SERVICE MANUAL

Colour Television PAL/SECAM/BG/DK

Models:

14” CTV-37V10

(chasis 3401)

21” CTV-55V10

(chasis 4401)

CCCCAAAAUUUUTTTTIIIIOOOONN

NN

Before serving the chassis, read the "X-Ray Radiation Precaution",

"Safety Precaution" and "Product Safety | Notice" on page 2 of this manual.

X-RAY RADIATION PRECAUTION

1. Excessive high voltage can produce potentially hazardous X-Ray Radiation.' To avoid such hazards,

the high voltage must not be above the specified limit. The normal value of the high voltage of this

receiver is 24KV at zero beam current (minimum brightness) under 220V AC power source. The high

voltage must not, under any circumstances, exceed 30KV.

2. Each time a receiver requires servicing, the high voltage should be checked following the High

Voltage Check procedure in this manual. It is recommended the reading of the high voltage be

recorded as a part of the service record, it is important to use an accurate and reliable high voltage

meter.

3. The primary source of X-Ray Radiation in this TV Receiver is the picture tube. For continued X-Ray

Radiation protection, the replacement tube must be exactly the same type tube as specified in the

part list.

4. Some parts in this receiver have special safety - related characteristics for X-Ray Radiation

protection. For continued safety, parts replacement should be undertaken only after referring to the

Product Safety Notice.

SAFETY PRECAUTION

Warning: Service should not be attempted by anyone unfamiliar with necessary precaution on this receiver.

The following are the necessary precautions observed before servicing this chassis.

1. Since the power supply circuit of this receiver is directly connected to the AC power line, an

isolation transformer should be used during any dynamic service to avoid possible shock hazard.

2. Always discharge the picture tube anode to the CRT conductive coating before handling the picture

tube. The picture tube is highly evacuated and if broken, glass fragment will be violently expelled.

Use shatter proof goggles and keep picture tube away from the unprotected body while handling.

3. When replacing a chassis in the cabinet, always be certain that all the protective devices are put

back in place, such as: non-metallic control knobs, insulating covers, shields, isolation resistorcapacitor network etc.

4. When replacing parts or circuit boards, disconnect the power cord.

5. When replacing a high wattage resistor (Metal oxide film resistor) on circuit board, keep the

resistor 10mm (1/2in.) away from circuit board.

6. Connection wires must be kept away from components with high voltage or high temperature.

7. If any fuse in this TV receiver is blown, replace it with the FUSE specified in the chassis part list.

8. The receiver is designed to operate with 220V(50/60Hz) AC mains.

PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in this chassis have special safety-related characteristics. These

characteristics are often passed unnoticed by a visual inspection and the X-Ray Radiation protection

afforded by them cannot necessarily be obtained by using replacement components rated for high wattage,

etc. Replaced parts which have these special safety characteristics are identified in this manual and its

supplements, electrical components having such features are shaded on the schematic diagram and the part

list.

Before replacing any of these components, read the part list in this manual carefully. The use of substitute

replacement parts, which do not have the same safety characteristics, as specified in the part list may create

shock, fire, and X-Ray Radiation or other hazards.

ALIGNMENT INSTRUCTION

1. Please notice the following before alignment and equipment:

1-1 Don't short any two soldering points, which should not be shorted and don't touch any components,

which should not be touched.

1-2 Please pull out plug before equipment.

1-3 For safety reasons, all components equipped or replaced should be identical with BOM.

1-4 Must he warm up for 30 minutes or more and degauss CRT thoroughly with demagnetizer before

alignment.

1-5 The data of EEPROM must be stored before the adjustment for main chassis.

