Quick Mill QM67 User Manual

Dual Boiler

Espresso Machine

by

Made In Italy

QM67 Dual Boiler Espresso Machine |

|

Diagrams ........................................................................................................................................................................................ |

2 |

Introduction..................................................................................................................................................................................... |

3 |

First Time Set Up............................................................................................................................................................................ |

3 |

Before Each Use............................................................................................................................................................................. |

5 |

Normal Operation ........................................................................................................................................................................... |

5 |

Gauges ...................................................................................................................................................................................... |

5 |

Lights ......................................................................................................................................................................................... |

6 |

Pump ......................................................................................................................................................................................... |

6 |

Water Reservoir......................................................................................................................................................................... |

7 |

PID Controller ................................................................................................................................................................................. |

8 |

Setting Temperature .................................................................................................................................................................. |

8 |

Advanced PID Settings.............................................................................................................................................................. |

9 |

Brewing Espresso......................................................................................................................................................................... |

10 |

Steaming Milk - Basics ................................................................................................................................................................. |

11 |

Steaming Milk - Technique ........................................................................................................................................................... |

12 |

Steaming Milk - Tips ..................................................................................................................................................................... |

13 |

Hot Water Wand Operation .......................................................................................................................................................... |

13 |

Maintenance ................................................................................................................................................................................. |

14 |

Backflushing............................................................................................................................................................................. |

14 |

Plain water backflushing .......................................................................................................................................................... |

14 |

Backflushing with espresso machine cleaner .......................................................................................................................... |

14 |

Setting Pump (Brew) Pressure................................................................................................................................................. |

15 |

Group Gasket And Shower Screen Replacement.................................................................................................................... |

16 |

Gasket and Screen Removal ................................................................................................................................................... |

16 |

Cleaning The Group................................................................................................................................................................. |

17 |

Gasket And Screen Installation................................................................................................................................................ |

17 |

Maintenance Tip ...................................................................................................................................................................... |

18 |

Descaling ................................................................................................................................................................................. |

19 |

PID Controller .......................................................................................................................................................................... |

19 |

Cleaning The Stainless Steel................................................................................................................................................... |

19 |

Troubleshooting............................................................................................................................................................................ |

20 |

No Steam From Steam Wand.................................................................................................................................................. |

20 |

No Water From Hot Water Wand ............................................................................................................................................. |

20 |

Not Heating.............................................................................................................................................................................. |

21 |

PID and Heating Lights Are Not Working................................................................................................................................. |

21 |

PID Buttons Not Working ......................................................................................................................................................... |

21 |

Espresso Coming Out Too Slow Or Not At All ......................................................................................................................... |

22 |

Espresso Coming Out Too Fast............................................................................................................................................... |

22 |

Warranty ....................................................................................................................................................................................... |

23 |

We Are Here To Help ................................................................................................................................................................... |

