Page 1

Handheld PID Monitors User’s Guide

Handheld PID Monitors

Rev. A

P/N: 059-4026-000

User’s Guide

1

November 2018

Page 2

Product Registration

Register your product online by visiting:

https://www.raesystems.com/customer-care

By registering your product, you can:

• Receive notification of product upgrades or enhancements

• Be alerted to Training classes in your area

• Take advantage of Honeywell RAE Systems special offers and promotions

© 2018 Honeywell International.

Handheld PID Monitors User’s Guide

2

Page 3

Handheld PID Monitors User’s Guide

Contents

1. Standard Contents ............................................................................................................................... 11

2. General Information ............................................................................................................................. 11

3. Physical Description ............................................................................................................................ 11

4. Charging The Battery .......................................................................................................................... 12

4.1. Charging A Spare Rechargeable Battery .................................................................................... 13

4.2. Low Voltage Warning .................................................................................................................. 13

4.3. Clock Battery ............................................................................................................................... 13

4.4. Data Protection While Power Is Off ............................................................................................. 13

5. User Interface ...................................................................................................................................... 14

6. Display ................................................................................................................................................. 16

6.1. Icons ............................................................................................................................................ 17

7. Operating The Instrument ................................................................................................................... 18

7.1. Turning The Instrument On ......................................................................................................... 18

7.2. Turning The Instrument Off ......................................................................................................... 18

7.3. Auto-Zero At Startup Option ........................................................................................................ 19

7.4. Operating The Built-In Flashlight ................................................................................................. 19

7.5. Pump Status ................................................................................................................................ 20

7.6. Calibration Status ........................................................................................................................ 20

7.7. Bump Status ................................................................................................................................ 20

7.8. Glance Mode ............................................................................................................................... 21

7.8.1. Enter Glance Mode ............................................................................................................... 21

7.8.2. Glance Mode Screens .......................................................................................................... 22

7.8.3. Exit Glance Mode.................................................................................................................. 22

7.9. Reverse Direction – Main Navigation .......................................................................................... 22

7.10. Policy Enforcement ..................................................................................................................... 23

7.10.1. Setting Policy Enforcement ................................................................................................... 23

8. Operating Modes – MiniRAE 3000+ & ppbRAE 3000+ ....................................................................... 25

8.1. Basic User Level/Hygiene Mode (Default Settings) – MiniRAE 3000+ & ppbRAE 3000+ .......... 26

9. Operating Modes – UltraRAE 3000+ ................................................................................................... 27

10. Compound-Specific Operation – UltraRAE 3000+ .............................................................................. 29

10.1. Compound-Specific Measurement .............................................................................................. 29

10.2. Measurement Phases ................................................................................................................. 29

10.3. Performing A Measurement – UltraRAE 3000+ .......................................................................... 29

10.4. Separation Tube Preparation ...................................................................................................... 30

10.5. Inserting The Separation Tube .................................................................................................... 32

10.6. Measuring .................................................................................................................................... 32

11. VOC Operation – UltraRAE 3000+ ...................................................................................................... 35

11.1. Basic User Level/Hygiene Mode (Default Settings) .................................................................... 35

11.2. Basic Operation – MiniRAE 3000+ .............................................................................................. 36

12. Alarm Signals ...................................................................................................................................... 36

12.1. Alarm Signal Summary ................................................................................................................ 36

12.2. Preset Alarm Limits & Calibration................................................................................................ 37

12.3. Testing The Alarm ....................................................................................................................... 37

12.4. Integrated Sampling Pump .......................................................................................................... 37

12.5. Backlight ...................................................................................................................................... 38

12.6. Datalogging ................................................................................................................................. 38

3

Page 4

Handheld PID Monitors User’s Guide

12.6.1. Datalogging event ................................................................................................................. 38

12.6.2. Datalogging sample .............................................................................................................. 38

12.6.3. Auto/Manual/Snapshot Datalogging ..................................................................................... 38

13. Accessories ......................................................................................................................................... 39

14. Standard Kit & Accessories ................................................................................................................. 40

14.1. AC Adapter (Battery Charger) ..................................................................................................... 40

14.2. Alkaline Battery Adapter .............................................................................................................. 40

14.3. External Filter .............................................................................................................................. 41

15. Optional Accessories ........................................................................................................................... 42

15.1. Calibration Adapter ...................................................................................................................... 42

15.2. Calibration Regulator ................................................................................................................... 42

15.3. Organic Vapor Zeroing Kit ........................................................................................................... 42

15.4. AutoRAE 2 Automatic Test & Calibration System ....................................................................... 42

16. Standard Two-Point Calibration (Zero & Span) ................................................................................... 43

16.1. Zero (Fresh Air) Calibration ......................................................................................................... 45

16.1.1. Reflex PID Technology™ ..................................................................................................... 45

16.2. Span Calibration .......................................................................................................................... 47

17. Three-Point Calibration........................................................................................................................ 49

18. Bump Test ........................................................................................................................................... 51

19. Programming Mode ............................................................................................................................. 52

19.1. Entering Programming Mode ...................................................................................................... 52

20. Programming Mode Menus ................................................................................................................. 54

20.1. Exiting Programming Mode ......................................................................................................... 54

20.2. Navigating Programming Mode Menus ....................................................................................... 55

20.3. Reverse Direction – Menu Selection ........................................................................................... 55

20.4. Calibration ................................................................................................................................... 56

20.4.1. Zero Calibration .................................................................................................................... 56

20.4.2. Span Calibration ................................................................................................................... 56

20.4.3. Bump Test ............................................................................................................................. 56

20.5. Measurement .............................................................................................................................. 57

20.5.1. Meas. Gas ............................................................................................................................. 57

20.5.2. Meas. Unit ............................................................................................................................. 57

20.5.3. Tube Selection (UltraRAE 3000+ only) ................................................................................. 59

20.5.4. Alarm Setting ........................................................................................................................ 60

20.5.5. High Alarm ............................................................................................................................ 60

20.5.6. Low Alarm ............................................................................................................................. 61

20.5.7. STEL Alarm ........................................................................................................................... 61

20.5.8. TWA Alarm ............................................................................................................................ 62

20.5.9. Alarm Mode ........................................................................................................................... 62

20.5.10. Buzzer & Light ..................................................................................................................... 63

20.6. Datalog ........................................................................................................................................ 63

20.6.1. Clear Datalog ........................................................................................................................ 64

20.6.2. Interval ............................................................................................................................... 64

20.6.3. Data Selection ....................................................................................................................... 64

20.6.4. Datalog Type ......................................................................................................................... 65

20.6.5. Manual Datalog ..................................................................................................................... 65

20.6.6. Snapshot Datalog ................................................................................................................. 66

4

Page 5

Handheld PID Monitors User’s Guide

20.7. Monitor Setup .............................................................................................................................. 66

20.7.1. Op Mode ............................................................................................................................... 66

20.7.2. Site ID ............................................................................................................................... 67

20.7.3. User ID ............................................................................................................................... 67

20.7.4. User Mode ............................................................................................................................ 68

20.7.5. Date ............................................................................................................................... 68

20.7.6. Time ............................................................................................................................... 68

20.7.8. Duty Cycle ............................................................................................................................. 69

20.7.9. Temperature Unit .................................................................................................................. 69

20.7.10. Pump Speed........................................................................................................................ 69

20.7.11. Language ............................................................................................................................ 69

20.7.12. Real Time Protocol .............................................................................................................. 70

20.7.13. Power On Zero .................................................................................................................... 70

20.7.14. Unit ID ............................................................................................................................... 70

20.7.15. LCD Contrast....................................................................................................................... 71

20.7.16. Lamp ID ............................................................................................................................... 71

20.7.17. PAN ID ............................................................................................................................... 71

20.7.18. Mesh Channel ..................................................................................................................... 71

20.7.19. Mesh Interval ....................................................................................................................... 72

21. Hygiene Mode ..................................................................................................................................... 73

21.1. Basic User Level & Hygiene Mode .............................................................................................. 73

21.2. Entering Search Mode From Hygiene Mode ............................................................................... 74

22. Advanced User Level (Hygiene Mode Or Search Mode) .................................................................... 75

22.1. Advanced User Level & Hygiene Mode ...................................................................................... 75

22.2. Basic User Level & Search Mode................................................................................................ 77

22.3. Advanced User Level & Search Mode ........................................................................................ 78

23. Diagnostic Mode .................................................................................................................................. 79

23.1.1. Entering Diagnostic Mode ..................................................................................................... 79

23.1.2. Adjusting The Pump Stall Threshold .................................................................................... 79

23.1.3. Pump High ............................................................................................................................ 79

23.1.4. Testing The Humidity Sensor ................................................................................................ 80

23.1.5. Pump Low ............................................................................................................................. 81

23.1.6. Exiting Diagnostic Mode ....................................................................................................... 81

24. Transferring Data To & From A Computer .......................................................................................... 82

24.1. Downloading The Datalog To A PC ............................................................................................ 82

24.2. Uploading Firmware To The instrument From A PC ................................................................... 82

25. Maintenance ........................................................................................................................................ 83

25.1. Battery Charging & Replacement ................................................................................................ 83

25.1.1. Replacing The Li-ion Battery ................................................................................................ 83

25.1.2. Replacing The Alkaline Battery Adapter ............................................................................... 84

25.2. PID Sensor & Lamp Cleaning/Replacement ............................................................................... 85

25.2.1. Cleaning The PID Sensor ..................................................................................................... 87

25.2.2. Cleaning The Lamp Housing Or Changing The Lamp ......................................................... 87

25.2.3. Determining The Lamp Type ................................................................................................ 88

25.2.4. Sampling Pump ..................................................................................................................... 89

25.2.5. Cleaning The Instrument ...................................................................................................... 89

25.3. Special Servicing Note ................................................................................................................ 89

5

Page 6

Handheld PID Monitors User’s Guide

25.4. Crash Recovery ........................................................................................................................... 90

26. Troubleshooting ................................................................................................................................... 91

27. Technical Support ................................................................................................................................ 92

28. Controlled Part Of Manual ................................................................................................................... 93

32. Specifications ...................................................................................................................................... 99

32.1. MiniRAE Lite+ Specifications ...................................................................................................... 99

32.2. MiniRAE 3000+ Specifications .................................................................................................. 100

32.3. ppbRAE 3000+ Specifications ................................................................................................... 102

32.4. UltraRAE 3000+ Specifications ................................................................................................. 103

6

Page 7

Handheld PID Monitors User’s Guide

WARNINGS

This Manual must be carefully read by all individuals who have or will have the responsibility of using,

maintaining, or servicing this product. The product will perform as designed only if it is used, maintained, and

serviced in accordance with the manufacturer’s instructions. The user should understand how to set the

correct parameters and interpret the obtained results.

For safety reasons, this equipment must be operated and serviced by qualified personnel only. Read and

understand the instruction manual completely before operating or servicing.

AVERTISSEMENT

Pour des raisons de sécurité, cet équipment doit être utilisé, entretenu et réparé uniquement par un

personnel qualifié. Étudier le manuel d’instructions en entier avant d’utiliser, d’entretenir ou de réparer

l’équipement.

Read Before Operating

This manual must be carefully read by all individuals who have or will have the responsibility of using,

maintaining, or servicing this product. The product will perform as designed only if it is used, maintained, and

serviced in accordance with the manufacturer’s instructions. The user should understand how to set the

correct parameters and interpret the obtained results.

CAUTION!

To reduce the risk of electric shock, turn the power off before opening this instrument or performing service.

Never operate the instrument when the instrument is open. Service this product only in an area known to be

non-hazardous.

ATEX WARNING!

To reduce the risk of electrostatic ignition, do not use the instrument without the rubber boot in place.

7

Page 8

Handheld PID Monitors User’s Guide

WARNINGS

STATIC HAZARD: Clean only with a damp cloth.

For safety reasons, this equipment must be operated and serviced by qualified personnel only. Read and

understand instruction manual completely before operating or servicing.

USE ONLY RAE SYSTEMS BATTERY PACKS, PART NUMBERS 059-3051-000, 059-3052-000, AND 0593054-000. THIS INSTRUMENT HAS NOT BEEN TESTED IN AN EXPLOSIVE GAS/AIR ATMOSPHERE

HAVING AN OXYGEN CONCENTRATION GREATER THAN 21%. SUBSTITUTION OF COMPONENTS

MAY IMPAIR INTRINSIC SAFETY. RECHARGE BATTERIES ONLY IN NON-HAZARDOUS LOCATIONS.

DO NOT MIX OLD AND NEW BATTERIES OR BATTERIES FROM DIFFERENT MANUFACTURERS.

