Page 1

Q-TECH

COR PORATI ON

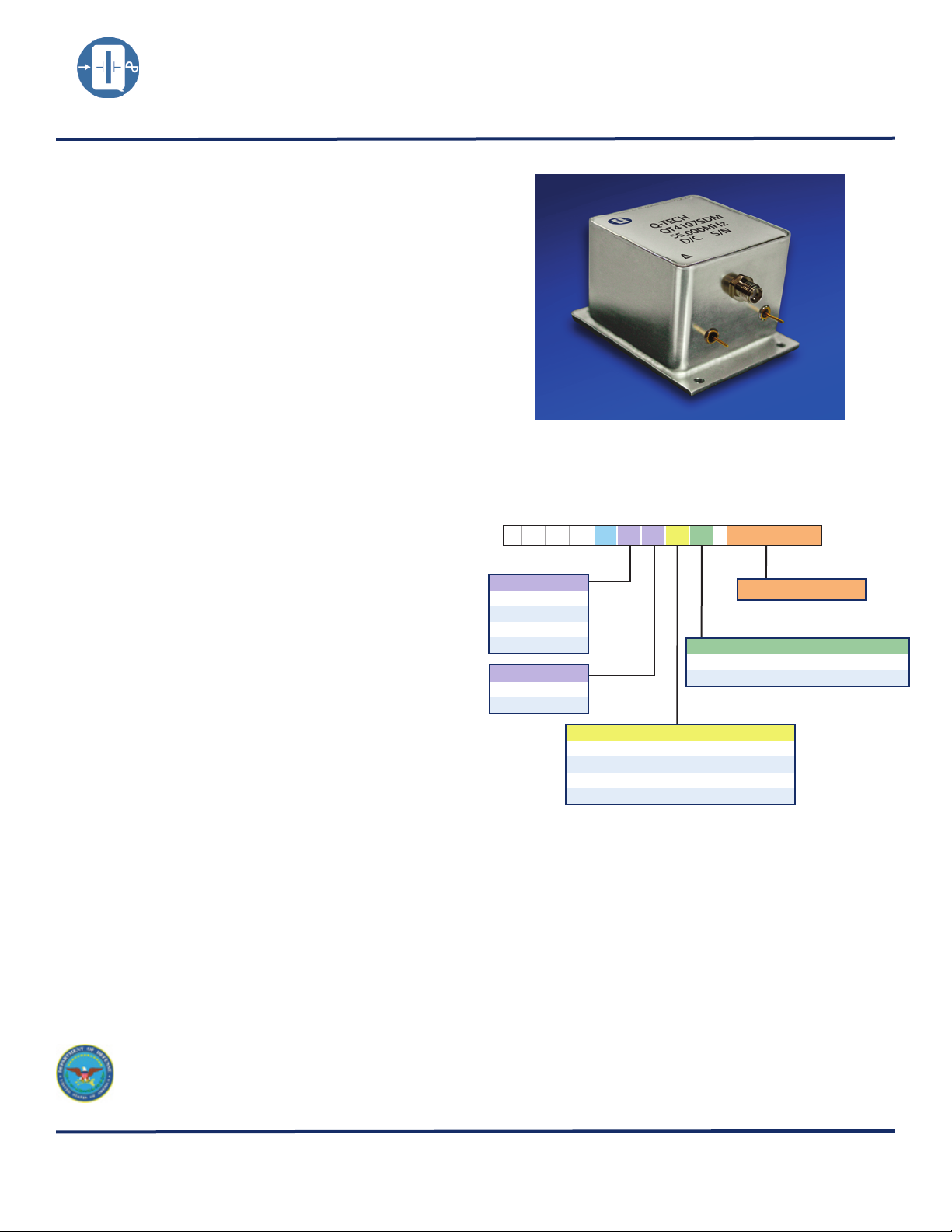

Description

Q-Tech’s High Stability Oven Controlled Crystal Oscillator

(OCXO) is a high reliability signal generator that provides Sine

wave or HCMOS output. The OCXO is designed to be used in

Aerospace applications.

It is designed to withstand radiation level up to 100kRad (*)

(total dose), high shock and vibration. The OCXO has very low

phase noise. Low G-Sensitivity SC-Cut Crystal utilized in the

design guarantees 1PPB/G or better. The reliable construction

of this design qualifies it for stringent environmental

applications.

