Quinny QSD 65040-AB User Manual

™

QSD

Oil-Free Rotary Screw Air Compressor

Instruction Manual

Series

This manual contains important safety information and should be made available to

all personnel who operate and/or maintain this product. Carefully read this manual

before attempting to operate or perform maintenance on this equipment.

Manual No. 65040-AB

January 2001 Edition

TABLE OF CONTENTS

Standard Warranty...................................................................................................................................................... 3

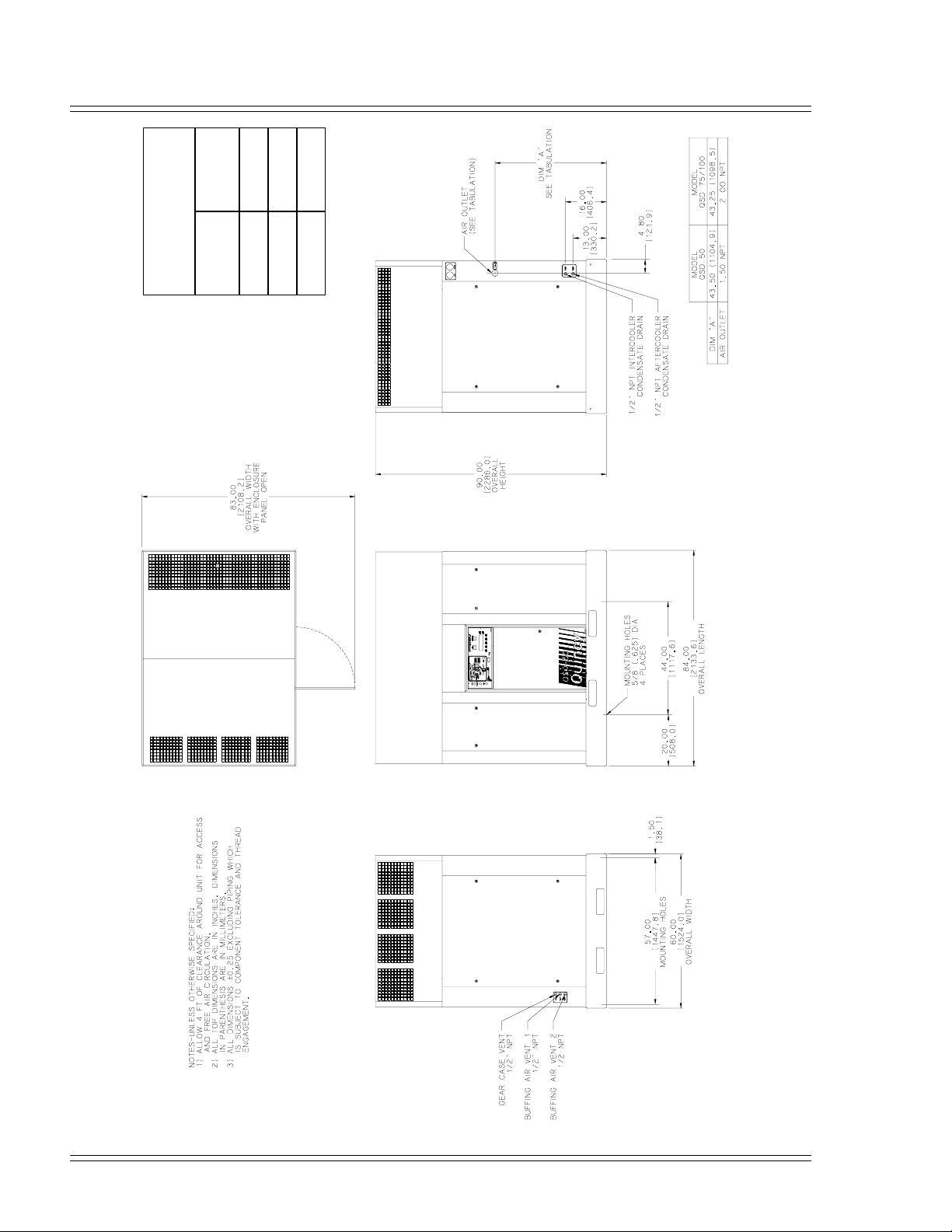

Dimensional Data ....................................................................................................................................................4-5

Section I

Safety Precautions ...................................................................................................................................................... 6

Safety Alert Symbols ................................................................................................................................................. 7

Serial/Model Identification Plate ............................................................................................................................... 7

Spare Parts Ordering Information .............................................................................................................................. 7

Section II - Description

Model Identification................................................................................................................................................... 8

General Description.................................................................................................................................................... 9

The Compression Cycle and Air Flow.......................................................................................................................9

Cooling System ........................................................................................................................................................ 10

Lubricating Fluid System ......................................................................................................................................... 10

Moisture Separator ................................................................................................................................................... 10

Capacity Control System.................................................................................................................................... 11-12

Electrical System................................................................................................................................................ 12-14

Indicators ............................................................................................................................................................ 14-15

Section III - Installation

Receiving.................................................................................................................................................................. 16

Moving the Unit to the Installation Site ................................................................................................................... 16

Location.............................................................................................................................................................. 16-17

Piping Connections ............................................................................................................. ............................... 17-18

Manual Shutoff Valve .............................................................................................................................................. 18

Pressure Relief Valves.............................................................................................................................................. 18

Electrical................................................................................................................................................................... 19

Guards ...................................................................................................................................................................... 19

Water and Sewer Facilities at the Installation Site............................................................................................ 19-20

Fluid Level ............................................................................................................................................................... 21

Compressor Rotation................................................................................................................................................ 21

Fan Rotation ............................................................................................................................................................. 21

Section IV - Operating Procedures

Prior To Starting....................................................................................................................................................... 22

Starting the Compressor ........................................................................................................................................... 22

Stopping the Compressor - Normal Operation......................................................................................................... 22

Stopping the Compressor - Emergency Operation ..................................................................................................23

Quincy Compressor - QSD™ 1

TABLE OF CONTENTS

Section V - Maintenance or Service Preparation

Preparing for Maintenance or Service...................................................................................................................... 24

Section VI - Servicing

Safety........................................................................................................................................................................ 26

Fluid Specifications............................................................................................................................................ 26-27

Air Filter ................................................................................................................................................................... 27

Input Shaft Seal .................................................................................................................................................. 28-29

Airend Sealing System ............................................................................................................................................. 29

Section VII - Service Adjustments

Pressure Switch ........................................................................................................................................................ 30

Section VIII - Power$ync II™ Operation

Introduction to Power$ync II™ (version 1.04) ......................................................................................................... 32

Back-up Mode Operation ................................................................................................................................... 32-33

Single Machine Operational Mode .......................................................................................................................... 33

Multiple Machine Operational Mode................................................................................................................. 33-34

Pressure Settings ................................................................................................................................................ 34-35

Network Installation ........................................................................................................................................... 35-37

Network Voltage Tests on Power$ync II™ Systems ................................................................................................37

Network Setup.......................................................................................................................................................... 37

Start-up ..................................................................................................................................................................... 38

Power-up Displays ............................................................................................................................................. 38-42

Start-up Displays ...................................................................................................................................................... 43

Operational Displays .......................................................................................................................................... 43-45

Compressor Settings and Maintenance Displays ............................................................................................... 45-58

Cautionary and Shutdown Displays ................................................................................................................... 59-65

Shutdown Log Messages.................................................................................................................................... 66-69

Section IX

Troubleshooting ................................................................................................................................................. 70-78

Section X

Maintenance Schedule ............................................................................................................................................. 79

Daily Operating Record

.................................................................................................................................................................................. 80

2 Quincy Compressor - QSD™

Standard Warranty

Quincy Compressor Division

Industrial Screw Products

QSD™ - Rotary Screw Air Compressors

Seller warrants products of its own manufacture against

defects in workmanship and materials under normal use

and service, as follows:

QSD™ Packaged Compressors - Twelve (12) months

from date of start-up or eighteen (18) months from date

of shipment from the factory, whichever occurs first.

Airend on Packaged Compressors - Thirty-six (36)

months from date of start-up or forty-two (42) months

from date of shipment from the factory, whichever occurs

first.

Parts - Ninety (90) days from date of Distributor sale or

one (1) year from date of factory shipment.

With respect to products not manufactured by Seller,

Seller will, if practical, pass along the warranty of the

original manufacturer.

Notice of the alleged defect must be given to Seller in

writing with all identifying details including serial

number, model number, type of equipment and date of

purchase, within thirty (30) days of the discovery of same

during the warranty period.

