Page 1

Q-EBH 750; EX; UK

Electric Tiller

Artikel-Nr.: 3431016

Ident-Nr.: 01019

Page 2

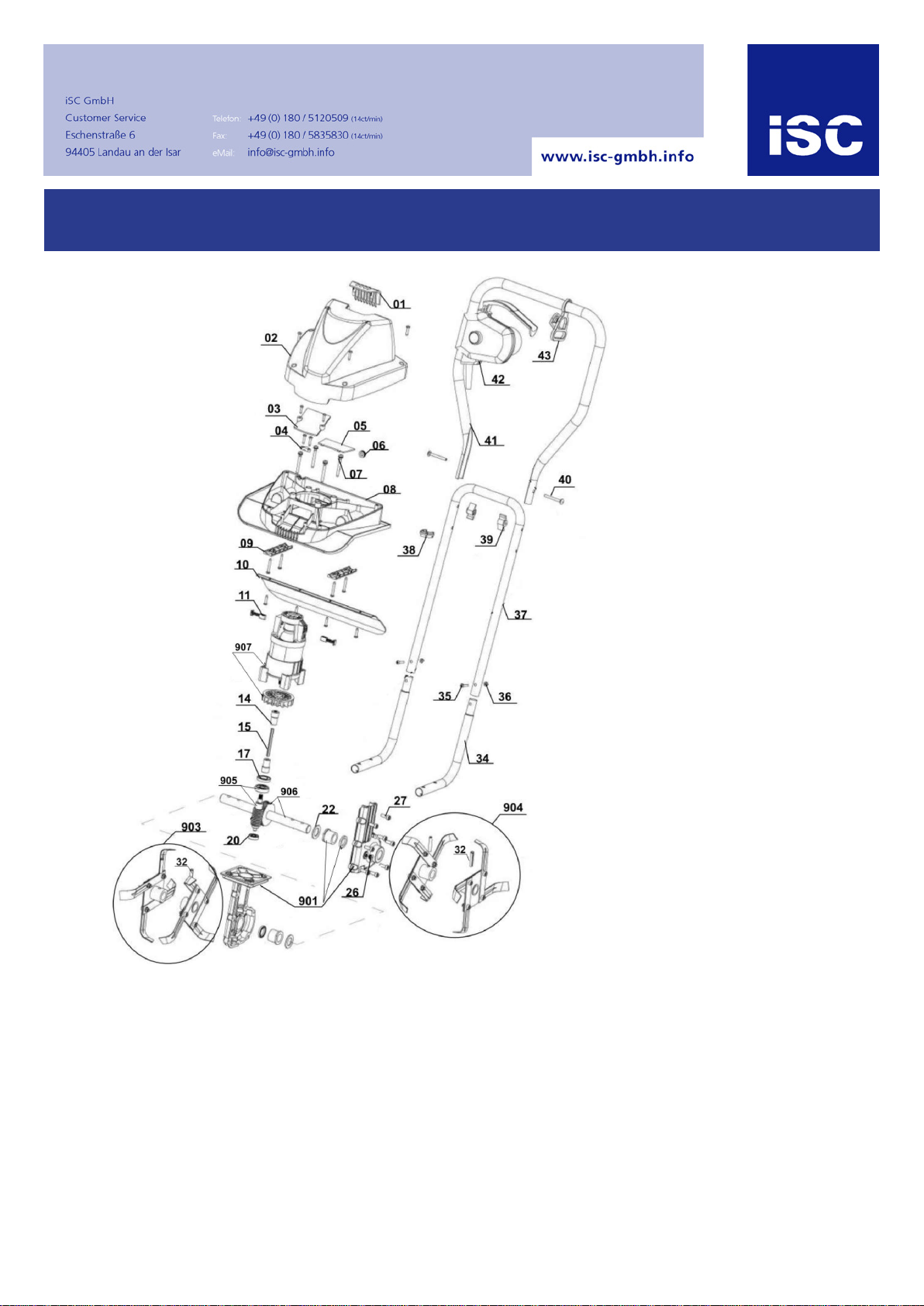

Komponenten / Ersatzteile

Position Artikel-Nr. Beschreibung

1 343101001001 Ventilator cover

2 343101001002 Upper housing

8 343101001008 Bottom housing

10 343101001010 Back shield

11 343101001011 Carbon brush (pair)

