TO 31R2-2TRC207-1

OPERATION AND MAINTENANCE INSTRUCTIONS

WITH ILLUSTRATED PARTS BREAKDOWN

ORGANIZATIONAL LEVEL

RADIO SET

AN/TRC-207

(BI-DIRECTIONAL REPEATER)

RACAL COMMUNICATIONS, INC.

5 RESEARCH PLACE

ROCKVILLE, MD 20850

CONTRACT NO: F19628-91-D-0012

DISTRIBUTION STATEMENT B - Distribution authorized to U.S. Government agencies only for administrative

or operational use 15 August, 1996. Other requests for this document shall be referred to Sacramento ALC/TILBE,

3200 Peacekeeper Way, Suite 1, McClellan AFB, CA 95652-1026.

WARNING - This document contains technical data whose export is restricted by the Arms Export Control Act (Title

22, U.S.C., Sec 2751 et seq.) or the Export Administration Act of 1979, as amended (Title 50, U.S.C., App 2401 et

seq.). Violations of these export laws are subject to severe criminal penalties.

HANDLING AND DESTRUCTION NOTICE - Handle in compliance with distribution statement and destroy by any

method that will prevent disclosure of contents or reconstruction of the document.

PUBLISHED UNDER AUTHORITY OF THE SECRETARY OF THE AIR FORCE

15 JULY 1997

LIST OF EFFECTIVE PAGES

TO 31R2-2TRC207-1

INSERT LATEST CHANGE PAGES, DESTROY SUPERSEDED PAGES.

NOTE: The portion of the text affected by the changes is indicated by a vertical line

DATES OF ISSUE FOR ORIGINAL AND CHANGED PAGES ARE:

TOTAL NUMBER OF PAGES IN THIS PUBLICATION IS 110 CONSISTING OF THE FOLLOWING:

Page * Change

No. No.

in the outer margin of the page. Changes to illustrations are indicated by a

vertical line adjacent to the illustration identification number.

ORIGINAL 0 15 JULY 1997

Page * Change

No. No.

Page * Change

No. No.

Title page........................ 0

A..................................... 0

i - ix ................................ 0

1-0 - 1-8.......................... 0

2-1 - 2-9.......................... 0

2-10 blank ...................... 0

3-1 - 3-4.......................... 0

4-1 - 4-14........................ 0

5-1 - 5-6.......................... 0

6-1 - 6-13........................ 0

6-14 blank ...................... 0

7-1 - 7-24........................ 0

8-1 .................................. 0

8-2 blank ........................ 0

8-3 .................................. 0

8-4 blank ........................ 0

GLOSSARY-1 ............... 0

GLOSSARY-2 blank...... 0

INDEX-1 - 4................... 0

* Zero in this column indicates an original page.

USAF

TO 31R2-2TRC207-1

TABLE OF CONTENTS

Chapter Page

LIST OF ILLUSTRATIONS.........................................................................................................................................

IV

LIST OF TABLES..........................................................................................................................................................

SAFETY SUMMARY...................................................................................................................................................

FOREWORD.................................................................................................................................................................

VI

IX

CHAPTER 1 GENERAL INFORMATION............................................................................................................1-3

1-1 DESCRIPTION AND PURPOSE.................................................................................................................1-3

1-1.1 Equipment Function and Purpose ........................................................................................................1-3

1-1.2 Equipment Description ........................................................................................................................1-3

1-2 LEADING PARTICULARS .........................................................................................................................1-5

1-3 CAPABILITIES AND LIMITATIONS........................................................................................................1-6

1-4 EQUIPMENT SUPPLIED ............................................................................................................................1-7

1-5 EQUIPMENT REQUIRED BUT NOT SUPPLIED ..................................................................................... 1-8

1-6 SPECIAL TOOLS AND TEST EQUIPMENT.............................................................................................1-8

1-7 RELATED TECHNICAL MANUALS.........................................................................................................1-8

CHAPTER 2 INSTALLATION ............................................................................................................................... 2-1

2-1 INTRODUCTION......................................................................................................................................... 2-1

S

ECTION

I. INSTALLATION LOGISTICS ................................................................................................................2-1

2-2 SITE PREPARATION.................................................................................................................................. 2-1

2-3 UNPACKING AND INSPECTIONS. ..........................................................................................................2-1

2-4 HOUSING.....................................................................................................................................................2-3

2-5 RECEIVING DATA. ....................................................................................................................................2-3

2-6 MATERIAL HANDLING. ........................................................................................................................... 2-3

2-7 CABLES........................................................................................................................................................2-4

2-8 BUILDING AND OTHER SUPPORTING STRUCTURES........................................................................ 2-4

S

ECTION

II. INSTALLATION PROCEDURES ......................................................................................................... 2-5

2-9 SPECIAL TOOLS AND EQUIPMENT REQUIRED FOR FIELD INSTALLATION................................2-5

2-10 INSTALLATION SEQUENCE ....................................................................................................................2-5

2-10.1 Antenna/Mast Installation .................................................................................................................... 2-5

2-10.2 Lithium Battery Installation. ................................................................................................................ 2-9

2-10.3 Ground Rod Installation.......................................................................................................................2-9

2-10.4 External Power Supply.........................................................................................................................2-9

2-10.5 Diplexer Installation.............................................................................................................................2-9

2-10.6 Receiver-Transmitter Transceiver Module Installation........................................................................2-9

V

CHAPTER 3 PREPARATION FOR USE AND RESHIPMENT .........................................................................3-1

3-1 INTRODUCTION......................................................................................................................................... 3-1

S

ECTION

I. PREPARATION FOR USE...................................................................................................................... 3-1

3-2 INSPECTION. .............................................................................................................................................. 3-1

3-3 POST-INSTALLATION CHECKOUT. ....................................................................................................... 3-1

3-3.1 Preliminary...........................................................................................................................................3-1

3-3.2 Alignment and Adjustment. .................................................................................................................3-2

3-3.3 Post-Installation Checkout Procedures ................................................................................................3-2

S

ECTION

II. PREPARATION FOR RESHIPMENT................................................................................................... 3-2

3-4 PREPARING UNIT FOR RESHIPMENT.................................................................................................... 3-2

3-5 PACKING. .................................................................................................................................................... 3-3

3-6 HANDLING AND STORAGE..................................................................................................................... 3-3

3-6.1 Protective Measures for Electrical Connectors....................................................................................3-3

3-6.2 Preparation for Shipment and Storage. ................................................................................................3-3

3-6.3 Handling. .............................................................................................................................................3-3

CHAPTER 4 OPERATION......................................................................................................................................4-1

S

ECTION

I. CONTROLS AND INDICATORS........................................................................................................... 4-1

4-1 INTRODUCTION......................................................................................................................................... 4-1

i

TO 31R2-2TRC207-1

4-2 CONTROLS AND INDICATORS................................................................................................................4-1

4-2.1 Indicators, Controls, and Switches. ......................................................................................................4-1

4-2.2 Power Supply Switches and Connectors. .............................................................................................4-1

4-2.3 Connectors............................................................................................................................................4-1

Diplexer Control................................................................................................................................................4-1

S

ECTION

II. OPERATING INSTRUCTIONS .............................................................................................................4-7

4-3 OPERATING MODES AND FREQUENCY RECOMMENDATIONS ......................................................4-7

4-3.1 Operating Modes..................................................................................................................................4-7

4-3.2 Frequency Recommendations...............................................................................................................4-7

4-4 INITIAL POWER-UP AND DIPLEXER TUNING PROCEDURES.........................................................4-11

4-5 RECEIVING AND RETRANSMITTING MESSAGES.............................................................................4-12

4-6 COVERT OPERATIONS............................................................................................................................4-13

4-7 RECEIVER-TRANSMITTERS ..................................................................................................................4-13

4-8 EQUIPMENT SHUTDOWN ......................................................................................................................4-13

S

ECTION

III. EMERGENCY OPERATION..............................................................................................................4-13

4-9 EMERGENCY POWER..............................................................................................................................4-13

4-10 ELECTROMAGNETIC PULSE PROTECTION........................................................................................4-13

4-10.1 EMP Susceptibility.............................................................................................................................4-13

4-10.2 EMP Protective Measures ..................................................................................................................4-13

4-11 NUCLEAR, BIOLOGICAL, AND CHEMICAL (NBC) CONTAMINATION..........................................4-14

CHAPTER 5 THEORY OF OPERATION ............................................................................................................ 5-1

S

ECTION

I. FUNCTIONAL SYSTEM(S) OPERATION ............................................................................................5-1

5-1 GENERAL.....................................................................................................................................................5-1

5-2 FUNCTIONAL SYSTEM(S) OPERATION.................................................................................................5-1

5-2.1 +15V DC-DC Converter Circuit Card Assembly (CCA) (A1A1) ........................................................5-1

5-2.2 Repeater Control/Audio Circuit Card Assembly (CCA) (A1A2).........................................................5-1

5-2.3 Repeater Interface CCA (A1A3) ..........................................................................................................5-1

5-2.4 Parent Board Circuit Card Assembly (CCA) (A1A4) ..........................................................................5-1

5-2.5 Control Panel (A1A5) ..........................................................................................................................5-1

5-2.6 RF Power Amplifier Assembly (A1A6) ...............................................................................................5-1

5-2.7 RF Matrix CCA (A1A7).......................................................................................................................5-2

5-2.8 Receiver-Transmitters ..........................................................................................................................5-2

5-2.9 Antenna System....................................................................................................................................5-3

5-2.10 Diplexer (A3) .......................................................................................................................................5-3

5-2.11 AC/DC Power Supply (A2)..................................................................................................................5-3

S

ECTION

II. FUNCTIONAL OPERATION OF ELECTRONIC CIRCUITS..............................................................5-3

5-3 REPEATER CONTROL/AUDIO CIRCUIT CARD ASSEMBLY (CCA) (A1A2)......................................5-3

5-4 15 WATT POWER AMPLIFIER ASSEMBLY (A1A6) ..............................................................................5-4

S

ECTION

III. FUNCTIONAL OPERATION OF MECHANICAL ASSEMBLIES.....................................................5-4

CHAPTER 6 MAINTENANCE............................................................................................................................... 6-1

6-1 GENERAL.....................................................................................................................................................6-1

6-2 OPERATIONAL CHECKOUT.....................................................................................................................6-1

6-2.1 Power-up Verification..........................................................................................................................6-1

6-2.2 Display Off Control..............................................................................................................................6-1

6-2.3 Radio A Tune Mode Verification.........................................................................................................6-2

6-2.4 Radio B Tune Mode Verification.........................................................................................................6-2

6-2.5 Fault LED.............................................................................................................................................6-3

6-3 SERVICING..................................................................................................................................................6-3

6-3.1 Servicing Intervals................................................................................................................................6-3

6-3.2 Inspection. ............................................................................................................................................6-3

6-3.3 Preventive Maintenance. ......................................................................................................................6-3

6-4 TROUBLESHOOTING.................................................................................................................................6-4

6-5 REMOVAL/REPLACEMENT PROCEDURES ...........................................................................................6-9

6-5.1 Removal/Replacement Procedures - Operator......................................................................................6-9

6-5.2 Removal/Replacement Procedures - Repair Specialist.......................................................................6-12

ii

TO 31R2-2TRC207-1

CHAPTER 7 ILLUSTRATED PARTS BREAKDOWN........................................................................................7-1

S

ECTION

I. INTRODUCTION .................................................................................................................................... 7-1

7-1 GENERAL ....................................................................................................................................................7-1

