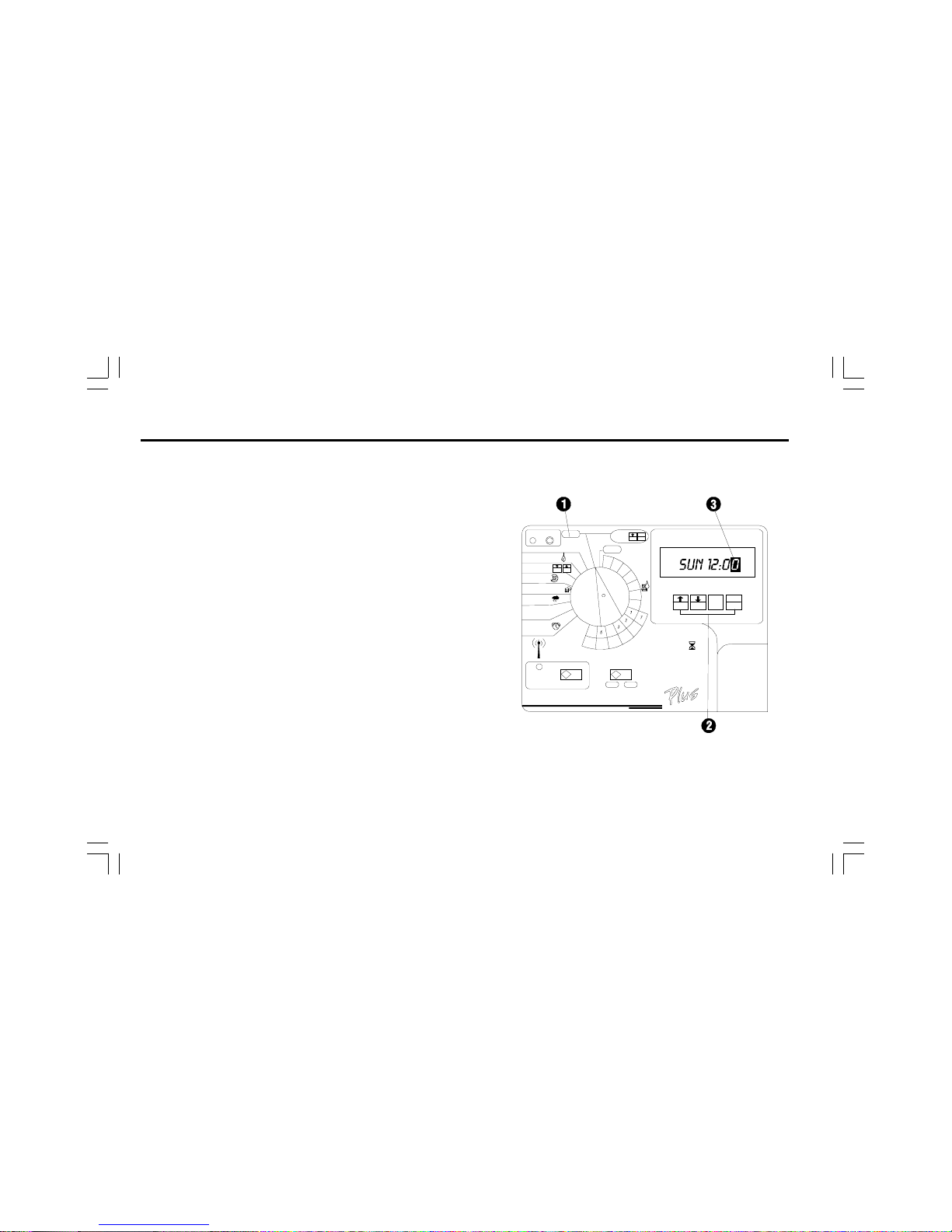

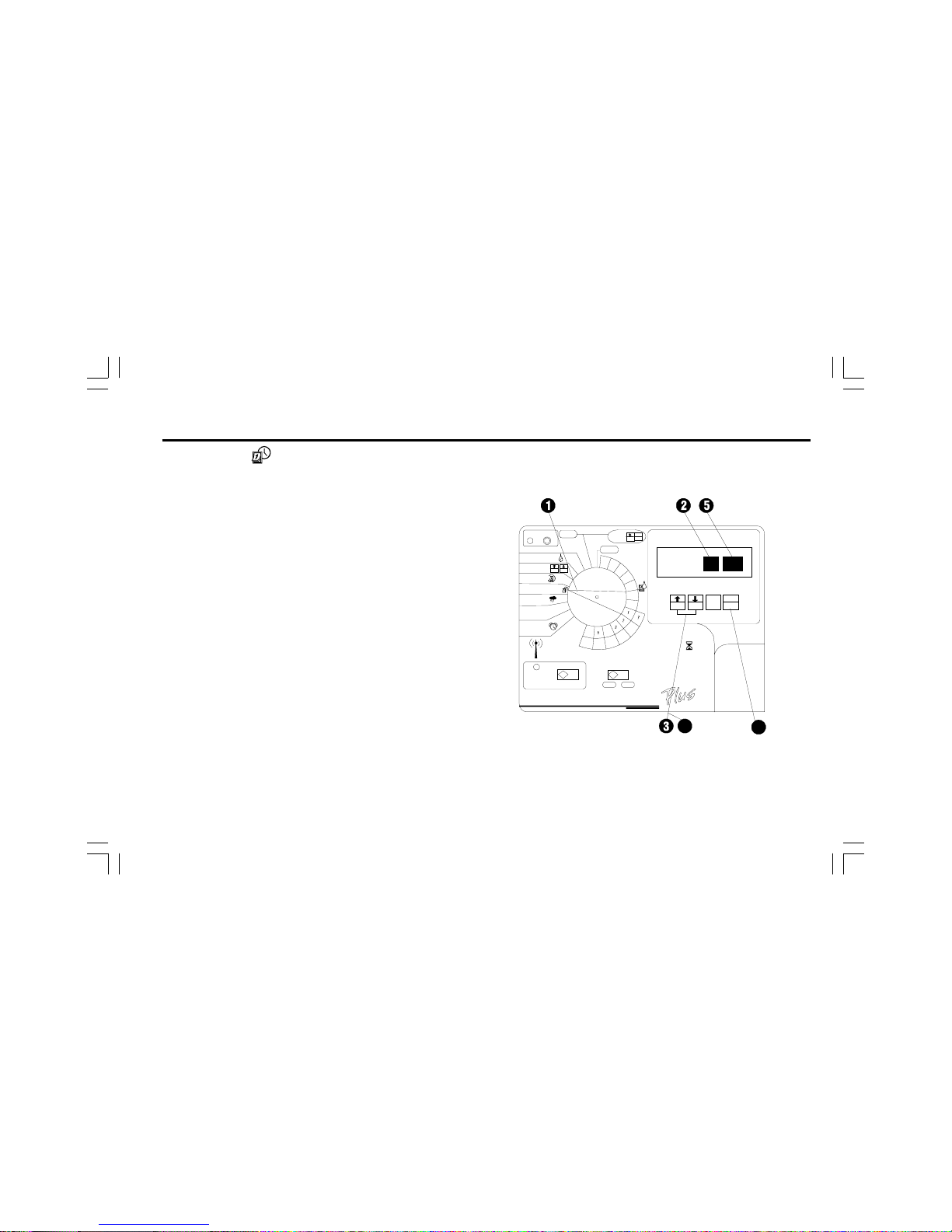

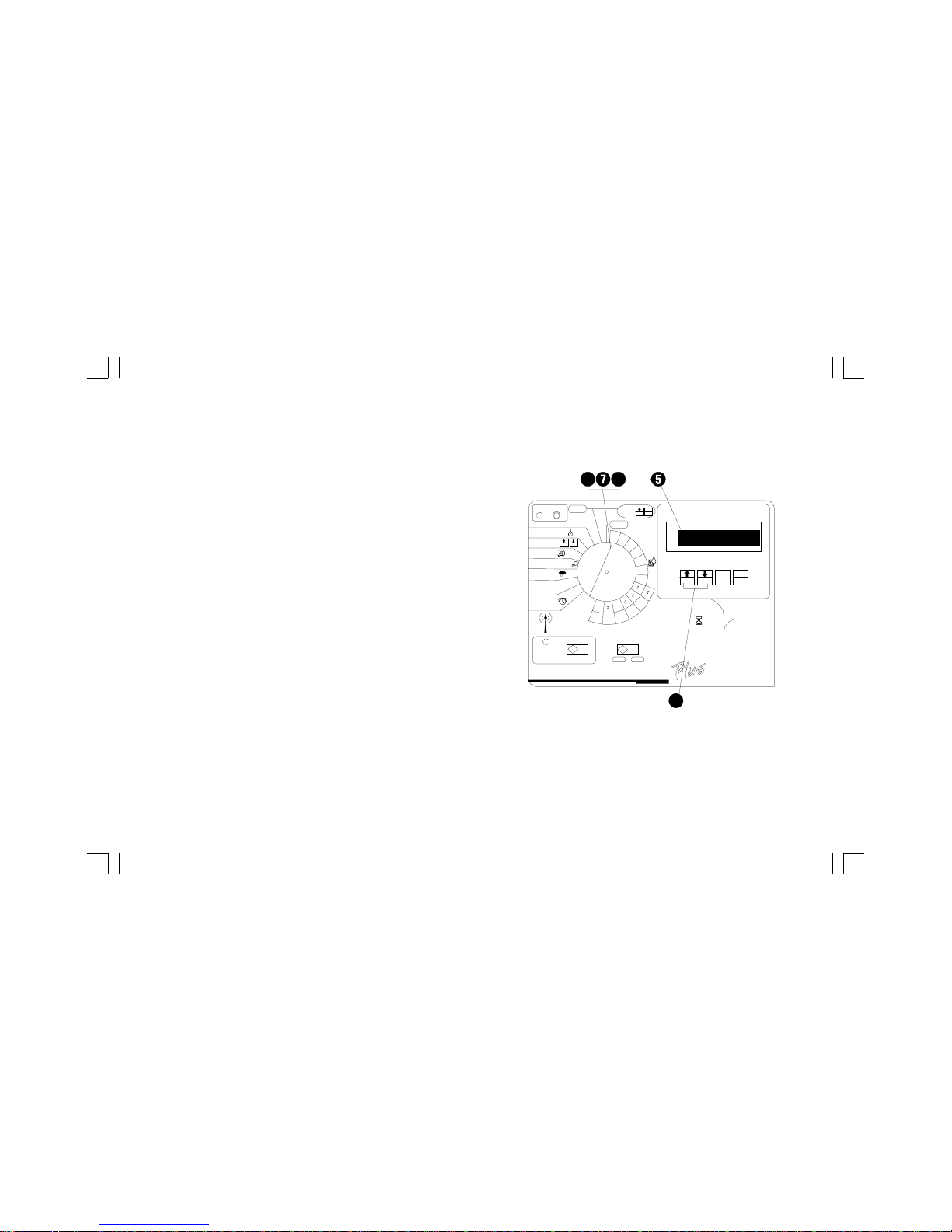

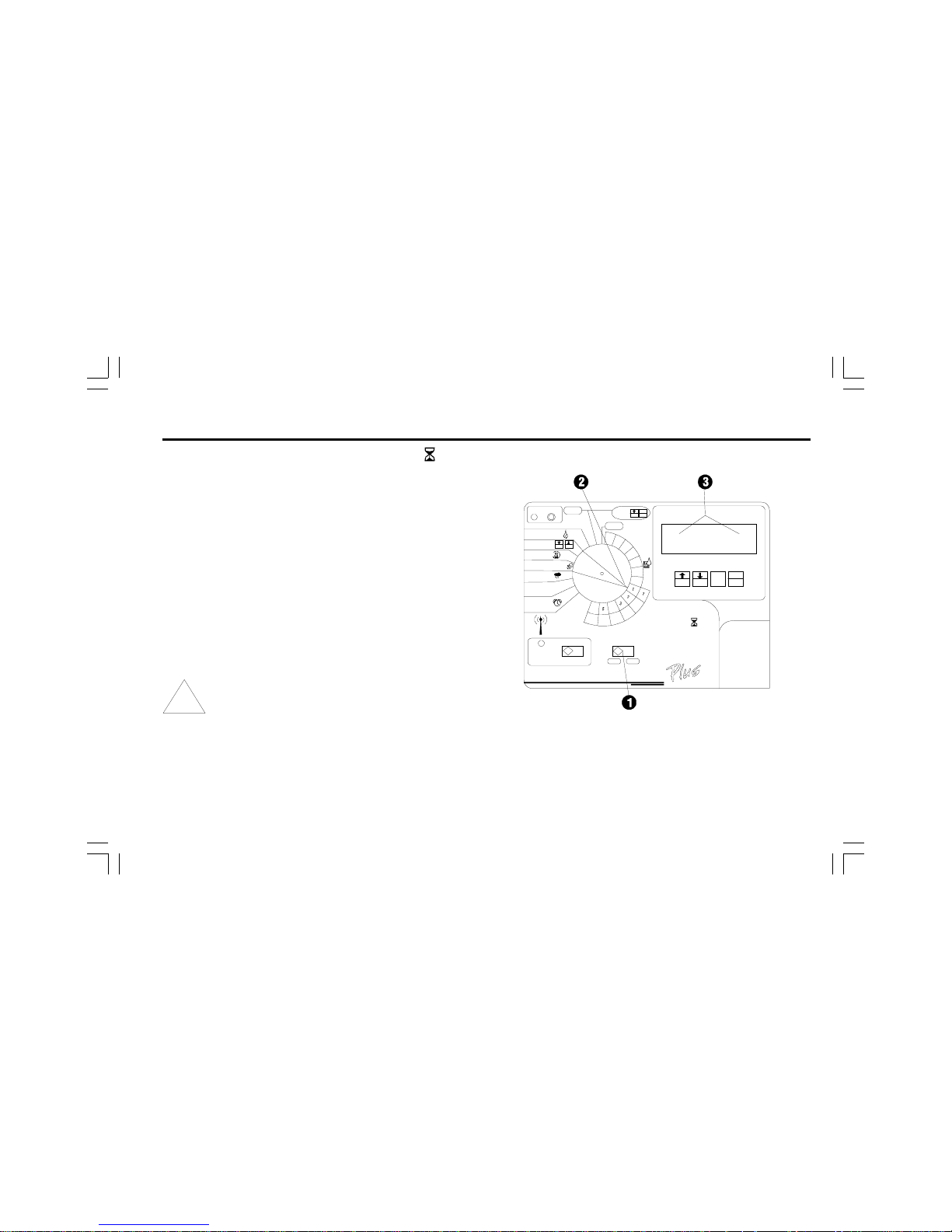

Controls, Switches, and Indicators

This illustration shows the controls, switches, and indicators on

ESP-LX+ and LXi+ controllers, including:

➊ Fault LED flashes when the controller senses a station

short circuit.

➋ Clear Fault Button used to turn off the Fault LED and

clear the flashing LCD Error indicator after the fault has

been corrected.

➌ LCD Display during normal operation, displays the time

of day; during programming, shows the result of your

commands; during watering, shows the station that is

running and the minutes remaining in its run time (when

program dial is set to the AUTO position).

➍ Manual Start / Advance Button used to start a program

manually or to manually advance watering from one

station to the next. Also used to make program changes.

➎ PGM Button used to select watering program A, B, C, or

D-drip.

➏ Arrow / ON-OFF Buttons used to set times and days, and

to make program changes.

Programming Dial used to turn the controller off and on,

and for programming.

Page 8

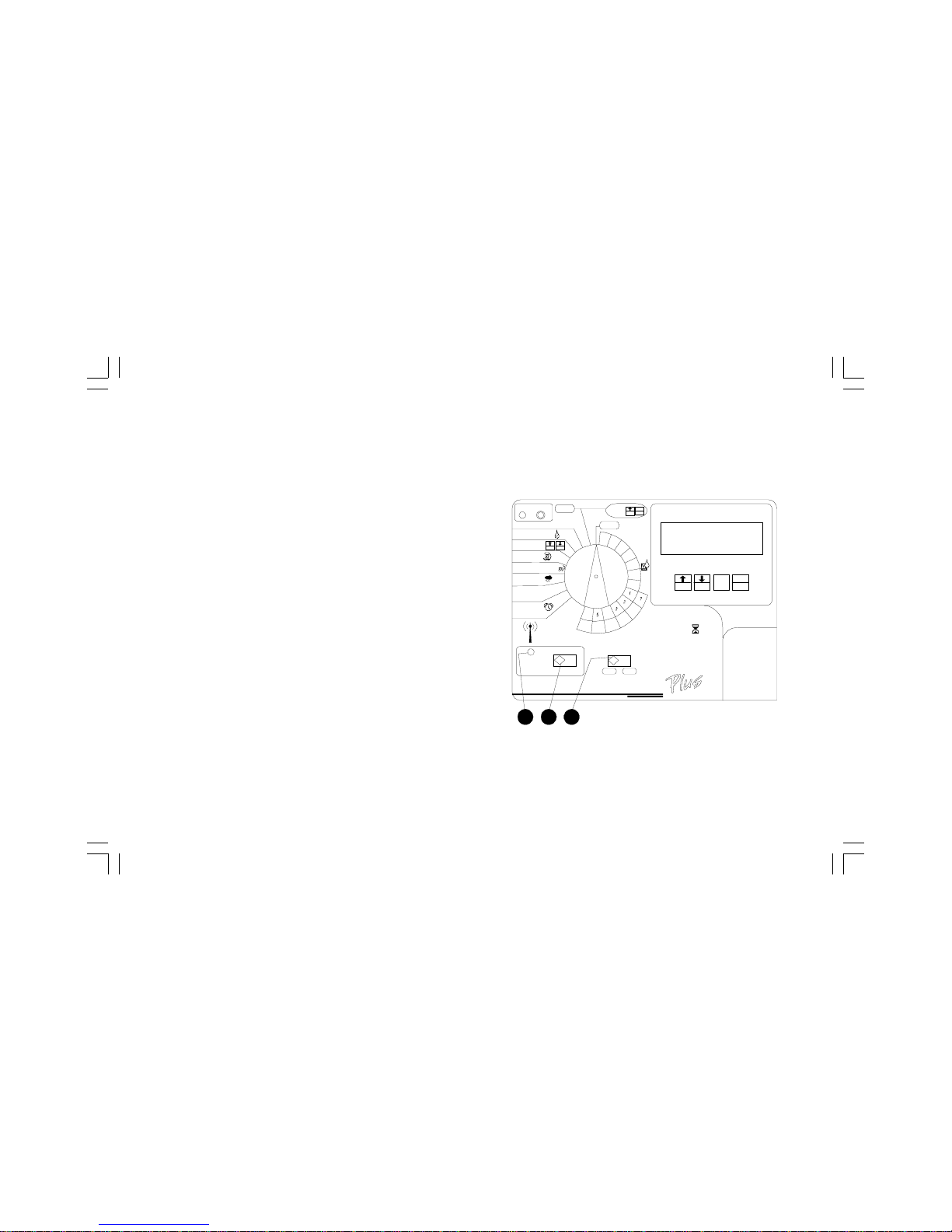

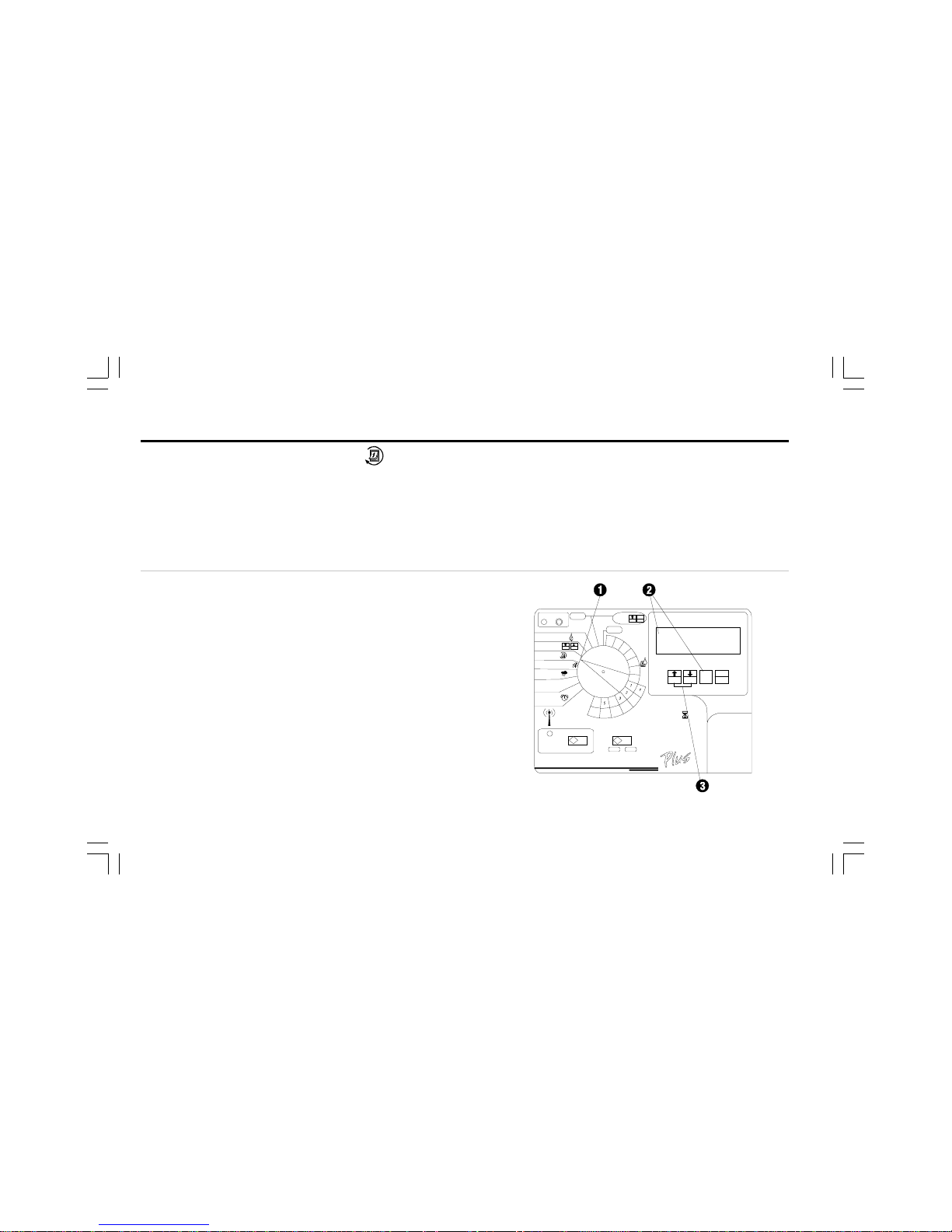

5ESP-LX+ & LXi+ Installation, Programming, & Operation Guide

➑ Watering Suspended by Sensor LED glows when watering

is prevented by a moisture sensor.

➒ Sensor Bypass Switch used to tell the controller to obey

or ignore input from a moisture sensor system. (Sensor

systems are optional.)

➓ Stations Slide Switch used to select one of the station

rows around the Programming Dial. (For 12-, 16-, 20-, and