THE CALIBRATION OF ALL NEWLY PURCHASED RAE SYSTEMS INSTRUMENTS SHOULD BE TESTED

BY EXPOSING THE SENSOR(S) TO KNOWN CONCENTRATION CALIBRATION GAS BEFORE THE

INSTRUMENT IS PUT INTO SERVICE.

FOR MAXIMUM SAFETY, THE ACCURACY OF THE INSTRUMENT SHOULD BE CHECKED BY

EXPOSING IT TO A KNOWN CONCENTRATION CALIBRATION GAS BEFORE EACH DAY’S USE.

DO NOT USE USB/PC COMMUNICATION IN HAZARDOUS LOCATIONS.

AVERTISSIMENT

DANGER RISQUE D'ORIGINE ELECTROSTATIQUE: Nettoyer uniquement avec un chiffon humide.

Pour des raisons de sécurité, cet équipment doit être utilisé, entretenu et réparé uniquement par un

personnel qualifié. Étudier le manuel d’instructions en entier avant d’utiliser, d’entretenir ou de réparer

l’équipement.

Utiliser seulement l'ensemble de batterie RAE Systems, la reference 059-3051-000 au 059-3052-000 au 0593054-000. Cet instrument n’a pas été essayé dans une atmosphère de gaz/air explosive ayant une

concentration d’oxygène plus élevée que 21%. La substitution de composants peut compromettre la sécurité

intrinsique. Ne charger les batteries que dans emplacements désignés non-dangereuse.

Ne pas melanger les anciennes et les nouvelles batteries, ou bien encore les batteries de differents

fabriquants.

La calibration de toute instruments de RAE Systems doivent être testé en exposant l’instrument a une

concentration de gaz connue par une procédure diétalonnage avant de mettre en service l’instrument pour la

première fois.

Pour une securite maximale, la sensibilité du l’instrument doit être verifier en exposant l’instrument a une

concentration de gaz connue par une procédure diétalonnage avant chaque utilisation journalière.

Ne pas utiliser de connection USB/PC en zone dangereuse.

Proper Product Disposal At End Of Life

EU Directive 2012/19/EU: Waste Electrical and Electronic Equipment (WEEE)

This symbol indicates that the product must not be disposed of as general industrial or domestic waste.

This product should be disposed of through suitable WEEE disposal facilities. For more information about

disposal of this product, contact your local authority, distributor, or the manufacturer

8

Page 9

Caution

This device complies with Part 15 of the FCC Rules / Industry Canada license-exempt RSS standard(s). Operation

is subject to the following two conditions: (1) this device may not cause harmful interference, and (2) this device

must accept any interference received, including interference that may cause undesired operation.

Le présent appareil est conforme aux CNR d'Industrie Canada applicables aux appareils radio exempts de licence.

L'exploitation est autorisée aux deux conditionssuivantes : (1) l'appareil ne doit pas produire de brouillage, et (2)

l'utilisateur del'appareil doit accepter tout brouillage radioélectrique subi, même si le brouillage estsusceptible d'en

compromettre le fonctionnement.

Changes or modifications not expressly approved by the party responsible for compliance could void the user's

authority to operate the equipment.

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to part 15

of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference in a

residential installation. This equipment generates uses and can radiate radio frequency energy and, if not installed

and used in accordance with the instructions, may cause harmful interference to radio communications. However,

there is no guarantee that interference will not occur in a particular installation. If this equipment does cause harmful

interference to radio or television reception, which can be determined by turning the equipment off and on, the user

is encouraged to try to correct the interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

Under Industry Canada regulations, this radio transmitter may only operate using an antenna of a type and

maximum (or lesser) gain approved for the transmitter by Industry Canada. To reduce potential radio interference to

other users, the antenna type and its gain should be so chosen that the equivalent isotropically radiated power

(e.i.r.p.) is not more than that necessary for successful communication.

Conformément à la réglementation d'Industrie Canada, le présent émetteur radio peutfonctionner avec une

antenne d'un type et d'un gain maximal (ou inférieur) approuvé pour l'émetteur par Industrie Canada. Dans le but

de réduire les risques de brouillage radioélectrique à l'intention des autres utilisateurs, il faut choisir le type

d'antenne et son gain de sorte que la puissance isotrope rayonnée équivalente (p.i.r.e.) ne dépasse pas l'intensité

nécessaire à l'établissement d'une communication satisfaisante.

Handheld PID Monitors User’s Guide

9

Page 10

Handheld PID Monitors User’s Guide

IMPORTANT! BUMP TEST THE MONITOR BEFORE EACH DAY’S USE

Prior to each day’s use, every gas detection monitor should be bump tested to confirm the response of

all sensors and activation of all alarms by exposing the monitor to a concentration of target gas that

exceeds the low alarm set point. A bump test is also recommended if the monitor has been subjected to

physical impact, liquid immersion, an Over Limit alarm event, or custody changes, or anytime the

monitor’s performance is in doubt.

To ensure greatest accuracy and safety, only bump test and calibrate in a fresh air environment.

The monitor should be calibrated every time it does not pass a bump test, but no less frequently than

every six months, depending on use and exposure to gas and contamination, and its operational mode.

• Calibration intervals and bump test procedures may vary due to national legislation.

• Honeywell recommends using calibration gas cylinders containing the gas that is appropriate to the

sensor you are using, and in the correct concentration.

Special Notes

When the instrument is taken out of the transport case and turned on for the first time, there may

be some residual organic or inorganic vapor trapped inside the detector chamber. The initial PID

sensor reading may indicate a few ppm. Enter an area known to be free of any organic vapor and

turn on the instrument. After running for several minutes, the residual vapor in the detector

chamber will be cleared and the reading should return to zero.

The battery of the instrument discharges slowly even if it is turned off. If the instrument has not

been charged for 5 to 7 days, the battery voltage will be low. Therefore, it is a good practice to

always charge the instrument before using it. It is also recommended to fully charge the instrument

for at least 10 hours before first use. Refer to this User Guide’s section on battery charging for

more information on battery charging and replacement.

10

Page 11

Handheld PID Monitors User’s Guide

1. Standard Contents

• Instrument

• Calibration Kit

• Charger Stand

• AC/DC Adapter

• Alkaline Battery Adapter

• Data Cable

• CD-ROM With User’s Guide, Quick Start Guide, and related materials

2. General Information

The compact instrument is designed as a broadband VOC gas monitor and datalogger for work in

hazardous environments. It monitors Volatile Organic Compounds (VOC) using a photoionization

detector (PID) with a 9.8 eV, 10.6 eV, or 11.7eV gas-discharge lamp. The instrument consists of a

PID with associated microcomputer and electronic circuit. The unit is housed in a rugged case with

a backlit LCD and 3 keys to provide easy user interface. It also has a built-in flashlight for

operational ease in dark locations.

Key Features

Lightweight and Compact

• Compact, lightweight, rugged design

• Built-in sample draw pump

Dependable and Accurate

• Up to 16 hours of continuous monitoring with rechargeable battery pack

• Designed to continuously monitor VOC vapor at parts-per-million (ppm) and/or parts-per-billion

(ppb) levels

User-friendly

• Preset alarm thresholds for STEL, TWA, low- and high-level peak values.

• Audio buzzer and flashing LED display are activated when the limits are exceeded.

Datalogging Capabilities

• 260,000-point datalogging storage capacity for data download to PC

3. Physical Description

The main components of the portable VOC monitoring instrument include:

• Three keys for user interaction with the instrument: 3 operation/programming keys for normal

operation or programming

• LCD display with back light for direct readout and calculated measurements

• Built-in flashlight for illuminating testing points in dark environments

• Buzzer and red LEDs for alarm signaling whenever exposures exceed preset limits

• Charge contacts for plugging directly to its charging station

• Gas entry and exit ports

• USB communication port for PC interface

• Protective rubber cover

Easy-to-use separation tube holder (UltraRAE 3000+)

11

Page 12

Handheld PID Monitors User’s Guide

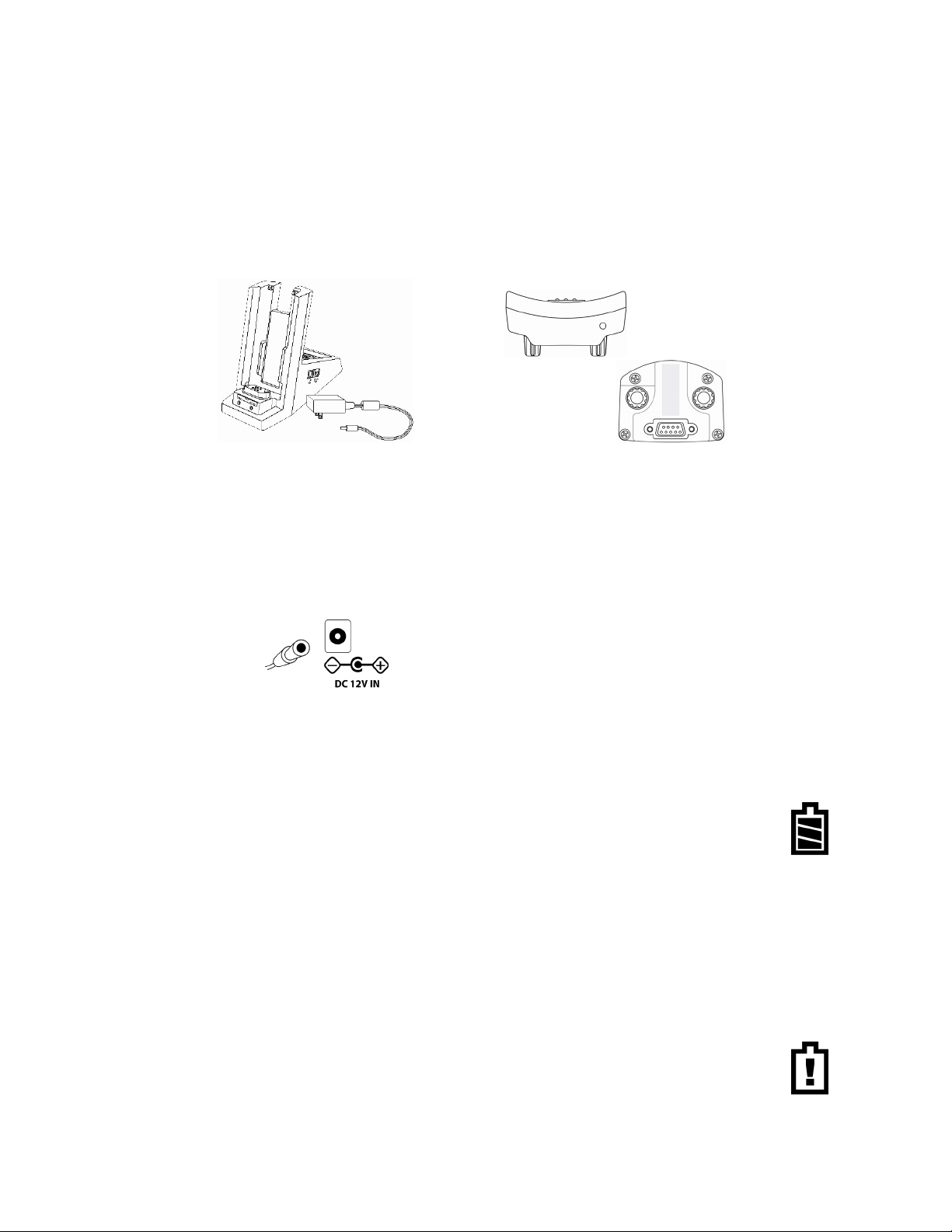

Charger Stand

Travel

Charger

4. Charging The Battery

Always fully charge the battery before using the instrument. The instrument’s Li-ion battery is

charged by attaching the instrument to the Travel Charger (or by placing the instrument in the

optional Charger Stand). Contacts on the bottom of the instrument meet the Travel Charger’s (or

Charger Stand’s) contacts, transferring power without other connections.

Note: Before connecting the charger to the instrument, visually inspect the contacts to make sure

they are clean. If they are not, wipe them with a soft cloth. Do not use solvents or cleaners.

Follow this procedure to charge the instrument:

1. Plug the AC/DC adapter’s barrel connector into the instrument’s Charger Stand or Travel

Charger.

2. Plug the AC/DC adapter into the wall outlet.

3. Connect the AC/DC adapter to the Travel Charger (or

Charger Stand).

4. Place the instrument into the Travel Charger or Charger Stand. The LED in the Travel Charger

(or Charger Stand) should glow.

The instrument begins charging automatically. (If the optional Charger Stand is used, the

“Primary” LED blinks green to indicate charging.) During charging, the diagonal lines in the

battery icon on the instrument’s display are animated and you see the message

“Charging...”

