Page 1

AirborneDirect™ User Manual

AirborneDirect™ DP500/IN5000/HD500

Family User Manual

Revision: 1.1

February 2011

File name: user manual abdg dp5xx family v1.1

Document Number: 100-8510-110

Page 2

Quatech, Inc. AirborneDirect™ User Manual

<Page Intentionally Left Blank>

2 2/21/2011 100-8510-110

Page 3

AirborneDirect™ Users Guide Quatech, Inc.

Quatech Confidential

Copyright © 2011 QUATECH ® Inc.

ALL RIGHTS RESERVED. No part of this publication may be copied in any form, by photocopy, microfilm, retrieval

system, or by any other means now known or hereafter invented without the prior written permission of QUATECH ® Inc..

This document may not be used as the basis for manufacture or sale of any items without the prior written consent of

QUATECH Inc. is a registered trademark of QUATECH Inc..

Airborne™ and AirborneDirect™ are trademarks of QUATECH Inc..

All other trademarks used in this document are the property of their respective owners.

The information in the document is believed to be correct at the time of print. The reader remains responsible for the

system design and for ensuring that the overall system satisfies its design objectives taking due account of the information

presented herein, the specifications of other associated equipment, and the test environment.

QUATECH ® Inc. has made commercially reasonable efforts to ensure that the information contained in this document is

accurate and reliable. However, the information is subject to change without notice. No responsibility is assumed by

QUATECH for the use of the information or for infringements of patents or other rights of third parties. This document is

the property of QUATECH ® Inc. and does not imply license under patents, copyrights, or trade secrets.

QUATECH Inc..

Disclaimer

Quatech, Inc. Headquarters

QUATECH ® Inc..

5675 Hudson Industrial Parkway

Hudson, OH 44236

USA

Telephone: 330.655.9000

Toll Free (USA): 800.553.1170

Fax: 330.655.9010

Technical Support: 800.553.1170 / support@quatech.com

Web Site: www.quatech.com

100-8510-110 2/21/2011 3

Page 4

Quatech, Inc. AirborneDirect™ User Manual

<Page Intentionally Left Blank>

4 2/21/2011 100-8510-110

Page 5

AirborneDirect™ Users Guide Quatech, Inc.

Contents

1.0 Conventions ....................................................................................................................................................... 9

1.1 Terminology ................................................................................................................................................... 9

1.2 Notes .............................................................................................................................................................. 9

1.3 Caution ........................................................................................................................................................... 9

1.4 File Format ..................................................................................................................................................... 9

2.0 Product Description .......................................................................................................................................... 10

3.0 Features .......................................................................................................................................................... 11

4.0 Device Types ................................................................................................................................................... 12

4.1 Serial ............................................................................................................................................................ 12

4.2 Ethernet ....................................................................................................................................................... 12

4.3 Serial + Ethernet........................................................................................................................................... 12

4.4 Enterprise Class ........................................................................................................................................... 13

4.5 Industrial Class ............................................................................................................................................. 13

4.6 Heavy Duty Class ......................................................................................................................................... 14

5.0 Block Diagram ................................................................................................................................................. 16

6.0 Pin out and Connectors .................................................................................................................................... 18

6.1 Serial Ports ................................................................................................................................................... 18

6.2 Ethernet Port ................................................................................................................................................ 19

6.3 Connector Definition ..................................................................................................................................... 20

6.4 OEM Reset Switch (Factory Reset) .............................................................................................................. 20

6.5 Enterprise Serial Interface Jumpers .............................................................................................................. 21

6.6 Indicator LED’s ............................................................................................................................................. 22

7.0 Electrical & RF Specification ............................................................................................................................ 24

7.1 AC Electrical Characteristics – Transmitter ................................................................................................... 26

7.2 Performance/Range ..................................................................................................................................... 26

8.0 Antenna ........................................................................................................................................................... 27

8.1 Antenna Selection ........................................................................................................................................ 27

8.2 Host Board Mounted Antenna....................................................................................................................... 27

8.3 Host Chassis Mounted Antenna ................................................................................................................... 28

8.4 Embedded Antenna ...................................................................................................................................... 28

8.5 Antenna Location ......................................................................................................................................... 29

8.6 Performance ................................................................................................................................................. 30

9.0 Mechanical Outline – Enterprise Class ............................................................................................................. 32

10.0 Mechanical Outline – Industrial Class............................................................................................................... 33

11.0 Getting Started ................................................................................................................................................. 34

11.1 Unpack the AirborneDirect™ Device ............................................................................................................ 34

11.2 Connect AirborneDirect™ to host ................................................................................................................. 34

11.3 Attach Antenna and Power-up the AirborneDirect™ ..................................................................................... 34

12.0 Configuring Device – Industrial Serial (ABDG-SE-IN5XXX) .............................................................................. 35

13.0 Configuring Device – Enterprise Serial (ABDG-SE-DP5XX) ............................................................................. 38

13.1 Connect a Host Computer ............................................................................................................................ 38

13.2 Interacting with the AirborneDirect™ device ................................................................................................. 38

13.3 Determine and Store the Access Point SSID ................................................................................................ 39

13.4 Determine the Device’s IP address ............................................................................................................... 39

13.5 Accessing the Device Using the Web Interface ............................................................................................. 40

13.6 Accessing the Device Using Telnet .............................................................................................................. 40

14.0 Configuring Device – Enterprise/Industrial Ethernet ......................................................................................... 41

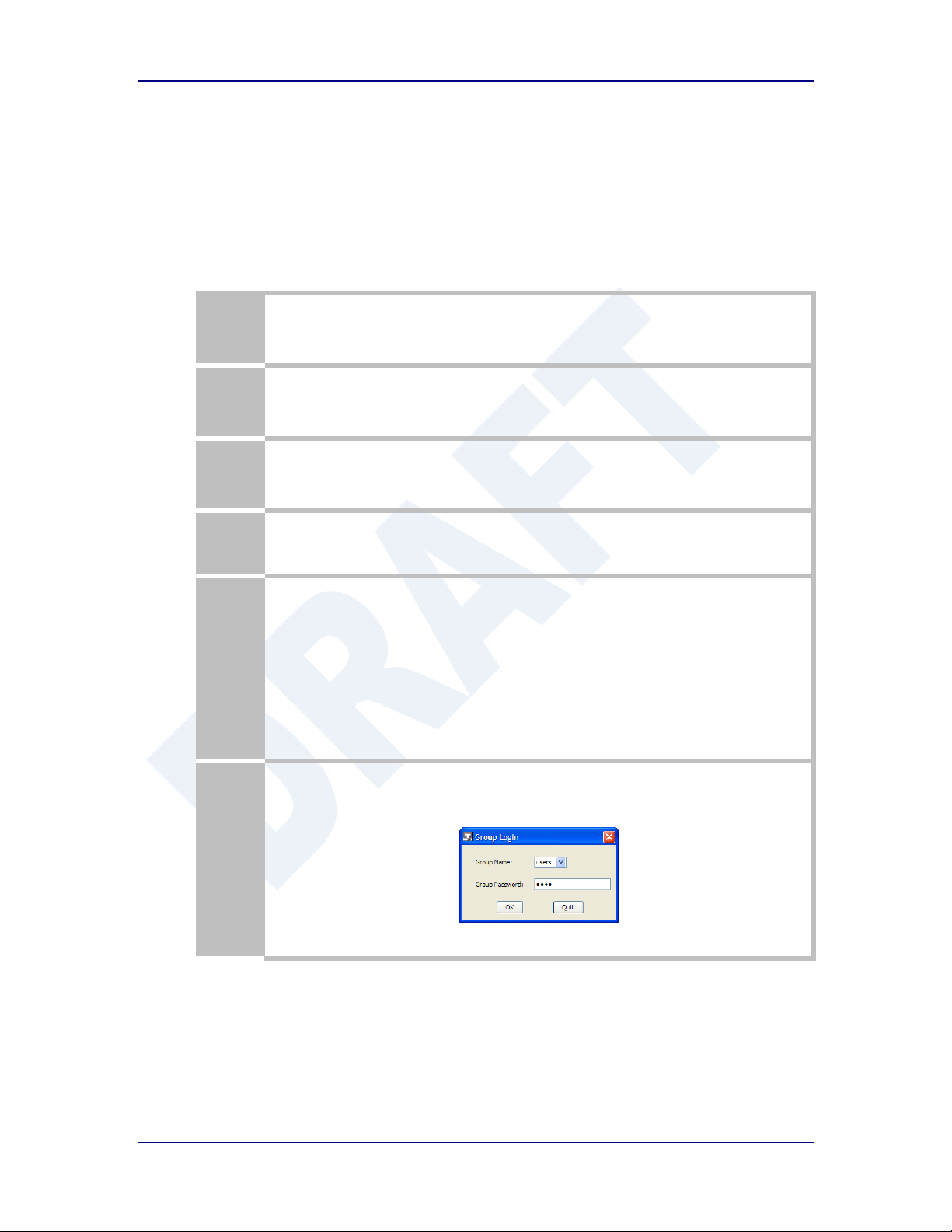

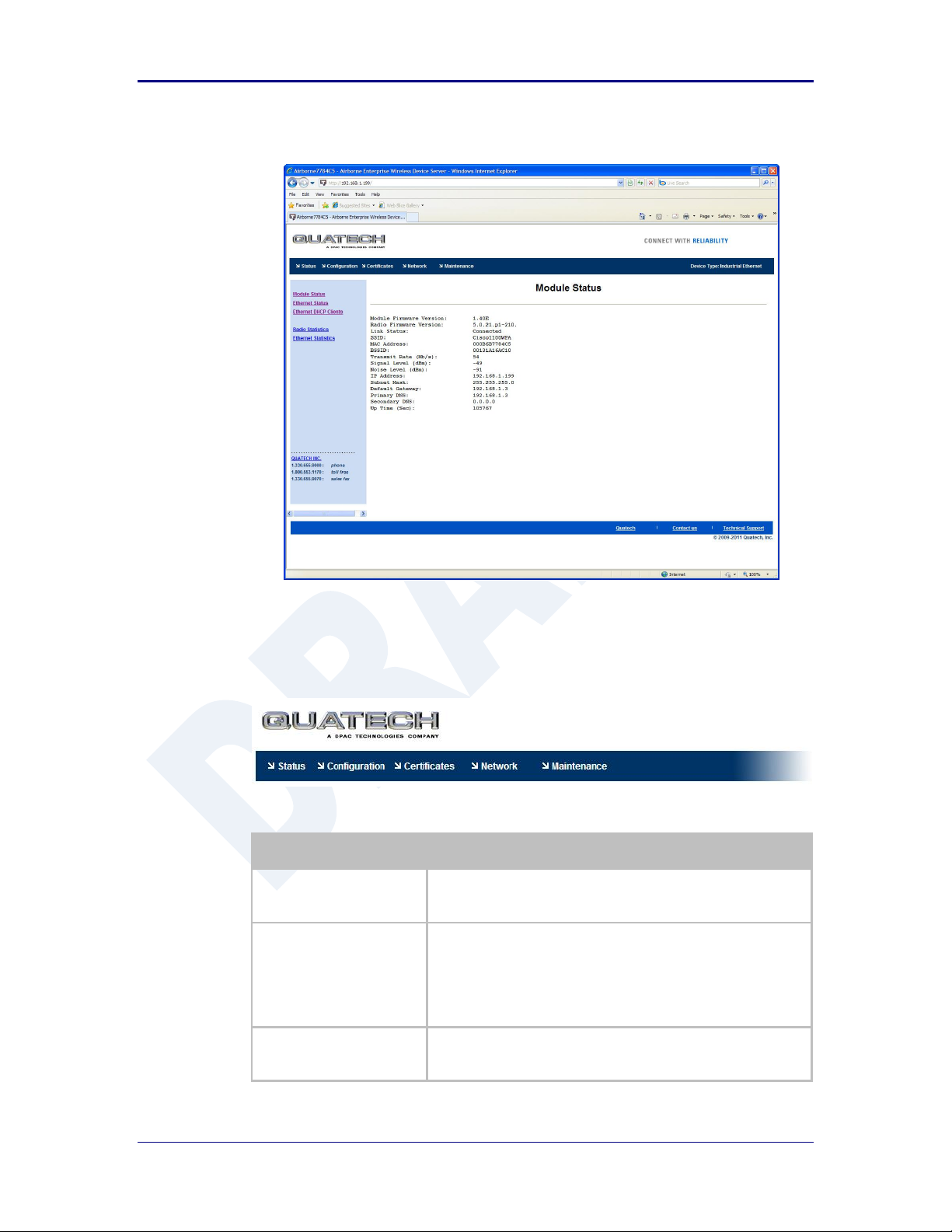

15.0 Using the Web Interface ................................................................................................................................... 44

15.1 Navigation Bar .............................................................................................................................................. 45

15.2 Feature Links ............................................................................................................................................... 46

15.3 Navigating the Website ................................................................................................................................. 46

15.4 Updating a Field ........................................................................................................................................... 47

15.5 Uploading Certificates .................................................................................................................................. 48

15.6 Upload Configuration Files ........................................................................................................................... 48

15.7 Updating Firmware ....................................................................................................................................... 50

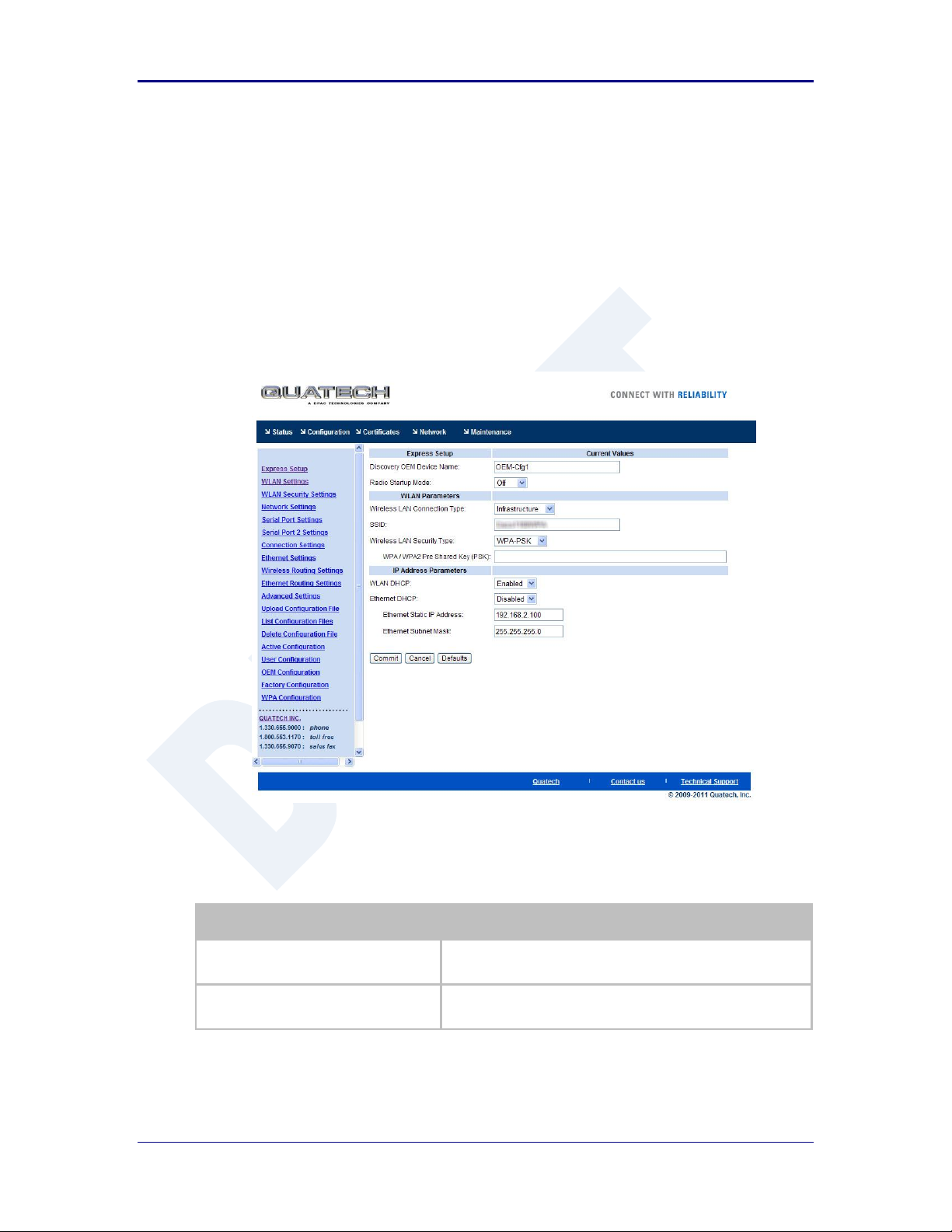

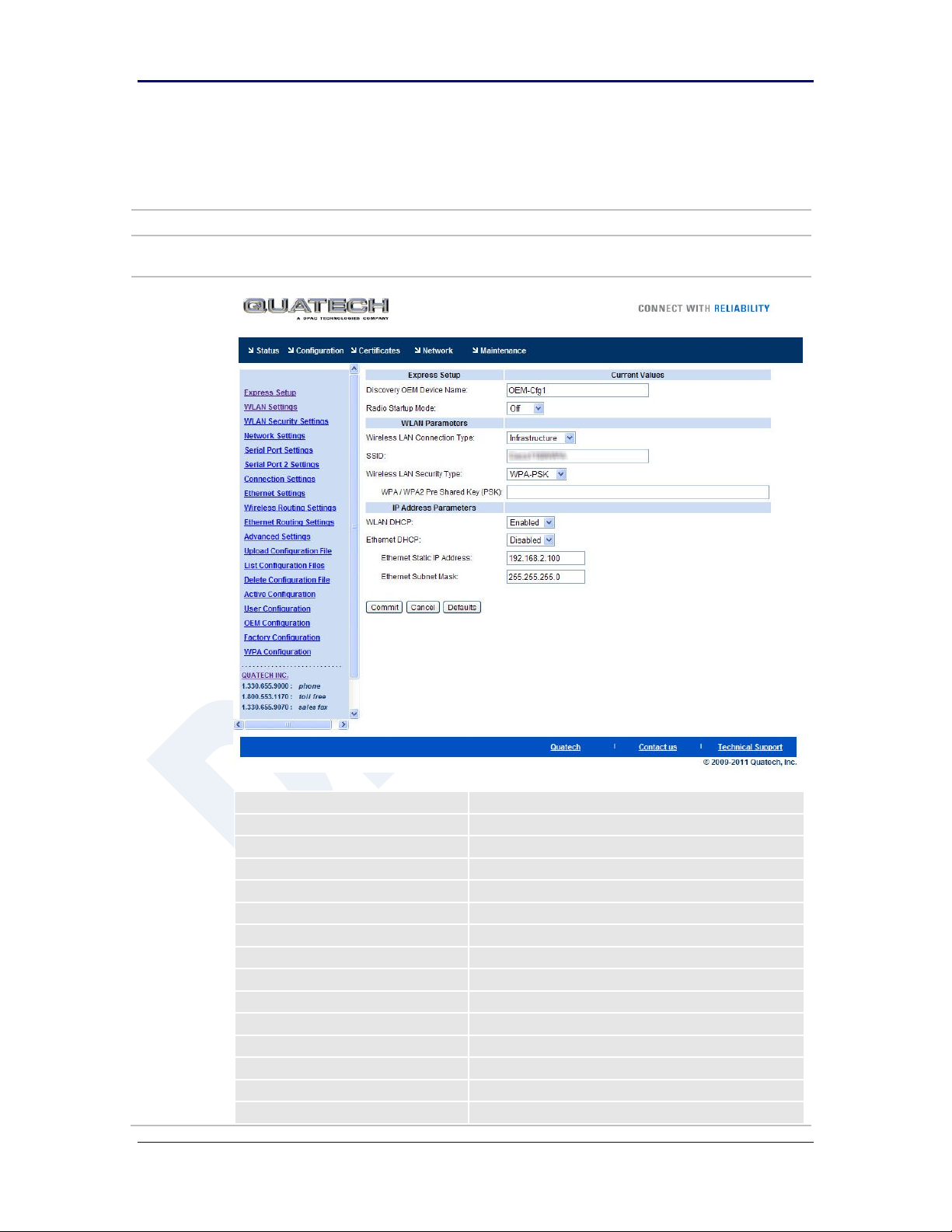

16.0 Express Setup Configuration Page .................................................................................................................. 53

