Page 1

046-4001-000, Revision C, June 2005

Page 2

b

This manual must be carefully read by all individuals who have

or will have the responsibility of using, maintaining, or servicing

this product. The product will perform as designed only if

manufacturer’s instructions.

Caution!

To reduce the risk of electric shock, turn off power before removing the

monitor cover. Disconnect the battery before removing sensor modules for

service. Never operate this monitor while the cover is removed. Remove

monitor cover and sensor modules only in an area known to be non-

hazardous.

Special Note

When the EntryRAE monitor is removed from the transport case and is

turned on for the first time, there may be residual vapors trapped inside the

monitor, and the initial toxic gas sensors values may indicate a few ppm.

After running the monitor for several minutes in clean air, the residual vapors

should clear and readings should return to near zero.

Attention! For European Applications

A. Recharge batteries in non-hazardous locations.

C. Use RAE Systems Charging cradle (P/N 046-3059-000) for connection to

communication port and charging jack only in a non hazardous area.

Only the combustible gas detection portion of this instrument has been

assessed for performance in accordance with C22.2 No.152-M1984.

Seulement la partie combustible de détection de gaz de cet instrument a été

evaluée pour l’exécution selon C22.2 No. 152-M1984.

5,393,979 , 5,561,344 , 5,773,833 , 6,225,633 ,

6,313,638 , 6,333,632 , 6,320,388

WARNING

To prevent ignition of flammable or combustible atmospheres, disconnect

power before servicing.

WARNING

manufacturers.

WARNING

Substitution of components may impair intrinsic safety.

!

!

!

!

!

!

!

Page 3

c

Warnings

serviced by qualified personnel only. Read and understand the

instrument has not been tested in an explosive gas/air atmosphere having an

oxygen concentration greater than 21%. Substitution of components may impair

intrinsic safety. Recharge/replace batteries only in non-hazardous atmospheres.

Computer Interface

atmospheres.

Static Hazard

Clean only with a damp cloth.

Calibration

While the EntryRAE has been factory calibrated prior to shipment, transport

and storage after leaving the factory can affect the sensors. Therefore, any

newly purchased RAE Systems Instrument should be fully calibrated by

exposing it to known concentration calibration gases before the instrument

is put into service for the first time. For safety, check the accuracy of the

monitor by exposing the sensors to calibration gas(es) before each day’s

use. (Refer to “Calibration” on page 10.)

Caution!

concentration of methane gas equivalent to 20% to 50% of full-scale

concentration. Accuracy must be within 0% to +20% of actual. Accuracy may

be corrected by calibration. Refer to “Calibration” on page 10.)

use after long storage requires installation of the batteries and a warm-up

period of at least 10 minutes for the sensors to equilibrate. The user should

recognize that sensor life is based upon the purchase date.

Any rapid up-scale reading followed by a declining or erratic reading may indicate

a gas concentration beyond the upper scale limit, which may be hazardous.

CAUTION:

HIGH OFF-SCALE READINGS MAY INDICATE AN EXPLOSIVE

CONCENTRATION!

!

!

!

!

!

!

!

!

!

Page 4

d

Avertissements

entretenu et réparé uniquement par un personnel qualifié.

d’entretenir ou de réparer l’équipement.

046-3007-000 ou 046-3051-000). Cet instrument n’a pas été essayé dans une

atmosphère de gaz/air explosive ayant une concentration d’oxygène plus élevée

que 21%. La substitution de composants peut compromettre la sécurité intrinsèque.

Câble de Computer

Connecter pas le câble externe que dans environnements non dangereux.

exposant l’instrument à une concentration de gaz connue par une procédure

diétalonnage avant de mettre en service l’instrument pour la première fois.

exposant l’instrument. (Référez la Calibration à la page 10.)

Attention!

Avant chaque utilisation journalière verifier la sensibilité avec une concentration

connue de methane equivalante a 20% à 50% de la pleine échelle. La precision

doit être comprise entre 0% à +20% de la valeur vraie et peut être corrigée par

une procédure diétalonnage. (Référez la Calibration à la page 10.)

Stockage à Long Term

utilisation régulière de celui ci. Lors d’un stockage à long terme, la batterie

doit être déconnectée. Le rédémarrage aprés une longue période d’arrêt,

nécessite la réinstallation de la batterie, et une période de chauffage de 10 mn

afin que les capteurs se mettent à l’équilibre. L’utilisateur doit être conscient

que la durée de vie indiquée pour le capteur démarre à sa date d’achat.

Toute lecture rapide et positive, suivie d’une baisse subite au erratique de la

valeur, peut indiquer une concentration de gaz hors gamme de détection qui

peut être dangereuse.

ATTENTION:

DES LECTURES SUPÉRIEURES A L’ÉCHELLE PEUVENT

!

!

!

!

!

!

!

!