Seller’s sole obligation on this warranty shall be, at its

option, to repair, replace or refund the purchase price of

any product or part thereof which proves to be defective.

If requested by Seller, such product or part thereof must

be promptly returned to Seller, freight collect for

inspection.

Seller warrants factory repaired or replaced parts of its

own manufacture against defects in material and

workmanship under normal use and service for ninety

(90) days or for the remainder of the warranty on the

product being repaired, whichever is longer.

This warranty shall not apply and Seller shall not be

responsible nor liable for:

a) Consequential, collateral or special losses or

damages;

b) Equipment conditions caused by fair wear and tear,

abnormal conditions of use, accident, neglect or

misuse of equipment, improper storage or damages

resulting during shipment;

c) Deviation from operating instructions, specifications,

or other special terms of sales;

d) Labor charges, loss or damage resulting from

improper operation, maintenance or repairs made by

person(s) other than Seller or Seller’s authorized

service station.

e) Improper application of product.

In no event shall Seller be liable for any claims, whether

arising from breach of contract or warranty of claims of

negligence or negligent manufacture, in excess of the

purchase price.

THIS WARRANTY IS THE SOLE WARRANTY OF SELLER AND ANY OTHER WARRANTIES, EXPRESS,

IMPLIED IN LAW OR IMPLIED IN FACT, INCLUDING ANY WARRANTIES OF MERCHANTABILITY

AND FITNESS FOR PARTICULAR USE, ARE HEREBY SPECIFICALLY EXCLUDED.

Quincy Compressor

®

- QSD™ 3

DIMENSIONAL DATA (air-cooled)

THGIEW

DELOOC-RIADSQ

).SBL(

ATADTHGIEW

PH

050034

001

57

4 Quincy Compressor

®

- QSD™

DIMENSIONAL DATA (water-cooled)

DELOOC-RETAWDSQ

ATADTHGIEW

PH

THGIEW

).SBL(

050054

570574

0010005

Quincy Compressor

®

- QSD™ 5

Section I - General

• Safety Precautions

• Safety Alert Symbols

• Serial/Model Identification Plate

• Spare Parts Ordering Information

Safety Precautions

Read this manual and follow all instructions prior to

installing or operating this compressor.

Listed below are some, but not all, safety precautions that

must be observed with compressors and compressed air

systems.

Failure to follow any of these warnings may result in

severe personal injury, death, property damage and/

or compressor damage.

• Air from this compressor will cause severe injury or

death if used for breathing or food processing. Air

used for these processes must meet OSHA 29 CFR

1910.134 regulations.

• Disconnect and lockout all power supplies to the

compressor plus any remote controllers prior to

servicing the unit.

• Never assume it is safe to work on the compressor

because it is not operating. Many installations have

automatic start/stop controls and the compressor may

start at any time.

• This compressor is designed for use in the

compression of normal atmospheric air only. No

other gases, vapors or fumes should be exposed to

the compressor intake, nor processed through the

compressor.

• Relieve all pressure internal to the compressor prior

to servicing. Do not depend on check valves to hold

system pressure.

• A properly sized pressure relief valve must be

installed in the discharge piping ahead (upstream) of

any shut-off valve (block valve), heat exchanger,

orifice or any potential blockage point. Failure to

install a pressure relief valve could result in the

rupturing or explosion of some compressor

component.

• Do not change the pressure setting of the pressure

relief valve, restrict the function of the pressure relief

valve, or replace the pressure relief valve with a

plug. Over pressurization of system or compressor

components can occur, resulting in death, severe

personal injury or property damage.

• Never use plastic pipe, rubber hose, or soldered

joints in any part of the compressed air system.

Failure to ensure system compatibility with

compressor piping is dangerous.

• Never use a flammable or toxic solvent for cleaning

the air filter or any parts.

• Do not remove any guards or cabinet panels or

attempt to service any compressor part while the

compressor is operating.

• Do not operate the compressor at pressures in excess

of its rating.

• Observe control panel displays daily to ensure

compressor is operating properly.

• Follow all maintenance procedures and check all

safety devices on schedule.

• Never disconnect or tamper with the high air

temperature (HAT) sensors.

• Compressed air is dangerous, do not play with it.

• Use the correct fluid at all times.

• Do not rely on the discharge air line check valve.

• Do not override any safety or shutdown devices.

• Keep doors closed during operation. The noise level

inside cabinet exceeds 100 decibels (dBA) and the

operating temperature of some components is

sufficient to burn the skin.

NOTICE

These instructions, precautions and descriptions

cover standard Quincy manufactured QSD

Series air compressors.

As a service to our customers, we often modify or

construct packages to the customers

specifications. This manual may not be

appropriate in those cases.

NOTE

Every effort has been taken to ensure complete

and correct instructions have been included in this

manual, however, possible product updates and

changes may have occurred since this printing.

Quincy Compressor reserves the right to change

specifications without incurring any obligation for

equipment previously or subsequently sold. Not

responsible for typographical errors.

™

6 Quincy Compressor

®

- QSD™

Section I - General

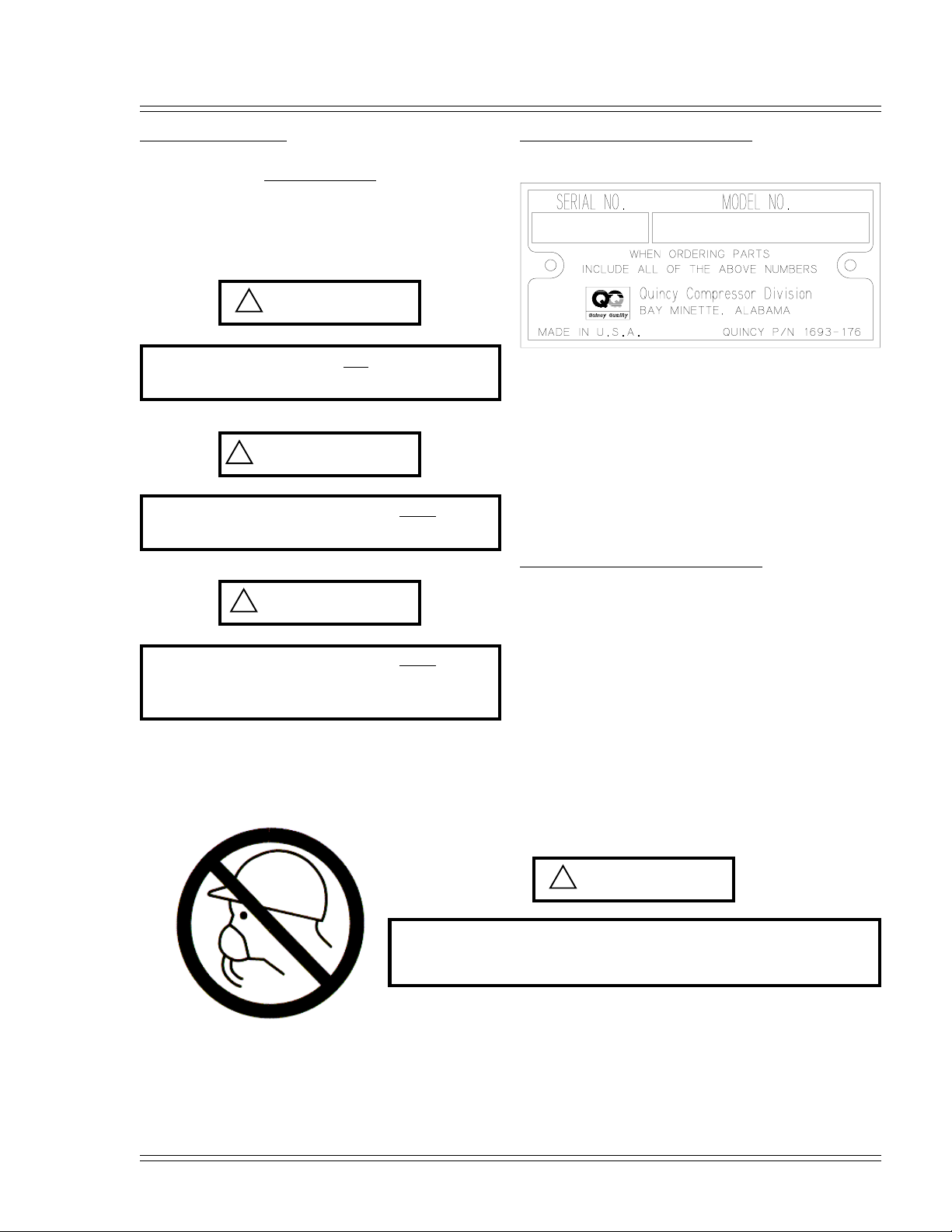

Safety Alert Symbols

IMPORTANT!

