Page 1

QTech SMS Controller

Quick Start Guide

Page 2

QTech SMS Controller - Quick Start Guide – v1.4 – February 2014 2

Introduction

The SMS Controller is a powerful cellular remote control unit. It uses text messages

to provide multiple people with status conditions, alarms and control options.

Setup and configuration of the SMS Controller is via “Workbench”, a user friendly PC

application for Microsoft Windows 7/XP. Setup can be performed “offline” allowing

you to pre-configure SMS Controllers. These configurations can then be saved for

future use.

There are two versions of the SMS Controller, P/N PD8610 GSM/GPRS for

Vodafone/2Degrees or P/N PD8611 Quad band for Telecom XT/Vodafone/2Degress.

Each SMS Controller is supplied with the following:

Qty 1x SMS Controller Module

Qty 1x Aerial (stub type), 2dBi gain (P/N PD9230)

Qty 1x USB (Type A-B) Programming Cable (P/N CB-USB-AB)

Qty 1x CD-ROM containing Workbench configuration software

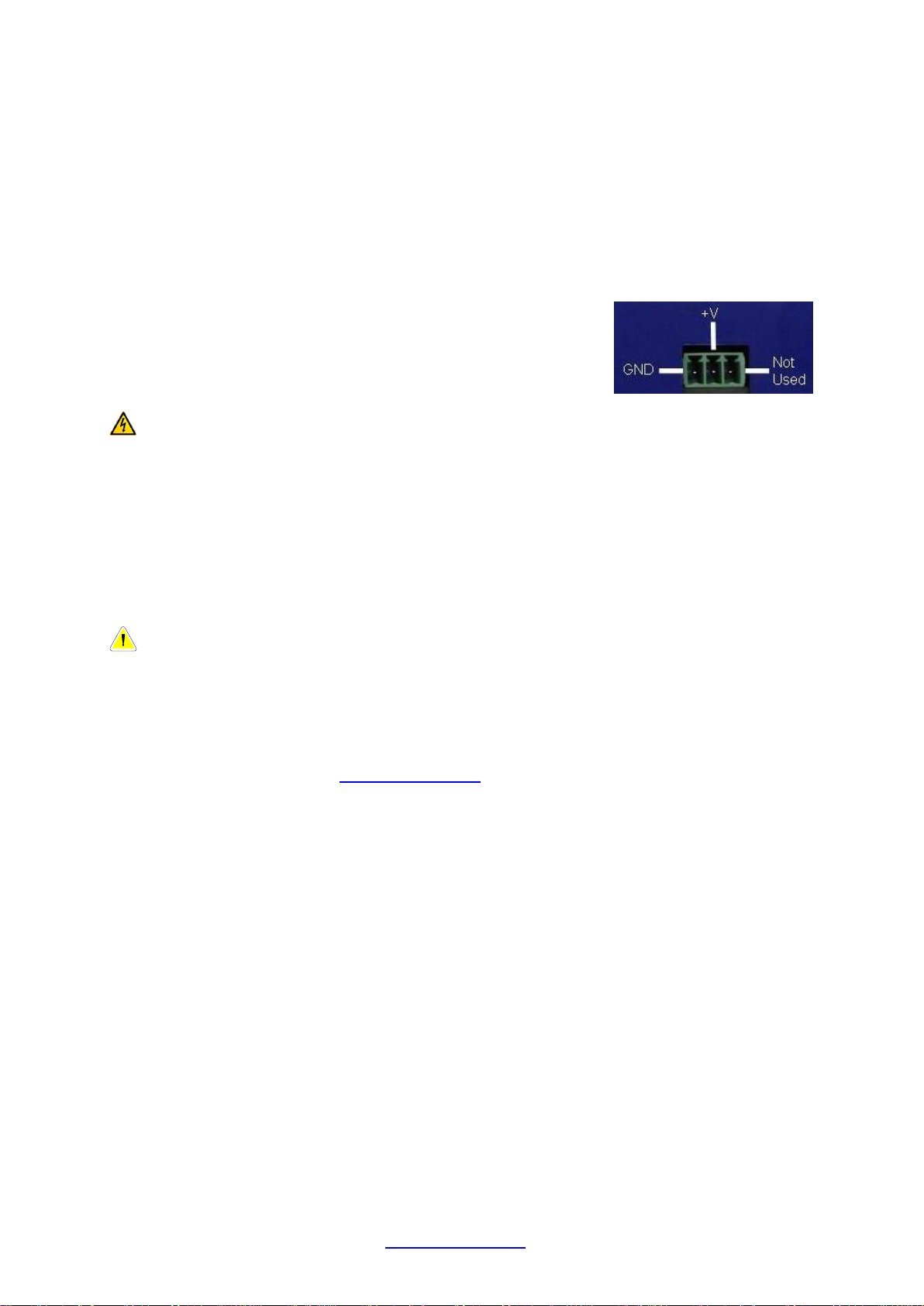

Install the SIM Card

Before installing the SIM card, ensure that it is activated. We recommend you insert

the SIM into a regular cell phone to prove this.

Carefully remove the SMS Controller cover by prising the side panels close to the

retaining dimples.

Locate the SIM card holder adjacent to the aerial. Push the top part of the holder in

the direction of the “Open” arrows (away from the aerial). Carefully insert the SIM

card from your chosen Telco. Be careful to orientate the card correctly. Finally,

carefully slide the plastic retainer towards the aerial.

Unlock Holder Insert SIM Close Holder Lock Holder

Note – The SIM card must be a “full size” card, not a “micro SIM”.

www.qtech.co.nz Tel: 03 3663713

Page 3

QTech SMS Controller - Quick Start Guide – v1.4 – February 2014 3