Note: If the Li-ion battery has been discharged below a certain threshold, the “Charging...”

message does not display immediately. The charging LED blinks to indicate that it is charging, and

after it has been charging for a while, the “Charging...” message appears.

When the instrument’s battery is fully charged, the battery icon is no longer animated and shows a

full battery. The message “Fully charged!” is shown. (If the Charger Stand or Travel Charger is

used, its LED glows continuously green.)

Note: If you see the “Battery Charging Error” icon (a battery outline with an exclamation

mark inside), check that the instrument or rechargeable battery has been properly set into

the Travel Charger (or Charger Stand). If you still receive the message, check the

Troubleshooting section of this guide.

12

Page 13

Handheld PID Monitors User’s Guide

Note: If the instrument or battery has been charging for more than 10 hours and you see the

“Battery Charging Error” icon and a message that says, “Charging Too Long,” this indicates that the

battery is not reaching a full charge. Try changing the battery and make sure the contacts on the

instrument are meeting the Travel Charger’s (or Charger Stand’s) contacts. If the message is still

shown, consult your distributor or RAE Systems Technical Services.

4.1. Charging A Spare Rechargeable Battery

A rechargeable Li-ion battery can be charged when it is not inside the monitor. The Charger Stand

is designed to accommodate both types of charging. Contacts on the bottom of the battery meet the

contacts on the cradle, transferring power without other connections, and a spring-loaded capture

holds the battery in place during charging.

1. Plug the AC/DC adapter into the monitor’s cradle.

2. Place the battery into the cradle, with the gold-plated contacts on top of the six matching

charging pins.

3. Plug the AC/DC adapter into the wall outlet.

The battery begins charging automatically. During charging, the Secondary LED in the cradle blinks

green. When charging is complete, it glows steady green.

Release the battery from the cradle by pulling it back toward the rear of the cradle and tilting it out

of its slot.

Note: If you need to replace the Li-ion battery pack, replacements are available from RAE

Systems. The part number is 059-3051-000.

Note: An Alkaline Battery Adapter (part number 059-3052-000), which uses four AA alkaline batteries

(Duracell MN1500), may be substituted for the Li-Ion battery.

WARNING!

To reduce the risk of ignition of hazardous atmospheres, recharge and replace batteries

only in areas known to be non-hazardous. Remove and replace batteries only in areas

known to be non-hazardous.

4.2. Low Voltage Warning

When the battery’s charge falls below a preset voltage, the instrument warns you by

beeping once and flashing once every minute, and the “empty battery” icon blinks on and

off once per second. You should turn off the instrument within 10 minutes and either

recharge the battery by placing the instrument in its cradle, or replace the battery with a

fresh one with a full charge.

4.3. Clock Battery

An internal clock battery is mounted on one of the instrument’s printed circuit boards. This long-life

battery keeps settings in memory from being lost whenever the Li-ion battery or alkaline batteries

are removed. This backup battery should last approximately five years, and must be replaced by an

authorized Honeywell service technician. It is not user-replaceable.

4.4. Data Protection While Power Is Off

When the instrument is turned off, all the current real-time data including last measured values are

erased. However, the datalog data is preserved in non-volatile memory. Even if the battery is

disconnected, the datalog data will not be lost.

13

Page 14

Handheld PID Monitors User’s Guide

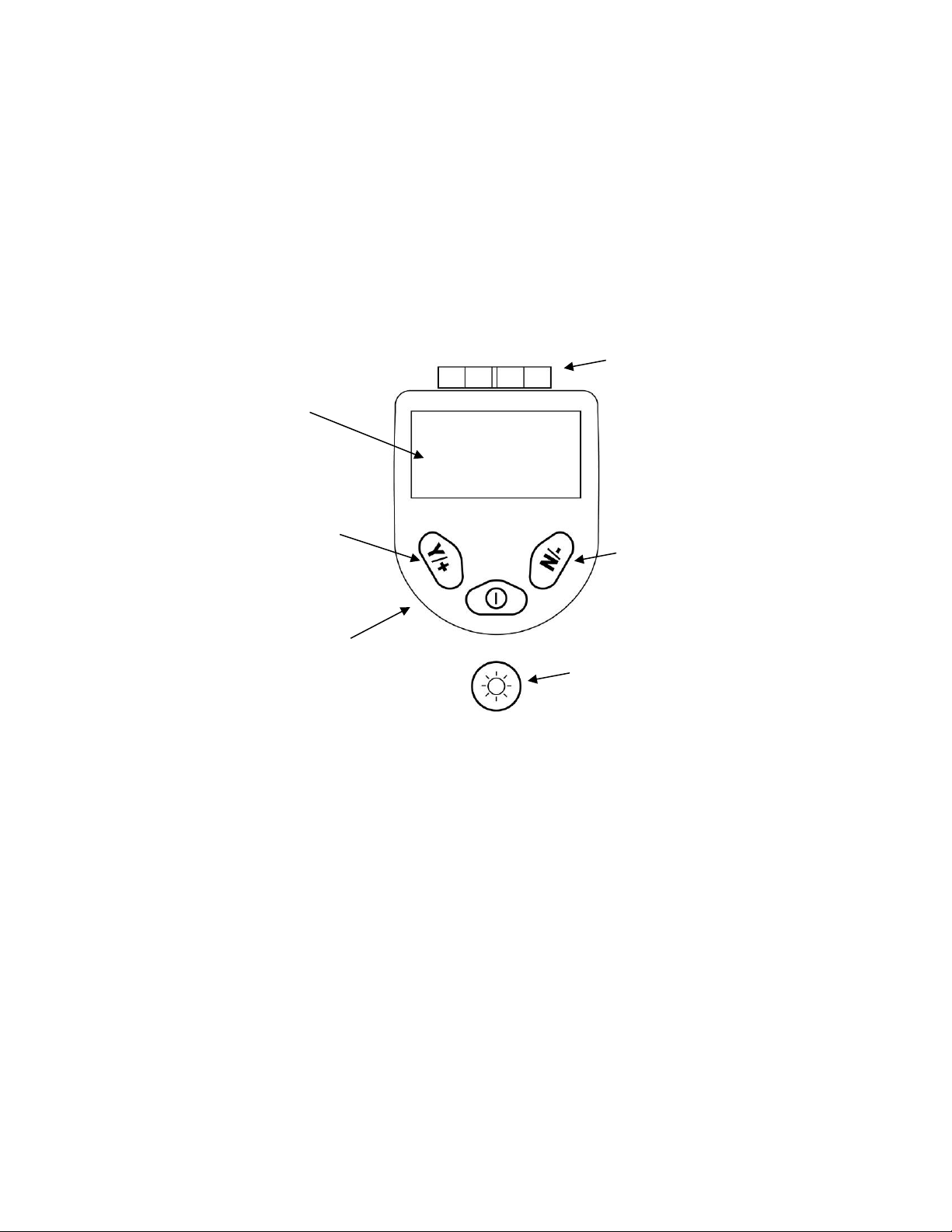

Display

Y/+ key

N/- key

MODE key

Flashlight

LEDs and

5. User Interface

The instrument’s user interface consists of the display, LEDs, an alarm transducer, and four keys.

The keys are:

Y/+

MODE

N/Flashlight on/off

The LCD display provides visual feedback that includes the reading, time, battery condition, and

other functions.

flashlight

on/off key

14

Page 15

Handheld PID Monitors User’s Guide

In addition to their labeled functions, the keys labeled Y/+, MODE, and N/- act as “soft keys” that

control different parameters and make different selections within the instrument’s menus. From

menu to menu, each key controls a different parameter or makes a different selection.

Three panes along the bottom of the display are “mapped” to the keys. These change as menus

change, but at all times the left pane corresponds to the [Y/+] key, the center pane corresponds to

the [MODE] key, and the right pane corresponds to the [N/-] key. Here are three examples of

different menus with the relationships of the keys clearly shown:

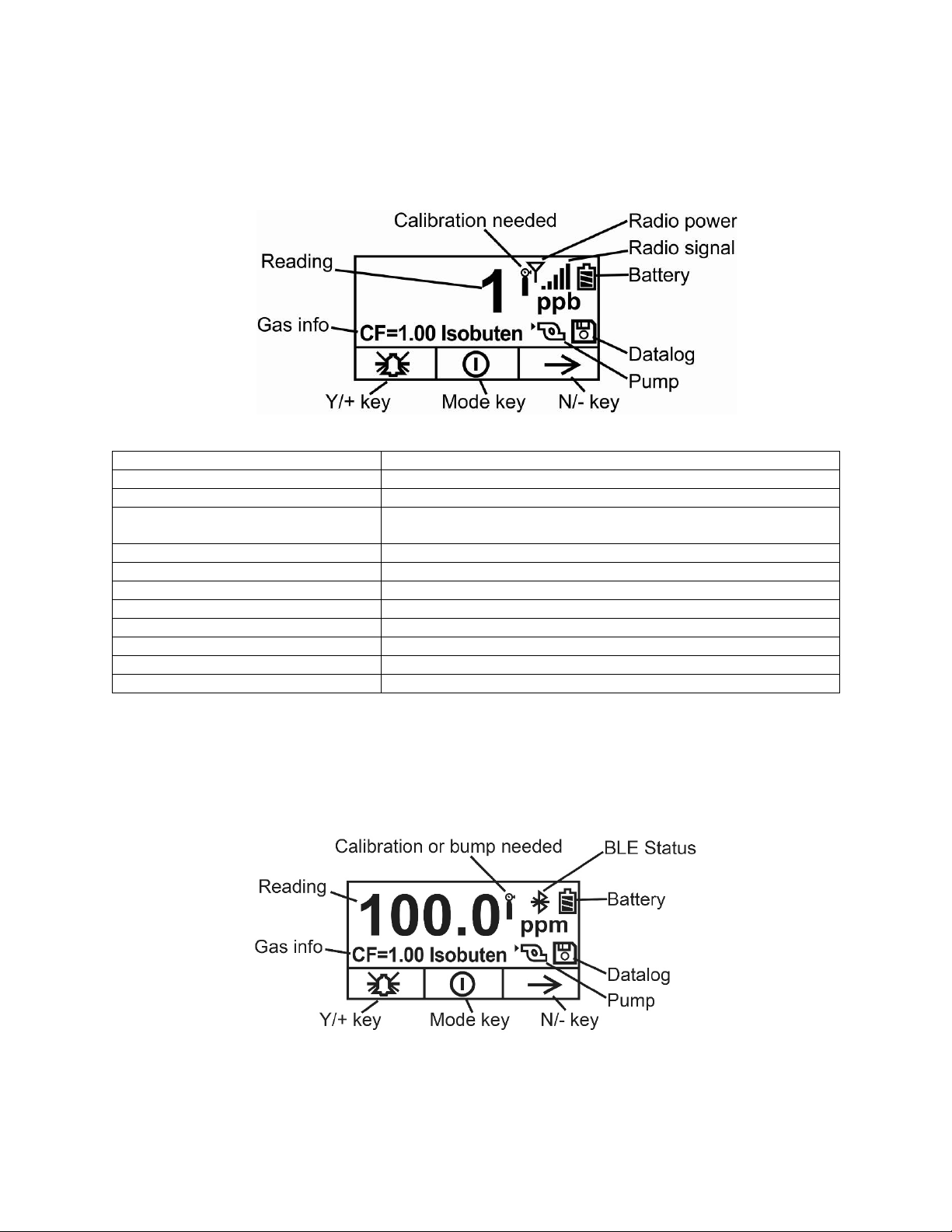

MiniRAE 3000+, ppbRAE 3000+, UltraRAE 3000+

MiniRAE Lite+

15

Page 16

Handheld PID Monitors User’s Guide

Gas info

Tells the Correction Factor and type of calibration gas

Reading

Concentration of gas as measured by the instrument

Calibration needed

Indicates that calibration should be performed

Calibration (or bump) needed

Dark icon indicates that calibration should be performed;

light icon indicates bump should be performed

Radio power

Indicates whether Mesh radio connection is on or off

Radio signal

Indicates signal strength (more bars = greater strength)

Battery

Indicates level in 3 bars

Pump

Indicates that pump is working

Datalog

Indicates whether datalog is on or off

Y/+

Y/+ key’s function for this screen

MODE

MODE key’s function for this screen

N/-

N/- key’s function for this screen

6. Display

The display shows the following information:

Note:The “Radio power” icon and “Radio signal” icon are only shown if a Mesh radio is installed in the

instrument. If the instrument has a BLE radio, the Bluetooth icons shown on the next page are used.

