Page 1

LRS-24

Order from: Cutter Networks

Ph:727-398-5252/Fax:727-397-9610

www.bestdatasource.com

12-slot Link Access Rack with SNMP

Version 3.00

Installation and Operation Manual

Notice

This manual contains information that is proprietary to RAD Data Communications. No part of this

publication may be reproduced in any form whatsoever without prior written approval by RAD Data

Communications.

No representation or warranties for fitness for any purpose other than what is specifically mentioned in

this manual is made either by RAD Data Communications or its agents.

For further information contact RAD Data Communications at the address below or contact your local

distributor.

RAD Data Communications

Headquarters

12 Hanechoshet Street

Tel Aviv 69710 Israel

Tel: 972-3-6458181

Fax: 972-3-6498250

E-mail: rad@rad.co.il

© 2000 RAD Data Communications Publication No. 695-211-08/00

RAD Data Communications

US East

900 Corporate Drive

Mahwah, NJ 07430 USA

Tel: (201) 529-1100

Fax: (201) 529-5777

E-mail: market@radusa.com

RAD Data Communications

US West

3631 South Harbor Boulevard

Suite 250

Santa Ana, CA 92704

Tel: (714) 850-0555

Fax: (714) 850-1555

Page 2

Order from: Cutter Networks

Ph:727-398-5252/Fax:727-397-9610

www.bestdatasource.com

Page 3

Warranty

Order from: Cutter Networks

Ph:727-398-5252/Fax:727-397-9610

www.bestdatasource.com

This RAD product is warranted against defects in material and workmanship for a period of one year

from date of shipment. During the warranty period, RAD will, at its option, either repair or replace

products which prove to be defective. For warranty service or repair, this product must be returned to

a service facility designated by RAD. Buyer shall prepay shipping charges to RAD and RAD shall pay

shipping charges to return the product to Buyer. However, Buyer shall pay all shipping charges, duties

and taxes for products returned to RAD from another country.

Limitation of Warranty

The foregoing warranty shall not apply to defects resulting from improper or inadequate maintenance

by Buyer, Buyer-supplied firmware or interfacing, unauthorized modification or misuse, operation

outside of the environmental specifications for the product, or improper site preparation or

maintenance.

Exclusive Remedies

The remedies provided herein are the Buyer’s sole and exclusive remedies. RAD shall not be liable for

any direct, indirect special, incidental, or consequential damages, whether based on contract, tort, or

any legal theory.

Page 4

Safety Warnings

Order from: Cutter Networks

Ph:727-398-5252/Fax:727-397-9610

www.bestdatasource.com

SEE INSTALLATION INSTRUCTIONS BEFORE CONNECTING TO THE SUPPLY!

The exclamation point within a triangle is intended to warn the operator or

service personnel of operation and maintenance factors relating to the

product and its operating environment which could pose a safety hazard.

Always observe standard safety precautions during installation, operation and maintenance of this

product. Only a qualified and authorized service personnel should carry out adjustment, maintenance

or repairs to this instrument. No adjustment, maintenance or repairs should be performed by either the

operator or the user.

Telecommunication Safety

1. The unit should be installed within 1.5m (5 feet) of a grounded, easily accessible AC outlet, or in

an adequately earthed rack mount. If the protective earth connection is not guaranteed by the

mains supply, the unit must be externally connected to a reliable protective earth. DC powered

units must be connected only to power sources which conform to the relevant safety standard.

2. In order to guarantee an uninterrupted flow of air stream, leave at least 15 mm spacing above

and below the top and bottom sides of the unit. The recommended maximum temperature of the

surrounding area is 40°C.

3. Vacant slots must always be covered with blank covers. This is necessary in order to guarantee a

definite cooling stream of air and to prevent unintentional and unauthorized access inside the

equipment.

4. The safety status of the ports on the LRS-24 is declared according to EN 41003 and is detailed in the

table below. Interconnection of these ports with other apparatus should be made so that the

equipment continues to comply with the requirements of EN 60950 connection of SELV and TNV

circuits to other circuits after such a connection is made.

Ports Safety Status

V.24, V.35, V.36, X.21, RS-530,

Unbalanced E1, E&M

Baseband modems, ISDN,

Balanced E1, T1, HDSL

FXS TNV-2 Circuit whose normal operating voltage exceeds

FXO, Ports with remote power

feeding (phantom)

SELV Circuit operating with Safety Extra-Low Voltage

TNV-1 Circuit whose normal operating voltage is within

the limits of SELV, on which overvoltages from

Telecommunications Networks are possible.

the limits of SELV, on which overvoltages from

Telecommunications Networks are not possible.

TNV-3 Circuit whose normal operating voltage exceeds

the limits of SELV, on which overvoltages from

Telecommunications Networks are possible.

Page 5

Additional conditions concerning the safety of connection to telecommunication networks:

Order from: Cutter Networks

Ph:727-398-5252/Fax:727-397-9610

www.bestdatasource.com

• The unit must be earthed prior to connection to telecommunication networks.

• The signal ground of the SELV circuits is connected at the factory to the protective earth.

Interrupting this connection may invalidate the safety of the connection to unprotected

telecommunication networks in certain locations where permanent excessive voltages are

present on the lines.

In order to comply with the requirements set out in EN 60950 for TNV-3 circuits, the maximum

•

phantom supply voltage must not exceed 120 VDC. The remote power feeding supply must be

floating and must comply with the requirements for TNV-3 circuits.

DC powered units must be powered from EN 60950 or UL-1950 approved power source. In

•

order to avoid a fire hazard, a suitable fuse or circuit breaker must be installed on the

non-earthed DC line.

Regulatory Information

FCC-15 User Information

This equipment has been tested and found to comply with the limits of the Class A digital device,

pursuant to Part 15 of the FCC rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a commercial environment. This

equipment generates, uses and can radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful interference to the radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference in which case

the user will be required to correct the interference at his own expense.

Warning per EN 55022

This is a Class A product. In a domestic environment, this product may cause radio interference, in

which case the user may be required to take adequate measures.

LRS-PS-FEED Output Voltage

The output voltage of the LRS-PS-FEED exceeds the limits of TNV-3 circuits. In the event of uncertainty

about the regulatory status of connecting such voltages to leased lines provided by certain service

providers, consult with a safety engineer.

Page 6

Declaration of Conformity

Order from: Cutter Networks

Ph:727-398-5252/Fax:727-397-9610

www.bestdatasource.com

Manufacturer’s Name: RAD Data Communications Ltd.

Manufacturer’s Address: 12 Hanechoshet St.

Tel Aviv 69710

Israel

declares that the product:

Product Name: LRS-24

Conforms to the following standard(s) or other normative document(s):

EMC: EN 55022 (1994) Limits and methods of measurement of radio disturbance

characteristics of information technology equipment.

EN 50082-1 (1992) Electromagnetic compatibility - Generic immunity

standards for residential, commercial and light industry.

Safety: EN 60950/A4 Safety of information technology equipment, including

electrical business equipment.

Supplementary Information:

The product herewith complies with the requirements of the EMC Directive 89/336/EEC and the

Low Voltage Directive 73/23/EEC. The product was tested in a typical configuration.

Tel Aviv, March 19th, 2000

Haim Karshen

VP Quality

European Contact: Rad Data Communications GmbH, Berner Strasse 77, 60437, Frankfurt am Main, Germany

Page 7

Quick Start Guide

Order from: Cutter Networks

Ph:727-398-5252/Fax:727-397-9610

www.bestdatasource.com

If you are familiar with LRS-24, use this guide to prepare it for operation. Choose

the section appropriate to the version of LRS-24 you are using.

1. LRS-24 with CM-1 Module

This section contains the startup instructions for LRS-24 with the CM-1 module.

Power-On

➤ To turn the power on:

1. Set the ON/OFF switches on the panels of the LRSI-PSP** modules to ON.

2. Supply the DC power, as applicable.

➤ To supply external phantom feed voltages:

1. Turn on LRS-24.

2. Turn on the source (for example, LRS-PS-FEED).

Normal Indications

• PS Module(s): All the indicators on the panel(s) of the PS module(s) must light

in green to indicate proper operation.

• CM-1 Module: The POWER indicator of the module must light. The TD and

RD indicators may flash (or may light steadily) when a management session is

in progress.

LRS-24 with CM-2 Module 1

Page 8

Quick Start Guide LRS-24 Installation and Operation Manual

Order from: Cutter Networks

Ph:727-398-5252/Fax:727-397-9610

www.bestdatasource.com

2. LRS-24 with CM-2 Module

This section contains the startup instructions for LRS-24 with the CM-2 module.

Power-On

➤ To turn the power on:

1. Set the ON/OFF switches on the panels of the LRSI-PSP** modules to ON.

2. Supply the DC power, as applicable.

➤ To supply external phantom feed voltages:

1. Turn on LRS-24.

2. Turn on the source (for example, LRS-PS-FEED).

Normal Indications

• PS Module(s): All the indicators on the panel(s) of the PS module(s) must light

in green to indicate proper operation.

• CM-2 Module: The POWER indicator of the module must light. The TD and

RD indicators may flash (or light steadily) when a management session is in

progress.

Normally, the STAT/ADD display shows the two least significant digits of the

management number assigned to LRS-24. For normal startup, a rotating red circle

is displayed. However, if a problem is detected during the power-up self-test, you

will see a flashing error code (E1 through E9).

Preliminary Configuration

Perform preliminary configuration on the LRS-24 hub (see Chapter 4).

