Page 1

User manual

of PUE C/31 H/EX indicator

applicable in:

WPT……../EX,

WTC……./EX.

Manual number:

EXI-01-04-06-14-GB

BALANCES AND SCALES

RADWAG 26 – 600 Radom, Bracka 28, POLAND

Phone +48 48 38 48 800, phone/fax: +48 48 385 00 10

Sales department +48 48 366 80 06

www.radwag.com

Page 2

- 2 -

JUNE 2014

EXI-01-04-06-14-GB

Page 3

- 3 -

TABLE OF CONTENTS

1. DESIGN AND INTENDED USE .......................................................................................... 4

2. SECURITY REQ UIREMENTS............................................................................................. 6

2.1. ATEX marking – symbols meaning .............................................................................. 7

2.2. Rating plates for indicator and scale ............................................................................ 8

2.3. Placement of information stickers ................................................................................ 9

3. START-UP ........................................................................................................................ 10

3.1. Scale placing ............................................................................................................. 10

3.2. Connecting power supplier ........................................................................................ 11

3.3. Switching on .............................................................................................................. 14

4. CLEANING ....................................................................................................................... 14

5. SERVICE AND REPAIRING ............................................................................................. 14

6. FUNCTIONS ..................................................................................................................... 15

7. KEYBOARD ..................................................................................................................... 16

8. FUNCTINS OF KEYS ....................................................................................................... 16

9. INSCRIPTIO NS AND PICTOGRAMS ............................................................................... 17

10. USER MENU ................................................................................................................... 17

11. BROWSING USER’S MENU ........................................................................................... 18

11.1.Keypad…. ................................................................................................................ 18

11.2.Return to weighing .................................................................................................... 19

12. WEIGHING...................................................................................................................... 19

12.1.Tarring….. ................................................................................................................ 19

12.2.Tarring by inscribing tare value ................................................................................. 20

12.3.Zeroing…. ................................................................................................................ 21

12.4.Weighing for two range scales .................................................................................. 21

12.5.Setting of basic unit for weighing .............................................................................. 22

12.6.Temporary weighing unit .......................................................................................... 23

13. MAIN PARAMETERS ..................................................................................................... 24

13.1.Adjustment of filtering level ....................................................................................... 24

13.2.Autozero.. ................................................................................................................. 25

13.3.Tare function operation ............................................................................................. 26

13.4.Median filter .............................................................................................................. 27

13.5.Determining the minimal mass .................................................................................. 28

14. OPERATION MODES ..................................................................................................... 28

14.1.Enabling operating modes (functions) ....................................................................... 28

14.2.Determining number of accessible modes ................................................................ 29

14.3.Counting parts of identical weight ............................................................................. 30

14.4.+/- control referring to the inscribed standard mass .................................................. 33

14.5.Per cent deviation with reference to standard mass .................................................. 35

14.5.1.Mass standard weight determined by the measuring process ................................ 35

14.5.2.Standard mass inscribed to scale memory ............................................................. 36

14.6.Automatic tare .......................................................................................................... 37

14.7.Measurement of the max force – peak hold .............................................................. 38

14.8.Totalizing. ................................................................................................................. 38

14.8.1.Operation mode activation procedure .................................................................... 38

14.8.2.Totalizing procedure .............................................................................................. 39

14.8.3.Storing the last sum of weighings .......................................................................... 40

15. ADJUSTMENT ................................................................................................................ 41

15.1.Adjustment procedure .............................................................................................. 41

15.2.Start mass estimation ............................................................................................... 43

16. ERRORS ......................................................................................................................... 45

17. RESPECTIVE STANDARDS .......................................................................................... 45

EXI-01-04-06-14-GB

Page 4

- 4 -

1. DESIGN AND INTENDED USE

Indicator of PUE C/31H/EX type, in cooperation w ith a weighi ng platf orm , is

intended for fast and precise meas urements performed i n explosive areas .

Tarring throughout the who le measuring range allo ws to determine the net

mass of measured loads.

The PUE C/31H/EX series indicator consists of:

• Main PCB (scale)

• Stainless steel housing

• Power supply connector

• Input cable gland (from weighing platform)

• Functional grounding clamp

• Overlay

• Indicator holder

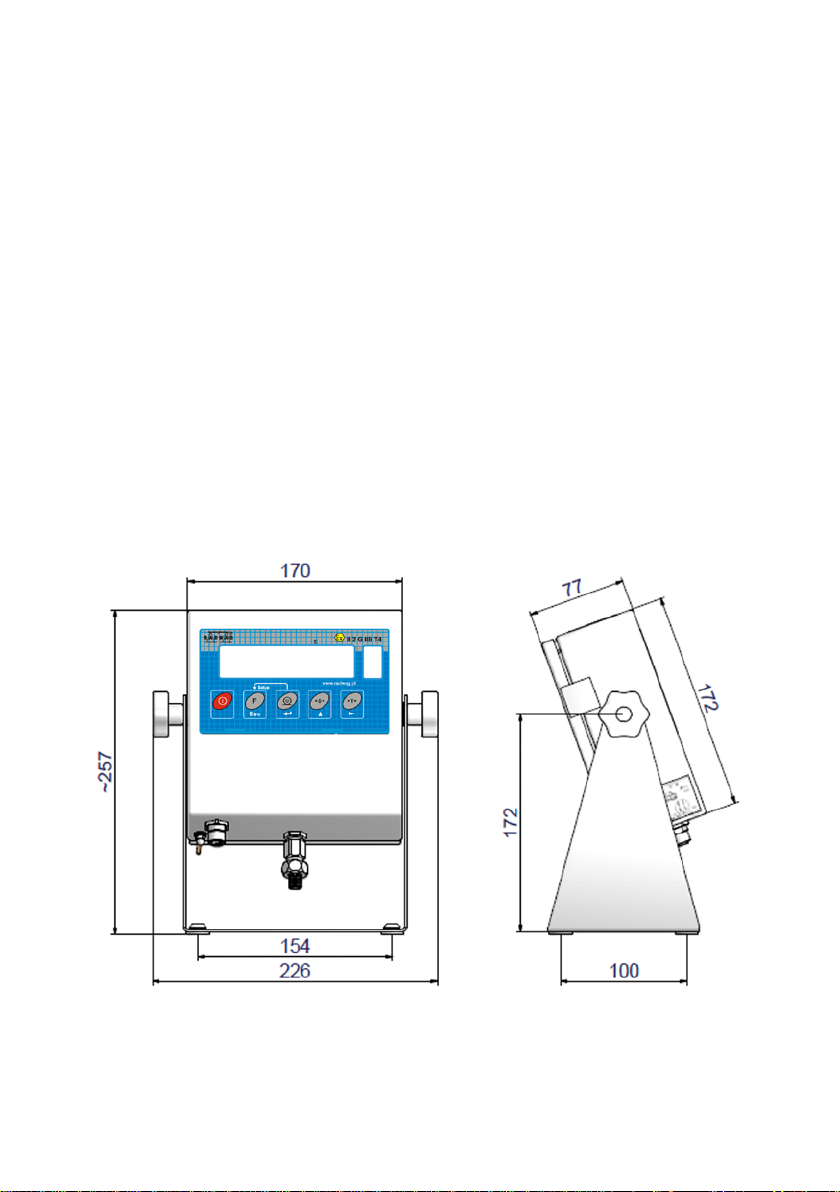

View - dimensions

Dimensions of PUE C/31H/EX indicator.