24-station models only.)

Page 9

6 ESP-LX+ & LXi+ Installation, Programming, & Operation Guide

• Start time(s) - the time(s) of day that the program

begins; this is the time that the first station in the program

begins watering; all other stations in the program then

follow in sequence.

NOTE: The term start time refers to the time that a

program starts not to the time that each individual

station begins to run.

• Run time - the number of minutes (or hours and minutes)

that each station runs.

PROGRAMMING THE CONTROLLER

Programming Under Battery Power

If you wish, you can remove the front face panel of the controller and program the unit under battery power. This feature can

be useful if the controller is installed in an area that is not

readily accessible. This feature also lets you enter program

information before installing the controller at the job site.

Definitions

Programming is the process of telling the controller exactly

when and how long you want to water. The controller opens

and closes the remote control valves according to the program you set.

Each program contains:

• Watering days - the specific days of the week on which

watering takes place (for example, Monday, Wednesday,

Friday), or the watering interval (for example, every third day,

or only on even or odd days of the month).

To program the ESP-LX+ or ESP-LXi+ controller under battery

power, install the battery as described on page 62. To remove

the face panel, see the instructions on page 48. The controller

can be programmed under battery power, but should not be

operated on battery power alone. Connect the controller to an

AC power source as soon as possible to avoid battery drain.