2 LRS-24 with CM-2 Module

Page 9

Contents

Order from: Cutter Networks

Ph:727-398-5252/Fax:727-397-9610

www.bestdatasource.com

Chapter 1. Introduction

1.1 Overview .......................................................................................................... 1-1

General ...................................................................................................................1-1

Versions...................................................................................................................1-3

Application..............................................................................................................1-3

Features...................................................................................................................1-4

1.2 Physical Description .......................................................................................... 1-6

Chassis Description..................................................................................................1-6

LRS-24 Module Slots..............................................................................................1-10

1.3 Functional Description .................................................................................... 1-11

Power Supply (PS) Modules ...................................................................................1-11

Common Logic Modules........................................................................................1-12

Management .........................................................................................................1-13

I/O (User) Modules ................................................................................................1-14

1.4 Technical Specifications .................................................................................. 1-14

Chapter 2. Installation and Setup

2.1 Introduction...................................................................................................... 2-1

Mechanical Data......................................................................................................2-1

2.2 Site Requirements and Prerequisites.................................................................. 2-4

AC Power ................................................................................................................2-4

DC Power................................................................................................................2-4

Grounding...............................................................................................................2-4

Interface Module Handling Precautions....................................................................2-4

Module Handling Precautions..................................................................................2-5

Front Clearance .......................................................................................................2-5

Ambient Requirements ............................................................................................2-5

Cooling....................................................................................................................2-5

2.3 Unpacking the Chassis ...................................................................................... 2-5

2.4 Installation and Setup........................................................................................ 2-6

PS Modules .............................................................................................................2-6

CM-1 Module..........................................................................................................2-8

CM-2 Module........................................................................................................2-12

2.5 Interfaces and Connections ............................................................................. 2-15

PS Interface Modules .............................................................................................2-16

LRSI-F-CM1...........................................................................................................2-17

LRSI-F-1-CM2 / LRSI-B-1-CM2 Interface Modules with 10BaseT.............................2-18

LRSI-F-2-CM2 Interface Module with 10Base2.......................................................2-21

LRS-24 Enclosure...................................................................................................2-24

2.6 Initial Operation and Basic Checks.................................................................. 2-27

LRS-24 with CM-1 Module ....................................................................................2-27

LRS-24 with CM-2 Module ....................................................................................2-28

LRS-24 Installation and Operation i

Page 10

Table of Contents

Order from: Cutter Networks

Ph:727-398-5252/Fax:727-397-9610

www.bestdatasource.com

Chapter 3. Management via the CM-1 Module

3.1 Introduction...................................................................................................... 3-1

CM-1 Functions.......................................................................................................3-1

Management Capabilities.........................................................................................3-1

3.2 Hardware Requirements ................................................................................... 3-2

Terminal Characteristics ...........................................................................................3-2

Management RS-232 Port Interface Characteristics...................................................3-2

Connecting the Terminal..........................................................................................3-2

3.3 Operating the CM-1 Supervision Terminal ........................................................ 3-4

General ...................................................................................................................3-4

Configuring the Terminal .........................................................................................3-4

Performing Preliminary Configuration.......................................................................3-5

Configuring Individual Modules................................................................................3-5

Chapter 4. Management via the CM-2 Module

4.1 Introduction...................................................................................................... 4-1

CM-2 Module Capabilities .......................................................................................4-1

CM-2 Functions.......................................................................................................4-2

Handling of Management Communication...............................................................4-3

Management Priorities .............................................................................................4-4

Preliminary Configuration Activities..........................................................................4-4

Initializing CM-2 ......................................................................................................4-5

4.2 Hardware Requirements ................................................................................... 4-6

Terminal Characteristics ...........................................................................................4-6

RS-232 Supervisory Port Interface Characteristics .....................................................4-7

Terminal Connection Methods.................................................................................4-7

Connection of Management Station ........................................................................4-7

4.3 CM-2 Supervision Terminal Language ............................................................. 4-11

General .................................................................................................................4-11

Index of Commands ..............................................................................................4-12

4.4 Supervision Terminal Operating Instructions.................................................... 4-13

General .................................................................................................................4-13

Configuring the Terminal .......................................................................................4-13

Changing the Password ..........................................................................................4-14

Preliminary Configuration ......................................................................................4-14

Configuring Individual Modules..............................................................................4-14

Configuration by SNMP Network Management Stations .........................................4-15

Transferring Control to the Supervision Terminal ....................................................4-15

Chapter 5. Troubleshooting and Diagnostics

5.1 Alarms............................................................................................................... 5-1

5.2 Diagnostic Tests ................................................................................................5-1

5.3 Troubleshooting ................................................................................................ 5-1

5.4 Error Messages .................................................................................................. 5-2

ii LRS-24 Installation and Operation

Page 11

Table of Contents

Order from: Cutter Networks

Ph:727-398-5252/Fax:727-397-9610

www.bestdatasource.com

Appendix A. Connector Wiring

Appendix B. LRS-PS-FEED Power Supply

Appendix C. SNMP Management

Appendix D. CM-2 Management Commands

List of Figures

1-1. Backbone Data Distribution up to Customer’s Premises............................................. 1-3

1-2. Management of Local and Remote Distribution Nodes .............................................. 1-4

1-3. LRS-24B 3-D View ....................................................................................................1-7

1-4. LRS-24B Enclosure ....................................................................................................1-8

1-5. LRS-24F 3-D View..................................................................................................... 1-9

1-6. LRS-24F Enclosure................................................................................................... 1-10

1-7. LRS-24F Enclosure, Typical Front View.................................................................... 1-11

1-8. Basic Management Configuration for LRS-24 with CM-2 Modules ........................... 1-14

2-1. LRS-24F Mechanical Diagram.................................................................................... 2-2

2-2. LRS-24B Mechanical Diagram ................................................................................... 2-3

2-3. PS Module Panels...................................................................................................... 2-7

2-4. Module CM-1 Front Panel......................................................................................... 2-9

2-5. Module CM-1, Internal Jumpers .............................................................................. 2-10

2-6. Module CM-2 Front Panel....................................................................................... 2-12

2-7. Module CM-2, Internal Jumpers .............................................................................. 2-14

2-8. LRSI-F-PSP/230/114 and LRSI-F-PS/48 Interface Module Panels ..............................2-17

2-9. Typical LRSI-F-CM1 Interface Module Panel............................................................ 2-18

2-10. LRSI-F-1-CM2 / LRSI-B-1-CM2 Interface Module Panel with 10BT ........................2-19

2-11. Interface Module LRSI-F-1-CM2 with UTP Connector, Internal Jumpers ................ 2-20

2-12. LRSI-F-2-CM2 Interface Module Panel with 10B2 ................................................. 2-22

2-13. Interface Module LRSI-F-2-CM2 with BNC Connectors, Internal Jumpers .............. 2-23

3-1. Typical Direct Connection of Supervision Terminal ................................................... 3-3

3-2. Typical Connection of Supervision Terminal Through Modem Link ........................... 3-4

4-1. Typical Direct Connection of Supervision Terminal ................................................... 4-8

4-2. Typical Connection of Supervision Terminal Through Modem Link ........................... 4-8

4-3. Typical Connection of Supervision Terminal Through Slip ......................................... 4-9

4-4. Typical Connection to Network Management Station .............................................. 4-10

4-5. Password Menu Screen ........................................................................................... 4-14

4-6. JP15 Settings............................................................................................................ 4-14

5-1. Error Indicators..........................................................................................................5-2

LRS-24 Installation and Operation iii

Page 12

Table of Contents

Order from: Cutter Networks

Ph:727-398-5252/Fax:727-397-9610

www.bestdatasource.com

List of Tables

2-1. PS Modules, Front Panel Indicators............................................................................ 2-7

2-2. Module CM-1, Front Panel Components ................................................................... 2-9

2-3. Module CM-1 Jumper Settings................................................................................. 2-11

2-4. Module CM-2, Front Panel...................................................................................... 2-13

2-5. Module CM-2 Jumper Settings................................................................................. 2-15

2-6. PS Interface Module Types ...................................................................................... 2-16

2-7. Management 10BT Ethernet LEDs ............................................................................2-19

2-8. LRSI-F-1-CM2 Module Jumper Settings.................................................................... 2-21

2-9. LRSI-F-2-CM2 Interface Module Jumper Settings ..................................................... 2-23

2-10. CM-2 Module STATION CLK Connector, Pin Allocation........................................ 2-26

2-11. CM-1 Module Management RS-232 Pin Allocation................................................. 2-27

4-1. Terminal Command Set Index for CM-2 Module ...................................................... 4-12

4-2. Terminal Command Set Index for CM-2 Module (Cont.) ......................................... 4-13

5-1. Front Panel Indicator Displays ................................................................................... 5-2

5-2. Error Messages........................................................................................................... 5-3

iv LRS-24 Installation and Operation

Page 13

General

Order from: Cutter Networks

Ph:727-398-5252/Fax:727-397-9610

www.bestdatasource.com

Chapter 1

Introduction

This chapter describes the basic physical and functional features of the LRS-24

modem rack, as well as some typical applications. The following topics are

discussed:

• Overview

• Physical Description

• Functional Description

• Technical Specifications.

1.1 Overview

LRS-24 is a high-density SNMP managed modem chassis. The chassis has 12 slots

that accommodate up to 24 modems. Using modular interface cards, LRS-24 can

support xDSL, fiber or baseband modems in the same chassis under a single

management application.

Supporting different modem technologies enables a wide range of data-rates,

starting from 1.2 kbps in IDSL modems, through 2 Mbps with HDSL/fiber

modems, and up to 43 Mbps using fiber modems. This also enables ranges from

4.8 km at

2 Mbps over copper to 100 km over fiber modems.

LRS-24 is available in two different physical hub versions: LRS-24B (ANSI) or

LRS-24F (ETSI).

All cards can be replaced or cables removed during operation, without causing

interference to data transmission to/from other cards in the chassis.

Modular data interfaces allow modem connectivity via a wide range of data

interfaces. These include: V.24, V.35, X.21, RS-530, V.36, G.703 codirectional,

E1, built-in Ethernet bridge, or built-in IP router.

LRS-24 accepts a system clock via the DB-15 connector placed on the CM-2 card.

Overview 1-1

Page 14

Chapter 1 Introduction LRS-24 Installation and Operation Manual

Order from: Cutter Networks

Ph:727-398-5252/Fax:727-397-9610

www.bestdatasource.com

Management/CM-2 functions

LRS-24 is managed by a UNIX-based or PC-based SNMP management system via

the Central Management card (CM-2). The software is user-friendly,

GUI-based and runs under PC/Windows (RADview-PC) or HP OpenView

(RADview-HPOV) systems. Configuration and monitoring are also provided via

TELNET or ASCII terminal.

Network management provides centralized control of all LRS-24 hubs, modem

cards and remote modems in the network, including interface configuration,

connection setup, alarm and monitoring. A single management station can control

up to 64,000 LRS-24 hubs.

Direct 10BaseT Ethernet connection enables real-time management of central and

remote sites. Performance information is available in graph and table format for

the last 24 hours. This information can be saved in a file for accounting purposes.

If a major alarm occurs, the LRS-24 CM-2 card can dial out through an external

dial-up modem to a central management site. This saves a direct connection to

remote sites, while providing alerts if critical events occur. In addition alarms can

activate dry contacts. The dry contacts are placed on the system clock connector

on CM-2.

Two types of modem cards are available on the LRS-24:

• S-Mode: Cards with a built-in SNMP agent

• I-Mode: Cards without an SNMP agent. For these cards CM-2 serves as the

SNMP proxy agent. The CM-2 built-in agent complies with SNMP MIB II and

supports generic SNMP HPOV applications.

A new software version can be downloaded from a remote site onto the CM-2 via:

• LAN by TFTP protocol

• Terminal by XMODEM.

CM-2 saves up to three software versions.

When the management station includes BootP software, the CM-2 card

automatically retrieves the IP address required for management connection. This

eliminates the need to configure IP addresses for new hub installations.

LRS-24 can also be managed from an ASCII terminal. It allows all functions of

SNMP except for GUI interface. The connection is made via a V.24 supervisory

port using SLIP or PPP protocol.

Telnet support enables terminal connection over any IP network.

The CM-2 panel includes an alphanumeric display with two characters used for

alerting on fault conditions and for the hub IP address.

1-2 Overview

Page 15

LRS-24 Installation and Operation Manual Chapter 1 Introduction

Order from: Cutter Networks

Ph:727-398-5252/Fax:727-397-9610

www.bestdatasource.com

Power Supplies

LRS-24 operates with single or dual, AC or DC power supplies. Each power supply

supports a full LRS-24 hub, including modem cards. Redundant power supply can

be replaced during operation, without affecting system performance

(hot-swapping).