(*) Please contact factory for higher level of radiation

hardness.

Features

• Made in the USA

• ITAR

• DFARS 252-225-7014 Compliant:

Electronic Component Exemption

• USML Registration # M17677

• Supply voltages 3.3Vdc to 15Vdc

• Wide temperature range (-40ºC to +85ºC)

• SC-Cut crystal

• Low phase noise and jitter

• Choice of output power and load

• Radiation Hardened

• Custom design available tailored to meet customer’s needs

• Q-Tech does not use pure lead or pure tin in its products

LOW PHASE NOISE, SPACE LEVEL OCXO

3.3 to 15Vdc - 1MHz to 125MHz

Ordering Information

(Sample part number)

QT4107SDM-55 . 0 0 0 M Hz

Q T 4 1 0 7 S D M- 55.000MHz

Supply Voltage:

3 = +3.3V

5 = +5.0V

6 = +12.0V

7 = +15.0V

Logic:

C = HCMOS

S = Sine Wave

Frequency vs. Temperature Code:

G = ± 100PPB at -20ºC to +70ºC

H = ± 10PPB at -20ºC to +70ºC

J = ± 200PPB at -40ºC to +85ºC

D = ± 20PPB at -40ºC to +85ºC

For Non-Standard requirements, contact Q-Tech Corporation at

Sales@Q-Tech.com

Blank=EM

Output Frequency

Screening Option:

M=Per MIL-PRF-55310, Level S

Applications

Packaging Options

• Designed to meet today’s requirements for Space Grade

applications

• Control and measurement

• Signal processing

• Standard packaging in black foam

Other Options Available For An Additional Charge

• P. I. N. D. test (MIL-STD 883, Method 2020)

• Phase Noise test (Static and under vibration)

• Jitter test

Specifications subject to change without prior notice.

ITAR Controlled

Q-TECH Corporation - 10150 W. Jefferson Boulevard, Culver City 90232 - Tel: 310-836-7900 - Fax: 310-836-2157 - www.q-te ch.co m

QPDS-0008 (Revision B, April 2013 )(ECO# 10835)