Page 5

e

Warnings

c

Avertissements

d

General Information

2

4

5

Operating the EntryRAE

6

Turning the Monitor On

6

Warm-up Sequence

6

Turning the Monitor Off

7

8

The Pump Cycle

8

Continuous Operation of the Pump

88Calibration

Calibration Equipment

Calibration Procedure

Optional Step: Zero Calibration for the Oxygen Sensor

4

Calibration Period

5

6

Alarm Signals

7

Testing Alarm Signals

7

Alarm Conditions

888

Sampling Pump

9

9

Charging the EntryRAE

9

Table of Contents

Page 6

f

T2121

Security

21

22

23

Change Monitor Setup

2327272

9

Sensor Replacement

30

CO Sensor Charcoal Filter

32

Cleaning the PID

33

Setting Pump Stall Threshold

34

Specifications

35 Certifications

36

Sensor Range and Resolution

3

6

Service and Repair Record

3

7

SPECIAL NOTE:

The

where the monitor was purchased; they will

return the monitor on your behalf,

or

The

monitor for service or repair, obtain a Returned Material Authorization (RMA)

number for proper tracking of your equipment. This number needs to be on

all documentation and posted on the outside of the box in which the monitor

is returned for service or upgrade.

Packages without RMA Numbers will be

refused at the factory.

Page 7

1

The EntryRAE is a 4-gas plus PID (photoionization detector) gas moni-

available today.

Also includes CO, H

2

S, LEL and O

2

sensors

Visual alarm with bright red flashing LEDs

tor. Reliable, easy to operate and simple to calibrate, the EntryRAE

delivers added protection without added complexity.

Simple, Modular, Durable PID

Page 8

2

Photo Item

Number

Part Name

Part Number

Monitor Only

*Shipping case

Monitor

701-3040-000

Sensors

Photoionization Detector

023-0102-000

Oxygen (O

)

046-1161-000

Combustible (%LEL, %Vol)

014-0212-000

Carbon Monoxide (CO)

032-0200-000

2

S)

032-0202-000

Rechargeable Li-Ion Battery

046-3007-000

3

Charging Cradle

- 120 V AC to 12 V DC wall charger, US plug or

- 230 V AC to 12 V DC wall charger, Euro plug

046-3059-000

500-0036-000

500-0036-001

4

Alkaline Battery Adapter

046-3051-000

5

Calibration Adapter/Tubing Assembly

046-3040-000

7

External Filters (5-pack)

046-3022-005

Charcoal Filters (for the CO Sensor)

008-3006-005

8

User Manual

046-4001-000

EntryRAE Resource CD

046-4013-000

Computer Interface Cable - RS232 to RS232 with USB

adapter

002-3009-000

9

Remote Sampling Probe with 15 feet (5 meters) of

self-coiling Teflon (tm) tubing

008-3015-002

5

Tool Kit

081-0005-000

O

S, 50 ppm CO)

600-0050-004

600-0002-000

6

Regulator (male) with tubing

007-3021-000

6

Regulator (female) with tubing

002-3011-000

4-year repair and replacement guarantee

SVC-PTC4-046

not shown

AutoRAE Docking Station Starter Kit

048-5900-000

not shown

Additional AutoRAE Cradle

048-0154-000

not shown

PID Cleaning Kit

500-0014-010

* Different shipping cases are used for monitor-only and calibration kits.

Optional Confined Space Kit II (CSK II) 046-0911-000

Optional Guaranteed Cost of Ownership

Optional Accessories (items sold separately)

Page 9

3

8

5

5, 6

9

3

Page 10

4

2. Operation / Program keys

3. Charge status

4. Visual alarm

5. Gas plate

6. Buzzer

7. Gas inlet with external filter

8. Charging contacts

9. Charging cradle

9

5

6

8

3

bottom of monitor

monitor in cradle

Page 11

5

2. Alarm conditions (

page 18

)

3. Pump on (

page 19

)

4. Pump off

5. Time (

page 25

)

6. Date (Day, Month, Year)

7. Apply calibration gas (

page 12

)

8. Battery charge status (

page 19

)

9. Password protected (

page 11, 26

)

HIGHLOW TWA STEL

D1

D2

D3

D4

D5

D6

D7

D8

D9

D10

D11

D12

D13

D14

D15

D16

D17

A

B

C

D

E

F

G

ALARM

H S

2 ppm

CO ppm

VOC

ppm

LEL %VOL

O

2 %VOL

.

D M Y

:

HIGHLOW TWA STEL

HIGHLOW TWA STEL

HIGHLOW HIGHLOW

.

?

S

PAN

O

OVER

D8

D9

D10

D11

D12

D13

D M Y

7

5

6

3

D4

D5

D6

D7

:

9

8

Page 12

6

3.1

The time is shown in 24-hour format, and the

date is shown in “ddmmyy” format.

3.2 If the monitor has never been programmed, you

will see a “date error” message. Press @ to

acknowledge the error. (Refer to “Adjust Date?”

on page 20 to reset the time and date.)

3.0 The

Time and Date settings are checked:

The external filter must always be used with the monitor.

