Page 1

R

O-T L

Tested and

Listed by

Beaverto

n

Oregon USA

OMNI-Test Laboratories, Inc

.

C

Garnet

R

1445 N. Highway

Colville, WA 99114-2008

DIRECT VENT ROOM HEATER

SAVE THESE

INSTRUCTIONS

Installation, Venting, Operation and Maintenance Manual

WARNING!

If the information in this Manual is not followed

exactly, a fire or explosion may result causing property

damage, personal injury or loss of life.

- Do not store or use gasoline or other flammable

vapors and liquids in the vicinity of this or any other

appliance.

- WHAT TO DO IF YOU SMELL GAS:

* Do not try to light any appliance.

* Do not touch any electrical switch; do not use any

phone in your building.

* Immediately call your gas supplier from a neighbor's

phone. Follow the gas supplier's instructions.

* If you cannot reach your gas supplier, call the

re department.

Installation and service must be performed by a qualied

installer, service agency or the gas supplier.

(In the Commonwealth of Massachusetts, installation

must be performed by a licensed plumber or gas tter.)

FOR YOUR SAFETY

The appliance area must be kept clear and free from

combustible materials, gasoline and other flammable

vapors and liquids.

This Manual must be used for installation of

the Garnet Gas-Fired Room Heater and retained

by the

homeowner for operating and maintenance

instructions.

WARNING!

Improper installation, adjustment, alteration, service or maintenance can cause injury or property

damage. Refer to this Manual. For assistance or

additional information, consult a qualified installer,

service agency or the gas supplier.

This appliance may be installed in an aftermarket, permanently located, Manufactured (Mobile)

Home, where not prohibited by Local Codes.

This appliance is only for use with the type of fuel

indicated on the Rating Plate. This appliance is

not

convertible for use with other gases, unless a

certified Conversion Kit is used.

This appliance may be installed as an OEM installation in manufactured home (USA only) or mobile

home and must be installed in accordance with the

manufacturer's instructions and the manufactured

home construction and safety standard, Title 24

CFR, Part 3280 or Standard for Installation in Mobile

Homes, CAN/CSA Z240 MH.

This appliance is only for use with the type(s) of

gas indicated on the rating plate. A conversion kit

is supplied with the appliance.

This Heater may be installed with a Vertical

or Horizontal Direct Vent Termination System.

250-6443B

October 7, 2003

www.quadrafire.com

Page 2

GARNET DIRECT VENT ROOM HEATER

R

Hearth & Home Technologies welcomes you to our tradition of excellence! In choosing a Quadra-Fire appliance,

you have our assurance of commitment to quality, durability, and performance.

This commitment begins with our research of the market, including ‘Voice of the Customer’ contacts, ensuring we

make products that will satisfy your needs. Our Research and Development facility then employs the world’s most

advanced technology to achieve the optimum operation of our stoves, inserts and fireplaces. And yet we are oldfashioned when it comes to craftsmanship. During manufacturing each unit is meticulously fabricated and gold

surfaces are hand-finished for lasting beauty and enjoyment. Our pledge to quality is completed as each model

undergoes a quality control inspection. Additionally, we feel it is important to offer you several finishing options and

accessories to compliment your home’s décor, individualize the use of your appliance, and provide financial options in

acquiring a quality hearth appliance. Ask your Quadra-Fire Dealer for information on these options. From design, to

fabrication, to shipping: Our guarantee of quality is more than a word, it’s Quadra-Fire tradition, and we proudly back

this tradition with a Lifetime Warranty.

Prior to installation, we ask you to take a few moments to read this manual. It has been our experience that your

overall enjoyment of your new appliance will be greatly enhanced by becoming familiar with its’ installation, operation

and maintenance requirements. We wish you and your family many years of enjoyment in the warmth and comfort of

your hearth appliance. Thank you for choosing Quadra-Fire.

With warm regards,

Alan Trusler

Senior Vice President

Dealer Channel

___________________________

Dan Henr

y

Vice President

Research & Development

___________________________

Mike Derosier

Vi

ce President

Marketing & Product Plannin

g

_________________________

Jason Olmstead

Vi

ce President &

General Manager

_________________________

Dave Fiebelkorn

Materials Manager

250-6443B October 7, 2003 Page 2

Page 3

R

GARNET DIRECT VENT ROOM HEATER

250-6443B October 7, 2003 Page 4

R

PLEASE RETAIN THIS MANUAL FOR FUTURE REFERENCE.

TABLE OF CONTENTS

Model Name:

Model Name:

GARNET DIRECT VENT ROOM HEATER

Serial Number:

Serial Number:

Date Purchased:

Date Purchased:

Dealership:

Dealership:

Dealer Phone:

Dealer Phone:

Additional Information:

Additional Information:

After completing your warranty card, attach your

After completing your warranty card, attach your

sales receipt and warranty stub here for future

sales receipt and warranty stub here for future

reference.

reference.

Dovre Garnet DV250

GARNET DIRECT VENT ROOM HEATER

GARNET DIRECT VENT ROOM HEATER

Listings and Code Approvals............................................ 4

Specifications.................................................................... 4

Notices............................................................................. 4

Safety Notices.................................................................. 5

Overview of Installation .................................................... 6

Dimensions....................................................................... 7

Clearances to Combustibles............................................. 7

LP Gas Conversion Instructions....................................... 8

Valve Regulator Replacement.......................................... 9

Thermostat Installation/Remote Control........................... 9

Log Set Installation......................................................... 10

Mineral Wool Installation ................................................ 10

Blower Kit Installation Instruction ................................... 11

VENTING

General Venting Instructions.................................... 12

Installation Methods & Notes ................................... 13

Safety Precautions for the Installer.......................... 13

Simpson-DuraVent and HTI Parts List.....................14

Installation Methods ...........................................15-19

HORIZONTAL INSTALLATION

Termination Requirements....................................... 20

Horizontal Installations....................................... 21-22

Vent Graph.............................................................. 23

VERTICAL INSTALLATION

Vertical Damper Adjustment/Flue Restrictor ........... 24

Using GS Series Pipe ........................................25-27

Roof Pitch Table...................................................... 27

Cathedral Ceiling Installation ..................................28

Class A Metal Chimney ........................................... 29

Existing Masonry Chimey................................... 30-32

Gas Line Requirements.................................................. 33

Checking Gas Inlet Pressure.......................................... 34

Leak Test........................................................................ 34

Lighting Instructions .......................................................35

High Altitude Operation Adjustment................................ 36

OPERATING PROCEDURES

Controls................................................................... 37

Normal Operating Sounds ...................................... 37

Maintenance............................................................ 37

Yearly Maintenance................................................. 38

Ignition Module and Battery Replacement .............. 39

Glass Replacement................................................. 39

Shutter Adjustment.................................................. 39

Electrical Schematic................................................ 40

Troubleshooting.............................................................. 41

Parts & Accessories & Explosed View Schematic..........42

Exploded View ............................................................... 43

Warranty ............................................................... 44

250-6443B October 7, 2003 Page 3

Page 4

GARNET DIRECT VENT ROOM HEATER

R

LISTINGS AND CODE APPROVALS

The Garnet Direct Vent Gas Appliance is listed to ANSI standard Z21.88(b)-1999/CSA 2.33b-M99 Vented Gas

F

ireplace Heaters and applicable sections of UL307b Gas Burning Heating Appliances for Manufactured Homes

and Recreational Vehicles, CAN/CGA 2.17-M91 Gas Fired Appliances for use at High Altitudes, by OMNI-Test

Laboratories, Inc., Beaverton, OR.

Natural Gas Propane

†0-2000' †0-2000'

Input Rate on "HI" (BTU/Hr) 17,500 16,000

Input Rate on "LO (Btu/Hr) 11,500 12,000

Max. Output (BTU/Hr)** 14,500 13,500

Main Burner Orifice .078 .0469

Min. Inlet Pressure (Inches W.C.) 4.5" 11"

Max. Inlet Pressure (Inches W.C.) 7.0" 14"

Manifold Pressure on "HI" (Inches W.C.) 3.5" 10"

**Max Venting, Blower ON

†This appliance is equipped for altitudes 0-2000' (0-610 M) in USA: and in Canada for altitudes of 0-4500' (0-1370 M). In

USA for Altitudes above 2000', the vent configuration, orifice, or combination of both may need to be changed. See page

36 of this manual for information on making these changes.

SPECIFICATIONS

NOTICES

Failure to follow all of the required installation procedures may result in property damage, bodily injury or

even death. This appliance must be installed in accordance with all local codes, if any (and approved by the

Commonwealth of Massachusetts); if none, follow the National Fuel Gas Code, ANSI Z223.1, or the Canadian

Installation Code, CAN/CGA 149. NOTE: Have the gas supply line installed in accordance with local building codes

by a qualified installer approved and/or licensed as required by the locality. (In the Commonwealth of Massachusetts,

installation must be performed by a licensed plumber or gas fitter.)

Manufactured Home or Mobile Home installation may occur only after the home is site located and must

conform with the Manufactured Home Construction and Safety Standard, Title 24 CFR, Part 3280, or, when such a

standard is not applicable, the Standard for Manufactured Home Installations, ANSI/NCSBCS A225.1, or Standard

for Gas Equipped Recreational Vehicles and Mobile Housing, CSA Z240.4.

When installed, the appliance must be electrically grounded in accordance with local codes or, in the absence

of local codes, with the National Electrical Code, ANSI/NFPA 70, or the Canadian Electrical Code, CSA C22.1.

The Garnet is manufactured to operate on Natural Gas (NG), it is field convertible to Liquid Propane (LP) using

the manufacturer's conversion kit.

All exhaust gases must be vented outside the structure of the living-area. Combustion air is drawn from outside

the living-area structure.

Notify your insurance company prior to connecting gas to this fireplace.

Installation requirements diagrammed and explained in this manual are grouped into segments for ease of

procedure. While these requirements must be met fully, the order of installation may be subject to the procedure best

suited for your specific placement of the fireplace.

NOTE: Illustrations throughout these instructions reflect typical installations and are for design purposes

only. Actual installation may vary slightly due to individual design preferences. However, minimum and

maximum clearances must be maintained at all times.

The illustrations and diagrams used throughout these installation instructions are not drawn to scale.

250-6443B October 7, 2003 Page 4

Page 5

R

GARNET DIRECT VENT ROOM HEATER

250-6443B October 7, 2003 Page 6

R

GARNET DIRECT VENT ROOM HEATER

SAFETY NOTICES

! Due to high temperatures, the appliance should be located

out of traffic and away from furniture and draperies.

! Do not place clothing or other flammable items on or near

the appliance at any time. Due to thermostatic control, the

possibility exists for the appliance to turn on, igniting any

items on or near it.

! Children and adults should be alerted to the hazards of

high surface temperature and should stay away to avoid

burns or clothing ignition.

! Young children should be carefully supervised when they

are in the same room as the appliance.

! Any safety screen or guard removed for servicing an

appliance must be replaced prior to operating the

appliance.