Throughout this manual we have identified key

hazards. The following symbols identify the level

of hazard seriousness:

!

DANGER

Immediate hazards which will result in severe

personal injury or death.

!

WARNING

Hazards or unsafe practices which

in personal injury or death.

could result

Serial/Model Identification Plate

Reference to the machine MODEL, SERIAL NUMBER

and DATE OF ORIGINAL START-UP must be made in

all communication relative to parts orders or warranty

claim. A model/serial number plate is located on the

frame OR IN the upper right corner of the control panel

door.

Spare Parts Ordering Information

!

CAUTION

Hazards or unsafe practices which could result

in minor personal injury, product or property

damage.

Air from this compressor will cause severe injury or death if used for

breathing or food processing. Air used for these processes must meet

OSHA 29 CFR 1910 OR FDA 21 XDE 178.3570 regulations.

BFGoodrich, Quincy Compressor Division maintains

replacement parts for Quincy compressors. A repair parts

list is shipped with all new machines. Order parts from

your Authorized Quincy distributor. Use only genuine

Quincy replacement parts. Failure to do so may void

warranty.

!

DANGER

Quincy Compressor

®

- QSD™ 7

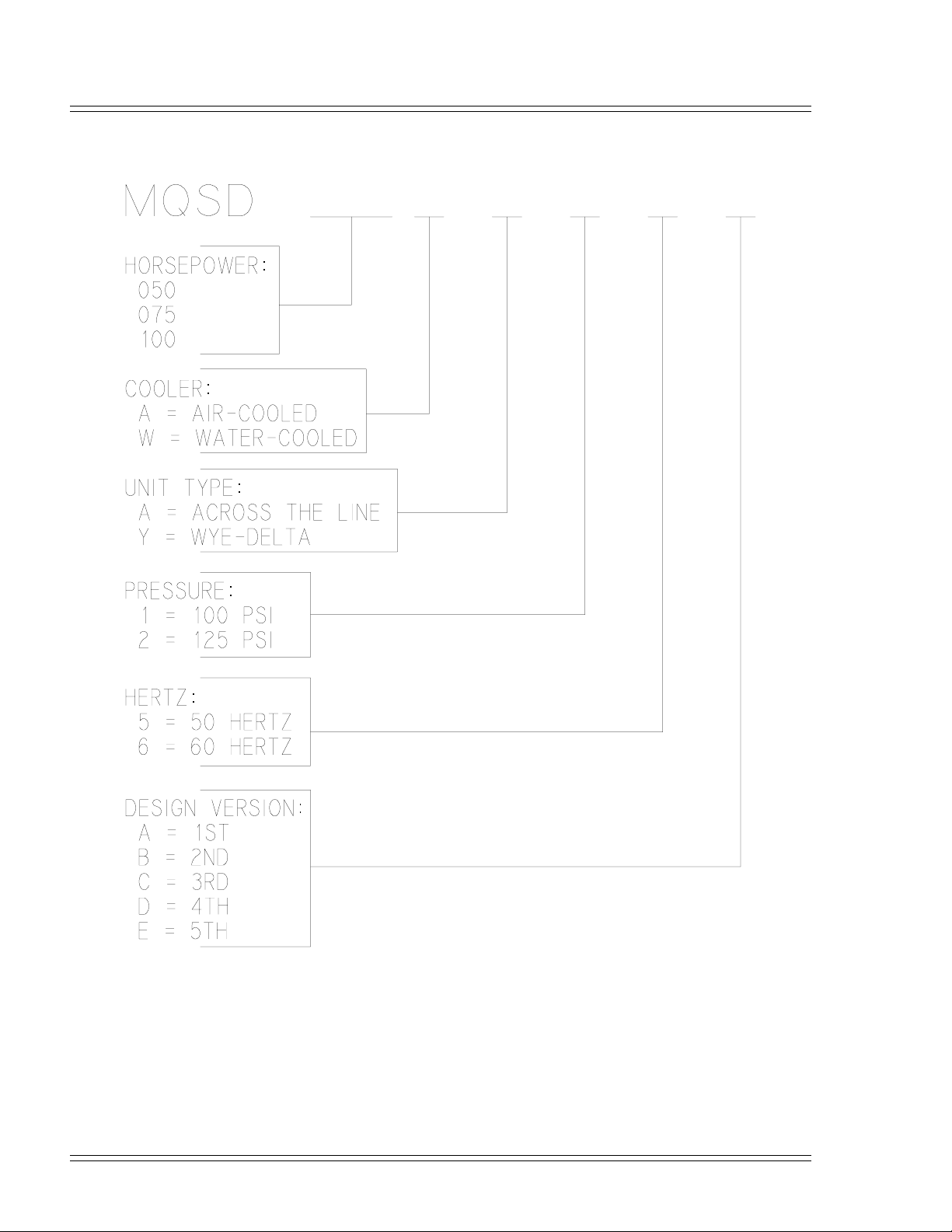

Section II - Description

MODEL IDENTIFICATION

8 Quincy Compressor

®

- QSD™

Section II - Description

• General Description

• The Compression Cycle

• Cooling System

• Lubricating Fluid System

• Moisture Separator

• Capacity Control System

• Electrical System

• Indicators

General Description

The QSD™ compressor is a two-stage, positive

displacement, oil-free rotary screw unit consisting of two

precision-machined rotors per stage. The male rotor of

each stage are turned by a set of precision timing gears

which are driven by the motor through a flexible drop-out

type coupling. Both rotors (of each stage) are housed in a

single cast iron cylinder with water jackets surrounding

them.

All models are equipped with a positive displacement

fluid pump mounted to the gearbox to circulate fluid

through the bearing system and to the gear mesh. The

fluid cooler, fluid pressure relief valve, and fluid filter are

also mounted on the gearbox.

All components are attached to a heavy-duty steel frame.

Controls and indicators are arranged on a control panel.

An acoustical cabinet is included to reduce machine

sound levels.

The Compression Cycle and Air Flow

The compression cycle of the two-stage QSD™ rotary

compressor is a continuous process from the intake of

stage one to the discharge of stage two. Each stage

consists of two rotors in constant mesh, housed in a

cylinder with two parallel adjoining bores. Each male

rotor has lobes that mesh with flutes in the female rotor.

The rotors are synchronized via AGMA12 timing gears.

All parts are machined to exacting tolerances.

As the rotors of stage one rotate, air is drawn into the

cylinder through the inlet port located immediately after

the air cleaner connection. A volume of air is trapped as

the rotor lobes pass the inlet cut off points in the

cylinders. Compression occurs as the male rotor rolls

into the female flute, progressively reducing the space,

thereby raising the pressure.

Compression continues until the lobe and flute pass the

discharge port. The compressed air is then discharged

into the intercooler. The air then flows through a

moisture separator/trap assembly to remove condensate

from the cooling process. From there the air flows to the

inlet of stage two. Air inlet pressure at the stage two inlet

should be between 30 to 36 psig.

In stage two, the above compression process is repeated.

Discharge air pressure from stage two will be the

requested system pressure. From stage two the

compressed air travels through an aftercooler and a

second moisture separator/trap assembly. The

compressed air passes through a minimum pressure

check valve and into the compressed air distribution

system.

Quincy Compressor

®

- QSD™ 9

Section II - Description

Cooling System

Water-cooled

The QSD™ water-cooled cooling system is divided into

two parallel circuits.

The coolant flows from the inlet manifold through the

intercooler, into the stage one compressor jacket and

from the compressor jacket to the outlet manifold.

The second circuit flow is to the aftercooler, to the fluid

cooler located in the gearbox and finally through the

stage two compressor jackets to the outlet manifold.

The inlet coolant manifold contains a coolant flow switch

which prevents the compressor from starting if there is

inadequate coolant flow. The switch will also shut down

the compressor if there is a loss of coolant.

NOTE

If the compressor is shut down during freezing

weather, the drain plugs located at both ends on

the underside of the coolers along with the plug

on the coolant line from the fluid cooler should

be removed. Compressed air at 15-20 psig should

be injected into the system to remove the

remaining coolant.

To maintain the efficiency of the cooling system

provisions have been made for chemical cleaning of the

system.