Page 10

7ESP-LX+ & LXi+ Installation, Programming, & Operation Guide

Programming Checklist

To program the ESP-LX+ or LXi+ controller for the first time,

we recommend that you complete the following steps in order.

For your convenience, a check-off box (❐) is provided for each

step.

❐ Fill out Programming Chart .................................................. Page 8

❐ Clear all program information ............................................... Page 10

❐ Set time and date................................................................. Page 11

For each program:

)*+,

❐❐❐❐Select program (A, B, C, or D-drip). ... Page 13

❐❐❐❐Set watering day cycle ....................... Page 14

❐❐❐❐Set station watering times. ................. Page 19

❐❐❐❐Set program start time(s). ................... Page 21

❐❐❐❐Set water budget (optional). ............... Page 23

❐❐❐❐Set station delays (optional). .............. Page 24

❐ Set master valve / pump starts for each station (optional). . Page 26

❐ Set rain delay (optional). ...................................................... Page 28

❐ Set calendar day(s) OFF (optional). ..................................... Page 29

❐ Set sensor system and bypass switch (optional). ............... Page 31

❐ Set controller to automatic operation. ................................. Page 33

❐ Run test program (optional). ................................................. Page 36

Page 11

8 ESP-LX+ & LXi+ Installation, Programming, & Operation Guide

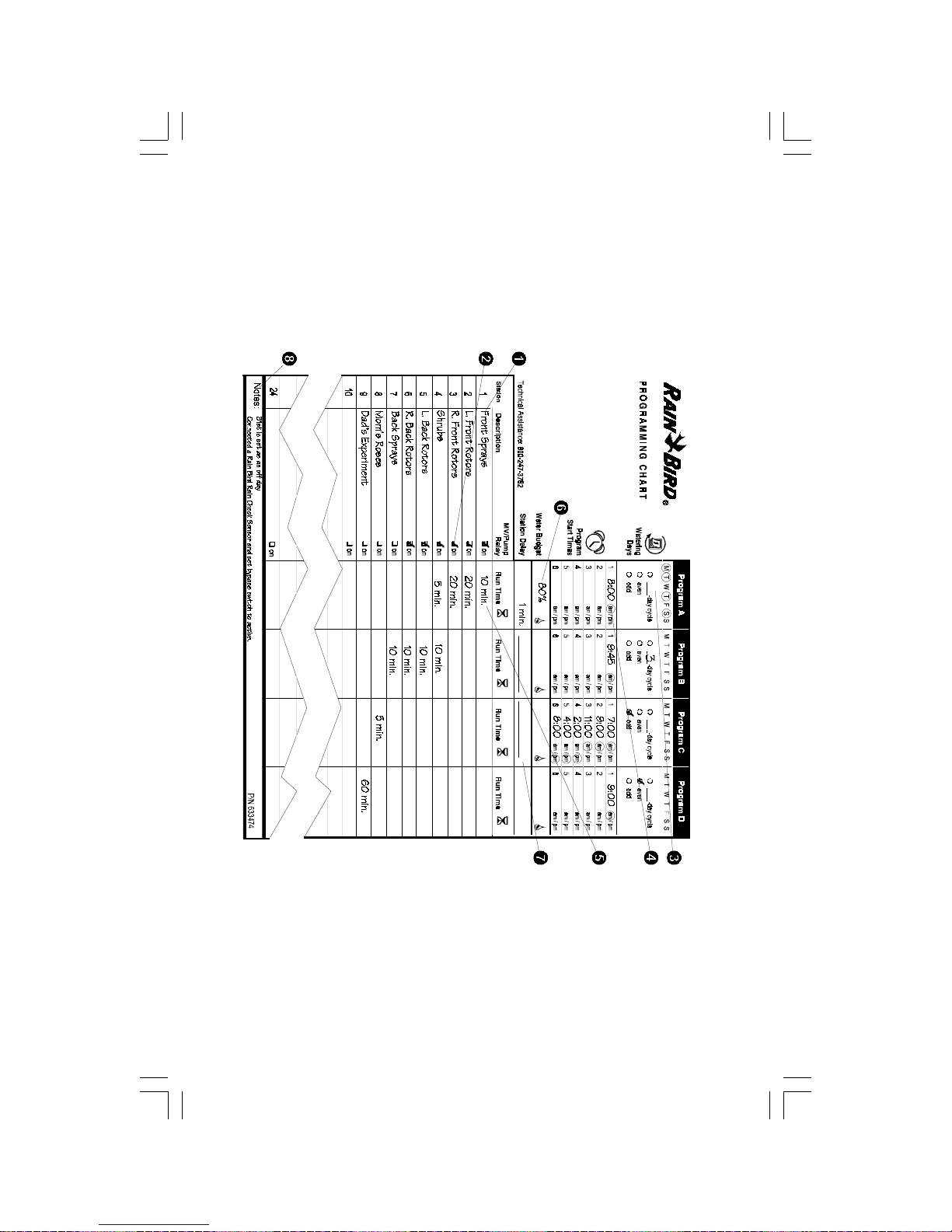

Fill Out Programming Chart

Before you begin programming, fill out the Programming Chart

and attach it to the inside of the controller door. A sample

Programming Chart is shown on page 9. Follow these instructions to complete the chart.

➊ Describe the sprinklers or plant zones covered by each

station on the controller.

➋ Indicate which stations drive a master valve or booster

pump relay by checking ON in the MV / Pump column.

(See page 26 for more information).

➌ In the Program A column, for Custom cycle, circle the

specific days of the week; for Cyclical schedule, write the

cycle period (e.g., 3-day cycle means every third day);

for ODD/EVEN-day watering, check ODD or EVEN.

➍ Enter the start time for Program A. You may enter up to six

start times for each program, but only one is needed to run

the program.

NOTE: Start times apply to the program, not to the

individual stations assigned to the program. In this

example, Program A begins watering at 8:00 a.m. on

Mondays, Tuesdays, Thursdays, and Saturdays.

Station 1 runs for ten minutes, followed by Station 2

for 20 minutes, Station 3 for 20 minutes, and Station 4

for 5minutes. The entire program takes about an

hour.

➎ Enter the watering run time (in hours and minutes) for each

station assigned to Program A.

➏ Enter the water budget percentage by program. The water

budget for sample Program A is set to 80%.

➐ Enter the station delays for Program A. A station delay is

the time between the end of one stations operation and

the beginning of the next. Use a station delay to let a water

well recover or to allow slow-closing valves to turn off

completely. If neither of these situations applies to your

site, leave the station delay set to 0. A station delay setting

applies to all stations in the program.

In the sample chart, Program A has a one-minute delay

between stations. When Station 1 ends, the controller waits

one minute before starting Station 2. There will also be a

one-minute delay between Station 2 and Station 3, etc.

➑ Make any special notes in the space provided.

➒ Repeat steps 2 through 7 for Programs B, C, and D.

NOTE: Stations assigned to Program D cannot be

used in any other programs. See page 19 for more

information.

Page 12

For E S P -LX + a nd LX i+ Co n trollers

D

9ESP-LX+ & LXi+ Installation, Programming, & Operation Guide

Page 13

10 ESP-LX+ & LXi+ Installation, Programming, & Operation Guide

Clear All Program Information

To ensure you begin with a clean setup, clear the controller of

all existing program settings.

➊ Turn the dial to OFF.

➋ Hold down ON and MAN. START/ADV. for about seven

seconds until the display reads INITSYS and then begins to

scroll.

➌ When the last digit in SUN 12:00 flashes in the display, the

existing program settings have been cleared.

Page 14

11ESP-LX+ & LXi+ Installation, Programming, & Operation Guide

Set Time

Before you can program the controller, you must set its internal

clock to the correct time and date.

➊ Turn the dial to TIME & CALENDAR.

➋ The hour digits in the display flash.

➌ Press ñ or ò to set the current hour. Make sure the AM/

PM indicator is set to the correct designation.

➍ Press MAN. START/ADV.

➎ The minutes digits in the display flash.

➏ Press ñ or ò to set the current minute.

Page 15

12 ESP-LX+ & LXi+ Installation, Programming, & Operation Guide

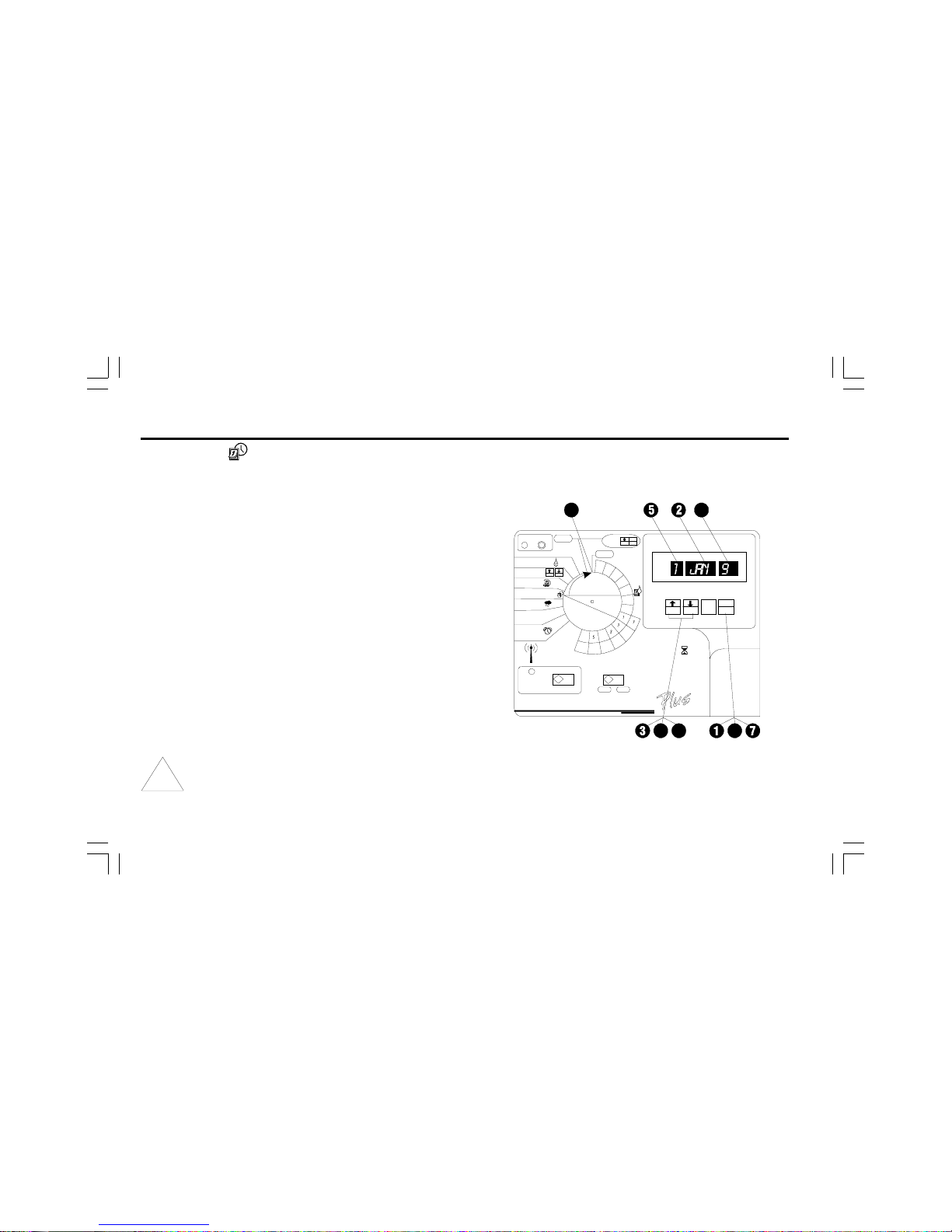

Set Date

➊ Press MAN. START/ADV. until the date (1/JAN/95) shows

in the display.

➋ The month flashes in the display.

➌ Press ñ or ò to set the current month.

➍ Press MAN. START/ADV.

➎ The day number flashes in the display.

➏ Press ñ or ò to set the current day of the month.

➐ Press MAN. START/ADV.

➑ The year flashes in the display.

➒ Press ñ or ò to set the current year.

➓ You are finished setting the time and date. Turn the dial to

AUTO.

NOTE: If you do not want to water on a specific day of

the month or on the 31st of any month, see Set

Calendar Days OFF on page 29.

