Page 1

ASMi-31

Order from: Cutter Networks

Ph:727-398-5252/Fax:727-397-9610

www.bestdatasource.com

Short Range Modem

Installation and Operation Manual

Notice

This manual contains information that is proprietary to RAD Data Communications. No part of this

publication may be reproduced in any form whatsoever without prior written approval by RAD Data

Communications.

No representation or warranties for fitness for any purpose other than what is specifically mentioned in

this manual is made either by RAD Data Communications or its agents.

For further information contact RAD Data Communications at the address below or contact your local

distributor.

RAD Data Communications

Headquarters

12 Hanechoshet Street

Tel Aviv 69710 Israel

Tel: 972-3-6458181

Fax: 972-3-6498250

E-mail: rad@rad.co.il

RAD Data Communications

US East

900 Corporate Drive

Mahwah, NJ 07430 USA

Tel: (201) 529-1100

Fax: (201) 529-5777

E-mail: market@radusa.com

RAD Data Communications

US West

3631 South Harbor Boulevard

Suite 250

Santa Ana, CA 92704

Tel: (714) 850-0555

Fax: (714) 850-1555

© 2000 RAD Data Communications Publication No. 646-200-03/00

Page 2

Order from: Cutter Networks

Ph:727-398-5252/Fax:727-397-9610

www.bestdatasource.com

Page 3

Warranty

Order from: Cutter Networks

Ph:727-398-5252/Fax:727-397-9610

www.bestdatasource.com

This RAD product is warranted against defects in material and workmanship for a period of one year

from date of shipment. During the warranty period, RAD will, at its option, either repair or replace

products which prove to be defective. For warranty service or repair, this product must be returned to

a service facility designated by RAD. Buyer shall prepay shipping charges to RAD and RAD shall pay

shipping charges to return the product to Buyer. However, Buyer shall pay all shipping charges, duties

and taxes for products returned to RAD from another country.

Limitation of Warranty

The foregoing warranty shall not apply to defects resulting from improper or inadequate maintenance

by Buyer, Buyer-supplied firmware or interfacing, unauthorized modification or misuse, operation

outside of the environmental specifications for the product, or improper site preparation or

maintenance.

Exclusive Remedies

The remedies provided herein are the Buyer's sole and exclusive remedies. RAD shall not be liable for

any direct, indirect special, incidental, or consequential damages, whether based on contract, tort, or

any legal theory.

Page 4

Safety Warnings

Order from: Cutter Networks

Ph:727-398-5252/Fax:727-397-9610

www.bestdatasource.com

The exclamation point within a triangle is intended to warn the operator or

service personnel of operation and maintenance factors relating to the

product and its operating environment which could pose a safety hazard.

Always observe standard safety precautions during installation, operation and maintenance of this

product. Only a qualified and authorized service personnel should carry out adjustment, maintenance

or repairs to this instrument. No adjustment, maintenance or repairs should be performed by either the

operator or the user.

Telecommunication Safety

The safety status of each of the ports on ASMi-31 is declared according to EN 41003 and is detailed in

the table below:

Ports Safety Status

V.24, V.35, X.21, RS-530, V.36,

LAN, balanced G.703

Line TNV-1 Telecommunications Networks Voltage within the

SELV Circuit operating with Safety Extra-Low Voltage

limits of SELV and subject to overvoltages.

Page 5

Regulatory Information

Order from: Cutter Networks

Ph:727-398-5252/Fax:727-397-9610

www.bestdatasource.com

FCC-15 User Information

This equipment has been tested and found to comply with the limits of the Class A digital device,

pursuant to Part 15 of the FCC rules. These limits are designed to provide reasonable protection against

harmful interference when the equipment is operated in a commercial environment. This equipment

generates, uses and can radiate radio frequency energy and, if not installed and used in accordance

with the instruction manual, may cause harmful interference to the radio communications. Operation

of this equipment in a residential area is likely to cause harmful interference in which case the user will

be required to correct the interference at his own expense.

Warning per EN 55022

This is a Class A product. In a domestic environment, this product may cause radio interference, in

which case the user may be required to take adequate measures.

Page 6

Declaration of Conformity

Order from: Cutter Networks

Ph:727-398-5252/Fax:727-397-9610

www.bestdatasource.com

Manufacturer's Name: RAD Data Communications Ltd.

Manufacturer's Address: 12 Hanechoshet St.

Tel Aviv 69710

Israel

declares that the product:

Product Name: ASMi-31/S

Conforms to the following standard(s) or other normative document(s):

EMC: EN 55022 (1994) Limits and methods of measurement of radio disturbance

characteristics of information technology equipment.

EN 50082-1 (1992) Electromagnetic compatibility – Generic immunity standards

for residential, commercial and light industry.

Safety: EN 60950 (1992/93) Safety of information technology equipment, including

electrical business equipment.

Supplementary Information:

The product herewith complies with the requirements of the EMC Directive 89/336/EEC and the Low

Voltage Directive 73/23/EEC. The product was tested in a typical configuration.

Tel Aviv, September 7th, 1997

Haim Karshen

VP Quality

European Contact: RAD Data Communications GmbH, Lyoner Strasse 14, 60528 Frankfurt am Main, Germany

Page 7

Quick Start Guide

Order from: Cutter Networks

Ph:727-398-5252/Fax:727-397-9610

www.bestdatasource.com

If you are familiar with ASMi-31, use this quick start guide to prepare the

unit for operation.

Perform the following steps for both the local and the remote units.

1. Disconnect all cables from the units.

2. Open the case of the units.

3. Adjust the jumpers (see Chapter 2, Installation and Setup).

Note

Make sure that there is only one clock source in the application. Select one

modem as INT or EXT, and the second modem as RCV.

4. Close the case of the units.

5. Connect the units to the DTEs.

6. Power up the units.

7. Connect the units to the line.

The units should operate properly after a few seconds.

1

Page 8

Quick Start Guide ASMi-31 Installation and Operation Manual

Order from: Cutter Networks

Ph:727-398-5252/Fax:727-397-9610

www.bestdatasource.com

2

Page 9

Contents

Order from: Cutter Networks

Ph:727-398-5252/Fax:727-397-9610

www.bestdatasource.com

CHAPTER 1 INTRODUCTION

1.1 Overview ....................................................................................................................... 1-1

General ................................................................................................................................ 1-1

Versions................................................................................................................................ 1-1

Application ...........................................................................................................................1-2

Features................................................................................................................................ 1-2

1.2 Physical Description....................................................................................................... 1-3

1.3 Functional Description ................................................................................................... 1-3

General ................................................................................................................................ 1-3

Remote Management............................................................................................................ 1-4

Data Transmission................................................................................................................. 1-4

Master/Slave Clock Modes ....................................................................................................1-4

Special Management Configurations...................................................................................... 1-4

Diagnostic Capabilities.......................................................................................................... 1-4

Overload Protection.............................................................................................................. 1-5

1.4 Technical Specifications ................................................................................................. 1-5

Line Interface........................................................................................................................ 1-5

Digital Interface (DTE)........................................................................................................... 1-5

Clock Source ........................................................................................................................1-6

Control Signals...................................................................................................................... 1-6

Diagnostics ...........................................................................................................................1-6

Indicators..............................................................................................................................1-6

Power................................................................................................................................... 1-6

Physical ................................................................................................................................ 1-7

Environment .........................................................................................................................1-7

CHAPTER 2 INSTALLATION AND SETUP

2.1 Site Requirements and Prerequisites .............................................................................. 2-1

Power................................................................................................................................... 2-1

Ambient Requirements .........................................................................................................2-1

2.2 Package Contents........................................................................................................... 2-2

2.3 Installation and Setup..................................................................................................... 2-2

Setting the Internal Jumpers ..................................................................................................2-2

Connecting the Interfaces...................................................................................................... 2-6

CHAPTER 3 OPERATION

3.1 Controls and Indicators .................................................................................................. 3-1

3.2 Operating Instructions.................................................................................................... 3-2

Turning ASMi-31 On ............................................................................................................3-2

Normal LEDs Indications....................................................................................................... 3-2

Turning ASMi-31 Off ............................................................................................................3-3

CHAPTER 4 TROUBLESHOOTING AND DIAGNOSTICS

4.1 Diagnostic Tests ............................................................................................................. 4-1

Local Analog Loopback (LLB) ................................................................................................4-2

Remote Loopback (RLB)........................................................................................................ 4-3

ASMi-31 Installation and Operation Manual i

Page 10

Table of Contents

Order from: Cutter Networks

Ph:727-398-5252/Fax:727-397-9610

www.bestdatasource.com

CHAPTER 5 CARD CAGE VERSION

5.1 ASM-MN-214 Card Cage ............................................................................................... 5-1

5.2 ASMi-31/R Card Version ................................................................................................ 5-3

5.3 Power Supply................................................................................................................. 5-4