To conserve water, an optional, normally closed solenoid

valve is available. This valve will automatically start and

stop the water flow in unison with the compressor. The

valve should be located in the inlet line to the compressor

to provide isolation of the compressor cooling system

from the supply.

The stage two cooler cools the water/glycol (70/30)

mixture which is circulated through the fluid cooler and

the jackets of the compressor stages.

The third cooling process takes place in the aftercooler

which cools the discharge air from stage two, which then

passes through a moisture separator/trap assembly before

entering the distribution system.

A coolant flow switch is installed to prevent the

compressor from starting if the coolant circulating pump

fails or to shut down the compressor if there is a loss of

coolant.

NOTE

If the compressor is shut down for an extended

period and temperatures are expected to be less

than 0°F, drain system of all coolant.

A fan located below the coolers draws air through a

baffled inlet over the airend and motor, discharges it

across the coolers and exhausts it out the top and end of

the machine.

Lubricating Fluid System

Lubrication is provided by a pump located on the

gearbox. The gearbox also acts as the fluid reservoir and

supports the fluid cooler and fluid filter.

The fluid from the pump passes through a filter then to

the fluid galley on the top of the gearbox where it is

distributed to the gears and bearings. A fluid pressure

relief valve is located under the fluid galley cover to

maintain a specified fluid pressure.

Moisture Separator

Air-cooled

The QSD™ air-cooled cooling system is comprised of

three separate cooling sections.

The first cooler is the intercooler, which reduces the stage

one discharge temperature. The air then passes through a

moisture separator/trap, then into stage two of the

compressor.

Two combination moisture separator and water traps are

provided for collecting and removing condensate at both

the intercooler and aftercooler discharge and expelling it

to the customer’s drain.

A drain valve is located below the buffing air vents. It is

recommended that this valve be opened daily or more

often as atmospheric (high humidity) conditions require.

10 Quincy Compressor

®

- QSD™

Section II - Description

Capacity Control System

The standard method of capacity control for the QSD

oil-free compressor is Continuous Run with load/no-load.

The Continuous Run Mode of operation is ideal for a

compressed air system that will operate at full load

conditions most of the time, with minimal unloaded time.

The QSD™ allows very consistent and tight control of air

system pressure by constantly monitoring package

discharge pressure and operating within a deadband of as

low as 5 PSI. This means the system pressure never

needs to fall below the normal required pressure.

The recommended receiver size for a QSD™ oil-free

compressor is a minimum of three (3) gallons per rated

compressor CFM; the more the better. If there is more

than one compressor, the receiver must be sized based on

the total CFM of all compressors. This should be

increased to a minimum of five (5) gallons per total

compressor CFM for systems with sharp changes in

demand. The receiver must be located immediately

adjacent to the compressor and before any additional

system components such as dryers and filters. This

allows the Power$ync II™ controller to operate the

compressor coincident to system demand changes

without dramatic episodes of rapid loading and unloading

(cycling) of the machine.

NOTE

Continuous operation with rapid load/no-load

cycles will reduce component life. Cycle rates

should never exceed six (6) per minute. Proper

receiver sizing is essential for reliable operation.

The QSD™ does not use an inlet valve, but rather the

patented Power$ync® lift valve technology to unload the

machine. With this type of control, the unit is operating

either at full capacity or 0% capacity, depending on

system pressure.

Suction or inlet valves on competitor designs act to close

the inlet to the compressor and induce a vacuum in both

compressor stages as it continues to try to compress air.

™

This vacuum creates a reverse pressure differential across

the bearing seals, causing the bearing fluid to migrate

toward the compression chamber when the machine is

unloaded.

The QSD™ incorporates patented Power$ync® lift valves

on both stages of compression. The valves, one per

stage, actually relieve the compressor stages ability to

compress air. Because the unloading is positive, and no

vacuum is created, unloaded horsepower is minimized.

Also, since the compressor stages are not creating a

vacuum in the unloaded state, there is no tendency for the

bearing fluid to migrate toward the compression

chambers, reducing the likelihood of fluid contamination

of the air.

The QSD™ loads and unloads in response to the air

system pressure. The Power$ync II™ controller monitors

package discharge pressure into the compressed air

system and either opens or closes the lift valves to load or

unload the compressor, based on preset pressure values.

Upon start-up, the QSD™ will operate at full capacity up

to a predetermined maximum value, usually 5 PSI above

the normal plant air system operating level. The

blowdown valve and both lift valves are closed at this

time. When the preset pressure value is reached, the

Power$ync II™ controller opens both lift valves and the

blowdown valve simultaneously, reducing the

compressor output to 0%. The QSD™ will continue to

operate in the unloaded condition, with the lift valves and

the blowdown valve in the open position, until the

Power$ync II™ controller detects a reduction in pressure

indicating a reset condition. This pressure, like the

unload, is determined by the customer, based on the air

system operating requirements. The Power$ync II

™

controller reacts to the signal by closing the lift valves

and the blowdown valve, thus reloading the compressor

and returning to 100% output to complete the cycle.

NOTE

If the stage two discharge blowdown valve fails

to open an excessive pressure differential across

stage two will occur. The unit will shut down

automatically to prevent excessive temperature

build-up in the stage two airend.

Quincy Compressor

®

- QSD™ 11

Section II - Description

The Power$ync II™ controller allows the customer to

select Auto Dual as an alternate control method. Auto

Dual incorporates a timer which will turn the compressor

off if it remains in the unloaded condition for a preset

length of time. If the system pressure remains above the

preset pressure for the programmed time interval,

Power$ync II

™

places the compressor in Standby Mode,

with the drive and fan motors de-energized. The

Power$ync II™ controller waits for an indication of

demand, recognized as a drop in system pressure to a

preset minimum pressure level, and automatically restarts

the compressor.

Essentially equal to Continuous Run, Auto Dual goes a

step beyond to offer the opportunity for additional power

savings in a system with more dramatic differences in

demand. As demand changes with shift changes or

varying operations, the Power$ync II™ controller will

allow the QSD™ compressor to go into Standby Mode

when compressor output is not needed. Like the

Continuous Run Mode, a properly sized air receiver will

ensure that the compressor operates and reacts properly

as air system demand changes.

NOTE

Refer to section VIII for Power$ync II™ operating

instructions.

Electrical System

A diagram of the electrical system is shown in the parts

manual shipped with the compressor. A wiring diagram

is also included in the control panel of all Quincy

compressors.

NOTE

Due to continuing product improvements and

updates, it is suggested that the wiring diagram

included in the control panel be used when

servicing the electrical control.

NOTE

Standard drive motors are open, drip-proof, with

a maximum ambient temperature rating of 40°C.

They are not suitable for salt laden, corrosive,

dirty, wet or explosive environments.

The standard QSD™ compressor utilizes 460V incoming

power through an across the line magnetic starter. A

transformer in the control panel reduces this voltage to

120 VAC for the various controls on the unit. These

controls include the selector switch, pressure switch,

timer, high air temperature (HAT) safety switches,

solenoid valve and various indicator lights. Other

incoming line voltages are available as options. A

NEMA 4 electrical enclosure is standard.

12 Quincy Compressor

®

- QSD™

Section II - Description

Back-up Control

The QSD™ Power$ync II™ controller is supplied with a

back-up control for emergency operations if the

electronic control is inoperative. The Back-up Mode is a

simplified system of operations and is not intended for

long-term operation. When Back-up Mode is selected all

power is removed from the Power$ync II

the indicator lights located on the annunciator panel will

be inoperable. The back-up control uses a PLC for the

logic circuit. In the Back-up Mode, the PLC monitors

several different areas of the unit to ensure they are in the

proper ranges for normal operation.

!

CAUTION

Under no condition should the QSD™ be switched

from Power$ync II to Back-up Mode or vice versa

without first removing all power to the unit.

!

CAUTION

™

controls, thus

Shutdown Conditions

NOTE

If one of the following conditions occurs at any

time the unit will immediately shutdown. The unit

should not be restarted until the problem has been

corrected.

• The fluid pressure does not reach 15 PSI within five

(5) seconds at start-up or does not maintain pressure

during normal operation.

• The HAT’s are open at start-up or at any time during

operation.

• The drive or fan contactor overloads trip.

• The coolant flow switch does not close within five

(5) seconds after start-up.

• The interstage pressure switch does not open within

five (5) seconds after start-up (Back-up Mode only).

• The second stage pressure switch does not open

within five (5) seconds after start-up (Back-up Mode

only).