Page 16

13ESP-LX+ & LXi+ Installation, Programming, & Operation Guide

Programs A, B, and C are not allowed to overlap each other. If

they are programmed to overlap, programs A, B, or C will

stack (run in consecutive order upon the completion of the

program in progress).

Program stacking prevents excessive flow demand and low

water pressure caused by having too many valves running at

one time.

NOTE: It is easier to select one program and program

it completely. Jumping from program to program can

be confusing.

Select Program

Four independent programs are available in the ESP-LX+,

LXi+ Series controller: A, B, C, and D-drip. Multiple independent programs let you enter watering schedules to meet the

requirements of different types of plant materials, soils, slopes,

shady or sunny areas, etc.

The D-drip program is designed for drip irrigation equipment.

Stations assigned to the D-drip program cannot be assigned

to any other program. The D-drip program can overlap, or run

concurrently, with programs A, B, or C.

➊ Turn the dial to AUTO.

➋ Press PGM to cycle through the available programs. The

program indicator on the far left side of the display shows

which program is currently selected.

Page 17

14 ESP-LX+ & LXi+ Installation, Programming, & Operation Guide

Set Watering Day Cycle

Each program can operate in one of four watering day cycles:

1. CUSTOM waters on the days of the week you select. See

the instructions below.

2. CYCLICAL waters on a selected daily interval (for example,

every other day, or every third day). See page 16.

3. ODD waters only on odd-numbered days of the month.

See page 18.

4. EVEN waters only on even-numbered days of the month.

See page 18.

Custom

To set a custom cycle:

➊ Turn the dial to DAY CYCLE.

➋ The display shows the currently selected program. If the

program you want is not displayed, press PGM until it

appears.

➌ Press ñ or ò until CUSTOM appears in the display.

Page 18

15ESP-LX+ & LXi+ Installation, Programming, & Operation Guide

➍ Turn the dial to MON.

➎ The display shows the selected day and either ON or

OFF. ON means the selected day is a watering day. OFF

means watering doesnt take place on that day.

➏ Press ñ or ò to set the day ON or OFF.

➐ Turn the dial to the next day of the week. Repeat steps 5 and

6 until you have set each day of the week ON or OFF.

➑ Turn the dial to AUTO.

Page 19

16 ESP-LX+ & LXi+ Installation, Programming, & Operation Guide

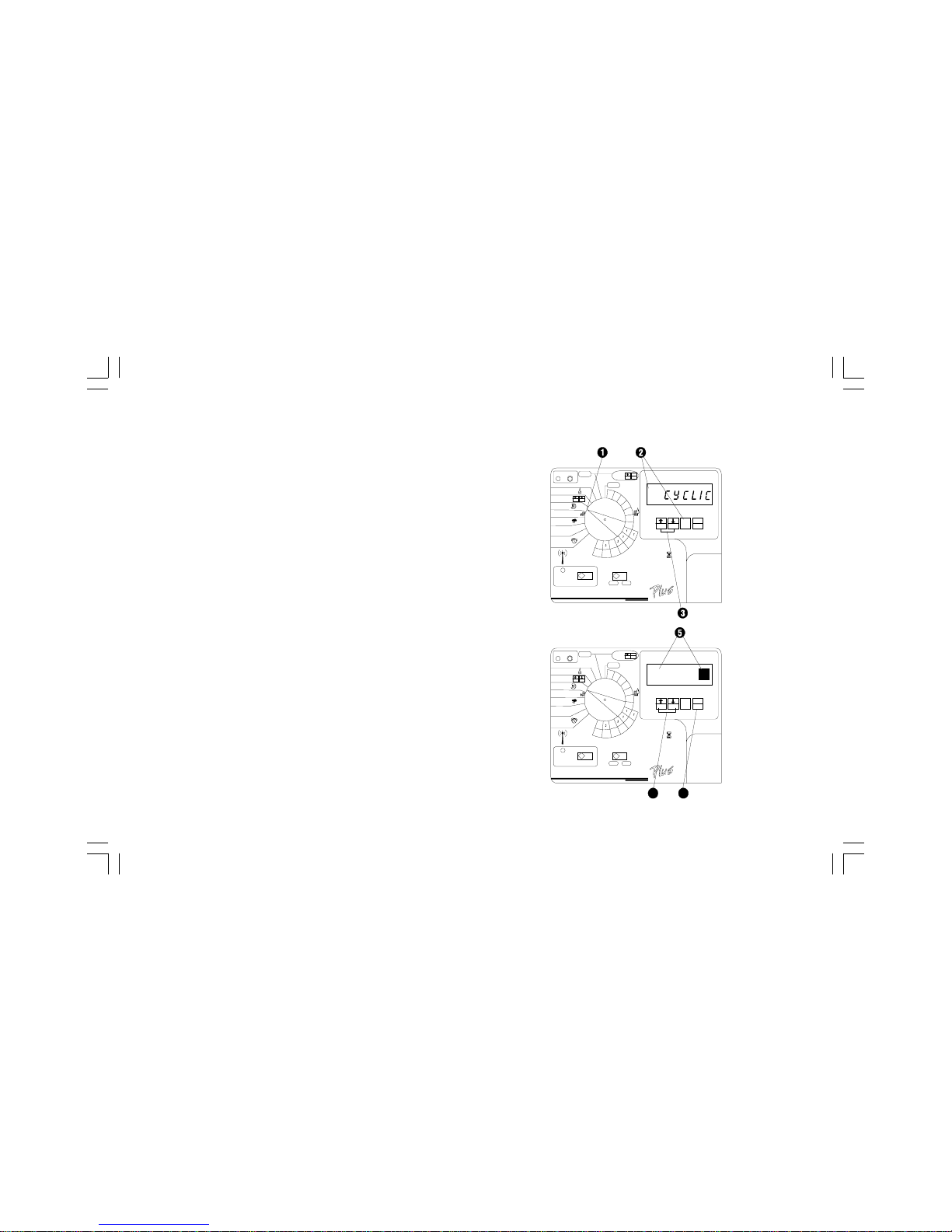

Cyclical

To set a cyclical schedule:

➊ Turn the dial to DAY CYCLE.

➋ The display shows the currently selected program. If the

program you want is not displayed, press PGM until it

appears.

➌ Press ñ or ò until CYCLIC appears in the display.

➍ Press MAN. START/ADV.

➎ The display shows the number of days remaining until a

watering day and the number of days in the cycle. The DAY

CYCLE digit flashes.

➏ Press ñ or ò to set the number of days in the cycle. For

example, if you want to water every other day, set the day

cycle to 2. If you want to water every third day, set the day

cycle to 3.

Page 20

17ESP-LX+ & LXi+ Installation, Programming, & Operation Guide

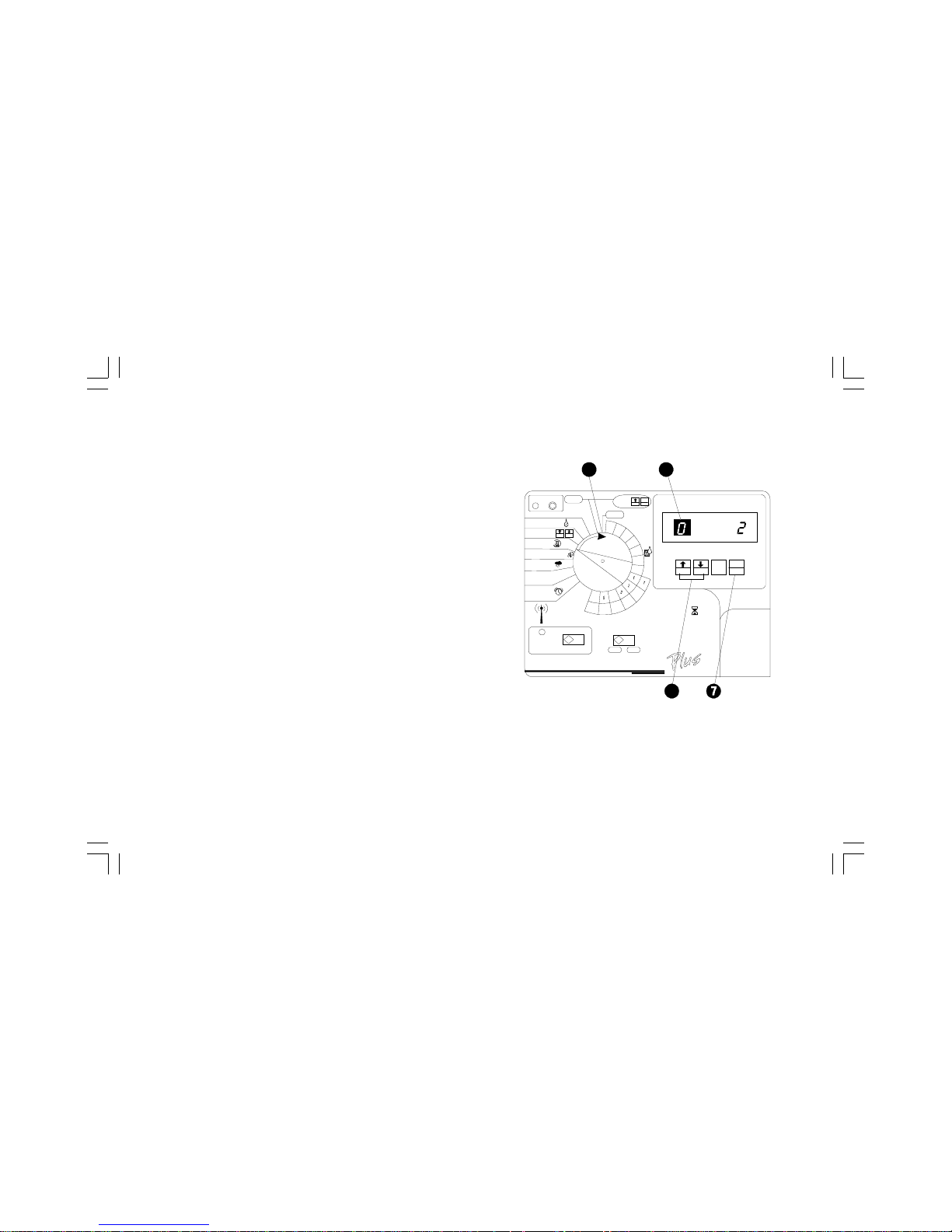

➐ Press MAN. START/ADV.

➑ The DAYS REMAINING digit flashes.

➒ Press ñ or ò to set the number of days remaining before

the next watering day. 0 means that today is a watering

day. So if you want watering to begin tomorrow, set the days

remaining to1.

➓ Turn the dial to AUTO.