2. Tools and equipment for adjustment

2-1 small"-'' screwdriver

2-2 screwdriver without inductance

2-3 Pattern Generator

2-4 DC Regulated power supply

2-5 Digital Voltmeter

2-6 Sweep Signal Generator

2-7 20MHz 2-channel Oscilloscope

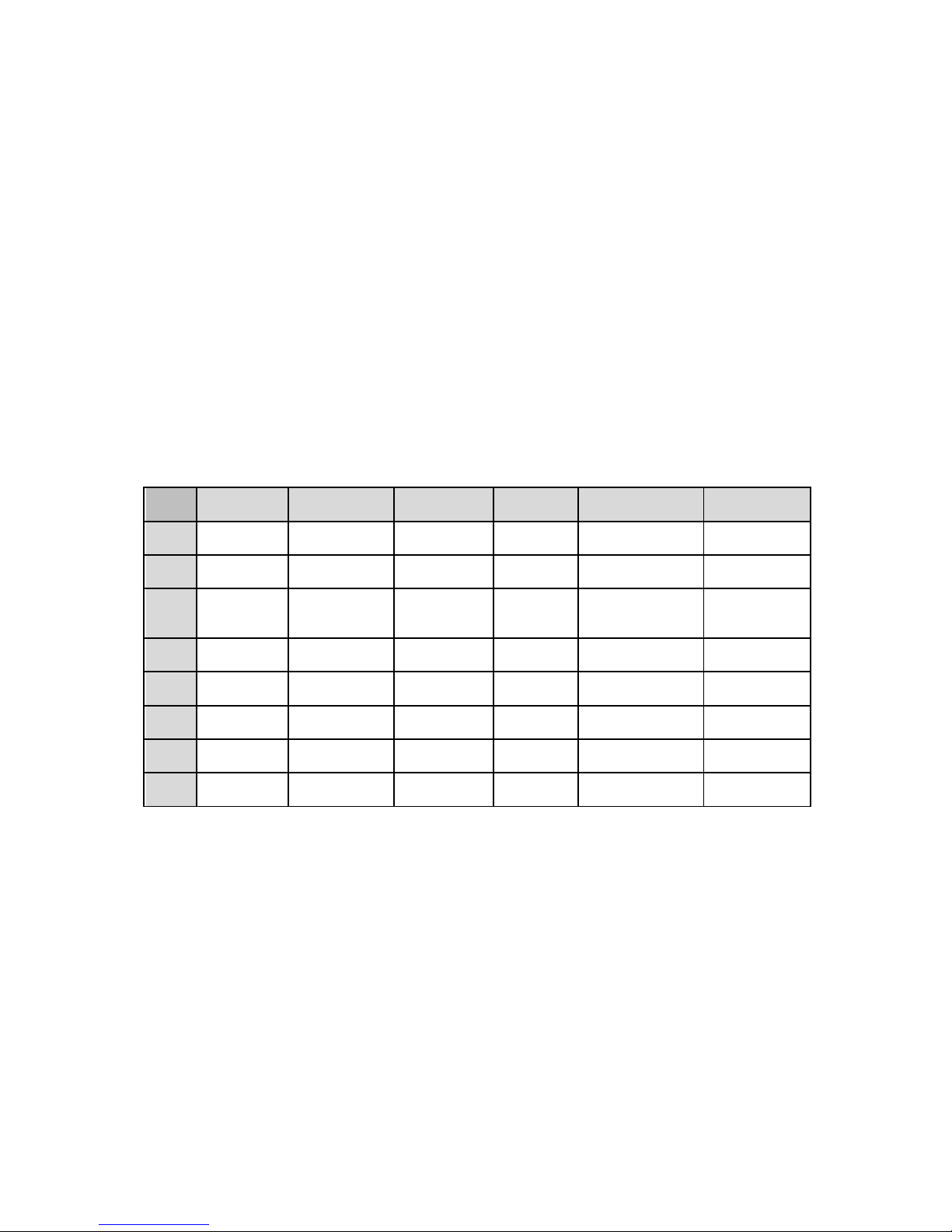

3. Signal condition

ITEMS LOGO PICTURE

CARRIER

PATTERN SYSTEM SOUND MODE REMARK

1 CHN-1CH 49.75MHz PHILIPS

PATTERN

PAL-I 1KHz

2 WE-6CH 182.25MHz RED PATTERN PAL-B/G L:-----

R:400Hz

STEREO

/TELETEXT

3 CHN-12CH 216.25MHz GREY

SCALE/COLOR

BAR

SECAM-D/K SWEEP SOUND

4 CHN-13CH 471.25 MHz CROSS HATCH

PATTERN

PAL-D/K 1KHz

5 USA-33CH 585.25 MHz COLOR BAR NTSC-M ----- WITHOUT

SOUND CARRIER

6 ---- 751.25 MHz MONOSCOPE

PATTERN

PAL-I SWEEP SOUND

7 ---- 85.25 MHz GREYSCALE

/COLOR BAR

SECAM-L’ 1KHz SYS-2

8 WE-S20CH 294.25 MHz Semi-COLOR

BAR

PAL-B/G A:400Hz

B:1KHz

DOUBLE SOUND

CARRIER

CHASSIS ALIGNMENT

1. PIF Adjustment

1-1 Tuner AGC connects to GND. Pattern Generator outputs 38.9MHz R.F. signal and connects to tuner