14 343101001014 connector

15 343101001015 Flexible shaft

32 343101001032 Spring pin

34 343101001034 nether handspike

35 343101001035 Screw M5*26

36 343101001036 Nut M5

37 343101001037 handspike down

38 343101001038 Cable clip

39 343101001039 knob

40 343101001040 Screw M6*45

41 343101001041 upper handspike

42 343101301042 10m mains cable with plug (UK)

43 343101001043 Cable hook

902 343101001045 handspike assy(34,37,41) (34,37,41)

903 343101001903 blade right

904 343101001904 blade left

905 343101001905 worm assy

906 343101001906 worm wheel + shaft

907 343101001907 motor with fan mit Lüfter 750W

Page 3

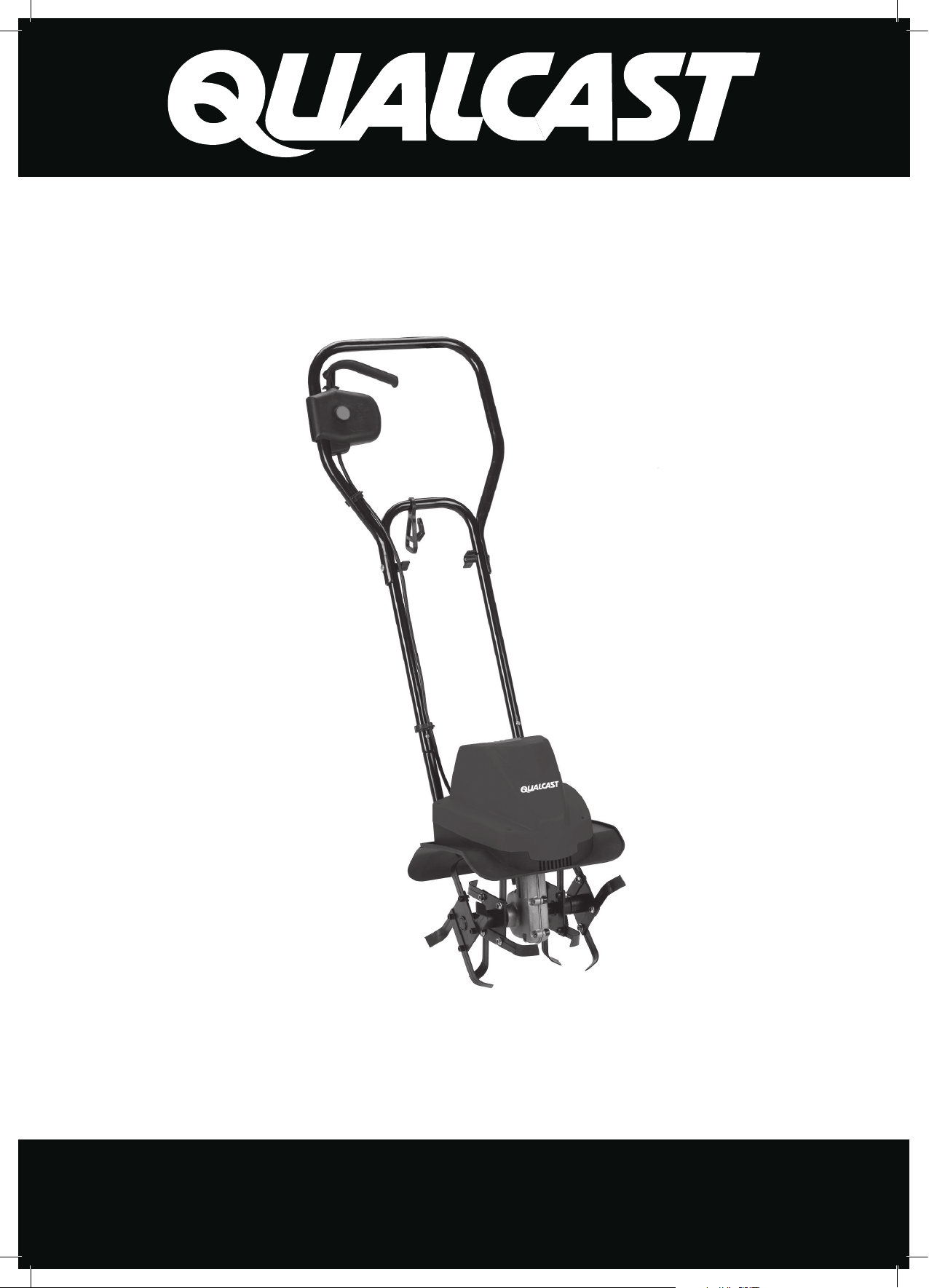

Q-EBH 750 ELECTRIC TILLER

OPERATING INSTRUCTIONS

Page 4

Page 5

Contents

1. Safety instructions 4

2. Layout and items supplied 9

3. Proper use 9

4. Proper operation 9

5. Installation 9

6. Starting up 9

7. Tips for proper working 9

8. Maintenance, care and storage 10

9. Replace the hoe blade 10

10. Ordering replacement parts 10

11. Technical data 10

12. Troubleshooting guide 10

Packaging

The unit is supplied in packaging to prevent its being

damaged in transit. This packaging is raw material and can

therefore be reused or can be returned to the raw material

system.

3

Page 6

Safety Notes 1. Safety Instructions

Warning! Read these instructions carefully, be

familiar with the controls and the proper use of the

tiller. Please keep the instruction safe for later use.

Explination of symbols on the tiller

Note the instructions for use!

Important. Rotating tool.

Caution! Danger from catapulted parts;

keep a safe distance.

Wear ear muffs!

Wear safety goggles!

Wear safety gloves

If the cable is damaged or cut, pull out the

power plug from the mains immediately.

Never use the equipment in damp locations.

Pull the power plug before carrying out

maintenance, cleaning and repair work.

Warning! When using electric tools, basic safety precautions

should always be followed to reduce the risk of fire, electric

shock and personal injury, in-cluding the following.

Read all these instructions before attempting to operate this

product and safe these instructions.

1. Keep work area clean

Cluttered areas and benches invite injuries.

2. Consider work area environment

Don’t expose power tools to rain. Don’t use power tools in

damp or wet locations. Keep work area well lit. Don’t use

power tools in presence of flammable liquids or gases.