Installation and repair should be performed by a

qualified, and/or where required by state and local codes,

licensed installer/service technician. (In the Commonwealth of

Massachusetts, installation must be performed by a licensed

plumber or gas fitter.) The appliance should be inspected before

use and at least annually by a professional service person.

More frequent cleaning may be required due to excessive lint

from carpeting, bedding material, et cetera. It is imperative that

control compartments, burners and circulating air passagways

of the appliance be kept clean.

Strict adherence to the instructions in this manual

must be followed. Improper installation will void the warranty

and safety listing.

This appliance is manufactured to operate on natural

gas (NG). It is field convertible to propane (LP) with the

manufacturers’ conversion kit. Burning incorrect fuel voids the

warranty and safety listing and may cause an extreme safety

hazard.

Contact local building officials to obtain a permit and

information on installation restrictions or requirements in your

locale. It is also important to notify your homeowner’s insurance

company of the installation of this appliance as well.

Do not use this appliance if any part has been under

water. Immediately call a qualified service technician to inspect

the appliance and to replace any part of the control system and

any gas control which has been under water.

Do not store or use gasoline or other flammable liquids

in the vicinity of the appliance.

If the flame becomes sooty, dark orange in color, or

extremely tall, DO NOT operate the appliance. Contact your

dealer and arrange for servicing immediately.

DO NOT op

erate

the

appliance if it is

not

operating

properly in any manner. Contact your dealer for assistance.

Open viewing glass for servicing only.

Operate the appliance in accordance with the

instructions contained in this manual.

If the main burners do not start correctly, turn the gas

off at the gas control valve and contact your dealer for service.

Do not operate with glass cracked or broken.

This unit is not for use with solid fuel.

DO NOT place anything inside the firebox (other than

the included logs and lava rock.

If the logs become damaged refer to the Parts and

Accessories page of this manual for replacement.

Instruct everyone in the house how to shut off the gas

to the appliance and also at the main gas shut-off valve. The

main gas shut-off valve is usually located next to the gas meter

or propane tank and requires a wrench to shut off.

Use the built-in electronic igniter to light the appliance.

DO NOT use matches or any other external device.

DO NOT remove, replace, modify or substitute any

part of the appliance unless instructions are given in this

manual. All other work must be done by a trained technician.

Allow the appliance to cool before carrying out any

maintenance or cleaning.

The pilot flame must contact the thermopile and

thermocouple. If it does not, turn the gas control valve to “OFF”

and call your Dealer.

DO NOT THROW THIS MANUAL AWAY. IMPORTANT

OPERATING AND MAINTENANCE INSTRUCTIONS ARE

INCLUDED.

WARNING!

Improper installation, adjustment, alteration, service or

maintenance can cause injury or property damage. Refer to

this manual for correct installation and operational procedures.

For assistance or additional information consult a qualified

installer, service agency, or the gas supplier.

CAUTION!

Do not operate appliance with the glass front removed,

cracked or broken. Only the door certified for use

with the appliance shall be used. Replacement of

the glass should be done by a licensed or qualified

service person. Do not strike the glass.

This appliance is equipped with a three pronged

(grounding) plug for your protection against shock

hazard and should be plugged directly into a

properly grounded three prong receptacle. Do not

cut or remove the grounding prong from this plug.

WARNING!

250-6443B October 7, 2003 Page 5

Page 6

GARNET DIRECT VENT ROOM HEATER

R

OVERVIEW OF INSTALLATION TO OPERATION

• Familiarize yourself with this Owner's Manual and the Safety Notices located in this manual,

and posted on the gas appliance.

• Remove and unpack the following components:

The Log Set is taped to the top of the stove.

• Inside the firebox will be the Component Bag.

• Unbolt the appliance from the pallet.

• Remove the top and then the face of the stove. The face is removed by lifting straight up.

• Remove the glass door by opening the latches located on both the left and right sides at the

top of the glass. Pull towards you and separate latch from notches. Lift the glass out of the

two notches at its base and carefully set aside.

• Convert to LP if necessary. (Use Conversion Kit included with appliance).

• Install Blower if purchased. (Part #844-9370).

• Finalize your installation decisions and requirements:

• Refer to Dimensions on page 7.

• Refer to Clearances to Combustibles on page 7.

• Refer to Horizontal and Vertical termination requirements on pages 20-32.

• Install damper if necessary for your venting plans, see page 24. (In the Commonwealth

of Massachusetts, the word damper shall be replaced with the words flue restrictor.)

• Refer to Vent Kits pertinent to your installation on page 14.

• Contact your local building inspector for code requirements in your area.

• Run thermostat lines to TH & TPTH connectors on valve, if applicable, see page 9.

• Set unit in place and install venting per your installation requirements.

• Install Log Set and lava rock. See instructions on page 10 of this manual.

• Connect the gas line. See page 33.

• Plug in blower, if purchased.

• Leak test gas line to manual shut-off valve. See page 34.

• Re-attach the glass door.

• Re-attach the face.

• Follow Lighting Instructions, page 35, to light the appliance. (A copy is attached to a beaded

chain on the lower right hand side of the appliance).

• Adjust gas control knob to "ON" (Following Lighting Instructions page 35).

• Set Thermostat or turn control panel switch to the "ON" position.

• Check flames and adjust shutter position, if necessary. See page 39.

• Familiarize yourself with the maintenance requirements of the stove. See pages 37 & 38.

• Familiarize yourself with the Troubleshooting section of this manual, page 41.

250-6443B October 7, 2003 Page 6

Page 7

R

GARNET DIRECT VENT ROOM HEATER

250-6443B October 7, 2003 Page 8

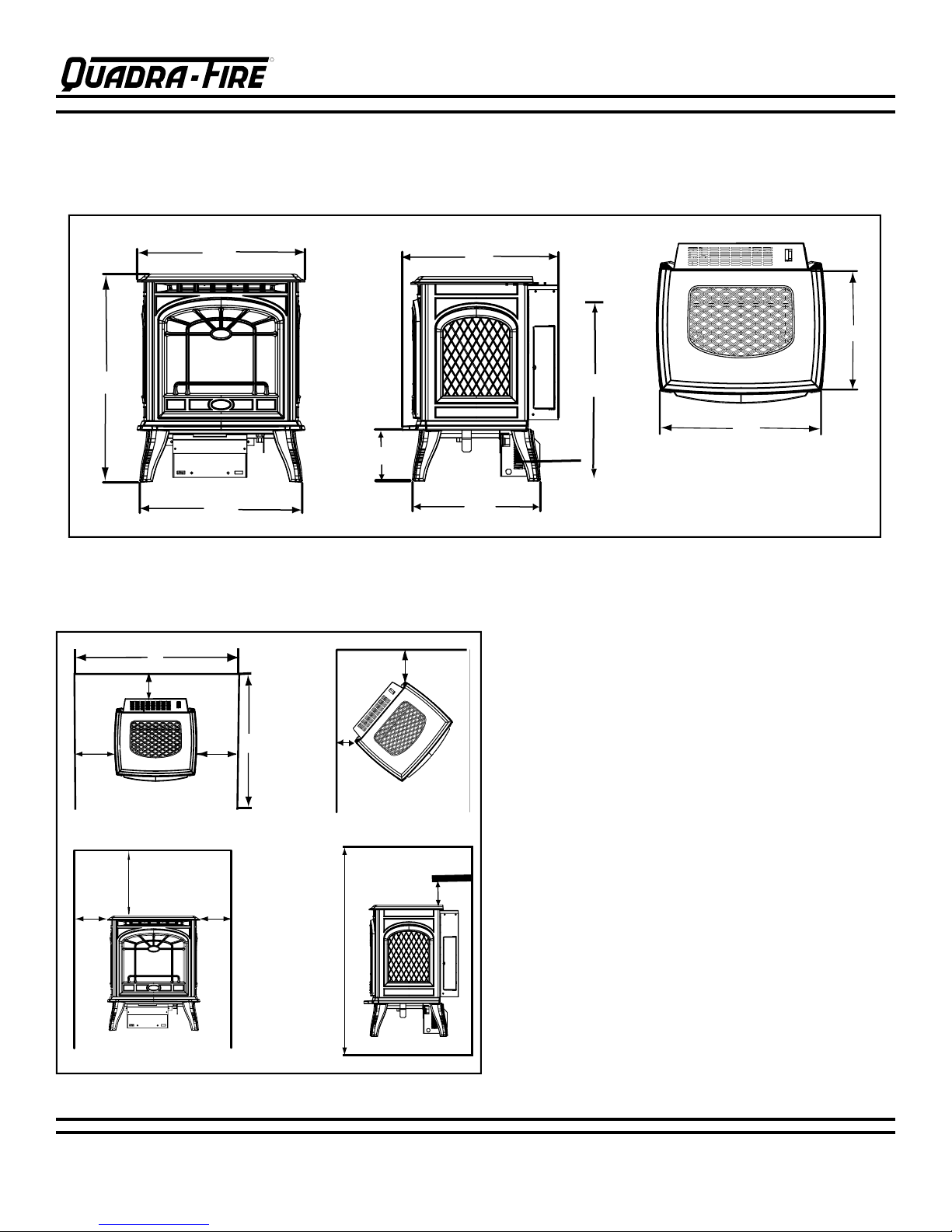

R

17-7/8"

(454mm)

13-1/4"

(337mm)

22-1/8"

(562mm)

17-7/8"

(454mm)

17-1/4"

(438mm)

16-7/8"

(429mm)

13-3/4"

(349mm)

C

L

16-5/8"

(422mm)

5-1/2"

(140mm)

NOTE: Diagrams show gas stove equipped with optional Blower, Part #844-9370.

GARNET DIRECT VENT ROOM HEATER

DIMENSIONS

CLEARANCES TO COMBUSTIBLES

Minimum clearances required from combustible construction for all appliance surfaces

F

B

A

A

E

3 1/2"

1

C

1"

C

2

Right

Left

"A" measurement is from

stove top, not side

G -Alcove

A

250-6443B October 7, 2003 Page 7

A

D

H

HEARTH: A non-combustible hearth pad is not required.

However, the oor beneath the stove must be stable,

level, and strong enough to support the stove without a

tipping hazard. Wood ooring, ceramic tile, brick hearths,

or high pressure laminate ooring applied directly over

the sub-ooring material meet this requirement. If the

appliance is installed over carpet or combustible tile (vinyl

tile), a metal or wood panel extending the full width and

depth of the appliance must be installed.

A. Side of stove top to side wall 6" (152mm)

B. Rear of stove to back wall 0" (0cm)

1

C

. Corner of stove top to side wall-Left 1" (25.4mm)

2

C

. Corner of stove top to side wall-Right 3-1/2" (88.9mm)

(

for valve clearance)

D. Minimum alcove height 43" (1092mm)

E. Maximum alcove depth 36" (914mm)

F. Minimum alcove width 30" (762mm)

G. Top of Stove to alcove ceiling 20-7/8" (530mm)

H. Mantle Clearance 21-1/2" (546mm)

NOTE: Flooring beneath appliance may reach 90 degrees

plus room ambient temperature. Check with flooring

manufacturer for maximum temperature allowed on

ooring surfaces.