EXI-01-04-06-14-GB

Page 5

- 5 -

PUE C/31H/EX

o

o

125 Ω

1200 Ω

I/O marking +5V, E, AGND, REF+, REF-, +IN, -IN

Parameters identical for each clamp

KDB 06ATEX250

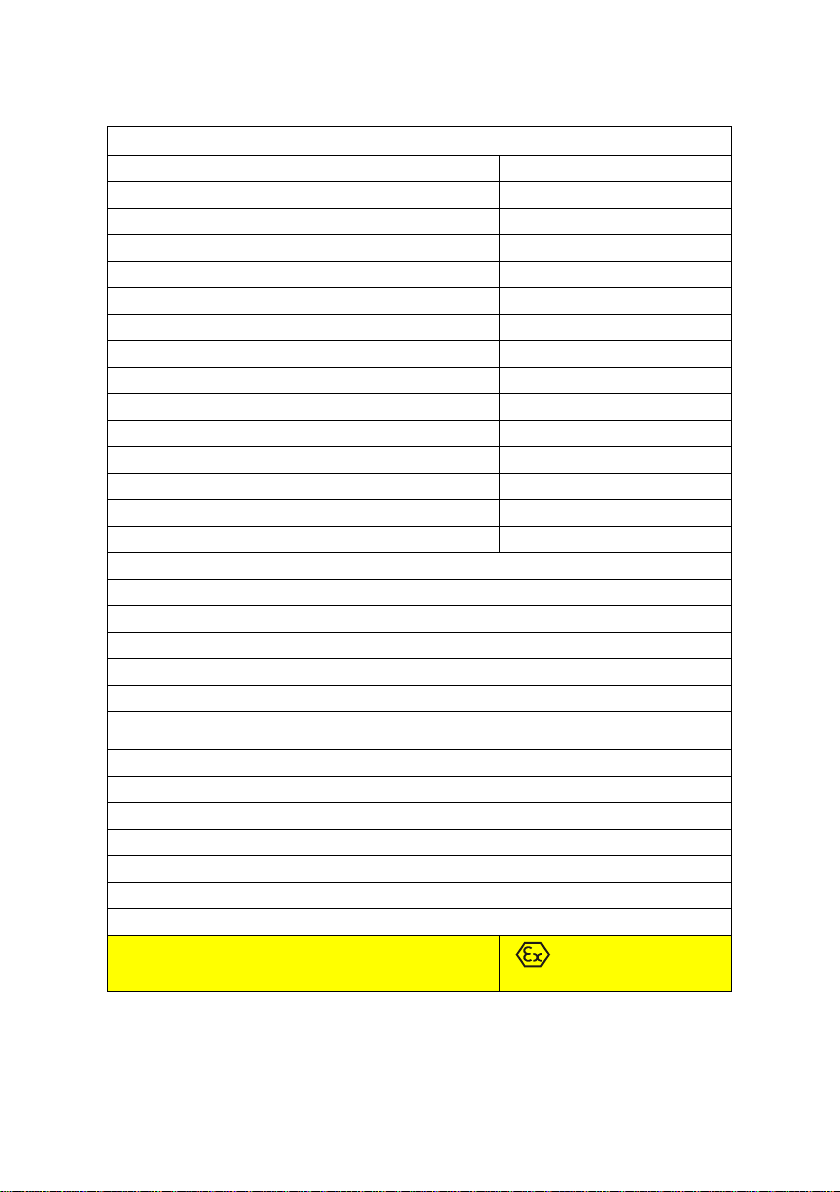

PUE C/31H/EX technical data:

Housing type stainless steel

Ingress Protection Rating IP66/67

Display type LCD

Keyboard Microswitch (500 000 cycles)

OIML class III

Maximum quantity of A/D converter divisions 8388608

Number of verification intervals 6 000

Maximum input voltage 19,5 mV

Maximum voltage per verification interval

Minimum voltage per verification interval

Ambient temperature -10

Minimum load cell impedance

Maximum load cell impedance

Connection of load cell 4 or 6 cables + shield

Number of ranges 1 or 2 ranges

Power supply - DC IN connector pin 1(4) pin 2(3)

Ui=9V

Ii=0,24A

Pi=0,6W

Ci≈0

Li≈0

3,25 µV

1 µV

C ≤ ta ≤ 40

C

DESIGNATION

EXI-01-04-06-14-GB

Uo=7,14V

Po=0,52W

Io=0,24A

Li≈0

Ci=6uF

Lo=40uH

Co=10nF

II 2G Ex ib IIC T 4

Page 6

- 6 -

2. SECURITY REQUIREMENTS

Please read this manual carefully prior the first usage. Following the

instruction, use the device as intended;

PUE C/31H/EX indicator, and scales with design based on the indicator,

can be used in explosive z one 1 and 2 where ther e is a mixtures of gases,

vapours and mists of II (second) explosion group and T1, T2, T3 or T4

temperature class.

WPT………/EX and W T C………/EX s cales, b ecaus e of the constr uction of

non-electric part of the platf orm and used materials, can be operated in 1

and 2 zone where t here are mixtures of gases , vapours and mists of IIA,

IIB, or IIC group – according to „Technical Documentation” of the scale.

Anti-explosive safety of the PUE C/31H/EX indicator, and of scales

with design based on the indicator is assured by:

• Power supplied from the ZRi02 power supplier II (2) G [Ex

ib] IIC KDB 06ATEX251 manufactured b y RADWAG, placed

behind the hazardous area or from another adapter with

appropriate parameters of intrinsically safe electrical circuit.

• Intrinsically safe design of PUE C/31H/EX indicator complying

with:

EN 60079-0 and EN 60079-11 standards, confirmed by

KDB 06ATEX250 certificate

• Using load cells certified for conformity with ATEX directive (on

anti-explosion safety)

• Making non-electric parts pf the scale in compliance with EN

13463-1 standard

• Observing recommendations in this manual by users

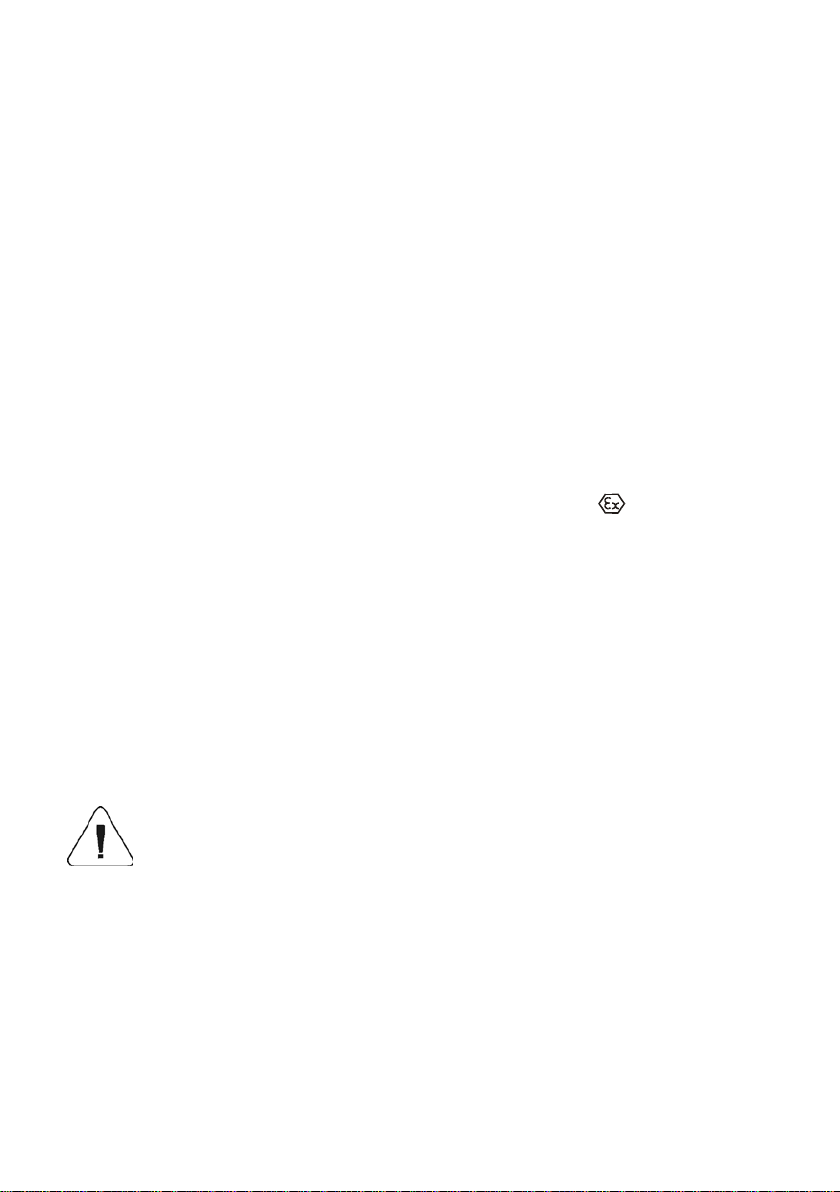

- marking of paragraphs crucial for anti-explosion safety

EXI-01-04-06-14-GB

Page 7

- 7 -

Electrical equipment -

Explosive atmosphere:

Symbol of the

Gas explosiveness group -

Temperature class –

Equipment group:

Categories for group II

zone 2

Security level

2.1. ATEX m ar ki ng – symbols meaning

I – underground parts

of mines

II – all other places liable

to be endangered by

explosive atmospheres

equipment:

1 - the device assures a

very high protection

level,

- to be operated in

zones 0,1,2

2 - the device assures a

high protection level,

- to be operated in

zones 1,2

3 - the device assures a

standard protection

level,

- to be operated in

G – caused by gas,

vapor and mist.

D – caused by dust.

compatible with one or

few kinds of antiexplosion designs

used anti-explosion

design type

o – oil protection

p – gas protection with an

excess pressure

q – sand protection

d – flame-proof protection

e – strengthened design

intrinsically safe design

ia -

for operation in zone

0,1,2,

ib -

intrinsically safe design

for operation in zone 1,2,

examples:

-IIA: propane (T1)

-IIB: ethylene (T2)

-IIC: acetylene (T2)

:

benzene (T3)

butane (T2)

ethanol (T2)

hydrogen (T1)

surface max temperature

of the equipment parts that

are in touch with explosive

:

mixture

T1: 450

T2: 300

T3: 200

T4: 135

T5: 100

T6: 85

Temperature class

of the gas or vapor

auto ignition

T1: > 450

T2: > 300

T3: > 200

T4: > 135

T5: > 100

T6: > 85

Gas atmosphere:

- Ga

- Gb

- Gc

Dust atmosphere:

- Da

- Db

- Dc

0

C

0

C

0

C

0

C

0

C

0

C

:

0

C

0

C

0

C

0

C

0

C

0

C

EXI-01-04-06-14-GB

Page 8

- 8 -

PUE C/31H/EX indicator is a device of group II with „ ib ” pr otec tio n theref or e

“Gb” protection symbol may be omitted.