1 of 6

Page 2

Q-TECH

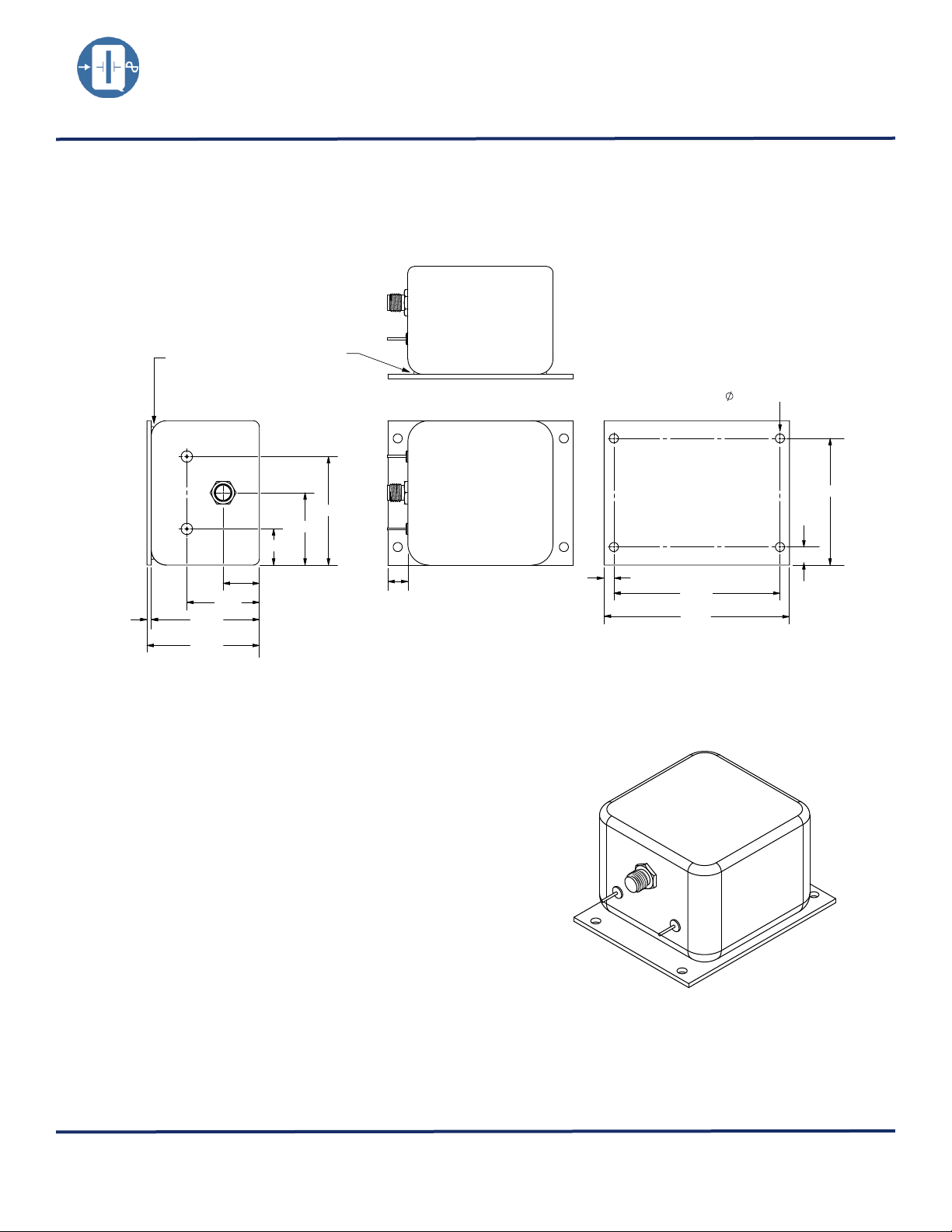

.275

VCC

CASE IS WELDED TO .060 PLATE

BRAZE BASEPLATE TO CASE AROUND

ENTIRE PERIMETER PRIOR TO PLATING

OUT

GND

.060

1.490

1.560

1.550

1.000

.500

1.500

1.000

.500

2.560

2.555

4X

.125±.003 THRU

2.290

.135

1.750

.250

COR PORATI ON

LOW PHASE NOISE, SPACE LEVEL OCXO

3.3 to 15Vdc - 1MHz to 125MHz

Package Outline -

Dimensions are in inches

Package Information

• Package Material: CRS

• Weight: 165g typ., 175g max.

• Package Finish: Nickel Plating 500 micro Inches

• SMA Connector: Body = Brass (QQ-B-626), Nickel Plated

Q-TECH Corporation - 10150 W. Jefferson Boulevard, Culver City 90232 - Tel: 310-836-7900 - Fax: 310-836-2157 - www.q-te ch.co m

QPDS-0008 (Revision B, April 2013 )(ECO# 10835)

Contact Pin = BeCu, Gold Plated

Insulators = Teflon, MIL-P-19468

• Power Connetors: Gold Plated per MIL-G-45204C, Class 00

2 of 6

Page 3

Q-TECH

COR PORATI ON

LOW PHASE NOISE, SPACE LEVEL OCXO

3.3 to 15Vdc - 1MHz to 125MHz

Electrical Characteristics

Parameters Conditions Requirements

Output Frequency Range (Fo)

Supply Voltage (Vdd) ±5.0% +3.3Vdc, +5Vdc, +12Vdc and +15Vdc

Initial Tolerance @+25ºC ±0.2ppm

Temperature Range See Option Codes

Frequency Stability vs. Temperature See Option Codes

Frequency Stability vs. Voltage Variation Over Temperature Range ±10PPB

Frequency Stability vs. Load Variation ±5.0% Load Variation ±20PPB

Warm-up Power max. @-40ºC 4.8W

Steady State Power max. @+25ºC 2.7W

Warm-up Time @+25ºC to ±100PPB (2 hours ref.)

Output Waveform Sine Wave HCMOS

Output Power (See note 1) +3.0±1.0dBm

Output Power Stability (See note 2) Over Temperature Range

Duty Cycle Over Temperature Range 50%±5.0%

Output Load 50Ω 10kΩ//15pF

Harmonics Over Temperature Range -35dBc

Spurious (See note 3) Over Temperature Range -90dBc

Aging

G-Sensitivity max. 1PPB/G

Phase Noise for 50MHz OCXO (typ.)