Page 8

GARNET DIRECT VENT ROOM HEATER

R

MILLIVOT GENERATOR

PILOT HOOD

THERMOCOUPLE

5/32" Allen

wrench

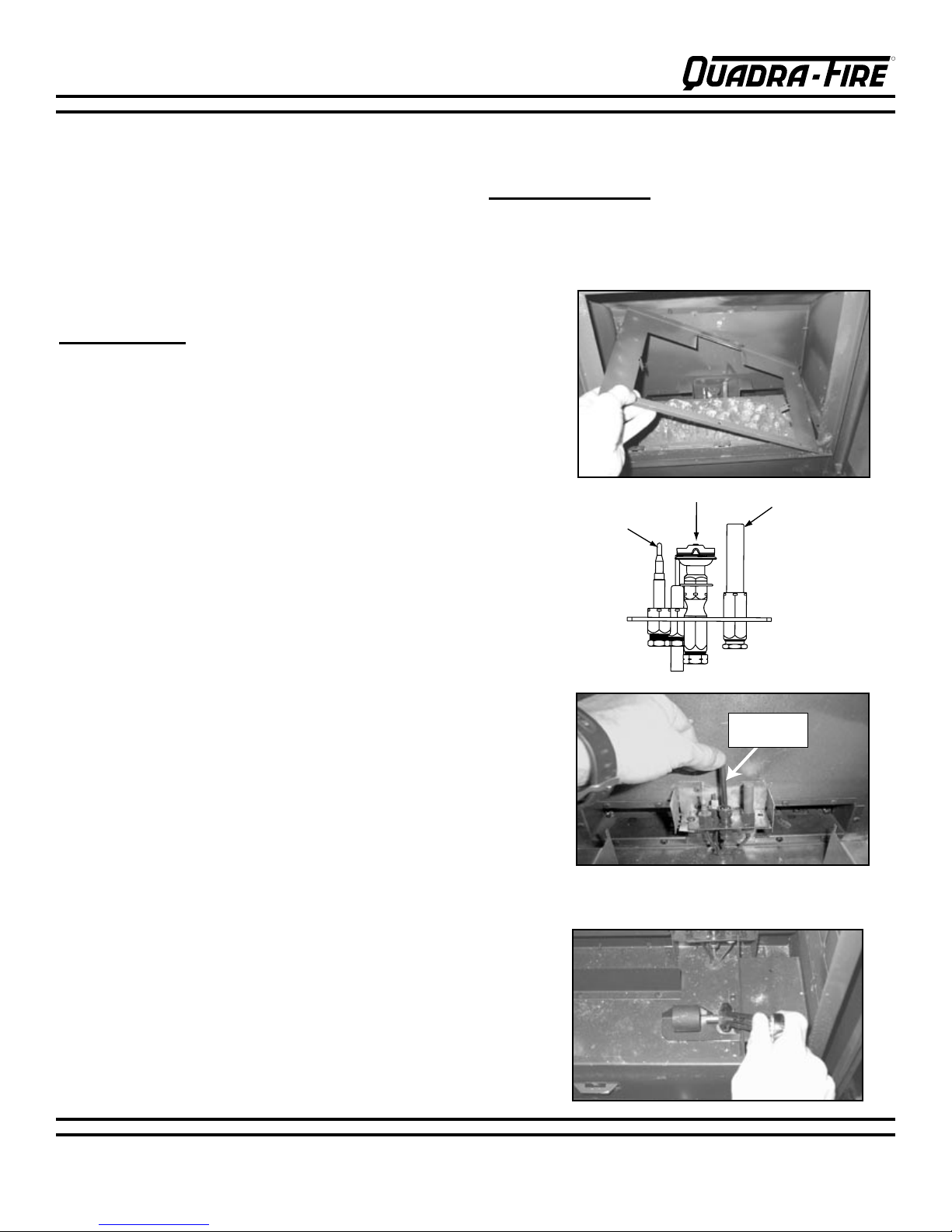

LP CONVERSION INSTRUCTIONS

NOTE: Have the gas supply line installed in accordance

with local building codes by a qualified installer

approved and/or licensed as required by the locality.

(In the Commonwealth of Massachusettes installation

must be performed by a licensed plumber or gas

TOOLS REQUIRED:

helpful) or slotted screwdriver or Torx TH20; #2

Phillips bit; 5/32" Allen wrench; 5/8" open end

wrench.

tter.)

FIG. 1

KIT CONTENTS:

Replacement orice; replacement

pilot injector; valve regulator; conversion label.

1

. Remove front (if installed), glass, and logs (if

installed).

2. Remove log/burner pan: First remove screws then lift

side of pan vertically and pull out of rebox. (Fig. 1)

3. Remove burner: Loosen shutter set screw and slide

shutter all the way to the right (closed). Lift left side of

burner and slide to the left.

4. Pull off pilot hood and set aside. (Fig. 2)

5. Use a 5/32" Allen wrench to remove the pilot injector.

(Fig. 3)

6.

Replace pilot injector with the appropriate size injector

supplied with the stove (#35 for Propane, #62 for Natural

Gas).

7. Replace pilot hood, snapping into position.

8.

Remove main burner orice using a 5/8" wrench. (Fig. 4)

9. Replace orice with the proper size as indicated below

for your gas type and venting.

PROPANE NATURAL GAS

.0469 .078

Power drill (a 90° handle is

FIG. 2

FIG. 3

5/32" Allen Wrench

FIG. 4

10. Reinstall burner. Slide burner neck into shutter and

over orice. Install log/burner pan using the three

screws removed.

See page 9 for Valve Regulator Replacement.

250-6443B October 7, 2003 Page 8

Page 9

R

GARNET DIRECT VENT ROOM HEATER

250-6443B October 7, 2003 Page 10

R

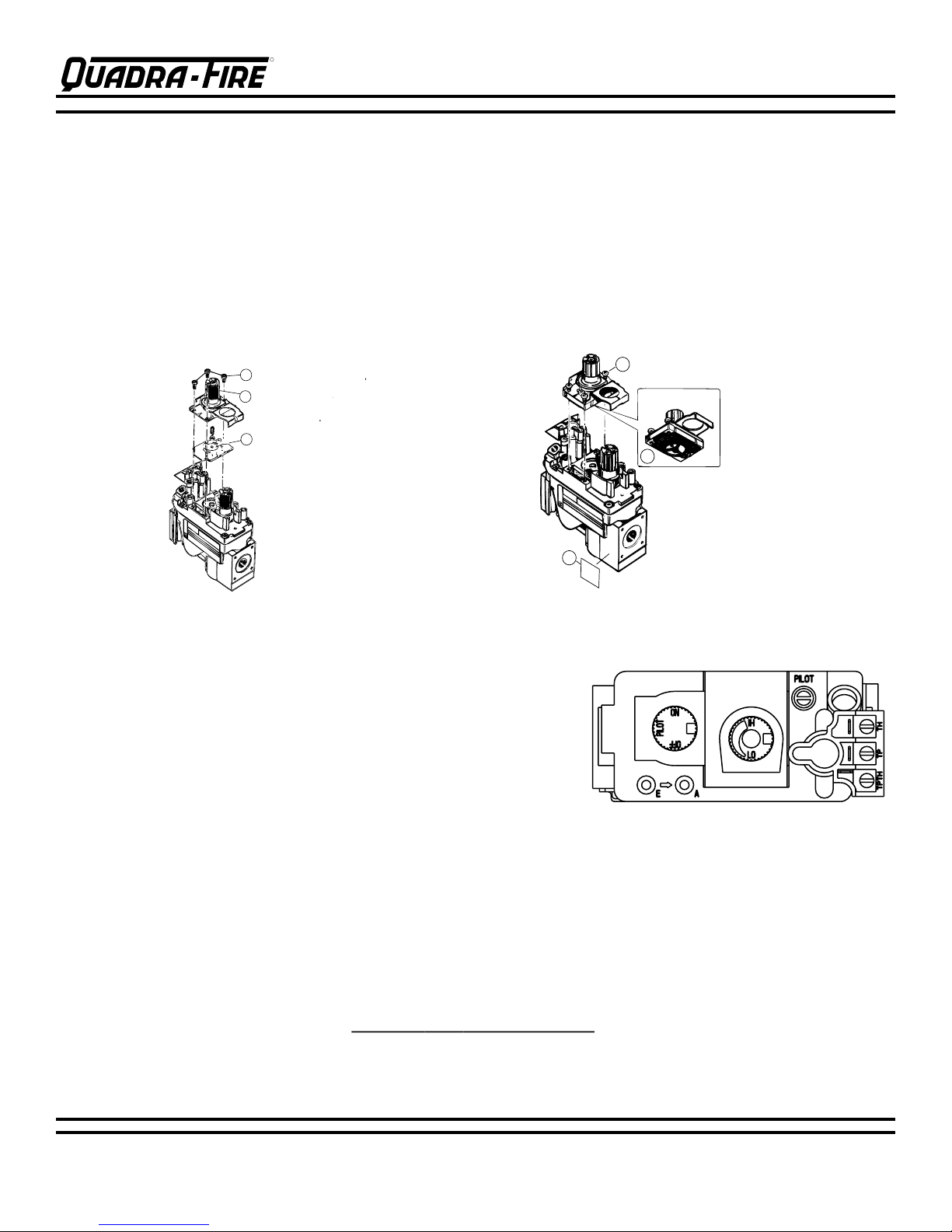

A

B

C

E

D

F

GARNET DIRECT VENT ROOM HEATER

LP CONVERSION (cont'd.)

Valve Regulator Replacement

1. Turn control knob to the OFF position, ensure that gas supply to the valve has been turned off.

2. Using a Torx TH20, or slotted screwdriver, remove the (A) three pressure regulator mounting screws, (B)

pressure regulator tower, and (C) diaphragm.

3. Ensure that the (D) rubber gasket is properly positioned and install the new HI/LO pressure regulator

assembly to the valve using the (E) new screws supplied with the kit. Tighten screws securely. (Reference

torque = 25 in/lb)

4. Install the enclosed (F) identication label to the valve body where it can be seen.

5. Fill out the Conversion Label and attach to the valve cover.

Mounting Screws

Pressure Regulator Tower

Diaphragm

New Screws provided with kit

Rubber Gasket

Identification Label

THERMOSTAT INSTALLATION

A thermostat may be installed to regulate the Garnet. It is important

to use a thermostat designed for millivolt operation. Do not connect

the heater to a thermostat serving any other appliance. Bedroom

installation in Canada requires this heater to be connected to a

thermostat.

Connect the thermostat wires to the outside valve terminals labeled

"TH" and "TPTH". Turn the manual switch on the control panel to

"OFF".

REMOTE CONTROL

A remote control or a wall switch may be wired to the thermostat terminals. Contact your Dealer for details.