IF output terminal or pin 5 of saw filter.

1-2 Connect Digital voltmeter across C227. DC Regulated power supply positive terminal output +20V

to pin 1 of IC302 and negative terminal of D608. DC Regulated power supply negative terminal

connects to pin 2 of IC302.

1-3 Adjust L203 coil to obtain 3.6V Digital voltage meter reading.

2. System NTSC Adjust(L108)

2-1 Tuner AGC connects to GND. Connect Sweep Signal Generator to tuner IF output terminal. Sweep

oscilloscope V-IN terminal connects to C109. And connect Q102 'b' pole to the power terminal of

R104. (shown in FIG.2)

Sweep Signal

Generator

Sweep

Osciloscope

DC Regulated

Power Supply

2-2 Apply +20V DC across IC302 as shown in FIG.2.

2-3 Adjust L108 to obtain waveform as following. There will be no alignment to it without NTSC

system.

3. B+ adjustment

3-1 Disconnect horizontal load. Connect a light bulb (100 W) AC 250V across C321.

3-2 Connect 220V AC 50 Hz to CN601 and switch on power switch.

3-3 Test the voltage with digital voltage meter between C321 two terminals.

3-4 Adjust VR601 to obtain +110V +/- 0.5V.

4. AGC alignment

4-1 Receive 60dB +/- 2dB RF signal. Connect Digital voltmeter positive terminal to AGC terminal of

TUNER and negative terminal to GND.

4-2 Press "MENU" key twin, till the PICTURE MENU appears, then press "Q.VIEW" key, "MUTE" key to

turn on CPU. TV SET will go to factory mode. Press "TIMER" key to go to the next factory menu. Go

to "MENU 3" status by this means.

4-3 Select RF.AGC by pressing "CH+" or "PROG+" and "CH." or "PROG-" keys. Adjust "VOL+" and

"VOL-" keys to obtain 4V Digital voltage meter reading.

4-4 Press "MENU" key to exit factory mode.

COMPLETE MACHINE GENERAL ADJUSTMENT

1. Go to factory mode according to 4-4-2 before warm up line,

2. Focus Adjustment.

2-1 Receive monoscope pattern.

2-2 Set TV to work in dynamic status.

2-3 Adjust the focus knob of FBT to get the clearest picture.

3. Screen Voltage Adjustment.

3-1 Go to factory mode "MENU 2" status according to 4-4-2.

3-2 Select "V-KILL" by pressing "CH+" or "PROG+" and "CH-" or "PROG-" keys..

3-3 Press "VOL+" key all the time, Adjust the screen knob of FBT to get a horizontal faintness beam

line. Then loose "VOL+" key.

4. White Balance Adjustment (Applied In factory only)

4-1 Set the TV set to AV mode. Receive black white pattern (Color Temperature test pattern). 4-2

Insert 6 Pin Service flat cable into CN002. Press adjustment keys, and then go to automatic white

balance adjustment.

4-2 After adjusting well, remove the 6 Pin Service flat cable.

4. (1) White Balance adjustment (Applied when servicing)

4-1 (1) Set the TV set to AV mode. Receive black white pattern (Color Temperature test pattern),

4-2 (1) Put the test probe 1 of CRT color analyzer (CA-100) on the Low Bright area and the test probe

2 on the High Bright area. Adjust bright and contrast to get 5nit of low bright area and 80 nit of

high bright area.

4-3 (1) Go to factory mode "MENU2" according to 4-4-2. Obtain Low Bright area to x=281and y=311

by adjusting R.bias and B.bias. Obtain High Bright area to x=281and y=311 by adjusting R.drive

and B.drive. Obtain both area to x=281 and y=311 by adjusting the two status repeatedly.