AC Supply (100, 115 or 230 VAC)......................................................................................... 5-4

DC Supply (-48 VDC) ...........................................................................................................5-4

Power Supply with Redundancy............................................................................................ 5-4

5.4 Installing ASMi-31/R....................................................................................................... 5-5

APPENDIX A ETHERNET INTERFACE

APPENDIX B IR-G.703 CODIRECTIONAL INTERFACE (64 KBPS)

APPENDIX C X.21 INTERFACE MODULE

APPENDIX D DTE INTERFACE CONNECTORS

APPENDIX E CONNECTING RS-530 TO RS-422

APPENDIX F INSTALLATION IN 19" RACK

ii ASMi-31 Installation and Operation Manual

Page 11

Table of Contents

Order from: Cutter Networks

Ph:727-398-5252/Fax:727-397-9610

www.bestdatasource.com

List of Figures

Figure 1-1 ASMi-31 Working Opposite HS-U Card in Megaplex-2100.......................................... 1-2

Figure 1-2 ASMi-31 Standalone Unit ............................................................................................ 1-3

Figure 2-1 ASMi-31 PCB Layout ................................................................................................... 2-4

Figure 2-2 ASMi-31 Rear Panel..................................................................................................... 2-6

Figure 2-3 Connecting the Line – Step 1....................................................................................... 2-7

Figure 2-4 Connecting the Line – Step 2....................................................................................... 2-7

Figure 2-5 Connecting the Line – Step 3....................................................................................... 2-7

Figure 3-1 ASMi-31 Front Panel.................................................................................................... 3-1

Figure 4-1 Local Analog Loopback ................................................................................................ 4-2

Figure 4-2 Remote Digital Loopback............................................................................................. 4-3

Figure 5-1 ASM-MN-214 Rear Panel ............................................................................................ 5-2

Figure 5-2 ASMi-31/R Front Panel ................................................................................................ 5-3

Figure 5-3 ASM-MN-214 Front Panel ........................................................................................... 5-4

ASMi-31 Installation and Operation Manual iii

Page 12

List of Tables

Order from: Cutter Networks

Ph:727-398-5252/Fax:727-397-9610

www.bestdatasource.com

List of Tables

Table 2-1 ASMi-31 Internal Jumpers and Switches........................................................................ 2-4

Table 2-2 DTE Interfaces and Matching Adapter Cables................................................................ 2-7

Table 3-1 Local Control Functions (via DTE) ................................................................................. 3-2

Table 3-2 ASMi-31 Controls and Indicators – Normal Operation .................................................. 3-2

iv ASMi-31 Installation and Operation Manual

Page 13

Chapter 1

Order from: Cutter Networks

Ph:727-398-5252/Fax:727-397-9610

www.bestdatasource.com

Introduction

This chapter describes basic physical and functional features of the

ASMi-31 standalone modem, as well as some typical applications. It

discusses the following topics:

•

An overview of the modem

•

Physical description

•

Functional description

•

Technical specifications.

1.1 Overview

General

Versions

The ASMi-31 modem is a synchronous/asynchronous short-range modem

which is managed by a remote master modem. ASMi-31 operates

synchronously or asynchronously at full duplex over 2-wire twisted pair,

unconditioned lines. The ASMi-31 modem has a transmission range of 8 km

(5 miles) over 24 AWG wire and operates at user-selectable data rates from

1.2 kbps to 128 kbps.

ASMi-31 is available in several versions:

•

ASMi-31 standalone – the standalone slave unit features a blank panel

•

ASMi-31/R – a plug-in card which may be installed in the ASM-MN-214

hub.

•

ASMi-31C – a plug-in card which may be installed in the LRS-12 or

LRS-24 hub (see ASMi-31C Installation and Operation Manual for details).

Power Supply Versions

The power supply options are:

•

AC power source: 115 VAC or 230 VAC

•

DC power source: -48 VDC.

16-03-00 15:51 Overview 1-1

Page 14

Chapter 1. Introduction ASMi-31 Installation and Operation Manual

Order from: Cutter Networks

Ph:727-398-5252/Fax:727-397-9610

www.bestdatasource.com

Application

Backbone

Features

Figure 1-1 illustrates the ASMi-31 application.

2-wire

HS-U card

MP-2100

ASMi-31

Figure 1-1 ASMi-31 Working Opposite HS-U Card in Megaplex-2100

The ASMi-31 short range modem supports full duplex transmission over

2-wire twisted pair unconditioned lines.

The ASMi-31 modem operates in pairs with either another standalone

modem, or as a card installed in the ASM-MN-214 hub.

A management channel transmitted in-band allows remote configuration for

the modem, real-time alerts on failures, and diagnostic testing. The line data

rate is selectable from 1.2 kbps up to 128 kbps and the line encoding is

2B1Q. ASMi-31 achieves an operating range up to 8 km (5 miles) over

24 AWG wire, independent of data rate.

The ASMi-31 modem is fully compatible with ASM-31 and SRM-31 and

works opposite MP-2100/HS-U module.

The ASMi-31 modem features automatic rate detection in external clock

mode for tail-end applications.

Control Signal Transfers

ASMi-31 supports end-to-end transfer of two control signals: DTR to DSR

and RTS to DCD, except for the V.35 interface or any other standard that

doesn't support this signal (such as X.21, G.703).

Interfaces

ASMi-31 supports the following interfaces: V.24/RS-232, V.35, X.21,

V.36/RS-449, RS-530, G.703 Codirectional, or built-in Ethernet bridge.

Diagnostics

ASMi-31 contains two diagnostic loops for complete diagnostics of both

local and remote modems:

•

Local analog loopback

•

Remote digital loopback

Both loopbacks are controlled via pins in the DTE interface and are

supported by their respective standards.

1-2 Overview 16-03-00 15:51

Page 15

ASMi-31 Installation and Operation Manual Chapter 1. Introduction

Order from: Cutter Networks

Ph:727-398-5252/Fax:727-397-9610

www.bestdatasource.com

1.2 Physical Description

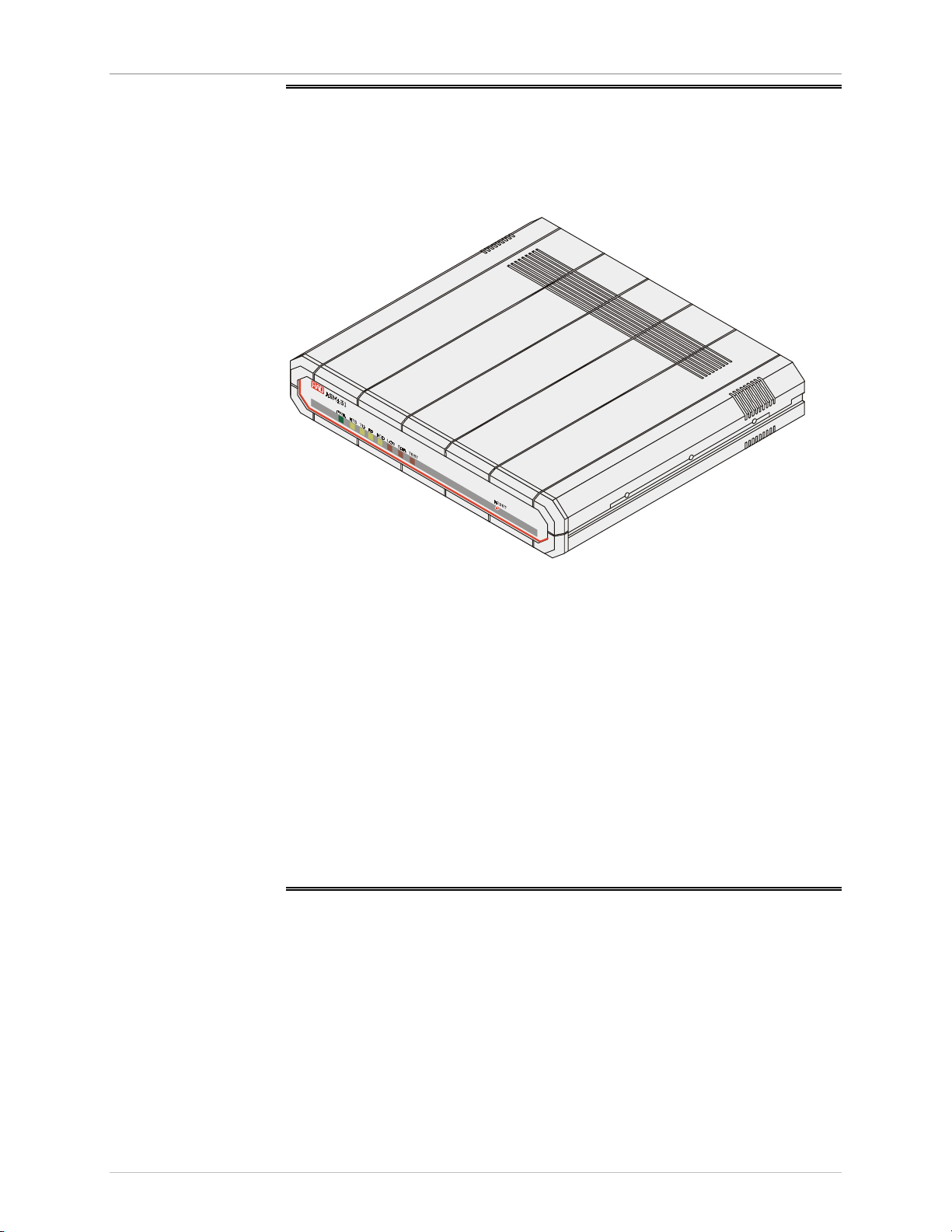

ASMi-31 is available as a standalone desktop unit or as a card for the

ASM-MN-214 hub. Figure 1-2 shows the 3D view of the ASMi-31

standalone unit.