Connect the supply to the power connector, positive to the

“+V” terminal, negative to “GND”. The third terminal on

the right is not used.

We recommend the QTech plug pack P/N PD5412.

Aerial Connection

Carefully connect the aerial. Do not operate the SMS Controller without an aerial

connected. Refer to the aerial notes section on page 6 for alternatives.

Power Supply Connection

The SMS Controller is powered from an external 12-30 V DC supply.

Warning – Do NOT use Switch Mode Power Supplies (SMPS) with this

product. The DC power supply used for this product MUST have a grounded

negative or be a “linear” transformer based plug pack. The reason is that the

aerial, programming port and external connections can provide exposed earth

points and the SMPS can impose an AC voltage on the DC ground, which can

lead to damage. Suitable cost effective power supplies are available from

QTech: Plug Pack - P/N PD5412 or Power Pack with flying lead - PD5414.

Software Installation

Note – The software must be installed before connecting the SMS

Controller to your PC with the USB programming cable.

Insert the supplied SMS Controller CD into your PC.

If the setup program doesn’t run automatically, run the program in the root directory

of the CD called SMSWorkbench_vxyz_Setup.exe. Alternatively, download the

configuration software from www.qtech.co.nz

This will install the software in your Program Files folder, create a desktop shortcut

and install the required USB driver.

Power up the SMS Controller and connect it to the PC using the supplied USB cable

(type A to B). Within a minute you should see a message bubble displayed in the

system tray saying “Found New Hardware”. The installation is automatic and a few

seconds later you will see a further message bubble saying “Hardware is installed

and ready for use”.