17.0 Configuring the Wireless Interface ................................................................................................................... 56

17.1 Configuring for Infrastructure Networks ........................................................................................................ 56

17.2 Configuring for AdHoc Networks ................................................................................................................... 56

18.0 Configuring the Security Settings ..................................................................................................................... 58

18.1 Configuring for WEP Security ....................................................................................................................... 58

18.2 Configuring for WPA-PSK Security ............................................................................................................... 59

18.3 Configuring for WPA2-PSK Security ............................................................................................................. 60

18.4 Configuring for PEAP Security ...................................................................................................................... 61

19.0 Configuring Network Settings ........................................................................................................................... 63

19.1 Configuring DHCP on WLAN Interface ......................................................................................................... 63

19.2 Configuring DHCP on Ethernet Interface ...................................................................................................... 64

19.3 Configuring a Static IP Address on WLAN Interface ..................................................................................... 65

100-8510-110 2/21/2011 5

Page 6

Quatech, Inc. AirborneDirect™ User Manual

19.4 Configuring a Static IP Address on Ethernet Interface .................................................................................. 66

20.0 Configuring Serial Device Server ..................................................................................................................... 68

20.1 Configuring Serial Port for Access on Telnet Port ......................................................................................... 68

20.2 Configuring Serial Port 1 for Access on Tunnel Port ..................................................................................... 69

20.3 Configuring Serial Port 2 for Access on Tunnel Port ..................................................................................... 71

20.4 Configuring Serial Port 1 as TCP Client ................................ ........................................................................ 72

20.5 Configuring Serial Port 2 as TCP Client ................................ ........................................................................ 73

21.0 Installing and Using the Airborne VirtualCOM Driver ........................................................................................ 75

22.0 Replacing a Serial Cable .................................................................................................................................. 78

23.0 Configuring Ethernet Adapter ........................................................................................................................... 81

23.1 Public Network Interface ............................................................................................................................... 82

23.2 Private Network Interface ............................................................................................................................. 83

24.0 Web Page Overview ........................................................................................................................................ 87

Module Status ........................................................................................................................................................ 88

Ethernet Status ...................................................................................................................................................... 89

Ethernet DHCP Clients........................................................................................................................................... 90

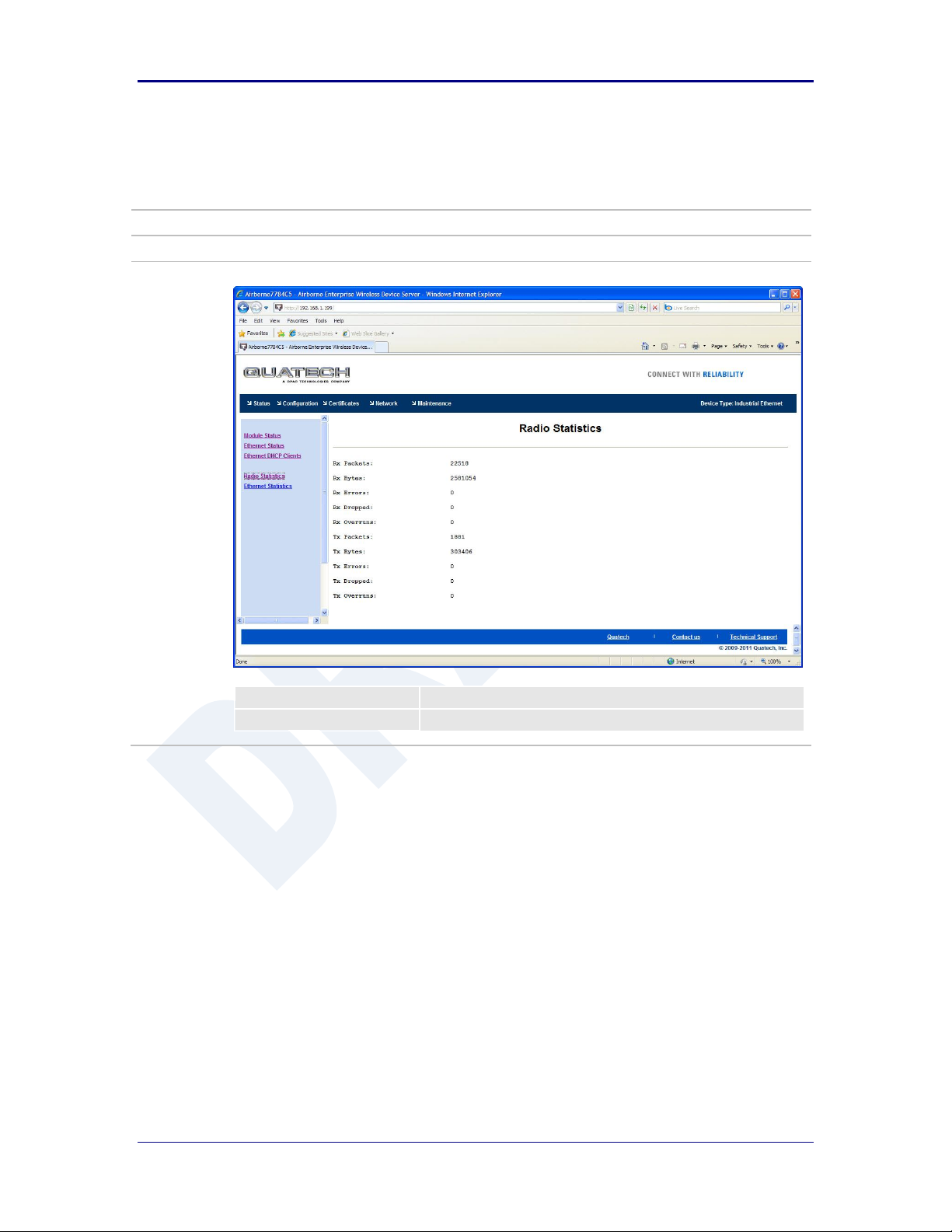

Radio Statistics ...................................................................................................................................................... 91

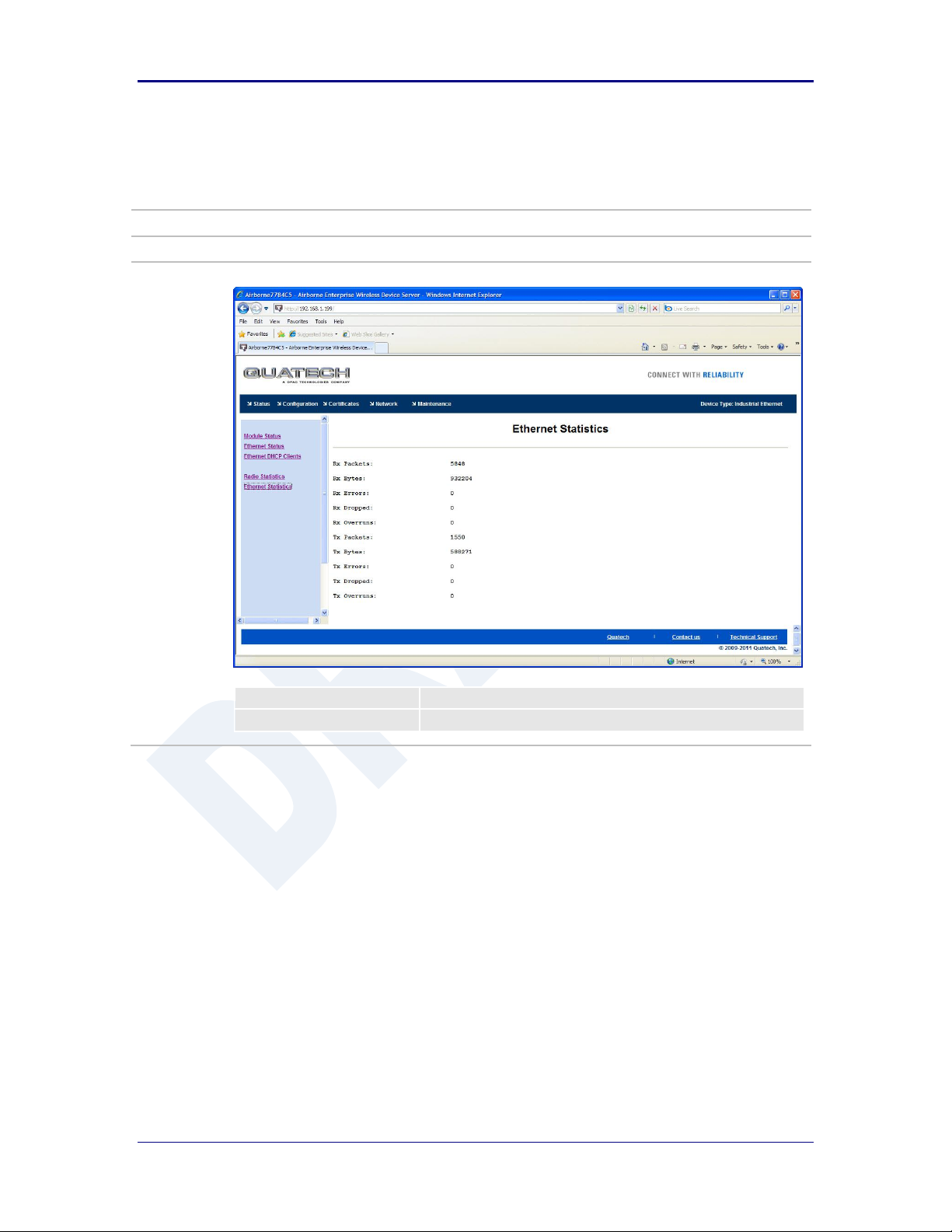

Ethernet Statistics .................................................................................................................................................. 92

Express Setup ........................................................................................................................................................ 93

WLAN Settings ....................................................................................................................................................... 95

WLAN Security Settings ......................................................................................................................................... 96

Network Settings .................................................................................................................................................... 98

Serial Port Settings .............................................................................................................................................. 100

Serial Port 2 Settings ........................................................................................................................................... 101

Connection Settings ............................................................................................................................................. 102

Ethernet Settings.................................................................................................................................................. 104

Wireless Routing Settings .................................................................................................................................... 105

Ethernet Routing Settings .................................................................................................................................... 106

Advanced Settings ............................................................................................................................................... 107

Upload Configuration File ..................................................................................................................................... 110

List Configuration File .......................................................................................................................................... 111

Delete Configuration File ...................................................................................................................................... 112

Active Configuration ............................................................................................................................................. 113

User Configuration ............................................................................................................................................... 114

OEM Configuration ............................................................................................................................................... 115

Factory Configuration ........................................................................................................................................... 116

WPA Configuration ............................................................................................................................................... 117

List Certificates .................................................................................................................................................... 118

Upload Certificate................................................................................................................................................. 119

Delete Certificate.................................................................................................................................................. 120

Network (Home Page) .......................................................................................................................................... 121

Discover Airborne Modules .................................................................................................................................. 122

Scan for Access Points ........................................................................................................................................ 123

Maintenance (Home Page) .................................................................................................................................. 124

Update Module Firmware ..................................................................................................................................... 125

Reset Factory Defaults ......................................................................................................................................... 126

Restart Module ..................................................................................................................................................... 127

Blink the POST LED ............................................................................................................................................. 128

Stop Blinking the POST LED ................................................................................................................................ 129

Change Module Personality ................................................................................................................................. 130

25.0 Certification & Regulatory Approvals .............................................................................................................. 131

25.1 FCC Statement ........................................................................................................................................... 131

25.2 FCC RF Exposure Statement ..................................................................................................................... 131

25.3 Information for Canadian Users (IC Notice) ................................................................................................ 132

25.4 FCC/IC Modular Approval ........................................................................................................................... 132

25.5 Regulatory Test Mode Support ................................................................................................................... 133

26.0 Physical & Environmental Approvals .............................................................................................................. 134

27.0 Change Log ................................................................................................................................................... 135

6 2/21/2011 100-8510-110

Page 7

AirborneDirect™ Users Guide Quatech, Inc.

Figures

Figure 1 - Enterprise AirborneDirect™ Device ................................................................................................................. 13

Figure 2 - Industrial AirborneDirect™ Device ................................................................................................................... 14

Figure 3 - Heavy Duty AirborneDirect™ Device ............................................................................................................... 14

Figure 4 - ABDG-SE/ET-DP5XX Block Diagram .............................................................................................................. 16

Figure 5 - ABDG-ET/SE-IN5XXX Block Diagram ............................................................................................................. 17

Figure 6 - DE-9 (DB-9) Connector Pin-out........................................................................................................................ 18

Figure 7 - Ethernet Jack Pin Out ...................................................................................................................................... 19

Figure 8- Interface Selection Jumpers.............................................................................................................................. 21

Figure 9 - Website Login .................................................................................................................................................. 44

Figure 10 - Default Home Page ....................................................................................................................................... 45

Figure 11 - Website Navigation Bar ................................................................................................................................. 45

Figure 12- Feature Links .................................................................................................................................................. 46

Figure 13 - Airborne Web Page ....................................................................................................................................... 47

Figure 14 - upload Certificate Web page .......................................................................................................................... 48

Figure 15 - Upload Configuration Web Page .................................................................................................................... 49

Figure 16 - Firmware Update Page .................................................................................................................................. 50

Figure 17 - Firmware Update in Progress ........................................................................................................................ 51

Figure 18 - Firmware Update Complete ........................................................................................................................... 51

Figure 19 - Express Setup Page ...................................................................................................................................... 53

Figure 20 - Ethernet Bridge Functionality ......................................................................................................................... 81

Figure 21 - Airborne Ethernet Bridge IP Configuration ..................................................................................................... 83

Tables

Table 1 – Serial Port Pin Definition .................................................................................................................................. 18

Table 2 - Serial Ports by Product Class ............................................................................................................................ 19

Table 3 - Ethernet Connector Pin Out .............................................................................................................................. 19

Table 4 - Connector Description....................................................................................................................................... 20

Table 5 - OEM Reset Procedure ...................................................................................................................................... 21

Table 6 - Enterprise LED Indicators ................................................................................................................................. 22

Table 7 - Industrial LED Indicators ................................................................................................................................... 23

Table 8- Absolute Maximum Values1 ............................................................................................................................... 24

Table 9 - RF Characteristics – 802.11b/g ......................................................................................................................... 24

Table 10 - Supported Data Rates by Band ....................................................................................................................... 25

Table 11 - Operating Channels ........................................................................................................................................ 25

Table 12 - Radio Typical Performance Range .................................................................................................................. 26

Table 13 - Embedded Antenna Options ........................................................................................................................... 28

Table 14 - SE-IN5XXX Accessing the Web Interface ....................................................................................................... 35

Table 15 - UART Authentication....................................................................................................................................... 38

Table 16 - UART SSID & Authentication .......................................................................................................................... 39

Table 17 - UART Determine Module's IP Address ........................................................................................................... 39

Table 18 - ET-DP5XX/IN5XXX Accessing the Web Interface ........................................................................................... 41

Table 19 - Navigation Bar Items ....................................................................................................................................... 45

Table 20 - Uploading Certificates ..................................................................................................................................... 48

Table 21 - Uploading Configurations ................................................................................................................................ 49

Table 22 - Updating Firmware .......................................................................................................................................... 51

Table 23 - Express Page Setup ....................................................................................................................................... 53

Table 24 - Configuring Wireless Interface - Infrastructure ................................................................................................ 56

Table 25 - Configuring Wireless Interface - AdHoc ........................................................................................................... 57

Table 26 - Configuring for WEP Security .......................................................................................................................... 58

Table 27 - Configuring for WPA Security .......................................................................................................................... 59

Table 28 - Configuring for WPA2 Security ........................................................................................................................ 60

Table 29 - Configuring for PEAP Security ........................................................................................................................ 61

Table 30 - Configuring DHCP - WLAN ............................................................................................................................. 63

Table 31 - Configuring DHCP - Ethernet .......................................................................................................................... 64

Table 32 - Configuring Static IP - WLAN .......................................................................................................................... 65

Table 33 - Configuring Static IP - Ethernet ................................................................................................ ....................... 66

Table 34 – Configure Data Tunnel on Telnet Port ............................................................................................................ 68

Table 35 - Data Tunnel using Telnet Port ......................................................................................................................... 69

Table 36 – Configure Data Tunnel on Serial Port 1 Tunnel Port (TCP) ............................................................................. 70

Table 37 - Data Tunnel using Tunnel Port on Serial Port 1............................................................................................... 70

Table 38 – Configure Data Tunnel on Serial Port 2 Tunnel Port (TCP) ............................................................................. 71

Table 39 - Data Tunnel using Tunnel Port on Serial Port 2............................................................................................... 72

Table 40 - Configure Serial Port 1 as TCP Client ............................................................................................................. 72

Table 41 - Configure Serial Port 2 as TCP Client ............................................................................................................. 73

Table 42 - Install VCOM ................................................................................................................................................... 75

Table 43 - Cable Replacement - Slave Configuration ....................................................................................................... 78

100-8510-110 2/21/2011 7

Page 8

Quatech, Inc. AirborneDirect™ User Manual

Table 44 - Cable Replacement - Master Configuration ..................................................................................................... 79

Table 45 - Ethernet Adapter interface Configuration - DHCP ........................................................................................... 83

Table 46 - Ethernet Adapter interface Configuration - Static IP ........................................................................................ 84

Table 47 - Regulatory Approvals .................................................................................................................................... 131

Table 48 - Modular Approval Grant Numbers ................................................................................................................. 132

Table 49 - Mechanical Approvals ................................................................................................................................... 134

8 2/21/2011 100-8510-110

Page 9

AirborneDirect™ Users Guide Quatech, Inc.