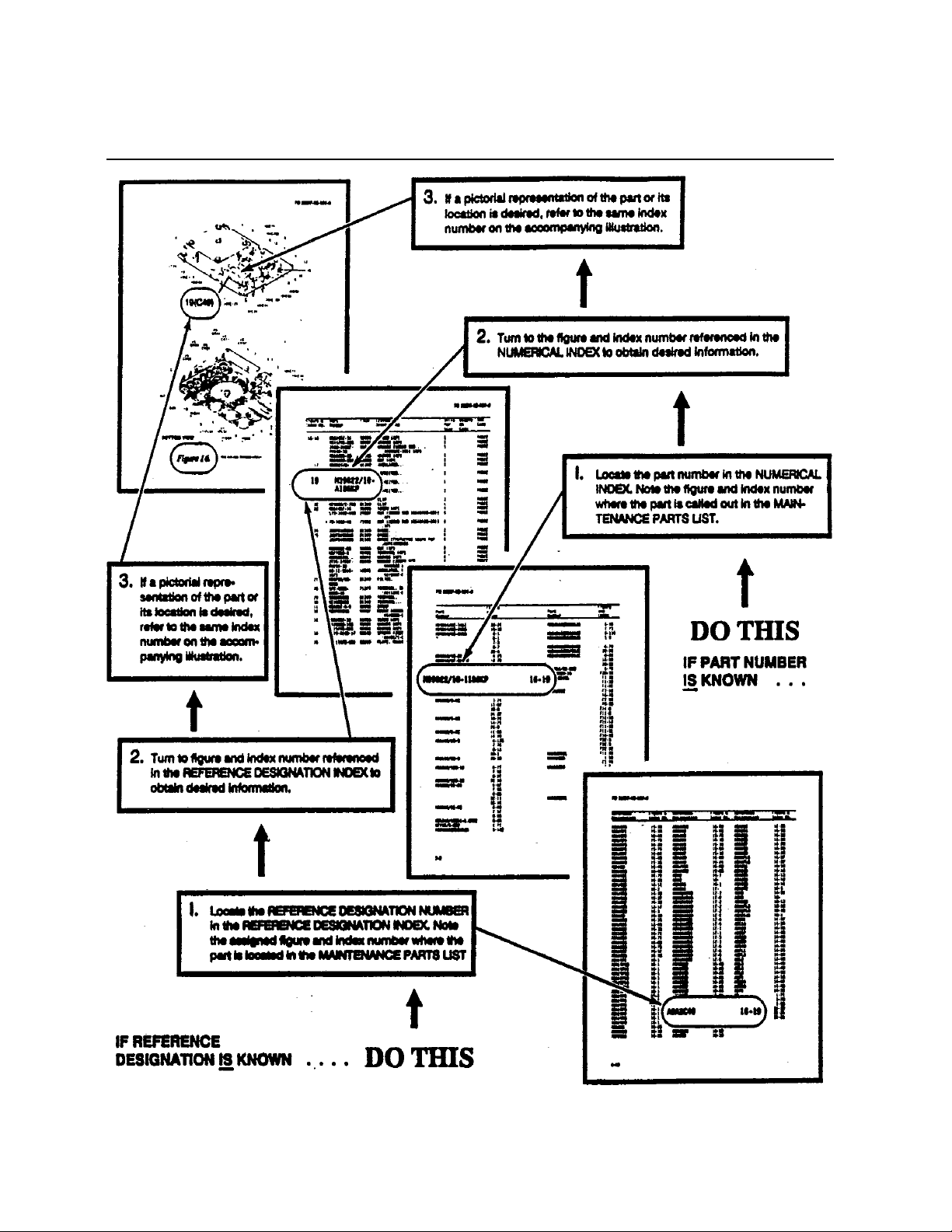

7-2 MAINTENANCE PARTS LIST................................................................................................................... 7-1

7-3 NUMERICAL INDEX.................................................................................................................................. 7-2

7-4 REFERENCE DESIGNATION INDEX.......................................................................................................7-3

7-5 ELECTROSTATIC DISCHARGE (ESD) SENSITIVE DEVICES. ............................................................7-3

7-6 CAGE CODE SUMMARY........................................................................................................................... 7-4

S

ECTION

II. MAINTENANCE PARTS LIST ............................................................................................................. 7-8

CHAPTER 8 CIRCUIT DIAGRAMS......................................................................................................................8-1

8-1 SCOPE ..........................................................................................................................................................8-1

GLOSSARY

ALPHABETICAL INDEX

iii

TO 31R2-2TRC207-1

LIST OF ILLUSTRATIONS

Figure Page

Figure 1-1. Radio Set AN/TRC-207........................................................................................................................... 1-0

Figure 1-2. Receiver-Transmitter RT-1695/TRC-199................................................................................................ 1-4

Figure 1-3. BDR Diplexer.......................................................................................................................................... 1-4

Figure 2-1. Packaging Diagram for the BDR ............................................................................................................. 2-2

Figure 2-2. Antenna Mast/Antenna Installation (Sheet 1 of 6).................................................................................. 2-5

Figure 2-3. Antenna Mast/Antenna Installation (Sheet 2 of 6).................................................................................. 2-6

Figure 2-4. Antenna Mast/Antenna Installation (Sheet 3 of 6).................................................................................. 2-6

Figure 2-5. Antenna Mast/Antenna Installation (Sheet 4 of 6).................................................................................. 2-7

Figure 2-6. Antenna Mast/Antenna Installation (Sheet 5 of 6)................................................................................... 2-7

Figure 2-7. Antenna Mast/Antenna Installation (Sheet 6 of 6)................................................................................... 2-8

Figure 4-1. Location of Bi-Directional Repeater Indicators, Controls, and Switches ................................................ 4-1

Figure 4-2. Location of Power Supply Switches (Power Supply Top View) ............................................................. 4-3

Figure 4-3. Location of Power Supply Connectors (Power Supply Side View)......................................................... 4-4

Figure 4-4. Location of Bi-Directional Repeater Unit Connectors............................................................................. 4-5

Figure 4-5. Location of Bi-directional Repeater Diplexer Controls........................................................................... 4-6

Figure 4-6. Standard BDR Cabling Set-up............................................................................................................... 4-10

Figure 4-7. BDR Cross-Banding Cabling Set-up ..................................................................................................... 4-10

Figure 5-1. Bi-directional Repeater System, Functional Block Diagram ................................................................... 5-2

Figure 5-2. Repeater Control/Audio CCA (A1A2), Functional Block Diagram ........................................................5-5

Figure 5-3. 15 Watt Power Amplifier Assembly (A1A6), Functional Block Diagram............................................... 5-6

Figure 6-1. Detail of diplexer shock mount assembly .............................................................................................. 6-11

Figure 7-1. Radio Set AN/TRC-207 (Sheet 1 of 2)................................................................................................... 7-8

Figure 7-2. Bi-directional Repeater Assembly (4101027-501) (Sheet 1 of 3) ......................................................... 7-13

Figure 7-3. Power Amplifier Assembly, 15W (SS-4100853-501) ........................................................................... 7-19

Figure 8-1. Radio Set AN/TRC-207, Interconnection Diagram................................................................................. 8-3

iv

TO 31R2-2TRC207-1

LIST OF TABLES

Table Page

Table 1-1. BDR Configurations (by Frequency Band) ...............................................................................................1-3

Table 1-2. Leading Particulars....................................................................................................................................1-5

Table 1-3. Capabilities and Limitations......................................................................................................................1-6

Table 1-4. Equipment Supplied ..................................................................................................................................1-7

Table 1-5. Equipment Required but Not Supplied......................................................................................................1-8

Table 1-6. Related Technical Manuals .......................................................................................................................1-8

Table 2-1. BDR Packaging.........................................................................................................................................2-3

Table 2-2. BDR Interconnecting Cables.....................................................................................................................2-4

Table 2-3. External Power Supply Switch Settings ....................................................................................................2-9

Table 4-1. Description of Indicators, Controls and Switches .....................................................................................4-2

Table 4-2. Description of Power Supply Switches .....................................................................................................4-3

Table 4-3. Description of Power Supply Connectors..................................................................................................4-4

Table 4-4. Description of Repeater Unit Connectors..................................................................................................4-5

Table 4-5. Description of Diplexer Controls .............................................................................................................. 4-6

Table 4-6. TR Simplex Mode Recommended Frequencies ........................................................................................4-8

Table 4-7. TR Half-Duplex Mode Recommended Frequencies..................................................................................4-8

Table 4-8. Single BDR Recommended Frequencies...................................................................................................4-8

Table 4-9. Tandemed BDR Recommended Frequencies............................................................................................4-9

Table 5-1. Antenna System Frequency Band Vs Gain................................................................................................5-3

Table 6-1. Initial Switch and Control Settings for Power-Up Verification.................................................................6-1

Table 6-2. Initial Switch and Control Settings for Radio A Tune Mode Verification ................................................6-2

Table 6-3. Initial Switch and Control Settings for Radio B Tune Mode Verification.................................................6-2

Table 6-4. Recommended Service Intervals ...............................................................................................................6-3

Table 6-5. Organizational Maintenance Guide - Operator..........................................................................................6-5

Table 6-6. Organizational Maintenance Guide - Repair Specialist............................................................................. 6-8

Table 6-7. Cross-Reference to Removal/Replacement Procedures............................................................................. 6-9

Table 7-1. Radio Set AN/TRC-207 ..........................................................................................................................7-10

Table 7-2. Bi-directional Repeater Assembly (4101027-501)..................................................................................7-16

Table 7-3. Power AMP Assembly, 15W (SS-4100853-501)....................................................................................7-20

v

TO 31R2-2TRC207-1

SAFETY SUMMARY

The following are general safety precautions that are not related to any specific procedure, and do not appear elsewhere

in this manual. These Safety Summaries are recommended precautions that all personnel must understand and apply

during any given phase of operation and maintenance. Each chapter has other specific warnings and cautions.

WARNING

KEEP AWAY FROM LIVE CIRCUITS

Personnel must at all times observe all safety regulations. Do not replace components or make

adjustments inside equipment with power turned on. Under certain conditions, dangerous

voltages may exist when the power switch is in the off position due to charges retained by

capacitors. To avoid injury, always remove power and discharge and ground a circuit before

touching it.

RESUSCITATION

Personnel working with or near high voltages should be familiar with modern methods of

resuscitation. Such information may be obtained from the Director of Base Medical Services.

WARNING

LITHIUM BATTERIES

Lithium oxide batteries or cells may be used in the battery enclosure and receiver-transmitters used in this equipment.

They are potentially hazardous if misused or tampered with before, during or after discharge. The following precautions

must be strictly observed to prevent possible injury to personnel or equipment damage.

heat, incinerate, crush, puncture, disassemble, or otherwise mutilate the batteries.

Do not

short-circuit, recharge, or bypass internal fuse.

Do not

Do not store batteries in equipment during long periods of non-use (in excess of 30 days).

Turn off

venting (hissing sounds), or smell irritating sulfur dioxide gas.

vi

the equipment immediately if you detect battery compartment becoming unduly hot, hear battery cells

TO 31R2-2TRC207-1

WARNING

VOLTAGES WITHIN THIS EQUIPMENT ARE HIGH ENOUGH TO ENDANGER LIFE.

Covers are not to be removed except by persons qualified and authorized to do so and these persons should always take

extreme care once the covers have been removed.

Page

2-1 WARNING - Installation of the bi-directional repeater requires a minimum of two people.

2-1 WARNING - Removing the bi-directional repeater assembly from the shipping carton requires a

minimum of two persons.

2-5 WARNING - Ensure proper use of safety tools (work gloves and hard hat) during assembly and

disassembly of antenna.

2-6 WARNING - Before using the hammer, ensure a wedge is placed in the top of the hammer so that the

hammer head does not come loose, thereby endangering personnel.

3-3, 6-10,

6-12

6-11 WARNING - This equipment is capable of generating RF power sufficient to cause RF burns. During

2-1 CAUTION - Exercise care when removing units from packing material in order to prevent damage to the

3-3 CAUTION - Never apply pressure sensitive tape directly to connectors. This could damage connector

3-3 CAUTION - Package all electrostatic discharge (ESD) sensitive assemblies in ESD bags before shipping

3-3 CAUTION - Rough handling may cause unnecessary damage to electronic assemblies.

3-3 CAUTION - Electronic assemblies containing solid-state devices are susceptible to damage from static

3-3 CAUTION - Forcing any tilted or cocked electronic assembly into position may result in bent or broken

3-4 CAUTION - When repairing an electronic assembly, be careful that the tool employed does not

3-4 CAUTION - Because of the miniaturization of parts for electronic assembly construction, the leads,

WARNING - Before performing removal/replacement procedures, make sure power is removed from

the unit by disconnecting from power source. Failure to do so could result in personal injury or

equipment damage.

transmit, care should be taken to eliminate the possibility of touching exposed RF output points such as

the center conductors of coaxial cables or antenna feedpoints.

unit.

pins.

or storing.

electrical discharges. Wear protective clothing and grounded wrist straps

pins.

inadvertently press against leads, pins, or other parts that are easily bent.

connectors, and pins have been stiffened to make them more rugged. As a result, such parts are brittle

and will break easily if bent too often or pulled on too hard. When handling an assembly that has been

removed from its chassis, be careful not to press against the leads and pins. When removing an assembly,

be sure to pull it straight out from the equipment. Do not cock, twist, pry, or carelessly jerk an electronic

assembly to remove it from the mounting or connector.