3. Guard against electric shock

Prevent body contact with grounded surfaces (e.g. pipes,

radiators, ranges refrigeratiors).

4. Keep children away

Do not let visitors contact tool or extension cord. All visitors

should be kept away from work area.

5. Store idle tools

When not is use, tools should be stored in dry, high, or

locked-up place, out of the reach of children.

6. Don’t force tool

It will do the job better and safer at the rate for which it

was intended.

7. Use right tool

Don’t force small tools or attachments to do the job of

heavy duty tool. Don’t use tools for purposes not intended:

for example, don’t use circular saw for cutting tree limbs

or logs.

8. Dress properly

Do not wear loose clothing or jewelry. They can be caught

in moving parts. Rubber gloves and nonskid footwear are

recommended when working outdoors. Wear protective

hair covering to contain long hair.

9. Use safety glasses

Also use face or dust mask if cutting operation is dusty.

10. Don’t abuse cord

Never carry tool by cord or yank it to disconnect it from

the socket. Keep cord from heat, oil and sharp edges.

11. Don’t overreach

Keep proper footing and balance at all times.

12. Maintain tools with care

Keep tools sharp and clean for better and safer

performance. Follow instructions for lubricating and

changing accessories. Inspect tool cords periodically

and, if damaged, have repaired by authorized service

facility. Inspect extension cords periodically and replace if

damaged. Keep handles dry, clean and free from oil and

grease.

13. Disconnect tools

When not in use, before servicing, and when changing

accessories such as blades, bits and cutters.

14. Remove adjusting keys and wrenches

Form the habit of checking to see that keys and adjusting

wrenches are removed from tool before turning it on.

15. Avoid unintentional starting

Don’t carry plugged-in tool with finger on switch. Be sure

switch is off when plugging in.

4

Helpline No. UK 0151 649 1500 / IRE 189 094 6244

Page 7

16. Outdoor use extension cords

When tool is used outdoors, use only extension cords

intended for use outdoors and so marked.

17. Stay alert

Watch what you are doing. Use common sense. Do not

operate tool when you are tired.

18. Check damaged parts

Before further use of the tool, a guard or other part that is

damaged should be carefully checked to determine that

it will operate properly and perform its intended function.