The area next to the indicator will identify the specific information and make any

references necessary.

The area next to the indicator will identify the specific information and make any

references necessary.

1.0 Conventions

The following section outlines the conventions used within the document, where

convention is deviated from the deviation takes precedence and should be followed. If

you have any question related to the conventions used or clarification of indicated

deviation please contact Quatech Sales or Wireless Support.

1.1 Terminology

Airborne Enterprise Device Server and AirborneDirect Enterprise Device

Server is used in the opening section to describe the devices detailed in this

document, after this section the term module will be used to describe the

devices.

1.2 Notes

A note contains information that requires special attention. The following

convention will be used. The area next to the indicator will identify the specific

information and make any references necessary.

1.3 Caution

A caution contains information that, if not followed, may cause damage to the

product or injury to the user. The shaded area next to the indicator will identify

the specific information and make any references necessary.

1.4 File Format

These documents are provided as Portable Document Format (PDF) files. To

read them, you need Adobe Acrobat Reader 4.0.5 or higher. For your

convenience, Adobe Acrobat Reader is provided on the Radio Evaluation Kit CD.

Should you not have the CD, for the latest version of Adobe Acrobat Reader, go

to the Adobe Web site (www.adobe.com).

100-8510-110 2/21/2011 9

Page 10

Quatech, Inc. AirborneDirect™ User Manual

2.0 Product Description

This guide describes the AirborneDirect™ device servers and wireless adapters from

Quatech, Inc. AirborneDirect™ is a fully integrated, 802.11 wireless Local Area Network

(LAN) connectivity device designed to provide wireless LAN and Internet connectivity in

industrial, scientific, medical, and transportation applications where an existing

communications interface already exists. The AirborneDirect family of products supports

Serial (RS232/422/485), Ethernet and a combination these interfaces in a range of

packaging options.

The AirborneDirect™ product family provides true plug-and-play wireless connectivity. By

delivering convenient, easy-to-deploy wireless network connectivity, the device servers

and adapters significantly reduce the complexities of wireless system deployment and

network implementation. At the same time, users can move equipment without the cost

and time associated with wired network drops and environment restrictions. This provides

flexibility for seasonal demands, line and staffing changes, and more.

The AirborneDirect™ Serial Bridges and device servers provide a simple connection

between the 802.11 wireless LAN and three leading serial interfaces: RS-232, RS-422,

and RS-485. The Bridge acts transparently between any device using these interfaces

and a wireless LAN. Using the Quatech virtual communications port Windows device

driver OEMs can communicate with their devices from any workstation on the same

network as if the workstation and devices were directly attached through a serial port.

The AirborneDirect™ Ethernet Adapter provides a link between the 802.11 wireless LAN

and any Ethernet-ready device with an RJ-45 connector. It acts transparently between

the device and a wireless LAN. By integrating AirborneDirect™ into existing and legacy

platforms, OEMs can significantly enhance their products by delivering increased value

and functionality to their entire customer base.

The Airborne family includes the ability to simultaneously use the serial-to-wireless and

Ethernet-to-wireless connectivity in the same unit. This capability provides for multiple

connections to the same machine or consolidation of multiple wireless units into a single

device.

The AirborneDirect™ products open the world of remote device monitoring and

management, as well as wide-area data collection, to any device, machine, or plant that

has an external serial or Ethernet connection and a network infrastructure. The

development kit provides quick and easy access to the Bridge’s configuration and

functions, while providing OEMs with a platform to develop their branded solutions. The

Bridge also provides the capability to perform firmware upgrades that allow new features

to be added quickly and easily, protecting your investment.

The Enterprise family includes the most advanced security support available for the

device class in the industry, including WPA, WPA2 and full Enterprise support. The

devices can be used with the most advanced WLAN networks being deployed today. The

Airborne products are based upon the industry leading Airborne device server and

wireless adapter technology from Quatech, providing a fully compatible and familiar

device interface across the all product ranges. If you’ve used one you have used them

all.

10 2/21/2011 100-8510-110

Page 11

AirborneDirect™ Users Guide Quatech, Inc.

3.0 Features

802.11b/g WiFi Radio with 32bit ARM9 CPU (128Mb SDRAM, 64Mb Flash)

Integrated Airborne Device Server and Wireless Adapter technology.

Supports WEP, WPA, WPA2 and 802.1x Supplicant, with Certificates.

The wireless device server includes integrated:

802.11b/g radio driver

TCP/IP stack, UDP, telnet, FTP server

Data bridging and buffering

Command Line Interface

Web interface

WPA Supplicant

802.11 Radio Driver

DHCP Server (Ethernet Interface)

Firewall and Port Forwarding (Ethernet)

FTP Server

Supports flexible antenna selection.

Operating Temperature (-40°C to 85°C)

Storage temp (-50°C to 125°C)

Industry standard wired connections:

D-9 Serial connectors (RS232/422/485)

RJ-45 (10/100 Ethernet)

Multiple host interfaces supported:

Single and Dual Serial (RS232/422/485) – up to 921K BAUD

10/100 Ethernet

Integrated standard and wide range (J1455) Power Supply (5-36VDC)

Power connector options include 2.1mm Barrel Jack, Terminal Block and

custom connectors.

Integrated Site Survey mode.

Advanced Low power modes.

Rugged mounting options.

Virtual COM port driver (WinXP, Vista, Win7)

Worldwide Regulatory Support (FCC, IC, CE)

100-8510-110 2/21/2011 11

Page 12

Quatech, Inc. AirborneDirect™ User Manual

4.0 Device Types

This manual covers all variations available in the AirborneDirect™ device family. The

following section identifies the different types both functional and classification. In most

cases the functional types are available in the listed classifications. If you are not certain

which type you have or would like clarify the available options please contact Quatech

Sales or Technical support.

4.1 Serial

This device supports a single or dual serial port and provides serial to 802.11

bridging. The serial devices can support one or more of the following serial

interface types:

RS232

RS422

RS485

Default configuration on all models is RS232, conversion to RS422/485 requires

software configuration and in some models jumper setting changes. These are

covered in the following sections.

This device allows the connection of a serial port to an 802.11 network.

4.2 Ethernet

The Ethernet adapter provides a wireless interface to an existing Ethernet port

(RJ-45). Depending upon the model of device the connection to the Ethernet port

of the host is made via a RJ-45 socket or pigtail with a RJ-45 plug.

The device supports a 10/100 Ethernet interface with auto configuration. Manual

control of the interface is possible through the web or CLI interface.

4.3 Serial + Ethernet

This device allows for simultaneous connection of Serial and Ethernet ports.

Providing the same functionality on each port that is available on the individual

devices, it is possible to maintain network based connections to both the

Ethernet and Serial ports without compromise of functionality or performance.

Each interface can be configured and operated independently of the others.

Connection to the serial port can be made via both the wireless and Ethernet

ports supporting redundant network connectivity for high reliability applications.

12 2/21/2011 100-8510-110

Page 13

AirborneDirect™ Users Guide Quatech, Inc.

4.4 Enterprise Class

The enterprise class product provides the best cost vs. performance in the

AirborneDirect™ product family. The packaging is compact and designed to fit

with non-industrial applications and markets. The product class supports the full

industrial operating temperature range and the complete set of functional

capabilities of the Airborne™ Device Server and Wireless Adapter technology.

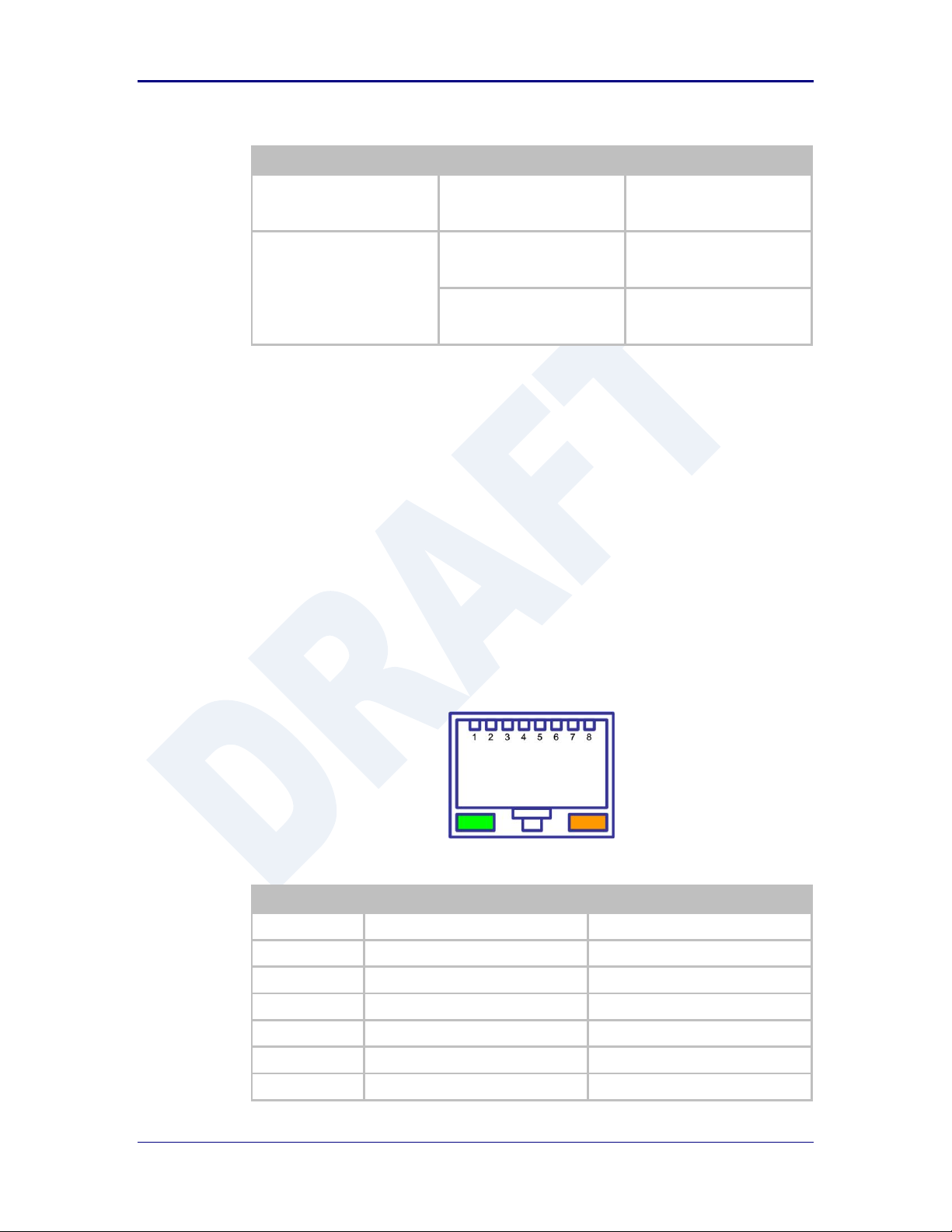

Figure 1 - Enterprise AirborneDirect™ Device

The Enterprise class product range includes devices that support a single serial

port and an Ethernet device.

The enterprise class product is ideal for the following application types:

Medical equipment.

Point-of-Sale devices.

CNC/DNC equipment.

Time clocks.

Scales.

Data collection devices.

Vehicle diagnostics.

The Enterprise Class products require a 5VDC power supply.

4.5 Industrial Class

Developed to support the demands of the industrial and automotive

environments, the features of the Industrial Class products offer a more flexible

and rugged alternative to the enterprise class devices. The product class

supports the full industrial operating temperature range and the complete set of

functional capabilities of the Airborne Device Server and Wireless Adapter

technology.

100-8510-110 2/21/2011 13

Page 14

Quatech, Inc. AirborneDirect™ User Manual

Figure 2 - Industrial AirborneDirect™ Device

The family includes a metal enclosure and a wide range power supply capable of

exceeding the SAE J1455 power supply requirements.

The enterprise class product is ideal for the following application types:

CNC/DNC equipment.

Vehicle diagnostics.

Telematics.

Remote monitoring and management.

Industrial control.

The Industrial class of products includes Ethernet only, Serial only and the dual

(Serial+Ethernet) capability.

4.6 Heavy Duty Class

These are the highest performing and most rugged Serial Device Server and

Ethernet adapter products in the market. The Heavy Duty product class supports

the highest level of ruggedization available allowing use in the most hazardous

and demanding environments. The product class supports the full industrial

operating temperature range and the complete set of functional capabilities of the

Airborne Device Server and Wireless Adapter technology.

Figure 3 - Heavy Duty AirborneDirect™ Device

The product family uses the Deutsch EEC-325X4B enclosure with sealed and

vented variations and a wide range power supply, capable of exceeding the SAE

J1455 power supply requirements.

14 2/21/2011 100-8510-110

Page 15

AirborneDirect™ Users Guide Quatech, Inc.

The Heavy Duty products are ideal for the following applications:

Mining equipment telematics.

Military vehicle diagnostics.

Avionics.

Construction heavy equipment diagnostics.

The HD class of products includes Ethernet only, Serial only and the dual

(Serial+Ethernet) capability, through a custom Deutsch connector (DTM06128A).

100-8510-110 2/21/2011 15

Page 16

Quatech, Inc. AirborneDirect™ User Manual

5.0 Block Diagram

The following outlines the block diagram for the devices:

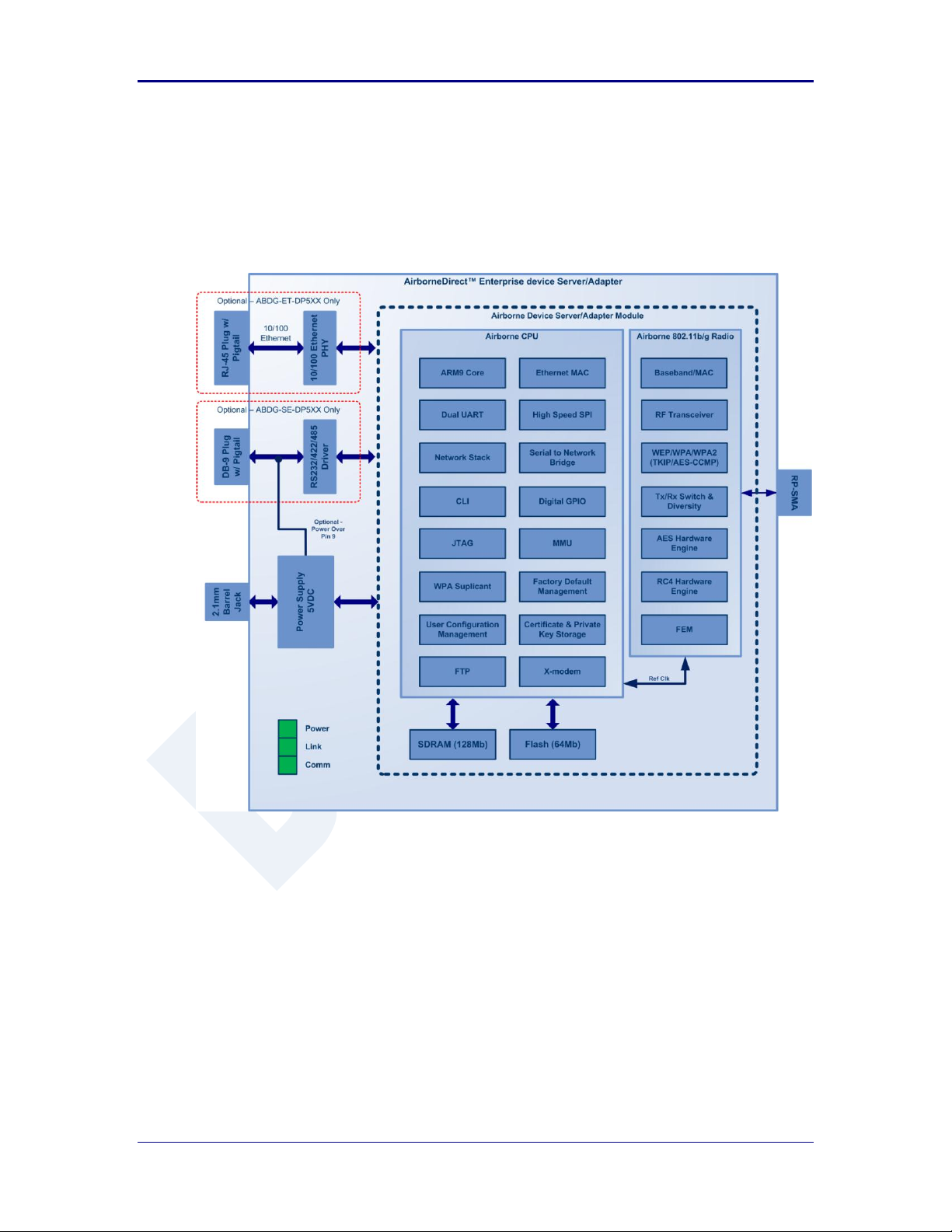

Figure 4 - ABDG-SE/ET-DP5XX Block Diagram

16 2/21/2011 100-8510-110

Page 17

AirborneDirect™ Users Guide Quatech, Inc.