General

Figure 1-2 ASMi-31 Standalone Unit

The front panel includes eight LEDs, which display the status of power, data

flow, control signals and diagnostics. For detailed description of the front

panel, see Chapter 3, Operation.

The back panel includes an power connector with fuse, an interface

connector, and a terminal block with a ground connection for connecting

the telephone lines. The ASMi-31 rear panel is described in greater detail, in

Chapter 2, Installation and Setup.

The internal switches and jumpers can be configured to support a variety of

modes for operating the modem. Refer to Setting the Internal Jumpers in

Chapter 2 for details on jumper location and setting.

1.3 Functional Description

The ASMi-31 standalone modem is managed by a master ASMi-31C modem

card mounted on a LRS-12 or LRS-24 hub. The management channel, which

is transmitted in-band, allows remote configuration, real-time alerts on

system failure, diagnostic testing, and the production of statistical

information on system performance.

16-03-00 15:51 Functional Description 1-3

Page 16

Chapter 1. Introduction ASMi-31 Installation and Operation Manual

Order from: Cutter Networks

Ph:727-398-5252/Fax:727-397-9610

www.bestdatasource.com

Remote Management

Data Transmission

Special Management Configurations

Diagnostic Capabilities

The ASMi-31 standalone modem is very conveniently managed from the

master station by means of RADview, a RAD SNMP application. This

user-friendly graphical user interface manages the ASMi-31C modem cards

installed in the LRS-12 or LRS-24 hub and, through them, the ASMi-31

standalone units.

Both data and management are transmitted inband over the same line,

simultaneously, without interference.

Full duplex operation over 2-wires is achieved using the adaptive

"echo-canceling" technique. The ASMi-31 modem uses 2B1Q line coding

to achieve the range of 8 km/5 miles, for all data rates. This coding

provides immunity to background noise, eliminates normal line distortion

and permits efficient transmission over 2-wire twisted cables.

An adaptive equalizer provides noise immunity and high performance over

low quality lines.

The ASMi-31 standalone modem unit has internal jumpers which allow for

special management configurations such as point-to-point applications

without ASMi-31C modem cards in the LRS-12 or LRS-24 hub, and also

on-site diagnostics testing.

In addition to the remote diagnostic capability, the ASMi-31 standalone

modem provides diagnostic capabilities which can be executed locally.

These include the Digital Loopback (RLB) and Analog Loopback (LLB)

diagnostics; they are executed via the DTE interface after the appropriate

jumpers are set. The ASMi-31 unit has a blank panel to prevent

unauthorized operation at the customer premises.

Overload Protection

Note

The local diagnostics are as follows:

•

Remote Digital Loopback – REM, activated by pin in DTE interface and

supported by respective standard.

•

Analog Loopback – Local (ANA defined by the standard as LLB),

activated by pin in DTE interface and supported by the respective

standard.

The ASMi-31 loopbacks do not operate with the X.21 and G.703

(Codirectional) because they are not supported by these standards.

The ASMi-31 modem is coupled to the line through an isolation transformer

which protects against AC or DC overvoltages. The protection circuitry

permits operation even when DC is connected to the line.

1-4 Functional Description 16-03-00 15:51

Page 17

ASMi-31 Installation and Operation Manual Chapter 1. Introduction

p

p

g

g

p

p

p

yp

p

p

p

p

p

Order from: Cutter Networks

Ph:727-398-5252/Fax:727-397-9610

www.bestdatasource.com

1.4 Technical Specifications

Line Interface

Digital Interface

(DTE)

Type 2-wire, full du

line (twisted

Line Codin

Ran

e U

Level U

Connector T

Standard Com

Types ITU V.24/RS-232, V.35, RS-530 or X.21,

Data Rates 1.2 kb

Connectors

e 3-cli

2B1Q

to 8 km (5 miles), over a 24 AWG wire,

inde

endent of data rate

to 14 dBm (assuming a 135Ω load)

terminal block and RJ-45 connector

lies with ANSI T1.601.1988

s

ecifications

G.703 Codirectional (64 kb

Ethernet (10BT), Ethernet 10B2 (BNC)

s to 128 kbps

•

V.24 – 25-pin, D-type female

•

V.35 – 34-pin, female

•

V.36 – 37-pin, D-type female, via supplied

cable adapter

lex unconditioned telephone

air), using echo-cancellation

s),

•

X.21 – 15-pin, D-type female

•

RS-530 – 25-pin, D-type female

•

G.703/TB – Terminal Block

•

G.703/RJ – RJ-45, female

•

Ethernet (10BaseT) – RJ-45, conforms to

IEEE 802.3

•

Ethernet (10Base2) – BNC

16-03-00 15:51 Technical Specifications 1-5

Page 18

Chapter 1. Introduction ASMi-31 Installation and Operation Manual

y

g

g

g

g

p

g

g

y

p

g

y

pp

y

q

y

y

y

g

g

q

y

g

Order from: Cutter Networks

Ph:727-398-5252/Fax:727-397-9610

www.bestdatasource.com

Clock Source

Control Signals

Diagnostics

Master Clock

Internal clock – The master clock uses its own

internal cr

stal when transmitting or receivin

data from the DTE interface and from the line.

External clock – The master clock uses the

clock derived from the di

ital interface to

receive data from the DTE and for transmittin

data to the line.

If the di

ital interface is X.21, the same clock is

used to transmit and receive data.

Slave Clock

back timin

Loo

from the line si

– The clock is recovered

nal and used to transmit and

receive data from the DTE interface to the

line.

Jumper-selectable:

•

RTS to DCD

•

DTR to DSR

Loopback Tests Remote Digital Loopback – REM activated b

in in DTE interface supported by the

appropriate standard

Indicators

Power

Analo

Loopback – Local (ANA defined b

the standard as LLB) activated by pin in DTE

interface su

orted by the appropriate

standard

PWR (green) Power

ellow) Re

RTS (

ellow) Transmit Data (Circuit 103)

TD (

ellow) Receive Data (Circuit 104)

RD (

DCD (

ellow) Data Carrier Detect (Circuit 109)

LOS (red) Loss of si

uest To Send (Circuit 105)

nal

ERR (red) Error is detected in received confi

information

TEST (red) A test is active

AC Voltage 115 VAC or 230 VAC (10%), 5W

Fre

uenc

50 or 60 Hz (47 to 63 Hz)

uration

1-6 Technical Specifications 16-03-00 15:51

DC Volta

e -48 VDC (-36 to -72 VDC)

Power Fuses 0.1A, slow-blow for 230V

Page 19

ASMi-31 Installation and Operation Manual Chapter 1. Introduction

p

g

g

y

g

Order from: Cutter Networks

Ph:727-398-5252/Fax:727-397-9610

www.bestdatasource.com

0.2A, slow-blow for 115V

Physical

Environment

Height 4.4 cm / 1.7 in

Width 19.3 cm / 7.6 in

De

th 24.3 cm / 9.6 in

Wei

ht 1.5 k

/ 3.3 lb

Temperature 0°-50° C / 32°-122° F

Humidit

Up to 90%, non-condensin

16-03-00 15:51 Technical Specifications 1-7

Page 20

Chapter 1. Introduction ASMi-31 Installation and Operation Manual

Order from: Cutter Networks

Ph:727-398-5252/Fax:727-397-9610

www.bestdatasource.com

1-8 Technical Specifications 16-03-00 15:51

Page 21

Chapter 2

Order from: Cutter Networks

Ph:727-398-5252/Fax:727-397-9610

www.bestdatasource.com

Installation and Setup

This chapter provides the following information for the ASMi-31 standalone

model:

•

Site requirements and prerequisites

•

Package contents

•

Instructions for mechanical installation

•

Instructions for electrical installation.

After installing the unit, refer to Chapter 3 to assure normal operation.

In case a problem encountered, refer to Chapter 4 for test and diagnostic

instructions.

Refer to Chapter 5 for additional information on the ASMi-31/R card

version.