3-4 CAUTION - The bi-directional repeater contains components that are susceptible to damage by static

electrical charges. Disassembly of the bi-directional repeater should only be done at a properly grounded

work station.

6-12 CAUTION - The bi-directional repeater contains components that are susceptible to damage by static

electrical charges. Disassembly of the bi-directional repeater should only be done at a properly grounded

work station.

vii

TO 31R2-2TRC207-1

This page left blank intentionally.

viii

TO 31R2-2TRC207-1

FOREWORD

This manual meets the technical content requirements of specification MIL-M-38798B, paragraph 3.3 (1 December 1975)

and MIL-M-38807A (1 June 1982) and format requirements of specification MIL-M-38784B (16 April 1983) for the bidirectional repeater.

a. Chapter 1 - General Information. This chapter provides general information for the bi-directional repeater

including equipment description and purpose, leading particulars, capabilities and limitations, equipment

supplied, equipment required but not supplied, optional equipment, special tools and test equipment, and

related technical manuals.

b. Chapter 2 - Installation. This chapter provides complete installation instructions for the receiver-transmitter

including installation logistics and installation procedure.

c. Chapter 3 - Preparation for Use and Reshipment. This chapter contains information which will permit

operation and maintenance personnel to prepare the equipment for use, including reference to postinstallation checkout procedures, preparing the unit for reshipment, packing, handling, and storage

procedures.

d. Chapter 4 - Operation. This chapter provides complete operating instructions for the bi-directional repeater.

e. Chapter 5 - Theory of Operation. This chapter provides complete theory of operation for the bi-directional

repeater.

f. Chapter 6 - Maintenance. This chapter provides all instructions required for on-equipment and off-

equipment maintenance of the bi-directional repeater. It includes preventive maintenance, troubleshooting

procedures, and repair procedures.

g. Chapter 7 - Illustrated Parts Breakdown (IPB). The IPB provides complete illustrated parts breakdown for

the bi-directional repeater. The IPB is prepared in accordance with MIL-M-38807A.

h. Chapter 8 - Circuit Diagrams. This chapter contains the BDR interconnection diagram.

i. Glossary - The glossary provides a definition of the special terms and abbreviations used in the technical

order.

j. Alphabetical Index - The index provides cross-references to applicable paragraphs, figures or tables.

ix

TO 31R2-2TRC207-1

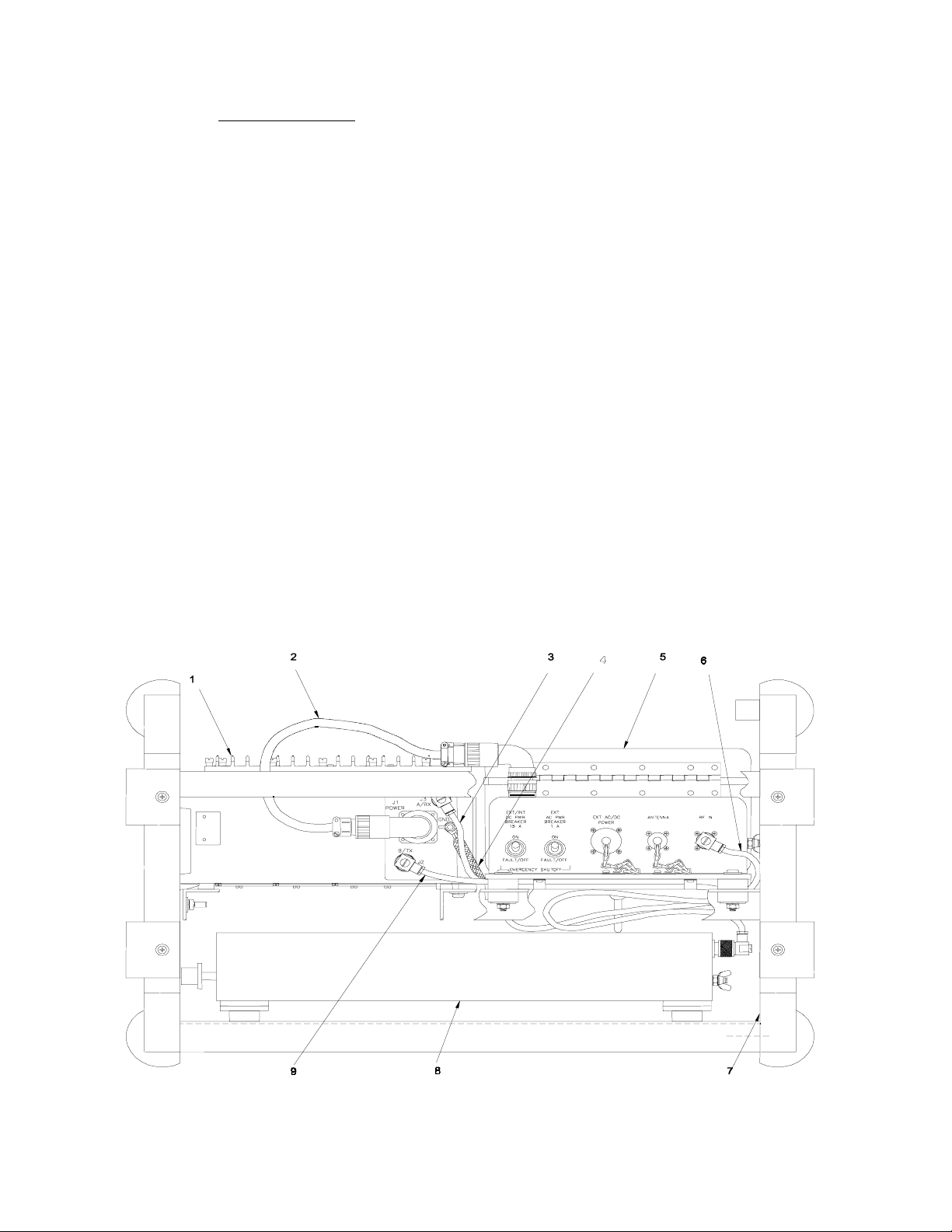

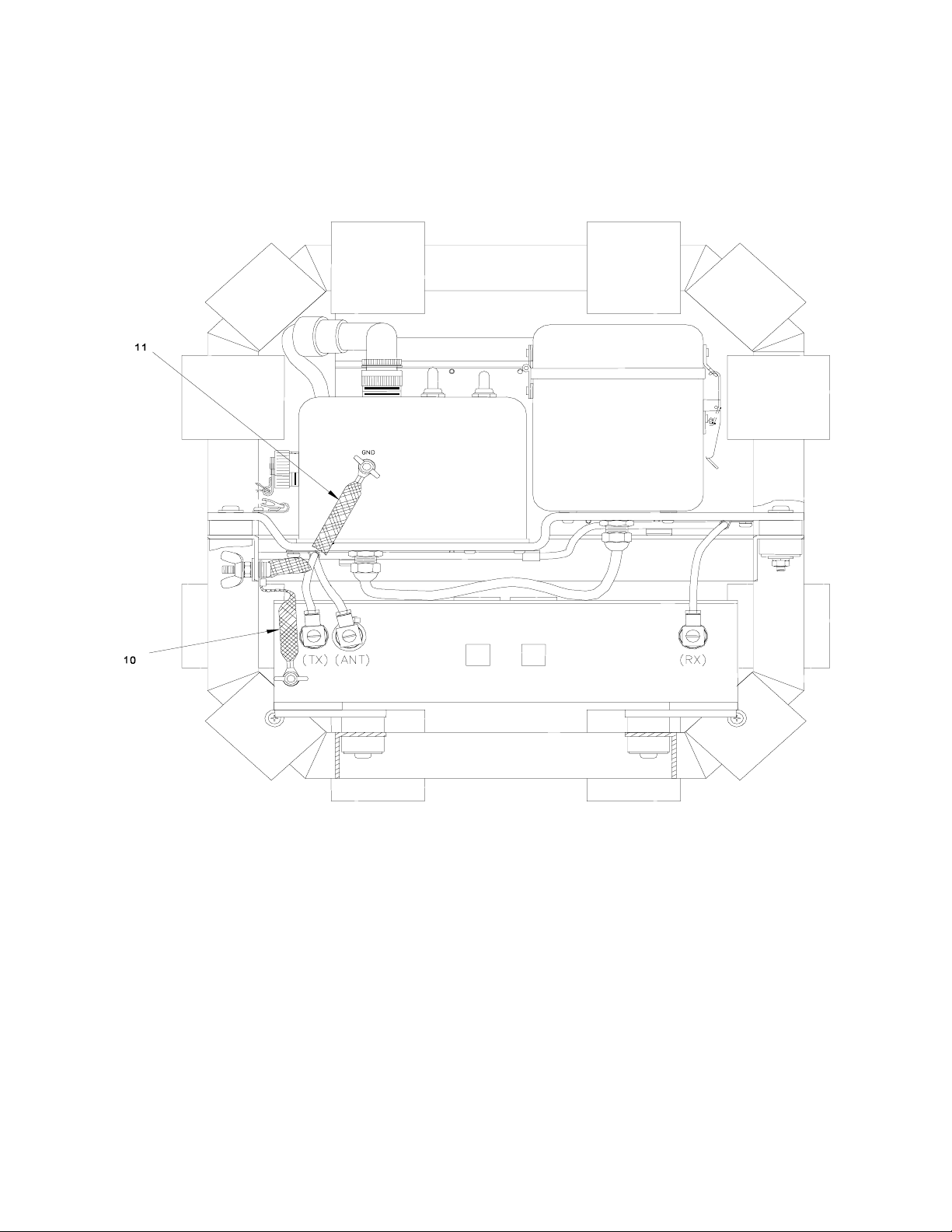

Legend for Figure 1-1:

1. Bi-directional Repeater (BDR) Assembly (A1)

2. Cable Assembly, PS Power (W1)

3. Cable Assembly, Coaxial, RF (W2)

4. Strap Assembly, Ground (W5)

5. Power Supply (A2) (includes Power Supply Enclosure and Battery Enclosure)

6. Cable Assembly, Coaxial, RF (W4)

7. Weldment, Repeater Frame

8. Diplexer Assembly, 30-88 MHz (A3)

9. Cable Assembly, Coaxial, RF (W3)

10. Strap Assembly, Ground (W6)

11. Strap Assembly, Ground (W7)

12. Antenna, 403-470 MHz

13. Antenna, Mast, TR

14. Antenna, 136-174 MHz

15. Antenna, 30-88 MHz

16. Receiver-Transmitter RT-1695/TRC-199 Unit (A4, A5)

16a. Additional transceiver modules (p/o Receiver-Transmitter RT-1695/TRC-199)

17. Diplexer Assembly, 136-174 MHz (A3)

18. Case, Transit, Diplexer

19. Diplexer Assembly, 403-470 MHz (A3)

20. Rod Assembly, Ground

21. Cable, Coaxial, Antenna (W10)

22. Cable Assembly, 240 VAC, Power (W9)

23. Cable Assembly, 120 VAC, Power (W9)

24. Cable Assembly, 10-32 VDC, Power (W9)

25. Case, Transit, Diplexer

26. Cover, Frame

1-0

Figure 1-1. Radio Set AN/TRC-207

(Sheet 1 of 3)