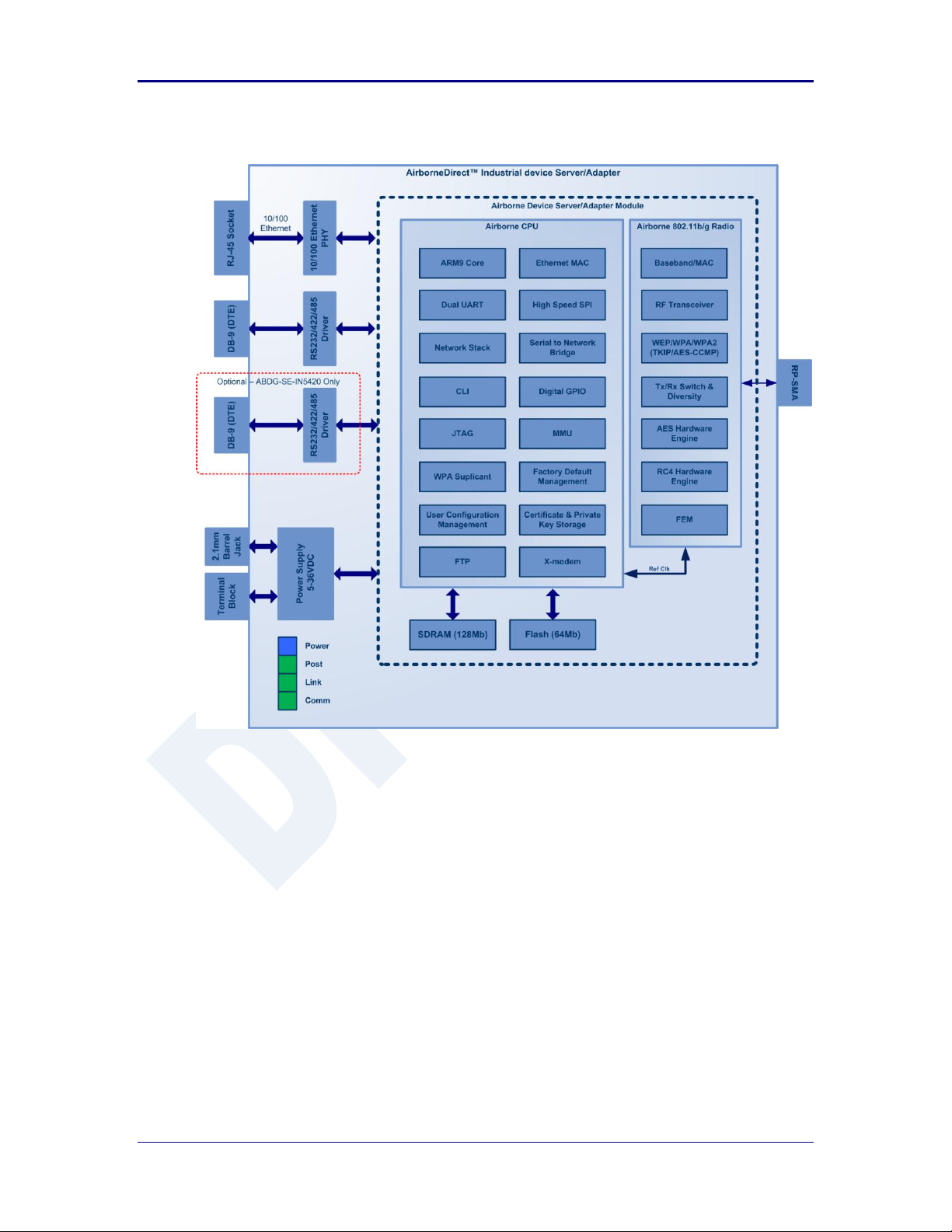

Figure 5 - ABDG-ET/SE-IN5XXX Block Diagram

100-8510-110 2/21/2011 17

Page 18

Quatech, Inc. AirborneDirect™ User Manual

Pin

RS232 (DTE)

RS232 w/

Power on pin 9

2

RS422

RS485

1

No Connect

No Connect

No Connect

No Connect

2

RxD

RxD

RxD+

Connect to pin 33

3

TxD

TxD

TxD+

TxD+/RxD+

4

No Connect

No Connect

No Connect

No Connect

5

GND

GND

GND

GND

6

No Connect

No Connect

RxD-

Connect to pin 93

7

RTS

RTS

No Connect

No Connect

8

CTS

CTS

No Connect

No Connect

9

No Connect

5VDC (Input)

TxD-

TxD-/RxD-

1. For 2-wire operation, the user must externally connect pin 3 to pin 2 and

pin 6 to pin 9.

2. Power on pin 9 only available on Enterprise devices (ABDG-SE-DP501).

3. Only required on Industrial products (ABDG-SE-IN54XX)

6.0 Pin out and Connectors

Pin definition is dependent upon the device type selected. The following defines the pin

outs for the individual interfaces.

6.1 Serial Ports

The AirborneDirect™ units support either a single or dual serial port

configuration. The Port pin out can change depending upon the interface

configuration chosen, Table 1 shows the pin out for the interface selected.

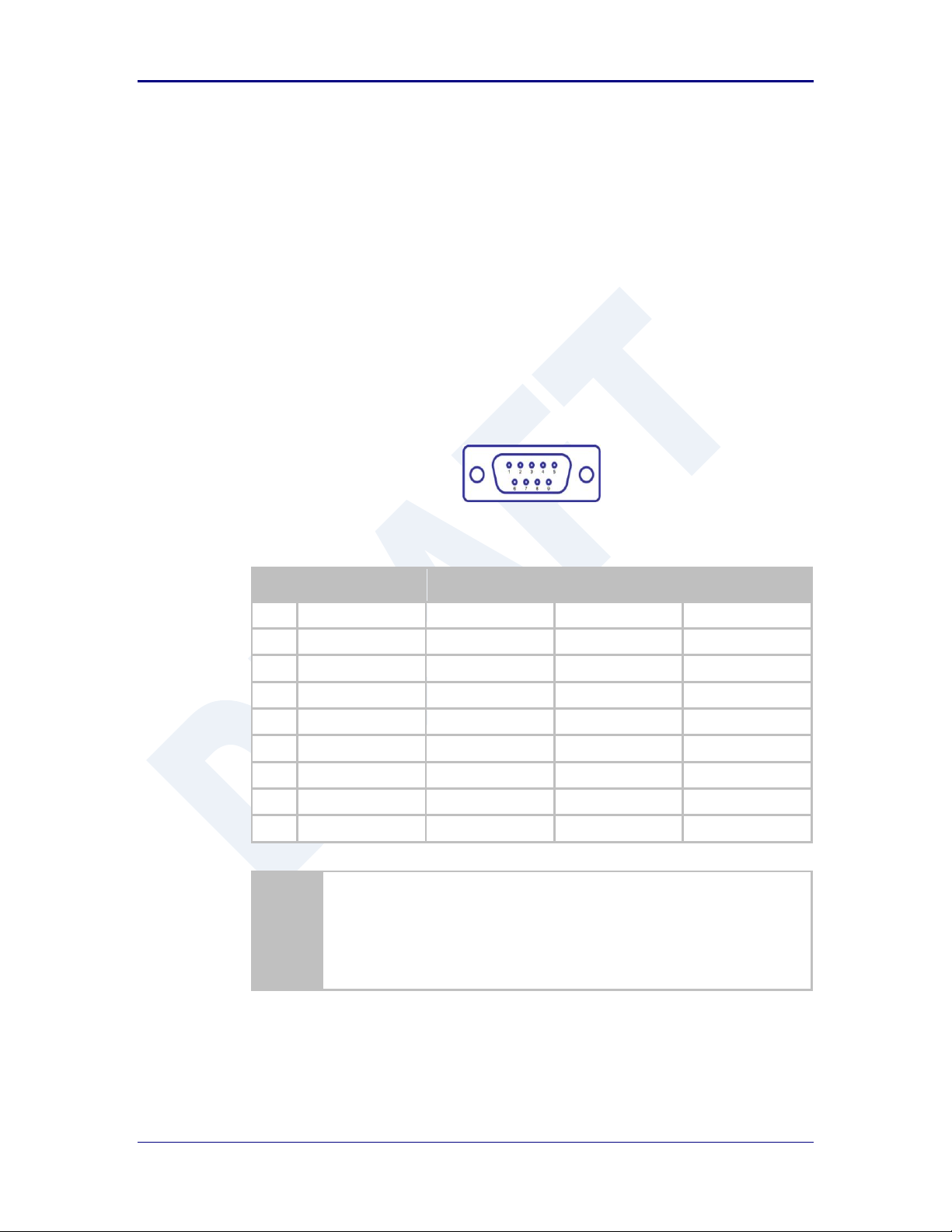

Figure 6 - DE-9 (DB-9) Connector Pin-out

Table 1 – Serial Port Pin Definition

Table 2 shows the availability of the serial ports and available interface types by

product class.

18 2/21/2011 100-8510-110

Page 19

AirborneDirect™ Users Guide Quatech, Inc.

Device Class

Port 1

Port 2

Enterprise

RS232

RS422 (4-wire)

RS485 (2-wire)

N/A

Industrial

RS232

RS422 (4-wire)

RS485(2-wire)

N/A

RS232

RS422 (4-wire)

RS485(2-wire)

RS232

RS422 (4-wire)

Pin

RJ45 Socket (Industrial)

RJ45 Plug (Enterprise)

1

TxD+

RxD+

2

TxD-

RxD-

3

RxD+

TxD+ 4 NC

NC 5 NC

NC 6 RxD-

TxD- 7 NC

NC

Table 2 - Serial Ports by Product Class

The Port 1 and Port 2 interfaces support the following configurations:

BAUD: 300, 600, 1200, 2400, 4800, 9600, 14400, 19200, 28800, 38400,

57600, 115200, 230400, 460800, 921600

Flow Control: None, Hardware (CTS/RTS), Software (XON/XOFF)

Port 1 Default settings: 9600, 8, N, 1, No Flow Control.

Port 2 Default settings: 9600, 8, N, 1, No Flow Control.

6.2 Ethernet Port

The AirborneDirect™ Ethernet devices support a single interface. This is a

10/100Mbps interface that supports auto negotiation and cross-over cabling. The

interface also supports both half and full duplex for 10Mbps and 100Mbps. Table

XX shows the interface pin out.

Figure 7 - Ethernet Jack Pin Out

Table 3 - Ethernet Connector Pin Out

100-8510-110 2/21/2011 19

Page 20

Quatech, Inc. AirborneDirect™ User Manual

Pin

RJ45 Socket (Industrial)

RJ45 Plug (Enterprise)

8

NC

NC

Green LED

Valid TCP/IP connection made with

Airborne Adapter:

Off No TCP/IP connection

On Valid TCP/IP Connection

N/A

Yellow LED

Power-on Self Test (POST):

Off Not powered or has failed POST

On Passed POST

N/A

Type

Description

Product Class

Serial

DE-9 Connector Male

Enterprise, Industrial

Ethernet

RJ45 Plug

Enterprise

Ethernet

RJ45 Socket

Industrial

Antenna

RP-SMA

Enterprise, Industrial

Power

2.1mm Barrel Jack

Enterprise, Industrial

Power

2 Position Terminal Block

Industrial

6.3 Connector Definition

There are a total of five connectors used by the AirborneDirect™ family. Which

connectors are available on your product depend upon the model you purchased.

The definition for the connectors is common to all product classes. Table 4

provides definitions for the connectors.

Table 4 - Connector Description

6.4 OEM Reset Switch (Factory Reset)

All AirborneDirect™ devices support the ability to reset the configuration back to

OEM defaults. This is useful when a device has been incorrectly configured and

has lost the ability to communicate on any of the available ports, preventing

access to one of the configuration interfaces and blocking your ability to recover

the device by correcting the configuration.

The following Table 5 describes the sequence for OEM resetting the

AirborneDirect™ devices. All devices use the same process however the

loo0cation of the OEM reset switch varies between the product families.

20 2/21/2011 100-8510-110

Page 21

AirborneDirect™ Users Guide Quatech, Inc.

1

Disconnect or turn off the power supply.

2

Press the OEM reset (factory reset) button.

This may require the use of a small narrow object, it is important that this object is

not sharp as it may cause damage to the unit.

3

While holding the OEM button pressed reapply power to the unit.

4

Hold the OEM reset button for 5-6 seconds after power has been applied.

5

Release the OEM reset button.

6

The device will restart with the installed OEM defaults. If no OEM Configuration is

applied the device will return to Quatech factory defaults.

See section 15.6 on use of OEM factory configurations.

RS-485 w/

Termination

RS-232 Power Pin 9,

Cable Sense

1

1

RS-232

Cable Sense

1

RS-422 w/

Termination

1

Table 5 - OEM Reset Procedure

The location of the OEM reset button for the Enterprise devices is on the back of

the enclosure, underneath the label near the pigtail. The Industrial devices OEM

reset button is on the Ethernet/Power end of the box next to the 2.1mm barrel

connector (See section 10.0)

6.5 Enterprise Serial Interface Jumpers

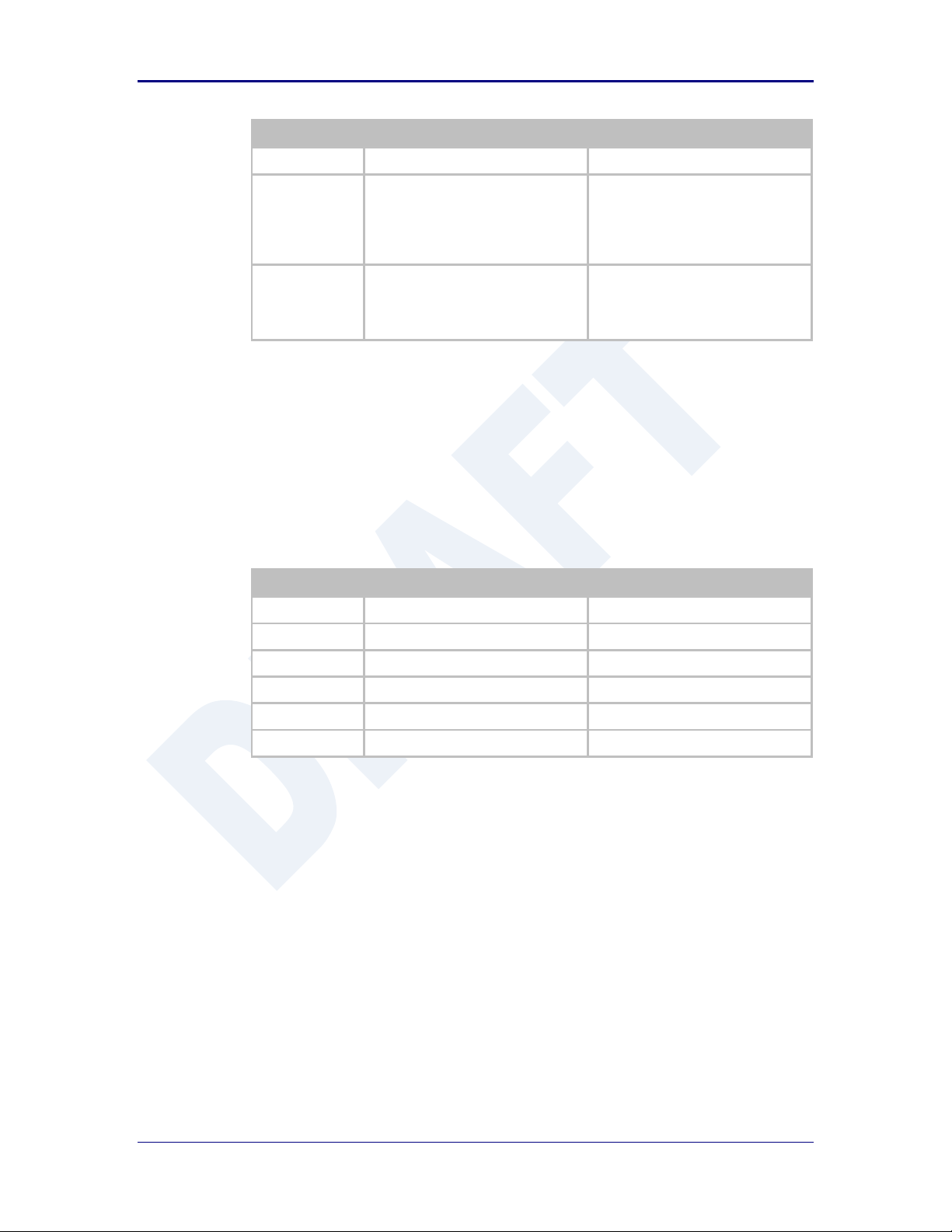

The Enterprise Serial device server supports RS232/422/485 interface drivers, as

well as power over pin 9. Selection of these options is made through both the

web interface and hardware jumpers. Figure 8shows the interface selection

jumpers for the different interface types.