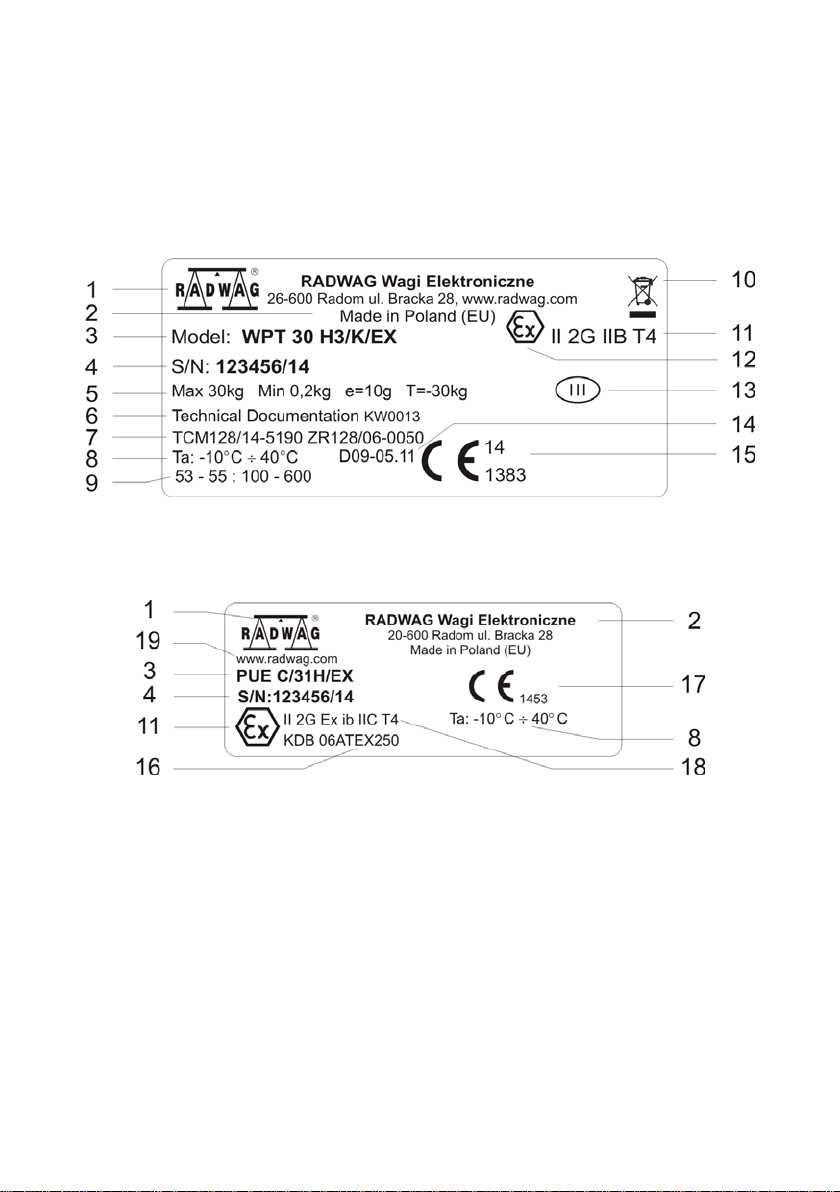

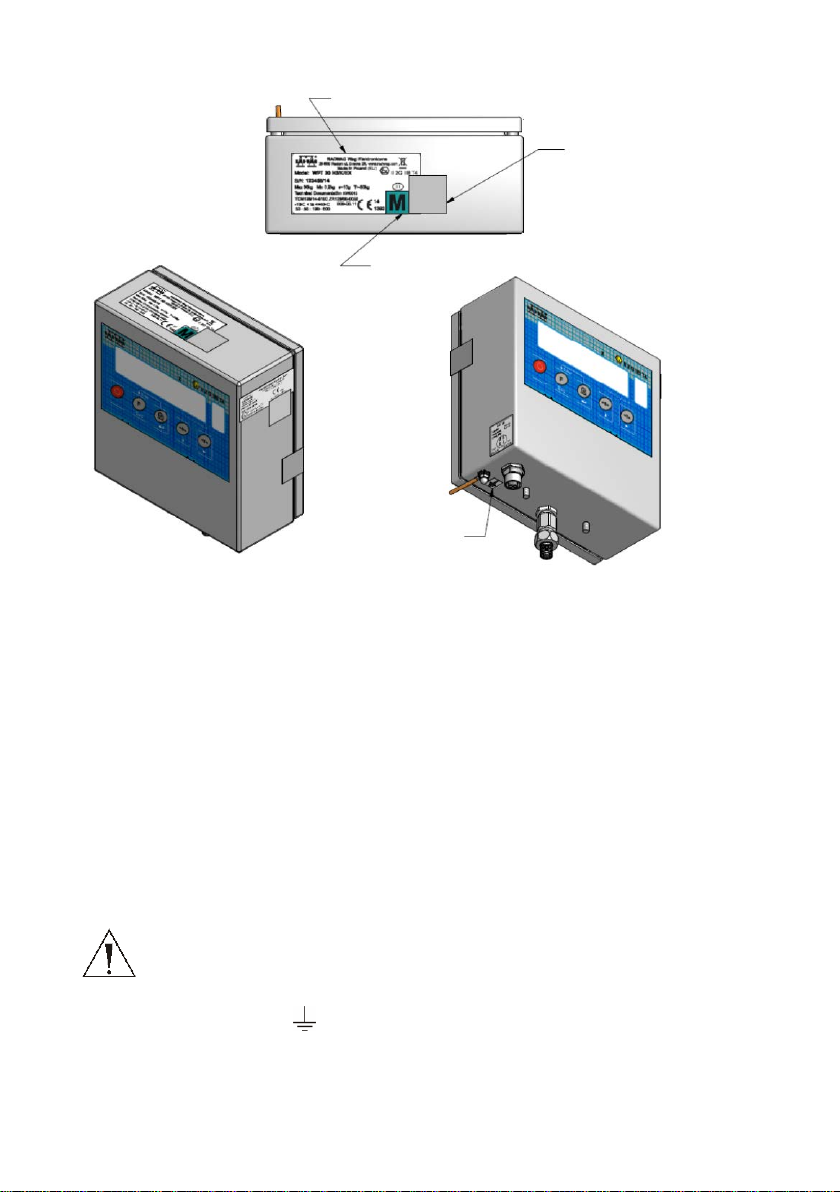

2.2. Rating plates for indicator and scales

Rating plate of the scale (exemplary)

Rating plate of the PUE C/31H/EX indicator

1 – Manufacturer’s Logo

2 – Name and phone number of the manufacturer

3 – Scale type, indicator type

4 – Factory number

5 – Metrological parameters of the scale

6 – Technical Documentation number

7 – Type approval certificate number (for verified scales)

8 – Ambient temperature

9 – geographical zone, ie. latitude and long itu de data and the hei ght abo v e

the level – only verified scales

EXI-01-04-06-14-GB

Page 9

- 9 -

Protective stickers

Rating plate of the PUE

C/31H/EX indicator

Protective sticker

Power supply marking

Overlay with

ATEX marking

10 – WEEE symbol

11 – ATEX marking relating to the scale (see point 2.1)

12 – EX marking stating that the device is intended for operation in

explosive areas

13 – accuracy class marking

14 – certificate number of used load cell

15 – CE marking with two last digits of the year of production and with a

number of notified body for NAWI directives

16 – ATEX certificate number relating to an indicat or

17 – CE marking with the number of a notified body supervising EX device

production

18 – ATEX marking relating to the indicator (see point 2.1)

19 – manufacturer website address

2.3. Placement of information stickers

EXI-01-04-06-14-GB

Page 10

- 10 -

Functional

grounding mark

Protective sticker

Verification sticker

Rating plate of the scale

3. START-UP

Please read this manual carefully prior the start-up. Following the

instruction, use the device as intended.

3.1. Scale placing

• The scale should be unpacked outside the hazardous area.

• Before moving the scale to the place of operation prepare a cable

for earthing the device against electrostatic charges.

NOTICE!!

In order to protect the indicator against gathering electrostatic

charge it is necessary to earth/zero its housing.

Connect the earthing lead/wire to cable connection points

marked with „

• Situate scales and an indicat or in hazardous area and connect

earthing/zeroing.

EXI-01-04-06-14-GB

” . See the manual for details about ea rthing.

Page 11

- 11 -

NOTICE!

Intrinsicaly safe circuit parameters for power supplier used

for PUE C31H/EX indicator

Uo

8,61

V

Io

0,24

A

Po

0,52

W

Um

255

V

Lo

200

uH

Co

5,7

uF

Li

≈0

uH

Ci

≈0

uF

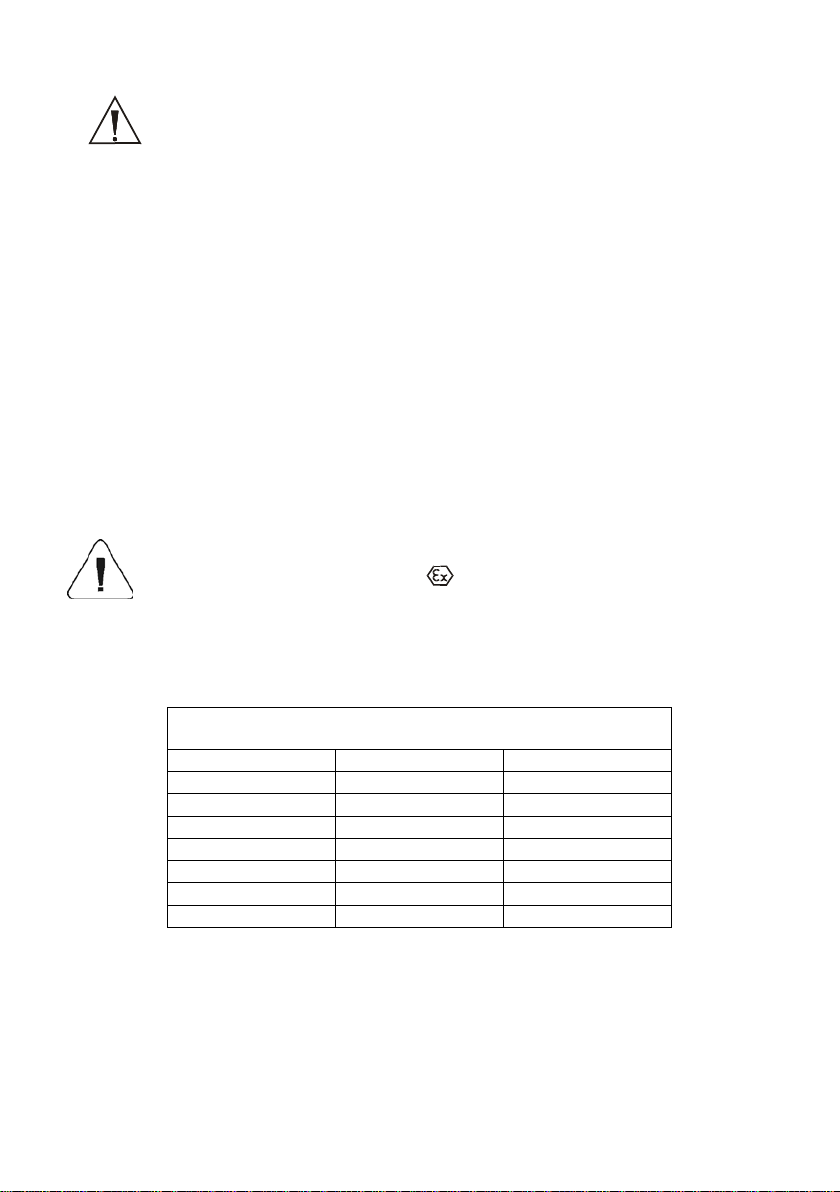

Mounting the indicator, placing the weighing platform and

earthing/zeroing should be performed when the explosive

atmosphere cannot appear.

Indicators with cable can be mounted on the rack, on the wall or on

the table using a special mounting kit.

Weighing platform should be placed on even and stable ground far

from sources of hit and draughts. It should be also levelled out

using the feet.