Manual Thermostat Part Number 812-3760

Anticipator Setting 1.2

Programmable Thermostat Part Number 811-0520

Recommended Maximum Lead Length (2 wire) when using wall thermostat/switch:

Wire Size Maximum Length

16 gauge 65 Feet

18 gauge 40 feet

20 gauge 25 feet

22 gauge 18 feet

250-6443B October 7, 2003 Page 9

Page 10

GARNET DIRECT VENT ROOM HEATER

R

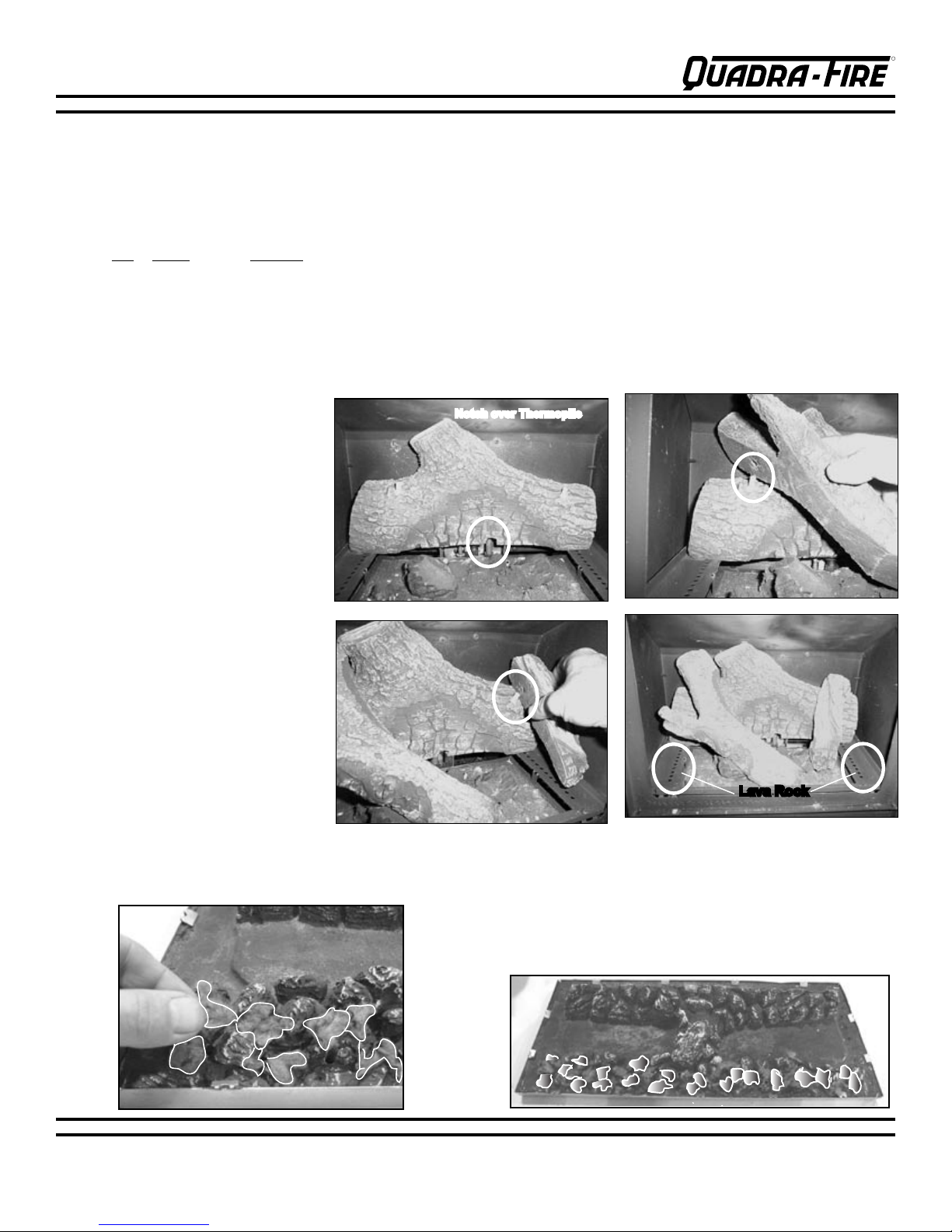

LOG SET INSTALLATION

Complete Set Part 842-4980

The three piece log set is packed in the components

box and consists of the following:

Qty Name Diagram

1 Rear Log Fig. 1

1 Left Twig Fig. 2

1 Right Twig Fig. 3

1 Lava Rock Fig. 4

Installation:

1. Place the notch in the Rear Log

over the Thermopile. Push the

log all the way to the rear of the

firebox (Fig. 1).

2. Place the hole in the bottom of the

Left Twig over the left pin in the

Rear Log (Fig. 2).

3. Place the hole in the bottom of the

Right Twig over the right pin in the

Rear Log. Lay the end of the twig

in ember bed (Fig. 3).

4. A complete assembled Log Set is

shown in Fig. 4.

5. The lava rock supplied with the

stove can be poured in the trays

along the left and right sides of

the burner pan.

NOTE: Do not pour any of the lava

rock onto the burner (Fig.4).

FIG. 1

While breakable, the logs do not become fragile until after

the stove is burned and they have cured. After curing, any

handling must be done with care as breakage may occur

easily.

PLEASE NOTE: Logs have been designed to work

specifically with the burner of the Garnet. Exact

placement will ensure proper operation of your gas

appliance and reduce sooting.

Notch over Thermopile

FIG. 2

FIG. 3

FIG. 4

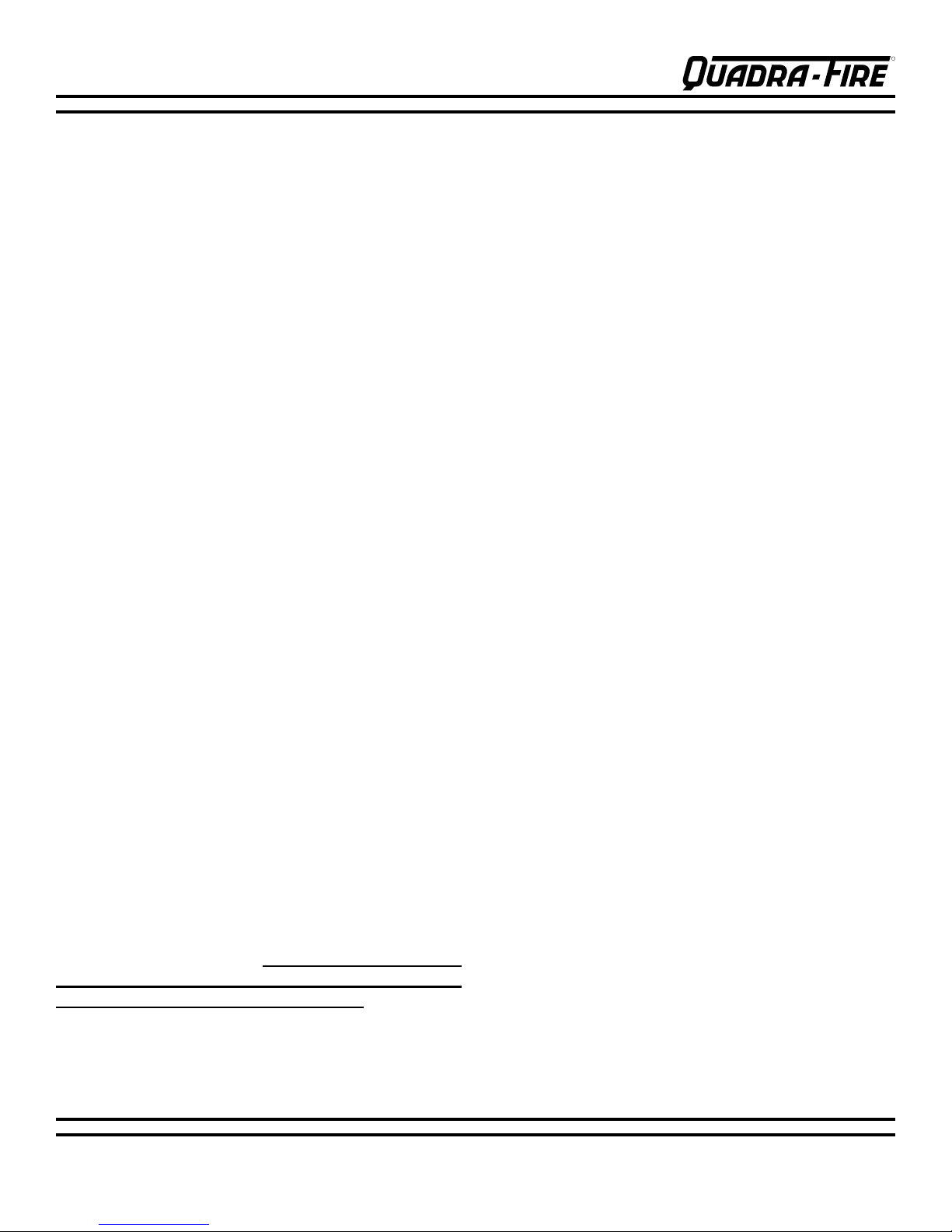

Apply dime size pieces sparingly along front edge of burner. Do not completely block ports.

250-6443B October 7, 2003 Page 10

MINERAL WOOL INSTALLATION

COMPLETE INSTALLATION

L

ava Rock

Page 11

R

GARNET DIRECT VENT ROOM HEATER

250-6443B October 7, 2003 Page 12

R

GARNET DIRECT VENT ROOM HEATER

BLOWER INSTALLATION

PART #844-9370

KIT CONTENTS: Blower motor, housing and snap disc assembly; rheostat (speed control); rheostat nut; knob; screws;

knob position label.

TOOLS REQUIRED: Short #2 Philips head screwdriver; 11/16" wrench.

The blower is held in place using 4-#6 screws. The scews are already installed in the bottom of the re box.

1. Remove the (4) screws from the rebox and slide the blower into place from the left side of the stove. (Fig. 1)

Notice the locations of the pilot assembly tubes and wires. The pilot tubes and wires may need to be moved to prevent

scraping the blower housing. (Fig. 2)

2. Re-use the (4) screws removed from the bottom of the rebox, to install the blower. Install the 2 screws on the right

rst, then use the other 2 screws to hold the snap disc in place and support the left side of the blower. (Fig. 2)

3. Remove the valve access panel by removing the (3) screws that secure it to the right side of stove and sliding it out.

4. Attach the rheostat to valve access cover and tighten with 11/16 wrench. Attach label showing knob positions on valve

cover. Install the knob on the rheostat. (Fig. 3)

5. Connect the black and white wires from the blower to the rheostat wires. (Fig. 4)

6. Re-install the valve access cover.

7. Route power cord away from unit. DO NOT route the power cord under or in front of the stove.

FIG. 1

FIG. 2

Snap Disc

FIG. 3

FIG. 4

Pilot Tubes and Wires

Mounting Screws

250-6443B October 7, 2003 Page 11

Page 12

GARNET DIRECT VENT ROOM HEATER

R

GENERAL VENTING INSTRUCTIONS

PLEASE NOTE: In order to comply with applicable

codes and product warranties, only Simpson DuraVent (SDV), Hearth & Home Technologies (HTI)

venting components, or Security Chimney's Secure

Vent Chimney System may be used. DO NOT USE

FIELD-FABRICATED VENTING COMPONENTS. The

Garnet is approved to be vented either horizontally,

through the side wall, or vertically, through the roof.