TO 31R2-2TRC207-1

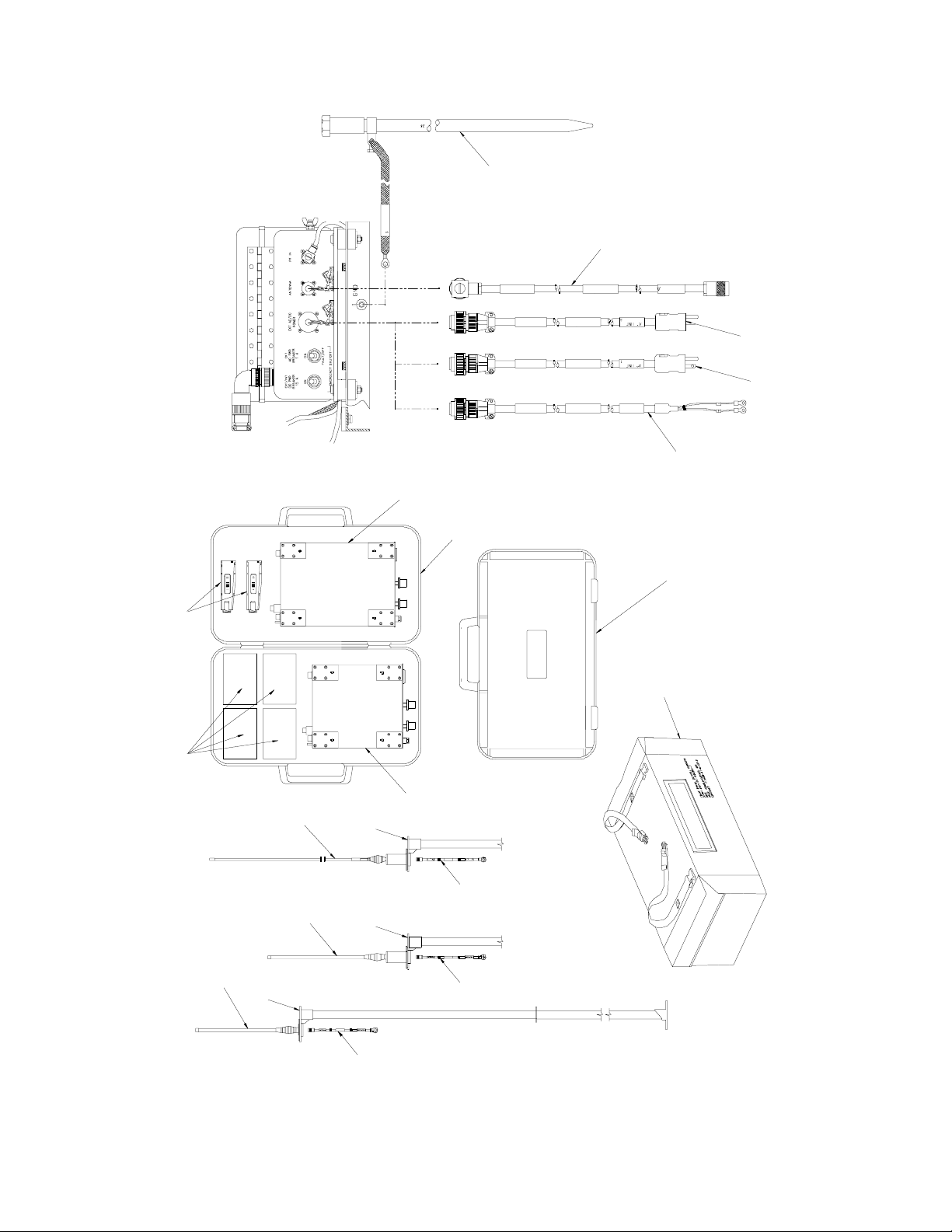

Figure 1-1. Radio Set AN/TRC-207

(Sheet 2 of 3)

1-1

TO 31R2-2TRC207-1

16

20

21

22

23

24

17

18

25

16

26

a

19

15

14

12

13

13

21

13

21

1-2

21

Figure 1-1. Radio Set AN/TRC-207

(Sheet 3 of 3)

TO 31R2-2TRC207-1

CHAPTER 1 GENERAL INFORMATION

1-1 DESCRIPTION AND PURPOSE.

1-1.1 Equipment Function and Purpose

Radio Set AN/TRC-6728 (hereinafter referred to as the bi-directional repeater or BDR) is a communications unit capable

of operating in the 30-88, 136-174, or 403-470 Megahertz (MHz) frequency bands. It is used to extend the

communications range of fixed, mobile, or portable receiver-transmitters. The BDR is COMSEC (Communications

Security) transparent and provides repeater capability for all modes without the need for COMSEC encryption/decryption.

1-1.2 Equipment Description

(See Figure 1-1.) The BDR includes a bi-directional repeater assembly, two non-CCI (Controlled Cryptographic Item)

Receiver-Transmitter Sets, Radio RT-1695/TRC-199 (hereinafter referred to as the receiver-transmitters), three antenna

systems, an antenna mast, three diplexers, a tubular (weldment) frame, a power supply enclosure, and a battery enclosure.

1-1.2.1 BDR Unit.

(See Figure 7-2.) The BDR unit includes three circuit card assemblies (CCAs) that are accessible through a removable

cover on the underside of the unit. These are the +15 volt (V) DC-DC converter CCA (A1), repeater control/audio CCA

(A2), and repeater interface (A3). These CCAs plug into the parent board (A4), which interfaces with the control panel

assembly (A5), power amplifier assembly (A6), the RF matrix CCA (A7), the external power supply, and the plug-in

receiver-transmitters. The receiver-transmitters plug into sleeves (A8, A9) located on the left and right sides of the front

panel of the BDR unit. The power amplifier (A6) is mounted under a heatsink on top of the BDR unit.

1-1.2.2 Receiver-Transmitters.

(See Figure 1-2.) The receiver-transmitters provide transmit/receive communication in the 30-88, 136-174, or 403-470

MHz frequency bands. The operating band of the receiver-transmitters is determined by the transceiver module installed.

When the transceiver modules are changed, the BDR must be fitted with the proper antenna and diplexer. The proper

configurations are listed in Table 1-1.

Table 1-1. BDR Configurations (by Frequency Band)

Frequency Band Receiver-Transmitter Antenna Diplexer

30-88 MHz

136-174 MHz

403-470 MHz

The CCI Receiver-Transmitter RT-1696/U(C) is mechanically different from the RT-1695/TRC199 to prevent full insertion into the BDR sleeves to avoid the possibility of leaving a CCI radio

in an unattended repeater.

1-1.2.3 Antenna Assembly.

The BDR antenna system provides half-duplex transmit and receive capability over one of three bands of operation. The

selected antenna is mast mounted. Three antennas are provided to cover the three bands of operation. Refer to Table 1-1.

A mast is provided to elevate the selected antenna up to 10 feet (in 5 foot increments) to increase transmission range and

quality of transmitted and received signals. The antennas and mast can be installed on a roof or existing tower to further

increase range.

SS-4100820-501

SS-4100821-501

SS-4100822-501

4242-MK2-RAC

4265-RAC

4266-RAC

NOTE

SS-1600322-501

SS-1600322-502

SS-1600322-503

1-3

TO 31R2-2TRC207-1

Figure 1-1Figure 1-2. Receiver-Transmitter RT-1695/TRC-199

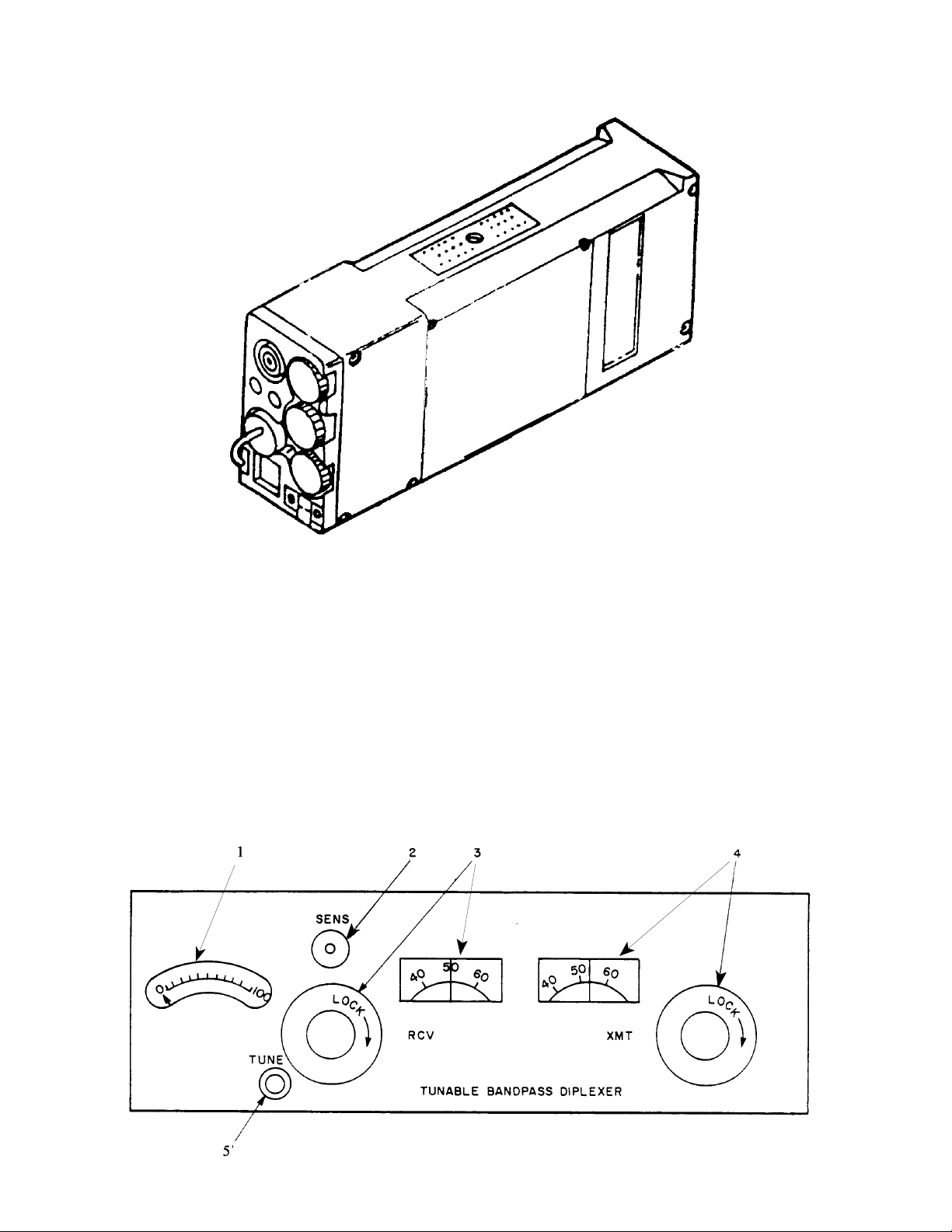

1-1.2.4 Diplexer.

(See Figure 1-3.) The BDR diplexer provides a method of using a receiver and a transmitter on a common antenna. The

diplexer has three coaxial connector ports - one port connects to the antenna via the power supply and the other two

connect to the Radio A and Radio B ports on the BDR. The diplexer, when properly tuned, provides a transmitter-toreceiver isolation of 70 decibels (dB) at any frequency spacing of 4 MHz or 3% of the operating frequency, whichever

is greater. There are three separate diplexers, one for each frequency band. The frequency band of the diplexer must

correspond to that of the receiver-transmitter and antenna.

Legend for Figure 1-3

(136-174 MHz and 403-470 MHz diplexers have the same controls, but their appearance is slightly different):

1. Tuning Meter 3. RCV Frequency Meter and Tuning Knob 5. TUNE Pushbutton

2. SENS Control 4. XMT Frequency Meter and Tuning Knob

1-4

Figure 1-3. BDR Diplexer

TO 31R2-2TRC207-1

1-1.2.5 Power Supply Assembly.

The power supply assembly provides power for the operation of the BDR. The power supply will operate from any direct

current (DC) voltage between 10 and 32 volts and from 120/240 or 220 volts alternating current (VAC). The operation

of the power supply is controlled by the AC/OFF/DC and internal/external (INT/EXT) DC switches on the power supply.

The power supply assembly consists of the power supply enclosure and the battery enclosure, which are mounted on a

tray that is bolted to the BDR frame. There are two circuit breakers located on the side of the power supply enclosure

that must be in the ON position for BDR operation.

1-1.2.5.1 Power Supply Enclosure.

The power supply enclosure provides the BDR with regulated 28 VDC power and unregulated 15 VDC power. The

power supply enclosure includes a +28V DC-DC converter CCA (A2) and circuit breakers for the AC and DC input lines.

1-1.2.5.2 Battery Enclosure.

The battery enclosure is a weather-resistant container that can hold up to four of either Type BA-5590/U Lithium batteries

or Type BB-590/U NiCd batteries. The battery connectors are mounted in the bottom of the battery enclosure box. (For

battery installation see paragraph 2-10.2.)

1-2 LEADING PARTICULARS

Leading particulars for the BDR are given in Table 1-2.