Figure 8- Interface Selection Jumpers

The jumper selections must be made while the device is unpowered and before

being used in the final application.

100-8510-110 2/21/2011 21

Page 22

Quatech, Inc. AirborneDirect™ User Manual

The interface type selected by the interface jumpers in Figure 8 must match the

selected configuration for the Configuration | Serial Port Settings | Serial

Interface Type setting in the web interface.

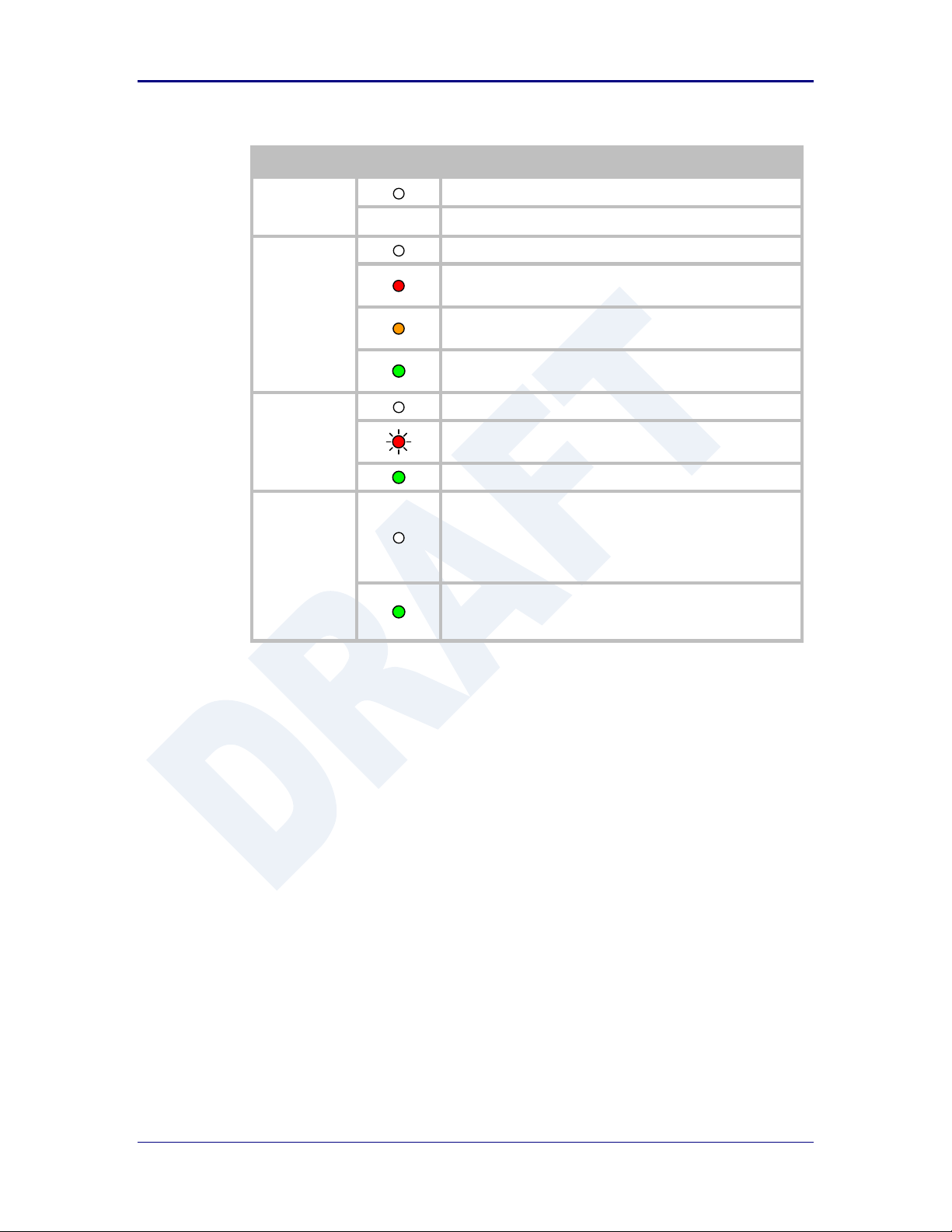

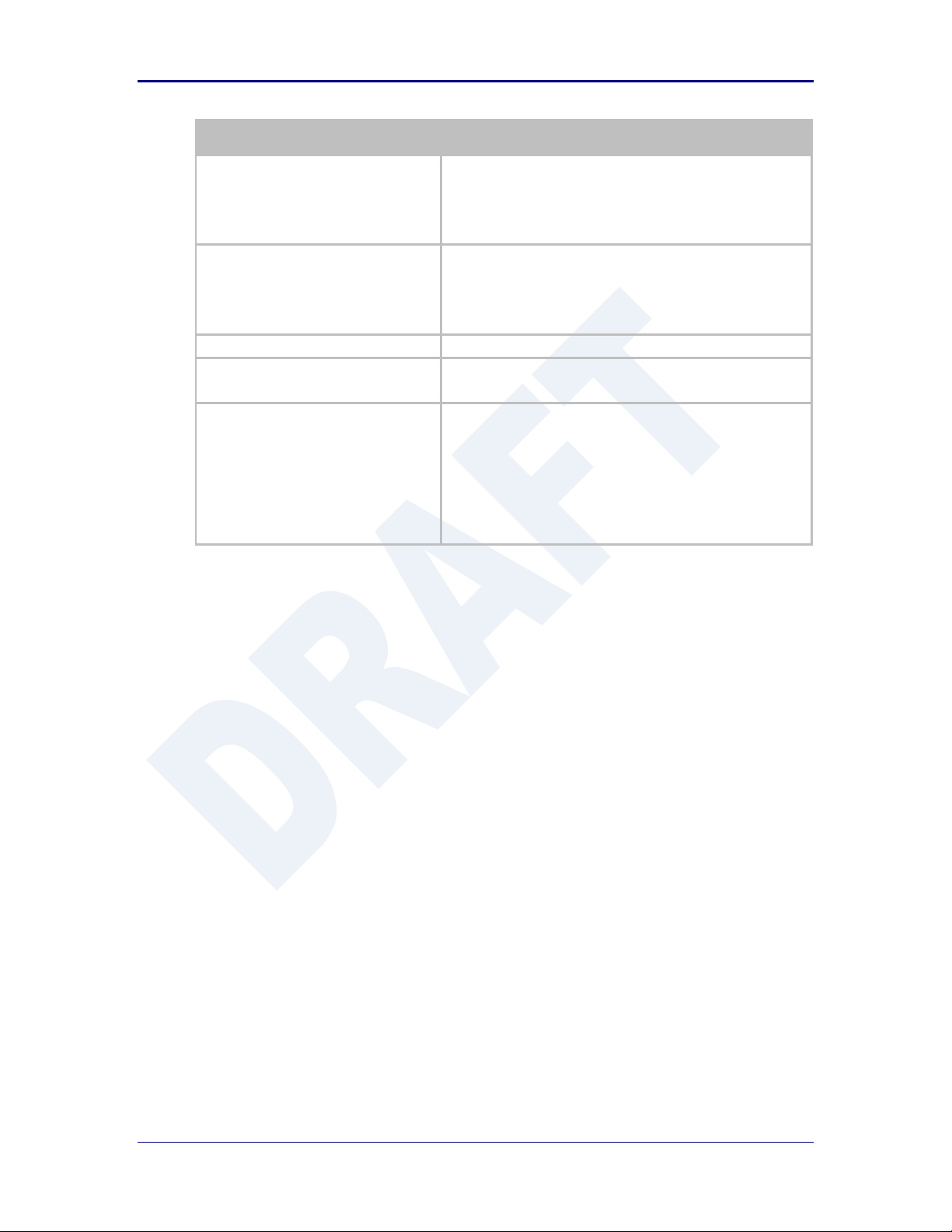

LED

Color

Airborne Device State

POWER

Adapter is not powered.

Adapter failed Power On Self Test (POST) and is not

configured for wireless communication.

Adapter passed POST but is not configured for wireless

network communication.

Adapter passed post and is configured for wireless

communication.

LINK

Adapter is not powered.

(Periodic Blinking) Adapter is searching for a valid network

(Access Point) that matches device’s configuration.

Adapter has successfully associated with an Access Point.

COMM

If Power LED is also Off then Adapter is not powered.

If Power LED is On then either:

A physical connection detected on Serial/Ethernet

cable.

No TCP session from wireless interface has been

established.

No physical Serial/Ethernet connection has been detected.

(Blinking – OFF/Red) A physical Serial/Ethernet connection

has been detected and there is traffic across the interface. No

TCP connection to the adapter has been established on the

wireless interface.

A TCP connection to the adapter from the wireless interface

has been established but no physical connection on the

Serial/Ethernet interface has been detected.

(Blinking – Green/Orange) A physical Serial/Ethernet

connection has been detected and there is Serial/Ethernet

traffic across the interface. A TCP connection to the adapter

has been established (On WLAN or Ethernet interface).

A physical Serial/Ethernet connection has been detected. A

TCP connection to the adapter has been established from the

WLAN or Ethernet interface but no traffic has been detected.

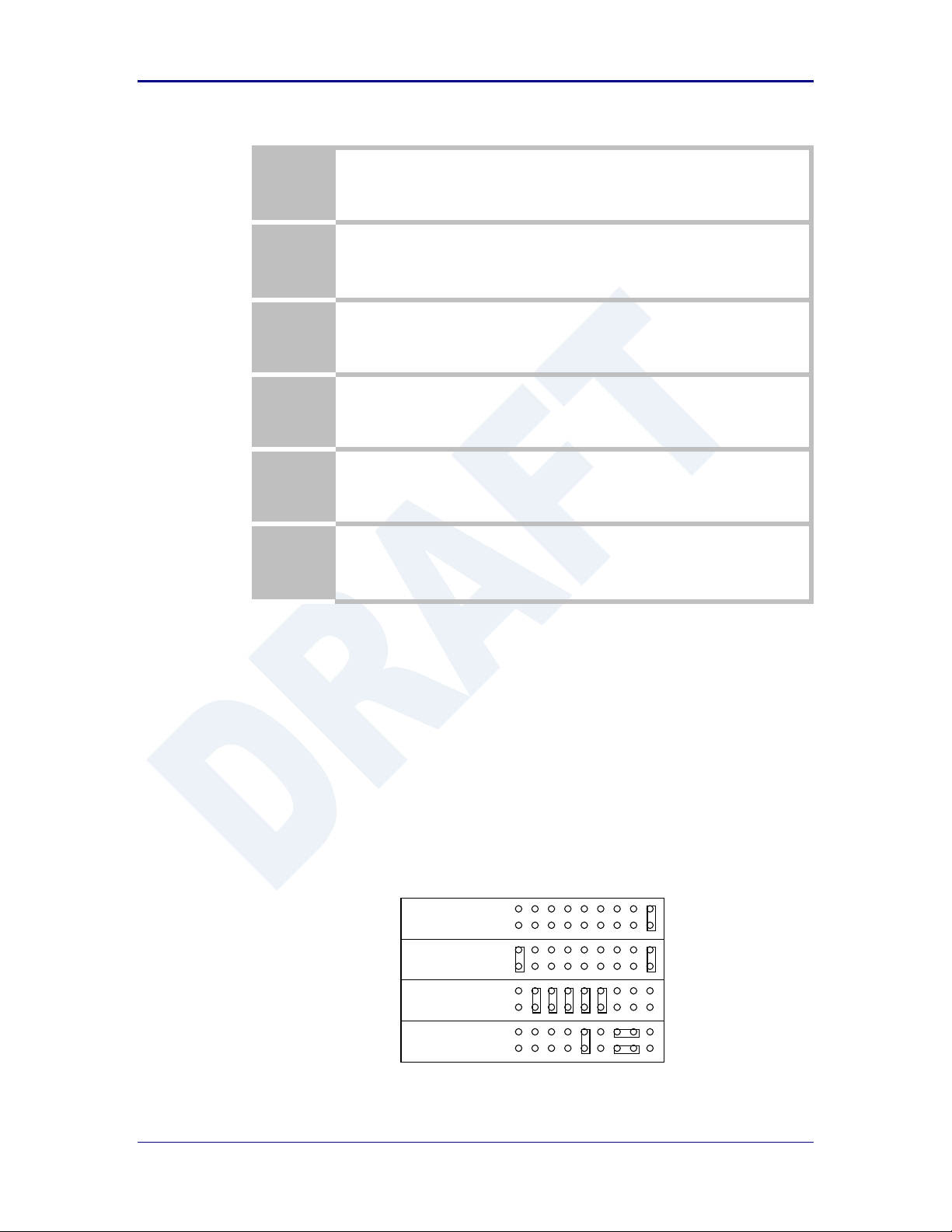

6.6 Indicator LED’s

The devices provide indicator LED’s to provide feedback on the state of the

device. These are a useful tool during installation and troubleshooting.

Table 6 - Enterprise LED Indicators

22 2/21/2011 100-8510-110

Page 23

AirborneDirect™ Users Guide Quatech, Inc.