You may vent through a Class A or masonry chimney

if a Simpson Dura-Vent adapter is used (for USA

installations only). Only use Simpson Dura-Vent, or

HTI components labeled and listed on page 14.

This appliance is a direct vent heater. All combustion

air must come directly from the outside of the building.

The vent pipe for this unit consists of an inner and an

outer pipe. The inner pipe carries the stove exhaust

out of the system, and the outer pipe brings fresh

combustion air into the stove.

! A wall thimble is required when the venting

passes through a wall.

! A support box or firestop is required when the

venting passes through a ceiling.

! Roof flashing and a storm collar are required when

venting passes through the roof. Follow instructions

provided with the venting for installation of these items.

IMPORTANT: Read all these instructions carefully

before starting the installation. Failure to follow

instructions may create a fire or other safety

hazard, and will void the warranty. Be sure to

follow these installation instructions for venting

and clearance to combustible requirements, which

may vary from one installation to another. Do

not extend the venting system in excess of

the distance prescribed in these manufacturer’s

installation instructions. This gas appliance must

not be connected to a chimney flue serving a

separate solid-fuel burning appliance.

INSTALLATION PRECAUTIONS:

The Quadra-Fire Garnet is an engineered product

that has been designed and tested. The warranty will

be voided, and serious fire, health, or other safety

hazards may result from any of the following actions:

Installation of any damaged venting component,

unauthorized modification of the venting system,

installation of any component part not approved by

Hearth & Home Technologies, or installation other than

as instructed by these instructions. Consult your local

building codes before beginning this installation.

WARNING: Always maintain the required clearances (air

space) to nearby combustibles to avoid creating a fire

hazard. Do not fill air space with insulation. Minimum

clearance between vent pipes and combustible surfaces is

1” (2.5cm). Be sure to check the horizontal vent termination

clearance requirements from decks, windows, soffits, gas

regulators, air supply inlets and public walkways, as

specified on page 20 of these installation instructions, the

vertical termination requirements on page 18, 19 and 27,

and local building codes.

The gas heater and vent system must be vented

directly to the outside of the building, and never be

attached to a chimney serving a separate solid fuel or

gas-burning appliance. This direct vent gas fireplace

must use its own separate vent system. Common vent

systems are prohibited.

250-6443B October 7, 2003 Page 12

Page 13

R

GARNET DIRECT VENT ROOM HEATER

250-6443B October 7, 2003 Page 14

R

INSTALLATION METHODS & NOTES

GARNET DIRECT VENT ROOM HEATER

Four types of direct vent system installations are

approved for use with the Garnet.

1. Horizontal Termination (Fig. 1, page 15)

2. Vertical Termination (Fig. 2, page 18)

3. Into a Class A Metal Chimney (Fig. 3, page 18)

USA installations only

4. Into a Masonry Chimney (Fig. 4, page 19) USA

installations only

Do not connect to a chimney serving a separate solidfuel burning appliance.

In each of these installation methods, it is very important

to maintain a balance between the combustion air

intake and the flue gas exhaust venting system.

Note: Certain limitations as to vent and vertical

termination configurations apply, and must be strictly

adhered to.

When planning your installation, it is necessary to

select the proper length of vent pipe for your particular

requirements.

1. For installations with any horizontal vent run or

horizontal termination, refer to the Vent Graph on page

23. This graph will show the relationship between

vertical and horizontal side wall venting, and help you

to determine the amount of vertical rise necessary for

“vertical-to-horizontal” type installations.

each floor level. If an offset is needed in the attic,

additional pipe and elbows will be required. When

determining the position of the stove, be sure to

adhere to minimum clearance to combustibles to the

appliance itself. (See page 7, Minimum Clearances to

Combustibles.)

3. When installing this appliance into an existing

masonry chimney, it is important to carefully measure

the length of flex needed to reach from the appliance

outlet to the termination cap. If the flex length is too

short, a flex coupler will be needed to attach an

additional length of flex liner to make up the difference.

If the flex length is too long, the liner could sag below

the appliance outlet, which could result in an airflow

restriction causing flow reversal or flame lift.

SAFETY PRECAUTIONS FOR THE INSTALLER

Wear gloves and safety glasses for protection when

installing this stove. Exercise extreme caution when

using ladders or on rooftops around power lines.

Be aware of electrical wiring locations in walls and

ceilings.

NOTE: Be sure to take into consideration the wall

thickness when calculating your venting needs.

2. To determine the length of pipe required for vertical

installations, measure the distance from the stove flue

outlet to the ceiling, the ceiling thickness, the vertical

rise in an attic or second story, and allow for sufficient

vent height above the roofline. Refer to the vertical

vent termination tables on page 27 for this information.

For two-story applications, fire stops are required at

250-6443B October 7, 2003 Page 13

Page 14

GARNET DIRECT VENT ROOM HEATER

R

SIMPSON DURA-VENT and HTI PARTS LIST

Termination Caps & Snorkels:

991 High Wind Vertical Termination Cap

985 High Wind Horizontal Termination Cap

983 Vertical Termination

981 Snorkel Termination (36”)

982 Snorkel Termination (14”)

950 Vinyl Siding Standoff (VSS)

Flashing:

941 Cathedral Ceiling Support Box

943 Flashing, 0/12 to 6/12 Roof Pitch

943S Flashing, 7/12 to 12/12 Roof Pitch

943F Flashing, Flat Roof

Support Boxes/Thimbles:

940 Round Ceiling Support/Wall Thimble Cover

941 Cathedral Ceiling Support Box

942 Wall Thimble

Pipe:

908 6” Pipe Length, Galv.

908B 6” Pipe Length, Black

907 9” Pipe Length, Galv

907B 9” Pipe Length, Black

906 12” Pipe Length, Galv.

906B 12” Pipe Length, Black

904 24” Pipe Length, Galv.

904B 24” Pipe Length, Black

903 36” Pipe Length, Galv.

903B 36” Pipe Length, Black

902 48” Pipe Length, Galv.

902B 48” Pipe Length, Black

911 11” -14 5/8” Pipe, Adj. Galv.

911B 11” -14 5/8” Pipe, Adj. Black.

912 12” - 17” Pipe, Adj. Galv.

912B 12” - 17” Pipe, Adj. Black.

917 17” -24” Pipe, Adj. Galv.

917B 17” -24” Pipe, Adj. Black.

945 45° Elbow, Galv.

945B 45° Elbow, Black

990 90° Elbow, Galv.

990B 90° Elbow, Black

Misc.

953 Storm Collar

963 Ceiling Firestop

988 Wall Strap

9546 Attic Insulation Shield

923GK Chimney Liner Termination Kit

923GCL

909B Retrot Adj. Chimney Connector Retrot

Chimney Connector Plate

Decorative Trim Kits

Co-axial / Co-lineal Appliance Connector

3951 Round Celing Support; Wall Thimble Trim Kit,

Polished Brass

3960

Cathedral Ceiling Support Trim Kit, Polished Brass

SDV KITS

970A Standard Termination Kit includes 1 each of:

990B, 940, & 985. See Note below.

971HW Standard Termination Kit includes 1 each of:

990B, 940, 985, 904B, 911B

973 Vertical Termination Kit includes 1 each of:

NOTE: Straight pipe lengths are needed to complete

installation; the black 45

943, 953, 991 (support box NOT included)

° elbow is NOT included in kit.

HTI'S VENT PARTS LIST

HHW2 841-0670 Horizontal High Wind Cap

(recommended for optimal perfor-

mance)

HHW2K 844-4490 Horizontal Kit (One 90° Black

Elbow, Wall Thimble, 24” Black Pipe,

11”-14-5/8” Adjustable Vent, HHW2

Termination Cap)

RHVK 844-8920 Snorkel Kit #844-8920 (with Dura Vent part #'s 911B and 940)

SECURITY CHIMNEY'S SECURE VENT CHIMNEY SYSTEM

& AMERIVENT DIRECT VENTING COMPONENTS

Your Quadra-Fire Garnet has been approved with Security Chimney's Secure Vent Chimney System and Amerivent Direct

Venting Components. All the required certification tests have been successfully completed with OMNI-Test Laboratories,

Inc. Please contact your local dealer and they will advise you of the required parts needed for your installation. It is required

to use High Temperature RTV Sealant at the inner and outer joint connection of the first section to the supplied listed direct

vent starter section.

250-6443B October 7, 2003 Page 14

Page 15

R

GARNET DIRECT VENT ROOM HEATER

250-6443B October 7, 2003 Page 16

R

90 DEG. ELBOW

PIPE LENGT

H

PIPE LENGT

H

WALL

THIMBLE

PART #942

center line

WALL THIMBLE COVER

PART #940

HTI Vent HHW2 Part #841-0670

(recommended for optimum

performance)

OR

HORIZONT

AL TERMINATION

CAP, Simpson Dura Vent Part

#985

HTI Vent HHW2 Part #841-0670

(recommended for optimum

performance)

OR

HORIZONTAL TERMINATION

CAP, Simpson Dura Vent Part

center line

16-5/8"

WALL THIMBLE

PART

#942

WALL THIMBLE COVER

PART #940

45° Elbow

1" Clearance from stove

corner to combustible wall

.

3-1/2" Clearance from

stove corner to combustible

wall (for valve access on

right side.)

Wall Thimble Part #942

INSTALLATION METHODS

FIG. 1 - HORIZONTAL TERMINATION

Refer to pages 20-22 for installation instructions and requirements.

Type A - Up & Out Installation

GARNET DIRECT VENT ROOM HEATER

250-6443B October 7, 2003 Page 15

Type B - Straight Out Installation

Type C - 45° Elbow in Corner

Installation

Page 16

GARNET DIRECT VENT ROOM HEATER

R

3/4

3/4

3/4

SLIM LINE WALL THIMBLE

Part #844-9550

BEFORE YOU BEGIN:

Venting conguration will determine which Trim Ring you

use in your installation. Review Figures A, B and C on

Page 17. Figures A and B can use either Trim Ring, while

Figure C REQUIRES the Ventilated Trim Ring.

ASSEMBLING SLIM LINE TRIM RING

and HEAT SHIELD

1. Choose the appropriate Trim Ring for your installation.

Lay on at surface and bend up the 6 welded brackets into

a 90 degree position. The brackets along the outer edge of

the ring are for locating the ring in the center of the hole.

See Fig. 1.

2. The Heat Shield is shipped at and must be hand bent

into a half circle before attaching to Trim Ring. Bend Heat

Shield. See Fig. 2.