Turning the Monitor On

!

2.1 The EntryRAE firmware version displays.

2.2 All of the display segments appear.

2.3 The buzzer sounds twice (if the unit has not

off.

2.4 The preset alarm limits appear in order:

To turn the monitor on

2.0 The warm-up sequence begins:

4.0 PID Warm-up:

4.1 If the monitor has not been used recently, PID

warm-up of up to three minutes (180 seconds)

occurs. During this time, the PID lamp icon

appears, as well as a countdown from 180 to 1.

Page 13

7

5.1

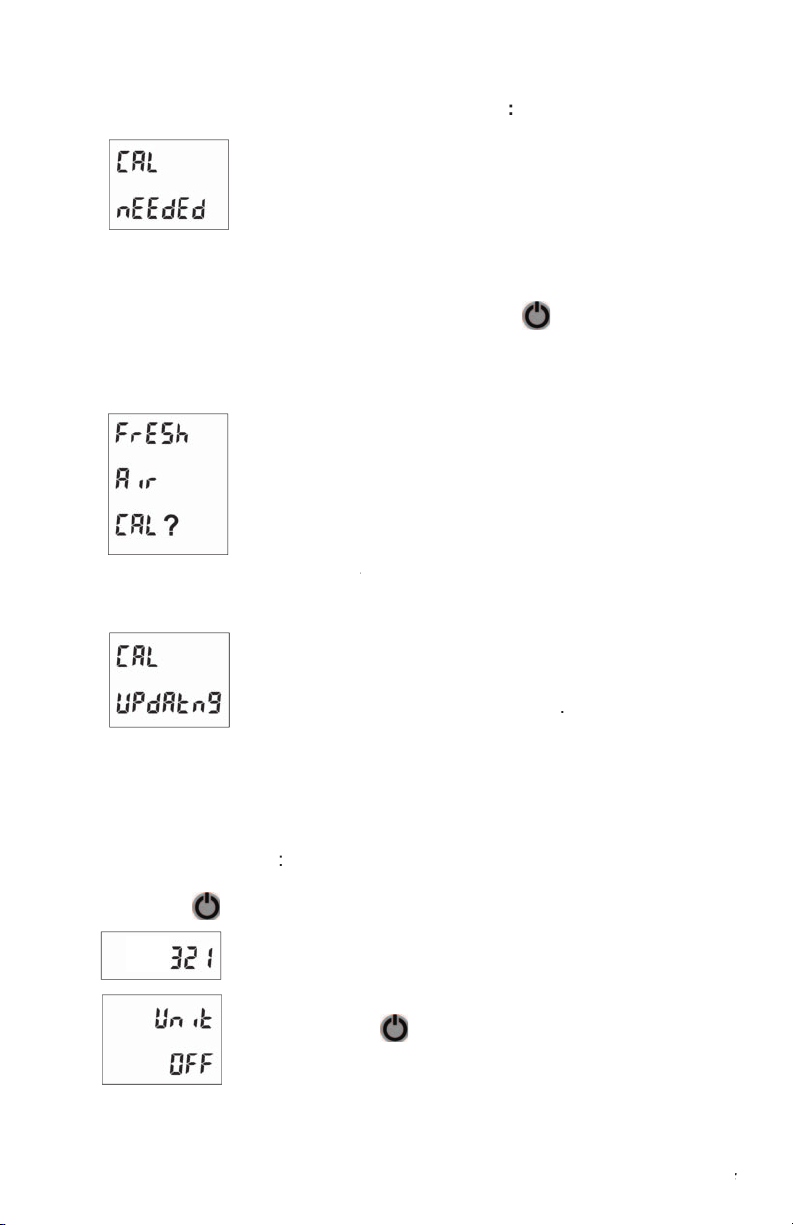

Calibration Needed

This message appears if the number of days

since the last calibration is greater than the “Cal

If the Time and Date are invalid or

were recently updated, then calibration is

automatically due. Press @ to acknowledge

the message.

6.1

6.2 The monitor must be in clean ambient air during

fresh air calibration.

6.3 Press

and the calibration begins. The display

counts down from 5 to 0 (6 seconds), at which

time the process is complete.

6.4 “Cal Updating.” The calibration data is updated,

the monitor warm-up is complete, and the

5.0 The date of the last calibration is checked

6.0 A

is requested

Press the @ button for 5 seconds.

Turning the Monitor Off

The monitor cannot be turned off until after the warm-up sequence is

completed.

To

turn the monitor off

The display counts down from 3 to 1

(3 seconds), and flashes the LED for each

count.

display.

Page 14

8

The Pump Cycle

state, the pump cycles on and off about every 8 seconds. This on/off cycle

The pump runs continuously when:

condition.

2.0 When the concentration of VOCs is nearing an alarm condition.

Continuous Operation of the Pump

Y

N

continuously for 5 minutes. This value can be changed using the ProRAE

Studio software.