If the instrument is equipped with BLE instead of other wireless, the BLE Status icon is shown:

16

Page 17

Handheld PID Monitors User’s Guide

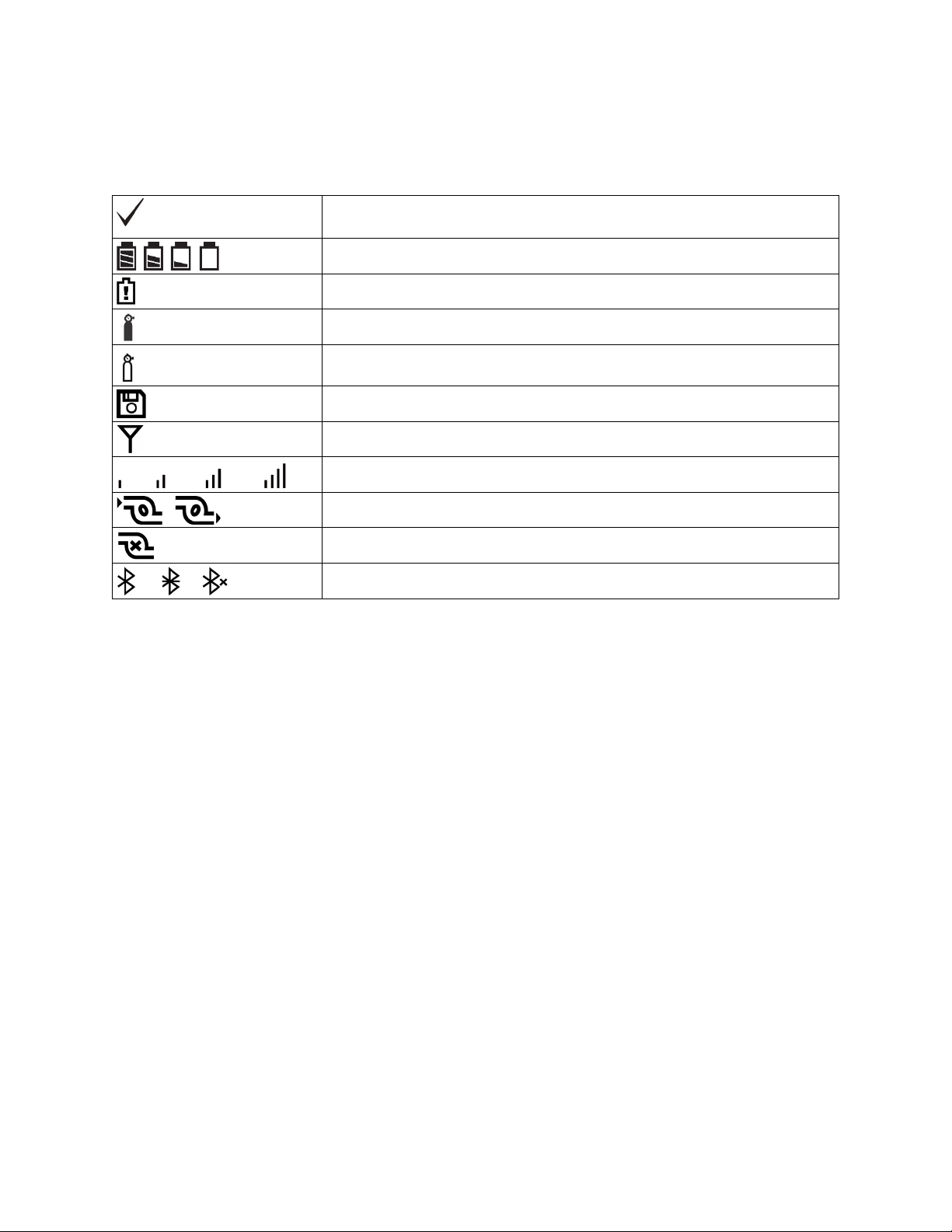

The instrument has been bump tested and calibrated in compliance with the

policy settings

Battery level

Charging error

Calibration required

Bump test required

Datalog on

Radio Power

Radio signal

Pump operational

Pump blocked or stalled

BLE status: Installed, Connected, Turned Off

6.1. Icons

These are the icons shown on the display to indicate functions or status.

17

Page 18

Handheld PID Monitors User’s Guide

7. Operating The Instrument

The instrument is designed as a broadband VOC gas monitor and datalogger for work in hazardous

environments. It gives real-time measurements and activates alarm signals whenever the exposure

exceeds preset limits. Prior to factory shipment, the instrument is preset with default alarm limits

and the sensor is pre-calibrated with standard calibration gas. However, you should test the

instrument and verify the calibration before the first use. After the instrument is fully charged and

calibrated, it is ready for immediate operation.

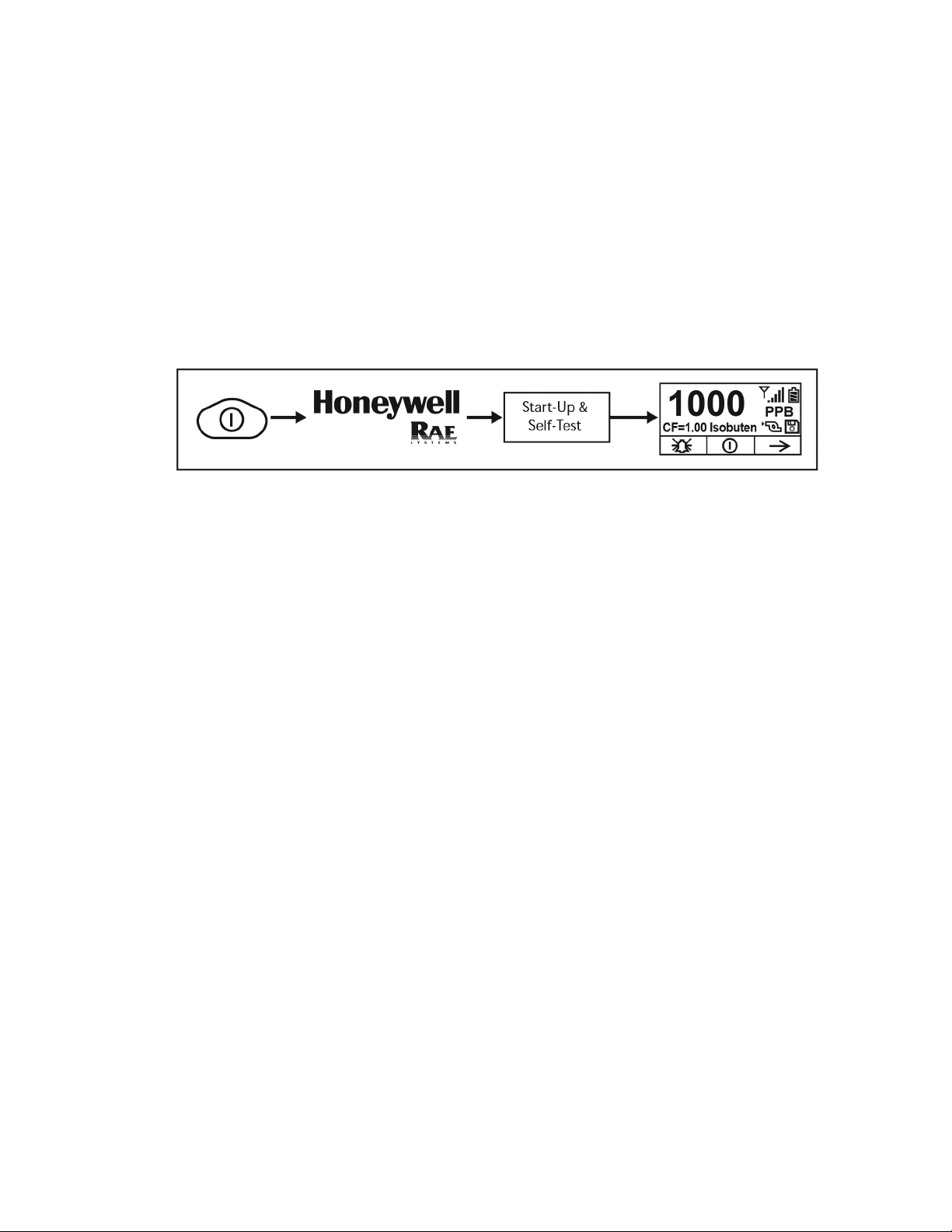

7.1. Turning The Instrument On

1. With the instrument turned off, press and hold [MODE].

2. When the display turns on, release the [MODE] key.

Note: The main display may show ppb or ppm and other features, depending on the instrument.

The Honeywell logo should appear first. (If the logo does not appear, there is likely a problem and

you should contact your distributor or Honeywell RAE Systems Technical Support.) The instrument

is now operating and performs self tests. If any tests (including sensor and memory tests fail), refer

to the Troubleshooting section of this guide.

Once the startup procedure is complete, the instrument shows a numerical reading screen with

icons. This indicates that the instrument is fully functional and ready to use.

7.2. Turning The Instrument Off

1. Press and hold the Mode key for 3 seconds. A 5-second countdown to shutoff begins.

2. Once the countdown stops, the instrument is off. Release the Mode key.

3. When you see “Unit off...” release your finger from the [MODE] key. The instrument is now off.

Note: You must hold your finger on the key for the entire shutoff process. If you remove your finger

from the key during the countdown, the shutoff operation is canceled and the instrument continues

normal operation.

18

Page 19

Handheld PID Monitors User’s Guide

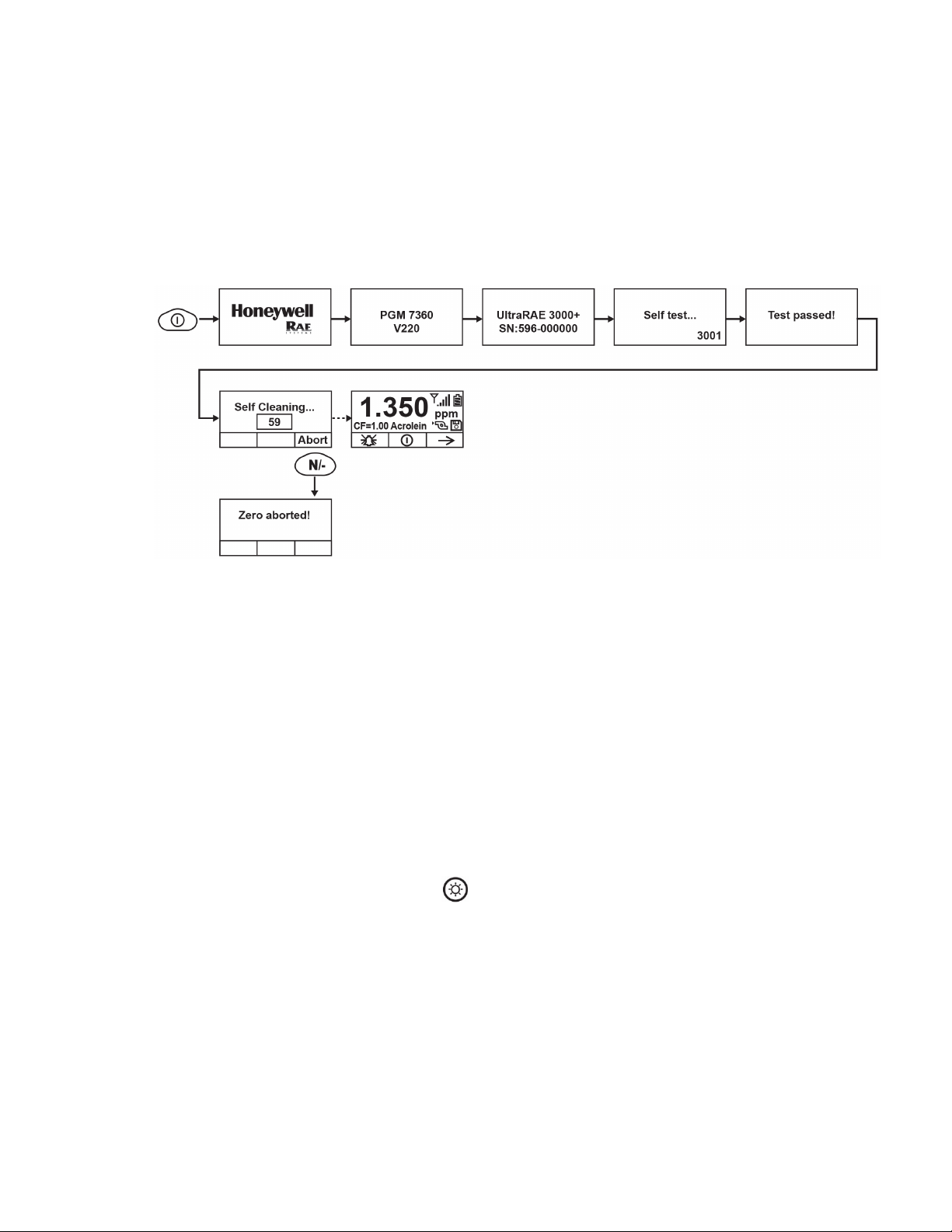

7.3. Auto-Zero At Startup Option

Using ProRAE Studio II (version 1.11.4 and above) or Honeywell™ Safety Suite Device

Configurator, the instrument can be programmed to automatically perform a zero calibration after

self-testing during startup.