Note: Wear leather gloves when bending the Heat Shield

to prevent injury.

Fig. 1 Solid Trim Ring Shown

Fig. 2 Bending Heat Shield

3. Attach the Heat Shield to the Trim Ring with the four

screws provided. Screws go through the Heat Shield and

into the brackets on the Trim Ring. See Fig. 3.

INSTALLING SLIM LINE TRIM RING

and HEAT SHIELD

1. Measure from oor to center line of the vent pipe. Cut

out a 9-1/2" hole in the wall. Hold the Trim Ring/Heat Shield

Assembly in place and place a mark on the shield with a

black marker where it protrudes through the exterior wall.

See Fig. A on Page 17.

2. Use that mark as a guide to trim off excess Heat Shield

with a pair of sheet metal shears.

Note: When installing the Trim Ring/Heat Shield assembly

make sure the Trim Ring is centered in the hole and that

the shield is above the pipe. There must be a minimum of

3/4" minimum clearance maintained to combustibles from

the top of the Heat Shield. See Fig. 4.

3.

Ensure that framing on the inside of the wall is a minimum

inner framing diameter of 10" x 10".

Fig. 3 Ventilated Trim Ring Shown

Fig. 4

3/4"

3/4"

3/4"

4. The four Trim Ring mounting screws provided should be

replaced with appropriate fasteners for stucco, brick, concrete,

or other types of sidings.

250-6443B October 7, 2003 Page 16

Maintain minimum 3/4" clearance to

combustibles from top of shield.

Page 17

R

GARNET DIRECT VENT ROOM HEATER

250-6443B October 7, 2003 Page 18

R

HTI Vent HHW2 Part

#841-0670

(recommended for

optimum performance

)

OR

HORIZONT

AL

TERMINATION CAP,

Simpson Dura Vent

Part #985

center line

HEAT SHIELD

OVER TOP HALF

OF PIPE

TRIM RING

VENTILATED

REQUIRED

Minimum of 6"

of pipe through

the wall

INTERIOR

WALL

WALL

THIMBLE

90 DEG. ELBOW

PIPE LENGTH

PIPE LENGTH

center line

TRIM RING

SOLID OR

VENTILATED

HTI Vent HHW2 Part #841-0670

(recommended for optimum

performance)

OR

HORIZONT

AL TERMINATION

CAP, Simpson Dura Vent Part

#985

Place mark where protrudes

through exterior wall to cut off

Use HEAT SHIELD or WALL THIMBLE

45° Elbow

1" Clearance from stove

corner to combustible wall.

3-1/2" Clearance from

stove corner to combustible

wall (for valve access on

right side.)

HEAT SHIELD

OVER PIPE

TRIM RING

SOLID OR VENTILATED

NOTE: Wall Thimble removed

to show Heat Shield

SLIM LINE WALL THIMBLE (cont'd.)

Note: When installing the Garnet to a rear

wall in the Zero Clearance conguration

remove the two heat shield knock-outs on

the rear of the stove. See Fig. 5 Below.

FIG. 5

GARNET DIRECT VENT ROOM HEATER

FIG. A 90 DEGREE ELBOW

FIG. C ZERO CLEARANCE

250-6443B October 7, 2003 Page 17

FIG. B 45 DEGREE ELBOW

Page 18

GARNET DIRECT VENT ROOM HEATER

R

VERTICAL

TERMINATION

CAP

STORM

COLLAR

FLASHING

FIRESTOP

PIPE

LENGTH

SUPPORT

BOX

TERMINATION

CAP

PA

RT #991

EXISTING

METAL

CHIMNEY

SYSTEM

TO

P

ADAPTOR

FLASHING

4" FLEX PIPE

RETRO CONNECTOR

DIRECT VENT PIPE

INSTALLATION METHODS (cont'd.)

FIG. 2 - VERTICAL TERMINATION

Refer to pages 25-27 for installation instructions

and requirements.

On vertical terminations use only Dura-vent Part #991.

Figure 2

FIG. 3 - CLASS A METAL CHIMNEY

(USA only)

Refer to page 29 for installation instructions

and requirements.

Figure 3

250-6443B October 7, 2003 Page 18

Page 19

R

GARNET DIRECT VENT ROOM HEATER

250-6443B October 7, 2003 Page 20

R

imney Line

r

mination Ca

p

art #923G

K

Co-Axial to

Co-Linear

Connector

3" Flex Liner

Pipe Length

Optional

Showing (2)

30 ft

Sections of

imney Line

r

mination Ca

p

art #923G

K

Co-Axial to Co-

Linear Connector

Part #923GCL

30 ft of 3" Flex Liner

Exhaust Section

Pipe Length

Optional

4 ft of 3" Flex Liner

Air Intake Section"

The chimney must be

sealed from

the 4 ft

section to termination

using a smoke

shelf

or a damper. The seal

should be 6" below

the end of the 4 ft Air

Intake section.

This section of the

chimney must be

sealed

TERMINATION

CAP

PART #99

1

FLASHING

"

TOP ADAPTO

R

RETRO

CONNECTO

R

90 DEG.

ELBO

W

DIRECT

Chimney Liner

ermination Ca

p

art #923G

K

30 ft of 3" Flex

Liner

4 ft of 3" Flex Liner

Air Intake Section"

Chimney mus t be

seal ed from 4 f t

section to termination

using a smoke shelf

or a

damper. Seal

should be 6" below

end of 4 ft Air Intake

section.

This section of the

chimney must be sealed

Co-Axial to Co-Linear Connector

DAMPER MUST BE INSTALLED FOR THIS APPLICATION (SEE PAGE 24)

Alcove Clearance to

Combustibles must

NOTE: In the Commonwealth of Massachusetts, the word damper shall be

replaced with the words flue restrictor.

INSTALLATION METHODS (cont'd.)

FIG. 4 - A, B C & D INTO A MASONRY CHIMNEY (USA only)

Refer to pages 30-32 for installation instructions and requirements.

GARNET DIRECT VENT ROOM HEATER

Type A & B Co-Axial to Co-Linear Part 923GCL

Type A

Type C - Up & Out Installation

Type D - Hearth Mount

Type B

250-6443B October 7, 2003 Page 19

Page 20

GARNET DIRECT VENT ROOM HEATER

R

J or K

X

V

M

I

H

A

V

G

B

V

V

A

B

OPENABLE

FIXED CLOSED

V

F

V

C

B

B

E

L

V

D

V

O

O

P

D*

V

V

V

V

Electrical

Service

HORIZONTAL TERMINATION REQUIREMENTS

A = 12" clearances above grade, veranda, porch, deck or balcony

B = 12" clearances to window or door that may be opened

C = 12" USA/12" Canada: clearance to permanently closed window

*D = 18" vertical clearance to ventilated soffit located above the terminal within a horizontal distance of 2 feet from the

* E = 12" clearance to unventilated soft

F = 9" Clearance to outside corner. Clearance in accordance with local installation codes and the requirements of the gas supplier.#

G = 6" Clearance to inside corner. Clearance in accordance with local installation codes and the requirements of the gas supplier.#

H = 3 ft Canada: not to be installed above a gas meter/regulator assembly within 3 feet horizontally from the center-line

I = 3 ft USA/6ft Canada: clearance to service regulator vent outlet

J = 9" USA/12" Canada: clearance to non-mechanical air supply inlet to building or the combustion air inlet to any other

K = 3 ft USA/6ft Canada: clearance to a mechanical air supply inlet

**L = 7 ft clearance above paved sidewalk or a paved driveway located on public property

***M = 12" clearance under veranda, porch, deck or balcony

N = Clearance to adjacent building or deck. Clearance in accordance with local installation codes and the requirements of

O = 6" min. clearance from sides of electrical service

P = 12" min. clearance above electrical service

#In the Commonwealth of Massachusetts, installation must be performed by a licensed plumber or gas tter.

center-line of the terminal

of the regulator

appliance

the gas supplier.#

* 30" (762mm) minimum for vinyl clad softs

** a vent shall not terminate directly above a sidewalk or paved driveway which is located between two single family dwellings and

serves both dwellings.

*** only permitted if veranda, porch, deck or balcony is fully open on a minimum of 2 sides beneath the oor.

NOTE: Local Codes or Regulations may require different clearances.

NOTE: Location of the vent termination must not interfere with access to the electrical service.

WARNING: In the U.S: Vent system termination is NOT permitted in screened porches. You must follow side wall, overhang and ground clearances

as stated in the instructions. In Canada: Vent system termination is NOT permitted in screened porches. Vent system termination is permitted in

porch areas with two or more sides open. You must follow all side walls, overhang and ground clearances as stated in the instructions.

CAUTION: IF EXTERIOR WALLS ARE FINISHED WITH VINYL SIDING, IT IS RECOMMENDED TO USE TERMINATION CAP SLK-01TRD, AS

THE EXTERIOR FIRESTOP IS BUILT IN. IF YOU ARE USING SIMPSON DURA-VENT PART #985 IT IS NECESSARY TO INSTALL THE VINYL

PROTECTOR KIT (PART #950) TO THE TOP OF THE EXTERIOR FIRESTOP (FOR ALL ROUND TERMINATION CAPS).

= AREA WHERE TERMINAL IS NOT PERMITTED

= VENT TERMINAL

V

= AIR SUPPLY INLET

X

250-6443B October 7, 2003 Page 20

Page 21

R

GARNET DIRECT VENT ROOM HEATER

250-6443B October 7, 2003 Page 22

R

CENTER

LINE

CENTER

LINE

CENTER OF

HOLE

WALL

THIMBL

E

HORIZONTAL INSTALLATION

Step 1.

Determine the desired location of the stove. Check to

ensure that wall studs or roof rafters are not in the way

when the venting system is attached. If this is the case,

you may want to adjust the location of the stove.

Step 2.

Simpson Dura-Vent pipe is designed with special twistlock connections. To connect the venting system to the

stove flue outlet, a twist-lock adapter is built into the stove

at the factory. Remember to include wall thickness in

minimum clearances when figuring the measurements for

your installation needs.

Note: Twist-lock procedure: Four indentations, located

on the female ends of pipes and fittings, are designed

to slide straight onto the male ends of adjacent pipes

and fittings by orienting the four pipe indentations so

they match and slide into the four entry slots on the

male ends, see Fig. 5 below. Push the pipe sections

completely together, then twist-lock one section clockwise

approximately one-quarter turn, until the two sections are

fully locked. The female locking lugs will not be visible

from the outside, on the pipe or fittings. They may be

located by examining the inside of the female ends.

GARNET DIRECT VENT ROOM HEATER

Step 3.

For installations using a Wall Thimble Dura-Vent Part #942,

mark the wall for a 10” x 10” (25.4m x 25.4m) square

hole. The center of the square hole should line up with the

centerline of the horizontal pipe, as shown in Fig. 6. Cut

and frame the hole in the exterior wall where the vent will

be terminated. If the wall being penetrated is constructed of

noncombustible material, i.e. masonry block or concrete, a

7” (17.8cm) diameter hole is acceptable.