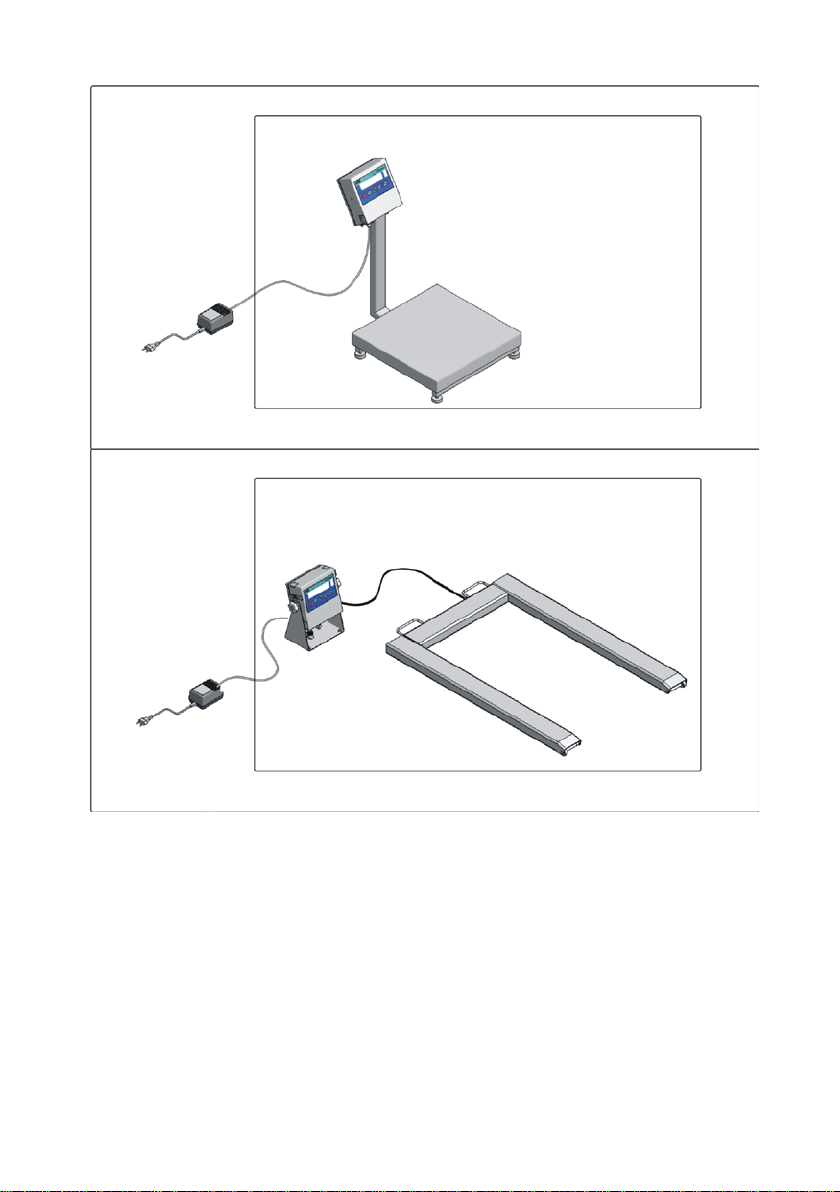

3.2. Connecting power supplier

1. Place the power supplier outside the hazardous area.

2. Connect the plug that terminates the supply cable (up to 20m) to

the socket marked as DC IN.

3. Connect the supplier to mains (230V AC).

4. In case of not using the scale unplug it from the mains.

NOTICE!

Scales with PUE C/31H/EX indicators can be supplie d o n ly

from ZRi02 power suppliers

II (2) G [Ex ib] IIC KDB

06ATEX251 of RADWAG production, placed outside the

hazardous area, or from another supplier characterized by

below presented parameters of intrinsically safe electrical

circuit.

EXI-01-04-06-14-GB

Page 12

- 12 -

Safe area

Hazardous area EX

AC 230v 50Hz

Safe area

Hazardous area EX

AC 230v 50Hz

ZRi02 power

ZRi02 power

Scale with the indicator on a cable

Scale with the indicator on a pillar

supplier

cable up to 20m

supplier

cable up to 20m

Supplier connection

EXI-01-04-06-14-GB

Page 13

- 13 -

1 – earthing terminal

2 – power supply socket description

3 – power supply socket

4 – power supply socket

5 – screened load cell cable

Power connector parameters

EXI-01-04-06-14-GB

Page 14

- 14 -

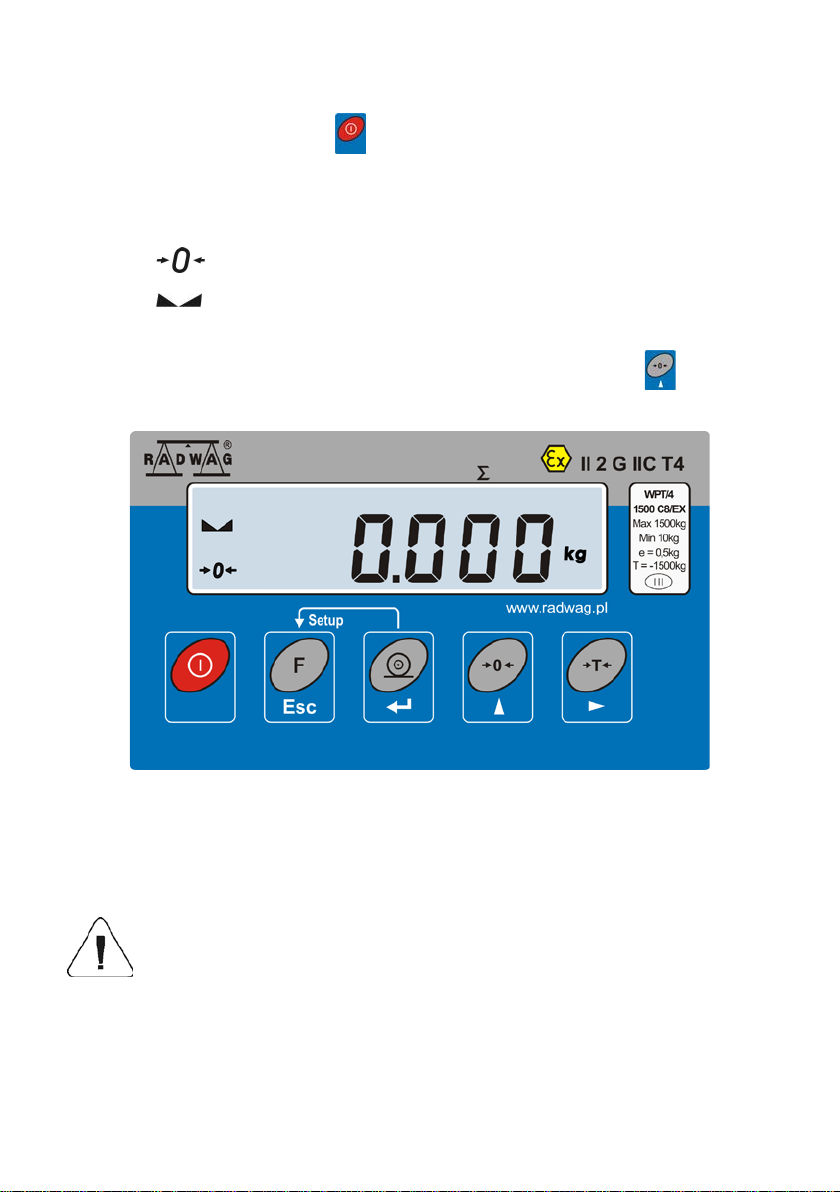

3.3. Switching on

• Press the ON/OFF key – keep pressing for about 1 sec.

• After switching on, wait for the test completion.

• The indication shall equal zero and the following pictograms shall be

seen:

- zero indication

- equilibrium

kg - weighing mode

• If the indication does not equal zero press the zeroi ng key

.

Ready to use.

4. CLEANING

Cleaning can be performed only after unplugging from mains (230V AC). Use agents and

materials that do not cause gathering electrostatic charges on elements of the scale!

Do not use abrasive agents and solvents because

it can cause damage of the casing.

Cleaning should be performed when the appearance of explosive

gases is impossible

5. SERVICE AND REPAIRING

EXI-01-04-06-14-GB

Page 15

- 15 -

In case of any problems with appropriate operation of the indicator, contact

the manufacturer’s service centre or any service centre authorised by

RADWAG.