Cards in the LRS-24 chassis are capable of providing remote power feeding for

repeaters and remote standalone modems. To provide remote power feeding

order a separate standalone power supply, LRS-PS-FEED.

Versions

Two different physical versions of the LRS-24 hub are available:

• ANSI −−−− card insertion, LEDs and switches are at the front, but cable

connections are at the rear of the hub. This compact, 4U high unit complies

with the American ANSI standard. Cards can be hot-swapped without

removing cables.

• ETSI −−−− card insertion, LEDs, switches and cable connections are at the front.

This version is 30 cm high (almost 6U), and complies with European ETSI

standard. Cards can be hot-swapped without removing cables.

Application

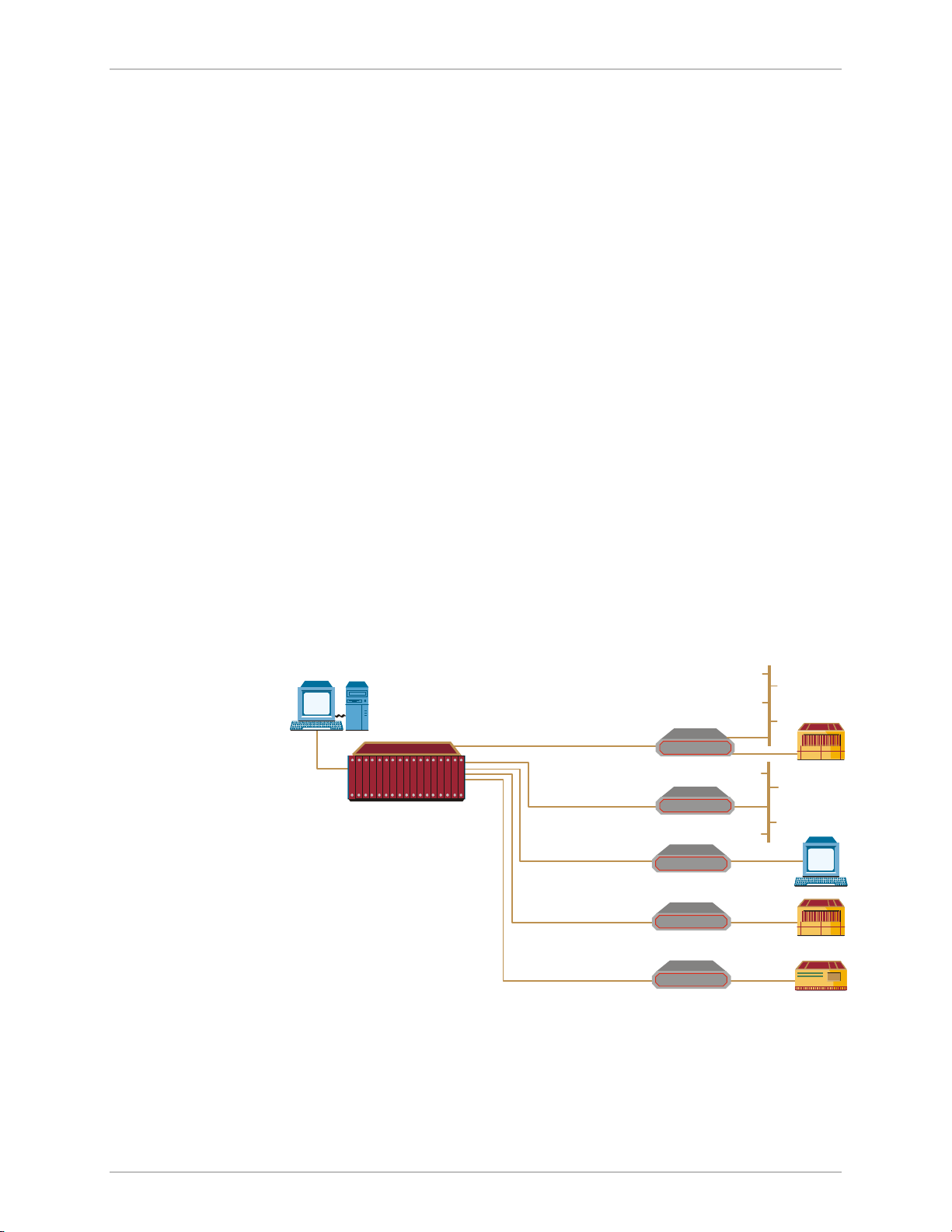

Figure 1-1 shows an application of Backbone Data Distribution up to Customer’s

Premises.

SNMP

Management

Station

HDSL

HCD-E1

LRS-24

MSDSL

IDSL

Fiber

Fiber

ASMi-51

ASMi-31-2

FOMi-E1/T1

FOMi-E3

HSSI

Router

PAB X

PAB X

Figure 1-1. Backbone Data Distribution up to Customer’s Premises

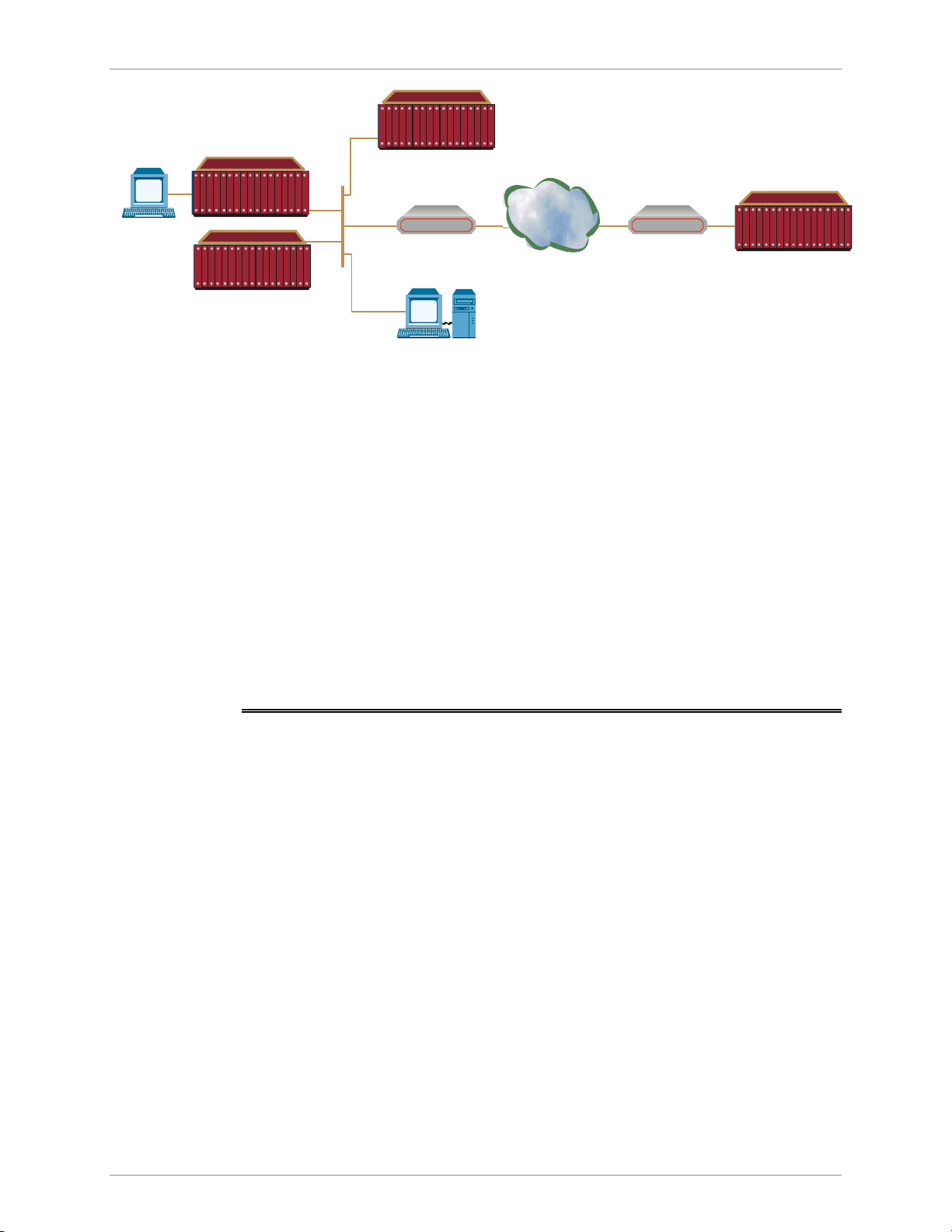

Figure 1-2 shows an application of Management of Local and Remote Distribution

Nodes.