• Both the interstage and second stage pressure

switches are open at start-up (Back-up Mode only).

• The second stage pressure switch does not close

within five (5) seconds after the load/unload pressure

switch opens and does not reopen within five (5)

seconds after the load/unload pressure switch closes

(Back-up Mode only).

Always inspect for component failure before

operating in Back-up Mode. Operating the unit

with faulty components may void warranty.

Quincy Compressor

!

WARNING

High voltage could cause death or serious injury.

Disconnect all power supplies before opening the

electrical enclosure or servicing.

®

- QSD™ 13

Section II - Description

Safety Sensors

Four (4) high air temperature RTD’s are standard on

QSD™ units. These protect the unit by sensing unusually

high temperatures and shutting the unit down.

Power$ync II

temperature conditions:

• Stage One Discharge • Stage Two Discharge

• Stage Two Inlet • Package Discharge

Shutdowns for the Power$ync II™ RTD’s is 435°F on

discharge locations, and 150°F on Stage 2 inlet and

165°F on package discharge.

In Back-up Mode, two HAT switches monitor stage one

and stage two discharge temperature. These switches are

nonadjustable and set to trip at approximately 470°F.

The back-up control circuit has two (2) HAT

switches. There are no indicator lights for these

HAT shutdowns. These HAT switches can also

cause a shutdown in Power$ync II™ Mode as a

back-up to the RTD’s.

™

monitors the following areas for high air

NOTE

Indicators

Main Power on Light

Indicates when power from the main disconnect switch

has been turned on and there is live power at the

compressor starter and control panel. This light will

remain on as long as there is power to the unit, regardless

of the position of the control selector switch.

!

CAUTION

Always check power supply disconnect. The

power on light may be inoperable.

High Discharge Air Temperature Lights

Indicates when the unit has sensed an unusually high

discharge temperature.

NOTE

There is no indication of high temperature

shutdown on the control panel in Back-up Mode.

!

WARNING

Never remove, bypass or tamper with any safety

HAT switch or sensor. Failure to provide this

safety feature could cause death, serious injury

and property damage. If the compressor is

shutting down due to high discharge temperature,

contact a qualified service technician

immediately.

Motor Overload Fault

Indicates excessive amp draw of drive motor.

NOTE

There is no indication of motor overload

shutdown on the control panel in Back-up Mode.

There is a mechanical indicator on the overload

relay.

14 Quincy Compressor

®

- QSD™

Section II - Description

Fluid Filter Change Light

Indicates excessive pressure differential across the fluid

filter. It is used to determine fluid filter change intervals.

NOTE

There is no indication of fluid filter change on

the control panel in Back-up Mode.

Air Intake Filter Service Light

This indicator signals when the filter element needs to be

replaced.

NOTE

There is no indication of air intake filter pressure

drop on the control panel in Back-up Mode.

Low Lube Light

This indicator signals that the compressor has shutdown

due to low fluid pressure.

NOTE

There is no indication of low fluid pressure on

the control panel in Back-up Mode.

There is no indication if the coolant flow switch is

not satisfied and the contacts are open. This will

shutdown the unit. Refer to troubleshooting

section for corrective action. Power$ync II™ will

show “Emergency Stop Button Pressed” if the

emergency stop button is pressed, the coolant flow

switch contacts open or either of the high air

temperature (HAT) switches open. These

shutdowns operate in any mode by using the

emergency stop circuit.

Quincy Compressor

®

- QSD™ 15

Section III - Installation

• Receiving

• Moving the Unit to the Installation Site

• Location

• Piping Connections

• Manual Shutoff Valves

• Relief Valves

• Electrical

• Guards

• Water and Sewer Facilities at the Installation

Site (Water-cooled models only)

• Fluid Level

• Compressor Rotation

• Fan Rotation

Receiving

Upon receipt of the compressor, immediately inspect for

any visible signs of damage which may have occurred in

shipment. If damage is found at the time of delivery,

have the delivering carrier make a notation on the freight

bill and request a damage report. If the shipment is

accepted and it is later found that the compressor unit

was damaged, this is classified as concealed damage. If

concealed damage is found, report it within 15 days of

delivery to the delivering carrier, who must prepare a

damage report. Itemized supporting papers are essential

to filing a claim.

Read the compressor nameplate to be sure the

compressor is the model and size ordered and that

optionally ordered items are included.

Check the pressure relief valves to be sure they are

adequate for the pressure at which you intend to operate.

Moving the Unit to the Installation Site

When a forklift is used to move the unit to its installation

site, use forklift slots provided in the side or end of the

main frame. Use of chains and slings should be limited

to the main frame. Do not attempt to lift the unit by

attachment to any components.

!

CAUTION

Improper lifting may result in component or

system damage or personal injury. Follow good

shop practices and safety procedures when

moving the compressor.

Location

Locate the compressor on a level surface, indoors, in a

clean, well lit and well ventilated area, free from

excessive dust, dripping liquids, hydrocarbons, and toxic,

corrosive or flammable gases. Allow sufficient space

(four feet of clearance on all sides and top of the

compressor) for safe and proper daily inspections and

maintenance. The entire length of the base must be

supported. Shim where necessary, but do not use wood.

Quincy recommends installing closed cell foam between

the base and the floor. The machine must be protected

against freezing and excessive ambient temperatures.

Sheltering from freezing temperatures is mandatory.

Ambient temperature should not exceed 110°F (failure to

heed this may result in a high air temperature shutdown).

For air-cooled units, careful consideration of room size

and shape must be done so that hot exhaust air from the

fan does not recirculate within the room, causing the

operating temperatures to rise. All models are intended

for indoor installation.

16 Quincy Compressor

®

- QSD™

!

CAUTION

This compressor should not be operated in

temperatures below 40°F or above 110°F.

Do not locate the unit where the hot exhaust air from

other compressors or heat generating equipment may be

drawn into the unit. Never restrict the flow of exhaust air

from the acoustic enclosure. This heated air must

be exhausted to the outside to prevent high ambient

conditions in the room. If the room is not properly

ventilated, the compressor operating temperatures will

increase and cause a high temperature shutdown.

NOTE

Clean, fresh air in sufficient quantity is required

for proper compressor operation.

Section III - Installation

™

Quincy QSD

however, some customers may choose to bolt the unit to

the floor to prevent the accidental breakage of piping or

electrical connections as a result of being bumped. Use

only lag bolts to secure the unit. Do not pull the bolts

down tight as this may, under certain circumstances,

place the frame in a twist or bind causing eventual

breakage of coolers, piping, etc.

Do not remove or deface any Danger, Warning, Caution

or instructional labels found on the compressor. Labels

should be provided with enough light to read and be

conspicuously located and maintained for legibility. .

Removal or defacing of safety labels will result in

uninformed conditions, which could result in

personal injury or property damage.

models are essentially vibration free;

!

WARNING

!

WARNING

Never locate the compressor inlet system where

it can ingest toxic, volatile or corrosive vapors,

air temperatures exceeding 110°F, water or

extremely dirty air. Death, serious injury or

property damage could result.

!

CAUTION

Removal or modification of sound insulation

could result in high sound levels which may be

hazardous to personnel.

Piping Connections

A drip leg with a drain valve should be mounted adjacent

to the QSD™ service connection and extend below the

package air connection. The drip leg should be drained

daily to avoid accumulation of condensate and debris.

Never join pipes or fittings by soldering. Lead-tin

solders have low strength, a low creep limit, and may,

depending on the alloy, start melting at 360°F. Silver

soldering and hard soldering are forms of brazing and

should not be confused with lead-tin soldering. Never

use plastic, PVC, ABS pipe or rubber hose in a

compressed air system.

Quincy Compressor

®

- QSD™ 17

Section III - Installation

Piping Fit-up

Care must be taken to avoid assembling the piping in a

strain with the compressor. Piping should line up without

having to be sprung or twisted into position. Adequate

expansion loops or bends should be installed to prevent

undue stress at the compressor resulting from the changes

between hot and cold conditions. Pipe supports should

be mounted independently of the compressor and

anchored, as necessary, to limit vibration and prevent

expansion strains. The piping should never be smaller

than the connection on the compressor.

Manual Shutoff Valve

Install a manual shut-off valve (block valve) to vent the

compressor and discharge line to the atmosphere. In

those instances where the air receiver tank services a

single compressor, the manual shut-off valve can be

installed in the receiver. When a manual shut-off valve is

used, a pressure relief valve is installed upstream from

the manual shut-off valve. These valves should be

designed and installed to permit maintenance to be

performed in a safe manner. Never substitute a check

valve for a manual shut-off valve if the purpose is to

isolate the compressor from a system for servicing. If a

manual shut-off valve is installed at the service

connection, it must be open to allow air to pass to the

service line when the compressor is operating. Provide

drip legs in the air piping from the compressor as good

installation practices dictate.