In case of any fault or dysfunction the device should be passed to the

manufacturer’s s ervice centre or, if this is not possible, the fault should be

reported in order to settle the conditions of repair.

Any intrusion (alteration, repair etc.) in the indicator or scale

based on PUE C/31H/EX indicator, by unauthorised persons

will cause a forfeiture of validity of certificates, declarations

and manufacturer’s warranty.

6. FUNCTIONS

• Filtering

• Autozero

• Minimal mass

• Counting pieces

• +/- control

• Deviation in per cents

• Peak hold

• Automatic tare

• Tare memory

• Manual tare inscription

• User’s calibration

• Totalizing

It is possible to disable selected functions thus making the scales adjusted

to one’s own needs. Access may be permitted to some particular functions

only if required. The user menu allows enabling/disabling a given

parameter, see the further part of the manual.

EXI-01-04-06-14-GB

Page 16

- 16 -

Information window

Display window

Function keys – „keypad”

7. KEYBOARD

8. FUNCTINS OF KEYS

NOTICE:

Pressing

wherein the change is valid until setting parameters procedure is

completed. See the further part of the manual for details.

EXI-01-04-06-14-GB

Power on/off – keep it pressed for about 1 sec

Function key (selection of operation mode)

Confirmation of changes

- zeroing

- tarring

and k eys results in change of particular keys functions,

Page 17

- 17 -

FIL

PCS

HiLo

PCS

kg (g)

Net

P1 rEAd

P 1.1 Fil

| 2 P 1.2 Auto

|

YES

P 1.3 tArA

|

no

P 1.4 Fnnd

|

no

P2 Prnt

P2.2 S_Lo

|

9. INSCRIPTIONS AND PICTOGRAMS

O.n. Inscription Description

1.

2.

3.

4. Auto

5. toP

6. Add

7.

8.

9.

10.

11.

12. Min

13. OK.

14. Max

Filtering level

Parts counting

+/- control in relation to reference mass

Control and correction of zero indication of scal e

Measurement of max. force influencing weighing pan

Totalizing

Scale in autozero range (indication = precise zero)

Result of measurement is stable (ready for readout)

Scale in operating mode counting pieces

Scale in operating mode weighing

Scale is tarred.

+/- control in relation to reference mass – setting lower

threshold or mass below first range

+/- control in relation to reference mass: mass of load

between set threshold

+/- control in relation to reference mass – setting upper

threshold or mass above upper threshold.

10. USER MENU

The menu is divided into 5 basic groups. Each group has its individual

name starting with the capital letter P.

EXI-01-04-06-14-GB

Page 18

- 18 -

P3 Unit

P3.1 StUn

|

kg

P4 Func

P4.1 FFun

|

ALL

P4.2 Funi

|

no

P4.3 PcS

|

no

P4.4 HiLo

|

no

P4.5 PrcA

|

no

P4.6 Prcb

|

no

P4.7 AtAr

|

no

P4.8 toP

|

no

P4.9 Add

|

no

P6 CAL

P6.1 St_u

|

* FUNCTION *

P6.2 uCAL

|

* FUNCTION *

11. BROWSING USER’S MENU

User moves in the menu using the scale keyboard.

11.1. Keypad

EXI-01-04-06-14-GB

+

entering the main menu

inscribing tare value

+

selecting parameter of a given menu level

or changing the active parameter value

entering selected submenu or activation of

a parameter for modification

change confirmation

leaving a function without changes or

moving one level higher in the m enu

Page 19

- 19 -

11.2. Re tu rn to weighing

NOTICE:

Changes introduced into the scale memory will be permanently

saved after return to weighing.

Press F key

several times, keep pressing until message

<SAvE?> is seen.

Return to weighing

Upon noticing the message press: key – for changes confirmation or

key – for resigning. After completion of this procedure the scale returns

to weighing.

12. WEIGHING

Place a load on a weighing pan. After noticing stability

pictogram,

12.1. Tarring

In order to determ ine a net mass , deposit a package of load on a pan and

, read the weighing result.

wait for the indication to b e stable, next press TARE key -

(indication

goes back to zero, Net symbol is displayed on the left side of the display).

After depositing a load on a pan, the display indicates net mass. Tarring

can be done repeatedly in full weighing range of the scale. When using tare

EXI-01-04-06-14-GB

Page 20

- 20 -

Select the digit value

Select the digit to be set

function pay attention to maximum weighing range, it cannot be exceeded.

After removing the load and the package, display shows indication of sum

of tarred weights with minus sign.

NOTICE:

Tarring may not be performed when minus value or zero is displayed. In

such a case the display shows <Err3> message, short sound signal is

heard.

12.2. Tarring by inscribing tare value

It is possible to inscribe a tare value.

Procedure:

• Press simultaneously

and keys

• On the display you will see:

– select the digit to be set

– select the digit value

• Using

• Press

• The scale returns to the weighing mode and the value of tare is

displayed with the “–“ sign,

• Tare value can be inscribed any time in weighing mode.

and keys set tare value,

,

EXI-01-04-06-14-GB

Page 21

- 21 -

NOTICE:

Tarring by inscribing tare value cannot be performed when the tare value

has already been implemented into the scale memory. In such a case the

display shows <Err3> message, short sound signal is heard.

12.3. Zeroing

In order to zero the indic ation press zeroing k ey - . Zero value is shown

on a display next to symbols:

and .

The new zero point is treated b y the scale as the precise zero. Zeroing is

possible while stable status is shown on the display.

NOTICE:

Display status zeroing is possible only in range up to ±2% of maximum

scale capacity. If zeroed value is bigger than ±2% of maximum capacity,

display shows Err 2 message, short sound signal is heard.

12.4. Weighing for two range scales

Switching from the I range to the II range is carried out automatically after

exceeding the switching point value (Max of the I range).

Weighing in the II ra nge is s igna lled by a pictogram, located in the upper

left-hand corner of a display.

After unloading, the scale returns to zero. Weighing in the II range takes

place until unloading the pan.

II range weighing automatically turns to I range weighing after taking the

load off the weighing pan when the scale returns to AUTOZERO zone – the

pictogram is seen.

EXI-01-04-06-14-GB

Page 22

- 22 -

12.5. Setting a basic weighing unit

The user may set a weighing unit to be active after turning on the scales.

Procedure:

• Following point 11 of this manual enter <P3.Unit> submenu, next:

• Press key several times to view available units:

Selection:

A. When the basic unit is set to [kg], users can toggle between: [kg, lb,

N]. For verified scales [lb] is not accessible.

B. When the basic unit is set to [g], users can toggle between: [g, ct].

For verified scales [lb] is not accessible.

• Upon unit selection press

following win do w :

key, wait for the scales to return to the

EXI-01-04-06-14-GB

Page 23

- 23 -

Save changes and return to weighing:

See point - 11.2. – return to weighing.

NOTICE:

Upon activation the scale operates with a set basic unit.

12.6. Temporary weighing unit

This function allows users to choose unit for indication.

The unit is valid until the scale is switched off or until another unit is

chosen.

In order to perform the following procedure, operation mode <P4.2.Funi>

must be accessible, see point 14.1.1 – Enabling operating modes.

Procedure:

• Press F key

, next:

• Confirm selection of a given unit and wait for the scale to return to

weighing.

Selection:

A. When the basic unit is set to [kg], users can toggle between: [kg, lb

– not accessible for verified scales, N].

B. When the basic unit is set to [g], users can toggle between: [g, ct,

lb – not accessible for verified scales].

EXI-01-04-06-14-GB

Page 24

- 24 -

13. M AIN PARAMETERS

User can adjust the scale to external ambient conditions (setting filters) or

individual requirements (autozero, tare value). Respective parameters can

be found in <P1.rEAd> parameters group.