Power

Ambient Requirements

2.1 Site Requirements and Prerequisites

AC-powered ASMi-31 units should be installed within 1.5m (5 ft) of an

easily accessible grounded AC outlet. The outlet should furnish 115 VAC or

230 VAC.

DC-powered ASMi-31 units require -48 VDC power source, which must be

adequately isolated from the mains supply.

•

Allow at least 90 cm (36 in) of clearance at the front for operating and

maintenance accessibility.

•

Allow at least 10 cm (4 in) clearance at the rear of the unit for signal lines

and interface cables.

The ambient operating temperature of ASMi-31 is 0 to 50°C (32 to 122°F)

at relative humidity of 90%, non-condensing.

16-05-01 13:37 Site Requirements and Prerequisites 2-1

Page 22

Chapter 2. Installation and Setup ASMi-31 Installation and Operation Manual

Order from: Cutter Networks

Ph:727-398-5252/Fax:727-397-9610

www.bestdatasource.com

2.2 Package Contents

•

One ASMi-31 unit (protected by adequate cushioning)

•

AC power cord or DC power supply connector kit

•

ASMi-31 Installation and Operation Manual

•

Interface adapter cable(s) (see Table 2-2) - Optional.

2.3 Installation and Setup

ASMi-31 is a standalone device intended for tabletop or bench installation.

It is delivered completely assembled. No provisions are made for bolting

ASMi-31 to the tabletop. For installation of the unit in a 19" rack, refer to

Appendix F.

➤

➤ To complete the installation of ASMi 31:

➤ ➤

Setting the Internal Jumpers

1. Determine the required configuration of the modem according to your

application, and set the internal jumpers and switches accordingly (see

and .

2. Connect the line (see Connecting the Line below).

3. Connect the DTE interface (see Connecting the DTE below).

4. Connect power to the unit (see Connecting the Power below).

This section provides information on the functions of the internal jumpers

and switches, to help you in the selection of the correct settings for

particular application, and gives you step-by-step instructions for

performing the internal settings. The default settings are also listed.

1. Open the ASMi-31 case.

2. Set the ASMi-31 internal jumpers and switches, referring to Figure 2-1

and Table 2-1.

3. Reinstall the ASMi-31 cover.

2-2 Installation and Setup 16-05-01 13:37

Page 23

ASMi-31 Installation and Operation Manual Chapter 2. Installation and Setup

Order from: Cutter Networks

Ph:727-398-5252/Fax:727-397-9610

www.bestdatasource.com

Access to the inside of the equipment is permitted only to the

authorized and qualified personnel.

Warning

To avoid accidental electric shock, always disconnect the interface

cables and the power cord before removing the unit from its casing.

Line voltages are present inside ASMi-31 when it is connected to power

and/or the lines. Moreover, under certain fault conditions, dangerous

voltages may appear on the lines connected to the unit.

Any adjustment, maintenance and repair of the opened instrument

under voltage must be avoided as much as possible and, when

inevitable, should be carried out only by a skilled technician who is

aware of the hazard involved. Capacitors inside the unit may still be

charged even after the unit has been disconnected from its source of

power.

Caution

ASMi-31 contains components sensitive to electrostatic discharge (ESD). To

prevent ESD damage, avoid touching the internal components, and before

moving jumpers, touch the ASMi-31 frame.

Opening the ASMi-31 Case

To reach the internal jumpers and switches of ASMi-31, it is necessary to

open its case.

➤

➤ To open the ASMi-31 case:

➤ ➤

1. Disconnect all the cables connected to ASMi-31.

2. Turn the unit over (bottom facing up).

3. Unscrew the four cover screws.

4. Turn the unit over (bottom facing down).

5. After the four screws released, remove the ASMi-31 top cover by

pulling it straight up.

Setting the Internal Jumpers and Switches

The internal jumpers and switches located on the ASMi-31 printed circuit

board (PCB) are identified in * Baud

rates not applicable.

16-05-01 13:37 Installation and Setup 2-3

Figure 2-1. Their numbers under heading "Item" in Table 2-1 correspond to

the identification numbers shown in Table 2-1.

Page 24

Chapter 2. Installation and Setup ASMi-31 Installation and Operation Manual

Order from: Cutter Networks

Ph:727-398-5252/Fax:727-397-9610

www.bestdatasource.com

CHASS-GND

2

1

CON

JP18

DIS

DIS

EN

JP14

RLB

DIS

EN

LLB

JP15

CLOCK

LBT

INT

JP9

EXT

B

C

A

D

9

SW7

8

7

6

SLAV MAST

DSR DTR

DCD CNT

1STB 2STB

EVEN ODD

P. E N DI S

8BIT 7BIT

ASY SYNC

87654

DIP

21

SW6

POS

E

F

1

2

5

4

3

BAUD

0

0.6K

1

1.2K

2

2.4K

3

4.8K

4

9.6K

5

19.2K

6

38.4K

7

48K

8

*56K

9

64K

A

128K

B

*144K

C

*57.6K

D

*115.2K

E

16K

F

32K

3

4

5

6

Baud rates not applicable

*

.

Figure 2-1 ASMi-31 PCB Layout

Table 2-1 ASMi-31 Internal Jumpers and Switches

Item Jumper Description Values Default Setting

1 RLB, JP14 Controls the remote loopback

activation from the DTE

2 CHASS-GND,

JP18

Controls the connection

between the ASMi-31 signal

ground and the frame (chassis)

ground

Note: Disconnecting the signal ground from the frame ground may render the unit unsafe for connection to

unprotected telecommunication networks in some locations.

DIS – The RLB activation from

the DTE is disabled

EN – The RLB activation from

the DTE is enabled

CON – Signal ground is

connected to the frame ground

DIS – Signal ground is

disconnected from the frame

ground

DIS

CON

2-4 Installation and Setup 16-05-01 13:37

Page 25

ASMi-31 Installation and Operation Manual Chapter 2. Installation and Setup

p

p

p

p

p

p

p

p

p

p

p

y

g

Order from: Cutter Networks

Ph:727-398-5252/Fax:727-397-9610

www.bestdatasource.com

Table 2-1 ASMi-31 Internal Jumpers and Switches (Cont.)

Item Jumper Description Values Default Setting

3 LLB, JP15 Controls the local loopback

activation from the DTE

DIS – The LLB activation from

the DTE is disabled

EN – The LLB activation from

the DTE is enabled

4 CLOCK Controls the ASMi-31 timing

reference

LBT – Loopback timing, clock is

recovered from the data at the

line side

INT – Internal clock

EXT – External clock

5 SW7 Selects the data rate

1 – 1.2 kb

2 – 2.4 kb

3 – 4.8 kb

4 – 9.6 kb

5 – 19.2 kb

6 – 38.4 kb

7 – 48 kb

9 – 64 kb

A – 128 kb

E – 16 kb

F – 32 kbps, sync

5 SW6 DIP switch, which consists of eight section

s, sync/async

s, sync/async

s, sync/async

s, sync/async

s, sync/async

s, sync/async

s, sync

s, sync

s, sync

s, sync

DIS

LBT

9 – 64 kb

s

Section 1 Controls the ASMi-31 operation

mode – s

nchronous or

asynchronous

Section 2 Defines the number of data bits

to be used

Section 3 Controls the use of parity ON – Parity enabled

ON – Async operation

OFF – Sync operation

ON – 8 bits

OFF – 7 bits

Sync

8 bits

P.EN

OFF – Parity disabled

Section 4 Defines the parity type ON – Even parity

Even

OFF – Odd parity

Section 5 Defines the number of stop bits ON – One stop bit

1STB

OFF – Two stop bits

Section 6 Controls the RTS to DCD

transfer

ON – DCD, the DCD signal

turns on when the two units

DCD

reach synchronization

OFF – CNT, the DCD si

nal of

the local unit follows the RTS

signal of the remote unit

Note: The DCD signal is OFF when a digital loopback is active (receiving RLB command) or when there is no

synchronization between the units).

16-05-01 13:37 Installation and Setup 2-5

Page 26

Chapter 2. Installation and Setup ASMi-31 Installation and Operation Manual

p

p

p

Order from: Cutter Networks

Ph:727-398-5252/Fax:727-397-9610

www.bestdatasource.com

Table 2-1 ASMi-31 Internal Jumpers and Switches (Cont.)

Item Jumper Description Values Default Setting

Section 7 Controls the DTR to DSR

transfer

Section 8 Controls the ASMi-31

erational status – slave or

o

master

Closing the ASMi-31 Case

After completing the internal settings, close the unit case.

➤

➤ To close the ASMi-31 case:

➤ ➤

1. Replace the upper half of the unit and press firmly until the plastic tabs

fit into the tab housing.

2. Insert the original cover screws in their positions and tighten carefully.

Do not use excessive torque.