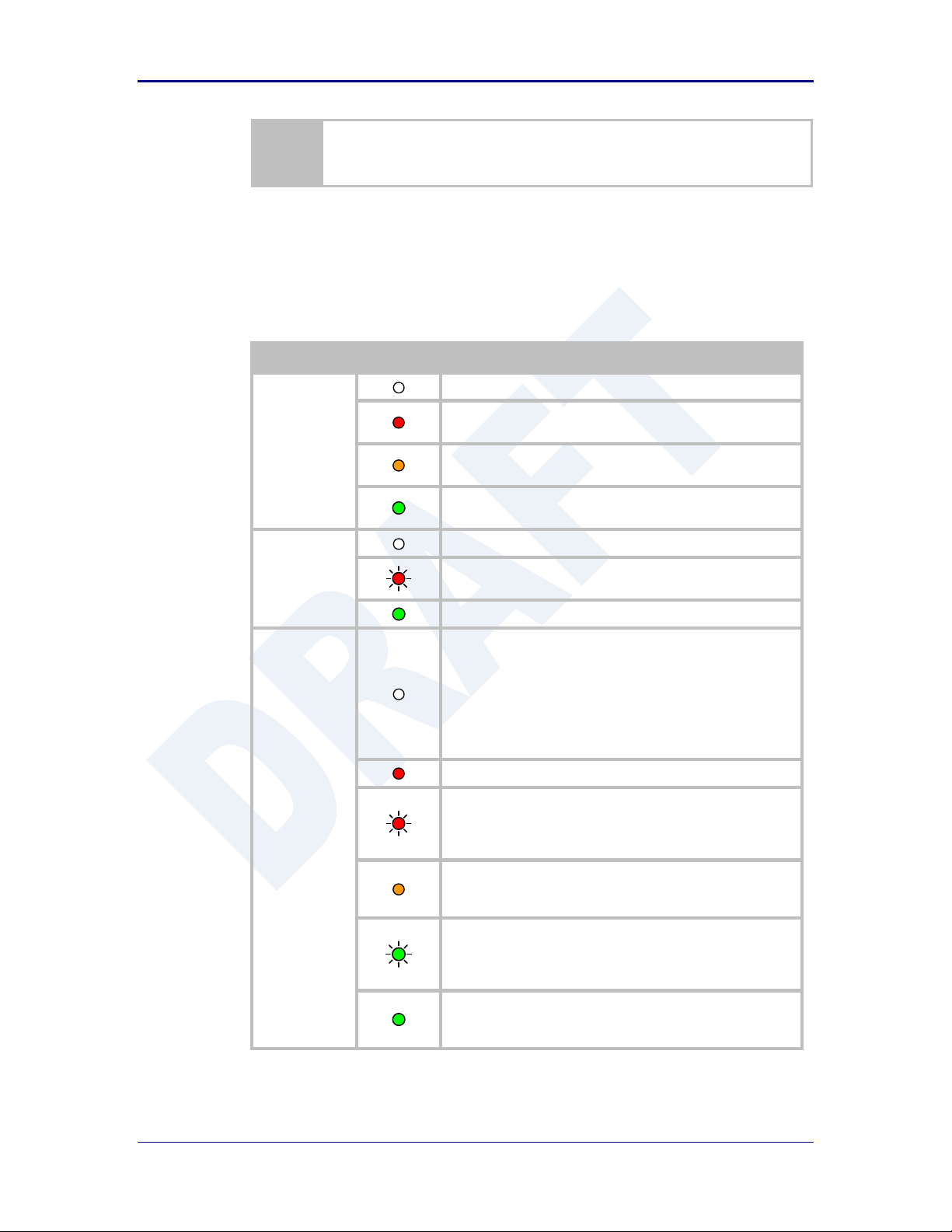

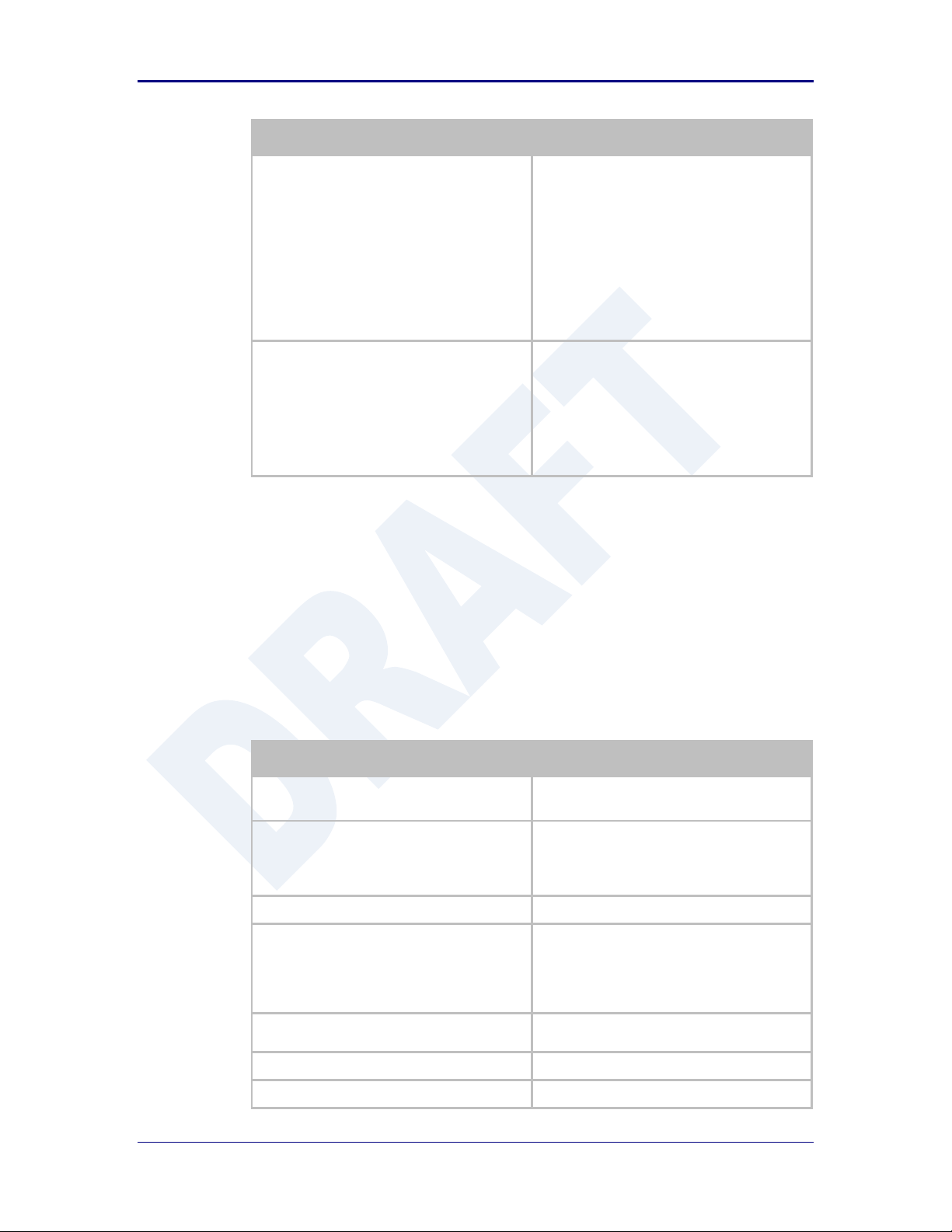

LED

Color

Airborne Device State

POWER

Adapter is not powered.

Adapter is powered.

POST

Adapter is not powered.

Adapter failed Power On Self Test (POST) and is not

configured for wireless communication.

Adapter passed POST but is not configured for wireless

network communication.

Adapter passed post and is configured for wireless

communication.

LINK

Adapter is not powered.

(Periodic Blinking) Adapter is searching for a valid network

(Access Point) that matches device’s configuration.

Adapter has successfully associated with an Access Point.

COMM

If Power LED is also Off then Adapter is not powered.

If Power LED is On then:

No TCP session from WLAN or Ethernet interface has

been established.

A TCP connection to the adapter has been established from

the Wireless or Ethernet interfaces but no traffic has been

detected.

Table 7 - Industrial LED Indicators

100-8510-110 2/21/2011 23

Page 24

Quatech, Inc. AirborneDirect™ User Manual

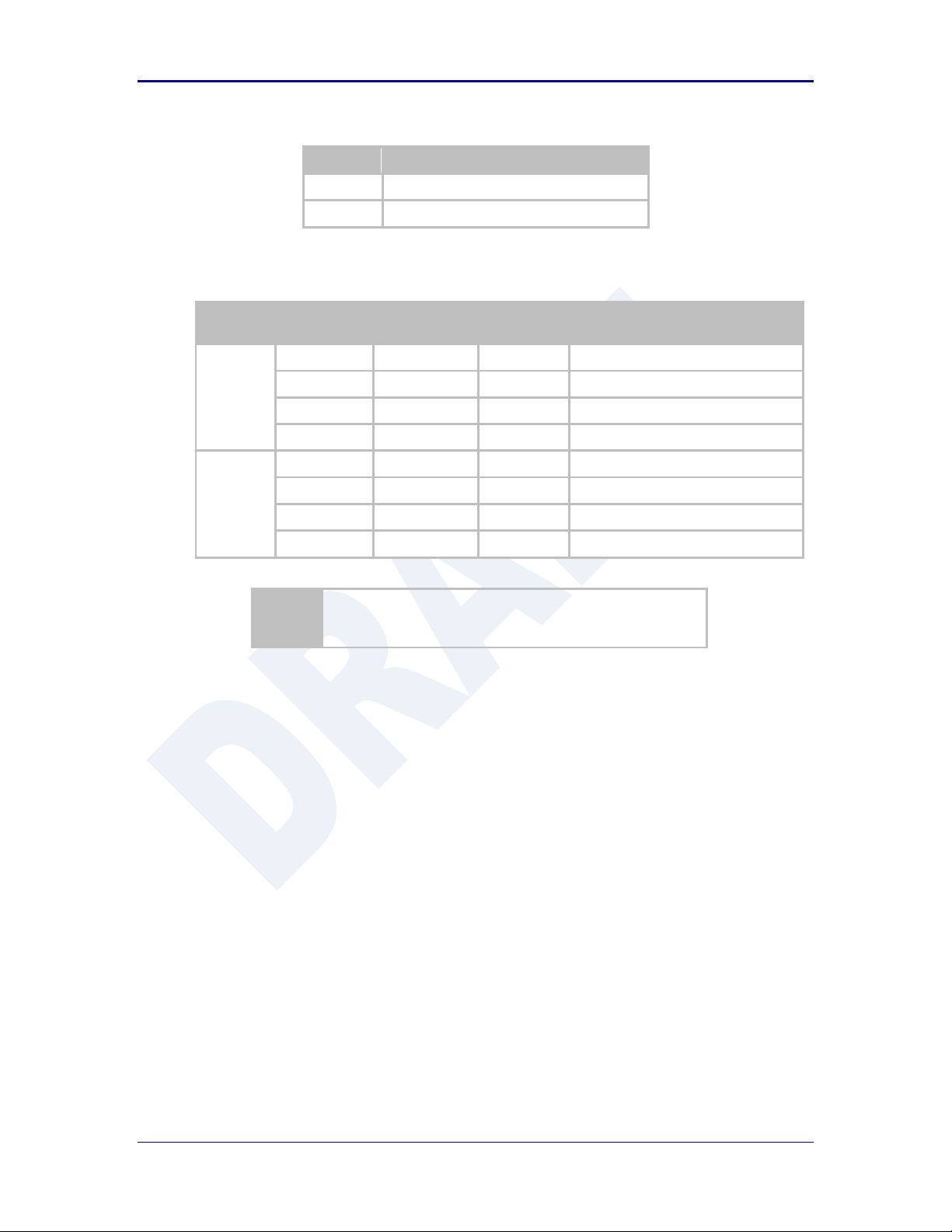

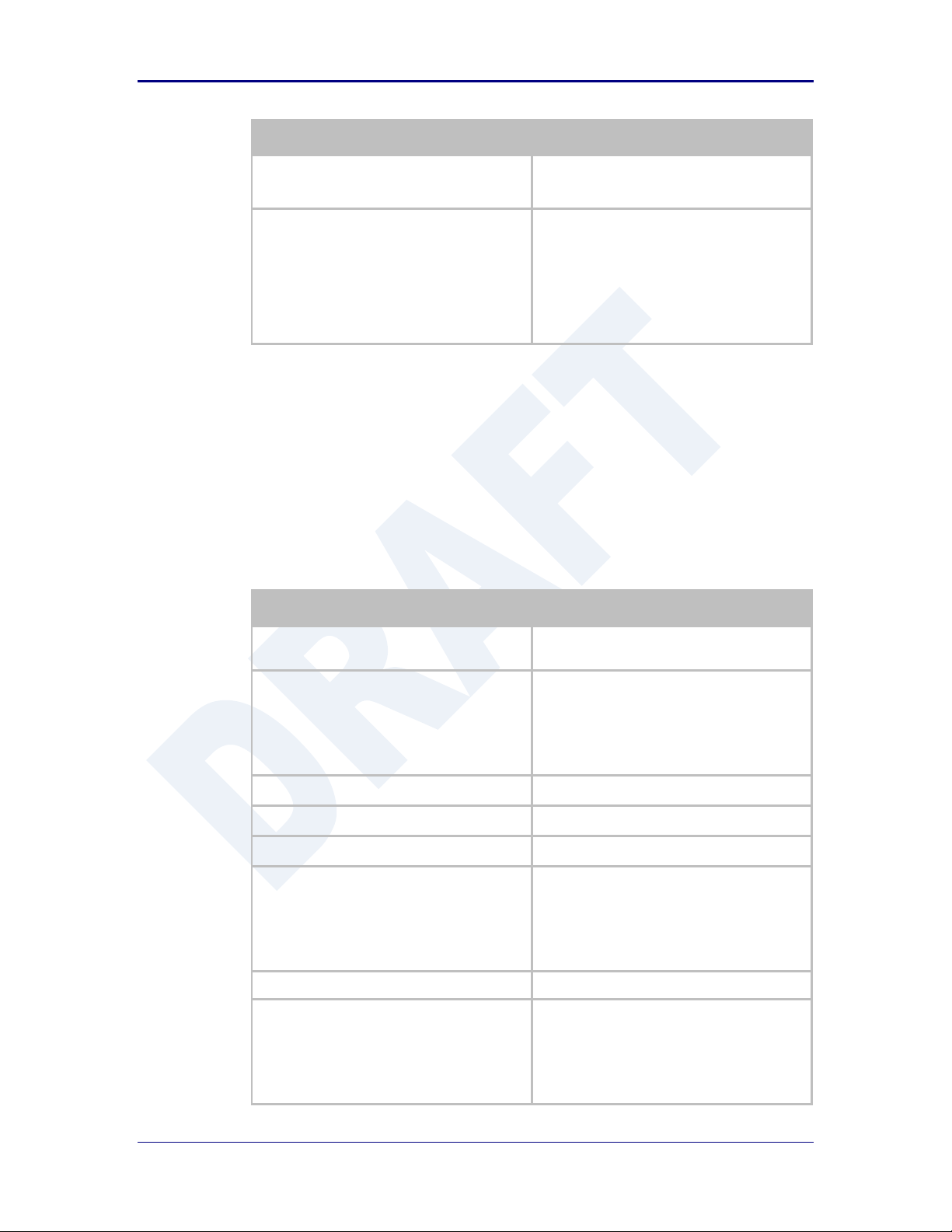

Parameter

Min

Max

Unit

Maximum Supply Voltage - Enterprise

4.5

5.5

VDC

Maximum Supply Voltage - Industrial

5.0

36

VDC

Power Dissipation

3.00

W

Operating Temperature Range

-40

85 oC

Storage Temperature

-50

125 oC

Symbol

Parameter

Rate (Mb/s)

Min

Average

dBm / mW

Peak

dBm / mW

Units

P

OUTB

Transmit Power

Output 802.11b

11, 5.5, 2, 1

13.0

15.0

31.6

dBm

P

OUTG

Transmit Power

Output 802.11g

6, 9, 12, 18, 24,

36, 48, 54

13.0

15.0

31.6

dBm

P

RSENB

Receive

Sensitivity

802.11b

11 -89

dBm

1 -93

P

RSENG

Receive

Sensitivity

802.11g

54 -72

dBm

36 -79 18 -85 6 -90

F

RANGEBG

Frequency

Range

2412 2484

MHz

The transmit power is automatically controlled by the device for minimum power

consumption.

The transmit power at the antenna connector is 15dBm±2dBm.

7.0 Electrical & RF Specification

Table 8- Absolute Maximum Values1

Note: 1. Values are absolute ratings, exceeding these values may cause permanent damage to the device.

Table 9 - RF Characteristics – 802.11b/g

24 2/21/2011 100-8510-110

Page 25

AirborneDirect™ Users Guide Quatech, Inc.

Band

Supported Data Rates (Mb/s)

802.11b

11, 5.5, 2, 1

802.11g

54, 48, 36, 24, 18, 12, 9, 6

Band

Region

Freq Range

(GHz)

No. of

Channels

Channels

802.11b

US/Canada

2.401 - 2.473

11

1 – 11

Europe

2.401 - 2.483

13

1 – 13

France

2.401 - 2.483

13

1 – 13

Japan

2.401 - 2.495

14

1 – 14

802.11g

US/Canada

2.401 - 2.473

11

1 – 11

Europe

2.401 - 2.483

13

1 – 13

France

2.446 - 2.483

13

1 – 13

Japan

2.401 - 2.483

13

1 – 13

1. Only channels 1, 6 and 11 are non-overlapping.

Table 10 - Supported Data Rates by Band

Table 11 - Operating Channels

100-8510-110 2/21/2011 25

Page 26

Quatech, Inc. AirborneDirect™ User Manual

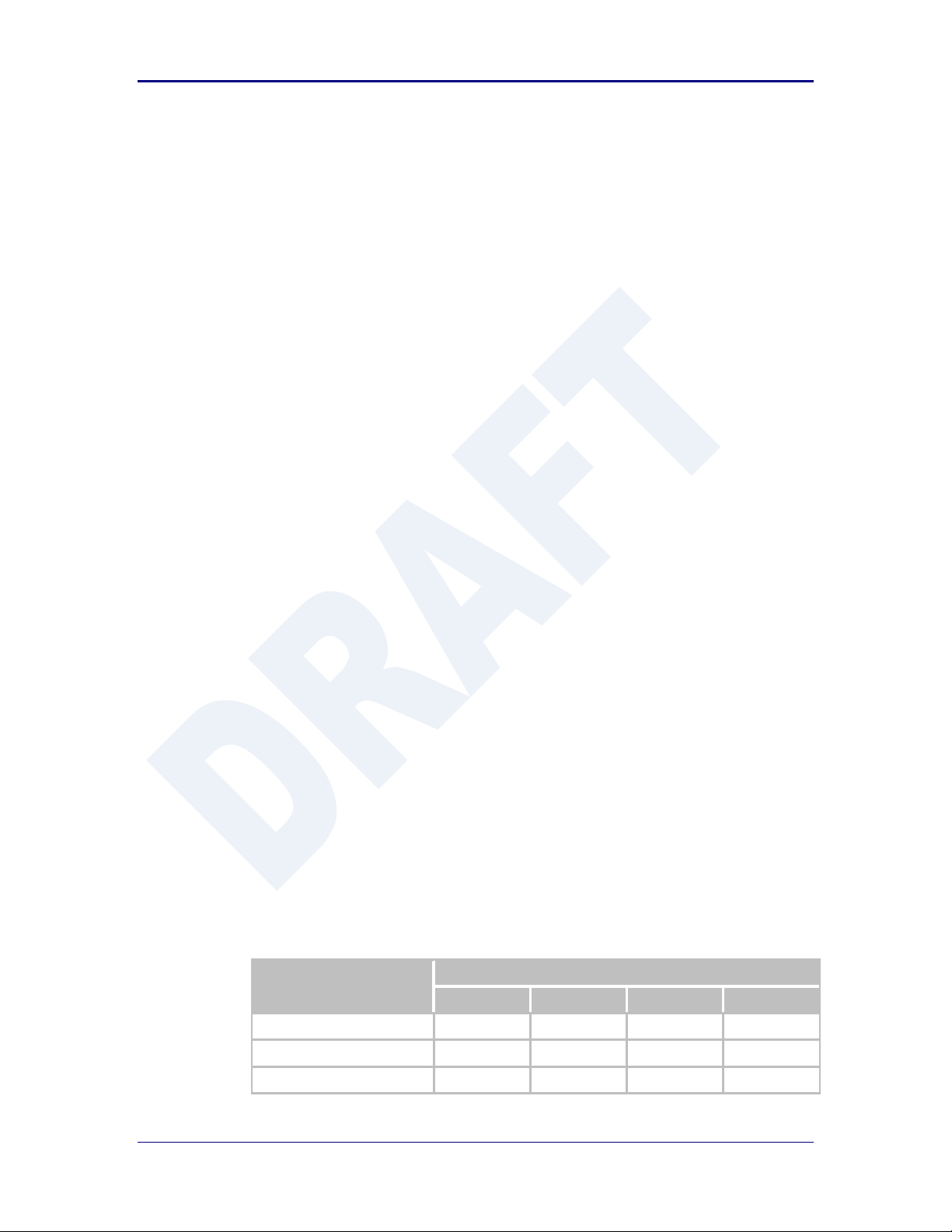

Data Rate

Typical Outdoor Distance

(Unity gain antenna)

Typical Outdoor Distance

(2dBi antenna gain on each end for

B/G mode)

1.0 Mb/s

240m

380m

11.0 Mb/s

135m

215m

6Mb/s 802.11g

135m

215m

6Mb/s 802.11a

49m

155m

54Mb/s 802.11g

12m

19m

54Mb/s 802.11a

4.5m

14m

7.1 AC Electrical Characteristics – Transmitter

Transmit power is automatically managed by the device for minimum power

consumption. The transmit power at the RF connector is +15dBm 2 dBm for

802.11b/g Modes (all rates).

7.2 Performance/Range

The following table illustrates the typical data rates, performance and range the

device is capable of providing using an omni-directional antenna.

Table 12 - Radio Typical Performance Range

Ranges are affected by receiver sensitivity; transmit power, free-space path loss,

antenna gain, and link margin. Actual range will vary from those stated. Non-lineof-site applications will result in typical values less than shown above.