13.1. Adjustment of filtering level Procedure:

• Following point 11 of this manual enter <P1.rEAd> submenu, next:

1 - 4 - filtering levels to be selected (depending on the ambient

conditions)

Return to weighing:

See point - 11.2. – return to weighing.

NOTICE:

The higher filtering level the longer stabilisation time.

EXI-01-04-06-14-GB

Page 25

- 25 -

13.2. Autozero

„AUTOZERO” function has been introduced in order to ensure precise

indication. The intended use of this function is automatic control and

correction of zero indication.

When function is active comparison of results takes place at specified time

intervals. If results differ by value smaller than declared AUTOZERO range,

e.g. one division, scale is zeroed aut omatically, stable state is marked –

and zero indication – is displayed.

When AUTOZERO function is enabled, each result starts from precise

zero. However there are some cases when this function can disturb

measurement, e.g. very slow process of load depositing on the pan (load

pouring). In such case, correction system for zero indication can also

correct indication of real mass of load.

Procedure:

• Following point 11 of this manual enter <P1.rEAd> submenu, next:

AUTO no - autozero disabled

AUTO YES - autozero enabled

Return to weighing:

See point - 11.2. – return to weighing.

EXI-01-04-06-14-GB

Page 26

- 26 -

tArA

AtAr

-

automatic tare function on - stored in scale memory

tArA

no

-

automatic tare function off (scale tarring by means of

tArA

tArF

-

tare memory function – stores last value of tare in

13.3. Tare fu n ction operation

This function enables the user to set appropriate parameters (depending on

needs) for tare function.

Procedure:

• Following point 11 of this manual enter <P1.rEAd> submenu, next:

after unplugging it from mains (see point 15.5 for

description);

T key )

scale memory. It is automatically displayed after

starting the scale.

Return to weighing:

EXI-01-04-06-14-GB

See point - 11.2. – return to weighing.

Page 27

- 27 -

13.4. Median filter

The role of the median filter is to eliminate short lasting interference (e.g.

mechanical shocks).

Procedure:

• Following point 11 of this manual enter <P1.rEAd> submenu, next:

Fnnd no - median filter disabled

Fnnd YES - median filter enabled

Return to weighing:

See point - 11.2. – return to weighing.

EXI-01-04-06-14-GB

Page 28

- 28 -

Select the digit to be set

Select the digit value

13.5. De termining the minimal load S_Lo parameter works for automatic tare.

The rule is that no automatic tare is performed until the indication drops

below S_Lo value (gross).

Procedure:

• Following point 11 of this manual enter <P2.Prnt> submenu, next:

Return to weighing:

See point - 11.2. – return to weighing.

14. OPERATION MODES

14.1. En abling operating modes (functions)

In this group of parameters users declare functions they want to use after

pressing F key -

Procedure:

• Following point 11 of this manual enter <P4.Func> submenu, next:

EXI-01-04-06-14-GB

while in weighing mode.

Page 29

- 29 -

no - mode disabled

YES - mode enabled

NOTICE:

Enabling procedure for other operation modes is analogous to the one

described above.

Return to weighing:

See point - 11.2. – return to weighing.

14.2. Determining number of accessible modes

The user may decide whether upon pressing F key

modes are to be accessible (option <ALL>), or only one, selected out of

the list.

Procedure:

• Following point 11 of this manual enter <P4.Func> submenu, next:

all the operation

EXI-01-04-06-14-GB

Page 30

- 30 -

Return to weighing:

See point - 11.2. – return to weighing.

14.3. Counting parts of identical weight

The standard solution is equipped with option of counting small pieces of

the same mass. If parts counting is to be performed in a container, its

weight must be recorded into the scale memory (the container must be

tarred).

NOTICE:

1. Counting pieces mode does not operate with other functions,

2. Parts counting function is not active after scale’s restart.

Procedure:

• Enter <PcS> submenu (first make the operation mode accessible -

see point 14.1):

EXI-01-04-06-14-GB

Page 31

- 31 -

• The blinking value on the display informs of quantity of a sample. By

means of

key, set quantity of a sample and press key to

confirm:

• If option <LASt> has been chosen than the most recent weight value

of a single piece is displayed for 3 sec., the program proceeds to

Parts Counting mode automatically setting the previously displayed

value.

• If option <FrEE> has been chosen, the program displays the following

window:

EXI-01-04-06-14-GB

Page 32

- 32 -

Pilsujący symbol

Blinking symbol

• Using and keys, enter the demanded quantity of sample,

where:

- selection of the digit to be set, - selection of the digit

value,

• Press

key for confirmation,

• <LoAd> message is displayed, the following window is seen:

• If pieces are to be weighed in a container, it is necessary to tare it,

next declared number of pieces must be put onto the weighing pan,

their mass confirmed after stabilization of the indication (symbol

on a display):

• The program automatically calculates weight of a single element and

proceeds to the Parts Counting mode displaying number of weighed

elements (pcs):

NOTICE:

1. If the user presses the

pan, the message -Lo- is indicated for a few seconds and the scale

automatically returns to weighing.

2. In order to obtain reliable results, it is recommended to load the

weighing pan with elements, mass of which is greater than 5 reading

units.

EXI-01-04-06-14-GB

key when there are no elements on the

Page 33

- 33 -

Select the digit to be set

Select the digit value

3. If a single element weight is not greater than a reading unit, then

message <Err5> is shown on the scale display (see point 19. Error

Messages), short sound signal is heard, next the scale returns to

weighing.

Function deactivation:

Press F key

twice.

14.4. +/- control referring to the inscribed standard mass The program allows entering checkweighing threshold values (Min, Max.

Procedure:

• Enter <HiLo> function (first make the operation mode accessible -

see point 14.1):

• The program proceeds to window for setting the lower threshold (Min):

EXI-01-04-06-14-GB

Page 34

- 34 -

load mass below the I threshold

load mass between the

load mass above the II threshold

Select the digit to be set

Select the digit value

• Press key to confirm, the program proceeds to window for setting

the upper threshold (Max):

• Press

key to confirm, the program automatically returns to

weighing with threshold values recorded into the memory.

• During setting the threshold values the following cases take place:

thresholds

NOTICE:

If a user erroneously enters a value of the lower threshold higher than the

upper one, the scale indicates an error message and returns to weighing.

Function deactivation:

Press F key

twice.

EXI-01-04-06-14-GB

Page 35

- 35 -

Blinking symbol

14.5. Per cent deviation with reference to standard mass

This program allows to meas ure deviation in per cent with reference to a

standard mass. The standard mass can be estimated by weighing (PrcA

function) or inscribed by a user (PrcB function).

14.5.1. Mass standard weight determined by the measuring process Procedure:

• Enter <PrcA> function (first make the operation mode accessible -

see point 14.1):

• Message <LoAd> is displayed, the following window is seen:

• On a weighing pan place the load, mass of which is to be taken as a

• The scale display shows indication 100,000%,

• From this moment display will indicate weight deviation of load placed

EXI-01-04-06-14-GB

standard, upon stabilization of the indication (symbol

press

key for confirmation,

displayed)

on a pan, wherein the said deviation is referred to the mass of

standard (in %):

Page 36

- 36 -

Blinking symbol

Function deactivation:

Press F key

14.5.2. Standard mass inscribed to scale memory Procedure:

• Enter <Prcb> function (first make the operation mode accessible -

see point 14.1):

• The program proceeds to the following window:

twice.

• Using and keys, set the mass standard weight,

• Press

• The scale display will show indication 0,000%,

• From this moment display will indicate weight deviation of load placed

EXI-01-04-06-14-GB

where:

- selection of the digit to be set, - selection of the digit

value

key for confirmation,

on a pan, wherein the said deviation is referred to the mass of

standard (in %).

Page 37

- 37 -

Function deactivation:

Press F key

twice.