Note: The option is disabled by default. If it is disabled, the instrument performs its self-test and

then goes directly to reading mode.

The zeroing process can be aborted by pressing the [N/-] key at any time during the process, and

the instrument will go directly to normal reading mode.

Notes:

• When a ppbRAE 3000+ is in normal reading mode and is not in system alarm (Low Alarm or

High Alarm), zero calibration is triggered in a locked interval (1 hour). If the instrument is in low

alarm, Auto Zero is skipped until the alarm clears.

• We do not recommend using this function on the UltraRAE3000+ and ppbRAE3000+.

• We highly recommend that you make sure the instrument is in a clean air environment during

startup and zeroing.

7.4. Operating The Built-In Flashlight

The instrument has a built-in flashlight that helps you point the probe in dark places. Press the

flashlight key to turn it on. Press it again to turn it off.

Note: Using the flashlight for extended periods shortens the battery’s operating time before it needs

recharging.

19

Page 20

Handheld PID Monitors User’s Guide

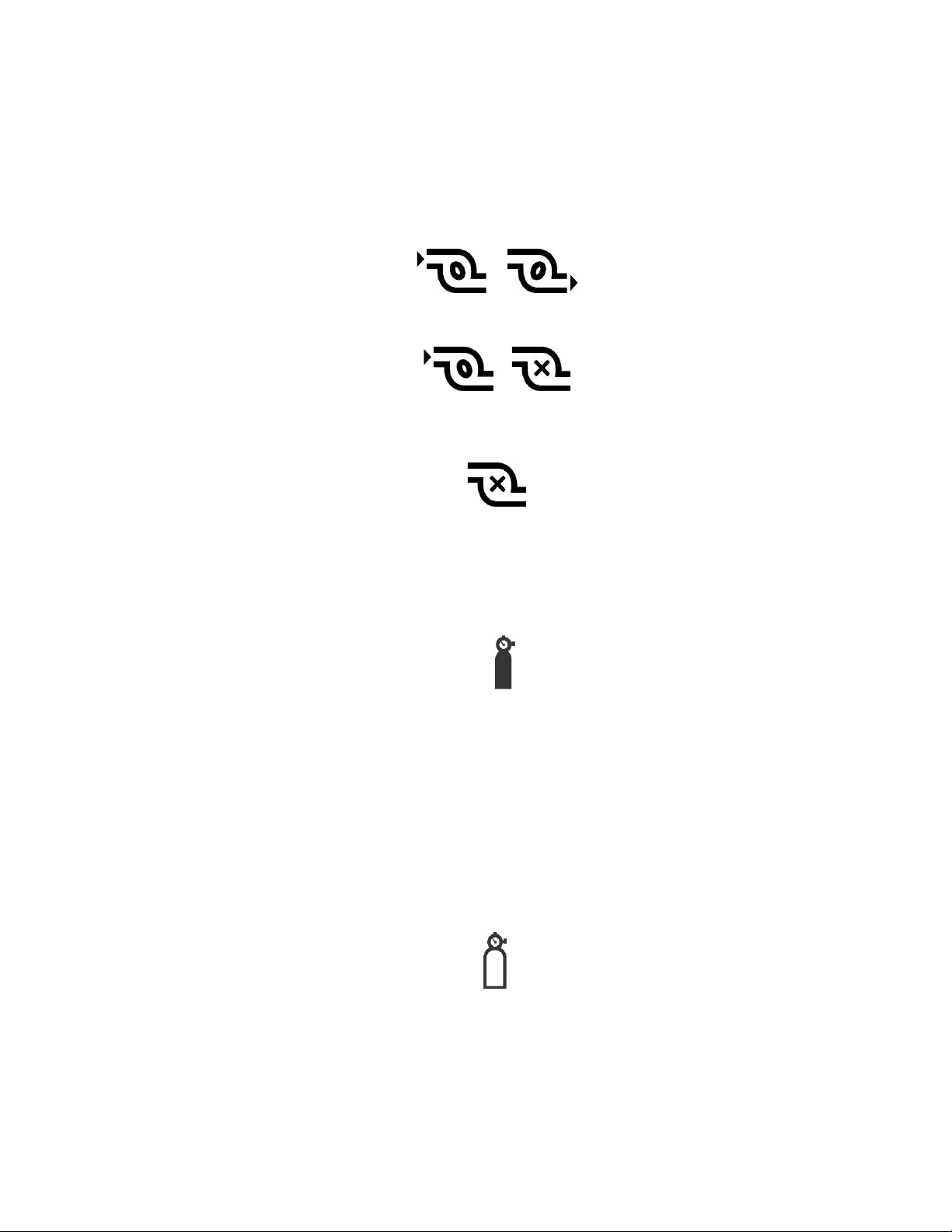

7.5. Pump Status

IMPORTANT!

During operation, make sure the probe inlet and the gas outlet are free of obstructions.

Obstructions can cause premature wear on the pump, false readings, or pump stalling. During

normal operation, the pump icon alternately shows inflow and outflow as shown here:

During duty cycling (PID lamp cleaning), the display shows these icons in alternation:

If there is a pump failure or obstruction that disrupts the pump, you will see this icon blinking on and

off:

If you see this blinking icon, consult the Troubleshooting section of this guide.

7.6. Calibration Status

The instrument displays this icon if it requires calibration:

Calibration is required (and indicated by this icon) if:

• The lamp type has been changed (for example, from 10.6 eV to 9.8 eV).

• The sensor has been replaced.

• It has been 30 days or more since the instrument was last calibrated.

• If you have changed the calibration gas type without recalibrating the instrument.

• If the instrument fails a bump test.

7.7. Bump Status

The instrument displays this icon if it requires a bump test:

A bump test is required (and indicated by this icon) if:

• The defined period between bump tests has been exceeded (bump test overdue).

• The sensor has failed a previous bump test.

• The sensor(s) should be challenged on a periodic basis.

20

Page 21

Handheld PID Monitors User’s Guide

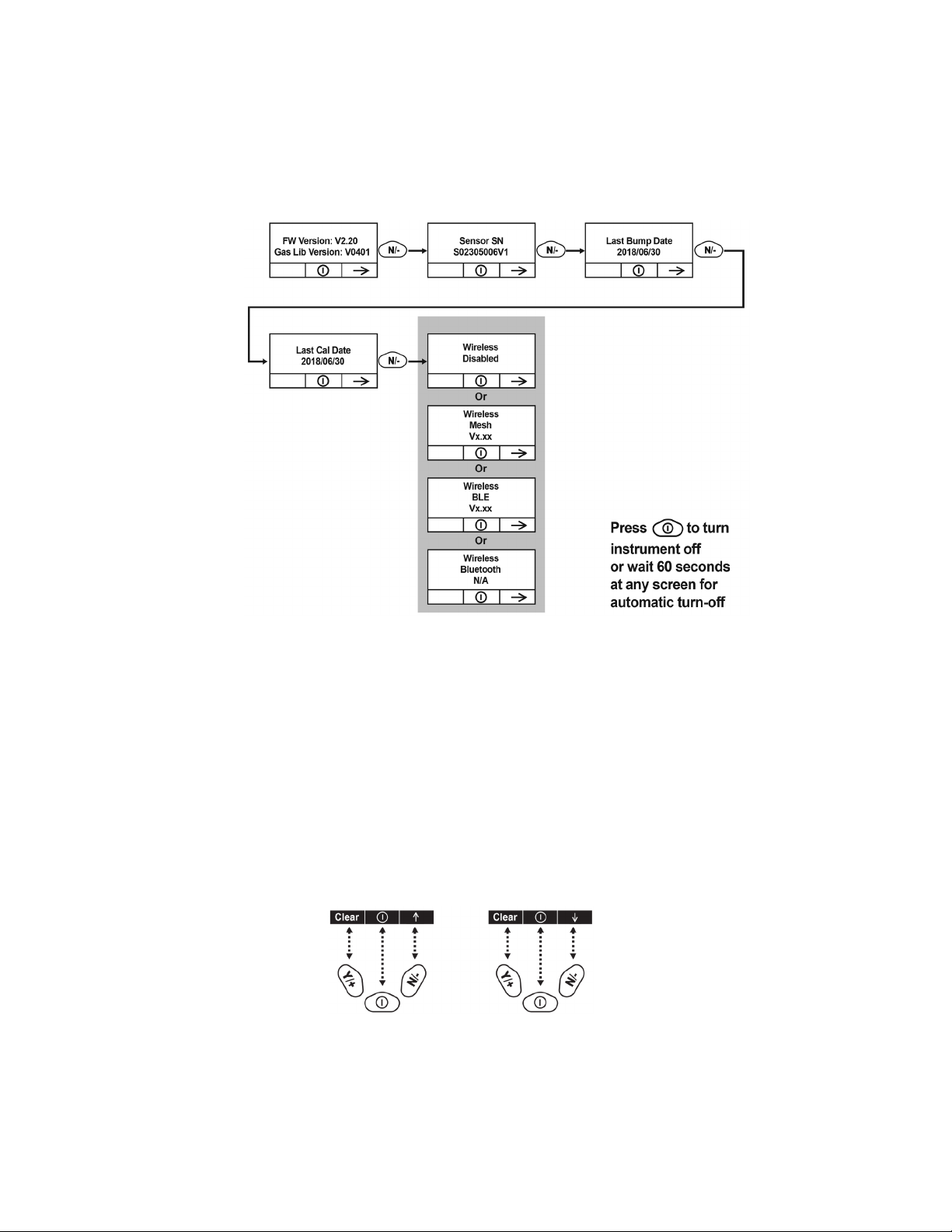

7.8. Glance Mode

Glance Mode allows you to get vital information without turning on the instrument. You can check

information such as the instrument’s model and serial number, installed sensor types, wireless

modules installed, etc., which may help when taking inventory of instruments and their sensors or

when working with service or support personnel. Glance Mode can be enabled/disabled via

ProRAE Studio II or Honeywell Safety Suite Device Configurator.

7.8.1. Enter Glance Mode

Note: The instrument must be configured so that Glance Mode is turned on (the default mode is

“Off”). This can be done in ProRAE Studio II or Honeywell Safety Suite Device Configurator. In

ProRAE Studio II or Honeywell Safety Suite Device Configurator, Glance Mode can be enabled or

disabled by checking or unchecking the box labeled “Enable Glance Mode.” You can also set which

screens will be displayed, as well as their order.

With the instrument turned off, press and hold [MODE] and [N/-] simultaneously for 2 seconds to

enter Glance Mode. If you see the message “GLANCE DISABLED,” you must configure the

instrument to use Glance Mode.

If Glance Mode is enabled, the first screen, with the Honeywell Logo, is displayed. Release the

[MODE] and [N/-] keys, and the first screen with information about the instrument is shown.

Note: If there is no information to show, the instrument will display “No Screen Display!” and turn

itself off.

21

Page 22

Handheld PID Monitors User’s Guide

7.8.2. Glance Mode Screens

Every screen displayed in sequence as configuration. Press [N/-] to advance to the next screen. If

the Wireless modem is turned off, the screen shows “Disabled”. Otherwise, the type of wireless is

shown. When the last screen is shown, pressing [N/-] “loops” to the first screen.

7.8.3. Exit Glance Mode

The instrument exits Glance Mode and turns off when you press the [MODE] key. The display

shows “Power Off”, and after 3 seconds, it turns off. In addition, if you do not press either key in 60

seconds, the instrument automatically exits Glance Mode and shuts off.

7.9. Reverse Direction – Main Navigation

Sometimes you want to go back to a previous screen rather than advance through an entire set of

screens before “wrapping around” to that screen again.

To reverse direction:

1. Press and hold [N/-] for 3 seconds.

2. When the arrow changes from pointing up to pointing down, release your finger.

Now when you press [N/-], you step back through the screens.

To change direction again: Press and hold [N/-] for 3 seconds and then release.

22

Page 23

Handheld PID Monitors User’s Guide

Note: Changing direction does not work with all screens. It works primarily in submenus.