Page 21

18 ESP-LX+ & LXi+ Installation, Programming, & Operation Guide

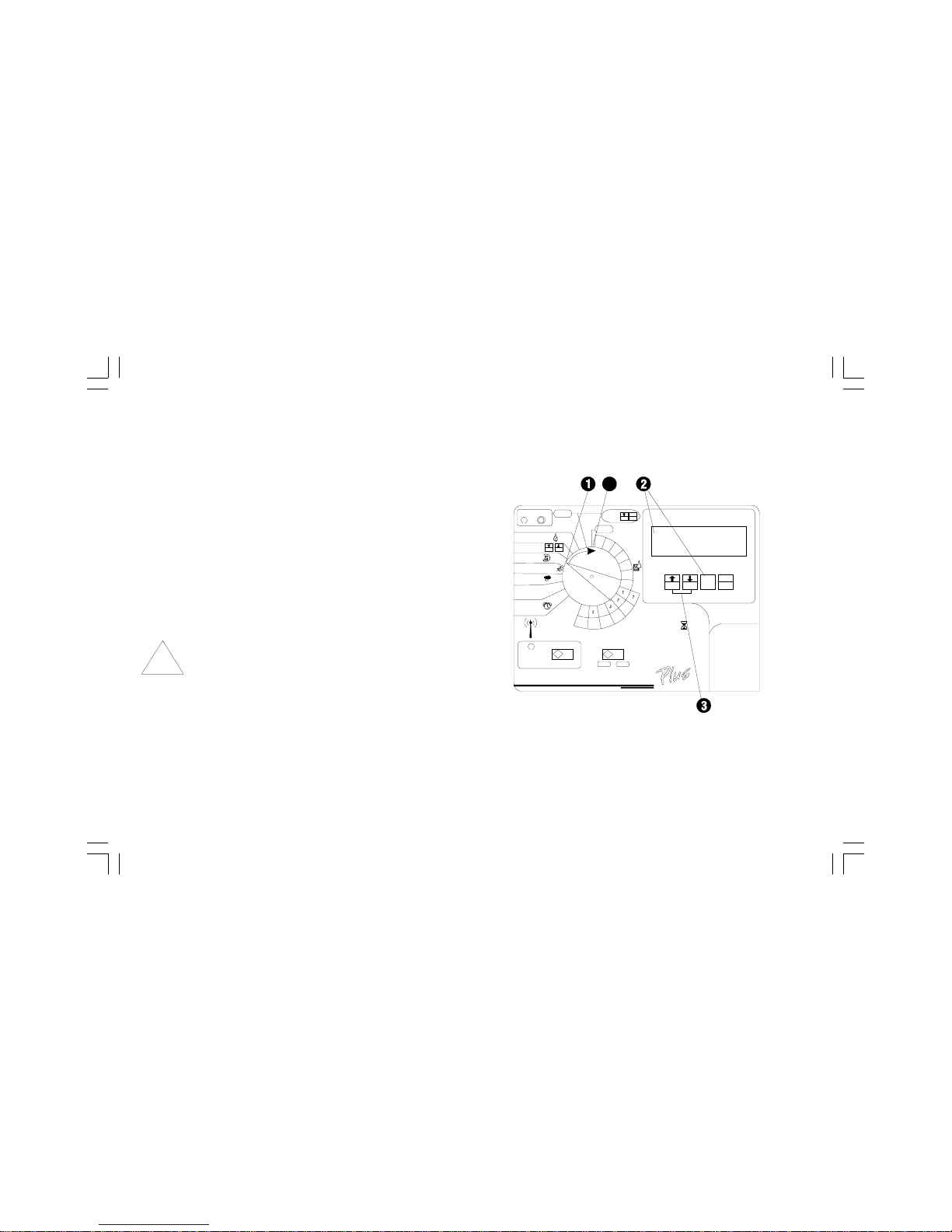

Odd/Even Cycle

To set an odd/even cycle:

➊ Turn the dial to DAY CYCLE.

➋ The display shows the currently selected program. If the

program you want is not displayed, press PGM until it

appears.

➌ Press ñ or ò until ODD or EVEN appears in the

display.

➍ Turn the dial to AUTO.

NOTE: If you do not want to water on the 31st of any

month (a restriction imposed in some local areas), you

must set the 31st day OFF. See page 29 for

instructions.

Page 22

19ESP-LX+ & LXi+ Installation, Programming, & Operation Guide

Set Station Watering Times

You can set any station to run from 0 to 12 hours. For the first

two hours, you can set the watering time in one-minute increments. For the remaining 10 hours, you can set the watering

time in 10-minute increments.

➊ On 12-, 16-, 20-, and 24-station models, set the STA-

TIONS slide switch to the block of stations you want to set.

➋ Turn the dial to the station number you want in the

WATERING TIME PER STATION section of the dial.

➌ The display shows the program, the station number, and

the currently set watering time. If the station has been

included in another program, USED appears in the

display.

NOTE: If USED appears, you can still set a watering

time for the station unless the station has been

previously assigned to the D-drip program. Stations

assigned to the D-drip program cannot be used by

any other program.

Page 23

20 ESP-LX+ & LXi+ Installation, Programming, & Operation Guide

➍ If the program you want is not displayed, press PGM

until it appears.

➎ Press ñ or ò to set the length of time you want the

station to run. Repeat steps 2 - 5 for all stations. If you do

not want to include a station in the program, set the run time

to zero.

➏ After you have set the run time for the last station, turn the

dial to AUTO.

NOTE: You can use the Water Budgeting feature to

set watering times of less than one minute. For

example, if you set a station watering time of one

minute and adjust Water Budgeting to 50 percent,

the station will run for 30 seconds. See page 23 for

instructions on setting the Water Budget.

Page 24

21ESP-LX+ & LXi+ Installation, Programming, & Operation Guide

Set Program Start Times

You may assign up to six start times to each program per day.

A program may start on any quarter hour. Multiple start times

let you run a program more than once on each watering day.

For example if you are growing new lawn seed, you may want

to water several times a day to keep the seedbed or top

dressing damp.

NOTE: Start times apply to the entire program, not to

an individual station.

➊ Turn the dial to PROGRAM START TIMES.

➋ The display shows the program, the number of the start

time, and the start time itself. The start time number flashes.

➌ If the program you want is not displayed, press PGM until

it appears.

➍ Press ñ or ò to select one of the six start time numbers

for the program.

➎ Press MAN. START/ADV.

➏ The program start time flashes.

Page 25

22 ESP-LX+ & LXi+ Installation, Programming, & Operation Guide

➐ Press ñ or ò to set the start time. Start times are

available in 15-minute intervals throughout the day.

To eliminate a start time, leave the dial on PROGRAM START

TIMES. Choose the start time to be deleted and push MAN.

START / ADVANCE until the time flashes. Then press the ñ or

ò buttons until the LCD displays the OFF setting, located

between 11:45 p.m. and 12:00 a.m. (between 23:45 and 24:00

for International models).

NOTE: Start times appear in chronological order. If you

delete a start time by setting it to OFF, all later start

times are automatically moved down one start time

number.

When you set a start time for any start time number,

the controller automatically reorganizes the start times

so they appear in chronological order. The earliest

start time will be number 1, and the latest start time will

be number 6. This reorganizing only occurs after you

move the dial off the PROGRAM START TIMES

position.

➑ If you want to set additional start times, press MAN.

START/ ADV. Repeat steps 2 - 7 to set the next start time.

➒ Turn the dial to AUTO.

Page 26

23ESP-LX+ & LXi+ Installation, Programming, & Operation Guide

Set Water Budget

The water budget feature lets you increase or decrease the run

times of all stations on each program by a selected percentage.

You can set the percentage from 0 to 300, in increments of one

percentage point. Each program (A, B, C, and D) can have a

different water budget percentage.

You can use the water budget feature to cut back watering

during cool winter months, or to increase watering during

periods of unusual heat.

In addition, you can use the 0% setting to shut off a program

temporarily.

Water budget percentages are calculated based on the

normal programmed run times for each station. For example, if

a station is programmed to run for 10 minutes, and you set the

water budget to 80%, the station will run for 8 minutes (80% of

10). If you set the water budget to 120%, that same station will

run for 12 minutes (120% of 10).

➊ Turn the dial to WATER BUDGET.

➋ The display shows the selected program and its current

water budget percentage. The default is 100%.

➌ If the program you want is not displayed, press PGM

until it appears.

➍ Press ñ or ò to set the percentage.

➎ To set water budgeting for another program, press PGM

until the program appears. Then repeat step4.

➏ Turn the dial to AUTO. When the water budget for a

program is set higher or lower than 100%, WATER

BUDGET appears in the display whenever the program is

selected.

Page 27

24 ESP-LX+ & LXi+ Installation, Programming, & Operation Guide

Set Station Delays

The station delay feature lets you program a pause between

the end of one stations watering operation and the beginning

of the next stations operation. You may set a delay from one

second to nine hours.

You can use station delays to let a water well recover or to

allow slow-closing valves to turn off completely. If neither of

these situations applies to your site, leave the station delay set

to 0.

You can set a different station delay for each program. A

station delay applies to all stations on a given program.

Because the station delay feature is not used very often, it has

been hidden behind the TEST / STATION DELAY position

on the dial.

➊ Turn the dial to TEST / STATION DELAY.

➋ The display shows TEST and the standard two-minute

run time for the test program.

➌ Press ñ AND ò at the same time.

Page 28

25ESP-LX+ & LXi+ Installation, Programming, & Operation Guide

➍ DELAY appears in the display momentarily, followed by

the delay time.

➎ If the program you want is not displayed, press PGM

until it appears.

➏ Press ñ or ò to set the delay time. To cancel station

delay, set the delay time to zero.

NOTE: The display initially shows the delay time in

seconds (SEC). When you advance past 59

seconds, the display changes to MIN for minutes

and seconds. When you advance past 60 minutes,

the display changes to HOUR for hours and

minutes.

➐ To set delays for additional programs, press PGM until the

program you want appears. Repeat step 6.

➑ Turn the dial to AUTO.

NOTE: During the delay between stations, the

master valve / pump relay is not active. See page 26

for instructions on setting the master valve / pump

relay.

Page 29

26 ESP-LX+ & LXi+ Installation, Programming, & Operation Guide

The MV / Pump start setting affects the station in all programs

to which it is assigned.

CAUTION: If an unused station is turned on and

activates a pump start relay, the pump may overheat

or cause a pipe to burst. To prevent operating a pump

with no flow (deadheading), make sure all unused

stations have a zero run time.

Set MV / Pump Starts

You can assign a master valve relay or a pump start relay to

each station. This means that any time the station operates, the

relay assigned to it will also turn on. For example, if a specific

station needs additional water pressure, you may want to

activate a booster pump whenever that station turns on.

NOTE: Stations that have a master valve / pump

relay assigned to them must be wired properly to

activate the relay. See pages 53-55 for instructions.

➊ Turn the dial to MV or PUMP SELECT.

➋ The display shows the station number and MV ON or

MV OFF. The station number flashes.

➌ Press ñ or ò to select the station number you want to

set.

➍ Press MAN. START/ADV.

Page 30

27ESP-LX+ & LXi+ Installation, Programming, & Operation Guide

➎ The ON or OFF flashes in the display.

➏ Press ñ for ON or ò for OFF.

➐ To set another station, press MAN. START/ADV. Repeat

steps 2 - 6 for each station you want to set.

➑ Turn the dial to AUTO.

Page 31

28 ESP-LX+ & LXi+ Installation, Programming, & Operation Guide

Set Rain Delay

ESP-LX+ and -LXi+ controllers let you manually delay

watering for up to 14 days. For example, if rainy weather lasts

for 2 or 3 days, you can set a Rain Delay of 5 or 6 days to let the

landscape dry out before resuming normal watering.

The Rain Delay setting applies to all programs. You can run

programs manually during the Rain Delay period.

NOTE: The Rain Delay feature lets you set a delay

period manually. If you have an automatic rain sensor

attached to your system, see the instructions on

page 31.

➊ Turn the dial to RAIN DELAY.

➋ The display shows RAIN DELAY and the number of days

remaining until the next watering day. If there is no Rain

Delay set, zero will appear in the display above the words

DAYS REMAINING.

➌ Press ñ or ò to set the number of days to wait until the

next watering day. To cancel a Rain Delay, set the number

of days to zero.

➍ Turn the dial to AUTO.

Page 32

29ESP-LX+ & LXi+ Installation, Programming, & Operation Guide

Set Calendar Days OFF

The Calendar Day OFF feature lets you:

• Temporarily suspend watering on a specific day of the

month (selected up to 30 days in advance). For example, if

you are planning a picnic on July 4th, you can set July 4th

OFF, so no watering will occur. After July 4th passes, the

fourth of each month will be automatically reset to ON.

• Permanently set the 31st day of any month OFF. This setting

complies with local watering ordinances that prohibit watering

on the 31st. Unlike settings for other days of the month, this

setting remains in effect until you change it.

A Calendar Day OFF setting applies to all programs.

➊ Turn the dial to TIME & CALENDAR.

➋ Press MAN. START/ADV five times.

➌ The display shows the day of the month and its ON or OFF

setting. The day of the month flashes.

➍ Press ñ or ò to select the day of the month you want to

set.

Page 33

30 ESP-LX+ & LXi+ Installation, Programming, & Operation Guide

➎ Press MAN. START/ADV.

➏ The ON or OFF setting flashes.

➐ Press ñ to set the day ON or ò to set the day OFF.

➑ Turn the dial to AUTO. When an OFF day occurs, the

display shows NON (for non-watering day), and no

watering occurs. The next time the date occurs, normal

watering schedules will resume (except for the 31st of the

month, which remains OFF until you reset it manually).

Page 34

31ESP-LX+ & LXi+ Installation, Programming, & Operation Guide

NOTE: For this feature to operate properly, the sensor

must be connected according to the instructions on

page 54.

➊ To activate the sensor system, set the sensor bypass

switch to ACTIVE. The controller will operate normally

until a wet condition is detected by the sensor.