Overview 1-3

Page 16

Chapter 1 Introduction LRS-24 Installation and Operation Manual

Order from: Cutter Networks

Ph:727-398-5252/Fax:727-397-9610

www.bestdatasource.com

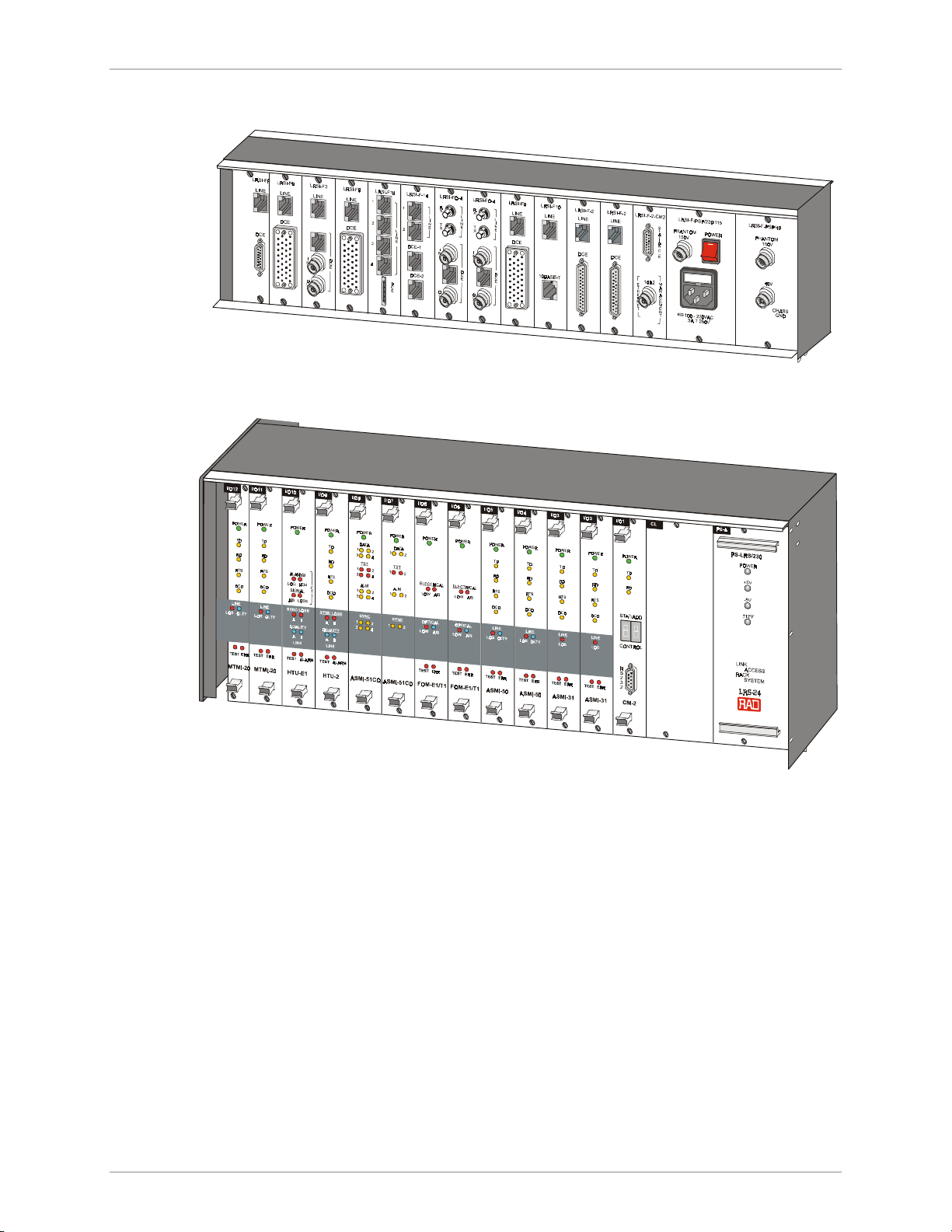

Central

Management

Station

PBX

PBX

PBX

Features

PSTN

ADM or Frame

Relay Switch

MP2100

Router

Backbone

ADM or

Frame Relay

Switch

Local SNMP

Management

Station

Modem Router

LRS-24

LRS-24

Switch

OP-XL

LRS-24

Dial-up

Modem

LRS-24

LRS-24

Figure 1-2. Management of Local and Remote Distribution Nodes

LRS-24 is a high-density, fully modular design with front-panel access to all the

functions. It supports up to 48 user modules in addition to redundant power

supply and management access modules.

It combines different technologies in a centrally-managed rack: DSL, fiber and

baseband.

Switch

LRS-24 offers single-point management access to the individual equipment

modules installed in the hub, and to the remote equipment units connected by

links to these modules. LRS-24 supports SNMP management, as well as

management by means of an ASCII terminal. No special software is required for

the terminal, which is controlled by the management software of the modules

installed in LRS-24.

Clock signals are distributed from an external source (station clock) to all the

equipment modules installed in the hub.

There is a standard set of regulated supply voltages. Power supply redundancy

ensures continuous availability of power.

The unit supports remote (phantom) feed of equipment connected to LRS-24.

The mechanical design separates user hardware modules from interface

(connector) modules, facilitates maintenance tasks.

The form factor is suitable for installation in standard 300 mm and 600 mm

ETSI racks; can be easily adapted for installation in 19" racks.

The flexible modular construction and management capabilities that are available

for the equipment installed in LRS-24 enable the user to easily configure individual

systems for specific requirements and applications.

1-4 Overview

Page 17

LRS-24 Installation and Operation Manual Chapter 1 Introduction

Order from: Cutter Networks

Ph:727-398-5252/Fax:727-397-9610

www.bestdatasource.com

Remote Management

The modem cards in the LRS-24 can be remotely managed by the

RADview-HPOV SNMP management system, the PC-based RADview-PC/MDM

management system or by a dumb terminal. The same RADview application can

manage the LRS-24, modems in the hub and other RAD products.

Audible and visual indicators provide status of alarms and tests at the network,

card and port levels, and include all links connected to the hub. Alarms are

automatically logged and presented upon request, unless otherwise masked.

RADview-HPOV SNMP Management System

Both electrical and fiber optic modem cards can be managed by the

RADview-HPOV SNMP management system. All cards in the hub, except for

ASM-40CD, have remote control abilities for monitoring and/or controlling remote

units, and several types of cards contain an internal SNMP agent. In some cases,

managed cards can work opposite non-manageable modems.

RADview-HPOV management is available for modules with or without integrated

SNMP agent, via the SNMP Control Module (CM-2). The RADview-HPOV station

is connected to LRS-24 via an integrated Ethernet connection on the CM-2

module; CM-2 acts as a proxy SNMP agent for those cards without an agent.

RADview-PC/MDM Management System

The RADview-PC/MDM management station communicates with LRS-24 using

out-of-band communication via Ethernet.

The RADview-PC/MDM has a windows-based Graphical User Interface (GUI)

platform for LAN and WAN networks. The graphical user interface allows

configuration with easy-to-use operations on graphical representations of the hub.

The configuration can be performed at the port, card, hub and network levels.

Management by Dumb Terminal

LRS-24 can also be managed from a dumb terminal. Control Module CM-1 is used

for ASCII terminal management of modules with SNMP agent on-board, such as

HTU-E1C.

Clock

Both control modules, CM-1 and CM-2, have a station clock connection enabling

clock distribution to all cards, so that all cards can be synchronized to the same

station clock. Refer to the specific card operation manual for a description of

station clock support.

Power Supplies

LRS-24 operates with single or dual power supplies: AC or DC. Each power supply

supports a full rack of cards of any combination. The redundant power supply can

be replaced during operation, without affecting the system performance

(hot- swapping).

Overview 1-5

Page 18

Chapter 1 Introduction LRS-24 Installation and Operation Manual

Order from: Cutter Networks

Ph:727-398-5252/Fax:727-397-9610

www.bestdatasource.com

1.2 Physical Description

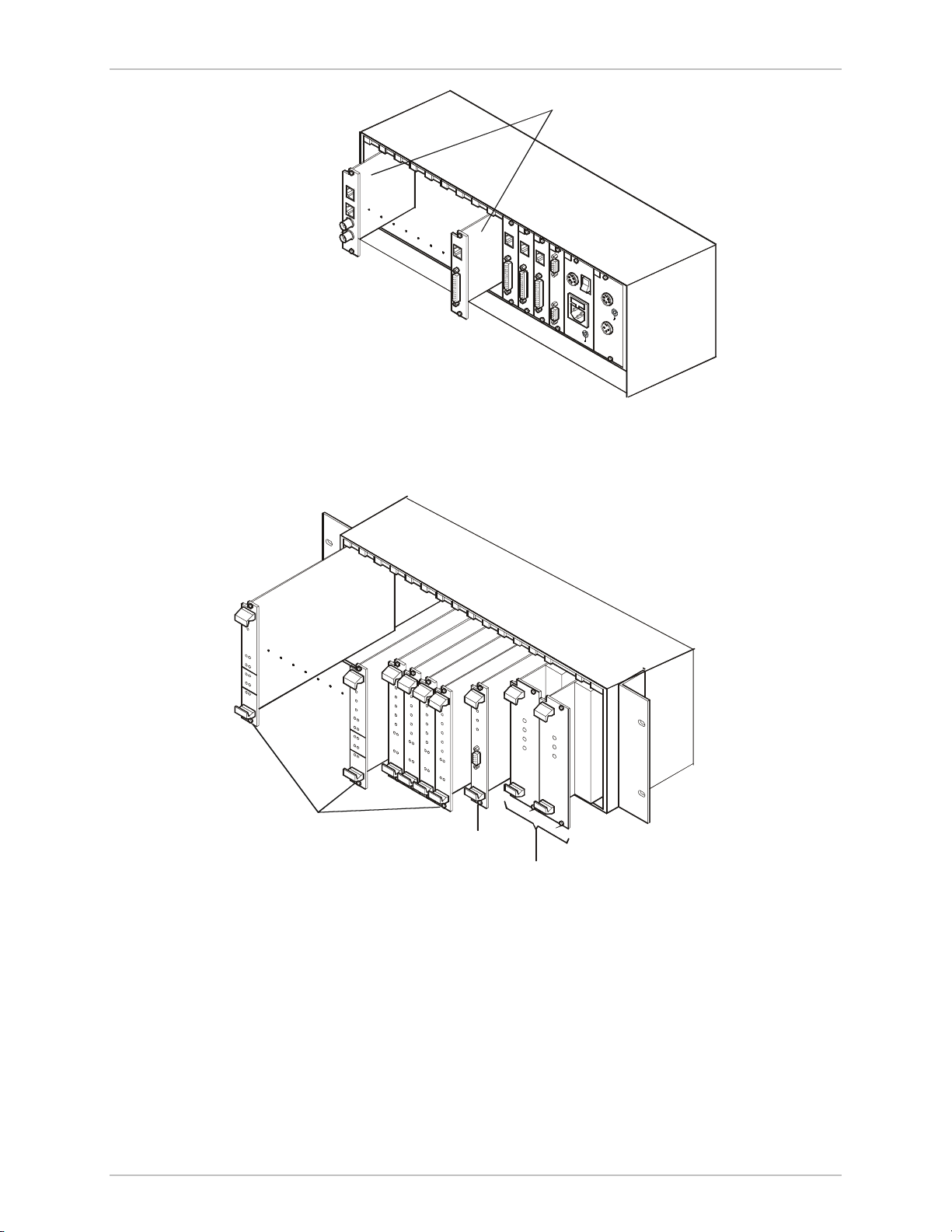

Chassis Description

There are two different physical versions of LRS-24: LRS-24B and LRS-24F.

LRS-24B ANSI UNIT

LRS-24B is a modular chassis suitable for installation in standard ANSI racks. It has

a height of 200 mm (4U). The chassis has physical slots arranged on the front and

back sides:

• The front side accepts 4U-high functional modules (the modules that perform

the various processing functions).

• The back side accepts 2U-high interface modules which contain the

connectors used to access the modules on the front side.

Figure 1-3 shows a 3-dimensional view of LRS-24B.

1-6 Physical Description

Page 19

LRS-24 Installation and Operation Manual Chapter 1 Introduction

Order from: Cutter Networks

Ph:727-398-5252/Fax:727-397-9610

www.bestdatasource.com

O

Rear View

Front View

Figure 1-3. LRS-24B 3-D View

Figure 1-4 shows the LRS-24B enclosure with the Interface Modules, User

Modules, Control Logic Module, and Power Supply Module.