7.10. Policy Enforcement

The instrument can be configured to enforce a facility/company’s requirements that calibration

and/or bump testing be performed at specified intervals, and to explicitly prompt the user that

calibration/bump testing is required. Depending on how Policy Enforcement features are

configured, the user may be required to perform a bump test or calibration prior to being able to use

the instrument. That is, it can be set to not allow normal operation of the instrument unless

calibration or bump testing is performed.

If the instrument has been bump tested and calibrated in compliance with the policy settings, a

check-mark icon is included along the top of the instrument screen:

If Policy Enforcement is enabled, then after startup the instrument displays a screen that informs

the user that the instrument requires either a bump test or a calibration. If both are required, then

they are shown in sequence.

Note: Policy enforcement features are disabled by default.

7.10.1. Setting Policy Enforcement

You must use ProRAE Studio II or Honeywell Safety Suite Device Configurator to make changes to

Policy Enforcement settings. You must use an AutoRAE 2 Cradle, a Travel Charger, or a Charger

Stand. Policy violations are captured in the datalog.

Using The Travel Charger, Charger Stand, or AutoRAE 2 Automatic Test And

Calibration System

To program an instrument via an AutoRAE 2, you need ProRAE Studio II Instrument Configuration

and Data Management Software, the AutoRAE 2 connected to a power source, and a USB PC

communications cable. Here are directions for using ProRAE Studio II. (For Device Configurator,

consult its manual.)

1. Connect a USB cable between a PC with ProRAE Studio II and the AutoRAE 2 Cradle,

Travel Charger, or Charger Stand.

2. Apply power to the AutoRAE 2 Cradle, Travel Charger, or Charger Stand.

3. Turn off the instrument (or put it into AutoRAE 2 Mode or Communication Mode) and set it in

the cradle.

4. Start ProRAE Studio II software on the PC.

5. Select “Administrator” and input the password (the default is “rae”).

6. Click “Detect the instruments automatically” (the magnifying glass icon with the letter “A” in it).

After a few seconds, the AutoRAE 2 Cradle is found and it is shown, along with its serial

number.

7. Click on the icon to highlight it, and then click “Select.”

8. In ProRAE Studio II, the instrument or AutoRAE 2 Cradle is shown, including its Serial

Number, under “Online.”

9. Expand the view to show the instrument or to show the instrument in the AutoRAE 2 Cradle

by clicking the “+” to the left of the image of the AutoRAE 2 Cradle.

10. Double-click on the icon representing the instrument

11. Click “Setup.”

23

Page 24

Handheld PID Monitors User’s Guide

12. In the menu that now appears on the left side, click “Policy Enforcement.” It is highlighted,

and the Policy Enforcement pane is shown. For “Must Calibrate” and “Must Bump,” you have

the options of no enforcement or enforcement (including “Can’t Bypass,” and “Can Bypass”).

Must Calibrate. The user is prompted to calibrate the instrument when calibration is due (as set by

the calibration interval). There are two programmable options:

• Can’t Bypass. Unless calibration is performed, the instrument cannot be used, and the only

option is to turn off the instrument.

• Can Bypass. If calibration is due but the user does not want to perform a calibration, the

instrument can still be used. In this case, the instrument records that the user has bypassed

the calibration requirement in a Policy Violation report.

Must Bump. The user is prompted to bump test the instrument when a bump test is due (as set by

the bump test interval). There are two programmable options:

• Can’t Bypass. Unless a bump test is performed, the instrument cannot be used, and the only

option is to turn off the instrument.

• Can Bypass. If a bump test is due but the user does not want to perform one, the instrument

can still be used. In this case, the instrument records that the user has bypassed the bump

testing requirement in a Policy Violation report.

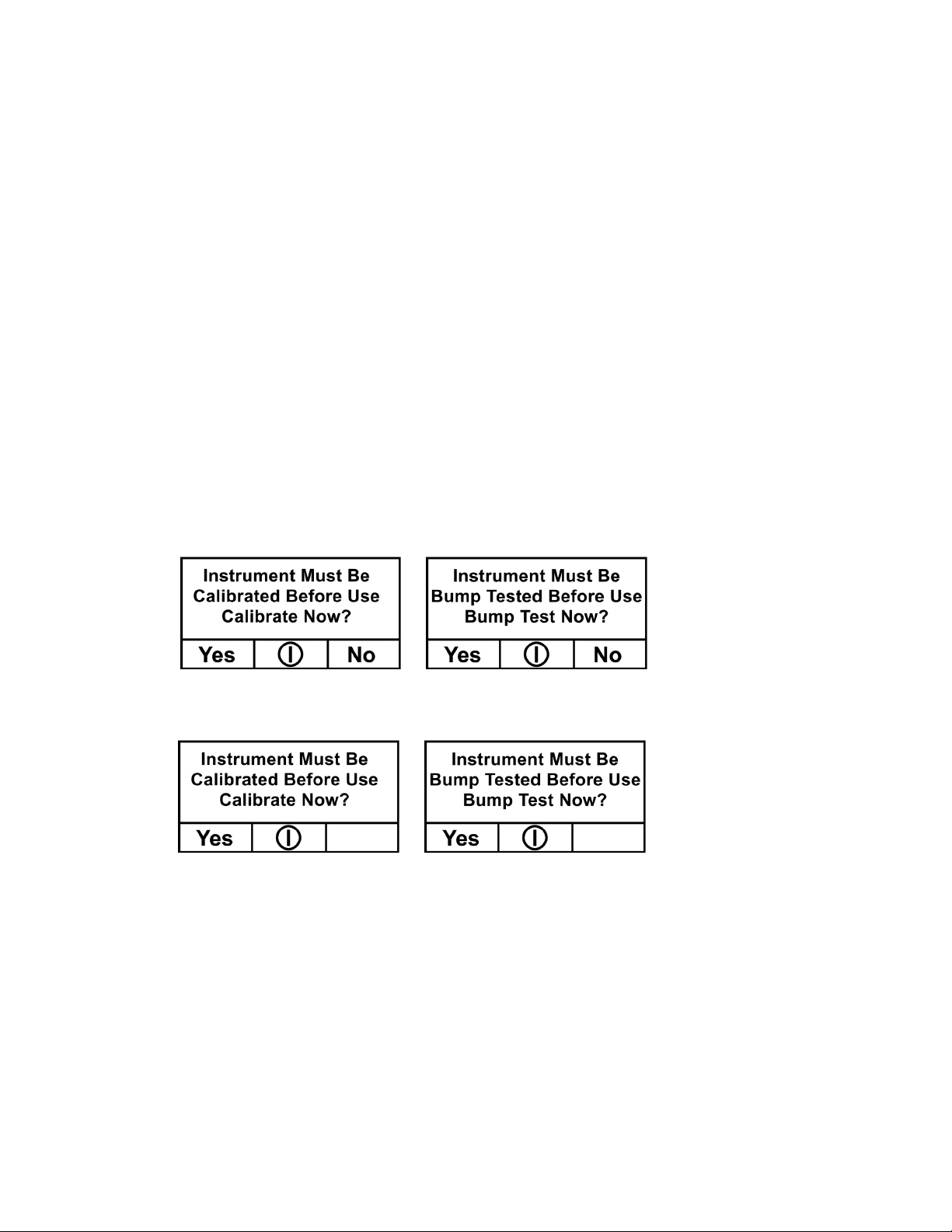

These are the screens that are shown on the instrument after startup if “Can Bypass” is selected:

If “Can’t Bypass” is selected, the display looks like this, and only allows the options of

performing the test or shutting down:

16. Once you have made your selections in ProRAE Studio II, you must upload the changes to the

instrument. Click the icon labeled “Upload all settings to the instrument.”

17. A confirmation screen is shown. Click “Yes” to perform the upload, or “No” to abort.

Uploading takes a few seconds, and a progress bar is shown. You can abort the upload by

clicking “Cancel.”

18. Exit ProRAE Studio II.

19. Press [Y/+] on the instrument to exit Communication Mode.

24

Page 25

Handheld PID Monitors User’s Guide

8. Operating Modes – MiniRAE 3000+ &

ppbRAE 3000+

Your instrument operates in different modes, depending on the model and its factory default

settings. In some cases, you can change modes using a password and the instrument’s navigation.

In other cases, you must use ProRAE Studio II or Honeywell Safety Suite Device Configurator

software.

The default setting for your instrument is:

User Level: Basic

Operation Mode: Hygiene

This is outlined in detail on page 73.

The other options, covered later in this guide, are:

User Level: Advanced (page 75)

Operation Mode: Hygiene

User Level: Advanced (page 75)

Operation Mode: Search

Using ProRAE Studio II or Honeywell Safety Suite Device Configurator allows access to other

options. In addition, Diagnostic Mode (page 79) is available for service technicians.

25

Page 26

Handheld PID Monitors User’s Guide

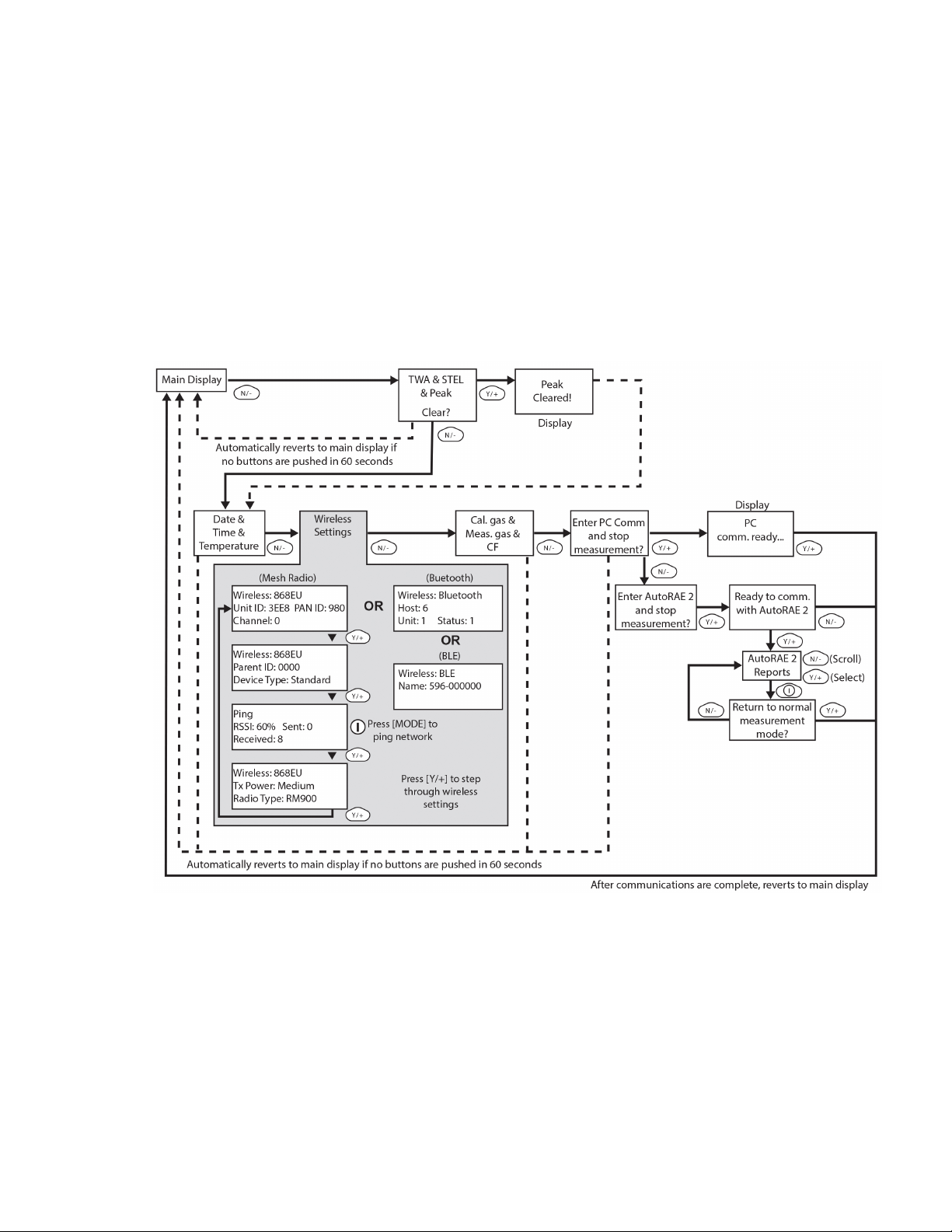

8.1. Basic User Level/Hygiene Mode (Default Settings) –

MiniRAE 3000+ & ppbRAE 3000+

The instrument is programmed to operate in Basic User Level/Hygiene Mode as its default. This gives you the

most commonly needed features while requiring the fewest parameter adjustments.