CAUTION:

HIGH OFF-SCALE READINGS MAY INDICATE AN

ATTENTION:

LES LECTURES HORS ÉCHELLE ÉLEVÉES PEUVENT

Page 15

9

the current measured readings for each enabled sensor.

sensors. Press @ to scroll through these readings:

STEL

- The Short Term Exposure Limit for CO, H

S,

and VOC gases only; the average reading of the

gas concentration for the last 15 minutes, which is

updated every minute. Dashes (“- - -”) appear for the

first 15 minutes.

- The Time Weighted Average for CO, H

S, and

VOC gases only; the accumulated reading of the

gas concentration since the monitor was turned on,

divided by 8 hours. Updated every minute.

– The lowest reading for each gas

concentration since the monitor was turned on;

updated every second. Press

Y

to reset the

- The highest reading for each gas

concentration since the monitor was turned on;

updated every second. Press

Y

to reset the high

values.

LOW

LOW

LOW

LOW

Page 16

for calibration.

for 3 seconds to

enter Programming.

While EntryRAEs are calibrated prior to leaving the factory, temperature

extremes and/or shocks during shipment can cause sensor drift. Therefore,

the accuracy of any newly purchased RAE Systems monitor should be

tested by exposing the sensor(s) to known concentration calibration gas

before the monitor is used or put into service. For maximum safety, the

accuracy of the monitor should be checked by exposing the sensor(s) to

known concentration calibration gas before each day’s use.

en exposant l’instrument à une concentration de gaz connue par une

procédure dietalonnage avant metre en service l’instrument pour la

première fois. Pour une sécurité maximale, la sensibilité du EntreRAE doit

être vérifie en exposant l’instrument à une concentration de gaz connue

par une procédure diétalonnage avant chaque utilisation journaliere.

Information regarding sensor expiration is listed in Technical Note TN-

Calibration Equipment

The sensors are calibrated using both fresh air and calibration (span)

gas. The EntryRAE span gas mixtures are xed. To calibrate an

A. A cylinder of four-gas mix containing:

50% LEL methane

s

20.9% O

2

s

10 ppm H

2

S

50 ppm CO

C. A calibration adapter to connect the monitor to the outlet of the gas

cylinder.

Calibration Procedure

The calibration procedure is broken down into three steps. All steps

should be performed whenever calibration is needed.

Step One: Enter Programming Mode

!

!

Page 17

11

If a password is enabled

to increase the digit and

to

decrease the digit.

Y

to enter the password.

2.1 Press

Y

and the calibration begins. The display

counts down from 5 to 1 (5 seconds), at which

time the process is complete.

Calibration Updating

The monitor is in the process of calibrating the

sensors. As it completes, the display shows

the sensors registering zero (or 20.9% for O

),

ambient air may be contaminated with hydrocarbons. Attach the filter

to the EntryRAE during fresh air calibration. The filter can be used up

to 20 times before disposing. This filter removes most heavier organic

and inorganic compounds, but may not completely remove lighter

compounds such as methane, propane and CO. Note that the filter

should be attached to the EntryRAE before the calibration adapter.

Step Three: Span Gas Calibration for Multiple Sensors

3.0 For this calibration step, the LEL, CO and H

2

S sensors are calibrated

using the 4-gas mix (P/N 600-0050-004).

Step Two: Fresh Air Calibration

The monitor must be in clean ambient air during fresh air calibration.

Page 18

3.1 Connect the calibration adapter to the EntryRAE and put a regulator

(500 cc per minute flow rate) on the 4-gas mix cylinder.

3.2 After “Span Cal?” appears on the display with the

CO, H

S, and LEL sensors indicated, press

3.3 Turn the gas all the way on.

3.3 Connect the open end of the calibration

adapter to the regulator.

The monitor starts to

countdown from 70 seconds.

3.4

When the countdown timer reaches zero, turn

off the gas, and disconnect the calibration

adapter from the regulator.

3.5 Compare the readings displayed to the span

gas values indicated on the gas cylinder. The

values.

Page 19

13

Step Four: Span Gas Calibration for the PID Sensor

4.1 The final step is to calibrate the PID sensor.

4.2 Connect the EntryRAE calibration adapter to the monitor (see Figure

6) and put a regulator (500 cc per minute flow rate) on the cylinder of

4.3 Connect the open end of the calibration adapter to the regulator.

3.6 If calibration fails, the monitor briefly displays “Err”

above each failed sensor.

Stop calibration in the event that the

gas runs out or is disconnected. To interrupt

calibration, press @ . When calibration stops, the

sensors revert to their previous calibration values.

3.7 After briefly displaying the concentration, the

4.4 When “Span Cal?” appears on the display

with the VOC sensor indicated, press

Y

and turn the gas all the way on. The

4.5 Turn off the gas, dicsconnect from the

adapter, and remove the calibration

adapter from the monitor.

displays “Err” above the failed sensor.

Stop calibration if the gas runs out

or is disconnected. To interrupt calibration,

sensors revert to their previous calibration

values.