FIG. 6

FIG. 5

Female Locking Lugs

Male Locking Lugs

NOTE:

Horizontal runs of vent must be supported every 3’

(91cm). Wall straps are available for this purpose.

Horizontal sections require a 1/4" (6mm) rise for

every 12" (30.5cm) of horizontal travel.

Exterior Vent Diameter = 6 5/8" (177mm); Inner Vent

Diameter = 4" (10.2cm).

NOTE:

(1) Installation requires a minimum of 6" (15.2cm) horizontal

run of vent with a 1/4” (6mm) rise run towards the

termination. Each 1’ (30.5cm) of horizontal venting

must include a 1/4” rise. Never allow the vent to run

downward. This could cause high temperatures and

may present the possibility of a fire.

(2) The location of the horizontal vent termination on an

exterior wall must meet all local and national building

codes, and must not be easily blocked or obstructed,

see page 20.

(3) For installations requiring a vertical rise on the exterior

of the building, HTI RHVK Snorkel Kit #844-8920, 14”

(35.5cm) or 36” (91cm) tall snorkel terminations are

available. Follow the same installation procedures as

used for standard horizontal terminations. If the snorkel

termination must be installed below grade (i.e. basement

application), proper drainage must be provided to

prevent water from entering the snorkel termination. Do

not backfill around snorkel termination.

250-6443B October 7, 2003 Page 21

Page 22

GARNET DIRECT VENT ROOM HEATER

R

HOT

WOOD

SCREW

WALL THIMBLE

#942

PART HHW2 PART

841-0670 (Preferred)

or #985

WALL THIMBLE

COVER PART 940

WALL THIMBLE

PART 94

2

VINYL SIDING STANDOFF

WITH SIDING BENEATH

REMOVE

D

SCREW

S

BOLT HORIZONTAL

TOP TO VINYL

STANDOF

F

SCREW

S

APPLY SEALANT

TO ALL FOUR

SIDE

S

VINYL SIDING

FOLD STRAP

WALL

THIMBLE

COVER 940

1/4"

STRAP

SHEET METAL SCREW

WALL THIMBLE #942

AS REQUIRED BY

LOCAL

JURISDICTIO

N

8"

6"

7"

7"

HORIZONTAL INSTALLATION (cont'd.)

Step 4.

Position the horizontal vent termination in the center of the 10" x 10" (25.4cm x 25.4cm) square hole and run a bead of non-hardening

mastic around its outside edges, so as to make a seal between it and the wall, attach termination cap to the exterior wall with the four

wood screws provided. The arrow on the vent cap should be pointing up (Fig. 7)

FIG. 7

FIG. 8-A

FIG. 8-B

NOTES:

(1) The four wood screws provided should be replaced with appropriate fasteners for stucco, brick, concrete, or other types

of sidings.

(2) Termination Cap HHW2 (HTI Part #841-0670) is highly recommended on a building with vinyl siding, as the vinyl siding

standoff is built in. The pilot hole will be 2 inches closer to the bottom of the square than the top. Using a framing square,

draw a 14" x 14" square around the pilot hole. See Fig. 8-A. (NOTE: If you are installing Termination Cap HHW2, the pipe

will be off center on the flashing). Ensure that proper clearances to combustible materials are maintained. If you are using

Simpson Dura-vent termination cap #985 on a building with vinyl siding, a vinyl siding standoff (Simpson Dura-vent

Part #950), should be installed between the vent cap and the exterior wall (Fig. 8-B). Attach the vinyl siding standoff to

the horizontal vent termination. The vinyl siding standoff prevents excessive heat from possibly melting the vinyl siding

material. Vent terminal shall not be recessed into a wall or siding. Remove siding from behind area of standoff.

Step 5.

Slide the stove and vent assembly towards the wall,

carefully inserting the vent pipe into the vent cap assembly.

It is important that the vent pipe extend into the vent cap

a sufficient distance so as to result in a minimum pipe

overlap of 1” (32mm). Secure the connection between

the vent pipe and the vent cap by attaching the two sheet

metal strips extending from the vent cap assembly into

the outer wall of the vent pipe. Use the two sheet metal

screws provided to connect the strips to the pipe section

(Fig. 9).

Note: The attachment from the vent pipe to the vent cap

must be sealed with silicone. Venting terminals shall not

be recessed into a wall or siding.

250-6443B October 7, 2003 Page 22

FIG. 9

Page 23

R

GARNET DIRECT VENT ROOM HEATER

250-6443B October 7, 2003 Page 24

R

35'

34'

32'

30'

28'

26'

24'

22'

20'

18'

16'

14'

12'

10'

8'

6'

4'

2'

6' Minimum

Vertical

Termination

6" Min.

starter pipe.

6' Maximum Horizontal run with no vertical pipe and with 1/4" rise

per foot. Must use HHW2 or 985 Termination Cap.

C

L

35' Maximum

Vertical

2' 4' 6' 8' 10' 12' 14' 15'

HHW2

Part No.

841-0670

Part #985

Part #991

or

or

HHW2 Part 841-0670

Part #985

Example 1

Example 2

No Damper

in this area

Damper position

CLOSED in this area

Damper position

OPEN in this area

GARNET DIRECT VENT ROOM HEATER

INSTALLATION VENT GRAPH

1. Measure the vertical distance from the center line of the flue pipe to the center of the 90° elbow. On the graph below,

draw a horizontal line from that measurement on the vertical axis across until it intersects with the slanted line.

2. From the point of this intersection, draw a vertical line to the bottom of the graph.

3. The point at which this line meets the bottom line of the graph is the maximum length of the horizontal run.

EXAMPLE 1: If the vertical dimension from the center

line of the flue vent to the center of the 90° elbow is 7’

(2.13m), the horizontal run to the outer wall flange must

not exceed 11’10” (360.8cm)

4. Each 90° elbow is equivalent to 3' of vent pipe and each 45° elbow is equivalent to 1' of vent pipe, and must be

subtracted from the vent pipe run. A single horizontal to vertical 90° elbow is already calculated into the allowable 15'

run. Each additional 90° elbow reduces the maximum horizontal distance by 3'.

Example: The use of 3 elbows would reduce the allowable

horizontal run to 9' (3 - 1 = 2 elbows x 3' = 6';

15' max. - 6' = 9' max.)

VERTICAL DISTANCE

FROM APPLIANCE TO

90° ELBOW

NOTE: IF YOUR INSTALLATION FALLS WITHIN A SHADED AREA ON THE GRAPH, A DAMPER MUST BE

INSTALLED. SEE INFORMATION ON DAMPER INSTALLATION AND ADJUSTMENT ON PAGE 24.

NOTE: In the Commonwealth of Massachusetts, the word damper shall be replaced with the words ue restrictor.

250-6443B October 7, 2003 Page 23

EXAMPLE 2: If the vertical dimension from the center line

of the flue vent is 21’ (6.4m), the horizontal run to the

outer wall flange must not exceed 7'10" (238.7cm).

NOTES

The maximum horizontal vent run is 15’

(4.57m) when the vertical vent rise is 10’

(3.05m).

The minimum horizontal vent run is 6”

(15.2cm).

Minimum wall thickness is 4” (10.2cm).

Horizontal sections require a 1/4” (6mm) rise

for every 12” (30.5cm) of horizontal travel.

Exterior Vent Diameter = 6-5/8” (177mm);

Inner Vent Diameter = 4” (10.2cm)

Horizontal sections require noncombustible

support every 3’ (91cm), e.g. plumbing tape.

EXCEPTIONS

FOR HORIZONTAL INSTALLATIONS:

The maximum horizontal vent run is 6'

(182.8cm)

The maximum horizontal vent run with a

45° elbow is 5' (152.4cm)

No external minimum rise is required.

The minimum horizontal vent run is 6"

(15.2 cm).

For any vertical termination a minimum

of 6' (182.8cm) vertical must be used.

Page 24

GARNET DIRECT VENT ROOM HEATER

R

DAMPER INSTALLATION AND ADJUSTMENT

WHEN YOUR INSTALLATION FALLS WITHIN A SHADED AREA ON THE VENT GRAPH (PAGE

23). A DAMPER MUST BE INSTALLED FOR PROPER OPERATION. (In the Commonwealth of

Massachusetts, the word damper shall be replaced with the words ue restrictor.)

Installation of the damper requires the removal of the bafe. Remove the bafe by removing the 4 screws holding the bafe in

place. (Two screws in back and one on each side). Angle the bafe slightly and remove from rebox (Fig. 1).

The two screws holding the bottom of the bafe in place also hold the damper in place. After removing the bafe

remove the two screws located at the back of the rebox. See Fig. 2. (These will also be used to secure the bafe

in place.) Hold the damper in position and install the four screws to hold it in place. See Fig. 3. Leave the lower

screws loose enough to slide bafe over them. Slide the bafe back into position. Tighten the screws and re-install

the screws on the sides.

FIG. 1 Removing Bafe

FIG. 2 Remove and re-use screws for installation

Figs. 3 and 4 show the damper installed in fully open and fully closed positions.

Refer to the vent graph for the best damper position for your installation.

FIG. 3 Damper In Fully Open Position

250-6443B October 7, 2003 Page 24

FIG. 4 Damper in Fully Closed Position

Page 25

R

GARNET DIRECT VENT ROOM HEATER

250-6443B October 7, 2003 Page 26

R

35'

MAXIMUM

PLUMBER'S TAPE

CONNECTED TO

WALL STRAP

WALL

STRAP

(2) 45 DEGREE

ELBOWS

GARNET DIRECT VENT ROOM HEATER

VERTICAL INSTALLATION INSTRUCTIONS

USING GS SERIES PIPE

Step 1.

Check the installation instructions for required 1” (25mm) clearances (air space) to

combustibles when passing through ceilings, walls, roofs, enclosures, attic rafters, or other

nearby combustible surfaces. See page 27, Fig. 16. Do not pack air space with insulation.

Check the instructions below for maximum vertical rise of the venting system, and any

maximum horizontal offset limitations. All offsets must fall within the set parameters of the vent

graph located on page 23.

NOTE: Maximum vertical rise allowable is 35’ (10.7m) (Fig. 10).

NOTE: Maximum number of 45° elbows permitted for a vertical installation is eight, provided

their installation does not decrease maximum allowable horizontal run (as specified by Vent

Graph, on page 23).

FIG. 10

FIG. 11

250-6443B October 7, 2003 Page 25

Page 26

GARNET DIRECT VENT ROOM HEATER

R

FRAMING

1 - 1/2" LONG

WOOD SCREWS

CEILING

JOISTS

SHINGLES OVERLAP ON

TOP EDGE OF FLASHING

CAP AND STORM

COLLAR NOT SHOWN

FOR CLARIT

Y

VERTICAL INSTALLATION

USING GS SERIES PIPE (cont'd.)

Step 2.