Pressing [N/-] steps you from one screen to the next, and eventually return to the main display. If you do not

press a key within 60 seconds after entering a display, the instrument reverts to its main display.

Note: While viewing any of these screens, you can shut off your instrument by pressing [MODE].

Note: At the Average & Peak, Date & Time & Temperature, Calibration Gas & Measurement Gas &

Correction Factor, and PC Communications screens, the instrument automatically goes to the main display

after 60 seconds if you do not push a key to make a selection.

26

Page 27

Handheld PID Monitors User’s Guide

9. Operating Modes – UltraRAE 3000+

The UltraRAE is actually two monitors in one:

• Compound-specific monitor

• VOC monitor

As a compound-specific monitor, it takes timed measurements and uses a separation tube in

conjunction with software that enables the UltraRAE 3000+ to give specific readings on one

particular type of compound, such as benzene or butadiene.

As a VOC monitor, the UltraRAE 3000+ operates in different modes. In some cases, you can

change modes using a password and using the instrument’s navigation. In other cases, you must

use ProRAE Studio II or Honeywell Safety Suite Device Configurator software.

The following two sections cover operation in the two modes.

• Compound Specific, page 29.

• VOC, page 35.

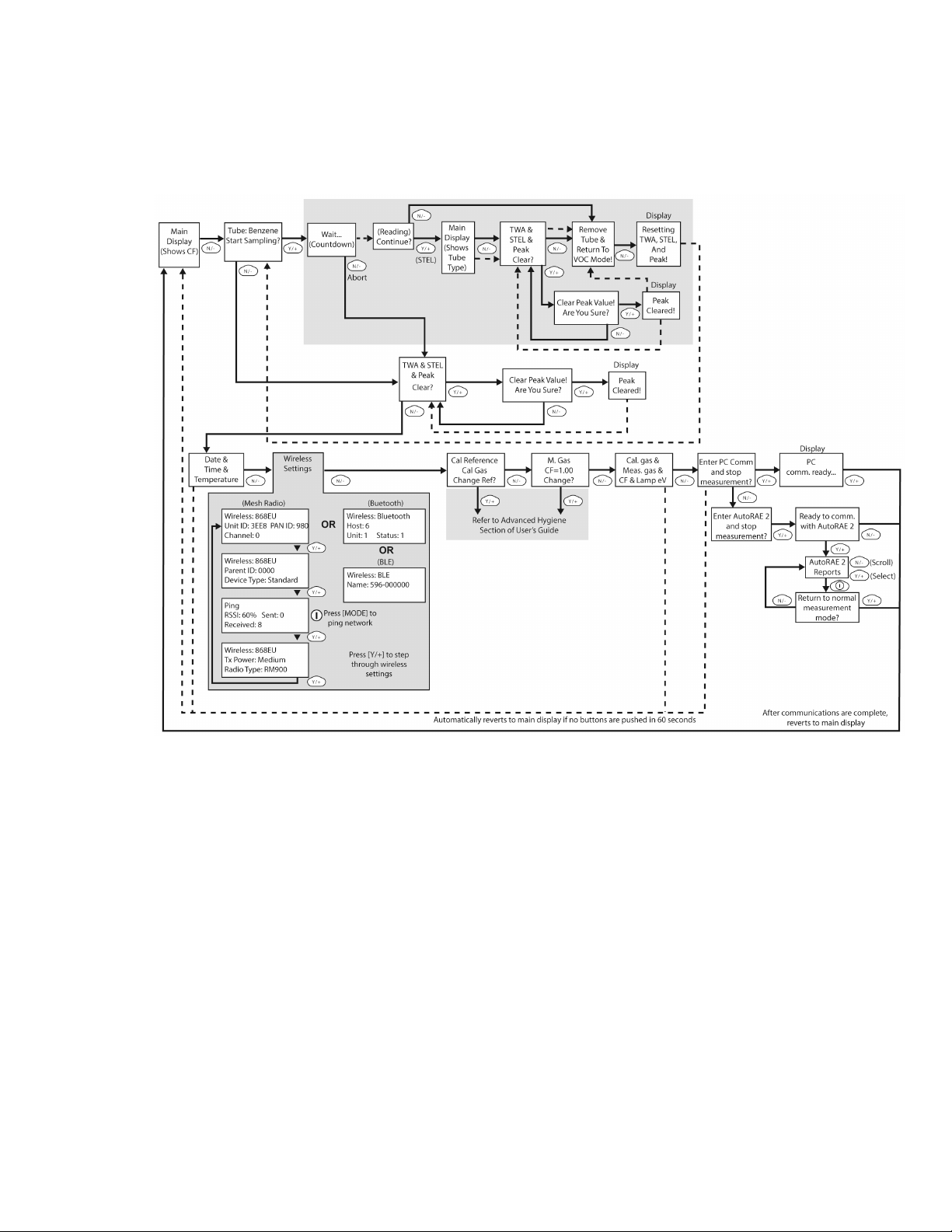

The diagram on the next page shows the basic flow of the UltraRAE 3000+’s functions. The area

with the gray field is the compound-specific (tube) mode, while the rest shows VOC mode. Navigate

through the steps by using the [Y/+] and [N/-] keys as shown in the diagram.

Note: If you use a password to access Programming Mode (see page 19), then the navigation

changes slightly, entering part of Advanced Hygiene Mode’s settings, as shown on page 75

.

27

Page 28

Handheld PID Monitors User’s Guide

Compound-Specific (Tube)

Note: Dashed line indicates automatic progression.

The default setting for your instrument is:

User Level: Basic

Operation Mode: Hygiene

This is outlined in detail on page 73.

The other options, covered later in this guide, are:

User Level: Advanced (page 75)

Operation Mode: Hygiene

User Level: Advanced (page 75)

Operation Mode: Search

Using ProRAE Studio II or Honeywell Safety Suite Device Configurator allows access to other

options. In addition, Diagnostic Mode (page 79) is available for service technicians.

28

Page 29

Handheld PID Monitors User’s Guide

10. Compound-Specific Operation – UltraRAE 3000+

10.1. Compound-Specific Measurement

The UltraRAE 3000+ can perform compound-specific measurement in addition to general VOC

measurement. This requires using a RAE-Sep separation tube (butadiene or benzene) and having

the UltraRAE 3000+ in Tube Mode, operating with a 9.8eV lamp.

10.2. Measurement Phases

To perform a compound-specific measurement, follow this order:

1. UltraRAE 3000+ is ready for sampling

2. Prepare the separation tube

3. Insert the separation tube

4. Start measurement

5. UltraRAE 3000+ displays and logs measurement

6. Remove the separation tube

10.3. Performing A Measurement – UltraRAE 3000+

Before performing a compound-specific measurement for Benzene or Butadiene using a RAESep™ separation tube, make sure the UltraRAE 3000+ is in Tube Mode and that the appropriate

tube type is selected. The UltraRAE 3000+ only acts as a compound-specific measurement device

when it is equipped with a 9.8eV lamp. The UltraRAE 3000+ is designed to auto-sense the lamp

type. It can also be manually set to default to a 9.8eV lamp type.

Make sure the UltraRAE 3000+ is set to operate with your selected tube:

1. Enter Programming Mode.

2. Select Measurement.

3. Select Tube Selection.

4. Make a choice of Benzene or Butadiene.

5. Save your choice.

To begin measuring, turn on the UltraRAE 3000+. This screen is shown, which includes the CF

(correction factor) and measurement gas type for calibration reference:

Press [N/-] to advance. You will see this screen:

Do not begin sampling yet!

29

Page 30

Handheld PID Monitors User’s Guide

Before you start sampling, you must insert a RAE-Sep separation tube into the inlet/holder. Follow the

Separation Tube Preparation and Placing A Tube Into The UltraRAE 3000+ instructions before pressing

any buttons on the UltraRAE 3000+. Once the tube is in place, then proceed to measuring.

IMPORTANT!

Once a tube’s ends are broken off, the material inside is exposed. Therefore, use the tube for

sampling as soon as possible.

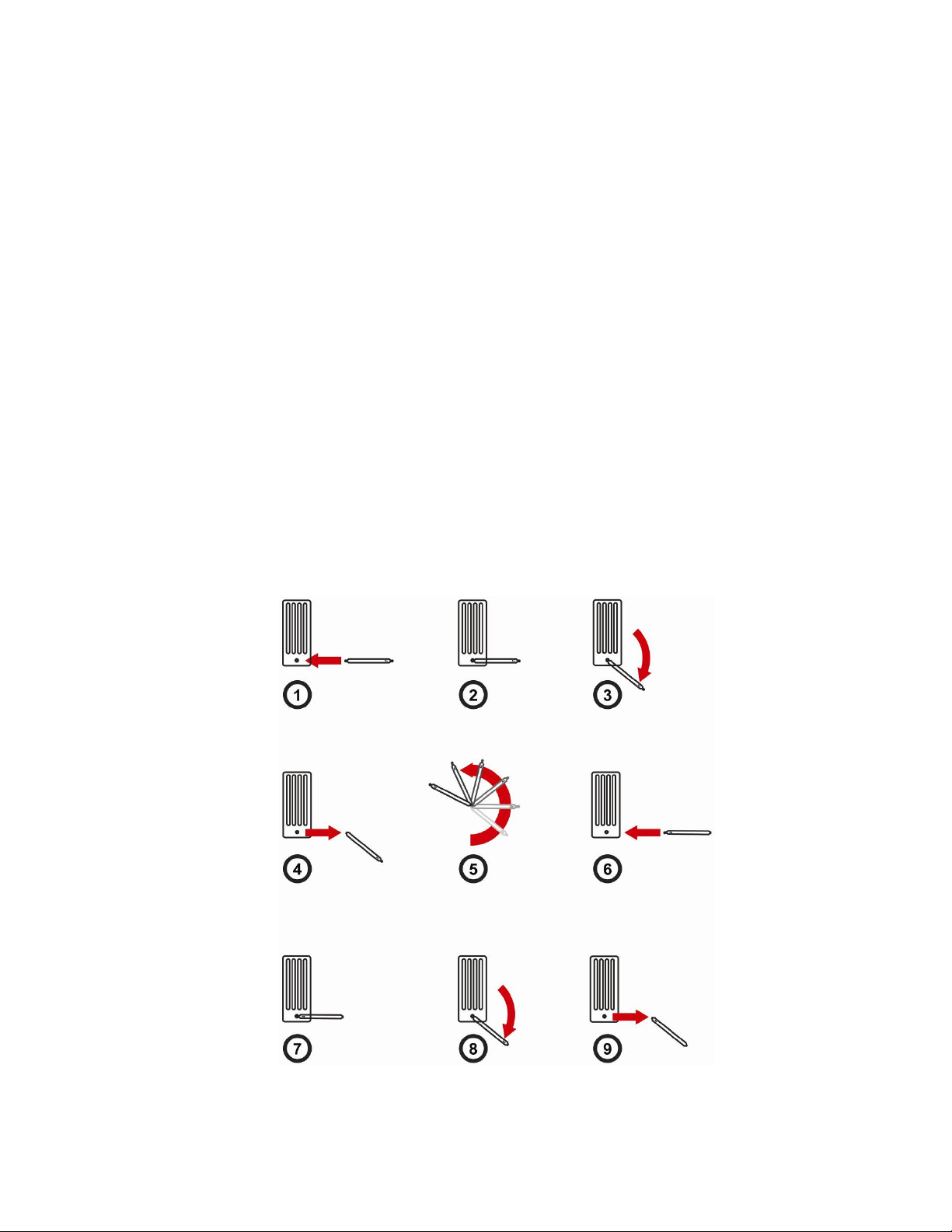

10.4. Separation Tube Preparation

CAUTION!

Wear hand and eye protection when breaking tube tips. Use caution in handling tubes with broken

ends. Keep away from children. RAE-Sep tubes should be disposed of according to local

regulations. See footnotes of data sheets for disposal information.

1. Open a package of RAE-Sep separation tubes and remove one.

2. Place the tip in the package’s tube tip breaker (the small hole on the front) and snap off the tip.

3. Turn the tube around and snap off the other end.

CAUTION!

Only use Honeywell RAE Systems tubes.

CAUTION!

30

Page 31

Handheld PID Monitors User’s Guide

Handle tubes with care. Tube ends are sharp after ends are broken off.

31

Page 32

Handheld PID Monitors User’s Guide

10.5. Inserting The Separation Tube

1. Unscrew the front of the sampling probe from the base.

2. Slip the tube into the rubber holder in the front portion. Make sure the arrow on the side of the tube

points toward the instrument.