Per Day 1PPB

15 years 1.5PPM

1Hz -70dBc/Hz

10Hz -102dBc/Hz

100Hz -132dBc/Hz

1kHz -148dBc/Hz

10kHz -155dBc/Hz

100kHz -155dBc/Hz

1MHz — 125MHz

10 min.

±1.0dBm

Other Design and Test Options

• Phase Noise and Jitter built to specification

including static and vibration.

• Low supply current

• QCI tests

• Tight frequency stability versus temperature,

supply voltage, and load variations

Notes:

1. The output level is determined by the supply

voltage, load, and package size.

2. Typical amplitude stability over temperature is

±10% or less.

3. Typical spurious level is better than -100dBc over

the spectrum of 100kHz to 1GHz.

• Low spurious (see note 3)

• Low frequency aging, Allan Variance

• High-shock resistant

Q-TECH Corporation - 10150 W. Jefferson Boulevard, Culver City 90232 - Tel: 310-836-7900 - Fax: 310-836-2157 - www.q-te ch.co m

QPDS-0008 (Revision B, April 2013 )(ECO# 10835)

3 of 6

Page 4

Q-TECH

COR PORATI ON

LOW PHASE NOISE, SPACE LEVEL OCXO

3.3 to 15Vdc - 1MHz to 125MHz

Environmental Specifications

Q-Tech Standard Screening similar to (MIL-PRF-55310) is available. Q-Tech can also customize screening and test procedures to meet

your specific requirements. The packages are designed and processed to exceed the following test conditions:

Environmental Test Test Conditions

Initial Accuracy at Reference Temperature MIL-PRF-55310, Type 4, Class 3

Frequency Warm-up MIL-PRF-55310, Type 4, Class 3

Initial Frequency-Temperature Accuracy MIL-PRF-55310 (4.8.10.1)

Frequency-Voltage Tolerance MIL-PRF-55310

Frequency-Load Tolerance MIL-PRF-55310

Phase Noise Steady-State MIL-PRF-55310

Phase Noise Random Vibration MIL-PRF-55310

Output Power (Sinusoidal Waveform) MIL-PRF-55310

Output Logic Voltage Levels (Square wave ) MIL-PRF-55310

Rise Time and Fall Time (Square wave ) MIL-PRF-55310

Duty Cycle (Square wave ) MIL-PRF-55310

Harmonic and Sub-harmonic Distortion MIL-PRF-55310

Spurious Response MIL-PRF-55310

Oven Input Current-Power MIL-PRF-55310, Type 4, Class 3

Temperature Cycling MIL-STD-883, Method 1010, Cond. B

Constant Acceleration MIL-STD-883, Method 2001, Cond. A, Y1

Seal Fine Leak MIL-STD-883, Method 1014, Cond. A & C

Burn-in 240 hours, At highest operating temperature with load

Aging 30 days, MIL-PRF-55310, Type 4, Class 3

Random Vibration MIL-STD-883, Method 2026

Shock, Non Operating MIL-STD-883, Method 2002

Thermal Shock, Non Operating MIL-STD-202, Method 107, Cond. B

Ambient Pressure MIL-STD-202, 105, Cond. G, 5 minutes dwell time minimum

Resistance to Solder Heat MIL-STD-202, Method 210, Cond. C

Terminal Strength MIL-STD-202, Method 211, Cond. C

Resistance to Solvents MIL-STD-202, Method 215

Solderability MIL-STD-202, Method 208

ESD Classification MIL-STD-883, Method 3015, Class 1HBM 0 to 1,999V

Non-destructive Bond Pull MIL-STD-883, Method 2023

Please contact Q-Tech for higher shock requirements

Q-TECH Corporation - 10150 W. Jefferson Boulevard, Culver City 90232 - Tel: 310-836-7900 - Fax: 310-836-2157 - www.q-te ch.co m

QPDS-0008 (Revision B, April 2013 )(ECO# 10835)

4 of 6

Page 5

Q-TECH

COR PORATI ON

LOW PHASE NOISE, SPACE LEVEL OCXO

3.3 to 15Vdc - 1MHz to 125MHz

Design and Construction

The design and construction of the crystal oscillator shall be as specified herein. As a minimum, the oscillators shall meet the design and

construction requirements of MIL-PRF-55310.