23 |

Owner’s Manual |

Page 1 |

QM67 Dual Boiler Espresso Machine

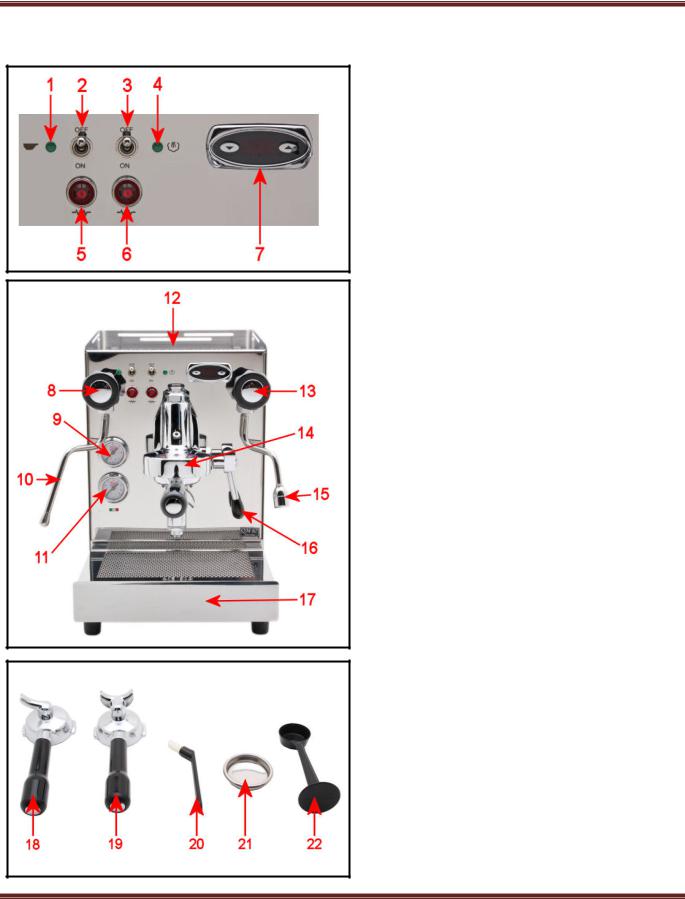

Diagrams

Owner’s Manual

1.Coffee Boiler Power Indicator

2.Coffee Boiler Power Switch

3.Steam Boiler Power Switch

4.Steam Boiler Power Indicator

5.Coffee Boiler Heating Indicator

6.Steam Boiler Heating Indicator

7.PID Controller

8.Steam Knob

9.Steam Pressure Gauge

10.Steam Wand

11.Pump Pressure Gauge

12.Cup Warming Tray (The water reservoir is located under the hinged lid of the cup warming tray)

13.Hot Water Wand (*Do not remove more than 6oz of water at one time until it has had time to refill or damage to the heating element may occur which will not be covered under warranty)

14.E61 Grouphead

15.Hot Water Faucet

16.E61 Brew Lever

17.Drip Tray

18.Single Portafilter

19.Double Portafilter

20.Cleaning Brush

21.Backflush Disc

22.Coffee Scoop/Tamper

Page 2

QM67 Dual Boiler Espresso Machine

Introduction

First of all, thank you for your business! You are going to love your new QM67 Dual Boiler Espresso Machine. It combines classic beauty, value, and great performance for making the best espressos, cappuccinos, and lattes you’ve ever tasted! These instructions include tips that will help bring out the Barista that’s hidden within! Enjoy your new machine!

First Time Set Up

•Before using your machine, test your water for hardness using the provided test strips. Fill a glass with cold tap water; dip the tip of the test strip into the water for one second, then pull the strip out of the water and hold it horizontally for fifteen seconds. After fifteen seconds, compare the color of the strip to the chart on the side of the package to determine how many grains of hardness is in your tap water. Three grains or less of hardness is acceptable to be used in the machine.

Note: Should your water’s hardness level exceed three grains, then it is strongly recommended that an in tank softener be used or a different source of water that has been tested for hardness. Some bottled water can be extremely hard and should always be tested before using. Using a Brita or PUR style pitcher or faucet filter does NOT remove any hardness from the water and should only be used in the machine if your water source is under 3 grains of hardness. Using hard water in the machine will affect its performance and may cause damage to the machine which is not covered under warranty.

•Open the hinged reservoir door on the top of the machine and remove the water reservoir. Rinse the water reservoir out and fill with cold softened water and then install it back into the machine being careful not to spill any water inside the machine.

•Be sure that both silicone lines are sitting in the bottom of the reservoir like shown. There is a notch on the right side of the reservoir for the lines to sit in and the float should be on the left side of the machine.

•Make sure the silicone lines are not pushing the float down or the PID and heating lights will not turn on.

Owner’s Manual |

Page 3 |

QM67 Dual Boiler Espresso Machine

First Time Set Up, Continued

•Before plugging the machine in, verify the steam and hot water knobs are closed and the brew lever is in the down position. Also make sure the power switches are in the off position and the drip tray is in place.

•Plug the machine into the outlet* and then turn the coffee boiler power switch to the on position.

•The pump will come on to fill the boilers and then will turn off after the boilers have completed filling.

•If the pump turns off and the PID and heating lights do not come on then the water reservoir needs to be refilled. It may take 2 reservoirs to completely fill both boilers.

•After the boilers have finished filling then place whichever portafilter you intend to use into the group head. Then lift the brew lever to activate the pump and keep the lever up until water comes out of the portafilter for at least 15 seconds and then lower the brew lever.

•The heating indicator light and PID will illuminate and the machine will start heating. You will hear some gurgling noises and a small amount of steam and water will be discharged into the drip tray. This is normal to allow for the release of air and the expansion of water in the boiler.

•If you plan on steaming milk or using the hot water wand then also be sure to turn on the steam boiler power switch. The coffee boiler power switch must also be on for the steam boiler to operate.

•The machine should reach temperature in approximately 15 minutes, but to make delicious espresso with thick rich crema it is necessary to allow the machine to be heated for 30-45 minutes with the portafilter kept in the grouphead.

*The electrical outlet must be a 3 prong 115V grounded outlet. No adaptors or extension cords should be used. A timer may be used to turn the machine on and off, but it must be a 3 prong grounded timer rated for 15 amps. A GFCI outlet is highly recommended but is not necessary.

