Page 1

Manual number

PTI-12-03/01/07/A

Integrated system for counting pieces and labelling

WLT/L series

WLL series

MANUFACTURER OF ELECTRONIC WEIGHING INSTRUMENTS

RADWAG, 26 – 600 Radom, Bracka 28 Street

POLAND

phone +48 48 38 48 800, phone/fax. +48 48 385 00 10

Sales Department +48 48 366 80 06

www.radwag.com

Page 2

TABLE OF CONTENTS

1. UNPACKING OF THE MAIN BALANCE.......................................................5

2. INTENDED USE............................................................................................. 6

3. GETTING STARTED......................................................................................7

3.1 Conditions of appropriate use................................................................................7

3.2 Time of warming-up...............................................................................................7

3.3. Balance levelling...................................................................................................8

4. UNDER-FLOOR WEIGHING.......................................................................... 8

5. BALANCE DESCRIPTION............................................................................. 9

5.1. Graphic display.....................................................................................................9

5.2. Balance keyboard...............................................................................................10

5.3. PC keyboard.......................................................................................................11

5.4. Connecting sockets............................................................................................12

6. USER MENU ................................................................................................13

6.1. Menu view..........................................................................................................16

6.2. Menu navigating.................................................................................................17

6.3. Return to weighing..............................................................................................18

7. WEIGHING ................................................................................................... 18

7.1. Tarring................................................................................................................19

7.2. Inscribing tare value ...........................................................................................20

7.3. Automatic tare....................................................................................................20

7.4. Zeroing...............................................................................................................21

8. BALANCE CALIBRATION .......................................................................... 22

9. SETTING OF PRINTOUTS CONTENTS FOR GLP PROCEDURES..........23

10. TIME AND DATE SETTING....................................................................... 23

11. SETTING WORK PARAMETERS.............................................................. 26

11.1. Filter setting......................................................................................................26

11.2. Median filter setting ..........................................................................................26

11.3. Setting the time of display refreshment ............................................................27

11.4. Setting of autozero operating ...........................................................................27

11.5. Last digit...........................................................................................................27

11.6. Negative...........................................................................................................28

11.7. Two platforms...................................................................................................28

11.8. Automatic tare..................................................................................................28

12. FUNCTIONS CONNECTED WITH RS 232 USE.......................................28

13. PRINTOUTS............................................................................................... 29

14. SETTING ACCESSIBILITY OF WEIGHT UNITS ...................................... 30

15. SETTING ACCESSIBILITY OF WORK MODES.......................................31

16. OTHER PARAMETERS............................................................................. 31

2

Page 3

17. COUNTING PIECES...................................................................................34

17.1. Databases........................................................................................................34

17.1.1. Database of operators............................................................................................. 34

17.1.2. Database of labels...................................................................................................35

17.1.3. Assortment database ..............................................................................................41

17.1.4. Contractors database..............................................................................................42

17.2. Settings of operating for counting pieces..........................................................43

17.2.1. Configuration...........................................................................................................43

17.2.2. Printer settings ........................................................................................................ 44

18. COUNTING PIECES...................................................................................45

18.1. Description of graphic display for Counting pieces mode.................................45

18.2. Reference mass setting....................................................................................46

18.2.1. Inserting known mass of single piece .....................................................................46

18.2.2. Determining (weighing) by declared quantity of sample .........................................46

18.2.3. Wprowadzenie masy detalu z bazy danych wagi.................................................... 48

18.3. Introducing reference mass to balance memory...............................................49

18.4. Counting pieces with checkweighing................................................................49

19. LABELLING ...............................................................................................50

19.1. Quick database search.....................................................................................50

19.1.1. Quick assortment database search......................................................................... 50

19.2. Operator selection and logging in.....................................................................51

19.3. Article selection ................................................................................................51

19.4. Contractor selection..........................................................................................51

19.5. Deleting „n1” and n”2” counters and „sums” variable........................................51

20. REGULAR LABELLING ............................................................................ 52

20.1. Cumulative label printing..................................................................................52

20.2. Printing of “cc” label”.........................................................................................54

20.3. Initiating “cc label” by “n2” counter....................................................................54

20.4. Initiating “cc label” by “n2” counter....................................................................55

20.5. Initiating “c label” and “cc label” by determined quantity of pieces ...................56

20.6. Labelling with checkweighing...........................................................................56

20.7. Automatic printout.............................................................................................57

21. BARCODES ...............................................................................................57

21.1. General description ..........................................................................................57

21.2. EAN code.........................................................................................................58

21.3. Other barcodes.................................................................................................58

21.4. Advantages of using barcodes .........................................................................58

21.5 The usage of EAN-128 barcode in scales.........................................................59

21.6. Operating with barcode scanners.....................................................................61

22. STATISTICS...............................................................................................64

3

Page 4

23. PRINTOUTS............................................................................................... 65

23.1. Standard printout..............................................................................................65

23.2. Non-standard printouts.....................................................................................66

23.2.1. Inscribing texts ........................................................................................................69

23.2.2. Choice of non-standard printouts............................................................................ 73

23.2.3. Changing set of characters for EPSON TM-U220 series (Polish characters).......73

24. COOPERATION WITH PRINTER OR WITH COMPUTER........................74

24.1. Drawings of connection cables.........................................................................74

25. COOPERATION WITH COMPUTER PROGRAM „DB editor” ...............75

26. TRANSMISSION POTOCOL ..................................................................... 76

26.1. Some basic information....................................................................................76

26.2. Transmission parameters.................................................................................76

26.3. Transmission characteristics ............................................................................77

26.4. Continuous transmission/automatic printout.....................................................77

26.4.1. Types of printouts.................................................................................................... 77

26.4.2. Continuous transmission.........................................................................................78

26.4.3. Continuous transmission „with pauses”...................................................................78

26.4.4. Stable result transmission.......................................................................................78

26.4.5. Survey of automatic printouts.................................................................................. 79

26.5. Commands and responses syntax...................................................................80

26.5.1. Commands syntax...................................................................................................80

26.5.2. Response syntax..................................................................................................... 81

26.6. List of commands computer - balance..............................................................82

27. ERROR MESSAGES..................................................................................85

28. TECHNICAL PARAMETERS.....................................................................86

28.1. WLT/L series ....................................................................................................86

28.2. WLL series .......................................................................................................87

APPENDIX A....................................................................................................88

APPENDIX B....................................................................................................89

APPENDIX C....................................................................................................89

4

Page 5

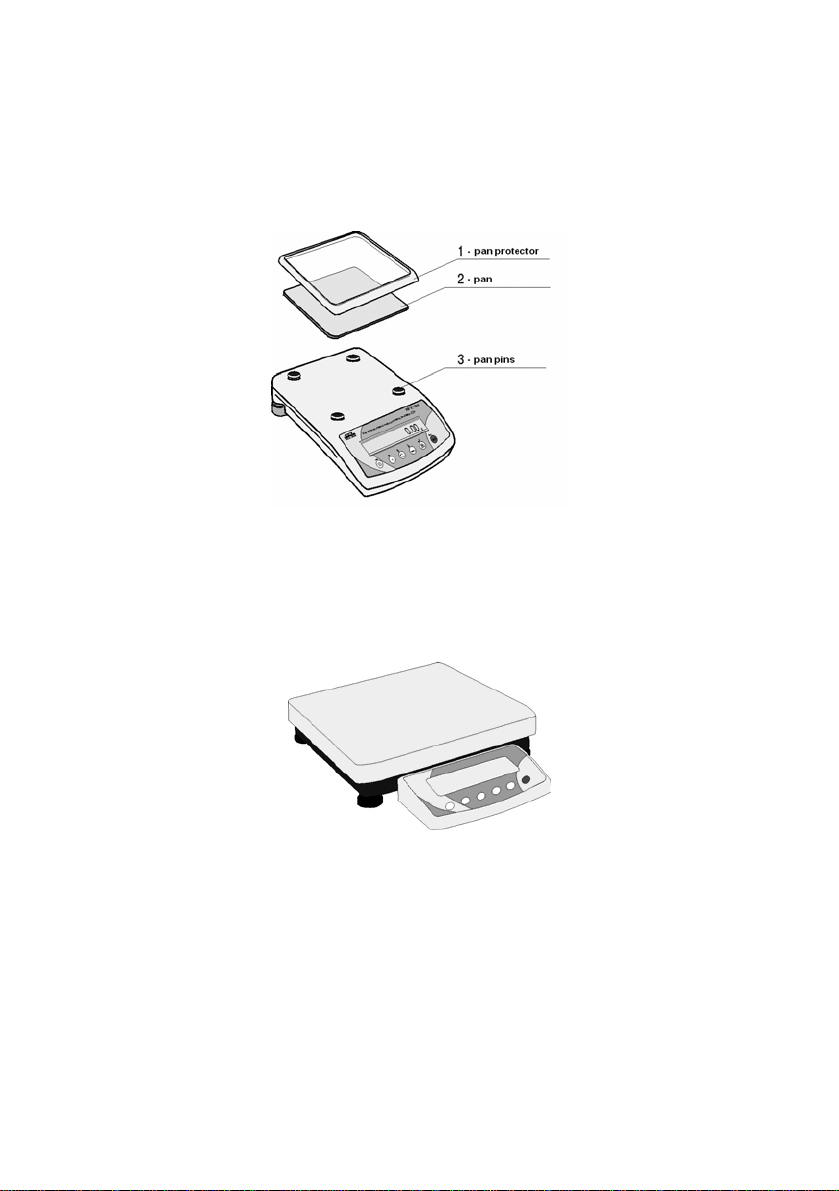

1. UNPACKING OF THE MAIN BALANCE

Cut open tape protecting the box. Take out the balance of factory package and

place it on a stable base. Take out all components and assemble them

according to below drawings:

Fig 1. The components installation for the balance with pan size 165 x 165mm

For balances 300 x 300mm or 410 x 410mm put on the pan and set the scale

working according to the chapter 2 of this manual.

Fig 1-1. The balance with pan size 300 x 300mm

5

Page 6

Fig 1-2. The balance with pan size 410 x 410mm

Balances are supplied from 230 V AC / 11 V AC adapters. Connect to the

power source and turn on the balance.

2. INTENDED USE

Counting – labelling balances are designed for COUNTING PIECES OF THE

SAME MASS. Connection with label printer enables labels printing.

Balances are equipped with data bases of operators, assortments, labels and

contractors. Connected with bar code scanner searching out assortment by bar

code is possible.

6

Page 7

Software of counting set makes possible:

- determining mass of single detail on main balance with highest

accuracy of weighing

- owing to application of graphic display, balance software is user-

friendly

- possibility of application PC type PS/2 keyboard simplifies moving in

software menu and data accessing

- printing basic labels, cumulative labels, „cc labels” (cumulative labels of

cumulative ones)

- cooperation with barcode scanner

- cooperation with additional balance platform

3. GETTING STARTED

3.1 Conditions of appropriate use

9 place balance on a stable and flat table or free from vibrations

9 balance should not be exposed to draughts and sudd en air movements

9 balance should be placed in room of stable temperature and humidity

9 balance should be placed far from heat sources

9 temperature of the room should be +15°C ÷ +30°C (for WLT balances)

9 if static electricity influence balances, indications, its base should be

earthed. Earthling clamp is in the back part of balance base

9 balances should be levelled according to a level condition indicator to

guarantee the appropriate weighing accuracy

3.2 Time of warming-up

Before performing measurements wait until balance reaches temperature

stabilization. It is so-called warm-up time. It takes about 15 minutes.

For weighing instruments that have been stored in low temperatures (e.g.

during winter) the warm-up time is about 2 hours.

The indications of display may change during temperature stabilization.

7

Page 8

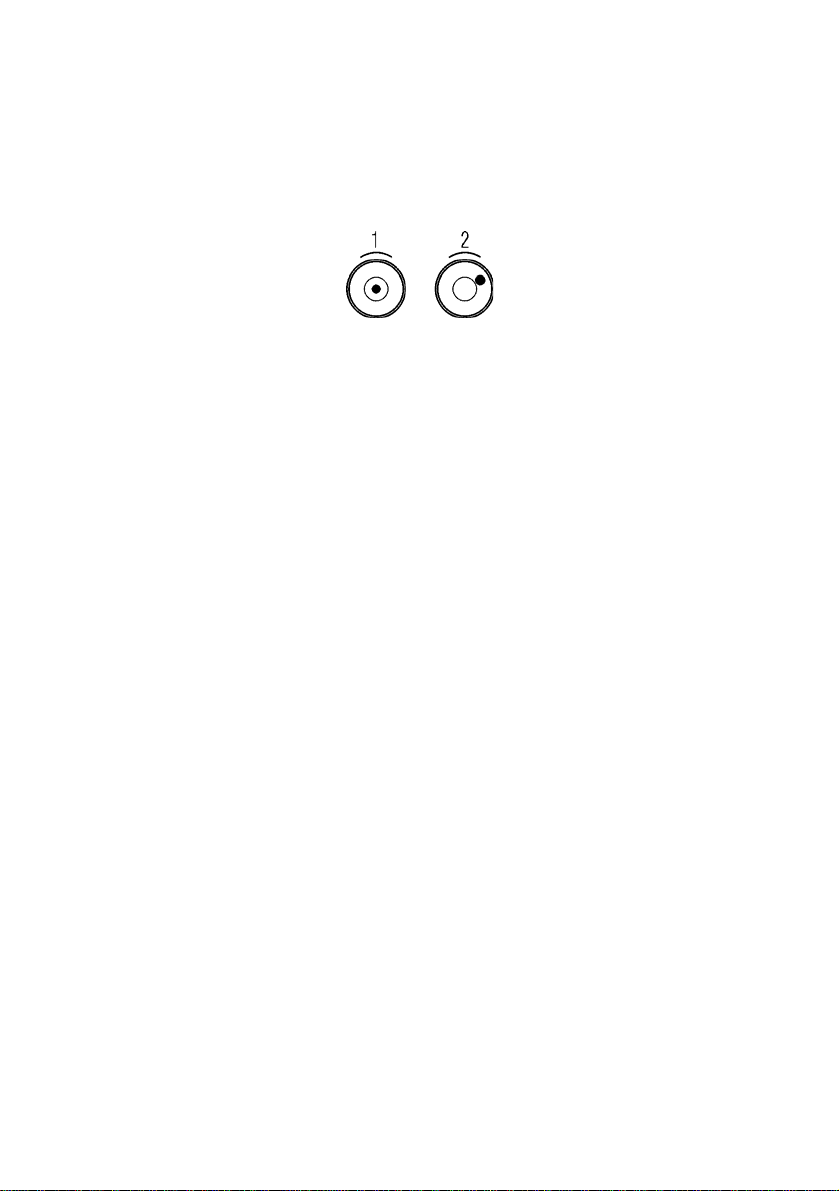

3.3. Balance levelling

To do the measurements correctly level the scale. Take the pan off carefully

(without rapid pulls and hits) and turn the legs in order to level the balance, air

bubble should be place in the centre of level condition indicator.