14.6. Automatic tare

This function is useful for fast net mass determination of weighed load

when the tare value for each next load to be weighed is different. In case

when the function is active the cycle of scales operation looks as follows:

• press zeroing key when the pan is empty,

• place the container for pieces,

• when indication is stable, automatic tarring of the container mass

gets started (Net marker appears in the upper part of the display),

• place a sample in the container,

• display indicates net mass of a sample,

• remove the sample together with the container,

• scale displays zero indication (zeroing),

• place a container for the next sample. When indication is stable

automatic tarring gets started (Net marker appears in the upper part of

the display),

• place next sample in the container.

Activation procedure:

Function deactivation:

Press F key

EXI-01-04-06-14-GB

twice.

Page 38

- 38 -

14.7. Measurement of the max force – peak hold Procedure:

• Enter <toP> function (first make the operation mode accessible - see

point 14.1):

• Max pictogram visible in upper part of the display is a confirmation of

toP function activation:

• Apply a force to the weighing pan. The display of scale

will latch the maximum value of the force.

• Remove loads from the pan.

• Before next measurement press

.

Function deactivation:

Press F key

twice.

14.8. Totalizing

The program enables totalizing the mass of weighed loads and the

totalized mass printout (for EX scales the printout is disabled).

14.8.1. Operation mode activation procedure

EXI-01-04-06-14-GB

Page 39

- 39 -

• Enter <Add> function (first make the operation mode accessible - see

point 14.1)

• „P” letter visible on the left of the display is a confirmation of <Add>

function activation:

14.8.2. Totalizing procedure

• Following point 14.8.1 enter <Add> function,

• Place the first load on a weighing pan. If the load is to be weighed in a

container, it is necessary to tare it before putting the first load into it,

its mass must be confirmed by pressing

the indication (symbol

on a display),

• Sum of weighings is displayed („▲” pictogram in the upper right-hand

corner of the display).

key after stabilization of

• Take off the load , the scale indication returns to ZERO, letter „P”

appears on the left,

• Place next load on the pan,

EXI-01-04-06-14-GB

Page 40

- 40 -

• Upon indication stabilization press key, sum of the first and

second weighing is displayed („▲” pictogram in the upper right-hand

corner of the display):

• In order to finish the procedure of totalizing, press

(either with a

load on the pan or after taking it off):

• If the

key is pressed again while load is being placed on a

weighing pan, the sum of previously performed measurements is

deleted, <unLoAd> message is displayed - unload the pan to return to

ZERO . Letter „P” will appear. The scale is ready for the next totalizing

procedure.

• If the

key is pressed again while load is not being placed on a

weighing pan, the sum of previously performed measurements is

deleted, the scale is ready for the next totalizing procedure.

14.8.3. Storing the last sum of weighings

After interrupting the procedure of totalizing (e.g. turning off the scale) it is

possible to restart with the last sum of weighings. In order to do it:

• enter <Add> function (see point 14.8.1),

• last sum of weighings is seen on the display, the displayed value

comes from the scale memory,

• press

key in order to continue totalizing, the indication returns to

ZERO and the letter „P” appears on the display; next load may be

placed on the scale.

• press

, or key in order to finish totalizing, the letter „P”

appears on the display; the scale is ready for the next totalizing

procedure.

EXI-01-04-06-14-GB

Page 41

- 41 -

NOTICE:

In case of a display range overflow in totalizing, the program displays error

<5-FULL>. The user must either take the load off the pan and press

key in order to complete totalizing or replace the load with ano ther one (of

lower mass) not resulting in display range overflow.

Function deactivation:

Press F key

twice.

15. ADJUSTMENT

Only for verified scales

In order to ensure perfect weighing accuracy it is required to introduce into

the scale memory a factor correcting the indications – it is so called

adjustment. Adjustment should be performed when the user starts weighing

or when dynamic change of temperature occurs. Before starting the

procedure, loads should be removed from the pan.

15.1. Adjustment procedure Procedure:

• Following point 11 of this manual enter <P6.CAL> submenu, next:

EXI-01-04-06-14-GB

Page 42

- 42 -

• The following messages are displayed:

• A new start mass is adjusted during this period of time. After that a

mass of calibration weight is shown (e.g. 3 000kg).

• Put the calibration weight on the weighing pan and press key,

adjustment process starts, the following message is seen:

• The <unLoAd> message informs about adjustment process

completion:

EXI-01-04-06-14-GB

Page 43

- 43 -

• Take off the load, message <donE> is displayed for 1 sec., the scale

shows the adjustment submenu name:

• Adjustment process may be interrupted at any time by pressing

key, the following message informs about abortion of a process:

NOTICE:

1. It must be remembered to perform calibration when the pan is

unloaded!

2. If the adjustment takes more than 15 sec. the program displays an

error message <Err8>, short sound signal is heard. Press

key and

perform the adjustment again simultaneously maintaining as stable

ambient conditions as possible!

Save changes and return to weighing:

See point - 11.2. – return to weighing.

15.2. Start mass estimation

If the scale does not require the f ull calibration pr ocess, or if the user lacks

demanded number of mass standards, it is possi ble to adjust only a new

start mass.

Procedure:

• Following point 11 of this manual enter <P6.CAL> submenu, next:

EXI-01-04-06-14-GB

Page 44

- 44 -

• the program displays the following set of messages:

• upon completion of the start mass estimation process the scale shows

the parameter name:

• start mass estimation process may be interrupted at any time by

key, the following message informs about abortion of a

pressing

process:

NOTICE:

If the start mass estimation takes more than 15 sec. the program displays

an error message <Err8>, short sound signal is heard. Press

key and

perform the adjustment again simultaneously maintaining as stable ambient

conditions as possible!

Save changes and return to weighing:

See point - 11.2. – return to weighing.

EXI-01-04-06-14-GB

Page 45

- 45 -

Err2

-

Value beyond the zero range

Err3

-

Value beyond the tare range

Err4

-

Calibration mass or start mass beyond the acceptable

Err5

-

Mass of a single piece lower than the scale division.

Err7

-

Power down time was to short (should be over 3s)

Err8

-

Operation time exceeded (tarring, zeroing, start mass

null

-

Zero value from the AD converter

FULL2

-

Measurement range overflow

LH

-

Start mass error, the mass on the weighing platform

start mass)

5–FULL

-

Display range overflow in totalizing

16. ERRORS

range (±1% for weight, ±10 for start mass).

estimation, adjustment)

is beyond the acceptable range (from -5% to +15% of

NOTICE:

1. The user is informed about occurrence of errors Err2, Err3, Err4,

Err5, Err8, null by means of a short sound signal (1 second).

2. Error FULL2 is signalled by a sound signal lasting until the over

excessive load is taken off the pan.

17. RESPECTIVE STANDARDS

PUE C/31H/EX indicator is manufactured in accordance with the following

standards:

- EN 61326-1:2006 Electrical equipment for measurement, control and

laboratory use - EMC requirements -- Part 1: General requirements,

- EN 61010-1:2011 Safety requirements for electrical equipment for

measurement, control, and laboratory use -- Part 1: General requirements,

- EN 60079-0:2013 + A11:2014-03 Explosive atmosph er es -- Part 0:

Equipment – General requirements,

- EN 60079-11:2012 Explosive atmospheres -- Part 11: Equipment

protection by intrinsic safety "i".

EXI-01-04-06-14-GB

Page 46

- 46 -

EXI-01-04-06-14-GB

Page 47

- 47 -

MANUFACTURER

OF ELECTRONIC EQUIPMENT

RADWAG WAGI ELEKTRONICZNE

POLAND, 26 – 600 Radom, Bracka 28

Phone: +48 48 38 48 800, phone/fax: + 48 48 385 00 10

Sales dpt.: + 48 48 366 80 06

www.radwag.com

EXI-01-04-06-14-GB

Loading...

Loading...