Table 1-2. Leading Particulars

Characteristic Parameter

Equipment dimensions and weight

(BDR assembly - does not include antennas,

antenna cable, or mast):

Length

Width

Height

Volume

Weight (30-88 MHz configuration BDR unit w/radios, power supply,

diplexer, frame)

Environmental requirements:

Temperature:

Operating

Storage

Humidity

Electrical power requirements 10V to 32V DC Battery Power

Nominal power consumption 24 VDC

28.4 inches (in.) (72.0 centimeters (cm))

18.9 in. (48.0 cm)

18.9 in. (48.0 cm)

10145 cubic in. (166,247 cubic cm)

140.0 pounds (lbs) (63.5 kilograms (kg))

-40° Celsius (C) (-40° Fahrenheit (F)) to +49° C (120°F)

-51° C (-60° F) to +68° C (155° F)

0 to 95 percent relative humidity

120/240 " 10% (1 phase, 3 wire) at 50/60 Hertz (Hz)

220 VAC " 10% (1 phase, 3 wire) at 50 Hz

Transmit 2W - 2500 mA

Transmit 10W - 5000 mA

Standby - 500 mA

1-5

TO 31R2-2TRC207-1

1-3 CAPABILITIES AND LIMITATIONS

Capabilities and limitations of the BDR are given in Table 1-3.

Table 1-3. Capabilities and Limitations

Characteristic Parameter

Frequency Range (RCV and XMT) 30-88 MHz

136-174 MHz

403-470 MHz

Transmitter Output 2 and 10 watts selectable

Security BDR is COMSEC transparent (contains no COMSEC

equipment). Equipment will receive and re-transmit analog

(nonsecure), 12 kbps (secure), and 16 kbps (secure) FM signals

Interoperability Radio Set AN/PRC-139/U (C)

AN/PRC-77 Manpack Radio

Radio Set AN/PRC-128

Radio Set AN/GRC-238

Adapter Group OF-228/U

Radio Set AN/TRC-199

SINCGARS-V (single channel)

FED-STD-1023 compatible, 12 kbps secure voice

VINSON (KY-57) compatible, 16 kbps secure voice

Analog 12.5 and 25 kHz frequency modulated (FM) radios

Receiving/Transmitting 25 kilohertz (kHz) Bandwidth on all frequency bands

12.5 kHz Bandwidth on 136-174 MHz and 403-470 MHz

bands

12.5 kHz tuning steps

Channels (receive and transmit) 14 channels each programmable with frequency bandwidth,

output power, and squelch tones as variables (squelch tones

available only in receive)

Adjacent Channel Selectivity 50 dB over 30-88 MHz, 25.0 kHz Bandwidth

52 dB over 136-174 MHz, 12.5 kHz Bandwidth

60 dB over 136-174 MHz, 25.0 kHz Bandwidth

40 dB over 403-470 MHz, 12.5 kHz Bandwidth

48 dB over 403-470 MHz, 25.0 kHz Bandwidth

Sensitivity

Spurious Response and Image Rejection 65 dB.

Intermodulation Spurious Response 60 dB.

Analog (nonsecure) voice: -113 dBm or 0.50µV for 12 dB

SINAD.

Digital: -105 dBm.

1-6

1-4 EQUIPMENT SUPPLIED

Equipment supplied with Radio Set AN/TRC-207 is listed in Table 1-4.

Table 1-4. Equipment Supplied

Official Nomenclature Part Number Quantity

TO 31R2-2TRC207-1

BDR Assembly

Power Supply Assembly

$ Power Supply Enclosure

$ Battery Enclosure

Diplexer Assembly, 30-88 MHz

Diplexer Assembly, 136-174 MHz

Diplexer Assembly, 403-470 MHz

Antenna, 30-88 MHz

Antenna 136-174 MHz

Antenna, 403-470 MHz

Mast, Antenna BDR

Case, Transceiver

Ground Rod Assembly

Receiver/Transmitter Set,

$ Radio RT-1695/TRC-199

$$ System Module, w/o COMSEC

$$ Transceiver Module, 30-88 MHz

$$ Transceiver Module, 136-174 MHz

$$ Transceiver Module, 403-470 MHz

Cable Assembly, BDR Power

Cable Assembly, Coaxial, RF

Cable Assembly, Coaxial, RF

Cable Assembly, Coaxial, RF

Strap Assembly, Ground

Strap Assembly, Ground

Strap Assembly, Ground

Cable Assembly, Power Supply, 120 VAC Input

Cable Assembly, Power Supply, 240 VAC Input

Cable Assembly, Power Supply, DC

Cable Assembly, Coaxial, Antenna

Bumpers, Tactical repeater Frame

Bushing, Shock Mount

Clamp, Rear

Clamp, Front

Frame, Weldment

Case, Transit, Diplexer

Case, Transit, Diplexer

Cover, Frame

4101027-501

4101028-501

SS-1600322-501

SS-1600322-502

SS-1600322-503

4242-MK2-RAC

4265-RAC

4266-RAC

SP10SS

SS-3100552-501

SS-3100551-501

SS-4100807-512

SS-4100819-502

SS-4100820-501

SS-4100821-501

SS-4100822-501

4500117-501

SS-3500292-504

SS-3500292-505

SS-3500292-503

SS-3500279-502

SS-3500279-503

SS-3500279-504

SS-4500107-501

SS-4500108-501

SS-4500109-501

CPRG223/U-30-XX

SS-3400353-1

SS-2400577-1

SS-3100546-501

SS-3400355-1

SS-4400225-1

275-160-100-000

275-160-070-000

IC-3300RC

1

1

1

1

1

1

1

1

1

2

1

2

2

2

2

2

1

1

1

1

1

1

1

1

1

1

1

24

8

1

1

1

1

1

1

1-7

TO 31R2-2TRC207-1

1-5 EQUIPMENT REQUIRED BUT NOT SUPPLIED

Table 1-5 lists equipment required but not supplied.

Table 1-5. Equipment Required but Not Supplied

Equipment Part Number

Programmer Unit, Frequency Radio MX-11531/U SS-4100797-501

Cloning Cable SS-3500272-501

Antenna Cable (for cross-banding operation) CPRG223/U-30-XX

Antenna Mast Kit (for cross-banding operation) SP10SS

Batteries (if internal DC power operation selected) Lithium Type BA-5590/U or NiCad

Type BB-590/U

NiCad Battery Charger/Conditioner (if NiCad BB-590/U

batteries used)

MRC-590

1-6 SPECIAL TOOLS AND TEST EQUIPMENT

There are no special tools or test equipment required for maintenance.

1-7 RELATED TECHNICAL MANUALS

Table 1-6 lists related technical manuals.

Table 1-6. Related Technical Manuals

Publication Number Publication Title

31R2-2PRC139-1 Operation and Maintenance Instructions with Illustrated Parts Breakdown

(Organizational Level) for Radio Set AN/PRC-139(C) (includes

RT-1695/TRC-199, RT-1696/U (C), Programmer Unit, Frequency, Radio

MX-11531/U, Battery Chargers, and Battery Reconditioner)

31R2-2GRC238-1 Operation and Maintenance Instructions with Illustrated Parts Breakdown

(Organizational Level) for Radio Set AN/GRC-238

31R2-4-1085-1 Operation and Maintenance Instructions with Illustrated Parts Breakdown

(Organizational Level) for Adapter Group OF-228/U

31R2-2TRC207-1 Operation and Maintenance Instructions with Illustrated Parts Breakdown

(Organizational Level) for Radio Set AN/TRC-207

31R2-2PRC-139-06 Work Unit Code Manual

35C3-2-113-2 NiCad Battery Reconditioner, MRC-590

1-8

TO 31R2-2TRC207-1

CHAPTER 2 INSTALLATION

2-1 INTRODUCTION.

This section is divided into two sections. Section I. Installation Logistics provides information for site preparation,

unloading, unpacking, and inspections, housing, receiving data, material handling, cabling, and buildings and other

structures. Section II. Installation Procedures lists tools and equipment required for field installation and describes the

installation sequence.

Section I. INSTALLATION LOGISTICS

WARNING

Installation of the BDR requires a minimum of two people.

2-2 SITE PREPARATION.

Select an operating site that is free of obstruction and has access to one of the electrical power sources specified in Table

1-2 under Electrical Requirements. The selected operating area must have sufficient room to accommodate the 9583 cubic

inch volume of the BDR assembly. The antenna should be at least two antenna lengths (e.g., 44 feet for 30-88 MHz) from

power lines and other antennas, etc.

2-3 UNPACKING AND INSPECTIONS.

CAUTION

Exercise care when removing units from packing material in order to prevent damage to the unit.

WARNING

Removing the BDR assembly from the shipping carton requires a minimum of two persons.

To unpack the BDR, remove the unit and any equipment from the carton and store the packing and carton for

reuse/shipment. Packing instructions are given in Chapter 3. Inspect contents for completeness, integrity, and damage.

Contents shall be in accordance with the packing slips and the list of supplied equipment in Table 1-4.

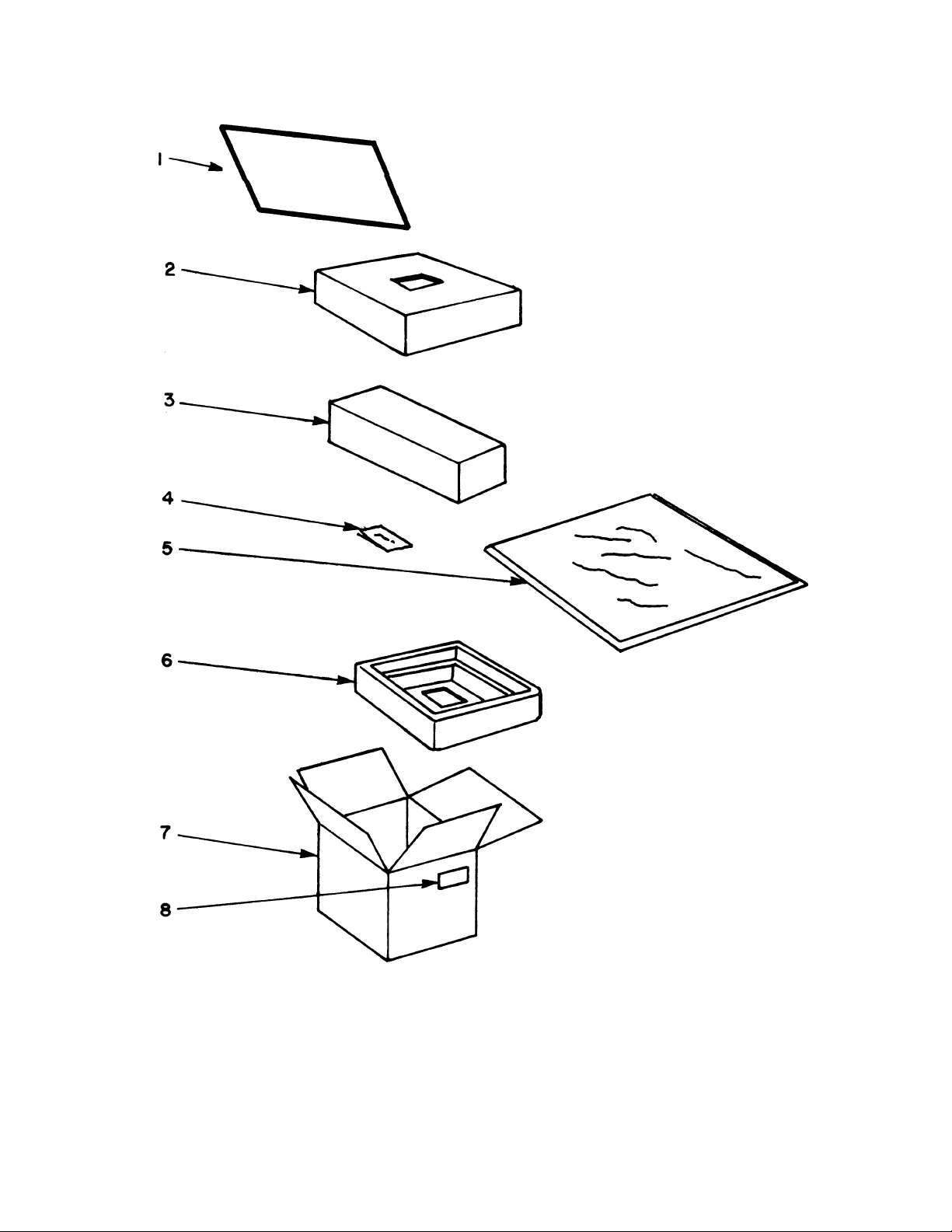

Refer to Figure 2-1 as a guide in performing the following unpacking procedures:

a. Open top of the fiberboard box (7, Figure 2-1) and remove the polystyrene top piece (2) from box.

b. Remove barrier bag (5) from the box.

c. Remove the BDR assembly (3) from barrier bag (5).

d.

Remove packing slip (8) from the plastic envelope on the fiberboard box and check to ensure that all

items listed on the packing slip were received.