Page 20

Optional Step: Zero Calibration for the

Oxygen Sensor

Zero calibration for the oxygen sensor is not required

under normal use. A span calibration using ambient

air (20.9% O

) is usually sufficient to establish its

for special applications. Zero gas (100% nitrogen) is

ordered separately (P/N 600-0062-000).

Zeroing the O

Sensor

Connect the calibration adapter to the EntryRAE and

cylinder of nitrogen.

Connect the open end of the calibration adapter to

the regulator.

The display reads “Zero Cal?” and only the O

segment

appears.

and turn on the gas.

above the failed sensor.

Stop calibration in the event that gas runs out

or is disconnected. To interrupt calibration, press @ .

When calibration stops, the sensors will revert back to

their previous calibration values.

gases, sensor sensitivity, and other sensor specifications are listed in

Technical Note TN-114, Sensor Specifications And Cross-Sensitivities,

available at www.raesystems.com. Information regarding LEL sensor

Page 21

15

After the optional zero calibration for the O

2

sensor, “Calib due day?” is

displayed. Press

to set a new date, or N to skip.

When setting a new day,

increases the digit,

decreases the digit,

and @ moves to the next digit. After the third digit is set, the question

to accept the changes. Press

to discard the

changes. Press @ to change the due date.

The EntryRAE should have a fresh air calibration before each use and

should be fully calibrated:

no less than every 30 days

if it does not pass a fresh air reading

if it does not pass a field calibration.

Page 22

Confined Space Pre-Entry Test

entering. Be aware of any hazardous chemicals you may be bringing into

the space. Remember that many cleaners, paints, adhesives, degreasers

and other modern industrial products (even treated wood) contain volatile

organic compounds that may be hazardous to your health and safety.

Test the atmosphere in the confined space by sampling air at three levels

(top, middle and bottom) in the confined space. Give the instrument time

to sample the gas at each level - the correct sampling time is 60 seconds

Alarms

ALARMS

at any level in the confined space, that

space is not safe.

Identify the alarm condition and then

start your preventive actions according to your company’s confined space

entry procedures.

the tubing before carrying the EntryRAE into the confined space. If

continue to monitor while you enter the area. If the monitor alarms and

“BAT” is displayed, the battery needs to be charged: There are 15 minutes

Storage

Always keep the EntryRAE on its charging

cradle in a dry indoor area when it is not in use.

See page c for long-term storage warnings and

After the EntryRAE is warmed up, calibrated, and charged, it is ready for

use to enhance your personal safety.

CAUTION:

HIGH OFF-SCALE READINGS MAY INDICATE AN

Page 23

17

Alarm Signals

When an alarm condition occurs, the monitor provides audible, visible

and vibration alarms to alert users of unsafe conditions.

Auto Reset and Latched Alarm

The EntryRAE comes from the factory with “Auto Reset Alarm” turned

on. This means that the alarms cease when the alarm condition is no

longer present. Alternatively, this feature can be changed and set up as a

“Latched Alarm.” When the alarm system is “Latched,”

to acknowledge the alarm condition and to reset the alarms.

The Auto Reset function does not automatically reset if a sensor fails

calibration and goes into alarm. The sensor must be successfully

calibrated in order to clear this alarm.

Testing Alarm Signals

Y

while in monitoring mode

If the alarm is functional, the buzzer

not

set to run silently; see page 24), the

alarm LED ashes once, and the vibration alarm turns on and off.

The display counts down from 3 to 1

(3 seconds).

display.

area and put it in its charger.

or less of run time remaining.

Leave the Confined Space immediately!

(Refer to

the Applications and Technical Notes Guide, P/N 000-4001-000,

for more information regarding confined space entry and other applications.)

After Usage

Page 24

Alarm Conditions

Alarm

Condition

Beep/sec

Flash/sec

Vibration

Alarm

Screen Message

Reset Alarm

Pump

Failure

3

Yes

alarm symbol on, pump

symbol blinks

unblock inlet, press Y

to restart pump

Lamp

Failure

3

Yes

alarm symbol on, lamp

symbol blinks

turn off/on or wait

Over Range

3

Yes

alarm symbol on, OVER

symbol on, blink “999”

move away from gas

Max

3

Yes

alarm symbol on, OVER

symbol on, blink reading

possible sensor failure;

cal sensor to verify

High

3

Yes

alarm and HIGH symbol

on, sensor name blinks

move away from gas

Low

2

Yes

alarm and LOW symbol

on, sensor name blinks

move away from gas

Yes

alarm and TWA symbol

on, sensor name blinks

move away from gas &

turn unit off/on

STEL

Yes

alarm and STEL symbol

on, sensor name blinks

move away from gas &

wait 15 min.

Negative

Yes

alarm symbol on, blink

“nEg”

perform zero

calibration

Battery Low

No

battery symbol blinks

charge battery

Gas

Cal Gas/

STEL

CO

50/Air

3535200

S

20

O220.9/N

2

%Vol

23.5

50/Air

%LEL

20

VOC

The back light makes it easy to read the display in poor lighting conditions.