ON – Indicates only that the

local unit is

does not indicate the status of

the communication channel or

erational status of the remote

o

site

OFF – Indicates that the DSR of

the local unit follows the DTR

signal of the remote unit

ON – Slave

OFF – Master

owered up. It

DSR

Slave

Connecting the Interfaces

Figure 2-2 illustrates the rear panel of the ASMi-31 modem.

DTE

~230V 0.1A T 250V

LINE

GND

245

Figure 2-2 ASMi-31 Rear Panel

Connecting the Line

The ASMi-31 line connector is a terminal block/RJ-45 connector. Connect

the transmission line (twisted pair) to the two clips marked LINE and the

cable shield to the clip marked GND (optional). High rate data

communication twisted pair cable is highly recommended in order to

prevent crosstalk.

Before connecting the cables, make sure that the equipment is earthed by

its power cable.

2-6 Installation and Setup 16-05-01 13:37

Caution

Insert the GND lead first.

Page 27

ASMi-31 Installation and Operation Manual Chapter 2. Installation and Setup

Order from: Cutter Networks

Ph:727-398-5252/Fax:727-397-9610

www.bestdatasource.com

➤

➤ To connect the line:

➤ ➤

1. Insert the screwdriver into a square hole (see Figure 2-3).

Figure 2-3 Connecting the Line – Step 1

2. Raise the inserted screwdriver, putting pressure on the ramp within the

square hole (see Figure 2-4).

Figure 2-4 Connecting the Line – Step 2

3. Insert the stripped end of the wire and remove the screwdriver (see

Figure 2-5).

Figure 2-5 Connecting the Line – Step 3

Connecting the DTE

The rear-panel DTE connector provides interface for data input/output,

clock reference and control signal exchange between ASMi-31 and the DTE.

The DTE interface is changeable module with the interface connector. The

DTE is connected to ASMi-31 via adapter cables depending on the interface

type, see Table 2-2 to select the correct cable for your DTE interface.

Table 2-2 DTE Interfaces and Matching Adapter Cables

DTE Interface Connector Description RAD Cable

V.24/RS-232 25-pin, D-type, female CBL-HBT/V24

V.35 34-pin, female CBL-HBT/V35

X.21 15-pin, female CBL-HBT/X21

16-05-01 13:37 Installation and Setup 2-7

Page 28

Chapter 2. Installation and Setup ASMi-31 Installation and Operation Manual

Order from: Cutter Networks

Ph:727-398-5252/Fax:727-397-9610

www.bestdatasource.com

Table 2-2 DTE Interfaces and Matching Adapter Cables (Cont.)

DTE Interface Connector Description RAD Cable

RS-530/RS-449 25-pin, D-type connector. For a description of the

cabling connection between the RS-530 interface and

the RS-449/RS-442 (V.36) 37-pin, D-type connector,

see Appendix E. The cable is provided with the

product.

G.703 Codirectional 64 kbps interface. For a description of

the G.703, see Appendix B.

Ethernet Interface RJ-45 or BNC connector. For a description of the

Ethernet interface, see Appendix A.

Connecting the Power

The AC power is supplied to the ASMi-31 unit through the 1.5m (5 ft)

standard power cable terminated in a standard 3-prong plug (see Figure 2-

2). The cable is provided with the unit.

The rated fuse for the unit is 250V / 0.1A slow-blow for 230V, or

250V / 0.2A slow-blow for 115V.

The unit has no power switch. Operation starts when the power is

applied to the rear-panel POWER connector.

Warning

Before switching on this instrument, the protective earth terminals of

this instrument must be connected to the protective ground conductor

of the power cord. The power plug shall only be inserted in a power

outlet provided with a protective earth contact. The protective action

must not be negated by use of an extension cord (power cable) without

a protective conductor (grounding).

CBL-HBT/RS-530

Make sure that only fuses with the required rated current, as marked on

the ASMi-31 rear panel, are used for replacement. The use of repaired

fuses and the short-circuiting of the fuse holders is forbidden.

Whenever it is likely that the protection offered by fuses has been

impaired, the instrument must be made inoperative and be secured

against any unintended operation.

➤

➤ To connect AC power to ASMi-31:

➤ ➤

1. Connect the power cable to the connector on the ASMi-31 rear panel.

2. Connect the power cable to the mains outlet.

The unit will be turned on automatically upon connection to the

mains.

➤

➤ To connect DC power to ASMi-31:

➤ ➤

•

Refer to DC Power Connection Supplement.

2-8 Installation and Setup 16-05-01 13:37

Page 29

Chapter 3

Order from: Cutter Networks

Ph:727-398-5252/Fax:727-397-9610

www.bestdatasource.com

Operation

This chapter provides the following information for the ASMi-31 standalone

modem:

•

ASMi-31 front-panel indicators and controls

•

Operating procedures (turn-on, front-panel indications, performance

monitoring and turn-off).

Installation procedures given in Chapter 2 must be completed and checked

before attempting to operate ASMi-31.

3.1 Controls and Indicators

Figure 3-1 illustrates the ASMi-31 standalone modem front panel. Table 3-1

lists the functions of the controls and indicators.

PWR RTS TD RD DCD LOS ERR TEST RESET

Figure 3-1 ASMi-31 Front Panel

Note

Name Type ITU Circuit Function

RESET Button This switch resets the unit; it is used in place of a power switch.

PWR Green LED On when ASMi-31 is powered up.

RTS Yellow LED 105 On when the DTE has emitted an active Request to Send signal

TD Yellow LED 103 On when a steady space is being transmitted.

RD Yellow LED 104 On when a steady space is being received.

In ASMi-31 modem/X.21 RTS LED is equivalent to Control signal (C), and

DCD LED is equivalent to Indication signal (I).

Table 3-1 Front Panel Controls and Indicators

It is not needed for normal operation.

(or Control in X.21).

Blinks when data is transmitted.

Blinks when data is received.

16-03-00 15:51 Controls and Indicators 3-1

Page 30

Chapter 3. Operation ASMi-31 Installation and Operation Manual

Order from: Cutter Networks

Ph:727-398-5252/Fax:727-397-9610

www.bestdatasource.com

Table 3-1 Front Panel Controls and Indicators (Cont.)

Name Type ITU Circuit Function

DCD Yellow LED 109 On when the local and remote modems are in sync, and the

section 6 of the internal SW6 switch is set to ON.

On when the local and remote modems are in sync, and the

section 6 of the internal SW6 switch is set to OFF, and the RTS at

the remote modem is ON.

LOS Red LED On when loss of synchronization occurs between the local and

remote modem.

ERR Red LED On when an error occurs in the configuration received from the

master unit.

TEST Red LED On when a test is active.

3.2 Operating Instructions

Turning ASMi-31 On

Normal LEDs

Indications

ASMi-31 turns on as soon as power is connected. When power is

connected, the PWR indicator lights up and remains lit as long as ASMi-31

receives power.

Check that the other front panel LEDs appear as listed in Table 3-2. This

indicates that the local and remote ASMi-31 units are operational and

passing data.

Table 3-2 ASMi-31 Controls and Indicators – Normal Operation

Name State Function

PWR On

TD On or blinking Flashing depends upon the data being transmitted.

RD Off or blinking Flashing depends upon the data being received.

RTS Lights when RTS status is On

DCD Lights when RTS is received from the remote

modem and the modems are synchronized

(DCD - OFF - switch SW6)

LOS On or blinking Blinks until synchronization between the modems

is achieved.

Constantly On when there is no synchronization.

ERR Off or blinking Blinks until synchronization between the modems

is achieved.

TEST On or blinking Blinks until synchronization between the modems

is achieved.

Constantly On while test is activated from either

local or remote unit.

3-2 Operating Instructions 16-03-00 15:51

Page 31

ASMi-31 Installation and Operation Manual Chapter 3. Operation

Order from: Cutter Networks

Ph:727-398-5252/Fax:727-397-9610

www.bestdatasource.com

If the above LED indicators are not obtained following initial power-up,

make sure that:

•

One modem is set to internal or external clock, and the other to LBT

clock.

•

None of the modems are in test mode.

Turning ASMi-31

Off

To turn off ASMi-31, simply remove the power cord from the power source.

16-03-00 15:51 Operating Instructions 3-3

Page 32

Chapter 3. Operation ASMi-31 Installation and Operation Manual

Order from: Cutter Networks

Ph:727-398-5252/Fax:727-397-9610

www.bestdatasource.com

3-4 Operating Instructions 16-03-00 15:51

Page 33

Chapter 4

Order from: Cutter Networks

Ph:727-398-5252/Fax:727-397-9610

www.bestdatasource.com

Troubleshooting and

Diagnostics

This chapter describes how to perform diagnostics tests on ASMi-31.

The function of diagnostic tests on ASMi-31 is to:

•

Check that the system is operating normally

•

Isolate faulty equipment or cables

•

Identify other sources of system malfunction.

Tests are activated via the corresponding DTE pins and monitored via the

ASMi-31 front-panel LED indicators.