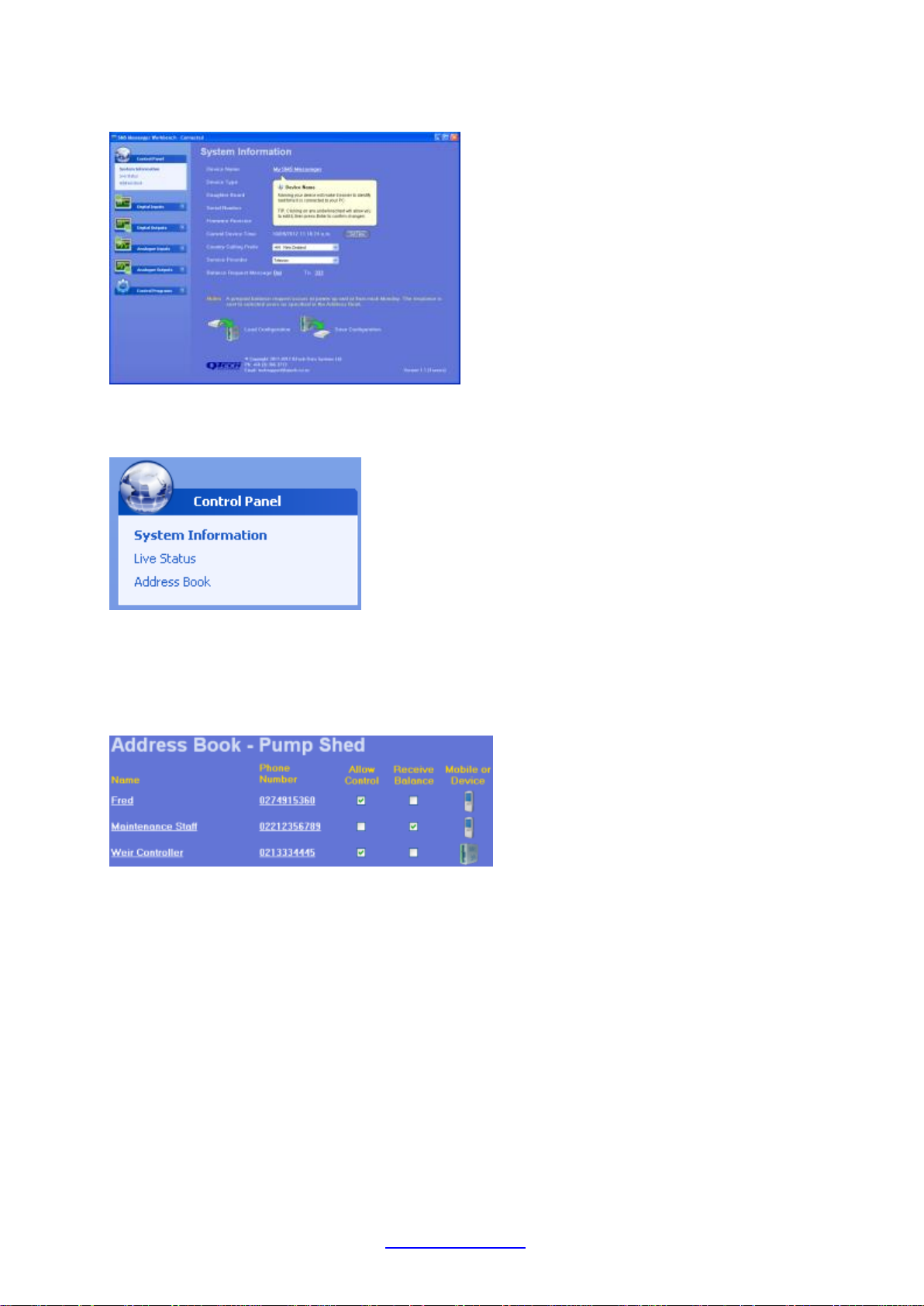

Workbench User Interface

This is where the entire configuration of the SMS Controller takes place.

www.qtech.co.nz Tel: 03 3663713

Page 4

QTech SMS Controller - Quick Start Guide – v1.4 – February 2014 4

Follow the steps shown in the help

bubbles to get the basic aspects of the

SMS Controller set up.

The configuration is really intuitive, user

friendly and only takes a few moments.

Click “Enter” to accept an entry or click

in the help bubble to advance.

Enter a Device name for the SMS

Controller. We recommend using the

actual site name or customer name e.g.

“Pump Shed” or “Fred’s Farm” as this

name will appear in all the text

messages.

Each user will only receive the

messages they are interested in.

This is configured in the “Sequence”

section for each relevant I/O point.

In this example, Fred has control

options but Maintenance Staff don’t.

System Information – This contains details about the system.