2-1

TO 31R2-2TRC207-1

Legend for Figure 2-1

1. Operating instructions 5. Barrier bag

2. Polystyrene top 6. Polystyrene bottom

3. BDR assembly 7. Fiberboard box

4. Desiccant bag 8. Packing slip

Figure 2-1. Packaging Diagram for the BDR

2-2

e. Store all packing materials (except the desiccant bag) in shipping container and store shipping container

for re-use. New desiccant material must be used when repacking.

f. Inspect top and bottom, both sides, and front and rear panels of equipment for dents, scratches or any

visually identifiable damage.

g. Inspect controls and indicators on control panel for missing, broken or cracked knobs or levers and note

any discrepancies on Receiving Report, DD Form 1348-1. Report any discrepancies in accordance with

standard internal receiving procedures.

2-4 HOUSING.

If necessary to store the BDR for any period of time before installation, proceed as follows:

a. Clean the BDR before placing in storage, if necessary. Refer to paragraph 6-3.3.2.

b. Disconnect antennas and accessories before placing the BDR in storage.

c. Remove receiver-transmitters from the BDR assembly before placing in storage.

d. Remove batteries.

NOTE

TO 31R2-2TRC207-1

The temperature of the storage area must be within the range -51°C (-60°F) to +68°C (155°F).

2-5 RECEIVING DATA.

Table 2-1 identifies the contents of the shipping container.

Table 2-1. BDR Packaging

Dimensions (in)

Box Description

1 BDR 34.625 68 33.75 195

WDL

Weight

(lb.)

2-6 MATERIAL HANDLING.

The weight of the equipment is such that a minimum of two persons are required to lift the (unpacked) equipment.

2-3

TO 31R2-2TRC207-1

y

t

y

f

2-7 CABLES.

Table 2-2 lists all BDR interconnecting cables.

Table 2-2. BDR Interconnecting Cables

Cable

Designation

W1 4500117-501 Cable Assembly, BDR Power Connects power supply DC output to bi-

W2 SS-3500292-504 Cable Assembly, Coaxial, RF Connects diplexer receiver (RX) output

W3 SS-3500292-505 Cable Assembly, Coaxial, RF Connects diplexer transmitter (TX)

W4 SS-3500292-503 Cable Assembly, Coaxial, RF Connects diplexer antenna (ANT) outpu

W5 SS-3500279-502 Strap Assembly, Ground Connects bi-directional repeater assembl

W6 SS-3500279-503 Strap Assembly, Ground Connects diplexer to external ground

W7 SS-3500279-504 Strap Assembly, Ground Connects power supply to external

W9 SS-4500107-501 Cable Assembly, Power Supply, 120

W9 SS-4500108-501 Cable Assembly, Power Supply, 240

W9 SS-4500109-501 Cable Assembly, Power Supply, DC Connects BDR to 10-32 VDC

Cable Part No. Description Use

directional repeater

to bi-directional repeater assembly

output to bi-directional repeater assembl

to RF IN of power supply

to external ground

ground

Connects BDR to 120 VAC

VAC Input

Connects BDR to 240 VAC

VAC Input

W10 SS-1600315-1 Cable Assembly, Coaxial, Antenna Connects antenna to antenna connector o

bi-directional repeater power supply

2-8 BUILDING AND OTHER SUPPORTING STRUCTURES

Not Applicable.

2-4

TO 31R2-2TRC207-1

Section II. INSTALLATION PROCEDURES

2-9 SPECIAL TOOLS AND EQUIPMENT REQUIRED FOR FIELD

INSTALLATION.

No special tools or equipment are needed for installation and initial setup of the BDR.

2-10 INSTALLATION SEQUENCE

(See FO-1.) Perform the following procedure to install the BDR. Cables required for installation are listed in Table 2-2.

FO-1 illustrates the required cable connections.

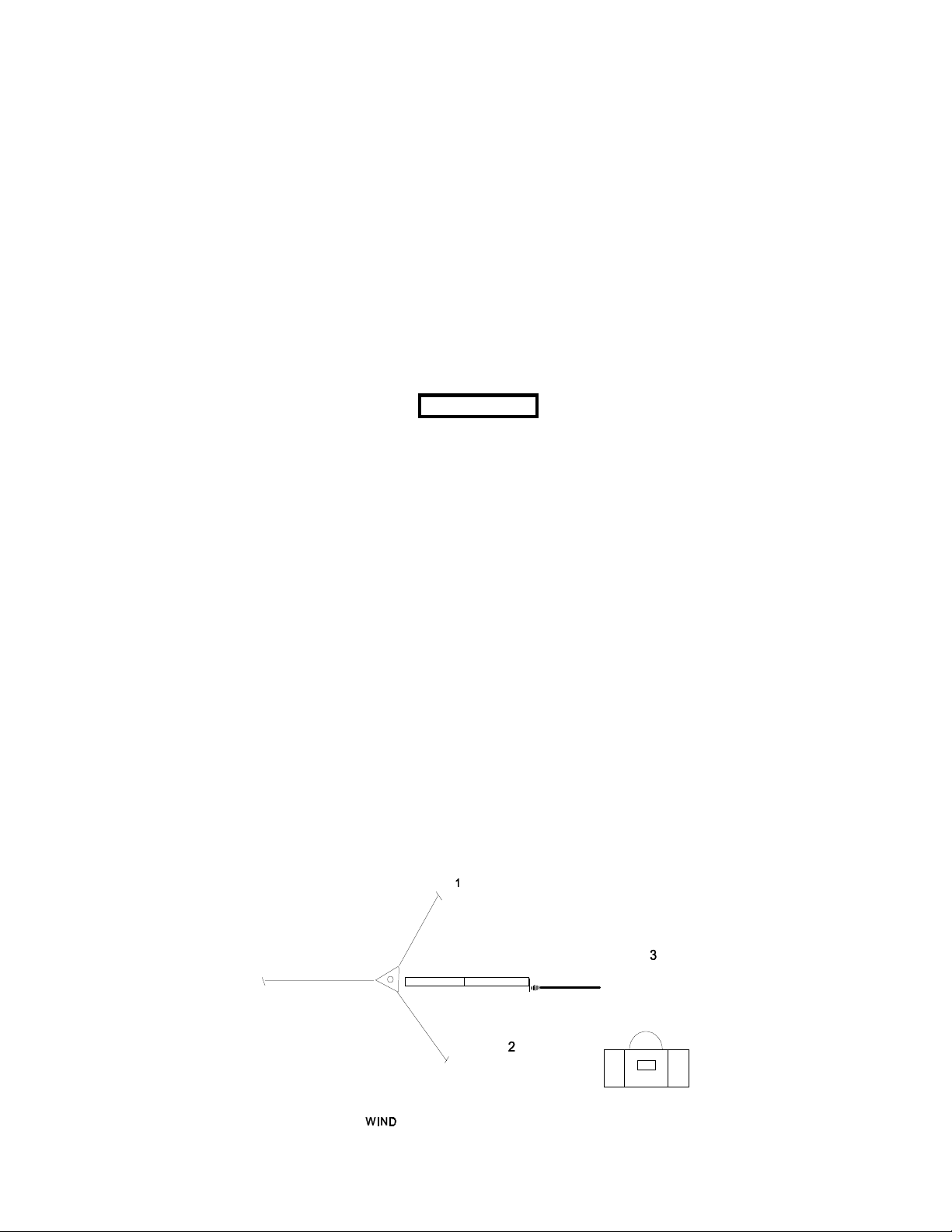

2-10.1 Antenna/Mast Installation

(Refer to Figure 2-2.) Install the antenna mast and selected antenna as follows:

WARNING

Ensure proper use of safety tools (work gloves and hard hat) during assembly and disassembly

of antenna and mast.

NOTE

The BDR assembly is shipped from the factory configured for 30-88 MHz operation, with the

appropriate receiver-transmitters and diplexer. If using a different configuration, substitute the

appropriate antenna, receiver-transmitters, and diplexer. Refer to Chapter 6 for antenna and

diplexer removal and replacement. Refer to TO 31R2-2PRC139-1 for changing receivertransmitter configuration.

NOTE

The assembled antenna base section/antenna adapter will fit in the mast transit bag (3) so that step

a may be carried out prior to field deployment, if required. When erecting the antennas in high

winds, ensure that a minimum of three personnel are used.

a. Bolt the antenna base section (1, Figure 2-2) to the antenna adapter (2) and connect the antenna ground

strap to its terminal.

b. Select an unobstructed site. Under windy conditions mast raising is made easier if the mast is laid out

on the ground with the base of the mast pointed into wind.

Figure 2-2. Antenna Mast/Antenna Installation (Sheet 1 of 6)

2-5

TO 31R2-2TRC207-1

c. Remove both mast sections from the transit bag (3). Note that the socketed end is the lower end of each

section. Place the tubes in line along the ground. Assemble the two tube sections together.

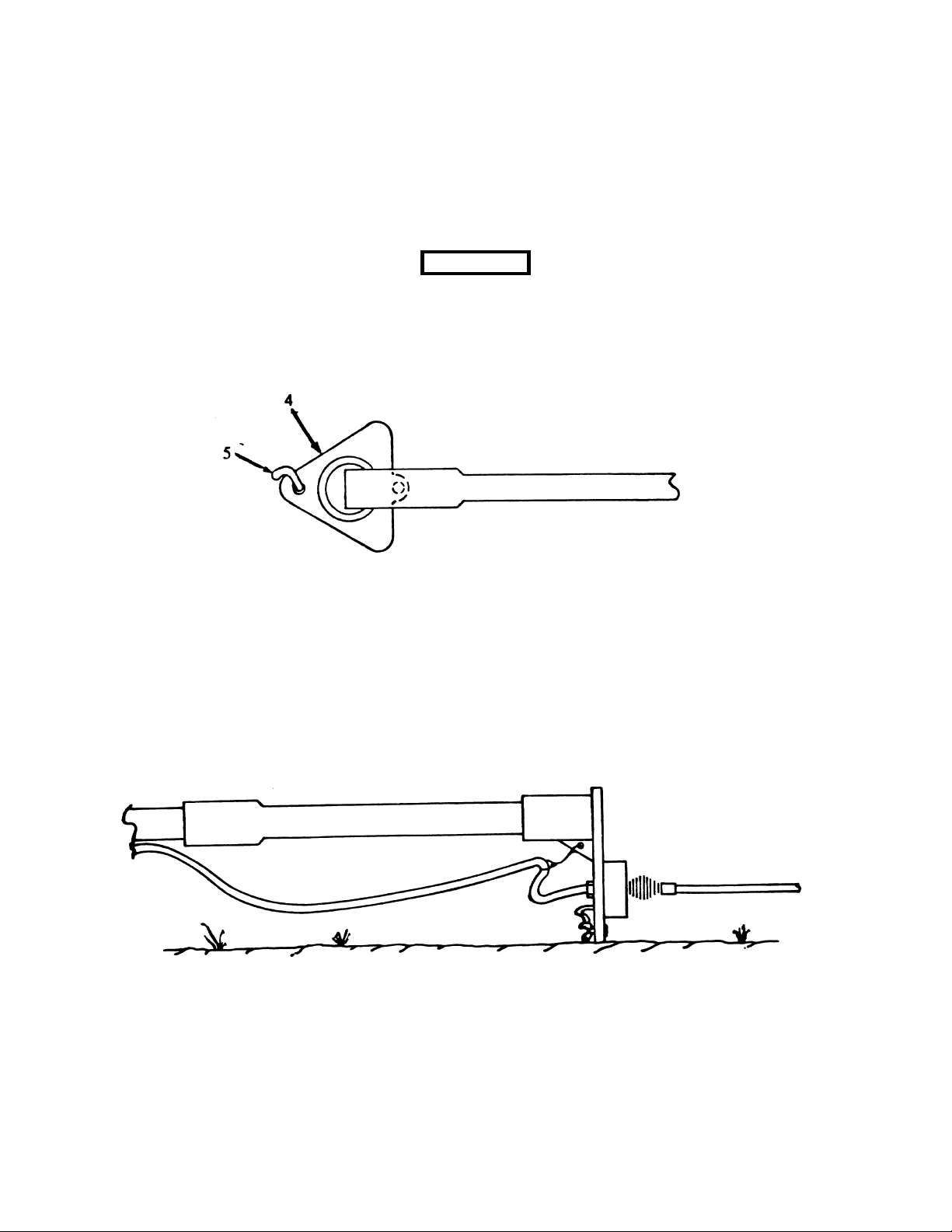

d. Remove the base plate (4), two ground spikes (5), and hammer from the transit bag. Place the base

plate at the mast base, arrowhead style, so that the socketed lower end of the mast will engage in the

heel. Secure the base plate by driving the two ground spikes through the holes.