NOTE

Never operate the compressor with the shut-off

valve closed. If the compressor is operated with

the shut-off valve closed, a pressure related

shutdown will occur.

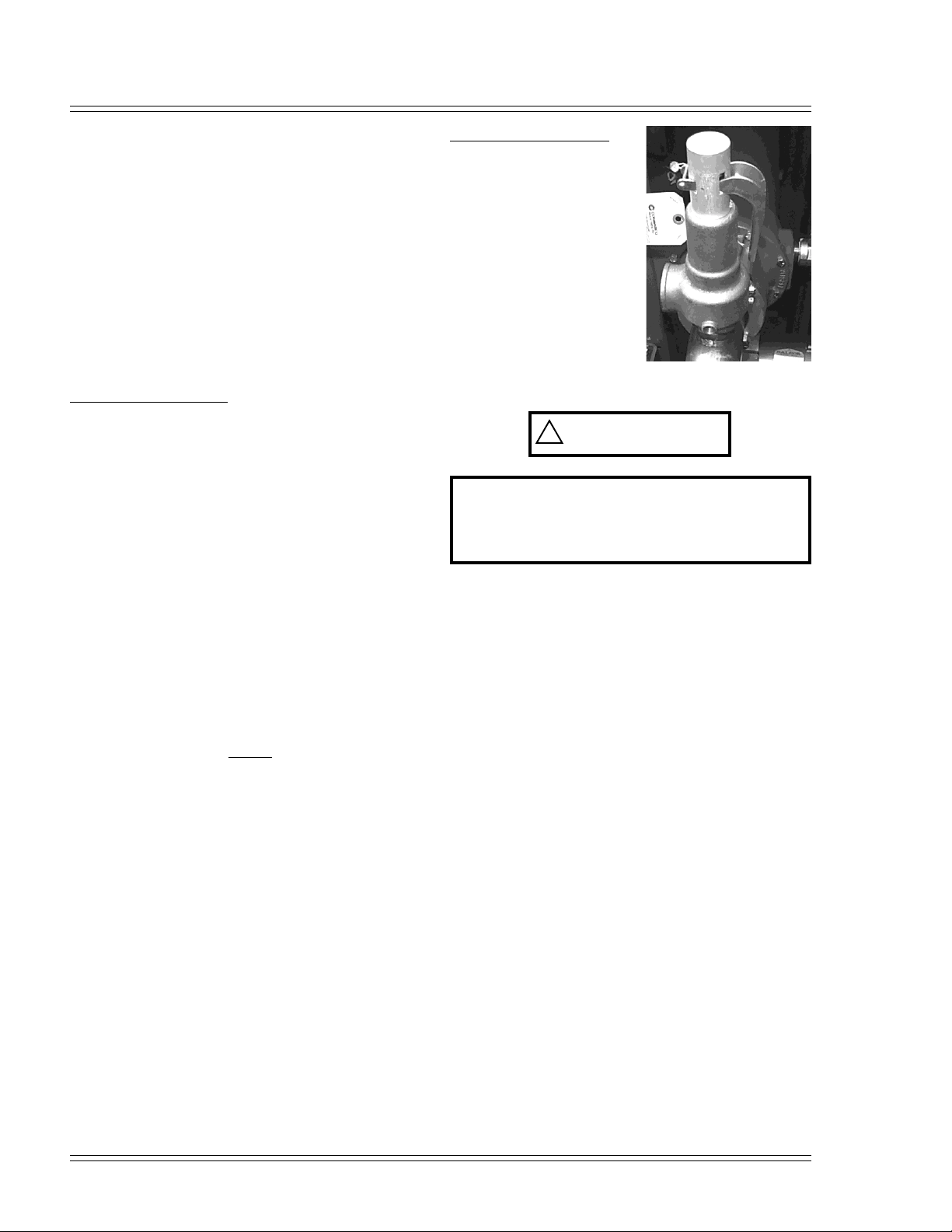

Pressure Relief Valves

Pressure relief valves are

sized to protect the system.

Never change the pressure

setting or tamper with the

valve. Only the relief valve

manufacturer or an

approved representative is

qualified to make such a

change.

!

WARNING

Relief valves are to protect system integrity in

accordance with ANSI/ASME B19 safety

standards. Failure to provide properly sized relief

valves could cause death or serious injury.

Relief valves are placed ahead of any potential blockage

point which includes, but is not limited to, such

components as shut-off valves, heat exchangers, and

discharge silencers. Ideally, the relief valve should be

threaded directly into the pressure point it is sensing, not

connected with tubing or pipe. Always direct discharge

from relief valves to a safe area away from personnel.

18 Quincy Compressor

®

- QSD™

Section III - Installation

Electrical

Before installation, the electrical supply should be

checked for adequate wire size and branch circuit

capacity. During installation, a suitable fused disconnect

switch or circuit breaker should be provided per local

electrical codes. Where a 3-phase motor is used to drive

the compressor, any unreasonable voltage unbalance

(5%) between the legs must be eliminated and any low

voltage corrected to prevent excessive current draw. The

installation and wiring must be in accordance with

National Electric Code and all state and local codes. A

qualified electrician must perform all electrical work.

This unit must be grounded in accordance with

applicable codes. See control panel for the proper

wiring diagram.

NOTE

Quincy would like to emphasize the importance

of providing adequate grounding for air

compressors. The common practice of grounding

units to building structure steel may not actually

provide adequate grounding protection, as paint

and corrosion build-up may exist.

!

CAUTION

NEMA electrical enclosures, conduit, motor

enclosures and components must be appropriate

to the area in which they are installed.

Pneumatic Circuit Breakers or Velocity Fuses

The Occupational Safety and Health Act, Section

1926.303, Paragraph 7, published in the Code of Federal

Regulations 29 CFR 1920.1, revised July 1, 1982, states

“all hoses exceeding 1/2” inside diameter shall have a

safety device at the source of supply or branch line to

reduce pressure in case of a hose failure.” The pneumatic

safety devices are designed to prevent hoses from

whipping which could result in a serious or fatal accident.

Guards

All mechanical action or motion is hazardous in varying

degrees and needs to be guarded. Guarding shall be in

compliance with OSHA Safety and Health Standards 29

CFR 1910.219 in OSHA manual 2206 Revised

November 7, 1978 and any state or local codes.

Water and Sewer Facilities at the Installation Site

(Water-cooled models only)

Make sure the water supply is connected and open.

Piping supplied by the user should be at least equal to the

connections provided on the compressor. Sewer facilities

should be readily accessible to the installation site and

meet all the requirements of local sewer codes, plus those

of the compressor. Make absolutely sure water inlet

and discharge connections are correct.

Quincy Compressor

®

- QSD™ 19

Section III - Installation

Clean air is essential for your Quincy compressor.

Always select a source providing the cleanest air

possible. When an outside air source is used, keep all

piping as short and direct as possible.