5. Sub-bright adjustment

5-1 Receive GREY SCALE signal.

5-2 Set TV at normal mode.

5-3 Get into factory mode, adjust sub-bright option to make the picture same as below.

The first bar is totally dark. Brightness will begin to appear from the second bar.

6. Vertical Size and PinCushion Adjustment

6-1 Receive monoscope pattern. Set TV standard status. Adjust V.size to obtain picture's vertical

redisplay ratio more than 90% in factory mode "MENU1".

6-2 Receive cross hatch pattern. Set TV standard status. Adjust V.LINE and V.SC to obtain picture's

vertical pin cushion a good status in factory mode "MENU1".

6-3 Receive cross hatch pattern. Set TV standard status. In factory mode "MENU1" adjust V.POSITION

to obtain picture's vertical center at the center of CRT screen.

7. Horizontal Center Adjustment

Receive PHILIPS PATTERN. Set TV standard status. Adjust H.PHASE to obtain horizontal center at the

center of CRT screen.

8. Secam color decoder alignment.

Receive the GREY SCALE /COLOR BAR signals. Enter into the factory mode. Adjust the values of Secam

R-Y DC and Secam B-Y DC to make the gray scale to the normal color.

COLOR PURITY ADJUSTMENT AND CONVERGENCE ADJUSTMENT

COLOR PURITY ADJUSTMENT

1. Before color purity adjustment, Warm up the TV set over 15 minutes and fully degauss.

2. Receive pure white signal in AV status and set the TV receiver dynamic.

3. Go to factory mode "MENU2". After write down the values of R-BIAS and B-BIAS, set the values of

R-BIAS and B-BIAS zero.

4. Loosen the clamp screw of the deflection yoke and pull the deflection yoke towards color purity

magnetic loop.

5. Adjust color purity magnetic loop to make the green area at the center of CRT screen,

6. Slowly push the deflection yoke toward the front of CRT and set it where a uniform green field is

obtained. Tighten the clamp screw of the deflection yoke.

7. Restore the values of R-BIAS, G-BIAS and B-BIAS.

CONVERGENCE ADJUSTMENT

8. Receive a dotted pattern. Set the TV receiver dynamic.

9. Loose the convergence magnet clamper and align red with blue dots at the center of the screen by

rotating (R, B) static convergence magnets.

10. Align Red/Blue with green dots at the center of the screen by rotating (RB-G) static convergence

magnet.

11. Remove the DY wedges and slightly tilt the deflection yoke horizontally and vertically to obtain the

good overall convergence, Fix them after the good overall convergence got.

12. Fix the convergence magnets by turning the clamper.

13. If purity error Is found, follow "PURITY ADJUSTMENT" instructions.

SERVISNI MENU ZA TV 55V10/37V10

shassis: 3Y/4Y01

MENU 1

V. SIZE 20

V. POS 33

V. LINE 10

V. SC 0

H. PHASE 13

H. BLK 0

PATTERN 0

H. FREQ 25

MENU 3

RF. AGC 15

VIF. SYS 1

SND. TRAP 7

VIDEO LEVEL 0 (4)

FM LEVEL 0

R. B. BALANCE 8

DIGITAL OSD 0

MENU 2

V. KILL 0

R. C. 128

G. C. 180

B. C. 125

R. D. 48

G. D. 10

B. D. 63

COLLOR TEST 0

MENU 4

SUB_BRI 123

OSD CONT 100

B. GAM SEL 0

RG GAM DEF 0

SCM B_Y DC 8

SCM R_Y DC 4

BLUE BLACK 1

C/E OSD 0

OPTION

2 AV CH 0

C. SYS. SEL 1

TXT ON 1

MONITOR OUT 0

LOGO ON 1 (0)

CUSTOM LOGO 1 (0)

N P00 VLT 1

TUNER TYPE 0

Ulaz u servisni menu:

1. Stisnuti MENU dva puta

2. Stisnuti Q.VIEW

3. Stisnuti MUTE

4. Menu-i se mjenjeju sa tipkom TIMER (sat na daljinskom)

Loading...

Loading...