Element De-rating

All active and passive elements shall be derated in accordance with the applicable hybrid microcircuit element requirements of

MIL-STD-975. Elements shall not operate in excess of de-rated values.

Worst Case Circuit Analysis

Worst case analysis shall be based on:

a. Maximum rated value

b. The worst case design value

c. Derating factor for each element

d. Temperature variation

e. Radiation

MTBF

Mean Time between Failure analysis shall be done based on MIL-HDBK-217

Element Evaluation

All piece parts shall be derived from lots that meet the element evaluation requirements of MIL-PRF-38534, Class K except for

the following exceptions:

Active Elements

a) Visual inspection of silicon on sapphire microcircuits. Semicircular crack(s) or multiple adjacent cracks, not in the active

area, starting and terminating at the edge of the die are acceptable. Attached (chip in place) sapphire is nonconductive

material and shall not be considered as foreign material and will be considered as nonconductive material for all

inspection criteria.

b) Subgroup 4, Scanning Electron Microscope (SEM) inspection. The manufacturer may allow the die distributor, at his

option, select two (2) dice from a waffle pack (containing a maximum quantity of 100 die), visually inspect for the worst

case metallization of the 2 dice, and take SEM photographs of the worst case.

c) Subgroup 5 radiation tests. Subgroup 5 radiation tests are not required unless otherwise specified in the detail

specification.

Package Elements

a) Salt spray. Salt spray testing is not required.

Quartz Crystal Material

Unless otherwise specified by the detail specification, the quartz Crystal material shall be swept synthetic, grade 2.2 or better.

Crystal Mounting

The crystal element shall be four-point mounted in such a manner as to assure adequate crystal performance when the oscillator

is subjected to the environmental conditions specified herein.

Q-TECH Corporation - 10150 W. Jefferson Boulevard, Culver City 90232 - Tel: 310-836-7900 - Fax: 310-836-2157 - www.q-te ch.co m

QPDS-0008 (Revision B, April 2013 )(ECO# 10835)

5 of 6

Page 6

Q-TECH

COR PORATI ON

LOW PHASE NOISE, SPACE LEVEL OCXO

3.3 to 15Vdc - 1MHz to 125MHz

Phase Noise and Phase Jitter Integration

Phase noise is measured in the frequency domain, and is expressed as a ratio of signal power to noise power measured in a 1Hz bandwidth

at an offset frequency from the carrier, e.g. 10Hz, 100Hz, 1kHz, 10kHz, 100kHz, etc. Phase noise measurement is made with an Agilent

E5052A Signal Source Analyzer (SSA) with built-in outstanding low-noise DC power supply source. The DC source is floated from the

ground and isolated from external noise to ensure accuracy and repeatability.

In order to determine the total noise power over a certain frequency range (bandwidth), the time domain must be analyzed in the frequency

domain, and then reconstructed in the time domain into an RMS value with the unwanted frequencies excluded. This may be done by

converting L(f) back to Sφ(f) over the bandwidth of interest, integrating and performing some calculations.

Symbol

∫L(f)

Sφ (f)=(180/Π)x√2 ∫L(f)df

RMS jitter = Sφ (f)/(fosc.360°) Jitter(in seconds) due to phase noise. Note Sφ (f) in degrees.

Integrated single side band phase noise (dBc)

Spectral density of phase modulation, also known as RMS phase error (in degrees)

Definition

The value of RMS jitter over the bandwidth of interest, e.g. 10kHz to 20MHz, 10Hz to 20MHz, represents 1 standard deviation of

phase jitter contributed by the noise in that defined bandwidth.

Typical Phase Noise of 50MHz OCXO

ECO REV REVISION SUMMARY Page

10572

10835

Q-TECH Corporation - 10150 W. Jefferson Boulevard, Culver City 90232 - Tel: 310-836-7900 - Fax: 310-836-2157 - www.q-te ch.co m

QPDS-0008 (Revision B, April 2013 )(ECO# 10835)

A Change from ECCN:EAR99 to ITAR 1

Fixed typo under “Other Design and Test Options” (from see note 5 to 3) 3

B

Add document # on footer (QPDS-0008) All

6 of 6

Loading...

Loading...