NOTE: If no sensor is attached to the controller, make

sure the supplied jumper connects the two SENSOR

terminals on the controllers circuit board. If you set

the sensor bypass switch to ACTIVE without a

sensor or jumper connected to these terminals, the

valves will not operate, and no watering will occur. See

page 54 for instructions.

➋ When the sensor detects a wet condition, power to the

valves will be interrupted, and no watering will occur

(including manual program or station operation.) The

WATERING SUSPENDED BY SENSOR indicator will light

up.

Set Sensor System and Bypass

Switch

ESP-LX+ and -LXi+ controllers let you connect a sensor

system that interrupts watering when a wet condition is

detected. For example, if you have a Rain Bird Rain Check

sensor connected to the controller, irrigation will be prevented

when rainfall reaches the shutoff level in the sensors collector

cup.

Page 35

32 ESP-LX+ & LXi+ Installation, Programming, & Operation Guide

➌ To bypass the sensor, set the sensor bypass switch to

OFF. The controller will ignore any sensor signals, and

normal watering schedules will resume. This setting

also lets you run programs and stations manually.

Page 36

33ESP-LX+ & LXi+ Installation, Programming, & Operation Guide

OPERATING THE CONTROLLER

After you have programmed the controller, you will normally set

it to operate automatically.

You can also manually run one or more programs, and you can

manually operate a single station or several stations.

In addition, you can run a test program to test the operation of

all stations on the system. To operate automatically, run

programs or stations manually, or run a test program, the

controller should be connected to a 120 volt AC power source

(230 volt AC for international models).

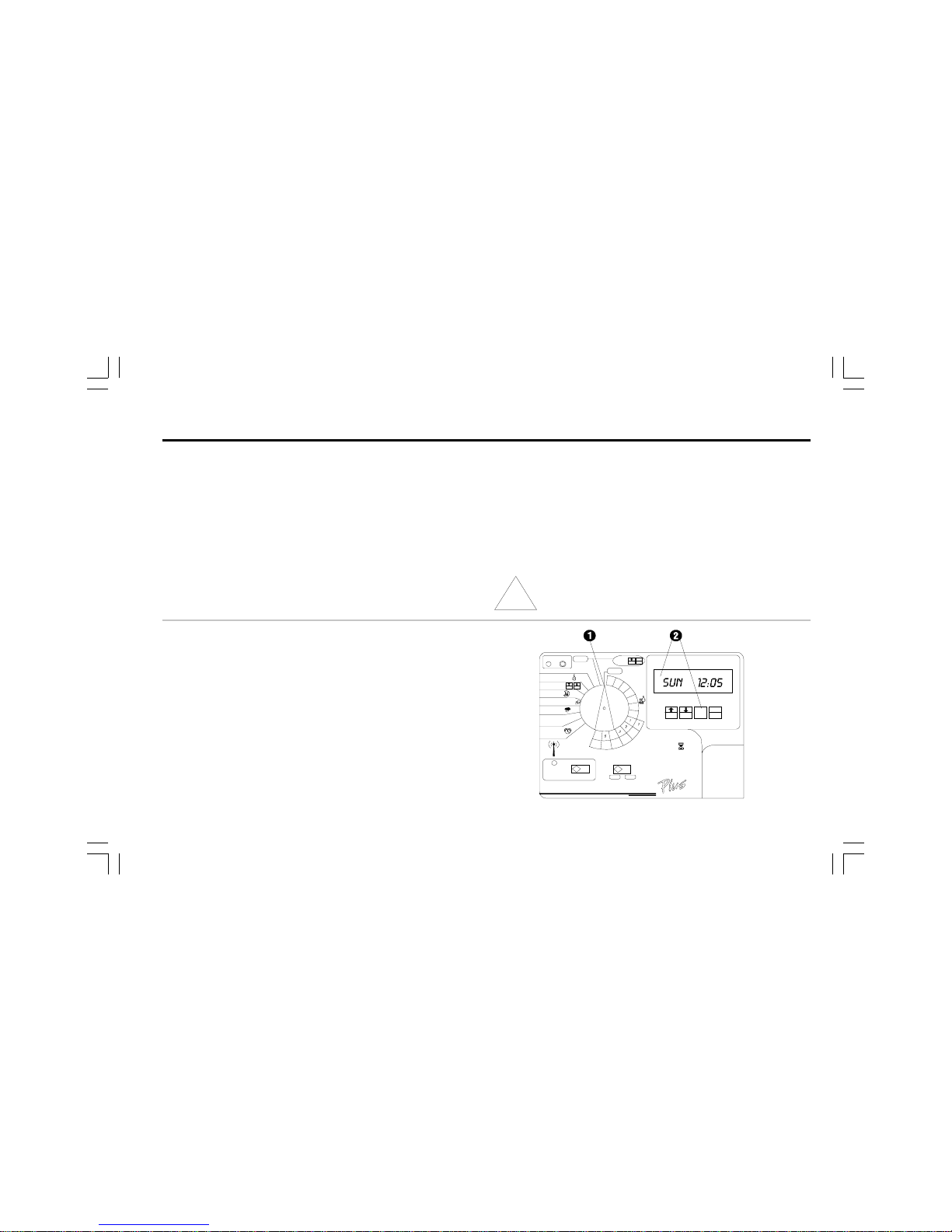

Operate Controller Automatically

➊ Turn the dial to AUTO. The controller runs the sprinklers

according to the programs you have set.

If you forget to turn the dial to AUTO, the controller will

eventually set itself to automatic operation. The only

setting that prevents automatic operation is OFF

(see step 2).

➋ To turn off the controller and prevent all watering, turn the

program dial to OFF. The display will show the current

day and time, and the right-hand minute digit will flash,

indicating that the controller has been turned off.

You can use the OFF setting to suspend watering during

rainy periods, seasonal shutdown, or system maintenance.

Page 37

34 ESP-LX+ & LXi+ Installation, Programming, & Operation Guide

Run Program(s) Manually

NOTE: To run a program manually, please follow the

instructions below carefully. Unlike other ESP

controllers, ESP-LX+ and -LXi+ controllers have

completely independent programs. Therefore, you

must select a program before you press the MAN.

START / ADV. button.

➊ Turn the dial to AUTO.

➋ The display shows the day of the week and time of day.

➌ Press PGM until the program you want is displayed.

➍ Press MAN. START / ADV. to start the selected program.

If you want to run additional programs, repeat steps 3 and

4. Each program you select will run when the previous

program has ended. You can stack all four programs to

run in sequence.

➎ To cancel all programs currently selected to run, turn the

dial to OFF for three seconds. Then turn the dial back to

AUTO.

Page 38

35ESP-LX+ & LXi+ Installation, Programming, & Operation Guide

Run Station(s) Manually

➊ On 12-, 16-, 20-, and 24-station models, set the

STATIONS slide switch to the block of stations

containing the one you want to run.

➋ Turn the dial to the station number you want in the

WATERING TIME PER STATION section of the dial.

➌ The display shows the currently selected program, the

station number, and the stations run time. If the station is

not used in the current program but is used in another

program, the word USED will appear in the display

instead of the run time.

➍ Press PGM until the display shows a run time for the

station.

➎ Press MAN. START / ADV. to operate the selected

station. If you want to run additional stations, repeat steps

3 to 5. Each station you select will run when the previous

station has ended.

➏ After selecting all the stations you want to run, turn the dial

to AUTO. The stations you have selected will operate for

their programmed run times and then shut off automatically.

➐ To cancel the manual operation of all selected stations, turn

the dial to OFF for three seconds. Then turn the dial back

to AUTO.

Page 39

36 ESP-LX+ & LXi+ Installation, Programming, & Operation Guide

Run Test Program

The controllers built-in test program will run each station that

has a non-zero watering time assigned to it. When you run the

test program, the controller will operate each station in

numerical sequence, from lowest to highest. You can use this

program to check the operation of all the sprinklers in the

system.

➊ Turn the dial to TEST/ Station Delay.

➋ The display shows TEST and the amount of time each

station will run. The default test run time is two minutes per

station.

➌ Press ñ or ò to increase or decrease the run times for

the TEST PROGRAM. The maximum test run time is 10

minutes.

➍ Press MAN. START/ADV. to start the test program.

➎ Turn the dial to AUTO.

➏ The display shows the number of the station that is

running, along with its remaining run time. The controller

runs each station in sequence, from lowest number to

highest. The test program skips any stations that have

zero watering times assigned to them. When the test

program is finished, the controller returns to automatic

operation.

➐ To cancel a test program after it has started, turn the dial

to OFF for three seconds. Then turn the dial back to

AUTO.

Page 40

37ESP-LX+ & LXi+ Installation, Programming, & Operation Guide

RAPID STATION TEST ROUTINE RASTER

The RASTER is available on indoor and outdoor versions of

Rain Birds ESP-LX+ and -LXi+ controllers.

Introduction

Rain Birds RApid Station TEst Routine (RASTER) lets you

diagnose and troubleshoot field wiring, solenoid, and controller

problems quickly and easily.

The RASTER sends an electric signal to each valve terminal on

the controller and then displays the valves current operating

condition. Results appear in the easy-to-read digital display.

The RASTER checks each station and displays one of three

results:

1. OPEN The circuit between the controller and the valve

is open; i.e., no current is flowing.

2. SHORT The circuit between the controller and the valve

has a short; i.e., current is flowing on an

unintended path.

3. FAIL The controller was unable to send the test signal

to the stations. This indicates a possible

problem with the controllers internal circuitry.

Page 41

38 ESP-LX+ & LXi+ Installation, Programming, & Operation Guide

RASTER Operation

Running a RASTER

(Rapid Station Test Routine)

NOTE: To run the RASTER, the controller must be

connected to a 120 Volt AC power source

(230 Volt for international models).

➊ Turn the Programming Dial to OFF.

➋ Press and release the ON and OFF buttons at the same

time.

➌ The display will look like this.

Page 42

39ESP-LX+ & LXi+ Installation, Programming, & Operation Guide

Press the MAN START/ADV button to begin the RASTER.

➎ The display shows TEST IO, and the FAULT Indicator

light flashes once as the RASTER confirms the proper

operation of the controllers front panel lights.

The RASTER then automatically checks the controllers

master valve and each station valve (in numerical order).

NOTE: If the front panel ribbon cable is not connected

to the circuit board or the controller is disconnected

from the main power supply, the LCD will display the

message NO OUT.

TEST IO

Page 43

40 ESP-LX+ & LXi+ Installation, Programming, & Operation Guide

Valve Testing

➊ The display briefly shows TEST (may flash too rapidly to

be seen) and the station number (or MV for master

valve) being tested.

➋ The display shows the valves operating condition

(PASS, FAIL, OPEN, or SHORT), followed by the

station number (up to 24 stations, depending on controller

model). This sample display indicates a short on valve

station number 4.

➌ The RASTER displays the condition of each valve for 10

seconds, (PASS displays for less than one second and

may flash too fast to be seen) and then moves to the next

valve. You can press MAN START/ADV (or any other

magenta button) at any time to advance to the next station

to be tested.

NOTE: Any controller station that does not have a valve

connected to it will appear as OPEN. This is normal

and does not indicate any problem with the controller

or system valves.

For example, if you have a 12-station controller with

only stations 1 through 10 connected to valves,

stations 11 and 12 will show OPEN on the RASTER.

Page 44

41ESP-LX+ & LXi+ Installation, Programming, & Operation Guide

➍ If the master valve and all station valves pass the RASTER,

the display flashes PASS for 10 seconds. The controller

then returns to normal operation (i.e., waiting for its next

start time).

NOTE: If any unconnected valve station caused the

RASTER to display an OPEN message, (see NOTE on

previous page), the PASS message will not be

displayed. This is normal and does not indicate any

problem with the controller or the valves.

➎ If the RASTER detects a problem on the master valve or

any station valve, the display flashes CHECK for three

seconds.

➏ The display shows the condition and number of each

problem station. Each problem station will flash in the

display for five seconds. Press MAN START/ADV at any

time to display the next problem station.

➐ If any station displays FAIL, it means the controller was

unable to send the test signal to the valve, indicating a

possible problem with the controllers internal circuitry. Call

Rain Bird Technical Assistance at 800-247-3782, or contact

your local authorized Rain Bird distributor to service your

controller.