3. Insert the other end of the tube into the middle of the base while turning the front portion to tighten it

onto the base’s threads.

IMPORTANT!

Do not overtighten any portion of the sampling assembly.

Note: When the UltraRAE 3000+ is used for VOC monitoring, no tube is inserted.

IMPORTANT!

To ensure that there are no leaks, periodically test the seals:

With the UltraRAE 3000+ running, place your finger over the end of the inlet probe. The alarm

should sound and the pump-stall icon should flash on the display. This indicates that all seals are

good. Stop the alarm by pressing [Y/+]. If the pump does not alarm or show the stalled-pump icon,

then check that all inlet parts are tight and inspect the O-ring for damage (replace it if necessary).

10.6. Measuring

Once the tube is in place, begin measuring by pressing [Y/+].

The display shows a countdown (60 seconds is shown here, but sampling time depends on the type of

separation tube selected and the temperature):

Note: You can abort the sampling by pressing [N/-] at any time.

32

Page 33

Handheld PID Monitors User’s Guide

Once the countdown is complete, the reading is shown:

Press [Y/+] to continue sampling with the tube for 15 minutes to establish a STEL reading, or press

[N/-] to return to the main menu.

WARNING!

At least 1/4 of the tube should still be yellow-orange at the bottom. If not, the STEL value is not

valid. Abort the measurement and change the tube. Then do a snapshot test instead of a STEL

test. Note: If the STEL is exceeded, the UltraRAE 3000+ goes into alarm.

If you press [N/-] to return to the main menu, which shows the tube type instead of the CF

(correction factor):

Press [N/-] to advance to this screen:

If you press [Y/+], you are asked, “Clear peak value! Are You Sure?” to confirm:

Press [Y/+] to clear the Peak value and exit to VOC operation.

33

Page 34

Handheld PID Monitors User’s Guide

If you press [N/-], this display is shown:

Remove the tube and put the inlet back together. Then press [N/-]. This display is shown:

After a few seconds, the UltraRAE 3000+ enters VOC mode and shows this display:

You can step through the rest of the steps by pressing [N/-] repeatedly until you reach the main

menu again.

34

Page 35

Handheld PID Monitors User’s Guide

Note: Dashed line indicates automatic progression.

11. VOC Operation – UltraRAE 3000+

11.1. Basic User Level/Hygiene Mode (Default Settings)

The instrument is programmed to operate in Basic User Level/Hygiene Mode as its default. This gives you the

most commonly needed features while requiring the fewest parameter adjustments.

Pressing [N/-] steps you from one screen to the next, and eventually return to the main display. If you do not

press a key within 60 seconds after entering a display, the instrument reverts to its main display.

Note: While viewing any of these screens, you can shut off your instrument by pressing [MODE].

Note: At the Average & Peak, Date & Time & Temperature, Calibration Gas & Measurement Gas &

Correction Factor, and PC Communications screens, the instrument automatically goes to the main display

after 60 seconds if you do not push a key to make a selection.

35

Page 36

Handheld PID Monitors User’s Guide

Message

Condition

Alarm Signal

HIGH

Gas exceeds “High Alarm” limit

3 beeps/flashes per second*

OVR

Gas exceeds measurement range

3 beeps/flashes per second*

MAX

Gas exceeds electronics’

maximum range

3 beeps/flashes per second*

LOW

Gas exceeds “Low Alarm” limit

2 beeps/flashes per second*

TWA

Gas exceeds “TWA” limit

1 Beep/flash per second*

STEL

Gas exceeds “STEL” limit

1 Beep/flash per second*

Pump icon

flashes

Pump failure

3 beeps/flashes per second

Lamp

PID lamp failure

3 beeps/flashes per second plus “Lamp”

message on display

Battery icon

flashes

Low battery

1 flash, 1 beep per minute plus battery icon

flashes on display

CAL

Calibration failed, or needs

calibration

1 beep/flash per second

NEG

Gas reading measures less than

number stored in calibration

1 beep/flash per second

11.2. Basic Operation – MiniRAE 3000+

The instrument is programmed to give you the most commonly needed information quickly.

Pressing [N/-] steps you from one screen to the next, and eventually return to the main display. If you do not

press a key within 60 seconds after entering a display, the instrument reverts to its main display.

Note: While viewing any of these screens, you can shut off your instrument by pressing [MODE].

Note: At the Average & Peak, Date & Time & Temperature, Calibration Gas & Measurement Gas &

Correction Factor, and PC Communications screens, the instrument automatically goes to the main display

after 60 seconds if you do not push a key to make a selection.

12. Alarm Signals

During each measurement period, the gas concentration is compared with the programmed alarm

limits (gas concentration alarm limit settings). If the concentration exceeds any of the preset limits,

the loud buzzer and red flashing LED are activated immediately to warn you of the alarm condition.

In addition, the instrument alarms if one of the following conditions occurs: battery voltage falls

below a preset voltage level, failure of the UV lamp, or pump stall.

12.1. Alarm Signal Summary

* MiniRAE 3000+, ppbRAE 3000+, and UltraRAE 3000+: Hygiene mode only. In Search mode, the

number of beeps per second (1 to 7) depends upon the concentration of the sampled gas. Faster

rates indicate higher concentrations.

36

Page 37

Handheld PID Monitors User’s Guide

Cal Gas

(Isobutylene)

Cal

Span

Unit

Low

High

MiniRAE Lite+

100

ppm

50

100

Cal Gas

(Isobutylene)

Cal

Span

Unit

Low

High

TWA

STEL

MiniRAE

3000+

100

ppm

50

100

10

25

Cal Gas

(Isobutylene)

Cal

Span

Unit

Low

High

TWA

STEL

ppbRAE

3000+

10

ppm

10

25

10

25

MiniRAE

3000+

100

ppm

50

100

10

25

MiniRAE

Lite+

100

ppm

50

100

10

25

Cal Gas

Cal

Span

Unit

Low

High

TWA

STEL

Isobutylene

100

ppm

50

100

10

25

Benzene

5

ppm 2 5

0.5

2.5

Butadiene

10

ppm 5 10 2 5

12.2. Preset Alarm Limits & Calibration

The instrument is factory calibrated with standard calibration gas, and is programmed with default

alarm limits. These settings can be changed in Programming Mode to align more precisely with

your standards.

MiniRAE Lite+

MiniRAE 3000+

ppbRAE 3000+

UltraRAE 3000+

12.3. Testing The Alarm

You can test the alarm whenever the main (Reading) display is shown. Press [Y/+], and the audible

and visible alarms are tested.

12.4. Integrated Sampling Pump

The instrument includes an integrated sampling pump. This diaphragm-type pump that provides a

450 to 550 cc per minute flow rate. Connecting a Teflon or metal tubing with 1/8" inside diameter to

the gas inlet port of the instrument, this pump can pull in air samples from 100' (30 m) horizontally

or vertically.

Note: In Search Mode, the pump turns on when a sample measurement is started, and turns off

when the sample is manually stopped.

If liquid or other objects are pulled into the inlet port filter, the instrument detects the obstruction and

immediately shuts down the pump. The alarm is activated and a flashing pump icon is displayed.

You should acknowledge the pump shutoff condition by clearing the obstruction and pressing the

[Y/+] key while in the main reading display to restart the pump.

37

Page 38

Handheld PID Monitors User’s Guide

12.5. Backlight

The LCD display is equipped with an LED backlight to assist in reading the display under poor

lighting conditions.

12.6. Datalogging

During datalogging, the instrument displays a disk icon to indicate that datalogging is enabled. The

instrument stores the measured gas concentration at the end of every sample period (when data

logging is enabled). In addition, the following information is stored: user ID, site ID, serial number,

last calibration date, and alarm limits. All data are retained (even after the unit is turned off) in nonvolatile memory so that it can be down- loaded later to a PC.

12.6.1. Datalogging event

When Datalogging is enabled, measurement readings are being saved. These data are stored in

“groups” or “events.” A new event is created and stored each time the instrument is turned on and

is set to automatic datalogging, or a configuration parameter is changed, or datalogging is

interrupted. The maximum time for one event is 24 hours or 28,800 points. If an event exceeds 24

hours, a new event is automatically created. Information, such as start time, user ID, site ID, gas

name, serial number, last calibration date, and alarm limits are recorded.

12.6.2. Datalogging sample

After an event is recorded, the unit records a shorter form of the data. When transferred to a PC

running ProRAE Studio II or Honeywell Safety Suite Device Configurator, this data is arranged with

a sample number, time, date, gas concentration, and other related information.

12.6.3. Auto/Manual/Snapshot Datalogging

The instrument has three datalog types:

Auto Default mode. Collects datalog information when the instrument is sampling.

Manual Datalogging occurs only when the instrument’s datalogging is manually started (see

page 65 for details).

Snapshot Datalogs only during snapshot (single-event capture, initiated by pressing [MODE])

sampling. See page 66 for details.

Note: You can only choose one datalog type to be active at a time.

38

Page 39

Handheld PID Monitors User’s Guide

13. Accessories

MiniRAE Lite+

The following accessories are included with the instrument:

• 10.6 eV lamp

• Flex-I-Probe

• External filter

• Green rubber boot

• Alkaline battery adapter

• Lamp cleaning kit

• Tool Kit

• Lithium-Ion (Li-Ion) battery, if specified

• Travel Charger, if specified

• Universal wall adapter, if specified

• Quick Start Guide

• Soft leather carrying case

MiniRAE 3000+ & ppbRAE 3000+

The following accessories are included with the instrument:

• AC Adapter (Battery Charger)

• Alkaline battery adapter

• External Filter

Hard-case kits also include these accessories:

• Calibration adapter

• Calibration regulator and Flow controller

UltraRAE 3000+

The following accessories are included with the instrument:

• AC Adapter (Battery Charger)

• Travel Charger

• Alkaline battery adapter

• External Filter

Hard-case kits also include these accessories:

• Calibration gas, if specified

• Calibration adapter

• Calibration regulator and flow controller

• Charger Stand (instead of Travel Charger)

39

Page 40

Handheld PID Monitors User’s Guide

14. Standard Kit & Accessories

14.1. AC Adapter (Battery Charger)

WARNING!

To reduce the risk of ignition of hazardous atmospheres, recharge battery only in area

known to be non-hazardous. Remove and replace battery only in area known to be nonhazardous.

Ne charger les batteries que dans emplacements designés non-dangereuses.

A battery charging circuit is built into the instrument cradle. It only needs a regular AC to 12 VDC adapter

(wall-mount transformer, part number 500-0114-000) to charge the instrument.

To charge the battery inside the instrument:

1. Power off the instrument.

2. Connect the AC adapter to the DC jack on the instrument’s cradle. If the instrument is off, it

automatically turns on.

3. While charging, the display message shows “Charging.” The Primary LED on the cradle

flashes green when charging.

4. When the battery is fully charged, the LED changes to glowing green continuously, and the

message “Fully charged” appears on the display. If there is a charging error, the LED glows

red continuously.

A completely discharged instrument can be charged to full capacity within 8 hours. Batteries drain

slowly even if an instrument is off. Therefore, if the instrument has been in storage or has not been

charged for several days or longer, check the charge before using it.

The factory-supplied battery is designed to last for 16 hours of normal operation (no alarm), for a

new battery under the optimum circumstances. As the battery becomes older or is subject to

adverse conditions (such as cold ambient temperature), its capacity will be significantly reduced.

14.2. Alkaline Battery Adapter

An alkaline battery adapter is supplied with each instrument. The adapter (part number 059-3052-

000) accepts four AA alkaline batteries (use only Duracell MN1500) and provides approximately 12

hours of operation. The adapter is intended to be used in emergency situations when there is no

time to charge the Li-ion battery pack.

To insert batteries into the adapter:

1. Remove the three Philips-head screws to open the compartment in the

adapter.

2. Insert four fresh AA batteries as indicated by the polarity (+/-) markings.

3. Replace the cover. Replace the three screws.

To install the adapter in the instrument:

1. Remove the Li-ion battery pack from the instrument by sliding the tab and

tilting out the battery.

2. Replace it with the alkaline battery adapter

3. Slide the tab back into place to secure the battery adapter.

IMPORTANT!

Alkaline batteries cannot be recharged. The instrument’s internal circuit detects alkaline batteries

and will not allow recharging. If you place the instrument in its cradle, the alkaline battery will not be

40

Page 41

Handheld PID Monitors User’s Guide

recharged. The internal charging circuit is designed to prevent damage to alkaline batteries and the

charging circuit when alkaline batteries are installed inside the instrument. If you try to charge an