Before using the hammer, ensure a wedge is placed in the top of the hammer so that the hammer

head does not come loose, thereby endangering personnel.

WARNING

Figure 2-3. Antenna Mast/Antenna Installation (Sheet 2 of 6)

e. Place the antenna/adapter assembly on the top mast section. Ensure the adapter is fully seated on the

mast section. Connect the top coaxial cable connector to the antenna and attach cable strain relief to

hole in web of adapter. Rest flat edge of adapter on ground to provide convenient access to guy rope

attachment points. Unwind cable along length of mast and secure to mast at centers of each section.

Secure using cable clamps.

Figure 2-4. Antenna Mast/Antenna Installation (Sheet 3 of 6)

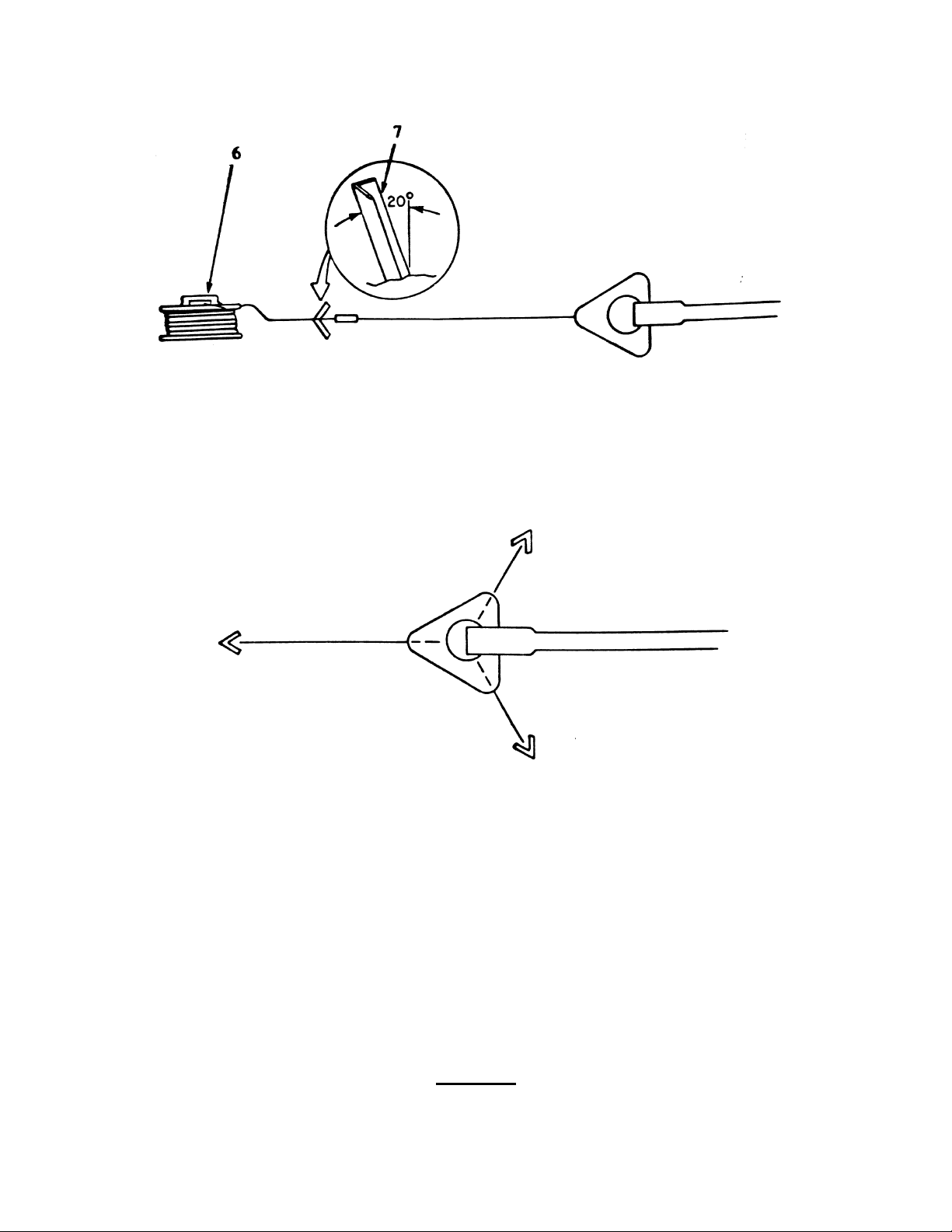

f. Remove three guy rope assemblies (6) and three ground anchors (7) from the transit bag. Disconnect

the first (fixed) snap hook off the winder and temporarily connect it to the base plate. Carrying the

hammer and one of the ground anchors, walk away in the exact opposite direction to the mast (i.e., in

the direction that the arrow head is pointing) unwinding the guy rope as you go, until the ground anchor

radius marker is reached. Drive in the ground anchor at this point ensuring that it leans away from the

mast (approximately 20

o

from vertical).

2-6

TO 31R2-2TRC207-1

Figure 2-5. Antenna Mast/Antenna Installation (Sheet 4 of 6)

g. Using the same guy rope as a radius guide, walk across to the approximate location of the second

ground anchor. Establish the required 120E from the first ground anchor by using the triangular shape

of the base plate as a reference. Drive in a second ground anchor at this point.

Figure 2-6. Antenna Mast/Antenna Installation (Sheet 5 of 6)

h. Repeat step g for the third ground anchor.

i. Disconnect the guy rope used for a radius marker. Attach the fixed (upper) snap hook to the attachment

point on the antenna adapter. Attach the running hook at the lower end to ground anchor 2. Note that

the winder remains attached to the lower ends of the guy rope to prevent accidental loss.

j. Take a second guy rope. Attach the fixed (upper) snap hook to the antenna adapter attachment point.

Attach the running hook at the lower end to ground anchor 3.

k. Attach the upper snap hook of the third guy rope to the adapter attachment point. Unwind the rope

along the length of the mast toward the ground anchor 1, but do not attempt to attach the lower end yet.

Ensure that guy ropes will not snag the coaxial cable when the mast is raised.

CAUTION

The adapter and antenna can lift off the mast while the mast is being raised if the adapter is not

completely seated on the top mast section.

2-7

TO 31R2-2TRC207-1

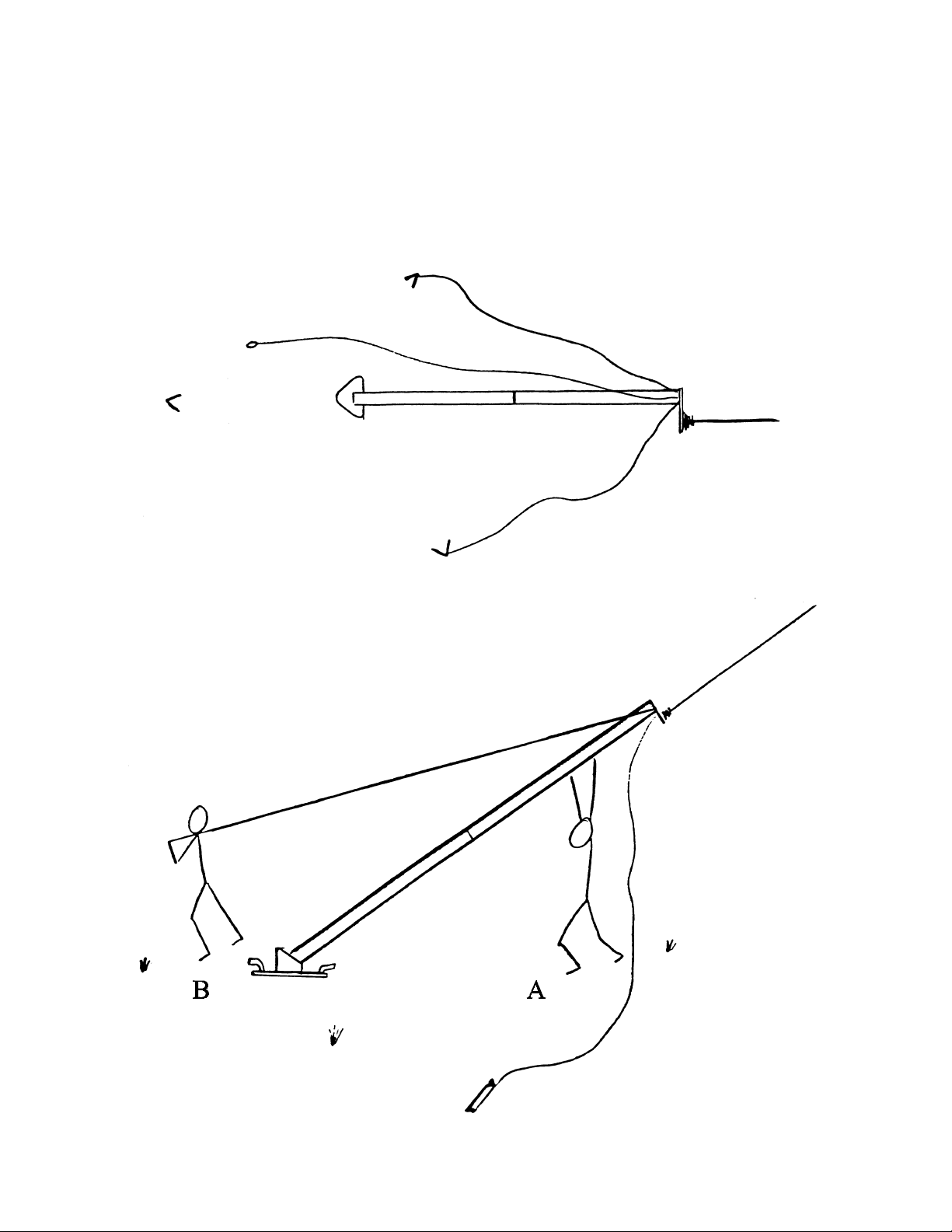

l. Ensure foot of mast is securely located in the base plate heel. While person A pushes up mast head Iwo

Jima style, person B pulls on guy ropes to raise mast to vertical. Person A should progressively walk

towards bottom of mast as it is raised and should hold mast steady as it reaches the vertical. Person B

attaches free guy ropes to ground anchor 1 and tightens all ropes.

m. Connect the coaxial antenna cable (SS-1600315-1) to the connector at the back of the power supply.

Refer to FO-1.

2-8

Figure 2-7. Antenna Mast/Antenna Installation (Sheet 6 of 6)

TO 31R2-2TRC207-1

2-10.2 Lithium Battery Installation.

(Optional) (This procedure is also applicable to the Type BB-590/U NiCd batteries.) The battery enclosure has

connectors for four type BA-5590/U Lithium batteries. The connectors are mounted in the bottom of the enclosure. To

install the batteries, first turn the BDR off using the switch on the top of the power supply enclosure. Open the battery

enclosure. Taking each battery, in turn, turn the battery so that the connector is facing down, align the connector on the

battery with the connector in the bottom of the enclosure, and push down on the battery until seated.

To power the BDR from the installed batteries, set the power supply POWER switch to DC, and the DC SEL switch to

INT. Ensure that both circuit breakers on the side of the power supply are ON. The repeater is capable of full operation

with either three or four batteries installed. For battery operation, use of the 2 WATT mode will greatly prolong battery

life.

2-10.3 Ground Rod Installation.

The ground rod assembly consists of a 3 foot long ground rod and an attached 10 foot grounding strap. The grounding

strap ends in a spade lug that is connected to a ground screw on the BDR assembly frame next to the power supply

assembly. (See Figure 1-1 for illustration of grounding strap connection.)

To install, place the BDR in its selected operating location. Locate the ground lug on the frame and select a spot for the

ground rod within a 10 foot arc of the ground screw. Drive the ground rod into the ground with a sledge hammer until

the grounding strap clamp is level with the ground. Remove the wing nut and washer from the ground screw, place the

spade lug over the screw, and reattach the washer and wing nut.

2-10.4 External Power Supply.

To connect the BDR to an external power supply, select the appropriate power supply cable to match the external source

(110/220 VAC, 240 VAC, or 10-32 VDC). Connect the power supply cable to the POWER IN connector on the power

supply and connect to the power source. Set the power supply POWER switch and DC SEL switch as indicated in Table

2-3.