Check for alignment of moving parts, binding of moving

parts, breakage of parts, mounting, and any other

conditions that may affect its operation. A guard or other

part that is damaged should be properly repaired or

replaced by an authorized service center unless otherwise

indicated elsewhere in this instructions manual. Have

defective switches replaced by an authorized service

center. Do not use tool if switch does not turn it on and off.

19. Warning

The use of any other accessory or attachment other than

recommended in this operating instruction or the Einhell

catalog may present a risk of personal injury.

20. Have your tool repared by an expert

This electric appliance is in accordance with the relevant

safety rules repairing of electric appliances may be

carried out only by experts otherwise it may cause

considerable danger for the user.

Additional safety instructions

Read the operating instructions with due care. Familiarize

yourself with the operator controls and proper operation of

the machine

Never allow children or other persons who are not familiar

with the operating instructions to use the machine. Contact

your local governmental agency for information regarding

minimum age requirements for operating the machine

Never work in the direct vicinity of persons - especially

children - or animals.

Always keep in mind that the machine operator or user is

responsible for accidents involving other persons and/or

damage to their property.

Preliminary measures

Always wear sturdy, non-slip footwear and long trousers when

working. Never operate the machine barefoot or in sandals.

Check the ground on which the machine will be used and

remove all objects that could be caught up and violently

flung out by it.

Before using the machine, always visually examine the tools

for excessive wear or damage. To prevent any imbalance,

replace worn out or damaged parts and mounting bolts as a

set only.

The power cables used are not to be of a lighter duty class

than light rubber-insulated H05RN-F in accordance with DIN

57282/VDE 0282 and they must have a cross section of at

least 1.5 mm2. The connection must be splash-proof. The

power cable must be fed through the stress-relief clips and

be plugged into the switch/plug block. Before use, check the

cable for damage and signs of aging. Never use the machine

with worn or damaged cables. If the cable is damaged while

working, pull the power plug immediately and only then

inspect the damage. Do not touch the power cable until the

plug has been pulled.

Socket couplers to connection elements must be made from

rubber, soft PVC or other thermal material of equal rigidity or

coated with such material.

Make sure that all nuts, bolts and screws are tightened

securely and that the machine is in safe working condition.

Handling

Work only in daylight or in good light.

Always maintain good footing on inclines.

Only operate the machine at a walking pace. Work

perpendicular to the slope, never up or down it.

Be particularly careful when you change direction on a

slope.

Do not work on overly steep inclines.

Be particularly careful when you turn the machine around or

pull it toward yourself.

Switch on the motor carefully as described in the instructions

from the manufacturer and ensure that you keep your feet at

a safe distance from the tool.

Never move your hands or feet toward or under any rotating

parts.

Never lift or carry a machine whilst the motor is running; in

addition the power plug should be pulled.

Switch off the motor whenever you leave the machine

unattended.

If the machine begins to experience unusual vibrations,

immediately switch it off and check it.

Ensure that you avoid paths that could restrict the free

movement of the extension cable.

Maintenance and storage

Always make sure that all nuts, bolts and screws are tightened

securely so that the machine is in safe working condition.

Allow the motor to cool before you put the machine in an

enclosed area.

For your own safety, replace worn or damaged parts without

delay.

Switch the machine off and pull the power plug before

carrying out any adjustment or cleaning work on it, and

before checking to see if the mains connection is entwined

or damaged.

Switch off the motor and pull the power plug:

before you dislodge any blockages or clogs.

before you clean the machine, inspect it or carry out work on

the machine.

after you have traveled over an obstacle.

if you have struck a foreign object.

Do not lose these safety regulations.

Helpline No. UK 0151 649 1500 / IRE 189 094 6244

5

Page 8

A

B C

6

Helpline No. UK 0151 649 1500 / IRE 189 094 6244

Page 9

D E

F G

H I

Helpline No. UK 0151 649 1500 / IRE 189 094 6244

7

Page 10

J K

L M

8

Helpline No. UK 0151 649 1500 / IRE 189 094 6244

Page 11

2. Layout and items supplied 5. Assembly

See Fig. A-C

1. Top push bar

2. Bottom push bar

3. Motor unit

4. Hoe blades

5. Cable strain-relief clamp

6. Two-hand safety switch

7. Cable securing clips

8. 2x screw for installing the top push bar

9. 2x screw for installing the bottom push bar

10. 2x screw for installing 2-hand safety switch

11. 2x nut M6

12. 2x wing nut

3. Proper use

The machine is designed for digging soil (for example

garden beds). Be sure to observe the restrictions in the safety

instructions.