The Data Rate is the supported connection rate for the wireless link, the actual

data throughput for the link will be less than the stated data rates.

26 2/21/2011 100-8510-110

Page 27

AirborneDirect™ Users Guide Quatech, Inc.

8.0 Antenna

The unit supports antenna connection through a single Hirose U.FL connector, located on

the top surface of the radio next to the RF shielding.

Any antenna used with the system must be designed for operation within the 2.4GHz

ISM band and specifically must support the 2.412GHz to 2.482GHz for 802.11b/g

operation. They are required to have a VSWR of 2:1 maximum referenced to a 50

system impedance.

8.1 Antenna Selection

The Airborne radio supports a number of antenna options, all of which require

connection to the U.FL connectors on the radio. Ultimately the antenna option

selected will be determined by a number of factors, including consideration of the

application, mechanical construction and desired performance. Since the number

of possible combinations is endless we will review some of the more common

solutions in this section. If your application is not covered during this discussion

please contact Technical Support for more specific answers.

The available antenna connections include:

Host board mounted antenna

Host Chassis mounted antenna

Embedded antenna

In addition to the above options, location and performance need to be

considered. The following sections discuss these items.

8.2 Host Board Mounted Antenna

Host board mounted requires that an antenna connection is physically mounted

to the host system board. It also requires that the host board include a U.FL

connector (two (2) if diversity is being used) to allow a U.FL to U.FL coaxial lead

to connect from the radio to the host board. It will then require 50 matched PCB

traces to be routed from the U.FL connector to the antenna mount.

There are several sources for the U.FL to U.FL coaxial cable these include

Hirose, Sunridge and IPEX. Please contact Quatech for further part numbers and

supply assistance.

This approach can simplify assembly but does require that the host system

configuration can accommodate an antenna location that is determined by the

host PCB. There are also limitations on the ability to seal the enclosure when

using this approach.

This approach also restricts the selection of available antenna. When using this

approach, antennas that screw or press fit to the PCB mount connector must be

used. There are many options for the antenna connector type, however if you

100-8510-110 2/21/2011 27

Page 28

Quatech, Inc. AirborneDirect™ User Manual

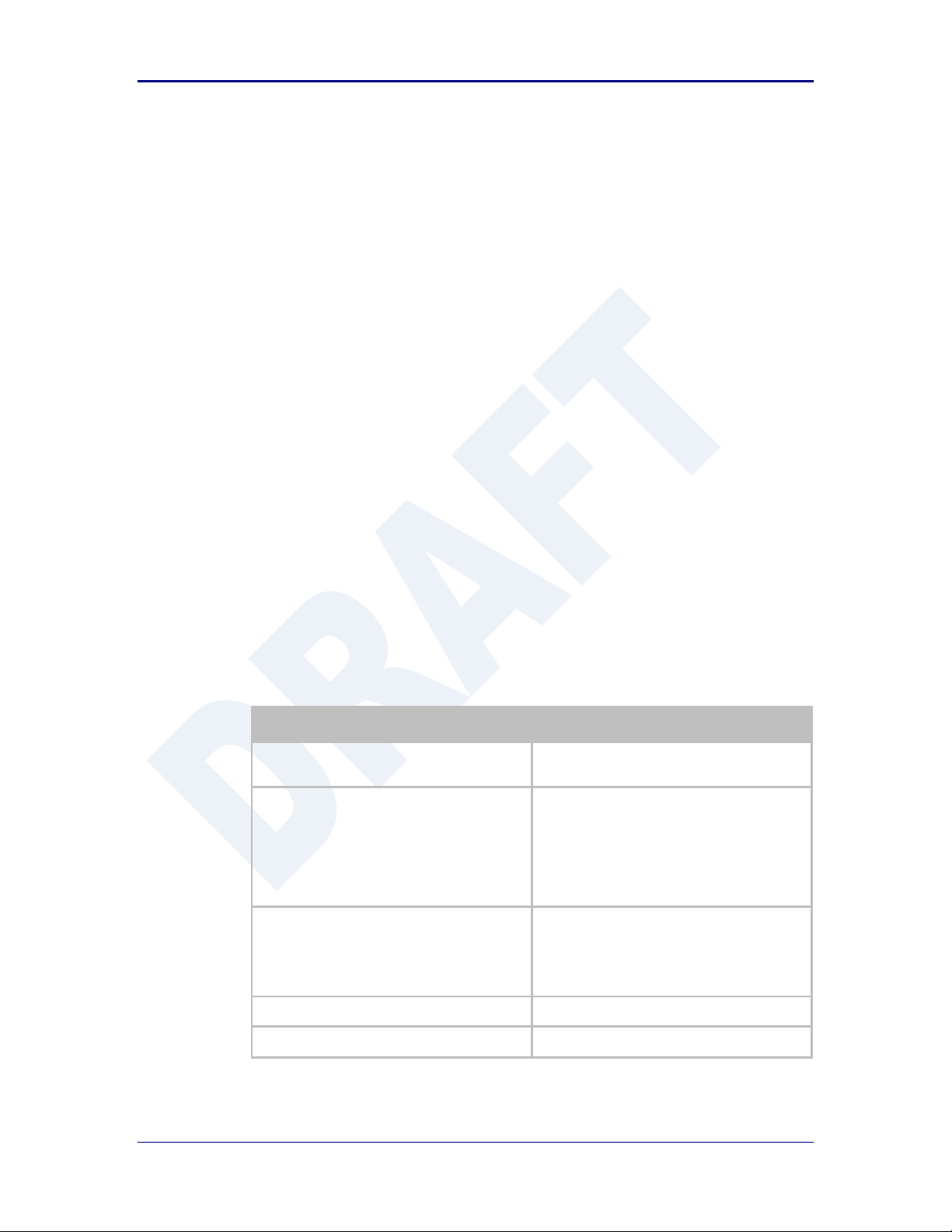

Antenna Type

Features

Cost

Size

Availability

Performance

PCB Embedded

Lowest

Largest

Custom

Poor

Chip

Low

Small

Standard

Poor

Flying Lead

Low

Small

Standard

Fair

wish to utilize the FCC/IC modular approval the connector choice must comply

with FCC regulations. These state that a non-standard connector, e.g. RPTNC/RP-SMA, is required. TNC/SMA connectors are not allowed.

8.3 Host Chassis Mounted Antenna

Host Chassis mounted antennas require no work on the host PCB. They utilize

an antenna type called ‘flying lead’. There are two types of flying leads; one

which provides a bulkhead mounted antenna connector and one which provides

a bulk head mounted antenna. The type you choose will be determined by the

application.

A flying lead system connects a U.FL coaxial lead to the radio’s U.FL connector.

The other end of the coax is attached to either a bulkhead mounted antenna

connector or directly to an antenna that has an integrated bulkhead mount.

In either of the two cases, the use of this approach significantly reduces the

antenna system development effort and provides for greater flexibility in the

available antenna types and placement in the host system chassis.

When using the flying lead antenna (integrated bulk head mounting), there are no

connector choice restrictions for use with the FCC/IC modular certification.

However if the flying lead connector is used, the same restrictions as identified

for the Host Mounted Antenna apply.

There are many suppliers of flying lead antenna and connectors. Quatech’s

Airborne Antenna product line offers a range of antenna solutions.

8.4 Embedded Antenna

Use of Embedded antenna can be the most interesting approach for M2M,

industrial and medical applications. Their small form factor and absence of any

external mounting provides a very compelling argument for their use. There is a

downside to this antenna type and it comes with performance. Antenna

performance for all of the embedded options will, in most cases, be less that that

achievable with external antenna. This does not make them unusable; it will

impact choice of antenna type and requires more focus on placement.

The three main embedded antenna types are PCB embedded, chip (PCB

mounted) and flying lead; each has its advantages and disadvantages (See

Table 13).

Table 13 - Embedded Antenna Options

28 2/21/2011 100-8510-110

Page 29

AirborneDirect™ Users Guide Quatech, Inc.

PCB Embedded – This approach embeds an antenna design into the host PCB.

This approach is very common with add-in WiFi cards (CF, PCMCIA, SDIO, etc.)

as it requires no external connections and is the cheapest production approach.

The lower production cost requires significant development cost and lack of

performance and flexibility.

Chip – The integration of a chip antenna is simple and requires a relatively small

footprint on the host system, however, it does suffer from the same limitations of

flexibility and performance seen with the PCB embedded approach. There are

relatively large numbers of suppliers of this type of antenna; there is also a range

of configuration and performance options.

Flying Lead – This approach is similar to the flying lead solution for external

antennas. The difference is that the form factors are smaller and provide a range

of chassis and board mounting options, all for internal use. This approach suffers

less from the performance and flexibility limitations of the other approaches,

since the location of the antenna it not determined by the host PCB design. The

assembly of a system using this approach maybe slightly more complex since

the antenna is not necessarily mounted on the host PCBA.

8.5 Antenna Location

The importance of this design choice cannot be over stressed. It can in fact be

the determining factor between success and failure of the WiFi implementation.

There are several factors that need to be considered when determining location:

Distance of Antenna from radio

Location of host system

Proximity to RF blocking or absorbing materials

Proximity to potential noise or interference

Position relative to infrastructure (Access Points or Laptops)

Orientation of host system relative to infrastructure

Is it known

Is it static

To minimize the impact of the factors above the following things need to be

considered during the development process:

Minimize the distance between the radio and the location of the antenna. The

coaxial cable between the two impacts the Transmit Power and Receive

Sensitivity negatively. Quatech recommends using 1.32-1.37mm outer

diameter U.FL coaxial cables.

Minimize the locations where metal surfaces come into contact or are close

to the location of the antenna.

Avoid locations where RF noise, close to or over lapping the ISM bands, may

occur. This would include microwave ovens and wireless telephone systems

in the 2.4GHz and 5.0GHz frequency range.

Mount the antenna as high on the equipment as possible.

100-8510-110 2/21/2011 29

Page 30

Quatech, Inc. AirborneDirect™ User Manual

Locate the antenna where there is a minimum of obstruction between the

antenna and the location of the Access Points. Typically Access Points are

located in the ceiling or high on walls.

Keep the main antenna’s polarization vertical, or in-line with the antenna of

the Access Points. 802.11 systems utilize vertical polarization and aligning

both transmit and receive antenna maximizes the link quality.

Even addressing all of the above factors does not guarantee a perfect

connection, however with experimentation an understanding of the best

combination will allow a preferred combination to be identified.

8.6 Performance

Performance is difficult to define as the appropriate metric changes with each

application or may indeed be a combination of parameters and application

requirements. The underlying characteristic that, in most cases, needs to be

observed is the link quality. This can be defined as the bandwidth available over

which communication between the two devices can be performed. The lower the

link quality the less likely the devices can communicate.

Measurement of link quality can be made in several ways: Bit Error Rate (BER),

Signal to Noise (SNR) ratio, Signal Strength, and may also include the addition of

distortion. The link quality is used by the radio to determine the link rate.

Generally as the link quality for a given link rate drops below a predefined limit,

the radio will drop to the next lowest link rate and try to communicate using it.

The reciprocal is also true. If the radio observes good link quality at one rate it

will try to move up to the next rate to see if communication can be sustained

using it. It is important to note that for a given position the link quality improves as

the link rate is reduced. This is because as the link rate drops the radios Transmit

power and Receive sensitivity improve.

From this it can be seen that looking at the link rate is an indirect way of

assessing the quality of the link between the device and an Access Point. You

should strive to make the communication quality as good as possible in order to

support the best link rate. However be careful not to over specify the link rate.

Consider your application’s bandwidth requirements and tailor your link rate to

optimize the link quality. For example, the link quality for a location at 6Mb/s is

better than it would be for 54Mb/s. If the application only needs 2Mb/s of data

throughput, the 6Mb/s rate would provide a better link quality.

Aside from the radio performance, there are a number of other things that

contribute to the link quality. These include the items discussed earlier and

choices made when looking at the overall antenna gain. The antenna gain

contributes to the Equivalent Isotropically Radiated Power (EIRP) of the system.

This is part of an overall measurement of the link quality called link margin.

30 2/21/2011 100-8510-110

Page 31

AirborneDirect™ Users Guide Quatech, Inc.

Link Margin provides a measure of all the parts of the RF path that impact the

ability of two systems to communicate. The basic equation looks like this:

EIRP (dB) = TxP + TxA – TxC

Link Margin (dB) = EIRP – FPL + (RxS + RxA – RxC)

Where: TxP = Transmitter output power (dBm)

TxA = Transmitter antenna gain (dBi)

TxC = Transmitter to Antenna coax cable loss (dB)

FPL = Free Path Loss (dB)

RxS = Receiver receive sensitivity (dBm)

RxA = Receiver antenna gain (dBi)

RxC = Receiver to Antenna coax cable loss (dB)

This is a complex subject and requires more information than is presented here,

Quatech recommends at reviewing the subject and evaluating any system at a

basic level.

It is then possible, with a combination of the above items and an understanding

of the application demands, to achieve a link quality optimized for the application

and host design. It is important to note that this is established with a combination

of hardware selection, design choices and configuration of the radio.

100-8510-110 2/21/2011 31

Page 32

Quatech, Inc. AirborneDirect™ User Manual

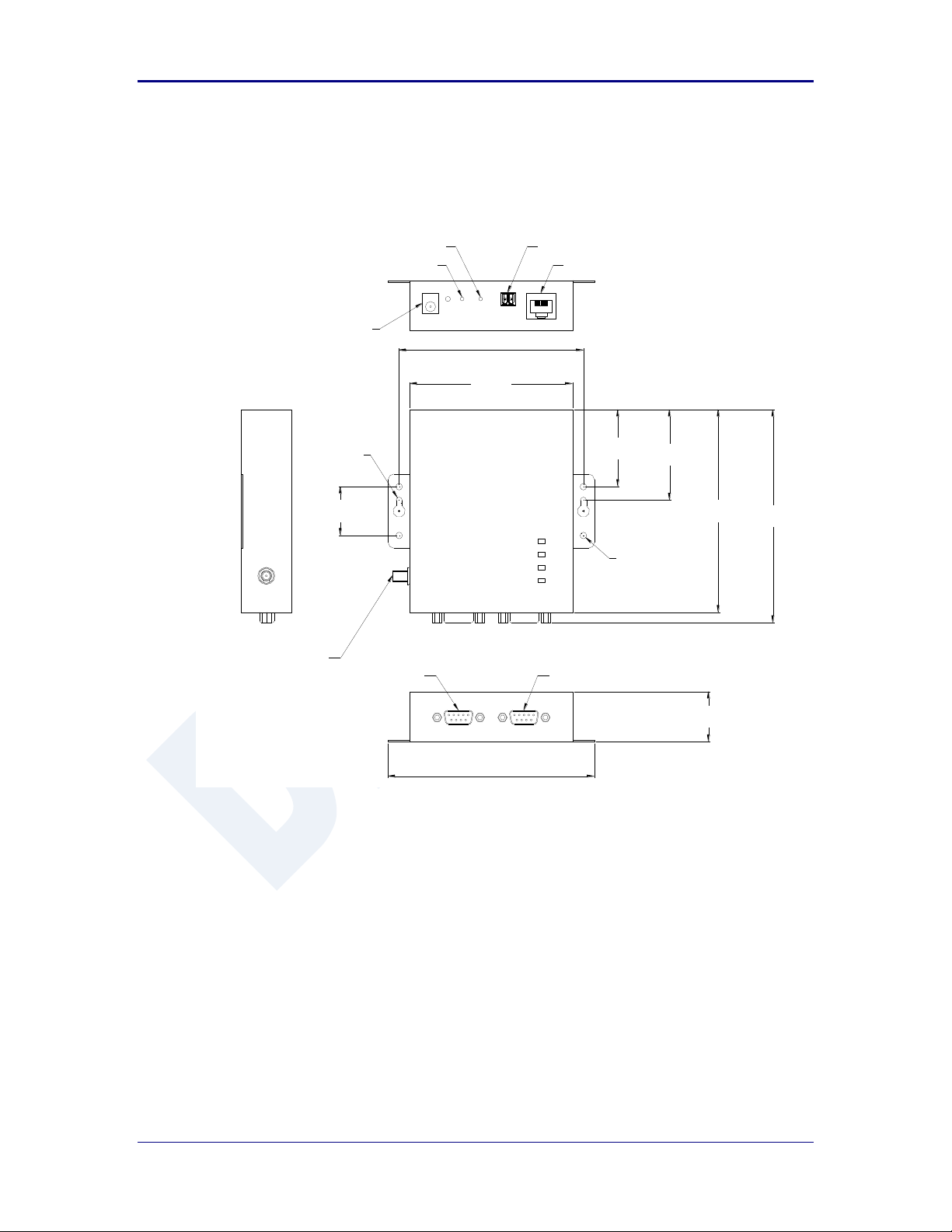

9.0 Mechanical Outline – Enterprise Class

Antenna Connector: RP-SMA (Reverse Polarity – SMA)

Requires 2.4GHz ISM band antenna, 50 input impedance, RP-SMA connector

Serial Connector: DB-9M (Male)

Requires DB-9 (Female)

Ethernet Connector: RJ-45 Plug

Requires RJ-45 socket, 10/100 Ethernet interface

Power Connector: 2.1mm Barrel Jack

Requires 2.1mm ID, 5.5mm OD, +5VDC center pin.

32 2/21/2011 100-8510-110

Page 33

AirborneDirect™ Users Guide Quatech, Inc.