Fig. 2. Balance levelling

1- correct levelling

2- incorrect levelling

4. UNDER-FLOOR WEIGHING

For scales with 165 x 165mm platforms can weigh underslinged loads (hanged

under the balance floor). In case of using this function:

− remove the hole plug made of plastic (placed in the balance floor),

− a suspension can be seen in the hole. It is standard equipment,

− Mount an appropriate hook for hanging loads (hook is non-standard

equipment).

1. The suspense cannot be rotated, revolved or tampered in any way,

because of direct connection with the weighing mechanism of the

balance.

2. All the additional elements like pan, string etc. should be tarred (TARE).

3. Balances with 300 x 300mm or 410 x 410mm platforms do not have the

under-floor weighing mechanism.

8

Page 9

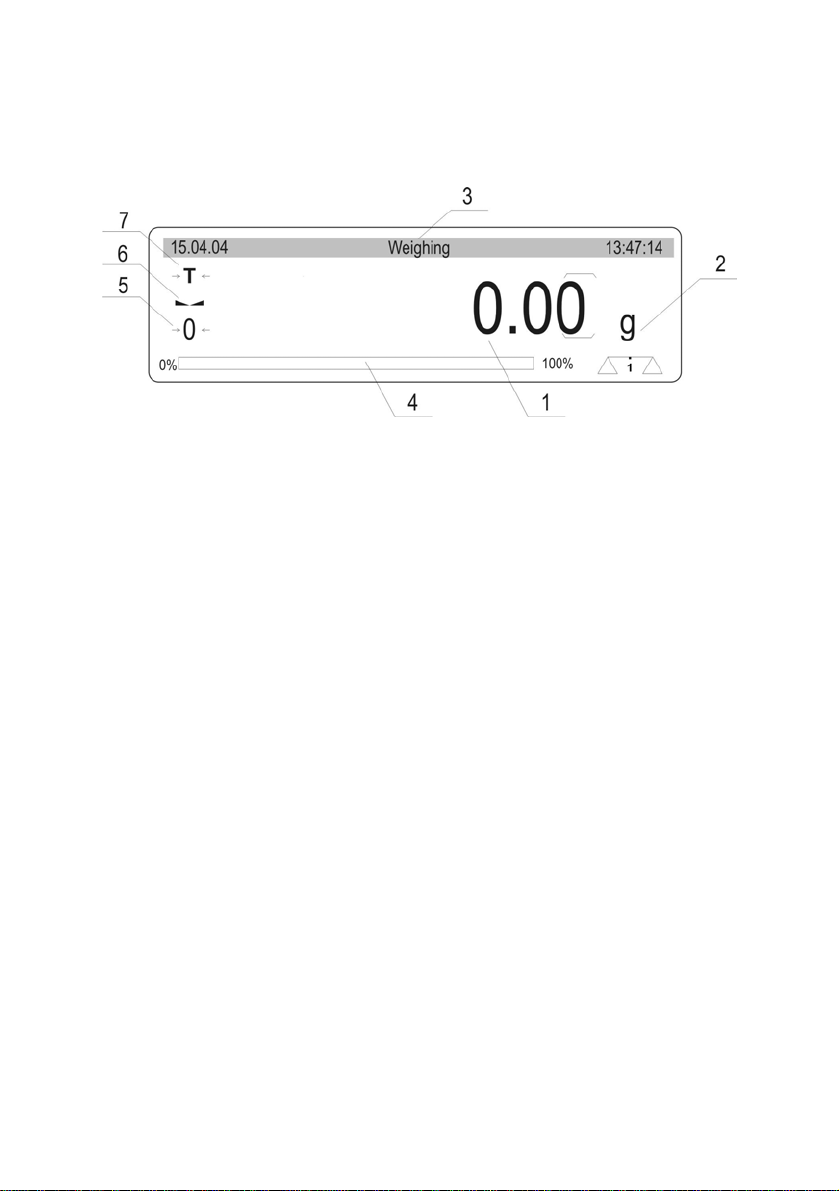

5. BALANCE DESCRIPTION

5.1. Graphic display

Fig. 3. Graphic display

1. displayed mass of currently weighed load

2. unit of mass

3. upper „bargraph” in which description of operating mode, date and time of

internal balance clock are displayed

4. lower „bargraph” in which part of mass from range of max capacity used

currently is displayed

5. symbol of precise zero

6. symbol indicating stable weighing result

7. symbol indicating weighing with tare

9

Page 10

5.2. Balance keyboard

Each key on balance keyboard is dual-function key, its function depends on

balance operating mode.

Balance

keyboard

Function in weighing mode

zeroing zeroing

Enter to balance menu Enter to counting pieces menu

Function in Counting pieces

mode

Enter to choice of operating mode

Change of weighing unit

Sending display state to external

device (PRINT)

Balance tarring Balance tarring

+

Introducing Id codes

+

Introducing mass of single pcs

+

Change of weighing platform Change of weighing platform

Enter to choice of operating

mode

Determining mass of single

detail by weighing

Label printout

10

Page 11

5.3. PC keyboard

PC keyboard is necessary for correct balance operating (moving in balance

menu). Without PC keyboard access to some functions is impossible, above

that database edition is more convenient and efficient by using PC keyboard.

PC

keyboard

F1

Function in weighing

mode

Indication zeroing Indication zeroing

Function in Counting pieces mode

F2

F3

F4

F5

F6

F7

F8

F9

F10

F11

INSERT

HOME

PAGE UP

Enter to balance menu Enter to counting pieces menu

Enter to choice of

operating mode

Change of weighing unit Determining mass of single detail by

Sending display state to

external device (PRINT)

Balance tarring Balance tarring

- Operators base – choice of operator

- Assortments base – choice of assortment

- Contractors base – choice of contractor

- Cumulative printout with counters deleting

- Printout of “cc” label with counters deleting

- Setting N1, N2 counters, V1, V2 any text,

- Printout of cumulative label without counter

Id codes edition Id codes edition

Enter to choice of operating mode

weighing

Label printout

M1, M2 sums of details quantity and

starting point of counter n1

deleting

END

PAGE

DOWN

- Printout of “cc” label without counters

deleting

- Introducing mass of single detail

11

Page 12

DEL

- Deleting counters and statistics

TAB

ESC

Change of weighing

platform

Resignation from

introduced changes

5.4. Connecting sockets

1. Adaptor socket (11V AC 50Hz)

2. PC keyboard socket

3. RS 232 socket

4. additional display socket

5. earthling screw

6. RS 485 socket

7. main switch

Change of weighing platform

Resignation from introduced changes

Fig. 4. Sockets

12

Page 13

6. USER MENU

User’s menu comprises 9 groups of parameters signed by P. Below you can

see listed groups and parameters.

P1 Calibration

P2 GLP

P3 Date/Time

P4 Reading

01 Ext. calibration |

02 User calibration |

03 Report printout | * * * * * *0.1 | on

01 User | No wak Jan |

02 Project | AR – 65/04 |

03 Time printout | * * * * * *0.0 | off

04 Date printout | * * * * * *0.0 | off

05 User printout | * * * * * *0.0 | off

06 Proj. printout | * * * * * *0.0 | off

07 Id printout | * * * * * *0.0 | off

08 Calibr. printout | * * * * * *0.0 | off

* * * * * * * *

* * * * * * * *

01 Date format | * * * * * * * 0 | DA/MO/YR

02 Time format | * * * * * * * 0 | 24 hours

03 Time |

04 Date |

05 Display time | * * * * * * * 1 | on

06 Display date | * * * * * * * 1 | on

01 Filter | * * * * * * * 3 | average

02 II - / - / - / - | * * * * * * * 3 | average

03 Median filter | * * * * * * * 3 | average

04 II - / - / - / - | * * * * * * * 3 | average

05 Refreshing | 0 | 0,04s

06 Autozero | * * * * * * * 1 | on

07 II - / - / - / - | * * * * * * * 1 | on

08 Last digit | * * * * * * * 1 | always

09 II - / - / - / - | * * * * * * * 1 | always

10 Negative. | * * * * * * * 0 | off

11 Both platforms | 0 | off

12 Aut. tare | 0 | off

* * * * * * * *

* * * * * * * *

| function

| function

| function

| function

13

Page 14

P5 RS - 232

P6 Printouts

P7 Units

01 Trans. speed | * * * * * * * 1 | 4800

02 Parity | * * * * * * * 0 | non e

03 Data bits | * * * * * * * 2 | 8 bits

04 Stop bits | * * * * * * * 1 | 1 bit

05 Trans. control | * * * * * * * 0 | none

06 Aut. printout | * * * * * * * 0 | none

07 Interval | * * * * * * * 1 | * 0.1 s

08 Min. mass | * * * * * * * 4 | 10 d

09 Print stab | * * * * * * * 1 | on

10 Pause | 1 | *0,1s

11 Printer type | 1 | CitizenCLP

01 Prn. memory | * * *

02 Prn. destination |* * * * * * * 0 | RS

03 Printout no. | * * * * * * * 0 | standard

04 Print. 1 start | * * * * * * * 1 |

05 Print. 1 stop | * * * * * * * 1 |

06 Print. 2 start | * * * * * * * 1 |

07 Print. 2 stop | * * * * * * * 1 |

... . . . . . . . . . . | * * * * * * * 0 |

12 Text 1 | * * * * * * * 1 |

13 Text 2 | * * * * * * * 4 |

... . . . . . . . . . . | * * * * * * * 1 |

92 Tekst 80 | * * * * * * * 0 |

* * * * * | function

01 Grams | * * * * * * * 1 | on

02 Kilograms | * * * * * * * 1 | on

03 Pounds | * * * * * * * 0 | off

04 Ounces | * * * * * * * 0 | off

05 Ounces troy | * * * * * * * 0 | off

06 Carats | * * * * * * * 0 | off

07 Dwt | * * * * * * * 0 | off

08 Taele Hk. | * * * * * * * 0 | off

09 Taele S. | * * * * * * * 0 | off

10 Taele T. | * * * * * * * 0 | off

11 Mommes | * * * * * * * 0 | off

12 Grains | 0 | off

13 Newton | 0 | off

14 Tical | 0 | off

15 Custom | 0 | off

16 User Factor | 1.0 |

14

Page 15

P8 Operating modes

01 Counting pieces | * * * * * * * 1 | on

02 Statistic | 1 | on

03 Starting mode | 1 | counting

P9 Other

01 Address | 1 |

02 ID setting | * * *

03 ID autoprinting | 0| off

04 Signal | * * * * * * *1 | on

05 Language | * * *

06 Backlight | * * * * * *

07 Contrast |

08 Screensaver | * * * * * *

09 Balance number | 1144 93 *

10 Software number | MCB e.08 * |

11 Par. printout |

12 Par. receive |

13 Password | 0 |

14 Bar code reader | * * *

Parameters in user menu can be:

* * * * * | function

* * * * * | function

1 | on

* * * * * * * *

* * * * * * * *

* * * * * * * *

* * * * * | function

| function

* 0 | off

* * |

| function

| function

• functional – for particular activities e.g. balance calibration

• selectable – enable choice one of few values which are permanently

declared in balance memory e.g. refreshing, display screensaver,

declaring measuring units, declaring functions

• introduced – enabling change of some of setting saved in balance

memory e.g. date, time, user number, texts

15

Page 16

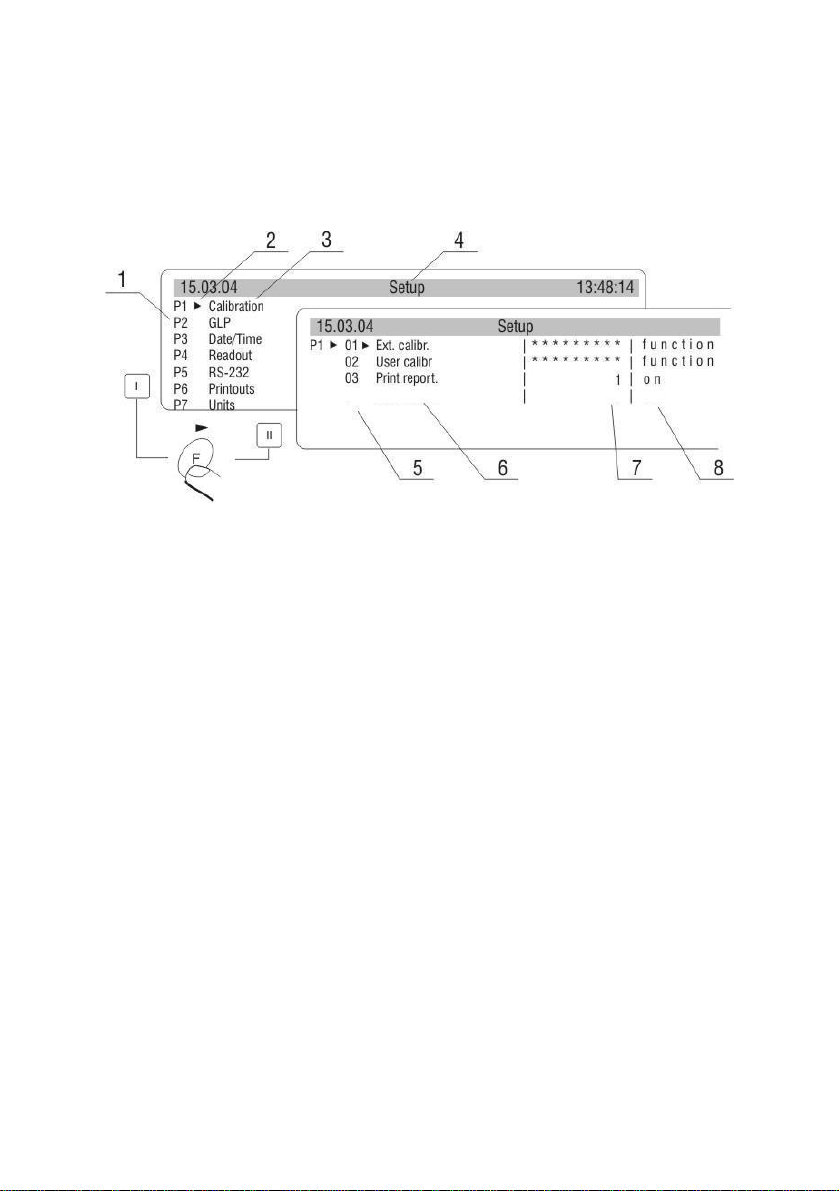

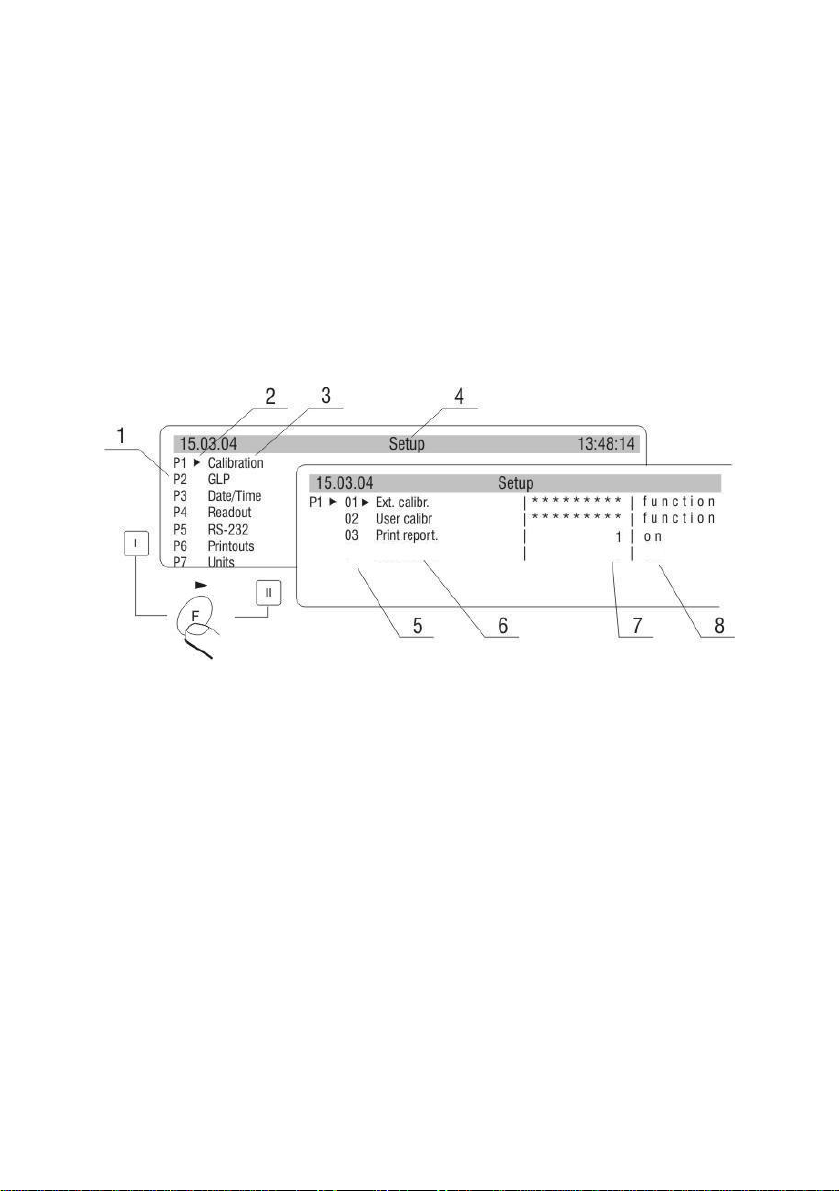

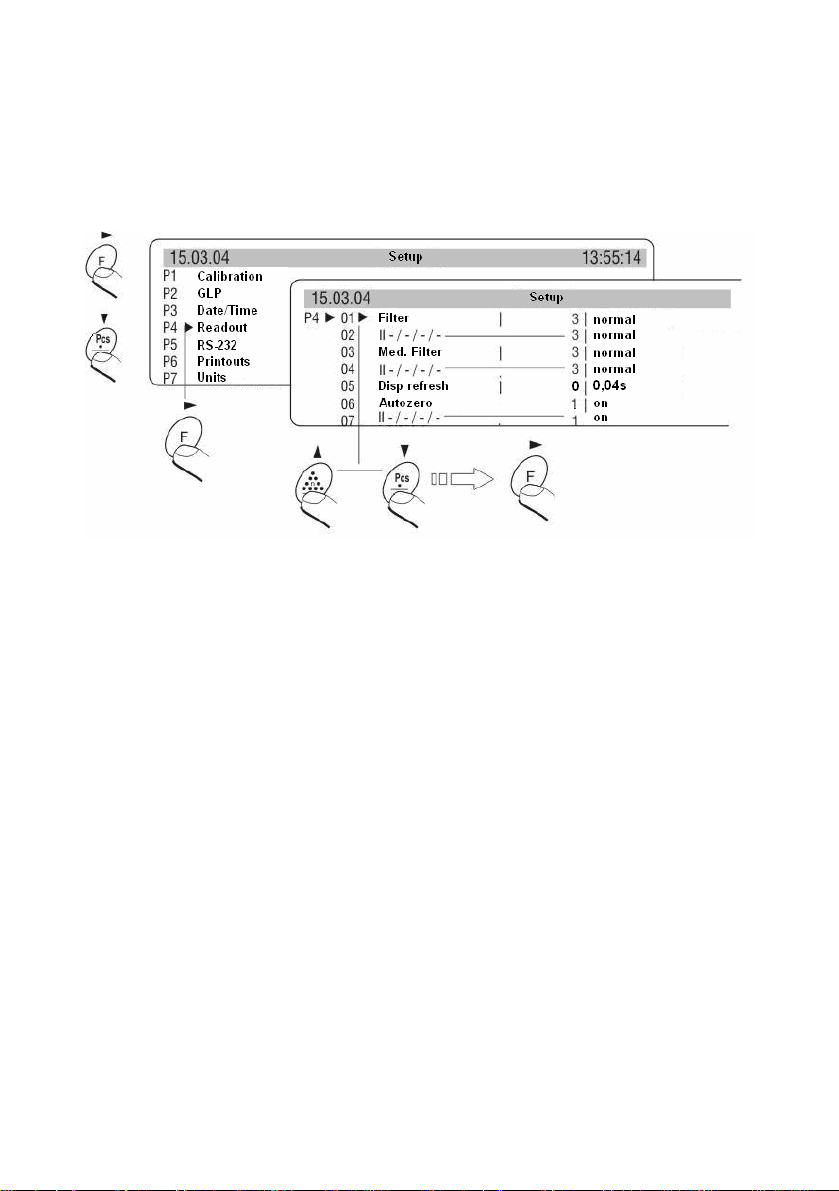

6.1. Menu view

While in weighing press F key, display shows main balance menu (display I).

Moving by marker up or down, set it next to submenu which contents you want

to see. Press → key, display will show contents of submenu (display II)

Fig. 5 View of balance menu

1 – number of main menu

2 – choice of function marker

3 – name of function

4 – name of currently performed activity

5 – number of submenu

6 – name of submenu

7 – attribute of submenu

8 – value referring to attribute

16

Page 17

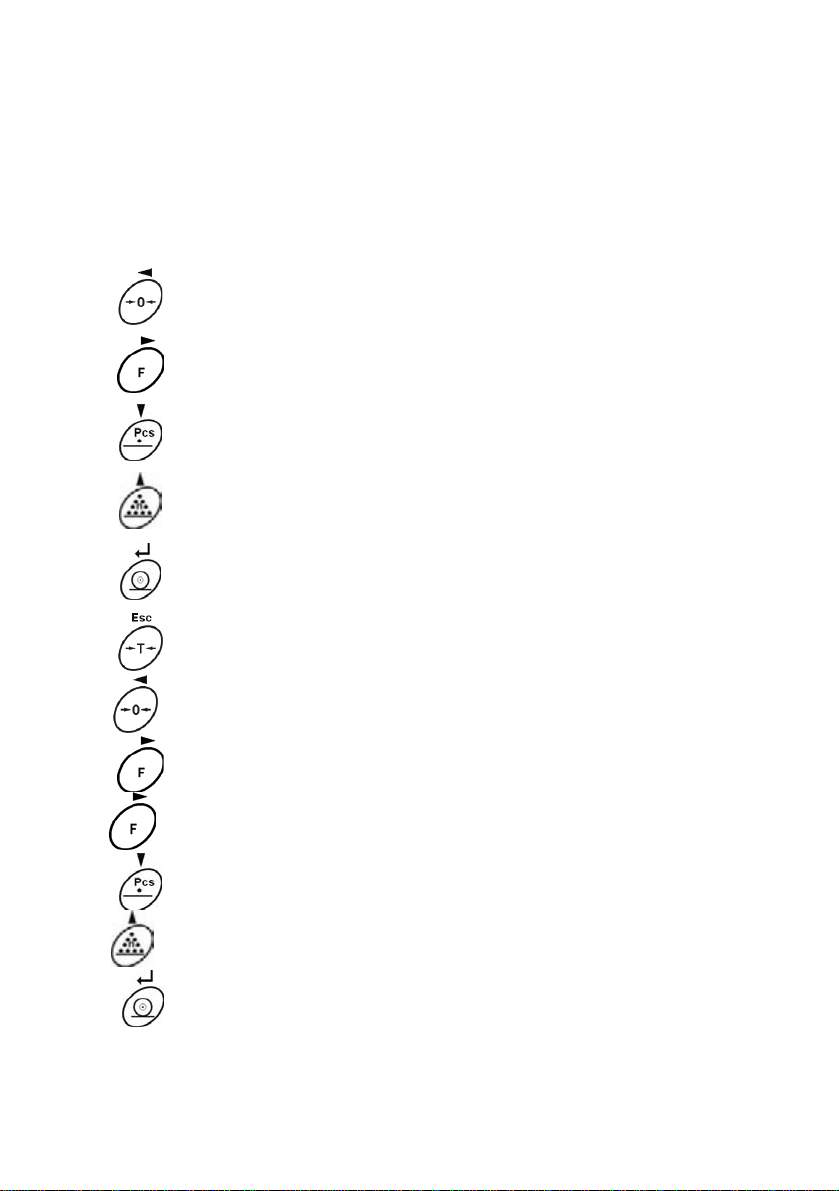

6.2. Menu navigating

Moving in user menu is possible by means of balance keyboard or attached PC

keyboard.