Physical Description 1-7

Page 20

Chapter 1 Introduction LRS-24 Installation and Operation Manual

Order from: Cutter Networks

Ph:727-398-5252/Fax:727-397-9610

www.bestdatasource.com

Interface Modules

LRS-24B Rear Section

1-8 Physical Description

User Modules

Control Logic

Module

Power Supply

(PS)

LRS-24 Front Section

Figure 1-4. LRS-24B Enclosure

Page 21

LRS-24 Installation and Operation Manual Chapter 1 Introduction

Order from: Cutter Networks

Ph:727-398-5252/Fax:727-397-9610

www.bestdatasource.com

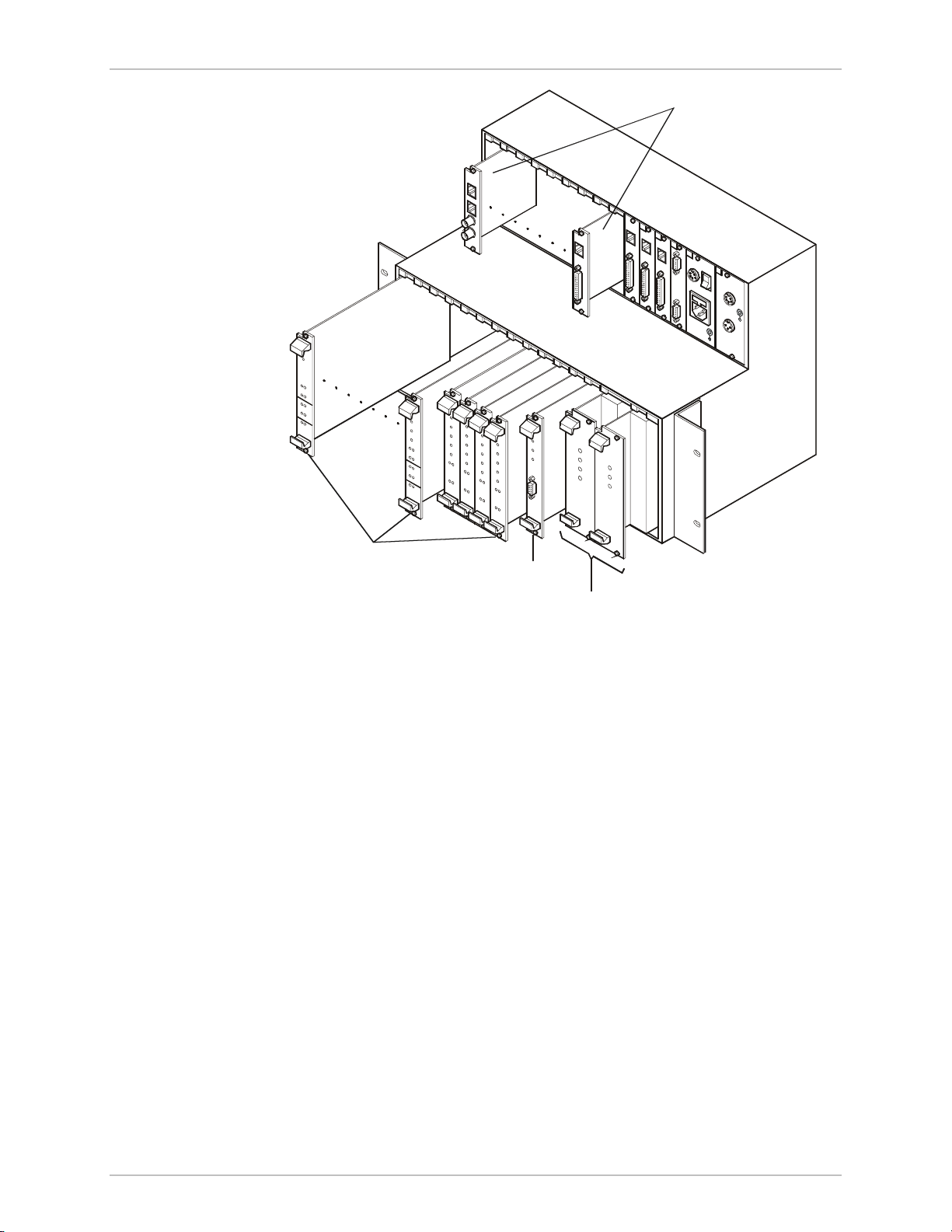

LRS-24F ETSI UNIT

LRS-24F is a modular chassis suitable for installation in standard ETSI racks, having

a height of 300 mm (6U). The chassis has physical slots arranged in two rows:

• The lower row accepts 4U-high functional modules (the modules that perform

the various processing functions).

• The top row accepts 2U-high interface modules, which contain the connectors

used to access the modules in the lower row. The interface modules enable

the connection of cables from the front side, and thus functional modules can

be easily removed for maintenance without disconnecting cables.

Figure 1-5 shows a 3-dimensional view of LRS-24F.

Figure 1-5. LRS-24F 3-D View

O

LRS-24F Enclosure

Figure 1-6 shows the LRS-24F enclosure including User Modules and Interface

Modules, Control Logic module, and Power Supply module.

Physical Description 1-9

Page 22

Chapter 1 Introduction LRS-24 Installation and Operation Manual

Order from: Cutter Networks

Ph:727-398-5252/Fax:727-397-9610

www.bestdatasource.com

Interface Modules

LRS-24 Module Slots

The LRS-24F enclosure has a lower section for the functional modules and a top

section for interface modules. The LRS-24B enclosure has a front section for the

functional modules and a rear section for interface modules.

Each section has 15 module slots:

• Two slots are reserved for PS modules.

• One slot is reserved for the common logic module (CM-1 or CM-2).

• The other 12 slots are intended for user (I/O) modules. Each I/O slot can

accept any type of I/O module. The modules are inserted from the front side.

The top section of LRS-24F (back section of LRS-24B) includes slots for the

interface modules.

Front View

User Modules

CONTROL LOGIC

Module

Power Supply

(PS)

Figure 1-6. LRS-24F Enclosure

1-10 Physical Description

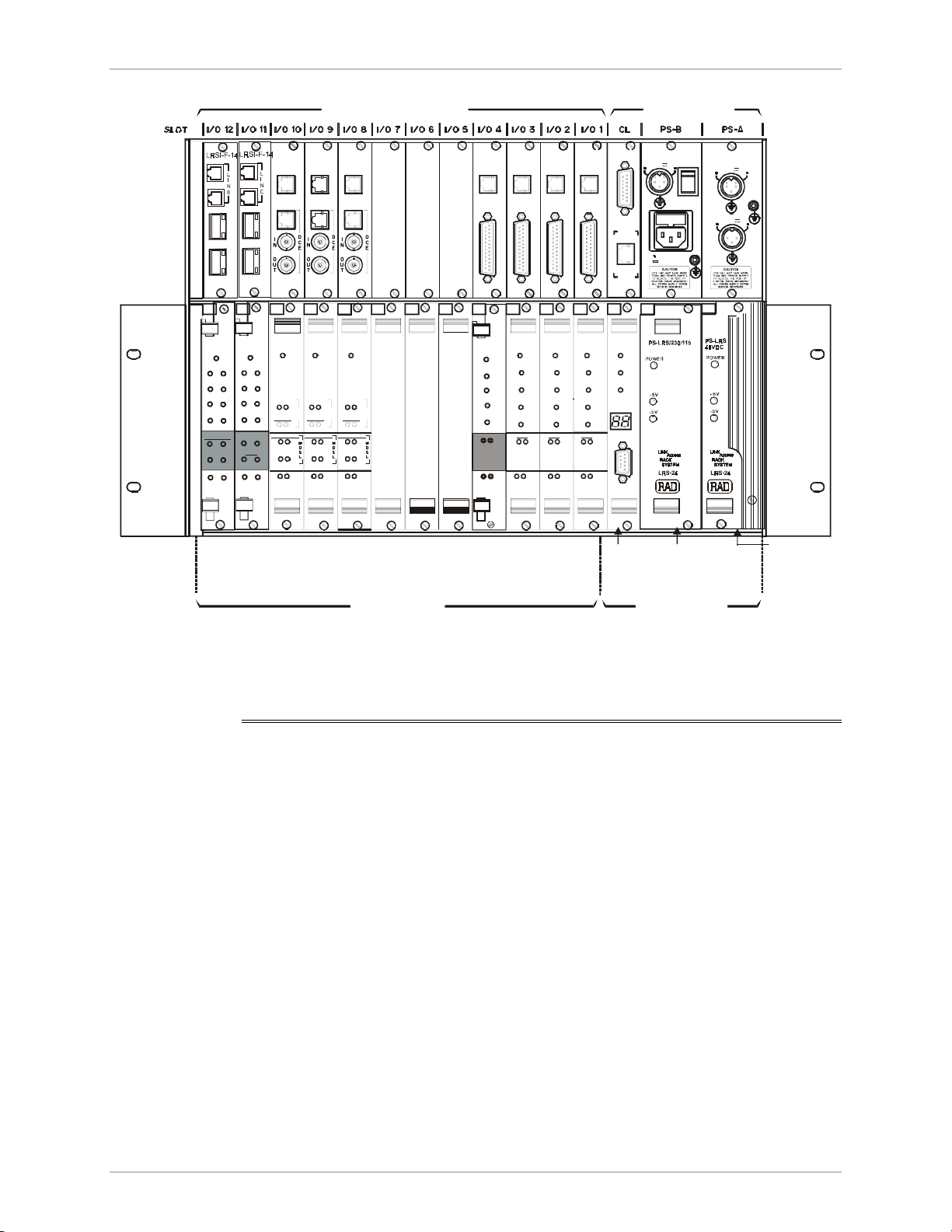

Figure 1-7 shows a typical front view of the LRS-24F enclosure, and identifies the

slots and their use. Note the labels that designate the type of module that can be

installed in each slot.

Page 23

LRS-24 Installation and Operation Manual Chapter 1 Introduction

Order from: Cutter Networks

Ph:727-398-5252/Fax:727-397-9610

www.bestdatasource.com

1

2

DCE-1

DCE-2

I/O12

POWER

TD1

RD1

RTS1

DCD1

SYNC LOSS

1 2

TEST

1 2

ERR1

ASM-40CD

TD2

RD2

RTS2

DCD2

ERR2

1

2

DCE-1

DCE-2

I/O11

POWER

TD1

RD1

RTS1

DCD1

SYNC LOSS

1 2

TEST

1 2

ERR1

ASM-40CD

TD2

RD2

RTS2

DCD2

ERR2

LRSI-F3

LINE

I/O10 I/O 9

POWER

ALARMS

E

1

SIGNAL

SYNC LOSS

A B

QUALITY

A B

LINE

TEST AL ARM

HTU-E1

Internal Modules

for User Modules

LRSI-F3

LRSI-F3

LINE

LINE

I/O 8

POWER

POWER

ALARMS

ALARMS

E

1

SIGNAL

SIGNAL

SYNC LOSS

SYNC LOSS

A B

A B

QUALITY

QUALITY

A B

A B

LINE

LINE

TEST AL ARM

TEST AL ARM

HTU-T1

HTU-E1

Internal Modules f or

System Slots

LRSI-F-PSP / 230 / 115

LRSI-F2

LRSI-F2

LRSI-F2

LINE

DCE

POWER

TD

RD

RTS

DCD

LINE

LOS QLTY

TEST AL ARM

ASMi-450

LINE

DCE DCE

POWER

TD

RD

RTS

DCD

LINE

LOS QLTY

TEST AL ARM

ASMi-450

LINE

DCE

I/O 6

I/O 7

E

1

I/O 5

I/O 4 I/O 3 I/O 2

POWER

TD

RD

RTS

DCD

LINE

QLTY

LOS

TEST ERR

ASMi-50C

LRSI-F2

LINE

I/O 1 CL

POWER

TD

RD

RTS

DCD

LINE

LOS QLTY

TEST AL ARM

ASMi-450

LRSI-F1-CM2

10BT

ETHERNET

POWER

TD

RD

STAT / ADD

CONTROL

R

S

2

3

2

CM-2

PHANTOM

S

POWER

150V

T

A

T

I

O

N

C

L

K

100-230 VAC

3A T 250V

MANAGEMENT

PS-B PS -A

LRSI-F-P SP / 48

PHANTOM

150V

48V

CHASS

GND

Figure 1-7. LRS-24F Enclosure, Typical Front View

1.3 Functional Description

The main functions of the LRS-24 chassis are to provide mechanical support and

connections between the various modules.