Heavy back light usage can shorten battery life 20% to 30%.

Page 25

19

Sampling Pump

state, the pump cycles on and off about every eight seconds. This on/off

cycle improves the reliability of the PID and saves battery life. Press the

Y

N

ve minutes. The pump also runs continuously when:

condition.

2.0 The concentration of VOCs approaches alarm conditions.

The monitor can detect any obstructions in the external lter that causes

a pump stall. The alarm activates and the pump symbol blinks in the

upper right corner of the display. Clear the obstruction.

to start the pump again.

the storage memory is reached, the monitor automatically wraps around

to the beginning of the log and overwrites the oldest stored data.

Datalogging pauses when the monitor goes into Programming

Charging the EntryRAE

The battery charge is indicated on the EntryRAE screen by the battery

charge status icon on the monitor’s LCD. When the icon’s segments are

lled in, the battery is charged. As the battery is discharged, the segments

disappear, indicating that the unit should be charged before use. Refer to

“Maintenance” for instructions on changing/removing the battery.

The Li-Ion battery pack can be charged alone or while it is installed in

the monitor. To charge an installed battery, simply plug the transformer

cradle. The monitor (or battery) is fully charged when:

The LED on the charging cradle is green

The “Fully Charged” message appears on the display

The segments of the battery icon are blinking.

Page 26

20

To charge the battery pack

alone, place the battery

on the charging cradle.

The monitor (or battery) is still in charging mode when:

The LED on the charging cradle is red

The “Monitor Charging” message appears on the display

The segments of the battery icon are scrolling.

Page 27

Programming Mode

21

The Li-Ion Battery Pack

The factory-supplied Li-ion battery pack is designed to last for 16 hours

of normal operation between charges (without alarm or back light

conditions). The rechargeable batteries have a 1-year warranty. Age,

ambient temperature, and heavy usage may impact battery life.

cradle. The battery can trickle-charge when not in use.

voltage will be low. Fully charge battery packs before going into the eld,

and recharge them upon returning from the eld.

To reduce the risk of ignition of hazardous atmospheres, recharge

battery only in areas known to be non-hazardous. Remove and replace

battery only in areas known to be non-hazardous.

dangereux.

settings to their requirements using the Programming Mode.

Monitoring gas concentrations pauses during Programming Mode

and during calibration. Datalogging also pauses during Programming

Security

access Programming Mode. The default password is “0000.” To enable

“Change Pass?” on page 26.)

!

Page 28

22

Programming Mode

Fresh Air Calibration? Must be in clean ambient air.

Span Calibration? Must use four-gas calibration mix (CO, H

2

S, O

2

and LEL).

Span Calibration? Must use 100 ppm Isobutylene gas (PID).

Zero Calibration? Must use Nitrogen 100%.

Calibration Due Day? Sets a reminder. Default: 30 days, Max: 365 days

Set Type? Auto Alarm Reset or Latch. Default: Auto

Set Run Silent? Runs in Silent Mode. Default: No

Adjust HIGH? Adjusts High Alarm presets.

Adjust LOW? Adjusts Low Alarm presets.

Adjust TWA? Adjusts TWA presets.

Adjust STEL? Adjusts STEL presets.

Enable Sensor? Enable or disable sensor.

Adjust Date? Adjust date and time.

Set LEL Unit? (This function is not available.)

Change Password? Change the password. Default: 0000

Secure Beep? Lets user know monitor is on. If on, beeps once per minute.

Monitor Mode (Sensor Reading Display)

Press

Y or N

Press

MODE & N

Press

MODE

Page 29

Programming Mode

23

together until the first program

to cycle through the submenu options.

3.

to enter a submenu.

4.

To modify a value, use

Y

to increase and

N

to

decrease.

5.

from sensor to sensor.

6.

When the “?” appears at the bottom of the display,

to save changes (or

to cancel changes)

and exit the submenu.

To discard changes or exit the Programming Mode,

Change Monitor Setup

The following submenus represent the programmable setup of the

Refer to

on page 11.

Span Calibration CO, H

S, LEL?

Refer to “Span

Gas Calibration for Multiple Sensors” on page 11 to

calibrate the CO, H

2

S and LEL sensors.

Page 30

24

Programming Mode

Span Calibration VOC?

Refer to “Span Gas Calibration

for the PID Sensor” on page 13.

Zero Calibration?

Oxygen Sensor” on page 14.

Calib Due Day?

calibrate regularly. Enter the number of days between

calibrations per your company’s standards. After 30 days

of no calibration, the monitor sounds. Once the monitor

Set Type?

Choose either automatic alarm reset or

latched (constant) alarm. To acknowledge and reset a

latched alarm, press

Y.

Set Run Silent?

Y

to let the monitor run in silent

during alarm conditions.

N

to let the audible alarm sound during alarm

conditions.

Adjust Alarm Limits?