Set the gas stove in its desired location. Drop a plumb bob

down from the ceiling to the position of the stove flue

exit, and mark the location where the vent will penetrate

the ceiling. Drill a small hole at this point. Next, drop a

plumb bob from the roof to the hole previously drilled in the

ceiling, and mark the spot where the vent will penetrate

the roof. Determine if ceiling joists, roof rafters, or other

framing will obstruct the venting system. You may wish to

relocate the stove, or to offset, as shown in Fig. 11, page

25 to avoid cutting loadbearing members.

Step 3.

To install the round support box/wall thimble in a flat

ceiling, cut a 10" (25.4cm) square hole in the ceiling,

centered on the hole drilled in Step 2. Frame the hole as

shown in Fig. 13.

FIG. 13

of pipe and elbows necessary to reach from the ceiling

support box up through the roof line. Galvanized pipe

and elbows may be utilized in the attic, as well as above

the roofline. The galvanized finish is desirable above the

roofline, due to its higher corrosion resistance.

NOTE:

(1) If an offset is necessary in the attic to avoid

obstructions, it is important to support the vent pipe

every 3’ (91.4cm) to avoid excessive stress on the

elbows, and possible separation. Wall straps are

available for this purpose, Fig. 11, page 25.

(2) Whenever possible, use 45° elbows, instead of 90°

elbows. The 45° elbow offers less restriction to the

flow of flue gases and intake air.

Step 6.

Slip the flashing over the pipe section(s) protruding

through the roof. Secure the base of the flashing to

the roof with roofing nails. Ensure the roofing material

overlaps the top edge of the flashing as shown in Fig. 14.

Verify that the chimney is the required height above the

roof. See Roof Pitch Table on page 27 of this manual

Step 4.

Assemble the desired lengths of GS pipe and elbows

necessary to reach from the stove up through the round

support box. Ensure that all pipe and elbow connections

are in their fully twist-locked position. Be sure to seal

the outer pipe with appropriate sealant (high temperature

silicone).

Step 5.

Cut a hole in the roof centered on the small drill hole

placed in the roof in Step 2. The hole should be of sufficient

size to meet the minimum requirements for clearance to

combustibles, as specified. Continue to assemble lengths

250-6443B October 7, 2003 Page 26

FIG. 14

Page 27

R

GARNET DIRECT VENT ROOM HEATER

250-6443B October 7, 2003 Page 28

R

Dimension "H"

Obtained From

Table 1

TABLE 1

MINIMUM HEIGHT

ROOF PITCH FEET METERS

Flat to 7/12 1 0.30

Over 7/12 to 8/12 1.5 0.46

Over 8/12 to 9/12 2 0.61

Over 9/12 to 10/12 2.5 0.76

Over 10/12 to 11/12 3.25 0.99

Over 12/12 to 14/12 5 1.52

Over 14/12 to 16/12 6 1.83

Over 16/12 to 18/12 7 2.13

Over 18/12 to 20/12 7.5 2.29

Over 20/12 to 21/12 8 2.44

H

The height of the vent cap must

meet the minimum building code

requirements described above

.

MIN. 1' CLEARANCE

CEILING FIRESTOP

NAILS

MIN. 1' CLEARANCE

MIN. 1' CLEARANCE

MIN. 1' CLEARANCE

VERTICAL INSTALLATION

USING GS SERIES PIPE (cont'd.)

Step 7.

Continue to assemble pipe sections until the height

of the vent cap (H) (Fig. 15) meets the minimum

code requirements as outlined in the current CAN/

CGA-B149 Installation Codes (in Canada), the

National Fuel Gas Code NFPA 54/ANSI Z223.1

(in USA), or local codes. Note that for steep roof

pitches, the vent height must be increased. See

Table 1 below. In high wind conditions, nearby trees

adjoining rooflines, steep pitched roofs, and other

similar factors can result in poor draft, or down

drafting. In these cases increasing the vent height

may solve this problem.

FIG. 15

GARNET DIRECT VENT ROOM HEATER

Step 8.

Twist-lock the vent cap and seal.

Note:

(1) For multi-story vertical installations, a ceiling

firestop (SDV part #963) is required at the

second floor, and any subsequent floors (Fig.

16). The opening should be framed to 10” x 10”

(25.4cm x 25.4cm) inside dimensions, in the

same manner as shown in Fig. 13, page 26.

(2) Any occupied areas above the first floor,

including closets and storage spaces, which the

vertical vent passed through must be enclosed.

The enclosure may be framed and sheetrocked

with standard construction materials; however,

refer to these installation instructions for the

minimum allowable clearance between the

outside of the vent pipe and the combustible

surfaces of the enclosure. Do not fill any of the

required air space with insulation.

250-6443B October 7, 2003 Page 27

FIG. 16

Page 28

GARNET DIRECT VENT ROOM HEATER

R

LEVEL

CATHEDRAL CEILING

SUPPORT BOX

2" MIN. BELOW

FINISHED CEILING

CUT HOLE 1/8" GREATER IN

SIZE THAN PATTER N OF

SUPP ORT BO X AS I T IS

PROJE CTED ONTO ROOF

LINE

VERTICAL INSTALLATION

CATHEDRAL CEILING INSTALLATION

Step 1.

Follow installation Steps 1 and 2 under vertical

termination section, pages 25 and 26.

Step 2.

Using the plumb-bob, mark the centerline of the

venting system on the ceiling, and drill a small hole

through the ceiling and roof at this point. From the

roof, locate the drill hole and mark the outline of the

cathedral ceiling support box.

Step 3.

Remove shingles or other roof covering as necessary

to cut the rectangular hole for the support box. Cut the

hole 1/8” (3mm) larger than the support box outline.

FIG. 17

Step 4.

Lower the support box through the hole in the roof

until the bottom of the box protrudes at least 2” (51cm)

below the ceiling (Fig. 17). Align the support box both

vertically and horizontally with a level. Temporarily tack

the support box in place through the inside walls and

into the roof sheathing.

Step 5.

Using tin snips, cut the support box from the top

corners down to the roofline, and fold the resulting

flaps over the roof sheathing (Fig. 18). Before nailing it

to the roof, run a bead of non-hardening mastic around

the top edges of the support box to make a seal

between it and the roof. Clean out any combustible

material from inside the support box.

Step 6.

Complete the cathedral ceiling installation by following

the same procedures outlined in steps 4 through 8 for

vertical terminations, pages 26 & 27.

FIG. 18

250-6443B October 7, 2003 Page 28

Page 29

R

GARNET DIRECT VENT ROOM HEATER

250-6443B October 7, 2003 Page 30

R

Sheet Metal Screws

High Wind

Te

rmination

Cap

Drill (4) 1/8"

Diameter Holes

Sheet Metal Screws

Flex Pipe

Top Adapter

VERTICAL INSTALLATION

INSTALLATION INTO A CLASS A METAL CHIMNEY (USA ONLY)

GARNET DIRECT VENT ROOM HEATER

NOTE: Have the existing installation inspected by

a qualified chimney sweep or professional installer

prior to converting to direct vent. The existing

chimney system must be in serviceable condition

and functionally sound and clean.

Step 1.

Remove existing chimney cap.

Step 2.

Measure the distance from the top of the chimney

to the bottom of the ceiling support box, add 3”

(76mm) to this measurement, and cut a section of 4”

(101mm) flex pipe to that length (the flex should be

extended to its nominal length).

Step 3.

Connect the end of the flex pipe section to the

underside of the top adapter (SDV #985K, 986K or

987K), using four sheet metal screws (Fig. 19).

FIG. 19

Step 4.

Pass the flex pipe down through the center of the

chimney system, and center the top adapter on the

top of the chimney pipe. Drill four 1/8” (3mm) diameter

holes through the top adapter, and into the chimney

top. Ensure that you are drilling into the metal on

the chimney. Twist lock the high wind termination cap

(SDV #991) onto the top adapter (Figs. 20 and 21).

FIG. 20

FIG. 21

Step 5.

Pull the flexpipe down through the ceiling support box,

until it protrudes approximately 3" (76mm). Connect

the flex pipe to the retro connector (SDV #909B), and

attach with sheet metal screws.

Step 6.

Push the flex pipe back up into the ceiling support box,

center the retro connector, and attach it to the support

box with sheet metal screws.

Step 7.

The connection between the appliance and the retro

connector may be completed with sections of direct

250-6443B October 7, 2003 Page 29

vent pipe.

Page 30

GARNET DIRECT VENT ROOM HEATER

R

10" x 10" FRAMED

OPENING IN WALL

STUDWALL

MASONRY

CHIMNEY

RETRO

CONECTOR

(4) MASONRY BOLTS

(NOT INCLUDED)

WALL THIMBLE

CUT AND BEND

FLASHING AS NEEDED

TO FIT CHIMNEY

SEALANT-ADHESIVE

VERTICAL INSTALLATION

INSTALLATION INTO AN EXISTING MASONRY CHIMNEY (USA ONLY)

Step 1.

Before cutting any holes, assemble the desired sections

of direct vent pipe to determine the center of the masonry

penetration.

Step 2.

Once the center point of the penetration has been determined,

cut a 6” (152mm) diameter hole in the masonry. If the hole

is too large, the retro connector might not mount properly; if

the hole is too small, the appliance might starve for intake air.

If there is a frame wall in front of the masonry wall, cut and

frame a 10” (254mm) square opening in the wall (centered

around the 6” (152mm) masonry opening). If there is sheet

rock only (no studs) in front of the masonry the 10” (254mm)

opening is still needed, but does not need to be framed. If the

hole is framed a wall thimble is required. This allows the retro

connector to mount directly on the masonry and provide the

correct clearances to combustibles (Fig. 22).

FIG. 22

Step 3.

Secure the flashing (SDV

#705C) to the top of the

masonry chimney using a bead

of non-hardening sealantadhesive. If the flashing is

larger than the top of the

chimney, cut and fold flashing

as needed to fit chimney (Fig.

23).

Step 4.

To determine the length of

flex needed, measure from 3”

(76mm) above the top of the

flashing down to the level of

the opening. Add the distance

from the center of the chimney

out through the wall. Cut a

piece of 4” (102mm) flex to this

length (extended to its nominal

length). Be sure to leave 2”-3”

(51mm-76mm) of flex above

the existing chimney to allow

for connection to the

termination kit.

FIG. 23

250-6443B October 7, 2003 Page 30

NOTE: FOR HEARTH APPLICATIONS

REFER TO PAGE 19 FOR THE USE

OF THE 923GCL CO-AXIAL TO COLINEAR APPLIANCE CONNECTOR.

Step 5.

Connect the flex liner to the top adapter using three (3)

sheet metal screws (Fig. 19, page 29).

Step 6.

Feed the flex liner through the flashing into the chimney.

Carefully feed the flex liner down the chimney to the bottom

and out the opening in the masonry wall, forming an angle to

line up the flex liner with the vent opening on the appliance.

WARNING: Do not let the flex liner sag below the level at

which it will connect to the appliance or connector. This

could allow hot gas to become trapped and potentially

become a fire hazard. The flex liner path should always

be sloped up toward the termination cap.

Page 31

R