The selections needed are the "Device Name", “County dialling prefix” (default is +64

for NZ) and “Service Provider”.

Address Book – Enter and edit user names and phone numbers for the texts.

Enter the name and phone number of all the people that you want to send texts to,

receive prepay balance messages or allow to control the system. Each person can

be individually given these abilities. Changes can easily be made in the future.

Press the test button to send a text to the person to show the system is working. This

test facility is also a great diagnostic tool to check the cellular network.

The SMS Controller can also text another SMS Controller! This powerful feature

allows a widespread use of the solution e.g. allows a weir upstream to be closed

when you have enough water. Use the “Device” option in the address book to

configure the other SMS Controllers.

Live Status – Summary page of the current status.

This shows all the inputs & outputs, their state and configuration information.

Click the I/O point to give it a name and set up what actions the SMS Controller is to

perform when the input changes.

www.qtech.co.nz Tel: 03 3663713

Page 5

QTech SMS Controller - Quick Start Guide – v1.4 – February 2014 5

We recommend using a

descriptive/the actual name e.g.

“Site Security”, as this name will

appear in all the text messages for

this point.

Please remember to save the configuration file

with a relevant/descriptive name e.g. “Smith Farm

Feb 2012”. This will be useful in the future and

will save you time making any changes or

enhancements.

If you are controlling outputs, try to keep the name short, as you need to type the

name in the text, e.g. “pump” would be a good suggestion as the control text would

be “turn on pump”.

The SMS Controller can automatically perform specified actions when something of

interest happens. The following screenshot shows that when the Site Security switch

opens, the security camera is switched on and after 30 seconds the alarm text is sent

to the owner.

Live Status is replaced with I/O Overview when you are offline and not connected to

an SMS Controller.

Note – Ensure the Notification “Do you want to receive SMS or Control for

this input” is set to “Yes” for all inputs you want to receive an SMS from or be

able to control that point. By default this is set to “No” to prevent unnecessary

SMS being sent when initially configuring the Controller

Physical I/O & Wiring Configurations

Digital Inputs

The digital inputs are normally open inputs that can be connected to suitable

mechanical switches, contacts and other closure devices. An input is active or ON

when the input switch is closed, and inactive or OFF when the input switch is open.

The digital input LED will light up when the input is ON.

Warning – Only mechanical switches or mechanical closure devices should

be connected to the inputs. No external voltage or other electrical source is to

be connected.

www.qtech.co.nz Tel: 03 3663713

Page 6

QTech SMS Controller - Quick Start Guide – v1.4 – February 2014 6

+ Supply

Dig Out 1

Tx

Anl In 1

G

Tx

G

Digital Outputs

The digital outputs are solid state devices designed to interface to a low power

relays. When an output is on, it will be connected to the power supply negative,

allowing current to flow into the output terminal to ground.

When in the OFF state, they have a high impedance to

ground and will float up to the power supply positive. The

digital output LED will light up when the output is ON.

To use a digital output with a relay, wire as shown in the

diagram opposite.

The maximum current available to drive all eight interface

relays is 1.5A. We suggest relays with a current of ~50mA.

Analogue Inputs

There are two analogue inputs configured for 4-20mA operation. (0-10V inputs are

available to order).

The Analogue Input LEDs show the status of the signal the RTU is receiving. If the

LED is off, it means the input signal is zero, or under-range. When the LED is on the

signal is within the measuring range that the input has been configured for. If the LED

is flashing, it shows the signal is over range.

4-20mA Devices

Any 4-20mA transducers must be powered using a separate

power supply from the analogue signal loop. If suitable, these

devices can be powered from the RTU power supply. If this is not

suitable, the analogue transducer can be powered from a

separate power supply as long as the grounds of both the RTU

and the other power supply are connected together.

Wiring of a 4-20mA device is as shown on the right.

0-10V Devices (Optional)

If your RTU is configured to use 0-10V transducers, these are

simply connected between the input and the Ground pin, as shown

on the right.

Analogue Outputs

There are two analogue outputs configured for 4-20mA operation. (0-10V outputs are

available to order).