The main modules are:

• Power Supply (PS) Modules

• Common Logic Modules

• I/O (User) Modules.

Power Supply (PS) Modules

Control

Logic

Module

Redundant

Power Supply

(Option)

System SlotsUser Modules

Power

Supply

The LRS-24 hub can be powered by AC and DC power supply modules. Two

power supply modules can be installed to provide redundancy. The following

types of AC and DC power supply modules are available for LRS-24:

• AC power supply module, PS-LRS/230/115 – operates on 100 to 240 VAC

nominal, and provides a maximum total output power of 120W.

Functional Description 1-11

Page 24

Chapter 1 Introduction LRS-24 Installation and Operation Manual

Order from: Cutter Networks

Ph:727-398-5252/Fax:727-397-9610

www.bestdatasource.com

• DC power supply module, PS-LRS/48 – operates on –48 VDC, and provides a

maximum total power of 120W.

The PS modules are installed in dedicated chassis slots. The chassis has two PS

slots, enabling the installation of two PS modules, for redundancy. When both

modules are operational, they share the load; in case of failure or loss of input

power, the remaining module continues to supply the power alone. Switchover is

thus automatic and does not interrupt normal operation.

A redundant module can be installed in an operating enclosure without turning off

the enclosure power. An AC and a DC PS module can be installed simultaneously.

Several I/O modules installed in the chassis can supply remote (phantom) feed

voltage for the remote equipment connected to the modules installed in the

LRS-24. This voltage must be provided by an external source.

RAD offers a standalone unit, LRS-PS-FEED, that can provide the required voltage

for the remote power source. LRS-PS-FEED is explained in Appendix B of this

manual.

The phantom feed voltage is connected through the power supply interface

module and through the corresponding PS to the internal phantom feed

distribution bus of the LRS-24.

Common Logic Modules

LRS-24 is managed by either of the two CM modules, CM-1 or CM-2. The main

functions of the two module types are:

• Interfacing between a management facility and the equipment modules

installed in LRS-24. The CM-1 module only supports management by means of

a supervision terminal; the CM-2 module also supports network management

stations.

• Distribution of an external clock signal (station clock) to the equipment

modules. The station clock interface circuits of the common logic modules

have the following user-selectable modes:

− T1 DSU interface per ANSI TR-62411 and ANSI T1.403, with 100Ω

balanced T1 line interface. This mode accepts an AMI-coded clock signal of

1544 kHz. The maximum signal attenuation is 10 dB.

− E1 DSU interface per ITU-T Rec. G.703, which accepts an

HDB3-coded clock signal of 2048 kHz. The E1 interface can be configured

to operate as a 120Ω balanced line interface, or a 75Ω unbalanced

interface. The maximum line attenuation is 10 dB.

− Square interface per TTL input.

1-12 Functional Description

The recovered clock signal is returned toward the equipment providing the clock

signal (remote loop condition, controlled by a user jumper).

Page 25

LRS-24 Installation and Operation Manual Chapter 1 Introduction

Order from: Cutter Networks

Ph:727-398-5252/Fax:727-397-9610

www.bestdatasource.com

Management

CM-1 Management Capabilities

An ASCII terminal can be used as a supervision terminal to manage the CM-1

module. The supervision terminal is connected to one of the RS-232 asynchronous

serial supervisory ports (one port is located on the CM-1 module itself and the

second port is located on the interface module serving the CM-1 module).

The CM-1 module operates as an interface module that does not process the

management information, but only transfers the management traffic transparently

to the modules installed in the LRS-24. Therefore, the supervision terminal is

controlled by the software stored in the managed modules, and the management

capabilities depend on the capabilities of the managed modules.

For a description of the management activities supported by a terminal connected

to the CM-1 module, refer to the Installation and Operation Manuals available for

the modules installed in LRS-24.

CM-2 Management Capabilities

The CM-2 module enhances the management capabilities available to the user by

including three different management functions:

• SNMP management. For SNMP management, the CM-2 module

communicates via an additional management interface located on the

interface module serving the CM-2 module. Currently, two types of interfaces

are available: an Ethernet 10BaseT interface (for UTP and STP media), and an

Ethernet 10Base2 interface (for coaxial media). This configuration is illustrated

in Figure 1-8.

• SNMP management communication with an LRS-24 module that includes

an SNMP agent is handled by an internal SNMP agent and bridge/router

located on the CM-2 module. To enable SNMP management of modules

without SNMP agents, the CM-2 module includes a proxy agent that converts

the management traffic to the proprietary internal protocol used to manage

such modules.

• Management by an ASCII terminal operating as a supervision terminal. The

terminal, which is controlled by the software stored in the managed modules,

connects to the serial RS-232 asynchronous supervisory port located on the

CM-2 module (see Figure 1-8). The management capabilities available through

the terminal are similar to those available through the CM-1 module.

• Management by means of Telnet. The CM-2 also supports the Telnet

protocol. This enables remote management via the same command line

interface used with a supervision terminal. Telnet uses TCP/IP communication

through the Ethernet port of the CM-2 card.

• Management via RS-232 by Slip Protocol with SNMP management.

Functional Description 1-13

Page 26

Chapter 1 Introduction LRS-24 Installation and Operation Manual

Order from: Cutter Networks

Ph:727-398-5252/Fax:727-397-9610

www.bestdatasource.com

LRS-24

LRS-24

WAN

Supervision

Ter min al

LRS-24

Management

Station

MBEMBE

LRS-24

Figure 1-8. Basic Management Configuration for LRS-24 with CM-2 Modules

I/O (User) Modules

LRS-24 can be equipped with various types of input/output (I/O) modules to

provide the required system functions. These include ASMi-24C, ASMi-31C,

ASMi-31CQ, ASMi-50C, ASMi-450C, HTU-E1C, FOMi-40C, FOMi-E1/T1C,

FOMi-E3C, FOMi-T3C, MTMi-20C, FOMi-40CD, ASM-40CD, FOMi-E1/T1/CD,

ASMi-50CD, and ASMi-51CQ.

Chassis

Characteristics

Power

The range of modules and options available for LRS-24 is continuously expanding.

Refer to the Installation and Operation Manuals of the corresponding modules for

information.

1.4 Technical Specifications

Number of

Functional Module

Slots

Slot Usage

Module

PS-LRS/230/115

Module PS-LRS/48

Remote (Phantom)

Source

15 – Each slot is connected to an interface module slot

2 power supply slots

1 common logic slot

12 identical slots for I/O (user) modules

100 – 240 VAC nominal, 50/60 Hz, maximum 160W

–48 VDC nominal, maximum 160W

LRS-PS-FEED standalone unit

1-14 Technical Specifications

Page 27

LRS-24 Installation and Operation Manual Chapter 1 Introduction

Order from: Cutter Networks

Ph:727-398-5252/Fax:727-397-9610

www.bestdatasource.com

External Clock Interface

T1 Mode

E1 Mode

Type

Clock Rate

Line Interface

Line Code

Receive Level

Transmit Level

Type

Bit Rate

Line Interface

Line Code

Receive Level

Transmit Level

Square

T1

1.544 MHz

100ΩΩΩΩ, balanced

Bipolar AMI

0 through -10 dB

±3V ±10%, balanced

E1

2.048 MHz

120Ω, balanced

75Ω, unbalanced

AMI

0 through -10 dB

±3V ±10%, balanced

±2.73V ±10%, unbalanced

Minimum 2.2V peak-to-peak amplitude

CM-1 Management Interface

Functionality

Hardware

Software

CM-2 Management Interface

Functionality

Transparent interfacing to internal management ports of

I/O modules

RS-232 asynchronous port, compatible with

VT-52, VT-100, FREEDOM-100, FREEDOM-110,

FREEDOM-220

Data rates up to 9.6 kbps

Word format: software-configurable

Terminal driven by software stored in each I/O module

Terminal management interface

SNMP agent with internal bridge/router and ARP server

for internal modules

Protocol conversion between internal management

protocols of I/O modules and external management

function

Technical Specifications 1-15

Page 28

Chapter 1 Introduction LRS-24 Installation and Operation Manual

Order from: Cutter Networks

Ph:727-398-5252/Fax:727-397-9610

www.bestdatasource.com

Physical Data

Hardware

Asynchronous Port

Characteristics

Software

LRS-24F

Height

Width including

brackets

Ethernet 10BaseT interface for UTP and STP media

Ethernet 10Base2 interface for coaxial media

RS-232 asynchronous port, compatible with VT-52,

VT-100, FREEDOM-100, FREEDOM-110, and

FREEDOM-220

Data rate: 38.4 kbps

Word format: one start bit, eight data bits, no parity, one

stop bit

SNMP over Ethernet LAN port

Terminal interface controlled by software stored in the

CM-2 module

299 mm/ 11.8 in

533.8 mm/ 21 in

Environment

Width without

brackets

Depth

LRS-24B

Height

Width including

brackets

Width without

brackets

Depth

Operating

Temperature

Storage

Temperature

Humidity

437.8 mm/ 17.2 in

252 mm/ 9.9 in

177 mm/ 7.0 in

533.8 mm/ 21 in

437.8 mm/ 17.2 in

324 mm/ 12.8 in

32°F to 113°F / 0°C to 45°C

0°F to 150°F / –20°C to +70°C

Up to 90%, non-condensing

1-16 Technical Specifications

Page 29

Chapter 2

Order from: Cutter Networks

Ph:727-398-5252/Fax:727-397-9610

www.bestdatasource.com

Installation and Setup

This chapter provides installation and operation instructions for the LRS-24 system,

and the basic system configuration of the power supply (PS) and common logic

(CM-1 and CM-2) modules. It includes the following topics:

• Site requirements and prerequisites

• Equipment needed

• Package contents

• Installation and setup

• Interfaces and connections

• Initial operation and basic checks

See Chapter 3 for management via a CM-1 module and Chapter 4 for

management via a CM-2 module.

2.1 Introduction

If LRS-24 includes a CM-2 module, you must configure management parameters

of the CM-2 module before the management functions are operable. This

procedure is explained in Chapter 4.

After installing the basic system, install the user modules according to the system

installation plan, as explained in the Installation and Operation Manual of the

individual modems.

No internal settings, adjustment, maintenance, and repairs may be performed

by either the operator or the user; such activities may be performed only by a

skilled technician who is aware of the hazards involved.