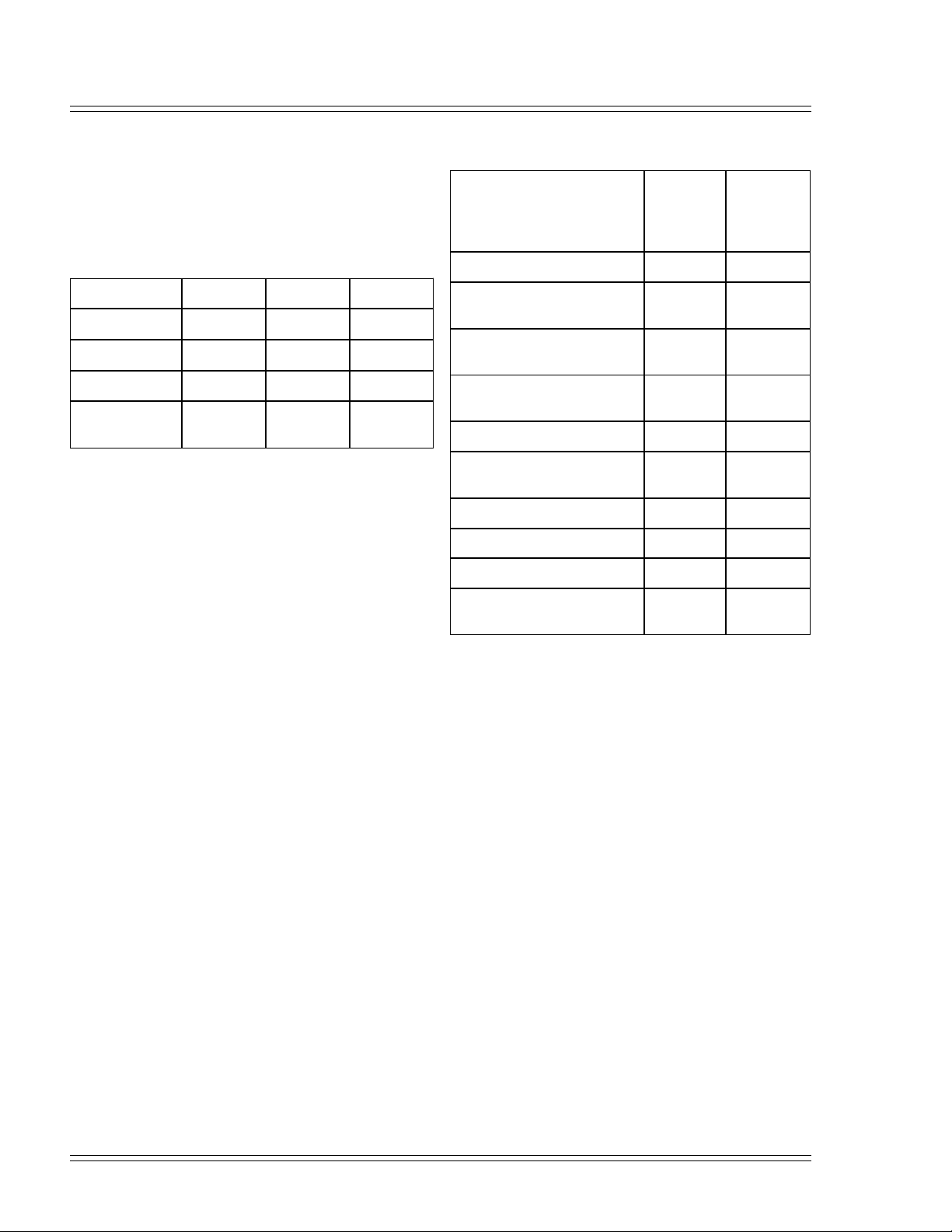

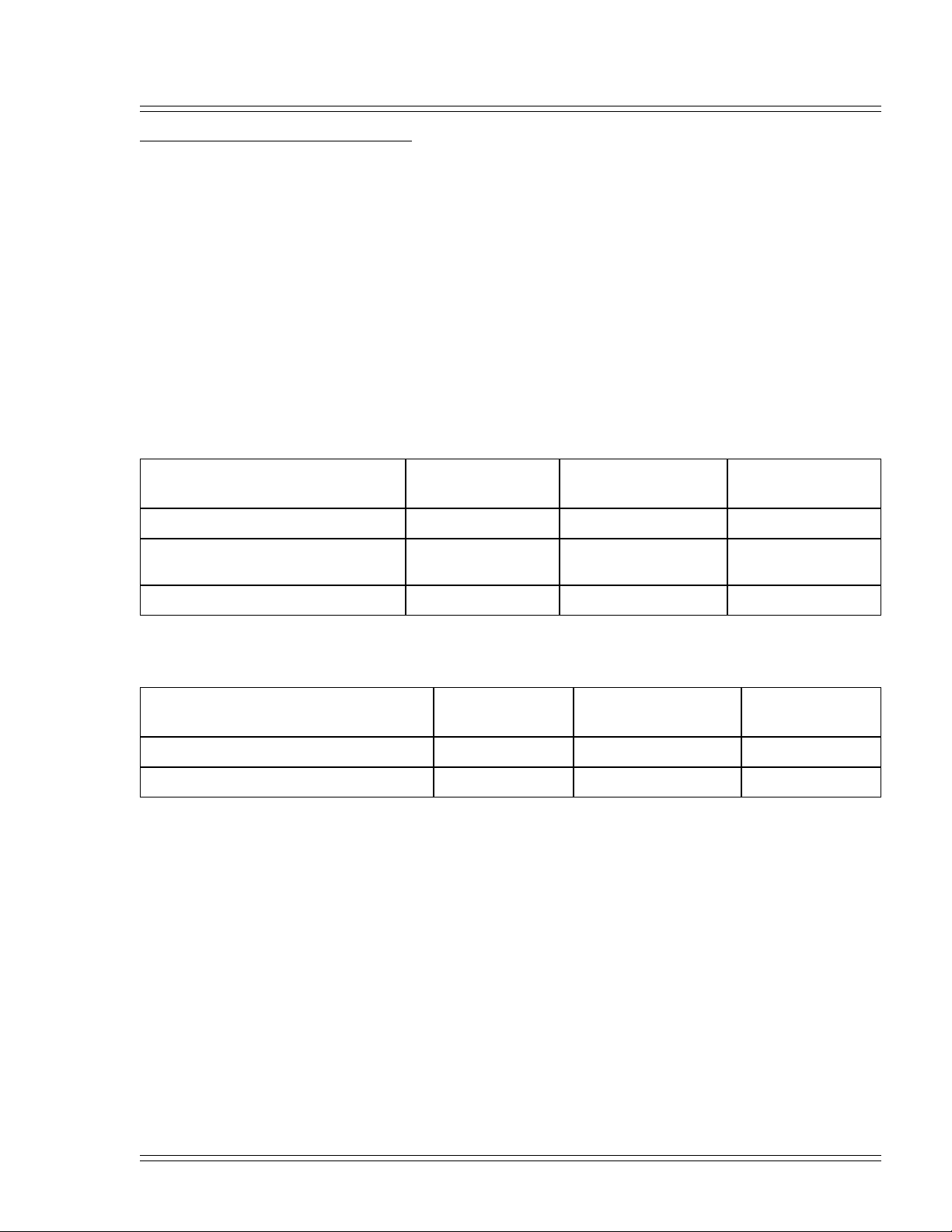

Table 3-1 – Water Flow

LEDOM0557001

F°05@MPG 013161

F°07@MPG216102

F°09@MPG510242

SSERPRETAW

)NIM/XAM(

Minimum water quality is listed in Table 3-2. The

quality of the cooling water should be tested regularly,

especially when using an open cooling tower.

Contact the factory if you plan to use a water/glycol

coolant, salt or brackish water.