NOTE

When using external DC power, use as large a DC voltage power source as possible (e.g., a 28 volt

battery rather than two 12 volt batteries). The BDR DC power supply operates more efficiently with

larger DC voltages.

Table 2-3. External Power Supply Switch Settings

POWER SOURCE POWER DC SEL

110/220 VAC AC N/A

240 VAC AC N/A

10-32 VDC DC EXT

2-10.5 Diplexer Installation

Refer to paragraph 6-5.1.6.

2-10.6 Receiver-Transmitter Transceiver Module Installation

Refer to TO 31R2-2PRC139-1.

2-9/(2-10 blank)

TO 31R2-2TRC207-1

CHAPTER 3 PREPARATION FOR USE AND RESHIPMENT

3-1 INTRODUCTION.

This chapter is divided into two sections. Section I. Preparation For Use provides post-installation operational checks

that must be performed prior to operating the BDR. Section II. Preparation For Reshipment contains procedures for

reshipment of the unit.

Section I. PREPARATION FOR USE

3-2 INSPECTION.

If the BDR has not been inspected as part of the installation process, or if the equipment has not been used recently, check

to ensure that all cable connections are tight and no damage is visible on the exterior of the BDR.

3-3 POST-INSTALLATION CHECKOUT.

3-3.1 Preliminary

Before performing the post-installation checkout procedures of paragraph 3-3.3, perform the following preliminary

procedures.

NOTE

The receive and transmit frequencies programmed into the receiver-transmitters must be separated

by at least 4 MHz or 3 percent of the lower frequency, whichever is greater. Similarly, the

frequencies on the two nets for bi-directional operation must have similar separations. If the

minimum frequency separation is not used, the BDR will not operate properly. See paragraph 4-3

for additional data.

NOTE

For all modes of operation, the receive and transmit frequencies on the channel in use on each

radio must be the same (simplex operation).

a. Ensure that both receiver-transmitters (SS-4100807-512) have been programmed with the correct

receive and transmit frequencies and CTCSS tones. (TO 31R2-2PRC139-1 describes procedures for

programming all programmable parameters.) Use of CTCSS tones is recommended for non-secure

operation. ATONES=NONE@ should be used for secure operation.

b. Ensure that the channel select switch on each radio is set to the correct channel, the mode switch is set

to CLR, and the SCAN switch is turned off. On/Off/Volume control setting is ignored.

NOTE

Other programmable parameters (RF power, data rate, etc.) may be set to any value.

NOTE

Be sure to align the receiver-transmitters so that the orientation of the control knobs and

connectors corresponds to the markings on the sleeve door. The receiver-transmitters cannot be

inserted in the bi-directional repeater with the battery attached. The CCI receiver-transmitter

(RT-1696/U (C)) cannot be inserted into the BDR.

3-1

TO 31R2-2TRC207-1

c. Insert the receiver-transmitter (SS-4100807-512) for the (primary) transmit frequency into the right

sleeve (marked "B")of the bi-directional repeater, with the side connector facing up (refer to Figure 1-

1). Turn the cam above the receiver-transmitter clockwise until it locks (1/4 turn).

d. Similarly, insert the receiver-transmitter for the (primary) receive frequency into the left sleeve (marked

"A") of the bi-directional repeater and lock it into place.

3-3.2 Alignment and Adjustment.

The BDR is aligned and adjusted for normal operation at the factory/depot. No other alignments or adjustments are

authorized or required. The diplexer will require retuning as described in paragraph 4-3 whenever the transmit or receive

frequencies are changed.

3-3.3 Post-Installation Checkout Procedures

After completion of installation, perform the following checkout procedures.

3-3.3.1 Power-Up Check.

Perform the power-up check as follows:

a. Ensure that both receiver-transmitters are programmed with the proper type squelch settings to receive

the desired modulation format (carrier squelch (ATONES=OFF@) or CTCSS tones) (since both are

capable of receiving signals).

b. Place the BDR MODE SELECT switch (6, Figure 4-1) in one of the RETRANS mode positions (either

BDR or TR operation.)

c. Place the BDR POWER switch (8, Figure 4-1) in the 2WATT or 10WATT position.

d. Place the power supply AC/DC POWER switch (1, Figure 4-2) in either AC or DC position, depending

on source of power. If DC is selected, the DC SEL switch must be set for internal (INT) or external

(EXT) power source, as appropriate. Ensure that both circuit breakers (1 and 2, Figure 4-3) are

switched ON.

e. Ensure that the green POWER LED is illuminated when the DISPLAY switch is ON. This indicates

that the unit is receiving power from the power supply.

3-3.3.2 Operational Check.

Perform the operational checkout included in paragraph 6-2 to verify that the major components of the BDR are

functioning properly.

3-3.3.3 Equipment Shutdown.

Shut down the BDR as follows:

a. Set the power supply POWER switch to OFF.

b. Ensure that the POWER LED is not illuminated (with the display switch on).

Section II. PREPARATION FOR RESHIPMENT

3-4 PREPARING UNIT FOR RESHIPMENT

Prepare the BDR for reshipment as follows:

a. Disconnect all external accessories, antennas, and cables.

b. Remove the receiver-transmitters prior to shipment.

c.

3-2

Remove batteries (if installed).

TO 31R2-2TRC207-1

3-5 PACKING.

Pack the BDR in the recommended packages illustrated in Figure 2-1. Use original packing materials if available.

3-6 HANDLING AND STORAGE.

Place electronic assemblies in individual containers. This will prevent damage during handling and storage. If a common

container is used, use suitable barrier material between electronic assemblies. Sufficient packing must be used to prevent

shifting of electronic assemblies within the container. Package the equipment in accordance with MIL-STD-2073-1A/2B.

Marking for reshipment and storage shall be in accordance with MIL-STD-129J.

CAUTION

Never apply pressure sensitive tape directly to connectors. This could damage connector pins.

3-6.1 Protective Measures for Electrical Connectors.

Protect all unmated connectors that are exposed to physical or environmental damage by covering with supplied protective

caps.

3-6.2 Preparation for Shipment and Storage.

Before preparing the equipment for shipment or storage, ensure that the receiver-transmitters, batteries, and any other

accessories have been removed from the bi-directional repeater.

CAUTION

Package all electrostatic discharge (ESD) sensitive assemblies in ESD bags before shipping or

storing.

For shipment to another facility or long-term storage, package the unit as shown in Figure 2-1. Regardless of the

electronic assembly design, fit all protruding parts with packing spacers, wrap the complete assembly with plastic or place

in a plastic air-lock bag. Wrap with a protective cellulose, foam, or similar material. Wrap assemblies that contain

electrostatic discharge sensitive (ESDS) parts in static protective materials.

3-6.3 Handling.

Following are general handling instructions which should be followed when handling the equipment.

WARNING

Before performing removal/replacement procedures, make sure power is removed from the unit

by disconnecting from power source. Failure to do so could result in personal injury or equipment

damage.

CAUTION

Rough handling may cause unnecessary damage to electronic assemblies.

CAUTION

Electronic assemblies containing solid-state devices are susceptible to damage from static

electrical discharges. Wear protective clothing and grounded wrist straps.

3-3

TO 31R2-2TRC207-1

CAUTION

Forcing any tilted or cocked electronic assembly into position may result in bent or broken pins.

Be very careful when removing or inserting an assembly into the equipment. If it is a plug-in CCA, be sure the guide pins

are properly aligned before pressing the assembly in place. If the CCA tilts while being inserted, do not continue to press

into position; straighten it, then apply even pressure to avoid tilting.

CAUTION

When repairing an electronic assembly, be careful that the tool employed does not inadvertently

press against leads, pins, or other parts that are easily bent.

CAUTION

Because of the miniaturization of parts for electronic assembly construction, the leads, connectors,

and pins have been stiffened to make them more rugged. As a result, such parts are brittle and

will break easily if bent too often or pulled on too hard. When handling an assembly that has been

removed from its chassis, be careful not to press against the leads and pins. When removing an

assembly, be sure to pull it straight out from the equipment. Do not cock, twist, pry, or carelessly

jerk an electronic assembly to remove it from the mounting or connector.

CAUTION

ELECTROSTATIC DISCHARGE

The bi-directional repeater contains components that are susceptible to damage by static electrical

charges. Disassembly of the bi-directional repeater should only be done at a properly grounded

work station.

3-4

TO 31R2-2TRC207-1

CHAPTER 4 OPERATION

Section I. CONTROLS AND INDICATORS

4-1 INTRODUCTION

This section describes and illustrates indicators, controls, switches, and connectors of the bi-directional repeater.

4-2 CONTROLS AND INDICATORS.

The following paragraphs describe and illustrate all operational controls and indicators of the bi-directional repeater.

4-2.1 Indicators, Controls, and Switches.

All indicators, controls, and switches for the bi-directional repeater are illustrated in Figure 4-1 and described in Table

4-1.

4-2.2 Power Supply Switches and Connectors.

The bi-directional repeater power switches and top connectors are located on the power supply assembly. The power

switches are illustrated in Figure 4-2 and described in Table 4-2.

4-2.3 Connectors.

External side connectors for the power supply are illustrated in Figure 4-3 and described in Table 4-3. External

connectors for the repeater unit are illustrated in Figure 4-4 and described in Table 4-4.

4-2.4 Diplexer Control

All diplexer controls for the bi-directional repeater are illustrated in Figure 4-5 and described in Table 4-5.

Figure 4-1. Location of Bi-Directional Repeater Indicators, Controls, and Switches

4-1

TO 31R2-2TRC207-1

Table 4-1. Description of Indicators, Controls and Switches

Fig & Index Number Control/Switch Function

STATUS:

4-1-1 DISPLAY Switch (two-

position rotary switch)

4-1-2 FAULT LED (red) When illuminated, indicates 1) RF power amplifier internal

4-1-3 RCV (Receive) LED

(amber)

4-1-4 XMT (Transmit) LED

(amber)

4-1-5 POWER LED (green) When illuminated, indicates power is applied to the bi-

4-1-6 MODE SELECT Switch

(six-position rotary switch)

Controls whether the front panel indicators are operational

(ON position) or not operational (OFF position) (The

DISPLAY switch should be kept in OFF position to

conserve battery life following initial power-up and

function check.)

temperature is excessive (greater than 90E C), 2) RF path

fault (diplexer or BDR is cabled incorrectly, diplexer is

tuned incorrectly, or frequency spacing is less than

recommended minimum), or 3) no or faulty radio in

Radio A sleeve.

When illuminated in the RETRANS and COMMS modes,

indicates reception of a transmission.

When illuminated in the RETRANS and COMMS modes,

indicates retransmission of a reception. Illuminates also

in the TUNE A or TUNE B mode to indicate that the A

or B receiver-transmitter is active.

directional repeater.

Allows selection of the bi-directional repeater operating

mode as follows:

RETRANS - Selects bi-directional repeater (BDR)

operation (receive or transmit on either radio) or single

direction tactical repeater (TR) operation (receive on

one radio, transmit on the other). Unencrypted through

traffic can be monitored via local accessory. Local

transmit capability is disabled.

COMMS - Selects Terminal A or Terminal B modes

(broadcast capability through radio A or radio B).

Unencrypted traffic reception is available through either

radio. Local transmit is available through the selected

radio.

TUNE A - Allows the "A" receiver-transmitter path of

the diplexer to be tuned. All other repeater functions are

disabled.

TUNE B - Allows the "B" receiver-transmitter path of

the diplexer to be tuned. All other repeater functions are

disabled.

4-1-7 POWER Select Switch Selects an output power level of 2 watts or 10 watts.

4-1-8 VOLUME Control Volume control for attached audio accessory.

4-1-9 Audio Connector Standard 6-pin connector for audio accessory.

4-2

TO 31R2-2TRC207-1

Figure 4-2. Location of Power Supply Switches (Power Supply Top View)

Table 4-2. Description of Power Supply Switches

Fig & Index Number Switch Function

4-2-1 DC SEL (INT/EXT) Select

switch (two-position toggle

switch)

4-2-2 AC/DC POWER (DC/OFF/

AC) switch (three-position

toggle switch)

4-2-3 POWER OUTPUT Connector for power output cable to bi-directional repeater

Allows selecting either the internal battery power source or

an external DC source when the AC/DC POWER switch is

in the DC position.

Allows the operator to turn the bi-directional repeater on

and off, and select either an AC or DC power source.

unit

4-3

TO 31R2-2TRC207-1

Figure 4-3. Location of Power Supply Connectors (Power Supply Side View)