4.1 Diagnostic Tests

The diagnostic capabilities of the ASMi-31 modem allow rapid checkout of

the DTEs, the ASMi-31 modem, and connecting lines. The test will

immediately verify the operational performance of each unit in the system

or provide an indication of equipment failure.

Before testing the operation of the data system equipment and 2-wire line

circuits, first ensure that all units are powered on and configured normally,

then perform the test steps described below, in order.

ASMi-31 supports two types of loopback tests for evaluating the operation of

the data system equipment and line circuits. Using these loopbacks, you can

test the communication between the attached equipment, internal circuitry

of the local ASMi-31 and the remote ASMi-31.

24-01-00 19:17 Diagnostic Tests 4-1

Page 34

Chapter 4. Tests and Diagnostics ASMi-31 Installation and Operation Manual

Order from: Cutter Networks

Ph:727-398-5252/Fax:727-397-9610

www.bestdatasource.com

Local Analog Loopback (LLB)

DTE

The Local Analog Loopback (LLB) test checks the performance of the local

ASMi-31, the local DTE, and the connections between them (see

Figure 4-1). Perform the test separately at the local and the remote site.

Data

Clock

Clock

Data

Tra nsm it

Line

Interface

Receive

ASMi-31

Figure 4-1 Local Analog Loopback

➤

➤ To perform the Local Analog Loopback test:

➤ ➤

•

Activate the test via the DTE interface analog loopback.

The TEST LED lights up.

The ASMi-31 modem transmit output is connected to the receiver circuits

internally at the line side. If a fault is indicated, call a technician or replace

the unit.

Set the DTE equipment in half duplex (which produces an "echo" through

the system). It is recommended that you repeat the LLB test using an

external Bit Error Rate Tester (BERT).

Perform the test at both ends. If the BERT equipment test indicates no faults,

but the data terminal indicates a fault, follow the DTE manufacturer's test

procedures . Also check the interconnecting cable interfacing between the

terminal and the ASMi-31 modem.

After completing the test (or when the fault has been corrected), deactivate

the LLB via the DTE interface and proceed to the Remote Loopback

(Communication Link) Test.

4-2 Diagnostic Tests 24-01-00 19:17

Page 35

ASMi-31 Installation and Operation Manual Chapter 4. Tests and Diagnostics

Order from: Cutter Networks

Ph:727-398-5252/Fax:727-397-9610

www.bestdatasource.com

Remote Loopback (RLB)

Data

Clock

Local

DTE

Clock

Data

➤ To activate the Remote Digital Loopback:

➤ ➤

This test determines the performance of both the local and the remote

ASMi-31 modems, as well their connecting 2-wire line between them. The

test activates a diagnostic loopback at the remote ASMi-31 modem (see

Figure 4-2).

Tra nsm it

Link

Interface

Receive

Local AS Mi-31 Remote ASMi-31

Link

Interface

Receive

Tra nsm it

Figure 4-2 Remote Digital Loopback

➤

•

Activate the Remote Loopback via the DTE interface.

The TEST LED lights on both units.

Remote

DTE

Set the DTE equipment in half duplex (which produces an "echo" through

the system), or run a Bit Error Rate test.

Perform the test at both ends. If the BER test indicates a fault and if the LLB

test was successful for both local and remote modems, then the 2-wire line

circuits inside the modem are not operating properly, or the line connection

between the modems is faulty.

24-01-00 19:17 Diagnostic Tests 4-3

Page 36

Chapter 4. Tests and Diagnostics ASMi-31 Installation and Operation Manual

Order from: Cutter Networks

Ph:727-398-5252/Fax:727-397-9610

www.bestdatasource.com

4-4 Diagnostic Tests 24-01-00 19:17

Page 37

Chapter 5

Order from: Cutter Networks

Ph:727-398-5252/Fax:727-397-9610

www.bestdatasource.com

Card Cage Version

This chapter describes the ASMi-31/R card version, designed for installation

in the ASM-MN-214 card cage. The chapter contains the following sections:

•

Section 5.1 describes the ASM-MN-214 card cage

•

Section 5.2 describes the ASMi-31/R card version

•

Section 5.3 describes the power supply to ASMi-31/R

•

Section 5.4 describes how to install ASMi-31/R.

5.1 ASM-MN-214 Card Cage

The ASM-MN-214 card cage contains one or two power supplies and up to

14 plug-in cards. The card types can be ASMi-31/R or other RAD rack

version modems/converters - any combination of up to 14 plug-in cards.

For each of the 14 cards, the rear panel (see Figure 5-1) contains a male

connector for the terminal block and a DB-25 connector. A protection cover

protects the terminal block connectors.

The terminal block (see Figure 5-1) is to be attached to the rear panel

terminal block connectors. It contains screws for connecting the transmit

and receive pairs and ground, if present.

The 25-pin D-type female interface connector provides all interface signals

for the digital interfaces. Modems with X.21 or V.35 interface require an

external mechanical adapter.

Two optional interface attachments, CIA/V.35/1 and CIA/X.21, can be

ordered separately from RAD. CIA/X.21 converts two adjacent DB-25

connectors to two X.21 15-pin connectors. CIA/V.35/1 converts one DB-25

connector to a V.35 34-pin connector.

V.36 modem cards are supplied with a RAD adapter cable CBL 530/449F,

which converts the DB-25 connector to a V.36 37-pin connector. The

adapter cable and two interface attachments are also shown in Figure 5-1.

16-03-00 15:51 ASM-MN-214 Card Cage 5-1

Page 38

Chapter 5. Card Cage Version ASMi-31 Installation and Operation Manual

Order from: Cutter Networks

Ph:727-398-5252/Fax:727-397-9610

www.bestdatasource.com

Te r m i n a l

Block

Te r m i n a l

Block

CIA/V.35/1

Protection

Cover

CIA/X.2 1

CBL-530/449

Figure 5-1 ASM-MN-214 Rear Panel

5-2 ASMi-31/R Card Version 16-03-00 15:51

Page 39

ASMi-31 Installation and Operation Manual Chapter 5. Card Cage Version

Order from: Cutter Networks

Ph:727-398-5252/Fax:727-397-9610

www.bestdatasource.com

5.2 ASMi-31/R Card Version

Figure 5-2 shows the ASMi-31/R card front panel. The LEDs and switches of

the card version are identical in their functionality to those of the standalone

device. For this information, refer to Section 3.1, Controls and Indicators, in

Chapter 3.

The jumper settings are the same as with ASMi-31 standalone version (refer

to Table 2-1).

PWR

RTS

TD

RD

DCD

LOS

ERR

TEST

RESET

ASMi-31

Figure 5-2 ASMi-31/R Front Panel

16-03-00 15:51 Power Supply 5-3

Page 40

Chapter 5. Card Cage Version ASMi-31 Installation and Operation Manual

Order from: Cutter Networks

Ph:727-398-5252/Fax:727-397-9610

www.bestdatasource.com

5.3 Power Supply

Power is supplied to the ASMi-31/R card from the ASM-MN-214 power

supply via the chassis. Each ASMi-31/R card has two fuses, which protect the

entire system against power failure resulting from a short circuit in one card.

The ASM-MN-214 card cage can accept both AC or DC power supplies.

LED indicators located on the ASM-MN-214 front panel (see Figure 5-3)

show activity when the power supply is connected to the mains plug. The

power supply supports the full card cage with any combination of cards.

AC Supply (100,

115 or 230 VAC)

DC Supply (-48 VDC)

Power Supply with Redundancy

Note

The AC power supply of the ASM-MN-214 is 100, 115 or 230 VAC, ±10%,

47 to 63 Hz.

The DC power supply is - 48 VDC (-36 to -72 VDC). It uses a DC/DC

converter module to provide the power required for the cards.

This special ordering option is equipped with two separate power supplies,

operating together and sharing the load of the whole card cage. If either of

the power supplies fails, the other one will continue to supply power to the

full card cage.

Two LED indicators show activity of each power supply. They should both

light when mains power is provided.

It is possible to combine AC and DC power supplies in the same cage.

5-4 Installing ASMi-31/R 16-03-00 15:51

Figure 5-3 ASM-MN-214 Front Panel

Page 41

ASMi-31 Installation and Operation Manual Chapter 5. Card Cage Version

Order from: Cutter Networks

Ph:727-398-5252/Fax:727-397-9610

www.bestdatasource.com

5.4 Installing ASMi-31/R

➤

➤ To install the ASMi-31/R card in the ASM-MN-214 card cage:

➤ ➤

1. Install the ASM-MN-214 card cage in the 19" rack.

2. Adjust the jumpers and switches on the card as required (see Figure 2-

1 and Table 2-1 in Chapter 2).

3. Insert the ASMi-31/R card into one of the ASM-MN-214 slots. Push the

bottom of the card into the cage to until it is fully inserted into the edge

connector inside the rack. Tighten the screws on the top and on the

bottom of each card.