Owner’s Manual |

Page 4 |

QM67 Dual Boiler Espresso Machine

Before Each Use

•Verify the steam and hot water knobs are both closed and your brew lever is pointing straight down.

•Fill the reservoir with cold softened water.

•Place whichever portafilter you intend to use into the group head and then turn the coffee boiler power switch to the on position. If you plan on using the steam or hot water wand then also turn on the steam boiler power switch.

•Let the machine warm up for 30-45 minutes for optimal performance.

Normal Operation

Gauges

•The top gauge is for your boiler steam pressure. After turning the machine on it will take approximately 15 minutes before the gauge will show any pressure. Once up to pressure the gauge will cycle back and forth roughly between 1.2-1.7 bar depending on the steam boiler temperature setting. Should you need to adjust the steam pressure please refer to the PID section of the owner’s manual.

•The lower gauge is for your pump (brew) pressure. When sitting idle the gauge is reading trapped pressure in the system and may vary. To get an accurate pump pressure reading install your backflush disc in the portafilter and lock it into the grouphead and then raise the brew lever. After a few seconds the pressure should rise to about 9 - 10 bar. When you make espresso the pressure on the gauge will be slightly less at about 8.5 - 9.5 bar which is normal. This can be helpful in setting up your grinder. If your pressure goes to 9 - 10 bar with the backflush disc, but when you make espresso it is less than 8 bar then that means you need to go finer with your grind which will create more resistance to raise the pressure. Should you need to adjust the pump pressure please refer to the maintenance section of the owner’s manual for instructions on setting the pump pressure.

Owner’s Manual |

Page 5 |

QM67 Dual Boiler Espresso Machine

Normal Operation, Continued

Lights

•On the front of the machine there are 4 indicator lights. The green indicator light to the left of the coffee boiler power switch will illuminate whenever the coffee boiler is turned on.

•The green indicator light to the right of the steam boiler power switch will illuminate whenever the steam boiler is turned on. The coffee boiler power switch must be turned on for the steam boiler to operate.

•The red coffee boiler heating indicator light located under the coffee boiler power switch will illuminate whenever the coffee boiler is heating.

•The red steam boiler heating indicator light located under the steam boiler power switch will illuminate whenever the steam boiler is heating. The coffee boiler must be up to temperature before the steam boiler is able to heat.

•It is normal for the red heating lights to flash rapidly back and forth to maintain the proper temperature in both boilers.

Pump

•The machine is equipped with a 52W vibratory pump that is thermally protected. Vibratory pumps can be loud by nature and their tone may change during the course of a shot which is normal.

•Periodically the pump will come on by itself to maintain the proper water level in the boiler. Sometimes the pump will come on when you turn on the machine and sometimes it may not depending on the water level in the boiler which is normal.

•The pump (brew) pressure is regulated by the expansion valve. To learn how to set the pump pressure please refer to the maintenance section of the owner’s manual.

Owner’s Manual |

Page 6 |

QM67 Dual Boiler Espresso Machine

Normal Operation, Continued

Water Reservoir

•The water reservoir can be accessed by opening the hinged reservoir door on the top of the machine. It is recommended that the reservoir be removed prior to filling to prevent the spilling of water inside the machine which can cause damage to sensitive electrical components. Should water accidently get spilled inside the machine then immediately turn the power switch to the off position and unplug the machine from the electrical outlet. Do not plug the machine back in until it has had at least 1 full day to dry out. If it does not operate after that time then unplug the machine and refer to the troubleshooting section of the owner’s manual.

•The reservoir must be installed properly for the machine to function. The float inside the reservoir must be on the left side of the machine. Also be sure the reservoir is seated as far down as possible and the silicone hoses are not pushing the float down or the PID and heating lights will not turn on.

•The machine is equipped with a magnetic float in the water reservoir to detect the water level. When the water level gets low the PID and heating lights will go out and the pump will no longer function until the reservoir has been refilled.

•The reservoir should be cleaned at least once a week with mild dish detergent and rinsed thoroughly before use. DO NOT PUT IN DISHWASHER!!!

•Depending on your water quality it may be necessary to periodically sanitize the reservoir or if you are using hard water and have a mineral build up inside. White vinegar can be used to sanitize and will also remove the mineral deposits that can accumulate. Fill the reservoir with white vinegar and then let it sit for an hour and then rinse and clean the reservoir thoroughly. If the reservoir still has a vinegar taste or odor you can mix some baking soda and water in the reservoir to remove the taste and odor and then wash it with a mild dish detergent and rinse thoroughly.

Owner’s Manual |

Page 7 |

Loading...

Loading...