- The highest reading for each gas concentration

since the monitor was turned on; updated every second.

to reset the high values.

Page 31

Programming Mode

25

– The lowest reading for each gas concentration

since the monitor was turned on, updated every second.

Y

to reset the minimum values.

TWA

- The Time Weighted Average for CO, H

2

S, and

VOC gases only; the accumulated reading of the gas

concentration, divided by 8 hours, since the monitor was

turned on. Updated every minute.

STEL

- The Short Term Exposure Limit for CO, H

2

S,

and VOC gases only; the average reading of the gas

concentration for the last 15 minutes, which is updated

every minute. Dashes “- - -” appear in the display for the

first 15 minutes.

a disabled sensor does not measure or display the

gas concentration. Use this if a sensor has failed or is

sensor to sensor. “Yes” means the sensor is enabled;

likewise, “No” means the sensor is disabled. Press

Y

to

enable or press

N

to disable.

Adjust Date?

Set the date and time using the standard

24-hour format.

Page 32

26

Programming Mode

Change Pass? (Password)

Set a four-digit password,

which is used to access Programming Mode. (Refer to

“Security” on page 21.)

Secure Beep?

Set LEL Unit?

The EntryRAE provides the option of

displaying the concentration of combustibles gases in

%LEL or %Vol.

Page 33

Maintenance

27

To reduce the risk of ignition of hazardous atmospheres, recharge the

battery only in areas known to be non-hazardous. Remove and replace

the battery only in areas known to be non-hazardous.

dangereux.

température de fonctionnement entre -4º à 122º F (-20º à 50º C).

(-20º to 50º C).

-4º à 122º F (-20º à 50º C).

The battery compartment is located on the back of the monitor.

screws with a screwdriver or a coin.

case screws for battery compartment

!

!

!

Page 34

28

Maintenance

The spent battery pack may be charged on the charging cradle by itself.

(Refer to “Charging the Li-Ion Battery Pack” on page 19.)

Page 35

Maintenance

29

the Li-Ion battery pack. The adapter (P/N 046-

3051-000) accepts four AA alkaline batteries (use

only Duracell MN1500 or Energizer 91) to provide

approximately 12 to 14 hours of operation.

adapter, making sure the battery polarity is correct.

The monitor automatically detects the alkaline batteries.

Page 36

30

Maintenance

Sensor Replacement

sensitivity after the expected operating life and need to be replaced.

Warranties: The oxygen (O

), combustible gas (LEL), hydrogen sul de

(H

S) and carbon monoxide (CO) sensors all have a 2-year warranty.

The PID sensor has 1 year warranty.

The sensors are located inside the front of the monitor.

See Technical Note TN-114, Sensor Speci cations And

Cross-Sensitivities, for additional information, available at

www.raesystems.com.

2

S

O

2

CO

Page 37

Maintenance

31

To replace a sensor

2. Remove the front sensor cover by

loosening the two screws on the

back

of the monitor below the battery cover.

See Figure 13.

3. Push the screws from the back of the

(Figure 14).

4. Using the sensor puller, remove the

sensor by carefully pulling straight out

(Figure 15).

The colored dots marked next to each

sensor socket should match the color

of the sensors.

5. To install new sensors, re-align the

dots on the sensors with the dots on

the monitor.

6. Press the sensors all the way into the

socket.

7. Replace the monitor cover and tighten

the screws in the back.

screws.

sensor puller to

Page 38

32

Maintenance

8. Turn the monitor on and the newly installed sensors should be

9.

Calibrate all sensors prior to use.

CO Sensor Charcoal Filter

The carbon monoxide (CO) sensor may be sensitive to hydrocarbons, so

use a charcoal lter (P/N 008-3006-005) to reduce or eliminate organic

vapor contamination or cross-sensitivity. The charcoal lter is installed in

the gas plate above the CO sensor. Under normal operation conditions,

the charcoal lter lasts from four to six weeks before it needs to be

VOC gases for a prolonged period of time, the carbon lter needs to be

The CO charcoal lter lowers the reading if it is accidentally used

on other sensors.

Page 39

Maintenance

33

Cleaning the PID

If the PID does not calibrate, it may need to be cleaned. Be sure to use

The pump in the EntryRAE is not eld replaceable. Call RAE Systems

Technical Support or an authorized service center when the pump needs

to be replaced.

the specially shaped swab included in the PID Cleaning Kit (p/n 5000014-010), shown in the Equipment List, to clean the PID.

1. Open the sensor compartment.

2. Remove sensor with sensor puller (follow procedure on page 31).

3. Using a swab, drip a little bit methanol on the lamp window through

the openings on the top of the PID.

4. Use the swab to carefully clean the lamp window through the two

openings.

5. Leave the PID to dry by itself for ve minutes.

the PID.

Page 40

34

Maintenance

Setting Pump Stall Threshold

This section should only be used by authorized technical users.

only be done if your EntryRAE is going into a pump alarm when the

when you block the pump inlet by holding your nger over it.

diagnostic screen blanks. Then release the keys

and the values reappear.