Warning

Mechanical Data

Always observe standard safety precautions during installation, operation, and

maintenance of this product.

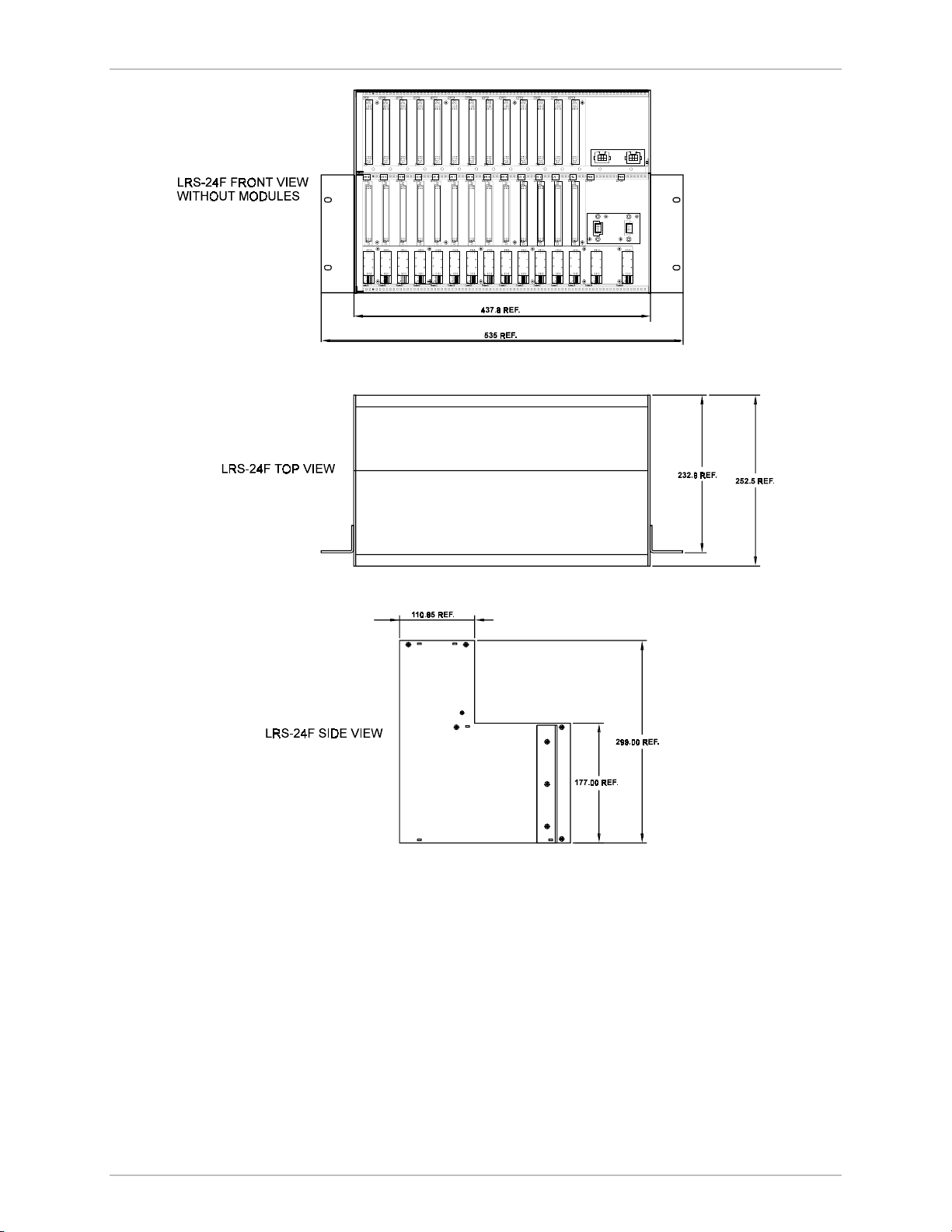

Figure 2-1 provides mechanical data on the LRS-24F chassis. Figure 2-2 provides

mechanical data on the LRS-24B chassis.

Introduction 2-1

Page 30

Chapter 2 Installation and Setup LRS-24 Installation and Operation Manual

Order from: Cutter Networks

Ph:727-398-5252/Fax:727-397-9610

www.bestdatasource.com

2-2 Introduction

Figure 2-1. LRS-24F Mechanical Diagram

Page 31

LRS-24 Installation and Operation Manual Chapter 2 Installation and Setup

Order from: Cutter Networks

Ph:727-398-5252/Fax:727-397-9610

www.bestdatasource.com

LRS-24B FRONT VIEW

WITHOUT MODULES

LRS-24B TOP VIEW

LRS-24B SIDE VIEW

Figure 2-2. LRS-24B Mechanical Diagram

Introduction 2-3

Page 32

Chapter 2 Installation and Setup LRS-24 Installation and Operation Manual

Order from: Cutter Networks

Ph:727-398-5252/Fax:727-397-9610

www.bestdatasource.com

2.2 Site Requirements and Prerequisites

This section describes how to prepare the site for installation of the LRS-24 hub.

AC Power

Install the LRS-24 chassis with AC power supply modules within 1.5m (5 feet) of an

easily accessible, grounded, 100 to 240 VAC outlet.

DC Power

LRS-24 chassis with DC power supply modules require a –48 VDC power source.

Since no power switch is provided for the DC power supply modules, connect the

DC power to LRS-24 through a circuit breaker located close to LRS-24. This

provides overcurrent protection for the input power line, and enables turning off

power to LRS-24.

Grounding

The LRS-24 case must be properly grounded at all times, both to protect the

user and to prevent possible damage to equipment. It will prevent damage

when a fault condition occurs on the lines connected to the equipment, such

Warning

as lightning stroke or contact with high-voltage power lines.

Never connect cables to an LRS-24 that is not properly grounded. Any

interruption of the protective (grounding) connection inside or outside the

equipment or the disconnection of the protective ground terminal can make

this equipment dangerous. Intentional interruption is prohibited. Before

switching on this equipment and before connecting any other cable, the

protective ground terminal of the enclosure must be connected to a protective

ground.

Caution

Interface Module Handling Precautions

2-4 Site Requirements and Prerequisites

The LRS-24 enclosures are grounded through the protective (grounding) conductor

of the power cable. In addition, each of the LRS-24 power supply interface

modules has a grounding screw located on its front panel. Connect this screw by a

short, wide copper strap to a reliable, low-resistance grounding system.

When LRS-24 is installed in racks, the rack itself should also be grounded in

accordance with standard practice and the locally applicable regulations. Installing

LRS-24 in a grounded rack provides additional protection against fault conditions.

LRS-24 interface modules are grounded by installation in a grounded LRS-24

chassis.

Page 33

LRS-24 Installation and Operation Manual Chapter 2 Installation and Setup

Order from: Cutter Networks

Ph:727-398-5252/Fax:727-397-9610

www.bestdatasource.com

Caution

For your safety, always disconnect all the cables connected to an LRS-24 interface

module before removing that module from LRS-24. Do not connect cables to an

interface module that is not installed in a grounded LRS-24.

Module Handling Precautions

Caution

The LRS-24 modules contain components sensitive to electrostatic discharge (ESD).

To prevent ESD damage, always hold a module by its sides, and do not touch the

module components or connectors. Before touching a module, we recommend

that you discharge the electrostatic charge of your body by touching the frame of a

grounded equipment unit.

Modules can be installed and removed from LRS-24 while LRS-24 is powered and

operating. However, if LRS-24 is not yet powered, turn off the input power while

inserting a PS module into LRS-24.

Front Clearance

Allow at least 90 cm (36 inches) of frontal clearance for operator access.

Ambient Requirements

Cooling

Caution

The ambient operating temperature of LRS-24 should be 32° to 113°F

(0° to 45°C), at a relative humidity of up to 90%, non-condensing.

LRS-24 units are cooled by free air convection. The cooling vents are located in

the top and bottom covers.

Do not obstruct these vents. Allow at least 1U of space below and above the unit.

2.3 Unpacking the Chassis

Before unpacking, make a preliminary inspection of the container. Evidence of

damage should be noted and reported immediately.

➤ To unpack the equipment:

1. Place the container on a flat surface, cut all straps, and open the top of the

container.

2. Carefully take LRS-24 out of the container and place it securely on a flat, clean

surface.

3. Inspect the unit for signs of damage. Report immediately any damage found.

Unpacking the Chassis 2-5

Page 34

Chapter 2 Installation and Setup LRS-24 Installation and Operation Manual

Order from: Cutter Networks

Ph:727-398-5252/Fax:727-397-9610

www.bestdatasource.com

4. Check the packing list against your order to ensure that the supplied modules

match your order. If modules have been pre-installed in accordance with your

order, check that all modules are in their proper slots and are secure. Report

immediately any deviations.

5. Check that all necessary cables have been included.

2.4 Installation and Setup

This section describes how to perform the mechanical installation of the following

items:

• PS module

• CM-1 module

• CM-2 module.

PS Modules

Warning

This section covers the installation of the PS modules in an LRS-24 enclosure. For

installation of the associated PS interface modules, see Section 2.5. Obtain the

system installation plan before starting the installation.

Dangerous voltages are present inside the PS modules when connected to

power.

Do not connect a PS interface module to power before it is properly installed

within the LRS-24 enclosure. Disconnect the input power from the module

before removing it from the enclosure.

Two types of PS modules are currently available: PS-LRS/230/115, and PS-LRS/48.

Each module is also available with the /P option, which supports the supply of

remote feed voltage from an external source.

Front Panels

Typical front panels for PS modules are shown in Figure 2-3. Indicator functions

are listed in Table 2-1.

2-6 Installation and Setup

Page 35

LRS-24 Installation and Operation Manual Chapter 2 Installation and Setup

Order from: Cutter Networks

Ph:727-398-5252/Fax:727-397-9610

www.bestdatasource.com

PS-LRS/230/115

POWER POWER

+5V +5V

-5V -5V

LRS-24

PS-LRS

48VDC

LRS-24

DC Power Supply ModuleAC Power Supply Module

Figure 2-3. PS Module Panels

Table 2-1. PS Modules, Front Panel Indicators

Indicator Function Status

POWER At least one of the PS modules installed in LRS-24

Lights up (green)

is receiving input power and can provide +5V

LRS-24 is not receiving power

+5V This PS module is providing a normal +5V output

Off

Green

voltage

+5V is not available in LRS-24

–5V This PS module is providing a normal –5V output

Off

Green

voltage

–5V is not available in LRS-24

Off

Fuses

The PS modules include internal fuses that should not be replaced by the user.

In addition, the AC power supply (PS-LRS/230/115) is protected by an external,

user-replaceable fuse located in the AC power connector of the corresponding

interface module, which protects the input line.

Installation and Setup 2-7

Page 36

Chapter 2 Installation and Setup LRS-24 Installation and Operation Manual

Order from: Cutter Networks

Ph:727-398-5252/Fax:727-397-9610

www.bestdatasource.com

PS Module Installation

➤ To install the first PS module:

1. Make sure that the POWER switches on the two LRSI-PS interface modules are

set to OFF.