Page 45

42 ESP-LX+ & LXi+ Installation, Programming, & Operation Guide

➑ Any valve displaying OPEN or SHORT should be

checked for field wiring or other circuit problems. See

Troubleshooting Open and Shorted Valves Circuits on

page 43 for more information.

➒ To exit the RASTER, turn the Programming Dial from OFF

to AUTO (or any other dial position).

➓ The controller returns to normal operation, awaiting its

next scheduled start time.

Page 46

43ESP-LX+ & LXi+ Installation, Programming, & Operation Guide

Open Circuits

An OPEN condition reported by the RASTER indicates a

complete break in the current flow between the controller and

the valve.

NOTE: The RASTER will display an OPEN condition if

no valve solenoid is connected to the controller

station. This is normal, and the system does not need

service.

Open circuits can be caused by:

• Malfunctioning valve solenoids

• Field wires that have been cut or pulled loose

• Loose wire connections on the controllers terminal strip or

at the valve solenoid

• Damaged components on the controllers internal circuit

board

Troubleshooting Open and Shorted Valve Circuits

Page 47

44 ESP-LX+ & LXi+ Installation, Programming, & Operation Guide

Short Circuits

A SHORT condition reported by the RASTER indicates an

unintended re-routing of current flow somewhere between the

controller and the valve.

Short circuits can be caused by:

• Shorted valve solenoids

• Nicked or skinned field wires

➌ If the OPEN or SHORT recurs on the original station,

the controllers internal circuitry may need service.

➍ If the OPEN or SHORT moves to the new station, check

the valves solenoid and field wiring.

• Loose or corroded wire connections on the controllers

terminal strip or at the valve solenoid

• Malfunctioning components on the controllers internal

circuit board

Troubleshooting Opens and Shorts

To troubleshoot a valve station identified as OPEN or

SHORT:

➊ Make sure the valves station wires are securely connected

to the controllers terminal strip.

➋ If the wires are securely connected, move the stations wires

to a station that passed the RASTER. Then re-start the test.

Page 48

45ESP-LX+ & LXi+ Installation, Programming, & Operation Guide

INSTALLING THE CONTROLLER

This section of the manual explains how to mount the controller

on the wall and connect the wiring.

NOTE: This controller must be installed in compliance

with local electrical codes.

The ESP-LXi+ controller must be installed indoors only. The i

in the model number stands for indoors.

The ESP-LX+ controller may be installed either indoors or

outdoors.

Installation Checklist

To install the ESP-LX+ controller, we recommend that you

complete the following steps in order. For your convenience, a

check-off box (❐) is provided for each step.

❐ Select location. ...................................................................... Page 46

❐ Remove door and face panel. . ............................................. Page 48

❐ Mount controller on wall. . ...................................................... Page 50

❐ Connect field wires. . ............................................................. Page 52

❐ Connect sensor system (optional). . ...................................... Page 54

❐ Connect main power wires. . ................................................. Page 56

❐ Install battery. . ....................................................................... Page 62

Page 49

46 ESP-LX+ & LXi+ Installation, Programming, & Operation Guide

Select Location

Follow these guidelines to select a location for the controller:

➊ Select an area protected from vandalism, where the user

can easily reach the controller. We recommend mounting

the controller at eye level in a utility room.

NOTE: To minimize electromagnetic interference,

select a location at least 15 feet (4,6 m) away from

high-draw motors such as air conditioners,

refrigerators, or pool pumps.

➋ Select a location that has access to 120-Volt AC electrical

power or 230-Volt AC electrical power (as required).

WARNING: A circuit breaker or cutoff switch is to be

provided in the fixed wiring to isolate the controller.

➌ Choose a flat, stable, vertical surface. Allow enough

clearance for electrical conduit and connections at the

bottom of the plastic cabinet.

➍ Allow at least 9½" (24,2 cm) of horizontal clearance so the

hinged cabinet door can swing fully open to the left.

➎ Allow at least 6¾" (17,2 cm) of clearance above the

cabinet door so the hinge pin can be removed to service

the controller.

Page 50

47ESP-LX+ & LXi+ Installation, Programming, & Operation Guide

Page 51

48 ESP-LX+ & LXi+ Installation, Programming, & Operation Guide

Remove Door and Face Panel

Before you mount the controller, we recommend that you

remove the door and face panel. Although these steps are not

absolutely necessary, they will make installation more convenient.

➊ Open the door and swing it to the left. If necessary, unlock

the door with the supplied key.

➋ Flip the upper tip of the hinge pin out of the groove in the

door so it is pointing at you.

➌ Support the door and slide the hinge pin upward until it

clears the hinges. Then remove the door.

➍ Open the face panel by grasping its lower right corner and

swinging it to the left.

➎ Disconnect the ribbon cable by grasping it along its two

flat sides. Then pull the cable gently out of its connector.

➏ Unplug the two-wire harness by releasing the latch on the

side of the connector. Then pull the connector away from

the terminal board.

➐ Press down on the upper flexible hinge to release the

hinge knob from its hole in the cabinet.

➑ Pull the lower hinge knob out of its hole and remove the

panel.

To reconnect the face panel and door, repeat the steps above

in reverse order. Make sure to reconnect the ribbon cable and

two-wire harness to their connectors for proper controller

operation.

Page 52

49ESP-LX+ & LXi+ Installation, Programming, & Operation Guide

Page 53

50 ESP-LX+ & LXi+ Installation, Programming, & Operation Guide

Mount Controller on Wall

The ESP-LX+ has four mounting holes on the back of the

cabinet three keyhole slots at the top of the cabinet and one

circular hole at the bottom of the cabinet. The shipping carton

for the controller contains a mounting template. You may wish to

cut this template out and use it to mark the controllers mounting

holes in the desired location before you begin drilling.

➊ To install the controller on a flat wall surface, use the left and

right keyhole slots at the top of the cabinet.

➋ To install the controller on a narrow stud, use the center

keyhole slot.

➌ For all installations, use the small round hole at the bottom

of the cabinet.

➍ Hold the controller or mounting template at eye level against

the mounting surface. Use a pencil to mark the position of

the holes on the mounting surface. Then remove the

controller cabinet or template.

➎ On flat wall surfaces, drive an appropriate fastener for the

type of wall into the two outside keyhole marks.

➏ For narrow stud installations, drive an appropriate fastener

for the type of wall into the middle keyhole mark.

➐ Use a nail to tap a small pilot hole on the mark for the

lower mounting hole. However, DO NOT drive a fastener

into this location yet.

➑ Use the keyhole slot(s) to hang the controller cabinet on

the fasteners. Make sure the shafts of the fasteners are well

up in the narrow part of the keyholes.

➒ Drive the last fastener through the lower mounting hole.

Verify that the cabinet is secure. If necessary, tighten the

fasteners in the upper keyhole slot(s).

Page 54

51ESP-LX+ & LXi+ Installation, Programming, & Operation Guide

COM COMMV

GND

MV11

9

9

2

2

10

10

3

3

11

11

4

4

12

12

5

5

13

13

6

6

14

14

7

7

15

15

8

8

16

16

24

VAC

SENSOR

#

"

!

$

%

COM COMMV

GND

MV11

9

9

2

2

10

10

3

3

11

11

4

4

12

12

5

5

13

13

6

6

14

14

7

7

15

15

8

8

16

16

24

VAC

SENSOR

&

'

Page 55

52 ESP-LX+ & LXi+ Installation, Programming, & Operation Guide

Connect Field Wires

Field Wire Entrances

The ESP-LX+ cabinet has four knockouts for routing field wires

from the valves. Two are located on the underside of the cabinet,

and two are located on the back of the cabinet.

➊ The underside of the cabinet has a hole sized for a 1"

(2,6 cm) PVC male adapter so you can easily install a

1" (2,6 cm) PVC pipe or conduit for the valve wires.

➋ A larger knockout for a 1¼" (3,2 cm) PVC male adapter is

molded into the underside of the cabinet, surrounding the

hole for the 1" (2,6 cm) PVC adapter. You may need this

larger hole if you are using #14 gauge wire or larger.

To use the larger hole, turn the cabinet upside down. Place

the blade of a slot-head screwdriver in the groove around

the knockout. Then firmly tap the handle of the screwdriver

to punch in the knockout. You may need to punch the

groove in two places.

➌ If you wish to route the field wires through the wall on which

the controller is mounted, use the knockout for the 1"

(2,6cm) PVC adapter on the back of the controller cabinet.

Use a screwdriver to punch out the knockout, as described

in step 2.

Page 56

53ESP-LX+ & LXi+ Installation, Programming, & Operation Guide

Station Valve Wiring

Connect each valve by its own separate power wire to one of

the numbered terminals on the ESP-LX+ terminal strip, as

shown in the illustration. You may connect up to two 24 VAC,

7VA solenoid valves per station. You may use the special Valve

Test position to help identify valve stations BUT NOT for

permanent connections.

To speed up installation, slide the stripped end of the valve

wire under the pinch plate at each terminal. The pinch plate

eliminates the need to wrap the wire around the screw head.

NOTE: The ESP-LX+ 20- and 24-station models have

a special screwless terminal strip for valve wire

connections.

Connect a common wire to one of the leads on each valve.

Connect the other end of the common wire to the COM terminal

on the flip strip. Wire used to connect the valves must be codeapproved for underground installation.

Master Valve Wiring

NOTE: Complete this section only if your system

requires a master valve (an automatic valve installed

on the mainline pipe upstream from the station valves)

or a pump relay. The controller does NOT provide

main power for a pump. Connect the master valve

wiring to the MV terminal and COM terminal as

shown in the illustration.

Page 57

54 ESP-LX+ & LXi+ Installation, Programming, & Operation Guide

Sensor System Wiring

NOTE: Complete this section only if your system has

an automatic rain sensor.

If you are not connecting a sensor to the controller,

make sure the supplied jumper is installed on the

two SENSOR terminals on the controllers vertical

terminal strip.

➊ Most sensors have two wires or two terminals designed to

be connected to the valve common wire. Instead of

connecting to the valve common wire, connect these wires

or terminals to the SENSOR terminals on the ESP-LX+ or

LXi+ controller.

➋ Route the pair of wires out of the controller cabinet to the

sensor system.

➌ Follow the sensor systems directions for placing and

connecting moisture probes, setting the rain shutoff level,

and making final adjustments.

Page 58

55ESP-LX+ & LXi+ Installation, Programming, & Operation Guide

Pump Start Relay Wiring

NOTE: Complete this section only if your system

requires a pump start relay.

The MV terminal on the controllers terminal strip can be

used to connect a pump start relay. Connect one lead of the

24VAC pump start relay to the MV terminal and the other

lead to the common wire, as shown in the illustration.

CAUTION:To prevent pump damage when using a

pump start relay, use a jumper wire to connect

any unused stations to a station that is being

used.

Page 59

56 ESP-LX+ & LXi+ Installation, Programming, & Operation Guide

WARNING: To prevent electrical shock, make sure all

supply power is OFF before connecting these wires.

Electrical shock can cause severe injury or death.

All electrical connections and wiring runs must be

made according to local building codes.

Connect Main Power Wires

ESP-LX+ (Outdoor / Indoor Controller)

NOTE: To connect main power wires on the

ESP-LXi+ indoor-only controller, see the instructions

on page60.

The ESP-LX+ controller has an internal transformer that

reduces standard supply voltage (117 VAC in U.S. models;

230 VAC in international models) to 24 VAC to operate the

valves connected to the controller. You will need to connect

power supply wires to the transformers three wires.

➊ With the door and face panel removed, locate the high-

voltage compartment in the lower left corner of the controller

cabinet.

➋ Remove the screw on the right edge of the compartment

cover. Then swing the cover open to expose the

transformers primary input wires.

Page 60

57ESP-LX+ & LXi+ Installation, Programming, & Operation Guide

➌ If you wish to bring the power supply wires through the

wall on which you mount the controller, use the ½"

(1,3cm) knockout in the rear of the cabinet. Also remove

the circular cutout in the flame-retardant fiberboard liner

at the rear of the high-voltage compartment. For safety

purposes, be sure to seal the unused entry at the bottom

of the cabinet.

➍ If you wish to bring the supply wires through the bottom of

the cabinet, attach a ½" (1,3cm) conduit fitting to the

bottom entrance of the high-voltage compartment. Then

attach conduit to the fitting.