2. Press @ 7 times to cycle through the diagnostic

screens until you reach the pump diagnostic

screen. The rst, CO, H

2

S, O

2

time screens are used for factory operation and

testing only. The pump diagnostic screen displays

a high and low pump rate. The rst digit of the last

3. To set the pump stall alarm, write down the “Hi”

value as found, and then block the pump inlet

while the pump is running (about 5 seconds), until

the “Hi” reading stabilizes.

4. Write down the new “Hi” value. Add the two “Hi”

values together, and then divide by two to get the

average value.

5. Enter the average into the bottom number on the

screen using the Y and N keys to increase and

decrease the digits, and @ to move between

digits.

6. Once the average is entered, press @ until you

see the blinking “?”. Press Y to save the pump

stall threshold value.

7. Exit the diagnostic mode by pressing @ and Y

together until the screen changes. Gas readings

Page 41

Specifications

35

Speci cations

Size

5.9" L x 3.3" W x 1.9" H (15 x 8.5 x 1.9 cm) without clip

Weight

20 oz with battery (567 g) and clip

Sensors (5)

Protected catalytic bead for combustible gases

Electrochemical sensors for oxygen and toxic gases

Photoionization detector for VOC broadband detection using 10.6 eV lamp

Battery

Drop-in rechargeable Li-ion battery pack

Standard alkaline battery adapter

Charging cradle doubles as external battery changer

Operating Hours

Battery Operation

Temperature

-4º to 113º F (-20º to 45º C)

Battery Storage

Temperature

-4º to 122º F (-20º to 50º C)

Display

Large 1.4" x 1.8" (3.5 x 4.5 cm) segmented display with LED back light

Keypad

Three-button operation

Direct Readout

Oxygen as percentage by volume

Combustible gas as %LEL or %Vol

VOCs, CO and H

2

S as parts per million

TWA and STEL values for VOCs, CO and H

2

S

Battery life displayed as icon in 1/4 increments

Alarms

Audible: 95dB at 30 cm

Visible: Bright LED bar visible from top, front and sides

Sensory: Built-in vibration alarm

Low: 2 beeps and ashes per second

STEL and TWA: 1 beep and ash per second

Low battery displays empty battery symbol, beep per second

EMI/RFI

IP Rating

water from all directions

Datalogging

Wrapping 120 hours ( ve days) of data at one minute intervals for all

ve sensors

Communication

PC-to-EntryRAE via RS-232 through charging cradle, with USB adapter

Calibration

Two-point eld calibration for zero and span gas

Sampling Pump

Low Flow Alarm

Auto shut-off at low- ow condition

Minimum Pump

Flow

Operation

Temperature

-4

o

to 122

o

o

to 50

o

C)

Storage

Temperature

o

to 126

o

o

to 47

o

C)

Humidity

0% to 95% relative humidity (non-condensing)

Pressure

Attachments

Stainless steel alligator clip (installed), wrist strap

Warranty

Lifetime on non-consuming components (per RAE Standard Warranty),

2 years for O

2

2

S sensors, 1 year for PID, 1 year for

pump, 1 year for battery

Page 42

36

Specifications

Certification

UL: Class I, Groups A, B, C, D, T3C

CE 0575

DEMKO 04 ATEX 0419092X

Eex ia d IIC T4

Monitor label (enlarged).

Sensor Range and Resolution

Sensor

Range

Resolution

PID

0-999 ppm VOC

Oxygen (O

2

)

0-30.0%

0.1

Combustible Gas (LEL)

0-100% LEL

Carbon Monoxide (CO)

0-500 ppm

2

S)

0-100 ppm

Note that each sensor has cross-sensitivities to multiple gases. Information on

these sensitivities is available in Technical Notes TN-114 and TN-144, available at

www.raesystems.com. Additional information about sensor calibration and expiration is also

available in these Technical Notes.

Page 43

Specifications

37

Service and Repair Record

Service / Repair Type

Page 44

RAE Systems World Headquarters

www.raesystems.com

3775 N. First St.

San Jose, CA 95134-1708 USA

Phone: 408.952.8200

Fax: 408.952.8480

E-mail: customerserv@raesystems.com

Web Site: www.raesystems.com

RAE Systems Technical Support

Monday through Friday, 7:00AM to 5:00PM Paci c Time

+1.888.723.4800 (toll-free)

email: tech@raesystems.com

RAE Systems Tubes

RAE Systems Europe ApS

Orestads Boulevard 69

DK-2300 Copenhagen, DENMARK

Phone: +45.8652.5155

Fax: +45.8652.5177

RAE Systems (Hong Kong) Ltd.

Room 8, 6/F, Hong Leong Plaza

33 Lok Yip Road

Fanling, N.T. HONG KONG

Phone: +852.2669.0828

Fax: +852.2669.0803

: 888.RAE.TUBE (888.723.8823)

P/N 046-4001-000

Rev C, June 2005

Loading...

Loading...