By means of balance keyboard

Balance keyboard Description

By means of PC keyboard

Key Description

F2

ESC

ENTER

↓

Exit to one step higher level to menu

Enter to parameter edition

Moving marker downwards

Moving marker upwards

Confirmation of introduced value

Cancellation of changes, exit from menu

Enter to balance menu

Cancellation of changes, exit from submenu

Confirmation of introduced value

Moving cursor downwards menu

↑

→

←

Moving cursor upwards menu

Enter to submenu, parameter edition

Exit to one step higher level e.g. from submenu to main

menu

17

Page 18

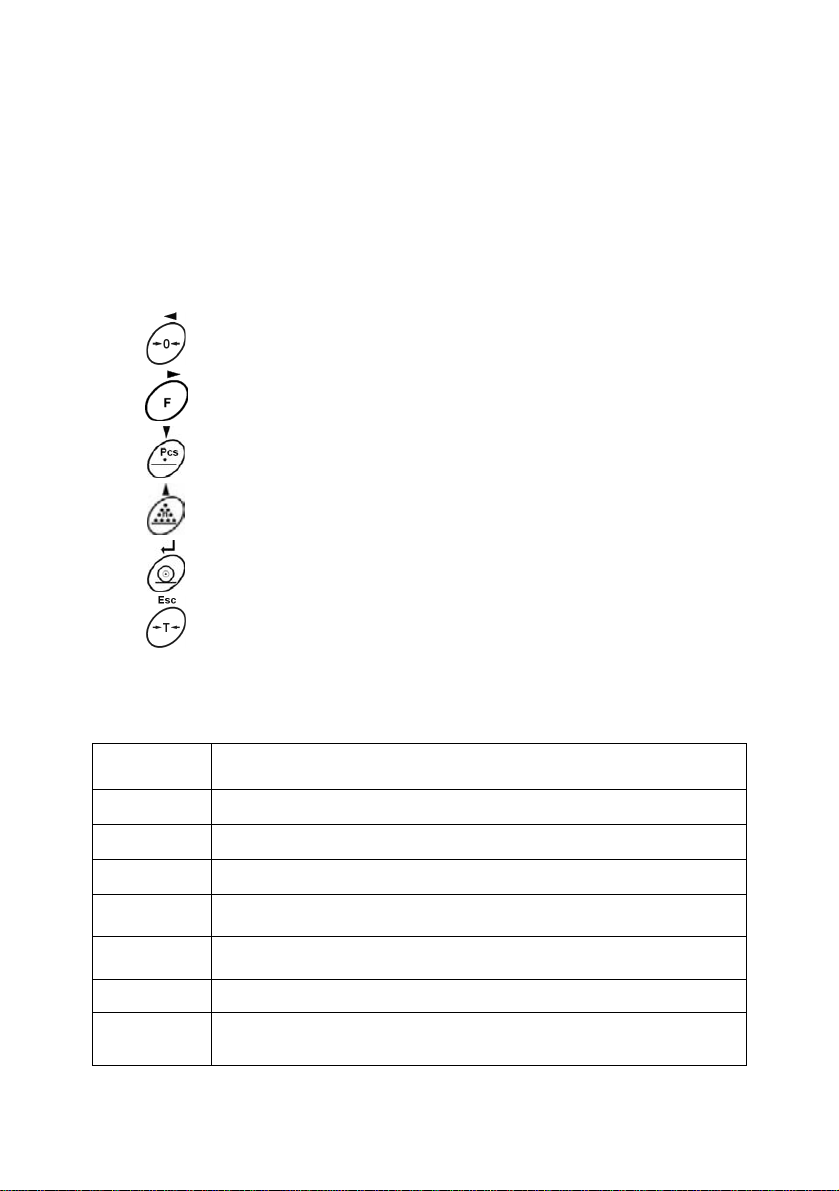

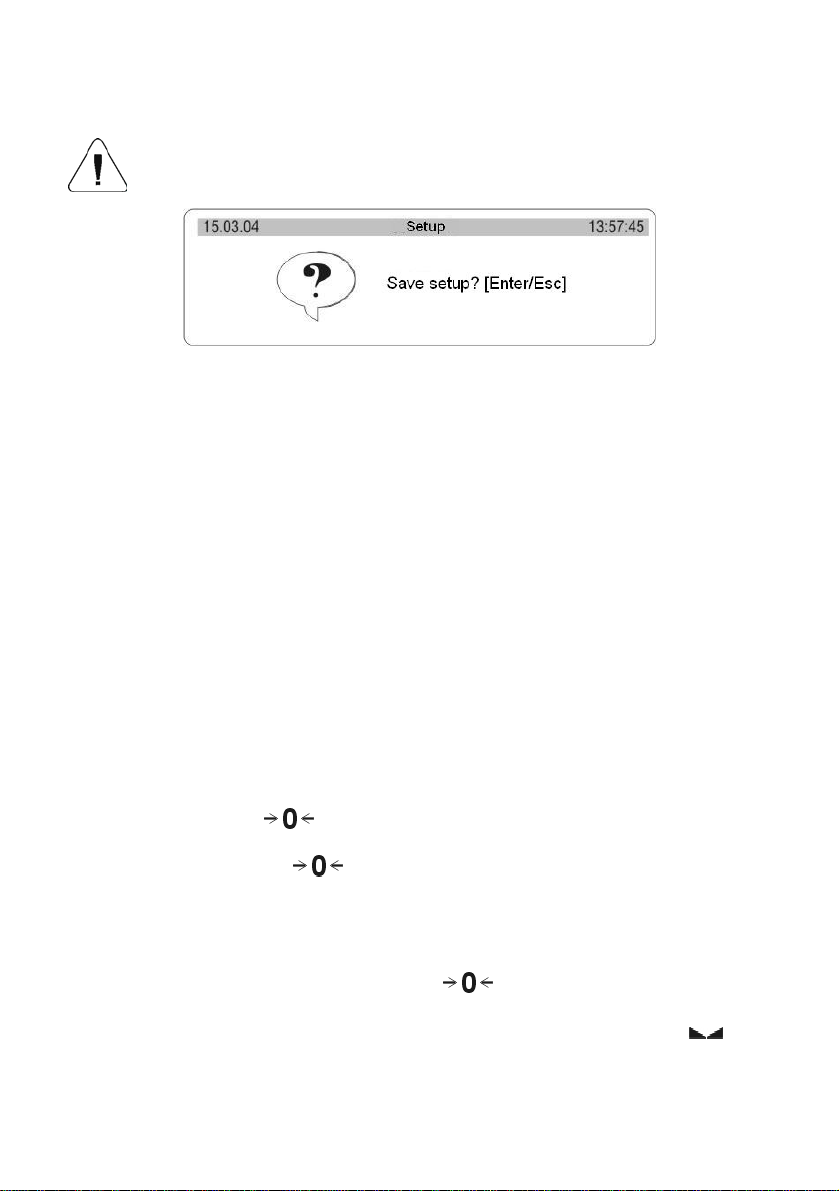

6.3. Return to weighing

Introduced changes in settings will be saved after return to weighing

mode with procedure of saving changes.

Fig. 6. Return to weighing

After introducing all changes in parameters settings press several times ESC

key. When display indicates message, choose one of two options:

ENTER – save changes

ESC – without saving

7. WEIGHING

Basic conditions which should be fulfilled to ensure reliability of measurements:

9 stable base for balance,

9 choice of appropriate parameters for existing external conditions

Before measurements or in case of essential changes of external conditions,

balance should be calibrated according to manual (for verified balances,

function of calibration is not accessible for user)

Before measurements check if unloaded balance indicates „precise zero” –

indicated pictogram -

parameter is set on 1: yes or P4 07 for second platform), if balance doesn’t

indicates zero press key:

If conditions for zeroing are unfavourable (lack of stable result), display

indicates horizontal lines. After exceeding set zeroing time of balance will

return to weighing without performing zeroing. In such case wait for

stabilization of conditions and press again

Place on the pan weighed load and when results are stable (indicated

read on the display result of weighing.

- in left lower corner (only when P4 06 Autozero

.

key.

)

18

Page 19

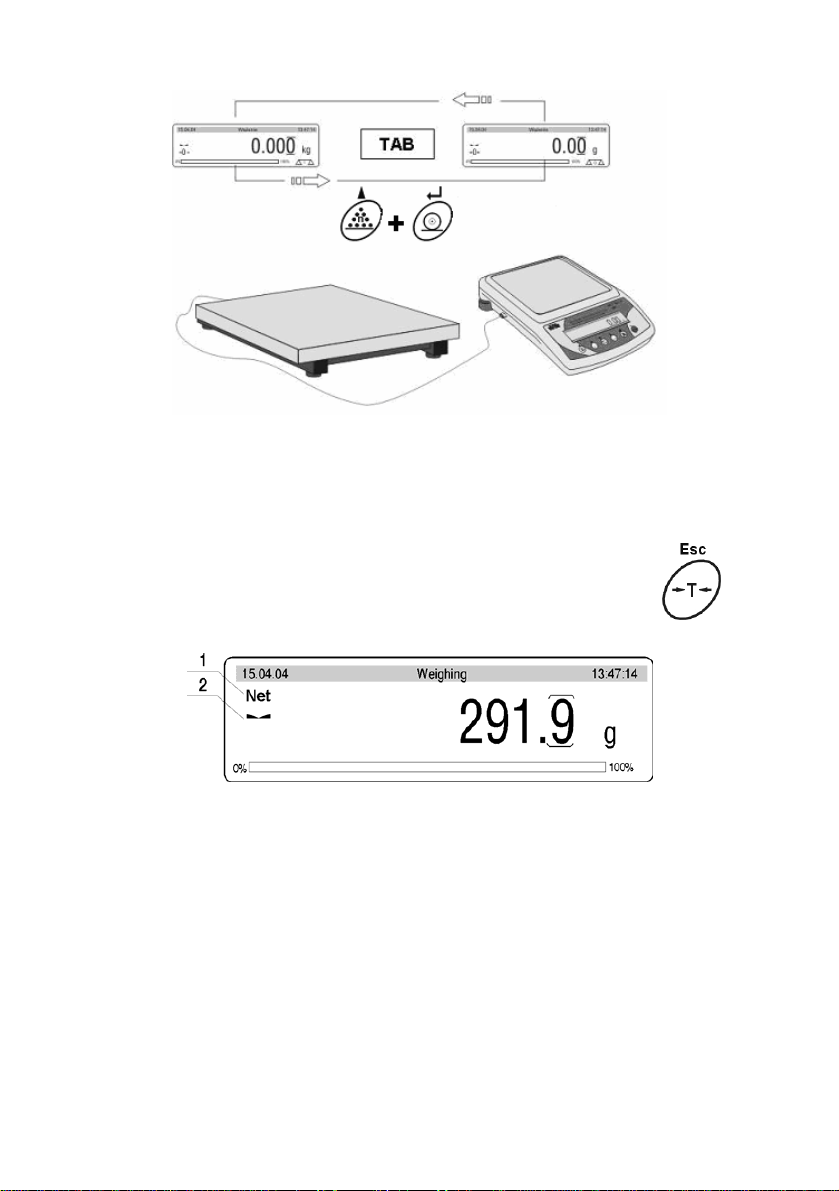

Fig. 7. Weighing- choice of weighing platform

TAB- by means of PC keyboard11

PRINT+n – by means of balance keyboard

7.1. Tarring

For determining net mass place on the pan package

of load and when indication is stable press T key.

Fig. 7a. Tarring – display view

1 –TARE signature (NET is being displayed)

2 –stable result signature

Tarring can be performed repeatedly in the whole balance weighing range.

Using tare function pay attention not to exceed the maximum weighing range.

After removing the load and package display will indicate mass equal to mass

of tare with minus sign.

Notice:

Tare value is not stored in balance memory and is deleted after disconnecting

from mains

19

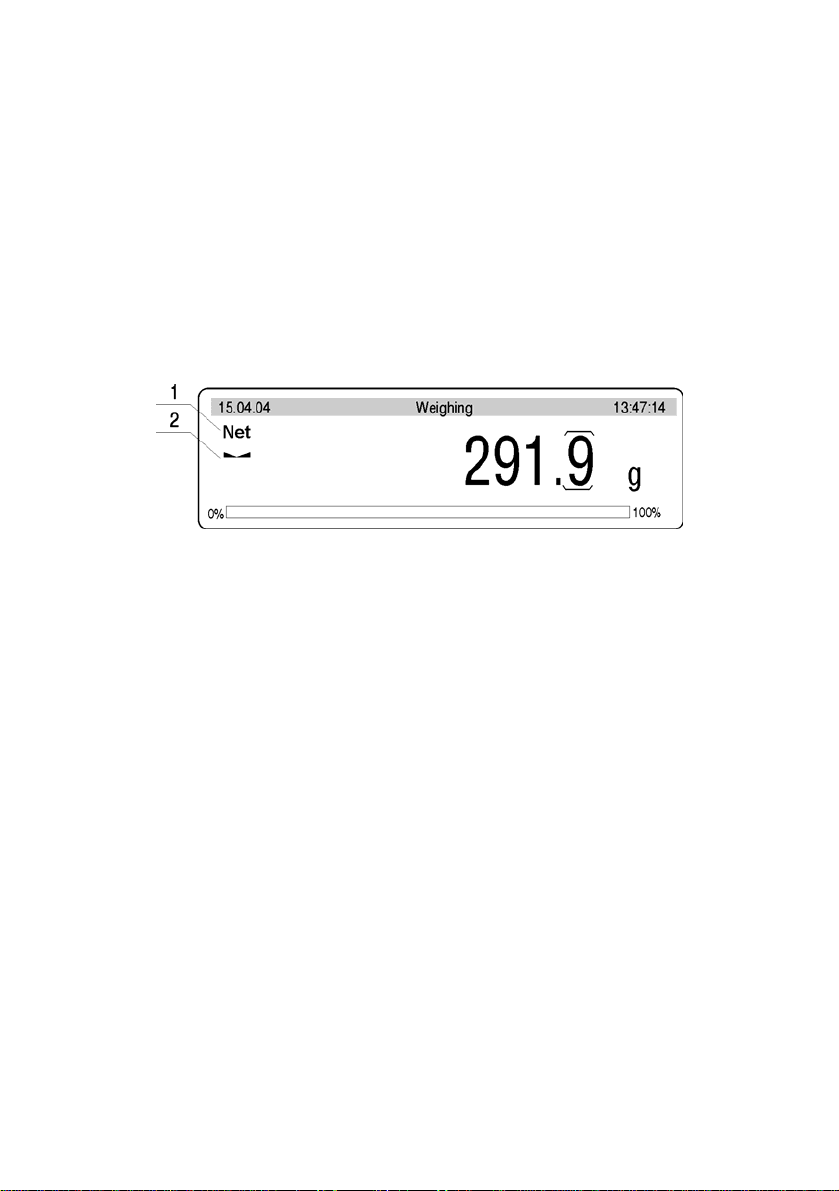

Page 20

7.2. Inscribing tare value

It is possible to inscribe tare value.