4. Remove the protection cover from the terminal block connectors.

5. Connect the terminal block to the ASM-MN-214 terminal block

connector.

6. Connect the line to the terminal block as follows: connect transmit pair

to the terminals marked XMT, the receive pair to the terminals marked

RCV, and the fifth screw to ground (optional).

Warning

7. If required, attach the appropriate CIA (CIA/X.21 or CIA/V.35/1) or V.36

adapter cable to the DB-25 connector on the card cage rear panel.

8. Connect the DTE cable to the DB-25 connector, other side of CIA or

adapter cable (depending on your version of the card interface).

9. Connect power to the ASM-MN-214 card cage:

•

To connect AC power, connect the power cable to the mains supply.

•

To connect DC power, refer to DC Power Supply Connection

Supplement of the ASM-MN-214 manual.

The ASM-MN-214 card cage has no power switch. Operation starts

when the power is applied to the rear panel POWER connector. When

applying power, first connect the plug of the power cord to the

ASM-MN-214 POWER connector and then to the mains power source

(outlet).

16-03-00 15:51 Installing ASMi-31/R 5-5

Page 42

Chapter 5. Card Cage Version ASMi-31 Installation and Operation Manual

Order from: Cutter Networks

Ph:727-398-5252/Fax:727-397-9610

www.bestdatasource.com

5-6 Installing ASMi-31/R 16-03-00 15:51

Page 43

Appendix A

Order from: Cutter Networks

Ph:727-398-5252/Fax:727-397-9610

www.bestdatasource.com

Ethernet Interface

A.1 General

This appendix:

•

Describes the IR-ETH for RAD modems

•

Describes the different IR-ETH connector options

•

Lists the Ethernet bridge specifications

•

Explains how to install and operate an Ethernet bridge.

A.2 Description

The IR-ETH is an interface module for RAD modems, used for converting

the Ethernet (10BaseT or 10Base2) electrical levels to the modem TTL levels.

It also converts the Ethernet protocol to HDLC to enable long distance

transmission and avoid the Ethernet collision limitation.

The IR-ETH includes an internal, self-learning Ethernet bridge, which

enables a high performance link between two Ethernet segments at a low

transmission rate. The low-speed HDLC transmission is sent over the link

using the modem modulation technique. It is converted back to an Ethernet

signal at the remote modem.

Figure A-1 shows a typical application using an Ethernet interface bridge.

Each modem is connected to an Ethernet network via the Ethernet Interface

bridge.

LINK

MODEM MODEM

Figure A-1 Ethernet Interface Typical Application

Description A-1

Page 44

Appendix A. Ethernet Interface ASMi-31 Installation and Operation Manual

Order from: Cutter Networks

Ph:727-398-5252/Fax:727-397-9610

www.bestdatasource.com

A.3 IR-ETH Connector Options

Figure A-2 and Figure A-3 show the rear panel of ASMi-31 with the IR-ETH

connector options. The IR-ETH connector for the ASMi-31/R card

(rack mount version) is shown in Figure A-4.

Line Connector

Figure A-2 ASMi-31 Rear Panel with IR-ETH/UTP Connector Option

Line Connector

Figure A-3 ASMi-31 Rear Panel with IR-ETH/BNC Connector Option

13

12

(13) RCV(+)

(12) RCV(-)

(11) XMT(+)

(9) XMT(-)

(7) GND

11

9

7

DB-25

Figure A-4 IR-ETH Connector for the ASMi-31/R Modem Card

A-2 IR-ETH Connector Options

Page 45

ASMi-31

Order from: Cutter Networks

Ph:727-398-5252/Fax:727-397-9610

www.bestdatasource.com

Installation and Operation Manual Appendix A. Ethernet Interface

When using the RJ-45 connector, the customer must prepare a mechanical

cable for adapting the DB-25 pinout to that of RJ-45. The pinouts of the

DB-25 and RJ-45 connectors are given in Table A-1.

Table A-1 DB-25 and RJ-45 Pin Assignment for IR-ETH Connection

Signal Pin

DB-25 RJ-45

RCV (+) 13 3

RCV (-) 12 6

XMT (+) 11 1

XMT (-) 9 2

GND 7 -

A.4 Ethernet Bridge Specifications

General

LAN

WAN

LAN Table

Filtering and

Forwarding

Buffer

Delay

Standard

Data Rate

Connectors

Protocol

Data Rate

10,000 addresses

15,000 pps

256 frames

1 frame

Conforms to IEEE 802.3/Ethernet

10 Mbps (20 Mbps 10BaseT FDX)

10BaseT (UTP): Shielded RJ-45

10Base2: BNC connector

HDLC

According to the modem transmission rate

Installation and Operation A-3

Page 46

Appendix A. Ethernet Interface ASMi-31 Installation and Operation Manual

Order from: Cutter Networks

Ph:727-398-5252/Fax:727-397-9610

www.bestdatasource.com

A.5 Installation and Operation

Figure A-5 and Figure A-6 show the Ethernet bridge layout, the locations of

the DIP switches, and the rear panel components for the UTP and the BNC

versions, respectively.

4

3

2

1

Figure A-5 Ethernet Bridge Layout (UTP Option)

Figure A-6 Ethernet Bridge Layout (BNC Option)

4

3

2

1

A-4 Installation and Operation

Page 47

ASMi-31

Order from: Cutter Networks

Ph:727-398-5252/Fax:727-397-9610

www.bestdatasource.com

Installation and Operation Manual Appendix A. Ethernet Interface

LAN Installation

For 10BaseT installation, either a straight cable or a cross-cable may be

required. Use a cross-cable when connecting to a port that does not

implement the crossover function internally. Otherwise, use a straight cable.

Note

Hubs usually implement the crossover function internally while NICs and other

devices do not.

Switch Settings

Set switches according to Table A-2.

Table A-2 DIP Switches Settings

Switch

Number

1 SQ/FD ON: Ethernet full-duplex mode

2 CMP ON: Strips padding bits inserted in 64-byte frame

3 FIL ON: Passes only frames destined for another LAN

4

Name Description Default

OFF: Ethernet half-duplex mode

OFF: Transmits frames over WAN as is

OFF: Disables LAN filter; passes all frames transparently

(nc) OFF

Setting

OFF

ON

ON

Note

LED Indicators

LED Name Description Location Color

LINK ON indicates good link integrity (available only in

COLL ON indicates collision on the attached Ethernet

RX ON when data is received from the Ethernet

TX ON when data is transmitted from the modem to

ERR D4 Bridge buffer overrun On board Red

The SQ/FD switch is not used in the Ethernet bridge with the BNC connector

option.

Table A-3 lists the IR-ETH LED indicators and describes their functions.

Table A-3 IR-ETH Bridge LED Indicators

Panel Green

the 10BaseT version)

Panel Yellow

segment

Panel Yellow

attached segment

Panel Yellow

the Ethernet segment

Installation and Operation A-5

Page 48

Appendix A. Ethernet Interface ASMi-31 Installation and Operation Manual

Order from: Cutter Networks

Ph:727-398-5252/Fax:727-397-9610

www.bestdatasource.com

A-6 Installation and Operation

Page 49

Appendix B

Order from: Cutter Networks

Ph:727-398-5252/Fax:727-397-9610

www.bestdatasource.com

IR-G.703 Codirectional

Interface (64 kbps)

B.1 Introduction

This appendix:

•

Provides a general description of the IR-G.703 Codirectional interface

(64 kbps)

•

Describes the EXT mode for the IR-G.703 Codirectional interface

(64 kbps)

•

Describes the INT/RCV mode for the IR-G.703 Codirectional interface

(64 kbps).

B.2 General Description

The IR-G.703 is an interface module for RAD modems, converting G.703

Codirectional signals to TTL levels. The converted data is sent over the

modem link using the modem modulation technique and converted back at

the other end into G.703 64 kbps Codirectional signals, or into any other

digital interface signal possible. The module is available in the following two

versions:

• The Standalone version fits into a standalone modem and is available

with two types of physical connections: a terminal block or an RJ-45.

• The Rack version is mounted on the rack version modem card and uses

the modem edge connector for communication. The edge connector is

wired, on the motherboard of the card cage, to the DB-25 connector on

the back plane of the ASM-MN-214 card cage. Figure B-1 illustrates the

pinout of the different connectors.

16-03-00 17:21 General Description B-1

Page 50

Appendix B. IR-G.703 Codirectional Interface (64 kbps) ASMi-31 Installation and Operation Manual

Order from: Cutter Networks

Ph:727-398-5252/Fax:727-397-9610

www.bestdatasource.com

LINE FUSE

230 V/0. 1A T 250V

Term i nal Block

(Standalone)

Note

Note

(9,11) RCV

G.703

XMT RCVGND

LINE

GND

245

RCV (3, 6)

GND (2)

1 8

(Standalone)

XMT

RJ-45

(4, 5)

(2,16) XMT

(7) GND

16

DB-25

(Rack Version)

Figure B-1 IR-G.703 Connector Options

In Figure B-1, RCV refers to the input signals to the interface module;

XMT refers to the output signals from the module.