The Analogue Output LEDs show the status of the outputs. If the LED is off the

output signal is zero. When the LED is on, it indicates the signal is greater than zero.

www.qtech.co.nz Tel: 03 3663713

Page 7

QTech SMS Controller - Quick Start Guide – v1.4 – February 2014 7

Our recommended optional aerial for external mounting,

is P/N PD9214, shown here.

This has ~4.2m of coax and is a panel mounting aerial.

To mount unscrew the plastic flange at the base of the

aerial to expose the mounting stud.

Drill a 6.5-7.5mm clearance hole in the panel, feed the

mounting stud through and carefully reinstall.

Other higher gain aerials are also available as options

for sites with inadequate signal strength.

Aerial Notes

The reliability of all cellular products is dependent on good signal strength. Before

deciding on the Telco to choose, please check coverage. We suggest that a cellular

phone is taken to site, to check the signal strength, ie how many “bars” are displayed.

The supplied stub aerial (P/N PD9230) should be suitable for locations with good

Telco coverage (full bars) and where the SMS Controller is in a non-conductive

enclosure (plastic etc).

Note – If the SMS Controller is to be enclosed in a metal cabinet, or the site

does not have full cellular signal, an optional external aerial will be required.

Note – Do not cut or join the coax cable, this will increase losses and

impact reliability.

Text Message Types

The following provide you useful information about the system:

Send “status” SMSC replies with all of the I/O values/states

Send “stats” SMSC replies with how many SMS’s have been sent; how many

SMS’s have failed the signal strength (RSSI) measurements and when the SMSC

was last reset by cycling the power supply

Send “stats reset” SMSC will reset the status information

Send the SMSC any text (even a blank one) and it will confirm the acceptable

message formats for the control abilities.

Notes for using the SMSC to SMSC text ability

The ability to send control texts between SMSC’s is very powerful. The following are

specific notes for these systems:

Only the digital outputs can be controlled (on/off/toggle/pulse), not analogues.

To receive status/stats info, you need to text the SMSCs individually:

remember to add all SMSC numbers to your phone’s contacts.

Digital Output Reply confirmations. This doesn’t work for SMSC to SMSC

control. Ensure “Reply with confirmation of control”: is set to No.

www.qtech.co.nz Tel: 03 3663713

Page 8

QTech SMS Controller - Quick Start Guide – v1.4 – February 2014 8

Symptom

Cause

Solution

Green PWR status LED

not blinking when power

applied

Blown fuse

Replace internal fuse. Use 2

Amp quick blow type.

Insufficient power

supply voltage

Check supply and provide

suitable power supply

No texts are received

Address book entry is

incorrect

Check settings and then send a

“test” text to the user

Telco credit expired

Top up as needed

SIM is not installed or

Reception/coverage is

poor

Check SIM card and send a

“test” text to the user from the

installed site

Unable to control an

output via text

Note, users who are in

the address book, will

receive a text to say they

do not have control

The user isn’t

configured as being

able to use control

Check address book settings

and select the “allow control”

option for the user.

The wrong command has

been sent to the

controller

Predetermined

formats are needed in

the text messages

Simply text the SMS Controller

(even a blank SMS) and it will

tell you the format of the allowed

messages. This is also shown in

Live Status of the Workbench

software

Consider saving frequently used

texts as a template in your cell

phone

Intermittent Operation

Telco signal strength

Send the SMS a “stats text.

Monitor it and/or upgrade aerial.

Status LEDs

PWR (Power) This LED is on when the device is powered on.

OK Flashes to show the device is active and not locked up.

ERR (Error) This LED flashes a number of times to indicate any errors.

COMS This LED shows the cellular communication status:

Off The cellular modem is off

Fast Blink (1s) Searching for network

Slow Blink (3s) Registered on network

On SMS in progress

RXD (Receive) This LED will flash when a SMS is received.

TXD (Transmit) This LED will flash when a SMS is sent.

Trouble Shooting and Tips

www.qtech.co.nz Tel: 03 3663713

Loading...

Loading...