To do it in weighing mode follow the below instructions:

• Select the platform for tarring,

• Using PC keyboard inscribe a tare value (in basic unit) according to

display format e.g.: if the basic unit is “kg” and 0,005kg is a scale division

and you want to inscribe 1.05kg as a tare value, enter it in the following

format: 1.050,

• In the bottom left corner the editing field appears for inscribing a tare

value,

Fig. 7b. Inscribing tare – display view

1 – tare designator

2 – stability designator

3 – tare value

• press T or F6 (PC keyboard),

• Tare can be inscribed any time.

Notice

Use “point” for decimal fractions.

7.3. Automatic tare

This function is useful for quick determining net mass of weighed goods when

tare values are different for each weighings. It is accessible in <P4 Readout>

parameters group.

20

Page 21

Enabling function:

Fig. 7c. Automatic tare – enabling

After setting an appropriate value of the parameter return to weighing 5.3. of

this manual.

The way of operation:

• Press ZERO button when the pan is empty,

• Put a package on the pan,

• After stabilizing tarring is performed (Net designator is displayed in the

top left corner of the display),

• Put an article on the pan,

• The display shows the net mass of the article,

• Unload the pan,

• Indication returns to zero,

• Put the next package … and the cycle repeats.

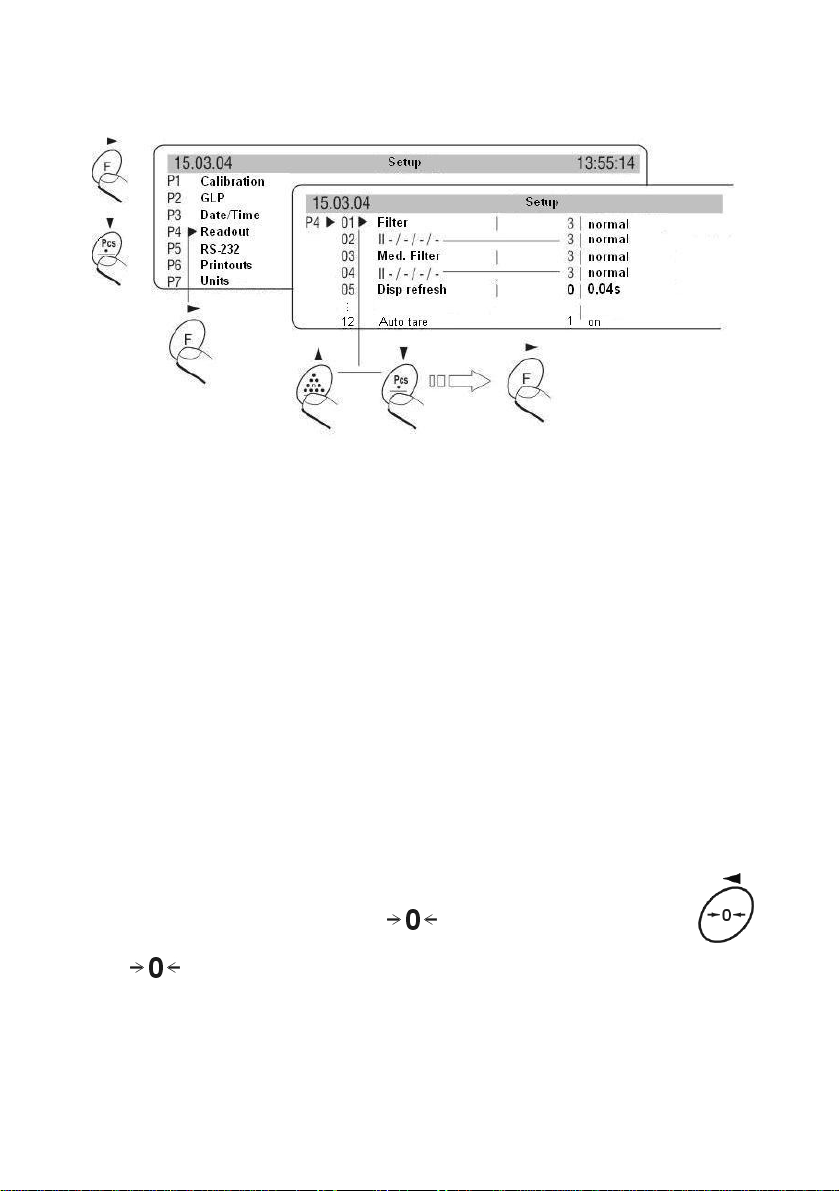

7.4. Zeroing

For zeroing display indication press

to zero and display will indicate a graphic signature in left lower

corner

.

Zeroing of indication is possible only in range of 2% of maximum capacity

currently displayed balance/platform. If zeroed value is bigger than 2% of

maximum capacity display will indicate error message and return to displaying

previous value – for main balance or displayed mass will not change.

key. Indication will return

21

Page 22

Notice:

Balance zeroing determines a new zero point treated by balance as precise

zero. Zeroing is possible only in stable states of the indication.

8. BALANCE CALIBRATION

To ensure very high accuracy of weighing, periodical entering to memory

correction factor of balance indication referring to standard mass is required; it

is so called balance calibration. In WLT balances it is inaccessible for user. The

procedure of calibration can be performed only by authorized services of the

manufacturer.

Fig. 8. Internal setting of calibration

1 – main menu number

2 – cursor

3 – group of parameters

4 – status bar

5 – parameter number

6 – parameter name

7 – parameter value

8 – parameter description

Notice:

In verified scales calibration can be accessed from the user’s menu. Calibration

should be performed with no load on the pan!

22

Page 23

9. SETTING OF PRINTOUTS CONTENTS FOR GLP PROCEDURES

P2 GLP his group of parameters allows to enable/disable printing some

variables on the standard printout and calibration report.

For variables:

User and project name (max 8 alphanumerical characters) enter names with

balance keyboard or with PS/2 keyboard.

For remaining fields, select digits:

- 0 no (do not print during report)

- 1 yes (print during report)

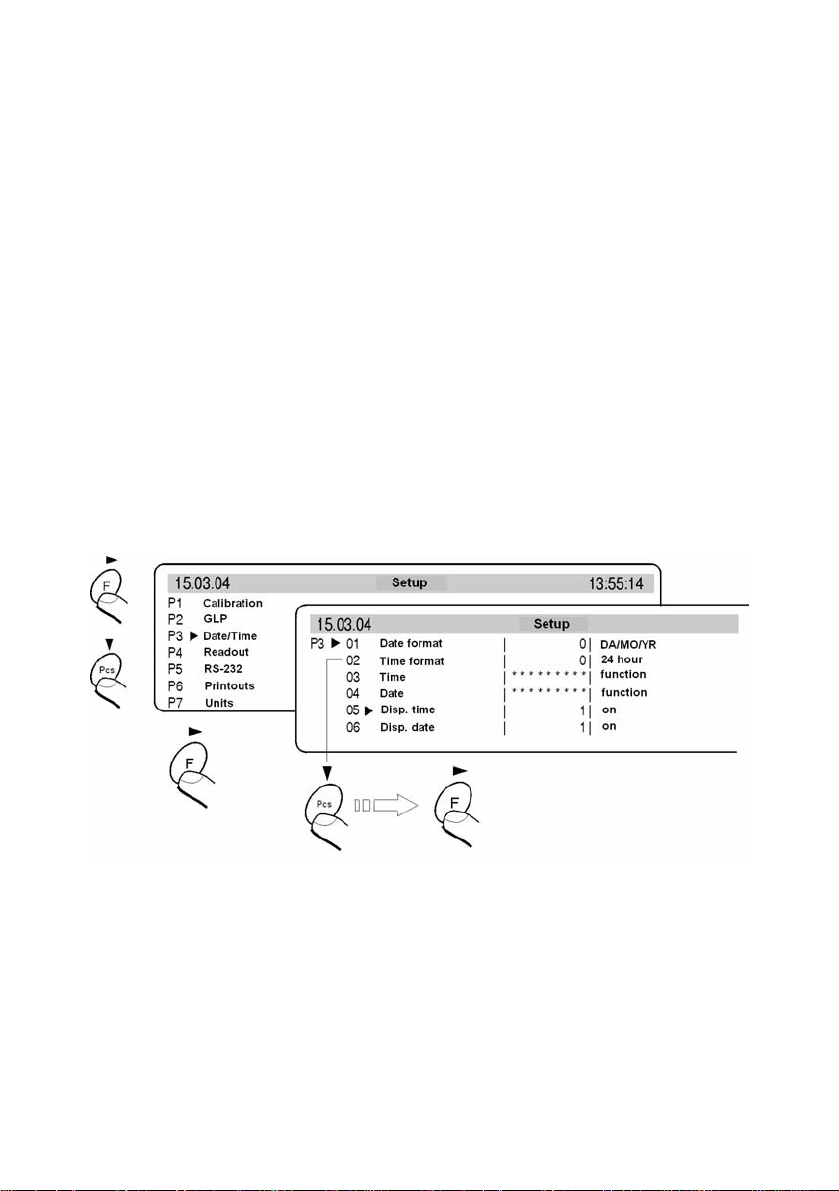

10. TIME AND DATE SETTING

Balances have a real time clock, which can be modified. Enter menu group P3

Date/Time according to the below scheme:

Fig. 9. Date/Time submenu

01 Date format

has doublestate choice according to below dependance

- 1 date format Month/Day/Year

- 0 date format Day/Month/Year

After choice of appropriate value confirm with ENTER key.

23

Page 24

02 Time format

has doublestate choice according to below dependance:

- 1 time format 12 hours

- 0 time format 24 hours

After choice of appropriate value confirm with ENTER key.

Format 12 hours. Is diffrentiated by placing letters PM or AM on printouts.

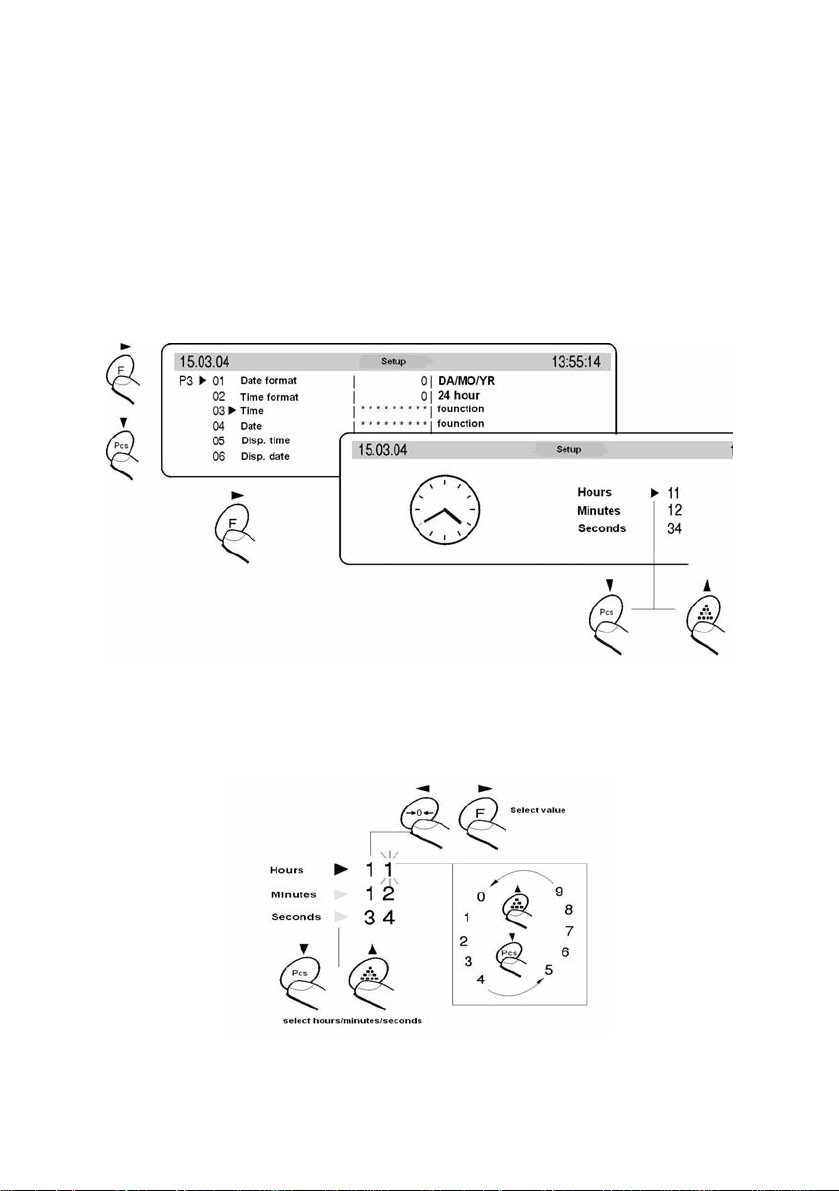

03 Time

With F key enter parameter 03 Time setting according to below scheme.