4. Proper operation

Power supply

The machine can be connected to any 13A socket outlet

(with 230 Volt alternating current). However, the socket outlet

must have an earthing contact protected by a 16 A circuit

breaker. Additionally, a residual current device (RCD)

circuit-breaker with max. 30 mA must be used!

Power cable for the device

Please only use power cables that are not damaged. The

total length of the power cable should not exceed 50 meters;

going beyond this distance will reduce the power output of

the electric motor. The power cable must have a crosssection of 3 x 1.5 mm2. The insulating sheath of such machines

is frequently damaged. Some of the causes for this are:

- Cracking due to old age of the insulation

- Kinking caused by improper fastening or

guidance of the power cable Even though power cables

with damaged insulation sheaths pose a lethal hazard, some

people still use them. Do not make this mistake! Cables, plugs

and socket couplers must meet the following requirements

listed below. Power cables used to connect machines must

have a rubber insulation sheath.

The power cables must, at the very minimum, be of type

HO5RN-F and 3-stranded. The cable type must be printed

somewhere on the power cable. Only purchase power

cables that are marked! Plugs and socket couplers for the

power cables must be made from rubber and splash-proof.

There is a limit to how long power cables can be. Longer

power cables require larger conductor cross-sections. Power

cables and connecting lines must be regularly checked for

damage. Ensure that the lines are deenergized before

checking them. Completely unwind the power cable. Also

check power cable entry points, plugs and socket couplers

for kinks.

The machine is intended for private use i.e. for use in home

and gardening environments.

The operating instructions as supplied by the manufacturer

must be kept and referred to in order to ensure that the

machine is properly used and maintained. The instructions

contain valuable information on operating, maintenance

and servicing conditions.

For safety reasons, the machine may not be used as a drive

unit for other work tools or tool sets of and kind.

See Fig. D-K

Place the motor unit and the push bars on the ground in

order (Fig. D). Important. Do not forget to slide the cable

strain-relief clamp (Fig. F/Item 5) over the bottom push bar.

Slide the bottom push bar on to the push bar holder and

secure the two components to each other (Fig. E). Now

secure the top push bar to the bottom push bar (Fig. F). Install

the 2-hand safety switch as shown in (Fig. G-I / Item 6). Secure

the cable using the supplied cable securing clips (Fig. K/A)

6. Starting up

Secure the power cable with the strain-relief clamp (Fig L/

Item 2).

Important!

To prevent accidental start-up of the machine, the push-bar

(Fig. M/Item 1) is equipped with a two-point switch (Fig. M/

Item 2) which must be pressed before the lever switch (Fig.

M/Item 3) can be pressed. If the lever switch is released, the

machine switches off. Repeat this process several times so

that you are sure that your machine functions properly. Before

you perform any repair or maintenance work on the machine,

ensure that the hoe blades are not rotating and that the

power supply is disconnected.

Always ensure that a safe distance (provided by the long

handles) is maintained between the machine and the user.

Be especially careful when changing direction on slopes

and inclines. Maintain a solid footing and wear sturdy, non-slip

footwear and long trousers. Always till along the incline (not

up and down).

Use special caution when backing up and pulling the

machine (tripping hazard).

7. Tips for proper working

Place the machine in front of the area you wish to hoe and

hold it securely on the push bar before you switch on the

machine. Guide the hoe blades over the area.

To achieve cleanly tilled soil always ensure that you guide the

machine in straight lines wherever possible. Insodoing, the

aeration swaths should always overlap each other by a few

centimeters in order to avoid bare strips.

Switch off the motor promptly when you arrive at the end of

the area you wished to till. The motor must be switched off

when you raise the machine (for example to change

direction).

Keep the underside of the machine clean and remove soil

deposits. Deposits make it more difficult to start the machine

and decrease the working depth. Work perpendicular to the

slop on inclined areas. The machine must be switched off

and the mains cable disconnected before you make any

checks on the hoe blades.

Important!

The tiller blades will continue to rotate for a few seconds after

the motor is switched off. Never attempt to manually stop

them. In the event that the rotating tiller blade strikes an

object, immediately switch off the machine and wait for the

tiller blades to come to a complete stop. Then inspect the

condition of the tiller blades. Replace any parts that are

damaged.