2. Insert the specified PS module in the PS-A slot, referring to the system

installation plan in LRS-24 Module Slots, Chapter 1.

3. Fasten the PS module with the two screws.

4. If an additional redundant module is used, install it in the PS-B slot.

Note

CM-1 Module

You can install a redundant module in an operating enclosure without turning off

the enclosure power. After the module is installed, connect the power cable and set

the power switch located on the corresponding interface module to ON.

An AC and a DC PS module can be installed at the same time.

This section covers installation of the CM-1 module and of the associated interface

module in an LRS-24 enclosure. The first part covers the installation of the CM-1

module. The second section covers the installation of the interface module for the

CM-1 module: LRSI-F-CM1.

Front Panel

A typical front panel for the CM-1 module is shown in Figure 2-4. The functions of

the components located on the front panel are listed in Table 2-2.

2-8 Installation and Setup

Page 37

LRS-24 Installation and Operation Manual Chapter 2 Installation and Setup

Order from: Cutter Networks

Ph:727-398-5252/Fax:727-397-9610

www.bestdatasource.com

POWER

TD

M

RD

A

N

A

G

E

R

S

2

3

2

M

E

N

T

CM-1

Figure 2-4. Module CM-1 Front Panel

Table 2-2. Module CM-1, Front Panel Components

Item Function

POWER Indicator Lights up when the CM-1 module is receiving input power

(+5V)

TD Indicator Lights up to indicate activity on the transmit (input) line of

the RS-232 MANAGEMENT port

RD Indicator Lights up to indicate activity on the receive (output) line of

the MANAGEMENT

RS-232 port

MANAGEMENT RS-232

Connector

Direct connection of supervision terminal to LRS-24

management port

Installation and Setup 2-9

Page 38

Chapter 2 Installation and Setup LRS-24 Installation and Operation Manual

Order from: Cutter Networks

Ph:727-398-5252/Fax:727-397-9610

www.bestdatasource.com

Internal Jumpers

Figure 2-5 shows the location of the user-selectable jumpers located on the CM-1

module. Figure 2-3 lists the jumper settings.

The CM-1 module includes additional factory-set jumpers, which must not be

moved by the user.

JP15 RCEN

EN

DIS

TTL Level

Convert er

Enabled

TTL Level

Convert er

Disabled

RCEN

EN

DIS

JP15

STATCLK

SYS

TTL

JP14 STATCLK

SYS

Clock at

System

Levels

Clock at

TTL

JP14

TTL Levels

JP12

RLOOP LCODE

AMI

ON

HDB3

OFF

Jumper JP 9, JP10

BAL

Balanced

Clock

Interface

Unbalanced

Clock

UNBAL

BAL

JP10

UBAL

JP11

JP9

JP4

JP5

JP6

E1-BAL

T1-DSU

E1-UBAL

Interface

2-10 Installation and Setup

JP12 RLOOP

Remote Loopback

ON

Tow ard St a t i on

Clock Source

No Loopback

OFF

JP11 LCODE

AMI

T1 Line

Code

E1 Line

HDB3

Code

Figure 2-5. Module CM-1, Internal Jumpers

Interface Selection

Jumpers JP4, JP5, JP6

JP4

E1-BAL

JP5

JP6

JP4

JP5

JP6

JP4

JP5

JP6

T1-DSU

E1-UBAL

Balanced

E1 Interface

Balanced

T1 Interface

Unbalanced

E1 Interface

Page 39

LRS-24 Installation and Operation Manual Chapter 2 Installation and Setup

Order from: Cutter Networks

Ph:727-398-5252/Fax:727-397-9610

www.bestdatasource.com

Table 2-3. Module CM-1 Jumper Settings

Jumpers Description Values

JP4, JP5, JP6,

JP9, JP10,

Select the station clock interface in the

STATION CLK connector of the

LRSI-F-CM1 interface module.

LCODE, JP11 Selects the line code accepted by the

station clock interface in the STATION

CLK connector of the LRSI-F-CM1

interface module.

RLOOP, JP12 Controls the operating mode of the

station clock interface in the STATION

CLK connector of the LRSI-F-CM1

interface module.

T1 interface (1544 kHz clock): Set jumper JP5 in

the T1-DSU position and jumpers JP9 and JP10 to

BAL.

Balanced E1 interface (2048 kHz clock): Set

jumper JP4 in the E1-BAL position, and jumpers JP9

and JP10 to BAL.

Unbalanced E1 interface (2048 kHz clock): Set

jumper JP6 in the E1-UBAL position, and jumpers

JP9 and JP10 to UBAL.

Default setting: Balanced E1 interface

AMI—AMI line code: Use this selection for the T1

interface.

HDB3—HDB3 line code: Use this selection for the

E1 interfaces.

Default setting: HDB3

ON: The station clock interface returns the

regenerated clock signal toward the clock source.

OFF: The station clock interface does not return

clock signal toward the clock source.

Unless your system has special requirements,

always set the jumper JP12 to ON.

STATCLK,

JP14

Selects the levels of the clock signal

provided by the CM-1 module as a

station clock signal for the user modules

installed in LRS-24.

RCEN, JP15 Connects the supply voltage to the line

receiver which provides a clock signal at

TTL levels when the jumper JP14 is set

to TTL.

Default setting: JP12 ON

SYS: Clock signal at G.703 levels regenerated from

the STATION CLK connector.

TTL: Clock signal at TTL levels, provided by a

dedicated line receiver.

Select the position best suited to the requirements

of the user modules installed in LRS-24: for

HTU-E1C module, always set the jumper JP14 to

SYS and the jumper JP15 to DIS.

Default setting: SYS

EN: Line receiver enabled. Always select this

position when the jumper JP14 is set to TTL.

DIS: Line receiver disabled. Always select this

position when the jumper JP14 is set to SYS.

Default setting: DIS

Installation and Setup 2-11

Page 40

Chapter 2 Installation and Setup LRS-24 Installation and Operation Manual

Order from: Cutter Networks

Ph:727-398-5252/Fax:727-397-9610

www.bestdatasource.com

CM-1 Installation Procedure

➤ To install CM-1:

• Insert the CM-1 module into the CL slot, and fasten it with the two screws.

CM-2 Module

This section covers the installation of the CM-2 module in an LRS-24 enclosure.

Front Panel

A typical front panel for the CM-2 module is shown in Figure 2-6. The functions of

the components located on the front panel are listed in Table 2-4.

POWER

TD

RD

STAT/ADD

CONTROL

R

S

2

3

2

CM-2

Power Indicator

Management Transmit

Activity Indicator

Management Receive

Activity Indicator

Status/Address

Display

Figure 2-6. Module CM-2 Front Panel

2-12 Installation and Setup

Page 41

LRS-24 Installation and Operation Manual Chapter 2 Installation and Setup

Order from: Cutter Networks

Ph:727-398-5252/Fax:727-397-9610

www.bestdatasource.com

Table 2-4. Module CM-2, Front Panel

Indicator Function

POWER Lights up when CM-2 is receiving input power (+5V)

TD Lights up to indicate activity on the transmit (input) line of

the ETHERNET MANAGEMENT port

RD Lights up to indicate activity on the receive (output) line of

the ETHERNET MANAGEMENT port

STAT/ADD Display If a failure is detected during the power-up self-test, displays

a code that identifies the failure type

During normal operation, displays the two least significant

digits of the hub number

MANAGEMENT

RS-232 Connector

Direct connection of supervision terminal to LRS-24

management port

Internal Jumpers

Figure 2-7 shows the location of the user-selectable jumpers located on the CM-2

module.

The module includes additional factory-set jumpers, which must not be moved by

the user.

Installation and Setup 2-13

Page 42

Chapter 2 Installation and Setup LRS-24 Installation and Operation Manual

Order from: Cutter Networks

Ph:727-398-5252/Fax:727-397-9610

www.bestdatasource.com

Clock Selection

E175E1

120T1100

JP2

JP8

JP9

JP3

JP1

JP4

JP5

JP7

JP6

E1 75

Unbalanced

E175E1

120T1100

E1 120

Balanced

JP2

JP8

JP9

JP3

JP1

JP4

JP5

JP7

JP6

E175E1

120T1100

T1 100

Balanced

JP2

JP8

JP9

JP3

JP1

JP4

JP5

JP7

JP6

JP14

Watchdog JP 14

ON

OFF

BY PAS S PA SSWO RD

JP15

JP16

E175E1

120T1100

JP2

JP8

JP9

JP3

JP1

JP4

JP5

JP7

JP6

N.C. GND

N.C. GND

J1

SCC1 SCC2

JP12

NC GND

J5

J7

GND Selection JP 12

Signal GND connected

to Frame GND

Signal GND not

connected to Frame GND

2-14 Installation and Setup

Figure 2-7. Module CM-2, Internal Jumpers

Table 2-5 lists the functions of the jumpers located on the CM-2 module.

Page 43

LRS-24 Installation and Operation Manual Chapter 2 Installation and Setup

Order from: Cutter Networks

Ph:727-398-5252/Fax:727-397-9610

www.bestdatasource.com

Table 2-5. Module CM-2 Jumper Settings

Jumpers Description Factory Settings

JP1 – JP9 Sets the jumpers according to the station clock applied to the STATION CLK

connector of the LRSI-F*-CM2 interface module. The available selections are

T1 clock source (1544 kHz clock), or E1 clock source (2048 kHz clock):

• T1 source: always select the balanced interface

• E1 source: select either the balanced or unbalanced interface, in

accordance with the source providing the clock signal

JP12 Selects connection of Signal Ground to Frame Ground:

E1 120

• GND – Connected

• N.C. – Disconnected

JP14 Enables Watchdog:

(see Figure 2-7)

JP15 Enables Password:

• Bypass – Password not required

• Password – Password required

JP16 Terminal Select:

• SCC1

• SCC2

* Interface module version, for example, LRSI-F-1, LRSI-F-2, etc.

Figure 2-7 identifies the jumper settings for each clock source interface.

CM-2 Installation

➤ To install CM-2:

1. Check that the POWER switch of the interface module is set to OFF.

2. Insert the CM-2 module in the CL slot.

GND

ON

Bypass

SCC1

3. Fasten with the two screws.

2.5 Interfaces and Connections

This section describes the installation and connections for:

• PS Interface Modules

• LRSI-F-CM1 Interface Module

• LRSI-F-1-CM2 Interface Module

• LRSI-F-2-CM2 Interface Module

• LRS-24 Enclosure.

Interfaces and Connections 2-15

Page 44

Chapter 2 Installation and Setup LRS-24 Installation and Operation Manual

Order from: Cutter Networks

Ph:727-398-5252/Fax:727-397-9610

www.bestdatasource.com

PS Interface Modules

This section explains the installation of the interface modules for PS modules.

Dangerous voltages are present inside the PS interface modules when

connected to power.

Warning

Do not connect a PS interface module to power before it is properly installed

within the LRS-24 enclosure, and disconnect the input power from the module

before removing it from the enclosure.

Table 2-6 shows the types of PS interface modules that are currently available for

LRS-24.