Fig. 10. Submenu Date / Time – time setting

Set cursor next to value which os to be changed (Hour, Minute, Second).

Confirm choice pressing F key. Using keys Pcs and n change values.

Fig. 11. Submenu Date / Time – time setting – steering keys

24

Page 25

Confirm set value (last changed digit will stop pulsing)

Above activities repeat for next values. After setting new values of time press

ENTER key. Balance will return to submenu P3 Date/Time and hour displayed

on upper bargraph will change.

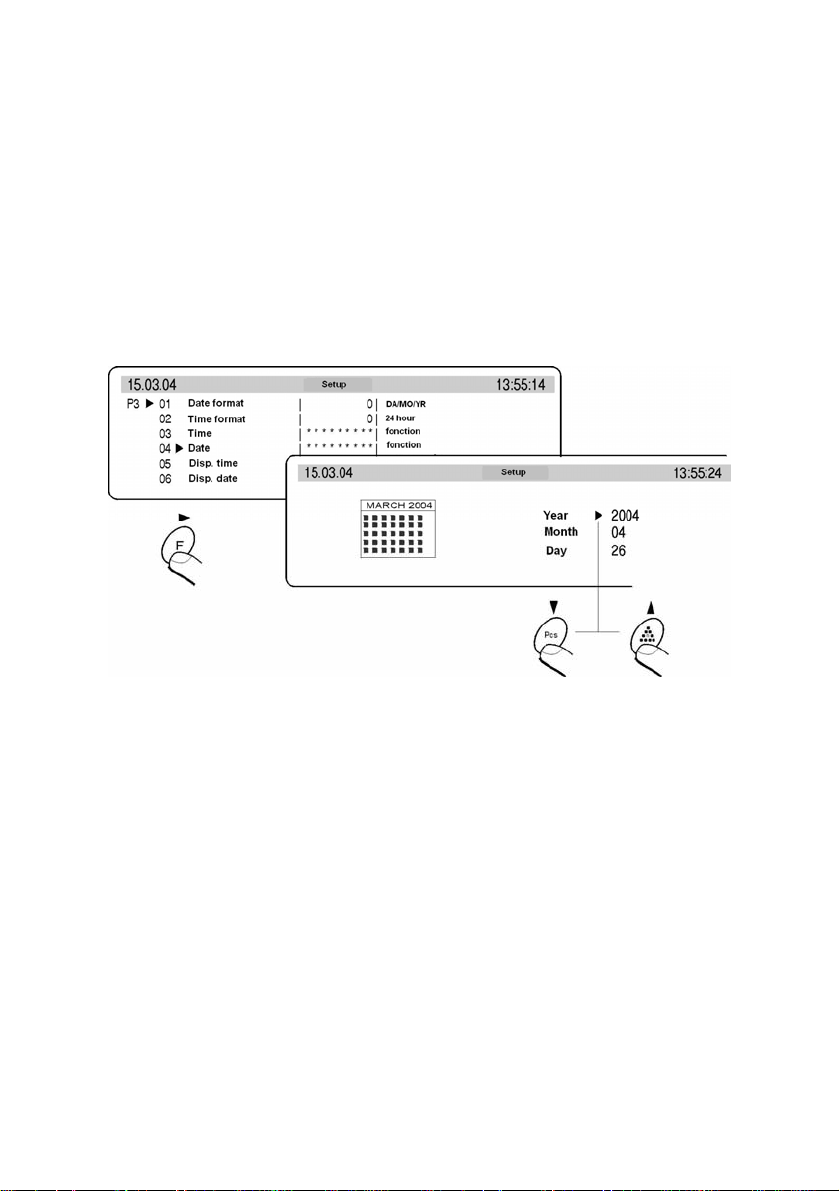

04 Date

With F key enter parameter 04 Date setting.. According to previous description

(03 Time) set current date. After date setting return to weighing mode with

changes saving in menu.

Fig. 12. Submenu Date / Time – date setting

05 Disp time

For setting 1 – YES on upper bargraph, time will be displayed, for setting 0-NO

time will not be displayed.

05 Disp date

For setting 1 – YES on upper bargraph, date will be displayed, for setting 0 –

NO date will not be displayed.

25

Page 26

11. SETTING WORK PARAMETERS

User by means of appropriate setting of parameters from menu group <P4

Readout> can adjust the balance to existing operating conditions (filter) and

one’s expectations (refreshing, autozero, last digit displaying)

Fig. 13. Submenu Readout – internal settings

11.1. Filter setting

For perfect conditions filter can be set as very fast, however if conditions are

bad (vibrations, draughts) filter should be set as slow or as very slow.

Effectiveness of filter operating is different for weighing range. Filter works

slower in time of “reaching” the final result, however stronger when mass gets

to set range of filter operating (parameter range of filter operating available only

in service menu – user do not have access to it).

11.2. Median filter setting

Task of median filter is to eliminate single big disturbances. By setting digital

value determines speed of filter operating. For zero option filter operating is off.

26

Page 27

11.3. Setting the time of display refreshment

This parameter determines how often indication of display is refreshed. It is

realized by comparing what in given moment is on the display with information

sent by balance processor about state of weighed mass placed on the pan.

For higher refreshment parameters value display do not indicate intermediate

unstable mass indication by placing and removing the load on balance pan,

however for low values all changes of mass during weighing are visible – e.g.

this enables dosing loose or liquid materials. Time of refreshment is set in

seconds.

11.4. Setting of autozero operating

To ensure accurate balance indications software “AUTOZERO” function was

introduced. Task of this function is automatic control and correction of balance

zero indication.

When function is active comparison of successive results takes place in

declared distance of time e.g. every 1 s. If these result differ in value lower than

declared range of AUTOZERO e.g. 1 interval, balance will automatically zero

and markers of stable result –

and zero indication – will be

displayed.

When AUTOZERO function is on every measurement starts from precise zero.

There are some special cases when this function interrupts in measurem ents.

Example of it can be very slow placing the load on the pan (e.g. pouring the

load) in such case system of zero indication correction can also correct

indication of real mass of load. AUTOZERO can be switch on or off in

parameter P4 06 – main platform 07 – additional platform.

11.5. Last digit

To ensure appropriate comfort of operating with balance user determines

(depending on needs) if last digit of mass indication is to be displayed and in

which states of balance. One of below values can be set:

- 0 never

- 1 always

- 2 when stab

For verified balance option 1 – always is set (without possibility of changing)

27

Page 28

11.6. Negative

Possibility to change displaying mode – negative effect (dark background, light

signs).

11.7. Two platforms

Setting the parameter to YES causes displaying on the display results of

weighing from both platforms at the same time.

11.8. Automatic tare

This function is useful for quick determining net mass of weighed goods when

tare values are different for each weighings (see chapter 7.3. of this manual).

12. FUNCTIONS CONNECTED WITH RS 232 USE

User can set parameters needed for correct communication of balance with

computer or printer.

Fig. 14. Submenu RS 232 – setting

28

Page 29

No and name

parameters

01 Speed of

transmission

02 Parity

03 Data bits

04 Stop bits

05 Transmission

control

Value of

parameters

0 : 2400;

1 : 4800;

2 : 9600;

3 : 19200

0 : none;

1 : par;

2 : odd

1 : 7 bits;

2 : 8 bits

1 : 1 bit;

2 : 2 bits

0 : none;

1 : RTS/CTS;

2 : XON/XOFF

No and name

parameters

07 Interval

08 Min mass Give value

09 Print stab

10 Gap

Value of

parameters

Interval determines

stroke (how often)

balance sends

through RS232 joint

display indication. It

is determined

according to formula

value of parameter x

0.04 s = time of

strokeinterval.Values from

1 to 9999 can be

introduced

0 : no;

1 : yes

Determines gaps

between successive

variables sent

through RS 232 joint

06 Automatic

printout

0 : none;

1 : continuous;

2 : with gaps

3 : by stab

11 Printer type

0 : receipt(EPSON)

1 : Citizen CLP

2 : Zebra

After setting appropriate parameters return to weighing mode with saving

changes.

13. PRINTOUTS

This function is used to configure standard and non-standard printouts. (see

chapter 23).

29

Page 30

14. SETTING ACCESSIBILITY OF WEIGHT UNITS

In this group of parameters user declares measure units which are accessible

for operators directly after pressing the key

.

All units which value of the parameters is set up at 1: yes are accessible from

the level of toggling between units.

For units described as 09 Taele Hk., 10 Taele S., 11 Taele T. there are

following relations:

• If all of them have attribute 1: yes the balance sh ow only first of them

09 Taele Hk

• If the measurement is done in units 11 Taele T set the attribute 0 : no

for two previous

Enter group of the parameters P7 Units according to the figure below.

Fig. 15. Units of measure - setting

NOTICE:

For verified scales (DRH enabled) users can weigh in grams or in kilograms.

Pressing the Units key do not effect changing the unit although they are set to

YES in parameters.

30

Page 31

15. SETTING ACCESSIBILITY OF WORK MODES

In P8 parameters group users can declare work modes that are accessible

directly under the Mode key during operation.

Fig. 16. Work modes - setting

Every operation mode can be enabled/disabled separately.

16. OTHER PARAMETERS.

Users can set parameters influence the operation of the balance in group of the

parameters P9 Others e.g. beep signals etc

01 Address

(not active)

02 ID Setting

it includes 6 digits 6 codes which can be used during printouts for product

specification, operator, batch etc.

03 ID autoprint

for the option YES all digital codes are printed, for option NO the codes

are not printed.

31

Page 32

04 Beep

beep sound for pressing keys

05 Language

selection of languages

According to software versions (last letter in software version „e” or „w”)

following languages are accessible:

(e) language versions (w) language versions

Polish Polish

English English

Czech Italian

German German

Dutch Dutch

Russian French

06 Backlight

switch on/off the backlight

07 Contrast

changes contrast – after entering this function a window appears, by

means of keys on the balance the contrast on the display can be changed

08 Screen server

if the screen server is enabled displayed values disappear after settled

time and if measurement does not change.

09 Balance Id

the information about factory number of the balance

10 Software rev.

information about software version of the balance

11 Par. printout

if the function is active the balance parameters are printed. User can set

numbers of the parameters which should be printed.

32

Page 33

Fig. 17 Submenu others - printing settings

After a confirmation, parameters are printed via RS 232 port.

12 Reception parameters

If the functions are activated all parameters of the balance are received

through RS 232. After reception the balance informs user how many

parameters are accepted, how many are changed, how many were

declared incorrectly and how many were not accepted by the software.

Printing and reception of the parameters is very easy and fast procedure of

introducing new setting. After printing actual parameters to file in the

computer user changes the parameters very fast and without any

problems. User sends new corrected setting to the balance software. After

these changes the balance accepts new set up. User must know all

parameters and computer operation very well.

13 Password

Entering a password results in the necessity of inscribing it whenever you

will try to enter the menu using F or F2 (PC keyboard)

14 Barcode scanner

Settings for barcodes used for the assortment database searching and

variables for labelling.

33

Page 34

17. COUNTING PIECES

17.1. Databases

17.1.1. Database of operators

While in Counting pieces mode press F key on the balance keyboard or F2 on

the PC keyboard.

Choice of operator is done by arrows up and down, enter to edition by arrow to

the right fig.18.

Fig.18. Screen operators base – choice of operator for edition

1 – number of operator

After enter to edition of operator a following window will open:

Fig.19. Screen operators base – edition of operator parameters

name Name of operator (28 signs)

index 4 digits

Id 6 signs

password Password for logging (6 digits)

authorization Authorization level of operator(1 to 5). Level 5 highest authorization

Change of any parameter is performed by pressing arrow to the right and next

using keyboard introduce appropriate value. Confirm changes by ENTER or

cancel them by ESC. Exit from edition (ESC key). Enter to one level of menu

higher (again ESC key).

2 – name of operator

34

Page 35

17.1.2. Database of labels

While in Counting pieces mode press F key on the balance keyboard or F2 on

PC keyboard.

After pressing arrow to the right list of defined labels will open. Choice of label

can be done by arrows up and down, however enter to edition arrow to the right

- fig.20.

Fig.20. Database of labels

1 – number of label

2 – name of label

name Name of label (28 signs)

index 4 digits

6 signs. This name must be the same as name of label design

Id

fields Submenu to choose variables to place on printout (on label)

C39/E128

saved in printer memory. Label design is made in “LABELS”

software attached to CITIZEN CLP printer equipment.

Submenu to choose variables, which are to be introduced as

bar code in code39/ EAN128 format

After choice of submenu “fields” (arrow to the right) following screen will open

fig.21.

Fig.21. Choice of variable to print

35

Page 36

In the field „Selection” you can find.