The IR-G.703 interface module is shown in Figure B-2. It has two operation

modes which are selectable on the PCB board. The selection is made by

means of the JP1 jumper located within the module as shown in Figure B-2.

The EXT mode is described in EXT Mode below and illustrated by Figure B-3.

The INT/RCV mode is described in INT/RCV Mode below and illustrated by

Figure B-4.

The IR-G.703 interface should be in accordance with the modem clock

mode. For example, if the modem is in the EXT mode, then JP1 should be set

to the EXT position.

11

2

7

9

Terminal Block

or RJ-45

(Standalone Version)

B.3 EXT Mode

This mode is used in applications, where the system timing is provided by

the G.703 network. The IR-G.703 module has an internal buffer to

compensate for the phase delay introduced to the system by the line delay

between the two modems. The buffer is an 8-bit FIFO connected as shown

in Figure B-3.

This mode corresponds to the modem clock working in the EXT mode.

INT/RCV

JP1

EXT

Figure B-2 Location of JP1 on the IR-G.703 Interface Module

B-2 EXT Mode 16-03-00 17:21

Page 51

ASMi-31 Installation and Operation Manual Appendix B. IR-G.703 Codirectional Interface (64 kbps)

Order from: Cutter Networks

Ph:727-398-5252/Fax:727-397-9610

www.bestdatasource.com

Modem A Modem B

IR-G.703 Module

G.703

Codirectional

64 kbps network

Timing Source

TX Data

RX Data

Clock

Out

Clock

Recovery

Data

CLK

FIFO

Data

Clock

Recovery

FIFO

EXT Clock Mode RCV Clock Mode

Clock In

TX

RX

RX

Clock

Recovery

TX

Figure B-3 IR-G.703 EXT Mode Timing Block

INT or RCV

Clock Mode

B.4 INT/RCV Mode

This mode is used in applications where the G.703 Codirectional 64 kbps

equipment connected to the modem recovers the clock signal from the

modem link. This mode is used mainly when the attached equipment has a

G.703 Codirectional interface, but is not able to produce clock signals. The

module has a 8-bit FIFO buffer to compensate for the phase delay

introduced by the G.703 device. Figure B-4 illustrates the buffer connection

and the required application setup.

This mode corresponds to the modem clock working in the INT or RCV

mode.

DTE

side

EXT, INT or RCV

(Depending on the

attached network)

Modem A

Clock Mode

TX

RX

LINK

side

RX

Clock

Out

TX

Clock

Recovery

FIFO

Modem B

Clock In

IR-G.703 Module

Data

CLK

FIFO

Data

Clock

Recovery

G.703

side

RX Data

TX Data

Equipment

with G.703

interface

16-03-00 17:21 INT/RCV Mode B-3

INT/RCV Clock Mode

Figure B-4 IR-G.703 INT/RCV Mode Timing Block

Page 52

Appendix B. IR-G.703 Codirectional Interface (64 kbps) ASMi-31 Installation and Operation Manual

Order from: Cutter Networks

Ph:727-398-5252/Fax:727-397-9610

www.bestdatasource.com

B-4 INT/RCV Mode 16-03-00 17:21

Page 53

Appendix C

Order from: Cutter Networks

Ph:727-398-5252/Fax:727-397-9610

www.bestdatasource.com

X.21 Interface Module

C.1 General

IR-X.21 is an interface module for RAD modems, converting X.21 signals to

TTL levels. The converted data is sent over the modem link, using the

modem modulation technique, and is converted back at the other end into

X.21 signals, or into any other digital interface signal.

ASMi-31 is generally supplied with IR-X.21. This is due to an internal FIFO

that assumes the phase mismatch when the clock is supplied by an external

source. ASMi-31 also has the option to order IR-X.21 for extra buffers.

Figure C-1 shows a typical application of the ASMi-31 standalone modem

with the IR-X.21 interface module.

Figure C-1 Typical ASMi-31 X.21 Application

C.2 X.21 Connectors

Figure C-2 shows the rear panel of a standalone ASMi-31 with the

IR-X.21 interface module.

Line Connector

Figure C-2 ASMi-31 Rear Panel with X.21 Connector

The ASMi-31 modem rack version requires an additional adaptor to connect

between the DB-15 connector of the X.21 equipment to the DB-25

connector of the ASM-MN-214 modem rack. For this purpose, an optional

DB-15 attachment CIA/X.21 can be ordered separately from RAD. The

attachment connects to the ASM-MN-214 rear panel as shown for the

CIA/V.35 attachment in Chapter 5.

X.21 Connectors C-1

Page 54

Appendix C. X.21 Interface Module ASMi-31 Installation and Operation Manual

Order from: Cutter Networks

Ph:727-398-5252/Fax:727-397-9610

www.bestdatasource.com

Pin Assignment

Table C-1 shows the X.21 DB-15 pin assignment.

Table C-1 IR-X.21 DB-15 (RS-422) Connector Pin Assignment

Pin ID Function

1 Shield Chassis connection

2 A Transmit signal A

3 A Control A

4 A Receive A

5 A Indication A

6 A Signal timing A

7 A External Timing

8 GND Common

9 B Transmit B

10 B Control B

11 B Receive B

12 B Indication B

13 B Signal Timing B

14 B External Timing

15 Not connected

C-2 X.21 Connectors

Page 55

ASMi-31 Installation and Operation Manual Appendix C. X.21 Interface Module

Order from: Cutter Networks

Ph:727-398-5252/Fax:727-397-9610

www.bestdatasource.com

INT/RCV

JP 2

EXT

clock setting

EXT

clock setting

Connector DB-15

Figure C-3 Location of Jumper JP2 in the IR-X.21 Interface Module

C.3 EXT Mode

This mode is used in applications of X.21 networks where the system timing

is provided by the X.21 network. The IR-X.21 module has an internal buffer

to compensate for the phase delay introduced to the system by the line

delay between the two modems. The buffer is a 16-bit FIFO connected as

shown in Figure C-4. When the modem's clock mode is EXT, the JP2 jumper

must be set to EXT (see Figure C-3).

EXT Mode C-3

Page 56

Appendix C. X.21 Interface Module ASMi-31 Installation and Operation Manual

Order from: Cutter Networks

Ph:727-398-5252/Fax:727-397-9610

www.bestdatasource.com

IR-X.21B

TXDTXD

(2, 9)

ETC

Signal Timing

(6, 13)

MODEM DTE

RXC

RXD

FIFO

Buffer

Rx

ETC

(7, 14)

RXD

(4, 11)

Figure C-4 EXT Mode Timing Block

C.4 INT/RCV Mode

This mode is used in applications where the IR-X.21 side uses the clock

signal from the modem link. This mode is used mainly when the attached

equipment has an IR-X.21 interface, but no ability to produce clock signals.

The module has a 16-bit FIFO buffer to compensate for the phase delay

introduced by the X.21 device. Figure C-5 illustrates the buffer connection

and the required application setup. When the modem's clock mode is INT

or RCV, the JP2 jumper must be set to INT/RCV (see Figure C-3).

IR-X.21B

TXDTXD

(2, 9)

TXC

Signal Timing

(6, 13)

MODEM DTE

RXC

FIFO

Buffer

RXD

Rx

RXD

(4, 11)

Figure C-5 INT/RCV Mode Timing Block

C-4 INT/RCV Mode

Page 57

Appendix D

Order from: Cutter Networks

Ph:727-398-5252/Fax:727-397-9610

www.bestdatasource.com

DTE Interface Connectors

D.1 General

Table D-1 provides detailed information about each DTE interface

connector.

Table D-1 DTE Interface Signal Assignments

RS-232 V.35 EIA-530 X.21

Signal

Function

Protective

Ground

Signal Ground 7 7 B Signal 102

Transmitted

Data

Received

Data

DB-25

Stand-

alone

and

Frame

1 1 A Frame 101 1 1 1 -

2119S TD(B) 103

31213R RD(A) 104

DB-25

Frame

34-pin

Standalone

Pin Circuit

Ground

P TD(A) 103

T RD(B) 104

DB-25

Standalone

and Frame

Pin Circuit

7AB 7 8 -

2 BA(A)

14 BA(B)214

3 BB(A)

16 BB(B)316

DB-25

Frame

DB-15

Standalone

Pin Circuit/

(Function)

[SHIELD]

[GND]

2 T(A)

9 T(B)

[TRANSMIT]

4 R(A)

11 R(B)

[RECEIVE]

Description

Chassis ground.

May be

isolated from

Signal Ground.

See Table 2-1.

Common

Signal and DC

power supply

ground.

Serial digital

data from DTE.

The data

transitions must