001/04001/04001/04

Table 3-2 – Water Quality

METI

)C°52(F°77TAHP0.8–5.60.8–5.6

F°77TAYTIVITCUDNOC

)MC/VU()C°52(

SASSENDRAHLATOT

)MPP(3OCAC

3OCACSAYTINILAKLA-M

)MPP(

)MPP(LC;NOLENIROLHC002<05<

4OS;NORIDICACIRUFLUS

)MPP(

)MPP(EF;NORILATOT0.1<3.0<

)MPP(2OIS,ACILIS05<03<

)MPP(2S;NOIRUFLUS00

+4HN;NOIMUINOMMA

)MPP(

ECNO

HGUORHT

RETAW

METSYS

005<002<

002<05<

001<05<

002<05<

00

GNILOOC

REWOT

RETAW

METSYS

20 Quincy Compressor

®

- QSD™

Section III - Installation

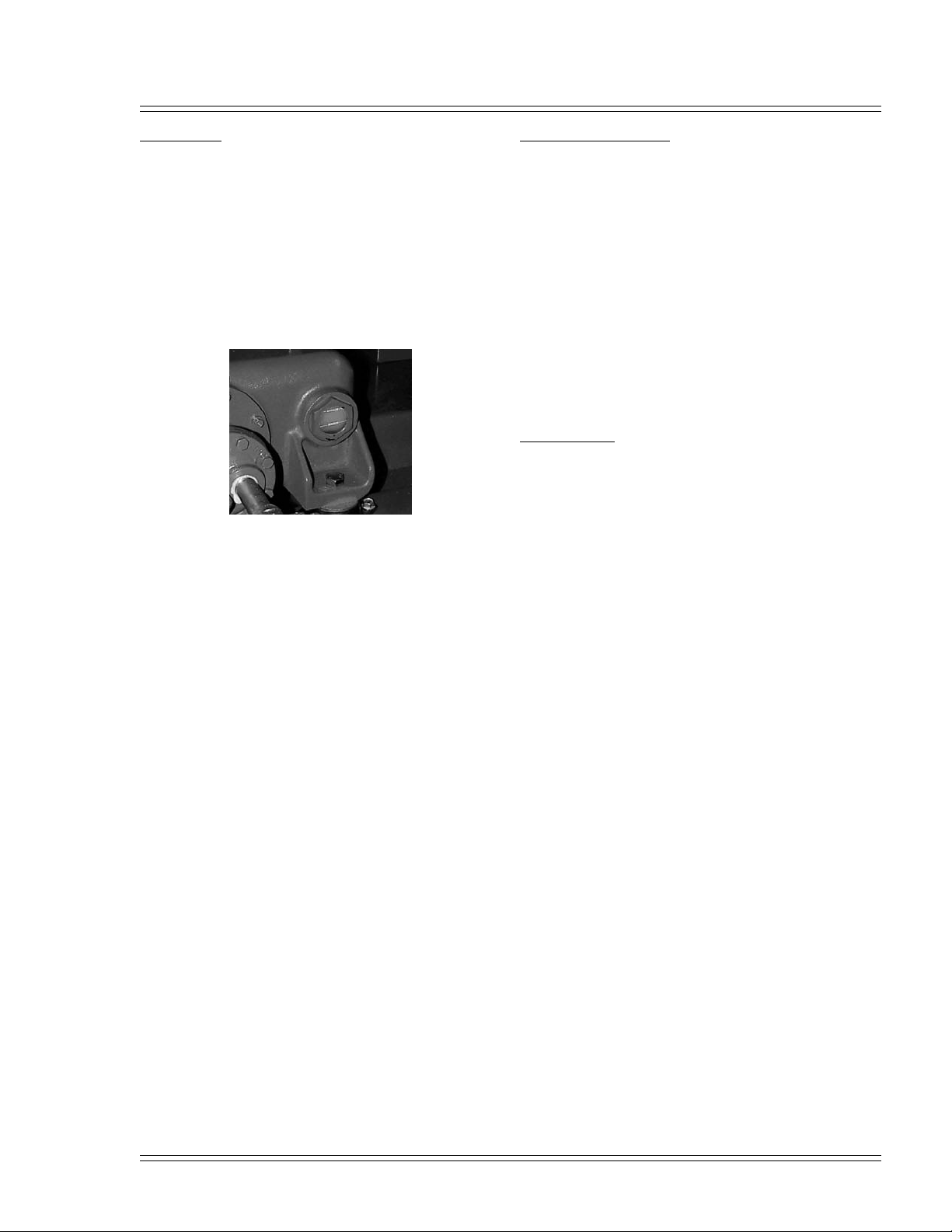

Fluid Level

The compressor is filled at the factory with the correct

amount of fluid. A fluid tag is provided which identifies

the type of fluid installed when the unit was shipped.

The fluid level is monitored by a sightglass with the

compressor running. The fluid level should be

maintained in the run zone. Fluid can be added by

removing the fill plug after the machine is shut down and

any internal pressure is relieved. DO NOT OVER

FILL.

Fluid Level Sightglass

Compressor Rotation

The compressor rotation must be checked prior to

start-up. Proper rotation is counter-clockwise as viewed

from the power-input end. The power-input end of the

compressor is marked with an arrow (located on the

motor adapter) noting the proper rotation. To check for

proper rotation, briefly jog the start button, allowing the

motor to turn two or three revolutions. Observe the drive

element for correct direction. If incorrect rotation is

observed, lock out power supply, reverse electrical leads

L1 and L3 at the motor starter. Recheck for correct

rotation. Allowing the compressor to rotate in the

wrong direction will result in extensive damage to the

compressor and will void warranty.

Fan Rotation

After the compressor rotation is checked, check the fan

rotation. Fan air flow should be outward, pushing the air

out the discharge vent of the acoustical enclosure. The

discharge vent is located just above the service line

connection on the end of the acoustical enclosure.

Quincy Compressor

®

- QSD™ 21

Section IV - Operating Procedures

• Prior to Starting

• Starting the Compressor

• Stopping the Compressor - Normal

Operation

• Stopping the Compressor - Emergency

Prior to Starting

!

CAUTION

Provisions should be made to have the instruction

manual readily available to the operator and

maintenance personnel. If the manual becomes

illegible or lost, have it replaced immediately. The

instruction manual should be read periodically

to prevent a serious accident.

Before starting the unit, review Sections II and III of this

manual and be certain that all installation requirements

have been met and that the purpose and use of each of the

controls and all warnings are thoroughly understood.

Adhere to the following checklist before placing the

compressor into operation:

• Remove all loose items and tools from around the

compressor.

• Check fluid level in the gearbox.

• Check the fan and fan mounting for tightness.

• Manually rotate the compressor through enough

revolutions to be certain there is no mechanical

interference.

• Ensure that all pressure relief valves are in place and

properly sized.

• Make sure all panels and guards are in place and

securely mounted.

• Check fuses, circuit breakers and thermal overloads

for proper size.

• After all the above conditions have been satisfied

close the main power disconnect switch, jog the

starter switch button to check the rotation of the

compressor

• Install the coupling guard.

• Check the fan rotation (air should push outward

through the enclosure).

• Check inlet and discharge water piping for proper

connections, adequate supply and open drain.

NOTE

When freezing temperatures are expected before

the next start-up, drain all cooling water as

follows:

• Drain inlet and outlet water lines at the cabinet

connections.

• Remove drain plugs from fluid cooler and stage

one water jacket tube.

• Inject compressed air at 15-20 psig into the system

to remove the remaining coolant.

Starting the Compressor

• Secure all enclosure panels on compressor.

• Select the mode of operation and start the

compressor.

• Watch for excessive vibration, unusual noises, or air/

fluid leaks. If anything unusual develops, stop the

compressor immediately and correct the condition.

• Control settings have been adjusted at the factory;

however, they should be checked during start-up and

readjusted, if necessary. Some applications may

require a slightly different setting than those

provided by the factory (never increase pressure

settings beyond factory specifications). Refer to

Section VII - Service Adjustments.

• Observe compressor operation closely for the first

hour of operation and frequently for the next seven

hours. Stop and correct any noted problems.

NOTE

If the unit fails to start consult Section IX Troubleshooting. Do not adjust the unload

pressure more than 5 PSIG beyond the full load

pressure rating of the machine.

Stopping the Compressor - Normal Operation

Press the shutdown button on the keypad below the main

display.

NOTE

It is always a good practice to close the service

valve when the compressor is not being used. It

will prevent the system’s air pressure from

leaking back into the compressor if the check

valve leaks or fails.

22 Quincy Compressor

®

- QSD™

Stopping the Compressor - Emergency

Press the emergency stop button or cut the power at the

main disconnect switch or panel.

Table 4-1 – Pressure Readings

Section IV - Operating Procedures

GNIKRAM

ERUSSERPEGRAHCSIDENOEGATSGISP83-72GISP4-2GISP05>

ERUSSERPEGRAHCSIDOWTEGATSGISP131-06GISP2-0

ERUSSERPDIULFGISP82-81GISP82-81GISP51<

DEDAOLLAMRON

GNIDAER

DEDAOLNULAMRON

GNIDAER

Table 4-2- Temperature Readings (Water-cooled)

GNIKRAM

ERUTAREPMETEGRAHCSIDENOEGATSF°014-003F°052<F°524>

ERUTAREPMETEGRAHCSIDOWTEGATSF°014-523F°052<F°524>

DEDAOLLAMRON

GNIDAER

DEDAOLNULAMRON

GNIDAER

NWODTUHS

NOITIDNOC

21+DAOLNUXAM

GISP

NWODTUHS

NOITIDNOC

Quincy Compressor

®

- QSD™ 23

Section V - Preparing for Maintenance or Service

The following procedure should be used for maximum

safety when preparing for maintenance or service:

1) Disconnect and lockout the main power switch and

hang a sign at the switch of the unit being serviced.

2) Close the manual shut-off valve (block valve)

between the receiver and plant air system to prevent

any back-up of air flow into the area to be serviced.

Never depend upon a check valve to isolate the

system.

3) Open the manual vent valve and wait for the pressure

in the system to be completely relieved before

starting service. DO NOT close the manual vent

valve at any time while servicing.

4) Shut off water and depressurize system if watercooled.

Never assume the compressor is ready for

maintenance or service because it is stopped. The

automatic dual control may start the compressor

at any time. Death or serious injury could result.

!

WARNING

24 Quincy Compressor

®

- QSD™

Loading...

Loading...