Operator Name of operator

Operator Id Identity number of operator

Product name Name of operator

Product IDt Id code of assortment

Product EAN Code assigned to particular assortment

Contractor name Name of contractor from contractors base

Contractor ID Code of contractor Id from contractors base

Country Contractors country

City Contractors city

ZIP Contractors postal code

Street Contractors street

TIN Contractors Tax Identification Number

Label NB Counter „n1”

c label NB Number of cumulative label counter„n2”

Pcs. Quantity of pieces

C pcs Quantity of pieces on cumulative label

cc pcs Quantity of pieces on “cc” label

Pcs mass Mass of single piece

Tare Tare

Gross Gross mass

Price price

VAT Value Addend Tax

Value Value of calculated pcs (quantity x price of piece)

c value Value of calculated pcs on cumulative label

cc value Value of calculated pcs on “cc” label

EAN13 pcs.

EAN13+ pcs.

EAN13 value Introduction of particular assortment Id (first 6 signs + control sum) with value

EAN13+ value

Date Current date

Time Current time

Date+ Constant defined date (in Operating setting)

Date+A Constant date assigned to assortment

Date+V Defined date + movement e.g. validity term

Valid Validity term

Introduction of particular assortment Id (first 6 signs + control sum) with quantity

of pcs

Introduction of particular assortment Id 7 signs (extended code for

supermarkets) with quantity of pcs

Introduction of particular assortment Id 7 signs (extended code for

supermarkets) with value

36

Page 37

V1

V2 as V1

V3 As V1

V4 As V1

ID1

ID2 As code1

ID3 As code 1

ID4 As code 1

ID5 As code 1

ID6 as code 1

Printout1 Variables to print defined in submenu “Printouts” P6 in mode “Weighing”

Printout2 Variables to print defined in submenu “Printouts” P6 in mode “Weighing”

Printout3 Variables to print defined in submenu “Printouts” P6 in mode “Weighing”

Printout4 Variables to print defined in submenu “Printouts” P6 in mode “Weighing”

CR,LF Inserting empty line in printout

Code buf. 1 Bar code read by scanner determined by parameters “Start 1” “Length 1”

Code buf. 2 Bar code read by scanner determined by parameters “Start 2” “Length 2”

AI 1 Application identifier (6 characters) defined in submenu M1 06 10 „AI defining”

AI 2 As AI 1

AI 3 As AI 1

AI 4 As AI 1

AI 5 As AI 1

AI 6 As AI 1

Net E128 Net mass for EAN128

Net c. E128 Net mass of cumulative label for EAN128

Net cc. E128 Net mass of cc label for EAN128

Net [lb] E128 Net mass (lb) for EAN128

Gross E128 Gross mass for EAN128

Price E128 Price for EAN128

Date E128 Present date for EAN128

Date+ E128 Constant date for EAN128

Date+A E128 Produkt date (in the assortment database) for EAN128

Date+V E128 Present date + number of validity days for EAN128

Code39/Ean128 Chosen variables presented in bar code

Field to place any text designed for printout on label (numbers, digits).

Edition – Insert key

Constant code (defined by user) Page Up list of six codes„ID”.

Code edition like base edition

37

Page 38

Window “Printout”

In this window list of chosen variables to print will open. Choice of variable is

done by arrows up and down in “variable to choose” window, while confirmation

(transfer to “printout” window) arrow to the right. Monitoring (rewinding the

variables in “printout” window is perform by keys Home (up) and End (down).

Deleting variables from the “printout” window is done by arrow to the left. The

variable which is directly above the cursor is deleted.

Method of assigning variables from “printout” field to fields edited on label

sample is as follows:

Variable from “printout” window with 01 number will be printed on label in first

field (first field on label sample do not have to have 01 number, order of fields

can be determined in PC software. Variable with 02 number will be printed in

next field (according to order in “order of objects” window of “Labels” software).

Next variables similarly to description above.

After choice of submenu „C39/E128” (arrow to the right) screen as on drawing

22 occurs.

Fig.22. Choice of variable to be printed on bar code C39/E128

38

Page 39

Operator Name of operator

Operator Id Identity number of operator

Product name Name of assortment

Product ID Code of assortment

Product EAN Code assigned to particular assortment

Contractor name Name of contractor from contractors base

Contractor ID Code of contractor Id from contractors base

Country Contractors country

City Contractors city

ZIP Contractors postal code

Street Contractors street

TIN Contractors tax identification number

Labels Nb Counter „n1”

c label Nb Number of cumulative label counter „n2”

Pcs Quantity of pieces

C pcs Quantity of pieces on cumulative label

Cc pcs quantity of pieces on „cc”

Pcs. Mass Mass of single piece

Tare Tare

Gross Gross mass

Price Price

VAT Value Addend Tax

Value Value of calculated pcs (quantity x price of piece)

C value Value of calculated pcs on cumulative label

cc value Value of calculated pcs on “cc” label

EAN13 pcs

EAN13+ pcs

EAN13 value

EAN13+ value

Date Current date

Time Current time

Date+ Constant defined date

Date+A Constant date assigned to assortment

Date+V Defined date + movement e.g. validity term

Valid Validity term

V1

V2 As V1

V3 As V1

Introduction of particular assortment Id (first 6 signs + control sum) with

quantity of pcs

Introduction of particular assortment Id 7 signs (extended code for

supermarkets) with quantity of pcs

Introduction of particular assortment Id (first 6 signs + control sum) with

value

Introduction of particular assortment Id 7 signs (extended code for

supermarkets) with value

Field to place any text designed for printout on label (numbers, digits)

Edition – Insert key

39

Page 40

V4 As V1

ID1

ID2 As code 1

ID3 As code 1

ID4 As code 1

ID5 As code 1

ID6 As code 1

Printout1 Variables to print defined in submenu “Printouts” P6 in mode “Weighing”

Printout2 Variables to print defined in submenu “Printouts” P6 in mode “Weighing”

Printout3 Variables to print defined in submenu “Printouts” P6 in mode “Weighing”

Printout4 Variables to print defined in submenu “Printouts” P6 in mode “Weighing””

CR,LF

Code buf. 1 Bar code read by scanner determined by parameters “Start 1” “Length 1”

Code buf. 2 Bar code read by scanner determined by parameters “Start 2” “Length 2”

AI 1

AI 2 As AI 1

AI 3 As AI 1

AI 4 As AI 1

AI 5 As AI 1

AI 6 As AI 1

Net E128 Net mass for EAN128

Net c. E128 Net mass of cumulative label for EAN128

Net cc. E128 Net mass of cc label for EAN128

Net [lb] E128 Net mass (lb) for EAN128

Gross E128 Gross mass for EAN128

Price E128 Price for EAN128

Date E128 Present date for EAN128

Date+ E128 Constant date for EAN128

Date+A E128 Produkt date (in the assortment database) for EAN128

Date+V E128 Present date + number of validity days for EAN128

Constant code (defined by user). In weighing mode press Page Up list of six

“ID” codes will occur Codes edition similar to base edition

Application identifier (6 characters) defined in submenu M1 06 10 „AI

defining”

Notice:

Edition of labels designs in “Labels” software and method of their recording to

memory of CITIZEN CLP and ZEBRA printer are described in software

instruction manual.

40

Page 41

17.1.3. Assortment database

While in Counting pieces mode press F key on balance keyboard or F2 on PC

keyboard. Set < ►> next to „M1 03 Articles DB”. After pressing right arrow you

will see the list of articles (up to 999 records). Choice of article is done by

arrows (up down), however enter to edition arrow to the right fig.23.

Fig.23. Assortment database – assortment edition

1- number of article

2- name of article

Fig. 24. Assortment database

Following parameters of chosen article occur:

Name Name of label (28 characters)

Index 4 digits

Id 7 signs

Mass of pc Mass of single piece of particular assortment

Min. Pcs. Minimum quantity of pieces for counting in thresholds (result control)

Max. Pcs. Maximum quantity of pieces for counting in thresholds (result control)

No. Lab. Number of assigned single label

No. Lab. C

No. Lab. cc

Ean Constant assortment code presented in bar code

Price Unit price

Number of assigned cumulative label (if we introduce 0 number for given

assortment there will be no possibility to print cumulative label)

Number of assigned cumulative label from cumulative labels (if we introduce

0 number for given assortment there will be no possibility to print cumulative

label of cumulative labels)

41

Page 42

VAT Value Addend Tax

Tare Value of tare

Validity Validity term (number of days 0 -1000)

Date+A Constant date assigned to assortment

To change any parameter press arrow to the right than inscribe the value.

Changes are confirmed by ENTER or canceled by ESC. Leaving editing field

by ESC. Returning to main level by ESC again.

17.1.4. Contractors database

While in Counting pieces mode press F key on balance keyboard or F2 on PC

keyboard. Set < ►> next to „M1 04 Contractors DB”. After pressing right arrow

you will see the list of contractors (up to 500 records). Choice of contractors is

done by arrows up and down, however confirmation by arrow to the right.

however enter to edition arrow to the right.

You will see following parameters:

Name Name of material (28 characters)

Index 4 digits

Id 6 signs

Country 16 signs

City 28 signs

Code Post code (8 characters)

Street Name of street (28 characters)

TIN TIN number (12 characters)

Discount 0.00 to 99.99

Change of any parameter is done by pressing arrow to the right and next using

keyboard, enter an appropriate values. Changes are confirmed with ENTER

key or cancelled with ESC key. Exit from edition with ESC key. Exit on menu

level higher (again ESC key).

Notice:

After any changes in bases reload them while in counting pieces mode. If this

is not performed changes will not be visible (having chosen assortment e.g.

nails and performing changes in it e.g. “Min Pcs” parameter after return to

counting pieces mode reload assortment “nails”) This concerns all databases.

42

Page 43

17.2. Settings of operating for counting pieces

17.2.1. Configuration

In this menu way of balance operating in counting pieces mode is defined.

After pressing arrow to the right list of parameters will open. Choice is done by

arrows up and down however enter to edition arrow to the right. Choice of

parameter value arrow up or down.

Fig.25. Screen operating settings

Following parameters are available for edition:

Auto Opt. Automatic accuracy correction

Data+ Constant defined date (e.g. date of assortment introduction)

Aut. printout Automatic printout activating

Connected with automatic printout.

Min. Pcs

Result control

C label Way of initiating printout of cumulative label (key, pieces, counter)

CC label Way of initiating printout of cumulative label from cumulative labels

Login Inactive

II line

AI defining Defining of application identifiers AI1 to AI6

DATABASE Transfer Database exchange via RS 232 using „DB editor” software

It is value of pieces below which indication must go by weighing next

portion of assortment (removing portion from the pan and placing

next portion). Automatic printout is possible if pieces quantity is

bigger than “Min. Pcs” value.

Activating terminal operating mode with result control (label is printed

when counted assortment fulfils conditions Min pcs Max pcs)

Choice of information displayed in II line of display to choose:

OPERATOR N1 – name of operator and counter of N1 labels are

displayed

N1 SUM1 N2 – value of N1 labels counter, total quantity of pieces

SUM1 and N2 counter (cumulative labels) are displayed

V1 N1 – text defined under V1 and N1 labels counter are displayed

V2 N1 – similarly as above

PRICE VALUE – price of an article and value according to mass

indication in real time

43

Page 44

Fig. 26. View of screen in counting pieces mode

II line

Change of any parameter is done by pressing arrow to the right and next

using keyboard enter appropriate values.

Changes are confirmed with ENTER key or cancelled with ESC key.

Exit from edition with ESC key. Exit on menu level higher again ESC key

17.2.2. Printer settings

In this menu printer operating is configured. Way of moving in menu is

analogical to previous ones.

Fig.27. Screen of printer settings

Quantity of labels Quantity of printed labels after single PRINT signal

Inch system By setting on NO metric system is on

Tear off dist. Distance in pixels left free space on printout (0 – 999)

Label cut

Gap sensor Switch on or off the gap sensor

Function activating label cutting device (when printer is

equipped with such device)

44

Page 45

18. COUNTING PIECES

To perform counting of the same details:

1. set appropriate options concerning counting pieces menu “Settings of

operating”

2. choose assortment from assortments base (after edition of data base)

18.1. Description of graphic display for Counting pieces mode

Fig. 28. Counting pieces – display view

1. displayed quantity of pieces on the pan

2. total mass of counted detail

3. cumulative labels counter (II line of display)

4. mass of single detail

5. symbol of stable result

6. symbol of stable zero

7. regular labels counter(II line of display)

8. marker of single detail mass

9. name of assortment chosen from assortments base

10 sum of counted pieces (II line of display)

To move from counting pieces mode to weighing press key on balance

keyboard Psc or on PC keyboard press key F3 and next choose Weighing

mode and press ENTER.

45

Page 46

18.2. Reference mass setting

18.2.1. Inserting known mass of single piece

ter pressing key F + PCS or PAGE DOWN (keyboard PC) screen will appear

f

A

as drawing below. By means of PC keyboard insert mass of single sample in

basic unit of balance.

Fig. 29. Counting pieces – view of display

Pressing ENTER will cause moving to Counting pieces mode with automatic

setting of single detail mass (SMP – description on display) as current one.

Notice:

One should not insert sample mass bigger than max range of main balance

weighing and smaller than 0.1 of reading unit of this balance.

18.2.2. Determining (weighing) by declared quantity of sample

Fig. 30. Counting pieces- sample quantity selection

46

Page 47

It is possible to set quantity of sample as quantities proposed by balance

software or in lowest line enter any sample quantity in range 1 – 100000,

remember that mass of element declared as sample can not be smaller than

0.1 of reading unit and total mass of all pieces (declared as quantity of pieces)

placed on the pan can not be smaller than 1 reading unit. If above conditions

are not fulfilled balance gives an error message and returns to the previous

step.