Terminal Block (Power)

10/100 Ethernet Socket

System Reset

Factory Reset

2.1mm Barrel Jack

Serial Port 1

Serial Port 2

RP-SMA Antenna Connector

Ø3.56mm

[Ø0.14"]

Ø3.81mm

[Ø0.15"]

107.42mm

[4.23"]

28.44mm

[1.12"]

52.72mm

[2.08"]

44.85mm

[1.77"]

118.14mm

[4.65"]

120.12mm

[4.73"]

29.21mm

[1.15"]

124.14mm

[4.89"]

94.72mm

[3.73"]

CONNECT

LINK

POST

POWER

10.0 Mechanical Outline – Industrial Class

Antenna Connector: RP-SMA (Reverse Polarity – SMA)

Requires 2.4GHz ISM band antenna, 50 input impedance, RP-SMA connector

Serial Connector: DB-9M (Male)

Requires DB-9F (Female)

Ethernet Connector: RJ-45 Socket

Power Connector: 2.1mm Barrel Jack

Requires RJ-45 plug, 10/100 Ethernet interface

Requires 2.1mm ID, 5.5mm OD, +5VDC center pin.

Power Connector: Terminal Block (2 connector)

Requires 16-30 AWG gauge wire.

100-8510-110 2/21/2011 33

Page 34

Quatech, Inc. AirborneDirect™ User Manual

11.0 Getting Started

11.1 Unpack the AirborneDirect™ Device

Unpack the AirborneDirect™ Device and compare the package contents with the

items listed on the front of the included Quick Start Guide. If any item is missing

or damaged, contact Quatech immediately.

Contact details can be found at www.quatech.com/support.

11.2 Connect AirborneDirect™ to host

Connect the Airborne Direct unit to a system capable of configuring it. The

preferred initial connection depends upon the class and type of product:

Serial – Enterprise: Connect to a serial port on the host or through a serial to

USB adapter.

Serial – Industrial: Connect the RJ-45 socket to a RJ-45 socket using a

CAT 5 Ethernet cable.

Ethernet – Enterprise: Connect to an RJ-45 socket on the host.

Ethernet – Industrial: Connect the RJ-45 socket to a RJ-45 socket using a

CAT 5 Ethernet cable.

11.3 Attach Antenna and Power-up the AirborneDirect™

Attach the supplied antenna to the RP-SMA connector on the AirborneDirect™

unit. Connect the supplied AC adapter to the power connector. If using your own

power supply make sure the correct power connector type and polarity are being

used, verify the appropriate voltage to be applied by checking Error! Reference

source not found. for the correct product class. Confirm that the device is

receiving power by verifying that the POST LED is lit when the supply is applied.

34 2/21/2011 100-8510-110

Page 35

AirborneDirect™ Users Guide Quatech, Inc.

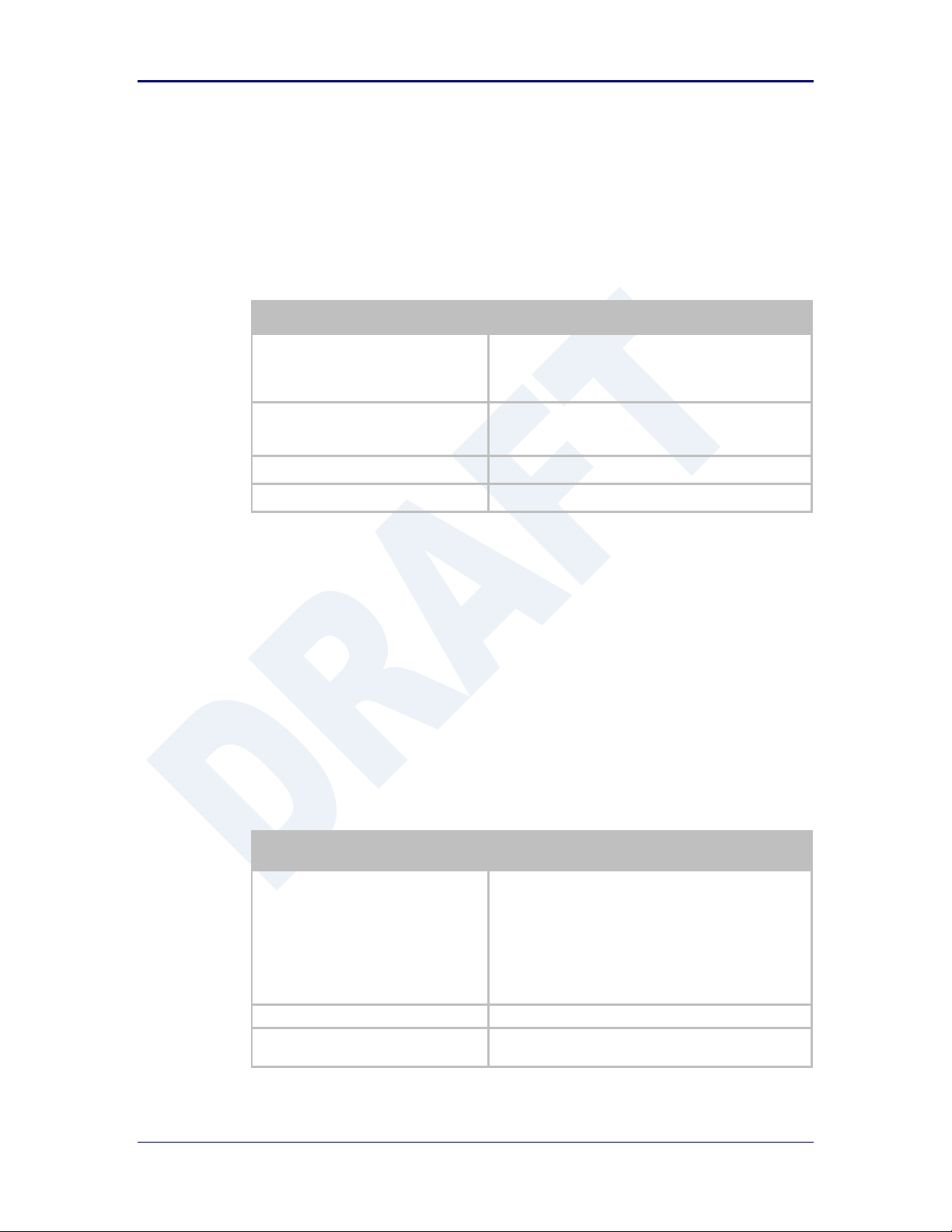

1

Open the AirborneDirect™ packaging and locate the Install CD.

2

Place the CD in the CD/DVD drive of the laptop or desktop you will be using to configure the

AirborneDirect™ device. Follow the on screen directions for installation of the appropriate device

software and documentation.

3

Connect the Ethernet cable on ABDG to an Ethernet port on the laptop or desktop system.

4

Apply power to the ABDG-SE-IN5XXX.

5

The unit will boot and display one of the following LED patterns:

ABDG-SE-IN5XXX

COMM: Off

LINK : Off

POST: Orange

POWER: Blue

6

Run the Airborne Management System application. This was installed during the CD installation and a

menu item will be found in the Airborne folder located in the programs directory of your system.

When the application opens the following dialog will be displayed:

Select Group Name: manuf and enter Group Password: dpac

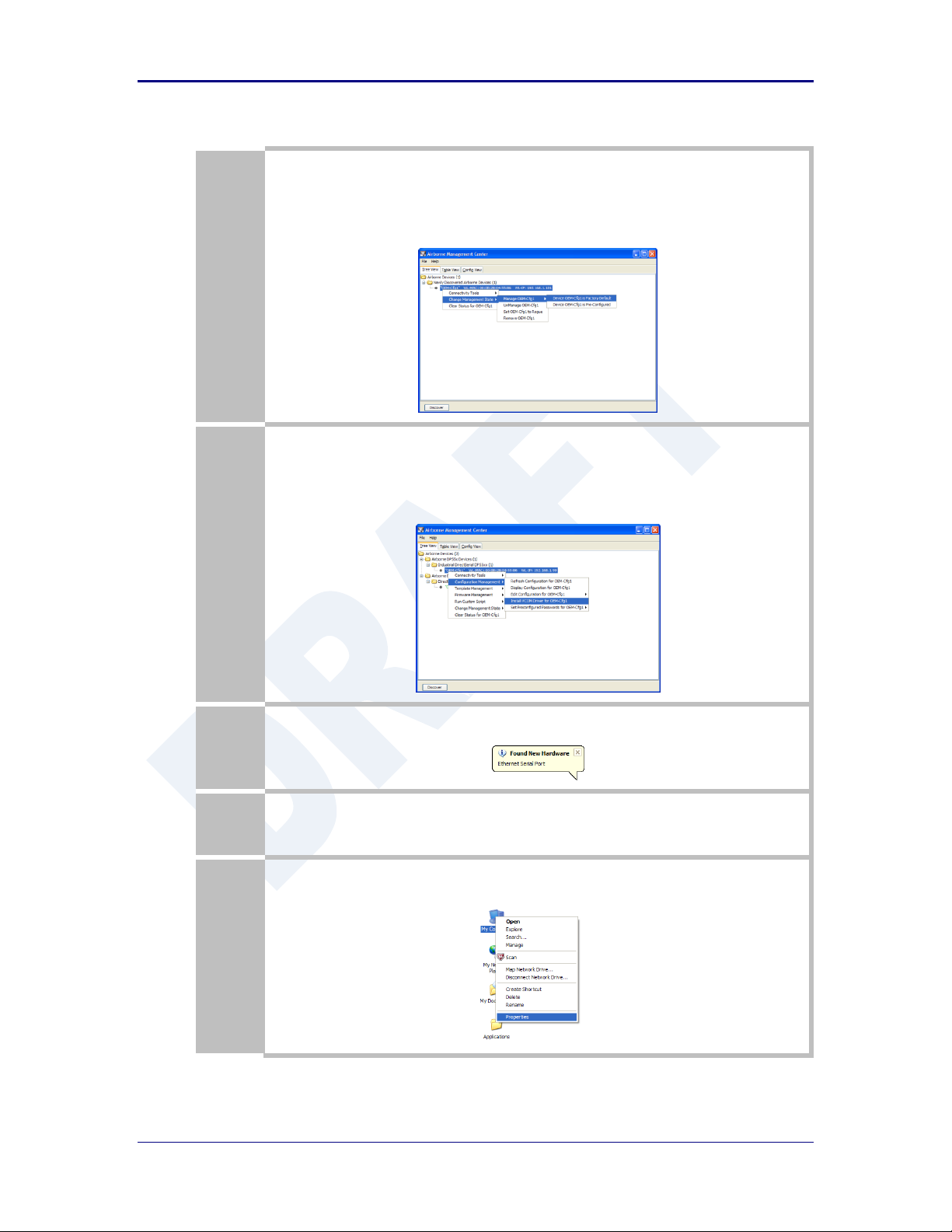

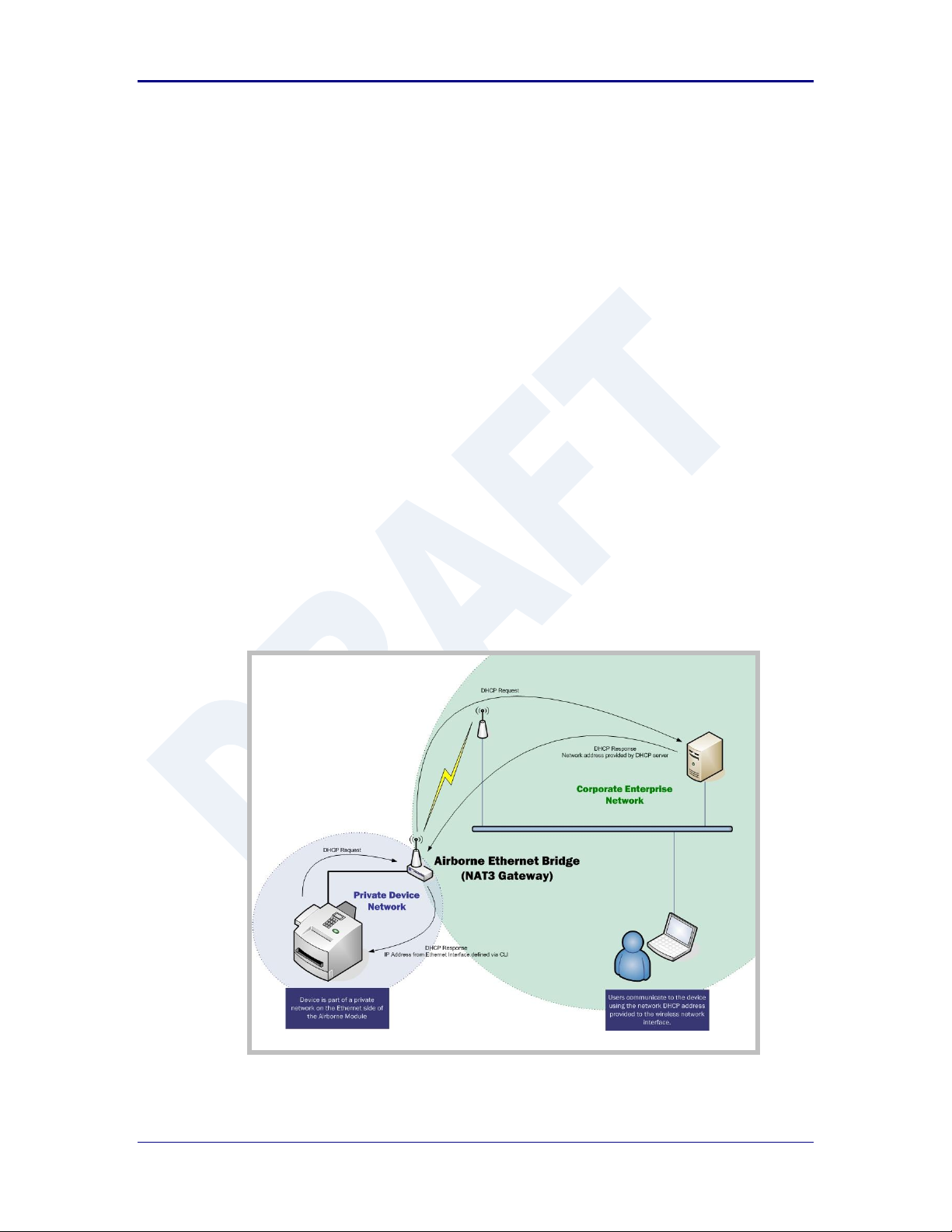

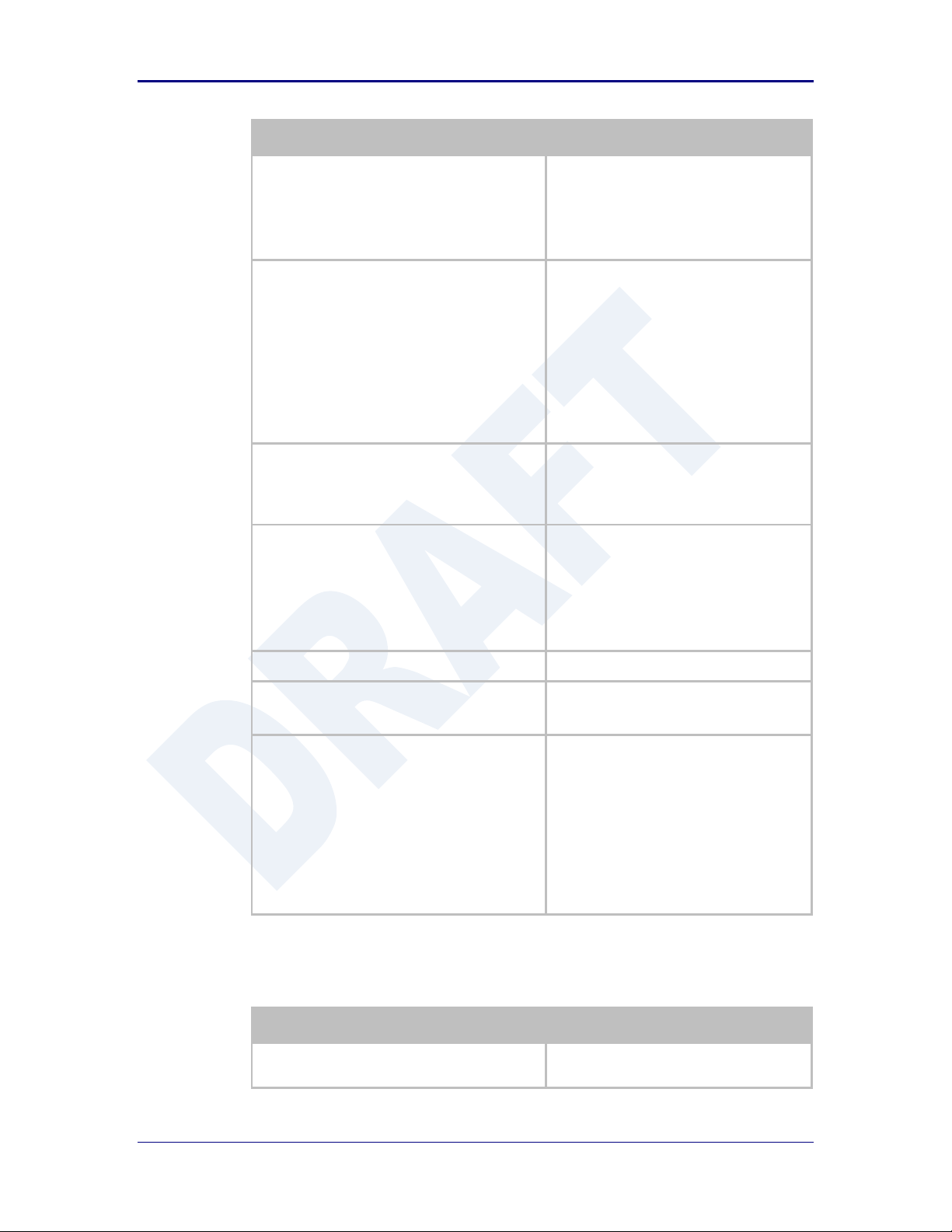

12.0 Configuring Device – Industrial Serial (ABDG-SE-IN5XXX)

The following describes initial connection to an AirborneDirect™ Serial Device Server

(ABDG-SE-IN5XXX). If you have an Ethernet device (ABGD-ET-DP5XX/IN5010), please

go to section 14.0. If you have purchased a SE-DP5XX device please go to section 13.0