Page 61

58 ESP-LX+ & LXi+ Installation, Programming, & Operation Guide

➎ Bring three supply wires from the power source through

the conduit into the high-voltage compartment. Strip the

insulation from the incoming wires to expose about ½"

(1,3cm) of bare wire.

➏ Using a code-approved wire connector, connect the wires

as follows:

• On 117-120 VAC models (U.S.), connect the black

supply wire (hot) to the black transformer wire.

• On 230 VAC models (international), connect the

brown supply wire (hot) to the brown transformer

wire.

➐ On 117-120 VAC models (U.S.), connect the white supply

wire (neutral) to the white transformer wire.

On 230 VAC models (international), connect the blue

supply wire (neutral) to the blue transformer wire.

➑ On 117-120 VAC models (U.S.), connect the green supply

wire (ground) to the green transformer wire.

On 230 VAC models (international), connect the greenwith-yellow-stripe supply wire (ground) to the greenwith-yellow-stripe transformer wire.

Page 62

59ESP-LX+ & LXi+ Installation, Programming, & Operation Guide

NOTE: The ground wires MUST be connected to

provide electrical surge protection.

➒ Verify that all connections are secure. Then close the

cover of the high-voltage compartment and secure it

with the screw.

COM COMMV

GND

MV11

9

9

2

2

10

10

3

3

11

11

4

4

12

12

5

5

13

13

6

6

14

14

7

7

15

15

8

8

16

16

24

VAC

SENSO R

CAUTION

HIGH

VOLTAGE

'

CAUTION

HIGH

VOLTAGE

Page 63

60 ESP-LX+ & LXi+ Installation, Programming, & Operation Guide

ESP-LXi+ (Indoor-Only Controller)

The ESP-LXi+ controller (117 VAC model only) has an external

transformer that reduces standard supply voltage to 24 VAC to

operate the valves connected to the controller.

You will need to connect the three wires from the transformer to

the vertical terminal strip in the controller cabinet.

CAUTION: To avoid electrical shock, do NOT plug in the

transformer until you have connected its cable to the

controller. If the transformer is plugged in while the

cable is not attached, any contact between the three

forked connectors will blow the transformers internal

fuse. A blown transformer fuse cannot be repaired.

All electrical connections and wiring runs must be

made according to local building codes.

➊ Make sure the transformer is NOT plugged in.

➋ Feed the three forked transformer wires through the

bottom left hole in the cabinet. Then pull about 12 inches

of the cable up into the controller cabinet.

➌ Tie a loose overhand knot in the cable just inside the

controller to prevent any strain on the connector terminals.

Page 64

61ESP-LX+ & LXi+ Installation, Programming, & Operation Guide

➍ On the vertical terminal strip, connect the green forked

wire to the terminal labeled GND.

NOTE: The green ground wire MUST be connected

properly to provide electrical surge protection.

➎ Snap open the protective cover and connect one of the

remaining two forked wires to one of the terminals labeled

24VAC. (In some units, these two terminals are labeled

ORN.) Connect the last forked wire to the other terminal

labeled 24VAC. Polarity of these two wires is not important. You may connect either wire to either terminal. Then

close the protective cover.

➏ Verify that all connections are secure. Then plug the

transformer into any standard three-prong grounded

117VAC electrical outlet.

CAUTION: To prevent electric shock, match the wide

blade of the plug to the wide slot, fully inserted.

cover

Protective

Page 65

62 ESP-LX+ & LXi+ Installation, Programming, & Operation Guide

Install Battery

The 9-Volt rechargeable nickel metal hydride (NiMH) battery

supplied with the controller provides power to maintain the

current time and date during a power outage. All program

information you have entered is maintained independently of

battery power. So if a prolonged power outage outlasts the life

of the battery, you will only have to update the time and date

after power is restored (your program is the default).

NOTE: Memory of the time and date is retained by a

battery which is to be disposed of in accordance

with local regulations.

The battery also lets you program the controller with the face

panel detached from the cabinet power supply.

➊ If you have removed the face panel and cabinet door for a

new installation, reinstall them now. Be sure to connect the

ribbon cable and two-wire harness from the face panel to

the controllers circuit board, as described on page 48.

➋ Loosen the screw on the battery cover, and slide the

battery out of its compartment. If you are replacing a used

battery, discard the old battery properly. The replacement

battery must be a 9-Volt rechargeable NiMH battery.

➌ If the battery has a protective cover installed over its

terminals, remove the cover. Then connect the two-wire

battery clip to the terminals.

Page 66

63ESP-LX+ & LXi+ Installation, Programming, & Operation Guide

➍ Slide the battery back into its compartment, and tighten

the screw.

➎ The controller will fully charge the supplied NiMH battery

in approximately 48 hours. The controller will continue to

trickle-charge the battery whenever the controller is supplied

with electrical power.

Page 67

64 ESP-LX+ & LXi+ Installation, Programming, & Operation Guide

Diagnostic Circuit Breaker

If the ESP-LX+ or ESP-LXi+ controller detects an electrical

short circuit on one of the sprinkler systems station wires or

valve solenoids, the controller automatically shuts off the

station with the fault. After shutting off the shorted station, the

controller advances to the next working station in the program.

Every three seconds, the LCD displays the problem stations

number and the message FAULT. The Fault LED will also flash,

indicating a station short circuit.

The controller will continue to run each operable station in the

program. As each station is running, the controller (at an

alternate 3-second interval) displays the working stations

number and run time remaining (when the programming dial is

set to the AUTO position).

When the controller finishes the program, it will continue to

display the problem stations number and the FAULT message

and the Fault LED will continue to flash.

After the program finishes, you should isolate and repair the

short circuit. Short circuits occur most frequently in the valve

solenoid (the plastic-encapsulated coil on the valve with the two

wire leads), or in the wire connectors to the valve leads.

After you find and repair the short circuit, press the Clear

Fault button to clear the FAULT message from the display

and stop the flashing Fault LED. Then you may wish to operate

the station manually to make sure it works properly. (See Run

Station(s) Manually on p. 35).

The LCD display shown below indicates that the controller has

detected a short circuit on station 2.

Page 68

65ESP-LX+ & LXi+ Installation, Programming, & Operation Guide

TROUBLESHOOTING

SYMPTOM POSSIBLE CAUSE SOLUTION

Program does not come

on automatically.

1. Dial is set to OFF position. Set the dial to AUTO.

2. Start time has not been entered for the

program.

Turn the dial to PROGRAM START TIMES and check

the start times entered for the program. If the start

time is missing, enter it as described on page 21.

3. Rain Delay feature is preventing watering.

(Display shows RAIN DELAY and DAYS

REMAINING.)

If the Rain Delay feature has been set properly, no

correction is needed. To cancel the Rain Delay, see

page 28.

4. Today may not be a watering day for the

program. (Display shows DAYS REMAINING

to the next watering day.)

Press the PGM button to check the days remaining

until the next watering day for each program.

5. Day Off feature is preventing watering.

(Display shows NON, followed by the time of

day.)

If the Day Off feature has been set properly, no

correction is needed. To run a program manually

(even on a Day Off), see page 34. To change the

Day Off feature, see page 29.

6. Programs Water Budget is set to 0%. Set the Water Budget above 0%. See page 23.

Page 69

66 ESP-LX+ & LXi+ Installation, Programming, & Operation Guide

Display shows a station

operating, but no watering

occurs.

7. Sensor system is preve nting irrigation.

(WATERING SUSPENDED BY SENSOR light is

on.)

Turn the sensor bypass switch to OFF. If watering

resumes, the sensor is operating properly, and no

correction is necessary.

8. No sensor or jumper is connected to the

controllers SENSOR terminals, and the

SENSOR BYPASS switch has been set to

ACTIVE.

Turn the sensor bypass switch to OFF. To prevent

future occurrences, install the supp lied jumper on

the controllers SENSOR terminals. See page 54.

Station does not come on. 9. No run time has been set for the station. Turn the dial to the station number, and press the

PGM button to check the run times set for the

station. To add a run time, see page 19.

10. A short circuit in the so lenoid or valve wiring

has disabled the station. (Display shows

FAULT and a station num ber, and the

FAULT light in the upper left corner of the face

panel is on.)

Identify and repair the fault in the circuit. Then press

the Clear Fault button, and start the station manually.

See page 35 for instructions.

11. Sensor system is preve nting irrigation.

(WATERING SUSPENDED BY SENSOR light is

on.)

See correction for Cause #7.

12. Start time has not been entered for the

program to which the station is assigned.

See correction for Cause #2.

13. Water Budget for the stations program is set

to 0%.

See correction for Cause #6.

SYMPTOM POSSIBLE CAUSE SOLUTION

Page 70

67ESP-LX+ & LXi+ Installation, Programming, & Operation Guide

Display sh ows P WR

OFF.

14. No pow er is being supplied to the controller.

Verify that the controller is plugged into a working

outlet. Check the main powe r supply to the

controller.

Display sh ows F USE. 15. Fuse has blown. Disconnect the controller from its power source.

Identify and repair the circuit fault that caused the

fuse to blow . Then replace the fuse with the spare

fuse sup plied on the inside of the face panel, just

above the 9-Volt battery. For the ESP-LX+, use a

1.5A SLO -BLO fuse. For the ESP-LXi+, use a 1.25A

SLO-BLO fuse. Reconnect power to the controller

and reset the time and date.

Display shows

MVFAULT.

16. An electrical fault has occurred in the master

valve or pump start relay circuit.

Identify and repair the fault in the m aster valve or

pump start relay circuit. Then press the Clear Fau lt

button in the upper left corner of the face panel. To

verify that the problem has been corrected, manually

start a program (page 34) or run a test program

(page 36).

Display is partially or

com pletely blank.

17. An electrica l surg e or lightning strike has

damaged the controllers electronics.

Turn off the controller and disconnect the 9-Volt

battery. Let the contro ller sit for two or three minu tes.

Then reconnect the battery and restore power to the

controller. Reset the time and date as described

beginning on page 11. If the electrical surge did no

perm anent dama ge, the c ontroller w ill accep t

programming commands and func tion normally. If

the controller does not operate properly, contact

Rain Bird Technical Assistance at 800-247-3782

(United States only).

SYMPTOM POSSIBLE CAUSE SOLUTION

Page 71

68 ESP-LX+ & LXi+ Installation, Programming, & Operation Guide

Watering starts when it

should not.

18. MAN START / ADV. key has been pressed.

To cancel a program that has been manually started,

set the dial to OFF for three seconds. Then set the

dial back to AUTO.

19. An unwanted start time may have been

entered.

Turn the dial to PROGRAM START TIMES and check

to see if any programs have an unwanted start time.

See page 21 for instructions on setting and

eliminating start times.

20. Programs may be stacked. Programs A, B, and C will stack behind each other if

they are scheduled to start while another program

(other than D) is running. Check to make sure

Programs A, B, and C are not scheduled to start

when any program other than D is scheduled. Refer

to page 13.

Display flashes

FAULT #

21. The controller has detected a short circuit on a

particular station. For example, if the display

flashes FAULT 4, it means there is a short

somewhere between the controller and station

#4.

Identify and repair the shorted circuit. See

Diagnostic Circuit Breaker on page 64, and

Troubleshooting Open and Shorted Valve Circuits

on page 43 for more information.

SYMPTOM POSSIBLE CAUSE SOLUTION

Page 72

69ESP-LX+ & LXi+ Installation, Programming, & Operation Guide

NOTES

Page 73

70 ESP-LX+ & LXi+ Installation, Programming, & Operation Guide

RAIN BIRD SALES, INC.

970 W. Sierra Madre, Azusa, California 91702, U.S.A. 626-963-9311

© 2001 Rain Bird Sprinkler Mfg. Corp.

® Registered trademark of Rain Bird Sprinkler Mfg. Corp.

Technical Services for United States only: 800-247-3782

www.rainbird.com

This equipment has been tested and found to comply with the limits for a

Class B digital device, pursuant to Part 15 of the FCC Rules. These limits

are designed to provide reasonable protection against harmful interference

in a residential installation.

This equipment generates, uses, and can radiate radio frequency energy

and, if not installed and used in accordance with the instructions, may

cause harmful interference to radio communications. However, there is no

guarantee that interference will not occur in a particular installation.

If the equipment does cause harmful interference to radio or television

reception, which can be determined by turning the equipment off and on,

the user is encouraged to try to correct the interference by the following

measures:

Reorient or relocate the receiving antenna.