Fig. 31. Declaring reference mass for 10 pieces

If details are weighed in container place it on the pan and tare its mass, next

place declared quantity of pieces on the pan and when result is stable

(displayed

symbol) confirm its mass.

Then balance software automatically calculates mass of single detail and

moves to Counting pieces mode indicating on the display mass of detail

(SMP), mass of all pieces placed on the pan and quantity of declared pieces.

At the same time function of Automatic Accuracy Correction will activate (if

it’s declared as on in Operating Settings menu Auto opt. YES) above pcs

graphic sign of this function activity will be displayed – triangle with arrow.

Fig. 32. Counting pieces – choice of sample quantity - determining

Automatic Accuracy Correction operates only for main balance

(platform).

Activity sign of Automatic Accuracy Correction will be displayed until user

finds quantity of sample sufficient and saves this value of single detail mass to

balance memory.

47

Page 48

Quantity of sample can be increased by adding on pan next details. Value of

pieces quantity and mass will be automatically increased and corrected by

balance software mass of single detail (SMP).

In balance software are four conditions of Automatic Accuracy Correction

function operating:

1. quantity of pieces must be increased

2. quantity of pieces after adding can not be bigger than double quantity

of previous pieces

3. current quantity of pieces must be in tolerance range ± 0,3 to total

value

4. result must be stable

If user finds quantity of pieces sufficient, it is necessary to save mass of single

detail to balance memory.

18.2.3. Wprowadzenie masy detalu z bazy danych wagi

After introducing assortment from assortment base sample mass SMP of

assortment is automatically introduced.

Press F8 key list of assortment will occur. Using directional keys (arrow up,

arrow down) choose required assortment. Press ENTER. Balance will return to

counting pieces and in left upper corner of display number of chosen

assortment and name of this assortment is displayed.

Fig. 33. Introducing mass of detail from assorment database

1- number of product from assortment database

2- Name of product

NOTICE:

For each assortment there must be introduced mass. This can be performed by

edition of assortment base.

48

Page 49

18.3. Introducing reference mass to balance memory

Mass of single piece sample or multiple can be introduced to assortment base

in following way:

a) determine reference mass (point 7.2 a, point 7.2 b)

b) enter assortment base F or F2 (PC keyboard)

c) choose assortment from assortment base (set indicator at given

assortment)

d) press INSERT key

Reference mass will be saved for given assortment under position “Pcs. mass"

18.4. Counting pieces with checkweighing

Fig. 34. Counting pieces with result control

1 - control indicator

LO- to small quantity of pieces (Min. Pcs. in assortment base)

OK.- value in range ( Min. Pcs. Max. Pcs. in assortment base)

HI- to big quantity (value bigger than Max. Pcs. parameter in assortment base)

To activate Result control set Aut. Printout parameter in Operating settings

on YES.

NOTICE:

For each assortment there must be Min pcs. and Max pcs. entered in

assortment base.

49

Page 50

19. LABELLING

Labelling procedure is started from edition of bases of: operators, labels,

assortments, contractors. Next set balance operating parameters and printer

settings. When configuration is finished start proper labelling.

NOTICE:

To move in data bases connection of PC keyboard is recommended. Balance

operating with PC keyboard makes this operation much more comfortable and

easy.

19.1. Quick database search

a) After entering a database inscribe a record number using PC keyboard,

b) Press arrow ↓,

c) Cursor <►> indicates the ecord you have chosen.

19.1.1. Quick assortment database search

rtment d

Asso

1. Entering a record number (19.1.)

2. Using barcode scanner (21.5)

3. Searching according to name:

• While in counting mode inscribe (PC keyboard) the searched name or

• You will see an editing field in the bottom line:

atabase search can be done by:

a part of it (software is case sensitive),

Fig. 35. Searching name

1 – article name

50

Page 51

• Press F8,

• Software enters the database and sets < ► > next to the searched

name,

• Press ENTER,

• Program comes back to counting pieces with the selected article.

NOTICE:

Quick search of article name can be performed in database but without editing

field. (No visual control of inscribed characters)

19.2. Operator selection and logging in

Press F7 key – operators base will open. After choice of operator (arrows up,

down) press ENTER. Screen with message “Password” will open. Enter the

password appropriate for given operator confirm with ENTER key.

Notice:

By first edition of operators base (when base is empty) after enter to base

press ENTER and introduce given password 1111. After this activity we have

possibility of base edition. First give operator with higher authorization level “5”.

19.3. Article selection

Press F8 key – assortments base. Choose appropriate assortment (arrow up or

down) confirm with ENTER key.

19.4. Contractor selection

Press F9 key – contractors base. Choose appropriate assortment (arrow up or

down) confirm with ENTER key.

19.5. Deleting „n1” and n”2” counters and „sums” variable

After choice of assortment delete (zero) labels counter with Del key (als o

“sums” indicator is zeroed).

51

Page 52

20. REGULAR LABELLING

After choice of assortment procedure of counting pieces can be started.

When result is stable press PRINT key.

Display will indicate value of “n1” labels, cumulative pieces quantity “sums”

and cumulative labels “n2” counter.

Fig. 36. Screen of labelling mode

1- labels counter

2- number of chosen assortment

3- name of chosen assortment

4- total quantity of pieces

5- cumulative labels counter

Printout of label is release after pressing PRINT or F5 (PC keyboard) key.

If the same type of material (assortment is not changed) is to be weighed when

result is stable place next batch on the pan and when result is stable press

PRINT key.

This procedure is repeated when the same assortment is labelled continuously.

When we want to change the assortment press F8 key – enter to assortments

base, chose the assortment and confirm with ENTER key. Counters “n1” and

“n2” are deleted with Del key.

Further procedure without changes.

20.1. Cumulative label printing

Cumulative label “label c” contains the sum of values from single labels till the

moment of printing this label. Cumulative label is stick on the parcel with

determined quantity of assortment e.g. parcel containing 20 cans with screws

and for these cans single labels were printed. It is possible to print cumulative

label only for assortment to which such label was assigned.

There are three criteria to print cumulative label:

52

Page 53

♦ After exceeding given quantity of basic labels (after exceeding given

state of “n1” counter)

♦ After exceeding given total quantity of assortment „sums”

♦ Printing in any moment

- Without deleting “n1” counter Home key

- With deleting “n1” counter F10 key

To print cumulative label without deleting “n1” counter:

♦ Press Home key

♦ Screen will occur as on drawing 28

♦ Press ENTER key

Fig 37. View of screen by cumulative label printing without counters deleting

Cumulative label will be printed without “n1” counter deleting with simultaneous

incrementing of “n2” counter.

♦ Press F10 key

♦ Screen will occur as on drawing 29

♦ Press ENTER key

Cumulative label will be printed, counter “n1” will be deleted (zeroed) with

simultaneous incrementing of “n2” counter.

Fig 38. View of screen by cumulative label printing without counters deleting

53

Page 54

20.2. Printing of “cc” label”

“cc label” contains data from whole cycle of given assortment editing.

Execution of such label closes given cycle. This label is done e.g. to mark

pallet with given assortment . This label can be printed only for assortment for

which such “cc label” was defined.

There are three criteria to print “cc label”:

♦ After exceeding given quantity of cumulative labels (after exceeding

given state of “n2” counter)

♦ After exceeding given total mass of assortment

♦ Printing in any moment

- Without deleting „n1” and „n2” counters End key

- With deleting „n1” and „n2” counters F11 key

To print “cc label” without deleting states of “n1” and “n2” counters:

♦ Press End key

♦ Press ENTER key

„cc label” will be printed without deleting states of „n1” and „n2” counters.

Incrementing of “n2” counter does not take place.

♦ Press F11 key

♦ Press ENTER key

“cc label” will be printed counters “n1” and “n2” will be deleted (zeroed).

20.3. Initiating “cc label” by “n2” counter

Labelling software enables initiating cumulative label printout by means of

determined state of “n1” counter

♦ In „Operating settings” menu choose „z label” position

♦ Change value of parameter on COUNTER

♦ Move to weighing window

♦ Press INSERT key. Following screen will occur:

Fig.39 Screen of initiating thresholds setting

54

Page 55

1- Field to introduce any text (digits, letters) to be placed on the label

2- As position 1

3- As position 1

4- As position 1

5- State of counter after which cumulative label will be initiated

6- Value of total quantity of pieces after which cumulative label will be initiated

7- Value of labels counter after which cc label will be printed

8- Value of total quantity of pieces after which cc label will be printed

9- Initial value of n1 counter

♦ After setting N1 parameter confirm with ENTER key.

♦ Move to weighing window

After exceeding set state of “n1” counter cumulative label will be printed (n2

counter will be incremented, n1 counter and “sums” indicator will be zero ed).

20.4. Initiating “cc label” by “n2” counter

Balance enables “cc label” initiating by means of determined state of “n2”

counter

♦ In “Operating settings” choose “cc label” position

♦ Change value of parameter on COUNTER

♦ Move to weighing window

♦ Press INSERT key. Screen as on drawing 30 will occur.

♦ After setting N2 parameter confirm with ENTER.

♦ Move to weighing window

After exceeding set state of “n2” counter cc label is printed (counter n1, n2 and

“sums” indicator will be zeroed).

Initial setting of „n1” counter is possible. This counter will be incremented from

given value. When function of cumulative labels printout initiating and/or “cc

labels” by states on “n1” and “n2” counters remember about dependence

n1 < N1

In case when:

n1 > N1 after pressing PRINT key cumulative label will be printed, “n1” will be

zeroed and “n2” will be incremented

n1 – value displayed in II line

N1 – introduced value (after pressing INSERT key)

55

Page 56

20.5. Initiating “c label” and “cc label” by determined quantity of pieces

Balance enables initiating cumulative label and “cc label” by determined state

of “sums” indicator

♦ In „Operating settings” choose position „c label” (or cc label depending

on what is to be initiated)

♦ Change value of parameter on PIECES

♦ Move to weighing window

♦ Press INSERT key. Screen as on drawing 30 will occur

♦ After setting M1 parameter confirm with ENTER key. For “cc label” set

value of parameter on M2

♦ Move to weighing window

After exceeding set state of “sums” indicator “c label” will be printed (n1 counter

and “sums” indicator will be zeroed).

After exceeding total quantity of pieces determined by M2 parameter “cc label”

will be printed, n1 and n2 and “sums” indicator will be zeroed.

20.6. Labelling with checkweighing

To turn on the control:

♦ In “Operating settings” menu change value of parameter “Result control”

on YES.

♦ In assortments base enter to edition of chosen assortment

♦ Set parameters “min. pcs”, “max pcs”

Return to weighing window fig.40.

Fig.40. Screen weighing with result control

1- Control indicator (LO, OK, HI)

If quantity of counted detail contains in Min. pcs. – Max. pcs, set in given

assortment on the display indicator pos. 1 will change on “OK” and label

printing will be possible.

If indicator pos.1 has value “LO” or “HI” it is not possible to print labels.

56

Page 57

20.7. Automatic printout

Automatic printout enables labels printing without pressing PRINT key.

Automatic printout takes place when result is stable . Function works in all

labelling modes if all conditions for given operating mode are fulfilled (e.g. by

result control quantity of pieces must contain in given thresholds, result must

be stable).

To turn the automatic printout on:

♦ In “Operating Settings” menu choose “Aut. printout"

♦ Change value of parameter on YES

♦ Return to weighing mode

Further actions depend on currently chosen labelling mode.

Notice:

Parameter “Min. Pcs.”(„Operating settings” menu) is connected with automatic

printout. It is quantity of pieces below which mass indication must go by

weighing next batch of assortment (removing batch from the pan and placing

next batch). Automatic printout is possible when quantity of pieces is highe r

than “Min. pcs.” value. Parameter is independent from “result control”. If “min

pcs” is set on 0 automatic printout will not take place.

21. BARCODES

21.1. General description

Barcodes are the most popular form of automatic identification of articles. They

are used to describe documents and products to allow automatic loading data

to computers. Barcode scanners are used to interpret barcodes and send

information to external devices. For receiving overprints of barcodes are used

label printers. (e.g. CITIZEN, ZEBRA)

There are many barcode types with deferent information content. Barcodes are

graphical interpretation of information in dark and white strips of different width.

The main objective of using codes is speeding up and increasing faithfulness of

read information, which substituted manual entering of information.

The number of industries which adapt barcode technologies is continuously

growing. More and more firms build they automatic identification system on the

basis of barcode scanners.

57

Page 58

Scanning technology for barcodes reading:

• laser – longer scanning range (e.g. QS-6000+, Cubit)

• diode – durable, faster operation (e.g. Dioder, QS-2500)

21.2. EAN code

One of the most popular barcodes are EAN (European Article Numbering),

which were approved for common use in retail trade in 1976. American

equivalent is UPC.

EAN code types:

• EAN-13 (zawiera 12 cyfr danych i jedną cyfrę kontrolną)

• EAN-8 (7 cyfr danych i 1 cyfra kontrolna).

• EAN-128 (digital version of CODE 128)

First 3 digits signify a country (e.g. 590 - Poland), with the exception of codes

that starts with the digit 2 – this codes are used to mark articles if different

weight and dimensions especially packed in shops. EAN 13 is used together

with ISSN (International Standard Serial Number), for newspapers and

magazines. 3-digit country code is substituted by 977.

21.3. Other barcodes

• Code 39 – Alphanumerical barcode with variable length. It allows to us

43 different characters; each character comprises 9 elements (dark

and white strips).