Lay the power cable on the ground in front of the outlet in a

figure of 8. Work away from the outlet or cable and ensure

that the power cable always trails in the tilled soil which will

prevent the tiller blades from traveling over the cable.

Helpline No. UK 0151 649 1500 / IRE 189 094 6244

9

Page 12

8. Maintenance, care and storage 10. Ordering replacement parts

Maintenance and cleaning work on the machine as well as

removal of the safety devices may only be performed when

the motor is switched off and the power cable has been

pulled. Worn out or damaged hoe blades should only be

replaced by an authorized professional (see address on

warranty certificate).

Do not clean the tool with running water - and particularly

not with a pressure hose.

Ensure that all mounting components (i.e. screws, bolts, nuts

etc.) are always tightened so that the machine can be safely

operated at all times.

Store the device in a dry room. All the metal parts should be

cleaned and then oil to ensure that they provide a long life.

For best results, clean the plastic parts of the machine with a

brush or rag. Do not use any solvents to remove dirt.

At the end of the season, perform a general inspection of the

machine and remove any deposits which may have

accumulated. At the start of each season, ensure that you

check the condition of the machine. If repairs are necessary,

please contact one of our customer service centers (see

address on warranty certificate).

9. Replace the tiller blades

For safety reasons, we recommend having the tiller blades

replaced by an authorized professional (see address on

warranty certificate).

Important!

Wear working gloves. Use only genuine spare parts since

otherwise the function and safety of the machine cannot be

guaranteed.

Please quote the following data when ordering replacement

parts:

Type of machine

Article number of the machine

Identification number of the machine

Replacement part number of the part required

Helpline numbers:

UK 0151 649 1500

IRE 189 094 6244

11. Technical data

Voltage 230V ~ 50Hz

Power input 750 W

Working width 30 cm

Tiller diameter 22 cm

Idle speed 400 rpm

Number of blades 4 pieces

LpA noise level 70 dB(A)

LWA peak noise level 93 dB(A)

Vibration at the handlebars ahv ≤ 2.5 m/s

2

12. Troubleshooting Guide

Fault Possible causes Remedy

Motor does not start a) No power at the plug a) Check the power cable and fuse

b) Cable defective b) Check

c) Switch/plug block defective c) By customer service workshop

d) Motor terminals or capacitor d) By customer service workshop

disconnected

e) Excessive working depth e) Reduce working depth

Motor performance drops a) Soil too hard a) Correct working depth

b) Blades badly worn b) Replace hoe blades

Important note!

For protection, the motor is equipped with a thermal switch

which cuts out when the motor is overloaded and switches

on again automatically after a short cooling period.

10

Helpline No. UK 0151 649 1500 / IRE 189 094 6244

Page 13

Declaration of conformity

Helpline No. UK 0151 649 1500 / IRE 189 094 6244

11

Page 14

Disposal

For EU countries only

Never place any electric tools in your

household refuse. To comply with European

Directive 2002/96/EC concerning old electric

and electronic equipment and its

implementation in national laws, old electric

tools have to be separated from other waste

and disposed of in an environment-friendly

fashion, e.g. by taking to a recycling depot.

Recycling alternative to the demand to return electrical

devices:

As an alternative to returning the electrical device, the owner

is obliged to cooperate in ensuring that the device is properly

recycled if ownership is relinquished. This can also be done by

handing over the used device to a returns center, which will

dispose of it in accordance with national commercial and

industrial waste management legislation. This does not apply

to the accessories and auxiliary equipment without any

electrical components which are included with the used

device.

ARGOS Product Guarantee

This product is guaranteed against manufacturing defects

for a period of 2 years. This does not cover the product where

the fault is due to misuse, abuse, use in contravention of the

instructions, or where the product has been the subject of

unauthorized modifications or alterations, or has been the

subject of commercial use.

In the event of a problem with the product within the

guarantee period please return it to your nearest Argos store.

If the item is shown to have had an inherent defect present

at the time of sale, the store will provide you with a

replacement. Your statutory rights remain unaffected.

Guarantor: Home Retail Group, 489 - 499 Avebury Boulevard,

Central Milton Keynes, MK9 2NW

If you wish to purchase spare parts, please contact the

Helpline No. below.

Helpline No. UK 0151 649 1500 / IRE 189 094 6244

Loading...

Loading...